AVL 415SE Maintenance Manual

October 2011

AT4234E, Rev.00

Maintenance Guide

AVL 415SE SMOKE METER

FROM S/N 7000)

Copyright 2011 AVL List GmbH, Graz - Austria

The contents of this document may not be reproduced in any form or communicated to any third party without the

prior written consent of AVL. While every effort is made to ensure its correctness, AVL assumes no responsibility

neither for errors and omissions which may occur in this document nor for damage caused by them.

All mentioned trademarks or registered trademarks are owned by their respective owners.

All rights reserved.

Warnings and Safety Instructions

This manual contains important warnings and safety instructions to be

observed by the user.

The product described in this manual is intended for one specific area of application which is defined in the instructions. The manual also explains the essential

requirements for the application and operatio n of the product as well as safety

precautions to ensure smooth operation. AVL can provide no guarantee or

accept any liability for applications other than those described in this manual or

for applications where the essential requirements an d safety precautions are no t

met.

The product may only be used and operated by qualified personnel capable of

observing the necessary safety precautions. All accessories and equipment

used with the product must be supplied or approved by AVL. The operating principle of this product is such that the accuracy of the measurement results

depends not only on the correct operation and functioning of the product, but

also on a variety of peripheral conditions beyond the control of the manufacturer .

The results obtained from this prod uct the refo re must be exa mined by an e xper t

(e.g. for plausibility) before any action is taken that is based on the results.

All adjustment and maintenance work necessary on instrument s when ope n and

under voltage must be carried out by a professional technician who is aware of

the dangers.

All repairs to the product are to be carried out by the manufacturer or qualified

service personnel only.

When the product is in use, an expert must ensure that neither th e test object nor

the testing equipment is operated under conditions that could lead to damage or

injury.

Warnings and Safety Instructions

3

AVL 415SE Smoke Meter — Maintenance Guide

4

Warnings and Safety Instruct ions

AVL 415SE Smoke Meter — Maintenance Guide

Table Of Contents

Table Of Contents

Warnings and Safety Instructions................................................................................................................ 3

1 What You Should Know.................................................................................................... 7

1.1 Safety Instructions.................................................................................................................... 7

1.2 About the AVL 415SE Smoke Meter........................................................................................ 7

1.3 About this Documentation ........................................................................................................ 8

1.3.1 Typografic Conventions......................................................................................................8

1.3.2 We Want to Hear from You.................................................................................................9

2 Maintenance .................................................................................................................... 11

2.1 Procedure............................................................................................................................... 11

5

2.2 Service Intervals..................................................................................................................... 12

2.2.1 AVL Service Engineer - Annual Maintenance Activities....................................................12

2.2.2 Service Engineer - Maintenance Schedule.......................................................................13

2.3 Components........................................................................................................................... 16

2.3.1 Disposal Instructions.........................................................................................................16

2.3.2 Paper Feed Mechanism....................................................................................................17

2.3.2.1 Lubricating and Cleaning Intervals ...................................................................17

2.3.2.2 Lubrication Points.............................................................................................19

2.3.3 Blackened Filter Area........................................................................................................22

2.3.4 Sampling Probe and Sampling Line..................................................................................23

2.3.5 Suction Unit ......................................................................................................................24

2.3.6 Reflectometer Head..........................................................................................................27

2.3.7 Clamping Lever and Ratchet Clip.....................................................................................28

2.3.8 Camshaft ..........................................................................................................................30

2.3.9 Fine Filters........................................................................................................................31

2.3.10 Filter Paper Transport and Spool Device..........................................................................32

2.3.11 Cooling..............................................................................................................................33

2.3.12 Pump ................................................................................................................................34

2.3.13 Pressure Reduction ..........................................................................................................36

3 Checks..............................................................................................................................37

3.1 Sampling Volume Check........................................................................................................37

3.1.1 Sampling Volume Check with AVL 4210 Instrument Controller........................................37

3.1.2 Sampling Volume Check via Terminal..............................................................................38

3.1.3 Check the Metering Pipe...................................................................................................40

