Page 1

D-Command

Version 7.3

™

Page 2

Copyright

Legal Notices

This guide is copyrighted ©2007 by Digidesign, a division of Avid Technology, Inc.

(hereafter “Digidesign”), with all rights reserved. Under copyright laws, this guide

may not be duplicated in whole or in part without the written consent of

Digidesign.

003, 003 Rack, 96 I/O, 96i I/O, 192 Digital I/O, 192 I/O, 888|24 I/O, 882|20

I/O, 1622 I/O, 24-Bit ADAT Bridge I/O, AudioSuite, Avid, Avid DNA, Avid Mojo,

Avid Unity, Avid Unity ISIS, Avid Unity MediaNetwork, Avid Xpress, AVoption,

AVoption|V10, Beat Detective, Bruno, Command|8, Control|24, D-Command,

D-Control, D-Fi, D-fx, D-Show, DAE, Digi 002, Digi 002 Rack, DigiBase,

DigiDelivery, Digidesign, Digidesign Audio Engine, Digidesign Intelligent Noise

Reduction, Digidesign TDM Bus, DigiDrive, DigiRack, DigiTest, DigiTranslator,

DINR, DV Toolkit, EditPack, Impact, Interplay, M-Audio, MachineControl, Maxim,

Mbox, MediaComposer, MIDI I/O, MIX, MultiShell, OMF, OMF Interchange, PRE,

ProControl, Pro Tools M-Powered, Pro Tools, Pro Tools|HD, Pro Tools LE,

QuickPunch, Reel Tape, Reso, Reverb One, ReVibe, RTAS, Smack!,

SoundReplacer, Sound Designer II, Strike, Structure, SYNC HD, SYNC I/O,

Synchronic, TL Space, Velvet, and X-Form are trademarks or registered

trademarks of Digidesign and/or Avid Technology, Inc. All other trademarks are

the property of their respective owners.

Product features, specifications, system requirements, and availability are

subject to change without notice.

PN 9106-55465-00 REV A 10/07

Comments or suggestions regarding our documentation?

email: techpubs@digidesign.com

Warning

This product contains chemicals, including lead, known to the State of California

to cause cancer and birth defects or other reproductive harm. Wash hands after

handling.

Communications & Safety Regulation Information

Compliance Statement

The models D-Command and XMON comply with the following standards

regulating interference and EMC:

• FCC Part 15 Class A

• EN55103 – 1, environment E4

• EN55103 – 2, environment E4

• AS/NZS 3548 Class A

• CISPR 22 Class A

• ICES-003 Class A

Canadian Compliance Statement:

This Class A digital apparatus complies with Canadian ICES-003

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

CE Compliance Statement:

Digidesign is authorized to apply the CE (Conformité Europénne) mark on this

compliant equipment thereby declaring conformity to EMC Directive

89/336/EEC and Low Voltage Directive 73/23/EEC.

Australian Compliance:

Radio and Television Interference

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules.

Communications Statement

This equipment has been tested to comply with the limits for a Class A digital

device. Changes or modifications to this product not authorized by Digidesign,

Inc., could void the Certification and negate your authority to operate the product.

This product was tested for CISPR compliance under conditions that included the

use of peripheral devices and shielded cables and connectors between system

components. Digidesign recommends the use of shielded cables and connectors

between system components to reduce the possibility of causing interference to

radios, television sets, and other electronic devices.

Safety Statement

This equipment has been tested to comply with USA and Canadian safety

certification in accordance with the specifications of UL Standards: UL60065 7th

/IEC 60065 7th and Canadian CAN/CSA C22.2 60065:03. Digidesign Inc., has

been authorized to apply the appropriate UL & CUL mark on its compliant

equipment.

Warning

Important Safety Instructions

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this apparatus near water.

6) Clean only with dry cloth.

7) Do not block any ventilation openings. Install in accordance with the

manufacturer’s instructions.

8) Do not install near any heat sources such as radiators, heat registers, stoves,

or other apparatus (including amplifiers) that produce heat.

9) Do not defeat the safety purpose of the polarized or grounding-type plug. A

polarized plug has two blades with one wider than the other. A grounding type

plug has two blades and a third grounding prong. The wide blade or the third

prong are provided for your safety. If the provided plug does not fit into your

outlet, consult an electrician for replacement of the obsolete outlet.

10) Protect the power cord from being walked on or pinched particularly at plugs,

convenience receptacles, and the point where they exit from the apparatus.

11) Only use attachments/accessories specified by the manufacturer.

12) Unplug this apparatus during lightning storms or when unused for long

periods of time.

13) Refer all servicing to qualified service personnel. Servicing is required when

the apparatus has been damaged in any way, such as power-supply cord or plug

is damaged, liquid has been spilled or objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture, does not operate normally, or

has been dropped.

Page 3

Do not attempt to service the equipment. There are no

user-serviceable parts inside. Please refer all servicing to authorized

Digidesign personnel.

Any attempt to service the equipment will expose you to a risk of

shock and will void the manufacturer’s warranty.

SPECIAL WARNING REGARDING VENTILATION:

Do not install D-Command anywhere or in any way that blocks free

air flow at any time around the back panel of the unit.

SPECIAL WARNING REGARDING AMBIENT TEMPERATURE:

Before powering on the D-Command unit, be sure to allow it to reach

room temperature. The unit includes some components that are

senstive to cold temperatures, so it is recommended that you

unpack the unit and allow it to acclimate before turning it on for the

first time.

Page 4

Page 5

Contents

Part I Introduction

Chapter 1. Introduction to D-Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

D-Command Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

D-Command System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

System Expansion Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operational Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connection Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2. D-Command Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

D-Command Main Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

D-Command Fader Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

D-Command XMON Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Part II Installation

Chapter 3. Setting Up the Fader Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Assembling an Expanded System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 4. Connecting D-Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

D-Command Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Audio Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 5. Configuring D-Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Starting Up and Shutting Down the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting D-Command Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

System Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Part III Reference

Chapter 6. Channel Strip Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Channel Strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Global Controls Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Miscellaneous Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Contents v

Page 6

Chapter 7. Plug-in Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Plug-ins and D-Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Dynamics Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

EQ Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Chapter 8. Transport and Navigation Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Transport Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Zoom/Navigate Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Nudge/Bank Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Chapter 9. Management Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Window Management Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Session Management Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Soft Keys Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter 10. Monitor and Meter Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Monitor Section Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Meter and Time Code Displays (Main Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Setting D-Command Meters for Different Reference Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Chapter 11. Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Custom Fader Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Working with Automation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix A. Utility Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Entering Utility Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Navigating Utility Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Exiting Utility Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

D-Command System Info Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

D-Command Name Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

D-Command Test Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Resetting D-Command to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

D-Command Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Appendix B. Audio Connections and Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

25-Pin Female Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

15-Pin Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Tech Pubs Style Guidevi

Page 7

Part I: Introduction

Page 8

Page 9

Chapter 1: Introduction to D-Command

Welcome to the D-Command™ worksurface for Digidesign®

ICON systems.

D-Command System Components

D-Command provides hands-on control of Pro Tools®, and

offers powerful options for customizing the Pro Tools mix

environment.

D-Command Features

The D-Command system provides controls for most Pro Tools

recording, editing and mixing tasks, and a versatile remote-controlled audio monitoring system.

Control Features

• Touch-sensitive, motorized 100mm faders

• Touch-sensitive, multi-purpose rotary controls

• Dedicated controls for assignment and activation of inputs,

outputs, inserts and sends

• Flexible display of pan, insert, send, plug-in and mic pre

controls

• Dedicated EQ and dynamics plug-in control sections

• Dedicated controls for all channel strip functions including

recording and input monitoring modes, mute, solo, and

channel select

• Dedicated controls for automation mode, enable and safe

status

• Custom Fader Mode for flexible channel and parameter

mapping

• Full transport and navigation controls, including location

commands and scrub/shuttle capability

Monitoring Features

• 6-channel control room monitoring system supports mono

through 5.1 surround monitoring, with up to 5 possible input sources and 3 selectable output paths

• 2-channel cue system with 4 separate outputs and selectable

talkback feed

• Built-in talkback microphone and external talkback mic

input

• Standalone mode for monitoring without Pro Tools

• External source metering

The following components are included in a D-Command

8-channel or 24-channel system:

Main Unit

• D-Command Main Unit

•AC power cord

•Ethernet cable

• Ethernet “crossover” cable (for direct connection to CPU

without a hub)

• Ethernet loopback plug (for Ethernet testing)

• 9/64-inch hex driver (for removing side panels)

• 5/32-inch hex driver (for connecting Main Unit and

Fader Module)

Fader Module

(Required for 24-Channel System)

• D-Command Fader Module unit

•AC power cord

•Ethernet cable

XMON Monitoring System

•XMON Interface

•AC power cord

•XMON cable

System Expansion Options

An additional 16-channel Fader Module can be added to

D-Command, for a total of 24 faders. For details on

D-Command expansion and customization options, visit the

Digidesign website (www.digidesign.com).

Chapter 1: Introduction to D-Command 3

Page 10

Operational Requirements

Connection Requirements

Temperature and Ventilation

D-Command should be installed and operated in a climate-controlled environment, away from heat sources, and

with adequate ventilation. D-Command should be operated at

an ambient temperature that does not exceed 100 degrees F

(35 degrees C).

The back panel and the front half of the bottom panel of each

unit should be exposed to ambient air. Blocking or partially

blocking the back panel or bottom panel of a D-Command

unit may cause the unit to malfunction and may void your

warranty.

Water and Moisture

D-Command units should be operated away from sources of

moisture or humidity and should be protected from liquid

spills.

Cleaning and Maintenance

If you need to clean the D-Command top surface, apply a

non-chlorine bleach based cleaning solution to a cloth or

paper towel, then carefully wipe the surface. Do not use

abrasives, cleaning solutions with chlorine bleach, or spray

cleaners.

Power Connections

Each unit (D-Command Main Unit, Fader Module, and

XMON Monitor Interface) requires its own power connection.

Make sure your power source is correctly rated for the number

of units you are connecting. A surge protected power source

(not included) is highly recommended.

Ethernet Connections

Each D-Command unit communicates with Pro Tools using

Ethernet. A single Main Unit can be connected to the host

computer without an Ethernet hub. To connect multiple

D-Command units to the host computer, an Ethernet hub

(not included) is required.

Audio Connections

All external analog audio inputs and outputs for control room

monitoring and studio communication are connected to the

XMON interface. D-Command connects to the XMON interface with a single 15-pin cable (included). All analog inputs

and outputs on the XMON use DB-25 connectors.

Audio Cables for D-Command Monitoring

Digidesign offers a range of DigiSnake cabling options for connecting Digidesign interfaces and external sources to the

XMON monitoring system. For details, visit the Digidesign

website (www.digidesign.com).

System Requirements

D-Command requires the following system components:

• Pro Tools|HD® system (which includes at least one

Pro Tools|HD audio interface)

An expanded Pro Tools|HD system is required for higher track

counts.

For complete system requirements, visit the Digidesign

website (www.digidesign.com).

Compatibility Information

Digidesign can only assure compatibility and provide support

for hardware and software it has tested and approved.

For a list of Digidesign-qualified computers, operating systems, and third-party devices, visit the Digidesign website

(www.digidesign.com).

