Page 1

P/N 9310 1015 0001F rev. 1.00

© 2006 Aviom, Inc.

User Guide

Page 2

ii

Trademarks

Aviom and the Aviom logo are trademarks of Aviom, Inc.

A-Net and the A-Net logo are trademarks of Aviom, Inc.

Pro16, Pro64, and Virtual Data Cables are trademarks of Aviom, Inc.

All other trademarks are the property of their respective owners.

Information in this document is subject to change without notice.

Copyright ©2006 Aviom, Inc.

Printed in USA

Certifications

ETL/cETL Listed

EMC: EN 55103-1, EN 55103-2, SAA AS/NZS 1053

Conforms to: IEC 60065, EN 60065, UL 60065

Certified to: CAN/CSA E60065, KETI

RoHS Status: Pb-free

Notice of Rights

All rights reserved. No part of this document may be reproduced or

transmitted in any form or by any means—electronic, mechanical,

photocopy, recording, or otherwise—without written permission of

Aviom, Inc.

Page 3

iii

NO USER SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL ONLY

To reduce the risk of fire or electrical shock, do not expose

this product to rain or other types of moisture.

Operating Temperature: 10˚C to 50˚C (50˚F to 122˚F)

•

•

WARNING!

!

CAUTION:

Using any audio system at high volume levels

can cause permanent damage to your hearing.

Set your system volume as low as possible.

Avoid prolonged exposure to excessive sound

pressure levels.

•

•

•

IMPORTANT:

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and

receiver.

Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician

for help.

Changes or modifications to the product not expressly approved by Aviom,

Inc. could void the user’s FCC authority to operate the equipment.

•

•

•

•

CAUTION

Risk of electric shock!

Do Not Open

WARNING!

To reduce the risk of fire or

electric shock do not expose

this product to rain or moisture.

AVIS: Risque de choc electrique!

Ne pas ouvrir

Page 4

iv

Important Safety Instructions

Read these instructions.

Keep these instructions

Heed all warnings.

Follow all instructions.

Do not use this apparatus near water.

Clean only with a dry cloth.

Do not block any ventilation openings. Install in accordance

with the manufacturer’s instructions.

Do not install near any heat sources such as radiators, heat

registers, stoves, or other apparatus (including amplifiers) that

produce heat.

Do not defeat the safety purpose of the polarized or groundingtype plug. A polarized plug has two blades with one wider than

the other. A grounding type plug has two blades and a third

grounding prong. The wide blade or third prong is provided

for your safety. If the provided plug does not fit your outlet,

consult an electrician for replacement of the obsolete outlet.

Protect the power cord from being walked on or pinched,

particularly at plugs, convenience receptacles, and the point

where they exit the apparatus.

Only use attachments/accessories specified by the

manufacturer.

Use only with the cart, stand, tripod, bracket, or table specified

by the manufacturer, or sold with the apparatus. When a

cart is used, use caution when moving the cart/apparatus

combination to avoid injury from tip-over.

Unplug this apparatus during lightning storms or when unused

for long periods of time.

Refer all servicing to qualified personnel. Servicing is required

when the apparatus has been damaged in any way, such as

when the power-supply cord or plug is damaged, liquid has

been spilled or objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture, the unit does

not operate normally, or it has been dropped.

The solid line over dashed line symbol ( ) indicates

that the input voltage must be a DC voltage.

The box within a box symbol ( ) indicates that the external

power supply is double insulated.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

Page 5

v

Warranty Information

Please record the following information for future reference:

Your Authorized Aviom Dealer:

Name:

Address:

Phone:

Serial Number of Your Aviom Product:

Date of Purchase:

Your Authorized Aviom Dealer is your primary source for service

and support. The information recorded above will be helpful in

communicating with your Authorized Aviom Dealer should you need to

contact Aviom Customer Service. If you have any questions concerning

the use of this unit, please contact your Authorized Aviom Dealer

first. For additional technical support, check the Aviom website at

www.Aviom.com.

To fulfill warranty requirements, your Aviom product should be serviced

only at an authorized Aviom service center. The Aviom serial number

label must appear on the outside of the unit, or the Aviom warranty is

void.

This manual and its contents are copyrighted by Aviom, Inc. All rights

are reserved by Aviom, Inc. This document may not, in whole or in part,

be copied, photocopied, reproduced, translated, or reduced to any

electronic medium or machine-readable form without prior written

consent from Aviom, Inc.

The software and/or firmware contained within Aviom products is

copyrighted and all rights are reserved by Aviom, Inc.

Although every effort has been made to ensure the accuracy of the text

and illustrations in this manual, no guarantee is made or implied as to

the accuracy of the information contained within.

Page 6

vi

Aviom, Inc. Limited Warranty

Aviom, Inc. warrants this product against defects in materials and workmanship

for a period of one year from the date of the original retail purchase.

This warranty does not apply if the equipment has been damaged due to

misuse, abuse, accident, or problems with electrical power. The warranty also

does not apply if the product has been modified in any way, or if the product

serial number has been damaged, modified, or removed.

If a defect is discovered, first write or call Aviom, Inc. to obtain a Return

Authorization number. No service will be performed on any product returned

without prior authorization. Aviom, Inc. will, at its discretion, repair or replace the

product at no charge to you. The product must be returned during the warranty

period, with transportation charges prepaid to Aviom, Inc., 1157 Phoenixville

Pike, Suite 201, West Chester, PA 19380, USA. You must use the product’s original

packing materials for shipment. Shipments should be insured for the value of

the product. Include your name, address, phone number, description of the

problem, and copy of the original bill of sale with the shipment. The Return

Authorization number should be written on the outside of the box.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE

OTHER RIGHTS, WHICH VARY FROM STATE TO STATE (OR JURISDICTION TO

JURISDICTION). AVIOM’S RESPONSIBILITY FOR MALFUNCTIONS AND DEFECTS

IN HARDWARE IS LIMITED TO REPAIR AND REPLACEMENT AS SET FORTH IN THIS

LIMITED WARRANTY STATEMENT. ALL EXPRESS AND IMPLIED WARRANTIES FOR

THE PRODUCT, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN

DURATION TO THE WARRANTY PERIOD SET FORTH ABOVE. NO WARRANTIES,

WHETHER EXPRESS OR IMPLIED, WILL APPLY AFTER SUCH PERIOD.

AVIOM, INC. DOES NOT ACCEPT LIABILITY BEYOND THE REMEDIES SET FORTH

IN THIS LIMITED WARRANTY DOCUMENT. AVIOM, INC.’S LIABILITY IS LIMITED TO

THE REPAIR OR REPLACEMENT, AT OUR OPTION, OF ANY DEFECTIVE PRODUCT,

AND SHALL IN NO EVENT INCLUDE INCIDENTAL OR CONSEQUENTIAL DAMAGES

OF ANY KIND.

SOME STATES DO NOT ALLOW EXCLUSIONS OR LIMITATION OF IMPLIED

WARRANTIES OR LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Page 7

vii

Table of ConTenTs

Warranty Information . . . . . . . . . . . . . . . . . . . . vi

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . 1

The EtherCon Connector . . . . . . . . . . . . . . . . 1

Cat-5e . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operating System Update. . . . . . . . . . . . . . . . 2

About A-Net . . . . . . . . . . . . . . . . . . . . . . . . . 3

Clocking . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Data . . . . . . . . . . . . . . . . . . . . . . 4

A-Net Ports . . . . . . . . . . . . . . . . . . . . . . . 4

Support For Pro16 Series Products . . . . . . . . . . . 5

AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AC Line Conditioning . . . . . . . . . . . . . . . . . . . . 6

Rack Mounting. . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Front Panel Components . . . . . . . . . . . . . . . . . . 8

Rear Panel Components . . . . . . . . . . . . . . . . . . . 9

Front Panel Features . . . . . . . . . . . . . . . . . . . 10

Network Mode Indicator . . . . . . . . . . . . . . . 10

A-Net Port LEDs . . . . . . . . . . . . . . . . . . . 11

A-Net LED . . . . . . . . . . . . . . . . . . . . . . 11

Managed Mode LED . . . . . . . . . . . . . . . . . 12

Rear Panel Features . . . . . . . . . . . . . . . . . . . . 13

AC Power . . . . . . . . . . . . . . . . . . . . . . . 13

Fuse . . . . . . . . . . . . . . . . . . . . . . 13

A-Net Ports . . . . . . . . . . . . . . . . . . . . . . 13

Manual Mode Configuration Button . . . . . . . . . 14

MH10 Configurations . . . . . . . . . . . . . . . . . . . 15

Auto Mode . . . . . . . . . . . . . . . . . . . . . . 15

Manual Mode . . . . . . . . . . . . . . . . . . . . 16

Configuration A (Merge All) . . . . . . . . . . 16

Configuration B (Merge 1-9) . . . . . . . . . . 16

Configuration C (Merge 1-8) . . . . . . . . . . 18

MH10 Configuration Errors . . . . . . . . . . . . . . 21

Data Loops . . . . . . . . . . . . . . . . . . 21

Changing from Manual Mode to Auto Mode . . 21

Specifications . . . . . . . . . . . . . . . . . . . . . . . 22

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 23

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 8

viii

Page 9

1

A

bout Your Pro 64 Produc t

Welcome

Thank you for purchasing the MH10 Merger Hub. This User Guide

is designed to familiarize you with the features and functions of your

new Pro64™ product. In developing the Aviom Pro64 Series product

line, we have made every effort to make the user interface as easy to

use and understand as possible. We encourage you to read the manual

completely, as some of the powerful features of your new product may

not be immediately apparent.

Features

The MH10 Merger Hub is designed to merge and distribute A-Net®

data streams and provides a host of professional features designed to

make audio networking with Pro64 Series products easy to set up and

configure in a variety of professional audio situations.

MH10 Merger Hub features:

Ten bidirectional A-Net ports

EtherCon® RJ45 network connectors

Three Manual Mode configurations

Multiple MH10 Merger Hubs can be used when creating a Pro64 audio

network.

The EtherCon Connector

Pro64 Series products feature locking connectors for all network I/O.

The Neutrik® EtherCon connector is a dual RJ45-type connector that can

receive a standard Category 5e cable or a cable fitted with the special

locking EtherCon connector.

When using a standard Cat-5e cable, plug the cable into the center of

the EtherCon jack; release the cable by pressing on the small plastic tab

built into the cable connector.

The locking EtherCon connector is similar to an XLR plug, the kind

commonly used on microphone cables. Insert an EtherCon-equipped

cable into the jack until it clicks and locks in place. To remove the cable,

press on the metal release tab at the top of the panel-mounted EtherCon

jack and pull the connector outward.

•

•

•

Page 10

2

A

bout Your Pro 64 Produc t

Cat-5e

All Cat-5e connections between A-Net devices should use Unshielded

Twisted Pair (UTP) cable. The cable can be of the stranded or solid type;

solid wire performs better over long distances while stranded wire is

more flexible and easier to manipulate and therefore easier to work

with in a performance situation.

Cables designated as Cat-5e in Pro64 documentation can be

interchanged with any Cat-6 (or better) cable. Cables will be referred to

simply as “Cat-5e.”

Connectors on Cat-5e cables can be of the standard RJ45 variety or of

the locking Neutrik EtherCon type.

Operating System Update

The Pro64 operating system can be updated in the field using a PC and

the Pro64 Update Tool. Modules can be updated over A-Net, while part

of an active audio network, or in local mode where no other modules

are connected at the time the update is being performed (such as may

be required for a bench configuration when setting up modules prior to

installation).

Updating a module requires the Aviom Pro64 Update Tool application, a

PC host computer with RS-232 connection capability, a null modem DB9

cable, and the update file for the particular Pro64 device being updated.

Refer to the Aviom web site for information about the availability of the

latest software upgrades and feature updates.

The MH10 must be connected to another Pro64 device with Virtual Data

Cable capability in order to be updated.

Page 11

3

A

bout A-Net

About A-Net

Aviom’s A-Net® is the only networking technology conceived, designed,

and optimized for managing and distributing audio using ordinary

Cat-5e cables. As implemented in the Pro64™ Series products, A-Net

can transmit up to 128 channels of uncompressed 24-bit audio with the

reliability and fidelity of analog, and the power and flexibility of a true

digital network.

Pro64 A-Net allows variable sample rates in three ranges, from 44.1kHz±

to 192kHz±, with ultra-low latency, jitter, and wander. Pro64 devices can

be connected in any combination of serial (daisy-chain) or parallel (star)

topologies. Cable runs between Pro64 devices can be up to 400 feet

(120 meters) on Cat-5e1, and miles on fiber optics (Aviom fiber-capable

equipment).

Because A-Net is designed specifically for audio, the technological

limitations of Ethernet and Ethernet-based products are removed,

while audio performance and system flexibility are increased. A-Net

incorporates Aviom’s unique patented and patent-pending algorithms

for controlling clock jitter and wander, as well as system-wide latency—

regardless of an installation’s size, design, or clocking setup. A-Net

offers significant advantages in fidelity, performance, and flexibility

over Ethernet-based products.

A-Net uses the “physical” layer of Ethernet, but it eliminates all the

protocol elements that are designed for computers and IT-style

networking. In audio applications, these other layers reduce efficiency,

impose system restrictions, and introduce latency and timing instability.

By eliminating Ethernet data structures, A-Net creates a superior

network, with enhanced audio performance. With A-Net and the

Pro64 Series, Aviom continues to break new ground in the design and

development of innovative digital audio networking technologies and

solutions.

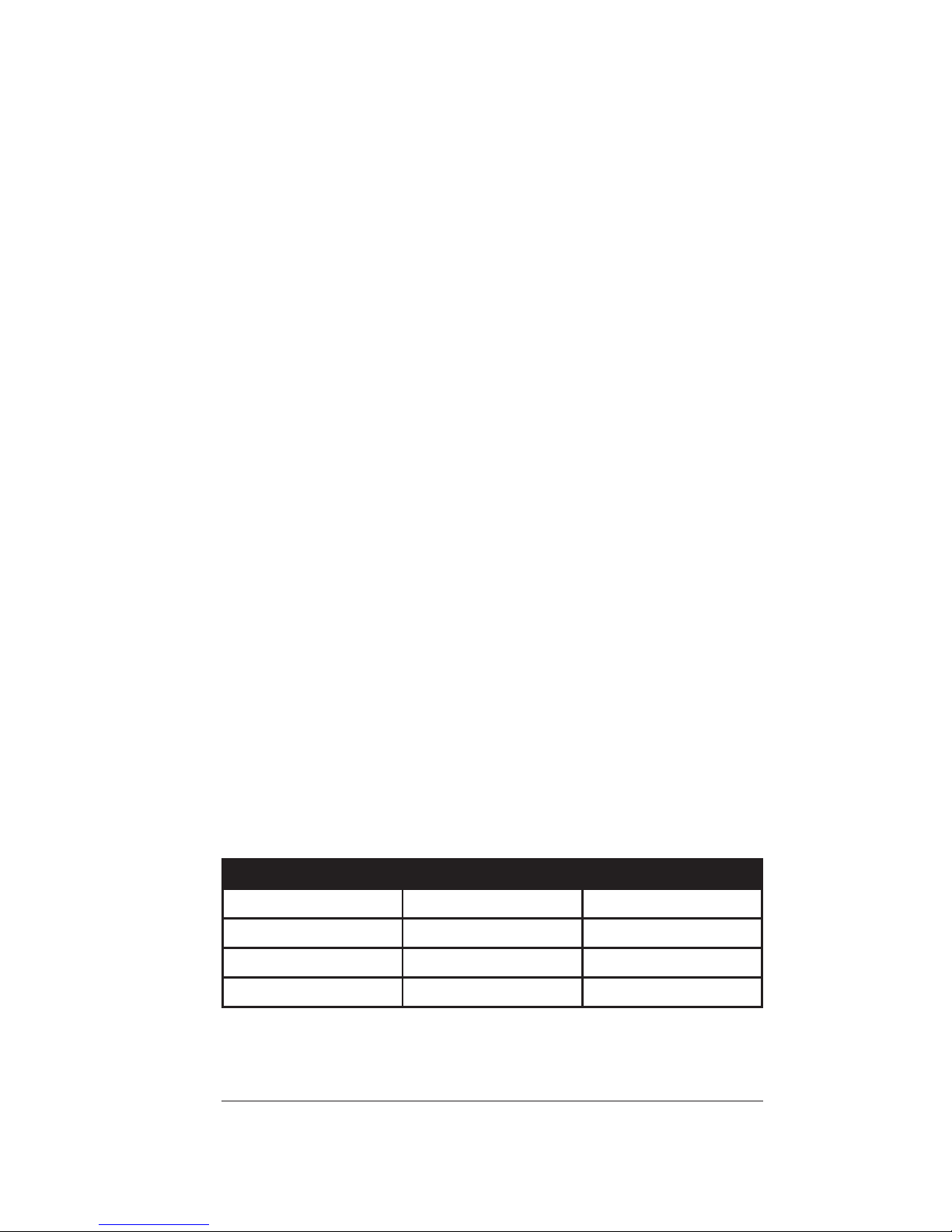

Pro64 Series Supported Sample Rates

Sample Rate Minimum Maximum

1x 44.1/48kHz

39.7kHz 52kHz

2x 88.2/96kHz

79.4kHz 104kHz

4x 176.4/192kHz

158.8kHz 208kHz

1 Cat-5e, Cat-6, or better, Unshielded Twisted Pair (UTP) cable

Page 12

4

A

bout A-Net

Clocking

The Pro64 network offers the most flexible clocking and synchronization

options in the industry. Pro64 devices support three ranges of variable

sample rates, from 44.1/48kHz± to 192kHz±. Because no sample rate

converters are used, audio transmission is kept fast and clean, eliminating

the audio artifacts and signal degradation inherent to sample rate

conversion—even when syncing to an external clock source.

Any Pro64 I/O module can be designated the clock master for the

network, either generating and distributing its internal clock, or syncing

to and distributing an external clock.

Control Data

The Pro64 Series has built-in, dedicated bandwidth for 14 channels of

non-audio control data through the use of Aviom’s innovative Virtual

Data Cables™. These data streams are always available to carry MIDI,

RS-232, or GPIO (General Purpose I/O), and they never compete with

the audio channels for network resources, regardless of the system

configuration.

Because VDC™ inputs are simply incorporated into the A-Net stream,

these control signals can be transmitted over very long cable runs

and even across an entire Pro64 network, significantly expanding the

applications possible with MIDI, RS-232, and GPIO. And as with audio

signals, VDC control data can be input anywhere and output anywhere

else in the network.

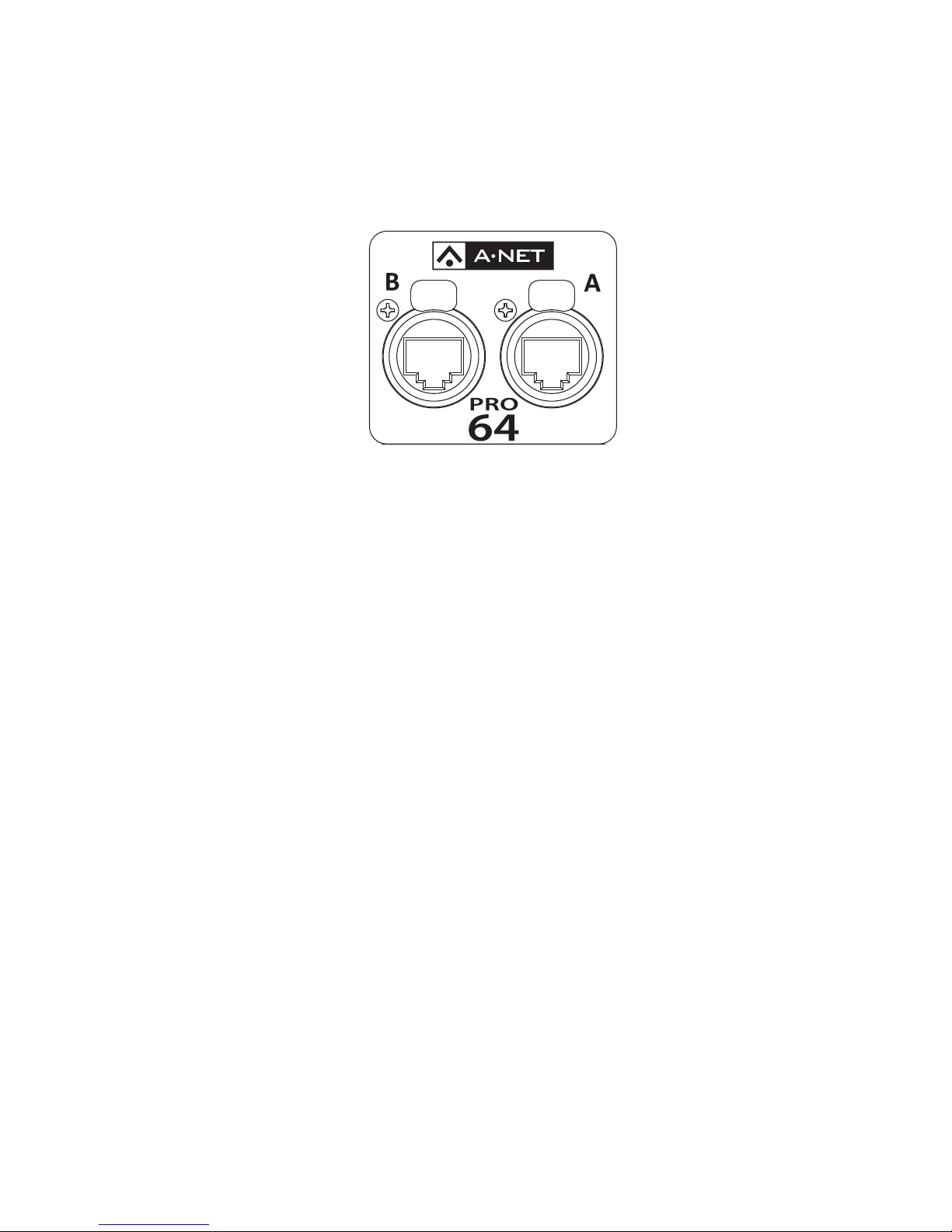

A-Net Ports

Pro64 I/O modules have dual A-Net ports, labeled A and B. Both ports

carry a bidirectional A-Net stream at all times. (That is, both ports are

always transmitting and receiving A-Net data.) Pro64 networks can be

configured in one of two operational modes, Auto Mode or Manual

Mode, depending on the requirements of a particular system.

In Auto Mode, there are no connection rules; connect a Cat-5e cable to

either the A or B port and the system does the rest. Auto Mode provides

a true audio network with 64 available “Slots” for transporting audio (at

44.1/48kHz). Every audio Slot is available everywhere in the system, with

no upstream/downstream restrictions.

In Manual Mode, the Pro64 network becomes a 64x64 system (at 48kHz),

similar to a traditional stage-to-FOH snake. At every point in the Manual

Mode network, two 64-channel streams are available on the cable and

in each module. The configuration of the cables and ports has an impact

Page 13

5

A

bout A-Net

on the makeup of the network and the distribution of audio signals. The

user can direct A-Net data from an input module to a specific port (A,

B, or both). Output modules can be configured to output audio signals

from a specific port (A or B).

Support For Pro16 Series Products

Pro64 Series products can be combined with Pro16™ Series output

products such as the Pro16 Monitor Mixing System by adding the Pro64

ASI A-Net Systems Interface. This 1U module converts Pro64 data to

Pro16 data, providing up to four streams of 16-channel data (depending

on the Pro64 sample rate) that can be used with A-16II and A-16R

Personal Mixers, A-Net Distributors, and AN-16/o Output Modules. (The

ASI is not compatible with the A-Net output of Pro16 input devices such

as the AN-16/i and AN-16/i-M and console interface cards such as the Y1

and D-16c. )

Page 14

6

M

AiNtAiNi Ng Your Pro64 Pro duct

AC Power

Always plug the unit into a properly grounded (earthed) outlet. Always

use the AC line cord that was shipped with the unit. Grasp the power

cable by the connector and never by the cord itself when connecting

and disconnecting it from the power source.

Do not expose the Pro64 device to moisture, rain, or excessively damp

environments.

AC Line Conditioning

Aviom products are digital devices and as such are sensitive to sudden

spikes and drops in the AC line voltage. Changes in the line voltage

from lightning, power outages, etc. can sometimes damage electronic

equipment.

To minimize the chance of damage to your equipment from sudden

changes in the AC line voltage, you may want to plug your equipment

into a power source that has surge and spike protection. Power outlet

strips are available with built-in surge protection circuits that may help

protect your equipment.

Other options for protection of your equipment include the use of an

AC line conditioner or a battery backup system (sometimes referred to

as an uninterruptible power supply, or UPS).

Rack Mounting

Pro64 products are designed to be mounted in a 19-inch equipment

rack. The rack ears on each side of the device are designed to support

the weight of the product without additional hardware. Each rack ear

contains holes for two screws per side. Always support the unit with all

four screws to avoid damage to the unit.

To rack mount the Pro64 product, position it in the equipment rack at

the desired location. Use standard rack-mounting screws (10-32 size) to

attach the unit to your rack hardware. Tighten all four screws firmly, but

avoid overtightening.

Aviom suggests the use of non-metallic washers between the rackmounting screws and the device’s finished surface to avoid marring the

finish on your Aviom products.

Page 15

7

M

AiNtAiNi Ng Your Pro64 Pro duct

Ventilation

Always allow adequate ventilation for devices mounted in equipment

racks. Avoid placing your Pro64 product directly above or below other

rack-mounted devices that produce high levels of heat, such as power

amplifiers.

Cleaning

Before cleaning a Pro64 product, turn off the power switch and unplug

the unit from the AC power source.

To clean the surface of the Pro64 product use a clean, soft lint-free cloth

that has been slightly moistened with water only. For tougher dirt, use a

cloth slightly dampened with water or with a mild detergent. Always be

sure to dry the surface of the unit before proceeding with use.

When cleaning your Aviom products, never spray cleaners directly onto

the product surfaces. Instead, spray a small amount of the cleaning

solution onto a clean cloth first. Then use the dampened cloth to clean

the product.

Never use solvents or abrasive cleaners on the finished surfaces of your

Aviom products.

Page 16

8

F

roNt PANel co MPoNeNts

Front Panel Components

Auto Mode LED

Manual Mode LED

Manual Mode configuration (A, B, C) indicator

Active A-Net port LED

A-Net LED

Managed Mode LED

1.

2.

3.

4.

5.

6.

Page 17

9

r

eAr PANel coM PoNeNts

Power On/Off Switch

IEC Power Inlet

Fuse Holder

A-Net ports, EtherCon connectors

Manual Mode configuration selector button

Manual Mode configuration LED

1.

2.

3.

4.

5.

6.

Rear Panel Components

Page 18

10

F

roNt PANel Fe Atures

Front Panel Features

This section describes the features and functions of all front-panel

components of the MH10 Merger Hub.

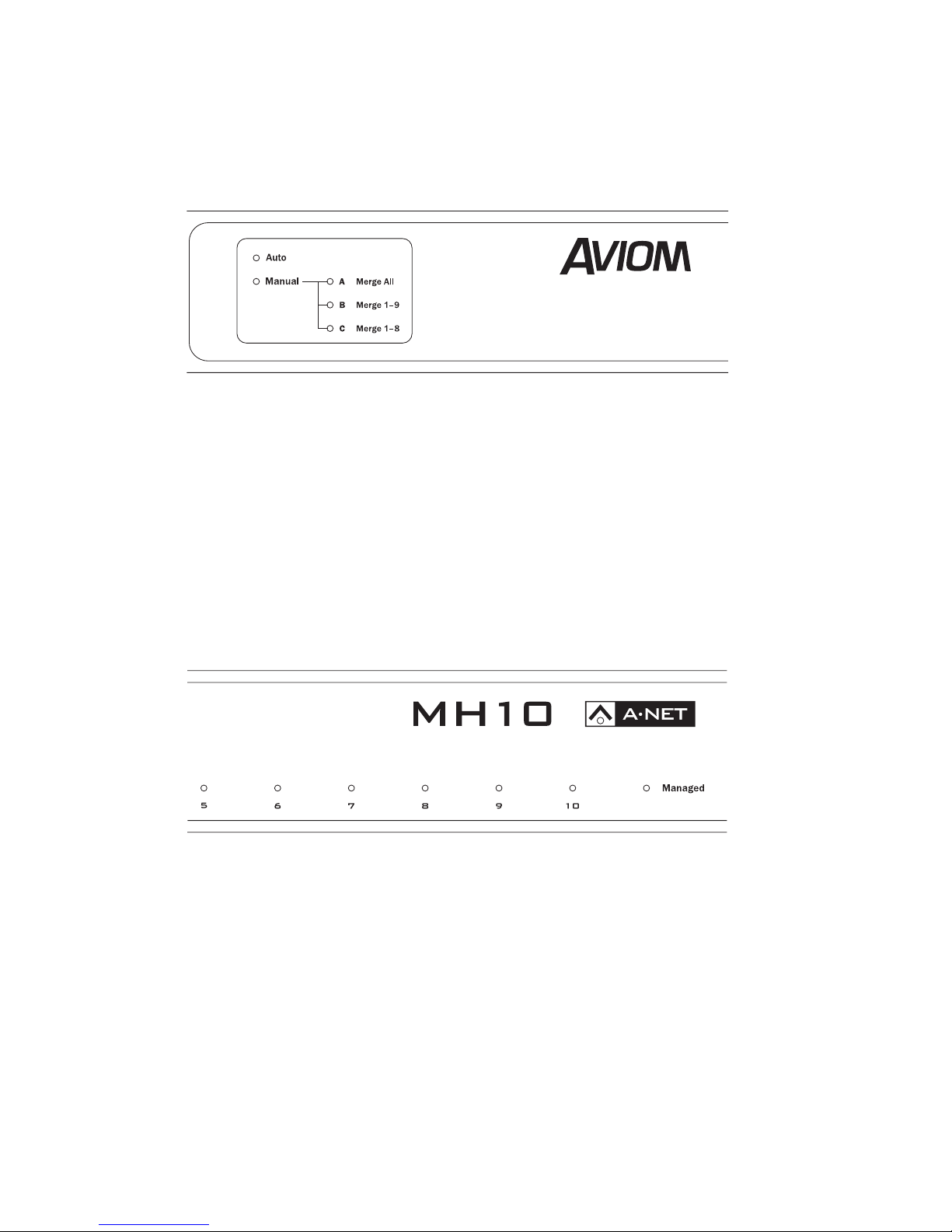

Network Mode Indicator

The mode LED lights to display the current network mode, which can be

set to Auto or Manual at the network’s Control Master. When the Pro64

network is operating in Auto Mode, the red Auto LED will be lit. In Auto

Mode, no user settings are available on the MH10; all ten A-Net ports

function identically. It does not matter which rear-panel A-Net port is

used when connecting Pro64 devices to the network.

One network mode is always selected. Here, the network is in Auto

Mode; the Auto LED is lit.

In Manual Mode, the user has the option of directing A-Net data to either

or both A-Net ports on input modules that are part of the network. Once

the network has been set to operate in Manual Mode, the red Manual

LED and one of the yellow configuration LEDs will be lit on the MH10.

By choosing one of the three Manual Mode configurations, A-Net digital

streams can be routed in different ways to accomplish a variety of audio

distribution tasks. (One configuration is always selected by default.)

Three Manual Mode configurations are available:

A Mer ge All — Merges all incoming A-Net data and

distributes this merged stream of data to all 10 ports

(this is the same as Auto Mode).

B Me rge 1-9 — Merges incoming A-Net data from

Ports 1-9 to a single stream and distributes this merged

Pro64 stream to Port 10 only.

Pro64 data streams arriving at Port 10 are distributed

•

•

Page 19

11

F

roNt PANel Fe Atures

out to Ports 1-9.

C Me rge 1- 8 — Merges the incoming A-Net data

from Ports 1-8 to one stream and distributes the

merged data to Ports 8-10. Ports 9 and 10 create a

redundant Cat-5 data path when two MH10s are

connected.

Port 8 is special when configuration C is used. It inputs

data to the Merger function and outputs the complete

merged 64-channel stream.

Incoming A-Net data streams from Ports 9 and 10 are

distributed to Ports 1-7.

A-Net Port LEDs

Valid A-Net data connected to any of the rear-panel A-Net ports is

indicated by a lit A-Net activity LED on the front panel.

The activity LED lights to indicate the presence of a valid A-Net stream.

Ports 4, 6, 7, and 9 are shown as active.

A-Net LED

The blue LED found within the A-Net logo functions as the network

activity indicator. When a module is powered up, its A-Net LED will flash

while a request to enter the network is sent to and then processed by

the Control Master. Once a module is enumerated and is part of the

Pro64 network, the blue A-Net LED will light solidly.

The blue A-Net LED is also used during the software update process.

Software updates on an MH10 must be initiated from another Pro64

device which has VDC capability.

•

Page 20

12

F

roNt PANel Fe Atures

The A-Net LED lights when a Pro64 device is active on a Pro64 network.

Managed Mode LED

Managed Mode puts the network under control of a computer for

software updates, system monitoring, etc. Managed Mode can only be

entered from the network’s Control Master.

When the network is placed under control of a computer, the Managed

LED will light on all modules in the network.

The Managed LED is for information only. No user settings are available

on the MH10 for Managed Mode.

Page 21

13

r

eAr PANel FeAtur es

Rear Panel Features

All MH10 rear-panel features and functions are described in this section.

AC Power

Pro64 modules use switching power supplies that can operate at 100-

240V and from 50-60Hz, meaning that they can be used with most of

the world’s AC power systems by simply changing the line cord. The

MH10 is equipped with a standard grounded IEC power inlet (with fuse)

which can accept the interchangeable IEC power cord.

Fuse

The fuse holder is spring-loaded and has space for two fuses, one main

and one spare (optional). Press the fuse holder cover to access the fuse.

When checking or replacing a fuse, always power off the Pro64 unit and

remove the line cord from the AC power source.

Always replace the fuse with one of the same rating as that being

changed.

A-Net Ports

Ten EtherCon jacks are provided for A-Net connections, numbered 1 to

10. Connections can use standard RJ45 cables or cables outfitted with

the locking Neutrik EtherCon connector.

The actual functionality of the ten ports is determined by the current

network mode (Auto or Manual) and the setting of the Manual Mode

configuration when using Manual Mode.

In Auto Mode, all ten A-Net ports are identical. Cables from any Pro64

device can be plugged into any available port. Multiple MH10s can

be connected simply by connecting them to any available A-Net port.

There is no need to match MH10 port numbers (Port 1 connected to

Port 1, etc.).

Page 22

14

r

eAr PANel FeAtur es

The ten A-Net ports on the MH10 each have EtherCon connectors.

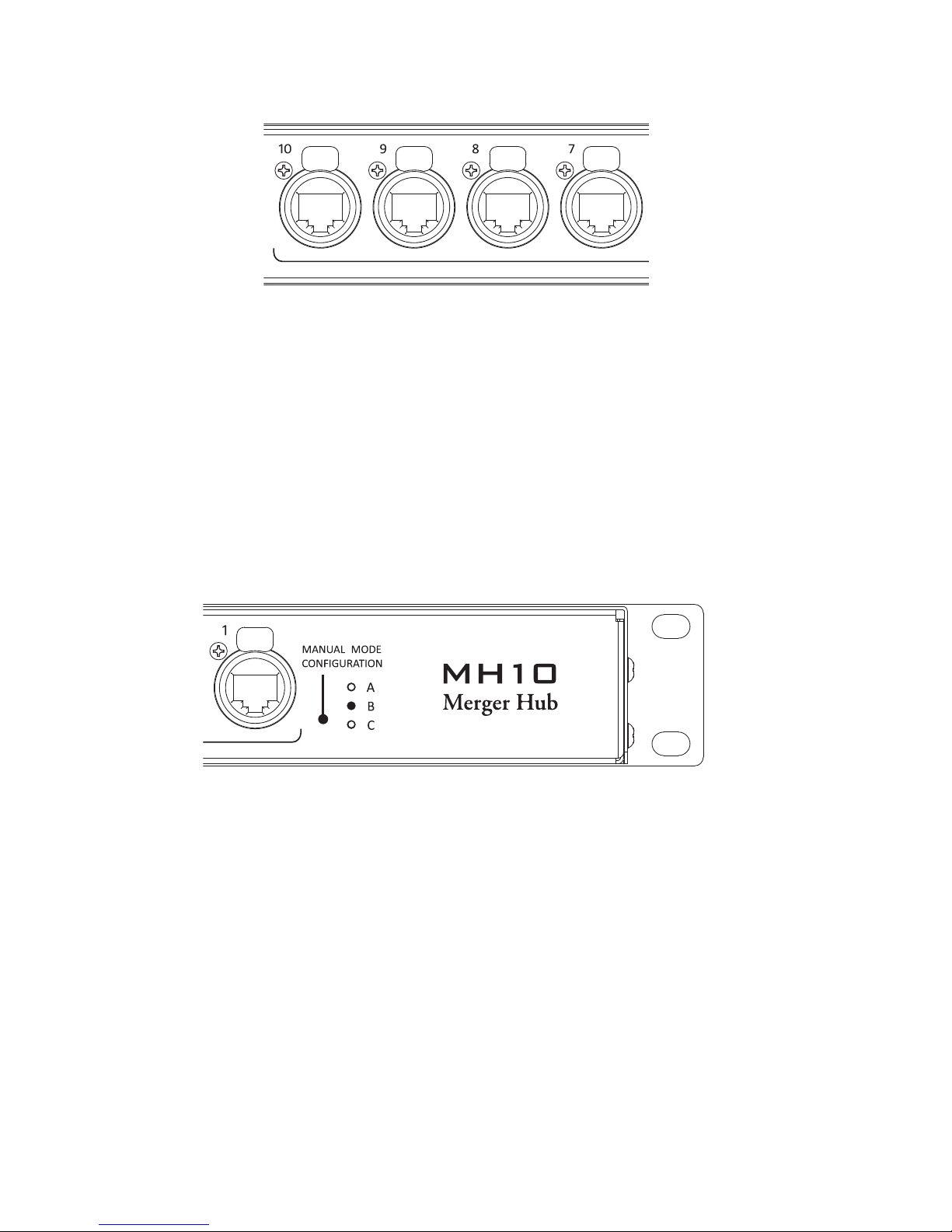

Manual Mode Configuration Button

In Manual Mode, the MH10 can be set to merge and distribute A-Net

data from different combinations of ports, making signal routing easy.

The functionality of the ports is determined by the setting of the Manual

Mode Configuration.

One configuration is always selected (its LED is lit), even if the network is

operating in Auto Mode.

One Manual Mode Conguration LED is always lit.

Press the MAn uAl Mo de Co nfigu rAtion button to cycle through the

three options (A, B, or C). The LED next to the selected configuration will

be lit regardless of the current network mode that is being used. When

Manual Mode is selected at the Control Master, the selected Manual

Mode Configuration is automatically applied. The corresponding LED

on the front panel of the MH10 will also light when Manual Mode is

active.

When multiple MH10 Merger Hubs are used in a network, note that each

can be configured as needed, making complex Manual Mode networks

easy to set up.

Page 23

15

MH10 c

oNFigu rAtioNs

MH10 Configurations

The MH10 has two functional sections, the Merger, which combines

A-Net data streams as they arrive at the MH10, and the Hub section,

which distributes the combined data. These subsections are part of the

internal structure of the MH10 and are not individually configurable.

It is important to remember that each A-Net cable in a Pro64 network

carries two streams of data, one in each direction at all times. Each

A-Net port on the MH10 is always contributing its data to the Pro64 data

stream (as in the case of a 6416i Input Module, for example) while at the

same time distributing the network data.

The MH10 provides three preset configurations (labeled A, B, and C) for

routing the digital audio and Virtual Data Cable (VDC) content of the

A-Net streams received at its ten ports in Manual Mode. Each MH10 in

a network can be set individually to one of the three configurations,

which is especially powerful when configuring Manual Mode networks.

Auto Mode

In Auto Mode, audio and VDC data received from the ten A-Net streams

are merged into a single stream, which is then distributed through the

transmitted streams to all ten ports.

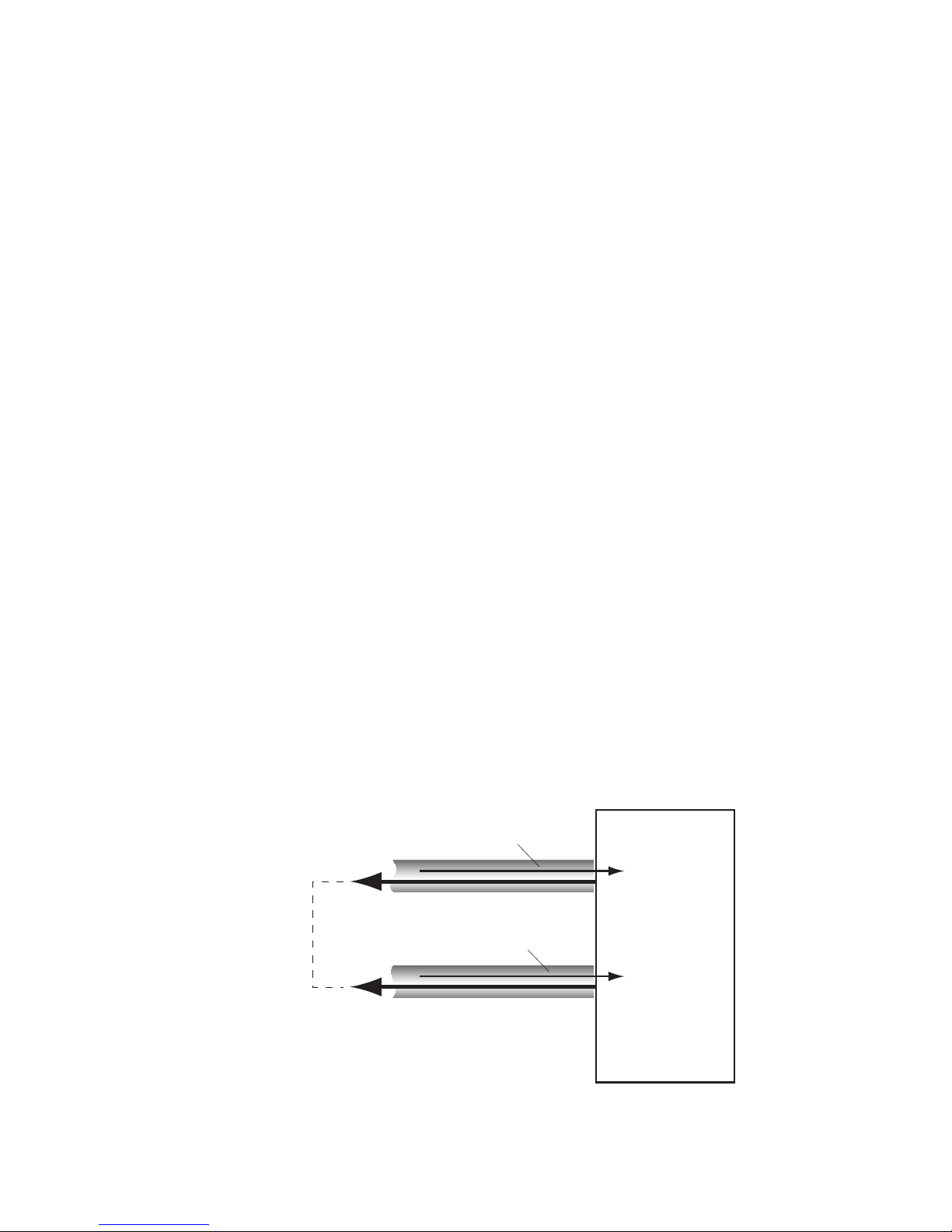

In the simplified example below, two cables connected to two ports

on an MH10 are shown. The upper cable in the diagram sends inputs

1-16 into the merger; the lower cable sends inputs 17-32. As channels

from the individual input modules reach the MH10, they are combined

by the merge function. The combined multi-channel stream is then

transmitted out of each port of the MH10.

MER G E

Inpu ts 1- 16

Out pu ts

1-3 2

Inpu ts 17 -32

+

Data enters the MH10, is merged, and is then distributed.

Page 24

16

MH10 c

oNFigu rAtioNs

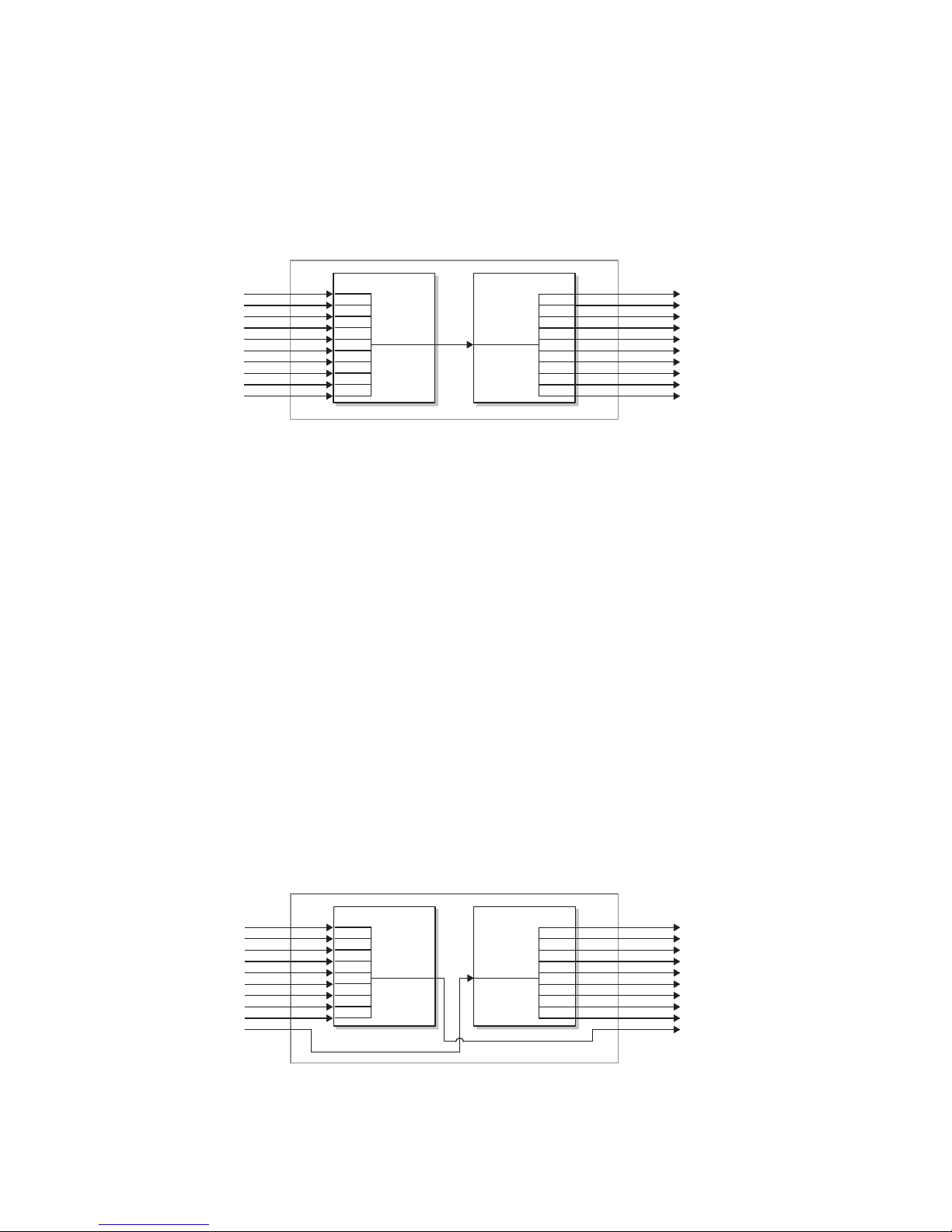

The merge functionality within the MH10 creates a single unified data

stream from all incoming ports. The following block diagrams illustrate

the routing of A-Net signals in Auto and Manual Modes. It is important

to remember that the Receive and Transmit sections shown are part of

each port on the MH10.

A-Net Receive

(Ports 1-10)

A-Net Transmit

(Ports 1-10)

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Merger Distributor

Auto Mode and Manual Mode conguration A

In Auto Mode, all ports on an MH10 have the same functionality; they

will accept digital audio inputs and VDC data and then transmit a

combined data stream with all audio and VDC data.

Manual Mode

Configuration A (Merge All)

Manual Mode Configuration A (Merge All) functions similarly to Auto

Mode. For digital splits and data copies, Manual Mode Configuration A

is ideal.

Configuration B (Merge 1-9)

This configuration is well suited for a basic digital snake using only one

MH10 Merger Hub.

A-Net Receive

(Ports 1-10)

A-Net Transmit

(Ports 1-10)

A-Net Receive

(Ports 1-10)

A-Net Transmit

(Ports 1-10)

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Merger Distributor

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Merger Distributor

Manual Mode conguration B

Page 25

17

MH10 c

oNFigu rAtioNs

In Manual Mode Configuration B (Merge 1-9), audio from the Pro64

streams received at ports 1-9 are merged into a single stream, which is

transmitted out Port 10. The stream received at Port 10 is distributed out

Ports 1-9. VDC data From all ten ports are merged, as in Auto Mode.

Configuration B Example 1

The following stage-to-FOH example shows a digital snake at 48kHz

with 64 inputs and 16 return lines, incorporating one MH10. The 64

inputs (mic, line-level, or digital) originating on the stage enter the MH10

at Ports 1-4 (marked as “Stage Inputs”). The audio inputs are merged in

the MH10 and a 64-channel stream is sent out of Port 10. One Cat-5e

cable spans the distance from stage to the front-of-house mixer. Port

10 is connected to a group of four output modules at FOH which are

connected to the mixing console (marked as “Stage Outputs”).

The engineer creates mixed audio for the speakers, amps, and processing

devices and connects this audio to the input module marked “FOH

Returns 1-16 In.” These channels appear at outputs 1-9 of the MH10. One

output module is shown (“FOH Returns 1-16 Out”), but by adding more

output modules, digital splits are easy to create.

MH 1 0

1

2

3

4

5

6

7

8

9

10

Stage Inputs 1-16

Stage Inputs 17-32

Stage Inputs 33-48

Stage Inputs 49-64

Stage Outputs 1-16

FOH Returns 1-16 Out

FOH Returns 1-16 In

Stage Outputs 17-32

Stage Outputs 33-48

Stage Outputs 49-64

STAGE

FO H

A 64x16 digital snake using only one MH10 Merger Hub

Configuration B Example 2

Adding more input modules at the FOH position allows the engineer to

create content for monitoring, recording, broadcast, etc.

Page 26

18

MH10 c

oNFigu rAtioNs

In this example, inputs from the stage and their associated outputs at

the front-of-house position are unchanged, as are the returns from FOH

to the processors and amps from the previous example.

Two additional input modules at front-of-house are used to send two

streams of monitor content to the stage area for performers. Here an

ASI A-Net Systems Interface is used to create two streams of Pro16 data

for use with A-16II and A-16R Personal Mixers. The digital snake is now

configured as 64x48.

MH 1 0

1

2

3

4

5

6

7

8

9

10

Stage Inputs 1-16

Stage Inputs 17-32

Stage Inputs 33-48

Stage Inputs 49-64

Stage Outputs 1-16

FOH Returns 1-16 Out

Pro16

Monitors 1

Pro16

Monitors 2

FOH Returns 1-16 In

Stage Outputs 17-32

Stage Outputs 33-48

Monitors 17-32

Monitors 33-48

Stage Outputs 49-64

ASI

STAGE

FO H

This 64x48 digital snake uses one MH10 Merger Hub. Input and

output modules at the FOH position are connected serially. The

ASI (connected to Port 8) translates Pro64 data for use with Pro16

monitoring devices.

Again, any of the ports numbered 1-9 on the MH10 can be connected to

additional Pro64 devices for splits. Remember that any output devices

connected in series to any Pro64 device already connected to the MH10

can also output the content coming from the FOH engineer.

Configuration C (Merge 1-8)

Manual Mode Configuration C is optimized for use with two MH10

Merger Hubs, typically with each placed on one side of a digital snake.

In Manual Mode Configuration C (Merge 1-8), Ports 9 and 10 serve as

a redundant pair, with one port available as a backup when two MH10

units are used. Audio from the A-Net streams received at Ports 1-8 are

merged into a single stream, which is transmitted out Port 8, as well as

Page 27

19

MH10 c

oNFigu rAtioNs

Port 9 or 10. Audio data received at Ports 9 and 10 are distributed out

Ports 1-7. VDC data from all ports are merged.

This configuration is ideal for creating a digital snake, and is capable

of creating multiple digital splits of the stage source material for

connection to a monitor console as well as to recording and broadcast

devices.

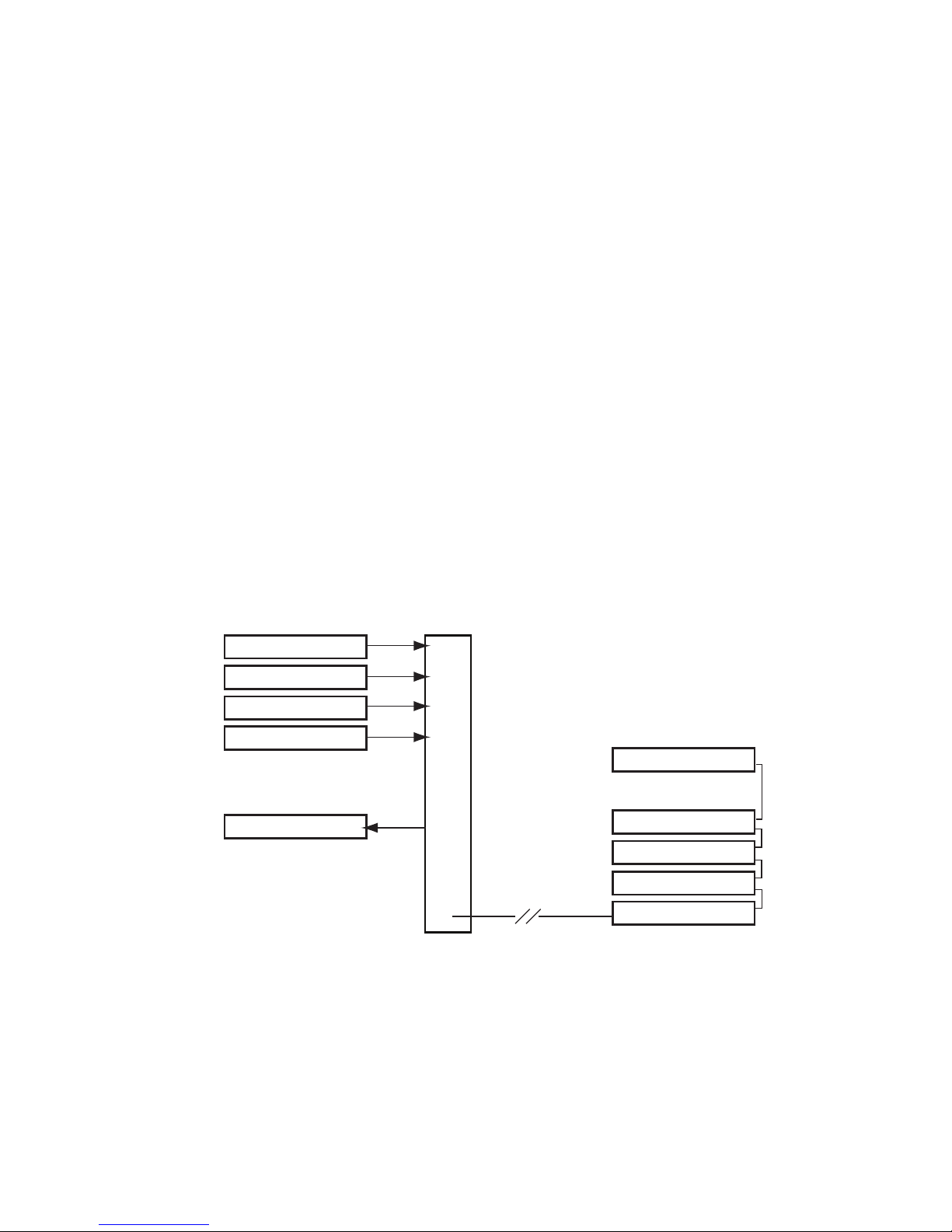

A-Net Receive

(Ports 1-10)

A-Net Transmit

(Ports 1-10)

A-Net Receive

(Ports 1-10)

A-Net Transmit

(Ports 1-10)

A-Net Receive

(Ports 1-10)

A-Net Transmit

(Ports 1-10)

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Merger Distributor

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Merger Distributor

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Merger Distributor

Manual Mode conguration C

Note: When using Configuration C in Manual Mode,

be sure that both MH10 Merger Hubs are set to

Configuration C to avoid creating a data loop.

