Page 1

Model 2060

Universal Weight Indicator

User Instructions

AWT35-501506

Issue AB

Page 2

Avery Weigh-Tronix is a trademark of the Illinois Tool Works group of companies whose ultimate parent company is

Illinois Tool Works Inc (“Illinois Tool Works”). Copyright © 2018 Illinois Tool Works. All rights reserved.

No part of this publication may be reproduced by making a facsimile copy, by the making of a copy in three dimensions of a two-dimensional

work and the making of a copy in two dimensions of a three-dimensional work, stored in any medium by electronic means, or transmitted in

any form or by any means, including electronic, mechanical, broadcasting, recording or otherwise without the prior written consent of the

copyright owner, under license, or as permitted by law.

This publication was correct at the time of going to print, however Avery Weigh-Tronix reserves the right to alter without notice the

specification, design, price or conditions of supply of any product or service at any time.

Model 2060_u_en_501506.book

Page 3

Table of Contents

Chapter 1 General Information and Warnings ........................................................................................ 7

About this Manual ..............................................................................................................7

Text Conventions ........................................................................................................7

Special Messages .......................................................................................................7

Installation ....................................... .................................... ...................................... .........8

Safe Handling of Equipment with Batteries .................................................................8

Routine Maintenance .........................................................................................................9

Cleaning the Machine ........................................................................................................9

Training ..................................... ................................................................ .........................9

Sharp Objects .............................................................................. .... ... ... ..........................10

FCC and EMC Declarations of Compliance ..................................................................... 10

Declaration of Conformity ......... ... ... ... .... ... ....................................................................... 11

Chapter 2 Overview .................................................................................................................................12

Front Panel and Keys ......................................................................................................12

Front Panel Keys .......................................................................................................13

Home Screen ...................................................................................................................14

Adjusting screen contrast .................................................................................................14

Using the alphanumeric keypad .......................................................................................14

Menus ..............................................................................................................................14

Standard Print Formats ....................................................................................................15

Chapter 3 Installation .............................................................................................................................. 17

Mounting the Model 2060 ................................................................................................17

Instructions for V mount ............................................................................................17

Instruction for Ram Mount .........................................................................................17

Cable Connections and Power Requirements .................................................................18

AWT05-509201 4+ Pin Amp Bottom Plate ................................................................18

AWT05-509202 4x 5Pin AWT Bottom Plate ..............................................................18

Connectors ................................................................................................................ 19

Routing the Scale Interface Cable ...................................................................................20

Connecting to a Convenience Outlet ...............................................................................20

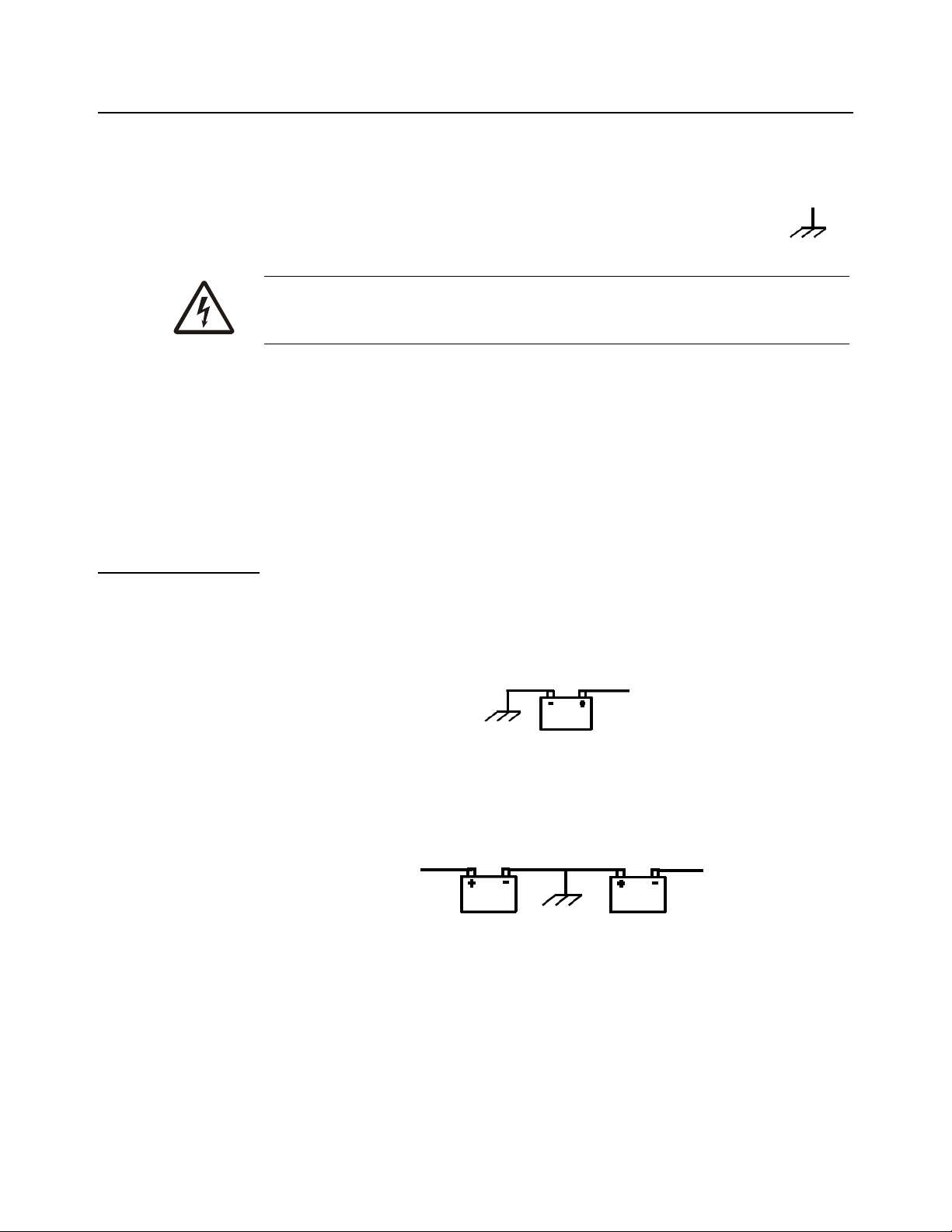

Power Connections - Battery ...........................................................................................21

Wiring 2060 Indicator to Equipment Power Systems .................................... ...................23

12 Volt Power Systems (one and two 12 V batteries) ...............................................23

24 Volt Power Systems .............................................................................................24

Grounded Power Systems ........................................................................................24

Power Connections - AC ..................................................................................................25

Optional Communications Connections .... .......................................................................26

Additional Connectors ........................ ... ....................................................................27

I/O Connector Pins (9 pin connector) ........................................................................27

Chapter 4 Quick Start Calibration Guide ............................................................................................... 28

Calibrate the 2060 with a Standard Configuration Number ............................................. 28

Determine the Configuration Number ........................... ...................... ....................... 28

Configuration Codes ..................................................................................................30

Enter the Configuration Code Number Parameter (Cfg Num) ................................... 31

Configuration Code Numbers for Common Applications: ............................. .............32

Custom Configuration Number for AWTX Weigh Bars ....................................................33

Determine Configuration Number .................................... ....................... ...................33

Determine Custom Calibration Number ....................................................................34

Custom Number Table .............................................................................................. 34

Enter Configuration Code Number (Cfg Num) .......................................................... 38

Enter Custom Configuration Number (Cust.Cfg) ................ .......................................38

Custom Configuration Number Calibration ............ .... ... ... ... ... .... ... ... ..........................39

Model 2060 User Instructions 3

Page 4

Configuring the 2060 for Other Brand Weigh Bars and Loadcells ...................................40

Custom Calibration Number ......................................................................................40

Chapter 5 Menus ............................................ ................................................... .......................................42

Accessing the menus .......................................................................................................42

Menu Navigation ......................................................................................................43

Exiting the Menus ............................................................................................................43

User menu ................................................... ... .... ...................................... .... ... ... .............45

The User submenu ....................................................................................................45

The About submenu ..................................................................................................46

The Audit submenu ...................................................................................................47

Diag menu .................................... ... ... ....................................... ... .... ... .............................48

Scale .........................................................................................................................48

Cur.Zero .................................................................................................................... 48

Display ...................................... ....................... ...................... ....................... .............49

Buttons ...................................................................................................................... 49

Ports ..........................................................................................................................49

Inputs .................................. ................... .................... ................... ................... ..........49

Outputs ..................................... .................................................... .............................50

Options ...................................................................................................................... 50

Logs ....................................... ....................... ...................... ....................... ................51

BSQ .................................... ................................................... .................................... 51

DigJbox .....................................................................................................................51

Admin menu .....................................................................................................................52

Calibrate .................................... ...... ....... ...... ....... ...... ....... ... ...... ....... ...... ....... ...... ...... .......54

Zero procedure ...................... ... ... .... ...................................... .... ... ... ... .... ... ................54

Span procedure .........................................................................................................55

Linearity (Linear) procedure ......................................................................................56

Build Up procedure ....................................................................................................56

Input procedure (key-in calibration) ....................... .................................................... 56

Gravity procedure ..................... ... .... ... ....................................... ... ... ... .... ... ... .............57

Display procedure .....................................................................................................57

Cal Unit procedure ....................................................................................................57

Print procedure ...................... ... ... .... ...................................... .... ... ... ... .... ... ................58

Cfg Num ....................................................................................................................58

Cust.Cfg ....................................................................................................................58

Span Adj ....................................................................................................................58

Scale menu ........... .... ... ....................................... ... ... ... ....................................... ... ... .......58

Capacty ..................................................................................................................... 59

Dvision .....................................................................................................................59

Units ..........................................................................................................................59

Stable ........................................................................................................................60

AZT ..................................... ................... .................... ................... ................... ..........60

Filter ..........................................................................................................................60

Ranges ...................................................................................................................... 62

2,3 Range .................... .... ...................................... .... ...................................... ... .......62

Type ..........................................................................................................................64

Roc ............................................................................................................................64

DigJbox .....................................................................................................................64

Traffic ........................................................................................................................64

System menu ........ .... ...................................... .... ... ... ....................................... ... ... ..........65

Site ............................................................................................................................65

Display ...................................... ....................... ...................... ....................... .............66

Buttons ...................................................................................................................... 67

D-Vals .................................... ....................... ...................... ....................... ................67

Tare ...........................................................................................................................69

Config ........................................................................................................................ 69

4 Model 2060 User Instructions

Page 5

Archive ......................................................................................................................70

Serial .........................................................................................................................70

Update ...................................... .................................................... .............................70

Password ..................................... ....................... ....................... ...................... ..........71

Z-Lock .......................................................................................................................71

Beeper ...................................... .................................................... .............................71

Num Scl .....................................................................................................................71

Ports menu .......................................................................................................................72

Serial .........................................................................................................................72

Enet ...........................................................................................................................73

Protcl .........................................................................................................................75

P.F. Edit ................. ... ....................................... ... ... .... ...................................... ... .... ...77

PLC ...........................................................................................................................77

Printer ....................................... ....................................................... ..........................79

File ...................................... ...................... .................... ...................... .......................79

Options ...................................................................................................................... 81

Opt232 ...................................... ....................... ...................... ....................... .............81

USB ........................................................................................................................... 81

Chapter 6 Application menu ................................................................................................................... 82

Accessing the Application menu ......................................................................................83

Auto Settings ....................................................................................................................84

Totals Settings ....................................... ... ... ....................................... ... ... .... ...................85

App Settings ................................. ... ... ....................................... ... .... ... .............................85

App Info .................................. ... ... ....................................... ...................................... .......86

Model 2060 User Instructions 5

Page 6

6 Model 2060 User Instructions

Page 7

1 General Information and Warnings

1.1 About this Manual

This manual is divided into chapters by th e chapter numb er and the large text at the top of a p age. Subsections

are labeled using the 1.1 and 1.1.1 convention. The names of the chapter and the next subsection level appear

at the top of alternating pages of the manual to re mind you of where you are in the manual. The manual name

and page numbers appear at the bottom of the pages.

1.1.1 Text Conventions

Key names are shown in bold and reflect the case of the key being described. If a key has dual functions, the

function is shown first followed by the key name in parentheses and in bold, such as in these examples: F1,

SELECT, PRINT, etc.

Displayed messages appear in bold italic type and reflect the case of the displayed message.

1.1.2 Special Messages

Examples of special messages you will see in this manual are defined below. The heading words have specific

meanings to alert you to additional information or the relative level of hazard.

DANGER!

THIS IS A DANGER SYMBOL.

DANGER MEANS THAT FAILURE TO FOLLOW SPECIFIC PRACTICES

OR PROCEDURES WILL CAUSE INJURY OR DEATH.

ELECTRICAL WARNING!

THIS IS AN ELECTRICAL WARNING SYMBOL.

ELECTRICAL WARNINGS MEAN THAT FAILURE TO FOLLOW

SPECIFIC PRACTICES OR PROCEDURES MAY RESULT IN

ELECTROCUTION, ARC BURNS, EXPLOSIONS OR OTHER HAZARDS

THAT MAY CAUSE INJURY OR DEATH.

WARNING!

This is a Warning symbol.

Warnings mean that failure to follow specific practices and procedures may

have major consequences such as injury or death.

