Page 1

P/N 9310 1010 0001F rev. 2.00

Line-Level Input Module

© 2009 Aviom, Inc.

User Guide

Page 2

Certifications

Pb

Pb-Free

ETL/cETL Listed

EMC: EN 55013, EN 55020, SAA AS/NZS 1053

Conforms to: IEC 60065, EN 60065, UL 6500‑2001

Certified to: CAN/CSA E60065, KETI

RoHS Status: Pb‑free

Notice of Rights

All rights reserved. No part of this document may be reproduced or

transmitted in any form or by any means—electronic, mechanical, photocopy,

recording, or otherwise—without written permission of Aviom, Inc.

Trademarks

Aviom, A‑Net, the A‑Net icon, Pro16, Pro64, and Virtual Data Cable are

trademarks of Aviom, Inc.

All other trademarks are the property of their respective owners.

© 2009 Aviom, Inc. All rights reserved.

Information subject to change without notice.

ii

Page 3

READ THIS FIRST

!

Important Safety Instructions

Read these instructions. 1.

Keep these instructions2.

Heed all warnings.3.

Follow all instructions.4.

Do not use this apparatus near water.5.

Clean only with a dry cloth.6.

Do not block any ventilation openings. Install in accordance with the 7.

manufacturer’s instructions.

Do not install near any heat sources such as radiators, heat registers, 8.

stoves, or other apparatus (including amplifiers) that produce heat.

Do not defeat the safety purpose of the polarized or grounding‑type 9.

plug. A polarized plug has two blades with one wider than the

other. A grounding type plug has two blades and a third grounding

prong. The wide blade or third prong are provided for your safety. If

the provided plug does not fit your outlet, consult an electrician for

replacement of the obsolete outlet.

Protect the power cord from being walked on or pinched, particu‑10.

larly at plugs, convenience receptacles, and the point where they exit

the apparatus.

Only use attachments/accessories specified by the manufacturer.11.

Use only with the cart, stand, tripod, bracket, or table specified by 12.

the manufacturer, or sold with the apparatus. When a cart is used,

use caution when moving the cart/apparatus combination to avoid

injury from tip‑over.

Unplug this apparatus during lightning storms or when unused for 13.

long periods of time.

Refer all servicing to qualified personnel. Servicing is required 14.

when the apparatus has been damaged in any way, such as when

the power‑supply cord or plug is damaged, liquid has been spilled

or objects have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally, or has been

dropped.

No on/off power switches are included in the system. The external 15.

power supply should be used to control power to an Aviom device.

This power supply should remain readily operable.

The solid line over dashed line symbol (16. ) indicates that the

input voltage must be a DC voltage.

The box within a box symbol ( 17. ) indicates that the external power

supply is double insulated.

ii i

Page 4

! !

WARNING!

TO REDUCE THE DANGER OF ELECTRICAL SHOCK DO NOT REMOVE COVERS.

NO USER SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL ONLY

To reduce the risk of fire or electrical shock, do not expose this

product to rain or other types of moisture.

To avoid the hazard of electrical shock, do not handle the

power cord with wet hands.

Replace fuse with same type and rating.

Operating Temperature: 10˚C to 50˚C (50˚F to 122˚F)

Risque de choc électrique – ne pas ouvrir. Pour réduire le risque de feu ou de choc

électrique, ne pas exposer cet équipement à la pluie ou la moisissure. Pour réduire

le risque de choc électrique, ne pas retirer le couvercle. Pièces non remplaçables

par l’utilisateur. Confier la réparation à une personne qualifiée. Attention – utiliser

seulement un fusible de rechange de même type.

Cet appareil est conforme à la section 15 de la norme FCC. Son fonctionnement est

soumis aux conditions suivantes : (1) cet équipement ne doit pas causer des interférences

nocives, et (2) cet équipement doit accepter toute interférence captée incluant les

interférences pouvant causer des opérations indésirables.

Cet appareil numérique de Classe B est conforme à la norme NMB‑003 du Canada.

CAUTION:

Using any audio system at high volume levels can cause permanent •

damage to your hearing.

Set your system volume as low as possible. •

Avoid prolonged exposure to excessive sound pressure levels.•

IMPORTANT:

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.•

Increase the separation between the equipment and receiver.•

Connect the equipment into an outlet on a circuit different from •

that to which the receiver is connected.

Consult the dealer or an experienced radio/T V technician for help.•

Changes or modifications to the product not expressly approved by Aviom, Inc. could

void the user’s FCC authority to operate the equipment.

iv

Page 5

Aviom, Inc. Limited Warranty

Aviom, Inc. warrants this product against defects in materials and workmanship for a

period of one year from the date of the original retail purchase.

This warranty does not apply if the equipment has been damaged due to misuse,

abuse, accident, or problems with electrical power. The warranty also does not apply

if the product has been modified in any way, or if the product serial number has been

damaged, modified, or removed.

If a defect is discovered, first write or call Aviom, Inc. to obtain a Return Authorization

number. No service will be performed on any product returned without prior

authorization. Aviom, Inc. will, at its option, repair or replace the product at no charge

to you. The product must be returned during the warranty period, with transportation

charges prepaid to Aviom, Inc., 1157 Phoenixville Pike, Suite 201, West Chester, PA

19380. You must use the product’s original packing materials for shipment. Shipments

should be insured for the value of the product. Include your name, address, phone

number, description of the problem, and copy of the original bill of sale with the

shipment. The Return Authorization number should be written on the outside of the

box.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE OTHER

RIGHTS, WHICH VARY FROM STATE TO STATE (OR JURISDICTION TO JURISDICTION).

AVIOM’S RESPONSIBILITY FOR MALFUNCTIONS AND DEFECTS IN HARDWARE IS

LIMITED TO REPAIR AND REPLACEMENT AS SET FORTH IN THIS LIMITED WARRANTY

STATEMENT. ALL EXPRESS AND IMPLIED WARRANTIES FOR THE PRODUCT, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO THE WARRANTY PERIOD

SET FORTH ABOVE. NO WARRANTIES, WHETHER EXPRESS OR IMPLIED, WILL APPLY

AFTER SUCH PERIOD.

AVIOM, INC. DOES NOT ACCEPT LIABILITY BEYOND THE REMEDIES SET FORTH IN THIS

LIMITED WARRANTY DOCUMENT. AVIOM, INC.’S LIABILITY IS LIMITED TO THE REPAIR

OR REPLACEMENT, AT OUR OPTION, OF ANY DEFECTIVE PRODUCT, AND SHALL IN NO

EVENT INCLUDE INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND.

SOME STATES DO NOT ALLOW EXCLUSIONS OR LIMITATION OF IMPLIED WARRANTIES

OR LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS MAY NOT APPLY TO YOU.

v

Page 6

Warranty Information

Please record the following information for future reference:

Your Authorized Aviom Dealer:

Name:

Address:

Phone:

Serial Numbers of Your Aviom Products:

Date of Purchase:

Your Authorized Aviom Dealer is your primary source for service and support.

The information recorded above will be helpful in communicating with your

Authorized Aviom Dealer should you need to contact Aviom Customer

Service. If you have any questions concerning the use of this unit, please

contact your Authorized Aviom Dealer first. For additional technical support,

or to find the name of the nearest Authorized Aviom Repair Station, check

the Aviom web site at www.aviom.com.

To fulfill warranty requirements, your Aviom product should be serviced

only at an authorized Aviom service center. The Aviom serial number label

must appear on the outside of the unit, or the Aviom warranty is void.

This manual and its contents are copyrighted by Aviom, Inc. All rights are

reserved by Aviom, Inc. This document may not, in whole or in part, be

copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine‑readable form without prior written consent from

Aviom, Inc.

The software and/or firmware contained within Aviom products is

copyrighted and all rights are reserved by Aviom, Inc.

Although every effort has been made to ensure the accuracy of the text

and illustrations in this manual, no guarantee is made or implied as to the

accuracy of the information contained within.

v i

Page 7

Table of Contents

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The EtherCon Connector. . . . . . . . . . . . . . . . . . . 1

Firmware Notice . . . . . . . . . . . . . . . . . . . . . . . 2

About A-Net . . . . . . . . . . . . . . . . . . . . . . . . . 3

Clocking . . . . . . . . . . . . . . . . . . . . . . . . 3

Control Data . . . . . . . . . . . . . . . . . . . . . . 4

A‑Net Ports . . . . . . . . . . . . . . . . . . . . . . . 4

Support For Pro16 Series Products . . . . . . . . . . . 5

AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AC Line Conditioning . . . . . . . . . . . . . . . . . . . . 6

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pro64 Interface Conventions . . . . . . . . . . . . . . . . 8

Cat‑5e . . . . . . . . . . . . . . . . . . . . . . . . . 8

Button Presses . . . . . . . . . . . . . . . . . . . . . 8

Changing Values . . . . . . . . . . . . . . . . . . . . 8

Selecting Values . . . . . . . . . . . . . . . . . 9

DIP Switches . . . . . . . . . . . . . . . . . . . 9

Pro64 User Interface . . . . . . . . . . . . . . . . . . . . 10

Basic Actions . . . . . . . . . . . . . . . . . . . . . . . . 10

A-Net Slot . . . . . . . . . . . . . . . . . . . . . . . . . 11

Slots versus Channels . . . . . . . . . . . . . . . . . 11

Slots and Sample Rate . . . . . . . . . . . . . . . . 12

A-Net Slot Display . . . . . . . . . . . . . . . . . . . . . 13

A‑Net Slot Example . . . . . . . . . . . . . . . 15

Network Modes . . . . . . . . . . . . . . . . . . . . . . 17

Auto Mode . . . . . . . . . . . . . . . . . . . . . . 17

Manual Mode . . . . . . . . . . . . . . . . . . . . . 17

Control Master . . . . . . . . . . . . . . . . . . . . . . 19

Setting Control Master Status . . . . . . . . . . . . . 20

Control Master Functions . . . . . . . . . . . . . . . . . 20

Enumeration . . . . . . . . . . . . . . . . . . . . . 20

Adding Pro64 Modules to a Network . . . . . . . . . 21

Changing Settings . . . . . . . . . . . . . . . . . . . . . 21

Control Master and Clock Source . . . . . . . . . . . . . 22

Clock Errors . . . . . . . . . . . . . . . . . . . . . . 23

Network Sample Rate . . . . . . . . . . . . . . . . . . . 23

Changing the Sample Rate . . . . . . . . . . . . . . 24

Auto/Manual Mode Selection . . . . . . . . . . . . . . . 24

Changing the Network Mode . . . . . . . . . . . . . 25

Managed Mode . . . . . . . . . . . . . . . . . . . . . . 25

Password Protection . . . . . . . . . . . . . . . . . . . 26

v i

Page 8

Front Panel Components . . . . . . . . . . . . . . . . . . . . 28

Rear Panel Components . . . . . . . . . . . . . . . . . . . . . 30

Front Panel Features . . . . . . . . . . . . . . . . . . . . . . 33

Enter/Cancel Buttons . . . . . . . . . . . . . . . . . . . . 33

A‑Net LED . . . . . . . . . . . . . . . . . . . . . . . . . 33

Control Master . . . . . . . . . . . . . . . . . . . . . . . 33

Control Master Errors . . . . . . . . . . . . . . . . . 34

A‑Net Slot Configuration . . . . . . . . . . . . . . . . . . 34

Setting the A‑Net Slot Range . . . . . . . . . . . . . 35

A‑Net Transmit . . . . . . . . . . . . . . . . . . . . . . . 35

Changing the A‑Net Transmit Port . . . . . . . . . . 36

Clock Master . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Sample Rate . . . . . . . . . . . . . . . . . . . . . . . . 37

