Page 1

XLR Agricultural Remote Display

XLR-6, XLR-8 AND XLR-12 Models

Installation and Technical Instructions

AWT35-500576

Issue AF

Page 2

Avery Weigh-Tronix is a trademark of the Illinois Tool Works group of companies whose ultimate parent company is

Illinois Tool Works Inc (“Illinois Tool Works”). Copyright © 2015 Illinois Tool Works. All rights reserved.

No part of this publication may be reproduced by making a facsimile copy, by the making of a copy in three dimensions of a two-dimensional

work and the making of a copy in two dimensions of a three-dimensional work, stored in any medium by electronic means, or transmitted in

any form or by any means, including electronic, mechanical, broadcasting, recording or otherwise without the prior written consent of the

copyright owner, under license, or as permitted by law.

This publication was correct at the time of going to print, however Avery Weigh-Tronix reserves the right to alter without notice the

specification, design, price or conditions of supply of any product or service at any time.

XLR6_8_12_i_en_500576.book

Page 3

Table of Contents

Chapter 1 General Information and Warnings ........................................................................................ 5

About this Manual ..............................................................................................................5

Text Conventions ........................................................................................................5

Special Messages .......................................................................................................5

Installation ....................................... .................................... ...................................... .........6

Routine Maintenance .........................................................................................................6

Cleaning the Machine ........................................................................................................6

Training ..................................... ................................................................ .........................6

Sharp Objects .............................................................................. .... ... ... ............................6

Declaration of Conformity (CE approval) ........................................................................... 7

FCC and EMC Declarations of Compliance .......................................................................8

Technical Support ..............................................................................................................8

Chapter 2 Introduction .............................................................................................................................. 9

Chapter 3 Installation .............................................................................................................................. 10

Mounting Brackets ...........................................................................................................10

Adapter Mounting Plate ..................... .... ... ... ... .... .............................................................11

Stainless Steel Shield ......................................................................................................11

Connecting the Display to Your Equipment .....................................................................12

XLR-8 / XLR-12 Connections ....................................................................................12

XLR-6 Connections ...................................................................................................13

Cables ....................................................................................................................... 14

Stainless Steel Shield Installation ....................................................................................15

Setup of AWT Ag Indicators for Use With XLR Displays .................................................16

Setup for 640 Series Indicators .................................................................................16

Setup for 1040 and 2040 Series Indicators ...............................................................17

Setup for 2060 Indicators ..........................................................................................17

Setup for 3060 Touch Screen Indicators ...................................................................18

Using two XLR's with 2060 or 3060 Indicators ..........................................................18

Setup for Digi-Star Indicators ....................................................................................19

Chapter 4 Communicating With the Remote Display .............................................................. ............. 20

Computer Control Protocol ..............................................................................................20

Transmit a Weight String ...........................................................................................21

Transmit Status Characters .......................................................................................21

Transmit an Alphanumeric Message / Data String ....................................................21

Control Commands ...................................................................................................22

Sample Data Strings Sent to the Display ..................................................................22

Connector Pin outs ................................................... ... .... ... ... ... ... ....................................23

Chapter 5 Learn a New Transmitter Code (channel 1) ......................................................................... 24

Chapter 6 Specifications and Parts Lists .............................................................................................. 25

Specifications .................................. .................................... ...................................... .......25

Service Parts List ...... ...................................... .... ... ....................................... ... ... ... ..........26

Accessory Parts List ........................................................................................................27

XLR-6, XLR-8 and XLR-12 Installation Instructions 3

Page 4

4 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 5

1 General Information and Warnings

1.1 About this Manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled as shown by the 1 and 1.1 headings shown above.

The names of the chapter and the next subsection level appe ar at the top of alternating

pages of the manual to remind you of where you are in the manual. The manu al name

and page numbers appear at the bottom of the pages.

1.1.1 Text Conventions

Key names are shown in bold and reflect the case of the key being described. This

applies to hard keys and onscreen or soft keys.

Displayed messages appear in bold italic type and reflect the case of the displayed

message.

1.1.2 Special Messages

Examples of special messages you will see in this manual are defined below. The

signal words have specific meanings to alert you to additional inform ation or the relative

level of hazard.