D-Command Guide4

Page 11

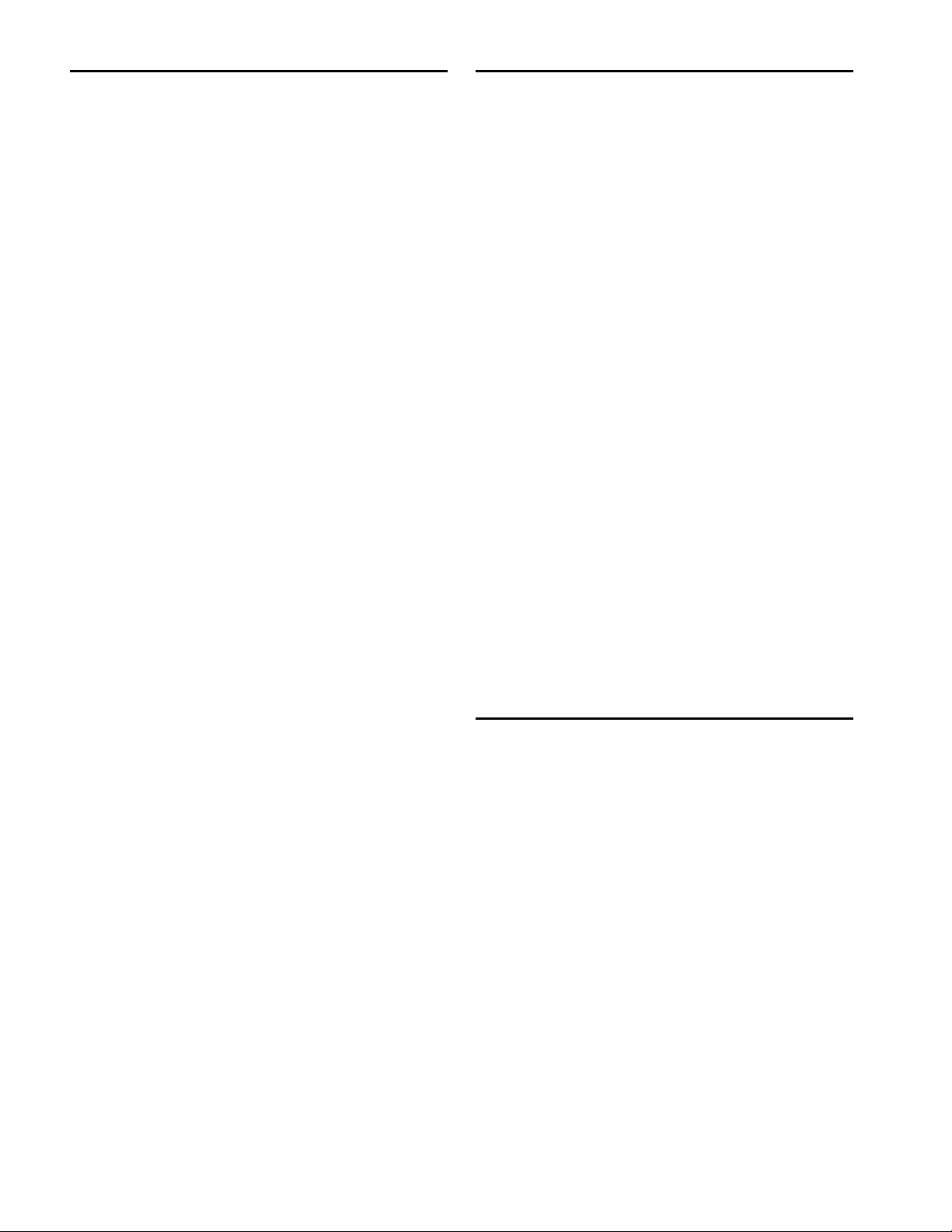

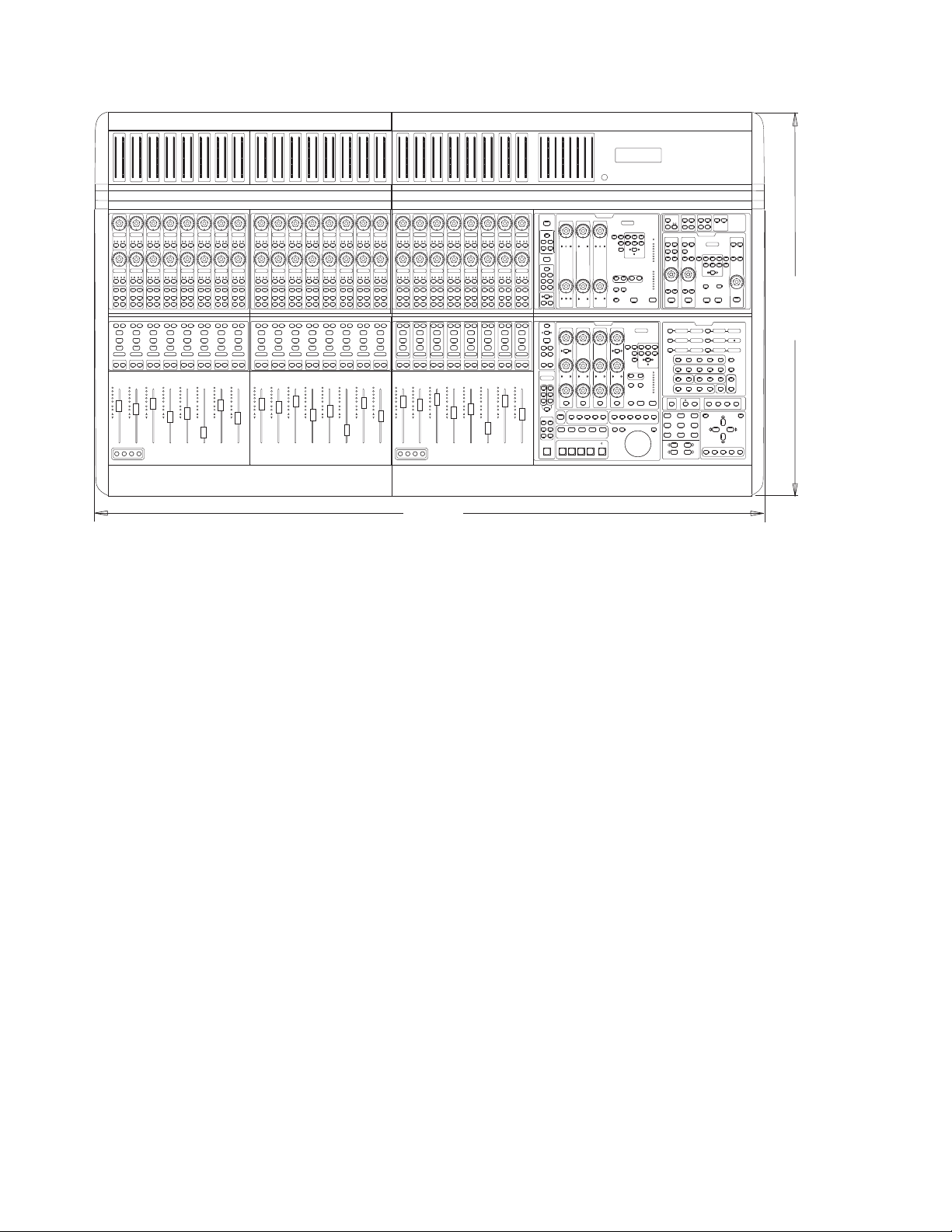

Mechanical Specifications

29.25 in

(74.3 cm)

14.4 in

(36.6 cm)

0.5 in

(1.27 cm)

2.55 in

(6.48 cm)

2.68 in

(6.79 cm)

4.24 in

(10.78 cm)

10.23 in

(25.98 cm)

32.3 in

(82 cm)

29.25 in

(74.3 cm)

D-Command side dimensions

D-Command top dimensions (Main Unit)

Chapter 1: Introduction to D-Command 5

Page 12

D-Command top dimensions (Main Unit and Fader Module)

55.6 in

(141.2 cm)

29.25 in

(74.3 cm)

D-Command Guide6

Page 13

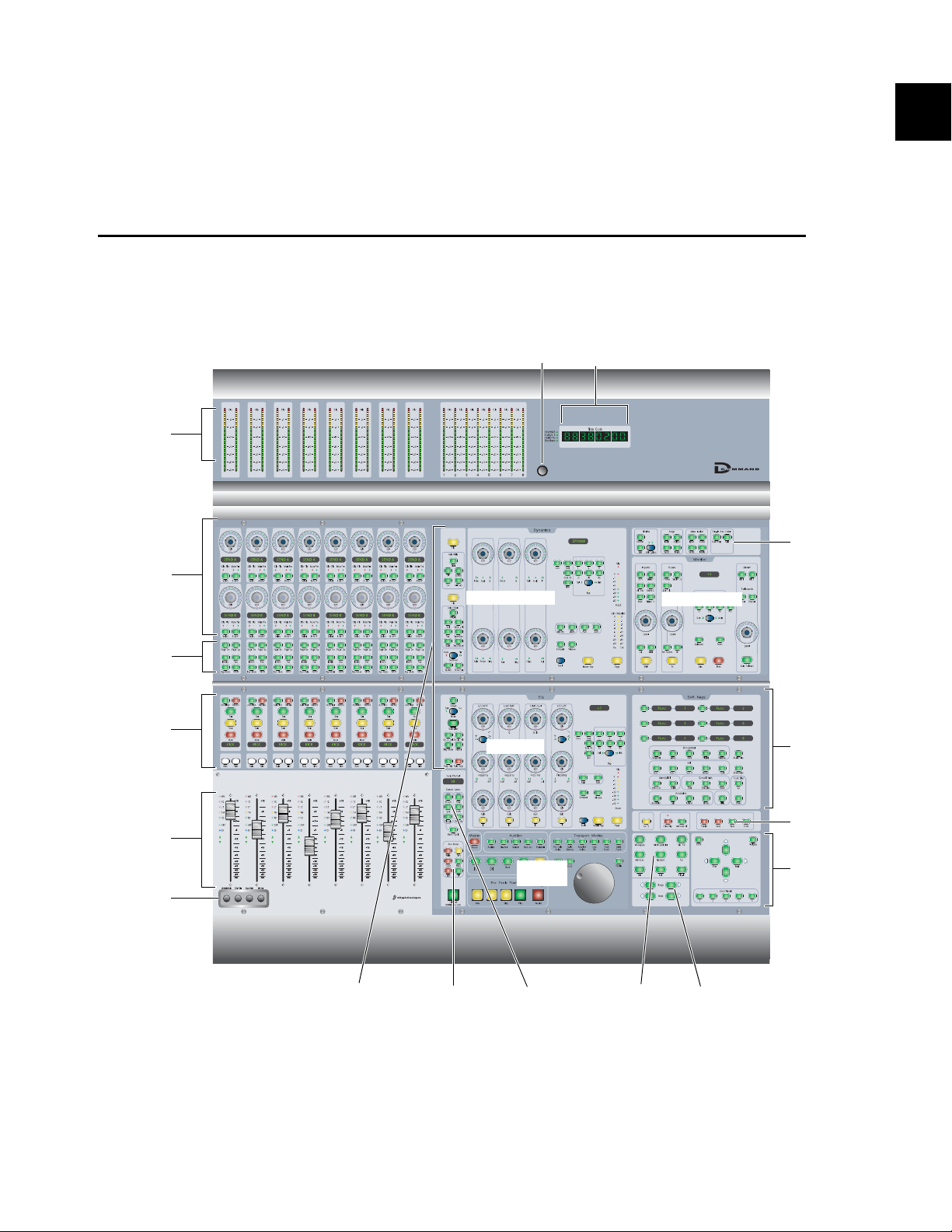

Chapter 2: D-Command Overview

Monitor Section

Global

controls

Custom Fader

controls

Window

Management

section

Session

Management

section

Soft Keys

section

Nudge/Bank

section

Zoom/Navigation

section

Miscellaneous

controls

Talkback Microphone

Main Time Scale display

Automation Mode

controls

Dynamics Section

EQ Section

Tra n sp or t

Section

Rotary Encoder

section

Meter

section

Channel Strip

Display controls

Channel

Channel Strip

Mode controls

Modifier

faders

keys

D-Command Main Unit

Main Unit Top Panel

Figure 1. D-Command Main Unit top panel

Chapter 2: D-Command Overview 7

Page 14

Meter Display

Soft Keys Section

The Meter display on the D-Command Main Unit can be set to

show the output levels, or levels associated with a track or

plug-in. See “Meter and Time Code Displays (Main Unit)” on

page 93.

Main Time Scale Display and Location Indicator

The Main Time Scale display and Location indicator mirrors

the Main Time Scale in Pro Tools. See “Meter and Time Code

Displays (Main Unit)” on page 93.

Dynamics and EQ Sections

The D-Command Main Unit provides dedicated Dynamics

and EQ sections for plug-ins that support Dynamics and EQ

plug-in mapping. See “Plug-ins and D-Command” on page 49.

Monitor Section

The Monitor section on the D-Command Main Unit includes

a full set of controls for the control room, headphone/cue,

and talkback/listenback sections of D-Command. See “Monitor Section Controls” on page 85.

Zoom/Navigation Section

The Zoom/Navigate section on the D-Command Main Unit is

used to control navigation, display, and selections in the

Pro Tools Edit window. See “Zoom/Navigate Section” on

page 72.

The Soft Keys section on the D-Command Main Unit provides

access to a wide range of Pro Tools commands directly from

the control surface. It also provides access to preferences and

settings specific to D-Command. See “Soft Keys Section” on

page 75.

Transport Section

The Transport section on the D-Command Main Unit includes a full set of transport controls, switches for setting the

transport mode, scrub/shuttle controls, as well as advanced

audition and locate controls. See “Transport Section” on

page 67.

Global Controls

The Global controls are a set of channel-related controls in the

center of the D-Command Main Unit, allowing easy access to

powerful assignment, display, and channel function controls.

See “Global Controls Section” on page 38.

Custom Fader Controls

The Custom Fader mode switches on the D-Command Main

Unit invoke a special set of D-Command modes, called Custom

Fader modes, which let you set aside and customize channel

strips for display and editing of a variety of functions. See

“Custom Fader Controls” on page 42.

Automation Mode Controls

Nudge/Bank Section

The Nudge/Bank section on the D-Command Main Unit is

used to control the display of Pro Tools tracks on the control

surface. See “Nudge/Bank Section” on page 72.

Window Management and Session Management

Sections

The Window Management and Session Management sections

on the D-Command Main Unit include controls for opening

and closing Pro Tools windows, and managing and saving

Pro Tools sessions. See “Window Management Section” on

page 73 and “Session Management Section” on page 74.

The Automation Mode controls mirror the function of the

on-screen Automation Mode selector for each track, and let

you change automation modes during playback. See “Automation Mode Controls” on page 44.

D-Command Guide8

Page 15

Main Unit Back Panel

Footswitch jack

Ethernet connector

XMON Monitoring System

connector

AC Power

Power switch

Figure 2. D-Command Main Unit back panel connectors

AC Power

The AC Power connector accepts a standard AC power cable.

