Page 1

P/N 9310 1017 0001F rev. 2.1

© 2013 Aviom, Inc.

A-Net Interface Card

User Guide

Page 2

Certifications

Pb

Pb-Free

ETL/cETL Listed

EMC: EN 55013, EN 55020, SAA AS/NZS 1053

Conforms to: IEC 60065, EN 60065, UL 6500‑2001

Certified to: CAN/CSA E60065, KETI

RoHS Status: Pb‑free

Notice of Rights

All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means—electronic,

mechanical, photocopy, recording, or otherwise—without written permission of Aviom, Inc.

Trademarks

Aviom, A‑Net, the A‑Net icon, Pro16, Pro64, AllFrame, m‑control, and Virtual Data Cable are trademarks of Aviom, Inc.

All other trademarks are the property of their respective owners.

©2013 Aviom, Inc. All rights reserved.

Information subject to change without notice.

ii

Page 3

READ THIS FIRST

Important Safety Instructions

Read these instructions. 1.

Keep these instructions2.

Heed all warnings.3.

Follow all instructions.4.

Do not use this apparatus near water.5.

Clean only with a dry cloth.6.

Do not block any ventilation openings. Install in accordance with the manufacturer’s 7.

instructions.

Do not install near any heat sources such as radiators, heat registers, stoves, or other 8.

apparatus (including amplifiers) that produce heat.

Do not defeat the safety purpose of the polarized or grounding‑type plug. A polar‑9.

ized plug has two blades with one wider than the other. A grounding type plug has

two blades and a third grounding prong. The wide blade or third prong are provided

for your safety. If the provided plug does not fit your outlet, consult an electrician for

replacement of the obsolete outlet.

Protect the power cord from being walked on or pinched, particularly at plugs, 10.

convenience receptacles, and the point where they exit the apparatus.

Only use attachments/accessories specified by the manufacturer.11.

Use only with the cart, stand, tripod, bracket, or table specified by the manufacturer, 12.

or sold with the apparatus. When a cart is used, use caution when moving the cart/

apparatus combination to avoid injury from tip‑over.

Unplug this apparatus during lightning storms or when unused for long periods of 13.

time.

Refer all servicing to qualified personnel. Servicing is required when the apparatus 14.

has been damaged in any way, such as when the power‑supply cord or plug is

damaged, liquid has been spilled or objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture, does not operate normally, or has

been dropped.

No on/off power switches are included in the system. The external power supply 15.

should be used to control power to an Aviom device. This power supply should

remain readily operable.

The solid line over dashed line symbol (16. ) indicates that the input voltage

must be a DC voltage.

The box within a box symbol ( 17. ) indicates that the external power supply is double

insulated.

ii i

Page 4

WARNING!

! !

TO REDUCE THE DANGER OF ELECTRICAL SHOCK DO NOT REMOVE COVERS.

NO USER SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL ONLY

To reduce the risk of fire or electrical shock, do not expose this product to rain or other types of moisture.

To avoid the hazard of electrical shock, do not handle the power cord with wet hands.

Replace fuse with same type and rating.

Operating Temperature: 10˚C to 50˚C (50˚F to 122˚F)

Risque de choc électrique – ne pas ouvrir. Pour réduire le risque de feu ou de choc électrique, ne pas exposer cet équipement à la pluie

ou la moisissure. Pour réduire le risque de choc électrique, ne pas retirer le couvercle. Pièces non remplaçables par l’utilisateur. Confier la

réparation à une personne qualifiée. Attention – utiliser seulement un fusible de rechange de même type.

Cet appareil est conforme à la section 15 de la norme FCC. Son fonctionnement est soumis aux conditions suivantes : (1) cet équipement ne

doit pas causer des interférences nocives, et (2) cet équipement doit accepter toute interférence captée incluant les interférences pouvant

causer des opérations indésirables.

Cet appareil numérique de Classe B est conforme à la norme NMB‑003 du Canada.

CAUTION:

Using any audio system at high volume levels can cause permanent •

damage to your hearing.

Set your system volume as low as possible. •

Avoid prolonged exposure to excessive sound pressure levels.•

IMPORTANT:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and

can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.•

Increase the separation between the equipment and receiver.•

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.•

Consult the dealer or an experienced radio/TV technician for help.•

Changes or modifications to the product not expressly approved by Aviom, Inc. could void the user’s FCC authority to operate the

equipment.

iv

Page 5

Aviom, Inc. Limited Warranty

Aviom, Inc. warrants this product against defects in materials and workmanship for a period of one year from the date of the original retail

purchase.

This warranty does not apply if the equipment has been damaged due to misuse, abuse, accident, or problems with electrical power. The

warranty also does not apply if the product has been opened or modified in any way; if the product serial number has been damaged,

modified, or removed; or if the original Quality Assurance label has been damaged, modified, or removed.

If a defect is discovered, first write or call Aviom, Inc. to obtain a Return Authorization number. No service will be performed on any product

returned without prior authorization. Aviom, Inc. will, at its option, repair or replace the product at no charge to you. The product must be

returned during the warranty period, with transportation charges prepaid to Aviom, Inc., 1157 Phoenixville Pike, Suite 201, West Chester,

PA 19380. You must use the product’s original packing materials for shipment. Shipments should be insured for the value of the product.

Include your name, address, phone number, description of the problem, and copy of the original bill of sale with the shipment. The Return

Authorization number should be written on the outside of the box.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE (OR

JURISDICTION TO JURISDICTION). AVIOM’S RESPONSIBILITY FOR MALFUNCTIONS AND DEFECTS IN HARDWARE IS LIMITED TO REPAIR

AND REPLACEMENT AS SET FORTH IN THIS LIMITED WARRANTY STATEMENT. ALL EXPRESS AND IMPLIED WARRANTIES FOR THE PRODUCT,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED

IN DURATION TO THE WARRANTY PERIOD SET FORTH ABOVE. NO WARRANTIES, WHETHER EXPRESS OR IMPLIED, WILL APPLY AFTER SUCH

PERIOD.

AVIOM, INC. DOES NOT ACCEPT LIABILITY BEYOND THE REMEDIES SET FORTH IN THIS LIMITED WARRANTY DOCUMENT. AVIOM, INC.’S

LIABILITY IS LIMITED TO THE REPAIR OR REPLACEMENT, AT OUR OPTION, OF ANY DEFECTIVE PRODUCT, AND SHALL IN NO EVENT INCLUDE

INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND.

SOME STATES DO NOT ALLOW EXCLUSIONS OR LIMITATION OF IMPLIED WARRANTIES OR LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

v

Page 6

Warranty Information

Please record the following information for future reference:

Your Authorized Aviom Dealer:

Name:

Address:

Phone:

Serial Numbers of Your Aviom Products:

Date of Purchase:

Your Authorized Aviom Dealer is your primary source for service and support. The information recorded above will be helpful

in communicating with your Authorized Aviom Dealer should you need to contact Aviom Customer Service. If you have any

questions concerning the use of this unit, please contact your Authorized Aviom Dealer first. For additional technical support,

or to find the name of the nearest Authorized Aviom Repair Station, check the Aviom web site at www.aviom.com.

To fulfill warranty requirements, your Aviom product should be serviced only at an authorized Aviom service center. The

Aviom serial number label must appear on the outside of the unit, or the Aviom warranty is void.

This manual and its contents are copyrighted by Aviom, Inc. All rights are reserved by Aviom, Inc. This document may not, in

whole or in part, be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine‑readable

form without prior written consent from Aviom, Inc.

The software and/or firmware contained within Aviom products is copyrighted and all rights are reserved by Aviom, Inc.

Although every effort has been made to ensure the accuracy of the text and illustrations in this manual, no guarantee is

made or implied as to the accuracy of the information contained within.

v i

Page 7

!

Failure to observe the following warnings may lead to risk of serious injury from fire or electric

shock.

Before installing the 6416Y2 card, you must refer to the owner’s manual of the host device or to the

Yamaha website to verify that your host device supports this card, and to verify the number of cards that

can be installed in combination with other Yamaha or third‑party cards.

Warning

Do not attempt to disassemble or modify the card. Do not apply excessive force to board •

connectors or other board components. (Mishandling the board may lead to shock, fire

hazard, or equipment failure.)

You must turn off the power of your device before you begin installing the 6416Y2 card. •

Be sure to disconnect the • power cable from the main unit before installing this card (to

eliminate shock hazard).

!

Failure to observe the following precautions may lead to personal injury, or may result in

damage to equipment or other property.

Caution

Do not touch the board’s metallic leads (pins) when handling the card. (Pins are sharp •

and may cause hand cuts.)

The card is • electrostatic‑sensitive. Before handling the card, you should briefly touch the

main unit’s metal casing with your bare hand so as to drain off any static charge from

your body.

v i i

Page 8

Table of Contents

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The EtherCon Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cat-5e Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

AC Line Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing Multiple 6416Y2 Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Clocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

A-Net Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Support For Pro16 Series Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

A-Net Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Slots versus Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Slots and Sample Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting Control Master Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Enumeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adding Pro64 Devices to a Network . . . . . . . . . . . . . . . . . . . . . . . . . 15

Control Master and Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Other Clock Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Clock Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Network Sample Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Changing the Sample Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Front Panel Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Thumb Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

RS‑232/422 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Clock and Control DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Stereo Link DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

System Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

m‑control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Local Code Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

vi ii

Page 9

Control Master/Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

A‑Net Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Auto LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control Master (CTL) LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Clock (CLK) LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Error (ERR) LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

A‑Net LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DIP Switch Block Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DIP Switch Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DIP Switch Block 1 (SW1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DIP Switch Block 2 (SW2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DIP Switch Block 3 (SW3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SW3 Switch Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DIP Switch Block (SW4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Baud Rate Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DIP Switch Block 8 (SW8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

VDC Slot Assignments ‑ Backplane VDC Port . . . . . . . . . . . . . . . . . . . 33

VDC Slot Assignments ‑ Front Panel VDC Port . . . . . . . . . . . . . . . . . . . 34

MY8 and MY16 Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DIP Switch Block 9 (SW9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Network Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

A‑Net Transmit Settings (Manual Mode) . . . . . . . . . . . . . . . . . . . . . . 35

A‑Net Receive Settings (Manual Mode) . . . . . . . . . . . . . . . . . . . . . . . 36

A‑Net Transmit Base Slot Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 36

A‑Net Receive Base Slot Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Managed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Choose a Control Master . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6416Y2 as Control Master. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Pro64 I/O Modules as Control Master . . . . . . . . . . . . . . . . . . . . . . . . 39

Set The Network Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MY8 and MY16 Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Choose I/O Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Activate Channels/Slots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

48 x 16 Digital Snake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Install the Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Yamaha Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Firmware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

DB9 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Remote Control Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ix

Page 10

Supported Remote Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Physical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Channel Count and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

m-control Remote Control Settings on the 6416Y2 . . . . . . . . . . . . . . . . . 50

SW3 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pad Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Signal Routing to the Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Clock Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Yamaha Console UI Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

External HA Settings on the LS9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Assigning Remote Preamp Channels to the LS9 Faders . . . . . . . . . . . . . . . 56

External HA Settings on the M7CL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Assigning Remote Preamp Channels to the M7CL . . . . . . . . . . . . . . . . . . 60

Baud Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Connection Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

RS-232/422 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Crossover Cable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Warranty Registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

1Ge n e r a l In f o

x

Page 11

We l c o m e

Thank you for purchasing the 6416Y2 A-Net® Interface Card for use with Yamaha® digital products that support

the mini‑YGDAI (MY) card format. This User Guide is designed to familiarize you with the features and functions

of your new Pro64® product. All Pro64 products are powered by A‑Net®, Aviom’s proprietary data transmission

protocol designed especially for the unique demands of live streaming audio.

In developing the Pro64 Series, we have made every effort to make the user interface as easy to use and

understand as possible. We encourage you to read the manual completely, as some of the powerful features of

your new product may not be immediately apparent.

Features

The 6416Y2 A‑Net Interface Card is a 16‑channel Pro64 A‑Net I/O expansion card for Yamaha’s digital devices

including digital mixing consoles and the Digital Mix Engine™ (DME) products. It provides a host of professional

features designed to make audio networking with Pro64 Series products easy to set up and configure in a variety

of professional audio situations.

