AVK SERIES 764 - ECCENTRIC PLUG VALVE

FIELD MAINTENANCE AND

INSTRUCTION MANUAL

TABLE OF CONTENTS

EXPLODED ASSEMBLY / PARTS LIST

SAFETY

INTRODUCTION / DESCRIPTION

RECEIVING AND STORAGE

INSTALLATION AND TESTING

- INSTALLATION

- TESTING

OPERATION AND MAINTENANCE

- TOOLS

- OPERATION

- MAINTENANCE PROCEDURES

- INSPECTION

- DISASSEMBLY FOR INSPECTION

- REASSEMBLY AFTER INSPECTION

REPAIR PROCEDURES

TROUBLESHOOTING GUIDE

PARTS AND SERVICE

WARRANTY

AMERICAN AVK COMPANY

American AVK Company

An ISO 9001 registered company

Maintenance Manual Series 764

*Subject to change without notice. (rev. 01/19 A)

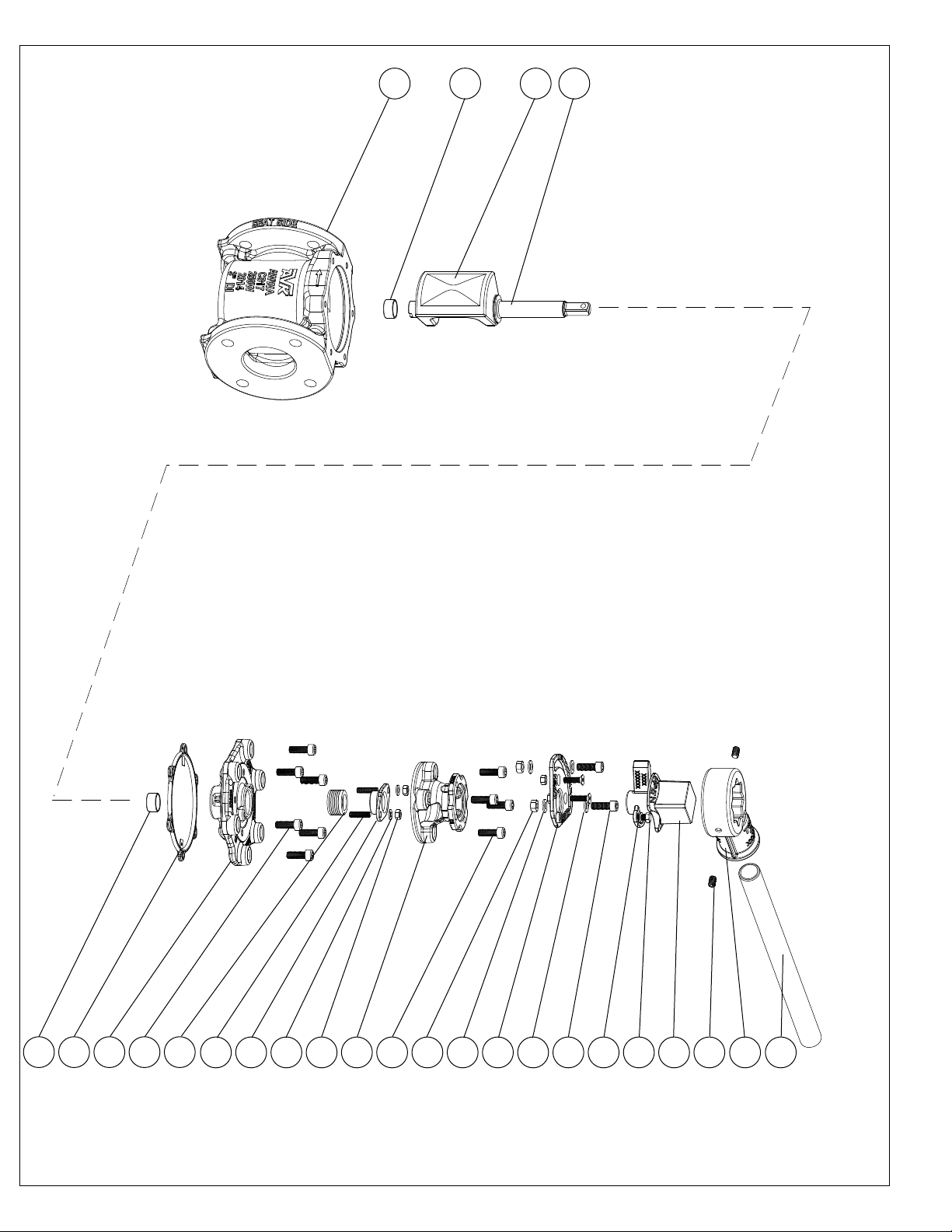

705

714

711

710

American AVK Series 764 Eccentric

Exploded Parts Breakdown

Plug Valve

714

704

703

702

709

706

708

715

707

701

702

723

722

page 1

718

722

721

725

724

726

730

728

729

Item No. Description Material

701 ISO Flange Grey iron, ASTM A126, "B"

702 Bolts NBR

703 Bonnet 304 Stainless steel

704 Chain Set Zinc Plated steel

705 Bonnet Gasket NBR

706 Body Grey iron, ASTM A126, "B"

707 Hex Nut Zinc Plate, 304,316 Stainless steel

708 Gland Ductile Iron, ASTM A536

709 V-Pack NBR

710 Plug Core Copper Alloy

711 Plug Rubber NBR

712 Thrust Washer Grey iron, ASTM A126, "B"

713 O-Ring 304 Stainless steel

714 Bearing 304 Stainless steel

715 Washer NBR, Neoprene

716 Gearbox Bolt Copper Alloy

717 Gearbox Washer NBR, Neoprene

718 Stop Plate Zinc Plate, 304,316 Stainless steel

719 Stop Plate Screw Copper Alloy

720 Stop Plate Nut NBR

721 Stop Bolt Copper Alloy

722 Stop Washer NBR

723 Stop Nut Copper Alloy

724 Wrench Nut Lock Bolt EPDM encapsulated ductile iron

725 Wrench Nut Lock Washer Copper Alloy

726 Wrench Nut Copper Alloy

727 Wrench Nut Key * 304 Stainless steel

728 Wrench Head 304 Stainless steel

729 Lever 304 Stainless steel

730 Wrench Head Screw 304 Stainless steel

731 Gearbox* 304 Stainless steel

* Not Shown

page 2

SAFETY

Make sure all relevant Health and Safety issues and regulations are adhered to prior to and during installation or

maintenance work carried out on this product. It is the end users responsibility to ensure that safe working practices are

followed at all times.

Whenever AVK’s products are installed, operated or maintained the inherent dangers of pressurized liquids and

