FXT 5000 Series Installation Guide

Avere Systems, Inc.

Apr 05, 2018

www.averesystems.com

Part number 0456-004-0171, rev E (electronic version)

Part number 0456-004-0191, rev E (printed version)

CONTENTS

1 Introduction 1

1.1 Cautions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 The FXT 5000 Series Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Avere Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Product Specifications and Requirements 3

2.1 Dimensions and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Power and Thermal Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 FXT 5000 Series Front and Rear Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Precautions for Product Use 9

3.1 Unpacking and Handling FXT Series Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Racked FXT Series Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5 Laser Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.6 Thermal Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.7 Electrostatic Discharge (ESD) Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Installing an FXT 5000 Series Edge Filer Node in a Rack 15

4.1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Removing an FXT 5000 Series Node from a Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Installing and Removing the Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Making Network Connections to the FXT 5000 Series Node 21

5.1 IP Address Requirements and Cluster Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Physical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Connecting Network Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Cable Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.5 Network Connections to the IPMI Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6 Connecting to the Serial Port (if necessary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6 Power Connections for the FXT 5000 Series Edge Filer 29

6.1 Connecting Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 Powering On an FXT 5000 Series Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3 Powering Off an FXT 5000 Series Edge Filer Node . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 Monitoring the FXT 5000 Series Edge Filer 31

7.1 Monitoring System Health . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2 Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 Regulatory Information for FXT 5000 Series Nodes 37

8.1 Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.2 Electromagnetic Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.3 Environmental Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

i

9 EU Declaration of Conformity 39

10 Preparing a Node for Return to Avere Systems 41

11 Copyright and Trademark Information 43

11.1 Copyright Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.2 Trademark Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11.3 Document Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

ii

CHAPTER

ONE

INTRODUCTION

The FXT 5000 Series Installation Guide is written for system administrators who need to install and administer

Avere FXT Edge Filer hardware nodes in an Avere cluster. It assumes that you have a basic knowledge of networked

storage, including planning for and installing networked data storage components in a data center.

1.1 Cautions and Warnings

The following highlights are used in this document:

1.1.1 Precaution Statements Used in this Document

This document uses the following highlights to draw attention to potentially hazardous or undesirable situations:

A warning indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury.

A caution indicates a potentially hazardous situation that, if not avoided, could result in minor or moderate injury.

A notice indicates information considered important, but not related to personal harm or injury.

1.2 The FXT 5000 Series Platform

The FXT 5000 Series platform describes a product line of servers, also called filers or nodes, that run the Avere OS

software.

Each model in the FXT 5000 Series contains and uses multiple types of storage media and high-speed Gigabit

Ethernet data ports (either 25GbE or 10GbE) to support high-bandwidth network traffic. FXT 5000 Series nodes

feature NVRAM to protect written data in the event of a power outage or other failure, and redundant power

supplies.

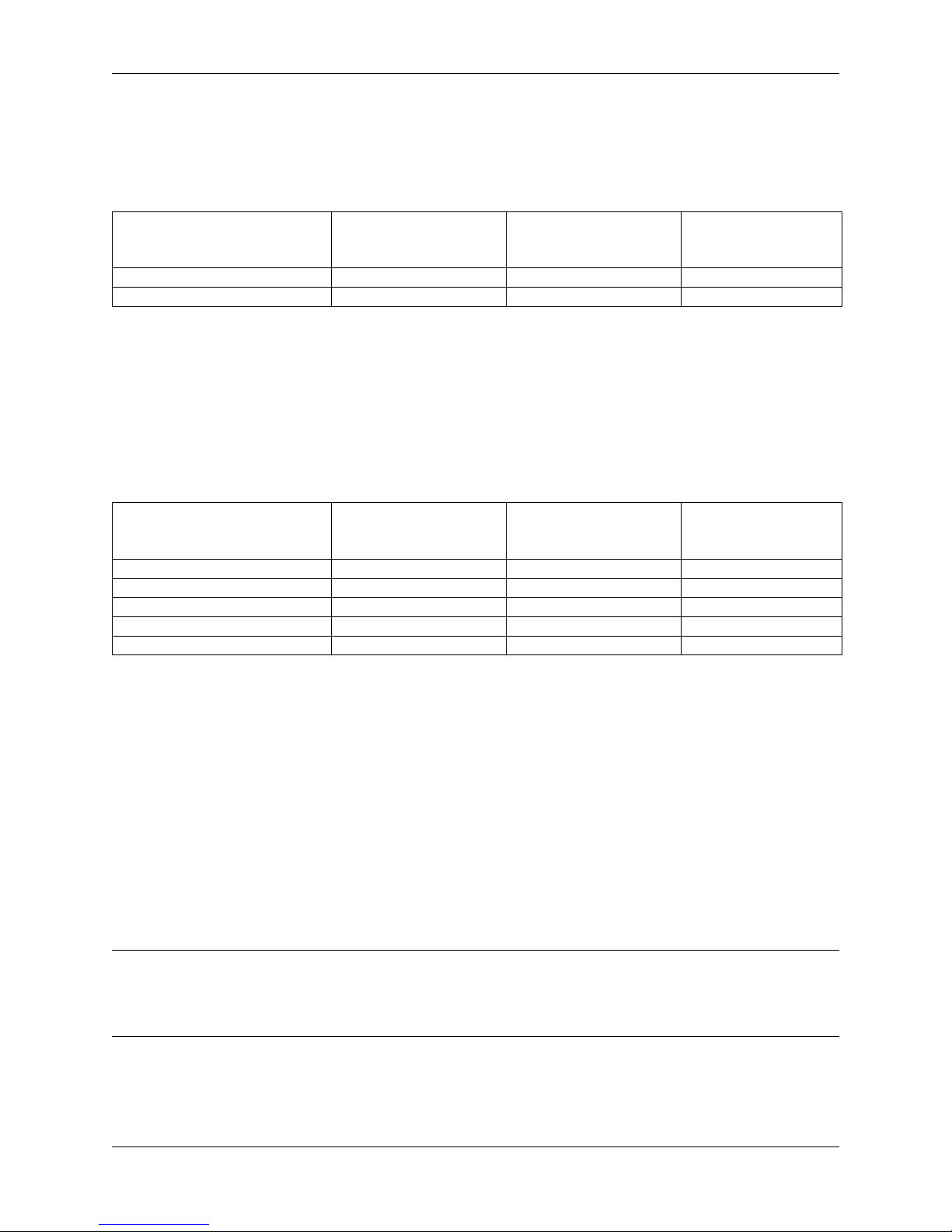

The table below shows the features for each server type.

1

FXT 5000 Series Installation Guide

1.2.1 FXT 5000 Series Specifications

FXT 5200 FXT 5400 FXT 5600 FXT 5850

CPU Cores 16 16 16 16

NVRAM (GB) 4 4 4 4

DRAM (GB) 128 256 384 768

Network Ports 4 10GbE,

4 1GbE

SAS HDD

Capacity

SAS SSD

Capacity

Multiple Avere FXT Edge Filer nodes are configured together to provide an Avere cluster.

Note that the FXT 5000 Series is physically different from the FXT 4000 Series and other older Avere products.

Read Differences from FXT 4000 Series and Earlier Models (page 15) in the rack installation section section to

familiarize yourself with the changes before starting to set up an FXT 5000 Series node.

7.2 TB – – –

– 4.8 TB 9.6 TB 19.2 TB

4 10GbE,

4 1GbE

4 10GbE,

4 1GbE

4 dual-rate 25GbE/10GbE,

4 1GbE

1.3 Avere Documentation

This document explains requirements and precautions for working with FXT 5000 Series hardware, and describes

how to install and set up FXT 5000 Series nodes. This document explains how to install a node in an equipment rack,

the type of network cables to use and how to install them, procedures for applying power and starting up or shutting

down a node, and information about using the chassis’s LED indicators to monitor status and troubleshoot a node.

After following the guidelines in this document, refer to the FXT Cluster Creation Guide

(http://library.averesystems.com/#fxt_cluster) for the software configuration steps to create an Avere cluster

from the hardware nodes you’ve installed.