6416Y2 A‑Net Interface Card Features:

16 input and 16 output channels •

Inputs from the console can be individually activated and sent into the Pro64 network •

The card can be programmed from the card’s circuit board DIP switches or by using •

Pro64 Network Manager software

The 6416Y2 card can be both the Pro64 network • Control Master and the network Clock

Master device

Flexible and robust clocking allows simple console‑to‑console digital connections •

Front‑panel • Stereo Link DIP switches for channel pairing for use with Pro16® Personal

Mixers

Two Pro64 A‑Net network ports •

• EtherCon® RJ45 network connectors

Support for Pro64 Virtual Data Cables™ (VDC) •

Variable • sample rates: 44.1/48kHz or 88.2/96kHz

RS‑232/422 • Virtual Data Cable™ I/O (compatible with the Yamaha remote control

protocol)

Compatible with Yamaha mini‑YGDAI (MY) expansion card format •

Multiple cards can be installed per console or DME •

• m‑control™ allows remote control of 6416m Mic Input Module or AllFrame preamp

settings directly from the Yamaha user interface

Page 12

Package Contents

The contents of the 6416Y2 A‑Net Interface Card box includes:

One 6416Y2 A‑Net Interface Card •

User documentation •

P No t e Retain the protective bag that encloses the 6416Y2 card. The card is static‑sensitive. Use the bag

whenever the card will be transported without being installed in a Yamaha device.

Check the contents of the shipping box carefully before making connections and continuing with installation.

DIP Switches

Illustrations of Pro64 DIP switch components in this document will indicate the switch handles in black.

In this diagram, all DIP switches are in the down position.

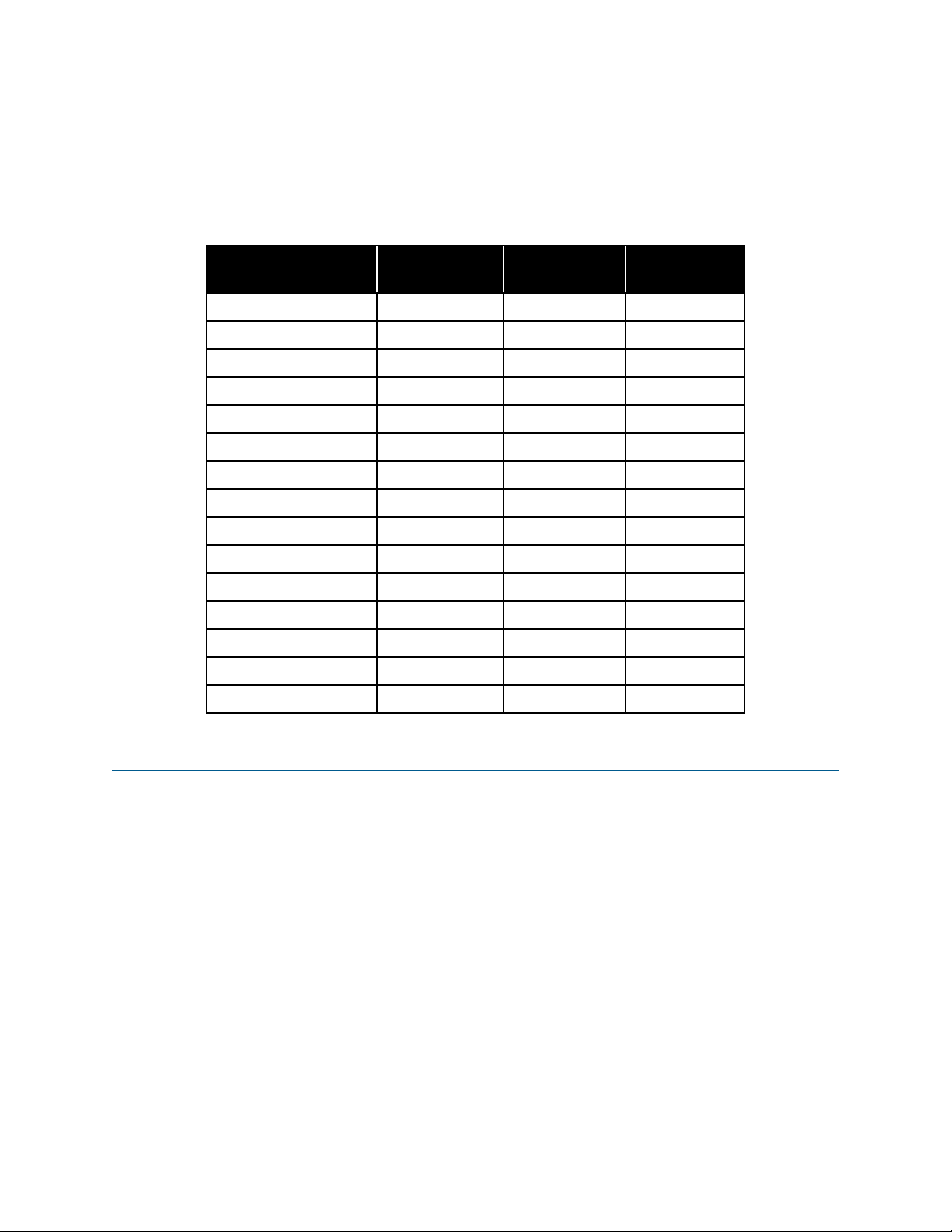

The EtherCon Connector

Pro64 Series products feature locking connectors for all network I/O. The Neutrik® EtherCon® connector is a dual

RJ45‑type connector that can receive a standard Category 5e cable or a cable fitted with the special locking

EtherCon connector.

When using a standard Cat‑5e cable, plug the cable into the center of the EtherCon jack; release the cable by

pressing on the small plastic tab built into the cable connector.

The locking EtherCon connector is similar to an XLR plug, the kind commonly used on microphone cables. Insert

an EtherCon‑equipped cable into the jack until it clicks and locks in place. To remove the cable, press on the metal

release tab at the top of the panel‑mounted EtherCon jack and pull the connector outward.

Ge n e r a l In f o

The 6416Y2 has two A-Net ports, labeled A and B.

2

Page 13

Cat-5e Cables

All Cat‑5e connections between A‑Net devices should use Unshielded Twisted Pair (UTP) cable. The cable can be

of the stranded or solid type; solid wire performs better over long distances, while stranded wire is more flexible

and easier to manipulate and therefore easier to work with in a live performance situation.

Cables designated as Cat‑5e in Pro64 documentation can be interchanged with any Cat‑6 (or better) cable. Cables

will be referred to simply as “Cat‑5e.”

Connectors on Cat‑5e cables used with Pro64 devices can be of the standard RJ45 variety or locking Neutrik

EtherCon type.

Cleaning

Before cleaning a Pro64 product, turn off the power switch and unplug the unit from the AC power source.

To clean the surface of the Pro64 product use a clean, soft lint‑free cloth that has been slightly moistened with

water only. For tougher dirt, use a cloth slightly dampened with water or with a mild detergent. Always be sure to

dry the surface of the unit before proceeding with use.

When cleaning your Aviom products, never spray cleaners directly onto the product surfaces. Instead, spray a small

amount of the cleaning solution onto a clean cloth first. Then use the dampened cloth to clean the product.

Never use solvents or abrasive cleaners on the finished surfaces of your Aviom products.

AC Power

The following applies to the host device that the 6416Y2 A‑Net Interface Card is installed in.

Always plug the unit into a properly grounded (earthed) outlet. Always use the AC line cord that was shipped with

the unit. Grasp the power cable by the connector and never by the cord itself when connecting and disconnecting

it from the power source.

Do not expose the Pro64 device to moisture, rain, or excessively damp environments.

AC Line Conditioning

Aviom products are digital devices and as such are sensitive to sudden spikes and drops in the AC line voltage.

Changes in the line voltage from lightning, power outages, etc., can sometimes damage electronic equipment.

To minimize the chance of damage to your equipment from sudden changes in the AC line voltage, you may want

to plug your equipment into a power source that has surge and spike protection. Power outlet strips are available

with built‑in surge protection circuits that may help protect your equipment.

Other options for protection of your equipment include the use of an AC line conditioner or a battery backup

system (sometimes referred to as an uninterruptible power supply, or UPS).

