Page 1

RD712 & RD712XL

Remote Displays

Model 615 / 615XL Indicator

Service Manual

Page 2

This page left intentionally blank.

2

Model 615/615XL Indicator Service Manual

Page 3

Table of Contents

Introduction ................................................................................................................................................... 5

Using the Hidden Keys .................................................................................................................................. 5

Entering Data with Hidden Arrow Keys .......................................................................................................... 6

Viewing the Current Configuration Code ....................................................................................................... 6

Entering a New Configuration Code .............................................................................................................. 8

Determining Axle Sizes ................................................................................................................................. 9

Determining a Configuration Code ................................................................................................................ 9

Table 1: A Sample Set of Configuration Choices & Its Corresp. Config. Code) ..................................... 9

Table 2. Configuration Code Chart for Weigh-Tronix Weigh Bars ....................................................... 11

Table 3: Valid Numbers for the Configuration Code ............................................................................. 12

Table 4: Model 615/XL Calibration Table ............................................................................................. 12

Determining the Custom Sensitivity Rating ................................................................................................. 13

Table 5: Row Numbers for Custom Capacity x Increment Size ........................................................... 14

Keying in the Custom Sensitivity Rating ............................................................................................... 14

Calibrating with a Known Weight ................................................................................................................. 15

Getting Ready to Calibrate with a BLH Model 625 Calibrator ............................................................... 16

Table 6: Calibrator Connections and Calibration Tables ...................................................................... 16

Calibrating with a BLH Model 625 Calibrator ....................................................................................... 17

Viewing the Internal Raw Counts Display .................................................................................................... 18

Viewing and Selecting Overcapacity ........................................................................................................... 18

Selecting Continuous Serial Output ............................................................................................................. 19

Viewing the Software Release Number ....................................................................................................... 19

Circuit Descriptions ..................................................................................................................................... 20

Power Supply ....................................................................................................................................... 20

Analog to Digital Circuitry ............................................................................................................................ 21

Microprocessor Circuitry ............................................................................................................................. 22

Display Circuitry .......................................................................................................................................... 23

Technical Illustrations, Parts Lists, and Schematics .................................................................................... 25

Programming Appendix: Using the Eaton and J-Star Configuration Code Charts ......................... Appendix 1

Table 7: Eaton: A Sample Set of Configuration Choices (& Corresp. Contig. Code) .............. Appendix 1

Table 8: J-Star: A Sample Set of Configuration Choices (& Corresp. Config. Code) ............. Appendix 1

Standard and Optional Procedures for Accessing Optional Setup Modes ............................. Appendix 2

Table 9: Eaton Configuration Code Chart .............................................................................. Appendix 3

Table 10: J-Star Configuration Code Chart ............................................................................ Appendix 4

Pages are numbered consecutively beginning with the cover page.

Model 615/615XL Indicator Service Manual

3

Page 4

Illustrations

Figure 1: Hidden Keys on the Front Panel of the Model 615/XL Farm Indicator.......................................... 5

Figure 2: Programming Flow Chart ............................................................................................................. 7

Model 615/615XL Indicator System Block Diagram ................................................................................. 25

Model 615 Indicator Parts and Assembly ................................................................................................. 26

Model 615 Keypad Overlay and Schematic.............................................................................................. 27

Model 615 Main PC Board A/D and Component Parts List ...................................................................... 28

Model 615 Main PC Board A/D Schematic .............................................................................................. 29

Model 615XL Parts and Assembly ........................................................................................................... 30

Model 615XL Keypad Board Assembly and Schematic ........................................................................... 31

Model 615XL Main PC Board A/D and Component Parts List ................................................................. 32

Model 615XL Main PC Board Assembly Schematic................................................................................. 33

Model 615XL Display PC Board Component Parts List and Schematic ................................................... 34

Model 615XL Weigh Bar Panel Assembly and Cable/Connector Schematics ......................................... 35

RD712/712XL Remote Display Parts List and Assembly ......................................................................... 36

RD712 Remote Display PC Board, Component Parts List and Schematic .............................................. 37

RD712XL Remote Display PC Board, Component Parts List and Schematic .......................................... 38

XM710-L Wireless Remote Installation .................................................................................................... 39

4

Model 615/615XL Indicator Service Manual

Page 5

Introduction

The Model 615/XL Farm Indicator allows front-panel programming through a

configuration mode and a calibration mode. Instructions for configuration

and calibration are provided as follows:

Using the Hidden Keys

• Using the Hidden Keys .............................................................Pg. 1

• Entering Data with Hidden Arrow Keys .....................................Pg. 2

• Viewing the Current Configuration Code ..................................Pg. 2

• Entering a New Configuration Code .........................................Pg. 4

• Determining Axle Sizes .............................................................Pg. 5

• Determining a Configuration Code ...........................................Pg. 5

• Determining a Custom Sensitivity Rating.................................. Pg. 9

• Keying in the Custom Sensitivity Rating ................................. Pg. 10

• Calibrating with a Known Weight ...........................................Pg. 11

• Getting Ready to Cal. w/ BLH Mdl. 625 Cal. ...........................Pg. 12

• Calibrating with BLH Model 625 Calibrator ............................. Pg. 13

• Viewing the Internal Raw Counts Display ............................... Pg. 14

• Viewing and Selecting Overcapacity ....................................... Pg. 14

• Selecting Continuous Serial Output ........................................Pg. 15

• Viewing the Software Release Number .................................. Pg. 15

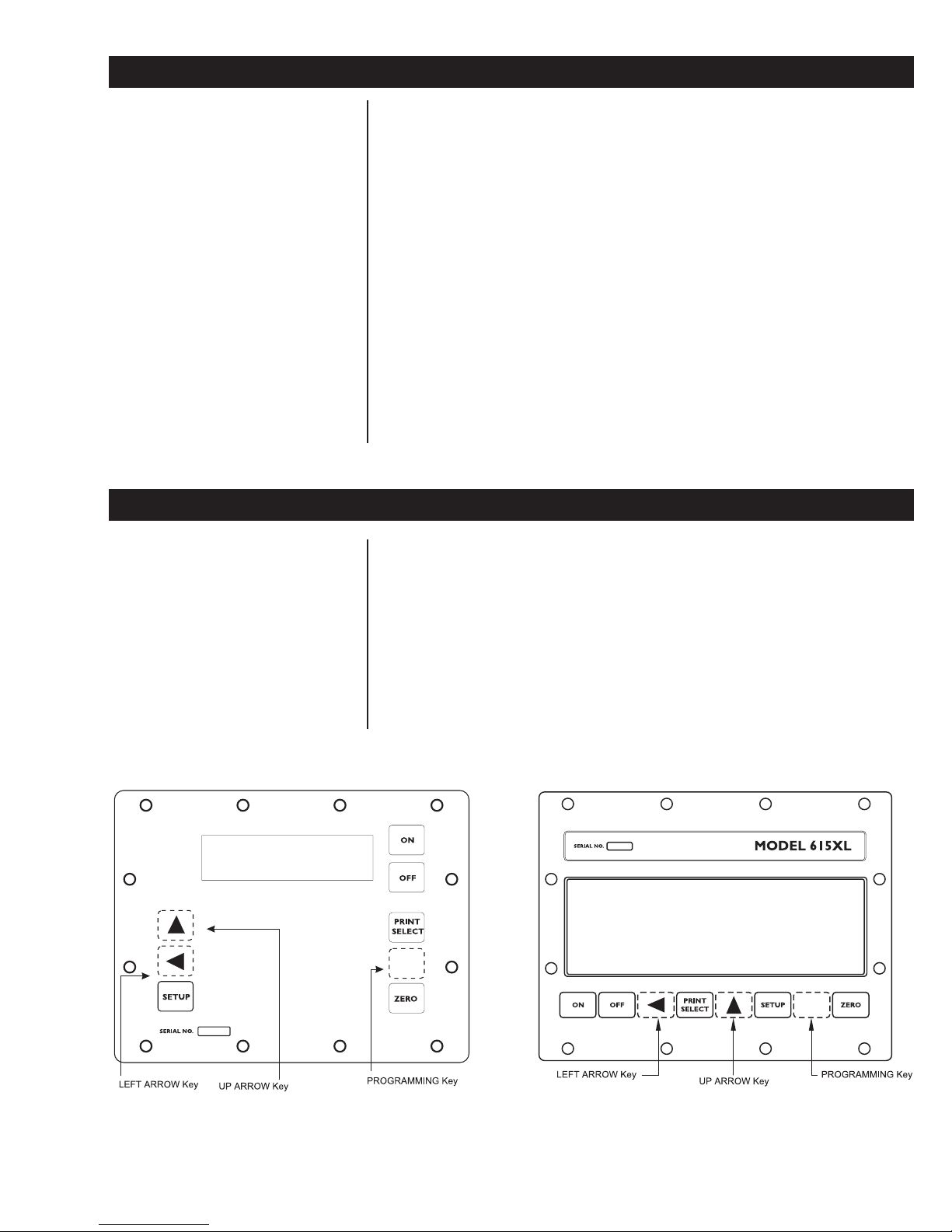

Configuration and calibration programming is entered with three hidden

keys—keys not intended for end-user access. A hidden programming key

accesses the set-up modes, and two hidden arrow keys select and enter

data within the set-up modes. The hidden keys also access the internal raw

counts value and the software release number. Figure 1 below shows the

locations of the hidden keys on the Model 615/XL.

