Page 1

PRE™ Guide

Version 9.0

Page 2

Legal Notices

This guide is copyrighted ©2010 by Avid Technology, Inc.,

(hereafter “Avid”), with all rights reserved. Under copyright

laws, this guide may not be duplicated in whole or in part

without the written consent of Avid.

003, 96 I/O, 96i I/O, 192 Digital I/O, 192 I/O, 888|24 I/O,

882|20 I/O, 1622 I/O, 24-Bit ADAT Bridge I/O, AudioSuite,

Avid, Avid DNA, Avid Mojo, Avid Unity, Avid Unity ISIS,

Avid Xpress, AVoption, Axiom, Beat Detective, Bomb Factory,

Bruno, C|24, Command|8, Control|24, D-Command, D-Control,

D-Fi, D-fx, D-Show, D-Verb, DAE, Digi 002, DigiBase,

DigiDelivery, Digidesign, Digidesign Audio Engine, Digidesign

Intelligent Noise Reduction, Digidesign TDM Bus, DigiDrive,

DigiRack, DigiTest, DigiTranslator, DINR, DV Toolkit, EditPack,

Eleven, EUCON, HD Core, HD Process, Hybrid, Impact,

Interplay, LoFi, M-Audio, MachineControl, Maxim, Mbox,

MediaComposer, MIDI I/O, MIX, MultiShell, Nitris, OMF,

OMF Interchange, PRE, ProControl, Pro Tools M-Powered,

Pro Tools, Pro Tools|HD, Pro Tools LE, QuickPunch, Recti-Fi,

Reel Tape, Reso, Reverb One, ReVibe, RTAS, Sibelius,

Smack!, SoundReplacer, Sound Designer II, Strike, Structure,

SYNC HD, SYNC I/O, Synchronic, TL Aggro, TL AutoPan,

TL Drum Rehab, TL Everyphase, TL Fauxlder, TL In Tune,

TL MasterMeter, TL Metro, TL Space, TL Utilities, Transfuser,

Trillium Lane Labs, Vari-Fi Velvet, X-Form, and XMON are

trademarks or registered trademarks of Avid Technology, Inc.

Xpand! is Registered in the U.S. Patent and Trademark Office.

All other trademarks are the property of their respective

owners.

Product features, specifications, system requirements, and

availability are subject to change without notice.

Guide Part Number 9320-65016-00 REV A 9/10

Documentation Feedback

At Avid, we are always looking for ways to improve our

documentation. If you have comments, corrections, or

suggestions regarding our documentation, email us at

techpubs@avid.com.

Page 3

contents

Chapter 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PRE Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

What’s Included . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Requirements and Compatibility Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Conventions Used in This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

About www.avid.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2. Hardware Overview and Stand-Alone Operation. . . . . . . . . . . . . . . . . . . . . . . 5

PRE Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PRE Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Using PRE in Stand-Alone Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Calibrating PRE and Other Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting Channel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adjusting Input Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Muting Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 3. Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting PRE to a Pro Tools System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configuring MIDI Studio in AMS for PRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configuring MIDI Studio Setup for PRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configuring Pro Tools Software for PRE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mic Preamps in Pro Tools Edit and Mix Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Viewing Mic Preamp Controls in Pro Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mic Preamp Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mic Preamp Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Adjusting Mic Preamp Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adjusting Controls on Multiple PREs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Mic Preamp Remote Control with Control Surfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Contents iii

Page 4

Appendix A. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Appendix B. Pinout Diagram for the PRE DB-25 Connector . . . . . . . . . . . . . . . . . . . . . 33

DB-25 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Appendix C. MIDI Controller Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

PRE MIDI Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Appendix D. Compliance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Environmental Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

EMC (Electromagnetic Compliance) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Safety Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

PRE Guideiv

Page 5

chapter 1

Introduction

PRE is designed especially for use with

Pro Tools

stand-alone microphone preamplifier. When

used with Pro Tools, most PRE features can be

controlled from within the Pro Tools application.

With or without remote control, PRE can be

configured manually using its front panel

switches and displays.

PRE can also be remotely-controlled by other

MIDI devices through standard MIDI controller

data. See Appendix C, “MIDI Controller Numbers.”

®

systems, but it can also be used as a

PRE Features

• Eight high-performance, discrete matched

transistor hybrid microphone preamplification circuits

• Remote control with qualified Pro Tools systems and control surfaces (such as D-Con-

®

trol

, D-Command®, C|24™, and

Command|8

• Industry-standard DB-25 output connectors

for easy connection to Pro Tools audio interfaces or any other recording or mixing medium

®

)

• Each channel features:

• Support for microphone (XLR), line level

inputs (1/4-inch), or direct instrument

(1/4-inch)

• Selectable impedance settings for Mic input

• Input gain variable from 0 dB to +69 dB, in

approximately 3 dB steps, with an optional

–18 dB pad

• +48V power for condenser microphones

• Balanced Insert points (Send and Return),

for easy integration of outboard gear (such

as compressors or EQs)

•Phase invert

• 85 Hz High-Pass Filter

• Up to nine PREs supported through software

for up to 72 channels of remote-controlled

preamplification

• All features available in Stand-alone mode

What’s Included

•PRE unit

•AC power cable

•PRE Guide

• Health and Safety Guide

• Registration Information Card

Chapter 1: Introduction 1

Page 6

System Requirements and Compatibility Information

Conventions Used in This Guide

When used as a stand-alone microphone preamplifier, PRE is ready to use.

For remote control within Pro Tools, PRE

requires a qualified Pro Tools system.

Avid can only assure compatibility and provide

support for hardware and software it has tested

and approved.

For complete system requirements and a list of

qualified computers, operating systems, hard

drives, and third-party devices, visit:

www.avid.com/compatibility

Registration

Review the enclosed Registration Information

Card and follow the instructions on it to quickly

register your purchase online. By registering,

you become eligible to receive the following:

• Technical support information

• Software update and upgrade notices

• Hardware warranty information

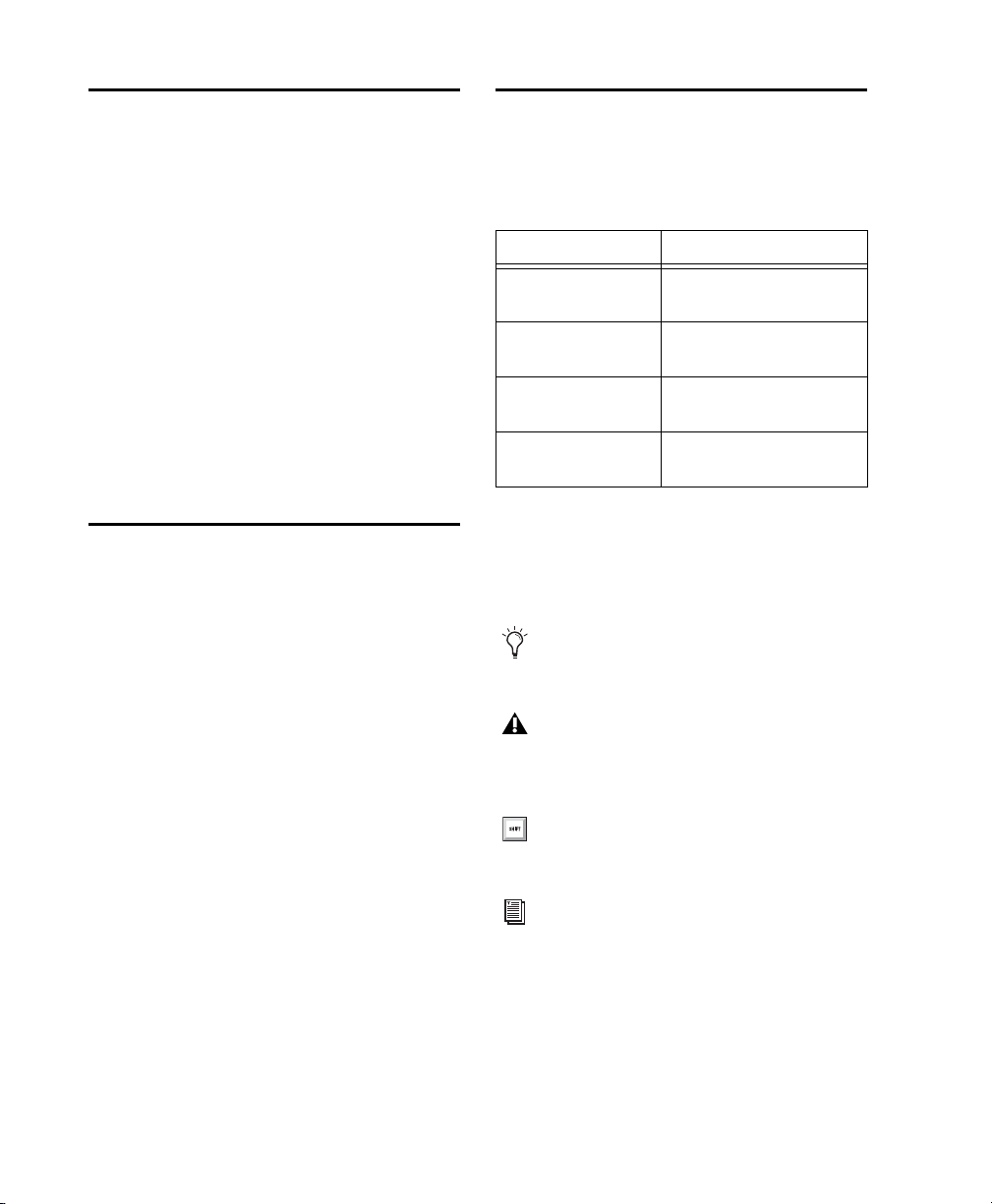

All of our guides use the following conventions

to indicate menu choices and key commands:

:

Convention Action

File > Save Choose Save from the

File menu

Control+N Hold down the Control key

Control-click Hold down the Control key

Right-click Click with the right

The names of Commands, Options, and Settings

that appear on-screen are in a different font.