Ge n e r a l In f o

3

Page 14

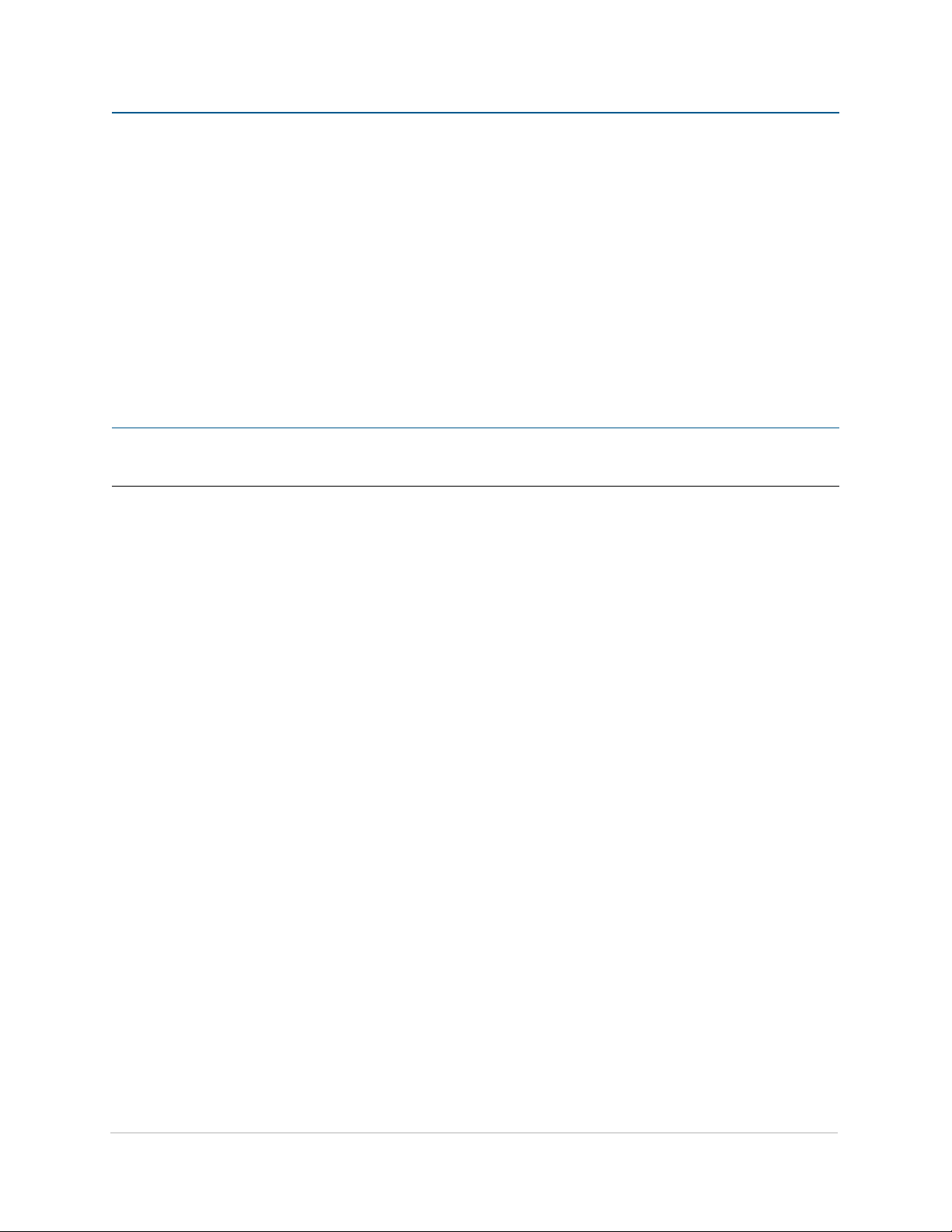

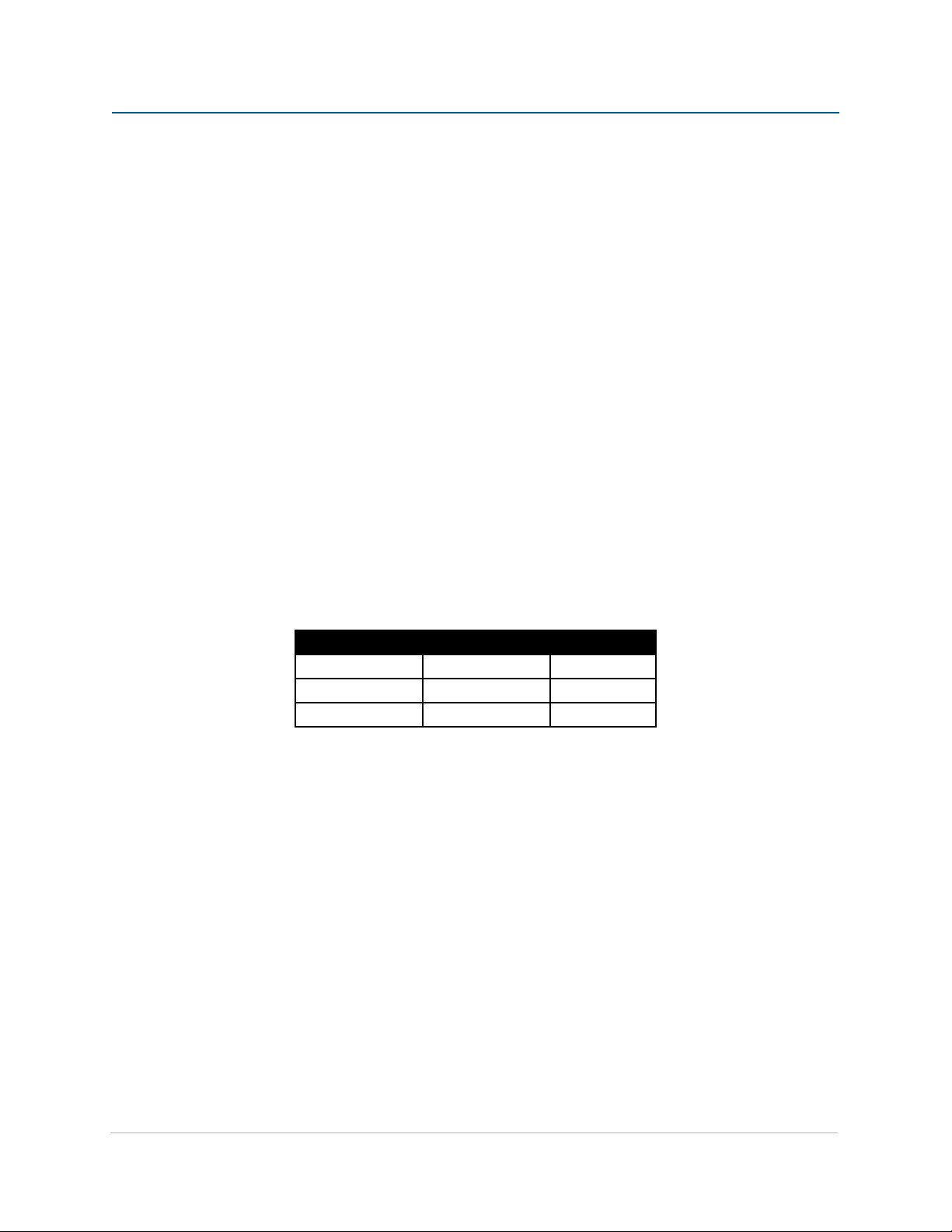

Compatibility

The Aviom 6416Y2 A‑Net Interface Card is compatible with the following Yamaha devices:

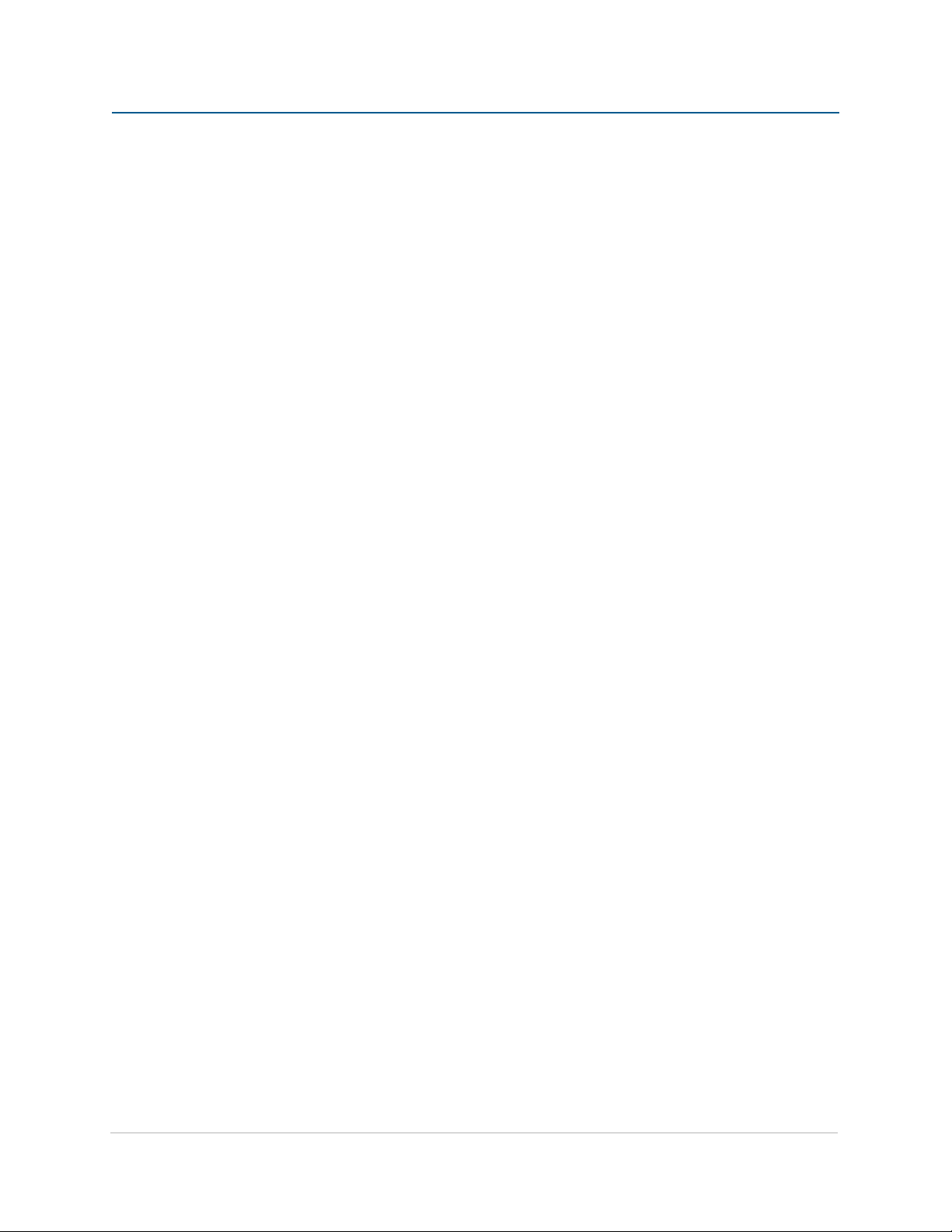

Device

AW24 00 1 1

O1V96 1 1

O1V9 6i 1 1

O2R96 4 4

DM1000 2 2 √

DM2000 6 5 √

DME24N 2 2 √

DME64N 4 4 √

M7CL-32 3 3 √

M7CL-48 3 3 √

L S9 -16 1 1 √

LS9-32 2 2 √

C L1 3 3 √

CL3 3 3 √

CL5 3 3 √

MY Expansion

Slots

Maximum

6416Y2 Cards

m-control

available

o t e ‑ The Pro64 6416Y2 A‑Net Interface Card can be used with the Pro16 Series Y1 A‑Net Interface Card

P N

simultaneously as long as the Yamaha device has available MY expansion slots.

Ge n e r a l In f o

4

Page 15

Fi r m W a r e No t i c e

All Pro64 devices in a network should be updated to use the most recent firmware version to ensure

trouble-free operation.

As new Pro64 devices are released, older Pro64 products need to be updated so that they recognize the features

and functions of the newer modules—something that is especially important if one of the older devices will be

used as the network’s Control Master.

Pro64 Network Manager is a free Windows software application designed for editing and managing your Pro64

devices; it also includes a built‑in utility for updating the firmware in Pro64 Series products. The current version of

Pro64 Network Manager can be downloaded from the Aviom website.

P No t e : AllFrame devices in a Pro64 network require the Pro64 Network Manager application for all I/O routing

and channel programming. There is no front panel user interface.

Pro64 Network Manager requires a direct RS‑232 (serial) connection between the computer and the Control

Master device on the Pro64 network. Normally this is accomplished by connecting a null modem DB9 cable

between the RS‑232 jack on the computer and the Pro64 device. Complete information on using RS‑232 (and

USB‑to‑RS‑232 adapters) is available on the Aviom website. Updates take just a few minutes per module.

The AllFrame F6 Modular I/O Frame includes a USB connector on its front panel for connecting a computer when

the device is used as the network’s Control Master. No DB9 RS‑232 cable is required when using the F6 as a Control

Master.

Pro64 Network Manager is designed to run on a PC under Microsoft® Windows® XP, Vista, or Windows 7. There

is no official Apple Mac support. However, Mac users can run Pro64 Network Manager using Windows running

under Apple’s Boot Camp or Parallels programs on Intel‑based Macs.

Get Pro64 Network Manager and firmware update files from the Aviom website, http://www.aviom.com.

fI r m w a r e no t I c e

5

Page 16

iN s t a l l i N g t h e 6416Y2 ca r d

Before installing the 6416Y2 card in a compatible Yamaha digital device, be sure to read the DIP switch configuration

section of this User Guide (page 25).

The 6416Y2 card can be used in any MY (mini‑YGDAI) expansion slot in a Yamaha digital mixing console or

compatible digital product (see the list on page 3). The specific number of available MY expansion slots varies

with each model. Yamaha expansion slots are identified by number, starting with “Slot 1.” Within an MY expansion

slot, its audio resources are referred to as “channels,” numbered from 1 to 16 in the Yamaha interface.

P No t e The 6416Y2 card is electrostatic‑sensitive. Before handling the card, you should briefly touch the host

unit’s metal casing with your bare hand to drain off any static charge from your body.

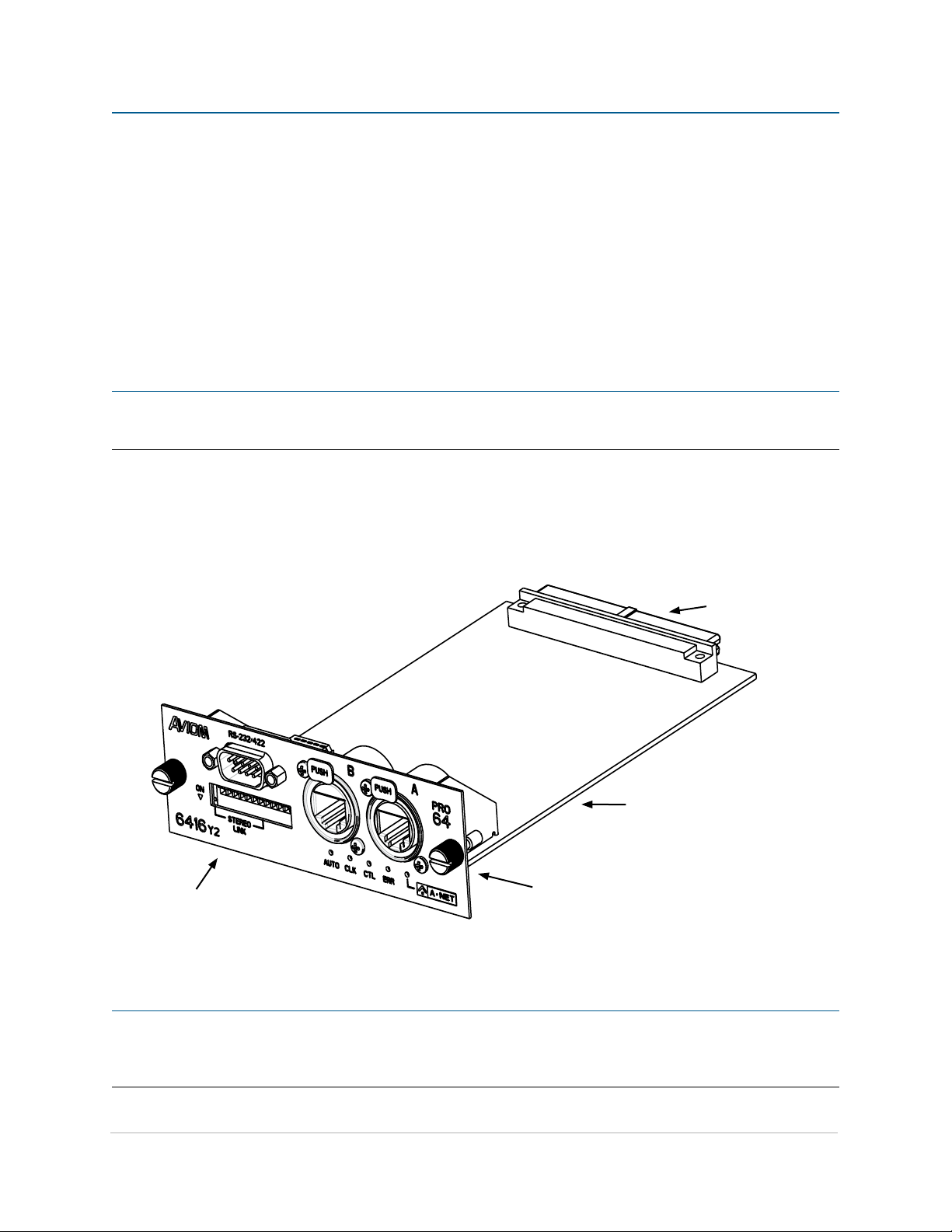

The components of the card are indicated in the diagram below.

