AVL 9120, 9130, 9140, 9180, 9181 Service Manual

MEDICAL INSTRUMENTS

AVL 9120, 9130,

9140, 9180, 9181

Electrolyte Analyzers

Service Manual

Tenth Edition

November 1997

Copyright, 1997, AVL Scientific Corporation. All rights reserved. Unless otherwise noted, no part of this

publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into

any language in any form without the written permission of AVL Scientific Corporation.

For information contact:

AVL Scientific Corporation AVL MEDICAL INSTRUMENTS AG AVL LIST GmbH

50 Mansell Court Stettemerstrasse 28 Kleiststrasse 48

P.O. Box 337 CH-8207 Schaffhausen A-8020 Graz

Roswell, Georgia USA 30077 Switzerland Austria

1-800-526-2272 41-848-800-885 43-316-787-0

Printed in USA

US0285 REV K

ii

Important Information!

This Operator´s Manual contains important warnings and safety information to be observed by the

user.

This instrument is only intended for one area of application which is described in the instructions. The most important prerequisites for application, operation and safety, are explained to

ensure smooth operation. No warranty or liability claims will be covered if the instrument is

applied in areas other than those described or if the necessary prerequisites and safety

measures are not observed.

The instrument is only to be operated by qualified personnel capable of observing these

prerequisites.

Only accessories and supplies either delivered by or approved by AVL are to be used with the

instrument.

Due to the operating principle of the instrument, analytical accuracy not only depends on

correct operation and function, but also upon a variety of external influences beyond the

manufacturers control. Therefore, the test results from this instrument must be carefully

examined by an expert, before further measures are taken based on the analytical results.

Instrument adjustment and maintenance with removed covers and connected power mains are

only to be performed by a qualified technician who is aware of the dangers involved.

Instrument repairs are only to be performed by the manufacturer or qualified service personnel.

Symbol Explanation

Attention symbol - Refer to the Operator's Manual or Service

Manual for further instructions. This symbol is located on the

inside of the instrument.

Type B instrument symbol - An instrument of the B type falls under

safety categories I, II, or III, or has an internal power supply providing

the required insulation against discharge current and reliable ground

connections.

Important Information!

iii

Operating Safety Information

• This instrument falls under Safety Category I.

• This instrument is a Class B instrument.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference’s, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Warning: Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to

radio communication. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does not cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio TV technician for help

Caution:

• The instrument is designed as a conventional device (closed, not waterproof type).

• Do not operate the instrument in an explosive environment or in the vicinity of

explosive anesthetic mixtures containing oxygen or nitrous oxide.

• This instrument is suitable for continuous operation.

• The power plug is to be plugged into a ground socket only. When using an extension

cord, make sure that it is of the proper size and is properly grounded.

• Any breakage of the ground lead inside or outside the instrument or a loose ground

connection can cause a hazardous condition when operating the instrument.

Intentional disconnection of the grounding is not permitted.

• When replacing the fuses, make sure that they are of the same type and rating as the

original fuses. Never use repaired fuses or short-circuit the fuse holders.

Operating Safety Information

iv

Contents

1 Introduction............................................................................................ 1

2 General Description .............................................................................. 2

2.1 Reported Parameters .................................................................. 2

2.2 Operating Parameters ................................................................. 2

3 Software ................................................................................................. 5

3.1 System Software Flow Charts 9120, 30, 40............................... 7

3.2 System Software Flow Charts 9180......................................... 17

3.3 System Software Flow Charts 9181......................................... 29

3.4 Service Functions .................................................................... 42

4 Description of Modules....................................................................... 48

4.1 Mechanical Assemblies ............................................................ 48

4.2 Fluidic Module ........................................................................ 52

4.3 Electronics............................................................................... 56

5 Maintenance and Troubleshooting ..................................................... 59

5.1 Maintenance Procedures......................................................... 59

5.2 Error Messages and Troubleshooting ...................................... 60

6 Adjustments ......................................................................................... 71

6.1 Sample Sensor Adjustment ...................................................... 71

6.2 Temperature Adjustment .......................................................... 71

7 Electronic Diagrams ............................................................................ 72

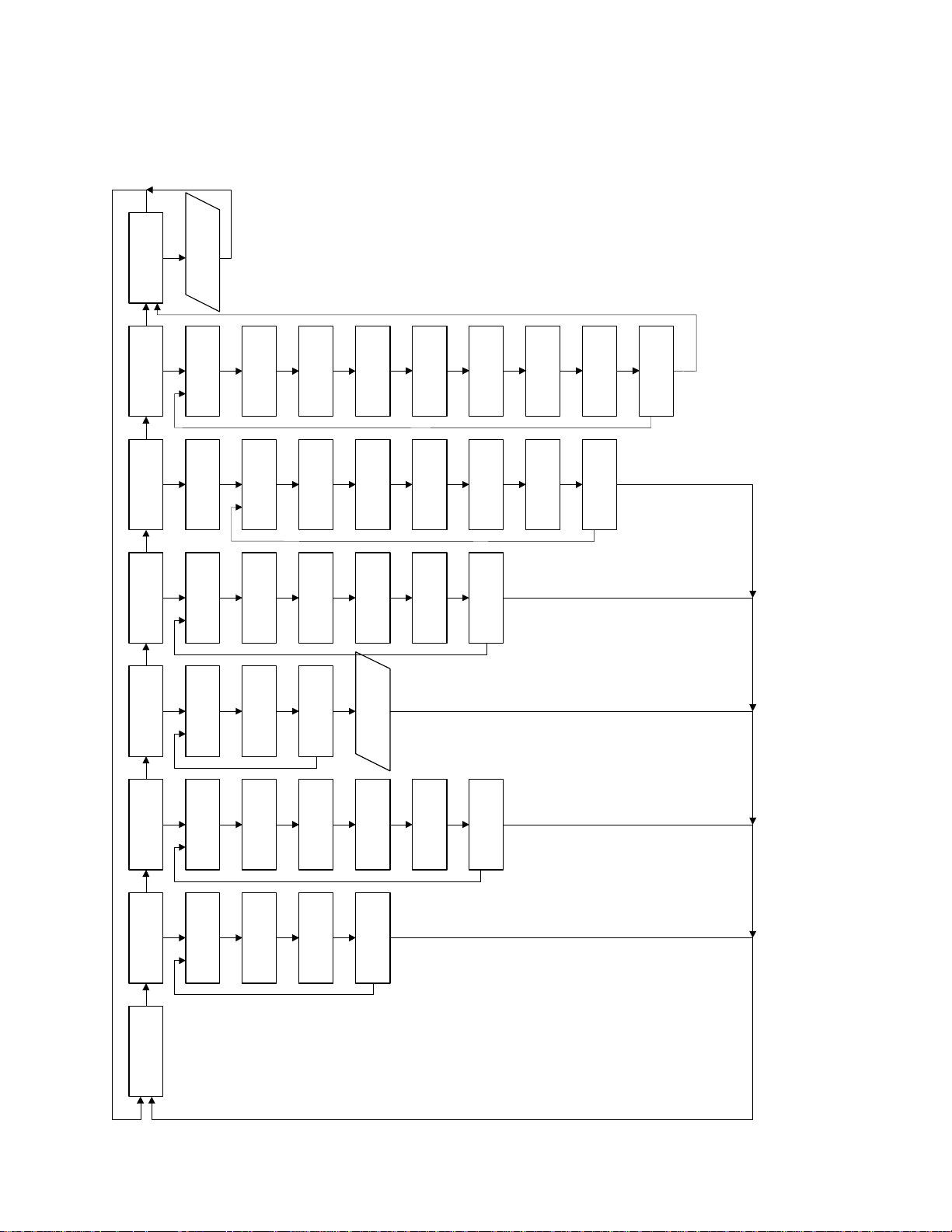

System Block Diagram 9120, 30, 40, 80 ........................................ 74

System Block Diagram 9181 .......................................................... 75

System Interconnect 9120, 30, 40 .................................................. 76

SBC PCB - Power Supply 9120, 30, 40 ........................................ 77

SBC PCB - Valve Drivers 9120, 30, 40 ......................................... 78

SBC PCB - Pump Motor Driver/Door Detect 9120, 30, 40............ 79

SBC PCB - Input Amplifiers 9120, 30, 40...................................... 80

SBC PCB - Temperature Circuit 9120, 30, 40 ............................... 81

SBC PCB - Analog Selector and A/D Converter 9120, 30, 40 ....... 82

v

SBC PCB - Microprocessor 9120, 30, 40 ..................................... 83

SBC PCB - Printer/Display Drivers 9120, 30, 40 ........................... 84

Printer Daughter PCB 9120, 30, 40, 80, 81 .................................... 85

Lamp PCB 9120, 30, 40 ................................................................ 86

Display Daughter PCB 9120, 30, 40............................................... 87

System Interconnect 9180/9181 ..................................................... 88

SBC PCB - Power Supply 9180/9181 ........................................... 89

SBC PCB - Valve Drivers 9180/9181 ............................................ 90

SBC PCB - Pump Motor Driver/Door Detect 9180/9181............... 91

SBC PCB - Input Amplifiers 9180/9181......................................... 92

SBC PCB - Temperature Circuit 9180/9181 .................................. 93

SBC PCB - Analog Selector and A/D Converter 9180/9181 .......... 94

SBC PCB - Microprocessor 9180/9181 ........................................ 95

SBC PCB - Printer/Display Drivers 9180/9181 .............................. 96

SBC PCB - Fluid Pack Detector 9180/9181 .................................. 97

Lamp PCB 9180/9181 ................................................................... 98

Display Daughter PCB 9180........................................................... 99

8 Parts List ........................................................................................ 100

Main Assembly Front ................................................................... 101

Main Assembly Rear .................................................................... 102

Electrode Holder Assembly .......................................................... 103

Needle Unit Assembly .................................................................. 104

Rear Panel Assembly .................................................................... 105

Front Door Assembly ................................................................... 106

9 Interface Specifications ..................................................................... 107

9.1 Interface Information.............................................................. 107

9.2 Example Data String Information............................................ 108

9.3 Data Link Information............................................................ 108

vi

1 Introduction

The Service Manual for the 9120, 30, 40, 80, and 81 Electrolyte Analyzers

contains the technical information needed to ensure easy fault identification.

This manual is intended to be complementary to the Operator's Manual where

detailed instructions for operation, maintenance and troubleshooting are

provided.

As for all clinical instrumentation, a thorough understanding of the principles

of operation is prerequisite to attempting service of this product. Training

along with experience will enhance the use of this manual.

Service and repair of 9120, 30, 40, 80, and 81 analyzers should be performed

only by qualified repair technicians. Care should be taken when removing the

covers as hazardous voltages are exposed. Use only accepted electronic test

procedures and static protection when replacing and handling all electronic

parts.

This manual is divided into 9 chapters to facilitate location of technical information. Chapter 2 provides specifications and operating parameter information. Chapter 3 includes flow charts for all system functions and detailed

operation of system test procedures. In Chapter 4, all mechanical, fluidic and

electronic assemblies are described. Chapter 5 outlines routine maintenance

and troubleshooting procedures. Chapter 6 includes electronic adjustments

and Chapter 7 provides the system block diagram and all circuit schematic

diagrams and wiring interconnection information. In Chapter 8, part identification, location and description is provided by the illustrated parts list.

Finally, in Chapter 9 interface specifications are provided for the RS232

output.

1

2 General Description

Specifications

2.1 Reported Parameters Measuring Range Resolution

Whole Blood

Serum

Plasma

Sodium Na

Potassium K

+

40 - 205 mmol/L 0.1 mmol/L

+

1.5 - 15 mmol/L 0.01 mmol/L

(0.8 - 15 mmol/L dialysate)

Chloride Cl

Calcium Ca

Lithium Li

-

50 - 200 mmol/L 0.1 mmol/L

++

0.2 - 5.0 mmol/L 0.01 mmol/L

+

0.1 - 6.0 mmol/L 0.001 mmol/L

Urine

Sodium Na

Potassium K

+

1 - 300 mmol/L 1.0 mmol/L

+

4.5 - 120 mmol/L 0.1 mmol/L

(60 - 120 mmol/L w. addit. dilution)

Chloride Cl

-

1 - 300 mmol/L 1.0 mmol/L

Calcium and Lithium are not measured in urine samples.

Lithium is not measured in dialysate samples.