Changing the Sample Rate . . . . . . . . . . . . . . 37

Sample Rates and A‑Net Slots . . . . . . . . . . . . . 38

Channel Activation Button . . . . . . . . . . . . . . . . . 38

Channel Activation Rules . . . . . . . . . . . . . . . 39

Level Meter LEDs . . . . . . . . . . . . . . . . . . . . . . 39

Stereo Link Button . . . . . . . . . . . . . . . . . . . . . 40

Gain Switch . . . . . . . . . . . . . . . . . . . . . . . . 41

Managed Button . . . . . . . . . . . . . . . . . . . . . . 41

Edit Lock Button . . . . . . . . . . . . . . . . . . . . . . 42

Query Functions (Get Info) . . . . . . . . . . . . . . 42

VDC Configuration . . . . . . . . . . . . . . . . . . . . . . . 43

VDC Slot Display . . . . . . . . . . . . . . . . . . . . . . 44

VDC In Use LED . . . . . . . . . . . . . . . . . . 45

Assigning a VDC Slot . . . . . . . . . . . . . . . . . . . . 45

Deactivate an Active VDC Slot . . . . . . . . . . . . . . . . 46

Advanced Functions . . . . . . . . . . . . . . . . . . . . . . . 47

Function Button . . . . . . . . . . . . . . . . . . . . . . 47

Clear A‑Net Resources. . . . . . . . . . . . . . . . . . . . 48

Password Lock . . . . . . . . . . . . . . . . . . . . . . . 48

Password Unlock . . . . . . . . . . . . . . . . . . . . . . 48

Set a New Password. . . . . . . . . . . . . . . . . . . . . 49

Sample Alignment . . . . . . . . . . . . . . . . . . . . . 49

Sample Alignment Lock Status . . . . . . . . . . . . 49

Get New Sample Alignment Lock Value . . . . . . . . 50

Use Stored Sample Alignment Lock Value . . . . . . . 51

Use Default Sample Alignment Lock Value . . . . . . 51

Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . 52

Update Connections . . . . . . . . . . . . . . . . . . . . 52

Firmware Update ‑ Local . . . . . . . . . . . . . . . . . . 52

Error Recovery . . . . . . . . . . . . . . . . . . . . 53

Firmware Update ‑ via A‑Net . . . . . . . . . . . . . . . . 53

Restore Factory Defaults . . . . . . . . . . . . . . . . . . 54

Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . 56

v i i

Page 9

AC Power . . . . . . . . . . . . . . . . . . . . . . . 56

Fuse . . . . . . . . . . . . . . . . . . . . . . 56

A‑Net Ports . . . . . . . . . . . . . . . . . . . . . . 56

Balanced Line‑Level Inputs . . . . . . . . . . . . . . 56

DB25 Audio Thru/Alternate In . . . . . . . . . . . . . 57

DB25 Pinout . . . . . . . . . . . . . . . . . . 57

Alternate Input . . . . . . . . . . . . . . . . . . . . 58

Virtual Data Cables . . . . . . . . . . . . . . . . . . . . 59

GPIO . . . . . . . . . . . . . . . . . . . . . . . . . 59

GPIO Configuration DIP Switches . . . . . . . . 59

GPIO Terminal Blocks . . . . . . . . . . . . . . 60

MIDI In, MIDI Out . . . . . . . . . . . . . . . . . . . 60

Configuring a MIDI VDC . . . . . . . . . . . . 60

RS‑232 Port . . . . . . . . . . . . . . . . . . . . . . 61

RS‑232 Configuration DIP Switches . . . . . . . 62

RS‑232 Baud Rates . . . . . . . . . . . . . . . 62

Control Master DIP Switch . . . . . . . . . . . . . . 63

Building a Pro64 Network . . . . . . . . . . . . . . . . . 64

Choosing a Network Mode . . . . . . . . . . . . . . 64

Connecting Pro64 Modules . . . . . . . . . . . . . . 64

Basic Routing . . . . . . . . . . . . . . . . . . . . . 64

Auto Mode Connections . . . . . . . . . . . . . . . . . . 65

Digital Copies in Auto Mode . . . . . . . . . . . . . 66

Adding a Merger Hub in Auto Mode . . . . . . . . . 67

Manual Mode Connections . . . . . . . . . . . . . . . . 68

Digital Copies in Manual Mode . . . . . . . . . . . . 72

Specifications . . . . . . . . . . . . . . . . . . . . . . . 75

Dimensions . . . . . . . . . . . . . . . . . . . . . . 77

6416i Block Diagram . . . . . . . . . . . . . . . . . . . . 78

GPIO Specifications . . . . . . . . . . . . . . . . . . . . 79

GPIO Plugs . . . . . . . . . . . . . . . . . . . 80

MIDI/GPIO Cable Lengths . . . . . . . . . . . . 80

Factory Default Settings . . . . . . . . . . . . . . . . . . 80

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Warranty Registration . . . . . . . . . . . . . . . . . . . 87

vi i i

Page 10

Welcome

Thank you for purchasing the 6416i Input Module. This User Guide is

designed to familiarize you with the features and functions of your new

Pro64® product. All Pro64 products are powered by A‑Net®, Aviom’s

proprietary data transmission protocol designed especially for the unique

demands of live streaming audio. In developing the Pro64 Series, we have

made every effort to make the user interface as easy to use and understand

as possible. We encourage you to read the manual completely, as some of the

powerful features of your new product may not be immediately apparent.

Features

The 6416i Input Module provides a host of professional features designed

to make audio networking with Pro64 Series products easy to set up and

configure in a variety of professional audio situations.

6416i Input Module Features:

Sixteen analog line‑level audio channels•

XLR line‑level input jacks •

• DB25 Audio Thru/Alternate In connections

Individual A‑Net• ® Slot activation buttons per channel

Link switches for stereo channel pairing•

Two A‑Net ports•

• EtherCon® RJ45 network connectors

The EtherCon Connector

Pro64 Series products feature locking connectors for all network I/O. The

Neutrik® EtherCon connector is a dual RJ45‑type connector that can receive

a standard Category 5e cable or a cable fitted with the special locking

EtherCon connector.

When using a standard Cat‑5e cable, plug the cable into the center of the

EtherCon jack; release the cable by pressing on the small plastic tab built into

the cable connector.

The locking EtherCon connector is similar to an XLR plug, the kind commonly

used on microphone cables. Insert an EtherCon‑equipped cable into the

jack until it clicks and locks in place. To remove the cable, press on the metal

release tab at the top of the panel‑mounted EtherCon jack and pull the

connector outward.

1Ab o u t Yo u r Pr o 64 Pr o d u c t

Page 11

Firmware Notice

All Pro64 devices in a network should be updated to use the most recent

rmware version to ensure trouble-free operation.

As new Pro64 modules are released, older Pro64 products need to be

updated so that they recognize the features and functions of the newer

modules—something that is especially important if one of the older devices

will be used as the network’s Control Master. (If for some reason you cannot

update the firmware on older Pro64 devices before using them, set the

newest module to be the network Control Master.)

Pro64 Update Tool is a free Windows software application for updating the

operating firmware in Pro64 Series products.

The Pro64 Update Tool requires a direct RS‑232 (serial) connection between

the computer and the Control Master device on the Pro64 network. Normally

this is accomplished by connecting a null modem DB9 cable between the

RS ‑232 jack on the computer and the Pro64 device. Complete information on

using RS‑232 (and USB‑to‑RS‑232 adapters) is available on the Aviom website.

Updates take just a few minutes per module.

Pro64 Update Tool is designed to run on a PC under Microsoft® Windows® XP.

It has also been tested and found to be compatible with Microsoft Windows

Vista®. Mac users can run Pro64 Update Tool using Windows XP running

under Apple’s Boot Camp program on Intel‑based Macs.

Get the Pro64 Update Tool and firmware update files from the Aviom website:

http://www.aviom.com

8Fi r m w A r e N ot i c e

Page 12

About A-Net

Aviom’s A‑Net® is the only networking technology conceived, designed, and

optimized for managing and distributing audio using ordinary Cat‑5e cables.

As implemented in the Pro64® Series products, A‑Net can transmit up to 128

channels of uncompressed 24‑bit audio with the reliability and fidelity of

analog, and the power and flexibility of a true digital network.

Pro64 A‑Net allows variable sample rates in three ranges, from 44.1kHz±

to 192kHz±, with ultra‑low latency, jitter, and wander. Pro64 devices can

be connected in any combination of serial (daisy‑chain) or parallel (star)

topologies. Cable runs between Pro64 devices can be up to 400 feet (120

meters) on Cat‑5e1, and miles on single‑ or multi‑mode fiber optics (using

Aviom fiber‑capable equipment such as the MH10f ).

Because A‑Net is designed specifically for audio, the technological limitations

of Ethernet and Ethernet‑based products are removed, while audio

performance and system flexibility are increased. A‑Net incorporates Aviom’s

unique patented and patent‑pending algorithms for controlling clock jitter

and wander, as well as system‑wide latency—regardless of an installation’s

size, design, or clocking setup. A‑Net offers significant advantages in fidelity,

performance, and flexibility over Ethernet‑based products.

A‑Net uses the “physical” layer of Ethernet, but it eliminates all the protocol

elements that are designed for computers and IT‑style networking. In

audio applications, these other layers reduce efficiency, impose system

restrictions, and introduce latency and timing instability. By eliminating

Ethernet data structures, A‑Net creates a superior network, with enhanced

audio performance. With A‑Net and the Pro64 Series, Aviom continues to

break new ground in the design and development of innovative digital audio

networking technologies and solutions.

Pro64 Series Supported Sample Rates

Sample Rate Minimum Maximum

1x 44.1/48kHz 39.7kHz 52kHz

2x 88.2/96kHz 79.4kHz 104k Hz

4x 176.4/192kHz 158 .8 kH z 208kHz

Clocking

The Pro64 network offers the most flexible clocking and synchronization

options in the industry. Pro64 devices support three ranges of variable sample

rates, from 44.1/48kHz± to 192kHz±. Because no sample rate converters are

1 Cat-5e, Cat-6, or better, Unshielded Twisted Pair (UTP) cable

2Ab o u t A- Net

Page 13

used, audio transmission is kept fast and clean, eliminating the audio artifacts

and signal degradation inherent to sample rate conversion—even when

syncing to an external clock source.

Any Pro64 I/O module can be designated the clock master for the network,

generating and distributing its internal clock. Digital I/O modules are capable

of syncing to and distributing an external word clock.

Control Data

The Pro64 Series has built‑in, dedicated bandwidth for 14 channels of non‑

audio control data through the use of Aviom’s innovative Virtual Data Cables™

(VDC). These data streams are always available to carry MIDI, R S‑232/RS‑422,

or GPIO (General Purpose I/O), and they never compete with the audio

channels for network resources, regardless of the system configuration.

Because VDC inputs are simply incorporated into the A‑Net stream, these

control signals can be transmitted over very long cable runs and even across

an entire Pro64 network, significantly expanding the applications possible

with MIDI, RS‑232/RS‑422, and GPIO. And as with audio signals, VDC control

data can be input anywhere and output anywhere else in the network.

The exact complement of VDC I/O connectivity varies per product.

A-Net Ports

Pro64 I/O modules have dual A‑Net ports, labeled A and B. Both ports carry

a bidirectional A‑Net stream at all times. (That is, both ports are always

transmitting and receiving A‑Net data.) Pro64 networks can be configured in

one of two operational modes, Auto Mode or Manual Mode, depending on

the requirements of a particular application.

Each A-Net port carries bidirectional data at all times.

3Ab o u t A- Net

Page 14

In Auto Mode, there are no connection rules; connect a Cat‑5e cable to either

the A or B port and the network does the rest. Auto Mode provides a true

audio network with 64 available “Slots” for transporting audio (at 44.1/48kHz).

Every audio Slot is available everywhere in the network, with no upstream/

downstream restrictions.

In Manual Mode, the Pro64 network becomes a 64x64 system (at 48kHz),

similar to a traditional stage‑to‑FOH snake. At every point in the Manual

Mode network, two 64‑channel streams are available on the cable and in

each module. The configuration of the cables and ports has an impact on the

makeup of the network and the distribution of audio signals. The user can

direct A‑Net data from a Pro64 input module to a specific port (A, B, or both).

Likewise, Pro64 output modules can be configured to output audio signals

received from a specific Pro64 network port (A or B).

Support For Pro16 Series Products

Pro64 Series products can be combined with Pro16® Series output products

such as the Pro16 Monitor Mixing System by adding the Pro64 ASI A‑Net

Systems Interface. This 1U module converts Pro64 data to Pro16 data,

providing up to four 16‑channel streams of data (depending on the Pro64

sample rate) that can be used with A‑16II and A‑16R Personal Mixers, A‑Net

Distributors, and AN‑16/o Output Modules.