gasses must be addressed. Before work on a valve or other piping component is undertaken, that may involve the release

of internal pressure, the valve or line must be fully isolated, depressurized and drained prior to commencing the work.

All workers handling the product must be aware of the weight of the components or assemblies to be handled and

manipulated during installation and maintenance. It is essential that staff undertaking these operations are adequately

trained and it is the responsibility of the end user that only trained and competent staff undertake these duties.

This manual has been designed to assist, but it cannot replace quality training in the workplace. However, AVK’s

technical staff are always available to answer questions relating to specic problems that may not be covered by this

manual.

AVK’s products are designed to be t for purpose and to a high reliability standard. This provides a safe, low risk

product when used correctly for the purpose for which it was designed. However, this assumes that the equipment is used

and maintained in accordance with this manual, and the user is advised to study it and to make it available to all staff that

may need to refer to it.

AVK Valves cannot be held responsible for incidents arising from incorrect installation, operation or maintenance.

The responsibility for this rests wholly with the end user.

page 3

INTRODUCTION / DESCRIPTION

AVK eccentric plug valves are designed with built-in safety in every detail. Plug valves are used for isolation purposes

in water and wastewater installations, for pump control shut-off and ow control applications. The plug is fully vulcanized

with AVK’s own rubber compound (either EPDM or NBR) which, due to its sturdy design and double bonding vulcanization,

features an outstanding durability, with the plugs rubber ability to regain its original shape. The valve has a welded nickel

seat and a full port design allowing high ow capability with minimal headloss when in the fully open position. The valve

body, bonnet and ISO mounting ange are all epoxy coated internally and externally for optimal corrosion resistance. The

valve design incorporates a unique integral ISO operator mounting ange which provides increased exibility when selecting

gearbox or electrical actuator units.

