Page 1

N0027684 01

April 4, 2005

BCM

R2MFC Media Bay Module

Installation and Configuration

Guide

Page 2

2

Copyright © Nortel Networks Limited 2005. All rights reserved.

The information in this document is subject to change without notice. The statements, configurations, technical data, and

recommendations in this document are believed to be accurate and reliable, but are presented without express or implied

warranty. Users must take full responsibility for their applications of any products specified in this document. The

information in this document is proprietary to Nortel Networks NA Inc.

Trademarks

NORTEL NETWORKS is a trademark of Nortel Networks.

Microsoft, MS, MS-DOS, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

All other trademarks and registered trademarks are the property of their respective owners.

North American Regulatory Information

Safety

This equipment meets all applicable requirements of both the CSA C22.2 No.60950 and UL

60950.

The shock hazard symbol within an equilateral triangle is intended to alert personnel

to electrical shock hazard or equipment damage. The following precautions should

also be observed when installing telephone equipment.

• Never install telephone wiring during a lightning storm.

• Never install telephone jacks in wet locations unless the jack is specifically designed

for wet locations.

• Never touch uninsulated telephone wires or terminals unless the telephone line has

been disconnected at the network interface.

• Use caution when working with telephone lines.

Danger: Risk of shock.

Read and follow installation instructions carefully.

Ensure the system and system expansion units are unplugged from the power socket and

that any telephone or network cables are unplugged before opening the system or system

expansion unit.

If installation of additional hardware and /or servicing is required, disconnect all telephone

cable connections prior to unplugging the system equipment.

Ensure the system and system expansion units are plugged into the wall socket using a

three-prong power cable before any telephone cables are connected.

N0027684 01

Page 3

Caution: Only qualified persons should service the system.

The installation and service of this hardware is to be performed only by service personnel

having appropriate training and experience necessary to be aware of hazards to which they

are exposed in performing a task and of measures to minimize the danger to themselves or

other persons.

Electrical shock hazards from the telecommunication network and AC mains are possible

with this equipment. To minimize risk to service personnel and users, the system must be

connected to an outlet with a third-wire ground. Service personnel must be alert to the

possibility of high leakage currents becoming available on metal system surfaces during

power line fault events near network lines. These leakage currents normally safely flow to

Protective Earth ground via the power cord. Therefore, it is mandatory that connection to

an earthed outlet is performed first and removed last when cabling to the unit. Specifically,

operations requiring the unit to be powered down must have the network connections

(central office lines) removed first.

Enhanced 911 Configuration

Caution: Warning

Local, state and federal requirements for Emergency 911 services support by Customer

Premises Equipment vary. Consult your telecommunication service provider regarding

compliance with applicable laws and regulations.

3

Radio-frequency Interference

Warning: Equipment generates RF energy.

This equipment generates, uses, and can radiate radio-frequency energy. If not installed

and used in accordance with the installation manual, it may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A

computing device pursuant to Part 15 of the FCC Rules and with ICES.003, CLASS A

Canadian EMI Requirements. Operation of this equipment in a residential area is not

permitted and is likely to cause interference.

Repairs to certified equipment should be made by an authorized maintenance facility designated

by the supplier. Any repairs or alterations made by the user to this equipment, or equipment

malfunctions, may give the telecommunications company cause to request the user to disconnect

the equipment. Users should ensure for their own protection that the electrical ground connections

of the power utility, telephone lines and internal metallic water pipe system, if present, are

connected together. This precaution may be particularly important in rural areas.

Caution: Users should not attempt to make such connections themselves, but

should contact the appropriate electric inspection authority, or electrician.

R2MFC Media Bay Module Installation and Configuration Guide

Page 4

4

Hearing Aid Compatibility

System telephones are hearing-aid compatible, as defined in Section 68.316 of Part 68 FCC Rules.

Repairs

In the event of equipment malfunction, all repairs to certified equipment will be performed by an

authorized supplier.

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

Important Safety Instructions

The following safety instructions cover the installation and use of the Product. Read carefully and

retain for future reference.

Installation

Warning: To avoid electrical shock hazard to personnel or equipment damage observe

the following precautions when installing telephone equipment:

1 Never install telephone wiring during a lightning storm.

2 Never install telephone jacks in wet locations unless the jack is specifically

designed for wet locations.

3 Never touch uninsulated telephone wires or terminals unless the telephone

line has been disconnected at the network interface.

4 Use caution when installing or modifying telephone lines. The exclamation

point within an equilateral triangle is intended to alert the user to the presence

of important operating and maintenance (servicing) instructions in the

literature accompanying the product. This symbol on the product is used to

identify the following important information: Use only with a CSA or UL

certified CLASS 2 power supply, as specified in the user guide.

N0027684 01

Page 5

Use

When using your telephone equipment, basic safety precautions should always be followed to

reduce risk of fire, electric shock and injury to persons, including the following:

1 Read and understand all instructions.

2 Follow the instructions marked on the product.

3 Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or aerosol

cleaners. Use a damp cloth for cleaning.

4 Do not use this product near water, for example, near a bath tub, wash bowl, kitchen sink, or

laundry tub, in a wet basement, or near a swimming pool.

5 Do not place this product on an unstable cart, stand or table. The product may fall, causing

serious damage to the product.

6 This product should never be placed near or over a radiator or heat register. This product

should not be placed in a built-in installation unless proper ventilation is provided.

7 Do not allow anything to rest on the power cord. Do not locate this product where the cord will

be abused by persons walking on it.

5

8 Do not overload wall outlets and extension cords as this can result in the risk of fire or electric

shock.

9 Never spill liquid of any kind on the product.

10 To reduce the risk of electric shock do not disassemble this product, but have it sent to a

qualified service person when some service or repair work is required.

11 Unplug this product from the wall outlet and refer servicing to qualified service personnel

under the following conditions:

a When the power supply cord or plug is damaged or frayed.

b If the product has been exposed to rain, water or liquid has been spilled on the product,

disconnect and allow the product to dry out to see if it still operates; but do not open up the

product.

c If the product housing has been damaged.

d If the product exhibits a distinct change in performance.

12 Avoid using a telephone during an electrical storm. There may be a remote risk of electric

shock from lightning.

13 Do not use the telephone to report a gas leak in the vicinity of the leak.

14 Caution: To eliminate the possibility of accidental damage to cords, plugs, jacks, and the

telephone, do not use sharp instruments during the assembly procedures.

15 Save these instructions.

R2MFC Media Bay Module Installation and Configuration Guide

Page 6

6

International Regulatory Information

The CE Marking on this equipment indicates

compliance with the following:

This device conforms to Directive 1999/5/EC on

Radio Equipment and Telecommunications

Terminal Equipment as adopted by the European

Parliament And Of The Council.

This is a class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

Hereby, Nortel Networks declares that this equipment is in compliance with the essential

requirements and other relevant provisions of Directive 1999/5/EC.

Information is subject to change without notice. Nortel Networks reserves the right to make changes in design

or components as progress in engineering and manufacturing may warrant. This equipment has been tested

and found to comply with the European Safety requirements EN 60950 and EMC requirements EN 55022

(Class A) and EN 55024. These EMC limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial and light industrial environment.

WARNING

This is a class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

The above warning is inserted for regulatory reasons. If any customer believes that

they have an interference problem, either because their Nortel Networks product

seems to cause interference or suffers from interference, they should contact their

distributor immediately. The distributor will assist with a remedy for any problems

and, if necessary, will have full support from Nortel Networks.

N0027684 01

Page 7

Safety

7

WARNING!

Only qualified service personnel may install this equipment. The instructions in this

manual are intended for use by qualified service personnel only.

Only qualified persons should service the system.

The installation and service of this hardware is to be performed only by service

personnel having appropriate training and experience necessary to be aware of

hazards to which they are exposed in performing a task and of measures to minimize

the danger to themselves or other persons.

Electrical shock hazards from the telecommunication network and AC mains are

possible with this equipment. To minimize risk to service personnel and users, the

system must be connected to an outlet with a third-wire Earth.

Service personnel must be alert to the possibility of high leakage currents becoming

available on metal system surfaces during power line fault events near network lines.

These leakage currents normally safely flow to Protective Earth via the power cord.

Therefore, it is mandatory that connection to an earthed outlet is performed first and

removed last when cabling to the unit. Specifically, operations requiring the unit to be

powered down must have the network connections (exchange lines) removed first.

Limited Warranty

Nortel Networks warrants this product against defects and malfunctions during a one (1) year period from the

date of original purchase. If there is a defect or malfunction, Nortel Networks shall, at its option, and as the

exclusive remedy, either repair or replace the telephone set at no charge, if returned within the warranty

period.

If replacement parts are used in making repairs, these parts may be refurbished, or may contain refurbished

materials. If it is necessary to replace the telephone set, it may be replaced with a refurbished telephone of the

same design and color. If it should become necessary to repair or replace a defective or malfunctioning

telephone set under this warranty, the provisions of this warranty shall apply to the repaired or replaced

telephone set until the expiration of ninety (90) days from the date of pick up, or the date of shipment to you,

of the repaired or replacement set, or until the end of the original warranty period, whichever is later. Proof

of the original purchase date is to be provided with all telephone sets returned for warranty repairs.

Exclusions

Nortel Networks does not warrant its telephone equipment to be compatible with the equipment of any

particular telephone company. This warranty does not extend to damage to products resulting from improper

installation or operation, alteration, accident, neglect, abuse, misuse, fire or natural causes such as storms or

floods, after the telephone is in your possession.

