Users Manual

Model 686 / 686 HT

AVERY DENNISON

Manual Edition 7.0

09 June, 2010

Manual Part Number 551398

This page intentionally left blank

Contents

Scope 4

Introduction ............................................................................................................................... 4

Safety Issues / Warnings 4

Caution....................................................................................................................................... 4

Warranty Information 5

Customer Responsibility 7

Location of Printer ..................................................................................................................... 7

AC Power Line .......................................................................................................................... 8

Unpacking.................................................................................................................................. 8

Inventory of Components .......................................................................................................... 9

Printer Setup 10

Installing the Stacker (Option) ................................................................................................. 10

Fuse Configuration .................................................................................................................. 11

P.C. Board Identification .........................................................................................................12

TCB Dip Switch Settings......................................................................................................... 13

Installing the Power Cord ........................................................................................................13

Installing the PC Interface Cable ............................................................................................. 14

Installing the PC Software ....................................................................................................... 14

Product Description 15

Printer Description................................................................................................................... 15

Personal Computer Specifications ........................................................................................... 16

Printer Specification ................................................................................................................ 17

Printer Operation & Quick Set-Up 19

Loading Ink.............................................................................................................................. 19

Loading Stock .......................................................................................................................... 20

Decurler / Turnbar ................................................................................................................... 21

Butt Splicing Stock .................................................................................................................. 22

Web Guide Adjustment ........................................................................................................... 22

Modified Drive Assembly ....................................................................................................... 23

Flash Disk Module................................................................................................................... 23

Sensor Adjustment................................................................................................................... 24

Ink Guide Adjustment.............................................................................................................. 25

Print Head Operation ............................................................................................................... 27

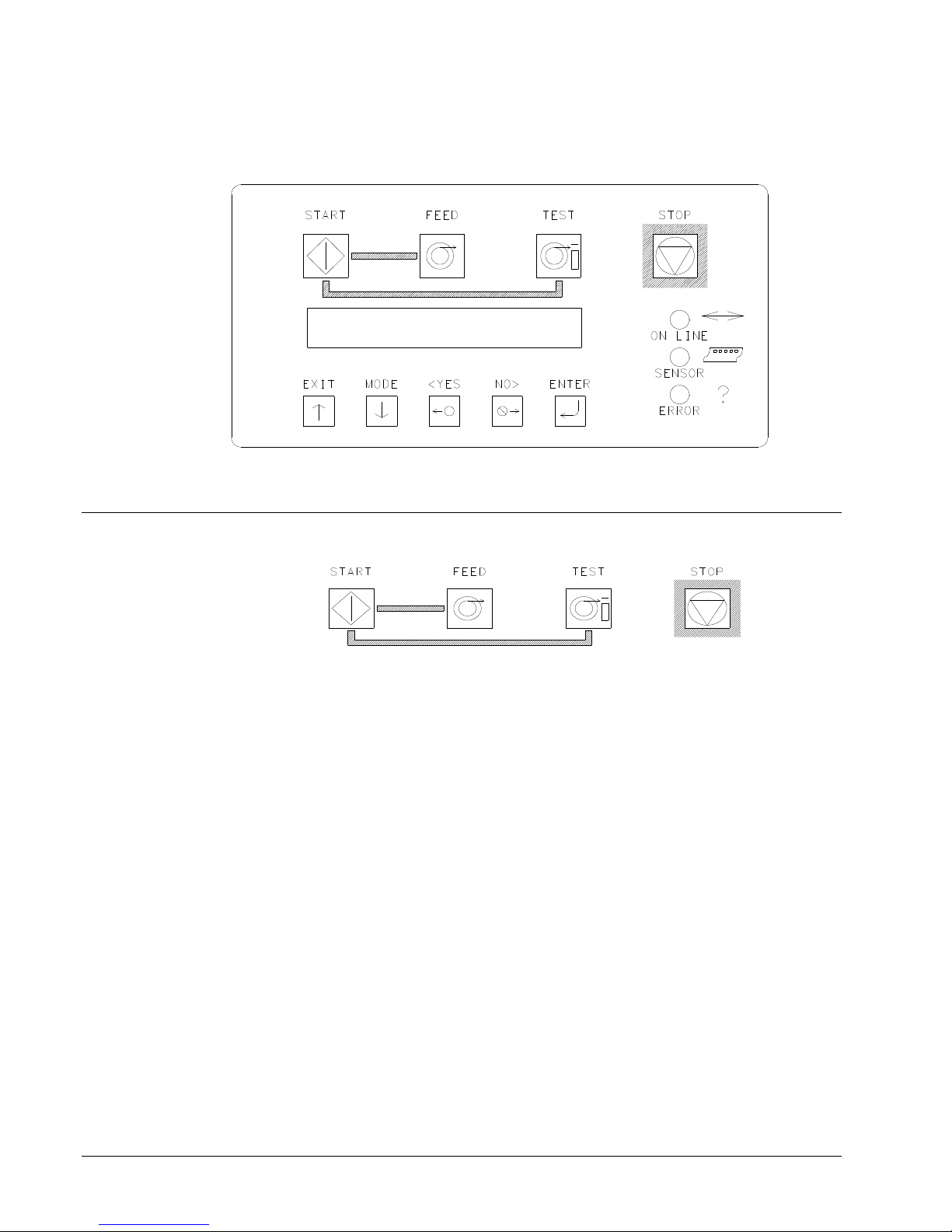

Control Panel Operation 28

Control Buttons........................................................................................................................28

Indicator Lights........................................................................................................................ 29

LCD Display............................................................................................................................ 30

Users Manual Model 686 / 686 HT •••• i

Front Panel Menu Map ............................................................................................................31

Front Panel Power Up / Home Screens....................................................................................32

Front Panel Mode Descriptions................................................................................................ 35

Adjustments / Maintenance 45

Print Head Handling ................................................................................................................ 45

Print Head Cleaning ................................................................................................................. 46

Print Head Replacement .......................................................................................................... 47

Print Head Adjustment............................................................................................................. 49

Stock Feed Roller Adjustment .................................................................................................49

Knife Square Adjustment......................................................................................................... 49

Stacker Adjustments ................................................................................................................50

Sensor Identification / Adjustment / Calibration......................................................................50

Print Registration Sensor .........................................................................................................52

Sensor Calibration.................................................................................................................... 53

Lubrication Procedure.............................................................................................................. 54

Printer Set Up Sequence .......................................................................................................... 55

Electrical Trouble Shooting 56

Power Up / Sign On / Communications................................................................................... 56

Stock / Ink Advance.................................................................................................................58

Print..........................................................................................................................................59

Cut / Stack................................................................................................................................61

Mechanical Trouble Shooting 62

Stock ........................................................................................................................................ 62

Ink ............................................................................................................................................ 64

Print..........................................................................................................................................64

Electrical Drawings 65

Printer Wiring ..........................................................................................................................66

Electrical System Schematic .................................................................................................... 67

Motherboard Power Connectors ..............................................................................................68

Appendix A 69

Error Messages ........................................................................................................................69

Appendix B 70

Software Upgrade Chip Placement Positions ..........................................................................70

Front Panel Diagnostic Descriptions........................................................................................ 72

Appendix C 73

Ink and Stock Transfer Types .................................................................................................. 73

Appendix D 74

Knife MFG Guideline .............................................................................................................. 74

Appendix E 77

Printhead Life Extension..........................................................................................................77

ii •••• Users Manual Model 686 / 686 HT

Printhead Fail Modes ............................................................................................................... 78

Printhead Cleaning Procedure ................................................................................................. 79

Printhead Installation and Removal Procedures ...................................................................... 80

Static Checks for 686 / 686 HT Printers .................................................................................. 81

Print Quality Adjustment ......................................................................................................... 82

Assembly Drawings 83

Unwind Assembly Drawing..................................................................................................... 84

Unwind Parts List .................................................................................................................... 85

Unwind Turnbar Assembly Drawing....................................................................................... 86

Unwind Turnbar Parts List ...................................................................................................... 87

Contrast Sensor Assembly Drawing ........................................................................................ 88

Contrast Sensor Parts List ........................................................................................................ 89

Web Guide

Web Guide

Drive Assembly Drawing ........................................................................................................ 92

Drive Parts List ........................................................................................................................ 93

Printhead Assembly Drawing .................................................................................................. 94

Printhead Parts List .................................................................................................................. 95

Printhead Module Assembly Drawing..................................................................................... 96

Printhead Module Parts List .................................................................................................... 97

Printhead Adjustment Assembly Drawing............................................................................... 98

Printhead Adjustment Parts List ..............................................................................................99

Ink Drive 686HT Assembly................................................................................................... 100

Ink Drive 686HT Parts List ................................................................................................... 101

Ink Save Assembly ................................................................................................................ 102

Ink Save Parts List ................................................................................................................. 103

Ink Save PC Board Assembly................................................................................................ 104

Ink Save PC Board Parts List ................................................................................................ 105

Timing Belt Threading Diagram............................................................................................ 106

Timing Belt Parts List............................................................................................................ 107

Timing Belt 686HT Threading Diagram ............................................................................... 108

Timing Belt 686HT Parts List ............................................................................................... 109

Knife Assembly Drawing ...................................................................................................... 110

Knife Parts List ...................................................................................................................... 111

Stacker Assembly Drawing (Part 1) ...................................................................................... 112

Stacker Parts List (Part 1) ...................................................................................................... 113

Stacker Assembly Drawing (Part 2) ...................................................................................... 114

Stacker Parts List (Part 2) ...................................................................................................... 115

Back Reflective Sensor Option Assembly Drawing .............................................................. 116

Back Reflective Sensor Option Parts List.............................................................................. 117

Cover Assembly Drawing...................................................................................................... 118

Cover Assembly Parts List .................................................................................................... 119

/

Sensor Assembly Drawing................................................................................. 90

/

Sensor Parts List ................................................................................................ 91

Users Manual Model 686 / 686 HT •••• iii

Scope

Introduction

This user manual was arranged for the person who is going to operate the printer.

