Page 1

Model / Modelo / Modelé: RIM49U3S-IS

INSTRUCTIONS.

Avanti has a policy of continuous improvement on its products and reserves

the right to change materials and specifications without notice.

Avanti Products LLC

www.avantiproducts.com

ICE MAKER

MAQUINA DE HACER HIELO

MACHINE A GLAÇONS

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

MANUEL D’INSTRUCTIONS

BEFORE USE, PLEASE READ AND FOLLOW ALL SAFETY RULES AND OPERATING

P.O. Box 520604

Miami, FL 33152

1

Page 2

TABLE OF CONTENTS

Appliance Safety

3

Important Safeguides

4

Electrical Connection

5

Help Us Help You

6

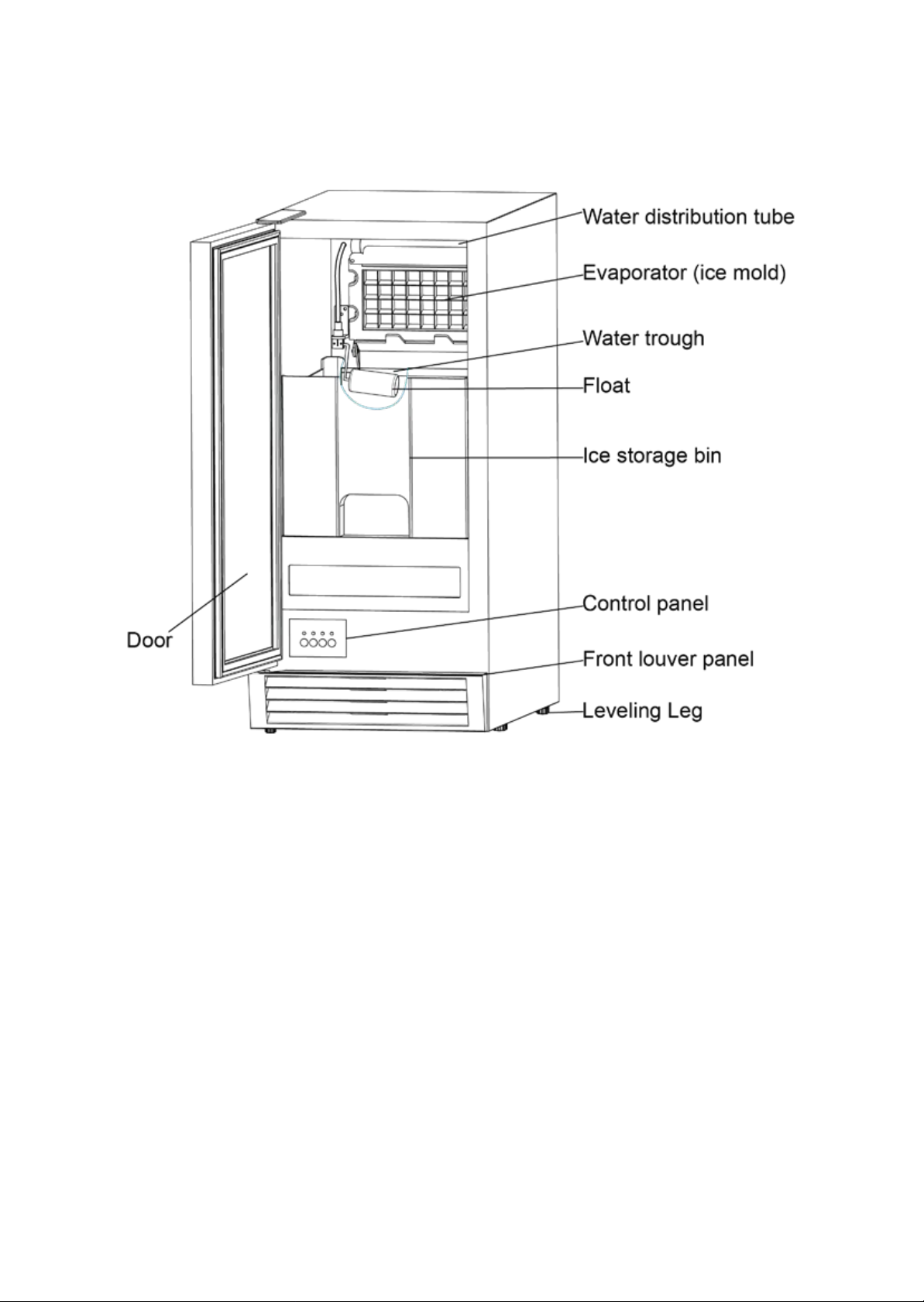

Parts and Features

7

Important Safety Instructions

8

Installation Instructions

8

Before Using Your Appliance

8

Installation of Your Appliance

9 -13

Operating Your Appliance

14 – 16

How Your Appliance Makes Ice

17

Care and Maintenance

18 – 21

Troubleshooting Guide

22 – 23

Service for Your Appliance

24

Wiring Diagram

24

Your Avanti Products Warranty

25

Instrucciones en Español

26 – 45

Instructions en Français

46 - 69

Registration Information and Registration Card

Last page

2

Page 3

APPLIANCE SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your

appliance. Always read and obey all safety messages.

Warning means that failure to heed

personal injury, or death.

Caution means that failure to heed

or property or equipment damage.

All safety messages will alert you to what the potential hazard is, tell you how to

are not followed.

This is the Safety Alert Symbol. This

symbol alerts you to potential

hazards that can kill or injure you

and others.

All safety messages will follow the

Safety Alert Symbol and either the

wards” DANGER”, “WARNING” or

“CAUTION”.

Danger means that failure to heed

this safety statement may result in

reduce the chance of injury, and let you know what can happen if the instructions

severe personal injury or death.

this safety statement may result in

extensive product damage, serious

this safety statement may result in

minor or moderate personal injur y,

PROP. 65 WARNING FOR CALIFORNIA RESIDENTS

WARNING:

Cancer And Reproductive Harm

www.p65warnings.ca.gov

3

Page 4

IMPORTANT SAF EGUARDS

Before the beverage cooler is used, it must be properly positioned and installed

Plug into a grounded 3-prong outlet, do not remove grounding prong, do not use an adapter, and do

in this material. All other servicing should be referred to a qualified technician.

• Use two or more people to move and install the appliance. Failure to do so can result in back or

• Do not use this apparatus for other than its intended purpose.

as described in this manual, so read the manual carefully. To reduce the risk of

fire, electrical shock or injury when using the beverage cooler, follow basic

precautions, including the following:

·

not use an extension cord

• Replace all panels before operating

• It is recommended that a separate circuit, serving only your beverage cooler, be provided. Use

receptacles that cannot be turned off by a switch or pull chain

• Never clean appliance parts with flammable fluids. These fumes can create a fire hazard or

explosion. And do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance. The fumes can create a fire hazard or explosion.

• Before proceeding with cleaning and maintenance operations, make sure the power line of the unit

is disconnected.

• Do not connect or disconnect the electric plug when your hands are wet

• Unplug the appliance or disconnect the power before cleaning or servicing. Failure to do so can

result in electrical shock or death.

• Do not attempt to repair or replace any part of your appliance unless it is specifically recommended

other injury.

• To ensure proper ventilation for your appliance, the unit must be completely unobstructed. Choose a

well-ventilated area with temperatures above 55

be installed in an area protected from the elements, such as wind, rain, water spray or sunlight.

• The appliance should not be located next to ovens, grills or other sources of high heat.

• The appliance must be installed with all electrical, water and drain connections in accordance with

state and local codes. A standard electrical supply (115 V AC only, 60 Hz), properly grounded in

accordance with the National Electrical Code and local codes and ordinances is required.

• Do not kink or pinch the power supply cord of the appliance.

• The fuse (or circuit breaker) size should be 15 amperes.

• It is important for the appliance to be leveled in order to work properly. You may need to make

several adjustments to level it.

• All installation must be in accordance with local plumbing code requirements.

• Make certain that the pipes are not pinched or kinked or damaged during installation.

• Check for leaks after connection.

• Never allow children to operate, play with or crawl inside the appliance

• Do not use solvent-based cleaning agents or abrasives on the interior. These cleaners may damage

or discolor the interior.

0

F (130C) and below 900F (32 0C). This unit must

4

Page 5

Electrical Connecti on

~Warning~

Improper use of the grounded plug can result in the risk of electrical shock. If the power cord

is damaged, have it replaced by an authorized Avanti Products service center.

This appliance should be properly grounded for your safety. The power cord of this

prong plug which mates with standard three

Do not under any circumstances cut or remove the third ground prong from the

p the plug firmly

a qualified electrician or service technician install an outlet near the appliance.

Ø EXTENSION CORD

Because of potential safety hazards under certain conditions, it is strongly

outlet and that the electrical rating of the cord be 115 volts and at least 10 amperes.

Ø SURGE PROTECTOR

Most electrical appliances use a series of electric control boards to operate. These

licensed electrician in your area.

Damages due to power surges are not considered a manufacturer covered defect

and will void your product warranty.

appliance is equipped with a threeprong wall outlets to minimize the possi bil i ty of electrical shock.

power cord supplied.

This appliance requires a standard 115Volts~/60Hz electrical outlet with three-prong

ground.

The cord should be secured behind the appliance and not left exposed or dangling to

prevent accidental injury.

Never unplug the appliance by pulling the power cord. Always gri

and pull straight out from the receptacle.

Do not use an extension cord with this appliance. If the power cord is too short, have

recommended that you do not use an extension cord with this unit. However, if you

must use an extension cord it is absolutely necessary that it be a UL/CUL-Listed, 3wire grounding type appliance extension cord having a grounding type plug and

boards are very susceptible to power surges and could be damaged or destroyed.

If the appliance is going to be used in an area or if your city / country is prone to

power surges / outages; it is suggested that you use a power surge protector for all

electrical devices / appliances you use. The surge protector that you select must

have a surge block high enough to protect the appliance it is connected to. If you

have any questions regarding the type and size of surge protector needed contact a

5

Page 6

HELP US HELP YOU...

Read this guide carefully.

IF YOU NEED SERVICE

We're proud of our service and want you to

NEXT, if you are still not pleased, write all the details,

CAUTION:

It is intended to help you operate and

maintain your new appliance properly.

Keep it handy to answer your questions.

If you don't understand something or you

need more help, please call:

Avanti Customer Service

800-220-5570

Keep proof of original purchase date (such as

your sales slip) with this guide to establish

the warranty period.

THIS APPLIANCE IS NOT

DESIGNED FOR THE STORAGE

OF MEDICINE OR OTHER

MEDICAL PRODUCTS.

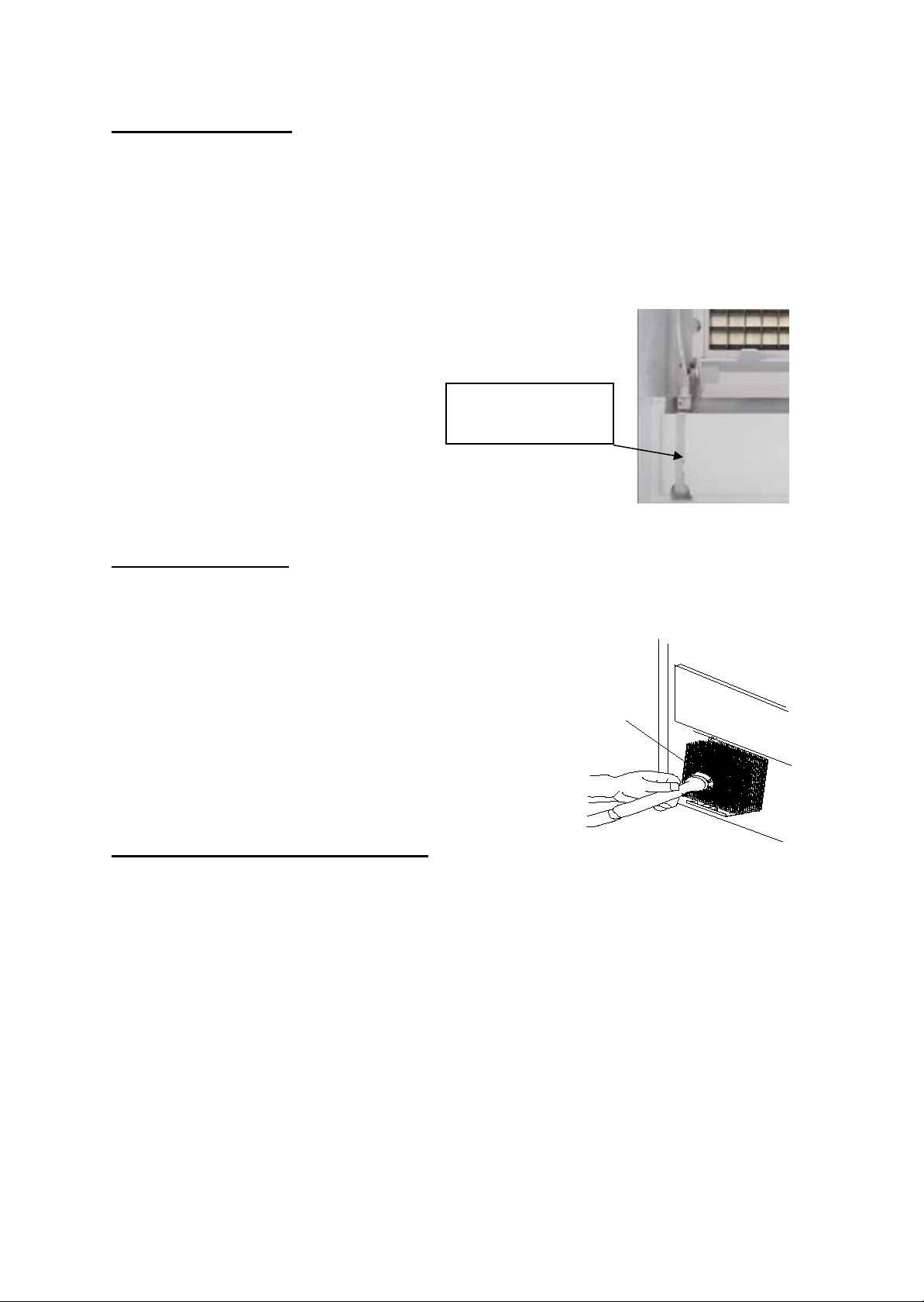

Write down the model and serial numbers.

