Page 1

CONFIDENTIAL

ZM401/405

Weight Indicators

Service Manual

original instructions

AWT35-501334

Issue AA

Page 2

Avery Weigh-Tronix is a trademark of the Illinois Tool Works group of companies whose ultimate parent company is

Illinois Tool Works Inc (“Illinois Tool Works”). Copyright © 2015 Illinois Tool Works. All rights reserved.

No part of this publication may be reproduced by making a facsimile copy, by the making of a copy in three dimensions of a two-dimensional

work and the making of a copy in two dimensions of a three-dimensional work, stored in any medium by electronic means, or transmitted in

any form or by any means, including electronic, mechanical, broadcasting, recording or otherwise without the prior written consent of the

copyright owner, under license, or as permitted by law.

This publication was correct at the time of going to print, however Avery Weigh-Tronix reserves the right to alter without notice the

specification, design, price or conditions of supply of any product or service at any time.

ZM401_405_s_en_501334.book

Page 3

Table of Contents

page

Manual revision history .............................................................................................................................7

Chapter 1 General information and warnings ............................................................. ............................ 9

About this manual ..............................................................................................................9

Text conventions .........................................................................................................9

Special messages .......................................................................................................9

Installation ....................................... .................................... ................................ .............10

Torque specifications ................................................................................................10

Proper grounding of cables .......................................................................................10

Panel mount scale interface cable installation ..........................................................11

Safe handling of equipment with batteries ................................................................12

Wet conditions ...........................................................................................................12

Routine maintenance .......................................................................................................12

Cleaning the machine ......................................................................................................13

Training ..................................... ............................................................. ..........................13

Sharp objects ........ .... ... ... ... .... ...................................... .... ... ... ... ... .... ................................13

FCC and EMC declarations of compliance ......................................................................13

Chapter 2 Introduction ............................................................................................................................ 14

Front panel .......................................................................................................................14

Front Display .............................................................................................................16

Powering up the ZM400 ...................................................................................................17

Alphanumeric entry procedure (ZM401 only) ...................................................................17

Using the alphanumeric keypad (ZM405 only) ................................................................18

Entering negative numbers or decimal point ....................................................................18

String index/character data entry .....................................................................................18

Chapter 3 Introduction to the menus ........................................................... ..........................................20

Accessing the menus .......................................................................................................21

Exiting the menus ............................................................................................................21

Menu annunciators ......... ... .... ... ....................................... ... ... ... ... .... ... .............................22

Quick Code parameter entry ............................................................................................23

Chapter 4 User level menus ............................................. ....................... ...................... ....................... ...24

User menu ......... ... .... ...................................... .... ... ... ... .... ... ...................................... .... ...24

Time ..........................................................................................................................25

Date ....................................... .................................................... ................................25

Site ID ........................................................................................................................26

Seal ...........................................................................................................................26

About menu ......................................................................................................................27

Boot (Bootloader) ......................................................................................................28

Firmware ...................................................................................................................28

App ............................................................................................................................28

Serial .........................................................................................................................28

Option ....................................... .................................................... ............................. 29

Enet ...........................................................................................................................29

Download ..................................................................................................................30

BSQ .................................... ................................................... .................................... 30

Audit menu ...... ....................................... ... ... ... .... ... ... ....................................... ... ... ... .......31

Counter ..................................... ....................... ................... ....................... ................31

Print ...........................................................................................................................32

ZM400 Series Indicators Service Manual 3

Page 4

Chapter 5 Diagnostics level menus .................................................... ................................................... 33

Diag menu ...................... .... ... ....................................... ... ... ... .... ... ... ................................ 33

Scale ......................................................................................................................... 34

Current Zero ............................................................................................................. 34

Display ...................................................................................................................... 35

Buttons ............................... .................................................................... ...................35

Ports ................................ ....................................... ...................................... .............35

Inputs ........................................................................................................................ 36

Outputs ...................................... ......... ....... ......... .......... .......... ......... .......... .......... ...... 36

Options ...................................... ...................................... ....................................... ... 37

Logs .......................................................................................................................... 37

BSQ ................................. .......... ...... .......... ......... .......... .......... ......... .......... .......... ...... 38

Chapter 6 ADMIN level menus ...................................... ............. ............. ............. ............. ............. ......... 39

Setup menu .....................................................................................................................39

Calibration Procedure ...................................................................................................... 40

Scale 1-2 ..... .... ... ... ... .... ... ... ....................................... ... ... .... ... ... ... ............................. 40

Zero Procedure .................................. ... .... ... ....................................... ... ... ... .... ... ... ... 41

Span Procedure ........................................................................................................ 42

Linearity Procedure ...... ... ... ... .... ... ... ... ....................................... ... ... .... ... ... ... ............. 42

Input procedure ......................................................................................................... 43

Gravity Factor Procedure .......................................................................................... 44

Display ...................................................................................................................... 45

Calibration Unit .......................................................................................................... 45

Print calibration report ..... ... ... .... ... ... ....................................... ... ... ... .... ... ... ................ 45

Scale ...................................... ...................... .................... ...................... .......................... 46

Scale 1-2 ..... .... ... ... ... .... ... ... ....................................... ... ... .... ... ... ... ............................. 47

Capacity .................................................................................................................... 47

Division ............................... .......... ......... .......... .......... .......... ......... .......... .......... ...... ... 47

Units ...................................... ....................................................................... .............48

Stable .................................... .................................................................... ................ 49

AZT ........................................................................................................................... 49

Filter ..........................................................................................................................50

Ranges ...................................... ...................................... ....................................... ... 51

2,3,Range .............................. .......... ...... .......... .......... .......... ......... .......... .......... ......... 52

Type .......................................................................................................................... 53

System ................................ ...................... ....................... ...................... .......................... 54

Default Values ........................................................................................................... 55

Site ..................................... .................................................................... ...................56

Display ...................................................................................................................... 56

Buttons ............................... .................................................................... ...................57

Display values ........................................................................................................... 57

Tare .................................... .......................................... .......................................... ...60

Config ................................. ....................................... ....................................... ......... 60

Archive ...................................................................................................................... 61

Serial ..................................... .................................................................... ................62

Update ....................................... ......... ....... ......... .......... .......... ......... .......... .......... ...... 62

Password .................................................................................................................. 63

Z-Lock ....................................................................................................................... 63

Beeper ....................................... ......... ....... ......... .......... .......... ......... .......... .......... ...... 63

Number of Scales ............................ ....................................... ... ... ... .... ... ... ................ 64

Ports ................................................................................................................................ 65

Serial ..................................... .................................................................... ................66

Ethernet ................................. ....... ... ...... ....... ...... ....... ...... ....... ...... ... ....... ...... ....... ...... 67

Protocol ..................................... ................................................................... .............69

P.F.Edit ..................................................................................................................... 72

PLC ........................................................................................................................... 72

4 ZM400 Series Indicators Service Manual

Page 5

Printer ....................................... ....................................................... ..........................74

File ...................................... ...................... .................... ...................... .......................74

Options ...................................................................................................................... 76

Chapter 7 Communication port protocols ................................................................ .......................... ...79

SMA Protocol ...................................................................................................................79

Level 1 and 2 Commands .............................................. ... ... .... ................................79

Standard Scale Response Message .........................................................................80

Unrecognized Command Response .........................................................................80

About Command Response ......................................................................................80

Scale Information Command Response ............................. .......................... .............81

Avery Weigh-Tronix Extended SMA Commands ............................................... .... ... 82

ENQ & B-Cast commands ...............................................................................................84

NCI commands ................................................................................................................85

R-Disp commands ...........................................................................................................86

PLC Configuration information .........................................................................................87

ModBus/TCP ............................................................................................................. 87

Ethernet/IP Implicit Messaging: ....................... ... ... .... ... ... ... ... .... ... ... ....... ... ... ... ... .... ... 89

Ethernet/IP Explicit Messaging: .................... ... ... ... .... ... ... ... ... .... ... ...... .... ... ... ... ... .... ... 89

Chapter 8 Option cards ........................................................................................................................... 90

Analog output card .......... ....................................... ... ... .... ... ... ... .......................................91

Current Loop/RS485/RS422 card .......... ... ... ... .................................................................92

USB Device option card ...................................................................................................93

Wireless Ethernet communication (802.11g) card ....... .... ... ... ... ... .... ... ... ... .... ...... ... ... .... ... 94

Internal 120 VAC relay card (for IP69K only) ...................................................................95

Specifications ............................................................................................................ 95

Installing the option card ...........................................................................................96

2nd Scale Input 5VDC Excitation card .............................................................................97

2nd Scale Input 10 VDC Excitation w/STVS card .................. ................................... .......98

External I/O Interface card ...............................................................................................99

AC input, 4 Inputs (120-240VAC) card ..........................................................................100

DC input, 4 inputs(4-30VDC) card .................................................................................101

AC output, 4 relays (20-240VAC) card ..........................................................................102

DC output, 4 relays (3-60VDC) card ......................... ..................................................... 103

Chapter 9 Printed reports .....................................................................................................................104

Configuration report .......................................................................................................104

Calibration report ...........................................................................................................104

Audit report ........... .... ... ... ....................................... ... ... .... ... ... ... .....................................105

Chapter 10 Print formatting .................................................................................................................. 106

Print Format Editor .... ...................................... .... ... ... ... .... ... ...................................... .... .106

Editing an existing print string ........................................................................................107

Inserting characters .................................................................................................108

Deleting characters .................................................................................................109

Inserting tokens, etc. ......................................................................................................111

Other scale tokens .........................................................................................................113

Transmitting leading zeroes ... ... ....................................... ... ... ... ... .... ... ...........................114

Print format errors ........... ... .... ... ... ... ... .... ...................................... .... ... ... ... .... ... ..............115

Chapter 11 Print tokens, parameters and default print formats ... ............................. ........................117

Notes on width syntax ....................................................................................................117

Explanation of width syntax for WEIGHT (integers) ................................................117

Explanation of width syntax for WEIGHT (strings) ..................................................117

Explanation of width syntax for UNITS OF MEASURE (strings) .............................117

Firmware tokens ............................................................................................................118

Additional token tables ............................. .... ... ... ... .... ... ... ... ... ....... ... ... .... ... ... ... ... .... .124

ZM400 Series Indicators Service Manual 5

Page 6

Network tokens .............................................................................................................. 125

ASCII characters ........................................................................................................... 127

Control codes ................................................................................................................ 128

Default print formats ...................................................................................................... 129

Chapter 12 Complete menu structures ............................................................................................... 131

Chapter 13 Technical illustrations ...................................................... ................................................. 137

Stainless steel enclosure assembly ............................................................................... 137

Stainless steel enclosure parts kits ............................................................................... 138

Panel mount enclosure parts and assembly .................................................................. 139

Panel mount enclosure parts lists .................................................................................. 140

System block diagram ................. .... ... ... ....................................... ... ... ... .... ... ... .............. 1 41

ZM umper and switch settings ....................................................................................... 142

ZM remote inputs and outputs, Opto-22 module ........................................................... 143

STVS (Severe Transient Voltage Suppressor) installation ............................................ 144

Outline dimensions (stainless steel) .............................................................................. 145

Outline dimensions (panel mount) ................................................................................. 146

Panel mount assembly .................................................................................................. 147

D-cell Battery pack option (AWT05-505852) and external battery circuitry ................... 148

Keypad overlay replacement procedure ........................................................................ 149

To change the keypad you will need these tools: ................................................... 149

Process to remove and replace the keypad overlay ............................................... 149

Index ....................................................................................................................................................... 151

6 ZM400 Series Indicators Service Manual

Page 7

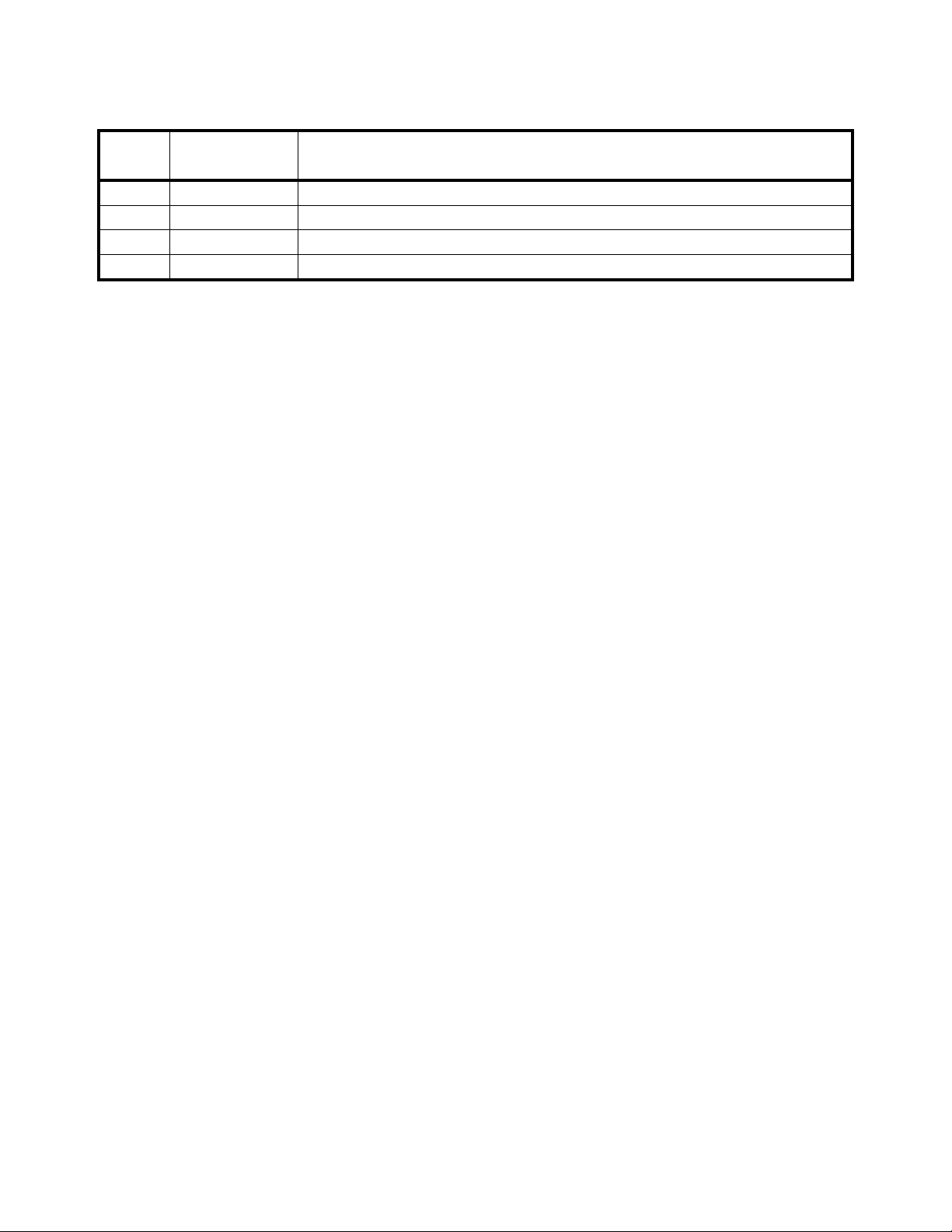

Manual revision history

Current

Issue

AA Sept. 2015 New manual

AB Sept. 2015 Changed file name and title.

Date Created Details of Changes

ZM400 Series Indicators Service Manual 7

Page 8

8 ZM400 Series Indicators Service Manual

Page 9

1 General information and warnings

1.1 About this manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled using the 1.1 and 1.1.1 convention. The names of

the chapter and the next subsection level appear at the top of alternating p ages of the

manual to remind you of where you are in the manual. The manual name and page

numbers appear at the bottom of the pages.

1.1.1 Text conventions

Key names are shown in bold and reflect the case of the key being described. If a key

has dual functions, the function is shown first followed by the key name in p arentheses

and in bold, such as in these examples: F1, SELECT, PRINT, etc.

Displayed messages appear in bold italic type and reflect the case of the displayed

message.