The information is arranged in the order that is needed to install and then operate the

printer. It starts with general information, then to unpacking the carton, setup,

installing the ink and stock, printer operation, control panel operation, and finally

care and maintenance of the printer.

We at AVERY DENNISON hope that you will come to appreciate the efforts and

quality that have gone into producing your AVERY DENNISON 686 / 686 HT

Printer and wish to remind you that you are our number one priority. We welcome

any constructive comments or criticisms so that we may continue to offer you the

best printer in the industry for years to come.

Safety Issues / Warnings

Caution

This printer has some pinch points. All of these areas have been well guarded and it

is recommended that the safety features of this printer are never altered or defeated.

4 •••• Scope Users Manual Model 686 / 686 HT

Warranty Information

Warranty Policy

Avery Dennison Retail Information Systems, In-Plant Printing Solutions provides the following warranty policy.

Scope

Warranties against defects from workmanship for equipment and parts manufactured and sold from Sayre,

PA. Includes time and material except as otherwise noted below.

Time

− New equipment and parts: 6 months

− Refurbished equipment and parts: 90 days

− Warranty period starts when equipment ships from selling location.

General Conditions

Avery Dennison extends warranty coverage under the following conditions.

− Equipment and parts will perform within published specifications. Promised or implied statements by any

Avery Dennison employee or representative will not be deemed to vary the terms of the warranty.

− Equipment and parts must be installed and operated according to recommended procedures and

operating conditions.

− Consumable elements are not covered. Consumable elements are those that show normal wear from

typical equipment usage including, without limitation, printheads, knives, rollers in contact with the web,

and sonic units. Avery Dennison reserves the right to determine which elements are defined as

“consumable.”

− No customer maintenance may be performed except as directed by qualified Avery Dennison personnel.

− Equipment and parts damaged by negligence or abuse are not covered.

− Avery Dennison US reserves the right in its sole discretion to incorporate any modifications or

improvements in the machine system and machine specifications which it considers necessary but does

not assume any obligation to make said changes in equipment previously sold.

Equipment Purchased In US and Shipped In US

− Avery Dennison US covers warranty for equipment and parts installed and operated in the Americas

(United States, Canada, Mexico, Central America, Caribbean Region, and South America excluding

Brazil).

− Outside the US, the local Avery Dennison office is responsible for equipment and parts warranty.

Customers must ensure coverage during machine purchase.

− Equipment purchased and exported to regions outside local Avery Dennison office coverage are not

covered by warranty. The purchasing agent must acquire a service contract from the Avery Dennison

Users Manual Model 686 / 686 HT Warranty Information •••• 5

office where the equipment or parts are operated to ensure machine coverage. For example, if an agent

purchases a printer in the US, exports to Brazil, and then needs warranty coverage, Avery Dennison

Brazil has no obligation to provide warranty coverage. The agent must purchase services from Avery

Dennison Brazil.

THE WARRANTIES PROVIDED HEREIN ARE EXCLUSIVE AND ARE IN LIEU OF ANY IMPLIED

WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHER WARRANTY

OF QUALITY OR PERFORMANCE, WHETHER EXPRESS OR IMPLIED. EXCEPT THE WARRANTY OF

TITLE, IN NO EVENT SHALL AVERY DENNISON BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, EVEN IF AVERY DENNISON HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES.

Service

When ordering machines and supplies in the U.S.A., reference all correspondence to the address below.

AVERY DENNISON Corporation

One Wilcox Street

Sayre, PA 18840

Call: 1-800-967-2927 or (570) 888-6641

Fax: (570) 888-5230

For spare parts, requests for service or technical support, contact

AVERY DENNISON Corporation

One Wilcox Street

Sayre, PA 18840

Call: 1-800-967-2927 or (570) 888-6641

Fax: (570) 888-5230

For parts and service in other countries, please contact your local AVERY DENNISON supplier

6 •••• Warranty Information Users Manual Model 686 / 686 HT

Customer Responsibility

Location of Printer

The printer weighs approximately 57 Lbs (~26Kg) and requires a table of sufficient

quality and strength to handle this load while the printer is operating. AVERY

DENNISON recommends an industrial type worktable having the approximate

dimensions of 96" wide to 30" deep to 32" high. (See Figure 1).

Figure 1 - Recommended Workstation Layout.

The location of the AVERY DENNISON 686 / 686 HT printer should be based on

human factors. The printer should be located in an area that maintains optimum flow

of your product while providing for the operator’s comfort. AVERY DENNISON

has taken significant steps to ensure that the operator controls and operations are

easily accessible. This goal can only be met, however, if the printer is also located

with human factors in mind. These include the height of the printer, the space

around the printer, and the accessibility to the printer.

The AVERY DENNISON 686 / 686 HT printer is a high-resolution thermal printer.

While AVERY DENNISON has designed the printer to be reasonably quiet, it is

recommended to locate the printer in an area where printing and cutting repetitious

noise is acceptable.

The unit should always be operated with the cover closed to minimize the amount of

dust and dirt in the printer.

Users Manual Model 686 / 686 HT Customer Responsibility •••• 7

AC Power Line

Unpacking

AVERY DENNISON requires that the electrical service be 10 Amps @ 115VAC or

10 Amps @ 230VAC. This will allow the computer and any additional support or

service equipment to be plugged into the same service.

Any electrical service that is supplying a AVERY DENNISON printer or peripheral

equipment connected to a AVERY DENNISON printer should follow standard

electrical code practices including proper grounding and neutral requirements.

The AVERY DENNISON printer was designed to operate in an industrial setting for

extended periods of time; however, the printer is controlled by a microprocessor that

is very sensitive to brownouts or power spikes. For this reason as well as the

minimum recommended current supply, AVERY DENNISON recommends that a

separate “clean” service be installed or reserved for the exclusive use of the AVERY

DENNISON printer and it’s peripherals.

The AVERY DENNISON printer is shipped in a large cardboard box that may be

difficult to move by hand.

DO NOT REMOVE THE PRINTER FROM THE BOX OR UNPACK IN THE

SHIPPING / RECEIVING DEPARTMENT.

NOTE: Unpacking in the shipping / receiving department is not recommended for

the following reasons.

First: The cardboard carton in which your AVERY DENNISON printer

was shipped allows the printer to be moved with a forklift, fork

cart or hand cart. Because of the weight of the printer, it is easier

and safer to use one of these devices to move the printer to its

intended installation location.

Second: Leaving the printer in the carton while it is being moved within

your facility will help to protect the printer during any movements

to this location. Once the printer has reached its intended location

you should begin the unpacking process.

Open the printer from the top of the box (See Figure 2). Do not cut deep into the

carton, as there are items located just under the top. Remove the items located on the

top insert. Remove the top insert. Lift the printer onto the table with the two

banding straps. Remove the two straps and the plastic from the printer. Inspect the

printer for shipping damage. If damage is discovered, contact AVERY DENNISON

for further instructions - in the U.S.A. at (570) 888-6641. In other countries please

contact your local AVERY DENNISON supplier. Once you are satisfied that there

was no obvious shipping damage to the printer, the printer can now be lifted to its

intended location.

8 •••• Customer Responsibility Users Manual Model 686 / 686 HT

In some cases, a double box has been used to ship your printer.

Figure 2 - Shipping Carton.

Save the shipping materials to relocate the printer or return to factory for service.

Inventory of Components

The following list shows the additional parts (pieces) that should be included in your

AVERY DENNISON 686 / 686 HT shipping container. If anything is missing,

notify AVERY DENNISON immediately - in the U.S.A. at (570) 888-6641. In other

countries please contact your local AVERY DENNISON supplier.

- AVERY DENNISON 686 / 686 HT "User's Manual” - 551398

- Tool kit – Option

- A quick-disconnect power cord

- Stacker assembly – Option

- Optional software ordered to drive the printer.

- A serial communications cable / converter.

