Page 1

CONFIDENTIAL

ZK830

Counting Scale

Service Manual

original instructions

AWT35-501610

Issue AE

Page 2

Avery Weigh-Tronix is a trademark of the Illinois Tool Works group of companies whose ultimate parent company is

Illinois Tool Works Inc (“Illinois Tool Works”). Copyright © 2018 Illinois Tool Works. All rights reserved.

No part of this publication may be reproduced by making a facsimile copy, by the making of a copy in three dimensions of a two-dimensional

work and the making of a copy in two dimensions of a three-dimensional work, stored in any medium by electronic means, or transmitted in

any form or by any means, including electronic, mechanical, broadcasting, recording or otherwise without the prior written consent of the

copyright owner, under license, or as permitted by law.

This publication was correct at the time of going to print, however Avery Weigh-Tronix reserves the right to alter without notice the

specification, design, price or conditions of supply of any product or service at any time.

ZK830_s_en_501610.book

Page 3

Table of Contents

page

Manual revision history .............................................................................................................................6

Chapter 1 General information and warnings ............................................................. ............................ 7

About this manual ..............................................................................................................7

Text conventions .........................................................................................................7

Special messages .......................................................................................................7

Installation ....................................... .................................... ................................ ...............8

Wet conditions .............................................................................................................8

Routine maintenance .........................................................................................................8

Cleaning the machine ........................................................................................................8

Training ..................................... ............................................................. ............................8

Sharp objects ........ .... ... ... ... .... ...................................... .... ... ... ... ... ......................................9

FCC and EMC declarations of compliance ........................................................................9

Chapter 2 Introduction ............................................................................................................................ 10

Front panel .......................................................................................................................10

Front Display .............................................................................................................12

Powering up the ZK830 ...................................................................................................12

Numeric entry procedure (without optional keypad) ........ ...... ... ... .... ... ... ... .... ... ... ... ... .... ... 13

Numeric entry procedure (with optional keypad) ............................................................. 13

Chapter 3 Introduction to the menus ........................................................... ..........................................14

Accessing the menus .......................................................................................................15

Exiting the menus ............................................................................................................15

Menu annunciators ......... ... .... ... ....................................... ... ... ... ... .... ... .............................16

Chapter 4 User level menus ............................................. ....................... ...................... ....................... ...17

User menu ......... ... .... ...................................... .... ... ... ... .... ... ...................................... .... ...17

Time ..........................................................................................................................18

Date ....................................... .................................................... ................................18

Site ID ........................................................................................................................19

Seal ...........................................................................................................................19

About menu ......................................................................................................................20

Boot (Bootloader) ......................................................................................................21

Firmware ...................................................................................................................21

App ............................................................................................................................21

Serial .........................................................................................................................21

Enet ...........................................................................................................................22

Download ..................................................................................................................23

BSQ .................................... ................................................... .................................... 23

Audit menu ...... ....................................... ... ... ... .... ... ... ....................................... ... ... ... .......24

Counter ..................................... ....................... ................... ....................... ................24

Chapter 5 Diagnostics level menus ....................................................................................................... 25

Diag menu .................................... ....................................... ... ... ... .... ... .............................25

Scale .........................................................................................................................26

Current Zero .............................................................................................................26

Display ...................................... ....................... ................... ....................... ................27

Buttons ...................................................................................................................... 27

Ports ..........................................................................................................................27

Inputs ............................... ................... ................... .................... ................... .............28

Outputs ..................................... .................................................... .............................28

ZM400 Series Indicators Service Manual 3

Page 4

Logs .......................................................................................................................... 29

BSQ ................................. .......... ...... .......... ......... .......... .......... ......... .......... .......... ...... 29

Chapter 6 ADMIN level menus ...................................... ............. ............. ............. ............. ............. ......... 31

Setup menu .....................................................................................................................31

Calibration Procedure ...................................................................................................... 32

Scale 1-2 ..... .... ... ... ... .... ... ... ....................................... ... ... .... ... ... ... ............................. 32

Zero Procedure .................................. ... .... ... ....................................... ... ... ... .... ... ... ... 33

Span Procedure ........................................................................................................ 34

Linearity Procedure ...... ... ... ... .... ... ... ... ....................................... ... ... .... ... ... ... ............. 34

Input procedure ......................................................................................................... 35

Gravity Factor Procedure .......................................................................................... 36

Display ...................................................................................................................... 37

Calibration Unit .......................................................................................................... 37

Print calibration report ..... ... ... .... ... ... ....................................... ... ... ... .... ... ... ................ 37

Scale ...................................... ...................... .................... ...................... .......................... 38

Scale 1-2 ..... .... ... ... ... .... ... ... ....................................... ... ... .... ... ... ... ............................. 39

Capacity .................................................................................................................... 39

Division ............................... .......... ......... .......... .......... .......... ......... .......... .......... ...... ... 39

Units ...................................... ....................................................................... .............40

Stable .................................... .................................................................... ................ 40

AZT ........................................................................................................................... 41

Filter ..........................................................................................................................41

Ranges ...................................... ...................................... ....................................... ... 43

2,3,Range .............................. .......... ...... .......... .......... .......... ......... .......... .......... ......... 44

Type .......................................................................................................................... 45

System ................................ ...................... ....................... ...................... .......................... 46

Default Values ........................................................................................................... 46

Site ..................................... .................................................................... ...................48

Display ...................................................................................................................... 48

Buttons ............................... .................................................................... ...................49

Display values ........................................................................................................... 49

Tare .................................... .......................................... .......................................... ...50

Config ................................. ....................................... ....................................... ......... 51

Serial ..................................... .................................................................... ................51

App ..................................... ....................................... ....................................... .........51

Password .................................................................................................................. 52

Z-Lock ....................................................................................................................... 52

Beeper ....................................... ......... ....... ......... .......... .......... ......... .......... .......... ...... 52

Number of Scales ............................ ....................................... ... ... ... .... ... ... ................ 53

Ports ................................................................................................................................ 54

Serial ..................................... .................................................................... ................55

Ethernet ................................. ....... ... ...... ....... ...... ....... ...... ....... ...... ... ....... ...... ....... ...... 55

Protocol ..................................... ................................................................... .............57

P.F.Edit ..................................................................................................................... 59

Interlock ..................................... ......... ....... ......... .......... .......... ......... .......... .......... ...... 59

Input ....................................... ...................... .................... ...................... .......................... 60

Output ....................................... .................................................... ................................... 61

Chapter 7 Communication port protocols ............................................................................................ 62

SMA Protocol ...................................................................................................................62

Level 1 and 2 Commands ................................. .... ... ... ... .... ... ................................... 62

Standard Scale Response Message ......................................................................... 63

Unrecognized Command Response ......................................................................... 63

About Command Response ...................................................................................... 63

Scale Information Command Response ................................................................... 64

Avery Weigh-Tronix Extended SMA Commands ...................................... ... .... ... ... ... 65

4 ZM400 Series Indicators Service Manual

Page 5

ENQ, Print & B-Cast command and response protocols ................................................. 66

Scanner commands and responses ................................... .......................................66

Scanner bar codes ...................... .... ... ... ....................................... ... ... .... ... ... ... ..........67

Commands and responses ............. ... .... ... ... ... .... ...................................... .... ... ... ... ... .......69

Chapter 8 Option cards ........................................................................................................................... 72

Wireless Ethernet communication (802.11g) card ....... .... ... ... ... ... .... ... ... ... .... ...... ... ... .... ... 73

Analog Scale Input Option with 5VDC Excitation ................ ... ...... ....... ...... ....... ...... ....... ...74

Error code ..................................................................................................................74

Chapter 9 Printed reports .......................................................................................................................75

Calibration report .............................................................................................................75

Chapter 10 Print formatting .................................................................................................................... 76

Print Format Editor .... ...................................... .... ... ... ... .... ... ...................................... .... ...76

Editing an existing print string ..........................................................................................77

Inserting characters ...................................................................................................78

Deleting characters ................................................................................................... 79

Inserting tokens, etc. ........................................................................................................81

Other scale tokens ...........................................................................................................83

Transmitting leading zeroes ... ... ....................................... ... ... ... ... .... ... .............................84

Print format errors ........... ... .... ... ... ... ... .... ...................................... .... ... ... ... .... ... ................85

Chapter 11 Application Notes ....................................................... .......................... ......................... .......87

I/O interfaces ....................................................................................................................87

Inputs ............................... ................... ................... .................... ................... .............87

Outputs ............................................................................................................................88

Relays .......................................................................................................................88

Opto module ..............................................................................................................88

Transistor outputs ........ .... ... ... ... ... .... ... ....................................... ... ... ... .... ... ... .............89

Diagnostics ......................................................................................................................89

Chapter 12 Print tokens, parameters and default print formats ... ............................. ..........................90

Notes on width syntax ......................................................................................................90

Explanation of width syntax for WEIGHT (integers) ..................................................90

Explanation of width syntax for WEIGHT (strings) .................................................... 90

Explanation of width syntax for UNITS OF MEASURE (strings) ...............................90

Firmware tokens ..............................................................................................................91

Additional token tables ............................. .... ... ... ... .... ... ... ... ... ....... ... ... .... ... ... ... ... .... ... 95

App tokens ......... ... .... ... ... ... .... ... ....................................... ... ... ... ... .... ... .............................96

ASCII characters ..............................................................................................................97

Control codes ...................................................................................................................98

Default print formats .........................................................................................................99

Chapter 13 Complete menu structures ........................................ ...................... .......................... ........103

Chapter 14 Technical illustrations ....................................................................................................... 109

ZK830 Exploded drawing ...............................................................................................109

BSQ 35 and 80kg base exploded drawing .......................................... ... ... .... ...... ... ... .... .110

BSQ 1 and 5kg base exploded drawing .........................................................................111

ZK830 and BSQ service parts kits .................................................................................112

ZK830 and BSQ service parts kits (continued) ..............................................................113

System block diagram ............................... ....................................... ... ... ... .... ... ... ...........114

Clamp down plate drilling templates ..............................................................................115

Index .......................................................................................................................................................117

ZM400 Series Indicators Service Manual 5

Page 6

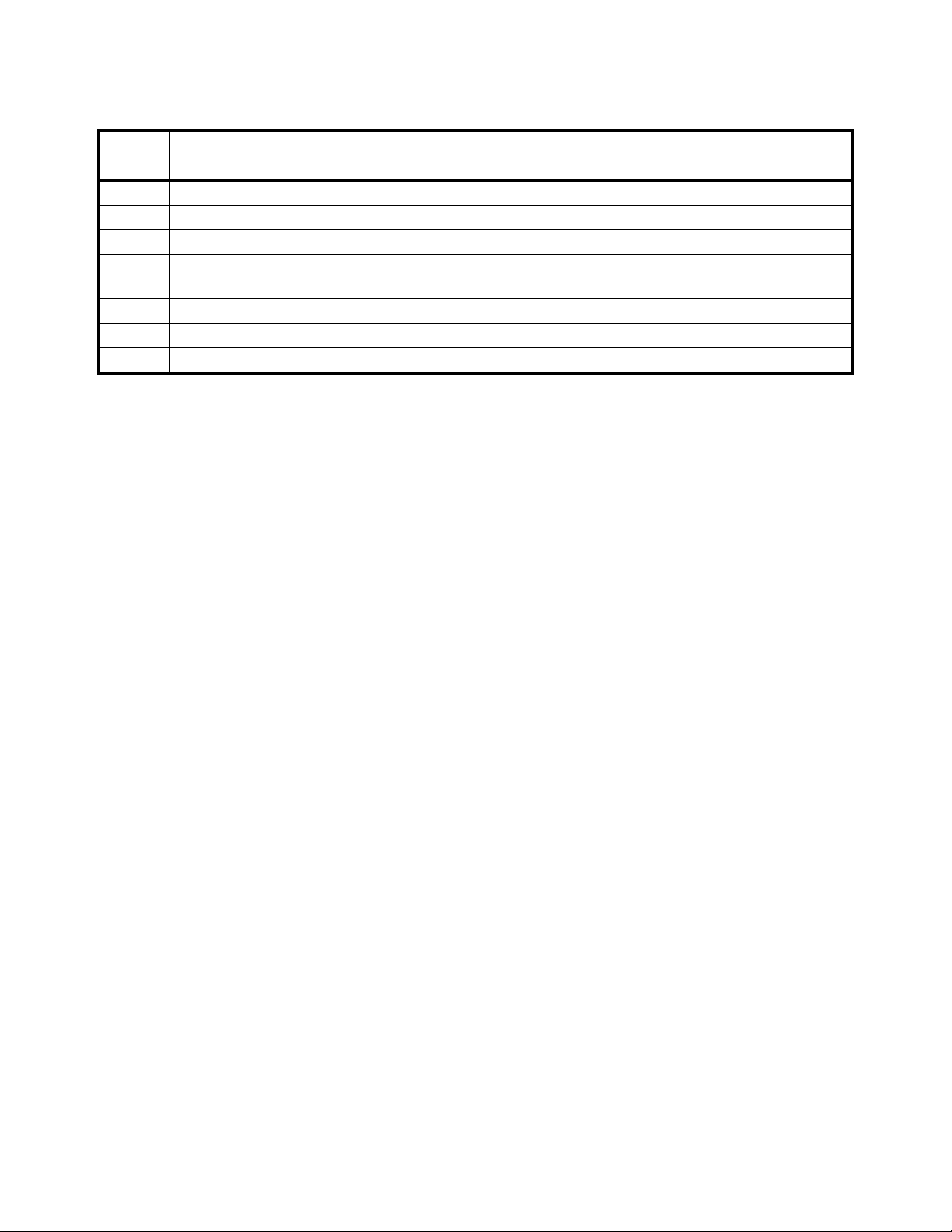

Manual revision history

Current

Issue

AA February 2017 New manual

AB August 2017 Added BSQ parts kits in chapter 12

AC November 2017 Updated token table in chapter 10.

AD May 2018 Fixed some items in table in section 7.4. Fixed scanner protocols. Added chapter 8 and 11 to the

AE June 2018 Added clamp down plate drilling templates in chapter 14.

Date Created Details of Changes

book.

ZK830 Counting Scale Service Manual 6

Page 7

1 General information and warnings

1.1 About this manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled using the 1.1 and 1.1.1 convention. The names of

the chapter and the next subsection level appear at the top of alternating p ages of the

manual to remind you of where you are in the manual. The manual name and page

numbers appear at the bottom of the pages.

1.1.1 Text conventions

Key names are shown in bold and reflect the case of the key being described. If a key

has dual functions, the function is shown first followed by the key name in p arentheses

and in bold, such as in these examples: F1, SELECT, PRINT, etc.

Displayed messages appear in bold italic type and reflect the case of the displayed

message.

1.1 About this manual

1.1.2 Special messages

Examples of special messages you will see in this manual are defined below. The

heading words have specific meanings to alert you to additional information or the

relative level of hazard.

ELECTRICAL WARNING!

THIS IS AN ELECTRICAL WARNING SYMBOL.

ELECTRICAL WARNINGS MEAN THAT FAILURE TO FOLLOW

SPECIFIC PRACTICES OR PROCEDURES MAY RESULT IN

ELECTROCUTION, ARC BURNS, EXPLOSIONS OR OTHER HAZARDS

THAT MAY CAUSE INJURY OR DEATH.

