AVENTICS Instrucciones de servicio: Descripción del sistema Drive & Diagnostic Link (DDL), Istruzioni per l'uso: Descrizione del sistema Drive & Diagnostic Link (DDL), Notice d’instruction: Description du système Drive & Diagnostic Link (DDL), Bedienungsanleitung: Systembeschreibung Drive & Diagnostic Link (DDL), Bruksanvisning: Systembeskrivning Drive & Diagnostic Link (DDL) Manuals & Guides [sv]

Page 1

Operating instructions

System description Drive & Diagnostic Link

DDL

R499050031/2016-12, Replaces: 08.2014, EN

English

Page 2

Page 3

AVENTICS | DDL | R499050031–BAL–001–AH 3

Contents

Contents

1 Safety Precautions ........................................................ 9

2 DDL General ................................................................. 11

2.1 DDL System Overview........................................................... 11

2.2 DDL Addressing ...................................................................... 12

2.2.1 Manual Addressing .............................................................. 13

2.2.2 Automatic Addressing ......................................................... 13

2.2.3 Error Upon Addressing ....................................................... 14

2.3 DDL Diagnosis ......................................................................... 15

2.4 DDL Data ................................................................................... 15

2.4.1 DDL Connection ..................................................................... 15

2.4.2 DDL Cable Length ................................................................. 16

2.4.3 DDL Cycle Times ................................................................... 16

2.4.4 Standards ............................................................................... 17

3 Bus Coupler ................................................................. 17

3.1 PROFIBUS DP 337 500 025 0/337 500 026 0 ................ 18

3.1.1 Overview .................................................................................. 18

3.1.2 Master Module ....................................................................... 19

3.1.3 Slave Module .......................................................................... 26

3.1.4 Connectors ............................................................................. 32

3.1.5 Technical Data ....................................................................... 35

3.1.6 Dimensions ............................................................................. 36

3.1.7 ATEX-Relevant Information ............................................... 37

3.2 DeviceNet R412006999/R412006998.............................. 37

3.2.1 Overview .................................................................................. 37

3.2.2 Master Module ....................................................................... 38

3.2.3 Slave Module .......................................................................... 43

3.2.4 Connectors ............................................................................. 48

3.2.5 Technical Data ....................................................................... 50

3.2.6 Dimensions ............................................................................. 51

3.2.7 ATEX-Relevant Information ............................................... 52

3.3 Interbus S 337 500 045 0/337 500 046 0 ....................... 52

3.3.1 Overview .................................................................................. 52

3.3.2 Master Module ....................................................................... 54

3.3.3 Slave Module .......................................................................... 65

3.3.4 Connectors ............................................................................. 70

3.3.5 Technical Data ....................................................................... 72

English

Page 4

4 AVENTICS | DDL | R499050031–BAL–001–AH

Contents

3.3.6 Dimensions ............................................................................. 73

3.3.7 ATEX-Relevant Information ............................................... 74

3.4 ControlNet 337 500 056 0 .................................................... 74

3.4.1 Overview .................................................................................. 74

3.4.2 Master Module ....................................................................... 75

3.4.3 Slave Module .......................................................................... 80

3.4.4 Connections ............................................................................ 85

3.4.5 Technical Data ....................................................................... 87

3.4.6 Dimensions ............................................................................. 88

3.5 CANopen R412008000/R412008002................................ 89

3.5.1 Overview .................................................................................. 89

3.5.2 Master Module ....................................................................... 90

3.5.3 Slave Module .......................................................................... 95

3.5.4 Connectors ........................................................................... 101

3.5.5 Technical Data ..................................................................... 103

3.5.6 Dimensions ........................................................................... 104

3.5.7 ATEX-Relevant Information ............................................. 105

3.6 ATEX-Relevant Information for Bus Couplers..............105

3.6.1 Ex-Relevant Excerpt from the Operating Instructions

for S-Design Bus Couplers .............................................. 105

4 DDL Participants ....................................................... 111

4.1 Valve Driver 337 500 005 0/337 500 015 0.................. 111

4.1.1 Overview ................................................................................ 111

4.1.2 DDL Address ........................................................................ 112

4.1.3 DDL Mode .............................................................................. 112

4.1.4 Output Data Length ............................................................ 112

4.1.5 Output Data Range in the Control .................................. 113

4.1.6 Diagnosis ............................................................................... 114

4.1.7 Parameter ............................................................................. 116

4.1.8 Connections .......................................................................... 117

4.1.9 Technical Data ..................................................................... 119

4.1.10 Dimensions ........................................................................... 120

4.2 Valve Driver V-Design

1 827 030 189 0/1 827 030 190 0 ...................................120

4.2.1 Overview ................................................................................ 121

4.2.2 DDL Address ........................................................................ 121

4.2.3 DDL Mode .............................................................................. 121

4.2.4 Output Data Length ............................................................ 122

Page 5

AVENTICS | DDL | R499050031–BAL–001–AH 5

Contents

4.2.5 Output Data Range in the Control .................................. 122

4.2.6 Diagnosis ............................................................................... 123

4.2.7 Parameter ............................................................................. 126

4.2.8 Connections .......................................................................... 127

4.2.9 Technical Data ..................................................................... 130

4.2.10 Dimensions ........................................................................... 131

4.3 Valve System LP04 .............................................................. 131

4.3.1 Overview ................................................................................ 132

4.3.2 DDL address ......................................................................... 132

4.3.3 DDL Mode .............................................................................. 133

4.3.4 Output Data Length ............................................................ 133

4.3.5 Output Data Range in the Control .................................. 133

4.3.6 Diagnosis ............................................................................... 134

4.3.7 Parameter ............................................................................. 137

4.3.8 Connections .......................................................................... 138

4.3.9 Technical Data ..................................................................... 139

4.3.10 Dimensions ........................................................................... 140

4.3.11 Extension for LP04 Valve System with Inputs ........... 141

4.4 Pressure Control Valve ED05 561 014 155 0...............145

4.4.1 Overview ................................................................................ 146

4.4.2 DDL Address ........................................................................ 146

4.4.3 DDL Mode .............................................................................. 147

4.4.4 Data Format ......................................................................... 147

4.4.5 Diagnosis ............................................................................... 149

4.4.6 Parameter ............................................................................. 150

4.4.7 Controller .............................................................................. 150

4.4.8 Connections .......................................................................... 151

4.4.9 Technical Data ..................................................................... 153

4.4.10 Dimensions ........................................................................... 154

4.5 Digital Input Module 337 500 200 0 ................................154

4.5.1 Overview ................................................................................ 155

4.5.2 DDL Address ........................................................................ 155

4.5.3 DDL Mode and Data Length ............................................. 156

4.5.4 Input Data Range in the Control ..................................... 156

4.5.5 Diagnosis ............................................................................... 157

4.5.6 Overload Protection and Parameter ............................. 158

4.5.7 Connections .......................................................................... 159

4.5.8 Technical Data ..................................................................... 160

English

Page 6

6 AVENTICS | DDL | R499050031–BAL–001–AH

Contents

4.5.9 Dimensions ........................................................................... 161

4.5.10 ATEX-Relevant Information ............................................. 161

4.6 Digital Output Module 337 500 202 0 .............................162

4.6.1 Overview ................................................................................ 163

4.6.2 DDL Address ........................................................................ 164

4.6.3 DDL Mode .............................................................................. 164

4.6.4 Output Data Range in the Control .................................. 164

4.6.5 Diagnosis ............................................................................... 165

4.6.6 Parameter ............................................................................. 167

4.6.7 Connections .......................................................................... 168

4.6.8 Technical Data ..................................................................... 170

4.6.9 Dimensions ........................................................................... 171

4.6.10 ATEX-Relevant Information ............................................. 172

4.7 Digital In/Output Module R412006712........................... 172

4.7.1 Overview ................................................................................ 173

4.7.2 DDL Address ........................................................................ 173

4.7.3 DDL Mode and Data Length ............................................. 174

4.7.4 Data Range in the Control ................................................ 174

4.7.5 Diagnosis ............................................................................... 176

4.7.6 Parameter ............................................................................. 179

4.7.7 Connections .......................................................................... 180

4.7.8 Technical Data ..................................................................... 182

4.7.9 Dimensions ........................................................................... 183

4.7.10 ATEX-Relevant Information ............................................. 183

4.8 ATEX-Relevant Information for I/O Modules ................184

4.8.1 Ex-Relevant Excerpt from the Operating Instructions

for I/O Modules .................................................................... 184

5 DDL Accessories ....................................................... 190

5.1 Cables....................................................................................... 190

5.1.1 DDL Cable ............................................................................. 190

5.1.2 Sensor Cables ...................................................................... 190

5.2 Plugs......................................................................................... 191

5.2.1 Terminating Plugs .............................................................. 191

5.2.2 Data Plugs ............................................................................. 191

5.2.3 Power Supply Plugs ........................................................... 191

5.2.4 Other Connectors ................................................................ 192

5.3 Subplates (for Pressure Control Valves) .......................192

5.3.1 Pressure Control Valve ED05 .......................................... 192

Page 7

AVENTICS | DDL | R499050031–BAL–001–AH 7

Contents

5.3.2 Pressure Control Valve ED07 .......................................... 193

6 List of Abbreviations ................................................. 193

7 Declaration of Conformity (ATEX) ............................ 194

7.1 Bus Coupler (3375000250, 3375000450,

R412006999, R412008000)...............................................194

7.2 DDL Input and Output Modules (33750020x0,

R412006712).......................................................................... 194

English

Page 8

8 AVENTICS | DDL | R499050031–BAL–001–AH

Contents

Page 9

AVENTICS | DDL | R499050031–BAL–001–AH 9

Safety Precautions

1 Safety Precautions

W Please pay attention to the general safety instructions and

notice the content of the user manual, before you install,

start up, put pressure or electrical power to the devices.

W The devices should be used only in areas and systems they

are specified for and also comply with the tolerances of the

technical data. In case of non compliance and upon

exceeding the limits, which are mentioned under the point:

technical data, the danger of overheating can be caused as

well as damage to the device, interference in the function

and/or the electrical security.

W The AVENTICS devices have been generally developed to be

used within the industrial sector. If devices shall be used in

living quarters (living and business and industry sector) a

special permission has to be procured from the licensing

authority. In Germany licences are issued by the

Regulierungsbehörde für Telekommunikation und Post

(RegTP).

W To observe the technical data you should only use cables

and wires, being mentioned in the user manual or quotation

drawing.

W The devices have to be grounded according to the

instructions. The relevant DIN/VDE standards or the country

specific standards have to be observed upon installation.

Note especially:

- VDE 0160 (EN 50178)

- VDE 0100

W The supply voltage has to be applied from a powerpack with

protective separation according to EN 60742, classification

VDE 0551. Please pay attention that the external fuse of the

devices is in accordance with the description.

W A faultless and safe operation of the devices requires an

appropriate transport, storage, installation and start up.

W The devices have to be opened only by qualified staff.

Electrostatic accidentally dangerous parts.

English

Page 10

10 AVENTICS | DDL | R499050031–BAL–001–AH

Safety Precautions

W The installation of the devices has to be effected only by

qualified staff and without power supply and pressure.

Please observe the installation position, mentioned in the

user manual.

W To avoid dangerous movements, the electrical start up has

to be made on in depressurized state.

W Start up the device only after installation and tests have

been completely finished.

W Plugs must not be plugged or unplugged under voltage.

To avoid electrical damage to the device, switch off the

power supply before plugs are plugged/unplugged.

W To achieve the protection class and function all seals have to

be intact and fit in correct position.

W The protection class can only be achieved if all unused plugs

are sealed with covers or endplugs.

W Switches and configuration must not be changed during

operation. Changed settings only become valid after power

recycle.

W No equalizing currents due to potential differences must run

via the shield, otherwise the earthing have to be made via

separate wires.

W Use in explosive Area:

Some DDL participants can be used in explosive areas. For

these certified devices at the end of the corresponding

chapter important notes can be found. If the devices are

used in explosive areas, these notes have to be read and

attention has to be paid.

W Further safety precautions in the user manual have to be

followed.

W We refuse all liability for nonobservance of these notes, for

handling of the device or use in an improper way.

Furthermore the guarantee on our devices and accessories

expires.