Users Manual Model 686 / 686 HT Customer Responsibility •••• 9

AVERY DENNISON 686 / 686 HT TOOL KIT (#551390 - Option)

241149 Anti-Static Gloves (2)

921309 Hex Key Set

921364 3/16" Ball Driver, Long

181301 2.5mm Ball Driver

351156 Chip Removal Tool

241132 Anti Static Wrist Strap

921341 T-T Printer Cleaning Kit

Printer Setup

Installing the Stacker (Option)

Remove the stacker from the separate packaging. Remove the packaging from

around the stacker and save with the rest of the printer packing supplies.

Swing open the top cover to the printer. Locate the large knob and two round pins

on the right hand side of the printer. Loosen the knob enough to allow the stacker to

slide between the printer housing and the knob. The stacker will rest on the two

pins. Slide the stacker to the back until it contacts the up-right frame. Tighten the

knob. Adjusting the stacker is covered later.

Install the stacker up-right rails. Remove one of the thumbscrews. Insert the

thumbscrew through the mating hole in the up-right rail assembly. Thread the

thumbscrew into the mounting block. Repeat the above procedure for the other

thumbscrew.

There is a cable with a connector leading from the back of the stacker that plugs into

a socket on the TCB (refer to the P.C. Board Identification section in this manual).

The socket and plug are polarized. Rotate the plug until the polarized keyway and

socket align and push the stacker connector into the socket.

10 •••• Printer Setup Users Manual Model 686 / 686 HT

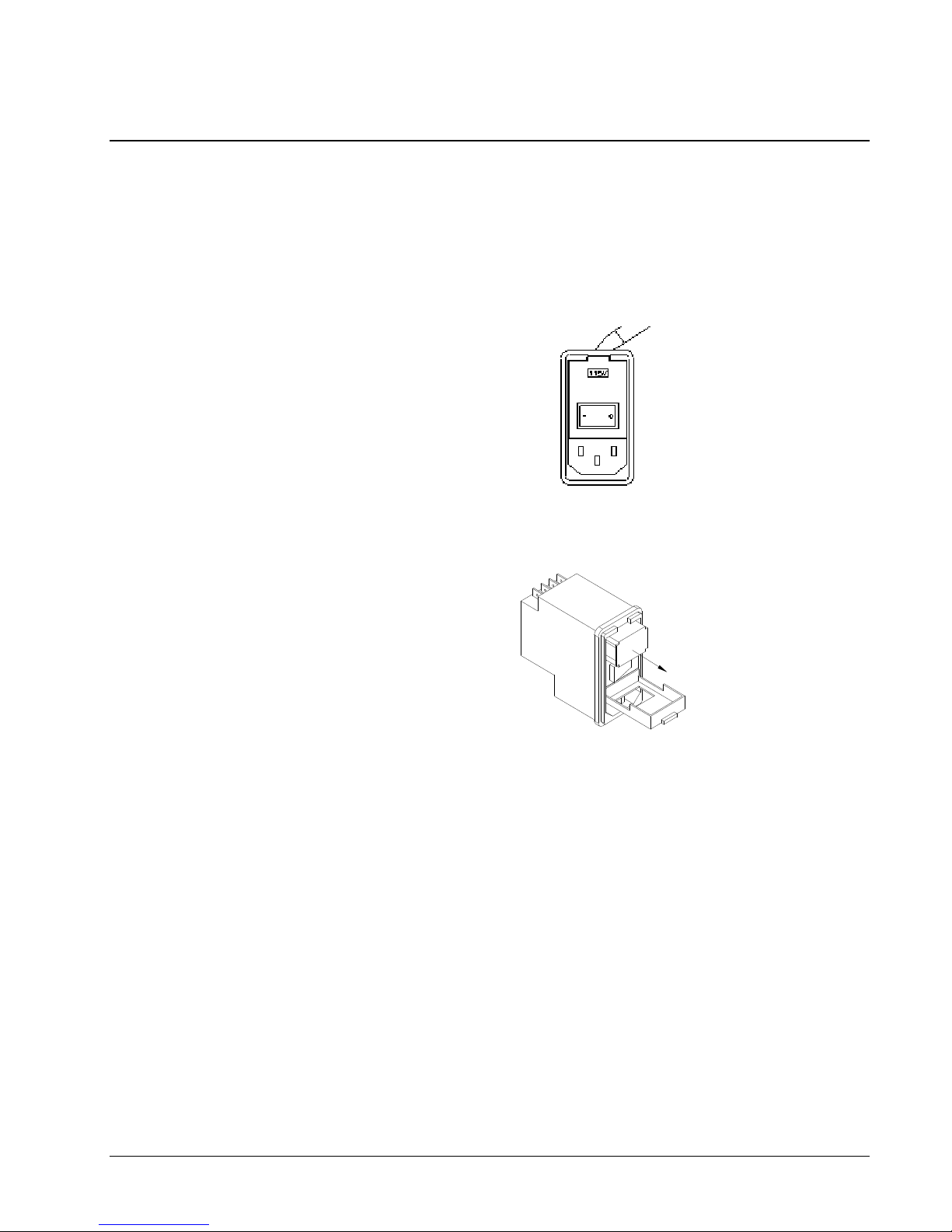

Fuse Configuration

The main fuse(s) on the AVERY DENNISON 686 / 686 HT are located inside the

AC entry. The entry has a fuse drawer that holds the fuse(s) and selects the

appropriate line voltage. If the voltage in the window DOES NOT match the AC

line amplitude intended to be supplied to the printer, DO NOT plug the power cord

in. Reconfigure as follows:

1) Using a flat blade screwdriver, open the AC entry by lifting the tab just above

the voltage indicator window.

AC Entry

2) Remove the red fuse drawer.

3) Remove all fuses and the fuse jumper if it is present.

4) Insert into the fuse drawer the correct number and style of fuse(s) and fuse jumper

for your application.

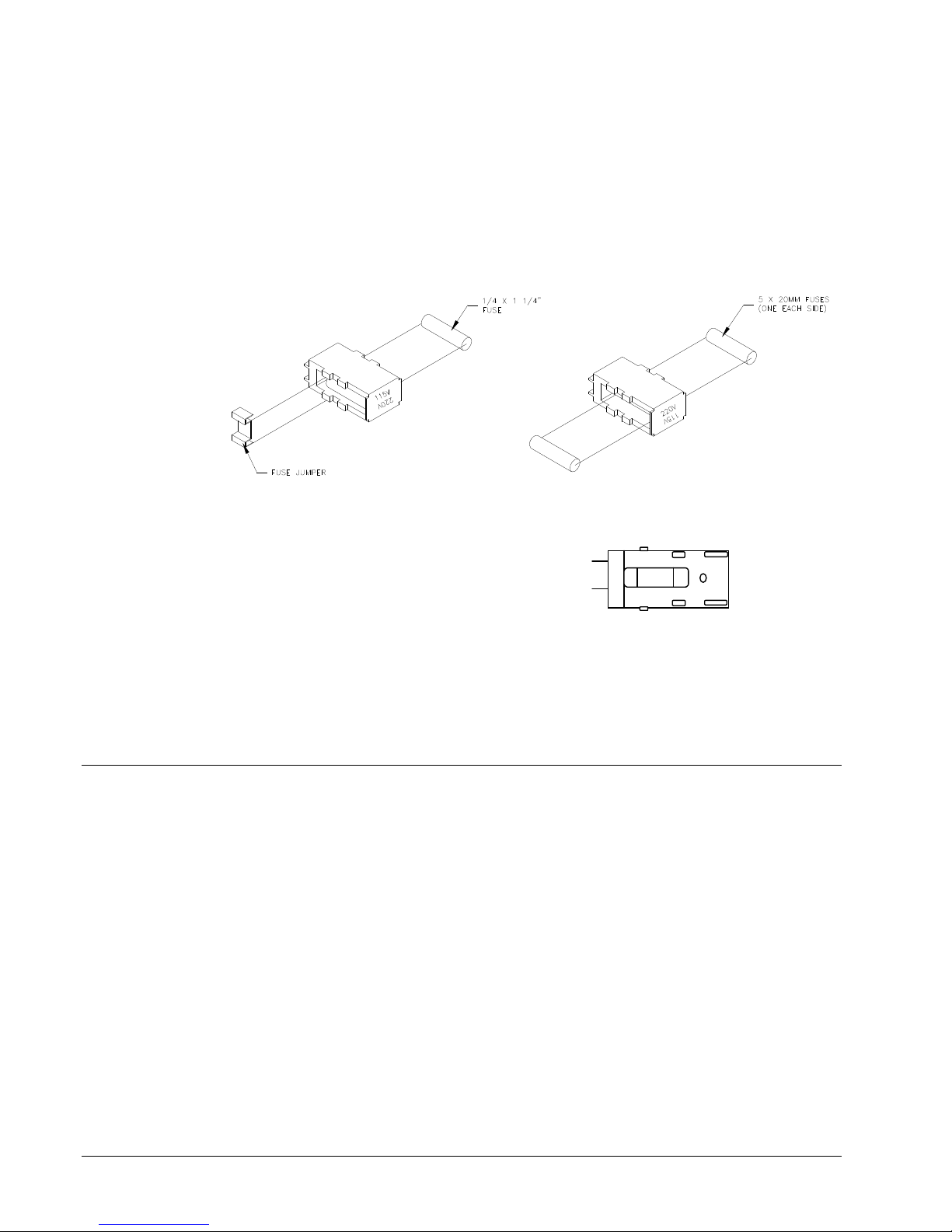

Configuration Number One: Line voltage within the range of

(See 115VAC Fuse Placement) 90 - 132VAC @ 50 - 60Hz

1) Install one 990689 – 6.25A 250V Fast Acting 1/4 x 1 1/4"

2) Install one Fuse Jumper

Users Manual Model 686 / 686 HT Printer Setup •••• 11

Configuration Number Two: Line voltage within the range of

A

(See 230VAC Fuse Placement) 180 - 265VAC @ 50 - 60Hz

1) Install two 990757 6.0A 250V Fast Acting 5 x 20MM

NOTE: The fuse jumper must be removed to install both 5 x 20mm fuses.

