Page 1

Model 640 Series Indicators

User Instructions

NORTH AMERICA

43108-0019 Issue AE October 2009

Page 2

© Avery Weigh-Tronix group of companies 2009. All rights reserved.

No part of this publication may be reproduced, stored in an electronic retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording or otherwise without the prior written consent of

the copyright owner, or as permitted by law or under license. Full acknowledgment of the source must be given.

Avery Weigh-Tronix is a registered trade mark of the Avery Weigh-Tronix group of companies. This publication was

correct at the time of going to print however, Avery Weigh-Tronix reserves the right to alter without notice the

specification, design, price or conditions of supply of any product or service at any time.

All third party brands and product names used within this document are trademarks or registered trademarks of

their respective holders.

640_u_en_43108_0019.book

Page 3

Table of Contents

page

Chapter 1 General Information and Warnings ....................................................................................... 5

About this manual ..............................................................................................................5

Installation .......................................................................................................................... 6

Safe handling of equipment with batteries .................................................................. 6

Routine maintenance ......................................................................................................... 6

Cleaning the machine ........................................................................................................ 7

Training .............................................................................................................................. 7

Sharp objects ..................................................................................................................... 7

FCC and EMC declarations of compliance ........................................................................ 8

Chapter 2 Introduction ........................................................................................................................... 10

Front Panel ......................................................................................................................10

Key Descriptions ....................................................................................................... 11

Annunciators ............................................................................................................. 11

Display Messages ............................................................................................................ 12

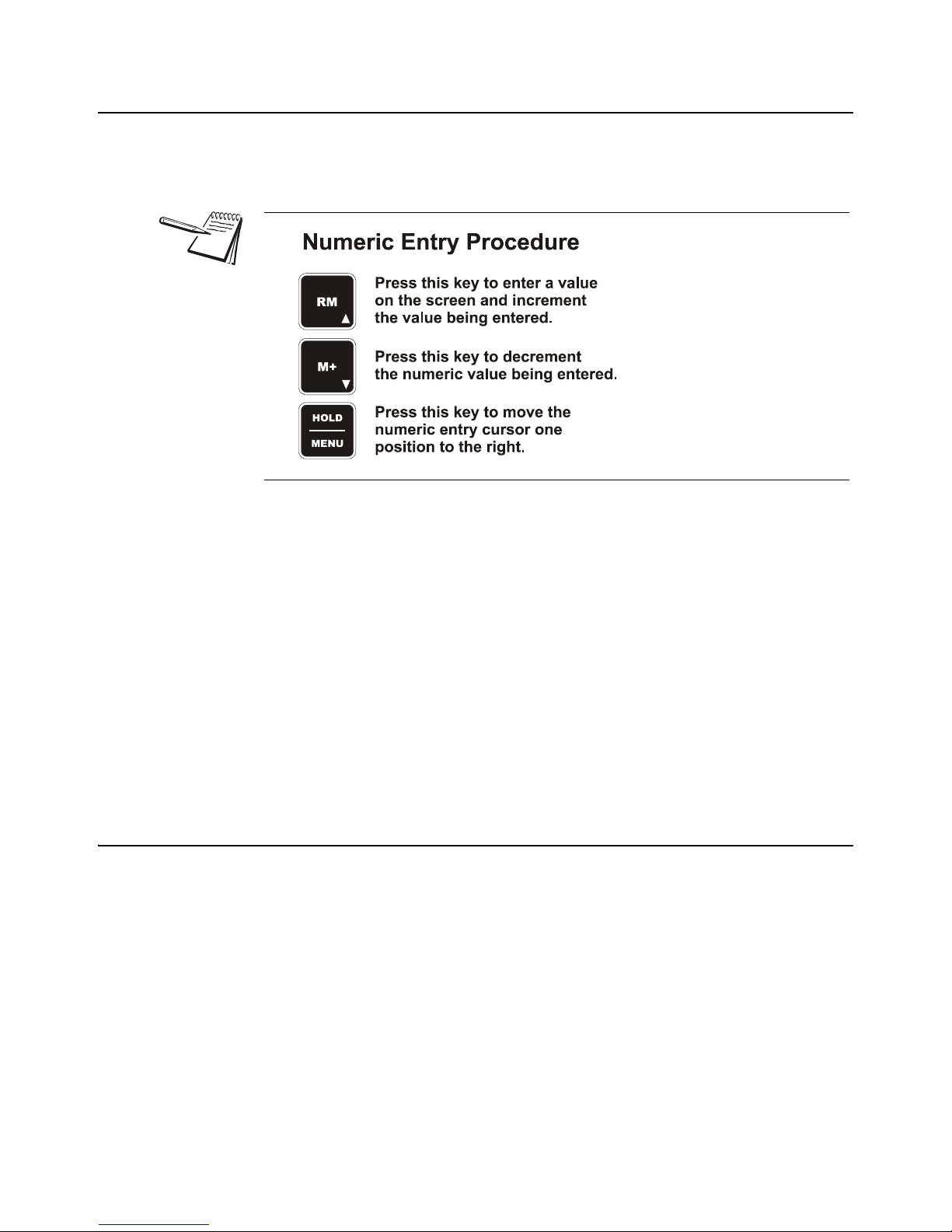

Numeric Entry Procedure ................................................................................................. 13

Getting Started ................................................................................................................. 13

Mounting the Model 640 .................................................................................................. 14

Cable Connections ........................................................................................................... 15

Model 640 and 640XL Bottom Panels ....................................................................... 15

Model 640M Lower Connector Options ..................................................................... 16

Connector Pin Descriptions ....................................................................................... 17

Chapter 3 User Menu .............................................................................................................................. 18

Editing The A-LIST ........................................................................................................... 20

Accessing the Accumulator Statistics .............................................................................. 21

Clearing Accumulators ..................................................................................................... 22

Viewing or Changing the Time ......................................................................................... 23

Viewing or Changing the Date ......................................................................................... 24

Entering / Viewing the Audible Keypad Setting ................................................................ 24

Entering / Viewing the Sleep Parameter .......................................................................... 25

Setting the Backlight Operation ....................................................................................... 25

Entering / Viewing the Language Selection (Not currently functioning) ........................... 27

Printing a Configuration Report ........................................................................................ 27

Chapter 4 Weighing Procedures ........................................................................................................... 29

Simple Weighing .............................................................................................................. 29

Gross/Tare/Net (GTN) Weighing (single tare example) ................................................... 29

Loading or Unloading Consecutive Net Amounts ............................................................ 30

Loading/Unloading Net Amounts (XM64 Transmitter) ..................................................... 30

Using Memory Channels to Accumulate .......................................................................... 31

Editing Memory Channel List .................................................................................... 31

Accessing Memory Channels .................................................................................... 32

Using Memory Channels to Accumulate ................................................................... 32

Clearing the Accumulators ........................................................................................ 32

To Clear a Specific Memory Channel ........................................................................ 34

To Print an Individual Memory Channel .................................................................... 34

To Print All Memory Channels ................................................................................... 34

Manual Hold for Mobile Systems ..................................................................................... 37

Using Hold Mode for Maintaining Weight Overnight ........................................................ 37

Animal Weighing Using AUTO-LOC Feature ................................................................... 37

How to Set Up AUTO-LOC ........................................................................................ 38

Model 640 Indicator Series User Instructions 3

Page 4

Weighing Individual Animals with Standard Mode AUTO-LOC ................................. 40

Weighing Individual Animals with Advanced Mode AUTO-LOC ............................... 40

Printing ............................................................................................................................. 42

Chapter 5 Test Menu .............................................................................................................................. 45

Test Menu Summary ........................................................................................................ 45

Access the Test Menu ..................................................................................................... 46

Test Menu Items .............................................................................................................. 46

VOLTS (Input voltage) ............................................................................................... 46

LCD (LCD Display test) ............................................................................................. 47

KEYPAD (Keypad test) ............................................................................................. 47

A/D (View /Test A to D counts) .................................................................................. 48

SERIAL (Testing Serial Ports) ................................................................................... 48

INPUT (Testing the Input) ......................................................................................... 49

SOFT (Software PN, version and revision) ............................................................... 49

Chapter 6 Remote Displays & XM64 Remote Transmitter .................................................................. 51

Remote Displays .............................................................................................................. 51

XM64 Wireless Remote Transmitter ................................................................................ 52

Chapter 7 Specifications ........................................................................................................................ 53

Chapter 8 Appendix: Quick Programming Guide ................................................................................ 55

How to Verify the Scale is Weighing Properly .................................................................. 55

To Access the Setup Menu (640) .............................................................................. 55

(CONFIG) Finding and Entering a Configuration Code Number ............................... 55

Configuration Code Numbers for Common applications: .......................................... 58

Configuring the Model 640 for Other Brand Weigh Bars and Loadcells .................... 58

Viewing/Entering a Custom Calibration Number ....................................................... 59

How to Configure Filtering ............................................................................................... 60

Chapter 9 Appendix: Troubleshooting ................................................................................................. 62

Power ON Problems ........................................................................................................ 62

Indicator +/- RANGE Problem .......................................................................................... 63

Indicator Over or Under Capacity Problem ...................................................................... 64

Inaccurate Weight Readings ............................................................................................ 64

Drifting Weight Readings ................................................................................................. 64

Loss of Data: Time & Date or Memory channels ............................................................. 65

How to Get Service Repairs ............................................................................................. 65

4 Model 640 Indicator Series User Instructions

Page 5

1 General Information and Warnings

1.1 About this manual

This manual is divided into chapters by the chapter number and the large text at the top

of a page. Subsections are labeled as shown by the 1 and 1.1 headings shown above.

The names of the chapter and the next subsection level appear at the top of alternating

pages of the manual to remind you of where you are in the manual. The manual name

and page numbers appear at the bottom of the pages.

Text conventions

Key names are shown in bold and reflect the case of the key being described. This

applies to hard keys and onscreen or soft keys.

Displayed messages appear in bold italic type and reflect the case of the displayed

message.

Special messages

1.1 About this manual

There are five types of special text messages, NOTE, CAUTION, WARNING,

DANGER, and ELECTRICAL HAZARD. Each will appear as illustrated below:

NOTE: This contains extra information on a concept or process.

CAUTION: This may cause damage to the product or data loss.

WARNING: This could result in injury or death

DANGER: THIS WILL RESULT IN INJURY OR DEATH

ELECTRICAL DANGER: THIS WILL RESULT IN INJURY OR DEATH.

