Page 1

XR Series

LED Remote Displays

Installation Instructions

NORTH AMERICA

AWT35-500303

Issue AD

Page 2

© Avery Weigh-Tronix, LLC 2012. All rights reserved.

No part of this publication may be reproduced, stored in an electronic retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior written consent of

the copyright owner, or as permitted by law or under license. Full acknowledgment of the source must be given.

Avery Weigh-Tronix is a registered trade mark of the Avery Weigh-T ronix, LLC. This publication was correct at the

time of going to print however, Avery Weigh-T ronix, LLC reserves the right to alter without notice the specification,

design, price or conditions of supply of any product or service at any time.

All third party brands and product names used within this document are trademarks or registered trademarks of

their respective holders.

XR SeriesTD_i_en_500303.book

Page 3

Table of Contents

page

Chapter 1 General information and warnings ............................................................. ............................ 5

About this manual ..............................................................................................................5

Installation ....................................... .................................... ...................................... .........6

Electrical installation .... ... ... .... ... ... ... ... .... ............................................................................6

Pluggable equipment ...................................................................................................6

Permanently wired equipment - Isolator requirements ................................................6

Wet conditions .............................................................................................................6

Routine maintenance .........................................................................................................7

Cleaning the machine ........................................................................................................7

Training ..................................... ................................................................ .........................7

FCC and EMC declarations of compliance ........................................................................8

Chapter 2 Introduction .............................................................................................................................. 9

Display ...............................................................................................................................9

Keypad ...................................... ................................ .................................... ...................10

Chapter 3 Installation .............................................................................................................................. 11

Installing the XR 4500, XR 4500TL or XR 6500 ..............................................................11

Pre-installation (Receiving Inspection) ......................................................................11

Opening an Enclosure ...............................................................................................11

Lowering the Electronics Plate ..................................................................................12

Mounting Instructions ................................................................................................12

Installing the XR 2000 ......................................................................................................15

Opening the XR 2000 Enclosure ...............................................................................15

Mounting Instructions ................................................................................................15

Chapter 4 Wiring ......................................................................................................................................17

Wiring the XR 4500, 4500TL or 6500 ..............................................................................17

Power Wiring .............................................................................................................17

Communications Wiring ........................... .... ... ... ... ....................................................17

Wiring the XR 2000 ..........................................................................................................21

Power Wiring .............................................................................................................21

Communication Wiring .............................................................................................. 21

Chapter 5 Wireless Communication ...................................................................................................... 24

Wireless Set-up for All XR Models ......................................... ... ... ....................................24

XR Remote Display ......................................................... ... ... .... ................................24

Indicator .............................. ................... .................... ................... ................... ..........24

Base Station Wireless Transceiver ...........................................................................25

Wireless Connection Test ...... ... ... ... ... .... ... .......................................................................26

Chapter 6 Start-Up ...................................................................................................................................27

Power On/Off ...................................................................................................................27

Reset Button ....................................................................................................................27

Auto-Learn .......................................................................................................................27

LEARN Button ........................... ... ... ... .... ... ... ... .... ...................................... .... ... ... ... ... .... ...28

Diagnostic Indicator Lights . .... ... ... ... ... .... ... ... ... .... ... ... .......................................... ... ... .... ... 28

Chapter 7 Configuration Mode ............................................................................................................... 30

Entering Configuration Mode ...........................................................................................30

Configuration Parameters ................................................................................................31

Parameter 1.0: Daytime Brightness Level .................................................................31

Parameter 1.1: Nighttime Brightness Level ...............................................................31

XR Series Installation Instructions 3

Page 4

Parameter 1.2: Power-save Mode ... ... ... ... .... ... ... ... .... ... .............................................31

Parameter 1.3: Mirror Display Mode .........................................................................31

Parameter 1.4: Multi-Drop ID ....................................................................................32

Parameter 1.5: Radio Channel Select .......................................................................32

Parameter 1.6: Utility Program Select .......................................................................32

Auto-Learn Parameters ....................................... ...... ....... ... ...... ....... ...... ....... ...... ...... ....... 33

Parameter 2.0: Manual Learn (Assisted Learn) ........................................................33

Parameter 2.1: Start-up Auto-Learn .......................................................................... 33

Parameter 2.2: Leading Zero Suppression ...............................................................33

Parameter 2.3: Set Scale Over .................................................................................34

Parameter 2.4: Lock Units .........................................................................................34

Parameter 2.5: Lock Weighing Mode ........................................ ... ... ... .... ... ... ... ..........34

Parameter 2.6: Lock Traffic LIght ..............................................................................34

Time / Date / Temp Parameters ................... ....... ...... ....... ...... ...... ....... ...... .... ...... ...... ....... 35

Parameter 3.0: Time Display ........................... ....................................................... ... 35

Parameter 3.1: Date Display .....................................................................................35

Parameter 3.2: Temperature Display ........... ... ... ... .... ... ... ... ... ....................................35

Parameter 3.3: Weight Display ........................ ...................... ....................... .............35

Parameter 3.4: Time Threshold .................................... .......................... ...................35

Diagnostic Parameters ................................. ... .... ... ... ... .... ... .......................................... ... 36

Parameter 9.0: Com Port ..........................................................................................36

Parameter 9.1: String Counter ..................................................................................36

Parameter 9.2: Baud Rate .........................................................................................36

Parameter 9.3: Configuration Lockout .......................................................................36

Parameter 9.4: Number Counter .................................................. ... ... .... ... ... ... ... .......36

Parameter 9.8: Test Display ......................................................................................37

Parameter 9.9: Reset Defaults ..................................................................................37

CONFIG Switches (XR 2000) ..........................................................................................38

Chapter 8 XR 4500 TL Traffic Light Control .......................................................................................... 41

Built-in Traffic Light (XR 4500TL Only) ............................................................................41

Chapter 9 Time and Date (not available on XR 2000) ........................................................................... 42

Set Time & Date ...............................................................................................................42

Adjust Time ...............................................................................................................42

Adjust Date ................................................................................................................42

Battery / Battery Replacement ........ ... .... ... ... ... .... ... ... ... .... ... .......................................... ... 42

Chapter 10 Temperature Probe Installation (not on XR 2000) .............................................................43

Chapter 11 XR Utility Programs ............................................................................................................. 45

XR 4500, XR 4500TL, and XR 6500 Utility Programs .....................................................45

Program 0: Normal Operation ...................................................................................45

Program 1: Simple Traffic Light .................................................................................45

Program 2: Motion Traffic Light .................................................................................45

Program 3: Normal Operation with Traffic Light Commands .....................................45

Program 4: Freeze Weight (Capture Print String) ....................................................45

Program 5: Command Mode .....................................................................................46

PROGRAM 12: LEGACY COMMAND MODE ..........................................................48

XR 2000 Utility Programs ................................ .... .............................................................49

Chapter 12 Troubleshooting & Error Messages ................................................................................... 52

Chapter 13 Spare Parts Lists ..................................................... ................................................... .......... 54

Chapter 14 Specifications ................................................... ....................................................... ............. 57

4 XR Series Installation Instructions

Page 5

1 General information and warnings

1.1 About this manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled as shown by the 1 and 1.1 headings shown above.

The names of the chapter and the next subsection level appe ar at the top of alternating

pages of the manual to remind you of where you are in the manual. The manu al name

and page numbers appear at the bottom of the pages.

Text conventions

Key names are shown in bold and reflect the case of the key being described. This

applies to hard keys and onscreen or soft keys.

Displayed messages appear in bold italic type and reflect the case of the displayed

message.

Special messages

1.1 About this manual

There are five types of special text messages, NOTE, CAUTION, WARNING,

DANGER, and ELECTRICAL HAZARD. Each will appear as illustrated below:

NOTE: This contains extra information on a concept or process.

CAUTION: This may cause damage to the product or data loss.

WARNING: This could result in injury or death

DANGER: THIS WILL RESULT IN INJURY OR DEATH

ELECTRICAL DANGER: THIS WILL RESULT IN INJURY OR DEATH.

XR Series Installation Instructions 5

Page 6

1 General information and warnings

1.2 Installation

DANGER: RISK OF ELECTRICAL SHOCK. NO USER SERVICEABLE

PARTS. REFER TO QUALIFIED SERVICE PERSONNEL FOR SERVICE.

1.3 Electrical installation

CAUTION: The power cable must be connected to an earth-grounded electrical

outlet. The electrical supply must have a circuit breaker with an appropriate

rating to protect from over-current conditions.

For your protection, all electrical (1 10V or 230V) equipmen t used out of doors or

in wet or damp conditions should be supplied from a correctly fused power

source and protected by an approved ground fault protection device (RCD,

GFCI etc.)

IF IN DOUBT SEEK ADVICE FROM A QUALIFIED ELECTRICIAN.

1.3.1 Pluggable equipment

Pluggable equipment must be installed near an easily accessible socket outlet.

1.3.2 Permanently wired equipment - Isolator requirements

Permanently connected equipment must have a readily accessible disconnect device

incorporated in the fixed wiring such as an isolator or circuit breaker with at lea st 3mm

contact separation.

The isolator MUST NOT be installed into the flexible power cable supplie d with the unit.

1.3.3 Wet conditions

Under wet conditions, the plug must be connected to the final branch circuit via an

appropriate socket / receptacle designed for washdown use.

Installations within the USA should use a cover that meets NEMA 3R specifications

as required by the National Electrical Code under section 410-57. This allows the unit

to be plugged in with a rain tight cover fitted over the plug.

Installations within Europe must use a socket which provides a minimum of IP56

protection to the plug / cable assembly. Care must be taken to make sure that the

degree of protection provided by the socket is suitable for the environment.

6 XR Series Installation Instructions

Page 7

1.4 Routine maintenance

IMPORTANT: This equipment must be routinely checked for proper operation

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

Always turn off the machine and isolate from the power supply before starting any

routine maintenance to avoid the possibility of electric shock.

Make sure that it is placed securely on a flat and level surface.

