Page 1

ZG354

DIRECT THERMAL BAR CODE PRINTER

MANUAL

USER’S

Page 2

COPYRIGHT DECLARATION ..................................... .................................................. ............... 1

C

OMPLIANCES ....................................................................................................................... 1

1. Introduction ............................................................................................................... 3

2. Getting Starte d ........................................................................................................... 3

2.1 Unpacking and Inspection ..................................................................................... 3

2.2 Equipment Checklist .............................................................................................. 3

2.3 Printer Parts .......................................................................................................... 4

2.3.1 Front View ...................................................................................................... 4

2.3.2 Rear View ...................................................................................................... 4

3 Setup ........................................................................................................................... 5

3.1 Setting Up the Printer ............................................................................................ 5

3.2 Loading Label Stock .............................................................................................. 6

3.3 Peel-Off Installation Assembly (Option) ................................................................. 8

3.4 Loading Label for Peel-off Mode (Option) ............................................................ 11

3.5 External Label Roll Mount Installation (Option) .................................................... 13

3.6 Cutter Module Installation (Option) ...................................................................... 14

3.7 Loading Label in Cutter Mode ............................................................................. 17

3.8 Diagnostic Tool ................................................................................................... 18

3.8.1 Start the Diagnostic Tool ............................................................................... 18

3.8.2 Printer Function (Calibrate sensor, Ethernet setup, RTC setup) ................... 19

3.9 Setting Ethernet by Diagnostic Utility (Option) ..................................................... 20

3.9.1 Using USB interface to setup Ethernet interface .......................................... 20

3.9.2 Using RS-232 interface to setup Ethernet interface ..................................... 21

3.9.3 Using Ethernet interface to setup Ethernet interface .................................... 22

3.10. Install Memory Card ......................................................................................... 24

Contents

4. Power on Utilities .................................................................................................... 26

4.1 Gap/Black Mark Sensor Calibration ..................................................................... 26

4.2 Gap/Black Mark Calibration, Self-test, Dump Mode ............................................ 27

4.3 Printer Initialization .............................................................................................. 30

4.4 Set Black Mark Sensor as Media Sensor and Calibrate the Black Mark Sensor .. 31

4.5 Set Gap Sensor as Media Sensor and Calibrate the Gap Sensor ....................... 31

4.6 Skip AUTO.BAS .................................................................................................. 31

5. Maintenance ............................................................................................................. 32

5.1 Cleaning .............................................................................................................. 32

6. Troubleshooting ...................................................................................................... 34

i

Page 3

LED Status ................................................................................................... 34

Print Quality .................................................................................................. 35

7. LED and Button Operation ...................................................................................... 36

7.1 LED ..................................................................................................................... 36

7.2 Button Operation ................................................................................................. 36

Revise History ............................................................................................................. 40

ii

Page 4

Compliances

CE Class B:

EN55022: 1998+A1: 2000+A2: 2003

EN55024: 1998+A1: 2001+A2: 2003 IEC 61000-4 Series

EN61000-3-2: 2006 & EN61000-3-3: 1995+A1: 2001

FCC Part 15, Class B

UL, CUL

C-Tick:

rd

CFR 47, Part 15/CISPR 22 3

ANSI C63.4: 2003

Canadian ICES-003

TÜV/Safety: EN60950: 2000

Wichtige Sicherheits-Hinweise

1. Bitte lesen Sie diese Hinweis sorgfältig durch.

2. Heben Sie diese Anleitung fűr den späteren Gebrauch auf.

3. Vor jedem Reinigen ist das Gerät vom Stromentz zu trennen. Verwenden Sie

keine Flüssig-oder Aerosolreiniger. Am besten eignet sich ein angefeuchtetes

Tuch zur Reinigung.

4. Die Netzanschluß-Steckdose soll nahe dem Gerät angebracht und leicht

zugänglich sein.

5. Das Gerät ist vor Feuchtigkeit zu schűtzen.

6. Bei der Aufstellung des Gerätes ist auf sicheren Stand zu achten. Ein Kippen oder

Fallen könnte Beschädigungen hervorrufen.

7. Beachten Sie beim Anschluß ans Stromnetz die Anschlußwerte.

8. Dieses Gerät kann bis zu einer Außentemperatur von maximal 40℃ betrieben

Edition: 1997, Class B

werden.

CAUTION

1. HAZARDOUS MOVING PARTS IN CUTTER MODULE. KEEP FINGER AND OTHER BODY

PARTS AW AY.

2. THE MAIN BOARD INCLUDES REAL TIME CLOCK FEATURE HAS LITHIUM BATTERY

CR2032 INSTALLED. RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN

INCORRECT TYPE.

3. DISPOSE OF USED BATTERIES ACCORDING TO THE MANUFACTURER INSTRUCTIONS.

1

Page 5

B

급기기

(

가정용 정보통신기기

)

이 기기는 가정용으로 전자파 적합등록을 한 기기로서

주거지역에서는 물론 모든 지역에서 사용할 수 있습니다

.

2

Page 6

1. Introduction

Thank you for purchasing the ZG354 Direct Thermal Bar Code Printer. Although it is a

compact desktop printer, it is reliable and with superior throughput performance.

This printer provides direct thermal printing at user selectable speed of: 2.0, 3.0, 4.0, 5.0,

6.0 or 7.0 inches per second. It accepts roll feed, die-cut, and fan-fold labels for direct

thermal printing. All common bar codes formats are available. Fonts and bar codes can

be printed in 4 directions, 8 different alphanumeric bitmap fonts and a build-in true type

font capability. You will enjoy high throughput for printing labels with this printer.