The ASI is not compatible with the A‑Net output of Pro16 input modules such

as the AN‑16/i and AN‑16/i‑M and console interface cards such as the Y1.

4Ab o u t A- Net

Page 15

AC Power

Always plug the unit into a properly grounded (earthed) outlet. Always use

the AC line cord that was shipped with the unit. Grasp the power cable by the

connector and never by the cord itself when connecting and disconnecting

it from the power source.

Do not expose the Pro64 device to moisture, rain, or excessively damp

environments.

AC Line Conditioning

Aviom products are digital devices and as such are sensitive to sudden spikes

and drops in the AC line voltage. Changes in the line voltage from lightning,

power outages, etc., can sometimes damage electronic equipment.

To minimize the chance of damage to your equipment from sudden changes

in the AC line voltage, you may want to plug your equipment into a power

source that has surge and spike protection. Power outlet strips are available

with built‑in surge protection circuits that may help protect your equipment.

Other options for protection of your equipment include the use of an AC

line conditioner or a battery backup system (sometimes referred to as an

uninterruptible power supply, or UPS).

Rack Mounting

Pro64 products are designed to be mounted in a 19‑inch equipment rack.

The rack ears on each side of the device are designed to support the weight

of the product without additional hardware. Each rack ear contains holes for

two screws per side. Always support the unit with all four screws to avoid

damage to the unit.

To rack mount the Pro64 product, position it in the equipment rack at the

desired location. Use standard rack‑mounting screws (10‑32 size) to attach

the unit to your rack hardware. Tighten all four screws firmly, but avoid

overtightening.

Aviom suggests the use of non‑metallic washers between the rack‑mounting

screws and the device’s finished surface to avoid marring the finish on your

Aviom products.

6mAi N tA i Ni N g Yo u r Pr o 64 Pr o d u c t

Page 16

Ventilation

Always allow adequate ventilation for devices mounted in equipment

racks. Avoid placing your Pro64 product directly above or below other rack‑

mounted devices that produce high levels of heat, such as power amplifiers.

Cleaning

Before cleaning a Pro64 product, turn off the power switch and unplug the

unit from the AC power source.

To clean the surface of the Pro64 product use a clean, soft lint‑free cloth that

has been slightly moistened with water only. For tougher dirt, use a cloth

slightly dampened with water or with a mild detergent. Always be sure to dry

the surface of the unit before proceeding with use.

When cleaning your Aviom products, never spray cleaners directly onto the

product surfaces. Instead, spray a small amount of the cleaning solution onto

a clean cloth first. Then use the dampened cloth to clean the product.

Never use solvents or abrasive cleaners on the finished surfaces of your

Aviom products.

7mAi N tA i Ni N g Yo u r Pr o 64 Pr o d u c t

Page 17

Pro64 Interface Conventions

Many Pro64 Series products have similar user interface components,

including buttons, LEDs, and switches. When describing the features and

functions of Pro64 Series products, the following conventions will be used.

Cat-5e

All Cat‑5e connections between A‑Net devices should use Unshielded

Twisted Pair (UTP) cable. The cable can be of the stranded or solid type; solid

wire performs better over long distances, while stranded wire is more flexible

and easier to manipulate and therefore easier to work with in a performance

situation.

Cables designated as Cat‑5e in Pro64 documentation can be interchanged

with any Cat‑6 (or better) cable. Cables will be referred to simply as “Cat‑5e.”

Connectors on Cat‑5e cables can be of the standard RJ45 variety or locking

Neutrik EtherCon type.

Button Presses

When referring to specific front‑panel labels, LEDs, and buttons or when

describing a Pro64 function that requires the press of a button on the front

panel of a device, a special typeface will be used. For example, “Press the

En t E r button to confirm the sample rate change.”

Buttons that work in combination, giving the user a choice when performing

an operation, will be referred to as one unit. For example, “Changing the

sample rate requires the user to confirm the change using the Enter/Cancel

buttons.“

Changing Values

When editing values on the front panel of a Pro64 device, some operations

will require the use of the inc/dec (short for increment/decrement) buttons.

These buttons scroll up and down through a list of available values. Holding

the button down does not accelerate scrolling. The front panel of a Pro64

module is marked only with indicator arrows. (See the drawing on the

following page.)

8Pr o 64 iN t e r F A c e co N v e N t i o N s

Page 18

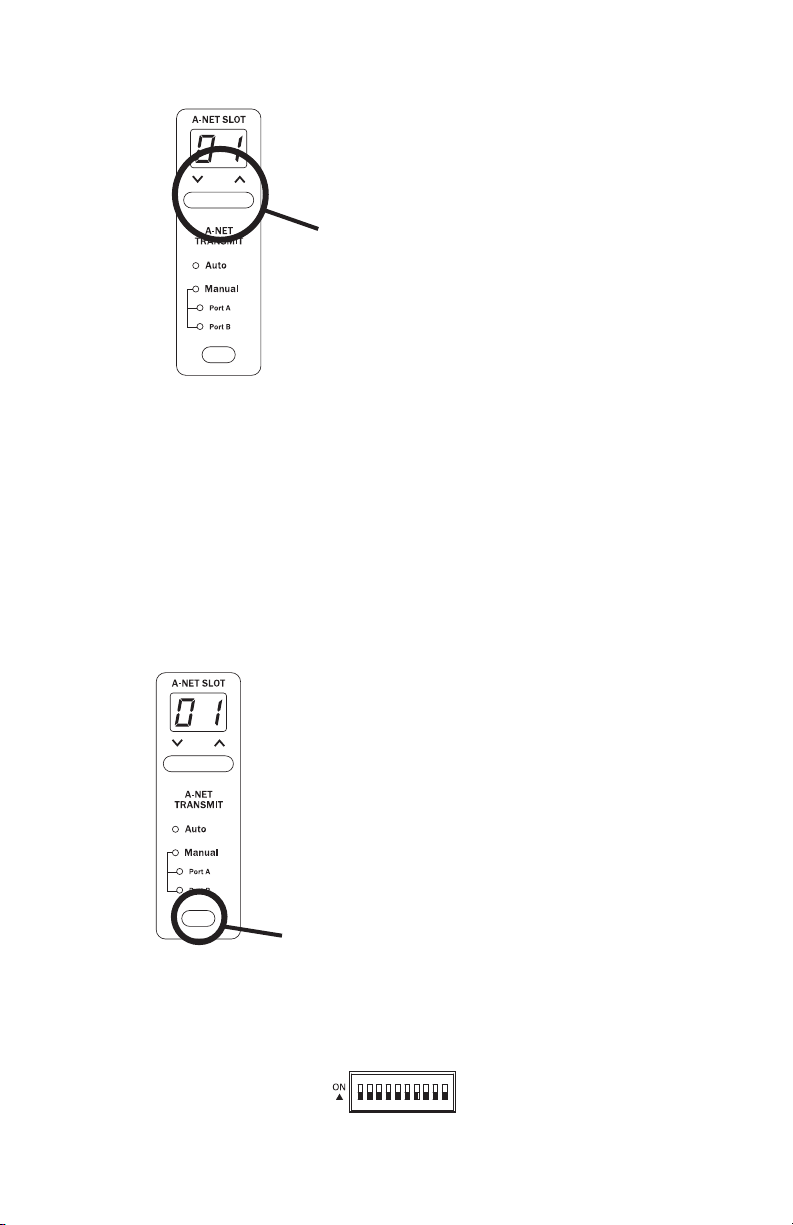

The buttons with up/down

indicator ar rows are used

for the inc/dec functions.

Buttons of this type will be referred to as “inc/dec” buttons.

Selecting Values

Some settings, including Sample Rate, network mode (Auto or Manual), and

Virtual Data Cable type, require the user to select from a range of values.

The button that controls the selection of a value is referred to generically as

the “selection button” for that function. For example, “Use the Sample Rate

selection button to scroll through the available rates.”

Pressing a selection button repeatedly will scroll through the available

settings and will wrap around when the end of the list is reached.

Pressing the s election button w ill

cycle thro ugh the available values.

DIP Switches

Illustrations of Pro64 DIP switch components indicate the switch handles in

black as seen below.

9Pr o 64 iN t e r F A c e co N v e N t i o N s

Page 19

Pro64 User Interface

This section outlines some basic concepts of operation for Pro64 products.

Pro64 I/O devices have some common user interface elements that make

setting up a digital snake or audio network easy to understand.

Common elements include:

Enter button•

Cancel button•

A‑Net Slot selection•

• Network Mode (Auto/Manual)

Sample Rate display•

Managed button•

Edit Lock button•

Virtual Data Cable (VDC) configuration•

In addition, each I/O module has the ability to be set as the Control Master

and/or Clock Master (depending on the actual makeup of the analog/digital

modules in the audio network). Only one device can have control of these

functions at a time in a properly configured Pro64 network.

Basic Actions

Most system‑level operations in the Pro64 user interface require the use of

the Enter button to confirm an action. For example, assigning a Virtual Data

Cable port to a VDC Slot or choosing a new sample rate (on the Clock Master

device only) will require the user to press the En t E r button to confirm the

request. If no press of the Enter button is detected within a predetermined

time frame, the system will automatically cancel the request and return the

device (or entire network) to the previous state.

Operations that do not require the use of the Enter/Cancel buttons include:

Stereo c• hannel link (input modules)

Channel activation (input modules)•

Channel • on/off (output modules)

Gain settings (input modules)•

Output • level settings (output modules)

10Pr o 64 us e r iN t e r F A c e

Page 20

The LED between the Enter and Cancel buttons ashe s when a button press

is required to continue.

Any operation that requires the use of the Enter/Cancel buttons will flash the

LED that is located between the two buttons to indicate that a button press

is required to complete the action. To confirm an operation, press En t E r . To

exit an operation without completing it, press the C a n C E l button.

A-Net Slot

Pro64 I/O devices come in a variety of configurations; to allow a large

number of hardware audio input devices to be available to the Pro64 audio

network, Aviom has implemented the concept of the A‑Net Slot to simplify

the configuration of potentially complex audio networks.

A Pro64 audio network will always have a finite number of A‑Net Slots

available that can be addressed by an unlimited number of hardware

channels. The actual number of available Slots is determined by the current

sample rate.

Slots versus Channels

You might be wondering why Aviom chose to refer to the audio I/O resources

in the Pro64 Series products as ‘’Slots.” Why not just call them “channels”?

We did this to avoid confusion between references to hardware audio

resources and network audio resources. The word ‘’channel’’ is ambiguous

and may cause confusion when configuring an audio network. “Channel”

appears in many contexts, including audio mixing consoles, mic preamps,

11Pr o 64 us e r iN t e r F A c e

Page 21

DSP processors, and DAW software.

We use the word ‘’channel’’ when referring to the physical audio inputs—

analog or digital—on a piece of hardware (such as the 16 line‑level XLR

input jacks on the 6416i Input Module). Each of these audio inputs can be

made active and added to the network individually, and it is only when

activated that they use any network resources (the A‑Net Slots). To allow

this functionality, Pro64 products separate the hardware resources from the

available network resources by giving each hardware input channel a button

that allows it to be added to the network as needed.

It is these activated hardware resources that are being referred to as “Slots.”

Pro64 audio networks can potentially have a greater number of audio

channels and hardware I/O devices connected than the network can make

use of at one time. This provides flexibility without requiring constant re‑

patching.

Keep in mind that a Pro64 A‑Net network can only manage a specific number

of Slots at a time, and this number varies with the sample rate being used.

The maximums are 64 Slots in Auto Mode at the 48kHz sampling rate and

64x64 Slots in Manual Mode at 48kHz.

In summary, think of “channels” as hardware resources that can be added

to the network as needed and “Slots” as locations within the digital audio

network pipeline that A‑Net uses to move data throughout the network.