UNLOADING:

All valves should be carefully unloaded. Each valve should be carefully lowered from the truck to the ground; it should

not be dropped. Do not lift valves with slings or chain around actuator or through waterway. Lift valves with eyebolts or rods

through flange holes or chain hook at the ends of valve parts. Failure to carefully follow these recommendations is likely to

result in damage to the valve as well as risk of personal injury.

INSPECTION AFTER UNLOADING:

AVK eccentric plug valves should be inspected for damage at the time of receipt. The initial inspection should verify

compliance with specifications, direction of opening, size and flange details. A visual inspection of the seating surfaces should

be performed to detect any damage in shipment or scoring of the seating surfaces. Inspection personnel should look for any

other evidence of mishandling during shipment. Each valve should be operated through one complete opening-and-closing

cycle in the position in which it is to be installed.

STORAGE:

1. The plug valves should be stored in a manner that protects them from the environment, preferably indoors.

2. The valves should be stored with the plug in the open position to prevent unnecessary compression of the rubber

compound.

3. The plug should also be protected from sunlight, ozone and chemical exposure.

4. In colder climates, valves should be drained and left slightly open before storage. Failure to do so may result in damage

to the valve castings from water freezing.

5. Valves stored outside should be stored with the plug core in the vertical position. If the valves are stored in the horizontal

or flat position, rainwater may accumulate in the valve cavity, potentially causing damage due to water freezing