115VAC Fuse Placement 230VAC Fuse Placement

C

B

5 X 20MM Fuse Placement

5) Reinsert the fuse drawer into the AC entry with the desired voltage up.

6) Close the AC entry and verify the correct voltage is now visible.

P.C. Board Identification

Mother Bd. (371170) - Horizontal on bottom

Front Panel Bd. (511108) - User interface system

686 Thermal Control Bd. (371105NE) - AT Slot 2

686 HT Thermal Control Bd. (371105HT) - AT Slot 2

Head Driver Bd. (341106NE) - AT Slot 1

686 Ink Drive Bd. (551105) - Back of upright frame

686 HT Ink Drive Bd. (551105HT) - Back of upright frame

The fuses must be between points A and B as shown not B and C.

of printer

12 •••• Printer Setup Users Manual Model 686 / 686 HT

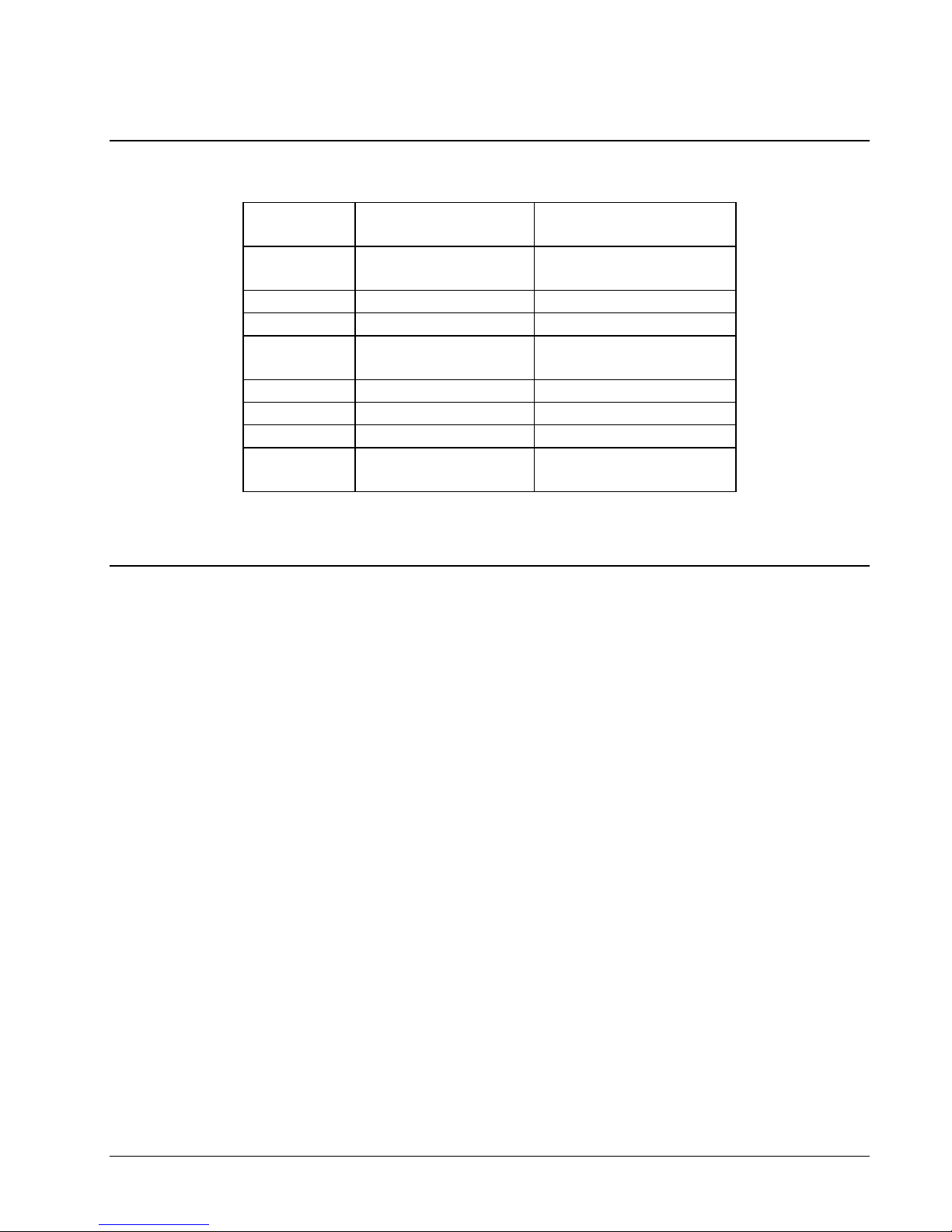

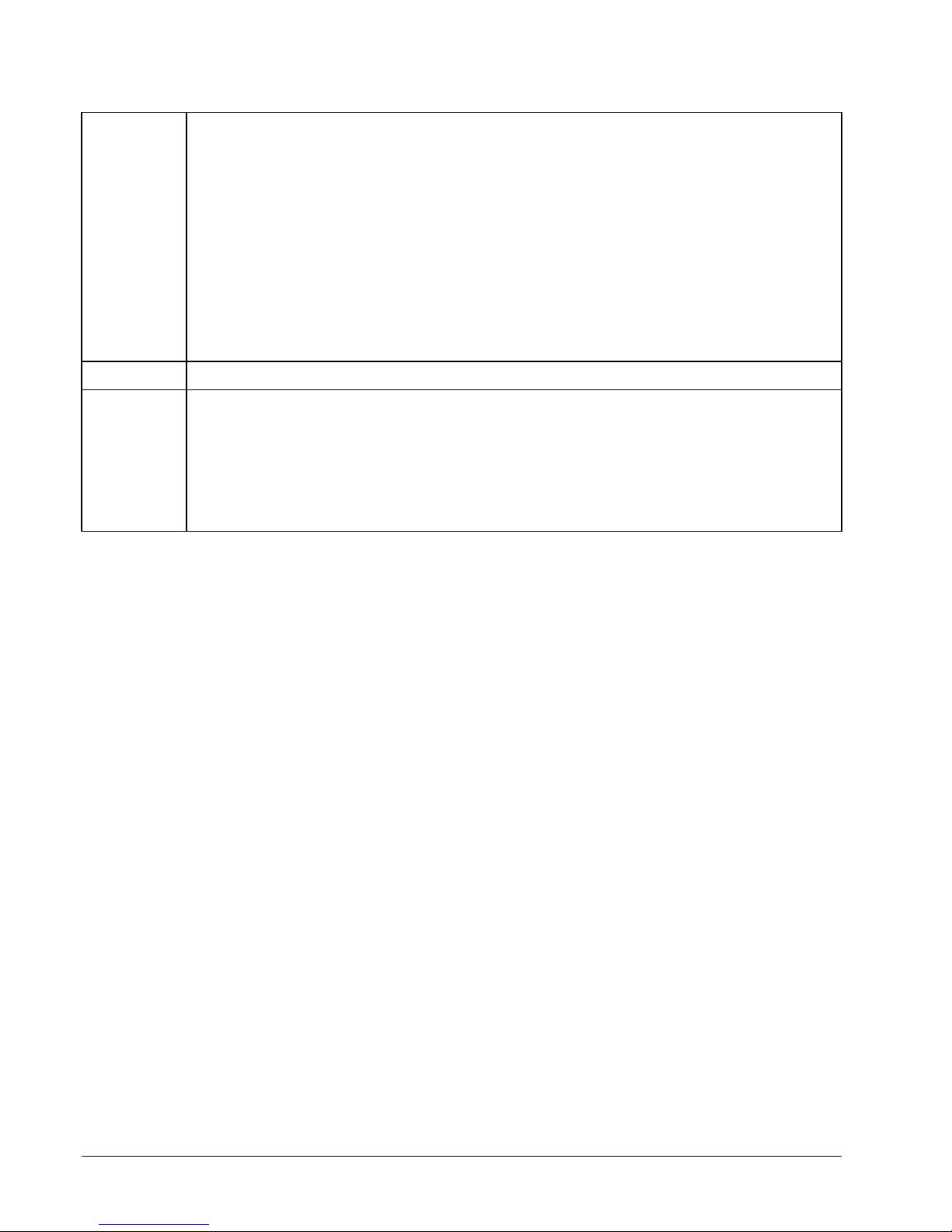

TCB Dip Switch Settings

DIP

DEFINITION 686 / 686 HT

SWITCH #

8 DOWNSTACKER/

LOKPRINT

7 UNUSED OFF

6 UNUSED OFF

5 STACKER JAM ENABLE ON

4 MACHINE TYPE ON

3 MACHINE TYPE ON

2 UNUSED ON

1 PRINTHEAD DPI ON – 300 DPI

Installing the Power Cord

DOWNSTACKER ON

LOKPRINT® OFF

DISABLE OFF

N/A OFF

A power cord is shipped with each printer. The cord for 115-volt printers will use

the standard three-prong plug used in the U.S.A. All other power configurations are

the customer’s responsibility to have the plug and alteration work done by a certified

electrician. AVERY DENNISON supplies printers to many countries with many

variations. Therefore we leave this to the customer to make the proper selection for

their country.