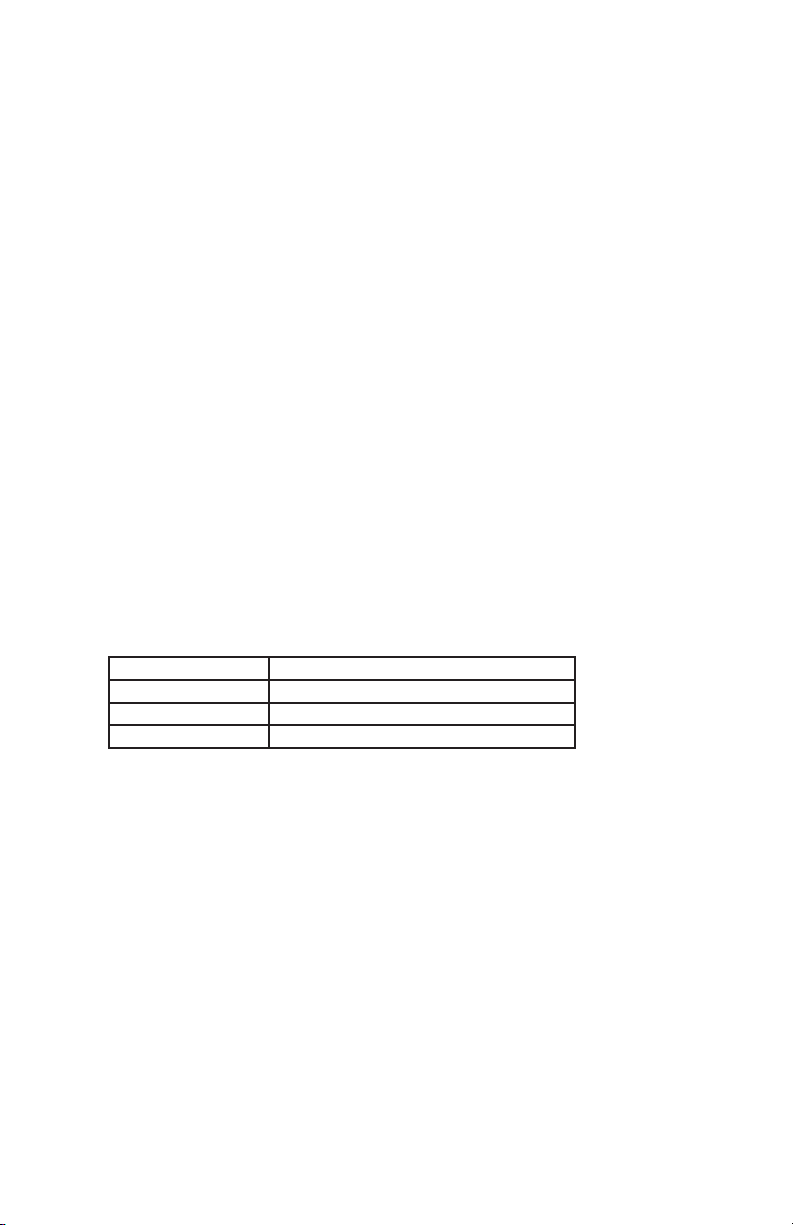

Slots and Sample Rate

The current system‑wide sample rate will determine the number of A‑Net

Slots that are available. Auto Mode and Manual Mode have the same number

of Slots at each sample rate; only the direction of the data is different.

Sample Rate A-Net Slots

4 4.1kH z 64

48kHz 64

88.2kHz 32

96kHz 32

176.4kHz 16

192kH z 16

Even though the network sample rate may change the available number of

A‑Net Slots, the capacity of a hardware device does not change. That is, a

16‑channel input module in a 192kHz network can still have all of its channels

activated; all of its physical inputs can operate at 192kHz.

The current sample rate will also affect the display of available A‑Net Slot

ranges. Slot ranges will always have the same maximum number as seen in

the sample rate chart. At 96kHz, for example, only Slots numbered 1 through

12Pr o 6 4 use r iN t e r F A c e

Page 22

32 are available; the Slot range from 33 to 64 is inactive and unavailable at

that sample rate. Slot ranges outside the maximum for the current sample

rate can be selected, but attempting to activate a channel in an unavailable

range will result in an error message (the selected channel button, A‑Net Slot

range, and sample rate LEDs will all flash).

A-Net Slot Display

Since the capacity of the Pro64 network could be as high as 64 A‑Net Slots,

Pro64 hardware I/O devices need a way of routing a selected hardware

channel to a selected network Slot. In the upper left corner of the front panel

of a Pro64 I/O device, the A‑Net Slot display and its associated inc/dec buttons

are used to select a range of Slots that the hardware device will address.

The A-Net Slot display and its inc/dec buttons are use d to set the base Slot

for a Pro64 I/O module.

The A‑Net Slot display will show the base number that is associated with the

first hardware input or output channel on an I/O device. The actual number

seen in this display will be determined by the physical I/O on the device. That

is, an 8‑channel device will display a different set of available starting points

than a 16‑channel device (see the following tables).

To select an A‑Net Slot range, use the inc/dec buttons below the display. Press

one of the buttons until the desired base Slot range is displayed, and then

press the En t E r button. To return to the current selection without making a

change, press the Ca n C E l button.

The following tables show examples of the channel‑to‑Slot correlation

for Pro64 Series modules in a network running at the 48kHz sample rate.

13Pr o 6 4 use r iN t e r F A c e

Page 23

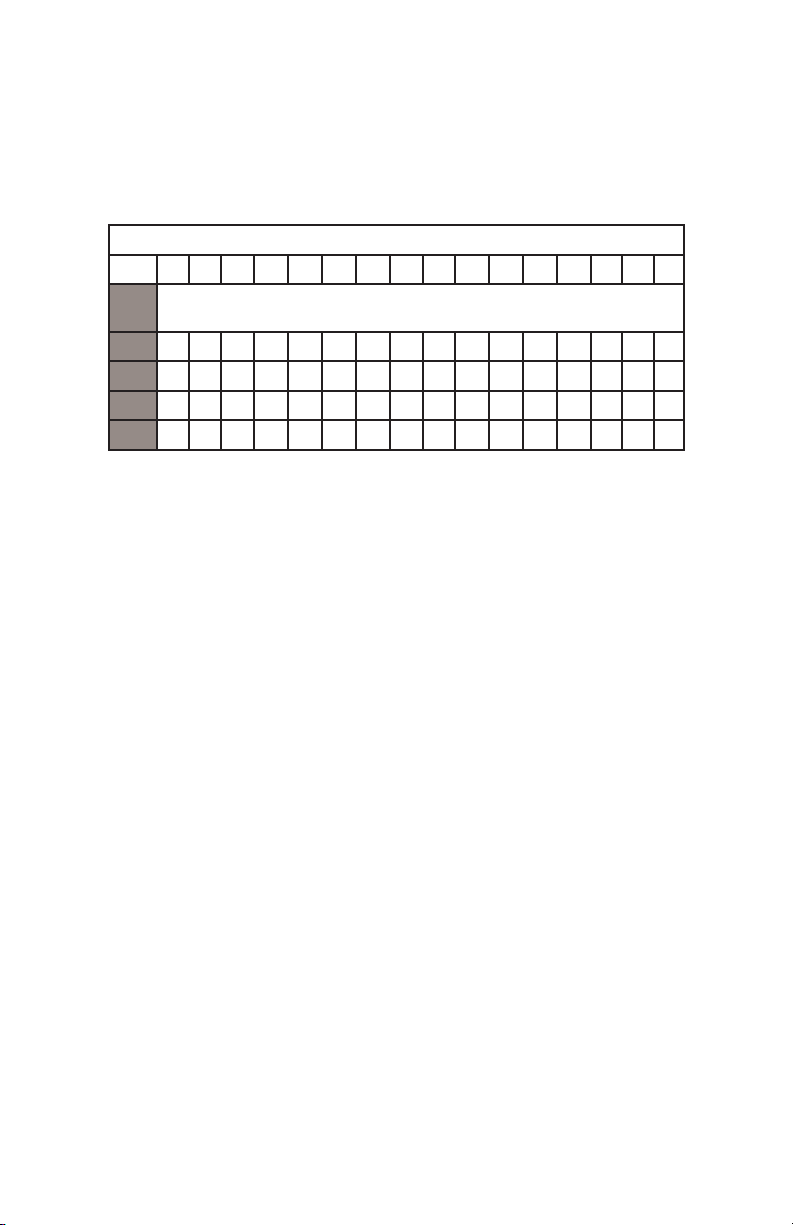

The numbers in the Slot column will appear in the A‑Net Slot display. The

numbers seen to the right of each gray base Slot number correspond to the

channel buttons on the front panel of the interface.

Pro64 Module Ha rdware Channels

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Base

Slot

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

17

33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

33

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

49

A-Net Slot

The use of Slot assignments allows for easy reconfiguration of audio

networks and sharing of hardware I/O resources and data without physical

re‑patching.