3.1.4 Examples of External Volume Measuring Systems..........................................................40

3.2 Leak Check............................................................................................................................. 41

3.2.1 Leak Check in SERVICE MODE (for Firmware Version 2.10 and Higher).......................42

AVL 415SE Smoke Meter — Maintenance Guide

6

Table Of Contents

4 Parts Lists ........................................................................................................................43

4.1 Consumables.......................................................................................................................... 43

4.2 Wear Parts.............. ... .... ... ....................................... ... ... ... ....................................... ............... 43

4.3 Spare Parts............................................................................................................................. 44

4.4 Maintenance Tools................................................................................................................. 48

AVL 415SE Smoke Meter — Maintenance Guide

1 What You Should Know

1.1 Safety Instructions

This documentation contains important Warnings and Safety Precautions

which should be observed by the user. Only by careful observance of these

requirements and safety precautions, a smooth operation can be guaranteed.

1.2 About the AVL 415SE Smoke Meter

Minimize your system downtimes by means of proactive measures. Our competent service engineers will carry out inspections and maintenance with technical

professionalism and cost efficiency in mind. Using original spare parts guarantees high system reliability. AVL preventive maintenance assures the highest

possible availability of the system and devices.

What You Should Know

7

Your benefits at a glance:

Best availability of equipment due to minimized down times

Guaranteed service quality through certified engineers

Easy budgeting due to transparent maintenance cost s

Maintenance plans optimized for the used equipment and its applications

A typical preventive maintenance proc ed ur e co mp r i ses the follow ing steps:

Visual check

Performance checks

Cleaning

Replacing wear parts

Calibration and re-adjustment

Calibration protocols

Failure diagnostics

Recommendation for repair

Required manpower:

The required time for an annual maintenance by an AVL Service Engineer is

6hours.

Obviously, this time might depend of the usage and the environment conditions

of the device.

The frequency we recommend in this document is based on normal operating

hours (8 hours/working day).

Information

This manual refers to the maintenance of a Smoke Meter 415SE.

Handling and actions are mainly the same as for the 415S Smoke Meter, but the

spare parts can be different.

AVL 415SE Smoke Meter — Maintenance Guide

8

What You Should Know

1.3 About this Documentation

The documentation adresses service enginee rs who perform ma intenance t asks

of the AVL 415SE Smoke Meter. All relevant tasks are described, all necessary

wear and spare parts are listed.

Detailed knowledge about the device and the relevant safety regulations is

essential.

For detailed information on the AVL 415SE Smoke Meter see the corresponding

manuals:

AT1240E 415S Smoke Meter, Operating Manual

AT3648E 415SE Smoke Meter, Product Guide

AT3803E 415SE Smoke Meter, Calibration Manual

The descriptions in this manual are based on the AVL Instrument Controller

IC 4210.

If the DUI (Device User Interface) is used for the maintenance work, see also:

AT3569E 415S Smoke Meter, Device User Interface, User’s Guide

1.3.1

Typografic Conventions

Safety messages:

WARNING

WARNING indicates a hazardous situation which – if not avoided – could result

in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which – if not avoided – could result in

minor or moderate injury.

Additional messages:

NOTICE

This text indicates situations or operation errors which could result in property

damage or data loss.

Information

This text indicates important information or operating instructions. Not observ ing

these instructions could inhibit or impede you from succesfully completing the

tasks described in this documentation.