1.5 Cleaning the machine

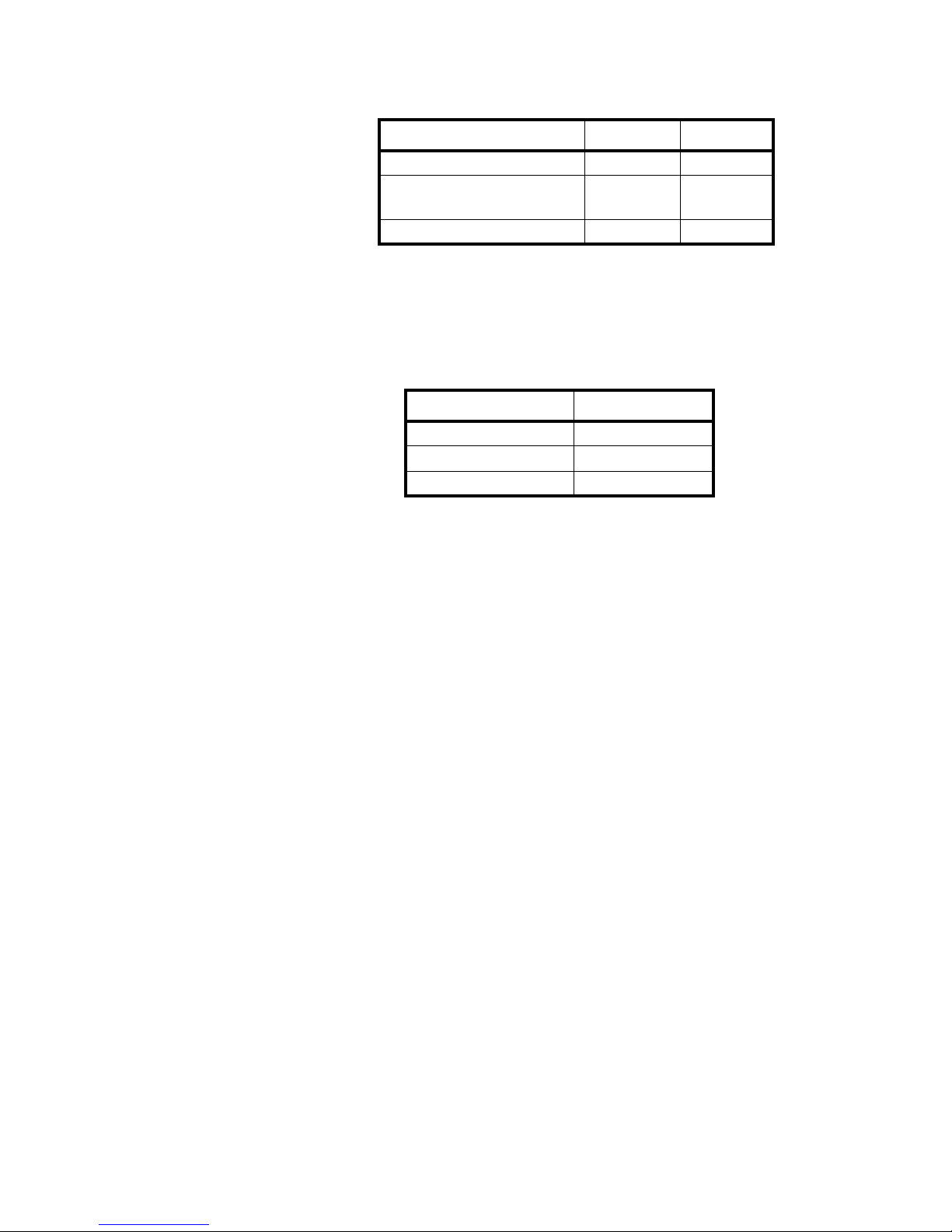

Table 1.1 Cleaning DOs and DON’Ts

DO DO NOT

1.4 Routine maintenance

1.6 Training

Wipe down the outside of standard products

with a clean cloth, moistened with water and

a small amount of mild detergent

Spray the cloth when using a proprietary

cleaning fluid

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instruction books.

T o avoid the ri sk of RSI (Repetitive S train Injury), place the machine on a surface which

is ergonomically satisfactory to the user. T ake frequent br eaks during prolonged usage.

Attempt to clean the inside of the machine

Use harsh abrasives, solvents, scouring cleaners or

alkaline cleaning solutions

Spray any liquid directly on to the display windows

XR Series Installation Instructions 7

Page 8

1 General information and warnings

1.7 FCC and EMC declarations of compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Canada

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la Classe A prescrites dans le Règlement sur le brouillage radioélectrique edicté par le ministère des Communications du Canada.

8 XR Series Installation Instructions

Page 9

2 Introduction

Thank you for purchasing an XR series remote display. The XR series incorporates the

highest performance standards and the most standard features of any weighing

display, making them the best choice for virtually any remote viewing application.

Like all Avery Weigh-Tronix products, the XR remote displays are designed with

durability , functionality and versatility in mind. If you should need technical assist ance,

please contact your local, authorized Avery Weigh-Tronix distributor.

ATTENTION! Unauthorized installation and service of this unit may void the

warranty.

2.1 Display

2.1 Display

The weight display is made up of 6 LED digits of 7 segments each. Up to 2 decimal

places can be displayed. (Five decimals on the XR 2000).

XR Series Installation Instructions 9

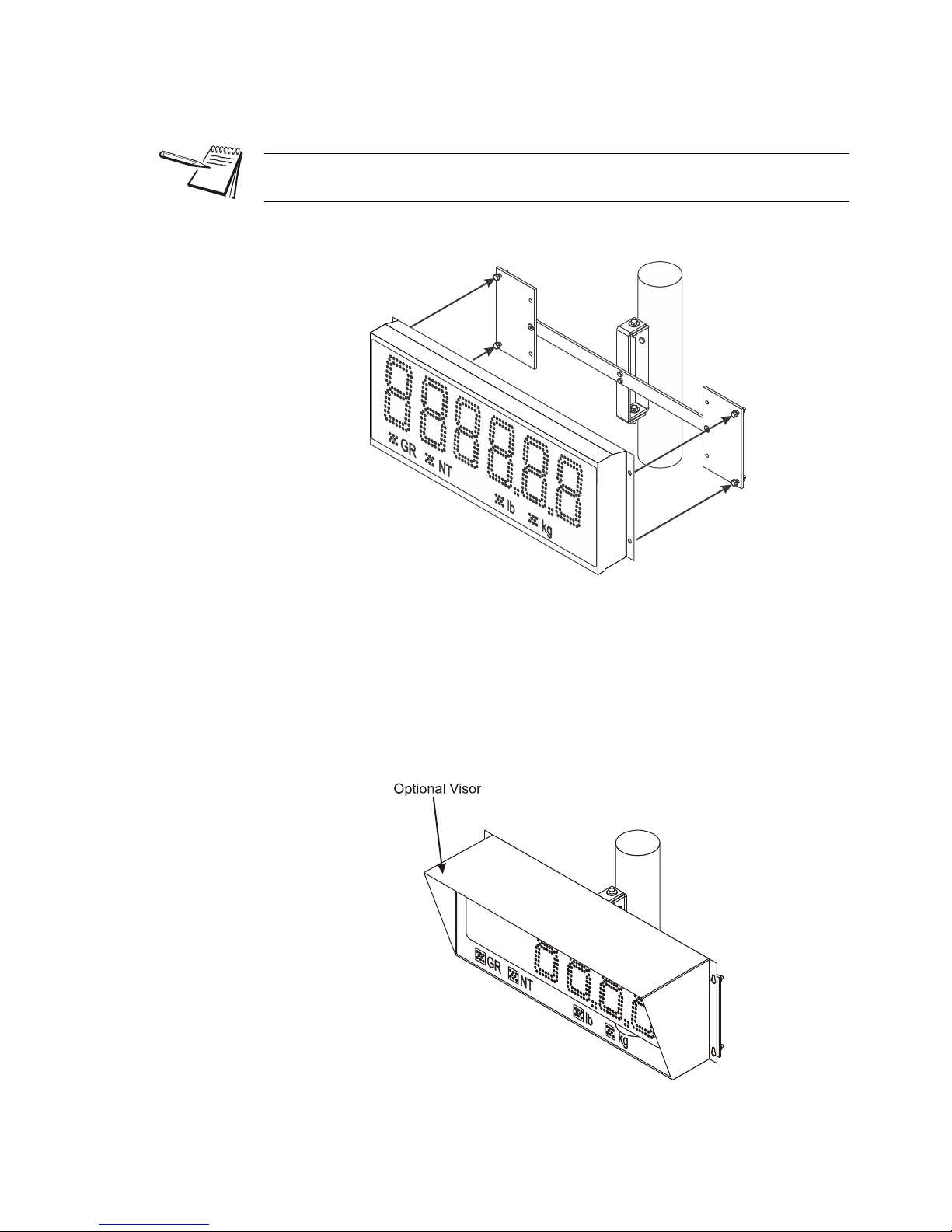

Figure 2.1 Display samples: Top-XR 4500, Bottom-XR 2000

Page 10

2 Introduction

2.2 Keypad

The units have four annunciators under the display with bright LED markers:

l GR = Gross Weighing Mode

l NT = Net Weighing Mode

l lb = Pounds

l kg = Kilograms

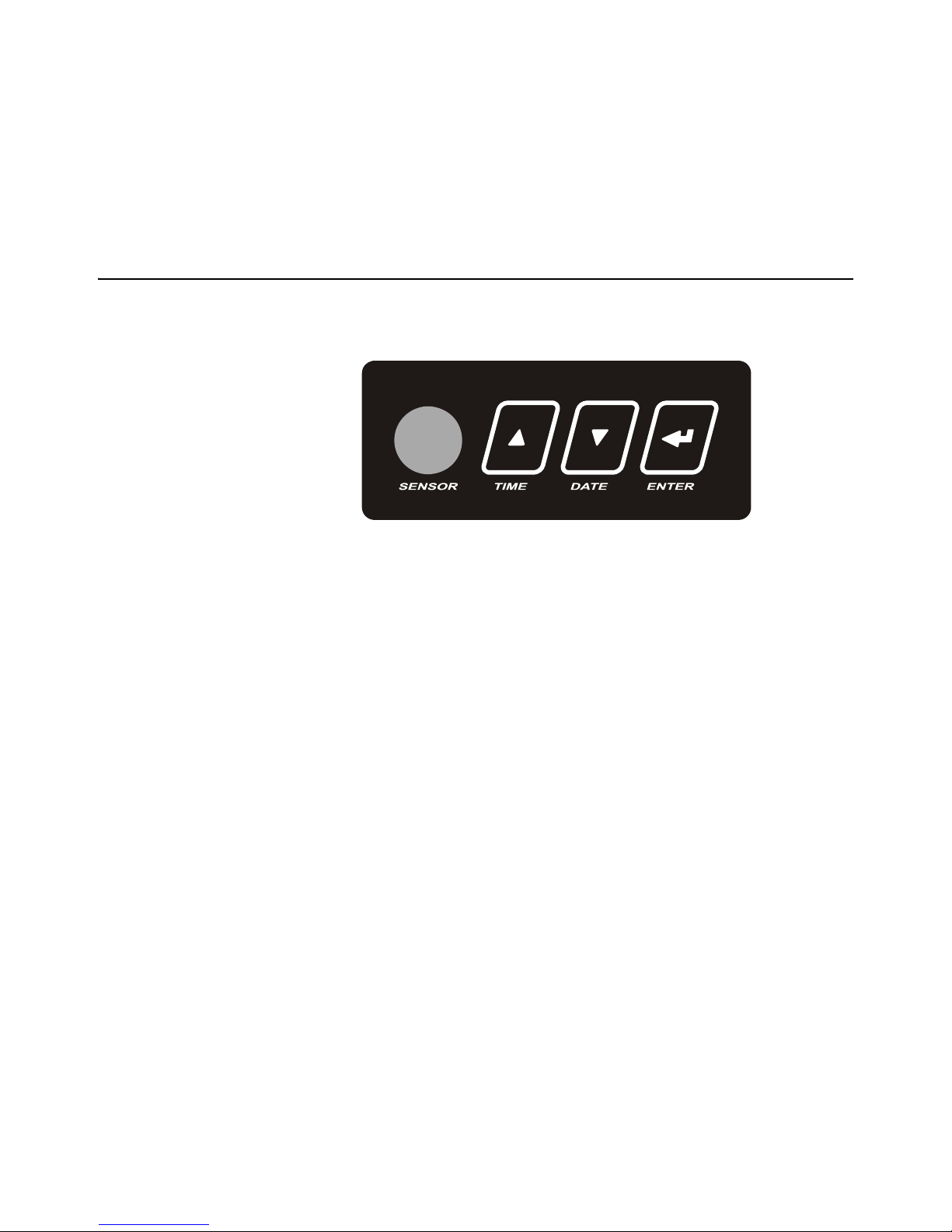

All models of the XR, except the XR 2000, have a keypad on the bottom of the unit. See

illustration of the keypad in Figure 2.2.

Figure 2.2 Keypad

The keypad has three pushbuttons or keys and a light sensor window. Use the keys to

set time and date and to access the configuration mode. The ligh t se nsor con trols the

brightness of the LEDs based on ambient light levels.