The following symbols are used to highlight

important information:

User Tips are helpful hints for getting the

most from your system.

Important Notices include information that

could affect your data or the performance of

your system.

and press the N key

and click the mouse button

mouse button

Shortcuts show you useful keyboard or

mouse shortcuts.

Cross References point to related sections in

this guide and other Pro Tools guides.

PRE Guide2

Page 7

About www.avid.com

The Avid website (www.avid.com) is your best

online source for information to help you get

the most out of your Pro Tools system. The following are just a few of the services and features

available.

Product Registration Register your purchase

online.

Support and Downloads Contact Avid Customer

Success (technical support); download software

updates and the latest online manuals; browse

the Compatibility documents for system requirements; search the online Knowledge Base

or join the worldwide Pro Tools community on

the User Conference.

Training and Education Study on your own using

courses available online or find out how you can

learn in a classroom setting at a certified

Pro Tools training center.

Products and Developers Learn about Avid

products; download demo software or learn

about our Development Partners and their plugins, applications, and hardware.

News and Events Get the latest news from Avid

or sign up for a Pro Tools demo.

Chapter 1: Introduction 3

Page 8

PRE Guide4

Page 9

chapter 2

Activity and Remote LEDs

Channel Select and Mute

switches and LEDs

Shift, Oscillator, and

MIDI Chan switches

Line/Inst 1 and 2

Gain/Param

Power switch

and LED ring

Peak Meter

Clear Clips

Peak Hold, Source,

and Input Impedance

Signal Present/Clip, 48V, Inser t, Pad,

Phase, and High-Pass Filter indicators

48V, Inser t, Pad, Phase,

and High-Pass Filter

Hardware Overview and Stand-Alone Operation

This chapter describes the PRE front and back panels, and includes instructions for using its switches,

indicators, and connectors for Stand-alone mode operation. To use PRE in Remote mode (remote control of PRE by Pro Tools or a dedicated control surface), see Chapter 3, “Remote Operation.”

PRE Front Panel

PRE has the following front panel switches, indicators, and connectors:

PRE front panel

Power Switch and LED Ring

This switch turns PRE on and off. When lit

(green), the LED ring around the power switch

indicates that the unit is switched on.

By default, PRE powers up in Stand-alone mode.

In this mode, controls can be adjusted from the

front panel or remotely. The Remote “LockOut” LED is unlit (signifying Remote Lock-Out

mode is inactive).

At power up, PRE units default to the last settings they had at power down, with the exception of Remote Lock-Out mode.

Chapter 2: Hardware Overview and Stand-Alone Operation 5

Page 10

Activity LED

When lit (green), this LED indicates MIDI data is

being received by PRE.

Remote “Lock-Out” LED

When lit (green), this LED indicates PRE is in Remote Lock-Out mode. In this mode, PRE is connected to a remote controller (such as Pro Tools

or a dedicated device), and the front panel controls are locked out.

PRE is placed in Remote Lock-Out mode (after

configuring PRE for remote control) by selecting

Remote Lock-Out Mode in the Mic Preamps tab

of the Pro Tools Peripherals dialog.

PRE can be taken out of Remote Lock-Out mode

by deselecting the Remote Lock-Out Mode box

in the Pro Tools Peripherals dialog, or by powering PRE off, and then back on.

For more information on locking and unlocking

PRE front panel controls, see Chapter 3, “Remote Operation.”

Shift Switch and LED

This switch (along with the channel Select

switches) is used in Stand-alone mode when

grouping channels in order to control multiple

channels simultaneously. When lit (green), this

LED indicates the Shift switch is active.

The oscillator generates a fixed tone of approximately 1k Hz at +4 dBu (= 1.228 Vrms).

Calibration can change with temperature.

The output is nominally +4 dBu, but may

vary up to ± 0.3 dB depending upon the

current operating temperature. Allow the unit

to warm up and stabilize the oscillator output

before using it for calibration purposes.

The PRE oscillator signal can be routed through

the OSC output on the back of the unit or

through individual channels on the DB-25

connector.

To route the signal to the OSC output:

Press the OSC switch on the front of the unit.

To route the signal through an individual channel

output on the DB-25 connector:

1 Disconnect any cable inserted into the chan-

nel’s Send jack.

2 Enable the Insert for that channel via the front

panel (see “Insert Switch and LEDs” on page 9)

or through software.

3 Press the OSC switch on the front of the unit.

The oscillator signal can only be activated via

the front panel. However, routing the oscillator

signal through the DB-25 connector can be controlled remotely or by the front panel.

OSC (Oscillator) Switch and LED

This switch enables the internal oscillator,

which can be used for calibrating the inputs of

audio interfaces (such as the HD I/O). When lit,

the OSC LED indicates the oscillator is on.

PRE Guide6

Oscillator routing through a channel output

is done after the channel’s metering point,

and therefore does not display in the PRE

meters.

Page 11

MIDI Chan (Channel) Switch and LED

Peak Meter

This switch activates MIDI Channel selection

mode. When lit, the MIDI Chan LED indicates

PRE is in MIDI Channel mode, and the PRE’s

MIDI channel can be changed with the

Gain/Param control.

Gain/Param Display

This three-character, seven-segment LED displays the input gain for the currently selected

PRE channel, or the PRE’s MIDI channel.

This display can also show the current firmware

version of PRE.

To display the firmware version of PRE in the

Gain/Param display:

1 Press Shift once, then release it.

2 Press OSC.

Gain/Param Control

The Gain/Param control can be used to add gain

to the input signal on one or more of the PRE’s

eight channels, or to set the PRE’s MIDI channel. Changes made with the Gain/Param control

appear in the Gain/Param display.

These fourteen-segment LEDs indicate input signal level for any channel that currently has its

Select switch enabled. If multiple channels have

their Select switch enabled, only the left-most

channel will be represented in the Peak Meter

display.

The meter is referenced from the clip point of

the amplifier (for example, –22 dB is 22 dB

below the clip point of the amplifier).

Clear Clips Switch

This switch clears Clip indicators on the Peak

meter and Signal indicators.

Peak Hold Switch and LEDs

This switch sets the clip hold action of the SIG

meters atop each of the 8 channels. Clips are

also indicated by a red Clip LED on the Peak Meter. The amount of time the clip stays lit is determined by the Peak Hold value, as follows:

Off When lit, the Peak Hold function is off. Clip

LEDs will light during clipping, then clear

shortly after clipping stops. This is the default

Peak Hold value, on power up.

The gain range for each input (Mic, Line, and Instrument) is 0 dB to +69 dB, adjustable in increments of approximately 3 dB (see Table 2 on

page 38).

3 sec When lit, Clip LEDs are displayed for

three seconds, then automatically clear, as long

as no additional peaks occur.

(Infinity Symbol) When lit, Clip LEDs will stay

lit until the Clear Clips switch is pressed.

To change Peak Hold (time constant)

performance:

Press Peak Hold once to change to the next

setting, or multiple times to toggle through the

three settings. Peak hold is a global command

which sets clip persistence for all channels.

Chapter 2: Hardware Overview and Stand-Alone Operation 7

Page 12

Source Switch and LEDs

Channel Status Section

This switch sets the active input source for individual PRE channels to Mic, Line, or Inst (instrument). The three Source LEDs indicate the active

input.

Input Impedance (Represented as Z)

The Input Z switch sets the input impedance for

a PRE channel to 1.5 k, 15 k, or 1.5 M.

The three Input Z LEDs indicate the current setting:

1.5K Typically used for microphone inputs, this

is the default setting when Source is set for Mic.

15K Typically used for line level inputs, this is

the default setting when Source is set for Line.

1.5M Typically used for instrument inputs, this

is the default setting when Source is set for Inst.

To change input impedance, do one of the

following:

If the input Source is Mic, press Input Z once

to change to the next setting, or multiple times

to toggle through the three settings.

Each PRE channel provides switched control for

48V (phantom power), phase reverse, input pad,

access to a unity gain insert send/return, and a

high-pass filter. In addition, all eight channels

have individual Mute switches and signal status

LEDs.