1.1 About this manual

1.1.2 Special messages

Examples of special messages you will see in this manual are defined below. The

heading words have specific meanings to alert you to additional information or the

relative level of hazard.

ELECTRICAL WARNING!

THIS IS AN ELECTRICAL WARNING SYMBOL.

ELECTRICAL WARNINGS MEAN THAT FAILURE TO FOLLOW

SPECIFIC PRACTICES OR PROCEDURES MAY RESULT IN

ELECTROCUTION, ARC BURNS, EXPLOSIONS OR OTHER HAZARDS

THAT MAY CAUSE INJURY OR DEATH.

WARNING!

This is a Warning symbol.

Warnings mean that failure to follow specific practices and procedures may

have major consequences such as injury or death.

CAUTION!

This is a Caution symbol.

Cautions give information about procedures that, if not observed, could result

in damage to equipment or corruption to and loss of data.

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

ZM400 Series Indicators Service Manual 9

Page 10

1 General information and warnings

1

2

3

4

5

6

7

89

10

11

12

13

14

Indicator back

plate

1.2 Installation

NO USER SERVICEABLE PARTS. REFER TO QUALIFIED SERVICE

PERSONNEL FOR SERVICE.

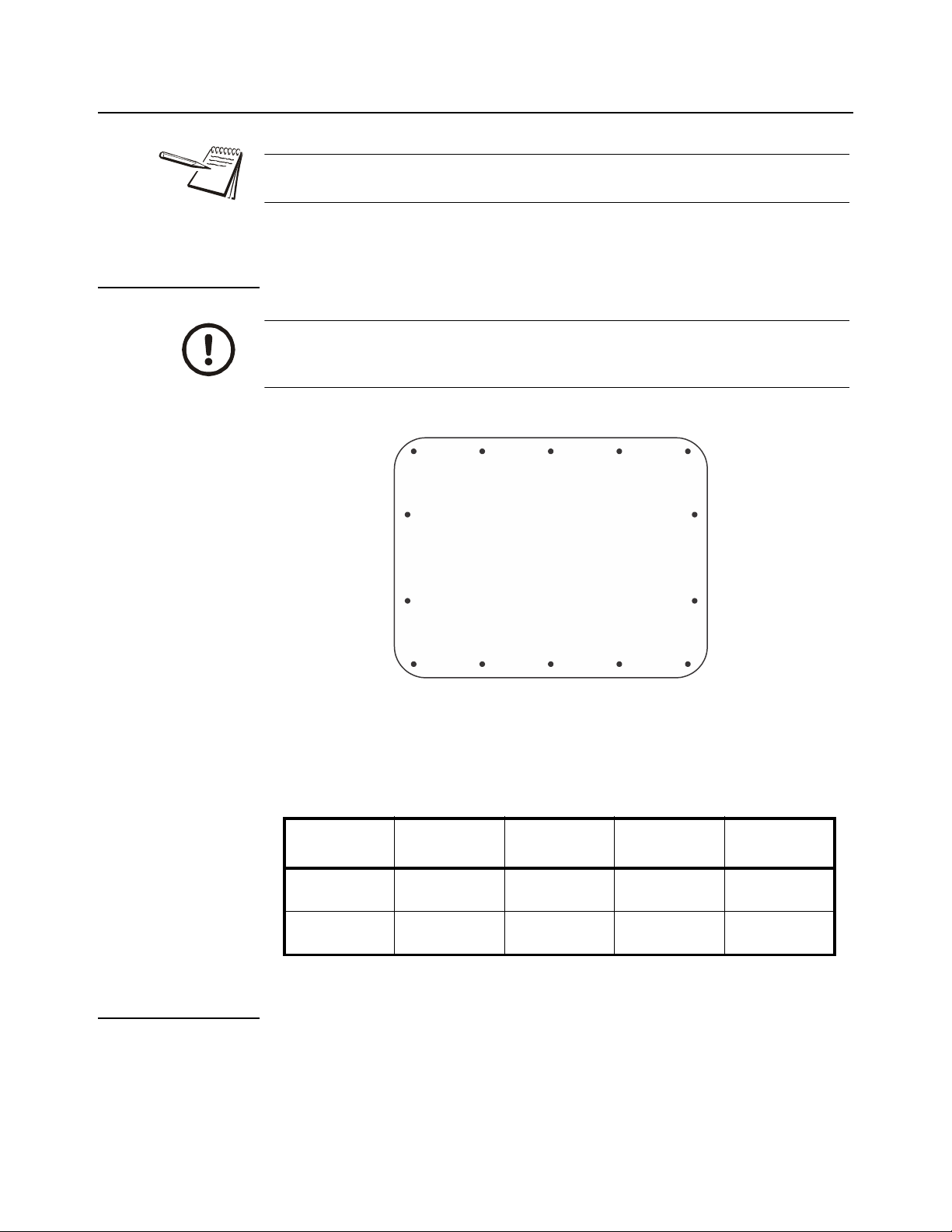

1.2.1 Torque specifications

CAUTION: The acorn nuts holding the back plate of the indicator in place must

each be tightened, in multiple passes, in the following pattern to a final torque

of 0.68 N-m (approximately 6 in-lbs) to ensure proper gasket sealing.

There are four sizes of strain reliefs exiting the indicator: PG11, PG7, PG13.5 and NPT

3/4”. The torque specifications for the locknuts which hold the strain reliefs to the

indicator housing and the specs for the dome nuts which seal the cable that passes

through the strain relief are shown in the table below.

3/4” NPT

Strain Relief

Dome Nut

Lock Nut

66.4 lb-in

7.5 N-m

44.2 lb-in

5 N-m

PG13.5 Strain

Relief

33.2 lb-in

3.75 N-m

22.1 lb-in

2.5 N-m

PG11 Strain

Relief

33.2 lb-in

3.75 N-m

22.1 lb-in

2.5 N-m

PG7 Strain

Relief

22.1 lb-in

2.5 N-m

14.4 lb-in

1.62 N-m

1.2.2 Proper grounding of cables

On the stainless steel desktop models, cable shield wires should be grounded directly

to the studs provided at the bottom of the enclosure, close to the strain relief entr y point,

with wire lengths at a minimum. On the aluminum and panel mount models the shield

wires should be connected to the SHLD connection on the corresponding terminal

block connectors.

10 ZM400 Series Indicators Service Manual

Page 11

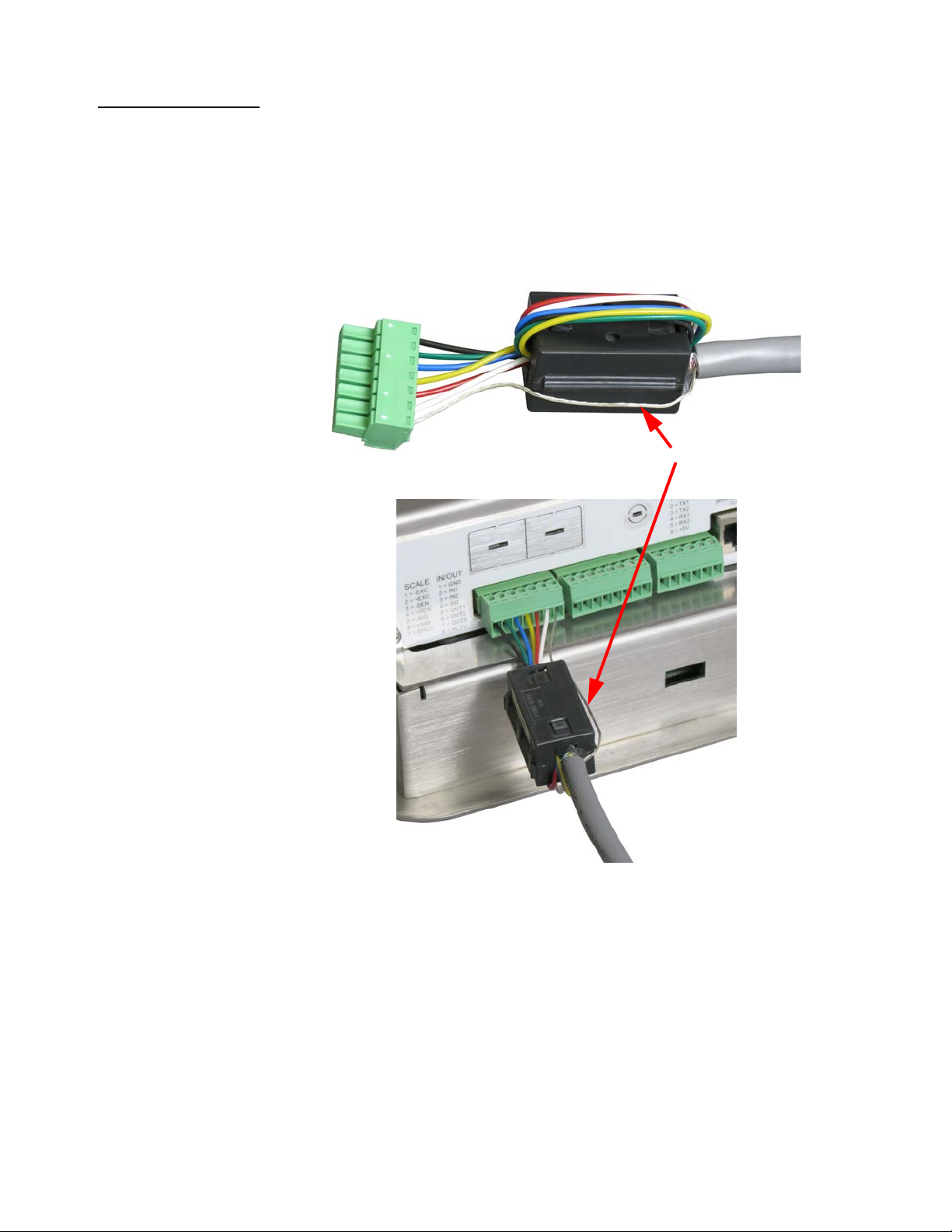

1.2.3 Panel mount scale interface cable installation

Shield drain wire

The ZM401 & ZM405 Panel Mount assemblies include the AWT25-501388 Ferrite.

Installing the Ferrite on the Scale Interface Cable on the Panel Mount models assists

with eliminating potential noise captured by the scale interface cable.

Attach the ferrite onto the scale interface cable by wrapping the unsh ielded wires once

around the ferrite as shown below. Leave the Shield drain wire outside the ferrite and

connect to the SHLD connection on the termina l block, as shown in the photos below.

1.2 Installation

The optional 2nd Scale Input 5VDC & 10VDC Excitation Modules also include the

AWT25-501388 Ferrite for use on the ZM401 & ZM405 Panel Mount Models. The

Ferrites are not needed on the stainless steel desktop models as the Shield of the

Scale Interface cable terminates directly to the studs on the bottom of the enclosure.

ZM400 Series Indicators Service Manual 11

Page 12

1 General information and warnings

1.2.4 Safe handling of equipment with batteries

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended by the manufactu r er. Dispose

of used batteries according to the manufacturer’s instructions.

ATTENTION: Il y a danger d'explosion s'il y a remplacement incorrect de la

batterie, remplacer uniquement avec une batterie du même type ou d'un type

équivalent recommandé par le constructeur. Mettre au rebut les batteries

usagées conformément aux instructions du fabricant.

1.2.5 Wet conditions

Under wet conditions, the plug must be connected to the final branch circuit via an

appropriate socket / receptacle designed for washdown use.

Installations within the USA should use a cover that meets NEMA 3R specifications

as required by the National Electrical Code under section 410-57. This allows the unit

to be plugged in with a rain tight cover fitted over the plug.

Installations within Europe must use a socket which provides a minimum of IP56

protection to the plug / cable assembly. Care must be taken to make sure that the

degree of protection provided by the socket is suitable for the environment.

1.3 Routine maintenance

IMPORTANT: This equipment must be routinely checked for proper operatio n

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

Always turn off the machine and isolate from the power supply before starting any

routine maintenance to avoid the possibility of electric shock.

12 ZM400 Series Indicators Service Manual

Page 13

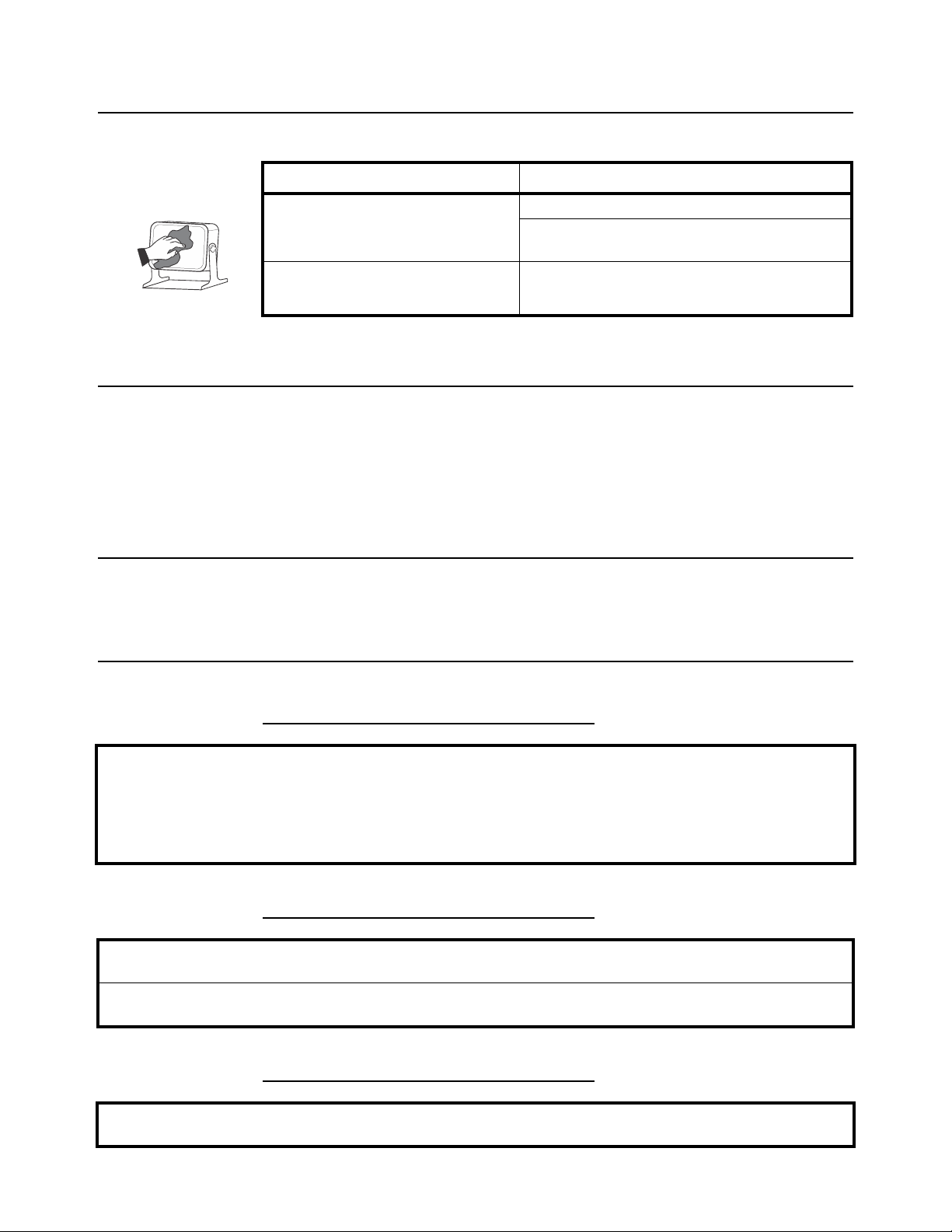

1.4 Cleaning the machine

Table 1.1 Cleaning DOs and DON’Ts

DO DO NOT

1.4 Cleaning the machine

Wipe down the outside of standard products

with a clean cloth, moistened with water and

a small amount of mild detergent

Spray the cloth when using a proprietary

cleaning fluid

Attempt to clean the inside of the machine

Use harsh abrasives, solvents, scouring cleaners or

alkaline cleaning solutions

Spray any liquid directly on to the display windows

1.5 Training

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instruction books.