The D-Command Main Unit is auto power-selecting (100V to

240V) and automatically works with a standard modular

power cord when connected to an AC receptacle in any

country.

Power Switch

The Power switch applies power to the D-Command Main

Unit.

Footswitch Jack

The footswitch jack on the back panel of the D-Command

Main Unit is a 1/4-inch TRS jack that supports two footswitch

connections. See “Footswitch Connections” on page 18.

Ethernet Connector

The Ethernet connector on the back panel of the D-Command

Main Unit provides communication to Pro Tools. See “Ethernet Connections” on page 17.

XMON Monitoring System Connector

The 15-pin connector on the back panel of the D-Command

Main Unit provides remote control of all audio monitoring

functions from the D-Command Monitoring section. See

“XMON Monitoring System Connection” on page 19.

Chapter 2: D-Command Overview 9

Page 16

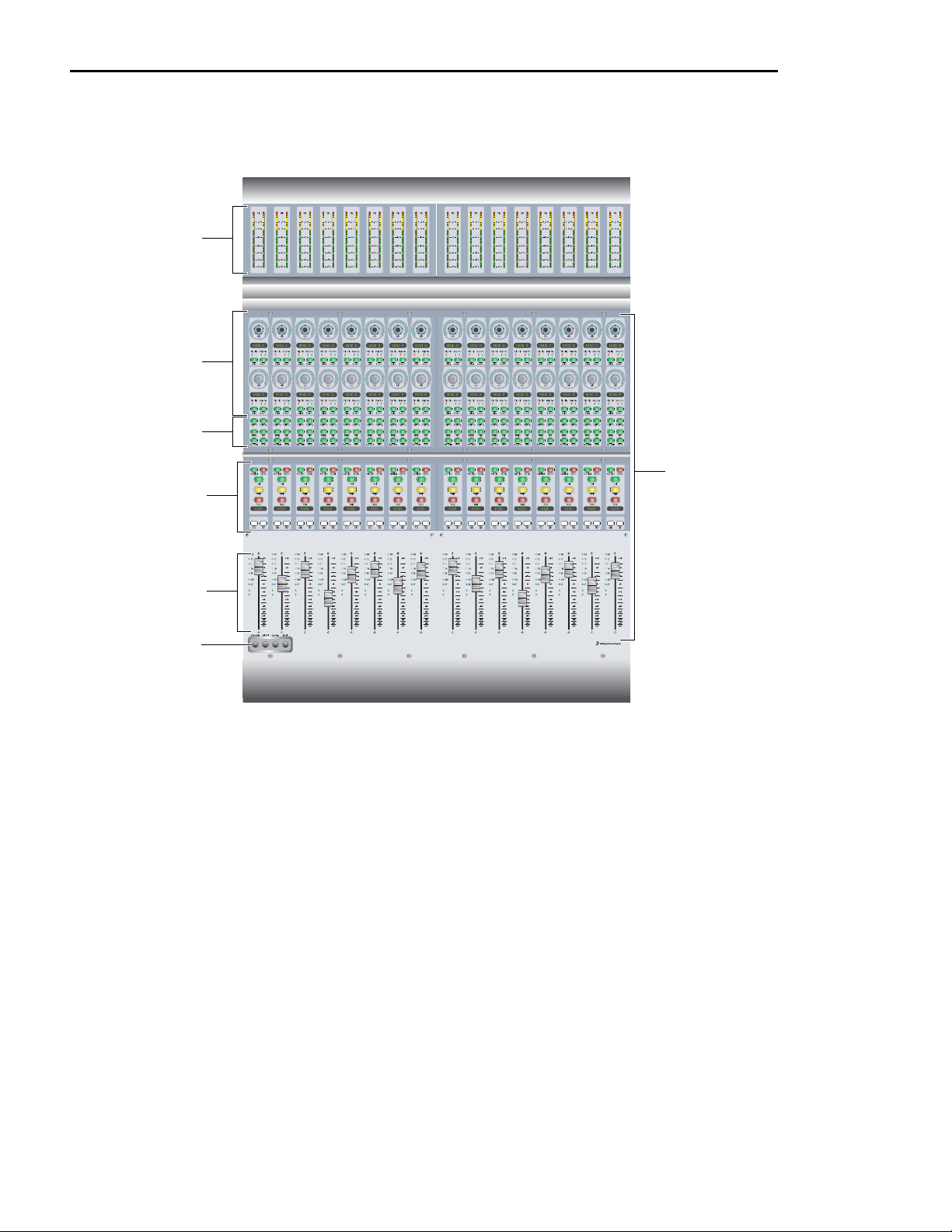

D-Command Fader Module

Channel Strip

Rotary Encoder

section

Meter

section

Channel Strip

Mode controls

Channel faders

Channel Strip

Function controls

Modifier keys

Fader Module Top Panel

Figure 3. D-Command Fader Module top panel

Meter Section

The Meter section on the D-Command Fader Module can display track levels, plug-in meters, and other parameters depending on D-Command metering preferences.

Channel Strip

Each channel strip on the D-Command Fader Module has

identical channel controls, including two touch-sensitive rotary encoders, display and mode controls, and a touch-sensitive fader. See “Channel Strips” on page 31.

Modifier Keys

Each D-Command Fader Module has a set of four switches in

its lower left corner that duplicate the function of the

Pro Tools computer keyboard modifiers. See “Modifier Key

Switches” on page 37.

D-Command Guide10

Fader Module Back Panel

AC Power

The AC Power connector accepts a standard AC power cable.

The D-Command Fader Module is auto power-selecting (100V

to 240V) and automatically works with a standard modular

power cord when connected to an AC receptacle in any

country.

Power Switch

The Power switch applies power to the Fader Module.

Ethernet Connector

The Ethernet connector on the back panel of the D-Command

Fader Module provides communication to Pro Tools. See

“Ethernet Connections” on page 17.

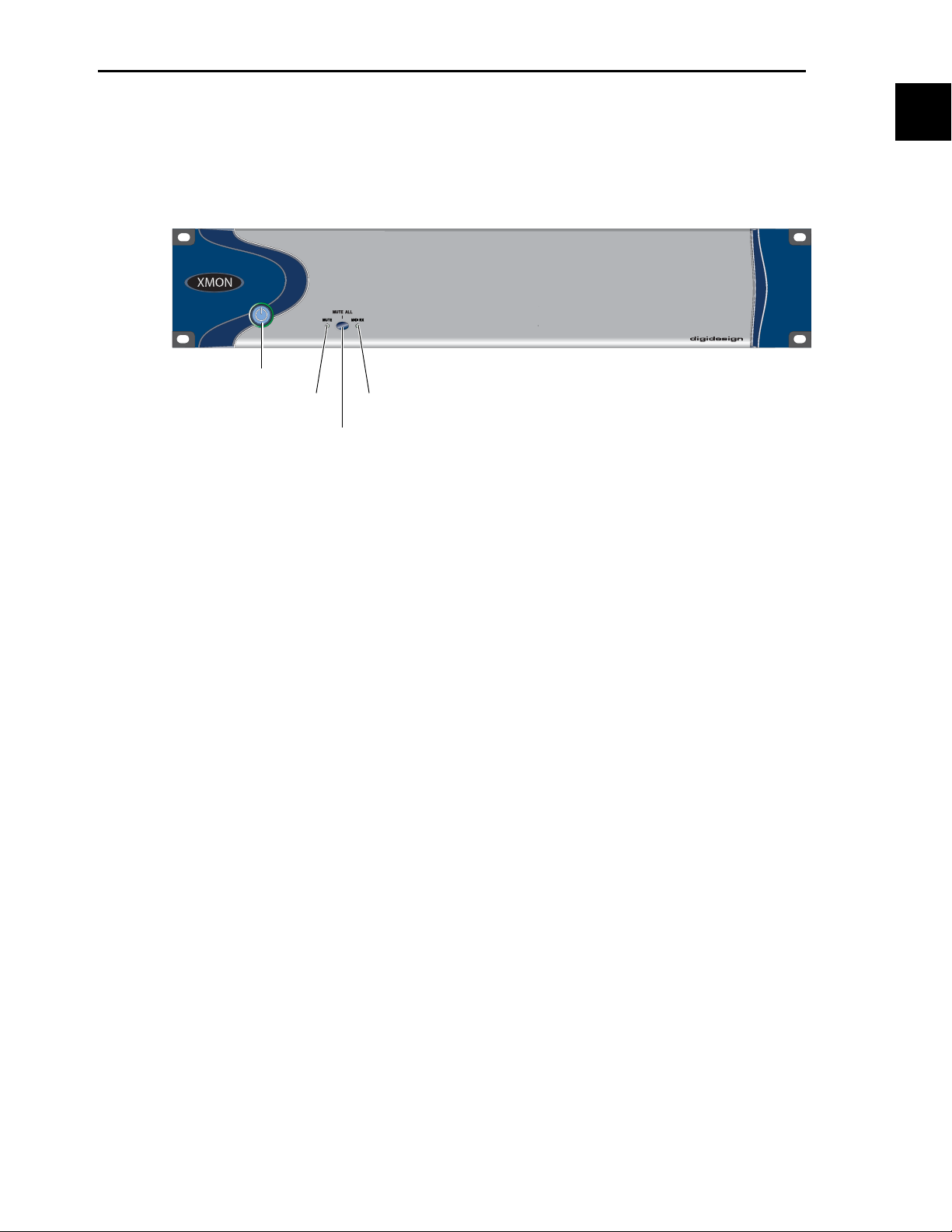

Page 17

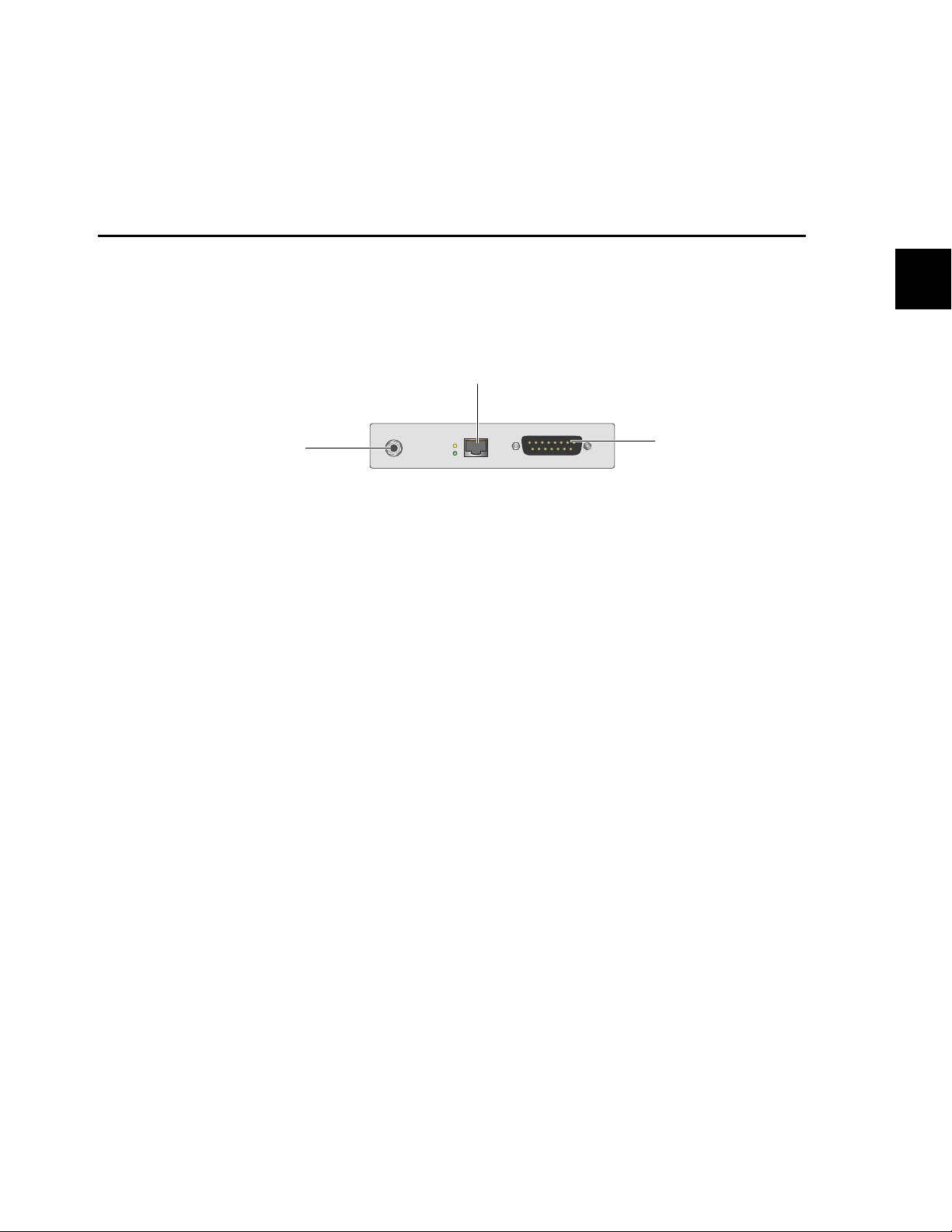

D-Command XMON Interface

Power

switch

MIDI Receive

indicator

Mute

indicator

Mute button

D-Command monitoring is based on the XMON analog interface, which is remotely controlled from the D-Command

monitoring section.