Multi-pin

backplane

connector

Align sides of 6416Y2

card with the guides in

the MY expansion slot.

Thumb screws

Front panel DIP switches,

connectors, and LEDs

P No t e : Some Pro64 network and audio routing settings cannot be changed once the card has been connected

to the Yamaha device since they are changed via DIP switches found on the circuit board of the card

itself.

In s t a l l I n G t h e 6416Y2 ca r d

6

Page 17

To install the 6416Y2 card:

Start with the power to the Yamaha digital device 1. off.

Remove the Yamaha device’s power cord from the wall receptacle.2.

Remove the cover plate on the Yamaha 3. device’s expansion slot to expose the expansion

connections.

Discharge any built‑up static charge by touching the metal casing of the host Yamaha unit. 4.

Remove the 6416Y2 card from its protective anti‑static sleeve. 5.

Ensure that the 6416Y2 card 6. DIP switches are set properly for your application at this

time—the card can be programmed using its internal DIP switches or from the Pro64

Network Manager software.

Slide the 6416Y2 card into place, aligning the sides of the card with the support guides in 7.

the MY expansion slot.

Press the 6416Y2 card firmly in place to attach the multi‑pin connectors on the card to 8.

those on the expansion slot backplane on the Yamaha device.

Tighten the thumb screws on the 6416Y2 to secure it.9.

Power up the Yamaha digital device. 10.

Connect the 6416Y2 to a Pro64 network. 11.

Once the 6416Y2 card has been configured and is installed in the Yamaha host device, all signal routing to/from the

6416Y2 A‑Net Interface Card for processing and/or mixing is done from within the Yamaha device’s user interface.

Consult the documentation that came with your Yamaha product for more specific signal routing information.

P No t e : Always power off the Yamaha host device before removing the 6416Y2 card.

Installing Multiple 6416Y2 Cards

A Yamaha host device can support as many Pro64 A‑Net cards as it has available MY (mini‑YGDAI) expansion slots

and internal power resources. When multiple 6416Y2 A‑Net Interface Cards are installed in a Yamaha host device,

each 6416Y2 card needs to be connected via its A‑Net ports to the Pro64 network. Simply use a short Cat‑5e

jumper cable to interconnect the 6416Y2 cards.

A list of compatible Yamaha products and the number of available MY expansion slots on each appears on

page 4.

P No t e : Remote mic preamp control for Pro64 devices from the Yamaha user interface is available using

m‑control. Some Yamaha devices (including the LS9 series) require that the card sending remote control

data be installed into the console’s MY expansion slot #1.

In s t a l l I n G t h e 6416Y2 ca r d

7

Page 18

ab o u t a-Ne t

Aviom’s A‑Net® is the only networking technology conceived, designed, and optimized for managing and

distributing audio using ordinary Cat‑5e cables (or fiber by adding fiber optic SFP transceivers to the AllFrame

F6 Modular I/O Frame or MH10f Merger Hub). As implemented in the Pro64® Series products, A‑Net can transmit

up to 64 channels of uncompressed 24‑bit audio with the reliability and fidelity of analog, and the power and

flexibility of a true digital network.

As implemented in the 6416Y2 card, Pro64 A‑Net allows variable sample rates in two ranges, 44.1/48kHz and

88.2/96kHz, with ultra‑low latency, jitter, and wander. Pro64 devices can be connected in any combination of

serial (daisy‑chain) or parallel (star) topologies. Cable runs between Pro64 devices can be up to 400 feet (120

meters) on Cat‑5e, and miles on fiber optics (with Aviom fiber‑capable equipment).

Because A‑Net is designed specifically for audio, the technological limitations of Ethernet and Ethernet‑based

products are removed, while audio performance and system flexibility are increased. A‑Net incorporates Aviom’s

unique patented and patent‑pending algorithms for controlling clock jitter and wander, as well as system‑wide

latency—regardless of an installation’s size, design, or clocking setup. A‑Net offers significant advantages in

fidelity, performance, and flexibility over Ethernet‑based products.

A‑Net uses the “physical” layer of Ethernet, but it eliminates all the protocol elements that are designed for

computers and IT‑style networking. In audio applications, these other layers reduce efficiency, impose system

restrictions, and introduce latency and timing instability. By eliminating Ethernet data structures, A‑Net creates a

superior network with enhanced audio performance. With A‑Net and the Pro64 Series, Aviom continues to break

new ground in the design and development of innovative digital audio networking technologies and solutions.

6416Y2 Card Supported Sample Rates

Sample Rate Minimum Maximum

1x 44.1/48kHz 39.7kHz 52kHz

2x 88.2/96kHz 79.4kHz 104k Hz

Clocking

The Pro64 network offers the most flexible clocking and synchronization options in the industry even when

syncing to an external clock source.

Any Pro64 I/O device can be designated the Clock Master for the network, generating and distributing its internal

clock. (The 6416Y2 Card uses the Yamaha host device’s clock and distributes that clock to the network if a 6416Y2

card is set to be the network’s Control Master.) Pro64 digital I/O devices are capable of syncing to and distributing

an external clock from a Word Clock or AES3 source to the network.

Control Data

The Pro64 version of A‑Net has built‑in, dedicated bandwidth for 14 channels of non‑audio control data through

the use of Aviom’s innovative Virtual Data Cables™. These data streams are always available to carry MIDI, RS‑232,

RS‑422, or GPIO (General Purpose I/O), and they never compete with the audio channels for network resources,

ab o u t a-ne t

8

Page 19

regardless of the system configuration. (Not all VDC data types are supported on every Pro64 device.)

Because VDC inputs are simply incorporated into the A‑Net stream, these control signals can be transmitted over

very long cable runs and even across an entire Pro64 network, significantly expanding the applications possible

with MIDI, RS‑232/422, and GPIO.

All VDC control data that enters the network stream from other Pro64 devices is retained in the A‑Net stream for

other devices to use; control data not supported by a particular device is simply ignored as it passes through.

A-Net Ports

Pro64 I/O devices have dual A‑Net ports, labeled A and B. Both ports carry a bidirectional A‑Net stream at all

times. (That is, both ports are always transmitting and receiving A‑Net data.)

Pro64’s Auto Mode provides a true audio network with 64 available “Slots” for transporting audio (at 44.1/48kHz).

Every audio Slot is available everywhere in the network, with no upstream/downstream restrictions. In Auto Mode,

there are no connection rules; devices can be connected in series, parallel, or combinations of series and parallel.

Connect a Cat‑5e (or fiber) cable to either the A or B A‑Net port and the system does the rest. No addressing or IT

configuration is required.

ab o u t a-ne t

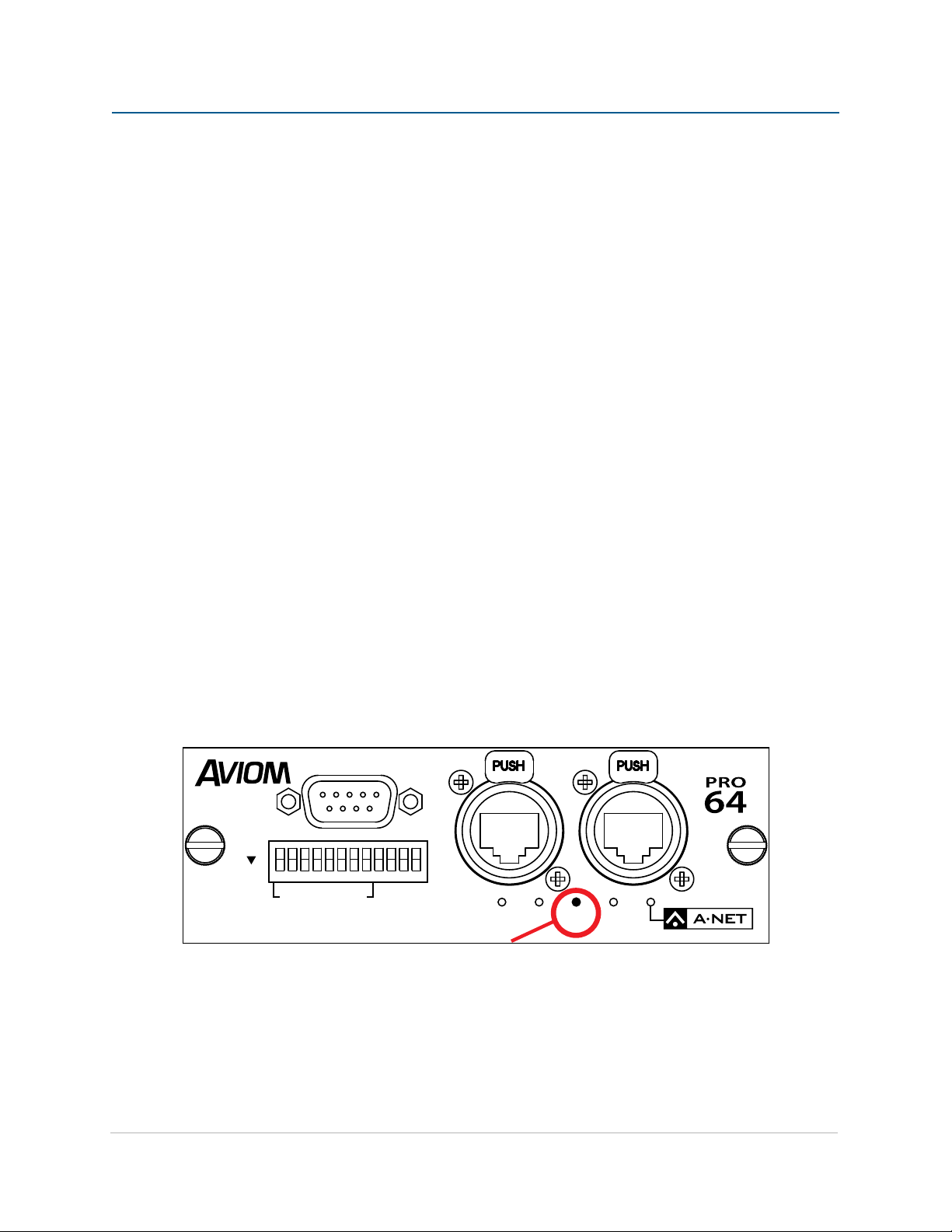

EtherCon Cat-5e A-Net ports on the front face of the 6416Y2 card

9

Page 20

Support For Pro16 Series Products

Pro64 Series products can be combined with Pro16® Series output products such as Personal Mixers or output

modules System by adding the Pro64 ASI A‑Net Systems Interface. This 1U device converts Pro64 A‑Net data

to Pro16 data, providing up to four streams of 16‑channel data (depending on the Pro64 sample rate) that can

be used with A360, A‑16II, and A‑16R Personal Mixers*, A‑Net Distributors, and the AV‑P2 and AN‑16/o Output

Modules.