Model 640 Indicator Series User Instructions 5

Page 6

1 General Information and Warnings

1.2 Installation

DANGER: RISK OF ELECTRICAL SHOCK. NO USER SERVICEABLE

PARTS. REFER TO QUALIFIED SERVICE PERSONNEL FOR SERVICE.

1.2.1 Safe handling of equipment with batteries

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended by the manufacturer. Dispose

of used batteries according to the manufacturer’s instructions.

ATTENTION: Il y a danger d'explosion s'il y a remplacement incorrect de la

batterie, remplacer uniquement avec une batterie du même type ou d'un type

équivalent recommandé par le constructeur. Mettre au rebut les batteries

usagées conformément aux instructions du fabricant.

1.3 Routine maintenance

IMPORTANT: This equipment must be routinely checked for proper operation

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

Always turn off the machine and isolate from the power supply before starting any

routine maintenance to avoid the possibility of electric shock.

Make sure that it is placed securely on a flat and level surface.

6 Model 640 Indicator Series User Instructions

Page 7

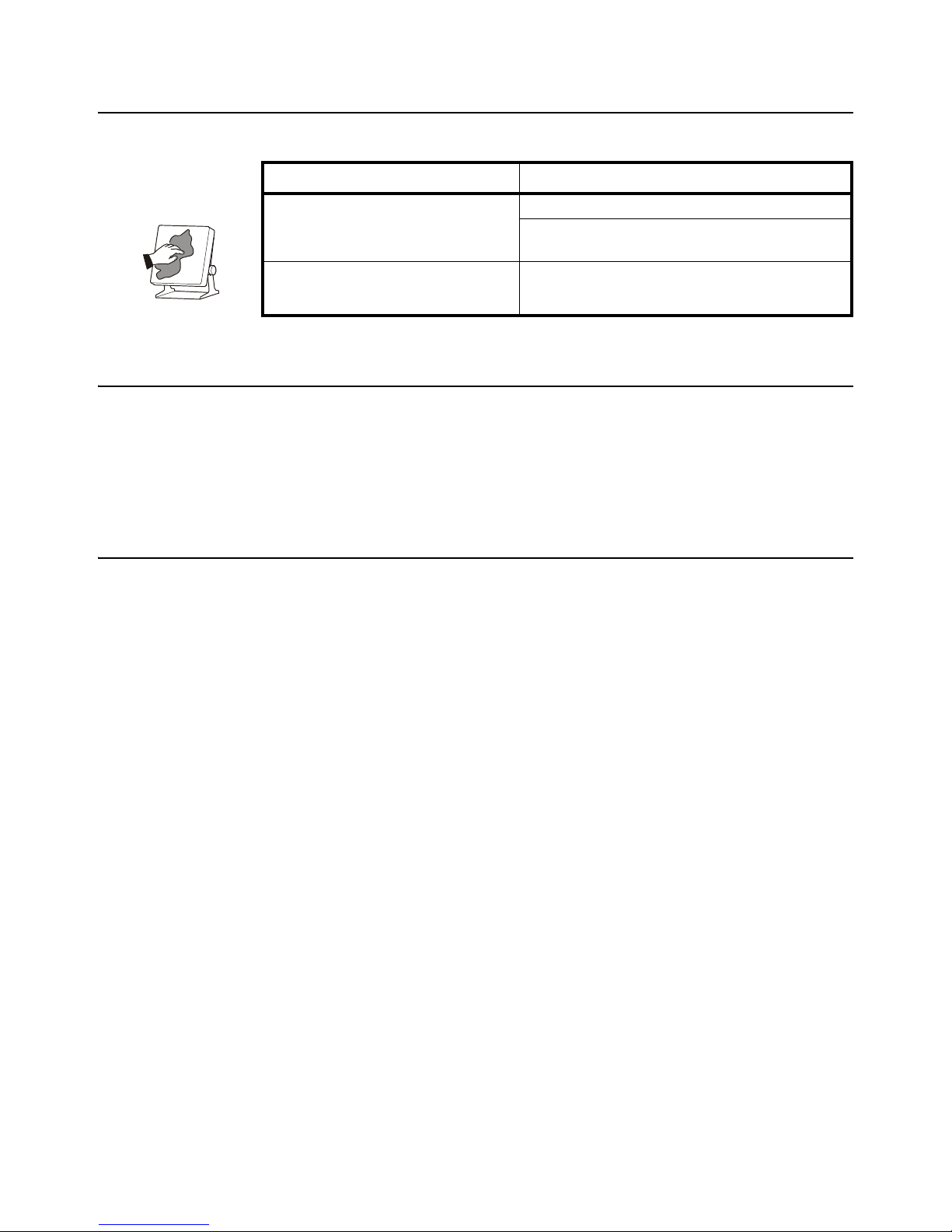

1.4 Cleaning the machine

Table 1.1 Cleaning DOs and DON’Ts

DO DO NOT

1.4 Cleaning the machine

Wipe down the outside of standard products

with a clean cloth, moistened with water and

a small amount of mild detergent

Spray the cloth when using a proprietary

cleaning fluid

1.5 Training

Do not attempt to operate or complete any procedure on a machine unless you have

received the appropriate training or read the instruction books.

To avoid the risk of RSI (Repetitive Strain Injury), place the machine on a surface which

is ergonomically satisfactory to the user. Take frequent breaks during prolonged usage.

1.6 Sharp objects

Do not use sharp objects such as screwdrivers or long fingernails to operate the keys.

Attempt to clean the inside of the machine

Use harsh abrasives, solvents, scouring cleaners or

alkaline cleaning solutions

Spray any liquid directly on to the display windows

Model 640 Indicator Series User Instructions 7

Page 8

1 General Information and Warnings

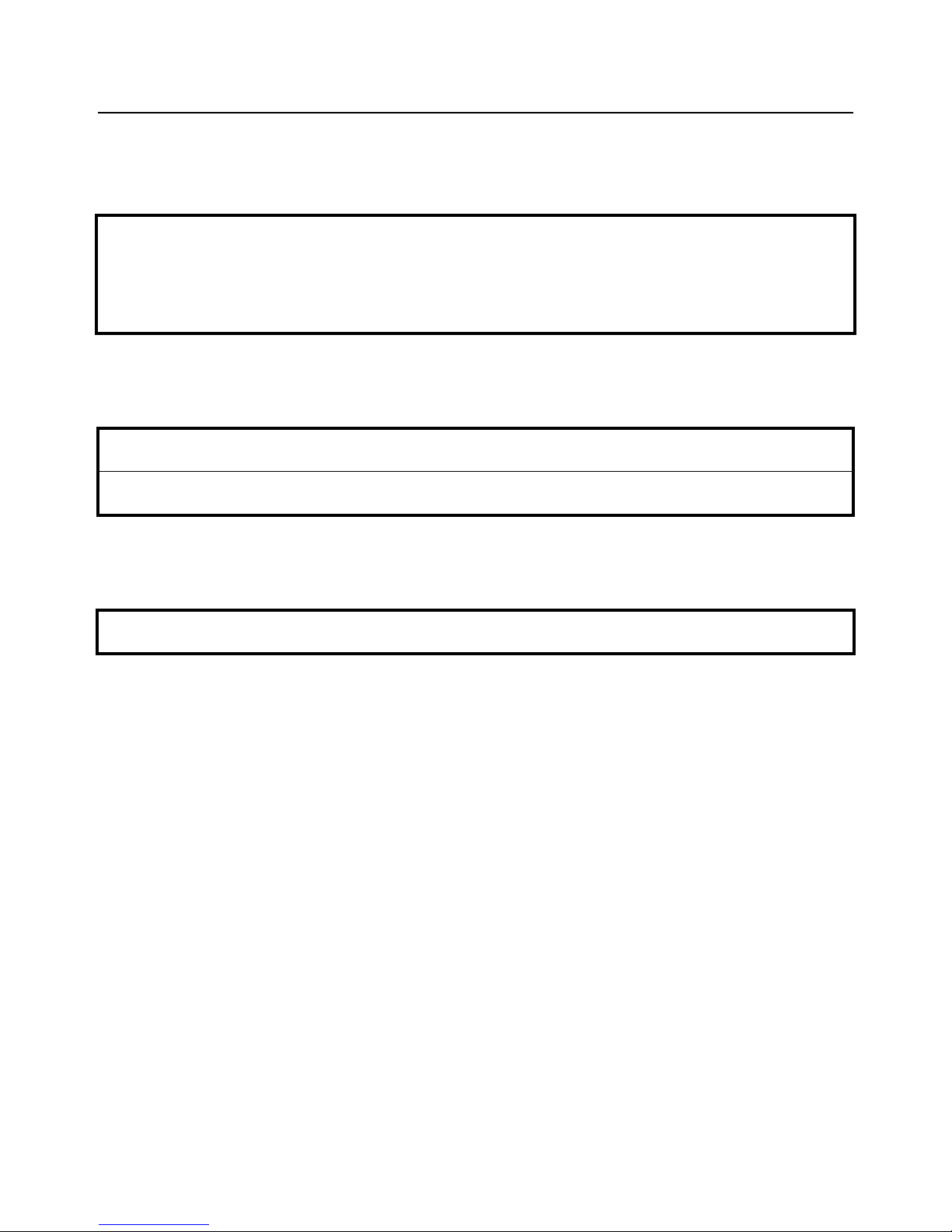

1.7 FCC and EMC declarations of compliance

United States

Table 1.2

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Canada

Table 1.3

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la Classe A prescrites dans le Règlement sur le brouillage radioélectrique edicté par le ministère des Communications du Canada.

European Countries

Table 1.4

WARNING: This is a Class A product. In a domestic environment, this product may cause radio interference in which the user may be

required to take adequate measures.

8 Model 640 Indicator Series User Instructions

Page 9

1.7 FCC and EMC declarations of compliance

Model 640 Indicator Series User Instructions 9

Page 10

2 Introduction

DEALER CONTACT key

2 Introduction

This manual covers the information you need to operate your

Avery Weigh-Tronix Model 640 indicator and remote display products.

Included in this manual are the Model 640, 640XL, 640M indicators and the RD40XL,

RD40, and RD40RF remote displays.

2.1 Front Panel

The Model 640 indicator face is shown in Figure 2.1.

10 Model 640 Indicator Series User Instructions

Figure 2.1 Front panel

Page 11

2.1.1 Key Descriptions

Key names will appear as bold, upper case words in this manual. Examples: TARE,

G/N, etc.