AVL 415SE Smoke Meter — Maintenance Guide

What You Should Know

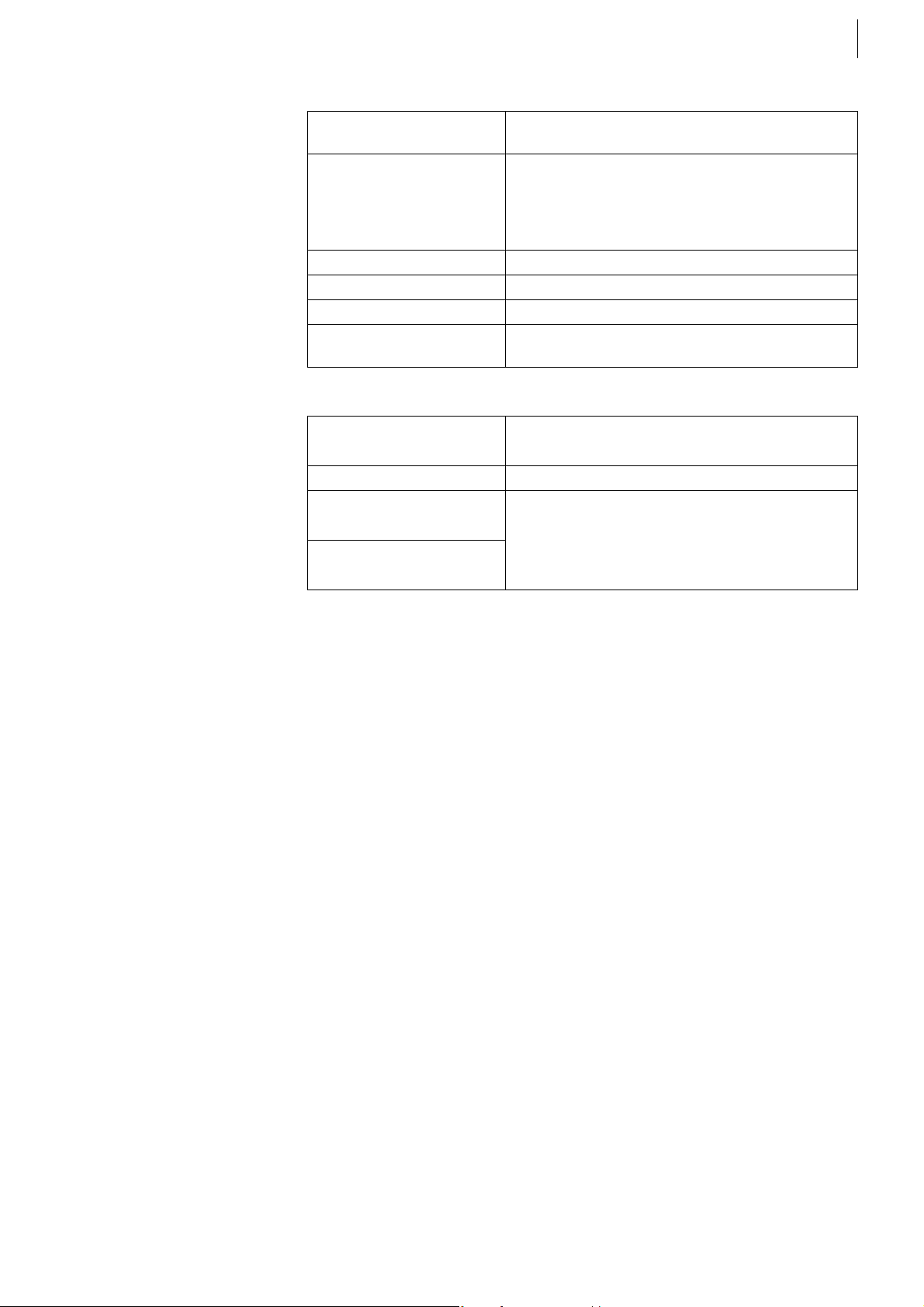

Standard text styles:

Bold Parameters; control elements in windows and

dialog boxes; important text

Italics Cross-references; foreign-language or new

terms; wild-card for elements that need to be

entered by the user, i.e. characters or text. If you

read, for example, macro name, you are required

to type the name of a macro.

UPPERCASE LETTERS Operating modes

Courier

Programming examples; source code

Times New Roman Formulas

Menu | Option Description of how to select a menu item from a

given menu

Lists:

9

1.3.2

1.

2.

• One-step instructions

–

–

We Want to Hear from You

Your comments and suggestions help us to improve the quality and practical

relevance of our manuals.

If you have any suggestions for improvement, please send them to:

docu@avl.com

We look forward to hearing from you!

