Page 1

- 1 -

Page 2

- 2 -

Page 3

- 3 -

CONTENTS

Important Safety Recommendations ………………………………………............. 4

Warranty Exclusions ………………………………………………………………. 5

Assembly Instructions ………………………………………………………………. 6

Identify Garage Door Type ……………………………………………………………… 6

Identify Installation Method ……………………………………………………………… 6

Assembly ……………………………………………………………………………… 7

Installation Instructions ……………………………………………………………… 9

Header Bracket Mounting ………………………….……………………………........... 9

Towing Bracket Mounting ……………………………………………………………… 9

Attaching Drive Rail to Header Bracket ……………………………………………… 9

Mounting Drive Rail Assembly to Ceiling ……………………………………………… 10

Attaching Towing Arms ……………………………………………………………… 11

Connecting to Power Supply ………………………............................................................ 11

Settings and Adjustments ……………………………………………………………… 12

Engaging / Disengaging ……………………………………………………………………… 12

Door Travel Adjustment ……………………………………………………………… 13

Safety Obstruction Force Adjustment ……………………………………………………… 13

Adaptive Mode ……………………………………………………………………… 14

Manual Mode ……………………………………………………………………… 15

Options and Features ……………………………………………………………… 17

Accessory Connections ……………………………………………………………………… 17

Auto Close ……………………………………………………………………………… 17

Back Jump ……………………………………………………………………………… 17

Battery Back-Up ……………………………………………………………………… 18

Battery Power ……………………………………………………………………………… 18

Control Box ………………………………………………………………………….. 19

Courtesy Lamp ……………………………………………………………………………… 21

Dip Switches ……………………………………………………………………… 21

Door Service Monitor ……………………………………………………………………… 21

Hand Transmitters ……………………………………………………………………… 22

Learn Button ……………………………………………………………………… 22

LED Indicator ……………………………………………………………………… 23

Run Button ……………………………………………………………………… 23

Safety Beams ……………………………………………………………………… 23

Safety Reverse ……………………………………………………………………………… 24

Soft Start ……………………………………………………………………………… 25

Soft Stop ……………………………………………………………………………… 25

Speed Control ……………………………………………………………………… 25

Vacation Mode ……………………………………………………………………… 25

Wall Switch (hard wired) ……………………………………………………………… 26

Wall Switch (wireless) ……………………………………………………………… 26

Maintenance ……………………………………………………………………………… 26

Technical Specifications ……………………………………………………………… 26

Trouble Shooting Guide ……………………………………………………………… 27

Page 4

- 4 -

IMPORTANT SAFETY RECOMMENDATIONS

FAILURE TO COMPLY WITH THE FOLLOWING SAFETY RECOMMENDATIONS MAY

RESULT IN SERIOUS PERSONAL INJURY, DEATH AND / OR PROPERTY DAMAGE.

1. PLEASE READ CAREFULLY AND ADHERE TO ALL SAFETY AND INSTALLATION

RECOMMENDATIONS

2. The installation of your new Automatic Garage Door Opener (herein after referred to as “AGDO”)

must be carried out by a technically qualified or licensed person. Attempting to install or repair the

AGDO without suitable technical qualification may result in severe personal injury, death and / or

property damage.

3. The AGDO must only be installed on a properly balanced well functioning garage door. An improperly

balanced or malfunctioning garage door could cause serious personal injury, death and / or property damage.

Have a qualified person check and if required, make repairs to your garage door before installing the AGDO.

The garage door is deemed to be well balanced and aligned if it;

a. requires an equivalent amount of applied force to either manually open or close, and

b. requires no more than 150N (15kg) of applied force to either manually open or close, and

c. does not rise or fall more than 100mm when released at any point between fully open or fully closed

positions, and

d. does not rub on or incorrectly make contact with any supporting or surrounding structures, and

e. the horizontal tracks have been installed level, and

f. the door panels have been installed level, and

g. the vertical tracks have been installed plum, and

h. the junction between the curved horizontal track and the vertical track does not cause the door to “jump”

4. The counter balance springs on sectional type garage doors must be properly lubricated between all of the

coils with heavy automotive bearing grease. Failure to adequately lubricate the springs may result in one or

more of the following symptoms:

a. Counter balance springs may become rusty over time resulting in additional operating friction between

the coils which may cause the AGDO to malfunction.

b. Seasonal temperature changes may cause the garage door springs to expand and / or contract. The

resultant increase and / or decrease in operating friction may cause the AGDO to malfunction. Properly

lubricating the springs will help to minimize changes in operating friction due to the effects of seasonal

temperature change.

5. Remove or render inoperative all existing locks and ropes prior to installation of the AGDO.

6. Repairs to the garage door must be carried out by technically qualified persons. Attempting to repair the

garage door without suitable technical qualification may result in severe personal injury, death and / or

property damage.

7. Where possible, install the AGDO at least 2 meters or more above the ground. Adjust the Engage / Disengage

Cord so that it hangs approximately 1.8 meters from the ground.

8. The Header Bracket carries ALL of the opening and closing thrust of the AGDO and as such must be securely

fastened to a rigid, structural member of the garage wall or ceiling. It is entirely up to the installer to determine

the fixing method and the structural suitability of the fixing points.

9. The ceiling structure must be adequate to support the weight of the GDO. It is entirely up to the installer to

determine the structural suitability of the fixing points.

10. The Engage / Disengage Instruction Tag must remain attached to the Engage / Disengage Cord.

11. Locate the Wall Switch;

a. within site of the garage door, and

b. at a minimum height of 1.5 meters above the ground so that it remains out of the reach of small children,

and

c. away from all moving parts of the garage door

12. The Entrapment Warning Label must be secured in a prominent position adjacent to the wall switch.

13. The AGDO must be connected to a properly earthed general purpose 230 ~ 240VAC power outlet which has

been installed by a qualified electrical contractor.

14. Do not connect the AGDO to the power outlet until this manual instructs you to do so..

Page 5

- 5 -

IMPORTANT SAFETY RECOMMENDATIONS

15. Subsequent to installation and adjustment, the AGDO the garage door must stop and reverse direction when

it comes into contact with a 35mm high solid object placed on the floor under the garage door.

16. The correct function of the Safety Obstruction Force System should be checked on a monthly basis.

17. Never use the AGDO unless the garage door is in full view and free from any object which may impede the

movement of the garage door such as cars, children and / or adults.

18. Never allow children to operate the AGDO.

19. Never operate the AGDO when any persons are under or near the path of the garage door. Children must be

supervised at all times when near the garage door and when the AGDO is in use.

20. Never attempt to disengage the AGDO to manual operation when there are children / persons and / or solid

objects including motor vehicles under or near the path of the garage door as the garage door may fall sharply

upon Manual Release from the AGDO.

21. Never attempt to open or close the garage door by pulling on the Engage / Disengage Cord.

22. Never attempt to make any repairs or remove covers from the AGDO without first disconnecting the power

supply cord from main power supply.

23. Removal of the AGDO’s protective covers must only be performed by a technically qualified person.

Attempting to remove the protective covers or repair the AGDO without suitable technical qualification may

result in severe personal injury, death and / or property damage.

24. For additional safety we strongly recommend the inclusion of Safety Beams. Although the AGDO

incorporates a pressure sensitive Safety Obstruction Force system the addition of Safety Beams will greatly

enhance the operating safety of an automatic garage door and provide additional peace of mind. In some

countries it is a mandate of law to fit Safety Beams. It is the sole responsibility of the owner / installer to fit

Safety Beams in those countries that so require.

25. Always ensure that the garage door is fully open & stationary before driving in or out of the garage.

26. Always ensure the garage door is fully closed and stationary before moving out of its view.

27. Adjustments to the Safety Stop / Reverse Force settings must only be carried out by a technically qualified

person. Attempting to adjust the settings without suitable technical qualification may result in severe personal

injury, death and / or property damage.

28. Keep hands and loose clothing clear of the AGDO and garage door at all times.

29. In order for the Safety Obstruction Force system to function it must first encounter an obstruction in the form

of an object / person on to which some force MUST be exerted. As a result the object / person / garage door

may suffer DAMAGE AND / OR INJURY.