T o avoid the ri sk of RSI (Repetitive S train Injury), place the machine on a surface which

is ergonomically satisfactory to the user. T ake frequent br eaks during prolonged usage.

1.6 Sharp objects

Do not use sharp objects such as screwdrivers to operate the keys.

1.7 FCC and EMC declarations of compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Canada

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la Classe A prescrites dans le Règlement sur le brouillage radioélectrique edicté par le ministère des Communications du Canada.

European Countries

WARNING: This is a Class A product. In a domestic environment, this product may cause radio interference in which the user may be

required to take adequate measures.

ZM400 Series Indicators Service Manual 13

Page 14

2 Introduction

This manual covers the installation, connections, configuration and servicing of the

ZM400 series indicators, shown in Figure 2.1. The ZM401 and ZM405 come in

stainless steel panel mount and desktop models. The ZM400 indicator will support up

to two scales with a maximum total of 16 x 350 ohm l oad cells. Th e st anda rd indi cator

can connect to a single analog scale, an analog and digit al scale o r two digit al scales.

With an option card they can support 2 analog scale inputs. The standard indicator

connectivity includes a USB Host, two RS232 ports and an Ethernet port. The following

internal module cards are available as options:

l Analog Output

l Current Loop/RS485/RS422

l USB Device

l Wireless 802.11g

l Internal 120 VAC relay

l 2nd Scale Input 5VDC Excitation

l 2nd Scale Input 10 VDC Excitation

l External I/O Interface (for existing GSE or 1310 I/O cards)

l AC input, 4 Inputs (120-240VAC)

l DC input, 4 inputs (4-30VDC)

l AC output, 4 relays (20-240VAC)

l DC output, 4 relays (3-60VDC)

The indicators also have three logic level inputs with configurable functions and thre e

set point outputs and can interface with remote analog or digital scales, PLC's and

scoreboards. See the Specification literature for a full list of specifications.

Figure 2.1 Front panels of the ZM401 and ZM405 indicators

The ZM400 can connect to USB flash drives, printers, remote displays, co mputers and

other peripheral devices.

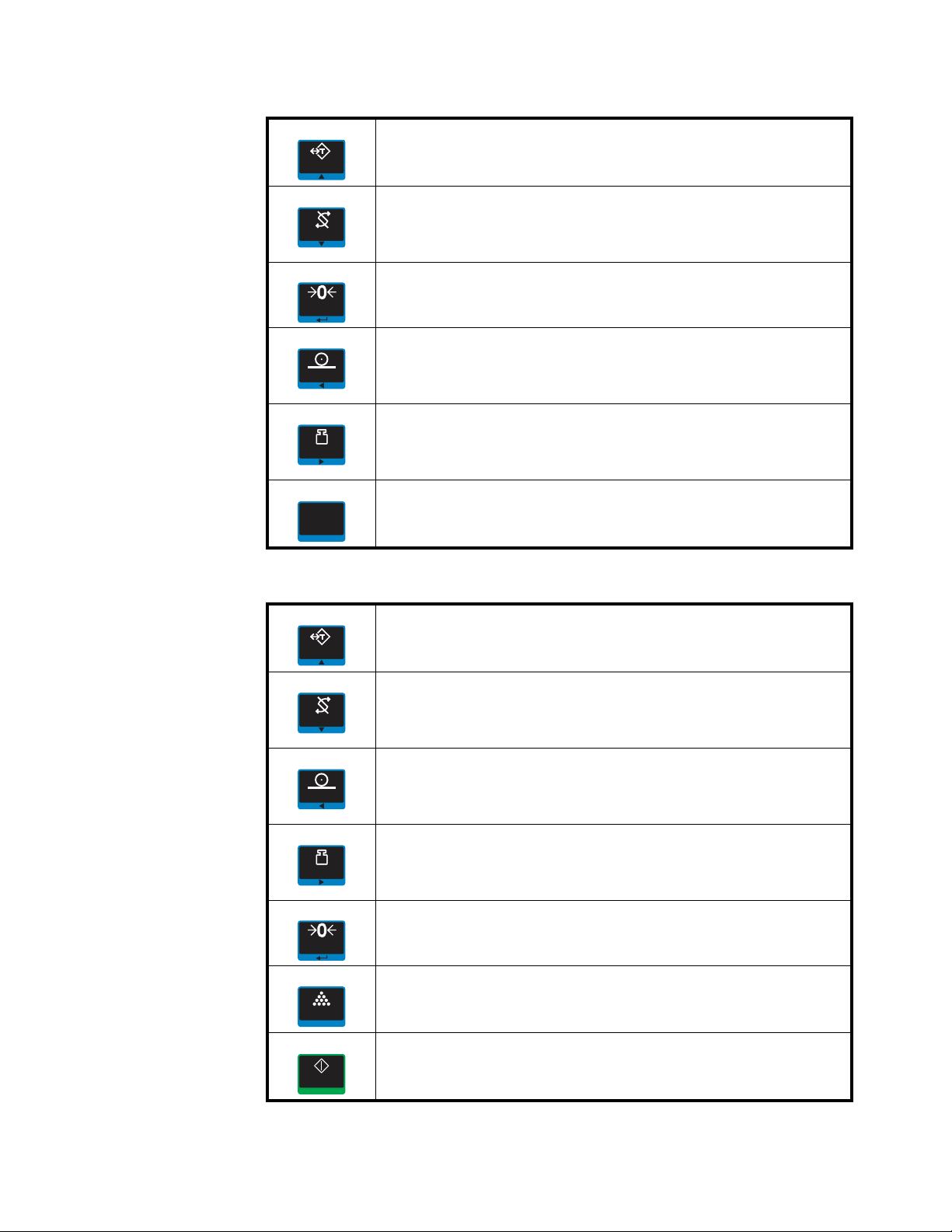

2.1 Front panel

The front panels for the ZM400 series are shown in Figure 2.1 and consists of the keys

and the display.

Never press a key with anything but your finger. Damage to the overlay may result if

sharp or rough objects are used.

ZM400 Series Indicators Service Manual 14

Page 15

2.1 Front panel

TAR E

SELECT

ZERO

PRINT

UNITS

F1

TAR E

SELECT

PRINT

UNITS

ZERO

SAMPLE

START

The normal function of the keys on the front panel of the ZM401 are listed below.

Press the TARE key to perform a pushbutton tare function.

Acts as an up arrow key for menu navigation.

Allows entry of numeric values.

Press the SELECT key to toggle between the active display values.

Press and hold to enter the setpoint editor.

Acts as a down arrow key for menu navigation.

Allows entry of numeric values.

Press the ZERO key to zero the display.

Acts as an ENTER key to accept a displayed value or function.

Press the PRINT key to send information to a peripheral device through a

configured communications port.

Acts as a left arrow key for menu navigation and removes last digit during numeric

entry.

Press the UNITS key to scroll through the available units of measure while in

normal operating mode.

Acts as a right arrow key for menu navigation and inserts new digit during numeric

entry.

Press the F1 key to select application specific choices.

Aborts a numeric entry and acts as an ESCAPE key in the menu navigation.

Press and hold to view the password entry screen for menu access.

The normal function of the keys on the front panel of the ZM405 are listed below.

Press the TAR E key for pushbutton, key entry or preset Tare functions.

Acts as an up arrow key for menu navigation.

Allows entry of numeric values.

Press the SELECT key to toggle between the active display values.

Press and hold to enter the setpoint editor.

Acts as a down arrow key for menu navigation.

Allows entry of numeric values.

Press the PRINT key to send information to a peripheral device through a

configured communications port.

Acts as a left arrow key for menu navigation and removes last digit during numeric

entry.

Press the UNITS key to scroll through the available units of measure while in

normal operating mode.

Acts as a right arrow key for menu navigation and inserts new digit during numeric

entry.

Press the ZERO key to zero the display.

Acts as an ENTER key to accept a displayed value or function.

The SAMPLE key can be used to perform custom application functions.

The START key can be used to perform custom application functions.

ZM400 Series Indicators Service Manual 15

Page 16

2 Introduction

STOP

ID

F1

SCAL E

SETUP

TAR G ET

C

123

456

789

Q

R

PS

X

Y

WZ

BACE

DF

KJLN

MO

H

GI

U

TV

0

:

,

-

%

#

bargraph

center-of-zero

motion

battery status

setpoints

preset

tare

custom

annunciators

Ethernet

activity

graphic

display area

The STOP key can be used to perform custom application functions.

The F1/ID key can be used to perform custom application functions. It can also be

used to abort a numeric entry and it acts as an ESCAPE key in the menu navigation.

The SCALE key can be used to perform custom application functions. It can also be

used to select the active scale when more than one scale is enabled.

The SETUP key can be used to perform custom application functions. It can also be

used to view the password entry screen for menu access.

The TAR GET key can be used to perform custom application functions.

Use the numeric keypad to enter numbers in the appropriate screens.

Press the C (CLEAR) key to clear the last entry.

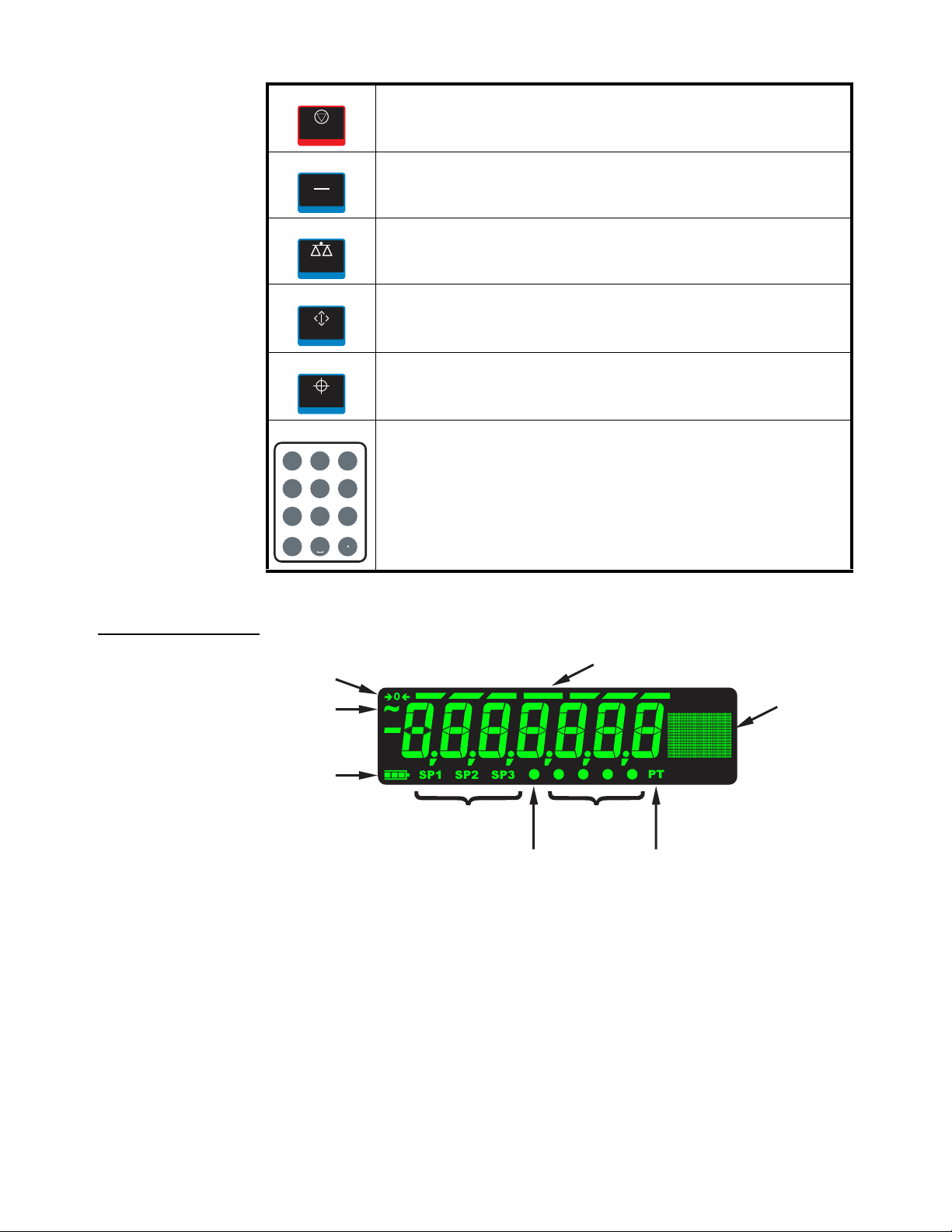

2.1.1 Front Display

16 ZM400 Series Indicators Service Manual

Page 17

2.2 Powering up the ZM400

These segments flash in alphanumeric entry mode

Press to increment the flashing number

Press to decrement the flashing number

Press to backspace cursor in a number

Press to advance cursor in a number

Press to accept a value

Press to escape an entry screen

TARE /

-

SELECT /

-

PRINT /

-

UNITS /

-

ZERO /

-

F1 /

ESC -

2.2 Powering up the ZM400

The indicator is always active as long as power is received. Power can be supplied by:

l AC power cord connected to a properly grounded outlet (100 V AC - 24 0 V AC,

50 or 60 Hz)

l External 12VDC @ 1.2 Amps up to 36VDC @400mA (14.4 W atts). These are

the power requirements for a fully loaded unit (16 x 350 load cell, 5 00mA out

the 5V COM port terminal block, 500mA load on USB Host, and Wireless

option card installed).

l AC to 24VDC power converter (optional accessory for panel mount version)

l Optional external battery pack with 4 D cells:

1 x 350 ohm load cell = 6 hours battery life

4 x 350 ohm load cell = 4 hours battery life

8 x 350 ohm load cell = 1 hour battery life

(See D-cell Battery pack option (AWT05-505852) and external battery

circuitry on page 148 for more information.)