page 4

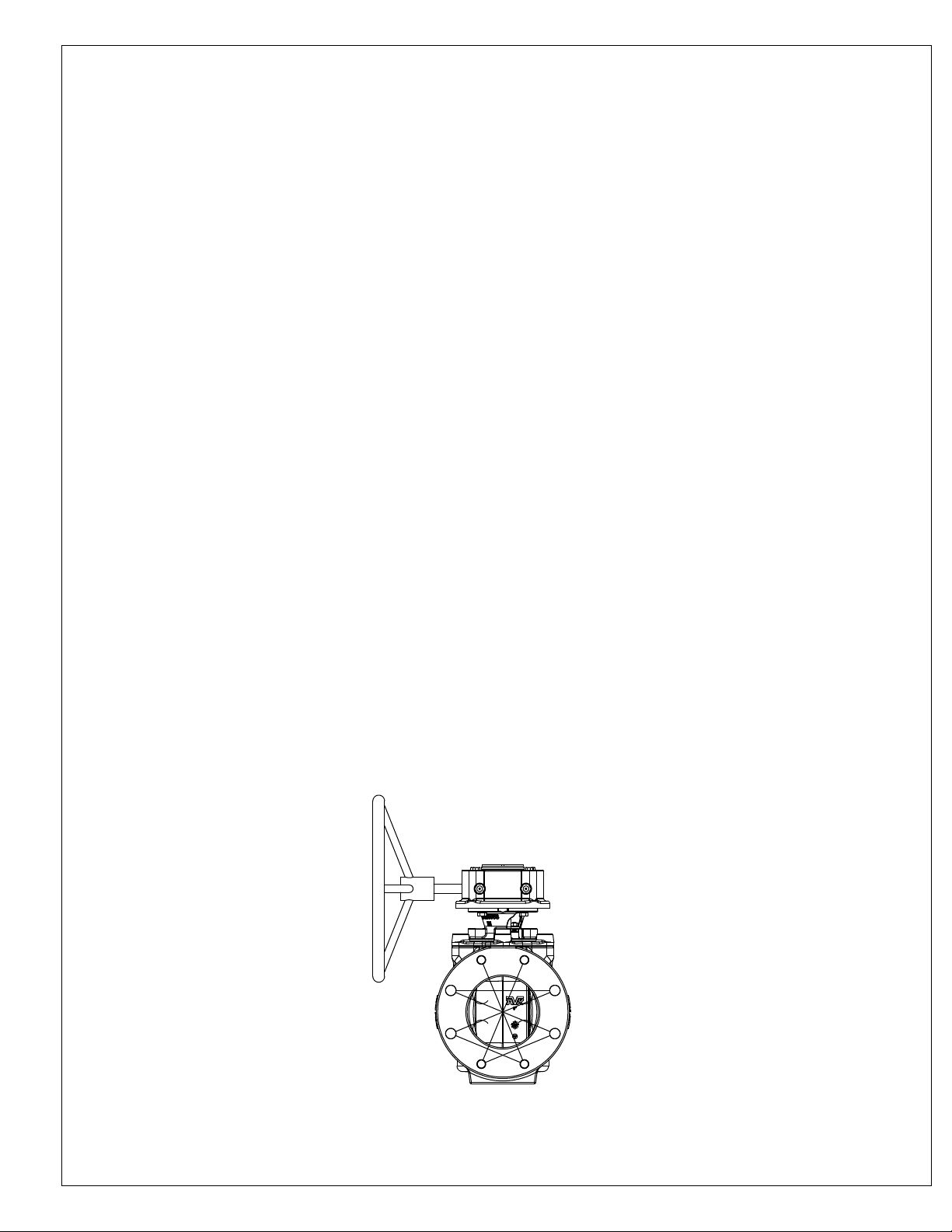

FLOW

Typical Eccentric Plug Valve

Installations

When eccentric plug valves are

mounted in a horizontal line, the

recommended installation is with

the plug rotating 90° upward to

open. This orientation reduces the

chance of solids preventing plug

operation.

Eccentric plug valves may

be installed vertically;

however, whenever

possible, horizontal

orientation is preferred.

FLOW

When installed in a vertical

line where solids may be

present, the seat should be

located in the top or upward

position, preventing solids

from accumulating in the

valve body.

FLOW

Fig. 1

Eccentric Plug Valve Installation

page 5

INSTALLATION AND TESTING

NOTE: Consult local codes and standards for valve placement and spacing

WARNING: All water lines must be isolated or depressurized and drained before installing or maintaining valves.

Failure to do so may cause pressure to be released resulting in severe injury or death.

INSPECTION PRIOR TO INSTALLATION:

1. Visually inspect each valve for any foreign material in the interior of the valve, and remove it if present.

2. Inspect each valve in a similar manner as described in the "INSPECTION AFTER UNLOADING" section of this manual.

INSTALLATION:

1. Open and close the valve to verify proper operation. Close the valve if it is going into a trench.

2. Take care when handling the valve. Use the proper lifting areas on the valve. Do not lift the valve by the actuating devices.

Do not use chains or other lifting devices through the waterway.

3. During installation there is the possibility of foreign materials inadvertently entering the valve. Foreign material can

damage the internal working parts during operation of the gate valve. For this reason, gate valves should be installed in

the closed position. Each valve should be placed on firm footing in the trench to prevent settling and excessive strain on

the connection to the pipe. Piping systems should be supported and aligned to avoid damage to the valve.

4. Valves should be installed in the proper flow direction and with adequate clearance for actuating devices. The valves are

designed o allow flow in both directions, however, they are normally installed in a "standard" flow direction with the seat on

the downstream of the flow and the flow against the back of the plug.

5. Tighten the bolts and nuts in the crossover method shown in Fig. 2, to load the pipe and valve evenly and prevent stress

on the joints.

6. Valves buried in unusually deep trenches should have special provisions for operating the valve. Either a riser on the

stem to permit use of a normal key or a notation on the valve records that a long key will be required.

7. When valves with exposed gearing or operation mechanisms are buried below ground, a vault designed to allow pipe

clearance and prevent settling on the pipe should be provided. The operating nut should be accessible from the top

opening of the vault with a valve key. The size of the vault should provide for easy removal of the valve bonnet and

internal parts of the valve for purposes of repair. Consideration should be given to the possibility of groundwater and/or

surface water and to the need to provide the disposal of such water.

