Page 1

Operating Manual

FiberDAS Distributed Antenna System

FiberDAS Manual, Rev. E14

Page 2

ii

Page 3

Table of Contents

1 LINK DESCRIPTION .................................................................................................................................. 1-1

1.1 C

1.2 G

AUTIONS AND WARNINGS

ENERAL DESCRIPTION

............................................................................................................................ 1-2

...................................................................................................................... 1-1

1.2.1 Basic Principles ............................................................................................................................... 1-2

1.2.2 Functional Description.................................................................................................................... 1-3

1.3 S

PECIFICATIONS

....................................................................................................................................... 1-7

2 INSTALLATION........................................................................................................................................... 2-1

2.1 G

2.2 I

ENERAL PROCEDURE

NSTALL FIBEROPTIC CABLES

.............................................................................................................................. 2-1

................................................................................................................... 2-5

2.2.1 Minimizing Optical Reflections ....................................................................................................... 2-5

2.2.2 Cleaning Optical Connectors .......................................................................................................... 2-6

2.3 S

2.4 H

YSTEM ALARMS

UB SHELF AND REMOTE POWER SUPPLY BATTERY CHARGE MONITORING AND REPLACEMENT

...................................................................................................................................... 2-7

........... 2-7

2.4.1 Replacing the Hub Shelf Battery...................................................................................................... 2-8

2.4.2 Replacing the Remote Power Supply Battery .................................................................................. 2-8

2.5 I

NSTALLATION CHECKLIST

....................................................................................................................... 2-9

2.5.1 Inspect Received Items..................................................................................................................... 2-9

2.5.2

2.6 I

Recommended Tools ........................................................................................................................ 2-9

NSTALLING THE HUB SHELF

.................................................................................................................... 2-9

2.6.1 Rack Installation.............................................................................................................................. 2-9

2.6.2 Connect Fiberoptic Cables ............................................................................................................ 2-10

2.6.3 Indentifying Remote Locations ...................................................................................................... 2-10

2.6.4 Serial Bus, Telephone and Local Alarm Connections ................................................................... 2-10

2.6.5 Mains Power and Fuses................................................................................................................. 2-10

2.6.6 RF Connections ............................................................................................................................. 2-11

2.7 I

NSTALLING THE REMOTE TRANSCEIVERS

.............................................................................................. 2-11

3 MONITORING AND TROUBLESHOOTING.......................................................................................... 3-1

3.1 F

3.2 T

3.3 R

IELD SUPPORT NUMBERS

ROUBLESHOOTING TIPS

EGULATORY

........................................................................................................................................... 3-4

........................................................................................................................ 3-1

.......................................................................................................................... 3-2

iii

Page 4

iv

Page 5

1 Link Description

1.1 Cautions and Warnings

Throughout this manual, these terms appear which highlight the care that should be exercised to ensure

personal safety and proper operation of the equipment.

WARNING: Warning statements identify conditions or practices that could result in injury

or loss of life.

CAUTION: Caution statements identify conditions or practices that could

result in damage to this product or other property.

CAUTION: any modifications to this device not expressly authorized by

Remec, Inc. could void the user’s authority to operate this device.

CLASS 1 LASER PRODUCT

FDA/CDRH Class 1 laser product. All versions of the FiberDAS are Class 1 lasers products per

CDRH, 21 CFR 1040 Laser Safety requirements. All versions are Class 1 laser products per EN

60825-1:1994.

NOTICE

UNTERMINATED OPTICAL RECEPTACLES MAY EMIT LASER RADIATION. DO NOT

VIEW WITH OPTICAL INSTRUMENTS.

1-1

Page 6

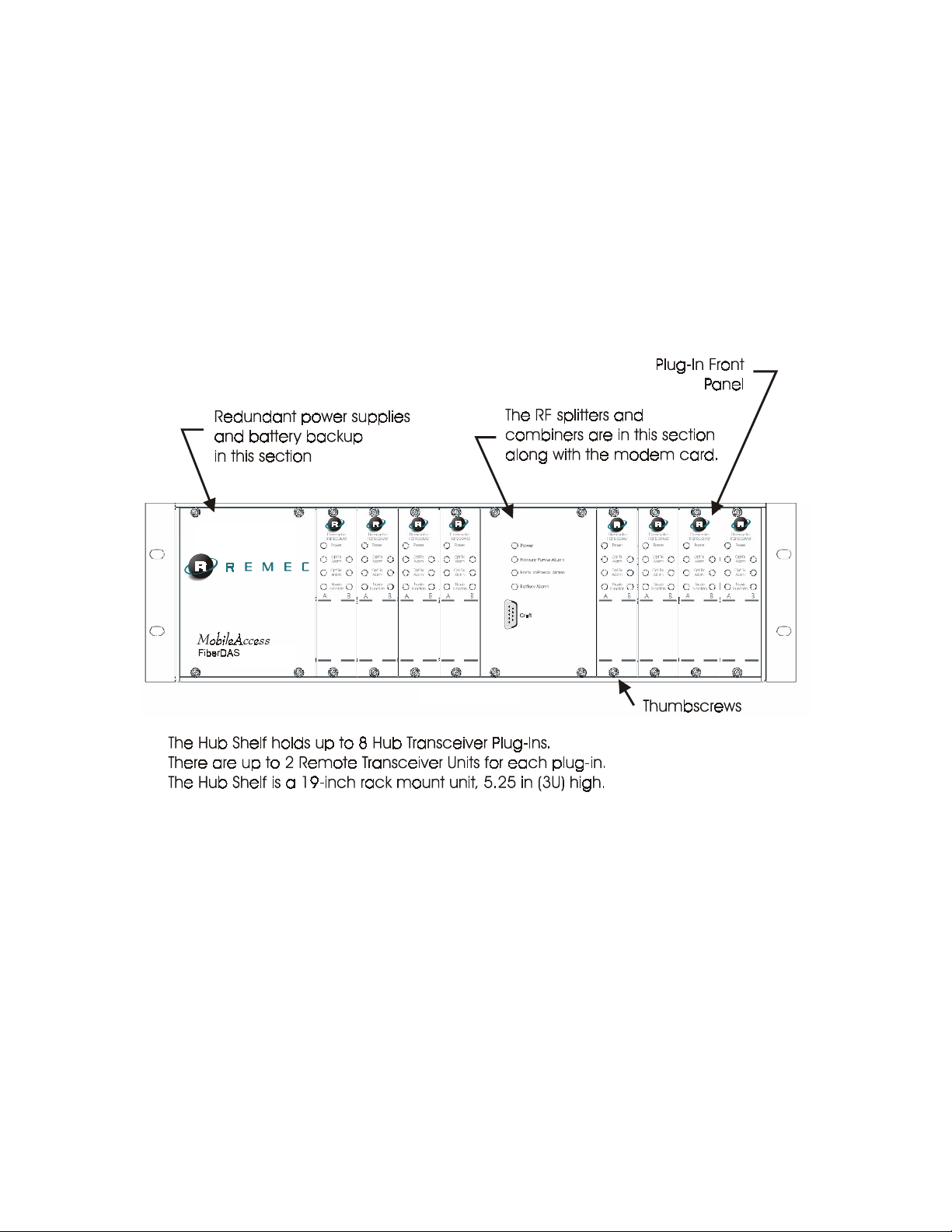

1.2 General Description

The FiberDAS Fiberoptic Distributed Antenna System provides extended coverage of wireless networks

throughout buildings and campus environments. The Hub Shelf is a 3U (5.25 inch) high, 19-inch wide

rack-mounted chassis. The Hub Shelf holds up to 8 Hub Transceiver Plug-Ins. The Hub Shelf is located in

a communications equipment room in the building and is connected to the wireless base station or repeater

via hardline connection. The Hub Shelf may also be connected to the radios of a wireless PBX. Each Hub

Shelf is configured with up to eight Hub Transceiver plug-in cards. Each card is connected to up to two

Remote Transceivers via two pairs of singlemode fiberoptic lines. The Remote Transceiver Units are

distributed throughout the building as necessary to provide coverage. The Remote Transceivers are

mounted, generally, above the suspended ceiling but may be mounted near the ceiling inside the room if

need be. The aesthetic and low-profile design of the Remote Transceiver makes it relatively unobtrusive.

The plastic cover may even be removed and/or painted to match the décor. Each Remote Transceiver is

connected to Hub Shelf via two singlemode optical fibers. Each Remote Transceiver has one RF port

which is connected to a user-supplied indoor coverage antenna. This port may also be routed through an Nway RF splitter to provide coverage from a number N antennas for the one Remote Transceiver. The

choice depends on the results of the engineering design for that particular structure as to the most costeffective way to provide uniform coverage. The Remote Transceiver is DC-powered, usually by the Remec

Central DC Power Supply. This is distributed from the power supply at the Hub location using the

conductor pairs in a composite fiber/conductor cable or by a separate two-wire cable pulled along with the

fiberoptic cable. The DC connector utilized at the Remote Transceiver can accommodate up to 14 AWG

wire.

The FiberDAS design is very versatile but certain options are available that target specific signal types and

applications. In addition to the single band versions from iDEN through UMTS, there are dual band

versions such as 800 MHz/1900 MHz and GSM900/GSM1800.

FiberDAS installation and setup is very simple. First, standard telcom grade singlemode fiberoptic cable

that is most suitable for the site is installed. The cable installer can terminate the cable on site easily with

the SC/UPC optical connectors. The Plug-Ins and Remote Transceivers of a given type are completely

interchangeable. The SC/UPC plugs directly into the Remote Transceiver at one end. The other end plugs

into an optical patch panel or directly into the Hub Shelf via an SC/UPC-to-SC/UPC adapter. If the patch

panel is used, SC/UPC-to-SC/UPC jumpers must be used to connect the Hub Shelf to the patch panel.

Built-in optical loss compensation automatically equalizes the gain in both the transmit and receive paths

so the transmit RF power is known for a given input RF power and the receive path sensitivity is

optimized. The only adjustment available is a manual setting for the static transmit power at the Remote

Transceiver which may be used to optimize coverage, if necessary. This is a one time adjustment during set

up.

