Page 1

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.2 Install the Repeater

Instructions in the left column are fast track instructions and can be used by experienced users. Other users

are recommended to read the complete text in this installation guide

4.2.1 Unpack the Repeater

Unpack the

repeater

Inspect the shipped material before unpacking the equipment, document any visual

damage and report according to routines.

A delivery of a repeater from Avitec contains:

! Checklist with delivered items

! Repeater

! Wall mounting kit or rack mounting kit (defined in order)

! 4 bolts for attaching repeater to mounting kit

! Cable cover

! Keys to repeater and cable cover

! CD containing Product Description and User’s Manual

! Any other specifically ordered item

4.2.2 Mount the Repeater

Mount the

repeater on a wall,

on a pole or in a

rack

Ensure proper

ventilation

Mount the repeater in an accessible location and in a location that fulfils the

environmental requirements.

The repeater can be mounted on the wall, on a pole or in a 19 inch rack. The

Repeater is delivered with a wall mounting kit or a rack mounting kit.

The repeater needs to be mounted tightly to eliminate vibrations

Wall mounting kit Rack mounting kit

Mount the repeater so that heat can be dispersed from it. The repeater wall mounting

kit ensures an optimum airflow between the wall and the repeater itself. Do not

block this air channel as it will cause the MTBF of the repeater to drop dramatically,

or even in the worst case cause the repeater to fail completely.

If possible use a wall in the shadow to minimize the overall sun loading. If sufficient

shielding cannot be obtained, an additional sun shield should be mounted.

© Avitec AB A1009300 A 104 (177)

Page 2

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Example of a sun shield

4.2.3 Ensure Proper Grounding

Connect the

grounding

protection

Ensure that good grounding protection measures are taken to create a

reliable repeater site. Make sure to use adequately dimensioned

grounding cables. The minimum recommended conductive area for a

grounding cable is 16mm

The antenna cabling should be connected to ground every 10m by a

reliable grounding kit.

Make sure the grounding product used is suitable for the kind and size

of cable being used.

Connect the repeater box bolt to the same ground.

2.

Ground

Ground connector on repeater

© Avitec AB A1009300 A 105 (177)

Page 3

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.2.4 Ensure Good EMV Protection (Lightning)

Caution

If insufficient Electro magnetic Protection is provided,

or if EMV measures are not taken, warranties issued by Avitec are not valid.

Connect the

lightning

protection

The lightning hazard to electric and electronic equipment consists in the

interferences of direct lightning current infections and high surge voltages induced

by the electromagnetic field of nearby lightning channels or down conductors.

Amplitudes from cloud-to-earth lightning amounts to several 10kA and may last

longer than 2 ms. The damage caused depends on the energy involved and on the

sensitivity of the electronics systems.

Ensure that lightning protection measures are taken to create a reliable repeater site.

Protect all coaxial cables and power cables from the transients caused by lightning.

Fit all cables with suitable lightning protection devices.

For detailed information please refer to IEC 61024-1 and 61312-1 for international

standards for protection of information systems against LEMP, Lightning

Electromagnetic Pulse, including radio transmitters. They define proper planning,

installation and inspection of effective lightni ng protection systems.

The top of the mast

must be higher than

the antennas and be

properly grounded

Antennas

The grounding

path must have

reliable continuity

and be correctly

dimensioned

Primary Protective Devices

Equipotential

Grounding Bars

Repeater

Secondary Protective

Devices

Protective Device

The Avitec repeaters comply with the EN standard ETS 301 498-8 which stipulates

demands on lightning/surge protection for typical infrastructure telecom equipment

installations.

Several lightning protection devices should be used in series with declining

threshold voltages to help attenuate the pulse component which makes it through the

first layer of protection.

The primary protective device is part of the site installation and is not supplied by

Avitec. Coaxial lightning protection is normally one of these three types: Gas

230V AC/48V DC

capsule, High-pass and Bandpass.

© Avitec AB A1009300 A 106 (177)

Page 4

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

There also need to be a protective device installed on the power supply cord.

Protective device installed in connection with the power supply

4.2.5 Attach Antenna Cables

Note!

Note!

Attach the antenna

cables to the

repeater antenna

connections

For Frequency Translating Repeaters see also 4.2.8 Mount the Coupler

For site installation advice and descriptions of antenna installation see 4.1 Prepare

the Site.

Connectors

The connector to the directional coupler (frequency translating repeaters donor unit)

is N-type female. Antenna connections are DIN 7/16” connectors, female.

Compatibility

Make sure that cables and connectors are compatible. Using cables and connectors

from the same manufacturer is helpful.

Waterproof all

outdoor

connections

Connectors

All connectors must be clean and dry

Waterproof all outdoor connections using silicone, vulcanizable tape or other

suitable substance as moisture and dust can impair RF characteristics.

Make sure enough room has been allocated for the bending radius of the cable. RF

cables must not be kinked, cut or damaged in any way

Connect the RF cables to the antennas tightly but without damaging threads

Fasten cables tight to cable ladder or aluminum sheet

Cable Dimensions

For short length of feeder cables use ½ “, for longer feeder cables use 7/8”. Chose

thicker coax cables for lower attenuation. Minimize the length of the coax cables to

reduce the attenuation

Jumper Cables

Use jumper cables for easy installation. The RF Coaxial cable can be substituted at

each end with a jumper cable.

© Avitec AB A1009300 A 107 (177)

Page 5

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.2.6 Attach Fiber Cable

Caution

Un-terminated optical receptacles may emit laser radiation.

Do not stare into beam or view with optical instruments.

4.2.6.1 Fiber Connector in the Repeater Casing

Select fibre

Connect the fiber

cable

4.2.6.2 Fiber Connector in the Opto Module

Select fibre

Insert the fiber

into the repeater

via the fitting

Attach the fiber to

the connector in

the Opto Module

Recommended fiber cable is single mode 9/125.

Connect the fibre directly to the FC/APC connector in the casing.

Note! Clean the fiber connector before it is connected to the Opto module, see

instruction below.

Note! This installation is only suitable for indoor use. The IP 65 classification of the

repeater casing is no longer valid.

Recommended fiber cable is single mode 9/125.

The casing of the repeater is equipped with a Pg connector for attachment of a

corrugated hose (NW 17 mm, outer diameter 21.2 mm).

The hose, together with the Pg connector, meet the protection standard IP50.

Supplemented by O-rings, the protection standard IP67 is met.

Make sure the fiber is not too sharply bent. Put the excess fiber cable in soft bends

in the repeater. See illustration. Fasten the cable to make sure it is not damaged

when the repeater lid is closed.

Note! Clean the fiber connector before it is connected to the Opto module, see

instruction below.

© Avitec AB A1009300 A 108 (177)

Page 6

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Make necessary

measurements

Mount the hose to

the connector

Seal the hose Seal the hose according to the demands at hand. If the IP classification of the casing

Make necessary measurements to ensure a correct installation.

When the cable has been installed, the quality of the optical path should be checked

for optical path loss and magnitude and location of any reflections. This can be done

with an Optical Time Domain Reflectometer (OTDR). The total return loss should

be > 45 dB.

Optical reflections can degrade the noise and linearity of a fiber optic link. In

particular, reflections that reach the laser can be a problem. Keep all discrete

reflections to > 60 dB. The FC/APC connectors are polished to a return loss >60 dB.

The casing of the repeater is equipped with a Pg connector for attachment of a

corrugated hose (NW 17 mm, outer diameter 21.2 mm). The hose, together with the

Pg connector, meet the protection standard IP50. Supplemented by O-rings, the

protection standard IP67 is met.

should be maintained O-rings should be used and both ends of the hose should be

sealed with for instance silicon (free of acetic acid).

If necessary to access the

repeater end of the hose,

the power plinth can be

loosened (two screws) and

moved forward.

The repeater seen from the

inside with the conduit

marked by an arrow.

(No fiber is present in this

illustration)

Cleaning Optical Connectors

Optical reflections from a discontinuity such as a poor connector interface appear on an RF spectrum

analyzer trace as stable variations in the noise floor amplitude that are periodic with RF frequency. If the

reflection is bad enough, it could impact the system performance. By far, the most common cause for a large

discrete reflection is a dirty optical connector. A bit of dust or oil from a finger can easily interfere with, or

block this light. Fortunately, it is very easy to clean the connector.

© Avitec AB A1009300 A 109 (177)

Page 7

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Be sure to use the correct procedure for the given connector. When disconnected, cap the FC/APC connector

to keep it clean and prevent scratching the tip of the ferrule.

Alternative 1

Swipe the tip of the ferule 2-3 times with a cotton

swab soaked in alcohol. Let it air dry.

Alternative 2

Use a product specially designed for the purpose.

4.2.7 Supply Power to the Repeater

Caution!

The antenna cables must be connected to the repeater before mains power is switched on. Alternatively the

antenna connections on the repeater can be terminated with 50ohm termination plugs.

Note!

Connect the

repeater to the

power supply

Avitec repeaters can be fed by 110/230 VAC, 50/60 Hz or 48 VDC. Ensure that the

right voltage is used.

Mains power is connected to the repeater via a plinth inside the repeater.

The strain relief fitting is a Pg 13.5 suitable for a 6-12 mm cable diameter.

230VAC or 110 VAC

Connect the power cable to the plinth with the phase linked to the brown cable,

neutral linked to the blue and ground to the yellow/green. See illustration below.

Phase

Neutral

Ground

L

N

Strain Relief Fitting

Connection Plinth

48 VDC

Connect the power cable to the plinth with negative (-48V) to the uppermost

connection and positive (0V) to the middle connection. Leave the lower connection

© Avitec AB A1009300 A 110 (177)

Page 8

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

empty. See illustration below.

Negative

Positive

-48V

0V

Strain Relief Fitting

Connection Plinth

Recommended cable areas for 48VDC

0 - 10 meters between repeater and

power supply

10 – 50 meters between repeater and

power supply

Over 50 meters between repeater and

power supply

2,5 mm²

4 mm²

Recommendation is to reconfigure the

installation, or to make special

arrangements to increase cable area

Note!

Back-up battery

Requirements on 48 V power supply

The 48V power supply must comply with SELV requirements, as defined in

EN60950, which implies double isolation. The output power needs to be 48VDC

+25%/-15%.

For a 2 channel repeater the maximum input current is 8A, for a 4-channel repeater

16A.

In 4-channel repeaters there are two power supplies – one in each part of the box.

Each power supply has its own power switch. Both need to be switched on.

Backup Battery

There is a back-up battery installed in connection with the power supply. If there is a

power failure the battery will supply enough power for the Control Module in the

repeater to send information about the power failure.

The backup battery can be switched on an off separately. The switch is placed

adjacent to the mains power switch on the power supply.

In 4-channel repeaters there is a backup battery only in connection to the main

power supply unit.

At delivery the back-up battery is connected. It can be replaced by lifting the battery

pack out of the crate and disconnecting the cable.