30. The Safety Obstruction System is designed to work on STATIONARY objects only. Serious personal

injury, death and / or property damage may occur if the garage door comes into contact with a moving

object during an open or close cycle

Warranty Exclusions

No claims whatsoever will be recognized under the terms of the AGDO’s warranty which pertain to

damage, injury, cost or expense, suffered by persons and / or to property, which either directly or

indirectly arise out of any one of the following occurrences;

i. Failure to install the AGDO in accordance with the captioned instructions.

ii. The garage door coming into contact with a moving object. (refer Point 30 in the above)

iii. The AGDO being used for other than a maximum 4 car residential application.

iv. Installing the AGDO on an improperly balanced and / or poorly functioning and / or misaligned

garage door. (refer Point 3 in the above)

v. Failure to adequately lubricate the garage door counter balance springs. (refer point 6 in the

above)

vi. Failure to adequately fix the GDO to the garage structure

vii. Attempting to open or close the garage door by pulling directly on the Manual Release Cord.

viii. Manually releasing the garage door in any position other than when it is fully closed.

ix. Failure to connect the AGDO to a properly earthed power supply

x. Note: Light bulb failures are not covered under the terms of this product’s warranty

Page 6

- 6 -

ASSEMBLY INSTRUCTIONS

1. Identify Garage Door Type

Identify the garage door type and then select the preferred installation method (Sec.2) and assembly type

(Sec.3) that is best suited to the application.

Method A Method B Method C

2. Identify Installation Method

Method A – Sectional Door & Track Type Tip-Up Door. (Hanging Installation)

Use 3 Drive Rail Sections (Fig.3-A) with the Control Box. (Fig.3-D)

Control Box may be mounted to the end of the Drive Rail OR mounted on the ceiling next to Drive Rail OR

mounted on side wall of garage. (optional cable extension kit required)

Drive Rail supported by Drive Rail Hanger (Fig.3-C) which is hung from the ceiling by appropriate hanging

material.

Drive Rail Hanger may be positioned anywhere between the Control Box and the first Drive Rail Joiner.

(Fig.3-B)

Header Bracket (Fig.5) may be mounted on front wall of garage or on ceiling adjacent to the front wall.

Method B – Sectional Door & Track Type Tip-Up Door (Flush Installation)

Use 3 Drive Rail Sections (Fig.3-A) with the Control Box. (Fig.3-D)

Control Box may be mounted to the end of the Drive Rail OR mounted on the ceiling next to Drive Rail OR

mounted on side wall of garage. (optional cable extension kit required)

Drive Rail supported by Drive Rail Hanger which is mounted flush to the ceiling using angle brackets.

Drive Rail Hanger may be positioned anywhere between the Control Box and the first Drive Rail Joiner.

Header Bracket may be mounted on front wall of garage or on the ceiling adjacent to the front wall.

Method C – Jamb Type Tip-Up Door (Hanging Installation)

Use 2 Drive Rail Sections (Fig.3-A) with the Control Box. (Fig.3-D)

Control Box may be mounted to the end of the Drive Rail OR mounted on the ceiling next to Drive Rail OR

mounted on side wall of garage. (optional cable extension kit required)

Drive Chain has been provided with an additional split link which when removed will shorten the Drive

Chain to a required 2 Drive Rail length configuration.

Drive Rail supported by Drive Rail Hanger which is hung from the ceiling by appropriate hanging material.

Drive Rail must be angled as shown depicted in “Method C” so that underside of Drive Unit is in line with

underside of the garage door when the garage door is in the fully open (horizontal) position.

Header Bracket may be mounted on front wall of garage or on the ceiling adjacent to the front wall.

Page 7

- 7 -

ASSEMBLY INSTRUCTIONS

3. Assembly

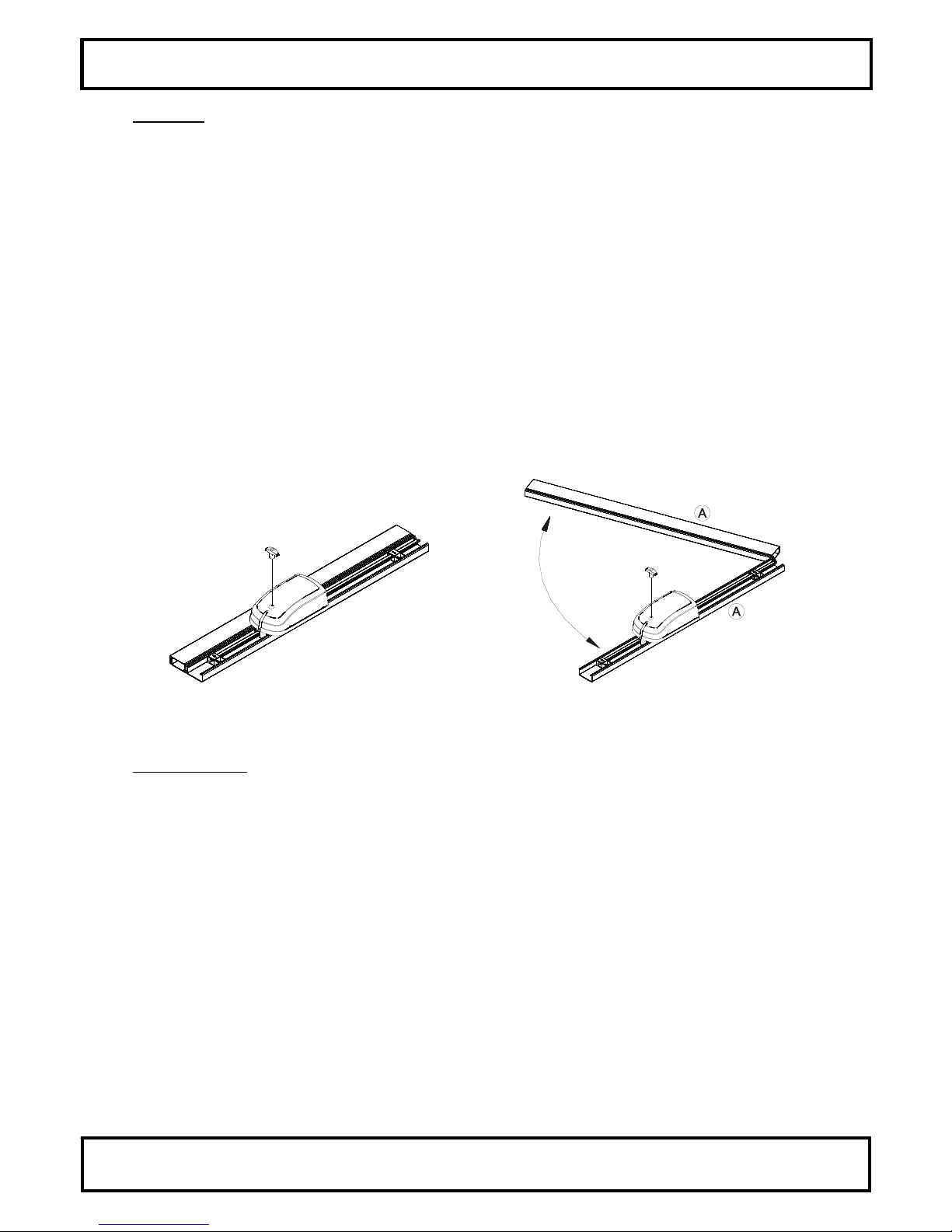

On a clean smooth surface open the packing carton and expose the AGDO components. (Fig.1)

Unfold the Drive Rail and Drive Chain Segments. (Fig.2-A)

Use the appropriate number of Drive Rails, Drive Rail Joiners and Chain Segments to suit the preferred

Installation Method, A, B or C. (Refer Sec.1 & 2)

Align and insert each Drive Rail Joiner (Fig.3-B) into a Drive Rail Segment (Fig.3-A) and push them

together until they are fully abutted and form one continuous Drive Rail Assembly.

Locate the Drive Rail Hanger (Fig.3-C) and insert the 2 gutter bolts provided. Slide the Drive Rail Hanger

onto the Drive Rail Assembly adjacent to the Control Box. (Fig.3-D) location.

Insert the Control Box into the Drive Rail Segment furthest from the garage door and then “Twist and Lock”

the Drive Chain (Fig.3B-D2) the Drive Chain into the Tensioning Block. (Fig.3B-D1).