XMON Front Panel

Figure 4. XMON front panel

Power Switch

The Power switch applies power to the XMON Interface.

Mute Indicator

The Mute indicator shows the mute status of XMON.

MIDI Receive Indicator

The MIDI Receive indicator shows MIDI activity between

XMON and D-Command.

Mute Button

The Mute button mutes all XMON outputs. It is not possible

to unmute XMON with this button. The XMON mute state

can only be cleared from the D-Command Monitor section

(see “Monitor Section Controls” on page 85).

Chapter 2: D-Command Overview 11

Page 18

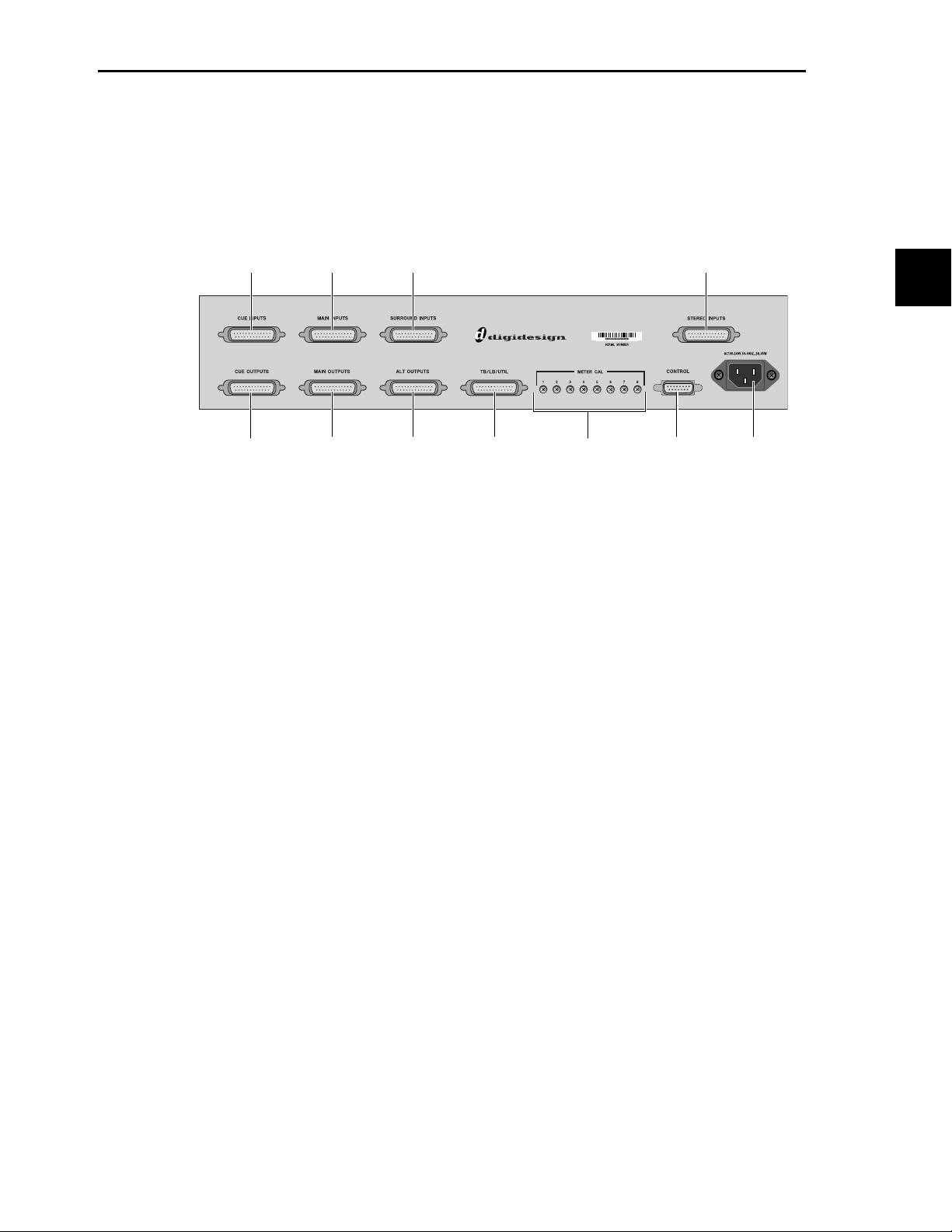

XMON Back Panel

Cue Inputs

Cue Outputs

Main Inputs Surround Inputs Stereo Inputs

Main Outputs Alt Outputs Talkback/ Meter Calibration Control Surface AC Power

Listenback/

Utility

Screws

The back panel of the XMON interface includes connectors for all external analog audio inputs and outputs for D-Command. See

“Audio Connections” on page 19.

Figure 5. XMON back panel

D-Command Guide12

Page 19

Part II: Installation

Page 20

Page 21

Chapter 3: Setting Up the Fader Module

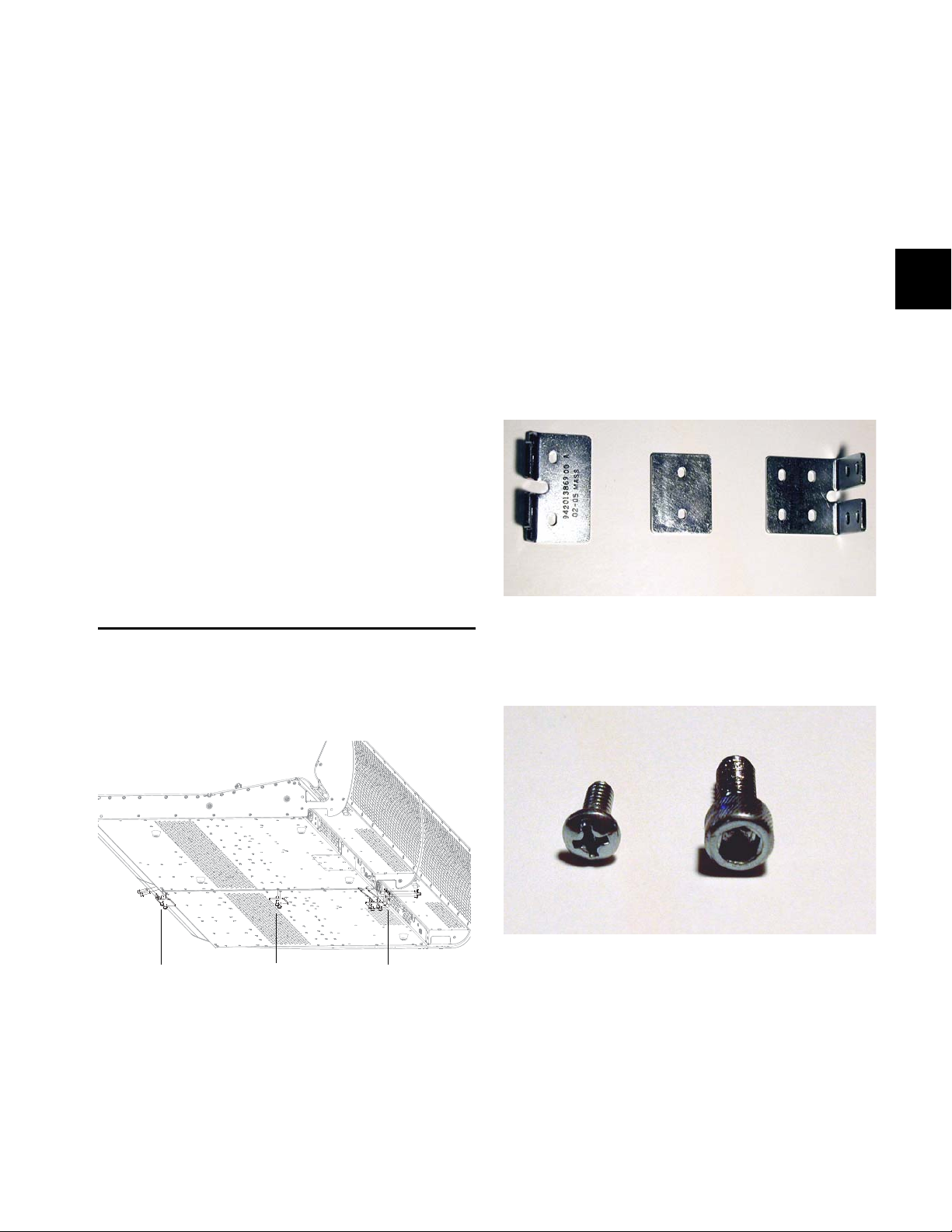

Front bracket Center bracket Rear bracket

Front bracket Center bracket Rear bracket

10-32 x 3/4-inch

socket cap screw

6-32 x 3/8-inch

Philips pan head screw

This chapter explains how to add the Fader Module to the

D-Command Main Unit.

Placement of D-Command Fader Module

When placing the D-Command Fader Module in studio furniture or on a table top, make sure to account for the dimensions of the assembled system, allowing for at least 1 inch

(2.5 cm) of open space behind the finished unit. This meets

the ventilation requirements for the D-Command units.

When bracketing together your system, you will need additional clearance on either side of the unit to push the Fader

Module and the Main Unit together, as well as sufficient clearance in front and behind the units to allow you to attach the

brackets. You will also need access to the rear of the unit to

make cable connections.

The Fader Module is designed to be attached to the left of the

D-Command Main Unit.

Assembling an Expanded System

The D-Command Main Unit can be attached to the D-Command Fader Module, using the front, middle, and rear brackets included with the D-Command Fader Module.

Assembly Hardware

The following hardware is provided with the D-Command

Fader Module (spare pieces may be included).

Brackets

• Front Bracket

• Center Bracket

• Rear Bracket

Figure 2. D-Command expanded system connecting brackets

Screws

• (10) 10-32 x 3/4-inch socket cap screw

• (4) 6-32 x 3/8-inch Philips pan head screw

Figure 1. D-Command with Fade Module (bottom view)

Figure 3. Screws for D-Command connecting brackets

Chapter 3: Setting Up the Fader Module 15

Page 22

Attaching the Units

Remove screws

D-Command

Fader Module

To attach the D-Command Fader Module to the Main Unit:

1 Remove the plastic end cap from the left end of the Main

Unit.

2 Place the Fader Module to the left of the Main Unit, and

press the D-Command units together.

3 Slide both units forward far enough to have complete access

to the front bracket screw holes.

4 Attach the front bracket, using four 10-32 3/4-inch socket

cap screws.

When bracketing together a D-Command system, leave all

sc rews on the Fade r Module loose e no ugh to allow you to adjust the position of the units relative to each other. After all

three brackets are installed, and the units are pressed fully

together, you will fully tighten the Fader Module screws.

5 Slide the connected units backwards far enough to have

complete access to the rear screws.

6 Remove the four Philips head screws indicated in Figure 4.

Figure 4. Rear view of D-Command and Fader Module

7 Attach the rear bracket, using four 10-32 3/4-inch socket cap

screws and four 6-32 x 3/8-inch Philips pan head screws.

8 Carefully slide the connected units forwards far enough to

have complete access to the center bracket screw holes.

9 Attach the center bracket, using two 10-32 3/4-inch socket

cap screws.

10 Press the D-Command units together. If necessary, use a

ratcheting nylon strap to press the units together by running

the strap around the two units. Make sure the nylon strap does

not contact any switches or encoders on the surface.

