ALS

204/206

256

USER MANUAL

Label Dispenser

Edition 7 04/2010

3

CONTENTS

ALS

20x

256

GB

1 Please note

1.1 General notes

1.1.1 Validity and binding effect of this manual . . . . 5

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Technical status . . . . . . . . . . . . . . . . . . . . . . . . .5

Copyright. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Manufacturer. . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1.2 Illustrations and descriptions. . . . . . . . . . . . . . 6

Signs and symbols . . . . . . . . . . . . . . . . . . . . . . . 6

Dangers and risk notes . . . . . . . . . . . . . . . . . . . .6

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Button symbols . . . . . . . . . . . . . . . . . . . . . . . . . .6

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Supplementary information . . . . . . . . . . . . . . . . .6

1.2 Safety instructions

1.2.1 Information and qualifications. . . . . . . . . . . . . 7

Follow the instructions. . . . . . . . . . . . . . . . . . . . .7

Keep the product information at hand. . . . . . . . . 7

Ensure the required qualifications are met . . . . .7

1.2.2 Operational safety of the unit . . . . . . . . . . . . . 8

Proper usage. . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Protection against injuries by electrical current. .8

Protection against injuries by mechanical action.9

Protection against injuries by chemicals . . . . . . .9

1.2.3 Before beginning production. . . . . . . . . . . . . 10

Due diligence of the operating company and the

service technician . . . . . . . . . . . . . . . . . . . . . . .10

Due diligence of the user. . . . . . . . . . . . . . . . . .10

1.2.4 Safety notes on the unit . . . . . . . . . . . . . . . . 11

2 Product description

2.1 Overview

2.1.1 Components . . . . . . . . . . . . . . . . . . . . . . . . . 12

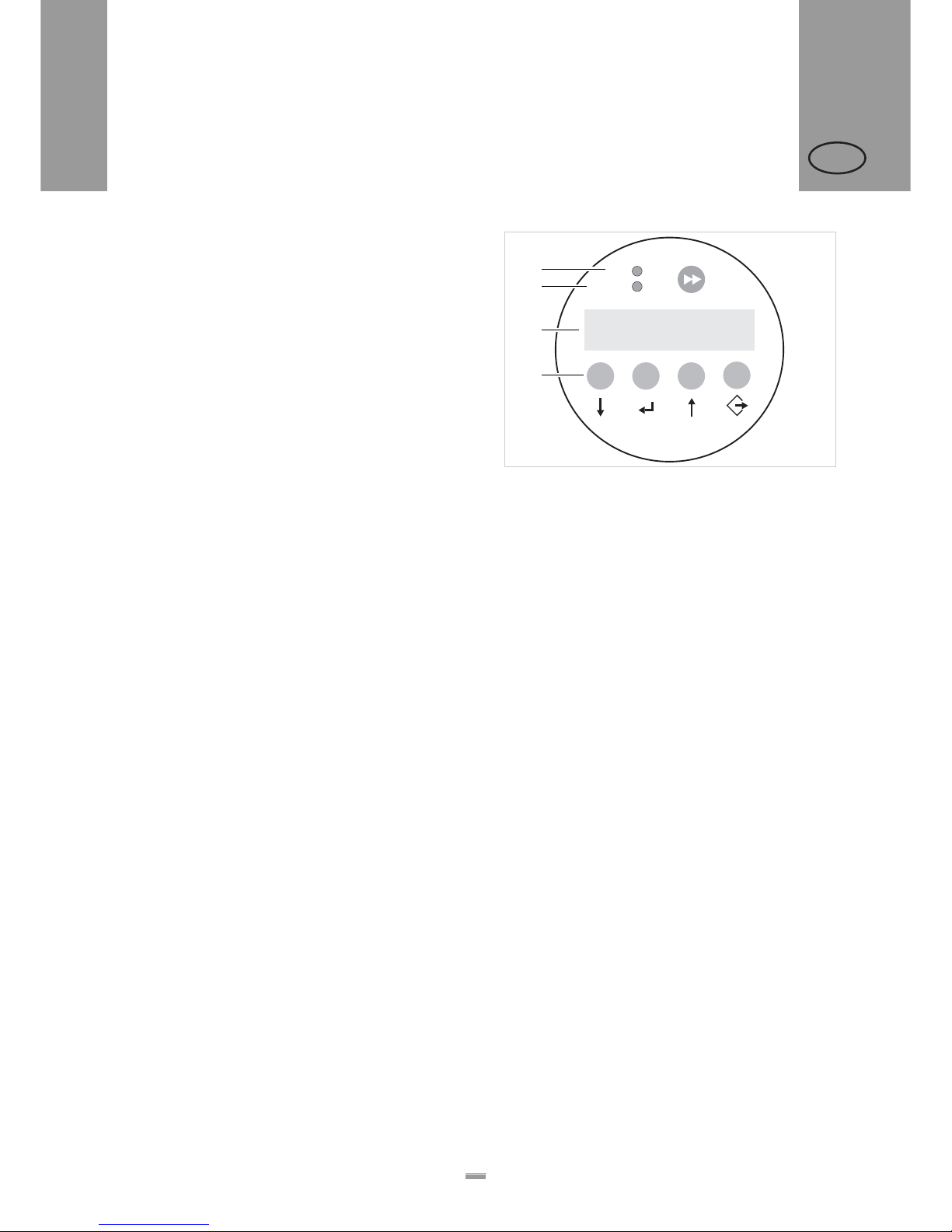

2.1.2 Control panel. . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating LED. . . . . . . . . . . . . . . . . . . . . . . . . .14

Error LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

LCD display. . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.1.3 Connection arrangement . . . . . . . . . . . . . . . 15

Connections on the back of the device . . . . . . .15

Sensor connections. . . . . . . . . . . . . . . . . . . . . .16

2.1.4 Mode of operation. . . . . . . . . . . . . . . . . . . . . 17

2.1.5 Technical specifications. . . . . . . . . . . . . . . . 18

Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . .18