ELECTRICAL WARNING!

THIS IS AN ELECTRICAL WARNING SYMBOL.

ELECTRICAL WARNINGS MEAN THAT FAILURE TO FOLLOW

SPECIFIC PRACTICES OR PROCEDURES MAY RESULT IN

ELECTROCUTION, ARC BURNS, EXPLOSIONS OR OTHER HAZARDS

THAT MAY CAUSE INJURY OR DEATH.

WARNING!

This is a Warning symbol.

Warnings mean that failure to follow specific practices and procedures may

have major consequences such as injury or death.

CAUTION!

This is a Caution symbol.

Cautions give information about procedures that, if not observed, could result

in damage to equipment or corruption to and loss of data.

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

XLR-6, XLR-8 and XLR-12 Installation Instructions 5

Page 6

1.2 Installation

DANGER: RISK OF ELECTRICAL SHOCK. NO USER SERVICEABLE

PARTS. REFER TO QUALIFIED SERVICE PERSONNEL FOR SERVICE.

1.3 Routine Maintenance

Always turn off the machine and isolate from the power supply before starting any

routine maintenance to avoid the possibility of electric shock.

Make sure that it is placed securely on a flat and level surface.

1.4 Cleaning the Machine

Table 1.1 Cleaning DOs and DON’Ts

DO DO NOT

Wipe down the outside of standard products

with a clean cloth, moistened with water and

a small amount of mild detergent

Spray the cloth when using a proprietary

cleaning fluid

1.5 Training

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instruction books.

1.6 Sharp Objects

Do not use sharp objects such as screwdrivers or long fingernails to operate the keys.