14Pr o 6 4 use r iN t e r F A c e

Page 24

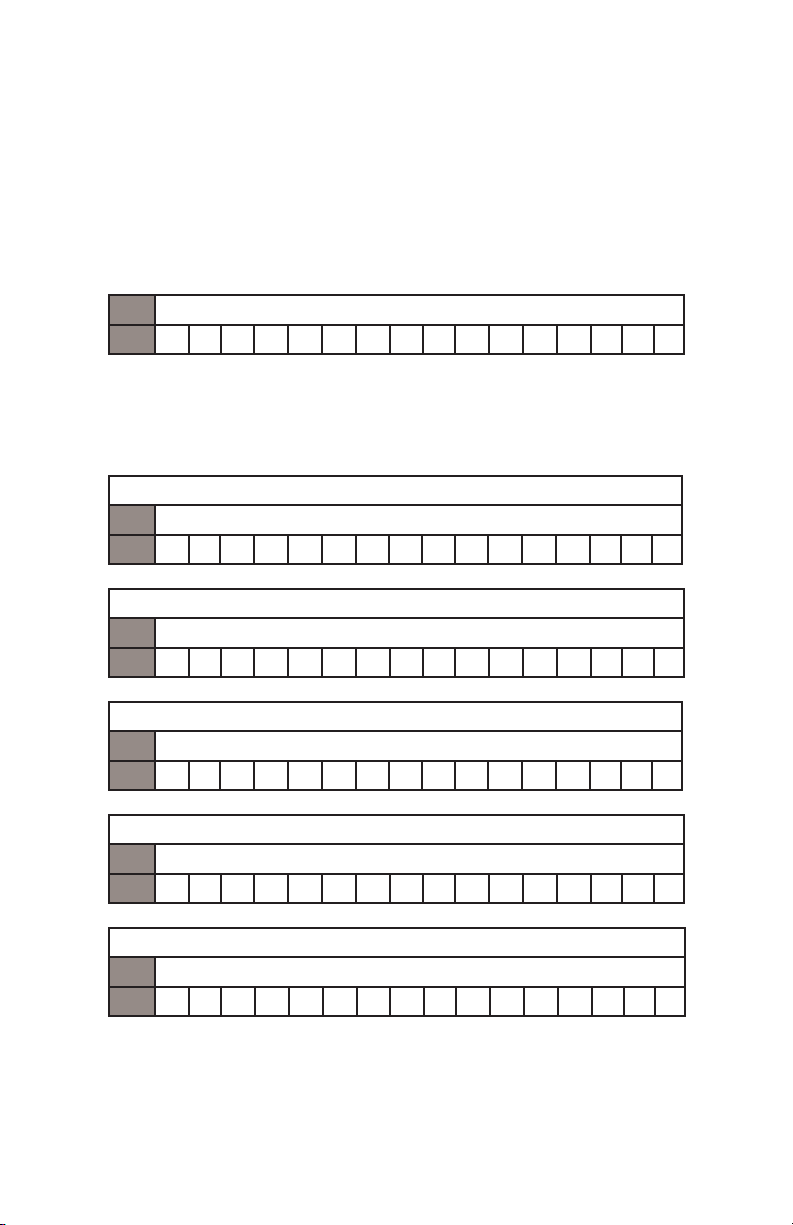

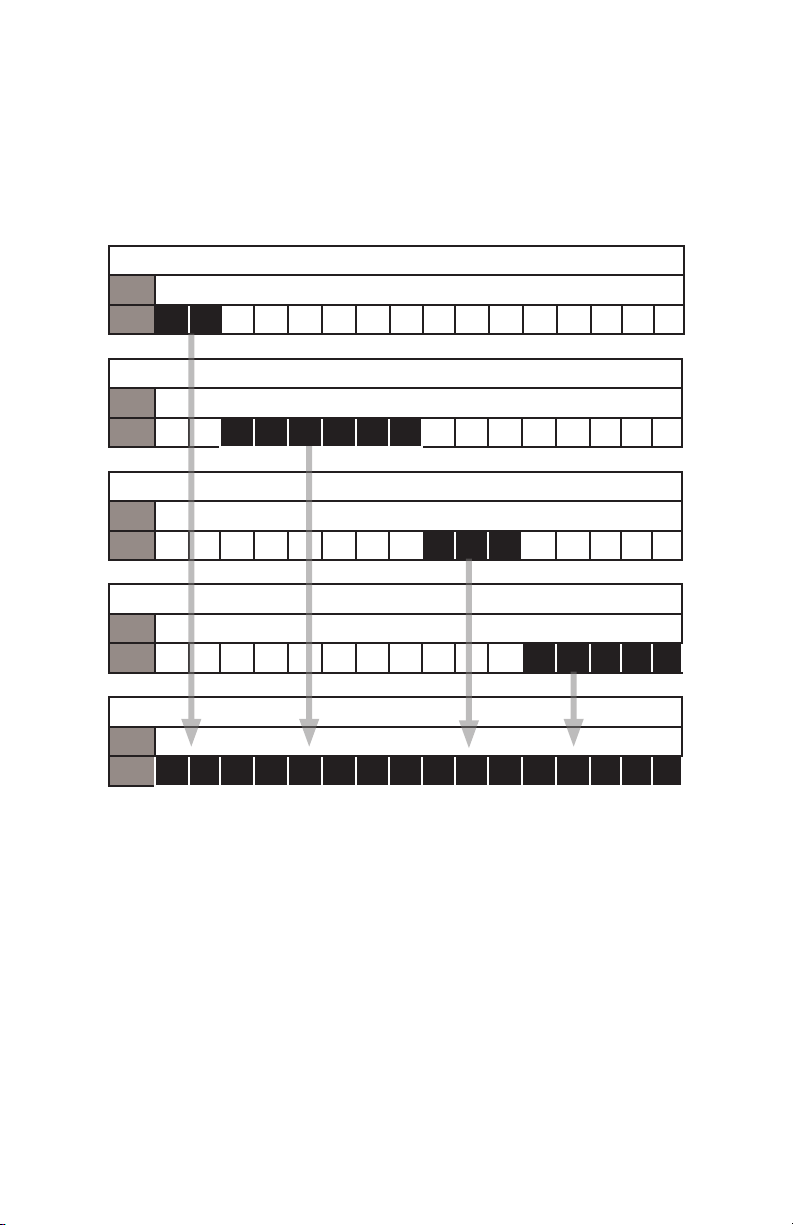

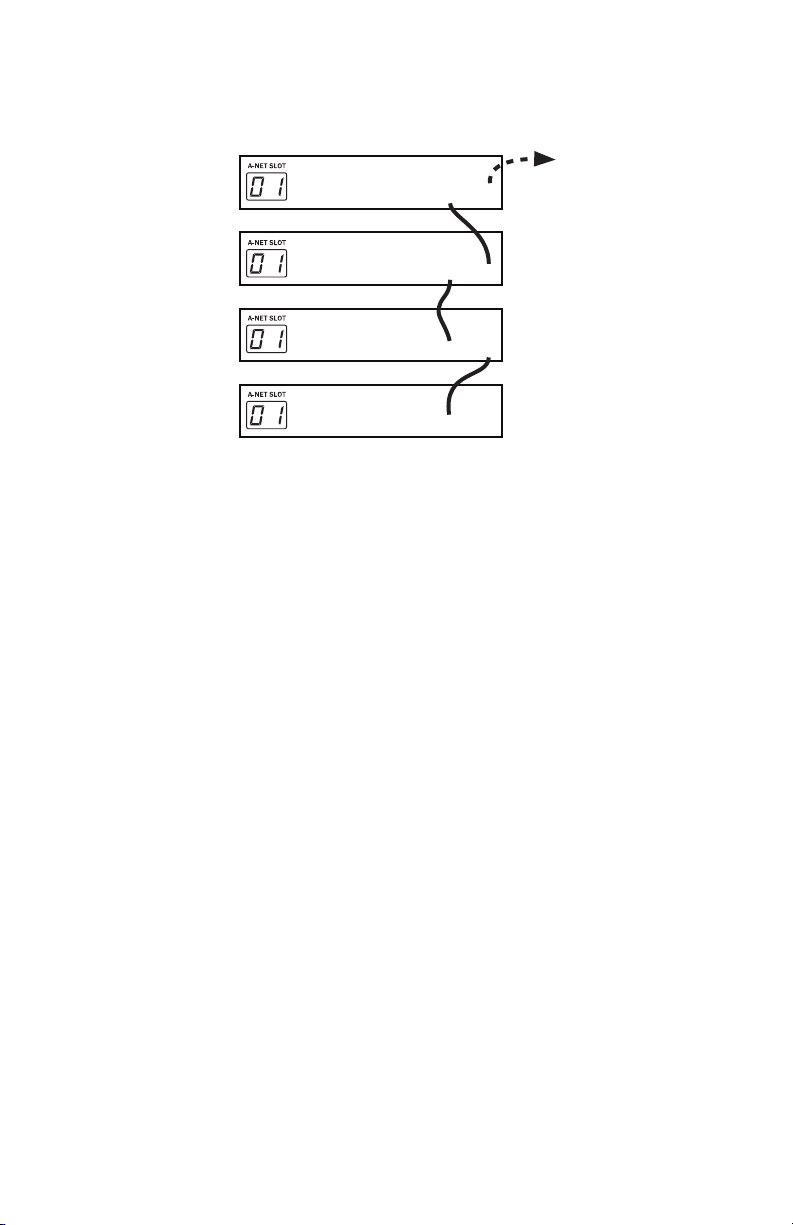

A-Net Slot Example

The following example shows the power of the Pro64 network and the A‑Net

Slots concept.

The range of A‑Net Slots used in the example has been limited to the group

from 1 to 16 for simplicity.

This graphic represents a Pro64 product set to Slot range 1.

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

One 16‑channel input module is placed in each of four rooms of a production

facility, designated as Studios A, B, C, and D. One 16‑channel output module

is installed in the facility’s Studio E. All modules are set to Slot range 1.

Studio A Input s

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

Studio B Input s

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

Studio C Input s

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

Studio D Input s

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

Studio E Outpu ts

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

15Pr o 6 4 use r iN t e r F A c e

Page 25

By activating a group of channels on each of the four input modules, a total

of sixteen inputs are used (indicated by reverse text). All of these inputs are

available on the network at every output module. The operator in Studio E

can use the sixteen inputs from Studios A, B, C, and D simultaneously.

The order in which the Pro64 devices are connected is irrelevant.

Studio A Input s

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

Studio B Input s

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

Studio C Input s

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

Studio D Input s

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

Studio E Outpu ts

Slot Channel

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1

16Pr o 64 us e r iN t e r F A c e

Page 26

Network Modes

A Pro64 audio network can be set to operate in one of two modes, Auto or

Manual. The network mode can be selected on the front panel of the device

designated as the system’s Control Master.

Both modes are fully bidirectional at all times, regardless of the system layout

or design.

Auto Mode

Pro64’s Auto Mode takes most of the work out of managing resources in an

audio network. This is the “everything everywhere” mode. Channels are sent

into the network and can be seen and used by all devices in the network,

regardless of how the modules are connected and regardless of the physical

location of any module. Output modules do not need to follow input

modules as in a traditional analog system. In Auto Mode, both A‑Net ports (A

and B) function identically.

Once configured for Auto Mode, the system ensures that only one hardware

input channel is activated into a given A‑Net Slot. There is no limit to the

number of hardware output channels that can use a given A‑Net Slot. The

actual number of available Slots is determined by the current sample rate.

The maximum number is 64 active channels at the 44.1/48kHz sample rate.

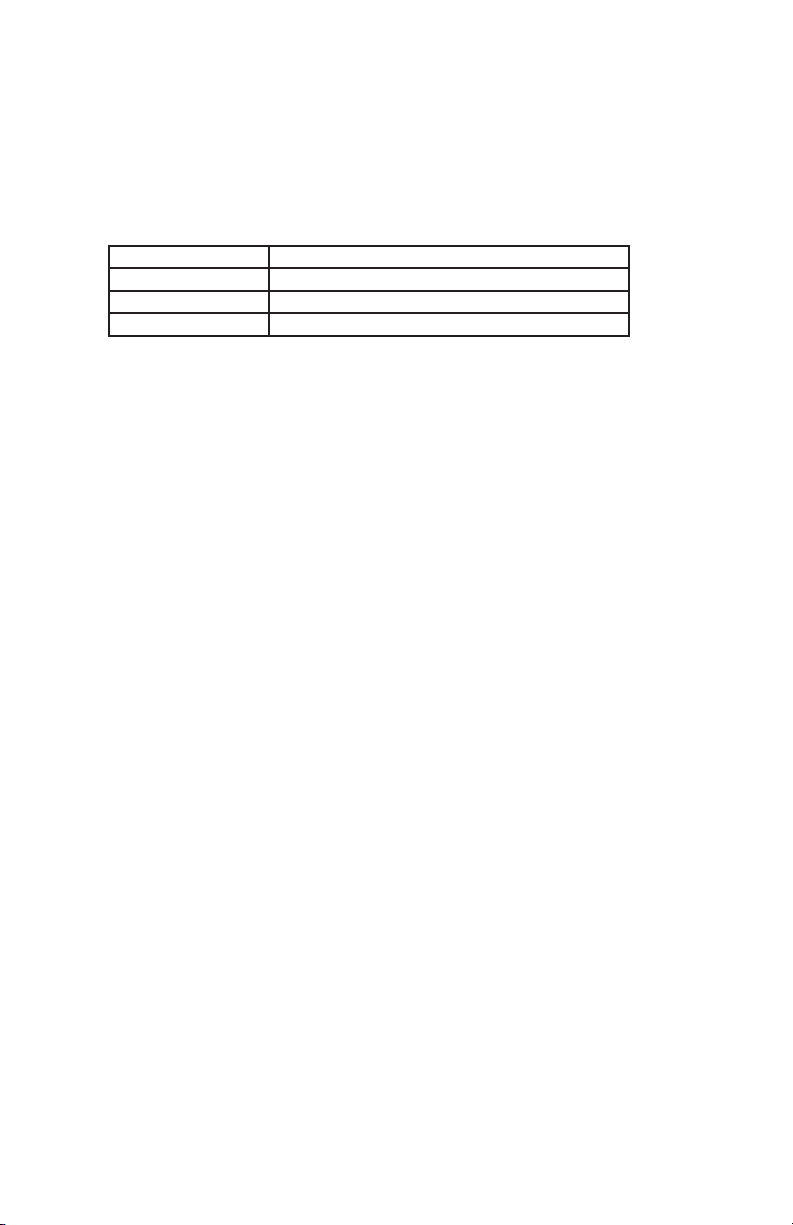

Sample Rate Available A-Net Slots in Auto Mode

44.1 / 48kHz 64

88.2 / 96kHz 32

176.4 / 192kHz 16

Manual Mode

When more than 64 channels are needed in a network, Manual Mode can

be used to provide configurations of up to 64 x 64 channels. Two unique

64‑channel streams are available at each module. In Manual Mode, the A and

B A‑Net port connections can be used to direct and route A‑Net data.

Pro64 input modules can send their audio inputs to either or both A‑Net

ports, while output modules can listen to data from either port. For a

traditional stage‑to‑FOH snake system, this allows the user to configure a

system with up to 64 sends from the stage and another unique stream of up

to 64 returns to the stage.

Manual Mode operation removes the restrictions of unique channel‑to‑Slot‑

range relationships found in Auto Mode. Slots can be overwritten, allowing

the user to replace channels from one part of the network with new data.

17Pr o 6 4 use r iN t e r F A c e

Page 27

This means that, while no more than 128 channels can be in the network at

a particular location, there is no practical limit to the total number of audio

channels in the system.

The number of available Slots in Manual Mode is dependent upon the current

sample rate.

Sample Rate Available A-Net Slots in Manual Mode

44.1 / 48kHz 64 x 64

88.2 / 96kHz 32 x 32

176 .4 / 192kHz 16 x 16

18Pr o 64 us e r iN t e r F A c e

Page 28

Control Master

In every Pro64 network, one device will always be designated as the Control

Master, the device that manages all A‑Net resources for the network. The

Control Master can be any I/O module in the network, and can be assigned or

changed by the user as needed. Only one device can be assigned as Control

Master in a Pro64 system at a time; an A‑Net network cannot function

without a Control Master.