CAUTION!

This is a Caution symbol.

Cautions give information about procedures that, if not observed, could result

in damage to equipment or corruption to and loss of data.

Model 2060 User Instructions 7

Page 8

NOTE: This is a Note symbol. Notes give additional and important information, hints

and tips that help you to use your product.

1.2 Installation

NO USER SERVICEABLE PARTS. REFER TO QUALIFIED SERVICE

PERSONNEL FOR SERVICE.

1.2.1 Safe Handling of Equipment with Batteries

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended by the manufactur er. Dispose

of used batteries according to the manufacturer’s instructions.

ATTENTION: Il y a danger d'explosion s'il y a remplacement incorrect de la

batterie, remplacer uniquement avec une batterie du même type ou d'un type

équivalent recommandé par le constructeur. Mettre au rebut les batteries

usagées conformément aux instructions du fabricant.

8 Model 2060 User Instructions

Page 9

1.3 Routine Maintenance

IMPORTANT: This equipment must be routinely checked for proper operation

and calibration.

Application and usage will determine the frequency of calibration required for

safe operation.

ELECTRICAL WARNING!

ALWAYS TURN OFF THE MACHINE AND ISOLATE FROM THE POWER

SUPPLY BEFORE STARTING ANY ROUTINE MAINTENANCE TO

AVOID THE POSSIBILITY OF ELECTRIC SHOCK.

CAUTION: Do not weld on or near the 3060 or any part of the scale system such

as Weigh Bars. Excessive heat and / or high currents may cause internal

damage. Physically remove the 2060 from any equipment it is mounted to and

disconnect it from the power source. Mak e ground connectio n as far away from

any scale part (cables, Weigh Bar, etc.) as possible.

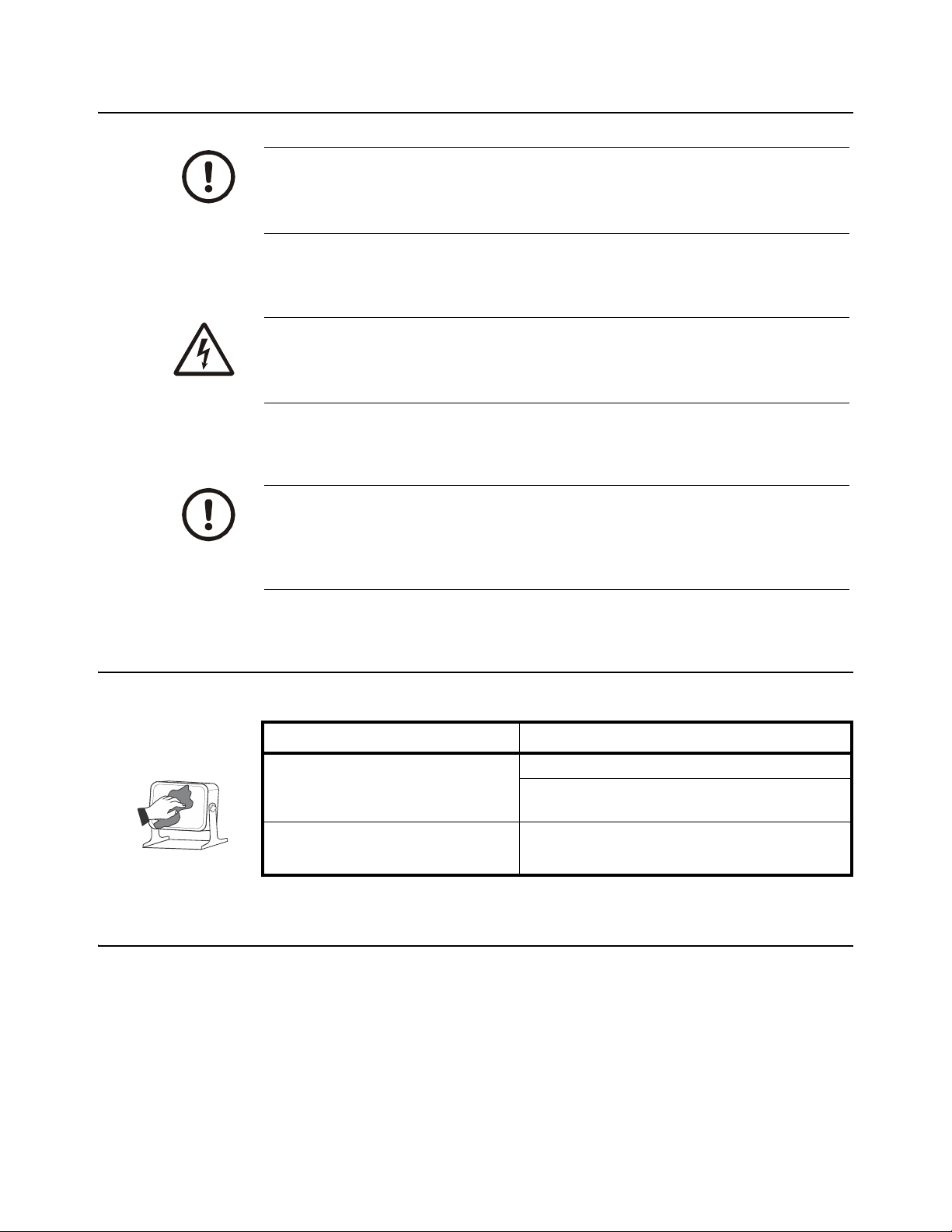

1.4 Cleaning the Machine

Table 1.1 Cleaning DOs and DON’Ts

DO DO NOT

Wipe down the outside of standard products

with a clean cloth, moistened with water and

a small amount of mild detergent

Spray the cloth when using a proprietary

cleaning fluid

Attempt to clean the inside of the machine

Use harsh abrasives, solvents, scouring cleaners or

alkaline cleaning solutions

Spray any liquid directly on to the display windows

1.5 Training

Do not attempt to operate or complete any procedure on a machine unless you have received the appropriate

training or read the instruction books.

To avoid the risk of RSI (Repetitive Strain Injury), place the machine on a surface which is ergonomically

satisfactory to the user. Take frequent breaks during prolonged usage.

Model 2060 User Instructions 9

Page 10

1.6 Sharp Objects

Do not use sharp objects such as screwdrivers to operate the keys.

1.7 FCC and EMC Declarations of Compliance

United States

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

Canada

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de

la Classe A prescrites dans le Règlement sur le brouillage radioélectrique edicté par le ministère des Communications du Canada.

European Countries

WARNING: This is a Class A product. In a domestic environment, this product may cause radio interference in which the user may be

required to take adequate measures.

10 Model 2060 User Instructions

Page 11

1.8 Declaration of Conformity

EN

EU

Declaration of

Conformity

Name and address of the manufacturer:

Avery Weigh-Tronix

1

Foundry Lane

Smethwick

West Midlands

B66 2LP

ENGLAND

This declaration of conformity is issued under the sole

responsibility of the manufacturer

Object of the declaration:

2060 / M2060

RD60M

RCV60-CE

The object of the declaration described above is in conformi-

ty with the relevant Union harmonisation legislation:

Applicable Directives Harmonised

standards

or other technical

specifications

Additional information:

Note

1

:

ITW Ltd trading as Avery Weigh-Tronix

Reg. Office : Nexus House, Station Road, Egham,

Surrey, TW20 9LB, England

Signed for and on behalf of:

Avery Weigh-Tronix

at

1000 Armstrong Drive, Fairmont, MN, 56031-1439,

USA

on

2017-05-08 K.Detert

Global Head of R&D

Model / Type:

2060/RD60/RCV60-CE

2014/30/EU

Electromagnetic Compatibility

EN61000-6-1:2007

EN61000-6-4:2007

EN14982:2009

2014/35/EU

Electrical equipment designed for use

within certain voltage limits

EN 60950–1 : 2006

+A2:2013

76501-556 Issue

2

DE

EU-

Konformitätserklärung

Name und Anschrift des Herstellers:

Avery Weigh-Tronix

1

Foundry Lane

Smethwick

West Midlands

B66 2LP

ENGLAND

Die alleinige Verantwortung für die Ausstellung dieser Kon-

formitätserklärung trägt der Hersteller.

Gegenstand der Erklärung:

2060 / M2060

RD60M

RCV60-CE

Der oben beschriebene Gegenstand der Erklärung erfüllt die

einschlägigen Harmonisierungsrechtsvorschriften der Union:

Angewandte Richtlinien Harmonisierte

Normen oder

sonstigen

technischen

Spezifikationen

Zusatzangaben:

Anmerkung

1

:

ITW Ltd Handel als Avery Weigh-Tronix

Sitz: Nexus House, Station Road, Egham,

Surrey, TW20 9LB, England

Unterzeichnet für und im Namen von:

Avery Weigh-Tronix

bei

1000 Armstrong Drive, Fairmont, MN, 56031-1439,

USA

am

2017-05-08 K.Detert

Globaler Leiter von

Forschung und Entwicklung

Modell / Typen:

2060/RD60/RCV60-CE

2014/30/EU

Elektromagnetische Verträglichkeit

EN61000-6-1:2007

EN61000-6-4:2007

EN14982:2009

2014/35/EU

Elektrischer Betriebsmittel zur

Verwendung innerhalb bestimmter

Spanungsgrenzen

EN 60950–1 : 2006

+A2:2013

FR

DéclaraƟonUE

de

Conformité

Nom et adresse du fabricant :

Avery Weigh-Tronix

1

Foundry Lane

Smethwick

West Midlands

B66 2LP

ANGLETERRE

La présente déclaration de conformité est établie sous la

seule responsabilité du fabricant.

Objet de la declaration:

2060 / M2060

RD60M

RCV60-CE

L’objet de la déclaration décrit ci-dessus est conforme à la

législation d’harmonisation de l’Union applicable:

Les directives en vigueur Les normes

harmonisées ou

d’autres

spécifications

techniques

Informations complémentaires:

Nota

1

:

ITW Ltd exerçant également sous le nom de Avery Weigh-

Tronix

Siège soc ial: Nexus House, Station Road, Egham,

Surrey, TW20 9LB, Angleterre

Signé par et au nom de:

Avery Weigh-Tronix à 1000 Armstrong Drive, Fairmont, MN, 56031-1439,

USA

le

2017-05-08 K.Detert

Responsable Mondial de la

Recherche et du Développement

Modèle / Type:

2060/RD60/RCV60-CE

2014/30/UE

Compatibilité Électromagnétique

EN61000-6-1:2007

EN61000-6-4:2007

EN14982:2009

2014/35/UE

Matériel électrique destiné à être

employé dans certaines limites de

tension

EN 60950–1 : 2006

+A2:2013

NL

EU-

Conformiteitsverklar-

ing

Naam en adres van de fabrikant :

Avery Weigh-Tronix

1

Foundry Lane

Smethwick

West Midlands

B66 2LP

ENGELAND

Deze conformiteitsverklaring wordt verstrekt onder volledige

verantwoordelijkheid van de fabrikant.

Voorwerp van de verklaring:

2060 / M2060

RD60M

RCV60-CE

Het hierboven beschreven voorwerp is in overeenstemming

met de desbetreffende harmonisatiewetgeving van de Unie:

Toepasselijke richtlijnen Geharmoniseerde

standaarden

of andere

technische

specificaties

Aanvullende informatie:

Noot

1

:

ITW Ltd trading als Avery Weigh-Tronix

Zetel: Nexus House, Station Road, Egham,

Surrey, TW20 9LB, England

Ondertekend voor en namens:

Avery Weigh-Tronix

bij

1000 Armstrong Drive, Fairmont, MN, 56031-1439,

VS

op

2017-05-08 K.Detert

Wereldwijd Hoofd van Onderzoek en

Ontwikkeling

Model / Type:

2060/RD60/RCV60-CE

2014/30/EU

Elektromagnetische compatibiliteit

EN61000-6-1:2007

EN61000-6-4:2007

EN14982:2009

2014/35/EU

Elektrisch materiaal bestemd voor

gebruik binnen bepaalde span-

ningsgrenzen

EN 60950–1 : 2006

+A2:2013

IT

Dichiarazione

di

Conformità UE

Nome e indirizzo del fabbricante:

Avery Weigh-Tronix

1

Foundry Lane

Smethwick

West Midlands

B66 2LP

INGHILTERRA

La presente dichiarazione di conformità è rilasciata sotto la

responsabilità esclusiva del fabbricante.

Oggetto della dichiarazione:

2060 / M2060

RD60M

RCV60-CE

L’oggetto della dichiarazione di cui sopra è conforme alla

pertinente normativa di armonizzazione dell’Unione:

Direttive applicabili Arm onizzato

standard

o altre specificazioni

tecniche

Informazioni supplementari:

Nota

1

:

ITW Ltd trading come Avery Weigh-Tronix

Sede dell' ufficio: Nexus House, Station Road, Egham,

Surrey, TW20 9LB, England

Firmato a nome e per conto di:

Avery Weigh-Tronix a 1000 Armstrong Drive, Fairmont, MN, 56031-1439,

U.S.A.

su

2017-05-08 K.Detert

Responsabile Globale della Ricerca e

Sviluppo

Modello / Tipo:

2060/RD60/RCV60-CE

2014/30/UE

Compatibilità elettromagnetica

EN61000-6-1:2007

EN61000-6-4:2007

EN14982:2009

2014/35/UE

Materiale elettrico destinato a essere

adoperato entro taluni limiti di ten-

sione

EN 60950–1 : 2006

+A2:2013

ES

DeclaraciónUE

de

Conformidad

Nombre y dirección del fabricante

Avery Weigh-Tronix

1

Foundry Lane

Smethwick

West Midlands

B66 2LP

INGLATERRA

La presente declaración de conformidad se expide bajo la

exclusiva responsabilidad del fabricante.