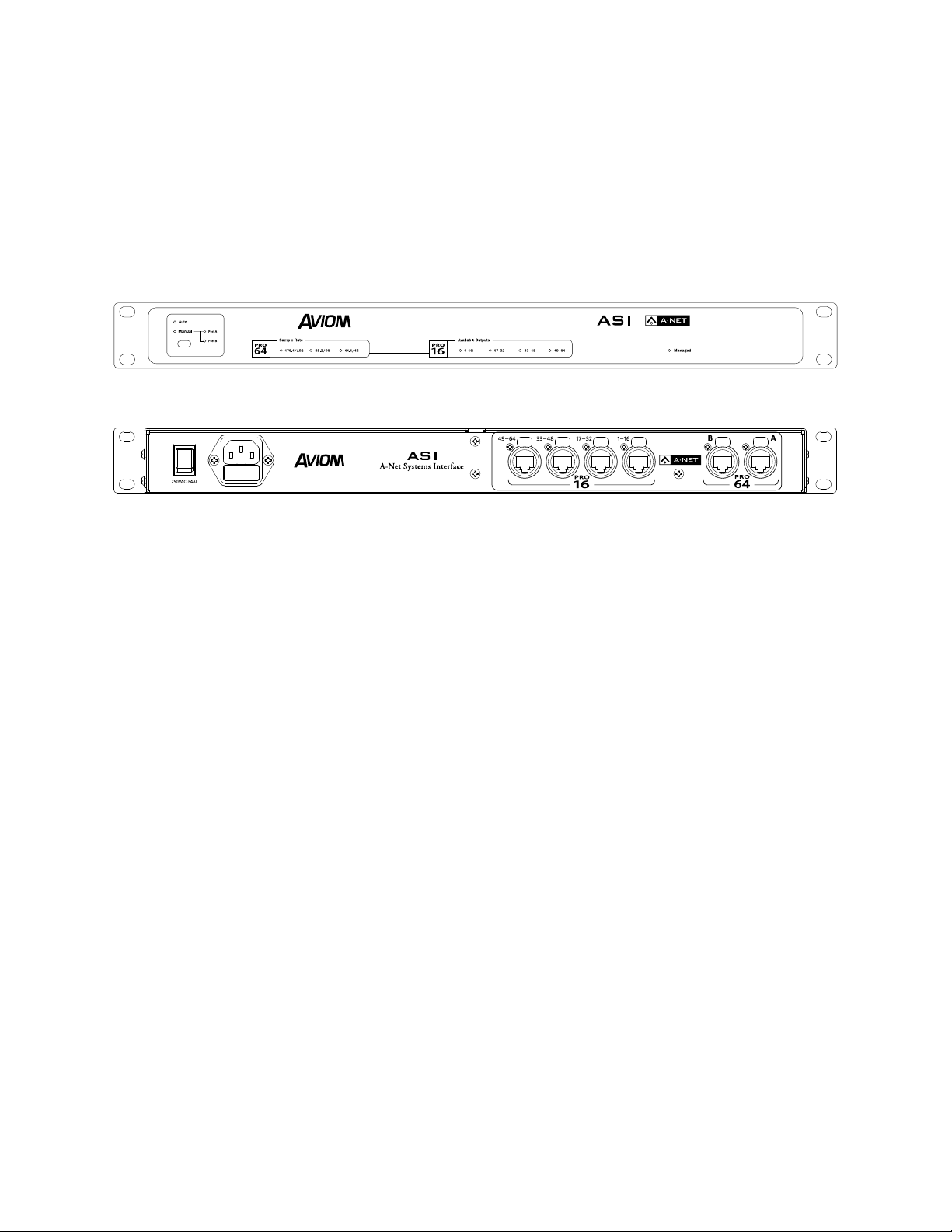

Front and rear panels of the ASI A-Net Systems Interface

The ASI is not compatible with the A‑Net output of Pro16 input devices such as the AN‑16/i, AN‑16/i‑M, the

Y1 console interface card (for Yamaha® digital products), and Pro16 A‑Net console cards built by third‑party

manufacturers for their digital console products.

* The original A‑16 Personal Mixer and some early A‑16R Personal Mixers are not compatible with the Pro16

output of the ASI A‑Net Systems Interface.

ab o u t a-ne t

10

Page 21

Pr o 64 us e r iN t e r F a c e

This section outlines some basic concepts of operation for Pro64 products. Pro64 I/O devices have some common

user interface elements that make setting up an audio network easy to understand. Although the 6416Y2

doesn’t have a front panel user interface with buttons and LEDs, its interface elements are similar to other Pro64

hardware I/O modules that use buttons and LEDs for comparable features (as seen in some of the examples). Any

combination of Pro64 devices can be used when setting up a Pro64 network.

A-Net Slot

Pro64 I/O devices come in a variety of configurations. To allow a large number of hardware audio input devices

to be available to the Pro64 audio network, Aviom has implemented the concept of the A‑Net Slot to simplify the

configuration of potentially complex audio networks. Simply put, an A‑Net Slot is a place in the network where an

audio input resource (analog or digital) is assigned so that it may be transported throughout the network.

A Pro64 network will always have a finite number of A‑Net Slots available that can be addressed by an unlimited

number of hardware channels. The actual number of available Slots is determined by the current sample rate.

Slots versus Channels

You might be wondering why Aviom chose to refer to the audio I/O resources in the Pro64 Series products as

‘’Slots.” Why not just call them “channels”?

We did this to avoid confusion between references to physical hardware audio resources and virtual network

audio resources. The word ‘’channel’’ is ambiguous and may cause confusion when configuring an audio network.

“Channel” appears in many contexts, including audio mixing consoles, mic preamps, DSP processors, and DAW

software.

We use the word ‘’channel’’ when referring to the physical audio inputs—analog or digital—on a piece of hardware

(such as the 16 line‑level XLR input jacks on the 6416i Input Module or a Yamaha console‑based resource such as

a direct output or aux bus send). Each of these audio input sources can be made active and added to the network

individually, and it is only when activated that they use any network resources (the A‑Net Slots). To allow this

functionality, Pro64 products separate the hardware resources from the available network resources by giving

each hardware input channel an on/off switch that allows it to be added to the network as needed.

It is these activated hardware resources that are being referred to as “Slots.” Pro64 audio networks can potentially

have a greater number of audio channels and hardware I/O devices connected than the network can make use of

at one time. This provides flexibility without requiring constant re‑patching. Managing resources in the network

can be simplified by using the Pro64 Network Manager software.

Keep in mind that a Pro64 A‑Net network can only manage a specific number of Slots at a time, and this number

varies with the sample rate being used (64 Slots at the 48kHz sampling rate).

In summary, think of “channels” as hardware resources that can be added to the network as needed and “Slots” as

locations within the Pro64 digital audio network pipeline that A‑Net uses to move data throughout the network.

Pr o 64 us e r In t e r f a c e

11

Page 22

Slots and Sample Rate

The current system‑wide sample rate will determine the number of A‑Net Slots that are available.

Sample Rate A-Net Slots Yamaha Compatibility

44.1kHz 64 Yes

48kHz 64 Yes

88.2kHz 32 Ye s

96kHz 32 Yes

176.4kHz 16 No

192k Hz 16 No

Even though the network sample rate may change the available number of A‑Net Slots, the I/O capacity of a

hardware device does not change. That is, a 16‑channel input module in a 96kHz network can still have all of its

channels activated.

The current network sample rate will also affect the display of available A‑Net Slot ranges. Slot ranges will always

have the same maximum number as seen in the sample rate chart. At 96kHz, for example, only Slots 1 through 32

are available; the Slot range from 33 to 64 is inactive and unavailable at 96kHz.

Slot ranges outside the maximum for the current sample rate can be selected, but attempting to activate a

channel in an unavailable range will result in an error message on hardware I/O modules (the selected channel

button, A‑Net Slot range, and sample rate LEDs will all flash). Note that console interfaces such as the 6416Y2 card

have no A‑Net Slot displays and cannot display these error messages. When using Pro64 Network Manager, Slots

outside the limits of the current sample rate cannot be activated.

P No t e : Yamaha devices do not support sample rates above 96kHz.

Pr o 64 us e r In t e r f a c e

12

Page 23

co N t r o l ma s t e r

RS–232/422

STEREO LINK

6416

Y

2

B A

ON

CTLCLKAUTO ERR

1 2 3 4 5 6 7 8 9 10 11 12

In every Pro64 network, one device will always be designated as the Control Master, the device that manages all

A‑Net resources for the network. The Control Master can be any I/O module in the network, and can be assigned

or changed by the user as needed. Only one device can be assigned as Control Master in a Pro64 network at a

time; an A‑Net Pro64 network cannot function without a Control Master.

The functions of the Control Master include:

System resource and information management •

Management of • active channels (Slots)

System‑level command and control functions •

Keeping track of all Pro64 devices in the network (by type and quantity) •

Control of the current system‑wide • sample rate

• Clock Master (analog modules only)

System lock via • password on/off for supported devices

Management of • Virtual Data Cable (VDC) resources

Management of • stereo link status

Requests to enter • Managed Mode for control with Pro64 Network Manager software

Communication with • Pro64 Network Manager software when configuring and managing a

network using a PC

The Control Master status is identified with a red LED on the front panel of the device currently assigned as the

Control Master. Depending on the type of device (rack‑mounted I/O module, AllFrame, or digital console interface

card), the method used for designating Control Master status may be different.

The Control Master LED is labeled CTL on the 6416Y2 card.

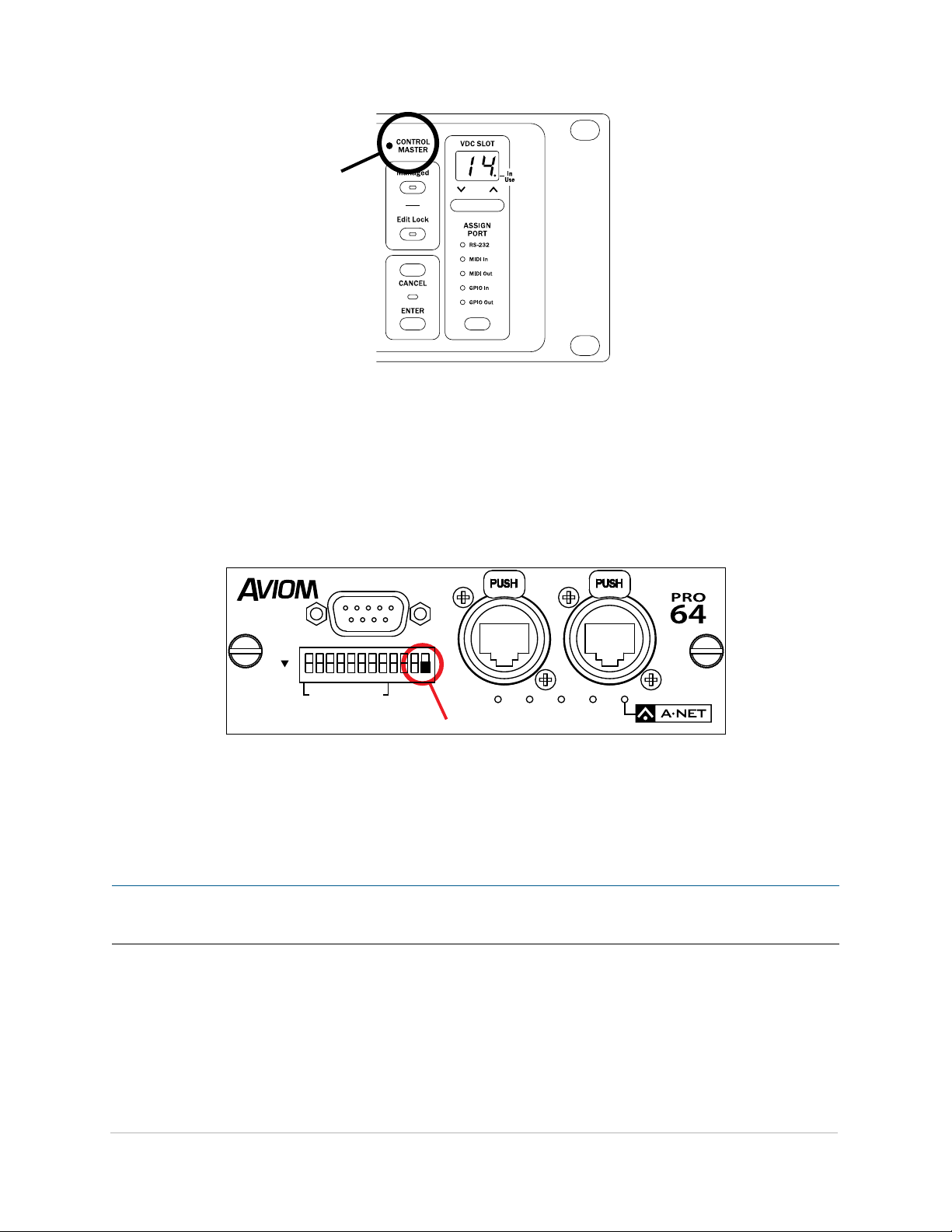

The Control Master LED (CTL) on the 6416Y2 card

co n t r o l ma s t e r

13

Page 24

Only one device in a Pro64 network can be designated as the Control Master. Here, a Pro64 I/O module is shown.

RS–232/422

STEREO LINK

6416

Y

2

B A

ON

CTLCLKAUTO ERR

1 2 3 4 5 6 7 8 9 10 11 12

Setting Control Master Status

Setting the 6416Y2 to be the network Control Master is done using the DIP switches found on the front panel.