8. Valves installed above ground or in a plant piping system should be supported and aligned to avoid damage to the valves.

Valves should not be used to correct the misaligned piping.

9. Do not test valve systems to greater than the rated valve pressure.

10. With the valves in the open positions, flush the entire system to prevent the valves from closing on foreign materials and

damaging the seats or plugs.

3

page 6

1

7

Fig. 2

8

45

6

2

INSTALLATION: ( cont. )

INSTALLATION: - Liquids without Suspended Solids and Clean Gases

For liquids without suspended solids and clean gas application, the plug valve can be installed for both horizontal and

vertical pipe orientations.

LIQUIDS AND GASES:

1. Before installation, remove foreign material such as weld spatter, oil, grease, and dirt from the valve and pipeline.

2. Install the valve as shown in Figure 1.

3. Ensure the valve and anges are concentric to effect proper ange sealing.

4. Tighten the ange bolts or studs in a sequence according to Figure 2.

SUSPENDED SOLIDS:

1. Before installation, remove foreign material such as weld spatter, oil, grease, and dirt from the valve and pipeline.

2. Install the valve as shown in Figure 1.

A. In horizontal pipelines install valve so plug is horizontal and rotates upward as valve opens.

B. For vertical pipelines, install valve with the end marked “Seat” at top of valve.

3. Tighten the ange bolts or studs in a sequence according to Figure 2.

4. Ensure the valve and anges are concentric to effect proper ange sealing.

DIRECT NUT OPERATED VALVES:

S764 valves up to DN200/8” are able to operate with a top-mounted 2” square nut for ¼ turn operation and is

mounted directly to the valve plug. To open the valve, rotate the nut 90 degrees in the counter-clockwise direction and to

close the valve, rotate the nut 90 degrees in the clockwise direction. The closed/open position is adjusted by using two

screws as shown in Figure 3.

Closed

Adjustment Bolt

Open

Adjustment Bolt

Fig. 3

page 7

LEVER OPERATED VALVES:

A wrench head and lever (Figure 4) are also available for use for direct quarter-turn operation. Various lever lengths

are available for specic pressure conditions as shown in the Table below. All lengths are in accordance with EN12570

Handle

L

Wrench Head

Fig. 4

Wrench Length ( In. ) ( L )

DN

Direct pressure 7 bar/100 PSI Direct pressure 2 bar/25 PSI

DN 65-100 20 20

DN 150-200 40 40

page 8

TESTING AFTER INSTALLATION:

In order to prevent time searching for potential leaks, it is recommended that excavation should not be backlled

until after pressure tests of the pipeline system have been made. After installation, it is desirable to test newly installed

piping sections, including valves, at some pressure above the system designed pressure. The test pressure should not

exceed the rated working pressure of the valve. After the test, steps should be taken to relieve any trapped pressure in the

body of the valve. The valve should not be operated in either the opening or closing direction at differential pressures above

the rated working pressure. It is also recognized that wear or foreign material may damage valve seating surfaces and may

cause leakage.

On completion of the installation, valve location, size, make, type, date of installation, angle to open, direction of opening,

and other information deemed pertinent should be entered on permanent records.

APPLICATION HAZARDS:

1. AVK eccentric plug valves should not be installed in lines where service pressure will exceed the rated working pressure

of the valve.

2. The valve should not be used in applications that are exposed to freezing temperatures unless sufcient ow is

maintained through the valve or other protection is provided to prevent freezing.

3. Pipe, ttings, and valves installed in underground pipelines are generally joined with mechanical joints. These joints are

considered unrestrained-type joints since no considerable restraint against longitudinal separation is provided.

4. Plug valves should not be installed in a dead end or near a bend in a pipeline without proper and adequate restraint to

support the valve and prevent it from damage.

5. It is good engineering practice to consider during the design whether or not thrust blocks, restrained joints, or other

means of restraint are needed on or adjacent to valves on pipelines and/or where unusual conditions exist, such as high

internal pressures, adjacent ttings, or unsuitable soils.