Signal Present/Clip (SIG) LEDs

These LEDs indicate the status of a channel’s input signal. Green indicates signal is present

(–45 dB) and red indicates clipping. When there

is no signal present or the signal is below –45 dB,

the LED is off.

When clipping occurs, the LED remains lit or

clears, depending on the Peak Hold setting.

Clips can also be manually cleared with the

Clear Clip switch.

If the input Source is Line, press Input Z to

change to 1.5K or 15K.

If the input Source is Inst (instrument), the In-

put Z cannot be changed from its default 1.5M

setting.

PRE Guide8

Page 13

48V Switch and LEDs

Insert Switch and LEDs

This switch applies 48V phantom power to the

Mic Inputs. When lit (red), these LEDs indicate

which channels have 48V enabled.

Mic Inputs can provide 48V phantom power for

microphones that require it to ope rate . If S our ce

is set to Line or Inst, phantom power automatically disengages to avoid sending phantom

power back to the line level device through the

XLR cable, eliminating unnecessary power draw

when not in use for powering microphones.

Dynamic microphones (like a Shure SM57) do

not require phantom power to operate, but are

not harmed by it. Most condenser microphones

(like an AKG C414) do require phantom power

to operate. If you are not sure about the phantom power requirements for your microphone,

contact the manufacturer, or read your microphone’s documentation.

Although phantom power can be used

safely with most microphones, ribbon microphones can be damaged by it. Always

turn off phantom power, and wait for the

red 48V indicator light to go completely off

and any signal to dissipate before connecting or disconnecting a ribbon microphone.

This switch enables insert points on individual

channels. When lit (yellow), Insert LEDs indicate which channels have their insert point enabled.

PRE’s back panel has eight pairs of send and return jacks for inserting external processors (such

as compressors or EQs) in the audio path. Insert

send levels are post output trim.

Pad Switch and LEDs

This switch applies an input pad to individual

channels to reduce input sensitivity by –18 dB.

When lit (green), Pad LEDs indicate which

channels have Pad enabled.

Phase Switch and LEDs

This switch applies phase reversal to individual

channels. When lit (green), Phase LEDs indicate

which channels have phase reverse enabled.

High-Pass Filter Switch and LEDs

This switch applies a high-pass filter to individual channels. When lit (green), HPF LEDs indicate which channels have the high-pass filter

enabled.

Condenser microphones requiring phantom

power should not be “hot-plugged” into a

PRE Mic Input where phantom power is

active before plugging the microphone in.

This could potentially cause damage to

PRE, as well as to un-muted monitoring

systems, due to a loud “click” or “pop.”

Each PRE channel includes a high-pass filter

with a center frequency of 85 Hz and a roll-off of

–18 dB/octave. Use the high-pass filter to remove microphone proximity effects, hum, rumble, wind, and other low frequency sounds.

Chapter 2: Hardware Overview and Stand-Alone Operation 9

Page 14

Channel Mute Switches and LEDs

Line/Inst 1 and 2

Each PRE channel has a dedicated Mute switch

to mute input signal. The respective Mute LED

lights when muting is enabled.

Channel Select Switches and LEDs

These switches are used to “focus” one or more

channels to adjust their controls. When lit

(green), the Channel Select LED indicates that

the channel’s controls can be adjusted.

To select multiple channels for adjusting, first

press the Shift key on the left-hand side of the

unit, then press the Select switches for corresponding channels. To return to single channel

selection, disengage the Shift key, then press the

Select switch for the individual channel you

wish to change.

The following channel controls can be adjusted:

• 48V Phantom Power; see “48V Switch and

LEDs” on page 9.

• Phase Reverse; see “Phase Switch and

LEDs” on page 9.

• Pad; see “Pad Switch and LEDs” on page 9.

• Insert; see “Insert Switch and LEDs” on

page 9.

• High-Pass Filter; see “High-Pass Filter

Switch and LEDs” on page 9.

• Mic/Line/Instrument Source Switching; see

“Source Switch and LEDs” on page 8.

• Input Gain; see “Gain/Param and Input

Gain” on page 15.

The front panel includes two 1/4-inch

balanced/unbalanced TRS jacks, with Tip wired

hot (or “+”), Ring cold (“–”), and Sleeve ground.

These jacks mirror Line/Inst Inputs 1 and 2 on

the back panel. Connecting to the front panel

Line/Inst input will break a connection made to

the respective back panel Line/Inst input.

Use these jacks for convenient access to high impedance instrument inputs.

When PRE is powered off, channel select states

are stored in memory and are subsequently restored at power up.

PRE Guide10

Page 15

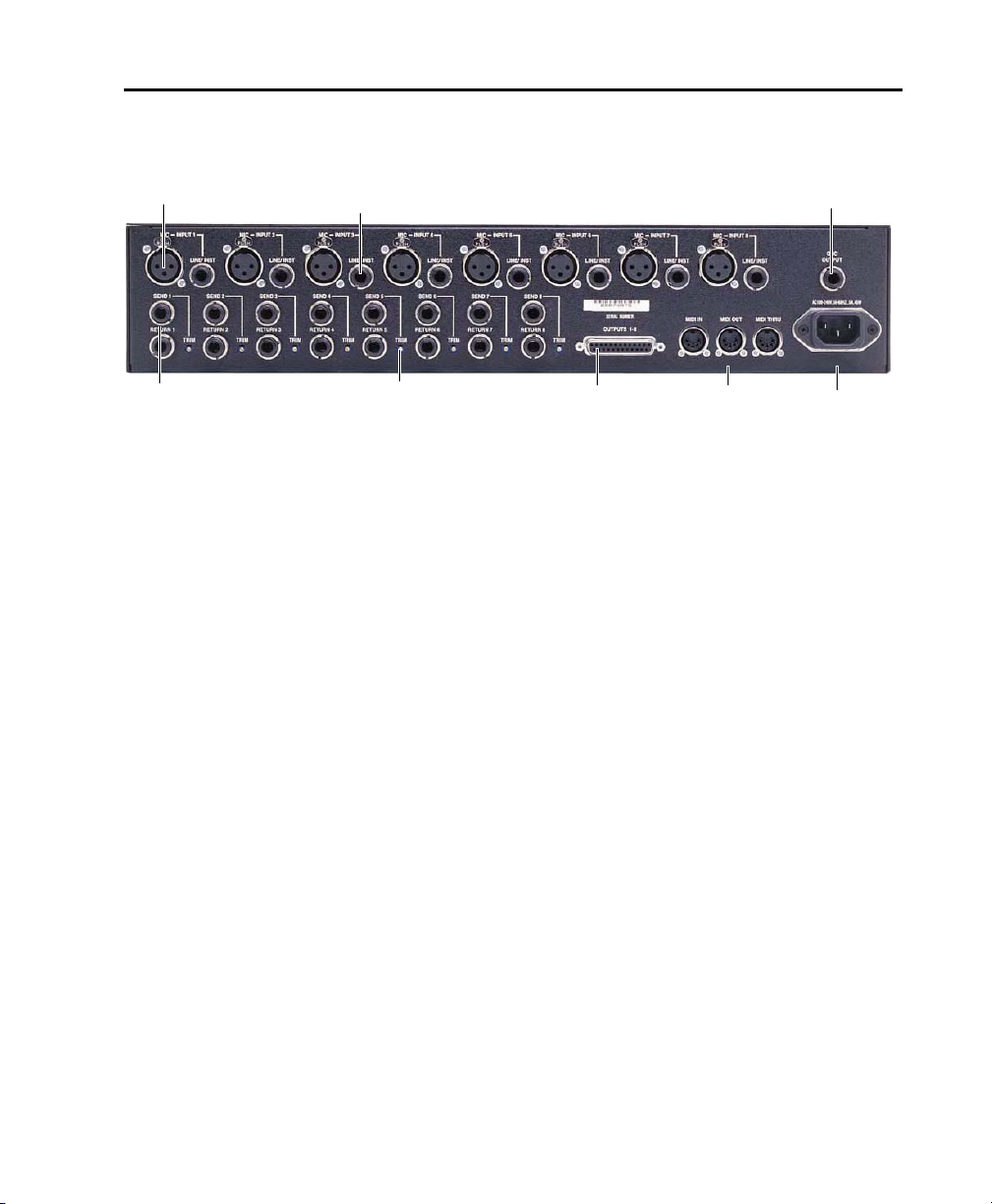

PRE Back Panel

Send and Return Inser ts 1–8

Mic Inputs 1–8

Line/Inst Inputs 1–8

DB-25 Outputs 1–8

Output Trims 1–8

MIDI In/Out/Thru

Oscillator Output

Auto-switching power

supply connector

PRE has the following back panel connectors:

PRE back panel

Mic Inputs 1–8

These are balanced XLR jacks, with Pin 1 wired

ground, Pin 2 wired hot (or “+”), and Pin 3 wired

cold (or “–”).

Use these jacks for microphone connections or

for line level devices that support balanced XLR

connectors.