© Avitec AB A1009300 A 111 (177)

Page 9

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Connector

4.2.8 Mount the Coupler

Caution!

When the coupler is connected the affected base station sector needs to be taken out of service. Turn the base

station off before detaching the cable to the base station cell antenna. It might shut down the whole network –

chose an off-peak time for this installation.

Note!

Mount the coupler

The Coupler is used only in connection with Frequency Translating Repeaters

The connection between the donor unit and the BTS is made using an Avi tec

Coupler. The attenuation from the BTS to the repeater is -30 dB. The attenuation

through the coupler from the BTS to the antenna is minimal.

Avitec Coupler

The coupler is connected in series with the BTS antenna. J1 and J2 are used for the

connection of the coupler in-between the BTS and the cable to the BTS antenna.

© Avitec AB A1009300 A 112 (177)

Page 10

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

To Antenna

Link Ante nna

RF Coaxial cable

Repeater

7/16 type connector, female

Cap

-30dB Coupler

7/16 type

connector

BTS

N-type

connector, female

7/16 type

connector

N-type connector, female

Coupler connections

J3 or J4 is connected to the repeater donor unit depending on the orientation of the

coupler. If J1 is connected to the BTS; J3 is used for connection with the repeater, if

J2 is connected to the BTS; J4 is used for connection with the repeater. The

connector not used (J3 or J4) must be sealed with a cap to prevent the ingression of

dust and water.

! J1 and J2 are DIN 7/16 connectors, one male and one female

! J3 and J4 are N-type connectors, female

1. Disconnect the antenna from the base station

2. Decide whether to connect a filter in series with the antenna cable (between the

coupler and the antenna) to prevent any disturbances from the repeater to reach

the antenna

3. Attach the coupler in-between the base station and the antenna cable. (J1 and

J2).

4. Attach the coupler connector closest to the base station to the repeater donor

antenna connector

5. Attach a cap to the connector closest to the antenna connection

6. Turn the base station back on and verify that it is operational.

7. Seal the coupler with rubber tape. Start on the base station antenna cable and

wrap to the base station port cable. Wrap in a circular motion downwards.

Cover the coupler and its connecting parts completely. This will provide a

weather resistant seal. Complete by adding three layers of PVC tape for UV

protection.

© Avitec AB A1009300 A 113 (177)

Page 11

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.2.9 Connect External Alarms

Connect external

alarms

If the repeater is equipped with an external alarm interface card the connector plinth

for the external alarms is located at the bottom of the repeater.

The strain relief fitting in is a Pg 13.5 suitable for a 6-12 mm cable diameter.

Connect the alarm cords to the plinth according to the pin layout below (in the

standard version pins 14 – 18 are not used).

Pin # Signal

1 External alarm 1A

2 External alarm 1B

3 External alarm 2A

4 External alarm 2B

5 External alarm 3A

6 External alarm 3B

7 External alarm 4A

8 External alarm 4B

9 Alarm +15V

10 Alarm 0V

11 Relay A

12 Relay B

13 GND

14 NC

15 NC

16 NC

17 NC

18 NC

External Alarm

Four external alarm sources can be connected to the repeater. These alarms operate on

a voltage between 12 and 24VDC. The presence or absence of this voltage will trigger

the alarm depending on how the alarm polarity has been configured via software.

The alarms can be configured active-low or active-high, so that the alarm is given

either in the presence or absence of applied power. Active high means that an applied

voltage of between 12 and 24 V will cause the external alarm indicator to turn red.

Active low means that when there is no voltage the alarm indicator will turn red.

The repeater can supply +15 VDC to an external alarm source through pin 9 and 10.

The maximum allowed load is 50mA.

The repeater contains a relay (pin 11 and 12) that can be connected to an external

device to indicate an alarm. The relay can be configured to trigger on any number of

internal and external alarms. The maximum current that can be supplied is 50mA.

For configuration of external alarms see section 4.4.4 Alarm Configuration.

4.2.10 Close Repeater

Close repeater Close lid and lock repeater, or continue with the next section: Start-up the Repeater

© Avitec AB A1009300 A 114 (177)

Page 12

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.3 Start-up the Repeater

Caution!

Make sure the antenna cables or 50 ohm terminations are connected to the repeater’s antenna connectors

before the repeater is turned on.

Install the RMC Install the RMC software on a computer from a CD or a diskette.

Connect to the LMT

port

Switch the repeater

on

Open the repeater and connect the computer to the LMT port via a DB9 male

connector with serial RS232 interface.

LMT port

The communication parameters are set automatically by the RMC.

Switch the repeater on by using the power switches on the power supply.

Note! See caution above!

Power switches

There are two switches. One is for the battery and one is for the mains.

Note! Always switch on both switches when the repeater should be switched on.

Note!

Note!

Check power supply

LEDs

© Avitec AB A1009300 A 115 (177)

The power switch has two positions; “on” and “stand by”. In the stand by position

the repeater is still connected to the mains power but not operational.

On 4-channel models both mains power supplies need to be switched on.

Power Supply LED

Check the LEDs on the Power unit and Control Module to ensure that normal

operation conditions have been attained.

The power supply has 4 LEDs to indicate the status.

Mains

Power

+6V +15V +28V

Page 13

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

LED 1: Mains Power, green

Slow flash Power supply unit operating on AC or DC

OFF Power supply unit not oper ating

LED 2: +6V, red

Slow flash (every 10 seconds) +6V power supply operating

Quick flash +6V power supply not operating or

operating with malfunction

LED 3: +15V, red

Slow flash (every 10 seconds) +15V power supply operating

Quick flash +15V power supply not operating or

operating with malfunction

LED 4: +28V, red

Slow flash (every 10 seconds) +28V power supply operating

Quick flash +28V power supply not operating or

operating with malfunction

Examples

Mains

Power

Mains

Power

Mains

Power

+6V +15V +28V

+6V +15V +28V

+6V +15V +28V

LED 1 is flashing slowly, LED 2 – 4 are

flashing slowly (once every 10 seconds)

=> power supply unit is operating without

problem

LED 1 is flashing slowly, one or two of

the red LEDs are flashing quickly

=> Mains power is operating but there is a

problem with some of the other voltages

LED 1 is flashing slowly, all of the red

LEDs are flashing quic kly

=> Mains power is out and unit is

operating on backup battery

© Avitec AB A1009300 A 116 (177)

Page 14

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Check Control

Module LEDs

Control Module LED

The Control Module has 3 LEDs to indicate the status.

123

LED 1: green

OFF GSM Module switched OFF

Permanent ON GSM Module Switched on, not registered on network

Slow Flash GSM Module switched on, registered on network

(approximately 1 flash per second)

Quick flash Module switched on, registered on network, call

active (approximately 3 flashes per second)

LED 2: red

OFF Control Module switched OFF

Slow Flash Control Module switched on, status OK (once every

10 seconds)

Quick flash Control Module switched on, one or more errors /

alarms detected (except door status)

Check optic module

LEDs.

LED 3: blue

OFF Control Module switched OFF, or no one logged in

Slow Flash Control Module switched on, nobody logged in

locally OK (once every 10 seconds)

Quick flas h Control Module switche d on, someone logged in

remotely or locally

Opto Module LED

On the optic module there are 4 green LEDs.

TEMP Local temperature in opto

module

POWER Power to unit green light = power on

OPTO TX Transmitted signal on fiber green light = OK

OPTO RX Received signal on fiber green light = OK

green light = OK

© Avitec AB A1009300 A 117 (177)

Page 15

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Start the RMC The RMC can be started from the Start menu (or by clicking on the RMC icon, if

made available).

Select “Cable”

connection

Select

communication port

Enter user name and

password

These are the default settings:

User Name Password Authority

USERNAM1 PASSWRD1 read/write

USERNAM2 PASSWRD2 read/write

USERNAM3 PASSWRD3 read only

USERNAM4 PASSWRD4 read only

The system does not differentiate between upper and lower case letters.

Note!

Note!

Do not use the number pad when entering numbers.

Failed login attempts are logged. Default maximum number is 8. It is

decremented by one every hour, which means that it takes one hour after the last

failed attempt before a new try can be made.

4.3.1 Choose Work View

Choose “Console”

mode, “Terminal”

mode or “Firmware”

mode

© Avitec AB A1009300 A 118 (177)

Page 16

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Console mode

The console mode displays a large number of repeater parameters and contains

a number of console pages. It adjusts its user interface to adapt to the features of

the connected repeater.

Terminal mode

Firmware mode

The terminal mode is used for communication with the repeater using its native

command line interface. This interface follows the VT100 standard. For some

special actions and error tracing, this mode gives an enhanced availability of the

repeater.

The firmware mode is used for monitoring the currently installed software and

for uploading new software to the repeater.

© Avitec AB A1009300 A 119 (177)

Page 17

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.4 Configure the Repeater

The following pages will guide you through the configuration of Channel Selective repeaters as well as

Frequency Translating repeaters utilizing the Repeater Maintenance Console (RMC) so ft ware.

Configuration of a repeater is made partially on site and partially remotely through the AEM. At site the RF

parameters are set and verified, the repeater is given a name (a tag) and the remote communication is set and

verified. All other configuration can, and should be made from the AEM.

4.4.1 Set up RF Configuration

4.4.1.1 Channel Selective Re peaters

Ensure online

communication with

the repeater

This image will

appear

Chain 1

Channel number

Uplink

Attenuation

Power level

Downlink

Attenuation

Power level

Select “Console” mode

Select “RF/Status” window

23

30 30

OFF

45

30

OFF

3030

OFFOFF

--

dBm

Saturation level

Set all power levels

Set “Power Level” in uplink and downlink to “OFF” in all chains

to “OFF”

In the “Power Level” menu the output power can be limited to a specific value or the

output power can be switched off completely by choosing “OFF”.

Set all attenuation

levels to a maximum

Set “Attenuation” to the maximum value in both chains uplink and downlink

(In a 4 channel repeater there are 4 chains).

© Avitec AB A1009300 A 120 (177)

Page 18

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Choose the maximum attenuation value from the drop down menu, in this case 30dB.

Set channel numbers

Monitor the input

power

Configure the

downlink of Chain1

Set the channel numbers for all chains that are to be used in the installation.

In this example the channel in Chain 1 is set to 23 and the channel in Chai n 2 is set to

45.

Note! Chain 1 must a lways contain the BCCH.

Click on the RF Levels icon to monitor the RF levels.

RF Levels icon

Input powe r level in do wnlink

chain 1 is -53 dBm

-53

dBm

--

dBm

Input power in the downlink of Chain 1 is dependant on the signal from the serving

Base Station, in this example it is -53 dBm

Set “Power Level” in Chain 1 downlink to the desired value, in this example

+37 dBm. This value can be based on a link budget, or be the maximum output the

repeater can generate.

