Avionics / Antennas / Kannad / Kannad Ant100 - Auxiliary Antenna (BNC) Kannad Ant100 - Auxiliary Antenna (BNC) Installation Manual 406 AP-H

Page 1

Emergency Locator Transmitter

Orolia S.A.S.

INSTALLATION MANUAL

OPERATION MANUAL

DOC06330F

P/N: S1820502-04 KANNAD 406 AP-H transmitter

P/N: S1820511-01 Mounting bracket, 1 strap

P/N: 0124206 ANT100, auxiliary antenna

© 2022 OROLIA S.A.S. ALL RIGHTS ARE STRICTLY RESERVED.

Revision 05

First issue: JUL /1999

KANNAD 406 AP-H

TP PAGE: 1

Date of rev. JUN 29/2022

Page 2

Users are kindly requested to notify Orolia Customer Support

of any discrepancy, omission or error found in this document.

Please register a support ticket via the Orolia website:

https://www.orolia.com/support/

THIS DOCUMENT IS COPYRIGHT © 2022 OROLIA S.A.S. ALL RIGHTS

ARE STRICTLY RESERVED. THIS DOCUMENT AND ANY ATTACHED

MATERIALS CONTAINS PROPRIETARY AND CONFIDENTIAL

INFORMATION AND DATA AND IS THE SOLE PROPERTY OF OROLIA

S.A.S. THE DOCUMENTS, ANY ATTACHED MATERIALS AND/OR

INFORMATION CONTAINED THEREIN MUST NOT BE USED,

DISSEMINATED, OR DISTRIBUTED EXCEPT FOR THE AGREED PURPOSE.

UNAUTHORIZED USE, REPRODUCTION, OR ISSUE TO ANY THIRD PARTY

IS NOT PERMITTED WITHOUT THE PRIOR WRITTEN CONSENT OF THE

OROLIA GROUP. THIS DOCUMENT IS TO BE RETURNED TO THE OROLIA

GROUP WHEN THE AGREED PURPOSE IS FULFILLED.

© 2022 Orolia S.A.S. All rights are strictly reserved.

Page 3

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

RECORD OF REVISIONS

REV. Nb REVISION DATE INSERTION DATE BY

00 OCT 18/2006

01 FEB 13/2008

02 SEP 12/2008

03 APR 30/2010

04 JUL 24/2013

05 JUN 29/2022

© 2022 Orolia S.A.S. All rights are strictly reserved.

ROR PAGE: 1

JUN 29/2022

Page 4

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

RECORD OF REVISIONS

PAGE INTENTIONALLY LEFT BLANK

© 2022 Orolia S.A.S. All rights are strictly reserved.

ROR PAGE: 2

JUN 29/2022

Page 5

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

LIST OF EFFECTIVE PAGES

SUBJECT PAGE DATE

Title Page

TP 1 JUN 29/2022

Record of Revisions

ROR 1 JUN 29/2022

ROR 2 JUN 29/2022

List of Effective Pages

LEP 1 JUN 29/2022

Table of Contents

Introduction

System Overview

LEP 2 JUN 29/2022

TOC 1 JUN 29/2022

TOC 2 JUN 29/2022

TOC 3 JUN 29/2022

TOC 4 JUN 29/2022

INTRO 1 JUN 29/2022

INTRO 2 JUN 29/2022

1 JUN 29/2022

2 JUN 29/2022

3 JUN 29/2022

System Functional Description and Operation

© 2022 Orolia S.A.S. All rights are strictly reserved.

4 JUN 29/2022

5 JUN 29/2022

6 JUN 29/2022

7 JUN 29/2022

8 JUN 29/2022

LEP PAGE: 1

JUN 29/2022

Page 6

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

LIST OF EFFECTIVE PAGES

SUBJECT PAGE DATE

101 JUN 29/2022

102 JUN 29/2022

103 JUN 29/2022

104 JUN 29/2022

105 JUN 29/2022

106 JUN 29/2022

107 JUN 29/2022

108 JUN 29/2022

Installation / Removal

109 JUN 29/2022

110 JUN 29/2022

201 JUN 29/2022

202 JUN 29/2022

203 JUN 29/2022

204 JUN 29/2022

205 JUN 29/2022

206 JUN 29/2022

207 JUN 29/2022

208 JUN 29/2022

209 JUN 29/2022

210 JUN 29/2022

Check

© 2022 Orolia S.A.S. All rights are strictly reserved.

301 JUN 29/2022

302 JUN 29/2022

303 JUN 29/2022

304 JUN 29/2022

LEP PAGE: 2

JUN 29/2022

Page 7

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

LIST OF EFFECTIVE PAGES

SUBJECT PAGE DATE

Troubleshooting

401 JUN 29/2022

402 JUN 29/2022

Schematics and Diagrams 501 JUN 29/2022

502 JUN 29/2022

503 JUN 29/2022

Servicing

504 JUN 29/2022

505 JUN 29/2022

506 JUN 29/2022

507 JUN 29/2022

508 JUN 29/2022

601 JUN 29/2022

602 JUN 29/2022

© 2022 Orolia S.A.S. All rights are strictly reserved.

LEP PAGE: 3

JUN 29/2022

Page 8

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

LIST OF EFFECTIVE PAGES

PAGE INTENTIONALLY LEFT BLANK

© 2022 Orolia S.A.S. All rights are strictly reserved.

LEP PAGE: 4

JUN 29/2022

Page 9

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

TABLE OF CONTENTS

INTRODUCTION ..................................................................................... 1

SYSTEM OVERVIEW ............................................................................. 1

COSPAS-SARSAT System ................................................................... 1

Description ............................................................................................................. 1

World coverage with the COSPAS-SARSAT system ............................................ 2

Environmental improvements of ELTs ................................................................... 2

G-Switch (shock detectors) .................................................................................... 2

KANNAD 406 AP-H Presentation ......................................................... 3

LINE REPLACEABLE UNITS ............................................................... 4

Transmitter ............................................................................................................ 4

Bracket .................................................................................................................. 4

Remote Control Panel ........................................................................................... 4

External antenna ................................................................................................... 4

Design features ..................................................................................... 5

Compatibility list .................................................................................... 6

Remote control panels (RCP) ................................................................................ 6

DIN-12 connector or programming dongles ........................................................... 6

ELT-NAV System Interface .................................................................................... 6

External antennas .................................................................................................. 7

SYSTEM FUNCTIONAL DESCRIPTION AND OPERATION ............ 101

Transmitter ........................................................................................ 101

Controls ............................................................................................. 102

Working mode information ................................................................ 103

Off ...................................................................................................................... 103

Self-Test ............................................................................................................ 103

Armed ................................................................................................................ 104

On ...................................................................................................................... 104

Endurance ......................................................................................... 105

Electrical characteristics .................................................................... 106

Electrical interface ............................................................................................. 106

Technical Specifications .................................................................... 107

Activation ........................................................................................... 108

Standby mode for automatic activation .............................................................. 108

Manual activation as fixed ELT .......................................................................... 108

Manual activation as survival ELT ..................................................................... 109

Reset ................................................................................................. 110

Manual reset ...................................................................................................... 110

Reset with Remote Control Panel ...................................................................... 110

Self-Test ............................................................................................ 110

© 2022 Orolia S.A.S. All rights are strictly reserved.

TOC PAGE: 1

JUN 29/2022

Page 10

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

TABLE OF CONTENTS

INSTALLATION / REMOVAL ............................................................. 201

Registration and Programming ......................................................... 201

Pin programming option .................................................................................... 202

ELT Installation ................................................................................. 203

Installation recommandations ............................................................................ 203

FAA Recommendations .................................................................................. 203

TSO C126a Section 5 b. Application Data Requirements .............................. 203

RTCA DO-182 Recommendations .................................................................. 203

RTCA DO-204a Requirements ....................................................................... 203

Bracket installation ............................................................................................ 204

Transmitter and auxiliary antenna installation ................................................... 206

Antenna Installation .......................................................................... 208

Antenna Installation Recommendations ............................................................ 208

FAA Recommendations .................................................................................. 208

RTCA DO-204 Requirements for ELT location ............................................... 208

Antenna installation procedure .......................................................................... 208

First power up ................................................................................... 210

Removal ............................................................................................ 211

CHECK ............................................................................................... 301

Self-test ............................................................................................. 301

Periodicity .......................................................................................................... 301

Self-test procedure ............................................................................................ 301

ELT operational tests ........................................................................ 302

Installation without programming dongle ........................................................... 302

Installation with Programming Dongle ............................................................... 302

RCP operational tests ....................................................................... 303

406 and 121.5 MHz transmission test ............................................... 304

ELT-Antenna link ............................................................................................... 304

406 MHz ............................................................................................................ 304

121.5 MHz ......................................................................................................... 304

TROUBLESHOOTING ........................................................................ 401

General ............................................................................................. 401

Faults on Self-test ............................................................................. 401

Visual indicator .................................................................................................. 401

3+1 flashes ..................................................................................................... 401

3+2 flashes ..................................................................................................... 401

3+3 flashes ..................................................................................................... 401

3+4 flashes ..................................................................................................... 401

Other faults detected ......................................................................... 401

Buzzer ............................................................................................................... 401

Buzzer does not operate ................................................................................. 401

Buzzer operates permanently when ELT in ARM mode ................................. 401

© 2022 Orolia S.A.S. All rights are strictly reserved.