10 XR Series Installation Instructions

Page 11

3.1 Installing the XR 4500, XR 4500TL or XR 6500

3 Installation

3.1 Installing the XR 4500, XR 4500TL or XR 6500

3.1.1 Pre-installation (Receiving Inspection)

It is always good practice to verify that the unit is complete and undamaged upon

receipt.

l Check over packaging for any signs of damage.

l Remove the XR from its protective packaging and check for da mage.

l Verify that the shipment includes:

m Correct XR remote display (complete and intact, with power cord).

m Installation and Technical Instructions.

l Displays ordered with the wireless option should include:

m Radio module

m External antenna

m Internal antenna cable

m Base station kit

m FCC/IC sticker

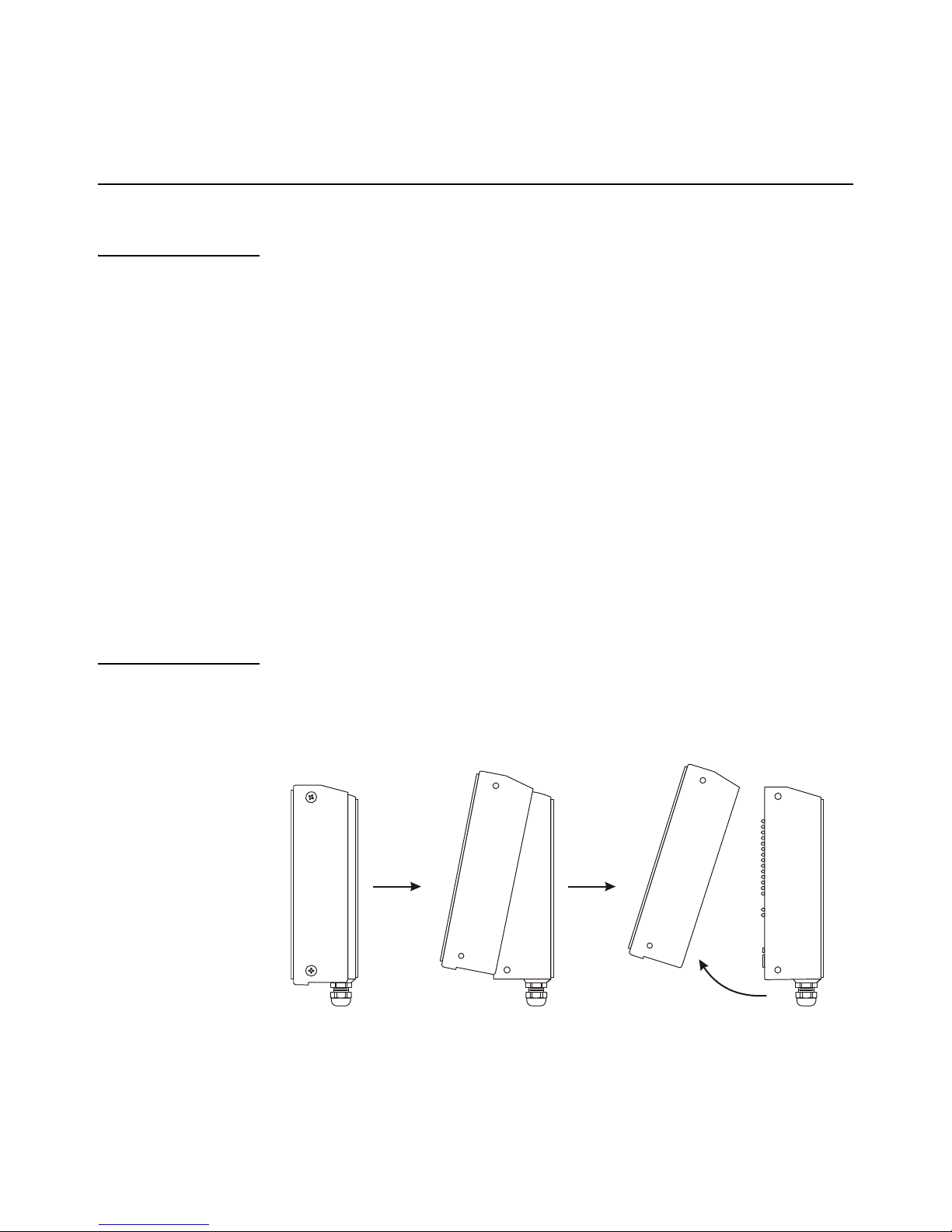

3.1.2 Opening an Enclosure

1. Make sure the unit is disconnected from power.

2. Remove the Phillips head screws from each side of the enclosure.

3. Slowly, guide the front cover off of the main enclosure. See Figure 3.1.

XR Series Installation Instructions 11

Figure 3.1 Opening the XR 4500 / 4500TL / 6500 (side view)

Page 12

3 Installation

Captive Screws

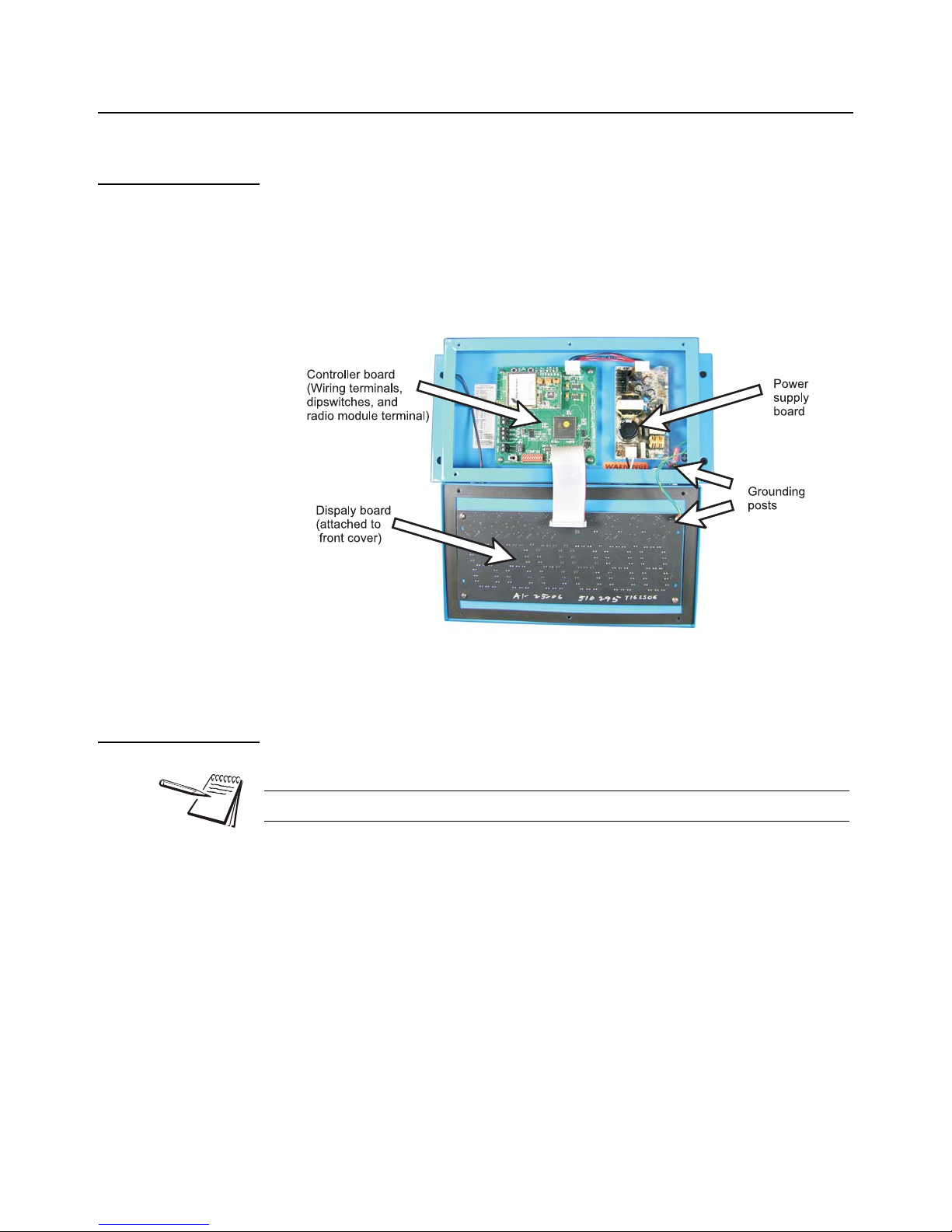

3.1.3 Lowering the Electronics Plate

1. Remove the three (3) captive screws holding the electronics plate to the main

enclosure. See Figure 3.2.

Figure 3.2 Open enclosure

2. Slowly, allow the electronics plate to swing down. The controller board and

power supply board are now accessible for installation, wiring and service.

See Figure 3.3.

3.1.4 Mounting Instructions

1. Inspect the installation site for properly grounded power. The outlet must be

installed near the XR and easily accessible.

2. Ensure that mounting structures (walls, pole brackets, etc.) will bear the weight

of the display (XR 4500: 20 lbs, XR 6500 & 4500TL: 28 lbs).

3. Allow proper clearance for lowering and removing the electronics carriage.

12 XR Series Installation Instructions

4. Use proper hardware, including wall anchors where necessary, when

mounting the enclosure. Secure the main enclosure to wall or pole mounted

bracket with 5/16ths bolts.

Figure 3.3 Electronics plate down

Page 13

3.1 Installing the XR 4500, XR 4500TL or XR 6500

Dia: .375in.[9.5mm]

24.00in.[609.6mm]

23.00in.[584.2mm]

10.125in.[257.2mm]

8.88in.[225.6mm]

6.00in.[152.4mm]

3.5in.[89mm]

3.5in.[89mm]

Dia: .375in.[9.5mm]

32.00in.[812.8mm]

31.00in.[787.4mm]

13in.[330.2mm]

11.75in.[298.4mm]

7.75in.[196.9mm]