Users Manual Model 686 / 686 HT Printer Setup •••• 13

Installing the PC Interface Cable

The 686 / 686 HT requires a 9-pin RS232 cable. This cable is provided with the

printer. If the cable was not found, it can be ordered from AVERY DENNISON

(Part number 351124).

The male end of the cable should be connected to the 9-pin D-shell female connector

that is located on the right side of the printer at the TCB (refer to the P.C. Board

Identification section in this manual). The female end of the cable is made to fit a 9pin male RS232 connector on the back of a PC. In case a 9 pin serial port is not

available - a 9 to 25-pin converter is also shipped with all printers.

Installing the PC Software

The software to drive the AVERY DENNISON family of printers is covered in

separate documentation. The "PcMate Platinum" software to create formats on site

for the AVERY DENNISON 686 / 686 HT printer is a Windows application. The

original "Selfform" will not create formats for the 686 / 686 HT. The new " PcMate

Platinum" package is capable of creating formats for all AVERY DENNISON

control printers.

PcMate Plus version 3.22 or above must be used to drive the 686 / 686 HT.

The printer is also capable of operating directly from a mainframe when using the

RS232 interface and AVERY DENNISON's PCL command language. (See AVERY

DENNISON PCL Command Language Manual)

14 •••• Printer Setup Users Manual Model 686 / 686 HT

Product Description

Printer Description

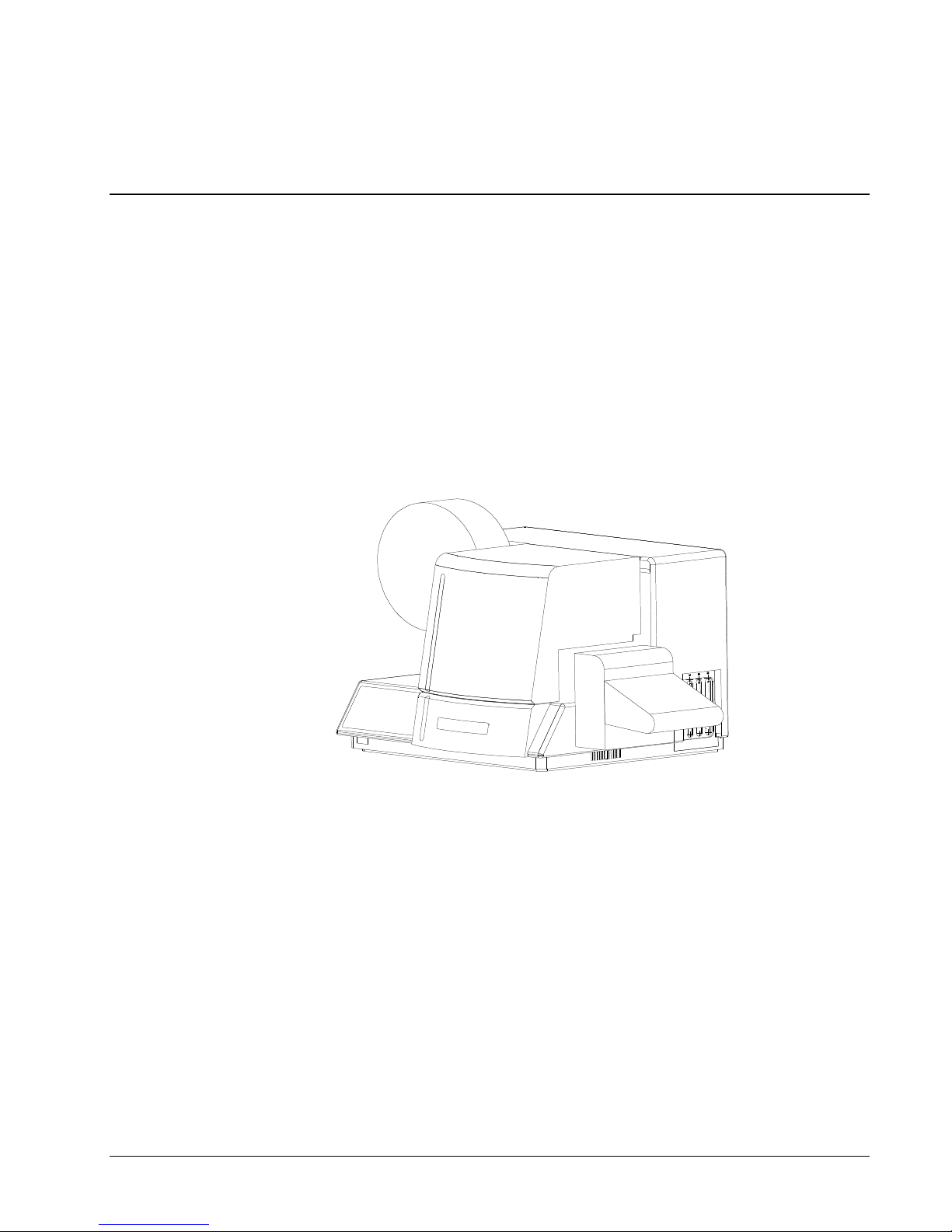

The AVERY DENNISON model 686 / 686 HT thermal printer (See Figure 4) is an

electronic printer that can print on Card Stock, Size Stickers, and Pressure Sensitive

rolled stocks. The printer interfaces to a computer or a mainframe system thus

allowing electronic data input or even custom design of labels with AVERY

DENNISON’S “PcMate Platinum" program. This printer can generate a complete

tag printed on one side.

• Design your own labels on a PC

• Computer interface = IBM Compatible

• Mainframe direct interface

• RS232 9 Pin D shell female Serial interface connector

Figure 4 - AVERY DENNISON Model 686 / 686 HT Label Printer

Users Manual Model 686 / 686 HT Product Description •••• 15

Personal Computer Specifications

This specification describes the hardware and application software requirements for

the Personal Computer that is used to download to the AVERY DENNISON 686 /

686 HT Printer.

The AVERY DENNISON 686 / 686 HT Printer uses a Windows version of

“PcMate Platinum”. This application will create the tag or label formats (layouts)

then fill and transfer data to the printer through the serial port of the computer.

When using PCMate™ Platinum 5.0, the following minimum system requirements is

highly recommended:

• IBM® PC or Compatible

• Microsoft Windows® 2000, XP or later

• 256 Megabytes of RAM

• At least 4 Gigabyte of available disk space

• Pentium III or later processor, 800Mhz minimum

• CD ROM drive

DISK DRIVES: You will need a hard disk with at least 4 Gigabytes of free disk

space to store the PCMate™ Platinum program. Additional space will be required to

store designs, print files, etc.

COMPATIBILITY: This application supports the conversion and use of basic tag

and label layouts and print files created with PCMate™ for DOS, and earlier

versions of PCMate™ for Windows. When importing tag and label layouts (designs)

from older versions of PCMate™ caution should be taken due to a chance that

feature changes and enhancements in your current version of PCMate™ Platinum

may require field modifications within the imported design

Refer to your specific software package for proper installation procedures.

16 •••• Product Description Users Manual Model 686 / 686 HT

Printer Specification

Print method: Thermal transfer, one sided, near edge printhead printer for tags and pressure sensitive

labels.

Speed - up to 12 IPS (305mm/second) - 7"(178mm), 10"(254mm), & 12"(305mm)

Label Size Max: 686 - Up to 5.125" (130.2mm) web x up to 7" (177.8 mm) feed - cut and stacked

686HT - Up to 3.00" (76.2mm) web x up to 7" (177.8 mm) feed - cut and stacked

Transfers tested as of June 9, 2006

- Up to 14.0" (355.6mm) feed w/ Rewind

Min: 1" (25.4mm) web x 1" (25.4mm) feed at speeds of 7"(178mm) or 10"(254mm) – using

the standard 558091 Stacker.