Objeto de la declaración:

2060 / M2060

RD60M

RCV60-CE

El objeto de la declaración descrita anteriormente es

conforme con la legislación de armonización pertinente de la

Unión:

Directivas aplicables Normas

armonizadas u

otras

especificaciones

técnicas

Información adicional:

Nota

1

:

ITW Ltd trading as Avery Weigh-Tronix

Oficina registrada: Nexus House, Station Road, Egham,

Surrey, TW20 9LB, Angleterre

Firmado en nombre de:

Avery Weigh-Tronix

en

1000 Armstrong Drive, Fairmont, MN, 56031-1439,

EE.UU

el

2017-05-08 K.Detert

Jefe Global de Investigación y

Desarrollo

Modelo / Tipo:

2060/RD60/RCV60-CE

2014/30/UE

Compatibilidad electromagnética

EN61000-6-1:2007

EN61000-6-4:2007

EN14982:2009

2014/35/UE

Material eléctrico destinado a utiliz-

arse con determinados límites de

tensión

EN 60950–1 : 2006

+A2:2013

Model 2060 User Instructions 11

Page 12

2Overview

2060

1 2

ABC

3

DEF

4

GHI

5

JKLJKL

6

MNO

7

PQRS8TUV

9

WXYZ

CLEAR

0

-#:,%

F1 F2 F3 F4 F5

HOLD

TARE ZEROPRINT

HOMEHOLDHOLD

GROSS/NET

BACK EN TER

Power key

This manual covers the installation, conne ctions and configuration of the Model 2060

indicator.

The 2060 can connect to USB flash drives, printers, remote displays, computers and

other peripheral devices.

Communications- Two standard RS-232 with optional third bi-directional serial ports

w/selectable output formats – Standard, Broadcast, T ransfer Data Module (TDM).

Standard Connectivity - USB 9-pin Amp Input/Output Connector.

Optional Connectivity- Internal WiFi, Internal ZigBee point to point wireless, RM 110

Bluetooth, RS 232 peripheral interface, Ethernet Transmitter/Receiver, Third RS-232

Port.

TTL Inputs- Three programmable inputs (Std, Zero Clear, Hold, or Print).

Outputs- Two setpoint outputs, open collector design.

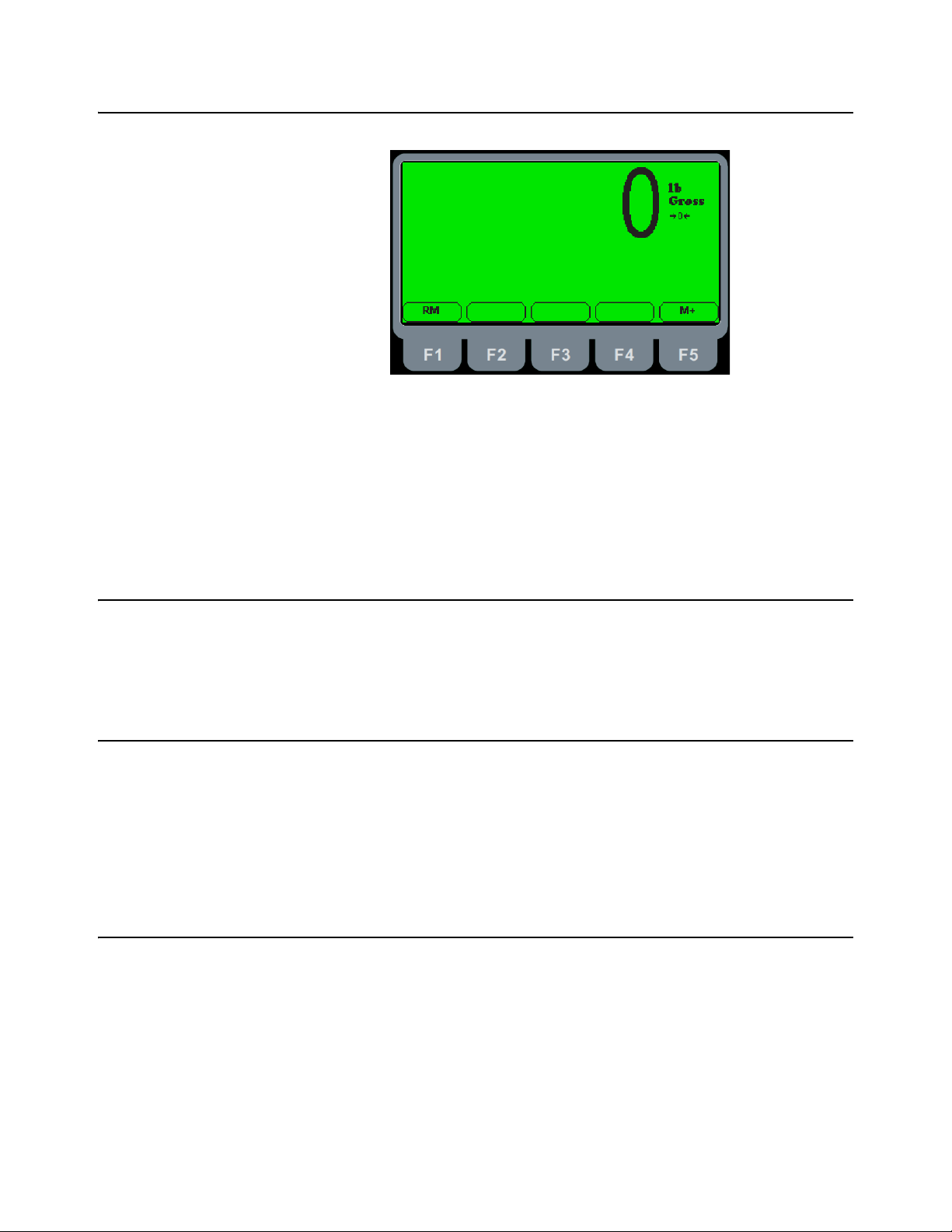

2.1 Front Panel and Keys

Figure 2.1 2060 Front Panel

Press the Power key to turn the unit on and press and hold the key for three seconds

to turn the unit off. The display will ask if you are sure. Use the up and down arrow keys

to highlight your answer and press the Enter (F3) key to confirm.

Model 2060 User Instructions 12

Page 13

2.1.1 Front Panel Keys

TARE

ENTER

PRINT

HOME

ZERO

BACK

HOLD

HOLDHOLD

GROSS/NET

1 2

ABC

3

DEF

4

GHI

5

JKL

JKL

6

MNO

7 8

TUV

9

CLEAR

0

The 2060 front panel shown in Figure 2.1 consists of the keys and the display.

Never press a key with anything but your finger. Damage to the overlay may result if

sharp or rough objects are used.

The functions of each key on the front panel are listed below.

Press to perform a tare function or prompts for a keyboard

tare, if enabled.

Press to toggle between Gross, Net, Tare and any other

active display values.

Press to send information to a peripheral device (printer,

computer or other serial device module).

Press in any mode to return to home screen or hold down for

3 seconds to access password screen.

Zeros the scale.

Press to back up one screen.

Press to hold a weight.

Press to toggle between the Gross and Net weight.

F1 - F5 Press these keys to select application specific choices.

Use the numeric keypad to enter numbers and letters in the

appropriate screens. Press the CLEAR key to clear the last

entry.

Model 2060 User Instructions 13

Page 14

2.2 Home Screen

The home screen has two softkeys, explained below:

RM (F1) Press this key to access a memory channel, so the indicator is ready for

M+ (F5) Press this key to accumulate weights in the active memory channel.

Figure 2.2 Home Screen

accumulations into that channel.

2.3 Adjusting screen contrast

To decrease the screen contrast press and hold the HOLD key and repeatedly press

the TARE key . To increase the contrast, press and hold the HOLD key an d repeatedly

press the ENTER key.

2.4 Using the alphanumeric keypad

Use the alphanumeric keypad to enter numbers and words when prompted by the

indicator. The action is similar to using a cell phone to select the number or letter. A

rapid succession of presses will scroll through the number on the key and then the

letters, starting with upper case and then lower case. The decimal key scrolls through

the negative sign, pound sign, colon, comma and percent sign. The 0 key toggles

between 0 and a space.

2.5 Menus

Menus used to configure the 2060 are accessed with passwords. See Menus on page

42 for a complete overview of each menu and how to navigate through them.

14 Model 2060 User Instructions

Page 15

2.6 Standard Print Formats

G: 32010 lb

G: 32010 lb

T: 16010 lb

N: 16000 lb

04-26-2006

03:02:47

G: 32010 lb

04-26-2006

03:02:47

G: 32010 lb

T: 16010 lb

N: 16000 lb

32010

The Model 2060 has 10 available print formats. See the examples below.

Format 0

Format 1

Format 2

Format 3 (default)

Format 4

Model 2060 User Instructions 15

Page 16

Format 5

32010 , 16010 , 16000

04-26-2006,03:02:47, 32010

04-26-2006,03:02:47, 32010 ,

16010 , 1600

N: 16000 lb

04-26-2006

03:02:47

N: 16000 lb

Format 6

Format 7

Format 8

Format 9

16 Model 2060 User Instructions

Page 17

3 Installation

The following section will cover installing the Model 2060 and cable connections.

3.1 Mounting the Model 2060

The Model 2060 mounts on a quick-detach V bracket or a 1.5" Ram Mount.

3.1.1 Instructions for V mount

Weld or bolt the quick-detach bracket into place, as follows:

1. Choose a mounting location that is

l convenient for operation of the indicator, and

l protected from moving parts or from other moving machinery

2. Hold the indicator at the proposed mounting location, and verify that the

display is legible and the controls accessible.

3. Position the quick-detach bracket with the wider end at the top, mark the

desired mounting location. If bolting, use the quick-detach bracket as a

template and mark and drill holes.

4. Weld or bolt the quick-detach bracket at the appropriate location. If bolting,

use double nuts or self-locking nuts to protect both indicator and machinery.

CAUTION: Do not weld on or near a Weigh Bar. Excessive heat or high

currents may cause internal damage.

5. Insert the indicator bracket into the quick-detach bracket and push it down into

place.

6. For mobile applications, wrap and twist a strong wire or zip tie around the

indicator bracket and the quick-detach bracket to stabilize the mounting.

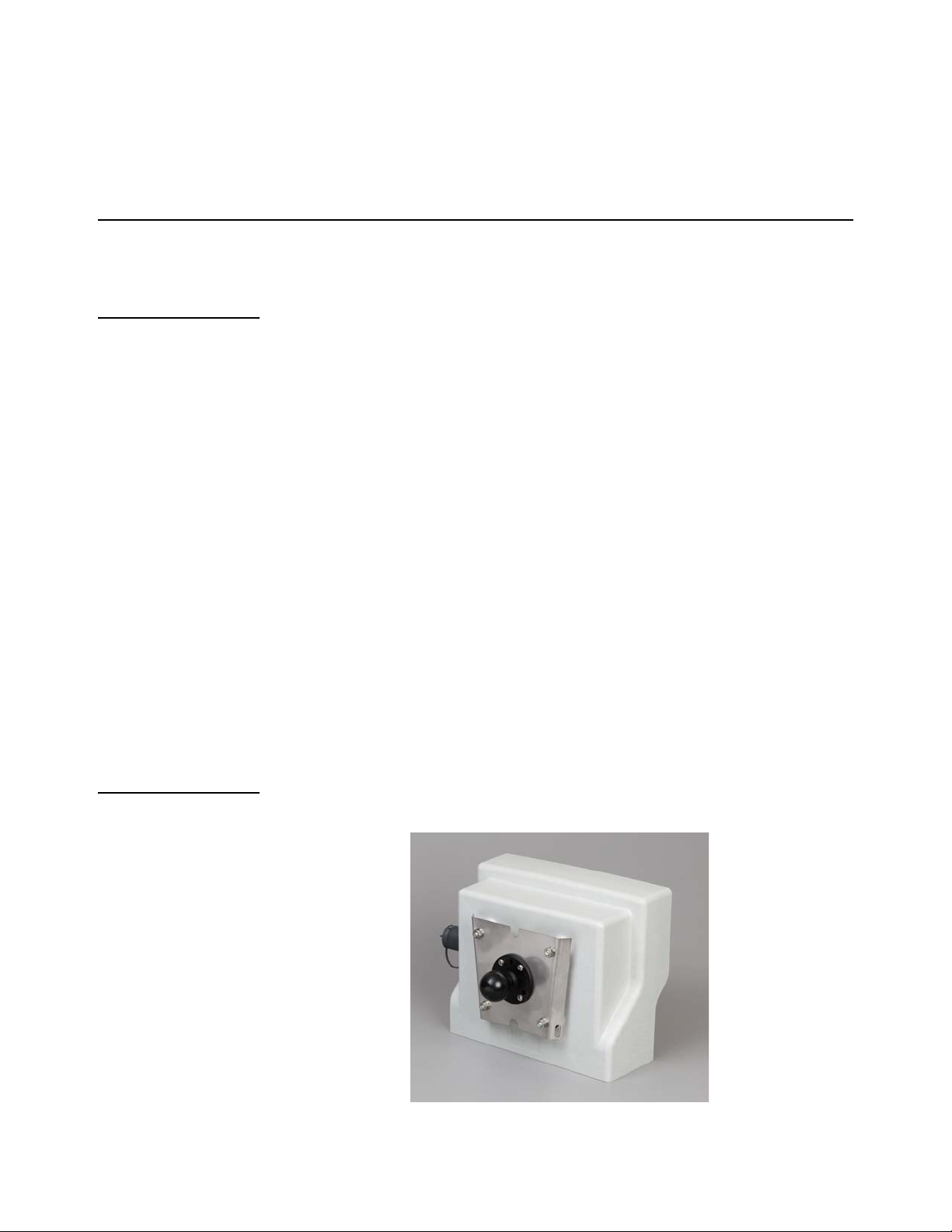

3.1.2 Instruction for Ram Mount

1. Order the Ram Mount Kit PN AWT05-508626.

2. Take nuts holding V bracket on 2060 off.

Model 2060 User Instructions 17

Page 18

3. Bolt one of the 2.5" Ram Mount bases onto the 2060 V mount bracket. It is

4-pin Power Input

I/O Connector

4-pin AMP J-box

Interface

Com-2

Default

Printer

Com-1

Default

Remote

Display

Com-2

Default

Printer

Com-1

Default

Remote

Display

2-pin Power Input

I/O Connector

4 Weigh Bars

Full Bridge

W/O J-box

recommend to bolt the Ram mount onto the Bracket so the V part of the

bracket will point towards the 2060 (reverse of how the bracket would be

mounted to use as a V mount).