WARNING!

This is a Warning symbol.

Warnings mean that failure to follow specific practices and procedures may

have major consequences such as injury or death.

CAUTION!

This is a Caution symbol.

Cautions give information about procedures that, if not observed, could result

in damage to equipment or corruption to and loss of data.

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

ZK830 Counting Scale Service Manual 7

Page 8

1 General information and warnings

1.2 Installation

NO USER SERVICEABLE PARTS. REFER TO QUALIFIED SERVICE

PERSONNEL FOR SERVICE.

1.2.1 Wet conditions

Under wet conditions, the plug must be connected to the final branch circuit via an

appropriate socket / receptacle designed for washdown use.

Installations within the USA should use a cover that meets NEMA 3R specifications

as required by the National Electrical Code under section 410-57. This allows the unit

to be plugged in with a rain tight cover fitted over the plug.

Installations within Europe must use a socket which provides a minimum of IP56

protection to the plug / cable assembly. Care must be taken to make sure that the

degree of protection provided by the socket is suitable for the environment.

1.3 Routine maintenance

IMPORTANT: This equipment must be routinely checked for proper operatio n

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

Always turn off the machine and isolate from the power supply before starting any

routine maintenance to avoid the possibility of electric shock.

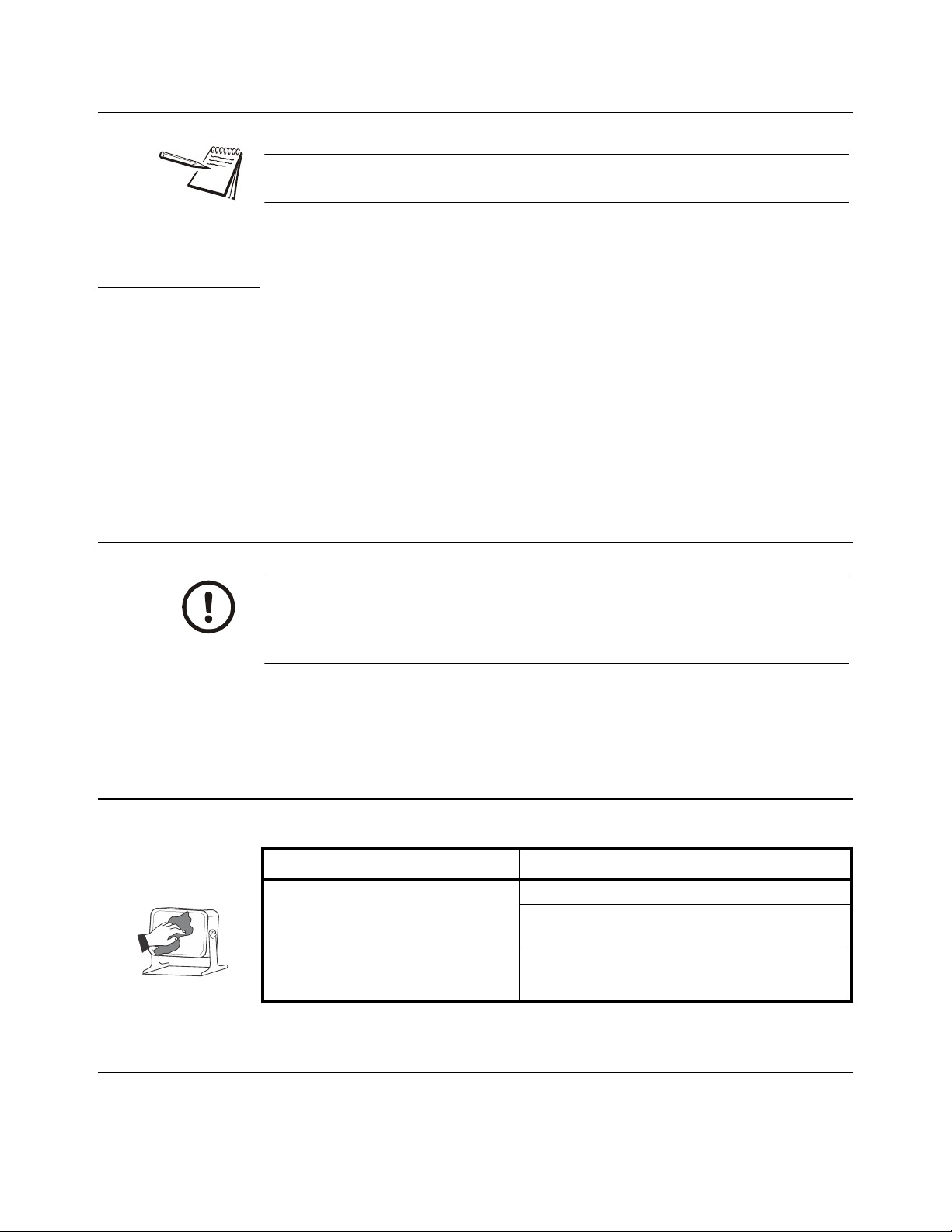

1.4 Cleaning the machine

Table 1.1 Cleaning DOs and DON’Ts

DO DO NOT

Wipe down the outside of standard products

with a clean cloth, moistened with water and

a small amount of mild detergent

Spray the cloth when using a proprietary

cleaning fluid

Attempt to clean the inside of the machine

Use harsh abrasives, solvents, scouring cleaners or

alkaline cleaning solutions

Spray any liquid directly on to the display windows

1.5 Training

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instruction books.

8 ZK830 Counting Scale Service Manual

Page 9

1.6 Sharp objects

T o avoid the ri sk of RSI (Repetitive S train Injury), place the machine on a surface which

is ergonomically satisfactory to the user. T ake frequent br eaks during prolonged usage.

1.6 Sharp objects

Do not use sharp objects such as screwdrivers to operate the keys.

1.7 FCC and EMC declarations of compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Canada

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la Classe A prescrites dans le Règlement sur le brouillage radioélectrique edicté par le ministère des Communications du Canada.

European Countries

WARNING: This is a Class A product. In a domestic environment, this product may cause radio interference in which the user may be

required to take adequate measures.

ZK830 Counting Scale Service Manual 9

Page 10

2 Introduction

lb

kg

GROSS

NET

TARE

PRINT

SP PCW T%TOTAL

g

COUNT

HI RES

ZK830

THE CO UNT IN G

FEATURE IS NO T L EGAL

FOR T RA DE

TARE SELECT UNITSPRINT

SAMPLE

ZERO

F1

SCALE

F2

PLU

PCWT

F3

F4

PT

12

1

23

4

56

7

89

C

0

.

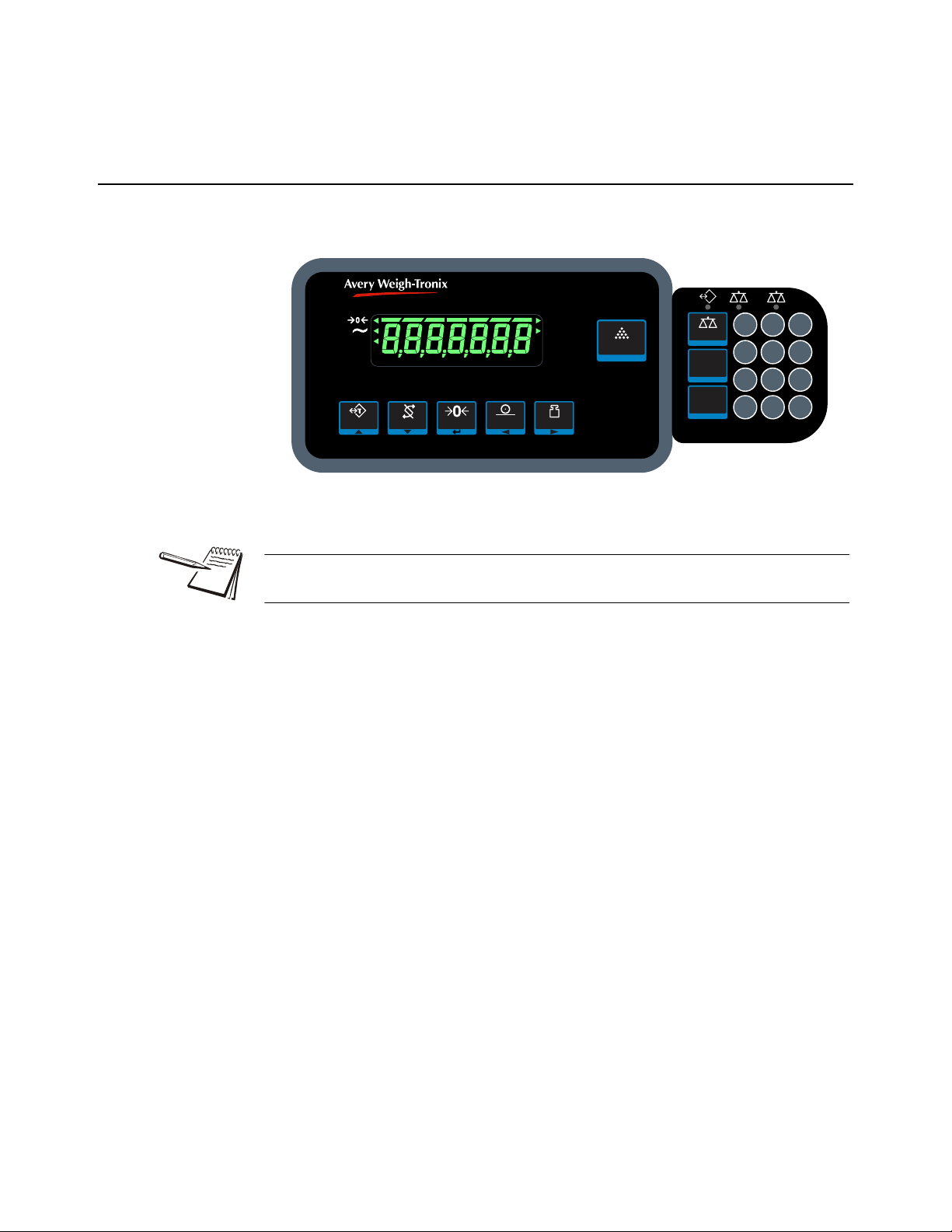

2.1 Front panel

The front panels for the ZK830 main display and optiona l ke ypad are shown in Figure

2.1 and consists of the keys and the display.

Figure 2.1 Front panel with optional keypad

Never press a key with anything but your finger. Damage to the overlay may result if

sharp or rough objects are used.

See the price list for option kits available for the ZK830. Installation instructions are

included in each kit.

ZK830 Counting Scale Service Manual 10

Page 11

2.1 Front panel

TAR E

SELECT

ZERO

PRINT

UNITS

SAMPLE

F1

SCALE

F2

PLU

PCWT

F4

1

23

4

56

789

C0

.

The normal function of the keys on the front panel of the ZK830 are listed below.

Press the TAR E key to perform a tare function.

With no weight on the scale, press the TAR E key to clear a tare value.

Acts as an up arrow key for menu navigation.

Allows you to access minus and comma signs.

Acts as an ABORT key during the sampling process.

Press the SELECT key to toggle between the active display values.

Press and hold to enter the setpoint editor in all applications.

Acts as a down arrow key for menu navigation.

Allows you to access minus and comma signs.

Press the ZERO key to zero the display.

Acts as an ENTER key to accept a displayed value or function.

Press the PRINT to send information to a peripheral device through a configured

communications port. Press and hold the PRINT key to print accumulated totals, if

enabled.

Acts as a left arrow key for menu navigation.

Press the UNITS key to scroll through the available units of measure while in normal

operating mode.

Acts as a right arrow key for menu navigation.

Press the SAMPLE key to select application specific choices.

Aborts a numeric entry and acts as an ESCAPE key in the menu navigation.

Also used to display or enter an accumulator channel.

Press and hold to view the password entry screen for menu access.

Keys on the optional keypad shown below:

Press the SCALE key to switch between two attached scales.

Press the PLU key to access the PLU list. In the counting application this key can be

used to update pieceweight and/or tare weight if enabled. With an active PLU, press

the PLU key three times to update pieceweight and tare weight.

Press the PCWT key to enter a known piece weight.

If enabled, allows the user to see a high resolution weight value.

In the count application allows you to enter or view piece weight values.

Use the numeric keypad to enter values or clear a value from the display (C key).

ZK830 Counting Scale Service Manual 11

Page 12

2 Introduction

lb

kg

GROSS

NET

TARE

0

g

COUNT

HI RES

PRINT SP % PCWT TOTAL

center-of-zero

motion

battery status

setpoints

print

bargraph

Net weight

Tare weight

pieceweight

Gross weight

percent

total

count

high resolution

Unit of

measure

Ethernet

connection

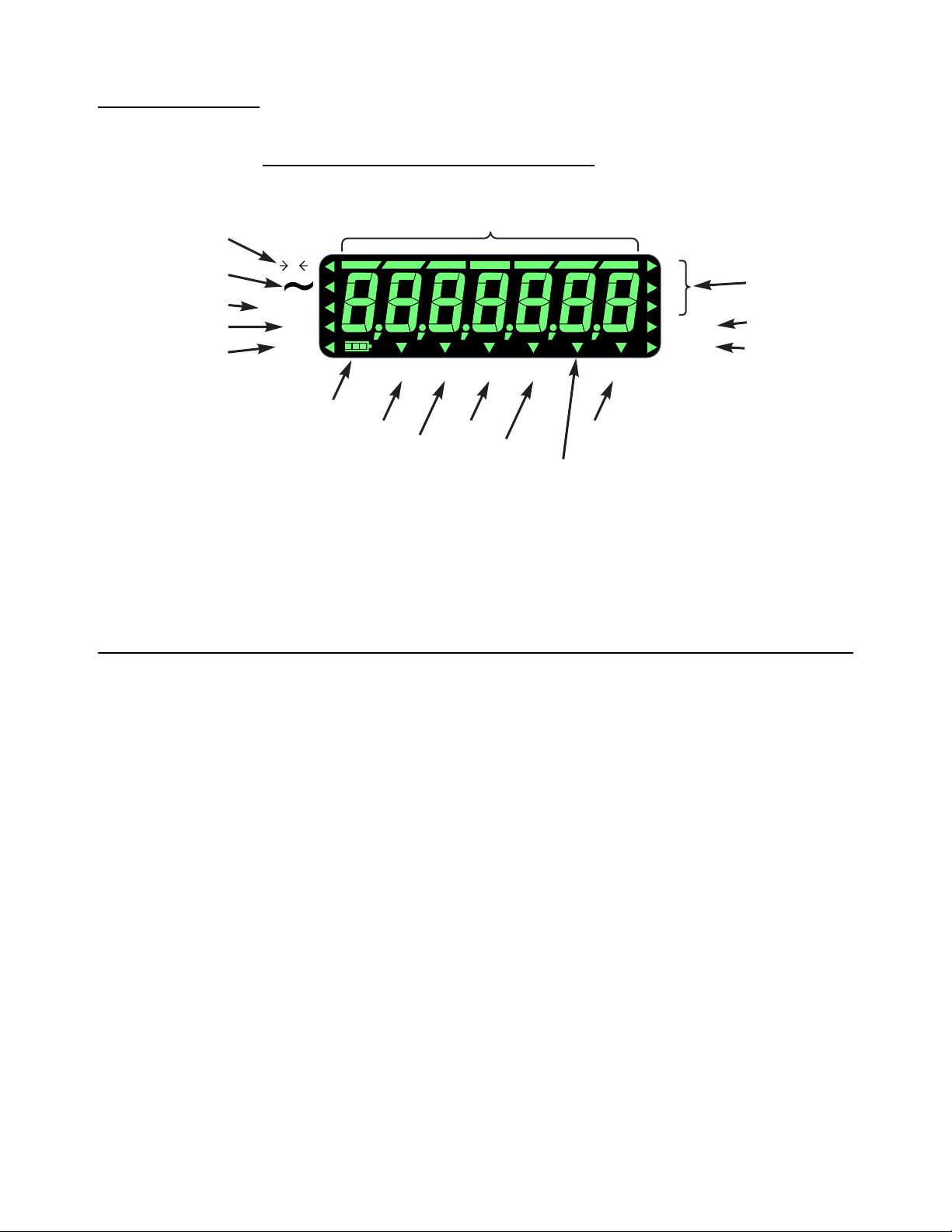

2.1.1 Front Display

Annunciators

The display annunciators are defined in Figure 2.2.