Step-by-step procedures with a given sequence

Unordered series of concepts, items or options

AVL 415SE Smoke Meter — Maintenance Guide

10

What You Should Know

AVL 415SE Smoke Meter — Maintenance Guide

2 Maintenance

2.1 Procedure

NOTICE

For permanent operation of the measuring device (fully automated endurance

runs, 24 h/day, 6 … 7 days/week), a service is recommended every 3 weeks.

A full service or replacing the pump is recommended every 3 months.

When the device is put to average use, we recommend:

1. Each time the paper is changed, perform the following steps:

– Inspect the reflectometer head - clean if necessary (do not forget to

clean also the light gate 1).

– Inspect the two fine filters and replace if there are any signs of soiling.

– Inspect the blackened filter area.

– Perform a leak check.

– Check white value disk for soiling and clean if necessary.

– Lubricate moving parts of the camshaft and the ratchet clip by using

Teflon lubricant oil (material number: HS0064) or Teflon lubricant spray

(material number: HS0058).

2. After 300 operating hours or 10 00 0 measurement s (correspo nds to 5 … 10

paper rolls - material number HP0153SP) do the following:

– Check the reflectometer head.

– Check the sampled volume.

– Clean sampling line tube with ultra-clean, oil-free and water-free com-

pressed air.

– Clean the light gate 1 with ultra-clean, oil-free and water free com-

pressed air.

– Check filter mat for cooling air.

– Check the ratchet clip and the clamping lever.

– Carry out all the activities described in the following sections.

– Replace all fine filters.

– Clean and lubricate moving parts of camshaft and ratched clip using

Teflon lubricant spray (material number HS0058) or Teflon lubricant oil

(material number HS0064).

– Check pump noise and check nominal pump flow.

