Page 1

Model 1310 Truck Scale

In/Out Application

User’s Manual

Page 2

Weigh Bar® is a registered trademark of Weigh-Tronix Inc.

01/10/03 1310TRUCK_IN_OUT_U.P65 PN 29805-0014A e1 Printed in USA

2

Model 1310 Truck Scale In/Out Application User’s Manual

Page 3

Table of Contents

Table of Contents ..................................................................................... 3

1310 Specifications ................................................................................... 4

Introduction ............................................................................................. 5

About This Manual ............................................................................... 5

1310 Indicator ........................................................................................... 5

1310 Front Panel .................................................................................. 6

Main Display ......................................................................................... 6

Front Panel Keys .................................................................................. 6

Truck Scale In/Out Application Introduction .............................................. 8

Overview ............................................................................................. 8

Operation ............................................................................................. 9

Powerup ............................................................................................. 9

Inbound Procedure ............................................................................... 9

Outbound Procedure .......................................................................... 10

TARE Soft Key (F2) Function ............................................................. 12

PRINT Key Function........................................................................... 13

CLEAR Key Function ......................................................................... 14

REPORT Key Function ...................................................................... 14

Accessing Software Version ................................................................... 16

Setting Time and Date ............................................................................ 16

Error Messages ....................................................................................... 17

Error Messages from SensorCommTM................................................ 17

Error Messages from the Ghost Feature ............................................ 17

911 Diagnostic Menu .......................................................................... 18

SCOMM Soft Key ............................................................................... 21

Ethernet 10/100 SMTP Option ................................................................ 25

Pages are numbered consecutively beginning with the cover page.

Model 1310 Truck Scale In/Out Application User’s Manual

3

Page 4

1310 Specifications

Power Input

Excitation

Operational Keys

Operational Annunciators

Display

Display Characters

Display rate

A to D Conversion Rate

Unit of Measure

Capacity Selections

Incremental Selections

Decimal locations

Displayed Resolution

Audio Output

Time and Date

Internal Resolution

Universal 85-265 VAC, 50/60Hz, 75VA

10 Volts DC or 10 volts AC square wave capable of driving up to thirty-two 350-ohm weight

sensors. Indicator is also capable of driving Quartzell

TM

transducers

Zero, Tare, Print, Units, Select, Enter, Escape, Clear, 0-9/Alpha,

Decimal Point and Five Soft Keys labeled per selected operational routine.

Displayed symbols indicate motion, center of zero, unit of measure and more.

Model 1310—Dot graphic display, 5"W x 1.33"H provides images and up to eight lines of

weight and/or text. 240 x 64 dots cold cathode flourescent backlit, white on blue.

Application defined. 1.16" to 0.145" high.

Selectable, from 1 in 10 seconds to 10 times per second

60 times per second

Pounds, kilograms, grams, ounces, pounds and ounces and four programmable custom units

Up to 10,000,000 selectable

Multiples and sub multiples of 1, 2, 5

88888888 pick any location relative to division size

Up to 1 part in 10,000,000

Audio tone for key contact assurance or operational alarms

Battery protected real time clock is standard

1,000,000 counts analog, Quartzell

TM

transducer higher

Harmonizer™ digital filtering

Memory

Standard input and outputs

Dimensions

Available Options

Fieldbus Network Interfaces

Operating Temperatures

Fully programmable to ignore noise and vibration

128K (expandable to 8MB)

Com 1: RS232, RS-485/422, QuartzellTM, SensorComm

Com 2: RS232, 20 mA current loop

Com 3: RS232, RS-485/422, QuartzellTM, SensorComm

Com 4: RS232, RS-485/422, QuartzellTM, SensorComm

TM

TM

TM

(One bi-directional signal per port)

Four set point I/O ports via OPTO 22 I/O modules

1 Analog scale input

PS/2 Keyboard port

7.25" H x 11" W x 8.25" D (184 mm x 279 mm x 205 mm)

- Multiple analog scale inputs, up to seven additional

- Eight fully isolated, programmable analog outputs (selectable 0-20mA, 0-24mA, 4-20mA,

0-5VDC, 0-10VDC, ±5VDC, ±10VDC)

- Remote expanded control interface for TTL or solid state up to 64

- OPTO 22 Generation 4 I/O Modules

- Internal modem

- Memory Expansion - 1, 4, 5, 8 MB (battery backed SRAM)

- PC (AT) style alphanumeric keyboard

- Up to sixteen pulse counter inputs

- SensorCommTM Digital j-box

- TraxleTM total truck and axle weighing

Device NetTM, ProfiBus®, ControlNetTM, InterBus, ModBus Plus, Ethernet 10/100 (ModBus

TCP, TCP/IP (sockets), HTTP, SMTP, FTP, EtherNet/IP)

NTEP 14 to 104° F (-10 to 40° C), 10 to 90% relative humidity

Enclosure

Weight

Agencies

Stainless steel wash down enclosure NEMA 4X

17 lb, 7.7 kg

NTEP Class III/IIIL:10,000d CC# 01-033 A1

FCC Class A

4

Model 1310 Truck Scale In/Out Application User’s Manual

Page 5

Introduction

About This Manual

1310 Indicator

This manual covers the information you need to understand the operation of

your Model 1310 indicator with the Truck In/Out application installed.

Major sections of this manual are headed by titles in a black bar like Intro-

duction above. Subheadings appear in the left column. Instructions and text

appear on the right side of the page. Occasionally notes, tips, and special

instructions appear in the left column.