3.2 Cable Connections and Power Requirements

Voltage to the Model 2060 must be 10-36 volts DC, negative ground only. Dropping

below eight volts will cause the Model 2060 to automatically shut itself off, protecting

the battery from being completely draine d.

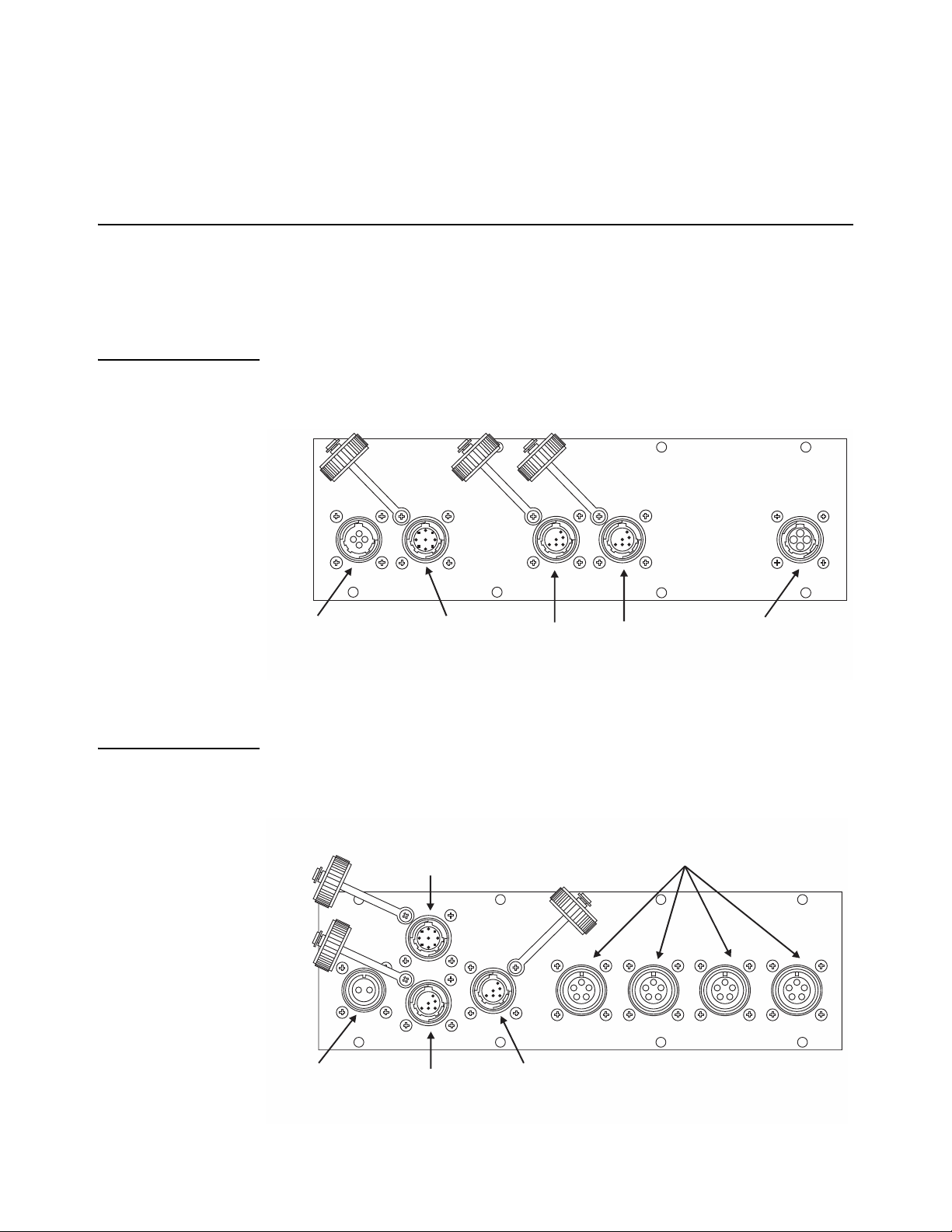

3.2.1 AWT05-509201 4+ Pin Amp Bottom Plate

This model has 4-pin power , Input/Output, printer, remote display and J-box home run

cable connector.

3.2.2 AWT05-509202 4x 5Pin AWT Bottom Plate

This model has 2-pin power, Input/Output, printer, remote display and input for 4

different weigh bars or J-box home run cable connector.

18 Model 2060 User Instructions

Page 19

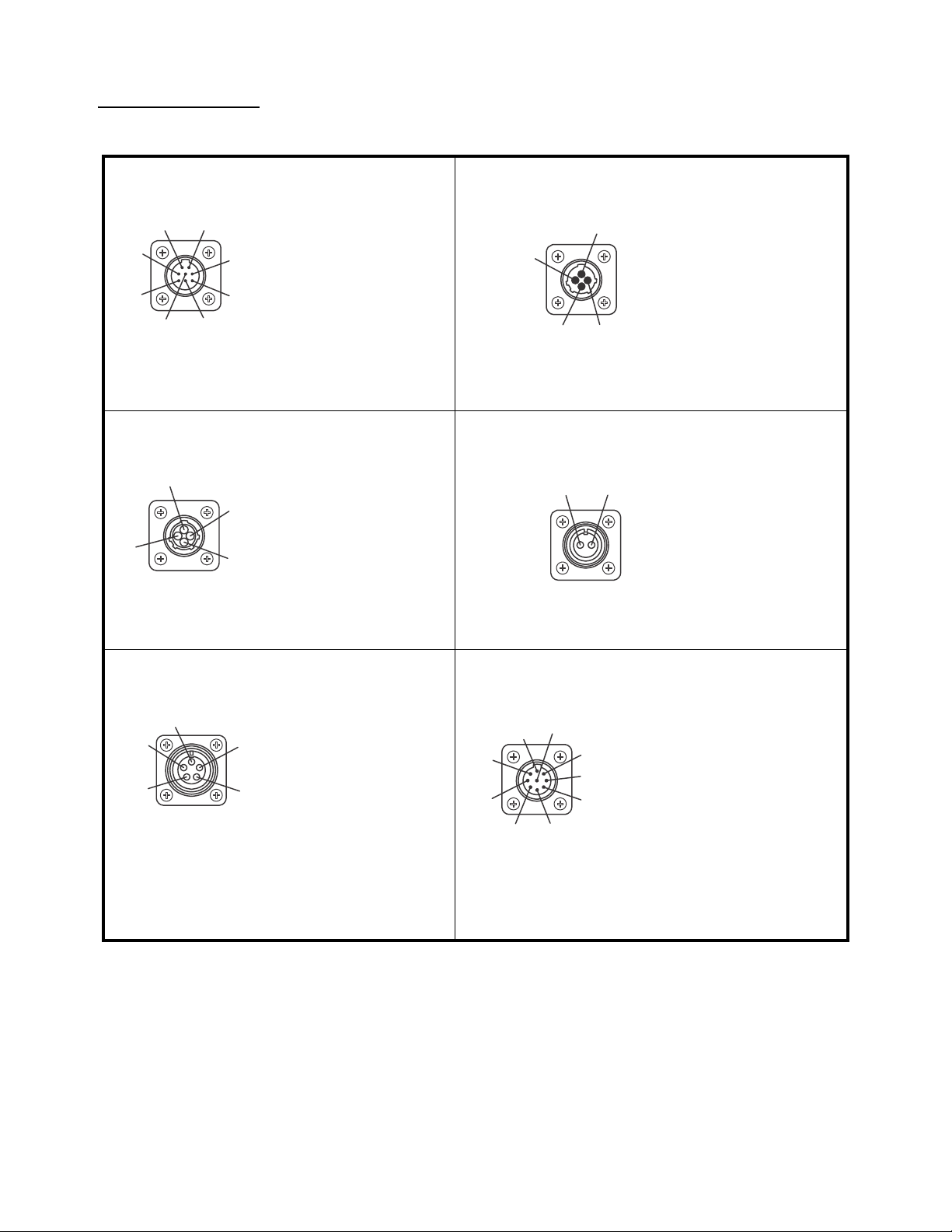

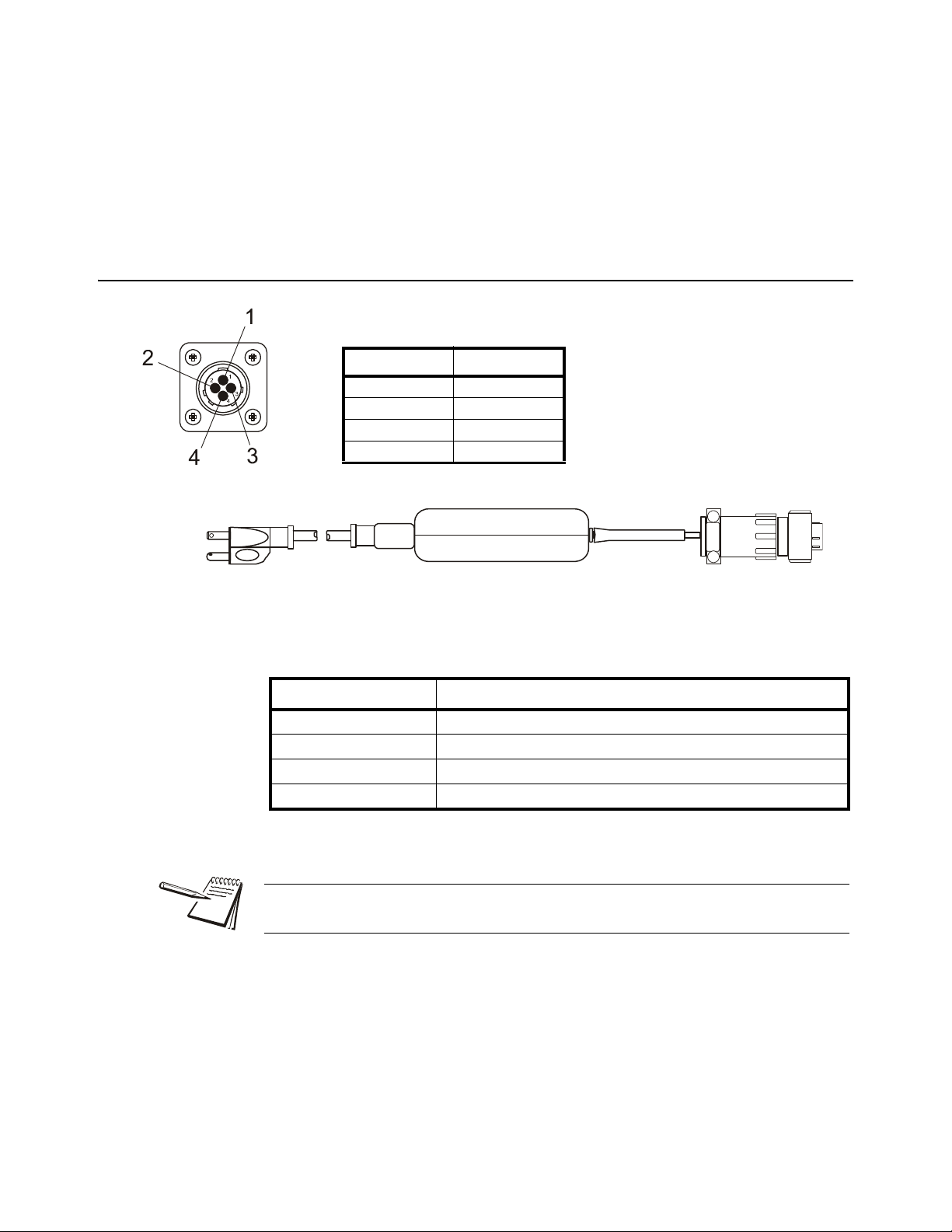

3.2.3 Connectors

RS-232 Port

Pin Description

1N/C

2XMT

3N/C

4RXD

5GND

6GND

7+5V

8+10-36V

Outside View

(Male)