Attempt to clean the inside of the machine

Use harsh abrasives, solvents, scouring cleaners or

alkaline cleaning solutions

Spray any liquid directly on to the display windows

6 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 7

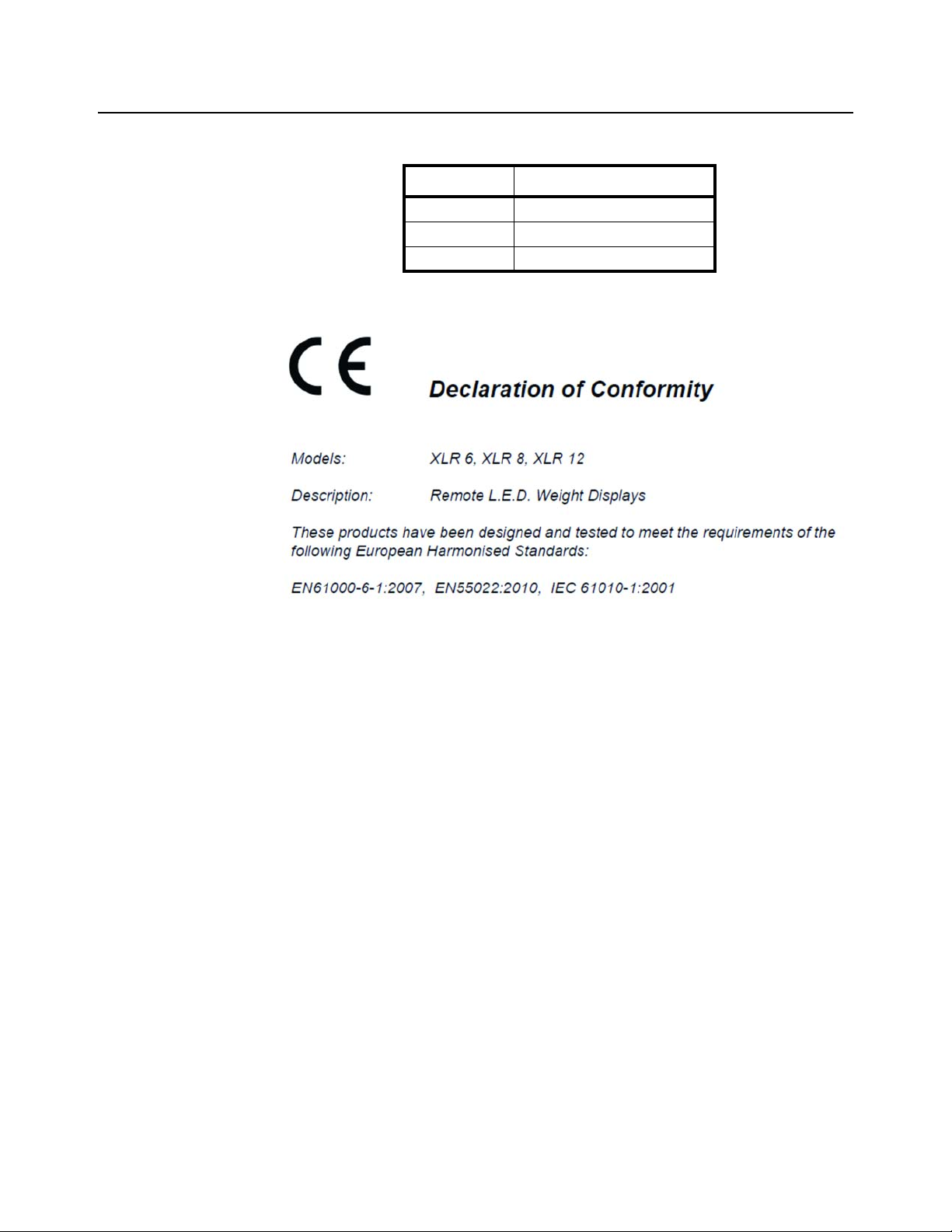

1.7 Declaration of Conformity (CE approval)

The following XLR-6, XLR-8, and XLR-12 part numbers are CE approved:

Model Part Number

XLR-6 AWT05-508584

XLR-8 AWT05-507376

XLR-12 AWT05-507377

XLR-6, XLR-8 and XLR-12 Installation Instructions 7

Page 8

1.8 FCC and EMC Declarations of Compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Canada

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la Classe A prescrites dans le Règlement sur le brouillage radioélectrique edicté par le ministère des Communications du Canada.

European Countries

WARNING: This is a Class A product. In a domestic environment, this product may cause radio interference in which the user may be

required to take adequate measures.

1.9 Technical Support

24/7 Customer Support

Avery Weigh-Tronix is dedicated to customer service. W e under sta nd downtim e is not

an option for AG producers and we're ready to help anytime. The technical suppo rt

team for all Avery Weigh-Tronix agri-business scales is available 24 hours a day 7 days

a week.

Ag Technical Support GroupUSA and Canada:

Toll free Phone: (800) 458 - 7062

Outside USA: (507) 238-8261

Tech Support Phone 7:00 am to 5:00 pm CST (800) 458-7062 Ext. 8261

Tech Support Phone/ after hours answering 5:00 pm to 7:00 am CST (800) 458-7062

Service e-mail:

usservice@awtxglobal.com

8 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 9

2 Introduction

The XLR-6, XLR-8 and XLR-12 remote displays incorporate the most features and

highest performance standards of any agricultural weighing display; making them the

best choice for remote viewing applications.

The XLR series features:

l Scrolling 8 or 12 character full Alphanumeric Display.

l Ultra wide viewing angles up to 120 degrees.

l Multi interface support including: Avery Weigh-Tronix, Digi-Star and RS-232

Computer interfaces.

l Quad (single for XLR-6) LED digits offering bold and easy to read digits in

direct sunlight.

l Dedicated bar graph assists in loading of ingredients.

l Large G and N annunciator for clear Gross/Net indication.

l Built-in standard Radio Clicker for ingredient advancement.

l Auto brightness control dims the display for ease of readin g dis pla y at night

time (XLR-8 and XLR-12 only).

l Easy to use communication protocol for custom applications.

l Same installation bracket and bolt pattern across all 3 models.

Figure 2.1 XLR-8 and XLR-12 Remote Display

Figure 2.2 XLR-6 Remote Display

NOTE: Remove the protective film on the XLR display. If the film is left on, it will

bake on the display over a period of time and decrease visibility.