Here is a quick reference list of other documentation you might find useful in addition to this FXT 5000 Series

Installation Guide. Click the links to visit the http://library.averesystems.com website, where you can download PDF

documents or view online information.

• FXT Cluster Creation Guide (http://library.averesystems.com/#fxt_cluster) - How to create and do the initial

configuration for a production Avere cluster. The cluster creation guide covers the next step after installing and

cabling the hardware according to the instructions in this guide.

• Configuration Guide (http://library.averesystems.com/#operations) - How to configure and administer your

Avere cluster

• Avere Control Panel Dashboard Guide (http://library.averesystems.com/#operations) - How to monitor the

status of your cluster from the Avere Control Panel

• Release Notes (http://library.averesystems.com/#release_notes) - Information about periodic Avere OS

software updates

• FXT 5000 Series Field Service Guide (http://library.averesystems.com/#service) - A technician’s guide to

servicing replaceable parts in the FXT hardware

Additional documentation may be available online - visit http://library.averesystems.com for the most recent

publications.

2 Chapter 1. Introduction

CHAPTER

TWO

PRODUCT SPECIFICATIONS AND REQUIREMENTS

This section gives product specifications and describes requirements for installing and using FXT 5000 Series nodes.

2.1 Dimensions and Specifications

These dimensions apply to each of the FXT 5000 Series models.

2.1.1 FXT 5000 Series Modular Dimensions

Modular Dimensions

The FXT 5000 Series is designed to fit in a standard equipment rack and is one rack unit high.

Height 1U (1.75 inches, 44.5 mm, nominal EIA standard)

Width 19 inches (482.6 mm, nominal EIA standard)

2.1.2 FXT 5000 Series Actual Dimensions

Actual Dimensions

Height 1.7 inches (43 mm)

Width (rack ears) 19.1 inches (485 mm)

Width (main enclosure with slide rails attached) 17.6 inches (447 mm)

Depth (rack ears to main enclosure rear) 27.9 inches (709 mm)

Depth (rack ears to furthest rear protrusion) 28.2 inches (716 mm)

Depth (rack ears to furthest front protrusion, without bezel) 0.9 inches (23 mm)

Depth (rack ears to furthest front protrusion, with bezel) 2.5 inches (64 mm)

2.1.3 FXT 5000 Series Weight

Weight

Gross Weight (includes all packaging) 48 pounds (21.8 kg)

Net Weight (without packaging, including accessories) 39 pounds (17.7 kg)

Node Weight (without packaging, without accessories) 33 pounds (15.0 kg)

3

FXT 5000 Series Installation Guide

2.2 Power and Thermal Specifications

FXT 5000 Series nodes use variable speed fans, so power depends on temperature. Maximum fan speeds are unlikely

to occur even at the highest specified ambient temperature (35° C/95° F). Power and thermal specifications are for a

system using 1+1 redundant power supplies, both supplying power.

2.2.1 FXT Series Nameplate Ratings

Nameplate Ratings for FXT 5000 Series Models

100 - 240 V ac

60 - 50 Hz

9.5 - 4.5 A

2.2.2 FXT 5850 Power and Thermal Measurements

FXT 5850 power at room temperature or at maximum fan speed

FXT 5850 At 22° C (71.6° F) Inlet Temperature At Maximum Fan Speeds

Voltage (V) 100 120 208 230 240 100 120 208 230 240

Frequency (Hz) 60 60 60 50 50 60 60 60 50 50

Current (A) 2.89 2.39 1.41 1.29 1.24 3.57 2.94 1.73 1.57 1.51

Apparent Power (VA) 289 287 293 297 298 357 353 360 361 362

Power Factor 0.99 0.99 0.95 0.95 0.95 0.99 0.99 0.96 0.96 0.96

Real Power (W) 286 284 279 282 283 353 349 345 347 348

Thermal Dissipation

(BTU/Hr)

976 969 951 962 965 1206 1192 1179 1183 1187

2.2.3 FXT 5600 Power and Thermal Measurements

FXT 5600 power at room temperature or at maximum fan speed

FXT 5600 At 22° C (71.6° F) Inlet Temperature At Maximum Fan Speeds

Voltage (V) 100 120 208 230 240 100 120 208 230 240

Frequency (Hz) 60 60 60 50 50 60 60 60 50 50

Current (A) 2.56 2.12 1.30 1.17 1.12 3.29 2.73 1.63 1.46 1.41

Apparent Power (VA) 256 255 270 269 268 329 328 339 336 338

Power Factor 0.99 0.99 0.94 0.93 0.93 0.99 0.99 0.96 0.96 0.95

Real Power (W) 254 252 253 250 249 326 324 325 322 321

Thermal Dissipation

(BTU/Hr)

866 861 865 854 851 1111 1107 1111 1100 1097

4 Chapter 2. Product Specifications and Requirements

FXT 5000 Series Installation Guide

2.2.4 FXT 5400 Power and Thermal Measurements

FXT 5400 power at room temperature or at maximum fan speed

FXT 5400 At 22° C (71.6° F) Inlet Temperature At Maximum Fan Speeds

Voltage (V) 100 120 208 230 240 100 120 208 230 240

Frequency (Hz) 60 60 60 50 50 60 60 60 50 50

Current (A) 2.48 2.06 1.22 1.11 1.06 3.21 2.67 1.56 1.40 1.35

Apparent Power (VA) 248 248 255 255 254 321 320 324 322 324

Power Factor 0.99 0.99 0.94 0.93 0.93 0.99 0.99 0.96 0.96 0.95

Real Power (W) 246 245 240 237 236 318 317 312 309 308

Thermal Dissipation

(BTU/Hr)

839 837 817 809 805 1084 1082 1063 1055 1050

2.2.5 FXT 5200 Power and Thermal Measurements

FXT 5200 power at room temperature or at maximum fan speed

FXT 5200 At 22° C (71.6° F) Inlet Temperature At Maximum Fan Speeds

Voltage (V) 100 120 208 230 240 100 120 208 230 240

Frequency (Hz) 60 60 60 50 50 60 60 60 50 50

Current (A) 2.52 2.09 1.24 1.15 1.10 3.21 2.70 1.59 1.43 1.37

Apparent Power (VA) 252 251 258 265 264 321 324 331 329 329

Power Factor 0.99 0.99 0.94 0.93 0.93 0.99 0.99 0.96 0.96 0.95

Real Power (W) 249 248 242 246 246 318 321 317 316 312

Thermal Dissipation

(BTU/Hr)

851 847 827 839 838 1084 1094 1083 1077 1066

2.2. Power and Thermal Specifications 5

FXT 5000 Series Installation Guide

2.3 FXT 5000 Series Front and Rear Illustrations

These diagrams show the front and rear layouts of FXT 5000 Series nodes. Front views are shown without the

optional bezel.

2.3.1 FXT 5850 Front Illustration

2.3.2 FXT 5600 Front Illustration

2.3.3 FXT 5400 Front Illustration

6 Chapter 2. Product Specifications and Requirements

FXT 5000 Series Installation Guide

2.3.4 FXT 5200 Front Illustration

2.3.5 Rear View of the FXT 5000 Series Models

The FXT 5200, FXT 5400, and FXT 5600 models have the same back layout. The FXT 5850 looks similar, but it

has four 25GbE ports instead of the 10GbE ports on the other models. (The 25GbE ports are also compatible with

10GbE traffic.)

FXT 5850 Rear Illustration

The 25GbE data ports on the rear of the FXT 5850 are also compatible with 10GbE connections.

FXT 5200, FXT 5400, and FXT 5600 Rear Illustration

2.3. FXT 5000 Series Front and Rear Illustrations 7

FXT 5000 Series Installation Guide

2.4 Environmental Requirements

Description Specification

Operating Temperature 10° to 35° C (50° to 95° F), sea level

Non-operating Temperature -40° to 60° C (-40° to 140° F)

Operating Relative Humidity 8% to 90% (noncondensing)

Non-operating Relative Humidity 5% to 95% (noncondensing)

Operating Elevation 0 to 2,000 m (0 to 6,562 ft.)