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Label sensor . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . .18

Electronics. . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Internal Interfaces . . . . . . . . . . . . . . . . . . . . . . .19

Status messages, test functions,

product profiles . . . . . . . . . . . . . . . . . . . . . . . . .19

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Environmental conditions . . . . . . . . . . . . . . . . .20

Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Certificates. . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.1.6 Design models . . . . . . . . . . . . . . . . . . . . . . . 21

Right-handed version . . . . . . . . . . . . . . . . . . . .21

Left-handed version. . . . . . . . . . . . . . . . . . . . . .21

2.2 Options

External control panel . . . . . . . . . . . . . . . . . . . .22

Fixed dispensing edge. . . . . . . . . . . . . . . . . . . .22

Swivelling dispensing edge . . . . . . . . . . . . . . . .22

Spring-loaded dispensing edge. . . . . . . . . . . . .22

Pneumatic dispensing edge . . . . . . . . . . . . . . .23

V-shape dispensing edge . . . . . . . . . . . . . . . . .23

Adjustable dispensing edge holder . . . . . . . . . .23

Outer Diameter control sensor . . . . . . . . . . . . .24

Dust/Splash guard. . . . . . . . . . . . . . . . . . . . . . .24

Additional material guide disk . . . . . . . . . . . . . .24

Capacitive label sensor . . . . . . . . . . . . . . . . . . .25

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Applicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Applicator interface . . . . . . . . . . . . . . . . . . . . . .25

Narrow label spring kit. . . . . . . . . . . . . . . . . . . .25

2.3 Operating modes

2.3.1 Dispensing mode . . . . . . . . . . . . . . . . . . . . . 26

Stopping/Continuing the dispensing. . . . . . . . .26

Changing the counter reading . . . . . . . . . . . . . .26

Starting the unit in configuration mode . . . . . . .26

Counting labels backwards . . . . . . . . . . . . . . . .26

Online settings. . . . . . . . . . . . . . . . . . . . . . . . . .27

2.3.2 Configuration mode . . . . . . . . . . . . . . . . . . . 28

Function of the double-arrow button . . . . . . . . .28

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4

CONTENTS

ALS

20x

256

GB

2.4 Function descriptions

2.4.1 Overview of functions . . . . . . . . . . . . . . . . . . 30

2.4.2 Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Function descriptions . . . . . . . . . . . . . . . . . . . .32

