Lynx ® NGT-9000

MultiLink Surveillance System

Part Number: 9029000-( )

Installation Manual

This manual contains installation instructions and

recommended flightline maintenance information

for the Lynx NGT-9000 MultLink Surveillance

System, Configuration Module, and Directional

Antenna. Guidelines for external equipment

necessary for installation are included. This

information is supplemented and kept current by

revisions, service letters and service bulletins.

0040-17001-01 (Revision A)

January 15, 2015

Foreword

This manual provides information intended for use by persons who, in accordance with current regulatory

requirements, are qualified to install this equipment. Installation requirements may vary, depending on the

particularities of each aircraft, and this manual is intended as a guideline for that purpose. This manual

assumes familiarity with the setup and operation of the aircraft systems that interface with the NGT-9000.

If further information is required, please contact:

L-3 Avionics Systems

Attn: Field Service Engineer ing

5353 52

Grand Rapids, MI USA 49512-9704

Telephone: (800) 453-0288 or (616) 949-6600

Fax: (616) 977-6898

Email:

Web: http:///www.L-3avionics.com

This manual is distributed with permission by:

L-3 Avionics Systems

5353 52

Grand Rapids, MI USA 49512-9704

Telephone: (800) 453-0288 or (616) 949-6600

Fax: (616) 977-6898

Email:

We welcome your comments concerning this manual. Although every effort has been made to keep it free

of errors, some may occur. When reporting a specific problem, please describe it briefly and include the

manual part number, the paragraph/figure/table number, and the page number. Send your comments to the

address or email above:

nd

Street, S.E.

fieldservice.avionics@L-3com.com

nd

Street, S.E.

avionics.techpubs@L-3com.com

WARNING

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This technical data is controlled under the Export Administration

Regulations (EAR) and may not be exporte d without p roper auth orizat ion

by the U.S. Department of Commerce.

Copyright 2015

ACSS

Trademarks

Lynx

®

is a trademark of L-3 Avionics Systems

Patent Pending

Page A 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

About This Manual

SECTION 1 – GENERAL INFORMATION

This section provides the following information: unit configurations, unit functionality, items

required but not supplied with the unit, equipment specifications, installation approval/limitations

and TSO approvals.

SECTION 2 - INSTALLATION

This section con tains instructi on s to locate, assemble a n d ins ta ll th e Lynx NGT-9000s MultLink

Surveillance System as well as information for unpacking equipment, and inspection procedure for

in-shipment damage.

SECTION 3 – INSTALLATION CHECKOUT

This section contains instructions for post installation setup, post installation and return to service

checkout.

SECTION 4 – MAINTENANCE

This section contains general flightline maintenance procedures. It includes periodic maintenance,

troubleshooting and instructions for the return of defective components.

APPENDIX A – SIGNAL AND CABLE CHARACTERISTICS

This appendix defines the electrical chara ct er istic s of all input and out put sig nal s.

APPENDIX B – ENVIRONMENTAL QUALIFICATION FORM

This appendix provides the environmental qualification test data.

APPENDIX C – CONFIGURATION AND CHECKOUT LOG

This appendix provides the installer a way to record configuration options.

References

PUBLICATION DESCRIPTION

0040-17000-01 Pilot’s Guide for t he NGT -9000

0040-17001-01 Page i

Revision A January 15, 2015

Lynx NGT-9000s

Total number of pages in this publication consists of the following:

Title page

Page A

i thru xvi

1-1 thru 1-40

2-1 thru 2-30

3-1 thru 3-34

4-1 thru 4-32

A-1 thru A-24

B-1 thru B-4

C-1 thru C-2

Installation Manual

List of Effective Pages

Dates of original and changed pages are: Revision A .............................. January 15, 2015

Disclaimer

This Installa tio n Man ua l co n ta ins information tha t is considered relevant only at the time of distribution

with the Avionics Systems product for which it is shipped. Information in this manual is subject to change

without notice and will not be updated after distribution.

Avionics Systems does provide a listing of all publications and directives with their current revision and

change levels to insure up-to-date information. See www.as.l-3com.com, Customer Care Section,

Technical Publications Page for the Publications Index to get an up-to-date listing of all Avionics Systems

technical publications and directives. Contact Avionics Systems Customer Service [1-800-453-0288] to

determine availability of technical publications and directives.

Revision A Highlights

Original release.

Page ii 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

This page intentionally left blank.

0040-17001-01 Page iii

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

Table of Contents

Paragraph Page

Foreword ....................................................................................................................................................... A

About This Manual ......................................................................................................................................... i

References ..................................................................................................................................................... i

List of Effective Pages .................................................................................................................................... ii

Revision A Highlights ..................................................................................................................................... ii

Table of Contents .......................................................................................................................................... iv

List of Illustrations ....................................................................................................................................... viii

List of Tables ................................................................................................................................................. x

Abbreviations, Acronyms, and Symbols ....................................................................................................... xi

Section 1

General Information

1.1 Introduction ................................................................................................................................. 1-1

1.2 Functional Description ................................................................................................................ 1-2

1.2.1 GPS Functional Overview .......................................................................................................... 1-2

1.2.2 ADS-B System Overview............................................................................................................ 1-3

1.2.3 ADS-R System Overview ........................................................................................................... 1-3

1.2.4 TIS-B System Overview ............................................................................................................. 1-3

1.2.5 FIS-B System Overview ............................................................................................................. 1-4

1.2.6 Traffic Awareness System (option) Overview ............................................................................ 1-4

1.2.7 Discrete Inputs and Outputs ....................................................................................................... 1-4

1.3 Equipment Descriptions.............................................................................................................. 1-6

1.3.1 Model Options ............................................................................................................................ 1-6

1.3.2 Detachable Configuration Module (DCM) .................................................................................. 1-6

1.3.3 System Unlock Code .................................................................................................................. 1-7

1.4 INterfaces ................................................................................................................................... 1-7

1.4.1 ADS-B Out Fail ........................................................................................................................... 1-8

1.4.2 AHRS Input ................................................................................................................................. 1-8

1.4.3 Altitude Encoder Input ................................................................................................................ 1-8

1.4.4 Audio Out .................................................................................................................................... 1-9

1.4.5 RF Suppression Input/output ...................................................................................................... 1-9

1.4.6 TAS Alert .................................................................................................................................... 1-9

1.4.7 TIS-B Not In Coverage ............................................................................................................... 1-9

1.4.8 WiFi Interface ............................................................................................................................. 1-9

1.4.9 WOW Input ................................................................................................................................. 1-9

1.4.10 Maintenance Interface ................................................................................................................ 1-9

1.4.11 GPS Antenna .............................................................................................................................. 1-9

1.4.12 L-Band (UAT/1090) Antenna .................................................................................................... 1-10

1.4.13 Directional Antenna .................................................................................................................. 1-10

1.4.14 Traffic Display ........................................................................................................................... 1-10

1.4.15 Weather Display ....................................................................................................................... 1-10

1.5 Installation Considerations ....................................................................................................... 1-11

1.6 Specifications ........................................................................................................................... 1-12

1.7 TSO Information ....................................................................................................................... 1-15

1.7.1 TSO Markings ........................................................................................................................... 1-16

1.7.2 TSO Deviations from Minimum Performance Standards ......................................................... 1-17

1.7.3 Non-TSO Functions .................................................................................................................. 1-18

1.8 Modifications ............................................................................................................................. 1-19

1.9 Software Versions .................................................................................................................... 1-19

1.10 Equipment Required Not Supplied ........................................................................................... 1-20

1.10.1 Installation Kits ......................................................................................................................... 1-23

1.10.2 Antenna Cables ........................................................................................................................ 1-24

Page iv 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

Table of Contents (continued)

Paragraph Page

1.11 Equipment Interfaces ................................................................................................................ 1-27

1.11.1 GPS Antenna ............................................................................................................................ 1-27

1.11.2 L-Band Antenna ........................................................................................................................ 1-27

1.11.3 Directional Antenna .................................................................................................................. 1-28

1.11.4 Traffic Displays ......................................................................................................................... 1-30

1.11.5 Weather Display ....................................................................................................................... 1-30

1.11.6 WIFI Accessory ........................................................................................................................ 1-30

1.11.7 Personal Electronic Device ( PED) Apps .................................................................................. 1-31

1.12 Software Updates ..................................................................................................................... 1-31

1.12.1 Website Download .................................................................................................................... 1-31

1.12.2 Compact Disc ........................................................................................................................... 1-33