1.2.1 Basic Principles

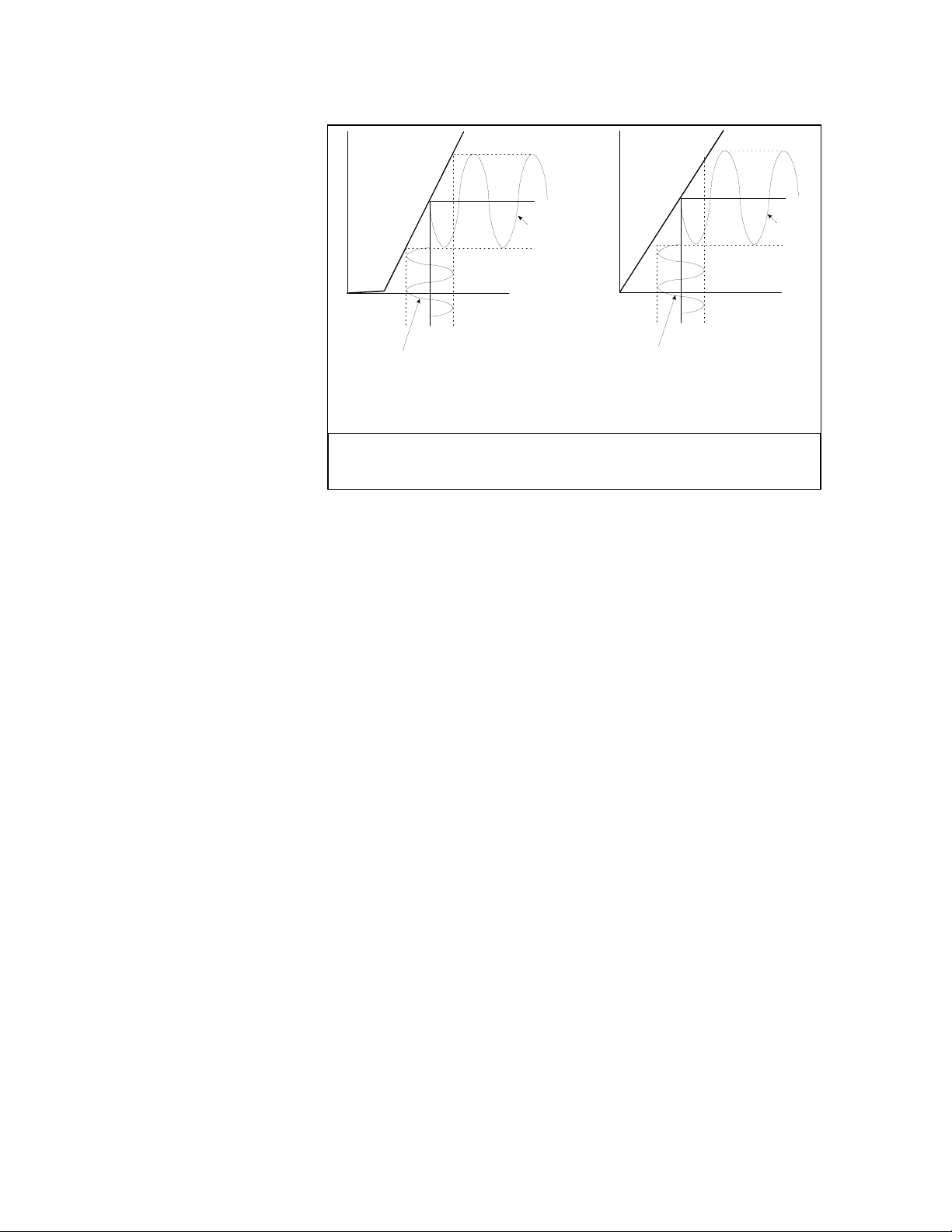

The FiberDAS operation is based on an analog RF fiberoptic link. The principles are illustrated in Figure 1.

Input RF signals are converted to light by direct intensity modulation of a semiconductor laser. This

modulated light is transmitted over optical fiber and detected by a semiconductor PIN photodiode. The

photodiode converts optical power to electrical current. This current is AC coupled and passed through a

load to recover the RF signal.

The basic RF loss in this link is determined by the inefficiencies of the conversions of RF to optical and

back. The fiber also contributes an RF loss equal to twice the optical loss. This is because the photodiode

converts optical power to electrical current and RF power is proportional to the square of the current. So,

for 1 km of fiber with a loss of 0.4 dB/km (this is typical at 1310 nm wavelength) the optical loss is 0.4 dB

1-2

Page 7

l

and the contribution to the

RF loss is 0.8 dB. In a real

installation, two optical

connectors will add

approximately 0.5 dB of

optical loss.

out

P (mW)

Opt ic al

Out put

in

P (mW)

Opt i ca

Input

The laser and, to a much

lesser degree, the

photodiode, add noise and

distortion to the RF signal.

This RF performance is

characterized just as any

RF link in terms of dB loss,

noise figure, third order

I

th

RF

Input

I (mA)

I

bias

RF

Out put (ac co upled

to remove dc component)

I (mA)

intercept, etc.

The fiber path itself can

contribute noise and

distortion. In the

Figure 1-1. Laser and photodiode characteristics.

LASER DIODE

CHARACTERI STIC

PHOTODIODE

CHARACTERI STIC

FiberDAS, the laser used is

a Fabry-Perot (FP) laser

instead of a Distributed Feedback (DFB). The DFB has a single spectral component. The FP laser has

multiple spectral components which can contribute noise and distortion for longer fiber runs. For the

distances used in the FiberDAS, this effect is not significant. Also, optical backscattering back into the

laser from less than perfect connections can cause additional noise and distortion. The FP lasers used in the

FiberDAS are much less sensitive to this than are DFB lasers. DFB lasers are also considerably more

expensive. However, if optical reflections are severe enough from a bad connection, the resulting optical

reflection may cause performance degradation even with FP lasers. To minimize this, SC/UPC optical

connectors with a return loss > 50 dB are used. Following standard practices in cleaning of the removable

optical connectors (see procedure outlined below) will keep the connections in spec and will avoid the

problems of performance degradation.

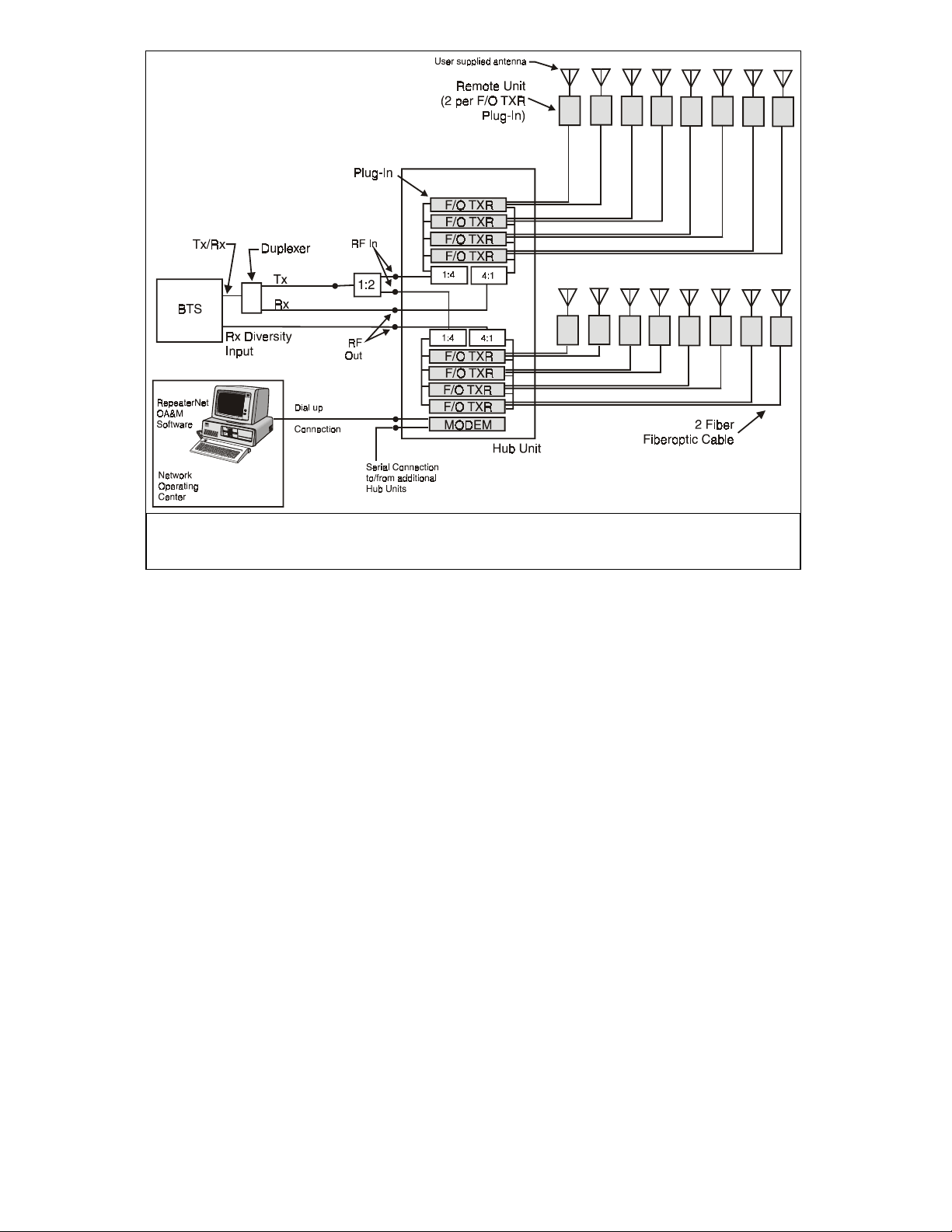

1.2.2 Functional Description

The FiberDAS Fiberoptic Antenna System connects to the mobile coverage RF ports of a repeater or base

station as an extended coverage antenna. The Hub Shelf mounts in a standard 19 inch rack close to the

repeater or base station transmit and receive RF ports. Generally, the appropriate configuration of the Entry

Shelf is used for convenience in combining multiple BTS channels, duplexing the signals to separate

Transmit and Receive, combining, setting the proper RF levels and routing the combined Tx and Rx

signals to and from one or more Hub Shelves, as necessary. The Hub Shelf RF connections are made via

the RF connectors on the rear panel. Inside the chassis, the transmit signal is split and routed to the Hub

Transceiver Plug-Ins. Each plug-in is a dual fiberoptic transceiver. The Hub Shelf holds up to eight plugins. Each plug-in interfaces with up to two Remote Transceivers by way of fiberoptic connections on the

Hub Shelf rear panel.

Transceiver optical output is the green connector. The Remote Transceiver units are generally mounted

above the false ceiling on a bulkhead or post. Each Remote Transceiver is connected to an indoor coverage

antenna by way of a customer-supplied flexible RF cable. Some indoor antennas are available with flexible

RF cable pigtails and an SMA connector termination. These units are distributed throughout the building or

campus as necessary to get full coverage. After installation, the transmit power from each Antenna Unit

may be adjusted manually by way of a rotary dip switch on the unit. This switch is indented in 2 dB steps.

This is a one time adjustment. For dual band units, there is a separate adjustment for each band.

1-3

Page 8

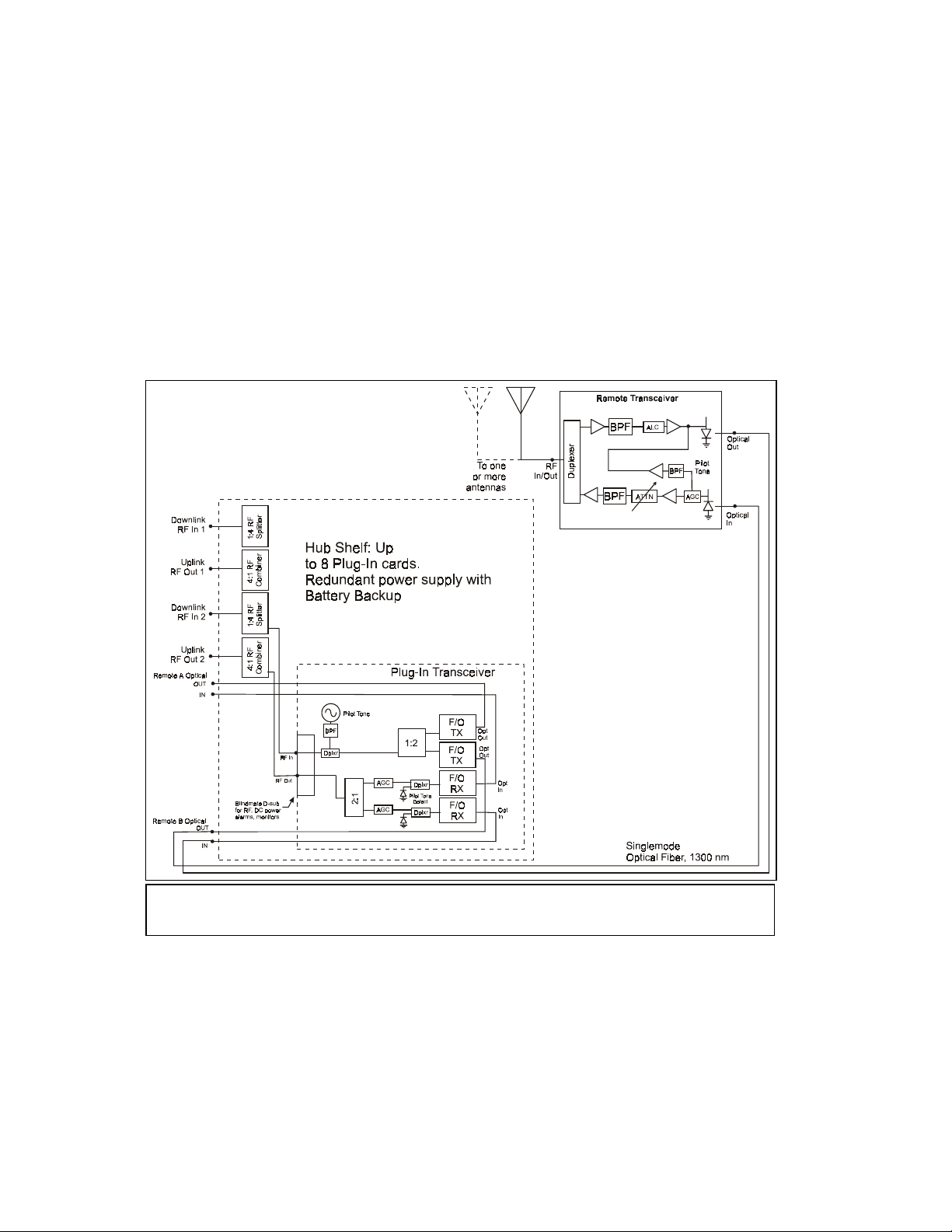

Figure 1-2. System Block Diagram.

The block diagram of the FiberDAS Fiberoptic Antenna System is shown in Figures 1-2 and 1-3. The input

transmit RF signal is split eight ways in the Hub Shelf. Each of these signals is routed to a Hub Transceiver

Plug-In where it is split in two and each path modulates the optical output of a solid state laser diode. This

optical output is routed through a singlemode optical fiber to one Remote Transceiver. The photodiode in

the Remote Transceiver detects this optical signal and outputs a proportional electrical current. This current

is ac coupled and passed through a load to recover the RF signal. The RF signal is amplified, filtered and

output to the antenna.

Depending on design requirements, a 1:2 or 1:4 may be used at the antenna port to route the signal to 1, 2

or 4 in-building coverage antennas. Several versions of the Remote Transceiver are available that are

optimized for specific formats such as AMPS, GSM900, GSM1800, etc. Dual band versions are available;

one providing simultaneous coverage for GSM900 and GSM1800 and one for PCS1900 and 800 MHz. In

these versions, a single RF port feeds a dual band antenna.

The output RF signal path includes a variable attenuator that permits the user to adjust the output level in 2

dB steps for optimum coverage. The RF subcarrier from the plug-in is detected at the photodiode output.

This level is used by the transmit AGC to set the downlink gain. The subcarrier is also amplified and

inserted into the uplink path. This signal is detected at the Hub Shelf Plug-In for the uplink AGC and Node

Function Alarm which acts the primary critical failure alarm. A loss of RF signal due to plug-in or Remote

Unit laser failure, photodiode failure or a break in the fiber path will trigger this alarm. Also, a failure of

any amplifier in the downlink path in the Remote Transceiver, shuts off the subcarrier in the return path

which, in turn, triggers the Node Function Alarm at the Hub.

The receive or uplink RF signal from the antenna is filtered and amplified then routed to the Remote

Transceiver laser. A fast ALC is included in this path which prevents RF overdrive damage to the laser

while recovering fast enough to minimize blocking for TDMA and GSM signals. The laser output in the

Remote Transceiver is then modulated by the receive RF signal and is transmitted through another

1-4

Page 9

singlemode optical fiber back to the Hub Shelf Plug-In. Each of the two photodiodes in the Hub

Transceiver Plug-In recovers the RF signals from each of two Remote Transceivers. The pilot tone on each

signal is split off and detected. This is used for the Node Function alarm. This LED is normally green and

turns red if the pilot tone is not detected. This alarm also appears at the Hub Shelf rear panel DB37

connector as a TTL level critical alarm. It would also be reported to the NOC or service technician by the

modem card depending on how the user configured the system alarms.

The receive RF signal from each photodiode is combined in the Hub Transceiver Plug-In. These combined

outputs are combined again in the and output to the rear panel RF uplink connectors. The Hub Shelf is

divided into two halves. The RF signals from each half are combined and routed to separate rear panel N

connectors. The combined uplink signals from one half can be routed to the BTS main receive port while

the other RF output is routed to the BTS receive diversity port. This method provides an overall 3 dB

system sensitivity improvement compared to routing all of the uplink signals into one receive port (see

Figure 1-2). Alternatively, both outputs may be combined and routed to a single BTS receive port.

Figure 1-3. FiberDAS RF path block diagram.

1-5

Page 10

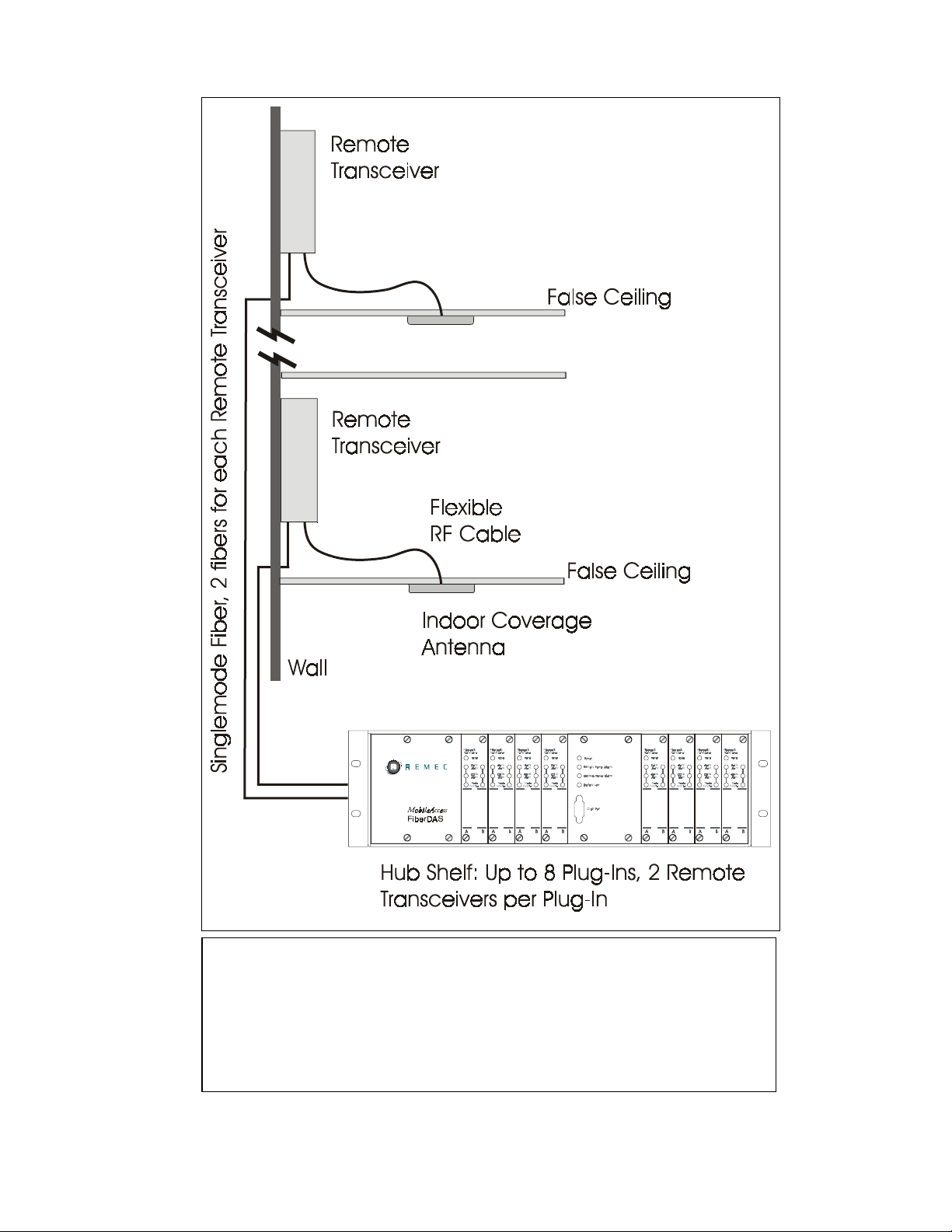

Figure 1-4. The Remote Transceivers are normally mounted above the false ceiling

but may be mounted in the room. Each Remote Transceiver is connected to the

Hub Shelf via 2 singlemode fibers. The Remote Transceiver is connected to a usersupplied antenna via flexible RF cable. The Remote Transceivers may be powered

using the optional universal Remote Power Supply with battery backup, or using a

central power supply that distributes DC power along with the fiber over a

composite fiber/conductor cable.

1-6

Page 11

1.3 Specifications

Description

This specification defines the uplink and downlink performance of the FiberDAS Fiberoptic Antenna

System. The terminal equipment consists of the Remote Transceiver and the Hub Transceiver Plug-In. The

latter is installed in the Hub Shelf. This system meets the requirements for GSM900, DCS1800 and

GSM1900 Class M3 micro-BTS as well as IS-136 TDMA, IS-95 CDMA, CDMA2000 and UMTS for

wireless PBX, in-building and campus coverage applications.

There are five frequency options for the FiberDAS: 850 MHz (AMPS), GSM900, DCS1800, PCS1900 and

UMTS. There are two downlink output power options: the P1 power option meets GSM 900 micro-BTS

M3 requirements and is available for the 850MHz and 900MHz versions only when they are part of a dual

band system. The P2 power option meets micro-BTS M3 requirements for 1800MHz and 1900MHz. For

850MHz and 900MHz, the High Power meets GSM micro-BTS power class M1 requirements and IS-136

in-building requirements for +20 dBm composite power. All of these system standards specifications are

met for optical loss of up to 4 dB.

RF Parameters (up to 4 dB optical loss)

Uplink

Frequency Range 850 MHz 824 - 849 MHz

GSM900 890 - 915 MHz

DCS1800 1710 - 1785 MHz

PCS1900 1850 - 1910 MHz

UMTS 1920 – 1980 MHz

Amplitude Flatness

824 – 849, 890 - 915 MHz; (Any 15 MHz band) ± 1.0 dB

DCS, PCS, UMTS (Any 15 MHz band) ± 1.5 dB

Noise Figure ≤ 13 dB

Low Noise Option (DCS, PCS and UMTS only) ≤ 7 dB

Input Third Order Intercept (IIP3), 2 carriers, -43 dBm/carrier ≥ -15 dBm

Low Noise Option (GSM1800/PCS1900) ≥ -25 dBm

High Dynamic Range Option ≥ 0 dBm

High Dynamic Range Option w/Low Noise ≥ -10 dBm

Link Gain (with external 20 dB attenuator; 30 dB attenuator with Low Noise Option, over full

band and 4 dB optical loss range)

850 MHz, GSM900 4 ± 2.0 dB

DCS, PCS, UMTS 4 ± 2.5 dB

Uplink Input ALC

Input RF Threshold - 25 dBm

Low Noise Option -35 dBm

High Dynamic Range Option -10 dBm

High Dynamic Range Option w/Low Noise -20 dBm

Range 30 dB

Response Time < 5 µsec

Gain Stability ± 1 dB

Input/Output Impedance 50 Ω

Input/Output VSWR ≤ 2 : 1

Downlink

Frequency Range 850 MHz 869 - 894 MHz

GSM900 935 - 960 MHz

GSM1800 1805 - 1880 MHz

1-7

Page 12

PCS1900 1930 - 1990 MHz

UMTS 2110 – 2170 MHz

Amplitude Flatness

850MHz, GSM900; (any 15 MHz band) ± 1.5 dB

850MHz, DCS, UMTS; (any 15 MHz band) ± 1.5 dB

Output Noise ≤ -95 dBm/Hz

Output Third Order Intercept

Option P1 +30 dBm

Option P2 +40 dBm

Output 1dB Compression (typical)

Option P1 +17 dBm

Option P2 +25 dBm

(Note: all single band systems are Power Option P2. Power Option P1 is only for the low band

in dual band systems. For example, the GSM900/DCS1800 dual band has Power Option P1 for

GSM900 and Power Option P2 for DCS1800. The same applies for the dual band 800MHz/PCS1900.)

Output Power/Carrier (dBm)

Power

Option

P1

Number of

Carriers

GSM800 &

GSM900

DCS1800 &

GSM1900

EDGE CDMA TDMA UMTS

1 17.0 - - 11.0 17.0 2 8.0 - - 8.0 8.0 4 5.0 - - 5.0 5.0 -

P2*

1 25.0 25.0 25.0 20.0 25.0 20.0

2 14.0 17.0 14.0 16.5 17.0 16.5

4 11.0 14.0 11.0 13.5 14.0 13.5

* For Dual Band Systems, the output power shown for Option P2 is reduced by 1 dB.

Intermodulation &

Spurious

GSM800 &

GSM900

DCS1800 &

GSM1900

CDMA TDMA UMTS

Meets GSM 05.05 and 11.26 Meets IS-

95/97 and JSTD-005

< -45 dBc

IMs for 2

Carriers

Meets

3GPP

TS25.104

Output Power Range ≥ 12 dB user adjustable (in 2 dB

increments at Remote Transceiver)

Input Power Threshold for Input Power Protect 11.5 to 15.5 dBm

Attenuation Step for Input Power Protect 10 dB

Gain at Maximum Output Power (output attenuator set at min, over full band and optical loss

range)

Output Power Option P1 4 ± 2.5 dB

Output Power Option P2 14 ± 2.5 dB

Gain Stability ± 1 dB

Input/Output Impedance 50 Ω

Input/Output VSWR ≤ 2 : 1

General

Loop back Carrier Frequency 100 MHz ± 10%

Optical Parameters

1-8

Page 13

Wavelength 1310 ± 20 nm

Output Power

Remote Transceiver 1.2 mW

Hub Transceiver Plug-In 1.2 mW

Optical Connector

Hub Shelf SC/UPC, > 50 dB return loss

Remote Transceiver SC/UPC, > 50 dB return loss

Fiber Singlemode

Absolute Maximum Ratings

RF Input Power

Uplink +5 dBm

Low Noise Option -5 dBm

Downlink +26 dBm total

Photodiode Input Optical Power +2.3 mW

Electrical

Remote Transceiver +12 V to +28 V, 12 W (single

band), 20 W (dual band)

Remote Power Supply 100 to 240 VAC, 50/60 Hz

Hub Transceiver Plug-In 6 W, 0.5 A max

Hub Shelf 100 - 240 VAC, 50/60 Hz, 1.0 A

max

1-9

Page 14

Shielded DC power cable

Mounting brackets for each unit

snap together using connecting

bracket

SMA RF Connector

to Antenna

Mounting

Bracket

Fiberoptic Connectors

(SC/APC)

Status LEDs

(32.8cm)

12.93"

(32.8cm)

12.93"

11.33"

2.26"

6.80"

(17.3cm) (5.7cm) (28.8cm)

1-10

(2 dB Steps)

Power Adjust

Static RF Output

Weight 4.5 lbs. (2.04 kg) Net

Dimensions See outline drawing below

Battery Backup

Indicator/Shutoff

Remote Transceiver

Remote AC Power Supply

Weight 4.8 lbs. (2.18 kg) Net

Dimensions See outline drawing below

Mechanical

Remote Transceiver

Front Cover

DC Connector

Front Cover

Cable

DC Power

Mains Power

Universal AC

Mounting

Input

Bracket

(32.8cm)

12.93"

4.93"

(12.5cm)

2.46"

(6.25cm)

Page 15

Hub Transceiver

Dimensions Plug-in card with 5.06” (12.85 mm)H x 1.2”

(3.05 cm) W front panel for Hub Shelf

Weight 0.9 lbs. (0.41 kg) Net

Hub Shelf

Dimensions 19”(48.26 cm), 3U (5.25”, 13.34 cm) H,

15.75” (40.01 cm)D rack mount

Weight 20 lbs. (9.1 kg) Net

1-11

Page 16

1-12

Page 17

Alarms and Monitors

Remote Transceiver

Description

Power On (Green LED)

Laser Optical Power Low Alarm (active if laser output < 90% of factory set point:

Red Front panel LED)

Received Optical Power Low Warning (active if optical loss > 4.2 dB: Yellow

front panel LED)

Transmit Amplifier Failure Alarm (active if any amplifier in transmit path fails as

detected by bias current: Red LED. Also causes shutoff of subcarrier in uplink

path which triggers Node Function Alarm at plug-in.)

Hub Transceiver Plug-In Node Function (loopback carrier detect:

Hub Shelf

LEDs Power On (Green, Normally ON)

Alarms, Rear Panel DB-37 (See Table) Critical Alarms: these include all Node

Dial-up Any critical alarm prompts the system to dial up

Craft Interface (Front Panel) Used to configure system including naming

Front panel LED; normally Green, Red if

RF subcarrier level drops more than 10 dB)

Received Optical Power Low Warning

(active if optical loss > 4.2 dB: Yellow front

panel LED, normally OFF)

Laser Optical Power Low Alarm (active if

laser optical output power drops 10%): Red

Front panel LED, normally OFF)

Main Power Alarm (Red Front panel LED;

normally OFF)

Backup Power Alarm (Red Front panel

LED; normally OFF)

Battery Alarm (Yellow front panel LED,

active if battery backup charge is low;

normally OFF)

Function Alarms and the Main and Backup

Power Supply Alarms.

Summary Contact Closure Alarm: active if

any alarm is active in chassis or plug-ins.

Remote Power Supply NOC. This is configured at

installation with a laptop computer via the front panel

Craft interface. Dial up connection is made with RJ11 interface on rear panel. The system may also be

polled through dial-up connection to get status of all

alarms and warnings.

system and Remote Transceiver locations, set up

critical and minor alarms, and setting telephone

numbers of system, NOC and/or service pager. Also

1-13

Page 18

configures Hub Shelf as master or slave. Master

provides dial up connection for itself and daisychained slave units. Connection to slave units via RJ45 jacks on rear.

DB-37 Pin Signal name Type Sense

1 1-A Node Function Alarm TTL Active Low

2 2-A Node Function Alarm TTL Active Low

3 3-A Node Function Alarm TTL Active Low

4 4-A Node Function Alarm TTL Active Low

5 5-A Node Function Alarm TTL Active Low

6 6-A Node Function Alarm TTL Active Low

7 7-A Node Function Alarm TTL Active Low

8 8-A Node Function Alarm TTL Active Low

9 Master P.S. Alarm TTL Active Low

10 Battery Alarm TTL Active Low

11 n.c.

12 n.c.

13 n.c.

14 n.c.

15 RTN

16 RTN

17 RTN

18 n.c.

19 n.c.

20 1-B Node Function Alarm TTL Active Low

21 2-B Node Function Alarm TTL Active Low

22 3-B Node Function Alarm TTL Active Low

23 4-B Node Function Alarm TTL Active Low

24 5-B Node Function Alarm TTL Active Low

25 6-B Node Function Alarm TTL Active Low

26 7-B Node Function Alarm TTL Active Low

27 8-B Node Function Alarm TTL Active Low

28 Back-up Power Supply Alarm TTL Active Low

29 n.c.

30 n.c.

31 n.c.

32 n.c.

33 n.c.

34 Summary Alarm N.C. Relay contact Connect to Common if O.K.

35 Summary Alarm Common Relay contact

36 Summary Alarm N.O. Relay contact Open if O.K.

37 n.c.

1-14

Page 19

Environmental

Operating (ETSI EN 300 019-1-3)

Temperature Range +5 to +45°C

Rate of Temperature Change 0.5 °C/minute

Relative Humidity 5 to 85% RH, non-

condensing

Storage and Transportation

(ETSI 300 019-1-1 STORAGE, class 1.2)

(ETSI 300 019-1-2 TRANSPORTATION, class 2.3)

Temperature Range -40 to +70°C

Rate of Temperature Change 0.5°C/minute

Relative Humidity 10 to 100%

Vibration (Storage)

PARAMETER FREQUENCY RANGE SEVERITY DURATION

(Hz) Vel; mm/s Accel; m/s2

Sinusoidal 5 – 62 5.0 3x5 sweep cycles

Sinusoidal 62 - 200 2 3x5 sweep cycles

Vibration Test (Transportation)

PARAMETER FREQUENCY RANGE SEVERITY DURATION

(Hz) ASD: m2/s3 Rolloff: dB/oct

Random 5 – 20 0.96 3 x 10 mins

Random 20 - 500 -3 3 x 10 mins

Shock Test (Transportation)

PARAMETER SHOCK SPECTRUM SEVERITY DURATION

(Hz) Accel: m/s2 Number ms

Shock (m≤100kg)

Half Sine 400 500 in each

6

of 6

directions

or

1000 in

normal

attitude

Drop Test (Transportation)

PARAMETER MASS DROP HEIGHT NUMBER OF DROPS

(kg) (m)

Free Fall < 30 0.5 1 on each face or 2 in normal attitude

Free Fall 30 - 40 0.4 1 on each face or 2 in normal attitude

Free fall 40 - 50 0.3 1 on each face or 2 in normal attitude

Regulatory UL, CSA, FCC Type

Acceptance for 800 MHz

and PCS versions.

CE Marking for GSM900

and GSM1800 versions

1-15

Page 20

2 Installation

2.1 General Procedure

Generally, the fiberoptic and DC power cable, the antennas with flexible coaxial cable connections and the

Remote Transceiver mounting plates can be installed first. Then, the FiberDAS components, Hub Shelf,

Remote Transceiver Units and Remote Power Supplies (if any), can be added easily and the system

powered on.

Before installing and, in fact, before even receiving the FiberDAS units, one can have the fiberoptic cables

installed and tested. The network planning has been completed which has determined the type, number and

location of Remote Transceivers needed for optimum coverage and capacity.

Install and check the fiberoptic cables first. Use any high quality, telcom grade singlemode fiberoptic

cable. If the central DC Power Supply is used, either use a composite cable with a singlemode fiber pair

and a pair of wires built into the same cable, or pull a separate two-fiber fiberoptic cable and a two wire

DC connection together. The gauge or size of the wire to be used depends on the distance to the Remote

Unit. The SC/UPC optical connectors can be installed on site using the Seicor Unicam connector system.

One can learn how to install the Unicam SC/UPC connectors easily. However, the terminations must be

done carefully and well to ensure proper performance. Poor optical connections are by far the most

common cause for system performance degradation.

! Make sure to specify SC/UPC, not SC/PC. The standard SC/PC has an optical return loss < 27 dB

which can cause degradation of the system noise performance. SC/UPC specifies an “ultra” polish for

a return loss > 50 dB.

General practice is to terminate the fiberoptic cables at a patch panel near the Hub Shelf. In this case,

optical jumper cables will be needed to make the connection between the patch panel and the Hub Shelf.

During this process, label each cable at each end to indicate whether it is transmit or receive and which

Remote Transceiver it is associated with. As part of the planning, decide whether it would be good to pull

one or two additional fiber pairs to each Remote Transceiver to allow for future expansion. Also, leave a

service loop near the Remote Transceiver location in case the unit needs to be moved. Next, mount the Hub

Shelf in the rack and connect the fiberoptic cables. Do not connect the RF cables yet.

Mount the Remote Transceivers. Install the wall mounting brackets first. For mounting above a false

ceiling, the preferred method is to orient the bracket so that the end of the Remote Transceiver with the

connectors is pointing downwards. The unit could also be mounted horizontally with the connectors to one

side. When mounting inside the room, the preferred method is to place the Remote Transceiver near the

ceiling with the connectors pointing upwards. This permits the most aesthetic routing of the cables. The

plastic cover on the Remote Transceiver may be removed by loosening the six screws on the back of the

Unit. This permits the user to paint the cover to match the room décor. If the Remote Transceiver is to be

installed with the Remote Power Supply, install the two mounting brackets next to each other linking them

with the connector piece supplied with the power supply mounting bracket. This will give the most

aesthetic mounting with the proper spacing for an easy DC power connection. ( Note: the Remote AC

Power Supplies are not to be installed above a false ceiling.) Orient the bracket so that the threaded tab

will be at the same end as the connectors on the Remote Transceiver.

Before mounting the Remote to the bracket, attach the Optical RF and DC cables to the Remote. If the

plastic cover is not to be used, you may remove it by removing the four screws that hold it on. This will

make it easier to attach the cables.

2-1

Page 21

Place the Remote Transceiver so that the rear panel studs slide into the keyhole slots on the mounting

bracket. Secure the unit by tightening the captive thumbscrew on the Remote Transceiver to the threaded

hole in the mounting bracket. The Remote Power Supply installs in the same way. For the Remote Power

Supply, if the red NO AC LED is on, press the reset switch located next to the AC power connector which

turns off the battery backup (when the mains is not connected). For AC powered units, connect the AC

power cords to the building mains according to local building electrical codes. Connect DC power to the

Remote Transceiver by connecting the DC cable to the DC input connector on the Remote Transceiver.

Mount the indoor coverage antenna to the ceiling or wall as needed and connect it to the Remote

Transceiver with a flexible RF cable rated to cover the highest frequency in use.

IMPORTANT NOTE! to comply with FCC RF Exposure compliance requirements, the following

antenna installation and device operating configurations must be satisfied:

Any antenna connected to this device must result in an ERP < 1.5W(800 and 900MHz) or < 3.0W

(1800MHz and 1900MHz)! and must be mounted such that there is at least 20 centimeter spacing

The RF cable must have an SMA male connector for the connection to the Remote Transceiver. If the

antenna has a different RF connector, say, N or TNC, an RF adapter must be used. If more than one

antenna is to be connected to the Antenna port of the Remote Transceiver, connect the Antenna port to the

appropriate RF splitter with a short flexible coaxial RF coaxial cable rated to at least 2.5 GHz. Then

connect the antennas to each of the RF splitter ports with another length of RF coaxial cable rated to at

least 2.5 GHz. Plug in the transmit (downlink) fiberoptic cable connector into the OPTICAL IN on the

Remote Transceiver and the receive (uplink) fiberoptic cable connector into the OPTICAL OUT (Green)

on the Remote Transceiver.

From the initial network design, the output power required from each Remote Transceiver should be

known. This can be preset before power is turned on by turning the Output Power adjustments on each

Remote Transceiver. From the maximum output power rating for each Remote Transceiver, the power can

be reduced in 2 dB by turning the indented rotary DIP switch on the Remote Transceiver..

Turn the power on to the Remote Transceivers and on the Hub Shelf. Proper operation of the optical

system is indicated by a green Node Function LED on each of the Hub Transceiver Plug-Ins that is

connected to an active Remote Transceiver. All other alarm indicators should be OFF. A yellow LED at the

plug-in or at the Remote Transceiver indicates that the optical loss in that path is > 4 dB and is, therefore,

out of the range of the guaranteed specification.

Before connecting the Hub Shelf to the BTS or Repeater, check that the RF transmit power from the

source (BTS or repeater) is within the safe operating range of the FiberDAS and that it is at the level

required for proper noise and distortion performance according to the network design (see Table 1).

Table 1. Transmit (Downlink) Input RF Levels/carrier

Power

Option

P1

Number of

Carriers

GSM800 &

GSM900

DCS1800 &

GSM1900

1 13.0 - 8.0 13.0 2 4.0 - 4.0 4.0 4 1.0 - 1.0 1.0 1 11.0 11.0 6.0 11.0 6.0

P2*

2 0.0 3.0 2.5 3.0 2.5

2-2

CDMA TDMA UMTS

Page 22

4 -3.0 0.0 -0.5 0.0 -0.5

Connect the RF cables between the BTS or repeater and the Hub Shelf. The Remote Transceivers and the

plug-ins have been calibrated at the factory and the optical loss compensation in each Remote Power

Supply and plug-in automatically equalizes the gain in each link so that the specified link gain is always

met. The system is now operational and no further adjustment is necessary.

2-3

Page 23

Remote Transceiver mounts

above false ceiling.Aesthetic

design permits mounting in room,

if necessary.

All optical and RF connectors along

with RF output adjust and LEDS at

same end for easy installation and servicing.

If Remote AC Power

Supply is used, it is attached

to common mounting plate

with the Remote Transceiver

FiberDAS

Installation

Remote Transceiver connects

to any standard indoor coverage

antenna

Singlemode fiber pair up to 4 dB

optical loss to each Remote Transceiver,

1300 nm wavelength. Composite

cable may be used to distribute

DC power as well

Hub Shelf

Hub Transceiver

Plug-Ins

Alarms reported through modem to NOC

or pager via POTS connection.Also, to local

TTL, Summary and LED.

Figure 2-1. FiberDAS Installation

2-4

RF Connects to BTS

or BDAs through the

passive Entry Shelf.

Page 24

2.2 Install Fiberoptic Cables

Once the location for each of the Remote Transceivers has been determined, the fiberoptic cable can be

installed between the Hub Shelf and these locations. The cable length can be up to 5 km.

You need to know the following:

Optical Fiber Singlemode, 1310nm wavelength

Optical Loss Good quality fiber should have an optical loss of

< 0.4 dB/km at 1310nm. There will be additional

optical loss due to connectors and splices but there

should be no more than about 0.5 dB loss through a

connector mating (optical connections are sexless)

and less through a splice.

Optical Connectors SC/UPC connectors. The “U” refers to “Ultra Polish”

which gives an optical return loss > 50 dB. One can

procure cable assemblies that are pre-terminated,

however the SC/UPC can be installed in the field

using the Seicor Unicam connector. The Hub Shelf

also uses SC/UPC connectors. IMPORTANT

NOTE: MAKE SURE TO USE AN SC/UPC

TERMINATION: THIS CONNECTOR IS AN

“ULTRA POLISHED” CONNECTOR WITH AN

OPTICAL RETURN LOSS > 50 dB. A

STANDARD SC/PC TERMINATION HAS A

HIGH RETURN LOSS AND WILL DEGRADE

LINK NOISE AND LINEARITY PERFORMANCE.

Once the cable has been installed, the installer should check the quality of the optical path using an Optical

Time Domain Reflectometer (OTDR). This will check the optical path loss and the magnitude and location

of any reflections. The total return loss should be > 45 dB.

While checking the cables in this way, it is useful to label each cable near the connector as to which

Remote Transceiver it is for and whether it is for the transmit or receive path. Labelling the cable in this

way permits complete interconnection during installation with the system powered off. Otherwise, the

Remote Transceivers will have to be installed with the Hub Shelf power on with all fiberoptic cables

connected to it. This allows the installer to check which fiber is transmit by using an IR sensitive card (see

Recommended Tools).

2.2.1 Minimizing Optical Reflections

As discussed in the Functional Description, optical reflections can degrade the noise and linearity of a

fiberoptic link. In particular, reflections that reach the laser can be a problem. Keep all discrete reflections

to > 50 dB. The SC/UPC connectors are polished to a return loss >50 dB.

2-5

Page 25

2.2.2 Cleaning Optical Connectors

Optical reflections from a discontinuity such as a poor connector interface appear on an RF spectrum

analyzer trace as stable variations in the noise floor amplitude that are periodic with RF frequency. If the

reflection is bad enough, it could impact the system performance. By far, the most common cause for a

large discrete reflection is a dirty optical connector. Remember that the optical aperture at the tip of the

fiberoptic connector is only 9 :m in diameter. A bit of dust or oil from a finger can easily interfere with or

block this light. Fortunately, it very easy to clean the connector. The procedures are indicated in the Figure.

Be sure to use the correct procedure for the given connector. When disconnected, cap the SC/UPC

connector to keep it clean and prevent scratching the tip of the ferrule.

Cleaning the SC/UPC optical connectors.

Swipe the tip of the ferrule 2 – 3 times with

a cotton swab soaked in alcohol. Let it air

dry. Do not use canned air to dry as this

may leave a residue.

Figure 2-2. Cleaning the optical connectors.

2-6

Page 26

2.3 System Alarms

The FiberDAS has four ways of indicating alarms.

1. LEDs: the Hub Shelf and the Remote Transceiver have status indicators for power on and

alarm conditions.

2. Hub Shelf Rear Panel DB37 Connector: The “critical” alarms are available here as TTL

levels. In addition, three pins provide a contact closure summary alarm (see Alarms in the

specifications).

3. Craft serial port: The system status may be monitored locally with a computer through the

front panel Craft serial port. The main purpose of this port is initial system setup. This

includes specifying which alarms are critical, setting the local system telephone number and

specifying the action to be taken when there is a critical alarm (dial up the NOC or a service

technician’s pager). If more than one Hub Shelf is being used at the same location, one of the

hubs may be configured as the Master, reporting alarms for all connected Hubs. One can also

give the system an easily recognizable name as well as naming the Remote Transceiver

locations so that the system and the fault location may be easily identified at the Network

Operating Center (NOC) using the NMS.

4. Dial-Up: the system may be connected to a standard RJ-11 telephone jack through which it

communicates with the NOC or a service technician’s pager. Using network management

software at the NOC, the network administrator can poll and monitor thousands of remote

FiberDAS systems. The system and alarms can be configured by way of the front panel serial

port using the Remec MobileCraft software (see separate MobileCraft manual).

Using the alarms provided, the cause of a critical failure can be determined with high confidence. For

instance, if the Node Function alarm is associated with a Plug-In laser alarm, the Plug-In has failed and

must be replaced. If the Node Function alarm is associated with a Received Optical Power Low at the PlugIn, either the Remote Transceiver laser has failed or the fiberoptic cable has been broken or damaged. The

service technician would come with a replacement Remote Transceiver. If, upon inspecting the Remote

Power Supply in question, the LEDs indicate no failure, the fiber path would have to be inspected. This

should be relatively easy to track down since damage would have to be associated with some other work

going on at the site or someone had deliberately disconnected the optical cable from the unit. Finally, a

Node Function alarm not associated with any other alarm at the Hub Shelf would indicate a failure of the

Remote Transceiver downlink amplifier chain. This would be confirmed by inspection of the Remote

Power Supply in question for that particular LED. The complete troubleshooting matrix is given at the end

of this manual and is included in the separate MobileCraft manual. Or, it can be used to program another

NMS to recommend the proper action to be taken.

2.4 Hub Shelf and Remote Power Supply Battery Charge Monitoring and

Replacement

Both the Hub Shelf and the Remote Power Supply have a battery backup. While connected to mains

power, the battery is kept charged by a charging circuit. Once AC mains power is first connected, the

charging circuit waits 48 hours before starting the battery test circuit. This circuit checks to open circuit

battery voltage every ten seconds. Once the circuit detects the battery voltage drops below approximately

12 Volts, the BATT LOW alarm is activated. At the beginning of life, the battery provides approximately

15 to 20 minutes of system backup. At end of life, the backup time is about 8 to 10 minutes. It is expected

that the batteries should be replaced every 1.5 to 2 years.

2-7

Page 27

2.4.1 Replacing the Hub Shelf Battery

The battery must be replaced with the AC mains power off.

CAUTION: DOUBLE POLE/NEUTRAL FUSING

1. Turn off the AC mains power (rear panel switch)

2. Disconnect AC mains power cable

3. Press the BATT OFF switch on the rear panel to switch off the battery power to the Hub

Shelf

4. Pull the Hub Shelf out of the rack from the front on the chassis rack mount slides. Be careful

not to pull on rear panel cable assemblies, especially the fiberoptic cables.

5. Remove the Hub Shelf top cover.

6. Locate the battery on the left behind the power supplies.

7. Remove the battery bracket by loosening the screws. Lift off the bracket.

8. Disconnect the battery terminal wires by pulling them off.

9. Lift the battery out.

10. Install the replacement battery by reversing the process.

Spent batteries must be treated as hazardous waste and disposed of or recycled according to

local, state and federal guidelines

2.4.2 Replacing the Remote Power Supply Battery

The battery must be replaced with the AC mains power off.

1. Disconnect the AC mains power cable.

2. Press the BATT OFF switch on the power supply to switch off the battery power.

3. Disconnect the DC power connector from the Remote Transceiver.

4. Loosen the thumbscrew that secures the power supply to the mounting bracket.

5. Slide the power supply housing so as to release from the mounting bracket keyhole slots.

6. Remove the smaller cover on the back of the housing (the far end from the connectors).

7. Lift out the battery and pull off the terminal wires.

8. Install the replacement battery by reversing the process.

Spent batteries must be treated as hazardous waste and disposed of or recycled according to

local, state and federal guidelines.

2-8

Page 28

I

2.5 Installation Checklist

Once the fiberoptic cable has been installed properly, the FiberDAS installation and set up is simple.

2.5.1 Inspect Received Items

nspect all received items thoroughly. If any item has been damaged during shipping, report it to the

shipping company and to Remec in the U. S. at 408-747-1946. Also, contact the factory immediately

if any item is missing.

Packing List Checklist (as applicable)

Hub Shelf w/mounting hardware and AC power cord

Hub Transceiver Plug-In (s); these are installed in the chassis unless they are spares

Plug-In Termination Cards: these are plug-ins behind blank front panels installed on unused slots.

They provide 50Ω RF terminations to the internal RF splitters and combiners ensuring a balanced

load.

Two 1:2 RF splitter/combiners (supplied with the Hub Shelf)

Remote Transceiver (s): These will be in a separate box.

Remote Power Supplies (not included if user is supplying DC power to Remote Transceiver).

Mounting Brackets for Remote Transceiver and Remote Power Supply. Included with Remote

Transceiver and Remote Power Supply.

1 Operating Manual

2.5.2 Recommended Tools

Fiberoptic Connector Cleaning Kit: For the SC/UPC: cotton swabs, alcohol

IR sensitive card: used to detect active laser port and active fiber. (eg. Quantex Model Q-42-R)

Small screwdriver or Adjustment Tool for transmit output power rotary DIP switch

Screwdriver for mounting chassis in rack and Remote Transceivers on the wall

4 #6 panhead or M3.5 mounting screws for each Remote Transceiver.

Appropriate screws, washers and mounting hardware for rack mounting the Hub Shelf.

2.6 Installing the Hub Shelf

2.6.1 Rack Installation

The Hub Shelf mounts in a standard 19 inch rack close to the RF source (BTS or repeater). The chassis

should be supported at the sides as well as from the front flanges. The Hub Shelf 3U high chassis is also

available with rails as an option.

Make sure that Hub Shelf is supported at both front and back in the rack. Do not mount with

!

front mounting ears only.

2-9

Page 29

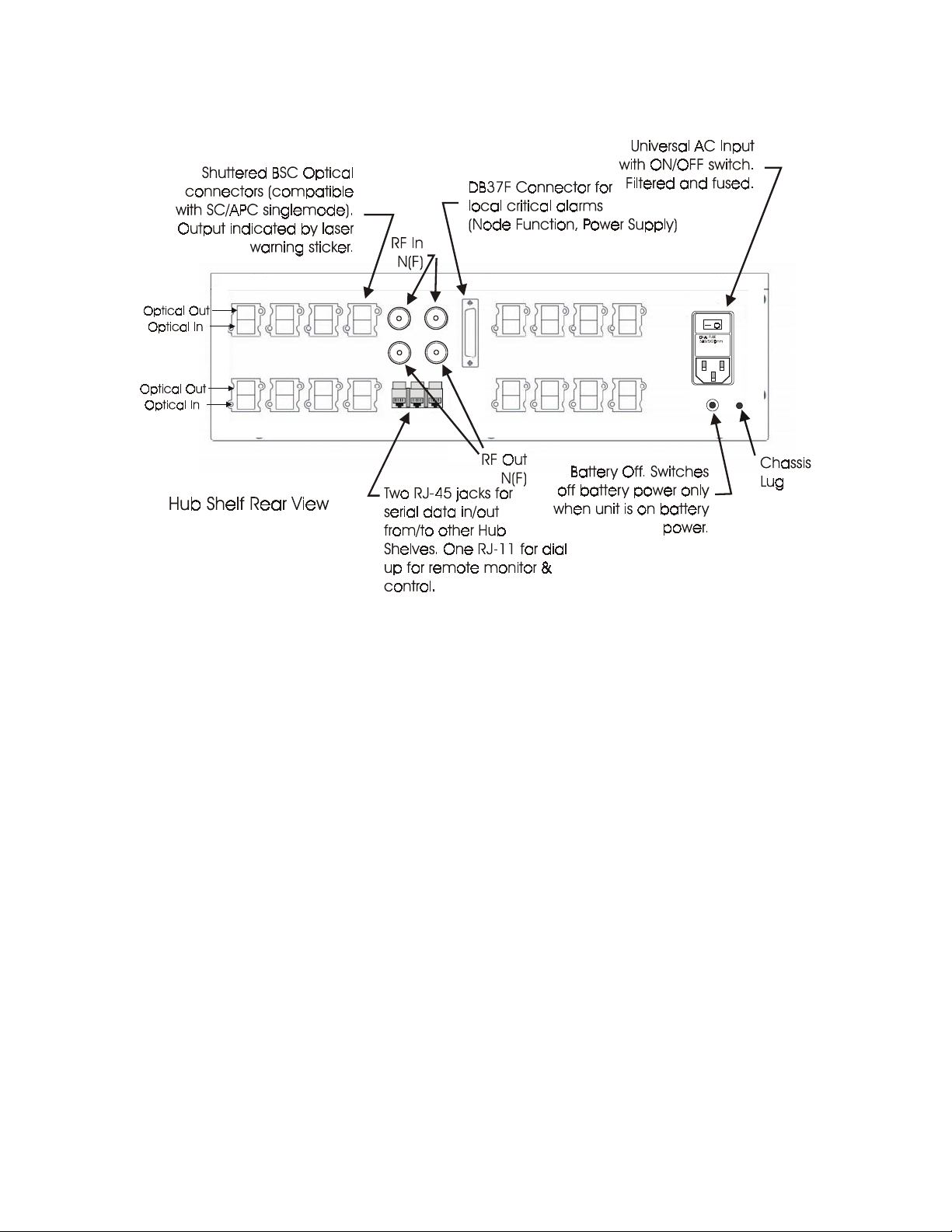

2.6.2 Connect Fiberoptic Cables

Before turning on the AC (or DC) power to the chassis, connect the fiberoptic cables at the rear panel.

During installation of the fiberoptic cables, each fiber should have been labelled as to which Remote

Transceiver it is to be connected to and whether it is for transmit or receive. The transmit or downlink

fibers are connected to the optical outputs on the rear panel. These are the red connectors with the laser

light warning labels. Make sure that the connectors used are associated with an active plug-in installed in

the chassis.

First, clean the tip of the connector on the cable according to the procedures in 2.2.2 above. Lift the spring

loaded cover on the Hub Shelf rear panel connector and, after orienting the connector so that the “key” on

the connector aligns with the slot in the mating adapter on the Hub rear panel, push in the SC/UPC cable

connector until firmly seated (the connector may or may not “click” into place; do not push too hard!!).

NOTICE

UNTERMINATED OPTICAL RECEPTACLES MAY EMIT LASER RADIATION. DO

NOT VIEW WITH OPTICAL INSTRUMENTS.

2.6.3 Indentifying Remote Locations

The front panel of each Plug-In has two 1.75” x 0.5” (4.4 cm x 1.3 cm) outlines labelled A and B which

can be used to affix standard “address” size labels (Avery 5167) to designate which Remote Transceiver is

connected to that path. These labels should correspond to the electronic names assigned to each path

through the front panel Craft serial port.

2.6.4 Serial Bus, Telephone and Local Alarm Connections

If more than one Hub Shelf is being used, connect the SERIAL DATA ports together using CAT-5

jumpers with RJ-45 connectors. The two SERIAL DATA ports on the rear panel are connected together;

two are provided to permit the use of simple jumpers when daisy-chaining several units.

Connect the LINE port to a POTS telephone jack for the dial-up modem connection.

If it is being used, connect the chassis to the local OA&M interface by way of the 37 pin D-Sub connector

on the rear panel of the Hub Shelf (see section 2.3: System Alarms).

2.6.5 Mains Power and Fuses

Turn on the chassis power. The AC powered version of the Hub Shelf operates on 100 to 240VAC. The

rear panel IEC receptacle is dual fused. The fuses used are FUSE, TIME LAG, 2 AMP, SLO-BLO

CAUTION: DOUBLE POLE/NEUTRAL FUSING

Certified power cords and ac plugs, appropriate for the country where equipment is installed,

shall be used for continued safety compliance.

Powering up the chassis will “light up” the fiber allowing those installing the Remote

Transceivers to identify the transmit and receive cables using an IR sensitive card (see Recommended

Tools) to see which fiber is emitting light. The fiber emitting light at the Remote Transceiver end is the

transmit path and is connected to the OPTICAL IN connector on the Remote Transceiver (after proper

cleaning; see section 2.2.2).

2-10

Page 30

pp

NOTICE: UNTERMINATED OPTICAL RECEPTACLES MAY EMIT LASER

RADIATION. DO NOT VIEW WITH OPTICAL INSTRUMENTS.

2.6.6 RF Connections

If the transmit RF signal from the BTS or repeater is to be routed to all the plug-ins in both sides of the

Hub Shelf, connect the external 1:2 RF splitter supplied with the Hub Shelf to both RF IN ports on the rear

panel. If the receive RF signals from all of the plug-ins in both halves of the Hub Shelf are to be routed to a

single receive port on the BTS or repeater, connect the other 2:1 RF combiner to both of the RF OUT ports

on the rear panel. If one of the RF OUT ports is to be connected to the BTS or repeater receive diversity

port, do not connect the RF combiner to the RF OUT port.

Connect the RF OUT to the BTS or repeater receive port(s).

Before connecting the RF transmit cables from the BTS or repeater to the RF IN of the Hub Shelf, verify

that the BTS or repeater RF output power levels are consistent with the desired output power at the Remote

Power Supply and will not overdrive or damage the FiberDAS Plug-Ins. Connect the BTS or repeater RF

transmit cables to the Hub Shelf.

2.7 Installing the Remote Transceivers

Each Remote Transceiver is usually mounted above the false ceiling against the wall with the connectors

pointing down for easy access. The Remote may also be mounted horizontally. In an area with no false

Figure 2-3. Remote Transceiver Mounting Plate. The Remote Power Supply uses a similar plate

and the two can be sna

ed together with the mating bracket supplied.

2-11

Page 31

ceiling, it can be mounted in the room near the ceiling with the connectors pointing up. This permits a more

aesthetic routing of the cables in the wall-ceiling corner. The Remote Transceiver is connected to the Hub

Shelf with a singlemode fiberoptic cable with a maximum optical loss of 4 dB, including connectors and

patch panels.

The minimum bend radius of the fiber is 2 inches (5 cm). Be careful not to kink the fiber.

!

To mount the Remote Transceiver, first install the mounting bracket. If the Remote Power Supply is being

used, snap the mounting brackets for the Remote and and the Remote Power Supply together using the

connector bracket that comes with the Remote Power Supply.

The Remote Power Supply is not to be installed above a false ceiling. In these cases, always use

!

the Central DC Power Supply and pull the DC supply wires along with the fiber duringcable

installation.

The bracket is attached to a wall or bulkhead using #6 pahhead or M3.5 screws. The Remote Transceiver

(and Power Supply, if applicable) are mounted on the bracket by inserting the rear panel studs into the

keyhole slots in the bracket. Each Unit is secured to the bracket by threading the captive thumscrew

(located at the connector end of the unit) into the threaded hole in the tab on the bracket. See the figures

below for more detail.

It is easier to make all of the optical, RF and DC connections to the Remote Transceiver before mounting

the unit on the plate. If the plastic cover is not needed, it may be removed by removing the four screws that

hold it on. This will also make access to the connectors easier. However, even if the plastic cover is not

needed for aesthetic reasons, it may be desirable to install it to provide some protection from dust buildup.

The Remote Transceiver takes +12 to +28 VDC power through a field-installable Molex connector. If the

Remote Power Supply is being used, the DC connection is provided by simply plugging in the DC cable

from the Remote Power Supply to the Remote Transceiver. The Remote Power Supply should be powered

through a sheilded AC power cable installed according to local building codes. The Remote Power Supply

takes 100 to 240VAC. It is dual fused using a TIME LAG, 1 A, (SLO-BLO) fuse.

CAUTION: DOUBLE POLE/NEUTRAL FUSING

For DC versions , the terminals can take wires 18 AWG to 14 AWG. The choice will depend on the

voltage used and the distance from the power supply (see Specification, Electrical).

Certified power cords and ac plugs, appropriate for the country where equipment is installed,

shall be used for continued safety compliance.

Next, install the indoor coverage antenna according to the manufacturer’s instructions. Connect the antenna

IMPORTANT NOTE! to comply with FCC RF Exposure compliance requirements, the

following antenna installation and device operating configurations must be satisfied:

Any antenna connected to this device must result in an ERP < 1.5W(800 and 900MHz) or <

3.0W (1800MHz and 1900MHz)! and must be mounted such that there is at least 20centimeter

spacing from the antenna structure and a human body.

2-12

Page 32

to the Remote Transceiver RF SMA connector using a flexible RF cable with VSWR < 1.5 : 1 at the

frequencies in use.

! RF SMA connectors should be tightened with a torque wrench set to 8 in-lbs. Do not

Connect the optical cable. The fiber for the transmit (downlink) path connects to the OPTICAL IN

connector. The fiber for the receive (uplink) path connects to the OPTICAL OUT connector (Green with

laser DANGER label). The fibers should be labelled accordingly during installation of the fiberoptic

cables. If not, they can be identified by turning the Hub Shelf power on with the plug-ins and fiberoptic

cables installed. Then, use an IR sensitive card (see Recommended Tools) to detect the light emitted from

the transmit fiber. Point the optical connector on each fiber at the card to see which fiber is emitting light

(you see a glowing spot on the card). This is the fiber for the transmit path. The other is for the receive

path.

NOTICE

UNTERMINATED OPTICAL RECEPTACLES MAY EMIT LASER RADIATION. DO

NOT VIEW WITH OPTICAL INSTRUMENTS.

Knowing the desired output power level from each Remote Transceiver as determined by the network

design, the Output RF Power can be preset before the system is powered up. Given the rated maximum

power from the Remote Transceiver, the antenna gain an the loss in the RF cable, the output RF power is

maximum when the Output Power adjustment is set at 0. The static output power can be reduced by turning

the adjustment. The adjustment is indented and each indent changes the output power by 2 dB.

Once all connections have been made, turn on the AC power (or DC power, depending on the option used)

to Hub Shelf and Remote Transceivers. Before connecting the transmit RF input from the source, check

that the level is that needed for optimum signal to noise and distortion as determined in the network design

(see Table 1 above). Connect the RF cables to the Hub Shelf.

! To prevent damage to the Hub Shelf plug-ins, do not exceed the maximum ratings for RF input to

2-13

Page 33

3 Monitoring and Troubleshooting

3.1 Field Support Numbers

The tips given below should help pinpoint most link problems. Often, problems are a result of a poor

optical interface which is easily fixed by properly seating a connector or cleaning the connector. There are

no user serviceable parts in the FiberDAS. Faulty units must be returned to Remec Inc. for repair or

replacement. For technical support call:

USA 714-765-5823

United Kingdom +44 (0)1296 319319

Malaysia +603 7785 1270

3-1

Page 34

3.2 Troubleshooting Tips

Alarms Probable Cause Action*

Node Function 1. Remote Transceiver Downlink Tx

amplifier chain failure

2. Pilot tone oscillator malfunction

3. Pilot tone detector malfunction

1. Node Function

2. Received Opt Pwr

Low (Remote

Transceiver)

1. Problem in downlink fiber path:

optical loss too high: fiber run is

too long, connector not seated

properly, damaged or in need of

cleaning, damaged splice

2. Remote Transceiver photodiode

failure

1. Node Function

2. Received Opt Pwr

Low (Plug-In)

1. Remote Transceiver laser failure

2. Problem in uplink fiber path:

optical loss too high: fiber run is

too long, connector not seated

properly, damaged or in need of

cleaning, damaged splice

3. Plug-In photodiode failure

1. If Remote Transceiver Rcvd

Opt Pwr LED is OFF, this

indicates downlink amplifier

chain failure: replace Remote

Transceiver.

2. Repair/replace failed Plug-In

3. Repair/replace failed Plug-In

1. Check Rcvd Optical

2. If fiber is OK, indicates

1. Check Laser Alarm in

2. If not, inspect fiber path,

3. Replace Plug-In

Power LED at Remote

Transceiver. If active

(Yellow), disconnect

downlink fiber and

check optical output

with light sensitive card.

If no light detected,

inspect fiber path, esp.

any connector recently

disconnected. Inspect for

proper seating. Clean

connectors. If necessary,

disconnect fiber from

FiberDASand check

fiber path with OTDR to

locate problem.

Remote Transceiver

photodiode failure:

replace Remote

Transceiver.

Remote Transceiver. If

active (Red), replace

Remote Power Supply.

esp. any connector

recently disconnected.

Inspect for proper

seating. Clean

connectors. If necessary,

disconnect fiber from

FiberDASand check

fiber path with OTDR to

locate problem.

3-2

Page 35

1. Node Function

Failing or failed Plug-In laser Replace Plug-In

2. Received Opt Pwr

Low

3. Laser Pwr Low (both

Hub Shelf Plug-In and

Remote Transceiver)

Laser Pwr Low (Hub

Failing laser Replace unit Hub Shelf Plug-In

Shelf Plug-In)

1. Laser Pwr Low

Failing laser Repair/replace unit (Hub Shelf

(either in Hub Shelf

Plug-In or Remote

Transceiver)

2. Received Opt Pwr

Low (opposite end)

Received Opt Pwr Low

(Hub Shelf Plug-In)

1. Failed/failing laser in Remote

Transceiver

2. Optical loss too high, link may

not be operating within

specifications. Fiber path may be

too long. Problem in fiber path:

connector not seated properly,

damaged or in need of cleaning,

damaged splice

Hub Shelf: Main Power

Alarm

Hub Shelf: Backup

Power Supply Alarm

Main Power Supply Failure (voltage

dropped more than 1 V from +15V)

Backup Power Supply Failure (voltage

dropped more than 1 V from +15V)

Battery Alarm 1. During battery only operation this

would be normal after unit has been

on for 10 to 20 minutes. Should go

off after main power is restored and

battery charges up.

2. If main and/or backup power supplies

are OK, this indicates battery or

recharging circuit failure

* All repairs of FiberDAS components must be performed by the factory

Plug-In or Remote Transceiver)

1. Inspect Remote

Transceiver for Laser

Alarm LED on (Red). If

so, replace Remote

Transceiver

2. Inspect fiber path, esp.

any connector recently

disconnected. Inspect for

proper seating. Clean

connectors. If necessary,

disconnect fiber from

system and check fiber

path with OTDR to

locate problem.

Replace Main Power Supply

Replace Backup Power Supply

1. No Problem

2. Replace Chassis

3-3

Page 36

3.3 Regulatory

FCC Part 22, Part 24 and Part 68 Regulation

Versions of this equipment designated to operate in the PCS1900 frequency bands have been

certified as compliant with FCC Part 22. Versions designated to operate in the AMPS frequency

bands have been certified as compliant with FCC Part 24. Versions of the Hub Unit that include

the dial-up modem have been certified as compliant with FCC Part 68. Testing and certification

was executed by MET Laboratories, Baltimore, MD, USA.

FCC Part 15 Regulation

NOTE: this equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected

• Consult the dealer or an experienced radio/TV technician for help.

Industry Canada

Versions of the Hub Unit that include the dial-up modem have been certified as compliant with

Industry Canada CS-03 Telecom regulations.

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numé rique de la classe B respecte toutes les exigencies du Regiement Canadien sur le

materiel brouilleur.

Testing and certification for Industry Canada compliance was carried out by MET Laboratories,

Baltimore, MD, USA.

UL

UL and CUL Safety certification testing and certification was provided by Underwriters

Laboratories, Inc., San Diego, CA, USA.

CE Mark

Versions of this equipment that are designated for operation in the GSM900, DCS1800 or UMTS

frequency bands each have a Technical Construction File certified as compliant with the Council

Directive 1999/5/EC, Articles 3.1 (a), 3.1 (b) and 3.2. Safety testing and certification was

executed by TÜV Product Service, San Diego, CA, USA. RF testing and compliance and

complete TCF certification was provided by BABT, Walton on Thames, Surrey, UK.

3-4

Loading...

Loading...