XLR-6, XLR-8 and XLR-12 Installation Instructions 9

Page 10

3 Installation

3.1 Mounting Brackets

The XLR-6, XLR-8 and XLR-12 all have the same mounting bracket options and bolt

pattern.

The display is to be mounted on a solid mounting bracket or surface. The antenna wire

at the bottom right side of the unit should never be cut or pinched during installation.

The XLR remote display is equipped to support equipment that already has a

preexisting rail mount type bracket which is commonly used ( refer to section 3.2). The

display can alternatively be mounted using 4 mounting holes shown below. Use

minimum 3/8-16 UNC, 3/4" bolts or equivalent to mount.

Figure 3.1 Standard Mounting Bracket

Figure 3.2 Rail Mount Bracket

10 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 11

3.2 Adapter Mounting Plate

When utilizing the Rail Mount bracket (refer to Figure 3.2), there is an adapter mounting

plate (PN AWT20-504460), see Figure 3.3.

Weld or mount the plate to a surface. You can use hose clamps through the slots

marked with a A in Figure 3.3 to mount it to a pole or post.

There must be a 1/2 space between the plate and the mountin g surface to allow room

for the XLR to fit over the mounting plate.

Slip the mounting plate up into the slot on the back of the XLR and use bolts to attach

the XLR to the mounting plate through the bottom, mating holes marked with the letter

B in Figure 3.3.

The other holes are used to mount various other Avery We igh-tronix V -mount bracket s

and objects.

Figure 3.3 Adaptor Mounting Plate

3.3 Stainless Steel Shield

It is highly recommended to use the optional S t ainless S teel Shield with the XLR series

remote display. The Stainless Steel shield will help keep dust and moisture off of the

display to improve viewing quality.

Part Number Description

AWT20-508532 Protective Stainless Steel Shield XLR-6

AWT20-504832 Protective Stainless Steel Shield XLR-8

AWT20-504833 Protective Stainless Steel Shield for XLR-12

XLR-6, XLR-8 and XLR-12 Installation Instructions 11

Page 12

3.4 Connecting the Display to Your Equipment

All connections are made at the bottom of the unit using Amphenol 8-pin RS-232

circular connectors. All power and communications goes through a single cable.

NOTE: The XLR remote never needs to be opened for wiring. There are no switch

settings or internal adjustments required.

CAUTION: Never pressure wash your display as water may be forced through

the connectors causing electrical problems.

3.4.1 XLR-8 / XLR-12 Connections

If you are connecting to Avery Weigh-Tronix or equipment that uses RS-232

communications, then you will be connecting to connector A (8 pin male). If you are

using Digi-Star equipment then connect to connector B (8 pin female). Use only

supplied cable assemblies from the manufacturer.

Figure 3.4 XLR-8 / XLR-12 Connector Configuration

12 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 13

3.4.2 XLR-6 Connections

If you are connecting to Avery Weigh-Tronix or equipment that uses RS-232

communications, then you will be connecting to connector B (8 pin male). If you are

using Digi-Star equipment then connect to connector A (8 pin female). Use only

supplied cable assemblies from the manufacturer.

Figure 3.5 XLR-6 Connector Configuration

XLR-6, XLR-8 and XLR-12 Installation Instructions 13

Page 14

3.4.3 Cables

Part Number Description

Remote Display Cable with Power Supply

Part Number Description

AWT25-500473 10 ft / 3.1 m Cable Assembly, Serial RD with power

AWT25-500477 30 ft / 9.2 m Cable Assembly, Serial RD with power

Extension Cable

AWT25-501728 10 ft / 3.1 m extension cable to use with Serial RD cable assembly. This creates a

disconnect point between the indicator in the cab's cable and the remote display's

cable. Very useful when connecting and disconnecting mixer wagon to tractor.

Digi-Star Remote Display Cables

Part Number Description

AWT25-500928 15 ft / 4.6 m Cable Assembly, Interface to Digi-Star

AWT25-500929 30 ft / 9.2 m Cable Assembly, Interface to Digi-Star

14 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 15

3.5 Stainless Steel Shield Installation

without shield

with shield

without shield

1. Loosen the screws (two on each side) on both ends of the XLR remote display.

Refer to Figure 3.6 for screw location.