1.12.3 Installation Procedure for LynxMMS USB Driver ..................................................................... 1-34

1.13 Installation Approval and Limitations ........................................................................................ 1-38

Section 2

Installation

2.1 Introduction ................................................................................................................................. 2-1

2.2 Unpacking and Inspecting .......................................................................................................... 2-1

2.2.1 Transport and Storage Considerations ...................................................................................... 2-1

2.3 Installation Procedures ............................................................................................................... 2-2

2.3.1 Location ...................................................................................................................................... 2-3

2.3.2 Electrical Connections ................................................................................................................ 2-6

2.3.3 Panel Installation ...................................................................................................................... 2-19

2.3.4 Installation ................................................................................................................................ 2-21

2.3.5 Antenna Installation Guidelines ................................................................................................ 2-21

2.3.6 Remove and Replacement Proc edures ................................................................................... 2-29

Section 3

Installation Checkout

3.1 Introduction ................................................................................................................................. 3-1

3.2 Basic Operation .......................................................................................................................... 3-1

3.2.1 Power On .................................................................................................................................... 3-2

3.3 Maintenance PC ......................................................................................................................... 3-3

3.4 Maintenance Mode ..................................................................................................................... 3-6

3.5 Configure WIFI Accessory .......................................................................................................... 3-7

3.6 Verify Software Version .............................................................................................................. 3-8

3.7 Select Configuration Options ...................................................................................................... 3-9

3.7.1 Aircraft Specific Options ........................................................................................................... 3-10

3.7.2 I/O Options – AHRS and Altitude ............................................................................................. 3-13

3.7.3 I/O Options – Misc .................................................................................................................... 3-14

3.7.4 Backup ...................................................................................................................................... 3-16

3.8 Calibration Setup ...................................................................................................................... 3-17

3.8.1 Audio Calibration and Test ....................................................................................................... 3-17

3.8.2 Screen Calibration .................................................................................................................... 3-17

3.8.3 TAS Antenna Calibration .......................................................................................................... 3-18

3.8.4 Clear Fault Log ......................................................................................................................... 3-18

3.9 Interface Check ........................................................................................................................ 3-19

3.9.1 Live Data - Discrete Inputs, Altitude, and Heading .................................................................. 3-19

3.9.2 Live Data - GPS ........................................................................................................................ 3-20

3.9.3 Live Data – ADS-B ................................................................................................................... 3-21

3.9.4 Live Data – Simulate ................................................................................................................ 3-22

3.9.5 Configuration Check Complete ................................................................................................ 3-22

0040-17001-01 Page v

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

Table of Contents (continued)

Paragraph Page

3.10 Installation Checkout ................................................................................................................ 3-23

3.10.1 Functional Checks .................................................................................................................... 3-23

3.10.2 Ground Checks ......................................................................................................................... 3-28

3.10.3 Electromagnetic Interference (E.M.I.) Check ........................................................................... 3-31

3.10.4 Display Check ........................................................................................................................... 3-33

3.10.5 Flight Test ................................................................................................................................. 3-33

3.10.6 Installation Checkout Complete ................................................................................................ 3-33

Section 4

Maintenance

4.1 Introduction ................................................................................................................................. 4-1

4.2 Continued Airworthiness ............................................................................................................. 4-1

4.3 Periodic Maintenance ................................................................................................................. 4-1

4.3.1 Screen Calibration ...................................................................................................................... 4-2

4.3.2 Directional Antenna (NY156 and NY164)................................................................................... 4-3

4.4 Fault Isolatio n ............................................................................................................................. 4-3

4.4.1 System Status Messages ......................................................................................................... 4-10

4.5 Using the Maintenance PC ....................................................................................................... 4-16

4.5.1 Load Software .......................................................................................................................... 4-16

4.5.2 Load Databases ....................................................................................................................... 4-17

4.5.3 View or Retrieve Data ............................................................................................................... 4-18

4.5.4 Configuration Restore............................................................................................................... 4-28

4.5.5 Service ...................................................................................................................................... 4-29

4.6 Return to Service ...................................................................................................................... 4-30

4.6.1 Lynx NGT-9000s ...................................................................................................................... 4-30

4.6.2 Detachable Configuration Module ............................................................................................ 4-31

4.6.3 Directional Antenna (NY156 and NY164)................................................................................. 4-32

4.6.4 L-Band (UAT/1090) Antenna .................................................................................................... 4-32

4.6.5 GPS Antenna ............................................................................................................................ 4-32

4.7 Disposition of Failed Items ....................................................................................................... 4-33

Appendix A

Interface Signal Name & Cable Characteristics

A.1 Introduction .................................................................................................................................A-1

A.2 Input and Output Interfaces ........................................................................................................A-1

A.2.1 Input Power ................................................................................................................................A-1

A.2.2 RF Suppression Bus ...................................................................................................................A-1

A.2.3 Audio Output ...............................................................................................................................A-1

A.2.4 Gilham Input (Altitude Input) .......................................................................................................A-1

A.2.5 RS-232 Interface ........................................................................................................................A-2

A.2.6 RS-422 Interface ........................................................................................................................A-3

A.2.7 ARINC 429 Input ........................................................................................................................A-4

A.2.8 ARINC 429 Output ......................................................................................................................A-5

A.2.9 Discrete Input .............................................................................................................................A-6

A.2.10 Discrete Output ...........................................................................................................................A-6

A.2.11 I2C Serial Bus (Detachable Configuration Module) ....................................................................A-7

A.2.12 Antenna Connections .................................................................................................................. A7

Pin Definition Summary ..............................................................................................................A-8

A.3

A.4 [J1 connector] .............................................................................................................................A-9

Page vi 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

Table of Contents (continued)

Paragraph Page

Appendix B

Environmental Qualification Form

B.1 Introduction .................................................................................................................................B-1

B.2 NGT-9000 Environmental Qual ificat io n Form ............................................................................B-1

B.3 NY156 and NY164 Environmental Qualification Form ...............................................................B-4

APPENDIX C

CONFIGURATION AND CHECKOUT LOG

0040-17001-01 Page vii

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

List of Illustrations

Figure Page

1-1: Lynx NGT-9000s .............................................................................................................................. 1-1

1-2: Example of Own Aircraft UAT, 1090ES, and TAS Traffic ................................................................ 1-5

1-3: System Block Diagram..................................................................................................................... 1-8

2-1: Outline Dimensions for Panel Mount NGT-9000 ............................................................................. 2-4

2-2: Outline Dimensions for Mounting Rack ........................................................................................... 2-5

2-3: Interconnect Wiring Diagra m ......................................................................................................... 2-10

2-4: Mating Connector (P1) and Pin Assignments ................................................................................ 2-13

2-5: P1 Mating Connector Assembly .................................................................................................... 2-14

2-6: Outline Dimensions for the Data Configuration Module (9230-17003-01) .................................... 2-15

2-7: Example of Assembled RF Cable .................................................................................................. 2-16

2-8: Coax Cable Preparation................................................................................................................. 2-17

2-9: Straight Coax Contact Shield Termination .................................................................................... 2-18

2-10: Right Angle Coax Contact Installation ......................................................................................... 2-18

2-11: Connector Assembly .................................................................................................................... 2-19

2-12: Panel Assembly ........................................................................................................................... 2-20

2-13: Example of Antenna Mounting Locations .................................................................................... 2-21

2-14: Directional Antenna Mounting Location ....................................................................................... 2-25

2-15: NY156 / NY164 Directional Antenna Outline Dimensions ........................................................... 2-26

2-16: Antenna Mounting Holes ............................................................................................................. 2-28

2-17: Directional Antenna Installation ................................................................................................... 2-28

3-1: Transponder/Traffic Screens ........................................................................................................... 3-1

3-2: Maintenance Application Tool – Ma in Pag e .................................................................................... 3-4

3-3: Lynx MAT – Main Screen ................................................................................................................ 3-4

3-4: Lynx MAT – Res tart U nit .................................................................................................................. 3-5

3-5: Activate Maintenance Mode Window ............................................................................................... 3-6

3-6: Maintenance Mode Screens ............................................................................................................