11 Tighten the bracket screws on the Fader Module.

12 Attach the plastic end cap to the Fader Module.

D-Command Guide16

Page 23

Chapter 4: Connecting D-Command

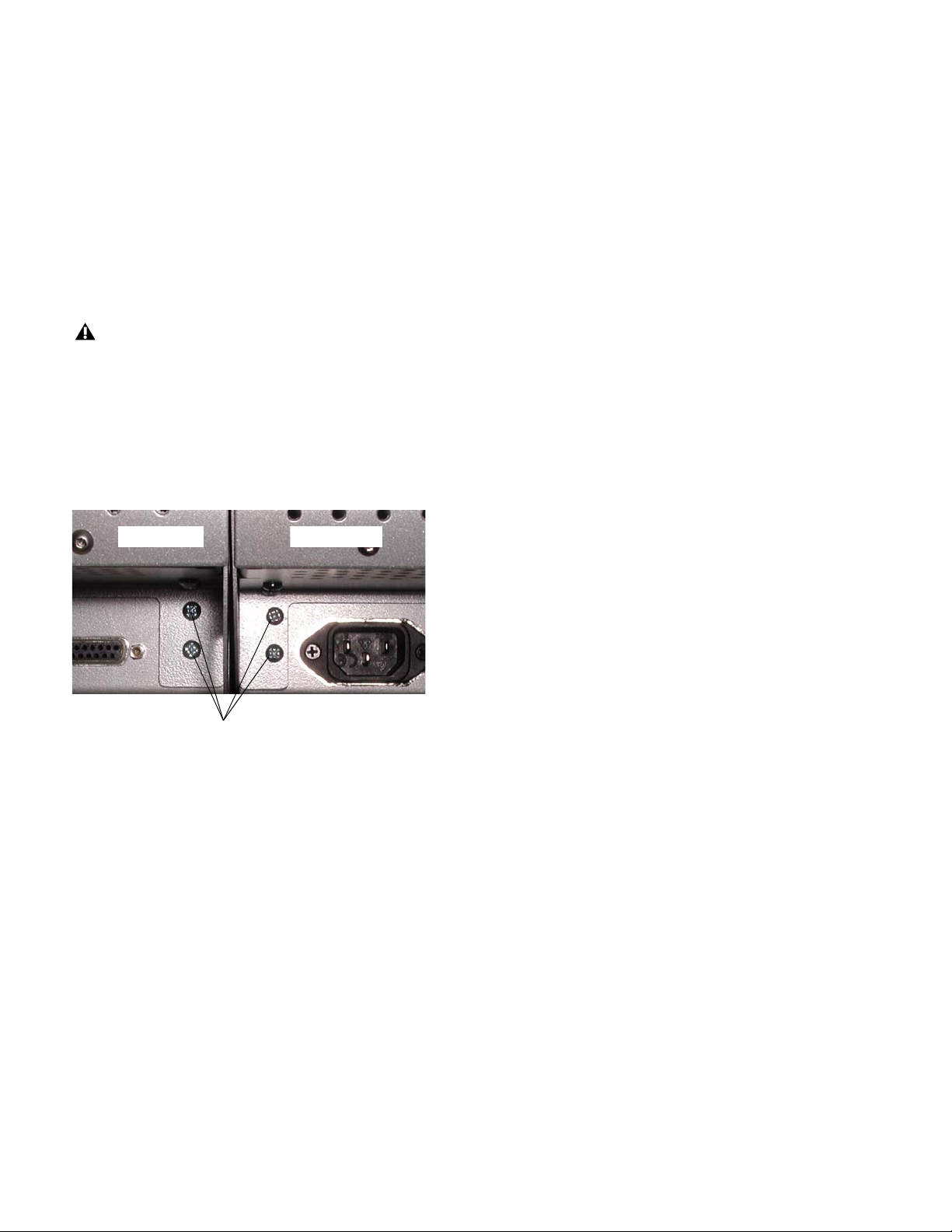

Footswitch jack

Ethernet connector

XMON Monitoring System connector

D-Command Connections

D-Command units require power and Ethernet connections to operate with Pro Tools. An optional footswitch connection is also

available on the Main Unit. The connectors on the back panel of the D-Command Main Unit are shown in Figure 5.

Be sure to make all connections with your D-Command units and computer turned off.

Figure 5. D-Command Main Unit back panel connectors

Power Connections

Each D-Command unit (Main Unit and Fader Module) and

the XMON Monitor Interface requires its own power connection. D-Command Main Units, Fader Modules, and XMON Interfaces are auto power-selecting (100V to 240V) and automatically work with a standard modular power cord when

connected to an AC receptacle in any country. A power cable

is provided with each D-Command unit and the XMON

interface.

To make D-Command power connections:

For each D-Command unit and the XMON Interface, con-

nect the included AC power cord the unit and to a power

source.

Ethernet Connections

Each D-Command unit communicates with Pro Tools using

Ethernet. An Ethernet cable is included with each D-Command unit.

If you are connecting only one D-Command unit to your computer:

1 Connect one end of the supplied Ethernet cable to the

Ethernet port on the back panel of D-Command.

2 Connect the other end of the cable to the appropriate Ether-

net port on the computer.

If you are connecting more than one D-Command unit to your

computer:

1 Install an Ethernet hub (not included) according to its in-

structions, apply power to it, and verify that it is functioning

properly.

2 Connect the Ethernet hub to the Ethernet port on your

computer.

3 For each D-Command unit, connect one end of the supplied

Ethernet cable to a port on the Ethernet hub (do not use any

port labeled for LAN connection), and connect the other end

of the Ethernet cable to the Ethernet port on the back of the

unit.

Chapter 4: Connecting D-Command 17

Page 24

Using D-Command on an Ethernet Network

You can purchase a combined 10/100-BaseT Ethernet hub that

can simultaneously support D-Command over 10-BaseT and

other network traffic over 100-BaseT. This will let you use

D-Command over a local area network.

Moderate network traffic (such as e-mail) should not affect

communication between D-Command and the computer. If

your network experiences heavy traffic, you may want to create a dedicated Ethernet network for D-Command.

Controlling Pro Tools Systems Over a Network

When D-Command is connected to an Ethernet network, it

will be available to be declared by any Pro Tools system on

that network. This lets you control different Pro Tools systems

on the network with a single D-Command console. (You can

only control one Pro Tools system at a time.)

Footswitch Connections

You can connect two SPST (single-pole, single-throw) footswitch units to the D-Command Main Unit to control any of

the following functions:

• Starting and stopping Pro Tools playback

• Starting Pro Tools recording

• Toggling Talkback on and off

The footswitch connector is a single 1/4-inch TRS jack on the

back panel of the D-Command Main Unit.

To wire a TRS connector for the D-Command footswitch jack:

Use the following wiring convention: Tip = Footswitch 1,

Ring = Footswitch 2, Sleeve = Ground.

D-Command Guide18

Page 25

Audio Connections

Cue Inputs

Cue Outputs

Main Inputs Surround Inputs Stereo Inputs

Main Outputs Alt Outputs Talkback/ Meter Calibration Control Surface AC Power

Listenback/

Utility

Screws

D-Command monitoring is based on the XMON analog interface, which is remotely controlled from the D-Command monitoring section. All external analog audio inputs and outputs for control room monitoring and studio communication are connected

to the XMON interface.

XMON provides 18V phantom for its three external mic inputs (External Talkback Mic, Listen Mic 1, Listen Mic 2).

All audio connections are made with standard DB-25 connectors. The back panel of the XMON is shown in Figure 6.

Figure 6. XMON back panel

XMON Monitoring System Connection

D-Command connects to XMON with a single 15-pin XMON cable. A 50-foot (15.25 m) cable is included with the D-Command

Main Unit. The system supports up to an 80-foot (24.5 m) cable.

To connect the XMON to D-Command:

1 Connect the included AC power cord to the back panel of the XMON and to a power source. A surge protected power source

is highly recommended.

2 Connect one end of the included XMON cable to the Control Surface port on your XMON unit, and the other end to the 15-pin

XMON Monitoring System connector on the back panel of the D-Command Unit.

Chapter 4: Connecting D-Command 19

Page 26

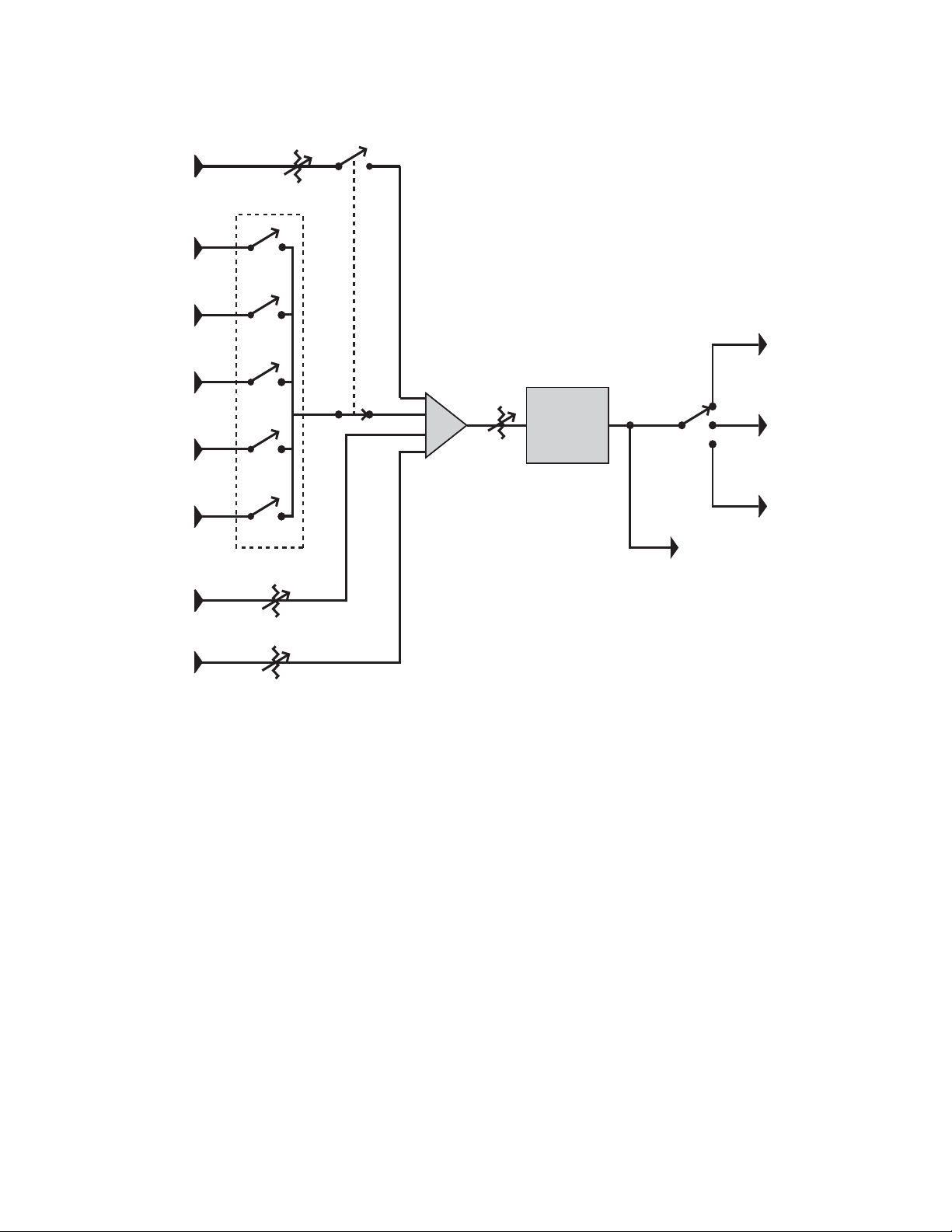

Control Room Monitoring Connections

AFL/PFL

Input

(2 channels)

Main

Input

(6 channels)

Surround

Input

(6 channels)

Stereo 1

Input

(2 channels)

Stereo 2

Input

(2 channels)

Stereo 3

Input

(2 channels)

Listen

Mic 1

Listen

Mic 2

Level

Level

Input

Source

Select

AFL/PFL

Level

Pro Tools

Solo

Command

Mono

Summing

Level, Dim,

Solo, Mute,

Trim + Cal

Control Room

Output Select

Main Output

(6 channels)

Alt Output

(6 channels)

Mini Output

(2 channels)

[To Cue System]

Figure 7. Control room monitoring system block diagram

Inputs

Outputs

• Main Inputs (6 channels), balanced, +4 dBu (from Pro Tools)

• Surround Inputs (6 channels), balanced, +4 dBu

• Stereo 1 Inputs (2 channels), balanced, +4 dBu/–10dBV

• Stereo 2 Inputs (2 channels), balanced, +4 dBu/–10dBV

• Stereo 3 Inputs (2 channels), balanced, +4 dBu/–10dBV

• AFL/PFL Inputs (2 channels), balanced, +4 dBu

• Listen Mic 1 (external), mic level (XMON provides 18V phantom power)

• Listen Mic 2 (external), mic level (XMON provides 18V phantom power)