The 1310 is a stand alone or network capable weight indicator and process

controller. Built into the 1310 are the following standard features:

• 4 serial ports

• Time

• Date

• Stainless steel enclosure

• Large graphic display

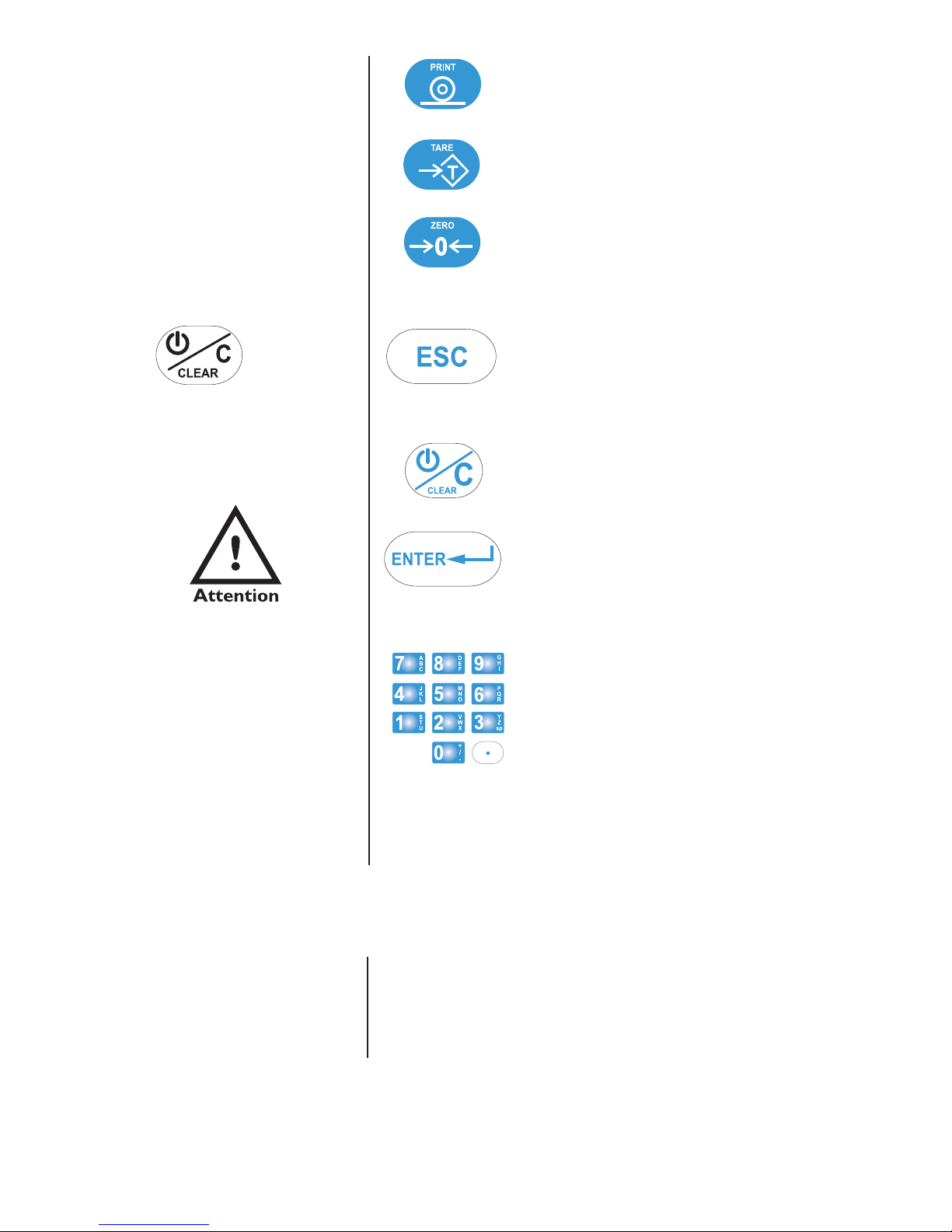

The 1310 front panel is shown in Figure 1. The front panel includes the

following:

• Dot graphic display, 5"W x 1.33"H provides images and up to eight

lines of weight and/or text. 240 x 64 pixel cold cathode flourescent

backlit, white on blue

• Five variable function soft keys (F1-F5)

• Alphanumeric keypad

• SELECT key

• UNITS key

• PRINT key

• TARE key

• ZERO key

• C (Clear) key, Power Off/On

• ESC (Escape) key

• ENTER key

• Decimal point key

Model 1310 Truck Scale In/Out Application User’s Manual

5

Page 6

1310 Front Panel

Plug the 1310 into an easily

accessible grounded outlet

only. Never use the unit

without an appropriate earthground connection.

Any computer based system

should have a separate,

grounded power circuit. We

recommend one for the

1310.

A power surge suppression

unit is recommended between

the 1310 and AC outlet.

Figure 1

1310 Front Panel

Main Display

To increase the contrast of the

display, press and hold the

DECIMAL POINT and 7 keys

until the desired contrast is

reached. To decrease the

contrast of the display, press

and hold the DECIMAL POINT

and 1 keys until the desired

contrast is reached.

Front Panel Keys

Hard Keys

Use this key to toggle

UPPER and lower case

alpha characters, while

entering alphanumeric

characters.

The main display is a 240 x 64 dot, dot-addressable, vacuum fluorescent

display. The ability to address each of the dots individually makes this

display nearly as versatile as a computer screen. It can display graphics,

words and numbers. This flexibility allows graphics and alphanumeric

characters to be displayed at the same time.

The keys on the front panel of the 1310 are of two types, hard keys and soft

keys. Hard keys are labeled directly and soft keys are labeled F1-F5. If a

soft key has a function, its label appears at the bottom of the display. Soft

keys function differently at different times and their labels change as

needed.

Below are brief descriptions for each of the hard key functions:

Repeatedly press the SELECT key to scroll through the

available weight reading displays. (Examples - gross,

net, tare, minimum, maximum, etc.)

For alpha entries, this key toggles UPPER/lower case

entry (if Lowercase Enable is turned on in the configuration). If lower case is selected, "abc" will appear in the

upper right of the display.

6

Model 1310 Truck Scale In/Out Application User’s Manual

Press the UNITS key to scroll through the available

units of measure (lb, kg, oz, etc.).

Page 7

Press the PRINT key to send data to a connected

printer. By default this key performs a DOPRINT

command followed by a DOACCUM command.

Press the TARE key to tare the current gross weight,

then repeatedly press SELECT to scroll through the

tare, gross and net weight displays.