6. The valve should not be used as a lifting device for pipes (or equal) mounted on the valve

page 9

OPERATION AND MAINTENANCE

OPERATION

WARNING: Flush the system prior to operating valves to prevent damage to seats and plugs.

1. Do not operate the valves in a system that exceed the valves rated working pressure of 250 PSI.

2. AVK Eccentric Plug Valves are "Open Left" or counter-clockwise to open, quarter turn or 90 degrees to open or close.

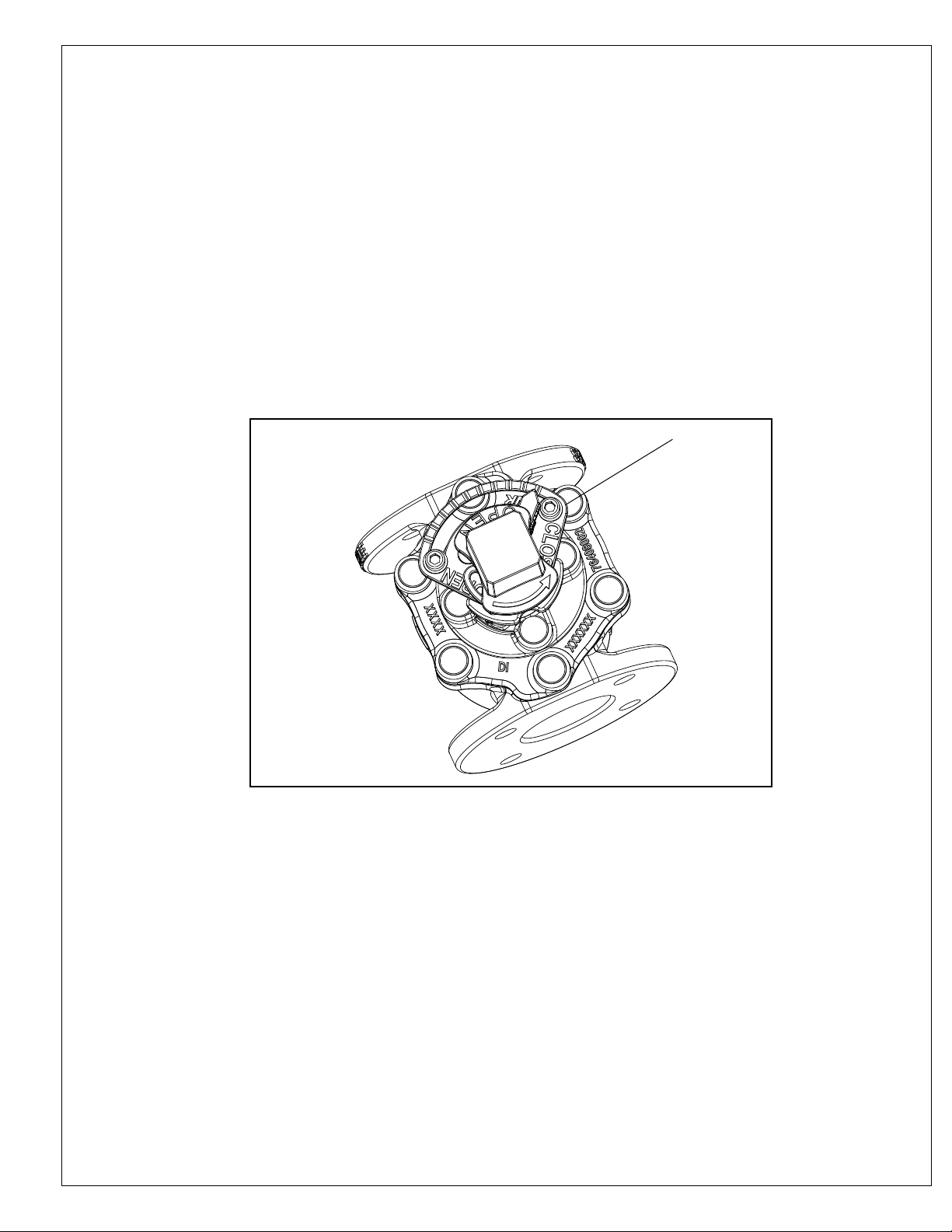

3. Manually actuated valves have mechanical stops for the open and closed positions that are clearly marked on the Stop

Plate (F718). There are also detents in the Stop Plate (F718), if valve throttling is desired. ( See Fig. 5 )