2. Slide the shield in place so that the 4 slots in the shield ends slide over the

screws.

3. Tighten the screws to secure the shield.

Figure 3.6 XLR-6 Protective Shield Installation

Figure 3.7 XLR-8 Protective Shield Installation

XLR-6, XLR-8 and XLR-12 Installation Instructions 15

Page 16

Figure 3.8 XLR-12 Protective Shield Installation

without shield

with shield

3.6 Setup of AWT Ag Indicators for Use With XLR Displays

Following are the instructions you need to setup an Avery Weigh-Tronix AG indicator

(Models: 640 Series; 640M, 640, 640XL, 1040/2040, 2060 and 3060) for use with an

XLR remote display

3.6.1 Setup for 640 Series Indicators

When using an XLR series remote display with an 640 Series indicator, an RS-232

serial port is required for the communication. Please verify that the 640 Series has one

free serial port before continuing through the setup steps. See the illustration of the port

connection in Figure 3.9.

Figure 3.9 RS-232 port Connection

To configure to communicate with th e XLR remote display, use the settings spelled out

in the list below. You may need to reference the 640 Series Service manual or contact

your Avery Weigh-Tronix provider for support. Multiple ports are available on the 640

Series, either Port1 or Port2 supports the XLR.

16 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 17

640 RS-232 Port Settings for XLR Series Remotes

l Baud = 9600

l Parity = None

l Data = 8

l Hand = None

l Layout = Remote

When these settings are used, the XLR remotes will show the same information that is

shown on the display of the 640 Series indicator. The XM60 transmitter is standard in

the XLR remote. When used, it will perform a programmable function for Input 2 in the

640 Series. Changing this function is done in the 640 Series menus and can be

changed by referencing the 640 Series service manual.

3.6.2 Setup for 1040 and 2040 Series Indicators

When using the XLR Series remotes with the 1040 or 2040 indicators, a serial port is

also required. This is the same connection as used in the 640 Series. Please r eference

the port connection shown in Figure 3.9 for reference whe n verifying the 1040/2040 has

the required ports.

1040 and 2040 RS-232 Port Settings for XLR Series Remotes

l Baud = 9600

l Parity = None

l Data = 8

l Hand = None

l Layout = RD40RF

All of the messages and weights that are show on the display of the indicator will be

shown on the XLR remote. The XM60 Transmitter is standard in the XLR remote

displays. When used with the 1040, it will advance to the next ingredient in the recipe.

3.6.3 Setup for 2060 Indicators

All 2060 indicators come standard with two Serial port s. Com port 1 is set as the default

remote display port. Com port 1 is always the serial port closest to the Weigh Bar

connectors.

2060 RS-232 Port Settings for XLR Series Remotes

l Baud = 9600

l Data (D-Bits) = 8

l Parity = None

l S-Bits = 1

l Hand (C-trol) = None

XLR-6, XLR-8 and XLR-12 Installation Instructions 17

Page 18

3.6.4 Setup for 3060 Touch Screen Indicators

From Indicator

From Power Supply

To XLR with Active Transmitter

To XLR with Inactive Transmitter

RS-232 Com port 2 or Com port 3 can run the XLR. If Feed Foreman is loaded on th e

3060, Com port 3 must be used.

3060 touch screen RS-232 Port Settings for XLR Series Remotes

l Baud = 9600

l Parity = None

l Data = 8

l Stop Bits = 1

l Hand = None

l Power = On

3.6.5 Using two XLR's with 2060 or 3060 Indicators

In order to run two XLR remotes with the 2060 or 3060, PN AWT05-505541 (XLR

Series Junction box) will be needed. Decide which XLR will have the active XM60

transmitter. In this setup one XLR will simply display weight and a second will also be

synced to a transmitter. Refer to Figure 3.10 for connection details.

18 XLR-6, XLR-8 and XLR-12 Installation Instructions

Figure 3.10 RS-232 Junction Box Connections

Page 19

3.6.6 Setup for Digi-Star Indicators

When using the XLR Series remotes with Digi-Star indicators:

1. Connect the XLR to the J-903 Remote port on the EZ-III indicator models (XLR

series is not compatible with EZ-II indicator models.)