Ensure that the plastic chain insulator ends are fully abutted and form one continuous piece.

Insert the Terminal Bracket (Fig.3-E) into the Drive Rail Segment closest to the garage door and then

“Twist and Lock” the Drive Chain (Fig.3A-E2) the Drive Chain into the Tensioning Block. (Fig.3A-E1)

Using a 12 mm socket wrench, tighten the Drive Chain Tensioner Bolt to the point where the underside of

the Bolt Head aligns with the Indicator Arrow on the Terminal Bracket. (Fig.3A-E3)

Fig. 1 Fig. 2

3.1 Options Selection

Refer to “Options and Features” on pages 17 ~ 26 and select the required Dip Switch functionality and

external accessory wiring as required.

Dip Switches and external accessory wiring connections (Fig.16) can be accessed by removing the Control

Box Cover. (refer Sec.18 for removal and replacement details)

Once functionality selection and wire connection has been completed replace the Control Box Cover / Lamp

Bulb / Courtesy Lamp Cover and the AGDO is now fully assembled and ready for installation.

Page 8

- 8 -

ASSEMBLY INSTRUCTIONS

(Sectional / Track Type Tip-Up assembly depicted)

Fig. 3

Fig. 3A Fig. 3B

Page 9

- 9 -

INSTALLATION INSTRUCTIONS

4. Header Bracket Mounting

Important Note: Before commencing the installation ensure that you have carefully read and

understood the Safety Recommendations outlined in pages 4 and 5 of this manual. In particular,

ensure that the installation of the garage door complies with the requirements specified in points 3, 4

and 5. Make any necessary adjustments to the garage door BEFORE commencing the installation!

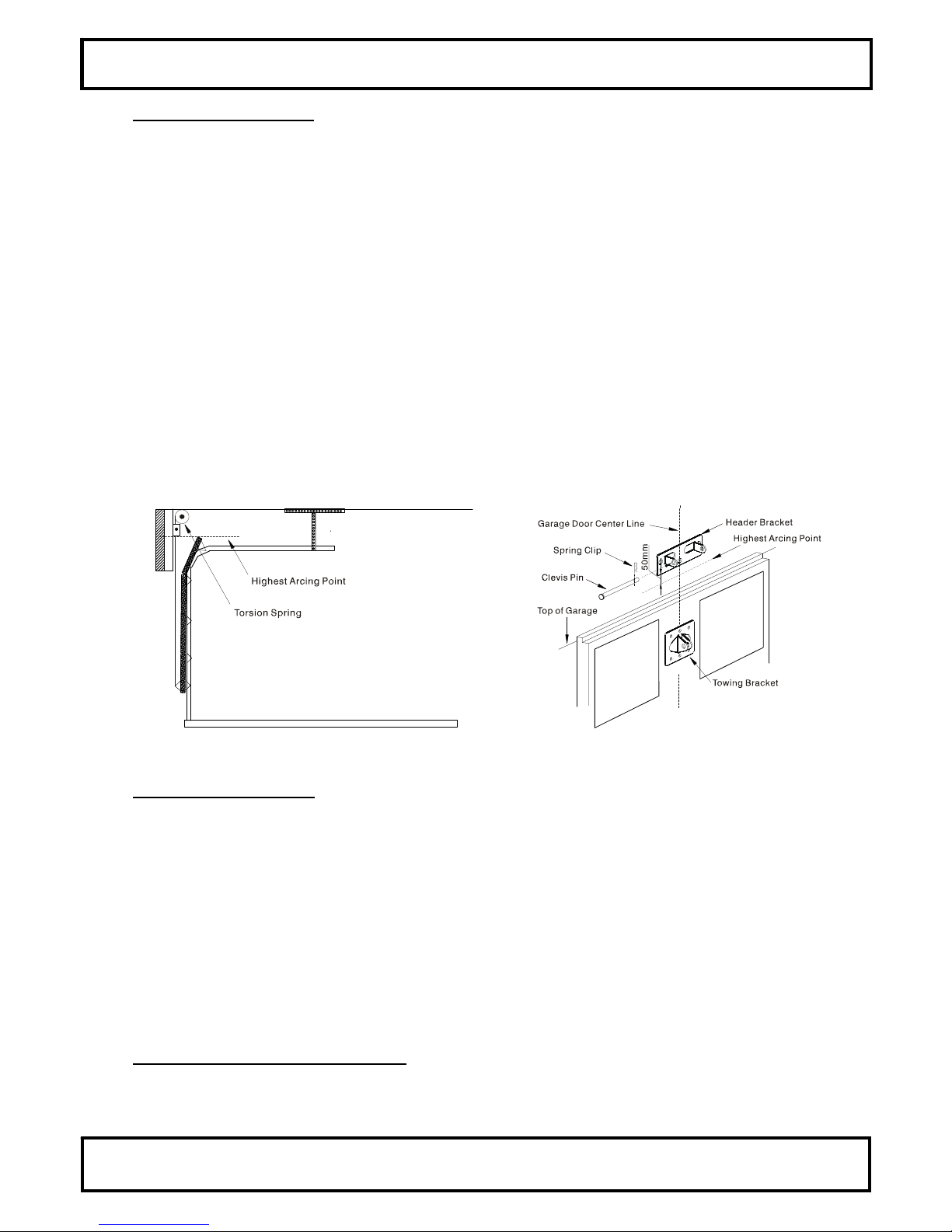

Determine the highest arcing point of the garage door and mark this as a horizontal line on the header above

the top edge of the garage door. (Figs.4 & 5)

Determine the Garage Door Center Line and mark a vertical line on the header above the door. (Fig.5)

Place the Header Bracket on the wall as depicted in Fig.5 and ensure that the bottom edge of the bracket is

no more than 50mm above the Highest Arcing Point. Mark the location of the 2 outer most screw holes.

Drill 2 screw holes and use screws of at least 8mm dia. x 50mm long to secure Header Bracket to Header.

Important Notes:

a. The Header Bracket carries ALL of the opening and closing thrust of the AGDO and as such

must be securely fastened to a rigid, structural member of the garage. It is entirely up to the

installer to determine the fixing method and the structural suitability of the fixing points.

b. Mounting the Drive Rail more than 50mm above the Highest Arcing Point of the garage door

may cause the Drive Rail to flex excessively. Always ensure that the bottom edge of the Drive

Rail is located within 50mm of the top edge of the top panel of the garage door. (Fig.7)

Fig. 4 Fig. 5

5. Towing Bracket Mounting

Determine the Garage Door Center Line (Fig.5) and affix the Towing Bracket to a structural member of the

garage door. The Towing Bracket should be mounted with reference to the top edge of the garage door in

accordance with the appropriate diagram as depicted in Sec.1.

Mark the location of the holes. (4 holes if using self drilling screws – 2 holes if using screws with nuts)

Drill the screw holes with an appropriate drill and securely mount the Towing Bracket to the garage door

using screws of at least 6mm dia.

Important Notes:

a. It is recommended to use fixing screws and nuts rather than self drilling screws.

b. For a sectional type garage door the pivot point of the Towing Bracket should be located

approx one third of the way down from the top edge of the top panel. For a tip-up type garage

door the pivot point should be as close to the top edge of the garage door as possible.

6. Attaching Drive Rail to Header Bracket

With the garage door in the fully closed position - lay the assembled AGDO on the garage floor in line with

the centerline of the garage door so that the Control Box is furthest from the garage door.

Page 10

- 10 -

INSTALLATION INSTRUCTIONS

Important Note: avoid scratches and potential damage to the AGDO plastic covers by placing the

Control Box and Drive Unit on cardboard or foam.

Raise the Drive Rail up to the Header Bracket so that the Drive Rail sits in between the ears of the Header

Bracket. (Fig.6)

Align the mounting holes of the Header Bracket and Terminal Bracket and fully insert the long clevis pin

and secure it with the spring clip.

7. Mounting Drive Rail Assembly to Ceiling

Select Method A, B or C according to the assembly and installation type (Refer Sec.2)

Method A - Hanging Installation

Raise the Drive Rail assembly off the floor and rest it on a support high enough that the Drive Rail runs

parallel to the ground. (Fig.7 depicts typical sectional type garage door installation)

Important Note: Do not lift the AGDO by the Control Box or damage may occur. Always lift the

AGDO via the Drive Rail.