4. For valves with gearboxes, the number of turns to open and close are as follows:

2½", 3", and 4" - 8.5 turns

6" - 9.5 turns

8" - 12 turns

10" and 12" - 24 turns

5. Valve operation and cycling should be scheduled more frequently for systems that have higher solid contents in the water.

6. Never force the valve to seat. Re-open the valve and ush the system again to verify that debris has been dislodged from

the seating area.

F718

Fig. 5

Stop Plate Detail

MAINTENANCE

WARNING: Flush the system prior to operating valves to prevent damage to seats and plugs. When performing

maintenance that requires disassembly on valves, ensure that the system pressure is at 0 PSI.

1. AVK Eccentric Plug Valves are designed to be relatively maintenance free. Do not disassemble valves unless an

interruption to normal service has occurred in the system.

2. Periodic lubrication is not required. Lubrication is only required if disassembly/reassembly of the valve is performed.

3. Regular functional inspections should be performed at a minimum of twice a year. When performing a functional

inspection, operate the valves under normal working pressure, making sure they operate normally without any vibrations.

4. For valves with gearboxes, refer to the gearbox manufacturer's maintenance procedures.

5. Proper records should be maintained for all maintenance procedures and schedules.

page 10

REPAIR PROCEDURES

Leakage, broken parts, hard operation, and other major defects should be corrected by a repair crew as soon as

possible after the defect has been reported. If repairs are to be performed in the eld, the repair crews should take a full

complement of spare parts to the jobsite. Provisions should be made to isolate the defective valve from water pressure

and relieve internal trapped pressure prior to performing any corrective maintenance. Disassembly of the valve should be

accomplished in accordance with the procedure supplied in the following sections. After repairing the valve, the operating

mechanism should be cycled through one complete operating cycle. With full line pressure applied to the valve in the open

position, an inspection should be made to detect leakage in the areas around the seat, bonnet, packing/stem, and body-end

connections. A record should be made to indicate that the valve has been repaired and is in working condition. Any marking

that the valve is inoperable should be removed. In addition, re department and other appropriate municipal departments

should be informed of satisfactory repair of the valve.

PACKING ADJUSTMENT

1. This can be carried out with the valve under pressure in the pipeline.

2. Tighten the two gland nuts (4) on gland (8) to stop the leakage

3. If the leakage continues, the packing should be replaced.

PACKING REPLACEMENT

Need a packing replacement without removing the actuator and top plate. Valmatic does it by cutting the packing.

1. Isolate the valve and depressurize the line.

2. Remove hot melt (1) to expose ISO ange bolts (2)

3. Remove actuator.

4. Remove ISO ange(3) with bolts (2)

5. Remove gland (8) & gland nuts(4) & washers(6) and replace packing (9)

6. Put gland (8) and tighten the gland nuts (4) to press packing (9) until no leakage

7. Put ISO ange (3) and tighten the ISO ange bolts (2) ( 4xthread size=req. Nm, See table )

8. Install actuator.

Valve Size Torque Ft. Lbs.

2 1/2" - 3" 30

4" - 6" 35

8" 50

10" -12" 60

page 11

REPLACE BONNET GASKET: (FIGURE 6)

1. Isolate valve and ensure there is no pressure in pipeline

2. Remove hot melt (1) to expose bonnet bolts (2)

3. Remove actuator

4. Disassembly ISO ange (3) , gland (8) & gland nuts (4) and packing (9)

5. Remove bonnet bolts (2) and lift bonnet (10)

6. Replace bonnet gasket (11) then reassemble bonnet (10) and tighten bonnet bolts (2) (4xthread = req. Nm , See table.).