The three hidden keys are touch-sensitive, as are all the keys on the Model

615/XL. However, unlike other keys, the three hidden keys do not have key

faces. These keys are hidden from end users because access to the set-up

modes is intended only for trained technicians who use this service manual.

Hidden Keys on the Front Panel of the Model 615/XL Farm Indicator

Figure 1

Model 615/615XL Indicator Service Manual

5

Page 6

Entering Data with Hidden Arrow Keys

The hidden arrow keys are used only for data entry. You will use this keying

procedure to enter two kinds of numeric data with the hidden arrow keys: a

configuration code and a custom sensitivity rating. The configuration code

and the custom sensitivity rating are each treated separately in sections

If at any time you enter an

incorrect number, press CLEAR

to delete the number, then rekey.

following this one. Refer to this section when you need to enter a number or

numbers. (See Figure 2: Programming Flow Chart.)

Example: To key in the number 5121

1. Press the ⇑ key repeatedly until the 5 appears on the display.

2. Press the ⇐ key once to move the 5 one space to the left.

3. Press the ⇑ key until 1 appears.

4. Press the ⇐ key once to move the 51 one space to the left.

5. Press the ⇑ key until the 2 appears.

6. Press the ⇐ key once to move the 512 one space to the left.

7. Press the ⇑ key until 1 appears.

8. After your desired number has been entered, press PRINT/SELECT to

display ConF. You may now:

a. Continue through the setup cycle by pressing SETUP (See Fig.

2: Programming Flow Chart)

or b. Return to the weigh mode by pressing ZERO.

Viewing the Current Configuration Code

A configuration code is a four- or five-digit number that configures the

indicator for the following operational parameters:

Parameter: Represented by:

Axle Size 1st & 2nd digits

Capacity x Increment Size 3rd digit

Auto Zero Tracking 4th digit

Units of Measure and Capture Mode 5th digit

Refer to Figure 2: Programming Flow Chart.

1. Press the hidden PROGRAMMING key for five seconds to display the

configured transducer trade name: [ 6 1 5 ] Weigh-Tronix Weigh Bar

2. Press SETUP to display [ C o n f ].

3. Press PRINT/SELECT to display the current configuration code.

[ E A t n ] Eaton Weight Transducer

[ J S t r ] J-Star Weight Transducer

4. Press PRINT/SELECT to redisplay [ C o n f ].

5a. Access the next programming display by pressing SETUP.

5b. Return to weighing mode by pressing ZERO.

6

Model 615/615XL Indicator Service Manual

Page 7

7

Model 615/615XL Indicator Service Manual

Figure 2

Programming Flow Chart for the Model 615/XL Farm Indicator

Page 8

Entering a New Configuration Code

Refer to Figure 2: Programming Flow Chart.

1. Determine an appropriate configuration code for your weighing system.

To do so, consult the following two sections:

• Determining Axle Sizes, and

• Determining a Configuration Code.

Refer also to:

• Table 2: Configuration Code Chart, and

• Table 3: Valid Numbers for the Configuration Code.

Study the text and tables listed above and carefully follow all accompanying

instructions to construct a unique four-digit or five-digit configuration code

for your weighing system. Use the following blanks to write out your configuration code for quick reference as you key in the code in step 5 below. Digit

place #1 is to be used only if you construct a five-digit configuration code. A

four-digit configuration code uses digit places #2, #3, #4, and #5, but not #1.

Your configuration code: ____ ____ ____ ____ ____

Digit place #s: #1 #2 #3 #4 #5

2a. Press the hidden PROGRAMMING key for five seconds to view the

transducer trade name display: [ 615] Weigh-Tronix Weigh Bar

[ E A t n ] Eaton Weight Transducer

[ J S t r] J-Star Weight Transducer

2b. Press the hidden PROGRAMMING key for five more seconds to change

the transducer trade name display. Repeat as needed to cycle through

all three trade names.

3. Press SETUP to display [ C o n f ].

4. Press PRINT/SELECT to display the current configuration code.

5. Key in the configuration code for your weighing system according to

previous instructions entitled Entering Data with Hidden Arrow Keys.

6. Press PRINT/SELECT to redisplay [ C o n f ].

7a. Access the next programming display by pressing SETUP.

7b. Return to the weighing mode by pressing ZERO.

8

Model 615/615XL Indicator Service Manual

Page 9

Determining Axle Sizes

To use the configuration code chart in Table 2 for determining an appropriate configuration code for your weighing system, you must first know the

calibration axle size of the Weigh Bar(s) or alternative weight transducer(s).

Physical axle size (the measured diameter of a bar) and calibration axle size

(the measurement marked on a bar) are not the same for some Weigh Bars.

Read about the following combinations of physical axle sizes and calibration

axle sizes, and follow the guideline that applies to your bar(s):

• If your weight transducer measures five-eighths inch (5/8") in diameter,

but is marked with a calibration axle size of 2-1/4" D (Dual), use data

shown in Table 2 for a five-eighths-inch (5/8") bar.

• If your weight transducer measures one inch (1") in diameter, but is

marked with a calibration axle size of 2-1/8", use data shown in Table 2

for a one-inch (1") bar.

• For weight transducers which have a physical axle size of either fiveeighths inch (5/8") or one inch (1"), but which are marked with a

calibration axle size other than 2-1/4" D or 2-1/8" respectively, use data

shown in Table 2 for Custom Sensitivity and Capacity x Increment.

• For all other weight transducers: Whether the physical axle size of the

bar and the calibration axle size marked on the bar do or do not match,

use data shown in Table 2 for the calibration axle size marked on the

bar.

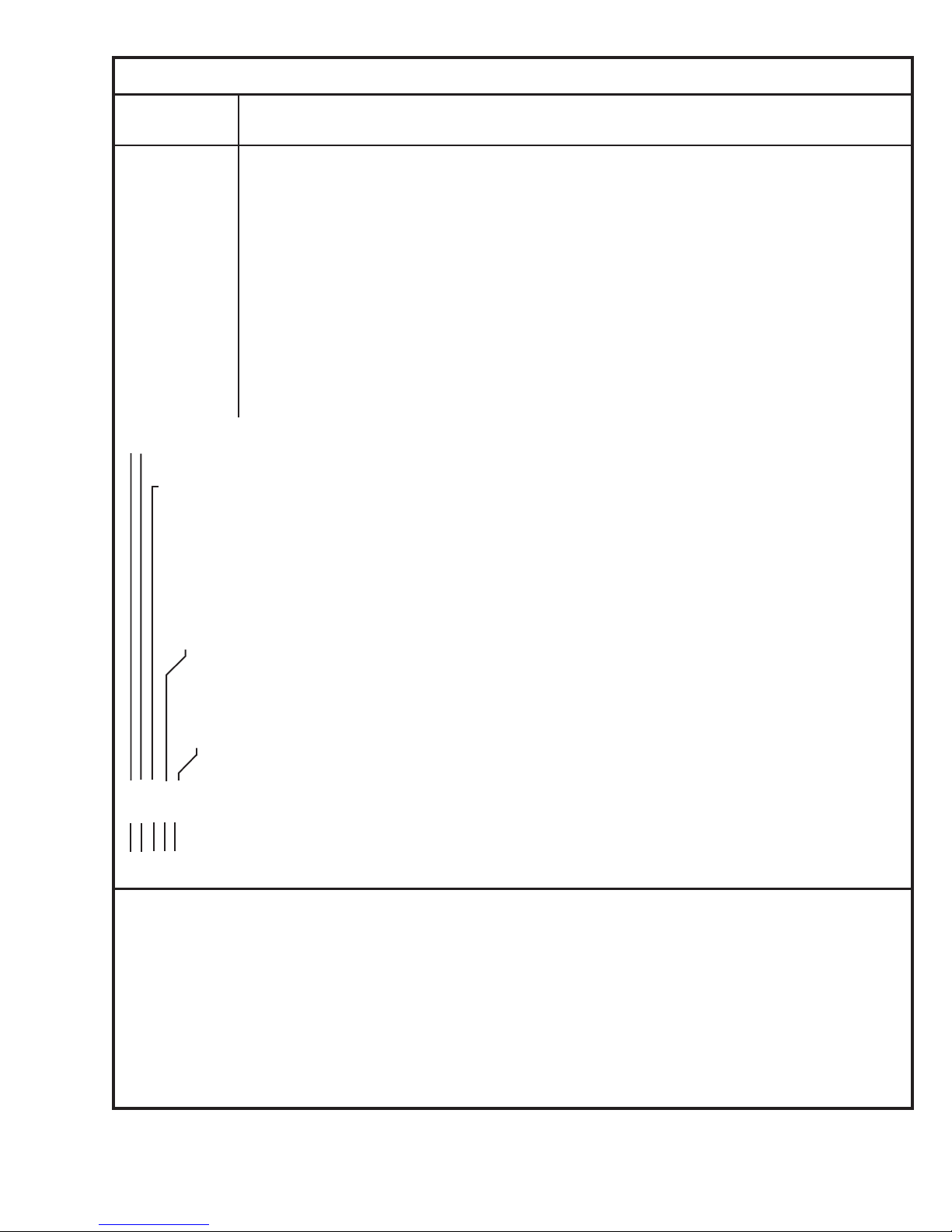

Determining a Configuration Code

Table 1 is an example of a set of configuration choices for a Model 615/XL

weighing system. Table 1 shows you how selections for the Model 615/XL’s

configurable parameters would be represented by a configuration code of

5121, according to the configuration code chart in Table 2. You can see that

each digit in the code represents a parameter, and the value of each digit

represents a selection for that parameter as shown in Table 2.

