Workshop Dobby Loom

User’s Manual

Figure 1 - 16" Workshop Dobby

Loom

AVL Looms

2360 Park Avenue

Chico, CA 95928-6785

800 626-9615

530 893-4915

530 893-1372 (fax)

Figure 2 - 24" Workshop Dobby

Loom

All Rights Reserved Worldwide

http:\\www.avlusa.com

e-mail: sales@avlusa.com

May 2018

Revision 1 Instructions

© Copyright 2018

Workshop Dobby Loom User’s Manual Introductory Information

Introductory Information ................................................................................................................ 1

Safety .......................................................................................................................................... 2

Introduction ................................................................................................................................. 4

WDL Specifications .................................................................................................................... 4

Parts............................................................................................................................................. 5

Tools You Will Need .................................................................................................................. 5

WDL Assembly ............................................................................................................................ 11

Assembly................................................................................................................................... 12

Interchangeable Design Unit (IDU) .......................................................................................... 15

Beater ........................................................................................................................................ 18

Treadles ..................................................................................................................................... 21

Beams ........................................................................................................................................ 23

Compu-Dobby® ....................................................................................................................... 28

Traveling with the WDL ............................................................................................................... 31

Traveling With Your Workshop Dobby Loom ......................................................................... 32

Using the WDL ............................................................................................................................. 37

Warping Section........................................................................................................................ 38

Threading, Sleying, and Tying On ............................................................................................ 50

Weaving Procedures ................................................................................................................. 53

Additional Loom Information ....................................................................................................... 55

Loom Maintenance ................................................................................................................... 56

Troubleshooting ........................................................................................................................ 57

The Fine Print ............................................................................................................................... 63

AVL Customer Service ............................................................................................................. 64

AVL Warranties ........................................................................................................................ 64

Notice to Users in the European Union .................................................................................... 65

ABLE OF CONTENTS

T

Table of Contents Page | i

Workshop Dobby Loom User’s Manual Introductory Information

INTRODUCTORY

INFORMATION

NTRODUCTORY INFORMATION

I

Introductory Information Page | 1

Introductory Information Workshop Dobby Loom User’s Manual

AFETY

S

Before Getting Started:

Please read the entire manual before using the loom.

Warnings:

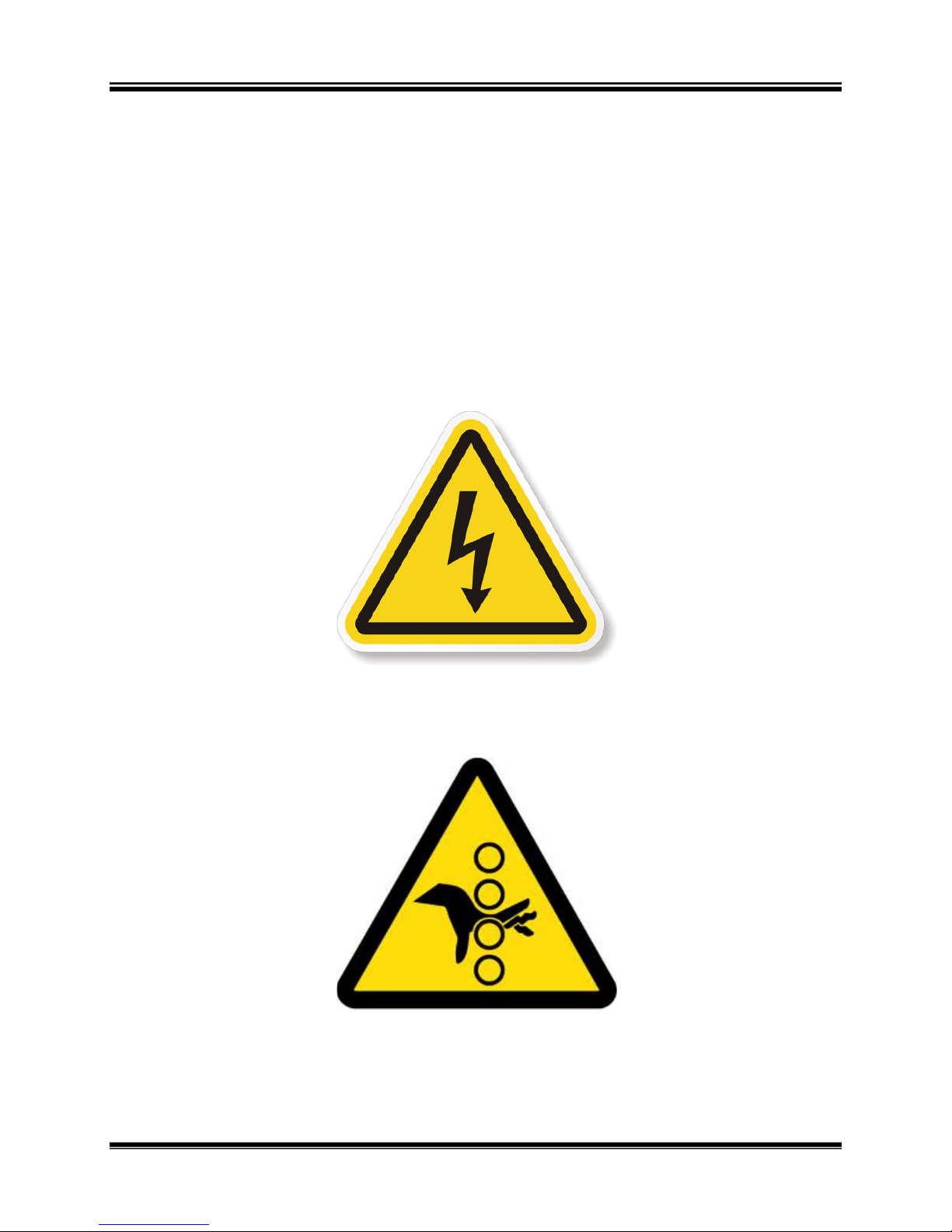

WARNING:

EQUIPMENT SHOULD ONLY BE USED FOR TEXTILE MANUFACTURING. IF

THE EQUIPMENT IS USED IN A MANNER NOT SPECIFIED BY THE

MANUFACTURER, THE PROTECTION PROVIDED BY THE EQUIPMENT MAY

BE IMPAIRED.

WARNING:

ELECTRICAL SHOCK HAZARD. DO NOT TAMPER WITH ELECTRICAL WIRES

OR OPERATE THE LOOM WITH SAFETY PANELS OPENED OR REMOVED.

WARNING:

PINCH, CRUSH, AND FINGER CUT-OFF HAZARDS. DO NOT OPERATE THE

LOOM WITH SAFETY PANELS OPENED OR REMOVED. DO NOT PLACE

HANDS IN MOVING MECHANISMS OR SCISSORS.

Page | 2 Safety

Workshop Dobby Loom User’s Manual Introductory Information

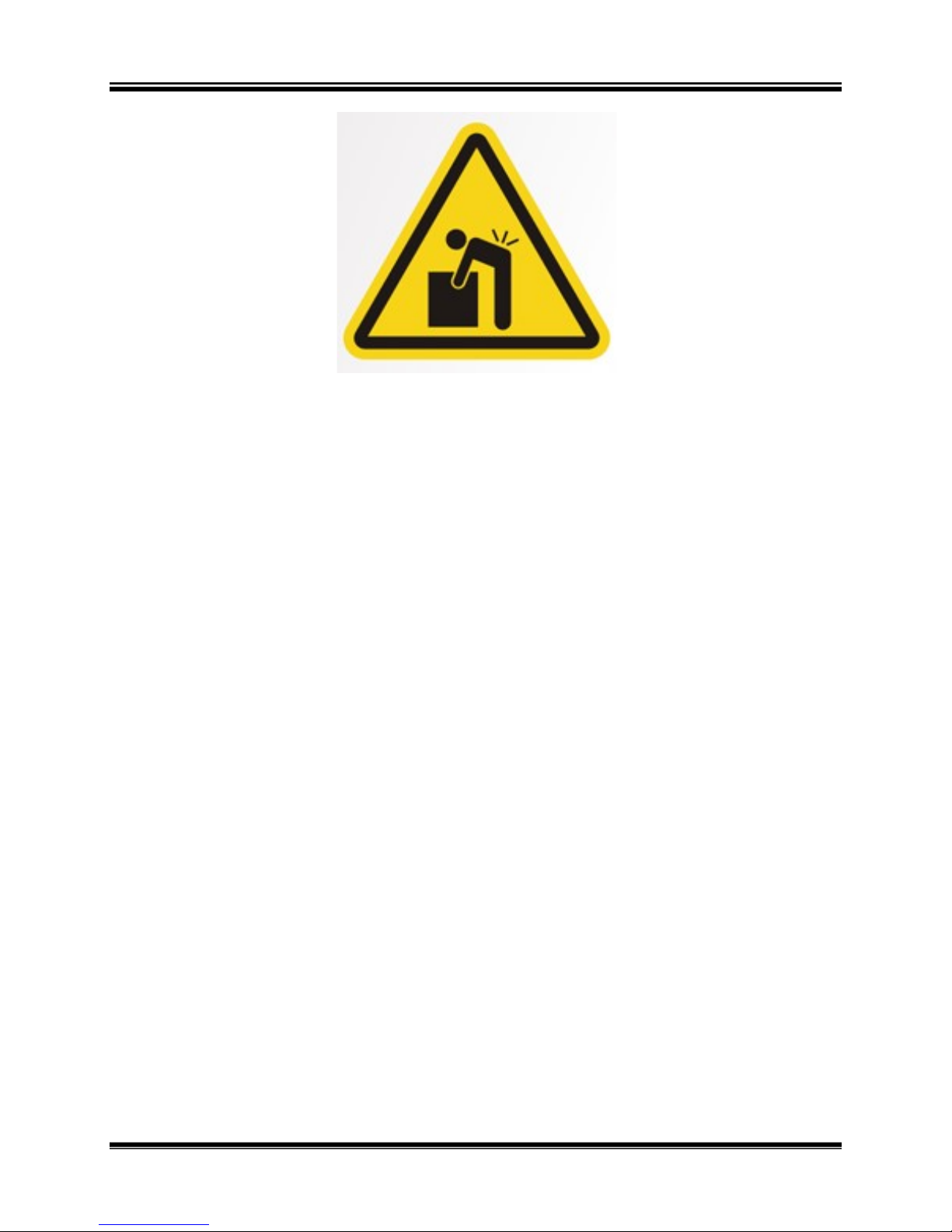

WARNING:

EQUIPMENT PANELS ARE AWKWARD AND HEAVY. TO AVOID MUSCLE

STRAIN OR INJURY, USE PROPER LIFTING TECHNIQUES AND A HELPER.

WARNING:

DO NOT POSITION EQUIPMENT IN A WAY TO BLOCK OR IMPEDE ACCESS

TO DISCONNECTING DEVICES, EMERGENCY STOPS, OR ON/OFF BREAKER

SWITCHES

WARNING:

USE OF CONDUCTIVE FIBER OR YARN ON OR AROUND THIS EQUIPMENT

WILL VOID WARRANTY AND MAY DAMAGE EQUIPMENT.

WARNING:

THIS EQUIPMENT IS CLASSIFIED FOR LIGHT INDUSTRIAL ENVIRONMENT

ONLY. OPERATION OF HIGH-CURRENT DRAW EQUIPMENT (EX. MIG

WELDER) ON THE SAME ELECTRICAL CIRCUITS MAY CAUSE EQUIPMENT

FAILURE.

Safety Features:

Covers and shielding separate weaver from moving components where pinch

hazards exist. Do not reach under covers and shielding while the loom is

operating.

Safety Page | 3

Introductory Information Workshop Dobby Loom User’s Manual

NTRODUCTION

I

Congratulations on your purchase and welcome to the AVL family. Your

Workshop Dobby Loom (WDL) is designed to provide you with years of

enjoyable service. And, with your purchase, you are entitled to AVL’s world

class loom support. Please contact us with any questions at info@avlusa.com

or 1-530-893-4915.

This manual provides setup and use information for all current WDL loom

configurations, including:

16” weaving width (16” WDL)

24” weaving width (24” WDL)

8, 16, or 24 harness configurations

Single or double Warp Beam configurations

Please read the entire manual before starting the assembly process. Also,

please note which diagrams and sections are applicable to your loom.

