Page 1

ZQ375

Checkweigher

User Instructions

AWT35-500812

Issue AC

Page 2

© Avery Weigh-Tronix, LLC 2012. All rights reserved.

No part of this publication may be reproduced, stored in an electronic retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior written consent of

the copyright owner, or as permitted by law or under license. Full acknowledgment of the source must be given.

Avery Weigh-Tronix is a registered trade mark of the Avery Weigh-Tronix, LLC. This publication was correct at the

time of going to print however, Avery Weigh-Tronix, LLC reserves the right to alter without notice the specification,

design, price or conditions of supply of any product or service at any time.

All third party brands and product names used within this document are trademarks or registered trademarks of

their respective holders.

ZQ375_u_en_500812.book

Page 3

Table of Contents

page

Chapter 1 General information and warnings ......................................................................................... 7

About this manual ..............................................................................................................7

Text conventions ......................................................................................................... 7

Special messages ....................................................................................................... 7

Installation .......................................................................................................................... 8

Safe handling of equipment with batteries .................................................................. 8

Wet conditions ............................................................................................................. 8

Routine maintenance ......................................................................................................... 8

Cleaning the machine ........................................................................................................ 9

ZQ375 cleaning process ............................................................................................. 9

Indicator ..................................................................................................................... 10

Cleaning the Rear of the Column .............................................................................. 11

Base Cleaning ........................................................................................................... 11

Training ............................................................................................................................ 11

Sharp objects ................................................................................................................... 12

FCC and EMC declarations of compliance ...................................................................... 12

United States ...................................................................................................... 12

Canada ............................................................................................................... 12

European Countries ............................................................................................ 12

Declaration of Conformity ................................................................................................ 13

Chapter 2 Introduction ............................................................................................................................ 14

Initial setup ....................................................................................................................... 14

Front panel ....................................................................................................................... 15

Annunciators ............................................................................................................. 17

Tolerance entry procedure ............................................................................................... 18

Example: To increase a value of 0.002 to 0.125: ................................................ 18

Numeric entry procedure ................................................................................................. 19

Example: To key in the number 507: .................................................................. 19

ID Entry Procedure .......................................................................................................... 19

Powering up the ZQ375 ................................................................................................... 20

Battery option ................................................................................................................... 20

Installation ................................................................................................................. 21

Proper charging of the ZQ-BAT ................................................................................. 22

Charging the battery pack using the supplied wall charger ................................ 22

Charging the battery pack through a ZQ375 indicator: ....................................... 23

Battery states indicated by LEDs .............................................................................. 23

Checkweigher Operation on Battery Power .............................................................. 24

Light stack option .............................................................................................................25

Light stack operation ................................................................................................. 25

Chapter 3 Checkweighing applications ................................................................................................. 26

Checkweighing terminology ............................................................................................. 26

Normal weighing procedures ........................................................................................... 28

Gross weighing .......................................................................................................... 28

Tare/Net weighing ..................................................................................................... 28

Using Pushbutton Tare (if enabled) .................................................................... 29

Using Preset Tare (if enabled) ............................................................................ 29

Sim375 application ........................................................................................................... 31

Checkweighing .......................................................................................................... 31

Switching Between Checkweighing and Normal Weighing Mode ....................... 31

ZQ375 Checkweigher User Instructions 3

Page 4

Setting a New Target Weight and Simple Checkweighing .................................. 31

View the High and Low Tolerances .................................................................... 32

Set New High and Low Tolerances ..................................................................... 32

Mid375 application ........................................................................................................... 33

SELECT key operation .............................................................................................. 33

Checkweighing .......................................................................................................... 33

Negative checkweighing ............................................................................................ 34

Sample mode checkweighing .................................................................................... 35

Sampling Method ................................................................................................ 35

Manual Target Weight Entry ............................................................................... 35

View the Target Weight and Upper and Lower Tolerances ................................ 36

Set New Upper and Lower Tolerances ............................................................... 36

Transaction counter ................................................................................................... 37

Adv375 application ........................................................................................................... 38

SELECT key operation .............................................................................................. 38

Checkweighing .......................................................................................................... 38

Setting a New Target Weight and Checkweighing .............................................. 39

Choosing a PLU and Checkweighing ................................................................. 39

View the Upper and Lower Tolerances ............................................................... 40

Set New Upper and Lower Tolerances ............................................................... 40

Transaction counter ................................................................................................... 41

Statistical Package and Packrun ............................................................................... 41

Printing the report: .............................................................................................. 41

Report Example: ................................................................................................. 42

X-Bar/R Program ....................................................................................................... 42

Per375 application ........................................................................................................... 43

Checkweighing .......................................................................................................... 43

Setting a New Target Percentage and Checkweighing ...................................... 43

Choosing a PLU and Checkweighing ................................................................. 44

View the Upper and Lower Tolerances ............................................................... 44

Set New Upper and Lower Tolerances ............................................................... 44

Grad375 application ......................................................................................................... 46

Positive vs. negative grading ..................................................................................... 46

Grade classifying ....................................................................................................... 46

Setting weight grades ................................................................................................ 46

Positive grading ......................................................................................................... 47

Negative grading with autotare enabled .................................................................... 47

Negative grading with autotare disabled ................................................................... 48

Chapter 4 Menus ...................................................................................................................................... 49

Accessing the menus ....................................................................................................... 49

Menu annunciators .......................................................................................................... 49

Exiting the menus ............................................................................................................ 50

USER level menus ........................................................................................................... 50

User menu ....................................................................................................................... 51

Time .......................................................................................................................... 51

Date ...........................................................................................................................52

Site ID ........................................................................................................................53

Seal ...........................................................................................................................53

About menu ...................................................................................................................... 54

Boot ...........................................................................................................................54

Firm and App ............................................................................................................. 55

Serial .........................................................................................................................55

Option ........................................................................................................................ 55

Enet ...........................................................................................................................56

Dload ......................................................................................................................... 57

Audit menu ....................................................................................................................... 57

4 ZQ375 Checkweigher User Instructions

Page 5

Counter ...................................................................................................................... 58

Print ........................................................................................................................... 58

Chapter 5 Error messages ...................................................................................................................... 59

PLU CSV file import error messages .............................................................................. 60

Chapter 6 Communications .................................................................................................................... 61

Default print formats ......................................................................................................... 61

Chapter 7 Supervisor menu .................................................................................................................... 63

Supervisor menu for Sim375 application ......................................................................... 64

Setpoint ..................................................................................................................... 65

Annunciators ....................................................................................................... 65

Inputs .................................................................................................................. 66

Print ..................................................................................................................... 66

Reset ................................................................................................................... 66

Check ........................................................................................................................ 67

Outputs ............................................................................................................... 67

Output-gross zero band ...................................................................................... 68

Under segment division ...................................................................................... 68

Over segment division ........................................................................................ 68

Reset ................................................................................................................... 69

Battery ....................................................................................................................... 69

Enable ................................................................................................................. 69

Timeout ............................................................................................................... 70

Supervisor menu for Mid375 application .......................................................................... 71

Setpoint ..................................................................................................................... 72

Tare ...........................................................................................................................72

Tare Register 1-10 .............................................................................................. 72

Printing ................................................................................................................ 73

Reset ................................................................................................................... 73

Check ........................................................................................................................ 73

Outputs ............................................................................................................... 74

Output-gross zero band ...................................................................................... 74

Under segment division ...................................................................................... 75

Over segment division ........................................................................................ 75

Digits ................................................................................................................... 75

Graph .................................................................................................................. 76

Type .................................................................................................................... 76

Auto Tare ............................................................................................................ 76

Reset ................................................................................................................... 77

Battery ....................................................................................................................... 77

Supervisor menu for Adv375 application ......................................................................... 78

Setpoint ..................................................................................................................... 79

Tare ...........................................................................................................................79

Check ........................................................................................................................ 79

Outputs ............................................................................................................... 80

Outputs-gross zero band .................................................................................... 80

Under segment division ...................................................................................... 80

Over segment division ........................................................................................ 81

Print total ............................................................................................................. 81

Total format ......................................................................................................... 82

Clear total ............................................................................................................ 82

Digits ................................................................................................................... 82

Graph .................................................................................................................. 83

Stats .................................................................................................................... 83

Packrun ............................................................................................................... 84

Type .................................................................................................................... 84

ZQ375 Checkweigher User Instructions 5

Page 6

Auto Tare ............................................................................................................ 84

Reset ................................................................................................................... 85

PLU ........................................................................................................................... 85

Edit ...................................................................................................................... 85

Print ..................................................................................................................... 87

Import .................................................................................................................. 87

Export .................................................................................................................. 88

Reset ................................................................................................................... 88

Battery ....................................................................................................................... 88

Supervisor menu for Per375 application .......................................................................... 89

Setpoint ..................................................................................................................... 90

Tare ...........................................................................................................................90

Check ........................................................................................................................ 90

PLU ........................................................................................................................... 90

Battery ....................................................................................................................... 90

Supervisor menu for the Grad375 application ................................................................. 91

Setpoint ..................................................................................................................... 92

Tare ...........................................................................................................................92

Grading ...................................................................................................................... 92

Battery ....................................................................................................................... 92

6 ZQ375 Checkweigher User Instructions

Page 7

1 General information and warnings

1.1 About this manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled using the 1.1 and 1.1.1 convention. The names of

the chapter and the next subsection level appear at the top of alternating pages of the

manual to remind you of where you are in the manual. The manual name and page

numbers appear at the bottom of the pages.

1.1.1 Text conventions

Key names are shown in bold and reflect the case of the key being described. If a key

has dual functions, the name of the key is shown first followed by the function in

parentheses and in bold, such as in these examples: TAR E(), UNITS(), etc.

Displayed messages appear in bold italic type and reflect the case of the displayed

message.

1.1 About this manual

1.1.2 Special messages

Examples of special messages you will see in this manual are defined below. The

heading words have specific meanings to alert you to additional information or the

relative level of hazard.

CAUTION!

This is a Caution symbol.

Cautions give information about procedures that, if not observed, could result

in damage to equipment or corruption to and loss of data.

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

ZQ375 Checkweigher User Instructions 7

Page 8

General information and warnings

1.2 Installation

NO USER SERVICEABLE PARTS. REFER TO QUALIFIED SERVICE

PERSONNEL FOR SERVICE.

1.2.1 Safe handling of equipment with batteries

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended by the manufacturer. Dispose

of used batteries according to the manufacturer’s instructions.

ATTENTION: Il y a danger d'explosion s'il y a remplacement incorrect de la

batterie, remplacer uniquement avec une batterie du même type ou d'un type

équivalent recommandé par le constructeur. Mettre au rebut les batteries

usagées conformément aux instructions du fabricant.

1.2.2 Wet conditions

Under wet conditions, the plug must be connected to the final branch circuit via an

appropriate socket / receptacle designed for washdown use.

Installations within the USA should use a cover that meets NEMA 3R specifications

as required by the National Electrical Code under section 410-57. This allows the unit

to be plugged in with a rain tight cover fitted over the plug.

Installations within Europe must use a socket which provides a minimum of IP56

protection to the plug / cable assembly. Care must be taken to make sure that the

degree of protection provided by the socket is suitable for the environment.

1.3 Routine maintenance

IMPORTANT: This equipment must be routinely checked for proper operation

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

Always turn off the machine and isolate from the power supply before starting any

routine maintenance to avoid the possibility of electric shock.

Before use in any NSF / ANSI 3-A food application this scale must be regularly

inspected to guarantee cleanliness at all times.

Scale needs to be regularly inspected to guarantee there are no loose or missing nuts

and that all bolt and knob threads are completely covered.