2. Getting Started

2.1 Unpacking and Inspection

This printer has been specially packaged to withstand damage during shipping. Please

carefully inspect the packaging and printer upon receiving the bar code printer. Please

retain the packaging materials in cover you need to reship the printer.

2.2 Equipment Checklist

Printer

BarTender UltraLite CD disk

Quick start guide

USB port cable

External universal switching power supply

Power Cord

Label Spindle

Fixing tab x2

1.5” core adapter x2

How to Create your own Logo Instructions

If any parts are missing, please contact the Customer Service Department of your

purchased reseller or distributor.

3

Page 7

2.3 Printer Parts

2.3.1 Front View

Clear Window

Top Cover

Label Opening

Backing Paper Opening

2.3.2 Rear Vi ew

6

LED Indicator

Feed Button

Top Cover Open Lever

Front Panel

1. USB Interface

2. Centronics Interface

3. RS-232C DB-9 Interface

4. Power Jack

5. Power Switch

6. Rear Label Guide

Note: The interface picture in the quick start guide is for reference only. Please refer to the product

specification for the interfaces availability.

2

1

3

4

5

4

Page 8

3 Setup

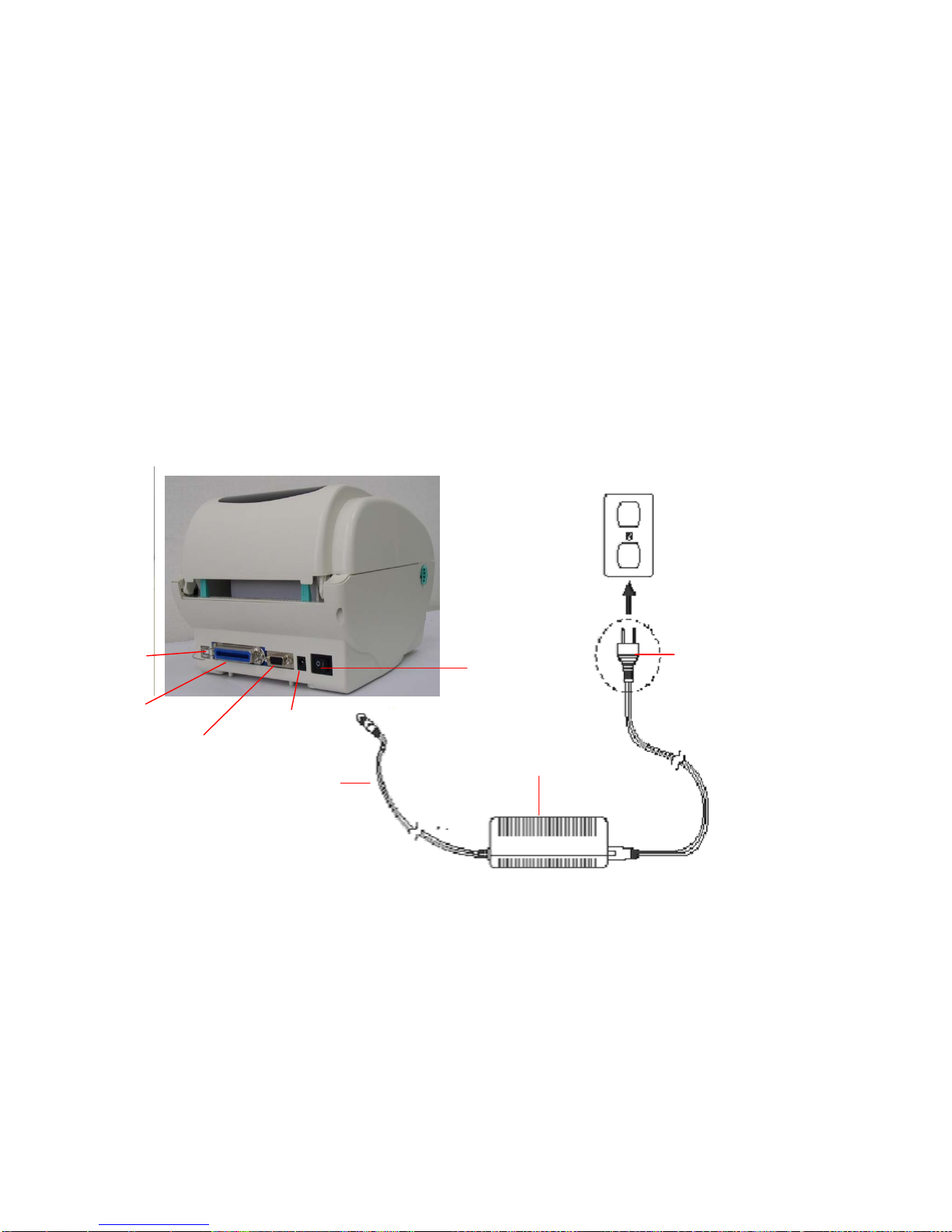

3.1 Setting Up the Printer

1. Place the printer on a flat, secure surface.

2. Make sure the power switch is off.

3. Connect the printer to the computer with the Centronics or USB cable.

4 Plug the DC power cord into the power jack at the rear of the printer, and then

plug the AC power cord into a properly grounded receptacle.

Note: When plug power code into the rear of printer please make sure the printer power switch is

off.