Use the AWT Digi-Star interface cable from Avery Weigh-Tronix (PN

AWT25-500928 or AWT25-500929) or the standard cable supplied by

Digi-Star.

2. Follow instructions below based on the Digi-Star model of indicator you are

interfacing to.

Avery Weigh-Tronix XLR series cables for inte rfacing to Dig i-Star

indicators

l AWT25-500928 15 ft / 4.6 m Cable Assembly, Interface to Digi-Star

l AWT25-500929 30 ft / 9.2 m Cable Assembly, Interface to Digi-Star

EZ3 Indicators with full alpha and alph anumeric keypad (GT460, NT460,

EZ4600, EZ3600V, EZ3400VL, and EZ3400)

1. Enter 234 and press Select.

2. Press Select until EZ3MUX is displayed.

3. Press Enter.

EZ3 Indicators with alphanumeric keypad (EZ2500V, EZ2400V, EZ400,

and GT400)

1. Press Net/Gross first and then press On and hold them both down at the same

time until scrolling message "Press Select or Net…." appears.

2. Press Select until Menu2 appears and press On.

3. Press On until RMDisp appears then the current selection appears (EZ3MUX

or EZ2).

4. Press Select until EZ3MUX appears then press On.

5. Cycle power by turning the indicator off then back on or press On until you get

into weighing mode.

XLR-6, XLR-8 and XLR-12 Installation Instructions 19

Page 20

4 Communicating With the Remote Display

The XLR display automatically selects which type of communications protocol is being

used. When connecting to Avery Weigh-T ronix or Digi-Star equipment, the display will

automatically translate the display information correctly. No configuring of the display

is required. There are no adjustable settings for this display.

When transmitting weights to the display the annunciator character located on the left

hand side of the display will clearly display a G for gross weight or N for net weight. For

Digi-Star equipment the annunciator character will also flash L when loading

ingredients.

When the display is displaying alpha numeric text messages, the annunciator character

is not displayed.

The bar graph located across the bottom indicat es how clo se yo u ar e to target when

loading product. This is displayed as % of target weight.

4.1 Computer Control Protocol

If the display information is sent from alternate equipment using RS-232, then the

equipment’s baud rate must be set to 9600 no parity and 1 stop bit (9600 N81).The

display will attempt to analyze and display the weight information automatically.

NOTE: When connecting to non-A very Weig h-Tronix equipment, 12V must be applied

to the remote power pin 7 on the connector.

Custom applications may communicate to the display using a simple command

protocol that allows applications to make full use of all of the displays features.

All commands sent to the display must terminate with a CR character ASCII 13.

20 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 21

4.1.1 Transmit a Weight String

Use numeric ASCII characters followed by a <CR> character. Weights are displayed

from right to left.

Example:

l To display “1000”, transmit: 1000<CR>

4.1.2 Transmit Status Characters

Status characters may be embedded anywhere in the weight string to control the

annunciator characters ‘G’ or ‘N’. Status characters may be upper or lowercase, and in

any order, before or after the weight.

STATUS COMMAND ASCII DEC

GROSS weight G or g 71 or 103

NET weight N or n 78 or 110

Example:

l To display 1000 lb gross, transmit: 1000G<CR> -or- g1000<CR>

If no gross/net character is sent to the XLR, the “G” annunciator will be displayed by

default.

4.1.3 Transmit an Alphanumeric Message / Data String

The XLR can display the entire printable ASCII character set and supports scrolling

messages. When an alphanumeric data string is longer than the unit’s number of

display characters, the message will scroll (right to left).The maximum data string

length is 40 characters.

Alphanumeric message data strings must be preceded by the “ character (decimal 34)

and followed by a Carriage Return <CR> character (decimal 13) to differentiate them

from weight strings. Characters are displayed from left to right.

Example:

l To display the message Mixing transmit: “Mixing<CR>

XLR-6, XLR-8 and XLR-12 Installation Instructions 21

Page 22

4.1.4 Control Commands

Control commands are ASCII characters (preceded by @ and followed by <CR>) that

are transmitted to the display to control modes of operation. Numeric parameters

(when needed) follow the command character before <CR>.