2.2 Operating Parameters

Sample type Whole blood, serum, plasma, urine,

dialysate (acetate or bicarbonate)

Sample device Syringe, sample cup, collection tube, capillary

Sample size 95 µL

Analysis time 50 seconds

Sample rate 45 per hour with printout

60 per hour without printout

2

Measurement

Sodium (Na+) sensor Ion-selective, flow-through, glass capillary

electrode

Potassium (K+) sensor Ion-selective, flow-through, liquid membrane

electrode

Chloride (Cl-) sensor Ion-selective, flow-through, liquid membrane

electrode

Calcium (Ca++) sensor Ion-selective, flow-through, liquid membrane

electrode

Lithium (Li+) sensor Ion-selective, flow-through, liquid membrane

electrode

Reference System Open liquid junction, flow-through electrode

Calibration Fully automatic

1 point with each sample

2 point every 3 hours (9180/9181 every 4 hrs.)

Standby Mode suspends calibrations

Warm-up time 1 minute

Temperature Room temperature, 15 - 32° C, 60 - 90° F

Humidity maximum 85% relative humidity,

non-condensing

Data management Quality Control memory storage, 3 levels,

35 values; calculation of mean, standard

deviation, and coefficient of variation (CV)

Diagnostic Programs user-controlled diagnostics,

YES/NO operation via the display

Electronics Microprocessor-controlled

Display LCD dot-matrix, 2 line, 16 characters per line

Printer Integral thermal printer, 16 character width

Autosampler (9181 only) Integral turntable - 18 positions,

2 mL or 0.25 mL sample cups

3

Interface RS232C Serial Port

Data Link Data link to Compact 2/3 (9180/9181)

Electrical requirements 100 - 240 V~, 50/60 Hz,

1.4 A max.

Self-adjusting

Nominal power

consumption 30 W

Dimensions

height 12.2"; 335mm

width 12.4"; 315m

depth 12.0"; 295mm

weight approx. 13 lbs; 6kg

Classifications

Safety category I

Device type B (according to ÖVE-MG/EN 60601-1,

IEC 601-1)

Mode of operation continuous operation

Protection classification IP 20

Explosion protection the device is not designed for operation in

explosive environments.

Approvals CSA, CE, FCC Class B

CLIA Complexity Category: Moderate

Test System Code: 04739

FDA 510(k) number: K972673

Analyte Codes: Na+: 5805

K+: 4910

Cl-: 1018

iCa++: 1004

Li+: 3712

Data subject to change without notice. Technical information is

supplied for general informational purposes only.