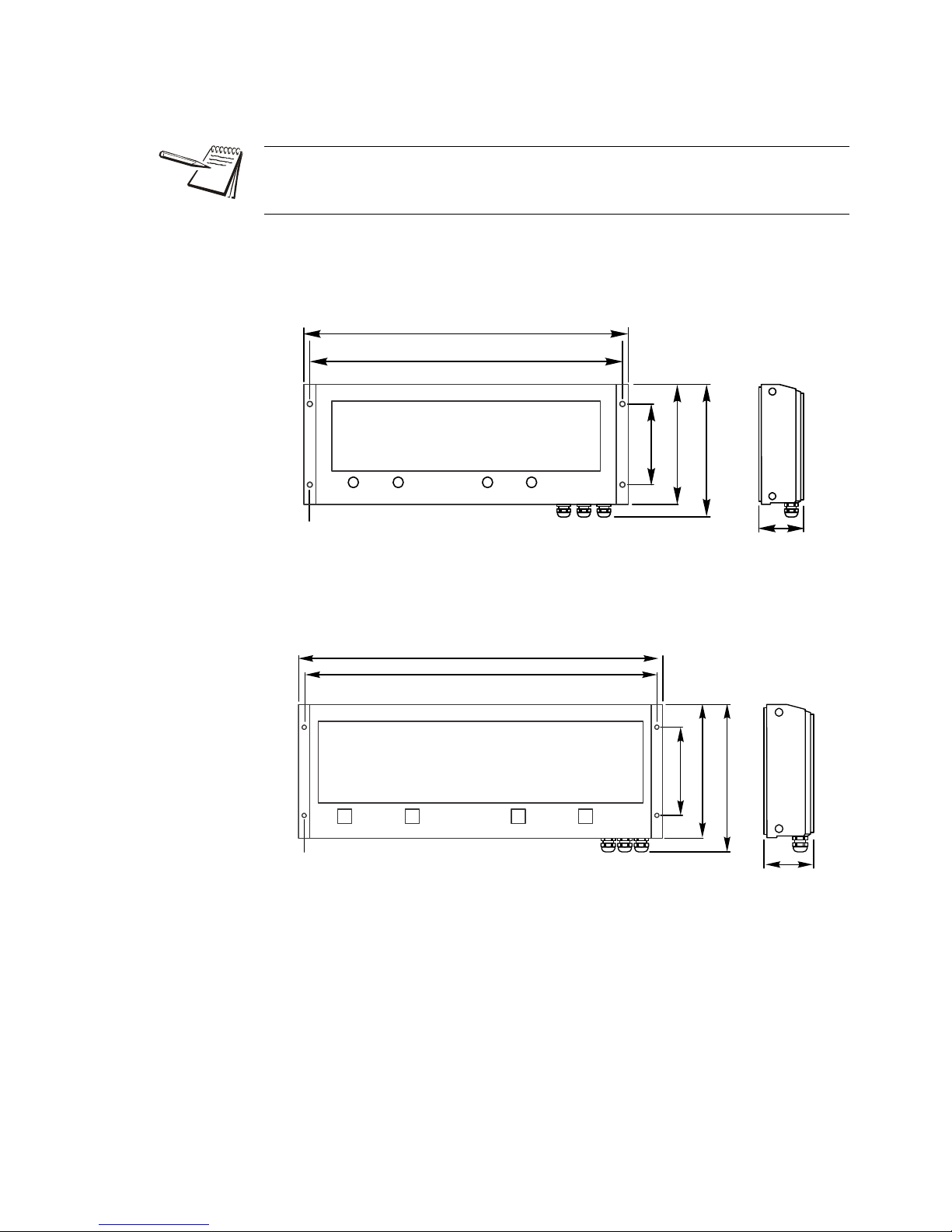

5. Run power and communication cables into the enclosure via strain reliefs (as

required).

The electronics carriage may be removed to reduce weight when installing.

Mounting hole size in the case is 3/8”.

Wall Mounting

Hole patterns for the XR series are given in Figure 3.4 and Figure 3.5.

Figure 3.4 XR 4500 Outline dimensions and hole pattern

Figure 3.5 XR 4500TL and XR 6500 Outline dimensio ns and hole pattern

Pole Mounting Bracket

1. Select appropriate height and fasten the small “C” bracket to the pole using the

mounting clamps provided.

2. Fasten the larger “C” bracket to the small “C” bracket using the hardware

provided.

XR Series Installation Instructions 13

Page 14

3 Installation

3. Fasten the XR display to the pole mounting bracket as outlined in the

mounting instructions (See Figure 3.6).

The pole mounting bracket allows use of poles or beams up to eight inches in

diameter.

Figure 3.6 Pole mounting bracket

Visor Option

1. Loosen the mounting hardware on the main enclosure 1/8th inch.

2. Rest the visor’s mounting brackets on the bolt between the bolt head and the

front of the side mounting plates.

3. Re-tighten the mounting hardware.

14 XR Series Installation Instructions

Figure 3.7 Optional visor

Page 15

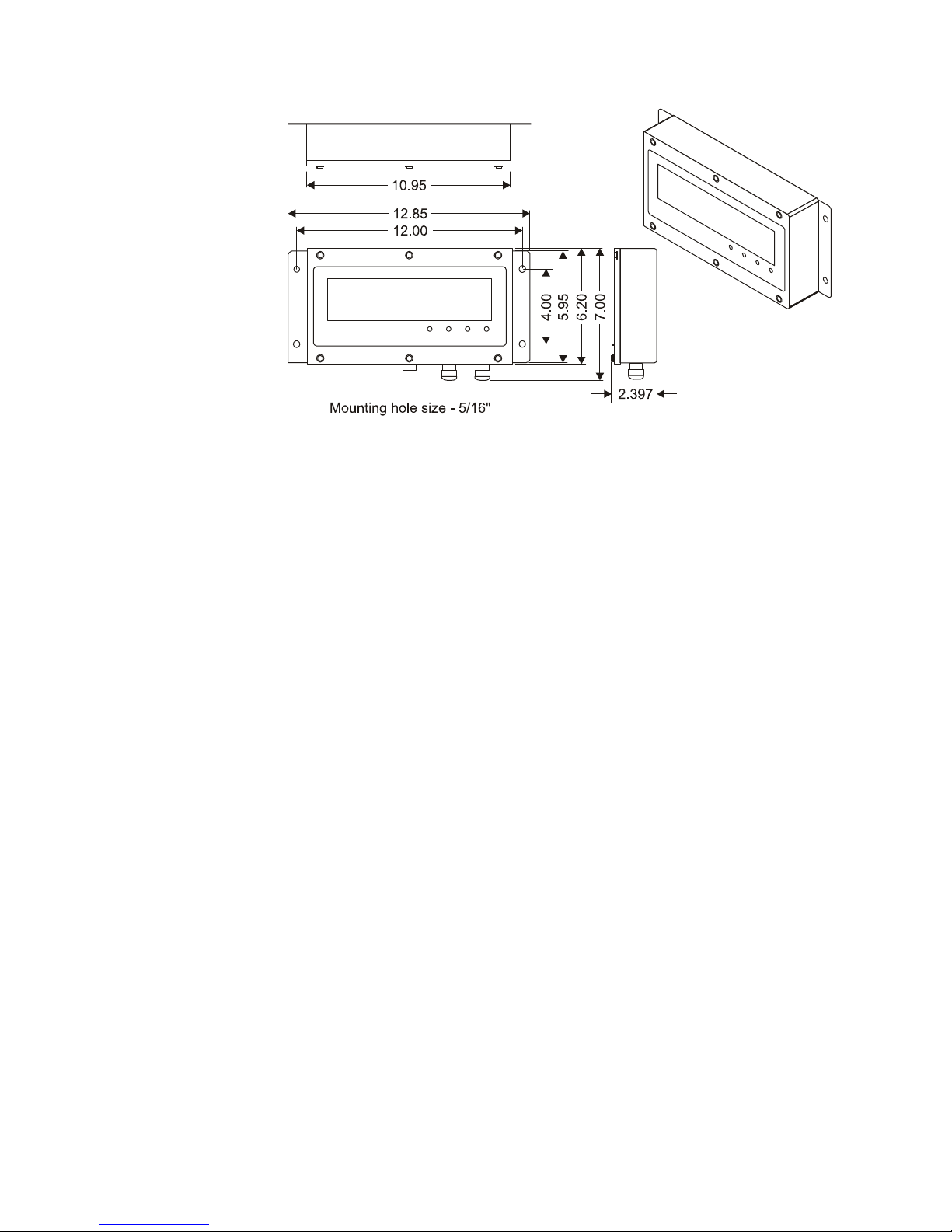

3.2 Installing the XR 2000

3.2.1 Opening the XR 2000 Enclosure

1. Make sure the unit is disconnected from power.

2. Remove the 6 screws (with sealing washers) from the front of the enclosure.

3. Guide the front panel away from the main enclosure. Be sure to watch the

internal cable connections! See Figure 3.8

3.2 Installing the XR 2000

3.2.2 Mounting Instructions

Mounting hole size in the case is 5/16”.

1. Inspect the installation site for properly grounded power.

2. Ensure that mounting structures (walls, posts, etc.) will bear the weight of the

display (XR 2000: 6 lbs).

3. Use proper hardware, including wall anchors where necessary, when

mounting the enclosure. Secure the main enclosure to wall or pole mounted

bracket with 5/16ths bolts.

4. Run power and communication cables into the enclosure via strain reliefs (as

required).

Figure 3.8 XR 2000 enclosure laid open

XR Series Installation Instructions 15

Page 16

3 Installation

Figure 3.9 XR 2000 dimensions

16 XR Series Installation Instructions

Page 17

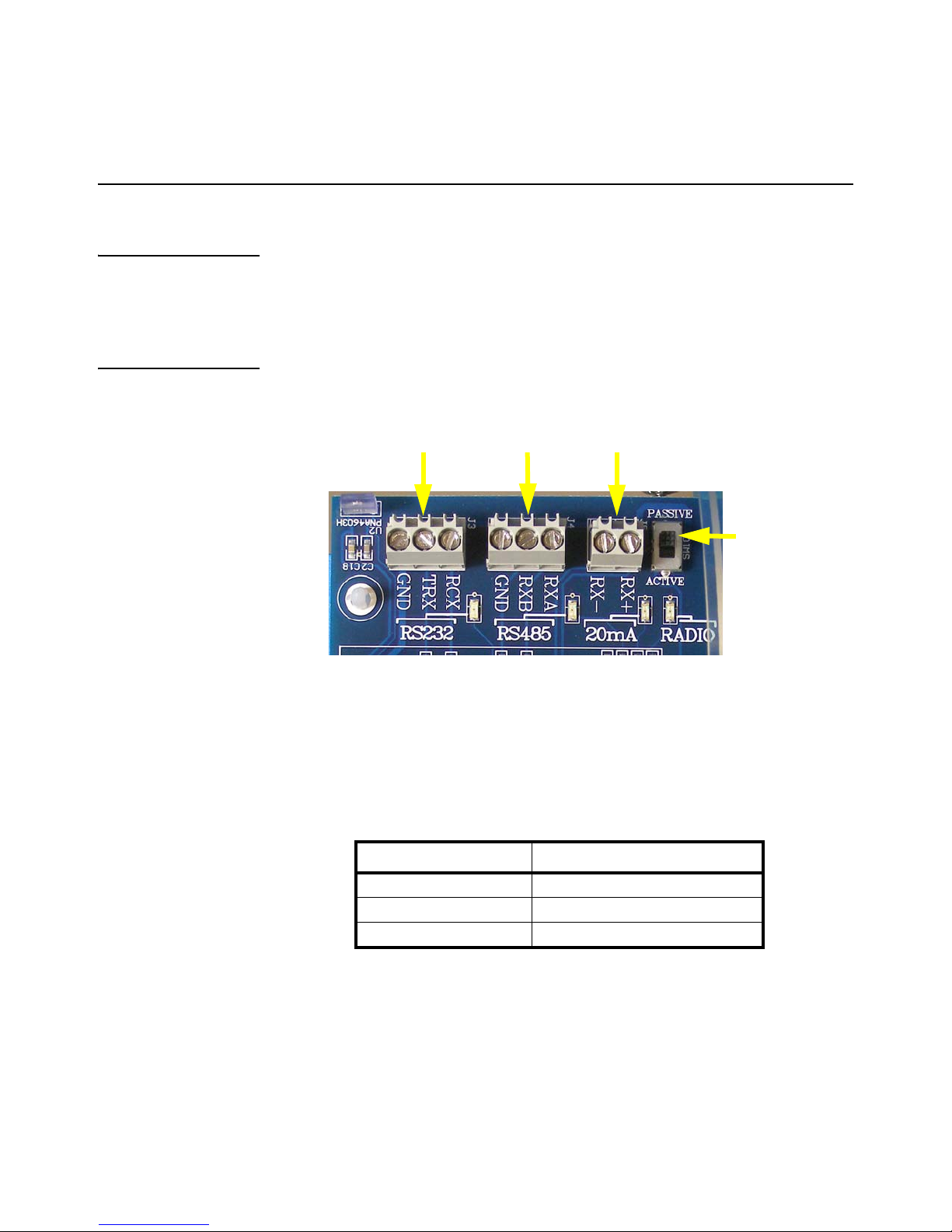

4Wiring

J3 J4 J5

20mA

Mode

Switch

(SW10)

4.1 Wiring the XR 4500, 4500TL or 6500

4.1.1 Power Wiring

XR displays are wired for power at the factory. The factory supplied power cable can

be removed for direct AC wiring if necessary.