3-7: Lynx MAT – WiFi Accessory ............................................................................................................ 3-7

3-8: Lynx MAT – Chec k Vers ions .......................................................................................................... 3-8

3-9: Lynx MAT –Airc raft Spec i fic Options ............................................................................................. 3-10

3-10: Lynx MAT – I/O Options – AHRS and Altitude ............................................................................ 3-13

3-11: Lynx MAT – I/O Options – Misc ................................................................................................... 3-14

3-12: Lynx MAT – Configuration - Backup ............................................................................................ 3-16

3-13: Lynx MAT – Setup - Calibration ................................................................................................... 3-17

3-14: Lynx MAT – Info – Fault Log ........................................................................................................ 3-18

3-15: Lynx MAT – Live Data - Inputs .................................................................................................... 3-19

3-16: Lynx MAT – Live Data - GPS ....................................................................................................... 3-20

3-17: Lynx MAT – Live Data - GPS ....................................................................................................... 3-21

3-18: Lynx MAT – Live Data - Simulate ................................................................................................ 3-22

3-19: Examples of Start-up Screens ..................................................................................................... 3-24

3-20: Example of Normal Operation ..................................................................................................... 3-24

3-21: Example of Flight ID Input Screen ............................................................................................... 3-24

3-22: Example of System Test Results ................................................................................................. 3-25

3-23: Options Screen… ......................................................................................................................... 3-26

3-24: Lynx MAT – Ground Test ............................................................................................................. 3-28

3-6

Page viii 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

List of Illustrations

Figure Page

4-1: Activate Maintenance Mode Window ............................................................................................... 4-2

4-2: Maintenance Mode Screens ............................................................................................................ 4-2

4-3: Lynx MAT – Updat e Software ........................................................................................................ 4-15

4-4: Lynx MAT – Updat e Dat ab ase ....................................................................................................... 4-16

4-5: Lynx MAT – Information ................................................................................................................. 4-17

4-6: Lynx MAT – Version....................................................................................................................... 4-17

4-7: Lynx MAT –Configuration - Restore .............................................................................................. 4-27

4-8: Lynx MAT – Service ....................................................................................................................... 4-28

A-1: RN370M Interconnect Option for RS-232 to WiFi Converter ......................................................... A-2

0040-17001-01 Page ix

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

List of Tables

Table Page

1-1: System Components........................................................................................................................ 1-1

1-2: Built-in Interfaces ............................................................................................................................. 1-7

1-3: Specifications for Lynx NGT-9000s ............................................................................................... 1-12

1-4: Specifications for Detachable configuration module ...................................................................... 1-14

1-5: Applicable TSO’s ........................................................................................................................... 1-15

1-6: TSO Markings ................................................................................................................................ 1-16

1-7: TSO Deviations .............................................................................................................................. 1-17

1-8: Failure Classification ...................................................................................................................... 1-19

1-9: Hardware Modifications ................................................................................................................. 1-19

1-10: Software Revisions ...................................................................................................................... 1-20

1-11: Equipment List ............................................................................................................................. 1-21

1-12: Installation Kit P/N 9060-17000-01 for Straight RF Connector .................................................... 1-24

1-13: Installation Kit P/N 9060-17000-02 for Right Angle RF Connector ............................................. 1-24

1-14: Coaxial Cable Specifications ....................................................................................................... 1-25

1-15: Directional Antenna SIGMA and DELTA Port Cable Vendors .................................................... 1-26

1-16: Cable to Connector Reference .................................................................................................... 1-27

1-17: GPS Antennas ............................................................................................................................. 1-28

1-18: L-Band Antennas ......................................................................................................................... 1-28

1-19: Directional Antenna Model Options and Specifications ............................................................... 1-29

1-20: Directional Antenna Installation Kit 817-10009-xxx ..................................................................... 1-30

1-21: Airframe Installation Kits .............................................................................................................. 1-30

1-22: Traffic Displays ............................................................................................................................ 1-31

1-23: FIS-B WX Displays ...................................................................................................................... 1-31

1-24: RS-232 to WiFi Accessories ........................................................................................................ 1-31

1-25: APPS for PED ..............................................................................................................................

1-26: List of Service Notices ................................................................................................................. 1-34

1-27: System Software CD Part Numbers and Contents ...................................................................... 1-35

4-1: Troubleshooting ............................................................................................................................... 4-3

4-2: System Status Messages ................................................................................................................ 4-9

4-3: List of Fault Log Messages ............................................................................................................ 4-18

A-1: Connector (P1) Pin Assignments ................................................................................................... A-8

1-32

Page x 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Abbreviations, Acrony m s , and S y mbol s

ITEM

DEFINITION

Installation Manual

°

°C

°F

1090ES 1090 megahertz extended s quitt er

AC Advisory Circular

ACSS Aviation Communication and Surveillance Systems

ADS-B Automatic Dependent Surveillance-Broadcast

ADS-R Automatic Dependent Surveillance - Rebroadcast

AHRS Attitude & Heading Reference System

AIRB Basic Airborne Situation Awar eness

ARINC Aeronautical Radio, Incorporated

ASA Aircraft Surveillance Applications

ASSAP Airborne Surveillance and Separ ati on Ass ur ance Pr oc es s ing

ATC Air Traffic Control

ATCRBS Air Traffic Control Radar Beacon System

ATM Air Traffic Management

AWG American Wire Gauge

BIT Built In Test

Cal Calibration

CCW Counter Clock Wise

CDTI Cockpit Display of Traffic Information

CFR Code of Federal Regulations

CONUS Continental United States

CW Clock Wise

dB Decibel

dBm Decibels referenced to one Milli-watt

dc Direct Current

DCM Detachable Configuration Module

DL Data Loading

DME Distance Measuring Equipment

DO- RTCA Document Number Prefix (i.e., DO-160)

DTIF Display Traffic Information File

EMI Electro-Magnetic Interference

EVAcq Enhanced Visual Acquisition Application

FAA Federal Aviation Administration

FAR Federal Aviation Regulations

FCC Federal Communications Commission

FIS-B Flight Information Services - Broadcast

FPGA Field Programmable Gate-Array

FSS Flight Service Stat ion

Degrees

Degrees Celsius

Degrees Fahrenheit

0040-17001-01 Page xi

Revision A January 15, 2015

Lynx NGT-9000s

Abbreviations, Acrony m s , and S y mbol s

ITEM

DEFINITION

Hz

Hertz

kHz

Kilohertz

MSS

MultiLink Surveillance System

NEXRAD

Next Generation Radar Reflectivity

Installation Manual

Ft feet

FW Firmware

g Gravitational Accelerat ion

GPS Global Positioning System

H/W Hardware

hPa Hectopascal

i.e. That is

IAW In Accordance With

ID Identification

in Hg Inches of Mercury

Kg Kilogram

Kts Knots

L-3 AS L-3 Communications Avionics Systems

LLC Limited Liability Company

LRU Line Replaceable Unit

Lynx MAT Maintenance Application Tool

m Meter

Max Maximum

MSG Message

MHz Megahertz

mm Millimeter

MPC Mainten anc e Pers on al Co mputer

Page xii 0040-17001-01

January 15, 2015 Revision A

N/A Not Applicable

NACp Navigation Accuracy Category for position

NAR Non Altitude Reporting

NAS National Airspace System

NC Not Connected

NGT Not an abbreviation

NIC Navigation Integrity Category

No. Number

NOTAM Notice to Airmen

NVM Non-V olati le Memory

Orig Original

P/N Part Number

PBIT Peri o dic Bu ilt -In Test

PED Personal Electronic Device

PFD Primary Flight Display

Abbreviations, Acrony m s , and S y mbol s

ITEM

DEFINITION

SBAS

Satellite Based Augmentation systems

TAF

Terminal Area Forecasts

RAIM Receiver Auto nomous Integrity Monitoring

RBA Risk-Based Authentication

RF Radio Frequency

RTCA RTCA, Inc.

S/N Serial Number

S/W Software

SPI Special Position Identification

STC Supplemental Type Certification

STIF Standard TCAS Intruder File

SUA Special Us e airspace

SURF Basic Surface application

TAS Traffic Advisory System

TCAS T raff ic Alert and Collision Avoidance System

TFR Temporary Flight Restrictions

TIS-B Traffic Information Service – Broadcast

TSAA Traffic and Situational Awareness Alerts

TSO Technical Standard Order

UAT Universal Access Transceiver

USB Universal Serial Bus

UTC Coordinated Universal Time

Vdc Volts Direct Current

VFR

VHF Very High Frequency

VOR VHF Omni-directional

W Watts

WAAS Wide Area Augmentation System

WiFi Wireless Fidelity

WOW Weight On Wheels

Wx Weather

Lynx NGT-9000s

Installation Manual

Visual Flight Rules

0040-17001-01 Page xiii

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

This page intentionally blank

Page xiv 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Section

1

Installation Manual

General Information

1.1 INTRODUCTION

This section includes descriptions, specifications, TSO information, equipment required but not supplied,

and installation approval and limitations for the Lynx® MultLink Surveillance System Lynx NGT-9000s

family (Release 1) See Figure 1-1. Available models of the Lynx NGT-9000s are detailed in Table 1-1.