Line/Inst (Line Level/Instrument)

Inputs 1–8

These are balanced 1/4-inch TRS jacks, with Tip

wired hot (or “+”), Ring cold (“–”), and Sleeve

ground.

Unbalanced connections are supported with the

use of standard 1/4-inch mono phone plugs. If

using line inputs with balanced line level devices, be sure to use balanced to balanced cables

to maximize performance.

DB-25 Outputs 1–8

This is a balanced DB-25 connector for line outputs 1–8. For pinouts, see Appendix B, “Pinout

Diagram for the PRE DB-25 Connector.”

This connector can also output a fixed oscillator

signal on each channel. For more information,

see “OSC (Oscillator) Switch and LED” on

page 6.

Send and Return Inserts 1–8

These are balanced 1/4-inch TRS Send and

1/4-inch TRS Return jacks, with Tip wired hot

(or “+”), Ring cold (“–”), and Sleeve ground. Insert send levels are post output trim.

Use these jacks for inserting external devices

such as compressors or equalizers in the audio

path before recording to disk. Sends can also be

used as line outputs; in this case, all front panel

controls will affect the signal, except Mute.

Return channels 1–8 can be bypassed from the

front panel, or through remote control.

Chapter 2: Hardware Overview and Stand-Alone Operation 11

Page 16

Output Trims 1–8

Oscillator (OSC) Output

The output trims are used to individually calibrate each channel’s output and send level.

The output trims are factory-calibrated so that

the clip point of the PRE output amplifier

matches the factory-set clip point of the HD I/O

and 192 I/O analog input. The PRE’s output

level is –6 dBu below its maximum output of

+28 dBu (+22 dBu). If you do not intend to use a

HD I/O or 192 I/O, you should turn the trims all

the way up (clockwise) to allow for maximum

signal output (+28 dBu) and maximum performance.

The Send jacks and the DB-25 connector

both use the output trims for adjustment.

Calibrating a DB-25 output will affect the

Send output level as well.

MIDI In/Out/Thru Connectors

The MIDI connectors on PRE accept standard

5-pin MIDI cables.

The MIDI In connector accepts MIDI input for

remote control of PRE (for example, from the

MIDI Out of a MIDI interface in a Pro Tools

system).

The MIDI Out connector sends MIDI data out of

the PRE to the MIDI input of a Pro Tools system,

or another PRE. To daisy-chain multiple PREs,

connect the MIDI Out of one PRE to the MIDI In

of the next PRE, and so on. You will also need to

set each unit to a unique MIDI channel number

(refer to “MIDI Connections” on page 18).

This is a balanced 1/4-inch TRS jack that outputs

a fixed oscillator signal (+4 dBu reference signal

at approximately 1 kHz) for calibrating the inputs of gear not connected through the DB-25

output. For more information, see “OSC (Oscillator) Switch and LED” on page 6.

AC Power

This connector accepts a standard AC power cable (included). PRE is auto power-selecting

(100V to 240V) and will automatically work

with a standard modular cable to connect to AC

power receptacles in any country.

Power Up Defaults

When you first power on PRE, it has the following settings.

Power Up Defaults

Function Status

Operation

Mode

Peak Hold Off

OSC Off

Shift Off

User Settings Stored in Memory

When PRE is powered down, it remembers its

last settings. When the unit is powered back on,

the last settings will be intact.

Stand-alone (Remote “Lock-Out”

LED off)

The MIDI Thru connector is not used for

Pro Tools remote control.

PRE Guide12

Page 17

Using PRE in Stand-Alone Mode

PRE can be used without Pro Tools as a standalone microphone preamplifier. PRE standalone operation requires power and audio

connections.

To connect a microphone:

1 Press the Channel Select switch for the Mic In-

put you will be using.

2 Change the input source to Mic, by pressing

Source one or more times.

3 Make sure the gain is turned down, especially

if the monitors are up.

Powering Up PRE

To use PRE as a stand-alone microphone

preamplifier:

1 Connect AC power to PRE.

2 Power on PRE.

At power up, PRE units will default to the last

settings they had at power down.

Making Signal Connections to PRE

Depending on how you plan to use PRE, the way

you connect it to your studio will vary.

While you can use PRE with a variety of audio

setups, all you really need is a line input device

(such as a mixer or an A/D converter) to monitor

PRE outputs.

Connecting Audio Sources

To prevent damage to PRE or your monitoring system, mute your monitoring system or

set levels to their minimums before making

audio connections. This will prevent sudden

spikes and surges, as well as possible feedback if a microphone is connected and left

“open.”

4 Verify that phantom power (48V) is disabled.

Press the 48V switch, so that the 48V LED is off.

Although phantom power (48V) can be

used safely with most microphones, some

ribbon microphones can be destroyed by it.

You should always turn off phantom power,

and wait for the red light to go completely

off before connecting or disconnecting a

ribbon microphone.

5 Plug a microphone directly into the Mic Input

on the back of PRE. These inputs accept XLR

connectors.

6 If your microphone requires phantom power,

press 48V.

7 Turn the Gain/Param control to raise the gain.

Use the Peak Meter to determine the proper

level.

If the output trim has been calibrated to the input trim of your HD I/O, the pre-fader meter in

Pro Tools should accurately reflect the Peak Meter of the PRE, allowing you to use the on-screen

meters to set your levels.

8 Repeat these steps for additional microphone

connections.

Chapter 2: Hardware Overview and Stand-Alone Operation 13

Page 18

To connect line level and instrument level sources:

1 Press the Channel Select switch for the

Line/Inst Input you will be using.

2 Change the input source to Line or Inst by

pressing Source one or more times.

3 Plug a line level source (such as a synth, out-

put from your mixer, or a microphone or guitar

that has been amplified by an outboard preamp)

or a DI (direct instrument) source into a

Line/Inst Input on the front or back of PRE.

These inputs accept balanced/unbalanced TRS

connectors.

If using line inputs with balanced line level

devices, be sure to use balanced to balanced

cables to maximize performance.

4 Repeat these steps for additional connections.

3 Press the Channel Select switch for the

Send/Return channel you will be using.

4 Press Insert.

Repeat these steps for additional connections.

Both the Send and Return jacks are balanced

1/4-inch jacks, with Tip wired hot (or “+”),

Ring cold (“–”), and Sleeve ground. Insert

send levels are post output trim.

Calibrating PRE and Other Devices

Before you use PRE, you may want to calibrate

its output level (as well as the input and output

levels of other devices) to the level of your mixing console.

Using External Devices

PRE can make dedicated connections to external

analog devices (such as compressors and equalizers) before committing the signal to disk in

Pro Tools. You can send and return signals to

these devices, using PRE’s back panel Send and

Return jacks.

To connect an external analog device to your

system:

1 Connect the Send jack of one PRE channel to

an input of the external signal processor.

2 Connect the output of the external signal pro-

cessor to the Return jack of the same PRE

channel.

The output trims are factory-calibrated so that

the clip point of the PRE output amplifier

matches the factory-set clip point of HD I/O and

192 I/O analog input. The PRE’s output level is

–6 dBu below its maximum output of +28 dBu

(+22 dBu). If you do not intend to use an HD I/O

or 192 I/O, you should turn the trims all the way

up (clockwise) to allow for maximum signal output (+28 dBu) and maximum performance.

PRE Guide14

Page 19

Adjusting Channel Controls

Most PRE parameters can be changed with front

panel channel control switches; for a description of each switch, see “PRE Front Panel” on

page 5. Input Gain is changed with the

Gain/Param control (see “Adjusting Input Gain”

on page 16).

PRE channel controls can be applied to one or

more channels at a time.

To select one channel:

Press the Select switch of the desired channel.

Selecting one channel deselects the previously

selected channel or channels.

To select multiple channels:

Hold Shift and press the Select switch of any

channels you want to adjust.

To quickly select all channels, drag your

finger across all the Select switches.

When more than one channel is selected, metering, control states, and Gain/Param settings

reflect the activity of the leftmost channel of the

group.

Adjustments made to any selected channel are

made to all selected channels. See “Mixed State

Operating Mode While Editing Multiple Channels” on page 15.

To change a setting with a channel control switch:

1 Select one or more channels.

2 Press a channel control switch to change its

current setting. For example, if the 48V LED is

off, pressing 48V will enable 48V phantom

power on all the selected channels. (48V can

only be enabled when input source is set for Mic

input. It is disabled as a choice when input

source is set for line or DI input.)

To return the selection to a single channel:

Press Shift to disengage, then press the Select

switch of the individual channel you want to

edit.

Mixed State Operating Mode While Editing

Multiple Channels

A mixed state operating mode exists when you

are editing multiple channels simultaneously,

and some of the channels have different settings.

Channel Control Switches

When multiple channels are selected, switch

modifications made to one selected channel are

automatically applied to all selected channels.

Gain/Param and Input Gain

If an offset exists between selected channels, the

offset will be maintained while moving the

Gain/Param control until you reach +69 dB

gain or 0 dB, at which point the selected channels will mirror each other.