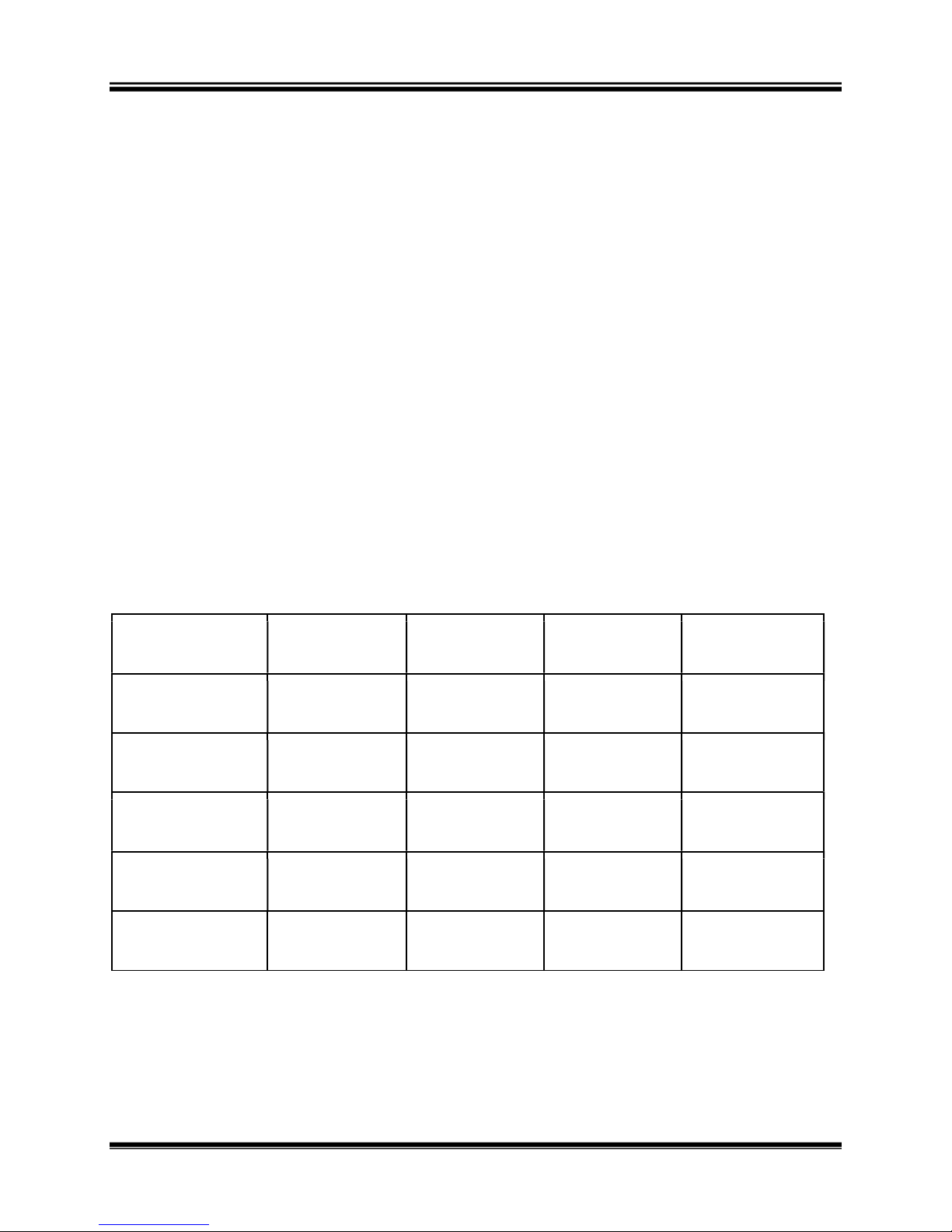

WDL S

Weaving

Width

No. of Warp

Beams

Height 43-1/2”

Width 30-1/2”

Depth 39” (99.1

Weight 47 lbs. (22

PECIFICATIONS

16” (40.6

cm)

1 2 1 2

(110.5 cm)

(77.5 cm)

cm)

KG)

16” (40.6

cm)

43-1/2”

(110.5 cm)

30-1/2”

(77.5 cm)

46” (116.8

cm)

53 lbs. (24.1

KG)

24” (61

cm)

43-1/2”

(110.5 cm)

35-1/2”

(90.2 cm)

39” (99.1

cm)

77 lbs. (35

KG)

24” (61 cm)

43-1/2”

(110.5 cm)

35-1/2”

(90.2 cm)

46” (116.8

cm)

83 lbs. (37.7

KG)

Page | 4 Introduction

Workshop Dobby Loom User’s Manual Introductory Information

OOLS YOU WILL NEED

T

1. Allen wrench (provided)

2. Socket wrench, with 7/16” socket

3. Wrench (7/16”)

4. Philips screwdriver

5. Hammer (optional)

ARTS

P

Note:

Items marked with an asterisk (*) indicate that there will be an additional,

identical item if you ordered a two-beam system.

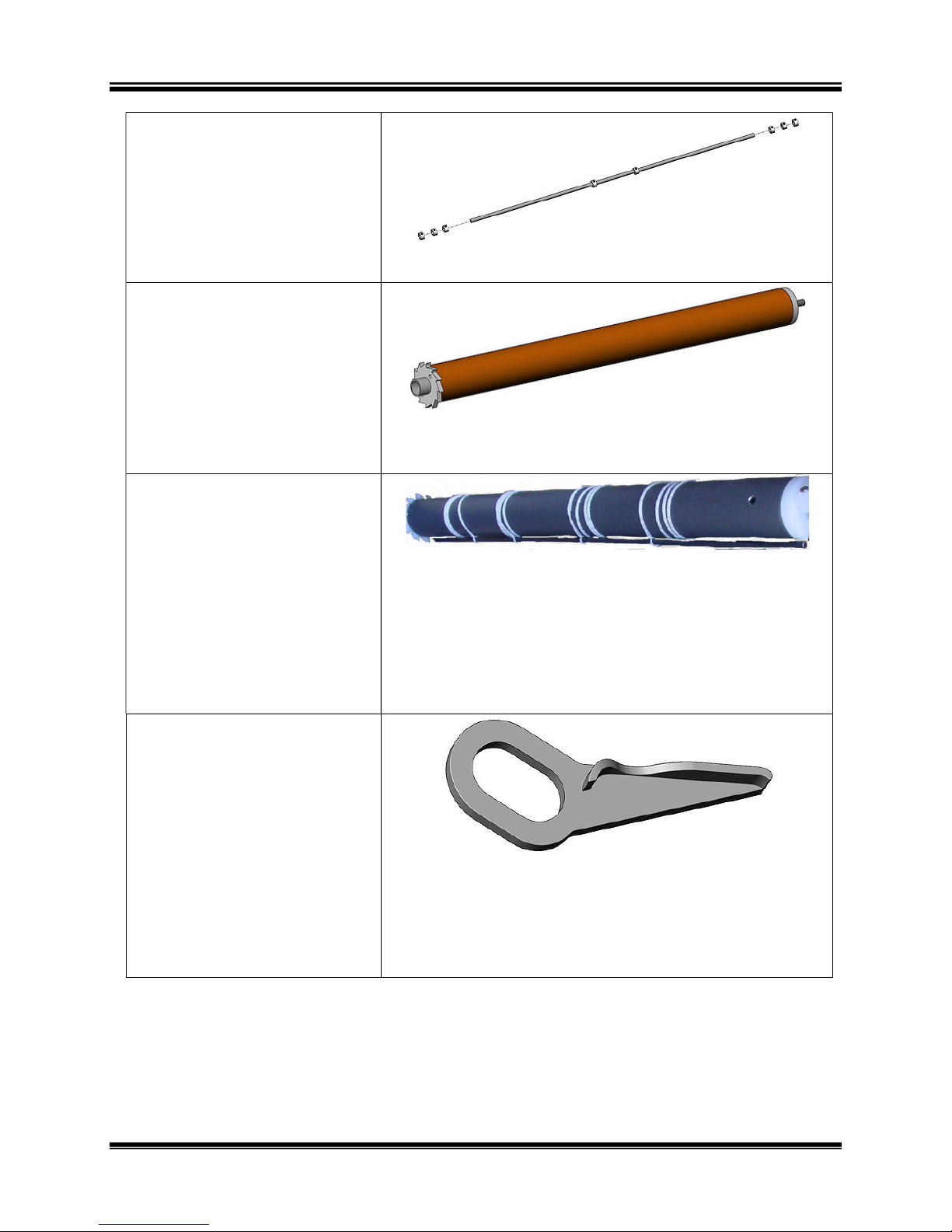

(1) Hardware Bag

(2) Beater Legs

(1) Travel Straps with Handle

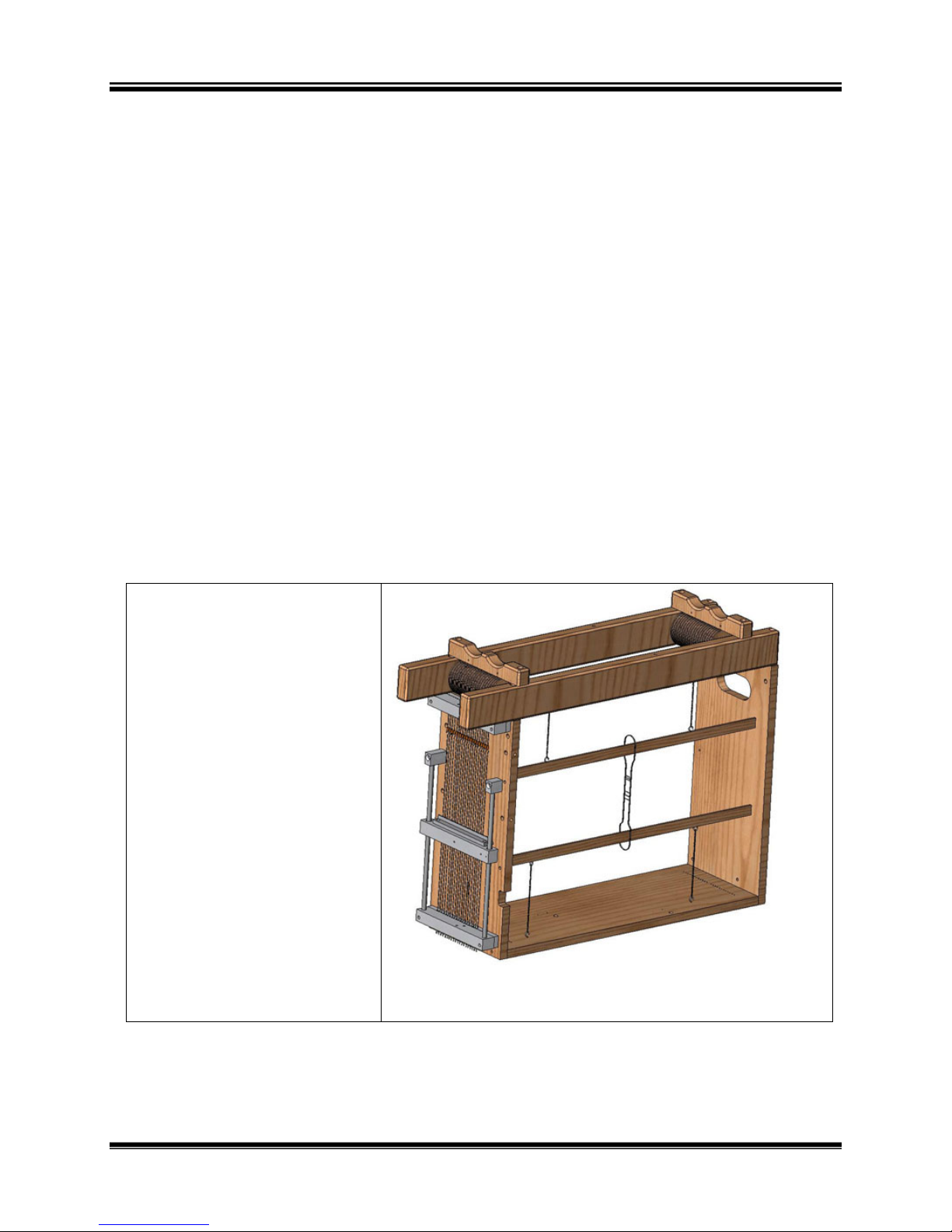

(1) Interchangeable

Design Unit (IDU):