4.1.2 Communications Wiring

All communications wiring terminates at the controller board. Communications should

be wired before applying power to the unit.

4.1 Wiring the XR 4500, 4500TL or 6500

RS 232 Wiring

Terminate the indicator’s communication wires at the RS 232 terminal (J3), shown in

Figure 4.1.

See the table below for pin assignments:

Figure 4.1 Communication terminals

INDICATOR TO XR

TRANSMIT (TX) RECEIVE (RX)

RECEIVE (RX) NO CONNECTION

SIGNAL GROUND (GND) SIGNAL GROUND (SIG GND)

XR Series Installation Instructions 17

Page 18

4 Wiring

RS 232 Daisy Chain / Multi-Drop Wiring

INDICATOR TO RD 1 TO RD 2

TX RX

No connection for Daisy Chain.

TX RX

RX for Multi-drop.

GND GND GND

RS 422/485 Wiring

Terminate the indicator’s communication wires at the RS 485 terminal (J4), shown in

Figure 4.1.

See the table below for pin assignments:

INDICATOR TO XR

TRANSMIT A (TX A) RECEIVE A (RX A)

TRANSMIT B (TX B) RECEIVE B (RX B)

SIGNAL GROUND SIGNAL GROUND

18 XR Series Installation Instructions

Page 19

4.1 Wiring the XR 4500, 4500TL or 6500

RS 485 Daisy Chain / Multi-Drop Wiring

Terminate the indicator’s communication wires at the RS 485 terminal (J4), shown in

Figure 4.1, using one of the following methods:

Parallel Multi-drop wiring

SCALE CONTROLLER TO RD 1 TO RD 2 TO RD 3 ETC.

TX A RX ARX ARX ARX A

TX B RX BRX BRX BRX B

Split Multi-Drop Wiring

Multi-Drop IDs are set using the Configuration Mode. For instructions see Parameter

1.4: Multi-Drop ID on page 32.

XR Series Installation Instructions 19

Page 20

4 Wiring

20mA Current Loop Wiring

T erminate the indicator’s communication wir es at the 20mA Current Loop terminal (J5),

shown in Figure 4.1.

See table below for pin assignments:

INDICATOR TO XR

20 mA TX + RECEIVE POSITIVE (RX +)

20 mA TX - RECEIVE NEG ATIVE (RX -)

20mA Current Loop Mode Switch

l After the current loop is wired, ACTIVE or PASSIVE mode must be selected

(SW 10) on the controller board. See Figure 4.2.

l Select Active mode if the XR is required to supply the current to the

communicating device.

l Select Passive mode if the communicating device (indicator) supplies the

current to the XR.

Figure 4.2 20mA Mode Switch

20 XR Series Installation Instructions

Page 21

4.2 Wiring the XR 2000

4.2.1 Power Wiring

XR displays are wired for power at the factory. The factory supplied power cable can

be removed for direct AC wiring if necessary.

4.2.2 Communication Wiring

All communications wiring terminates at the controller board. Communications should

be wired before applying power to the unit.

Communication Input Jumper

A communications input type (RS 232, RS 422/485, or 20 mA Loop) must be selected

by placing the jumper on the appropriate pins. See Figure 4.3.

4.2 Wiring the XR 2000

RS 232 Wiring

1. Set the Communication Input Jumper (JP 1) to RS232.

XR Series Installation Instructions 21

Figure 4.3 Jumper positions

Page 22

4 Wiring

2. Terminate the indica tor’s communication wires at the RS 232 terminal (J3).

See table below:

INDICATOR TO XR

TRANSMIT (TX) RECEIVE (RX)

RECEIVE (RX) NO CONNECTION

SIGNAL GROUND (GND) SIGNAL GROUND (SIG GND)

RS 422 Wiring

1. Set the Communication Input Jumper (JP 1) to RS422 / 485.

2. Terminate the indica tor’s communication wires at the RS 422 / 485 terminal

(J4). See table below:

INDICATOR TO XR

TRANSMIT A (TX A) RECEIVE A (RX A)

TRANSMIT B (TX B) RECEIVE B (RX B)

22 XR Series Installation Instructions

Page 23

4.2 Wiring the XR 2000

RS 485 Multi-Drop Wiring

Set the Communication Input Jumper (JP 1) to RS422 / 485.

Parallel Multi-drop wiring

SCALE CONTROLLER TO RD 1 TO RD 2 TO RD 3 ETC.

TX A RX A RX A RX A RX A

TX B RX B RX B RX B RX B

Split Multi-Drop Wiring

Multi-Drop IDs are set using Parameter 1.4: Multi-Drop ID on page 32.

20 mA Current Loop Wiring

1. Set the Communication Input Jumper (JP 1) to 20mA LOOP.

2. Terminate the indica tor’s communication wires at the 20 mA Current Loop

terminal (J5). See table below:

INDICATOR TO XR

20 mA TX + RECEIVE POSITIVE (RX +)

20 mA TX - RECEIVE NEGATIVE (RX -)

20 mA Current Loop Mode Switch

l After the current loop is wired, ACTIVE or PASSIVE mode must be selected

(SW 10) on the controller board.

l Select Active mode if the XR is required to supply the current to the

communicating device.

l Select Passive mode if the communicating device (indicator) supplies the

current to the XR.

l If unsure of these requirements, check the device’s manual.

XR Series Installation Instructions 23

Page 24

5 Wireless Communication

5 Wireless Communication

5.1 Wireless Set-up for All XR Models

5.1.1 XR Remote Display

1. Install the radio module. Plug the module into terminals on the main PC board.

See Figure 5.1. The radio module plugs into the XR 2000 controller board in

similar fashion.

2. Route the radio signal cable to the bottom of the electronics carriage and

secure the SMA terminal through the available hole. Connect the external

antenna to the SMA terminal.

3. Power up the XR. The XR is ready to receive radio signals.

4. If problems are experienced, ensure that the radio module is seated properly

on the PC board. Check for bent pins.

5.1.2 Indicator

1. Connect the base statio n to the indicator (or other communicating device) as

directed in the ScaleLink installation manual.

2. Ensure the indicator is set-up to output CONTINUOUSLY.

3. Connect the base station to the scale indicator (or other appropriate device)

as directed in the ScaleLink installation manual.

Note the indicator’s communication settings, as the base station’s settings may

need to be adjusted to match.

24 XR Series Installation Instructions

Figure 5.1 Radio Module (outlined in white) on controller board

Page 25

5.1.3 Base Station Wireless Transceiver

The ScaleLink wireless transceiver is shown in Figure 5.2. Refer to the installation

manual that is included with the ScaleLink for connection and configuratio n information.

5.1 Wireless Set-up for All XR Models

Figure 5.2 Base station (connects to the indicator)

Figure 5.3 shows the inside of the ScaleLink.

Figure 5.3 Internal view

XR Series Installation Instructions 25

Page 26

5 Wireless Communication

5.2 Wireless Connection Test

Verify that both th e base station wireless transceiver and the XR are set to the same

radio channel.

If the XR’s readings are incorrect, erratic, or very slow, a different radio channel may

need to be selected.

26 XR Series Installation Instructions

Page 27

6Start-Up

6.1 Power On/Off

The XR has no ON/OFF button or switch. Plugging the unit into AC power will turn the

unit ON.

Disconnecting AC power will turn the unit OFF.

When power is applied the XR performs a self test by counting up 1 to 9, flashing the

annunciators and decimals, and displaying the software revision num ber.

6.2 Reset Button

The RESET button (marked as RST on the XR 2000) on the controller board allows the

technician to cycle power on the unit without disconnecting/connecting AC power. See

Figure 6.1.

6.1 Power On/Off

6.3 Auto-Learn

On power up, the XR automatically enters Auto-Learn mode, analyzing the serial

communications settings and the incoming data from the indicator.

The indicator’s output string must contain number characters. Also, an STX character

(ASCII 02) must precede all other characters and/or the string must end with <CR>

character. CR is ASCII 13. See example below:

<STX><Annunciator><Weight><Units><CR>

Once Auto-Learn is successful (about 10 seconds after power up) the XR will display

the current weight.

XR Series Installation Instructions 27

Figure 6.1 RESET button (not the XR2000)

Page 28

6 Start-Up

6.4 LEARN Button

Automatic Start-up Auto-Learn may be disabled for custom applications. See Auto-

Learn Parameters on page 33.

If Automatic Start-up Auto-Learn is disabled, the LEARN button (marked as LRN on

the XR 2000) on the Controller board must be pressed to enter Auto-Learn mode.

6.5 Diagnostic Indicator Lights

The XR has seven diagnostic indicator lights located on the controller board. See the

arrows in Figure 6.2. The lights are in a differ ent a rrangeme nt on the XR 2000 but are

labeled similarly.

Figure 6.2 Indicator lights on the XR 4500, 4500TL and 6500 controller bo ard

28 XR Series Installation Instructions

Page 29

6.5 Diagnostic Indicator Lights

Figure 6.3 Lights and switches on the XR 2 000 con tro ller boa rd

3.3V Light Turns on when voltage is supplied to the controller board.

12V Light Turns on when voltage is supplied to the display boards.

STATUS Light The STATUS light blinks when power is applied to the unit.

Rapid blinking (3 times per second) indicates that the XR is in

Auto-Learn mode, attempting to interpret a data string.

Regular blinking (once per second) indicates that the XR has

successfully learned a data string and is running properly.

COM Light The COM light flashes on each time the XR receives a character

through any of its COM Ports (including the radio). Only on the

XR2000 controller board

RS232 Light Flashes on each time the XR receives a character through the

RS232 port.

RS485 Light Flashes on each time the XR receives a character through the

RS485 port.

20mA Light Flashes on each time the XR receives a character through the

20mA Current Loop port.

RADIO Light: The RADIO light flashes on when the XR’s radio module receives

XR Series Installation Instructions 29

data. This light will only illuminate if the radio module is installed.

Page 30

7 Configuration Mode

7 Configuration Mode

To set the different parameters available in the XR series, you must enter a

configuration mode and then set each parameter to your desired value. Follow the

steps below to enter the configuration mode and to set the parameters.

7.1 Entering Configuration Mode

1. On the keypad on the bottom of the display press the UP and DOWN arrow

keys together. Release the keys when …

ConFig flashes on the display. This is followed very shortly by P1.0. This

stands for the first parameter, Daytime Brightness Level. See sequence

illustrated below:

In Configuration Mode, if no keys are pressed for 10 seconds, the scale weight is

displayed with a blinking C on the left-hand side.

Navigating Configuration Parameters

Use the UP and DOWN arrow keys to move through the list of parameters. Press and

hold an UP or DOWN key for more than one second to scroll quickly through the

parameter sections (Ex. P1.0, P2.0, P3.0 …). See the illustration below:

Editing Configuration Parameters

Navigate to the parameter and press ENTER to display the current parameter value.

Use the UP and DOWN arrow keys change the value. Press the ENTER key to select

the displayed value. See the illustration below:

Exiting and Saving Configuration

Press the UP and DOWN arrow keys at the same time to exit the configuration mode.

The display will flash SAvE and rESEt. All configuration information is saved and

display resets itself for normal operation.

30 XR Series Installation Instructions

Page 31

7.2 Configuration Parameters

Use the instructions in ’Entering Configuration Mode’, section 7.1 to access and

change the following parameters.

7.2.1 Parameter 1.0: Daytime Brightness Level

Value Description

7.2 Configuration Parameters

0 = Low

1 = Med Low

2 = Med High

3 = High<

Set the brightness of the display for daytime viewing. The built-in light sensor

automatically detects daylight conditions and sets the display brightness to this level.