Page 11

AVENTICS | DDL | R499050031–BAL–001–AH 11

DDL General

2 DDL General

The Drive & Diagnostic Link (DDL) from AVENTICS is a system to

use solenoids, pressure control valves and digital and analog

I/O modules with different field bus systems. Independent from

the used field bus, the systems can be projected and with the

corresponding bus coupler connected to common field busses

like PROFIBUS DP, Interbus S, ControlNet and DeviceNet. DDL

provides, independent from fieldbus, 128 inputs and 128

outputs per bus coupler. For the reason of the transfer mode

system, there is a high data security which is even increased by

the diagnostic functionality. In this way the DDL participants and

the supply voltages are controlled and reported to the

diagnostics. Furthermore the coils of valve units are observed

according to open load and short circuit. Therefore errors can

be quickly recorded up to the affected valve and measures

initiated. In addition some DDL participants offer the possibility

to determine via parameter the reaction upon failure of fieldbus

and DDL. On the basis of the employment of M12 connectors the

connection is very simple and safe. A total length of the cable of

40 m is permitted and offers a high flexibility with the DDL. Here

the gap between the modules is regardless. Because of the high

modularity most of the AVENTICS valve families can be

employed with DDL.

English

2.1 DDL System Overview

Basically the DDL consists of two types of participants:

W The bus coupler makes it possible to transfer data between

the fieldbus system (PROFIBUS DP, Interbus S, DeviceNet, ...)

and the DDL. The bus coupler is therefore the DDL master

and has to be existent once.

W The DDL participant is therefore the slave within the DDL

system. Up to 14 participants can be connected to the DDL.

Page 12

12 AVENTICS | DDL | R499050031–BAL–001–AH

DDL General

The bus coupler with drivers contains, in addition to the Master

module, which is the real bus coupler, also a Slave module

which represents the DDL participant. This Slave module is

therefore a DDL participant and up to 13 other DDL participants

can be connected.

2.2 DDL Addressing

In the DDL system a definite address has to be assigned to each

participant (except for the Master module of the bus coupler).

This is effected via a hex rotary switch at the devices.

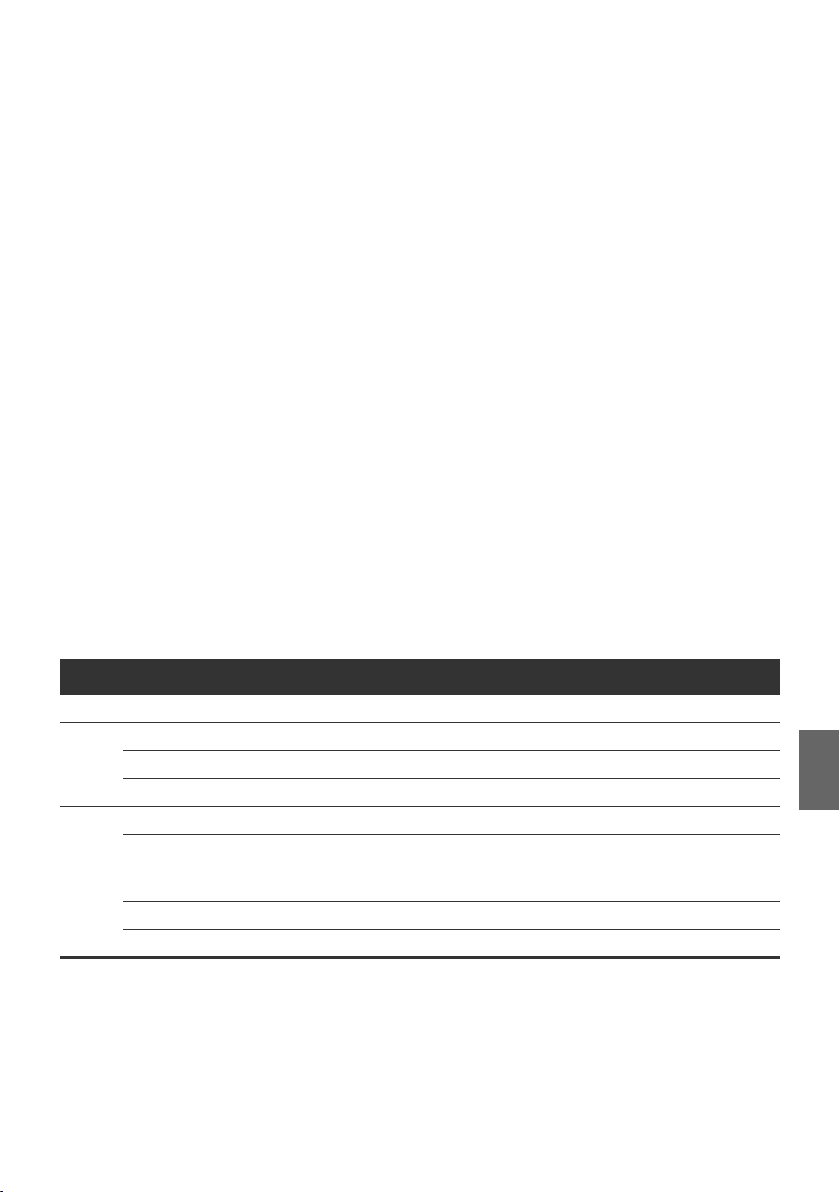

Table 1: DDL address switch

Position of Switch Meaning

0 automatic addressing

1 DDL address 1

2 DDL address 2

3 DDL address 3

4 DDL address 4

5 DDL address 5

6 DDL address 6

7 DDL address 7

8 DDL address 8

9 DDL address 9

A DDL address 10

B DDL address 11

C DDL address 12

D DDL address 13

E DDL address 14

F no function

The addressing can be effected in two different ways:

1. Manual addressing

2. Automatic addressing

Page 13

AVENTICS | DDL | R499050031–BAL–001–AH 13

Manual and automatic addressing cannot be effected at the

same time.

Please take into consideration that upon effecting the address

adjustments, changes will only be taken over after a reset of

voltage.

2.2.1 Manual Addressing

A definite address, between 1 and 14, is allocated to each

participant. No participant must have the address 0.

Furthermore the lowest address must be 1 and there must not

be any gaps between the addresses. The addressing is,

however, independent from the physical position of the

participant in the DDL and its type.

Example: 5 DDL participants are connected to a bus coupler

Stand alone (needs no DDL address).

Table 2: Example for manual DDL addressing

Correct: Incorrect: Gap (4) and

lowest address 1

DDL General

Incorrect:

Address 0 is used

DDL

Address

1 pressure control

2 valve driver 3 valve driver 1 valve driver

3 valve driver 5 valve driver 2 valve driver

4 input module 6 input module 3 input module

5 output module 7 output module 4 output module

DDL Node DDL

Address

2 pressure control

valve

DDL Node DDL

Address

0 pressure control

valve

DDL Node

valve

2.2.2 Automatic Addressing

If there is only one participant per type in the DDL system, the

DDL can automatically address itself. For this the address 0 has

to be allocated to all DDL participants. In this case the DDL

system allocates the address automatically to the participants.

The following table shows, what kinds of module types are

available and where to find them in the data and the diagnosis

range.

English

Page 14

14 AVENTICS | DDL | R499050031–BAL–001–AH

DDL General

If not all module types are used, the following modules move up.

If the automatic addressing is used, addresses between 1 ... 14

must not be used.

Table 3: Data range at automatic DDL addressing

Output

Data

Position

1 EP pressure

2 valve driver – valve driver 1 EP pressure control

– input module 2 input module 2 valve driver

3 output module – output module 3 input module

1)

4

– – – – 5 combi module

1)

only, if input or output data are configured.

DDL Node Type Input

control valve

combi module 3

Data

Position

1 EP pressure

1)

DDL Node Type Diagnosis

Data

Position

BC bus coupler

control valve

combi module 4 output module

DDL Node Type

valve

2.2.3 Error Upon Addressing

In order that the DDL is able to recognize and control all

participants, the above mentioned regulations have to be

observed. If the DDL has not been addressed correctly, this will

be indicated by the participant’s red DDL LED. If two participants

have the same address, this cannot be recognized that safely

that the DDL gets not into Run mode. This type of wrong

addressing can be recognized by checking the number of

livebits. In case of a DDL communication diagnosis, the

addressing of all participants shall be checked. Furthermore

the same baud rate has to be adjusted with all participants, also

with the Master module. In addition it has to be checked that all

cables have been correctly connected. Upon problems with very

long cables we recommend to run the DDL with 125 kBaud. For

further information on the baud rate adjustments, please refer

to the description of the device.

Page 15

AVENTICS | DDL | R499050031–BAL–001–AH 15

DDL General

2.3 DDL Diagnosis

The DDL participants/bus couplers have two kinds of diagnosis.

On the one hand, each DDL device has LEDs to indicate the

diagnosis visually. On the other hand the DDL participants send

diagnosis data via the DDL to the bus coupler, which transmits

its own data and the diagnosis data of the DDL participants to

the control. The meaning of the diagnosis data and further

information can be taken from the corresponding chapters. The

DDL communication respectively the availability of the DDL

participants is constantly controlled by the bus coupler. As soon

as all configured DDL participants exist and communicate, the

red DDL LED turns off. If a participant does not communicate

any more, the red DDL LED will light at the corresponding

participant and the bus coupler reports the interference. In

addition the corresponding livebit and the DDL LED at the bus

coupler (Master module) lights (if existing). The communication

to the other DDL participants will however be maintained. If the

bus coupler recognizes the recurring participant (DDL LED at

the participant will go off), that way the configuration will be all

right, the DDL LED at the bus coupler will also go off.

In order to initialize the system correctly, the valves must not be

controlled. All supply voltages must exist correspondingly.

2.4 DDL Data

2.4.1 DDL Connection

The connection of the DDL is effected via 5 pin M12x1 plugs.

5-wire, shielded lines have to be used as connecting cables. The

shield has to be connected to the thread of the plug. The

diameter of the wires is 0.34 mm

connection is performed by a mounting male plug and the DDL

OUT connection as mounting female plug at the DDL

participants. As DDL participants can be damaged if 24 V are

applied to the signal line DDL H and DDL L or the supply lines

have been exchanged, we recommend to use pre fabricated and

2

minimum. The DDL IN

English

Page 16

16 AVENTICS | DDL | R499050031–BAL–001–AH

DDL General

examined wiring. This is also mentioned in chapter 5 “DDL

Accessories“.

2

1

5

4

3

Fig. 1: DDL connection

1 Pin 1 = 24 V electronics 4 Pin 4 = DDL H

2 Pin 2 = 24 V valves 5 Pin 5 = DDL L

3 Pin 3 = 0 V

2.4.2 DDL Cable Length

The total cable length of DDL system is limited to 40 m. Thereby

it is irrelevant, whether the length between the two participants

will be used or distributed equally.

With great cable length and great consumption of electricity, the

voltage drop over the cables can provoke, that the supply

voltages at the DDL participants fall below the respective

tolerance limits. In such cases the DDL valve drivers can be

used with an external power supply (337 500 015 0 or

1 827 030 190 0), which, because of the additional supply,

indicate the voltage supply level.

2.4.3 DDL Cycle Times

DDL is constructed for a fast and secure data transfer. The DDL

cycle times depend on several parameters. In that way the baud

rate, number of participants and configured in and output data

length (max. 128 bit) have influence on the cycle time.

In table 4 some applications and the corresponding DDL cycle

times are shown.

The process times in the bus coupler (approx. 0.8 ms) and the

cycle time of the field bus are not included in this overview. The

cycle time can be seen as an average value. With an ideal data

transmission the signal can be transmitted considerably earlier.

With critical applications it should be taken into consideration

that with an unfavorable data transmission it could take a cycle

time twice as long, until the signals are output or transmitted to

the field bus.

Page 17

AVENTICS | DDL | R499050031–BAL–001–AH 17

Bus Coupler

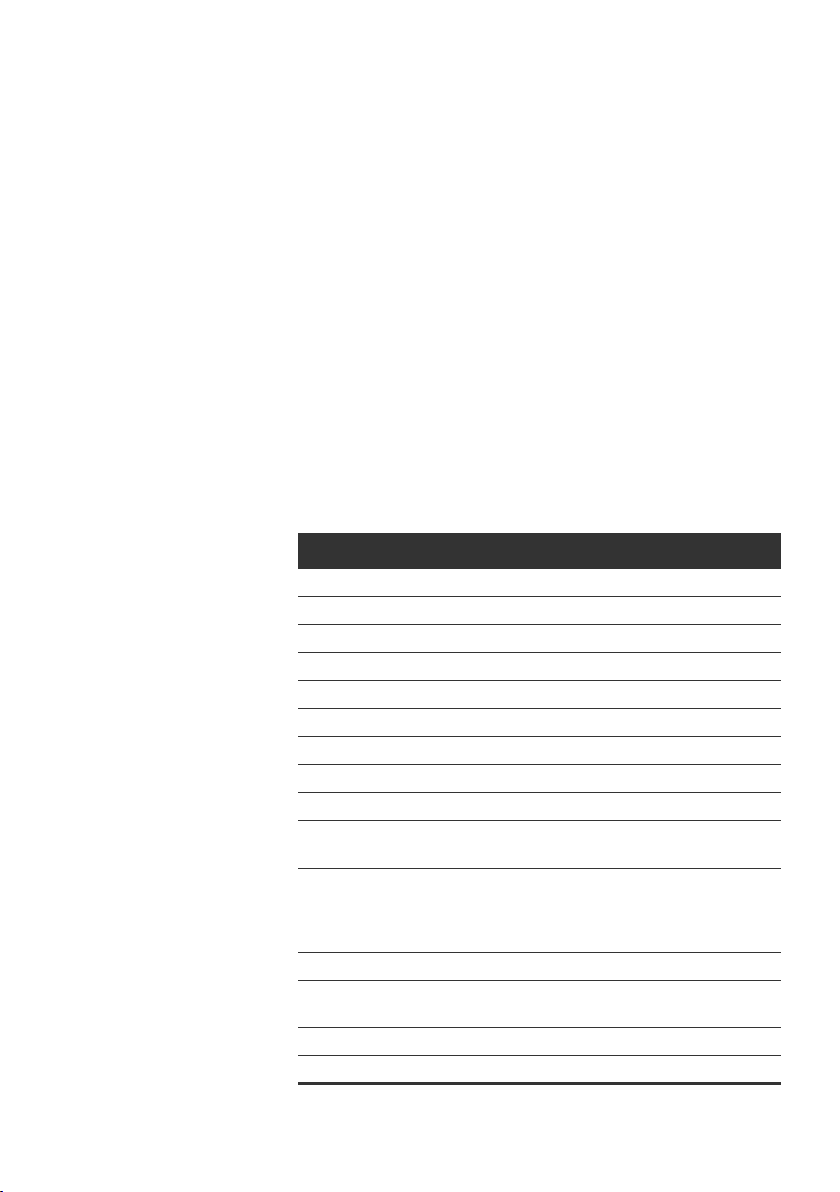

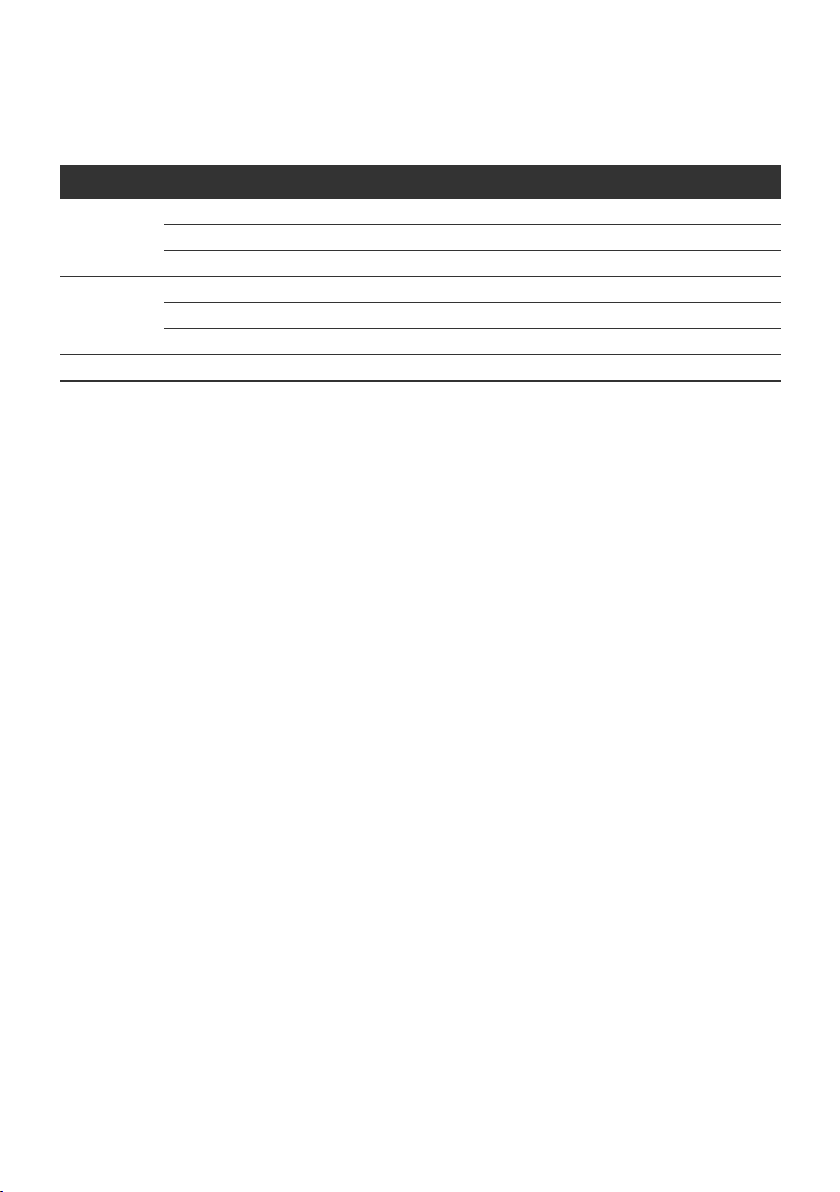

Table 4: Examples for DDL cycle times with different DDL configurations

Example DDL Baud rates DDL Participants DDL Data length I/O DDL Cycletime

1 250 kBaud 2 0/32 3.0 ms

2 250 kBaud 5 128/128 7.0 ms

3 250 kBaud 14 128/128 14.0 ms

4 125 kBaud 2 0/16 4.2 ms

5 125 kBaud 5 128/128 13.0 ms

2.4.4 Standards

The DDL system fulfills the standards for EMC, listed below:

W EN 61000-6-4

W EN 61000-6-2

3 Bus Coupler

AVENTICS bus couplers allow to connect pressure control

valves, valve units and digital and analog in and output modules

to a programmable logic control (PLC) by using a field bus

system like PROFIBUS DP, Interbus S, ControlNet, DeviceNet,

CANopen,... . One advantage of a serial control is the saving of

the parallel output cards in the PLC as well as the necessary

wiring. Another one is the possibility to transfer further

information like Diagnosis and parameters.

Bus couplers are available in two different designs. On the one

hand there is the Stand alone module. It consists only of the

Master module. The Master module communicates with the

field bus system and controls the DDL. On the other hand bus

couplers with drivers to control the valve via a 25 pin D-Sub

plug, are available. They have, in addition to the Master module,

also a Slave module which operates like a single DDL

participant, but is situated within the same housing.

English

Page 18

18 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

3.1 PROFIBUS DP 337 500 025 0/337 500 026 0

The bus coupler for PROFIBUS DP is available in two different

designs. The bus coupler with drivers (337 500 026 0) can be

directly mounted onto a valve unit. Apart from controlling this

unit, the DDL is also available for other DDL participants.

The bus coupler Stand alone (337 500 025 0) is mounted

separately and offers only the DDL. The parts of description of

the Slave module, do not apply to the bus coupler Stand alone.

Both modules are connected to the PROFIBUS DP via a shielded

2 wire cable.

3.1.1 Overview

PROFIBUS DP

The field bus system PROFIBUS DP which is used for the

communication with the control, is a fast working bus system

for the cyclic exchange of user data. PROFIBUS DP is a master

slave bus system, where 2 master and 122 passive participants

maximum can be connected to. Two designs as transmission

medium are available:

W 2 wire line (shielded)

W optical fibre

For installation information of the networks and for the

configuration of the lines, please refer to the documentation

of the PROFIBUS association. http://www.profibus.com

Page 19

Bus Coupler PROFIBUS DP

1

POWER SUPPLY

2

DDL

STOP

RUN

VALVE

SENSOR

POWER SUPPLY

12141214121412

VALVESENSOR

3

0

1

9

2

8

3

7

9

4

8

7

21

4321

4

6

5

0

1

2

3

4

6

5

9

8

A

7

B

6

C

5

D

4

E

3

F

2

1

0

5

6

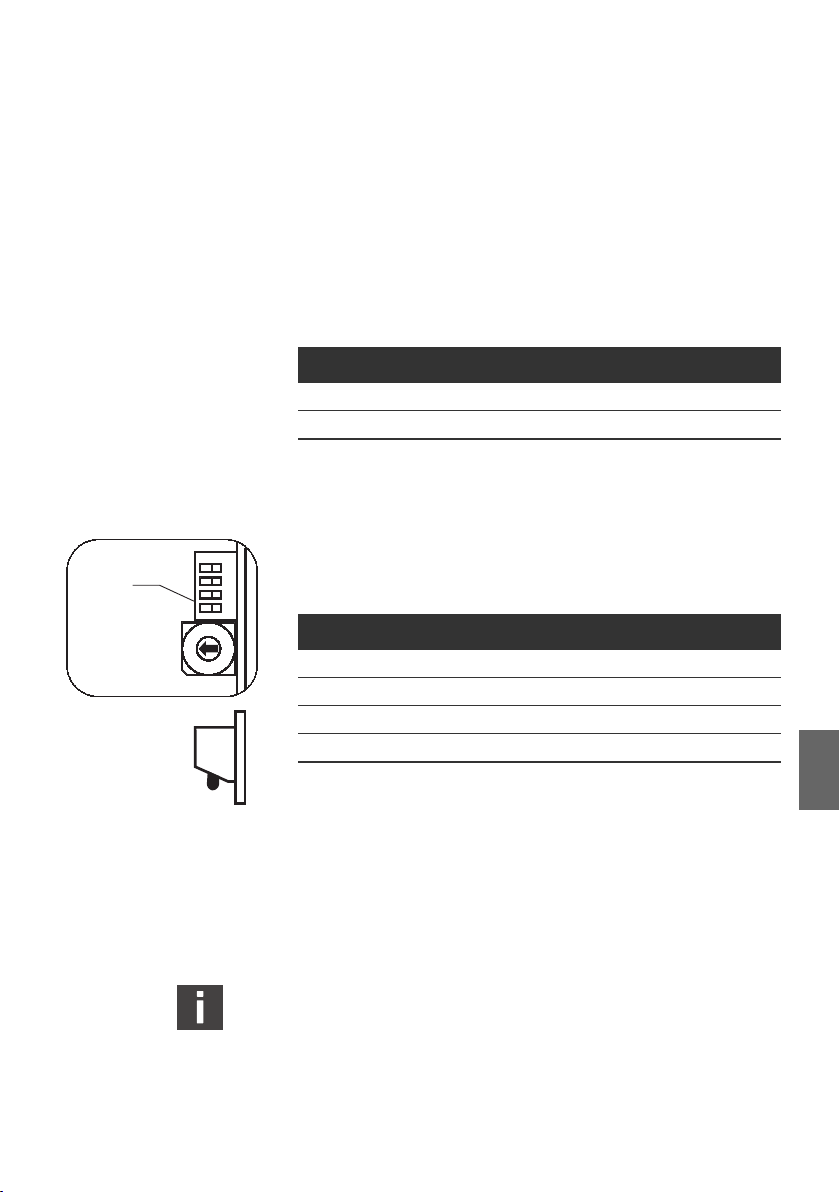

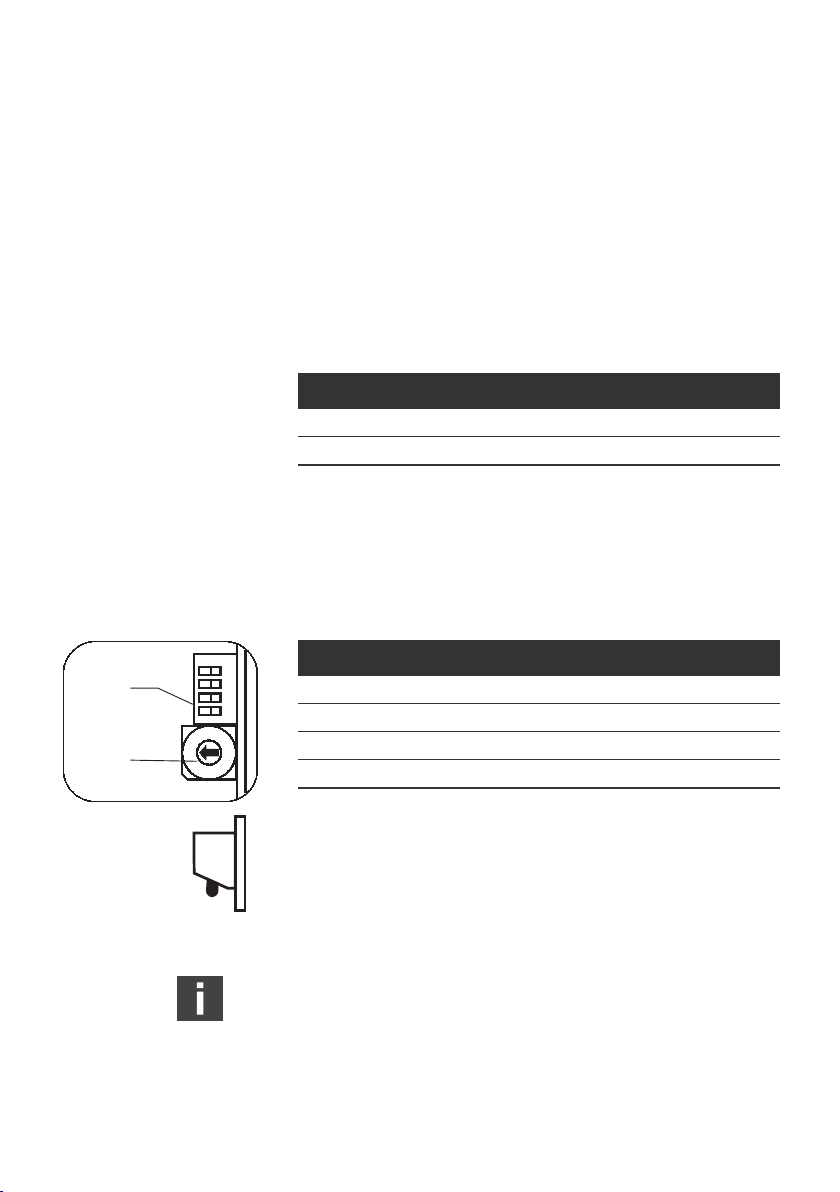

Fig. 2: LED and switch of 337 500 026 0

AVENTICS | DDL | R499050031–BAL–001–AH 19

Bus Coupler

7

8

1

9

1 DDL LEDs

2 PROFIBUS LEDs

3 DP address S1

4 DP address S2

6 DDL mode S3

7 DDL mode S4

8 Slave module

9 DDL address S5

5 Master module

3.1.2 Master Module

The Master module is the interface between the PROFIBUS DP

and the DDL. It controls the DDL and monitors the supply

voltages.

PROFIBUS DP Addresses

Before a connection to the PROFIBUS DP System, an address

will have to be assigned to the bus coupler. After opening the

sealing cap, the address is assigned by two rotary switches.

Addresses from 0 ... 99 can be assigned. With switch S1 the ten

digit is set, with S2 the one digit is set. In the factory the devices

are already adjusted to address 3.

English

Page 20

20 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

The switches must not be changed during operation.

Changed switch positions will only become valid, after the

device has been turned off and restarted.

PROFIBUS DP – Baud Rates

The PROFIBUS transfer rates are adjusted with the PROFIBUS

master (PLC) and are then automatically recognized by the slave

(bus coupler). The following values can be adjusted as rates of

transmission:

9.6 / 19.2 / 93.75 / 187.5 / 500 / 1500 / 3000 / 6000 / 12000 kBaud.

PROFIBUS DP Configuration

For the PLC configuration software, e. g. COM PROFIBUS the

device master file RXP_05EF.gsd will be needed. This file is

included in the delivery or can be ordered separately under the

following no.: 546 046 941 2. The file has to be copied into the

directory which was defined by the PLC configuration software.

On this disk are also two Icon files for this bus coupler

(RX_D05EF.dip/RX_R05EF.dib).

For the configuration of the bus coupler, the type of station bus

coupler has to be selected (above folder Valves/AVENTICS).

After selection of the field "configuration" and modules, the

corresponding DDL modules have to be inserted. Each

participant of the DDL has to be singly configured as a module.

The DDL participant with address 1 has to be configured as

module 0, participant 2 as module 1 etc.

Combi modules need 2 modules, but only one DDL address.

Thereby the number of the module moves one digit per

module towards the DDL address.

Also the length of the data of the valve unit and the input module

must be correctly adjusted. Arbitrary addresses in the address

area of the control can be assigned to each module (if the

control permits this).

If the configuration differs from the real DDL system, the bus

coupler will not be recognized correctly by the PROFIBUS

master!

Page 21

AVENTICS | DDL | R499050031–BAL–001–AH 21

Parameter

These functions are deposited in the GSD file and can be

displayed as plain text via a configuration tool (e.g. COM

PROFIBUS or S7 Hardware configuration). Per each DDL

participant one byte is transferred and also one byte for the bus

coupler. Each single parameter byte for the participants can be

individually adjusted. If no parameters are adjusted, the DDL

participants use their default parameter.

Changed parameters only become valid if the device has been

turned off and on again.

Bus Coupler Parameter

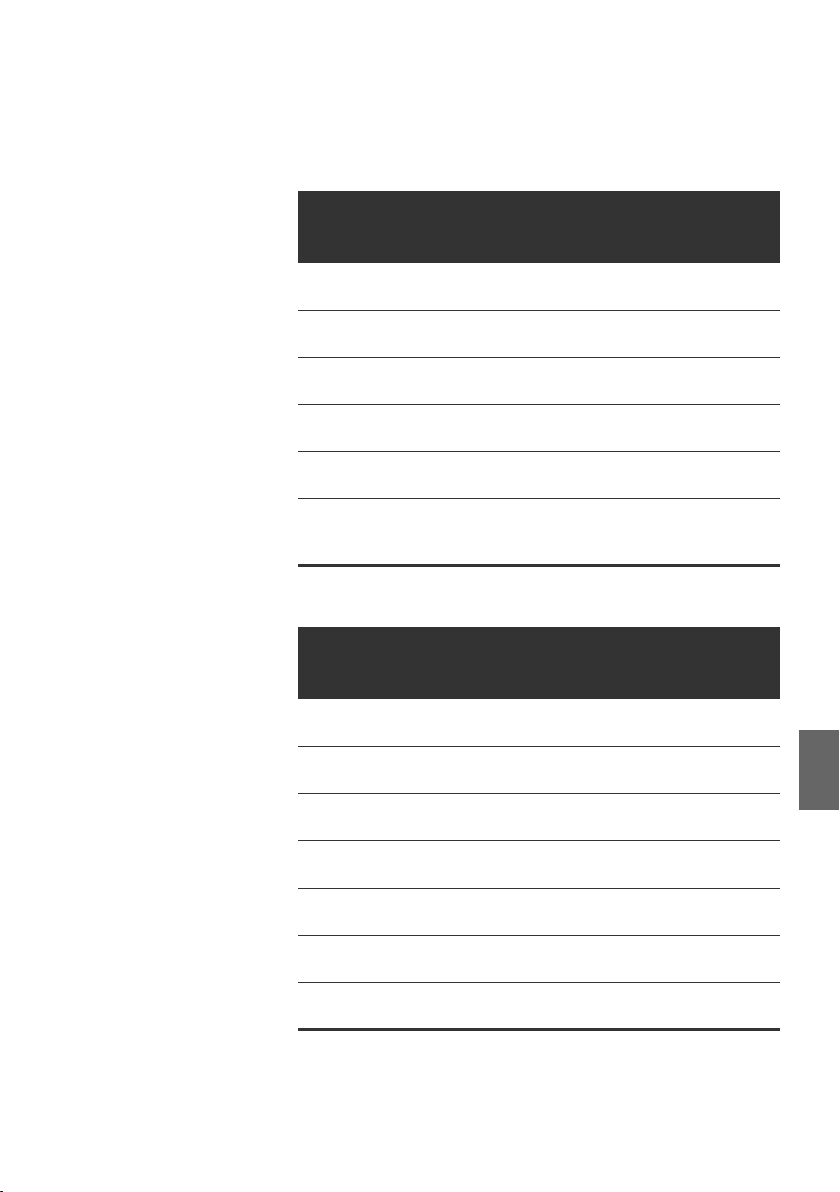

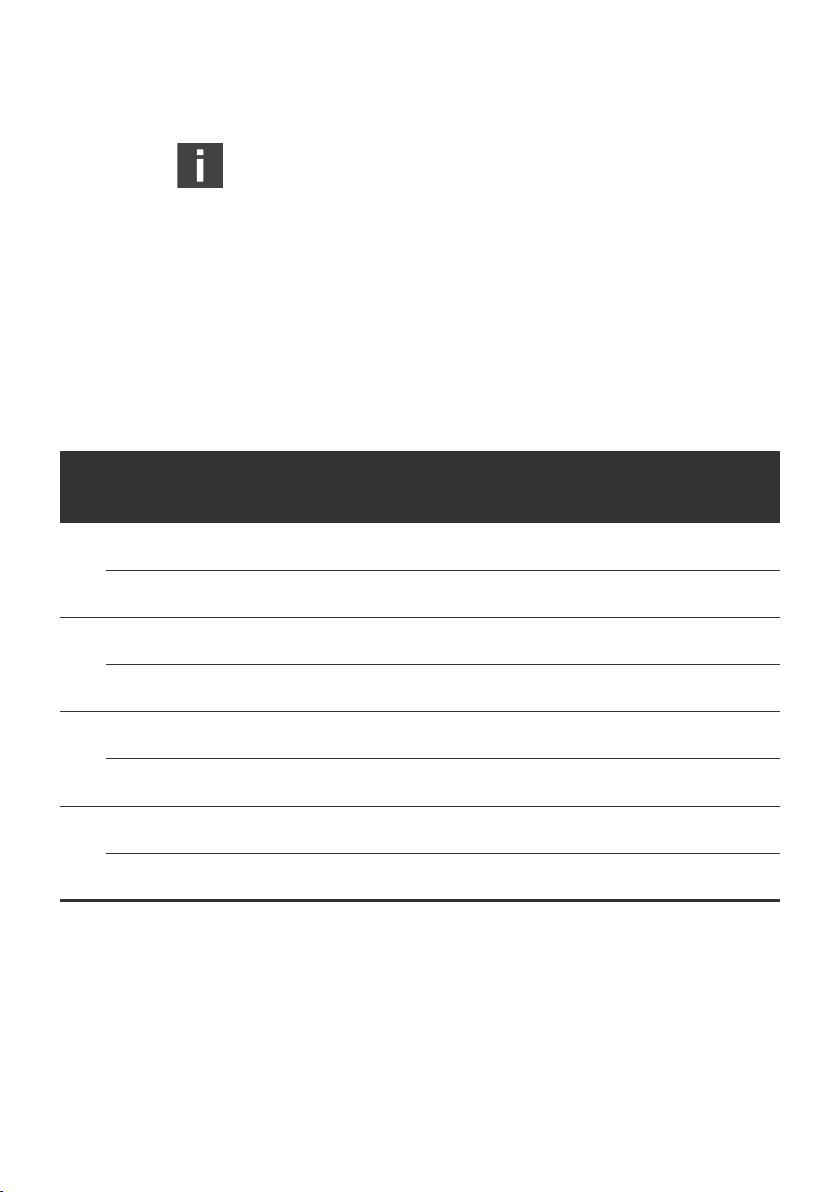

Table 5: Bus coupler parameter

Bit Name of Parameter Bit = 0 Bit = 1

7 reserved

6 reserved

5 reserved

4 reserved

3 reserved

2 reserved

1 diagnosis send to PLC no (default) yes

0 reaction upon PROFIBUS failure values at 0 (default) freeze values

Bus Coupler

Bit 0 = 0 Upon failure of the PROFIBUS DP, the output data in the bus

coupler are set at 0 (default).

Bit 0 = 1 Upon failure of the PROFIBUS DP, the output data in the bus

coupler remain with the last value and the coils will be kept

driven (values frozen).

Upon return of the PROFIBUS communication the outputs

can be set at 0 of short duration.

Bit 1 = 0 No diagnosis data which go beyond the PROFIBUS DP standard

diagnosis are sent to PLC (default).

English

Page 22

22 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

Bit 1 = 1 User diagnosis data (DDL diagnosis) are send to the PLC via the

PROFIBUS DP.

DDL Participant Parameter

The parameter descriptions of the individual DDL participants

can be taken from the corresponding chapters.

DDL Address

At the Master module respectively. Stand alone bus coupler no

DDL Address has to be set.

For correct function of the DDL (Drive & Diagnostic Link)

following items must be fulfilled.

W same Baud rate at all DDL modules

W DDL Address within 1 ... 14, starting with 1, without gap, no

double used Address

W DDL Address 0: see chapter 2.2 “DDL Addressing“.

DDL Mode

The transmission rate of the DDL is adjusted with the 2 bit DIP

switch S3, next to the PROFIBUS DP address switches at the

forefront. All DDL participants have to be adjusted to the same

transmission rate.

Table 6: DDL baud rate

Bit Open On

1 DDL 125 kBaud DDL 250 kBaud (default)

2 no function no function

Page 23

AVENTICS | DDL | R499050031–BAL–001–AH 23

Bus Coupler

0

1

9

2

8

3

7

4

6

5

0

1

9

2

8

3

7

4

6

5

21

ON OPEN

OPEN

ON

Fig. 3: DIP switch S3:

DDL mode

Table 7: Overview on the LED indications

Description Color of LED Meaning

STOP red lighting bus stop / DDL configuration not ok / Hardware not OK

Run green bus in operation / configuration ok / DATA exchange

SUPPLY

SENSOR

SUPPLY

VALVE

S3

red flashing bus stop / DDL configuration ok / PROFIBUS configuration

green lighting voltage within the tolerance

green flashing voltage below or beyond the tolerance

green off no voltage at connection of sensor supply (X1S, Pin 1)

green lighting voltage within the tolerance

green flashing voltage below or beyond the tolerance

green off no voltage at connection of sensor supply (X1S, Pin 1)

Diagnosis

LED Diagnosis

On the top side of the device LEDs indicate the state of the

PROFIBUS DP interface as well as of the power supply.

meets not the actual DDL configuration

English

Voltage Monitoring The applied voltage is indicated by two green LEDs. The voltages

at plug DDL are indicated. The liminal supply voltage is at

19.2 V/21.6 V for low voltage and at 26.4 V/28.8 V for

overvoltage.

Short Circuit Monitoring The bus coupler has a short circuit monitoring for the DDL. Both

power supplies are monitored independently from each other. If

the short circuit monitoring in the bus coupler starts up, the

corresponding green LED begins to flash.

Page 24

24 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

Software Diagnosis In case of error, an „EXT_DIAG“ message is send via the

PROFIBUS DP, to the control. The length of the ext. diagnosis

message depends on the number of participants. For the bus

coupler Stand alone 337 500 025 0 the length is 4 byte diagnosis

+ 1 byte header (PROFIBUS Norm). After the bus coupler the

diagnosis for the participants is sorted upwards, according to

the DDL addresses. For each further DDL participant the

commensurate diagnosis bytes are added. The diagnosis length

of a valve driver consists of 1 Byte + the configurated data

length. The Diagnosis data length for other DDL nodes can be

read up on the corresponding chapters.

The bus coupler with drivers (337 500 026 0) behaves like the

Stand alone module and an additional DDL participant for valve

control (see Slave Module).

To use the diagnosis function, the corresponding parameter has

to be adjusted (see table 5, parameter for the bus coupler).

Page 25

AVENTICS | DDL | R499050031–BAL–001–AH 25

Bus Coupler

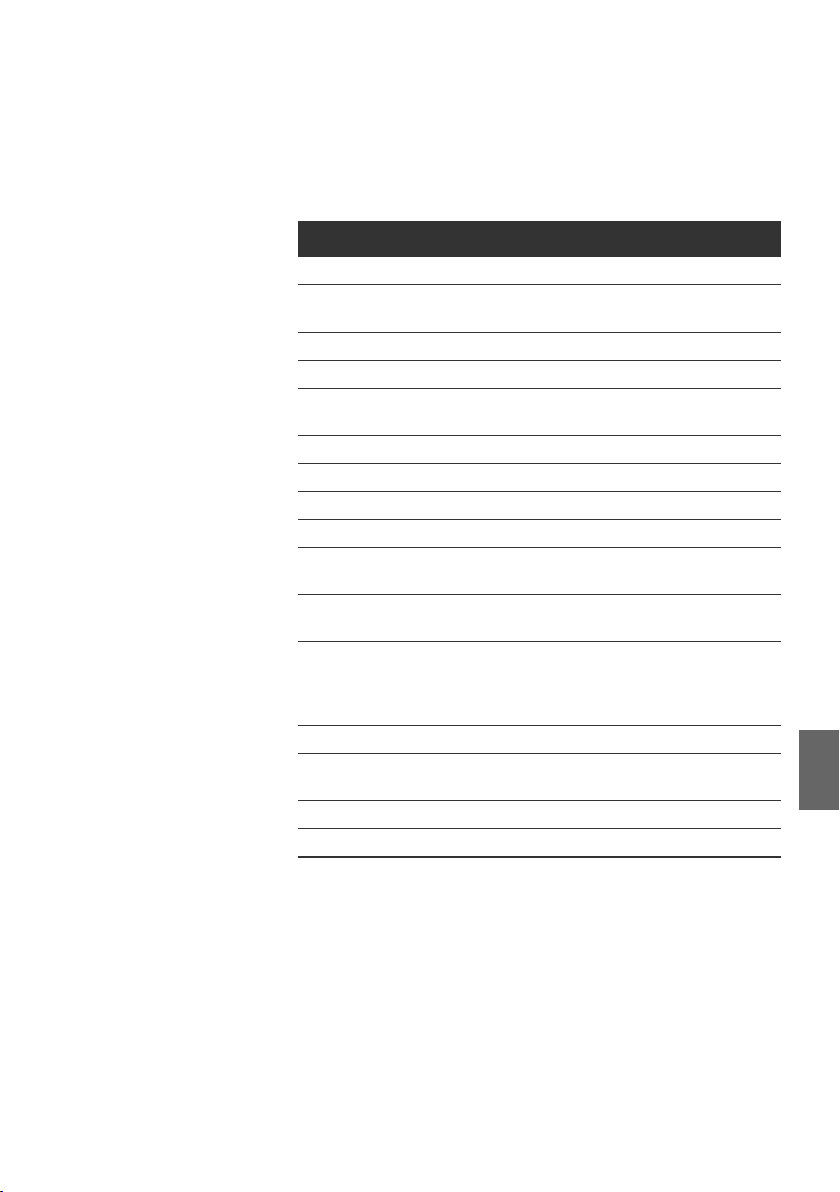

Table 8: Example: diagnosis fieldbus module PROFIBUS DP with one valve unit incl. standard diagnosis

DDL

gaps

between

or

address 0

and

1

...

14

mixed

DDL

addr.#5

exists

DDL

addr.#13

exists

output

4

output

12

output

20

output

28

Bit

DDL

no units

at DDL

DDL

addr.#4

exists

DDL

addr.#12

exists

output

diagnosis

output

diagnosis

output

diagnosis

output

diagnosis

11

19

27

3

24 V

electronic

input

diagnosis

DDL

addr.#3

exists

DDL

addr.#11

exists

output

2

diagnosis

output

10

diagnosis

output

18

diagnosis

output

26

diagnosis

24 V

valve

voltage at

DDL

output

diagnosis

DDL

addr.#2

exists

DDL

addr.#10

exists

24 V

valve

supply

diagnosis

output

1

diagnosis

output

9

diagnosis

output

17

diagnosis

output

25

diagnosis

24 V

electronic

voltage at

DDL

output

diagnosis

DDL

addr.#1

exists

DDL

addr.#9

exists

24 V

electronic

supply

diagnosis

output

0

diagnosis

output

8

diagnosis

output

16

diagnosis

output

24

diagnosis

Regarding

Byte

0 DP Norm

1 DP Norm

2 DP Norm

3 DP Norm

4 DP Norm

5 DP Norm

6 Headerbyte 0 0 block length in Byte

Bus coupler

7

8 Bus coupler

Bus coupler DDL

9

Bus coupler

10

module with

address 1

11

(valve unit)

module with

12

address 1

(valve unit)

module with

13

address 1

(valve unit)

module with

14

address 1

(valve unit)

module with

15

address 1

(valve unit)

7 6 5 4 3 2 1 0

addresses

––

have been

addr.#8

exists

––

DDL

comm.

diagnosis

output

7

diagnosis

output

15

diagnosis

output

23

diagnosis

output

31

diagnosis

DDL

addr.#7

exists

output

6

diagnosis

output

14

diagnosis

output

22

diagnosis

output

30

diagnosis

DDL

addr.#6

exists

DDL

addr.#14

exists

––––

output

5

diagnosis

output

diagnosis

output

diagnosis

output

diagnosis

diagnosis

13

diagnosis

21

diagnosis

29

diagnosis

English

Page 26

26 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

Meaning of the

diagnosis bits

W Byte 6:

– Bit 0 ... 5: total length of the diagnosis data in byte

W Byte 7:

– Bit 0: Electronic power supply of succeeding DDL modules

below 19.2 V or beyond 28.8 V

– Bit 1: Valve power supply of succeeding DDL modules

below 21.6 V or beyond 26.4 V

– Bit 2: Power supply of Master module electronics below

19.2 V or beyond 28.8 V

– Bit 3: No external modules connected to DDL

– Bit 4: Gaps between addresses, address 0 and 1 ... 14 have

been mixed up or addresses have been assigned twice.

(It cannot be assured that double addresses are

recognized safely)

W Byte 8:

– free

W Byte 9 + 10:

– Bit 0 ... 7: For each existing address the corresponding bit

will be set.

With automatic addressing the following is valid:

W Byte 9:

– Bit 0: Pressure control valve

– Bit 1: Valve driver

– Bit 2: Input module

– Bit 3: Output module

– Bit 4: Combi module

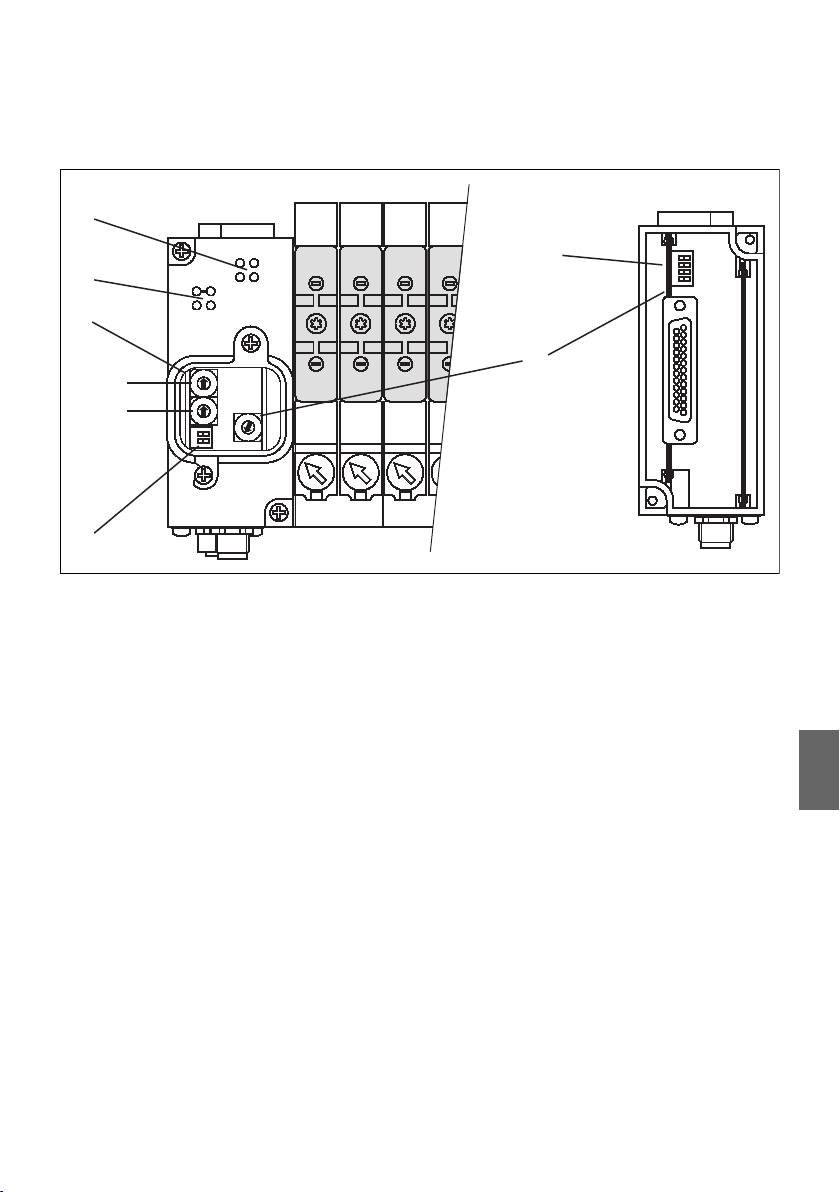

3.1.3 Slave Module

The Slave module behaves like a DDL participant for valve

control but it is situated within the housing of the bus coupler.

According to this a DDL address and a baud rate have to be

adjusted! The connection to the valve unit is effected via a 25 pin

D-Sub plug at the bottom side of the module.

Page 27

OPEN ON

S4

2

1

0

F

OPEN

Fig. 4: DIP switch S4

AVENTICS | DDL | R499050031–BAL–001–AH 27

Bus Coupler

DDL Address

The DDL address is adjusted with the switch S5. The regulation for

the adjustment can be found in chapter 2.2 “DDL Addressing“.

DDL Mode

The DDL baud rate is adjusted with switch S4. All participants

have to be adjusted to the same baud rate.

Table 9: DDL baud rate

Bit Open On

1 DDL 125 kBaud DDL 250 kBaud (default)

2 no function no function

Output Data Length

With switch S4 the number of outputs is adjusted. With this it is

possible to optimize the needed data range of the control for

43

21

5

4

3

6

7

8

9

A

B

E

C

D

ON

smaller valve units.

Table 10: Data length

Bit 3 Bit 4 Data length

Open Open 1 Byte

On Open 2 Byte

Open On 3 Byte

On On 4 Byte (default)

English

The 4 byte mode offers a conformity with 16 bit PLC systems.

But only the first 3 bytes are transferred to the outputs of the

D-Sub plug.

The switches must not be changed during operation.

Changed switch positions will only become valid, after the

device has been turned off and restarted.

Page 28

28 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

Output Data Range of the Control

The DDL address determines the position of the output data in

the data range of bus coupler and therefore the position in the

address range of the control. The valve driver occupies,

depending on the length set, 1 ... 4 byte in the output range of the

control. Whereby the 4th byte does not represent real outputs

and serves only for the 16 bit conformity.

Table 11: Output bits

Byte Regarding

valve unit

X

Pin 25 pol.

D-Sub

valve unit

X + 1

Pin 25 pol.

D-Sub

valve unit

X + 2

Pin 25 pol.

D-Sub

valve unit

X + 3

Pin 25 pol.

D-Sub

7 6 5 4 3 2 1 0

output7output6output5output4output3output2output1output

87654321

output15output14output13output12output11output10output9output

16 15 14 13 12 11 10 9

output23output22output21output20output19output18output17output

24 23 22 21 20 19 18 17

not

existent

Nc Nc Nc Nc Nc Nc Nc Nc

not

existent

not

existent

not

existent

Bit

existent

not

not

existent

not

existent

0

8

16

not

existent

At Pin 25 of 25 pol. D-Sub plug 0 V is connected.

If address 0 (automatic addressing) is set, the bus coupler with

driver behaves like a valve driver. Further information can be

taken from chapter 2.2 “DDL Addressing“.

The valve driver does not occupy any data in the input range,

only within the diagnosis range of the DDL.

Byte X is the start address of the output data range of the DDL

participant in the control (see PROFIBUS DP Configuration).

Page 29

LED Diagnosis

AVENTICS | DDL | R499050031–BAL–001–AH 29

Bus Coupler

Diagnosis

Table 12: Overview of the DDL LED indication

Description Color of LED Meaning

SUPPLY

SENSOR

SUPPLY

VALVE

DDL red lighting no DDL communication (see below)

The limits of power supply (electronics/valves) are at 19.2 V/

21.6 V for low voltage and at 28.8/26.4 V for overvoltage. The

voltages are measured at plug DDL OUT.

The LED DDL indicates that no reference data communication

takes place in the DDL system. This can be due to:

W The adjusted baud rate of the DDL modules is not equal

W Gaps in the addressing

W Same address has been assigned for 2 modules

W Address 0 and 1 ... 14 have been assigned at the same time

W Configuration has changed during operation

green lighting voltage within the tolerance

green flashing voltage below or beyond the tolerance

green off no voltage at connection sensor supply

(X1S, Pin 1)

green lighting voltage within the tolerance

green flashing voltage below or beyond the tolerance

green off no voltage at connection sensor supply

(X1S, Pin 1)

Voltage Monitoring The applied voltage supplies are indicated by two green LEDs:

Voltages at the plug DDL are shown. The threshold of the power

supply (electronic/valves) are at 19.2 V/21.6 V for under voltage

and at 28.8 V/26.4 V for overvoltage.

Software Diagnosis The software diagnosis of the Slave module is 1 byte standard

diagnosis + configured data length long.

With bus coupler 337 500 026 0 the outputs from 24 ... 31 are

not really existent. For this reason there is no rational diagnosis.

With smaller valve units further outputs and their diagnosis can

not be used.

The address range of the diagnosis drives from the DDL address.

English

Page 30

30 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

If address 0 (automatic addressing) is set, the bus coupler with

driver behaves like a valve driver. Further information can be

taken from chapter 2.2 “DDL Addressing“.

Table 13: Diagnosis bits

Byte

Z + 1

Z + 2

Z + 3

Z + 4

Z

7 6 5 4 3 2 1 0

DDL

comm.

diagnosis

output

7

diagnosis

output

15

diagnosis

output

23

diagnosis

output

31

diagnosis

–––––

output

6

diagnosis

output

14

diagnosis

output

22

diagnosis

output

30

diagnosis

output

5

diagnosis

output

13

diagnosis

output

21

diagnosis

output

29

diagnosis

diagnosis

diagnosis

diagnosis

diagnosis

Bit

output

4

output

12

output

20

output

28

output

3

diagnosis

output

11

diagnosis

output

19

diagnosis

output

27

diagnosis

output

2

diagnosis

output

10

diagnosis

output

18

diagnosis

output

26

diagnosis

24 V

valve

supply

diagnosis

output

1

diagnosis

output

9

diagnosis

output

17

diagnosis

output

25

diagnosis

24 V

electronic

supply

diagnosis

output

0

diagnosis

output

8

diagnosis

output

16

diagnosis

output

24

diagnosis

Meaning of the bits W Byte Z Bit 0: Power supply of the electronics below 19.2 V or

beyond 28.8 V

W Byte Z Bit 1: Power supply of the valves below 21.6 V or

beyond 26.4 V

W Byte Z Bit 7: Communication to the DDL module interrupted

W Byte (Z + 1) – (Z + 4) Bit 0 ... 7: Output short circuit or open

(see description of the parameter).

W Byte Z is the start address of the diagnosis range of the DDL

participant in the control.

NOTICE

A short circuit can only be detected if the output is driven. An

open output can only be detected if it is not driven.

Page 31

AVENTICS | DDL | R499050031–BAL–001–AH 31

Bus Coupler

Parameter

The Slave module provides the DDL master module for

PROFIBUS DP with these functions. For each DDL participant

one byte for parameter is available. The parameters are

transferred only with the DDL initialization. Each parameter

byte for the participants can be adjusted individually. In

connection with the PLC the PROFIBUS provides comfortable

possibilities for adjustment. If the control does not provide these

functions, default parameters will be used.

Table 14: Parameter for the Slave module

Bit Parameter Name Bit = 0 Bit = 1

7 reserved

6 reserved

5 reserved

4 reserved

3 reaction at DDL failure values at 0 (default) freeze values

2 reserved

1 diagnosis message of the coils for controlled outputs (default) changes are transferred

0 reserved

Bit 1 = 0 Output based diagnosis messages are only sent, if the output is

controlled. Upon starting the system it is not checked, which

coils do exist. If an output is controlled, where no coil exists, a

diagnosis message is generated.

Bit 1 = 1 Upon starting the system it is first determined what coils do

exist. This information is then transferred via a diagnosis

message to the control. In the control this message can be

compared with a deposited configuration of the system. (This

function is only supported by PROFIBUS DP; with other field bus

systems the diagnosis data are transferred cyclic). Missing coils

can be determined upon the start of the system. During the

cyclic operation only diagnosis messages are sent, if there have

been changes according to this configuration. Thereby the

complete diagnosis range is transferred. Open load is

immediately reported, the valve needs not to be controlled.

English

Page 32

32 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

Bit 3 = 0 Upon failure of the DDL, the output data are set at 0 in the Slave

module.

Bit 3 = 1 Upon failure of the DDL, the output data are stored in the Slave

module and the coils are still controlled (freezing values).

Changed parameters only become valid, if the device has

been switched off and has been restarted.

3.1.4 Connectors

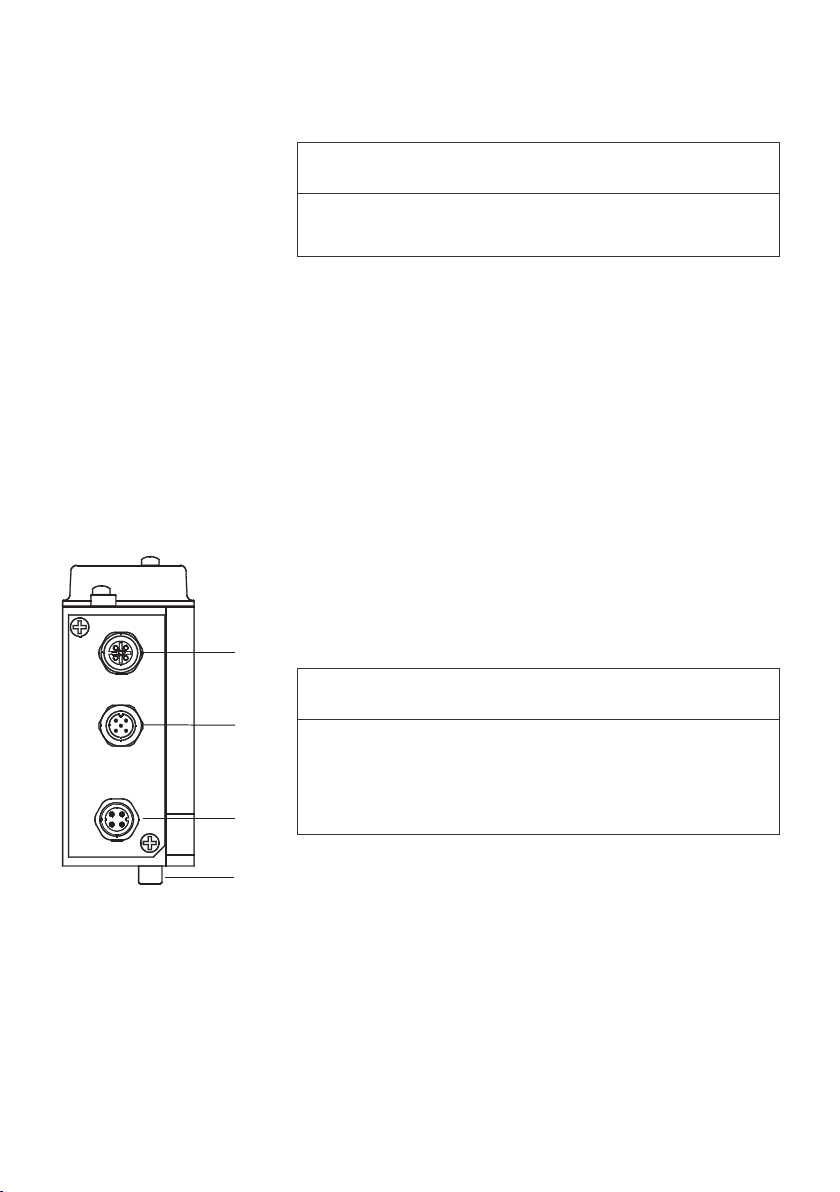

1 X7P2: PROFIBUS DP Input

2 X7P2: PROFIBUS DP Output

3 XPD: DDL OUT

4 X1S: Power supply

1

5 X2O: Valve driver (only 3375000260)

2

.

Fig. 5: Connectors

3

NOTICE

The connectors must not be plugged or pulled under load.

4

The assembly or the plugging and pulling of the bus coupler

onto the valve driver is only allowed when the device is off

5

circuit!

Power Supply

The power supply is connected via the circular plug X1S. Only

4 pin M12 connecting bushes should be used, where pin 5 is

closed; in order to avoid a mix up with other connections. The

diameter of the wires should be chosen as big as possible, but

at least 0.5 mm

Both power supplies must be secured with external 3 A T fuses.

The maximum allowed voltage in the O V line is limited to 4 A by

the connector.

2

.

Page 33

AVENTICS | DDL | R499050031–BAL–001–AH 33

Bus Coupler

1

4

2 3

Fig. 6: X1S power supply

1 Pin 1: 24 V sensor voltage / electronics

2 Pin 2: 24 V valve voltage

3 Pin 3: 0 V

4 Pin 4: Function earth

The electronics of the bus coupler and the electronics of all

I/O modules and initiators connected to the DDL (with modules

without ext. power supply) are supplied via X1S, pin 1.

If modules without an external power supply are used, the

switching voltage for connected valves must be supplied via

X1S, pin 2.Because of the separate supply of this power supply

it is possible, in an emergency stop situation, only to turn off the

valves, whereas the PLC, the serial interfaces and the initiators

remain in operation. Turning off the power supply for the serial

interface can lead to the state STOP of the PLC.

The 24 V supplies must be effected out of a common power

supply unit respectively with a common O V connection. A

power supply unit with a secure separation according to

EN 60742, classification VDE 0551 should be used.

4

X7P1: OUT

(female)

2

X7P2: IN

(male)

1

5

2 3

Fig. 7: PROFIBUS DP

1

data plug

Data Line PROFIBUS DP

The connection to the PROFIBUS system is done with data plug

M12 5 pin. B coded female at PROFIBUS DP IN (X7P2) or male at

PROFIBUS DP OUT (X7P1). Both connections are connected in

parallel and have the following assignment:

1 Pin 1: 5 V Supply for the connecting plug

3

4

2 Pin 2: A data line

3 Pin 3: 0 V supply voltage for the terminating plug (5 V)

4 Pin 4: B data line

5

5 Pin 5: shield

The connection is in correspondence with the recommendations

of the PROFIBUS association for the allocation of the 5 pin M12

B coded plug.

English

Page 34

34 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

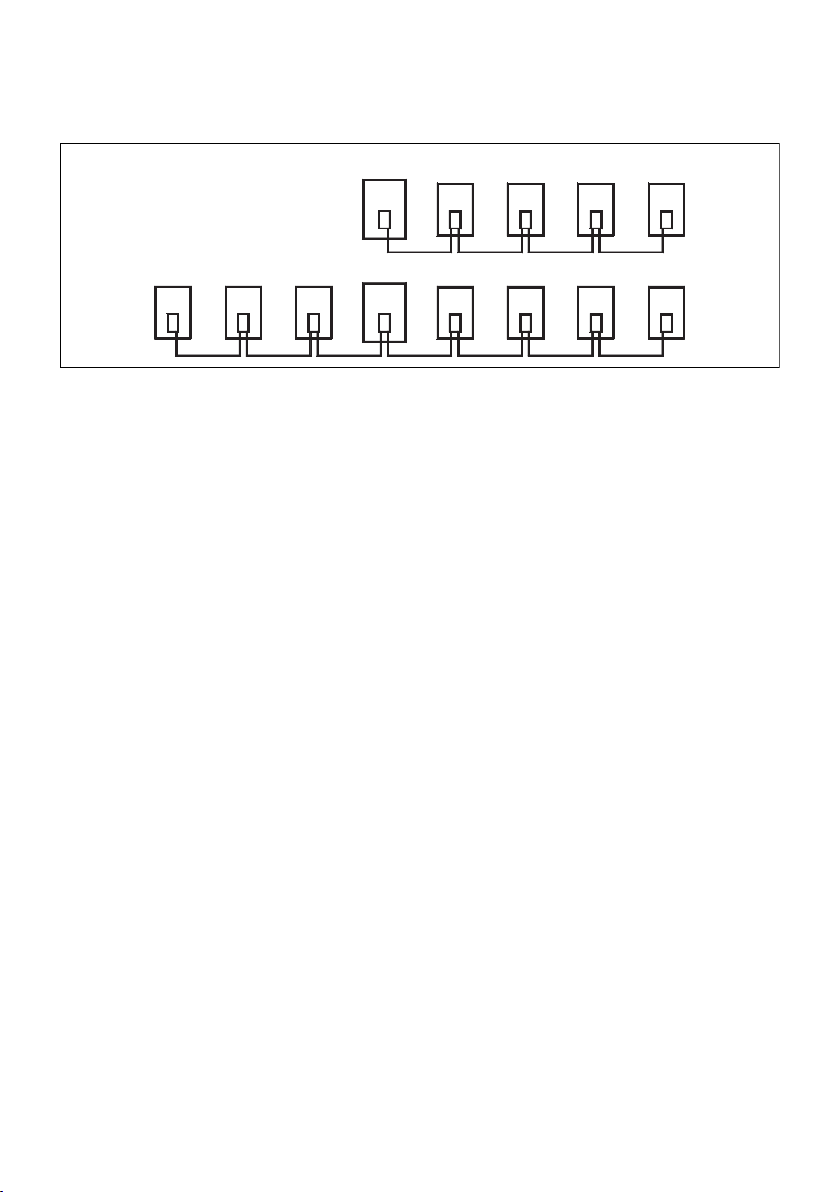

R

Fig. 8: Possible layout of bus participants

The terminating resistors integrated in the connecting plugs of

the participants marked with a “R” have to be activated or with

the bus coupler, the PROFIBUS DP terminating plug M12,

B coded (see chapter 5 “DDL Accessories“) has to be plugged to

the connector PROFIBUS DP OUT.

There has to be a terminator for the first and also for the last

participant of a bus line (see illustration 8). The termination

resistor is designed for a PROFIBUS DP cable of type A (wave

resistance 135 ... 165 Ω) and integrated into the end plug.

Data Line DDL

The output of the DDL is short circuit protected at all lines.

Nevertheless DDL participants can be damaged if 24 V are

applied to signal lines DDL H and DDL L. For this reason it is

recommend to use pre fabricated cables (see chapter 5 “DDL

Accessories“). The allocation of the DDL connections are

described in chapter 2.4 “DDL Data“.

The DDL end plug (see chapter 5 “DDL Accessories“) is

necessary to guarantee a definite termination of the line and the

protection degree IP 65, if the module is the last or the only

participant of a DDL line.

MASTER

SPS

R

SPS

SLAVE

R

R

Page 35

AVENTICS | DDL | R499050031–BAL–001–AH 35

Bus Coupler

3.1.5 Technical Data

Profibus DP

Technical Data

Operating voltage valves 24 V DC +10 -0 %

Operating voltage initiators and

electronics

Fuse of the valve voltage external 3 A T

Fuse of electronics external 3 A T

Attention: Maximum current

in the 0 V line

Voltage drop, internal 0.8 V

Required power electronics 90 mA

Power supply for sensors max. 3 A per DDL branch

Power supply for valves max. 3 A per DDL branch

Number of output bytes

(only 337 500 026 0)

Run up period after switching on the

power supply

Ambient temperature range +5°C ... +50°C

Stock temperature -20°C ... +70°C

Protection class (with closed connectors) IP 65

Installation position arbitrary

Further technical data s. quotation drawing

* With a current I of max. 2 A per valve and sensor

24 V DC ±20 %

max. 4 A

1 / 2 / 3 / 4 byte

2 s

+5°C ... +40°C (ATEX)

+5°C ... +50°C (ATEX)*

IP 54 (ATEX)

English

Page 36

36 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

3.1.6 Dimensions

45 107

POWER SUPPLY

VALVE

SENSOR

DDL

STOP

RUN

VALVE

SENSOR

POWER SUPPLY

0

1

9

2

8

3

4321

7

4

6

5

0

1

9

2

8

3

7

4

6

5

9

8

7

A

B

6

C

5

D

4

E

3

F

2

0

1

21

Fig. 9: Dimensions of the bus coupler with drivers (337 500 026 0)

104

113

STOP

RUN

VALVE

SENSOR

POWER SUPPLY

0

1

9

2

8

3

7

4

6

5

0

1

9

2

8

3

7

4

6

5

21

120

140

30

45

Fig. 10: Dimensions of the bus coupler Stand alone (337 500 025 0)

Page 37

AVENTICS | DDL | R499050031–BAL–001–AH 37

Bus Coupler

3.1.7 ATEX-Relevant Information

If the bus coupler PROFIBUS DP 337 500 025 0 is used in zone 2,

attention has to be paid to the following ATEX-relevant

information.

See chapter 3.6.1 “Ex-Relevant Excerpt from the Operating

Instructions for S-Design Bus Couplers“.

3.2 DeviceNet R412006999/R412006998

The bus coupler DDL for DeviceNet is available in two different

designs. The bus coupler with drivers (R412006998) can be

directly mounted onto a valve unit. In addition to the control of

this unit the DDL is also available for other DDL participants.

The bus coupler Stand alone (R412006999) is separately

mounted and provides only the DDL.

Parts of the description concerning the Slave module are not

valid for the bus coupler Stand alone.

3.2.1 Overview

DeviceNet

DeviceNet is a CAN protocol that is based on a definite master/

slave connection. Several masters can share a physical CAN

data line and control several slaves. A slave though is always

dedicated to one master and can only exchange data with this

one. A master must first release a slave before another master

is able to ask for the slave and activate him.

The electronic data sheet (EDS) can be downloaded from the

Internet at www.aventics.com/mediadirectory:

0064000000040205.eds

Type: EDS Configuration File

For information concerning the installation of the network and

regarding the preparation of the line, please refer to the

documentation of the company Rockwell Automation/AllenBradley.

English

Page 38

38 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

Bus Coupler DeviceNet

1

POWER SUPPLY

2

5 V

RUN

DDL

STATUS

MNS

12141214121412

VALVESENSOR

7

4321

3

0

1

9

2

8

3

7

6

0

9

4

8

7

6

21

4321

4

5

1

2

3

4

5

9

8

A

7

B

6

C

5

D

4

E

3

F

2

1

0

5

6

Fig. 11: LED and switches of R412006998

1 DDL LEDs

2 DeviceNet LEDs

3 DN address S1

4 DN address S2

5 Master module

3.2.2 Master Module

The Master module is the interface between the DeviceNet and

the DDL. It controls the DDL and monitors the supply voltages.

8

1

9

6 DeviceNet baud rate S3

7 Master module S4

DDL baud rate

8 Slave module DDL mode S6

9 DDL address S5

DeviceNet Addresses

A definite address is allocated to each participant in the

network. Via two rotary switches addresses from 0 ... 63 can be

set. With switch S1 the ten digit and with S2 the one digit is

adjusted. If the ID has been adjusted higher, it is reduced by 64.

In the factory the devices are adjusted to address 2.

Page 39

AVENTICS | DDL | R499050031–BAL–001–AH 39

Bus Coupler

DeviceNet Baud Rates

The baud rate of the DeviceNet system is adjusted with the 2 bit

DIP switch S3 next to the DeviceNet address switches at the

front side.

0

1

9

2

8

3

7

4

6

5

0

1

9

2

8

3

7

4

6

5

S1

S2

S3

21

Table 15: Adjustment of the DeviceNet baud rates

Bit 1 Bit 2 Baud Rate

On Open 500 kBaud

Open On 250 kBaud (default)

Open Open 125 kBaud

ON OPEN

OPEN

ON

Fig. 12: DIP switch S3:

DeviceNet

baud rates

DeviceNet Data

The length of the output data range (valves, nominal value, ...) is

fixed to 16 byte (10 hex) maximum. The length of the input data

range (sensors, actual values, ...) is also adjusted to 16 byte

maximum. Due to the diagnosis data of the bus coupler and the

DDL participants the total input data range is enlarged up to

50 byte (32 hex). The diagnostic data is transmitted cyclic within

the input data range to in the PLC.

Parameters

Some field bus systems offer the possibility to transfer

parameters to the bus coupler and the DDL participants.

At present the bus coupler for DeviceNet does not offer this

opportunity.

Bus Coupler Parameters

The bus coupler does not provide parameters for a modification.

Upon a failure of the DeviceNet the bus coupler behaves that

way that all output data are set at 0. Diagnostic data are

transmitted cyclic within the input data.

English

Page 40

40 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

DDL Participants Parameters

As with the bus coupler there is no parameter transfer for the

DeviceNet available, the default parameters are used with all

DDL participants. They are mentioned in the corresponding

device descriptions.

DDL Address

At the Master module, respectively Stand alone bus coupler, no

DDL Address has to be set.

For correct function of the DDL (Drive & Diagnostic Link)

following items must be fulfilled:

W same Baud rate at all DDL modules

W DDL Address within 1 ... 14, starting with 1, without gap, no

double used Address

W DDL Address 0: see chapter 2.2 “DDL Addressing“

DDL Mode

The transfer rate of the DDL is set with the 4 bit DIP switch S4

next to the D-Sub plug at the back side. All participants must be

adjusted to the same baud rate.

For access to switch S4 at the bus coupler Stand alone

R412006999 the bottom plate has to be removed.

Table 16: DDL baud rate

Bit Open On

1 DDL 125 kBaud DDL 250 kBaud (default)

2 running mode (default) assembly test

3 no function (default) no function

4 no function (default) no function

With switch S4 only the DDL Baud rate of the Master module will

be configured. At the bus coupler R412006998 the Slave module

has to be configured separately.

Page 41

AVENTICS | DDL | R499050031–BAL–001–AH 41

Bus Coupler

Diagnosis

LED Diagnosis On the top side of the device LEDs indicate the state of the

DeviceNet interface.

Table 17: Overview of the DN LED indications

LED Function

+5V/

STATUS

+5V flashing 1 Hz

STATUS flashing 1 Hz

+5V/

STATUS

MNS

RUN

MNS

RUN2

MNS

RUN

MNS

RUN

MNS lighting red major connection error

flashing 2 Hz

green

green

green

lighting green

off

off

off

lighting green

flashing red

off

off

flashing green

DDL configuration not OK

voltage sensor below or beyond the

tolerance

voltage valve below or beyond the

tolerance

after power reset:

power supplies within tolerances, DDL

OK

module waits for „Allocation“ from master

otherwise:

no process data transferred,

Timeout „expected packet rate“ without

timeout

Process data communication

Timeout „expected packet rate“ with

timeout, module waits for new

configuration

Power supply interruption in DeviceNet

cable, module waits for new

configuration

English

Voltage Monitoring The thresholds for under voltage of the valve supply is at 21.6 V,

for over voltage it is 26.4 V. The thresholds of the electronic

voltage are at 19.2 for under voltage and 28.8 V for over voltage.

Short Circuit Monitoring The bus coupler has a short circuit monitoring for the DDL. Both

power supplies are observed individually from each other. If the

short circuit monitoring is activated, the corresponding green

LED (see Voltage Monitoring) will be flashing.

Page 42

42 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

Software Diagnosis After activating the power the configuration of the DDL is

determined. Thereby the figure and the address of the

connected DDL participant, its data length and the type is

ascertained. After approx. 5 sec this configuration is redone and

compared to the first one. A difference of the determined

configurations is reported as a configuration error (byte 0, bit 5).

In addition the configuration is also examined when the total

output data range is set at 0 for more than 5 sec (set value = 0).

The in- and output data of the participants will not be influenced

thereby.

The software diagnosis of the Master module can be found in

the first 4 bytes of the adjusted input data area of the control,

before the input data. The whole software diagnosis of the other

DDL participants is behind the input data area of all DDL

participants. The length of the diagnosis range of further DDL

participants is 1 byte + the adjusted output data length with

valve driver. With other participants the diagnosis length can be

taken from the corresponding descriptions.

Table 18: Diagnosis bits

DDL

gaps

between

0 and

1 ... 14

#5

exists

#13

exists

Bit

DDL

no units

connected

to the DDL

DDL addr.

exists

DDL addr.

#12

exists

#4

24 V

electronic

supply

diagnosis

DDL addr.

#3

exists

DDL addr.

#11

exists

supply at

DDL OUT

diagnosis

DDL addr.

DDL addr.

Byte

0– –

1

2

3– –

7 6 5 4 3 2 1 0

DDL

heartbeat

DDL addr.

exists

#8

DDL addr.

#7

exists

DDL length

of the

output data

has

changed

since the

last

configura-

tion

DDL addr.

#6

exists

DDL addr.

#14

exists

addresses

or address

have been

mixed up.

length of the total input range (7 Bit)

DDL addr.

DDL addr.

24 V

valve

#2

exists

#10

exists

24 V

electronic

supply at

DDL OUT

diagnosis

DDL addr.

#1

exists

DDL addr.

#9

exists

Page 43

AVENTICS | DDL | R499050031–BAL–001–AH 43

Bus Coupler

Meaning of the

diagnosis bits

W Byte 0:

– Bit 0: Electronic power supply of the succeeding DDL

modules below 19.2 V or beyond 28.8 V

– Bit 1: Valve power supply of the succeeding DDL modules

below 21.6 V or beyond 26.4 V

– Bit 2: Power supply of the Master module electronic below

19.2 V or beyond 28.8 V

– Bit 3: No external modules connected to the DDL

– Bit 4: Gaps between addresses, address 0 and 1 ... 14 have

been mixed up or addresses have been assigned twice

– Bit 5: Since the last configuration the number of DDL

participants or the data length of the participants has

changed. This diagnosis appears also after a reset of the

power supply

W Byte 1:

– Bit 0 ... 6: Total length of the input data, including the

diagnosis data plus 4 byte of diagnosis data of the master

– Bit 7: Heartbeat, is reversed all 2 ... 3 seconds

W Byte 2 + 3:

– Bit 0 ... 7: For each existent address the corresponding bit

is set. With automatic addressing the following is valid:

W Byte 2:

– Bit 0: Pressure control valve

– Bit 1: Valve unit

– Bit 2: Input module

– Bit 3: Output module

– Bit 4: Combi module

English

3.2.3 Slave Module

The Slave module behaves like a DDL participant for valve

control but it is situated within the housing of the bus coupler.

According to this a DDL address has to be adjusted! The

connection to the valve unit is effected via a 25 pin D-Sub plug

at the bottom side of the module.

Page 44

44 AVENTICS | DDL | R499050031–BAL–001–AH

Bus Coupler

DDL Address

The DDL address is adjusted with a S5 switch.

The adjustment regulations for the addressing are described in

chapter 2.2 “DDL Addressing“.

DDL Mode

The DDL baud rate is adjusted with switch S6.

All participants must be adjusted to the same baud rate.

Table 19: DDL baud rate

Bit Open On

1 DDL 125 kBaud DDL 250 kBaud (default)

2 no function no function

Output Data Length

With switch S6 the number of outputs is adjusted. This provides

the possibility to optimize the required data range in the control

of smaller valve units.

Table 20: Data length

Bit 3 Bit 4 Data Length

Open Open 1 Byte

On Open 2 Byte

Open On 3 Byte

On On 4 Byte (default)

S6

S5

OPEN ON

43

21

5

4

3

6

7

2

1

8

9

0

A

F

B

E

C

D

OPEN

Fig. 13: DIP switch S6

The 4 byte mode offers conformity with 16 bit PLC systems. Only

the first 3 bytes are transferred to the outputs of the D-Sub plug.

ON

The switches must not be changed during operation.

Changed switch positions will only become valid, after the

device has been turned off and restarted.

Page 45

Table 21: Output bits

Byte Regarding

valve unit

X

Pin 25 pol.

D-Sub

valve unit

X + 1

Pin 25 pol.

D-Sub

valve unit

X + 2

Pin 25 pol.

D-Sub

valve unit

X + 3

Pin 25 pol.

D-Sub

AVENTICS | DDL | R499050031–BAL–001–AH 45

Bus Coupler

Output Data Range in the Control

The DDL address determines the position of the output data in

the data range of the bus coupler and therefore the position of

the address range of the control.

The valve unit occupies, depending on the adjusted length,

1 ... 4 bytes of the output range. Whereby the 4th byte does not

represent real outputs and serves only for the 16 bit conformity.

Bit

7 6 5 4 3 2 1 0

output7output6output5output4output3output2output1output

87654321

output15output14output13output12output11output10output9output

16 15 14 13 12 11 10 9

output23output22output21output20output19output18output17output

24 23 22 21 20 19 18 17

not

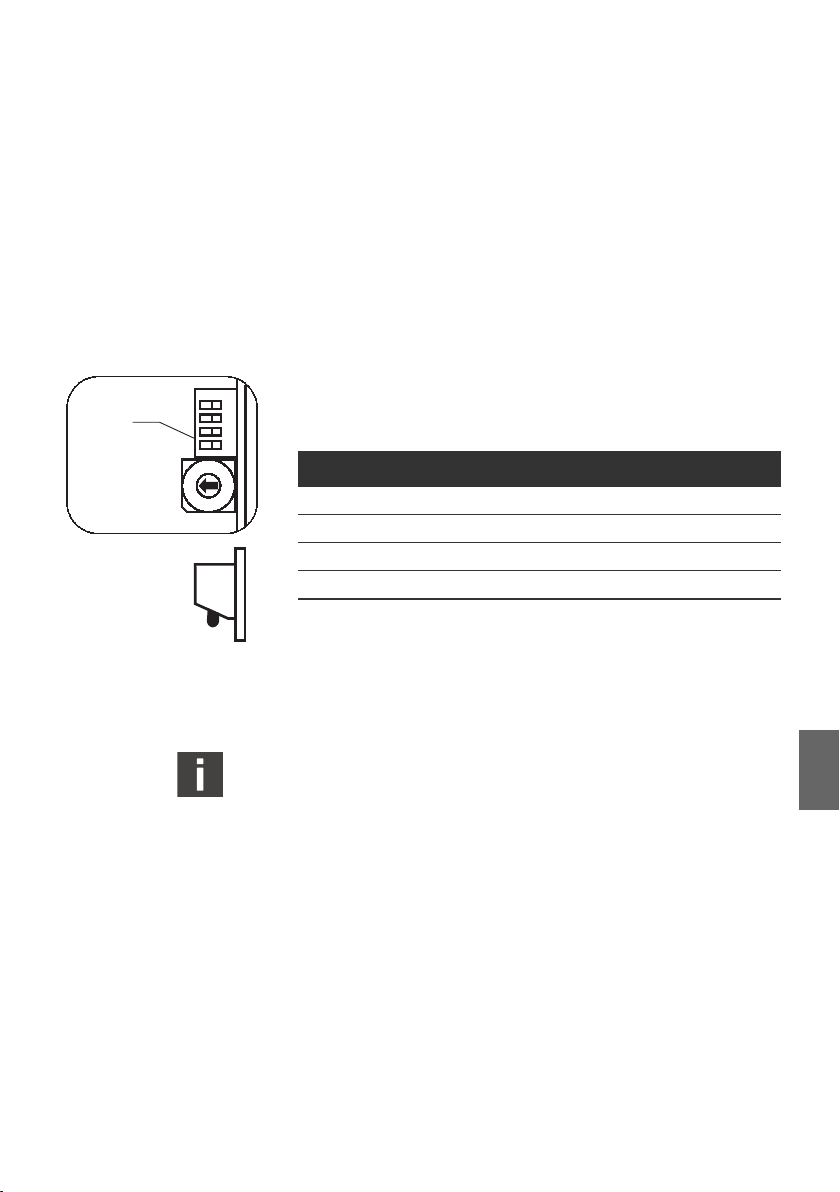

existent