Annunciators will appear as italic words. Examples: G/N, Lb, etc.

Displayed messages will appear as bold, italic words. Examples: HELLO, LO-BAT,

etc.

There are a total of 8 keys. All keys except the ON/OFF will have audible feedback with

low, medium, or high volume settings.

ON/OFF Press to turn the unit On/Off

TARE Press to tare the weight on the scale

ZERO/CLEAR Press to zero G/N weight. It also is used to clear memory

G/N Press to toggle between gross and net weight

2.1 Front Panel

channels.

HOLD/MENU Press this key to hold a displayed weight. Press again to release

PRINT/SELECT Press this key to send data to an attached data collection device,

RM Press this key to access a memory channel, so the indicator is

M+ Press this key to accumulate weights. Also, use this key to

SERVICE Press this key if you need contact information for your scale

2.1.2 Annunciators

the hold mode. The weight is retained in memory in case the unit

is turned off. When powered up again the weight reading will still

be displayed. This key is also used to move to the right in the

menu structure. Use this key to also move the numeric entry

cursor one space to the right. This will be explained in the User

Menu on page 18 of this manual.

printer, TDM or computer. This key is also used to move down in

the menu structure.

ready for accumulations into that channel. Also, use this key to

increment numbers during the numeric entry procedure.

decrement numbers during the numeric entry procedure.

dealer. A key sticker will be placed in the location shown in Figure

2.1 if contact information was programmed by the dealer.

The Model 640 uses six triangle annunciators for Lb, kg, G/N, Net, Auto and Motion.

G/N Indicates the unit is in the gross/net weighing mode.

NET Indicates the unit is in the net weighing mode.

MOTION Displayed when there is scale motion. This is based off the stability window

Lb Indicates the unit is weighing in pounds.

Model 640 Indicator Series User Instructions 11

parameters. See the Service Manual.

Page 12

2 Introduction

AUTO Displayed if the unit is programmed for AUTO-LOC. AUTO-LOC is used in

animal weighing applications. Reference Animal Weighing Using AUTO-

LOC Feature on page 37.

Kg Indicates the unit is weighing in kilograms.

2.2 Display Messages

Following are the messages that may appear on the display and what they mean:

Message Meaning

HELLO Message displayed on power-up sequence for 3 seconds

- - - - - - UPPER DASHES, Indicator is in a state of overcapacity, or analog

- - - - - - LOWER DASHES, Indicator is in a state of undercapacity, or

- - - - - - MIDDLE DASHES, This means the 640 is setup in Remote Mode.

input is too high.

analog input is too low.

Call support to change setup to perform as a scale.

NO TARE Displayed when you press the G/N key and there is no tare weight

established.

PRINT Indicator is transmitting data. Appears after pressing the print key

for a second.

LO-BAT Alternates on the display between current mode and LO-BAT

when input voltage is between 9-10 volts.

HOLD Used when moving a portable system.

L XXXX XXXX = weigh value Displayed when the indicator is in AUTO-

LOC mode and has locked on a weight.

+RANGE Displayed when weight input exceeds 8 mV/V.

-RANGE Displayed when weight input exceeds -8 mV/V.

SHTDWN Is shown on the display prior to shutting the indicator off after the

sleep timer has expired, or when you press the ON/OFF key. (10

seconds before sleep timer shutdown the alarm beeps several

times).

CAN’T Displayed when attempting to access too large of a numeric entry

OR memory channel number greater than 100 OR if trying to zero

in net mode.

MAINT Maintenance required. A timer was set by the dealer as a reminder

to perform maintenance.

12 Model 640 Indicator Series User Instructions

Page 13

2.3 Numeric Entry Procedure

Anytime you need to enter numeric values, use the keys as described below. The note

below will appear throughout areas of the manual to remind you of the key presses

needed to enter numbers.

2.3 Numeric Entry Procedure

EXAMPLE: To enter the number 5230:

1. At the data entry screen, press the RM key several times until…

2. Press the HOLD/MENU key and…

3. Press the RM key several times until…

4. Repeat process until…

2.4 Getting Started

Before using your new Model 640 indicator:

l Please verify that everything has been properly connected. Reference Cable

Connections on page 15

l If you are mounting the indicator, see the next section: Mounting the Model

640.

5 is displayed

5_ is displayed

52 is displayed.

5230 is shown.

l Check the scale system to ensure proper units are set (lb, kg)

l Verify the system is weighing properly. Do this by following these steps:

1. In the gross weighing mode, zero the indicator by pressing the ZERO/CLEAR

key

Model 640 Indicator Series User Instructions 13

Page 14

2 Introduction

2. Stand on the scale and note the scale reading.

If the weight reading is correct, your system is working properly and

you can continue with operation of the system.

If the weight reading is not correct, read through Appendix: Quick

Programming Guide on page 55. This will tell you how to access the

SETUP menu to change the Configuration Code Number (CCN). This

should get your system up and running properly. If you have further

problems, call your local dealer or Avery Weigh-Tronix.

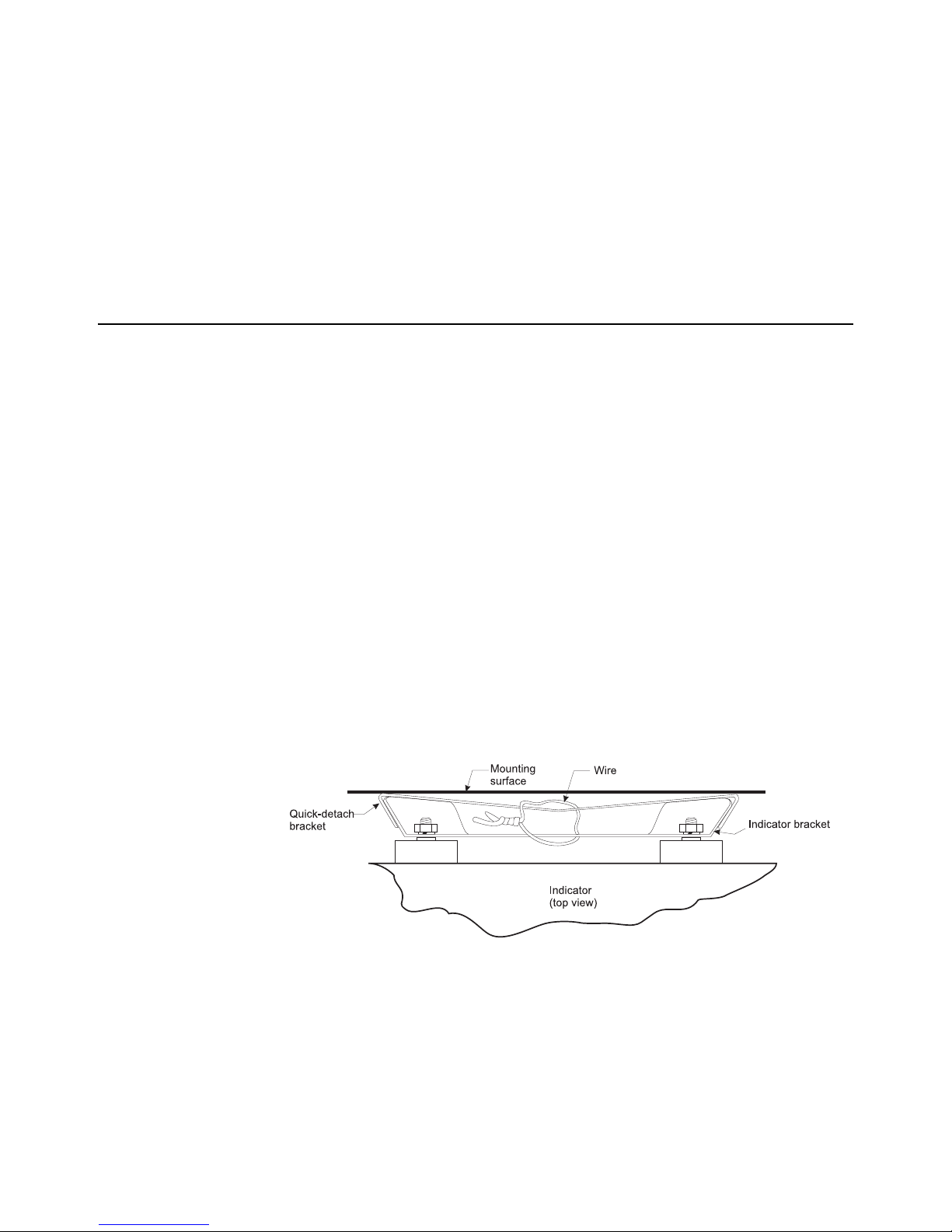

2.5 Mounting the Model 640

The Model 640 mounts on a quick-detach bracket. Weld or bolt the quick-detach

bracket into place, as follows:

1. Choose a mounting location that is

l convenient for operation of the indicator, and

l protected from moving parts or from other moving machinery.

2. Hold the indicator at the proposed mounting location, and verify that the

display is legible and the controls accessible.

3. Positioning the quick-detach bracket with the wider end at the top, mark the

desired mounting location. If bolting, use the quick-detach bracket as a

template and mark and drill holes.

4. Weld or bolt the quick-detach bracket at the appropriate location. If bolting,

use double nuts or self-locking nuts to protect both indicator and machinery.

5. Insert the indicator bracket into the quick-detach bracket and push it down into

place.

6. For mobile applications, wrap and twist a strong wire around the indicator

bracket and the quick-detach bracket, through the slotted hole provided, to

stabilize the mounting. See the illustration below.