TOC PAGE: 2

JUN 29/2022

Page 11

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

TABLE OF CONTENTS

SCHEMATICS & DIAGRAMS ............................................................ 501

Outline Dimensions ........................................................................... 501

Drilling Mask ..................................................................................... 502

Wiring ................................................................................................ 503

ANT AV200, outline dimensions and drilling mask ........................... 504

ANT AV300, outline dimensions and drilling mask ........................... 505

ANT300, outline dimensions and drilling mask ................................. 506

ANT 410, outline dimensions and drilling mask ................................ 507

SERVICING ........................................................................................ 601

Maintenance Schedule ..................................................................... 601

Periodic inspection ............................................................................................ 601

Battery replacement .......................................................................................... 601

Battery replacement requirements .................................................... 602

© 2022 Orolia S.A.S. All rights are strictly reserved.

TOC PAGE: 3

JUN 29/2022

Page 12

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

TABLE OF CONTENTS

PAGE INTENTIONALLY LEFT BLANK

© 2022 Orolia S.A.S. All rights are strictly reserved.

TOC PAGE: 4

JUN 29/2022

Page 13

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

INTRODUCTION

The instructions in this manual provide the information necessary for the

installation and the operation of KANNAD 406 AP-H ELT.

Servicing instructions (Refer to SERVICING page 601) are normally performed

by shop personnel.

For servicing and maintenance instructions, refer to relevant CMM.

For regulatory requirements, please consult your national aviation authority.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE INTRO 1

JUN 29/2022

Page 14

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

PAGE INTENTIONALLY LEFT BLANK

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE INTRO 2

JUN 29/2022

Page 15

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

SYSTEM OVERVIEW

1. COSPAS-SARSAT System

A. Description

Launched in the early eighties by the four founder countries (Canada, France,

Russia, USA), the COSPAS-SARSAT system provides satellite aid to search

and rescue (SAR) operations for maritime, aeronautical and terrestrial vehicles

anywhere in the world.

It uses distress beacons fitted on mobiles and a constellation of LEO and GEO

satellites which relay the 121.5 / 243 MHz signals and process the 406 MHz

signal to ground stations (LUT) where the beacon positions are determined

(with a precision of 10 NM with 121.5 / 243 signals and less than 2 NM with 406

signals).

Several types of beacons are designed to match the various applications of the

COSPAS-SARSAT system:

• EPIRB (Emergency Position Indicating Radio Beacon) for maritime

applications.

• ELT (Emergency Locator Transmitter) for aeronautical applications.

• PLB (Personal Locator Beacon) for land expeditions.

Figure 1: COSPAS-SARSAT System

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 1

JUN 29/2022

Page 16

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

B. World coverage with the COSPAS-SARSAT system

The major improvement is the use of the COSPAS-SARSAT system for

processing aeronautical emergencies.

The difference with the 121.5 / 243 MHz is that the 406 MHz transmission

carries digital data which enable the identification of the aircraft in distress and

facilitate SAR operation (type of the aircraft, number of passengers, type of

emergency).

The 406 MHz message is transmitted to the COSPAS-SARSAT satellites. This

message is downloaded to one of the 64 ground stations (44 LEOLUTs and 20

GEOLUTS).

The aircraft is located by Doppler effect by the LEO satellites with a precision

better than 2 NM (4 km) at any point of the earth.

C. Environmental improvements of ELTs

The certification of an ELT includes a range of severe mechanical tests:

• resistance to flame;

• impact and crush tests;

• resistance to 100 G and 500 G shocks;

• watertightness;

• antideflagration;

• extreme temperatures (-20°C to 55°C for more than 48 hours).

D. G-Switch (shock detectors)

The shock detectors equipping old automatic ELTs are the cause of a large

number of false alarms. Major work has consisted in studying aircraft crashes

(study made by the “Crash Research Institute”) and evaluating the acceleration

amplitudes involved. As a consequence, G-Switch specifications have been

modified to optimize the accuracy of the crash detection.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 2

JUN 29/2022

Page 17

INSTALLATION MANUAL OPERATION MANUAL

. Power Supply

. Nav System

1

2

465

2

3

System with optional CS144

1

2

3

5

4

BNC Connector

4 wire bundle

AWG 24

Coaxial cable

Max cable loss = 1 dB

(i.e 2 mtrs with RG 58)

System without optional CS144

7

7

KANNAD 406 AP-H

2. KANNAD 406 AP-H Presentation

The KANNAD 406 AP-H belongs to the AP type of ELTs which are intended to

be rigdly attached to the aircraft before the crash, but readily removable from

the aircraft after a crash.

The KANNAD 406 AP-H is designed to be installed on helicopters only

.

The KANNAD 406 AP-H is composed of:

1. a transmitter;

2. a mounting bracket;

3. a remote control panel (mandatory if ELT controls are not available from

the pilot’s position, refer to RTCA/DO-183, RTCA/DO-204, EUROCAE

ED-62);

4. an outside antenna;

5. a “Programming Dongle” for pin-programming function (option);

6. CS144 Interface Module (option);

7. an auxiliary antenna (for use as a survival beacon).

The transmitter, bracket, Programming Dongle and CS144 Interface Module

are installed in the aircraft near the tail. The outside antenna is mounted on the

fuselage near the tail. The remote control panel is installed in the cockpit and

connected to the ELT with a 4 or 5 wire bundle.

© 2022 Orolia S.A.S. All rights are strictly reserved.

Figure 2: ELT system description

PAGE: 3

JUN 29/2022

Page 18

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

3. LINE REPLACEABLE UNITS

A. Transmitter

The KANNAD 406 AP-H is an ELT designed to be installed on board

helicopters to transmit a distress signal on 3 frequencies:

• 406 MHz (COSPAS-SARSAT frequency) for precise pinpointing and

identification of the aircraft in distress.

• 121.5 and 243 MHz used for homing in the final stages of the rescue

operations.

It is certified as an Automatic Portable (AP) ELT and works with a three

frequency outside antenna when installed on board the aircraft or with a small

whip antenna (auxiliary antenna) when used as a survival ELT.

B. Bracket

The bracket installed near the tail is designed to fix the ELT with a Velcro®

strap. This enables quick removal of the ELT for maintenance or exchange.

C. Remote Control Panel

A remote control panel can be supplied for installation in the cockpit in order to

enable the pilot to monitor and control the ELT status.

The following controls are to be found on the panel:

• 3-position switch (ON, ARMED, RESET&TEST);

• red or amber visual indicator;

• beeper (on certain versions).

The remote control panel is connected to the ELT via a 4 or 5-wire cable

equipped with a “Programming Dongle” or a DIN 12 connector on the ELT side

and the connector corresponding to the Remote Control Panel version on the

other side.

D. External antenna

The external antenna, also installed near the tail, can be either rod or blade type

according to aircraft speed.

Connection to the ELT will be carried out with a 50 Ohm coaxial cable (RG58

for example) ended with a BNC connector.

IMPORTANT: Orolia S.A.S. recommends a cable with radio electric

properties similar or better to those of a RG58 cable.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 4

JUN 29/2022

Page 19

INSTALLATION MANUAL OPERATION MANUAL

ANT

ARM OFF ON

RC

KANNAD 406 AP-H

4. Design features

The KANNAD 406 AP-H is made of moulded plastic with excellent mechanical

resistance (ASA/PC, light yellow colour).

The housing is designed with no sharp edges.

Figure 3: KANNAD 406 AP-H with mounting bracket

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 5

JUN 29/2022

Page 20

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

5. Compatibility list

A. Remote control panels (RCP)

Orolia Designation Orolia P/N

RC100 KIT S1820513-03

RC150 KIT S1820513-07

RC200 S1820513-11

RC200-NVG S1820513-14

RC300 S1820513-09

RC400 S1820513-05

RC500-320 S1820513-02

RC600 NVG (Y) S1820513-12

RC600 NVG (W) S1820513-13

RC800 S1820513-15

RC810 S1820513-23

B. DIN-12 connector or programming dongles

Orolia Designation Orolia P/N

DIN-12 connector S1820514-03

Programming dongle S1820514-01

Programming dongle A320 S1820514-04

Programming dongle A330-340 S1820514-05

Programming dongle Assy S1820514-06

C. ELT-NAV System Interface

Orolia Designation Orolia P/N

CS144-RS S1825502-01

CS144-A S1825502-02

Connecting cable for CS144-RS or CS144-A S1825502-03

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 6

JUN 29/2022

Page 21

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

D. External antennas

Orolia Designation Manufacturer Orolia P/N

ANT100 PROCOM 0124206

WHIP ANTENNA AV200 RAMI AV-200 0146150

ROD ANTENNA AV300 RAMI AV-300 0146151

ROD ANTENNA ANT300 CHELTON 1327-82 0124220

ROD ANTENNA ANT410 DAYTON GRANGER ELT

N/A

720063

ROD ANTENNA ANT560 DAYTON GRANGER

0145787

ELT10-696-1

BLADE ANTENNA ANT700 CHELTON 2632-82 1002063

N/A ARTEX 110-340 N/A

N/A HR-SMITH 10-118-32 N/A

NOTE: ANT100 can be only used as auxiliary antenna when the ELT is used

as portable equipment.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 7

JUN 29/2022

Page 22

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

PAGE INTENTIONALLY LEFT BLANK

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 8

JUN 29/2022

Page 23

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

SYSTEM FUNCTIONAL DESCRIPTION AND OPERATION

1. Transmitter

The KANNAD 406 AP-H can be activated either automatically when the crash

occurs (thanks to a shock sensor) or manually (thanks to a switch on the

transmitter itself or on a Remote Control Panel).