harness pulley support,

harnesses, and dobby

Figure 3 - IDU

Tools You Will Need Page | 5

Introductory Information Workshop Dobby Loom User’s Manual

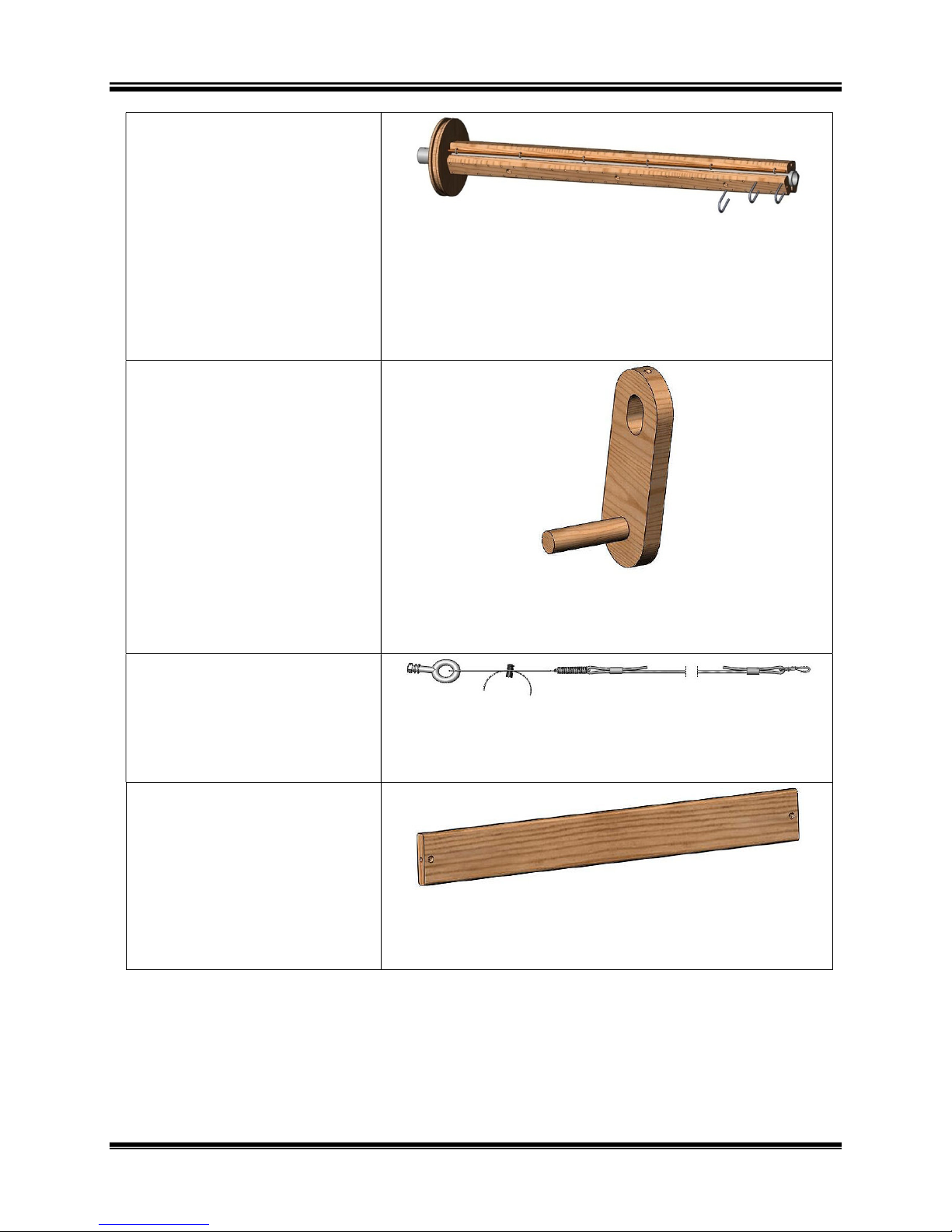

(4) X-frame legs (left

and right sets)

(2) Center Braces

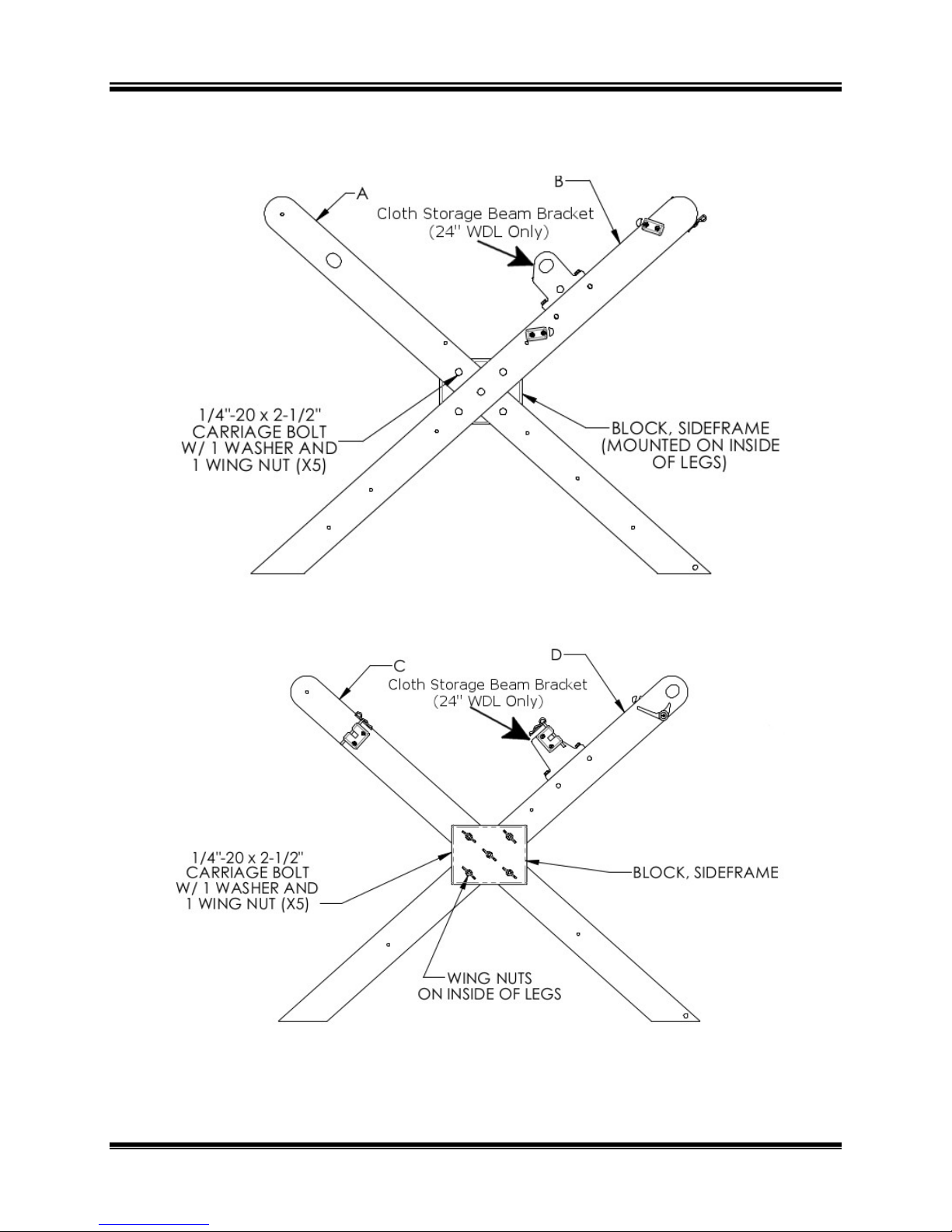

Figure 4 - X-Frame Legs (4)

Note:

The X-Frame Legs are marked A, B, C, and

D. The holes for assembly are in different

places on each one. If you ordered a twobeam system, you will have legs E and F in

place of C and D. These legs are longer.

Figure 5 - Center Brace

(1) Cross Brace, Birch

hardwood plywood

(1) Reed Assembly includes Reed, Beater

Top and Beater Race

(2) Treadles (left and

right)

Figure 6 - Cross Brace

Figure 7 - Reed Assembly

Figure 8 - Left (longer)

Figure 9 – Right

Page | 6 Parts

Workshop Dobby Loom User’s Manual Introductory Information

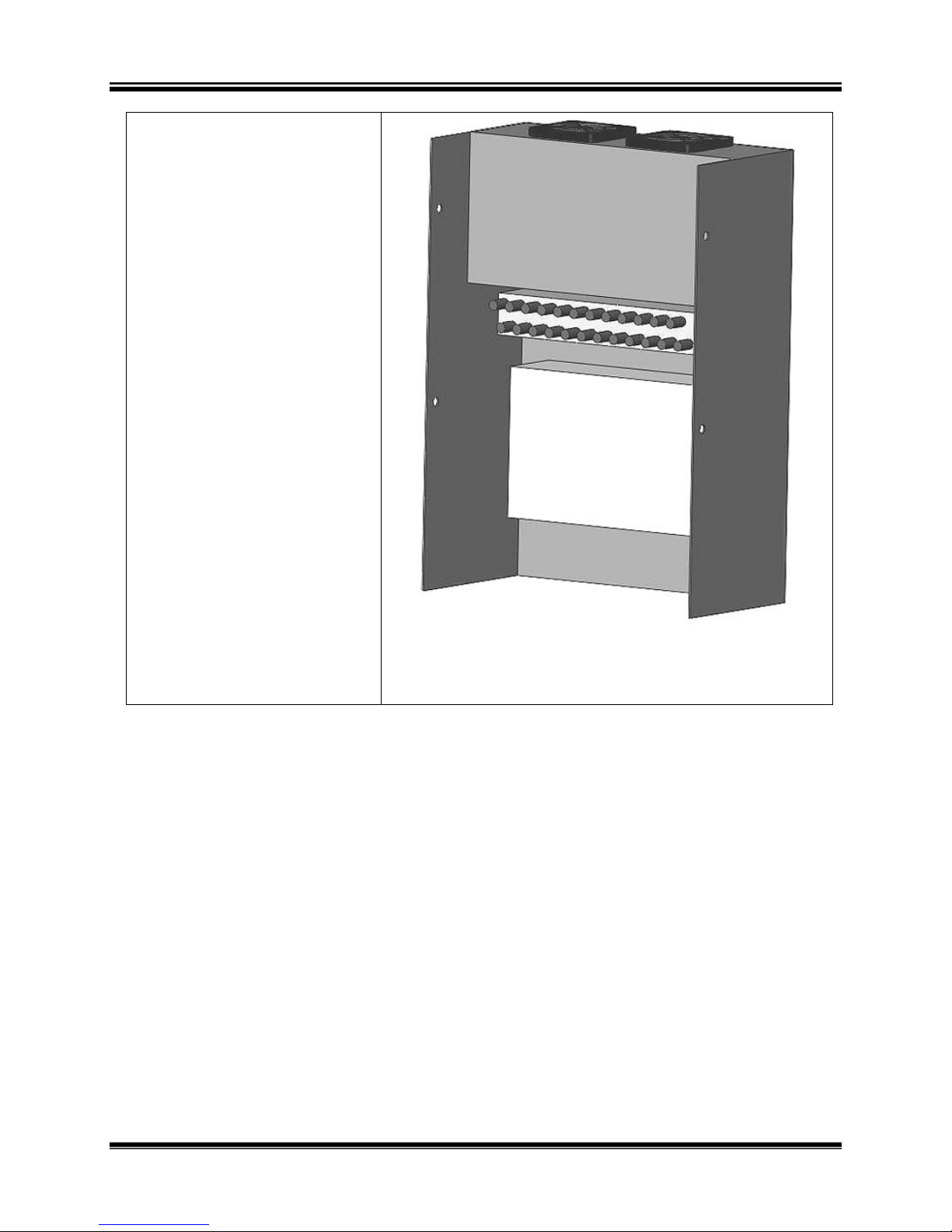

(1) Treadle Rod and Stop

Collars (8)

Figure 10 - Treadle Rod and Stop Collars

(1) Cloth Beam with

Ratchet

(1) Cloth Storage Beam

with Tie-On Rod and

Attaching Cords

(1) Cloth Beam Ratchet

Handle, aluminum

(1) Cloth Storage Beam

Ratchet Handle,

aluminum

Figure 11 - Cloth Beam with spacer on

right

Figure 12 - Cloth Storage Beam

Note:

The Cloth Storage Beam comes standard

only with the 24” WDL. If you ordered a 16”

WDL, you will not receive a Cloth Storage

Beam unless it was ordered as an option.

Parts Page | 7

Figure 13 - Ratchet Handle

Note:

You will only receive a Cloth Storage Beam

handle if you received a Cloth Storage Beam.