Carefully open the garage door and ensure that no part of it comes into contact with the Drive Rail or the

Control Box during its entire movement.

Align the Drive Rail with the centerline of the garage door.

Slide the Drive Rail Hanger along the drive rail (up to max 600mm from the Control Box) in order to align

it with a structural member of the garage. Securely fasten the Drive Rail Hanger to the structural member of

the garage using 2 lengths of appropriate hanging material. (Fig.7)

Once the Drive Rail is hung it should sit parallel to the floor along both planes. (For sectional and track-type

tilt doors only. For jamb-type tilt door refer Pg.6 Method C)

Important Notes:

a. With the garage door in the fully open position the underside of the Drive Rail should be no

more than 50mm above the highest arcing point for its entire length. Mounting the Drive Rail

more than 50mm above the Highest Arcing Point of the garage door may cause the Drive Rail

to flex excessively. (Fig. 7)

a. The ceiling structure must be adequate to support the weight of the GDO. It is entirely up to

the installer to determine the structural suitability of the fixing points.

Method B - Flush Mount Installation

Raise the Drive Rail off the floor and rest it on a support high enough that the Drive Rail runs parallel to the

ground. (Fig.8 depicts a typical sectional type garage door installation)

Important Note: Do not lift the AGDO by the Control Box or damage may occur. Always lift the

AGDO via the Drive Rail.

Align the Drive Rail with the centerline of the garage door.

Raise the Drive Rail to the ceiling and mark out and drill 2 mounting points through the holes in the angle

brackets and then affix the Drive Rail to the ceiling using 2 appropriate screws.

Important Notes:

b. With the garage door in the fully open position the underside of the Drive Rail should be no

more than 50mm above the highest arcing point for its entire length. Mounting the Drive Rail

more than 50mm above the Highest Arcing Point of the garage door may cause the Drive Rail

to flex excessively. (Fig. 7)

c. The ceiling structure must be adequate to support the weight of the AGDO. It is entirely up to

the installer to determine the structural suitability of the fixing points.

Method C - Independent Mounting of Control Box

The Control Box may be mounted independently from the Drive Rail either along side the Drive Rail on the

ceiling (cable provided) or on a side wall of the garage. (optional cable extension kit required)

Demount the rear Terminal Bracket from the Control Box by removing its fixing screw.

Page 11

- 11 -

INSTALLATION INSTRUCTIONS

Mount the Drive Rail as per Method A or B.

Mount the Control Box either next to the Drive Rail (via the Control Box mounting holes located within the

Control Box cover) utilizing the standard cable provided OR on a side wall of the garage (via the 3 hanging

mounts located on the base of the Control Box) using the optional cable extension kit.

Important Notes:

a. With the garage door in the fully open position the underside of the Drive Rail should be no

more than 50mm above the highest arcing point for its entire length. Mounting the Drive Rail

more than 50mm above the Highest Arcing Point of the garage door may cause the Drive Rail

to flex excessively. (Fig. 7)

b. The ceiling structure must be adequate to support the weight of the AGDO. It is entirely up to

the installer to determine the structural suitability of the fixing points.

8. Attaching Towing Arms

Close the garage door.

Remove the Drive Unit cover and insert the Straight Towing Arm through the slot in the cover (use the end

of the arm which has only one single hole)

Attach the arm to the Drive Unit using the short clevis pin and spring clip and then replace the cover.

Attach the Bent Towing Arm to the Towing Bracket (use the end of the arm which has only one hole)

With the Drive Unit disengaged (Fig.10) position the Drive Unit in either one of the following ways;

i. Adaptive mode ~ any distance from the end of the Drive Rail. (Fig.9)

ii. Manual Mode ~ 225mm from the end of the rail to the front of the Drive Unit. (Fig.9)

Bring the Straight and Bent Towing Arms together and align the 2 furthest apart sets of holes.

Important Note: The 2 arms should be connected in a way that makes them as long as possible.

Securely fix the arms together using 2 x 8mm screws and nuts.

Fig. 6 Fig. 7

Fig. 8 Fig. 9

Page 12

- 12 -

INSTALLATION INSTRUCTIONS

9. Connecting to Power Supply

Plug the AGDO into a properly earthed 230 ~ 240 VAC power outlet.

Ensure that no excess power cord hangs below the Control Box.

10. Engaging / Disengaging

The unique engage / disengage mechanism provides the following features:

a. Positive garage door locking even during power outages.

b. Re engagement in any position without the need to line up chain and carriage components.

Functionality

TO DISENGAGE - pull down on the release handle (Fig.10) until a click is “felt” and then release the

handle.

TO ENGAGE - pull down on the release handle once again until a click is “felt” and then release the handle.

Important Notes:

a. Never attempt to open or close the garage door by pulling on the release handle. Doing so may

result in SERIOUS PERSONAL INJURY and / or PROPERTY DAMAGE.

b. Always disengage the AGDO with the garage door in the fully closed position.

c. If attempting to disengage the AGDO from any position other than with the garage door fully

closed ensure that there are no persons and / or property near or directly under the path of

the door.

Fig. 10

Page 13

- 13 -

SETTINGS AND ADJUSTMENTS

11. Door Travel Adjustment

The Drive Rail mounted Limit Prongs provide a 1 to 1 ratio between Limit Prong movement and garage

door movement thereby ensuring 100% accuracy and ease of adjustment. Garage door fully open and fully

closed positions can be easily adjusted by moving the Limit Prong to the desired location in order to

increase or decrease garage door travel.

Door Travel Adjustment – Close Direction

Locate the Close Direction Limit Prong within the Drive Rail - nearest to front wall of garage (Fig.11)

Loosen the Limit Prong Lock Screw by half a turn and slide the Limit Prong towards the front wall of the

garage to increase garage door travel and away from the front wall to decrease garage door travel.

Re tighten the Limit Prong Lock Screw once correct adjustment has been attained.

Note: The Limit Prongs work on a one to one ratio with the garage door, meaning that if the Limit Prong is

moved by 10 mm then the garage door will also move by 10 mm.

Door Travel Adjustment – Open Direction

Locate the Open Direction Limit Prong within the Drive Rail – nearest to Control Box. (Fig.11)

Loosen the Limit Prong Lock Screw by half a turn and slide the Prong towards the Control Box to increase

garage door travel and away from the Control Box to decrease travel.

Re-tighten the Limit Prong Lock Screw once correct adjustment has been attained.

Note: The Limit Prongs work on a one to one ratio with the garage door - meaning that if the Limit Prong is

moved by 10 mm then the garage door will also move by 10 mm.

Fig. 11

12. Safety Obstruction Force Adjustment

Dual Safety Obstruction Force Adjustment modes ensure that the AGDO can be optimized to suit virtually

any sectional or tip-up type garage door.

ADAPTIVE MODE – constantly monitors incremental drive force value changes that occur due to seasonal

conditions and / or garage door aging. Adaptive Mode compensates for these variables by automatically

adjusting Safety Obstruction Force values during every complete cycle, resulting in enhanced safety and

minimized chances of garage door *ghosting. (Refer Sec.12.1 for set up details)

*Ghosting is defined as a Safety Stop or Safety Reverse without the garage door actually encountering an

obstruction.

MANUAL MODE – features conventional one time Safety Obstruction Force value adjustment and is more

suited for use on badly worn or improperly balanced garage doors. (Refer Sec.12.2 for set up details)

Page 14

- 14 -

SETTINGS AND ADJUSTMENTS

12.1 Adaptive (A) Mode

Enabling

If Manual Mode is your desired selection then skip to Sec.12.2.

If Adaptive Mode is already enabled then skip to the next section titled “Functionality”.