Quick setting . . . . . . . . . . . . . . . . . . . . . . . . . . .32

2.4.3 LABEL SETUP menu . . . . . . . . . . . . . . . . . . 32

2.4.4 MACHINE SETUP menu . . . . . . . . . . . . . . . 33

3 Before operation

3.1 Electrical connections

3.1.1 Power supply connection . . . . . . . . . . . . . . . 34

Checking the power supply setting . . . . . . . . . .35

Connecting the power cable.. . . . . . . . . . . . . . .35

3.1.2 Connecting sensors . . . . . . . . . . . . . . . . . . . 36

3.2 Inserting label material

3.2.1 Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2.2 Inserting a label roll. . . . . . . . . . . . . . . . . . . . 38

Removing spent backing paper. . . . . . . . . . . . .38

Removing glue residue . . . . . . . . . . . . . . . . . . .38

Inserting a new label roll . . . . . . . . . . . . . . . . . .38

3.2.3 Threading the label roll . . . . . . . . . . . . . . . . . 39

Threading guide . . . . . . . . . . . . . . . . . . . . . . . .39

Threading the label roll at the dispensing edge.40

Threading the label roll onto the drive roller . . .41

Fastening the label roll to the rewinder . . . . . . .41

3.3 Mechanical settings

3.3.1 Adjusting the unwinder’s core diameter . . . . 42

3.3.2 Positioning the pressure roller . . . . . . . . . . . 42

3.3.3 Positioning the label sensor . . . . . . . . . . . . . 43

3.3.4 Setting the dancer arm restoring force . . . . . 43

4 Operation

4.1 Start-up and shutdown

4.1.1 Turning on the unit . . . . . . . . . . . . . . . . . . . . 44

4.1.2 Starting label dispensing. . . . . . . . . . . . . . . . 44

Dispensing with a product sensor . . . . . . . . . . .44

Dispensing without a product sensor . . . . . . . .44

4.1.3 Stopping/Continuing the dispensing process 44

4.2 Configuration and monitoring

4.2.1 Function menu settings . . . . . . . . . . . . . . . . 45

Label pitch. . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Label stop position. . . . . . . . . . . . . . . . . . . . . . .45

Dispensing speed . . . . . . . . . . . . . . . . . . . . . . .46

Suppressing start signals . . . . . . . . . . . . . . . . .46

Label position on the product . . . . . . . . . . . . . .47

4.2.2 Monitoring functions. . . . . . . . . . . . . . . . . . . 48

Material end / Roll diameter. . . . . . . . . . . . . . . .48

Missing labels . . . . . . . . . . . . . . . . . . . . . . . . . .49

Material tear. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.3 Using product profiles

4.3.1 What are product profiles?. . . . . . . . . . . . . . 50

4.3.2 Loading a product profile . . . . . . . . . . . . . . . 50

4.3.3 Storing a product profile. . . . . . . . . . . . . . . . 50

Selecting the memory location . . . . . . . . . . . . .50

Entering profile names. . . . . . . . . . . . . . . . . . . .50

4.3.4 Deleting a product profile. . . . . . . . . . . . . . . 51

5 After operation

5.1 Maintenance and cleaning

5.1.1 Replacing fuses . . . . . . . . . . . . . . . . . . . . . . 52

5.1.2 Cleaning agents. . . . . . . . . . . . . . . . . . . . . . 53

5.1.3 Regular maintenance. . . . . . . . . . . . . . . . . . 54

Removing paper debris . . . . . . . . . . . . . . . . . . .54

Renewal of the dust filter liner (ALS256) . . . . .54

6 Operational failures

6.1 Status messages

6.1.1 Types of status messages . . . . . . . . . . . . . . 55

Error messages. . . . . . . . . . . . . . . . . . . . . . . . .55

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

6.1.2 List of warnings . . . . . . . . . . . . . . . . . . . . . . 55

6.1.3 List of error messages . . . . . . . . . . . . . . . . . 56

7 Appendix

7.1 EC declaration of conformity

5

1PLEASE NOTE

1.1 GENERAL NOTES

ALS

20x

256

GB

1.1.1 Validity and binding effect of this manual

Contents

The present manual refers exclusively to the ALS204,

ALS206 and ALS256 label dispensers. It is written for

the purpose of ensuring professional usage and

calibration of the unit.