Press the ZERO key to establish a zero reference. A

center-of-zero icon will be displayed when the weight is

within ¼ division of zero. During motion an M will appear

below the center-of-zero icon.

ON/OFF

Clear

key

If the indicator is powered down

via the ON/OFF/Clear key or

by sleep mode time-out, press

this key to power the indicator

back up.

If a display appears in which

alpha or numeric characters

can be entered, key function

switches automatically so

that repeated pressing of

one key causes the number

to appear first followed, by

the alpha characters in

descending order as labeled

on the key. If you wait for the

cursor to appear on the

display and press a key, a

new character is added to

the previous one entered.

Press the ESCAPE key to back out of menus or cancel

a numeric entry without accepting the value. Press and

hold the ESCAPE key for 3-5 seconds to gain access to

Password Entry Mode.

Press the C(Clear) key to clear values from the display

prompts. Press and hold the C key for five seconds to

power down the indicator.

Press the ENTER key to enter a keyed in value or

accept a displayed choice.

The alphanumeric keypad is for entering number and

alpha characters. If a display for entering numbers only

appears, you can key in the numbers using the keypad

normally.

If a display appears in which alpha or numeric characters can be entered, key function switches automatically

so that repeated pressing of one key causes the number to appear first, followed by the alpha characters in

descending order as labeled on the key. If you wait for

the cursor to appear on the display and press a key, a

new character is added to the previous one entered.

Soft Keys

Soft keys are so-called because their function is not fixed. Function can

change as mode of operations change or as the program for your particular

setup changes.

There are five predefined soft keys used in the Truck In/Out application. See

Figure 1.

Model 1310 Truck Scale In/Out Application User’s Manual

7

Page 8

Truck Scale In/Out Application Introduction

Overview

Serial Port Configuration

The Truck Scale In/Out software application installed in the 1310 allows you

to automate truck weighing. You can track up to 500 different open transactions and store up to 1,000 completed transactions. You can also store up to

4,000 tare weights.

Serial ports are configured for transmitting information to different devices;

printer, computer and remote display.

Serial port #1 is configured for use with WP-250, TM-295, WP-233, or

WP-234 printers. Configuration is 9600 baud, 8 data bits, no parity, no

handshake, basic control mode.

Serial port #2 is configured for use with a computer. Configuration is 9600

baud, 8 data bits, no parity, no handshake, basic control mode.

Serial port #3 is configured for use with the Weigh-Tronix flip digit remote

display. Configuration is 9600 baud, 8 data bits, no parity, no handshake,

basic control mode.

Serial port #4 is configured for use with the Truck Weigh PC software

program. Configuration is 9600 baud, 8 data bits, no parity, no handshake,

basic control mode.

Open Transaction Database

Data stored in the databases is

in calibration units.

Completed Transaction

Database

Tare Database

The following data is stored for each open transaction and is included in the

open transaction report:

• Truck identification number (up to 16 alphanumeric characters)

• Inbound weight

• Time of inbound transaction

• Date of inbound transaction

The following data is stored for each completed transaction and is included

in the transaction report:

• Truck identification number (up to 16 alphanumeric characters)

• Inbound weight

• Time of inbound transaction

• Date of inbound transaction

• Outbound weight

• Time of outbound transaction

• Date of outbound transaction

The Tare database stores up to 4,000 tare weights. You can print tare

weight tickets using the PRINT key.

Remote Display

8

Serial port #3 is used to send the displayed weight to a Weigh-Tronix flip

digit remote display. The data is sent 1 times/second.

Model 1310 Truck Scale In/Out Application User’s Manual

Page 9

Operation

Powerup

Inbound Procedure

If you have an optional PS2style keyboard attached to the

indicator, below is a list of

keyboard key strokes and their

equivalent on the indicator:

Keyboard Indicator

ALT-S SELECT key

ALT-Z ZERO key

ALT-T TARE key

ALT-C C key (clear)

ALT-U UNITS key

ALT-P PRINT key

ALT-ESC Access to setup menu

ENTER ENTER key

or YES soft key

ESCAPE ESC key

or NO soft key

1..9 Numeric entry

A..Z Alphabet entry

F1..F5 F1..F5 key

F6 PRINT key

. Decimal point

Y YES soft key

N NO soft key

Follow these steps to perform truck in/out operations:

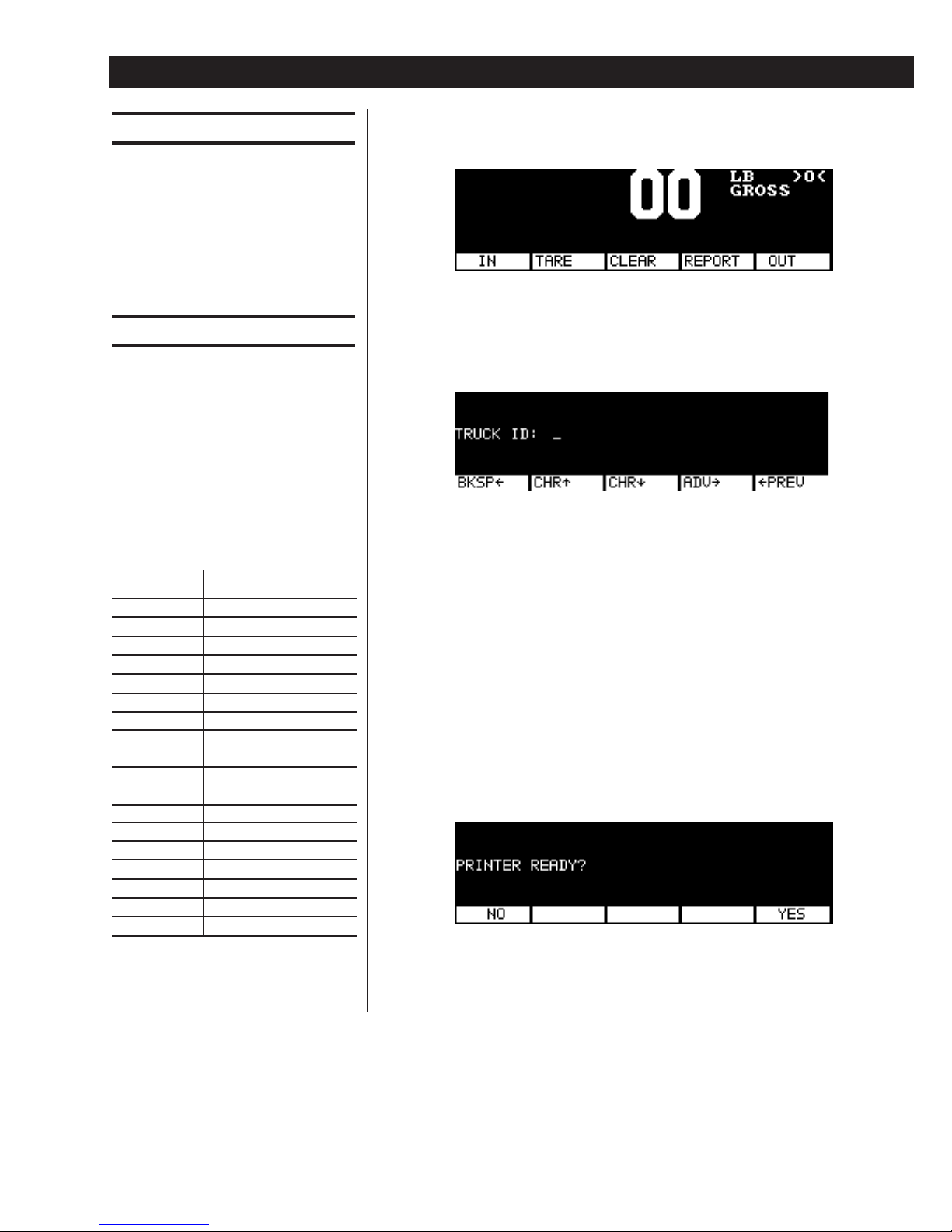

1. When the indicator is powered up you will see this screen. . .

2. Be sure scale is zeroed by pressing the ZERO key. After an inbound

truck comes onto the scale, press the IN key. . .

The inbound weight is stored in the OPEN database and the

screen below is displayed.

3. Key in up to 16 alphanumeric characters for the truck ID. You can enter

alphanumerics in several ways.

A) Use the CHR soft keys to scroll through the alphanumeric list

and move the cursor using the ADV and PREV soft keys.

B) Use the keypad on the 1310, following the directions for

alphanumeric entry in the Front Panel Keys section of this

manual.

C) Use an optional remote keyboard to enter the numbers and

alpha characters. With a remote keyboard attached, only

alpha entries are allowed from the front panel keys.

When you have entered the ID, press the ENTER key. . .

is displayed.

This is a friendly reminder to have a printer attached and ready to

print if you want to have an inbound ticket printed.

Model 1310 Truck Scale In/Out Application User’s Manual

9

Page 10

INBOUNDINBOUND

INBOUND

INBOUNDINBOUND

TRUCK ID: BALC1254TRUCK ID: BALC1254

TRUCK ID: BALC1254

TRUCK ID: BALC1254TRUCK ID: BALC1254

WEIGHTWEIGHT

WEIGHT

WEIGHTWEIGHT

TIMETIME

TIME

TIMETIME

DATEDATE

DATE

DATEDATE

: 1344: 1344

: 1344

: 1344: 1344

: 11:54:28: 11:54:28

: 11:54:28

: 11:54:28: 11:54:28

: 11-12-01: 11-12-01

: 11-12-01

: 11-12-01: 11-12-01

lblb

lb

lblb

4. Press YES and information, like in the Inbound ticket example at left, is

sent to the printer:

5. Press NO if you don't want the ticket printed. . .

The 1310 searches the OPEN database for the ID number. If the

ID number is found, see A below.

OR

If there is no previous use of this ID number, see B below.

A. The following is displayed:

Press 1 on the keypad to overwrite the current ID number. Press 2 to

abort the transaction. . .

If you choose to abort the transaction, the previously stored

information remains unchanged and the indicator returns to the

weight display.

Outbound Procedure

If you choose to overwrite the previous information, the gross

weight on the scale is stored as the inbound weight and the

current time and date are stored as the inbound time and date.

After the information is stored, an inbound ticket is printed. See

sample in Figure 2.

B. The gross weight on the scale is stored as the inbound weight and the

current time and date are stored as the inbound time and date. After the

information is stored, an inbound ticket is printed. See sample at left.

1. Be sure scale is zeroed by pressing the ZERO key. After an outbound

truck stops on the scale, press the OUT key. . .

The following is displayed (your display may show a currently

active ID):

2. Key in up to 16 alphanumeric characters for the truck ID. You can enter

10

Model 1310 Truck Scale In/Out Application User’s Manual

alphanumerics in several ways.

A) Use the CHR soft keys to scroll through the alphanumeric list

and move the cursor using the ADV and PREV soft keys.

Page 11

B) Use the keypad on the 1310, following the directions for

alphanumeric entry in the Front Panel Keys section of this

manual.

C) Use an optional remote keyboard to enter the numbers and

alpha characters. With a remote keyboard attached, only

alpha entries are allowed from the front panel keys.

When you have entered the truck ID, press the ENTER key. . .

is displayed.

This is a friendly reminder that if you want to have an outbound

ticket printed, you must have a printer attached and ready to print.

3. Press YES if you want the ticket printed. Press NO if you don't want the

ticket printed. . .

The 1310 searches the OPEN database for the ID number. If the

number is not found, the display informs you of that fact and

returns to the weight display.

If the number is found, the outbound weight, date and time are

stored in the transaction database and an outbound ticket is

printed (if you have chosen to print the ticket). See example in

Figure 2.