Nortel Networks shall not be liable for any incidental or consequential damages, including, but not limited to,

loss, damage or expense directly or indirectly arising from the customers use of or inability to use this

telephone, either separately or in combination with other equipment. This paragraph, however, shall not apply

to consequential damages for injury to the person in the case of telephones used or bought for use primarily

for personal, family or household purposes.

R2MFC Media Bay Module Installation and Configuration Guide

Page 8

8

This warranty sets forth the entire liability and obligations of Nortel Networks with respect to breach of

warranty, and the warranties set forth or limited herein are the sole warranties and are in lieu of all other

warranties, expressed or implied, including warranties or fitness for particular purpose and merchantability.

Warranty Repair Services

Should the set fail during the warranty period:

In North America, call 1-800-574-1611 for further information.

Outside North America, contact your sales representative for return instructions. You will be responsible

for shipping charges, if any. When you return this telephone for warranty service, you must present proof of

purchase.

After Warranty Service

Nortel Networks offers ongoing repair and support for this product. This service provides repair or

replacement of your Nortel Networks product, at Nortel Networks’s option, for a fixed charge. You are

responsible for all shipping charges. For further information and shipping instructions:

In North America, contact our service information number: 1-800-574-1611.

Outside North America, contact your sales representative.

Repairs to this product may be made only by the manufacturer and its authorized agents, or by others who are legally

authorized. This restriction applies during and after the warranty period. Unauthorized repair will void the warranty.

N0027684 01

Page 9

Contents

North American Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Enhanced 911 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Radio-frequency Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Hearing Aid Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

International Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Exclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Warranty Repair Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

After Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9

Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

How to get help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Technical Support Contact Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Administration and maintenance tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

R2MFC MBM faceplate elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

System Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Config DIP switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

RS232 port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

E1 Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Bantam jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

BNC and RJ-48 connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

R2MFC MBM back and underside elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

MBM DIP switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

R2MFC Media Bay Module Installation and Configuration Guide

Page 10

10

Chapter 2

Preparing to install the R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installation process map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Host system setup requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

R2MFC MBM setup requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Config DIP switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

MBM DIP switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Environment checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electrical requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Software requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Customer supplied hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 3

Installing the R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Shutting down the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing an R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installing an R2MFC MBM in the BCM platform base chassis . . . . . . . . . . . . . . . 32

Installing an R2MFC MBM in the expansion unit . . . . . . . . . . . . . . . . . . . . . . . . . 33

Reconnecting the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Removing an R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Removing an R2MFC MBM from the BCM platform base chassis . . . . . . . . . . . . 35

Removing an R2MFC MBM from the expansion unit . . . . . . . . . . . . . . . . . . . . . . 37

Wiring an R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connecting an R2MFC MBM to a service provider . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 4

Configuring the R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

MFCR2 side (External Link) configurable parameters . . . . . . . . . . . . . . . . . . . . . . . . . 42

Physical line characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

E1 framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Line signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Register signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

End of dialing (incoming) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

End of dialing (outgoing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Disable ANI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Default category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Default subscriber status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

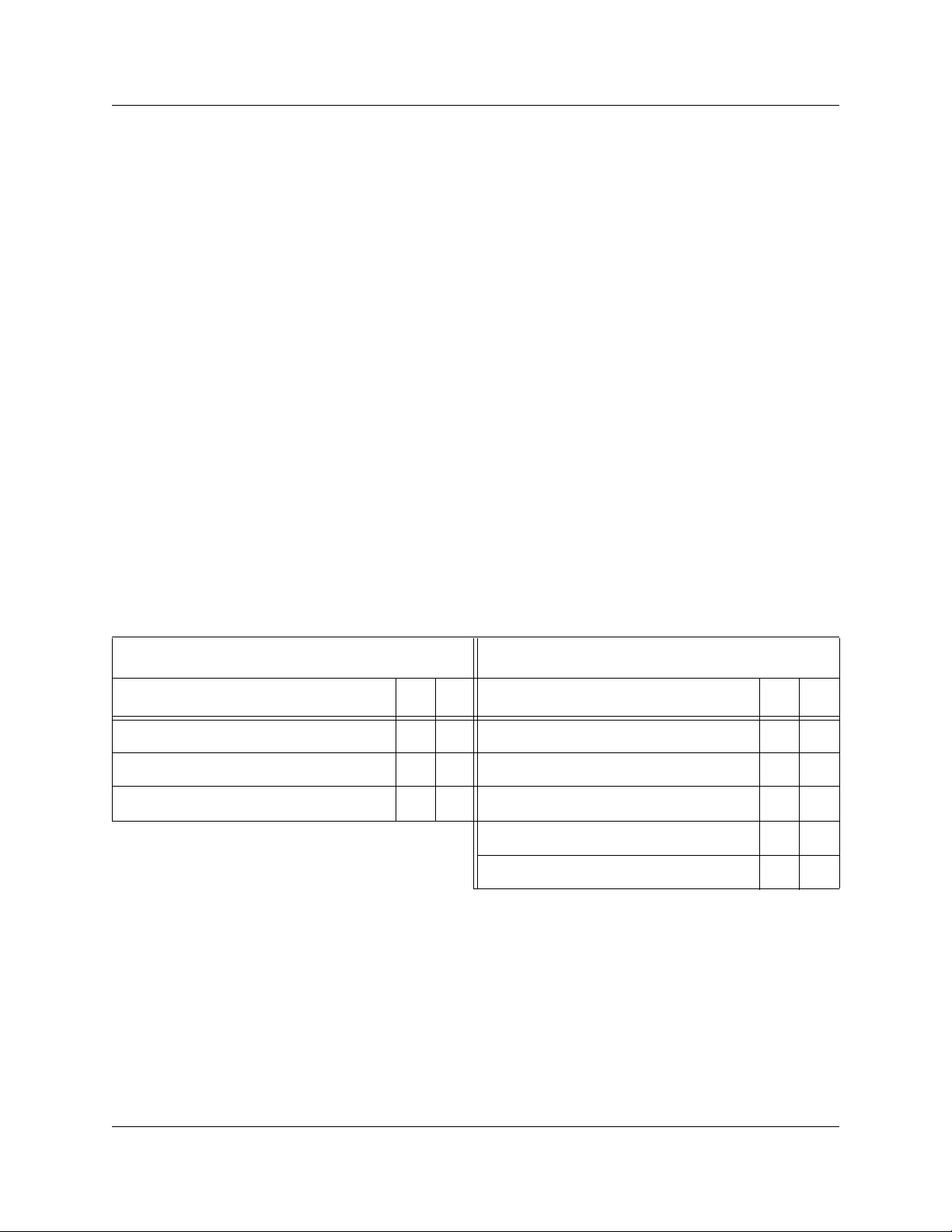

Configuring the MFCR2 (external) link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Setting Config DIP switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Creating a customized country code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

PRI side (Internal Link) configurable parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

E1 Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

N0027684 01

Page 11

Configuring the PRI (internal) link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Turning on second dial tone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Chapter 5

R2MFC MBM maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Inter-working functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Clock synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Diagnostic tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Setting the R2MFC MBM to diagnostic mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Alarms Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Group I errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Group II errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Alarms propagation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Faceplate LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Logs and traces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Replacing an R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Upgrading firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11

Chapter 6

Command Line Interface (CLI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Users and passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Accessing the CLI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

LOad directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

INfo directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

VIew directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

CNtrl directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

COnfig directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

ALarm directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

SWerr directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

MFC directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

R2 directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

PRI directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Appendix A

Config DIP switch settings and definitions . . . . . . . . . . . . . . . . . . . . . . . . . 85

Country code defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Mexico Config 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

E1 physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

E1 framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Register signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

R2MFC Media Bay Module Installation and Configuration Guide

Page 12

12

R2 line signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

MFC register signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Mexico Config 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

E1 physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

E1 framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Register signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

R2 line signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

MFC register signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Brazil Config 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

E1 physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

E1 framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Register signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

R2 line signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

MFC Register Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Brazil Config 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

E1 physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

E1 framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Register signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

R2 line signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

MFC Register Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Argentina Config 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

E1 Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

E1 Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Frame mode: Alternate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Register signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

R2 Line Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

MFC Register Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Appendix B

Diagnostic and loopback DIP switch settings. . . . . . . . . . . . . . . . . . . . . . 101

Appendix C

MFC Signal Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix D

CLI Cable Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

N0027684 01

Page 13

Figures

Figure 1 R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2 R2MFC MBM faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 3 Config DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 4 R2MFC MBM back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 5 DIP switch location on the R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

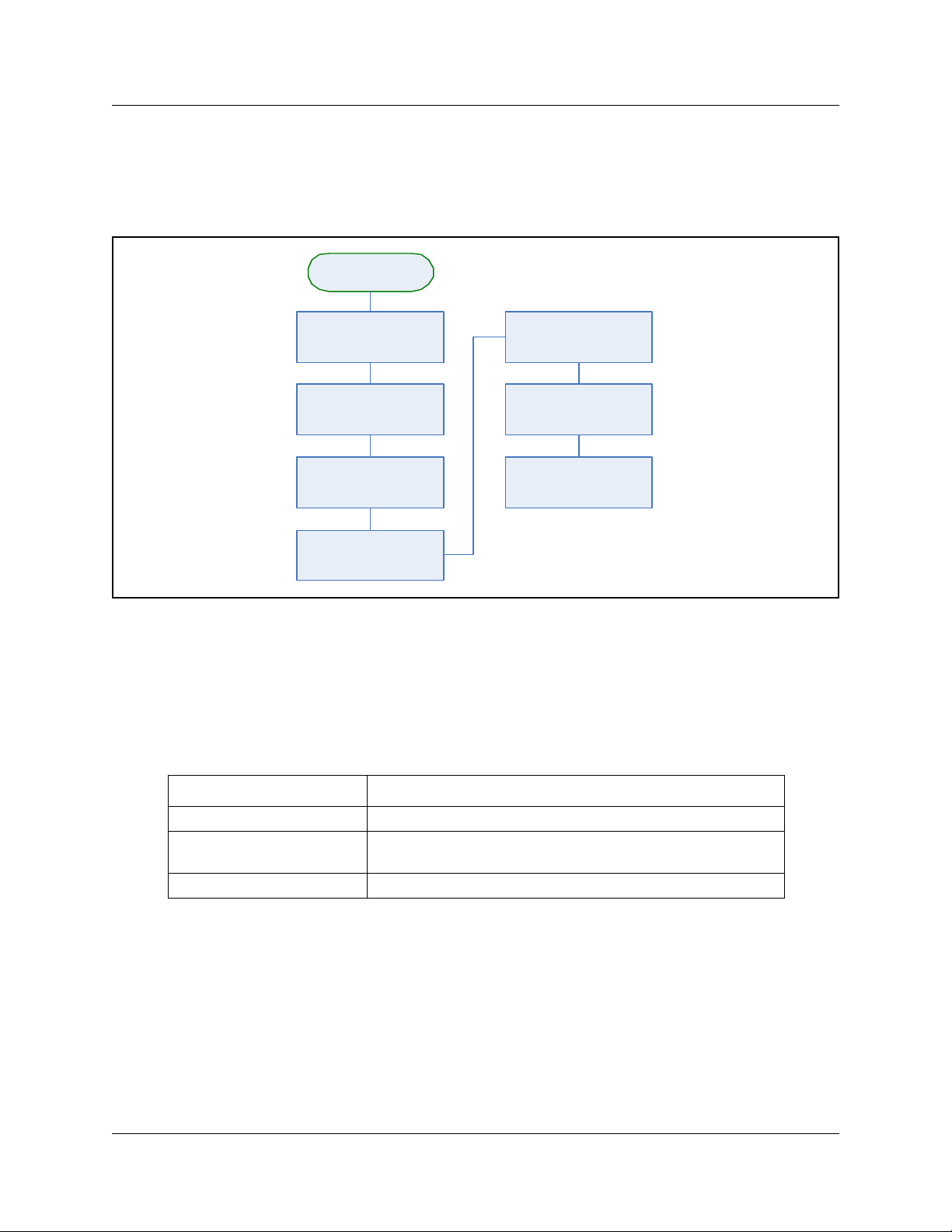

Figure 6 Overview of the R2MFC MBM installation preparation . . . . . . . . . . . . . . . . . . . 28

Figure 7 Overview of the R2MFC MBM installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 8 Overview of removing an R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 9 How to remove a BCM200 R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 10 How to remove a BCM400 R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 11 How to remove the expansion unit front bezel . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 12 R2MFC MBM RJ48 wiring array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 13 Trunk wiring overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 14 Configuring the R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 15 Config DIP switch layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 16 Custom profile DIP switch setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 17 BCM Bus configuration for R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 18 BCM module configuration for R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 19 BCM E1 parameters configuration for R2MFC MBM . . . . . . . . . . . . . . . . . . . . . 51

Figure 20 BCM lines configuration for R2MFC MBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 21 Outgoing dialing configuration for second dial tone . . . . . . . . . . . . . . . . . . . . . . 53

Figure 22 Overview of module replacement process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 23 Upgrading firmware overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 24 Config DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 25 Country selection DIP switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 26 Second dial tone DIP switch settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 27 Diagnostics and Loopback Dip Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 28 Cable pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figures 13

R2MFC Media Bay Module Installation and Configuration Guide

Page 14

14 Figures

N0027684 01

Page 15

Tables

Table 1 Host system setup requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 2 Minimum (or fixed) number length + timer parameters . . . . . . . . . . . . . . 43

Table 3 E1 framing default parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 4 Layer 2 signaling parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 5 Layer 3 signaling parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 6 Module configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 7 Translation of Subscriber Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 8 Diagnostic and loopback modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 9 Incoming signal errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 10 Group I Alarms propagation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 11 Group II alarms propagation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 12 System status monitor LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 13 System status monitor LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 14 Hyper-terminal setup parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 15 Hyper-terminal setup parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 16 LOad directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 17 INfo directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 18 VIew directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 19 CNtrl directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 20 COnfig directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 21 ALarm directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 22 SWerr directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 23 MFC directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 24 R2 directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 25 PRI directory CLI commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 26 Mexico Config 1 R2 A/B signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 27 Interpretation of received MFC signals . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Table 28 Interpretation of transmitted MFC signals . . . . . . . . . . . . . . . . . . . . . . . . 88

Table 29 Mexico Config 2 R2 A/B signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 30 Interpretation of received MFC signals . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 31 Interpretation of transmitted MFC signals . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 32 Brazil Config 1 R2 A/B signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Table 33 Interpretation of received MFC signals . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 34 Interpretation of transmitted MFC signals . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 35 Brazil Config 2 R2 A/B signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 36 Interpretation of received MFC signals . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 37 Interpretation of transmitted MFC signals . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 38 Argentina Config 1 R2 A/B Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Table 39 Interpretation of received MFC signals . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Tables 15

R2MFC Media Bay Module Installation and Configuration Guide

Page 16

16 Tables

Table 40 Interpretation of transmitted MFC signals . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 41 MFC signal definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

N0027684 01

Page 17

Preface

This guide explains how to install, configure, and maintain the Nortel Networks R2MFC Media

Bay Module (R2MFC MBM).

The guide also provides information about the Command Line Interface (CLI) tool used to

configure, operate, administer and maintain the R2MFC MBM from a computer.

The document contains the following chapters:

Chapter 1, “Overview” — introduces the elements of the R2MFC MBM.

Chapter 2, “Preparing to install the R2MFC MBM” — describes the process of preparing for

R2MFC MBM installation.

Chapter 3, “Installing the R2MFC MBM” — describes the process of installing the R2MFC

MBM and connecting the R2MFC MBM to the host system.

17

Note: The CLI is separate from the Business Communications Manager

(BCM) system configuration tool.

Chapter 4, “Configuring the R2MFC MBM” — describes the configuration tools and the process

of configuring the R2MFC MBM.

Chapter 5, “R2MFC MBM maintenance” — describes the maintenance tools and the process of

maintaining the R2MFC MBM.

Chapter 6, “Command Line Interface (CLI)” — describes the Command Line Interface and the

commands used to configure, operate, administer, and maintain the R2MFC MBM.

Before you begin

This guide assumes the following:

• The host system is installed and initialized and is working correctly.

• The host system is running BCM 2.5 FP 1, or greater.

• Users have a working knowledge of the host system operations.

• All configuration installers have a working knowledge of the Windows operating system and

graphical user interfaces.

R2MFC Media Bay Module Installation and Configuration Guide

Page 18

18 Preface

How to get help

Technical Support Contact Numbers

If you do not see an appropriate number in this list, go to www.nortel.com/cs

• USA and Canada Authorized Distributors

Technical Support - GNTS/GNPS

Telephone: 1-800-4NORTEL (1-800-466-7835)

If you already have a PIN Code, you can enter Express Routing Code (ERC) 196#.

If you do not yet have a PIN Code, or for general questions and first line support, you can

enter ERC 338#.

Web s ite:

Presales Support (CSAN)

Tel ep hon e: 1-800-4NORTEL (1-800-466-7835)

Use Express Routing Code (ERC) 1063#.

• EMEA (Europe, Middle East, Africa)

Technical Support - CTAS

Telephone: *European Free phone 00800 800 89009

www.nortel.com/cs

European Alternative/

United Kingdom +44 (0)870-907-9009

Africa +27-11-808-4000

Israel 800-945-9779

*Note: Calls are not free from all countries in Europe, Middle East, or Africa.

Fax: 44-191-555-7980

e-mail:

• CALA (Caribbean & Latin America)

Technical Support - CTAS

Telephone:

e-mail:

• APAC (Asia Pacific)

Technical Support - GNTS

Telephone: +612 8870 8800

Fax: +612 8870 5569

e-mail:

emeahelp@nortelnetworks.com

1-954-858-7777

csrmgmt@nortelnetworks.com

asia_support@nortelnetworks.com

N0027684 01

Page 19

• In-country toll-free numbers:

Australia 1-800-NORTEL (1-800-667-835)

China 010-6510-7770

India 011-5154-2210

Indonesia 0018-036-1004

Japan 0120-332-533

Malaysia 1800-805-380

New Zealand 0800-449-716

Philippines 1800-1611-0063

Singapore 800-616-2004

South Korea 0079-8611-2001

Taiwan 0800-810-500

Thailand 001-800-611-3007

Service Business Centre & Pre-Sales Help Desk +61-2-8870-5511

Preface 19

R2MFC Media Bay Module Installation and Configuration Guide

Page 20

20 Preface

Acronyms

This guide uses the following acronyms (listed in alphabetical order):

AIS Alarm Indication Signal

ANI Automatic Number Identification

BCM Business Communication Manager

BPV Bipolar Violations

CLI Command Line Interface

CLID Calling Line Identification

CO Central Office

CRC4 Cyclic Redundancy Check 4

CSU Channel Service Unit

DCH D-Channel Handler

DTMF Dual Tone Multi-Frequency

EEPROM Electrically Erasable Prorammable Read Only Memory

ETSI European Telecommunications Standards Institute

FBER Frame Bit Error

FEBE Far End Block Error

ISDN Integrated Services Digital Network

LFA Loss of Frame Alignment

LMA Loss of Multiframe Alignment

LOS Loss of Signal

MBM Media Bay Module

MFC Multi-Frequency Compelled

MSC Media Services Card

OOF Out-of-Frame

OOM Out of CRC-4 Multiframe Alignment

OOS Out Of Service

PCM Pulse Code Modulation

PRI Primary Rate Interface

RAI Remote Alarm Indication

N0027684 01

Page 21

Chapter 1

Overview

This chapter provides an overview of the R2MFC Media Bay Module (R2MFC MBM).

This chapter includes the following information:

• “General information”

• “Administration and maintenance tools”

• “R2MFC MBM faceplate elements” on page 22

• “R2MFC MBM back and underside elements” on page 24

General information

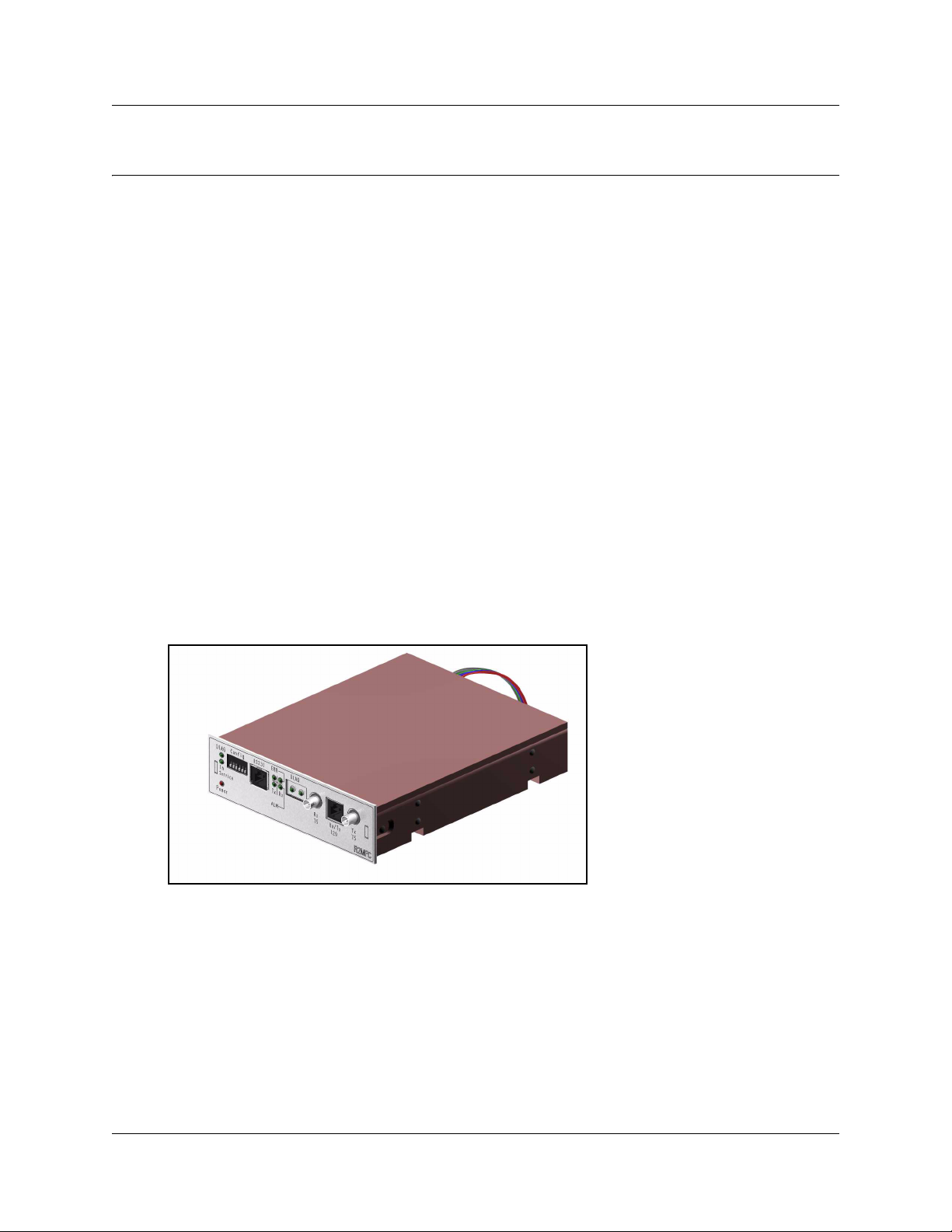

The R2MFC MBM is a media bay module (MBM) that provides MFC-R2 connectivity over an E1

trunk. The module works as a converter between Euro-ISDN and MFC-R2 protocols, allowing the

MFC-R2 protocol E1 to work directly with the BCM without the use of an external converter. The

BCM recognizes the converter as a Euro-ISDN trunk MBM and, therefore, provides all of the

functionality on the MFC-R2 E1 that is available on a Euro-ISDN E1. The MFC-R2 trunk is

controlled by DIP switches and the Command Line Interface (CLI) on the R2MFC MBM. Figure 1

provides an illustration of the R2MFC MBM.

21

Figure 1 R2MFC MBM

Administration and maintenance tools

R2MFC MBM configuration involves the following:

• Internal link configuration for the PRI internal link to the BCM. The internal link uses preset

characteristics and therefore does not require localization.

• External link configuration of the MFC-R2 E1 the external interface to public network. The

external link allows for localization in different countries.

R2MFC Media Bay Module Installation and Configuration Guide

Page 22

22 Chapter 1 Overview

External link configuration is performed using the DIP switches on the front of the R2MFC MBM

or by using the CLI, which is accessed through a serial port on the faceplate of the R2MFC MBM.

Internal link configuration is performed using Unified Manager. Refer to “Configuring the

R2MFC MBM” on page 41 for information on how to use the configuration tools.

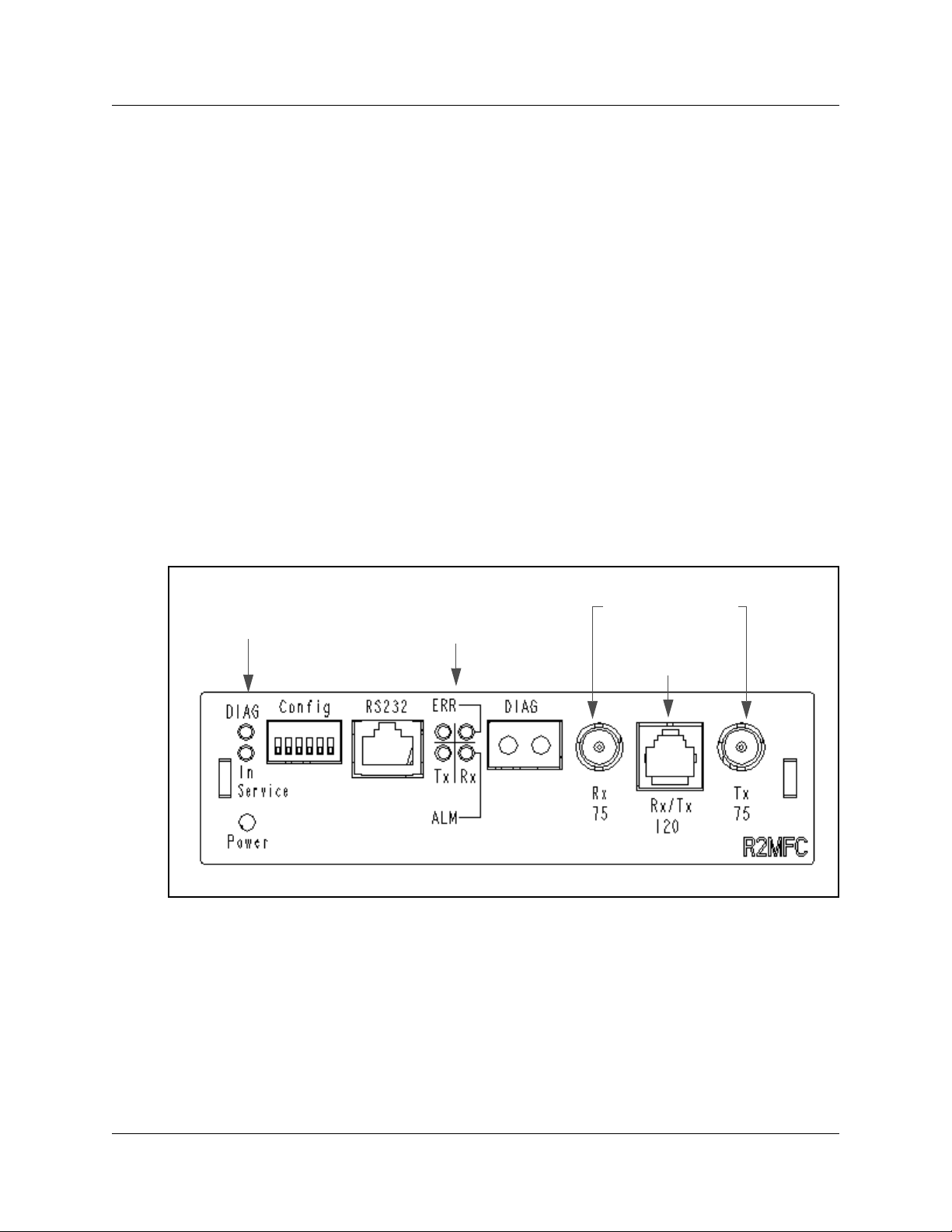

R2MFC MBM faceplate elements

The faceplate of the R2MFC MBM consists of the following elements:

• “System Status LEDs” on page 23

• “Config DIP switches” on page 23

• “RS232 port” on page 24

• “E1 Status LEDs” on page 24

• “Bantam jacks” on page 24

• “BNC and RJ-48 connectors” on page 24

Figure 2 illustrates the placement of these elements.

Figure 2 R2MFC MBM faceplate

MBM status

3 LEDS

DIP

switches

RJ-45

E1 status

4 LEDS

Bantam

jacks

75 Ω E1 BNC

120 Ω E1

RJ-48

N0027684 01

Page 23

Chapter 1 Overview 23

s

System Status LEDs

The R2MFC MBM has three visual status monitor indicators on the left side of the faceplate. They

are:

• Power LED — This green LED indicates the status of power to the R2MFC MBM.

• In Service LED — This green LED indicates the status of the E1 signal coming to the

R2MFC MBM from the BCM.

• Diag LED — This red LED indicates if the R2MFC MBM is in a diagnostic or loopback

mode.

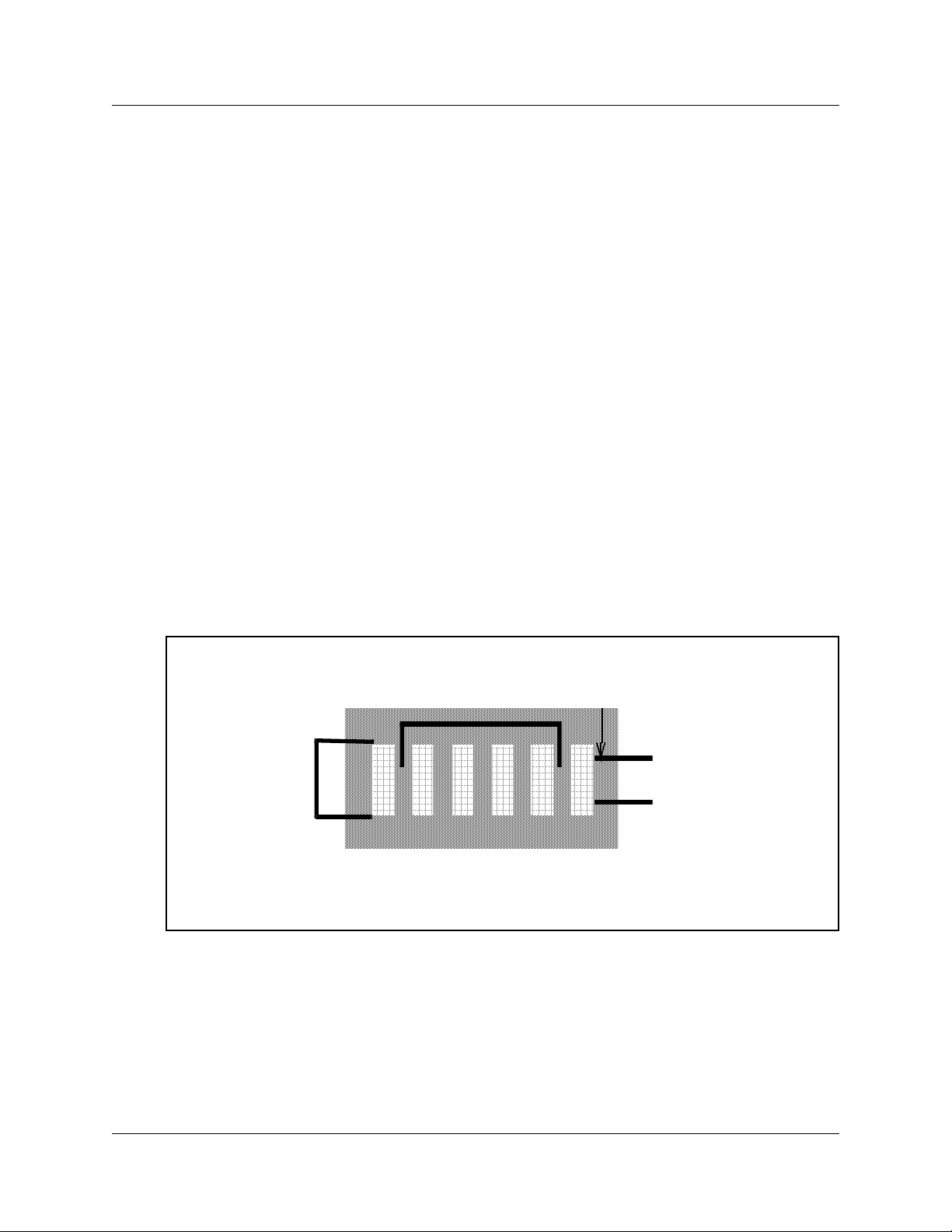

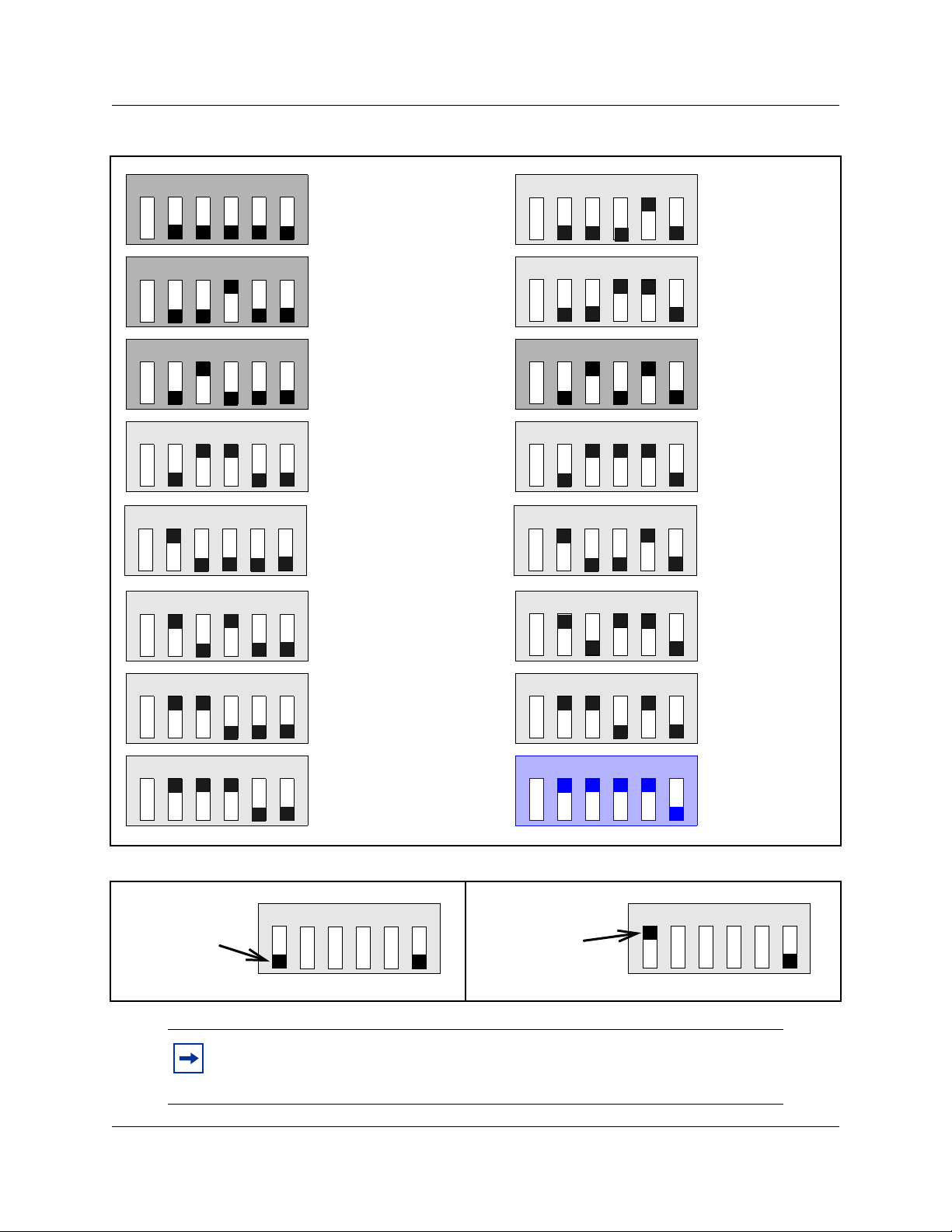

Config DIP switches

The R2MFC MBM has six config DIP switches on its faceplate. These DIP switches are used to

set the following configurations for the R2MFC MBM:

• country

• problem diagnosis

• second dial tone

DIP switches must be set before power is connected to the R2MFC MBM. Figure 3 shows the

Config DIP switches.

Figure 3 Config DIP Switches

country

configuration

second

dial

tone

123456

diagnostic

N

O

country

123456

ON

For DIP switch values and configuration information, see “Configuring the MFCR2 (external)

link” on page 45.

These DIP switches are also used for problem diagnostics. For specific settings and uses, see

“Diagnostic tools” on page 57.

R2MFC Media Bay Module Installation and Configuration Guide

Page 24

24 Chapter 1 Overview

RS232 port

There is an RJ-45 serial port connector named RS232 on the faceplate of the R2MFC MBM. The

N0026100 cable, shipped with the R2MFC MBM, is used to connect a computer to the RS232 port

for advanced configuration or for CLI-based diagnostics of the R2MFC MBM. Appendix D, “CLI

Cable Pinout,” on page 105 shows the pinout information to make a new N0026100 cable.

E1 Status LEDs

The R2MFC MBM has four visual status monitor indicators in the middle section of the faceplate.

They are:

• ERR Tx — indicates a Transmit error on the E1

• ERR Rx — indicates a Receive error on the E1

• ALM Tx — indicates a Transmit alarm on the E1

• ALM Rx — indicates a Receive alarm on the E1

Bantam jacks

The R2MFC MBM contains Bantam Jacks in the middle of the faceplate, to be used for connecting

diagnostic equipment. The jacks are labeled DIAG.

BNC and RJ-48 connectors

The R2MFC MBM has both BNC and RJ-48 external E1 connectors located on the far right of the

faceplate. These connectors are used to connect the R2MFC MBM to the Central Office (CO).

The default interface will be based on the country code selected. Mexico is the factory default. See

Appendix A, “Config DIP switch settings and definitions,” on page 85 for the country code default

settings.

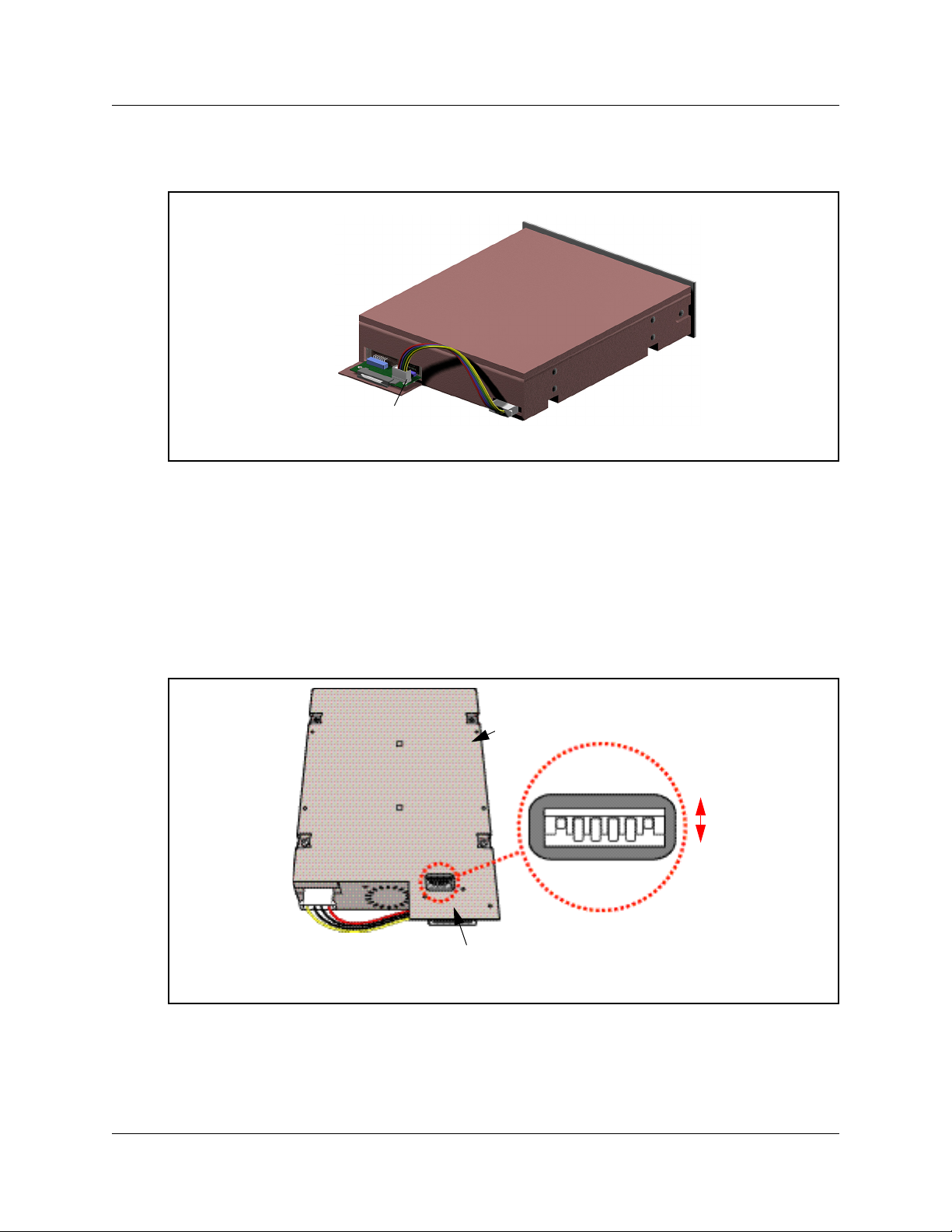

R2MFC MBM back and underside elements

The back and underside of the R2MFC MBM contain the following elements:

• “Power connectors” on page 24

• “MBM DIP switches” on page 25

Power connectors

The R2MFC MBM receives its power from the BCM chassis through a power connector on the

back of the module.

N0027684 01

Page 25

Figure 4 on page 25 shows the placement of the power connectors.

Figure 4 R2MFC MBM back

DS256 and

power connector

MBM DIP switches

Chapter 1 Overview 25

There are DIP switches located on the underside of the R2MFC MBM. These DIP switches are

used to select the DS30 buses from the DS256 bus. These DIP switches must be set before the

R2MFC MBM is installed.

Figure 5 shows the location of the DIP switches.

Figure 5 DIP switch location on the R2MFC MBM

Underside of the R2MFC

6543 21

DIP switches

Back of the R2MFC MBM

Off

On

R2MFC Media Bay Module Installation and Configuration Guide

Page 26

26 Chapter 1 Overview

N0027684 01

Page 27

Chapter 2

Preparing to install the R2MFC MBM

This chapter provides an overview of the preparation required to install the R2MFC MBM in a

host system. (The host system is the BCM system to which the R2MFC MBM connects.)

The information in this chapter is based on the following assumptions:

• The host system is installed, initialized, and tested.

• The installer has a working knowledge of the host system and an understanding of

telecommunications.

This chapter contains the following information:

• “Installation process map” on page 28

• “Host system setup requirements” on page 28

• “R2MFC MBM setup requirements” on page 29

• “Customer supplied hardware requirements” on page 30

27

R2MFC Media Bay Module Installation and Configuration Guide

Page 28

28 Chapter 2 Preparing to install the R2MFC MBM

Installation process map

Figure 6 provides an overview of the R2MFC MBM installation preparation.

Figure 6 Overview of the R2MFC MBM installation preparation

Installation

pr eparation

Ensure that BCM is

installed and configured

properly

Deter min e the correct

country and variant

Deter min e the correct

DS30 settin g

information

Ensu re enviro nmen tal

req uir ements ar e met

Ensure that all of the

customer supplied

hardware is present

Ensu re el ectrical

requirements are met

Ensure software

requirements are met

Host system setup requirements

Table 1 describes the tasks that must be completed on the host system before proceeding with the

installation of the R2MFC MBM.

Table 1 Host system setup requirements

Task Location of task information

Install host system BCM: Installation and Maintenance Guides

Determine if host system has

enough system capacity

Configure E1 Settings BCM: Programming Guide

N0027684 01

BCM: Installation and Maintenance Guides

Page 29

Chapter 2 Preparing to install the R2MFC MBM 29

R2MFC MBM setup requirements

This section provides the following information about the setup requirements for the R2MFC

MBM:

• “Config DIP switches”

• “MBM DIP switches”

• “Environment checklist”

• “Software requirements” on page 30

• “Electrical requirements” on page 30

Config DIP switches

Determine and set the Config DIP switches to the correct country code, and second dial tone

setting for the R2MFC MBM. Predefined country codes are set by the Config DIP switches.

Special configurations are set through the CLI. See “Configuring the MFCR2 (external) link” on

page 45 for a procedure on how to set the DIP switches for a predefined country code or how to

create a special configuration to meet the installation needs.

The default country code setting is Mexico config 1. See Appendix A, “Config DIP switch settings

and definitions,” on page 85 for a list of the available country codes, the country default settings,

and the second dial tone settings.

Second dial tone, when turned on, generates and supplies a second dial tone to the end user, after

the end user dials the trunk access code. The end user hears a dial tone between the last digit of the

access code, indicating that a line was accessed. See “Turning on second dial tone” on page 52 for

a procedure on how to set the DIP switches, and configure the BCM for second dial tone to work

properly.

MBM DIP switches

Before the R2MFC MBM is installed, DS30 buses and offsets must be set by DIP switches. Use

the six DIP switches on the underside of the R2MFC MBM, behind the power connector.

The R2MFC MBM occupies two DS30 buses from the DS256 bus; however, only the first is

actually used. Buses 1 and 8 are reserved for internal BCM communications. Therefore, the

R2MFC MBM DIP switches can only be set to use buses 2 through 6 on a 2/6 split or buses 2

through 5 on a 3/5 split. If there are not enough DS30 resources available, an expansion module

can be installed to provide the extra resources required. For information about setting DIP

switches and installing an expansion module, refer to the BCM Installation and Maintenance

guides supplied with the host system.

R2MFC Media Bay Module Installation and Configuration Guide

Page 30

30 Chapter 2 Preparing to install the R2MFC MBM

Environment checklist

The R2MFC MBM environmental requirements are covered by the host system environment

setup. See the BCM Installation and Maintenance guide supplied with the host system for details

of environmental requirements.

Electrical requirements

The R2MFC MBM power is supplied through the chassis on the host sytem. See the BCM

Installation and Maintenance guide supplied with the host system for details of the electrical

requirements.

Software requirements

R2MFC MBM firmware upgrades will be posted at www.nortel.com under Support & Training >

Technical Support > Software Downloads. Access this web site to see if there is a newer version

of firmware available than the firmware shipped on the R2MFC MBM. See “Upgrading firmware”

on page 63 for information on how to upgrade to the latest release of firmware.

Customer supplied hardware requirements

The following equipment is required to install of the R2MFC MBM:

• Computer with monitor and serial port for access to the CLI.

• E1 connection from local telephony service provider. Full description of the signaling

provided over the E1 by the CO.

N0027684 01

Page 31

Chapter 3

Installing the R2MFC MBM

This chapters describes how to install and remove an R2MFC MBM in a host BCM system.

This chapter provides the following installation and removal procedures:

• “Shutting down the system”

• “Installing an R2MFC MBM” on page 32

• “Removing an R2MFC MBM” on page 35

• “Wiring an R2MFC MBM” on page 37

Figure 7 provides an overview of the steps for installing the R2MFC MBM.

Figure 7 Overview of the R2MFC MBM installation

Set module DIP

switches

31

Disconnect power from

both units

Disconnect cables from

the front of the server and

expansion unit

Remove front bezel from

the expansion unit to

eject blank filler on MBM

Install new module

Replace bezel

Restore power to BCM

and expansion unit

Reconn ect all cables

Monitor LEDs fo r po wer

Shutting down the system

Before you shut down the system or perform any maintenance procedures, read the following

warnings to ensure you and your system are properly protected.

and status

NO YES

Use the Unified Manager

to identify the module to

the syst em

Is this

installation part

of a new system

installation?

Continue with

system initialization

Warning: If you are installing a new BCM or an expansion unit, refer to the

Installation and Maintenance guide for the host system for instructions about installing

a new system before you connect the system to the AC power outlet.

R2MFC Media Bay Module Installation and Configuration Guide

Page 32

32 Chapter 3 Installing the R2MFC MBM

Warning: Failure to follow procedures to properly disconnect the BCM and

expansion unit can result in module or system damage.

Warning: Ensure you are properly grounded before handling modules or any

components that are part of the BCM hardware.

1 If you are adding or replacing an R2MFC MBM in an active system, perform the following

steps:

a Access the Unified Manager.

b Choose System.

c Select the Logoff menu and then click Shutdown.

d Click Ye s .

e Wait until the Status changes to Complete! It is safe to turn off the system.

f Click Done.

g Exit the Unified Manager.

2 Attach one end of the grounding strap to your wrist and the other end to a grounded metal

surface.

3 Ensure the cables connected to the front of the BCM and the expansion unit are clearly marked

as to how they are connected.

4 Disconnect the BCM and expansion unit power cords from the AC outlet.

5 Remove the cables from all the R2MFC MBMs and the media services card (MSC) on the

BCM base function tray and the expansion unit (if attached).

Installing an R2MFC MBM

Follow the procedures in this section to install an R2MFC MBM in a BCM platform base chassis

or expansion unit.

Installing an R2MFC MBM in the BCM platform base chassis

Perform the following steps to install an R2MFC MBM in the BCM platform base chassis:

Caution: Only install the R2MFC MBM when the system is powered down. See

“Shutting down the system” on page 31.

1 Ensure that both the faceplate and underside DIP switches on the R2MFC MBM are set

N0027684 01

correctly. For information on how to set the faceplate switches, refer to “Setting Config DIP

Page 33

Chapter 3 Installing the R2MFC MBM 33

switches” on page 45. For information about how to set the underside switches, refer to the

Installation and Maintenance guide for the host BCM.

2 Select an open media bay.

3 With the face of the R2MFC MBM facing toward you, insert the R2MFC MBM into the open

bay.

4 Push the R2MFC MBM completely into the unit. You will hear a click when the module is

firmly seated in the media bay.

Installing an R2MFC MBM in the expansion unit

Perform the following steps to install an R2MFC MBM in the BCM expansion unit chassis. Install

the R2MFC MBM when the system is powered down:

Caution: Only install the R2MFC MBM when the system is powered dow. See

“Shutting down the system” on page 31.

Warning: Failure to follow procedures to properly disconnect the BCM and

expansion unit can result in module or system damage.

1 Ensure that both the faceplate and underside DIP switches on the R2MFC MBM are set

correctly. For information on how to set the faceplate switches, refer to “Setting Config DIP

switches” on page 45. For information about how to set the underside switches, refer to the

BCM Installation and Maintenance guide for the host system.

2 Remove the front bezel from the expansion unit.

3 Select an open media bay.

4 With the faceplate of the R2MFC MBM facing toward you, insert the R2MFC MBM into the

open bay. Ensure that any cables at the rear of the module are clear of the platform base

chassis.

5 Push the R2MFC MBM into the unit. You will hear a click when the module is firmly seated

in the media bay.

6 Install the front bezel on the expansion unit.

Reconnecting the equipment

After you install the module correctly into the bay, you must return the equipment to operation.

Caution: Complete the following steps carefully to ensure you return your

system to operation without endangering the equipment or yourself.

R2MFC Media Bay Module Installation and Configuration Guide

Page 34

34 Chapter 3 Installing the R2MFC MBM

1 Plug the power cords for the BCM and any expansion units back into the AC outlets.

Note: The Business Communications Manager system starts up when you

connect the AC power cord. System startup takes several minutes to complete.

2 Connect the cables to the proper outlets on the R2MFC MBM and the MSC on the BCM.

3 Check that the LEDs on the newly installed R2MFC MBM are on and indicating the correct

state. Refer to “Faceplate LEDs” on page 60 for a detailed description of the LED states.

4 Confirm that the BCM is functioning properly by testing to make sure it works the same as it

did before installing the R2MFC MBM.

5 Configure the module. Refer to Chapter 4, “Configuring the R2MFC MBM,” on page 41 for

details.

N0027684 01

Page 35

Removing an R2MFC MBM

Follow the procedures in this section to remove an R2MFC MBM from a BCM platform base

chassis or expansion unit.

Figure 8 provides an overview of the process for removing an R2MFC MBM.

Figure 8 Overview of removing an R2MFC MBM

Shut down BCM and

expansion unit

Disconnect power from

both unit s

Remove module cables

Chapter 3 Installing the R2MFC MBM 35

Re mo ve mo d ule

Removing an R2MFC MBM from the BCM platform base chassis

Perform the following steps to remove an R2MFC MBM from the BCM platform base chassis.

Remove the R2MFC MBMs after the system is powered down.

1 Power-down the BCM system (see “Shutting down the system” on page 31).

2 Remove any cabling from the R2MFC MBM faceplate.

3 Grasp the right edge of the MBM ejector lever with your thumb, index, and middle fingers.

Pull outward to partially eject the R2MFC MBM. Pull further on the lever to eject the R2MFC

MBM from the bay. Figure 9 on page 36 shows how to remove a BCM 200 R2MFC MBM.

Figure 10 on page 36 shows how to remove a BCM 400 R2MFC MBM.

4 Grasp the top and bottom edges of the R2MFC MBM. Remove the R2MFC MBM from the

BCM platform base chassis MBM bay (see Figure 9 on page 36 and Figure 10 on page 36).

Place the R2MFC MBM in a clean, safe, and static-free area.

R2MFC Media Bay Module Installation and Configuration Guide

Page 36

36 Chapter 3 Installing the R2MFC MBM

Figure 9 How to remove a BCM200 R2MFC MBM

Grasp the edge

of the R2MFC

MBM ejector lever and pull out.

Figure 10 How to remove a BCM400 R2MFC MBM

Grasp the edge of the

R2MFC MBM ejector lever

N0027684 01

Page 37

Chapter 3 Installing the R2MFC MBM 37

Removing an R2MFC MBM from the expansion unit

Use this procedure to remove an R2MFC MBM from the BCM expansion unit.

Warning: Remove the R2MFC MBM after the system is powered down.

1 Power-down the BCM expansion unit system (see “Shutting down the system” on page 31).

2 Remove any cabling from the R2MFC MBM faceplate.

3 Remove the expansion unit front bezel.

4 Grasp the edge of the MBM ejector lever. Pull outward to eject the R2MFC MBM. Refer to

Figure 11.

Figure 11 How to remove the expansion unit front bezel

BCM expansion unit

5 Grasp the top and bottom edges of the R2MFC MBM. Remove the R2MFC MBM from the

BCM expansion unit. Place the R2MFC MBM in a clean, safe, and static-free area.

Wiring an R2MFC MBM

This section describes how to wire the cables that connect to the R2MFC MBM. The R2MFC

MBM is connected to the CO by either RJ48C or BNC connectors. The BNC connector is the

default interface. The default connector can be changed either by setting the country - selection

DIP switches or by creating a custom country code profile through the CLI. See “Configuring the

MFCR2 (external) link” on page 45 for information on how to change the active interface.

If the 75 Ω BNC connector pair is used, two coax cables are required for transmit and receive.

1. Push against the bottom

2. Pull out from the top

MBM latches

If the 120 Ω RJ-48 connector is used, the cable pinout must be set up as follows:

R2MFC Media Bay Module Installation and Configuration Guide

Page 38

38 Chapter 3 Installing the R2MFC MBM

Figure 12 R2MFC MBM RJ48 wiring array

R2MFC MBM

connector

To network To plug

Receive from

network

RJ48 jack

Transmit to network

1- Rtip

2 - Rring

3 - Rshield

4-Ttip

5-Tring

6-Tshield

Warning: Only allow qualified persons to service the BCM system.

The installation and service of this unit must be performed by service personnel with the

appropriate training and experience. Service personnel must be aware of the hazards of

working with telephony equipment and wiring. They must have experience in techniques

that minimize any danger of shock or equipment damage.

Warning: Leakage currents

Service personnel must be alert to the possibility of high-leakage currents becoming

available on metal system surfaces during power line fault events on network lines. These

leakage currents normally safely flow to Protective Earth ground through the power cord.

However, if the AC power is unplugged prior to disconnecting the cables from the front of

the base function tray, high-leakage currents available on metal system surfaces can occur.

Figure 13 on page 39 provides an overview of the process for connecting trunk wiring to the BCM

R2MFC MBMs.

N0027684 01

System shutdown: You must disconnect the R2MFC MBM cables from the system before

disconnecting the power cord from a grounded outlet.

System startup: You must reconnect the power cords to a grounded outlet before

reconnecting the cables to an R2MFC MBM.

Danger: Electrical shock hazards

Electrical shock hazards from the telecommunications network and AC mains are possible

with this equipment. To minimize risk to service personnel and users, the BCM system

must be connected to an outlet with a third-wire ground. In addition, all unused slots must

have blank faceplates installed. The covers on all units must be in place at the completion

of any servicing.

Page 39

Figure 13 Trunk wiring overview

Install R2MCF MBM

Read warnings

Chapter 3 Installing the R2MFC MBM 39

Connect cables to

appropriate trunk

modules

Determine the correct

connector to use

Continue with setup

procedures

Connecting an R2MFC MBM to a service provider

Warning: Electrical shock warning.

The Business Communications Manager R2MFC MBMs have been safety-approved for

installation into BCM base units and expansion units. Both the installer and user are

responsible to ensure that installation of the Business Communications Manager hardware

does not compromise existing Safety approvals.

BEFORE YOU OPEN the Business Communications Manager base unit or Business

Communications Manager expansion unit, ensure that the network telecom cables are

unplugged, and that the unit is then disconnected from the ac power source.

Station modules: The ports on these modules are meant to be connected only to approved

digital telephones and peripherals, with the proper cables, on a protected internal wiring

system.

Do not connect any telephones to wiring that runs outside the building.

Read and follow the installation instructions carefully.

Perform the following steps to connect an R2MFC MBM to the network:

1 Determine the connector type to be used, either RJ48C or BNC connectors.

2 Locate the appropriate connector on the front of the module.

3 Attach the transmit BNC cable to the connector labeled Tx and the receive BNC cable to the

connector labeled Rx, for countries using BNC connections. Insert the connector into the RJ48

R2MFC Media Bay Module Installation and Configuration Guide

Page 40

40 Chapter 3 Installing the R2MFC MBM

jack on the module, for countries using the RJ48 connections. Figure 12 on page 38 shows the

wiring pinouts for an R2MFC MBM to connect to a service provider using RJ48 connectors.

Warning: If you are using a service provider channel service unit (CSU), you must

disable the Business Communications Manager system internal CSU by using Business

Communications Manager Unified Manager. For more information, refer to the

Programming Operations guide for the host system.

4 Use the Unified Manager to configure the lines or sets associated with the module. Refer to the

BCM Programming Operations guide for the host system for more information.

Refer to the BCM Programming Operations guide for the host system for information on

changing the default settings for each line/loop.

N0027684 01

Page 41

Chapter 4

Configuring the R2MFC MBM

Trunk protocol conversion provides interworking between two different trunk protocols, and

requires configuration for the following:

• E1- MFCR2

• E1- ETSI Euro-PRI

The MFCR2 is the external interface. The external interface connects to a public network. The

R2MFC MBM contains preprogrammed country-specific MFCR2 settings that can be selected

using the DIP switches on the faceplate of the R2MFC MBM. The MFCR2 settings can also be

customized. The PRI is an internal link to the BCM. The PRI setting are configured to predefined

settings when the region is selected during BCM initialization. The PRI does not require

customization, but it must be configured as detailed in “Configuring the PRI (internal) link” on

page 48.

This chapter lists the configurable parameters of both the MFCR2 side and the PRI side of the

R2MFC MBM, and explains how to configure them. Figure 14 provides an overview of the

configuration process.

41

Figure 14 Configuring the R2MFC MBM

Install the

R2MFC MBM

Determin e the correct

config uration

parameters for the

external link

Does the

setup req uire custom

settings?

NO

Set Confi g DIP switch es

YE S

Create a n ew

customiz ed country

code

Determin e the correct

configuration

parameters for the

internal link

Confi gure the inter nal

PRI li nk thr ough th e

Unified Manager

R2MFC Media Bay Module Installation and Configuration Guide

Page 42

42 Chapter 4 Configuring the R2MFC MBM

MFCR2 side (External Link) configurable parameters

Physical line characteristics

The MBM has two options for physical connections on the faceplate:

1 RJ-48 connector for twisted pair cable (line impedance of 120 Ohms)

2 a pair of BNC connectors for coax cables (line impedance of 75 Ohms)

The BNC connectors can have one of the following:

• TX shielding connected to ground (default)

• RX and TX shielding not connected to ground

Only one of the two connector types can be active. The default active interface is the BNC

connector. The BCN connector is part of the country-specific defaults for Mexico. Each of the

country codes activates the appropriate connector, based on the country standard for connectors.

The active interface can be customized in the firmware through the CLI by using commands in the

COnfig directory.

E1 framing

The external link uses Channel Associated Signaling on timeslot 16, therefore; TS16 multiframe

format is always used. In addition, optional CRC4 multiframe can be used (for monitoring digital

transmission quality), instead of basic “alternate frame” format.

The CRC4 multiframe option is activated by the firmware as part of the country-specific defaults.

PCM coding is A-law.

These settings can be customized in the firmware through the CLI by using commands in the

ALarm directory.

Note: Changes made to the framing parameters must be configured in both the R2MFC

and the BCM.

Line signaling

Line signaling (for example, seize, answer, and disconnect) are implemented by R2 Channel

Associated Signaling known as ABCD bits. Only the two bits AB are used for line signaling. The

state (value) of the bits indicate the signal.

N0027684 01

Page 43

Chapter 4 Configuring the R2MFC MBM 43

The channels are always bidirectional, (that is, they accept incoming calls or originate outgoing

calls). The channel behavior also supports one-way trunks. The direction of the signal does not

need to be configured. Because the R2MFC MBM is passive, the R2MFC MBM does not initiate

calls; it only passes call origination attempts from one side to the other. The R2MFC MBM

assumes that the two sides (BCM and CO) respect the direction of the trunk as agreed between

them.

The meaning of the bit states are part of the country-specific parameters; however, they can be

customized through the CLI by using commands in the R2 directory.

The following are additional options included in country-specific parameters:

• use backward force-release signal to clear back (yes/no)

• release-guard state (timer) when clearing back (timer value)

• optional CD bits value (usually ignored)

Register signaling

Register signaling (digits transmission) is implemented by in-band dual-tone signals known as

MFC-R2. Physically, there are 15 forward signals and 15 backward signals. The standard defines

two stages of the signaling. The meaning of the signal depends on the stage and the direction of the

call. In total, there are four tables of 15 signals each. See Appendix A, “Config DIP switch settings

and definitions,” on page 85 for MFC country-specific signal tables.

The meaning of MFC signals can be different when transmitted or received. MFC signal tables are

part of the country-specific parameters. The meaning of the MFC signals in the R2MFC MBM are

configurable through the CLI by using commands in the MFC directory.

The following are other options included in country-specific parameters:

End of dialing (incoming)

End of dialing for an incoming call can be configured by using the CLI. See Table 2, for the end of

dialing options.

Table 2 Minimum (or fixed) number length + timer parameters (Sheet 1 of 2)

Option Parameters Meaning Default

Explicit ‘End of dial’ signal

(I-15)

None The preset option for all

countries. However, signal

has low significance, because

the end of dialing is

determined by the BCM (PRI

side) when it receives the last

digit of the number.

Yes

R2MFC Media Bay Module Installation and Configuration Guide

Page 44

44 Chapter 4 Configuring the R2MFC MBM