2.3 Alphanumeric entry procedure (ZM401 only)

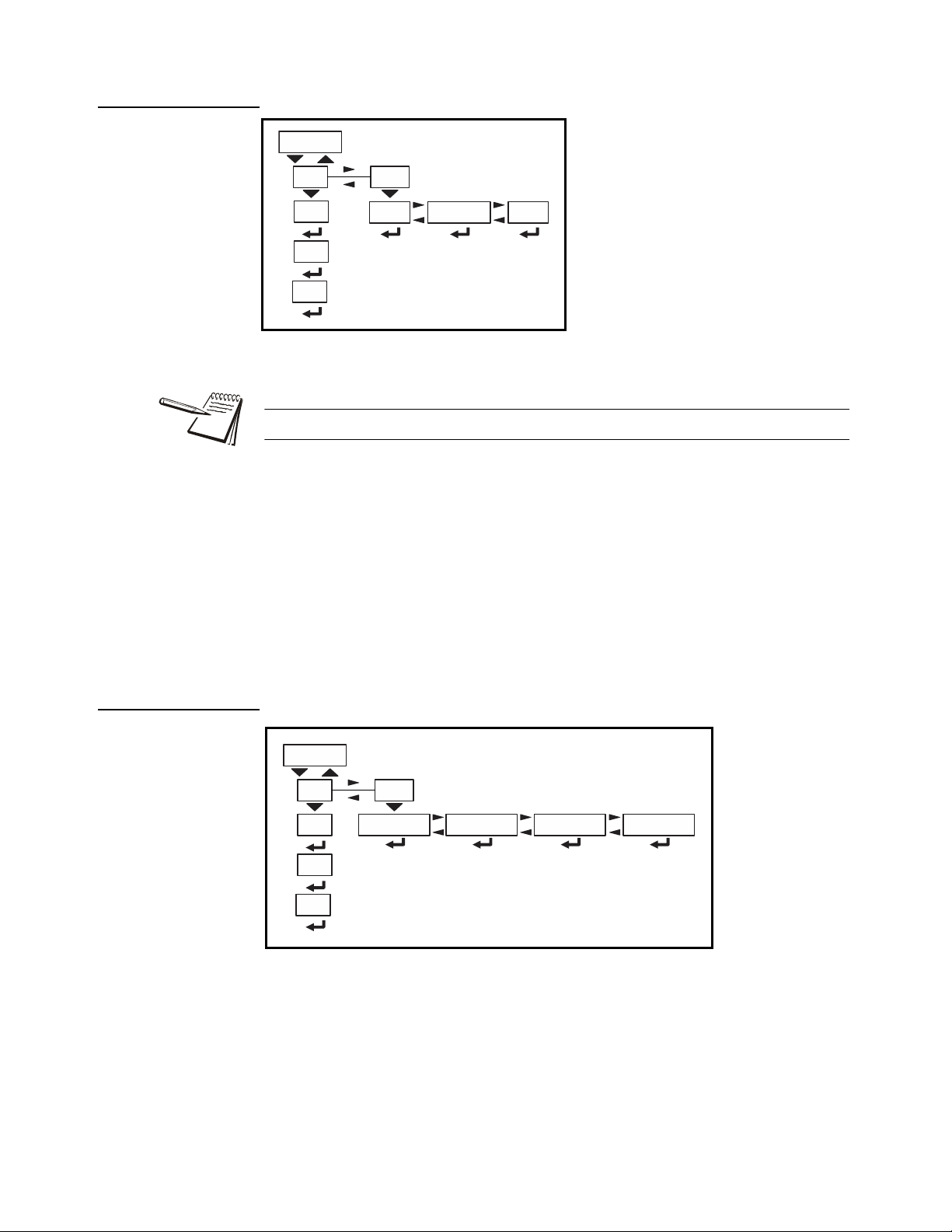

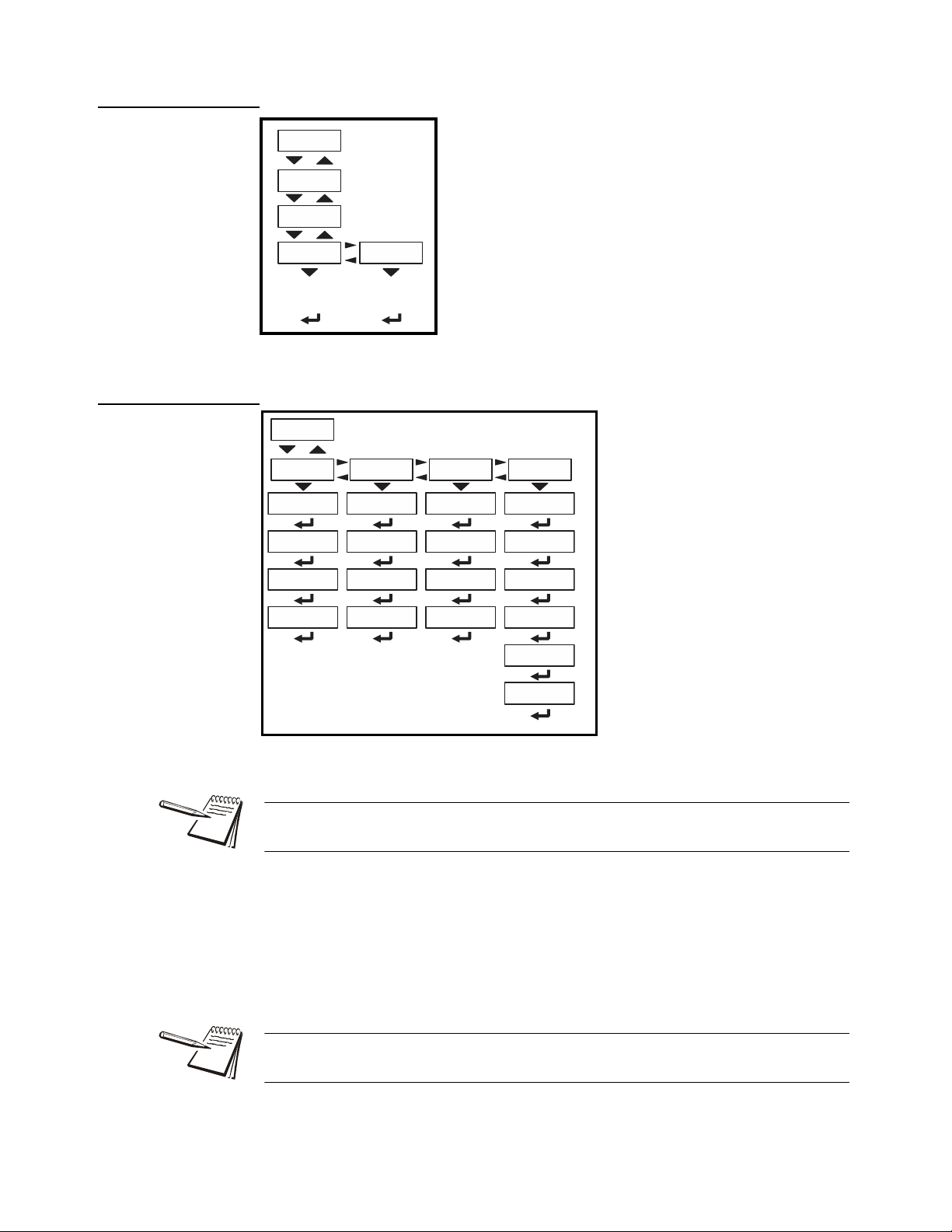

The keys in Figure 2.2 have alternate functions in alphanumeric entry screens.

Figure 2.2 Key function during numeric entry

When the graphic display is present you can scroll through numbers, alpha

characters and symbols by repeatedly pressing the TARE or SELECT keys.

Use the keys, as described in Figure 2.2, to enter an alphanumeric value on th e display .

For alphanumeric menu entries the graphics display will only show the last six

characters entered. Following is an example:

Example: To key in ZM4:

Repeatedly press the TARE() or SELECT() key until Z appears on the display.

Press the UNITS() key once to move cursor one space to the right.

Repeatedly press the TARE() or SELECT() key until M appears on the display.

Press the UNITS() key once to move cursor one space to the right.

ZM400 Series Indicators Service Manual 17

Repeatedly press the TARE() or SELECT() key until 4 appears on the display.

Press the ZERO key to enter or accept the value.

Press the PRINT() key to move the entry function one digit to the left. This effectively

deletes the current value in that position and allows you to enter a new value in that

position.

Page 18

2 Introduction

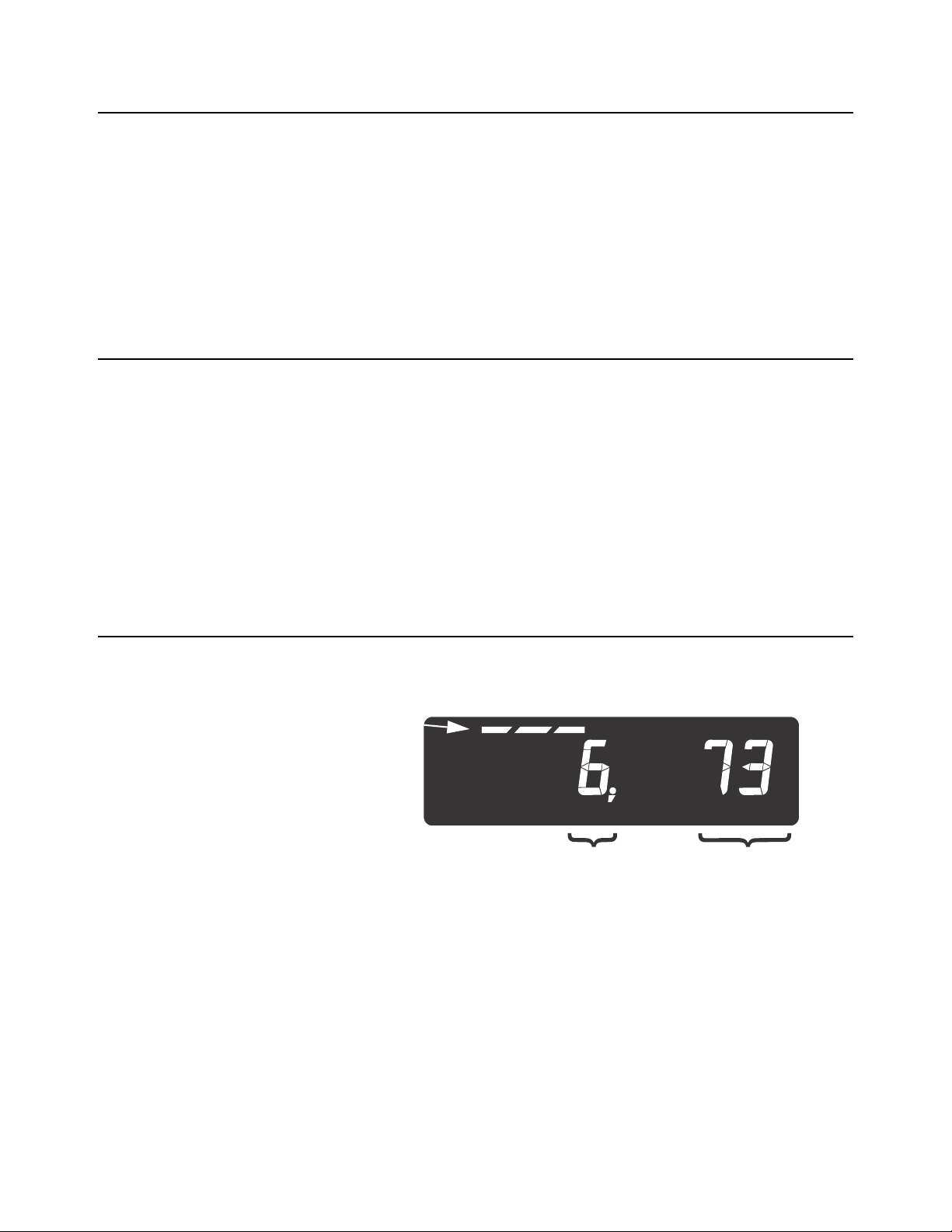

When these segments

are flashing, you are in

the string index select

mode. In this mode you

select the index

character you want to

edit or add/delete a

character.

String Index

number

Character

(ASCII characters

are entered as

decimal values)

2.4 Using the alphanumeric keypad (ZM405 only)

Use the alphanumeric keypad to enter numbers and words when prompted by the

indicator. For alphanumeric menu entries the graphics display will only show the last

six characters entered.

The action is similar to using a cell phone to select the number or letter. A rapid

succession of presses will scroll through the number on the key and then the letters,

starting with upper case and then lower case. The decimal key scrolls through the

negative sign, pound sign, colon, comma and percent sign. The 0 key toggles between

0 and a space.

2.5 Entering negative numbers or decimal point

To enter a minus sign for a negative number or a decimal point (or comma), press the

C key (or PRINT key) to clear the current value from the display.

Then to enter a negative number, with a single 0 displayed press SELECT. The first

character will then change to a (-) negative sign. Enter the rest of the digits normally.

To enter a decimal point (or comma), on a ZM405 use the decimal point key. On a

ZM401 when the flashing digit is a 0 press the SELECT key and a decimal point (or

comma) will appear. Then press the UNITS key to scroll in the next digit to follow the

decimal and enter the rest of the digits normally. To enter a value less than 1 requires

the entry of the leading 0 before a decimal point is allowed.

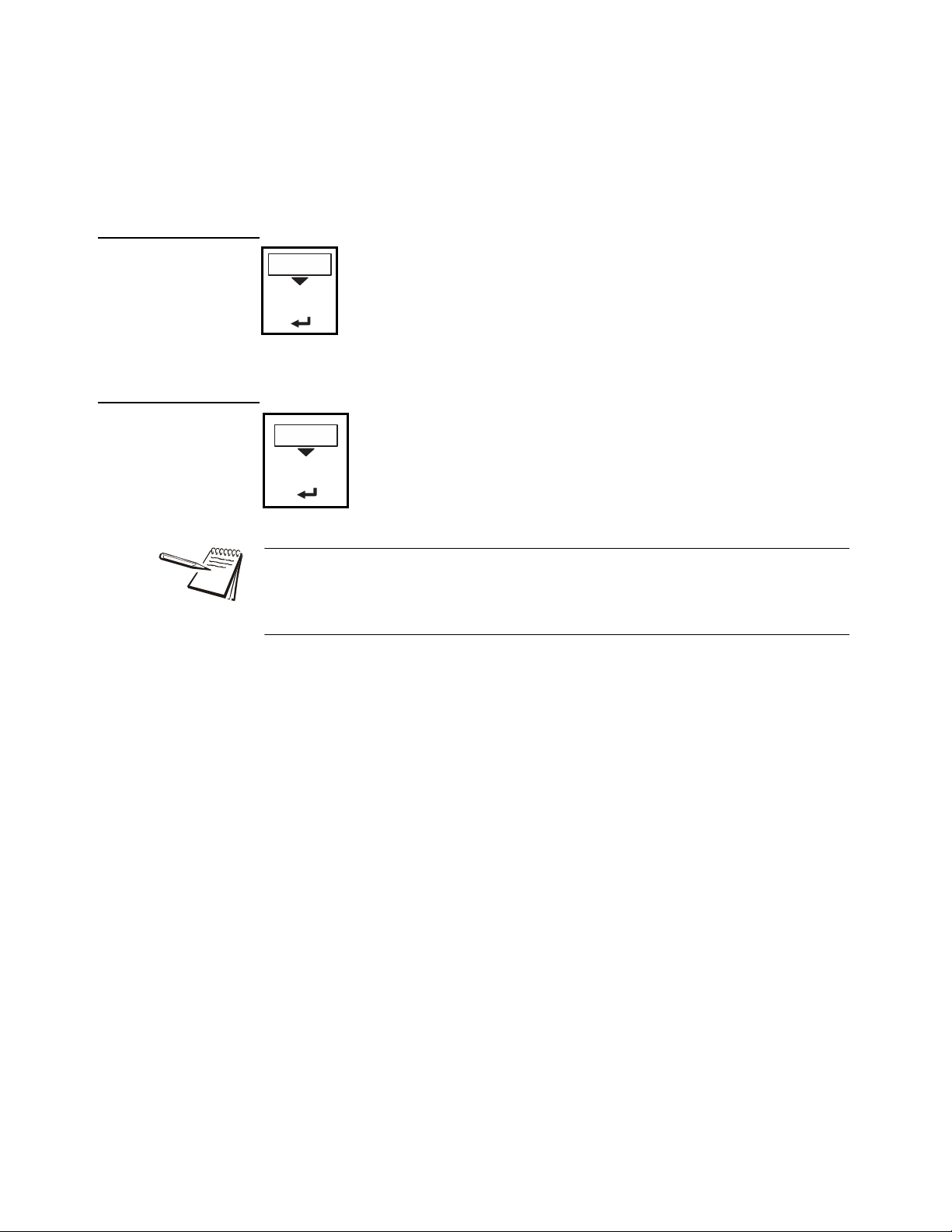

2.6 String index/character data entry

18 ZM400 Series Indicators Service Manual

Below are guidelines to create or edit text and scale information for print format s. This

is a sample of a string entry display.