Introductory Information Workshop Dobby Loom User’s Manual

(1) Warp Beam with

Brake Drum*

(1) Warp Beam Handle,

wood*

(1) Tension Tie-Up

Assembly for Warp

Beam*

Figure 14 - Sectional / Plain Beam

Note:

To use as a sectional warp beam, insert

metal hoops. To use as a plain beam, remove

the metal hoops.

Figure 15 - Warp Beam Handle

Figure 16 - Tension Tie-Up Assembly

(1) Separation Beam,

solid Ash hardwood*

Figure 17 - Separation Beam

Page | 8 Parts

Workshop Dobby Loom User’s Manual Introductory Information

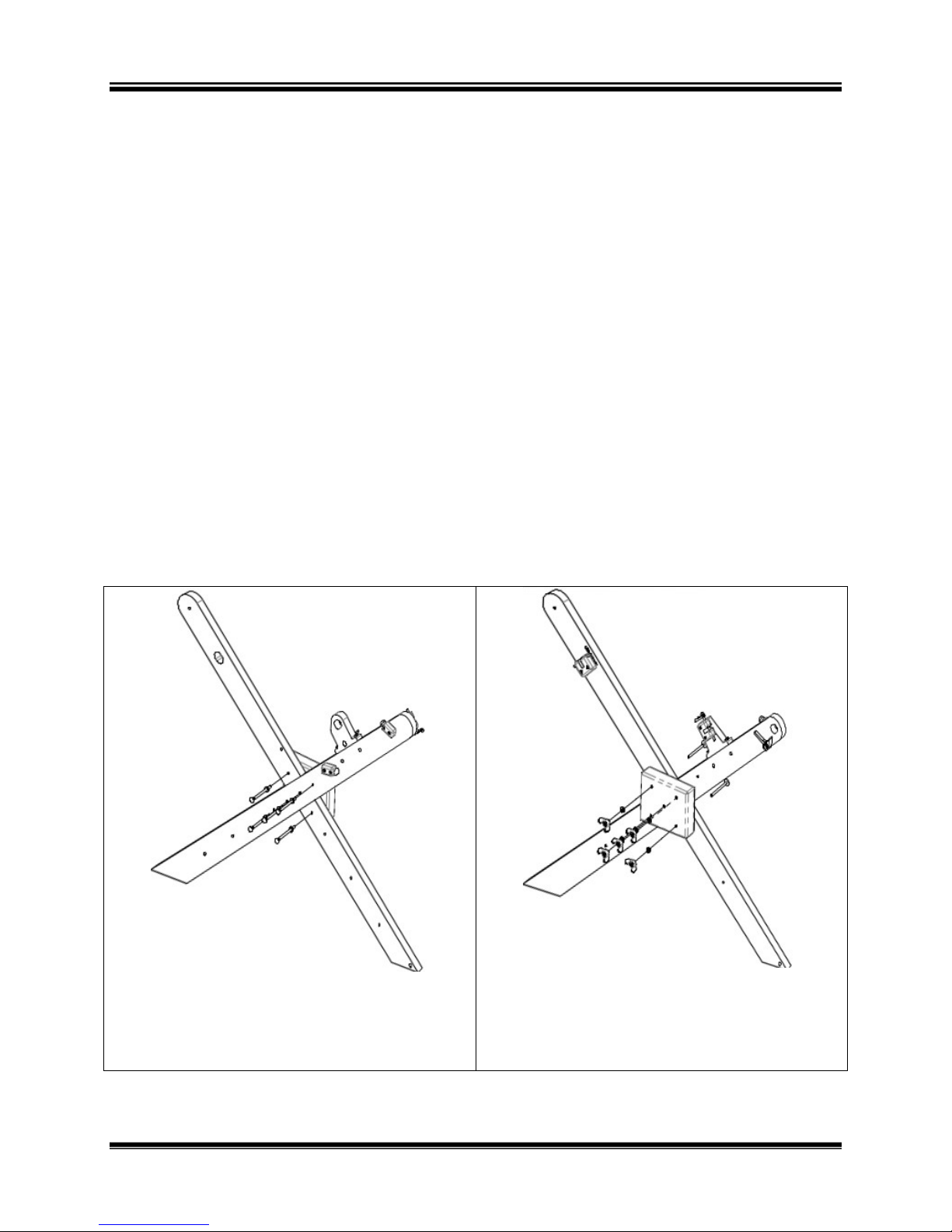

(1) Compu-Dobby® with

Cables

Figure 18 - Compu-Dobby

Parts Page | 9

Workshop Dobby Loom User’s Manual WDL Assembly

WDL ASSEMBLY

WDL A

SSEMBLY

WDL Assembly Page | 11

WDL Assembly Workshop Dobby Loom User’s Manual

SSEMBLE THE

A

X-F

RAME

X-Frame sides:

1)

2)

Note:

The Cloth Beam Bracket is on the inside of the frame.

3)

4)

For the left side you will need legs A and B. If you are assembling

the frame for the two-beam version, use legs B and E. Fit the legs

together at the notch in the center

Slide a 2-1/2” carriage bolt from the outside through the center

hole at the crossing of the legs.

Slide a Center Brace onto the bolt. Install a washer and wing nut,

and tighten to ‘finger tight’ condition.

Repeat this process for the remaining four holes using the 2 1/2”

carriage bolts, washers and wing nuts to fully secure the Center

Brace to the legs.

Figure 19 - X-Frame Bolts from

Outside

5)

Page | 12 Assemble the X-Frame

Tap carriage bolt heads with a hammer until flush to the legs.

Figure 20 - X-Frame Bolts from

Inside

Workshop Dobby Loom User’s Manual WDL Assembly

6)

Repeat these steps for the right side using legs C and D. Use legs D

and F for the two-beam frame.

Figure 21 - X-Frame Outside (Left)

Figure 22 - X-Frame Inside (Right)

Assemble the X-Frame Page | 13

WDL Assembly Workshop Dobby Loom User’s Manual

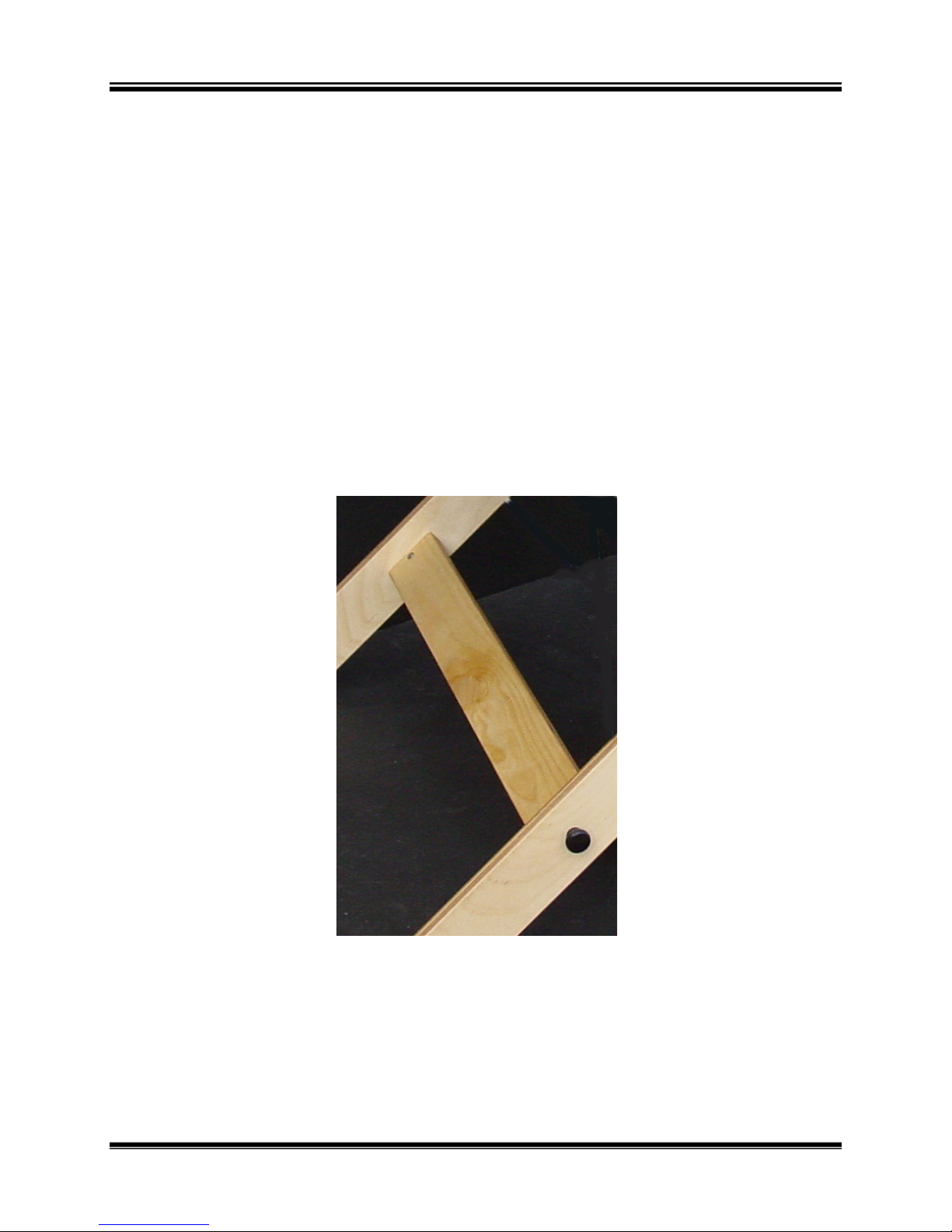

Cross Brace Installation

IMPORTANT:

The Cross Brace is plywood and should not be confused with the solid wood

Separation Beam.

1)

2)

3)

The X-Frame should now stand without support.

Attach the Cross Brace to the inside of the Right Side and secure

with black thumbscrew (long) from the outside of the leg.

Stand the Left and Right Sides approximately 17” apart (for the 16”

WDL) or 25” apart (for the 24” WDL) with Center Braces facing

each other.

Secure the Cross Brace to the Left Side with a black thumbscrew

(long) from the outside of the leg.

Figure 23 – X-Frame Cross Brace

Page | 14 Assemble the X-Frame

Workshop Dobby Loom User’s Manual WDL Assembly

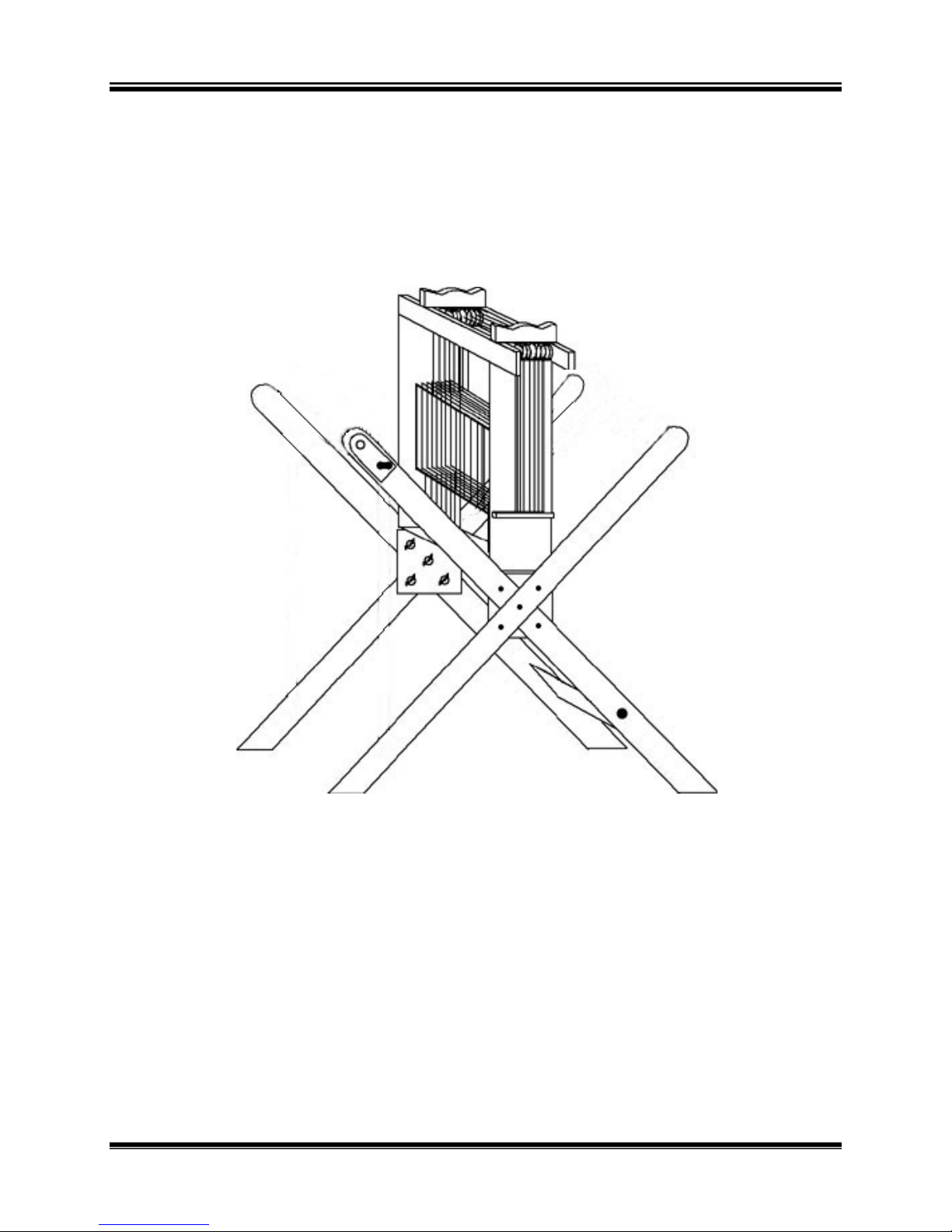

NTERCHANGEABLE DESIGN UNIT

I

(IDU)

Install the IDU

1)

Set the IDU onto the Center Braces inside the X-Frame so that the

Dobby is on the right side of the loom.