4

3 Software Operation

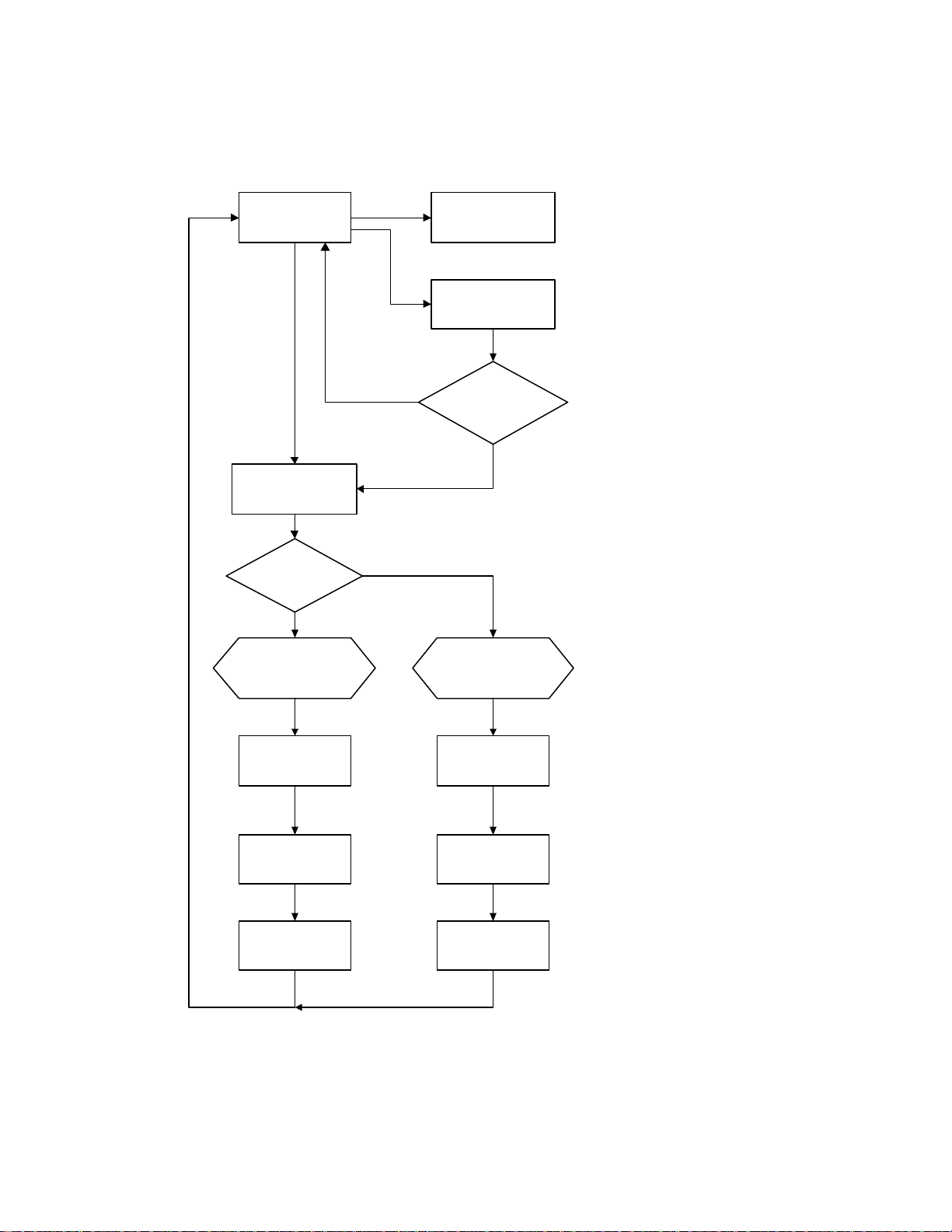

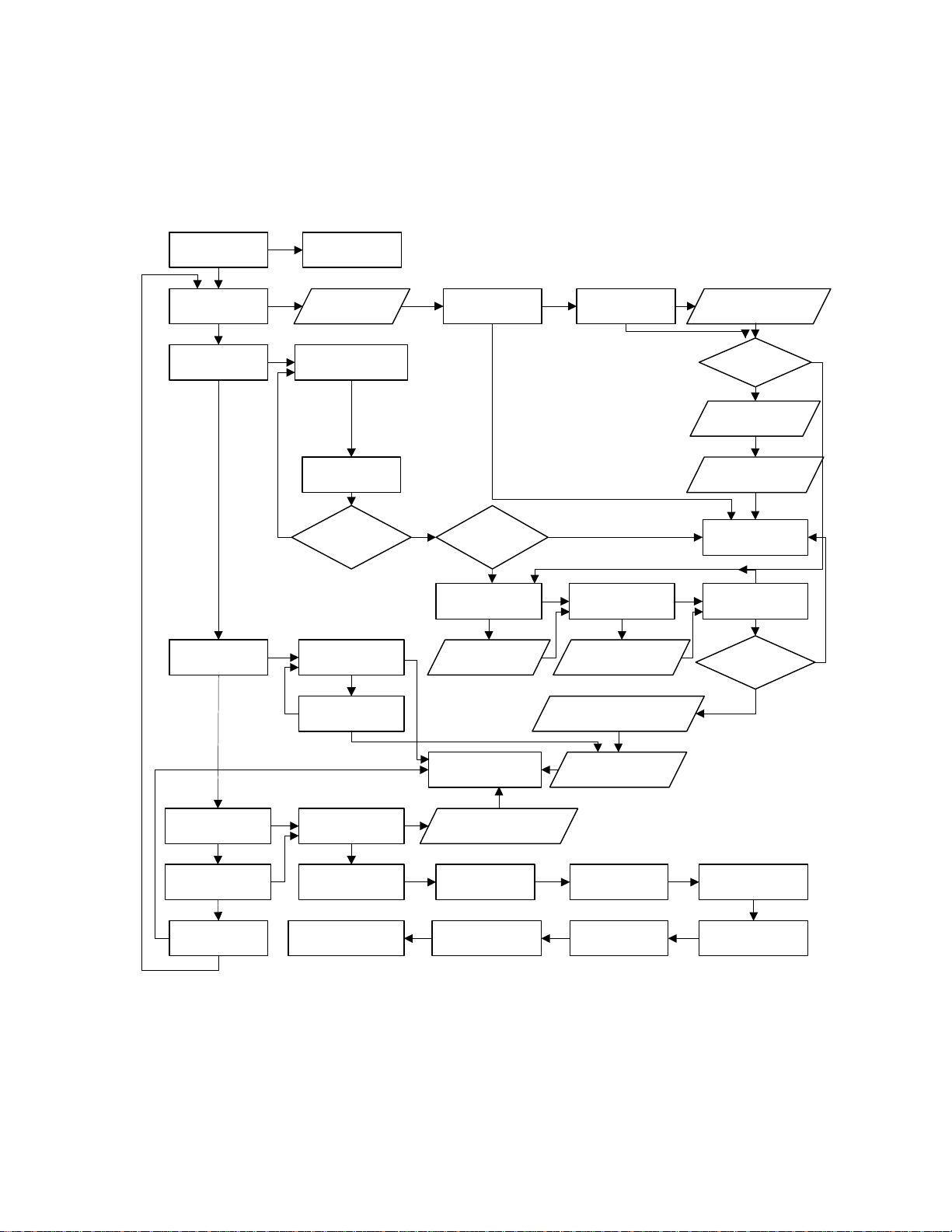

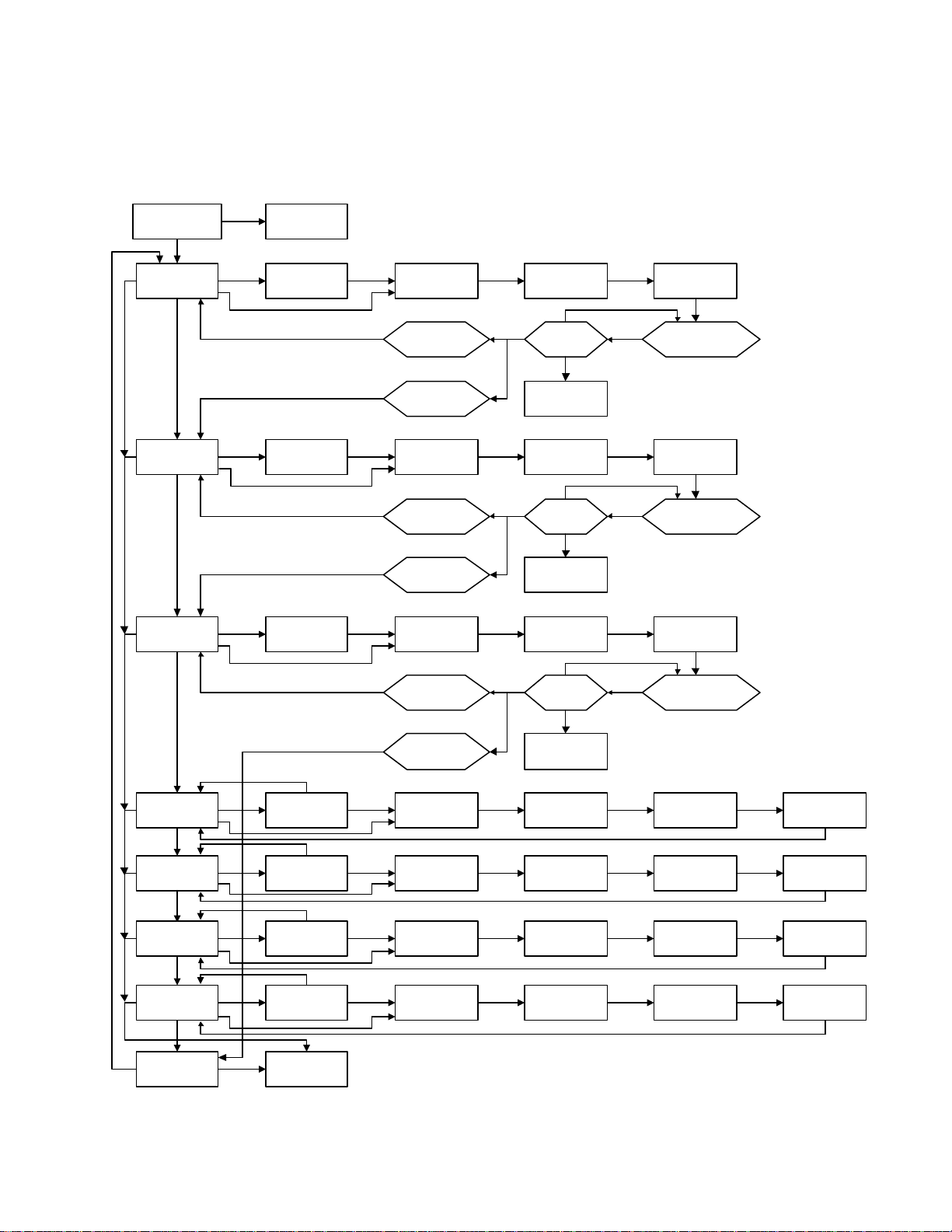

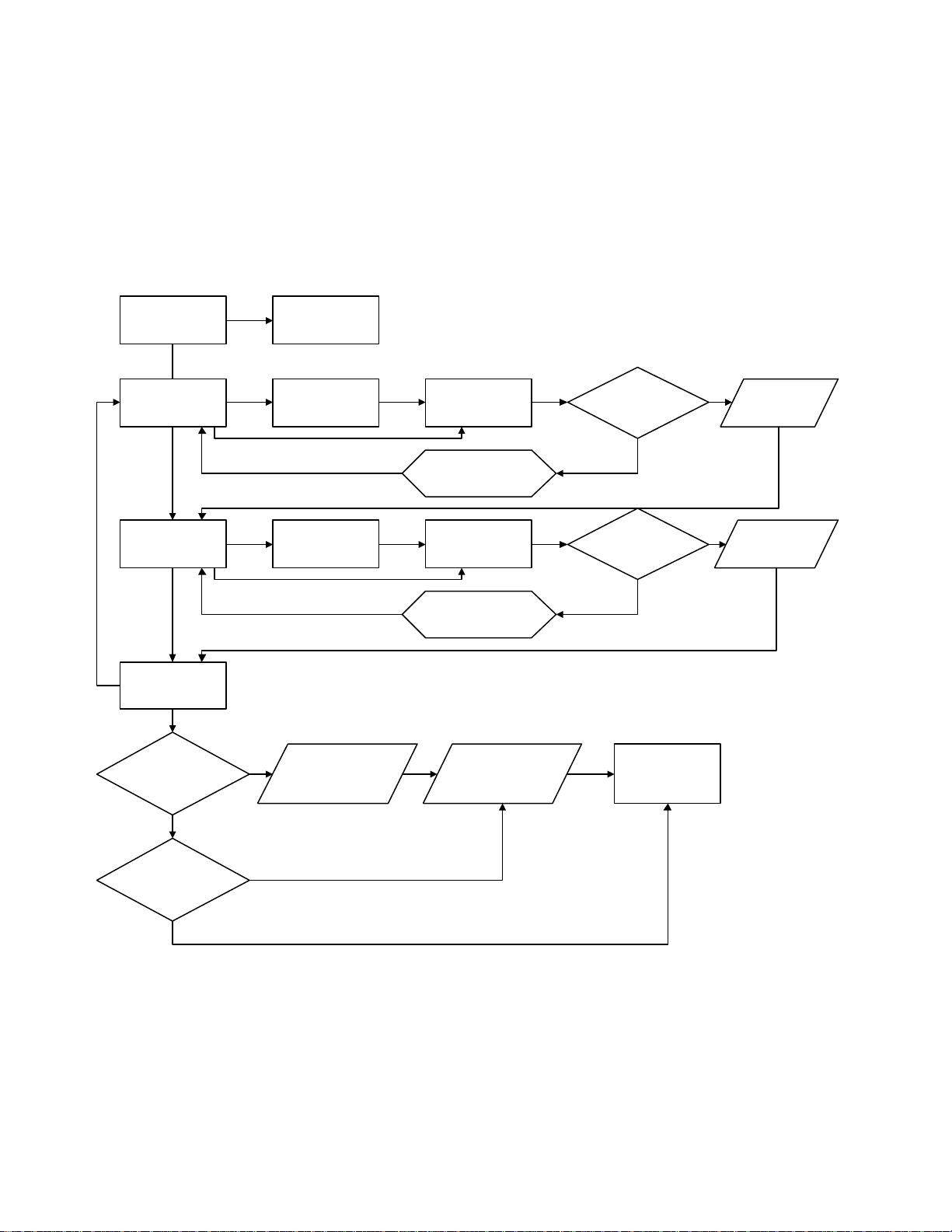

3.1 Software Operation - 9120, 9130, 9140

Software operation of the 9120, 9130, 9140 analyzers can be accessed by YES/

NO selection on the analyzer front panel. The following flow chart diagrams are

provided to identify operating sequences of the 9120, 9130, 9140 Analyzers:

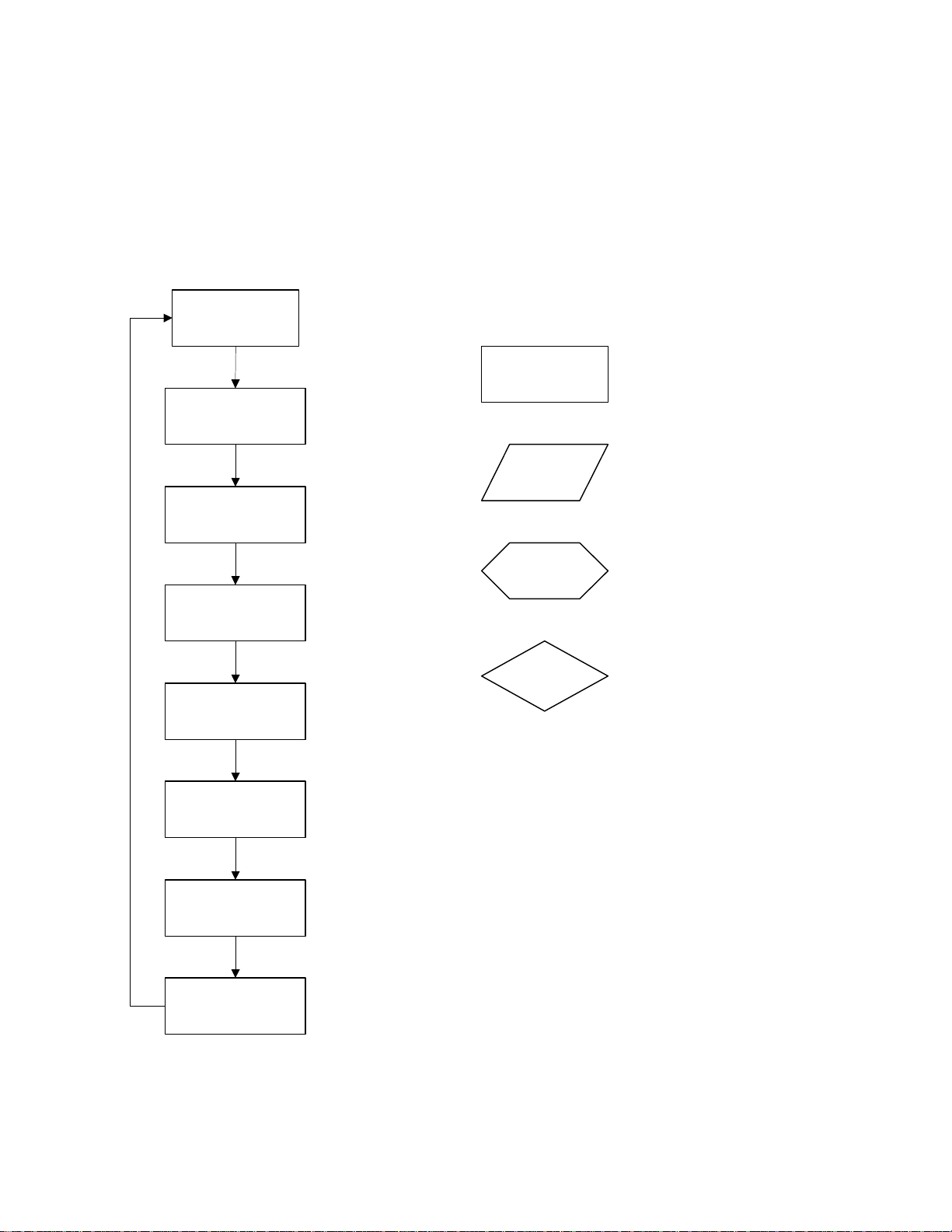

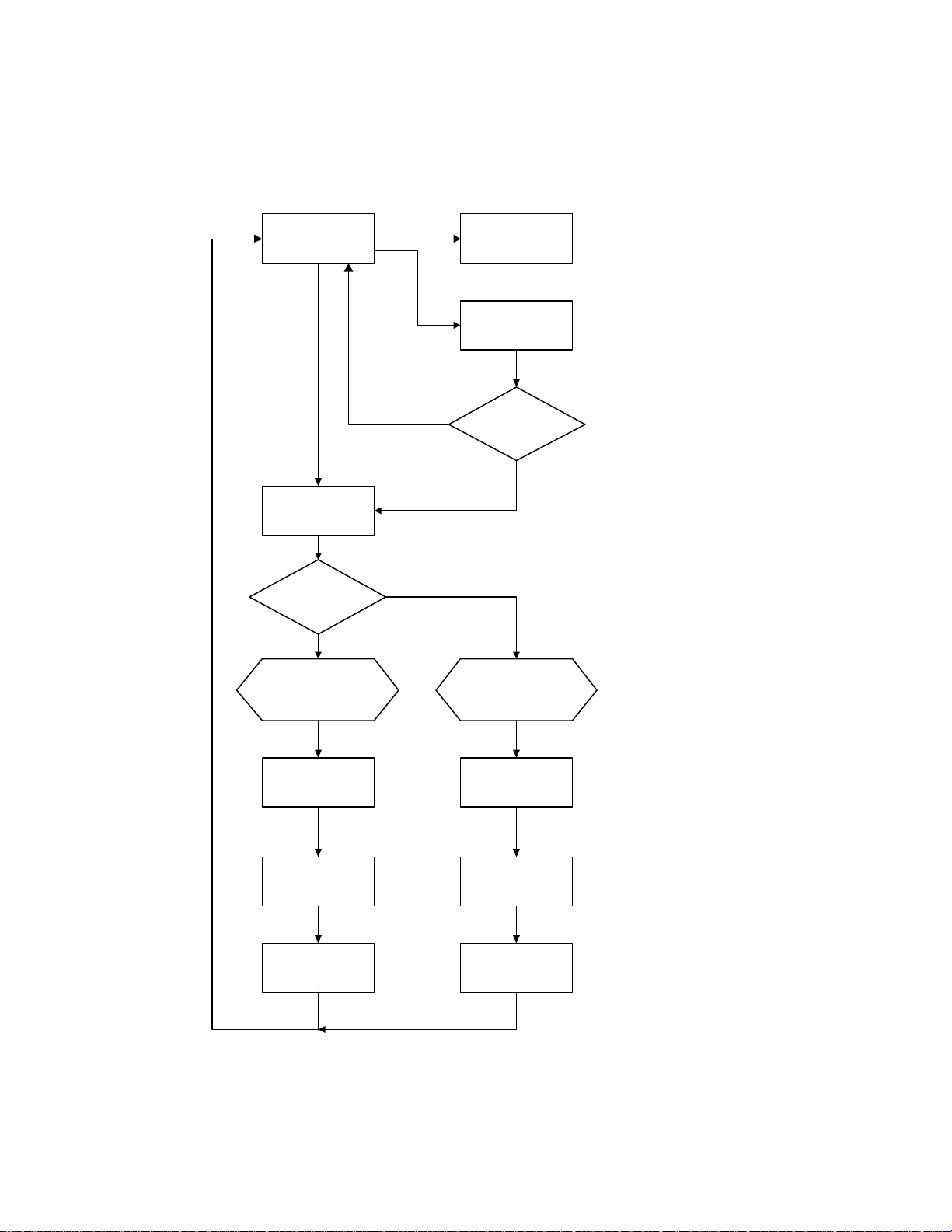

1. Overall Program Operating Flow

2. Main Menu

3. Measurement Sequence

4. Print Functions Menu

5. QC/Standard/Urine Sample Menu

6. Daily Maintenance Menu

7. Operator Functions Menu

8. Program Instrument Menu

9. Service Functions Menu

10. Calibration Sequence

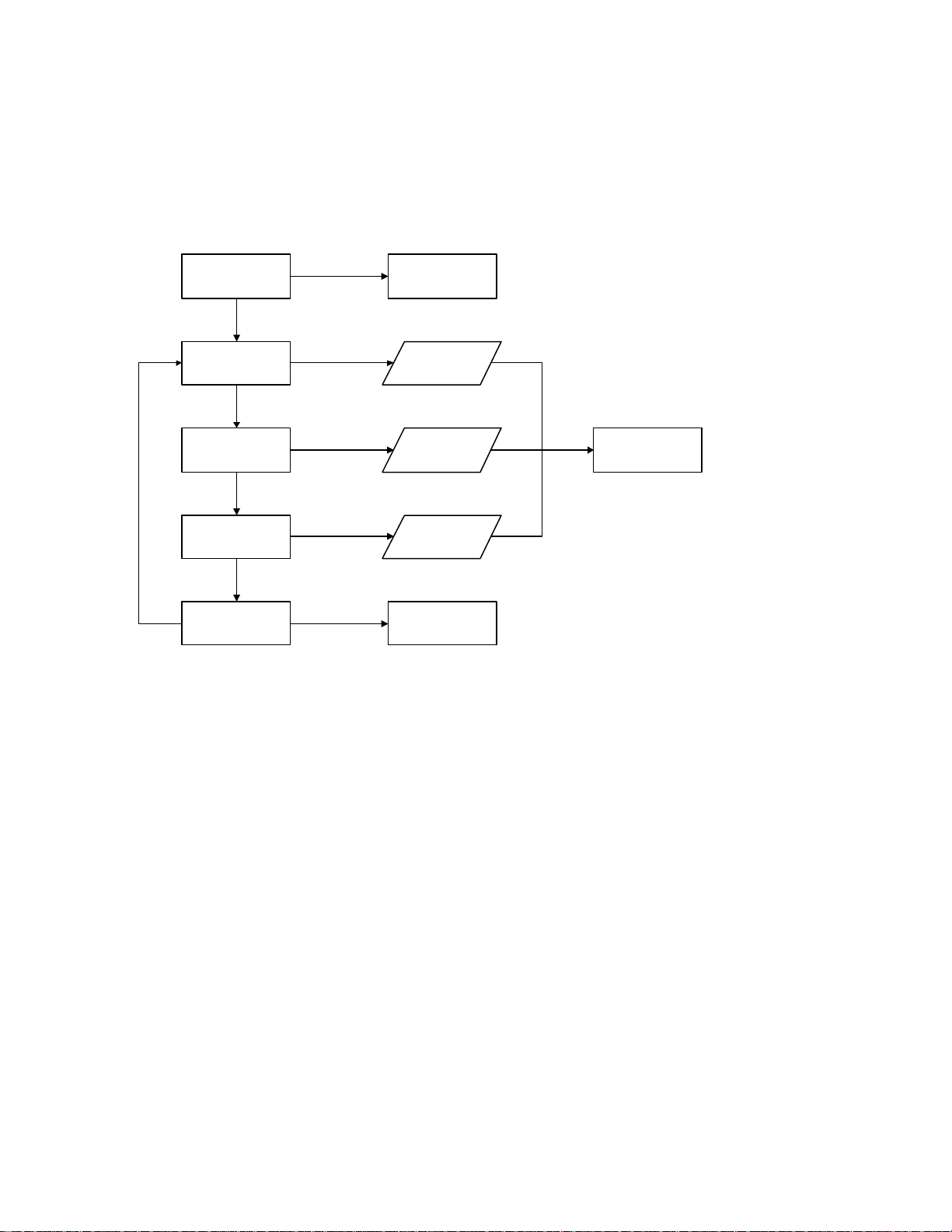

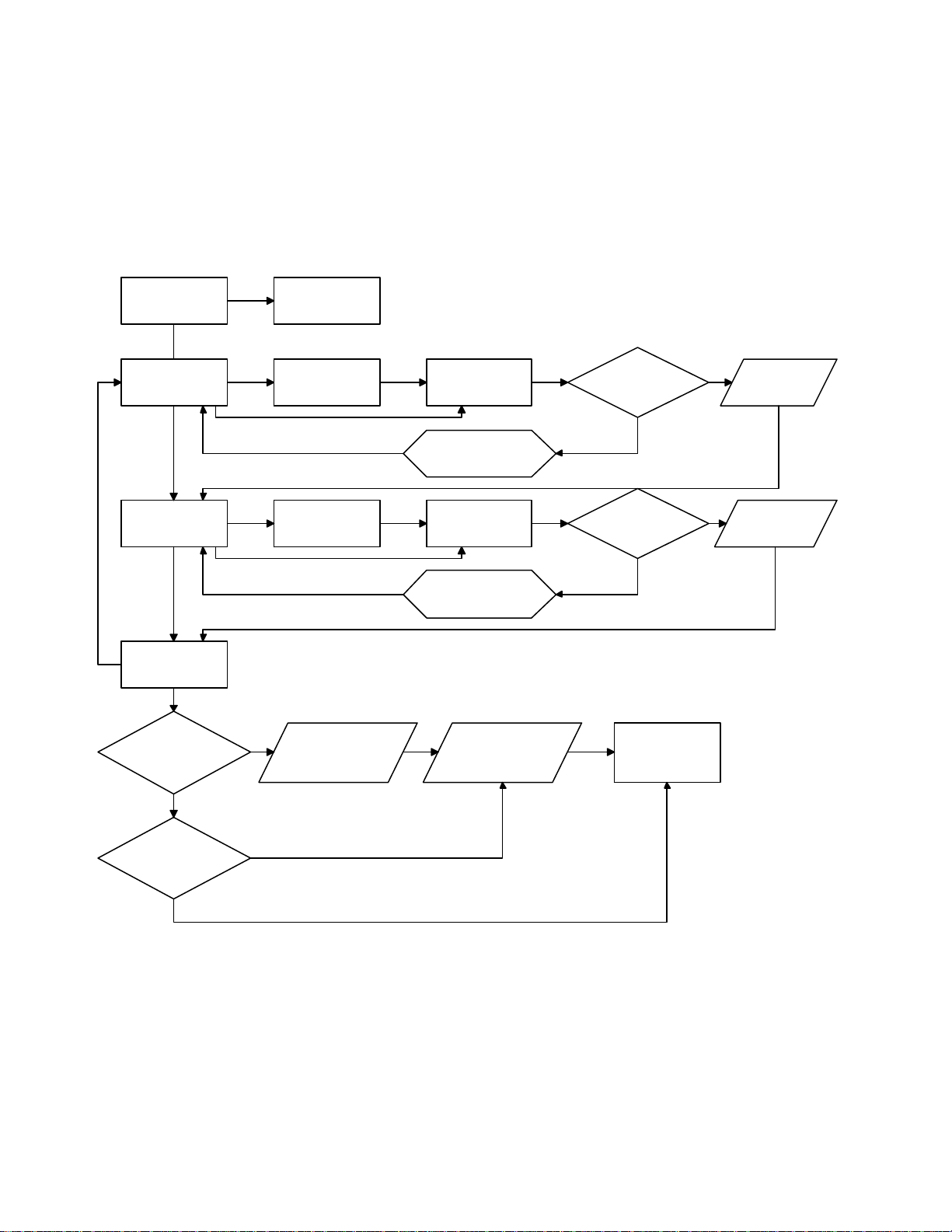

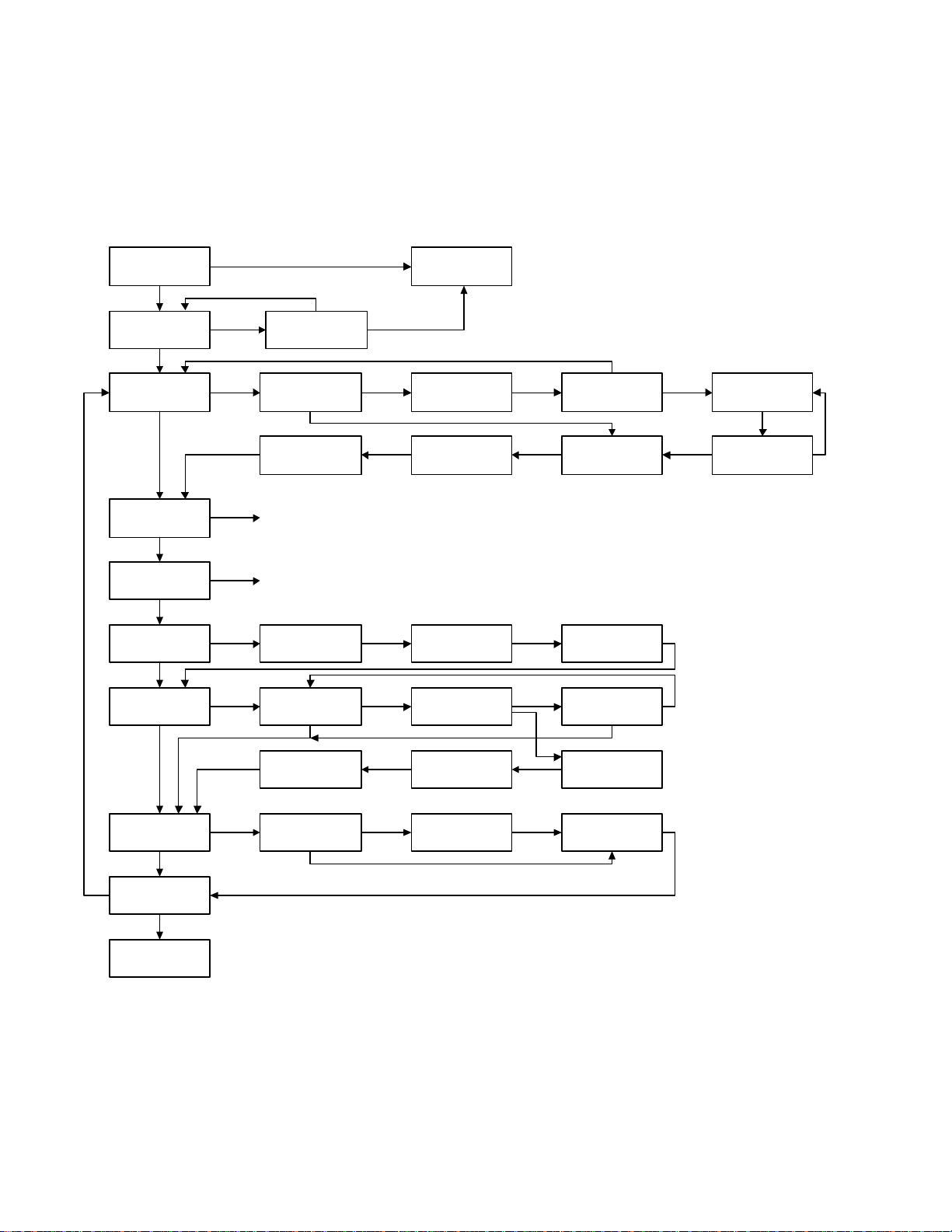

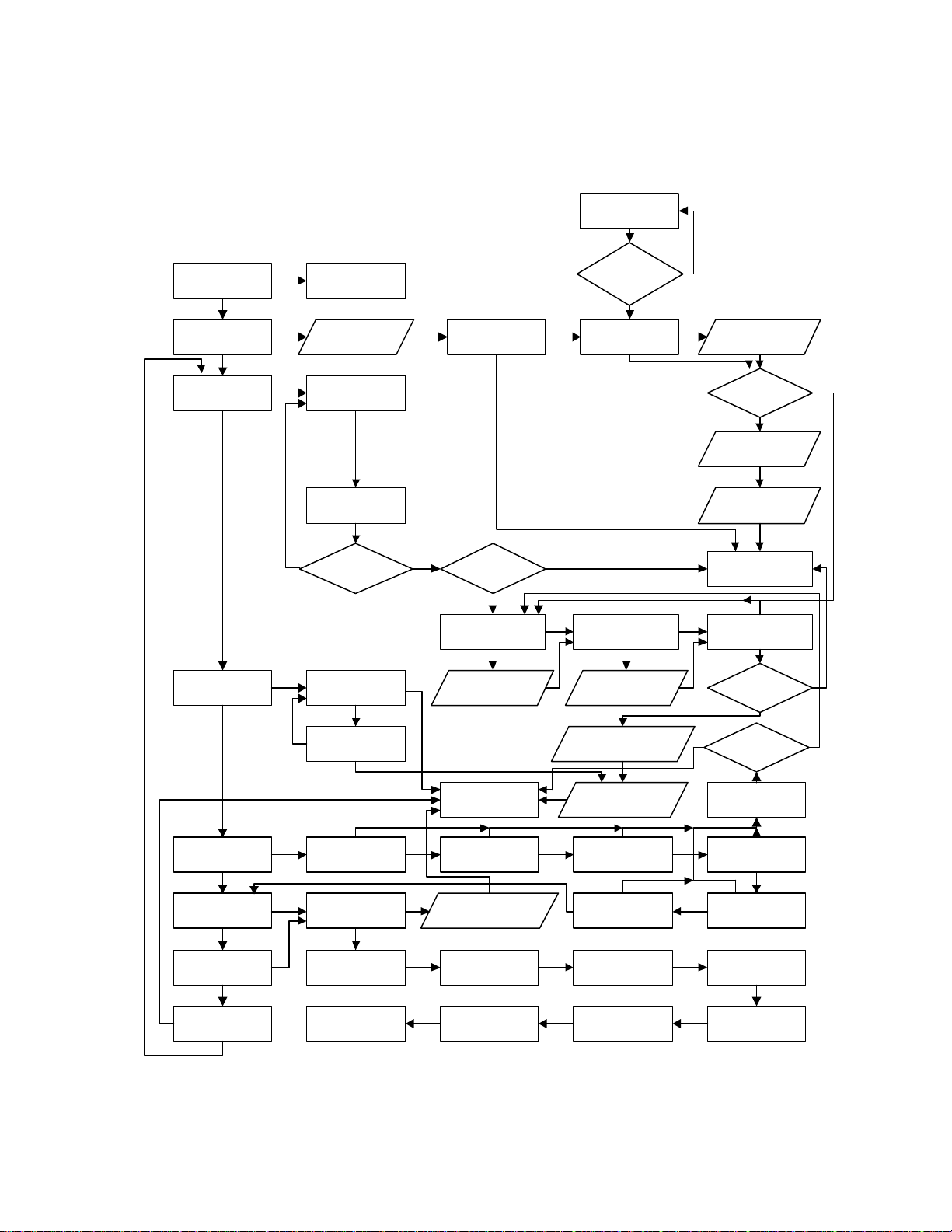

3.2 Software Operation - 9180

1. Overall Program Operating Flow

2. Main Menu

3. Measurement Sequence

4. Print Functions Menu

5. QC/Std/Dialysate/Urine Sample Menu

6. Daily Maintenance Menu