2.2 Powering up the ZK830

Figure 2.2 Display annunciators

The triangular annunciators will light during operation to inform the user of the weighing

mode, active unit of measure, etc.

The ZK830/BSQ comes with a base mounted AC power supply un it (PSU) conn ected

to the back of the BSQ. This supplies the required input power of 12 to 36 VDC @

200ma minimum and is connected to a properly grounded outl et (100 VAC - 240 VAC,

50 or 60 Hz). The indicator is always ON as long as power is received.

If using the optional rechargeable battery pack mounted on the rear of the base you

can expect 16 hours of operation between charges. Recharge time is four hours using

the in-line PSU. The battery pack requires 24 to 36V to charge. The battery timer

setting can be used to turn the indicator display OFF automatically.

The ZQ-BA T can a lso be use when using the optional column. This battery can la st up

to 25 hours of continuous use or one to two weeks of occasional operation.

You can also power the indicator with a 12 to 36 VDC power su pply (15 0ma minimu m

at 24VDC) via a 2.1mm center positive barrel jack plugged into the receiver on the back

of the indicator.

12 ZK830 Counting Scale Service Manual

Page 13

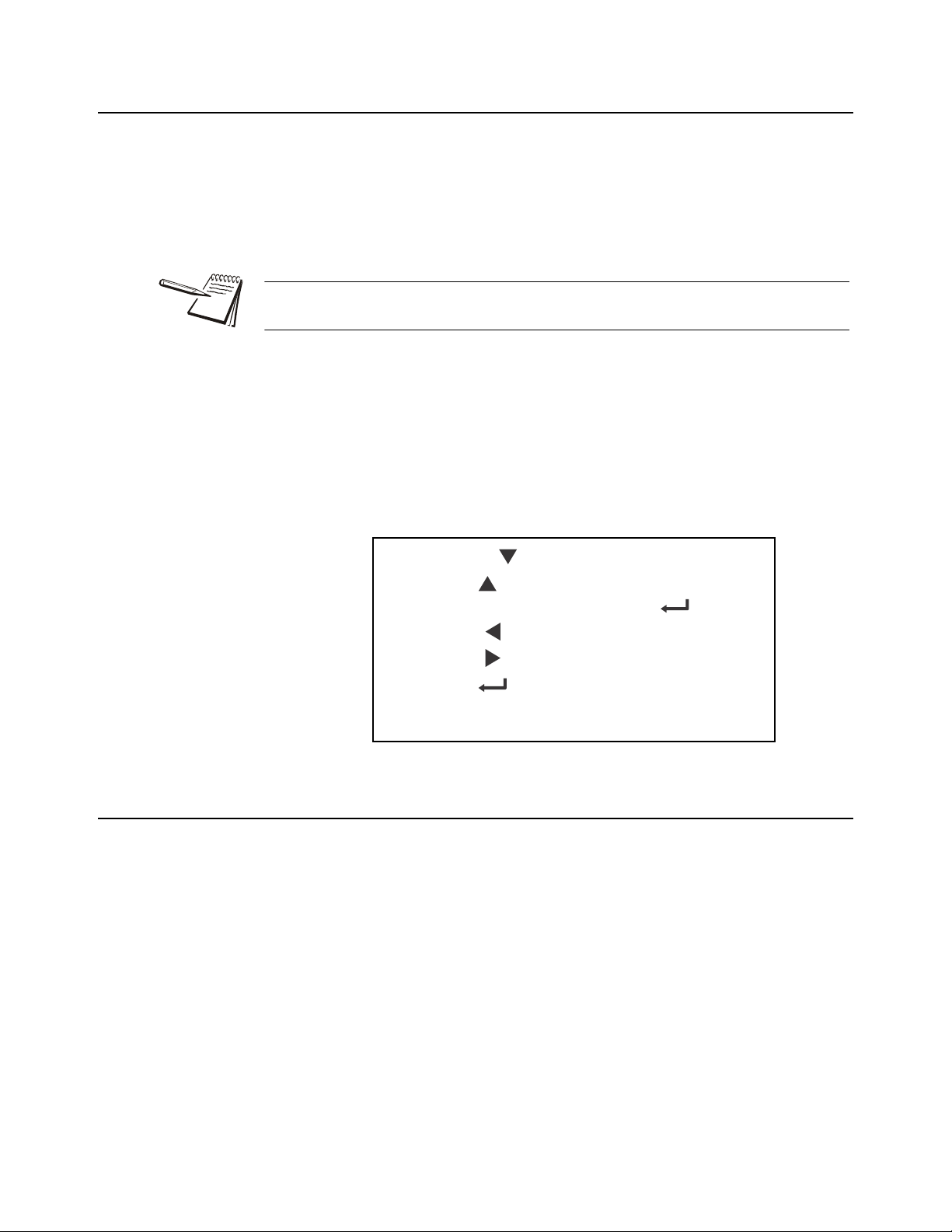

2.3 Numeric entry procedure (without optional keypad)

These segments flash in alphanumeric entry mod e

Press to increment the flashing number

Press to decrement the flashing number

Press to backspace cursor in a number

Press to advance cursor in a number

Press to accept a value

Press to escape an entry screen

TARE /

-

SELECT /

-

PRINT /

-

UNITS /

-

ZERO /

-

F1 /

ESC -

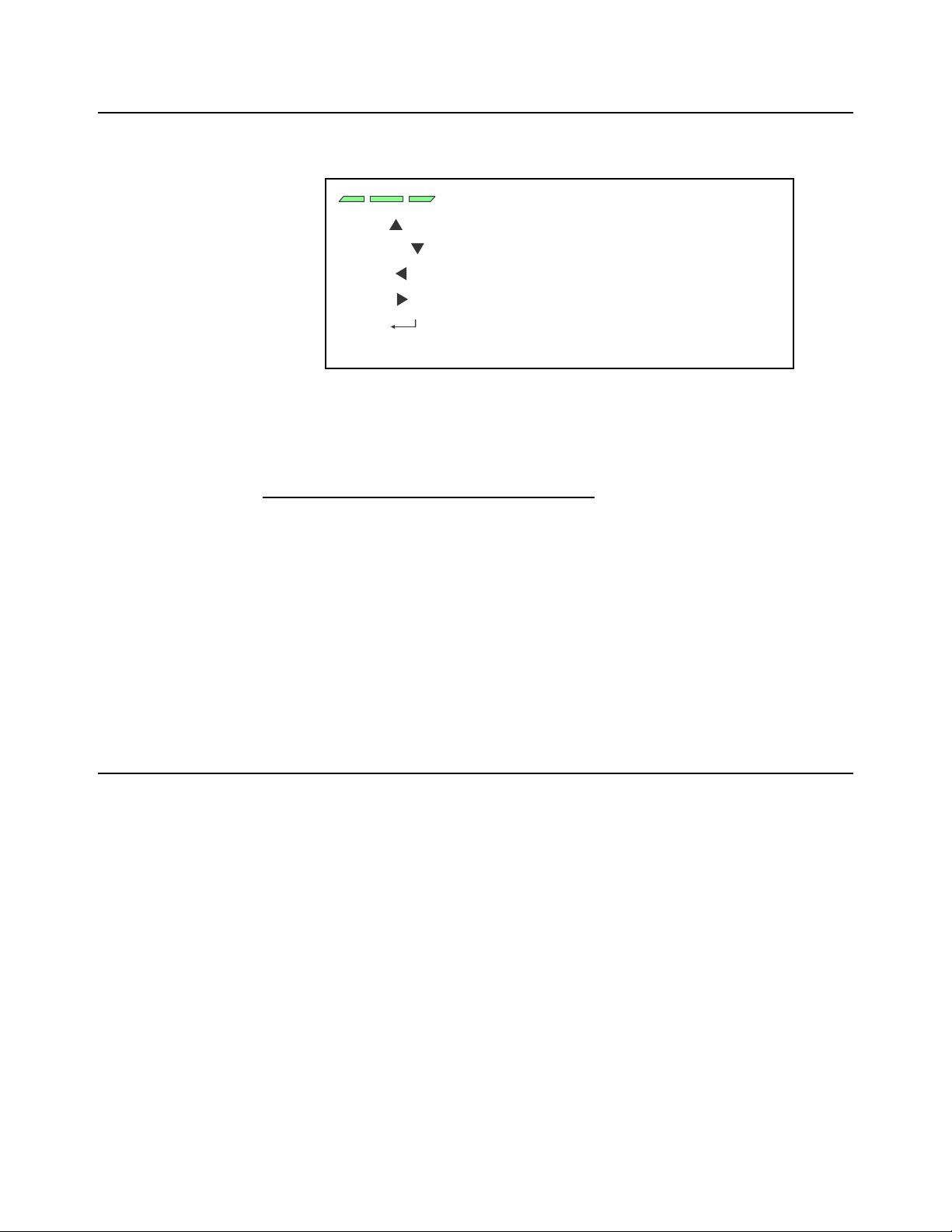

2.3 Numeric entry procedure (without optional keypad)

The keys in Figure 2.3 have alternate functions in numeric entry screens.

Figure 2.3 Key function during numeric entry

In numeric entry screens, the center segments shown in Figure 2.3 flash. Use the keys,

as described in Figure 2.3, to enter a value on the display. Following is an example:

Example: To key in the number 507:

Repeatedly press the TARE() or SELECT() key until 5 appears on the display.

Press the UNITS() key once to move cursor one space to the right.

Repeatedly press the TARE() or SELECT() key until 0 appears on the display.

Press the UNITS() key once to move cursor one space to the right.

Repeatedly press the TARE() or SELECT() key until 7 appears on the display.

Press the ZERO key to enter or accept the value.

Press the PRINT() key to move the entry function one digit to the left. This effectively

deletes the current value in that position and allows you to enter a new value in that

position.

2.4 Numeric entry procedure (with optional keypad)

Use the optional numeric keypad to input all numbers. Press the ZERO key to enter or

accept the value.

ZK830 Counting Scale Service Manual 13

Page 14

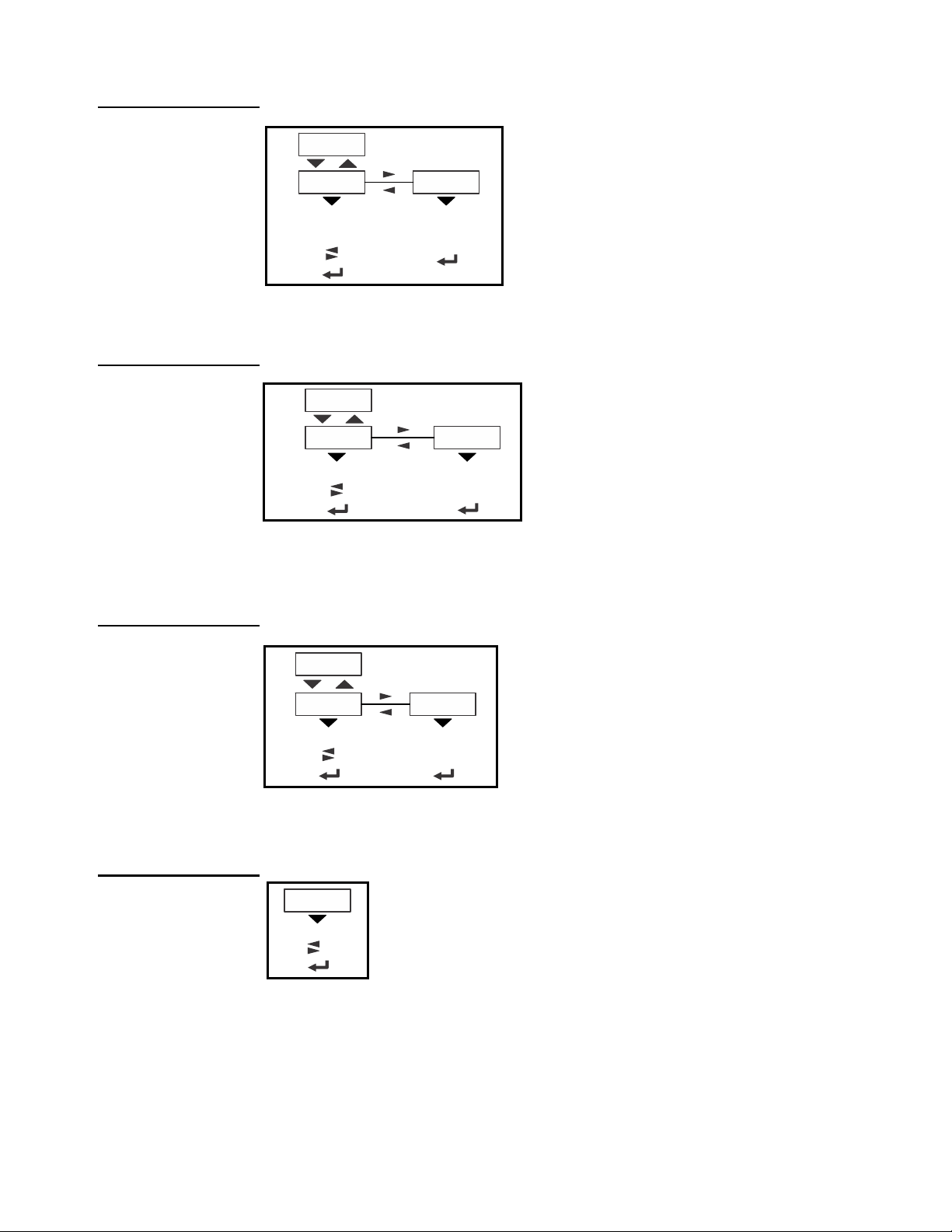

3 Introduction to the menus

Press SELECT/ to move down in a menu

Press TARE/ to move up in a menu, except at the

bottom item in a menu, then use ZERO/ or F1

Press PRINT/ to move left in a menu

Press UNITS/ to move right in a menu

Press ZERO/ to accept a value or choice and

move up in the menu.