The KANNAD 406 AP-H is designed to transmit on three frequencies (121.5,

243 and 406 MHz). The two basic emergency frequencies (121.5 and 243

MHz) are mainly used for homing in the final stages of the rescue operations.

The 406 MHz frequency is used by the COSPAS-SARSAT satellites for precise

pinpointing and identification of the aircraft in distress.

Once activated, the transmitter operates continuously on 121.5 and 243.0 MHz

with an output power of 100 mW on each frequency. The modulation is an audio

frequency sweeping downwards from 1420 Hz to 490 Hz with a repetition rate

of 3 Hz.

During the first 24 hours of operation, a digital message is transmitted on

406.025 MHz every 50 seconds. The output power on 406 MHz is 5 W.

The KANNAD 406 AP-H can transmit two types of messages on 406 MHz:

• 112 bits for a short message (identification only);

• 144 bits for a long message (identification + aircraft position).

The long messages are generated by a separate interface module (called

CS144) connected to the ELT and either NAV equipment of the aircraft by

RS232, RS422 or RS485 link or to an ARINC429 bus.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 101

JUN 29/2022

Page 24

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

2. Controls

The following controls are to be found on the ELT front panel (from left to right):

1. 3-position switch ARM/OFF/ON;

2. Red visual indicator;

3. DIN 12 connector for connection to Remote Control Panel, CS144

interface module, dongle or programming equipment;

4. BNC connector for the antenna.

IMPORTANT: The switches are protected against inadvertent operation

by a locking latch. To operate the switches, the lever shall be pulled to

unlock then set to position.

Figure 101: Front Panel

The red visual indicator gives an indication on the working mode of the beacon:

• after the self test: a series of short flashes indicate the self test failed, one

long flash indicates a correct self test;

• in operating mode: periodic flashes during 121.5 / 243 transmission;

• long flash during 406 transmission.

A buzzer gives audio information on the beacon working:

• continuous tone during self test;

• 2 beeps per second during 121.5 / 243 transmission;

• silence during 406 transmission.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 102

JUN 29/2022

Page 25

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

3. Working mode information

CAUTION: WHEN OPERATING THE ARM/OFF/ON SWITCH, PULL LEVER

TO UNLOCK AND SET TO POSITION.

The KANNAD 406 AP-H has 4 different modes:

•Off.

• Self-test (temporary mode).

• Armed (standby mode to enable automatic activation by the shock sensor

or by the remote control panel).

• On (transmission).

Transmission is effective if the beacon is activated (either manually on the ELT

control panel, remotely by the “ON” switch on the remote control panel or

automatically by the shock sensor).

A. Off

The ELT is off when the switch is in position “OFF”. No part of the ELT is

energized. This mode must only

be selected when the ELT is removed from

the aircraft or parked for a long period or for maintenance.

B. Self-Test

The self-test mode is a temporary mode (max duration 5 sec) in which the ELT

checks the main characteristics of the transmitter (Battery voltage,

Programming) and enables digital communication with a programming and test

equipment.

This mode is selected:

• when switching from “OFF” to “ARM”;

• when switching to “RESET / TEST” on the Remote Control Panel

(provided that the switch of the ELT is in the “ARM” position);

• when switching to “ON” prior to transmission.

The buzzer operates during the self-test procedure.

After about 3 seconds, the test result is displayed on the visual indicator as

follows:

• One long flash indicates valid test.

• A series of short flashes indicates false test result.

The number of flashes indicates the type of failure:

• 3 + 1 = LOW BATTERY VOLTAGE.

• 3 + 2 = LOW TRANSMISSION POWER.

• 3 + 3 = FAULTY VCO LOCKING (FAULTY FREQUENCY).

• 3 + 4 = NO IDENTIFICATION PROGRAMMED.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 103

JUN 29/2022

Page 26

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

It is recommended to test the ELT regularly in order to detect any possible

failure (Refer to A. Periodicity, page 301)

The number of self-tests carried out is recorded. This information is available

when the ELT is connected to a programming and test equipment (PR600).

C. Armed

In order to enable activation by the G-Switch or with the Remote Control Panel,

the ELT must be in standby mode with the switch in the “ARM” position

This mode is mandatory during flight.

The ELT should remain in the “ARM”

position all the time except when the ELT is removed from the aircraft or parked

for a long period or for maintenance.

The Remote Control Panel is energized by the ELT when switched to “ARM”.

D. On

This mode is selected:

• manually by switching to position “ON”;

• by switching the Remote Control Panel switch to position “ON” (provided

that the ELT switch is in the “ARM” position);

• when a crash occurs (provided that the ELT switch is in the “ARM”

position).

When this mode is selected, the ELT starts transmission:

• on 121.5 MHz & 243 MHz immediately (continuous transmission);

• on 406 MHz after 50 seconds (406 burst every 50 sec during 24 hours).

The red visual indicator on the ELT (and on the remote control panel if installed)

flashes and the buzzer operates.

In case of accidental activation, the ELT can be reset either by switching it to

“OFF” or by switching to “RESET” on the Remote Control Panel.

The number of 406 MHz bursts effectively transmitted is recorded. This

information is available when the ELT is connected to a programming and test

equipment (PR600).

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 104

JUN 29/2022

Page 27

4. Endurance

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

The energy is provided by a battery pack composed of 3 LiMnO

D cells (See

2

pages 107 & 602 for Kit battery reference).

Lithium cells, lithium batteries and equipment containing such

batteries are subjected to regulations and classified under class 9 as

from 1st of January 2003.

The endurance of the 121.5/243 transmission is close to 100 hours at -20°C

with new batteries.

In the worse conditions possible, a distress is pinpointed 5.5 hours maximum

after the ELT activation and the position is subsequently updated (if necessary)

every 2 hours.

As it is therefore preferable to keep the battery power for 121.5/243 MHz

homing frequency transmission for the rescue operations, the 406 MHz

transmission is deliberately stopped after 24 hours to extend the 121.5/243

transmission for as long as possible.

The transmitter battery expiry date is fixed at 7 years from date of cell

manufacturing (CDOM). If no activation of the ELT occurs during the battery

lifetime, it shall be replaced before or at battery expiry date

(see note below)

.

NOTE: The expiry date takes into account FAR 91-207 (i.e. batteries to be

replaced when 50 percent of their useful life has expired).

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 105

JUN 29/2022

Page 28

INSTALLATION MANUAL OPERATION MANUAL

5. Electrical characteristics

KANNAD 406 AP-H

Transmitter power supply: 3 x LiMnO

D type cells.

2

A. Electrical interface

When installed on board, the ELT has to be connected:

• to a Remote Control Panel via a DIN12 connector;

• to an external antenna via a BNC connector.

The DIN12 connector is also used to connect a programming dongle, a CS144

interface or a programming and test equipment.

J1

This connector is dedicated for connection to the Remote Control Panel, to the

Programming or Maintenance Dongles, to a CS144 interface and/or to the

programming equipment (PR600).

IMPORTANT: Shielded cables are recommended. The required wires are

AWG24.