7. Operator Functions Menu

8. Program Instrument Menu

9. Service Functions Menu

10. Calibration Sequence

11. Power-up Sequence

5

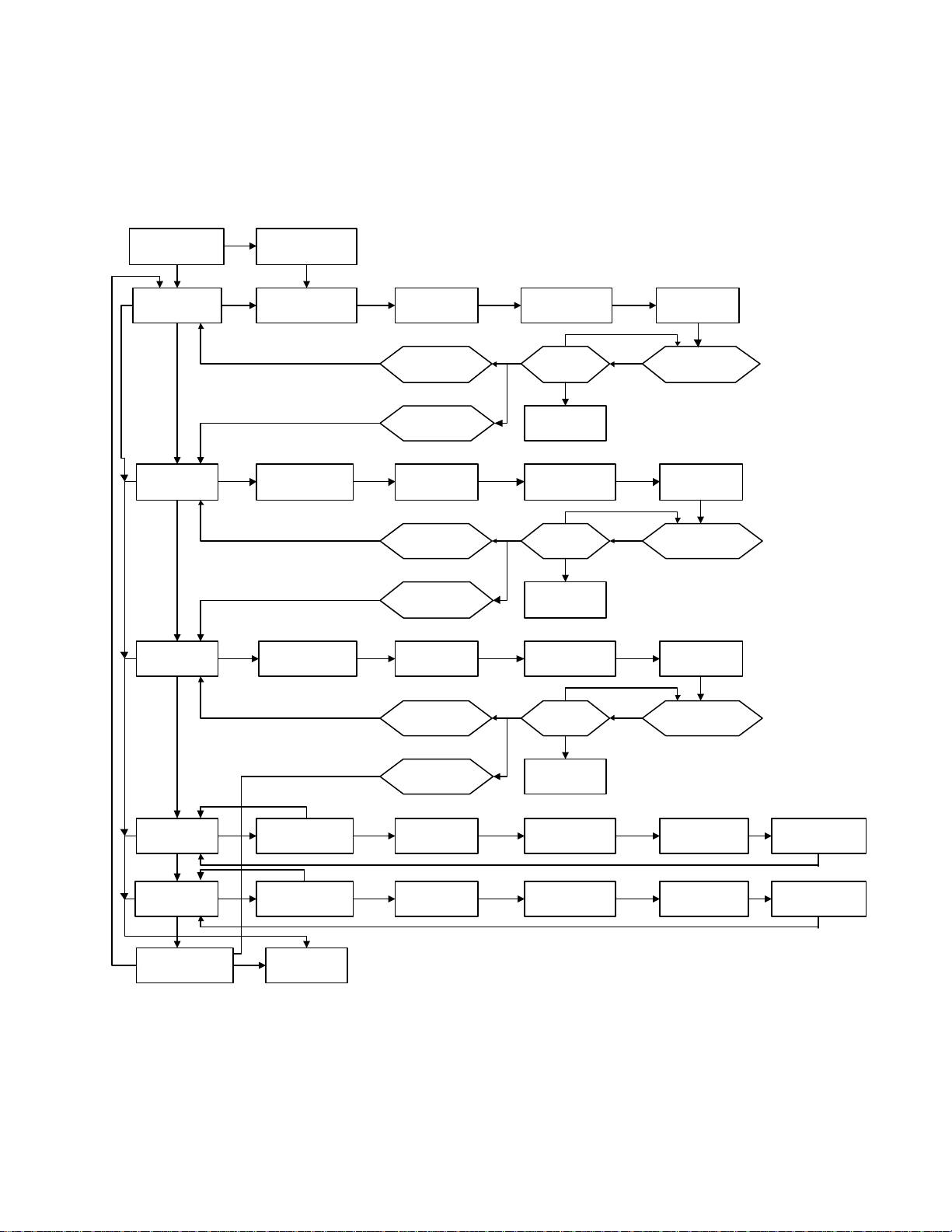

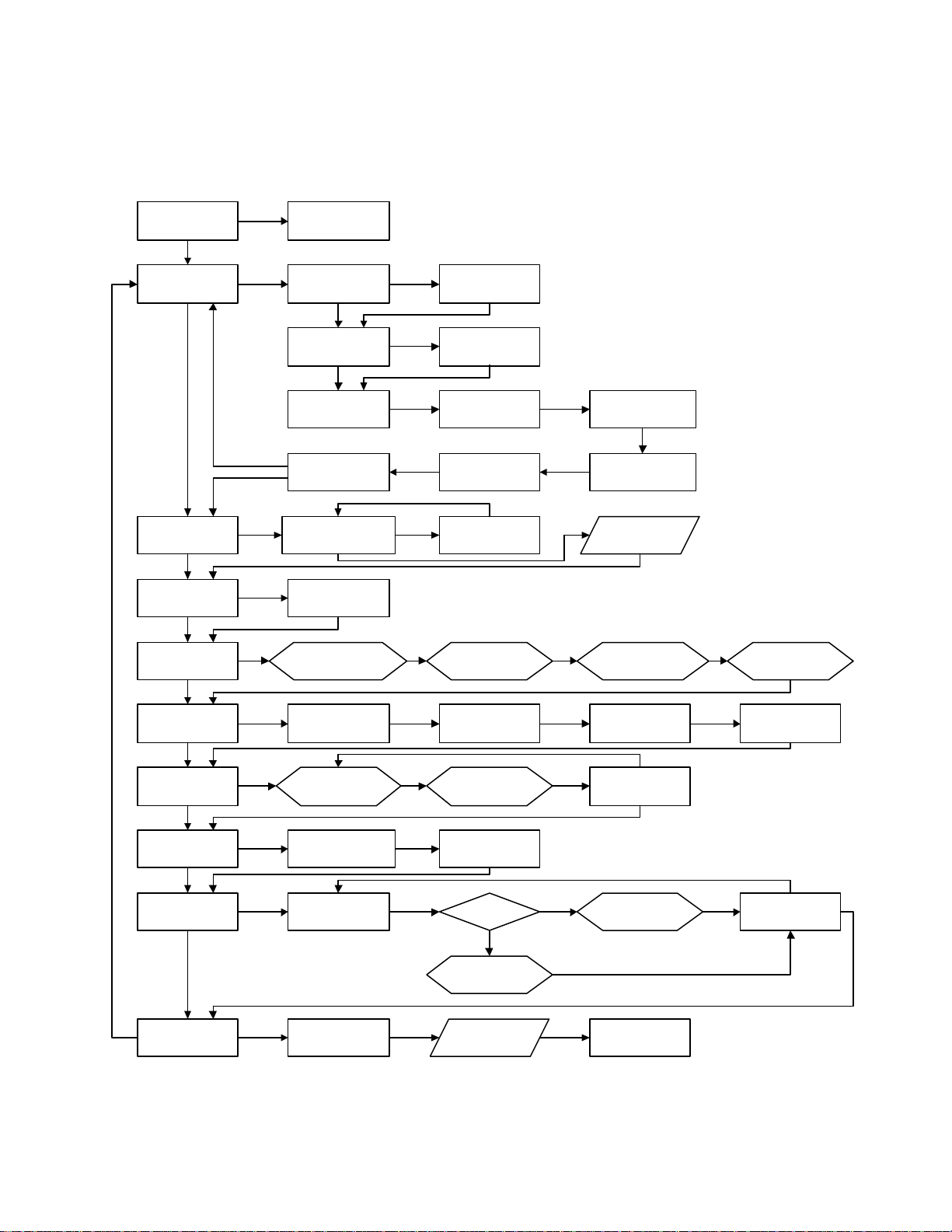

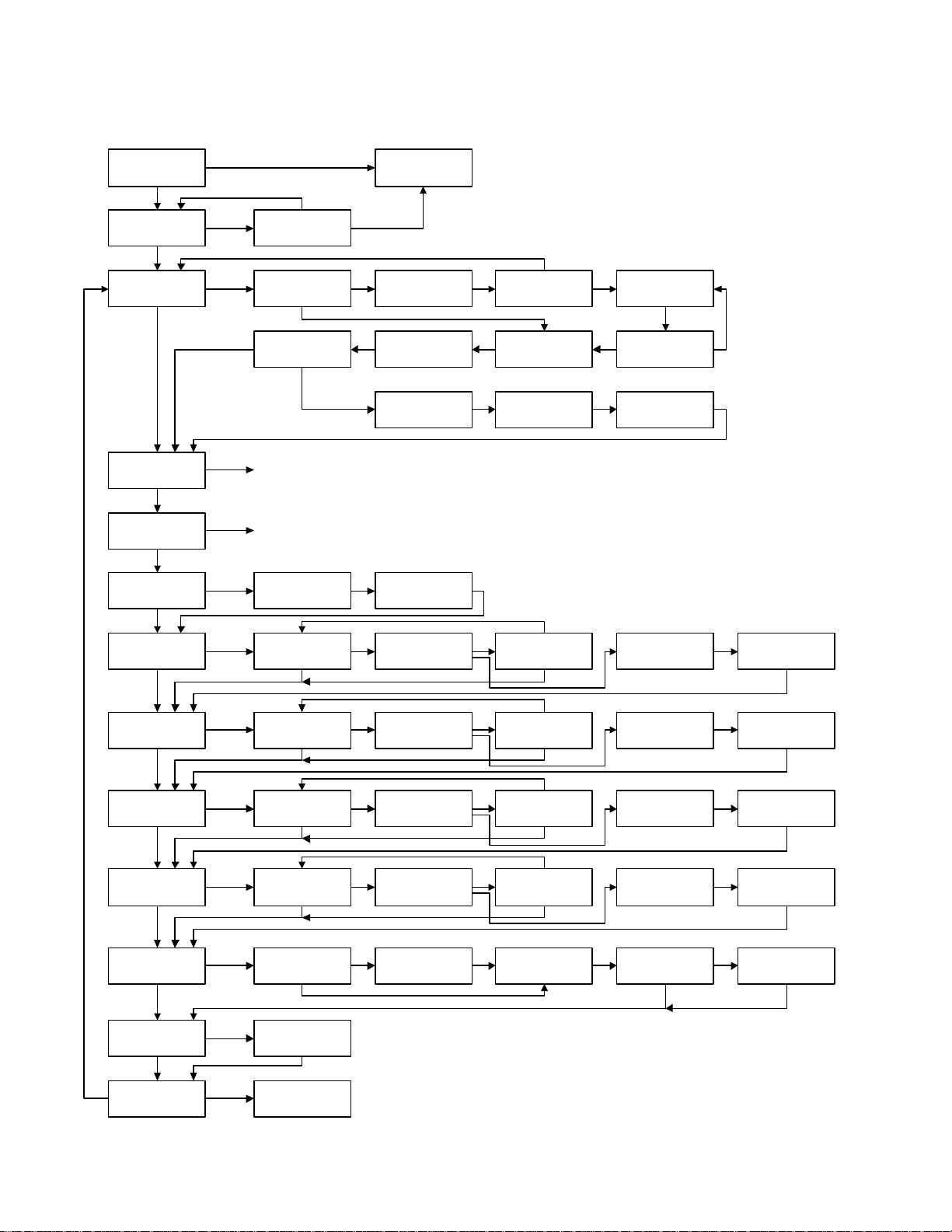

3.3 Software Operation - 9181

1. Overall Program Operating Flow

2. Main Menu

3. Measurement Sequence

4. Print Functions Menu

5. QC/Std/Dialysate/Urine Sample Menu

6. Daily Maintenance Menu

7. Operator Functions Menu

8. Program Instrument Menu

9. Service Functions Menu

10. Calibration Sequence

11. Power-up Sequence

The Service Functions Menu is also provided with a more detailed description

of each test parameter for use in testing instrument subassemblies.