OUTBOUNDOUTBOUND

OUTBOUND

OUTBOUNDOUTBOUND

TRUCK ID: BALC1254TRUCK ID: BALC1254

TRUCK ID: BALC1254

TRUCK ID: BALC1254TRUCK ID: BALC1254

INBOUND WEIGHTINBOUND WEIGHT

INBOUND WEIGHT

INBOUND WEIGHTINBOUND WEIGHT

INBOUND TIMEINBOUND TIME

INBOUND TIME

INBOUND TIMEINBOUND TIME

INBOUND DATEINBOUND DATE

INBOUND DATE

INBOUND DATEINBOUND DATE

GROSS WEIGHTGROSS WEIGHT

GROSS WEIGHT

GROSS WEIGHTGROSS WEIGHT

TARE WEIGHTTARE WEIGHT

TARE WEIGHT

TARE WEIGHTTARE WEIGHT

NET WEIGHTNET WEIGHT

NET WEIGHT

NET WEIGHTNET WEIGHT

OUTBOUND WEIGHT: 3485OUTBOUND WEIGHT: 3485

OUTBOUND WEIGHT: 3485

OUTBOUND WEIGHT: 3485OUTBOUND WEIGHT: 3485

OUTBOUND TIMEOUTBOUND TIME

OUTBOUND TIME

OUTBOUND TIMEOUTBOUND TIME

OUTBOUND DATEOUTBOUND DATE

OUTBOUND DATE

OUTBOUND DATEOUTBOUND DATE

: 1344: 1344

: 1344

: 1344: 1344

: 11:54:28: 11:54:28

: 11:54:28

: 11:54:28: 11:54:28

: 11-12-01: 11-12-01

: 11-12-01

: 11-12-01: 11-12-01

: 3485: 3485

: 3485

: 3485: 3485

: 1344: 1344

: 1344

: 1344: 1344

: 2141: 2141

: 2141

: 2141: 2141

: 11:58:43: 11:58:43

: 11:58:43

: 11:58:43: 11:58:43

: 11-12-01: 11-12-01

: 11-12-01

: 11-12-01: 11-12-01

lblb

lb

lblb

lblb

lb

lblb

lblb

lb

lblb

lblb

lb

lblb

lblb

lb

lblb

Figure 2

Outbound ticket sample

Model 1310 Truck Scale In/Out Application User’s Manual

11

Page 12

TARE Soft Key (F2)

Function

When you are given a numbered list to choose from, press

the number key on the number

keypad to select your choice.

The TARE soft key allows you to add tare weights to the TARE database.

You can recall and edit existing tare weights.

1. Press the TARE soft key (F2). . .

If you press 1 to choose Enter Tare Weight, see Step 2 below.

If you press 2 to Recall Stored Tare, see Step 7 below.

2. When you press 1. . .

is displayed.

3. Key in a tare number to store the tare weight in. This must be a number

between 0 and 3999. Press the ENTER key. . .

If that number already has a tare weight stored in it, the following

is displayed, showing the tare number and current tare weight:

12

If you press 1, go to step 4.

If you press 2, skip to step 6.

4. When you press 1. . .

is displayed.

5. Key in the weight and press ENTER. . .

The tare weight is stored under that tare number and the display

returns to a net weight display with that tare value active.

Model 1310 Truck Scale In/Out Application User’s Manual

Page 13

See the section below to

generate a print with a stored

tare weight.

6. When you press 2. . .

The operation is aborted and the screen returns to the following:

7. When you press 2 to recall a tare number. . .

is displayed.

8. Key in the tare number (0-3999) and press ENTER. . .

If no tare weight exists for this tare number, the display briefly

informs you of this and then returns to the weight display.

If a weight exists for this tare number, the display briefly shows

the tare number and tare weight, then display returns to a net

weight display with that tare value active.

PRINT Key Function

The PRINT key allows you to print a tare ticket. The tare ticket includes the

tare number, gross weight, tare weight, net weight, time and date. A example is shown in Figure 3 below.

TARE TRANSACTIONTARE TRANSACTION

TARE TRANSACTION

TARE TRANSACTIONTARE TRANSACTION

TARE NUMBERTARE NUMBER

TARE NUMBER

TARE NUMBERTARE NUMBER

GROSS WEIGHTGROSS WEIGHT

GROSS WEIGHT

GROSS WEIGHTGROSS WEIGHT

TARE WEIGHTTARE WEIGHT

TARE WEIGHT

TARE WEIGHTTARE WEIGHT

NET WEIGHTNET WEIGHT

NET WEIGHT

NET WEIGHTNET WEIGHT

TIME: 11:58:43TIME: 11:58:43

TIME: 11:58:43

TIME: 11:58:43TIME: 11:58:43

DATE: 11-12-01DATE: 11-12-01

DATE: 11-12-01

DATE: 11-12-01DATE: 11-12-01

: 3999: 3999

: 3999

: 3999: 3999

: 3485: 3485

: 3485

: 3485: 3485

: 60: 60

: 60

: 60: 60

: 3425: 3425

: 3425

: 3425: 3425

lblb

lb

lblb

lblb

lb

lblb

lblb

lb

lblb

lblb

lb

lblb

Figure 3

Tare ticket sample

Model 1310 Truck Scale In/Out Application User’s Manual

13

Page 14

CLEAR Key Function

When you are given a numbered list to choose from, press

the number key on the number

keypad to select your choice.

The CLEAR key allows you to delete information from one or more of the

databases.

1. Press the CLEAR key. . .

The following is displayed:

2. Press 1, 2 or 3. . .

You are asked if you really want to do this. If you choose NO, the

display returns to the weight display. If you choose YES the

database selected is cleared of all data. When you choose 3, you

delete both the completed transaction and open transaction

databases.

OR

Press 4. . .

The display returns to the weight display with no data deleted.

REPORT Key Function

The REPORT key allows you to upload the contents of the completed or

open databases to a computer through serial port 2. The reports are in a

comma-delimited format.