14 Model 640 Indicator Series User Instructions

Page 15

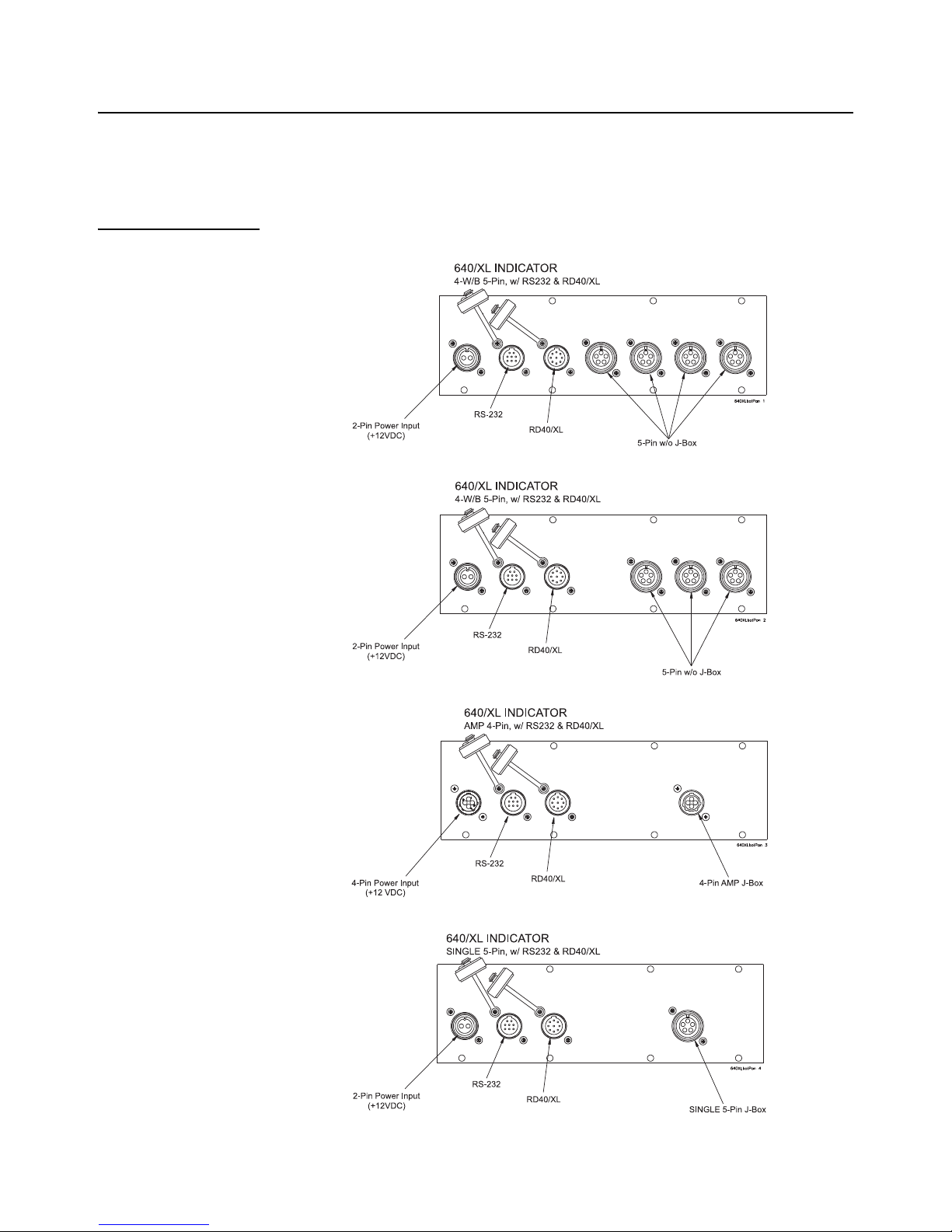

2.6 Cable Connections

Below are illustrations to help you make the proper connections to the different versions

of the Model 640.

2.6.1 Model 640 and 640XL Bottom Panels

2.6 Cable Connections

Model 640 Indicator Series User Instructions 15

Page 16

2 Introduction

640M INDICATOR

Single 5-Pin, w/RS232 & RD40RF

2-Pin Power Input

(+12VDC)

Antenna

RS-232

5-Pin J-Box

NOT L AL FOR T DE

FAI , MN SA

S/N: YYMMXXXXX

10-17 VDC @ 500mA

MODEL 640M

Contains FCC ID:

R68WIPORT

Contains FCC ID:

R68WIPORT

Contains FCC ID:

R68WIPORT

640M INDICATOR

Single 5- Pi n, W- T Power , w/ RS232 & RD40RF

Single 5-Pin,W-T Power, RS232 & RD40 or RD40XL

640M INDICATOR

640M INDI CATOR

Single AMP, AMP Power , w/ RS232 & RD40 RF

640M INDICATOR

Single AMP,AMP Po wer,RS 232 & RD40 o r RD40XL

640M INDICATOR

Two 5-Pin, W-T Power, RS232

Single 5-Pi n & W/T Po wer

640M INDICATOR

Single AMP, AMP Power , RS23 2

640M INDICATOR

640M INDICATOR

Single 5-Pin, W-T Power, RS232

640M INDICATOR

Two 5-Pin & W-T Power

Single AMP, AMP Power

640M INDICATOR

1

93

2

5

9

3

6

1

7

3

2

4

4

4

5 7

3

6

4

1

3

8

1

2

3

5

6

1

3

2

4

4

1

8

5

6

4

640M INDICATOR

AMP 4-Pin, w/RS232 & RD40RF

4-Pin Power Input

(+12 VDC)

4-Pin AMP J-Box

RS-232

Antenna

MODEL 640M

10-17 VDC @ 500mA

S/N: YYMMXXXXX

FAI , MN SA

NOT L AL FOR T DE

Contains FCC ID:

R68WIPORT

640M INDICATOR

AMP 4-Pin, w/RS232 & RD40RF or RD40XL

RD40/XL

RS-232

(+12 VDC)

4-Pin Power Input

4-Pin AMP J-Box

DEL 640M

17 VDC @ 500mA

S/N: YYMMXXXXX

FAI , MN SA

NOT L AL FOR T

640M INDICATOR

2 W/B 5-Pin, w/RS232

2 Weigh Bar

(Alley or Chute Weigh)

RS-232

2-Pin Power Input

(+12VDC)

ODEL 640M

17 VDC @ 500mA

S/N: YYMMXXXXX

FAIRMONT, MN USA

NOT LEGAL FOR T E

2.6.2 Model 640M Lower Connector Options

16 Model 640 Indicator Series User Instructions

Page 17

2.6.3 Connector Pin Descriptions

2.6 Cable Connections

Model 640 Indicator Series User Instructions 17

Page 18

3 User Menu

3 User Menu

This section takes you through the User menu. You will use this menu to set many of

the scale functions.

Access this menu from the G/N mode by pressing the HOLD/MENU key for two beeps.

See Figure 3.1.

18 Model 640 Indicator Series User Instructions

Figure 3.1 User Menu

Page 19

Below is a summary of the items in this menu, followed by a comprehensive

explanation of each item:

A-LIST Used to edit the memory accumulator descriptions

A-STAT Used to access statistics of the memory accumulator channels

CLR.ACC Use this to clear accumulator channels

MEM.ENA Use this to disable or enable memory channel functions. If enabled, A-

LIST, A-STAT and CLR.ACC do not appear in the user menu.

TIME Use to set the time

DATE Use to set the date

VOLUME Use to set the volume of the audible key buzzer.

SLEEP Use to set the amount of inactive time before the indicator turns itself off.

BKLGHT Use to set the backlight brightness.

NATION Use to set the spelling of messages in the following: English, Spanish,

French, German, Dutch and Danish

REPORT Use to print out indicator ‘system configuration settings’.

Model 640 Indicator Series User Instructions 19

Page 20

3 User Menu

3.1 Editing The A-LIST

The A-LIST item is only active if the MEM.ENA menu item is set to YES.

If the application requires alphanumeric channel names, go through the memory

channel list and edit their descriptions accordingly. For example, if you want to record

grain cart loads from five different fields, then create a list of FIELD1, FIELD2,

…FIELD3. Now the custom names of the memory channels can be used, otherwise all

memory channels will be the default descriptions of MEM.001, MEM.002, etc.

1. From the G/N mode, press HOLD/MENU for 2 beeps…

A-LIST is shown on the display. (Only appears if MEM.ENA is enabled)

2. Press the PRINT/SELECT key…

EdiT is displayed

3. Press PRINT/SELECT again and …

MEM.001 is displayed, or the last memory channel accessed.

4a. Use the MENU key to scroll to the channel you want to edit

OR

4b. Use the RM^ and MENU keys to enter in the position on the list of the memory

channel name to edit.

EXAMPLE: To edit MEM.025, press RM^ three times to enter the ‘2’.

Press MENU to move the cursor. Enter the ‘5’ by pressing RM^ six times

and press ENTER. This procedure takes you directly to the 25th channel

in the list.

5. When the desired channel name is found, press SELECT and you are

Edit mod

6. Using the RM^ key, start entering the new channel name. Press MENU to

move the cursor. To move the cursor back one character, press the TARE key.

20 Model 640 Indicator Series User Instructions

now in

e. The annuncatiors should be flashing when in this mode.

Page 21

3.2 Accessing the Accumulator Statistics

7. Press SELECT when the desired name has been entered. The display will

now show the channel name list. Repeat steps 3 - 7 to edit more channel

names.

8. Press G/N three times to return to G/N weighing mode.

3.2 Accessing the Accumulator Statistics

This item is only active if the MEM.ENA menu item is set to YES.

This section allows you to access the accumulator statistics.

1. From the G/N mode, press and hold the HOLD/MENU key for two beeps (2

sec), then release…

A-LIST is displayed.

2. Press the HOLD/MENU key once…

A-STAT is displayed. This stands for accumulator statistics.

3. Press the PRINT/SELECT key…

WT.TOT is displayed.

4. Press the PRINT/SELECT key…

Total weight accumulated in all the accumulators is displayed.

5. Press the PRINT/SELECT key…

WT.TOT is displayed.

6. Press the HOLD/MENU key once…

CNT.TOT is displayed.

7. Press the PRINT/SELECT key…

The total number or count of accumulations performed is shown.

8. Press the PRINT/SELECT key…

CNT.TOT is displayed.

9. Press the HOLD/MENU key …

AVG.TOT is displayed.

10. Press the PRINT/SELECT key…

11. Press the PRINT/SELECT key…

12. Press the HOLD/MENU key …

Model 640 Indicator Series User Instructions 21

The average weight of all accumulations is displayed.

AVG.TOT is displayed.

PRINT is displayed.

Page 22

3 User Menu

13. Press the PRINT/SELECT key …

The statistics printout is transferred to the TDM or printer device. A

sample is shown below:

04-25-2006

14:20:26

TOTAL WEIGHT: 1938370 lb

AVG. WEIGHT: 44050 lb

TOTAL COUNT: 44

14. Press the G/N key to return to A-STAT. Press G/N key again to return to G/N

weighing mode.

3.3 Clearing Accumulators

This item is only active if the MEM.ENA menu item is set to YES.

This section allows you to clear the accumulators.

1. From the G/N mode, press and hold the HOLD/MENU key for two beeps (2

sec), then release…

2. Press the HOLD/MENU key repeatedly until…

3. Press the PRINT/SELECT key…

4. Press the HOLD/MENU key…

22 Model 640 Indicator Series User Instructions

A-LIST is displayed.