• Main Control Room Outputs (6 channels), balanced or unbalanced, +4 dBu

• Alt Control Room Outputs (6 channels), balanced or unbalanced, +4 dBu

• Mini Control Room Outputs (2 channels), balanced or unbalanced, +4 dBu

D-Command Guide20

Page 27

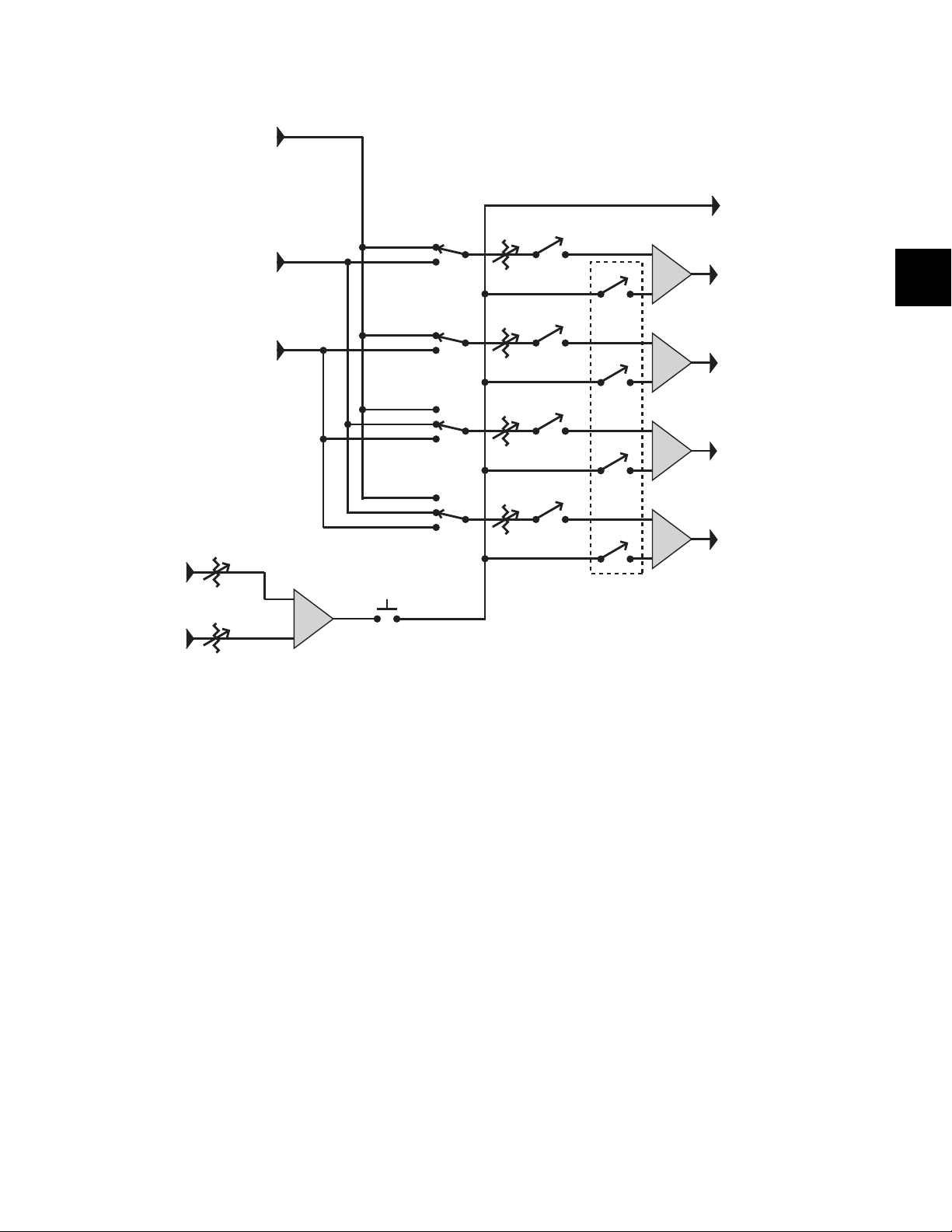

Headphone/Cue System Connections

Main Monitor

Input

Cue 1

Input

(2 channels)

Cue 2

Input

(2 channels)

Internal

Talkback

Input

External

Talkback

Input

Talkback

switch Talkback

Assign

Internal

Talkback

Level

External

Talkback

Level

Talkback/Slate Out

(1 channel)

Cue 1 Out

(2 channels)

Cue 2 Out

(2 channels)

HP Out

(2 channels)

Studio LS

(2 channels)

(2 channels)

[from Control Room System]

Figure 8. Headphone/Cue system block diagram

Inputs

• Main Monitor Input (2 channels)

• Cue 1 Input (2 channels), balanced, +4 dBu

• Cue 2 Input (2 channels), balanced, +4 dBu

• Internal Talkback Mic (from internal mic)

• External Talkback Mic, mic level (XMON provides 18V phantom power)

Outputs

• Cue 1 (2 channels), +4 dBu

• Cue 2 (2 channels), +4 dBu

• Headphone (2 channels), to internal headphone jack

• Studio Loudspeaker (2 channels)

• Talkback/Slate Output (1 channel)

Chapter 4: Connecting D-Command 21

Page 28

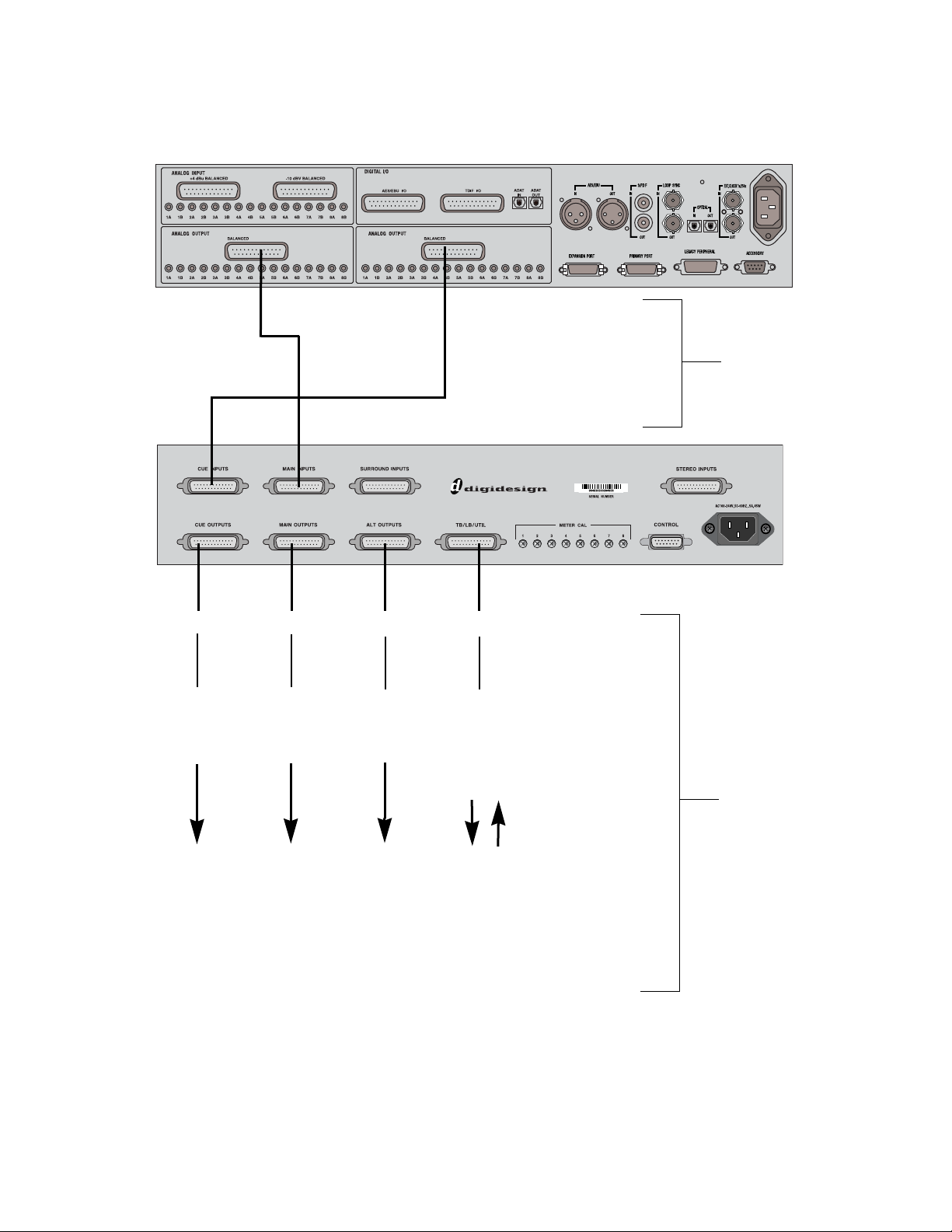

Analog Outputs 1-8

Analog Outputs 9-16

Cue Inputs Main Inputs

Main OutputsCue Outputs Talkback/ListenbackAlt Outputs

Analog Outputs 1-8

1-2: Studio

3-4: Cue 1

5-6: Cue 2

1 = L

2 = (Lc*)

3 = C

4 = (Rc*)

5 = R

6 = Ls

7 = Rs

8 = LFE

1 = L

2 = (Lc*)

3 = C

4 = (Rc*)

5 = R

6 = Ls

7 = Rs

8 = LFE

1 = Ext Talkback Mic Input

2 = Listen Mic 1 Input

3 = Listen Mic 2 Input

4 = AFL Input 1

5 = AFL Input 2

6 = Mini Speaker Out 1 (L)

7 = Mini Speaker Out 2 (R)

8 = Talkback/Slate (Out)

To

Cue System

Amplifiers

To

Main

Speakers

To

Alternate

Speakers

To

Various

Inputs

and

Outputs

DB-25 to DB-25

connectors

DB-25 to XLR

snakes

192 I/O

XMON

* Main Speaker Outputs 2 and 4 are active on XMON, but Lc and Rc outputs cannot be controlled independently from the

D-Command monitor section. Global Volume, Solo, and Mute controls affect all outputs.

Example XMON Wiring Diagram

The following diagram shows basic XMON connections for a Pro Tools|HD system with a Digidesign 192 I/O with 16 analog outputs (with a 192 AD card installed).

Figure 9. Wiring diagram for 192 I/O and XMON

D-Command Guide22

Page 29

Chapter 5: Configuring D-Command

Starting Up and Shutting Down the System

Your D-Command-based system must be started up and shut

down in a specific order.

Start your D-Command-based system in this order:

1 Turn on external hard drives first. Wait 10 to 15 seconds for

them to come up to speed.

2 Turn on the D-Command units.

3 If you plan to work with MIDI equipment, turn on MIDI in-

terfaces and other MIDI devices.

4 Turn on all Pro Tools audio interfaces.

5 Turn on the computer.

6 Turn on the XMON interface.

7 Turn on monitor amplifiers or self-powered speakers.

Shut down your D-Command-based system in this order:

1 Turn off monitor amplifiers or self-powered speakers.

2 Turn off the XMON interface.

Software Configuration

All D-Command software is included when Pro Tools software

is installed. The Pro Tools software installer places the D-Command Personality folder on the system drive.

Refer to the Getting Started Guide that came with your system

for instructions on installing or updating Pro Tools software.

Updating System Firmware

Each release of Pro Tools software includes the most current

D-Command firmware. When you declare a D-Command unit

in the Pro Tools Peripherals dialog, Pro Tools compares the

firmware of all connected units to the version available in

Pro Tools software, and prompts you if an update is available.

If you are prompted to update firmware, follow the on-screen

instructions to load the latest firmware to each D-Command

unit.

Declaring D-Command Units in Pro Tools

Communication between D-Command and Pro Tools is configured from Pro Tools.

3 Turn off all Pro Tools audio interfaces.

4 Shut down the computer.

5 If using MIDI equipment, turn off MIDI interfaces or con-

trollers.

6 Turn off the D-Command units.

7 Turn off external hard drives.

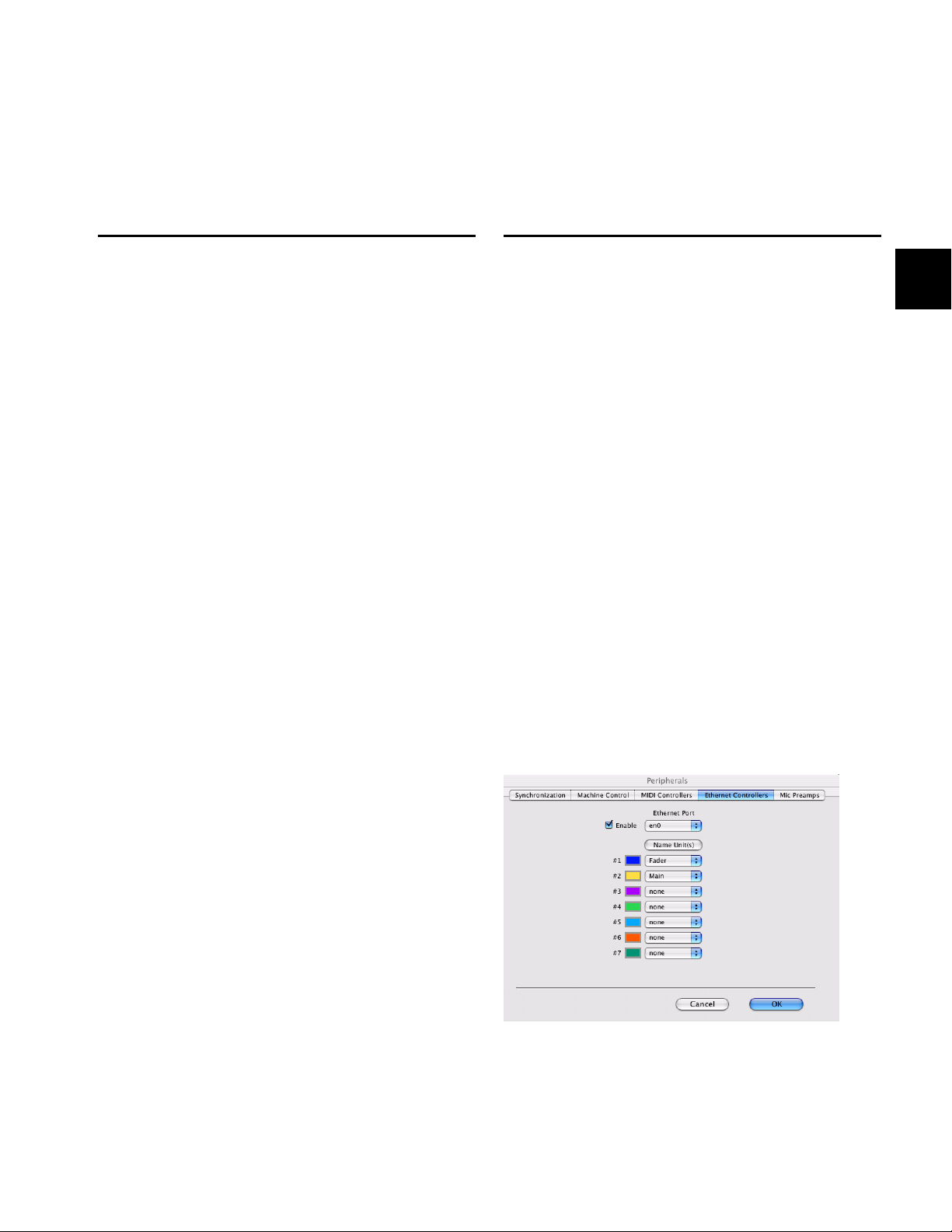

To declare D-Command units in Pro Tools:

1 Choose Setups > Peripherals, and click Ethernet Controllers.

Ethernet Controllers display in the Peripherals dialog

2 Select Enable. Pro Tools scans the Ethernet connection for

any Ethernet controllers connected to the system.