1

2

3

6

4

7

8

5

4-Pin Power Input

Pin Description

1 +12V Input

2GND

3N/C

4N/C

Outside View

(Male)

1

2

3

4

1

2

4

3

4-Pin Amp J-Box Interface

Pin Description

1+ Excitation

2- Bridge

3+ Bridge

4-Excitation

Outside View

(Female)

1

2

3

4

2-Pin Power Input

Pin Description

A+12V

BGND

Outside View

(Female)

AB

5-Pin Weigh Bar Input

Pin Description

A - Bridge

B + Excitation

C+ Bridge

D - Excitation

EShield

Outside View

(Female)

A

E

D

C

B

I/O Connector (9 pin)

Pin Description

1+12V

2+5V

3GND

4 Input 2 (ZERO)

5 Input 3 (RESET target)

6GND

7 Output 1

8 Output 2 (N.O)

9 Input 1 (TARE)

Outside View

(Male)

1

2

3

4

5

6

7

9

8

Model 2060 User Instructions 19

Page 20

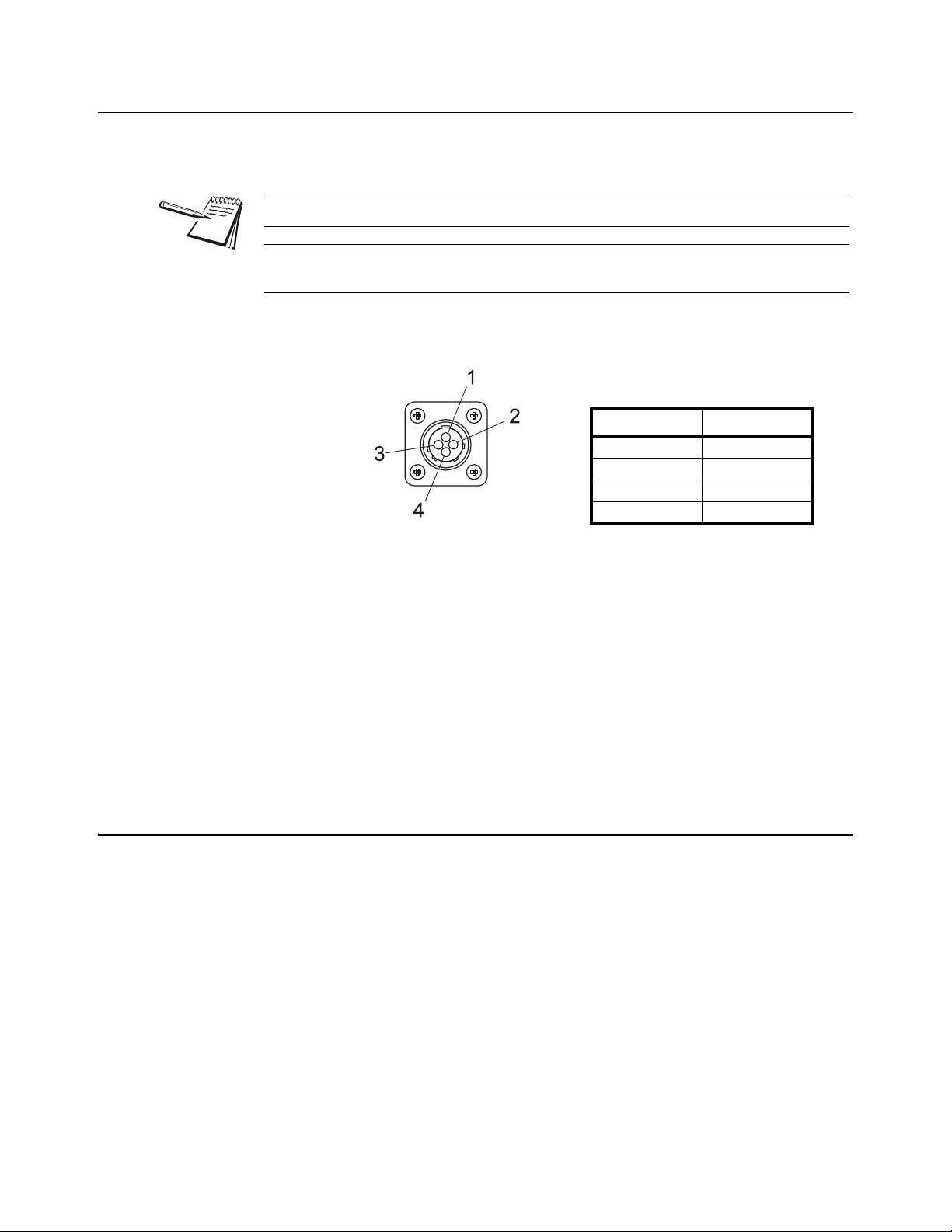

3.3 Routing the Scale Interface Cable

Scale Connector

Pin Description

1 + Excitation

2 - Bridge

3+ Bridge

4 - Excitation

The scale interface cable is the cable that runs from the junction box (j-box) to the

indicator.

For the AWT05-509201 Single Amp you will need to use a J-box.

For the AWT05-509202 4 by 5-pin AWT you will only need to use a j-box for systems

with 5 or more weigh bars.

1. Loosely connect the scale interface cable to the SCALE connector on the

indicator.

Figure 3.1 Scale Connector

2. Run the cable from the indicator to the junction box, allowing some slack in the

cable.

3. Connect the other end of the scale interface cable to the junction box.

4. Inspect the cable run and make sure that the cable is not pinched, kinked or in

the way of moving parts or sharp objects.

5. Be sure to allow some slack when zip tyeing or tucking away the cable.

6. Tighten the connector at the indicator.

3.4 Connecting to a Convenience Outlet

If the equipment you are using has an Auxiliary Power Outlet Strip it is preferred to

supply power to the indicator from the outlet strip rather than the battery.

Most power strip outlets have sp ades that provide constant power (unswitched power)

or key-switched power. Decide which one works best for your application and identify

which spades provide this power type.

If you have a tinned lead power supply and want to connect to the auxiliary power you

need to add a spade to each wire.

l Connect the white wire to the key-switched or unswitched power spade.

l Connect the black wire to the ground spade.

20 Model 2060 User Instructions

Page 21

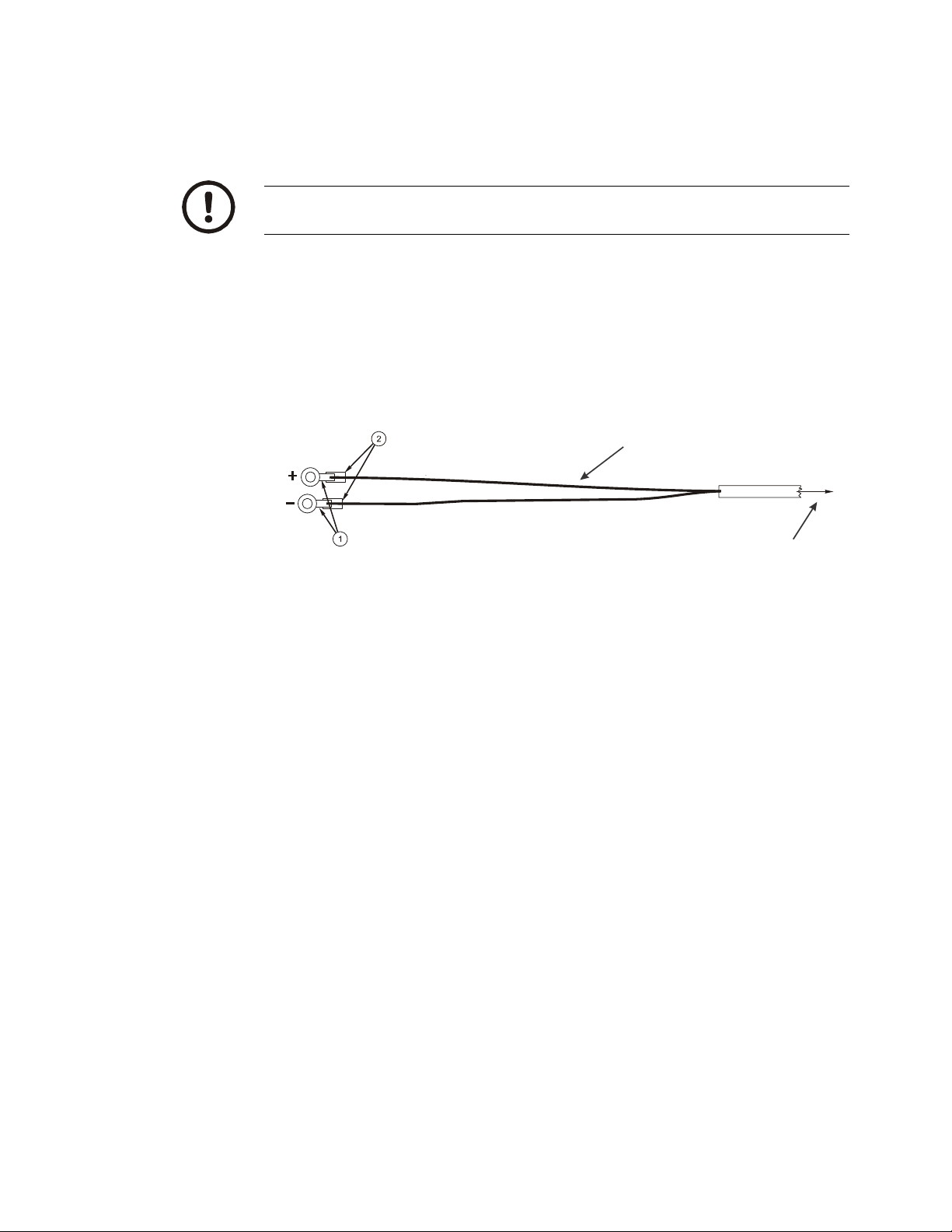

3.5 Power Connections - Battery

Power Connector

Pin Description

1 +12 VDC

2 Ground

3N/C

4N/C

Available Power Cables

Part Number Description

50474-0036 15 ft / 4.6 m power c ord, Amp

with tinned leads

50474-0051 25 ft / 7.6 m power c ord, Amp

with tinned leads

To indicator

To power

Figure 3.2 Power Connector and Battery Cable

NOTE: Although the above recommends a +12V connection the 2060 specification

allows it to be connected to a +36V power system.

CAUTION!

This indicator can only be connected to positive power terminal with negative

terminal ground battery system.

NOTE: The +ve supply is fused inside of the indicator. Ground battery connection

means that one terminal of the battery is connected to the equipment metal chassis.

The current returns to the battery through the metal work of the equipment ch assis.

1. Disconnect the negative wire from the battery terminal before performing an y

electrical work.

2. Loosely attach the connector end of the power cable to the 2060 indicator.

Model 2060 User Instructions 21

3. Route the cable to the desired power source connection point. If possible, run

the power cable through existing holes and channels so that it will be out of the

way and cannot be damaged by any moving parts. Be sure to keep the cable

from running near a distributor cap, the spark plugs or wires, or the alternator

on the motor. Keep the cable around the periphery of the engine compartment

whenever possible.

Page 22

4. Pull through all the slack in the cable and cable tie the power cable in

To battery

connection

White Wire

Power Cable

to Indicator

appropriate places to hold it in place.

5. Disconnect the power connector from the back of the indicator.

CAUTION: Non-approved power connections may damage equipment and void

warranty.

5a. Crimp the ring terminals (item 1) onto the wires as shown in Figure 3.3 below.

5b. Using a heat gun, shrink all of the heat shrink tubing (item 2) in place.

If the battery terminals have bolts to which you can connect the ring

terminals, do so. The white wire should be attached to the positive (+)

terminal. The black wire should be attached to the negative (-) terminal.

Skip to step 9

Figure 3.3 Power Cable Wiring

6. Connect the white power cable as close as possible to the battery's positive

voltage terminal without attaching it directly to the battery terminal. In other

words, the first place the positive terminal is connected to is where you should

tap in with the white power cable for the instrument.

7. Connect the black ground cable as close as possible to the battery's negative

terminal without attaching it directly to the battery. In other words, the first

place the negative terminal is connected to is where you should tap in with the

black ground cable for the instrument. The chassis may not provide the proper

ground potential. Check with the equipment manufacturer to de termine if

battery ground is isolated from chassis ground.

8. Tighten the AMP or AWT connector on the underside of the indicator. See

figure 3.2.

9. Reconnect battery power.

10. Press and hold the On/Off key on the 2060 until the red light above the key

comes on.

11. Check that the instrument powers on.

22 Model 2060 User Instructions

Page 23

3.6 Wiring 2060 Indicator to Equipment Power Systems

In all cases it is advised that you consult the equipment manufacturer or authorized

agents for advice before installing a weighing system. These are configurations that

you may find on different equipment manufacturers models.