The functions of the Control Master include:

System resource and information management •

Setting • network mode (Auto or Manual)

Management of • active channels in Auto Mode

System‑level command and control functions •

Keeping track of all Pro64 devices in the network (by type •

and quantity)

Control of the current system‑wide • sample rate

• Clock Master (analog modules only)

System lock via • password on/off

Management of • Virtual Data Cable (VDC) resources

Management of • stereo link status

Requests to enter Managed Mode •

The Control Master status is identified with a red LED on the front panel of

the device currently assigned as the Control Master.

Only one device in a Pro64 network can be designated as the Control Master.

47co N t r o l mA s t e r

Page 29

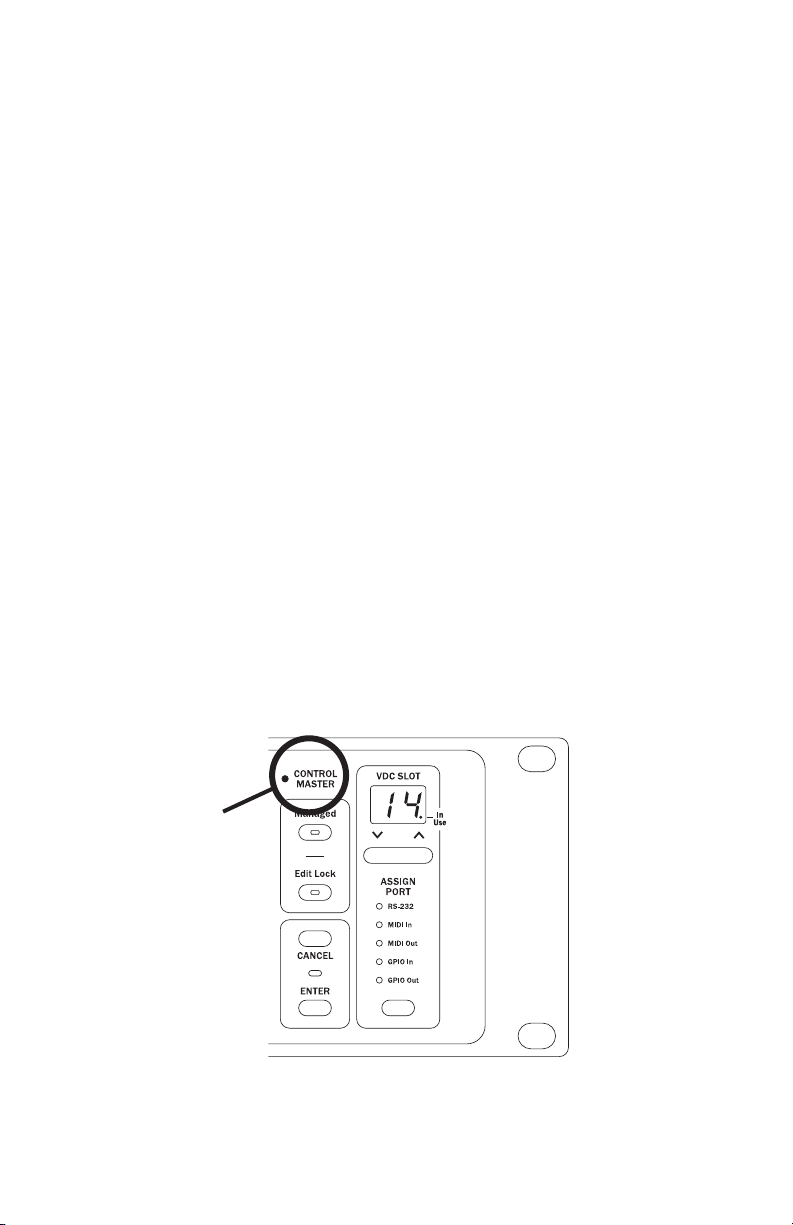

Setting Control Master Status

Setting a device to be the Control Master is done using the DIP switches

found on the rear panel. The Control Master switch is part of the Virtual Data

Cable port section of the interface.

Switch 10 in the RS-232 conguration group is used to set the Control Master

status for a module.

In the VDC section, locate the 10‑position DIP switch in the RS‑232 area of the

rear panel. Switch #10 will set a module to be the Control Master for an audio

network when the switch is in the On (up) position (the up position is shown

in black in the diagram above).

Control Master Functions

This section describes the individual functions that the designated Control

Master device in a Pro64 network controls.

Enumeration

When the Control Master is powered on, its first job is to identify and count

all connected A‑Net modules in the network in a process called enumeration,

similar to a PC booting up and loading its operating system. The time for this

process will vary based upon the number of modules in a system.

Enumeration is an automated process performed by the command and control

portion of the system. There are no user‑controllable functions or settings.

48co N t r o l mA s t e r

Page 30

During the enumeration process, all connected A‑Net modules will flash

their A‑Net LEDs, indicating that a request to be added to the network is

being made. Once granted entry by the Control Master, the individual

module’s blue A‑Net LED will light solid to indicate that it is now receiving

valid A‑Net packets and is part of the network.

The blue LED in the A- Net icon, shown here on a 6416i Input Module, is us ed

to indicate network status.

If valid A‑Net packets are not received, the module will reset and wait until a

valid A‑Net stream is detected.

During enumeration, any conflicts will also be resolved. For example, consider

a new Auto Mode installation using eight input modules set to the same

A‑Net Slot range with all channels activated during a bench configuration.

When all these input modules are connected and then powered up, only

one of them will be allowed to have all 16 channels activated. The remaining

seven modules will have their audio channels deactivated.

Adding Pro64 Modules to a Network

When a new device is added to an existing network, the new device makes a

request to the Control Master for inclusion in the network. During this time,

the new module’s blue A‑Net LED will flash. When the new module has been

enumerated by the Control Master, its blue A‑Net LED will then light solidly

to indicate that the Control Master has granted the module access to the

network. Adding a new module will interrupt network operation briefly.

Changing Settings

Most operations on Pro64 modules that make system‑wide changes require

the use of the Enter and Cancel buttons. For any operation that requires

confirmation, the LED between the Enter and Cancel buttons will flash

to indicate that the user needs to press one of these buttons in order to

continue.

Press En t E r to complete the operation or press Ca n C E l to exit without making

a change. This rule applies to all functions that can be changed by only the

Control Master.

49co N t r o l mA s t e r

Page 31

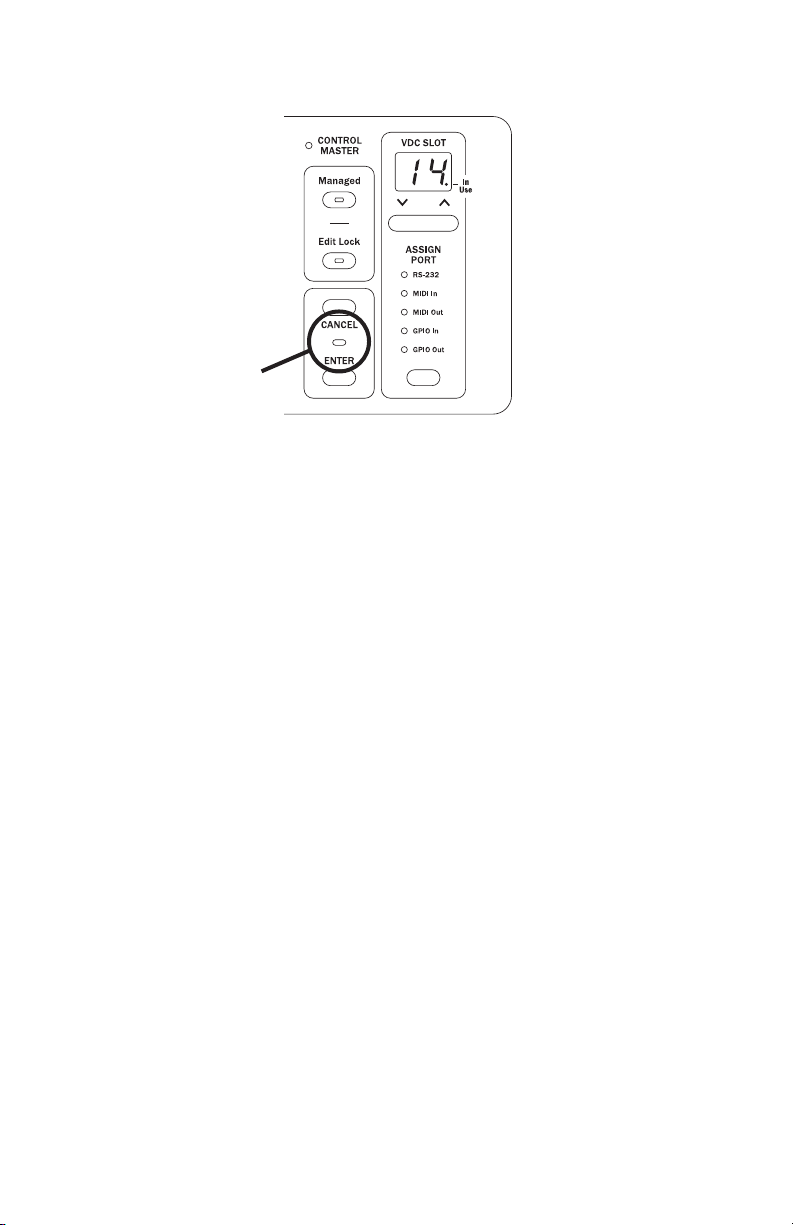

The Enter/Cancel LED will ash when the user is required to press one of

these but tons in order to complete an operation.

Control Master and Clock Source

By default, the device designated as Control Master in a network consisting

of all analog modules is also the device in control of the network master

clock. The front‑panel Clock Master LED lights to indicate that a module is

designated as the master clock device.

The red Clock Master LED lights when a Pro64 device is the Control Master.

When an analog I/O module is the Control Master, there is no other analog

module that can be used as a clock source. When a digital I/O module is part

of an audio network, the digital I/O device can be used as a clock master for

the network, even if this digital device is not the network’s Control Master.

50co N t r o l mA s t e r

Page 32

External clock sources on digital modules can include:

• Word Clock ‑ via the dedicated BNC Word Clock jack

• AES3 (AES/EBU) ‑ from any of the available AES3 digital

streams

Clock coming from a Yamaha® console when a • 6416Y2

A‑Net Interface Card is installed

Clock Errors

If a clock error occurs, the Clock Master LED will blink indicating that an error

has occurred. Common causes for a clock error include:

Attempting to change the sample rate on an analog device •

other than the Clock Master in an all‑analog network

Attempting to change the clock source when the network •

is password protected

Removing or changing external clock sources on a digital •

I/O module

Incorrect configuration of an external clock source on a •

digital I/O module

Network Sample Rate

When an analog device is the Control Master, the Control Master is

automatically designated as the Clock Master. It will remain the Clock Master

until a different analog module is made the Control Master or until a digital

module is added to the network and requests to be the Clock Master.

The Clock Master LED will light automatically on the Control Master when

that module is powered on. (Only a digital I/O module can be the source of

the network’s master clock without being the Control Master.)

The system’s internal master clock is derived from the sample rate currently

in use. The sample rate also affects the total number of available A‑Net Slots

available for use in the network.

The Sample Rate section of an I/O module’s front‑panel interface includes a

group of LED indicators for displaying the current network sample rate. One

LED will be lit at all times.

51co N t r o l m As t e r

Page 33

Press the selection but ton to cycle through the available sample rates.

The current sample rate for the network will be displayed on all I/O modules

in the network. Only one sample rate can be used at a time.

Changing the Sample Rate

To set or change a network‑wide sample rate from the Clock Master, use the

button below the Sample Rate LEDs to select a new rate. Pressing the Sample

Rate selector button will cycle through all available sample rates, flashing

the value for the new rate. At the same time, the LED between the Enter and

Cancel buttons will flash, indicating that pressing one of these buttons is

required to confirm and complete (or cancel) the operation.