Figure 24 - WDL with IDU

2)

Note:

As before, the bolts are inserted from the outside through the X-Frame and

through the IDU.

Secure the IDU to the X-Frame using the (4) 2” carriage bolts,

washers and wing nuts.

3)

NOTE:

A light tap with a hammer on the end of the bolt may be used to help seat the

bolt.

Interchangeable Design Unit (IDU) Page | 15

Tighten all the wing nuts so that the square part of the carriage bolt

head sinks into the outside of the X-Frame.

WDL Assembly Workshop Dobby Loom User’s Manual

HANGING THE HARNESSES ON THE IDU

Review the lay of the harness cables to make sure that they are arranged on

their proper pulleys. Cable ends should hang freely over the pulleys and

down inside the IDU.

Heddles:

You have been supplied with 25 heddles per harness plus 200 extra. You can

purchase additional heddles from AVL. Heddles are shipped in bundles of

100.

You can divide the bundle of 100 heddles into smaller bundles to place on the

harness. Without removing the original twist-ties, count out the number of

heddles you want on the harness. Place a new twist-tie around each smaller

bundle. Remove the original twist tie and cut the smaller bundles apart.

1)

Insert an Eye Hook Retainer Tube over each harness cable loop and

up above the crimped Nico. You will slide the eye hook retainer

back down over the loop once it has been hooked onto the harness

stick.

2)

Figure 25 - Eyehook cover on Harness

Lay two harness sticks flat on a table or floor with the screw eyes

facing away from each other.

Page | 16 Interchangeable Design Unit (IDU)

Workshop Dobby Loom User’s Manual WDL Assembly

Figure 26 - Parallel Harness Sticks

3)

Slide the top harness stick through the loop at one end of a heddle

bunch, then slide the bottom harness stick through the opposite

loop of the heddle bundle.

Figure 27 - Place heddle bundle on heddle sticks

4)

5)

Remove the ties on the bundles.

Now clip the loops of your heddles -- it is easier to cut the loops

when your harnesses are off the loom. You now have one harness.

Figure 28 - Cut heddle loops

Interchangeable Design Unit (IDU) Page | 17

WDL Assembly Workshop Dobby Loom User’s Manual

Hang the Harnesses

When hanging the harnesses, start at the rear most harness position and

work forward.

1)

2)

3)

EATER ASSEMBLY

B

The Reed Assembly (as typically delivered from the factory) is the Beater

Top, Reed, and Race, pre-assembled and secured with strapping tape. The

strapping tape should be removed before the Reed Assembly is attached to

the Beater Legs. The WDL Beater Race faces the front of the loom. You will

put together the Beater Assembly first, and then put it on the loom.

Holding the top harness stick, lift the Harness and hook the left and

right harness cables to the eyehooks on the top harness stick. The

harness will hang from the IDU.

Attach the correct harness springs to the eyehooks on the bottom

harness stick.

Repeat these steps for the remaining harnesses.

1)

Locate the Beater Legs and Reed Assembly.

Figure 29 - WDL Beater

Page | 18 Beater Assembly

Workshop Dobby Loom User’s Manual WDL Assembly

2)

Each leg has a straight side and a tapered side. Place the legs so

that the tapered side is to the outside.

3)

4)

Separate the Beater Top and Reed from the Race.

Place the Beater Race so that the cut-out sides lock around each leg

and the holes are aligned.

5)

6)

Slide a carriage bolt through each of these holes from the front.

Insert a washer and secure with a nut. Do not tighten the nuts yet.

Repeat for each hole on both sides.

7)

Use a small square to make sure the Beater Race is square to the

Beater legs. Adjust as needed before securing the bolts.

8)

Set the Beater Top and Reed onto the Race with the cut-outs on the

sides facing the legs.

9)

Slide a bolt from the back of the beater through the slot in the leg,

continuing through the hole in the Beater top.

10) Insert a washer and secure with a wing nut. Repeat for the other

side.

Beater Assembly Page | 19

WDL Assembly Workshop Dobby Loom User’s Manual

To install or change the Reed:

1)

Remove the wing nuts from the bolts holding the Beater Top to the

Beater Legs.

2)

3)

4)

5)

Lift off the Beater Top.

Insert and seat the Reed into the Beater Bottom

Slide the Beater Top down and seat it on the Reed.

Re-install the hardware to secure the Reed.

NOTE:

If you have room, it is generally easier to transport the beater as a unit, rather

than disassemble it.

To place the Beater Assembly on the loom:

1)

Place a carriage bolt through the hole at the front bottom of the Xframe on each side.

2)

3)

Place a washer on each bolt.

Position the Beater Assembly on the loom so that the slot at the

bottom of the legs is over the bolt on each side.

4)

Place another washer and a nut on each bolt to hold the Beater

Assembly to the loom.

5)

When the beater is pushed back and pulled forward, both sides

should hit the bumpers at the same time. If they do not, check that

the beater is square. You may also need to adjust the tightness of

the bolts holding the beater to the loom.

Page | 20 Beater Assembly

Workshop Dobby Loom User’s Manual WDL Assembly

READLES

T

The metal Treadle Rod comes with eight stop collars. The inner-most two

stop collars are pre-located for your convenience. They are not

symmetrically placed on the Treadle Rod.

1)

2)

3)

Remove the outer three stop collars on each side with the 1/8”

Allen Wrench. The two inner stop collars are locked in the correct

position for your loom.

Slide the Right Treadle (shorter treadle) onto the shorter end of the

Treadle Rod with the Treadle Cable up.

Slide the Left Treadle (longer treadle) onto the longer end of the

Treadle Rod with the Treadle Cable up.

Figure 30 - Left and Right Treadles

4)

5)

Slide a stop collar onto each end of the rod and loosely position

them next to the treadles.

Tighten the stop collar into place using an Allen Wrench. You now

have the Treadle Assembly.

Treadles Page | 21

WDL Assembly Workshop Dobby Loom User’s Manual

NOTE:

There should be enough space left between the stop collar and the treadle to

avoid binding the treadle movement.

6)

Place the Treadle Assembly under the front of the loom with Treadle

Cables facing up and directly beneath the IDU.

7)

8)

Figure 31 - WDL treadle positioning

Slide another stop collar on each side of the Treadle Assembly, and

leave it loose for later adjustment.

Slide the left end of the rod into the hole on the lower front left XFrame leg; slide the right end of the rod into the hole on the lower

front right X-Frame leg.

9)

Slide a stop collar onto each end of the rod. The X-Frame legs

should be sandwiched by stop collars.

Page | 22 Treadles

Workshop Dobby Loom User’s Manual WDL Assembly

10) Adjust the four stop collars until they are snug against the X-Frame

and tighten.

11) Unclip the cables from under the IDU.

12) Clip the left hanging cable from IDU to the left Treadle Cable and

the right hanging cable from IDU to the right Treadle Cable.

13) These cables connect the treadles to the dobby.

Depressing the right Treadle raises the Harnesses. Depressing the left

Treadle signals the Compu-Dobby® to advance to the next pick.

NOTE:

While rare, it has been noted that the Treadle Cable pulleys located inside the

bottom shelf of the IDU can loosen during travel and/or very heavy weaving. It

is a good practice to routinely check the pulley bracket screws for tightness

and verify that the cable retainer brackets are seated flush on the pulley and

the retaining bolts are also tight.

EAMS

B

The Cloth Beam

The Cloth Beam (or sandpaper beam) with Ratchet is inserted in the front of

the loom. For the 24” WDL, the upper position is used.

1)

2)

3)

4)

5)

Place the Ratchet handle on the ratchet end of the beam.

Hold the Ratchet handle so it is horizontal while placing the beam

on the loom. The long straight side of the handle should go to the

front of the loom.

Slide the beam end with the ratchet into the hole on the right front

frame leg.

Slide the other end of the beam into the Cloth Beam Retainer

Bracket on the other leg.

Insert the retainer pin into the Cloth Beam Retainer Bracket and

secure with a small pin.

Beams Page | 23

WDL Assembly Workshop Dobby Loom User’s Manual

Figure 32 -WDL Beams

The Warp Beam

The Warp Beam goes on the back of the loom.

1)

2)

3)

4)

Slide the beam end with the brake drum into the hole on the back

frame leg

Slide the other end of the beam into the Beam Retainer Bracket on

the other leg.

Insert the retainer pin into the Beam Retainer Bracket and secure

with a small pin.

Place a washer on the Tension Tie-Up Assembly eye-bolt.

Page | 24 Beams

Workshop Dobby Loom User’s Manual WDL Assembly

5)

6)

7)

8)

NOTE:

The cord should not overlap itself on the drum.

From the inside of the X-Frame, insert the eye-bolt of the Tension

Tie-Up Assembly into the hole near the IDU on the lower left leg of

the X-Frame and secure with another washer and nut.

Wrap the Tension Tie-Up cord over and down the rear side of Warp

Beam Brake Drum.

Wrap the cord around the drum twice working towards the center of

the loom. The cord wraps counter-clockwise if you are looking at

the drum from the left side of the loom.

Extend the cord back down to the eye-bolt and clip it on.

The Separation Beam

The Separation Beam is located at the upper rear of the X-Frame and is

secured with Phillips-head screws.

IMPORTANT:

The Separation Beam is solid wood and should not be confused with the

plywood Cross Brace.

1)

2)

Insert the Separation Beam between the upper rear members of

the X-Frame

Secure with Phillips-head screws from the outside of the leg.

The Cloth Storage Beam (24” WDL Only)

The Cloth Storage Beam is inserted in the front, lower position on the XFrame, just in front of the IDU. The Cloth Storage Beam is included with the

24” WDL only. It is available as an option for the 16” WDL.

1)

2)

3)

Place the Ratchet handle on the ratchet end of the beam.

Hold the Ratchet handle so it is horizontal while placing the beam

on the loom. The long straight side of the handle should go to the

back of the loom.

Slide the beam end with the ratchet into the hole on the left front

frame leg.

Beams Page | 25

WDL Assembly Workshop Dobby Loom User’s Manual

4)

Slide the other end of the beam into the Beam Retainer Bracket on

the other leg.

5)

Insert the retainer pin into the Beam Retainer Bracket and secure

with a small hair pin.

Two-Beam

The Two-Beam system has longer left and right legs that allow room for the

additional beam. To switch to the two-beam system, disassemble the Xframe and reassemble it using the longer legs (E and F).

Figure 33 - WDL with two beams

1)

2)

Place the top warp beam into position as described earlier.

Place the lower warp beam into position.

Page | 26 Beams

Workshop Dobby Loom User’s Manual WDL Assembly

3)

Attach the tension tie-up assembly for the upper beam using the

lower eye-bolt.

4)

Attach the tension tie-up assembly for the lower beam using the

upper eye-bolt.

Figure 34 - WDL with two beams

5)

Insert a separation beam for each warp beam. The upper

Separation Beam is used for the upper beam and the lower

Separation Beam is used for the lower beam.