USB

Centronics

RS-232C

Plug

Power Switch

Power Jack

Power Supply

Power Cord

5

Page 9

3.2 Loading Label Stock

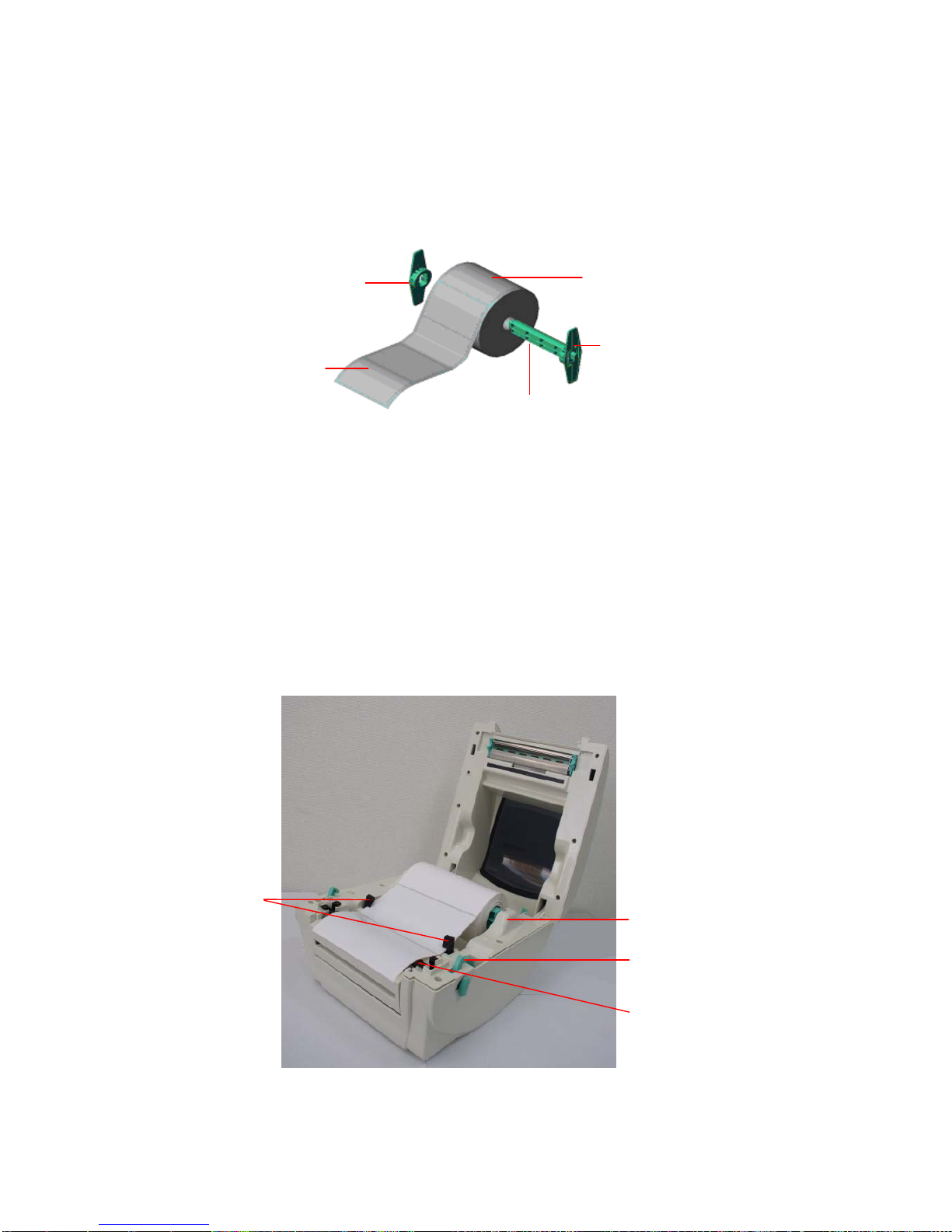

1. Insert a 1” label spindle into a paper roll (If your paper core is 1 inch, remove the 1.5

inch core adapter from the fixing tab).

1.5” Core Adapter

Printing Side Face up

1” Label Spindle

Label Roll

Fixing Tab

2. Open the printer’s top cover by releasing the green top cover open levers located

on both sides of the printer and lifting the top cover.

3. Place a roll of paper into internal paper roll mount.

4. Feed the paper, printing side face up, through the label guides and place the label

over the platen.

5. Adjust the black center-biased label guides in or out by turning adjustment knob so

they are slightly touch the edges of the label backing.

Label Guide

Label Roll Mount

Adjustment Knob

Platen

6

Page 10

6. Close the printer top cover slowly and make sure the cover locks levers securely.

Note: Failure to securely close and lock the cover will result in poor print quality.

7

Page 11

3.3 Peel-Off Installation Assembly (Option)

1. Open the top cover.

2. Unscrew the 6 screws in the lower inner cover.

Screws

3. Upside down the printer.

4. Unscrew the 2 screws at the lower inner cover

Remove the

screw

Screws

Remove the

screw

5. Remove the screw at memory card cover.

Screw

8

Page 12

6. Hold the lower cover and lift up the top cover opening levers to separate the lower

inner cover from the lower cover.

Lower inner

cover

Lower cover

7. Thread the harness red connector through the cable hole at the front side of lower

inner cover. Plug the red peel off module harness connector at the location / JP19

(ZG354) on the main board. Place lower inner cover to the lower cover. Install the

peel-off module to the lower inner cover slot.

Peel-off module

assembly

8. Gently push peel-off panel to lock to the lower inner cover.

Install one side first

and install another

side

9

Page 13

9. Reassemble parts in reverse procedures after installing the module.

10

Page 14

3.4 Loading Label for Peel-off Mode (Option)

1. Open the peel-off module by pulling it out.

Peel-off Roller

Peel-off Panel

2. Thread the label, printing side facing up, through the label guides and place it on top

of the platen.

3. Thread the label through the liner opening, which is beneath the roller.

4. Adjust the black center-biased label guides by turning adjustment knob to fit the

edge of the label backing.