Prerequisites for the use and adjustment are the

professional installation and configuration of the unit.

For any technical questions you may have that are not

described in this manual, see:

£ The service manual of the label dispenser

or

£ Request a technician from one of our sales partners.

– Our sales representatives are available to assist

you, particularly with configuring the unit as well as

in the case of malfunctions.

Technical status

Technical state: 12/2009

Software versions: 1.34

Avery Dennison reserves the right:

– To make modifications to construction parts,

components and software, as well as to employ

comparable components in place of the parts

specified, in keeping with technical advances.

– To modify information in this document.

No commitment will be made to expand these

modifications to include any units delivered earlier.

Copyright

Avery Dennison holds all rights to this manual and its

appendices. Reproduction, reprinting or any other

types of duplication, even of portions of this manual,

may only be carried out with express written consent.

Third persons, in particular competitors, should not be

given access to the information in this manual.

Printed in Germany

Manufacturer

Avery Dennison Deutschland GmbH

Ohmstrasse 3

85386 Eching, Germany

Phone: +49-8165-925-0

Fax: +49-8165-925-231

http://www.machines.averydennison.com

1 PLEAS E NOTE

1.1 GENERAL NOTES

6

1PLEASE NOTE

1.1 GENERAL NOTES

ALS

20x

256

GB

1.1.2 Illustrations and descriptions

Signs and symbols

Various information types are indicated in differ en t

ways within the document in order to simplify

readability and comprehension.

Sentences starting with an arrow are instructions and

guidelines.

£ Perform the instructions one after another in the

specified order.

The following information begins with a dash:

–Lists

– Mode descriptions

– Descriptions of prior steps

– Prerequisites for following actions

Dangers and risk notes

Important directions that you must absolutely observe

are particularly emphasized:

WARNING!

A warning refers to risks that can lead to

serious injury or death! The warning

contains safety measures to protect the

relevant persons.

£ Always follow the instructions.

CAUTION!

A caution indicates risks that can lead to

property damage or injuries to persons

(minor injuries). The caution note contains

instructions for preventing dama ge s .

£ Always follow the instructions.

Figures

Texts are accompanied by figures where necessary.

Figures are indicated using figure numbers in [square

brackets]. A capital letter after a figure number, for

example [12A], refers to a specific section of the figure.

Generally, the label dispenser shown is a right-handed

version. The left-handed version is only shown where it

is necessary to differentiate between the two.

Button symbols

– The buttons of the control panel are depicted as

symbols.

– The symbols are depicted with a ‘+’ (PLUS SIGN)

between them if more than one button is to be

pressed. +

Parameters

Parameters are displayed in grey in the text with the

following structure, MENU NAME > Function name.

Supplementary information

The expert symbol indicates actions that are

only to be performed by qualified and specially

trained personnel.

The information symbol indicates notes and

recommendations, as well as additional

information.

Equipment:

– Equipment, for example lubricants or

cleaning agents

7

1PLEASE NOTE

1.2 SAFETY INSTRUCTIONS

ALS

20x

256

GB

1.2.1 Information and qualifications

Follow the instructions

WARNING!

Safe and efficient operation of the label

dispenser can only be guaranteed if you

observe all necessary information.

Product liability and warranty claims can

only be asserted if the unit was operated in

accordance with the directions in the

manual.

£ Before operating the unit, read the

operating instructions and all other notes

carefully.

£ Observe the additional safety and

warning notes on the label dispenser.

£ Only permit competent people to operate

and configure the label dispenser.

Keep the product information at hand

With respect to this manual:

£ It should be kept at the location where the

unit is installed and be available to the

operator.