Below is an example of the data transmitted from the open transaction

database (truck ID, inbound weight, inbound time, inbound date):

1,3485,12:01:45,11-12-01

11,3485,12:01:51,11-12-01

111,3485,12:01:55,11-12-01

1111,3485,12:02:01,11-12-01

11111,3485,12:02:06,11-12-01

15,3485,12:02:12,11-12-01

16,3485,12:02:17,11-12-01

17,3485,12:02:21,11-12-01

89,4015,12:02:27,11-12-01

125,4486,12:02:34,11-12-01

115,3938,12:02:44,11-12-01

4589,3551,12:02:50,11-12-01

47,3551,12:02:55,11-12-01

4789,3183,12:03:07,11-12-01

789,4523,12:03:14,11-12-01

456,4263,12:03:18,11-12-01

14

Model 1310 Truck Scale In/Out Application User’s Manual

Page 15

Below is an example of the data transmitted from the completed transaction

database (truck ID, inbound weight, inbound time, inbound date, outbound

weight, outbound time, outbound date):

1,3485,12:01:45,11-12-01,5004,12:04:52,11-12-01

11,3485,12:01:51,11-12-01,5004,12:05:00,11-12-01

111,3485,12:01:55,11-12-01,5004,12:05:05,11-12-01

1111,3485,12:02:01,11-12-01,5004,12:05:12,11-12-01

11111,3485,12:02:06,11-12-01,5004,12:05:19,11-12-01

15,3485,12:02:12,11-12-01,5004,12:05:26,11-12-01

16,3485,12:02:17,11-12-01,5004,12:05:32,11-12-01

17,3485,12:02:21,11-12-01,5004,12:05:37,11-12-01

89,4015,12:02:27,11-12-01,5004,12:05:41,11-12-01

125,4486,12:02:34,11-12-01,5004,12:05:46,11-12-01

115,3938,12:02:44,11-12-01,5004,12:05:52,11-12-01

4589,3551,12:02:50,11-12-01,5004,12:05:59,11-12-01

47,3551,12:02:55,11-12-01,5004,12:06:06,11-12-01

4789,3183,12:03:07,11-12-01,5004,12:06:12,11-12-01

789,4523,12:03:14,11-12-01,5004,12:06:25,11-12-01

456,4263,12:03:18,11-12-01,5004,12:06:32,11-12-01

Model 1310 Truck Scale In/Out Application User’s Manual

15

Page 16

Accessing Software Version

The time may come when you are asked by a service technician what the

software version of your software is. There is a series of key strokes which

will bring that number up on the screen. Below are the instructions for

accessing this information.

1. Press and hold the ESCAPE key until the 1310 beeps.

2. Within five seconds, key in the number 111 and press ENTER.

3. Press the soft key labeled VIEW.

4. Press the soft key labeled VERS. The software version will appear on

the display.

Setting Time and Date

1. Press and hold the ESCAPE key until the Model 1310 beeps. . .

The display asks for a password and looks like the example

shown below:

2. Key in 111 and press ENTER. . .

A new soft key set appears.

3. Press the CLOCK soft key to access the time and date setting function.

4. The display shows the current hour value. If this is not correct key in a

new value and press ENTER or press ENTER to accept the current

value. . .

The display shows the minutes value.

5. Repeat step 4 for minutes, seconds, year, month and day. (The day of

the week is calculated automatically from the four digit year.)

6. Press the EXIT soft key to return to normal operating mode.

16

Model 1310 Truck Scale In/Out Application User’s Manual

Page 17

Error Messages

Error Messages from

SensorComm

TM

All error messages below which mention components

are referring to components within the SensorComm product.

You may see the error messages listed in the table below. Also listed is a

description of the error and possible causes. These may help with servicing.

Error messages will appear in the upper right corner of the display window

as shown in the example of error message #8 shown below.

Error # Error Description of Error Possible Cause

1 Communications error SensorComm not responding -Cable

-SensorComm hardware failure

-1310 hardware falure

2 Power fault +Vin, +EXC, or -EXC has fallen out -Power supply failure

of tolerance. Voltage ±5%. -Cable

3 A to D overrange More than +5mV/V has been applied -Cable

to the A to D converter -Weight sensor failure

4 A to D underrange Less than -5mV/V has been applied -Cable

to the A to D converter -Weight sensor failure

5 A to D Initialization A to D converter not responding -Component failure

failure -Power supply problems

6 Weight sensor overrange The weight sensor output has -Abuse of scale

exceeded the configured amount. -Weight sensor failure

7 Weight sensor deadload The output of the weight sensor is -Gauging problem on the weight

shift warning greater than a configurable percent of sensorf

capacity since calibration -Mechanical issuse with the scale

8 Weight sensor deadload The output of the weight sensor has -Gauging problem on the weight

shift error increased more than a configurable sensor

percent of capacity since calibration -Mechanical issuse with the scale

9 Weight sensor stability The output of 1 or more weight -Mechanical issuse with the scale

sensor is not in the same range as -Weight sensor problem

the rest of the scale.

Error Message from

the Ghost Feature

You may see an error message when the Ghost feature is enabled.

The display at left tells you the

Ghost option is functioning and that

Cell X has failed.

Model 1310 Truck Scale In/Out Application User’s Manual

17

Page 18

911 Diagnostic Menu

The 1310 has an emergency help menu with a password of 911 to help you

diagnose problems with SensorComm components. Following are the

instructions you need to access this menu and explanations of each part of

the menu that pertain to the SensorComm option. Figure 4 shows a flow

chart of the soft keys in the 911 menu.

Flowchart of soft keys in the Test menu

Hold the ESCAPE key for 5 seconds then key in 911 at the prompt and

press ENTER. The following is displayed:

This manual covers the information needed to use and

understand SensorComm. For

information on the soft keys not

covered in this manual, see the

1310 Service Manual

PN 29750-0019.

18

Model 1310 Truck Scale In/Out Application User’s Manual

Figure 4

Page 19

These softkeys appear:

KEYPAD This test lets you check each front panel key for proper opera-

tion. Follow the instructions on the display.

SCALE Press this soft key to view weight sensor outputs. Disabled

when SensorComm active.