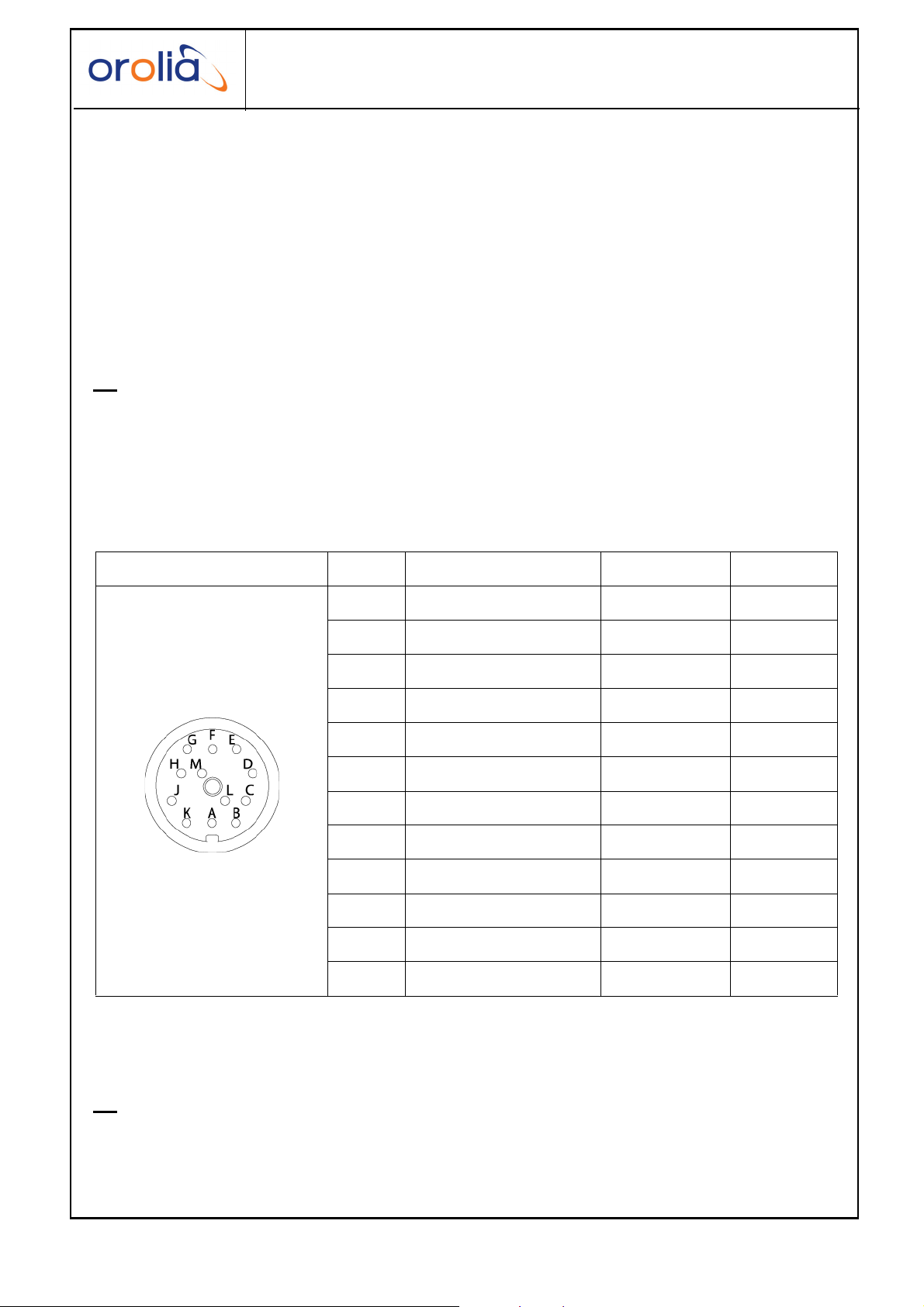

J1 PIN Signal Name Destination Direction

J1-A RCP TEST/RESET RCP IN

J1-B DONGLE RX SMM / PGM IN

Viewed from

Front Face

J1-C DONGLE CS SMM OUT

J1-D DONGLE SK SMM OUT

J1-E DONGLE TX SMM / PGM OUT

J1-F DONGLE ALE2P SMM OUT

J1-G RCP COMMON RCP OUT

J1-H RCP BUZZER RCP(*) OUT

J1-J RCP LED RCP OUT

J1-K RCP ON RCP IN

J1-L DONGLE GND SMM / PGM OUT

J1-M N/C

Table 1: J1 connector pin-out

(*)This wire is not used with some versions of Remote Control Panels. For

precise information, refer to Remote Control Panel technical description.

J2

Connector J2 is used to connect the external antenna through a 50 coaxial

cable for use as fixed ELT or the auxiliary antenna for use as survival ELT.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 106

JUN 29/2022

Page 29

INSTALLATION MANUAL OPERATION MANUAL

6. Technical Specifications

KANNAD 406 AP-H

TYPE

• Three-frequency ELT

(121.5 / 243.0 / 406.025 MHz)

• Automatic fixed

• COSPAS-SARSAT Class 2

(-20°C to +55°C).

406 MHz TRANSMISSION

• Frequency: 406.025 MHz+/-2 kHz

• Output power: 5W (37 dBm +/- 2 dB)

• Modulation type: 16K0G1D (Biphase

L encoding)

• Transmission duration:

440ms (short message) every 50

sec. compatible with long message

transmission (520ms)

• Endurance: Over 24 hours at

-20°C

121,5/243 MHz TRANSMISSION

• Frequencies:

121.5 MHz +/- 6 kHz

243.0 MHz +/- 12 kHz

• Output power:100 to 400 mW

(20dBm to 26 dBm)

for each frequency

• Modulation type: 3K20A3X

• Modulation rate: between 85 and

100%

• Frequency of modulation signal:

1420 Hz to 490 Hz with decreasing

sweep

• Endurance: Over 48 hours at

-20°C

CONTROLS

• ARM / OFF / ON switch

• Bright red visual indicator

• BNC antenna connector

• DIN12 connector for remote control

panel (RCP) and pin programming

option.

•Buzzer

G-SWITCH SENSOR

Mechanical G-switch sensor at 45°

compliant with EUROCAE ED62

specifications.

BATTERY

KIT BAT300, P/N : S1820516-99

3 x LiMnO

D type cells for transmitter

2

power supply

Expiry date: 7 years from date of cell

manufacturing (CDOM)

HOUSING

Material: Molded plastic

Color: Yellow (color compounded)

Transmitter dimensions:

172 mm x 82 mm x 82 mm

Overall dimensions:

max 290 mm x 115 mm x 95 mm

Weight: typical 1235 g / max 1300 g

(including battery)

Tightness: O-rings

ENVIRONMENTAL CONDITIONS

RTCA DO-160D / EUROCAE Ch1 to 25

[D1]XBA[ED62][YLMC]AWXXXXZXXXZ

WL[(A1)(A2)(A3)XX]XXA

Note: chapters 6, 8, 9 & 10 according to

DO160C.

QUALIFICATIONS

ETSO-2C91a & ETSO-2C126

(EUROCAE ED62)

TSO-C91a & TSO-C126 (RTCA DO183 &

DO204)

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 107

JUN 29/2022

Page 30

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

7. Activation

CAUTION: WHEN OPERATING THE ARM/OFF/ON SWITCH, PULL LEVER

TO UNLOCK AND SET TO POSITION.

A. Standby mode for automatic activation

In order to be automatically activated by the crash sensor, the ELT must be in

standby mode. This mode is mandatory during the flight. We recommend to

switch the ELT off only when the aircraft is parked for a long period or for a

maintenance operation.

• Check that the antenna is correctly connected.

• Switch to “ARM”.

To operate the ELT with the Remote Control Panel, ensure that:

• The ELT switch is in the “ARM” position.

B. Manual activation as fixed ELT

• Check that the external antenna is correctly connected.

• Switch to “ON” (either on the ELT or on the Remote Control Panel):

- The ELT starts with the self-test sequence.

- 121.5 / 243 MHz transmission starts immediately after the self-test.

- 406 MHz starts after 50 seconds (406 burst every 50 sec during 24

hours).

- During transmission, buzzer operates and visual indicator flashes.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 108

JUN 29/2022

Page 31

INSTALLATION MANUAL OPERATION MANUAL

ANT

ARM

OFF

ON

RC

OFF

1

3

4

5

6

2

Antenna

2

RCP

KANNAD 406 AP-H

C. Manual activation as survival ELT

The KANNAD 406 AP-H can be used external the aircraft in survival version. A

tether is used to fix the transmitter to a liferaft in case of ditching.

ANT

ARM

OFF

ON

RC

ON

ANT

ARM

OFF

ON

RC

1. Switch to “OFF”.

2. Disconnect the external antenna (ANT) and the Remote Control Panel

(RC).

3. Unfasten the Velcro® strap.

4. Remove the transmitter and the auxiliary antenna from the bracket.

5. Connect the auxiliary antenna (ANT).

6. Switch to “ON”:

IMPORTANT: Put the antenna in a vertical position.

- The ELT starts with the self-test sequence.

- 121.5 / 243 MHz transmission starts immediately after the self-test.

- 406 MHz transmission starts after 50 seconds.

- During transmission, buzzer operates and visual indicator flashes

periodically.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 109

JUN 29/2022

Page 32

INSTALLATION MANUAL OPERATION MANUAL

OFF

ANT

TST

OFF

ON

RC

KANNAD 406 AP-H

8. Reset

CAUTION: WHEN OPERATING THE ARM/OFF/ON SWITCH, PULL LEVER

TO UNLOCK AND SET TO POSITION.

It is possible to stop the ELT in case of unintentional activation.

Regulations state that no transmission must be interrupted unless

every means are used to contact and inform the Air Traffic Controller

of this action.

IMPORTANT: As 406 MHz transmission is effective 50 seconds after the

ELT activation, if it is reset within this delay, no further radio contact will

be necessary.

A. Manual reset

• Switch to “OFF”.

B. Reset with Remote Control Panel

• The switch has to be in the “ARM” position on the ELT.

• Switch to “RESET & TEST” on the remote control panel.

9. Self-Test

Refer to 1. Self-test, page 301

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 110

JUN 29/2022

Page 33

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

INSTALLATION / REMOVAL

CAUTION: WHEN OPERATING THE ARM/OFF/ON SWITCH, PULL LEVER

TO UNLOCK AND SET TO POSITION.

1. Registration and Programming

The ELT must be registered prior to installation on board.

The registration card available from the local registration authority

must be completed and returned to this authority.

The “Programming Datasheet” (DIM0300) must be completed and

returned to your distributor.

Any change of ownership shall also be declared and registered with

the local registration authority and with the distributor.

The KANNAD 406 AP-H is fully compatible with the four programming protocols

defined by the COSPAS-SARSAT C/S G005 document:

• Serialised Number.

• Aircraft 24 bit Address (the same as MODE S ATC or TCAS).

• Aircraft Operator Designator + serialised number up to 4096.

• Aircraft Nationality and Registration marking (Tail Number). This

identification consists of up to 7 alphanumeric characters.

Programming of the ELT can be carried out either:

• by Orolia S.A.S. or the distributor (order must include programming

details).

• in the shop with a programming equipment (PR600 and Kannad e-Prog

software).

• on board the aircraft with a programming equipment or programming

dongle.