Note that the electrical connection to the metal wor k of the equipment is

shown by the following symbol:

ENSURE THAT YOU DO NOT SHORT CIRCUIT THE BATTER Y ;

SPARKS AND ARCING FROM A BATTERY SHORT CIRCUIT CAN

CAUSE SEVERE BURNS.

? Always connect to the supply battery terminal last.

? Complete the wiring to the weighing indicator before connecting to the

indicator. Check with a resistance meter to insure there is no connection

between the supply wire and chassis ground.

? Verify battery system you are connecting to has negative ground.

? When you are satisfied with the above connect to the battery supply.

3.6.1 12 Volt Power Systems (one and two 12 V batteries)

Single Battery

12 V Battery negative terminal ground connection +12V power supply. DO NOT

REVERSE THE POLARITY!

Figure 3.4 Single Battery Connection

Two 12 Volt Batteries Wired in Series

Center ground connection +12V power supply

Figure 3.5 Two 12 Volt Battery Connection

Model 2060 User Instructions 23

Page 24

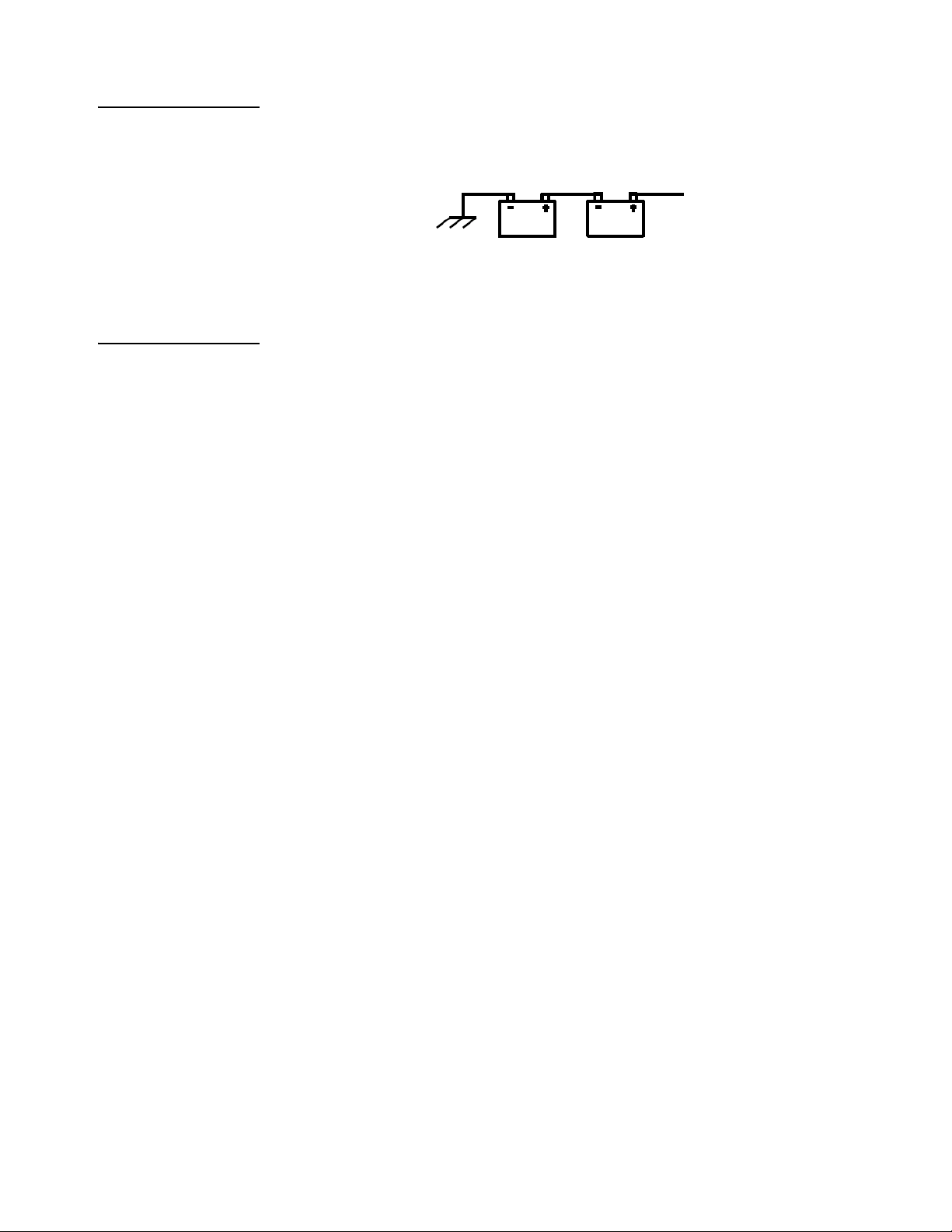

3.6.2 24 Volt Power Systems

The negative terminal connection of the first battery connected to ground, +ve

connection wired to the negative terminal of the second battery, the +ve is the +24V

power supply. DO NOT REVERSE THE POLORITY!

3.6.3 Grounded Power Systems

Ground battery connection means that one terminal of the battery is connected to the

equipment metal chassis. The current returns to th e battery throu gh the met al work of

the equipment chassis.

If the power system used is not connected to the chassis ground and is electrically

isolated from other equipment then this should not cause any problems with weighing

indicators. Normally the indicator is connected to the equipment power supply using

one of the grounded power systems described above.

Problems Using Chassis Ground

Figure 3.6 24 Volt Battery Connection

If the mating parts of the chassis are corroded then the resistance can be high which

depending on the current flow may reduce the voltage available to drive accessories.

There may be high power devices such as light s or motors which when switched on or

off because they share the current path could cause the voltage available to drive

accessories to be electrically noisy . In the case of motors then the y can cause very high

voltage spikes which could damage accessories.

Grounding Weight Indicators

For weighing indicators it is advised that the one of the power supply inputs is

connected to the equipment ground battery terminal through a sep arate insulated wire.

The separate return wire reduces the risk of chassis corrosion problems and over

voltage caused by other equipment electrical systems.

The ground connection ensures that the current flow in the indicator power wires is

always in the same direction, so that the built in circuit protection is effective.

If the system described in section 3.6.2 is used then there is available a 12V power

connection between 12V and 24 V. If this is used as a 12V power supply connection

the following problems could occur;

? On some indicators the metal housing of the indicator is connected to on e of

the power connections the 12V from the grou n d conn ec t ion. If th er e is an

accidental connection from the indicator housing to the equipment metal

work then there will be a large fault current which will cause the power cable

0V wire to heat up.

24 Model 2060 User Instructions

Page 25

? The internal power surge protection in the indicator which protects it, the

Power Connector

Pin Description

1 + 12 VDC

2 Ground

3 Output #1

4 Input #1

weigh bars and other components such as external displays will not be

effective against over voltages with resp ect to the ground. This could lead to

damage of the weigh bars which are connected by their load connections to

the ground although internally electrically isolated. Other accessories such

as the external displays, which have metal housings, may also be damaged

if there is a high voltage between the power supply and housing.

3.7 Power Connections - AC

Figure 3.7 AC Power Connections

Table 3.1 AC to DC Cables

Part Number Description

AWT15-501422 China AC to DC power converter 12VDC 5A Amp

AWT15-501275 EU AC to DC power converter 12VDC 5A Amp

AWT15-501273 NA AC to DC power converter 12VDC 5A Amp (Replaces 28300-0057)

AWT15-501274 UK AC to DC power converter 12VDC 5A Amp

Refer to the Ag power supply price sheet for more details on available cables and

drawings.

For applications requiring AC power, follow these instructions.

1. Loosely attach the AC power adapter to the area near the outlet with a cab le tie.

2. Route the cable from the electrical outlet to the indicator. If possible, run the

power cable through existing channels or conduit so that it will be out of the

way and cannot be damaged by any moving parts.

3. Inspect the cable run and make sure that the cable is not pinched, kinked or in

the way of moving parts or sharp objects.

Model 2060 User Instructions 25

Page 26

4. Tuck or cable tie the excess cable along the run as necessary.

COM Port

Pin Description

1N/C

2XMT

3N/C

4RXD

5GND

6GND

7+5 V

8+8 V

5. Tighten the AMP connector on the underside of the indicator.

6. Plug the AC adapter in to the outlet.

7. Press and hold the On/Off key on the 2060 until the red light above the key

comes on.

8. Check that the indicator powers on.

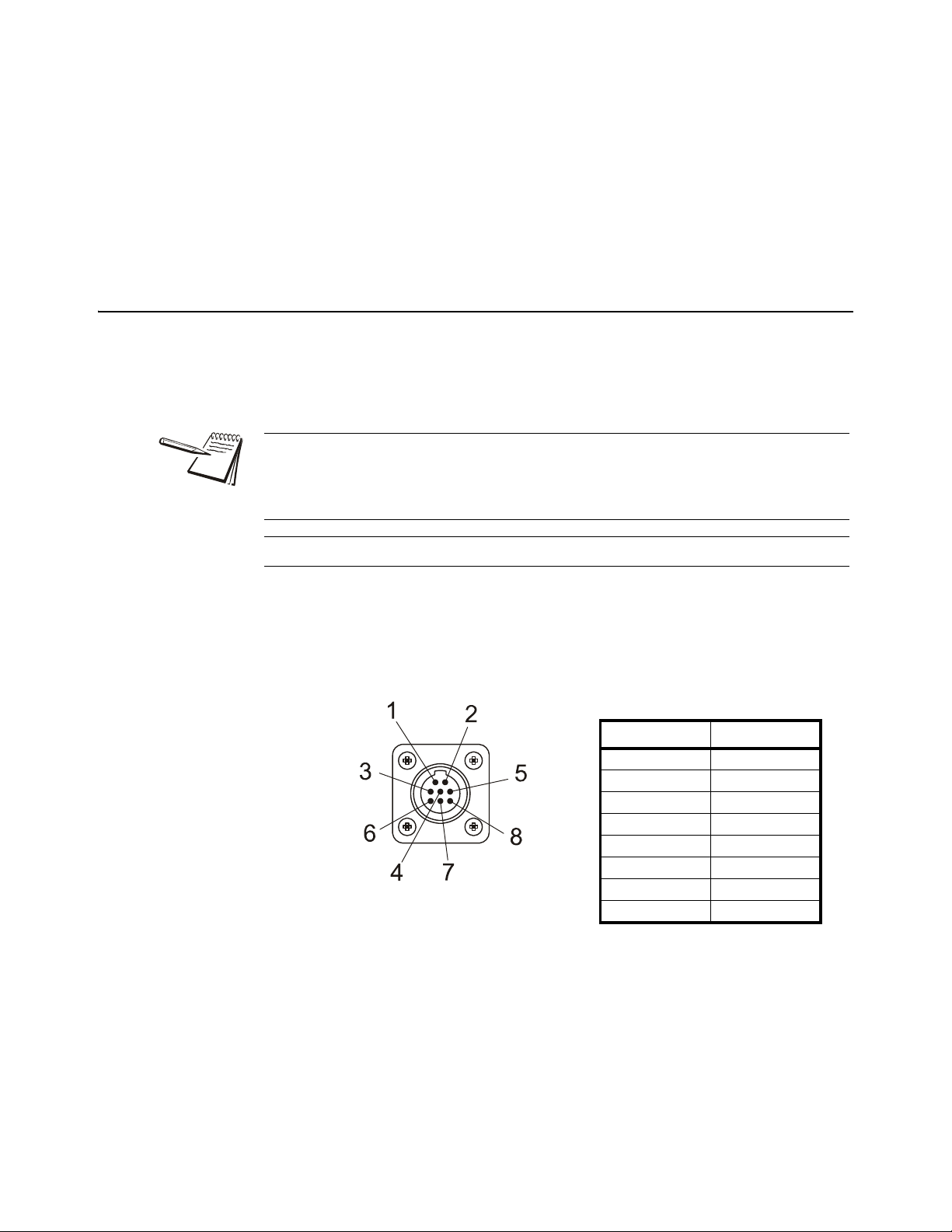

3.8 Optional Communications Connections

The 2060 comes with two standard an d a third optiona l serial commu nications (C OM)

ports which can be used for various peripheral equip ment such as a the XLR Series

remote displays, printer,RM200 or other device. Use the following instructions for

connecting a serial peripheral device to the 2060.

All COM ports on the 2060 indicator have the same pinouts as shown in Figure 4.11.

COM 1 is configured for XLR Series Remote Displays, COM 2 is configured for

Printer COM 3 Selectable default settings for each port are: Baud: 9600, Data Bits:8,

Parity: None, Stop Bits:1, C-trol: None.

Contact your Avery Weigh-Tronix representative if you need to change these settings.

1. Disconnect the indicator and peripheral device from the power source.

2. Loosely connect the communications cable (serial cable) to the required COM

port.

Figure 3.8 Sample COM Port

3. Route the serial cable to the peripheral device using existing channels or

conduit whenever possible.

4. Connect the serial cable to the device.

5. Inspect the cable run and make sure that the cable is not pinched, kinked or in

the way of moving parts or sharp objects.