£ It should always be legible.

£ If the unit is sold, the manual should be made

available to the new owner.

£ The safety and warning notes affixed to the

unit itself must be kept clean and legible.

Missing or damaged signs must be replaced.

Ensure the required qualifications are met

£ Ensure that only trained and authorized personnel

operate, configure and service the unit.

£ Only allow qualified and well-trained expert

personnel or service technicians to perform

configurations.

£ The responsibilities with regard to operation,

configuration and maintenance should be cl ea rly

defined and consistently maintained.

£ In addition, personnel should also be instructed on

a regular basis in matters of occupational safety and

environmental protection.

Qualification for operation

The instruction of personnel using the unit must ensure

that:

– The operating perso nnel can use the unit on their

own and safely.

– The operating personnel can remedy small

operational disruptions on their own.

£ At least two people must be instructed in the unit’s

usage.

£ Enough label material must be provided for testing

and instructional purposes.

Qualifications for configuring

The configuration of the controls requires

qualified expertise:

– Personnel configuring the unit must be

acquainted with the functionality of the label

dispenser.

– Personnel configuring the unit must be

acquainted with the modes of operation

within the facility in which the label dispenser

is integrated.

– The personnel configuring the unit must be

able to use the additional menus properly

and appropriately for specific project

requirements.

1.2 SAFETY INSTRUCTIONS

8

1PLEASE NOTE

1.2 SAFETY INSTRUCTIONS

ALS

20x

256

GB

1.2.2 Operational safety of the unit

Proper usage

The label dispenser is a fully automatic unit for

attaching self-adhesive labels to products or

packaging. The company operating the unit must install

it with suitable equipment to protect operating

personnel from danger; for example, the danger of the

hands or fingers being crushed by reaching in between

the product and the dispensing edge.

WARNING!

Improper usage of the unit can cause

accidents, property damage and production

downtime!

£ Only use the unit in accordance with the

instructions specified in this manual.

£ Do not oper at e th e u ni t wit h ou t the

required safeguards.

£ Only configure the unit in accordance

with this manual and with the required

care.

£ Only use original accessories.

£ Do not make any modifications or

alterations to the unit.

£ Repairs to the device may only be

performed by authorised specialists who

are aware of the risks involved.

Protection against injuries by electrical

current

WARNING!

The machine operates using mains voltage!

Touching live electrical parts may exp ose

you to hazardous electrical currents and

may lead to burns.

£ Only operate the unit once the housing

has been reassembled properly.

£ The machine may only be connected by

authorised specialists, who are aware of

the risks involved.

£ Before cleaning, switch off the unit and

remove the power cable from the socket.

£ Only link the unit to devices that fulfil the

SELV (safety extra-low voltage) circuit

requirements specified in EN60950.

£ Make sure that the power switch at the

machine is accessible.

£ In case of emergency, switch off the

device.

WARNING

The unit is not protected against splashing

water in its standard model.

£ Keep the unit dry.

£ If liquids have penetrated the unit, switch

it off and disconnect or unplug the power

cable immediately. Inform a service

technician.

CAUTION

A too high or low supply voltage can damage

the unit.

£ Only operate the device using the system

voltage indicated on the nameplate.

£ Ensure that the mains voltage set on the

unit is the same voltage as that provided

by the electricity supplier.

9

1PLEASE NOTE

1.2 SAFETY INSTRUCTIONS

ALS

20x

256

GB

Protection against injuries by mechanical

action

WARNING!

Risk of injury due to moving and rapidly

rotating parts!

– Long hair, loose jewellery, long slee ves,

and so on are not permissible when using

the unit.

£ Sufficient protective clothing must be

worn.

£ Keep moving parts free from

obstructions even when the unit is not

switched on, if there is a chance the

machine might be turned on.

£ Switch off the machine before making

any mechanical settings.

£ Do not wear ties, loose clothing,

jewellery, wrist watches or similar items

on your person when near the operating

unit.

WARNING!

There is a risk that you may get your fing ers

or hands crushed on the dispensing edge by

products on the conveyor belt!