SERIAL Use this to test your ports. Select Port #1 through 4 then short

the TX and RX on the selected port. The display will change

from NO LOOP to LOOP indicating the port is good. Jumper

RTS to CTS to test the handshake lines.

MORE Accesses the following keys:

Inputs and outputs have to be

defined in the WT-BASIC

program for them to work.

INPUT Allows you to Activate/Deactivate any input setpoint

device such as a switch or contact closure remotely and

monitor it with this menu.

OUTPT Allows you to Activate/Deactivate any output setpoints

to verify correct hardware operation during installation or

for troubleshooting purposes.

DISP This test continuously cycles the display through a test

pattern.

SCOMM Present only if SensorCommTM is active. It accesses the

SensorComm diagnostics which are explained the

following section, SCOMM Soft Key.

MORE Accesses the following keys:

NET This diagnostic will only appear if a network option card

is installed. Follow the instructions on the display. For

more information reference the 1310 Network Installa-

tion Guide PN29806-0013.

Model 1310 Truck Scale In/Out Application User’s Manual

19

Page 20

Modem status list:

1 = initialize

2 = set auto answer

3 = set user config

4 = port ready

5 = dialing

6 = error

7 = connected

8 = disconnected

9 = initialize 2

MODM Appears only if modem is enabled by a SimPoser

program. The display will show Port #, Status (see list at

left), User configuration information.

TRAFF Press this soft key to see the System Counter Menu.

This shows you the traffic, overload, and underload

counter values. See example below.

If the scale experiences a load exceeding 105% of

capacity, an overload event is logged. Press the OVER

soft key to see the log of overloads. Example below.

Press the PREV or NEXT soft keys to scroll through the

list of overload event times and dates. Press the

CLEAR soft key to clear the displayed event.

If the scale experiences a negative weight exceeding

105% of capacity, an underload event is logged. Example below.

Press the PREV or NEXT soft keys to scroll through the

list of overload event times and dates. Press the

CLEAR soft key to clear the displayed event.

The traffic counter increments when weight exceeds the

configured trigger point (% of scale capacity). (See the

Service Manual for configuration information.) For the

next weightment to increment the counter, the weight

must fall below the configured re-arm point (% of scale

capacity).

20

Model 1310 Truck Scale In/Out Application User’s Manual

Page 21

SCOMM Soft Key

Refer to Figure 4 as the soft keys and functions which apply to

SensorComm are explained below.

When you press the SCOMM soft key, the following keys

appear:

INFO See INFO Soft Key section.

OUTPT See OUTPT Soft Key section.

ERR# See ERR# Soft Key section.

VOLT See VOLT Soft Key section.

MORE Brings up the following keys:

INFO Soft Key

The displays on the next few

pages are illustrations of

examples, not actual screen

captures.

SIG See SIG Soft Key section.

DLOAD See DLOAD Soft Key section.

G_LOG See G_LOG Soft Key section.

Press this key to view SensorComm and weight sensor

specifications.

VERS soft key Brings up a display similar to this ex-

ample:

This display shows you the serial number,

part number and software revision level of

SensorComm #1. Press the NEXT or

PREV soft key to other active

SensorComm J-boxes.

Model 1310 Truck Scale In/Out Application User’s Manual

21

Page 22

Press the ESC key to back out

of most displays and return to

the previous display.

SETUP soft key Brings up a display similar to this example:

This display shows you the configuration of the

SensorComm system. In this example the system has

two SensorComm j-boxes with a total of eight weight

sensors. Press any key and the following is displayed:

This screen lets you scroll through all the sensors using

the PREV and NEXT soft keys. Information displayed

for each sensor is programmed capacity, output in mV/

V, serial number and span factor.

VALS soft key Brings up a display similar to this example:

OUTPT Soft Key

Press DONE to return to

the previous level display.

Press DONE to return to

the previous level display.

This display shows you the stored cornering values for

each sensor attached to a SensorComm j-box. Press

any key to see the next SensorComm values if there is

another attached. Returns to VERS-SETUP-VALS soft

key set after viewing the last set of values.

Press this key to view the current output of each weight sensor in raw

counts or mV/V. You will see a display similar to this example:

This display shows you the current output in raw counts for each sensor

attached to SensorComm #1. Press the PREV or NEXT soft key to move

between multiple SensorComm j-box displays.

If you press the CNTS soft key, you will see a display similar to this example:

This display shows you the current output in mV/V for each sensor attached

to SensorComm #1. Press the PREV or NEXT soft key to move between

multiple SensorComm j-box displays.

22

Model 1310 Truck Scale In/Out Application User’s Manual

Page 23

ERR# Soft Key

Press the ERR# soft key to see a record of the last 10 error code numbers

and the dates and the times these occurred. The screen will look similar to

the example below:

The top line tells you how many errors are in the list and which one you are

viewing.

The second line shows the error number and time and date it occurred.

The third line gives you the name of the error. This corresponds to the list of

errors in Error Messages from SensorCommTM.

Press NEXT or PREV to see the entire list of error messages.

Press CLEAR to clear all the messages. You will be asked if you are sure

and be shown YES and NO keys. If you press NO, the display returns to the

error message screen. If you press YES, the display returns to the following

screen:

VOLT Soft Key

If you press the ERR# key and there are no active errors, you will see this

display:

Press the VOLT soft key to see current Voltage In and Excitation voltage

reports. The screen will look similar to the one below:

View other connected SensorComm j-boxes by using the PREV or NEXT

soft key. Press DONE to return to the previous level display.

Model 1310 Truck Scale In/Out Application User’s Manual

23

Page 24

SIG Soft Key

Press the ESC key to back out

of most displays and return to

the previous display.

Press the SIG soft key to see a constantly changing display similar to the

example below:

This screen shows the number of packets of information sent to the

SensorComm system and the number received back correctly. This is a

measure of the relative reliability of your communication setup. If the signal

strength shows a lower percentage, chances are the system is experiencing

some kind of line noise and thus, less reliable communication.

DLOAD Soft Key

G_LOG Soft Key

Press the DLOAD soft key to view the deadload analysis for each weight

sensor. You will see a display similar to the example below:

This display shows the calibration counts, current raw counts and difference

for sensor #1.