Beams Page | 27

WDL Assembly Workshop Dobby Loom User’s Manual

OMPU

C

The Compu-Dobby® is packed with a wood backing plate. This plate also

serves as a tool tray when set upon the IDU. The Compu-Dobby is installed

on the right side of the IDU.

1)

On the loom, find the strap holding the dobby slide plate in place.

OBBY®

-D

2)

Note:

When traveling with, or shipping, your loom, please strap the Dobby Slide

Plate in place so that it cannot move.

3)

4)

NOTE:

Always travel or ship the Compu-Dobby with the wood backing plate in place

to provide the best possible protection. Take care to save the barrel nuts

inserted in the backing plate as these are used with the thumbscrews to hold

the board to the Compu-Dobby.

Cut the strap and remove it so that the Dobby Slide Plate moves

freely.

Remove the wood backing plate from the Compu-Dobby by

removing the 4 black thumbscrews (short).

Place the wood backing plate on the top of the IDU with the metal

dowels facing down and inserted in the matching holes on the IDU.

Page | 28 Compu-Dobby®

Workshop Dobby Loom User’s Manual WDL Assembly

5)

Align each plastic solenoid tip in the Compu-Dobby such that the

“U” or concave indentures of the tips aligns in a vertical orientation.

Figure 35 - Compu-Dobby Solenoids

NOTE:

In this orientation, the solenoid tips will cradle the Dobby Wires and ensure

that the solenoids properly capture and engage the Dobby Wires.

6)

While carefully avoiding jostling the solenoid tips from their

orientation, place the Compu-Dobby onto the IDU, aligning the

holes on the Compu-Dobby and the IDU, and secure with the 4

black thumbscrews (short).

Figure 36 - WDL with Compu-Dobby

Compu-Dobby® Page | 29

WDL Assembly Workshop Dobby Loom User’s Manual

Connecting Your Compu-Dobby® To Your Computer

1)

2)

NOTE:

AVL strongly recommends that you use a surge protector with your CompuDobby.

3)

Plug the female end of the Compu-Dobby power cord into the

Compu-Dobby.

Plug the male end of the Compu-Dobby power cord into your power

source (wall outlet).

Attach the USB cable between the Compu-Dobby and your

computer.

Loom Software

Many software providers have developed drivers for the AVL Compu-Dobby.

Make sure the software you choose will correctly run your Compu-Dobby

version and number of harnesses.

AVL offers a feature rich design and loom control program for Windows

computers: WeavePoint. It comes with the exact loom driver needed to run

the Compu-Dobby with your number of harnesses. You can download a

demo of WeavePoint at http://www.weavepoint.com/.

You will need to setup the software to communicate with your CompuDobby. Please refer to the manual for the software you’ve chosen for help

with this.

Page | 30 Compu-Dobby®

Workshop Dobby Loom User’s Manual Traveling with the WDL

TRAVELING WITH

THE WDL

RAVELING WITH THE

T

WDL

Traveling with the WDL Page | 31

Traveling with the WDL Workshop Dobby Loom User’s Manual

RAVELING

T

When traveling with your WDL, it is a good idea to replace loose hardware

on the loom or to put it in a sealable plastic bag and pack it with your tools.

ITH YOUR

W

ORKSHOP DOBBY LOOM

W

24” WDL Disassembly

Remove the Compu-Dobby

1)

2)

3)

4)

Turn off the Compu-Dobby, unplug the power cord from your outlet

and the Compu-Dobby and coil up the power cord for travel.

Disconnect the cable from the Compu-Dobby and your PC and coil it

up for travel.

Remove the Compu-Dobby from the IDU and set it down.

Remove the shuttle tray/wood backing plate from the top of the

IDU (the one that originally came attached to the back of the

Compu-Dobby).

5)

6)

Remove the beater

1)

2)

Attach the wood backing plate to the back of the Compu-Dobby.

Strap the Dobby Slide Plate in place on the loom.

Remove the bolts securing the Beater Top to the Beater Legs and

remove it from on top of the Reed.

Lift the Reed out of the Race and secure it inside the IDU. Make

sure the Reed Assembly is positioned vertically.

Page | 32 Traveling With Your Workshop Dobby Loom

Workshop Dobby Loom User’s Manual Traveling with the WDL

Figure 37 - 16" WDL with Compu-Dobby removed

Remove the beams

1)

2)

Disengage the Cloth Beam ratchet.

For the 16” WDL:

a. Roll any loose fabric onto the Cloth Beam and place it on top

of the IDU in the front beam rest cradle.

3)

For the 24” WDL with the Cloth Storage Beam:

a. Roll any loose fabric onto the Cloth Storage Beam.

b. Disengage the Cloth Storage Beam ratchet.

c. Remove the Cloth Storage Beam and place it on top of the

IDU in the front beam rest cradle.

d. Set the Cloth Beam aside for packing.

Traveling With Your Workshop Dobby Loom Page | 33

Traveling with the WDL Workshop Dobby Loom User’s Manual

Note:

If you have a 2-beam setup, complete steps 7-10 for the upper separation

beam and warp beam, then repeat them for the lower separation beam and

warp beam. Place the additional warp beam on top of the two beams on the

IDU to create a pyramid.

4)

Unclip the Tension Tie-Up from the screw eye on the back right leg

and unwrap it from the Warp Beam Drum.

5)

6)

Remove the Separation Beam from its mounting.

Remove the Warp Beam, carefully wrapping any loose warp around

it, and place it on top of the IDU in the rear beam rest cradle.

Figure 38 - 16" WDL with beams removed

7)

To hold the beams in place, loop the two straps under the IDU and

around the beams. Then feed the loose end of the straps into each

of their buckles.

Page | 34 Traveling With Your Workshop Dobby Loom

Workshop Dobby Loom User’s Manual Traveling with the WDL

Remove the IDU and disassemble the frame

1)

2)

3)

Unclip the left and right Treadle Cables from the IDU.

Unscrew the four wing nuts holding the IDU to the X-Frame.

Lift the IDU out of the X-Frame and place on the ground on its

rollers. It is now ready to roll.

Figure 39 - 16" WDL with beams tied in place

4)

Loosen the two outside stop collars on the Treadle Rod. Remove the

Treadle Assembly from the X-Frame.

5)

If you need to break down the Treadle Assembly further for travel,

remove the next two sets of stop collars and remove the Treadles.

Note:

Always leave the inner stop collars on the Treadle Rod to avoid having to

adjust these at re-assembly.

Traveling With Your Workshop Dobby Loom Page | 35

Traveling with the WDL Workshop Dobby Loom User’s Manual

6)

For packing, replace the stop collars back onto the rod and tighten

the outside stop collars to retain them.

7)

Remove the Beater Assembly as a whole if you can transport it. If

needed, unbolt the Race from the Beater Legs and remove them

separately.

8)

9)

Remove the Cross Brace and Separation Beam from the X-Frame.

Disassemble the X-Frame.

NOTE:

The X-Frame can be completely disassembled and re-packed into the box it

was shipped in.

Now, you are ready to pack up your WDL for travel.

Reassembly (For 16” or 24” WDL)

When re-assembling your beams, keeping tension is important.

1)

2)

3)

Reassemble the X-Frame and replace the IDU.

Attach the treadles to the treadle cables.

Install the Warp Beam first. If you are using the two-beam system,

replace the lower warp beam first, then the upper warp beam. The

beams should be on the pyramid on top of the IDU in this order.

4)

Install the Cloth Beam. For the 24” WDL, install the Cloth Storage

Beam next. Carefully unroll the warp as you bring the beam from

its IDU cradle to its mounting location.

5)

6)

Replace the reed assembly on the beater.

Replace the Compu-Dobby on the IDU.

NOTE:

During this process, keep the warp square and with some tension to create

as little disturbance to your warp as possible.

Page | 36 Traveling With Your Workshop Dobby Loom

Workshop Dobby Loom User’s Manual Using the WDL

USING THE WDL

SING THE

U

Note:

Unless otherwise noted, the instructions in this section are basic, general

instructions for weaving and are applicable to many AVL and non-AVL looms.

They should not be regarded as a substitute for training or experience.

WDL

Using the WDL Page | 37

Using the WDL Workshop Dobby Loom User’s Manual

ARPING SECTION

W

AVL advocates warping from back to front. We believe that this system

works best with our looms and our warping tools are designed around this

philosophy. If you prefer other warping methods, you will be able to adapt

them to work on your new loom. However, we suggest you study the

following warping techniques and try them out to get the most out of the

Workshop Dobby Loom.

To learn more about your AVL loom and to learn how to get the most out of

it, you may want to take a class at the AVL Weaving School. Complete

information and a current class schedule can be obtained by phoning the

AVL office (1 800 626-9615 or 530 893-4915) or on-line at

http://www.avlusa.com/workshops.

Tying onto the Warp Beam

The WDL comes with a sectional beam that can be used as a plain beam

when the metal hoops are removed. You might want to make a permanent

set of Extension Cords to use when warping the Beam. Extension Cords are

also called “apron cords” and serve the same function as the apron on other

Plain Beams. They give you “reach” from the Warp Beam and allow you to

weave every possible inch until the end of the warp touches the last Harness

you are using. Make them out of a strong non-stretchable linen or cotton

cord. You will need to make one Extension Cord for each section of your

warp. When using the beam as a sectional beam, this will be one cord per

section. Using the same number for the sectional beam and the plain beam

will work well. For each Extension Cord:

1)

2)

Measure a piece of cord long enough to reach from the axle of the

Warp Beam, at least one and a half revolutions around the Beam

and then reach to the back most Harness.

When measuring the length of the cords, take into account that,

when the warp is attached to the Extension Cord the knot between

the cord and the warp needs to fall between the Crosspieces of the

Sectional Beam, not on them. This will keep the warp smooth on

the Beam so it doesn’t go over the knots created when attaching

the warp to the cords.

3)

Page | 38 Warping Section

Now double that length and cut it. All Extension Cords should be

exactly the same length, so cut them all at the same time.

Workshop Dobby Loom User’s Manual Using the WDL

4)

5)

6)

Take the two ends of the cord and knot them together, using an

overhand knot.

Wrap the cord around the center bar of the sectional beam with a

larks head knot. You will also use a larks head knot to secure the

warp threads to the extension cord.

Route the extension cords in a “Z” shape, from under the Warp

Beam up and over the Separation Beam to the rear of the loom and

under the Warp Beam, when looking from the left side of the loom.

Adjusting the Tension Device on the WDL

Before winding on the warp, check the tension device to make sure the rope

is wrapped twice around the tension drum and that the rope end is clipped

to the eyebolt. This will prevent the warp beam from slipping backwards

during winding and threading.

Warping the Plain Beam

To warp a plain beam we recommend the following method in which the

warp is wound on with the use of a Raddle. We have found that this method

aids in getting a uniform warp tension, especially when dealing with long

warps.

Creating Two Crosses

To begin, wind the warp on a warping board or reel. Make sure you put in

two crosses, one at each end of your warp:

1)

2)

The Threading Cross (each thread crosses the next thread in

opposite directions; all are secured in a single loop).

The Raddle Cross (warp threads are tied in groups, depending on

how many ends will be put in each section of the raddle).

Warping Section Page | 39

Using the WDL Workshop Dobby Loom User’s Manual

Figure 40 - Warping Board with Two Crosses

Securing the Crosses

Before removing the warp from the board or the reel, secure the crosses.

Use four ties to secure each cross. These ties go on each side of both pegs

holding the cross.

It is usually a good idea to use different color threads for the ties on the tops

of the pegs and another color to tie the bows underneath the pegs. By color

coding your ties, you are less likely to twist the warp later.

Removing the Warp for the Warping Boards

Remove the warp from the warping board by chaining or by winding on the

kitestick. Start from the threading cross and proceed to the raddle cross.

Since the capacity of the warping board is limited, for wide warps you will

end up making a number of mini-warps and taking them off individually.

Page | 40 Warping Section

Workshop Dobby Loom User’s Manual Using the WDL

Attaching the Raddle

Now secure the raddle to the back of the loom.

Sticks in the Raddle Cross

Place two lease sticks in the raddle cross and secure together with string

through the holes in the ends of the sticks. Now remove the ties from the

raddle cross and spread the warp out on the sticks.

Measure the center of your raddle to use it as a center of your warp. The

warp threads should go through the middle of the raddle.

Feeding the Raddle

To feed the raddle, distribute yarns through the raddle by dropping each

raddle cross group into a dent in the raddle.