Ambient temperature is specified at sea level. For altitudes above sea

level, derate 1.0° C per 305 m, or 1.8° F per 1,000 ft., above sea level.

The maximum derated altitude is 2,000 m (6,562 ft.)

Non-operating Elevation 0 to 12,192 m (0 to 40,000 ft.)

8 Chapter 2. Product Specifications and Requirements

CHAPTER

THREE

PRECAUTIONS FOR PRODUCT USE

This section discusses considerations you must take before installing and using Avere FXT Edge Filer nodes.

3.1 Unpacking and Handling FXT Series Equipment

To prevent damage to the Avere FXT Edge Filer or components, carefully unpack and handle the FXT Series node

and related components.

Inspect the boxes the node or component was shipped in and note whether there is any damage. If the shipment

shows evidence of damage, file a damage claim with the carrier that delivered it.

3.1.1 No User-Serviceable Parts

There are no user-serviceable parts in an FXT 5000 Series node. All servicing of FXT 5000 Series

nodes must be performed by trained personnel. Refer to the FXT 5000 Series Field Service Guide

(http://library.averesystems.com/#service) for more information.

3.1.2 Restricted Access

The FXT 5000 Series nodes must be installed in a restricted-access location. A restricted-access location is defined

as a location that can be accessed only by use of a tool, lock and key, or other means of security and is controlled by

the authority responsible for the location.

Anyone entering the restricted-access location, or installing or replacing modules in an FXT 5000 Series node, must

be trained in the potential hazards associated with the FXT 5000 Series node, including but not limited to exposure to

hazardous energy levels when the cover is removed, when modules have been removed, or when modules are being

replaced.

3.1.3 Preventing Condensation

Condensation can occur when exposing a colder product to a warmer and/or more humid environment.

9

FXT 5000 Series Installation Guide

If an item has been moved from an environment that is colder and less humid than the current installation and

operating environment, allow it to reach the same temperature as the current environment before unpacking it, and

before installing it or powering it on.

If you notice condensation on any part of the item, Avere Systems recommends waiting a minimum of 24 hours for it

to acclimate before installation and use.

3.2 Electrical Considerations

This section lists guidelines for safe electrical handling of the FXT 5000 Series node.

3.2.1 Electrical Code Compliance

To avoid the possibility of an electrical shock hazard, the electrical installation of an FXT 5000 Series node and its

associated rack(s) and power distribution units (PDUs) must comply with all applicable local, state, and national

electrical codes and regulations. Contact a qualified electrician if you are unsure about proper electrical installation.

3.2.2 Earth Grounding

• The building site, rack, and PDU electrical receptacles powering the FXT 5000 Series node must be properly

grounded during the lifetime of the installation.

• The earth-ground connection for the rack must be designed and installed specifically for the rack, and must not

rely solely on unintentional grounding connections made through FXT 5000 Series nodes and other equipment

installed into the rack.

• The Avere FXT Edge Filer node has been approved for use only with TN-type earth grounding systems. It has

not been approved for use with IT-type earth grounding systems. Do not connect the node to any non-TN type

of earth grounding system.

• To avoid the possibility of an electrical shock hazard, the FXT 5000 Series node must be properly connected to

earth ground during the lifetime of the installation. The node receives its earth ground connection through the

AC power cords.

To ensure the integrity of the ground connection, observe the following guidelines:

– Use only power cords with a grounding plug.

– Inspect the ground pins of each power cord before initial use.

– Never remove or disable the grounding pin on a power cord or use an adapter that might affect the

integrity of the ground connection.

10 Chapter 3. Precautions for Product Use

FXT 5000 Series Installation Guide

3.2.3 AC Mains Disconnect

• The AC power cords serve as AC mains disconnect for the FXT 5000 Series node and therefore must remain

readily accessible during the lifetime of the installation.

• The FXT 5000 Series node is provided with multiple power cords, and has a power-on/standby type power

switch. This switch does not function as an AC mains disconnect. To disconnect all power for maintenance or

an electrical emergency, remove all power cords.

3.2.4 Power Supply Replacement

The power supply units for FXT 5000 Series nodes have detachable power cords. Disconnect the power cord at the

power supply unit before removing it from the node. When installing a power supply unit, insert the unit into the

node before connecting the power cord.

When running on a single power supply unit, the node has an increased probability of losing all power as a result of

the single unit failing. Always replace a failed power supply unit as soon as possible after failure.

3.2.5 Hazardous Energy Levels

• To avoid potential injury, remove all chains, rings, watches, and other metal jewelry before performing

maintenance on powered-on equipment. Burns and other injuries can be caused by the flow of current through

a metallic object if the metallic object comes in contact with powered circuits.

• When replacing externally accessible components while power is applied to the node, never reach into the

empty space created by the removed components, because hazardous energy levels may be present.

3.3 Racked FXT Series Nodes

To avoid the potential of serious injury and equipment damage, observe the following precautions before installing

nodes into racks or before removing them from racks:

• Ensure that the node’s weight is fully supported by two people at all times while it is being installed into or

removed from a rack.

• The rack installation must be designed to remain stable while supporting the full weight of the installed

equipment in its maximum extended position.

3.3. Racked FXT Series Nodes 11

FXT 5000 Series Installation Guide

• Follow the rack manufacturer’s recommendations and use the appropriate load calculator if available when

designing and installing rack systems.

• Contact the rack manufacturer or an engineering consultant if you require assistance determining the stability

of the rack for its intended purpose.

• For single-rack installations, specify and install stability options such as ballast kits, bolt-down kits, and

extensible or permanent stabilizing mechanisms.

• In multiple-rack installations, specify and install a multirack tie kit option. If the multirack tie kit is not

sufficient to guarantee stability, then install ballast kits, bolt-down kits, and extensible or permanent stabilizing

mechanisms.

• Unless the rack installation is designed otherwise, extend only one piece of equipment from the rack at a time.

• Install the first piece of equipment into the bottom of the rack, with future equipment installed above that.

• For installing multiple pieces of equipment at the same time, first install the heavier equipment at the bottom,

then install the lighter equipment sequentially above that.

• Rack-mounted equipment should not be used as a shelf, work space, step, or seat.

3.4 General Precautions

Observe the following precautions to prevent injury to yourself and damage to the FXT 5000 Series node.

3.4.1 Service Area Clearance

To permit service personnel to perform maintenance procedures on the FXT 5000 Series node, a minimum of 24

inches of clearance must be provided in front of and behind the immediate area being serviced.

3.4.2 California Perchlorate Warning

This product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive

harm.

The following notice is provided in accordance with California Code of Regulations Title 22, Division 4.5 Chapter

33. Best Management Practices for Perchlorate Materials. This product includes a lithium manganese dioxide battery

that contains a perchlorate substance.

Perchlorate Material – special handling may apply. See www.dtsc.ca.gov/hazardouswaste/perchlorate.

12 Chapter 3. Precautions for Product Use

FXT 5000 Series Installation Guide

3.4.3 Two-Person Lift

A bare node without accessories and outer rails weighs 33 pounds (15.0 kilograms). For ease of installation it is

recommended to use two people to lift and install the node into the rack. When lifting a node, handle it in such a way

that the weight is evenly distributed and stabilized. Be sure to comply with any personal lifting limits that may be in

effect for your locale.

3.4.4 Battery Replacement

DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED. REPLACE ONLY WITH THE SAME

OR EQUIVALENT TYPE RECOMMENDED BY THE MANUFACTURER. DISPOSE OF USED BATTERIES

ACCORDING TO THE MANUFACTURER’S INSTRUCTIONS.

ATTENTION: IL Y A DANGER D’EXPLOSION S’IL Y A REMPLACEMENT INCORRECT DE LA BATTERIE,

REMPLACER UNIQUEMENT AVEC UNE BATTERIE DU MÊME TYPE OU D’UN TYPE ÉQUIVALENT

RECOMMANDEÉ PAR LE CONSTRUCTEUR. METTRE AU REBUT LES BATTERIES USAGÉES CONFORMÉMENT AUX INSTRUCTIONS DU FABRICANT.