A Sample Set of Configuration Choices

Its Corresponding Configuration Code (5121)

Parameter Represented Selection Config.

Axle size 2nd digit 2-1/8" 5

Capacity X increment size 3rd digit 20k x 2 1

Auto zero tracking 4th digit ±1.0 division 2

Units of measure and

Capture mode 5th digit Ib/On 1

Configuration code 5121 uses only the

2nd, 3rd, 4th and 5th of five available digits.

Table 1

and

by Code

Model 615/615XL Indicator Service Manual

9

Page 10

The sample configuration code, shown in bold type in Table 1, may be

written horizontally, with digit places numbered, as follows:

Sample configuration code: 51 2 2

Digit place #s: 1 2 3 4 5

Remember, a four-digit configuration code uses digit places #2, #3, #4, and

#5, but not #1. Digit place #1 is to be used only if the configuration code has

five digits. Five digits are required only for bars with calibration axle sizes of

3-1/8 inches and 4 inches and when custom sensitivity (with capacity x

increment) is appropriate (See Table 2).

10

Model 615/615XL Indicator Service Manual

Page 11

Table 2 Configuration Code Chart for Weigh-Tronix Weigh Bars

CALIBRATION

AXLE SIZE+ CAPACITY x INCREMENT SIZE

0: 5/8"* 200 x 0.01 200 x 0.02 200 x 0.05 2K x 0.1 2K x 0.2 2K x 0.5

1: 1"* 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

2: 1-1/4" 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

3: 1-7/8" 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

4: 2" 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

5: 2-1/8 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

6: 2-1/4" 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

7: 2-1/4"D 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

8: 2-1/4"D-P 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

9: 2-1/2 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

10: 3-1/8" 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

11: 4" 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

12: CC-20 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

13: Alley Weigh 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

19: Custom Sensitivity and Capacity x Increment (See text: Configuring Custom Sensitivity with Capacity x Increment Size.)

➤

➤

➤

Column

Numbers 0 1 2 3 4 5

➤

AZT (Divisions)

0: OFF

1: ±.5

2: ±1.0

3: ±3.0

4: ±10.0

➤

UNITS CAPTURE

0: lb Off

1: lb On

2: kg Off

3: kg On

➤

➤

➤

➤

➤

{

{

{

{

{

{

_ 5 1 2 1 is the Configuration Code number representing selections cited in USING TABLE 1: CONFIGURATION CODE EXAMPLE.

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

1 2 3 4 5 are place numbers for each digit in Configuration Code.

+ Axle size determines Weigh Bar sensitivity in mV/V. Refer to Table 4 to relate axle sizes to exact sensitivity

values.

K = Multiply by 1000

* If physical axle size of your Weigh Bar equals 5/8" or 1", but differs from its identifying calibration axle size,

see text: AXLE SIZES.

D-P =Dual Platform: Eight 350-ohm Weigh Bars and junction box with span pots.

D =Dual: double-ended Weigh Bar

Model 615/615XL Indicator Service Manual

11

Page 12

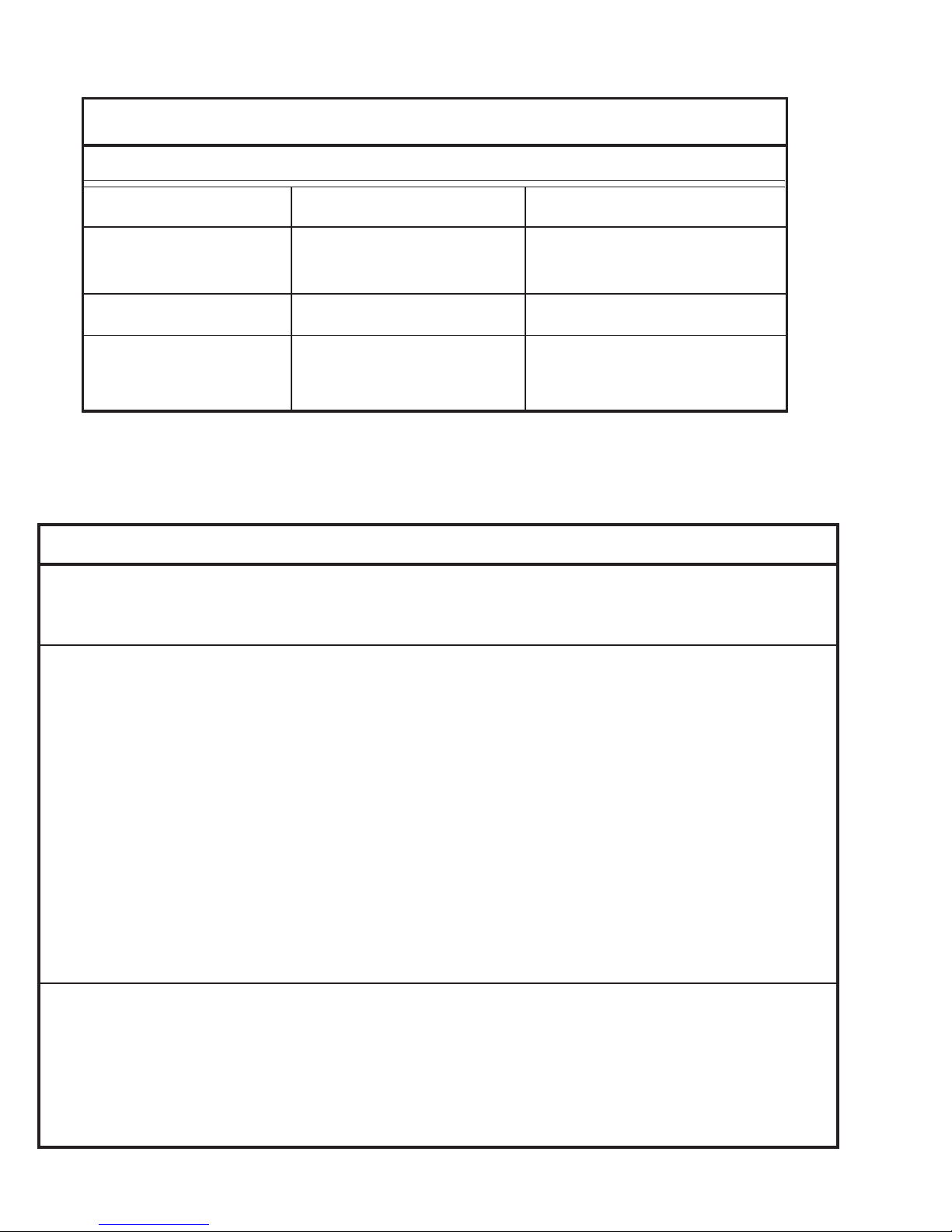

Table 3: Valid Numbers for the Configuration Code

PARAMETERS VALID #'S INVALID #'S

Axle Size 0 - 13, 19 14 - 18

Capacity x Increment Size 0 - 5 Any number greater than 5 will be

recognized as a 5.

Warning Alarm Factor 0 - 9

Units and Auto Hold 0 - 3 Any number greater than 3 will be

recognized as a 3.

Table 4: Model 615/XL Calibration Table

Calibration

Axle Scale Number of

Size Capacity Weigh Bars mV/V Calibration

5/8"* 200 lb 4 0.2 180.039 lb

1"* 2,000 lb 4 0.5 1,831.03 lb

1-1/4" 2,000 lb 4 0.2 1,742.58 lb

Alley Weigh 2,000 lb 2 1.0 1,913.8 lb

1-7/8" 20,000 lb 4 0.7 17,965.8 lb

2" 20,000 lb 4 0.6 19,143.8 lb

2-1/8" 20,000 lb 4 0.5 18,310.3 lb

2-1/4" 20,000 lb 4 0.4 18,003.9 lb

2-1/4"D 20,000 lb 4 0.2 18,003.9 lb

2-1/2" 20,000 lb 4 0.3 18,811.4 lb

2-1/4"D 200,000 lb 4 1.0 90,019.3 lb

2-1/4"D-P 200,000 lb 8/350 1.0 186,816.0 lb

3-1/8" 200,000 lb 4 1.0 126,402.0 lb

* If physical axle size of your Weigh Bar equals 5/8" or 1", but differs from its identifying calibration axle size,

see previous text: AXLE SIZES.

D-P is Dual Platform: Eight 350-ohm Weigh Bars and junction box with span pots.

D is Dual: double-ended Weigh Bar.

12

Model 615/615XL Indicator Service Manual

Page 13

Determining the Custom Sensitivity Rating

This procedure allows you to configure a sensitivity rating for a weight

transducer that is not referenced in Table 2. You may configure another

manufacturer’s weight transducer for interface with the Model 615/XL.

Before starting the keying procedure for configuring custom sensitivity, you

must verify three facts about the transducer(s) being used:

• Trade name of the transducer

• Sensitivity rating of the transducer

• Capacity x increment size of the transducer

Trade Name of the Transducer

To configure custom sensitivity for Weigh-Tronix Weigh Bars, see the next

subsection, Sensitivity Rating of the Transducer.