Gain offsets are retained when multiple

channels are adjusted in Stand-alone mode,

but not in Pro Tools Remote mode.

Chapter 2: Hardware Overview and Stand-Alone Operation 15

Page 20

Adjusting Input Gain

To set input gain on a channel:

1 If the Gain/Param display currently shows a

MIDI channel, press MIDI. The display should

now show an input gain level.

2 Press the Select 1 switch (for example, for Mic

Input 1).

3 If the Source Mic LED is not lit, press Source

one or more times until the Mic LED is lit (so

that the Mic Input is active).

4 Rotate the Gain/Param control to change the

input gain level.

Muting Channels

To mute a channel:

Press the Mute switch on each channel you

want to mute. To mute additional channels,

press their corresponding Mute switches. Meters

remain active, and Channel Status controls can

still be changed.

To quickly mute all channels, drag your

finger across all the Mute switches.

To unmute a channel:

Press Mute again.

PRE Guide16

Page 21

chapter 3

Remote Operation

Installation of PRE remote control in Pro Tools

includes:

• Making audio and MIDI connections to PRE

(See “Connecting PRE to a Pro Tools System”

on page 18.)

• Configuring MIDI (See “Configuring MIDI

Studio in AMS for PRE” on page 20 or “Configuring Pro Tools Software for PRE” on

page 22.)

• Configuring Pro Tools (See “Configuring

Pro Tools Software for PRE” on page 22.)

This includes:

• Declaring PRE in the Peripherals dialog

• Mapping PRE outputs to an audio interface’s inputs in the I/O Setup dialog

Once PRE is configured in Pro Tools, Mic Preamp controls can be displayed in Pro Tools Mix

and Edit windows, and you can do one of the

following:

• Control PRE remotely from the Pro Tools Mix

or Edit window

• Use PRE front panel controls to adjust Mic

Preamp controls

• Use a control surface to adjust Mic Preamp

controls. For specific controls, see “Mic Preamp Remote Control with Control Surfaces”

on page 30.

PRE Remote Control in Pro Tools

The following PRE front panel controls can be

remotely controlled in Pro Tools:

•Input Gain

• Input Source

• Selecting one or more channels for editing

• Input Impedance (Input Z)

•48V

•Insert

•Pad

•Phase Invert

• High-Pass Filter

The following PRE front panel controls cannot

be remotely controlled:

• Oscillator on/off

• MIDI channel assignment

• Changing the Peak Hold setting of front

panel Clip LEDs

• Clearing of Clips on the front panel

• Muting individual PRE outputs

Chapter 3: Remote Operation 17

Page 22

Connecting PRE to a Pro Tools System

Audio Connections

PRE must be physically connected to an audio

interface (such as HD I/O or 192 I/O) in your

Pro Tools system.

To connect a PRE to a Pro Tools system:

Connect PRE outputs to analog inputs on

your audio interface. (For example, to connect

PRE to an HD I/O, use a DB-25 cable to connect

the PRE outputs to the Analog Inputs on the

HD I/O; for a 96 I/O, use a DB-25 to TRS cable.)

To connect a PRE to a MIDI interface:

1 Connect a MIDI cable between the MIDI Out

port on your PRE and the MIDI In port on your

MIDI interface.

2 Connect a MIDI cable between the MIDI In

port on your PRE and the MIDI Out port on your

MIDI interface.

3 For additional PREs, daisy-chain them by con-

necting the MIDI Out port on the first PRE to

the MIDI In port of the second PRE, and so on.

For multiple PRE MIDI cabling considerations,

see “Installations with Multiple PREs” on

page 19.

Setting the PRE MIDI Channel

For installations with multiple PREs, repeat this

step.

For each PRE output, note the respective audio interface input channels, as these will be

the physical inputs you map PRE outputs to

in Pro Tools. For example, PRE outputs 1–8

attached to a standard HD I/O map to analog inputs 1–8; however, PRE outputs 1–8

attached to the second A/D card on a

HD I/O represent analog inputs 9–16.

MIDI Connections

The following are basic instructions for connecting your PRE to a MIDI interface (such as an

M-Audio MIDI Sport) for remote control.

Before you connect PRE MIDI Ins and Outs, connect and configure your MIDI interface according to the manufacturer’s instructions.

To set the global receive/transmit MIDI channel:

1 On the PRE front panel, press the MIDI Chan

switch so the LED lights.

The Gain/Param display displays the current

MIDI channel (1–16).

2 Turn the Gain/Param control clockwise to in-

crement MIDI channel numbers, or counterclockwise to decrement channel numbers. (The

MIDI channel will be set once you stop moving

the control; you do not need to press an Enter

switch to set the channel.)

3 To exit MIDI Channel mode, press the MIDI

Chan switch again.

4 Repeat the above steps for additional PREs.

PRE Guide18

Page 23

Installations with Multiple PREs

To control multiple PREs through a single MIDI

port, set each unit to a unique MIDI channel

number. Keep in mind that if PRE units are set to

the same MIDI channel on a single MIDI port,

their controls will operate in a ganged fashion—changing a setting on one unit will change

the setting on all units.

With a multi-port MIDI interface, every unit

must be daisy-chained from a single port on

your MI DI in terface. Connect the MIDI Out port

of the MIDI interface to the MIDI In port of the

first PRE, then connect the MIDI Out port of the

first PRE to the MIDI In port of the second PRE,

and so on. Make sure to connect the MIDI Out

port of the last PRE to the MIDI In port of the

MIDI interface.

Powering Up a Pro Tools System

In order for Pro Tools to communicate properly

with audio interfaces and other peripherals, it is

important that you start up and shut down your

system in the following order:

Power up your system in this order:

1 Turn on your Pro Tools hard drives. Wait ap-

proximately ten seconds for them to spin up to

speed.

2 Turn on PRE.

3 Turn on synchronization or other MIDI pe-

ripherals or interfaces.

4 Turn on your Pro Tools audio interfaces.

5 Turn on your computer.

With multiple PREs, it is easier to keep track

of each unit in Pro Tools by setting MIDI

channels in ascending order, in relation to

the physical position of the PREs (for example, in the order they are stacked in a rack).

6 Turn on your speakers or monitor system.

Power down your system in this order:

1 Turn off your speakers or monitor system.

2 Quit Pro Tools.

3 Shut down the computer.

4 Power off your audio interfaces.

5 Turn off PRE.

6 Turn off any synchronization, MIDI, or other

peripherals or interfaces.

7 Tur n off your drives.

Chapter 3: Remote Operation 19

Page 24

Configuring MIDI Studio in AMS for PRE

(Mac Only)

The following are basic instructions for configuring PRE in the Apple Audio MIDI Setup application (AMS).

To configure your PRE with AMS:

1 Do one of the following:

• Launch the Apple Audio MIDI Setup (Applications/Utilities).

– or –

• In Pro Tools, choose Setup > MIDI > Studio

Setup.

2 If the MIDI Studio window is not shown in

Audio MIDI Setup, choose Window > MIDI Studio.

3 Do one of the following:

• Double-click the PRE icon.

– or –

• If there is no icon for the PRE, click Add Device

in the toolbar at the top of the window and do

the following:

• Double-click the New External Device icon.

• Select Digidesign as the Manufacturer.

• Select PRE as the Model.

4 Click Properties.

MIDI Device Properties for PRE

5 Enable the appropriate Channels for the Trans-

mits and Receives options.

6 Click Apply and close the Properties window.

7 Connect the PRE icon to the correct port on

the MIDI interface icon:

• Click the arrow for the output port of the

PRE and drag a connection to the input arrow of the corresponding port of the MIDI

interface.

• Click the arrow for the input port of the

PRE and drag a connection to the output

arrow of the corresponding port of the

MIDI interface.

Connecting the PRE to the MIDI interface in the AMS

MIDI Studio window

PRE Guide20

Page 25

8 Pro Tools supports the use of up to nine PREs

at the same time. If you use multiple PREs, make

sure that none of the PREs are assigned to the

same MIDI channel, and that all PREs are daisychained together (as noted in “MIDI Connections” on page 18).

9 Quit Audio MIDI Setup (Audio MIDI Setup >

Quit Audio MIDI Setup).

10 Continue with “Configuring Pro Tools Soft-

ware for PRE” on page 22.

Configuring MIDI Studio Setup for PRE

(Windows Only)

The following are basic instructions for configuring PRE in MIDI Studio Setup (MSS). For more

information on MSS, see the Setup Guide for your

system.

To define PRE with MIDI Studio Setup:

1 In Pro Tools, choose Setup > MIDI > MIDI Stu-

dio. The MIDI Studio Setup window opens.

4 Select Digidesign and PRE from the corre-

sponding pop-up menus.

5 From the Input pop-up menu, choose the in-

put port on your MIDI interface that is connected to the MIDI Out of the PRE.

6 From the Output pop-up menu, choose the

output port on your MIDI interface that is connected to the MIDI In of the PRE.

7 Enable the appropriate MIDI channels (1–16)

for the Send Channels and Receive Channels

options (These determine which channels send

and receive MIDI.)