This operation takes less than 2 minutes and does not need any hardware

operation. The identification is simply downloaded in the ELT when connected

to the programming equipment via the DIN 12 connector.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 201

JUN 29/2022

Page 34

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

A. Pin programming option

The KANNAD 406 AP-H offers pin-programming capabilities to facilitate

maintenance operations especially in case of removals and/or replacement.

A special DIN 12 connector with a Serial Memory Module (called “Programming

Dongle”) is connected to the ELT when installed on board. This Programming

Dongle contains the identification information of the aircraft and remains on

board the aircraft. When an unprogrammed ELT is installed and connected to

this Programming Dongle and the “ELT” is switched to “ARM”, it automatically

updates its own memory with the identification data contained in the

Programming Dongle memory.

When the ELT is removed from the aircraft, it keeps its identification data.

For maintenance purposes, it is possible to delete the identification information

of the ELT by connecting a “Maintenance Dongle” to the ELT. Any accidental

transmission with this “maintenance dongle” will not involve SAR operation as

the identification code transmitted is recognised by COSPAS-SARSAT as “not

on board”.

When a maintenance dongle is connected:

• Country code is 227 (France).

• Protocol is Test.

• Identification number is SI + 5 digits (the last 5 digits of CSN number) or

K + 6 digits (the 6 digits of the CSN number).

If the pin programming option is selected by the operator, the following

equipment are required:

• a “Programming Dongle” on each aircraft;

• a “Maintenance Dongle” on each ELT spare.

Figure 1: Maintenance Dongle

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 202

JUN 29/2022

Page 35

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

2. ELT Installation

A. Installation recommandations

“The ELT shall not be installed within 60cm (2 ft) of a compass or flux gate.

The distance between ELT and antenna shall be determined so that, according

to the coaxial cable chosen, the cable lost should be

1dB at 400 MHz.

The ELT front panel should be easily accessible to connect the outside antenna

and the remote control panel device and to check the ELT good operation

(controls and lights).”

(1)FAA Recommendations

Installation must be made by qualified personnel in accordance with

FAA regulations. Duplicating a previous installation may not be

acceptable. Refer to:

FAA - Advisory Circular 43.13-2A (Acceptable Methods, Techniques,

and Practices - Aircraft Alterations), specifically, Chapters 1, 2, 11 and

13.

(2) TSO C126a Section 5 b. Application Data Requirements

“The conditions and tests for TSO approval of this article are minimum

performance standards. Those installing this article, on or in a specific

type or class of aircraft, must determine that the aircraft installation

conditions are within the TSO standards. TSO articles must have

separate approval for installation in an aircraft. The article may be

installed only according to 14 CFR part 43 of the applicable

airworthiness requirements”.

(3) RTCA DO-182 Recommendations

“All ELT system components which must survive to a crash

intact,...should be attached to the airframe in such a manner that the

attachment system can support a 100g load... in the plus and minus

directions of the three principal axes of the aircraft.”

(4) RTCA DO-204a Requirements

“The ELT unit shall be mounted to primary aircraft load-carrying

structures such as trusses, bulkheads, longerons, spars or floor beams

(not aircraft skin) or a structure that meets the requirements of the

following test. The mounts shall have a maximum static local deflection

no greater than 2.5 mm when a force of 450 Newtons (l00 lbf) is applied

to the mount in the most flexible direction. Deflection measurements

shall be made with reference to another part of the airframe not less than

0.3 m or more than 1.0 m from the mounting location. Typical

approaches for adding shelf and rail platform mounting provisions to

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 203

JUN 29/2022

Page 36

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

aircraft structure as shown an FAA Advisory circular 43.13-2(), Chapter

2."

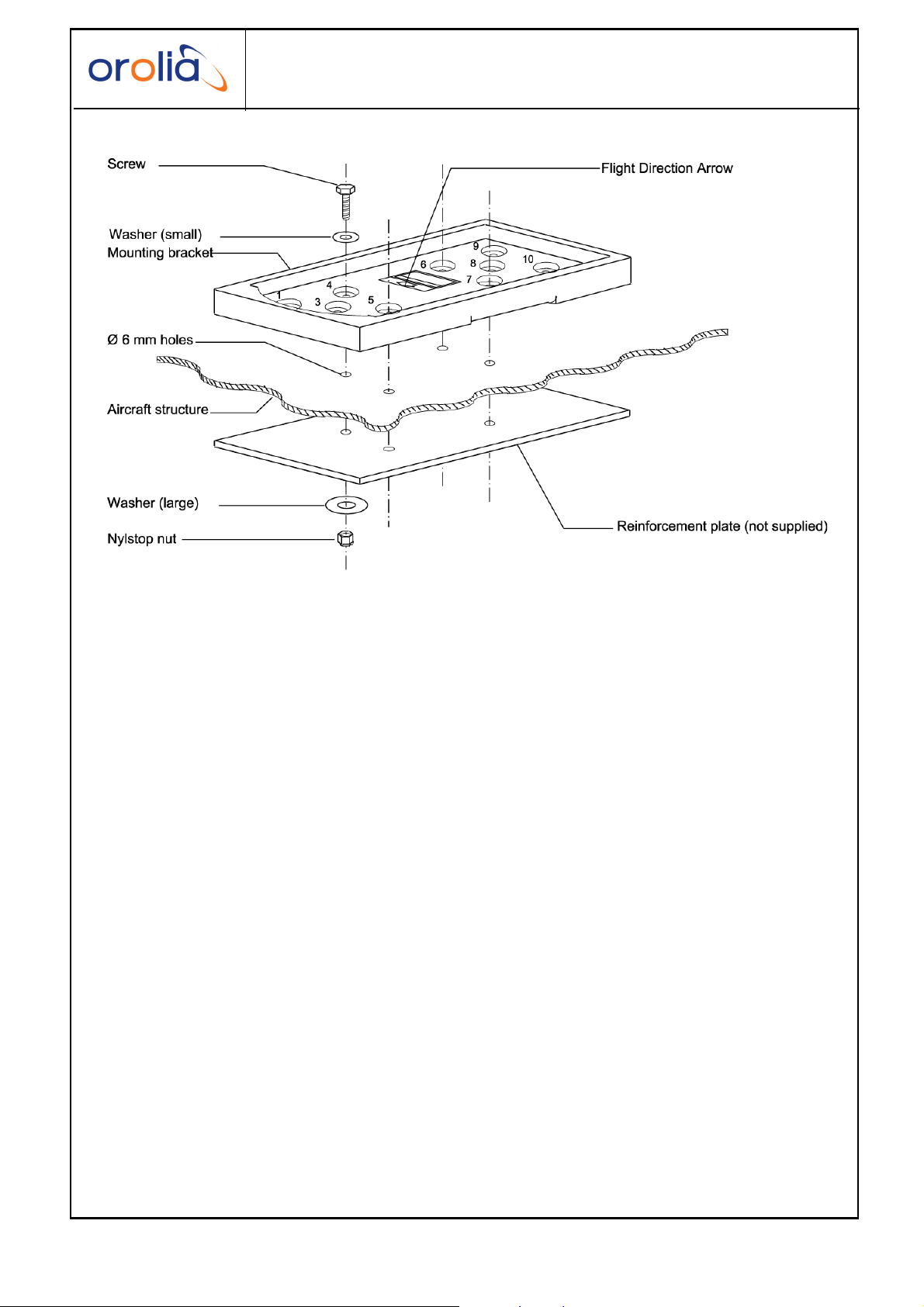

B. Bracket installation

• Determine the location of the ELT on board according to FAR/RTCA

recommendations.

• The G-Switch axis shall be directed to sense the primary crash pulse along

the longitudinal axis of the aircraft. Reference to the G-Switch is given by

the arrow “Sens du Déplacement / Flight direction”.

Figure 2: KANNAD 406 AP-H, installation

IMPORTANT: The KANNAD 406 AP-H is designed to be installed on board

helicopters only.

The “Direction of Flight " arrow shall point towards the front or the bottom of the

helicopter (and not pointing 45° downwards) with maximum tolerance of 15°:

• If the KANNAD 406 AP-H is installed with the “Direction of Flight " arrow

pointing towards the front of the helicopter, the ELT shall be mounted with

the upper side pointing towards the top of the helicopter.

• If the KANNAD 406 AP-H is installed with the “Direction of Flight " arrow

pointing towards the bottom of the helicopter, the ELT shall be installed

with the lower side pointing towards the front of the helicopter.

Drill 4 holes Ø 6 mm in the aircraft structure according to “Drilling mask”. Holes

4,5,6,7 shall be preferred.

If the aircraft structure is not solid enough to withstand a 500 kg traction on the

bracket, a reinforcement plate (not supplied) should be installed as shown

Figure 3: Bracket installation.

Fix the bracket with the 4 screws, 8 washers and 4 nylstop nuts supplied.