8 ZQ375 Checkweigher User Instructions

Page 9

1.4 Cleaning the machine

Check that the indicator and any battery or external OPTO22 relay box are secured

correctly in place with the correct locking knob.

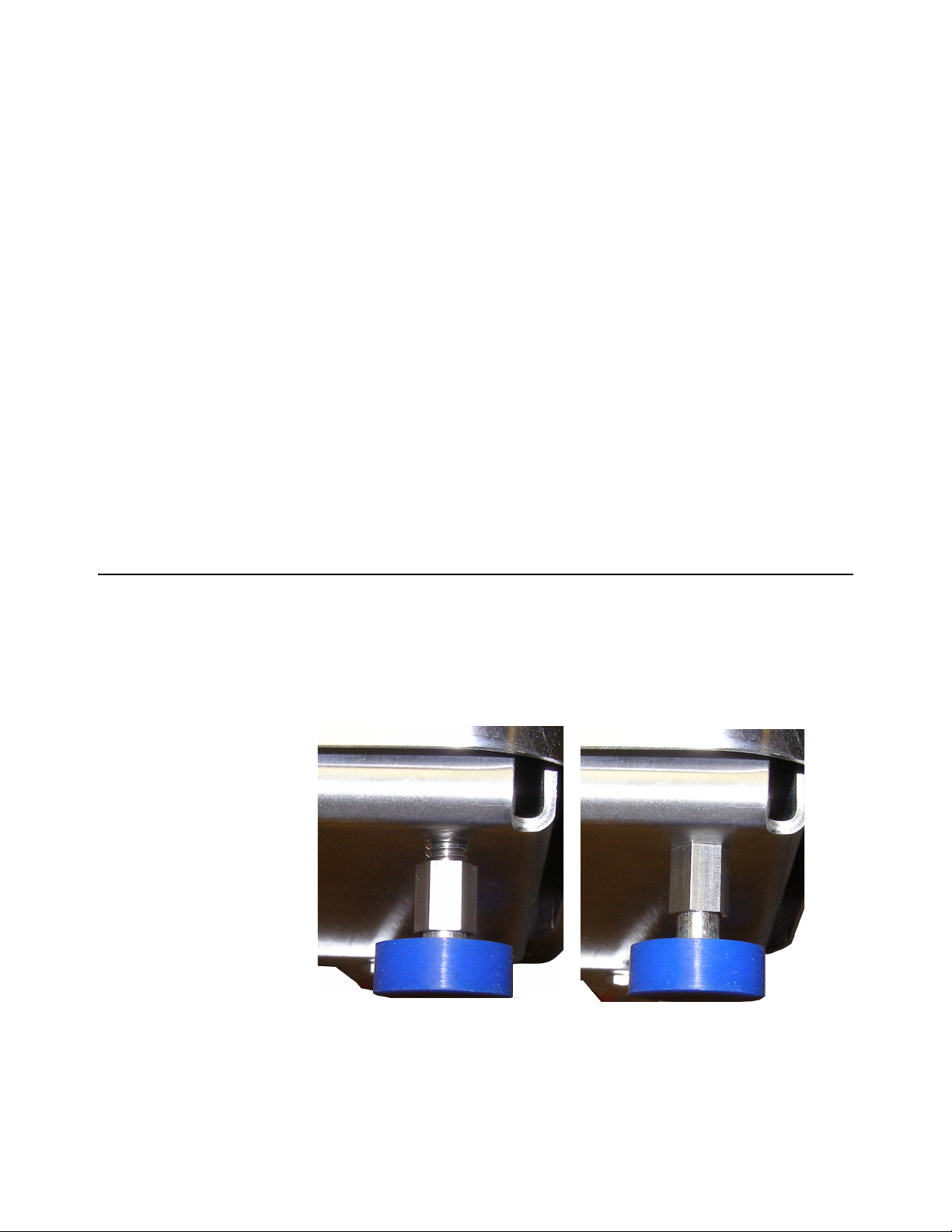

Check that the scale is set on a clean, flat, stable surface and levelled using the scale

feet and bubble level found between the column and the base.

Feet can be adjusted by loosening the locking sleeve and rotating the foot in or out until

the base becomes level.

Once level, the locking sleeve needs to be retightened with a spanner onto the base,

guaranteeing there are no threads visible once locked in place. See the illustration

below:

1.4 Cleaning the machine

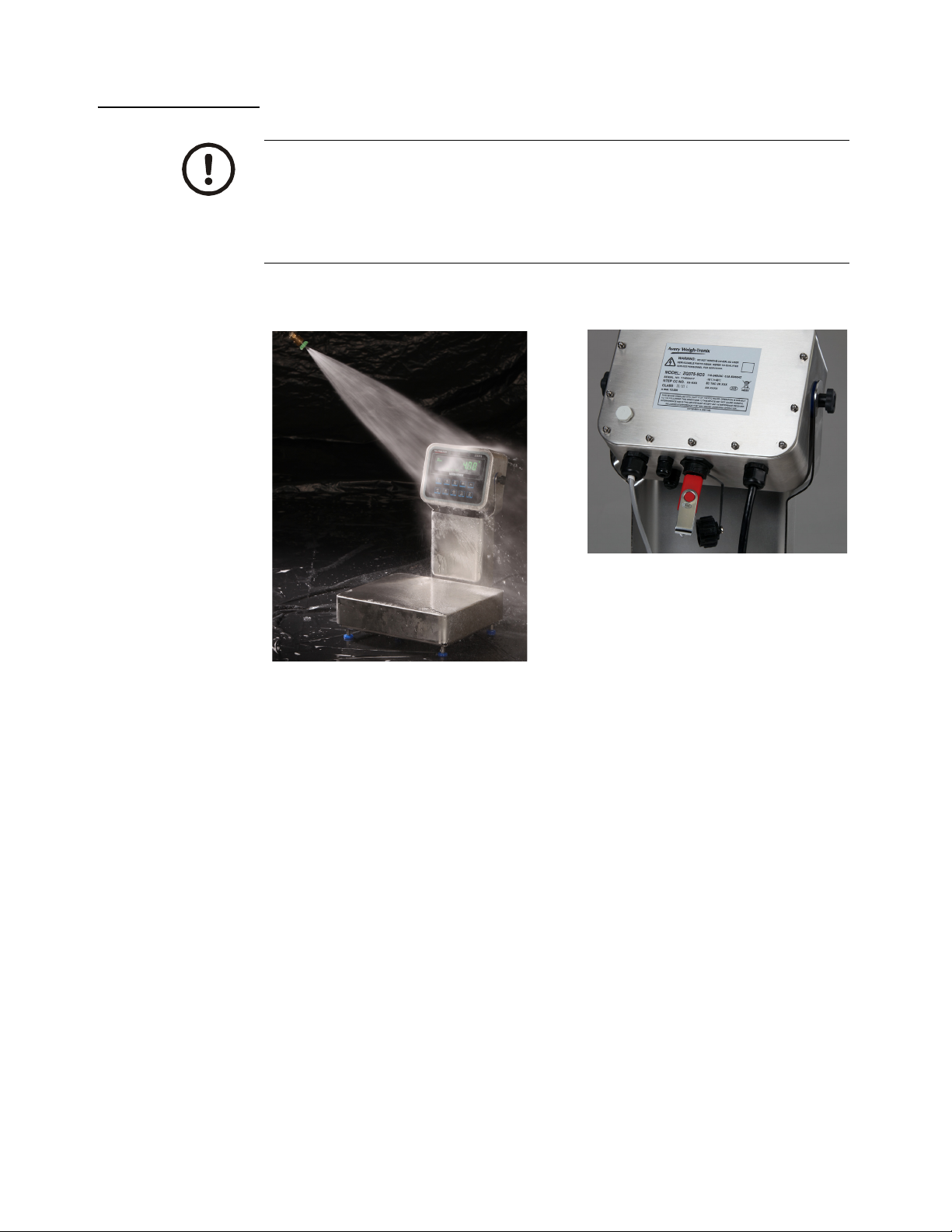

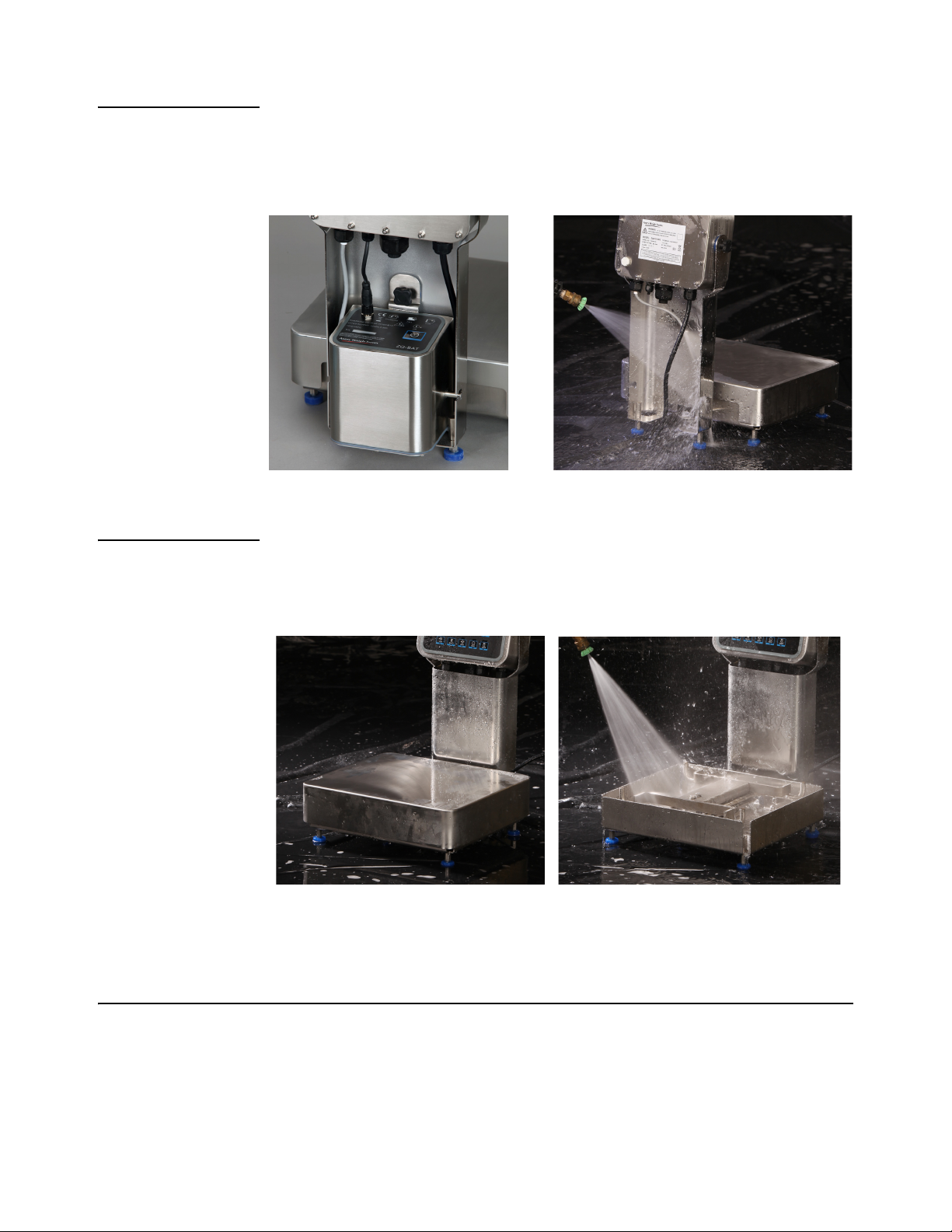

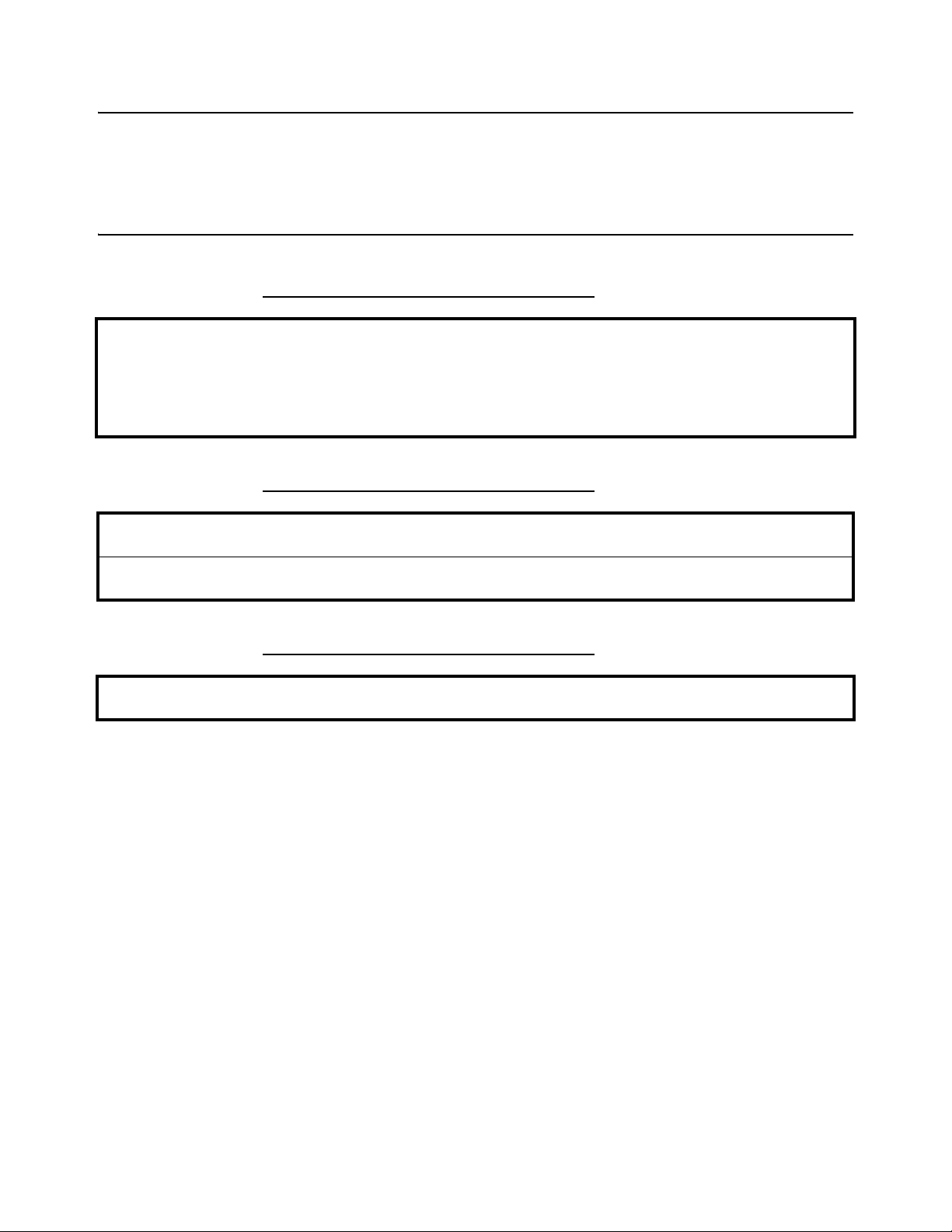

1.4.1 ZQ375 cleaning process

The ZQ375 checkweigher has been designed for use within NSF / ANSI 3-A food

applications.

It has minimum food trap areas to aid fast and efficient cleaning. All versions of the

ZQ375 scale, indicator, remote battery pack and external opto22 relay box can be

subjected to external high pressure cleaning to IP69K standards.

Bases marked with Model number BSF are suitable for high pressure cleaning

externally and under the scale platter in line with IP69K standards.

Bases marked with model number BSG are only suitable for high pressure cleaning

externally. Extra care has to be taken cleaning under the scale platter in line with IP65

/ Nema4X standards.

ZQ375 Checkweigher User Instructions 9

Page 10

General information and warnings

1.4.2 Indicator

CAUTION: It is essential that the power plug is kept in a safe dry area while

cleaning is in progress.

If external USB or Ethernet glands are installed in the indicator, it is essential

these be sealed with water tight caps prior to cleaning or when the connectors

are not in use.

10 ZQ375 Checkweigher User Instructions

Page 11

1.4.3 Cleaning the Rear of the Column

For rigorous cleaning it is recommended that the external battery pack or external relay

box, if installed, are removed to allow better access to the rear of the column while

cleaning. Before high pressure washing the battery, protect the battery connector with

the water tight cap supplied.

1.5 Training

1.4.4 Base Cleaning

While cleaning, it is essential that the weighing platform and the support plate should

be removed to allow full easy access into the base to aid the cleaning process and help

to sanitize all areas of the base.

1.5 Training

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instruction books.

To avoid the risk of RSI (Repetitive Strain Injury), place the machine on a surface which

is ergonomically satisfactory to the user. Take frequent breaks during prolonged usage.

ZQ375 Checkweigher User Instructions 11

Page 12

General information and warnings

1.6 Sharp objects

We do not recommend the use of sharp objects such as knives or screwdrivers to

operate the keys. This may shorten the life span of the keys.

1.7 FCC and EMC declarations of compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Canada

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la Classe A prescrites dans le Règlement sur le brouillage radioélectrique edicté par le ministère des Communications du Canada.

European Countries

WARNING: This is a Class A product. In a domestic environment, this product may cause radio interference in which the user may be

required to take adequate measures.

12 ZQ375 Checkweigher User Instructions

Page 13

1.8 Declaration of Conformity

1.8 Declaration of Conformity

ZQ375 Checkweigher User Instructions 13

Page 14

Introduction

2 Introduction

This manual covers operation of the ZQ375 Checkweigher from Avery Weigh-Tronix.

The checkweigher consists of a bench scale, an attached column and the ZQ375

Checkweigher head or indicator.

The ZQ375 Checkweigher is a reliable, easy to operate, high speed weighing scale,

designed to allow entry of a target weight, along with selected over and under weight

limits for the rapid processing of items that must be checked for conformity to a precise

weight range. It offers a range of standard statistical packages to allow precise

monitoring of any pack run. The data received enables the operation to be fine-tuned

to maximise performance and profitability.

It may be used in stand-alone or interfaced applications. The ZQ375 incorporates serial

multi-scale communications capabilities. The scale is housed in a watertight enclosure

to permit use in wet environments and can be washed down as necessary to meet

sanitary requirements.

This scale has been calibrated and inspected for mechanical and electronic integrity

prior to shipment. It should be free of defects and in perfect operating condition upon

receipt. To confirm this, the scale should be inspected immediately for any physical

damage incurred in transit. If the scale is damaged, contact your local Avery Weigh-

Tronix supplier.

2.1 Initial setup

Unpack the unit and place the it on a stable, non-vibrating, level surface. Feet can be

adjusted to level the scale by loosening the locking sleeve and rotating the foot in or

out until the base becomes level. Use the bubble level located between the scale and

the column.

Once level, tighten the locking sleeve up against the base to completely cover the feet’s

threads and to keep the feet from turning. See Figure 2.1.

Figure 2.1 Locking sleeve shown in unlocked and locked position

Plug the unit into an easily accessible, grounded power receptacle. See General

information and warnings on page 7 for a complete list of precautions concerning the

electrical safety of this product and for cleaning procedures.

14 ZQ375 Checkweigher User Instructions

Page 15

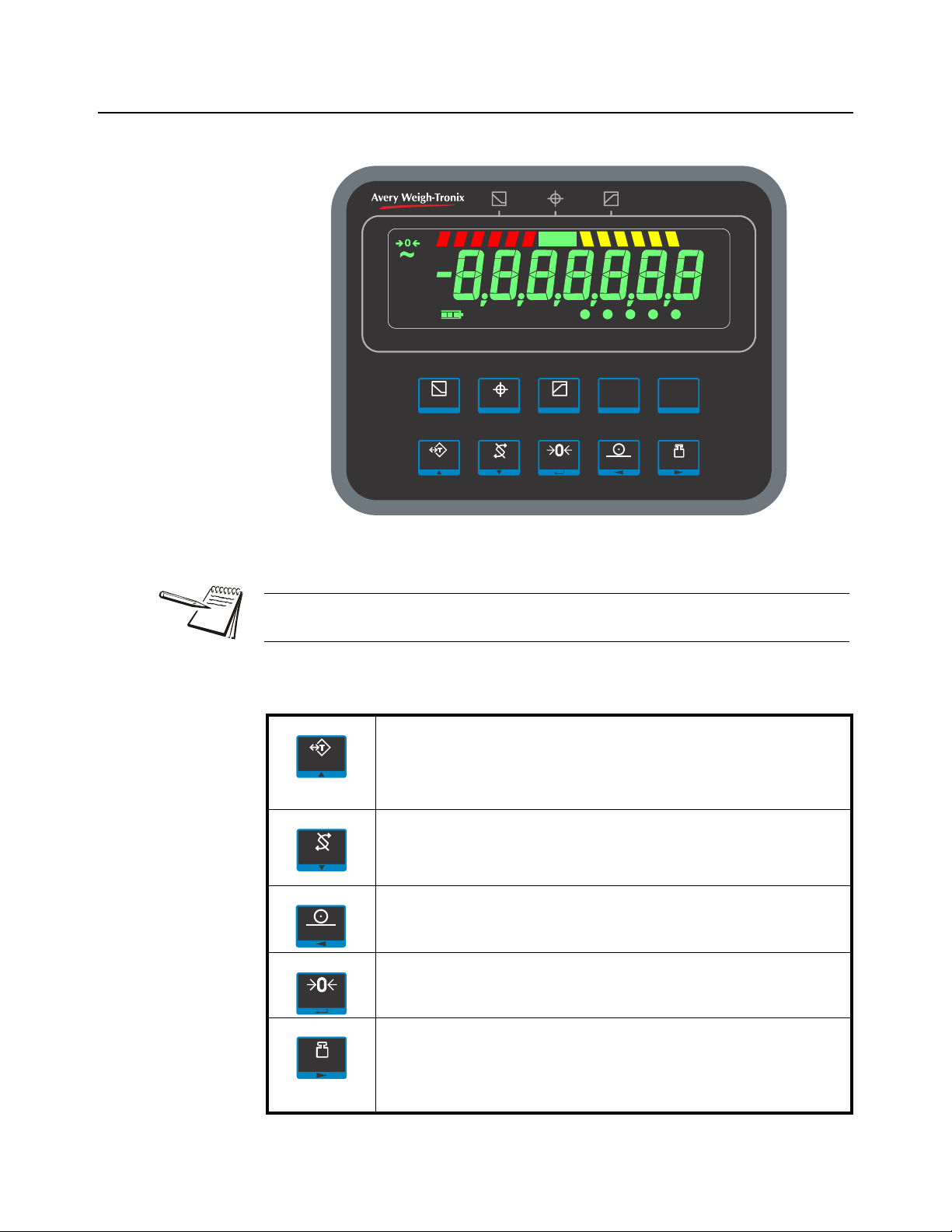

2.2 Front panel

ZQ375

GROSS

NET

TARE

COUNT

PRINT

SP1 SP2 SP3

%

PT

oz

g

kg

lb

TAR E SELECT

ZERO PRINT

UNITS

F1

ESC

OVERTAR GETUNDER

ID

TAR E

SELECT

PRINT

ZERO

UNITS

The front panel, shown in Figure 2.2, consists of the keys and the display.