You'll find them on a plate located on the rear

outside wall of the appliance.

Please write these numbers here:

__________________________________

Date of Purchase

__________________________________

Model Number

__________________________________

Serial Number

Use these numbers in any correspondence or

service calls concerning your appliance.

If you received a damaged appliance, immediately

contact the dealer (or builder) that sold you the

appliance.

Save time and money. Before you call for service,

check the Troubleshooting Guide. It lists causes of

minor operating problems that you can correct

yourself.

be pleased. If for some reason you are not

happy with the service you receive, here are

some steps to follow for further assistance.

FIRST, contact the people who serviced your

appliance. Explain why you are not pleased.

In most cases, this will solve the problem.

including your telephone number, and send it to:

Customer Service

Avanti Products

10880 NW 30 Street

Miami, FL 33172 USA

6

Page 7

PARTS AND FEATURES

7

Page 8

FAILURE TO DO SO CAN RESULT IN BACK OR OTHER INJURY

~

~

- SAVE THESE INSTRUCTIONS -

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of fire, electrical shock, or

injury when using your icemaker, follow these

WARNING

basic precautions:

This Unit Is For Indoor Use Only

− Read all instructions before using the icemaker.

− DANGER or WARNING: Risk of child entrapment. Child entrapment and suffocation are not problems

of the past. Junked or abandoned icemakers are still dangerous . . . even if they will “just sit in the

garage a few days”.

− Before you throw away your old icemaker: take off the doors. Leave the shelves in place so that

children may not easily climb inside.

− Never allow children to operate, play with, or crawl inside the icemaker.

− Never clean

− Do not store or use gasoline or any other flammable vapors and liquids in the vic inity of this or any other

icemaker. The fumes can create a fire hazard or explosion.

icemaker parts with flammable fluids. The fumes can create a fire hazard or explosion.

INSTALLATION INSTRUCTIONS

Before Using Your Icemaker

• Remove the exterior and interior packing.

• Check to be sure you have all of the following parts:

o 1 Ice Scoop

o 1 Water Supply Hose

o 1 Water Drain Hose

o Instruction Manual

• Before connecting the unit to the power source, let it stand upright for approxim ately 2 hours.

This will reduce the possibility of a malfunction in the cooling system from handling during

transportation.

• Clean the interior surface with lukewarm water using a soft cloth.

EXCESSIVE WEIGHT HAZARD

USE TWO OR MORE PEOPLE TO MOVE AND INSTALL THE ICEMAKER

8

Page 9

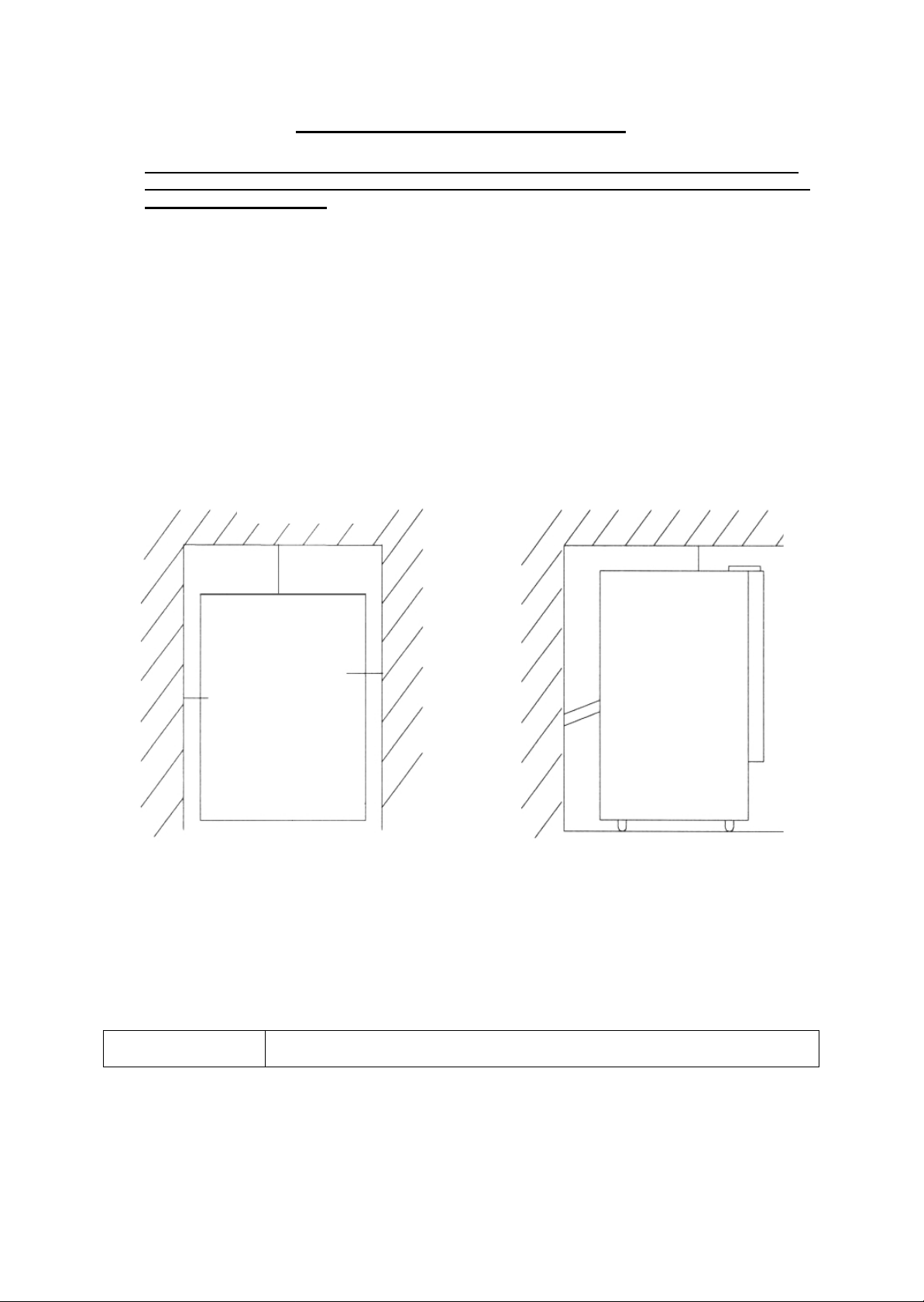

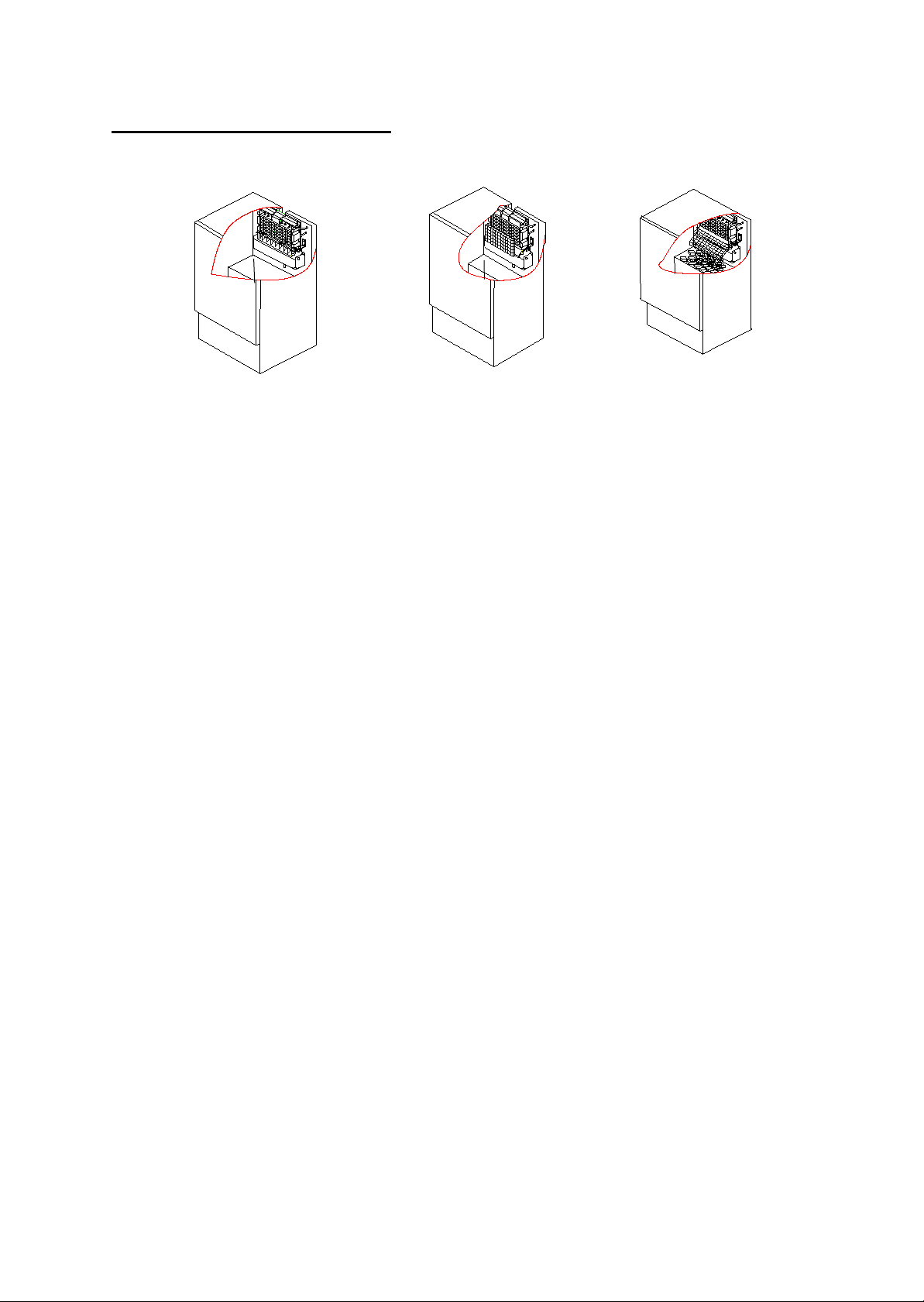

INSTALLATION OF YOUR ICEMAKER

Operation of the icemaker for extended periods outside of the normal

temperature ranges as described above may affect product performance.

SIDE VIEW

TOP VIEW

Top of unit

Rear of unit

Front of unit

Side Side

4”

1”

1”

1”

• THIS ICEMAKER SHOULD BE PROPERLY INSTALLED BY A QUALIFIED PROFESSIONAL

This icemaker MU ST be i nst alled with electrical an d water connections in ac co rdan c e with

all state and local codes.

• Allow a minimum of 1 inch of space between the top and sides of the icemaker and a

minimum of 4 inches at the back, which allows the proper air circulation to cool the

compressor. Ensure the front of the unit is completely unobstructed.

• Place your icemaker on a floor that is strong enough to support the icemaker when it is fully

loaded. To level your icemaker, adjust the legs at the front of the icemaker.

• Locate the icemaker away from direct sunlight an d sources of heat (stove, heater , radiator, etc .).

Direct sunlight may affect the acrylic coating and heat sources may increase electrical

consumption. Extrem e cold ambient tem peratures may also cause the icemaker not to perform

properly.