Maintenance

11

AVL 415SE Smoke Meter — Maintenance Guide

12

Maintenance

2.2 Service Intervals

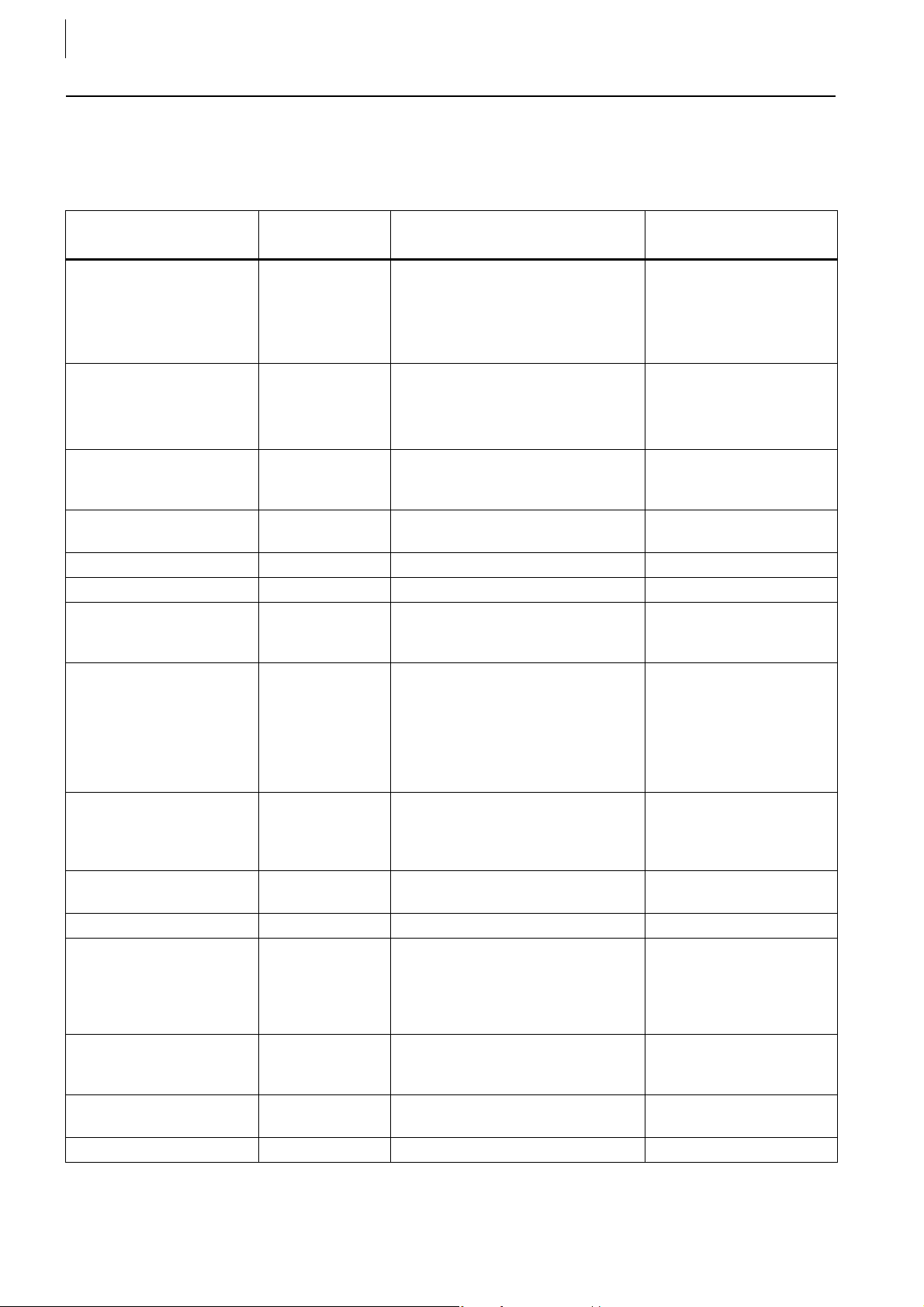

2.2.1

Component / Test Lifetime /

Leak check Annually For checks of sample lines and

Reflectometer head Annually Check and clean or replace if

Light gate 1 Annually Check and clean if necessary. If damaged, replacement

Camshaft Annually Check and clean or replace if

Fine filters Annually Replace. Annually

White value plate Annually Clean the deposit on the standard. If necessary.

Filter paper Annually Check the homogeneous black-

Sealing ring of the

suction unit

Clamping piece

rolls, axles

press fit bush

bearing

Sampling probe,

sampling line

Filter mat Annually Replace. Annually

Check sampled volume Annually Check. Replacement of the glass

Adjustment of the transport paper mechanism

Adjustment of the slip

clutch

Ratchet clip Annually Replace. Annually

AVL Service Engineer - Annual Maintenance Activities

Maintenance Replacement

Service interval

probes:

supported on SERVICE MODE

only perform with sampling probe &

line

necessary.

Adjustment if necessary and cali-

bration.

necessary.

ening with exactly delineated round

contour.

Annually Check there is no deposit, clean if

needed.

Glue the sealing rings into the

clamping device (suction unit).

Check the sealing ring for defects

and correct sealing ring position.

Annually Clean and lubricat e all po ints. If necessary.

Annually Check and clean. 1 000 – 2 000 operating

Annually Function check and adjustment

necessary every time spare parts

are exchanged.

Annually Check the tension and adjustment

if necessary.

–

Every 2 years

is done by an A VL Service

Engineer.

Every 2 … 3 years or after

3 000 operating hours.

–

Replacement of the

sealing rings if damaged.

hours.

caliber of the volume

tester is necessary when

it is scratched, or contaminated with dirt.