Changing the sample rate will affect the number of available A‑Net Slots

when the sample rate changes from the 1x range (44.1/48kHz), to the 2x

range (88.2/96kHz), to the 4x range (176.4/192kHz) or vice versa.

Auto/Manual Mode Selection

The Control Master can be used to set the current network mode for the

system to Auto or Manual. As with the system‑wide sample rate, the network

mode is also a global setting.

The network mode selection controls are in the same part of the user interface

as the A‑Net Slot selection. The exact front panel text of an I/O module seen

in this area will vary based on the type of module. For example, an input

module front panel will read A‑Net Transmit, while an output module will

read A‑Net Receive.

52co N t r o l mA s t e r

Page 34

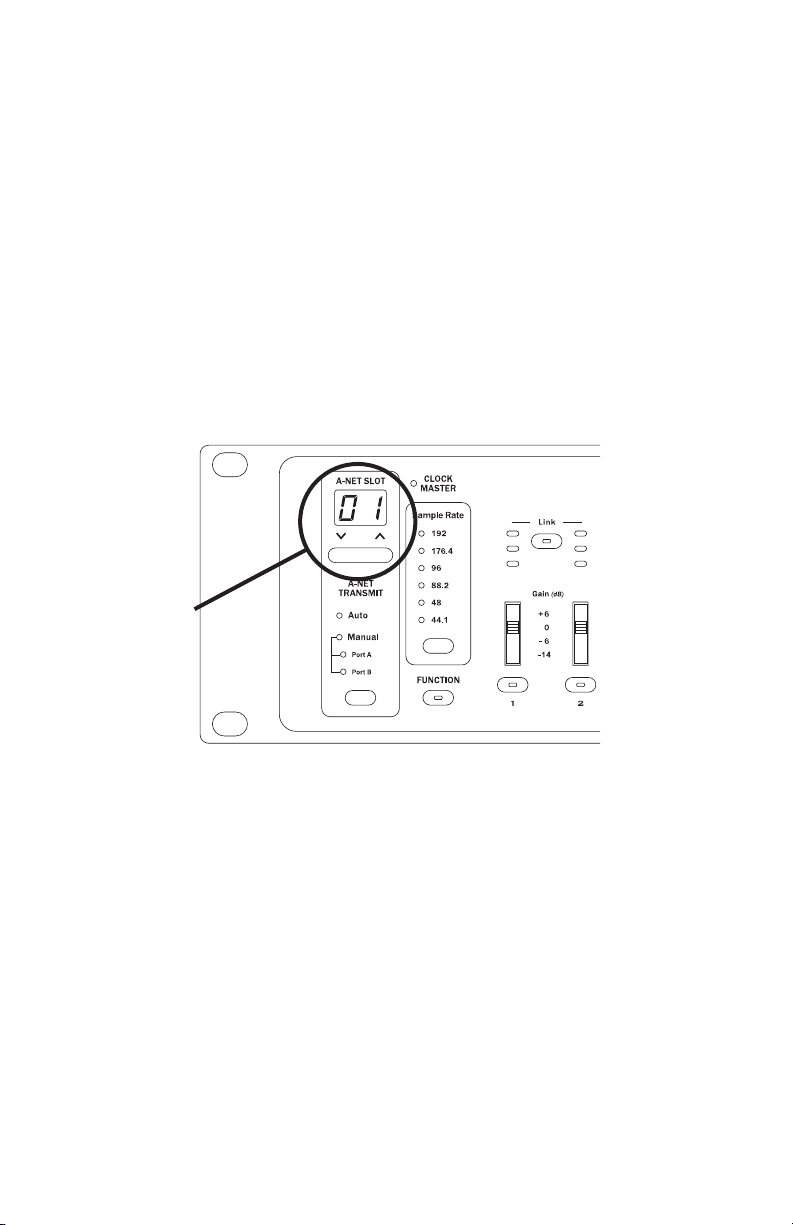

The selec tion button in the A-Net

Transmit/Receive section of the

interface is used to choose the network

mode on the Control Master. (Seen here

is the 6416i.)

Changing the Network Mode

The button beneath the Auto/Manual Mode LEDs is used to select the

network mode and to set the transmit or receive port in Manual Mode.

Pressing the selection button will cycle through the available settings and

will flash both the mode LED and the Enter/Cancel LED. To confirm and

change the network mode, press the E n t E r button. The Control Master will

update the display on all modules in the network to reflect the change. Press

the Ca n C E l button to exit the mode change and return to the current state.

Managed Mode

Managed Mode requires the use of a computer with the Pro64 network for

tasks such as firmware updates, system monitoring, control, and editing.

The Control Master is the only module that can allow the network to enter

Managed Mode.

Entering Managed Mode requires the user to press the En t E r button after

pressing the Ma n a g E d button on the Control Master. Once the network

enters Managed Mode, all modules will light their Managed LEDs.

53co N t r o l mA s t e r

Page 35

Managed Mode allows the networ k to be controlled from a computer and

can only be entered from the Control Master.

To manage a Pro64 network with a PC, the PC needs to be connected to the

Control Master using a DB9 null modem cable connected to the RS‑232 port.

Exiting Managed Mode is also done from the Control Master. Pressing the

lit Ma n a g E d button followed by the En t E r button will return the network to

local control. Attempting to enter or exit Managed Mode from any module

other than the Control Master will cause the Managed button LED to blink to

indicate the error.

Password Protection

All Pro64 devices ship with a default password. However, a Pro64 network

can be password protected from the Control Master only. Once protected,

the front‑panel interface on all modules is locked, preventing changes to

A‑Net Slots, sample rate, clock source, channel activation, stereo links, and

Virtual Data Cable assignments. Hardware switches, such as gain settings

on input and output modules, and rear‑panel DIP switches are in the analog

domain and are not affected.

Password protection remains in force even when a Pro64 system is power

cycled.

When a network is password protected, the front panel interface can be used

to get information on channel Slot assignments and VDC routings. Pressing

a channel button will display its Slot assignment in the A‑Net Slot display.

Pressing the VDC inc/dec buttons will cycle through the fourteen VDC Slots,

54co N t r o l mA s t e r

Page 36

displaying any port assignments on the current module, as well as the In Use

LED for all active VDC Slots in the network. This query behavior is similar to

the behavior of an individual module when it is edit locked.

See the section on Advanced Functions for a detailed description of the

password protection commands.

55co N t r o l mA s t e r

Page 37

Front Panel Components

1. A‑Net Slot Configuration

2. Auto/Manual Mode Selection

Clock 3. Master

4. Sample Rate

5. Level Meter LEDs

6. Stereo Link Button

7. Gain Switch

8. Function Button

9. Channel Activation Button

10Fr o N t PA N e l co m P o N e N t s

Page 38

1. A‑Net LED

2. Control Master LED

3. VDC Slot and Port Configuration

4. Managed Mode Button

5. Edit Lock Button

6. Enter/Cancel Buttons and LED

11Fr o N t PA N e l co m P o N e N t s

Page 39

Rear Panel Components

1. Power On/Off Switch

2. IEC Power Inlet

3. Fuse Holder

Balanced 4. Line‑Level Inputs, XLR

12re A r PA N e l co m P o N e N t s

Page 40

1. DB25 Audio Thru/Alternate In, x2

2. Virtual Data Cable Ports

3. GPIO Configuration DIP Switches

4. GPIO Terminal Blocks

5. MIDI In, MIDI Out

6. RS‑232 Port

7. RS‑232 Configuration DIP Switches (1‑8)

13re A r PA N e l co m P o N e N t s

Page 41

1. Control Master DIP Switch (#10)

2. A‑Net Ports, EtherCon Jacks

14re A r PA N e l co m P o N e N t s

Page 42

Front Panel Features

This section describes the features and functions of all front‑panel

components of the 6416i Input Module.

Enter/Cancel Buttons

The pair of buttons marked En t E r and Ca n C E l will be used to confirm

functions and mode changes or to exit a change request. The LED between

the two buttons will flash whenever the user is required to press one of these

buttons in order to continue with an operation or edit.

A-Net LED

The blue LED found within the A‑Net logo functions as the network activity

indicator. When a module is powered up, its A‑Net LED will flash while a

request to enter the network is sent to and then processed by the device

designated as Control Master. Once a module is enumerated and is part of

the network, the blue A‑Net LED will light solid. The LED will remain lit as

long as valid A‑Net network data is received.

The A-Net LED lights blue when the 6 416i is active on the network.

The A‑Net LED will flash during an operating system upgrade when the

module being updated is part of an active network. When a module is being

bench configured (it is not part of an active network), the A‑Net LED will

be off during the firmware update. (Check the Aviom website for current

firmware updates.)

Control Master

One Pro64 module in every network must be designated as the Control

Master. To set the 6416i as the Control Master, one of the DIP switches on the

rear panel in the VDC section is used. In the group of RS‑232 DIP switches,

switch #10 is used to designate a module as the Control Master. Set this

switch to the up position with the power off to avoid conflicts with network

resources.

15Fr o N t PA N e l Fe A t u r e s

Page 43

When the Control Master module is powered up, the network will be

enumerated and the blue A‑Net LEDs on all Pro64 devices will be lit. On the

Control Master device, its red Control Master LED will also be lit. The Control

Master LED will be off on all remote/slave modules in a network.

Control Master Errors

The following rules apply to the Control Master and active Pro64 networks.

If a slave module in an active network is incorrectly switched to be a Control

Master (in addition to the network’s already functioning Control Master),

that module’s Control Master LED will light and the A‑Net LED will go out to

indicate the error. The Control Master LED will remain lit until the module is

returned to slave status. All other module functions will operate normally.

If a new powered module set to be the Control Master is added to an active

running network (one that already has a valid Control Master), the new

module’s Control Master LED will light. Its audio I/O resources will remain

unavailable until the module is returned to slave status. All audio on this

module will be muted until the module is set to be a slave.

If the Control Master is removed from a functioning network (by being

disconnected, power failure, etc.), all slave units will reset and audio will be

muted. Slave units will wait for a new Control Master to be designated and at

that point will begin the enumeration process.

A-Net Slot Configuration

The A‑Net Slot section of the interface is used to set the range of A‑Net Slots

that the 6416i will use to send its active audio channels into the network.

There are two components: the A‑Net Slot display and the inc/dec buttons

used to select a value.

Press the up/down buttons to selec t an A-Net Slot range.

On a sixteen‑channel module like the 6416i, the A‑Net Slot display will move

in increments of sixteen Slots. The A‑Net Slot range display will wrap as it

reaches the end of the list of available values. The number shown in the

display corresponds to the first Slot in a group of sixteen sequential Slots,

one per channel button. The available base Slots are 1, 17, 33, and 49.

16Fr o N t PA N e l Fe A t u r e s

Page 44

Starting Slot Displayed A-Net Slot Range

Selection button

01 Slots 1‑16

17 Slots 17‑32

33 Slots 33‑48

49 Slots 49‑64

Keep in mind that the number of available Slots is determined by the current

network sample rate as set by the Clock Master.

Setting the A-Net Slot Range

To set a Slot range, use the inc/dec selection buttons found below the A‑Net

Slot display to select the desired range. When the selection button is pressed,

the new range displayed will start to blink, as will the Enter/Cancel button’s

LED. This indicates that confirmation is required to complete the change.

Press En t E r to set a new range or press Ca n C E l to exit without changing

the A‑Net Slot range and return to the previous setting. If no press of the

Enter/Cancel button is detected within a brief period of time, the interface

will automatically cancel the range change request, returning to the previous

state.

Setting a new Slot range on the 6416i will deactivate any currently active

channels.

A-Net Transmit

The A‑Net Transmit section displays information about the current network

mode, which can be set to Auto or Manual only at the network’s Control

Master. When the Pro64 network is operating in Auto Mode, the red Auto LED

will be lit, and no user settings are available on a per‑module basis. It does

not matter which rear‑panel A‑Net port (A or B) is used when connecting

devices to the network.

The Control Master can set the ne twork mode to Auto or Manual.

In Manual Mode, the user has the option of directing A‑Net data to either or

17Fr o N t PA N e l Fe At u r e s

Page 45

both A‑Net ports on the rear of the 6416i Input Module. Once the Control

Master has set the network to operate in Manual Mode, the red Manual

LED and at least one of the yellow Port LEDs will be lit on every Pro64 I/O

module.