Min: 1" (25.4mm) web x 1.250" (31.75mm) feed at speeds of 12"(305mm) or when using the

High Volume Stacker at any speed.

Print Area Max: up to 5" (127mm) web x up to 13.875" (352.4 mm) feed

Min: None

Resolution 300 DPI x 300 DPI

Fonts - Six scalable fonts resident: condensed, standard, and bold typefaces, upper and lower case

- 4pt up to 96pt (300 DPI)

- All rotations 0°, 90°, 180°, 270°

Logos - No restriction on number or size per tag (up to maximum image area)

- All rotations 0°, 90°, 180°, 270°

Care

Symbols

Justification Left, Right, and Center - field selectable

Stock Support for blank or pre-printed card stock and blank or pre-printed pressure sensitive

Interface AVERY DENNISON PCL via RS232 serial port - 9 pin D-shell

Control Panel Push-button printer function with 2 Line x 24 Character International LCD Backlit Display

Dimensions 16.0" (406.4 mm) high x 27" (685.8 mm) wide

Weight 57 Lbs. ( 26Kg.)

Electrical 90-132 / 180-265 VAC 50-60Hz 10Amp - Switch selectable

Temperature

Humidity 5% to 90% non-condensing

- Full Ginetex Care Symbol set and full NAFTA / ASTM Care Symbol Set

- Fully Scaleable

- All rotations 0°, 90°, 180°, 270°

Including stacker x 18.5" (469.9mm) deep

41°F (5°C) to 104°F (40°C)

Users Manual Model 686 / 686 HT Product Description •••• 17

Other

Features

- Downloading of information while printer is operating

- Sequenced Fields

- Time / Date Stamping

- Life Counts

- Operator adjustable: strobe, cut position, print position, baud rate, and buffer size

- Error Detection of: stock out, ink out, print head open, full stacker, stacker jam, and print

head over-temperature

- Display: labels left to print in a batch, batch ID, total life inches, total life cuts

- Self Diagnostics

- Missed sense mark detection and correction

- Slot, Notches, Hole or Reflective registration detection

Ink Ribbon AVERY DENNISON standard thermal colors and widths

Options - SV-100 Barcode Verifier System

- Rewind Unit

- Reflective Sensor (Back of web)

- PcMate Platinum

- Spare Parts Kit

- International Hardware Kit

18 •••• Product Description Users Manual Model 686 / 686 HT

Printer Operation & Quick Set-Up

Loading Ink

INK ROLLER

(NOT SUPPLIED IN 686 HT)

TRANSFER STOCK

FIXED

TURNBAR

INK UNWIND

TAG STOCK

FIXED

TURNBAR

Figure 5 - Ink Threading Path

The ink ribbon comes packaged in a plastic bag. For best results, leave the ink

ribbon wrapped in this bag until you are ready to use it in the printer. Use the

procedure and diagram above for loading the ink.

1) Unwrap the ink ribbon and put it on the ink-ribbon unwind arbor (See Figure 5)

by pressing it on to the arbor when the three slots are lined up.

ADJUSTABLE

TURNBAR

WEB GUIDE

686

686 HT

PRINTHEAD

ADJUSTABLE

TURNBAR

DRIVE

KNIFE

Users Manual Model 686 / 686 HT Printer Operation & Quick Set-Up •••• 19

2) Make sure the ink ribbon comes off the roll in the direction shown above and is

threaded as illustrated.

NOTE: A new ink ribbon has a leader that makes it easier to use when threading the

ribbon through the print area.

3) Put an empty ink-ribbon take-up core on the ink rewind arbor. The ink take-up

core must be at least as wide as the ink supply. The adhesive on the supply roll

of ink can be used to fasten the leader to the rewind core.

4) Advance the ink until ink starts to wrap around the take-up core.

5) You should rotate the ink arbors to keep excess slack ink from between the print

head and the ink cores.

NOTE: Make sure that the ink-ribbon take-up core and the ink-ribbon supply roll

are against the ink backer plate so that the ink ribbon tracks straight through

the print station.

Loading Stock

TRANSFER STOCK

FIXED

TURNBAR

INK ROLLER

(NOT SUPPLIED IN 686 HT)

INK UNWIND

TAG STOCK

FIXED

TURNBAR

ADJUSTABLE

TURNBAR

FIGURE 6 – Tag Stock / Transfer Threading

Loading Stock for the First Time

1) Adjust the unwind width wider than the roll of stock to be loaded. Set the

ADJUSTABLE

TURNBAR

KNIFE

WEB GUIDE

686

686 HT

PRINTHEAD

DRIVE

stock roll on the unwind - between the guides with the stock unwinding

from the top clockwise. Adjust the unwind width down to the stock size

without clamping the core.

20 •••• Printer Operation & Quick Set-Up Users Manual Model 686 / 686 HT

2) Adjust the web guides to a width wider than the stock.

3) Remove the tape or pull the glued end of the stock loose from the supply

roll of stock. Pull off about 2 feet (.5 m) of stock to thread it through the

printer.

NOTE: If the end of the material was glued down, cut off all material that has

glue on any surface. Do not feed sticky adhesive or rough surfaces

through the printer because they can damage the print head.

4) Open the hinged cover to the printer.

5) When the printer stops, the platen roller under the print head will rotate

open enough to slide the stock through without opening the head assembly.

This has been designed for quick & easy loading without splicing on new

rolls. If for some reason the roller doesn't provide easy passage, open the

print head upper assembly by rotating the knob.

NOTE: Platen roll in 686HT will not rotate open

Decurler / Turnbar

6) Open the print head by turning the knob.

7) After looping the leading edge of the stock over the two-decurler bars, slide

it through the web guides.

8) As the stock exits the web guide, continue to slide the stock through the

print station.

9) Push the stock until it touches the blue roller.

10) Clear all errors on the front panel. Push and hold the upper feed button to

move the stock through the drive, knife, and into the stacker. The bottom

feed button can be used to reverse the stock if necessary.

• 686-HT you must open the feed and push the material through – there

is no feed button

11) Check that the stock is center and tracking straight through the printer.

Adjust as needed.

12) Adjust the web guides on the decurler and web guides down to the edges of

the stock without deforming the stock.

Users Manual Model 686 / 686 HT Printer Operation & Quick Set-Up •••• 21

The 686 / 686 HT printer is equipped with an adjustable turn bar system to allow

optimum adjustment of multiple supplies in an effort to control flatness through the

printer.

The system consists of one large diameter (1.125 Dia.) fixed position roller and two

smaller (.500 Dia.) turnbars. One turnbar is fixed; the other is horizontally

adjustable. Web guide supplies at the start of the roll require less de-curl than

narrow web or end-of-roll supplies. The adjustable roll is equipped with wrench

flats to allow loosening so it can be moved in its mount key slot.

• Web tension is not required on the 686-HT

• By-pass the turnbar shafts to avoid damage to the transfers

Butt Splicing Stock

NOTE: DO NOT RUN BUTT SPLICES THROUGH THE PRINT STATION.

The AVERY DENNISON 686 / 686 HT has been designed so that supplies can be

changed / replenished quickly. Removing the stock trailer remaining in the printer

and re-threading the stock altogether is quicker than butt splicing.

Web Guide Adjustment

The AVERY DENNISON 686 / 686 HT printer has been designed with only three

web guides in the printer that need to be changed as the width of the rolls change

from format to format. None of these adjustments requires any tools.

The first guide is on the unwind itself. A knob located on the front of the unwind

adjusts the width of the guides on the unwind while maintaining center justification.

To increase the width - turn the knob counter clockwise - to decrease the width, turn

the knob clockwise. Adjust the unwind width wider than the roll of stock to be

loaded. Set the stock roll on the unwind between the guides with the stock

unwinding from the top clockwise. Adjust the unwind width down to the stock size

without clamping the core. It is important not to pinch the supply roll: This is a

guide only - not a brake.

The second set of guides is center justified to the left of the print station. Close the

guides to the width of the stock using the adjustment knob. Do not pinch the stock

as it will deform the edges of the tags and can affect print registration.

The only other web guide adjustment is the stacker up-right rails (refer to the Stacker

Adjustments section in this manual). To fine-tune the location of the up-rights,

loosen the knob behind each upright rail and slide the rail in or out as needed. The

up-right rails should be located approximately 1/16" (1.5mm) to the back or front of

the label or tag as it enters the stacker.

22 •••• Printer Operation & Quick Set-Up Users Manual Model 686 / 686 HT

Modified Drive Assembly

The spring loaded drive assembly mounted in the 686 / 686 HT printer has been

modified to prevent it from being left in the “Drive Open” position. In addition the

drive open sensor has been eliminated. The drive can be opened, if necessary, to

clear a jam or remedy other problems, but must be held in the open position.

To aid in threading, the printer is equipped with a button controlled drive system.

The buttons are on the lower right side of the front housing.

To thread the printer, the stock should be pushed through the web guide and

printhead up to and touching the bottom of the blue roller.