Press F1 to escape and move up in the menu

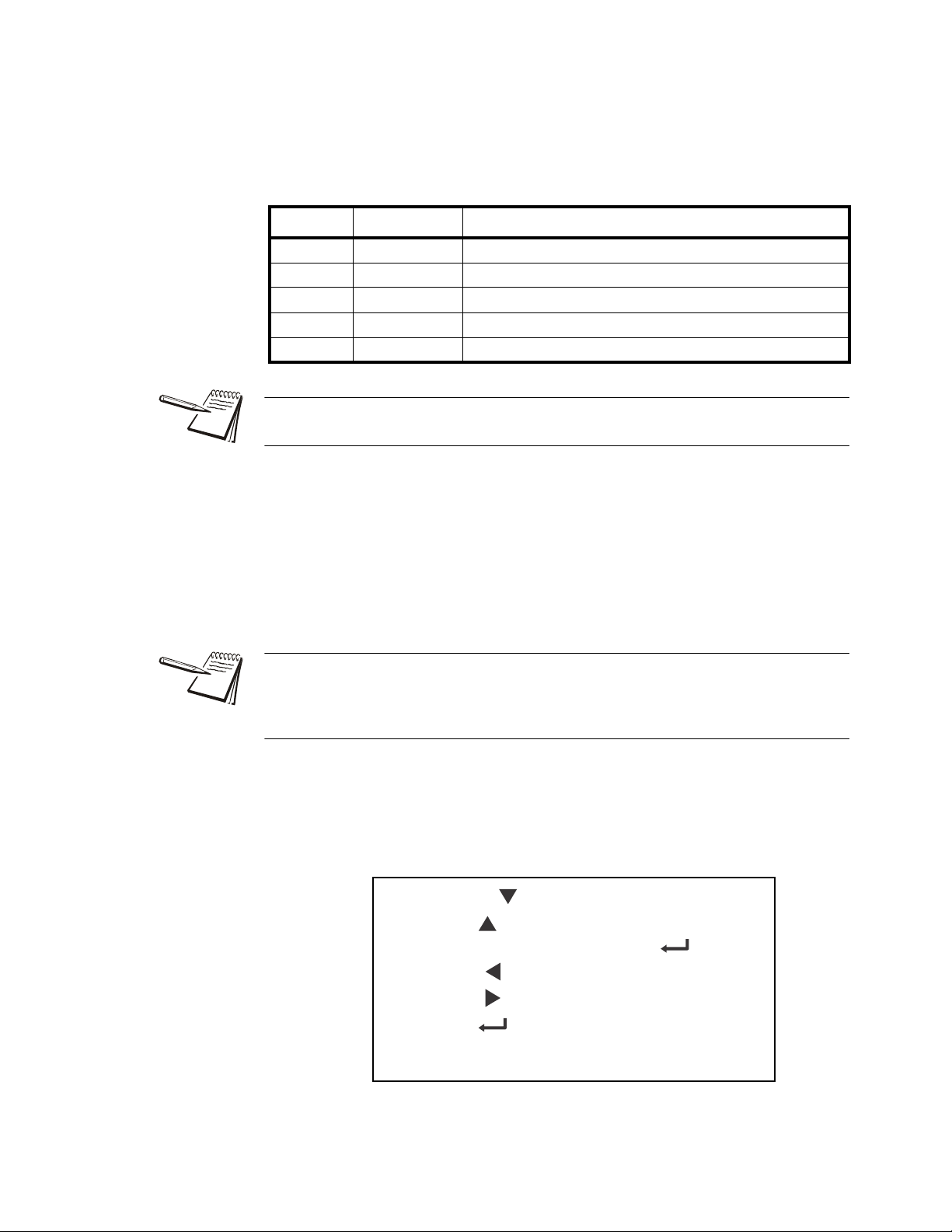

Menus, accessed through passwords, are available in the indicator to customize and

configure the indicator for your purposes. The menu levels and their passwords are

shown below:

Password Menu Level Accessed Menus

111 USER User, About, Audit

3570 DIAGNOSTICS Diag, User, About, Audit

3088 ADMIN Setup, Diag, User, About, Audit

2580 CALIBRATE Calib

1793 SUPER Application specific items. See User manual.

The CALIBRATE menu level accesses the calibration procedure only. You can also

access the calibration menu through the Setup menu using the ADMIN password.

Some menus appear in more than one menu level. As you can see in the ta ble above,

the 111 password gives you access to three menus; User, About and Audit. The 3570

password gives you access to those three plus the Diagnostics menu. The 3088

password gives you access to those four plus the Setup menu.

This allows the supervisor to control access to some or all of the menus b ased on the

passwords shared. The menus are the same no matter which menu level you access

them from.

The menus are always explained in a sequential manner to cover all information in a

logical fashion. You will probably never access all the menu items in this manner . You

can navigate to the area of the menu that needs to be changed by using the menu

maps and key navigation legends which are inserted as a reminder with most menus.

See Numeric entry procedure (without optional keypad) on page 13 for instructions on

how to enter a password to get to the menus. Key functions in the menu s ar e sh own

below.

Menu Navigation Keys:

ZK830 Counting Scale Service Manual 14

Page 15

3.1 Accessing the menus

Press SELECT/ to move down in a menu

Press TARE/ to move up in a menu, except at the

bottom item in a menu, then use ZERO/ or F1

Press PRINT/ to move left in a menu

Press UNITS/ to move right in a menu

Press ZERO/ to accept a value or choice and

move up in the menu.

Press F1 to escape and move up in the menu

Follow these steps to access the various menus in the indicator.

1. With the indicator powered up and in normal operating mode, press and hold

the SAMPLE/F1 key …

Pass is briefly displayed, then a flashing 0, prompting you to enter the

password.

When the 0 is flashing, press F1 and the application name is briefly displayed, then

the indicator returns to normal operating mode.

2. Key in the p assword for the menu you want to access and press the ZERO key

to accept it …

The first item in the top level of the menu you accessed is displayed.

3. Use the navigation keys, shown below, to navigate through the menu

structure. The symbols appear on the bottom of the keys.

3.1 Accessing the menus

Menu Navigation Keys:

3.2 Exiting the menus

1. If you are at the bottom item in a menu use ZERO to accept a choice or value

and move up a level, or use F1 to escape and move up one level without

accepting the choice or value. From that point, press the TARE key repeatedly

until …

SAVE no is displayed. This means “Do not save changes. “

2. Use the PRINT or UNITS key to scroll through the choices: SAVE no,

SAVEYES and CAnCEL. Press ZERO to accept the displayed choice.

If you choose SAVE no or SAVEYES the indicator exits the menu and

ZK830 Counting Scale Service Manual 15

If you choose CAnCEL, the indicator remains in the menu.

returns to normal weighing mode.

OR

Page 16

3 Introduction to the menus

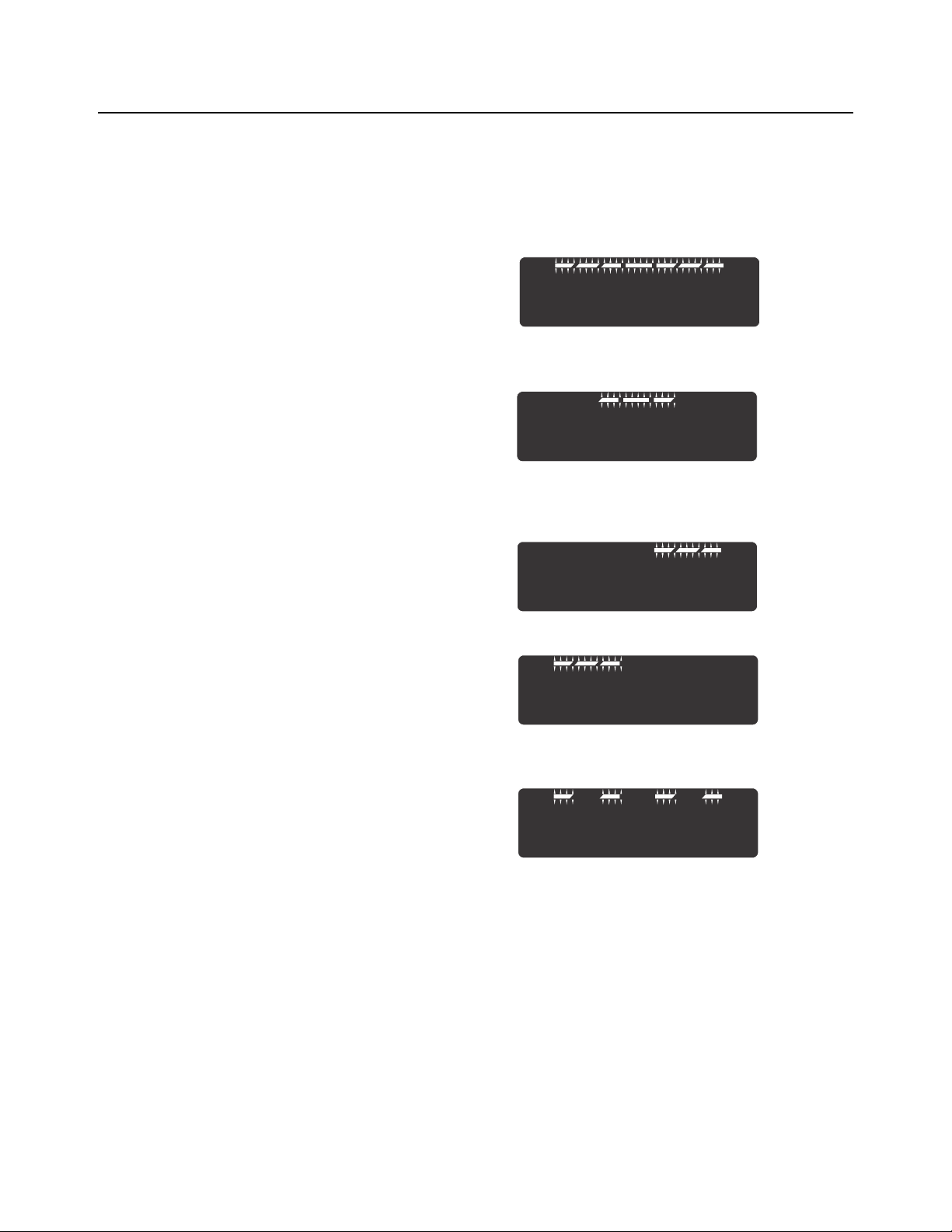

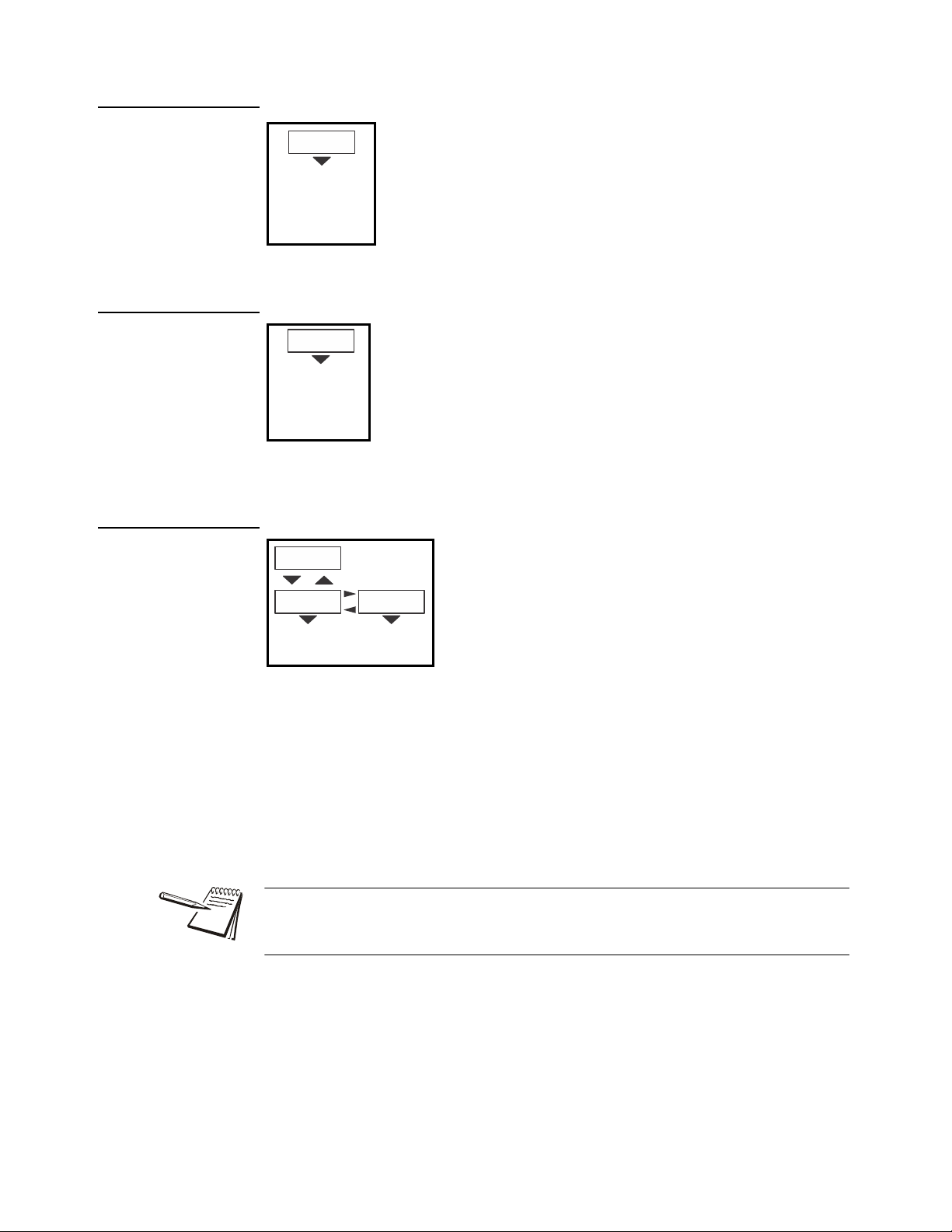

3.3 Menu annunciators

The menu structure is made up of menu items, parameters, value entry screens and

lists from which you choose one item. To help you know where you are in the menu,

the bar graph at the top of the display is on while the indicator is in the menus and will

change appearance according to the following rules:

All segments flashing This means you are in the menu structure but not

Center flashing / others off This means you are in a numeric entry screen.

Right flashing / others off This means you are in a list. Scroll through the

in any of the following screens.

Enter a number and press ZERO to accept.

choices with the PRINT and UNITS keys and

press ZERO to accept.

Left flashing / others off This means you are in a data entry.

Every alternate segment flashing This means you are in octet entry for IP, Subnet

or Gateway address.