To configure for transducers from manufacturers other than Weigh-Tronix,

refer now to instructions located in the Programming Appendix. If you find

that custom configuration of sensitivity is required for your transducer(s),

return to this section and proceed to the next topic.

Sensitivity Ratings of the Transducer

1. Determine the sensitivity rating, that is, the mV/V output at full capacity,

for the weight transducer(s) you are using. You will probably find this

information stamped or printed on the transducer.

2. Call the factory at 1-800-458-7062 for help in determining the Model 615/

XL sensitivity rating for your transducer(s). Because a number of

different types of bars are used by various manufacturers of weight

transducers, it is impossible to provide generic instructions on determining Model 615/XL sensitivity ratings for all the weight transducers

available.

3. Write down your calculated sensitivity rating here using the following format:

n. nnnnnnn = your sensitivity rating

1 2345678 = digit places

You may key in a mV/V value of up to eight digits. Selection range for

sensitivity is from 0.075 to 6.0 mV/V. Keep your notation handy for entry

in steps 5, 6, 7, and 8 of the following keying procedure.

Capacity x Increment Size of the Transducer

4. Refer to Table 5 and locate a capacity x increment size combination that

is appropriate for your Model 615/XL.

5. Look on the right end of Table 5, and identify the number of the row in

which your selected capacity x increment size is located. Then write

down that row number here: __________________

You will need this row number in step 11 of Keying In the Custom

Sensitivity Rating.

Model 615/615XL Indicator Service Manual

13

Page 14

Table 5: Row Numbers for Custom Capacity x Increment Size

Column Numbers: Row

012345#’s

200K x 10.0 200K x 20.0 200K x 50.0 200K x 100.0 200K x 200.0 200K x 500.0 0

20K x 1.0 20K x 2.0 20K x 5.0 200K x 10.0 200K x 20.0 200K x 50.0 1

2K x .1 2K x .2 2K x .5 20K x 1.0 20K x 2.0 20K x 5.0 2

200 x .01 200 x .02 200 x .05 2K x .1 2K x .2 2K x .5 3

Keying In the Custom

Sensitivity Rating

Refer to Figure 2: Programming Flow Chart.

1. Press the hidden programming

key for five seconds... [ 6 15 ] is displayed.

2. Press SETUP twice... [ C u S t ] is displayed.

3. Press PRINT/SELECT... [ U P P r ], which stands for “upper,”

is displayed.

U P P r announces the next display and is an arbitrary label for the first

four digits of the eight-digit custom sensitivity rating (from step 3 of the

previous section, Determining the Custom Sensitivity Rating).

4. Press PRINT/SELECT again... the first four digits of the currently

configured eight-digit custom

sensitivity rating are displayed.

5. Use the UP ARROW and

LEFT ARROW keys (see

Entering Data with Hidden Arrow

Keys) to enter the first four digits

of the custom configuration

rating appropriate for your

Model 615/XL (from step 3 of

Determining the Custom

Sensitivity Rating).

6. Press PRINT/SELECT after

7. Press SETUP... [ L o ], which stands for “lower,” is

8. Press PRINT/SELECT to display

9. Then use the UP ARROW and

14

Model 615/615XL Indicator Service Manual

entering your first four digits... [ U p p r ] is redisplayed.

displayed.

L o announces the next display and is an arbitrary label for the final four

digits of your custom sensitivity rating.

the final four digits of the

currently configured eight-digit

custom sensitivity rating.

LEFT ARROW keys (See

Entering Data with Hidden Arrow

Keys) to key in the final four

digits of your custom

configuration rating.

Page 15

10. Press PRINT/SELECT after

entering your final four digits... [ L o ] is redisplayed.

11. Press SETUP... [ C A P ], which indicates the capac-

ity value, will be displayed.

12. With [ C A P ] displayed, press

PRINT/SELECT to display the

currently configured capacity.

13. Then use UP ARROW and

LEFT ARROW keys to enter the

row number that you noted in

step 5 of Determining the

Custom Sensitivity Rating.

14. Press PRINT/SELECT... [C A P ] is redisplayed.

15. Press SETUP... [ C u S t ] is displayed.

16. You now have two choices:

(See Figure 2: Programming

Flow Chart):

16a. Continue through the setup

cycle to the SPAn (span)

display by pressing SETUP,

and refer to the appropriate

calibration instructions in

this manual, OR

16b. Return to the weigh mode

by pressing ZERO.

Calibrating with a Known Weight

Use a reliable known calibration weight equal to or greater than the maximum weight of material that will be weighed.

1. Empty and zero the scale.

2. Press the hidden

PROGRAMMING key for five

seconds to display [ 6 1 5 ].

3. Press SETUP, repeating two

or three times. . . Display shows [ S P A n ].

4. Press PRINT/SELECT... Zero weight value should be dis-

5. Place a known calibration weight

on the scale.

played before you continue. If rezeroing is necessary, press ZERO.

Model 615/615XL Indicator Service Manual

15

Page 16

6. Adjust the span, using the

UP ARROW key and the

LEFT ARROW key until the value

of the known calibration weight is

displayed...

• To increase the displayed span value, press UP ARROW.

• To decrease the displayed span value, press LEFT ARROW.

• To return to the factory calibration value, press the hidden PROGRAM-

MING key.

7. Press PRINT/SELECT to redisplay

[ S P A n ] indicating that

calibration is complete.

8. You now have two choices below: (See Figure 2: Programming Flow

Chart).

A. Continue in the setup cycle to the internal raw counts display by

pressing SETUP ([ I n t r ] appears), and proceed to the section

Viewing the Internal Raw Counts Display, OR

B. Return to the weighing mode by pressing ZERO.

Getting Ready to

Calibrate with a BLH

Model 625 Calibrator

Table 6: Calibrator Connections and Calibration Tables

Number of Weigh Bars and Instructions for Connecting Indicator Calibration Tables

Type of Connector with E3LH Calibrator

Calibrating with a BLH Model 625 Calibrator is a procedure intended only for

trained technicians using specialized equipment in a controlled environment.

1. Refer to Table 6 and follow the appropriate instruction shown in Table 6

to connect the BLH Model 625 Calibrator to the Model 615/XL Indicator.

2. Using the appropriate calibration table as referenced in Table 6, find the

highest mV/V reading on that calibration table for the Weigh Bars on

your scale system. The mV/V readings are categorized on the calibration table according to Weigh Bar size and scale capacity.

3. In this blank, , write down your highest mV/

V reading. You will use this mV/V reading in step 6 of the next set of

instructions, Calibrating with a BLH Model 625 Calibrator.

Four Weigh Bars w/ 5-Pin Connectors Connect single cable from BLH Calibrator Use W-T Spec P/N 24375 Model 700

Four Weigh Bars w/ 4-Pin Connectors Connect four cables from modified BLH Use W-T Spec P/N 14599 Farm Scale

One Weigh Bar w/ 7-pin Connector Connect single cable from BLH Calibrator Use W-T Spec P/N 24375 Model 700

16

to one of the 5-pin Weigh Bar connectors. Calibration Tables

Calibrator to all four 4-pin Weigh Bar connectors Calibration Tables.

to the single 7-pin Weigh Bar Connector Calibration Tables

Model 615/615XL Indicator Service Manual

Page 17

Calibrating with a BLH

Model 625 Calibrator

1. Dial the BLH calibrator to zero

mV/V.

2. Press the ZERO key to zero the

indicator.

3. Press the hidden

PROGRAMMING key for 5

seconds [ 6 15 ] is displayed.

4. Press SETUP, repeating as

necessary (either two or three

times) [ S P A n ] is displayed.

5. Press PRlNT/SELECT... Zero weight value should be dis-

played.

If zeroweight is not displayed,

press ZERO.

6. Turn the dial to the highest mV/V

setting for this system, as

determined in step 2 and noted

in step 3 of Getting Ready to

Calibrate with a BLH Model 625

Calibrator... The value displayed by the indicator

is the scale’s gross weight reading

for the known weight prior to calibra-

tion and may be inaccurate.

7. Adjust the span, using the

UP ARROW key and the

LEFT ARROW key until the

value of the known calibration

weight is displayed.

· To increase the displayed span value, press UP ARROW.

· To decrease the displayed span value, press LEFT ARROW.

· To return to the factory calibration value, press the hidden

PROGRAMMING key.

8. Press PRINT/SELECT... [ S P A n ] is redisplayed, indicating

that calibration is complete.

(See Figure 2: Programming Flow

Chart):

A. Continue in the setup cycle

to the internal raw counts

displayby pressing SETUP... [ I n t r ] is displayed.

and referring to the

instructions, Viewing the

Internal Raw Counts Display.

OR

B. Return to the weighing mode

by pressing ZERO.

Model 615/615XL Indicator Service Manual

17

Page 18

Viewing the Internal Raw Counts Display

1. Press the hidden

PROGRAMMING key for five

seconds... [ 6 1 5] is displayed.

2. Press SETUP until... [I n t r] is displayed.

3. Press PRINT/SELECT... The internal raw count value is

You May Adjust Absolute

Zero if your scale system

includes a junction box

4. Press PRINT/SELECT again... [I n t r] is displayed.

5. You now have two choices: 5a or 5b (See Figure 2: Programming Flow

Chart):

a. Continue in the setup cycle to view and adjust the over range by

pressing SETUP [O V E r], and referring to instructions, Viewing the

Software Version Number, OR

b. Return to the weighing mode by pressing ZERO.

displayed. At 1.0 mV/V, the display

will always read 10,955 counts.