8 Pro Tools supports the use of up to nine PREs

at the same time. If you use multiple PREs, make

sure that none of the PREs are assigned to the

same MIDI channel, and that all PREs are daisychained together (as noted in “MIDI Connections” on page 18).

9 Continue with “Configuring Pro Tools Soft-

ware for PRE” on page 22.

2 Click Create.

3 In the Instrument Name field, type PRE, and

press enter.

If you do not enter an instrument name, the

Instrument Name field will automatically

inherit information from the Manufacturer

and Model pop-up menu.

Chapter 3: Remote Operation 21

Page 26

Configuring Pro Tools Software for PRE

Once PRE has been configured in AMS or MSS, it

can be declared in the Pro Tools Peripherals dialog and mapped in the I/O Setup dialog, in order

to establish communication between Pro Tools

and PRE.

Declaring PRE in Pro Tools

Each PRE must be declared in the Pro Tools Peripherals dialog.

To declare PRE in Pro Tools:

1 Choose Setup > Peripherals and click the Mic

Preamps tab.

2 Select PRE from the Type pop-up menu.

3 From the Receive From menu, choose the

source port for the connected PRE and the corresponding MIDI channel to receive data. It is important to choose the correct MIDI channel if

using multiple PREs, as the software will not

know how the PREs are connected to your system except by MIDI channel assignments.

4 From the Send To pop-up menu, choose the

destination port for the connected PRE and

MIDI channel to transmit data. Again, be sure

you choose the correct MIDI channel in multiple PRE configurations.

5 Click OK.

6 Open or create a Pro Tools session.

7 Choose Setup > MIDI > Input Devices and make

sure PRE is enabled as an Input Device.

For more information on enabling input

devices, see the Pro Tools Reference Guide.

Declaring a PRE in the Peripherals dialog

PRE Guide22

Page 27

Declaring Multiple PREs

You can configure additional PREs (up to a total

of nine) by repeating the above steps. Make sure

that none of the PREs are assigned to the same

MIDI channel (if daisy-chained) or port (if connected to separate ports on your MIDI interface)

in the Pro Tools Peripherals dialog (unless you

want them to operate in ganged fashion).

Press and hold Alt (Windows) or Option

(Mac) while making changes to simultaneously apply changes to the selected Mic Preamp and all Mic Preamps below it.

When changing Mic Preamp sources and

destinations with the Alt/Option key, updates are applied sequentially (for example,

changing the Receive From destination in

the second row to PRE #2-2, will update the

destination in the third row to PRE #3-2,

and so on).

Additional Options in the Peripherals Dialog

The front panel settings that Pro Tools can remotely control are stored with the session,

whereas the number of PREs declared, their

lockout and retain current settings status, as

well as their online/offline status and output assignments are stored as global (system) preferences.

When Retain Current settings is not selected, PRE settings will be overridden

whenever you open a session that has PRE

settings, even if no tracks exist in the

session.

To ensure you retain your current settings,

check the Retain Current Settings box,

before you open a session.

Remote Lock-Out Mode Sets PRE to ignore front

panel controls. Remote Lock-Out mode can be

disabled by deselecting this option in the

Pro Tools Peripherals dialog, or by power-cycling the PRE.

The following options can be set while you are

declaring PRE in Pro Tools, but are also useful

during sessions to lock out front panel controls

or to globally change PRE settings.

Reset Click Reset to return PRE parameters to

their defaults. Resetting takes place immediately; you do not need to click OK to reset parameters.

Retain Current Settings Select this option to retain PRE channel settings when an existing session with different settings is loaded. New sessions will automatically retain the current

settings.

Mapping PRE Outputs to Audio Interface Inputs in Pro Tools

Individual PRE outputs must be manually

mapped to audio interface inputs before their

audio and remote controls will be available

within Pro Tools.

After mapping PRE channels to Pro Tools analog

input paths, whenever you associate a track with

an input path (created in I/O Setup) which is

also a physical input that the PRE channel was

mapped to, the PRE controls (identified as Mic

Preamps) appear on top of the channel strip,

giving you audio and control. Make sure that

Display > Mix Windows Shows > Mic Preamps View

is selected.

Chapter 3: Remote Operation 23

Page 28

For each declared PRE, the I/O Setup Mic Preamps page includes the PRE path name, and

provides tools to map PRE output channels to an

audio interface.

PRE path in I/O Setup window

Paths can be:

• Renamed, for easier identification after

changing or renaming audio interfaces. See

“Naming Paths (Optional)” on page 25.

• Remapped to different input destinations (audio interface analog). See “Remapping Channels” on page 24.

• De-activated (or re-activated) to manage unavailable or unnecessary I/O resources. See

“Active and Inactive Paths” on page 25.

PRE paths cannot be deleted. Additionally, their

I/O Setup configuration cannot be exported or

imported.

If you have multiple PRE units in I/O setups, the

order in which the PRE paths appear corresponds to the order in which they were assigned

in the Mic Preamps tab of the Peripherals dialog.

Channel Mapping

Existing PRE paths must be mapped to specific

audio interface inputs in the Grid in order for

audio and remote control to be available in

Pro Tools.

To map channels:

1 Choose Setup > I/O and click the Mic Preamps

tab.

2 In the row for the selected path—the high-

lighted PRE name—click in the Grid column under the audio interface and channels to which

PRE is connected. The first output channel of

the PRE appears in this column (as the number

1), while the remaining seven channels fill to

the right.

3 When you are finished mapping channels,

click OK.

Remapping Channels

You can move the individual PRE assignments

to different audio interface input channels.

To remap channels in a path, do one of the

following:

Drag the PRE channel to the new location in

the Grid.

– or –

Command-click the PRE channel in the Grid

to open the PRE Output Channel pop-up menu,

then select an output channel. If you select a

channel that is already in use, the old and new

assignments will swap Grid positions.

To update the Grid with new mapping,

Command-click a white box in the Grid,

then select an output channel. If the channel was already in use, the old assignment is

removed.

PRE Guide24

Page 29

To remap multiple channels in a path do one of the

following:

Shift-click multiple channels, then drag the

channels to the new locations in the Grid.

– or –

Marquis-select multiple channels, then drag

them in the Grid.

Channel Shuffling

If the destination channel is already occupied,

moving a signal from right to left results in a

shuffle of other signals after the new destination

channel. If the destination channel is already

occupied, moving a signal from left to right

shuffles any and all signals after the new destination channel and leaves the previous channel

empty.

Resetting Paths (with the Default Button)

The Default button in the I/O Setup dialog lets

you:

• Reset selected path names to PRE #1, PRE #2,

and so on, corresponding to the order that

PREs appear in the Peripherals dialog.

• Create default mappings for all eight channels

on all the currently selected PREs.

To reset path names:

1 Do one of the following:

• Select a PRE path by clicking on its name.

– or –

• Select multiple PRE paths by Shift-clicking

the desired path names.

2 Click Default.

Additional Options in the I/O Setup

Dialog

Naming Paths (Optional)

You can name PRE paths with custom names.

To name a path:

1 Choose Setup > I/O.

2 Click the Mic Preamps tab.

3 Double-click the PRE path name and enter a

name for the path. Press Tab to move to the next

path (if any), or press Enter to set the new path

name.

4 Click OK to close the I/O Setup dialog. If there

are any identically named paths, you will be instructed to correct them before the I/O Setup dialog will close.

Active and Inactive Paths

Paths can be globally configured for Active or

Inactive status in the I/O Setup Dialog. When

PRE paths are inactive, they do not appear in the

Mix or Edit windows.

Making a Mic Preamp inactive can be useful if

the PRE will be disconnected from the MIDI port

or powered off during a session. You can also

make Mic Preamps inactive so that they do not

appear in the Mix and Edit windows.

Chapter 3: Remote Operation 25

Page 30

Display of Active and Inactive Status

Unhighlighted (Italics) Indicates the path is inac-

tive.

Highlighted (Non-Italics) Indicates the path is active. This is the default state.

To de-activate or activate a path:

1 Choose Setup > I/O.

2 Click the Mic Preamps tab.

Mic Preamps in Pro Tools Edit and Mix Windows

After you create a new track and set the track input to an analog input that the PRE output

channel is mapped to, the PRE controls (identified as Mic Preamps) appear on top of the track

channel strip. If you do not see these controls,

choose Display > Mix Windows Shows > Mic Pre-

amps View.

3 Set the Active/Inactive control to the appro-

priate choice.

Default Path Order, Import Settings,

Export Settings

These options do not directly affect PRE settings,

but do change settings on other peripherals in

your Pro Tools system. For information, see the

Pro Tools Reference Guide.

PRE settings can be imported into a session

using the Import Session Data command.

PRE settings from the selected session are

imported into the current session.

To create a track with a Mic Preamp

1 Choose Track > New, and create a mono or ste-

reo audio or Auxiliary Input track.

2 Select an input path from the track Input Se-

lector. Make sure you choose an input that a PRE

output was mapped to in I/O Setup.