The Control Master is set with switch 12, found in the same DIP switch block as the Stereo Link section of the

interface.

DIP switch 12 in the down position (shown in black) is used to set the Control Master status for a 6416Y2 card.

Move DIP switch 12 to the down position to make the 6416Y2 card the Pro64 network’s Control Master. In a

network with multiple 6416Y2 cards installed, only one card needs to be set as Control Master.

P No t e : When a 6416Y2 card is set to be Control Master, it is automatically set to be the Clock Master. The clock

comes from the Yamaha device in this case.

co n t r o l ma s t e r

14

Page 25

co N t r o l ma s t e r Fu N c t i o N s

RS–232/422

STEREO LINK

6416

Y

2

B A

ON

CTLCLKAUTO ERR

1 2 3 4 5 6 7 8 9 10 11 12

This section describes the individual functions of the Control Master device in a Pro64 network.

Enumeration

When the Control Master is powered on, its first job is to identify and count all connected A‑Net devices in the

network in a process called enumeration. The time for this process will vary based upon the number of Pro64

devices in a system. This process cannot begin until the host Yamaha device has finished its own power‑up cycle

when a 6416Y2 A‑Net Interface Card is the Control Master. Electrical power for the card comes from the Yamaha

host device.

Enumeration is an automated process performed by the command and control portion of A‑Net. There are no

user‑controllable functions or settings.

During the enumeration process, all connected A‑Net devices will flash their blue A‑Net LEDs, indicating that a

request to be added to the Pro64 network is being made. Once granted entry by the Control Master, the individual

device’s blue A‑Net LED will light solid to indicate that it is now receiving valid A‑Net packets and is part of the

Pro64 network.

If valid A‑Net packets are not received, the device will reset and wait until a valid A‑Net stream is detected.

During enumeration, any conflicts will also be resolved. For example, consider a new installation using eight

input devices set to the same A‑Net Slot range with all channels activated during a bench configuration. When all

these input devices are connected and then powered up, only one of them will be allowed to have all 16 channels

activated. The remaining seven modules will have their audio channels deactivated. Conflicts with channel

activation on 6416Y2 cards must be resolved manually if Slot activation is controlled via DIP switches or by using

the card’s Device Window from within Pro64 Network Manager.

Adding Pro64 Devices to a Network

When a new device is added to an existing Pro64 network, the new device makes a request to the Control Master

for inclusion in the network. During this time, the new device’s blue A‑Net LED will flash. When the new device

has been enumerated by the Control Master, its blue A‑Net LED will then light solidly to indicate that the Control

Master has granted the device access to the network. Adding a new device will interrupt network operation

briefly while enumeration occurs, except if the new device is connected to an open port on an MH10 or MH10f

Merger Hub already in the network.

co n t r o l ma s t e r

The blue LED is used to indicate network status.

15

Page 26

Control Master and Clock Source

RS–232/422

STEREO LINK

6416

Y

2

B A

ON

CTLCLKAUTO ERR

1 2 3 4 5 6 7 8 9 10 11 12

The Pro64 device designated as Control Master is also in control of the network master clock. The Clock Master

LED lights to indicate that a module is designated as the network’s master clock source. (The 6416dio Digital I/O

Module is the only exception to this rule.)

The red Clock Master (CLK) LED lights when a Pro64 device is the Control Master.

When an analog I/O module is the Control Master, no other analog module can be used as a clock source in an

all‑analog network. When a 6416Y2 console interface card is part of a Pro64 network, the 6416Y2 can be used as a

Clock Master for the network, but it must also be the network’s Control Master to do so.

When using a 6416Y2 card as the Clock Master, the clock is derived from the Yamaha host device and shared

throughout the Pro64 network. That clock reference can be the Yamaha host’s internal clock or an external clock

to which the Yamaha host device is synced. Changes to the host device’s sample rate will affect available A‑Net

Slots.

Multiple 6416Y2 cards can be used in a Yamaha host device, but only one can be set to be Control Master, which

automatically makes this card the Clock Master. If a 6416Y2 card is the Control Master it cannot simultaneously

send m‑control remote mic preamp control data.

Other Clock Sources

External clock sources for the Pro64 network can include:

The • internal clock from the Yamaha device —the 6416Y2 card must be the network’s

Control Master

Word Clock received via the external Word Clock inputs on a • Yamaha device—the

6416Y2 card must be the network’s Control Master

• Word Clock connected to the dedicated BNC Word Clock jack on a Pro64 digital I/O

device, such as the 6416dio Digital I/O Module or AllFrame F6

• The AES3 (AES/EBU) clock signal embedded in an AES3 digital signal connected to a

Pro64 digital I/O module such as the 6416dio or AllFrame

co n t r o l ma s t e r

16

Page 27

Clock Errors

If a clock error occurs, the Clock Master LED will blink indicating that an error has occurred. Common causes for a

clock error include:

Attempting to change the • sample rate on a device other than the Clock Master

Attempting to change the clock source when the network is password protected •

Removing or changing external clock sources on a digital I/O module •

Incorrect configuration of an • external clock source on a digital I/O module

Attempting to use a sample rate higher than 96kHz with the 6416Y2 card •

Network Sample Rate

When an analog device is the Control Master, the Control Master device is automatically designated as the

network Clock Master. It will remain the Clock Master until a different analog module is made the Control Master

or until a digital module such as the 6416Y2 card is added to the network and is assigned to be the Control Master

and Clock Master.

The network’s internal master clock is derived from the sample rate currently in use. The sample rate also affects

the total number of available A‑Net Slots available for use in the Pro64 network.

The Clock Master LED on the 6416Y2 card (labeled CLK) will light automatically when its Yamaha host is powered

on if the 6416Y2 card is Control Master and Clock Master for the Pro64 network.

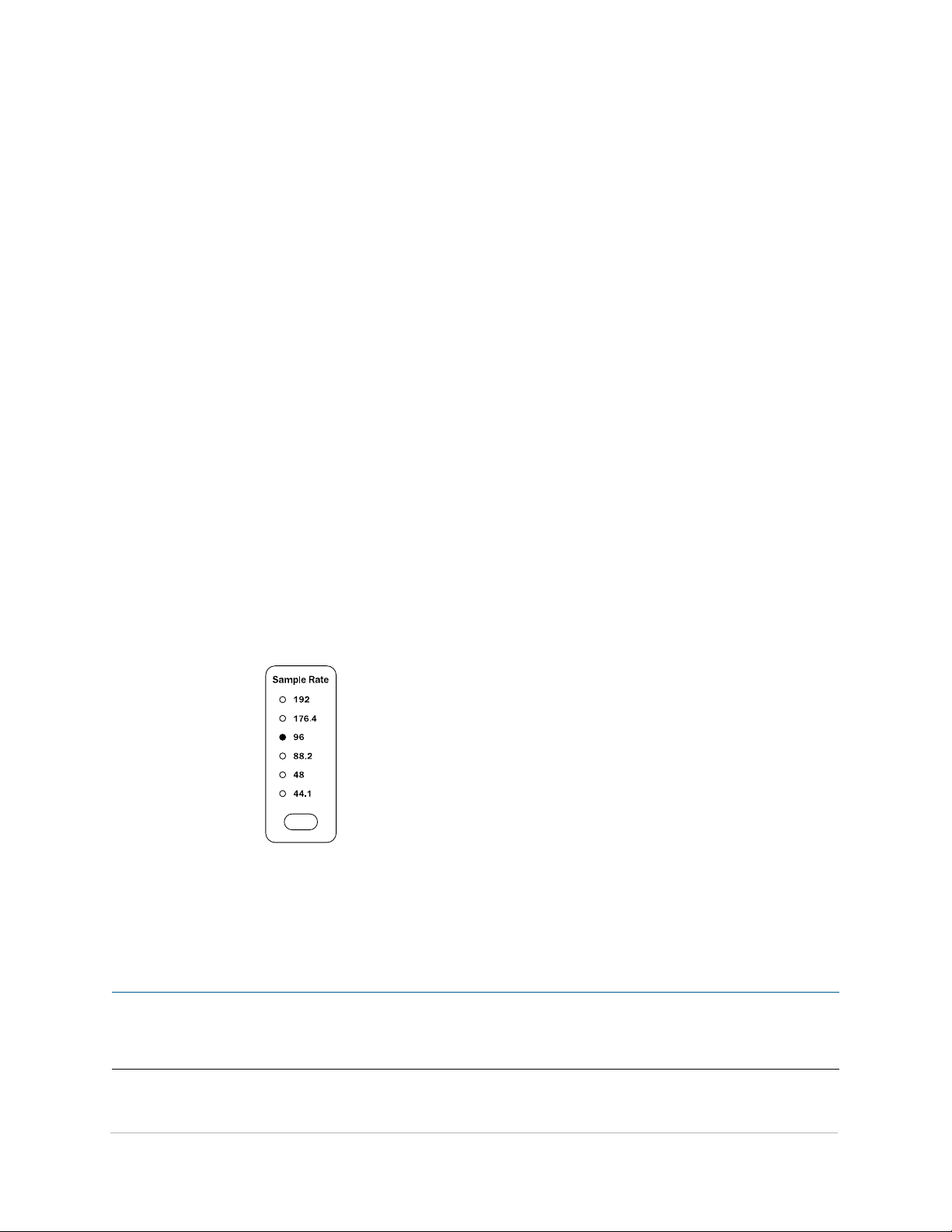

The Sample Rate section of a rack‑mounted hardware I/O module’s front‑panel interface (e.g., 6416i Input Module)

includes a group of LED indicators for displaying the current network sample rate. One LED will be lit at all times.

The 6416Y2 card has no such LEDs. However, the current sample rate information will be sent to all Pro64 network

devices when a 6416Y2 card is Control Master/Clock Master.

The sample rate display on Pro64 I/O modules

will display the current network-wide sample

rate when a 6416Y2 A-Net Interface Card is

the Clock Master, receiving its clock from the

Yamaha host device.

The current sample rate for the network will be displayed on all I/O modules in the network, and will update

to reflect any changes made from the Yamaha host (such as changing the sample rate from 44.1kHz to 48kHz,

or from 48kHz to 96kHz). Only one sample rate can be used at a time in a Pro64 network. When using Pro64

Network Manager to configure a network, the current sample rate will be displayed in the status bar. The network

sample rate can be changed from the software but all rules outlined previously still apply.

P No t e : If multiple Yamaha devices with 6416Y2 cards installed are used in a Pro64 network, only one 6416Y2

card can be set as the Pro64 network Control Master. Each additional Yamaha device must be a clock

slave in this situation.

co n t r o l ma s t e r

17

Page 28

Changing the Sample Rate

RS–232/422

STEREO LINK

6416

Y

2

B A

ON

CTLCLKAUTO ERR

1 2 3 4 5 6 7 8 9 10 11 12

Changing the sample rate when a 6416Y2 A‑Net Interface Card is the Clock Master is done from within the

Yamaha user interface. The range of available sample rates varies per Yamaha device; consult the Yamaha user

documentation for complete information on the available sample rates that are supported on a particular digital

product.

Changing the Yamaha host device’s sample rate will affect the number of available A‑Net Slots when the sample

rate changes from the 1x range (44.1/48kHz), to the 2x range (88.2/96kHz), or vice versa. Note that only sample

rates up to 96kHz are supported by Yamaha digital devices.

Password Protection

A Pro64 network can be password protected from the Control Master only. Once protected, the front‑panel

interface on all devices is locked, preventing changes to A‑Net Slots, sample rate, clock source, channel activation,

stereo links, and Virtual Data Cable assignments. Hardware switches, such as gain settings on input and output

devices, and rear‑panel DIP switches are in the analog domain and are not affected. Password protection remains

in force even when a system is power cycled.

All Pro64 hardware I/O devices except console interface cards and AllFrame devices ship with a default password.

The 6416Y2 card can be used to lock the network, but no password is available.

To lock the Pro64 network, move switch 9 in the front‑panel DIP switch block to the down position. Changes

to the network lock status will be instantly reflected on other network modules. No edits are possible until the

network is unlocked. When the 6416Y2 card is Control Master, simply move switch 9 in the front‑panel DIP switch

block to the up position to unlock the network and allow changes to be made.

DIP Switch 9 on the front panel can be used to lock the Pro64 network when in the down position.