Adjustment Knob

Roller

5. Push the peel-off panel back to the printer.

Peel-off panel

11

Page 15

6. Close the top cover.

12

Page 16

3.5 External Label Roll Mount Installation (Option)

1. Attach an external label roll mount on the bottom of the printer.

2. Install a roll of label on the external label roll mount.

Label

External Label

Roll Mount

3. Feed the label to the external label feed opening through the rear label guide.

External Label

Feed Opening

Rear Label Guide

4. Open the printer top cover by pulling the top cover open levers.

5. Thread the label, printing side face up, through the label guide and place it on top the

platen.

6. Adjust the label guides by turning adjustment knob to fit the edge of the label

backing.

7. Close the printer top cover.

13

Page 17

3.6 Cutter Module Installation (Option)

1. Pull the top cover open levers to open the top cover.

2. Remove the front panel from the lower cover.

3. Remove 6 screws on the lower inner cover.

Screws

4. Upside down the printer.

5. Remove two screws at the hinge

Screws

6. Remove the screw that fixes the memory card cover.

Screw

14

Page 18

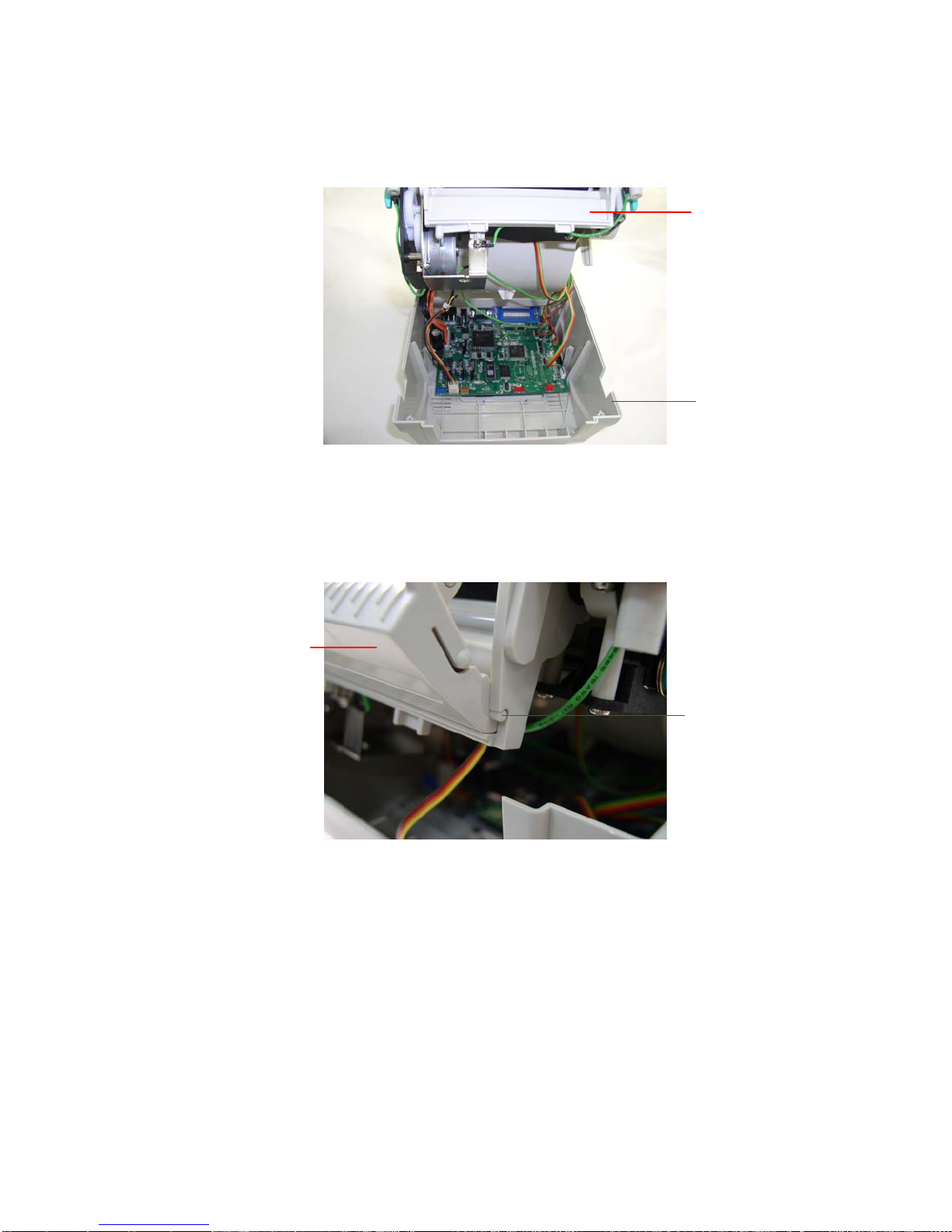

7. Plug in the Cutter Driver IC at U30 (ZG354) socket on the main board.

ZG354 Model

Cutter Driver IC

Note:

For Non-RoHS PCB, use cutter driver IC A3952SB

For RoHS PCB, use cutter driver IC A3953SB

8. Hold the lower cover and lift up the lower inner cover.

9. Arrange the cutter module harness through the bezel.

10. Connect the cutter module harness to the 4-pin socket on printer PCB.

Socket

11. Reassemble lower inner cover back to the lower cover.

15

Bezel

Page 19

12. Install the cutter module into the niche of the printer.

13. Reassemble the parts in the reverse order.

14. Close the top cover.

Niche

16

Page 20

3.7 Loading Label in Cutter Mode

1. Open the printer top cover.

2. Insert the label spindle into label roller

3. Place a label roll to label roll mount.

4. Thread the paper, printing side face up, through the label guide, platen and cutter

module paper outlet.