£ Never reach between the product and the

dispensing edge while the unit i s in

operation or ready for operation.

£ Never reach behind the safety guard or

remove it while the unit is in operation.

Protection against injuries by chemicals

CAUTION!

Operating materials such as cleaning agents

or the solvents in glues can be damaging to

health.

£ Always follow the instructions, use and

safety regulations specified by the

manufacturer!

10

1PLEASE NOTE

1.2 SAFETY INSTRUCTIONS

ALS

20x

256

GB

1.2.3 Before beginning production

Due diligence of the operating company

and the service technician

£ Ensure that the following prerequisites are fulfilled in

accordance with the service instructions:

– The machine is installed properly and configured in

accordance with the guidelines.

– All required safety mechanisms have been installed.

– The unit has performed at least one successful test

run.

– The unit is connected to the power supply.

£ The users have the required personal protective

equipment, for example, a hairnet. Ensure that the

protective equipment is utilised correctly.

Due diligence of the user

£ Check that the safety installations are working

properly.

£ Inspect the machinery for any visible damage.

Report any ascertained defects immediately.

£ Use the required personal protective equipment

correctly, for example, wear a hairne t.

£ Remove any unnecessary materials and objects

from the operating area of the unit.

£ Ensure that only au th or ise d pe rs on s ar e with in th e

operating range of the machine.

£ Ensure that starting up the machine will not injure

anyone.

11

1PLEASE NOTE

1.2 SAFETY INSTRUCTIONS

ALS

20x

256

GB

1.2.4 Safety notes on the unit

CAUTION!

Warning notes on the unit represent

important information for the personnel

using it.

£ Do not remove warning notes.

£ Replace any missing or illegible

warnings.

The ‘Pinch Point’ warning ] note warns you of the

danger posed by the machine’s rota ting parts; they can

trap items and draw them in.

The blue label ‘Read manual’ [2] demands that users

read the unit instructions.

[1] Left: ‘Pinch Point’ warning. Right: Position of the warning note on the ALS 20x. Item number of the label: A5346.

WARNING

!

Pinch point.

Keep hands clear

of rollers.

A5346

[2] Left: ‘Read manual’ notice. Right: Position of the notice on the ALS20x. Item number of the label: A5331.

Handbuch lesen!

Read the manual!

Lisez le manuel!

Lea el manual!

Legga il manuale!

12

2PRODUCT DESCRIPTION

2.1 OVERVIEW

ALS

20x

256

GB

2.1.1 Components

[3] ALS204 Label Dispenser (right-handed version)

A

CD

E

F

H

I

J

K

L

M

N

O

B

G

ALS256

2 PRODUCT DESCRIPTION

2.1 OVERVIEW

13

2PRODUCT DESCRIPTION

2.1 OVERVIEW

ALS

20x

256

GB

A Control panel

– For sending commands to the device and for

displaying operating states and error messages.

– An optional external control panel can also be

connected to the device.

B Dancer arm

– Keeps the label material stretched tight evenly.

– Arrests the rotation of the material roll if tension

diminishes.

C Dispenser

– Dispenser mandrel grasps the label roll.

D Core diameter adapter

– For adjusting the diameter of the dispenser mandrel

to match the core diameter of the label roll.

E Adjusting knob

– Turning this in a clockwise direction secures the

label roll on the dispenser.

F Deflection rollers

G Dispensing edge bracket

H Label sensor

– Stops the label feed after a label has been

dispensed.

I Pressure roller

– Prints the label once it is stuck to the product.

J Dispensing edge

– Standard: (non-adjustable) L-shaped dispensing

edge

– The following options are available: V-shaped

dispensing edge, adjustable L-shaped dispensing

edge, spring-loaded L-shaped dispensing edge,

pneumatic L-shaped dispensing edge

K Drive roller

– Drives the label material forwards.

L Pressure mechanism

– Presses the pressure roller against the drive roller.

– Prevents the backing paper from slipping through.

– Releases automatically once the backing paper has

been drawn around the drive roller.

M Dancer arm

– Controls the rewind speed.

N Rewinder

– Rolls up the used backing paper.