6

3.1 Software Operation - 9120, 30, 40

1 Overall Program Operating Flow - 9120, 30, 40

NoNoNoNoNoNoNoNo

.

CALIB R AT ION?

SERVICE

PROGRAM

OP E R AT OR

DAILY

CALI B R AT E ..

No

Test

Yes Yes Yes

Enter Code:

Check/Change

D aily

E lectrodes?

No

AAA

No

SnapPak?

No

Cleaning?

FUNCTIONS?

INS T R U ME N T ?

FUNCTIONS?

MAIN T E N ANCE ?

No

Test

Sample Sensor?

No

Program QC

Level 1 Ranges?

No

Go to

S t andby M ode?

No

D aily

Conditioning?

No

Test

S am ple D oor ?

No

Program QC

Level 2 Ranges?

No

Set

Time/Date?

No

Maintenance?

R emain in Daily

Yes

No

Test

Pump?

No

Program QC

Level 3 Ranges?

No

Reset

Sample Number?

CALI B R AT E

No

Test

Valves?

No

Program

Normal Ranges?

No

Operation?

Take Out of

Test Interface?

Program

Rem ain in

Jump Pins 2 & 3

Corr. Factors?

Operator F unc.?

Yes

No

No

No

No

Test

Am plifier?

No

Program

P ri nter S etup?

Enter

Rem ain in

S ervice Code?

Program Func.?

Yes

No

No

R emain in

No

Service Func.?

Yes

Yes Yes Yes

QC/S T ANDAR D /

URINE SAMPLE?

Yes

FUNCTIONS?

R E ADY 12:45 PRINT

No

Sample?

QC Level 1

No

P rint las t

Sample Report?

No

Sample?

QC Level 2

No

Print

Cal. R eport?

No

Sample?

QC Level 3

No

and S tatis tics ?

Print QC Values

No

Sample?

Standard

No

Functions?

Rem ain in P r int

Yes

No

Urine

Sample?

No

Remain in QC/

Std/Urine Sample?

Yes

7

2 Main Menu - 9120, 30, 40

MAIN MENU

READY 12:45

NO

PRINT

FUNCTIONS?

NO

QC/STANDARD/

URINE S AMPLE?

NO

DAILY

MAINTENANCE?

NO

OPERATOR

FUNCTIONS?

NO

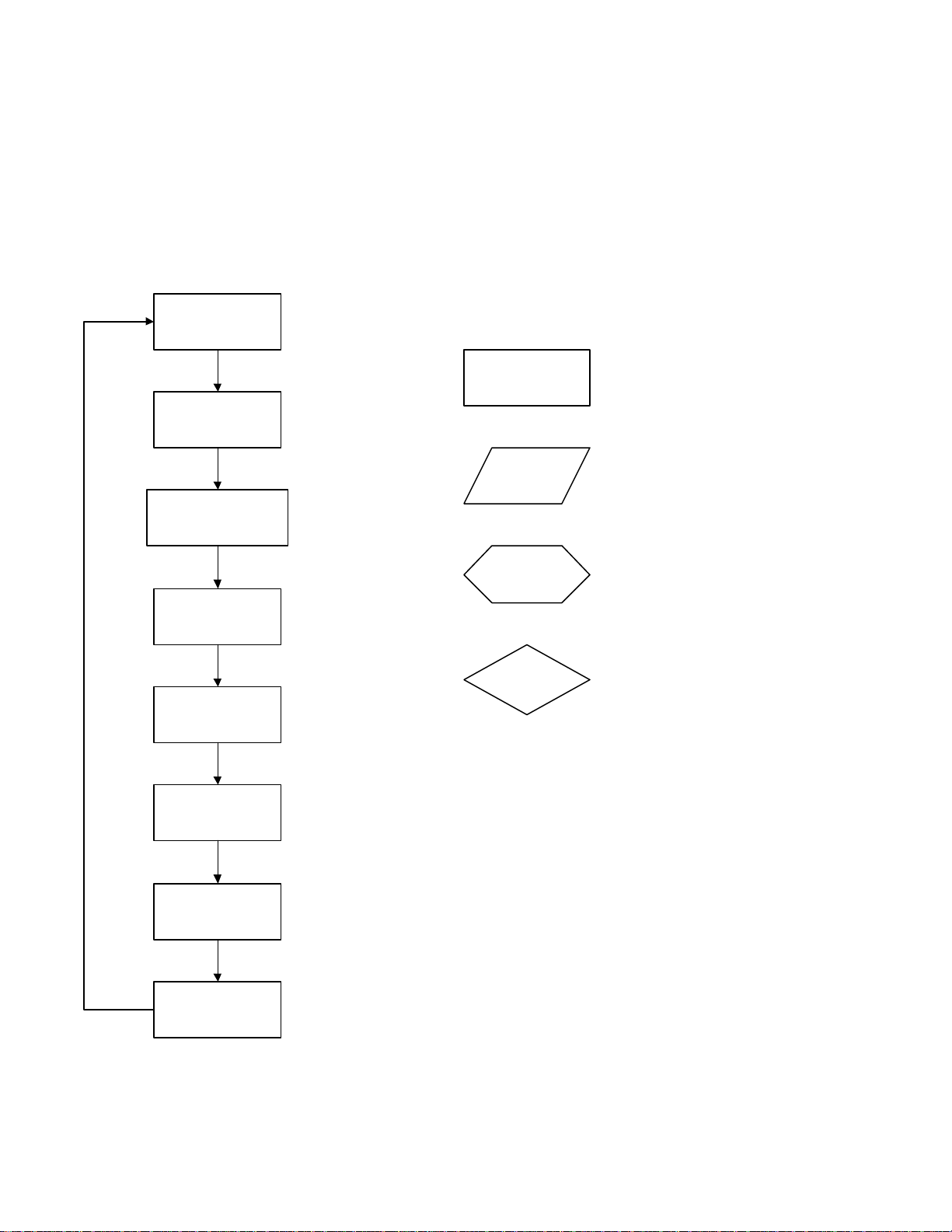

LEGEND

Display prompt

Action performed by analyzer

2-second display prompt

Decision-making by analyzer

PROGRAM

INSTRUMENT?

NO

SERVICE

FUNCTIONS?

NO

NO

CALIBRATION?

8

3 Measurement Sequence - 9120, 30, 40

READY 12:45

OPEN

FLAP

Please

Introduce Sample

CHECK SS

VOLTAGE

> air

voltage

YES

NO

NO

< air

voltage

PRINT

FUNCTIONS?

Open Sample Door

Introduce Sample

DOOR OPENED

WITHIN 2s?

YES

Remove Sample

and Wipe Probe

Please Close

Sample Door

Serum Sample

in Process 49

Na K Cl

151 5.1 114

YES/NO

1 min.

Remove Sample

and Wipe Probe

2s 2s

Please Close

Sample Door

FLAP

CLOSED

Blood Sample

in Process 49

Na K Cl

151 5.1 114

CLOSED

FLAP

YES/NO

1 min.

9

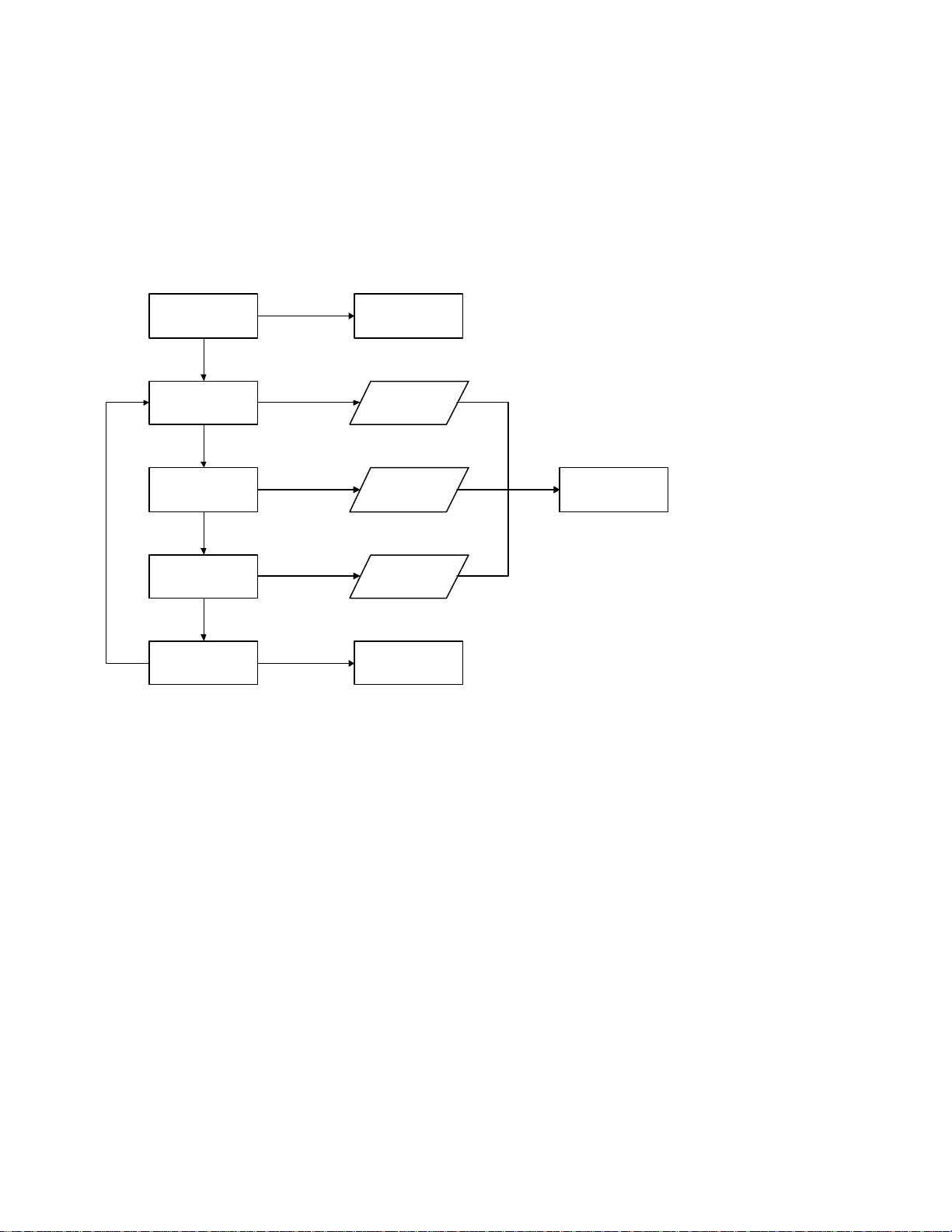

4 Print Functions Menu - 9120, 30, 40

YES

PRINT

FUNCTIONS?

YES

Print Last

Sample Report?

NO

Print

Cal. Report?

NO

Print QC Values

and Statistics?

NO

Remain in Print

Functions?

NO

YES

YES

YES

NO

QC/STANDARD/

URINE SAMPLE?

PRINTING

...

READY 12:45PRINTING

...

PRINTING

...

READY 12:45

10

5 QC/Standard/Urine Sample Menu - 9120, 30, 40

QC/STANDARD/

URINE SAMPLE?

YES

QC Level 1

Sample?

2 min.

2 min.

2 min.

NO

QC Level 2

Sample?

NO

QC Level 3

Sample?

NO

NO

YES OPEN SAMPLE

YES OPEN SAMPLE

YES

DAILY

MAINTENANCE?

Open Sample Door

Introduce Sample

Open Sample Door

Introduce Sample

Open Sample Door

Introduce Sample

2s

2s

2s

2s

OPEN

2s

2s

Introduce

Sample

VALUES

REJECTED!

VALUES

ACCEPTED!

Introduce

Sample

VALUES

REJECTED!

VALUES

ACCEPTED!

Introduce

Sample

VALUES

REJECTED!

VALUES

ACCEPTED!

IN

NO

YES

IN

NO

YES

SAMPLE

IN

NO

YES

Wipe Probe/Close

Sample Door

2s

Store

Values?

2 min

READY 12:45

Wipe Probe/Close

Sample Door

2s

Store

Values?

2 min

READY 12:45

Wipe Probe/Close

Sample Door

2s

Store

Values?