The motherboard battery maintains clock and CMOS settings when the node is without power for any reason.

Contact Avere Global Services if you suspect that the motherboard battery needs to be replaced.

3.5 Laser Radiation

CLASS 1 LASER PRODUCT

FXT Series nodes that contain optical networking ports may emit invisible laser radiation from those ports. When

no fiber-optic cable is connected, do not stare into the open apertures. In addition, install protective covers over any

optical ports that will not have a cable connected.

3.6 Thermal Considerations

• FXT 5000 Series nodes use front-to-back cooling airflow. If the node is installed in a rack, the installer is

responsible for ensuring that adequate airflow is available through the rack to effectively cool the node.

• Environmental ambient temperature requirements apply to the area immediately around the node. For a node

installed into an enclosed rack or a rack with perforated doors, the ambient temperature requirement applies to

the area inside the rack or door, immediately around the node.

3.5. Laser Radiation 13

FXT 5000 Series Installation Guide

• Operating the FXT 5000 Series node in a rack with open EIA U spaces can cause unintended airflow paths

and associated temperature inconsistencies. To maintain proper airflow and temperatures, cover all open rack

spaces with blank panels.

• Ensure that the node cover is in place when the node is operating to assure proper airflow and cooling.

Thermal damage to the system can occur if this practice is not strictly followed.

• Do not remove disk drives or power supply units unless a replacement component is immediately available.

If you remove a replaceable component, replace it before putting the unit back into service to ensure proper

airflow and cooling. Damage to the system can occur if this practice is not strictly followed.

3.7 Electrostatic Discharge (ESD) Precautions

An ESD event occurs when two objects with different electrical charges come into contact with each other. Electronic devices can be severely damaged by ESD.

When handling electronic modules such as disk drives, printed circuit boards (PCBs), and power supplies, observe

the following basic ESD precautions to prevent damage.

• If possible, perform any maintenance at an approved ESD-safe workstation.

• Do not unpack or install electronic modules without using a properly grounded wrist or heel strap.

• Keep all electronic modules such as power supplies, PCBs, and disk drives in their original ESD-protective

packaging until you are ready to install them. Handle all electronic modules carefully. Do not touch connectors, contacts, or component leads.

• Ensure that electronic modules do not come into contact with insulators such as clothing and plastics.

14 Chapter 3. Precautions for Product Use

CHAPTER

FOUR

INSTALLING AN FXT 5000 SERIES EDGE FILER NODE IN A RACK

This chapter provides safety notices, instructions, and guidelines for installing an FXT 5000 Series node into a

typical square-hole, non-threaded four-post server rack.

4.1 Precautions

To avoid injury and equipment damage, observe the electrical and other cautions listed in Precautions for Product

Use (page 9).

To avoid the potential for serious injury and equipment damage caused by rack tip-over, the equipment rack must be

properly designed and installed.

These instructions are for installing an Avere FXT 5000 Series node into a typical four-post server rack. Every

effort has been made to supply the most accurate instructions possible. However, rack designs can vary greatly from

model to model and from manufacturer to manufacturer. Because Avere Systems cannot anticipate every known rack

design, the installer assumes the following responsibilities:

1. The installer must determine if the instructions provided apply to the installer’s specific rack.

2. The installer must determine whether or not the instructions provided will result in a safe rack installation in

the installer’s specific rack.

If there is any doubt about the applicability or safety of using the provided instructions, do not proceed. Immediately

contact Avere Global Services, the rack manufacturer, or both for assistance.

In addition to the information provided by Avere Systems, also refer to the installation and safety instructions that

came with the rack unit that you are using. If there is any conflicting information, do not proceed. Immediately

contact Avere Global Services, the rack manufacturer, or both for assistance.

4.1.1 Differences from FXT 4000 Series and Earlier Models

The physical design of the FXT 5000 Series node is significantly different from earlier Avere products like the FXT

4000 and 3000 series:

• The node height of the FXT 5000 Series is 1U instead of 2U.

• Rail assemblies are different in the FXT 5000 Series, and different installation steps are required.

• Inner rails on the FXT 5000 Series do not extend the full length of the node’s chassis. The back of the node

must be supported when removing it from a rack. Read Removing an FXT 5000 Series Node from a Rack

(page 17) to learn how to safely extract a node.

15

FXT 5000 Series Installation Guide

• Several connectors and ports are different from previous systems, and some are installed in a different

orientation than they were in other Avere Systems products.

Even if you have previously worked with Avere FXT systems, be sure to read the instructions here before attempting

to install an FXT 5000 Series filer.

4.2 Rack Installation

These instructions are for installing an FXT 5000 Series node in a square-hole, non-threaded, four-post server rack.

For any other type of installation, contact Avere Global Services.

The FXT 5000 Series ships with two snap-together outer rail assemblies. Inner rails are pre-installed on the sides of

the node chassis.

Installation steps include:

• Assembling the rails

• Attaching the rails to the server rack

• Sliding the FXT 5000 Series node into the rails in the rack

Read the detailed instructions below before beginning the process.

4.2.1 Tools

No tools are required to install the FXT 5000 Series node in a standard rack. However, if your rack is not pre-marked

with rack unit measurements, you might want the following tools for setting the rail height:

• A tape measure to find holes at the correct height on each corner of the rack where the rails should be installed

• A marker, grease pencil, or other means to mark the holes on the rack where the rails should be installed

4.2.2 Assembling the Rails

The left and right outer rails for the FXT 5000 Series are identical. Follow these instructions to assemble the slide

rails.

1. Find the four rail pieces included in the package with the node. There are two identical short pieces and two

identical long pieces.

2. Join the short and long rail pieces by latching the t-shaped fastener in the center of the short piece into the

keyhole slot in the center of the long piece:

(a) Locate the protruding circular T fastener (resembling a nail head) in the center channel of the shorter

piece.

(b) Position the short piece, fastener facing up, underneath the long piece. (The concave surfaces should nest

together.)

(c) Align the circular head of the fastener on the short piece with the circular hole on the long piece.

(d) Set the fastener inside the hole, and slide the shorter piece down the keyhole slot to latch the two

together.

Repeat this procedure for the second set of rails.

16 Chapter 4. Installing an FXT 5000 Series Edge Filer Node in a Rack

FXT 5000 Series Installation Guide

4.2.3 Attaching the Rails to the Rack

After assembling the slide rails, install them in the equipment rack:

1. Decide where to install the rails for your FXT 5000 Series node. If necessary, use a tape measure and marker

to identify the same set of holes on each of the four corners.

2. Locate the FRONT and BACK markings on each rail. Use these to position the rails appropriately in the rack.

3. Set the square pegs on the front of one of the rails into the appropriate holes in the rack. Apply pressure from

the front until the latch behind the pegs engages.

4. Repeat this step to latch the back of the rail into the appropriate holes in the rack.

5. Repeat steps 3 and 4 with the remaining rail on the other side of the rack.

4.2.4 Placing the Node in the Rack

A bare node without accessories and outer rails weighs 33 pounds (15.0 kilograms). For ease of

installation it is recommended to use two people to lift and install the node into the rack. When lifting

a node, handle it in such a way that the weight is evenly distributed and stabilized. Be sure to comply

with any personal lifting limits that may be in effect for your locale.

To install the node in the rack:

1. Make sure that the rails are correctly installed and secure in the rack slots.

2. Align the rails attached to the side of the node chassis with the rails at the front of the rack.

3. Slide the node into the outer rails, maintaining equal pressure on both sides.

4. As the node slides into the rack, you should hear a click when the safety latches engage. There is one latch on

each side.

(a) Verify that the safety latches operate properly by pulling the node forward and making sure that it stops

in its fully extended position.

(b) Verify that the rack and rail installation can safely hold the node’s weight in the extended position.

5. Slide the node into its final position in the rack.

6. To secure the node from sliding out of the rack, tighten the captive screws at the front of each rail.

4.3 Removing an FXT 5000 Series Node from a Rack

The inner rails on the FXT 5000 Series node chassis do not extend completely to the back of the chassis.