Label Guide

Cutter Paper Opening

Adjustment Knob

Platen

Cutter

5. Adjust the black center-biased label guides to fit edge of the label backing.

6. Close the top cover.

17

Page 21

3.8 Diagnostic Tool

The Diagnostic Utility is a toolbox that allows users to explore the printer's settings

and status; change printer settings; download graphics, fonts, and firmware; create

printer bitmap fonts; and to send additional commands to the printer. Using this

convenient tool, you can explore the printer status and settings and troubleshoot

the printer.

Note: This utility works with printer firmware V6.00 and later versions.

3.8.1 Start the Diagnostic Tool

1. Double click on the Diagnostic tool icon to start the software.

2. There are four features (Printer Configuration, File Manager, Bitmap Font

Manager, Command Tool) included in the Diagnostic utility.

Features tab

Printer functions

Printer Status

Interface

Printer setup

18

Page 22

3.8.2 Printer Function (Calibrate sensor, Ethernet setup, RTC setup………)

1. Select the PC interface connected with bar code printer.

2. Click the “Function” button to setting.

3. The detail functions in the Printer Function Group are listed as below.

Function Description

Calibrate Sensor

Ethernet Setup

RTC Time Synchronize printer Real Time Clock with PC

Print Test Page Print a test page

Reset Printer Reboot printer

Factory Default

Dump Text To activate the printer dump mode.

Ignore AUTO.BAS Ignore the downloaded AUTO.BAS program

Configuration Page Print printer configuration

Calibrate the sensor specified in the Printer

Setup group media sensor field

Setup the IP address, subnet mask, gateway

for the on board Ethernet (Please refer to next

section)

Initialize the printer and restore the settings to

factory default.

Note:

For more information about Diagnostic Tool, please refer to the diagnostic utility quick start

guide in the CD disk \ Utilities directory.

19

Page 23

3.9 Setting Ethernet by Diagnostic Utility (Option)

The Diagnostic Utility is enclosed in the CD disk \Utilities directory. Users can use

Diagnostic Tool to setup the Ethernet by RS-232, USB and Ethernet interfaces. The

following contents will instruct users how to configure the Ethernet by these three

interfaces.

3.9.1 Using USB interface to setup Ethernet interface

1. Connect the USB cable between the computer and the printer.

2. Turn on the printer power.

3. Start the Diagnostic Utility by double clicking on the icon.

Note: This utility works with printer firmware V6.00 and later versions.

4. The Diagnostic Utility default interface setting is USB interface. If USB interface

is connected with printer, no other settings need to be changed in the interface

field.

5. Click on the “Ethernet Setup” button from “Printer Function” group in Printer

Configuration tab to setup the IP address, subnet mask and gateway for the on

board Ethernet.

20

Page 24

3.9.2 Using RS-232 interface to setup Ethernet interface

1. Connect the computer and the printer with a RS-232 cable.

2. Turn on the printer power.

3. Start the Diagnostic Utility by double clicks on the icon.

Note: This utility works with printer firmware V6.00 and later versions.

4. Select “COM” as interface then click on the “Setup” button to setup the serial

port baud rate, parity check, data bits, stop bit and flow control parameters.

5. Click on the “Ethernet Setup” button from printer function of Printer

Configuration tab to setup the IP address, subnet mask and the gateway for the

on board Ethernet.

21

Page 25

3.9.3 Using Ethernet interface to setup Ethernet interface

1. Connect the computer and the printer to the LAN.

2. Turn on the printer power.

3. Start the Diagnostic Utility by double clicks on the icon.

Note: This utility works with printer firmware V6.00 and later versions.

4. Select “Ethernet” as the interface then click on the “Setup” button to setup the IP

address, subnet mask and gateway for the on board Ethernet.

5. Click the “Discover Device” button to explore the printers that exist on the

network.

6. Select the printer in the left side of listed printers, the correspondent IP address

will be shown in the right side “IP address/Printer Name” field.

7. Click “Change IP Address” to configure the IP address obtained by DHCP or

static.

22

Page 26

The default IP address is obtained by DHCP. To change the setting to static IP

address, click “Static IP” radio button then enter the IP address, subnet mask

and gateway. Click “Set IP” to take effect the settings.

Users can also change the “Printer Name” by another model name in this fields

then click “Set Printer Name” to take effect this change.

Note: After clicking the “Set Printer Name” or “Set IP” button, printer will

reset to take effect the settings.

8. Click “Exit” button to exit the Ethernet interface setup and go back to Diagnostic

Tool main screen.

Factory Default button

This function will reset the IP, subnet mask, gateway parameters obtained by

DHCP and reset the printer name.

Web setup button

Except to use the Diagnostic Utility to setup the printer, you can also explore

and configure the printer settings and status or update the firmware with the IE

or Firefox web browser. This feature provides a user friendly setup interface and

the capability to manage the printer remotely over a network.

23

Page 27

3.10. Install Memory Card

1. Upside down the printer.

2. Remove 1 screw and open the memory card cover.

3. Plug the memory card on main board.

ZG354 Model

Memory Card

24

Page 28

4. Revert the memory card cover.

* Recommended SD card specification.