IMPORTANT: tighten to a torque between 4 and 5 Newton x meter.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 204

JUN 29/2022

Page 37

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

Figure 3: Bracket installation

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 205

JUN 29/2022

Page 38

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

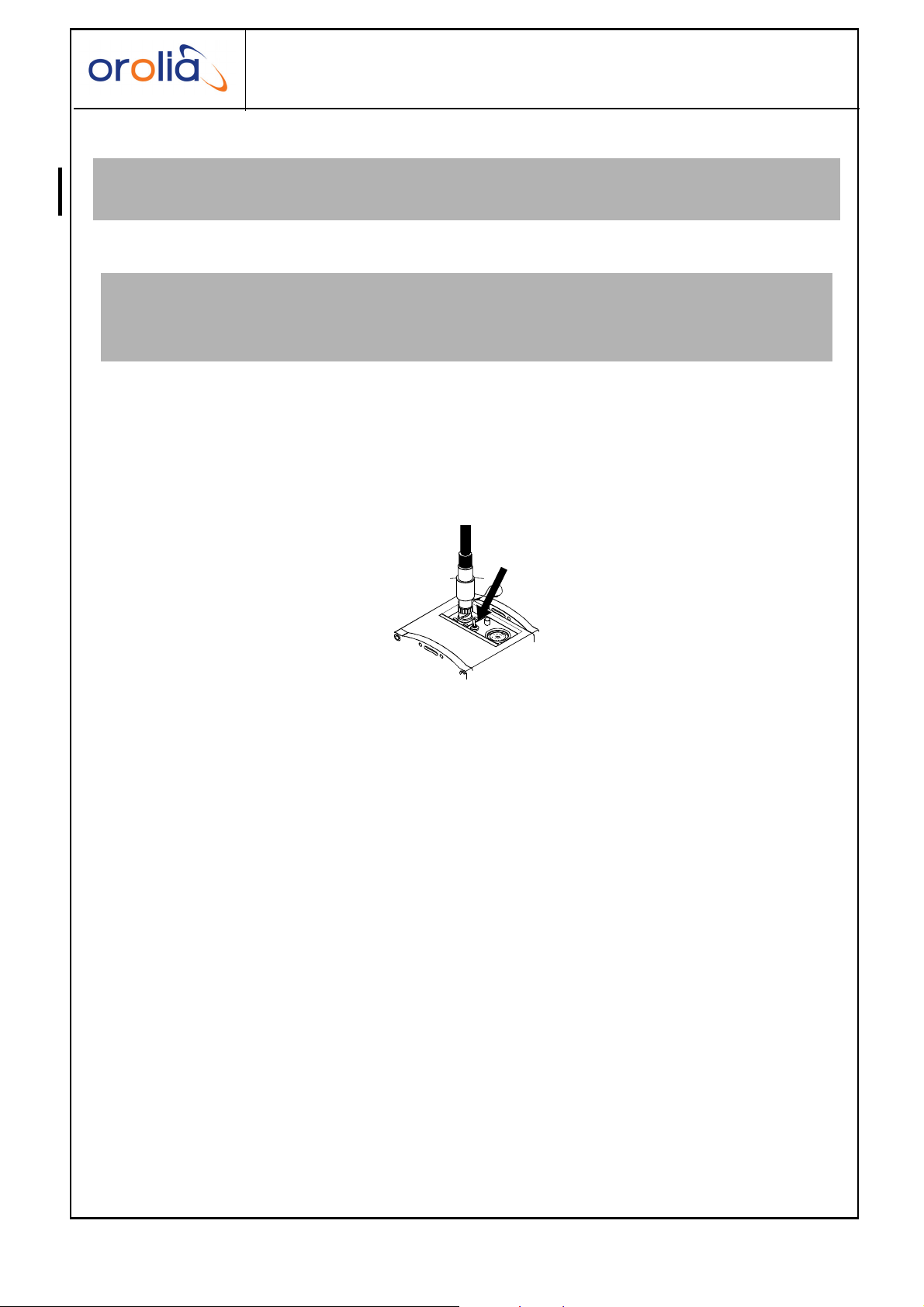

C. Transmitter and auxiliary antenna installation

CAUTION: WHEN OPERATING THE ARM/OFF/ON SWITCH, PULL LEVER

TO UNLOCK AND SET TO POSITION.

• Verify that the ELT identification label matches the aircraft tail number.

• Mount the transmitter on the bracket.

• Slide the self-stripping strap thought the buckle and fasten it tightly.

Figure 204:Installing the transmitter on the bracket

CAUTION: AN INCORRECT TIGHTENING OF THE HOOK AND LOOP

FASTENER COULD LEAD TO AN UNSAFE SITUATION BY THE ELT

PREVENTING THE TRANSMISSION OF THE DISTRESS MESSAGE

IMPORTANT: Once installed in the mounting bracket, the installer must

be sure that the transmitter is firmly attached in its bracket by trying to

extract it manually, thereby verifying there is no play and that it remains

attached when extraction from the bracket is attempted.

• Fold the antenna and slide it under the Velcro® strap.

• Connect the external antenna to the BNC connector (Refer to Figure 5:

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 206

JUN 29/2022

Page 39

INSTALLATION MANUAL OPERATION MANUAL

ARM/OFF/ON

Switch

Remote Control Panel

Connector

Antenna connector

ANT

ARM

OFF

ON

RC

KANNAD 406 AP-H

Installation, controls and connectors) as shown Figure 2: ELT system

description page 3.

NOTE (regarding the external antenna): The specific installation

(tightening torque, etc.) of the external antenna is not covered by this

manual. Refer to antenna manufacturer's instructions. General

instructions for an external antenna installation are detailed 3.

Antenna Installation page 208.

• Connect the Remote Control Panel (or CS144) to the DIN12 connector

(Refer to Figure 5: Installation, controls and connectors) as shown Figure

2: ELT system description page 3.

NOTE: The DIN 12 connector shall be tighten by hand.

• Set the 3-position switch (Refer to Figure 5: Installation, controls and

connectors) to ARM.

Figure 5: Installation, controls and connectors

• Perform the first power up procedure (Refer to 4. First power up, page

210).

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 207

JUN 29/2022

Page 40

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

3. Antenna Installation

The external antenna can be either of whip, rod or blade type according to

aircraft speed. Use only approved antennas.

Connection to the ELT will be carried out with a 50 Ohm coaxial cable (RG58

for example) ended with two male BNC connectors.

A. Antenna Installation Recommendations

(1)FAA Recommendations

Installation must be made by qualified personnel in accordance with FAA

regulations. Duplicating a previous installation may not be acceptable. Methods

for installing antenna are outlined in AC43.13-12, refer to:

FAA - Advisory Circular 43.13-2A (Acceptable Methods, Techniques, and

Practices - Aircraft Alterations), specifically, Chapters 1, 3, 11 and 13.

(2) RTCA DO-204 Requirements for ELT location

“ELT antennas should be located away from other antennas to avoid disruption

of antenna radiation patterns.”

“Idealistically, for the 121.5 MHz ELT antenna, 2.5 meter separation is sufficient

separation from VHF communications and navigation receiving antennas to

minimize unwanted interferences.”

“ELT antennas should be vertically polarized when the aircraft is in the normal

flight attitude.”

“ELT antenna mounting surface should be able to whistand a static load equal

to 100 times the antenna weight applied at the antenna mounting base in all

directions.”

“The antenna should be mounted as close to the respective ELT as applicable.

The proximity of the ELT antenna to any vertically-polarized communications

antenna shall be such as to minimize radio frequency interference and radiation

pattern distorsion of either antenna. Coaxial cable connecting the ELT antenna

installation should not cross the aircraft production breaks and should have

vibrations proof RF connectors on each end. The coaxial connecting the ELT

transmitter to the external Antenna should be secured to the aircraft structure

and when the coaxial cable is installed and the connectors are mated, each end

should be have some slack.”

B. Antenna installation procedure

The antenna must be mounted on the top of the aircraft to assure maximum

visibility of satellites. The upper aft portion of the fuselage should be preferred.

It should be mounted away from projections such as a propeller, tail surfaces,

or the shadow of large antennas. It is the responsibility of the installation

agency to determine the appropriate and adequate antenna installation.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 208

JUN 29/2022

Page 41

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

Locate a position on the fuselage according to Refer to (2) RTCA DO-204

Requirements for ELT location, page 208:

A double plate may be necessary for the antenna to meet rigidity specifications

in Section (2) RTCA DO-204 Requirements for ELT location page 208.

A 9 Kilogram force (20 pound force) applied in all direction should not cause an

appreciable distorsion in the aircraft skin.

Each of the approved antennas requires a ground plane. On fabric-covered

aircraft or aircraft with other types on nonmetallic skins, a ground plane must

be added. This can be accomplished by providing a number of metal foil strips

in a radial position from the antenna base and secured under the fabric or wood

skin of the aircraft. The length of each foil radial should be at least equal to the

antenna length and width at least 1 inch due to the diameter of the antenna. The

ground plane must be connected to the shield of the antenna connector.

Figure 6: Antenna ground plane for non metallic aircraft

According to the antenna to be installed, use the appropriate outline drawings

and drilling masks to determine the hole patern and drill size (Refer to

SCHEMATICS & DIAGRAMS, page 501).

Fabricate a 50 Ohms coaxial cable long enough to reach between the ELT

installation location and the antenna location.

IMPORTANT: The length of the coaxial cable should not exceed 2.7

meters (9 ft) for a standard RG58 or equivalent coaxial cable. If the cable

length exceeds 2.7 meters, a low loss cable of attenuation less than 1

dB@400 MHz must be used (See Important notice, D. External antenna

page 4).

Fit both ends of coaxial cable with a waterproof Male BNC connector (not

supplied), reference RADIALL R141007 or equivalent.

Connect one Male BNC connector to the antenna Female BNC socket.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 209

JUN 29/2022

Page 42

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

4. First power up

CAUTION: WHEN OPERATING THE ARM/OFF/ON SWITCH, PULL LEVER

TO UNLOCK AND SET TO POSITION.