After disengaging the side locks, it is possible to completely pull the node out of the rack and off the

rails.

To avoid possible injury and equipment damage, always support the node completely after disengaging

the safety locks.

4.3. Removing an FXT 5000 Series Node from a Rack 17

FXT 5000 Series Installation Guide

The FXT 5000 Series comes with locking rails that allow the node to be pulled forward, partially out of the rack, in

preparation for removal.

To slide the node out to its extended position:

1. Loosen the captive screws at the front of each rail.

2. Slide the node forward until the latches on each side engage, stopping the chassis from moving forward.

To remove the node from the rack completely:

1. Follow steps 1 and 2 above to put the node into the locked extended position.

2. Locate the black plastic latches on the sides of the inner rails, and disengage them.

CAUTION: There is only one set of locks on the rack slides. After these locks are disengaged, the node can

slide off the outer rail and be unsupported. Always fully support the node from the front and back when locks

are disengaged.

Disengage the locks by pushing the long lever up or down, depending on the orientation of the lock. If

standing in front of the rack, the latch on the left side releases by pushing the lever up, and the latch on the

right side releases by pushing the lever down.

3. Make sure that the node is fully supported by two people.

4. Carefully slide the node farther out until the inner rails slide out of the rack. The inner rails extend only

19 inches (48 centimeters), which is about two thirds of the depth of the chassis, so be alert for the rails to

disengage.

4.4 Installing and Removing the Front Bezel

This section provides instructions for installing or removing the FXT 5000 Series’ front bezel (faceplate). Installing

the bezel is optional.

The front bezel hides some indicator lights, including the power status indicator, and it prevents access to the node’s

power button. If you do not plan to power on the node immediately after installation, consider waiting to install the

bezel until after the node is up and running.

To install the front bezel:

1. Position the bezel with the decorative face outward and the latch to the left.

2. Hold the left side of the bezel away from the chassis and insert the two pins on the right side of the bezel into

the holes located on the node’s right side rack mount flange.

3. Press the bezel’s latch to the right to retract the two locking pins on the bezel’s left side.

4. Move the left side of the bezel into position so that the entire faceplate is flush with the node’s front panel.

5. Release the latch so that the two locking pins on the latch engage with the holes in the left side rack mount

flange. If the pins do not engage fully, adjust the bezel’s position. Make sure that it is pressed against the face

of the node chassis.

6. Pull on the bezel to test that it is correctly attached.

7. To ensure the bezel remains securely attached under all conditions, locking the bezel is recommended. Use the

key provided in the accessory kit.

18 Chapter 4. Installing an FXT 5000 Series Edge Filer Node in a Rack

FXT 5000 Series Installation Guide

To remove the front bezel:

1. If necessary, unlock the front bezel with the key provided in the accessory kit.

2. Press the latch tabs on the left side of the bezel to the right and gently pull the bezel, left to right, from the

node.

4.4. Installing and Removing the Front Bezel 19

FXT 5000 Series Installation Guide

20 Chapter 4. Installing an FXT 5000 Series Edge Filer Node in a Rack

CHAPTER

FIVE

MAKING NETWORK CONNECTIONS TO THE FXT 5000 SERIES

NODE

This section describes the network connections required for an FXT 5000 Series Edge Filer node. For information on configuring the cluster to use the network infrastructure described in this section, see the

FXT Cluster Creation Guide (http://library.averesystems.com/#fxt_cluster) and the Configuration Guide

(http://library.averesystems.com/#operations).

The USB, VGA, and serial ports are designated and compliance-tested only for locally attached devices. To maintain

compliance, use shielded cables with maximum cable lengths of 3m (9.8 feet) when connecting to these ports.

5.1 IP Address Requirements and Cluster Configuration

Each node will require at least one IP address in order to participate in an Avere cluster. However, setting up and

configuring IP addresses is done through the Avere Control Panel after the nodes have been installed. Refer to the

prerequisites section of the FXT Cluster Creation Guide (http://library.averesystems.com/#fxt_cluster) for more

information about networking requirements.

5.2 Physical Connections

Each FXT 5000 Series node includes the following network ports:

• Four high-speed optical data ports, provided by two dual-port Ethernet adapters:

– The FXT 5850 has four 25GbE ports, which are dual-rate ports that also are compatible with 10GbE

traffic.

– The FXT 5200, FXT 5400, and FXT 5600 models each have four 10GbE ports.

• Four 1GbE ports, provided by the network adapter on the motherboard riser

The high-speed data ports are equipped with SFP+ or SFP28 connectors and optical modules. (The optical module

must be removed if you want to use copper cable in these ports, as described below in Removing SFP+ or SFP28

Optical Modules (page 22).)

21

FXT 5000 Series Installation Guide

5.2.1 Removing SFP+ or SFP28 Optical Modules

Each of the 10GbE and 25GbE ports on all FXT 5000 Series nodes comes with an SFP+ or SFP28 optical module

pre-installed. (10GbE ports come with SFP+ modules, and the 25GbE ports on the FXT 5850 come with SFP28

modules.)

If you are using copper twinaxial cable with these ports instead of optical cables, you must remove the optical

module.

To remove the optical module from a 10GbE or 25GbE port:

1. Locate the metal latching handle at the bottom of the connector.

2. Use your fingers or a nonconductive tool to gently pull the handle upward and out.

3. Use the handle to pull the module out of the chassis.

4. If the module does not slide out easily, try pushing the module in to loosen it. Pulling with excessive force can

break the handle, and using hand tools on the module can damage the module and the boards.

If a module becomes stuck in the chassis, refer to the instructions for extracting stuck modules in the FXT 5000

Series Field Service Guide (http://library.averesystems.com/#service). If necessary, contact Avere Global Services

for assistance.

5.3 Connecting Network Cables

Connect the FXT 5000 Series node to your network by using the appropriate cables and interfaces for your hardware

model and network type, described in the tables below.

Note that the FXT 5850 has different cabling requirements because it uses 25GbE/10GbE dual rate ports instead of

the standard 10GbE ports used in the other FXT 5000 Series models.

22 Chapter 5. Making Network Connections to the FXT 5000 Series Node

5.3.1 Network Cable Types - FXT 5850

Port (quantity) Cable and Connector Type Notes

25GbE/10GbE Dual

Rate (4)

Connecting to a 25GbE network:

Use one of the following for each port:

• Optical cable with duplex LC

connectors

Read Guidelines for 25GbE Optical

Cables (page 25).

• 25GbE SFP28 direct-attach copper

twinaxial cable Read Guidelines for

25GbE Copper Cables (page 25).

Connecting to a 10GbE network:

Use one of the following for each port:

• Optical cable with duplex LC

connectors

Read Guidelines for 10GbE Optical

Cables (page 25).

• 25GbE SFP28 or 10GbE SFP+

direct-attach copper twinaxial cable.

Read Guidelines for 25GbE Copper

Cables (page 25) or Guidelines for

10GbE Copper Cables (page 26) for

details.

If using copper cable, remove the optical

modules (instructions above (page 22))

Cabling notes for dual-rate ports:

FXT 5000 Series Installation Guide

• 25GbE SFP28 direct-attach copper

twinaxial cables are backward

compatible with 10GbE SFP+ directattach copper twinaxial cables.

25GbE SFP28 direct-attach cables

can run at both 25GbE and 10GbE

port speeds.

• 10GbE SFP+ direct-attach copper

twinaxial cables are not forward

compatible with 25GbE SFP28

direct-attach copper twinaxial cables.

If you use 10GbE SFP+ cables with

the dual-rate 25GbE/10GbE ports,

the port speed will be limited to

10GbE.

• For full 25GbE port speed, 25GbE

SFP28 direct-attach cables must be

used.

Connecting to a 10/100/1000- Base-T

network:

These ports are not used.

1GbE (4) Connecting to a 10GbE network:

These ports are not used.

Connecting to a 10/100/1000- Base-T

network:

Use Cat3 or Cat5 cable consistent with

Guidelines for 1GbE Copper Cables

(page 26).