Figure 41 - Raddle

Warping Section Page | 41

Using the WDL Workshop Dobby Loom User’s Manual

If you are using an AVL raddle with a sliding cover, slide it on after the

raddle is threaded and secure it with two or three cord ties so it can’t come

off. Remove the raddle cross sticks when this is completed.

Preparing the Paper

Prepare the paper for winding between the warp layers. Again, for the most

professional results, and fewer tension problems, we suggest that the warp

be as smooth, tight, and compact as possible. This would mean not using

corrugated paper or sticks as they will make the warp too fat and/or lumpy.

Corrugated paper is just too soft and the warp can never be wound tight

enough with it. Heavy wrapping paper works well; seventy pound craft paper

is good. If you are going to be using smooth, slippery warp yarns like fine

linens or perle cottons, the edge yarns are going to need extra help in order

not to slip off.

Figure 42 - Prepared Paper with Folded Edge

To do this, cut your paper 4” wider than the warp width and then fold over

the edges an inch on each side. Be sure the warp is wound between the two

folded edges not overlapping them.

Winding the Warp On

NOTE:

From the left side of the loom, the warp is wound onto the beam by turning in

the counter-clockwise direction.

Before you start winding the warp onto the warp beam, attach the section of

the warp to an extension cord. To do so, tie an overhead knot in the warp

threads from one section and slip that knot into the opening of the larkshead

knot you created in the extension cord. Pull it tight.

Page | 42 Warping Section

Workshop Dobby Loom User’s Manual Using the WDL

When winding the warp on from the back, i.e., with the warp spread out in

back of the loom, turn the crank in a counterclockwise direction so that the

warp comes in from the bottom.

Remember; wind the warp on tightly under a lot of tension. This will vary

with each warp material, but a good rule to remember is that the tension of

the wound on warp must be greater than the tension during the weaving

operation. You will need one person to hold a warp under tension on the

back and one person to wind the warp on the beam using a handle. The

person winding the warp can also insert the paper.

If you have to do it yourself, you can use the jerking method. Make one turn

around with your beam crank and then go to the back of the loom and jerk

one section at a time to make the warp that is already on the beam tight.

The idea of this method is that the warp does not need to be under tension

all the time, but the part that is on the beam has to be tight. Make another

turn, go to the back of the loom and jerk all the sections again and so on. If

you have a wide warp, you might need to do up to ten jerking motions after

each turn.

Threading Cross

When you come to the end of your warp, insert lease sticks in your

threading cross.

Remove the Raddle

Now remove the ties from each individual threading cross and spread the

warp out on the sticks.

When the warping is completed, free the warp from the raddle. If you have

an AVL raddle, first untie the security strings, lift the raddle top off, and

remove the warp from the raddle. Afterwards, replace the top on the raddle

and leave it in its place on the back of the loom if so desired as it will not

interfere with the weaving process. Then be sure to bring the end of the

warp around the separation beam so that it now travels into the loom.

Warping Section Page | 43

Using the WDL Workshop Dobby Loom User’s Manual

Warping the sectional beam

The WDL Sectional Beam can be warped in sections using a Warping Wheel.

Throughout the warping process, the Warping Wheel automatically keeps a

constant and uniform tension on the warp.

Using the Warping Wheel

The Setup

1)

2)

Adjust height so position of mini-raddle is just below eye level.

Adjust the wind-off tension with toggle and cord. Tie cord to

prevent slipping.

Figure 43 - Adjust Wind-off Tension

3)

4)

5)

Adjust the warp length by moving the spools on the arms.

Reset the Revolution Counter to Zero

Setup Cones with the Cone Caddy

Making the First Section

6)

Open and secure the raddle top using the removable pin.

Page | 44 Warping Section

Workshop Dobby Loom User’s Manual Using the WDL

7)

Slide the thread(s) under the metal catch clip, tails facing to the

left. Tails should be about 5 inches long.

Figure 44 - Catch Thread Ends

8)

Bring the thread(s) up and over the left side of the top spool so that

you are ready to wind the Warping Wheel in a counter clockwise

motion.

9)

Continue in this manner until you have the number of threads you

need for the section.

Figure 45 - Wind Counter Clockwise

10) After you have wound one length bring the thread(s) around the

back of the raddle and through a dent (working from right to left).

Warping Section Page | 45

Using the WDL Workshop Dobby Loom User’s Manual

Figure 46 - Bring Thread through Raddle

11) Bring thread(s) down over the end you just wound and secure in

the silver clip (swooping under from left to right).

Tying Off

12) Put the raddle top back on. Cut the bout threads just to the left of

the clip and under the threads going over the wheel.

13) Hold onto the threads securely at the raddle (so they don’t slip

through. Below, wrap the cut threads around the clip.

Figure 47 - Hold Threads at Raddle

14) With the raddle top secure, remove the pin from the raddle holder

while holding onto the threads.

Page | 46 Warping Section

Workshop Dobby Loom User’s Manual Using the WDL

Figure 48 - Remove Raddle from Top Position

15) Bring the raddle down to the winding-on position and secure with

the pin. Tie a knot in the thread past the raddle so it won’t slip

through.

Figure 49 - Place Raddle in Lower Position

16) Take the extension cord from your beam. Create a larks head loop

at its end and loop it around the knotted end of your warp section.

Figure 50 - Place Extension Cord around Thread Bundle

17) Before the last part of the threads pass through the raddle, tape the

threads on the loom-side of the raddle in their sequence using

masking tape. This will help you keep the threads in order when

you thread the harness.

Warping Section Page | 47

Using the WDL Workshop Dobby Loom User’s Manual

18) As you wind on, pivot the raddle to adjust the width of the section

to fit exactly in-between the pegs on your sectional beam.

Figure 51 - Pivot Raddle

Winding the Warp On

NOTE:

From the left side of the loom, the warp is wound onto the beam by turning in

the counter-clockwise direction.

Before you start winding the warp onto the warp beam, attach the section of

the warp to an extension cord, tie an overhead knot in the warp threads

from one section and slip that knot into the opening of the larkshead knot

you created in the extension cord. Pull it tight.

When winding the warp on from the back, i.e., with the warp spread out in

back of the loom, turn the crank in a counterclockwise direction so that the

warp comes in from the bottom. Warp tension will be set by the Warping

Wheel. When you reach the end of the warp section, remove the threads

from the Warping Wheel catch being careful not to drop any. Stroke the

threads to achieve uniform tension on the threads, and then continue

winding while maintaining tension on the thread ends with your hand. When

you reach the Warping Wheel Reed, grab the threads on the other side of

the Warping Wheel reed with your other hand without losing tension on the

Warp Beam and release the threads from the other side of the reed. Switch

hands and pull the warp through the Sectional Beam Reed. Tie the warp

ends into a slip knot and continue winding onto the beam.

Routing the Warp

Routing the warp for threading is different than for winding on. The warp

goes rearward under the bottom of the warp beam, then up over the

Separation Beam toward the heddles forming a clockwise arc when viewed

from the left side.

Page | 48 Warping Section

Workshop Dobby Loom User’s Manual Using the WDL

Figure 52 - Single Beam Warp Path

Two-Beam

For those who ordered the Two-Beam, it is wound on in exactly the same

manner as the first warp beam except when winding on the warp to the

upper beam, the warp goes under Separation Beam and up to the top warp

beam. To route the thread for the upper beam, he warp goes over the top of

the warp beam, then down under the upper Separation Beam toward the

heddles.

Figure 53 - 2-Beam Warp Path

Warping Section Page | 49

Using the WDL Workshop Dobby Loom User’s Manual

HREADING, SLEYING, AND TYING ON

T

To make it easier to reach the heddles, you may want to remove the cloth

beam and the beater and place a stool (or exercise ball) in front.

Unused Heddles

The heddles are part of the harness structure and you should have at least

one near the end of each harness stick to help hold the harness together.

Groups of empty heddles can interfere with the movement of the shafts if

they are left near the threaded heddles. After threading is complete, make

sure that the unused heddles are pushed to the far sides of the harness

sticks. Before threading the loom, you may want to determine which heddle

to start with so that you will have approximately the same number on both

sides.

For balance, there should be approximately equal numbered groups of

unused heddles on both sides of each harness. In some cases, such as a

very wide warp with a lot of unused heddles on the ends of the harnesses,

you may need to tie each group of unused heddles into a tight bundle to

keep them from falling off the ends of the harness sticks or you may wish to

take heddles off the loom altogether.

Note:

In the first six months of using a new loom with polyester heddles, the

heddles may stretch out slightly to adjust to the harnesses.

Threading the Harnesses

Now we’re ready to thread the loom. If you are right-handed, it is

recommended to start at the right side of the warp. Grasp one group of ends

in your left hand and your sley hook in your right hand. Direct the “hook

end” of the sley hook through the “eye” of the first heddle you need to

thread. Pull the thread through (for example, if you had a straight draft on

eight harnesses, your first thread would go through the eye of a heddle on

the 8th harness. The second thread would be threaded through the eye of

the heddle on the 7th harness, the third thread through the 6th harness, and

so on).

Threading the Reed

Now sley the warp ends through the reed. Some weavers start from the

right side; some from the left; some in the middle. But, in all cases, be sure

to measure accurately before starting so that the warp will be centered in

Page | 50 Threading, Sleying, and Tying On

Workshop Dobby Loom User’s Manual Using the WDL

the reed. Position the reed for sleying in whatever manner works best for

you.

Combing onto the Cloth Beam/Sandpaper Beam (16” or 24” WDL)

Note:

If you are using the Cloth Storage Beam on the 24” WDL, move on to the next

section.

Take a group of ends about 3” wide with one hand and use the other hand to

comb them “flat”. This can be done using a common hair comb. Starting at

the reed, gently comb the yarn toward the ends until the yarn is flat and

spread out. Now gently pull with the other hand to give it a little tension and

lay it over the abrasive surface of the cloth beam with the ends hanging

down. Repeat this procedure all the way across the warp. Now that you have

nice even tension, you can wrap the ends around the bottom of the cloth

beam.

Figure 54 - Wrapping Warp around the Cloth Beam

If you find that you are having trouble with this method, a thin stick, an

aluminum blind slat or something similar can be used as an aid. Place the

stick across the top of the beam and slide it around the in the direction of

the loose warp ends, clockwise if viewed from the left side of the loom, until

the stick has reached the underside of the warp where the warp first touches

the Cloth Beam. Check that this action has not distorted your even warp

tension. If it has, repeat the step. While continuing to hold the stick, rotate

the Cloth Beam to wind on the warp and trap the stick under the warp.

Threading, Sleying, and Tying On Page | 51

Using the WDL Workshop Dobby Loom User’s Manual

Tying onto the Cloth Storage Beam (24” WDL Only)

Note:

When using the Cloth Storage Beam, you will need to advance the warp from

the Cloth Storage Beam instead of the Cloth Beam for the first several inches

until the apron has passed completely over the Cloth Beam. Once the apron

has been advanced so that your cloth is laying on the Cloth Beam, you will be

able to advance the warp from the Cloth Beam.

Unwind the Tie-On Cord and Rod from the Cloth Storage Beam and route

around the Cloth Beam towards the reed. This appears as a counterclockwise arc when viewed from the left side of the loom.

Now tie the ends to the metal rod. Starting from the middle, bring a first

bundle toward you over the apron rod, then around and under it. Divide it in

half and bring one half up on each side of the bundle. Use the ends to tie a

surgeon’s knot. It is the same as the first tie you make tying a shoelace,

except you loop the end through twice. This kind of knot is very good for

readjusting the tension.

Figure 55 - Tying On

Start with one section in the middle, then the far right and the far left

outside ones. Work your way in.

By now, the sections that were tied first are quite a bit looser than the ones

tied last. To correct this, you do not need to untie the knots, simply grasp

the ends and pull them away from you, then re-tighten the knots. Repeat

this until all of the sections are at approximately the same tension.

Setting the Warp Tension

Ensure that the Cloth Beam and Cloth Storage Beam (24” WDL ONLY) pawls

are set in the ratchets. To establish tension, wind the warp forward slowly

Page | 52 Threading, Sleying, and Tying On

Workshop Dobby Loom User’s Manual Using the WDL

and just a small amount using the Cloth Beam or Cloth Storage Beam

handle. Now feel the warp for tension. If the warp is too loose, pull the two

loose Tension Tie-Up Cord ends to tighten. Wind the warp forward a little

and check it again. If the tension becomes too tight, squeeze the button

holding the Tension Tie-Up Cord to release it.