2.2 Front panel

Figure 2.2 ZQ375 front panel

Never press a key with anything but your finger. Damage to the overlay may result if

sharp or rough objects are used.

The function of the keys on the front panel are listed below.

Weigh / Checkweigh mode - In weigh mode the TARE key will work as configured

via the Admin menu.(See the Service manual). In checkweigh mode, the TARE key

does not function and the display will show cAnt.

Menu navigation - Acts as an up arrow key.

Numeric / Tolerance Entry - Increments a value.

Weigh / Checkweigh mode - Press this key to change from weighing mode to

checkweighing mode and vice versa.

Menu navigation - Acts as a Down Arrow key.

Numeric / Tolerance Entry - Decrements a value.

Weigh / Checkweigh mode - Press to perform a print function.

Menu navigation - Functions as the Left Arrow key.

Numeric / Tolerance Entry - Functions as a backspace.

Weigh / Checkweigh mode - Press to zero the weight display.

Menu navigation - Functions as an Enter key to accept displayed choices.

Numeric / Tolerance Entry - Functions as an Enter key.

Weigh / Checkweigh mode - Press UNITS to cycle the displayed unit of measure

through all the available units of measure.

Menu navigation - Functions as the Right Arrow key.

Numeric / Tolerance Entry - Moves the cursor position to the right in the Numeric

Entry Procedure.

ZQ375 Checkweigher User Instructions 15

Page 16

Introduction

UNDER

TAR GET

OVER

ID

F1

Weigh / Checkweigh mode - Press UNDER to briefly display the active under

value. Press and hold UNDER to add or modify an existing under value tolerance.

Menu navigation - N/A

Numeric / Tolerance Entry - N/A

Weigh / Checkweigh mode - TARGET key acquires a target value, when

applicable. Its function changes in different applications. See the appropriate

application section.

Menu navigation - N/A

Numeric / Tolerance Entry - N/A

Weigh / Checkweigh mode - Press OVER to briefly display the active over value.

Press and hold OVER to add or modify an existing over value tolerance.

Menu navigation - N/A

Numeric / Tolerance Entry - N/A

Weigh / Checkweigh mode - Press the ID key briefly to view the active ID number.

Press and hold the ID key to view a prompt for ID number entry. Use the Numeric

Entry Procedure on page 18 to scroll in a new ID.

Menu navigation - N/A

Numeric / Tolerance Entry - N/A

Weigh / Checkweigh mode - Press to access PLU database, if enabled.

Press and hold to access the menu password display.

Menu navigation - Press to escape a screen without doing anything and move up

in the menu.

Numeric / Tolerance Entry - Press to escape a screen without doing anything and

move up in the menu.

EU trade regulations state a scale is not allowed to display more than 20 divisions

below gross zero. Any weight below this allowable limit will cause the display to show

under bars (_ _ _ _).

When a tare is active, EU trade regulations do not allow the scale to be zeroed. If the

scale displays under bars with no weight on the scale and the ZERO key will not rezero the scale, this could mean the zero was changed prior to setting a tare.

To clear this, press and hold the TA R E key until CLEAr is displayed and then press

the ZERO key. The scale should now display gross zero.

16 ZQ375 Checkweigher User Instructions

Page 17

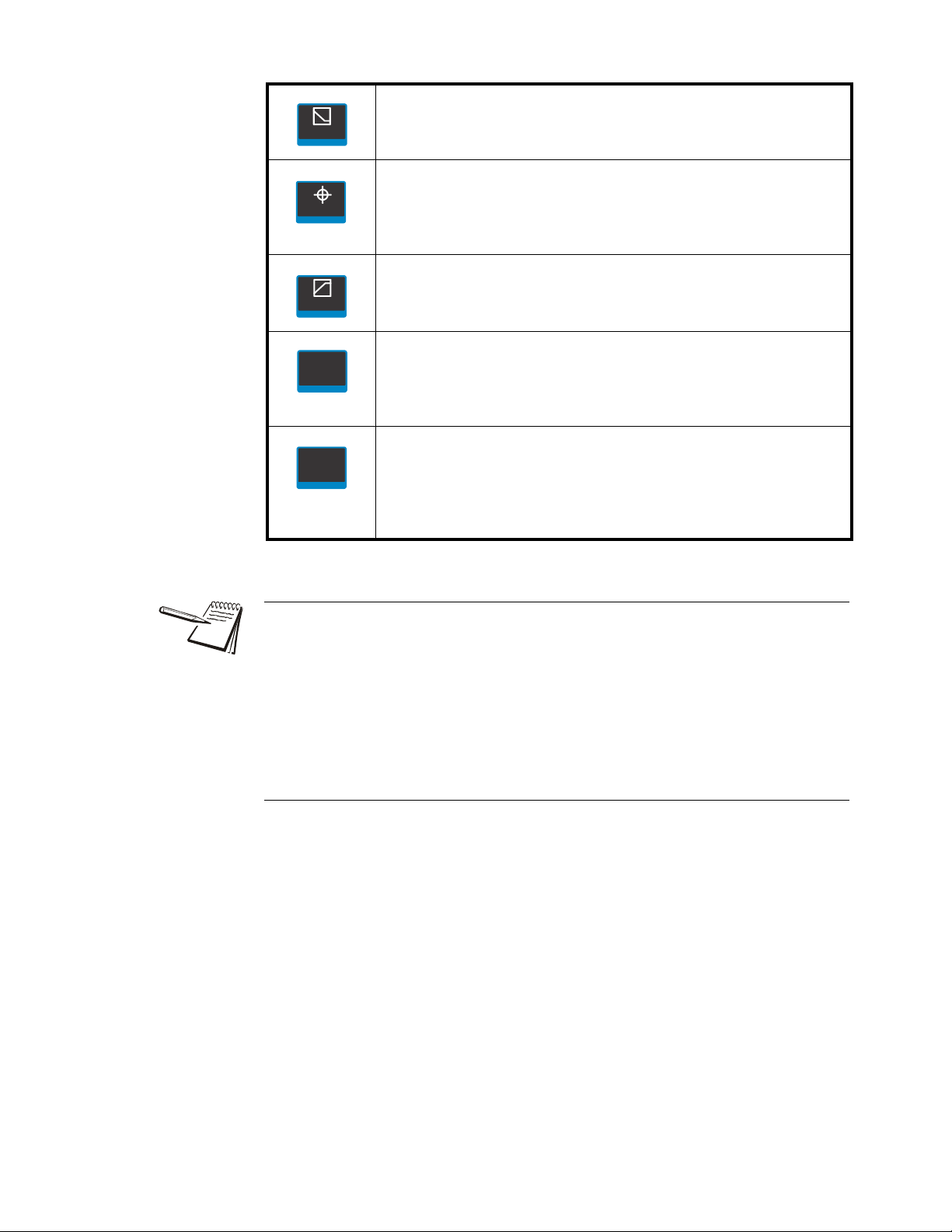

2.2.1 Annunciators

GROSS

NET

TARE

COUNT

PRINT

SP1 SP2 SP3

%

PT

oz

g

kg

lb

Target

segment

Over

segments

Under

segments

Units of

measure

See Table 2.1Setpoints

Battery

level

Active

Display

Stable

Center

of Zero

Print

Preset tare

Percent

Transaction

counter

The annunciators on the display are shown and labeled in Figure 2.3.

These annunciators will light during operation to inform the user of the weighing mode,

active unit of measure, etc.

2.2 Front panel

Figure 2.3 Annunciators

Table 2.1 Circle Annunciator assignments

Annunciator Indicates

Circle 1 (left most) Network activity

Circle 2 Custom unit

Circle 5 Transaction counter

Gross + Circle 5 Gross total

Net + Circle 5 Net total

Tare + Circle 5 Transaction total

ZQ375 Checkweigher User Instructions 17

Page 18

Introduction

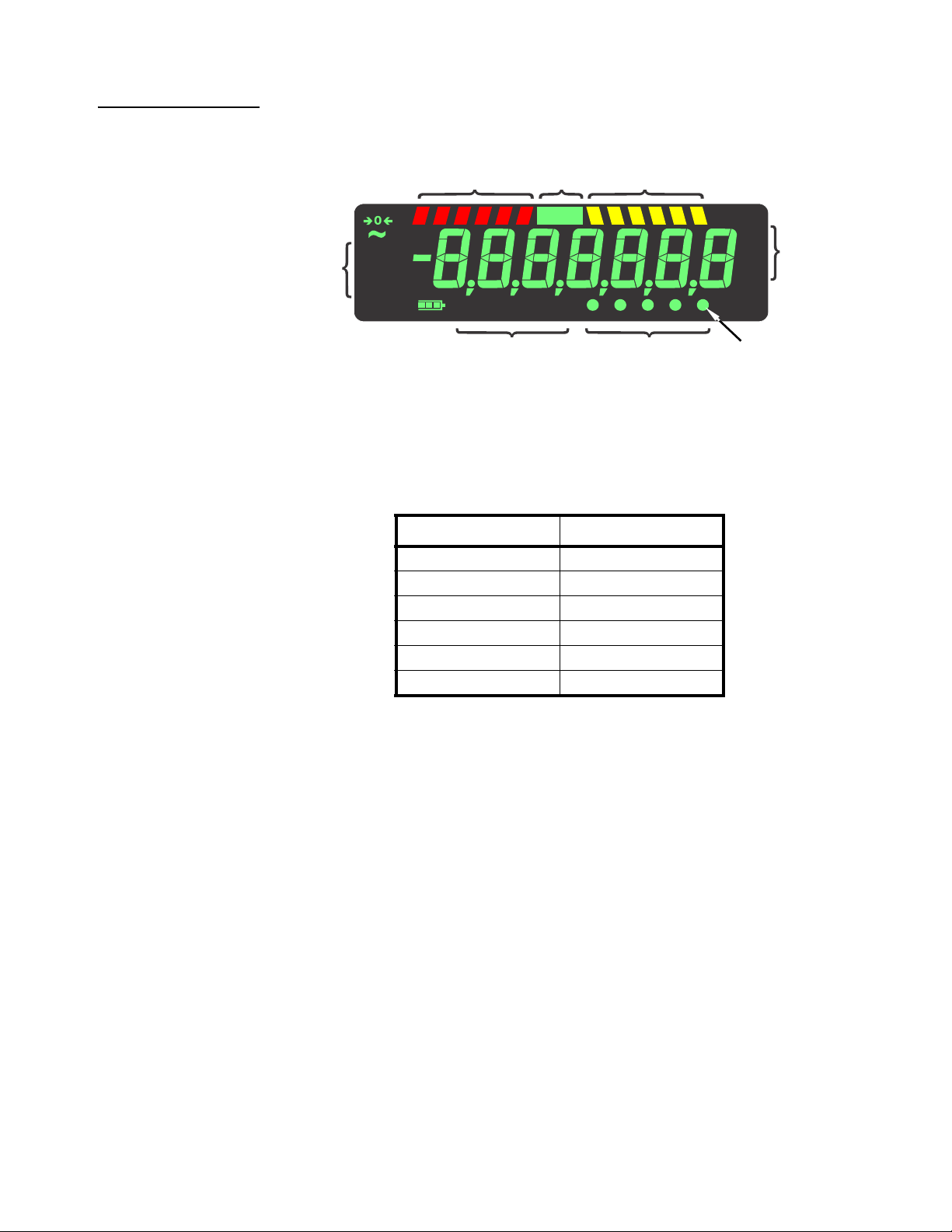

TARE /

-

SELECT /

-

These segments flash in tolerance entry mode

Press to increment right most digit by 1.