16 ZK830 Counting Scale Service Manual

Page 17

4 User level menus

See

page 17

See

page 20

See

page 24

User About Audit

User

Site ID

Seal

Enter

Site ID

View Seal

Status

Time

Date

Set

12hr 12hr-AP 24hr

Set

Style

MMDD4YMMDD2Y DDMM2Y DDMM4Yy- x

m- x

d- x

Style

h- x

m- x

s- x

Reference

Numeric entry procedure

(without optional keypad)

on page 13

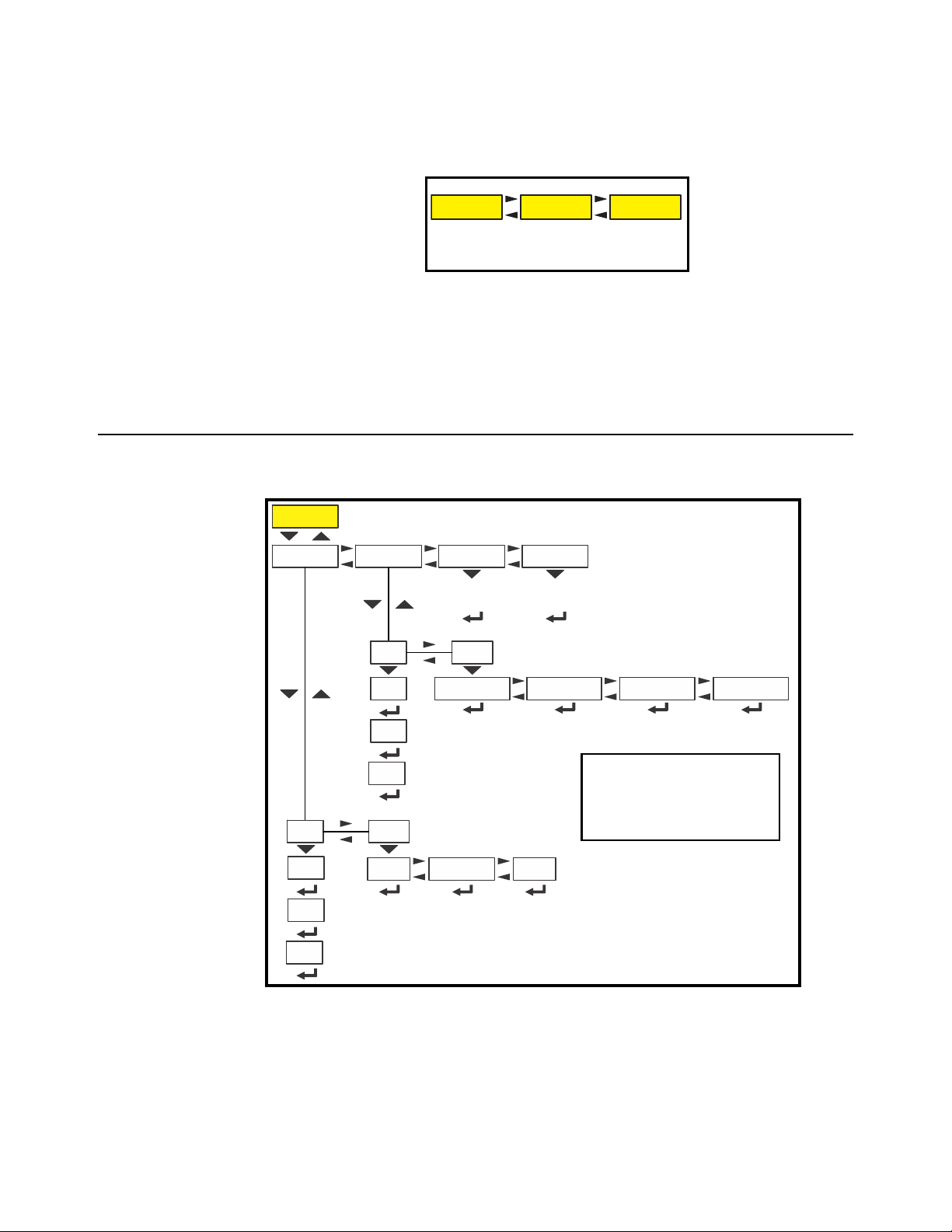

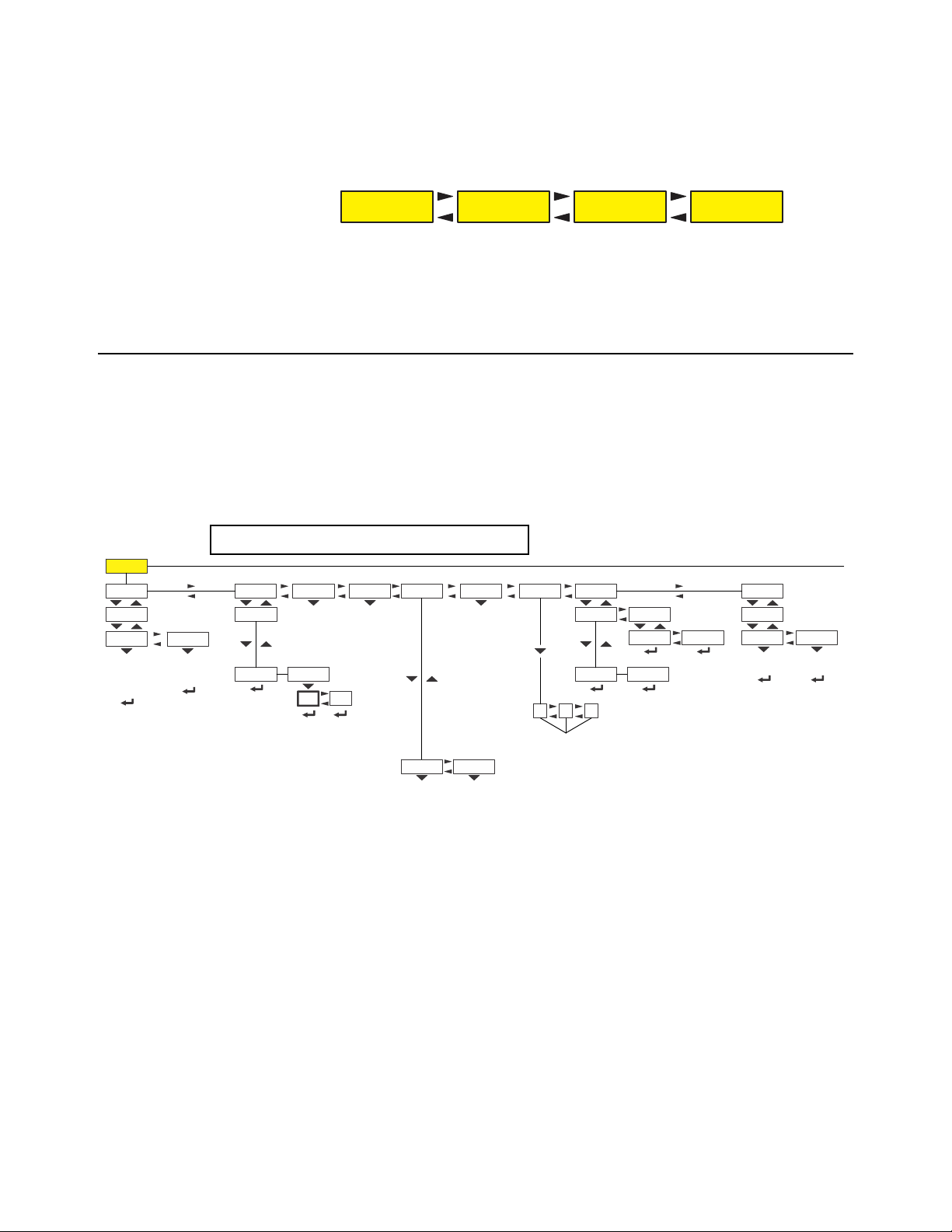

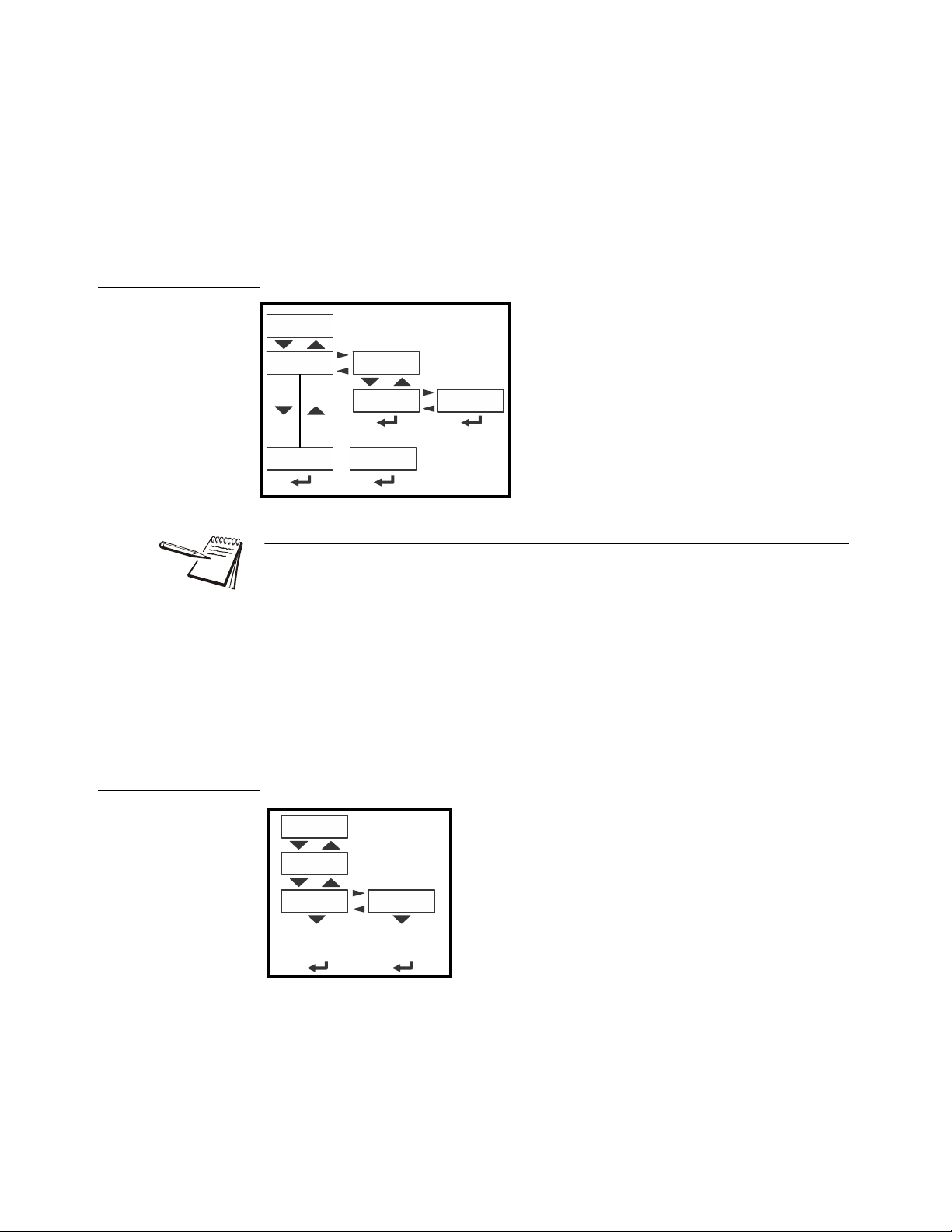

The USER level (password 111) contains the User, About, and Audit menus arranged

as shown in Figure 4.1.

Figure 4.1 USER level (password 111) menus

To access the USER level, from normal weighing mode, press and hold the SAMPLE/

F1 key. Enter password 111 and press the ZERO key.

4.1 User menu

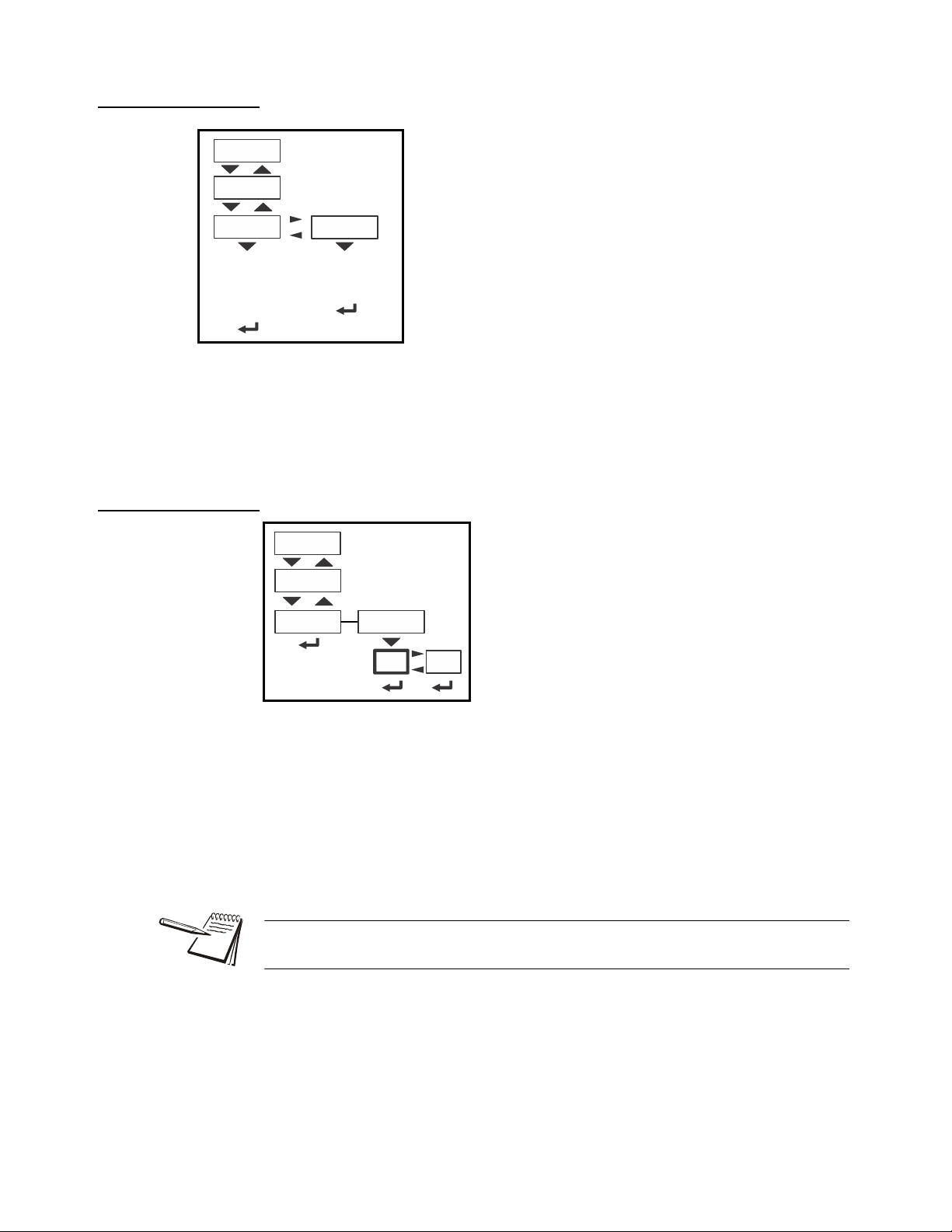

The User menu is shown in Figure 4.2.

4.1 User menu

ZK830 Counting Scale Service Manual 17

Figure 4.2 User menu

Use this menu to set the time, date, site ID, to see the physical seal status and print

archive information. Each is explained below:

Page 18

4 User level menus

Use the tiME menu item to set the clock

(SEt) and to choose the style of the time

display (StYLE) 12 hr, 12 hr AM/PM or

24 hr.

Time

Set

12hr 12hr-AP 24hr

Style

h- x

m- x

s- x

Date

Set

Style

MMDD4YMMDD2Y DDMM2Y DDMM4Yy- x

m- x

d- x

4.1.1 Time

The Time and Date can be used in print formats.

SEt Use this to enter values for the time.

h- x, = Hour

m- x = Minute

s- x = Seconds

4.1.2 Date

StYLE Choose the style of the time display. Choices are:

12hr, = 12 hour clock

12hr-AP = 12 hour clock with AM/PM

24hr = 24 hour military time

Use the dAtE item to set the year, month and day and the style of the displayed date.

SEt Enter values for the date.

y- x = Year

m- x = Month

d- x = Day

18 ZK830 Counting Scale Service Manual

Page 19

4.1.3 Site ID

SitE Use this to enter a Site ID.

The Site ID can be used in a print format. Use the

alphanumeric entry methods described in 2.3 to enter a

Site ID. (maximum 6 digits)

Site ID

Enter

Site ID

SEAL Use this to view the seal status of the indicator.

This is the status of the physical seal jumper inside the

indicator. If the unit is sealed, no changes can be made to

the configuration of the indicator. See the note below.

Seal

View Seal

Status

4.1.4 Seal

4.1 User menu

StYLE Choose the style of the date display. Choices are:

MMdd2Y = Month, Day, 2-digit Year

MMdd4Y = Month, Day, 4-digit Year

ddMM2Y = Day, Month, 2-digit Year

ddMM4Y = Day, Month, 4-digit Year

The seal switch jumper, P7, is located near the bottom center of the ma in PCB. See

jumper settings in chapter 13. If the jumper is installed, the indicator is sealed. This

means the only the Diagnostic, User, About, Audit and Supervisor menus can be

accessed. Other menus cannot be accessed - the display will flash SEALEd.

To exit the menu, see Exiting the menus on page 15.

ZK830 Counting Scale Service Manual 19

Page 20

4 User level menus

BSQ

Sw Part

Version

Cur. Ser

xxxx

xxxxx

(View

software PN)

(View

software

version)

xxxx

(View

cell SN)

xxxxxx

Serial

About

App.

EnetFirmBoot

VersionPartno

IP

GatewaySubnet

VersionPartno

(View

bootloader PN)

VersionPartno

(View version)

Mac

1 xx

2 xx

3 xx

4 xx

5 xx

6 xx

1 xx

2 xx

3 xx

4 xx

1 xx

2 xx

3 xx

4 xx

1 xx

2 xx

3 xx

4 xx

(View SN)

xxxx

xxxxx

Dload

Sserial Dserial

(View

license

number)

(View

license

number)

(View App PN)

AWT30

XXXXX

(View version)

X.X.X.XX

(View Firmware PN)

AWT30 XXXXX

(View version)

X.X.X.XX

AWT30

XXXXX

X.X.X.XX

Scale X

Cal. Ser

(View SN of

calibrated

cell)

Reference Numeric entry procedure (without

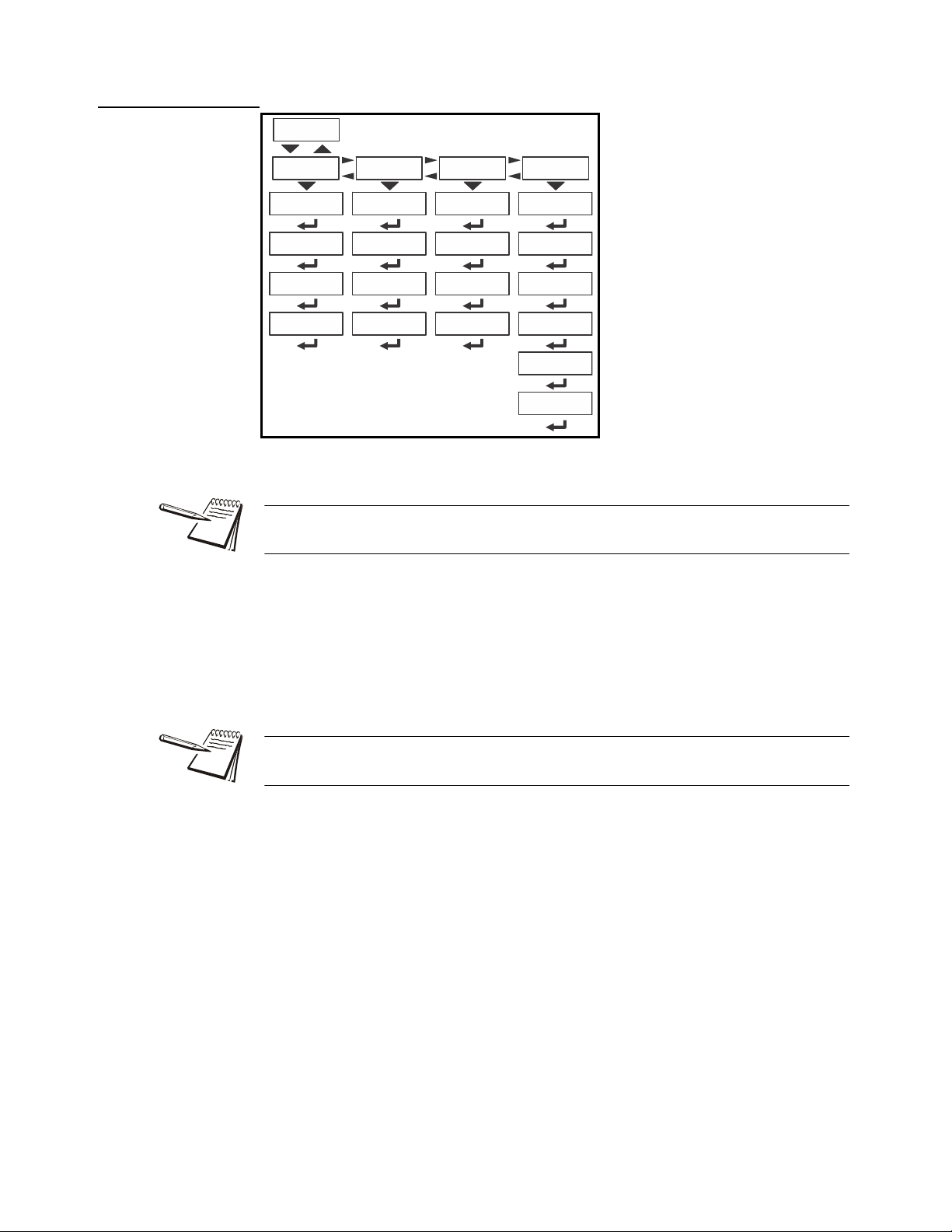

4.2 About menu

The About menu is shown in Figure 4.3.

Figure 4.3 About menu

Use this menu to display information about the various items shown in Figure 4.3. Each

is explained below:

Definitions:

Bootloader Software that makes the electronics run.

Firmware Embedded system software that creates core functions of the product.

App Specific software that controls the behaviour for a given installation.

20 ZK830 Counting Scale Service Manual

Page 21

4.2.1 Boot (Bootloader)

PArtno Use this to view the bootloader part

number. The part number is

displayed in two parts. Press RIGHT

arrow key or LEFT arrow key to

toggle the display between the first

and second parts of the part number.

VErSion Use this to view the version of the

bootloader.

Boot

(View

bootloader PN)

VersionPartno

(View version)

AWT30 XXXXX

X.X.X.XX

PArtno Use this to view the firmware part

number. The part number is

displayed in two parts. Press

RIGHT arrow key or LEFT arrow

key to toggle the display between

the first and second parts of the

part number.

VErSion Use this to view the version of the

firmware.

Firm

VersionPartno

(View Firmware PN)

AWT30

XXXXX

(View version)

X.X.X.XX

PArtno Use this to view the App part number.

The part number is displayed in two

parts. Press RIGHT arrow key or

LEFT arrow key to toggle the display

between the first and second parts of

the part number.

VErSion Use this to view the version of the

App.

App.

VersionPartno

(View App PN)

AWT30 XXXXX

(View version)

X.X.X.XX

SEriAL Use this to view the Serial Number of the indicator . The

number is displayed in two parts. Press RIGHT arrow

key or LEFT arrow key to toggle the display between the

first and second parts of the serial number.

Serial

(View SN)

xxxx

xxxxx

4.2.2 Firmware

4.2 About menu

4.2.3 App

4.2.4 Serial

ZK830 Counting Scale Service Manual 21

Page 22

4 User level menus

Enet

IP

GatewaySubnet Mac

1 xx

2 xx

3 xx

4 xx

5 xx

6 xx

1 xx

2 xx

3 xx

4 xx

1 xx

2 xx

3 xx

4 xx

1 xx

2 xx

3 xx

4 xx

4.2.5 Enet

EnEt This stands for Ethernet. Use this to view the network addresses.

If the indicator is connected to an Ethernet network, the values displayed will be the

current assigned addresses.

iP Use this to view the IP address.

SubnEt Use this to view the Subnet address.

gAtEWAY Use this to view the Gateway address.

MAc Use this to view the Mac address.

The IP, Subnet and Gateway addresses are a series of four double digit values.

The MAC address is a series of six double digit values: 1 XX, 2 XX, 3 XX, etc.

22 ZK830 Counting Scale Service Manual

Page 23

4.2.6 Download

dLoAd This stands for download. Use this to view

these items:

SSEriAL View the license number that

created the configuration file.

dSEriAL View the license number that

downloaded the configuration

file.

This is used for security and licensing purposes.

Dload

Sserial

Dserial

(View

license

number)

(View

license

number)

BSQ

Sw Part Version Cur. Ser

xxxx xxxxx

(View

software PN)

(View

software

version)

xxxx

(View

cell SN)

xxxxxx

Scale X

Cal. Ser

(View SN of

calibrated

cell)

4.2.7 BSQ

4.2 About menu

To upload a configuration file, the license number of the Configurator (Ztools)

software must match one of the license numbers in the indicator Contact AWTX

Technical Support for assistance.

ZK830 Counting Scale Service Manual 23

This stands for Bench Scale - Quartzell.

SW PArt View the software part number of the ce ll that is connected.

VErSion View the software version of the cell that is connected.

cur.SEr View the serial number of the cell that is connected.

cAL.SEr View the serial number of the cell that was connected at the time of

calibration.

To exit the menu, see Exiting the menus on page 15.

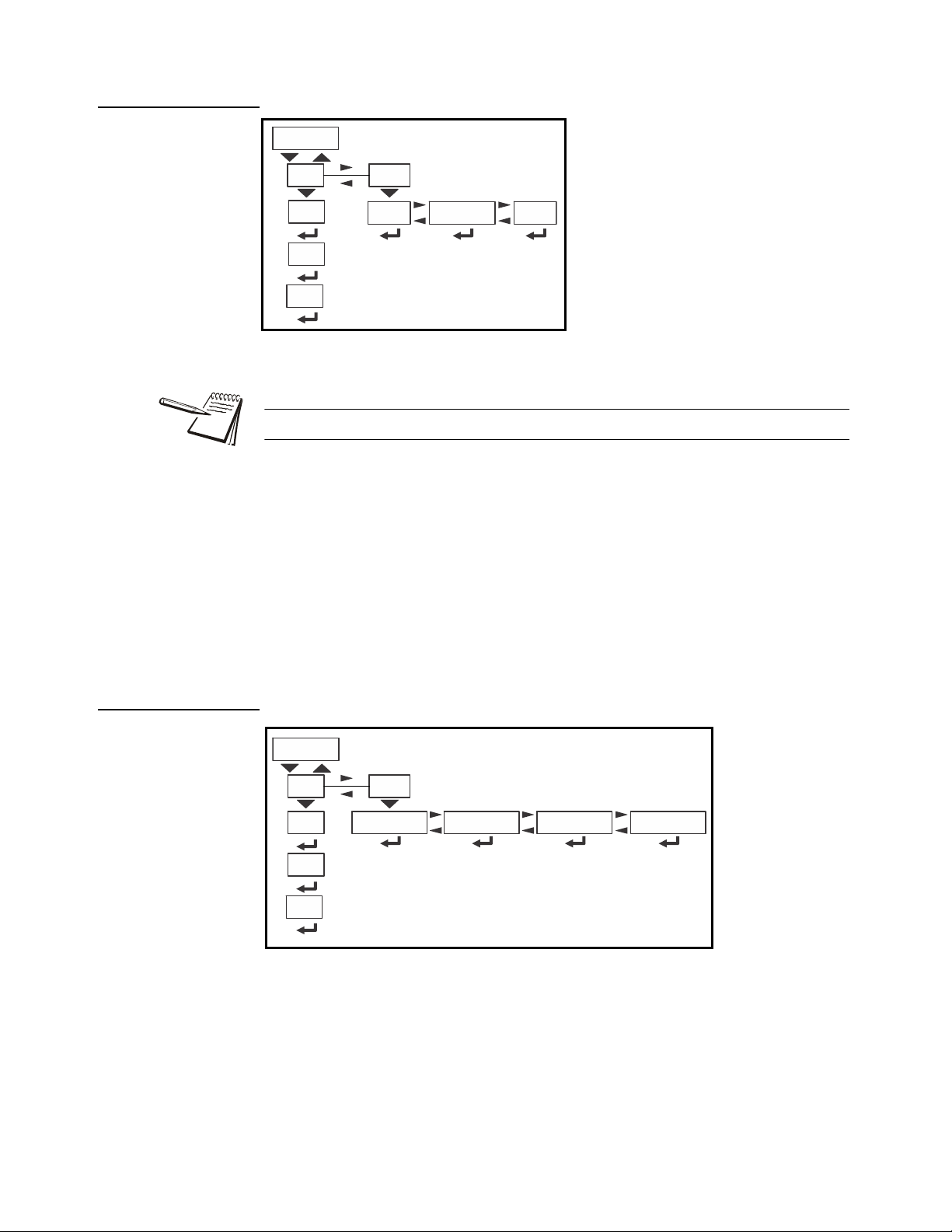

Page 24

4 User level menus

Counter

Config

Displays

number of

configurations

Audit

Calib

Displays

number of

calibrations

countEr Use this to view these items:

conFig View how many times the

indicator has been

configured.

cALib View how many times the

indicator has been

calibrated.

Counter

Config

Displays

number of

configurations

Calib

Displays

number of

calibrations

4.3 Audit menu

Use this menu to display audit counters for configuration and calibration.

4.3.1 Counter

Figure 4.4 Audit menu

To exit the menu, see Exiting the menus on page 15.

24 ZK830 Counting Scale Service Manual

Page 25

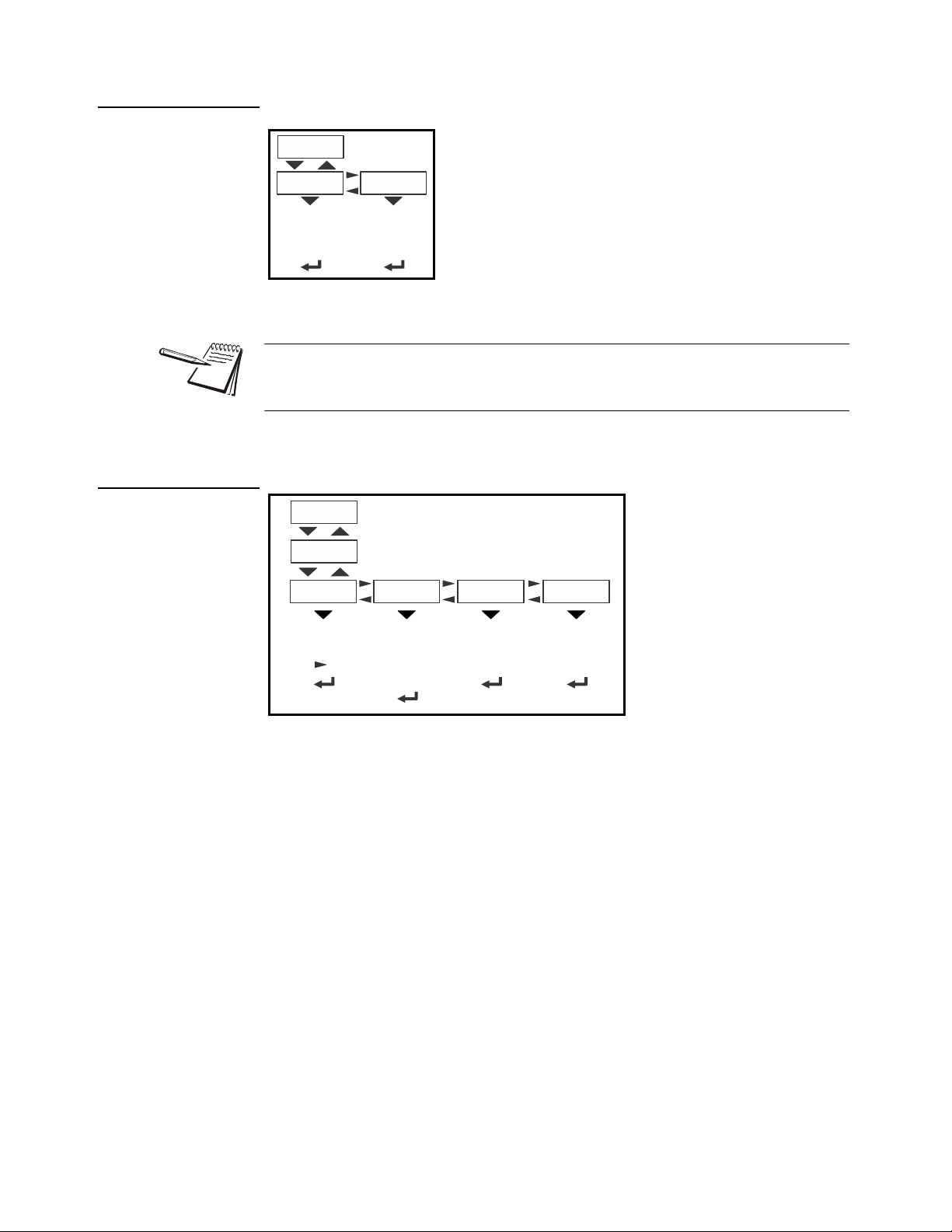

5 Diagnostics level menus

See page 17 See page 20 See page 24See page 25

Diag User About Audit

Reference Numeric entry procedure (without

Diag

Buttons

Display

Scale

Test button

function

( exits

ZERO

the test)

Continuous

display test

( exits

ZERO

the test)

ScaleX

View scale

output in

A to D or

mV/V

Cur.Zero

ScaleX

Value Clear

Ports

Serial1 Serial2

Loopback

test

Loopback

test

Tension

Compres

Tension

frequency

Compression

frequency

Logs

Print

Clear

Serial 1 Serial 2

Clr no

Clr yes

Inputs Outputs

Test configured

inputs

1 2

3

Toggles selected

output on or off

(Must be turned

ON in Outputs

menu)

BSQ

ScaleX

Counts

Std Dev

View standard

deviation for

last X seconds

no

YES

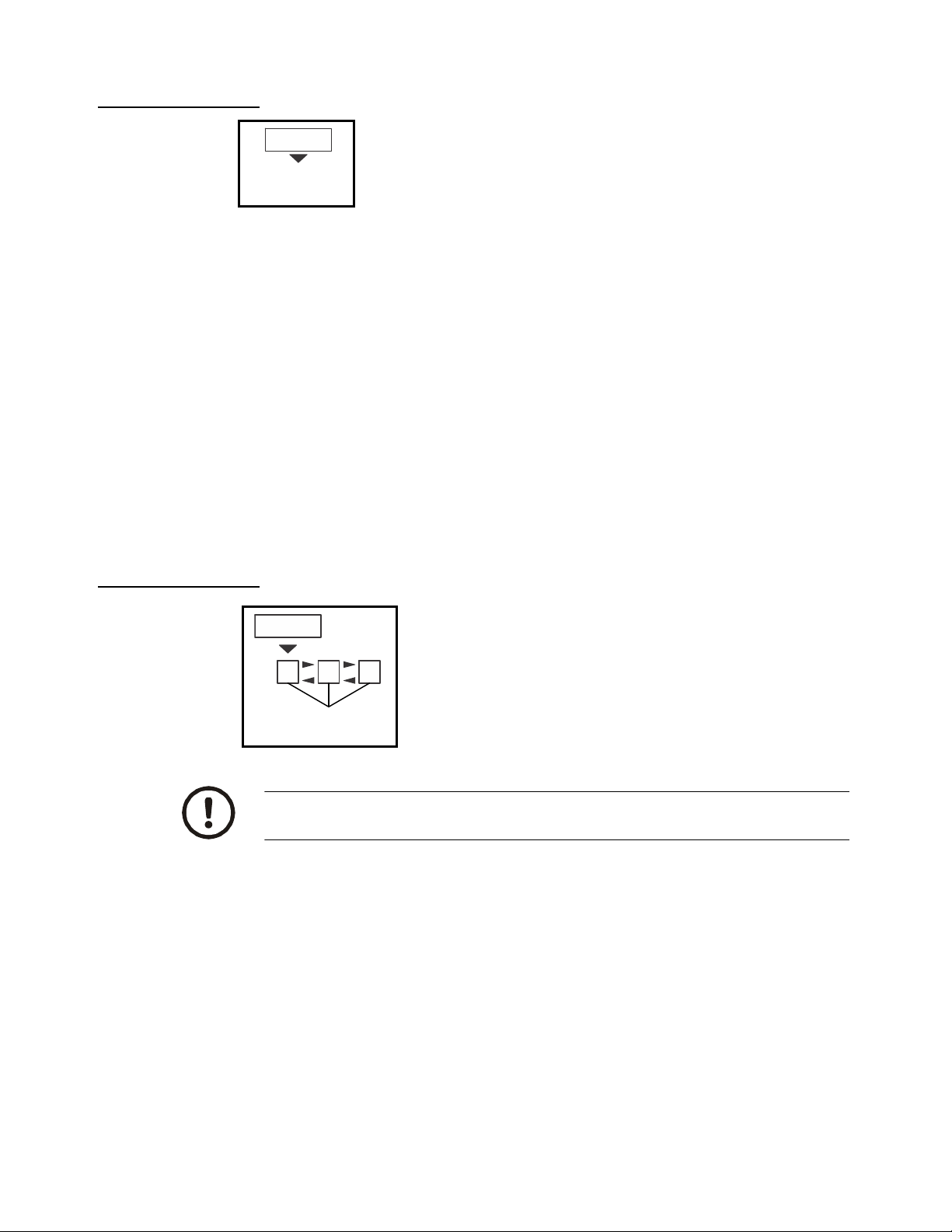

The DIAGNOSTICS level (password 3570) is the same as the USER level except it

adds the Diag menu. The DIAGNOSTICS level is shown in Figure 5.1.

Figure 5.1 DIAGNOSTICS level (password 3570) menus

5.1 Diag menu

Use the Diag menu to check or verify the performance of the ind icator. The diagnostic

tests available include: Scale A to D to view output from the connected scale base or

load device, the current zero offset from ca libration zero, a display segment test, a front

panel keypad or button test, serial Com port s and USB host port test, remote inputs and

outputs test, and an option card test if installed. You can print an error log report that

provides information on previous error conditions such as overloads or underloads.

The Diag menu is shown in Figure 5.2.

5.1 Diag menu

Each of the items in the Diag menu is explained below:

ZK830 Counting Scale Service Manual 25

Figure 5.2 Diag menu

Page 26

5 Diagnostics level menus

ScALE Select to view values for Scale 1 or Scale 2, if

installed.

countS Use this to view a number representing the A to

D counts. The value is only for diagnostic

purposes. The value should increase as weight

on the scale increases and decrease as weight

decreases.

Press

SELECT to toggle to a mV/V display.

This is an approximate value for the mV/V value

output by the loadcell. If the scale is a BSQ then

you can only view counts, not mV/V.

Std d Ev This stands for Standard Deviation. This gives

you the standard deviation of the counts for the

last, set number of seconds.

Scale

ScaleX

View scale

output in

A to D or

mV/V

Counts

Std Dev

View standard

deviation for

last X seconds

Cur.Zero

ScaleX

Value

Clear

no

YES

5.1.1 Scale

5.1.2 Current Zero

cur.ZEro This stands for current zero and represents the weight of fset between the

calibration zero setting and the current zero setting due to pushbutton zero

or Auto-Zero Tracking (AZT) adjustments.

Select to view values for Scale 1 or Scale 2, if installed.

VALuE View the zero offset.

cLEAr Clear the zero offset to return the indicator to calibration zero. C hoose no

YES.

or

This can restore the original calibration zero point if the ZERO key is accidently

pressed when a tank or vessel contains product that cannot be emptied.

26 ZK830 Counting Scale Service Manual

Page 27

5.1.3 Display

diSPLAY Use to test the segments of the display. Each digit

area lights up in progression and continues until you

press

ZERO.

Display

Continuous

display test

( exits

ZERO

the test)

buttonS Use to test the keys. When you begin the test tESting is

briefly displayed followed by dashes.

Press any key to test if it is functioning and its name or

value will be displayed.

Press

ZERO to stop the test.

Buttons

Test button

function

( exits

ZERO

the test)

Ports

Serial1 Serial2

Loopback

test

Loopback

test

5.1.4 Buttons

5.1 Diag menu

5.1.5 Ports

PortS Use this to do a loopback test for serial port 1 or 2 or to perform a write/

read test on the USB port.

SEriAL1 or 2 When you pick a serial port to test, tESting is briefly displayed and

PASS or FAiL, depending on if the send and receive lines are

then

jumpered (pass) or not (fail). Add a jumper or wire between the

transmit output and receive input. On an external 9 pin conn ector the

transmit line is pin 2 and the receive line is pin 3.

It is recommended that you insert the jumper (a paper clip works) into the external

cable connector to validate the wiring and not just the internal port s. See System

block diagram on page 114 for I/O configuration of the serial ports TB3.

ZK830 Counting Scale Service Manual 27

Page 28

5 Diagnostics level menus

inPutS The input test is used to verify if external switches wired

to the input ports on TB2 are functioning properly.

Follow the steps below to perform the inputs test.

Inputs

Test configured

inputs

outPutS The output test is used to verify if external relays or

lights (etc.) connected to TB2 are properly wired

and functioning properly.

Follow the steps below to perform the output test.

Outputs

1 2

3

Toggles selected

output on or off

5.1.6 Inputs

1. Press SELECT …

in 000 is displayed, if no inputs are jumpered.

2. To test input 1, jumper pins 1 and 2 of the I/O connector on the indicator …

5.1.7 Outputs

The first digit becomes

3. To test input 2, jumper pins 1 and 3 of the I/O connector on the indicator …

The second digit becomes

4. To test input 3, jumper pins 1 and 4 of the I/O connector on the indicator ….

The third digit becomes

5. Press

ZERO …

inPutS is displayed.

1 until the jumper is removed.

2 until the jumper is removed.

3 until the jumper is removed.

CAUTION: Be sure to take proper precautions to ensure material controlled by

the scale outputs will not create a hazardous condition during an output test.

1. WithoutPutS is displayed, press SELECT …

outPut1 is displayed.

2. Press

3. Press

28 ZK830 Counting Scale Service Manual

SELECT …

o.1-oFF is displayed.

PRINT or UNITS to toggle the output on (o.1-on) and repeat to turn it

oFF.

Output 1 will be toggled on and off as you press the keys. This is shown

by the annunciator (

SP1) on the display turning on and off.

Page 29

4. Press ZERO or F1 to stop the test …

Logs

Print Clear

Serial 1 Serial 2

Clr no

Clr yes

Tension

Compres

Tension

frequency

Compression

frequency

BSQ

ScaleX

outPut1 is displayed.

5.1 Diag menu

5.1.8 Logs

5. Press

6. When finished, press

The logs report will print any error conditions that may have occurred such as

overloads and underloads

UNITS to go to the next output. Repeat the steps to test output 2 and 3.

TARE …

outPutS is displayed.

5.1.9 BSQ

LogS These are logs of various functions. You can print or clear them from

memory.

Print Choose to print the log from Po rt 1 or Port 2.

cLEAR Choose to clear the log from memory.

bSQ The BSQ menu item provides the digital frequency information for the

crystals on the QDT (Quartzell Digital Transducer).

ScALE 1 or ScALE 2:

Select which Scale number the BSQ is assigned, ScALE 1 or

ScALE 2

ZK830 Counting Scale Service Manual 29

Page 30

5 Diagnostics level menus

coMPrSS This stands for compression frequency.

tEnSion This stands for tension frequency.

The nominal value for the tension and compression frequency is 47,200 ± 2000 kHz.

The tension and compression frequencies should each be as stable as the other and

within 10% of each other. As weight increases the tension frequency should increase

and the compression frequency should decrease.

This completes the Diag menu. To exit the menu, see

Exiting the menus on page 15.

30 ZK830 Counting Scale Service Manual

Page 31

6 ADMIN level menus

See page 17 See page 20 See page 24See page 25See page 31

Setup Diag User About Audit

See page 32 See page 38 See page 46 See page 54

Setup

Calib Scale System Ports

Input

Output

See page 60 See page 61

The ADMIN level (password 3088) is the same as the DIAG level except it adds the

Setup menu. The ADMIN level is shown in Figure 6.1.

6.1 Setup menu

In the Setup menu there are various submenus available to configure specific sections

of the scale operation. The top level items in the Setup menu are shown in Figure 6.2.

6.1 Setup menu

Figure 6.1 ADMIN level

Figure 6.2 Setup menu (password 3088)

Each of the items in the Setup menu are explained in the following sections.

ZK830 Counting Scale Service Manual 31

Page 32

6 ADMIN level menus

Calib

Span Linear Gravity

Pt2

G-fact

Lat

Alt

Calc

Display

Cal.Unit

LB

1000g

View

live weight

(F1 to stop)

Print

Port 1 Port 2

Calculates

gravity

factor

Enter

altitude

Enter

latitude

View or

enter

G-factor

Enter

Pt 2 test

weight

Live weight

displayed.

Place Pt 2

weight on

scale.

Live weight

displayed.

Pt3

Enter

Pt 3 test

weight

Live weight

displayed.

Place Pt 3

weight on

scale.

Live weight

displayed.

Pt4

Enter

Pt 4 test

weight

Live weight

displayed.

Place Pt 4

weight on

scale.

Live weight

displayed.

View or

enter new

span

Live weight

displayed.

Place span

weight on

scale.

Live weight

displayed.

Live weight

displayed.

Remove

all weight.

Live weight

displayed.

Zero

Cal.Zero

Scale 1 Scale 2

gram

Current

weight assigned

as temp

Cal. Zero

Temp

Last acquired

zero used

as

Cal. Zero

Last

Input

Zero

Span

Counts

mV

Counts

mV

6.2 Calibration Procedure

Use the Calib menu to perform Zero and Span calibration, add Linearity correction

points, manually input calibration para meters for Zero and Span, manually input

Gravitational correction values, view the live weight, set the calibration unit of measure

and print out a calibration report. Follow the menu in Figure 6.3 and the steps that

follow.

Figure 6.3 Calibrate menu

Access the calibration procedure directly using the calibration password, 2580, or

6.2.1 Scale 1-2

access it through the Setup menu, password 3088. See

(without optional keypad) on page 13

Select the scale to be calibrated, Scale 1 or Scale 2. The Number of Scales on page

must be set to 2 to access Scale 2 settings.

53

.

32 ZK830 Counting Scale Service Manual

Numeric entry procedure

Page 33

6.2.2 Zero Procedure

Zero

displayed.

Remove

all weight.

displayed.

Cal.Zero

Current

weight assigned

as temp

Cal. Zero

Temp

Last acquired

zero used

as

Cal. Zero

Last

ZEro Access the scale zeroing process.

On the initial zero calibration of the indicator to a new scale, the zero cal counts may

appear unstable. Continue to the span calibration and when completed the condition

should correct itself.

6.2 Calibration Procedure

cAL.ZEro Use this to record the zero point. Follow the menu above to

complete the zero calibration. A

c on the display denotes the

fact you are in the calibration procedure.

tEmP This is an alternate zeroing procedure. Use this when the

product weight on the scale, such as in a tank or vessel,

appears to be inaccurate but cannot be re moved to establish

a no-load condition.

Enter the calibration procedure and select

Temp. zero. The

current weight on the scale will be temporarily assigned as the

Cal Zero value. Continue to the SPAN procedure, key in the

value of the test weights and place them on the scale and

complete the SPAN procedure. The original Cal Zero is

restored after exiting the span procedure and the current

product weight will now be correctly represented.

Due to factors that created the original inaccuracy, it may be

necessary to re-zero the scale when the tank or vessel is

empty.

LASt This is an alternate zeroing procedure. Use this if certified test

weights placed on the scale display a slightly inaccurate

value. Be sure that the scale is at zero before the test weights

are added and enter the calibration procedure and select

Last

zero. The last acquired zero value will be assigned as the new

Cal Zero value.

Continue to the SPAN procedure without removing the test

weights. Key in the value of the test weights on the scale and

complete the SPAN procedure. The test weights will now read

accurately.

ZK830 Counting Scale Service Manual 33

Page 34

6 ADMIN level menus

SPAn To set the Span Calibration point press the DOWN

arrow

key and XXXX is displayed with a flashing

right digit. This is the current span weight.

Press

ZERO to accept the displayed span weight or

key in your span weight (not to exceed the

configured capacity) and press

ZERO.

c xxx is displayed. This is the current weight on the

scale.

Place the span weight on the scale and pres s

ZERO.

buSy is briefly displayed and then c XXXX is

displayed, which should be the same as the span

weight you keyed in. Press

ZERO and SPAn is

displayed.

Span

View or

enter new

span

displayed.

weight on

scale.

displayed.

Linear

Pt2

Enter

Pt 2 test

weight

displayed.

Place Pt 2

weight on

scale.

displayed.

Pt3

Enter

Pt 3 test

weight

Live weight

displayed.

Place Pt 3

weight on

scale.

Live weight

displayed.

Pt4

Enter

Pt 4 test

weight

Live weight

displayed.

Place Pt 4

weight on

scale.

Live weight

displayed.

6.2.3 Span Procedure

6.2.4 Linearity Procedure

Perform the linearity procedure only if test weights applied to the scale between the

zero and span calibration points are showing slight inaccuracies, such as ± a few

divisions. If large inaccuracies are recorded, this indicates a possible mechanical

problem or possible loadcell failure which linearity calibration may not be able to

correct.

34 ZK830 Counting Scale Service Manual

LinEAr Add up to thre e additional calibration points to improve the linearity

performance of the scale.

Page 35

Linearity points are cleared if a new span calibration is performed.

Input

Zero

Span

Counts

mV

Counts mV

6.2.5 Input procedure

6.2 Calibration Procedure

Pt2-Pt4 The points are numbered 2 through 4 because, internally, the

zero reference point is point 1 and the span point is point 5.

Follow the same steps as described in the SPAN procedure to

enter each linearity point.

ZEro Use this to enter a value for the zero point.

CountS Use this to enter a zero point using ADC counts.

mV Use this to enter a zero point using a mV/V value.

SPan Accept the flashing displayed span weight (XXXX) or key in the span

weight that corresponds with the span ADC or mV/V value.

CountS Use this to enter a span using ADC counts.

mV Use this to enter a span using a mV/V value.

The BSQ base only allows entry of Counts for Zero or Span points

The Span value is the differenti al valu e of th e actual Ca libration Zero and Sp an count

(or mV/V) values.

ZK830 Counting Scale Service Manual 35

Page 36

6 ADMIN level menus

Gravity

G-fact

Lat Alt Calc

Calculates

gravity

factor

Enter

altitude

Enter

latitude

View or

enter

G-factor

6.2.6 Gravity Factor Procedure

grAvitY Use this item to key in a gravity constant value. If the scale has been

calibrated at a different location that has a significantly different

gravitational factor than the installation site, and it is not possible to recalibrate with known test weights, the scale can be adjusted using this

gravity factor.

g-FACt If you know the local gravitation factor (allowable range is

9.70000 to 9.90000), key it in here

OR

If you do not know the local gravitation factor but can

determine the approximate latitude and altitude of the

installation site, then the indicator can calculate the gravity

factor from these two values.

LAt This stands for latitude. Key in the latitude for the installation

site. The valid range is 0 to 90. A positive value works for north

or south of the equator.

ALt This stands for altitude. Key in the altitude for the installation

site. The valid range is 0 to 30,000 ft. (10000 m).

CALC This stands for calculate . Th e indica to r ca lcu lates the gravity

factor and loads this value as the gravity factor.

Be sure to save the changes when you exit the menu and test the accuracy with a

known weight.

CAUTION: Verify with local agencies if adjusting the gravity factor is accepted

in your area. It may be required that calibration be done with certified weights.

36 ZK830 Counting Scale Service Manual

Page 37

6.2.7 Display

diSPLAY Use this item to view live scale weight while in the

calibration menu.

Display

View

live weight

CAL.unit Us e this item to set t he unit o f

measure of the weights used

during calibration. Choices are

Lb,

1000g or gr.

Cal.Unit

LB 1000g gram

Print Use this print function to print a calibration report

through

Port 1, Port 2 or to USB. This

information can be used in the future to restore

calibration.

See

Calibration report on page 75 to view a

representation of the printed report.

Print

Port 1 Port 2

Use the ZERO key to zero the indicator so you can add test weights to validate the

accuracy of the scale.

6.2.8 Calibration Unit

6.2 Calibration Procedure

6.2.9 Print calibration report

This completes the Calib menu. To exit the menu, see Exiting the menus on page 15.

ZK830 Counting Scale Service Manual 37

Page 38

6 ADMIN level menus

Scale 2 only

Scale

Capacty

Dvision Units Stable AZT Filter

Key in

scale capacity

Avg

Const

T-hold

Div

Time

Unit 1

Unit

Unit 2

Lb 1000 g

Oz

Gr Lb-oz Cust 1

Ranges Type

CAP 1

CAP 2

Div 1

Div 2

M.range

0-rnge

O-cap G-zero

Key in %

of scale

capacity

Key in

0 to 10000

div.

Basis

Percent

Div

O-Load

U-Load

Key in value

based on Basis

chosen

2,3,Range

Key in

CAP 2

capacity

Key in

CAP 1

capacity

Key in

value

1 thru 10

Key in

value

Key in

value

Key in

time

Div

Time

Key in

value

Key in

time

0.000001

10

to

0.001

1to0.001

1

to

Analog

Lb Off1000 g

Off

0.000002 0.000005

20 50

Custom

Cust 1

Ratio1

String 1

Key in ratio Enter string

Scale 1 Scale 2

Appears only if

Num Scl = 2

6.3 Scale

CAUTION: Be sure you follow all local weights and measures regulations.

Some parameters may be set automatically by your choice of SitE in the

System menu item.

Use the Scale menu to configure the scale operating parameters such as capacity and

division size, available units of measure, motion and auto zero tracking values, filtering

parameters, range of operation for zeroing the scale, over and underload conditions

and the return to gross zero region or band. Refer to the menu in Figure 6.4 and the

steps that follow.

.

Access the Scale menu. See Numeric entry procedure (without optional keypad) on

page 13

38 ZK830 Counting Scale Service Manual

Figure 6.4 Scale menu

Page 39

6.3.1 Scale 1-2

ScALE 1-2 Select the scale to setup, ScALE 1 or

ScALE 2.

Scale 2 appears only if a second scale is

installed and the Num Scl menu item in the

SYSTEM menu, on page 53 must be set to

2.

Scale 1 Scale 2

Only if a 2nd

scale installed

cAPActY Key in a new capacity or accept the displayed

capacity.

Capacty

Key in

Dvision

0.000001

10

to

0.000002 0.000005

20 50

6.3.2 Capacity

6.3 Scale

The capacity that you enter should never exceed the rated cap acity of the scale that is

connected.

6.3.3 Division

dViSion This stands for division size.

Choices are

0.0001, 0.0002, 0.0005, 0.001, 0.002, 0.005, 0.01, 0.02, 0.05, 0.1, 0.2, 0.5,

1, 2, 5, 10, 20, 50, 100, 200 and 500. The default value is 0.001.

Division sizes for other units of measure are automatically calculated by the indicator.

0.000001, 0.000002, 0.000005, 0.00001, 0.00002, 0.00005,

ZK830 Counting Scale Service Manual 39

Page 40

6 ADMIN level menus

Units

Unit 1

Unit

Unit 2

Lb 1000 g

Oz

Gr

Lb-oz

Cust 1

Lb

Off

1000 g

Off

Custom

Cust 1

Ratio1

String 1

Key in ratio Enter string

Stable

Div

Time

Key in

value

Key in

time

6.3.4 Units

unit From this item you can choose which units of measure are available when

the user presses the

to two units for viewing. They are listed as:

be LB, 1000 g or Off. Unit 2 can be any of the following units of measure:

lb, 1000g, oz, gr, lb-oz, cuSt 1, or oFF.

UNITS key during normal weighing. You can have up

unit 1 and unit 2. Unit 1 can

cuStoM This stands for custom unit. To use a custom unit you must first create

them by entering a ratio and a string to define it.

cuSt 1 You can set up a custom unit using these parameters:

rAtio The ratio is the number you divide into the

calibration unit of measure to create the custom

unit. Example: Ratio would equal 2000 if you

wanted to convert pounds to tons.

String Use this to enter a string label for the custom unit.

This is only used when data is transmitted out one

of the communication ports.

6.3.5 Stable

40 ZK830 Counting Scale Service Manual

StAbLE Use this parameter to set the stability window for the scale. Set a division

window and a time window which will be used to determine when the

stability icon will be displayed.

diV Set the division window size to define stability.

Page 41

6.3.6 AZT

AZT

Div

Time

Key in

value

Key in

time

Filter

Avg

Const

T-hold

Key in

value

1 thru 10

Key in

value

6.3 Scale

timE Set the time window in seconds to define stability. Set both

diV and timE to 0 to disable stability.

The StAbLE time value is used during normal operation as the length of time the

indicator will continue to check for a ‘motion stable’ condition after the ZERO, TARE

or PRINT button is pressed. If the intended operation can not be completed befo re the

timeout, cAnt is displayed and the key request is ignored.

AZt This stands fo r Automatic Zero Tracking. The diV value defines a ± range

around zero. When scale weight is not at the center of zero but inside this

range for the time value entered, ½ of the weight will be subtracted. This

process is repeated until weight is inside the center of zero region.

6.3.7 Filter

diV Set the AZT window size to define stability. 3 divisions is the

default value. Set

timE Set the time window in seconds. 1 second is the default value.

0 to disable AZT.

Set to

In certain applications, such as when adding product slowly onto the scale, it may

require disabling AZT or changing the default values to reduce the effect.

FiLtEr Use this to filter out vibrations affecting the scale. Under this item you have

the following three parameters to set.

diV to 0 to disable AZT.

AVg This stands for average. 10 is t he defa u l t value .

conSt This stands for constant. 1 is t h e d e fault v a l ue.

ZK830 Counting Scale Service Manual 41

Page 42

6 ADMIN level menus

t-hoLd This stands for threshold. 0.1 is the default value. When 0 is

the threshold value, filtering is always on.

To find the best settings for your filter needs, follow steps 1 to 7.

Default settings are:

AVG = 1 0

Const = 1

t-hold = 0.1

These values will provide the best weight response for the majority of scale

installations. In adverse conditions, where wind, vibration or other conditions are

affecting the stability of the weight displayed, refer to the following instructions to

improve the performance of the indicator.

If you are using Ztools to configure your scale it will attempt to calculate

filtering based upon your capacity and division size used.

1. Using the Threshold setting is only recommend ed if the items to be weighed are

similar in weight. If the item weights vary considerably then set the threshold

value to 0 and proceed to step 2.

To determine the threshold value first set

t-hoLd to 0.0, conSt to 0, and AVg to

1.0. Return to weigh mode and, with a typical item on the scale, observe the

weight swings. Record the difference between the highest and lowest displaye d

weight values. Add 30 to 50% to this value. This is a good starting value for the

t-hoLd setting. Do not set your indicator to this value until told to in step 7.

2. Setting

To do this: Set

AVg to higher values increases the filtering effect.

t-hoLd to 0.0, conSt to 0, and AVg to 10. Check the stability of

the scale by exiting to normal weigh mode, remove all weight from the scale

and/or press

ZERO and observe the Center of Zero annunciator. If it is on all

the time your scale is stable. If the Center of Zero light blinks, more filtering is

required. Go to step 3.

3. Repeat step 2 but increase

AVg by 10.

Keep repeating steps 2 and 3 until the scale is stable or you’ve tried an

Average value up to 80. If the scale is still not stable go to step 4.

4. Setting the

To do this: Set

conSt to higher values increases the filtering effect.

t-hoLd to 0.0, conSt to 1, and AVg to 80. Check the stability of

the scale by exiting to normal weight mode and observe the Center of Zero

annunciator. If it is on all the time your scale is stable. If the Center of Zero light

blinks, more filtering is required. Go to step 5.

5. Repeat step 4 but increase the

conSt by 1. Keep repeating steps 4 and 5 until