If the Mic Preamps view doesn’t appear at the

top of the channel strip, you may need to set the

Mix or Edit window to show PRE controls (see

“Viewing Mic Preamp Controls in Pro Tools” on

page 27).

PRE Guide26

Page 31

Mic Preamp Paths

Source and

Impedance

HPF

Insert

Mic Pre window

Pad

Phantom

Power

Phase

Gain

When audio tracks or Auxiliary Inputs are created, their mono, stereo, or multichannel format is defined. This format determines the Mic

Preamp behavior. Mono tracks control a single

channel, stereo tracks control two channels, and

multichannel tracks control multiple channels.

Using multi-channel input paths

Pro Tools allows you to create multichannel input paths in the Inputs tab of I/O Setups. When

these multichannel inputs use a physical input

which has been mapped to a PRE output, their

controls will become automatically ganged together when a multichannel track input assignment is made.

This is useful for stereo-pair miking situations

where you may want both microphones to behave in a similar manner—for example, gain

and phantom power controls affect both channels simultaneously.

If you are using advanced miking patterns, such

as M/S pairing, you will not want the microphones to be ganged together. In this example,

you would want phantom power enabled on the

condenser mic, but not on the dynamic mic.

Furthermore, it is unlikely that they would have

the same gain setting. If you need to use multimicrophone configurations and do not want

their PRE controls to be linked, use individual

mono inputs and mono paths.

Viewing Mic Preamp Controls in Pro Tools

Mic Preamps View, Mix window

Both the Mix and Edit windows can be configured to show or hide PRE controls.

To show or hide Mic Preamp controls in the Mix

and Edit windows:

Choose View > Mix Window or View > Edit Win-

dow, or click the View Selector in the Edit win-

dow or Mix window, and do one of the

following:

• Select Mic Preamps View to show all Mic Preamp controls, or deselect to hide.

• Select All to display the Pro Tools input/output controls, Mic Preamps, inserts, sends,

and comments.

• Select None to hide Pro Tools input/output

controls, Mic Preamps, inserts, sends, and

comments.

Chapter 3: Remote Operation 27

Page 32

Mic Preamp Controls

The Mic Preamps view provides all the essential

controls for a PRE channel in the Mix and Edit

windows.

Pad Button and LED

This button applies an input pad to individual

channels to reduce input sensitivity by 18 dB.

Insert Button

Source and Input Impedance Selector

Clicking the up/down arrows in the Mic Preamp

window accesses two sets of controls. The top

half of this pop-up menu sets the input source

for the PRE channel to Mic, Line, or DI (instrument). The bottom half of this pop-up menu

sets the input impedance for a PRE channel to

1.5 k, 15 k, or 1.5 M.

For more information see “Input Impedance

(Represented as Z)” on page 8 and “Source

Switch and LEDs” on page 8.

Mic Preamp Window Button

Clicking the Mic Preamp Window button

(labeled mic, inst, or DI) opens a floating Mic

Preamp window, an alternative to Mix and Edit

window views. See “Mic Preamp Window” on

page 29.

Phase Button

This button applies phase reversal to individual

channels.

This button enables insert points on individual

channels. PRE’s back panel has eight pairs of

Send and Return jacks for inserting external processors (such as compressors or EQs) in the audio path. Inserts are post the output trims.

If you do not have your signal routed through

an external effects unit, enabling the Insert will

effectively mute your signal.

Gain Indicator and Mini Fader

The Gain indicator features a mini fader to adjust gain to the input signal on the PRE. The

gain range for each input (Mic, Line, and Instrument) is 0 dB to +69 dB, adjustable in increments of approximately 3 dB.

Phantom Power

This button toggles 48V phantom power to Mic

inputs. For more information, see “48V Switch

and LEDs” on page 9.

High-Pass Filter Button

This button applies a high-pass filter to individual channels.

Each PRE channel includes a high-pass filter

with a center frequency of 85 Hz and a roll-off of

–18 dB/octave. Use the high-pass filter to remove microphone proximity effects, hum, rumble, wind, and other low frequency sounds.

PRE Guide28

Page 33

Mic Preamp Window

Target

HPF

Insert

Source

Pad

Phase

Input

Gain

Phantom

Power

The Mic Preamp window provides all the essential PRE controls, plus a gain fader and access to

the channel strip Input Selector, as an alternative to Mix and Edit window views.

To open a Mic Preamp window:

Click the Mic Preamp Window button

(labeled mic, line, or DI).

To view a different Mic Preamp window:

Click the Mic Preamp Windows button

(labeled mic, line, or DI).

To open additional Mic Preamp windows:

Shift-click the Source button in another Mic

Preamp window.

To set a window to remain open:

Make sure the Target is deselected (gray, unlit).

For more information, see the Pro Tools Reference

Guide.

Mic Preamp Window Controls

Mic Preamp windows provide standard selectors

for PRE controls and other controls in the top

area of the window.

Mic Preamp window standard controls

Standard Controls

Refer to “Mic Preamp Controls” on page 28 for a

description of Mic Preamp view controls that are

mirrored in the Mic Preamp window. The following controls are not available in Mic Preamps view:

Input Selector Allows you to change which

channel you wish to assign this track. Changing

the Mic Preamp channel will also change the input of the track.

Chapter 3: Remote Operation 29

Page 34

Gain Level Fader and Field Mic Preamp gain can

be changed by clicking on the fader and moving

the mouse, or by typing a valid gain value in the

field and clicking Enter.

You can enter values that correspond to the gain

values in Table 2 on page 38. Other values will

snap to the closest permitted value (for example,

entering 10 will snap to +9 dB).

Tar get When the Target icon is red, the next

window opened of the same type replaces the

current display. When unlit, the current window anchors to its current contents and location on-screen. Opening additional windows

does not affect anchored windows.

Adjusting Controls on Multiple PREs

When working with PRE controls on multiple

channels in Pro Tools, you must select tracks

from within Pro Tools. Pro Tools does not register selections from the PRE front panel.

To adjust PRE controls on multiple channels:

1 Hold Shift and select the tracks whose PRE

controls you want to adjust.

2 Hold Shift+Option (Mac) or Shift+Alt (Win-

dows) and adjust PRE parameters on any selected track.

To set an open Mic Preamp window as the Target

window:

Click to enable the Target (it is red when en-

abled, gray when disabled).

Adjusting Mic Preamp Controls

To adjust a control on a single channel:

1 Choose View > Mix Window Views > Mic Pre-

amps.

2 Click the Mic Preamp control that you want to

adjust.

Adjustments made to any control on a selected

track are made to the corresponding controls on

all selected tracks.

To adjust controls on all channels:

Hold Option (Mac) or Alt (Windows) and ad-

just PRE controls on any track.

Mic Preamp Remote Control with Control Surfaces

Pro Tools systems configured with PRE remote

control and a supported control surface can use

the control surface to control one or more Mic

Preamps in Pro Tools.

For instructions, see the guide for your work surface (D-Control or D-Command) or control surface (such as C|24 or Command|8).

PRE Guide30

Page 35

appendix a

Specifications

Gain Range 0 dB to +69 dB, in approximately

3 dB steps. With Pad enabled, –18 to +51 dB.

Input Impedance (Input Z): 1.5k ohm (low impedance); 15k ohm (mid impedance);

1.5M ohm (high impedance)

Frequency Response: ±0.1 dB; 20 Hz to 20 kHz,

@+48dB gain

Total Harmonic Distortion + Noise <0.0005%

@ 1 kHz, 0 dB gain @ 20 dB signal; <0.001%

(20Hz to 20kHz), 0dB gain @ 0dB signal

Equivalent Input Noise –128 dB @ 66 dB gain

(20 Hz to 20 kHz unweighted) 150 ohm

Phase Response <2.5 degrees (20 Hz to 20 kHz)

Dynamic Range 124 dB @ 0 dB gain

(20Hzto20kHz unweighted)

Maximum Input Level +47 dBu Pad In, @ 1 kHz,

<0.1% THD

Maximum Output Level +29 dBu balanced,

@ 1 kHz, <0.1% THD

Common Mode Rejection Ratio <–75 dB @ 1 kHz,

140 mVcm, +6 dB gain

Crosstalk <<90 dB, 20 Hz to 20 kHz

Phantom Power 48V ±1V

High-Pass Filter –3 dB @ 85 Hz 18 dB/octave

Appendix A: Specifications 31

Page 36

PRE Guide32

Page 37

appendix b

Pinout Diagram for the PRE DB-25 Connector

DB-25 Connector

Figure 1. DB-25 Connector pinouts

Appendix B: Pinout Diagram for the PRE DB-25 Connector 33

Page 38

PRE Guide34

Page 39

appendix c

MIDI Controller Numbers

If you do not have a Pro Tools Control Surface,

you can use a third-party MIDI control surface

to control PRE in Pro Tools.

The following information assumes you have a

familiarity with MIDI protocol.

For more information on reprogramming your

control surface, refer to its documentation, or

contact the manufacturer.