Viewing and Selecting Overcapacity

1. Press the hidden

PROGRAMMING key for five

seconds... [ 6 1 5] is displayed.

2. Press SETUP until... [O V E r] is displayed.

3. Press PRINT/SELECT... [ - - - - ] is displayed, representing

4a. With the correct capacity

displayed, press PRINT/SELECT

and proceed to Step 5... [O V E r] is displayed.

4b. If the incorrect capacity is

displayed, key in a new value

using the hidden arrow keys (see

Entering Data with Hidden Arrow

keys on page 2)... New amount is displayed.

5. You now have two choices: 5a or 5b (See Figure 2: Programming Flow

Chart):

20,000 capacity.

18

Model 615/615XL Indicator Service Manual

a. Continue in the setup cycle to the continuous serial output selection

by pressing SETUP [b r d], and referring to instructions, Selecting

Continuous Serial Output, OR

b. Return to the weighing mode by pressing ZERO.

Page 19

Selecting Continuous Serial Output

1. Press the hidden PROGRAMMING

key for five seconds... [ 6 1 5] is displayed.

2. Press SETUP until... [b r d] is displayed.

3. Press PRINT/SELECT... [O F F] or [o n] is displayed.

4. Press SETUP to toggle between

the two options.

4. Press PRINT/SELECT with the

chosen option displayed... [b r d] is displayed.

5. You now have two choices:

5a or 5b (See Figure 2:

Programming Flow Chart):

a. Continue in the setup cycle to

the software version display by

pressing SETUP [S o F t], and

referring to instructions,

Viewing the Software Version

Number, OR

b. Return to the weighing mode

by pressing ZERO.

Viewing the Software Release Number

1. Press the hidden PROGRAMMING

key for five seconds... [6 1 5] is displayed.

2. Press SETUP several times to

display... [S o F t].

3. Press PRINT/SELECT... the software release number for the

4. You now have two choices: 4a or 4b (See Figure 2: Programming Flow

Chart):

a. Continue in the setup cycle to

the transducer trade name

display by pressing SETUP,

OR

version of software installed in your

indicator is displayed.

b. Return to the weighing mode

by pressing ZERO.

Model 615/615XL Indicator Service Manual

19

Page 20

Circuit Descriptions

Main Printed Circuit Card

This printed circuit card contains the

• Power Supply

• Analog-To-Digital Circuitry

• Microprocessor Circuitry

• Display Circuitry.

Power Supply

To prevent the unit from turning

off below 10 volts, remove CR5

and C36. When configured this

way, the unit will return to the

Gross mode if it loses power.

This indicator, which is energized by 10 to 18 vdc in reference to a NEGATIVE GROUND utilizes one five amp fuse mounted on the bottom of the

chassis for current protection. (Systems with a positive ground are modified

by cutting jumpers from E11 to E12 and E9 to E10. Then install jumpers

from E9 to E12 and E10 to E11.)

The circuit card receives power from the fuse at P2 and is protected against

high voltage transients with varistor RV1.

Input voltage is monitored by 16 volt zener diode VR2. If the voltage across

VR2 exceeds 16 vdc, Q3 will turn “ON” holding the power circuitry in the

“OFF” condition. In addition, if the input voltage drops below 10 volts DC,

PA7 disables the power circuitry by outputting a low signal.

A “Power On” command is generated when the ON key is pressed. This

turns Q5 on and provides a low signal to +8v regulator (u18) pin1 enable

input. When the power is turned off, the Q5 turns off, the Q4 turns on and a

high signal disables (U18) the +8 regulator and turns it off.

20

Model 615/615XL Indicator Service Manual

Page 21

The -7.5 vdc supply voltage is established by U7, a voltage convertor. This

device inverts the input voltage to a -7.5 vdc level.

The +5 vdc voltage is provided by U8, a 7805 regulator.

As soon as the +8 volt power supply voltage is present, Q2 turns on which

turns on the DS2 and DS3 LEDS

Analog to Digital

Circuitry

The analog-to-digital circuitry consists of two weight voltage amplifiers (U1

and U2), a reference amplifier (U3), an analog switch (U4), switch control

logic gate (U14C), a dual slope integrator (U5), and a comparator (U6).

An 8 vdc excitation voltage is supplied to the weight sensors from P1 pins 1

and 6. The millivolt signal received back from the weight sensors enters the

analog-to-digital circuitry at P1, pins 3 and 4.

This millivolt signal is amplified and filtered by U1 and U2 to establish the

amplified weight voltage (0 to +9 vdc) at U2 pin 6. This weight voltage is

then provided to U4 pin 5. A logic low during the weight voltage interval at

U4 pin 1 enables the amplified weight voltage to be received by the dual

slope integrator (U5). Starting at zero volts, the integrator capacitor (C20)

charges at ramp angle directly proportional to the amplified weight voltage

but of opposite polarity. As the amplified weight voltage increases, the

integrator output ramps more in the negative direction.

The voltage received from the sense lines enters the analog-to-digital

circuitry at P1 pins 2 and 5. This sense voltage establishes a reference

voltage of -9 vdc at U3 pin 6. The reference voltage is applied to U4 pin 10.

After the integrator capacitor has been charged for a fixed period of time,

the Weight Voltage Interval, U4 pin 1 goes high. U14 applies a logic low to

pin 14 of U4 which allows the reference voltage to be applied to the integrator. Since the reference voltage (-9 vdc) is of opposite polarity to the amplified weight voltage, it causes the integrator output to ramp back toward zero.

(This period of time is known as the Reference Voltage Interval.)

While the integrator output is ramping back to zero, the comparator (U6)

signals the microprocessor to record this period of time in clock pulses. The

microprocessor uses this number of pulses to calculate the amount of

weight on the scale.

When the integrator reaches zero, the comparator output goes low which

triggers U14C to remove the logic low at U4 pin 14 completing one analogto-digital cycle.

This analog-to-digital conversion repeats at a frequency of 30 hertz.

Model 615/615XL Indicator Service Manual

21

Page 22

Microprocessor

Circuitry

The Microprocessor Circuitry consists of a Motorola MC68HC11A1 8-bit

microprocessor IC (u11), a 74HC573 tristate latch (U12), a 27C128 EPROM

(U13), and various other components.

The microprocessor features on chip memory 256 bytes of RAM, 512 bytes

of EEPROM, along with a Computer Operating Properly (COP) watch dog

system.

A 2 MHZ internal clock is contained in the microprocessor and is controlled

by an external crystal (Y1). Output (ECLK) from this clock provides timing

reference for the EPROM (U13), and input to voltage monitoring circuit U9.

The microprocessor communicates with Analog-to-Digital switch control

logic gate U14 through ports PA2 and PA6. Through U14, the timing reference for the Reference Voltage Interval and Weight Voltage Interval are

provided.

The switches on the front panel receive a signal from ports PD2-PD5 on the

microprocessor and they are monitored for an electrical change by ports

PE0PE3 on the microprocessor.

As signals are received by the microprocessor, it will send them to the

EPROM (U13) on the address lines A0-A15. The signals will be translated

and held by U12. Once all translating is completed, the microprocessor will

enable U12 to return the new information on data lines D0-D7 to the microprocessor. Then, the appropriate device will receive a signal from the

microprocessor.

The Computer Operating Properly (COP) watch dog system in the microprocessor detects errors introduced by electromagnetic interference. If an error

is detected, the microprocessor is reset and operation continues. When the

indicator is powered up, the momentary displayed "hi" message, indicates

the watch dog system is active.

If a "hi" message is displayed, the indicator will perform correctly, but will not

be guarded by the COP watch dog system. This may happen when a new

microprocessor IC is installed. The COP watch dog system can be activated

by following this procedure:

• Turn the indicator OFF jumper P7-1 to P7-2 and P6-1 to P6-2

• Turn the Model 615/XL ON for a few seconds

• Turn the Model 615/XL OFF

• Remove the jumpers

22

Model 615/615XL Indicator Service Manual

Page 23

Display Circuitry

The six digit liquid crystal display (DS1) features black segments against a

silver transflective background.

Liquid crystal display driver U15 requires a +5 vdc power supply and two

signal inputs from the microprocessor to function: (1) a 33-bit serial data

input and (2) a microprocessor controlled input. When both of these conditions have been met, the display driver will energize the appropriate segments on the display.

Optional RS-232 or Remote

Circuitry

To Install Remote Receiver

Additional circuitry required to provide either an RS-232 communications

interface or a remote display interface requires R49-57, C48-51, U16, U10,

and P6 connector.

The RS-232 transmitter/receiver (U10) internally generates +10v and -10 v

supplies and meets all EIA RS-232C specifications. Through U10, the

microprocessor communicates with peripherals which will accept the following protocol: baud rate 1200, 1start bit, 8 data bits, no parity, and one stop

bit. The RS-232 communications port supports X-on (HEX 11), X-off (HEX

13_) handshake and responds to an inquire character (HEX 05) print

request.

The invertor/buffer gates (U16) are used in the remote clock, remote data,

remote zero, and remote print lines to provide isolation and assure proper

logic; levels to and from the remote display.