Three options are available:

Po r t a• ‑ the 6416i transmits data from its active channels

only out of port A on the rear panel

Po r t • B ‑ the 6416i transmits data from active channels only

out of port B

• Po r t a a n d B ‑ (both LEDs are lit) the 6416i transmits

its active channels out of both the A and B ports.

A-Net data is set to transmit out

of Port B in Manual Mode in this

example.

Changing the A-Net Transmit Port

This applies to Manual Mode only; no user settings are available in Auto

Mode. The VDCs are not affected by the network mode.

Use the selector button below the Auto/Manual Mode LED readout to cycle

through the three options. When a new configuration is selected, the selected

Port LED and the Enter/Cancel LED will blink; confirmation is required. Press

En t E r to set a new transmit port or press Ca n C E l to exit without making a

change and return to the previous setting.

Changing the port transmit settings in Manual Mode has no effect on the

current channel activation settings.

Clock Master

One device in a Pro64 network will always be set as the network’s Clock

Master. In a network with only analog I/O modules, the module set as the

Control Master is also set to be the Clock Master by default. The Module set

as the Clock Master will have its Clock Master LED lit.

When digital I/O modules are used in a network, incoming word clock or AES3

(also referred to as AES/EBU) digital data streams can also be clock sources. It

18Fr o N t PA N e l Fe A t u r e s

Page 46

is only when a digital module is part of the network that the Control Master

and Clock Master can be separate devices.

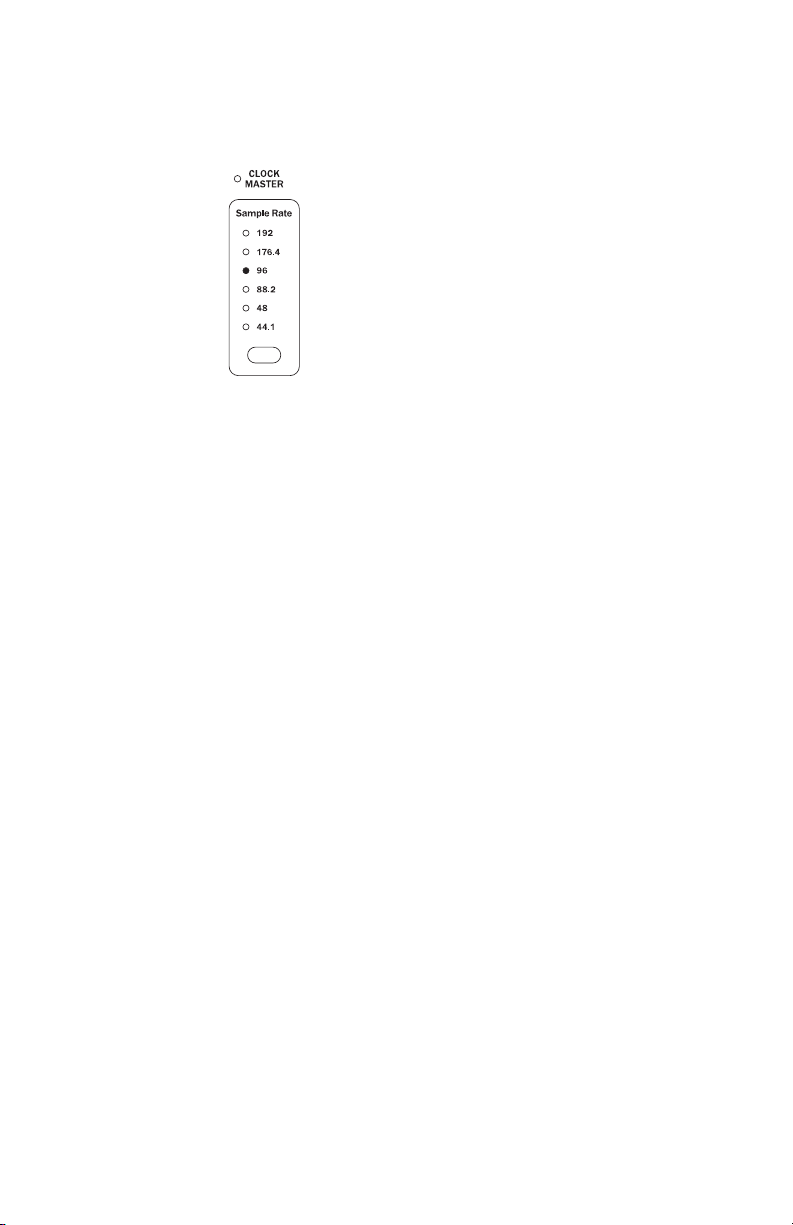

Sample Rate

Pro64 networks can operate at sample rates in three ranges without the use

of sample rate converters. The current network sample rate also determines

the number of available A‑Net Slots.

Sample Rate A-Net Slots Available

44.1/48kHz 64

88.2/96kHz 32

176 .4 /19 2k Hz 16

In an all‑analog network, the sample rate can be set at the Control Master to

the following:

4 4.1kH z•

48• kHz

88.2• kHz

96• kHz

176 .4• kHz

192• kHz

When an external clock is used with a Pro64 digital I/O device, the system

can lock to any sample rate within the range sample rate that is displayed in

the table below.

Pro64 Series Supported Sample Rates

Sample Rate Minimum Maximum

1x 44.1/48kHz 39.7kHz 52kHz

2x 88.2/96kHz 79.4k Hz 104 kHz

4x 17 6. 4/ 192 kH z 158 .8 kH z 208kHz

Changing the Sample Rate

The network sample rate can be changed only at the Clock Master. Changing

the sample rate is done with the selection button found below the Sample

Rate LED readout.

To choose a new sample rate, press the selection button beneath the sample

rate list. Pressing the button selects the next sample rate in the list and

immediately starts blinking the new rate’s LED and the Enter/Cancel LED;

19Fr o N t PA N e l Fe A t u r e s

Page 47

confirmation is required. To confirm the new sample rate, press the En t E r

button. To exit without changing the sample rate, press Ca n C E l .

Pressing the s election

button will cycle through the

available sample rates.

Attempting to change the sample rate on a module that is not the Clock

Master will cause the Sample Rate and Clock Master LEDs to flash to indicate

the error.

Sample Rates and A-Net Slots

Changing the network sample rate has a direct effect on the availability of

A‑Net Slots. For example, setting the sample rate to 96kHz makes only 32

Slots available, numbers 1 through 32. Slot numbers 33‑64 are no longer

available.

If at the 48kHz sample rate an input module such as the 6416i is set to the

Slot range starting at 33 or 49 and has active channels, these channels will be

deactivated when the sample rate changes to 96kHz. These Slot assignments

no longer exist in the network.

Channel Activation Button

Each of the sixteen line‑level input channels on the 6416i can be made active

on the network individually using the lighted Active button found below

the gain range switch on each channel. Activating a channel assigns it to an

A‑Net Slot, making it part of the network and available to any output module

in the network.

20Fr o N t PA N e l Fe A t u r e s

Page 48

Channel act ivation buttons

are found below the Gain

switches. Here, Channels 1, 3,

and 4 have been made ac tive

on the netwo rk.

In Auto Mode, each A‑Net Slot is unique. The Control Master manages the

availability of A‑Net Slots and will grant or deny a channel activation request

from an input module based on the current makeup of the network, the

sample rate, and the Slots already in use.

To activate a 6416i input channel within a given A‑Net Slot range, press its

numbered aC t i v E button. (Note that the word “Active” does not appear on

the front panel user interface.) If the Slot is available, the Control Master

will enable the Slot and the channel’s green LED will light. If the Slot is not

available, the LED will flash briefly, indicating that the requested Slot is in use

elsewhere in the network.

In Manual Mode, a channel can be activated at any time. Depending on how

the network is set up and configured, activating a channel can replace a

channel that was added to the network elsewhere.

Channel Activation Rules

It is not necessary to press the En t E r button to activate or deactivate a

channel.

Each Pro64 module remembers a unique set of active channels for Auto and

Manual Modes. For example, an input module could have channels 1‑8 active

for an Auto Mode application and channels 5‑6 and 12‑16 active for a Manual

Mode application. Changing network modes will restore the active channel

status for each connected module.

Changing the A‑Net Slot range will clear the currently active channels on an

input module automatically to protect against channel/Slot conflicts a or

unintentional overwriting.

Level Meter LEDs

Each audio input channel on the 6416i Input Module has its own set of level

LEDs—green, yellow, and red. Green indicates signal present; it turns on

21Fr o N t PA N e l Fe A t u r e s

Page 49

when a signal level of ‑40dB or higher is present. The yellow LED lights when

the signal level reaches ‑10dB. Clipping is indicated with the red LED, which

lights when the level reaches 0dB.

The level meter LEDs will always show the level of the incoming analog audio

signal, even when the channel is not active on the network.

Always try to optimize the input level to assure proper gain staging

throughout both the network and the connected audio devices.

Stereo Link Button

Adjacent pairs of channels on the 6416i can be linked together as a stereo

pair. The channels must be an odd‑even pair, such as 1‑2, 7‑8, etc. There is

one Link button for each channel pair, eight in all.

To link a pair of channels, both channels must be active on the network

first; the Active button below the Gain switch must be lit on both channels.

Once the two channels are active, pressing the li n k button will link the two

channels immediately; no confirmation is required.

Attempting to link channels that do not meet the requirements above will

cause the Link button and one or more channel button LEDs to flash to

indicate the error.

To link a pair of channels, both channels must be active rst.

22Fr o N t PA N e l Fe A t u r e s

Page 50

Gain Switch

Each line‑level input channel on the 6416i has an individual four‑position

gain switch that can be used to best match the incoming signal level. The

default setting (no gain change) is 0dB.

The available gain settings are:

+6dB •

0dB •

‑6dB •

‑1• 4dB

Gain switches are in the analog domain and are not locked out from being

changed when either the Edit Lock or Password protection features are

used.

Managed Button

The Managed button is used to put the network under control of a computer

for firmware updates, system monitoring, etc. Managed Mode can only be

engaged from the network’s Control Master.

When using a PC for firmware updates, etc., a Pro64 module cannot have its

RS‑232 or MIDI port assigned to a VDC when the PC is connected. Deactivate

VDC assignments of this type before entering Managed Mode.

Managed Mode and Edit Lock buttons

To enter Managed Mode, press the Ma n a g E d button; its LED will flash. The

Enter/Cancel LED will also flash. Press En t E r to confirm the mode change or

Ca n C E l to return to the previous state.

To exit Managed Mode, press the Ma n a g E d button; its LED will flash and the

23Fr o N t PA N e l Fe A t u r e s

Page 51

Enter/Cancel LED will flash. Press En t E r to confirm the mode change. The

network returns to the previous local mode, Auto or Manual.

In Managed Mode, Virtual Data Cable and channel Active buttons behave as

if the module is edit locked; they provide information only when pressed. All

other front panel edits are prohibited.

Edit Lock Button

The front panel of the 6416i can be locked to prevent accidental changes or

low‑level unauthorized access. Once edit locked, all front‑panel functions

under digital control cannot be changed. Analog functions, including

channel gain settings can still be changed. Edit Lock can be used on a

module‑by‑module basis.

To lock a module’s front panel, press the Ed i t lo C k button. The Enter/Cancel

LED will blink. Press En t E r to lock the unit. No other Pro64 modules in the

network are affected. Press the Ca n C E l button to exit the operation without

locking the device’s front panel.

To unlock a Pro64 device, press the Ed i t lo C k button again. The Enter/Cancel

LED will blink. Press the En t E r button to unlock the unit. Press Ca n C E l to exit,

leaving the unit locked.

When a Pro64 module is edit locked, all front panel operations are inactive

with the following exceptions:

The Edit Lock button, along with the Enter button,• can be

used to unlock the unit.

• Gain switches on I/O modules are analog controls. These

cannot be locked.

Channel • Active buttons can be used to get information

about the channel‑to‑Slot relationships.

The • VDC inc/dec buttons can be used to get info on Virtual

Data Cable port assignments.

Query Functions (Get Info)

When a module is edit locked, its front‑panel channel buttons can be used to

get Slot info. Pressing any channel button will display the selected channel’s

A‑Net Slot number in the A‑Net Slot display.

For example, if an input module is set to the A‑Net Slot range starting at 17,