O Release button

– Pressing this button reduces the diameter of the

rewinder core.

– Allows the easy removal of the rewound backing

paper.

14

2PRODUCT DESCRIPTION

2.1 OVERVIEW

ALS

20x

256

GB

2.1.2 Control panel

Operating LED

Lights up green when the device is switched on.

Error LED

Lights up red when an error occurs.

LCD display

– Displays functions, configured values, operating

states and error messages.

– What is displayed at any one time depends on the

operating status of the device; these screens are

explained in the section “Operating modes” on

page 26.

Buttons

The functions of the buttons depend on the operating

status of the device; these functions are exp la i ne d in

the section “Operating modes” on page 26.

Language

– The display language can be selected from a choice

of seven languages.

– Default setting is English

– For selecting another language see chapter

“Functions” on page 29

[4] The ALS20x control panel (in dispensing mode)

A Operating LED

B Error LED

C LCD display

D Buttons

+

+

–

–

ON

STATUS

Online

292

Labels

A

B

C

D

15

2PRODUCT DESCRIPTION

2.1 OVERVIEW

ALS

20x

256

GB

2.1.3 Connection arrangement

Connections on the back of the device

[5] Connections on the back of the device (ALS20x):

A Power supply connection

B Network connection (Ethernet 10/100)

C Serial interface (RS232)

D Connection for external control panel (RS485)

E Plug-in card slot (CompactFlash cards)

F USB device interface

G PLC signal interface

H Optional: Applicator interface

For information on connecting the unit, see section “Power supply connection” on page 34.

B

C

D

E

F

G

H

A

16

2PRODUCT DESCRIPTION

2.1 OVERVIEW

ALS

20x

256

GB

Sensor connections

[7] Arrangement of the sensor connections (schematic) on the LH

(left figure) and RH (right figure) devices:

A Product sensor

B Signal outputs (optional)

C Signal inputs (optional)

D Rotary encoder (for automatic speed adaption)

E Roll diameter sensor

F Label sensor

G (ALS20x) Alternative label sensor

H (ALS 256) Alternative label sensor

For information on connecting the sensors, see

section “Connecting sensors” on page 36.

[6] Sensor connections on the ALS20x (RH)

START

PLC-OUT

PLC-IN

LABEL

ROTARY

ENCODER

OD

CAP

CAP for 256

START

PLC-OUT

PLC-IN

LABEL

ROTARY

ENCODER

OD

CAP

CAP for 256

RHLH

A

B C

F

D E

G

A

C B

E D

F

G

H H

17

2PRODUCT DESCRIPTION

2.1 OVERVIEW

ALS

20x

256

GB

2.1.4 Mode of operation

In labelling mode, the strip is first pulled from the label

roll around the dancer arm [8A], which consistently

maintains even tension in the label strip. The feed roller

[8D] behind the dispensing edge [8C] draws the strip

across the dispensing plate. The label is unfixed from

the backing paper on the dispensing plate and is

pressed onto the product by the pressure roller [8B].

The feed roller drives the label strip forwards the length

of one label and stops until the next product arrives at

the dispensing plate. The strip feed is started by the

product sensor mounted on the conveyor belt. The stop

control provided by the label sensor on the dispensing

edge ensures the feed is halted as soon as a gap is detected between two labels.

The spent backing paper runs from the dispensing

edge around the drive roller [8D] to the rewinder [8E].

The dancer arm regulates the rewinding speed.

The entire operation of the label dispenser is controlled

and monitored electronically. If errors occur, the device

controls output an appropriate notification for the operator. If necessary, the labelling operating mode is halted automatically. An electronic signal is output at the

same time. The signal can be fed to an external controller and evaluated.

[8] The ALS20x Label Dispenser is ready for operation in its

idle mode.

A Dancer arm

B Pressure roller

C Dispensing edge

D Drive roller

E Rewinder

D

A

E

B

C

18

2PRODUCT DESCRIPTION

2.1 OVERVIEW

ALS

20x

256

GB

2.1.5 Technical specifications

Characteristics

1) The maximum usable dispensing speed depends on the label geometry.