Left-flashing bar graph segment s indicate you are in the S tring Index select mode. Use

the Table 1 key legend to:

l move to the index number you want to edit

l add a new index number

Page 19

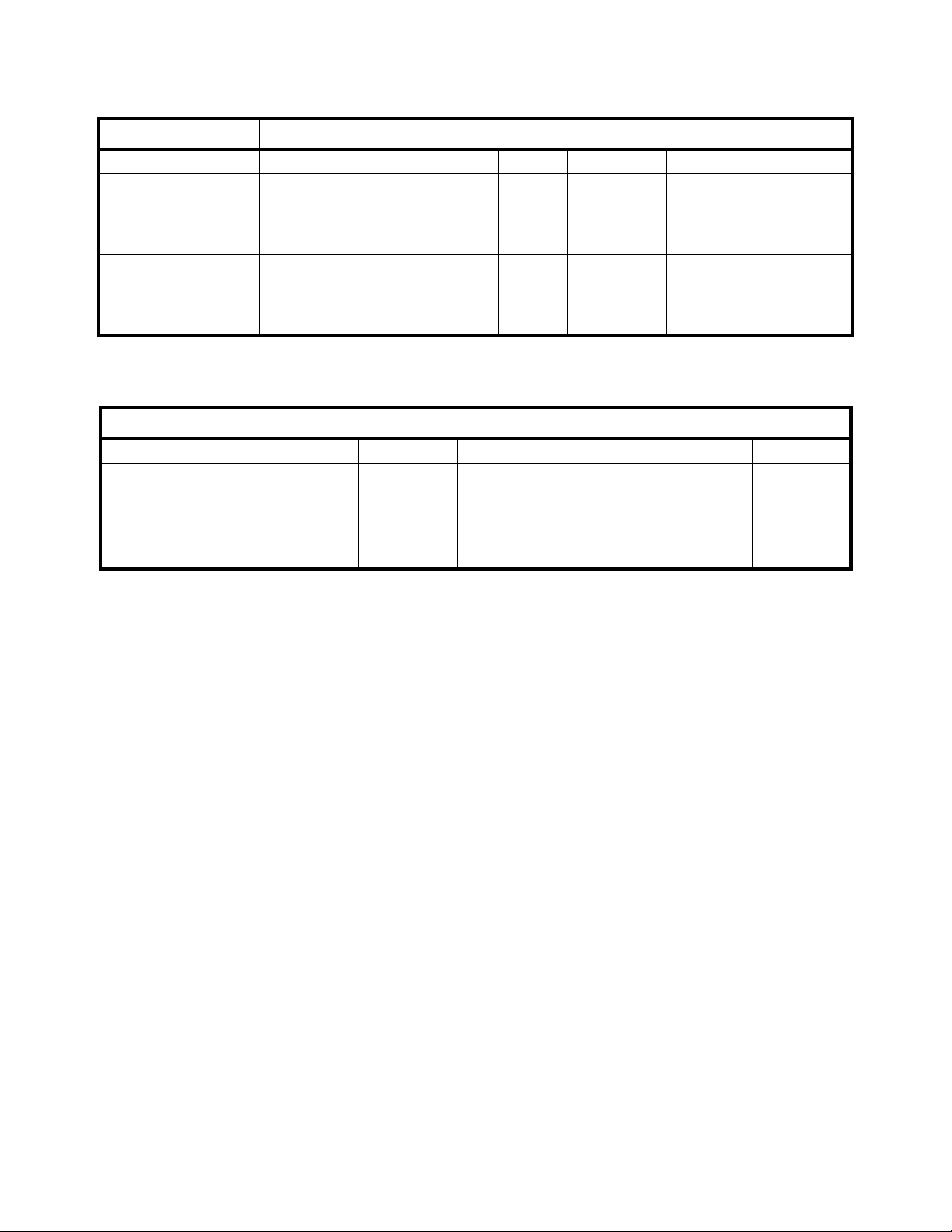

Action TARE SELECT ZERO PRINT UNITS F1

Momentary Key Press

Long Key Press

Action TARE SELECT ZERO PRINT UNITS F1

Single Key Press

Long Key Press

2.6 String index/character data entry

l delete an existing index number.

Table 1: Key Action When In The String Index Select Mode

Selects the index

Deletes current

character

character for editing

using the key actions in

EXIT

Table 2

Inserts new character

Deletes current

character

before this point.

Default character

EXIT

added is 32 (space)

l After you select the index number, use the Table 2 key actions to edit the

Moves left one

position in the

index

Page Up

(Decrements

index by 10)

Moves right

one position in

the index

Page Down

(Increments

index by 10)

character for that index number.

Table 2: Key Action When In The Character Edit Mode

Increments the

flashing digit by

1

Move flashing

digit left

Decrements

the flashing

digit by 1

Move flashing

digit right

Enter

Enter

Delete flashing

digit

Delete the

entire entry

Add Digit ESC/Abort

Does nothing ESC/Abort

Escape Edit

mode and

Abort all

changes

Escape Edit

mode and

Abort all

changes

ZM400 Series Indicators Service Manual 19

Page 20

3 Introduction to the menus

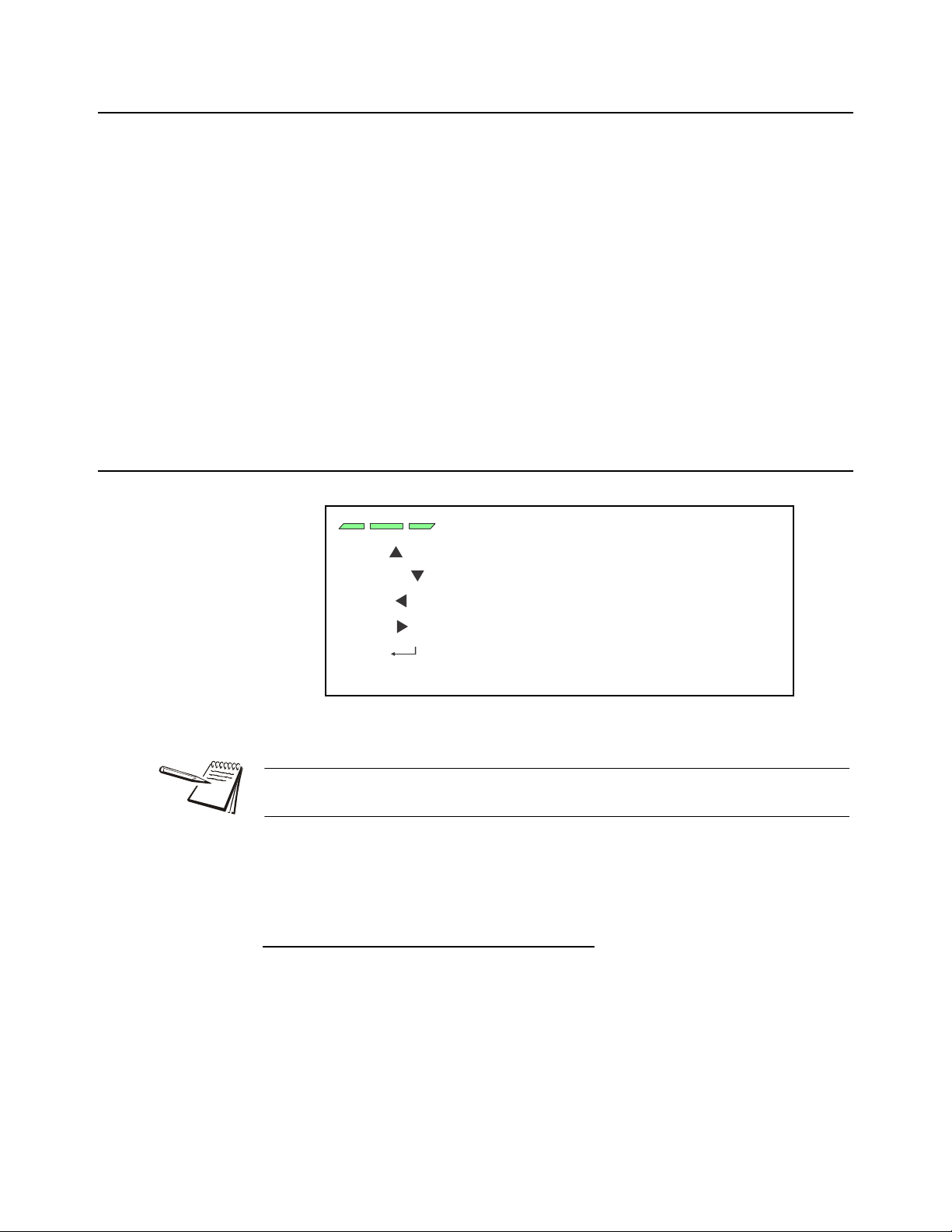

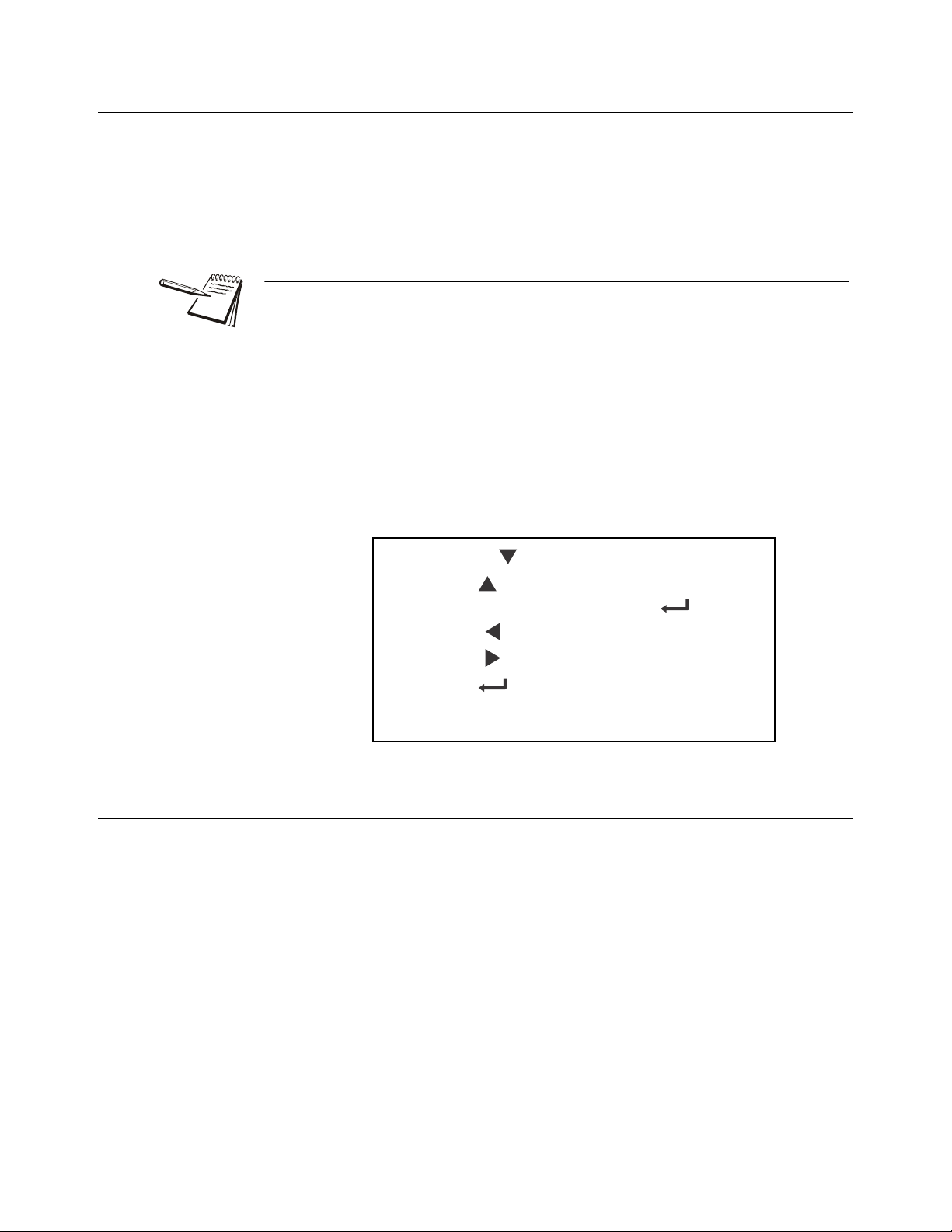

Press SELECT/ to move down in a menu

Press TARE/ to move up in a menu, except at the

bottom item in a menu, then use ZERO/ or F1

Press PRINT/ to move left in a menu

Press UNITS/ to move right in a menu

Press ZERO/ to accept a value or choice and

move up in the menu.

Press F1 to escape and move up in the menu

Menus, accessed through passwords, are available in the indicator to customize and

configure the indicator for your purposes. The menu levels and their passwords are

shown below:

Password Menu Level Accessed Menus

111 USER User, About, Audit

3570 DIAGNOSTICS Diag, User, About, Audit

3088 ADMIN Setup, Diag, User, About, Audit

2580 CALIBRATE Calib

1793 SUPER Application specific items. See User manual.

The CALIBRATE menu level accesses the calibration procedure only. You can also

access the calibration menu through the Setup menu using the ADMIN password.

Some menus appear in more than one menu level. As you can see in the ta ble above,

the 111 password gives you access to three menus; User, About and Audit. The 3570

password gives you access to those three plus the Diagnostics menu. The 3088

password gives you access to those four plus the Setup menu.

This allows the supervisor to control access to some or all of the menus b ased on the

passwords shared. The menus are the same no matter which menu level you access

them from.

The menus are always explained in a sequential manner to cover all information in a

logical fashion. You will probably never access all the menu items in this manner . You

can navigate to the area of the menu that needs to be changed by using the menu

maps and key navigation legends which are inserted as a reminder with most menus.

See Alphanumeric entry procedure (ZM401 only) on p age 17 for instructions on how to

enter a password to get to the menus. Key functions in the menu s ar e sho wn be low.

Menu Navigation Keys:

ZM400 Series Indicators Service Manual 20

Page 21

3.1 Accessing the menus

Press SELECT/ to move down in a menu

Press TARE/ to move up in a menu, except at the

bottom item in a menu, then use ZERO/ or F1

Press PRINT/ to move left in a menu

Press UNITS/ to move right in a menu

Press ZERO/ to accept a value or choice and

move up in the menu.

Press F1 to escape and move up in the menu

Follow these steps to access the various menus in the indicator.

1. With the indicator powered up and in normal operating mode, press and hold

the F1 key …

Pass is briefly displayed, then a flashing 0, prompting you to enter the

password.

When the 0 is flashing, press F1 and the application name is briefly displayed, then

the indicator returns to normal operating mode.

2. Key in the p assword for the menu you want to access and press the ZERO key

to accept it …

The first item in the top level of the menu you accessed is displayed.

3. Use the navigation keys, shown below, to navigate through the menu

structure. The symbols appear on the bottom of the keys.

3.1 Accessing the menus

Menu Navigation Keys:

3.2 Exiting the menus

1. If you are at the bottom item in a menu use ZERO to accept a choice or value

and move up a level, or use F1 to escape and move up one level without

accepting the choice or value. From that point, press the TARE key repeatedly

until …

SAVE no is displayed. This means “Do not save changes. “

2. Use the PRINT or UNITS key to scroll through the choices: SAVE no,

SAVEYES and CAnCEL. Press ZERO to accept the displayed choice.

If you choose SAVE no or SAVEYES the indicator exits the menu and

ZM400 Series Indicators Service Manual 21

If you choose CAnCEL, the indicator remains in the menu.

returns to normal weighing mode.