Press and hold to rapidly increase the value,

first by 10s and then by 100s

Press to decrement right most digit by 1.

Press and hold to rapidly decrease the value,

first by 10s and then by 100s

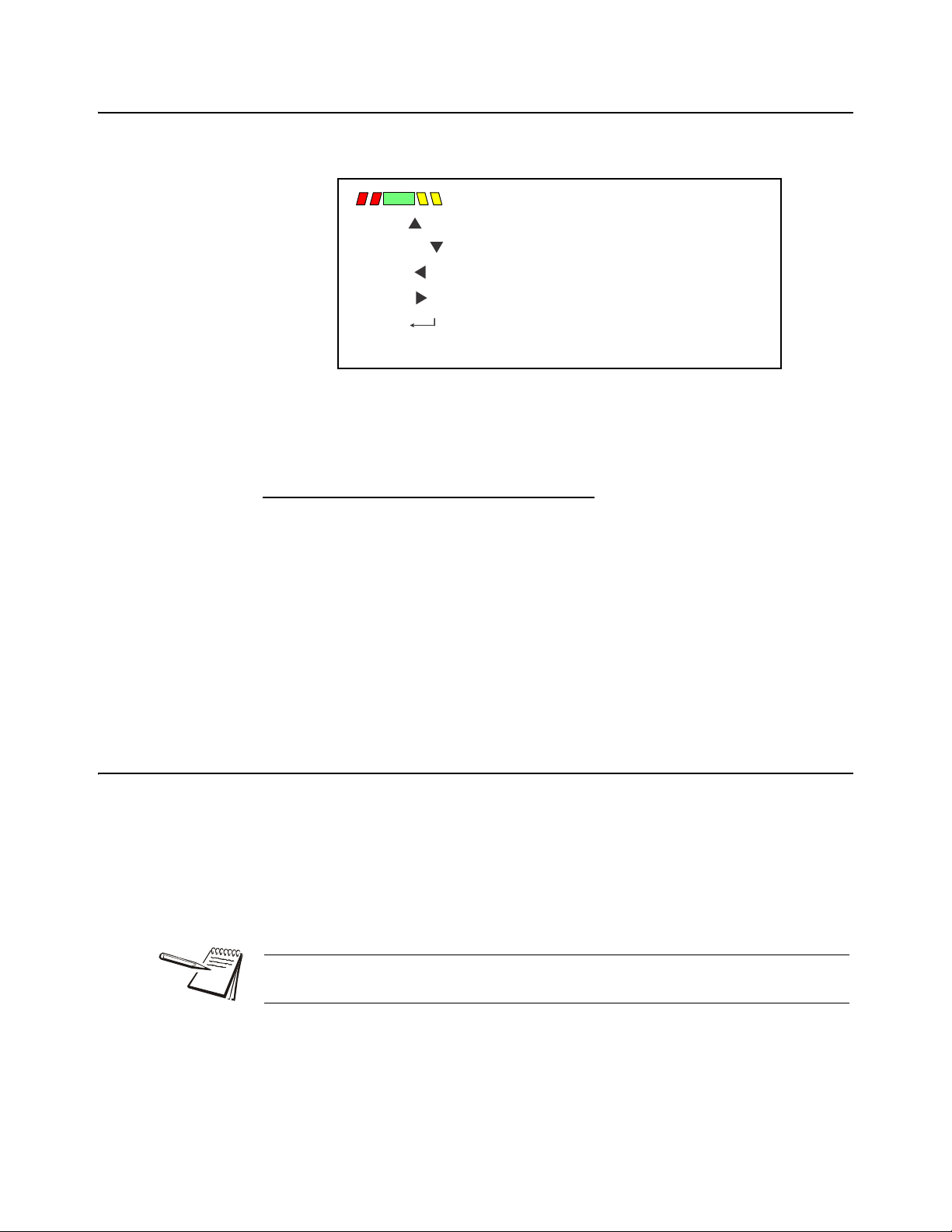

2.3 Tolerance entry procedure

If you are in a target or tolerance value entry screen and no key is pressed within five

seconds, the scale will act as if the F1/Escape key was pressed and return to the

previous screen without saving any information.

When you are in a tolerance entry screen the yellow OVER segments flash as a

reminder. Figure 2.4 shows the key functions when in this mode.

Figure 2.4 Key functions in tolerance entry

In tolerance entry screens, the segments shown in Figure 2.4 flash. Use the keys, as

described in Figure 2.4, to enter a value on the display. Following is an example:

Example: To increase a value of 0.002 to 0.125:

Press and hold TAR E() key until the number approaches 0.125. Number will increase

by 0.010s for a short time and then by 0.100s.

Press and release TAR E() to increment the right most digit by 1.

If you overshoot, press and release SELECT() to decrement the right most digit by 1.

Press and hold SELECT() to decrease the value by 0.010s and then by 0.100s, the

longer you hold it.

When the display show 0.125, or the value you desire, press the ZERO key to enter or

accept the value. The screen returns to the previous mode.

18 ZQ375 Checkweigher User Instructions

Page 19

2.4 Numeric entry procedure

TARE /

-

SELECT /

-

PRINT /

-

UNITS /

-

ZERO /

-

F1 /

ESC -

These segments flash in numeric entry mode

Press to increment the flashing number

Press to decrement the flashing number

Press to backspace cursor in a number

Press to advance cursor in a number

Press to accept a value

Press to escape an entry screen

The keys in Figure 2.5 have alternate functions in numeric entry screens.

Figure 2.5 Key function during numeric entry

Use the keys, as described in Figure 2.5, to enter a value on the display. Following is

an example:

Example: To key in the number 507:

2.4 Numeric entry procedure

Repeatedly press the TARE() or SELECT() key until 5 appears on the display.

Press the UNITS() key once to move cursor one space to the right.

Repeatedly press the TARE() or SELECT() key until 0 appears on the display.

Press the UNITS() key once to move cursor one space to the right.

Repeatedly press the TARE() or SELECT() key until 7 appears on the display.

Press the ZERO key to enter or accept the value.

Press the PRINT() key to move the entry function one digit to the left. This effectively

deletes the current value in that position and allows you to enter a new value in that

position.

2.5 ID Entry Procedure

1. To enter an ID number, press and hold the ID key …

The current ID number is displayed with the digit or digits flashing.

2. Within five seconds begin to use the Numeric entry procedure on page 19 to

scroll in a new ID and press ZERO to accept.

3. The new ID number is now active.

If the entry screen times out and disappears, repeat step 1 and try again. You must

start the number entry procedure within five seconds.

ZQ375 Checkweigher User Instructions 19

Page 20

Introduction

2.6 Powering up the ZQ375

Power is always on as long as the power cable is plugged into the appropriate electrical

outlet. Power can be supplied by:

l AC power cord connected to a properly grounded outlet (100 VAC - 240

VAC, 50 or 60 Hz)

l AC to DC power converter. (12 to 36 VDC)

l Optional ZQ-BAT rechargeable battery

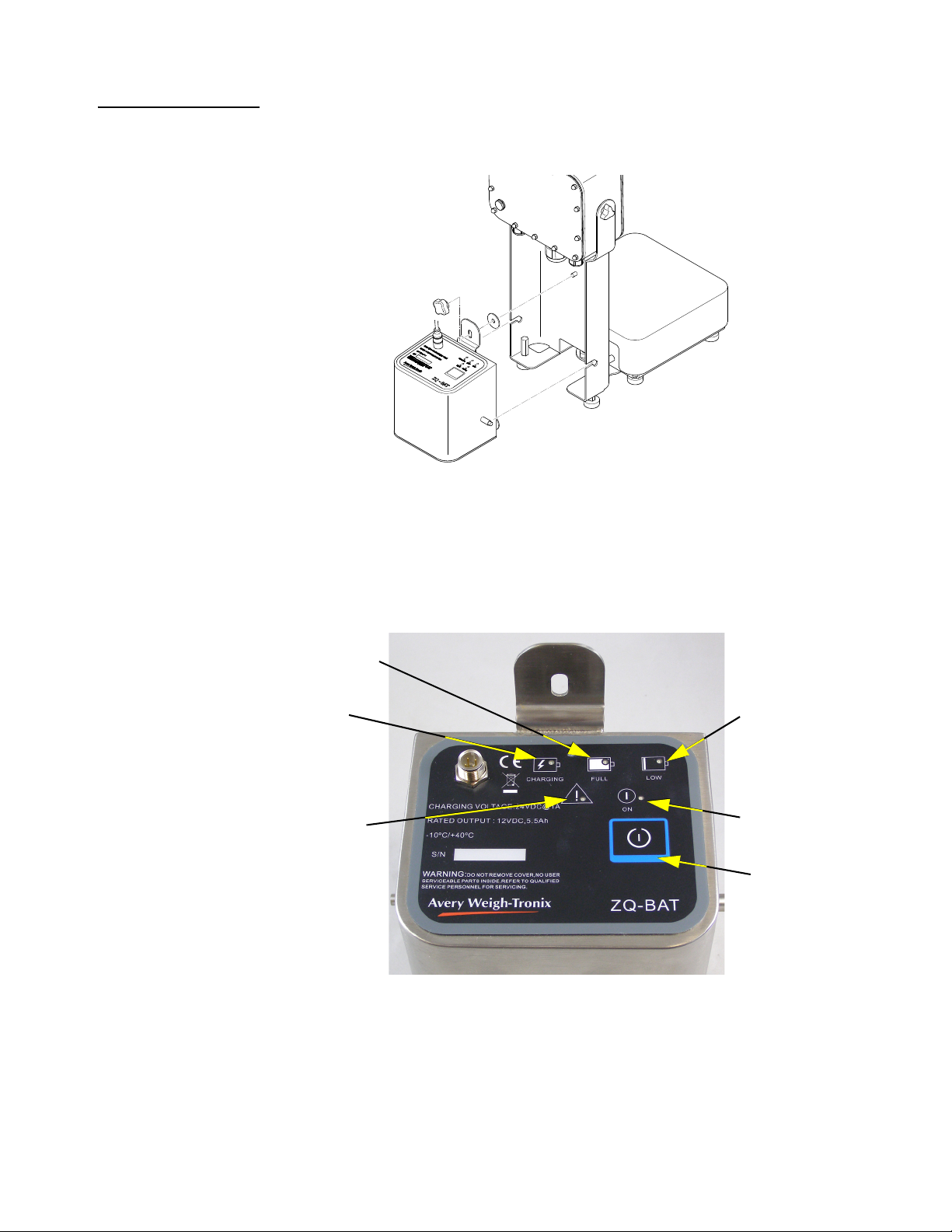

2.7 Battery option

The ZQ375 can be operated on battery power by the ZQ-BAT battery option. See

Figure 2.6.

Figure 2.6 ZQ-BAT battery option installed in the column

20 ZQ375 Checkweigher User Instructions

Page 21

2.7.1 Installation

Battery Full

LED

Battery

Charging

LED

Battery

Fault LED

Battery

ON LED

Battery

Low LED

ON/OFF

Key

The battery pack is easy to install. The projections on the side of the pack slide into the

slots in the column. The tab on the top of the pack goes over the threaded stud on the

column and the pack is secured in place with the star knob. See Figure 2.7.

2.7 Battery option

Figure 2.7 ZQ-BAT installation

Attach the battery cable from the indicator to the connector on the top of the battery.

The battery has five annunciator lights to tell you when the unit is charging, when the

battery level is low or high, when there is a fault in the battery and when the battery is

on or off. Below these lights is the ON/OFF button. See Figure 2.8.

Figure 2.8 Top of ZQ-BAT battery pack

ZQ375 Checkweigher User Instructions 21

Page 22

Introduction

2.7.2 Proper charging of the ZQ-BAT

Charging the battery pack using the supplied wall charger

1. Turn the battery pack ON.

2. Plug the charger into an outlet, then connect it to the battery.

The LOW and FAULT indicators may turn on if the battery pack is not

switched on.

3. Once connected to the charger, the CHARGING indicator will blink green to

indicate the battery is in a slow charge state.

4. After 75 seconds the charger will automatically switch to its fast charge state,

and the indicator will stay solid green.

5. Once the battery is fully charged, the CHARGING indicator will shut off and the

FULL indicator will turn green.

6. Disconnect the battery from the charger and turn the battery pack OFF.

Frequent charging of a battery that is not in a low state will decrease the battery life

span.

22 ZQ375 Checkweigher User Instructions

Page 23

2.7 Battery option

ON

Charging the battery pack through a ZQ375 indicator:

1. Connect the battery pack to a ZQ375 indicator and turn the battery pack ON.

2. Plug the indicator power cord into an outlet

The LOW and FAULT indicators may turn on if the battery pack is not

switched on.

3. The CHARGING indicator will blink green to indicate the battery is in a slow

pre-charge state.

4. After 75 seconds the charger will automatically switch to its fast charge state,

and the indicator will stay solid green.

5. Once the battery is fully charged, the CHARGING indicator will shut off and the

FULL indicator will turn green. At this point the indicator will stop the charging

sequence and simply maintain the voltage of the battery until it is needed. This

prevents the battery from being overcharged, allowing it to be left either ON or

OFF without damage.

6. The battery can now be used to power your ZQ indicator and scale system.

Battery life is rated at 16 hours continuous duty.

If so configured, the checkweigher will automatically switch off the battery after a set

amount of time if no scale motion or keypad activity occurs.

WARNING: Ensure the battery is fully charged before its first use.

Begin recharging the battery pack as soon as possible after the LOW indicator

LED comes on. Discharging the battery too far beyond this point may damage

the battery.

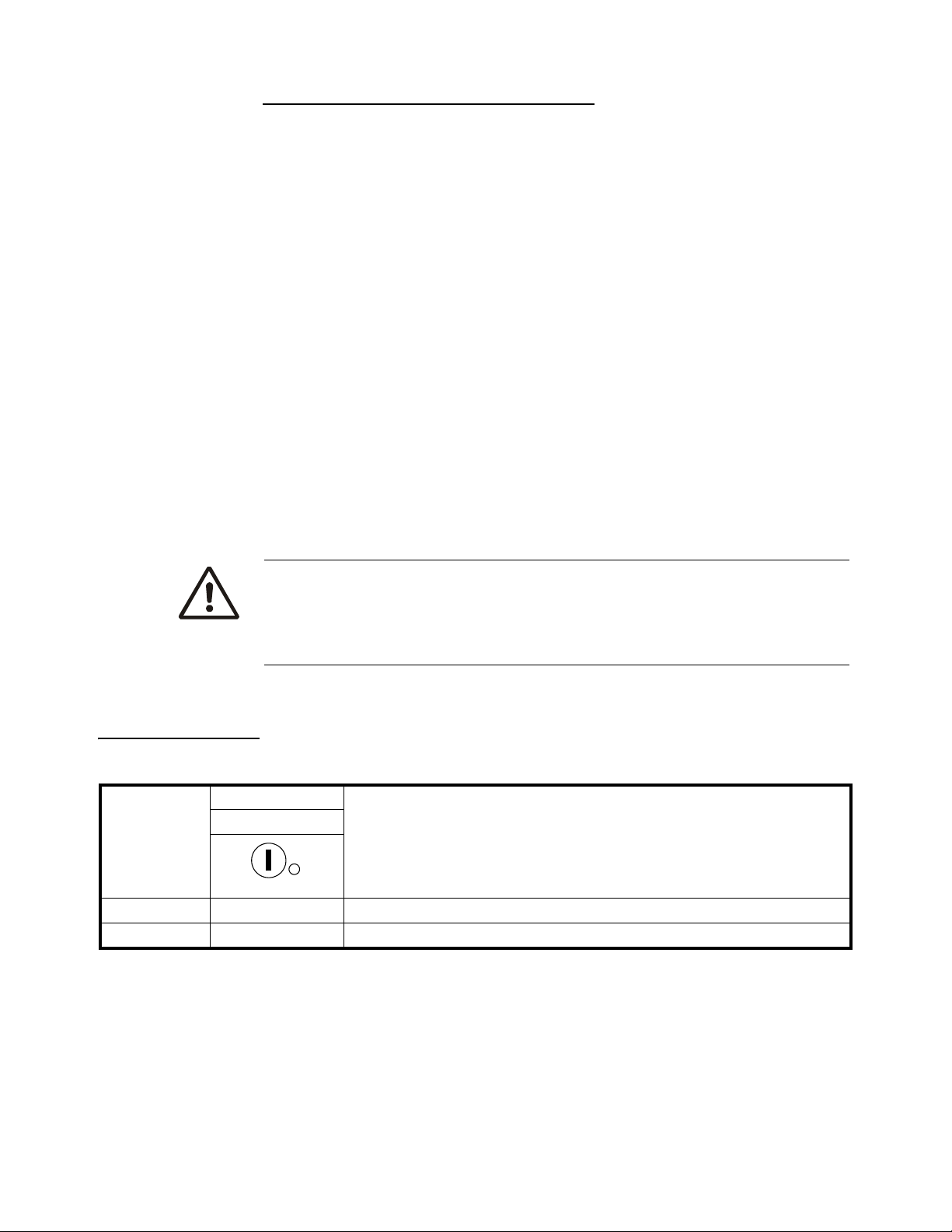

2.7.3 Battery states indicated by LEDs

Table 2.2 Battery Power States

LED Status

Battery Power

State

Powered ON ON The battery must be powered on to power an indicator and to be recharged

Powered OFF OFF The battery can be powered off to conserve charge when not in use

Power

Notes

ZQ375 Checkweigher User Instructions 23

Page 24

Introduction

LOW

CHARGING

FULL

Table 2.3 Battery Voltage States

LED Status

Battery

Voltage

LOW Fault

Notes

States

Above 9.3V OFF OFF The battery can be used to power an indicator

Below 9.3V ON OFF The battery should be recharged as soon as possible

Fault ON FLASHING A charger has been connected without the battery being powered on

Table 2.4 Battery Charging States

LED Status

Battery

Charging States

Charging Full Fault

Notes

Pre-Charge FLASHING OFF OFF The battery is slowly charged for 75 seconds

Fast Charge ON OFF OFF

Fully Charged

(Wall Charger)

OFF ON OFF

Maintenance

Charging

OFF ON OFF

(QZ375)

No faults were found so the battery is now charged

quickly

The unit is fully charged and should be disconnected

from the power supply

The unit is fully charged and the indicator is simply

maintaining the correct voltage

Over Temp - Battery is hot and needs to cool before

Waiting OFF OFF FLASHING

charging continues

No Power - The battery circuit has not been turned on

Battery is above the allowed voltage

Charging

Failure

OFF OFF ON

Battery has been discharged below 5V

Other failure

2.7.4 Checkweigher Operation on Battery Power

1. To operate the checkweigher using the battery pack, be sure the pack is fully

charged and connected to the checkweigher. Press the ON/OFF key on the

battery pack …

The Battery ON LED will light.

2. The ZQ375 should power up as soon as the battery is turned on.

3. To power down the battery and the ZQ375, press the ON/OFF key …

The Battery ON LED light will go out and the ZQ375 will power down.

24 ZQ375 Checkweigher User Instructions

Page 25

2.8 Light stack option

The ZQ375 has an optional light stack for a bright, visual sign that an object on the

scale is over, under or at the acceptable target weight. The unit, shown installed in

Figure 2.9, attaches to the column in exactly the same was as the battery pack and

connection is also made with a simple screw-in connector.

2.8 Light stack option

2.8.1 Light stack operation

The lights function the same way as the bargraph, showing red for under, orange for

over and green for accept conditions.

Figure 2.9 Light stack option

ZQ375 Checkweigher User Instructions 25

Page 26

Checkweighing applications

3 Checkweighing applications

The ZQ375 has five applications for different levels of checkweighing and specialty

checkweighing.

Sim375 Simple, quick checkweighing application. Fast and simple to set up.

Displays a ± deviation reading from the target weight set within the scale.

See Sim375 application on page 31.

Mid375 Mid-level checkweighing. This application uses weigh mode versus

deviation mode. It is fast and simple to set up and displays target weight in

gross or net weight. Target weight is setup by either the TARGET key or

entered through the indicator keypad. See Mid375 application on page 33.

Adv375 Advanced checkweighing. This is like Mid375 but adds a Product Look Up

(PLU) database. This allows you to quickly activate target weights and high

and low tolerances for up to 500 products from the PLU database.

Statistical packages like X-bar/R and Standard Deviation are also included

in this application. See Adv375 application on page 38.

Per375 Percent checkweighing allows the operator to accurately increase the

weight of a product by a set percentage of the starting weight. See Per375

application on page 43.

Grad375 This application categorizes weight within up to 10 bands or weight

windows. See Grad375 application on page 46.

Applications are enabled in a password protected menu. See the Service manual (PN

AWT35-500813 for the English version).

3.1 Checkweighing terminology

There are some terms you should understand when checkweighing.

Target The exact weight desired

Target-Hi Target weight plus the Tolerance-Hi

Target-Low Target weight minus the Tolerance-Low

Tolerance-Low Weight allowed under the target weight but still considered

acceptable

Tolerance-Hi Weight allowed over the target weight but still considered

acceptable

Sample Adds “Toler-Hi” and subtracts “Toler-Lo” from target weight for

over/accept/under ranges.

Example: Toler-Hi = 1.0 Toler-Lo = 2.0 Target = 4.0

“Target” – “Toler-Lo” = “Lower Acceptable Target Limit” or (4-2=2)

Therefore all weights below 2 are considered under weight.

“Target” + “Toler-Hi” = “Upper Acceptable Target Limit” or (4+1=5)

Therefore all weights above 5 are considered over weight.

This would mean all weights above 2 and below 5 would be

acceptable as being within target sample tolerances.

26 ZQ375 Checkweigher User Instructions

Page 27

3.1 Checkweighing terminology

Limits Any weight above “Targ-Lo” and below “Targ-Hi” is acceptable as

being within target limits.

Example: Targ-Hi = 6.0 Targ-Lo = 2.0

All weights below 2 are considered under the target weight.

All weights above 6 are considered over the target weight.

Halfway between the upper and lower target value limits is the

value 4, This is the calculated target value.

This would mean all weights above 2 and below 6 would be

acceptable as being within the target limits.

ZQ375 Checkweigher User Instructions 27

Page 28

Checkweighing applications

3.2 Normal weighing procedures

The Sim375, Mid375 and Adv375 applications allow normal weighing using gross and

net weighing. Below are the steps for the normal weighing practices.

3.2.1 Gross weighing

If enabled, press UNITS to change the unit of measure.

To perform gross weighing, power up the unit and follow these steps:

1. Press the SELECT key if the GROSS annunciator is not lit …

The GROSS annunciator lights and the scale is in gross weighing mode.

2. Empty the scale and press ZERO to zero the display …

0 is displayed and the center-of-zero annunciator lights.

3. Place item to be weighed on the scale …

4. Repeat steps 1 through 3.

3.2.2 Tare/Net weighing

In the Sim375 application, the tare functionality is not available

There are two kinds of tare entry. These are enabled when the indicator is configured.

l Pushbutton tare

l Preset tare

If Preset Tare is enabled, Pushbutton Tare is automatically disabled.

Weight is displayed.

There is also a function called auto tare clear. If this is enabled, after a weighment,

when the weight falls into the gross zero band and is steady, any tare is removed from

the indicator. No tare remains active between weighments.

The two types of tare are explained below.

28 ZQ375 Checkweigher User Instructions

Page 29

3.2 Normal weighing procedures

Using Pushbutton Tare (if enabled)

To perform a net weighment using pushbutton tare, power up the unit and follow these

steps:

1. Empty the scale and press ZERO …

0 is displayed and the center-of-zero annunciator lights.

2. Place item to be tared on the scale …

Weight is displayed.

3. Press TAR E …

0 is displayed and the NET annunciator lights.

To clear a tare weight, remove all weight from the scale and press TA R E .

4. Place material to be weighed on the scale …

Net weight of material is displayed.

5. Repeatedly press SELECT to view the gross, tare, and net values.

6. Remove all weight from the scale.

7. To repeat weighing the net weight, place a container of the same weight on the

scale and then the material to be weighed …

Net weight of material is displayed.

8. To remove the tare, remove all weight from the scale. With 0 displayed, press

TARE.

The tare is cleared and the scale is in gross weigh mode.

Using Preset Tare (if enabled)

Preset tares are entered in a password protected menu. Check with your supervisor on

this Mid375 and Adv375 feature. There can be up to 10 tare registers numbered 1-10.

To perform a net weighment using one of the preset tares, power up the unit, go to

normal gross weighing mode and follow these steps:

1. Empty the scale and press ZERO …

0 is displayed and the center-of-zero annunciator lights.

2. Press TARE …

Tare register number entry screen appears.

3. Use the Numeric entry procedure on page 19 and key in the preset tare register

number and press ZERO …

-X is displayed and the NET annunciator lights. X is the recalled tare

value.

ZQ375 Checkweigher User Instructions 29

Page 30

Checkweighing applications

4. Place the container or object (equal to tare value) to be tared and material to

be weighed on the scale …

Net weight of material is displayed.

5. Repeatedly press SELECT to view the gross, tare, and net values.

6. Remove all weight from the scale …

-X is displayed.

7. Repeat steps 4 - 6 until you are finished using that tare weight.

30 ZQ375 Checkweigher User Instructions

Page 31

3.3 Sim375 application

This section applies if the Sim375 application is enabled. See the Service manual for

information on enabling the applications.

The SIM375 application is a fast and efficient checkweighing application that displays

the ± deviation from a target point set by the operator.

Using Pushbutton or Preset Tare is not available in the SIM375 application

3.3.1 Checkweighing

Switching Between Checkweighing and Normal Weighing Mode

To switch between checkweighing and normal weighing mode, press SELECT. When

the GROSS annunciator is displayed, the unit is in normal weighing mode. Press

SELECT again and the GROSS annunciator disappears. The unit is now in

checkweighing mode. The display may show a negative weight and the Under

segments of the bargraph may be lit if there is an active target value.

3.3 Sim375 application

Setting a New Target Weight and Simple Checkweighing

1. With the unit in Checkweighing mode, press ZERO to zero the scale and place

an item of the correct weight on the scale and press TAR G ET …

The scale will read 0 weight and the center Accept segment will light

showing the target weight has been set successfully.

If motion is present for greater than 2-3 seconds after the TARGET key press, the

target operation will be aborted and the word cant will be displayed briefly.

2. Clear the scale and place the next item on the scale …

The bargraph will show the item is under the target weight, over the

target weight or on target.

By default the Target segment lights if the weight is within ± the high and low

tolerance of the target weight. The over and under segments each represent 1

division.

3. Repeat step 2 for all the other items to be weighed.

ZQ375 Checkweigher User Instructions 31

Page 32

Checkweighing applications

View the High and Low Tolerances

1. To view the high tolerance, press and hold OVER …

toL-hi (high tolerance) is briefly displayed, then the value for this high

tolerance is briefly displayed before the normal checkweighing mode

returns.

2. To view the low tolerance, press and hold UNDER …

toL-Lo (low tolerance) is briefly displayed then the value for this low

tolerance is briefly displayed before the normal checkweighing mode

returns.

Set New High and Low Tolerances

You can escape from an entry screen or choice level. Press F1 and the action is

aborted and the display returns to its previous state.

To set custom tolerances follow these steps:

1. Press UNDER to set the low tolerance …

x.xxx is displayed. This is the current low tolerance. The Under

segments also flash.

2. Refer to the Tolerance entry procedure on page 18 and key in a new tolerance

and press ZERO to accept …

Display returns to checkweighing mode with the new low tolerance

active.

3. Press OVER to set the high tolerance …

x.xxx is displayed. This is the current high tolerance. The Over

segments also flash.

4. Refer to the Tolerance entry procedure on page 18 and key in a new tolerance

and press ZERO to accept …

Display returns to checkweighing mode with the new high tolerance

active.

The tolerances can be set from 1 division to the capacity of the scale.

32 ZQ375 Checkweigher User Instructions

Page 33

3.4 Mid375 application

Tar ge t

Target + Tol-Hi

By default Tol-Lo and

Tol-Hi are 1 division

This section applies if the Mid375 application is enabled. See the Service manual for

information on enabling the applications.

In the Mid375 application the checkweigher mode is always active and the target

weight is always displayed in either gross or net weight. Unlike the Sim375 application

that only displays the deviation from target, the Mid375 application displays the weight.

3.4.1 SELECT key operation

In the Mid375 application, press SELECT to cycle through the active display values:

GROSS, NET, TARE and TRANSACTION COUNT. The appropriate annunciator will

light for each display value. (The transaction count annunciator is the green circle

under the right digit on the display.)

3.4.2 Checkweighing

To start checkweighing you need to enter a target weight by using live weight or keying

in the value. By default the lower tolerance (Tol-Lo) is -1 division and the high tolerance

(Tol-Hi) is +1 division. These tolerances can be adjusted. These steps are described in

the following sections.

3.4 Mid375 application

The ZQ375 adds Tol-Hi and subtracts Tol-Lo from the target weight for over/accept/

under ranges.

Example: Tol-Hi = 0.1

Tol-Lo = 0.2

Target = 4.0

Target – Tol-Lo = Lower Acceptable Target Limit or (4 - 0.2 = 3.8).

Therefore all weights below 3.8 are considered under weight.

Target + Tol-Hi = Upper Acceptable Target Limit or (4 + 0.1 = 4.1).

Therefore all weights above 4.1 are considered over weight.

This would mean all weights above 3.8 and below 4.1 would be acceptable

as being within target sample tolerances.

ZQ375 Checkweigher User Instructions 33

Page 34

Checkweighing applications

3.4.3 Negative checkweighing

Negative checkweighing is functional in the MID375 and ADV375 applications. Follow

these steps:

1. Place a full container on the scale and press TARE.

2. Remove a desired amount of material from the container and press TARGET.

3. Press TARE and start the negative checkweigh process by removing material

until inside the target zone.

Tolerance values work in opposite fashion:

Target + Lo Tolerance = Target Lo

Target – Hi Tolerance = Target Hi

34 ZQ375 Checkweigher User Instructions

Page 35

3.4.4 Sample mode checkweighing

Setting a target weight can be done in two ways:

l Sampling an item of the correct weight

l Entering a known target weight through the front panel

By default in both the quick check and preset target methods, the low tolerance

(toL-Lo) is -1 division and the high tolerance (toL-hi) is + 1 division. These tolerances

can be adjusted. See Set New High and Low Tolerances on page 32.

When inside the Gross Zero Band, press TAR G E T and you can adjust the target

weight using the Tolerance entry procedure on page 18.

Sampling Method

1. Place an item of the correct weight on the scale and press TARGET …

3.4 Mid375 application

The scale will show the target weight and the center Accept segment will

light showing the target weight has been set successfully.

If motion is present for greater than 2-3 seconds after the TARGET key press, the

target operation will be aborted and the word cant will be displayed briefly.

2. Clear the scale and place the next item on the scale …

The bargraph will show the item is under the target weight, over the

target weight or on target.

3. Repeat step 2 for all the other items to be weighed.

Manual Target Weight Entry

1. Empty the scale and press ZERO to zero the scale, then press TARGET …

The current value for target is displayed.

2. Use the Tolerance entry procedure on page 18 to key in a value for target and

press ZERO to accept …

The target weight becomes active.

3. Place an item on the scale …

The weight will be displayed and OVER, UNDER or ACCEPT segments

will light depending on the weight.

4. Clear the scale.

5. Repeat steps 3 and 4.

ZQ375 Checkweigher User Instructions 35

Page 36

Checkweighing applications

View the Target Weight and Upper and Lower Tolerances

1. To view the target weight, press and hold TARGET …

tArGEt is briefly displayed, then the value is briefly displayed before the

normal checkweighing mode returns.

2. To view the upper tolerance, press and hold OVER …

toL-hi or tArGhi (high tolerance) is briefly displayed, then the value is

briefly displayed before the normal checkweighing mode returns.

3. To view the lower tolerance, press and hold UNDER …

toL-Lo or tArGLo (low tolerance) is briefly displayed, then the value is

briefly displayed before the normal checkweighing mode returns.

Set New Upper and Lower Tolerances

You can escape from an entry screen or choice level. Press F1 and the action is

aborted and the display returns to its previous state.

To set custom tolerances follow these steps:

1. Press UNDER to set the lower or under tolerance …

x.xxx is displayed. This is the under tolerance value. The Under

segments also flash.

2. Refer to the Tolerance entry procedure on page 18 and key in a new tolerance.

Press ZERO to accept …

Display returns to checkweighing mode with the new lower tolerance

active.

3. Press OVER to set the upper tolerance …

x.xxx is displayed. This is the over tolerance value. The Over segments

also flash.

4. Refer to the Tolerance entry procedure on page 18 and key in a new tolerance.

Press ZERO to accept …

Display returns to checkweighing mode with the new upper tolerance

active.

The tolerances can be set from 1 division to the capacity of the scale.

36 ZQ375 Checkweigher User Instructions

Page 37

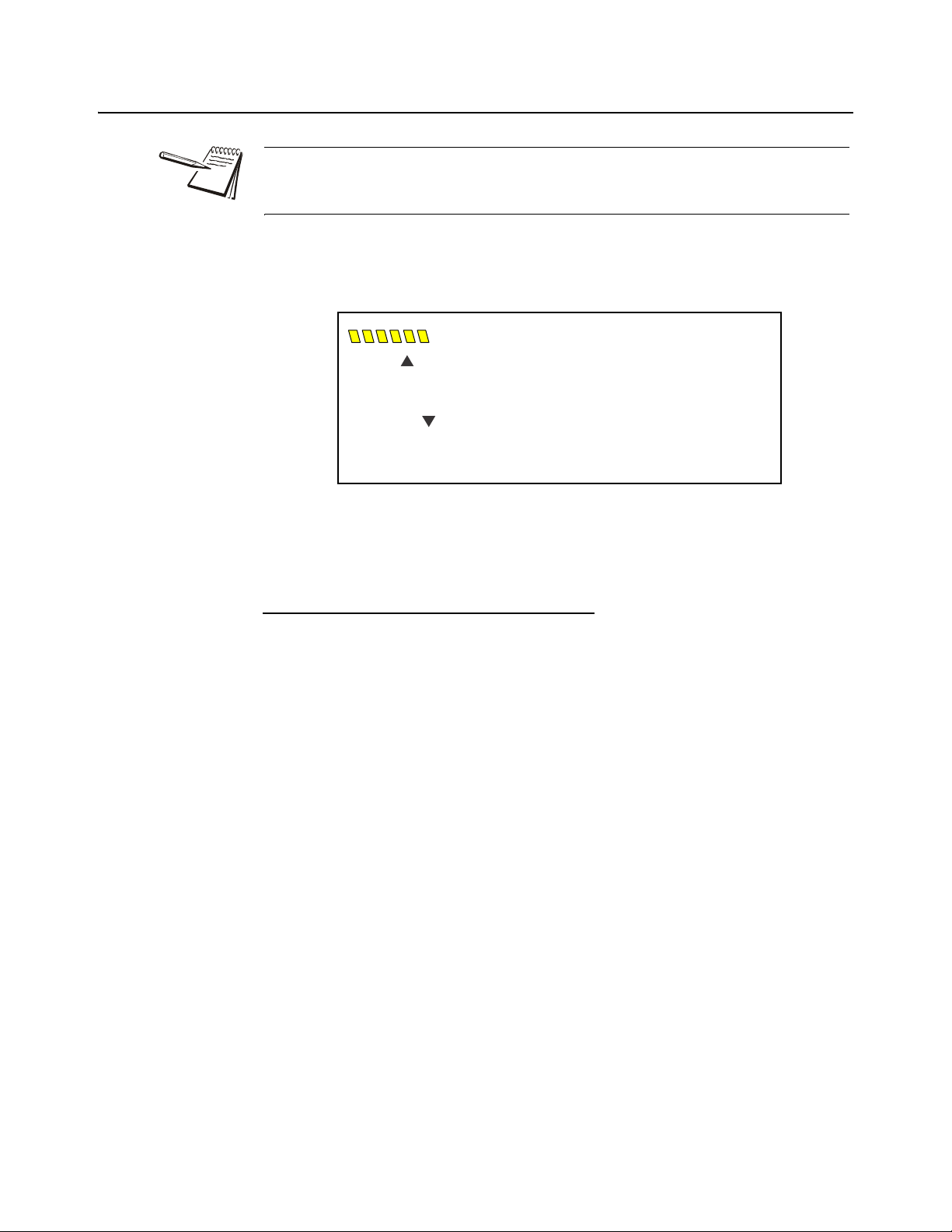

3.4.5 Transaction counter

You can view the number of transactions since the last clearing by pressing the

SELECT key until the transaction count display is shown. The counter is incremented

every time PRINT is pressed. See example in Figure 3.1.

If enabled in a password protected menu, press and hold PRINT to clear the

transaction count.

3.4 Mid375 application

Figure 3.1 Transaction count display

ZQ375 Checkweigher User Instructions 37

Page 38

Checkweighing applications

3.5 Adv375 application

This section applies if the Adv375 application is enabled. See the Service manual for

information on enabling the applications.

3.5.1 SELECT key operation

In the Adv375 application, press SELECT to cycle through the active display values:

GROSS, NET, TARE and TRANSACTION COUNT. The appropriate annunciator will

light for each display value. (The transaction count annunciator is the green circle

under the right digit on the display.)

3.5.2 Checkweighing

The Adv375 application is identical in function to the Mid375 application with the

addition of Product Look Ups (PLUs). PLUs consist of a PLU# (1-500), the lower

tolerance, the target weight and the upper tolerance. These are created and edited in

a password protected menu. See your supervisor for more information.

A short key press of the OVER, UNDER, and TARG E T keys will do nothing if the

active PLU# is from 1 to 500. If the active PLU# = 0, these keys will work like in the

Mid375 application. See Set New Upper and Lower Tolerances on page 36.

If you press and hold the OVER, UNDER, and TARGET keys and the active PLU# = 1

to 500, you will see hi tolerance, target and low tolerance, respectively. If the active

PLU# = 0, then the over, under, target values will be shown, but the values are only

temporary ones since the active PLU#=0. PLU#0 values are not retained during

power down or reboot from menu access.

38 ZQ375 Checkweigher User Instructions

Page 39

3.5 Adv375 application

Setting a New Target Weight and Checkweighing

You can escape from an entry screen or choice level. Press F1 and the action is

aborted and the display returns to its previous state.

When inside the Gross Zero Band, press TAR G E T and you can adjust the target

weight using the Tolerance entry procedure on page 18.

These steps apply only if the active PLU# is 0.

1. In gross weighing mode, press ZERO to zero the scale. Place an item of the

correct weight on the scale and press TARGET …

The scale will read show the weight of the item, the center Accept

segment will light showing the target weight has been set successfully

and the Gross or Net annunciator will be lit.

If motion is present for greater than 2-3 seconds after the TARGET key press, the

target operation will be aborted and the word cant will be displayed briefly.

2. Clear the scale and place the next item on the scale …

The bargraph will show the item is under the target weight, over the

target weight or on target.

3. Repeat step 2 for all the other items to be weighed.

Choosing a PLU and Checkweighing

Over, under and target values for the PLU registers are entered in a password

protected menu. Contact your supervisor for information.

Use these steps when you want to recall a PLU and checkweigh.

1. Press ZERO to zero the scale, then press F1 …

A flashing 0 is displayed prompting you for the PLU # you wish to recall.

2. Use the Numeric entry procedure on page 19 to enter the PLU number and

press ZERO to accept …

The PLU values are recalled. The target, upper and lower tolerances

become active. If that PLU number has no values assigned, the display

will show cAnt.

3. Place an item on the scale …

The scale will show the weight and the bargraph segments will light in

accordance with the target and tolerances that are active.

ZQ375 Checkweigher User Instructions 39

Page 40

Checkweighing applications

4. Clear the scale and place the next item on the scale …

The bargraph will show the item is under the target weight, over the

target weight or on target.

5. Repeat step 2 through 4 for all the other items to be weighed.

View the Upper and Lower Tolerances

1. To view the upper tolerance, press and hold OVER …

toL-hi (high tolerance) is briefly displayed, then the value is briefly

displayed before the normal checkweighing mode returns.

2. To view the lower tolerance, press and hold UNDER …

toL-Lo (low tolerance) is briefly displayed, then the value is briefly

displayed before the normal checkweighing mode returns.

Set New Upper and Lower Tolerances

You can escape from an entry screen or choice level. Press F1 and the action is

aborted and the display returns to its previous state.

If the active PLU# is 0, you can set custom tolerances. Follow these steps:

1. Press UNDER to set the lower or under tolerance …

x.xxx is displayed. This is the under tolerance value. The Under

segments also flash.

2. Refer to the Tolerance entry procedure on page 18 and key in a new tolerance.

Press ZERO to accept …

Display returns to checkweighing mode with the new lower tolerance

active.

3. Press OVER to set the upper tolerance …

x.xxx is displayed. This is the over tolerance value. The Over segments

also flash.

4. Refer to the Tolerance entry procedure on page 18 and key in a new tolerance.

Press ZERO to accept …

Display returns to checkweighing mode with the new upper tolerance

active.

The tolerances can be set from 1 division to the capacity of the scale.

40 ZQ375 Checkweigher User Instructions

Page 41

3.5.3 Transaction counter

You can view the number of transactions since the last clearing by pressing the

SELECT key until the transaction count display is shown. The counter is incremented

every time PRINT is pressed.

If enabled in a password protected menu, press and hold PRINT to clear the

transaction count for the active PLU.

Transaction counts and accumulators are stored with each PLU.

3.5.4 Statistical Package and Packrun

If the statistical package, Standard Deviation, is enabled, after a configurable number

of transactions have occurred (packrun quantity), the ZQ375 will totalize the number of

transactions and compute the standard deviation of the transactions.

Pack Run is the same as the Sample Size or quantity of weighments before a report is

automatically printed.

3.5 Adv375 application

If standard deviation is turned on and Pack Run is set to 0 (zero) you will get individual

weights each time the PRINT key is pressed and the statistical report when the PRINT

key is held for 4 seconds. The samples are cleared from memory when printed

If the Pack Run is set for any number of samples, you will get individual weights until

you reach the number set for the sample size (pack-run). Once this value has been

reached the statistical report will print out, then the samples are cleared from memory.

With Pack Run at 0 place product on scale. When the weight stabilizes press the

PRINT key. The individual weight will be stored and printed. (Auto Print Feature may

be used) Continue weighing product until a statistical report is required.

ACCEPT: 12.34 lb

OVER: 12.36 lb

OVER: 12.64 lb

UNDER: 9.72 lb

ACCEPT: 12.29 lb

UNDER: 0.00 lb

Printing the report:

Press and hold print key for 4 seconds, display will flash “Std-dEv Prn-tot” and the

report will be printed, then the samples will be cleared from memory.

ZQ375 Checkweigher User Instructions 41

Page 42

Checkweighing applications

Report Example:

Tolerance Hi = 0.35 lb

Tolerance Lo = 0.25 lb

Cnt of Over Wt = 2

Cnt of Under Wt = 1

Cnt of Target Wt = 3

Mean Net Wt = 10.30 lb

Max Net Wt = 12.64 lb

Min Net Wt = 0.00 lb

SD Net Wt = 5.05

CV Net Wt = 0.49 PCT

Cnt of Tot Wt = 6

If autoprint is enabled or the PRINT key is pressed a valid transaction occurs. Valid

transactions are counted as one entry in a packrun.

To end a packrun before the configured quantity is met, press and hold PRINT and the

valid transactions are totaled and standard deviation is performed.

If enabled, the standard deviation report is printed automatically upon completion of the

packrun.

3.5.5 X-Bar/R Program

The X-bar/R program is designed to weigh process samples, establish the average

weight, calculate the range between high and low weights, and the trend of deviation.

If the X-bar/R feature is enabled, the ZQ375 will keep a queue of the average weights

of the last eight sample sets. This queue of averages is used to print trend information

on the statistical reports.

The Report Printout for the X-Bar/R program can be customized to present statistical

data of your choosing. This information is found in the Service manual.

Trend Message Meaning

1 of 1 The last average in the queue has an error greater than 3x the limit

2 of 3 Two of the last three averages in the queue have an error greater that the limit.

4 of 5 Four of the last five averages have an error greater than the limit.

8 of 8 Eight of eight averages are on the same side of the target weight.

42 ZQ375 Checkweigher User Instructions

Page 43

3.6 Per375 application

This section applies if the Per375 application is enabled. See the Service manual for

information on enabling the applications.

3.6.1 Checkweighing

The Per375 application is identical in function to the Adv375 application with the

exception that weights are now expressed in percentages. PLUs consist of a PLU#, the

lower tolerance, the target percentage and the upper tolerance. These are created and

edited in a password protected menu. See your supervisor for more information.

A short key press of the OVER, UNDER, and TARG E T keys will do nothing if the

active PLU# is from 1 to 500. If the active PLU# = 0, these keys will work like in the

Mid375 application. See Set New Upper and Lower Tolerances on page 36.

If you press and hold the OVER, UNDER, and TARGET keys and the active PLU# = 1

to 500, you will see hi tolerance, target and low tolerance, respectively. If the active

PLU# = 0, then the over, under, target values will be shown, but the values are only

temporary ones since the active PLU#=0.

3.6 Per375 application

Setting a New Target Percentage and Checkweighing

You can escape from an entry screen or choice level. Press F1 and the action is

aborted and the display returns to its previous state.

These steps apply only if the active PLU# is 0.

1. In gross weighing mode, press ZERO to zero the scale. Press TARGET …

The display will show the last target value in percentage and the%

annunciator will turn on. The Target segment will light.

If motion is present for greater than 2-3 seconds after the TARGET key press, the

target operation will be aborted and the word cant will be displayed briefly.

2. Press ZERO to accept the displayed value or use the Tolerance entry