• Choose a well ventilated area with temperatures above 50ºF (10ºC) and below 100ºF (38ºC).

This unit MUST be installed in an area protected from the elements.

• Avoid locating the icemaker in moist areas. Too m uch moisture in th e air will cau se frost to f orm

quickly on the evaporator requiring more frequent defrosting of the icemaker.

INSTALLATION CLEARANCES:

• The installation of this icemaker requires a cold water supply inlet of ¼” (6.35mm) soft copper tubing

with a shut off valve.

• The icemaker requires a continuous water supply with a minimum pressure of 15 psig and a static

pressure not to exceed 80 psig. The temperature of the water supply into the icemaker should be

between 41ºF (5ºC) and 90ºF (32ºC) for proper operation.

• It is strongly recommended that a water filter be used. A filter, if it is of the proper type, can remove

taste and odors as well as particles. Some water is very hard, and softened water may result in

white, mushy cubes that stick together. De-Ionized water is NOT recommended.

Warning

9

Page 10

Leveling the ice maker

down

up

It is important for the icemaker to be leveled in order to

work properly. It can be raised or lowered by rotating

the plastic sheaths around each of the four feet on the

bottom of the machine .If you find that the surface is

not level, rotate the feet until the ice maker becomes

level .You may need to make several adjustments to

level it. We recommend using a carpenter’s level to

check the machine.

1. Place a carpenter’s level on top of the product to see if

the ice maker is level from front to back and side to side.

2. Adjust the height of the feet as follows:

Turn the leveling feet to the right to lower that side of the ice maker.

Turn the leveling feet to the left to raise that side of the ice maker.

IMPORTANT: Once you are ready to install it in a cabinet or directly on the floor, you must adjust the

feet to level the ice maker. If the floor is level, just revolve the two front feet to touch the floor.

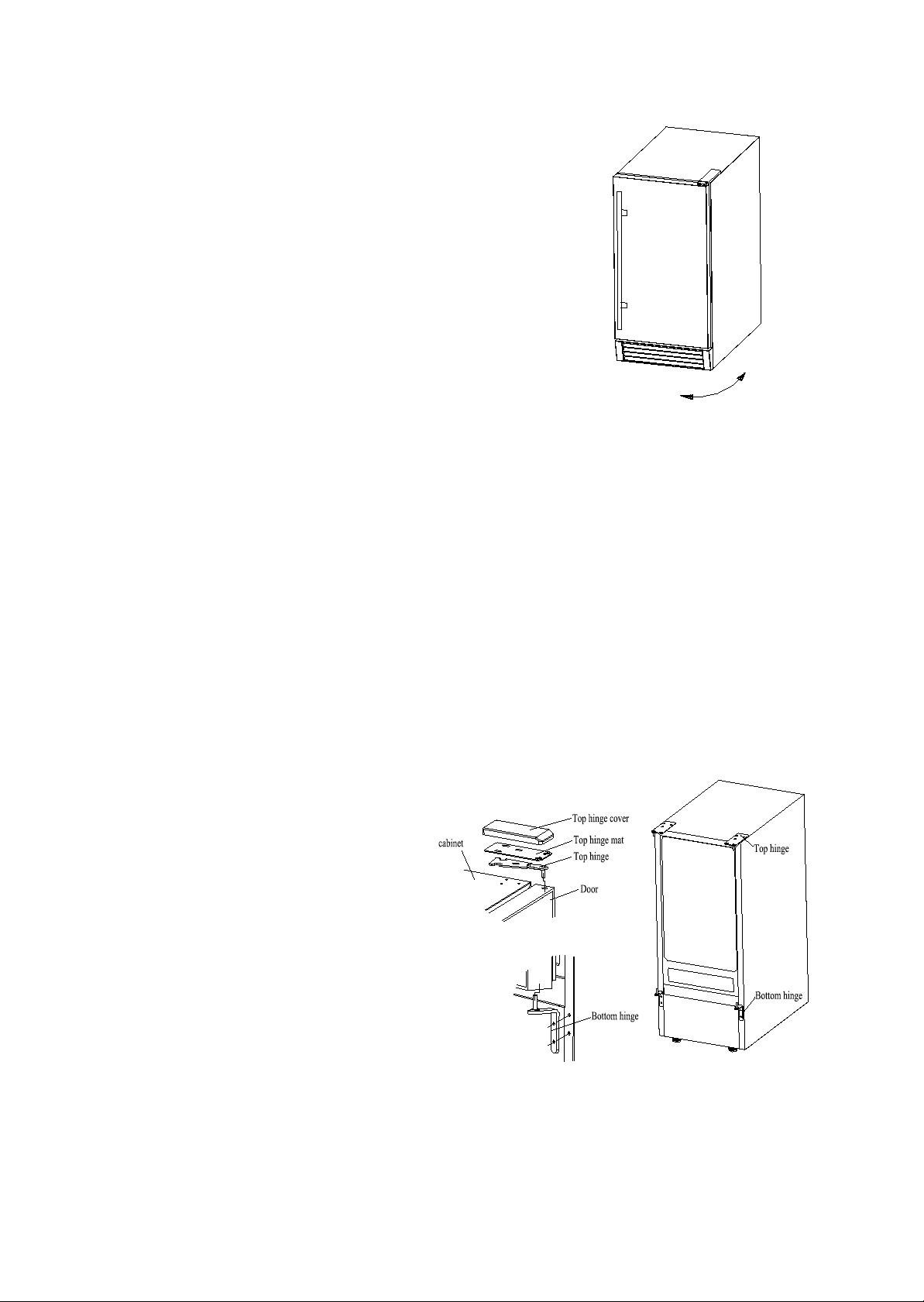

Reversing the door swing

Tools needed: Flat head screwdriver, Phillips screwdriver

IMPORTANT: Before you begin, unplug the ice maker or disconnect power.

To remove door from hinges:

1. Remove top hinge cover by pushing it toward the back of the unit, then lifting it off.

2. U sing a Phillips screwdriver, remove the screws, th en remove the top hinge mat and to p hinge.

Keep the parts together and set them aside.

3. Lift the door off of the bottom hinge and set the door aside.

To replace door on hinges:

1. Using a flathead screwdriver, remove

the plug buttons from the screw holes

opposite the door hinges, top and

bottom. Set aside.

2. Remove the front louver. Set aside.

3. Remove the bottom hinge and place it

on the opposite side at th e bott om of the

door.

4. Position the door on the bottom hinge.

5. Al ign the door on the botto m hinge and

replace the top hinge and top hinge mat.

6. Replace top hinge cover by pressing it

down over the hinge mat and then

pushing it forward.

7. Push the plug buttons into the original

screw holes.

10

Page 11

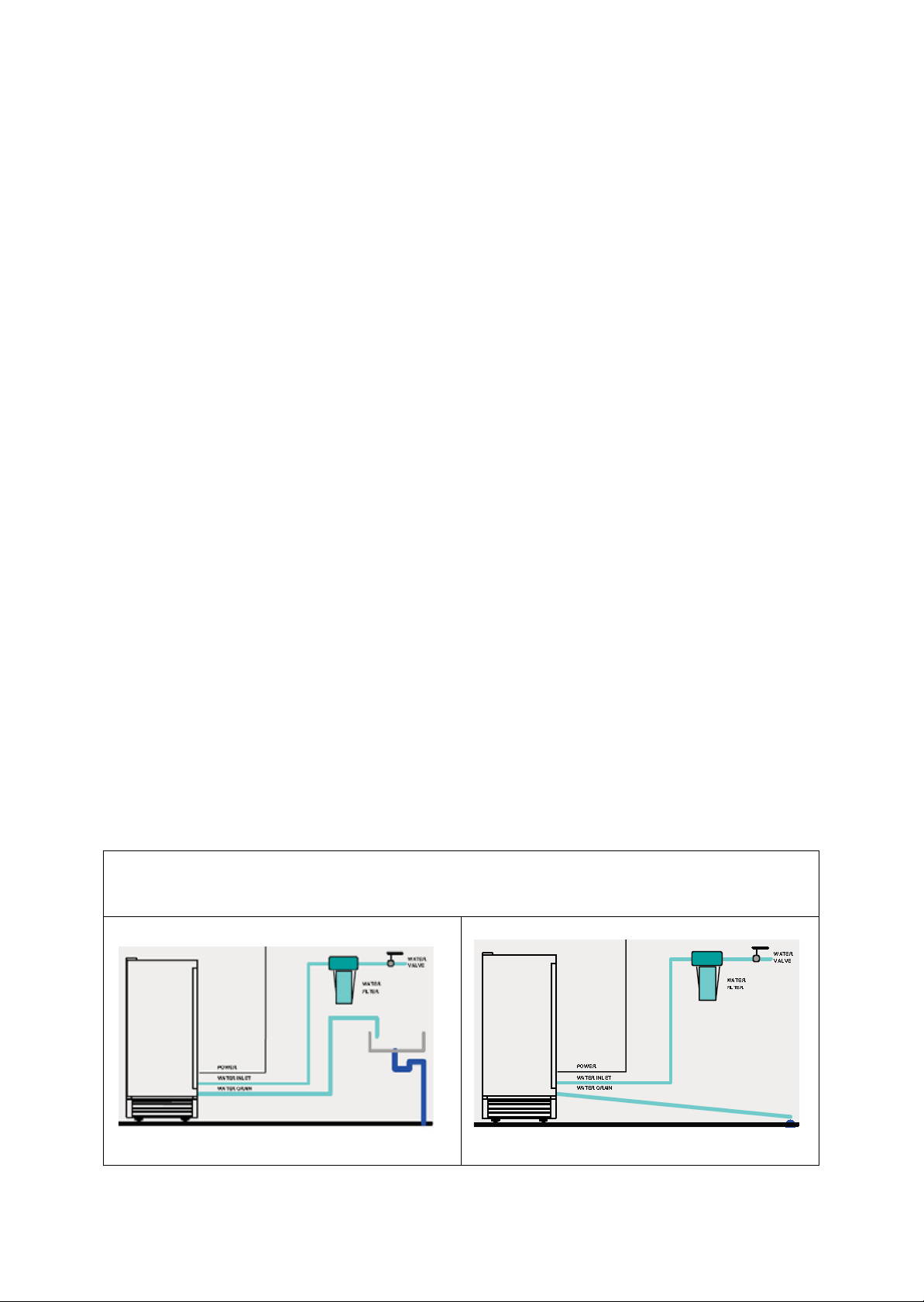

Water Supply

This unit can pump out water up to a rise of 1.5m (59”) or over a horizontal

length of 1.5m (59”).

Vertical Drain

The water supply should be ready at the point of installation. The water supply pressure should be a

minimum of 15 psig with a static pressure not more than 80 psig. (A wall outlet directly behind the ice

machine will make installation easier.)

IMPORTANT:

1. All installations must be in accordance with local plumbing code requirements. Professional

installation is recommended.

2. Make certain the hoses are not pinched or kinked or damaged during installation.

3. Check for leaks after connection.

Tools required: ½-in. open-end wrench, Philli ps scr ewdr iver

Connecting the water line:

1. Turn off main water supply. Turn on the nea rest faucet long enough to clear line of water.

2. F ind a ½-in. to ¾-in. vertical cold water p ipe near the i nstallat ion loc atio n. The d is tance sho uld b e

less than 6 feet. The water supply hose provided with the ice maker is approximately 6 feet long.

3. A s hut-off valve mus t be installed t o the main w ater suppl y. If the water p ipe has a p lain piece of

copper tubing, attach a ¼” O.D. compression union to the tubing and install the valve.

4. C onnect the nut of the water supply hose to the ta p, and connect the other end with the water

inlet. Tighten firmly by hand, then one-ha lf turn with wrenc h.

5. Turn on main water supply and tap. Check for water supply connection leaks. Tighten every

connection (including connection at the water inlet).

IMPORTANT: When you connect the water supply hose and the drain hose, pay

attention to the indications of “Water inlet” and “Drain outlet” on the machine.

Drain

You must connect the drain line before using the ice maker. Follow the steps outlined below.

There are two types of ice machine modes, one that drains by gravity and one

that has an internal drain pump.

Horizontal Drain

11

Page 12

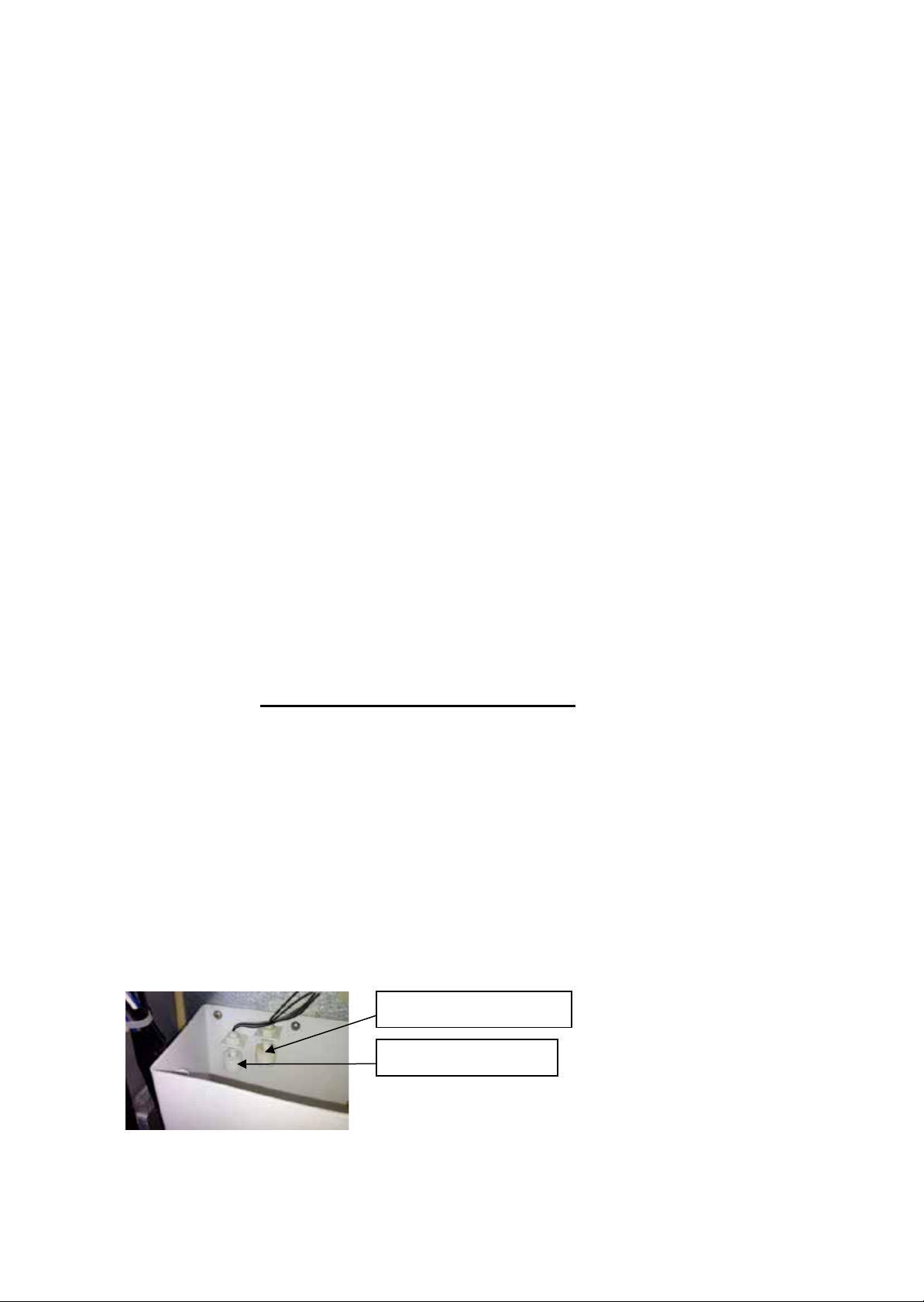

Connecting the drain line:

Water level switch 2

Water level switch 1

NOTE: If there is a drain line near the ice maker, the best choice is to drain

water to the drain line through the drain water hose provided with ice

maker.

1. Locate the floor drain near the ice maker. The distance should be less than 5 feet

since the length of the long drain water hose provided with the ice maker is about

5 feet.

2. Find the drain outlet on the back of ice maker. Connect the drain outlet to the

water draining hose, and insert the other end of the hose into the drain line.

NOTE: Never allow the drain hose to hang or loop higher than the floor of the ice

storage bin.

3. All horizontal runs of drain lines must have a fall of ¼” per foot. An air gap will

likely be required between the ice maker drain tube and the drain/waste

receptacle. A standpipe with a trap below it would be acceptable for the

drain/waste receptacle. A floor drain is also acceptable. If this is not possible, the

use of a condensate pump is recommended.

4. Pour 1 gallon of water into the ice storage bin to check for leaks in the drainage system.

Tighten any connections that leak.

IMPORTANT: This ice maker is not a freezer. Infrequent drainage

will cause a high rate of melting in the ice storage bin.

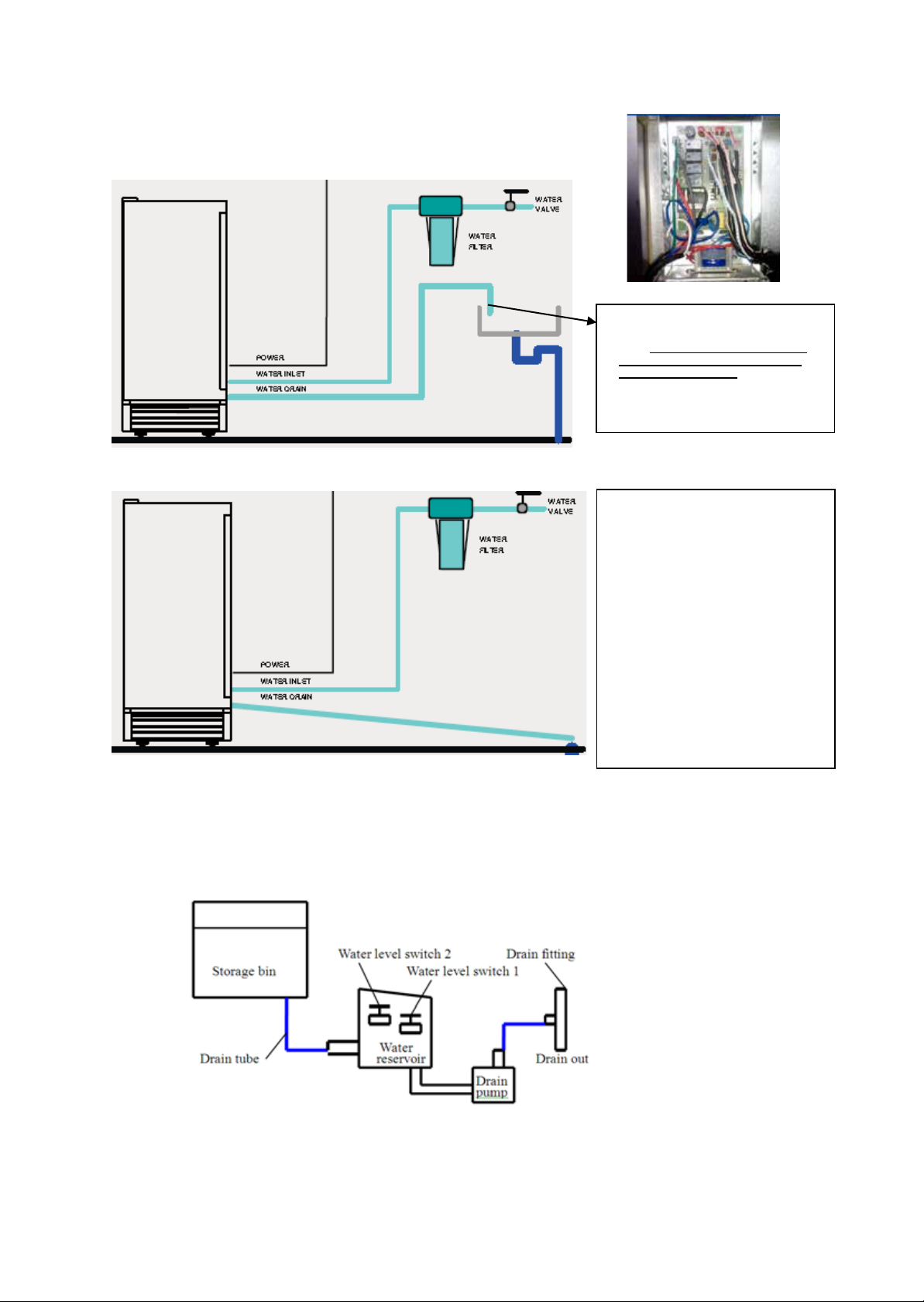

How the drain system operates when water is pumped out

The components of the Pump-Out Water Drain System are

• Water reservoir PC Board & Water level switch 1, 2

• Water Drain Pump

OPERATION

• All water coming from the overflow and the melted ice is collected in the water reservoir.

• As soon as the wate r in the rese rvoir r eaches t he max imum level , the wate r level swi tch 1

closes, transmitting a low voltage current to the PC Board.

12

Page 13

• The PC board activates the water drain pump for 20 seconds,

NOTE:

WARNING!

pumping out most of the water contained in the water reservoir.

• The water can be pumped out up a rise of to 1.5m (59”) or

over a on horizontal length of 1.5m (59”).

The outlet of the drain hose

must be raised higher than

the water surface to prevent

the drained water from

flowing back into the water

reservoir.

If alarm buzzer sounds, turn

off the ice maker and the

water supply, remove all ice

from storage bin, and wipe up

any water that may have

overflowed. Check if there is

any water in water trough at

back of unit; if no water,

drainage pump may not be

receiving the proper amount

of power. Check power

source. If the problem can be

corrected, turn on the unit

again. Also check that none

of the water lines are kinked.

If the problem remains,

contact Customer Service.

• If water level switch 2 closes, transmitting a low-voltage

current to the PC board, the PC board activates the

buzzer alarm, informing you that the drain pump, water

level switch or drain tube may be malfunctioning.

Schematic Diagram

13

Page 14

OPERATING YOUR ICEMAKER

+

_

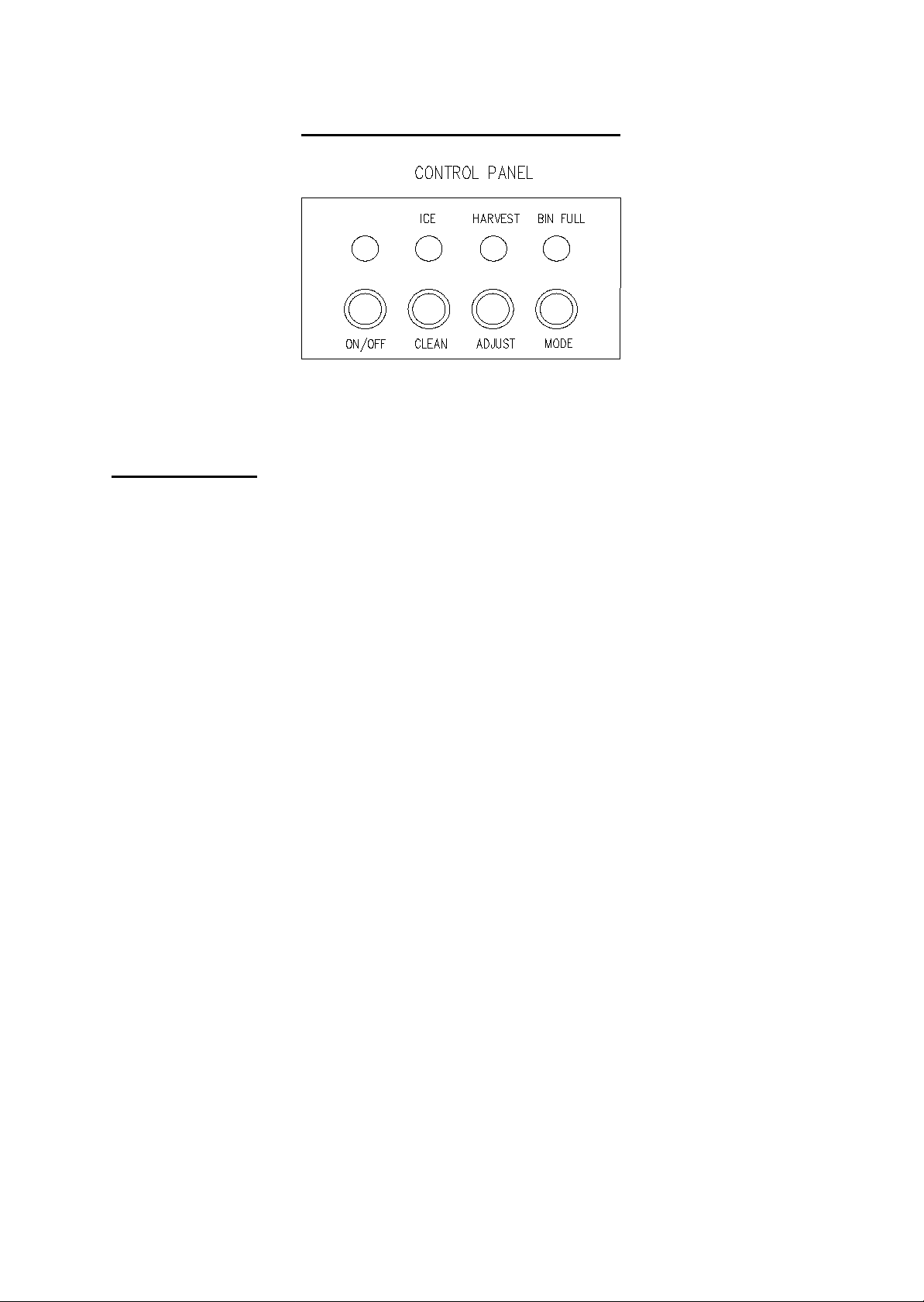

Control Panel: Description of buttons and indicator lights:

Indicator Lights:

1. BIN FULL (RED): Bin is full

When this light is illuminated, the ice storage bin is full of ice or there is something blocking the

bin full sensor. The unit will stop the ice making process until the level of ice has reduced or the

object blocking the sensor is removed.

When ice-cubes are removed and the bin full sensor is cleared; the bin-full indic ator light will blink

for 3 minutes, then the unit will restart and return to the ice-making process.

2. ICE (Green): Ice making process.

When this light is illuminated, the unit is working in the ice-making process which is controlled by

a temperature sensor on the evaporator. When the indicator light flashes green, the unit is

working to produce ice and is based on a fixed timer.

3. HARVEST (Yellow): Ice Harvest process.

When this light is illuminated, the unit is in the process of harvesting the ice that was produced.

The machine will continue to make and harvest ice until the bin-full sensor notes that the bin is

full or until the unit is turned off or the system mode is changed by touching the “MODE” button.

4. Mode button: This button is use d primarily for t he quick star t of the Ice mak ing process or

for service / repa ir iss ues. You can “ quick start” the system b y pressing t he “MO DE” button when

first plugged in, power has been lost or if the unit has been turned off for a period of time.

5. Adjust button: This button is used primarily for service and or to select the size of the ice-

cubes. To select the ice cubes, press and hold the button for approximately 3 seconds, the

“HARVEST” (Yellow) indicator light will illuminate and the system will enter the Ice Size Selection

mode. Release the button once the Harvest light (yellow) blinks and simply press the ( + ) or ( - )

to select larger or smaller cubes, the unit is shipped from the factory set to the normal sized cubes.

14

Page 15

OPERATING YOUR ICE-MAKER

Bin full stage

Ice making stage

Ice harvest stage

1. Turn on the water tap.

2. Press the ON/OFF button.

3. After 3 minutes, the machine will automatically go to the ice-making stage, and the sound of water

flowing will be heard. (The ICE indicator light (GREEN) will blink during this process.)

4. Press the MODE butto n to quick start the Ice-Making proc ess and a llo w the water trough to be gin

to fill automatically. (The ICE indicator light (GREEN) will blink during this process.)

5. When the batch of ice has been f ully formed, the ice will autom atically be harvested and dro p to

the ice storage bin. (The HARVEST indicator light (YELLOW) will blink during this process.)

6. When the ice storage bin is full, the sheet of cubes will not f all com pletel y and will hold the bin-full

sensor open. The machine will s top making ice automatical l y. (The BIN-Full indic ator l ig ht ( RE D)

will blink to indicate the bin is full or the sensor is being blocked.)

7. The unit will start making ice again after ice cubes are removed or when the bin-full sensor swings

back to operating position. (The BIN-Full indicator light (RED) will continue to blink for

approximately 3 minutes, then the system will automatically begin the ice-making process again.)

IMPORTANT:

• Although the unit has been tested and clea ned at the fac tory , due to long-term transit and

storage, the first batch of cubes must be discarded.

• Never turn the water supply tap off when the ice maker is working.

• Never touch the evaporator when unit is running!

• To prevent ice from melting and to ensure proper ice formation, keep the door closed except

when removing ice from the bin.

15

Page 16

Ice Size Adjustment Guide:

1. Press and hold the “Adjust” button for approximately 3 seconds. The unit will enter the Ice Size

Adjustment mode. The “HARVEST” LED (yellow) will be blinking continuously while the ice size is

being selected. Release the button when the LED blinks continuously to adjust the ice size.

2. While in the Ice Size Selection mode, press the “Clean” (-) button or the “Mode” (+) button for the

desired ice size.

Smaller ice setting:

By pressing the “Clean” (-) button, you can select the SMALL size of the ice cubes. The “ICE” LED

(GREEN) will flash as you select the smaller ice size.

Larger ice setting:

By pressing the “Mode” (+) button, you can select the large size of the ice cubes. The “BIN FULL”

LED (RED) will flash as you select the larger ice size.

After 10 seconds without any operation, the unit will return to the previous mode.

NOTE:

• If during the ice size adjus tment mode t he “BIN FULL” , “ICE” and “ HARVEST” LEDS blink all a t

once; this indicates that the unit is in the regular (middle) setting of the ice size.

• When the m achine is in t he clea ning s tage or ice f ull st age, t he ice s i ze adjus tm ent mode c annot

be accessed

16

Page 17

HOW THE ICE MAKER PRODUCES ICE

Set the ON/OFF button to the ON position.

The machine will automatically go in to the ice making stage.

The unit will go through two distinct cycles during the production of your ice.

The first cycle is the “freeze” where the ice is actually produced and the

second is the “harvest” where the ice is dropped into the ice-bin.

The freeze cycle happens when water flows to the evaporator surface. The harvest cycle is when the

ice is released and water enters the machine. A complete cycle takes about 20 minutes, but it

depends on temperature and operating conditions.

Freeze: During the freeze cycle the compressor is pumping refrigerant, the fan motor is blowing air,

and the water pump is circulating water. When the batch of ice has been fully formed, the ice maker

stops the freeze cycle and the harvest cycle will begin.

Harvest: During the harvest cycle the compressor is still operating, but the water pump has stopped.

The hot gas valve opens, diverting hot refrigerant gas into the evaporator. The hot refrigerant gas

warms the evaporator, causing the cubes to slide as a unit off the evaporator and into the storage bin.

The freeze cycle will restart when all the cubes have been harvested.

How the machine uses the water

The ice maker begins with a fixed charge of water which is contained in the water trough. As the

water flows to the freezing evaporator surface, the portion of water that does not contain mineral

impurities freezes and sticks to the ice cube molds. The water containing impurities falls back into the

water trough. During the ice making process, fresh water enters into the water trough continuously as

the water in the trough freezes continuously in the evaporator.

Normal sounds

Your new ice maker may make sounds that are not familiar to you. Most of the new sounds are

normal. Hard surfaces like the floor and walls can make the sounds louder than they actually are. The

following list describes the sounds that might be new to you and what may be causing them.

• Rattling no ises ma y come from the f low of the refrigerant or the water lin e. Items s tored on top of

the ice maker can also make noises due to vibration.

• The high efficiency compressor may make a pulsating or high-pitched sound.

• Running water may make a splashing sound.

• You may hear air being forced over the condenser by the condenser fan.

• During the harvest cycle, you may hear the sound of ice cubes falling into the ice storage bin.

17

Page 18

CARE AND MAINTENANCE

Before proceeding with cleaning and maintenance operations, make sure the

If the ice maker is left unused for a long time, before the next use it

If the ice maker is left unused for a long time, before the next use it must

Cleaning The Icemaker

be thoroughly cleaned. Follow carefully any instructions provided for

Periodic cleaning and proper maintenance will ensure efficiency, top performance, and long life. The

maintenance intervals listed are based on normal conditions. You may want to shorten the intervals if

you have pets, or there are other special considerations.

Important Note:

Never keep anything in the ice storage bin that is not ice: objects like wine and beer

bottles are not only unsanitary, but the labels may slip off and plug up the drain.

must be thoroughly cleaned. Follow carefully any instructions provided

cleaning or use of sanitizing solutions. Do not leave any solution inside

for cleaning or use of sanitizing solutions. Do not leave any solution

the ice maker after cleaning.

inside the ice maker after cleaning.

power line of the unit is disconnected and the water line is shut off.

Cleaning the exterior

The door and cabinet may be cleaned with a mild detergent and warm water solution such as 1 oz. of

dishwashing liquid mixed with 2 gallons of warm water. Do not use solvent-based or abrasive

cleaners. Use a soft sponge and rinse with clean water. Wipe with a soft clean towel to prevent water

spotting.

If the door panel is stainless steel, it may discolor when exposed to chlorine gas and moisture. Clean

stainless steel with a mild detergent and warm water solution and a damp cloth. Never use an

abrasive cleaning agent.

18

Page 19

Cleaning the interior

Right location of the

Condenser

Surface

The ice storage bin should be sanitized occasionally. Clean the water trough before the ice maker is

used first time and reused after stopping for an extended period of time. It is usually convenient to

sanitize the trough after the ice making system has been cleaned, and the ice storage bin is empty.

1. Disconnect the power to the unit.

2. O pen the door and take out t he removable ice storage bin. W ith a clean cloth, wipe do wn the

interior of unit and ice bin with a sanitizing solution made of 1 ounce of household bleach or

chlorine and 2 gallons of hot (95ºF – 115ºF) w ater.

3. Pull off the drain hose of the water trough to drain off all water.

4. Rinse thoroughly with clear water.

5. After draining off all water, put back the drain hose of the water

through to the original location.

6. Put the ice storage bin inside the unit.

7. Reconnect power to the unit.

The ice scoop should be washed regularly. Wash it just like any other food

container.

drain hose

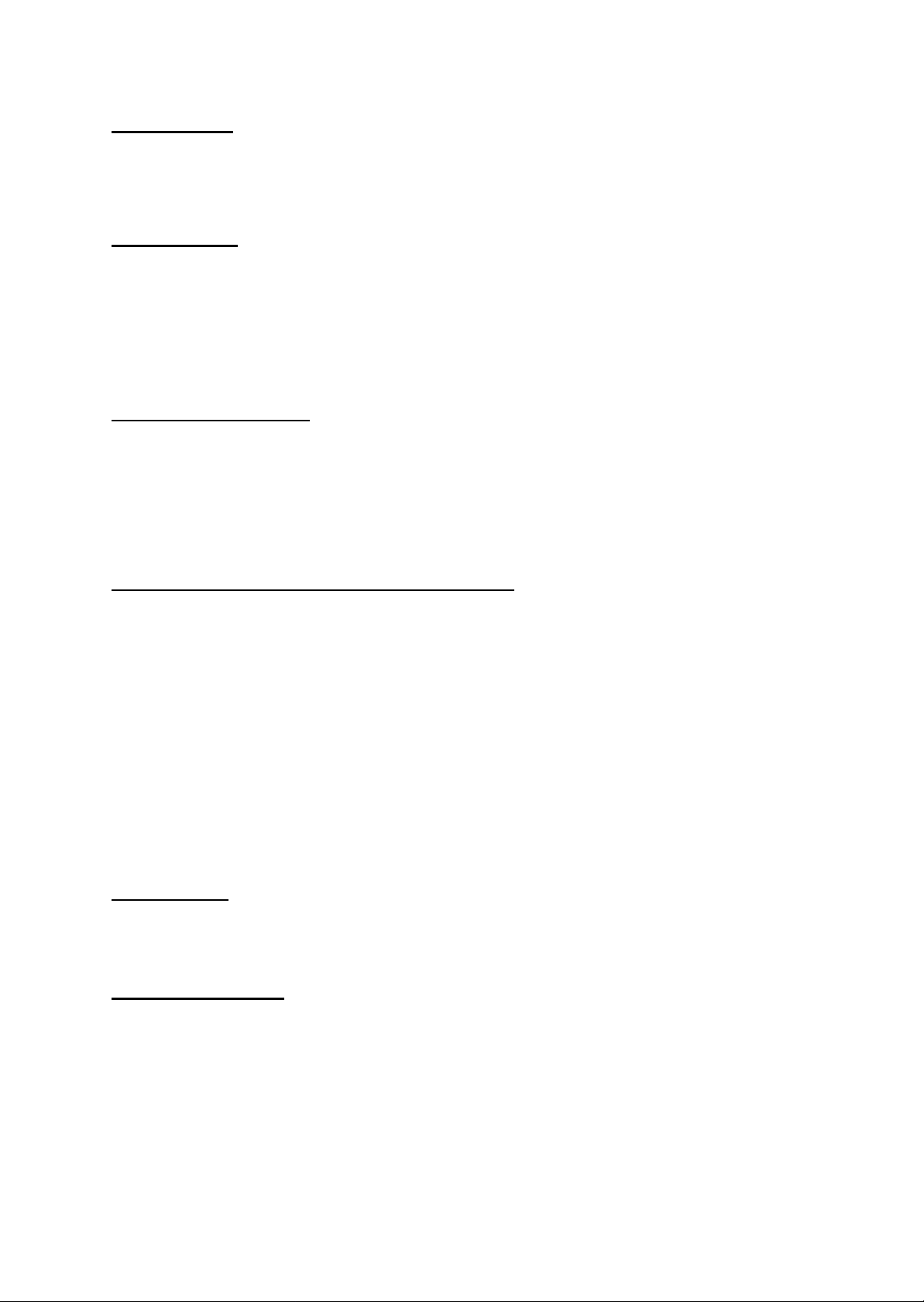

Condenser cleaning

A dirty or clogged condenser prevents proper airflow, reduces ice making capacity, and causes higher

than recommended operating temperatures that may lead to component failure. Have the condenser

cleaned at least once every six months.

1. Unplug the ice maker or disconnect power.

2. Gently pull off the lower front louver.

3. Remove dirt and lint from the condenser and the

unit compartment with the brush attachment of a

.

vacuum cleaner

4. Reassemble the lower front louver.

5. Plug in the ice maker or reconnect power.

Cleaning the water distribution tube

When you find the ice cubes are incompletely formed or the output is low, the water distribution tube

may be blocked. Turn off the power button, gently take out the water distribution tube, locate the holes

in the distribution tube and use a pointed object such as a toothpick to dredge the holes. Then put the

water distribution tube back to its original position. If the tube is badly blocked, clean it as follows:

1. Shut off the water supply

2. D isc onnect the water hose from the distribution tube.

3. Gently take out the distribution tube.

4. W ith a brush, clean the tube with a di lute solution of warm water and a m ild detergent such as

dishwashing liquid. After removing the dirt and lint from the surface, rinse the tube with clean

water.

5. Replace the distribution tube.

6. Reconnect the water supply.

19

Page 20

Ice-making system cleanin g (CLEAN BUTTON)

The ice machine cleaner contains acids.

DO NOT use or mix with any other solvent-based cleaner produc t s.

Use rubber gloves to protect hands. Carefully read the material safety instructions

on the container of the ice machine cleaner.

Discard the first batch o f ice produc ed a ft er cleani ng .

Minerals that are removed from the water during the freezing cycle will eventually form a hard, scaly

deposit in the water system. Cleaning the system regularly helps remove the mineral scale buildup.

How often to clean the system depends upon ho w har d your wat er is or how ef f ective your filtration

may be. With hard water of 15 to 20 grains/gal. (4 to 5 grains/ liter), you may need to clean the system

as often as once every 6 months.

1. Make sure that all the ice is off the evaporator. If ice is being formed, wait until the cycle is

completed, then press the machine’s ON/OFF button on the control panel.

2. Remove all ice from the storage bin.

3. Kee p the ice maker connec ted to the water supply. Pour 8 o z. of Nickel-Safe Ice Mak er Cleaner

Solution into the water tr ough. Then press the ON/OFF button and the CLEAN button, initiating

the wash cycle. The machine will run in the Automatic Clean Mode.

4. Al low 30 m inutes for pr oper clean ing. Af ter clean ing, pres s the ON /OFF button again. Use a dr ain

hose on the front of the water trough to drain off the waste water to a convenient container.

NOTE: Don’t drain off the waste water to the inside of the cabinet.

5. R epeat steps 3 and 4 ( without Ice Maker Cleaning Solution) thre e times to rinse th e ice making

system thoroughly.

6. Pr epare a sanitizing solution made of 1 ounc e of household bleach and 2 gallons of hot water

(95ºF to 115ºF). Wipe the entire bin inside and outside, covering the entire surface of the walls.

7. Fill a spray bottle with the sanitizing solution and spray all corners and edges, making sure to

cover all surfaces with the solution.

8. Allow the solution to be in contact for at least 3 minutes, and then dry.

9. Repeat step 5 to rinse the ice making system one more time.

10. Press the ON/OFF button again. The machine will return to the regular ice making mode.

11. Discard the first batch of ice.

20

Page 21

Power Failure

Most power failures are corrected within a few ho urs and should not aff ect the temperature of your

icemaker if you minimize th e number of times the door is opened. If the power is going to be off for a

longer period of time, you need to take the proper steps to protect your food.

Vacation Time

Short vacations: Leave the unit operating during vacations of less than three weeks.

Long vacations: If the icemaker will not be used f or severa l months, remove all of the ic e and unplug

the power cord. Clea n and dry the interi or thoroughly. To pr event odor and m old growth, leave the

door open slightly: blocking it open if necessary

Moving Your Icemaker

• Remove all the food.

• Securely tape down all loose items inside your unit.

• Turn the leveling screws up to the base to avoid damage.

• Tape the doors shut.

• Be sure the unit stays in the upright position during transportation.

Preparing the ice maker for long term storage

If the ice maker will not be used for a long time, or is to be moved to another place, it will be

necessary to drain the system of water.

1. Shut off the water supply at the main water source.

2. Disconnect the water supply line from the water inlet.

3. Shut off the electric supply at the main electrical power source.

4. Take out the ice storage bin to remove any remaining ice and water. Dry the bin.

5. Pull off the drainage tube of the water trough to drain off all water.

6. Leave the door open to allow for circulation and to prevent mold and mildew.

7. Leave water supply line and power cord disconnected until ready to reuse.

IMPORTANT:

• Do not touch the power plug when your hands are wet.

• Never unplug the unit by pulling on the cord. Grasp the plug and pull out firmly.

Energy Saving Tips

• The unit should be located in the coo lest area of the r oom, away from heat producing appliances

or heating ducts, and out of direct sunlight.

21

Page 22

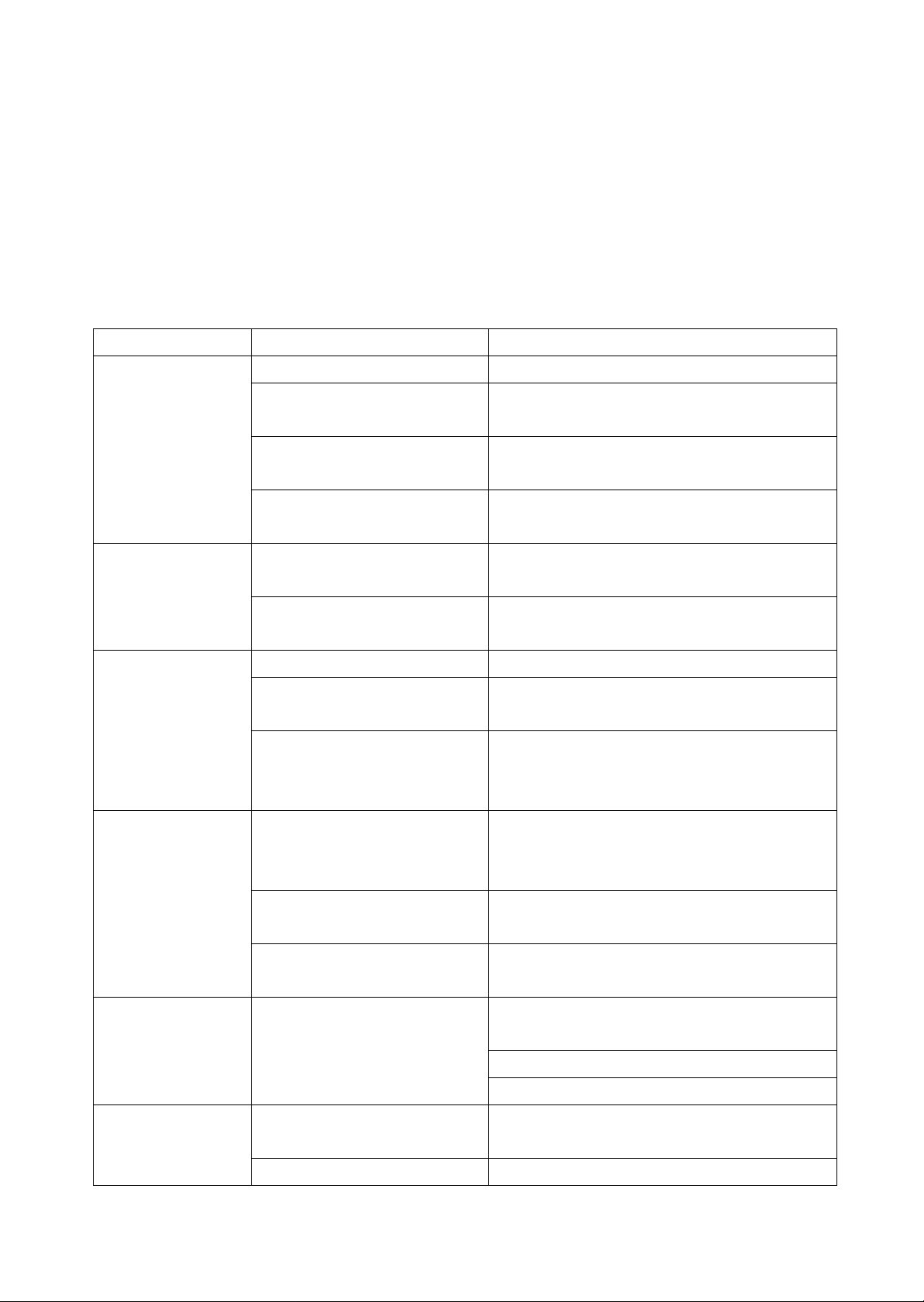

TROUBLESHOOTING

Problem

Possible Cause

Probable Correction

The ice maker is unplugged.

Plug the ice maker in.

service to check for a short circuit in t he un i t.

set at OFF.

probe is free of ice.

off.

properly connected.

The condenser may be dirty.

Clean the condenser.

may be obstructed.

unit is near some heat source.

remove ice from storage bin.

ice.

leaking.

outlet.

psig.

Check water supply or filter may be restricted.

Check for a water leak at the water trough.

locked.

Maker.

Certain sounds are normal.

See Normal Sounds.

Before Calling for Service

If the unit appears to be malfunctioning, read through the OPERATION section of this manual first. If

the problem persists, check the Troubleshooting Guide on the following pages. Some of the problems

mentioned in the Guide can be solved easily without a service call.

The machine

doesn’t operate.

The water doesn't

feed in after the

machine starts.

Machine makes ice,

but bin does not fill

up with ice.

The fuse is blown.

The ice maker power button is

The ice storage bin is full of ice.

The water supply tap is turned

The water supply pipe is not

The air flow to the ice maker

The ambient temperature and

water temperature are high, or

Some water falls to the floor

Replace fuse. If it happens again, call for

Switch the ice maker power button to ON.

Remove some ice cubes. Be sure the ice-full

Turn on the water supply tap.

Reconnect the water supply pipe.

Check the installation.

Check the installation.

Normal condensation on the door or some water

when you open the door to

Water is leaking out

of the unit.

Cubes are partially

formed or are white

on the bottom.

Noise during

operation

Water supply connection is

Drain pipe higher than drain

Not enough water in the water

trough.

The feet are not leveled and

together with ice. Take care when you take out

Tighten fitting. See Connecting the water line.

Lower drain pipe.

Check if the water supply pressure is below 15

Level and lock the feet. See Leveling the Ice

22

Page 23

The ice maker stops

The electricity is off.

Reconnect the power supply line.

within the stated range.

probe is free of ice.

maker is electrified

socket.

requirements.

machine.

the floor of the ice storage bin.

suddenly while

The room temperature is out of

Cut off the electricity and leave the ice maker

disconnected until the temperature returns to

the stated range.

making ice.

The body of the ice

Scaling occurs

frequently inside the

Water leaks from

the ice storage bin

The ice storage bin is full of ice. Remove some ice cubes; make sure the ice-full

The ground line isn't in the

The hardness level of the water

is too high.

The drain hole below the ice

storage bin is blocked.

The drain hose is kinked or

improperly placed higher than

Use a socket meeting the grounding

Install a water-softeni ng de vice in fr ont of the

water inlet.

Remove the ice storage bin and clean the drain

hole.

Check the drain hose to be sure water can be

drained out unhindered.

23

Page 24

SERVICE FOR YOUR APPLIANCE

We are proud of our customer service organization and the network of professional service

Avanti Products Customer Service team will be here for you. Just call us toll-free.

AVANTI PRODUCTS CUSTOMER SERVICES

800-323 5029

help is available.

You may order parts and accessories that will be

money order, Master Card, or Visa.

know your appliance inside and out.

WIRING DIAGRAM

technicians that provide service on your Avanti appliances. With the purchase of your Avanti

appliance, you can have the confidence that if you ever need additional information or assistance the

Product Information

Part Orders

800-220 5570

In-Home Repair Service

800-220 5570

Whatever your questions are about our products,

delivered directly to your home.

You may order these items by personal check,

An Avanti Products authorized service center will

provide expert repair service, scheduled at a time

that is convenient for you. Our trained servicers

24

Page 25

YOUR AVANTI PRODUCTS

Staple your sales receipt here. Proof of

obtain service under warranty.

WHAT IS COVERED – LIMITED ONE-YEAR WARRANTY

center for repair.

LIMITED SECOND THROUGH FIFTH YEAR WARRANTY

user’s responsibility.

WARRANTY EXCLUSIONS / WHAT IS NOT COVERED:

Products, including without limitation, one or more of the following:

•

lightning, power surges, structural failures surrounding the appliance, and acts of God.

•

• Shipping and handling costs associated with the

In no event shall Avanti Products have any liability or responsibility whatsoever for damage to surrounding

cabinetry, walls, floors, shelving etc., as well as the resetting of breakers or fuses.

OUT OF WARRANTY PRODUCT

repairs, pro-rates, or product replacement, once this warranty has expired.

WARRANTY – REFRIGERATION - COMPRESSOR

WARRANTY

Avanti Products warrants that the product is free from defects in materials and/or workmanship for a period of

twelve (12) months from the date of purchase by the original owner. The foregoing timeline begins to run upon

the date of purchase, and shall not be stalled, tolled, extended, or suspended for any reason whatsoever unless

described in detail in the warranty document. For one year from the date of purchase by the original owner,

Avanti products will, at its option, repair or replace any part of the product which proves to be defective in

material or workmanship under normal use. Avanti Products will provide you with a reasonably similar product

that is either new or factory refurbished. During this period Avanti Products will provide all parts and labor

necessary to correct such defects free of charge, so long as the product has been installed and operated in

accordance with the written instructions in this manual. In rental or commercial use, the warranty period is 90

days. All Avanti appliances of 4.4 cubic feet capacity or less must be brought/sent to the appliance service

For the second through the fifth year from the date of original purchase, Avanti Products will provide a

replacement compressor free of charge due to a failure. You are responsible for the service labor and freight

charges. In rental or commercial use, the limited compressor warranty is one year and nine months. Costs

involved to move the product to the service center and back to the user’s home, as maybe required, are the

The warranty coverage described herein excludes all defects or damage that are not the direct fault of Avanti

A failure to comply with any applicable state, local, city, or county electrical, plumbing and/or building codes,

regulations, or laws, including failure to install the product in strict conformity with local fire and building codes

and regulations.

original purchase date is needed to

• Any external, elemental and/or environmental forces and factors, including without limitation, rain, wind, sand,

floods, fires, mud slides, freezing temperatures, excessive moisture or extended exposure to humidity,

Content losses of food or other content due to

spoilage.

• Incidental or consequential damages

• Parts and labor costs for the following will not be

considered as warranty:

• Repairs performed by unauthorized servicers.

• Service calls that are related to external problems,

• Evaporator doors, door springs, and/or frames.

• Inner door panels, door shelves, door rails,

and/or door supports.

• Light bulbs and/or plastic housing.

• Failure of the product if it is used for other than it

• The warranty does not apply outside the

• Plastic cabinet liners.

• Punctured evaporator that voids the warranty on

the complete sealed system.

property, including cabinetry, floors, ceilings, and other structures and/or objects around the product. Also

excluded from this warranty are scratches, nicks, minor dents, and other cosmetic damages on external surfaces

and exposed parts; Products on which the serial numbers have been altered, defaced or removed; service visits

for customer education, or visits where there is nothing wrong with the product; correction of installation problems

(you are solely responsible for any structure and setting for the product, including all electrical, plumbing and/or

other connecting facilities, for proper foundation/flooring, and for any alterations including without limitation

Avanti Products is under no obligation, at law or otherwise, to provide you with any concessions, including

• Surcharges including but not limited to, any after

replacement of the unit.

such as abuse, misuse, inadequate electrical

power, accidents, fire, floods, or any other acts of

God.

intended purpose.

Continental USA.

hour, weekend, or holiday service calls, tolls, ferry

trip charges, or mileage expense for service calls to

remote areas.

25

Page 26

INSTRUCCIONES DE SEGURIDAD

Su seguridad y la seguridad de los demás son muy importantes.

Hemos incluido muchos mensajes importantes de seguridad en este manual y en su

electrodoméstico. Lea y obedezca siempre todos los mensajes de seguridad.

Todo mensaje de seguridad le avisará a cuál es el peligro potencial, le dirán

siguen las instrucciones.

Éste es el símbolo de alerta de

seguridad. Este símbolo le avisa de

los peligros potenciales que

pueden matar o lesionar a usted y

otros. Toda la seguridad mensajes

seguirá a el símbolo de alerta y

cualquiera de los pabellones"

PELIGRO","ADVERTENCIA" o

"PRECAUCIÓN".

Peligro significa que el

incumplimiento de la medida de

seguridad podría causar lesiones

graves o la muerte.

Advertencia significa que si no se

respeta esta medida de seguridad

podría resultar en graves daños al

producto, lesiones personales

graves o la muerte.

Advertencia significa que si no se

respeta esta medida de seguridad

podría resultar en graves daños al

producto, lesiones personales

graves o la muerte.

cómo reducir el riesgo de lesiones, y le hará saber lo que puede suceder si no se

26

Page 27

MEDIDAS DE SEGURIDAD IMPORTANTES

Antes de enfriador de bebidas se utiliza, debe ser colocado correctamente e

•Enchufe en unas 3 clavijas con conexión a tierra toma de corriente, hacer No retire de puesta a

técnico cualificado.

• Se recomienda utilizar dos o más personas para mover e instalar el electrodoméstico. El aparato es

instalado como descrito en este manual, así que lea cuidadosamente el

manual. Para reducir el riesgo de incendio, descarga eléctrica o lesiones al

utilizar el enfriador de bebidas, Siga las precauciones básicas, incluyendo las

tierra púa, hacer No utilice un adaptador, y no utilice un cable de extensión

• Reemplazar todos los paneles antes operativos

• Eso se recomienda usar un circuito separado, que sólo sirve a su enfriador de bebidas, ser

proporcionado. Use recipientes ese no poder ser desactivado por un interruptor o cadena

• Nunca limpia electrodoméstico piezas con líquidos inflamables. Estos vapores pueden crear un

riesgo de incendio o explosión. Y no almacene ni use gasolina u otros vapores y líquidos

inflamables en la proximidad de este o cualquier otro electrodoméstico. Los vapores pueden crear

un riesgo de incendio o explosión.

• Antes de proceder con las operaciones de limpieza y mantenimiento, asegúrese de que la línea de

alimentación de la unidad se desconecta.

• hacer No conecte o desconecte el enchufe eléctrico con las manos mojadas

• Desenchufe el electrodoméstico o desconectar la alimentación antes de la limpieza o el

mantenimiento. El no hacerlo puede provocar una descarga eléctrica o la muerte.

• hacer No intente reparar o reemplazar cualquier parte de su electrodoméstico a menos que se

recomiende específicamente en este material. Cualquier otro servicio debe ser realizado por un

siguientes

pesado y puede resultar en daños de la espalda u otras lesiones.

• Para garantizar una ventilación adecuada para su electrodoméstico, la unidad debe estar

completamente despejada. Elija un área bien ventilada con temperaturas superiores a 55ºF (13ºC)

y por debajo de 90ºF (32ºC). Esta unidad debe ser instalada en un área protegida de los

elementos, tales como el viento, la lluvia, rocío de agua o luz de sol.

• El electrodoméstico no debe colocarse cerca de hornos, parrillas u otras fuentes de calor.

• El electrodoméstico debe ser instalado con todas las conexiones eléctricas, de agua y de desagüe

según los códigos estatales y locales. Hace falta un suministro eléctrico estándar (sólo 115 V CA,

60 Hz), debidamente conectada a tierra de acuerdo con el Código Eléctrico Nacional y los códigos

y ordenanzas locales.

• Hacer No doble ni apriete el cable de alimentación del electrodoméstico.

• Los fusibles (o disyuntor) tamaño debe ser de 15 amperios.

• Eso Es importante que el electrodoméstico a nivelarse con el fin de funcionar co rr ec tam ente. Pue de

que tenga que hacer varios ajustes para nivelarla.

• Toda la instalación debe realizarse de acuerdo con los requerimientos locales de plomería.

• Asegúrese de que los tubos no están aplastar ni dañado durante instalación.

• Compruebe si hay fugas des pués de la con exió n.

• Nunca permita que los niños operen, jueguen o gatear el interior del electrodoméstico

• Hacer No utilice productos de limpieza a base de disolvente-abr as ivos en el inte r ior. Estos

limpiadores pueden dañar o decolorar el interior.

• No utilice este electrodoméstico para que no sea su finalidad.

27

Page 28

Conexión eléctrica

~Advertencia~

El uso inapropiado del enchufe a tierra puede resultar en el riesgo de descarga eléctrica. Si

autorizado de Avanti Products.

Este electrodoméstico debe estar conectado a tierra adecuadamente para su

de tres puntas que encajan con tres enchufes de pared standard para reducir al

Bajo ninguna circunstancia corte o remueva la punta de tierra del cable de

electrodoméstico tirando del cable de alimentación. Siempre

. Si el cable de

electricista o técnico calificado

instale un tomacorrient e cer ca del electrodoméstico.

Ø CABLE EXTENSIÓ N

Debido a los peligros potenciales de seguridad bajo ciertas condiciones, se

clasificación eléctrica del cable sea de 115 voltios y al menos 10 amperios.

Ø PROTECTOR CONTRA SOBRETENSIONES

La mayoría de los electrodomésticos utilizan una serie de paneles de control

protector contra sobretensiones a un electricista autorizado en su área.

Los daños debidos a sobrecargas de energía no se consideran un defecto cubierto

por el fabricante y anulará la garantía del producto.

el cable de alimentación está dañado, haga que sea reemplazado por un centro de servicio

seguridad. El cable eléctrico de este electrodoméstico está equipado con un enchufe

mínimo la posibilidad de una descarga eléctrica.

alimentación suministrado.

Este electrodoméstico requiere una toma de corriente eléctrica 115Volts ~ / 60 Hz

estándar con tierra de tres clavijas.

El cable debe ser asegurado detrás del electrodoméstico y no déjelo expuesto para

evitar lesiones accidentales.

Nunca desenchufe el

sostenga firmemente el enchufe y tire en línea recta desde el receptáculo.

No utilice un cable de extensión con este electrodoméstico

alimentación es demasiado corto, haga que un

recomienda encarecidamente que no se utilice un cable de extensión con esta

unidad. Sin embargo, si debe utilizar un cable de extensión es absolutamente

necesario que se trate de un UL / CUL, 3 hilos con toma de tierra del

electrodoméstico cable de extensión que tiene un enchufe y la toma a tierra y que la

eléctricos para operar. Estas placas son muy susceptibles a las subidas de tensión y

podrían ser dañados o destruidos.

Si el electrodoméstico va a ser usado en un área o si su ciudad / país es propenso a

subidas de tensión / interrupciones; se sugiere que utilice un protector contra

sobretensiones alimentación de todos los dispositivos / electrodomésticos que

utiliza. El estabilizador de tensión que se selecciona debe tener un bloque oleada

suficientemente alto como para proteger el electrodoméstico está conectado a. Si

usted tiene alguna pregunta relacionada con el tipo y tamaño de contacto necesario

28

Page 29

Ayúdenos a ayudarte...

Si necesita servicio

Estamos orgullosos de nuestro servicio y

A continuación, si usted todavía no está contento,

PRECAUCIÓN:

Lea detenidamente esta guía.

Se pretende que ayudan a utili zar y

mantener su nuevo electrodoméstico

correctamente.

Mantenga a la mano para responder a sus

preguntas.

Si no entiende algo o si necesita más ayuda,

por favor llame a:

Avanti Servicio al Cliente

800-220-5570

Mantenga prueba de la fecha original de

compra (como el recibo de venta) con esta

guía para establecer el período de garantía.

ESTE ELECTRODOMÉSTICO NO

ESTÁ DISEÑADO PARA EL

ALMACENAMIENTO DE

MEDICINA U OTROS

PRODUCTOS MÉDICOS.

Escribir se establece el modelo y número de

serie.

Los encontrará en una placa situada en la pared

exterior trasera del electrodoméstico.

Por favor, escriba estos números aquí:

__________________________________

_

Fecha de compra

__________________________________

_

Número de modelo

__________________________________

_

Número de serie

Utilice estos números en cualquier correspondencia

o llamadas de servicio con respecto a su

electrodoméstico.

Si ha recibido un electrodoméstico dañado,

póngase inmediatamente en contacto con el

distribuidor (o constructor) que le vendió el

electrodoméstico.

Ahorrar tiempo y dinero. Antes de llamar al servicio

técnico, consulte la Guía de solución de problemas.

En él se enumeran las causas de los problemas de

funcionamiento de menor importancia que se

pueden corregir a sí mismo.

queremos que usted esté satisfecho. Si por

alguna razón usted no está satisfecho con el

servicio que recibe, aquí hay algunos pasos

a seguir para obtener más ayuda.