CLR.ACC is displayed.

NO is displayed.

YES is displayed.

Page 23

5. Press the PRINT/SELECT key…

WAIT is displayed while clearing, then MEM.CLR is briefly displayed,

then unit returns to the G/N weighing mode.

3.4 Viewing or Changing the Time

The Model 640 has standard battery backed time and date features. The time can be

configured for 24 hour or 12 hour clock for printouts in the 640 menu, but must always

be entered first as 24 hr entry:

1. From the G/N mode, press and hold the HOLD/MENU key for two beeps (2

sec), then release…

A-LIST is displayed.

2. Press the HOLD/MENU key repeatedly until…

TIME is displayed.

3. Press PRINT/SELECT and …

Current time is shown ticking.

3.4 Viewing or Changing the Time

4a. Press PRINT/SELECT to accept displayed time…

TIME is displayed.

OR

4b. To change time, use the numeric entry procedure to enter HHMMSS and press

PRINT/SELECT to accept…

TIME is displayed.

5. Press the G/N key…

Returns to the G/N mode.

Model 640 Indicator Series User Instructions 23

Page 24

3 User Menu

3.5 Viewing or Changing the Date

The indicator has battery backed time and date standard. The date can be entered as

follows:

1. From the G/N mode, press and hold the HOLD/MENU key for two beeps (2

sec), then release…

A-LIST is displayed.

2. Press the HOLD/MENU key repeatedly until…

dATE is shown.

3. Press the PRINT/SELECT key

MMddYY (lb)

or

ddMMYY(kg) is displayed momentarily, then current date setting is

shown.

4. Use the numeric entry procedure to enter the date.

(lb) enter MMddYY

(kg) enter ddMMYY

5. Press the PRINT/SELECT key to accept the displayed date…

dATE is shown.

6. Press the G/N key…

Indicator returns to the G/N mode.

3.6 Entering / Viewing the Audible Keypad Setting

The Model 640 keys have audible feedback that can be configured for off, low, medium,

or high. (Default is high)

1. From the G/N mode, press and hold the HOLD/MENU key for two beeps (2

sec), then release…

A-LIST is displayed.

2. Press the HOLD/MENU key repeatedly until…

VOLUME is displayed

3. Press the PRINT/SELECT key…

4. Press HOLD/MENU repeatedly until appropriate setting is shown, then press

PRINT/SELECT…

5. Press the G/N key…

24 Model 640 Indicator Series User Instructions

Current setting is shown.

VOLUME is displayed.

Returns to the G/N weighing mode.

Page 25

3.7 Entering / Viewing the Sleep Parameter

3.7 Entering / Viewing the Sleep Parameter

The Model 640 has a sleep mode that can shut the unit off if the following conditions

occur:

l The indicator doesn’t see any keys being pressed, or

l The weight hasn’t changed by more than 1% over the number of minutes that

was entered for the sleep setting.

Setting the Sleep setting (DEFAULT = 0, for off)

1. From the G/N mode, press and hold the HOLD/MENU key for two beeps (2

sec), then release…

A-LIST is displayed.

2. Press the HOLD/MENU repeatedly until…

SLEEP is displayed.

3. Press the PRINT/SELECT key…

Current setting is displayed.

When the unit goes to sleep, the unit will first activate the audible alarm, and user has

10 seconds to press a key to reset the SLEEP timer. If a key hasn’t been pressed

within these 10 seconds the display shows SHTDWN, and the unit shuts off.

4. Use the numeric entry procedure and enter in the sleep shutoff setting from 099 minutes…

Entered value is displayed.

5. Press the PRINT/SELECT key…

SLEEP is displayed.

6. Press the G/N key…

Returns to the G/N mode.

3.8 Setting the Backlight Operation

The Model 640 has a backlight you can configure. Follow these steps to configure

backlight operation.

1. From the G/N mode, press and hold the HOLD/MENU key for two beeps (2

sec), then release…

2. Press the HOLD/MENU key repeatedly until….

3. Press the PRINT/SELECT key…

Model 640 Indicator Series User Instructions 25

A-LIST is displayed.

BKLGHT is displayed.

Current setting is displayed. (ON or OFF)

Page 26

3 User Menu

4. Press the HOLD/MENU key to toggle between the two settings. Press PRINT/

SELECT when your choice is displayed. If you choose ON…

LEVEL is displayed. Use this to set the illumination level of the backlight

(10% to 100%).

5. Press the PRINT/SELECT key to access the level…

Current setting is displayed. (100% is default value)

6. Scroll through the choices by repeatedly pressing the HOLD/MENU key. Press

PRINT/SELECT when your choice is displayed.

LEVEL is displayed.

7. Press the HOLD/MENU…

TIMER is displayed. Use this to set the amount of time which must pass

with no scale or indicator activity before the unit shuts down the

backlight for power saving.

8. Press the PRINT/SELECT key to access the timer function…

Current setting is displayed.

9. Use the numeric entry procedure to enter a choice in seconds (0-99). Press

PRINT/SELECT to accept your choice.

TIMER is displayed.

10. Press G/N key twice…

BKLGHT is displayed.

11. Press the G/N key…

Indicator returns to the G/N mode.

26 Model 640 Indicator Series User Instructions

Page 27

3.9 Entering / Viewing the Language Selection (Not currently functioning)

3.9 Entering / Viewing the Language Selection (Not currently

functioning)

The Model 640 has a selectable language for the displayed messages and reports.

1. From the G/N mode, press and hold the HOLD/MENU key for two beeps (2

sec), then release…

A-LIST is displayed.

2. Press the HOLD/MENU key repeatedly until….

NATION is displayed.

3. Press the PRINT/SELECT key…

Current setting is displayed.

4. Use the HOLD/MENU keys and scroll to the proper language selection…

Proper selection is shown.

5. Press the PRINT/SELECT key to accept displayed choice…

NATION is displayed.

6. Press the G/N key…

Returns to the G/N mode.

3.10 Printing a Configuration Report

1. From the G/N mode, press and hold the HOLD/MENU key for two beeps (2

sec), then release…

A-LIST is displayed.

2. Press the HOLD/MENU key repeatedly until….

REPORT is displayed.

3. Press the PRINT/SELECT key…

A configuration report on the current status of your indicator is output

through the RS-232 port to your connected device.

4. Press the G/N key…

Returns to the G/N mode.

Model 640 Indicator Series User Instructions 27

Page 28

3 User Menu

A sample report is shown below:

----------------------------System Configuration Settings

04-25-2006 11:29:00

----------------------------PART : 60259-0026

REV : 1.9.0

User's Menu

----------VOLUME: HIGH

SLEEP TIMER : OFF

BKLGHT: ON

LEVEL : 100%

NATION: ENGLSH

MEM.ENA: ON

640 Setup Menu

--------------

MODE : 640

CONFIG: S130

1.0 mV/V: 37470 lb

O-CAP : 200000 lb

DIV : 10 lb

PRINT FORMAT: G-T-N w/ Date-Time

CLOCK : 24 HR

DATE : MM-DD-YY

AUT.LOC: OFF

AUT.ACC: OFF

INPUT1: STD

INPUT2: STD

UPDATE: 5 Hz

AVERGE: 30

FILTER: ON

CONST : 2

WINDOW: 0 lb

AZT : OFF

STABLE: 1 DIV

STABLE: 1.0 SEC

RS232 :

BAUD : 9600

DATA : 8

PARITY: NONE

HAND : NONE

LAYOUT: STD

ENQR : 5

AUTO : OFF

ACC.PRN: OFF

CH.NAME: OFF

Factory Menu

-----------FAC.SPN: 99779

FAC.ZERO: 76370

28 Model 640 Indicator Series User Instructions

Page 29

4 Weighing Procedures

This section covers the procedures for different weighing processes.

4.1 Simple Weighing

1. Press ON…

Display shows HELLO then the current weight value is displayed.

2. Press G/N and access gross mode…

Live scale weight is displayed in the G/N weighing mode.

3. Remove all material from the scale and press ZERO/CLEAR

0 is displayed, and the system is zeroed.

Establishing zero here is the same as doing the calibration zero.

If unit is in AUTO-LOC mode and L is displayed, to zero the scale, press and hold the

ZERO/CLEAR key for two seconds.

4.1 Simple Weighing

4.2 Gross/Tare/Net (GTN) Weighing (single tare example)

For GTN weighing (weighing net amounts), follow these steps:

1. Press ON…

Display shows HELLO then the current weight value is displayed.

2. Press G/N to access the gross mode…

Live scale weight is displayed in the G/N weighing mode.

3. Remove all material from the scale and press ZERO/CLEAR

0 is displayed, and the system is zeroed.

The zero point established at this point is the same as calibration zero. If a system is

set at 20000 lb, and a user tares at 18000, then the system can only allow another

2000 lb before displaying (- - - - - -) upper dash lines for overcapacity.

If no tare weight has been established, push G/N key to show NO TARE.

4. Place material to be tared on the scale…

Weight of material is displayed.

5. Press the TA RE key to tare the weight from the display…

Model 640 Indicator Series User Instructions 29

0 weight is displayed and the Net annunciator lights to indicate there is

an active tare weight.

Page 30

4 Weighing Procedures

6. Place the material to be weighed on the scale…

Net weight is displayed.

7. Remove the weighed material from the scale (leaving the tared item).

8. Repeat steps 6 through 7 for each weighment using the same tare weight.

9. To remove the tare weight, press the G/N key to return to gross weigh mode,

then press the ZERO/CLEAR key…

The tare weight is removed and you can repeat this process to weigh

more material with a different tare.

4.3 Loading or Unloading Consecutive Net Amounts

This procedure allows the user to load/unload a series of net amounts. This procedure

is ideal for TMR mixers, weigh carts, grain carts, etc. for viewing and recording net

amounts of material loaded and unloaded.

1. In gross mode, press the ZERO/CLEAR key to zero the indicator when the

mixer or scale system is empty.

2. After initial amount is placed on the scale, press the TARE key…

Weight is tared off and goes into net mode, showing 0 weight.

3. Load or Unload material as needed…

Shows + when loading and a – value when unloading.

4. When the display reaches the proper amount, stop loading or unloading

material.