Included at the end of this section is a list of compatible equipment and equipment required but not

supplied with the system.

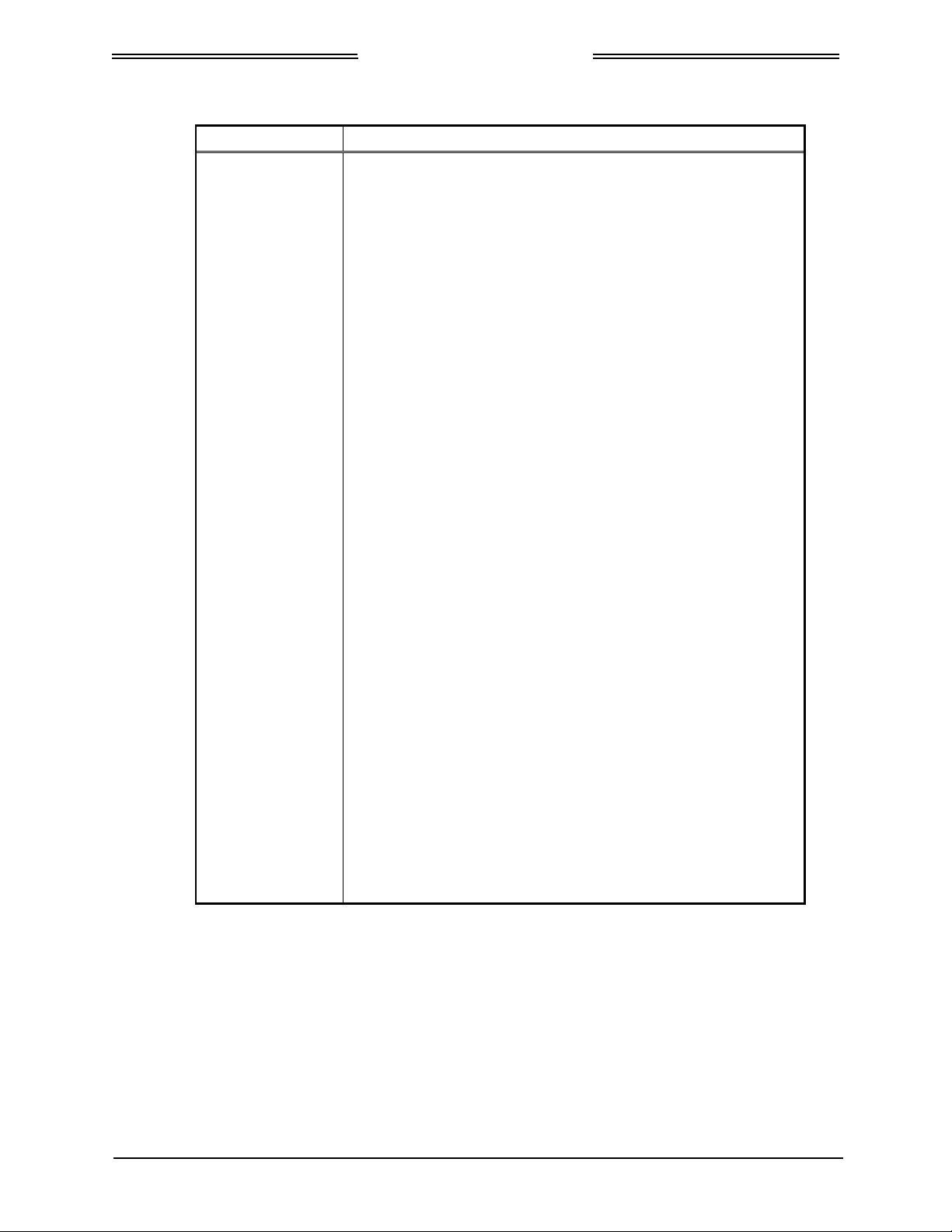

Table 1-1: System Components

COMPONENT MODELS H/W PART NO. S/W PART NO.

MultiLink Surveillance Sys tem

Detachable Configuration Module DCM 9230-17003-01 - -

NGT-9000+

NGT-9000D

(1)

9029000-20000 9020010-001

(1)

(2)

GPS Antenna See Table 1-17 - - - L-Band Antenna See Table 1-18 - - - Directional Antenna (optional) See Table 1-19 - - - -

Notes:

(1) The

(2) Details on software releases are located in paragraph 1.9.

(3) The “+” at the end of the model number indicates TAS functionality. The “D” at the end of the model number

NGT-9000D and NGT-9000+ require an unlock code that is set up during installation. See paragraph1.3.3.

indicates Diversity functionality.

0040-17001-01 General Information Page 1-1

Revision A January 15, 2015

Figure 1-1: Lynx NGT-9000s

Lynx NGT-9000s

Installation Manual

1.2 FUNCTIONAL DESCRIPTION

The Lynx MultiLink Surveillance System (also referred to in this manual as the Lynx NGT-9000s) is a

Mode S Level 2 dens Class 1 Transponder with an integrated GPS receiver providing Automatic

Dependent Surveillance-Broadcast (ADS-B) output using a 1090ES (Extended Squitter). The unit also

receives ADS-B data via 1090ES and UAT (978 MHz Universal Access Transceiver). Some models

support optional Active Traffic Awareness System (TAS) or antenna Diversity functionality.

The unit replies to Mode A, Mode C and Mode S interrogations receiving interrogations at 1030 MHz and

transmitting responses at 1090 MHz. The unit is equipped with IDENT capabil ity tha t activat es the

Special Identification (SPI) pulse for 18 seconds.

Ground stations can interrogate Mode S Transponders individually using a 24-bit ICAO Mode S address,

which is unique to the particular aircraft. In addition, ground stations may interrogate the unit for its

transponder data capability and the aircraft's Flight ID.

The ADS-B provides own aircraft data with Enhanced Visual Acquisition (EVAcq) traffic information

that improves situational awareness and flight safety by providing aircraft position, velocity, and heading

information that is automatically transmitted to other aircraft and ground stations providing immediate

surveillance of air-to-air traffic.

The 1090ES and UAT ADS-B datalink have the following capabilities:

• 1090ES In - Receive ADS-B, ADS-R and TIS-B

• 1090ES Out - Transmit ADS-B

• UAT In - Receives ADS-B, ADS-R and TIS-B, FIS-B, NOTAMS, and TFR’s

The unit also provides TAS traffic adviso r ie s w hen TAS configuration is enabled. A voice or tone audio

output announces traffic alerts. The unit has multiple transmit/receive ARINC 429, RS-422 and RS-232

data ports used to transmit data to traffic, weather, an d PED display s.

The unit provides the transponder code, reply symbol and mode of operation to the display.

Maintenance and configuration setup can be accomplished via the USB port located on the front of the

unit or by an optional WiFi connection.

Models are available that provide Active Traffic Awareness System (TAS) function and antenna

Diversity. Both models require additional equipment to be installed.

1.2.1 GPS Functional Overview

The GPS function utilizes signals from Global Positioning System (GPS) satellite constellation and

Satellite-Based Augmentation Systems (SBAS) such as the USA Wide Area Augmentation System

(WAAS), European EGNOS, Indian GAGAN and the Japanese MSAS. Currently it supports WAAS and

WAAS compatible SBAS systems.

The internal GPS function provides position, velocity, time, and integrity (NIC, NAC etc.) information to

the ADS-B functions and is ADS-B rule compliant with the requirements of AC20-165A.

Page 1-2 General Information 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

1.2.2 ADS-B System Overview

The Automatic Dependent Surveillance-Broadcast (ADS-B) improves situational awareness and flight

safety by providing real time traffic information. The ADS-B In function is used to receive ground station

supported TIS-B and ADS-R traffic, and direct communication with nearby like equipped aircraft (with

Mode S or UAT). The ADS-B Out (1090ES) function is used to periodically broadcast (without

interrogation) information about the aircraft that includes aircra ft id en ti fi c a tion, position, al ti tu de , ve loc ity

and other aircraft status information.

• The traffic display shows the relative position of ADS-B or standard traffic using text, shapes, and

colors. ADS-B also provides similar information on ADS-B equipped ground vehicles.