5.3. Connecting Network Cables 23

FXT 5000 Series Installation Guide

5.3.2 Network Cable Types - FXT 5200, FXT 5400, FXT 5600

Port (quantity) Cable and Connector Type Notes

10GbE (4) Connecting to a 10GbE network:

Use one of the following for each port:

• Optical cable with duplex LC

connectors

Read Guidelines for 10GbE Optical

Cables (page 25).

• SFP+ direct-attach copper twinaxial

cable

Read Guidelines for 10GbE Copper

Cables (page 26).

Connecting to a 10/100/1000- Base-T

network:

These ports are not used.

1GbE (4) Connecting to a 10GbE network:

These ports are not used.

Connecting to a 10/100/1000- Base-T

network:

Use Cat3 or Cat5 cable consistent with

Guidelines for 1GbE Copper Cables

(page 26), below.

If using copper cable, remove the optical

modules (instructions above (page 22))

5.4 Cable Guidelines

This section shows the recommended standards for optical or copper cables used with the various ports in an FXT

5000 Series node.

Click the links to jump to specific sections:

• Optical Cables:

– Guidelines for 25GbE Optical Cables (page 25)

– Guidelines for 10GbE Optical Cables (page 25)

• Copper Cables:

– Guidelines for 25GbE Copper Cables (page 25)

– Guidelines for 10GbE Copper Cables (page 26)

– Guidelines for 1GbE Copper Cables (page 26)

24 Chapter 5. Making Network Connections to the FXT 5000 Series Node

FXT 5000 Series Installation Guide

5.4.1 Guidelines for 25GbE Optical Cables

This table shows the specifications and operating range for optical cables used with the FXT 5850 at the 25 Gigabit

Ethernet data rate.

Fiber Type Overfilled Launch

(OFL) Bandwidth at

850 nm (MHz*km)

50/125 𝜇m OM3/M5E MMF 1500 2000 2 to 70

50/125 𝜇m OM4/M5F MMF 3500 4700 2 to 100

Effective Modal

Bandwidth (EMB)

at 850 nm (MHz*km)

Operating Range

(meters)

5.4.2 Guidelines for 10GbE Optical Cables

This table shows the specifications and operating range for optical cables used with the FXT 5200, FXT 5400, FXT

5600, and FXT 5850 at the 10 Gigabit Ethernet data rate.

10GbE Optical Cable Guidelines

Fiber Type Overfilled Launch

(OFL) Bandwidth at

850 nm (MHz*km)

62.5/125 𝜇m MMF 160 N/A 2 to 26

62.5/125 𝜇m OM1/M6 MMF 200 N/A 2 to 33

50/125 𝜇m MMF 400 N/A 2 to 66

50/125 𝜇m OM2/M5 MMF 500 N/A 2 to 82

50/125 𝜇m OM3/M5E MMF 1500 2000 2 to 300

Effective Modal

Bandwidth (EMB)

at 850 nm (MHz*km)

Operating Range

(meters)

5.4.3 Guidelines for 25GbE Copper Cables

When using 25GbE copper twinaxial cables with the FXT 5850 25GbE ports, the cables must meet these requirements to provide full 25GbE port speed:

• Use SFP28 direct-attach cables.

• Only passive type cables are supported. Active twinax and active optical cables (AOC) are not supported.

• For passive cables, the maximum length is 5 meters (16.4 feet).

• Cables must comply with SFF-8431 v4.1 and SFF-8472 v10.4 specifications.

• The cable’s SFF-8472 physical device identifier value must be 03h (SFP or SFP+). The value can be verified

with the cable manufacturer.

Note: 10GbE SFP+ direct-attach copper twinaxial cables are not forward-compatible with 25GbE SFP28 directattach copper twinaxial cables. 10GbE SFP+ cables can be used with the dual rate 25GbE/10GbE ports in the FXT

5850, but the port speed will be limited to 10GbE. To obtain full 25GbE port speed, you must use 25GbE SFP28

direct-attach cables.

5.4. Cable Guidelines 25

FXT 5000 Series Installation Guide

5.4.4 Guidelines for 10GbE Copper Cables

When using 10GbE copper twinaxial cables with FXT 5000 Series 10GbE ports (either the 10GbE ports in the FXT

5200/5400/5600 models or the dual rate 25GbE/10GbE ports in the FXT 5850), make sure that the cables meet these

requirements:

• Use SFP+ direct-attach cables.

• Only passive type cables are supported. Active twinax and active optical cables (AOCs) are not supported.

• The maximum length for passive cables is 7 meters (23 feet).

• Cables must comply with SFF-8431 v4.1 and SFF-8472 v10.4 specifications.

• The cable’s SFF-8472 physical device identifier value must be 03h (SFP or SFP+). The value can be verified

with the cable manufacturer.

Note: 25GbE SFP28 direct-attach copper twinaxial cables are backwards compatible with 10GbE SFP+ directattach copper twinaxial cables. 25GbE SFP28 direct-attach cables can run at both 25GbE and 10GbE port speeds.

5.4.5 Guidelines for 1GbE Copper Cables

This table shows requirements for copper twisted pair cabling used with the FXT 5000 Series 1GbE ports.

1GbE Ethernet Cable Guidelines

Port Mode Cable Specification

10BASE-T Cat3 or higher, 100 m maximum length

100BASE-TX Cat5 or higher, 100 m maximum length

1000BASE-T Cat5 or higher, 100 m maximum length

5.5 Network Connections to the IPMI Port

Each model in the FXT 5000 Series has a 1Gb Intelligent Platform Management Interface (IPMI) port for emergency

node management.

Because IMPI is able to bypass the operating system and interact directly with platform hardware, Avere Systems

recommends using the following security strategies when connecting and configuring the IPMI port:

• Connect IPMI ports to a network that is physically separated from the data network used to access the cluster.

• Change the default IPMI administrator password on each node at installation time. Use a web browser to

navigate to the node’s IPMI port IP address and use the provided interface to modify the user configuration.

• The default IPMI port configuration uses DHCP for IP address assignment. Ensure that the DHCP environment is well protected and that connectivity is restricted between DHCP clients and the DHCP server. (You

can change the nodes’ IPMI address configuration method from the Avere Control Panel after creating the

cluster.)

The IPMI port does not require a high-speed network; a 100 Mbps or 1GbE connection is sufficient for troubleshooting and emergency node administration.

26 Chapter 5. Making Network Connections to the FXT 5000 Series Node

FXT 5000 Series Installation Guide

5.6 Connecting to the Serial Port (if necessary)

For diagnostic purposes, Avere Global Services might instruct you to connect a terminal to a node’s serial port to

access the console locally.

To attach the console:

1. Locate the serial (COM1) port on the rear of the appropriate FXT 5000 Series node. (For a diagram of the

ports, consult the rear view illustration (page 7) in Product Specifications and Requirements (page 3).)

2. Use a null modem cable to connect the COM1 serial port to a terminal configured for ANSI-115200-8N1.

3. Log in to the console and perform additional steps as directed by Avere Global Services.

5.6. Connecting to the Serial Port (if necessary) 27

FXT 5000 Series Installation Guide

28 Chapter 5. Making Network Connections to the FXT 5000 Series Node

POWER CONNECTIONS FOR THE FXT 5000 SERIES EDGE FILER

This section describes the power connections required for an FXT 5000 Series Edge Filer node.

Review the cautions and warnings in Precautions for Product Use (page 9) and verify that proper steps

have been taken before connecting the FXT 5000 Series node to a power source.

6.1 Connecting Power Cables

To connect power cables to an FXT 5000 Series node:

1. Locate the AC power cords in the accessory kit that came in the node’s carton. If you received the incorrect

type of power cords, contact Avere Global Services.

2. Make that both power supply units (PSUs) are fully seated in the node.

CHAPTER

SIX

3. Attach an AC power cord to each PSU AC inlet on the node.

4. Attach the plug of each AC power cord to a power receptacle of the appropriate voltage and capacity.

Tip: To take full advantage of PSU redundancy, attach the AC power cords to different power branch circuits.