P6 connector provides external access to power supply voltages, RS-232

data lines, remote display drive lines, remote zero lines, and remote print

lines.

After installing PC board assembly P/N 27643-0030 as shown in assembly

section, plug 3 pin cable assembly into P8. This enables user to have

remote zero capabilities within the Model 615/XL. Be sure to match dip

switch selections between receiver card and transmitter.

Model 615/615XL Indicator Service Manual

23

Page 24

24

Model 615/615XL Indicator Service Manual

Page 25

MODEL 615 / 615XL INDICATOR 12VDC

SYSTEM BLOCK DIAGRAM

25

Page 26

MODEL 615 INDICATOR 12VDC

PARTS AND ASSEMBLY

26

ITEM

NO. DESCRIPTION W-T P/N QTY

1 MOUNTING BRACKET 11899-0043 1

2 RUBBER MOUNT 17807-0058 4

3 NEOPRENE WASHER 27357-0010 4

4 ENCLOSURE 47017-0010 1

5 MAIN PC BOARD 47301-0049 1

6 MAIN PC BOARD W/ RS-232, R/D 47301-0056 1

7 “REMOTE ZERO” RECEIVER KIT (OPTIONAL) 27643-0030 1

8 BEZEL 21356-0014 1

9 SCREW, #10-32 x .75"L 18087-0073 12

10 KEYPAD ASS'Y 47697-0017 1

11 SCREW, #10-32 x .31"L 14473-0348 8

12 XM710, HAND HELD REMOTE (OPTIONAL) 27809-0014 1

13 PNL ASSY, SINGLE W/B CONN (7-PIN) 52955-0055 1

PNL ASSY, SINGLE W/B CONN (7-PIN) W/RD or RS232 52955-0105 1

PNL ASSY 3-W/B CONN (4-PIN) 52955-0048 1

PNL ASSY 3-W/B CONN (4-PIN) W/RD or RS232 52955-0097 1

PNL ASSY 3-W/B CONN (5-PIN) 52955-0030 1

PNL ASSY 3-W/B CONN (5-PIN) W/RD or RS232 52955-0089 1

PNL ASSY 4-W/B CONN (4-PIN) 52955-0022 1

PNL ASSY 4-W/B CONN (5-PIN) 52955-0014 1

PNL ASSY 4-W/B CONN (4-PIN) W/RD or RS232 52955-0071 1

PNL ASSY 4-W/B CONN (5-PIN) W/RD or RS232 52955-0063 1

14 FUSE HOLDER 15455-0016 2

15 FUSE (5 AMP) 15453-0042 2

Page 27

MODEL 615 INDICATOR 12VDC

KEYPAD OVERLAY (P/N 47697-0017)

AND SCHEMATIC

27

Page 28

MODEL 615 INDICATOR 12VDC

MAIN PC BOARD A/D (P/N 47301-0049 –0056) AND

COMPONENT PARTS LIST

28

SYMBOL DESCRIPTION W-T P/N

B1 BATTERY, 3.6 V 23957-00 21

C1,2,5,6,9,

11,12,14,1

5,22,23,29

,30,32,33

CAP. 0.1 UF 100 V 15623-0120

C3,4 CAP. .22 UF 50 V 23267-0117

C7,8,18,19

,27,28

CAP. 1.0 UF 35 V 22327-2519

C10,38-46,

49,55-58

CAP. 47 UF 16 V 17993-0094

C13,17,21,37CAP. 100PF 200 V 15619-0134

C16 CAP. 1.0 UF 50 V 23267-0158

C20 CAP. .15 UF 100 V 18083-0127

C24 CAP. 4700PF 100 V 15620-0018

C25,36,59,

60,61

CAP. 0.01 UF 100 V 15620-0123

C26,47,48,

50,53

CAP. 0.1 UF 50 V 46684-0048

C31 CAP. 470 UF 35 V 17995-0134

C34 CAP. 1000 UF 35 V 17995-0142

C35 CAP. 10 UF 35 V 22327-2618

C51,52 CAP. 22PF 200 V 15619-0050

C54 CAP. 1000 PF 200 V 15619-0258

CR1,4 DIODE, 1N4142 15668-0076

CR,6,7 DIODE, 1N4004 15668-0043

CR5 DIODE, 1N4148 15668-0035

DS1 DISPLAY, LCD 22329-0040

DS2,3 LED, H-2000 27472-00 10

FL1-6 FILTER, EMI 46547-0011

L1,2 CHOKE, 10 UHY 15779-0015

P1,2 CONN. 6 PIN 17794-0053

P4 CONN. 12 PIN 17731-0117

P5 (used with

-0056 only)

CONN. 14 PIN 17794-0137

P6,7 CONN. 2 PIN 17734-0015

P8 (used with

-0049 only)

CONN. 3 PIN 17794-0020

Q2 TRANSISTOR, TIP122 16271-0032

Q3-5 TRANSISTOR, 2N3904 15665-0012

R57,12,17,

19,43

RESISTOR, 100 OHM 14477-0492

R8 RESISTOR, 9.09 K 17873-1899

R9 RESISTOR, 64.9 K 17873-2715

R10 RESISTOR, 196 K 17873-31 76

R11 RESISTOR, 8.06 K 15677-3764

R13,14 RESISTOR, 37.4 K 17873-2483

R15,16 RESISTOR, 42.2 K 17873-2533

R18 RESISTOR, 110 K 15673-48 57

R20,21 RESISTOR, 182 OHM 15677-2188

R22 RESISTOR, 470 K 14477-13 75

SYMBOL DESCRIPTION W-T P/N

R23 RESISTOR, 510 K 14477-1383

R26,30 RESISTOR, 2.0 K 14477-0807

R27 RESISTOR, 330 OHM 15670-0619

R28 RESISTOR, 750 OHM 15670-0700

R29 RESISTOR, 910 OHM 14477-0724

R31-34 RESISTOR, 15 K 14477-1011

R35 RESISTOR, 0.475 OHM 46602-0179

R41,42 RESISTOR, 10.0 K 15677-3855

R44 RESISTOR, 3.9 K 14477-0872

R45,51 RESISTOR, 4.7 OHM 14477-0179

R46,47 RESISTOR, 22 OHM 14477-0336

R48 RESISTOR, 78.7 K 15677-4713

R49 RESISTOR, 13.0 K 15677-3962

R52 RESISTOR, 10 MEG 14477-1698

R53 RESISTOR, 5.1 K 14477-0906

R54-57 RESISTOR, 120 OHM 14477-0518

R58-52 RESISTOR, 22K 14477-1052

R63,64 RESISTOR, 39 K 14477-1110

R65 RESISTOR, 22 MEG 14477-1771

R66 RESISTOR, 5.23K 15673-3586

R67 1.0K 15673-2893

RN1 RESISTOR NETWORK, 5.62/301 K 23256-0011

RN2-4 RESISTOR NETW ORK, 9 X 10 K 17852-0045

RN5,6 RESISTOR NETWORK, 4 X .1 K 17852-0037

RV1 VARISTOR, V827A12 16046-0028

U1 IC, 7652 14323-0464

U2,3,5,7 IC, 308A 14323-0266

U4 IC, DG200 14323-0241

U6 IC, 311 14323-0258

U8 VO LTAGE REGULATOR 7660 15658-0227

U9 IC, 690 15657-0673

U10 VOLTAGE REGULATOR 7805 15658-0011

U11 IC, MC68HC11A1P 15657-0632

U12 IC, 74HC573 18080-055 9

U13 IC, PROGRAMMED MOD 615 29443-0020

U14 IC, 74HC00 18080-0013

U15 IC, 5453N 15657-0624

U16 (used

with -0056

only)

IC, 74HC14 18080-0096

U17 (used

with -0056

only)

IC, MAX232CPE 14323-0621

U18 REGULATOR, TL751MO8KC 15658-0300

U19 REGULATOR, 29412 15658-0359

VR2 DIODE, ZENER 1N5353B 16V 15669-0158

XDS1 SOCKET, SIP 25 PIN 17847-1017

XDS1 SOCKET, SIP 10 PIN 17847-1066

XDS1 BACKLIGHT, DISPLAY 27459-0041

XU13 SOCKET, IC 28 PIN 14361-0079

XU18 HEAT SINK 15556-0014

Y1 CRYSTAL, 8.00 MHZ 16125-0212

Page 29

MODEL 615 INDICATOR 12VDC

MAIN PC BOARD A/D SCHEMATIC

29

Page 30

MODEL 615XL INDICATOR 12VDC

PARTS AND ASSEMBLY

30

ITEM

NO.

DESCRIPTION W-T P/N QTY

1 MOUNTING BRACKET 11899-0043 1

2 RUBBER MOUNT 17807-0058 4

3 NEOPRENE WASHER 27357-0010 4

4 ENCLOSURE 47017-0010 1

5 DISPLAY PC BOARD 48466-0014 1

6 MAIN PC BOARD W/ RS-232, R/D 47301-0064 1

7 “REMOTE ZERO” RECEIVER (OPTIONAL) 51763-0018 1

8 BEZEL 21356-0014 1

9 SCREW, #10-32 x .75"L 18087-0073 12

10 KEYPAD ASS'Y 48715-0013 1

11 SCREW, #10-32 x .31"L 14473-0348 8

12 XM710, HAND HELD REMOTE (OPTIONAL) 51760-0011 1

ITEM

NO.