7.2.2 Parameter 1.1: Nighttime Brightness Level

Value Description

0 = Low<

1 = Med Low

2 = Med High

3 = High

Lowering the brightness level at night helps reduce ni ghttime glare and en ergy costs.

Passing headlights, spotlights, etc. will NOT activate the daytime brightness level.

Set the brightness of the display for nighttime viewing. The built-in light sensor

automatically detects night conditions and sets the display brightness to this level.

7.2.3 Parameter 1.2: Power-save Mode

Value Description

0 = OFF

1 = ON<

7.2.4 Parameter 1.3: Mirror Display Mode

Value Description

0 = OFF<

1 = Mirror

2 = Cycle

XR Series Installation Instructions 31

Automatically dims display brightness one level below the selected brightness level

(day or night, as applicable) if there is no activity on the scale for 10 minutes.

Brightness levels are restored when motion is detected on the scale. This feature

saves power and increases LED longevity.

Mirror mode causes the display to reverse so it can be read from a vehicle’s rear or

sideview mirror. Select Cycle and the display cycles between normal and mirror

mode every five seconds.

Page 32

7 Configuration Mode

7.2.5 Parameter 1.4: Multi-Drop ID

Value Description

0 = ID 0<

1 = ID 1

2 = ID 2

3 = ID 3

Etc.

IMPORTANT: If Multi-Drop is not being used, the ID must be set to 0.

Sets the unit ID if multiple remote displays are networked together. Up to four XR

displays can be networked on a single serial or radio connection. Messages are sent

to individual displays using control codes and these IDs. For Multi-Drop instructions

see Multi-Drop addressing on page 48.

7.2.6 Parameter 1.5: Radio Channel Select

Value Description

0 = Ch 0<

1 = CH 1

2 = Ch 2

3 = Ch 3

4 = Ch 4

5 = Ch 5

Sets the radio frequency channel (0-5) for the optional integrated Wireless Module. If

there are multiple scale/remote display installations at a give site, each installation

must have its own unique radio channel selected to prevent interference.

The XR Remote Display must be set to the same radio channel as the scale

indicator’s wireless transceiver

If the wireless connection experiences interference problems fr om another radio site,

switching radio channels will most likely correct the problem.

7.2.7 Parameter 1.6: Utility Program Select

Value Description

0 = OFF<

1 = Pgm 1 - Green light at 0

2 = Pgm 2 - Red light on motion

3 = Pgm 3 - Normal w/ Cmds

4 = Pgm 4 - Freeze weight

5 = Pgm 5 - Command mode-G2

12 = Pgm 12 - Legacy Command Mode

(Command Mode from previous

generation Controller board; Use when

interfacing a new scoreboard to an older

installation.)

Etc.

Several Utility Programs are pre-installed in the XR remote display .

For a complete list of programs and descriptions, see XR Utility

Programs on page 45.

32 XR Series Installation Instructions

Page 33

7.3 Auto-Learn Parameters

7.3.1 Parameter 2.0: Manual Learn (Assisted Learn)

Value Description

Lxxxxx Manual Learn activates Auto-Learn Mode from inside Configuration

Mode. The remote display will analyze and attempt to learn the

string. The message LEARN is displayed. When the remote

display is successful, the weight will be shown on the display.

A blinking L will be displayed in the left hand corner to indicate you

are still in learning mode.

To lock in the learned string’s settings, press ENTER.

7.3.2 Parameter 2.1: Start-up Auto-Learn

7.3 Auto-Learn Parameters

Value Description

0 = OFF

1 = ON<

The XR automatically enters Auto-Learn Mode on start up. If OFF,

the display will startup using settings stored in memory from the last

learn.

7.3.3 Parameter 2.2: Leading Zero Suppression

Value Description

0 = OFF<

1 = ON

Leading zeros may also be disabled using the scale indicator (if possible).

In some cases the scale indicator may transmit leading zeros in the

output string. If leading zeros are not required they may be

suppressed. If ON the XR will automatically remove the leading

zeros and replace them with blank spaces on the display.

XR Series Installation Instructions 33

Page 34

7 Configuration Mode

7.3.4 Parameter 2.3: Set Scale Over

Value Description

0 = Auto<

Value for scale over target weight

If there is no scale over status character in the weight string, or the

indicator continues to transmit past maximum capacity, the unit can

be set to blank the display when the weight goes past a preset

weight value.

Use the UP/DOWN keys to set the weight threshold and press

ENTER. Hold the keys down to cause the weight threshold to

change in steps of 10000. Single key presses cause the weight

threshold to change in steps of 100.

7.3.5 Parameter 2.4: Lock Units

Value Description

0 = Auto<

1 = lb ON (or t)

2 = 2 kg ON

3 = Both OFF

Weight Units (lb, kg, and t) are automatically displayed from the

indicator’s output string. The Units annunciators may be locked on

or off as required.

On European models the lb annunciator is replaced with t.

7.3.6 Parameter 2.5: Lock Weighing Mode

Value Description

0 = Auto<

1 = Gross ON

2 = Net ON

3 = Both OFF

Weighing Mode (gross/net) is automatically displayed from the

indicator’s output string. The Mode annunciators may be locked on

or off as required.

7.3.7 Parameter 2.6: Lock Traffic LIght

Value Description

0 = Auto<

1 = RED

2 = GREEN

3 = OFF

The traffic light (XR 4500 TL) display may be locked RED, GREEN

or OFF as required.

34 XR Series Installation Instructions

Page 35

7.4 Time / Date / Temp Parameters

The XR remote display can cycle between displaying weight, time, date and

temperature every five seconds when: a) the weight display is at zero AND

no activity on the scale for the selected time period.

7.4.1 Parameter 3.0: Time Display

Value Description

7.4 Time / Date / Temp Parameters

; b) there is

0 = OFF<

1 = Time (AM/PM)

2 = Military (24 hour)

Activates the time function in 12 hour or 24 hour clock formats.

7.4.2 Parameter 3.1: Date Display

Value Description

0 = OFF<

1 = MMDDYY (US Format)

2 = YYMMDD (International)

3 = DDMMYY (UK)

Activates the date function in US, ISO or UK format.

7.4.3 Parameter 3.2: Temperature Display

Value Description

0 = OFF<

1 = F (degrees Fahrenheit)

2 = C (degrees Celsius)

Activates the temperature function (in F or C) when the optional

temperature probe is installed.

7.4.4 Parameter 3.3: Weight Display

Value Description

0 = OFF

1 = Cycle

2 = No Cycle<

7.4.5 Parameter 3.4: Time Threshold

Value Description

1 to 20 min.

1 min<

XR Series Installation Instructions 35

OFF: Weight will not be displayed at all.

ON: Weight is displayed in the Time/Date/Temp/ Weight cycle.

No Cycle: Weight is not in the Time/Date/Temp/ Weight cycle.

Selects the number of minutes that the scale must be at zero

before the Time/Date/Temp/ Weight cycle is displayed.

Page 36

7 Configuration Mode

7.5 Diagnostic Parameters

7.5.1 Parameter 9.0: Com Port

Value Description

0 = RS232

1 = RADIO

2 = 20mA

3 = RS485

7.5.2 Parameter 9.1: String Counter

Value Description

0 to 65535 Counter indicates the number of characters received. Counter rolls

7.5.3 Parameter 9.2: Baud Rate

Value Description

300

600

1200

4800

9600

19200

Displays the currently active Com Port.

over after 65535.

Displays the baud rate currently being used for serial

communications.

7.5.4 Parameter 9.3: Configuration Lockout

Value Description

0 = Disabled<

1 = Enabled

7.5.5 Parameter 9.4: Number Counter

Value Description

0 to 65535 Counter indicates the number of numeric characters received.

36 XR Series Installation Instructions

When enabled, no configuration parameters can be changed.

Disable this parameter to restore user changes.

Counter rolls over after 65535.

Page 37

7.5.6 Parameter 9.8: Test Display

Value Description

N/A Cycles through time, digits, annunciators and decimal characters.

7.5.7 Parameter 9.9: Reset Defaults

Value Description

7.5 Diagnostic Parameters

0 = Do Not Reset

1 = RESET

Resets the configuration parameters to factory defaults.

XR Series Installation Instructions 37

Page 38

7 Configuration Mode

7.6 CONFIG Switches (XR 2000)

The CONFIG bank of dip switches (SW 3), shown in Figure 7.1, is for the following

features:

Figure 7.1 SW 3 (CONFIG Switch bank)

Switch 1: Brightness Level

There are 2 selectable brightness levels. Outdoor (brighter) and indoor (less bright).

BRIGHTNESS LEVEL SWITCH 1

Indoor (default) OFF

Outdoor ON

Switch 2: Leading Zeros (see note at left)

Leading Zeros may also be disabled using the scale indicator (if possible).

In some cases, the scale indicator may transmit leading zeros in the output string. If

leading zeros are NOT required, they may be suppressed. The XR 2000 will

automatically remove the leading zeros and replace them with blank spaces on the

display.

LEADING ZEROS SWITCH 2

ENABLED (Default) OFF

DISABLED (Remove Leading Zeros) ON

Switch 3: Start-up Auto-Learn

On power up, the XR 2000 automatically enters Auto-Learn mode, analyzing the serial

communications and string type. In certain situations, it may be necessary to disable

this feature. Once disabled, the LEARN button on the controller bo ard must be pressed

before the XR will go into Auto-Learn mode.

38 XR Series Installation Instructions

START-UP AUTO-LEARN SWITCH 3

ENABLED (Default) OFF

DISABLED ON

Page 39

7.6 CONFIG Switches (XR 2000)

Switches 4 & 5: Multi-Drop ID

If Multi-Drop is not being used, it is very important that Switches 4 & 5 be set in

the OFF position.

Up to four (4) XR displays can share a serial or radio connection. Messages are sent

to individual displays using control codes and these Multi-Drop IDs. For Multi-Drop

instructions, see Multi-Drop addressing on page 48.

MULTI-DROP I.D. SWITCH 4 SWITCH 5

0 (Default) OFF OFF

1ONOFF

2OFFON

3ONON

Switches 6 & 7: Radio Channel Select

The 900 MHz Radio Module (optional) has 4 frequency channels. If ther e ar e multiple

scale/remote display installations at a given site, each installation must have its own

radio channel selected.

RADIO CHANNEL SWITCH 6 SWITCH 7

0 (Default) OFF OFF

1ONOFF

2OFFON

3ONON

If the wireless connection experiences interference problems from another radio site,

switching radio channels will most likely correct the problem.

The XR 2000 remote display must be configured with the same radio channel as the

wireless transceiver connected to the indicator . See Wireless Set-up for All XR Models

on page 24.

XR Series Installation Instructions 39

Page 40

7 Configuration Mode

Switches 8 & 9: Utility Program Select

Please see the XR 2000 Utility Programs on page 49 for program overviews.

The XR 2000 has built-in utility programs that run in conjunction with the normal display

functions.

PROGRAM SW 8 SW 9

1 – NORMAL Mode (No program) OFF OFF

2 – FREEZE Weight ON OFF

3 – Reserved for future use OFF ON

4 – COMMAND mode. ON ON

40 XR Series Installation Instructions

Page 41

8.1 Built-in Traffic Light (XR 4500TL Only)

8 XR 4500 TL Traffic Light Control

8.1 Built-in Traffic Light (XR 4500TL Only)

The built-in traffic light may be controlled by remote switch, serial commands, or the

pre-installed utility programs.