–

–

Tab. 1

AVL 415SE Smoke Meter — Maintenance Guide

Maintenance

13

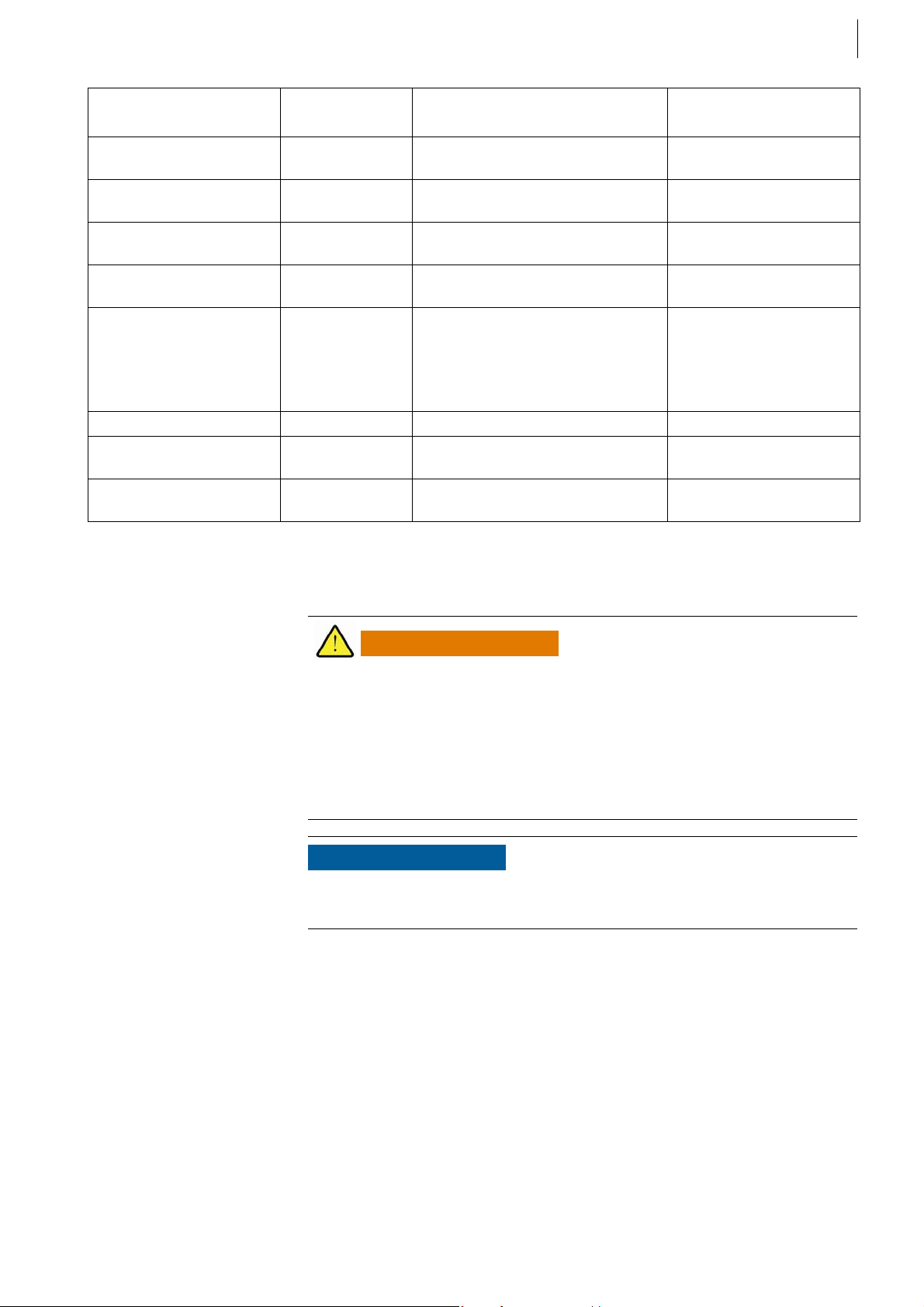

Component / Test Lifetime /

Service interval

Clamping lever Annually Visual check. If damaged or if any part

Pump Annually Check and replace if necesary. Every 2 000 - 3 000 oper-

Nipple & hose connections

Cleaning of electronical

boards

Filters of shop air filter

unit

Check valve Annually Check and replace if necesary. Annually

Pressure reduction

assembly

Pressure switch of shop

air option

Tab . 1

Annually Replace. Annually

Annually Clean with high purity compressed

air.

Annually Check and replace if necessary. once every 1 … 2 years;

Annually Check. After assembly.

Annually Check and adjust if necessary. Annually

Maintenance Replacement

is bent off.

ating hours.

If necessary or defective.

much more often for oil

lubricant compressors:

at least: every

1…2months

2.2.2

Service Engineer - Maintenance Schedule

WARNING

Fire hazard

When using the required appliances like sprays, mounting pastes, lubricants,

always observe the relevant handling instructions and safety measures of the

various products.