DESCRIPTION W-T P/N QTY

13 PNL ASSY, SINGLE W/B CONN (7-PIN) 52955-0055 1

PNL ASSY, SINGLE W/B CONN (7-PIN) W/RD or RS232 52955-0105 1

PNL ASSY 3-W/B CONN (4-PIN) 52955-0048 1

PNL ASSY 3-W/B CONN (4-PIN) W/RD or RS232 52955-0097 1

PNL ASSY 3-W/B CONN (5-PIN) 52955-0030 1

PNL ASSY 3-W/B CONN (5-PIN) W/RD or RS232 52955-0089 1

PNL ASSY 4-W/B CONN (4-PIN) 52955-0022 1

PNL ASSY 4-W/B CONN (5-PIN) 52955-0014 1

PNL ASSY 4-W/B CONN (4-PIN) W/RD or RS232 52955-0071 1

PNL ASSY 4-W/B CONN (5-PIN) W/RD or RS232 52955-0063 1

14 FUSE HOLDER 15455-0016 2

15 FUSE (5 AMP) 15453-0042 2

Page 31

MODEL 615XL INDICATOR 12VDC

KEYPAD BOARD ASSEMBLY (P/N 48715-0013)

AND SCHEMATIC

31

Page 32

MODEL 615XL INDICATOR 12VDC

MAIN PC BOARD A/D (P/N 47301-0064) AND

COMPONENT PARTS LIST

32

SYMBOL DESCRIPTION W-T P/N

B1 BATTERY, 3.6 V 23957-0021

C1,2,5,6,9,11,12,

14,15,22,23,26,3

0,32,33 CAP. 0.1 UF 100 V 15623-0120

C3,4 CAP. .22 UF 50 V 23267-0117

C7,8,18,19,27,

28 CAP. 1.0 UF 35 V 22327-2519

C10,38-46,49,

55-58 CAP. 47 UF 16 V 17993-0094

C13,17,21, 37 CAP. 100 PF 200 V 15619-0134

C16 CAP. 1.0 UF 50 V 23267-0158

C20 CAP. .15 UF 100 V 18083-0127

C24 CAP. 4700 PF 100 V 15620-0081

C25,36,59,60 CAP. 0.01 UF 100 V 15620-0123

C26,47,48,50,53 CAP. 0.1 UF 50 V 46684-0048

C31 CAP. 470 UF 35 V 17995-0134

C34 CAP. 1000 UF 35 V 17995-0142

C35 CAP. 10 UF 35 V 22327-2618

C51,52 CAP. 22PF 200 V 15619-0050

CR1,4 DIODE, 1N4142 15668-0076

CR6,7 DIODE, 1N4004 15668-0043

CR5 DIODE, 1N4148 15668-0035

FL1-6 FILTER, EMI 46547-0011

J5 CONN 14 PIN 27487-0054

L1,2 CHOKE, 10 UHY 15779-0015

P1,2 CONN. 6 PIN 17794-00 53

P4 CONN. 12 PIN 17731-0117

P5 CONN. 14 PIN 17794-0137

P6,7 CONN. 2 PIN 17734-00 15

P8 CONN. 3 PIN 17794-0020

Q3-5 TRANSISTOR, 2N3904 15665-0012

R5-7,12,17,19,43 RESISTOR, 100 OHM 14477-0492

R8 RESISTOR, 9.09 K 17873-1899

R9 RESISTOR, 64.9 K 17873-2715

R10 RESISTOR, 196 K 17873-3176

R11 RESISTOR, 8.06 K 15677-3764

R13,14 RESISTOR, 37.4 K 17873-2483

R15,16 RESISTOR, 42.2 K 17873-2533

R18 RESISTOR, 110 K 15673-4857

R20,21 RESISTOR, 182 OHM 15677-2188

R22 RESISTOR, 470 K 14477-1375

R24 RESISTOR, 3.3 K 14477-0856

SYMBOL DESCRIPTION W-T P/N

R26,30 RESISTOR, 2.0 K 14477-0 807

R28 RESISTOR, 750 OHM 15670-0700

R29 RESISTOR, 910 OHM 14477-0724

R31-34 RESISTOR, 15 K 14477-1011

R35 RESISTOR, 0.475 OHM 46602-0179

R41,42 RESISTOR, 10.0 K 15677-3855

R44 RESISTOR, 3.9 K 14477-0872

R45,51 RESISTOR, 4.7 OHM 14477-0179

R46,47 RESISTOR, 22 OHM 14477-0336

R48 RESISTOR, 78.7 K 15677-4713

R49 RESISTOR, 13.0 K 15677-3962

R52 RESISTOR, 10 MEG 14477-1698

R53 RESISTOR, 5.1 K 14477-0906

R54-57 RESISTOR, 120 OHM 14477-0518

R58-62 RESISTOR, 22K 14477-1052

R63,64 RESISTOR, 39 K 14477-1110

R65 RESISTOR, 22 MEG 14477-1771

R66 RESISTOR, 5.23K 15673-3586

R67 RESISTOR, 1.0 K 15673-2893

RN1 RES NET, 5.62/301 K 23256-0011

RN2-4 RES NET, 9 X 10 K 17852-0045

RN5,6 RES NET, 4 X .1 K 17852-0037

RV1 VARISTOR, V827A12 16046-0028

U1 IC, 7652 14323-0464

U2,3,5,7 IC, 308A 14323-0266

U4 IC, DG200 14323-0241

U6 IC, 311 14323-0258

U8 VOLTAGE REG 7660 15658-0227

U9 IC, 690 15657-0673

U10 VOLTAGE REG 7805 15658-0011

U11 IC, MC68HC11A1P 15657-0632

U12 IC, 74HC573 18080-0559

U13 IC, PROG MOD 615XL 29443-0038

U14 IC, 74HC00 18080-0013

U16 IC, 74HC14 18080-0096

U17 IC, MAX232CPE 14323-0621

U18 REGULATOR, TL751MO8KC 15658-0300

U19 REGULATOR, 29412 15658-0359

VR2 DIODE, ZEN 1N5353B 16 V 15669-0158

XU13 SOCKET, IC 28 PIN 14361-0079

XU18 HEAT SINK 15556-0014

Y1 CRYSTAL, 8.00 MHZ 16125-0212

Page 33

MODEL 615XL INDICATOR 12VDC

MAIN PC BOARD ASSEMBLY SCHEMATIC

33

Page 34

MODEL 615XL INDICATOR 12VDC

DISPLAY PC BOARD (P/N 47301-0064)

COMPONENT PARTS LIST AND SCHEMATIC

34

SYMBOL DESCRIPTION W-T P/N

C1 2 CAP .1 UF 100 V 15623-0120

C3 CAP 100 UF 25 V 17994-0101

C4 CAP 47 UF 16 V 17993-0094

C5 CAP 47 UF 10 V 17992-0095

C6 7 CAP 0.1 UF 50 V 46684-0048

C8 CAP 1000 PF 100 V 46684-0022

CR1 DIO 1N4142 15668-0076

DS1 DISPLAY LCD 2" 46643-0014

DS2 3 4 LED 27472-0010

L1 INDUCTOR 10 UHY 15779-0015

P5 CONN 14 PIN 17734-0130

Q1 TRANS TIP122 16271-0032

SYMBOL DESCRIPTION W-T P/N

R1 RES 303 K 14477-0856

R2 RES 1.0 K 14477-0732

R3 RES 1 MEG 14477-1458

R4 6 10 14 RES 10 K 14477-0971

R5 7 RES 22 K 14477-1052

R11 RES 33 OHM 14477-0377

U1 IC 74HC14 18080-0096

U2 IC 5453N 15657-0624

U3 VOLT REG 15658-0292

XDS1 SOCKET 25 PIN 17847-1017

XDS1 SOCKET 10 PIN 17847-1066

XDS1 BASCKLIGHT DSPL FIB OP 27459-0066

Page 35

MODEL 615XL INDICATOR 12VDC

WEIGH BAR PANEL ASSEMBLY AND CABLE/

CONNECTOR SCHEMATICS

35

Page 36

RD712 / 712XL REMOTE DISPLAY

PARTS LIST AND ASSEMBLY (P/N 48406)

36

ITEM

NO. DESCRIPTION W-T P/N QTY

1 Mounting Bracket 11899-0043 1

2 Rubber Mount 17807-0058 4

3 Neoprene Washer 27357-0012 4

4 Enclosure 47017-0010 1

5 Main Pc Board Assy W/Display (RD712) 48445-0010 1

6 Main Pc Board Assy W/Display (RD712XL) 48865-0029 1

7 “Remote Zero” Receiver Assy (Optional) 51763-0018 1

8 Screw, #6-32 x .25"L 14473-0223 4

9 Lock Washer #6 14474-0032 4

10 Rd712 Keypad/Backer Plate Assy (incl.: keypad, backer

plate, gasket) 48279-0029 1

11

Rd712xl Keypad/Backer Plate Assy (incl.: keypad,

backer plate, gasket)