6.2 Powering On an FXT 5000 Series Node

To turn on the node:

1. If required, unlock the node’s front bezel by using the key provided in the accessory kit.

2. Remove the bezel by pressing the latch on the left-hand side of the bezel to the right and gently pulling the

bezel, left to right, from the node.

3. Press the power button. The “Power” LED is illuminated green when power is being supplied normally to the

node.

4. Optionally, replace and lock the front bezel.

29

FXT 5000 Series Installation Guide

6.3 Powering Off an FXT 5000 Series Edge Filer Node

To avoid potential data corruption, always use the Avere Control Panel software to shut down an FXT 5000 Series

filer.

In an electrical emergency, disconnect all power from the node by removing all power cords or by

operating the emergency power disconnect mechanism installed for the node.

6.3.1 Normal Shutdown

To power off an FXT 5000 Series node:

1. Log in to the Avere Control Panel.

2. Click the Settings tab, then click FXT Nodes in the Cluster section to load the FXT Nodes page.

3. Locate the node that you want to power off from the listing of nodes and click its Power down button on the

page.

4. Wait a few moments for the node to shut down.

Except when instructed by Avere Global Services, do not use the physical Power button on the front

of the FXT 5000 Series node to power off the node. Using the physical power control button can

potentially result in lost or corrupted data.

30 Chapter 6. Power Connections for the FXT 5000 Series Edge Filer

CHAPTER

SEVEN

MONITORING THE FXT 5000 SERIES EDGE FILER

This section explains how to monitor an FXT 5000 Series node and describes the meanings of the node’s status

lights.

7.1 Monitoring System Health

For general system monitoring, view the Avere Control Panel’s Dashboard tab, as described in the Avere Control

Panel Dashboard Guide (http://library.averesystems.com/#operations).

7.2 Status LEDs

This section describes the meanings of the LEDs on the FXT 5000 Series nodes. See FXT 5000 Series Front and

Rear Illustrations (page 6) for LED locations.

7.2.1 Front Panel: SAS Drive LEDs

LED Name State Meaning Action (if applicable)

Activity LED Unlit Drive is not installed

or

The unit is not powered on

Solid blue Drive is installed N/A

Blinking blue Drive is active N/A

Locate/Fail

LED

Unlit Normal state N/A

Solid red Drive has failed Check the management interface for a

Blinking red

four times per

second (4 Hz)

Drive locate function has been

activated

or

Drive has failed

Check for proper drive installation or

power on the unit

failed drive alert. Use the information

provided in the alert and follow instructions

in the FXT 5000 Series Field Service Guide

(http://library.averesystems.com/#service)

to replace the failed drive.

Turn off the LED by deactivating the drive

locate function

or

Check the management interface for a

failed drive alert. Use the information

provided in the alert and follow instructions

in the FXT 5000 Series Field Service Guide

(http://library.averesystems.com/#service)

to replace the failed drive.

31

FXT 5000 Series Installation Guide

7.2.2 Front Panel: Control Panel LEDs

LED Name State Meaning Action (if applicable)

Information

LED

1GbE port

activity/link

LEDs (e0a,

e0b)

SATA drive

activity LED

Power LED Unlit Neither power supply is

Unlit Normal state (no information to

report)

Solid red The node is overheated Check the ambient room temperature and

Blinking

red once per

second (1Hz)

Blinking red

once every

four seconds

(0.25Hz)

Unlit The port is not linked Check networking cables and associated

Blinking

green

Solid green The port is linked but there is

Not used - there are no SATA connected drives in the FXT 5000 Series

Solid green Unit is powered on and power

Fan failure Check the management interface for a

Power failure Check that all power supplies are fully

The port is linked and there is

network activity

no network activity

receiving AC power,

or

At least one power supply is is

receiving power but the unit is

powered off

is being supplied to at least

one of the node’s power supply

units

N/A

improve cooling if needed. If the room

temperature is within normal operating

range, contact Avere Global Services.

failed fan alert message. Use the information in the alert and follow instructions in

the FXT 5000 Series Field Service Guide

(http://library.averesystems.com/#service)

to replace the failed fan.

seated and that power cords are correctly

installed. Ensure that AC power is being

applied to the power supply. Reseat, install

cords, and/or apply power as required.

Check the power supply LEDs and the

management interface for a failed power

supply alert. Use the information in

the alert and follow instructions in the

FXT 5000 Series Field Service Guide

(http://library.averesystems.com/#service)

to replace the failed power supply.

Ethernet switch ports. Replace or reconnect

cable as required and/or enable the switch

port.

N/A

N/A

Check that at least one power supply has

AC power

Power the unit on by pressing the front

panel power switch or by using the

management interface

N/A

32 Chapter 7. Monitoring the FXT 5000 Series Edge Filer

FXT 5000 Series Installation Guide

7.2.3 Front Panel: Unit Identifier LED

LED Name State Meaning Action (if applicable)

Unit Identification (UID)

LED

(within the UID button)

Unlit Normal state (unit identification has

not been activated)

Solid blue Local UID has been activated by

pressing the UID button on the front

panel

Blinking blue Remote UID has been activated from

the IPMI remote web interface

N/A

Push the UID button

again to turn off the light

Turn off the LED by

deactivating remote UID

in the IPMI web interface

7.2.4 Rear Panel: Power Supply LEDs

LED Name State Meaning Action (if applicable)

Power Supply

LEDs (PS1,

PS2)

Unlit Neither power supply is

receiving AC power

Solid green Power is being supplied and the

unit is powered on

Blinking

green

Solid yellow This power supply is not

Blinking

yellow

Power is being supplied but the

unit is powered off

receiving AC power, but the

other power supply is receiving

power

Overheat warning: The power

supply internal temperature has

reached at least 63° C (145.4°

F).

If the power supply temperature

reaches 70° C (158° F), the

system will automatically

power down. It will restart

when the power supply

temperature falls below 60 °C

(140° F).

Check that each power supply is fully

seated, has a power cord installed, and is

connected to AC power. Reseat each power

supply, install cords, and/or apply power as

required.

N/A

To power on the system, press the power

button on the front of the node.

Check that the power supply is fully seated,

has a power cord installed, and that AC

power is being applied. Reseat the power

supply, install a cord, and/or apply power

as required.

Check the ambient room temperature and

improve cooling if needed.

7.2. Status LEDs 33

FXT 5000 Series Installation Guide

7.2.5 Rear Panel: 1GbE Port LEDs (e0a, e0b, e0c, e0d)

LED Name State Meaning Action (if applicable)

Activity/ Link

LED

Link Speed

LED

Unlit Port is not linked Check networking cables and associated

Ethernet switch ports. Replace or reconnect

cable as required and/or enable the switch

port.

Solid yellow Port is linked to the LAN and

there is no network activity

Blinking

yellow

Unlit Port is linked at the 10Base-T

Solid green Port is linked at the 100Base-

Solid yellow Port is linked at the 1000Base-

Port is linked and there is

activity on the port

(10 Mbps) rate

TX (100 Mbps) rate

T (1000 Mbps) rate

N/A

N/A

If this port link speed is incorrect, check

that the port on the associated Ethernet

switch is set to the desired speed. Change

the switch port speed setting if necessary.

7.2.6 Rear Panel: IPMI Remote Management Port LEDs

LED Name State Meaning Action (if applicable)

Activity/Link

LED

Link Speed

LED

Unlit Port is not linked Check networking cables and associated

Ethernet switch ports. Replace or reconnect

cable as required and/or enable the switch

port.

Solid yellow Port is linked to the LAN and

there is no network activity

Blinking

yellow

Unlit Port is linked at the 10Base-T

Solid green Port is linked at the 100Base-

Solid yellow Port is linked at the 1000Base-

Port is linked and there is

activity on the port

(10 Mbps) rate

TX (100 Mbps) rate

T (1000 Mbps) rate

N/A

N/A

If this port link speed is incorrect, check

that the port on the associated Ethernet

switch is set to the desired speed. Change

the switch port speed setting if necessary.