All sprays used are a fire hazard and highly inflammable. Installation work using

the appliances on and inside measurement devices and on test beds must only

be carried out on cooled-down parts and in well ventilated areas.

NOTICE

The compressed air used to clean, has to be absolutely free from oil, water, and

particles.

For the disposal of environmentally sensitive substances, see the AVL 415S

Smoke Meter Operating Manual, chapter Disposal of Environmentally Sensitive

Substances.

AVL 415SE Smoke Meter — Maintenance Guide

14

Maintenance

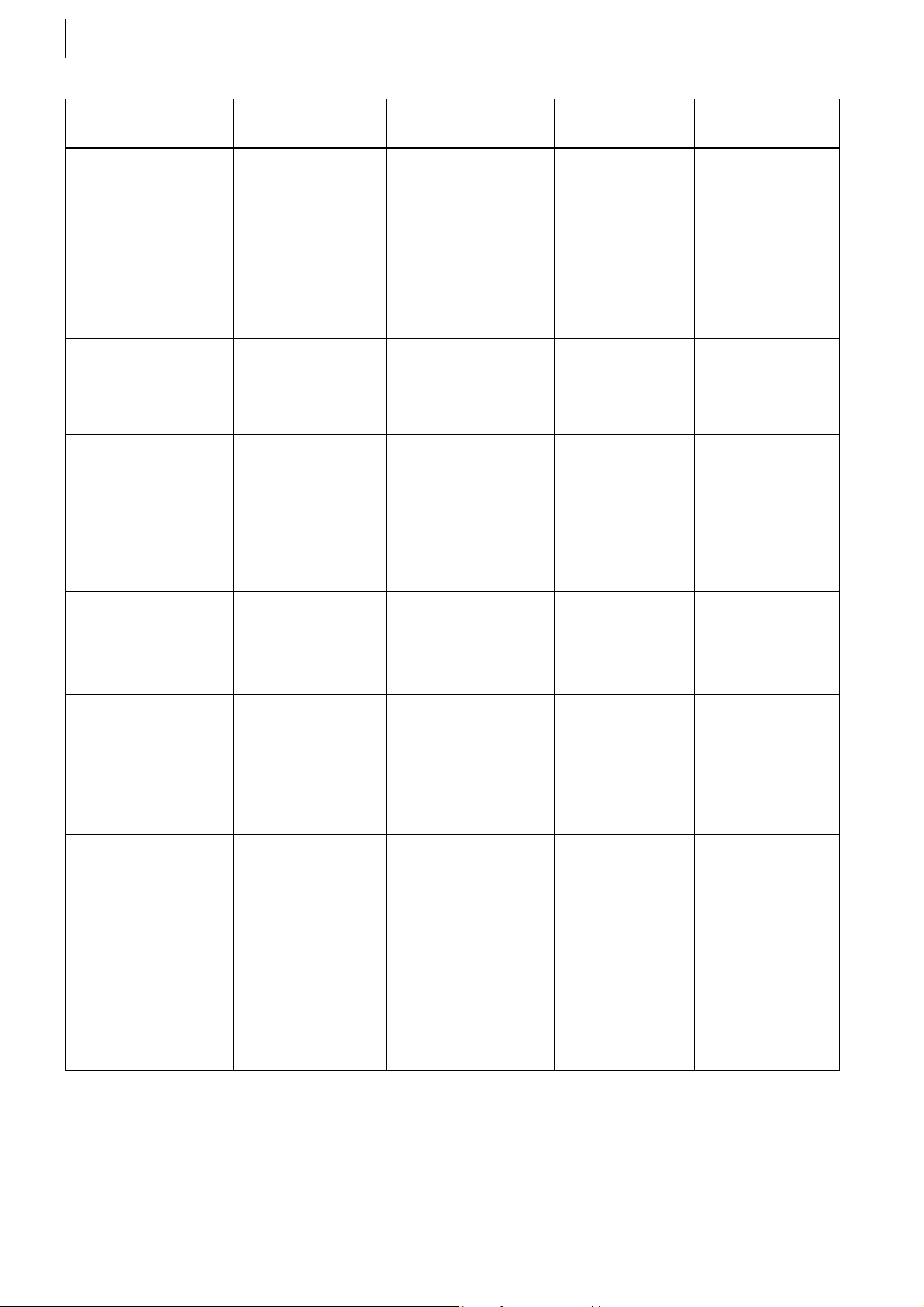

Component / Test Lifetime /

Service interval

Leak check Minimum every day.