OR

Page 22

3 Introduction to the menus

3.3 Menu annunciators

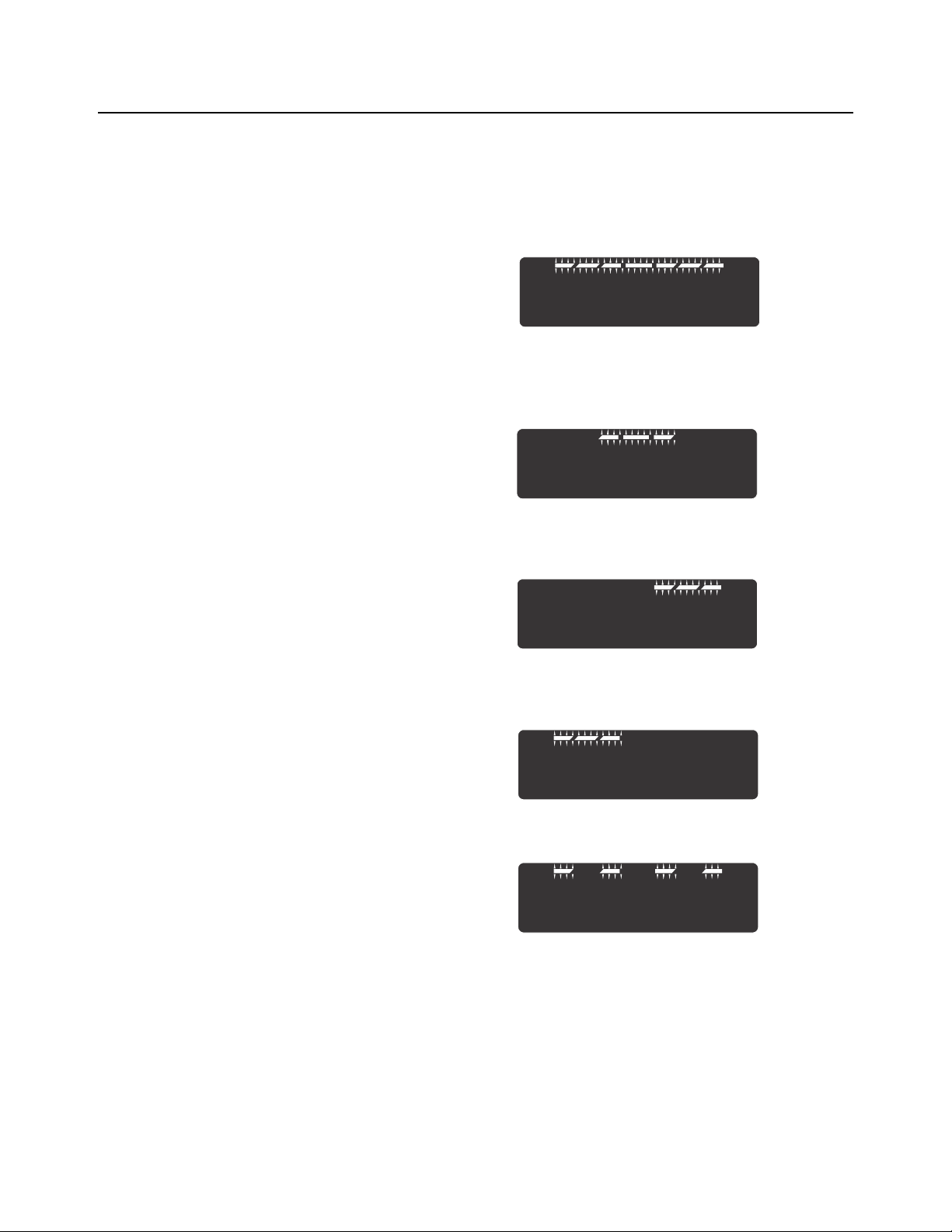

The menu structure is made up of menu items, parameters, value entry screens and

lists from which you choose one item. To help you know where you are in the menu,

the bar graph at the top of the display is on while the indicator is in the menus and will

change appearance according to the following rules:

All segments flashing This means you are in the menu structure but not

Center flashing / others off This means you are in a numeric entry screen or

in any of the following screens.

the Quick Code prompt screen. See Quick Code

parameter entry on page 23. Enter a number and

press ZERO to accept.

Right flashing / others off This means you are in a list. Scroll through the

choices with the PRINT and UNITS keys and

press ZERO to accept.

Left flashing / others off This means you are in a data entry. See String

index/character data entry on page 18 for more

information.

Every alternate segment flashing This means you are in octet entry for IP, Subnet

or Gateway address.

22 ZM400 Series Indicators Service Manual

Page 23

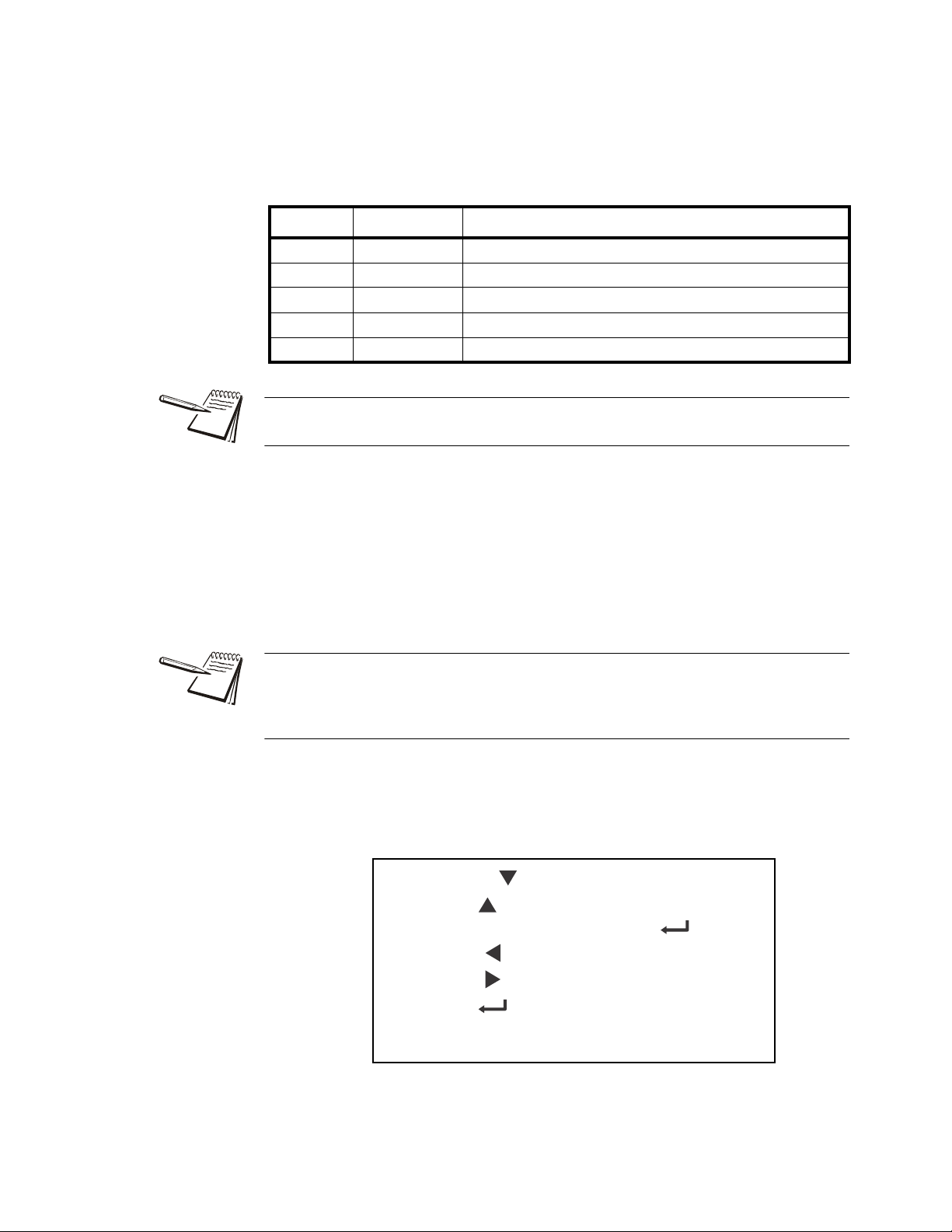

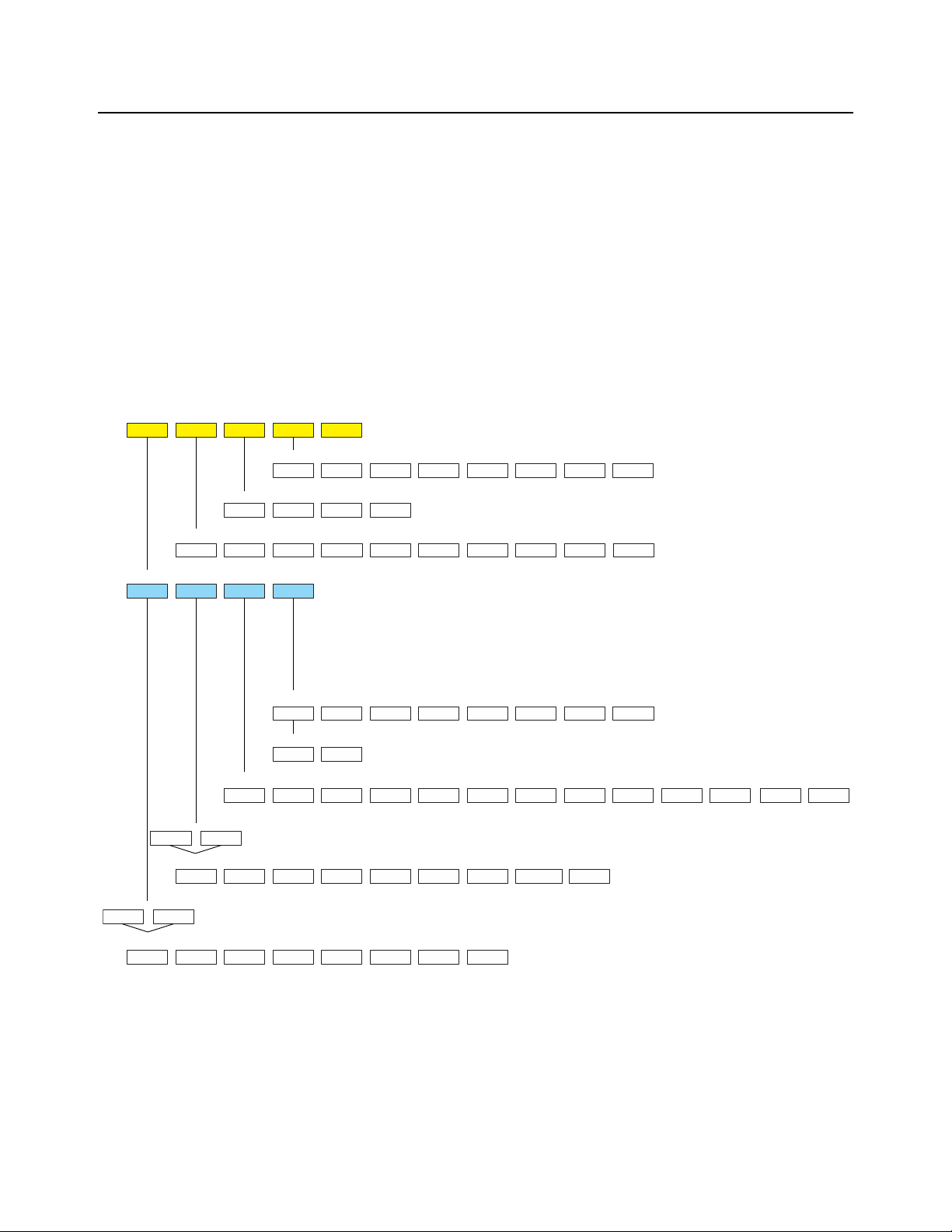

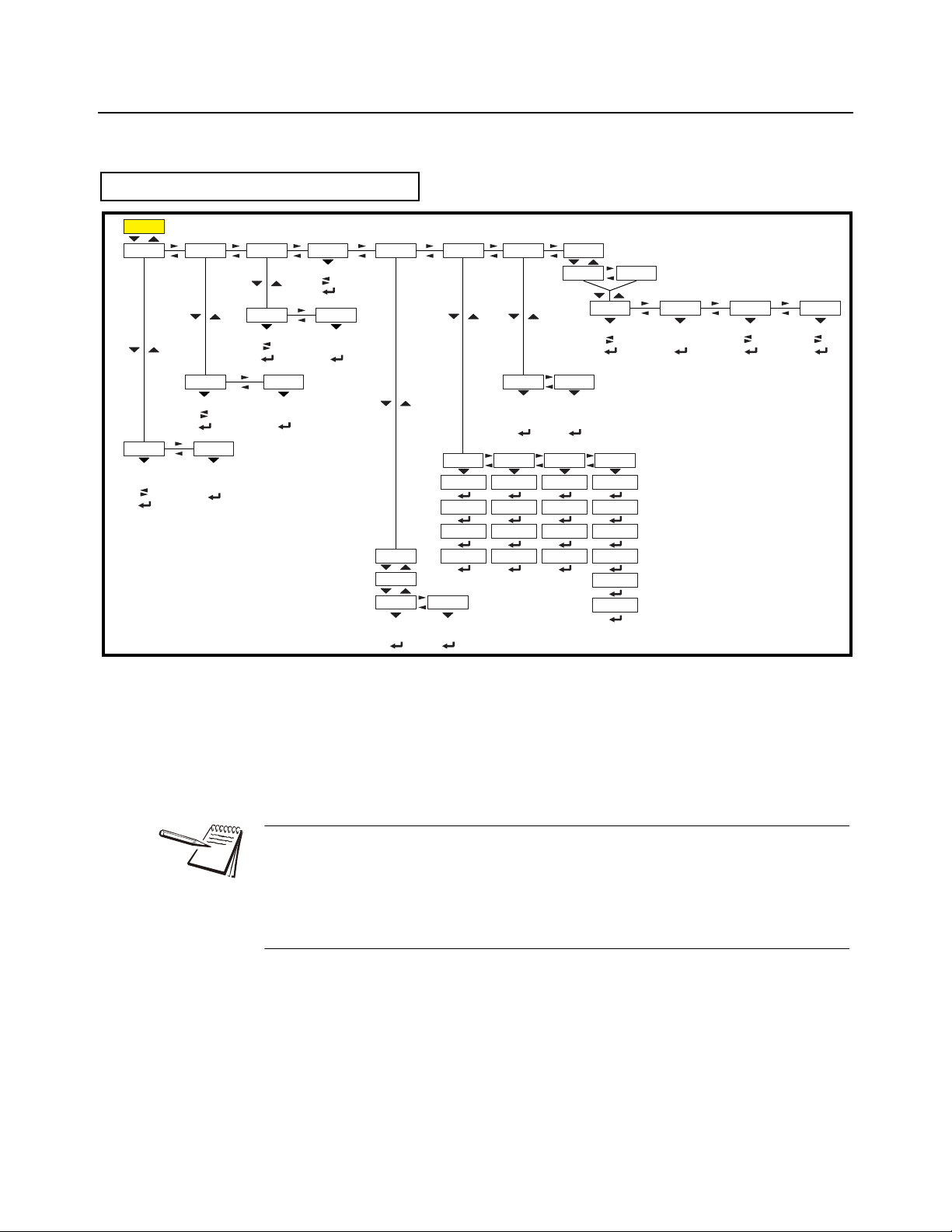

3.4 Quick Code parameter entry

Setup AuditUser

Diag

About

54321

SerialApp. EnetOptionFirmBoot Dload

4.1 4.2

4.3

4.4

4.5 4.6

4.7

Site ID

SealTime Date

3.13.23.33.4

Buttons Ports InputsDisplayScale Options LogsOutputsCur.Zero

2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9

Calib Scale System Ports

1.1 1.2 1.3 1.4

E-net Protcl P. F. Ed it PLC Printer OptionsFileSerial

1.4.1 1.4.2 1.4.3 1.4.4 1.4.5 1.4.6 1.4.8 1.4.9

Port1 Port2

1.4.1.1 1.4.1.2

Site Display Buttons D-vals Tare Config Archive Serial Update Passwd

1.3.1 1.3.2 1.3.3 1.3.4 1.3.5 1.3.6 1.3.7 1.3.8 1.3.10 1.3.11

Capacty

Dvision Units Stable AZT Filter Ranges

1.2.1.1 1.2.1.2 1.2.1.3 1.2.1.4 1.2.1.5 1.2 .1 .6 1.2.1.7

Scale 1

1.1.1

Zero Span Linear Input Gravity

Display

Cal.Unit Print

1.1.1.1 1.1.1.2 1.1.1.3 1.1.1.4 1.1.1.5 1.1.1.6 1.1.1.7 1.1.1.8

Z-Lock

1.3.12

BSQ

4.8

BSQ

2.10

Scale 2

1.1.2

Scale 1

1.2.1

Scale 2

1.2.2

2,3,Range Type

1.2.1.8 1.2.1.9

Beeper

1.3.13

Num Scl

1.3.14

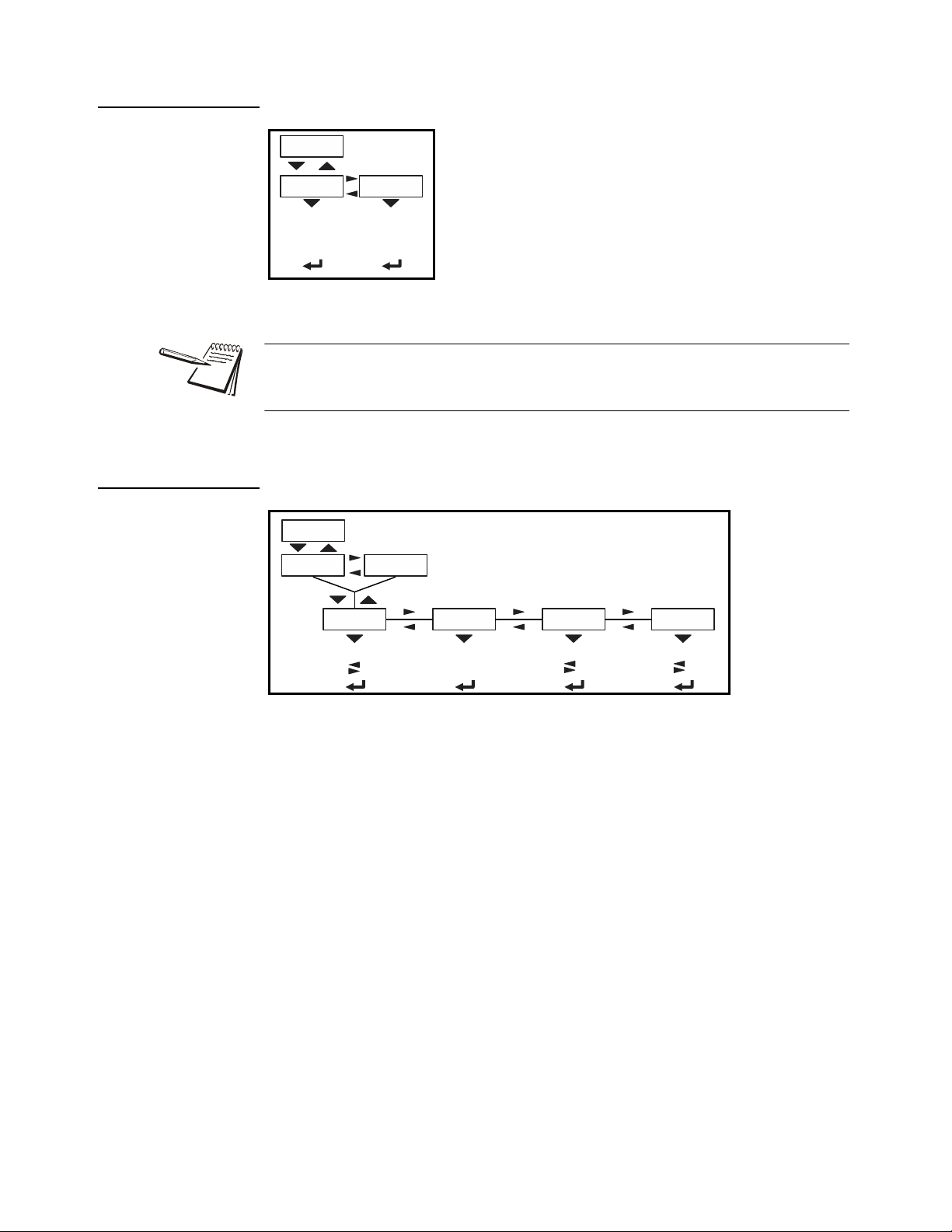

The Quick Code parameter entry let s you quickly jump to sections of the menu. Here’s

how it works:

1. Access the 3088 ADMIN menu. Press and hold the ZERO key for one second.

When you release the key …

P- 0 is displayed and the three center bargraph segments flash.

2. Refer to the Quick Code table in Figure 3.1, find the parameter you want to

access, key in that number and press ZERO …

The screen will show the associated menu item.

3. Use the normal procedures to set the menu item and to save the changes you

make.

3.4 Quick Code parameter entry

Figure 3.1 Quick Code table

ZM400 Series Indicators Service Manual 23

Page 24

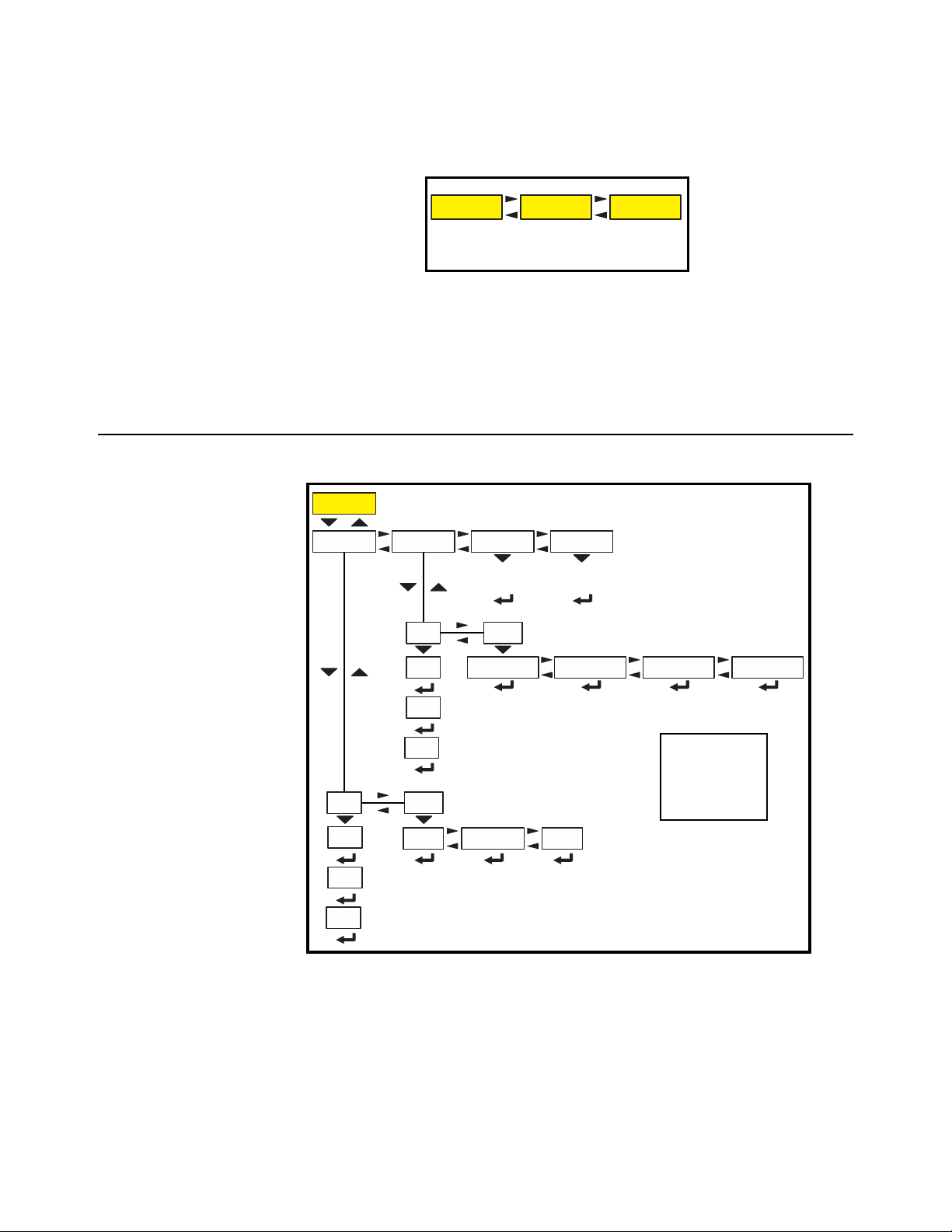

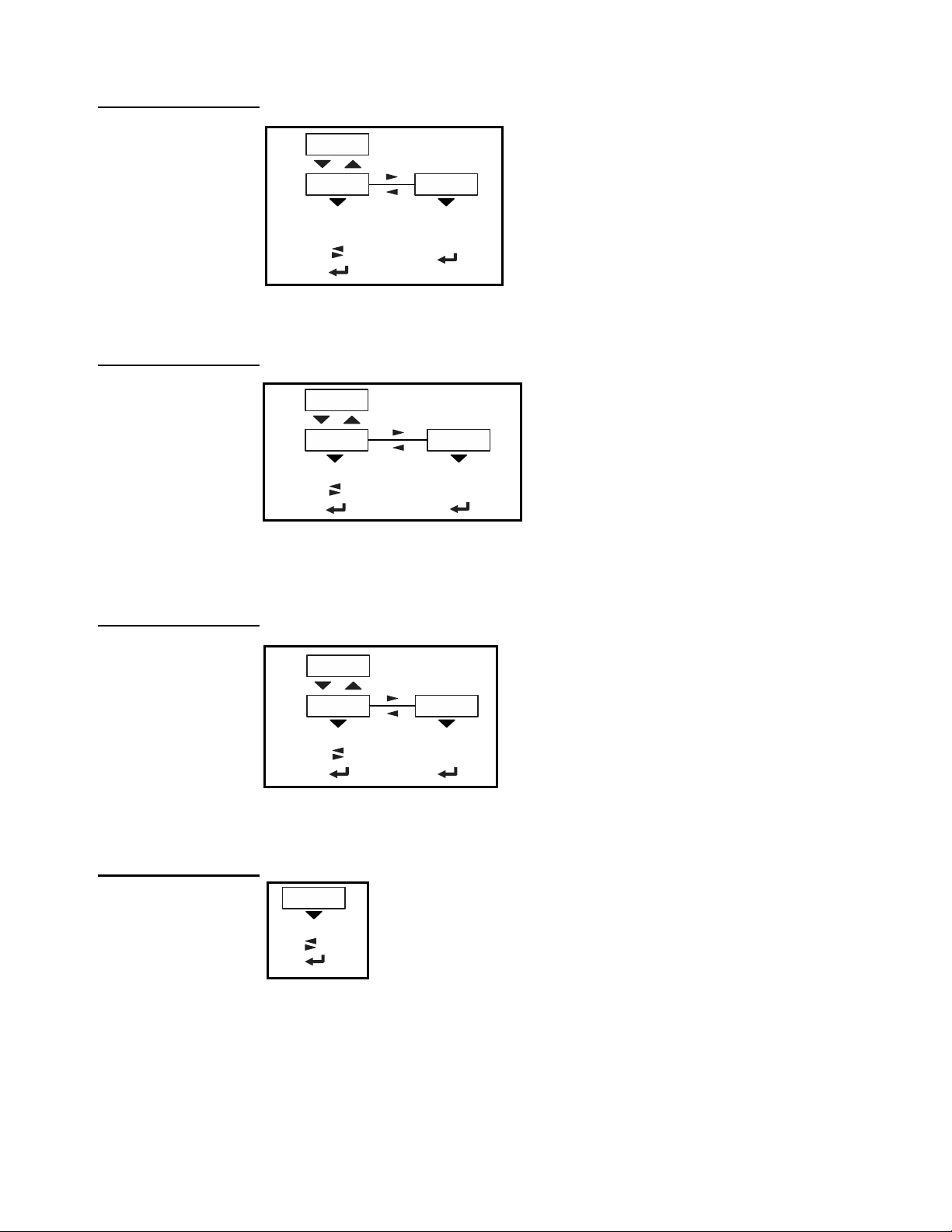

4 User level menus

See

page 24

See

page 27

See

page 31

User About Audit

User

Site ID SealTime Date

Set

12hr 12hr-AP 24hr

Set Style

MMDD4YMMDD2Y DDMM2Y DDMM4Yy- x

m- x

d- x

Style

h- x

m- x

s- x

Reference

Alphanumeric entry procedure

Enter

Site ID

View Seal

Status

4 User level menus

The USER level (password 111) contains the User, About, and Audit menus arranged

as shown in Figure 4.1.

Figure 4.1 USER level (password 111) menus

To access the USER level, from normal weighing mode, press and hold the F1 key.

Enter password 111 and press the ZERO key .

4.1 User menu

The User menu is shown in Figure 4.2.

24 ZM400 Series Indicators Service Manual

Figure 4.2 User menu

Use this menu to set the time, date, site ID, and to see the physical seal status. Each

is explained below:

Page 25

4.1.1 Time

Use the tiME menu item to set the clock

(SEt) and to choose the style of the time

display (StYLE) 12 hr, 12 hr AM/PM or

24 hr.

Time

Set

12hr 12hr-AP 24hr

Style

h- x

m- x

s- x

Date

Set Style

MMDD4YMMDD2Y DDMM2Y DDMM4Yy- x

m- x

d- x

4.1 User menu

The Time and Date can be used in print formats.

SEt Use this to enter values for the time.

h- x, = Hour

m- x = Minute

s- x = Seconds

4.1.2 Date

StYLE Choose the style of the time display. Choices are:

12hr, = 12 hour clock

12hr-AP = 12 hour clock with AM/PM

24hr = 24 hour military time

Use the dAtE item to set the year, month and day and the style of the displayed date.

SEt Enter values for the date.

y- x = Year

m- x = Month

d- x = Day

ZM400 Series Indicators Service Manual 25

Page 26

4 User level menus

Site ID

SitE Use this to enter a Site ID.

The Site ID can be used in a print format. Use the

alphanumeric entry methods described in 2.3 and 2.4 to

enter a Site ID. (maximum 6 digits)

Enter

Site ID

Seal

SEAL Use this to view the seal status of the indicator.

This is the status of the physical seal jumper inside the

indicator. If the unit is sealed, no changes can be made to

the configuration of the indicator. See the note below.

View Seal

Status

4.1.3 Site ID

4.1.4 Seal

StYLE Choose the style of the date display. Choices are:

MMdd2Y = Month, Day, 2-digit Year

MMdd4Y = Month, Day, 4-digit Year

ddMM2Y = Day, Month, 2-digit Year

ddMM4Y = Day, Month, 4-digit Year

The seal switch jumper, E7, is located in the top lef t quadrant of the main PCB. See

ZM umper and switch settings on page 142. If the jumper is installed, the indicator is

sealed. This means the only the Diagnostic, User , About, Audit and Supervisor menus

can be accessed. Other menus cannot be accessed - the display will flash SEALEd.

To exit the menu, see Exiting the menus on page 21.

26 ZM400 Series Indicators Service Manual

Page 27

4.2 About menu

About

SerialApp. EnetFirmBoot

VersionPartno

VersionPartno

VersionPartno

Dload

Sserial Dserial

AWT30 XXXXX X.X.X.XX

AWT30 XXXXX X.X.X.XX

AWT30 XXXXX

X.X.X.XX

IP GatewaySubnet Mac

1 xx

2 xx

3 xx

4 xx

5 xx

6 xx

1 xx

2 xx

3 xx

4 xx

1 xx

2 xx

3 xx

4 xx

1 xx

2 xx

3 xx

4 xx

Option BSQ

VersionType

Bus 1

Card 1

Scale 1 Scale 2

Version

SW Part

Cur.Ser Cal.Ser

xxxx xxxxx

X.X.X.XX

AWT30 XXXXX

xxxx xxxxx xxxx xxxxx

Reference Alphanumeric entry procedure

View App PN

View SN

View version

View version

View version(View

bootloader PN)

(View Firmware PN)

(View

license

number)

(View

license

number)

(View card

description)

(View card

version)

View SN View SNView version(View App PN)

The About menu is shown in Figure 4.3.

4.2 About menu

Use this menu to display information about the various items shown in Figure 4.3. Each

is explained below:

Definitions:

Bootloader Software that makes the electronics run.

Firmware Embedded system software that creates core functions of the product.

App Specific software that controls the behavior fo r a given installation.

ZM400 Series Indicators Service Manual 27

Figure 4.3 About menu

Page 28

4 User level menus

Boot

VersionPartno

AWT30 XXXXX

X.X.X.XX

PArtno Use this to view the bootloader part

number. The part number is

displayed in two parts. Press RIGHT

arrow key or LEFT arrow key to

toggle the display between the first

and second parts of the part number.

VErSion Use this to view the version of the

bootloader.

(View

bootloader PN)

(View version)

Firm

VersionPartno

AWT30 XXXXX X.X.X.XX

PArtno Use this to view the firmware part

number. The part number is

displayed in two parts. Press

RIGHT arrow key or LEFT arrow

key to toggle the display between

the first and second parts of the

part number.