Clear all errors on the front panel. Push and hold the upper button to move the stock

through the drive, knife, and into the stacker. The lower button will reverse the stock

if necessary.

Flash Disk Module

The Flash Disk Module contains information that is loaded during power up only.

The Flash Disk Module may also contain logos, fonts, formats, and may even in the

future contain some operating system updates. Logos fonts and formats can be

copied to the Flash Disk Module using PCMCIA manager that is provided with

PcMate Platinum.

Users Manual Model 686 / 686 HT Printer Operation & Quick Set-Up •••• 23

Sensor Adjustment

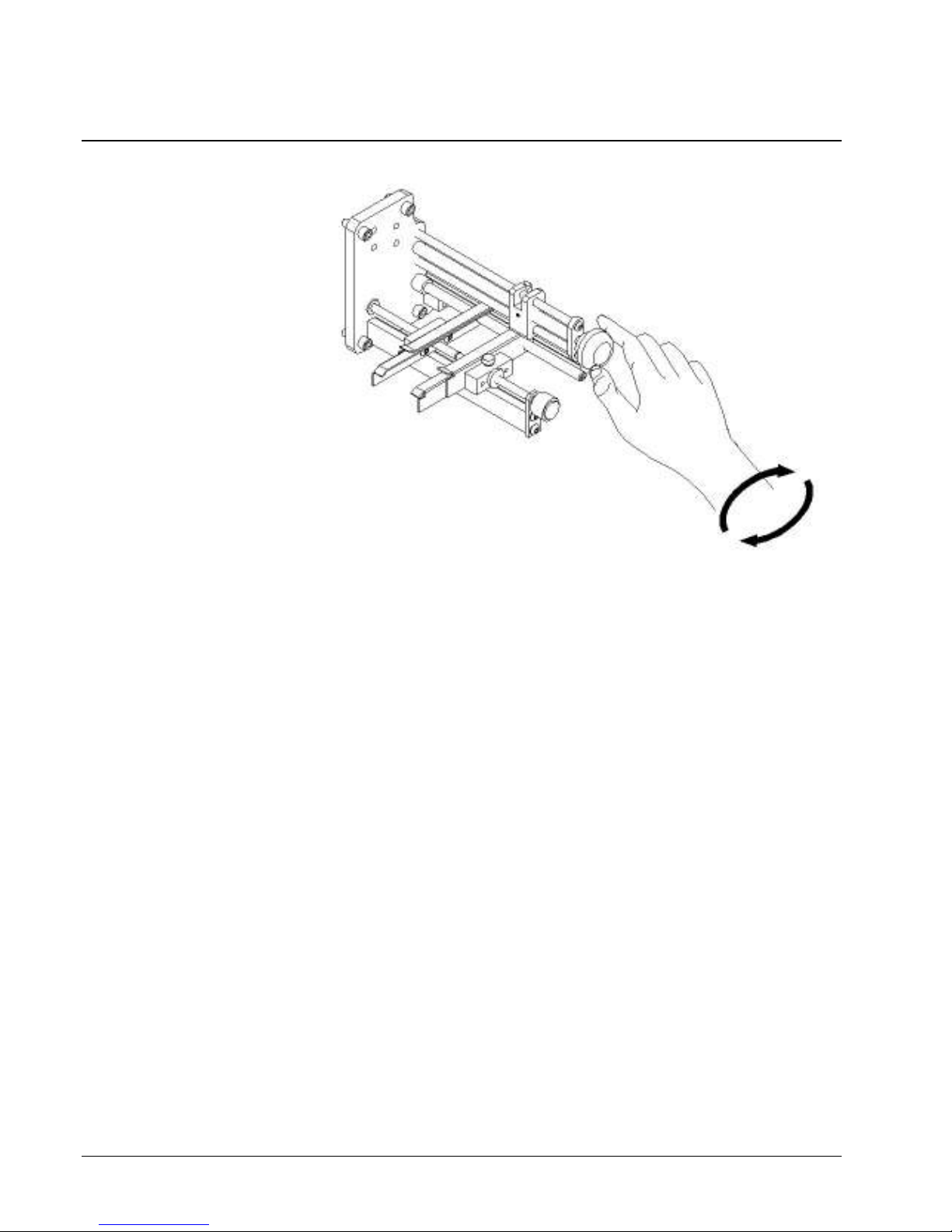

The hole and top reflective registration sensor can be adjusted by turning the knob as

shown above. Move the sensor over the desired registration mark. To ensure the

sensor is in the right location - hold the feed lever open and move the stock back and

forth. If the sensor LED in the front panel flashes as the hole passes through the

sensor - it is in the correct location. If the sensor LED does not flash, readjust the

sensor.

NOTE: The hole and top reflective sensor registration is selected from PC Mate

Platinum in the Design Layout Information.

See "Print Registration Sensor" for more detail.

• The 686-HT uses a top reflective setting in PcMate. The bottom part of the

sensor assembly is blocked with a metal plate for better reflection.