PRE MIDI Data

These messages are all of the form:

BXh cc vv

In this case, X means zero-based MIDI channel

(1–16), cc means controller number, and vv

means value.

X indicates the PRE’s MIDI channel minus

one (for example, for PRE MIDI channel 1,

X = 0).

All values are in hexadecimal format and may

need to be converted to decimal for some MIDI

devices.

Table 1. PRE MIDI Implementation

cc Name PRE

Channel

0Eh Reset to Default N/A N/A

00h Input Source 1 00h=mic,

01h Input Impedance 1 00h=1.5k,

02h Pad 1 00h=out,

03h Insert 1 00h=out,

04h 48V 1 00h=off,

05h Phase 1 00h=off,

06h High-Pass Filter 1 00h=out,

07h Mute 1 00h=off,

09h Input Gain 1 See Table 2

10h Input Source 2 00h=mic,

vv

01h=line,

02h=inst

01h=15k,

02h=1.5M

7Fh=in

7Fh=in

7Fh=on

7Fh=on

7Fh=in

7Fh=on

01h=line,

02h=inst

Appendix C: MIDI Controller Numbers 35

Page 40

Table 1. PRE MIDI Implementation

cc Name PRE

vv

Channel

11h Input Impedance 2 00h=1.5k,

01h=15k,

02h=1.5M

12h Pad 2 00h=out,

7Fh=in

13h Insert 2 00h=out,

7Fh=in

14h 48V 2 00h=off,

15h Phase 2 00h=off,

16h High-Pass Filter 2 00h=out,

17h Mute 2 00h=off,

19h Input Gain 2 See Table 2

20h Input Source 3 00h=mic,

21h Input Impedance 3 00h=1.5k,

22h Pad 3 00h=out,

23h Insert 3 00h=out,

24h 48V 3 00h=off,

25h Phase 3 00h=off,

26h High-Pass Filter 3 00h=out,

27h Mute 3 00h=off,

29h Input Gain 3 See Table 2

30h Input Source 4 00h=mic,

7Fh=on

7Fh=on

7Fh=in

7Fh=on

01h=line,

02h=inst

01h=15k,

02h=1.5M

7Fh=in

7Fh=in

7Fh=on

7Fh=on

7Fh=in

7Fh=on

01h=line,

02h=inst

Table 1. PRE MIDI Implementation

cc Name PRE

vv

Channel

31h Input Impedance 4 00h=1.5k,

01h=15k,

02h=1.5M

32h Pad 4 00h=out,

7Fh=in

33h Insert 4 00h=out,

7Fh=in

34h 48V 4 00h=off,

35h Phase 4 00h=off,

36h High-Pass Filter 4 00h=out,

37h Mute 4 00h=off,

39h Input Gain 4 See Table 2

40h Input Source 5 00h=mic,

41h Input Impedance 5 00h=1.5k,

42h Pad 5 00h=out,

43h Insert 5 00h=out,

44h 48V 5 00h=off,

45h Phase 5 00h=off,

46h High-Pass Filter 5 00h=out,

47h Mute 5 00h=off,

49h Input Gain 5 See Table 2

50h Input Source 6 00h=mic,

7Fh=on

7Fh=on

7Fh=in

7Fh=on

01h=line,

02h=inst

01h=15k,

02h=1.5M

7Fh=in

7Fh=in

7Fh=on

7Fh=on

7Fh=in

7Fh=on

01h=line,

02h=inst

PRE Guide36

Page 41

Table 1. PRE MIDI Implementation

cc Name PRE

vv

Channel

51h Input Impedance 6 00h=1.5k,

01h=15k,

02h=1.5M

52h Pad 6 00h=out,

7Fh=in

53h Insert 6 00h=out,

7Fh=in

54h 48V 6 00h=off,

55h Phase 6 00h=off,

56h High-Pass Filter 6 00h=out,

57h Mute 6 00h=off,

59h Input Gain 6 See Table 2

60h Input Source 7 00h=mic,

61h Input Impedance 7 00h=1.5k,

62h Pad 7 00h=out,

63h Insert 7 00h=ofut

64h 48V 7 00h=off,

65h Phase 7 00h=off,

66h High-Pass Filter 7 00h=out,

67h Mute 7 00h=off,

69h Input Gain 7 See Table 2

70h Input Source 8 00h=mic,

7Fh=on

7Fh=on

7Fh=in

7Fh=on

01h=line,

02h=inst

01h=15k,

02h=1.5M

7Fh=in

7Fh=in

7Fh=on

7Fh=on

7Fh=in

7Fh=on

01h=line,

02h=inst

Table 1. PRE MIDI Implementation

cc Name PRE

vv

Channel

71h Input Impedance 8 00h=1.5k,

01h=15k,

02h=1.5M

72h Pad 8 00h=out,

7Fh=in

73h Insert 8 00h=out,

7Fh=in

74h 48V 8 00h=off,

75h Phase 8 00h=off,

76h High-Pass Filter 8 00h=out,

77h Mute 8 00h=off,

79h Input Gain 8 See Table 2

7Fh=on

7Fh=on

7Fh=in

7Fh=on

Note that for certain switches, such as the

Mute switches, each “on” message toggles

the state of the switch on or off.

Appendix C: MIDI Controller Numbers 37

Page 42

PRE Gain Step Table

Table 2 . P R E G a i n Ste p s

Table 2. PRE Gain Steps

Step vv Level dB

1 00h 0

2 01h 3

3 02h 6

4 03h 9

5 04h 12

6 05h 15

7 06h 18

8 07h 21

9 08h 24

10 09h 27

11 0Ah 30

12 0Bh 33

Step vv Level dB

23 16 66

24 17 69

13 0Ch 36

14 0Dh 39

15 0Eh 42

16 0Fh 45

17 10 48

18 11 51

19 12 54

20 13 57

21 14 60

22 15 63

PRE Guide38

Page 43

appendix d

Compliance Information

Environmental Compliance

Disposal of Waste Equipment by Users

in the European Union

This symbol on the product or its packaging indicates that this

product must not be disposed of with other waste. Instead, it

is your responsibility to dispose of your waste equipment by

handing it over to a designated collection point for the recycling

of waste electrical and electronic equipment. The separate

collection and recycling of your waste equipment at the time of

disposal will help conserve natural resources and ensure that

it is recycled in a manner that protects human health and the

environment. For more information about where you can drop

off your waste equipment for recycling, please contact your

local city recycling office or the dealer from whom you

purchased the product.

Proposition 65 Warning

This product contains chemicals, including lead,

known to the State of California to cause cancer and

birth defects or other reproductive harm. Wash hands

after handling.

Perchlorate Notice

This product may contain a lithium coin battery. The State of

California requires the following disclosure statement:

“Perchlorate Material – special handling may apply, See

www.dtsc.ca.gov/hazardouswaste/perchlorate.”

Recycling Notice

Appendix D: Compliance Information 39

Page 44

EMC (Electromagnetic

Avid

Compliance)

Avid declares that this product complies with the following

standards regulating emissions and immunity:

• FCC Part 15 Class A

• EN55103-1 E4

• EN55103-2 E4

• AS/NZS 3548 Class A

• CISPR 22 Class A

FCC Compliance for United States

Radio and Television Interference

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules.

DECLARATION OF CONFORMITY

We, Avid, 75 Network Drive

Burlington, MA 01803, USA

650-731-6300

declare under our sole responsibility that the product

PRE

complies with Part 15 of FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

Communication Statement

This equipment has been tested to comply with the limits for

a Class A digital device. Changes or modifications to this

product not authorized by Digidesign, Inc., could void the

Certification and negate your authority to operate the

product. This product was tested for CISPR compliance

under conditions that included the use of peripheral devices

and shielded cables and connectors between system

components. Digidesign recommends the use of shielded

cables and connectors between system components to

reduce the possibility of causing interference to radios,

television sets, and other electronic devices.

Australian Compliance

Canadian Compliance

This Class A digital apparatus complies with Canadian

ICES-003

Cet appareil numérique de la classe A est conforme à la norme

NMB-003 du Canada

Taiwan Compliance

CE Compliance

(EMC and Safety)

Avid is authorized to apply the CE (Conformité Europénne)

mark on this compliant equipment thereby declaring conformity

to EMC Directive 89/336/EEC and Low Voltage Directive

2006/95/EEC.

PRE Guide40

Page 45

Safety Compliance

Safety Statement

This equipment has been tested to comply with USA and

Canadian safety certification in accordance with the

specifications of UL Standards: UL6500 and Canadian CAN

E60065. Avid Inc., has been authorized to apply the

appropriate UL & CUL mark on its compliant equipment.

War ning

Important Safety Instructions

1) Read these instructions.

2) Keep these instructions.

3) Heed all warnings.

4) Follow all instructions.

5) Do not use this equipment near water.

6) Clean only with dry cloth.

7) Do not block any ventilation openings. Install in accordance

with the manufacturer’s instructions.

8) Do not install near any heat sources such as radiators, heat

registers, stoves, or other equipment (including amplifiers)

that produce heat.