NOTE:

Avoid using too much tension as over-tensioning the warp will stress the

fabric and potentially cause warp end breakage.

EAVING PROCEDURES

W

Bobbins

AVL shuttles use stationary, open end bobbins. The advantage of using this

type of bobbin over the conventional spinning bobbin is that as soon as the

shuttle is caught, thread stops coming off the bobbin, whereas the spinning

bobbin tends to keep spinning and unwinding thread even after the shuttle is

caught. The stationary bobbin allows the weaver to more easily obtain a

clean selvage edge. To purchase Shuttles or additional bobbins from AVL,

please call us at 530-893-4915 or go to our website:

http://www.avlusa.com. Instructions on winding bobbins and using our

shuttles are included with the shuttles. If you are using shuttles from

another source, please refer to their instructions.

Starting Your Weaving

When beginning your project, first weave in 1” of a strong, medium weight

weft with a tabby weave. Check the tabby weave for errors. Any errors in

the threading or sleying will show up here and it is an excellent time to

make corrections.

Advancing the Cloth

To advance the cloth, you simply wind it forward by using the ratchet handle

while the beater is in its forward position. Make sure the fell of the cloth

does not go beyond the front of the beater in order not to have to wind it

backwards. This easy, rapid method of advancing the cloth makes it practical

to advance the cloth about every 2” of weaving. By maintaining this 2”

weaving space, the swing of the beater and the shed angle are kept more

nearly constant and this makes it much easier to weave a uniform fabric.

Weaving Procedures Page | 53

Workshop Dobby Loom User’s Manual Additional Loom Information

ADDITIONAL

LOOM

INFORMATION

DDITIONAL LOOM INFORMATION

A

Additional Loom Information Page | 55

Additional Loom Information Workshop Dobby Loom User’s Manual

OOM MAINTENANCE

L

Tightening the Bolts

The Workshop Dobby Loom frame is designed to be disassembled for easy

traveling. When reassembling it, make sure to tighten the bolts snugly and

check the tightness of any bolts that were not removed. If you leave your

loom assembled for long periods, check the bolts for tightness periodically.

Lubrication and Cleaning

There are several mechanisms on your loom which will benefit from the

occasional light application of an appropriate lubricant. Not all lubricants are

suitable in the weaving environment. Machine oils and greases, for example,

may provide plenty of slick, but they also capture yarn dust and will, over

time, actually impede the action of your loom.

Loom Parts Lubrication and Cleaning

Shuttles, Shuttle Race Paste Wax

Axles (pulleys) Silicon Spray

Warp Beam Metal Rods (where metal works

against the wood frame)

Warp Beam Brake Drum Sandpaper

Paraffin

Checking Cords and Cables

Check the cords and cables on your loom periodically. All machines wear and

cords are usually the first things that fatigue on a loom.

Tool Kit and Spare Parts

Here’s a list of the basics, nice-to-have-around items:

[ ] socket wrench with

[ ] 7/16” socket

[ ] 6” or 8” crescent wrench

[ ] 4-1 screwdriver or medium Phillips and standard

Screwdrivers

Page | 56 Loom Maintenance

Workshop Dobby Loom User’s Manual Additional Loom Information

[ ] paste wax

[ ] 0000 steel wool pad

[ ] 220# sandpaper

[ ] paraffin wax

ROUBLESHOOTING

T

Harnesses

Your WDL has polyester heddles. The polyester heddles are carried on

transverse harness sticks, top and bottom, and stabilized at the bottom by a

series of springs. These hold the harnesses down and prevent your heddles

from floating.

On occasion you will find that one or more of your harnesses will misbehave.

There are a finite number of things that can cause these problems.

Symptom Possible Cause How to Fix It

A) The top harness

stick collapses; it

assumes a diagonal

angle and one leg of

the harness cable

from which it is

suspended goes slack.

1) Your heddles are

bunched together

towards the center of

the harness or on one

side only. This is a

problem because the

heddles are part of

the harness structure.

Move a few heddles to each

end of your harness sticks;

just to the inside of the

eyehooks. That way your

harnesses will be balanced.

Troubleshooting Page | 57

Additional Loom Information Workshop Dobby Loom User’s Manual

Rearrange the cables according

2) The harness cable

supporting the shaft

has come out of its

pulleys at the top of

the loom.

B) The heddles float;

they are lifted

upwards by the warp

thread when you

tension the warp and

1) The tension in your

warp is greater than

the tension in the

springs that hold the

harnesses down.

your shed is not even

or not large enough.

Trace the cable back through

its pulleys in the Harness

Pulley Support and make sure

that the cable is properly

seated. Check the action of the

Dobby Cable as well. Make

sure that it moves easily up

and down. If the Dobby Cable

seems to bind, check for debris

n the hole where it comes

through the Dobby Top. You

may need to use a very thin

piece of wire to dislodge

accumulated yarn dust or

other debris.

Reduce the warp tension at the

Tension Tie-Up or add

additional springs to the

harnesses.

C) One or more

harnesses that are

supposed to be raised

1) Left treadle isn’t

being pressed all the

way down.

don’t.

2) Dobby Cables out

of solenoid tip slots.

D) Harnesses don’t

rise properly.

1) Harness cables

have been hooked to

the wrong harness.

2) Springs have been

hooked to the wrong

harnesses.

E) Harnesses jam up

on each other.

1) Heddles are not

distributed evenly

over the harness

sticks.

Concentrate on getting both

treadles all the way through

their travel.

to the assembly instructions.

Rearrange the cables.

Rearrange the springs.

Redistribute the heddles

evenly on both sides from the

center of the harness sticks.

Page | 58 Troubleshooting

Workshop Dobby Loom User’s Manual Additional Loom Information

is different in different

Tension

Symptom Possible Cause How to Fix It

A) Your Warp Beam

won’t hold tension.

1) Your Tension TieUp has loosened.

2) You have misrouted your brake

cable. If you have

just installed the

system, disconnected

your Brake Cable, to

move the loom, or

warp the beam, you

may very well have

incorrectly replaced it.

3) You may have

warped your beam

backwards. Consult

the Weaving Section

on page 37 which

illustrates how your

warp should be

routed.

Readjust the tie-up and either

tie a bow in the cord ends or

bind it tightly with a double

wrap of cord.

Review the cable routing as

shown in the Assembly Section

(Page 11 and following).

If you did warp your beam

backwards, you will need to

reverse your tension cable.

Unclip the cord, loosen the

cable, and wind it in the

opposite direction. This is not a

permanent fix. Use it only to

weave off the warp you wound

backwards.

4) The sandpaper on

5) The surface of the

B) Your warp tension

Troubleshooting Page | 59

your Cloth Beam is

not grabbing the warp

and pulling it around

as it should

Brake Drum has

become polished and

no longer offers

sufficient friction to

grab and hold the

Brake Cable

1) It is not indicative

of a tensioning

You’ll very likely need to add

SoftGrip or another kind of

beam cover in order to get

satisfactory warp tension,

Disconnect and unwind the

Brake Cable. Lightly sand the

surface of the groove in the

Brake Drum with your #220

sandpaper. Replace the cable

(but be sure about its

routing!).

You should have used a

Warping Wheel for sectional

Additional Loom Information Workshop Dobby Loom User’s Manual

places over the width

of the warp.

C) Excessive tension

on the warp.

2) The tension rope

problem. It is a

matter of not having

maintained even

tension when warping

the beam and there’s

no redress from the

Tension System. It’s

just too late for this

warp to be well

tensioned.

1) Tension Tie-Up too

tight.

has gotten crossed

over itself on the

warp beam brake

drum.

warping or craft paper for plain

beam warping. If you do not

want to waste this warp, place

something (folded paper or

cloth) in the areas on the

beam where your tension is

looser. You will have to move

your paper every time you

advance the warp and also

keep adding more since it will

probably become looser and

looser.

Adjust the Tension Tie-Up

Cord.

Straighten out the rope.

The Shed

AVLs are designed with a shed which exactly meets the need; not too wide,

not too narrow. And there is, of course, a reason for this precision. Raising

harnesses higher than you need may give you a larger shed, but it’s also a

waste of time and effort. You only need enough warp separation for the

shuttle to pass freely. However, because the shed on AVLs is so precisely

calibrated, you do need to be sure that you’re getting all that the loom can

deliver.

Symptom Possible Cause How to Fix It

A) Restricted Sheds. 1) Treadle cables fell

off the pulleys.

Replace the treadle cables so

they go over the pulleys.

Beaters

Symptom Possible Cause How to Fix It

A) Shuttle flying off

the track.

1) Tensioner in your

shuttle is not

adjusted.

The advantage of an end-feed

shuttle is that it allows you to

tension the feed of your yarn.

Most shuttles of this design

have adjustable tensioners. Be

Page | 60 Troubleshooting

Workshop Dobby Loom User’s Manual Additional Loom Information

sure yours is set to match the

characteristics of the yarn

used.

2) Bobbins not wound

consistently.

B) One side of your

fabric is beaten more

tightly than the other,

even if you are

holding your beater in

the middle. You have

a diagonal beat line

rather than

horizontal.

1) Your beater is out

of alignment.

If it’s soft on the end and the

wraps collapse and pull into

one another, you will have to

wind it again. Use an AVL

Bobbin-Winding Guide.

To check, push your beater all

the way back against the

Beater Bumper Blocks, it

should strike both sides at

exactly the same time. If it

doesn’t, you’ll need to adjust

the bolts holding the beater to

the loom.

Dobby

Symptom Possible Cause How to Fix It

A) Dobby skips. 1) Pressing too hard

or too quickly on the

treadles.

Press the treadles with a

smooth, rhythmical motion.

B) Dobby slide plate

jams.

1) Left treadle out of

adjustment.

Check routing of left treadle

cable. Make sure it is still in

the pulley with keeper inside

the Compu-Dobby box.

Left Treadle Issues

If you do not fully depress the left treadle each time you lift, you will

experience problems with your harnesses. Because the left treadle is

unweighted, it’s easy to forget that you need to do this. However, this

treadle does something very important — it releases the harnesses that

were engaged for the previous pick, but only in the last fraction of its stroke.

So, if you seem to be experiencing harness lifting problems, your use of the

left treadle is the first thing to suspect.

Troubleshooting Page | 61

Workshop Dobby Loom User’s Manual The Fine Print

THE FINE PRINT

HE FINE PRINT

T

The Fine Print Page | 63

The Fine Print Workshop Dobby Loom User’s Manual

AVL C

AVL offers free technical support to the original owner of all our looms. This

means if you ever have a problem, you can call, fax, or e-mail us and we’ll

help you find a solution. Please take advantage of this service; your

satisfaction is extremely important to us.

AVL W

Your loom carries a full warranty on parts and labor for two years from the

date we ship it to you. Your Compu-Dobby is fully warranted for two years.

If a part wears or breaks during this period, we will replace or repair it at our

discretion, but at no charge to you.

USTOMER SERVICE

Customer Service Phone: (530 893-4915)

Fax: (530) 893-1372

E-Mail: sales@avlusa.com

ARRANTIES

AVL Returns Policy

All goods, excepting software, may be returned for refund within thirty (30)

days of the shipping date.

A 15% restocking fee will be assessed for all but defective items.

AVL will pay all shipping costs for defective items within the continental

United States for the entire warranty period. Special provisions apply for the

return of looms (please contact your sales person for more information).

AVL will generally return repair or replacement items via UPS Ground

service. Additional charges for expedited shipping are the responsibility of

the customer.

Page | 64 AVL Customer Service

Workshop Dobby Loom User’s Manual The Fine Print

OTICE TO USERS IN THE EUROPEAN UNION

N

Products bearing the CE mark are in conformity with the protection

requirements of EC Council directives 2004/108/EC, 2006/95/EC,

1999/5/EC, and 2009/125/EC on the approximation and harmonization of

the laws of the Member States relating to electromagnetic compatibility,

safety of electrical equipment designed for use within certain voltage limits,

radio equipment and telecommunications terminal equipment and on the

ecodesign of energy-related products.

Compliance is indicated by the CE marking.

The manufacturer of this product is: AVL Looms, Inc., 2360 Park Avenue,

Chico, CA 95928 USA. A declaration of conformity to the requirements of the

Directives is available upon request from the Authorized Representative. This

product satisfies the Class B limits of EN 55022 and safety requirements of

EN 60950.

Notice to Users in the European Union Page | 65

The Fine Print Workshop Dobby Loom User’s Manual

Page | 66 Notice to Users in the European Union

Loading...

Loading...