Chapter 5: Configuring D-Command 23

Page 30

3 Select the units in the order you want them arranged left to

right.

Setting D-Command Preferences

It is not necessary to declare units in the same sequence

as they are physically arranged.

As each unit is selected, Pro Tools scans it and brings it online.

The current status of each unit is indicated in the Peripherals

dialog in the following ways:

• Bold indicates a connected unit.

• Italics indicate an offline or disconnected unit.

• Underlining indicates that the selected unit is in use by

another Pro Tools system.

4 After declaring one or both units, click OK to close the Pe-

ripherals window.

When communication is established, Pro Tools displays colored outlines identifying each bank of Pro Tools tracks.

The colors in each unit row are used to identify controller focus on-screen in Pro Tools. The bank, track, insert, send, or

other element currently the focus of D-Command is outlined

in the color associated with each unit.

Naming D-Command Units in Pro Tools

You can set the names for D-Command units from Pro Tools.

To name D-Command units in Pro Tools:

1 Choose Setup > Peripherals, and click Ethernet Controllers.

2 Click Name Units.

This section describes the settings and preferences for D-Command that are set directly from the control surface. For details

on preferences that are set from Pro Tools, refer to the

Pro Tools Reference Guide.

Fader and Switch Preferences

The following settings and preferences affect operation of the

faders and switches on D-Command.

Fader Bank Justification

The Bank Justification preference determines whether banks

of channels in Normal mode are left-, center-, or right-justified

on the control surface.

To set bank justification:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes the Bank

Justification preference (“BnkJus”).

2 Press the Soft Key that corresponds to “BnkJus” to choose

between the “Left,” “CentrL,” “CentrR,” and “Right” settings.

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

Faders On/Off

The Faders On/Off preference lets you temporarily turn off

D-Command faders to prevent fader movement when monitoring a mix.

Naming D-Command units

3 Enter the names for the units and click OK.

You can also set the names for D-Command Main Units and

Fader Modules directly from the units themselves, by using

Utility mode. For details on naming D-Command units in

Utility mode, see “D-Command Name Page” on page 112.

D-Command Guide24

To toggle D-Command faders on and off:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes the Faders

On/Off preference (“Faders”).

2 Press the Soft Key that corresponds to “Faders” to toggle all

faders on and off.

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

Page 31

Touch Value

Maximum Custom Fader Bank Size

The Touch Value preference determines whether faders and

encoders, when touched, temporarily show the value of the

parameter they are controlling.

To toggle display of values on or off:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes Touch

Value (“TchVal”).

2 Press the Soft Key that corresponds to “TchVal” to cycle dis-

play of all values On, all values Off or just fader values off

(“NoVol”).

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

Select Switch Latch Mode

The Select Switch Latch mode determines whether channel

Select buttons follow latching or non-latching (exclusive-or)

behavior when in Select mode.

To set the Select switch mode:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes Select

Switch Latch mode (“Select”).

2 Press the Soft Key that corresponds to “Select” to toggle the

setting between the “Latch” and “ExclOr” (non-latching) settings.

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

The Maximum Custom Fader Bank Size preference determines

the number of channels to be used when displaying channels

in the Custom Fader modes. Options are 4 and 8 faders for a

Main Unit, and 4, 8, 16 and 24 faders for an expanded system.

You can choose settings for each of these sizes (indicated by

the prefix “Min”) that use the minimum number of channels

necessary, so that the Custom Fader section dynamically resizes to match the number of channels in the group.

To set the maximum Custom Fader bank size:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes the following Custom Fader Bank Size preferences:

CFPIug (CF Bank Size for Plug-ins) Determines the number of

channels allocated for Custom Fader Plug-in mode.

CFGrp (CF Bank Size for Custom and Mix/Edit Groups) Determines the number of channels allocated for Custom Groups

mode.

CFTyp (CF Bank Size for Track Type) Determines the number

of channels allocated for Custom Fader Tracks mode.

2 Do one of the following:

• To increment the number of channel strips, press the Soft

Key that corresponds to the preference setting you want

to change.

– or –

• To decrement the number of channel strips, hold Shift

and press the Soft Key that corresponds to the preference

setting you want to change.

Custom Fader Preferences

Custom Fader Justification

The Custom Fader Justification preference determines

whether channels in Custom Fader mode are left-, center-, or

right-justified on the control surface.

To set Custom Fader justification:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes Custom

Fader Justification (“CFJus”).

2 Press the Soft Key that corresponds to “CF Jus” to choose be-

tween the “Left,” “CentrL,” “CentrR,” and “Right” settings.

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

Display of Hidden Tracks in Custom Faders

You can set D-Command to show hidden tracks in the Custom Fader views. You can then mix those hidden tracks, but

you cannot select or record-enable them. Hidden track names

are displayed in yellow in the Custom Faders.

To make hidden tracks visible in Custom Fader views:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes Custom

Fa der Tracks (“C FTrks” ).

2 Press the Soft Key that corresponds to “CFTrks” to toggle the

setting between Show Hidden Tracks (“ShwHdn”) and Hide

Hidden Tracks (“HidHdn”).

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

Chapter 5: Configuring D-Command 25

Page 32

Custom Fader Plug-In Mode View Definition

Encoder Order

There are three view options available for display of plug-in

parameters in the channel displays of the Custom Faders.

These options, or view definitions, are accessible from the

D-Command operation preferences.

To set the Custom Fader Plug-In Mode view:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes Plug-In

View Definition (“PIDef”).

2 Repeatedly press the Soft key that corresponds to “PIDef” to

choose between the following settings for the Plug-In Mode

view:

Name View Shows the track name, plug-in name and channel

format of the currently focused plug-in in the channel displays of the Custom Faders.

Expanded View Shows additional plug-in controls in the channel displays of the Custom Faders. This view can also be seen

at any time by pressing and holding the Plug-In switch in the

Custom Fader section until the switch flashes. See “Expanded

Plug-In View” on page 105.

Fade r View Maintains track names on channel displays and

fader control of track volume while Custom Fader plug-in parameters are displayed in the channel encoders. Entering Expanded view or Plug-In Map mode automatically exits Fader

view.

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

Encoder Preferences

The following preferences affect operation of the rotary encoders on D-Command.

The Encoder Order preference determines whether inserts,

sends, and pan controls will be displayed in order from

top-to-bottom or bottom-to-top on D-Command rotary encoders.

To set the Encoder Order preference:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes Encoder

Order (“Encod”).

2 Press the Soft Key that corresponds to “Encod” to toggle the

setting between “Bot-Tp” (bottom-to-top ordering) and

“Tp-Bot” (top-to-bottom ordering).

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

Display Preferences

The following preferences affect the interaction of D-Command with on-screen display of elements in Pro Tools.

Target Track from Application

The Target Track from Application preference determines

whether selecting an Insert or Send on-screen makes its track

the focused track on the D-Command Main Unit. For details

on focusing a track on D-Command, see “Focusing a Track”

on page 97.

To set the Target Track from Application preference:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes Target

Track (“ApTrgt” ).

2 Press the Soft Key that corresponds to “ApTrgt” to toggle the

setting between “Yes” and “No.”

Rotary Encoder Mode

The Rotary Encoder mode affects responsiveness of rotary encoder knobs. Fixed mode is at normal resolution. The velocity

modes set different rates of encoder acceleration. In Fine

mode, response is fixed and at fine resolution.

To set the Rotary Encoder mode:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes Rotary Encoder mode (“Rotary”).

2 Press the upper Soft Key that corresponds to “Rotary” to step

through the “Fixed,” “Vel-Sl” (velocity-sensitive, slow),

“Vel-Md” (velocity-sensitive, medium), “Vel-Fa” (velocity-sensitive, Fast), and “Fine” settings.

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

D-Command Guide26

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

Channel Window Display

The Channel Window display preference determines whether

displaying plug-in or send pan parameters (by pressing an encoder Select switch) on D-Command opens the corresponding

plug-in or send window on-screen in Pro Tools.

This preference also determines whether the Channel Select

switches in the Dynamics or EQ sections change the channel

display of multi-mono plug-ins.

When this preference is set to “Yes,” the on-screen display

of plug-in and send windows changes to reflect the state of the

control surface.

Page 33

When this preference is set to “No,” the on-screen display of

plug-in and send windows does not change to reflect the state

of the control surface.

To set the Channel Window display preference:

1 In the Console Prefs Soft Keys section, press the Operation

switch repeatedly to display the page that includes Channel

Window (“ChanWn”).

2 Press the Soft Key that corresponds to “ChanWn” to toggle

this setting between “Yes” and “No.”

3 Hold Control (Windows) or Command (Mac) and press the

Operation switch to exit.

Meters Pre/Post Fader

The Meters Pre/Post Fader preference toggles channel metering between pre- and post-fader modes.

To toggle channel meters between pre- and post-fader metering:

1 Press the Meters switch in the Console Prefs Soft Keys sec-

tion.

2 Press the Soft Key that corresponds to “Meters” to toggle the

setting between “PreFad” (pre-fader metering) and “PostFd”

(post-fader metering).

3 Press the Meters Console Prefs Soft Key switch to exit.

Meter Preferences

The following preferences affect operation of the meters on

D-Command.

Send Meters On/Off

The Send Meters On/Off preference toggles send metering on

and off. Send levels are displayed on the LED rings surrounding the D-Command rotary encoders. This metering follows

Send pre- or post-metering settings in Pro Tools.

To toggle send meters on and off:

1 Press the Meter switch in the Console Prefs Soft Keys sec-

tion.

2 Press the Soft Key that corresponds to “SndMtr” to toggle

the setting On and Off.

3 Press the Meters Console Prefs Soft Key switch to exit.

Insert Meter On/Off

The Insert Meters On/Off preference toggles insert metering

on and off. This preference applies when inserts are displayed

on the LED rings surrounding the D-Command rotary encoders.

To toggle insert meters on and off:

1 Press the Meter switch in the Console Prefs Soft Keys sec-

tion.

Center Meters Track/Output

The Center Meters Track/Output preference toggles the

8-channel meter display on the Main Unit meter bridge between main output levels and the focused track.

When set to meter the focused track, you can view levels for

multichannel tracks up to 6 channels (5.1 surround).

To toggle the center meters between output and track metering:

1 Press the Meters switch in the Console Prefs Soft Keys sec-

tion.

2 Press the Soft Key that corresponds to “CtrMtr” to toggle the

setting between “Output” and “Track.”

3 Press the Meters Console Prefs Soft Key switch to exit.

VCA Slave Metering On/Off

The VCA Meters On/Off preference toggles metering of VCA

slave track levels on VCA channel rotary encoders on and off.

To toggle VCA slave track metering on and off:

1 In the Soft Keys section, press the Meter switch repeatedly to

display the page that includes the VCA Meters On/Off preference (“VCAMtr”).

2 Press the Soft Key that corresponds to “VCAMtr” to toggle

the setting On and Off.

3 Press the Meters Console Prefs Soft Key switch to exit.

2 Press the Soft Key that corresponds to “InsMtr” to toggle the

setting On and Off.

3 Press the Meters Console Prefs Soft Key switch to exit.

Chapter 5: Configuring D-Command 27

Page 34

System Calibration

Recalibrating D-Command Faders

If a fader on a D-Command Unit shows response problems,

you can recalibrate the faders with the Recal command in Utility mode. See “Recal” on page 115 for details.

Calibrating the Output Meters

You can calibrate the output meters on the Main Unit meter

bridge from XMON, in order to match metering levels in

Pro Tools with metering levels of external sources. The example below uses a Digidesign 192 I/O as the reference source.

To calibrate the D-Command output meters:

1 Set the reference level of your 192 I/O according to the in-

structions in the 192 I/O Guide.

2 With the 192 I/O analog output connected to the XMON

Main Input, send a calibration tone to the D-Command Main

Outputs, and note the output level on the D-Command

meters.

3 Disconnect the 192 I/O analog output from the XMON

Main Input and connect it to an XMON Stereo Input.