After every filter

paper change.

After every manipulation of the paper

transport.

Before & after every

volume tester calibration.

Reflectometer head Every time the filter

paper is exchanged.

Light gate 1 Every time the filte r

paper is exchanged.

Camshaft Every time the filter

paper is exchanged.

Fine filters Every time the filter

paper is exchanged.

White value plate Every time the filter

paper is exchanged.

Filter paper Every time the filter

paper is exchanged.

Sealing ring of the

suction unit

Minimum every 5

times of filter paper

exchanged.

Maintenance Replacement Procedure

For checks of sample

lines and probes:

supported on

SERVICE MODE only

perform with sampling

probe & line

Check and clean if

necessary with a

puffer or a soft brush

or with compressed

air.

Check and clean if

necessary with

compressed air.

Check and clean if

necessary with

compressed air.

Check. Following the

Clean the deposit on

the standard with a

soft, wet cloth.

Check the homogeneous blackening with

exactly delineated

round contour.

Check the backside of

the filter paper fpr

back flushed particles.

Check if there is no

deposit, clean if

necessary with a soft

or a damp cloth.

Glue the sealing rings

into the clamping

device (suction unit)

with Adhesive

3M-B20.

Check the sealing ring

for defects and correct

ling ring position.

sea

– Section Leak

Check on page 41

Every 2 years Section Reflecto-

meter Head on

page 27

If damaged –

Replacement is

done by an AVL

Service Engineer.

Every 2-3 years or

after 3 000 operating hours.

usage conditions.

– Section Clamping

– Section Blackened

Replacement of

the sealing rings if

damaged; in this

case also order

mounting ring

30 mm.

Section Camshaft

on page 30

Section Fine Filters

on page 31

Lever and Ratchet

Clip on page 28

Filter Area on

page 22

Section Suction

Unit on page 24

Tab. 2

AVL 415SE Smoke Meter — Maintenance Guide

Maintenance

15

Component / Test Lifetime /

Service interval

Clamping piece

rolls, axles

press fit bush

bearing

Sampling probe,

sampling line

Required after 4-5

exchanges of the

filter paper roll,

or after 10 000

measurements,

or after 300 operating hours of the

pump.

For Diesel engine:

minimum once a

week,

or after 300 operating hours of the

pump.

For low meas. emission:

once a week

For high HC

concentration:

everyday

Maintenance Replacement Procedure

Clean and lubricate all

points with Teflon

lubricant spray or

Teflon lubricant oil.

Check and clean with

compressed air.

If necessary. Section Lubri-

cating and

Cleaning Intervals

on page 17,

section Lubrica-

tion Points on

page 19

1000 – 2000

operating hours.

Section Sampling

Probe and

Sampling Line on

page 23

For measuring

systems with activated option "Shop

Air" the cleaning

may be omitted or

can be performed

via the shop air

purging option

Filter mat Every 300 oper-

ating hours of the

pump,

or after 10 000

measurements

Check sampled

volume

Recommended:

every 300 operating

hours of the pump,

or after 10 000

measurements.

Necessary:

after 1 000 operating hours.

Visual check and

clean if necessary with

compressed air.

Check recommended

after:

Installing/reinstalling

the device on the test

bed.

When changing the

dead volume.

After cleaning the

device from the soot

contamination.

After repairing the

device.

Re-adjustment.

- Section Cooling on

page 33

Replacement of

the glass caliber of

the volume tester

is necessary if it is

scratched or

contaminated with

dirt.

Section Sampling

Volume Check on

page 37

Tab . 2

AVL 415SE Smoke Meter — Maintenance Guide

Loading...

Loading...