5. Repeat steps 2 through 4 until complete.

4.4 Loading/Unloading Net Amounts (XM64 Transmitter)

This procedure allows the user to load/unload a series of ingredient/unload amounts by

using the XM64 transmitter/receiver. This procedure implies that the end user knows

the net amounts that must be loaded or unloaded. The XM64 gives the user the ability

to tare or zero each ingredient and view the net amount as loading or unloading. It also

can be used to indicate the G/N amount between ingredients and can return the

indicator to the G/N mode when done loading by holding down on the XM64 for three

or more seconds.

1. In gross mode, press the ZERO/CLEAR key to zero the indicator when the

mixer or scale system is empty.

2. After material is placed on the scale, press the XM64 key…

3. Load or Unload material as needed…

4. When the display reaches the proper amount, stop loading or unloading

material.

30 Model 640 Indicator Series User Instructions

Weight is tared off and goes into net mode, showing 0 weight.

Shows + when loading and a – value when unloading.

Page 31

4.5 Using Memory Channels to Accumulate

5. Repeat steps 2 through 4 until complete.

You may now view the G/N weight by pressing and holding the XM64 button, once.

Releasing the button if within three seconds unit returns to the net mode showing zero.

If you are done loading and now want to return to the G/N mode for unloading, press

and hold the XM64 for more than three seconds.

4.5 Using Memory Channels to Accumulate

The Model 640 has 100 memory channels available for accumulating weights. This can

be helpful in accumulating loads of feed on a mixer, grain cart or weigh cart yields, or

setting up groups of livestock. Each channel will also have the total number of

accumulations obtained, total weight and the average weight of all weights

accumulated, both total and for each individual channels.

4.5.1 Editing Memory Channel List

If the application requires alphanumeric channel names, go through the memory

channel list and edit their descriptions accordingly. For example, if you want to record

grain cart loads from five different fields, then create a list of FIELD1, FIELD2,

…FIELD3. Now the custom names of the memory channels can be used, otherwise all

memory channels will be the default descriptions of MEM.001, MEM.002, etc.

1. From the G/N mode, press HOLD/MENU for 2 beeps…

A-LIST is shown on the display. (Only appears if MEM.ENA is enabled)

2. Press the PRINT/SELECT key…

EdiT is displayed

3. Press PRINT/SELECT again and …

MEM.001 is displayed, or the last memory channel accessed.

4a. Use the MENU key to scroll to the channel you want to edit

OR

4b. Use the RM^ and MENU keys to enter in the position on the list of the memory

channel name to edit.

EXAMPLE: To edit MEM.025, press RM^ three times to enter the ‘2’.

Press MENU to move the cursor. Enter the ‘5’ by pressing RM^ six times

and press ENTER. This procedure takes you directly to the 25th channel

in the list.

5. When the desired channel name is found, press SELECT and you are snow in

Edit mode. The annuncatiors should be flashing when in this mode.

6. Using the RM^ key, start entering the new channel name. Press MENU to

move the cursor. To move the cursor back one character, press the TARE key.

7. Press SELECT when the desired name has been entered. The display will

now show the channel name list. Repeat steps 3 - 7 to edit more channel

names.

8. Press G/N three times to return to G/N weighing mode.

Model 640 Indicator Series User Instructions 31

Page 32

4 Weighing Procedures

4.5.2 Accessing Memory Channels

1. From the G/N mode, press the RM^ key…

MEM.001 is shown or the last accessed channel.

This will now access the MEM.001 channel. If you want any other

channel either use the HOLD/MENU key to scroll to the proper channel,

or use the RM^ and the HOLD/MENU key to access directly to channel

XX, then press PRINT/SELECT.

2. Press HOLD/MENU twice, and…

MEM.003 is shown

3. Either press the G/N key to return to gross weighing, or wait 3 seconds and it

will automatically return to the gross weighing mode.

4.5.3 Using Memory Channels to Accumulate

1. Press M+ and the following is displayed:

Active memory channel is shown

M+

TOTAL

Actual Accumulated total is shown

2. If accumulated in error, press and hold M+ until the second beep and the

following is displayed…

Active memory channel is shown

DELETE

TOTAL

New Actual Accumulated total is shown

4.5.4 Clearing the Accumulators

1. From the G/N mode, press and hold on the HOLD/MENU key for two beeps (2

sec) and release…

A-LIST is shown.

2. Press HOLD/MENU twice…

CLR.ACC is shown

3. Press PRINT/SELECT…

4. Press HOLD/MENU…

32 Model 640 Indicator Series User Instructions

NO is displayed.

YES is displayed.

Page 33

4.5 Using Memory Channels to Accumulate

5. Press PRINT/SELECT…

WAIT is displayed, then MEM.CLR. Once the unit is done clearing

accumulators CLR.ACC is displayed again.

6. After the accumulators are cleared press G/N to return to the G/N weighing

mode.

Model 640 Indicator Series User Instructions 33

Page 34

4 Weighing Procedures

4.5.5 To Clear a Specific Memory Channel

1. Access the proper memory channel.

2. From the G/N mode, press and hold ZERO/CLEAR key until the second

beep…

MEM.XXX is displayed then MEM.CLR is displayed. MEM.XXX is now

cleared.

4.5.6 To Print an Individual Memory Channel

1. From the G/N mode, press the RM key…

MEM.001 is displayed or the last accessed memory channels.

This will now access the MEM.001 channel. If you want any other

channel either use the HOLD/MENU key to scroll to the proper channel,

or use the RM and the HOLD/MENU key to access directly to channel

XX, then press PRINT/SELECT.

Accumulators can go as far as 99,000,000.

2. Once the proper channel is displayed, press PRINT/SELECT and the following

report will be printed to the printer or TDM module.

Before printing PR-RM is shown on the display…

09-11-2007

11:12:17

CHANNEL: 1

NAME: MEM.001

ACCUM. WEIGHT: 1000000 lb

ACCUM. COUNT: 20

ACCUM. AVERAGE: 50000 lb

3. The indicator automatically returns to the gross weighing mode.

4.5.7 To Print All Memory Channels

1. Press RM^…

34 Model 640 Indicator Series User Instructions

Latest memory channel is displayed.

Page 35

4.5 Using Memory Channels to Accumulate

2. Press PRINT/SELECT for 2 secs…

PR-ALL is momentarily displayed and information is transmitted.

The indicator will only print out memory channels that have accumulated weight

amounts.

3. Indicator returns to gross weighing mode.

Mem channel printout

04-25-2006

14:17:19

MEM CH COUNT AVG WT TOTAL

FIELD1 18 29980 lb 539550 lb

FIELD2 14 51390 lb 719390 lb

CUSTOM 12 56620 lb 679430 lb

TOTAL 44 44050 lb 1938370 lb

Model 640 Indicator Series User Instructions 35

Page 36

4 Weighing Procedures

36 Model 640 Indicator Series User Instructions

Figure 4.1 Menu

Page 37

4.6 Manual Hold for Mobile Systems

The Model 640 has a manual hold using the HOLD/MENU key to prevent a zero shift

from occurring on any portable scale system (i.e. mixer, weigh cart, grain cart, etc.). To

use the HOLD/MENU key to prevent any small zero shifts from occurring while moving

a system over rough farm terrain, follow these steps.

When using the hold mode, user must be sure hold mode has been deactivated when

loading or unloading to the mixer.

1. In the G/N Mode, before moving the mixer system press HOLD/MENU…

HOLD will be displayed.

2. Now move the system and when reaching the new loading or unloading point,

press either the HOLD/MENU or G/N key…

G/N weight will be displayed.

4.6 Manual Hold for Mobile Systems

4.7 Using Hold Mode for Maintaining Weight Overnight

The Model 640 has a HOLD/MENU key to prevent minimal scale weight shifts due to

temperature changes.

1. In the gross weighing mode, when you are finished with the scale for the day,

but material is left on the scale, press the HOLD/MENU key…

HOLD is displayed.

2. Turn the system off for the night.

3. The following day turn the unit on by pressing the ON/OFF key…

HOLD is displayed.

4. Press G/N key and…

Exact weight from the previous day is displayed.

4.8 Animal Weighing Using AUTO-LOC Feature

The Model 640 has a feature called AUTO-LOC. It is specifically designed for use in

weighing livestock. Once the indicator has determined the animal’s weight, the

indicator display automatically locks on that weight. The weight reading will not change

as long as the animal is on the scale. This makes the weight easy to record since the

numbers are not rapidly changing as the animal moves on the scale.

AUTO accumulate feature can be turned on or off to work with AUTO-LOC. Refer to

Figure 8.3 Table for 5th CCN Digit on page 55 to choose a 5th digit of the CCN which

will turn on the accumulator.

There are two modes in the Auto–LOC feature:

Model 640 Indicator Series User Instructions 37

Page 38

4 Weighing Procedures

Standard LOC Mode

In standard mode, an animal’s weight is locked on the display until the animal leaves

the scale.

Advanced LOC Mode

In advanced mode, an animal’s weight is locked on the display until the next animal

comes onto the scale.

4.8.1 How to Set Up AUTO-LOC

Follow these steps to set up the AUTO-LOC feature:

1. Access the Setup menu from the G/N mode. Press and hold the HOLD/MENU

key for three beeps (3 seconds), then release…

SET.PAS is displayed.

2. Use the numeric entry procedure, described below, to enter the password 640.

Press PRINT/SELECT to accept it…

640 is shown.

3. Press PRINT/SELECT once more…

4. From CONFIG, press PRINT/SELECT…

5. If attempting to enter an invalid number display will show CAN’t and return to

CONFIG.

6. Use the numeric entry procedure to enter the new number and press the

PRINT/SELECT key when finished.

38 Model 640 Indicator Series User Instructions

CONFIG is displayed. Change your current configuration code number

to one that turns AUTO-LOC on. Refer to Figure 8.3 Table for 5th CCN

Digit on page 57. Once you have your five digit number, enter it as

follows:

Current code number is shown.

CONFIG is shown.

Page 39

4.8 Animal Weighing Using AUTO-LOC Feature

7. Press the HOLD/MENU key several times until…

AUT.LOC appears. The AUTO-LOC menu selection only shows up when

a configuration code number turns on this feature.

This menu item is where you choose standard or advanced LOCK,

minimum weight (MIN.WT), and release tolerance (REL.TOL)

appropriate for the livestock application.

8. Press the PRINT/SELECT key…

MODE is displayed.

9. Press the PRINT/SELECT key…

STD.LOC is displayed. This is the standard LOCK. Toggle between this

and the ADV.LOC by pressing the HOLD/MENU key.

10. When your choice is displayed, press the PRINT/SELECT key…

Your choice is selected and MODE is displayed.