SD card spec SD card capacity Approved SD card manufacturer

V1.0, V1.1 128 MB SanDisk, Transcend

V1.0, V1.1 256 MB SanDisk, Transcend, Panasonic

V1.0, V1.1 512 MB SanDisk, Transcend, Panasonic

V1.0, V1.1 1 GB SanDisk, Transcend, Panasonic

V2.0 SDHC CLASS 4 4 GB

V2.0 SDHC CLASS 6 4 GB SanDisk, Transcend, Panasonic

V1.0, V1.1 microSD 128 MB Transcend, Panasonic

V1.0, V1.1 microSD 256 MB Transcend, Panasonic

V1.0, V1.1 microSD 512 MB Panasonic

V1.0, V1.1 microSD 1 GB Transcend, Panasonic

V2.0 SDHC CLASS 4 microSD 4 GB Panasonic

V2.0 SDHC CLASS 6 microSD 4 GB Transcend

V1.0, V1.1 miniSD 128 MB Transcend, Panasonic

V1.0, V1.1 miniSD 256 MB Transcend, Panasonic

V1.0, V1.1 miniSD 512 MB Transcend, Panasonic

V1.0, V1.1 miniSD 1 GB Transcend, Panasonic

V2.0 SDHC CLASS 4 miniSD 4 GB Transcend

V2.0 SDHC CLASS 6 miniSD 4 GB

- The DOS FAT file system is supported for the SD card.

- Folders/files stored in the SD card should be in the 8.3 filename format

- The miniSD/microSD card to SD card slot adapter is required.

25

Page 29

4. Power on Utilities

There are six power-on utilities to set up and test printer hardware. These utilities are

activated by pressing FEED button and by turning on the printer power simultaneously.

The utilities are listed as below:

1. Gap/Black mark sensor calibration

2. Gap/black mark sensor calibration, Self-test and Dump mode

3. Printer initialization

4. Set black mark as media sensor and calibrate the black mark sensor

5. Set gap sensor as media sensor and calibrate the gap sensor

6. Skip AUTO.BAS

4.1 Gap/Black Mark Sensor Calibration

Gap/black mark sensor sensitivity should be calibrated at the following conditions:

1. A brand new printer

2. Change label stock.

3. Printer initialization.

Please follow the steps below to calibrate the gap/black sensor:

1.Turn off the power switch.

2. Hold on the button then turn on the power switch.

3 Release the button when LED becomes red and blinking. (Any red will do during the 5

blinks).

It will calibrate the gap/black mark sensor sensitivity.

The LED color will be changed as following order:

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber

(5 blinks) red/amber (5 blinks) solid green

It calibrates the sensor and measures the label length.

Note:

Please select gap or black mark sensor by GAP or BLINE command prior to calibrate the sensor.

For more information about GAP and BLINE command, please refer to TSPL2 programming

manual.

26

Page 30

4.2 Gap/Black Mark Calibration, Self-test, Dump Mode

While calibrate the gap/black mark sensor, printer will measure the label length, print the

internal configuration (self-test) and then enter the dump mode.

Please follow the steps as below.

1.Turn off the power switch.

2. Hold on the button then turn on the power switch.

3. Release the button when LED becomes amber and blinking. (Any amber will do

during the 5 blinks).

The LED color will be changed as following order.

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber

(5 blinks) red/amber (5 blinks) solid green

It calibrates the sensor and measures the label length and prints internal

settings then enter the dump mode.

Note:

Please select gap or black mark sensor by Diagnostic Tool or by GAP or BLINE command prior to

calibrate the sensor.

For more information about GAP and BLINE command, please refer to TSPL2 programming

manual.

27

Page 31

Self-test

Printer will print the printer configuration after gap/black mark sensor calibration.

Self-test printout can be used to check if there is any dot damage on the heater element,

printer configurations and available memory space.

Self-test printout

Print head check pattern

Model name and F/W version

Printed mileage (meter)

Firmware checksum

Serial port configuration

Code page

Country code

Print speed (inch/sec)

Print darkness

Label size (inch)

Gap distance (inch)

Gap/black mark sensor sensitivity

Numbers of download files

Total & available memory space

Note:

1. The physical flash memory for RoHS compliant version is 2MB Flash and 2MB DRAM (

2. System occupies 960 KB in Flash memory so total flash memory space for user downloading is

1088 KB

3. System occupies 1792 KB in DRAM so total DRAM memory space for user downloading is 256

KB

System occupies 7936 KB in SDRAM so total SDRAM memory space for user downloading is

256 KB

28

Page 32

Dump mode

Printer will enter dump mode after printing printer configuration. In the dump mode, all

characters will be printed in 2 columns as following. The left side characters are received

from your system and right side data are the corresponding hexadecimal value of the

characters. It allows users or engineers to verify and debug the program.

Dump mode printout

Note:

Turn off and on the power switch to reset the printer for normal printing.

29

Page 33

4.3 Printer Initialization

Printer initialization is used to clear DRAM and restore printer settings to defaults. The

only one exception is ribbon sensitivity, which will note be restored to default.

Printer initialization is activated by the following procedures.

1. Turn off the power switch.

2. Hold on the button then turn on the power switch.

3. Release the button when LED turns green after 5 amber blinks. (Any green will do

during the 5 blinks).

The LED color will be changed as following:

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber

(5 blinks) red/amber (5 blinks) solid green

Printer configuration will be restore to defaults as below after initialization.

Parameter Default setting

Speed 127 mm/sec (5 ips)

Density 8

Label Width 4” (101.6 mm)

Label Height 4” (101.6 mm)

Media Sensor Type Gap sensor

Gap Setting 0.12” (3.0 mm)

Print Direction 0

Reference Point 0,0 (upper left corner)

Offset 0

Tear Mode On

Peel off Mode Off

Cutter Mode Off

Serial Port Settings 9600 bps, none parity, 8 data bits, 1 stop bit

Code Page 850

Country Code 001

Clear Flash Memory No

IP Address DHCP

Note:

Always do gap/black mark sensor calibration after printer initialization.

30

Page 34

4.4 Set Black Mark Sensor as Media Sensor and Calibrate the Black Mark Sensor

Please follow the steps as below.