Remote Switch

1. Wire a dry contact, push to make switch to the Stop Light Remote Switch

terminal (J23) on the Controller board. DO NOT supply any extern al power to

this terminal.

Figure 8.1 Stop light terminal wiring

Remote switches will be disabled if the XR has a traffic light controlling utility program

selected.

2. The default condition (switch contact open) is GREEN. When the switch

contact is closed, the light turns RED.

The remote switch will be disabled if the built-in traffic light is locked GREEN, RED or

OFF in Configuration Mode, Parameter 2.6.

Pre-installed Utility Programs

Some of the XR’s pre-installed utility programs control the built-in traffic light. For

program overviews, see XR Utility Programs on page 45

Serial Commands

When the XR is set to Program 3: Normal Operation with Traffic Light Commands or

Program 5: Command Mode, it will accept serial commands to switch the built-in traffic

light.

For a list of serial control commands, see page Control Commands on page 47.

XR Series Installation Instructions 41

Page 42

9 Time and Date (not available on XR 2000)

9 Time and Date (not available on XR 2000)

The XR remote display has a precision time clock that compensates for variable

temperature conditions. The battery on the Controller board (J22) provides back-up

power for this clock.

9.1 Set Time & Date

9.1.1 Adjust Time

1. Make sure Time is enabled in Configuration Mode (Parameter 3.0)

2. Press and hold the UP/TIME key.

3. Use the UP and DOWN ARROW keys to select the correct hour and press

ENTER.

4. Repeat for minutes and AM/PM if enabled (12 hour clock).

9.1.2 Adjust Date

1. Make sure Date is enabled in Configuration Mode (Parameter 3.1)

2. Press the DOWN/DATE key.

3. Use the UP and DOWN ARROW keys to select the correct year/month/day

(International) or month/day/year (USA) and press ENTER.

9.2 Battery / Battery Replacement

The XR displays use a 3 Volt lithiu m battery . Power is drawn from the battery only when

the unit is disconnected from AC power. If time and date are lost when the unit is

disconnected from AC power, the battery likely needs replacement.

1. Remove the old battery from the J22 terminal on the Controller board by hand.

2. Observe proper battery polarity before inserting new battery.

3. Ensure the battery is seated correctly in the J22 terminal.

CAUTION! Risk of explosion if battery is replaced by an incorrect type. Dispose

of used batteries according to their instructions.

CAUTION! Never use metal objects such as screwdrivers to remove batteries!

This may result in personal injury or damage to the unit.

42 XR Series Installation Instructions

Page 43

10 Temperature Probe Installation (not on XR 2000)

1. Unpack the optional Temperature Probe Assembly. This assembly consists of

the weather-sealed temperature probe contained in a Strain-Relief.

A 4-conductor cable runs from the temperature probe to a 4 pin connector.

2. Ensure the XR display is disconnected from power and open the enclosure.

3. Remove the rubber plug from the hole in the bottom of the XR enclosure.

4. Remove the nut from the Strain-Relief and run the cable up through the hole in

the bottom of the enclosure. See Figure 10.1.

5. Run the connector and cable through the nut and use it to fasten the StrainRelief to the enclosure.

6. Plug the Temperature Probe connector into the terminal (J9) on the Controller

Board. See Figure 10.2.

7. Power up the XR. Enter Configuration Mode and set Parameter 3.2 to 1 for

Fahrenheit or 2 for Celsius.

8. Exit Configuration Mode. The temperature will be displayed once the remote

display has been reading zero for the time specified in Parameter 3.4 (Time

Threshold).

XR Series Installation Instructions 43

Figure 10.1 Temperature probe installation

Page 44

10 Temperature Probe Installation (not on XR 2000)

Figure 10.2 J9 terminal for temperature probe connection

The XR’s Digital Temperature Probe ensures accuracy to within ± 1 degree and will

never need to be calibrated.

44 XR Series Installation Instructions

Page 45

11.1 XR 4500, XR 4500TL, and XR 6500 Utility Programs

11 XR Utility Programs

11.1 XR 4500, XR 4500TL, and XR 6500 Utility Programs

The XR remote displays have several auxiliary functions that may be activated via

Parameter 1.6 in Configuration Mode.

11.1.1 Program 0: Normal Operation

No utility program is selected.

11.1.2 Program 1: Simple Traffic Light

Traffic light is GREEN on zero weight. Otherwise the traffic light is RED.

11.1.3 Program 2: Motion Traffic Light

Traffic light is RED when there is scale motion. Otherwise the traffic light is GREEN.

11.1.4 Program 3: Normal Operation with Traffic Light Commands

The display accepts a continuous data stream for the indicator. This stream may be

interrupted by control commands used to switch the traffic light. See the table below:

Control Command ASCII DEC

RED light XR 4500TL only &<CR> 38, 13

GREEN light XR 4500TL only *<CR> 42, 13

11.1.5 Program 4: Freeze Weight (Capture Print String)

This program is useful for cattle auctions and othe r app lica tions whe re a we ight va lue

must be displayed regardless of what is happenin g on the scale .

A weigh ticket (using ASCII characters) must be created on the scale indicator that

sends the scale weight and a <CR> character to the XR display with a button press.

Example: 123456 lb g<CR>

When the XR receives the ticket, it displays the weight and keeps displaying it until the

next weigh ticket is received.

This application assumes a legal-for-trade indicator is used to send the weigh ticket.

Please review local Weights and Measures requirements.

XR Series Installation Instructions 45

Page 46

11 XR Utility Programs

11.1.6 Program 5: Command Mode

All XR displays can be setup to receive commands directly from the scale system or

PC. Supported commands include transmitting weights, basic alphanumeric

messaging, traffic light control, and additional display functions.

Command mode disables Auto-Learn and fixes communications at 9600-N-8-1. The

XR looks only for specific commands sent by the indicator or scale controller.

NOTE: This improved Command Mode is for the G2 Controller board. Use Legacy

Command Mode (Pgrm 12) when replacing older Controller boards.

Activating Command Mode

To enable Command Mode for XR 4500 / XR 4500 TL / XR 6500, set Parameter 1.6 in

Configuration Mode to 5.

Transmit a Weight String

Use numeric ASCII characters followed by a <CR> character.

Example: To display 1000, transmit: 1000<CR>

Transmit Status Characters

Status characters may be embedded anywhere in the weight string to control the

annunciator lights. Status characters may be upper or lowercase, and in any order,

before or after the weight.

STATUS COMMAND CHARACTER A SCII

GROSS weight G or g 71 or 103

NET weight N or n 78 or 110

POUNDS L or l 76 or 108

KILOGRAMS K or k 75 or 107

Example: To display 1000 lb gross, transmit: 1000LG<CR> -or- GL1000<CR>

If no gross/net character is sent to the XR, the “GR” annunciator will illuminate by

default.

Alphanumeric messaging to the scoreboard

All XR models can display alphanumeric messages within the limitations of a 7

segment digit. Text and numbers sent as a message must be preceded by the @

character (decimal 64) and followed by a Carriage Return <CR> character (decimal

13). All characters in the data string are then treated as an alphanu meric message, and

not a weight value.

Alphanumeric messages are displayed from left to right.

46 XR Series Installation Instructions

Page 47

11.1 XR 4500, XR 4500TL, and XR 6500 Utility Programs

Control Commands

Control commands are single ASCII characters (preceded by @ and followed by

<CR>) that are transmitted to the XR to control additional features such as the built-in

traffic light (XR 4500 TL).

CONTROL COMMAND CHARACTER ASCII

RED light – XR 4500 TL only & 38

GREEN light – XR 4500 TL only * 42

Light OFF - XR 4500 TL only % 37

Turn ON flashing display ( 40

Turn OFF flashing display ) 41

FLASH weight display 3 times ! 33

Sample Command Mode Data Strings:

DATA STRING DISPLAY

0 <CR> “0” gross

1000 <CR> “1000” gross

LN 1234 <CR> “1234” lb net

1234 GK <CR> “1234” kg gross

1234 L g <CR> “1234” lb gross

@hello<CR> - XR 4500 TL only “hELLo”

@*<CR> - XR 4500 TL only GREEN light

@stop &<CR> - XR 4500 TL only “StoP”, RED light

IMPORTANT: Do not transmit Control Commands within a WEIGHT data string.

Control Commands must be transmitted alone or in conjunction with an Alph anumeric

message data string.

XR Series Installation Instructions 47

Page 48

11 XR Utility Programs

Multi-Drop addressing

The XRs using Multi-drop networking must be in Command Mode. The Multi-d rop ID (0

to 3) must also be set. (See Parameter 1.4: Multi-Drop ID on page 32).

When using Multi-drop, the XR will only respond after it has been selected.

T o select a display , transmit a # character (ASCII 35) followed by the correct ID number

and a <CR> character (ASCII 13). Once this command is executed, control codes,

alphanumeric messages and weight strings can be tra nsmitted to the selected display.

See Program 5: Command Mode on page 46

An XR display will remain selected until it receives a command containing a different ID.

Examples:

1. Select Multi-drop ID 1:

Transmitting #1<CR> selects the display with ID #1.

2. Select Multi-drop ID 3 and send a weight of 1000lb gross:

#3<CR>

1000LG<CR>

The ID number may also be embedded with the weight string:

#3 1000LG<CR>

3. Send 3 different weights to 3 different scoreboards:

#0 2000LG<CR>#1 3000LG<CR>#2 5000LG<CR>

4. Send the text hello to scoreboard ID 3.

#3@HELLO<CR>

11.1.7 PROGRAM 12: LEGACY COMMAND MODE

• Command Mode from previous generation Controller board;

• Used when interfacing a new scoreboard to an older installation.

48 XR Series Installation Instructions

Page 49

11.2 XR 2000 Utility Programs

The XR 2000 has several auxiliary functions that may be activated via the CONFIG dip

switches on the controller board.

PROGRAM SW 8 SW 9

1 – NORMAL Mode (No program) OFF OFF

2 – FREEZE Weight ON OFF

3 – Reserved for future use OFF ON

4 – COMMAND mode. ON ON

PROGRAM 1: NORMAL MODE

NO SPECIAL PROGRAM IS SELECTED.

PROGRAM 2: FREEZE WEIGHT

FOR USE WITH CATTLE AUCTIONS, ETC.

11.2 XR 2000 Utility Programs

This application assumes a legal-for-trade indicator is used to send the weigh ticket.

Please review local Weights and Measures requirements

l This program is useful for cattle auctions and other applications where a

weight value must be displayed regardless of what is happening on the

scale.

l A weigh ticket (using ASCII characters) must be created on the scale

indicator that sends the scale weight and a <CR> character to the XR 2000

display with a button press.

Example: 123456 lb g<CR>

l When the XR 2000 receives this information, it displays the weight and

keeps displaying it until another weigh ticket is received.

PROGRAM 3: RESERVED FOR FUTURE USE.

PROGRAM 4: COMMAND MODE (Legacy command mode)

All XR displays can be setup to receive commands directly from the scale system or

PC. Supported commands include transmitting weights, basic alphanumeric

messaging, stoplight relay control, and additional display functions.

Command mode disables Auto-Learn and fixes communications at 9600-N-8-1. The

XR 2000 looks only for specific commands sent by the indicator or scale controller.

XR Series Installation Instructions 49

Page 50

11 XR Utility Programs

Activating Command Mode

1. To enable command mode, CONFIG dip switches 8 and 9 on the controller

board must be set as follows:

PROGRAM SW 8 SW 9

4 – COMMAND Mode ON ON

Switch settings do not take affect until the XR is reset or powered up again.

Transmit a Weight String

Use numeric ASCII characters followed by a <CR> character.