11. Press the HOLD/MENU key…

MIN.WT is displayed. This is where you set the minimum weight that

must be on the scale to activate the AUTO-LOC feature. This prevents

smaller weights from locking on the display. See the example below.

EXAMPLE: If you are weighing 1200 pound cattle, you may set the minimum weight

at 800 pounds and a release tolerance of 25%. Anything thing that goes on the scale

that weighs less than 800 pounds (like a person or the neighborhood dog) will not

cause the weight to lock. When an animal steps off the scale and the weight drops by

at least 300 pounds (25% of 1,200 pounds), the system will reset to lock on the next

weight above 800 pounds.

12. To set the minimum weight, press the PRINT/SELECT key…

Use the numeric entry procedure to enter the minimum weight value.

13. When the value is entered, press the PRINT/SELECT key to accept it and…

MIN.WT is displayed.

14. Press the HOLD/MENU key…

REL.TOL is displayed. This is the release tolerance. This is set in steps

12 and 13 which must be removed from the scale before the AUTO-LOC

resets. See example in the left margin of page 39.

15. Press the PRINT/SELECT key…

Use the numeric entry procedure to enter the release tolerance in

percentage of the minimum weight.

16. When the value is entered, press the PRINT/SELECT key to accept it and…

Model 640 Indicator Series User Instructions 39

Your choice is selected and REL.TOL is displayed.

Page 40

4 Weighing Procedures

You can exit the menu and return to normal weighing mode by repeatedly pressing the

G/N key. If, during operation the AUTO-LOC feature seems very slow, this can be due

to excessive weight fluctuations. In this case you can access the Setup menu and

increase the FILTER-CONSTANT parameter until it works properly. Reference How to

Configure Filtering on page 60 for instructions on adjusting the filtering.

4.8.2 Weighing Individual Animals with Standard Mode AUTO-LOC

The following describes how a Model 640 can be used for weighing and recording an

animal’s weight automatically on a single animal livestock scale with standard mode

AUTO-LOC. Unit must be setup for AUTO-LOC and set for standard (STD.LOC) mode.

1. Turn indicator on, press the G/N key to access the gross mode and press the

ZERO key…

0 is displayed.

2. Move animal onto the scale…

L WWWW is shown

WWWW = animals auto-locked weight

If a false locked weight occurred, press ZERO/CLEAR to recheck the

animals weight. This will also delete from the accumulators the last

locked-on weight and replace it with the new locked-on weight.

If auto-accumulate is on, once the weight is locked-on, the Model 640

will automatically accumulate to the last selected memory channel.

Weight stays locked until the weight on the scale drops by the

programmed release tolerance. (Example: weighing a 2000 lb animal

with a 25% release tolerance, means the lock will release when weight

drops below 1500 lb).

If the animal is released and the weight falls below the tolerance it may

be possible to lock on another weighment. We recommend putting in a

high release tolerance like 75% to insure reliable operation.

Also to prevent an inadvertent AUTO-LOC if someone leans/steps on

the scale, we recommend putting in a large amount for the MIN.WT

parameter to prevent this from occurring. (EX: 300 lb)

3. Remove the animal from the scale…

Scale returns to live weighing mode

4. Repeat steps 2 and 3.

4.8.3 Weighing Individual Animals with Advanced Mode AUTO-LOC

The following describes how a Model 640 can be used for weighing and recording

animal’s weight automatically on a single animal livestock scale using the advanced

AUTO-LOC mode. The indicator must be setup for AUTO-LOC and set for advanced

(ADV.LOC) mode. In addition, the auto-accumulate feature can be turned on or off.

40 Model 640 Indicator Series User Instructions

Page 41

4.8 Animal Weighing Using AUTO-LOC Feature

The M640 will lock on an animals weight and stay locked even after the animal is off

the scale. A new AUTO-LOC weight will only be retriggered upon placing the next

animal on the scale.

1. Turn indicator on use the G/N key to access the gross mode, and press the

ZERO CLEAR key…

Display shows 0

2. Move animal onto the scale…

L WWWW is shown. WWWW = animals auto-locked weight

If a false locked weight occurred, press ZERO/CLEAR to recheck the

animals weight. This will also delete from the accumulators the last

locked-on weight and replace it with the new locked-on weight.

If autoaccumulate is on, once the weight is locked-on, the Model 640 will

automatically accumulate to the last selected memory channel.

Weight stays locked until the next animal is on the scale.

Also to prevent an inadvertent AUTO-LOC if someone leans/steps on

the scale, we recommend putting in a large amount for the MIN.WT

parameter to prevent this from occurring. (EX: 300 lb)

3. Remove the animal…

L WWWW is shown

4. Repeat steps 2 and 3…

After weight starts rising and goes beyond the MIN.WT the scale will

briefly show actual weight before triggering a new auto-locked weight.

Model 640 Indicator Series User Instructions 41

Page 42

4 Weighing Procedures

4.9 Printing

Press the PRINT key from G/N mode to print the currently configured print format 0-9

formats.

The default print format is #3. To use any of the other nine formats, see the Service

Manual on how to select formats, by changing the configuration code number (CCN).

If the CHNAME parameter is set to ON, the current memory channel name will be

added to the start of each print format. To enable this, reference the Service Manual

or call your dealer for support.

EXAMPLES:

OR

Format 0

Format 1

Format 2

42 Model 640 Indicator Series User Instructions

Page 43

Format 3 (default)

Format 4

Format 5

4.9 Printing

Format 6

Format 7

Format 8

Model 640 Indicator Series User Instructions 43

Page 44

4 Weighing Procedures

Format 9

44 Model 640 Indicator Series User Instructions

Page 45

5 Test Menu

5.1 Test Menu Summary

The test menu, shown in Figure 5.1,allows you to test the functions of the indicator

shown below.

VOLTS Monitor the input voltage of the indicator

LCD Do a LCD display test.

KEYPAD Do a keypad test

A / D Do an Analog to Digital Test (A/D)

SERIAL Check the serial ports (Port 1).

INPUTS Check the inputs.

SOFT Verify the software version of the indicator.

5.1 Test Menu Summary

Model 640 Indicator Series User Instructions 45

Figure 5.1 Test menu

Page 46

5 Test Menu

5.2 Access the Test Menu

To access the Test menu, follow these steps:

1. From the G/N mode, press and hold the HOLD/MENU key for three beeps (3

seconds), then release…

SET.PAS is displayed.

2. Use the numeric entry procedure, shown below, and enter the password 111…

111 is displayed.

3. Press the PRINT/SELECT key…

VOLTS, the first menu item, is displayed.

5.3 Test Menu Items

5.3.1 VOLTS (Input voltage)

This allows a user to check the voltage coming into the indicator.

1. Access the test menu…

VOLTS is displayed.

2. Press the PRINT/SELECT key, and…

Current voltage is displayed.

3. Press the G/N key to return to the G/N weighing mode.

46 Model 640 Indicator Series User Instructions

Page 47

5.3.2 LCD (LCD Display test)

Use this to perform a self test on the LCD, either a complete display test or a segment

test.

1. From VOLTS press menu…

LCd is displayed.

2. Press the PRINT/SELECT key…

TEST is shown.

3. Press the PRINT/SELECT key…

Display performs a test (15 sec).

4. When test is completed…

TEST is shown.

5. Press HOLD/MENU…

SEGMNT is displayed.

6. Press the PRINT/SELECT key…

5.3 Test Menu Items

Display performs a segment test.

7. When test is completed…

SEGMNT is displayed.

8. Press G/N key to…

Return to LCd display.

9. Press G/N key to return to the G/N weighing mode.

5.3.3 KEYPAD (Keypad test)

This test allows testing of all active keys…

1. From VOLTS, press HOLD/MENU…

LCd is displayed.

2. Press the HOLD/MENU key repeatedly until…

KEYPAd is shown.

3. Press the PRINT/SELECT key…

HIT.KEY is displayed briefly, then NO KEY is shown if a key isn’t being

pressed. Test the key by pressing it. If it is working the corresponding

key name will be displayed. See table below:

4. Press and hold the HOLD/MENU key to return to KEYPAD.

Model 640 Indicator Series User Instructions 47

Press the G/N key G/N is displayed.

Press the HOLD/MENU key HOLD is displayed.

Press the ZERO/CLEAR key ZERO is displayed.

Press the PRINT/SELECT key PRINT is displayed.

Press the RM key RM is displayed.

Press the M+ key M+ is displayed.

Page 48

5 Test Menu

5.3.4 A/D (View /Test A to D counts)

1. From VOLTS, press menu…

LCd is displayed.

2. Press HOLD/MENU repeatedly until…

A/d is shown.

3. Press the PRINT/SELECT key…

CNTS is shown.

4. Press the PRINT/SELECT key…

A/D raw counts are shown.

5. Press the PRINT/SELECT key…

CNTS is shown.

6. Press the HOLD/MENU key…

mV/V is shown.

7. Press PRINT/SELECT key…

The mV/V value is shown.

8. Press PRINT/SELECT key…

mV/V is shown.

9. Press HOLD/MENU key…

A/d.TST is shown.

10. Press PRINT/SELECT key…

Counts PASS or FAIL is shown.

11. Press PRINT/SELECT key…

A/d.TST is shown.

12. Press the G/N key two times…

Returns to the G/N weighing mode.

5.3.5 SERIAL (Testing Serial Ports)

1. From VOLTS, press menu…

2. Press HOLD/MENU repeatedly until…

3. Press the PRINT/SELECT key and …

48 Model 640 Indicator Series User Instructions

LCd is displayed.

SERIAL is shown.

NOLOOP is displayed.

Page 49

4. Short the XMT to RCV and…

LOOP will be displayed.

5. Press PRINT/SELECT and…

SERIAL is displayed.

6. Press the G/N key…

Returns to the G/N weighing mode.

5.3.6 INPUT (Testing the Input)

1. From VOLTS, press menu…

LCd is displayed.

2. Press HOLD/MENU repeatedly until…

INPUT is shown.

3. Press the PRINT/SELECT key and …

INPUT is displayed.

5.3 Test Menu Items

4. Press the PRINT/SELECT key and…

OPEN or CLOSED is displayed.

5. Press the PRINT/SELECT key…

INPUT is displayed

Press G/N to return to G/N weighing mode.

5.3.7 SOFT (Software PN, version and revision)

1. From VOLTS, press menu…

LCd is displayed.

2. Press HOLD/MENU repeatedly until…

SOFT is shown.