Perform the following tests:

1. ELT operational tests:

• connect RCP to J1 and outside antenna to J2;

• switch the ELT from OFF to ARM;

• check that the Self-Test result is OK (one long flash).

2. RCP operational tests:

Refer to 3. RCP operational tests, page 303.

3. 406 & 121.5 MHz transmission tests (optional):

Refer to 4. 406 and 121.5 MHz transmission test, page 304.

At the end of the first power up procedure, switch the ELT to ARM.

The ELT is now in stand by mode and ready to be activated either automatically

by G-Switch sensor if a crash occurs or manually by RCP (if any).

NOTE : switching to ON directly on the ELT front panel will also activate

the ELT.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 210

JUN 29/2022

Page 43

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

5. Removal

CAUTION: WHEN OPERATING THE ARM/OFF/ON SWITCH, PULL LEVER

TO UNLOCK AND SET TO POSITION.

• Switch the ELT to OFF (Refer to Figure 5: Installation, controls and

connectors).

• Disconnect the Remote Control Panel (or CS144) from the DIN12

connector (Refer to Figure 5: Installation, controls and connectors).

• Disconnect the outside antenna from the BNC connector (Refer to Figure

5: Installation, controls and connectors).

• Unfasten the self-stripping strap.

• Remove the auxiliary antenna.

• Remove the transmitter from the bracket.

Figure 7: Removing the transmitter

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 211

JUN 29/2022

Page 44

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

PAGE INTENTIONALLY LEFT BLANK

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 212

JUN 29/2022

Page 45

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

CHECK

CAUTION: WHEN OPERATING THE ARM/OFF/ON SWITCH, PULL LEVER

TO UNLOCK AND SET TO POSITION.

1. Self-test

A. Periodicity

It is recommended by the manufacturer to test the ELT to detect any possible

failure.

It is recommended to perform a self-test once a month by pilot or maintenance

personnel from the cockpit (Remote Control Panel) but it should not be done

more than once a week.

However, each self-test consumes energy from the battery. Should self-tests

be carried out more often than the maximum allowed, the battery life-time might

be shorter than specified.

Do not perform Self-test without the antenna connected.

B. Self-test procedure

• Check that the antenna is correctly connected.

• Switch from position “OFF” to position “ARM” or press “RESET & TEST”

on the Remote Control Panel (ensure that the ELT switch is in the “ARM”

position).

- The buzzer operates during the whole Self-test procedure.

- After a few seconds, the test result is displayed with the visual indicator

as follows:

• One long flash indicates that the system is operational and that no

error conditions were found.

• A series of short flashes

(see note below)

indicates the test has failed.

If self-test fails, contact the distributor as soon as possible.

Unless a waver is granted, flight should be cancelled.

NOTE: The number of flashes gives an indication of the faulty parameter

detected during the self-test.

3+1 LOW BATTERY VOLTAGE

3+2 LOW RF POWER

3+3 FAULTY VCO LOCKING (FAULTY FREQUENCY)

3+4 NO IDENTIFICATION PROGRAMMED

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 301

JUN 29/2022

Page 46

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

2. ELT operational tests

A. Installation without programming dongle

• connect RCP to J1 and outside antenna to J2;

• switch the ELT from OFF to ARM;

• check that the Self-Test result is OK (one long flash).

B. Installation with Programming Dongle

• connect the outside antenna to J2;

• switch the ELT from OFF to ARM;

• check that the Self-Test fails (3+4 flashes);

• if not, connect a maintenance dongle to J1:

- Switch the ELT from OFF to ARM;

- Check that the Self-Test fails (3+4 flashes);

- Remove the maintenance dongle from J1.

• connect the “Programming Dongle” to J1;

• switch the ELT from OFF to ARM:

the buzzer operates during the whole self-test procedure, after a few

seconds the LED displays the result.

• check that the Self-Test result is OK (one long flash).

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 302

JUN 29/2022

Page 47

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

3. RCP operational tests

Check correct operation of RCP LED and external buzzer by switching ELT and

RCP as described in the sequential procedure hereunder (with ELT switch in

the “ARM” position).

Figure 301: RCP LED and buzzer operation

IMPORTANT: (2) before switching the RCP to ON, wait for the end of the

self-test.

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 303

JUN 29/2022

Page 48

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

4. 406 and 121.5 MHz transmission test

A. ELT-Antenna link

ELT -Antenna link can be checked by testing VSWR.

Orolia S.A.S. recommends the use of SWR3000 VSWR meter manufactured

by PROCOM or IFR 4000 Opt1 manufactured by AEROFLEX.

Refer to manufacturer’s user manual for a VSWR measurement.

B. 406 MHz

This test must be carried out with a COSPAS-SARSAT decoder.

• Perform self-test (Press RESET and TEST on the RCP or switch ELT from

OFF to ARM).

• Check with the COSPAS-SARSAT decoder that, except for the 5th and the

6th digits, the decoded message is identical to the programmed message.

NOTE:The message transmitted during self-test sequence always begins with

FF FE D0 whereas a programmed message begins with FF FE 2F.

Example of message programmed in ELT:

FF FE 2F 53 C3 24 97 38 0B A6 0F D0 F5 20

Example of same message decoded by SARTECH ARG5410:

FF FE D0 53 C3 24 97 38 0B A6 0F D0 F5 20

C. 121.5 MHz

IMPORTANT: this test must only be carried out between H and H+5

minutes. Do not exceed 30 seconds of transmission.

This test must be carried out with a VHF receiver.

• Tune VHF receiver to 121.5 MHz;

• Start transmission:

- either on ELT: ON position;

- or on the RCP: ON position (the ELT shall be in the ARM position);

• Listen to the 121.5 MHz “sweep tone”;

• Stop transmission:

- either on ELT: OFF or ARM position;

- or on the Remote Control Panel: press TEST and RESET (the ELT shall

be in the ARM position).

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 304

JUN 29/2022

Page 49

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

TROUBLESHOOTING

1. General

Procedure for fault isolation on board uses the visual indicator of the ELT’s front

panel. This visual indicator is activated by a self-test capability within the ELT.

Repair and battery replacement can only be carried out by PART 145 /

FAR 145 avionics workshops (or equivalent agreement according to

local regulations).

Additional approval from Orolia is required. Refer to Service Letter SL

S18XX50X-25-02 Maintenance Policy for KANNAD ELTs.

2. Faults on Self-test

A. Visual indicator

When the self-test is carried out, the number of flashes gives an indication of the

faulty parameter detected during the self-test.

(1)3+1 flashes

- Low battery voltage:

Check battery, refer to relevant CMM for tests and repair.

(2) 3+2 flashes

- Low RF power:

Check 406 MHz power, refer to relevant CMM for tests and repair.

(3) 3+3 flashes

- Faulty VCO locking (faulty frequency):

Check 406 MHz frequency, refer to relevant CMM for tests and repair.

(4) 3+4 flashes

- No identification programmed

refer to relevant CMM for tests and repair.

NOTE: for CMM download and other servicing instructions, refer to Service &

Support section of Orolia’s Web site: https://www.orolia.com/support/

3. Other faults detected

A. Buzzer

(1)Buzzer does not operate

- Refer to refer to relevant CMM for tests and repair

(2) Buzzer operates permanently when ELT in ARM mode

- refer to relevant CMM for tests and repair

© 2022 Orolia S.A.S. All rights are strictly reserved.

(see note above)

(see note above)

.

JUN 29/2022

.