1. Turn off the power switch.

2. Hold on the button then turn on the power switch.

3. Release the button when LED turns green/amber after 5 green blinks. (Any

green/amber will do during the 5 blinks).

The LED color will be changed as following:

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber

(5 blinks) red/amber (5 blinks) solid green

4.5 Set Gap Sensor as Media Sensor and Calibrate the Gap Sensor

Please follow the steps as below.

1. Turn off the power switch.

2. Hold on the button then turn on the power switch.

3. Release the button when LED turns red/amber after 5 green/amber blinks. (Any

red/amber will do during the 5 blinks).

The LED color will be changed as following:

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber

(5 blinks) red/amber (5 blinks) solid green

4.6 Skip AUTO.BAS

TSPL2 programming language allows user to download an auto execution file to flash

memory. Printer will run the AUTO.BAS program immediately when turning on printer

power. The AUTO.BAS program can be interrupted without running the program by the

power-on utility.

Please follow the steps as below.

1. Turn off printer power.

2. Press the FEED button and then turn on power.

3. Release the FEED button when LED becomes solid green.

The LED color will be changed as following:

Amber red (5 blinks) amber (5 blinks) green (5 blinks) green/amber

(5 blinks) red/amber (5 blinks) solid green

4. Printer will be interrupted to run the AUTO.BAS program.

31

Page 35

5. Maintenance

5.1 Cleaning

This session presents the clean tools and methods to maintain your printer.

Please use one of following material to clean the printer.

Cotton swab (Head cleaner pen)

Lint-free cloth

Vacuum / Blower brush

100% ethanol

The cleaning process is described as following

Printer Part Method Interval

Print Head

Platen Roller

1. Always turn off the printer

before cleaning the print head.

2. Allow the print head to cool for

a minimum of one minute.

3. Use a cotton swab (Head

cleaner pen) and 100% ethanol

to clean the print head surface.

1. Turn the power off.

2. Rotate the platen roller and

wipe it thoroughly with 100%

ethanol and a cotton swab, or

lint-free cloth.

Clean the print head when

changing a new label roll

Clean the platen roller when

changing a new label roll

Tear Bar/Peel

Bar

Sensor

Exterior

Use the lint-free cloth with 100%

ethanol to wipe it.

Compressed air or vacuum Monthly

Wipe it with water-dampened As needed

As needed

32

Page 36

cloth

Interior

Brush or vacuum As needed

Note:

Do not touch printer head by hand. If you touch it careless, please use ethanol to clean it.

Please use 100% Ethenol. DO NOT use medical alcohol, which may damage the printer head.

Regularly clean the print head and supply sensors once change a new ribbon to keep printer

performance and extend printer life.

33

Page 37

6. Troubleshooting

The following guide lists the most common problems that may be encountered when

operating this bar code printer. If the printer still does not function after all suggested

solutions have been invoked, please contact the Customer Service Department of your

purchased reseller or distributor for assistance.

LED Status

This section lists the common problems that according to the LED status and other

problems you may encounter when operating the printer. Also, it provides solutions.

LED

Status /

Printer

Status

Possible Cause Recovery Procedure

Color

OFF No response No power * Turn on the power switch.

* Check if the green LED is lit on power supply.

If it is not lit on, power supply is broken.

* Check both power connections from the

power cord to the power supply and from the

power supply to the printer power jack if they

are connected securely.

Solid Green ON The printer is ready

to use

Green with

blinking

Red with

blinking

Pause The printer is paused * Press the FEED button to resume for printing.

Error The out of label or

the printer setting is

not correct

* No action necessary.

1. Out of label

* Load a roll of label and follow the instructions

in loading the media then press the FEED

button to resume for printing.

2. Printer setting is not correct

* Initialize the printer by instructions in “Power

on Utility” or “Diagnostic Tool”.

Note:

Printer status can be easily shown on the Diagnostic Tool. For more information about the

Diagnostic Tool, please refer to the instruction in the software CD disk.

34

Page 38

Print Quality

Problem Possible Cause Recovery Procedure

Check if interface cable is well

connected to the interface connector.

Re-connect cable to interface.

Not Printing

No print on the

label

Continuous

feeding labels

Paper Jam

Poor Print Quality

The serial port cable pin configuration

is not pin to pin connected.

The serial port setting is not consistent

between host and printer.

The port specified in the Windows

driver is not correct.

The Ethernet IP, subnet mask, gateway

is not configured properly.

Label loaded not correctly.

The printer setting may go wrong.

Gap/black mark sensor sensitivity is

not set properly (sensor sensitivity is

not enough)

Make sure label size is set properly.

Labels may be stuck inside the printer

mechanism near the sensor area.

Top cover is not closed properly.

Check if supply is loaded correctly. Reload the supply.

Media are incompatible.

Check if dust or adhesives are

accumulated on the print head.

Check if print density is set properly.

Check print head test pattern if head

element is damaged.

Please replace the cable with pin to

pin connected.

Please reset the serial port setting.

Select the correct printer port in the

driver.

Configure the IP, subnet mask and

gateway.

Follow the instructions in loading the

media.

Please do the initialization and

gap/black mark calibration.

Calibrate the gap/black mark sensor.

Set label size exactly as installed

paper in the labeling software or

program.

Remove the stuck label.

Close the top cover completely and

make sure the right side and left side

levers are latched properly.

Change the label combination.

Clean the print head.

Adjust the print density and print

speed.

Run printer self-test and check the

print head test pattern if there is dot

missing in the pattern.