To enable Adaptive Mode carry out the following procedure;

i. switch off power at power supply

ii. remove the Courtesy Lamp and Control Box Covers to expose the Control Board (Refer Sec.18 for

removal and replacement details)

iii. select Dip switch No.1 to the “ON” position (Fig.16)

iv. replace the Control Box and Lamp Covers

v. switch power on at power supply

Functionality

In order to learn the required run time and drive force values the AGDO will be required to complete 5

(manually activated) uninterrupted open and close cycles. (commencing from the Close Limit Point)

During the course of the cycles the LED Indicator will quick flash and the operating parameters will be

learned in the following order;

i. Open Stroke 1 – Alignment stroke

ii. Close Stroke 1 – Learn run time between Open Limit Point and Close Limit Point

(during Close Cycle 1 the AGDO will not Slow Stop)

iii. Open Stroke 2 – Learn run time between Close Limit Point and Open Limit Point

(during Open Cycle 1 the AGDO will not Slow Stop)

iv. Close Stroke 2 – Learn Drive Force Values between Open Limit Point and Close Limit Point

v. Open Cycle 3 – Learn Drive Force Values between Close Limit Point and Open Limit Point

Once Learning has been successfully completed the LED Indicator will commence to slow flash.

Important Note: During initial power-up learning, the Safety Obstruction Force values of the AGDO

default to a maximum setting. Encounter a solid obstruction during the course of the initial learning

cycles may result in garage door damage. It is recommended that initial learning cycles be carefully

supervised in order to prevent the possibility of the garage door hitting an obstruction causing

personal and / or property damage.

Safety Obstruction Force Adjustment

Hinge open the Courtesy Lamp Cover (Fig.18) to expose the adjustment controls.

Rotate the (green) “Offset” Adjustment Pin (Fig.17-G) in a clockwise direction to increase Safety

Obstruction Offset Value and in an anti clockwise direction to decrease the value.

The Safety Obstruction Offset Value may be adjusted within a range of 30N (3kg) ~ 100N (10kg)

The selected value remains identical for both open and close direction travel.

Testing Open Direction Safety Obstruction Force Value

With the garage door in the fully closed position – stand in the middle of the garage doorway and just

behind the path of the garage door.

Activate the AGDO so that the garage door begins to open.

When the garage door has opened to approx 450mm from the ground apply some firm downward force to

one of the structural members of the garage door.

If the Safety Obstruction Force Value is correct the AGDO will stop (Safety Stop) the garage door upon

sensing the applied force.

If too little or too much force is required to make the AGDO stop - turn the (green) “Offset” Adjustment Pin

(Fig.18 - G) 5 degrees in the appropriate direction - clockwise to increase force - anti-clockwise to decrease

force - and then repeat the previous testing steps.

Page 15

- 15 -

SETTINGS AND ADJUSTMENTS

Testing Close Direction Safety Obstruction Force Value

With the garage door in the fully open position - stand in the middle of the garage doorway and just behind

the path of the garage door.

Ensure that the Close Limit Travel Adjustment (Sec.11) has been set so that bottom of the garage door is

resting firmly against the ground.

Place a 32mm thick block of wood under the line of the garage door (approx at the mid point of the garage

door) so that the garage door will close onto the block of wood.

Activate the AGDO so that the garage door begins to close.

If the Safety Obstruction Force Value is correct the AGDO will stop and reverse the direction of the garage

door (Safety Reverse) upon encountering the block of wood.

If too little or too much force is required to make the AGDO Safety Reverse - turn the (green) “Offset

Adjustment Pin (Fig.18-G) 5 degrees in the appropriate direction - clockwise to increase force - anticlockwise to decrease force - and then repeat the previous testing steps.

Forced Learn

A Forced Learn may be initiated by holding down the “Learn” Button (Fig.18-D) for 2 sec – LED Indicator

will begin to quick flash.

Cycle the AGDO through 5 complete uninterrupted strokes (commencing from the close limit point) in

order for it to complete the learning process.

The LED Indicator will cease to quick flash once learning has been completed.

Important Note: During a Forced Learn the Safety Obstruction Force values default to a maximum

setting. Encounter a solid obstruction during the course of the initial learning cycles may result in

garage door and / or property damage. It is recommended that the learning cycles be carefully

supervised during this time.

Automatic Re-Learn

A re-learn of Drive Force and Run Time parameters will be automatically initiated immediately subsequent

to either one of the following occurrences;

a. Run Time deviation becoming excessive

b. Safety Reversing on 3 consecutive occasions

c. Safety Stopping on 3 consecutive occasions

During this period the LED Indicator will quick flash.

12.2 Manual (M) Mode

Enabling

If Adaptive Mode is your desired selection then refer to Sec.12.1

To enable Manual Mode;

i. switch off power at power supply

ii. remove the Courtesy Lamp and Control Box Covers to expose the Control Board (Refer Sec.18 for

removal and replacement details)

iii. select Dip switch No.1 to the “OFF” position (Fig.16)

iv. replace the Control Box and Lamp Covers

v. switch power on at power supply

Entering Safety Obstruction Force Adjustment Mode

Hinge open the Courtesy Lamp Cover to expose the adjustment controls. (Fig.18)

Press and hold down the “Learn” Button (Fig.18-D) for 2 sec - LED Indicator will commence a paused

double flash.

Safety Obstruction Force adjustment can be carried out while LED Indicator is “paused double flashing”

Page 16

- 16 -

SETTINGS AND ADJUSTMENTS

To close out Safety Obstruction Force Adjustment Mode momentarily press “Learn” Button.

Note: Mode will close out automatically after 10 mins if not closed out manually beforehand.

Safety Obstruction Force Adjustment – Open Direction

Hinge open the Lamp Cover (Fig.18-A) to expose the adjustment controls.

With the garage door in the fully closed position - press the black “Run” Button (Fig.18-G) so that the

garage door begins movement in the open direction.

As the garage door is opening slowly turn the (green) Open / Offset Adjustment Pin (Fig.18-G) in an anti-

clockwise direction until the garage door stops.

Now turn the same pin clockwise 5 degrees.

Testing Safety Obstruction Force – Open Direction

With the garage door in the fully closed position - stand inside the garage just behind the path of the garage

door close to its middle position.

Press the black “Run” Button (Fig.18-G) so that the garage door begins to open.

When the garage door has opened by approx 450mm apply some firm downward force to one of its

structural members.

If the Safety Obstruction Force Adjustment is correct the AGDO will stop the garage door upon sensing the

applied force.

If too little or too much force is required to make the AGDO stop - rotate the (green) Open / Offset

Adjustment Pin 5 degrees in the appropriate direction (clockwise to increase force, anti-clockwise to

decrease force) and then repeat the previous testing steps.

Safety Obstruction Force Adjustment – Close Direction

With the garage door in the fully open position, press the black “Run” Button (Fig.18-F) so that the garage

door begins to close.

As the garage door is closing - slowly turn the (red) Close / Speed Adjustment Pin (Fig.18-F) in an anti-

clockwise direction until the garage door stops and begins to Safety Reverse.

Now turn the same pin clockwise 5 degrees.

Testing Safety Obstruction Force – Close Direction

With the garage door in the fully open position stand inside the garage just behind the path of the garage

door close to its middle position.

Ensure that the Close Limit Travel Adjustment (Sec.11) has been set so that bottom of the garage door is

resting firmly against the ground.

Press the black “Run” Button so that the garage door begins to close.

Place a 32mm thick block of wood under the line of the garage door (approx at the mid point of the garage

door) so that the garage door will close onto the block of wood.

If the Safety Obstruction Force Adjustment is correct the AGDO will stop and reverse the direction of the

garage door upon sensing the block of wood.

If the AGDO stops but does not reverse then turn the (red) Close / Speed Adjustment Pin 5 degrees in an

anti-clockwise direction. (Fig.18-F)

Page 17

- 17 -

OPTIONS AND FEATURES

13. Accessory Connections

6 Output Terminals are provided to support the connection of the most common external accessories.

The Output Terminals can be accessed by removing the Courtesy Lamp and Control Box Covers. (Refer

Sec.18 for removal and replacement details)

Connection Diagrams

a. Genuine 2 wire Safety Beams (Fig.12)

b. 3

rd

party normally open 24VDC 4 wire Safety Beams (Fig.13)

c. 24VDC universal receiver (Fig.14)

d. Normally open momentary contact Wall Switch (Fig.15)

Fig. 12 Fig. 13

Fig. 14 Fig. 15

14. Auto Close

Auto Close can enhance the security of your property by ensuring that your garage door is never

unintentionally left open.

Auto Close will automatically close the garage door;

i. 3 sec after reaching the open limit point - provided that a person or object has passed through the

Safety Beams during the open cycle, or

ii. upon expiry of the pre set 30sec delay time – provided that a person or car has not passed through

the Safety Beams within the delay time

Auto Close will only function when used in conjunction with Safety Beams.

Enabling

i. Remove the Courtesy Lamp and Control Box Covers to expose the Control Board (Refer Sec.18 for

removal and replacement details)

ii. Select Dip Switch Nos.2 (SB) & 3 (AC) to the “ON” position. (Fig.16)

iii. Replace the Control Box and Courtesy Lamp Covers once selection has been completed

15. Back Jump

Back Jump will reverse the closed garage door by an incremental amount (1 ~ 5mm) in order to reduce

motor gear lock up and ensure effortless disengagement in the event of power outage.

Page 18

- 18 -

OPTIONS AND FEATURES

Enabling

Remove the Courtesy Lamp and Control Box Covers to expose the Control Board (Refer Sec.18 for removal

and replacement details)

Select Dip Switch No.6 (BJ) to the “ON” position. (Fig.16)

Replace the Control Box and Courtesy Lamp Covers.

16. Battery Back-Up

For areas that suffer from frequent power outages the Transformer Powered AGDO can be supplied with an

optional external battery power source thus ensuring uninterrupted use even during those times.

Connection

Remove the Courtesy Lamp and Control Box Covers (Refer Sec.18 for removal and replacement details)

Connect the Battery Back-Up connection cable to the Control Board terminals “+BBU-”

Replace the Control Box and Courtesy Lamp Covers.

Connect the Battery Back-Up power cable to a properly earthed 230 ~ 240VAC power supply.

Important Note: The Battery Back-Up system must be genuine Avanti brand

17. Battery Powered AGDO

The Battery Powered AGDO has several battery monitoring and battery saving features which are detailed

in the following sections

Important Note: Batteries will suffer permanent damage if not charged within a 3 month period

17.1 Battery Charger

The Battery Charger, provided with Battery Powered AGDO only, should be plugged-in to a dedicated

power supply and remain permanently on.

A red LED located on the back of the charger will glow solid to indicate that the charger is powered on.

Important Note: The Battery Charger must be genuine Avanti brand

17.2 LED Indicator

Will glow green when battery charger is charging (Fig.18-C)

Will glow red when battery charger is not charging

Will extinguish when AGDO enters Shut-Down Mode

17.3 Shut-Down Mode

In the event of prolonged power outage the AGDO will automatically shut down (when battery voltage

drops below 22 volts) in order to conserve remaining voltage - LED Indicator (Fig.18-C) will extinguish and

the AGDO will cease to function.

Automatic Shut-Down

Shut-down will only occur when the battery charger is inactive.

Prior to shutting down an audible buzzer will;

a. Single “beep” every 30 seconds to indicate that Battery Charger is not active.

b. Double “beep” every 30 seconds to indicate that the Battery Charger is not active and that

remaining battery voltage is low therefore Shut- Down is imminent.

c. Once the battery charger becomes active the green LED Indicator will illuminate.

d. Note: Immediately subsequent to Shut-Down Mode the batteries may require up to 20 minutes re

charge time before the voltage is adequate to run the garage door.

Page 19

- 19 -

OPTIONS AND FEATURES

Manual Shut-Down

To manually shut down the AGDO perform the procedure as follows;

i. press and hold Learn Button

ii. whilst continuing to hold down the Learn Button, press and hold Run Button

iii. AGDO will have entered Shut-Down Mode once the LED extinguishes

17.4 Solar Power

An optional Solar Power kit is available. Contact your AGDO dealer for further information.

Connect the Solar connection cable to the Control Board terminals “+CH-”

Important Note: The Battery Charger must be genuine Avanti brand

17.5 Warning Buzzer

An audible buzzer will;

a. Single “beep” every 30 seconds to indicate that Battery Charger is not active.

b. Double “beep” every 30 seconds to indicate that the Battery Charger is not active and that

remaining battery voltage is low therefore Shut- Down is imminent.

18. Control Box

The Control Box houses most of the controls from which the AGDO may be adjusted and functionality

customized to suit individual requirements.

Most commonly used functionality controls are accessible from within the Courtesy Lamp Cover.

Less commonly used controls are accessible by removing both the Courtesy Lamp and Control Box Covers

to expose the Control Board.

Fig. 16

Removal and Replacement of Courtesy Lamp and Control Box Covers

Important Note: The control board and power supply contain high voltage components. Coming into

contact with these components may cause severe injury or death. Always switch of the AGDO and un

plug the power cord BEFORE removing the main Control Box cover. The Control Box cover should

only be removed buy a suitably qualified technician

Remove Courtesy Lamp and Control Box Covers as follows;

i. Switch off AGDO at power point and unplug the power cord

ii. open the Courtesy Lamp Cover by pulling it down at the finger recess point (Fig.17–A)

iii. remove the lamp bulb (Fig.18–A) by first pushing in and then turning anti clockwise (same as

removing household light bulb)

Page 20

- 20 -

OPTIONS AND FEATURES

iv. remove the Control Box Cover Lock Screw point (Fig.18–B) Note: the Control Box Cover can be

removed once the head of the screw is protruding by approx 5mm.

v. remove the Control Box Cover by pulling first outwards and then downwards at the finger recess

points (Fig.17-B & C)

Replacement of all components is the reversal of removal.

Fig. 17

Fig. 18

Page 21

- 21 -

OPTIONS AND FEATURES

19. Courtesy Lamp

The in built Courtesy Lamp will switch on each time the AGDO is activated and then switch off

automatically 90 sec after receiving the last Hand Transmitter or run signal.

In order to conserve remaining battery power the Courtesy Light will not function once battery voltage falls

below 24V. (Battery Powered AGDO only)

Bulb Replacement

Hinge open the Courtesy Lamp Cover to expose the bulb (Fig.18-A)

Remove the bulb by first pushing-in and then turning anti clockwise (same as removing and replacing a

household light bulb)

Replace bulb with identical 24V 20W Incandescent

Close the Courtesy Lamp Cover

Important Note: Replacing the bulb with 12V version will cause the transformer to overheat and may

permanently damage the transformer and Control Board. Always ensure that replacement bulb is

rated at 24V and no more than 20W.

20. Dip Switches

The Dip Switches located on the Control Board (Fig.16) enable or disable specific functionality.

The Dip Switches can be accessed by removing the Courtesy Lamp and Control Box Covers (Refer Sec.18

for removal and replacement details)

Read through the following table and select the specific functionality best suited your specific personal or

garage door requirements.

Functionality Table

Function Dip No. Dip Position Details

Adaptive Mode (A/M) – Enable 1 ON Sec.12.1

Manual Mode (A/M) – Enable 1 OFF Sec.12.2

Safety Beams (SB) - Enable 2 ON Sec.26

Safety Beams (SB) – Disable 2 OFF Sec.26

Auto Close (AC) - Enable 2 & 3 ON Sec.14

Auto Close (AC) – Disable 3 OFF Sec.14

Door Service Monitor (DSM) – Enable 4 ON Sec.21

Door Service Monitor (DSM) – Disable 4 OFF Sec.21

Soft Stop (SS) – Enable 5 ON Sec.29

Soft Stop (SS) – Disable 5 OFF Sec.29

Back Jump (BJ) – Enable 6 ON Sec.15

Back Jump (BJ) – Disable 6 OFF Sec.15

Safety Reverse - Partial (PR) 7 ON Sec.27

Safety Reverse - Full (PR)* 7 OFF Sec.27

*Not available within battery powered AGDO

Enabling

Remove the Courtesy Lamp and Control Box Covers to expose the Control Board (Refer Sec.18 for removal

and replacement details)

Select the Dip Switches as required to enable the desired functionality (Fig.16)

Replace the Control Box and Courtesy Lamp Covers

21. Door Service Monitor (DSM)

Door Service Monitor will monitor the spring balance of the garage door by logging the run time differential

between open and close cycles.

Page 22

- 22 -

OPTIONS AND FEATURES

The Courtesy Lamp will triple flash once every 15 seconds once the run time differential exceeds 3 seconds.

At this point the garage door should be serviced by a suitably qualified technician.

Note: Door Service Monitor function is available only when Adaptive Mode has been selected.

Enabling

Remove the Courtesy Lamp and Control Box Covers to expose the Control Board (Refer Sec.18 for removal

and replacement details)

Select Dip 4 (DBM) to the “ON” position. (Fig.16)

Replace Control Box and Courtesy Lamp Covers

22. Hand Transmitters

The 433MHz hopping code Hand Transmitter provides state of the art security by providing up to 1.2 billion

possible code combinations. A new digital code is generated each time the Hand Transmitter is pressed

thereby ensuring the total security of your garage and its contents from potential coded scanning devices.

Up to 12 individual Hand Transmitter codes may be stored.

Code Learning

Hand Transmitters may be coded as follows;

i. hinge open the Courtesy Lamp Cover to expose the “Learn” Button (Fig.18)

ii. locate one of the Hand Transmitters supplied with the AGDO

iii. momentarily press the “Learn” Button (Fig.18–D) – LED Indicator will glow solid (Fig.18–C)

iv. momentarily press the Hand Transmitter button – LED Indicator will extinguish

v. momentarily press the Hand Transmitter button again – LED Indicator will begin to quick flash

rapidly - programming is completed once the LED Indicator ceases to quick flash

vi. close the Courtesy Lamp Cover

Code Deleting

All Hand Transmitter codes may be deleted as follows;

i. hinge open the Courtesy Lamp Cover to expose the “Learn” Button (Fig.18)

ii. momentarily press the “Learn” Button (Fig.18–D) – LED Indicator (Fig.18–C) will glow solid

iii. press and hold the black “Run” Button – LED indicator will begin to rapid flash

iv. all Hand Transmitter Codes will have been deleted once the LED Indicator ceases to flash

v. close the Courtesy Lamp Cover

Battery Replacement

Battery may be replaced as follows;

i. remove the fixing screw located under the sticker on the bottom face of the Hand Transmitter

ii. open the 2 halves of the Hand Transmitter and replace the battery with one of identical specification

iii. test that the Hand Transmitter LED Indicator illuminates when on of the Hand Transmitter buttons

is pressed and then replace the fixing screw and sticker

23. Learn Button

The Learn” Button (Fig.18 - D) is located within the Lamp Cover adjacent to the “Learn LED” and serves to

initiate the functions as described in the following table;

Function Action

Learn Hand Transmitter Codes Momentary press

Formal Force Learning Press and hold for 2 sec.

Sleep Mode Press and hold in conjunction with “Run” Button

Page 23

- 23 -

OPTIONS AND FEATURES

24. LED Indicator

The LED Indicator (Fig.18-C) is located under the Courtesy Lamp Cover and serves to indicate the

functions as described in the following tables;

Green LED – Transformer and Battery Powered AGDO

Provides visual indication of functionality sequences as described in the following table;

Display Indicator

Glow Solid Reached close limit position.

Slow Flash Reached open limit position.

Medium Flash Learning or deleting Hand Transmitter codes

Quick Flash (A Mode) Learning new drive force parameters

Quick Flash (M Mode) Force adjust mode activated

Sleep Mode Intermittent Flash

Red LED – Battery Powered AGDO only.

Provides visual indication of functionality sequence as described in the following table;

Display Indicator

Glows Solid Battery Charger inactive

Returns to Green Battery Charger Active

25. Run Button

The black “Run” Button (Fig.18-E) is located under the Lamp Cover and serves to initiate the functions as

described in the following table;

Function Action

Activate AGDO Momentary press

Safety Beam override Press and hold until garage door is fully closed

Sleep Mode Press and hold in conjunction with “Learn” Button

26. Safety Beams

Genuine 2 wire or aftermarket 4 wire Safety Beams may be connected to the AGDO

The installation of Safety Beams greatly enhances safety by constantly monitoring for persons or objects

which may pass within the path of the moving garage door. The AGDO will commence to Safety Reverse if

the Safety Beams become momentarily or permanently interrupted during a Close Cycle.

Mounting

Locate the Safety Beam mounting brackets provided.

Mark the inside garage door framing so that the bottom edge of the mounting bracket sits 125mm off the

floor.

Use the 2 mounting screws provided to fasten each mounting bracket to the wall.

Use the 2 screws and nuts provided to fasten the Safety Beams to the mounting brackets so that the indicator

lamp on each Safety Beam is facing upwards.

Connection

Genuine 2 Wire

Using the Figure 8 Cable provided - strip back and connect the 2 strands of one end of the cable to each of

the 2 terminals located on the outer cover of each Safety Beam.

Securely fix the cable up and along the wall and run one length of each cable adjacent to the Control Box.

Strip back and connect one strand of each cable to the Output Terminals “SB2” (Fig.16)

Page 24

- 24 -

OPTIONS AND FEATURES

Aftermarket 4 Wire

Follow Safety Beam manufacturers instructions and connect to the Output Terminals depicted in Fig.13

Important Note: AGDO provides 24VDC output and Normally Open input.

Alignment

Adjust the Safety Beam module marked “Transmitter” (by turning the mounting bracket) so that it is aimed

directly at the lens of the Safety Beam module marked “Receiver”. An indicator lamp located along the top

edge of the “Receiver” will glow green once the correct alignment has been achieved.

Test the Safety Beam alignment several times each time ensuring that when the Safety Beams are obstructed

the green indicator lamp extinguishes and when unobstructed the indicator lamp glows solid.

Firmly tighten the Safety Beam mounting bracket fixing screws.

Installation of the Safety Beams is now complete.

Enabling

Remove the Courtesy Lamp and Control Box Covers to expose the Control Board (Refer Sec.18 for removal

and replacement details)

Select Dip 2 (SB) to the “ON” position (Fig.16)

Replace the Control Box and Courtesy Lamp Covers

Testing

Initiate a close cycle. As the garage door is closing interrupt the Safety Beams by passing an object through

the line of the Safety Beams. If the Safety Beams are functioning correctly the AGDO should stop and then

immediately reverse direction.

If the garage door commences a close cycle but within 1 second stops and reverses, check that the Safety

Beams are aligned correctly as outlined in “Alignment”

Override

In the event of Safety Beam malfunction the can be closed by pressing and holding the black “Run” Button

(Fig.18-E) until such time as the garage door is fully closed and has stopped.

Note: If the black “Run” Button is released prior to the garage door reaching the fully closed position the

AGDO will Safety Reverse.

27. Safety Reverse

In the event that the garage door encounters a sufficient obstruction during a close cycle the AGDO will

immediately stop and then begin to reverse direction. (Safety Reverse) The degree of Safety Reverse may be

selected as follows;

a. Full Safety Reverse – the AGDO will reverse to the fully open position. (Not available with battery

powered AGDO)

b. Partial Safety Reverse – the AGDO will reverse and then stop after 3 sec. Partial Safety Reverse

ensures that the garage door does not open fully and thereby present an unwanted security risk. Upon

receiving a Signal immediately subsequent to partial Safety Reverse the AGDO will recommence

movement in the open direction.

Enabling

i. Remove the Courtesy Lamp and Control Box Covers to expose the Control Board. (refer Sec.18 for

removal and replacement details)

ii. Full Safety Reverse – select Dip 6 (PR) to “OFF” (Fig.16)

iii. Partial Safety Reverse – select Dip 6 (PR) to “ON” (Fig.16)

iv. Replace the Control Box and Courtesy Lamp Covers once selection has been completed.

Page 25

- 25 -

OPTIONS AND FEATURES

28. Soft Start

When commencing movement from any stationary position the AGDO will slowly ramp up to full speed in

order to minimize start-up load on the AGDO and garage door and provide smooth, quiet operation.

29. Soft Stop

By intelligently reducing the speed of the garage door as it approaches a limit point the AGDO ensures

quieter garage door closing and enhanced AGDO and garage door life. (Standard function within Adaptive

Mode only)

Adaptive Mode is factory configured to provide soft stopping prior to reaching a limit point. However, for

garage doors that are improperly balanced it may be necessary to disable the soft stop function in order for

the garage door to fully close or fully open

Soft Stop is available only when adaptive mode has been selected

Enabling / Disabling

i. Remove the Courtesy Lamp and Control Box Covers to expose the Control Board (refer Sec.18 for

removal and replacement details)

ii. TO ENABLE – select Dip Switch No.7 (SS) to the “ON” position (Fig.16)

iii. TO DISABLE – select Dip Switch No.7 (SS) to the “OFF” position (Fig.16)

iv. Replace the Control Box and Courtesy Lamp Covers once selection has been completed.

30. Speed Control

Running speed may be adjusted within the range of 70 ~ 100% of maximum speed.

Note: Available only when Adaptive Mode has been selected.

Adjustment

To enter Speed Control adjustment mode;

i. move the Drive Unit so that it is positioned mid way between the 2 Limit Adjust Prongs (Fig.11)

ii. hinge open the Courtesy Lamp Cover to expose the adjustment controls (Fig.18)

iii. press and hold the “Learn” Button (Fig. 18-D) for 2 sec in order to initiate Forced Learn – LED

Indicator will begin to quick flash

iv. rotate the (red) “Speed” Adjustment Pin (Fig.18-F) in a clockwise direction to increase running

speed and anti-clockwise to decrease running speed

v. Close the Courtesy Lamp Cover once adjustment has been completed

Running speed may only be adjusted while the Drive Unit is traveling between Limit Points.

Speed Control adjustment will close out automatically once the Drive Unit reaches either one of the Limit

Adjust Prongs.

31. Vacation Mode

During Vacation Mode all functionality is disabled and the AGDO will only function upon receiving a

signal from a pre-learned Hand Transmitter.

Vacation Mode will not function unless at least one Hand Transmitter has been previously learned into the

AGDO.

Entering / Exiting

i. hinge open the Courtesy Lamp Cover to expose the adjustment controls (Fig.18)

ii. TO ENTER - press and hold down the “Learn” Button (Fig.18-D) and whilst continuing to hold

down the “Learn” Button press the black “Run” Button. (Fig.18-E)

iii. TO EXIT - activate the AGDO with one of the pre-learned Hand Transmitters.

Page 26

- 26 -

OPTIONS AND FEATURES

32. Wall Switch – Hard Wired

A permanently wired Wall Switch may be connected to the AGDO in a convenient location such as adjacent

to a side entry door into the garage.

Connection

Use a normally open momentary contact type switch (similar to spring loaded front door bell type switch)

Use figure 8 cable and connect the wires from the switch to the Output Terminals as depicted in Fig.15

Important Note: The Wall Switch must be mounted within sight of the garage door and a reasonable

distance away from moving parts. It should be mounted at least 1500mm above the ground and the

Entrapment Warning Label provided must be attached adjacent to and within clear sight of it.

33. Wall Switch – Wireless

The wireless wall switch provides ease of installation without the need for running hard wires to the switch

and is can be mounted in a convenient location such as adjacent to a side entry door into the garage.

Mounting

The switch can be permanently screwed to the wall through the mounting holes provided or alternatively

“hooked” on the wall, providing the convenience of easy demount ability, through the “hook” holes

provided on the base plate.

Use the mounting template and mounting instructions provided with the switch.

The Wireless Wall Switch may be learned into be AGDO as per the procedure outlined on Sec.22 “Code

Learning”

Important Note: The wireless Wall Switch must be mounted within sight of the garage door and a

reasonable distance away from moving parts. It should be mounted at least 1500mm above the

ground and the Entrapment Warning Label provided must be attached adjacent to the switch.

34. Maintenance

Once every 6 months;

i. spray the inside of the Drive Rail (Fig.3 Item A) along its entire length with a light coating of

WD40 or silicone spray lubricant.

ii. disengaged the AGDO from the door (Fig.10) and then test the door to ensure that it meets with the

requirements detailed on Pg.4 Items 3 & 4

TECHNICAL SPECIFICATIONS

INPUT VOLTAGE: 230 ~ 240VAC 50 ~ 60Hz

OPERATING VOLTAGE: 24VDC

MAX DOOR HEIGHT: 2440mm using Standard 3174mm rail

MAX DOOR WIDTH: 6500mm

MAX DOOR AREA: 14 Square Meters

MAX LIFTING CAPACITY: 1200N

MOTOR TYPE: 120W DC

SAFETY OBSTRUCTION FORCE SYSTEM: Selectable Manual / Adaptive

DOOR TRAVEL ADJUSTMENT: Manually Adjustable Limit Prongs

RECEIVER CODE STORAGE CAPACITY: 12 Individual Hand Transmitters

TRANSMITTER FREQUENCY: 433.92 MHz Hopping Code

LIGHT GLOBE: 20W 24V Bayonet

DOOR TRAVEL SPEED: Adjustable ~ 125mm / sec max

AUTO CLOSE: Dip Switch Selectable

SAFETY BEAMS: Optional

Specifications subject to change without prior notice

Page 27

- 27 -

TROUBLESHOOTING GUIDE

Symptom Suggested Remedies/Reasons

Reference

Page Sec.

• AGDO will not function at all

• Check that power chord is plugged-in and turned on ~ ~

• Check power point by plugging-in an alternate appliance ~ ~

• Check that AGDO is engaged to door 12 10

• No LED display indicates that AGDO has entered Shut-Down Mode

18 17

due to low battery voltage - check power supply (battery version only)

• Opener may have entered Vacation Mode 25 31

• AGDO runs very slowly

• Speed Control setting may be too low - increase speed setting 25 30

• Batteries are running low - check that charger is charging 18 17.1

• Garage door may be binding or out of balance 4 3

• Disengage AGDO from door and check for obstructions 12 10

• Door stops before reaching • Disengage AGDO from door and check for correct spring balance 4 3

fully open position • Check for correct Safety Obstruction Force adjustment settings 13 12

• Check for correct Open Limit adjustment 13 11

• Door may be incorrectly balanced - disable soft stop 25 29

• Disengage AGDO from door and check for obstructions 12 10

• Door stops & reverses before • Disengage AGDO from door and check for correct spring balance 4 3

reaching fully closed position • Check for correct Safety Obstruction Force adjustment settings 13 12

• Check for correct Safety Beam alignment where fitted 23 26

• Door may be incorrectly balanced - disable soft stop 25 29

• Door stops before reaching

• Check for correct Close Limit adjustment 13 11

fully closed position

• Door will not Safety Reverse

• Check for correct Safety Obstruction Force adjustment settings

13 12

• Battery voltage may be low - check that battery charger is active

18 17.1

• Door requires excessive force

• Check for correct Safety Obstruction Force adjustment settings 13 12

to Safety Reverse

• Door requires excessive force

• Check for correct Safety Obstruction Force adjustment settings 13 12

to Safety Stop

• Check function of AGDO by operating from "Run" button 23 25

• AGDO will not function from • Check function of AGDO with substitute Hand Transmitter 22 22

Hand Transmitter • Re learn Hand Transmitter code into AGDO 22 22

• Replace Hand Transmitter battery 22 22

• Hand Transmitter operating • Replace Hand Transmitter battery 22 22

range is poor • Extended AGDO antenna ~ ~

• Courtesy Lamp will not • Replace Courtesy Lamp bulb 21 19

function • Battery charger inactive (Battery version only) 18 17.1

• Courtesy Lamp triple flashes • Door balance is incorrect 4 3

every 15 sec • Lubricate garage door springs and hinges 4 3

• Call serviceman if lubricating springs does not correct problem 4 3

• LED Indicator glows solid • AGDO has reached fully closed position 23 24

• LED Indicator slow flashes • AGDO has reached fully open position 23 24

• LED Indicator quick flashes • AGDO is learning new Safety Obstruction Force values 13 12.1

• LED Indicator glows red • Battery charger is not charging - check batt ery charger 18 17.1

• Buzzer single beeps every 30 sec • Battery charger is not charging - check batter y charger 18 17.5

• Buzzer double beeps every 30 sec • Battery is nearing fully deplet ed state - check battery charger 19 17.5

• Door will not Auto Close

• Check for Safety Beam damage 23 26

• Check for correct Safety Beam alignment 23 26

• Check that Dips 2 & 3 have been selected to the "ON" position 17 14

• Will not Safety Reverse when

• Check that Dip 2 has been selected to the "ON" position 24 27

Safety Beams are interrupted

• AGDO makes "squeaking" sound • Lubricate inside of Drive Rail with WD40 or silicone lubricant 26 34

Page 28

- 28 -

NOTES

Loading...

Loading...