VErSion Use this to view the version of the

firmware.

(View Firmware PN) (View version)

App.

VersionPartno

AWT30 XXXXX X.X.X.XX

(View App PN) (View version)

PArtno Use this to view the App part number .

The part number is displayed in two

parts. Press RIGHT arrow key or

LEFT arrow key to toggle the display

between the first and second parts of

the part number.

VErSion Use this to view the version of the

App.

Serial

xxxx xxxxx

SEriAL Use this to view the Serial Number of the indicator . The

number is displayed in two parts. Press RIGHT arrow

key or LEFT arrow key to toggle the display between the

first and second parts of the serial number.

(View SN)

4.2.1 Boot (Bootloader)

4.2.2 Firmware

4.2.3 App

4.2.4 Serial

28 ZM400 Series Indicators Service Manual

Page 29

4.2.5 Option

Option

VersionType

Bus 1

Card 1

(View card

description)

(View card

version)

Bus 1 There is only 1 Bus in the ZM400.

Card 1 There is only 1 Card in the ZM400.

oPtion Use this to view the descr iption and version of

an installed option card.

Enet

IP GatewaySubnet Mac

1 xx

2 xx

3 xx

4 xx

5 xx

6 xx

1 xx

2 xx

3 xx

4 xx

1 xx

2 xx

3 xx

4 xx

1 xx

2 xx

3 xx

4 xx

4.2.6 Enet

4.2 About menu

ZM400 Series Indicators Service Manual 29

EnEt This stands for Ethernet. Use this to view the network addresses.

If the indicator is connected to an Ethernet network, the values displayed will be the

current assigned addresses.

iP Use this to view the IP address.

SubnEt Use this to view the Subnet address.

gAtEWAY Use this to view the Gateway address.

MAc Use this to view the Mac address.

The IP, Subnet and Gateway addresses are a series of four double digit values.

The MAC address is a series of six double digit values: 1 XX, 2 XX, 3 XX, etc.

Page 30

4 User level menus

Dload

Sserial Dserial

dLoAd This stands for download. Use this to view

these items:

SSEriAL View the license number that

created the configuration file.

dSEriAL View the license number that

downloaded the configuration

file.

This is used for security and licensing purposes.

(View

license

number)

(View

license

number)

BSQ

Scale 1 Sc ale 2

Version

SW Part

Cur.Ser Cal.Ser

X.X.X.XX

AWT30 XXXXX

xxxx xxxxx xxxx xxxxx

View SN View SNView version(View App PN)

4.2.7 Download

4.2.8 BSQ

To upload a configuration file, the license number of the Configurator (Ztools)

software must match one of the license numbers in the indicator Contact AWTX

Technical Support for assistance.

30 ZM400 Series Indicators Service Manual

This stands for Bench Scale - Quartzell.

SW PArt View the firmwa re part number of the cell that is connected.

VErSion View the firmware version of the cell that is connected.

cur.SEr View the serial number of the cell that is connected.

cAL.SEr View the serial number of the cell that WAS connected at the time of

calibration.

To exit the menu, see Exiting the menus on page 21.

Page 31

4.3 Audit menu

Audit

PrintCounter

Config Calib

Port 1 Port 2 USB

Column Ticket

Column Ticket

Displays

number of

configurations

Displays

number of

calibrations

Counter

Config Calib

countEr Use this to view these items:

conFig View how many times the

indicator has been

configured.

cALib View how many times the

indicator has been

calibrated.

Displays

number of

configurations

Displays

number of

calibrations

4.3 Audit menu

Figure 4.4 Audit menu

Use this menu to display audit counters for configuration and calibration and to pr int the

information. Each is explained below:

4.3.1 Counter

ZM400 Series Indicators Service Manual 31

Page 32

4 User level menus

Print

Port 1 Port 2 USB

Column Ticket

Column Ticket

4.3.2 Print

Print Use these to select which port to print the audit report through. Choices

are:

Port 1 Under Port 1 choose to print to a column or ticket printer.

Port 2 Under Port 2 choose to print to a column or ticket printer.

uSb Printing to USB requires that a USB flash drive is connected

to the indicator host USB. Printing to USB will create a folder

on the flash drive and a comma separated file with the data.

To exit the menu, see Exiting the menus on page 21.

32 ZM400 Series Indicators Service Manual

Page 33

5 Diagnostics level menus

See page 24 See page 27 See page 31See page 33

Diag User About Audit

Ports OptionsOutputs

USB

Cur.Zero

Value Clear

1 2 3

ButtonsDisplay Logs

Print Clear

Port1 Port2

Clr no Clr yes

Serial1 Serial2

BSQ

Comprss Tens ion

Scale 1 Scale 2

Yes

No

Inputs

Bus 1

Card 1

Scale 1 Scale 2

Diag

Scale

Scale 1 Scale 2

Reference Alphanumeric entry procedure

View scale output

in A to D

counts or mV/V

Continuous

display test

(ZERO exits

the test)

Test button

function

(ZERO exits

the test)

Test

configured

inputs

Toggles

selected

output

on and off

Loopback

test

Performs

write/read

test

Loopback

test

Comp. Freq

displayed

Tension freq

displayed

Test

installed

options

The DIAGNOSTICS level (password 3570) is the same as the USER level except it

adds the Diag menu. The DIAGNOSTICS level is shown in Figure 5.1.

Figure 5.1 DIAGNOSTICS level (password 3570) menus

5.1 Diag menu

Use the Diag menu to check or verify the performance of the indicator. The diagnostic

tests available include: Scale A to D to view output from the connected scale base or

load device, the current zero offset from calibr ation zero, a display segment test, a front

panel keypad or button test, serial Com ports and USB host port test, remote inputs and

outputs test, and an option card test if installed. You can print an error log report that

provides information on previous error conditions such as overloads or underloads.

The Diag menu is shown in Figure 5.2.

5.1 Diag menu

The and symbols stand for direction moved in the menu. So Diag Scale

illustrates that you move down from Diag to Scale. This will help you keep track of

where you are in the menu structure.

Each of the items in the Diag menu is explained below:

ZM400 Series Indicators Service Manual 33

Figure 5.2 Diag menu

Page 34

5 Diagnostics level menus

Scale

Scale 1 Sc ale 2

ScALE Select to view values for Scale 1 or Scale 2, if

installed. Use this to view a number

representing the A to D counts. The value is

only for diagnostic purposes. The value should

increase as weight on the scale increases and

decrease as weight decreases.

Press SELECT to toggle to a mV/V display.

This is an approximate value for the mV/V value

output by the loadcell. If the scale is a BSQ then

you can only view counts, not mV/V.

View scale

output in A to

D counts or

mV/V

Cur.Zero

Value Clear

Scale 1 Scale 2

YesNo

5.1.1 Scale

5.1.2 Current Zero

34 ZM400 Series Indicators Service Manual

cur.ZEro This stands for current zero and represents the weight offset between the

calibration zero setting and the current zero setting due to pu shbutton zero

or Auto-Zero Tracking (AZT) adjustments.

Select to view values for Scale 1 or Scale 2, if installed.

VALuE View the zero offset.

cLEAr Clear the zero offset to return the indicator to calibration zero. Choose Yes

or No.

This can restore the original calibration zero point if the ZERO key is accidently

pressed when a tank or vessel contains product that cannot be emptied.

Page 35

5.1.3 Display

Display

Continuous

display test

(ZERO exits

the test)

diSPLAY Use to test the segments of the display. Each digit

area lights up in progression and continues until you

press ZERO.

Buttons

Test butt on

function

(ZERO exits

the test)

buttonS Use to test the keys. When you begin the test

tESting is briefly displayed followed by dashes.

Press any key to test if it is functioning and its name

or value will be displayed.

Press ZERO to stop the test.

Ports

USBSerial1 Serial2

Loopback

test

Loopback

test

Performs

write/read

test

5.1.4 Buttons

5.1 Diag menu

5.1.5 Ports

PortS Use this to do a loopback test for serial port 1 or 2 or to perform a write/

read test on the USB port.

SEriAL1 or 2 When you pick a serial port to test, tESting is briefly displayed and

then PASS or FAiL, depending on if the send and receive lines are

jumpered (pass) or not (fail). Add a jumper or wire between the

transmit output and receive input. On an external 9 pin connector the

transmit line is pin 2 and the receive line is pin 3.

It is recommended that you insert the jumper (a paper clip works) into the external

cable connector to validate the wiring and not just the internal port s. See System

block diagram on page 141 for I/O configuration of the serial ports TB3.

uSb Use this to test a connected USB flash drive.

oPEn is briefly displayed, then WritE is briefly displayed, then rEAd is

briefly displayed, then PASS or FAiL, depending on if the USB device

is working correctly or not.

ZM400 Series Indicators Service Manual 35

If no USB device is plugged in when you begin the test, oPEn is briefly

displayed, then no uSb is briefly displayed, then uSb.

Page 36

5 Diagnostics level menus

Inputs

Test

configured

inputs

inPutS The input test is used to verify if external switches wired

to the input ports on TB2 are functioning properly.

Follow the steps below to perform the inputs test.

Outputs

1 2 3

Toggles

selected

output

on and off

outPutS The output test is used to verify if external relays or

lights (etc.) connected to TB2 are properly wired

and functioning properly.

Follow the steps below to perform the output test.

5.1.6 Inputs

1. Press SELECT …

in 000 is displayed, if no inputs are jumpered.

2. To test input 1, jumper pins 1 and 2 of the I/O connector on the indicator …

The first digit becomes 1 until the jumper is removed.

3. To test input 2, jumper pins 1 and 3 of the I/O connector on the indicator …

The second digit becomes 2 until the jumper is removed.

4. To test input 3, jumper pins 1 and 4 of the I/O connector on the indicator ….

The third digit becomes 3 until the jumper is removed.

5.1.7 Outputs

5. Press ZERO …

inPutS is displayed.

CAUTION: Be sure to take proper precautions to ensure material controlled by

the scale outputs will not create a hazardous condition during an output test.

1. WithoutPutS is displayed, press SELECT …

outPut1 is displayed.

2. Press SELECT …

o.1-oFF is displayed.

36 ZM400 Series Indicators Service Manual

Page 37

5.1.8 Options

Options

Bus 1

Card 1

Test

installed

options

outPutS Use this to test the various installed option cards.

buS 1 Refers to Bus 1, where the option card is

attached.

cArd 1 Refers to the option card that is installed.

Logs

Print Clear

Port1 Port2

Clr no Clr yes

5.1 Diag menu

3. Press PRINT or UNITS to toggle the output on (o.1-on) and repeat to turn it

oFF.

Output 1 will be toggled on and off as you press the keys. This is shown

by the annunciator (SP1) on the display turning on and off.

4. Press ZERO or F1 to stop the test …

outPut1 is displayed.

5. Press UNITS to go to the next output. Repeat the steps to test output 2 and 3.

6. When finished, press TARE …

outPutS is displayed.

5.1.9 Logs

ZM400 Series Indicators Service Manual 37

The logs report will print any error conditions that may have occurred such as

overloads and underloads

LogS These are logs of various functions. You can print or clear them from

memory.

Print Choose to print the log from Port 1 or Port 2.

cLEAR Choose to clear the log from memory.

Page 38

5 Diagnostics level menus

BSQ

Comprss Tension

Scale 1 Sc ale 2

Comp. freq.

displayed

T ension freq.

displayed

5.1.10 BSQ

bSQ The BSQ menu item provides the digital frequency information for the

crystals on the QDT (Quartzell Digital Transducer).

ScALE 1 or ScALE 2:

Select which Scale number the BSQ is assigned, ScALE 1 or

ScALE 2

coMPrSS This stands for compression frequency.

tEnSion This stands for tension frequency.

The nominal value for the tension and compression frequency is 47,200 ± 2000 kHz.

The tension and compression frequencies should each be as stable as the other and

within 10% of each other. As weight increases the tension frequency should increase

and the compression frequency should decrease.

This completes the Diag menu. To exit the menu, see Exiting the menus on page 21.

38 ZM400 Series Indicators Service Manual

Page 39

6 ADMIN level menus

See page 24 See page 27 See page 31See page 33See page 39

Setup Diag User About Au dit

See page 40 See page 46 See page 54 See page 65

Setup

Calib

Scale System Ports

The ADMIN level (password 3088) is the same as the DIAG level except it adds the

Setup menu. The ADMIN level is shown in Figure 6.1.

6.1 Setup menu

In the Setup menu there are various submenus available to configure specific sections

of the scale operation. The top level items in the Setup menu are shown in Figure 6.2.

6.1 Setup menu

Figure 6.1 ADMIN level

Figure 6.2 Setup menu (password 3088)

Each of the items in the Setup menu are explained in the following sections.

ZM400 Series Indicators Service Manual 39

Page 40

6 ADMIN level menus

Calib

Zero Linear Input Gravity

LastCal.Zero Temp

Zero Span

Counts mV

Counts

mV

XXXX

USB

Print

Port 1 Port 21000g

Cal.Unit

LB

Display

G-fact Lat Alt Calc

Pt2 Pt9

Span

Scale 1 Scale 2

View or

enter new

span

Live weight

displayed.

Place span

weight on

scale

Enter

Pt 2 test

weight

Live weight

displayed.

Remove

all weight.

Live weight

displayed.

Live weight

displayed.

Place Pt 9

weight on

scale.

Enter

Pt 9 test

weight

View or

enter

G-factor

Enter

latitude

View

live weight

(F1 to stop)

Enter

altitude

Calculate

s gravity

factor

Live weight

displayed.

Live weight

displayed.

Live weight

displayed.

Place Pt 2

weight on

scale.

Live weight

displayed.

to

6.2 Calibration Procedure

Use the Calib menu to perform Zero and Span calibration, add Linearity correction

points, manually input calibration parameters for Zero and Span, manu ally input

Gravitational correction values, view the live weight, set the calibration unit of me asure

and print out a calibration report. Follow the menu in Figure 6.3 and the steps that

follow.

Access the calibration procedure directly using the calibration password, 2580, or

access it through the Setup menu, password 3088. See Alphanumer ic entry procedure

(ZM401 only) on page 17.

6.2.1 Scale 1-2

40 ZM400 Series Indicators Service Manual

Select the scale to be calibrated, Scale 1 or Scale 2. The Number of Scales on page

64 must be set to 2 to access Scale 2 settings.

Figure 6.3 Calibrate menu

Page 41

6.2.2 Zero Procedure

Zero

LastCal.Zero Temp

Live weight

displayed.

Remove all weight.

Live weight

displayed.

ZEro Access the scale zeroing process.

On the initial zero calibration of the indicator to a new scale, the zero cal counts may

appear unstable. Continue to the span calibration and when completed the condition

should correct itself.

6.2 Calibration Procedure

cAL.ZEro Use this to record the zero point. Follow the menu above to

complete the zero calibration. A c on the display denotes the

fact you are in the calibration procedure.

tEmP This is an alternate zeroing procedure. Use this when the

product weight on the scale, such as in a tank or vessel,

appears to be inaccurate but cannot be re move d to establish

a no-load condition.

Enter the calibration procedure and select Temp. zero. The

current weight on the scale will be temporarily assigned as the

Cal Zero value. Continue to the SPAN procedure, key in the

value of the test weights and place them on the scale and

complete the SPAN procedure. The original Cal Zero is

restored after exiting the span procedure and the current

product weight will now be correctly represented.

Due to factors that created the original inaccuracy, it may be

necessary to re-zero the scale when the tank or vessel is

empty.

LASt This is an alternate zeroing procedure. Use this if certified test

weights placed on the scale display a slightly inaccurate

value. Be sure that the scale is at zero before the test weights

are added and enter the calibration procedure and select Last

zero. The last acquired zero value will be assigned as the new

Cal Zero value.

Continue to the SPAN procedure without removing the test

weights. Key in the value of the test weights on the scale and

complete the SPAN procedure. The test weights will now read

accurately.

ZM400 Series Indicators Service Manual 41

Page 42

6 ADMIN level menus

Span