4 Activate the corresponding Alt Output.

5 Adjust the trim pots on the back panel of the XMON until

the output level for each channel on the D-Command

matches the level displayed for the Main Output.

6 When you are finished, reconnect the 192 I/O analog out-

put to the XMON Main Input.

Calibrating SPL Indication on the Monitor Section

The D-Command Monitor section lets you display output

level in dB or dB SPL. You can calibrate the SPL display to reflect the sound pressure level at the mix position. See “Calibration Mode Switch” on page 91.

D-Command Guide28

Page 35

Part III: Reference

Page 36

Page 37

Chapter 6: Channel Strip Controls

Channel Strip

Channel Strip

Channel Fader

Mode controls

Function controls

Automation Mode

and

Channel Status

indicators

Rotary Encoders

Encoder

LED ring

Encoder knob

Encoder display

Mute/Pre indicators

Bypass/Mute/Pre

switch

Encoder

Automation Mode

indicator

Clip/Flip indicators

Select switch

Channel Strips

The D-Command Main Unit has 8 channel strips, and the

D-Command Fader Module has 16 channel strips. Each channel strip (Figure 1) has identical controls, including two

touch-sensitive rotary encoders, display and mode controls,

and a touch-sensitive fader.

Rotary Encoder Section

Each channel strip has two touch-sensitive rotary encoders

with LED ring, alphanumeric display, mode switches, and status indicators. Rotary encoders control channel input, send,

pan, and mic pre parameters.

Channel Strip Rotary Encoder

Encoder Knob

The encoder knobs on D-Command channel strips are

touch-sensitive. When you touch the encoder, the encoder

display switches from the parameter name to the parameter

value. Touch display of parameter values can be turned off.

Figure 1. D-Command Channel Strip

When you are automating a parameter controlled by an encoder, touching the encoder knob starts writing automation.

When assigning a channel input or output, or an insert or

send, the encoder knob is used to scroll through available inputs, outputs, inserts, or sends.

Inputs, Outputs, Inserts and Sends

When assigning a channel input or output, or an insert or

send, the encoder knob is used to scroll through available inputs, outputs, inserts, or sends. When adjusting the phantom

power on a remote-controlled mic preamplifier (such as the

Digidesign PRE), the encoder knob can be used to toggle phantom power on and off.

Instrument Tracks

On Instrument tracks, the bottom encoder knob is used to

control MIDI Volume.

VCA Master Tracks

On VCA Master tracks, the encoder knobs are used to control

the Volume of slave tracks.

Chapter 6: Channel Strip Controls 31

Page 38

Encoder LED Ring

Inserts

Each encoder has a ring of 15 LEDs. Discrete or stepped information is shown by single LEDs, and continuously variable information is shown by an expanding series of LEDs.

In Normal mode, encoder LED rings can show send level, pan

position, plug-in parameter values, and mic pre settings. In

Flip mode, they show track level.

Instrument Tracks

On Instrument tracks, the bottom encoder LED ring shows

MIDI Velocity.

VCA Master Tracks

On VCA Master tracks, encoder LED rings show levels of slave

tracks.

Encoder Automation Mode Indicator

Below each encoder knob is an LED marked “auto,” which

lights when the corresponding parameter is enabled for automation. The indicator lights green for Read mode, yellow

when armed for automation in any of the Write modes, and

red when writing automation in any of the Write modes.

Encoder Display

Each encoder has a six-character display that shows parameter

names. When the corresponding encoder knob is touched or

moved, the display shows parameter values.

When assigning an insert, the encoder Select switch is used to

confirm the selection of the following elements on each level:

• Insert type (TDM plug-in, RTAS plug-in, Multi-Mono

TDM plug-in, Multi-Mono RTAS plug-in, or Hardware

Insert)

• Plug-in subfolder (such as EQ, Dynamics, Pitch Shift,

Reverb, or Delay)

• Individual insert or plug-in

Sends

When assigning a send, the encoder Select switch is used to

confirm the selection of the following:

• Send type (interface or bus)

• Send assignment

When viewing a send, the encoder adjusts level. In Send Pan

mode, the fader adjusts level and the encoder adjusts Pan.

VCA Master Tracks

On VCA Master tracks, encoder Select switches focus the corresponding slave tracks in the Focus Channel section.

Bypass/Mute/Pre Switch

Each encoder has a Bypass/Mute/Pre (B/M/P) switch whose

function depends on what is currently displayed on the encoder. With Sends, the function of the B/M/P switch also depends on the current Switch Mode setting.

Encoder displays use color inversion to indicate the following:

• Green: Default color for input, insert, send, pan, and mic

pre parameter names and values

• Inverted green: Inactive input, inactive output, inactive

plug-in or inactive send names

Clip and Flip Indicators

When viewing inserts on an encoder, these LEDs light to indicate the send or insert has clipped (red LED) or has been

flipped to the fader (yellow LED).

Mute and Pre Indicators

When viewing sends on an encoder, these LEDs light to indicate that the send is muted (red LED) or set to pre-fader operation (green LED).

Encoder Select Switch

Each encoder has a Select switch that is used to assign an insert or send to that encoder, or to display send parameters for

editing.

See “Switch Mode Switch” on page 40 for more information

on changing the Switch mode and viewing the current function of the B/M/P switch.

Inserts

When a plug-in name is displayed on an encoder (in the top

level Inserts display), the B/M/P switch bypasses the corresponding plug-in. The B/M/P switch lights when the plug-in is

bypassed.

Sends

When a send name is displayed on an encoder, the B/M/P

switch does one of the following:

• If the Switch Mode is set to Mute, the B/M/P switch

mutes the corresponding send. The red Mute LED lights

to indicate that the send is muted.

• If the Switch Mode is set to Pre, the B/M/P switch toggles

the corresponding send between pre- and post-fader operation. The green Pre LED lights to indicate that the

send is set for pre-fader operation.

D-Command Guide32

Page 39

Mic Pre

Page Up switch

Inserts switch

Pan switch

Bypass/Mute

switch

Sends switch

Page Down switch

In Mic Pre mode, mic pre parameters are displayed on a channel strip’s encoders. In addition, the B/M/P switches do the

following:

• Top encoder, page 1: toggles phantom power on and off

• Bottom encoder page 1: toggles mic pre Pad on and off

• Top encoder, page 2: toggles mic pre HPF on and off

• Bottom encoder page 2: toggles mic pre Polarity

• Top encoder, page 3: toggles phantom power on and off

• Bottom encoder, page 3: toggles mic pre Insert on and off

Instrument Tracks

Channel Strip Mode Controls

Each channel strip has a set of Channel Strip Mode controls

for displaying and editing pan, plug-in, mic pre, insert, or

send parameters on the encoder section of the D-Command

channel strip.

On Instrument Tracks, the bottom B/M/P switch is used to

control MIDI Mute state.

VCA Master Tracks

On VCA Master tracks, B/M/P switches are used to control the

Mute state of slave tracks.

MIDI Controls on Instrument Tracks

The Instruments View in Pro Tools contains MIDI controls

that can be displayed on the encoders of D-Command channel strips.

To display MIDI controls on an Instrument track:

In the Channel Strip Mode controls section of the Instru-

ment channel strip, press the Inserts switch and the Sends

switch simultaneously.

The MIDI controls appear on the encoders as follows:

• Top encoder: MIDi Pan

• Bottom encoder: MIDI Volume

• Bottom B/M/P switch: MIDI Mute

• Bottom encoder LED ring: MIDI Velocity meter

To exit display of MIDI controls:

Press another switch in the Channel Strip Mode section.

Channel Strip Mode controls

Page Up and Page Down Switches

Control parameters are arranged on channel strip rotary encoders in pages, or groups of up to two parameters at a time.

The Page Up and Page Down switches light to indicate the

presence of additional pages of pan, plug-in, mic pre parameters, or (for VCA Master tracks) slave tracks, in the corresponding direction on each channel strip. If no additional pages are

available, neither switch is lit.

To move the page display of parameters on the encoders up or

down:

Press a lit Page Up or Page Down switch.

Inserts Switch

When you press the Inserts switch, you enter Inserts mode,

and the plug-in names for the first two plug-ins on that channel strip are displayed on the encoder displays. If there are additional plug-ins on the channel, the channel’s Page Up

switch lights.

To open a plug-in window from any channel on D-Command:

Hold Start (Windows) or Control (Mac) and press the Select

switch for the plug-in.

Slave Track Display on VCA Master Tracks

In normal Mode, VCA Master tracks show their slave tracks in

their rotary encoders, as follows:

• Encoder knob: Slave track Volume control

• Encoder LED ring: Slave track meter level

• Encoder B/M/P switch: Slave track mute

• Encoder Select switch: Focuses slave track in Focus Channel Strip

If there are more than two slave tracks for a VCA Master, you

can the press the channel Page Up/Page Down switches to display the additional slave tracks on the rotary encoders.

To close the plug-in window:

Hold Start (Windows) or Control (Mac) and press the Select

switch again.

The Inserts switch flashes when a plug-in on that channel has

clipped. To clear a clip, press the Clear Clip switch in the Session Management section. See “Clear Clip Switch and Plug-in

Clip Indicator” on page 74 for more information.

Chapter 6: Channel Strip Controls 33

Page 40

Pan Switch

When you press the Pan switch, you enter Pan mode, and the

pan controls for the channel strip are displayed on the encoder displays.

To open/close the Output window on-screen for a track:

1 Press the Pan switch on the channel.

2 Hold Start (Windows) or Control (Mac) and press the chan-

nel’s encoder switch.

If the track is a multichannel track, its Page Up switch lights to

indicate that there are multiple pages of pan controls. Multichannel pan controls are arranged as follows:

Surround Pan Display, Page 1

Display Pan Control

LFE LFE channel

Cntr% Center Speaker Percentage

Surround Pan Display, Page 2

Display Pan Control

F Div Front Divergence

Rear Rear Pan

Surround Pan Display, Page 3

Display Pan Control

F/R Front/Rear Balance

Front Front Pan

Surround Pan Display, Page 4

Display Pan Control

R Div Rear Divergence

Rear Rear Pan

Two-Knob Surround Panning

When working in surround, you can link the front and rear

pan controls on D-Command to facilitate X-axis motion in

the sound field.

To link front and rear surround panners:

1 Press the Operation switch in Console Prefs section until

“2KbPan” appears in the Soft Keys.

2 Press the Soft Key that corresponds to “2KbPan” to toggle

the preference on or off.

Mic Pre Mode

When you press a channel strip’s Inserts switch and Pan

switch simultaneously, you enter Mic Pre mode. In Mic Pre

mode, the controls for an available remote-controlled microphone preamplifier (such as the Digidesign PRE) are displayed

on the channel strip’s rotary encoders for editing. The Page Up

switch lights to indicate more available parameter pages.

Microphone preamplifiers are declared in the Pro Tools peripherals dialog, and assigned to channels in the Pro Tools I/O

Setup dialog.

Bypass/Mute Switch

The function of the Bypass/Mute switch depends on what is

currently displayed on the channel strip’s encoders.

Surround Pan Display, Page 5

Display Pan Control

F/R Div Front/Rear Divergence

F/R Front/Rear Balance

Surround Pan Display, Page 6

Display Pan Control

F Div Front Divergence

Front Front Pan

D-Command Guide34

Inserts

In the top level Inserts view (when plug-in names are dis-

played on a channel strip’s encoders), the Bypass/Mute switch

bypasses all plug-ins on that channel.

Sends

In the top level Sends view (when send names are displayed

on a channel strip’s encoders), the Bypass/Mute switch mutes

all sends on that channel.

VCA Master Tracks

On VCA Master tracks, the Bypass/Mute switch uses

Mix/Edit Groups mode to display (or “spill”) the slave tracks

for the VCA in Custom Faders.

Page 41

Sends Switch

Input Monitor Mode

switch

Channel Select

switch

Solo switch

Mute switch

Channel display

Automation Mode

switch

Record Enable

Automation Trim

switch

switch

Channel Strip Function Controls

When you press the Sends switch, you enter Sends mode, and

the send names for the first two sends on that channel strip

are displayed on the encoder displays. If there are additional

sends on the channel, the channel’s Page Up switch lights.

The 10 available sends are displayed in five pairs (A–B, C–D,

E–F, G–H, I–J).

Send Pan Mode

Send Pan mode allows you to adjust send panning and level at

the same time. Send Level is controlled by the channel fader

and Send Pan is controlled by the encoder.

To enter Send Pan mode:

1 Press the Sends switch to display sends on the channel’s en-

coders.

2 Press the encoder Select switch that corresponds to the send

you want to display.

To return to the top level display of sends on the channel strip:

Press the Sends switch again.

To link a Send’s Pan controls to the Main Pan controls of a track:

1 Put the track in Send Pan mode for the Send you want to

link.

2 Press the B/M/P switch on any of the active encoders on the

track to toggle the FMP status of the send.

Each channel strip has a set of Channel Strip Function controls for controlling channel selection and focus, mute, solo,

and record enable status, input monitor mode, and automation mode.

Channel Strip Function controls

Input Monitor Mode Switch

The Input Monitor Mode switch toggles the input monitoring