• The effective surveillance range is 60 nmi. The passive-mode surveillance range is 160 nmi and

maintains report messages for a minimum of 200 1090ES ADS-B participants and 300 UAT ADS-B

participants simultaneously. To reduce display clutter a set number of other aircraft of the highest

priority other aircraft are displayed at a time. See Figure 1-2 for an example of own aircraft traffic

(UAT, 1090ES, TIS-B, and TAS).

• The Lynx NGT-9000 is equipped with a dual-link receiver. ADS-R service is unnecessary to provide

a complete picture of traffic in the area.

1.2.3 ADS-R System Overview The Automatic Dependent Surveillance – Re-broadcast (ADS-R) is a ground based broadcast service that

repeats ADS-B messages from one link (1090ES or UAT) to the other link for aircraft with ADS-B In.

• ADS-R transmissions are updated at least every 2 seconds on the surface, 5 seconds in the term ina l

area, and 10 seconds in the en-route airspace.

• An aircraft on the ground receiving ADS-R is provided both ground aircraft and vehicles as well as

airborne other aircraft within 5nm and 2,000 ft above ground level of the airport reference point.

• Other aircraft are provided by the ground station if within a 15 nm horizontal range and +/-5,000 ft

of altitude of the receiving aircraft. ADS-B equipped ground aircraft and vehicles are not displayed

to airborne aircraft. See Figure 1-2 for an example of own aircraft traffic (UAT, 1090ES, TIS-B, and

TAS).

1.2.4 TIS-B System Overview

Traffic Information Service Broadcast (TIS-B) is a ground based broadcast service that provides

secondary surveillance radar (SSR) derived traffic data (aircraft not equipped with ADS-B Out capability)

to ADS-B In equipped aircraft.

• The actual availability of services depends upon the availability of ground-based radar to support

TIS-B source data.

• Receiving aircraft must be in both radar coverage and ground based transceiver (GBT) coverage in a

given area to receive TIS-B service in that area. When ownship is above 24,000 ft, the ground station

will no longer provide TIS-B service. To reduce display clutter, the TIS-B service provides traf fic

information on other aircraft within 15 nmi and +/- 3500 ft of ownship.

• Other aircraft are provided by the ground station if within a 15nm horizontal range and +/-3,500 ft of

altitude of the receiving aircraft. ADS-B equipped ground aircraft and vehicles are not displayed to

airborne aircraft. See Figure 1-2 for an example of own aircraft traffic (UAT, 1090ES, TIS-B, and

TAS).

0040-17001-01 General Information Page 1-3

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

1.2.5 FIS-B System Overview

The Flight Information Services - Broadcast (FIS-B) function provides pilots with a cockpit display of

certain aviation weather and aeronautical information for awareness of own aircraft location with respect

to reported weather, including hazardous meteorological conditions (CONUS/ NEXRAD /AIRMETS/

SIGMETS/ NOTAMS/ METARS, etc) and SUA status and TAF (FIS-B products).

NOTE

CONUS and Regional NEXRAD may not always contain complete data.

The data is refreshed every 15 minutes and it is likely to be updated in a

future cycle.

FIS-B is advisory information only and is intended to enhance pilot decision-making during strategic

flight planning. FIS-B augments traditional sources of this information such as ATC and Flight Service

Station (FSS). FIS-B information is provided over the ADS-B Services network on the 978 MHz UAT

link when in ground station coverage.

1.2.6 Traffic Awareness System (option) Overview

The TAS option is an active system that operates as an aircraft-to-aircraft interrogation device. The unit

interrogates transponders in the surrounding airspace similar to ground based radar. When rep lies to these

active interrogations are received, the responding aircraft’s range, altitude, and closure rates are computed

to plot traffic location and predict collision threats. The unit alerts the flight crew to nearby transponder

equipped aircraft and assists the pilot in the visual acquisition of aircraft that may represent a danger.

Traffic information, out to a selected range, is graphically displayed on the unit or alternate display. See

Figure 1-2 for an example of own aircraft traffic (UAT, 1090ES, TIS-B, and TAS).

• The system display shows the relative position of traffic using text, shapes (i.e., Traffic Advisory =

solid circle; Other Traffic = open diamond) and colors.

• The effective active-mode surveillance range is 35 nmi and track 35 ATCRBS intruders

simultaneously with the target bearing relative to the nose of own aircraft.

• The tracking of targets is in a cylindrical volume centered on own aircraft that has, at a minimum, a

radius of 35 nmi and extends 10,000 ft above and 10,000 ft below own aircraft.

1.2.7 Discrete Inputs and Outputs

The Lynx NGT-9000s have discrete inputs and outputs available that can be interfaced to indi cat or lam ps

and cockpit switches. These are optional installations and are not required.

• The WOW input discrete signals the On Ground status to the unit via a squat switch, airspeed

monitor, or a collective switch.

• The IDENT switch activates the IDENT pulse which highlights the aircraft’s symbol on the ATC’s

radar screen and is identified on the NGT-9000 when active.

• The Audio Mute switch is used to signal the unit to suppress all audio output. The discrete is set to

GND/Open. The active position indicates Audio Muted. When grounded this input mutes all audio

from the NGT-9000. This input is typically only used if the aircraft equipped with TAWS or other

aircraft alerting systems.

• The TAS Alert lamp is used to indica te Tra f fi c Ale rt ( TA ). Th e dis c re te is set to G N D /O pen . The

GND (active) position indicates Traffic Alert. The GND (active) position illuminates the lamp.

• The TIS-B Not In Coverage lamp is used to indicate that the unit is not receiving a ground station

signal. The discrete is set to GND/Open. The GND (active) position illuminates the lamp.

• The ADS-B Out Fail lamp is used to indicate that ADS -B out is not operating. The discrete is set to

GND/Open. The GND (active) position illuminates the lamp. Depending on the situation the lamp

has the following functions: flashes while the GPS is initializing and stays illuminated when the

ADS-B Out has failed.

Page 1-4 General Information 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

Figure 1-2: Example of Own Aircraft UAT, 1090ES, and TAS Traffic

0040-17001-01 General Information Page 1-5

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

1.3 EQUIPMENT DESCRIPTIONS

The Lynx MultiLink Surveillance System includes a Detachable Configuration Module (DCM). A panel

mounted rack is required for installation. Ad d i tional 3

installation. Refer to paragraph 1.5 for component requirem ents and installation considerations. Details on

these components are provided in paragraph 1.11.

The unit has a bezel containing a multifunction touch screen that is designed to fit into a MARK width

panel. LED backlighting is controlled by either the auto-dimming functionality provided by the ambient

light sensor or using the pilot adjustable brightness control. The unit is equipped with a main sub-D

connector (J1) and RF connectors. A USB port is available to establish communication between the unit

and a maintenance computer for installation and maintenance activities.

The multifunction touch screen has full operational control providing the means to select screen views

and interface with transponder, traffic, and weather information. The following information is available

for display and control:

• Flight ID or aircraft Tail Number

• Transponder and Traffic Mode of Operation

• ADS-B Status

• VFR Select and Squawk Code Input

• IDENT

• Traffic (graphic and textual)

• Weather (graphic and textual)

• TAS Mode (model specific)

1.3.1 Model Options

The Diversity option offers enhanced traffic awareness receiving data via 1090MHz using the ADS-B

service.

rd

party components are necessary to complete the

The Traffic Awareness System (TAS) option provides additional traffic awareness when ADS-B

equipped aircraft are not in the area providing Traffic Alert (TA) warnings to the flight crew. See

paragraph 1.2.6 for TAS functionality.

The Diversity and TAS options require an unlock codes that are entered using the Lynx MAT.

Models with Diversity require the installation of an additional L-Band antenna. The TAS option requires

the installati on of a directional antenna.

1.3.2 Detachable Configuration Module (DCM)

The DCM part number 9230-17003-01 is part of the Lynx NGT-9000s and is used for the storage of

configuration data. The DCM is permanently installed with the wire harness and interfaces to the unit via

a 4 wire interface from the DCM.

The configuration settings are stored in the unit’s non-volatile memory and are entered via commands

sent over the maintenance interface to configure such items as; input / output interface options, aircraft

specific options (including TAS and Diversity), and installation calibration parameters.

When the configuration data is set, Lynx NGT-9000s units may be swapped and the configuration

remains with the aircraft.

Page 1-6 General Information 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

1.3.3 System Unlock Code

Unlock codes are required if installing and activating the TAS and Diversity options. The unlock codes

are 10 digit codes that are entered during installation using the Lynx MAT to install either of these

options. The unlock codes may be purchased and shipped with the unit. If the unlock code is not included,

contact L-3 Avionics Systems Customer Service to obtain the code. Be sure to have the Mode-S ID (e.g.

ICAO) available for the service representative. The unlock code is associated with the aircraft ICAO

address and will only work for that aircraft ID.

1.4 INTERFACES

The unit supports a number of built-in interfaces as described in Table 1-2. A system block diagram is

provided in Figure 1-3. Additional information on these interfaces is detailed below. Refer to Appendix A

for interface options and the installation section for an interconnect diagram.

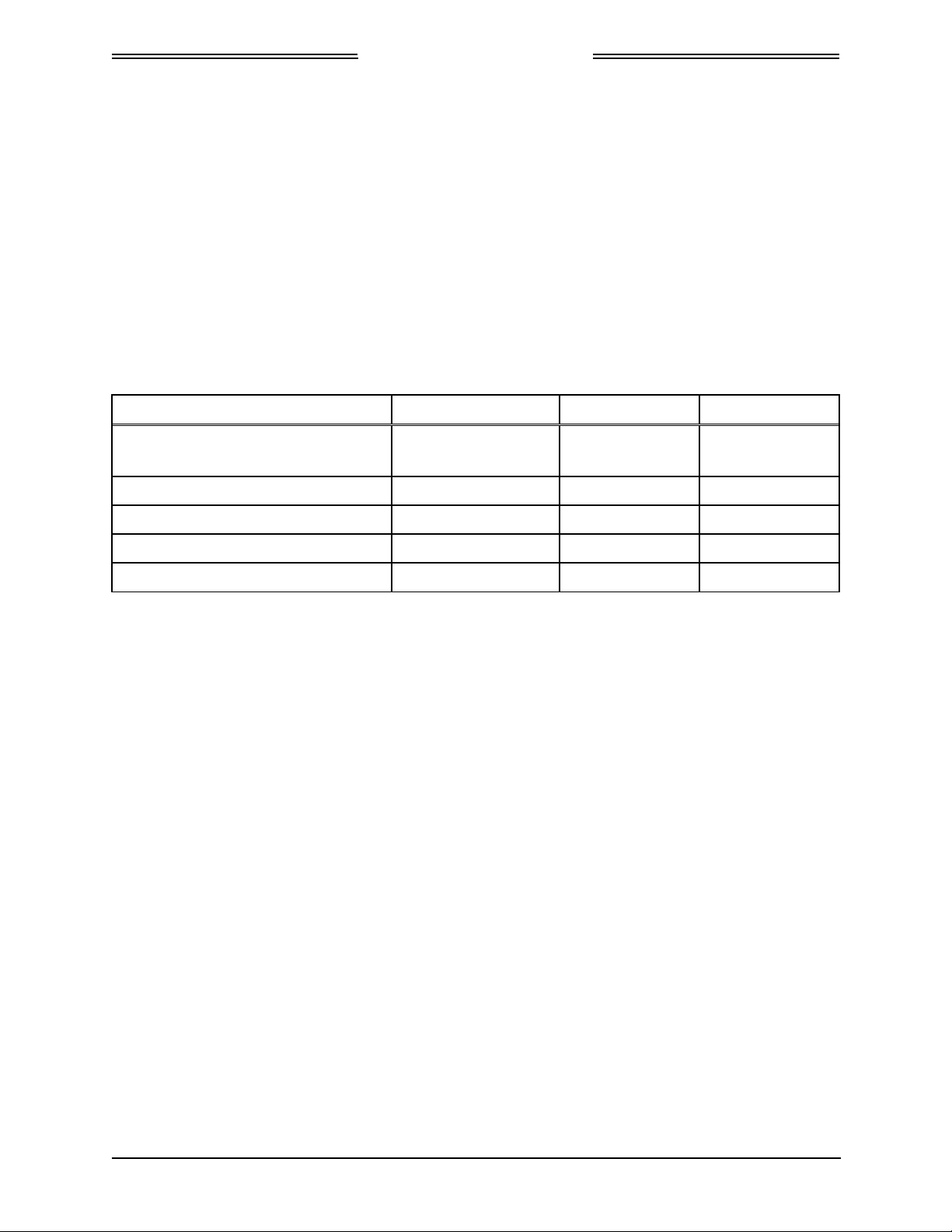

Table 1-2: Built-in Interfaces

Interface (No.) Function

ARINC 429 Input (4) Receive ADC and AHRS data

ARINC 429 Output (1) Transmit to a traffic display

Discrete Inputs (17) Receive Gillham Altitude Encoder, Audio Mute, IDENT

Command, and In Air / On Ground (WOW) status

Discrete Output (9) Transmit ADS-B Out Fail, TIS-B Out of Coverage, Traffic Alert

output

RS-232 Input / Output (4) Wi-Fi accessory port

RS-232 Input (1) Altitude Encoder port

RS-422 Input / Output (1) External display port

RF Suppression Input / Output (1) Provides on aircraft suppression of the L-band equipment

Analog Audio Output (1) Connects to Audio Panel un-muted input.

I2C Port (1) Detachable configuration module

GPS Antenna Port Connect to a top mount antenna providing GPS data to support

ADS-B functionality

L-Band Antenna Port Connects to the bottom mount antenna. Provides UAT 978

MHz input, 1030/1090 MHz extended squitter input/output to

support ADS-B/ATAC Transponder functionality.

Extra Antenna Ports Connects to a top mounted antenna (L-Band or Directional)

providing optional TAS or Diversity functionality.

Note: Not all interfaces are used. Some are spares, reserved for future use, or optional.

0040-17001-01 General Information Page 1-7

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

Figure 1-3: System Block Diagram

1.4.1 ADS-B Out Fail

The ADS-B Out Fail is a discrete output that provides an indication of when there is a loss of ADS-B Out.

The discrete output is a ground/open type and is able to sink 250mA.

1.4.2 AHRS Input

An optional ARINC 429 input is provided to interface to an AHRS (heading) system in order to provide

data for Enhanced Surveillance (EHS) and ADS-B data.

1.4.3 Altitude Encoder Input

Altitude input is req u ir ed on either and an RS-232 input port, 11 Wire Gillham Input Port or ARINC 429

Input Port.

Page 1-8 General Information 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

1.4.4 Audio Out

Two audio out discrete outputs are available that can output a 40 mW signal to equipment with a load of

600 Ohms.

1.4.5 RF Suppression Input/output

The mutual suppression input/output is used to provide suppression of L-band equipment on the aircraft.

The transponder uses the signal as an input to inhibit decoding of receiver signals when other equipment

on the aircraft is transmitting. When the transponder transmits, it asserts a positive voltage on the output

to provide the suppression to other systems on the airplane.

1.4.6 TAS Alert

Traffic Alert is a discrete output that provides an indication of when a TAS Alert exists. Discrete outputs

are ground/open type and are able to sink 250mA.

1.4.7 TIS-B Not In Coverage

The TIS-B Not In Coverage discrete output provides an indication that the unit is not in an Radar

coverage area or that power has been removed from the unit. Discrete outputs are ground/open type and

are able to sink 250mA.

1.4.8 WiFi Interface

The Unit uses a RS-232 bus to interface with a commercially available RS-232 to Wifi accessory. This

interface provides traffic and weather information on a personal electronic device via an approved

software application (APP).

1.4.9 WOW Input

The WOW input discrete is optional. The input signals the On Ground status to the unit via squat switch,

Airspeed monitor, or a collective switch. The discrete input is active (ON) when the input is grounded.

• Do not connect this to a gear switch or a manual pilot switch input.

• An internal algorithmic override that uses ground speed and altitude inputs may override this input

and change the air/ground state (ex. a WOW "in-air" state could get changed back to on ground if the

Aircraft is sitting on the ground). This is expected behavior. If simulated in-air tested is requir ed,

use the ground test mode.

1.4.10 Maintenance Interface

The Unit can interface to a maintenance computer using either the WiFi interface or the USB port located

on the front of the unit. This interface is used for installation setup and fault isolation and is only available

while on ground.

1.4.11 GPS Antenna

Antenna performance is critical to the operation of the Unit. The unit requires that the GPS Antenna meet

performance requirements s peci fi ed in TSO-145c.

0040-17001-01 General Information Page 1-9

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

1.4.12 L-Band (978/1030/1090 MHz) Antenna

The L-Band antenna is used by the Unit to receive 978 MHz, 1030 MHz, and transmit/receive 1090 MHz.

The unit requires that the L-Band Antenna meet performance requirements specified in DO-181E and

DO-282B Section 2.2.14.

If the NGT-9000 is configured for Diversity, then two L-Band antennas are required.

1.4.13 Directional Antenna

L-3 Avionics Systems has two models of Directional Antenna available: the NY156 (P/N 805-10003-001)

and model NY164 (P/N 805-10890-001).The teardrop-shaped antenna is sealed against environmental

extremes and used by the Unit to receive Active Traffic (TAS) information.

1.4.14 Traffic Display

Traffic information is output to a compatible traffic display from the unit using an ARINC 735B interface

format. Possible traffic output format selections include Standard TCAS Intruder File (STIF or TIF) and

Display Traffic Information File (DTIF). The unit allows installed configuration selection of STIF, DTIF,

or both formats of output data via the ARINC 429 bus to the traffic display.

1.4.15 Weather Display

The Unit interfaces to supported FIS-B Wx displays via a RS-422 Input and Output data bus.

Page 1-10 General Information 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

1.5 INSTALLATION CONSIDERATIONS

The installation of the following equipment is the minimum required by the Unit to provide ADS-B

functionality as well as the optional TAS and Diversity functionality.

• Each installation requires at a minimum the following equipment installed:

1. Lynx NGT-9000s

2. Detachable configuration module

3. GPS Antenna

4. L-Band (978/1030/1090 MHz) Antenna

5. Altitude Source (ARINC 429, RS-232, or Gilham Code)

• A Unit with TAS (model: NGT-9000+) also requires the following:

1. Unlock code to unlock TAS option via the Lynx MAT

2. Directional Antenna (NY156 or NY164)

• A Unit with Diversity (model: NGT-9000D) also requires the following:

1. Unlock code to unlock Diversity option via the Lynx MAT

2. Additional L-Band Antenna, located on the top of the aircraft.

0040-17001-01 General Information Page 1-11

Revision A January 15, 2015

1.6 SPECIFICATIONS

Lynx NGT-9000s

Installation Manual

Table 1-3: Specifications for Lynx NGT-9000s

PART NUMBERS:

CERTIFICATION:

ADVISORY CIRCULARS:

RTCA COMPLIANCE:

COMPLIANCE:

SIZE:

9029000-20000

USA (FAA): TSO-C112d, C113a, C145c, C147, C154c, C157a, C166b, C195a.

See paragraph 1.7 for specific TSO information.

Listed are current authorizations at time of publication, contact Field Service Engineering for

latest certification information

AC20-21-46, AC20-115B, AC20-152, AC20-165A, AC20-172A

Environmental Category: DO-160G (See Environmental Qualification Form in Appendix B.)

Software Category: DO-178B, Design Assurance Level C

Hardware Category: DO-254, Design Assurance Level C

Other: DO-181E, DO-197A, DO-229D, DO-260B, DO-267A, DO-282B, DO-317A,

ARINC 718A-4 and SAE AS8034B.

ATC transponder functionality: 14 CFR 91.215, 91.217, 91.413

ADS-B Out functionality: 14 CFR 91.225, and 91.227

The Lynx NGT-9000s has been shown to meet the requirements in TSO-C166b and meets

the requirements of 14 CFR 91.227 installed in accordance with these installation

instructions.

Case

Width 1.48 inches [12.83 cm] MAX

Height: 5.75 inches [7.42 cm] MAX

Depth*: 8.99 i nches [3.81 cm] MAX

Bezel

Width 6.25 inches [13.44 cm] MAX

Height: 1.8 inches [7.62 cm] MAX

* Does not include connectors.

Note: Unit Fits into a “MARK width” panel.

WEIGHT:

CHASSIS GROUND:

POWER REQUIREMENTS:

ELECTRICAL CONNECTORS:

INTERFACE (S):

Nominal 1.0 Lbs (0.5 kg) Maximum 4.0 Lbs (0.8 kg)

Bonding impedance between aircraft ground and the Lynx NGT-9000s Chassis must be less

than 2.5 milliohms.

+14.0 VDC nominal. 19.0 watts nominal (24.0 wa tts max imum)

+28.0 VDC nominal. 19.0 watts nominal (24.0 watts maximum)

• 78 position d-subminiature connector receptacle (shell size 5) with swaged float plate.

Connector insert per MIL-DTL-24308, Appendix A, Figure A-5, Arrangement 2.

Connector insert shall accommodate 22D removable crimp contacts (socket) per

M39029/57-324, or equivalent.

• RF Connectors: 5W5 Coax D-Sub

• Mini-B USB: Maintenance Port

• ARINC 429

• RS-422

• RS-232

• Discrete Input/Outputs

• RF Suppression Bus

2

C serial interface (detachable configuration module interface)

• I

Note: Refer to Appendix A for signal names and characteristics

Page 1-12 General Information 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

Table 1-3: Specifications for Lynx NGT-9000s

OPERATING TEMPERATURE:

STORAGE TEMPERATURE:

MAXIMUM ALTITUDE:

FUNCTIONALITY:

OPERATION:

-20° to +55°C (-4° to +131°F)

-55° to +85°C (-67° to +185°F)

55,000 ft (installation environment)

• Mode S Transponder

• Global Positioning System (GPS)

• UAT/1090ES ADS-B In

• 1090ES ADS-B Out: Automatic Dependent Surveillance – Broadcast

• Traffic Awareness System (TAS) (optional)

Start Up Time: On Ground 20 seconds or less

In air 5 seconds or less.

Display Luminance: Range 0.05 fl to 150 fl

Built In Test: Fault Monitoring on all stages of operation from start up to

UAT Receiver Sensitivity

(Class A1S)

power down.

-95.0dBm for 90% Message Decoding for Long ADS-B

Messages

-96.0dBm for 90% Message Decoding for Short ADS-B

Messages

-93.0dBm for 90% Message Decoding for Ground Uplink

Messages

SCHEDULED MAINTENANCE:

SERVICE LIFE:

REPAIRABILITY:

Mode S Transponder Power (Class 1 T ransponder). 125W minimum, 250 W maximum.

TAS Output Power (Class A TAS). 125W minimum, 250 W maximum.

The Lynx NGT-9000s is a transponder device and must be tested and inspected every 24

months subject to the requirements of FAA documents 14 CFR Part 43 Appendix F.

The Lynx NGT-9000s has unlimited service life.

Repairs performed at the FAA certificated Repair Station co-located at the OEM

(equipment) facility.

0040-17001-01 General Information Page 1-13

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

Table 1-4: Specifications for Detach able configuration module

PART NUMBER:

CERTIFICATION:

RTCA COMPLIANCE:

WEIGHT:

SIZE:

POWER REQUIREMENTS:

INTERFACE (S):

OPERATING TEMPERATURE:

STORAGE TEMPERATURE:

MAXIMUM ALTITUDE:

SCHEDULED MAINTENENACE:

SERVICE LIFE: Unlimited.

9230-17003-01

USA (FAA): TSO-C145c, C154c, C157a, C195a.

See paragraph 1.7 for specific TSO information.

Listed are current authorizations at time of publication, contact Field Service Engineering for

latest certification information

The DCM is tested as part of the NGT-9000.

Negligible

Length: 6 inches (includes wires)

3.3 Vdc (regulated via J1 connector)

I

C serial interface

2

-40° to +70°C (-40° to +158°F)

-55° to +85°C (-67° to +185°F)

55,000 ft (installation environment)

None.

REPAIRABILITY:

Replacement only.

Page 1-14 General Information 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

1.7 TSO INFORMATION NOTE

Unless otherwise specified Relea se 1 refers to Rel ease 1.0 and any

subsequent minor changes to Release 1.0.

The NGT-9000D Release 1 and DCM Release 1 meet the requirements of the following TSO’s.

