Page 1

Installing Synchronous Net

Modules in an ASN Platform

BNX Software Version <x.x>

Part No. Test Part Number

January 1996

Page 2

4401 Great America Parkway 8 Federal Street

Santa Clara, CA 95054 Billerica, MA 01821

Copyright © 1988–1996 Bay Networks, Inc.

All rights reserved. Printed in the USA. January 1996.

The information in this document is subject to change without notice. The statements, configurations, technical data,

and recommendations in this document are believed to be accurate and reliable, but are presented without express or

implied warranty . Users must take full responsibility for their applications of an y products specified in this document.

The information in this document is proprietary to Bay Networks, Inc.

The software described in this document is furnished under a license agreement and may only be used in accordance

with the terms of that license. A summary of the Software License is included in this document.

Restricted Rights Legend

Use, duplication, or disclosure by the United States Government is subject to restrictions as set forth in subparagraph

(c)(1)(ii) of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013.

Notice for All Other Executive Agencies

Notwithstanding any other license agreement that may pertain to, or accompany the delivery of, this computer

software, the rights of the United States Government regarding its use, reproduction, and disclosure are as set forth in

the Commercial Computer Software-Restricted Rights clause at FAR 52.227-19.

Trademarks of Bay Networks, Inc.

ACE, AFN, AN, BCN, BLN, BN, BNX, CN, FN, FRE, GAME, LN, Optivity, PPX, SynOptics, SynOptics

Communications, Wellfleet and the Wellfleet logo are registered trademarks and ANH, ASN, Bay•SIS, BayStack,

BCNX, BLNX, EZ Install, EZ Internetwork, EZ LAN, PathMan, PhonePlus, Quick2Config, RouterMan, SPEX,

Bay Networks, Bay Networks Press, the Bay Networks logo and the SynOptics logo are trademarks of

Bay Networks, Inc.

Third-Party T rademarks

All other trademarks and registered trademarks are the property of their respective owners.

Statement of Conditions

In the interest of improving internal design, operational function, and/or reliability, Bay Networks, Inc. reserves the

right to make changes to the products described in this document without notice.

Bay Networks, Inc. does not assume any liability that may occur due to the use or application of the product(s) or

circuit layout(s) described herein.

Portions of the code in this software product are Copyright © 1988, Regents of the Univ ersity of California. All rights

reserved. Redistribution and use in source and binary forms of such portions are permitted, provided that the above

copyright notice and this paragraph are duplicated in all such forms and that any documentation, advertising materials,

and other materials related to such distribution and use acknowledge that such portions of the software were

developed by the University of California, Berkeley. The name of the University may not be used to endorse or

promote products derived from such portions of the software without specific prior written permission.

SUCH PORTIONS OF THE SOFTWARE ARE PROVIDED “AS IS” AND WITHOUT ANY EXPRESS OR

IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

In addition, the program and information contained herein are licensed only pursuant to a license agreement that

contains restrictions on use and disclosure (that may incorporate by reference certain limitations and notices imposed

by third parties).

ii

Test Part Number

Page 3

Electromagnetic Emissions

Meets requirements of:

FCC Part 15, Class A

EN 55 022 (CISPR 22:1985), Class A <and Class B>

VCCI Class 1 ITE

Canada Requirements Only

Canada CS-03 Rules and Regulations

Note:

The Canadian Department of Communications label identifies certified equipment. The certification means that

the equipment meets certain telecommunications network protective operations and safety requirements. The

Department does not guarantee the equipment will operate to the user's satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed using an acceptable method of connection. In

some cases, the company's inside wiring associated with a single line individual service may be extended by means of

a certified connector assembly (telephone extension cord). The customer should be aware that compliance with the

above conditions may not prevent the degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the

supplier. Any repairs or alterations made by the user to this equipment or equipment malfunctions, may give the

telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility, telephone lines

and internal metallic water pipe system, if present, are connected together. This precaution may be particularly

important in rural areas.

Caution:

inspection authority, or electrician, as appropriate.

Users should not attempt to make such connections themselves, but should contact the appropriate electric

Canada CS-03 -- Règles et règlements

Note:

L’étiquette du ministère des Communications du Canada indique que l’appareillage est certifié, c’est-à-dire

qu’il respecte certaines exigences de sécurité et de fonctionnement visant les réseaux de télécommunications. Le

ministère ne garantit pas que l’appareillage fonctionnera à la satisfaction de l’utilisateur.

Avant d’installer l’appareillage, s’assurer qu’il peut être branché aux installations du service de télécommunications

local. L’appareillage doit aussi être raccordé selon des méthodes acceptées. Dans certains cas, le câblage interne du

service de télécommunications utilisé pour une ligne individuelle peut être allongé au moyen d’un connecteur certifié

(prolongateur téléphonique). Le client doit toutefois prendre note qu’une telle installation n’assure pas un service

parfait en tout temps.

Les réparations de l’appareillage certifié devraient être confiées à un service d’entretien canadien désigné par le

fournisseur. En cas de réparation ou de modification effectuées par l’utilisateur ou de mauvais fonctionnement de

l’appareillage, le service de télécommunications peut demander le débranchment de l’appareillage.

Pour leur propre sécurité, les utilisateurs devraient s’assurer que les mises à la terre des lignes de distribution

d’électricité, des lignes téléphoniques et de la tuyauterie métallique interne sont raccordées ensemble. Cette mesure de

sécurité est particulièrement importante en milieu rural.

Attention:

aux pouvoirs de réglementation en cause ou à un électricien, selon le cas.

Test Part Number

Les utilisateurs ne doivent pas procéder à ces raccordements eux-mêmes mais doivent plutôt faire appel

iii

Page 4

Canada Requirements Only

(continued)

D. O. C. Explanatory Notes: Equipment Attachment Limitations

The Canadian Department of Communications label identifies certified equipment. This certification meets certain

telecommunication network protective, operational and safety requirements. The department does not guarantee the

equipment will operate to the users satisfaction.

Before installing the equipment, users should ensure that it is permissible to be connected to the facilities of the local

telecommunications company. The equipment must also be installed using an acceptable method of connection. In

some cases, the company’s inside wiring associated with a single line indi vidual service may be e xtended by means of

a certified connector assembly (telephone extension cord). The customer should be aware that compliance with the

above condition may not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the

supplier. Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give the

telecommunications company cause to request the user to disconnect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power utility, telephone lines

and internal metallic water pipe system, if present, are connected together. This precaution may be particularly

important in rural areas.

Caution:

inspection authority, or electrician, as appropriate.

Users should not attempt to make such connections themselves, but should contact the appropriate electrical

Notes explicatives du ministère des Communications: limites visant les accessoires

L’étiquette du ministère des Communications du Canada indique que l’appareillage est certifié, c’est-à-dire qu’il

respecte certaines exigences de sécurité et de fonctionnement visant les réseaux de télécommunications. Le ministère

ne garantit pas que l’appareillage fonctionnera à la satisfaction de l’utilisateur.

Avant d’installer l’appareillage, s’assurer qu’il peut être branché aux installations du service de télécommunications

local. L’appareillage doit aussi être raccordé selon des méthodes acceptées. Dans certains cas, le câblage interne du

service de télécommunications utilisé pour une ligne individuelle peut être allongé au moyen d’un connecteur certifié

(prolongateur téléphonique). Le client doit toutefois prendre note qu’une telle installation n’assure pas un service

parfait en tout temps.

Les réparations de l’appareillage certifié devraient être confiées à un service d’entretien canadien désigné par le

fournisseur. En cas de réparation ou de modification effectuées par l’utilisateur ou de mauvais fonctionnement de

l’appareillage, le service de télécommunications peut demander le débranchment de l’appareillage.

Pour leur propre sécurité, les utilisateurs devraient s’assurer que les mises à la terre des lignes de distribution

d’électricité, des lignes téléphoniques et de la tuyauterie métallique interne sont raccordées ensemble. Cette mesure de

sécurité est particulièrement importante en milieu rural.

Attention:

aux pouvoirs de réglementation en cause ou à un électricien, selon le cas.

Les utilisateurs ne doivent pas procéder à ces raccordements eux-mêmes mais doivent plutôt faire appel

iv

Test Part Number

Page 5

Canada Requirements Only

(continued)

Canadian Department of Communications Radio Interference Regulations

This digital apparatus (Access Feeder Node, Access Link Node, Access Node, Access Stack Node, Backbone

Concentrator Node, Backbone Concentrator Node Switch, Backbone Link Node, Backbone Link Node Switch,

Concentrator Node, Feeder Node, Link Node) does not exceed the Class A limits for radio-noise emissions from

digital apparatus as set out in the Radio Interference Regulations of the Canadian Department of Communications.

Réglement sur le brouillage radioélectrique du ministère des Communications

Cet appareil numérique (Access Feeder Node, Access Link Node, Access Node, Access Stack Node, Backbone

Concentrator Node, Backbone Concentrator Node Switch, Backbone Link Node, Backbone Link Node Switch,

Concentrator Node, Feeder Node, Link Node) respecte les limites de bruits radioélectriques visant les appareils

numériques de classe A prescrites dans le Réglement sur le brouillage radioélectrique du ministère des

Communications du Canada.

Test Part Number

v

Page 6

Bay Networks Software License

Note:

This is Bay Networks basic license document. In the absence of a

software license agreement specifying varying terms, this license -- or the

license included with the particular product -- shall govern licensee’s use of

Bay Networks software.

This Software License shall govern the licensing of all software provided to licensee by Bay Networks (“Software”).

Bay Networks will provide licensee with Software in machine-readable form and related documentation

(“Documentation”). The Software provided under this license is proprietary to Bay Networks and to third parties from

whom Bay Networks has acquired license rights. Bay Networks will not grant any Software license whatsoev er , either

explicitly or implicitly, except by acceptance of an order for either Software or for a Bay Networks product

(“Equipment”) that is packaged with Software. Each such license is subject to the following restrictions:

1. Upon delivery of the Software, Bay Networks grants to licensee a personal, nontransferable, none xclusiv e license

to use the Software with the Equipment with which or for which it was originally acquired, including use at any

of licensee’s facilities to which the Equipment may be transferred, for the useful life of the Equipment unless

earlier terminated by default or cancellation. Use of the Software shall be limited to such Equipment and to such

facility. Software which is licensed for use on hardware not offered by Bay Networks is not subject to restricted

use on any Equipment, however, unless otherwise specified on the Documentation, each licensed copy of such

Software may only be installed on one hardware item at any time.

2. Licensee may use the Software with backup Equipment only if the Equipment with which or for which it was

acquired is inoperative.

3. Licensee may make a single copy of the Software (but not firmware) for safekeeping (archives) or backup

purposes.

4. Licensee may modify Software (but not firmware), or combine it with other software, subject to the provision

that those portions of the resulting software which incorporate Software are subject to the restrictions of this

license. Licensee shall not make the resulting software available for use by any third party.

5. Neither title nor ownership to Software passes to licensee.

6. Licensee shall not provide, or otherwise make available, any Software, in whole or in part, in any form, to any

third party. Third parties do not include consultants, subcontractors, or agents of licensee who have licensee’s

permission to use the Software at licensee’s facility, and who have agreed in writing to use the Software only in

accordance with the restrictions of this license.

7. Third-party owners from whom Bay Networks has acquired license rights to software that is incorporated into

Bay Networks products shall have the right to enforce the provisions of this license against licensee.

8. Licensee shall not remove or obscure any copyright, patent, trademark, trade secret, or similar intellectual

property or restricted rights notice within or affixed to any Software and shall reproduce and affix such notice on

any backup copy of Software or copies of software resulting from modification or combination performed by

licensee as permitted by this license.

vi

Test Part Number

Page 7

Bay Networks Software License

9. Licensee shall not reverse assemble, reverse compile, or in any way reverse engineer the Software. [Note: For

licensees in the European Community, the Softw are Directiv e dated 14 May 1991 (as may be amended from time

to time) shall apply for interoperability purposes. Licensee must notify Bay Networks in writing of any such

intended examination of the Software and Bay Networks may provide review and assistance.]

10. Notwithstanding any foregoing terms to the contrary, if licensee licenses the Bay Networks product “Site

Manager,” licensee may duplicate and install the Site Manager product as specified in the Documentation. This

right is granted solely as necessary for use of Site Manager on hardware installed with licensee’s network.

11. This license will automatically terminate upon improper handling of Software, such as by disclosure, or Bay

Networks may terminate this license by written notice to licensee if licensee fails to comply with any of the

material provisions of this license and fails to cure such failure within thirty (30) days after the receipt of written

notice from Bay Networks. Upon termination of this license, licensee shall discontinue all use of the Software

and return the Software and Documentation, including all copies, to Bay Networks.

12. Licensee’s obligations under this license shall survive expiration or termination of this license.

(continued)

Test Part Number

vii

Page 8

Page 9

Contents

About This Guide

Conventions .....................................................................................................................xv

Acronyms .........................................................................................................................xvi

Ordering Bay Networks Publications ...............................................................................xvi

Technical Support and Online Services

Bay Networks Customer Service ...................................................................................xviii

Bay Networks Information Services .................................................................................xix

World Wide Web ........................................................................................................xix

Customer Service FTP ..............................................................................................xix

Support Source CD ................................................................................................... xx

CompuServe ............................................................................................................. xx

InfoFACTS .................................................................................................................xxi

How to Get Help ........................................................................................................xxi

Chapter 1

Installing a Net Module

Removing the Component Tray ......................................................................................1-2

Attaching the Antistatic Wrist Strap ................................................................................1-4

Removing Filler Brackets ................................................................................................1-5

Removing a Net Module .................................................................................................1-5

Installing a Net Module ...................................................................................................1-8

Installing a Filler Bracket .................................................................................................1-9

Replacing the Component Tray .....................................................................................1-11

Chapter 2

Checking the Net Module LEDs

Dual Sync Net Module LEDs ..........................................................................................2-1

Quad Sync Net Module LED ..........................................................................................2-2

Test Part Number

ix

Page 10

Appendix A

Cabling Requirements for the Net Modules

RS-232 Compliance ...................................................................................................... A-2

RS-422 Compliance ...................................................................................................... A-6

V.28 Compliance .......................................................................................................... A-10

V.35 Compliance .......................................................................................................... A-14

X.21 Compliance ......................................................................................................... A-18

Dial-Up Services Cabling Requirements ..................................................................... A-21

Net Module to an RS-232 Dial-on-Demand and Dial Backup Device ................... A-21

Net Module to an RS-422 Dial-on-Demand and Dial Backup Device ................... A-24

Net Module to a V.35 Dial-on-Demand and Dial Backup Device ........................... A-26

Appendix B

Requirements for European Operation

Installation Requirements .............................................................................................. B-1

Power Requirements ............................................................................................... B-1

Clearances and Creepage Distances ..................................................................... B-2

Safety Status ................................................................................................................. B-4

Index

x

Test Part Number

Page 11

Tables

Table 2-1. Functions of the Dual Sync Net Module LEDs .........................................2-1

Table 2-2. Functions of the Quad Sync Net Module LED .........................................2-2

Table A-1. Summary of Compliance Cabling Requirements for

the Net Modules ...................................................................................... A-1

Table A-2. Summary of Dial-Up Services Cabling Requirements for

the Net Modules ...................................................................................... A-2

Table A-3. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-232 Cable

(Order No. 7826) ..................................................................................... A-3

Table A-4. Pin-to-Pin Connections for the 50-Pin to RS-232 Cable

(Order No. 7934) ..................................................................................... A-4

Table A-5. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-422 Cable

(Order No. 7318) ..................................................................................... A-6

Table A-6. Pin-to-Pin Connections for the 50-Pin to RS-422 Cable

(Order No. 7937) ..................................................................................... A-8

Table A-7. Pin-to-Pin Connections for the 44-Pin D-Sub to V.28 Cable

(Order No. 7837) ................................................................................... A-10

Table A-8. Pin-to-Pin Connections for the 50-Pin to V.28 Cable

(Order No. AA0018023) ........................................................................ A-12

Table A-9. Pin-to-Pin Connections for the 44-Pin D-Sub to V.35 Cable

(Order No. 7220) ................................................................................... A-14

Table A-10. Pin-to-Pin Connections for the 50-Pin to V.35 Cable

(Order No. 7932) ................................................................................... A-16

Table A-11. Pin-to-Pin Connections for the 44-Pin D-Sub to X.21 Cable

(Order No. 7224) ................................................................................... A-18

Table A-12. Pin-to-Pin Connections for the 50-Pin to X.21 Cable

(Order No. 7936) ................................................................................... A-20

Table A-13. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-232: Raise

DTR Cable (Order No. 7138) ................................................................ A-22

Table A-14. Pin-to-Pin Connections for the 50-Pin to RS-232: Raise

DTR Cable (Order No. 7935) ................................................................ A-23

Table A-15. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-422: Raise

DTR Cable (Order No. 7139) ................................................................ A-24

Test Part Number BNX Software Version <x.x>

xiii

Page 12

Table A-16. Pin-to-Pin Connections for the 44-Pin D-Sub to V.35: Raise

DTR Cable (Order No. 7137) ................................................................ A-26

Table A-17. Pin-to-Pin Connections for the 50-Pin to V.35: Raise DTR Cable

(Order No. 7933) ................................................................................... A-28

Table B-1. Net Module Power Requirements ........................................................... B-1

Table B-2. Net Module Clearances and Creepage Distances .................................. B-2

Table B-3. Net Module Safety Status ....................................................................... B-4

xiv

BNX Software Version <x.x> Test Part Number

Page 13

.

.

.

About This Guide

Read this guide if you are responsible for installing a Dual or Quad Sync net

™

module in a Bay Networks

describes how to

• Install a net module (Chapter 1)

• Interpret the LEDs on the net module (Chapter 2)

This guide also describes requirements for cabling a net module (Appendix A)

and for operating it in Europe (Appendix B).

Access Stack Node (ASN™) platform. This guide

Conventions

ellipsis points Horizontal (. . .) and vertical ellipsis points indicate

omitted information.

italic text

quotation marks (“ ”) Indicate the title of a chapter or section within a book.

separator ( > ) Separates menu and option names in instructions and

Test Part Number BNX Software Version <x.x>

Indicates variable values in command syntax

descriptions, new terms, file and directory names, and

book titles.

internal pin-to-pin wire connections.

Example: Protocols > AppleTalk identifies the

AppleTalk option in the Protocols menu.

Example: Pin 7 > 19 > 20

()

xv

Page 14

Installing Synchronous Net Modules in an ASN Platform

Acronyms

LED light emitting diode

SELV safety extra-low voltage

TNV telecommunications network voltage

WAN wide area network

Ordering Bay Networks Publications

To purchase additional copies of this document or other Bay Networks

publications, order by part number from the Bay Networks Press

telephone or fax numbers:

• Telephone - U.S./Canada 1-888-4BAYPRESS

• Telephone - International 1-510-490-4752

• Fax 1-510-498-2609

You can also use these numbers to request a free catalog of Bay Networks Press

product publications.

™

at the following

xvi

BNX Software Version <x.x> Test Part Number

Page 15

Technical Support and Online Services

To ensure comprehensive network support to our customers and partners

worldwide, Bay Networks Customer Service has Technical Response Centers

in key locations around the globe:

• Billerica, Massachusetts

• Santa Clara, California

• Sydney , Australia

• Tokyo, Japan

• Valbonne, France

Test Part Number

The Technical Response Centers are connected via a redundant Frame Relay

Network to a Common Problem Resolution system, enabling them to transmit and

share information, and to provide live, around-the-clock support 365 days a year.

Bay Networks Information Services complement the Bay Networks Service

program portfolio by giving customers and partners access to the most current

technical and support information through a choice of access/retrieval means.

These include the World Wide Web, CompuServe, Support Source CD, Customer

Support FTP, and InfoFACTS document fax service.

xvii

Page 16

Installing Synchronous Net Modules in an ASN Platform

Bay Networks Customer Service

If you purchased your Bay Networks product from a distributor or authorized

reseller, contact that distributor’s or reseller’s technical support staff for assistance

with installation, configuration, troubleshooting, or integration issues.

Customers can also purchase direct support from Bay Networks through a variety

of service programs. As part of our PhonePlus

sets the industry standard, with 24-hour, 7-days-a-week telephone support

available worldwide at no extra cost. Our complete range of contract and

noncontract services also includes equipment staging and integration, installation

support, on-site services, and replacement parts delivery -- within approximately

4 hours.

To purchase any of the Bay Networks support programs, or if you have questions

on program features, use the following numbers:

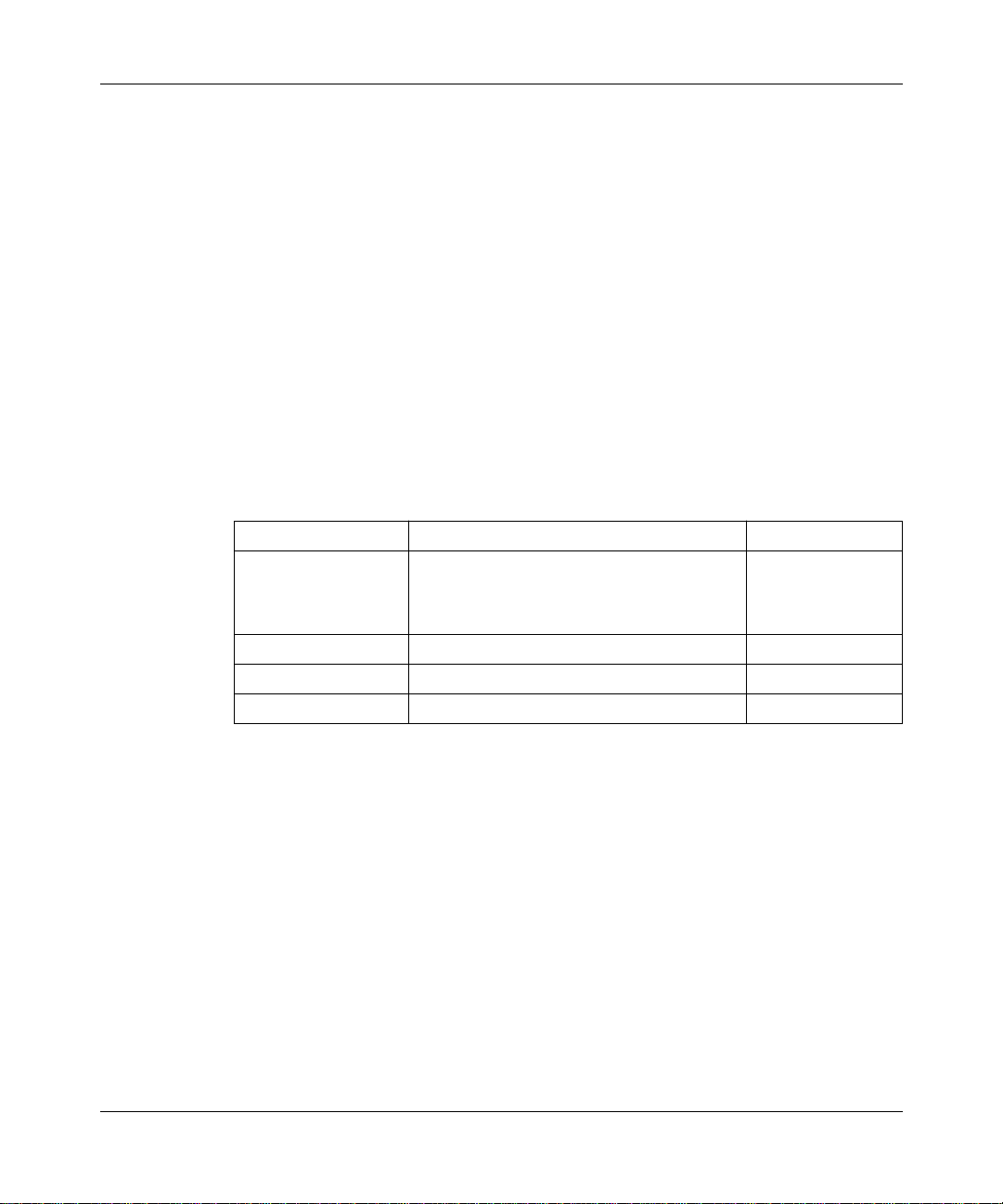

Region Telephone Number Fax Number

United States and

Canada

1-800-2LANWAN; enter Express Routing

Code (ERC) 290 when prompted

™

program, Bay Networks Service

(508) 670-8766

xviii

(508) 436-8880 (direct)

Europe (33) 92-968-300 (33) 92-968-301

Asia/Pacific Region (612) 9927-8800 (612) 9927-8811

Latin America (407) 997-1713 (407) 997-1714

In addition, you can receive information on support programs from your local

Bay Networks field sales office, or purchase Bay Networks support directly

from your authorized partner.

Test Part Number

Page 17

Bay Networks Information Services

Bay Networks Information Services provide up-to-date support information as a

first-line resource for network administration, expansion, and maintenance. This

information is available from a variety of sources.

W orld Wide Web

The Bay Networks Customer Support Web Server offers a diverse library of

technical documents, software agents, and other important technical information

to Bay Networks customers and partners.

A special benefit for contracted customers and resellers is the ability to access the

Web Server to perform Case Management. This feature enables your support staff

to interact directly with the network experts in our worldwide Technical Response

Centers. A registered contact with a valid Site ID can

• View a listing of support cases and determine the current status of any open

case. Case history data includes severity designation, and telephone, e-mail,

or other logs associated with the case.

Bay Networks Information Services

• Customize the listing of cases according to a variety of criteria, including

date, severity, status, and case ID.

• Log notes to existing open cases.

• Create new cases for rapid, efficient handling of noncritical network

situations.

• Communicate directly via e-mail with the specific technical resources

assigned to your case.

The Bay Networks URL is

menu item on that home page.

Customer Service FTP

Accessible via URL

combines and organizes support files and documentation from across the

Bay Networks product suite, including switching products from our Centillion

and Xylogics

site lets you quickly locate information on any of your Bay Networks products.

Test Part Number

®

http://www.baynetworks.com

ftp://support.baynetworks.com

. Customer Service is a

(134.177.3.26), this site

™

business units. Central management and sponsorship of this FTP

xix

Page 18

Installing Synchronous Net Modules in an ASN Platform

Support Source CD

This CD-ROM -- sent quarterly to all contracted customers -- is a complete Bay

Networks Service troubleshooting knowledge database with an intelligent text

search engine.

The Support Source CD contains extracts from our problem-tracking database;

information from the Bay Networks Forum on CompuServe; comprehensive

technical documentation, such as Customer Support Bulletins, Release Notes,

software patches and fixes; and complete information on all Bay Networks

Service programs.

You can run a single version on Macintosh Windows 3.1, Windows 95,

Windows NT, DOS, or UNIX computing platforms. A Web links feature enables

you to go directly from the CD to various Bay Networks Web pages.

CompuServe

For assistance with noncritical network support issues, Bay Networks Information

Services maintain an active forum on CompuServe, a global bulletin-board

system. This forum provides file services, technology conferences, and a message

section to get assistance from other users.

xx

The message section is monitored by Bay Networks engineers, who provide

assistance wherever possible. Customers and resellers holding Bay Networks

service contracts also have access to special libraries for advanced levels of

support documentation and software. To take advantage of CompuServe’s recently

enhanced menu options, the Bay Networks Forum has been re-engineered to allow

links to our Web sites and FTP sites.

We recommend the use of CompuServe Information Manager software to access

these Bay Networks Information Services resources. To open an account and

receive a local dial-up number in the United States, call CompuServe at

1-800-524-3388. Outside the United States, call 1-614-529-1349, or your nearest

CompuServe office. Ask for Representative No. 591. When you are on line with

your CompuServe account, you can reach us with the command

GO BAYNET

Test Part Number

.

Page 19

InfoFACTS

InfoFACTS is the Bay Networks free 24-hour fax-on-demand service. This

automated system has libraries of technical and product documents designed to

help you manage and troubleshoot your Bay Networks products. The system

responds to a fax from the caller or to a third party within minutes of being

accessed.

To use InfoFACTS in the United States or Canada, call toll-free 1-800-786-3228.

Outside North America, toll calls can be made to 1-408-764-1002. In Europe,

toll-free numbers are also available for contacting both InfoFACTS and

CompuServe. Please check our Web page for the listing in your country.

How to Get Help

Use the following numbers to reach your Bay Networks Technical Response

Center:

Technical Response Center Telephone Number Fax Number

Billerica, MA 1-800-2LANWAN (508) 670-8765

Santa Clara, CA 1-800-2LANWAN (408) 764-1188

Valbonne, France (33) 92-968-968 (33) 92-966-998

Sydney, Australia (612) 9927-8800 (612) 9927-8811

Tokyo, Japan (81) 3-5402-0180 (81) 3-5402-0173

Bay Networks Information Services

Test Part Number

xxi

Page 20

Page 21

Chapter 1

Installing a Net Module

This chapter describes tasks that you perform to install a net module in an ASN.

Each of the synchronous net modules requires the ASN to be running a specific

version of router software as follows:

• The Dual Sync net module requires Version 8.00 or later.

• The Quad Sync net module requires Version 11.00 or later.

To install a net module:

1. Remove the ASN component tray.

2. Attach the antistatic wrist strap.

3. Remove the filler brackets.

4. Remove the net module you want to replace from the ASN (if necessary).

5. Install the new net module.

6. Replace the filler brackets.

7. Disconnect the antistatic wrist strap.

8. Replace the component tray.

Note:

Experienced network operators can safely perform the user-serviceable

procedures that are described in this book.

Test Part Number BNX Software Version <x.x>

Installing a Net Module1

Page 22

Installing Synchronous Net Modules in an ASN Platform

Removing the Component Tray

You need a Phillips screwdriver to complete this procedure.

To remove the component tray:

1.

Power off the ASN.

2.

Detach all cables, including the power cable, from the ASN back panel.

3.

Using a Phillips screwdriver, loosen the two captive screws that fasten the

tray to the chassis (Figure 1-1).

a.

Pull the two captive screws and gently slide the tray out of the chassis

a few inches (Figure 1-1).

b.

Hold the sides and bottom of the tray to support it as you slide it out.

Try to keep the tray level as you slide it out.

4.

Place the tray on a sturdy work surface.

Caution:

Do not touch any components or boards in the ASN until you have

attached an antistatic wrist strap. See the next section, “Attaching the

Antistatic Wrist Strap.”

Installing a Net Module2

BNX Software Version <x.x> Test Part Number

Page 23

Removing the Component Tray

Component tray

Figure 1-1. Removing the Component Tray

Captive

thumbscrews

ASN0031A

Test Part Number BNX Software Version <x.x>

Installing a Net Module3

Page 24

Installing Synchronous Net Modules in an ASN Platform

Attaching the Antistatic Wrist Strap

Your ASN comes with an antistatic wrist strap. An antistatic wrist strap directs the

discharge of static electricity from your body to the chassis of the router, thereby

avoiding discharge to sensitive electronic components. You must wear an

antistatic wrist strap whenever you remove, install, or handle the net module.

Caution: Electrostatic discharge can damage hardware. Follow the procedure

in this section to protect your equipment from damage.

Attach the antistatic wrist strap as follows:

1.

Remove the wrist strap from its package.

2.

Place the looped end of the strap around your wrist.

3.

Adjust the strap so that it fits snugly around your wrist and makes good

contact with your skin.

4. Attach the alligator clip at the other end of the wrist strap to any

unpainted, metal surface on the component tray.

Installing a Net Module4

BNX Software Version <x.x> Test Part Number

Page 25

Removing Filler Brackets

Filler brackets cover empty ASN net module positions and the openings above

positions 1 and 3 (Figure 1-2). When you install a net module, you must remove

the filler brackets from the openings above positions 1 and 3, and also from the

position in which you want to install the net module.

Note: This manual refers to the end of the component tray where the net

module ports are exposed as the “back end” of the tray. To perform

maintenance tasks on the ASN components, you face the back end of the tray.

To remove a filler bracket, grasp its top edges. Then lift the brack et up and to w ard

the front of the tray to release the metal tabs. (Remember that the net module ports

are exposed at the back of the tray.)

Removing Filler Brackets

Net module

positions 1 and 2

1

2

2

Expansion

bracket

XMT/RCV

Net module filler

bracket

ETHERNET

34000

F

1

CONSOLE

DCD

2

DCD

2

Figure 1-2. Locating Net Modules and Filler Brackets

Removing a Net Module

Read this section if you need to install the net module in a slot that already

contains one. T o remo ve a module from position 2 or 4 (Figure 1-2), you must first

remove the filler bracket and net module (if any) above it. See the previous

section, “Removing Filler Brackets.”

Caution: Do not touch any components or boards in the ASN until you have

attached the antistatic wrist strap.

Net module

positions 3 and 4

DCD

DCD

1

1

SYNC

34001

F

SYNC

34001

F

1

2

4

3

SPEX

SLOT

ASN0042A

3

4

Test Part Number BNX Software Version <x.x> Installing a Net Module5

Page 26

Installing Synchronous Net Modules in an ASN Platform

To remove a net module:

1. Grasp the handle on the net module. Use your thumb to push back the

white retaining tab (Figure 1-3).

Retaining

tab

Retaining

post

Handle

AMC0006A

Figure 1-3. Preparing to Remove a Net Module

Installing a Net Module6 BNX Software Version <x.x> Test Part Number

Page 27

Removing a Net Module

Pull up to release the module from the connector (Figure 1-4).

2.

Caution: You must lift the module straight up. If you rock the module back

and forth or side to side, you can bend the connector pins. Attempting to

reinstall a net module with bent connector pins can damage the power supply.

AMC0010A

Figure 1-4. Removing a Net Module from the Connector

Lift the module bracket up and toward the front of the tray to release it

3.

from the metal tabs that hold it in place (refer to Figure 1-3).

Test Part Number BNX Software Version <x.x> Installing a Net Module7

Page 28

Installing Synchronous Net Modules in an ASN Platform

Installing a Net Module

Before you install the net module, note that

• To access position 2 or 4, you must remove the filler bracket and net module

(if any) above it. See the earlier sections “Removing Filler Brackets” and

“Removing a Net Module.”

• To install a net module in a position from which you just removed a net

module of a different type, you must first delete the old net module from the

router’s configuration file. Then install the new module in the chassis. See

Configuring Routers for information.

To install a net module:

1. Align the slots in the module bracket with the metal tabs in the net

module position that you want to use (Figure 1-5).

Do not rest the module bracket on the metal tabs; doing so makes it difficult to

align the module connector with the connector on the system board.

2. Align the module connector with the connector on the system board.

Make sure that the white retaining post on the system board aligns

through the hole in the net module (Figure 1-5).

Note: If you accidentally turn the white retaining post on the system board, it

will not align through the hole in the net module. In this case, turn the post so

that its rectangular base is perpendicular to the net module connectors on the

system board.

3. Firmly press the handle on the net module so that the net module is

secure in its connector on the system board. Make sure that the white

retaining tab snaps into place.

4. Press down on the module bracket so that it rests on the metal tabs.

Installing a Net Module8 BNX Software Version <x.x> Test Part Number

Page 29

Installing a Filler Bracket

Slot in

module bracket

Retaining

Metal

tab

Retaining

post

Handle

tab

AMC0007A

Figure 1-5. Aligning a Net Module

Installing a Filler Bracket

Install filler brackets in any unused net module positions. You must replace the

filler brackets that fill the openings above positions 1 and 3.

Note: The filler brackets you use above positions 1 and 3 are different from

the brackets that fill unused net module positions 1 through 4. To fill the

openings above positions 1 and 3, make sure that you use the brackets labeled

“Expansion Filler” (refer to Figure 1-2). The filler brackets for net module

positions are not labeled.

Test Part Number BNX Software Version <x.x> Installing a Net Module9

Page 30

Installing Synchronous Net Modules in an ASN Platform

To install a filler bracket:

1. Align the slots at each end of the bracket with the metal tabs of the

position where you are installing the bracket (Figure 1-6).

Make sure that the edge of the bracket labeled “Top Surface” faces up.

2. Position the bracket so that it rests on the metal tabs.

Slot in

bracket

Filler

bracket

Metal

tab

ASN0043A

Figure 1-6. Installing a Filler Bracket

Installing a Net Module10 BNX Software Version <x.x> Test Part Number

Page 31

Replacing the Component Tray

Before you replace the component tray, remove the alligator clip of the antistatic

strap from the chassis. Then remove the antistatic wrist strap from your wrist.

To replace the component tray:

1. Gently slide the tray into the chassis.

2. Use a Phillips screwdriver to tighten the two captive screws that fasten

the tray to the chassis (refer to Figure 1-1).

3. Reattach the cables to the proper connectors on the back panel.

See Chapter 2 for information about the LEDs on the net module.

Replacing the Component Tray

Test Part Number BNX Software Version <x.x> Installing a Net Module11

Page 32

Page 33

Checking the Net Module LEDs

This chapter describes the LEDs on the Dual and Quad Sync net modules.

Dual Sync Net Module LEDs

The Dual Sync net module has three LEDs. Figure 2-1 shows the LEDs on the

Dual Sync net module. Table 2-1 describes the function of each LED.

Chapter 2

SYNC

2 1

DCDDCD

34001

F

ASN0021A

Figure 2-1. Dual Sync Net Module LEDs

Table 2-1. Functions of the Dual Sync Net Module LEDs

LED Function

DCD1 Indicates that data carrier detect is present on the COM1 port.

DCD2 Indicates that data carrier detect is present on the COM2 port.

F (FAIL) Lights during power up, and can flash during diagnostic testing.

The F AIL LED turns off once the diagnostics complete successfully

and the router boots.

The LED remains lit if the net module or any connector on the net

module fails diagnostics. In this case, the DIAG LED on the ASN

front panel will also be lit.

Test Part Number BNX Software Version <x.x> Checking the Net Module LEDs1

Page 34

Installing Synchronous Net Modules in an ASN Platform

Quad Sync Net Module LED

The Quad Sync net module has one LED. Figure 2-2 shows the LED on the Quad

Sync net module. Table 2-2 describes the function of the LED.

4

Figure 2-2. Quad Sync Net Module LED

Table 2-2. Functions of the Quad Sync Net Module LED

LED Function

F (FAIL) Lights during power up, and can flash during diagnostic testing.

The F AIL LED turns off once the diagnostics complete successfully

and the router boots.

QUAD SYNC

NET MODULE

123

F

ASN0068A

The LED remains lit if the net module or any connector on the net

module fails diagnostics. In this case, the DIAG LED on the ASN

front panel will also be lit.

Checking the Net Module LEDs2 BNX Software Version <x.x> Test Part Number

Page 35

Appendix A

Cabling Requirements for the Net Modules

This appendix provides technical information about the cabling requirements for

the net modules. Tables A-1 and A-2 summarize the compliance and dial-up

cabling requirements for the net modules including the following:

• Required cable and its order number

• Page number for the cable’s pin-to-pin and connector information

• Industry interface type

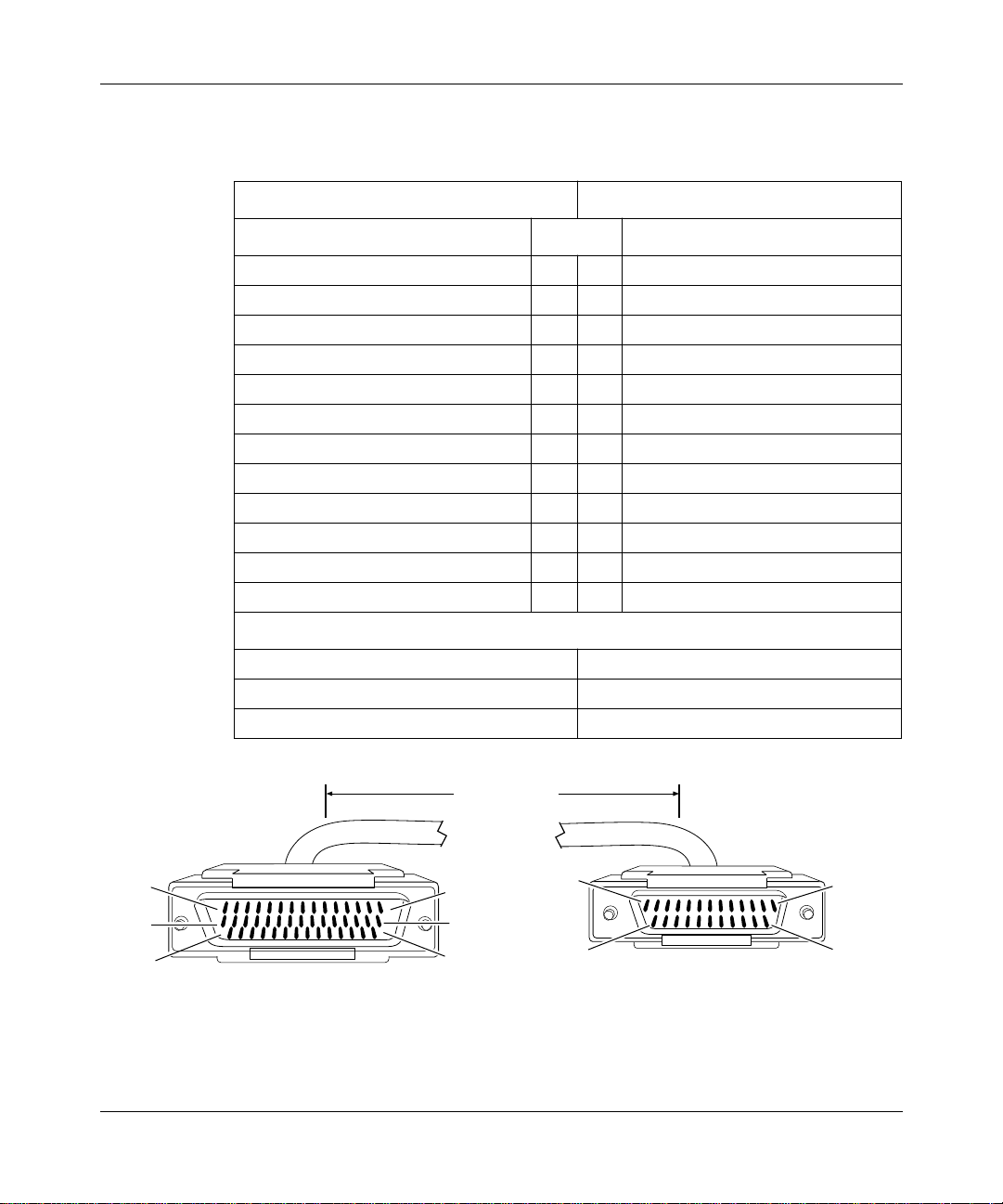

Table A-1. Summary of Compliance Cabling Requirements for the Net Modules

Net

Compliance

RS-232 Dual 44-pin D-Sub to RS-232 7826 Page A-3 RS-232-C

RS-422* Dual 44-pin D-Sub to RS-422 7318 Pages A-6 and A-7 RS-449/RS-422

V.28 Dual 44-pin D-Sub to V.28 7837 Pages A-10 and A-11 V.28 (V.10)

V.35 Dual 44-pin D-Sub to V.35 7220 Pages A-14 and A-15 V.35 (V.10, V.11)

X.21 Dual 44-pin D-Sub to X.21 7224 Pages A-18 and A-19 X.21 (V.11)

*. For high data rates, Bay Networks recommends a V.35 interface.

Module Required Cable

Quad 50-pin to RS-232 7934 Pages A-4 and A-5 RS-232-C

Quad 50-pin to RS-422 7937 Pages A-8 and A-9 RS-449/RS-422

Quad 50-pin to V.28 AA0018023 Pages A-12 and A-13 V.28 (V.10)

Quad 50-pin to V.35 7932 Pages A-16 and A-17 V.35 (V.10, V.11)

Quad 50-pin to X.21 7936 Page A-20 X.21 (V.11)

Order

No.

Pin-to-Pin and

Connector Information

Industry

Interface Type

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 36

Installing Synchronous Net Modules in an ASN Platform

Table A-2. Summary of Dial-Up Services Cabling Requirements for the Net Modules

Remote

Device T ype

RS-232 Dual 44-pin D-Sub to RS-232 7138 Page A-22 RS-232-C

RS-422* Dual 44-pin D-Sub to RS-422 7139 Pages A-24 and A-25 RS-449/RS-422

V.35 Dual 44-pin D-Sub to V.35 7137 Pages A-26 and A-27 V.35 (V.10, V.11)

*. For high data rates, Bay Networks recommends a V.35 interface.

Net

Module

Quad 50-pin to RS-232 7935 Page A-23 RS-232-C

Quad 50-pin to V.35 7933 Pages A-28 and A-29 V.35 (V.10, V.11)

Required Cable:

Raise DTR

Order

No.

Pin-to-Pin and

Connector Information

Industry

Interface Type

RS-232 Compliance

RS-232 compliance for the net modules is as follows:

• The Dual Sync net module requires a 44-pin D-Sub to RS-232 cable, Order

No. 7826 (Table A-3 and Figure A-1).

• The Quad Sync net module requires a 50-pin to RS-232 cable, Order No.

7934 (Table A-4 and Figure A-2).

Cabling Requirements for the Net Modules2 BNX Software Version <x.x> Test Part Number

Page 37

RS-232 Compliance

Table A-3. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-232 Cable

(Order No. 7826)

Bay Networks T ermination Remote T ermination

Signal Pin to Pin Signal

Frame Ground 1 1 Frame Ground

Send Data+ 2 2 Send Data

Receive Data+ 3 3 Receive Data

Request to Send+ 4 4 Request to Send

Clear to Send+ 5 5 Clear to Send

Data Set Ready+ 6 6 Data Set Ready

Data T erminal Ready+ 8 20 Data Terminal Ready

Data Carrier Detect+ 9 8 Data Carrier Detect

Send Timing+ 10 15 Send Timing

Receive Timing+ 11 17 Receive Timing

Transmitter Signal Element Timing+ 12 24 Transmitter Signal Element Timing

Signal Ground 7 7 Signal Ground

Internal Wire Connections

Pin 7 > 19 > 20 > 23

> 28

Pin 13

> 29

Pin 14

15 Feet

Pin 1

Pin 16

Pin 31

44-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 15

Pin 30

Pin 44

Pin 1

Pin 14

25-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 13

Pin 25

CAB0069A

Figure A-1. 44-Pin D-Sub to RS-232 Cable (Order No. 7826)

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 38

Installing Synchronous Net Modules in an ASN Platform

Table A-4. Pin-to-Pin Connections for the 50-Pin to RS-232 Cable

(Order No. 7934)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Frame Ground 1 1 Frame Ground

Send Data+ 2 2 Send Data

Receive Data+ 3 3 Receive Data

Request to Send+ 4 4 Request to Send

Clear to Send+ 5 5 Clear to Send

Data Set Ready+ 6 6 Data Set Ready

Signal Ground 7 7 Signal Ground

Data T erminal Ready+ 8 20 Data T erminal Ready

Data Carrier Detect+ 9 8 Data Carrier Detect

Send Timing+ 10 15 Send Timing

Receive Timing+ 11 17 Receive Timing

T erminal Timing+ 12 24 Terminal Timing

Internal Connections

Pin 7 > 30 > 31 > 34

Pin 13 > 38

Pin 14 > 39

Cabling Requirements for the Net Modules4 BNX Software Version <x.x> Test Part Number

Page 39

RS-232 Compliance

15 Feet

Pin 1

Pin 26

50-position 0.8-mm plug

(ground shield connected to internal shell)

Pin 25

Pin 50

Pin 1

Pin 14

Figure A-2. 50-Pin to RS-232 Cable (Order No. 7934)

Pin 13

Pin 25

25-position D-Sub plug with screw locks

(ground shield connected to backshell)

CAB0073A

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 40

Installing Synchronous Net Modules in an ASN Platform

RS-422 Compliance

RS-422 compliance for the net modules is as follows:

• The Dual Sync net module requires a 44-pin D-Sub to RS-422 cable, Order

No. 7318 (Table A-5 and Figure A-3).

• The Quad Sync net module requires a 50-pin to RS-422 cable, Order No.

7937 (Table A-6 and Figure A-4).

Table A-5. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-422 Cable

(Order No. 7318)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Data Carrier Detect- 23 31 Receiver Ready B

Data Carrier Detect+ 9 13 Receiver Ready A

Send Data+ 2 4 Send Data A

Send Data- 16 22 Send Data B

Receive Timing+ 11 8 Receive Timing A

Receive Timing- 25 26 Receive Timing B

Send Timing+ 10 5 Send Timing A

Send Timing- 24 23 Send Timing B

Receive Data+ 3 6 Receive Data A

Receive Data- 17 24 Receive Data B

Clear to Send- 19 27 Clear to Send B

Clear to Send+ 5 9 Clear to Send A

Request to Send+ 4 7 Request to Send A

Request to Send- 18 25 Request to Send B

Data Set Ready+ 6 11 DM A

Data Set Ready- 20 29 DM B

Terminal Ready+ 8 12 Terminal Ready A

Terminal Ready- 22 30 Terminal Ready B

(continued)

Cabling Requirements for the Net Modules6 BNX Software Version <x.x> Test Part Number

Page 41

RS-422 Compliance

Table A-5. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-422 Cable

(Order No. 7318)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

T erminal Timing+ 12 17 T erminal Timing A

T erminal Timing- 26 35 Terminal Timing B

Send Common 44 37 Send Common

Signal Ground 41 19 Signal Ground

Internal Wire Connections

> 43 Pin 20 > 37

Pin 41

> 28

Pin 13

> 29

Pin 14

(continued)

15 Feet

Pin 1

Pin 16

Pin 31

Pin 15

Pin 30

Pin 44

44-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 1

Pin 20

Pin 19

Pin 37

37-position D-Sub plug with screw locks

(ground shield connected to backshell)

CAB0051A

Figure A-3. 44-Pin D-Sub to RS-422 Cable (Order No. 7318)

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 42

Installing Synchronous Net Modules in an ASN Platform

Table A-6. Pin-to-Pin Connections for the 50-Pin to RS-422 Cable

(Order No. 7937)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Data Carrier Detect- 34 31 Receiver Ready B

Data Carrier Detect+ 9 13 Receiver Ready A

Send Data+ 2 4 Send Data A

Send Data- 27 22 Send Data B

Receive Timing+ 11 8 Receive Timing A

Receive Timing- 36 26 Receive Timing B

Send Timing+ 10 5 Send Timing A

Send Timing- 35 23 Send Timing B

Receive Data+ 3 6 Receive Data A

Receive Data- 28 24 Receive Data B

Clear to Send- 30 27 Clear to Send B

Clear to Send+ 5 9 Clear to Send A

Request to Send+ 4 7 Request to Send A

Request to Send- 29 25 Request to Send B

Data Set Ready+ 6 11 Data Mode A

Data Set Ready- 31 29 Data Mode B

Terminal Ready+ 8 12 Terminal Ready A

Terminal Ready- 33 30 Terminal Ready B

T erminal Timing+ 12 17 Terminal Timing A

T erminal Timing- 37 35 Terminal Timing B

Send Common 49 37 Send Common

Signal Ground 48 19 Signal Ground

Internal Wire Connections

Pin 46 (UNBE) > 48 (SGRD) Pin 20 > 37

Pin 13 > 38

Pin 14 > 39

Cabling Requirements for the Net Modules8 BNX Software Version <x.x> Test Part Number

Page 43

RS-422 Compliance

15 Feet

Pin 1

Pin 26

50-position 0.8-mm plug

(ground shield connected to internal shell)

Pin 25

Pin 50

Pin 1

Pin 20

Figure A-4. 50-Pin to RS-422 Cable (Order No. 7937)

Pin 19

Pin 37

37-position D-Sub plug with screw locks

(ground shield connected to backshell)

CAB0075A

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 44

Installing Synchronous Net Modules in an ASN Platform

V.28 Compliance

V.28 compliance for the Dual Sync net module requires a

44-pin D-Sub to V.28 cable, Order No. 7837 (Table A-7 and Figure A-5).

V.28 compliance for the Quad Sync net module requires a 50-pin to V.28 cable,

Order No. AA0018023 (Table A-8 and Figure A-6).

Table A-7. Pin-to-Pin Connections for the 44-Pin D-Sub to V.28 Cable

(Order No. 7837)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Frame Ground 1 1 Frame Ground

Send Data+ 2 2 Send Data

Receive Data+ 3 3 Receive Data

Request to Send+ 4 4 Request to Send

Clear to Send+ 5 5 Clear to Send

Data Set Ready+ 6 6 Data Set Ready

Data Terminal Ready+ 8 20 Data Terminal Ready

Data Carrier Detect+ 9 8 Data Carrier Detect

Send Timing+ 10 15 Send Timing

Receive Timing+ 11 17 Receive Timing

Transmitter Signal Element Timing+ 12 24 Transmitter Signal Element Timing

Signal Ground 7 7 Signal Ground

Internal Connections

Pin 7 > 19 > 20 > 23

Pin 13 > 28

Pin 14 > 29

Cabling Requirements for the Net Modules10 BNX Software Version <x.x> Test Part Number

Page 45

V.28 Compliance

15 Feet

Pin 1

Pin 16

Pin 31

Pin 15

Pin 30

Pin 44

44-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 1

Pin 14

25-position D-Sub plug with M-3 jack screws

(ground shield connected to backshell)

Figure A-5. 44-Pin D-Sub to V.28 Cable (Order No. 7837)

Pin 13

Pin 25

CAB0069B

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 46

Installing Synchronous Net Modules in an ASN Platform

Table A-8. Pin-to-Pin Connections for the 50-Pin to V.28 Cable

(Order No. AA0018023)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Frame Ground 1 1 Frame Ground

Send Data+ 2 2 Send Data

Receive Data+ 3 3 Receive Data

Request to Send+ 4 4 Request to Send

Clear to Send+ 5 5 Clear to Send

Data Set Ready+ 6 6 Data Set Ready

Signal Ground 7 7 Signal Ground

Data T erminal Ready+ 8 20 Data T erminal Ready

Data Carrier Detect+ 9 8 Data Carrier Detect

Send Timing+ 10 15 Send Timing

Receive Timing+ 11 17 Receive Timing

T erminal Timing+ 12 24 T erminal Timing

Internal Connections

Pin 7 > 30 > 31 > 34

Pin 13 > 38

Pin 14 > 39

Cabling Requirements for the Net Modules12 BNX Software Version <x.x> Test Part Number

Page 47

V.28 Compliance

15 Feet

Pin 1

Pin 26

50-position 0.8-mm plug

(ground shield connected to internal shell)

Pin 25

Pin 50

Pin 1

Pin 14

25-position D-Sub plug with M-3 jack screws

(ground shield connected to backshell)

Figure A-6. 50-Pin to V.28 Cable (Order No. AA0018023)

Pin 13

Pin 25

CAB0103A

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 48

Installing Synchronous Net Modules in an ASN Platform

V.35 Compliance

V.35 compliance for the net modules is as follows:

• The Dual Sync net module requires a 44-pin D-Sub to V.35 cable, Order No.

7220 (Table A-9 and Figure A-7).

• The Quad Sync net module requires a 50-Pin to V.35 cable, Order No. 7932

(Table A-10 and Figure A-8).

Table A-9. Pin-to-Pin Connections for the 44-Pin D-Sub to V.35 Cable

(Order No. 7220)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

VSD+ 38 P Send Data A

VSD- 36 S Send Data B

VRT+ 34 V Receive Timing A

VRT- 33 X Receive Timing B

VST+ 32 Y Send Timing A

VST- 31 AA Send Timing B

VRD+ 37 R Receive Data A

VRD- 35 T Receive Data B

Data Set Ready+ 6 E Data Set Ready

Data T erminal Ready+ 8 H Data T erminal Ready

Request to Send+ 4 C Request to Send

Clear to Send+ 5 D Clear to Send

VTT+ 40 U Terminal Timing A

VTT- 39 W T erminal Timing B

Frame Ground 1 A Frame Ground

(continued)

Cabling Requirements for the Net Modules14 BNX Software Version <x.x> Test Part Number

Page 49

V.35 Compliance

Table A-9. Pin-to-Pin Connections for the 44-Pin D-Sub to V.35 Cable

(Order No. 7220)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Data Carrier Detect+ 9 F Data Carrier Detect

Signal Ground 7 B Signal Ground

Internal Wire Connections

> 19 > 20 > 23

Pin 7

> 42 > 43

Pin 41

> 28

Pin 13

> 29

Pin 14

(continued)

15 Feet

Pin 1

Pin 16

Pin 31

44-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 15

Pin 30

Pin 44

B

D

F

R

T

V

X

Y

34-position V.35 plug with screw jack retainers

(ground shield connected to backshell)

A

C

E

H

P

S

U

W

AA

CAB0106A

Figure A-7. 44-Pin D-Sub to V.35 Cable (Order No. 7220)

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 50

Installing Synchronous Net Modules in an ASN Platform

Table A-10. Pin-to-Pin Connections for the 50-Pin to V.35 Cable

(Order No. 7932)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

VSD+ 44 P Send Data A

VSD- 19 S Send Data B

VRT+ 42 V Receive Timing A

VRT- 17 X Receive Timing B

VST+ 41 Y Send Timing A

VST- 16 AA Send Timing B

VRD+ 43 R Receive Data A

VRD- 18 T Receive Data B

Data Set Ready+ 6 E Data Set Ready

Data T erminal Ready+ 8 H Data Terminal Ready

Request to Send+ 4 C Request to Send

Clear to Send+ 5 D Clear to Send

VTT+ 45 U Terminal Timing A

VTT- 20 W T erminal Timing B

Frame Ground 1 A Frame Ground

Data Carrier Detect 9 F Data Carrier Detect

Signal Ground 7 B Signal Ground

Internal Wire Connections

Pin 30 > 31

Pin 46 > 47 > 48

Pin 13 > 38

Pin 14 > 39

> 7 > 34

Cabling Requirements for the Net Modules16 BNX Software Version <x.x> Test Part Number

Page 51

V.35 Compliance

15 Feet

Pin 1

Pin 26

50-position 0.8-mm plug

(ground shield connected to internal shell)

Pin 25

Pin 50

Figure A-8. 50-Pin to V.35 Cable (Order No. 7932)

B

D

F

R

T

V

X

Y

34-position V.35 plug with screw jack retainers

(ground shield connected to backshell)

A

C

E

H

P

S

U

W

AA

CAB0070A

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 52

Installing Synchronous Net Modules in an ASN Platform

X.21 Compliance

X.21 compliance for the net modules is as follows:

• The Dual Sync net module requires a 44-pin D-Sub to X.21 cable, Order No.

7224 (Table A-11 and Figure A-9).

• The Quad Sync net module requires a 50-pin to X.21 cable, Order No. 7936

(Table A-12 and Figure A-10).

Table A-11. Pin-to-Pin Connections for the 44-Pin D-Sub to X.21 Cable

(Order No. 7224)

Bay Networks T ermination Remote T ermination

Signal Pin to Pin Signal

Send Data+ 2 2 Transmitted Data A

Send Data- 16 9 Transmitted Data B

Request to Send+ 4 3 Control A

Request to Send- 18 10 Control B

Receive Data+ 3 4 Receive Data A

Receive Data- 17 11 Receive Data B

Data Carrier Detect+ 9 5 Indication A

Data Carrier Detect- 23 12 Indication B

Send Timing+ 10 6 Timing A

Send Timing- 24 13 Timing B

Signal Ground 7 8 Signal Ground

Frame Ground 1 1 Frame Ground

Internal Wire Connections

> 15

Pin 14

> 30

Pin 28

> 43

Pin 41

Cabling Requirements for the Net Modules18 BNX Software Version <x.x> Test Part Number

Page 53

X.21 Compliance

15 Feet

Pin 1

Pin 1

Pin 16

Pin 31

44-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 15

Pin 30

Pin 44

Pin 9

15-position D-Sub plug with locking posts

(ground shield connected to backshell)

Figure A-9. 44-Pin D-Sub to X.21 Cable (Order No. 7224)

Pin 8

Pin 15

CAB0068A

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 54

Installing Synchronous Net Modules in an ASN Platform

Table A-12. Pin-to-Pin Connections for the 50-Pin to X.21 Cable

(Order No. 7936)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Send Data+ 2 2 Transmitted Data A

Send Data- 27 9 Transmitted Data B

Request to Send+ 4 3 Control A

Request to Send- 29 10 Control B

Receive Data+ 3 4 Receive Data A

Receive Data- 28 11 Receive Data B

Data Carrier Detect+ 9 5 Indication A

Data Carrier Detect- 34 12 Indication B

Timing+ 10 6 Timing A

Timing- 35 13 Timing B

Frame Ground 1 1 Frame Ground

Signal Ground 7 8 Signal Ground

Internal Connections

Pin 46 > 48 (GRD)

> 40

Pin 38

Pin 14 > 15

15 Feet

Pin 1

Pin 26

50-position 0.8-mm plug

(ground shield connected to internal shell)

Pin 25

Pin 50

Pin 1

Pin 9

15-position D-Sub plug with locking posts

(ground shield connected to backshell)

Pin 8

Pin 15

CAB0074A

Figure A-10. 50-Pin to X.21 Cable (Order No. 7936)

Cabling Requirements for the Net Modules20 BNX Software Version <x.x> Test Part Number

Page 55

Dial-Up Services Cabling Requirements

Dial-Up Services Cabling Requirements

This section identifies the dial-up services cables necessary for linking the Dual

and Quad Sync net modules to the following types of WAN dial-on-demand and

dial backup devices:

• RS-232

• RS-422

• V.35

Net Module to an RS-232 Dial-on-Demand and Dial Backup Device

The cabling requirements for a net module to an RS-232 WAN dial-on-demand

and dial backup device are as follows:

• A Dual Sync net module requires a 44-pin D-Sub to RS-232: Raise DTR

cable, Order No. 7138 (Table A-13 and Figure A-11).

• A Quad Sync net module requires a 50-pin to RS-232: Raise DTR cable,

Order No. 7935 (Table A-14 and Figure A-12).

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 56

Installing Synchronous Net Modules in an ASN Platform

Table A-13. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-232:

Raise DTR Cable (Order No. 7138)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Frame Ground 1 1 Frame Ground

Send Data+ 2 2 Send Data

Receive Data+ 3 3 Receive Data

Request to Send+ 4 4 Request to Send

Clear to Send+ 5 5 Clear to Send

Data Set Ready+ 6 6 Data Set Ready

Signal Ground 7 7 Signal Ground

Data T erminal Ready+ 8 20 Data T erminal Ready

Data Carrier Detect+ 9 22 Ring Indicator

Send Timing+ 10 15 Send Timing

Receive Timing+ 11 17 Receive Timing

Transmitter Signal Element Timing+ 12 24 Transmitter Signal Element Timing

Internal Wire Connections

Pin 7 > 19 > 20 >

23

Pin 13 > 28

Pin 14 > 29

15 Feet

Pin 1

Pin 16

Pin 31

44-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 15

Pin 30

Pin 44

Pin 1

Pin 14

25-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 13

Pin 25

CAB0069A

Figure A-11. 44-Pin D-Sub to RS-232: Raise DTR Cable (Order No. 7138)

Cabling Requirements for the Net Modules22 BNX Software Version <x.x> Test Part Number

Page 57

Dial-Up Services Cabling Requirements

Table A-14. Pin-to-Pin Connections for the 50-Pin to RS-232: Raise DTR

Cable (Order No. 7935)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Frame Ground 1 1 Frame Ground

Send Data+ 2 2 Send Data

Receive Data+ 3 3 Receive Data

Request to Send+ 4 4 Request to Send

Clear to Send+ 5 5 Clear to Send

Data Set Ready+ 6 6 Data Set Ready

Data T erminal Ready+ 8 20 Data Terminal Ready

Data Carrier Detect+ 9 22 Ring Indicator

Send Timing+ 10 15 Send Timing

Receive Timing+ 11 17 Receive Timing

T erminal Timing+ 12 24 T erminal Timing

Signal Ground 7 7 Signal Ground

Internal Wire Connections

Pin 7 > 30 > 31 > 34

Pin 13 > 38

Pin 14 > 39

15 Feet

Pin 1

Pin 26

50-position 0.8-mm plug

(ground shield connected to internal shell)

Pin 25

Pin 50

Pin 1

Pin 14

25-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 13

Pin 25

CAB0073A

Figure A-12. 50-Pin to RS-232: Raise DTR Cable (Order No. 7935)

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 58

Installing Synchronous Net Modules in an ASN Platform

Net Module to an RS-422 Dial-on-Demand and Dial Backup Device

The cabling requirement for a Dual Sync net module to an RS-422 WAN

dial-on-demand and dial backup device is a 44-pin D-Sub to RS-422: Raise DTR

cable, Order No. 7139 (Table A-15 and Figure A-13).

Table A-15. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-422:

Raise DTR Cable (Order No. 7139)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Send Data+ 2 4 Send Data A

Send Data- 16 22 Send Data B

Receive Data+ 3 6 Receive Data A

Receive Data- 17 24 Receive Data B

Request to Send+ 4 7 Request to Send A

Request to Send- 18 25 Request to Send B

Clear to Send+ 5 9 Clear to Send A

Clear to Send- 19 27 Clear to Send B

Data Set Ready+ 6 11 Data Mode A

Data Set Ready- 20 29 Data Mode B

Terminal Ready+ 8 12 Data Terminal Ready A

Terminal Ready- 22 30 Data Terminal Ready B

Data Carrier Detect+ 9 15 Ring Indicator

Send Timing+ 10 5 Send Timing A

Send Timing- 24 23 Send Timing B

Receive Timing+ 11 8 Receive Timing A

Receive Timing- 25 26 Receive Timing B

T erminal Timing+ 12 17 T erminal Timing A

T erminal Timing- 26 35 Terminal Timing B

(continued)

Cabling Requirements for the Net Modules24 BNX Software Version <x.x> Test Part Number

Page 59

Dial-Up Services Cabling Requirements

Table A-15. Pin-to-Pin Connections for the 44-Pin D-Sub to RS-422:

Raise DTR Cable (Order No. 7139)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Send Common 44 37 Send Common

Signal Ground 41 19 Signal Ground

Internal Wire Connections

Pin 13 > 28

Pin 14 > 29

Pin 23 > 41 > 43

15 Feet

(continued)

Pin 1

Pin 16

Pin 31

Pin 15

Pin 30

Pin 44

44-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 1

Pin 20

Pin 19

Pin 37

37-position D-Sub plug with screw locks

(ground shield connected to backshell)

CAB0051A

Figure A-13. 44-Pin D-Sub to RS-422: Raise DTR Cable (Order No. 7139)

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 60

Installing Synchronous Net Modules in an ASN Platform

Net Module to a V.35 Dial-on-Demand and Dial Backup Device

The cabling requirements for a net module to a V.35 WAN dial-on-demand and

dial backup device are as follows:

• A Dual Sync net module requires a 44-pin D-Sub to V.35: Raise DTR cable,

Order No. 7137 (Table A-16 and Figure A-14).

• A Quad Sync net module requires a 50-pin to V.35: Raise DTR cable, Order

No. 7933 (Table A-17 and Figure A-15).

Table A-16. Pin-to-Pin Connections for the 44-Pin D-Sub to V.35: Raise

DTR Cable (Order No. 7137)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

Frame Ground 1 A Frame Ground

Request to Send+ 4 C Request to Send

Clear to Send+ 5 D Clear to Send

Data Set Ready+ 6 E Data Set Ready

Data T erminal Ready+ 8 H Data T erminal Ready

Data Carrier Detect+ 9 J Ring Indicator

VTT+ 40 U Terminal Timing A

VTT- 39 W Terminal Timing B

Signal Ground 7 B Signal Ground

VST+ 32 Y Send Timing A

VST- 31 AA Send Timing B

VRT+ 34 V Receive Timing A

VRT- 33 X Receive Timing B

VRD+ 37 R Receive Data A

VRD- 35 T Receive Data B

(continued)

Cabling Requirements for the Net Modules26 BNX Software Version <x.x> Test Part Number

Page 61

Dial-Up Services Cabling Requirements

Table A-16. Pin-to-Pin Connections for the 44-Pin D-Sub to V.35: Raise

DTR Cable (Order No. 7137)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

VSD+ 38 P Send Data A

VSD- 36 S Send Data B

Internal Wire Connections

Pin 7 > 19 > 20 > 23

Pin 41 > 42 > 43

Pin 13 > 28

Pin 14 > 29

15 Feet

(continued)

Pin 1

Pin 16

Pin 31

44-position D-Sub plug with screw locks

(ground shield connected to backshell)

Pin 15

Pin 30

Pin 44

B

D

J

R

T

V

X

34-position V.35 plug with screw jack retainers

(ground shield connected to backshell)

A

C

E

H

P

S

U

W

Y

AA

CAB0018A

Figure A-14. 44-Pin D-Sub to V.35: Raise DTR Cable (Order No. 7137)

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 62

Installing Synchronous Net Modules in an ASN Platform

Table A-17. Pin-to-Pin Connections for the 50-Pin to V.35: Raise DTR

Cable (Order No. 7933)

Bay Networks T ermination Remote Termination

Signal Pin to Pin Signal

VSD+ 44 P Send Data A

VSD- 19 S Send Data B

VRT+ 42 V Receive Timing A

VRT- 17 X Receive Timing B

VST+ 41 Y Send Timing A

VST- 16 AA Send Timing B

VRD+ 43 R Receive Data A

VRD- 18 T Receive Data B

Data Set Ready+ 6 E Data Set Ready

Data T erminal Ready+ 8 H Data Terminal Ready

Request to Send+ 4 C Request to Send

Clear to Send+ 5 D Clear to Send

VTT+ 45 U Terminal Timing A

VTT- 20 W Terminal Timing B

Frame Ground 1 A Frame Ground

Data Carrier Detect+ 9 J Ring Indicator

Signal Ground 7 B Signal Ground

Internal Wire Connections

Pin 30 > 31 > 7 > 34

Pin 46 > 47 > 48

Pin 13 > 38

Pin 14 > 39

Cabling Requirements for the Net Modules28 BNX Software Version <x.x> Test Part Number

Page 63

Dial-Up Services Cabling Requirements

15 Feet

Pin 1

Pin 26

50-position 0.8-mm plug

(ground shield connected to internal shell)

Pin 25

Pin 50

34-position V.35 plug with screw jack retainers

B

D

J

R

T

V

X

(ground shield connected to backshell)

Figure A-15. 50-Pin to V.35: Raise DTR Cable (Order No. 7933)

A

C

E

H

P

S

U

W

Y

AA

CAB0071A

Test Part Number BNX Software Version <x.x> Cabling Requirements for the

Page 64

Page 65

Requirements for European Operation

This appendix provides technical specifications and notes about operating the

following net modules in Europe:

• Dual Sync net module (Order No. 34001, Part No. 107287)

• Quad Sync net module (Order No. AF2111005, Part No. 112499)

Installation Requirements

Appendix B

The net modules are approved only for installation in a host, and with host

attachments, which are either type approved for such apparatus or, if supplied

after March 1, 1989, are marked with or supplied with a statement that the host is

supplied under the terms of General Approval No. NS/G/1234/J/100003.

Installation of the net modules in an ASN will satisfy the conditions stated in this

appendix. The ASN is supplied under the terms of General Approval No.

NS/G/1234/J/100003.

Power Requirements