6. Tighten the connector at the indicator.

26 Model 2060 User Instructions

Page 27

7. Reconnect power to the indicator and device.

8. Press and hold the On/Off button on the 2060 until the red light comes on and

the indicator powers on.

3.8.1 Additional Connectors

The 2060 also has the following connectors:

? USB connector - located on the right side of the enclosure. Use the USB

connector to connect a USB keyboard or flash drive.

? Ethernet connector - Standard internal with optional port on bottom plate.

This port is application dependent

Your scale is now installed and ready for use. If you have any questions during

installation, please contact your local Avery Weigh-Tronix representative.

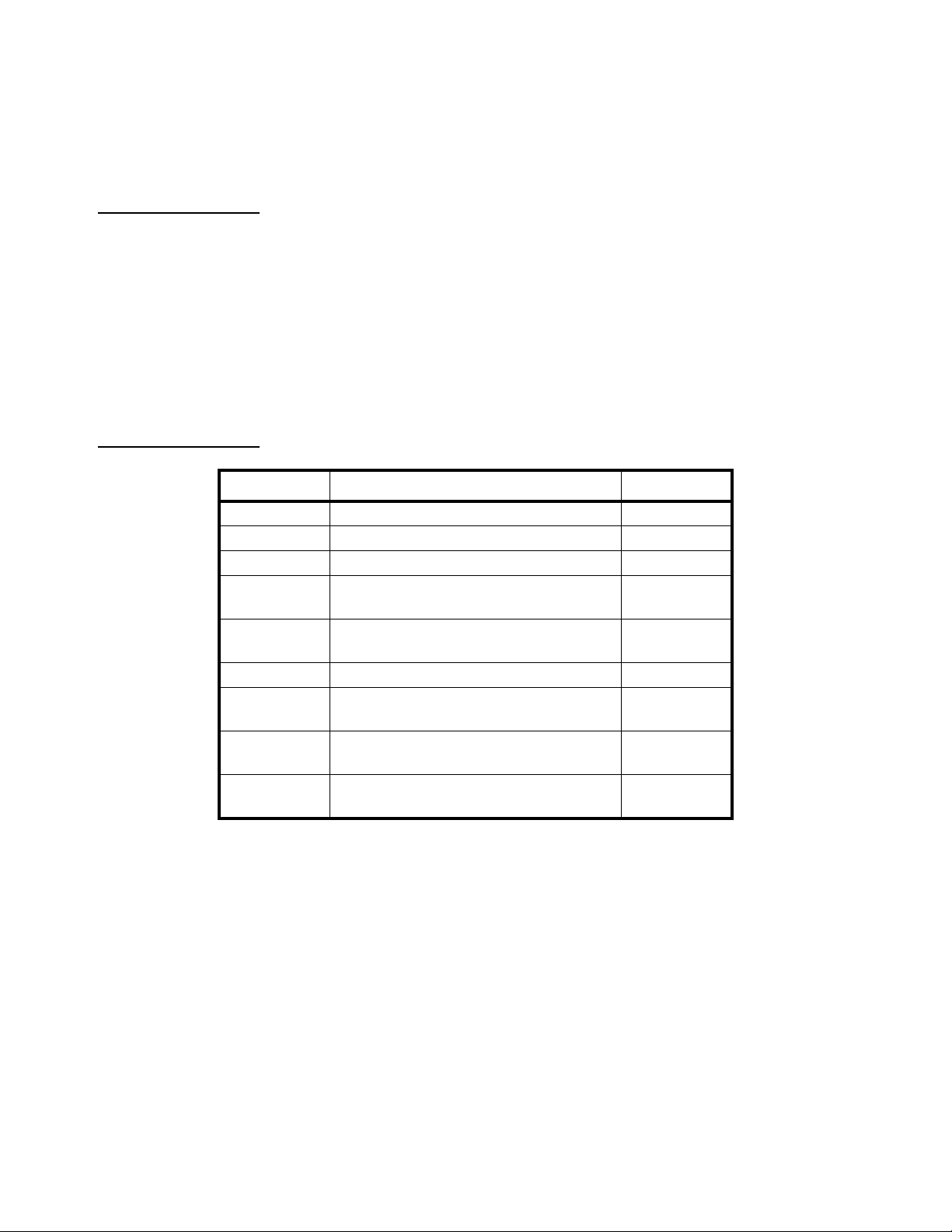

3.8.2 I/O Connector Pins (9 pin connector)

Connector / Pin Description Wire Color

P12-1 +12V BLK

P12-2 +5V BRN

P12-3 GND RED

P12-4 Input 2

(ZERO)

P12-5 Input 3

(RESET Target)

P12-6 GND GRN

P12-7 Output-1

(GND signal output once Alarm light is engaged)

P12-8 Output-2

(currently not used)

P12-9 Input 1

(TARE)

ORN

YEL

BLUE

GRAY

VIOLET

Example: External wiring to RESET Target weight:

To activate and RESET Target amount, connect the yellow and RED wire.

Example: External Wiring to turn off Target (auger/Conveyor):

Connect to the Blue Wire (Gnd Output) and BLACK (+12V) to turn on 12 volt relay

Model 2060 User Instructions 27

Page 28

4 Quick Start Calibration Guide

This Quick Start Guide includes calibration details for AWTX Weigh Bars standard

configuration or Custom configuration, and custom configuration for other brands of

Weigh Bars.

4.1 Calibrate the 2060 with a Standard Configuration Number

This section covers the standard calibration process for the scale system using precalibrated Avery Weigh-Tronix weigh cells. If using other brands of weigh cells or

configurations of AWTX weigh cells not mentioned below you will need to use Custom

Configuration. Refer to section 4.2 for an example of Custom Configuration and

Custom Configuration table.

4.1.1 Determine the Configuration Number

This section shows you how to find and enter a configuration number that sets up the

indicator for the following: type of Weigh Bar calibrati on diameter, capacity, increment,

and units.

The following are instructions for determining what number needs to be entered into

the calibration configuration number menu. The calibration diameter ( size) establishes

the first two numbers for the configuration code. These nu mbers are on the top center

of the label below the heading calibration diameter. In this example the calibration

diameter will be 2 1/8.

Figure 4.1 Sample Weigh Bar Label

Example:

All standard configuration numbers consist of five digits. Follow the example below.

1st & 2nd digit = Calibration Diameter

3rd Digit= Capacity and increment (Division) size. Note that capacity

refers to the max weight the scale will display not the actual capacity of

the equipment that scale system is installed on.

4th Digit= 0 (Print format will always be 0 for 2060)

5th Digit= Selection of Pounds (0) or Kilograms (4)

Model 2060 User Instructions 28

Page 29

2 1/8 calibration diameter , 20,000 (capacity limit) x 5 (increments the scale counts

03

1-7/8 20K x 1 20K x 2 20K x 5

200K x 10

200K x 20

200K x 50

04

2 20K x 1 20K x 2 20K x 5

200K x 10

200K x 20

200K x 50

05

2-1/8 20K x 1 20K x 2 20K x 5

200K x 10

200K x 20

200K x 50

06

2-1/4 20K x 1 20K x 2 20K x 5

200K x 10

200K x 20

200K x 50

1st & 2nd

Digits

CALIBRATION SIZE

CAPACITY X INCREMENT SIZE

03

1-7/8 20K x 1 20K x 2 20K x 5

200K x 10

200K x 20

200K x 50

04

2 20K x 1 20K x 2 20K x 5

200K x 10

200K x 20

200K x 50

05

2-1/8 20K x 1 20K x 2 20K x 5

200K x 10

200K x 20

200K x 50

06

2-1/4 20K x 1 20K x 2 20K x 5

200K x 10

200K x 20

200K x 50

1st & 2nd

Digits

CALIBRATION SIZE

CAPACITY X INCREMENT SIZE

3rd DIGIT 0 1 23

4

5

in), Print format is always 0, unit = lb.

Configuration code = 05204

1. The first two digits are the calibration size. In our example the calibration size is

2 1/8. The corresponding number is found in Table 4.1 on page 30. Find the

desired calibration size. In this example, 05 are the first two digits.

Figure 4.2 1st and 2nd Digit (Calibration Size)

2. The third digit is the capacity and increment (division) size within the

calibration size. In this example 20,000 x 5 is being used. The corresponding

number is also found in T able 4.1. Follow the row of the chosen calibration size

(i.e. 05) until you find the desired capacity and increment size. Follow the

column down to the bottom row. The third digit is located on the bottom row.

For this example, 2 is the number.

Model 2060 User Instructions 29

Figure 4.3 3rd Digit (Capacity and Increment Size)

3. The fourth digit is for print formats. The 2060 print formats are determined by

the application so the 4th digit will always be 0.

4. The 5th digit solely selects lb or kg in this example we want kg so the 5th digit

becomes 4. Auto-loc, or Auto-acc is determined by the application software.

Page 30

4.1.2 Configuration Codes

The following tables show how to establish a Configuration Code Number (CCN) to

configure the 2060 indicator . Table 4.1 applies to all 3 Weigh Bar junction box systems

and 4 Weigh Bar junction box systems.

? The only exception is the Calibration Size 2 1/4D-P, which can be used with

8 Weigh Bars that are 2 1/4 D cal size.

? If you use any other number of Weigh Bars, use custom settings 97, 98, or

99 and refer to section 4.2 to find your configuration numbers based on

reading of .4mV/V.

T able 4.1 1st/2nd (Weigh Bar Size) and 3rd CCN Digit s (Capacity and Increment)

1st and

2nd

CALIBRATION SIZE

CAPACITY x INCREMENT SIZE

Digit

00 5/8 200 x 0.01 200 x 0.02 200 x 0.05 2K x 0.1 2K x 0.2 2K x 0.5

01 1 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

02 1-1/4 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

03 1-7/8 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

04 2 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

05 2-1/8 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

06 2-1/4 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

07 2-1/4D 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

08 2-1/4D-P 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

09 2-1/2 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

10 3-1/8 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

11 4 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

12 CC20/CC30 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

13 Alley Weigh 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

14 CC30-3 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

15 Chute Weigh 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

16 CC-50 200K x 10 200K x 20 200K x 50 200K x 100 200K x 200 200K x 500

18 SPARE 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

20 1-digi 2K x 0.1 2K x 0.2 2K x 0.5 20K x 1 20K x 2 20K x 5

21 1 P OLY(DIGI) 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

22 1-7/8,2(DIGI) 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

23 2-1/8,2-1/2,2-7/8,3-3/4

20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

(DIGI)

97 Custom Setting 200 x 0.01 200 x 0.02 200 x 0.05 2K x 0.1 2K x 0.2 2K x 0.5

98 Custom Setting 20K x 1 20K x 2 20K x 5 200K x 10 200K x 20 200K x 50

99 Custom Setting 200K x 100 200K x 200 200K x 500 - - -

3rd DIGIT 0 1 2 3 4 5

30 Model 2060 User Instructions

Page 31

The fourth digit is for print formats. The 2060 print formats are determined by the

HOME

application so the 4th digit will always be 0.

Table 4.2 4th CCN Digit (Print Format)

4th

Digit

Print Formats

0

The 5th digit selects the calibration unit; lb (0) or kg (4).

Table 4.3 5th CCN Digit (Calibration Unit)

5th

Digit

Units

0 lb

4 kg

4.1.3 Enter the Configuration Code Number Parameter (Cfg Num)

1. From the home screen, press and hold the key for three beeps (3

seconds), then release. The password screen will be displayed.

2. Enter the password 3088 within 5 seconds and press the F3/ . Busy will be

displayed briefly and the calibration menu will be accessed.

3. The Calib menu will be highlighted.

? If you have Avery Weigh-Tronix Ag Weigh Cells you can chose between

standard and custom calibration codes to calibrate your system.

? If you are using weighs from a different manufacturer you will want to go to

section 4.2 for custom calibration.

4. Press F3/ . Scale 1 will be highlighted.

5. Press F3/ . The calibration choices will be displayed.

6. From Scale 1 Calib screen, use the F1/ or F2/ to highlight Cfg Num.

7. Press the F3/ key.

8. Enter the calibration number and press the F3/ key. The Scale 1 Calib

screen will be displayed.

9. To save and exit, press the BACK key until SAVE SETTINGS screen is

displayed. SAVE no will be the first choice displayed.

Model 2060 User Instructions 31

Page 32

10. Press the F2/ key to scroll to SaveYes. Press the F3/ key to accept and

save the configuration number. Busy will be displayed.The number will be

saved and the display will return to the home screen.

If attempting to enter an invalid number display will show CAN’t and return to

CONFIG.

4.1.4 Configuration Code Numbers for Common Applications:

SEED TENDERS & TMR MIXERS:

2 1/8 inch calibration weigh bar 20,000 x 5 lb (05200)

2 ½ inch calibration weigh bar 200,000 x 10 (09300)

2 1/4D calibration weigh bar 200,000 x 10 lb (07300)

CC-30 Compression Cell 200,000 x 10 lb (14300)

GRAIN CARTS:

2 1/4D calibration weigh bar 200,000 x 20 lb (07400)

CC-30 Compression Cell 200,000 x 20 lb (14400)

If it is impossible to know exactly which weigh bars are on the scale system, try one of

the recommended Configuration Code Numbers and keep entering the recommended

code numbers until the scale appears to be weighing properly . (See section 4.2.4: Enter

Configuration Code Number (Cfg Num).