2 min

READY 12:45

CLOSED

2s

CLOSED

2s

CLOSED

2s

QC Level 1

in Process 49

Na K Cl

99.65.34 88.2

QC Level 2

in Process 49

Na K Cl

99.6 5.34 88.2

QC Level 3

in Process 49

Na K Cl

99.6 5.34 88.2

Standard

Sample?

2 min.

Sample?

2 min.

Remain in QC/

Std/Urine Sample?

YES

Urine

YES OPEN SAMPLE

Open Sample Door

Introduce Sample

NO

YES OPEN SAMPLE

Open Sample Door

Introduce Sample

NO

READY 12:45

NO/

2 min.

5s

5s

Introduce

Sample

Introduce

Sample

IN

IN

Wipe Probe/Close

Sample Door

Wipe Probe/Close

Sample Door

CLOSED

CLOSED

Standard Sample

in Process 49

Urine Sample

in Process 49

Na K Cl

158.8 5.82 113.2

1 min.

NO/

YES

Na K Cl

238 18.8 198

1 min.

NO/

YES

11

6 Daily Maintenance Menu - 9120, 30, 40

DAILY

MAINTENANCE?

Daily

Cleaning?

Daily

Conditioning?

Remain in Daily

Maintenance?

YES

CLEANING AND/OR

COND. PERFORMED?

YES

NO

NO/1min.

NO

YES

Open Sample Door

OPEN

OPEN

Introduce Sample

YES

Open Sample Door

Introduce Sample

YES

OPERATOR

FUNCTIONS?

30 SECOND

STABILIZATION

OPEN CLOSE YES

OPEN CLOSE YES

Wipe Probe/Close

Sample Door

Cleaning Solution

not detected!

Wipe Probe/Close

Sample Door

Condition. Solution

not detected!

CALIBRATE

Cleaning Solution

detected?

NO

Condition. Solution

detected?

NO

READY 12:45

CLEAN

CONDITION

12

NO

Calibration

due?

NO

YES

7 Operator Functions Menu - 9120, 30, 40

OPERATOR

FUNCTIONS?

YES

Check/Change

SnapPak?

NO

Go to

Standby Mode

NO

Set

Time/Date?

NO

NO

YES

YES

NO

PROGRAM

INSTRUMENT?

37%

remaining

***STANDBY!***

YES -> REA D Y

YES/NO

Leave

Standby Mode?

YES

NO YES

PRESS YES

WITHIN 2s

Date: 01- FEB-9 4

Time: 12:00 ok ?

NO

Date: 01- FEB-9 4

Time: 12:00 ok

YES

YES

Change

SnapPak?

NO

IS

CALIBRATION

DUE?

YES

Daily

Cleaning?

YES

READY 12:45

YES

New Snap Pa k

installed?

NO

NO

NO NO

Daily

Conditioning?

YES

CONDITIONCLEAN

30 SECON D

STABILIZATION

CALIBRATE

YES

Fluid Counter

reset to 100%

Maint . due?

NO

New Pack

Prime ...

CALIBRATE

READ Y 12:45

YES

Remain in Daily

Maintenance?

1min/NO

IS

CALIBRATION

DUE?

YES

YESYES

NO

Sample Number?

Operator Func?

NO

Take out of

Operation?

Remain in

YES

NO

NO

YES

Are you sure?Reset

Shutdown Plug /

Water installed?

YES

ShutdownComplete

Turn Pow er Off

YES

YES/

NO

YES

YES

SET SAMPL E

NUMBER TO 0

Transp Housing

Ref installed?

Do You Wish to

DELETE all Data?

YES YES

Remove Water

and Pres s YES

YES

Pump Windings

Relieved?

YES

All Electrodes

& Plug Rem oved?

YES

4 Relief Clam ps

Inserted?

13

8 Program Instrument Menu - 9120, 30, 40

PROGRAM

INSTRUMENT?

YES

Enter Code:

AAA

CORRECT

Program QC

Level 1 Ranges?

NO

Program QC

Level 2 Ranges?

NO

Program QC

Level 3 Ranges?

NO

Program

Normal Ranges?

NO

Program

Corr Factors

NO

NO

IN-

CORRECT

YES

YES

YES

YES YES YES YES

Current Lot: 0000

Cl low = 050

Cl high = 200

"see Level

"see Level

Na low = 135.0

Na high = 150.0

Factor (default)?

YES

Cl (b) = +00.0

Cl (m) = 1.000

YES

CODE ERROR!

RETRY?

Change Lot?

NO

1"

1"

Reset Corr

YES

NO

YES

NOYES

SERVICE

FUNCTIONS?

Print old Values

and Statistics?

K low = 1.5

K high = 15.0

K low = 3.50

K high = 5.50

Input/Verify

Corr Factors?

K (b) = +00.0

K (m) = 1.000

NO

NO YES

NO

YES

YESYES

New Lot!

Delete old Data?

Na low = 040

Na high = 205

Cl low = 95.0

Cl high = 108.0

Remain in

Corr Factors?

NO

Na (b) = +00.0

Na (m) = 1.000

YESYESYESYES

YES

Enter last 4 Dig

of Lot#: 0000

YES

Lot Number

ok?

NO

Program Printer

NO

Program Func?

YES

NO

READY 12:45

14

Setup?

Remain in

YES

Patient Report

off?

YES

NO

Print two

Patient Reports?

YES/

NO

Automatic

Cal Report?

YES/

NO

9 Service Functions Menu - 9120, 30, 40

SERVICE

FUNCTIONS?

YES

Test

Electrodes?

NO

Test

Sample Sensor?

NO

Test

Sample Door?

NO

Test Pump?

NO

Test Valves?

NO

Test Interface?

Jump Pins 2&3

NO

Test

Amplifier?

NO

Enter

Service Code?

NO

NO

YES YES

YES

YES

YES

YES

YES

YES YES YES

CALIBRATION?

Test

Standard A?

NO NO

Test

Standard B?

NO NO

Test

External Sample?

YES

Remain in

Test Electrodes?

NO

DRY: 80-120: 102

YES=Pump/NO=Exit

Sample Door: C

C:Closed O:Open

Test Pump!

Very slow speed

Test Valve A:

YES/NO=ON/OFF

-- Test --

-- Interface --

Na=-1030 K=-1200

Cl = -1093

Enter Code:

AAA ok?

NO

YESYES

YES

YES

NO

2s 2s 2s

NO NO NO

NO

Std. A: Na =0000

K =0000 Cl =0000

Std. B: Na =0000

K =0000 Cl =0000

Open Door and

Introduce Sample

Ext.: Na =0000

K =0000 Cl =0000

NO

External: 102

Pump: NO=OFF

Test Pump!

Slow speed

Test Valve B:

YES/NO=ON/OFF

Interface

ok!

Ground = 2

-2500mV = -2496

Is Code

valid?

NO

Code

Error!

CLOSED

OPEN

Introduce Sample

Wipe Probe and

Close Sample Door

wash...

Test Pump!

Medium speed

Test Valve V:

YES/NO=ON/OFF

YES

Remain in

Test Interface?

NO

Code

Accepted!

Test Pump!

Fast speed

2s

Test Valve R:

YES/NO=ON/OFF

NO

YES

Enter Other

Service Code?

NO

YES

Remain in

Service Func?

NO

Calibration?

Calibrate...

READY 12:45

15

10 Calibration Sequence - 9120, 30, 40

CALIBRATION?

YES

Calibration in

Process 124

Clear Sample

Path

Calibrate

Sample Sensor

Sample Sensor

Voltage ok?

YES

Prime

Standard B

Standard B

detected?

YES

Prime

Standard A

Standard A

detected?

NO

SAMPLE SENSOR

NO

**STANDARD B**

NOT DETECTED

NO

**STANDARD A**

NOT DETECTED

***CHECK***

A

Asp. Std. A into

Meas. Chamber

Standard A

detected?

YES

Obtain Electrode

Voltages Std. A

3 Std. A Values

obtained?

YES

Are Values

reproducible?

YES

Aspir. Std. B into

Meas. Chamber

Standard B

detected?

YES

Obtain Electrode

Voltages Std. B

NO

**STANDARD A**

NO

NO

NO

**STANDARD B**

NOT DETECTED

NO

6 Aspir. of

Std.A performed?

YES

***CHECK***

ELECTRODES

NOT DETECTED

16

YES

Pressurize Ref.

Asp. Std. A into

Meas. Chamber

Reference

Housing ok?

YES

A

NO

***CHECK***

REF HOUSING

Perform

Wash Cycle

Aspir. Std. A

into Meas.

Chamber

Standard A

detected?

Calculation of

Std.A-Std.B

(slope)

Slope of all

Electrodes in

Range?

YES YES

READY 12:45 READY 12:45

NO

**STANDARD A**

NOT DETECTED

YES

NO NO

At least 1 slope

XX NOT CAL'D

in Range?

***CHECK***

ELECTRODES

3.2 Software Operation - 9180

1 Overall Program Operating Flow - 9180

NoNoNoNoNoNoNoNo

CALIBRATION?

SERVICE

PROGRAM

OPERATOR

DAILY

CALIBRATE...

No

Test

FUNCTIONS?

INSTRUMENT?

FUNCTIONS?

MAINTENANCE?

Electrodes?

AAA

Enter Code:

SnapPak?

Check/Change

Cleaning?

Perform Daily

No

No

No

Yes Yes Yes

No

Test

Sample Sensor?

No

Program QC

Level 1 Ranges?

No

Go to

Standby Mode?

No

Perform Daily

Conditioning?

No

Test

SnapPak Sensor?

No

Program QC

Level 2 Ranges?

No

Set

Time/Date?

No

Maintenance?

Remain in Daily

No

Test

Language Switch?

No

Program QC

Level 3 Ranges?

No

Configuration?

Select Parameter

CALIBRATE...

Test

Program

Reset

No

Sample Door?

No

Normal Ranges?

No

Sample Number?

Test

Program

Take Out of

No

Pump?

No

Corr. Factors?

No

Operation?

No

Test

Valves?

No

Corr Facto r s?

Program Bicarb.

No

Remain in

Operator Func.?

Yes

No

Test Interface?

Jump Pins 2 & 3

No

Corr Facto r s?

Program Acetate

No

Test

Amplifier?

No

Corr Facto r s?

Program Urine

Enter

Program

Service Code?

Printer Setup?

No

No

Program

No

Remain in

Service Func.?

Yes

No

Interface?

No

Remain in

Program Func.?

Yes

Yes

Yes Yes Yes

/URINE SAMPLE?

QC/STD/DIALYSATE

Yes

FUNCTIONS?

Na K Cl READY PRINT

No

Sample?

QC Level 1

No

Print last

Sample Report?

No

Sample?

QC Level 2

No

Print

Cal. Report?

No

Sample?

QC Level 3

No

and Statistics?

Print QC Values

No

Sample?

Standard

No

Functions?

Remain in Print

Yes

No

Sample?

Bicarbonate

No

Acetate

Sample?

No

Urine

Sample?

No

Remain in QC/

Std/Urine Sample?

Yes

17

2 Main Menu - 9180

MAIN MENU

NA K CL

READY

NO

PRINT

FUNCTIONS?

NO

QC/STD/DIALYSATE

/URINE SAMPLE?

NO

DAILY

MAINTENANCE?

NO

OPERATOR

FUNCTIONS?

LEGEND

Display prompt

Action performed by analyzer

2-second display prompt

Decision-making by analyzer

18

NO

PROGRAM

INSTRUMENT?

NO

SERVICE

FUNCTIONS?

NO

NO

CALIBRATION?

3 Measurement Sequence - 9180

NA K CL READY

OPEN

FLAP

Please

Introduce Sample

CHECK SS

VOLTAGE

> air voltage

NO

YES

NO

< air voltage

PRINT

FUNCTIONS?

Open Sample Door

Introduce Sample

DOOR OPENED

WITHIN 2s?

YES

Remove Sample and

Wipe Probe

Please Close

Sample Door

Serum Sample

in Process 49

Na K Cl

151 5.1 114

YES/NO

1 min.

Remove Sample and

Wipe Probe

2s 2s

Please Close

Sample Door

FLAP

CLOSED

Blood Sample

in Process 49

Na K Cl

151 5.1 114

FLAP

CLOSED

YES/NO

1 min.

19

4 Print Functions Menu - 9180

NO

YES

PRINT

FUNCTIONS?

YES

Print Last

Sample Report?

NO

Print

Cal. Report?

NO

Print QC Values

and Statistics?

NO

Remain in Print

Functions?

YES

YES

YES

NO

QC/STD/DIALYSATE

/URINE SAMPLE?

PRINTING...

PRINTING...

PRINTING...

NA K CL READY

NA K CL READY

20

5 QC/Standard/Dialysate/Urine Sample Menu - 9180

QC/STD/DIALYSATE

/URINE SAMPLE?