CONTROL COMMAND ASCII DEC

Turn ON flashing display ( 40

Turn OFF flashing display ) 41

FLASH display 3 times ! 33

Scroll speed (1-3) 1=fast, 2=medium, 3=slow (default is 2) = 61

Bar Graph (0 – 100) ^ 94

Control Commands must be transmitted alone. Do not transmit Control Commands

within a WEIGHT data string or an alphanumeric message data string.

4.1.5 Sample Data Strings Sent to the Display

DATA STRING DISPLAY

0<CR> “G 0”

1000 <CR> “G 1000”

N 1234 <CR> “N 1234”

1234 g <CR> “G 1234”

“COTTON<CR> “ COTTON”

“Pen 12<CR> “ Pen 12”

“HOLD!<CR>@!<CR> “ HOLD!” flashing 3 times

“Avery Weigh-Tronix<CR> “Avery Weigh-Tronix” scrolling

@=3<CR>“Next Pen Number<CR> “Next Pen Number” slow scroll

@^50<CR> Bar graph = 50%

22 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 23

4.2 Connector Pin outs

When using Connector A, 12V must be supplied to Pin 7 for the unit to turn on.

Avery Weigh-Tronix RS-232 (8 pin male)

Pin 1 Not used

Pin 2 RS232 Tx

Pin 3 Not used

Pin 4 RS232 Rx

Pin 5 GND

Pin 6 GND

Pin 7 PWR ON

Pin 8 +12V

Digi-Star (8 pin female)

Pin 1 +12V

Pin 2 +12V

Pin 3 Clicker

Pin 4 Data

Pin 5 Clock

Pin 6 GND

Pin 7 Not used

Pin 8 GND

XLR-6, XLR-8 and XLR-12 Installation Instructions 23

Page 24

5 Learn a New Transmitter Code (channel 1)

1. Press the mode switch, pointed out in Figure 5.1.

The green LED will start to flash quickly.

Figure 5.1 Mode button on the remote receiver (PN AWT25-500927)

2. While the green LED is flashing quickly (approximately 15 seconds), press the

button on the remote transmitter shown in Figure 5.2.

The green LED will flash once and then turn off to show that the button

was learned.

Figure 5.2 Remote button (AWT15-501088)

3. Repeat steps 1 and 2 to learn more buttons into ch annel 1.

24 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 25

6 Specifications and Parts Lists

6.1 Specifications

Power

Supply Voltage: 11V to 24V DC

XLR-6 Max 3A (all LEDs on)

Typically >1A at 12V

XLR-8 Max 3.5A (all LEDs on)

Typically >1.5A at 12V

XLR-12 Max 4.5A (all LEDs on)

Typically >2.5A at 12V

Input Protection: Reverse Polarity with Thermal Fuse

Display

Display color: RED

Display Viewing Angle: 120 degrees

Number of Characters: 8 (XLR-6), 8 (XLR-8) and 12 (XLR-12)

Longest scrolling message displayable: 40 characters

Bargraph: 48 segments

Dimensions

Width: 13.25” (336.5 mm)

Height: 10.250” (260.4 mm)

Depth: 2.580” (65.5 mm)

Weight:

7lbs (3.2 kg)

Communication

Avery Weigh-Tronix Connector:

Voltage levels: RS-232

Input protocol: Avery Weigh-Tronix and Computer Control

Baud Rate: 9600 N81

Remote power ON signal pin 7: 5V -12V DC

Digi-Star Connector:

Voltage Levels: 5V Synchronous Clocked Data

Input Protocol: Digi-Star Remote display

Remote Clicker output: Transistor Open Collector to GND

Environment

Operating Temperature: -20° F to 140° F (-30° C to 60° C)

Agencies

FCC: CFR47 Part 15

Industry Canada: ICES-003 Issue 5

CE Approved

Warranty:

Three years

XLR-6, XLR-8 and XLR-12 Installation Instructions 25

Page 26

6.2 Service Parts List

AWTX Part # AWTX Description

XLR-6 Remote Display

AWT05-508244 Complete Remote Display, XLR-6 LED

AWT25-501915 Digit Board, 8 digit x 2”, XLR-6

AWT20-508551 Enclosure, Rear XLR-6 LED Remote

AWT20-508552 Enclosure, Front XLR-6 LED Remote

AWT20-508553 Lens Assy, Non-Glare XLR-6 (adh. gasket inc.)