Press the G_LOG soft ket to view the log of error messages concerning

ghosted weight sensors. See example below.

Press the appropriate softkey to scroll through the available error messages.

Time and dates of errors are displayed.

X = active error

Y = Number of errors

2 = Cell number that was "ghosted"

24

Model 1310 Truck Scale In/Out Application User’s Manual

Page 25

Ethernet 10/100 SMTP Option

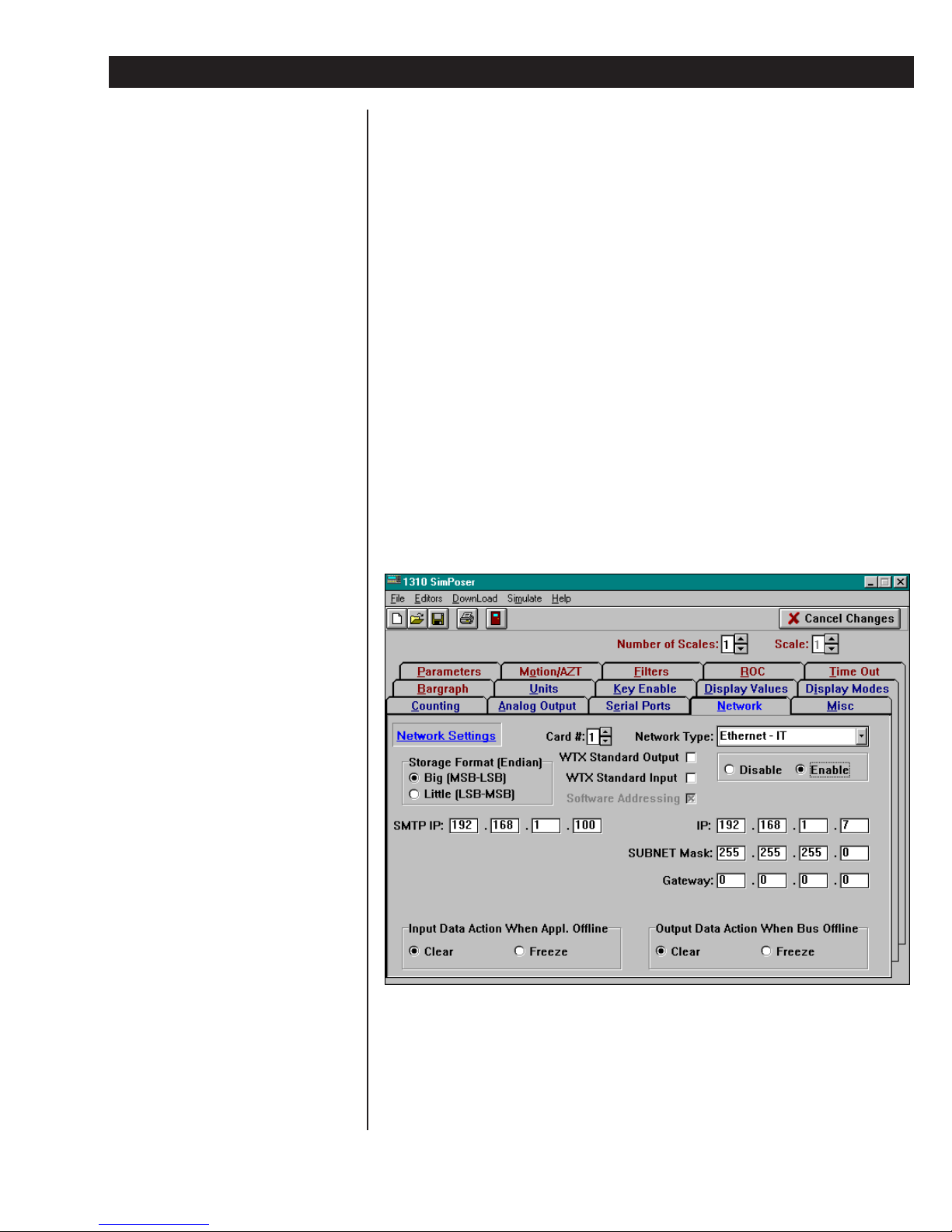

If your 1310 has the optional Ethernet 10/100 SMTP card installed, your

system can be configured to send you an email informing you of system

Email data will display system

overload and underload counts

only.

errors as they occur. Follow the steps below to set up your 1310 for autonotification.

1. Open SimPoser.

2. Open the standard truck IN/OUT application file.

3. Click on the CONFIG button.

4. Click on the Parameters tab.

5. Click on the Diagnostics button.

6. Enable Email under Alarm Levels.

7. Click OK.

8. Click on the Network tab.

9. Choose Ethernet IT from the Network Type list.

10. Click on Enable.

11. Configure the IP, SUBNET MASK, GATEWAY and SMTP IP as shown

in the example below:

12. Click File>Save.

13. Download to your 1310.

14. To configure the TO and FROM email addresses, press and hold the

ESC key for five seconds on the 1310. Enter the password 411. A

prompt will appear for the From address then the To address, as you fill

in the information. Exit the menu and save your changes.

Model 1310 Truck Scale In/Out Application User’s Manual

25

Page 26

26

Model 1310 Truck Scale In/Out Application User’s Manual

Page 27

Model 1310 Truck Scale In/Out Application User’s Manual

27

Page 28

Weigh Bar® is a registered trademark of Weigh-Tronix Inc.

Avery Weigh-Tronix

1000 Armstrong Dr.

Fairmont, MN 56031 USA

Telephone: 507-238-4461

Facsimile: 507-238-4195

e-mail: industrial@weigh-tronix.com

www.wtxweb.com

Avery Weigh-Tronix Canada, ULC

217 Brunswick Boulevard

Pointe Claire, QC H9R 4R7 Canada

Telephone: 514-695-0380

Toll free: 800-561-9461

Facsimile: 514-695-6820

www.weigh-tronix.ca

Loading...

Loading...