Adjust attenuation in

the downlink

View the power meter in the top right corner of the screen. In this example the output

power is +22 dBm.

Output power levelin downlink

-53

dBm

+ 22

dBm

chain 1 is +22 dBm

Lower the attenuation level step by step until the desired output power level is

reached. In this example +37 dBm. Zero attenuation is the same as maximum gain.

© Avitec AB A1009300 A 121 (177)

Page 19

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

23

30

OFF

14

37

The attenuation is

adjusted in this box

The desired power level

is set in this box

Saturation leve l

indicator

-53

dBm

+ 37

dBm

The current output

power level is

displayed in this box

Note! The accuracy

of this measure is

±2dBm

Also use the saturation level indicator. The saturation level is indicated with plain text

as well as with LEDs. The saturation level can be: Low (green), Ok (green), High

(yellow) or Critical (red).

The optimal level is Ok, on the verge of High. To reach this value lower the

attenuation step by step until the saturation reaches High. Then raise the attenuation

one step. The saturation should now be back on Ok.

Note! Since the repeater has an ALC function (Automatic Level Control), the repeater

will not transmit more power even if the attenuation is lowered even more.

Configure the

downlink of Chain 2

Configure the uplink

of Chain 1 and 2

Apply the same Power Level and Attenuation in downlink Chain 2 as in downlink

Chain 1.

The presence of the BCCH in Chain 1 will ensure stable power levels whereas

downlink and uplink power levels in Chain 2 will be dependant on the amount of

traffic. This will make Chain 2 appear unstable.

In a 4-channel repeater also configure the downlink of Chain 3 and Chain 4.

Note! All channels that are not to be used should always be switched off (set Power

Level to “OFF”.)

Set the Power Level for the uplink in Chain 1 and Chain 2 to the same value as for the

downlink, in this example +37dBm, or any other level decided in the link budget.

Set the Attenuation 2dB higher than in the downlink. In this example 16dB (14dB +

2dB)

In a 4-channel repeater also set the uplink for Chain 3 and Chain 4

Since the BTS is more sensitive than a mobile unit there may be less signal gain from

the mobile unit in to the BTS (UL) than in the opposite direction. The uplink

attenuation can be adjusted more accurately later on, once the drive test signal

measurements have been completed.

© Avitec AB A1009300 A 122 (177)

Page 20

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Make an antenna

See 4.1.3 Antenna Isolation

isolation test

4.4.1.2 Frequency Translating Repeaters

Start with the donor

unit

The Single Donor (SD) and Double Donor (DD) units are configured in the same

way.

Ensure online

communication with

Select “Console” mode

the repeater

This image will

Select “RF/Status” window

appear

Chain 1

Channel number

Link channe l

23 4512

30 30

OFF

Link Ch

30

OFF

Link Ch

39

Uplink

Attenuation

Power Level

Downlink

Attenuation

Power Level

Saturation Status

Set all power levels

to “OFF”

Set all attenuation

levels to a maximum

3030

OFFOFF

Set “Power Level” in uplink and downlink to “OFF” in all chains

In the “Power Level” menu the output power can be limited to a specific value or the

output power can be switched off completely by choosing “OFF”.

Set “Attenuation” to the maximum value in both chains uplink and downlink.

Choose the maximum attenuation value from the drop down menu, in this case

30dB.

Set channel numbers

Set the channel numbers for all chains that are to be used in the installation.

In this example the channel in Chain 1 is set to 23 and the channel in Chai n 2 is set

© Avitec AB A1009300 A 123 (177)

Page 21

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

to 45.

Note! Chain 1 must a lways contain t he BCCH.

Set Link channel

numbers

View the input

power

Configure the

downlink of Chain1

Set the Link channels to the desired values. In this example channel 12 in Chain 1

and channel 39 in Chain 2.

Click on the RF Levels icon to monitor the RF levels.

RF Levels icon

Input power level in downlink

chain 1 is +13 dBm

+ 13

dBm

--

dBm

The input power in the downlink of Chain 1 is in this example approximately

+13dBm (output power of the BTS -30dB from the coupler)

Set “Power Level” in Chain 1 downlink (the link) to the desired value, in this

example +37 dBm. This value can be based on a link budget and depends for

instance on the distance to the remote unit.

View the power meter in the top right corner of the screen. In this example the

output power is +22 dBm.

Output power lev elin downlink

+ 13

dBm

+ 22

dBm

chain 1 is +22 dBm

Adjust attenuation in

the downlink

Lower the attenuation level step by step until the desired output power is reached. In

this example +37 dBm. Zero attenuation is the same as maximum gain

© Avitec AB A1009300 A 124 (177)

Page 22

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Link Ch

23

12

30

OFF

14

37

+ 13

dBm

+ 37

The attenuation is

adjusted in this box

The desired power level

is set in this box

Saturation level

indicator

dBm

The current output

power level is

displayed in th is b o x

Note! The accuracy

of this measure is

±2dBm

Also use the saturation level indicator. The saturation level is indicated with plain

text as well as with LEDs. The saturation level can be: Low (green), Ok (green),

High (yellow) or Critical (red).

The optimal level is Ok, on the verge of High. To reach this value lower the

attenuation step by step until the saturation reaches High. Then raise the attenuation

one step. The saturation should now be back on Ok.

Note! Since the repeater has an A LC function ( Automatic Leve l Control), the

repeater will not transmit more power even if you continue to lower the attenuation.

Configure the

downlink of Chain2

Configure the uplink

in Chain 1 and 2

Continue wit h the

remote unit

Apply the same Power Level and Attenuation in downlink Chain 2 as in downlink

Chain 1.

The presence of the BCCH in Chain 1 will ensure stable power levels whereas

downlink and uplink power levels in Chain 2 will be dependant on the amount of

traffic. This will make Chain 2 appear unstable.

Note! All channels that are not to be used should always be switched off. (Set Power

Level to “OFF”.)

Set the Power Level for the uplink to -10/-13/-15 dBm depending on the site design,

for instance the number of sectors in the BTS and the level of noise allowed.

Set the Attenuation 2dB higher than in the downlink. In this example the attenuation

in the uplink is set to 16dB (14dB + 2dB= 16dB)

Since the BTS is more sensitive than a mobile unit there may be less signal gain

from the mobile unit in to the BTS (UL) than in the opposite direction. The uplink

attenuation can be adjusted more accurately later on once the drive test signal

measurements have been completed.

The configuration of the Remote Unit is almost identical to the configuration of the

Donor Unit apart from the gain and output power settings.

© Avitec AB A1009300 A 125 (177)

Page 23

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Set all power levels

to “OFF”

Set all Attenuation

levels to a maximum

Set channel numbers

Set link channel

numbers

View the input

power in the

downlink

See instruction for donor unit above

See instruction for donor unit above

Set the same channel numbers as for the donor unit.

Set the same link channel numbers as for the donor unit.

Click on the RF Levels icon to monitor the RF levels.

RF Levels icon

Input power level in downlink

Chain 1 is -65 dBm

-65

dBm

--

dBm

The input power in the downlink of Chain 1 is in this example approximately

-65dBm.

Note! The input signal level will vary between different repeater installations

depending on the distance between the Donor Unit and the Remote Unit and other

parameters affecting the signal’s propagation.

Configure the

downlink of Chain1

Adjust attenuation in

the downlink

Configure the

downlink of Chain2

Configure the uplink

in Chain 1 and

Chain 2

Set “Power Level” in Chain 1 downlink to the desired value, in this example

+43 dBm. This value can be based on a link budget, or be the maximum output the

repeater can generate.

43

Lower the attenuation level step by step until the desired output power is reached. In

this example +43 dBm. See instruction for donor unit above

Apply the same Power Level and Attenuation in downlink Chain 2 as in downlink

Chain 1.

The presence of the BCCH in Chain 1 will ensure stable power levels whereas

downlink and uplink power levels in Chain 2 will be dependant on the amount of

traffic. This will make Chain 2 appear unstable.

Note! All channels that are not to be used should always be switched off. (Set Power

Level to “off”.)

Set the Power Level in the uplink of both Chain 1 and 2 (the link) to +37 dBm (the

same as for downlink in the donor unit).

Set the Attenuation 2dB higher than in the downlink.

© Avitec AB A1009300 A 126 (177)

Page 24

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.4.1.3 Fiber Fe d Repeaters

Configuration of the repeater amplification can be made locally. If the repeater is connected to a Hub the

configuration can also be made via this Hub. See Hub User’s Manual.

Ensure online

communication with

the repeater

This image will

appear

Status and alarms

Uplink input and

output power

Uplink attenuation

Downlink input and

output power

Downlink

attenuation

Select “Console” mode

Select “RF/Status” window

Check that the fibre

is OK

Set attenuation level

in uplink and

downlink to a

maximum

Configure the

downlink

Make sure there are no alarms relating to the fibre.

Choose the maximum attenuation value from the drop down menu, in this case

30dB.

© Avitec AB A1009300 A 127 (177)

Page 25

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Lower the attenuation level step by step until the desired output power level is

reached. In this example +33 dBm. Zero attenuation is the same as maximum gain.

The input signal contains the MCCH and will have a stable value.

Configure the uplink

In the uplink direction the attenuation needs to be set based on a measurement of a

known signal which is transmitted through the repeater and the Hub as well as the

fibre. There are two ways of performing this measurement.

Alternative 1

Use a signal generator to insert a signal of approximately -65dBm to -75dBm into

the repeater’s server antenna port. Measure the signal level on the BTS or on the

coupler and adjust the attenuation so that the total gain in the uplink is close to 0dB.

(At 0dB gain the signal level at the coupler should be -35dBm and on the BTS 65dBm in this example.)

Alternative 2

Use a signal generator to insert a signal of approximately -65dBm to -75dBm into

the repeater’s server antenna port. Log into the Hub and monitor the uplink via the

RMC. This measurement is not as accurate as alternative 1.

-35dBm

-65dBm

Hub

-30dB

Coupler

BTS

Fiber

Repeater

Signal

Generator

-65dBm

Note! If there are problems to reach 0dB gain in the whole chain extra attenuators

might need to be added to the system.

Note! If several repeaters are connected to the same Hub the total gain in each chain

should be slightly lower than 0dB not to insert too much noise into the BTS.

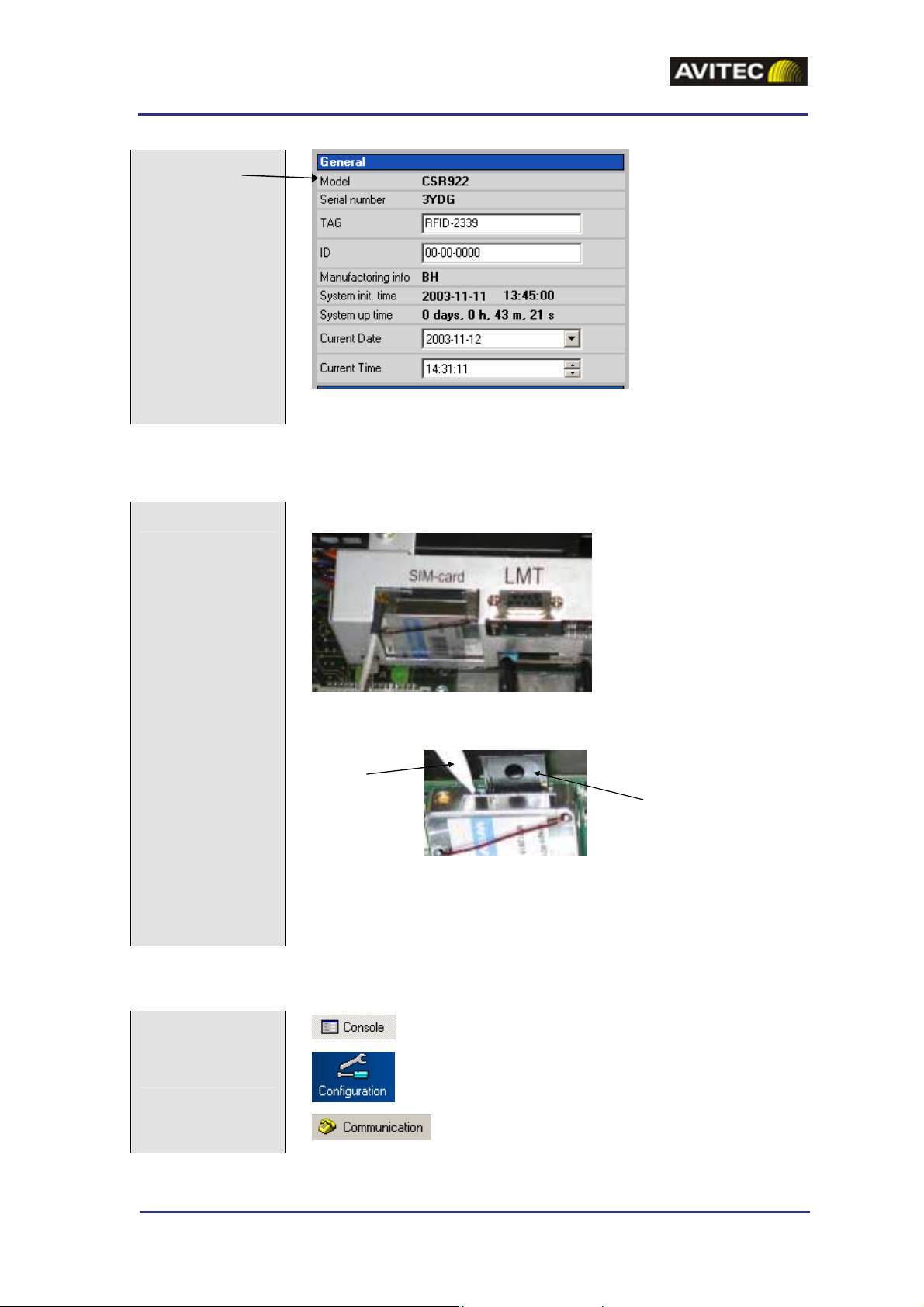

4.4.2 Set Repeater Name (TAG)

Give the repeater a

unique name.

Select “Console” mode”

Select “Configuration” window

Select “Product” page

Alternative 2: Use the

RMC to measure the

uplink at the Hub

© Avitec AB A1009300 A 128 (177)

Page 26

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Insert the name in

this box

4.4.3 Set Up Remote Access

Insert the SIM card

Note! Make sure the SIM card has a Data Call/SMS number and is activated.

The modem is placed next to the LMT port close to the power supply

Pen

SIM card holder

The SIM card holder is on top of the modem

Insert the SIM card by pressing the lever on the left side of the card holder on the

modem (with a pen or another narrow item) so that the card holder pops up. Insert

the SIM card and press the card holder back into place.

4.4.3.1 Data Call Configuration

Note! If the repeater should be controlled by the AEM this Data Call configuration needs to be made.

Set modem

parameters

© Avitec AB A1009300 A 129 (177)

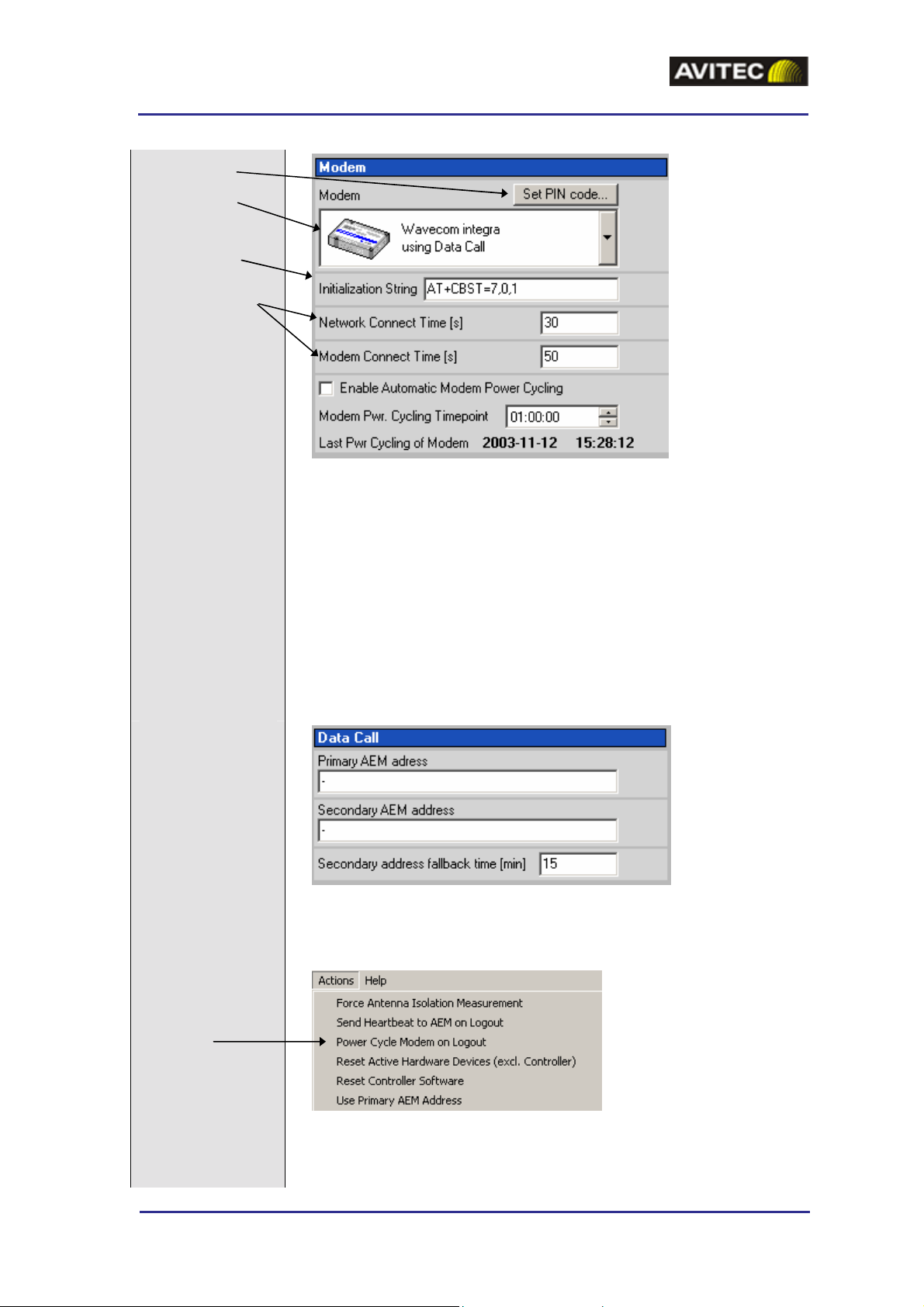

Select “Console” mode

Select “Configuration” window

Select “Communication” page

Page 27

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Pin Code

Data Call

Initialization string

Connect times

1. Choose Data Call

2. Set pin code, if the SIM card has PIN code request enabled

3. Set the modem initialization string. This string differs bet we en networks.

Primary recommendation is AT+CBST=7,0,1. If remote communication

cannot be established try 7,0,3 or 0,0,3 or 0,0,1.

Data call address

Note! Not to be set at

local installation

Power Cycle Modem

4. Leave Network Connect Time and Modem Connect Time at default values.

5. Tick “Enable Automatic Modem Power Cycling” for the modem to be power

cycled once every 24 hours. Set the time at which the modem should be tested.

This function ensures that the repeater always is logged in to the network.

Note! Do not set addresses for the Data Call. The AEM will call the repeater after

the installation is ready and initiate this communication.

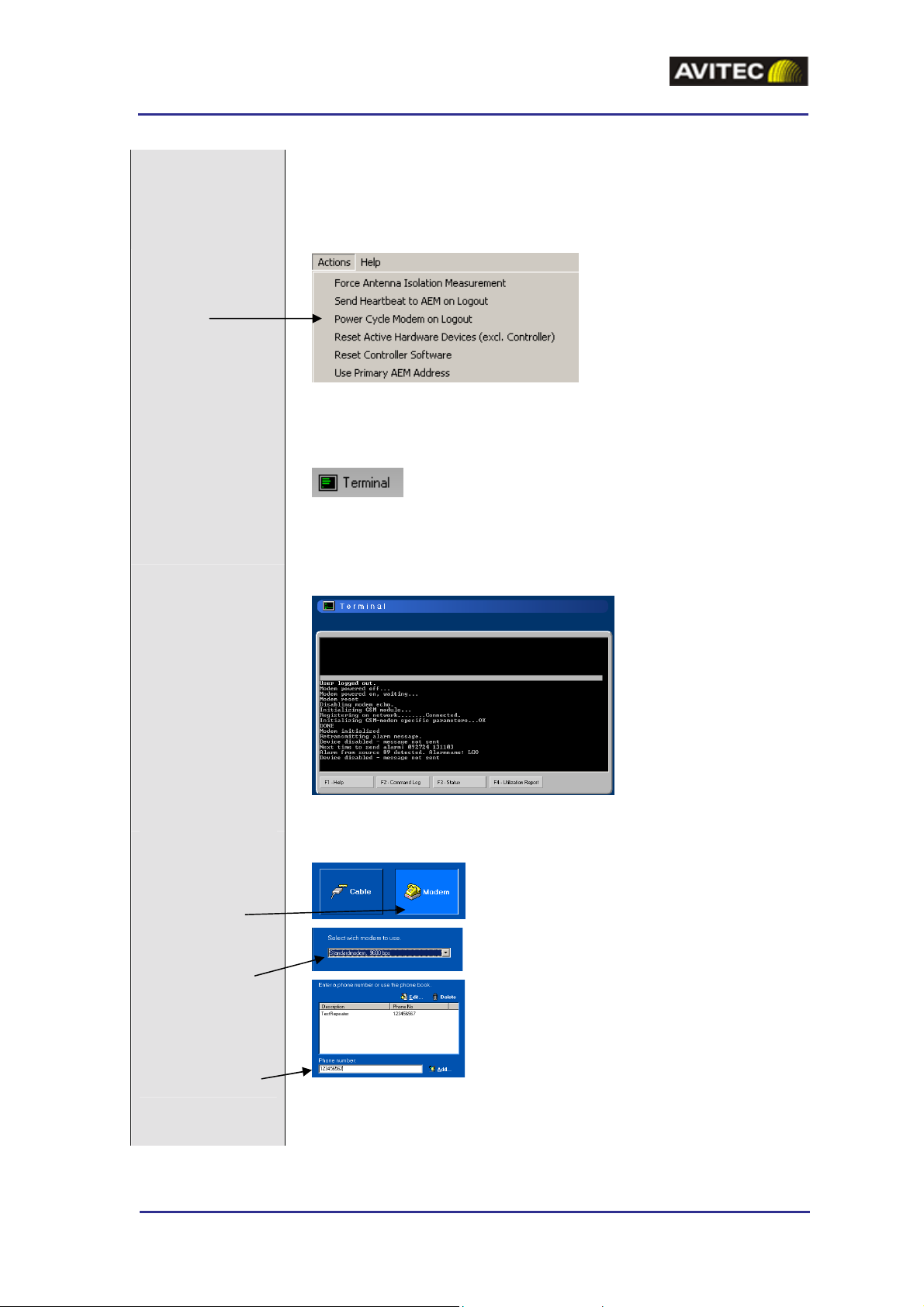

Select Actions and initiate a Power Cycle Modem Logout from the drop-down

menu.

© Avitec AB A1009300 A 130 (177)

Page 28

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Log out

Wait Wait until verification is ready

Log in remotely

Select “Modem”

connection

Select “terminal” mode. Type <LOGOUT>

Note! Do not choose “Disconnect”.

Log in via the modem.

Select

communication port

Save the repeater’s

phone number in the

RMC phone book

Test Test that the remote access is functioning correctly

© Avitec AB A1009300 A 131 (177)

Page 29

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

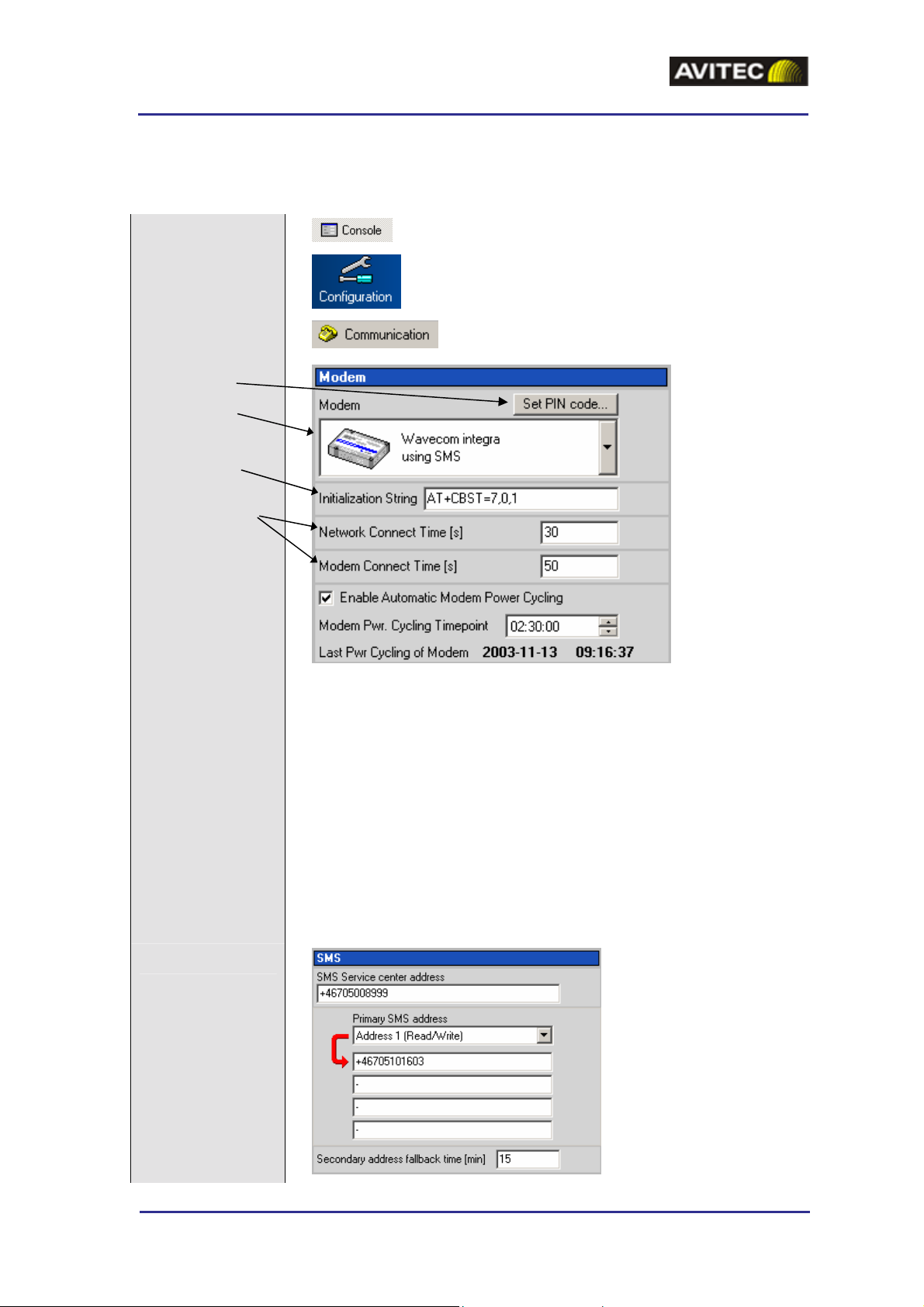

4.4.3.2 SMS Configuration

Note! AEM can not be used if the repeater is configured for SMS communication.

Set modem

parameters

Pin Code

SMS

Initialization string

Connect times

Select “Console” mode

Select “Configuration” window

Select “Communication” page

Set SMS addresses

1. Choose SMS

2. Set pin code, if the SIM card has PIN code request enabled

3. Set modem initialization string. This string di ffers b etween networks. Primary

recommendation is AT+CBST=7,0,1. If remote communication cannot be

established try 7,0,3 or 0,0,3 or 0,0,1.

4. Leave Network Connect Time and Modem Connect Time at default values.

5. Tick “Enable Automatic Modem Power Cycling” for the modem to be power

cycled once every 24 hours. Set the time at which the modem should be tested.

This function ensures that the repeater always is logged in to the network.

© Avitec AB A1009300 A 132 (177)

Page 30

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Set SMS service centre address (the SMSC number to be used).

Set Address 1. This is the address to which all SMS alarms and reports will be sent.

Note! Always set this address.

Set Address 2, 3 and 4 if needed.

Power Cycle Modem

Select Actions and initiate a Power Cycle Modem Logout from the drop-down

menu.

Log out

Wait Wait until verification is ready

Log in remotely

Select “Modem”

connection

Select “terminal” mode Type <LOGOUT>

Note! Do not choose “Disconnect”.

Log in via the modem

Select

communication port

Save the repeater’s

phone number in the

RMC phone book

Test Test that the remote access is functioning correctly

© Avitec AB A1009300 A 133 (177)

Page 31

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

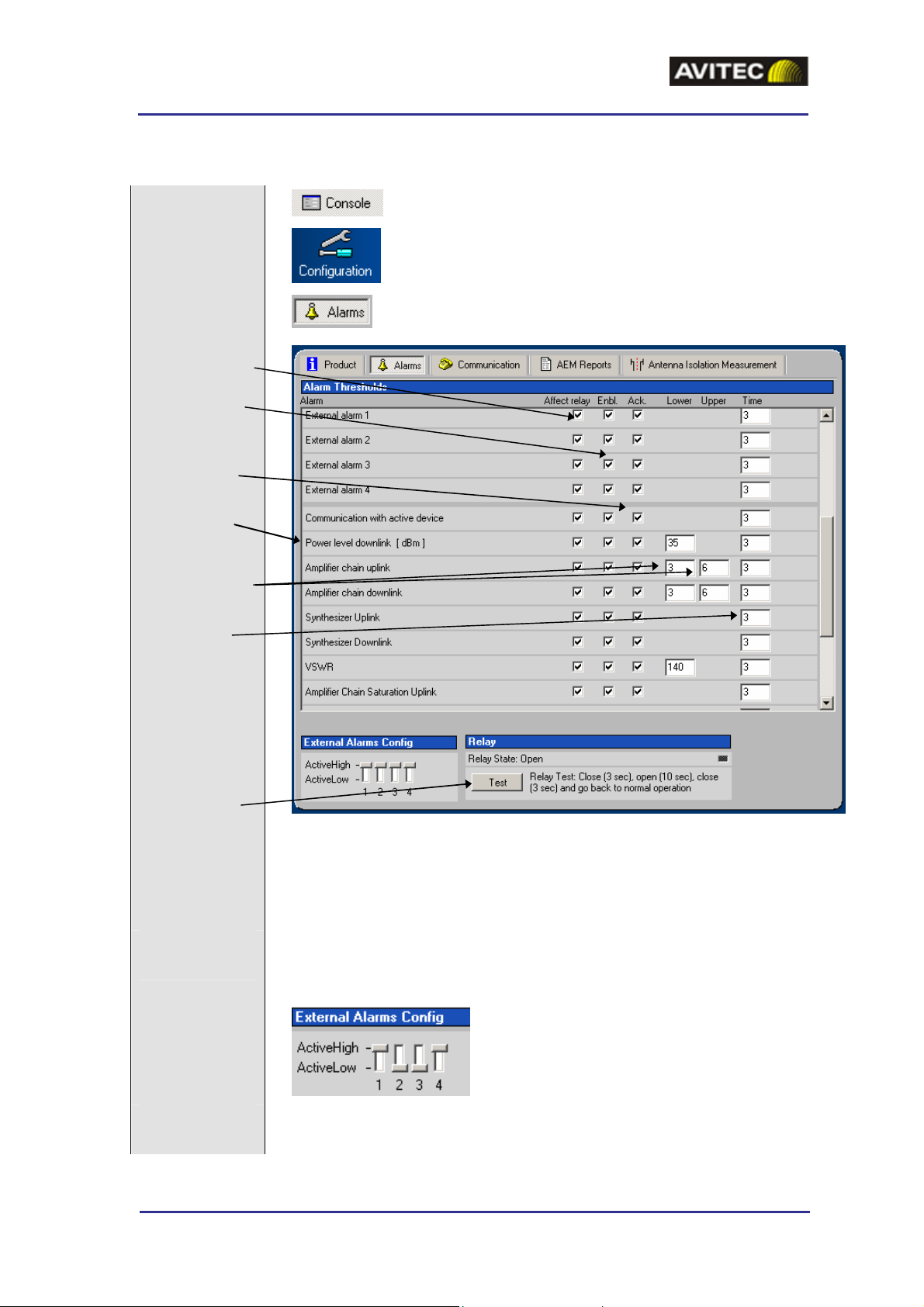

4.4.4 Alarm Configuration

Monitor alarm set

up

Relay connection

enabled

Alarm enabled

Acknowledgement

is required

BCCH alarm

Trigger le vels

Delay time

Select “Console” mode

Select “Configuration” window

Select “Alarms” page

Relay test

Configure external

alarms

The alarm configuration is set up automatically and should be left unmodified, except

for “Power level downlink”.

Note! Power level downlink (BCCH) should be adjusted to fit the installation in regards

to the output power set. In this example a 3 second drop below 35dBm will cause an

alarm.

Four external alarms can be connected to the repeater. See section 4.2.9 Connect

External Alarms.

Set active high or active low for each of these four alarms.

Test the relay The built in relay can be tested by clicking on “Test”. The relay will then be closed for 3

seconds, open for 10 seconds and closed for 3 seconds.

© Avitec AB A1009300 A 134 (177)

Page 32

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.4.5 Heartbeat Configuration

Monitor heartbeat set

up

Repetition cycle

Retransmissions

Repetition cycle

Select “Console” mode

Select “Configuration” window

Select “AEM Reports” page

4.4.6 AEM Report Configuration

Monitor set up

Select “Console” mode

Select “Configuration” window

Select “AEM Reports” page

Heartbeat

Alarm

© Avitec AB A1009300 A 135 (177)

Page 33

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.5 Installation Checklists

4.5.1 Channel Selective Repeater Installation

Check box when done

1 Repeater Installation

1.1 Ensure isolation between server and donor antenna is adequate,

repeater’s gain plus 10– 25 dB (depending on situation)

1.2 Measured isolation ____

1.3 Proper grounding made and EMV protection installed

1.4 Cable from donor antenna connected to donor antenna port

1.5 Cable to server antenna connected to server antenna port

1.6 Mains cable connected to the repeater unit

1.7 Cable protection cover bolted to repeater unit, any outdoor

connections waterproofed

2 Repeater Unit Setup

2.1 Repeater switched on

2.2 Power Supply led and Control Module led shows no error

2.3 Channels set to: 1 ___ 2 ___ 3___ 4___

2.4 BCCH in chain 1

2.5 Power level channel 1 downlink set to _____

2.6 Attenuation channel 1 downlink set to ___ (saturation level checked)

2.7 Power level channel 1 uplink set to same as downlink

2.8 Attenuation channel 1 uplink set to same as downlink

2.9 Power level and attenuation channel 2, 3 and 4 set to same levels as channel 1

2.10 Power Supply led and Control Module led shows no error

2.11 Output power downlink channel 1 ____ (reading from RMC)

2.12 Repeater TAG set to ___________

2.13 Repeater secured and locked

Installation date:_______________ Installer signature:_____________________

Site name: ________________Site number: ______________ GPS coordinates:________

© Avitec AB A1009300 A 136 (177)

Page 34

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.5.2 Preparation Sheet, Frequency Translating Repeater

General

Channels to be repeated____ and _____ => to donor checklist

Link channel (s) to be used ___ and ___ => to donor checklist

Donor Unit

BTS output power + __dBm

Feeder loss between BTS and coupler - ___dB

Coupling loss in coupler - ___dB

Feeder loss between coupler and donor unit - ___dB

__________________________________________________________________

Downlink input power to donor unit (P_in) = __dBm

Desired link power (P

): (+37/+34/+31dBm) ___dBm*

link

=> to donor checklist (Power level downlink)

Required donor downlink gain (G) = P

– Pin = ___dB

link

Donor downlink attenuation = 42 – G (SD) / 45 - G (DD) = ___dB

Attenuation setting to be used (closest larger even number) ___ dB

=> to donor checklist (Attenuation downlink)

Desired uplink ALC level -10/-13/-16 (SD) / -7/-10/-13 (DD) ___dBm

=> to donor checklist (Power level uplink)

Link path

Donor link antenna feeder loss + ___dB

Donor link antenna gain - ___dBi

Link path loss + ___dB

Remote link antenna gain - ___dBi

Remote link antenna feeder loss + ___dB

_________________________________________________________________

Total link loss (L) = ___dB

Remote Unit

Downlink i nput power from link antenna (Pin) = P

Desired remote server power (P

): 40/37/34 (IR) / 43/40/37 (ER) ___dBm

out

-L ___dBm

link

=> to remote checklist (Power level downlink)

Required remote downlink gain (G) = P

– Pin = ___dB

out

Remote unit downlink attenuation = 105–G (IR) / 108-G (ER) = ___dB

© Avitec AB A1009300 A 137 (177)

Page 35

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Attenuation setting to be used (closest larger even number) ___dB

=> to remote checklist (Attenuation downlink)

Desired link power (+37/+34/+31) ___dBm*

=> to remote checklist (Power level uplink)

*Note! Link power should be the same for remote and donor

Date:__________________ Calculated by:_____________________

Site Name: __________________________ Site Number: _____________________

© Avitec AB A1009300 A 138 (177)

Page 36

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.5.3 Frequency Translating Repeater, Donor Unit

Check box when done

1. Coupler Installation

1.1 -30dB Coupler installed on BTS main antenna feeder

1.2 Type N connector closer to antenna terminated with 50 ohm plug

1.3 Type N connector closer to BTS connected to donor cable

1.4 BT S operating normally with coupler installed verified

1.5 Coupler weath erproof ed

2. Donor Unit Installation

2.1 Proper grounding made and EMV protection installed

2.2 Cable from coupler connected to donor port

2.3 Cable to link antenna connected to link antenna port

2.4 Mains cable connected to the repeater unit

2.5 Cable protection cover bolted to donor unit, any outdoor

connections waterproofed

3. Donor Unit Setup

3.1 Donor unit switched on

3.2 Power Supply led and Control Module led shows no error

3.3 Channels set to: 1 ___ 2 ___

3.4 Link channels set to: 1 ___ 2 ___

3.5 Power level link channel 1 downlink set to _____

3.6 Attenuation link channel 1 downlink set to ___ (according to budget)

3.7 Power level channel 1 uplink set to ___ (according to budget)

3.8 Attenuation channel 1 uplink set to same as link channel downlink

3.9 Power levels and attenuation link channel 2 and channel 2 set to same

levels as link channel and channel 1

3.10 Power Supply led and Control Module led shows no error

3.11 Output power downlink channel 1 ____ (reading from RMC)

3.12 Repeater TAG set to _______________

3.13 Repeater secured and locked

Installation date:_______________ Installer signature:_____________________

Site name: ________________Site number: ______________ GPS coordinates:________

© Avitec AB A1009300 A 139 (177)

Page 37

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

4.5.4 Frequency Translating Repeater, Remote Unit

Check box when done

1. Remote Unit Installation

1.1 Ensure adequate isolation between link and serving antenna (>75dB)

1.2 Proper grounding made and EMV protection installed

1.3 Cable from link antenna connected to link antenna port

1.4 Cable to server antenna connected to server antenna port

1.5 Mains cable connected to the repeater unit

1.6 Cable protection cover bolted to donor unit, any outdoor

connections waterproofed

2. Remote Unit Setup

2.1 Remote unit switched on

2.2 Power Supply led and Control Module led shows no error

2.3 Channels set to same as donor

2.4 Link channels set to same as donor

2.5 Power level channel 1 downlink set to ___ (according to budget)

2.6 Attenuation channel 1 downlink set to ___ (according to budget)

2.7 Power level link channel 1 uplink set to same as power level

link channel 1 downlink i n donor unit

2.8 Attenuation link channel 1 uplink set to same as attenuation channel 1

downlink

2.9 Power level and attenuation link c hannel 2 and channel 2 set to same

levels as channel 1

2.10 Power Supply led and Control Module led shows no error

2.11 Output power downlink channel 1 ____ (reading from RMC)

2.12 Repeater TAG set to ___

2.13 Repeater secured and locked

Installation date:_______________ Installer signature:_____________________

Site name: ________________Site number: ______________ GPS coordinates:________

© Avitec AB A1009300 A 140 (177)

Page 38

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

5 Maintenance

5.1 General

The system normally operates without any operator intervention or maintenance. In the unlikely event of a

unit failure, the field replaceable components (antenna unit, cables, etc.) should be checked and replaced if

faulty and the system restored. A failed unit can be removed and replaced with a spare while the rest of the

system (other repeaters) is operating. However, the power supply of the failed repeater should be isolated

from AC mains and DC power before any module is replaced.

Should the system malfunction, the condition of the antenna systems as well as the continuity of the cabling

should be checked before replacing any of the repeater modules.

Caution

Please be aware that the equipment may, during certain conditions become very warm and can cause minor

injuries if handled without any protection, such as gloves.

5.2 Preventive Maintenance

The Avitec repeaters do not require any preventative maintenance apart from changing the backup battery

once every three years.

Caution

Risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to local laws and instructions.

© Avitec AB A1009300 A 141 (177)

Page 39

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

6 Specifications

6.1 CSR 922

Electrical Specifications

Frequency range Uplink, UL 880 – 915 MHz (E-GSM900)

Frequency range Downlink, DL 925 – 960 MHz (E-GSM900)

Frequency range Uplink, UL 876 – 911 MHz (R-GSM900)

Frequency range Downlink, DL 921 – 956 MHz (R-GSM900)

Operational bandwidth 35 MHz

Number of channels 1 – 2

Channel programming 200 kHz channel spacing

Selectivity > 60 dB at 400 kHz

> 70 dB at 600 kHz

Ripple in pass band < 2 dB

Sensitivity < - 109 dBm at S/N 9 dB

Noise figure 2.5 dB typical, < 3 dB at max gain

Maximum input level, non destructive +10 dBm

Propagation delay 5.5 µs typical

Output power per carrier (UL/DL) +37 dBm GSM/ GMSK

+34 dBm EDGE / 8-PSK average power

Modulation Accuracy

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +37 dBm

EDGE / 8-PSK < 3 % EVM RMS at + 34 dBm

Intermodulation < - 36 dBm (two carriers at + 37 dBm, 600 kHz spacing)

Spurious responses < - 36 dBm for 9 kHz – 1 GHz

< - 30 dBm for 1 GHz – 13 GHz

Gain 60 – 90 dB, adjustable, in 1 dB steps

System impedance 50 ohm

Return loss at antenna connections > 16 dB

Antenna connectors DIN 7/16

Electrical ratings 110/230 VAC, 50/60 Hz or -48 VDC

Power Consumption 100 W typical / 200 W maximum (traffic dependent)

© Avitec AB A1009300 A 142 (177)

Page 40

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Mechanical Specifications

Dimensions 470 x 340 x 145 mm

Enclosure Aluminum (IP 65)

Weight 16 kg

Environmental Specifications

EMC See compliance below

Operating Temperature - 25 to + 55 ° C

Storage - 30 to + 70 ° C

Humidity ETSI EN 300 019-2-4 (see compliance below)

MTBF > 100 000 hrs

Complies with R&TTE Directive including

ETS EN 301 502 (ETS EN 300 609-4/GSM 11.26)

ETS EN 301 498-8

EN 60 950

© Avitec AB A1009300 A 143 (177)

Page 41

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

6.2 CSR 924

Electrical Specifications

Frequency range Uplink, UL 880 – 915 MHz (E-GSM900)

Frequency range Downlink, DL 925 – 960 MHz (E-GSM900)

Frequency range Uplink, UL 876 – 911 MHz (R-GSM900)

Frequency range Downlink, DL 921 – 956 MHz (R-GSM900)

Operational bandwidth 35 MHz

Number of channels 1 – 4

Channel programming 200 kHz channel spacing

Selectivity > 60 dB at 400 kHz

> 70 dB at 600 kHz

Ripple in pass band < 2 dB

Sensitivity < - 108 dBm at S/N 9 dB

Noise figure 3 dB typical, < 3.5 dB at max gain

Maximum input level, non destructive +10 dBm

Propagation delay 5.5 µs typical

Output power per carrier (UL/DL) +34 dBm GSM/ GMSK

+31 dBm EDGE / 8-PSK average power

Modulation Accuracy

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +34 dBm

EDGE / 8-PSK < 3 % EVM RMS at +31 dBm

Intermodulation < - 36 dBm (two carriers at + 34 dBm, 600 kHz spacing)

Spurious responses < - 36 dBm for 9 kHz – 1 GHz

< - 30 dBm for 1 GHz – 13 GHz

Gain 54 – 84 dB, adjustable, in 1 dB steps

System impedance 50 ohm

Return loss at antenna connections > 16 dB

Antenna connectors DIN 7/16

Electrical ratings 110/230 VAC, 50/60 Hz or -48 VDC

Power Consumption 180 W typical / 400 W maximum (traffic dependent)

© Avitec AB A1009300 A 144 (177)

Page 42

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Mechanical Specifications

Dimensions 470 x 340 x 220 mm

Enclosure Aluminum (IP 65)

Weight 30 kg

Environmental Specifications

EMC See compliance below

Operating Temperature - 25 to + 55 °C

Storage - 30 to + 70 °C

Humidity ETSI EN 300 019-2-4 (see compliance below)

MTBF > 100 000 hrs

Complies with R&TTE Directive including

ETS EN 301 502 (ETS EN 300 609-4/GSM 11.26)

ETS EN 301 498-8

EN 60 950

© Avitec AB A1009300 A 145 (177)

Page 43

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

6.3 CSR 924 H

Electrical Specifications

Frequency Ranges

Frequency range Uplink, UL 880 – 915 MHz (E-GSM900)

Frequency range Downlink, DL 925 – 960 MHz (E-GSM900)

Frequency range Uplink, UL 876 – 911 MHz (R-GSM900)

Frequency range Downlink, DL 921 – 956 MHz (R-GSM900)

Operational bandwidth 35 MHz

Number of channels 1 – 4

Channel programming 200 kHz channel spacing

Selectivity > 60 dB at 400 kHz

> 70 dB at 600 kHz

Ripple in passband < 2 dB

Sensitivity < - 108 dBm at S/N 9 dB

Noise figure 3 dB typical, < 3,5 dB at max gain

Maximum input level, non destructive + 10 dBm

Propagation delay 5,5 µs typical

Output power per carrier, DL + 37 dBm GSM/ GMSK,

+ 34 dBm EDGE / 8-PSK average power

Output power per carrier, UL + 34 dBm GSM/ GMSK

+ 31 dBm EDGE / 8-PSK average power

Modulation Accuracy

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at + 37 dBm

EDGE / 8-PSK < 3 % EVM RMS at + 34 dBm

Intermodulation < - 36 dBm (two carriers at + 37 dBm, 600 kHz spacing)

Spurious responses < - 36 dBm for 9 kHz – 1 GHz

< - 30 dBm for 1 GHz – 13 GHz

Gain DL/UL 63 – 93 dB, adjustable, in 1 dB steps

System impedance 50 Ω

Return loss at antenna connections > 16 dB

Antenna connectors DIN 7/16

Electrical ratings 110/230 VAC, 50/60 Hz or -48 VDC

Power Consumption 180 W typical / 400 W maximum

© Avitec AB A1009300 A 146 (177)

Page 44

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Mechanical Specifications

Dimensions 470 x 340 x 220 mm

Enclosure Aluminium (IP 65)

Weight 30 kg

Environmental Specifications

EMC See compliance below

Operating Temperature - 25 to + 55 ° C

Storage - 30 to + 70 ° C

Humidity ETSI EN 300 019-2-4 ( see compliance below)

MTBF > 100000 hrs

Complies with R&TTE Directive including

ETS EN 301 502 (ETS EN 300 609-4 / GSM 11.26)

ETS EN 301 498-8

EN 60 950

© Avitec AB A1009300 A 147 (177)

Page 45

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

6.4 CSR1822

Electrical Specifications

Frequency range Uplink, UL 1710 - 1785 MHz (DCS-1800)

Frequency range Downlink, DL 1805 - 1885 MHz (DCS-1800)

Operational bandwidth 75 MHz

Number of channels 1 - 2

Channel programming 200 kHz Channel spacing

Selectivity > 60 dB at 400 kHz

>70 dB at 600 kHz

Ripple in passband < 2 dB

Sensitivity < - 109 dBm at S/N 9 dB

Noise figure 2.5 dB typical, < 3 dB at max gain

Maximum input level, non destructive + 10 dBm

Propagation delay 5,5 µs typical

Output power per carrier (UL/DL) + 37dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

Modulation Accuracy

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +37 dBm

EDGE / 8-PSK < 3 % EVM RMS at + 34 dBm

Intermodulation < - 36 dBm (two carriers at + 37 dBm, 600 kHz spacing)

Spurious responses < - 36 dBm for 9 kHz - 1 GHz

< - 30 dBm for 1 GHz - 13 GHz

Gain 60 - 90 dB, adjustable, in 1 dB steps

System impedance 50 ohm

Return loss at antenna connections > 16 dB

Antenna connectors DIN 7/16

Electrical ratings 110/230 VAC, 50/60 Hz or -48 VDC

Power Consumption 100 W typical / 200 W maximum (traffic dependent)

Mechanical Specifications

Dimensions 470 x 340 x 145 mm

Enclosure Aluminum (IP 65)

Weight 16 kg

© Avitec AB A1009300 A 148 (177)

Page 46

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Environmental Specifications

EMC See compliance below

Operating Temperature - 25 to + 55 ° C

Storage - 30 to + 70 ° C

Humidity ETSI EN 300 019-2-4 (see compliance below)

MTBF > 100 000 hrs

Complies with R& TTE Directive including

ETS EN 301 502 (ETS EN 300 609-4 / GSM 11.26 )

ETS EN 301 498-8

EN 60 950

© Avitec AB A1009300 A 149 (177)

Page 47

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

6.5 CSR1824

Electrical Specifications

Frequency range Uplink, UL 1710 - 1785 MHz (DCS-1800)

Frequency range Downlink, DL 1805 - 1885 MHz (DCS-1800)

Operational bandwidth 75 MHz

Number of channels 1 - 4

Channel programming 200 kHz channel spacing

Selectivity > 60 dB at 400 kHz

>70 dB at 600 kHz

Ripple in passband < 2 dB

Sensitivity < - 108 dBm at S/N 9 dB

3 dB typical, < 3,5 dB at max gain

Maximum input level, non destructive + 10 dBm

Propagation delay 5,5 µs typical

Output power per carrier (UL/DL ) + 34 dBm GSM/ GMSK

+ 31 dBm EDGE / 8-PSK average power

Modulation Accuracy

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +37 dBm

EDGE / 8-PSK < 3 % EVM RMS at + 34 dBm

Intermodulation < - 36 dBm (two carriers at + 34 dBm, 600 kHz spacing)

Spurious responses < - 36 dBm for 9 kHz - 1 GHz

< - 30 dBm for 1 GHz - 13 GHz

Gain 54 - 84 dB, adjustable, in 1 dB steps.

System impedance 50 ohm

Return loss at antenna connections > 16 dB

Antenna connectors DIN 7/16

Electrical ratings 110/230 VAC, 50/60 Hz or -48 VDC

Power Consumption 180 W typical / 400 W maximum (traffic dependent)

Mechanical Specifications

Dimensions 470 x 340 x 220 mm

Enclosure Aluminum (IP 65)

Weight 30 kg

© Avitec AB A1009300 A 150 (177)

Page 48

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Environmental Specifications

EMC See compliance below

Operating Temperature - 25 to + 55 ° C

Storage - 30 to + 70 ° C

Humidity ETSI EN 300 019-2-4 (see compliance below)

MTBF > 100 000 hrs

Complies with R& TTE Directive including

ETS EN 301 502 (ETS EN 300 609-4 / GSM 11.26 )

ETS EN 301 498-8

EN 60 950

© Avitec AB A1009300 A 151 (177)

Page 49

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

6.6 CSR1922

Electrical Specifications

Frequency range Uplink, UL 1850 - 1910 MHz (PCS-1900)

Frequency range Downlink, DL 1930 - 1990 MHz (PCS-1900)

Operational bandwidth 60 MHz

Number of channels 1 - 2

Channel programming 200 kHz Channel spacing

Selectivity > 60 dB at 400 kHz

>70 dB at 600 kHz

Ripple in passband < 2 dB

Sensitivity < - 109 dBm at S/N 9 dB

Noise figure 2.5 dB typical, < 3 dB at max gain

Maximum input level, non destructive + 10 dBm

Propagation delay 5,5 µs typical

Output power per carrier (UL/DL) + 37dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

Modulation Accuracy

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +37 dBm

EDGE / 8-PSK < 3 % EVM RMS at + 34 dBm

Intermodulation < - 36 dBm (two carriers at + 37 dBm, 600 kHz spacing)