24 •••• Printer Operation & Quick Set-Up Users Manual Model 686 / 686 HT

Ink Guide Adjustment

686

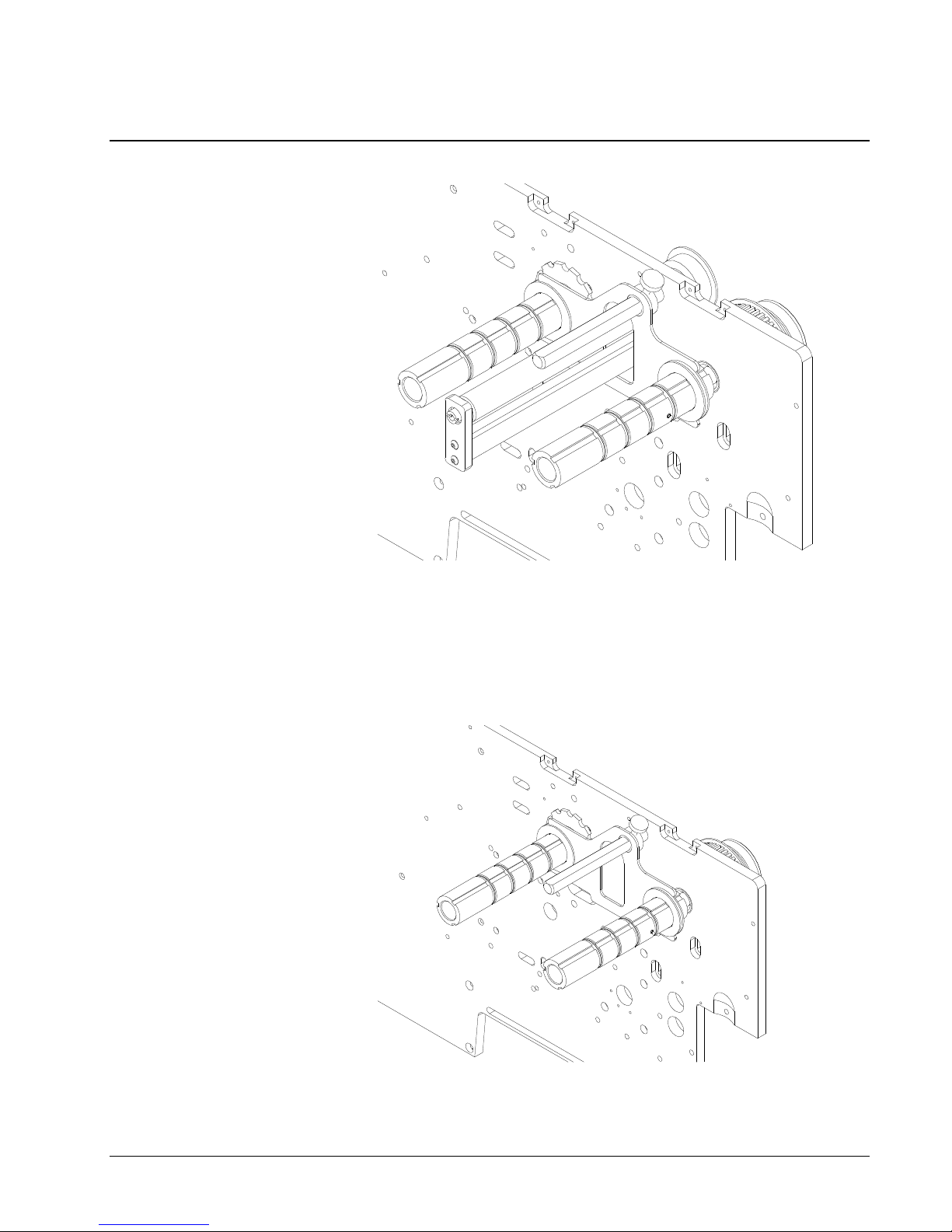

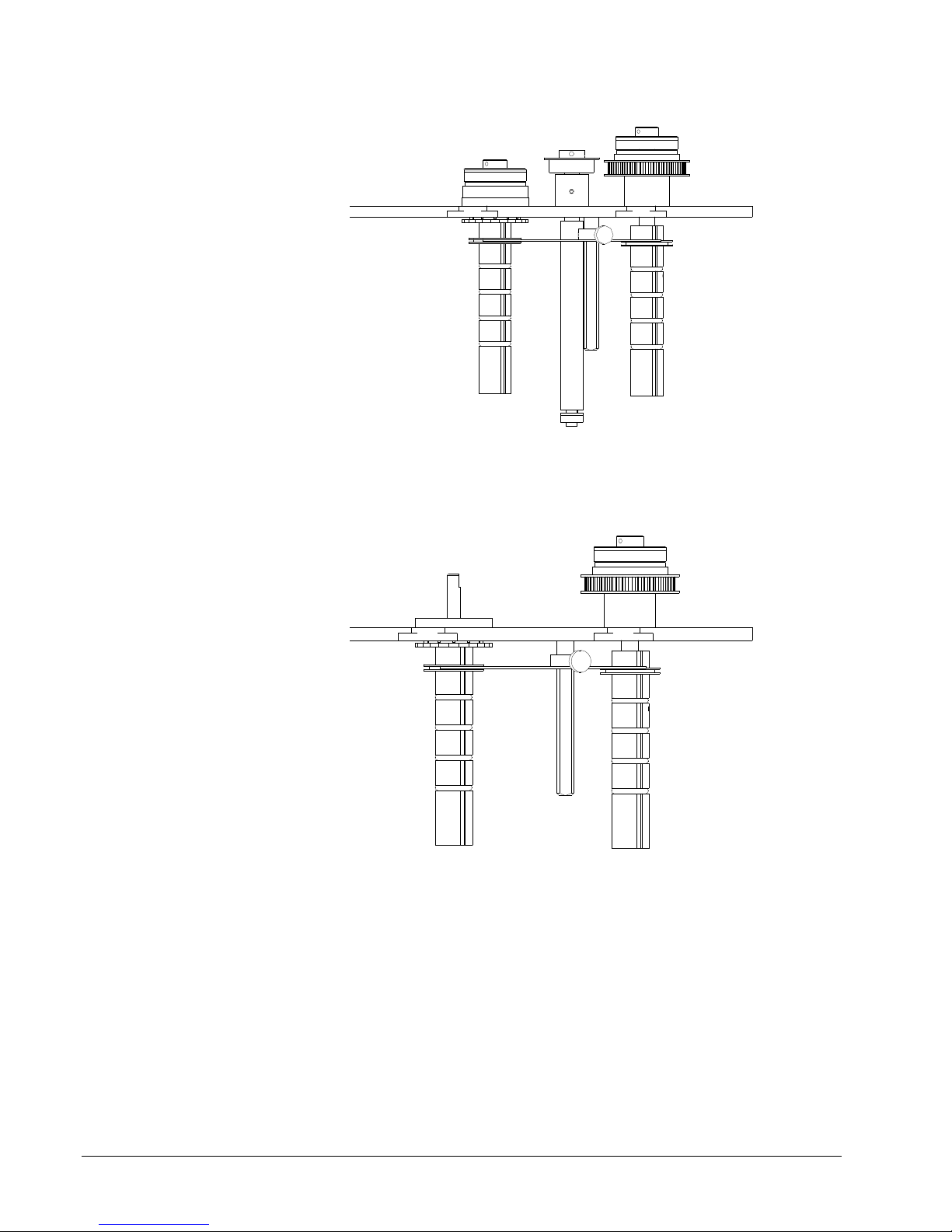

The ink guides on the 686 / 686 HT will move together as shown above and below.

To adjust the guides - loosen the thumbscrew and slide the ink guide into position,

then retighten the thumbscrew.

686 HT

Users Manual Model 686 / 686 HT Printer Operation & Quick Set-Up •••• 25

686

The ink guides must be even with each other in order for the system to work

correctly.

686 HT

26 •••• Printer Operation & Quick Set-Up Users Manual Model 686 / 686 HT

Print Head Operation

The print head module is to be opened and closed for threading the stock and ink.

The head must also be opened to clean the head and for print head replacement.

Later in the manual, under Print Head Cleaning, and Print Head Replacement,

cleaning and replacement will be covered.

The print head has an interlock switch that prevents the printer from running with the

head in the open position. If the head is open the display will read - HEAD OPEN.

WARNING: DO NOT TOUCH THE PRINT HEAD WITHOUT WEARING THE

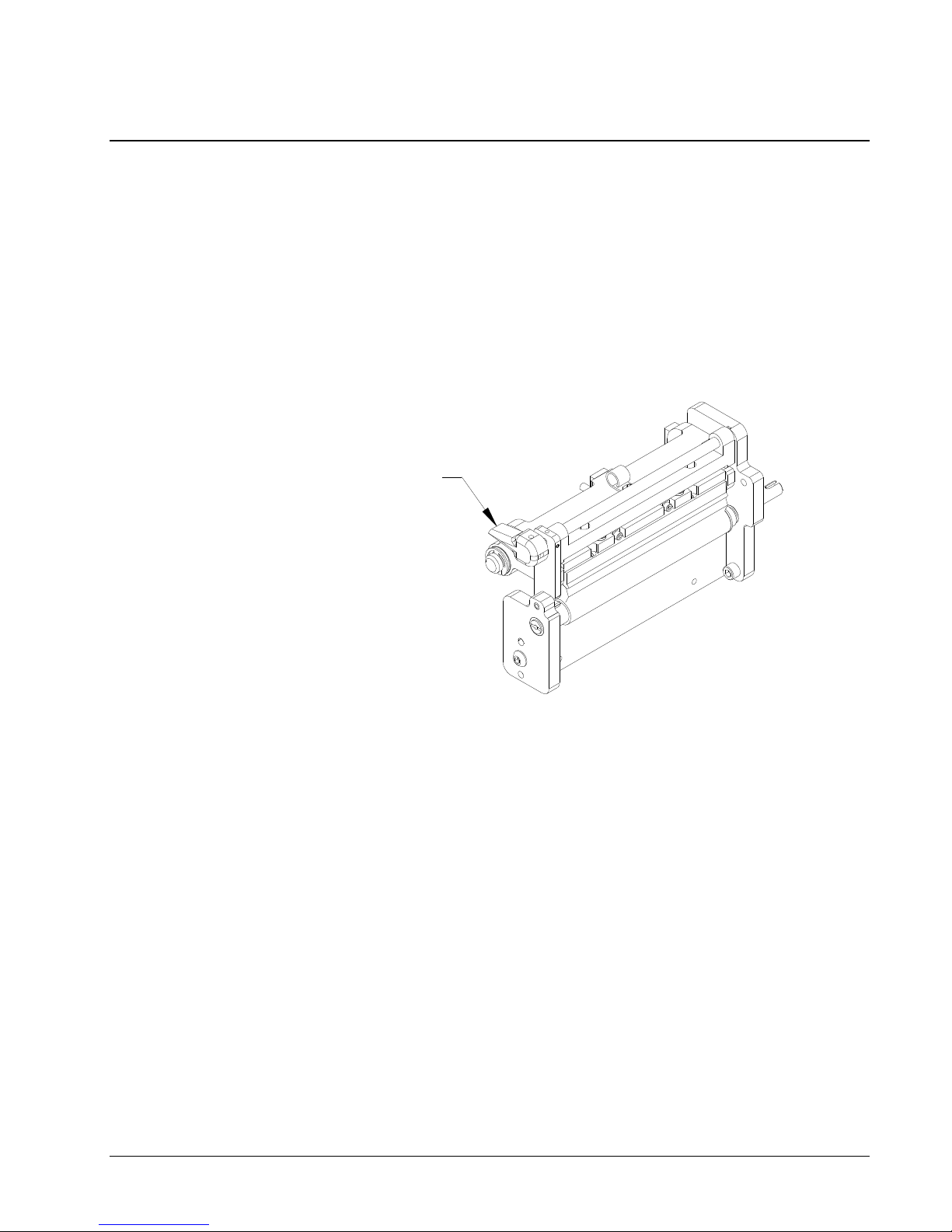

To open the print head for threading supplies, turn knob “A” clockwise and pull out.

(See figure 7).

ANTI-STATIC GLOVES AND THE STATIC WRIST STRAP.

A

Figure 7 - Print Head Operation

To close the head mount plate, pull the knob out and lower the head assembly. Turn

knob “A” counterclockwise to its original position as shown above.

Users Manual Model 686 / 686 HT Printer Operation & Quick Set-Up •••• 27

Control Panel Operation

Control Buttons

Start

- Starts the printer.

- ON LINE light must be GREEN.

(Batches downloaded to be printed)

Feed

- FEED and START must both be used.

- Feed will stop when the buttons are released.

- Labels between the head and knife will be cut and stacked as finished

labels.

- Stock moves through in one continuous strip.

- Stock moves through without printing.

- Ink will not advance; ink save on the 686 / 686 HT will automatically be

activated.

- The print head must be closed.

28 •••• Control Panel Operation Users Manual Model 686 / 686 HT

Loading...

Loading...