35

Page 39

7. LED and Button Operation

This printer has one button and one three-color LED indicator. By indicating the

LED with different color and pressing the button, printer can feed labels, pause the

printing job, select and calibrate the media sensor, print printer self-test report, reset

printer to defaults (initialization). Please refer to the button operation below for

different functions.

7.1 LED

LED Color Description

Green/ Solid

Green/ Flash This illuminates that the system is downloading data

Amber

Red / Solid This illuminates printer head open, cutter error.

Red / Flash This illuminates a printing error, such as head open,

This illuminates that the power is on and the device is

ready to use.

from PC to memory and the printer is paused.

This illuminates that the system is clearing data from

printer.

paper empty, paper jam, or memory error etc.

7.2 Button Operation

Feed

Pause

Press the button when the LED is green.

It feeds the label to the beginning of the next label.

Press the feed button during printing.

The printing job is suspended.

36

Page 40

Gap/Black Mark

Sensor Calibration

1.Turn off the power switch.

2. Hold on the button then turn on the power switch.

3 Release the button when LED becomes red and blinking.

(Any red will do during the 5 blinks).

It will calibrate the gap/black mark sensor sensitivity.

The LED color will be changed as following order:

Amber red (5 blinks) amber (5 blinks) green

(5 blinks) green/amber (5 blinks) red/amber (5

blinks) solid green

It calibrates the sensor and measures the label length.

Note:

Please select gap or black mark sensor by GAP or BLINE

command prior to calibrate the sensor.

For more information about GAP and BLINE command,

please refer to TSPL2 programming manual.

Gap/Black Mark

Sensor Calibration,

Label Length

Measurement,

Self Test and enter

Dump Mode

1.Turn off the power switch.

2. Hold on the button then turn on the power switch.

3. Release the button when LED becomes amber and blinking.

(Any amber will do during the 5 blinks).

The LED color will be changed as following order.

Amber red (5 blinks) amber (5 blinks) green

(5 blinks) green/amber (5 blinks) red/amber (5

blinks) solid green

It calibrates the sensor and measures the label length

and prints internal settings then enter the dump mode.

Note:

Please select gap or black mark sensor by GAP or BLINE

command prior to calibrate the sensor.

For more information about GAP and BLINE command,

please refer to TSPL2 programming manual.

37

Page 41

Printer

Initialization

1. Turn off the power switch.

2. Hold on the button then turn on the power switch.

3. Release the button when LED turns green after 5 amber

blinks. (Any green will do during the 5 blinks).

The LED color will be changed as following:

Amber red (5 blinks) amber (5 blinks) green

(5 blinks) green/amber (5 blinks) red/amber (5

blinks) solid green

Always do gap/black mark sensor calibration after

printer initialization.

Set Black Mark

Sensor as Media

Sensor and

Calibrate the Black

Mark Sensor

Set Gap Sensor as

Media Sensor and

Calibrate the Gap

Sensor

1. Turn off the power switch.

2. Hold on the button then turn on the power switch.

3. Release the button when LED turns green/amber after 5

green blinks. (Any green/amber will do during the 5 blinks).

The LED color will be changed as following:

Amber red (5 blinks) amber (5 blinks) green (5

blinks) green/amber (5 blinks) red/amber (5

blinks) solid green

1. Turn off the power switch.

2. Hold on the button then turn on the power switch.

3. Release the button when LED turns red/amber after 5

green/amber blinks. (Any red/amber will do during the 5

blinks).

The LED color will be changed as following:

Amber red (5 blinks) amber (5 blinks) green (5

blinks) green/amber (5 blinks) red/amber (5

blinks) solid green

38

Page 42

Skip AUTO.BAS

1. Turn off printer power.

2. Press the FEED button and then turn on power.

3. Release the FEED button when LED becomes solid green.

The LED color will be changed as following:

Amber red (5 blinks) amber (5 blinks) green (5

blinks) green/amber (5 blinks) red/amber (5

blinks) solid green

4. Printer will be interrupted to run the AUTO.BAS program.

39

Page 43

Revise History

Date Content Editor

* Revise the section 3.8: Internal Ethernet Print Server

Module Installation (Option)

2008/2/29

* Add section 3.9: Diagnostic Tool

*.Add the IP Address default setting

Camille

*.Add section 3.10: Install Memory Card

2008/3/5

2008/3/6 Revise the section 2.2 Camille

2008/3/7 Revise the sections 4.2 & 5.1 Camille

2008/3/10 Revise the section 6 Camille

2008/11/18 Revise section 3.5 Camille

2009/3/11 Revise section 3.10 (Recommended SD card

2009/6/19 Revise compliances section Camille

2009/10/14 * Revise section 3.9

2009/12/3 Add TDP-247 and TDP-345 model Camille

2010/3/5 * Revise compliances section

2010/7/28 Revise section 2.3.2 Camille

2010/8/13 Revise compliances section Camille

*.Revise the sections 3.3 and 3.8.

*.Revise the default setting.

specification)

* Add section 3.10

* Revise section 3.1

Camille

Camille

Camille

Camille

2011/1/14 Remove internal Ethernet print server module installation

section

2011/1/25 Modify TSC address Camille

40

Camille

Page 44

ZG354_u_en_501061.pdf

Avery Weigh-Tronix USA Avery Weigh-Tronix UK

1000 Armstrong Drive Foundry Lane

Fairmont MN 56031 USA Smethwick, West Midlands

TEL: 507-238-4461 England B66 2LP

FAX: 507-238-4195 TEL: +44(0) 8453 66 77 888183

E-mail: usinfo@awtxglobal.com FAX: +44(0) 121 224

Website www.wtxweb.com E-mail: info@awtxglobal.com

www.averyweigh-tronix.com

10/12 AWT35-501061

Loading...

Loading...