Example: To display 1000, transmit: 1000<CR>

Transmit Status Characters

Status characters may be imbedded anywhere in the weight string to control the

annunciator lights. Status characters may be upper or lowercase, and in any order,

before or after the weight.

STATUS COMMAND CHARACTER A SCII

GROSS weight G or g

NET weight N or n

POUNDS L or l

KILOGRAMS K or k

Example: To display 1000 lb gross, transmit: 1000LG<CR> -or- GL1000<CR>

Multi-Drop addressing

The XRs using Multi-drop must be in Command Mode. The Multi-drop address (0 to 3)

is set using SW8 and SW9 on the CONFIG dip switch bank (See Switches 4 & 5: Multi-

Drop ID on page 39).

When using Multi-drop, the XR will only respond after it has been selected. To select

the display, transmit a “#” character (ASCII 35), followed by the correct ID number and

a CR (ASCII 13) character. The XR will remain selected until it receives a command

containing a different addres s.

Examples:

1. Select multi-drop address 1:

Transmitting “#1<CR>” selects the display with ID #1.

2. Select multi-drop address 3, then send a weight of 1000lb gross:

50 XR Series Installation Instructions

“#3<CR>”

“1000LG<CR>

The ID number may be embedded with the weight string:

“#3 1000LG<CR>

Page 51

11.2 XR 2000 Utility Programs

3. Send 3 different weights to 3 different scoreboards:

“#0 2000LG<CR>#1 3000LG<CR>#2 5000LG<CR>“

4. Send the text “hello” to scoreboard address 3.

“#3 HELLO<CR>

XR Series Installation Instructions 51

Page 52

12 Troubleshooting & Error Messages

12 Troubleshooting & Error Messages

Problem C ause and/or Probable Solution

Unit won’t power up: • Verify AC power source (Outlets, breakers, etc.)

• Check terminal block connections inside the main

enclosure.

• Verify power wiring from terminal block to the power

supply board.

• Check fuse on power supply board and controller

board.

Unit has power, but there is

no display.

Dashes across the display. • Communications have failed.

Display reads “Err 1”. • Baud Rate Auto-Learn has failed.

Display reads “Err 2”. • Data String Auto-Learn has failed or Radio not

Display reads “Err 3”. • The XR is receiving data on multiple communications

STATUS light NOT blinking

(OFF)

STATUS light blinking fast

(3/second) for longer than

30 seconds:

RS232 light not flashing • Verify the RS232 terminal is being used and check

• Verify ribbon cable connections from controller board

to the display board.

• Check 12V light and fuse on controller board.

• If the unit is in COMMAND mode, the display will

remain blank until data is received.

• Verify the correct terminal (RS 232, 422/485, 20 mA)

is being used and check wiring.

• Verify cable or radio connection to indicator.

• Verify indicator serial port function

• Verify the correct terminal (RS 232, 422/485, 20 mA)

is being used and check wiring.

• Verify cable to indicator.

• Verify that data is being transmitted to the XR from

the indicator and that the data string contains numeric

characters.

receiving.

• Verify the correct terminal (RS 232, 422/485, 20 mA)

is being used and check wiring.

• Verify cable or radio connection to indicator.

• Verify that a data string is being sent to the XR from

the indicator and that the data string contains either

an STX character (ASCII 02) or a CR character

(ASCII 13).

ports.

• Verify that unit has power. When powered, if the

Status light remains OFF, the processor is not

running.

• The XR is not able to Auto-Learn the data string or

baud rate. See Error Messages “Err 1” and Err 2”.

communications wiring at the indicator.

• Verify that data is being sent to the XR from the

indicator and that the data string contains numeric

characters.

52 XR Series Installation Instructions

Page 53

RS485 light not flashing: • Verify the RS485 terminal is being used and check

communications wiring at the indicator.

• Verify that data is being sent to the XR from the

indicator and that the data string contains numeric

characters.

20mA light not flashing: • Verify the 20mA terminal is being used and check

communications wiring at the indicator.

• Verify that data is being sent to the XR from the

indicator and that the data string contains numeric

characters.

• Make sure the correct mode (ACTIVE or PASSIVE) is

selected on the Controller board (SW10).

RADIO light not flashing: • Check that the radio module is properly installed.

Ensure that the internal antenna cable is connected

to the radio module and the external antenna.

• No data is being sent from the ScaleLink radio

connected to the scale indicator.

COM light not flashing: XR

2000 only

• Verify the correct terminal (RS 232, 422/485, 20 mA)

is being used and check communications wiring at

the indicator.

• Verify that the communications “Input Select” jumper

is set to the proper communication mode (RS 232,

422/485, 20 mA).

• If the radio module is being used, also see Probable

Solutions for “Radio light not flashing”

• Verify that data is being sent to the XR from the

indicator and that the data string contains numeric

characters.

XR Series Installation Instructions 53

Page 54

13 Spare Parts Lists

13 Spare Parts Lists

Following are the part numbers for the spare parts needed for the XR series remote

displays.

AWT PN 60339 DESCRIPTION

-4016 XR 2000 REMOTE DISPLAY, COMPLETE ASSY.

-4024 DISPLAY BOARD

-4032 CONTROLLER BOARD

-4040 POWER SUPPLY BOARD

-4057 NON-GLARE LENS

-4065 ENCLOSURE BASE

-4073 ENCLOSURE LID W/GASKET

-4081 POWER SUPPLY TO CONTROLLER BOARD CABLE

-4099 5" RIBBON CABLE

-4107 EXTERNAL POWER CORD

-4115 2" GROUND WIRE

-0113 INTEGRATED WIRELESS RADIO MODULE WITH

-0121 BASE STATION WIRELESS RADIO MODULE WITH

60314-0013 GORTEX BREATHER VENT

Additional Parts for the XR 2000

ANTENNA

CABLE FOR INDICATOR

54 XR Series Installation Instructions

Page 55

Additional Parts for the XR 4500

DESCRIPTION

AWT25-500612 CONTROLLER BOARD

60314-0013 GORTEX BREATHER VENT

AWT25-500616 KEYPAD W/LIGHT SENSOR WINDOW

60339-0048 POWER SUPPLY BOARD

60339-0055 10" RIBBON CHT SENSOR WINDOW

60339-0063 20" RIBBON CABLE

60339-0071 9" GROUND WIRE

60339-0089 11" GROUND WIRE

60339-0097 POWER SUPPLY TO CONTROLLER BOARD CABLE

60339-0105 EXTERNAL POWER CORD

60339-0113 INTEGRATED WIRELESS RADIO MODULE WITH

ANTENNA

60339-0121 BASE STATION WIRELESS RADIO MODULE WITH

CABLE FOR INDICATOR

60339-1012 XR 4500 REMOTE DISPLAY, COMPLETE ASSY.

60339-1020 DISPLAY DIGIT PC BD

60339-1079 VISOR

AWT05-503348 POLE MOUNT KIT

AWT25-500617 TEMPERATURE OPTION

Additional Parts for the XR 4500 TL

DESCRIPTION

AWT25-500615 XR CONTROLLER BOARD

60314-0013 GORTEX BREATHER VENT

AWT25-500616 KEYPAD W/LIGHT SENSOR WINDOW

60339-0048 POWER SUPPLY BOARD

60339-0055 10" RIBBON CABLE

60339-0063 20" RIBBON CABLE

60339-0071 9" GROUND WIRE

60339-0089 11" GROUND WIRE

60339-0097 POWER SUPPLY TO CONTROLLER BOARD CABLE

60339-0105 EXTERNAL POWER CORD

60339-0113 INTEGRATED WIRELESS RADIO MODULE WITH

ANTENNA

60339-0121 BASE STATION WIRELESS RADIO MODULE WITH

CABLE FOR INDICATOR

60339-3018 XR 4500 TL REMOTE DISPLAY, COMPLETE ASSY.

XR Series Installation Instructions 55

Page 56

13 Spare Parts Lists

Additional Parts for the XR 4500 TL

60339-3026 DISPLAY DIGIT WITH SIGNAL LIGHT

60339-3034 DISPLAY DIGIT PC BD

60339-2077 VISOR

AWT05-503348 POLE MOUNT KIT

AWT25-500617 TEMPERATURE OPTION

Additional Parts for the XR 6500

DESCRIPTION

AWT25-500612 XR CONTROLLER BOARD

60314-0013 GORTEX BREATHER VENT

AWT25-500616 KEYPAD W/LIGHT SENSOR WINDOW

60339-0048 POWER SUPPLY BOARD

60339-0055 10" RIBBON CABLE

60339-0063 20" RIBBON CABLE

60339-0071 9" GROUND WIRE

60339-0089 11" GROUND WIRE

60339-0097 POWER SUPPLY TO CONTROLLER BOARD CABLE

60339-0105 EXTERNAL POWER CORD

60339-0113 INTEGRATED WIRELESS RADIO MODULE WITH

ANTENNA

60339-0121 BASE STATION WIRELESS RADIO MODULE WITH

CABLE FOR INDICATOR

60339-2010 XR 6500 REMOTE DISPLAY, COMPLETE ASSY.

60339-2028 DISPLAY DIGIT PC BD

60339-2077 VISOR

AWT05-503348 POLE MOUNT KIT

AWT25-500617 TEMPERATURE OPTION

56 XR Series Installation Instructions

Page 57

14 Specifications

Power: • Input - 90 to 240 VAC, 50/60 Hz

• 115/230 VAC autosensing power supply

• Consumption - XR2000: 25 watt (60 watt max)

XR4500, 4500TL, 6500: 60 watt

Display: • 6 digit, 7 segment, high intensity (Precision Optical Performance) red LED lamp

• 2” characters (XR 2000), 60 foot viewing range

4.5” characters (XR 4500 and XR 4500TL), 275 foot viewing range

6.5” characters (XR 6500), 325 foot viewing range

• 1 or 2 decimals (XR 4500, XR 4500TL and XR 6500) up to 5 decimals (XR 2000)

• 4 annunciators (GR, NT, lb, KG)

• Capacity - (-99999 to 999999)

Input Data

Interface:

Data Format: • Baud Rates - 300 to 19,200, Auto-learning or selectable

Output Interface • Echo out port - RS-232

Update: • Continuous or demand, selectable

Operating

Environment:

Enclosure: • Weatherproof, powder-coated, mild steel

Dimensions: • XR 2000 - 12.85” x 6” x 2.40” (326mm x 152mm x 61mm)

Shipping Weight: • XR 2000 - 6 lb (3kg)

• RS-232, RS-485, 20 mA Current Loop (active or passive), wireless RF

• 7 or 8 data bits, even, odd, or no parity; 1 or 2 stop bits, Auto-learning or

selectable

• -40°F to 120°F (-40°C to 50°C) 0% to 100% humidity, noncondensing

• Nonglare, contrast lens

• XR 4500 - 24” x 8.88” x 10” (610mm x 226mm x 89mm)

• XR 4500TL / XR 6500 - 32” x 11.75” x 3.5” (813mm x 298mm x 89mm)

• XR 4500 - 18 lb (9kg)

• XR 4500TL / XR 6500 - 28 lb (13kg)

Warranty • 2 year limited

XR Series Installation Instructions 57

Page 58

14 Specifications

58 XR Series Installation Instructions

Page 59

Page 60

Avery Weigh-Tronix USA

1000 Armstrong Dr.

Fairmont MN 56031 USA

Tel:507-238-4461

Fax:507-238-4195

Email: usinfo@awtxglobal.com

www.wtxweb.com

Avery Weigh- Tronix UK

Foundry Lane,

Smethwick, West Midlands,

England B66 2LP

Tel:+44 (0) 8453 66 77 88

Fax: +44 (0)121 224 8183

Email: info@awtxglobal.com

www.averyweigh-tronix.com

Loading...

Loading...