7. Put packing (9) , gland (8), washers (6) and tighten the gland nuts (4) to press packing (9) until no leakage

8. Put ISO ange (3) and tighten the ISO ange bolts (2) ( 4xthread size=req. Nm, See table )

9. Install actuator

REPLACE OTHER COMPONENTS: (FIGURE 7)

1. Isolate valve and ensure there is no pressure in pipeline

2. Remove hot melt (1) to expose bonnet bolts (2)

3. Remove actuator

4. Disassembly ISO ange (3) , gland (8) & gland nuts (4) and packing (9)

5. Remove bonnet bolts (2) and lift bonnet (10)

6. Push plug (15) out of body (17), replace needed components then reassemble

7. Put assembly of plug , gasket , bonnet (10) and tighten bonnet bolts (2) (4xthread = req. Nm, See table)

8. Put packing (9) , gland (8), washers (6) and tighten the gland nuts (4) to press packing (9) until no leakage

9. Put ISO ange (3) and tighten the ISO ange bolts (2) ( 4xthread size=req. Nm, See table )

10. Install actuator

page 12

TROUBLESHOOTING GUIDE

PROBLEM: Hydrant leaking from around nozzle.

Probable Cause: Damaged valve disc or nozzle sealing surface.

Corrective action: Inspect valve disc and nozzle sealing surfaces and replace if necessary.

PROBLEM: Hydrant leaking from around stem nut.

Probable Cause: Damaged stem o-rings.

Corrective action: Replace stem o-rings.

PROBLEM: Nozzle section facing the wrong direction.

Corrective action: Loosen the Nozzle Section hardware and carefully rotate the Nozzle Section to the desired

position. Tighten the mounting hardware to 60 Ft. Lbs..

PROBLEM: Hydrant ow is low.

Probable Cause: Hydrant or supply vale is not fully open.

Corrective action: Verify that the hydrant is fully open. The AVK Series 24 hydrant valve discs are fully opened

in approximately 9-14 turns.

Also locate and verify that the supply valve is fully open.

page 13

PARTS AND SERVICE

For information on parts and service for your area contact American AVK. Make a note of the hydrant model number and size

located on the hydrant and contact:

American AVK Company

2155 N. Meridian Blvd.

Minden, NV 89423

PH: 775-552-1400

FAX: 775-783-7502

www.americanavk.com

AMERICAN AVK COMPANY WARRANTY

SERIES 24 WET BARREL HYDRANTS

American AVK Company warrants all models of Series 24 Wet Barrel Fire Hydrants to be free from defects in workmanship

and materials for a period of ten (10) years from the date of shipment from American AVK Company. American AVK Company

shall have no obligation under this warranty unless it is notied of claims hereunder promptly and in writing upon discovery

thereof and within the warranty period, and unless the product is delivered to an American AVK Company facility within thirty

(30) days of such notice.

American AVK shall have the right to inspect said product before it is removed from installation. If the product is removed from

installation prior to approval from American AVK this warranty shall be void.

As to motors, gearing or accessory equipment purchased by American AVK Company from others manufacturers, and used

or incorporated into American AVK Company’s products, those manufacturers’ warranties shall apply.

American AVK Company will honor all reasonable costs to repair or replace any American AVK Company Wet Barrel Fire

Hydrant found to be defective.

American AVK Company's sole responsibility shall be, in its sole discretion, to replace the product with the same or a similar

product, repair the product, or refund the price paid for the product provided the product has been properly applied and used

under normal service and under conditions for which it is designed. American AVK Company shall not be liable for indirect,

special, incidental, or consequential damage or penalties and does not assume any liability of purchase to others or to anyone

for injury to persons or property.

THIS IS THE EXCLUSIVE WARRANTY GIVEN IN CONNECTION WITH THE SALE OF THIS PRODUCT. THERE ARE

NO OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING EXPRESSED OR IMPLIED WARRANTY OF

MERCHANTABILITY, OR ANY EXPRESSED OR IMPLIED WARRANTY OF SUITABILITY FOR ANY PARTICULAR

PURPOSE, GIVEN BY AMERICAN AVK COMPANY IN CONNECTION WITH THIS PRODUCT.

page 14

Loading...

Loading...