7.2.7 Rear Panel: Unit Identifier LED

LED Name State Meaning Action (if applicable)

UID LED Unlit Normal state (Local or remote

UID has not been activated)

Solid blue Local UID has been activated

by pressing the front UID

switch

Blinking blue Remote UID has been activated

from the IPMI web interface

N/A

Push the UID button again to turn off the

light

Deactivate remote UID from the IPMI web

interface to turn off the light

34 Chapter 7. Monitoring the FXT 5000 Series Edge Filer

FXT 5000 Series Installation Guide

7.2.8 Rear Panel: Data Port LEDs ( e2a, e2b, e3a, e3b)

This table shows status information for the dual rate 25GbE/10GbE ports on the FXT 5850 and for the 10GbE ports

on the other FXT 5000 Series models. Note that the link speed LED shows solid yellow for a low-speed connection

and solid green for the maximum speed, but that the actual speed varies depending on the model.

LED Name State Meaning Action (if applicable)

Activity/Link

LED

Link Speed

LED

Unlit Port is not linked Check networking cables and associated

Ethernet switch ports. Replace or reconnect

cable as required and/or enable the switch

port.

Blinking

green

Solid green Adapter is linked to the LAN N/A

Unlit Port is not linked Check networking cables and associated

Solid yellow FXT 5850:

Activity on port N/A

Ethernet switch ports. Replace or reconnect

cable as required and/or enable the switch

port.

If this port link speed is incorrect, check

• Port is linked at the

10Gbps rate

Other FXT models:

• Port is linked at the

1Gbps rate

that the port on the associated Ethernet

switch is set to the desired speed. Change

the switch port speed setting if necessary.

Solid green FXT 5850:

• Port is linked at the

25Gbps rate

Other FXT models:

• Port is linked at the

10Gbps rate

7.2. Status LEDs 35

FXT 5000 Series Installation Guide

36 Chapter 7. Monitoring the FXT 5000 Series Edge Filer

CHAPTER

REGULATORY INFORMATION FOR FXT 5000 SERIES NODES

This section provides regulatory information for Avere FXT 5000 Series Edge Filer nodes.

8.1 Electrical Safety

Country/Locale Directive/Test Standard(s) Regulatory Marks

USA ANSI/UL 60950-1, Second Edition, Issued 3/27/2007

+ Amd1 12/19/2011 + Amd2 10/14/2014

Canada CAN/CSA C22.2 No. 60950-1, Second Edition, Issued

3/27/2007 + Amd1 12/19/2011+ Amd2 10/14/2014

European Community 2014/35/EU Low Voltage Directive (LVD)

EN 60950-1:2006 +A11:2009 +A1:2010 +A12:2011 +

A2:2013

International IEC 60950-1:2005 +A1:2009 + A2:2013, CB Scheme

with all Group and National Differences

cCSAus

cCSAus

CE Marking

N/A

EIGHT

8.2 Electromagnetic Compatibility

Country/Locale Directive/Test Standard(s) Regulatory

Marks/Notices

Emissions:

USA FCC 47CFR Part 2 and Part 15 Subpart B Class A,

2014

ANSI C63.4-2014

Canada ICES-003, Issue 5, August 2012

CAN/CSA-CEI/IEC CISPR 22:02, Class A

European Community 2014/30/EU Electromagnetic Compatibility (EMC)

Directive

EN 55022:2010 +AC:2011

EN 61000-3-2:2014

EN 61000-3-3:2013

Japan Voluntary Control Council for Interference by

Information Technology Equipment (VCCI)

V-3/2015.04

V-4/2012.04

Immunity:

European Community 2014/30/EU Electromagnetic Compatibility (EMC)

Directive

EN 55024:2010

FCC Class A Notice

ICES Class A Notice

CE Marking

VCCI Class A Notice

CE Marking

37

FXT 5000 Series Installation Guide

8.3 Environmental Compliance

Country/Locale Directive/Regulation/Test Standard(s) Regulatory Marks

European Community 2012/19/EU, Waste Electrical and Electronic Equip-

ment (Recast WEEE Directive)

European Community 2011/65/EU, Restriction of the use of certain hazardous

substances in electrical and electronic equipment

(Recast RoHS Directive)

European Community EC 1907/2006, Registration, Evaluation, Authorisation

and Restriction of Chemicals (REACH Regulation)

European Community 2006/66/EC, Batteries and accumulators and waste

batteries and accumulators (Battery Directive)

European Community 94/62/EC, Packaging and packaging waste (Packaging

Directive)

For further information on any of these directives and regulations, please contact Avere Systems at

www.averesystems.com/about-us/contact-us

Crossed-out wheeled bin

with bar

CE Marking

None required

None required

None required

38 Chapter 8. Regulatory Information for FXT 5000 Series Nodes

CHAPTER

NINE

EU DECLARATION OF CONFORMITY

39

FXT 5000 Series Installation Guide

40 Chapter 9. EU Declaration of Conformity

CHAPTER

TEN

PREPARING A NODE FOR RETURN TO AVERE SYSTEMS

In some circumstances – for example, at the end of an evaluation, or because of hardware failure – it can be necessary to return an FXT 5000 Series node to Avere Systems. To ship an FXT 5000 Series node safely, all of its power

sources must be completely powered down.

In most cases you can safely power down a node by using the Avere Control Panel software. If the node is unavailable over the network, use the instructions below to power the node down completely from the serial console.

(Pressing the power button on the FXT 5000 Series node chassis is not a recommended way to completely power

down the node.)

Note: Use these procedures only at the direction of Avere Global Services.

To shut down a node that cannot be reached by the Avere Control Panel:

1. Attach a serial console to the node’s serial port as described in the last section of Making Network Connections to the FXT 5000 Series Node (Connecting to the Serial Port (page 27)).

2. Log in to the node with the username maintenance and the cluster’s administrative password.

Note: If the node was unjoined from its cluster, the administrative password was reset to the default password

tiered2010.

3. The console displays the maintenance menu:

You have logged into the AvereOS maintenance menu. If you are configuring a

cluster for the first time, use menu item 1 to configure a network port, and

then access https://ip/fxt to complete the cluster configuration.

Node [name] running [AvereOS_version]

Maintenance Menu

1. Configure network parameters before cluster join

2. Modify cluster management network parameters

3. Configure a new cluster

4. Reboot node

5. Power down node

6. Disable NVRAM batteries

7. Install new software packages

8. Configure node IPMI networking

9. Reformat node

Enter menu item number or type "exit" to log out:

4. Enter 5.

5. The menu prompts you for verification; enter y to confirm:

41

FXT 5000 Series Installation Guide

Enter menu item number or type "exit" to log out:

5

THIS OPERATION TURNS THE POWER OFF ON THE NODE; THE NODE CAN ONLY BE

POWERED ON AGAIN VIA IPMI OR THE FRONT PANEL POWER SWITCH

Are you sure? [yn]: y

Node powerdown

The node powers down. The power-down process can take from 60 to 120 seconds to complete.

6. Disconnect all power and network connections from the node, and remove it from its rack.

7. Return the node to Avere Systems as directed by your Avere Systems representative.

42 Chapter 10. Preparing a Node for Return to Avere Systems

CHAPTER

ELEVEN

COPYRIGHT AND TRADEMARK INFORMATION

11.1 Copyright Information

Copyright © 2009-2018 Avere Systems, Inc. All rights reserved. Specifications subject to change without notice.

No part of this document covered by copyright may be reproduced in any form or by any means – graphic, electronic, or mechanical, including photocopying, recording, taping, or storage in an electronic retrieval system –

without prior written permission of the copyright owner.

The product described in this manual may be protected by one or more U.S. patents, foreign patents, or pending

applications.

11.2 Trademark Information

Avere, FlashCloudTM, FlashMove®, and FlashMirror®are registered trademarks or trademarks of Avere Systems,

Inc. in the United States and/or other jurisdictions.

For licensing information on the third-party software used by this Avere product, contact your Avere Systems

representative.

11.3 Document Numbers

Part number 0456-004-0171, rev E (electronic version)

Part number 0456-004-0191, rev E (printed version)

43

Loading...

Loading...