3. Press PRINT/SELECT and…

PART is displayed. This stands for the part number for the software.

4. Press PRINT/SELECT and…

60259 is displayed. This is the software part number.

5. Press the GN or PRINT/SELECT key…

6. Press HOLD/MENU and…

Model 640 Indicator Series User Instructions 49

PART is displayed.

DASH is displayed.

Page 50

5 Test Menu

7. Press PRINT/SELECT and…

-0010 is displayed. This is the software dash number.

8. Press the GN or PRINT/SELECT key…

DASH is displayed.

9. Press HOLD/MENU and…

REV is displayed. This is the software revision number.

10. Press PRINT/SELECT and…

Rev A is displayed, for example. This is the software revision level.

11. Press the GN or PRINT/SELECT key…

REV is displayed.

12. Press GN key twice to return to the G/N weighing mode.

50 Model 640 Indicator Series User Instructions

Page 51

6.1 Remote Displays

6 Remote Displays & XM64 Remote Transmitter

6.1 Remote Displays

The RD40/XL/RF are remote displays that are compatible with the Model 640

indicators. See the photos below. An RD40 output option is required on the Model 640

for interfacing. The interface cable plugs directly into the bottom of the Model 640. Any

data displayed on the Model 640 is also displayed on the RD40.

Figure 6.1 RD40XL remote display (XM64 optional)

Figure 6.2 RD40 remote display (mirror mount)

The RD40RF is a wireless remote display which allows full control of the Model 640

from the seven keys on the RD40RF. This is ideal for feed rooms and front end loaders.

Model 640 Indicator Series User Instructions 51

Page 52

6 Remote Displays & XM64 Remote Transmitter

Figure 6.3 RD40RF remote display (wireless)

6.2 XM64 Wireless Remote Transmitter

An optional radio remote transmitter (XM64) and receiver can be installed in either the

Model 640/XL or the RD40XL.

This option lets the user tare and access net amounts from a remote location, usually

a front-end loader. Reference Loading/Unloading Net Amounts (XM64 Transmitter) on

page 30.

The XM64 can also be configured to simulate any of the seven active keys. See the

Service Manual for instructions.

Figure 6.4 XM64

52 Model 640 Indicator Series User Instructions

Page 53

7 Specifications

Power 10 - 17 VDC

Enclosure Water and dust resistant, Structural Polycarbonate

Display 6 digit, 14 segment, alpha-numeric

Display Rate Selectable 1, 2, or 5 times/second

Unit of Measure lb or kg

Excitation 5 volts, drives ten 350 – ohm weigh bars

Analog Range -0.5 mv/v to 10 mv/v

Annunciators lb, kg, Auto, Motion, Gross and Net

Operational Keys ON/OFF, RM, M+, TARE, G/N, HOLD/MENU, PRINT/

55mA @ four weigh bar load, backlight off

270 mA @ four weigh bar load, backlight

Optional: 115VAC/12VDC converter

8.7” H x 10.5”W x 6.0”D

LED green-yellow backlight, Ten adjustable brightness

levels

Model 640 - 1.1 inch (28mm)

Model 640XL - 2.0 inch (50.8 mm)

SELECT, ZERO/CLEAR (audible key feedback),

(Optional: Dealer Service key)

Capacity Range 999,999 lb/kg with decimal down to 2 places

Increment Sizes Multiples and sub-multiples of 1,2,5 (.01 up to 500)

Internal Resolution 32,212,260 counts per mv/v per second

A/D Conversion Rate 60 times/second

Zero Tracking Off, 0.5, 1, 2, 3, 5, 10 divisions

Time and Date Battery backed up real time clock

RS-232 port Optional bidirectional RS-232 port

AMP 8 pin circular connector

Response to ASCII character inputs

Baud rates (1200 – 115200)

Xon/Xoff; Parity selectable, 7/8 data bits

Broadcast rate: 1, 2, 5, 10 Hz

RD40/XL Port Proprietary RD40/XL protocol, required to Interface to

RD40 or RD40XL.

(9 pin AMP circular connector)

RF Port 802.11G 2.4 GHz WIPORT

(required to interface to the wireless RD40RF)

TTL Inputs XM64 transmitter, programmable inputs

Option on 640 or from RD40XL

(RM, M+,TARE, G/N, HOLD, PRINT or ZERO/CLEAR)

Environment -20 to 140 degrees F

Model 640 Indicator Series User Instructions 53

-29 to 60 degrees C

Page 54

7 Specifications

Weight 5.2 lb / 2.4 kg

7.2 lb / 3.3 kg shipping weight

Agencies FCC Class A

CE marked

54 Model 640 Indicator Series User Instructions

Page 55

8.1 How to Verify the Scale is Weighing Properly

8 Appendix: Quick Programming Guide

In most cases your Avery Weigh-Tronix Model 640 arrives from your dealer or

distributor preprogrammed with a Configuration Code Number (CCN) that sets the

Model 640 to work and weigh properly with the appropriate scale system, whether it is

a TMR mixer, grain cart, livestock scale, weigh cart, platform scale, bin scale, or all

other applications.

Before beginning to use the new Model 640 scale system, please verify the system has

been programmed correctly and is weighing properly and it is configured for the proper

unit of measure.

8.1 How to Verify the Scale is Weighing Properly

1. Zero the indicator by pressing the ZERO/CLEAR key from the gross mode.

2. Stand on the scale system and note the scale reading.

If the weight reading is correct, your system is working properly and

you can continue with operation of the system.

If the weight reading is not correct, read through this Appendix. This

will tell you how to access the SETUP menu to change the Configuration

Code Number (CCN). This should get your system up and running

properly. If you have further problems, call your local dealer or Avery

Weigh-Tronix.

8.1.1 To Access the Setup Menu (640)

Follow these steps to access the Setup menu.

1. From the G/N mode, press and hold the HOLD/MENU key for three beeps (3

seconds), then release…

SET.PAS is displayed.

2. Use the numeric entry procedure to enter the password 640. Press PRINT/

SELECT to accept it…

640 is shown

3. Press PRINT/SELECT once more…

CONFIG is displayed. Continue with the next section for instructions on

finding and entering the correct Configuration Code Number (CCN) for

your indicator.

8.1.2 (CONFIG) Finding and Entering a Configuration Code Number

This section shows you how to find and enter a Configuration Code Number (CCN)

that sets ups the indicator for the type of weigh-bar, capacity, increment, print format (0-

9), units, and AUTO-LOC.

Example:

20,000 x 5 lb, 2 1/8 calibration, print format 3, therefore code= 05233

Model 640 Indicator Series User Instructions 55

Page 56

8 Appendix: Quick Programming Guide

The Model 640 indicator is precalibrated at Avery Weigh-tronix with appropriate code

number specified by the OEM, or leaves with a factory calibration number of 18033.

The following tables show how to establish a configuration code number to configure

the Model 640 indicator: Find the specs which match your system to find the

appropriate code number. Find the first and second digits of the CCN in Table 8.1.

Table 8.1 .Table for 1st, 2nd and 3rd CCN Digits

1st & 2nd

Digits

CALIBRATION SIZE

CAPACITY x INCREMENT SIZE

00 5/8 * 200 x 0.01 200 x 0.02 200 x 0.05 2K x 0.1 2K x 0.2 2K x 0.5

01 1 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

02 1-1/4 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

03 1-7/8 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

04 2 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

05 2-1/8 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

06 2-1/4 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

07 2-1/4D 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

08 2-1/4D-P 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

09 2-1/2 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

10 3-1/8 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

11 4 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

12 CC20/CC30 20K x1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

13 Alley Weigh 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

14 CC30-3 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

15 Chute Weigh 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

16 CC-50 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

18 SPARE 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

20 1-digi 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

21 1 POLY(DIGI) 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x50

22 1-7/8,2(DIGI) 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

23 2-1/8,2-1/2,2-7/8,3-3/4 (DIGI) 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

97 Custom Setting 200 x 0.01 200 x 0.02 200 x 0.05 2K x 0.1 2K x 0.2 2K x 0.5

98 Custom Setting 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

99 Custom Setting 200K x 100 200K x 200 200K x 500

3rd Digit 0 1 2 3 4 5

The third digit of the CCN is found in Table 8.2.

56 Model 640 Indicator Series User Instructions

Page 57

8.1 How to Verify the Scale is Weighing Properly

Table 8.2 Table for 4th CCN Digit

4th

Digit

Print Formats

0 G

1 GTN

2 G w/ TD

3 GTN w/TD (STD)

4 CSV-G

5 CSV-GTN

6 CSV-G w/TD

7 CSV-GTN w/TD

8 Displayed Wt.

9 Displayed Wt. w/TD

The fourth digit of the CCN is found in Table 8.3.

Table 8.3 Table for 5th CCN Digit

5th

Digit

units Auto-Loc Auto-Acc

0 Lb Off Off

1 Lb Off On

2 Lb On Off

3 Lb On On

4 Kg Off Off

5 Kg Off On

6 Kg On Off

7 Kg On On

Once you have your five digit number, enter it as follows:

1. From CONFIG, press PRINT/SELECT…

If attempting to enter an invalid number display will show CAN’t and return to

CONFIG.

2. Use the numeric entry procedure to enter the new number and press the

PRINT/SELECT key when finished.

3. Press the G/N key…

Model 640 Indicator Series User Instructions 57

Current code number is shown.

CONFIG is shown.

Indicator returns to the G/N weighing mode.

Page 58

8 Appendix: Quick Programming Guide

8.1.3 Configuration Code Numbers for Common applications:

TMR MIXERS:

2 1/8 inch calibration weigh bar 20,000 x 5 lb (5230)

2 ½ inch calibration weigh bar 200,000 x 10 (9330)

2 1/4D calibration weigh bar 200,000 x 10 lb (7330)

CC-30 Compression Cell 200,000 x 10 lb (14330)

GRAIN CARTS:

2 1/4D calibration weigh bar 200,000 x 20 lb (7430)

CC-30 Compression Cell 200,000 x 20 lb (14430)

LIVESTOCK:

2 1/8 inch calibration weigh bar 20,000 x 1 lb (5030)

Chute Weigh System 20,000 x 1 lb (15030)

Alley Weigh System 2,000 x 1 lb (13330)

If it is impossible to know exactly which weigh bars are on the scale system, try one of

the recommended Configuration Code Numbers and keep entering code numbers until

the scale appears to be weighing properly. (See section below entitled: Entering A New

Configuration Code Number)