For details see separate performance matrix in the service manual.

2) At a dispensing speed range of 5m/min to the max. speed

Labels

3) Depending on the dispensing edge width.

Label sensor

Power supply

4) For more information on fuses, see section “Replacing fuses” on page52.

5) Not accessible for user or service technician.

Dispensing speed 1):

ALS204

ALS206

ALS256

max. 40m/min

max. 30m/min

max. 50m/min

Labelling halt precision

2)

at the peeling edge:

±1 mm

Speed control: Fixed setting or automatic

speed adaption via the

rotary encoder

Label material: Converted self-adhesive

label material with liner

Internal rewinding yes

Material width (including

backing paper)

3)

:

ALS204

ALS206

ALS256

up to 110mm

up to 160mm

up to 160mm

Label length: 5 to 600mm

Label roll:

Winding direction

Unwinder (outer) Ø:

Rewinder (outer) Ø:

Core (inner) Ø:

inner or outer

up to 300mm

up to 200mm

38.1/76.2 /101.6mm

(1.5/3 /4")

Distance to peel edge

L-shape dispensing

edge:

V-shape dispensing

edge:

19mm

77mm

Transmission sensor: Wenglor OPT242-P800

optical, NPN

System voltage:

ALS20X

ALS256

110V (AC) at 60Hz power frequency (permissible

tolerance ±10%)

230V (AC) at 50Hz power frequency (permissible

tolerance ±10%)

100-240V (AC) at

60/50Hz power frequency (permissible tolerance

±10%)

Current consumption:

ALS20X

ALS256

max. 4A at 110V

max. 2A at 230V

max. 4A at 100V

max. 2A at 240V

Power consumption:

ALS20X

ALS256

max. 460VA

max. 460VA

Fuses:

ALS20X

ALS256

F1, F2: T5AH 250V

4)

Fuses integrated in the

power supply

5)

19

2PRODUCT DESCRIPTION

2.1 OVERVIEW

ALS

20x

256

GB

Electronics

Interfaces

Internal Interfaces

6) Not yet available

Status messages, test functions,

product profiles

Processor: 32Bit CPU MIPS Core

RAM: 16MB

ROM: 4MB

Control panel: graphical display with

128x32 pixels, 2/4 lines,

5 buttons

Sensor interfaces for

external sensors

Label sensor:

Alternative label

sensor:

Product sensor:

APSF-sensor (Rotary

encoder):

Stock sensor:

(plug in each case 4-

pin M12)

Wenglor OPT242-P800

optical, NPN, 24V, con-

trollable sensitivity

PNP/NPN, 24V

PNP/NPN, 24V

single-phase/two-phase,

PNP/P-P, 24V, max.

20kHz

PNP, 24V

Internal sensor interfac-

es:

Material unwinder

Pressure roller

Dancer arm

Light barrier

not used

bi-phase light barrier en-

coder

PLC interface

Outputs:

Inputs:

Sub D15, optically insu-

lated, optionally via two

8-pin M12 (separate in-

puts/outputs in each

case)

4x PNP, 24V, a maxi-

mum of 500mA/channel,

total permissible output

current: 1500mA

3x PNP/NPN, 24V

Data interfaces:

Serial:

Ethernet:

USB:

CF card:

Control panel

interface:

RS232C (Sub-D9),

max. 115200 Baud

10/100 BaseT (RJ45)

Device V1.1 (USB B),

‘Full speed’ operating

mode, 12MBit/s

Slot for 1 CompactFlash

card

RS485 (Mini DIN 6 connection) for remote control

RFID Connection for RFID

read/write unit (special

equipement)

6)

Applicator Interface Connection for Applicator

Interface (AI) board (special equipement)

Connector for additional

motor driver

not used

Automatic halt, if ... the label roll is spent or

no gap was found.

...the max. admissible

number of missing labels

is reached.

Test functions: Automatic diagnostics

check when switched on

Output of system data via

data interface

Status indicators: Label counter

Operating hours counter

Storage locations for

product profiles:

up to 16

Loading...

Loading...