P No t e : The password lock state cannot be accessed from within Pro64 Network Manager.

co n t r o l ma s t e r

18

Page 29

ma N a g e d mo d e

ON

ON

ON

ON

ON

ON

SW7

SW8

SW3

SW9

SW4

SW1

SW2

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

Managed Mode requires the use of a computer and the free Pro64 Network Manager software connected to the

Pro64 network for tasks such as configuration and channel routing, system monitoring, preamp remote control,

and firmware updates. The Control Master is the only module that can allow the network to enter Managed

Mode.

Entering Managed Mode from a 6416Y2 card requires that the 6416Y2 card be the network’s Control Master.

DIP Switch Block 9 (SW9) is used to set the network for Managed Mode operation. This means that changes to

the Pro64 network mode require the host Yamaha device to be powered down so that the 6416Y2 card can be

removed.

To change the network mode from a 6416Y2 card that is the network Control Master, move switches 9 and 10 in

SW9 to the up position. Switch 9 enables configuration and routing settings to be stored in memory on the card

bypassing the need to program the card using its DIP switches. Most users want the Pro64 Network Manager

software to be able to control the settings for the 6416Y2 card; setting DIP Switch 9 to the up position enables

this feature. DIP Switch 10 activates Managed Mode. Note that m‑control must be off when using Pro64 Network

Manager to configure a network connected to a 6416Y2 card.

To manage a network with a computer and Pro64 Network Manager, the PC needs to be connected to the Control

Master using a DB9 null modem cable (or compatible USB‑to‑RS‑232 converter) connected to the RS‑232 port

on the card. The 6416Y2 card must be set for RS‑232 operation and not for RS‑422; this is done from DIP Switch

Block 8 (SW8) on the circuit board. See page 32 for more information.

RS-232/RS-422

MY16/MY8

Settings source:

Stored in Memory or

Read DIP Switche s

The basic DIP switch setting to enable conguration from Pro64 Network Manager are shown.

Managed Mode

co n t r o l ma s t e r

19

Page 30

Exiting Managed Mode also requires that the host Yamaha device be powered down so that the 6416Y2 card can

be removed to have its DIP switch settings changed.

Refer to the Pro64 Network Manager software’s documentation for complete information about its use with a

Pro64 network.

co n t r o l ma s t e r

20

Page 31

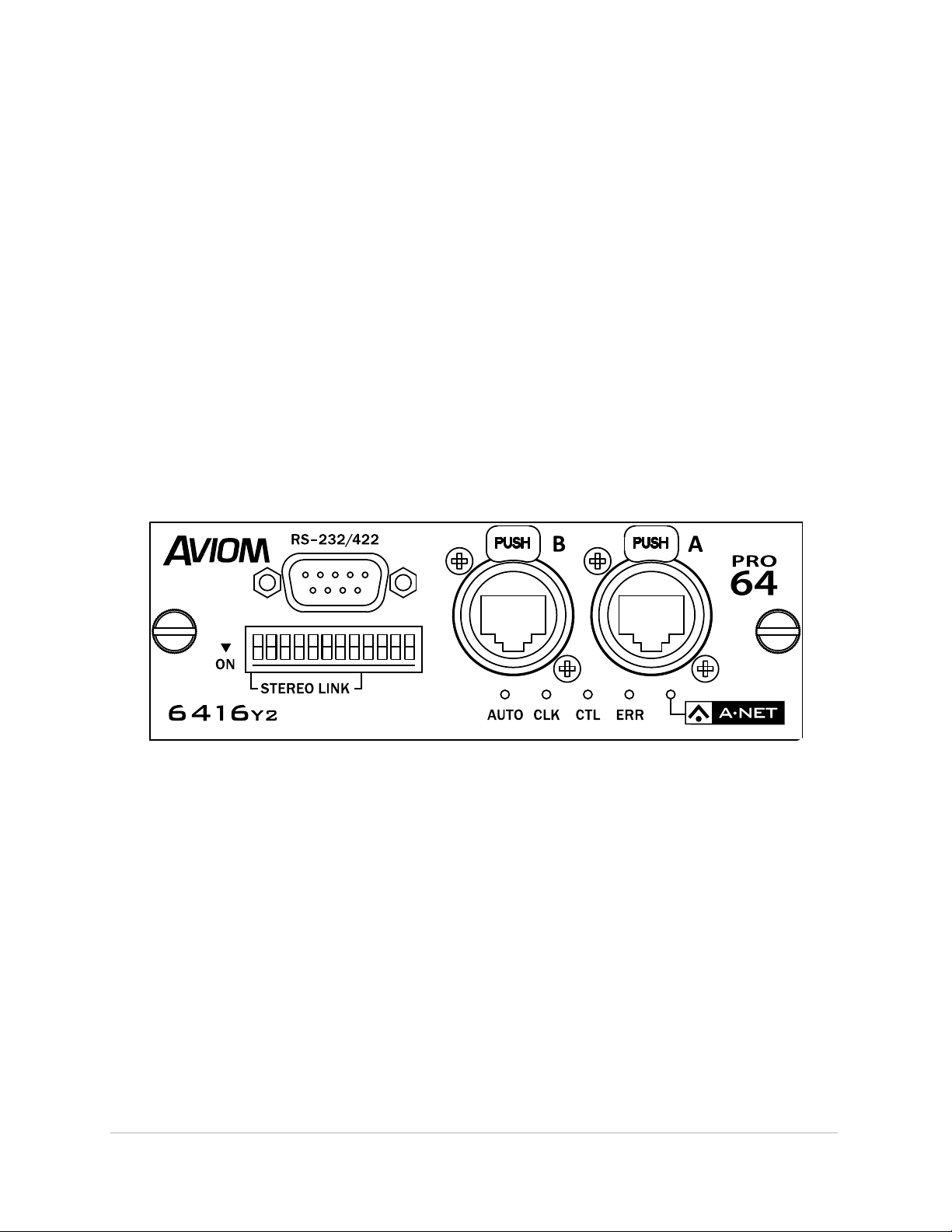

6416Y2 ca r d co m P o N e N t s

Thumb Screws 1.

2. RS‑232/422 DB9 connector

3. DIP Switches 1‑8 – Stereo Link

DIP Switches 9‑12 – system control4.

Locking 5. EtherCon RJ45 A‑Net connections

Auto Mode, 6. Clock Master (CLK), Control Master (CTL), and Error (ERR) LEDs

7. A‑Net active LED

Front Panel Features

This section describes the features and functions of the front panel of the 6416Y2 A‑Net card interface.

Thumb Screws

The two permanently attached thumb screws on the 6416Y2 card are used to secure the card to an MY expansion

slot in the Yamaha device. Always make sure that both thumb screws are firmly attached when using or

transporting the Yamaha device with a 6416Y2 installed.

RS-232/422 Port

The nine‑pin DB9 RS‑232/422 port can be configured to send/receive control data from the Yamaha interface or

from the Pro64 Virtual Data Cables. Selection of RS‑232 or RS‑422 and baud rate configuration is done via the DIP

switches on the circuit board of the 6416Y2 card.

Each type of control data communication—RS‑232 and RS‑422—requires a unique cable. RS‑232 requires a

null modem cable; RS‑422 requires a straight‑through cable. Cable pinouts for RS‑232 and RS‑422 are available

elsewhere in this document.

ca r d co m P o n e n t s

21

Page 32

DIP Switches

There is one 12‑position DIP switch block on the front panel of the 6416Y2, referred to as SW7 in the diagrams

that follow. Note the mounting direction of the DIP switches; to activate a switch on SW7, move it to the down

position. The default setting for all switches in this block is up.

In this diagram, channels 7-8, 13-14, and 15-16 are stereo linked. This 6416Y2 is also the network Control Master.

DIP switch handles are indicated in black.

Clock and Control DIP Switches

Within front panel DIP Switch Block SW7 is a group of four system‑level DIP switches. These control the system

lock via password, 6416m or AllFrame preamp remote control via m‑control, firmware update status, and Control

Master vs. Slave status respectively.

Switch Function Off (up) Function On (down)

1‑8 Single channel control Stereo Link per channel pair:

1‑2, 3‑4, etc.

9 System Unlocked System Locked

10 m‑control Off m‑control On

11 Local Code Update Off

(This switch is scanned only

at power up.)

12 Slave Device Control Master

Local Code Update Active

ca r d co m P o n e n t s

22

Page 33

Stereo Link DIP Switches

Eight Stereo Link DIP switches are provided allowing odd‑even channels to be paired for use with Aviom Pro16

personal monitoring products such as the A360, A‑16II, and A‑16R Personal Mixers. (This application requires the

ASI A‑Net Systems Interface.) Each DIP switch controls a pair of channels. Stereo Link information will be passed

to all Pro64 modules. If applicable, a Stereo Link LED will light on Pro64 output modules such as the analog 6416o

Output Module and 6416dio Digital I/O Module when stereo information is present in the network.

System Lock

When the 6416Y2 card is the Pro64 network Control Master, DIP switch 9 controls the Password Lock feature,

allowing all devices in the network to be locked from a single location. Unlike Pro64 hardware I/O devices, there is

no way to set a password code on the 6416Y2 card. The Pro64 network is locked/unlocked immediately when the

DIP switch is moved. No edits are possible when the network is locked.

m-control

Use DIP switch 10 on the 6416Y2 front panel to activate the m‑control™ for Yamaha Digital Consoles feature,

allowing remote control of 6416m Mic Input Module and AllFrame preamp settings such as gain, phantom power,

and low cut filter directly from the Yamaha user interface.

Local Code Update

The Local Code Update DIP switch is used in conjunction with Pro64 Network Manager’s firmware update utility.

This switch is scanned only when the host Yamaha device is powered up. Changing the position of this DIP switch

requires a reboot of the host device for the switch position to be recognized.

Control Master/Slave

DIP switch 12 is used to set the 6416Y2 card as either the network Control Master (down) or as a slave device

(up). Note that only one Pro64 device can be Control Master in a network. Although this DIP switch setting can

be changed on the fly, note that the Pro64 network will need to reset if a new Control Master device is selected.

Audio and control data are interrupted while the network resets.

A-Net Ports

Two Pro64 A‑Net ports are provided on the 6416Y2 card, labeled A and B. Each port has a Neutrik® EtherCon®

connector and can support standard RJ45 cables or those fitted with the heavy‑duty EtherCon plug.

Multiple 6416Y2 cards can be used in compatible Yamaha devices by linking them together via the A‑Net ports

with a short Cat‑5e or Cat‑6 jumper cable.

Front Panel LEDs

A set of five LEDs on the front panel of the 6416Y2 card is used to inform the user of various network conditions

and/or error states as described below.

ca r d co m P o n e n t s

23

Page 34

Auto LED

The Auto LED will be on and lit yellow to indicate that the Pro64 network is running in Auto Mode. In the off state,

this LED indicates that the network is operating in Managed Mode.

Control Master (CTL) LED

The yellow Control Master (CTL) LED indicates that the 6416Y2 card is set to be the network’s Control Master. A

6416Y2 card set to be the network’s Control Master is automatically set to be the network Clock Master as well,

deriving the network clock from the Yamaha host device. Only one Pro64 device can be set to be the Control

Master, regardless of the number of 6416Y2 cards installed.

When off, this LED state indicates that the card is a slave device. For more info about the Control Master, see

page 17.

Here, DIP switch 12 is in the down position, making this 6416Y2 card the Pro64 network Control Master. Both the Control Master

(CTL) and Clock Master (CLK) LEDs will be lit. (DIP switch handles are shown in black.)

Clock (CLK) LED

The Clock (CLK) LED will light yellow when the 6416Y2 card is set to be the Pro64 network’s Control Master, which

automatically sets the card to be the network Clock Master. When the 6416Y2 card functions as the network Clock

Master, its clock is derived from the Yamaha host device.

Only one Clock Master is possible in a Pro64 network. The Clock LED will remain unlit when the 6416Y2 card is

a slave device to another clock source (either the Pro64 network internal clock or from an external Word Clock

reference connected to a Pro64 digital I/O module such as the 6416dio).

Error (ERR) LED

The Error LED will light red to indicate errors in enumeration, configuration, or clocking.

A-Net LED

Whenever a valid A‑Net connection is detected, the blue A‑Net LED will light solid. The A‑Net LED will flash during

the network enumeration process as Pro64 devices are added to the network, or during a firmware update. If no

valid Pro64 A‑Net signal is detected, the A‑Net LED remains off.

ca r d co m P o n e n t s

24

Page 35

ci r c u i t bo a r d diP sW i t c h e s

The 6416Y2 A‑Net Interface Card can be configured using either the on‑board DIP switches or from the Pro64

Network Manager software. Although the card can be programmed manually by using the circuit board DIP

switches, the process can be greatly simplified by using the free Pro64 Network Manager software, allowing

almost all of the card’s DIP switches to be left in their default state.