After several attempts at a code number, if the scale still does not weigh properly

please consider the following:

? Contact your dealer or distributor where the scale was purchased.

? Access the Avery Weigh-Tronix website at www.agscales.com for more

debugging tips.

? Contact the Avery W eigh-Tronix service department at 1-800-458-7062 for

assistance.

32 Model 2060 User Instructions

Page 33

4.2 Custom Configuration Number for AWTX W eigh Bars

97

Custom Setting 200 x 0.0 1 200 x0.0 2 200 x 0.05 2K x 0.1 2K x 0.2 2K x 0.5

98

Custom Setting 20K x 1 20K x 2 20K x 5 200K x 10

200K x 20

200K x 50

99

Custom Setting 200K x 1 200K x 2 200K x 5

---

1st & 2nd

Digits

CALIBRATION SIZE

CAPACITY X INCREMENT SIZE

3rd DIGIT 0 1 23

4

5

97

Custom Setting 200 x 0.0 1 200 x0.0 2 200 x 0.05 2K x 0.1 2K x 0.2 2K x 0.5

98

Custom Setting 20K x 1 20K x 2 20K x 5 200K x 10

200K x 20

200K x 50

99

Custom Setting 200K x 1 200K x 2 200K x 5

---

1st & 2nd

Digits

CALIBRATION SIZE

CAPACITY X INCREMENT SIZE

3rd DIGIT 0 1 23

4

5

For use with all AWTX Ag Weigh Bars. Two numbers (Configuration Code and Custom

Configuration) must be entered into the 2060. Refer to Enter Configuration Code

Number (Cfg Num) on page 38.

? Configuration Code Number (Cfg Num)

? Custom Calibration Number (Cust.Cfg)

4.2.1 Determine Configuration Number

The following are instructions for how to determine what number needs to be entered

into the calibration configuration number menu. This selection appears as Cfg Num.

Example:

6 2 1/2 calibration weigh bars, 200,000 (capacity limit) x 20 (increments the scale

counts in), print format 0, kg configuration code = 98404

1. In our example the weigh bars are 2 ½ calibration. Figure 4.4:1st and 2nd Digit

(Custom Setting) is an excerpt from Table 4.1 on page 30. In this example, 98

are the first two digits.

Figure 4.4 1st and 2nd Digit (Custom Setting)

2. The third digit is the Capacity and Increment Size within the custom setting. In

this example 200,000 x 20 is being used. Figure 4.5:3rd Digit (Capacity and

Increment Size) is an excerpt from Table 4.1. Follow the column down to the

bottom row. The third digit is located on the bottom row. For this example, 4 is

the number.

Figure 4.5 3rd Digit (Capacity and Increment Size)

3. The fourth digit is for print formats. The 2060 print formats are determined by

the application so the 4th digit will always be 0.

4. The 5th digit selects the calibration unit; lb (0) or kg (4).

Model 2060 User Instructions 33

Page 34

4.2.2 Determine Custom Calibration Number

2 1/2

5

32133

2 1/2

6

38559

2 1/2

7

44986

Cal Size

No. of bars

CUSTOM # (lb/kg)

This number will be entered in the CUSTOM Configuration parameter which appears

as Cust.Cfg in the 2060 menu. In this example we have 6 2 ½ Cal Size weigh bars.

Figure 4.6 is an excerpt from Table 4.4:Custom Number Table.

Example for Custom Configuration:

6 2 1/2 cal size weigh bars, 200,000 x 20 kg = 38559

1. First you go down left hand column (Cal Size) in Table 4.4 and find 2 1/2.

2. Next, in the 2nd column find 6 for 6 weigh bars.

3. The third column 38559 is the custom number.

Figure 4.6 Custom Configuration Number

Refer to section 4.2.4 on page 38. Refer to Table 4.4 on page 34 for Custom Number

codes.

4.2.3 Custom Number Table

Table 4.4 Custom Number Table

Cal Size

Number of

Bars

Custom # (lb)

@.4mV/V

Custom # (kg)

@.4mV/V

5/8 1 92.3 41.8

5/8 2 184.5 83.7

5/8 3 276.8 125.5

5/8 4 369 167.4

5/8 5 461.3 209.2

5/8 6 553.6 251.1

5/8 7 645.8 292.9

5/8 8 738.1 334.8

1 1 375.3 170.2

1 2 750.6 340.5

1 3 1126 510.7

1 4 1501.3 681

1 5 1876.6 851.2

1 6 2251.9 1021.5

1 7 2627.2 1191.7

1 8 3002.6 1361.9

34 Model 2060 User Instructions

Page 35

Cal Size

Number of

Bars

Custom # (lb)

@.4mV/V

Custom # (kg)

@.4mV/V

1 1/4 1 893 405

1 1/4 2 1785.9 810.1

1 1/4 3 2678.9 1215.1

1 1/4 4 3571.9 1620.2

1 1/4 5 4464.9 2025.2

1 1/4 6 5357.8 2430.3

1 1/4 7 6250.8 2835.3

1 1/4 8 7143.8 3240.4

1 7/8 1 2630 1193

1 7/8 2 5261 2386

1 7/8 3 7891 3579

1 7/8 4 10522 4773

1 7/8 5 13152 5966

1 7/8 6 15782 7159

1 7/8 7 18413 8352

1 7/8 8 21043 9545

2 1 3270 1483

2 2 6540 2967

2 3 9810 4450

2 4 13080 5933

2 5 16350 7416

2 6 19620 8900

2 7 22890 10383

2 8 26160 11866

2 1/8 1 3753 1702

2 1/8 2 7506 3405

2 1/8 3 11260 5107

2 1/8 4 15013 6810

2 1/8 5 18766 8512

2 1/8 6 22519 10215

2 1/8 7 26272 11917

2 1/8 8 30026 13619

2 1/4 1 4613 2092

2 1/4 2 9226 4185

2 1/4 3 13839 6277

2 1/4 4 18452 8370

2 1/4 5 23065 10462

2 1/4 6 27678 12554

2 1/4 7 32291 14647

2 1/4 8 36904 16739

Model 2060 User Instructions 35

Page 36

Cal Size

Number of

Bars

Custom # (lb)

@.4mV/V

Custom # (kg)

@.4mV/V

2 1/4Dual 1 9226 4185

2 1/4Dual 2 18452 8370

2 1/4Dual 3 27678 12554

2 1/4Dual 4 36904 16739

2 1/4Dual 5 46130 20924

2 1/4Dual 6 55356 25109

2 1/4Dual 7 64582 29294

2 1/4Dual 8 73808 33479

2 1/2 1 6427 2915

2 1/2 2 12853 5830

2 1/2 3 19280 8745

2 1/2 4 25706 11660

2 1/2 5 32133 14575

2 1/2 6 38559 17490

2 1/2 7 44986 20405

2 1/2 8 51412 23320

3 1/8 1 12955 5876

3 1/8 2 25910 11752

3 1/8 3 38864 17629

3 1/8 4 51819 23505

3 1/8 5 64774 29381

3 1/8 6 77729 35257

3 1/8 7 90684 41133

3 1/8 8 103638 47010

4 1 26523 12031

4 2 53046 24061

4 3 79569 36092

4 4 106092 48122

4 5 132615 60153

4 6 159137 72184

4 7 185660 84214

4 8 212183 96245

Alley Weigh bar 1 389 176

Alley Weigh bar 2 778 353

Alley Weigh bar 3 1167 529

Alley Weigh bar 4 1556 706

Alley Weigh bar 5 1946 882

Alley Weigh bar 6 2335 1059

Alley Weigh bar 7 2724 1235

Alley Weigh bar 8 3113 1412

36 Model 2060 User Instructions

Page 37

Cal Size

Number of

Bars

Custom # (lb)

@.4mV/V

Custom # (kg)

@.4mV/V

Chute Weigh bar 1 2630 1193

Chute Weigh bar 2 5261 2386

Chute Weigh bar 3 7891 3579

Chute Weigh bar 4 10522 4773

Chute Weigh bar 5 13152 5966

Chute Weigh bar 6 15782 7159

Chute Weigh bar 7 18413 8352

Chute Weigh bar 8 21043 9545

CC-20/CC-30 1 5634 2555

CC-20/CC-30 2 11268 5111

CC-20/CC-30 3 16901 7666

CC-20/CC-30 4 22535 10222

CC-20/CC-30 5 28169 12777

CC-20/CC-30 6 33803 15333

CC-20/CC-30 7 39437 17888

CC-20/CC-30 8 45070 20444

CC-30-3 1 4000 1814

CC-30-3 2 8000 3629

CC-30-3 3 12000 5443

CC-30-3 4 16000 7257

CC-30-3 5 20000 9072

CC-30-3 6 24000 10886

CC-30-3 7 28000 12701

CC-30-3 8 32000 14515

CC-50 1 8000 3629

CC-50 2 16000 7257

CC-50 3 24000 10886

CC-50 4 32000 14515

CC-50 5 40000 18144

CC-50 6 48000 21772

CC-50 7 56000 25401

CC-50 8 64000 29030

Model 2060 User Instructions 37

Page 38

4.2.4 Enter Configuration Code Number (Cfg Num)

1. From the home screen press and hold the HOME key for three beeps (3

seconds), then release. The password screen will be displayed.

2. Enter the password 3088 within 5 seconds and press the F3/ . Busy will be

displayed briefly and the calibration menu will be accessed.

3. The Calib menu will be highlighted. Press the F3/ .key.

? If you have Avery Weigh-Tronix Ag Weigh Cells you can chose between

standard and custom calibration codes to calibrate your system.

? If you are using weighs from a different manufacturer you will want to go to

section 4.2 for custom calibration.

4. From Scale 1 Calib screen press the F3/ .key.

5. Use the F1/ or F2/ to highlight Cfg Num.

6. Press the F3/ key.

7. Enter the calibration number and press the F3/ .key. The Scale 1 Calib

screen will be displayed.

8. If you are using standard configuration codes proceed to step 8a if you are

using a custom code proceed to step 8b.

8a. To save and exit, pr ess the BACK key. The SAVE SETTINGS screen will be

displayed. SAVE no will be the first choice displayed.

8b. If you used a Custom Configuration Number that starts with 97, 98, 99,

press F2/ to highlight Cust. Cfg (Custom Configuration) and press F3/

8c. Enter the custom number a nd press F3 / .

9. Use the F1/ or F2/ key to scroll to SaveYes. Press the F3/ key to

accept and save the configuration number.The number will be saved and the

display will return to the home screen.

4.2.5 Enter Custom Configuration Number (Cust.Cfg)

This parameter will only be visible if a custom configuration number has been entered

previously (starts with 97, 98, 99).

1. From the home screen press and hold the HOME key for three beeps (3

seconds), then release. The password screen will be displayed.

2. Enter the password 3088 within 5 seconds and press the F3/ . Busy will be

displayed briefly and the calibration menu will be accessed.

3. The Calib menu will be highlighted.

? If you have Avery Weigh-Tronix Ag Weigh Cells you can chose between

standard and custom calibration codes to calibrate your system.

? If you are using weighs from a different manufacturer you will want to go to

section 4.2 for custom calibration.

4. From Scale 1 Calib screen, use the F1/ or F2/ to highlight Cust.Cfg.

38 Model 2060 User Instructions

Page 39

5. Press the F3/ key.

6. Enter the calibration number and press the F3/ key. The Scale 1 Calib

screen will be displayed.

7. To save and exit, press the BACK key. The SAVE SETTINGS screen will be

displayed. SAVE no will be the first choice displayed.

8. Use the F1/ or F2/ key to scroll to SaveYes. Press the F3/ key to

accept and save the configuration number.The number will be saved and the

display will return to the home screen.

4.2.6 Custom Configuration Number Calibration

When using Custom Configuration you must use test weights or verify a load on

another scale. Refer to section 4.2.4 on page 38 for instructions on entering the custom

number into the calibration menu.

Example:

Grain Cart Scale Shows net weight of 52,500 lbs loaded onto Truck Calibrated Truck

Scale shows net weight of 53,800 lbs Current Custom Configuration number 38559

Step 1: Calculate difference in weight between Grain Cart Scale and

Truck Scale: 52,800-53,800=1,300 lbs

Step 2: Divide difference by Grain Cart Weight to figure % (1,300/

52,500=.025 or 2%)

Step 3: In this case the Grain Cart weight was to low so we need to raise

the custom number by 2% (38559x1.02=39,330.18) We round this to

39,330 and enter this in place of the old custom number 38559

If we where 2% to high we simply would lower the custom number by 2%

(38,559x.98=37,787.82)

Step 4: Verify if the next load is within 1% of the Calibrated Truck scale.

If it is not within 1% you can repeat the process above.

Model 2060 User Instructions 39

Page 40

4.3 Configuring the 2060 for Other Brand Weigh Bars and Loadcells

The 2060 will work with any brand of strain gage based weigh bar or load cell. Once

the system is installed, the 2060 will then need to be calibrated using the Configuration

Code Number (Cfg Num) and (Cust.Cfg).

4.3.1 Custom Calibration Number

The Custom Configuration can be accomplished by either of the methods below

? Use the mv/V information from the weigh bars (Example 1 below)

? Placing Known Weight on Scale (Example 2 below)

Example 1: