Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

EZTouch Panel

Hardware User Manual

Revision 4

Manual Part Number EZ-TOUCH-M

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

WARNING!

Programmable control devices such as EZTouch Panels must not be used as stand-alone protection in any application. Unless proper safeguards are used, unwanted start-ups could result in

equipment damage or personal injury. The operator must be made aware of this hazard and appropriate precautions must be taken.

In addition, consideration must be given to the use of an emergency stop function that is independent of the programmable controller.

The diagrams and examples in this user manual are included for illustrative purposes only. The

manufacturer cannot assume responsibility or liability for actual use based on the diagrams and

examples.

CAUTION

Do not press the EZTouch Panel touchscreen with any sharp objects. This practice may damage

the unit beyond repair.

Trademarks

This publication may contain references to products produced and/or offered by other companies.

The product and company names may be trademarked and are the sole property of their respective

owners. AVG disclaims any proprietary interest in the marks and names of others.

© Copyright 2000-2003, Autotech Technologies, L.P.

All Rights Reserved

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior

written consent of Autotech Technologies, L.P. Autotech Technologies, L.P. retains the exclusive

rights to all information included in this document.

MANUFACTURED by AVG

4140 Utica Ridge Rd. • Bettendorf, IA 52722-1327

MARKETED by AUTOMATIONDIRECT.COM

3505 Hutchinson Road • Cumming, GA 30040

Phone: 1-800-633-0405 or 1-770-889-2858 • Fax: 1-770-889-7876 • www.Automationdirect.com

MAN-EZTCH-HDW, Rev 4, 07/03

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

TABLE OF CONTENTS

WARNING/Caution ............................................................ inside front cover

Table of Contents ........................................................................................ i

Manual Revisions ....................................................................................... v

EU Information ........................................................................................... vi

1 GETTING STARTED .................................................................................1

Manual Organization ..............................................................................1

Manual Sections Table.....................................................................1

Introduction ....................................................................................... 2

What you need to get started ................................................................. 3

Hardware .......................................................................................... 3

Software ............................................................................................ 3

Need Help? ............................................................................................. 3

Onscreen HELP ...............................................................................3

Fly-Over HELP .................................................................................. 3

PLC HELP ........................................................................................3

Technical Support ............................................................................4

2 MODELS, FEATURES AND ACCESSORIES ............................................ 5

6-inch EZTouch Panel Models ............................................................... 5

8-inch, 10-inch, and 15-inch EZTouch Panel Models ........................... 6

Features ................................................................................................7

PLCs Supported by EZTouch Panels .................................................... 8

Replacement and Optional Equipment ................................................. 9

PLC Cable Part Numbers ................................................................... 10

Programming Cable Part Number ..................................................... 1 0

3 SPECIFICATIONS .................................................................................. 11

All 6-inch Models .................................................................................. 11

8-inch and 10-inch Standard Bezel Models ....................................... 12

8-inch, 10-inch, and 15-inch Slim Bezel Models ................................ 1 3

4 INSTALLATION ................................................................................... 1 5

Mounting ............................................................................................. 16

Method 1. Stud Mounting ............................................................... 16

EZ-S6M-R, EZ-S6M-F, EZ-S6M-FH, EZ-S6K, EZ-S6C-F,

EZ-S6C-FH Dimensions & Cutout ..................................... 17

EZ-S6M-RS, EZ-S6M-FS, EZ-S6M-FSH, EZ-S6C-KS,

EZ-S6C-FS, EZ-S6C-FSH Dimensions & Cutout ............ 1 8

EZ-S8C-F and EZ-S8C-FH Dimensions & Cutout ................. 19

EZ-S8C-FS and EZ-S8C-FSH Dimensions ............................ 2 0

EZ-S8C-FS and EZ-S8C-FSH Cutout ..................................... 2 1

EZ-T10C-F and EZ-T10C-FH Dimensions & Cutout .............. 22

EZ-T10C-FS, EZ-T10C-FSH, EZ-T10C-FSD, EZ-T10C-FSE,

EZ-T10C-FSM, and EZ-T10C-FSP Dimensions ................ 23

i

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

TABLE OF CONTENTS

Connections and Wiring ..................................................................... 29

Communications Setup ...................................................................... 41

EZ-T10C-FS, EZ-T10C-FSH, EZ-T10C-FSD, EZ-T10C-FSE,

EZ-T10C-FSM, and EZ-T10C-FSP Cutout ........................ 24

EZ-T15C-FS, EZ-T15C-FSH , EZ-T15C-FSD, EZ-T15C-FSE,

EZ-T15C-FSM, and EZ-T10C-FSP Dimensions ................ 25

EZ-T15C-FS, EZ-T15C-FSH , EZ-T15C-FSD, EZ-T15C-FSE,

EZ-T15C-FSM, and EZ-T10C-FSP Cutout ........................ 26

Method 2. DIN Clips ...................................................................... 27

Wiring Diagram ............................................................................. 2 9

Power Terminal ............................................................................. 3 0

PLC Port ........................................................................................ 30

COM1 Port ..................................................................................... 31

Option Card Installation ................................................................ 32

Allen-Bradley Data Highway Plus Option Card ...................... 33

EZ Ethernet Option Card ......................................................... 3 4

EZ Ethernet Option Card Outline Drawing ......................... 35

Generic DeviceNet I/O Option Card ........................................ 36

Generic Ethernet/IP Option Card ............................................. 37

Modicon Modbus Plus Option Card ........................................ 38

Generic Profibus-DP Option Card .......................................... 3 9

Clock ............................................................................................. 41

COM1 ............................................................................................. 4 2

Contrast ......................................................................................... 43

Touchpad Test ............................................................................... 43

Display Test ................................................................................... 44

Exit ............................................................................................. 44

Reboot ........................................................................................... 44

5 MAINTENANCE .................................................................................... 45

Shutting Off Power to EZTouch Panel ................................................. 45

Lithium Battery Replacement .............................................................. 47

Gasket Replacement .......................................................................... 48

Panel Status Indicator Light ................................................................ 4 8

RAM Upgrade ....................................................................................... 49

FLASH Program Backup ..................................................................... 50

Fuse Reset .......................................................................................... 5 0

Fluorescent Backlight Bulb Replacement .......................................... 50

Precautions .......................................................................................... 51

Touchscreen/Chemical Compatibility ................................................ 52

Standard Bezel .............................................................................. 5 2

Slim Bezel ...................................................................................... 52

Touchscreen Cleaning ........................................................................ 5 4

6 TROUBLESHOOTING .......................................................................... 55

Warranty Repairs ........................................................................... 57

ii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

TABLE OF CONTENTS

APPENDIX A (PLC Cable Wiring Diagrams) ........................................... A-1

Allen-Bradley SLC500, 5/01, /02, /03 DH-485/AIC

(P/N EZ-DH485-CBL) ................................................................... A-2

Allen-Bradley SLC DF1 RS-232C (P/N EZ-SLC-232-CBL) .............. A-3

Allen-Bradley Micrologix 1000/1200/1500 RS-232C

(P/N EZ-MLOGIX-CBL) ................................................................. A-3

Allen-Bradley PLC5 DF1 RS-232C (P/N EZPLC5-232-CBL) ........... A-3

DirectLogic PLC RJ-12, DL05, DL105, DL205, DL350, and DL450,

RS-232C (P/N EZ-2CBL) ............................................................. A-4

DirectLogic PLC VGA 15-pin, 250, RS-232C (P/N EZ-2CBL-1) ........ A-4

DirectLogic PLC RJ-11, 340, RS-232C (P/N EZ-3CBL).................... A-4

DirectLogic PLC 15-pin D-SUB, DL405, RS-232C

(P/N EZ-4CBL-1) .......................................................................... A-5

DirectLogic PLC 25-pin D-SUB, DL405, 350, 305 DCU, and all DCMs

RS-232C (P/N EZ-4CBL-2) .......................................................... A-5

General Electric 90/30 and 90/70 15-pin D-SUB, RS-422A

(P/N EZ-90-30-CBL) ..................................................................... A-6

Mitsubishi FX Series 25-pin, RS-422A (P/N EZ-MITSU-CBL) ........... A-6

Mitsubishi FX Series 8-pin MINI-DIN, RS-422A

(P/N EZ-MITSU-CBL-1) ................................................................ A-7

Modicon Modbus RS-232 ................................................................... A-7

Wiring Diagram for the 984 CPU, Quantum 113 CPU ................ A-7

Wiring Diagram for AEG Modicon MICRO Series: 110 CPU 311-xx,

110 CPU 411-xx, 110 CPU 512-xx, 110 CPU-612-xx .............. A-8

Modicon Modbus with RJ45 ............................................................... A-8

Omron C200, C500, RS-232C (P/N EZ-OMRON-CBL) .................... A-9

Omron CQM1 and CPM1 .................................................................... A-9

Siemens S7 MPI Adaptor, RS-232C (P/N EZ-S7MPI-CBL) ............. A-10

EZTouch RS-422A/RS-485A Wiring Connections for

DirectLogic PLCs ....................................................................... A-11

EZTouch RS-422A Wiring Connections for Allen-Bradley SLC

503/504, RS-232C Port .............................................................. A-12

INDEX ............................................................................................. I-1

iii

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

This page intentionally left blank.

iv

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

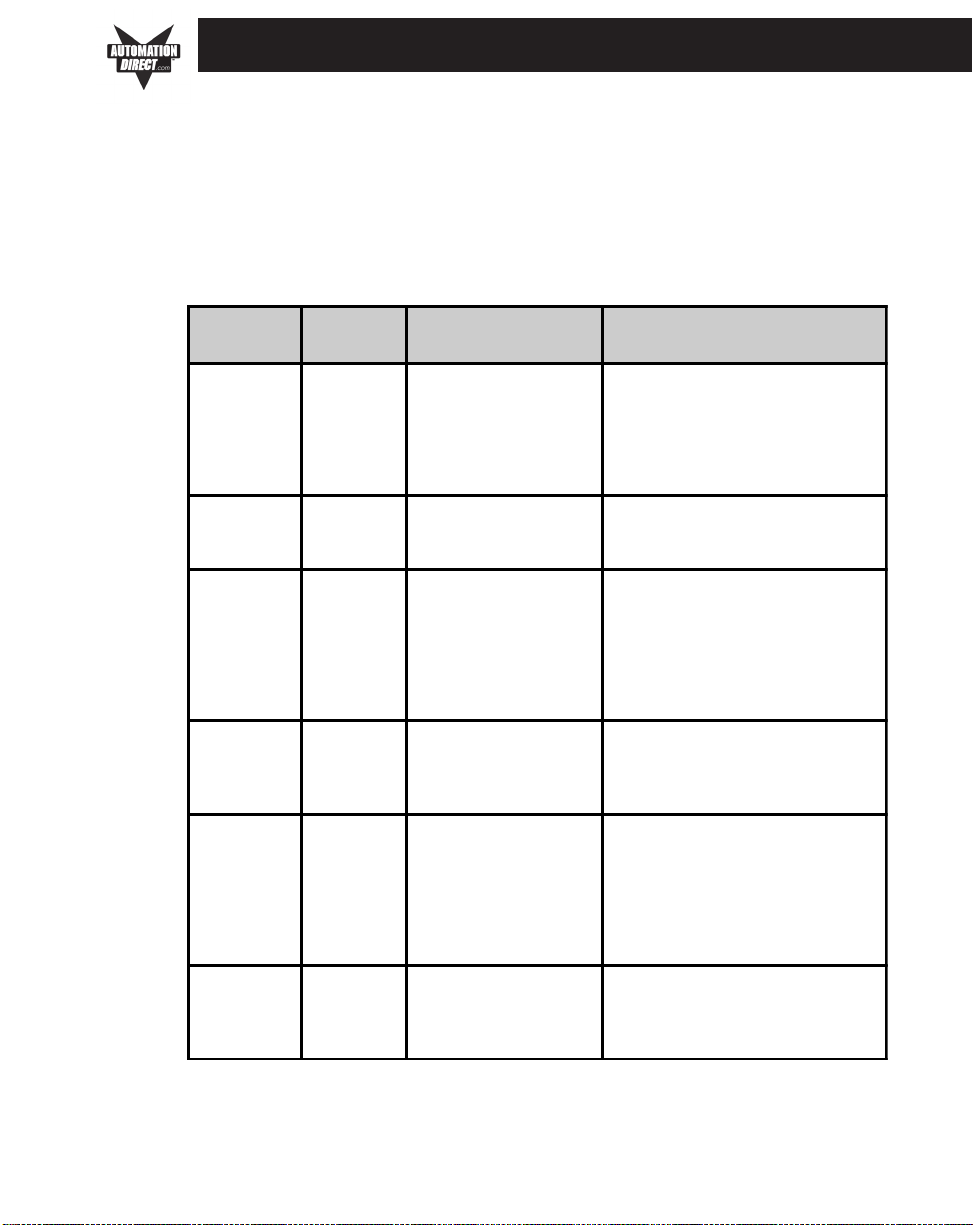

MANUAL REVISIONS

Manual Revisions

Manual Part Number: EZ-TOUCH-M

Manual Title: EZTouch Panel Hardware User Manual, Revision 4

The following table provides you with update information. If you call technical support with a

question about this manual, please be aware of the revision number.

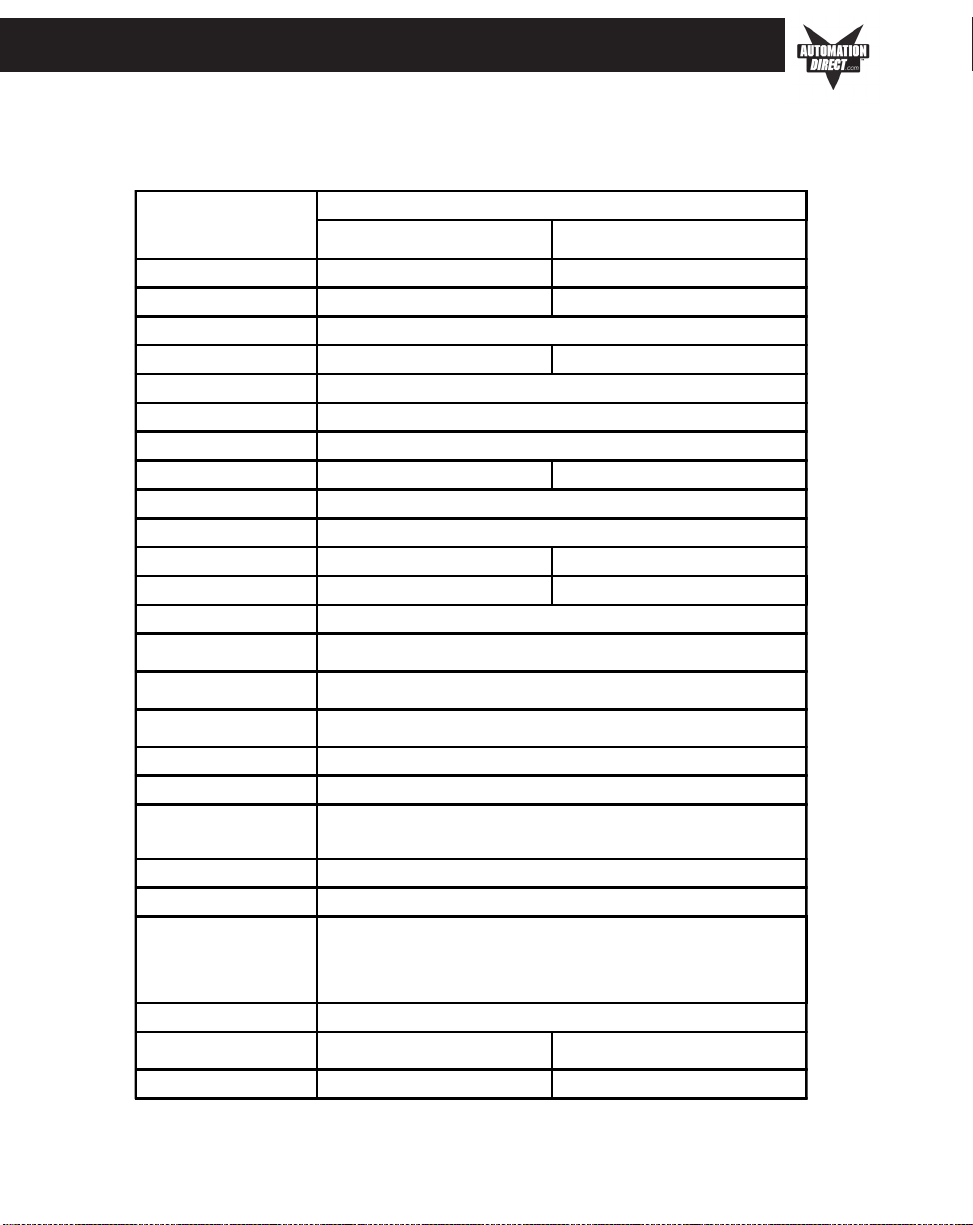

Revision Date Effective Pages Description of Changes

Original

Release

Mai ntenance

Release 1

Revision 1 3/2002 All 6" Slim Bezel Models added. AB

Revision 2 9/2002 Pages i-iv, 2, 3, 5, 6, 8-

Revision 3 02/2003 Pages i-vi, 1, 2, 6, 8, 10,

11/2000 Cover

Warning/Copyright

i–iv

1–40

Appendix

Ind ex

04/2001 Warning/Copyright, pp. 4,

6, 7, 9, 21, 22, 32, 39

Appendix, pages 45-46

13, 15, 16, 18, 20, 21,

23-25, 28, 31, 37, 40-46

Ind ex

13, 15, 23-26, 29, 30,

32-39, 43, A-8, A10, A11, Index

Original Release of Manual

Miscellaneous clerical changes.

Cable wiring diagram added.

DH+ option card added. EZEthernet

option card added. Siemens PLC

Cable added. EZTouch Panel RS422A wiring connections added.

Mounting options for 8- and 10-inch

models changed.

8-, 10-, and 15-inch Slim Bezel

Models added. Touchscreen

chemical compatibility table added

(for Slim Bezel models)

Modicon Modbus Plus, Generic

Devicenet I/O, Generic Ethernet/IP,

Ge ner ic Profibus -D P o ption c ar d

information added. Added wiring

diagram for Omron PLC. Added RS485A wiring diagram for DirectLogic

PLCs.

Revision 4 07/2003 Pages i, iii, v, vi, 8, 17,

18, A-1, A-7–A-12

v

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Added wiring diagrams for Modicon

ModBus RS-232, minor changes to

outline dimensions, changed OMRON

wiring diagram for CQM1 and CPM1

Page 9

EU INFORMATION

EU Information

The EZTouch Panel is manufactured in compliance with European Union (EU) Directives and

carries the CE mark. The EZTouch Panel has been tested under CE Test Standard #EN55011,

and is listed under UL File #E209355. The following information is provided to comply with EU

documentation requirements.

Please NOTE: Products with CE marks perform their required functions safely

and adhere to relevant standards as specified by EU directives provided they

are used according to their intended purpose and that the instructions in this

manual are adhered to. The protection provided by the equipment may be

impaired if this equipment is not used in accordance with this manual. Only

replacement parts supplied by Automationdirect.com or its agents should be

used.

Technical

Support

SELV Circuits

Environmental

Specifications

Preventative

Maintenance

and Cleaning

Consult EZTouch Programming Software Help or you may find answers to

your questions in the operator interface section of our web site @

www.Automationdirect.com. If you still need assistance, please call our

technical support at 1-770-844-4200 or FAX us at 1-770-886-3199.

All electrical circuits connected to the communications port receptacle are

rated as Safety Extra Low Voltage (SELV).

Operating Temperature

6" Monochrome/6" Color ......................................................... 0 to 45 °C

8" Color ................................................................................. 0 to 40 °C

10" Color ................................................................................. 0 to 50 °C

15" Color ................................................................................. 0 to 45 °C

Storage Temperature

6" Mono ........................................................................... –20 to +60 °C

6" Color ........................................................................... –25 to +60 °C

8" Color ........................................................................... –20 to +60 °C

10" Color ........................................................................... –25 to +60 °C

15" Color ........................................................................... –25 to +60 °C

Operating Humidity .................................... 10–95% R.H., noncondensing

Air Composition .......................................... No corrosive gases permitted

No preventative maintenance is required. The EZTouch Panel touchscreen

should be cleaned as needed with warm, soapy water. See Chapter 5, Mainte-

nance, for a list of compatible/incompatible chemicals and compounds.

vi

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

1 GETTING STARTED

Manual Organization

The table, below provides an overall description of the topics covered within this manual.

Chapters

1

Getting Started

Models, Features,

2

and Accessories

Specifications

3

Installation

4

5

Maintenance

Provides Manual Organization, and lists what you need

to get started, hardware and software. Discusses how

to get help with questions or problems you might

encounter through Onscreen Help and Technical

Support.

Provides you with a table listing the various models,

their part numbers and special features. Lists the

important features of all EZTouch Panels. Lists the

PLCs supported by the panels, by brand, model and

protocol. Lists the replacement and optional equipment

available, including memory cards, PLC cables and

programming cable.

Specifications for each model provide detailed information. Included are display size, brightness and pixels;

CPU type; service power requirements; operating and

storage temperatures; available memory; serial

communications specs; dimensions, weight, etc.

Shows the mounting and cutout dimensions for the

panel models. Tells you how to connect the unit to

power supply, programming computer, printer, and a

PLC. Special option card connector instructions are also

provided.Shows the setup screens displayed after initial

powerup of the panel. Describes each setup screen and

how to use it to set up your panel.

Provides instructions on battery replacement, gasket

replacement, memory upgrade (FLASH and RAM),

Fuse Reset, and fluorescent backlight replacement.

Discusses precautions and cleaning necessary to

ensure longevity of the panel.

Troubleshooting

6

A

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Appendix A

Aids in diagnosing problems you might encounter when

installing or operating your EZTouch Panel. Provides

steps to take to isolate and correct problems.

PLC Cable Wiring Diagrams are provided.

1

Page 11

1 GETTING STARTED

Introduction

There are two manuals that you will need to use the EZTouch Panel — this

manual, the EZTouch Panel Hardware User Manual, and the EZTouch Panel

Programming Software User Manual (included with P/N EZ-TOUCHEDIT, EZTouch Programming Software). Don’t worry — you won’t be bouncing back

and forth between them — and we’ll always let you know exactly where the

information is that you will need for the next step.

These manuals will take you through the steps necessary to get your EZTouch

Panel up and running in the shortest possible time. Although your familiarity

with programmable graphic operator interface devices will determine how quickly

Easy as 1 - 2 - 3

you move through the steps — it’s as easy as 1 — 2 — 3. The flow chart below

will show you where you need to go, and — how to get there from here!

1

Install

Software

2

Install

Hardware

3

Design

Screens

EZTouch Programming Software is a user-friendly Windows-based program

that allows you to design screens for the EZTouch Panel series of operator

interfaces. To install EZTouch Panel Programming Software, run the install

program from the CD and follow the onscreen prompts. For more information,

please refer to the EZTouch Programming Software Manual.

You can start designing your screen off-line immediately after installing EZTouch Programming Software — you don’t need to have the

hardware installed!

This manual will provide you with the instructions you need to install the EZTouch Panel. Included are mounting diagrams for both Stud Mounting (page

16) and DIN Clip Mounting (page 27). Connections and wiring requirements

are provided beginning on page 29. Option Card connector information is

provided beginning on page 32. Panel Setup instructions begin on page 41.

For Maintenance information, see Chapter 5 (page 45) and for Troubleshooting, refer to Chapter 6 (page 55).

You may design your screen on-line or off-line (without connection to an EZTouch Panel). When designing screens with EZTouch Programming Software,

you will program objects on the EZTouch Panel providing a graphical interface

designed to interchange and display data from a PLC by merely viewing or

touching the screen — all unique to your particular application. For instructions on how to design screens, refer to the EZTouch Panel Programming Soft-

ware User Manual.

2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

EZ-TOUCH-M Revision 4

Page 12

What you need to get started:

Hardware

• EZTouch Panel (6" Monochrome, 6" Color, 8" Color, or 10" Color,

including 6", 8", and 10" Slim Bezel Models, 15" Slim Bezel Model,

and Option Card models)

• 24 Volt Power Supply (24 VDC with 1.5A switching supply is

recommended) (1.5 Amp Slo-Blo input power fuse is also

recommended)

• RS-232C Programming Cable (P/N EZTOUCH-PGMCBL)

• RS-232C PLC Interface Cable (see page 10 for part numbers)

• PC requirements:

— IBM or compatible PC (486 or better) with a mouse

and separate serial port

— VGA display with at least 800 x 600 resolution (1024 x 768

recommended)

— Standard Windows 98/NT4.0/ME/2000® /XP Home/XP Pro

Requirements

— CD ROM Drive

Software

• EZTouch Programming Software (P/N EZ-TOUCHEDIT)

1 GETTING STARTED

Need HELP?

Help is never more than a mouse click or a key press away!

Onscreen HELP

One of the most important features of the EZTouch Programming Software is

the availability of context sensitive onscreen help. To access the Help windows, simply press the F1 function key while on the topic where you need

help. For example, if you need help while working with screens, hit the F1

function key while in that area and a popup window will be displayed. Also,

most dialog boxes contain a Help button, you may click on it to get help, too!

Fly-Over HELP

When the mouse cursor comes to rest over any tool bar or object button for a

short while, a small window will appear containing a brief description of the

function of that particular button. The window will disappear as soon as the

cursor has been moved off the button.

PLC HELP

If you need help with the PLC to EZTouch Panel Interface, consult the EZTouch Panel Programming Software Help. Each PLC Driver has a Help Topic

that lists the error messages and provides an explanation for each. Also provided are PLC to EZTouch Panel wiring diagrams.

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

Page 13

1 GETTING STARTED

Technical Support

Although most questions can be answered with EZTouch HELP or the manuals, if you are still having difficulty with a particular aspect of installation or

screen design, technical support is available at 1-770-844-4200 or FAX us at

1-770-886-3199. Visit our website at www.Automationdirect.com.

PLEASE NOTE: Chapter 6, Troubleshooting, at the end of this

manual should be able to help you with most problems you might

encounter.

4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

EZ-TOUCH-M Revision 4

Page 14

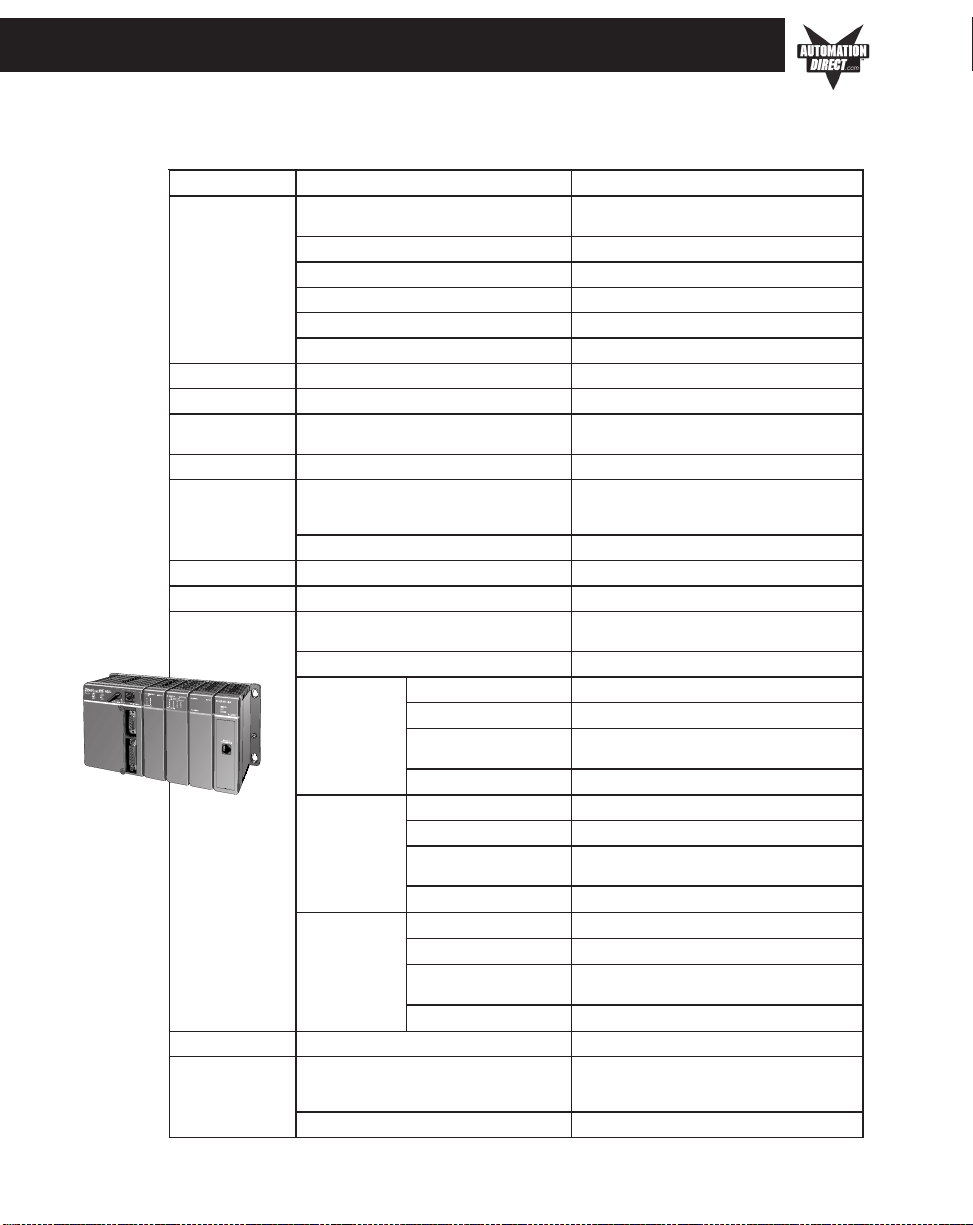

Models

6-inch EZTouch

Panel Models

2 MODELS, FEATURES AND ACCESSORIES

The EZTouch Panel is an intelligent, programmable, flat panel display. It has

been designed to interchange and display graphical data from a PLC by

merely viewing or touching the screen.

The EZTouch Panel is available in a variety of models to suit your application. Refer to the table below for a list of part numbers, descriptions and

options for all 6-inch Models (including Option Board Models and Slim Bezel

Models.) See next page for 8-, 10-, and 15-inch Models.

Nonvolatile

Part Number Description

EZ-S6M-R 6" Monochrome

EZ-S6M-RS 6" M onochrome

EZ-S6M-F 6" Monochrome

EZ-S6M-FH 6" DH+ Mono

EZ-S6M-FS 6" M onochrome

EZ-S6M-FSH 6" DH+ Mono

EZ-S6C-K 6" Color

EZ-S6C-KS 6" Color

EZ-S6C-F 6" C olor

EZ-S6C-FH 6" DH+ C olor

EZ-S6C-FS 6" C olor

EZ-S6C-FS H 6" D H+ Colo r

* List of PLC Drivers supported is provided on page 8 of this manual.

Note #1: Supports all drivers in list, but NO OPTION BOARDS.

Note #2: Supports AutomationDirect (DirectLogic) Serial Drivers including H2-WPLC-XX.

Touch P ane l

Touch P ane l

with Slim Bezel

Touch P ane l

Touch P ane l

Touch P ane l

with Slim Bezel

Touch P ane l

with Slim Bezel

Touch P ane l

Touch P ane l

with Slim Bezel

Touch P ane l

Touch P ane l

Touch P ane l

with Slim Bezel

Touch P ane l

with Slim Bezel

User

Memory

256K No No See Note #1

256K No No See Note #1

512K Yes — to 1 or

512K Yes — to 1 or

512K Yes — to 1 or

512K Yes — to 1 or

512K Yes — to 1 or

512K Yes — to 1 or

512K Yes — to 1 or

512K Yes — to 1 or

512K Yes — to 1 or

512K Yes — to 1 or

Field

Expandable

User RAM?

1.5 MEG

1.5 MEG

1.5 MEG

1.5 MEG

1.5 MEG

1.5 MEG

1.5 MEG

1.5 MEG

1.5 MEG

1.5 MEG

Flash Backup

Card Option

for Program

Backup?

Yes All, plus

Yes All, plus Allen-

Yes All, plus

Yes All, plus Allen-

Yes See Note #2

Yes See Note #2

Yes All, plus

Yes All, plus Allen-

Yes All, plus

Yes All, plus Allen-

PLC Drivers

Supported? *

EZ Ethernet

Bradley DH+

and Remote I/O

EZ Ethernet

Bradley DH+

and Remote I/O

EZ Ethernet

Bradley DH+

and Remote I/O

EZ Ethernet

Bradley DH+

and Remote I/O

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

Page 15

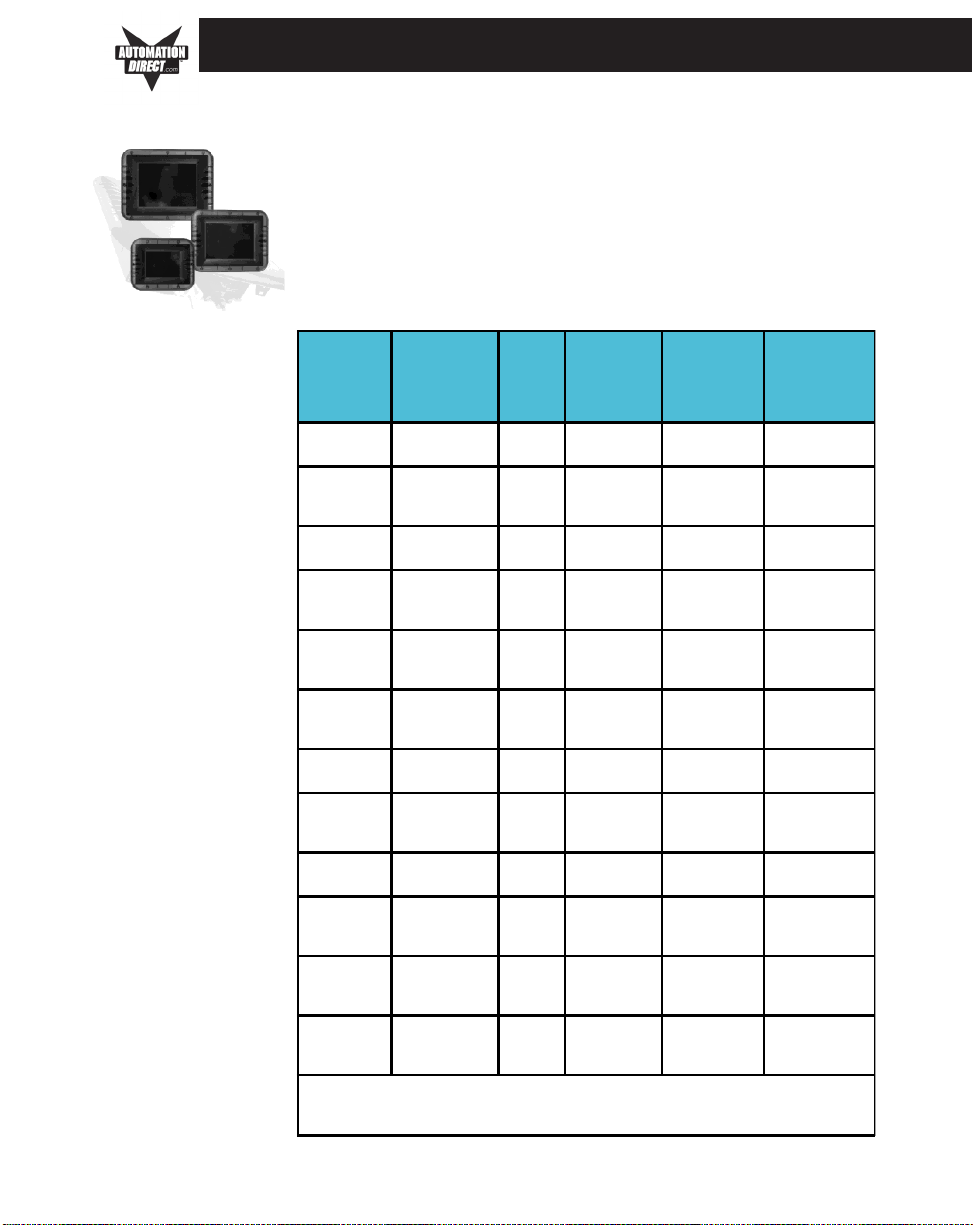

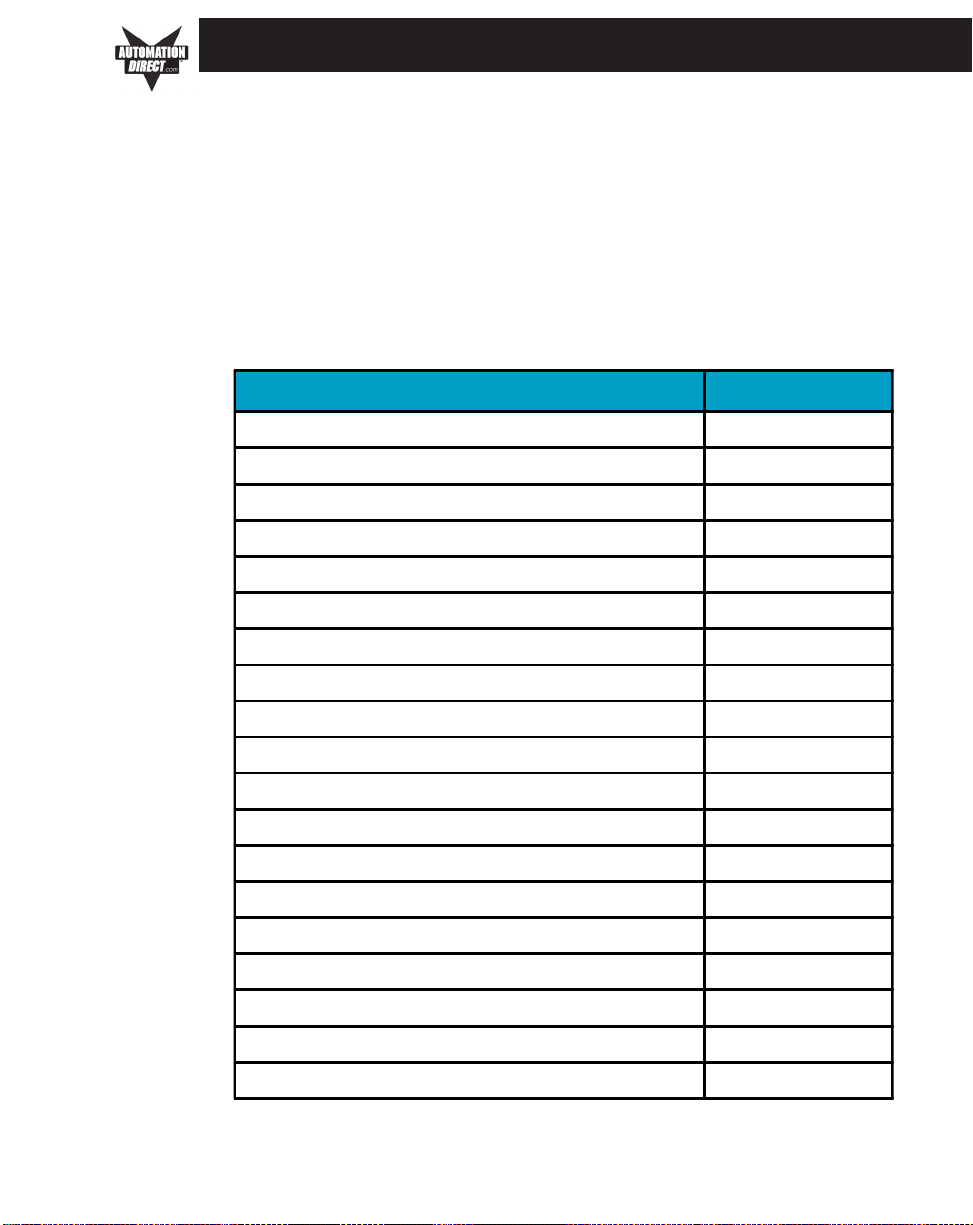

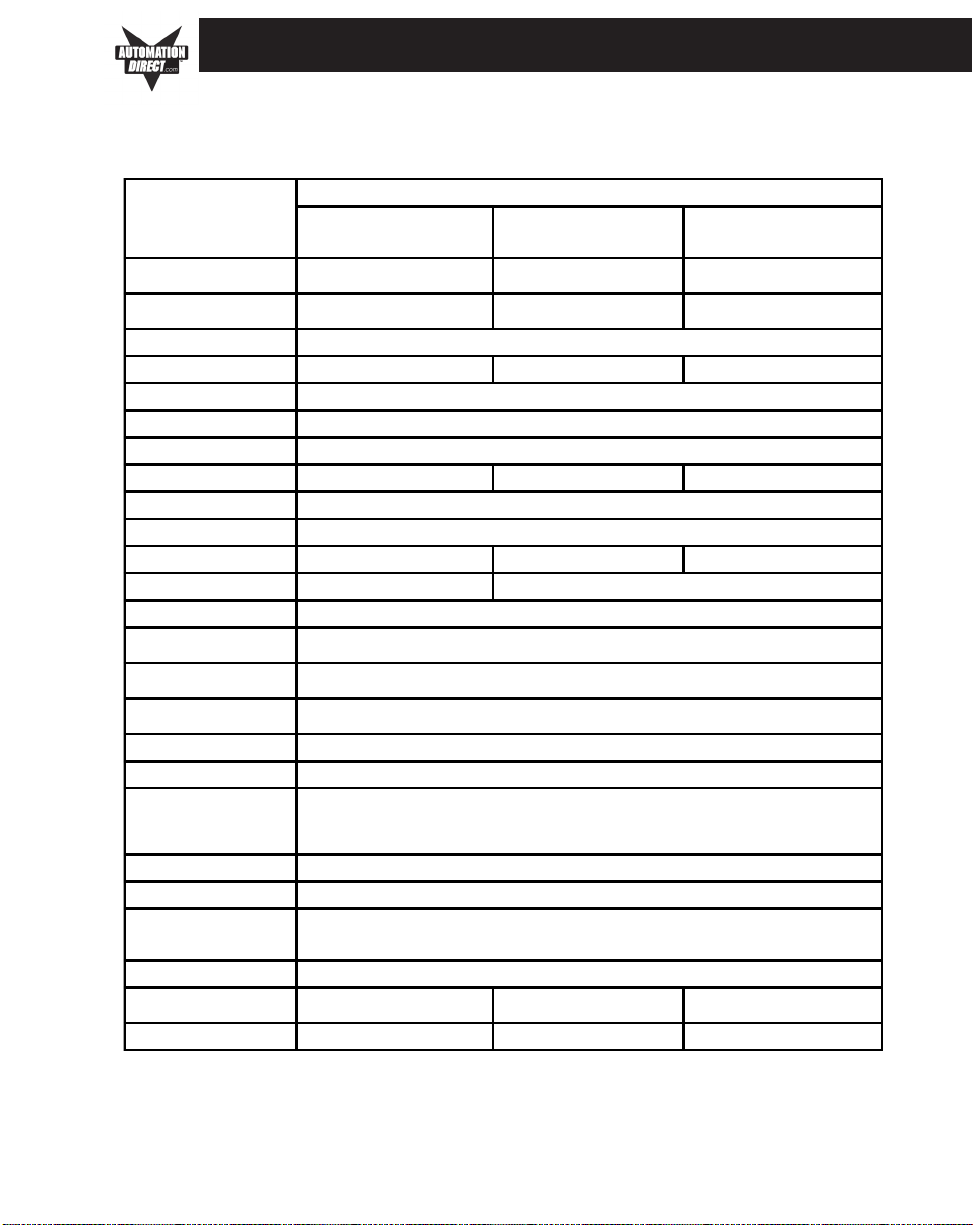

2 MODELS, FEATURES AND ACCESSORIES

8-inch, 10-inch, and 15-inch EZTouch Panel Models

In the table below are the 8-, 10-, and 15-inch EZTouch Panel models including the Slim

Bezel Models and Models with the A-B Data Highway Plus (and Remote I/O), DeviceNet I/O,

Ethernet/IP, Modicon ModBus Plus, or Profibus-DP Network interface module (option card)

installed. If using an option board connector, you cannot use the PLC port at the same time

to connect to another type PLC. The panel supports only one PLC driver at a time.

Nonvolatile

Flash

Backup

Part Number Description

EZ-S8C-F 8" Color Touch Panel 512K Yes — to 1 or 1.5 MEG Yes All, plus EZ Ethernet

EZ-S8C-FS 8" Color Touch Panel with

EZ-S8C-FH 8" DH+ Color Touch Panel 512K Yes — to 1 or 1.5 MEG Yes All, plus Allen-Bradley DH+ and

EZ-S8C-FSH 8" D H+ Color Touch Panel

EZ-T10C-F 10.4" Color Touch Panel 512K Yes — to 1 or 1.5 MEG Yes All, plus EZ Ethernet

EZ-T10C-FH 10.4" DH+ Color Touch

EZ-T10C-FS 10.4" Color Touch Panel

EZ-T10C-FSH 10.4" DH+ Color Touch

EZ-T10C-FSD 10.4" DeviceNet I/O Color

EZ-T10C-FSE 10.4" Ethernet/IP Color

EZ-T10C-FSM 10.4" Modbus Plus Color

EZ-T10C-FSP 10.4" Profibus-DP Color

EZ-T15C-FS 15" Color Touch Panel with

EZ-T15C-FSH 15" DH+ Color

EZ-T15C-FSD 15" DeviceNet I/O Color

EZ-T15C-FSE 15" Ethernet/IP Color

EZ-T15C-FSM 15" Modbus Plus Color

EZ-T15C-FSP 15" Profibus-DP Color

* List of PLC Drivers supported is provided on page 8 of this manual.

Slim Bezel

with Slim Bezel

Panel

with Slim Bezel

Panel with Slim Bezel

Touch P anel with S lim B ezel

Touch P anel with S lim B ezel

Touch P anel with S lim B ezel

Touch P anel with S lim B ezel

Slim Bezel

Touch P anel with S lim B ezel

Touch P anel with S lim B ezel

Touch P anel with S lim B ezel

Touch P anel with S lim B ezel

Touch P anel with S lim B ezel

User

Memory

512K Yes — to 1 or 1.5 MEG Yes All, plus EZ Ethernet

512K Yes — to 1 or 1.5 MEG Yes All, plus Allen-Bradley DH+ and

512L Yes — to 1 or 1.5 MEG Yes All, plus Allen-Bradley DH+ and

512K Yes — to 1 or 1.5 MEG Yes All, plus EZ Ethernet

512K Yes — to 1 or 1.5 MEG Yes All, plus Allen-Bradley DH+ and

512K Yes — to 1 or 1.5 MEG Yes All, plus DeviceNet I/O

512K Yes — to 1 or 1.5 MEG Yes All, plus Ethernet/IP

512K Yes — to 1 or 1.5 MEG Yes All, plus Modbus Plus

512K Yes — to 1 or 1.5 MEG Yes All, plus Profibus-DP

1024K Yes — to 1.5 or 2 MEG Yes All, plus EZ Ethernet

1024K Yes — to 1.5 or 2 MEG Yes All, plus Allen-Bradley DH+ and

1024K Yes — to 1.5 or 2 MEG Yes All, plus DeviceNet I/O

1024K Yes — to 1.5 or 2 MEG Yes All, plus Ethernet/IP

1024K Yes — to 1.5 or 2 MEG Yes All, plus Modbus Plus

1024K Yes — to 1.5 or 2 MEG Yes All, plus Profibus-DP

Field Expandable

User RAM?

Card Option

for Program

Backup?

PLC Drivers Supported? *

Remote I/O

Remote I/O

Remote I/O

Remote I/O

Remote I/O

6

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

Features

2 MODELS, FEATURES AND ACCESSORIES

! Pre-built panel components for easy screen design

! Special parts, such as: Toggle Switch, Slide Switch,

Selector Switch, Throw Switch, Thumbwheel Object,

Meters, PID Faceplates, and Analog/Digital Clock

! Flash based design for easy firmware upgrade

! Field expandable user RAM (not all models)

! Nonvolatile flash card option for user program

backup (not all models)

! Color models support 128-color palette for

components and bitmaps

! 16 shades of gray on monochrome models

! Multiple languages (up to 9)

! Two communications ports — Computer (RS-232C)

and PLC (RS-232C, RS-422A, or RS-485A)

! Up to 999 screens

! Built-in clock and calendar or reference the PLC

clock

! Built-in soft keypad for numeric and alphanumeric

entry

! Password Protection for every touch object

! Passwords for up to 8 user groups

! 16 level undo and redo

! Import bitmaps

! Serial Printer support

! 40-character tag names allows you to use meaningful

names for PLC memory locations instead of cryptic

PLC addresses

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

Page 17

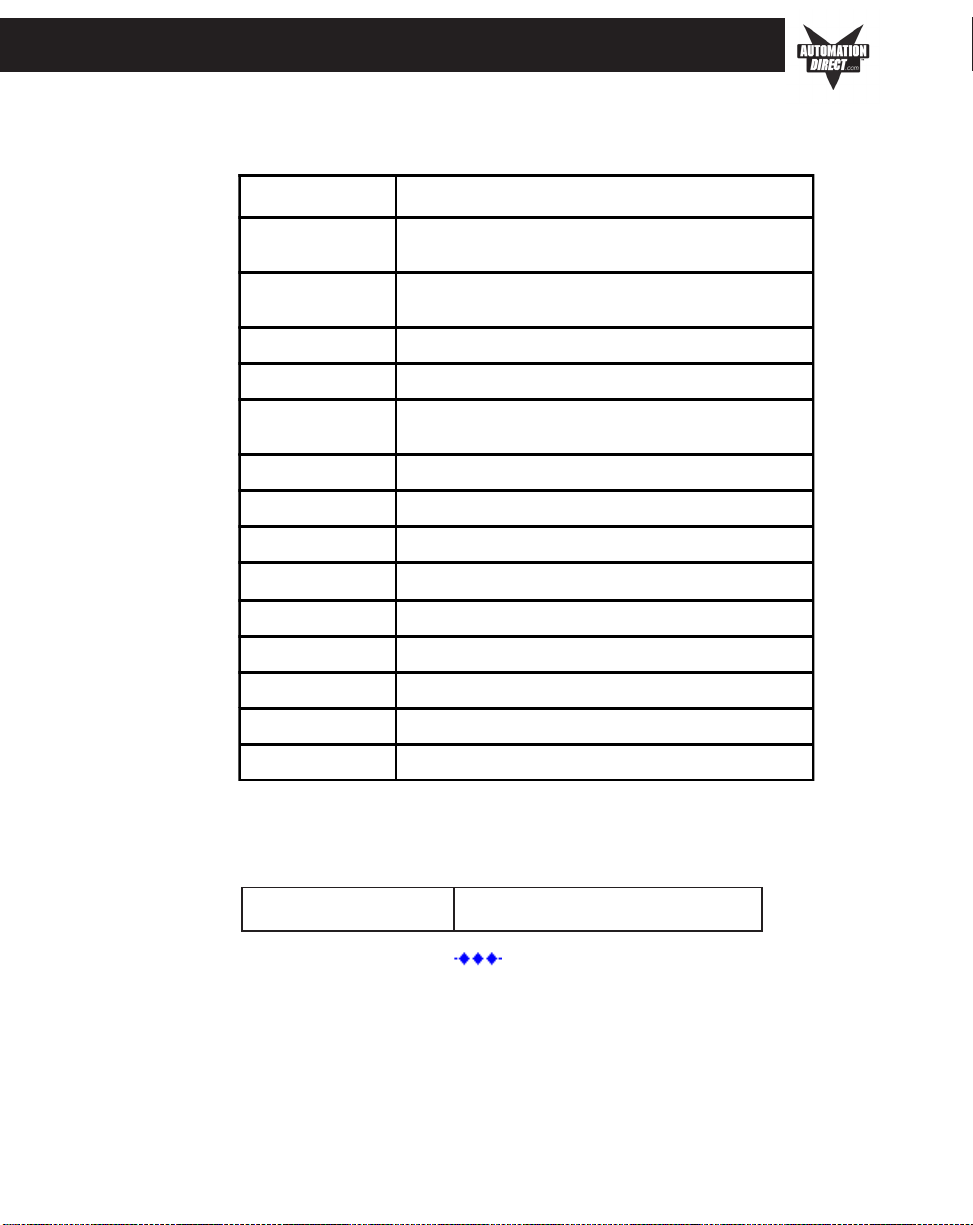

2 MODELS, FEATURES AND ACCESSORIES

PLCs Supported by the EZTouch Panels

dnarBCLPledoMdetroppuSslocotorP

yeldarB-nellA,0051/0021/0001xigolorciM

5CLP1FD

teNeciveDO/IteNeciveD)draCnoitpO(O/IteNeciveD

tenrehtE)xigoL-lortnoC(PI/tenrehtE)draCnoitpO(PI/tenrehtE

cirtcelElareneG07/09dna03/09

ihsibustiM)lla(seireSXFtceriD,XF

nocidoMUPC311mutnauQ,UPC489

normO1MPC,1MQC,005C,002CkniLtsoH

subiforPPD-subiforP)draCnoitpO(PD-subiforP

cigoLtceriD

snemeiS004,003rotpadAIPM7SsnemeiSR4693

rehtO)oD&knihT(ytivitnE[CLPniW-2H

xamasreV

60LD,50LD

501LDecneuqeS-K

502LD

503LD

504LD

30/,20/,10/5,005CLS

0051/0021/0001xigolorciMxelpuDlluF1FD;xelpuDflaH1FD

50/5dna,40/5,30/5CLSxelpuDlluF1FD;xelpuDflaH1FD

5CLP,40/5CLS)draCnoitpO(+HD

5dna3,2CLP )draCnoitpOsulP+HD/w(O/IetomeR

xx-216,xx-215,xx-114,xx-113

seireSmutnauQ,seireS489)draCnoitpO(sulPsubdoM

032-2DecneuqeS-K

042-2DteNtceriD;ecneuqeS-K

P033/033-3DteNtceriD

043-3DteNtceriD

053-3D

MCD/w053-3DteNtceriD

034-4DteNtceriD;ecneuqeS-K

044-4DteNtceriD;ecneuqeS-K

054-4D

MCDhtiwllAteNtceriD

]ytilibitapmoc

noisrevrofkcehc,retalro2.5V

CBE-H1T,CBE4H/2H)troplaires(ecneuqeS-K

:UPC011seireSorciMnocidoMGEA

062/1-052-2D/052-2D

MCD/w052/042-2DteNtceriD

+CIA/CIA/584HD

XPNS

PNS

UTRsubdoM

;teNtceriD;ecneuqeS-K

)gnisserddaoyoK(suBdoM

;teNtceriD;ecneuqeS-K

)gnisserddaoyoK(suBdoM

;teNtceriD;ecneuqeS-K

)gnisserddaoyoK(suBdoM

;teNtceriD;ecneuqeS-K

)gnisserddaoyoK(suBdoM

)trop

laires(UTRsubdoM)oD&knihT(ytivitnE

8

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

2 MODELS, FEATURES AND ACCESSORIES

Replacement and Optional Equipment

There are replacement parts and other optional equipment available to customize or upgrade the EZTouch Panel to fit your application. The table, below, provides you with a list of this equipment. Instructions, if necessary, on

how to install this equipment to upgrade your unit are also provided. (For

instructions to mount the 6-inch EZTouch Panel with DIN clips, see pages 27

and 28.)

To order from this list, phone Automationdirect.com at 1-800-663-0405.

Item Part Number

EZTouch Panel Programming Software EZ-TOUCHEDIT

512K RAM Card EZ-RAM-1

1 MEG RAM Card EZ-RAM-2

512K Flash Option (Flash backup card) EZ-FLASH-1

1 MEG Flash Option (Flash backup card) EZ-FLASH-2

2 MEG Flash Option (Flash backup card) EZ-FLASH-3

EZTouch Replacement Battery EZ-BAT

EZTouch Optional DIN Mounting Clips (package of 6) EZ-BRK-1

Mounting Studs (package of 8) EZ-TOUCH-STUDS

Standard Replacement Gasket (6" Model) EZ-TOUCH6-GSK

Standard Replacement Gasket (8" Model) EZ-TOUCH8-GSK

Standard Replacement Gasket (10" Model) EZ-TOUCH10-GSK

Slim Replacement Gasket (6" Model) FDA Compliant EZ-6SLIMF-GSK

Slim Replacement Gasket (8" Model) FDA Compliant EZ-8SLIMF-GSK

Slim Replacement Gasket (10" Model) FDA Compliant EZ-10SLIMF-GSK

Slim Replacement Gasket (15" Model) FDA Compliant EZ-15SLIMF-GSK

EZTouch Panel Ethernet Card EZ-ETHERNET

EZTouch Panel Hardware User Manual EZ-TOUCH-M

EZ Ethernet Option Card Manual EZ-ETHERNET-M

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

Page 19

2 MODELS, FEATURES AND ACCESSORIES

PLC Cable Part Numbers — 3m (9.8 ft.)

Part Number Cable Description

EZ-2CBL Direct Logic PLC RJ12 port, DL05, DL06 DL105,

EZ-2CBL-1 Direct Logic (VGA Style) 15-pin port, DL 250 (250-1),

EZ-3CBL Direct Logic PLC RJ11 port, DL340 (RS-232C)

EZ-4CBL-1 Direct Logic PLC 15-Pin Dsub port, DL405 (RS-232C)

EZ-4CBL-2 Direct Logic PLC 25-Pin Dsub port, DL405, DL350,

EZ-90-30-CBL GE 90/30 and 90/70 15-pin Dsub port (RS-422A)

EZ-DH458-CBL AB SLC DH-485 port (RS-232C)

EZ-SLC-232-CBL AB SLC 5/03/04/05 DF1 port (RS-232C)

EZPLC5-232-CBL AB PLC5 DF1 port (RS-232C)

EZ-MLOGIX-CBL AB MicroLogix 1000, 1200 & 1500 (RS-232C)

EZ-MITSU-CBL Mitsubishi FX Series 25-pin port (RS-422A)

EZ-MITSU-CBL-1 Mitsubishi FX Series 8-pin (RS-422A)

EZ-OMRON-CBL Omron C200, C500 (RS-232C)

EZ-S7MPI-CBL Siemens 7 MPI Adapter (RS-232C)

DL205, DL350 & DL450 (RS-232C)

DL260, DL06 (RS-232C)

DL305 DCU, and all DCM's (RS-232C)

Programming Cable Part Number — 2m (6.56 ft.)

EZTOUCH-PGMCBL RS-232 Programming Cable

10

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

EZ-TOUCH-M Revision 4

Page 20

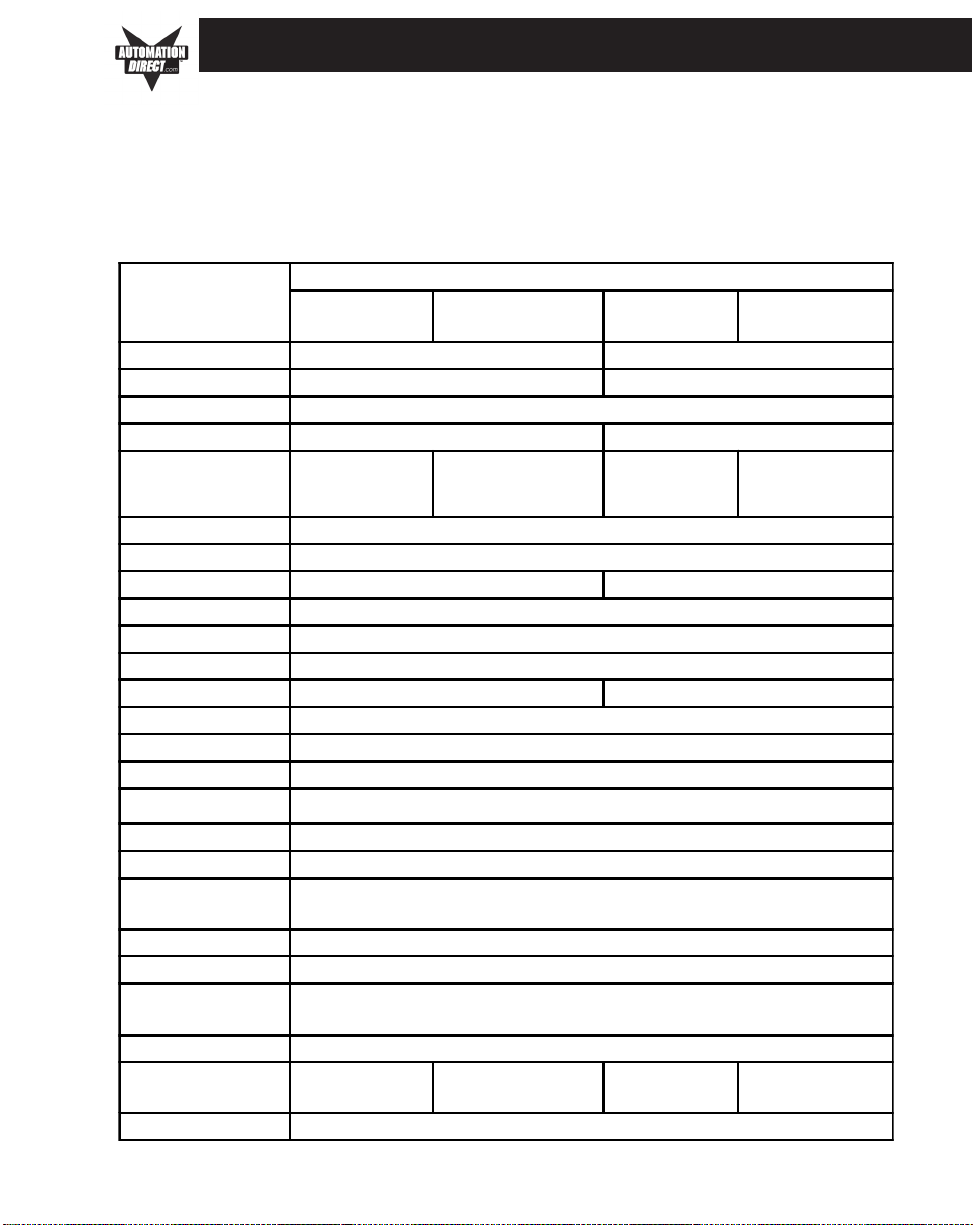

3 SPECIFICATIONS

Hardware Specifications

Specifications for all 6-inch EZTouch Panel Models (including Slim Bezel and A-B DH+ Option

Card Models) are provided in the table below. * An “H” at the end of a part number indicates an AB DH+ option card has been installed. An “S” indicates a Slim Bezel Model.

EZTouch Panel Specifications — all 6-inch Models

EZTouch Panel 6-inch Models

Specification

Display Type 5.7" STN (16 Shades of Gray) 5.7" STN (128-Color Palette)

Display Size (Viewing Area) 4.72" x 3.5" (119.4 x 88.9 mm) 4.65" x 3.5" (118.1 x 88.9 mm)

Screen Pixels 320 x 240

Display Brightness 140 nits 180 nits

Touch Screen

CPU Type Motorola Coldfire 32 bit CPU (40 MHZ)

Service Power 24 VDC (20–30 VDC operating range)

Power Consumption 13 Watts @ 24VDC 15 Watts @ 24VDC

Enclosure NEMA 4, 4X (indoor)

Agency Approvals UL, CUL, CE

Operating Temperature 0 to 45 °C (32 to 113 °F)

Storage Temperature –20 to +60 °C (–4 to +140 °F) –25 to +60 °C (–13 to+140 °F)

Humidity 10–95% R.H., noncondensing

Electrical Noise Interference NEMA IC S 2-230 showering arc ANSI C37.90a-1974 SWC Level C Chattering Relay Test

Withstand Voltage 1000 VDC (1 minute), between power supply input terminal and protective ground (FG)

Insulation Resistance

Vibration 5 to 55 Hz 2G for 2 hours in the X, Y, and Z axes

Shock 10G for under 12 ms in the X, Y, and Z axes

Use r Memor y

Number of Screens Up to 999, limited by memory

Real-time Clock Built into panel (PLC clock is still accessible, if available)

Serial Communications

Screen Saver Yes, backlight off

Ext erna l Di mensi ons

Weight 1.7 lbs.

6" Mono

EZ-S6 M-R, EZ- S6M-F,

and *EZ-S6M-FH

48 resisti ve touch cells

(8 x 6)

Over 20 M-ohm, between power supply input and terminal and protective ground (FG)

EZ-S6 M-R, EZ-S 6M-RS : 256K system RAM Memory (only)

All other models: 512K System RAM Memory, 512K Option RAM Card for Memory Expansion, 512K

Option Flash Card for Memory Backup, 1 Meg Option Flash Card for Memory Backup

PLC Port: RS-232C, RS-422A, RS-485A, 15-pin D-Sub (Female)]

Do wnload /Pro gra m Port: RS-232C, RS-422A, RS-485A, 9-pin D-Sub (Female)

DH+ Port: (EZ-S6M-FH/FSH, EZ-S6C-FH/FSH Models) DH+ option board 25-pin connector (Female)

7.30" x 8.94" x 2.94"

(185.42 x 226.076 x

74.68 mm)

6" Mono Slim

EZ-S6M-RS, EZ-S6M-FS,

and *EZ-S6M-FSH

EZ-S6M-RS: 48 resistive

touch cells (8 x 6)

EZ-S6M-FS/FSH: 192

resistive touch cells (16 x 12)

7.250" x 8.048" x 2.68"

(156.078 x 204.407 x 68.07

mm)

6" Color

EZ-S6C-K, EZ-S6C-F,

and *EZ-S6C-FH

48 resistive touch cells

(8 x 6)

7.30" x 8.94" x 2.94"

(185.42 x 226.076 x

74.68 mm)

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6" Color Slim

EZ-S6C-KS, EZ-S6C-FS,

and *EZ-S6C-FSH

192 resistive touch cells

(16 x 12)

7.250" x 8.048" x 2.68"

(156.078 x 204.407 x

68.07 mm)

11

Page 21

3 SPECIFICATIONS

EZTouch Panel Specifications — 8-inch and 10-inch Standard Bezel Models

Specification

Display Type 8.2" STN (128-Color Palette) 10.4" TFT (128-Color Palette)

Display Size (Viewing Area) 6.65" x 5.024" (168.9 x 127.61 mm) 8.31" x 6.22" (211.07 x 158 mm)

Screen Pixels 640 x 480

Display Brightness 90 nits 200 nits

Touch Screen 192 resistive touch cells (16 x 12)

CPU Type Motorola Coldfire 32 bit CPU (40 MHZ)

Service Power 24 VDC (20–30 VDC operating range)

Power Consumption 16 Watts @ 24VDC 18 Watts @ 24VDC

Enclosure NEMA 4, 4X (indoor)

Agency Approvals UL, CUL, CE

Operating Temperature 0 to 40 °C (32 to 104 °F) 0 to 50 °C (32 to 122 °F)

Storage Temperature –20 to +60 °C (–4 to +140 °F) –25 to +60 °C (–13 to +140 °F)

Humidity 10–95% R.H., noncondensing

Electrical Noise Interference

Withstand Voltage

Insulation Resistance

Vibration 5 to 55 Hz 2G for 2 hours in the X, Y, and Z axes

Shock 10G for under 12 ms in the X, Y, and Z axes

User Memory

Number of Screens Up to 999, limited by memory

Real-time Clock Built into panel (PLC clock is still accessible, if available)

Seri al Communicati ons

Screen Saver Yes, backlight off

External Dimensions

Weight 1.6 lbs. 3.8 lbs.

512K System RAM Memory, 512K Option RAM Card for Memory Expansion,

512K Option Flash Card for Memory Backup, 1 Meg Option Flash Card for

Memory Backup

PLC Port: RS-232C, RS-422A, RS-485A, 15-pin D-Sub (Female)

Download/Program P ort: RS-232C, RS-422A, RS-485A, 9-pin D-Sub

(Female)

DH+ Port: (EZ-S8C-FH, EZ-T10C-FH Models) DH+ option board 25-pin

connector (Female)

(222.38 x 277.24 x 78.56 mm)

8" Color

EZ-S8C-F and EZ-S8C-FH

NEMA ICS 2-230 showering arc ANSI C37.90a-1974

SWC Level C Chattering Relay Test

1000 VDC (1 minute), between power supply

input terminal and protective ground (FG)

Over 20 M-ohm, between power supply input

and terminal and protective ground (FG)

8.76" x 10.915" x 3.093"

EZ-T10C-F and EZ-T10FH

(269.22 x 345.186 x 81.03 mm)

10" Color

10.60" x 13.59" x 3.19"

EZTouch Panel Models

12

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

3 SPECIFICATIONS

EZTouch Panel Specifications — 8-inch, 10-inch, and 15-inch Slim Bezel Models

EZTouch Panel Models

Specification

EZ-S8C-FS and EZ-S8C-FSH

Display Type

Display Size (Viewing Area)

Screen Pixels 640 x 480

Display Brightness 90 nits 200 nits 250 nits

Touch Screen 192 resistive touch cells (16 x 12)

CPU Type Motorola Coldfire 32 bit CPU (40 MHZ)

Service Power 24 VDC (20–30 VDC operating range)

Power Consumption 16 Watts @ 24VDC 18 Watts @ 24VDC 33 Watts @ 24VDC

Enclosure NEMA 4, 4X (indoor)

Agency Approvals UL, CUL, CE

Operating Temperature 0 to 40 °C (32 to 104 °F) 0 to 50 °C (32 to 122 °F) 0 to 45 °C (32 to 113 °F)

Storage Temperature –20 to +60 °C (–4 to +140 °F) –25 to +60 °C (–13 to +140 °F)

Humidity 10–95% R.H., noncondensing

Electrical Noise Interference

Withstand Voltage

Insulation Resistance

Vibration 5 to 55 Hz 2G for 2 hours in the X, Y, and Z axes

Shock 10G for under 12 ms in the X, Y, and Z axes

8" and 10" Models: 512K System RAM Memory, 512K and 1 MEG Option RAM Card for Memory

User Memory

Number of Screens Up to 999, limited by memory

Real-time Clock Built into panel (PLC clock is still accessible, if available)

Serial Communications

Screen Saver Yes, backlight off

External Dimensions

Weight 2.9 lbs. 5.0 lbs. 8.9 lbs.

Expansion; 512K, 1 or 2 MEG Option Flash Card for Memory Backup

15" Model: 1024K System RAM Memory, 512K and 1 MEG Option RAM Card for Memory

Expansion; 1or 2 Meg Option Flash Card for Memory Backup

PLC Port: RS-232C, RS-422A, RS-485A, 15-pin D-Sub (Female)

Download/Program Port: RS-232C, RS-422A, RS-485A, 9-pin D-Sub (Female)

DH+ Port: (EZ-S8C-FH, EZ-T10C-FH Models) DH+ option board 25-pin connector (Female)

8" Color

8.2" STN

(128-Color Palette)

6.65" x 5.024"

(168.9 x 127.61 mm)

NEMA IC S 2-230 showering arc ANSI C37.90a-1974

8.75" x 10.89" x 2.76"

(222.25 x 276.61 x 70.10 mm)

SWC Level C Chattering Relay Test

1000 VDC (1 minute), between power supply

input terminal and protective ground (FG)

Over 20 M-ohm, between power supply input

and terminal and protective ground (FG)

10" Color

EZ-T10C-FS and EZ-T10-

FSH/FSD/FSM/FSE/FSP

10.4" TFT

(128-Color Palette)

8.31" x 6.22"

(211.07 x 158 mm)

10.59" x 13.58" x 2.86"

(268.99 x 344.93 x 72.64 mm)

15" Color

EZ-T15C-FS and EZ-T15C-

FSH/FSD/FSM/FSE/FSP

15.0" TFT

(128-Color Palette)

12.02" x 9.01"

(305.28 x 228.96 mm)

13.00" x 16.75" x 4.66"

(330.2 x 425.45 x 118.36 mm)

EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

13

Page 23

3 SPECIFICATIONS

This page intentionally left blank.

14

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

EZ-TOUCH-M Revision 4

Page 24

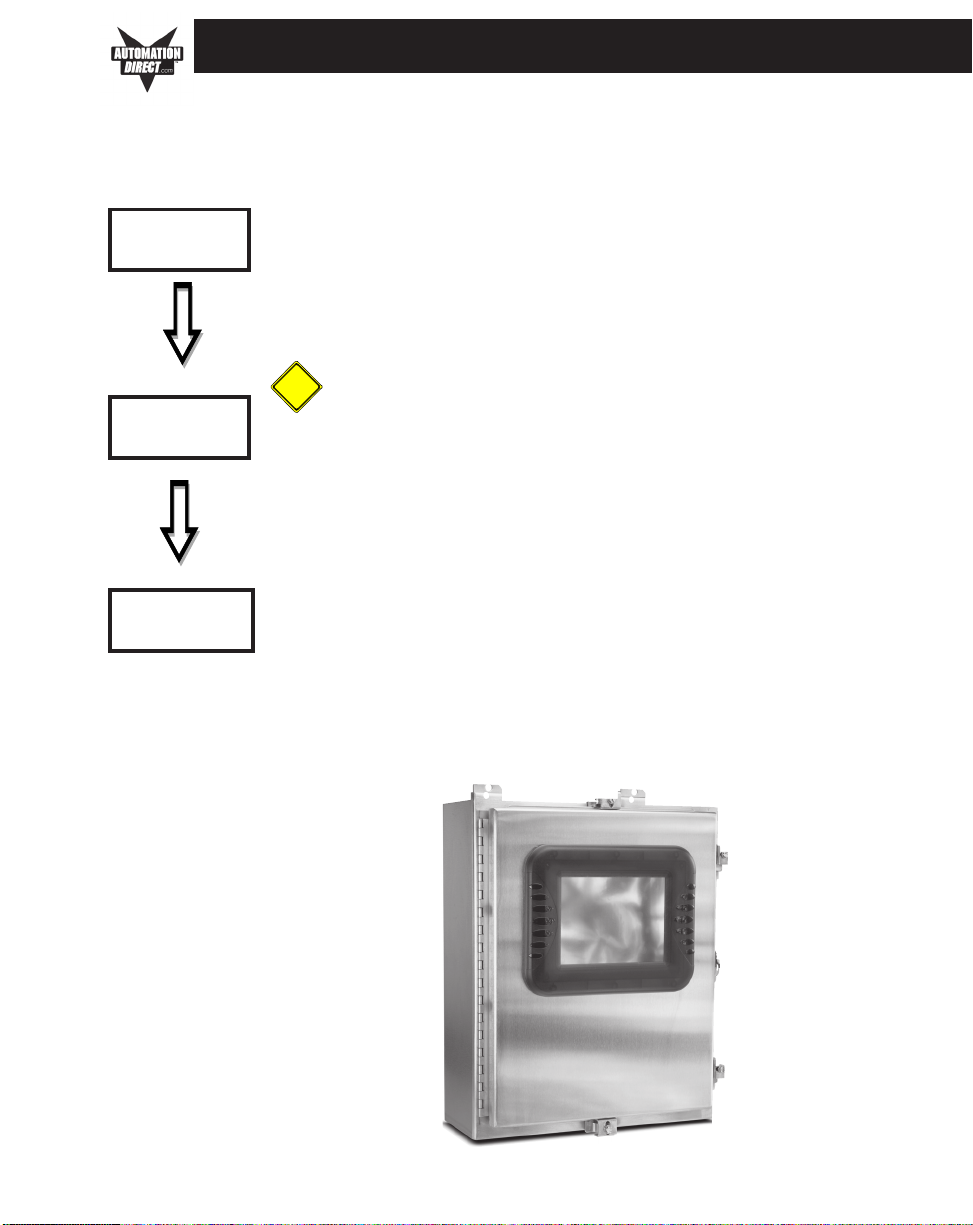

Mounting

Connections

and Wiring

Communications

Setup

4 INSTALLATION

Installing the EZTouch Panel requires the following three major steps:

The EZTouch Panel is a front-panel mount unit. Mounting of the unit requires

a panel cutout, and drilling six, eight, or ten holes (depending on the model) for

the mounting screws. You may also mount the 6-inch units using the optional

DIN clips. Some 6-inch units (Slim Bezel models) can only be mounted using

DIN clips. The 8-, 10- and 15-inch Slim Bezel Models are Stud Mount ONLY.

Please see the Mounting section beginning on page 16 for mounting diagrams

and instructions.

CAUTION: DO NOT use any thread locking compounds to secure

the studs to Plastic Bezel Models. Many of these compounds will

!!

!

!!

degrade the plastic housing.

Now that your EZTouch Panel is mounted, you are ready to connect your unit

to the power source, PLC, and programming computer or printer. The EZTouch

Panel’s PLC Port and COM1 Port support RS-232C, RS-422A and RS-485A

connections. Note that the EZTouch Panel is a DC powered unit (24 VDC).

See the section on Connections and Wiring, beginning on page 29 for further

information. See the section on Option Card Installation, beginning on page

32 if you have an option card installed in your EZTouch Panel.

The EZTouch Panel has some adjustable features and panel tests, such as,

Contrast, Clock, and Touchpad Test. You will also select whether the COM1

port will be used to connect to a Programming PC or a printer. The unit is

shipped with factory default values for some of these features, but they can be

adjusted by the user. To change any value, enter the SETUP MODE on powerup

and follow the procedures provided in the Communications Setup section be-

ginning on page 41.

EZ-TOUCH-M Revision 4 15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

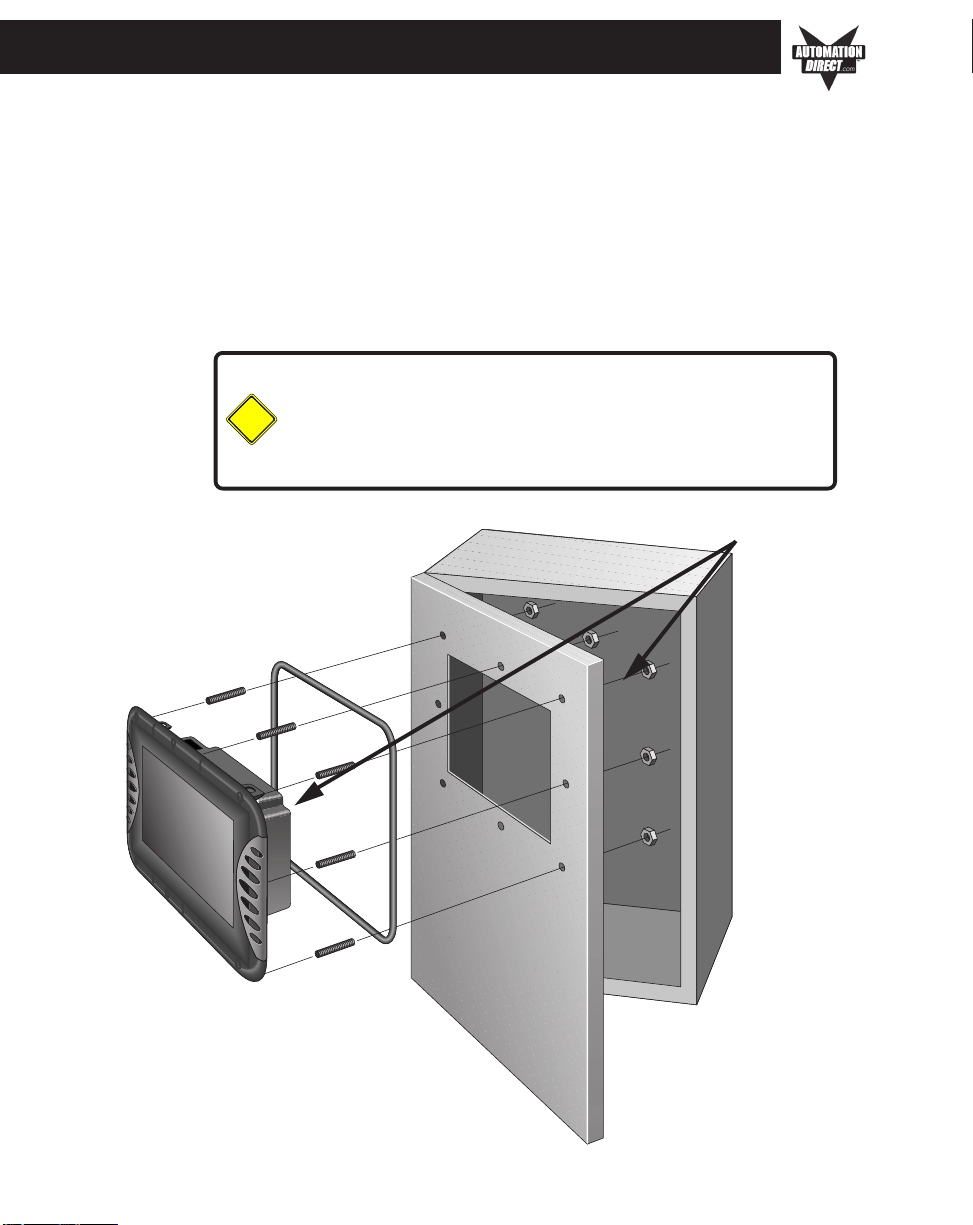

4 INSTALLATION

Mounting

EZTouch is a panel-mount unit. Most 6-inch units (6-inch Slim models are DIN Clip mounted only)

can be mounted using one of the following methods: 1. Studs; or 2. DIN Clips. 8-, 10-, and 15-inch

units are stud mounted only. The following diagrams show the outline and cutout dimensions necessary to mount the panel using Method 1. Studs. (See pages 27 and 28 for diagrams showing

Method 2. DIN Clips.)

METHOD 1. Stud Mounting

CAUTION

1) DO NOT use any thread locking compounds to secure the studs.

Many of these compounds will degrade the plastic housing.

!!

!

!!

2) Mount on a VERTICAL SURFACE ONLY in order to ensure proper

cooling of the panel.

Allow 1-inch

clearance

between rear of

EZTouch Panel mounting in a

NEMA4 rated enclosure

panel and

enclosure

Allow 4-inches

for panel X - Y

clearance.

16 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

4 INSTALLATION

EZ-S6M-R, EZ-S6M-F, EZ-S6M-FH, EZ-S6C-K,

EZ-S6C-F, EZ-S6C-FH Outline & Cutout Dimensions

All the necessary mounting hardware is provided with the unit. Use the 6 studs and 6 nuts

with captive washers to secure the unit to the mounting surface. Dimensions are provided

in inches and millimeters, mm appear in brackets [ ].

EZ-TOUCH-M Revision 4 17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

4 INSTALLATION

EZ-S6M-RS, EZ-S6M-FS, EZ-S6M-FSH, EZ-S6C-KS,

EZ-S6C-FS, EZ-S6C-FSH Outline & Cutout Dimensions

All the necessary mounting hardware is provided with the unit. See page 28 for DIN Clip installation instructions. Dimensions are provided in inches and millimeters, mm appear in brackets [ ].

18 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

4 INSTALLATION

EZ-S8C-F and EZ-S8C-FH Outline & Cutout Dimensions

All the necessary mounting hardware is provided with the unit. Use the 8 studs and 8 nuts with captive

washers to secure the unit to the mounting surface. Dimensions are provided in inches and millimeters, mm

appear in brackets [ ].

EZ-TOUCH-M Revision 4 19

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

4 INSTALLATION

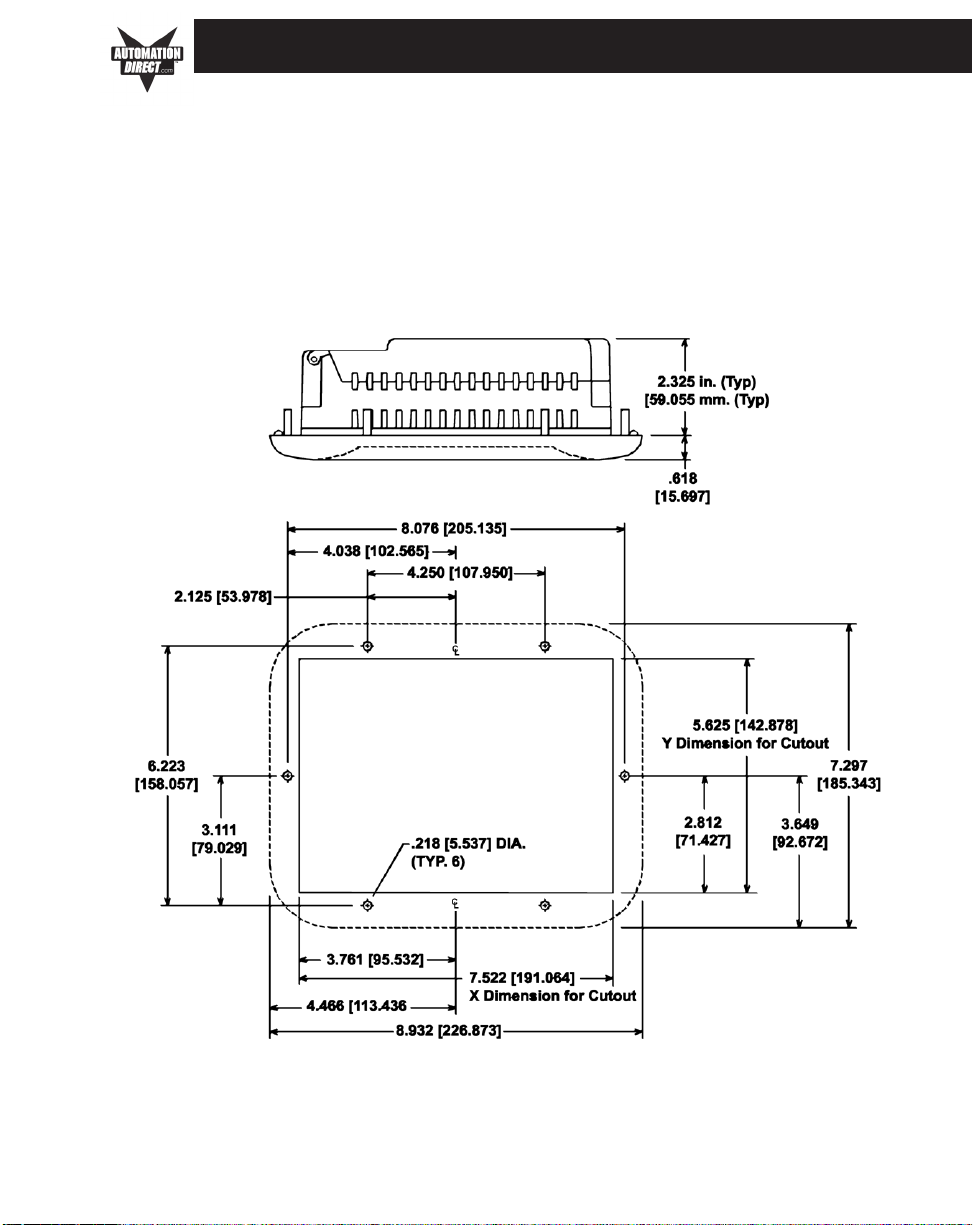

EZ-S8C-FS and EZ-S8C-FSH Outline Dimensions

The 8-inch Slim Bezel Models are Stud Mount only. All the necessary mounting hardware is provided with the

unit. Use the 8 studs and 8 nuts with captive washers to secure the unit to the mounting surface. Dimensions

are provided in inches and millimeters, mm appear in brackets [ ].

20 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

4 INSTALLATION

EZ-S8C-FS and EZ-S8C-FSH Cutout Dimensions

The 8-inch Slim Bezel Models are Stud Mount only. All the necessary mounting hardware is provided with the

unit. Use the 8 studs and 8 nuts with captive washers to secure the unit to the mounting surface. Dimensions

are provided in inches and millimeters, mm appear in brackets [ ].

EZ-TOUCH-M Revision 4 21

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

4 INSTALLATION

EZ-T10C-F and EZ-T10C-FH Outline & Cutout Dimensions

All the necessary mounting hardware is provided with the unit. Use the 8 studs and 8 nuts

with captive washers to secure the unit to the mounting surface.

22 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

4 INSTALLATION

EZ-T10C-FS, EZ-T10C-FSH, EZ-T10C-FSD, EZ-T10C-FSE, EZ-T10C-FSM,

and EZ-T10C-FSP Outline Dimensions

The 10-inch Slim Bezel Models are Stud Mount ONLY. All the necessary mounting hardware is provided with the unit. Use the 8 studs and 8 nuts with captive washers to secure

the unit to the mounting surface.

EZ-TOUCH-M Revision 4 23

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

4 INSTALLATION

EZ-T10C-FS, EZ-T10C-FSH, EZ-T10C-FSD, EZ-T10C-FSE, EZ-T10C-FSM,

The 10-inch Slim Bezel Models are Stud Mount ONLY. All the necessary mounting hardware is provided with the unit. Use the 8 studs and 8 nuts with captive washers to secure

the unit to the mounting surface.

and EZ-T10C-FSP Cutout Dimensions

24 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

4 INSTALLATION

EZ-T15C-FS, EZ-T15C-FSH, EZ-T15C-FSD, EZ-T15C-FSE, EZ-T15C-FSM,

and EZ-T15C-FSP Outline Dimensions

The 15-inch Slim Bezel Models are Stud Mount ONLY. All the necessary mounting hardware is provided with the unit. Use the 18 studs and 18 nuts with captive washers to

secure the unit to the mounting surface.

EZ-TOUCH-M Revision 4 25

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 35

4 INSTALLATION

EZ-T15C-FS, EZ-T15C-FSH, EZ-T15C-FSD, EZ-T15C-FSE, EZ-T15C-FSM,

The 15-inch Slim Bezel Models are Stud Mount ONLY. All the necessary mounting hardware is provided with the unit. Use the 18 studs and 18 nuts with captive washers to

secure the unit to the mounting surface.

and EZ-T15C-FSP Cutout Dimensions

26 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

METHOD 2. DIN Clips

The 6-inch Slim Bezel models must be mounted using DIN Clips. It is

optional for the other 6-inch models. DIN Clips are metal brackets (P/N EZBRK-1, package of 2 brackets and 4 screws) that attach to the panel and

secure the front panel to a mounting surface with 4 screws. Use the diagram

and instructions below to mount the EZTouch Panel using DIN Clips.

1. There are 4 rectangular holes in each side (two at the top and two at

2. On each DIN Clip there are two metal tabs (bent inward) that fit into

CAUTION: Tighten DIN Clips to a maximum of 1.5 inch-pounds to pro-

CAUTION

vide a proper seal. Automationdirect.com assumes no responsibility for

“liquids” damage to the unit or other equipment within the enclosure

because of improper installation.

4 INSTALLATION

the bottom) of the chassis as shown in the following figure. Choose

the holes that allow the appropriate space for your mounting panel

thickness.

these holes. Insert the two clip tabs into two holes (top and bottom)

and secure the panel by alternately tightening the DIN Clip screws (4)

until the back edge of the EZTouch Panel front bezel is flush with the

mounting panel.

EZ-S6M-R, EZ-S6M-F, EZ-S6M-FH, EZ-S6C-K, EZ-S6C-F, EZ-S6C-FH DIN Clip Slot Location

Front Bezel

Mounting Panel

DIN Clip location Screws (4)

DIN Clip tab inserted into rectangular

hole closest to the front bezel

EZ-TOUCH-M Revision 4 27

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

4 INSTALLATION

Slim Bezel Models EZ-S6M-RS, EZ-S6M-FS, EZ-S6M-FSH,

EZ-S6C-FS, EZ-S6C-KS, EZ-S6C-FSH DIN Clip Slot Location

Front Bezel

Mounting Panel

DIN Clip location

DIN Clip tab inserted

into rectangular hole

closest to the front bezel

Screws (4)

28 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

Connections and Wiring

Back View

Power Terminals

Connect (+) on the

unit to the (+) lead of

your power source;

(-) on the unit is connected to the (-)

lead, and chassis

GND (on the unit) is

connected to the

chassis ground of

the cabinet. See

page 30 for more information on power

connector.

Wiring Diagram

4 INSTALLATION

Status LED

The Status LED provides

an indication of unit status.

It will illuminate as RED or

GREEN. If the LED does

not light, this indicates that

there is NO POWER to unit

or the power supply failed.

Check or replace power

supply. If the LED turns

RED and stays RED, check

power supply to ensure it

has sufficient current

capability. If the LED

flashes RED and turns

GREEN that indicates

normal operation. For more

information, see the

Troubleshooting section of

this manual.

Power Connector

Bottom View

RS-232C, RS-422A or RS-485A Female 15-pin DSub Connector. Most PLCs connect to 15-pin D-

Sub with cable specific to the PLC type (see

table, page 30, for cable part numbers.) Special

interface boards with PLC connector are avail-

able for PLCs requiring a special connector.

For special Option Card Connector information,

see pages 32 through 39.

PLC Cable

See page 32 for more

information.

PLC Port

PLC Port

COM 1 Port

COM 1 Port

RS-232C, RS-422A, or RS-485A Female 9-pin

D-Sub Connector for connection to programming computer. When not in use for programming, it may be used for connection to

a serial printer. See page 31.

Programming PC Cable

P/N EZTOUCH-PGMCBL

See page 31 for more

information.

EZ-TOUCH-M Revision 4 29

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

4 INSTALLATION

Power Terminal

It is recommended you use a regulated power source isolated from relays,

valves, etc.

Power Connector (P4, Phoenix 3-pin Header, 0.2 cntr)

Pin # Connection

+V

1

24VDC (20–30 VDC)

–V

2

PLC Port

The table, below left, provides the pinout for the panel PLC connector. The

table,below right, provides the PLC Cable Part Number that is specific to your

PLC. Cable wiring diagrams for each PLC are provided in Appendix A. Special

interface boards with PLC connector are available for PLCs requiring a special

connector. For EZTouch Panels with A-B DH+ option cards installed, see tables

on pages 5 and 6 in Chapter 2. See page 33 for EZEthernet Option Card port.

PLC Cable Part Numbers

rebmuNtraP noitpircseDelbaC

LBC2-ZE tceriD ,501LD,60LD,50LD,trop21JRCLPcigoL

1-LBC2-ZE tceriD ,)1-052(052LD,tropnip-51)elytSAGV(cigoL

LBC3-ZE tceriD )C232-SR(043LD,trop11JRCLPcigoL

1-LBC4-ZE tceriD )C232-SR(504LD,tropbusDniP-51CLPcigoL

2-LBC4-ZE tceriD ,053LD,504LD,tropbusDniP-52CLPcigoL

LBC-03-09-ZE)A224-SR(tropbusDnip-5107/09dna03/09EG

LBC-854HD-ZE)C232-SR(trop584-HDCLSBA

LBC-232-CLS-ZE)C232-SR(trop1FD50/40/30/5CLSBA

LBC-232-5CLPZE)C232-SR(trop1FD5CLPBA

LBC-XIGOLM-ZE)C232-SR(0051&0021,0001xigoLorciMBA

LBC-USTIM-ZE)A224-SR(tropnip-52seireSXFihsibustiM

1-LBC-USTIM-ZE)A224-SR(nip-8seireSXFihsibustiM

LBC-NORMO-ZE)C232-SR(005C,002CnormO

LBC-IPM7S-ZE)C232-SR(retpadAIPM7snemeiS

3

Chassis Ground

8

1

PLC Connector

Pinout

915

)C232-SR(054LD&053LD,502LD

)C232-SR(60LD,062LD

)C232-SR(s'MCDlladna,UCD503LD

Pin

Number

Chassis GND

1

PLC TXD (RS-232C)

2

PLC RXD (RS-232C)

3

+5V (1 00Ω)

4

Logic GND

5

LE

6

PLC CTS (RS-232C)

7

PLC RTS (RS-232C)

8

RXD+ (RS-422A)

9

RXD- (RS-422A)

10

TXD+ (RS-422A)

11

TXD- (RS-422A)

12

Terminating Resistor (connect to pin 9)

13

NC

14

NC

15

Connec tion

30 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

4 INSTALLATION

COM1 Port

The COM1 Port is used to connect a programming computer or a printer to the

EZTouch Panel. The panel only needs to be connected to a PC when you are

programming the unit. You will use the EZTouch Panel Programming Software

to design the touch panel screens. A wiring diagram for the EZTouch Panel

RS-232C Programming Cable is shown below. The table shows EZTouch’s

pinout for RS-232C and RS-422A connections.

RS-232C EZTouch Panel Programming Cable (P/N EZTOUCH-PGMCBL)

Connect a

Programming PC

or

Printer

PC COM Port

TXD

RXD

D-sub 9-pin

Fem ale

GND

DTR

DSR

CTS

(2)

(5)

(4)

(6)

(8)

RS-232

EZ TOUCH

RXD(3)(3)

(2)

TXD

(5)

(Shell)

D-sub 9-pin

Male

COM1

COM1 Connector

Pin # RS-232C Connection RS-422A Connection

1 DO NOT USE TXD– (RS-422/485) TXD– (RS-422/485)

2 TXD (RS-232C) DO NOT USE TXD (RS-232C)

3 RXD (RS-232C) DO NOT USE RXD (RS-232C)

4 DO NOT USE RXD– (RS-422/485) RXD– (RS-422/485)

5 Logic GND Logic GND

6 DO NOT USE TXD+ (RS-422/485) TXD+ (RS-422/485)

7 DO NOT USE CTS (NOT USED) DO NOT USE CTS (NOT USED)

8 DO NOT USE RTS (NOT USED) DO NOT USE RTS (NOT USED)

9 DO NOT USE RXD+ (RS-422/485) RXD+ (RS-422/485)

EZ-TOUCH-M Revision 4 31

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

4 INSTALLATION

Option Card Installation

The EZTouch Panel Models EZ-S6M-FH, EZ-S6M-FSH, EZ-S6C-FH, EZ-S6CFSH, EZ-S8C-FH, EZ-S8C-FSH, EZ-T10C-FH, EZ-T10C-FSH, and EZ-T15CFSH have the Allen-Bradley Data HIghway Plus/Remote I/O Option Card installed. (Allen-Bradley option cards are designated by an “H” at the end of the

part number.

Also, EZ Ethernet Models (P/N EZ-ETHERNET) and EZTouch Panel Models

EZ-T10C-FSD, EZ-T10C-FSE, EZ-T10C-FSM, EZ-T10C-FSP, EZ-T15C-FSD,

EZ-T15C-FSE, EZ-T15C-FSM, and EZ-T15C-FSP, have an option card installed.

Those with a “D” at the end of the part number have a generic DeviceNet I/O

card installed, with an “E” have a generic Ethernet I/O card installed, those

with a “M” have a Modicon Modbus Plus card installed, and those with a “P”

have a generic Profibus-DP option card installed. A connector, unique to each

option, is attached to these option boards and is accessible from the bottom of

the unit.

The option card has been installed to the backplane connector shown below.

(The connector on the bottom right side of the card installs into the backplane

connector.) The card is secured with two screws.

A section of the plastic back cover has been removed to allow access to option

card connectors that extend over the edge of the board. See the following

pages for more information on each board.

DH+ Option Card is

installed into the

Backplane connector

shown here

Panel open, showing installed

Option Card (Allen-Bradley DH+

is shown)

32 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

Allen-Bradley Data Highway Plus Option Card

62-PIN SOCKET

MOUNT ON BACK SIDE

4 INSTALLATION

The Allen-Bradley Data Highway Plus

PLC connector that extends over the

edge of the board is shown below. Next

to the connector are two LEDs that illuminate to indicate status.

EZTouch Panel A-B PLC Data

Remote I/O Highway Plus

Option Card Connector

1 Blue ______________________________ 1

Shield ______________________________ Shield

2 Clear _____________________________ 2

EZ-TOUCH-M Revision 4 33

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

A-B DH+

Connector

Configuration

“ERROR” LED

Transmit

Enable LED

Page 43

4 INSTALLATION

EZ Ethernet Option Card

The EZ Ethernet Option Card (P/N EZ-ETHERNET) comes with two different

type screws. Remove the screws from the packaging and set aside.

a. Connect EZTouch Panel to a computer and, following instructions in

EZTouch Panel Software Help Topics or User Manual, upload the user

program from the Panel to the computer. Save the user program to

DO NOT FORCE THE

CARD CONNECTOR

into the backplane —

to do so may bend or

break the pins and

permanently damage

the card. First, ensure

that the pins are

aligned properly, and

then press firmly into

place.

disk.

b. Disconnect panel power source.

c. Open back cover (shown open in figure to

the right) to install the card.

d. The connector on the bottom right side of

the card installs into the backplane

connector.

e. Secure the card into place by installing the

two screws.

f. The bottom of the plastic back cover has a

section that must be removed to allow access to the EZ Ethernet

connector that extends over the edge of the board. To remove this

plastic section, look for the perforation and snap it out along the

performation with a pair of pliers.

g. Close rear cover and press so that it snaps into place.

h. Reconnect power source, connect to PC, run EZTouch Programming

Software and follow instructions to download the user program

previously saved to disk.

i. Consult the EZ Ethernet Option Card Manual (P/N EZ-ETHERNET-M)

for programming instructions.

BACKPLANE

DIP Switches

Connector

LEDs

34 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

MAC ID

4 INSTALLATION

EZ Ethernet Option Card Outline Drawing

For more information about the card, connector, LEDs and Switches, see the

EZ Ethernet Option Card Manual (P/N EZ-ETHERNET-M)

62-PIN SOCKET

MOUNT ON BACK SIDE

(only visible with rear panel

LEDs

housing open)

For information about LEDs, DIP Switches, Connections

and programming, refer to the EZ Ethernet Option Card

Manual, P/N EZ-ETHERNET-M.

EZ-TOUCH-M Revision 4 35

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Connector

(RJ45)

DIP Switches

(only visible with rear panel open)

Page 45

4 INSTALLATION

Generic DeviceNet I/O Option Card

The EZTouch Panel Models EZ-T10C-FSD, and EZ-T15C-FSD have the

DeviceNet I/O Option Card installed. A special connector is attached to these

option boards and is accessible from the bottom of the unit.

The bottom of the plastic back cover has a section that has been removed to

allow access to the DeviceNet connector that extends over the edge of the

board. Next to the connector are DIP Switches and then four LEDs that illuminate to indicate status. The Watchdog LED is only visible when you open the

back cover.

DeviceNet Connector

DIP Switches

Watchdog LED

Status LEDs

Connector

Pin

1 V- Negative supply voltage

2 CAN_L CAN_L bus line

3 SHIELD Cable shield

4 CAN_H CAN_H bus line

5 V+ Positive supply voltage

Signal Description

36 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

Generic Ethernet/IP Option Card

EZTouch Panel Models EZ-T10C-FSE, and EZ-T15C-FSE have the Ethernet/

IP Option Card installed. A special connector is attached to these option boards

and is accessible from the bottom of the unit.

The bottom of the plastic back cover has a section that has been removed to

allow access to the Ethernet /IPconnector that extends over the edge of the

board. Next to the connector are DIP Switches used for configuration, and

four LEDs that illuminate to indicate status. The Watchdog LED is only visible

when you open the back cover. The module uses twisted-pair cables, and no

external termination is required.

4 INSTALLATION

RJ45 (Standard)

Pin Signal

1TD+

2TD-

3RD+

4 Termination

5 Termination

6RD-

7 Termination

8 Termination

EZ-TOUCH-M Revision 4 37

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 47

4 INSTALLATION

Modicon Modbus Plus Option Card

The EZTouch Panel Models EZ-T10C-FSM, and EZ-T15C-FSM have the Modbus

Plus Option Card installed. A special connector is attached to these option

boards and is accessible from the bottom of the unit.

The bottom of the plastic back cover has a section that has been removed to

allow access to the Modbus connector (9-pin Female D-SUB) that extends over

the edge of the board. Two types of connectors are available from Modicon for

connecting devices to the network. Each inline drop requires a line connector,

Modicon part number AS-MBKT-085. This part number contains one connector. The drops at the two ends of the cable, each require a terminating connector, Modicon part number AS-MBKT-185. This contains two connectors.

The Modbus Plus node address can be set using the first six positions of the

DIP switches located at the top of the option board as shown in the diagram

below. When the board is seated in the panel, setting the DIP Switch in the UP

position is the ON position. There are three Status LEDs on the Modbus Plus

option card: MBP, TXD, and RXD. The TXD and RXD LEDs indicate the board

is transmitting or receiving data. The MPB LED (leftmost LED) indicates Modbus

Plus status.

38 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 48

Generic Profibus-DP Option Card

The EZTouch Panel Models EZ-T10C-FSP, and EZ-T15C-FSP have the

Profibus-DP Option Card installed. A special connector is attached to these

option boards and is accessible from the bottom of the unit.

The bottom of the plastic back cover has a section that has been removed to

allow access to the Profibus-DP connector that extends over the edge of the

board. Next to the connector are a Termination Switch, Rotary Address

Switches, and four LEDs that illuminate to indicate status.

4 INSTALLATION

FIELDBUS CONNECTOR

9-pin female D-SUB connector

D-SUB Screw Terminal Name

Housing Shie ld C onnected to PE

1 Not connected -

2 Not connected -

3 B-Line Positive RxD/TxD according

4 RTS Request to Send*

5 GND BUS Isolated GND from RS-485

6 +5 V BUS Isolated +5 V from RS-485

7 Not connected -

8 A-Line Negative RxD/TxD according

9 Not connected -

* +5V BUS and GND BUS are used for bus termination. Some

devices, like optical transceivers (RS-485 to fiber optics) might

require external power supply from these points. RTS is used in some

equipment to determine the direction of transmission. In normal

applications only A-Line, B-Line, and Shield are used.

to RS-485 specification

side*

side

to RS-485 specification

EZ-TOUCH-M Revision 4 39

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 49

4 INSTALLATION

This page intentionally left blank.

40 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 50

Communications Setup

memory. Below that is displayed the time and date, whether the COM1 port is

connected to a computer or a printer, and the current Contrast setting. There

are six buttons at the bottom of the screen. They are labeled Clock, COM1,

Contrast, Touchpad Test, Display Test and Exit.

4 INSTALLATION

After the EZTouch Panel is powered up, you may

enter the Setup Mode by simultaneously pressing

the extreme upper left and lower left touch cells

on the panel screen. The following screen is dis-

played. Information is displayed in the upper left

hand corner about the current revision of the Firmware, Hardware, and Boot program. Also shown

is RAM memory — Used, Free and Total, and Flash

Main Setup Screen

Clock

Clock Setup Screen

SET TIME AND DATE

When you press the Clock button, the screen shown above will appear.

EZ-TOUCH-M Revision 4 41

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 51

4 INSTALLATION

Enter the current time and date. Press the keypad button of the number you

want to enter. It will show in the display window. If correct, press Hr, Min, Sec,

or Day, Mon, Yr corresponding to the time or date position you are setting. If

not correct, press CL to clear the window. For the month, enter the number of

the month and the three letter abbreviation for the month will be displayed

(e.g., 7 = July = JUL).

COM1

COM1 Port

Setup Screen

ASSIGN COM1

The COM1 button is used to assign the COM1 port for use with an external

device. When you press the COM 1 button, the screen shown above will appear. Press the Computer button if the port will be connected to the programming computer. Press the Printer button if the port will be connected to a printer.

Please Note: If you are in Setup Mode, it doesn’t matter what the COM1

setting is (Printer or Computer), you CAN STILL TRANSFER A PROGRAM

from EZTouch Programming Software to the panel. The COM1 setting to

Printer is OVERRIDEN while in Setup Mode. When you exit Setup Mode,

however, the Printer assignment to COM1 becomes effective—you WILL

NOT have a connection established between the computer and the panel

and WILL NOT be able to transfer a program. You must return to Setup

Mode and REMAIN in Setup Mode while transferring, OR change the COM1

assignment on the ASSIGN COM1 screen, shown above, to Computer,

exit Setup Mode, and THEN you can transfer the program to the panel.

To enter Setup Mode from the user program, press on the extreme upper

and extreme lower touch cell on the EZTouch Panel touchscreen. On the

first Setup Mode Screen, press the COM1 button. From the ASSIGN COM1

screen (shown above), press Computer. You are automatically taken back

to the first setup screen. Press the Exit button to return to the user program.

42 EZ-TOUCH-M Revision 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 52

4 INSTALLATION

Contrast