Spurious responses < - 36 dBm for 9 kHz - 1 GHz

< - 30 dBm for 1 GHz - 13 GHz

Gain 60 - 90 dB, adjustable, in 1 dB steps

System impedance 50 ohm

Return loss at antenna connections > 16 dB

Antenna connectors DIN 7/16

Electrical ratings 110/230 VAC, 50/60 Hz or -48 VDC

Power Consumption 100 W typical / 200 W maximum (traffic dependent)

Mechanical Specifications

Dimensions 470 x 340 x 145 mm

Enclosure Aluminum (IP 65)

Weight 16 kg

© Avitec AB A1009300 A 152 (177)

Page 50

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Environmental Specifications

EMC See compliance below

Operating Temperature - 25 to + 55 ° C

Storage - 30 to + 70 ° C

Humidity ETSI EN 300 019-2-4 (see compliance below)

MTBF > 100 000 hrs

Complies with R& TTE Directive including

ETS EN 301 502 (ETS EN 300 609-4 / GSM 11.26 )

ETS EN 301 498-8

EN 60 950

© Avitec AB A1009300 A 153 (177)

Page 51

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

6.7 CSR1924

Electrical Specifications

Frequency range Uplink, UL 1850 - 1910 MHz (PCS-1900)

Frequency range Downlink, DL 1930 - 1990 MHz (PCS-1900)

Operational bandwidth 60 MHz

Number of channels 1 - 4

Channel programming 200 kHz channel spacing

Selectivity > 60 dB at 400 kHz

>70 dB at 600 kHz

Ripple in passband < 2 dB

Sensitivity < - 108 dBm at S/N 9 dB

3 dB typical, < 3,5 dB at max gain

Maximum input level, non destructive + 10 dBm

Propagation delay 5,5 µs typical

Output power per carrier (UL/DL ) + 34 dBm GSM/ GMSK

+ 31 dBm EDGE / 8-PSK average power

Modulation Accuracy

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +37 dBm

EDGE / 8-PSK < 3 % EVM RMS at + 34 dBm

Intermodulation < - 36 dBm (two carriers at + 34 dBm, 600 kHz spacing)

Spurious responses < - 36 dBm for 9 kHz - 1 GHz

< - 30 dBm for 1 GHz - 13 GHz

Gain 54 - 84 dB, adjustable, in 1 dB steps

System impedance 50 ohm

Return loss at antenna connections > 16 dB

Antenna connectors DIN 7/16

Electrical ratings 110/230 VAC, 50/60 Hz or -48 VDC

Power Consumption 180 W typical / 400 W maximum (traffic dependent)

Mechanical Specifications

Dimensions 470 x 340 x 220 mm

Enclosure Aluminum (IP 65)

Weight 30 kg

© Avitec AB A1009300 A 154 (177)

Page 52

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Environmental Specifications

EMC See compliance below

Operating Temperature - 25 to + 55 ° C

Storage - 30 to + 70 ° C

Humidity ETSI EN 300 019-2-4 (see compliance below)

MTBF > 100 000 hrs

Complies with R& TTE Directive including

ETS EN 301 502 (ETS EN 300 609-4 / GSM 11.26 )

ETS EN 301 498-8

EN 60 950

© Avitec AB A1009300 A 155 (177)

Page 53

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

6.8 CSFT 922

Electrical Specification

Frequency range Uplink, UL 880 – 915 MHz (E-GSM900)

Frequency range Downlink, DL 925 – 960 MHz (E-GSM900)

Frequency range Uplink, UL 876 – 911 MHz (R-GSM900)

Frequency range Downlink, DL 921 – 956 MHz (R-GSM900)

Operational bandwidth 35 MHz

Number of channels 1 – 2

Channel programming 200 kHz Channel spacing

Selectivity > 60 dB at 400 kHz

> 70 dB at 600 kHz

Ripple in passband < 2 dB

Sensitivity

Donor unit (SD) and (DD)

UL < - 109 dBm at S/N 9 dB

DL N/A

Remote unit (IR) and (ER) < - 109 dBm at S/N 9 dB

Noise figure

Donor unit (SD) and (DD)

UL 2.5 dB typical, < 3 dB at max gain

DL N/A

Remote unit (IR) and (ER) UL/DL 2.5 dB typical, < 3 dB at max gain

Maximum input level, no damage

Donor unit (SD) and (DD)

UL + 23 dBm

DL + 10 dBm

Remote unit (IR) and (ER) UL/DL + 10 dBm

Propagation delay 5.5 µs typical

© Avitec AB A1009300 A 156 (177)

Page 54

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Output power per carrier

Donor unit (SD)

DL + 37 dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

UL - 10 dBm GSM/ GMSK

- 13 dBm EDGE / 8-PSK average power

Donor unit (DD)

DL + 37 dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

UL - 7 dBm GSM/ GMSK

- 10 dBm EDGE / 8-PSK average power

Remote unit (IR)

DL + 40 dBm GSM/ GMSK

+ 37 dBm EDGE / 8-PSK average power

UL + 37 dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

Remote unit (ER)

DL + 43 dBm GSM/ GMSK

+ 40 dBm EDGE / 8-PSK average power

UL + 37 dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

Gain

Donor unit (SD) max 42 dB, adjustable, in 1 dB steps

Donor unit (DD) max 45 dB, adjustable, in 1 dB steps

Remote unit (IR)

DL/UL 75 - 105 dB, adjustable, in 1 dB steps

Remote unit (ER)

DL/UL 78 - 108 dB, adjustable, in 1 dB steps

Gain Flatness (200 kHz BW) ± 1 dB

Gain Flatness (15 MHz BW) ± 1 dB

Input to Link Channel Fre quency Erro r < 1 x 10

-9

Modulation Accuracy

Donor unit (SD) and (DD)

DL

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +33 dBm

EDGE / 8-PSK < 3 % EVM RMS at +30 dBm average power

UL

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at -10 dBm

© Avitec AB A1009300 A 157 (177)

Page 55

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

EDGE / 8-PSK < 3 % EVM RMS at -13 dBm average power

Remote unit (IR)

DL

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +40 dBm

EDGE / 8-PSK < 4 % EVM RMS at +37 dBm average power

UL

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +37 dBm

EDGE / 8-PSK < 3 % EVM RMS at +34 dBm average power

Remote unit (ER)

DL

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +43 dBm

EDGE / 8-PSK < 4 % EVM RMS at +40 dBm average power

UL

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +37 dBm

EDGE / 8-PSK < 3 % EVM RMS at +34 dBm average power

Intermodulation

Donor unit (SD) and (DD) < -36 dBm (two carriers at + 33 dBm DL, 600 kHz

spacing)

< -70 dBm (two carriers at -10 dBm UL, 600 kHz

spacing)

Remote unit (IR) < -36 dBm (two carriers at + 40 dBm DL, 600 kHz

spacing)

< -36 dBm (two carriers at +37 dBm UL, 600 kHz

spacing)

Remote unit (ER) < -36 dBm (two carriers at + 43 dBm DL, 600 kHz

spacing)

< -36 dBm (two carriers at +37 dBm UL, 600 kHz

spacing)

Spurious responses < - 36 dBm for 9 kHz – 1 GHz

< - 30 dBm for 1 GHz – 13 GHz

System impedance 50 ohm

Return loss at antenna connections > 16 dB

Antenna connectors DIN 7/16

Electrical ratings 110/230 VAC, 50/60 Hz or -48 VDC

Power Consumption 100 W typical / 200 W maximum (traffic dependent)

Mechanical Specifications

Dimensions 470 x 340 x 145 mm

© Avitec AB A1009300 A 158 (177)

Page 56

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

Enclosure Aluminum (IP 65)

Weight 16 kg

Environmental Specifications

EMC See compliance below

Operating Temperature - 25 to + 55 ° C

Storage - 30 to + 70 ° C

Humidity ETSI EN 300 019-2-4 (see compliance below)

MTBF > 100 000 hrs

Complies with R& TTE Directive including

ETS EN 301 502 (ETS EN 300 609-4 / GSM 11.26)

ETS EN 301 498-8

EN 60 950

© Avitec AB A1009300 A 159 (177)

Page 57

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

6.9 CSFT 1822

Electrical Specifications

Frequency range Uplink, UL 1710 - 1785 MHz (DCS 1800)

Frequency range Downlink, DL 1805 - 1880 MHz (DCS 1800)

Operational bandwidth 75 MHz

Number of channels 1 - 2

Channel programming 200 kHz Channel spacing

Selectivity > 60 dB at 400 kHz

> 70 dB at 600 kHz

Ripple in passband < 2 dB

Sensitivity

Donor unit (SD) and (DD)

UL < - 109 dBm at S/N 9 dB

DL N/A

Remote unit (IR) and (ER) < - 109 dBm at S/N 9 dB

Noise figure

Donor unit (SD) and (DD)

UL 2.5 dB typical, < 3 dB at max gain

DL N/A

Remote unit (IR) and (ER) UL/DL 2.5 dB typical, < 3 dB at max gain

Maximum input level, no damage

Donor unit (SD) and (DD)

UL + 23 dBm

DL + 10 dBm

Remote unit (IR) and (ER) UL/DL + 10 dBm

Propagation delay 5,5 µs typical

Output power per carrier

Donor unit (SD)

DL + 37 dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

UL - 10 dBm GSM/ GMSK

- 13 dBm EDGE / 8-PSK average power

Donor unit (DD)

© Avitec AB A1009300 A 160 (177)

Page 58

GSM-EDGE Repeaters

PRODUCT DESCRIPTION AND USER'S MANUAL

DL + 37 dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

UL - 10 dBm GSM/ GMSK

- 13 dBm EDGE / 8-PSK average power

Remote unit (IR)

DL + 40 dBm GSM/ GMSK

+ 37 dBm EDGE / 8-PSK average power

UL + 37 dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

Remote unit (ER)

DL + 43 dBm GSM/ GMSK

+ 40 dBm EDGE / 8-PSK average power

UL + 37 dBm GSM/ GMSK

+ 34 dBm EDGE / 8-PSK average power

Gain

Donor unit (SD) max 42 dB, adjustable, in 1 dB steps

Donor unit (DD) max 45 dB, adjustable, in 1 dB steps

Remote unit (IR)

DL/UL 75 - 105 dB, adjustable, in 1 dB steps

Remote unit (ER)

DL/UL 78 - 108 dB, adjustable, in 1 dB steps

Gain Flatness (200 kHz BW) ± 1 dB

Gain Flatness (15 MHz BW) ± 1 dB

Input to Link Channel Fre quency Erro r < 1 x 10

-9

Modulation Accuracy

Donor unit (SD) and (DD)

DL

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +33 dBm

EDGE / 8-PSK < 3 % EVM RMS at +30 dBm average power

UL

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at -10 dBm

EDGE / 8-PSK < 3 % EVM RMS at -13 dBm average power

Remote unit (IR)

DL

GSM / GMSK < 2.5 ° RMS and < 10 ° peak at +40 dBm

EDGE / 8-PSK < 4 % EVM RMS at +37 dBm average power

UL