YES

QC Level 1

Sample?

2 min.

2 min.

2 min.

2 min.

2 min.

2 min.

2 min.

NO

QC Level 2

Sample?

NO

QC Level 3

Sample?

NO

Standard

Sample?

NO

Bicarbonate

Sample?

NO

Acetate

Sample?

NO

Urine

Sample?

NO

NO

YES OPEN SAMPLE

OPEN

YES OPEN SAMPLE

OPEN

YES OPEN SAMPLE

OPEN

YES OPEN SAMPLE

OPEN

YES OPEN SAMPLE

OPEN

YES OPEN SAMPLE

OPEN

YES OPEN SAMPLE

OPEN

DAILY

MAINTENANCE?

Open Sample Door

Introduce Sample

Open Sample Door

Introduce Sample

Open Sample Door

Introduce Sample

5s

Open Sample Door

Introduce Sample

5s

Open Sample Door

Introduce Sample

5s

Open Sample Door

Introduce Sample

5s

Open Sample Door

Introduce Sample

Introduce Sample Wipe Probe/Close

IN

2s

2s

2s

2s

2s

2s

VALUES

REJECTED!

VALUES

ACCEPTED!

Introduce Sample Wipe Probe/Close

VALUES

REJECTED!

VALUES

ACCEPTED!

Introduce Sample Wipe Probe/Close

VALUES

REJECTED!

VALUES

ACCEPTED!

Introduce Sample Wipe Probe/Close

Introduce Sample Wipe Probe/Close

Introduce Sample Wipe Probe/Close

Introduce Sample Wipe Probe/Close

NO

YES

IN

NO

YES

IN

NO

YES

IN

IN

IN

IN

Sample Door

2s

Store

Values?

2 min

NA K CA READY

Sample Door

2s

Store

Values?

2 min

NA K CA READY

Sample Door

2s

Store

Values?

2 min

NA K CA READY

Sample Door

Sample Door

Sample Door

Sample Door

CLOSED

2s

CLOSED

2s

CLOSED

2s

CLOSED

CLOSED

CLOSED

CLOSED

QC Level 1

in Process 49

Na K Ca

99.6 5.34 1.250

QC Level 2

in Process 49

Na K Ca

99.6 5.34 1.250

QC Level 3

in Process 49

Na K Ca

99.6 5.34 1.250

Standard Sample

in Process 49

Bicarb. Sample

in Process 49

Acetate Sample

in Process 49

Urine Sample

in Process 49

Na K Ca

158.8 5.82 1.250

1 min. NO/YES

Na K Ca

158.8 5.82 1.250

1 min. NO/YES

Na K Ca

158.8 5.82 1.250

1 min.

NO/YES

Na K Cl

238 18.8 198

1 min. NO/YES

Remain in QC/

Std/Urine Sample?

YES

NO/2 min.

NA K CA READY

21

6 Daily Maintenance Menu - 9180

DAILY

MAINTENANCE?

Perform Daily

Cleaning?

Perform Daily

Conditioning?

Remain in Daily

YES

Maintenance?

CLEANING AND/OR

COND. PERFORMED?

YES

NO

NO/1min.

NO

YES

OPEN

YES

OPEN

YES

OPERATOR

FUNCTIONS?

Open Sample Door

Introduce Sample

Open Sample Door

Introduce Sample

30 SECOND

STABILIZATION

OPEN CLOSE YES

OPEN CLOSE YES

Wipe Probe/Close

Sample Door

Cleaning Solution

not detected!

Wipe Probe/Close

Sample Door

Condition. Solution

not detected!

CALIBRATE

Cleaning Solution

detected?

NO

Condition. Solution

detected?

NO

NA K CA READY

CLEAN

CONDITION

22

NO

Calibration

due?

NO

YES

7 Operator Functions Menu - 9180

*****STATUS*****

**NO SnapPak**

Check/Change

Select Parameter

Sample Number?

Operator Func?

NO

OPERATOR

FUNCTIONS?

YES

SnapPak?

NO

Go to

Standby Mode

NO

Set

Time/Date?

NO

Configuration?

NO

NO

Take out of

Operation?

NO

Remain in

YES

NO

YES

YES

YES NO NO NO

YES

YES

PROGRAM

INSTRUMENT?

37%

remaining

***STANDBY!***

YES -> READY

YES/NO

Leave

Standby Mode?

YES

NO YES

PRESS YES

WITHIN 2s

Date: 01-FEB-94

Time: 12:00 ok ?

Date: 01-FEB-94

Time: 12:00 ok

NO

YES

Sel. Parameter:

[Na] [K] [ ] ok?

Are you sure?Reset

Shutdown Plug and

Water installed?

Shutdown

Complete

Turn Power Off

YES YES YES

YES

NO

YES/

NO

YES

YES

YES

Change

SnapPak?

NO

IS

CALIBRATION

DUE?

YES

Daily

Cleaning?

YES

NA K READY

Sel. Parameter:

[Na] [K] [Cl] ok?

SET SAMPLE

NUMBER TO 0

Transp Housing

Ref installed?

Do You Wish to

DELETE all Data?

YES

NO

NO NO

NO

YES YES

Pack

detected?

GLOBAL*

New SnapPak

installed?

NO

Daily

Conditioning?

CONDITIONCLEAN

30 SECOND

STABILIZATION

CALIBRATE

Sel. Parameter:

[Na] [K] [Ca] ok?

Sel. Parameter:

([Na]) [ ] [Li] ok?

Remove Water

and Press YES

Pump Windings

Relieved?

NO

YES

YES

YES

YESYES

*Background check in all menus

except "Take out of Operation?"

YES

Fluid Counter

reset to 100%

Maint. due?

CALIBRATE

Na K READY

Remain in Daily

Maintenance?

CALIBRATION

YES

Parameter

NO

Electrodes

Sel. Parameter:

[Na] [K] [Li] ok?

YES

NO

Sel. Parameter:

[Na] [ ] [Li] ok?

All Electrodes

& Plug Removed?

5 Relief Clamps

Inserted?

New Pack

Prime ...

IS

DUE?

New

added?

in place?

YESYES

NO

YES

1min/NO

NO

YES

YES

YES

NO

YES

23

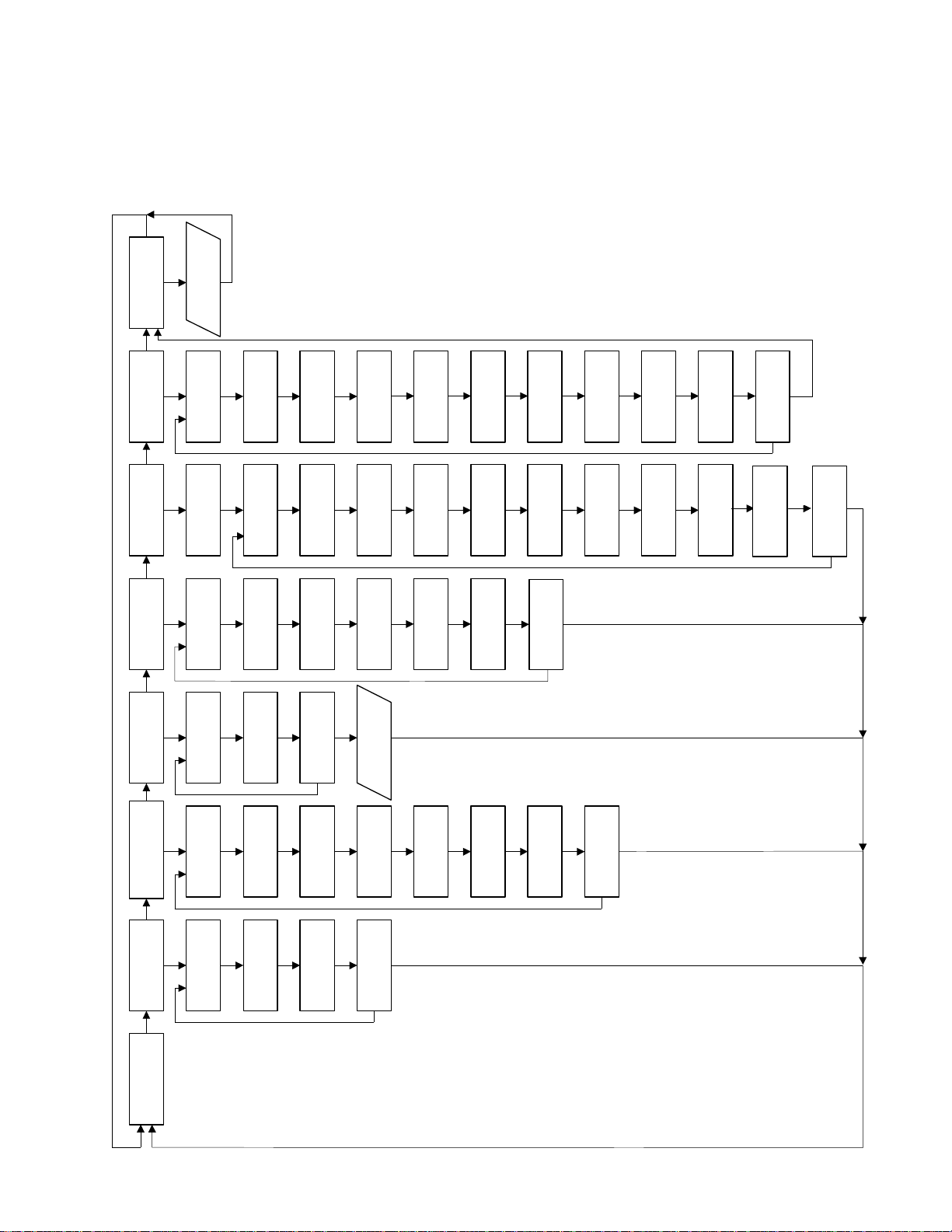

8 Program Instrument Menu - 9180

PROGRAM

INSTRUMENT?

YES

Enter Code:

AAA

CORRECT

Program QC

Level 1 Ranges?

NO

Program QC

Level 2 Ranges?

NO

Program QC

Level 3 Ranges?

NO

Program

Normal Ranges?

NO

Program

Corr Factors

NO

Program Bicarb.

Corr Factors

NO

Program Acetate

Corr Factors

NO

Program Urine

Corr Factors

NO

NO

IN-

CORRECT

YES

NO

YES

YES

YES

YES

SERVICE

FUNCTIONS?

YES

CODE ERROR!

RETRY?

Current Lot: 0000

Change Lot?

NO

Additional

Parameters?

YES

"see Level 1"

"see Level 1"

Na low = 136

Na high = 145 ok?

Reset Corr

Factor (default)?

YES

Reset Bicarb.

Factor (default)?

YES

Reset Acetate

Factor (default)?

YES

Reset Urine

Factor (default)?

YES YES

NO

YES NO YES

Print old Values

and Statistics?

K low = 1.5

K high = 15.0 ok?

Cl low = 050

Cl high = 200 ok?

YES YES

K low = 03.5

K high = 05.1 ok?

NOYES

Input/Verify

Corr Factors?

NO

Input/Verify

Bicarb. Factors?

NOYES

Input/Verify

Acetate Factors?

NOYES

Input/Verify

Urine Factors?

NO

New Lot!

Delete old Data?

Na low = 040

Na high = 205 ok?

Ca low = 0.2

Ca high = 5.0 ok?

YES

NO YES

YES

NO

YES

NO YES

YES

NO YES

Remain in

Corr Factors?

NO

YES

Remain in

Bicarb Factors?

NO

YES

Remain in

Acetate Factors?

NO

YES

Remain in

Urine Factors?

NO

Enter last 4 Dig

of Lot#: 0000

YESYESYES

Enter last 4 Dig

of Lot#: 0000 ok?

Li low = 0.1

Li high = 6.0 ok?

Na (b) = +00.0

Na (m) = 1.000

Na (b) = +00.0

Na (m) = 1.000

Na (b) = +00.0

Na (m) = 1.000

Na (b) = +00.0

Na (m) = 1.000

YES

NO

YESYES YES

K (b) = +00.0

K (m) = 1.000

YES

K (b) = +00.0

K (m) = 1.000

K (b) = +00.0

K (m) = 1.000

K (b) = +00.0

K (m) = 1.000

YES

YES

YES

YES

YES

24

Program Printer

Setup?

NO

Program

Interface?

NO

Remain in

Program Func?

YES

YES

NO

Patient Report

off?

YES

Activate

Data Link?

YES/NO

NA K READY

NO

Print two

Patient Reports?

YES/

NO

Automatic

Cal Report?

YES/

NO

Enter Comment

Line?

NO YES

YES

Enter Comment:

_

Loading...

Loading...