PAGE: 401

Page 50

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

PAGE INTENTIONALLY LEFT BLANK

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 402

JUN 29/2022

Page 51

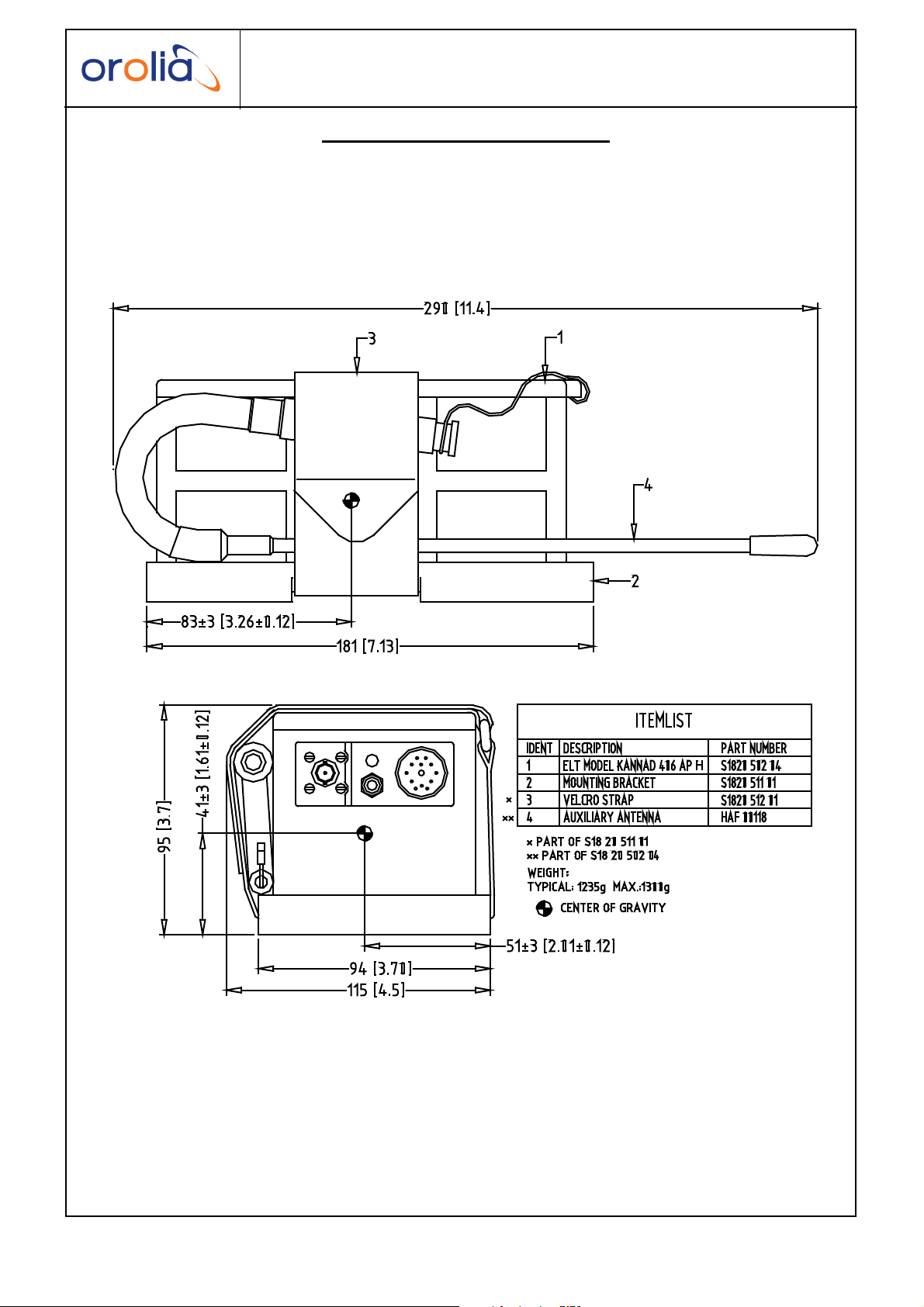

1. Outline Dimensions

Note: all dimensions are in millimeters

(inches in bracket)

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

SCHEMATICS & DIAGRAMS

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 501

JUN 29/2022

Page 52

2. Drilling Mask

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 502

JUN 29/2022

Page 53

3. Wiring

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 503

JUN 29/2022

Page 54

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

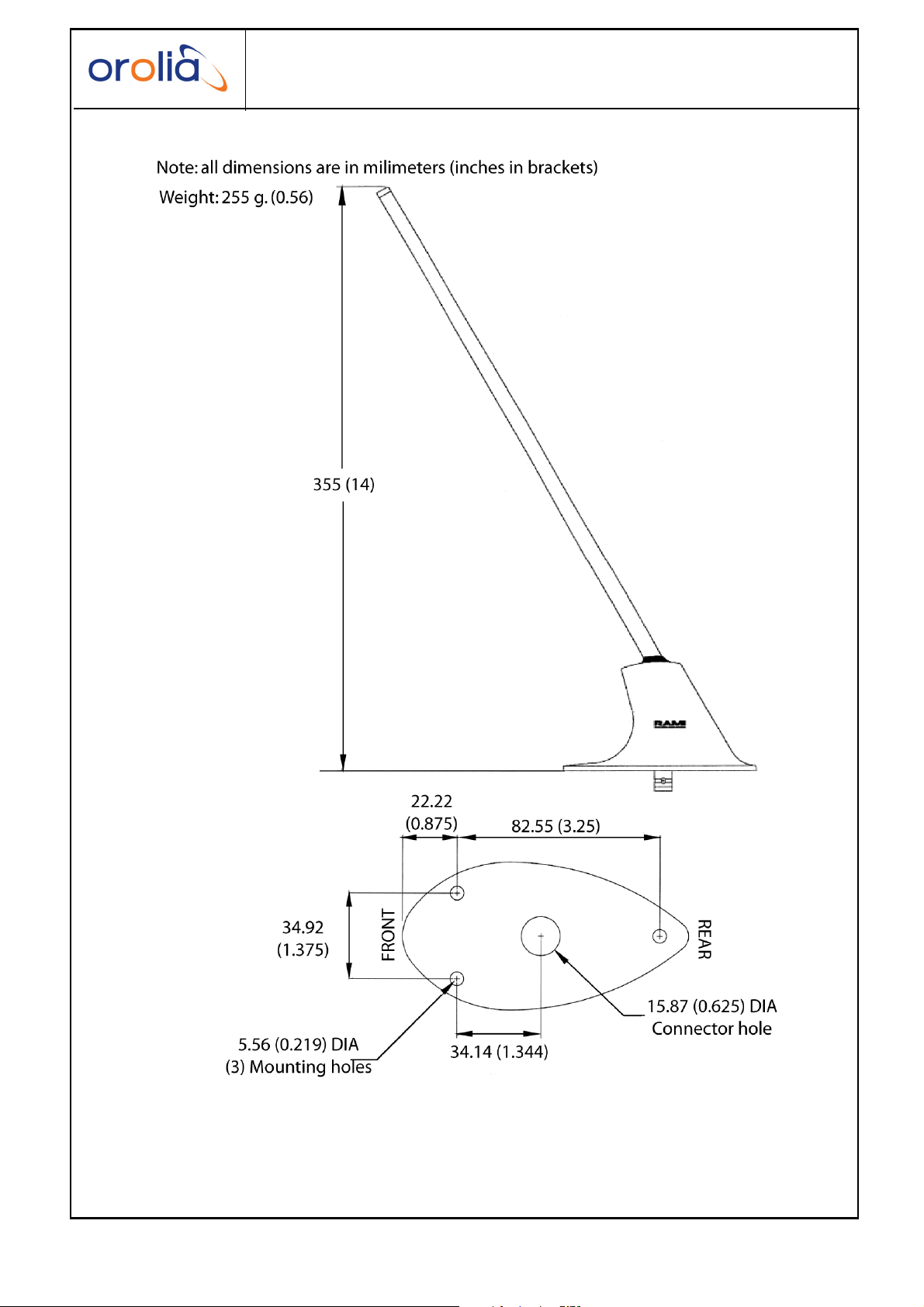

4. ANT AV200, outline dimensions and drilling mask

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 504

JUN 29/2022

Page 55

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

5. ANT AV300, outline dimensions and drilling mask

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 505

JUN 29/2022

Page 56

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

6. ANT300, outline dimensions and drilling mask

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 506

JUN 29/2022

Page 57

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

7. ANT 410, outline dimensions and drilling mask

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 507

JUN 29/2022

Page 58

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

PAGE INTENTIONALLY LEFT BLANK

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 508

JUN 29/2022

Page 59

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

SERVICING

1. Maintenance Schedule

Battery replacement:

carried out by a PART 145 or FAR 145 (or equivalent) maintenance

station as described in Service Letter SL S18XX50X-25-02 Maintenance

Policy for KANNAD ELTs.

Periodic inspection

:

depending if the ELT is opened or not, PART 145 or FAR 145 (or

equivalent) may be required. Refer to local regulations

A. Periodic inspection

Note: (if required by the relevant Civil Aviation Authority).

Some Civil Aviation Authorities may require the ELT be tested periodically.

In this case, refer to Service Letter SL S18XX50X-25-12 “Guidelines for

periodic inspection” available on the Support section of Orolia website.

B. Battery replacement

Testing of the various elements of the ELT is mandatory when the battery is

replaced:

• For battery replacement intervals, Refer to 2. Battery replacement

requirements, page 602.

• The testing procedure associated with the battery replacement is

described in the level 2 CMM 25-63-05.

For CMM download and other servicing instructions, refer to the Support

section of Orolia website: https://www.orolia.com/support/

© 2022 Orolia S.A.S. All rights are strictly reserved.

.

PAGE: 601

JUN 29/2022

Page 60

INSTALLATION MANUAL OPERATION MANUAL

KANNAD 406 AP-H

2. Battery replacement requirements

Battery replacement is mandatory:

• after more than 1 hour of real transmission (cumulated duration);

• before or on the battery expiration date;

• after use in an emergency;

• after an inadvertent activation of unknown duration.

Only original and approved battery pack included in battery KIT

BAT300 supplied by Orolia S.A.S. can be installed.

The battery replacement can only be carried out by a Kannad Approved

Service Center.

For more information, refer to Kannad ELT Maintenance Policy

available on Orolia website.

Orolia S.A.S. refuses all responsibility and invalidates all warranty

should unapproved maintenance be carried out.

List of KANNAD Battery Replacement Center is available on our Website:

https://www.orolia.com/support/

Orolia S.A.S.

Z.I. des Cinq Chemins CS10028

56520 GUIDEL - FRANCE

Telephone: +33 (0)2 97 02 49 49

Web: https://www.orolia.com

Support: https://www.orolia.com/support/

© 2022 Orolia S.A.S. All rights are strictly reserved.

PAGE: 602

JUN 29/2022

Page 61

© 2022 Orolia S.A.S. All rights are strictly reserved.

Page 62

Distributed by

Manufactured by

Z.I. des Cinq Chemins CS10028

56520 GUIDEL - FRANCE

Phone: +33 (0) 2 97 02 49 49

Web: https://www.orolia.com

DOC06330F

© 2022 Orolia S.A.S. All rights are strictly reserved.

Orolia S.A.S

Loading...

Loading...