Each block of DIP switches is labeled on the circuit board with the abbreviation “SW” followed by a number. There

is one DIP switch block on the front face of the card (SW7), and there are six DIP switch blocks on the card’s circuit

board. These will be hidden once the card is installed. There are a few DIP switches that must be set manually by

the user when using Pro64 Network Manager—the rest of the DIP switches are ignored.

The following table lists the functions of the various DIP switch blocks on the 6416Y2. Note the locations of the

various switches on the diagram that follows the table. Also note that Switch Block SW7 is on the front panel of

the card, facing the user.

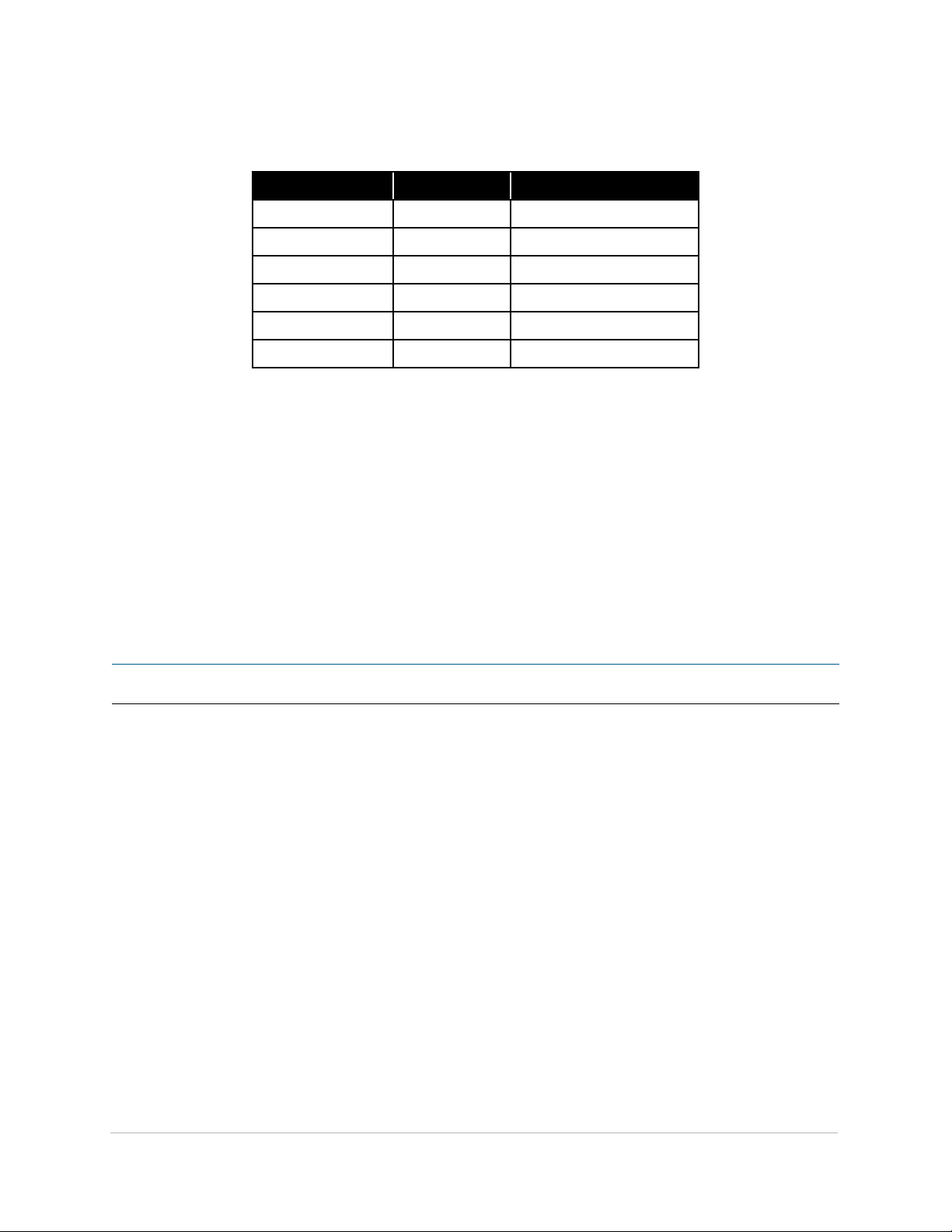

DIP Switch Block Functions

Switch Label Location

SW1 Circuit board 8

SW2 Circuit board 8

SW3 Circuit board 8 m‑control configuration

SW4 Circuit board 8

SW7 Front panel 12

SW8 Circuit board 10 VDC Port configuration

SW9 Circuit board 10

o t e : Always power off the Yamaha host device before removing a 6416Y2 card to make changes to any DIP

P N

switch settings.

Total

Switches

Function(s)

Activation on/off for channels 1‑8 from the Yamaha

device being routed into the Pro64 network

Activation on/off for channels 9‑16 from the Yamaha

device being routed into the Pro64 network

Configuration of RS‑232/422 Virtual Data Cable (VDC) on

rear panel of 6416Y2 card

Stereo Link, Network Password Lock, m‑control on/off,

Code Update on/off, Control Master/Slave configuration

Pro64 Network Mode, Transmit/ Receive Port and Slot

selection, Managed Mode on/off

ca r d co m P o n e n t s

25

Page 36

DIP Switch Locations

ON

ON

ON

ON

ON

ON

SW7

SW8

SW3

SW9

SW4

SW1

SW2

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

This diagram shows the locations of the 6416Y2 DIP switches.

Mode

Remote Control

Channel Activation (1-8)

Channel Activation (9-16)

Front Panel

MY16/MY8VDC

Transmit Port

Transmit Slots (from console)

Control Source

Managed Mode

Receive Slots (to console)

Receive Port

VDC

The 6416Y2 DIP switches; the arrow indicates SW7, on the front of the card, shown below.

(DIP switch handles are indicated in black.)

SW7, Front of Card

Control

Master

Remote

Control

dIP sw I t c h e s

26

Page 37

diP sW i t c h Fu N c t i o N s

The individual switch functions for circuit board DIP switch blocks SW1, SW2, SW3, SW4, SW8, and SW9 are

detailed in this section.

DIP Switch Block 1 (SW1)

Use Switch Block 1 (SW1) to activate channels 1‑8 on the 6416Y2 card and assign them to Slots within the Pro64

network. In the down position, channels 1‑8 are off; move a DIP switch to the up position to activate a channel

and assign it to a Slot in the Pro64 network.

The default position for the SW1 DIP switches is down (channel‑to‑Slot activation is off). These switches are

ignored when using Pro64 Network Manager.

P No t e : Signals from the Yamaha device cannot be routed into the Pro64 network unless these DIP switches are

activated.

(Applies only when programming the 6416Y2 card from its on-board DIP switches)

DIP Switch Block 2 (SW2)

Switch Block 2 (SW2) is used to assign channels 9‑16 on the 6416Y2 card to Slots in the Pro64 network when

operating in MY16 Mode (channels 9‑16 are not available in MY8 Mode). In the down position, channels 9‑16 are

off; move a DIP switch to the up position to activate a channel, which assigns it to a Slot and makes it available

throughout the network. These switches are ignored when using Pro64 Network Manager.

P No t e : Routing an audio resource from within the Yamaha user interface to the 6416Y2 installed in an

expansion slot requires that the SW1 and SW2 Slot activation DIP switch settings be set correctly in

order to pass digital information from the Yamaha device to the Pro64 network.

(Applies only when programming the 6416Y2 card from its on-board DIP switches)

The exact Pro64 Slot range to which the channels from the 6416Y2 card are routed is determined by the settings

of DIP switches 5 and 6 on block SW9 or from the settings within Pro64 Network Manager.

The default position for the SW2 switches is down (channel‑to‑Slot activation is off). When operating in MY8

mode, leaving these switches in the down position will help avoid potential Slot availability conflicts with other

Pro64 devices in the network.

A blank DIP switch template is provided at the end of this User Guide to allow you to record and save 6416Y2 card

settings.

dIP sw I t c h e s

27

Page 38

DIP Switch Block 3 (SW3)

ON

ON

ON

ON

ON

ON

SW7

SW8

SW3

SW9

SW4

SW1

SW2

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

The DIP switches in block SW3 are used to configure m‑control, a feature that allows the user to control preamp

settings on 6416m Mic Input Module or AllFrame devices in the Pro64 network directly from compatible Yamaha

consoles.

See page 42 for more info on setting up m‑control.

SW3 congures the m-control feature, for use with 6416m mic preamps.

dIP sw I t c h fu n c t I o n s

28

Page 39

SW3 Switch Functions

The switches on SW3 have the following functions. Unless otherwise noted, these settings apply only when

programming the 6416Y2 card manually from its on‑board DIP switches.

DIP Switch Block SW3 Functions

DIP Switch Parameter Function

1 Channel/Slot Control 1‑16 Activates m‑control for 6416m channels 1‑16 from the current

Yamaha device

2 Channel/Slot Control 17‑32 Activates m‑control for 6416m channels 17‑32 from the current

Yamaha device

3 Channel/Slot Control

33‑48

4 Channel/Slot Control

49‑64

5 RS‑422 Control Source

Select

(Backplane or DB9

connector)

6 Pad Mode Controls how the 24dB pad built into the remote Pro64

7

Preamp Control Group

8

assignment

Activates m‑control for 6416m channels 33‑48 from the current

Yamaha device

Activates m‑control for 6416m channels 49‑64 from the current

Yamaha device

Selects the source of the Yamaha RS‑422 remote control

information—directly from the console’s backplane connector,

or from the DB9 Remote connector (depends on the console)

preamps operate. Two choices are available: Auto Pad and

Manual Pad.

Sets a Control Group (1‑4) for the console and 6416Y2 card;

allows only mic preamps in the same Control Group to be

changed

Note that any combination of switches 1‑4 on block SW3 can be used to send control to a specific range of active

Pro64 6416m mic preamp channels. This set of DIP switches will typically be set to less than or equal to the

total number of channels that the console can support—16 channels on the LS9‑16, 32 channels on the LS9‑32,

48 channels on the M7CL, and 64 channels on the PM5D.

dIP sw I t c h fu n c t I o n s

29

Page 40

The table below shows parameters that can be changed on DIP switch block SW3 when programming the 6416Y2

manually. Remember that any combination of DIP switches 1‑4 can be used to allow remote control data to be

sent to a specific range of active Pro64 mic preamp channels.

DIP Switch Block SW3 Settings

DIP Switch Parameter Down Up

1 m‑control Channel/Slot Control 1‑16 Control off Control on (1‑16)

2 m‑control Channel/Slot Control 17‑32 Control off Control on (17‑32)

3 m‑control Channel/Slot Control 33‑48 Control off Control on (33‑48)

4 m‑control Channel/Slot Control 49‑64 Control off Control on (49‑64)

5 RS‑422 Control Source Select Use backplane connector Use DB9 Remote

6 Pad Mode Manual Auto

7/8 Control Group See table below

Control Group DIP Switch 7 DIP Switch 8

1 Down Down

2 Up Down

3 Down Up

4 Up Up

connector

The m‑control Channel/Slot Control settings are separate from the audio I/O setup (including A‑Net Transmit and

Receive settings). This parameter sets up remote control communications for all 6416Y2 cards installed in the

same console. Each 6416Y2 card needs its A‑Net Transmit and A‑Net Receive range properly configured in order

to get the desired results for your application.

DIP Switch Block (SW4)

The DB9 RS‑232/422 Virtual Data Cable (VDC) port on the 6416Y2 card’s front panel is configured using SW4.

Use the eight DIP switches in this block to choose baud rate settings for communicating with other RS‑232/422

compatible devices. Setting these switches properly is an important part of the firmware update process.

The switches on SW4 have the following functions.

Switch Function Off (down) Function On (up)

1 One Stop Bit Two Stop Bits

2 7 Data Bits 8 Data Bits

3 Parity Even Parity Odd

4 No Parity Parity

5

6

7

8

Baud Rate Select

See Baud Rate Table

dIP sw I t c h fu n c t I o n s

30

Page 41

Baud Rate Table

ON

SW4

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8

Use the following table to set baud rates for DIP switches 5‑8 in Switch Block SW4. The down position is o f f and

the up position is o n for each DIP switch.

DIP Switches in Block 4 (SW4) 8

Baud Rate

120 0 off off off off

2400 on off off off

4800 off on off off