48715-0021 1

12 Cable Assy 15' 48412-0027 1

Cable Assy 30' 48412-0019 1

13 Bezel 21356-0014 1

14 Screw #10-32 x .75"L 18087-0073 12

15 Xm710-L Hand Held Remote (optional) 51760-0011 1

Page 37

RD712 REMOTE DISPLAY

DISPLAY PC BOARD (P/N 48445-0010

COMPONENT PARTS LIST AND SCHEMATIC

37

SYMBOL DESCRIPTION W-T P/N

BL 1 BASCKLIGHT DSPL FIB OP 27459-0058

C1 2 CAP .1 UF 100 V 15623-0120

C3 CAP 100 UF 25 V 17994-0101

C4 CAP 47 UF 10 V 17992-0095

C5 6 CAP 0.1 UF 50 V 46684-0048

C7 CAP 1000 PF 100 V 46684-0022

CR1 DIO 1N4142 15668-0076

DS1 DISPLAY LCD 2" 46671-0019

DS 2 3 LED 27472-0010

L1 CHOKE 10 UHY 15779-0015

P1 CONN 10 PIN 17794-0095

P2 CONN 12 PIN 17731-0117

P3 CONN 3 PIN 17794-0020

SYMBOL DESCRIPTION W-T P/N

Q1 TRANS TIP122 16271-0032

R1 RES 303 K 14477-0856

R2 RES 1.0 K 14477-0732

R3 RES 510 K 14477-1383

R4 6 10 14 RES 10 K 14477-0971

R5 7 RES 22 K 14477-1052

R8 9 12 13 RES 120 OHM 14477-0518

R11 RES 330 OHM 15670-0619

RV1 VARIS V82ZA12 16046-0028

U1 IC 74HC14 18080-0096

U2 IC 5453N 15657-0624

XDS1 SOCKET 25 PIN 17847-1017

XDS1 SOCKET 10 PIN 17847-1066

Page 38

RD712XL REMOTE DISPLAY

DISPLAY PC BOARD (P/N 48865-0029)

COMPONENT PARTS LIST AND SCHEMATIC

38

SYMBOL DESCRIPTION W-T P/N

BL 1 BACK LITE DSPL FIB OP 27459-0066

C1 2 CAP .1 UF 100 V 15623-0120

C3 CAP 100 UF 25 V 17994-0101

C4 CAP 47 UF 16 V 17993-0094

C5 CAP 47 UF 10 V 17992-0095

C6 7 CAP 0.1 UF 50 V 46684-0048

C8 CAP 1000 PF 100 V 46684-0022

CR1 DIO 1N4142 15668-0076

DS1 DISPLAY LCD 2" 46643-0014

DS2 3 4 LED 27472-0010

L1 INDUCTOR 10 UHY 15779-0015

P1 CONN 10 PIN 17794-0095

P2 CONN 12 PIN 17734-0114

P3 CONN 3 PIN 17794-0020

SYMBOL DESCRIPTION W-T P/N

Q1 TRANS TIP122 16271-0032

R1 RES 303 K 14477-0856

R2 RES 1.0 K 14477-0732

R3 RES 1 MEG 14477-1458

R4 6 10 14 RES 10 K 14477-0971

R5 7 RES 22 K 14477-1052

R8 9 12 13 RES 120 OHM 14477-0518

R11 RES 33 OHM 14477-0377

U1 IC 74HC14 18080-0096

U2 IC 5453N 15657-0624

U3 VOLT REG 15658-0292

XDS1 SOCKET 25 PIN 17847-1017

XDS1 SOCKET 10 PIN 17847-1066

Page 39

MODEL 615 / 615XL INDICATOR 12VDC

XM710-L WIRELESS REMOTE INSTALLATION

39

The XM710-L hand-held transmitter provides the ability to remotely perform a zero/reset command and can be installed

in MODEL 615 / 615XL or RD712 / 712XL. The XM710-L wireless remote system is similar to those used on garage door

openers. For selectable security, the transmitter and receiver assembly boards have programmable security code switches.

The eight position switch is used to determine the security code. These can be programmed to a different code, but the

programmed code must match on both the transmitter and receiver.

The unit is shipped from the factory with the following settings:

1, 3, 5, 7 = ON (closed)

2, 4, 6, 8 = OFF (open)

Page 40

Programming Appendix

To determine an appropriate configuration code for J-Star or Eaton transducers, consult Table 9 for Eaton or Table 10 for J-Star.

Using the Eaton

Configuration Code

Chart (Table 9)

The Eaton Configuration Code Chart (See Table 9) shows you how selections listed below for five configurable parameters would be represented by

a configuration code of 4121. Notice that each digit in the code represents a

parameter, and the value of each digit represents a selection for that parameter as shown in Table 9: Eaton Configuration Code Chart.

Table 7

Eaton: A Sample Set of Configuration Choices

and

Its Corresponding Configuration Code, 4121

Parameter Represented by Selection Config.Code

Sensitivity 2nd digit 034/1K 4

Capacity x increment size 3rd digit 20K x 2 1

Auto zero tracking 4th digit ±1.0 division 2

Units of measure and

Capture mode 5th digit lb/On 1

Configuration code 4121 uses only the 2nd, 3rd, 4th and 5th of five available digits.

Using the J-Star

Configuration Code

Chart (Table 10)

The J-Star Configuration Code Chart (See Table 10) shows you how

selections listed below for five configurable parameters would be represented by a configuration code of 3121. Notice that each digit in the code

represents a parameter, and the value of each digit represents a selection for that parameter as shown in Table 10: J-Star Configuration Code

Chart.

Table 8

J-Star: A Sample Set of Configuration Choices

and

Its Corresponding Configuration Code, 3121

Parameter Represented by Selection Conflg. Code

Axle size 2nd digit 2-l/8" 3

Capacity x increment size 3rd digit 20K x 2 1

Auto zero tracking 4th digit ±1.0 division 2

Units of measure and

Capture mode 5th digit Ib/On 1

Configuration code 3121 uses only the 2nd, 3rd, 4th and 5th of five available digits.

Model 615/615XL Indicator Service Manual

Appendix 1

25

Page 41

Appendix 2

26

Model 615/615XL Indicator Service Manual

Page 42

Table 9: Eaton Configuration Code Chart

TRANSDUCER

DESCRIPTION:

SENSITIVITY CAPACITY x INCREMENT SIZE

0: .068/100 (5-pin) 2K x .1 2K x .2 2K x .5 20K x 1 20K x 2 20K x 5

1: .034/100 2K x .1 2K x .2 2K x .5 20K x 1 20K x 2 20K x 5

2: .017/100 2K x .1 2K x .2 2K x .5 20K x 1 20K x 2 20K x 5

3: .068/1K 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

4: .034/1K 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

5: .017/1K (5-pin) 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

6: .100/1K (5-pin) 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

19: Custom Sensitivity and Capacity x Increment (See text: Configuring Custom Sensitivity with Capacity x Increment Size.)

➤

➤

Column

Numbers 0 1 2 3 4 5

➤

AZT (Divisions)

0: OFF

1: ±.5

2: ±1.0

3: ±3.0

4: ±10.0

{

{

{

FIELD RECALIBRATION

To insure accuracy, recalibrate the scale system with a

known weight after reconfiguring for Eaton (See

Calibrate With a Known Weight, p. 11).

{

{

{

➤

UNITS CAPTURE

0: lb Off

1: lb On

2: kg Off

3: kg On

➤

➤

➤

➤

➤

➤

➤

_ 5 1 2 1 is the Configuration Code number representing selections cited in USING EATON TABLE 6.

➤

➤

➤

➤

➤

➤

➤

➤

➤

1 2 3 4 5 are place numbers for each digit in Configuration Code.

Symbols Used in Table 7

K Multiply by 1000

Model 615/615XL Indicator Service Manual

Appendix 3

27

Page 43

Table 10: J-Star Configuration Code Chart

TRANSDUCER

DESCRIPTION:

AXLE SIZE CAPACITY x INCREMENT SIZE

0: 1" 2K x .1 2K x .2 2K x .5 20K x 1 20K x 2 20K x 5

1: 1" (Poly) 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

2: 1-7/8" 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

2" 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

3: 2-1/8" 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

2-1/2" 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

2-7/8" 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

3-3/4" 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

4: CT 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

19: Custom Sensitivity and Capacity x Increment (See text: Configuring Custom Sensitivity with Capacity x Increment Size.)

➤

➤

➤

Column

➤

Numbers 0 1 2 3 4 5

AZT (Divisions)

0: OFF

1: ±.5

2: ±1.0

3: ±3.0

4: ±10.0

➤

UNITS CAPTURE

0: lb Off

1: lb On

2: kg Off

3: kg On

➤

➤

➤

➤

➤

{

{

{

FIELD CALIBRATION

To insure accuracy, recalibrate the scale system with a

known weight after reconfiguring for J-Star (See Cali-

brate With a Known Weight, p. 11).

{

{

{

_ 5 1 2 1 is the Configuration Code number representing selections cited in USING TABLE 1: CONFIGURATION CODE EXAMPLE.

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

1 2 3 4 5 are place numbers for each digit in Configuration Code.

Symbols Used in Table 8

K Multiply by 1000

Appendix 4

28

Model 615/615XL Indicator Service Manual

Page 44

29

Page 45

Weigh Bar® is a registered trademark of Weigh-Tronix Inc

05/27/04 615_S.P65 PN 29594-0019F e2 Printed in USA

Weigh-Tronix

1000 Armstrong Dr.

Fairmont, MN 56031 USA

Telephone: 507-238-4461

Facsimile: 507-238-8283

e-mail: ag@weigh-tronix.com

www.agscales.com

Loading...

Loading...