Configuration C Example

This example shows a stage-to-FOH application with a monitor console,

a 64-channel recording split, and a broadcast feed from the front-ofhouse mix outputs. Two MH10 Merger Hubs are used.

Inputs on the stage (mic, line-level, or digital) are connected to Ports

1-8 of the MH10 on stage. Port 8 on this MH10 is connected to output

modules that feed the monitor console and recording devices.

(Optionally, another MH10 could be connected to Port 8 to create a

parallel rather than serial digital split.)

Digital audio from the stage inputs is merged and then transmitted

via Port 10 to the second MH10 at the front-of-house mixing position.

(Port 9 is the redundant backup cable, shown with a dotted line in the

diagram that follows.)

At FOH, Port 10 is connected to four output modules which feed the

front-of-house mixing console. The engineer creates mix content and

sends it into an input module (marked as “Returns 1-16”) at Port 5 in

the diagram. Port 8 on the front-of-house MH10 is also connected to an

output module located in the broadcast area. This module outputs the

same FOH mix content.

Page 28

20

MH10 c

oNFigu rAtioNs

MH 1 0

1

2

3

4

5

6

7

8

9

10

Stage Inputs 1-16

Stage Inputs 17-32

Stage Inputs 33-48

Stage Inputs 49-64

Stage Outputs 1-16

FOH Returns 1-16 Out

FOH Returns 1-16 In

Stage Outputs 17-32

Stage Outputs 33-48

FOH Returns 1-16 Out

Stage Outputs 49-64

Stage Outputs 1-16

Stage Outputs 17-32

Stage Outputs 33-48

Stage Outputs 49-64

Stage Outputs 1-16

Stage Outputs 17-32

Stage Outputs 33-48

Stage Outputs 49-64

STAGE

RE C O RDI NG

BR O A DC A ST

FO H

MO N ITOR

CON S OLE

MH 1 0

1

2

3

4

5

6

7

8

9

10

64 inputs on stage feed a monitor console and recording devices. The

front-of-house mix (FOH Returns) is sent to the broadcast area and to

amps and speaker processors on stage.

Ports 1-7 will output audio coming from the front-of-house mixer, either

monitoring content or audio for the speaker systems. Port 8 will output

Page 29

21

MH10 c

oNFigu rAtioNs

all audio inputs from the stage (Ports 1-8) for use in a monitor console or

in a recording or broadcast room.

All Cat-5e network cables shown in the example diagrams can be up to

400 feet (120 meters) long.

MH10 Configuration Errors

Data Loops

When using multiple MH10 Merger Hubs in a digital network, never

connect a pair of ports between MH10s other than Ports 9-10 in Manual

Mode Configuration C. Doing so will cause an A-Net data loop. Only

Manual Mode, and its Configuration C specifically, can use a pair of

Cat-5e cables connected between Ports 9 and 10 in a backup/redundant

cable setup.

Changing from Manual Mode to Auto Mode

When changing from a Manual Mode using two MH10 Merger Hubs

in Configuration C to an Auto Mode setup, make sure that the Cat-5e

backup cable connected between Port 9 on each MH10 is disconnected

to avoid a data loop.

Page 30

22

s

PeciFic AtioNs

Specifications

A-Net I/O 10 EtherCon RJ45 connectors

Network Sample Rates 44.1/48kHz; 88.2/96kHz; 176.4/192kHz

Network Sample Rate

Range

1x 44.1/48kHz, 39.7kHz to 52kHz

2x 88.2/96kHz, 79.4kHz to 104kHz

4x 176.4/192kHz, 158.8kHz to 208kHz

Network Bit Depth 24-bits

Network Latency Total latency is less than 800μs (measured

from analog in to analog out).

Cable Length, Cat-5e Maximum 400 feet (120 meters);

Use Unshielded Twisted Pair (UTP) cable

Power Supply 100-240VAC 50-60Hz, 24W

Internal switching power supply;

IEC connector, interchangeable

Fuse F4AL

Dimensions 1U; 19”w x 8”d x 1.75”h

482.6 x 203 x 45 mm

Weight 6 pounds;

2.72 kg

All Aviom products are designed and manufactured in the USA.

Page 31

23

s

PeciFic AtioNs

Dimensions

Page 32

24

Index

Index

A

A, B, C LEDs

Manual Mode 14

A-16II, A-16R 18

Personal Mixers 5

A-Net

Pro64 Series 3

A-Net Distributor 5

A-Net LED 8, 11

A-Net Ports 4, 8, 13

A-Net Systems Interface 18

A-Net Transmit 10

About A-Net 3

AC fuse

changing 13

AC Line Conditioning 6

AC Power 13

ASI 18

ASI A-Net Systems Interface 5

Auto/Manual Mode Selection 8

Auto LED 10

Auto Mode 4, 10, 16

B

bidirectional 4

Bit Depth 22

C

Cables

Cat-5e, Cat-6 3

cable specification, Cat-5e 2

Cat-5

stranded vs. solid 2

Cat-5e 1, 2, 22

Unshielded Twisted Pair (UTP) 2

Cat-5e Cable Distance 3

Cat-6 2

Certifications iii

Cleaning 7

Clock 4

jitter and wander 3

Clock Master 4

computer 2, 12

Configuration A 16

Configuration B 17

Configuration C 18, 21

Configuration Errors 21

Configurations

Manual Mode 15

Control Data 4

Control Master 12

D

DB9 cable

null modem 2

digital snake 18

digital split 16, 17

Dimensions 22, 23

E

Enter/Cancel button 10

Errors 21

EtherCon 1, 2, 13

Ethernet 3

F

FCC info iv

FOH 17

Front Panel Components 8

Fuse 22

AC 13

Fuse Holder 9

G

Gain Range Switch 11

GPIO

General Purpose I/O 4

Page 33

25

Index

I

IEC connector 22

IEC power cord 13

IEC Power Inlet 9

input module 15, 17

J

jitter 3

L

Latency 22

LED

A, B, C 14

Network Mode 10

M

Managed button 8, 12

Managed LED 12

Managed Mode 12

Manual LED 10

Manual Mode 4, 8, 10, 16, 21

A, B, C LEDs 14

Manual Mode Configuration Button

14

Manual Mode configurations 10

Merge 1-8 11

Merge 1-9 10

Merge All 10

Merger 15

MH10

using multiple 14

MH10 Configurations 15

MIDI 4

Monitor Mixing System

Pro16 5

Mounting, Rack 6

N

Network Mode 10

Neutrik EtherCon. See EtherCon

null modem cable

DB9 2

O

Operating System Update 2

output module 17

P

PC

software update 2

Personal Mixer

A-16II, A-16R 5

Personal Mixers 18

Port 17

Port A, B. See A-Net Ports

Ports

A-Net 4

Ports 9 and 10

redundant/backup 21

Power On/Off Switch 9

Power Supply 13, 22

Pro16 18

Pro16 Series 5

Pro64 1, 3

Pro64 Update Tool 2

R

Rear Panel Components 9

redundancy 11, 18

redundant/backup

Ports 9 and 10 21

RJ45 1, 2

RoHS iii

RS-232 4

null modem cable 2

S

Safety Instructions v

Safety Warnings iv

Sample Rate 3, 22

minimum/maximum 3

sample rate conversion 4

Slot 4

software update 11, 12

Specifications 22

splits 17

stranded vs. solid Cat-5 2

Page 34

26

Index

U

Unshielded Twisted Pair 2

UTP 22

Update

Operating System 2

Update Tool 2

UPS 6

UTP 2

UTP cable

Cat-5e, Cat-6 3

V

VDC data 17

Ventilation 7

Virtual Data Cables 4

VDC 15

W

wander 3

Warnings iv

Warranty vii

Weight 22

Page 35

Page 36

Loading...

Loading...