AWT20-508554 Gasket, XLR-6 Remote

AWT20-508550 Cover, connector, XLR-6

AWT20-508532 Protective Stainless Steel Shield XLR-6

XLR-8 Scoreboard Remote Display

AWT05-503508 Complete Remote Display, XLR-8 LED

AWT20-504260 Enclosure, Rear XLR-8 LED Remote

AWT20-504261 Enclosure, Front XLR-8 LED Remote

AWT20-504262 Lens Assy, Non-Glare XLR-8 (adh. gasket inc.)

AWT20-504263 Gasket, XLR-8 Remote

AWT20-508548 Cover, connector, XLR-8

AWT20-504832 Protective Stainless Steel Shield XLR-8

AWT20-504269 Display Card, 4 Digit XLR Series

XLR-12 Scoreboard Remote Display

AWT05-503509 Complete Remote Display, XLR-12 LED

AWT20-504264 Enclosure, Rear XLR-12 LED Remote

AWT20-504265 Enclosure, Front XLR-12 LED Remote

AWT20-504266 Lens Assy, Non-Glare XLR-12 (adh. gasket inc.)

AWT20-504267 Gasket, XLR-12 Remote

AWT20-508549 Cover, connector, XLR-12

AWT20-504833 Protective Stainless Steel Shield for XLR-12

AWT20-504269 Display Card, 4 Digit XLR Series

XLR Common Parts

AWT20-504268 Controller Board, XLR Series

AWT25-501916 Wiring Harness, male conn., XLR

AWT25-501917 Wiring Harness, female conn., XLR

AWT15-501088 Remote Transmitter

AWT25-500927 Remote Receiver

26 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 27

6.3 Accessory Parts List

Part Number Description

AWT25-500473 10 ft / 3.1 m Cable Assembly, Serial RD with power

AWT25-500477 30 ft / 9.2 m Cable Assembly, Serial RD with power

AWT25-501728 10 ft / 3.1 m extension cable to use with Serial RD cable assembly. This creates

a disconnect point between the indicator in the cab's cable and the remote

display's cable. Very useful when connecting and disconnecting mixer wagon to

tractor.

AWT25-500928 15 ft / 4.6 m Cable Assembly, Interface to Digi-Star

AWT25-500929 30 ft / 9.2 m Cable Assembly, Interface to Digi-Star

AWT20-508532 Protective Stainless Steel Shield XLR-6. Helps keep dust and moisture off

display to improve viewing quality.

AWT20-504832 Protective Stainless Steel Shield XLR-8. Helps keep dust and moisture off

display to improve viewing quality.

AWT20-504833 Protective Stainless Steel Shield for XLR-12. Helps keep dust and moisture off

display to improve viewing quality.

AWT15-50188 Extra XM60 Remote Transmitter

AWT20-504460 XLR Mounting Plate Adapter

AWT05-505541 2 Remote Splitter Box for connecting 3060 with Feed Foreman to 2 XLR remote

displays (2nd separate Amp power source is needed for J-box)

XLR-6, XLR-8 and XLR-12 Installation Instructions 27

Page 28

28 XLR-6, XLR-8 and XLR-12 Installation Instructions

Page 29

Page 30

To access manuals on

Avery Weigh-Tronix USA

1000 Armstrong Dr.

Fairmont MN 56031 USA

Tel: 507-238-4461

Fax: 507-238-4195

Email: usinfo@awtxglobal.com

www.agscales.com

Avery Weigh-Tronix UK

Foundry Lane,

Smethwick, West Midlands,

England B66 2LP

Tel: +44 (0) 8453 66 77 88

Fax: +44 (0)121 224 8183

Email: info@awtxglobal.com

www.averyweigh-tronix.com

Loading...

Loading...