Table 1-5: Applicable TSO’s

TSO NO. FUNCTION TSO TITLE

TSO-C112d ATCRBS / MODE S

Airborne Equipment

TSO-C113a Electronic Display Airborne Multipurpose Elec tronic Display s

TSO-C145c GPS SBAS Output Airborne Navigation Sensors Using The Global Positioning

TSO-C147 TAS System Traffic Advisory System (TAS) Airborne Equipment

TSO-C154c UAT-IN Universal Access Transceiver (UAT) Automatic Dependent

TSO-C157a FIS-B Display Aircraft Flight Information Services-Broadcast (FIS-B) Data

TSO-C166b 1090ES MHz ADS-B

and TIS-B equipment

TSO-C195a ADS-B System Avionics Supporting Automatic Dependent Surveillance –

Air Traffic Control Radar Beacon System/Mode Select

(ATCRBS / MODE S) Airborne Equipment

System Augmented By The Satellite Based Augmentation

System

Surveillance-Broadcast (ADS-B) Equipment Operating on

Frequency of 978 MHz

Link Systems and Equipment

Extended Squitter Automatic Dependent Surveillance -

Broadcast (ADS-B) and Traffic Information Service Broadcast (TIS-B) Equipment Operating on the Radio

Frequency of 1090 Megahertz (MHz)

Broadcast (ADS-B) Airc raft Sur vei ll anc e Applic at io ns (ASA)

0040-17001-01 General Information Page 1-15

Revision A January 15, 2015

Lynx NGT-9000s

Installation Manual

1.7.1 TSO Markings

The following information summarizes the TSO application for the NGT-9000D Release 1 and DCM

Release 1.

Table 1-6: TSO Markings

TSO No. TSO MARKING TSO TITL E

C112d Level 2 dens Class 1 Air Traffic Control Radar Beacon System/Mode Select

(ATCRBS/Mode S) Airborne Equipment

C113a Airborne Multipurpose Elec tronic Display s SAE

AS8034B, Multipurpose Display

C145c Class Beta 1 Airborne Navigation Sensors Using The Global

Positioning System Augmented By The Satellite Based

Augmentation System

C147 Class A Traffic Advisory System (TAS) Airborne Equipment, DO-

197A, Traffic Advisory System

C154c Class A1S Receive Only Universal Access Transceiver (UAT) Automatic

Dependent Surveillance- Broadcast (ADS-B) Eq uip me nt

Operating on Frequency of 978 MHz

C157a Class 2 Aircraft Flight Information Services-Broadcast (FIS-B)

Data Link Systems and Equipment

C166b Class A2 Extended Squitter Automatic Dependent Surveillance -

Broadcast (ADS-B) and Traffic Information Service –

Broadcast (TIS-B) Equipment Operating on the Radio

Frequency of 1090 Megahertz (MHz)

C195a Class B1, B5, C1, C5 Avionics Supporting Automatic Dependent Surveillance –

Broadcast (ADS-B) Airc raft Sur vei ll anc e Applic at io ns

(ASA)

Page 1-16 General Information 0040-17001-01

January 15, 2015 Revision A

Lynx NGT-9000s

Installation Manual

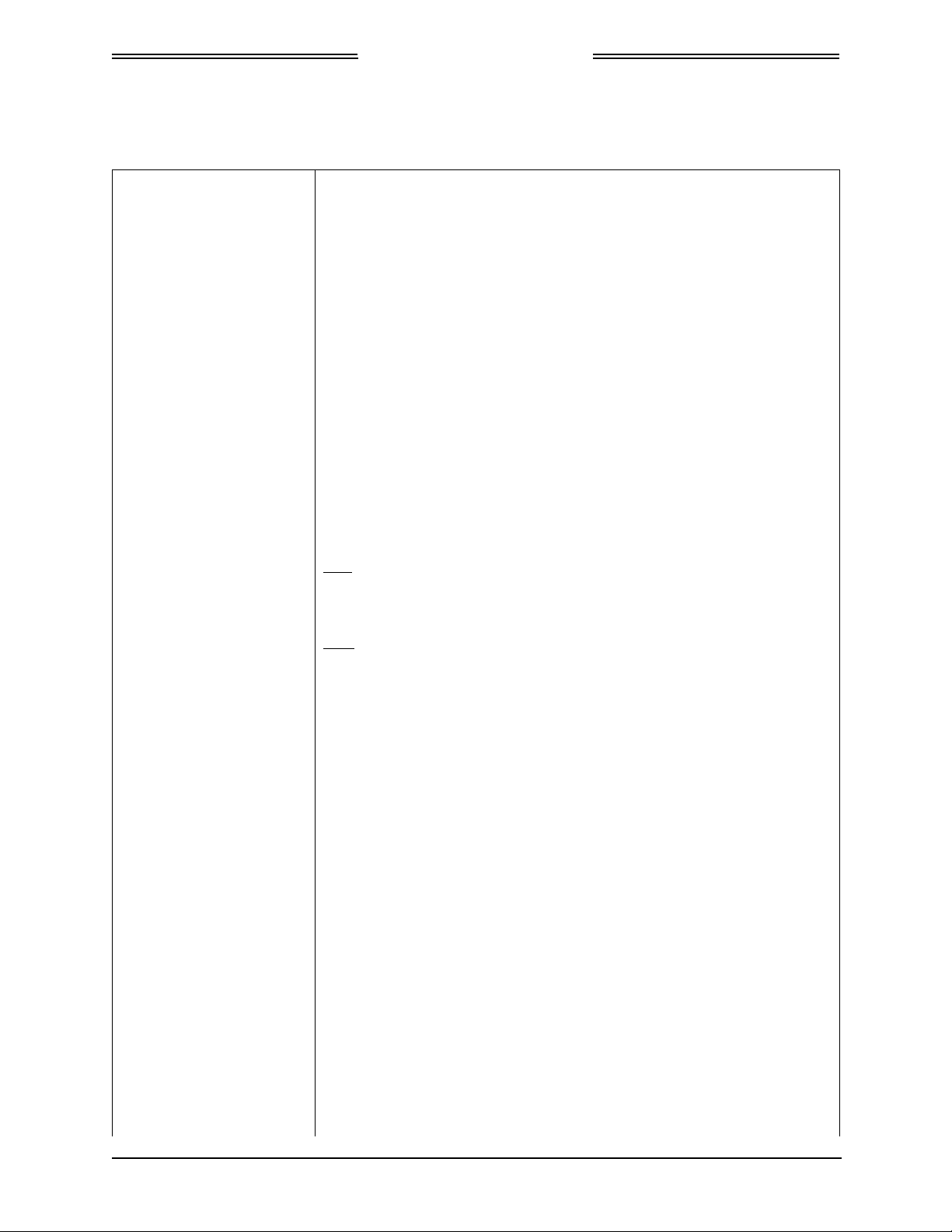

1.7.2 TSO Deviations from Minimum Performance Standards

The following info rmation lists the TSOs for the unit that re quires a deviatio n to M inimum Performance

Standards (MPS) that are called out in the TSO and provides the justification for the deviation.

Deviations to TSO-C147 are applicable to the diversity variants only. Deviations to TSO-C113a are

applicable to the panel mount variants only.

Table 1-7: TSO Deviations

TSO NO. DEVIATION

TSOC-145c, 3.d TSO requires use of DO-160E for environmental qualification testing; DO-

160G was used instead.

TSOC-147, 1.c TSO requires use of DO-160D for environmental qualification testing; DO -

160G was used instead.

TSO-C145c, 4.c

TSO-C147, 2.c

TSO-C154c, 4.d

TSO-C166b, 4.d

TSO-C113a, 4.a

TSO-C145c, 4.a & 4.e

TSO-C147, 2.a

TSO-C154c, 4.a

TSO-C157a, 4.a

TSO-C166b, 4.a

TSO-C195a, 4.a

TSO-C112d, 3.d

TSO-C166b, 3.d

The Lynx NGT-9000s utilizes electronic part marking for the software part

number, which is stored in non-volati le memor y .

Per the guidance in FAA Order 8150.1c, the appliances are marked with the

primary TSO along with a reference to the Installation Manual for the other

TSO information (other applicable TSOAs, devia tio ns , etc .).

The Lynx NGT-9000s has an RF transmitter which is used to generate both

the 1030MHz and 1090MHz waveforms for Mode S Transponder , ADS-B

Out, and TAS functions. Due to the RF power requirement and inherent nonlinearities in RF transmitters, the harmonics of the transmitter exceed the RF

radiated emissions limit in DO-160G. ACSS deviates from DO—160G

Section 21 Category M Radiated RF Emissions in the following frequency

bands when the transmitter is active:

2180MHz ± 7MHz (2nd Transmitter harmonic) Exceeds Cat M by as much

as 19.3dB

3270MHz ± 23MHz (3rd Transmitter harmonic) Exceeds Cat M by as much

as 22.0dB

4360MHz ± 23MHz (4th Transmitter harmonic) Exceeds Cat M by as much

as 24.4dB