PRIMERA, póngase en contacto con las

personas que servicio de reparación del

electrodoméstico. Explicar por qué usted no

está satisfecho. En la mayoría de los casos,

esto va a resolver el problema.

escribir todos los detalles, incluyendo su número de

teléfono, y enviarlo a:

Servicio al cliente

Avanti Products

10880 NW 30 Street

Miami, FL 33172 EE.UU.

29

Page 30

PARTES Y CARACTERISTICAS

30

Page 31

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

~

~

, siga las siguientes

- GUARDE ESTAS INSTRUCCIONES -

Para reducir el riesgo de incendio, descarga eléctrica, o

PRECAUCIÓN

daño cuando use su aparato

precauciones.

Esta unidad es para uso en interiores

− Leer todas las instrucciones antes de usar el aparato.

− PELIGRO o ADVERTENCIA: Riesgo de encierro para niños. Niños atrapados y sofocación no son

problemas del pasado. Aparatos desechados o abandonados siguen siendo peligrosos. . . incluso si van a

"sentarse en el garaje de unos pocos días".

− Antes de deshacerse de su aparato viejo: quite las puertas. Deje los estantes en su lugar para que los

niños no puedan meterse con facilidad.

− Nunca permita que los niños manejen, jueguen o se arrastren dentro del aparato.

− Nunca limpie las piezas del aparato con líquidos inflamables. Los vapores pueden crear un peligro de

incendio o explosión.

− No almacene ni use gasolina u otros vapores y líquidos inflamables en la proximidad de este o cualquier

otro aparato. Los vapores pueden crear un peligro de incendio o explosión.

INSTRUCCIONES DE INSTALACIÓN

Antes de usar el aparato

• Retire la envoltura interna y externa.

• Verifique para asegurarse de que tiene todas las siguientes partes:

o 1 Cucharón

o 2 mangueras (1 para alimentación de agua / 1 para el desagüe)

o Manual de Instrucciones

• Antes de conectar el aparato a la fuent e d e a lim ent aci ón, es s u geri do d ej ar lo en posic ió n vertic a l

durante aproximadam ente 2 horas. Esto reducirá la posibi lidad de un mal funcionamiento en e l

sistema de refrigeración del aparato de la manipulación durante el transporte.

• Limpie la superficie interior con agua tibia usando un paño suave.

31

Page 32

Instalación del aparato

Uso del aparato bajo temperaturas fuera de los rangos recomendados puede

afectar el funcionamiento del aparato.

Vista Lateral

Vista Frontal

Panel Superior

Trasero

frente

Lado Lado

4”

1”

1”

1”

• Este aparata debe ser instalado por un profesional. Este aparato debe estar instalado en

conformidad con todas las regulaciones locales y estatales.

• Coloque la unidad en u n piso que sea l o suficientem ente fuerte para so portar la unidad cu ando

está completamente cargado. Para nivelar la unidad, ajuste las patas niveladoras en la parte

inferior de la unidad.

• Deje un espacio de un mínimo de 4 pulgadas entre la parte posterior y un mínimo de una

pulgada a los lados y panel s uperior d e la unidad , lo que per m ite la circ ulació n de aire nec esar ia

para enfriar el compresor y el condensador.

• Coloque la unidad l ej os de la lu z so lar directa y de fue ntes d e c a lor ( estufa, calentador, r adi ad or,

etc.) La luz solar directa puede afectar a la capa de acrílico y las fuentes de calor puede

aumentar el consumo eléctrico. Temperaturas ambientales extremadamente frías también

pueden causar que la unidad no funcione correctamente.

• Evite colocar la unidad en áreas húmedas.

Dimensiones requeridas para empotrar:

• La instalación de este aparato requiere una alimentación de agua por tubería de cobre flexible y

válvula de seguridad con una conexión de ¼ de pulgada.

• El aparato requiere una alimentación de agua continua con una presión de 15 psi y una presión

estática que no excede 80 psi. La temperatura de la alimentación debe estar entre 41ºF (5ºC) y

90ºF (32ºC).

Aviso

32

Page 33

Conexión eléctrica

~ PRECAUCIÓN ~

La conexión incorrec ta del conduc tor a tierr a puede re sultar en ries go de descar ga eléctrica. Si el

cable de alimentación de la estufa o aparato está dañado, hágalo cambiar por un centro de

servicio de Avanti Products.

Este aparato debe es tar correctamente conectado a tierra para su seguridad. El c able eléctrico de

este aparato está equipado con un e nchufe de tres patas que se acop la con las tom as de corriente

estándar de tres clavijas para minimizar la posibilidad de cho que el éc tric o.

Bajo ninguna circunstancia corte o quite la tercera clavija de tierra del cable de alimentación

suministrado. Para su seguridad personal, este aparato debe estar correctamente conectado a tierra.

Este aparato requiere un 1 15/120 Volt AC ~ / 60Hz enchuf e estándar de conexión eléctrica a tier ra

con tres clavijas. Haga revisar el tomacorriente y el circuito por un electricista calificado para

asegurarse que el tom acorriente está conectado a tierra correctam ente. Cuando se encuentra una

toma de corriente estándar de 2 patas, es su responsabilidad y obligación reemplazarlo por un

tomacorriente de 3 clavijas debidamente conectado a tierra.

El cable debe manten erse detrás del aparato y no dejó la vista ni colgando para prevenir les iones

accidentales.

El aparato debe ser conectado siempre en su propio contacto eléctrico individual que tenga un voltaje

que vaya de la placa de ca racterís ticas del aparat o. Esto pr oporciona e l mejor rendimiento y también

evitar la sobrecarg a de los circuitos e léctricos de la c asa que podrían causar un riesgo de ince ndio

por sobrecalentado. N unca desench ufe el apar ato tirando del cable de alim entación. S iempre agarre

firmemente el enchufe y tire derecho hacia afuera del tomacorriente. Repare o reemplace

inmediatamente todos l os cables eléctricos que se h ayan desgastado o daña do. No utilice un cable

que muestre grietas o rasp aduras en toda su longitud o en cua lquier extremo. Al m over el aparato,

tenga cuidado de no dañar el cable de alimentación.

Cable de extensión

Debido a peligros potenciales de seguridad bajo ciertas condiciones, se recomienda

encarecidamente que no se utilice un cable de extensión con este aparato. Sin embargo, si debe

utilizar un cable de extensión, es absolutamente necesario que sea un cable de UL / CUL 3 cables de

extensión con puesta a tierra con enchufe con toma de tierra y la salida y que la clasificación eléctrica

del cable sea de 115 voltios y al menos 10 amperios.

Protector contra sobretensiones

La mayoría de los aparatos eléctricos utilizan una serie de tableros de control eléctrico para

funcionar. Estas tarjetas son muy susceptibles a sobretensiones y podrían resultar dañados o

destruidos.

Si el aparato no va a s er ut il i zado en un área o si s u c i udad / país es propenso a s ubid as de t e nsió n /

interrupciones; se sugiere que utilice un protector contra sobrecargas de energía para todos los

dispositivos / aparatos e léctric os que esté tomando. El es tabili zador de te nsión q ue usted selecc ione

debe tener un bloqueo suf i c ientemente alto como para prote ger el aparato está conectado a. Si usted

tiene alguna pregunta relacionada con el tipo y tamaño de protector contra sobretensiones es

necesario ponerse en contacto con un electricista cualificado en su área.

Los daños debidos a las sobrecargas de energía no se consideran un defecto cubierto por el

fabricante y anulará la garantía del prod uc to.

33

Page 34

Alimentación de agua

El aparato requiere una alimentación de agua continua con una presión de 15 psi y una presión

estática que no excede 80 psi. La temperatura de la alimentación debe estar entre 41ºF (5ºC) y

90ºF (32ºC).

IMPORTANTE:

1. Se recomienda instalación por un profesional. Todas las conexiones deben estar en conformidad

con las regulas y regulaciones locales y estatales.

2. Este seguro que las mangueras no están dobladas o comprimidas durante la conexión.

3. Después inspecciona que no hay goteras de las conexiones.

Herramientas necesarias: Llave de boquilla abierta de ½”, destornillador tipo Phillips ( + ).

Como conectar la tubería de alimentación de agua:

1. Apag ar la válvula princip al del suministro de agua. Abre el g rifo para vaciar la tu bería de

suministro, cuando la tubería este vacía cierre el grifo.

2. Bus c a una manguera (½” o ¾”) en pos ici ón ver tic a l cer ca del área de instalación. La distancia del

aparato debe ser menos de 6 pies. La manguera que está incluida con el aparato mide

aproximadamente 6 pies.

3. Requiere una válvula de seguridad conectada al suministro principal de agua.

4. Enr osca un lado de la m anguera al grifo y enrosca el otro lado al aparat o. Apriete con la m ano y

luego con la llave.

5. Abr e la válv ula e inspecciona por goteras en las conexiones.

34

Page 35

Desagüe

Debe conectar la línea de drenaje antes de usar la fábrica de hielo. Siga los pasos descritos a

continuación.

Hay dos tipos de modos de máquina de hielo, uno que drena por gr av eda d y otro que tiene una

bomba de drenaje interna.

Esta unidad puede bombear agua hasta una altura de 1,5 m (59 ") o sobre una longitud horizontal de

1,5 m (59").

Conexión de la línea de drenaje:

NOTA: Si hay una línea de drenaje cerca de la fábrica de hielo, la mejor opción es drenar el agua a la

línea de drenaje a través de la manguera de agua de drenaje provista con la máquina de hielo.

1. Ubique el drenaje del piso cerca de la fábrica de hielo. La distancia debe ser inferior a 5 pies ya que

la longitud de la manguera de agua de drenaje larga pr ovista con la fábric a de hielo es de

aproximadamente 5 pies.

2. Busque la salida de drenaje en la parte posterior de la fábrica de hielo. Conecte la salida de drenaje

a la manguera de drenaje de agua e inserte el otro extremo de la manguera en la línea de

drenaje.

NOTA: Nunca permita que la manguera de drenaje cuelgue o se enrolle más alto que el piso del hielo

cesta de almacenaje.

3. Todas las líneas horizontales de las líneas de drenaje deben tener una caída de ¼ "por pie. Es

probable que se requiera un espacio de aire entre el tubo de drenaje de la fábrica de hielo y el

receptáculo de drenaje / desechos. Una tubería vertical con una trampa debajo sería aceptable

para el receptáculo de drenaje / desechos. Un drenaje de piso también es aceptable. Si esto no

es posible, se recomienda el uso de una bomba de condensado.

4. Vierta 1 galón de agua en el depósito de hielo para verificar si hay fugas en el sistema de drenaje.

Apriete cualquier conexión que tenga fugas.

IMPORTANTE: Esta fábrica de hielo no es un congelador. El drenaje poco frecuente causará una alta

tasa de fusión en el depósito de hielo.

35

Page 36

Los componentes del sistema de drenaje de agua de bombeo son

Interruptor de nivel de agua 2

Interruptor de nivel de agua 1

NOTA:

AVISO!

• Depósito de agua Tarjeta de PC e interruptor de nivel de agua 1, 2

• Bomba de drenaje de agua

OPERACIÓN

• Toda el agua que proviene del desbordamiento y el hielo derretido se recoge en el

depósito de agua.

• Tan pronto como el agua en el depósito alcanza el nivel máximo, el interruptor de

nivel de agua 1 se cierra y transmite una corriente de bajo voltaje a la tarjeta de PC.

• La placa de PC activa la bomba de drenaje de agua durante 20

segundos, bombeando la mayor parte del agua contenida en el

depósito de agua.

• • El agua se puede bombear hasta una altura de 1,5 m (59 ") o

o sobre una longitud horizontal de 1,5 m (59").

• Si el interruptor de nivel de agua 2 se cierra, transmitiendo una

corriente de bajo voltaje a la placa de PC, la placa de PC activa el

La salida de la manguera de

drenaje debe elevarse más

alto que la superficie del

agua para evitar que el agua

drenada regrese al depósito

de agua.

Si suena el timbre de la

alarma, apague la fábrica

de hielo y el suministro de

agua, retire todo el hielo

del depósito de

almacenamiento y limpie el

agua que pueda haberse

desbordado. Verifique si

hay agua en el canal de

agua en la parte posterior

de la unidad; Si no hay

agua, la bomba de drenaje

puede no estar recibiendo

la cantidad adecuada de

energía. Verifique la fuente

de energía. Si se puede

corregir el problema,

encienda la unidad

nuevamente. También

verifique que ninguna de

las líneas de agua esté

doblada. Si el problema

persiste, comuníquese con

el Servicio al cliente.

36

Page 37

alarma del zumbador, informándole que la bomba de drenaje, el interruptor de nivel de agua o el tubo

de drenaje pueden estar funcionando mal.

37

Page 38

FUNCIONAMIENTO DEL APARATO

+

_

Descripción de las luces y botones:

1. Bin Full (Rojo)/(Gaveta llena):

Indica que la gaveta está llena y no continuará haciendo hielo.

Cuando este alumbrado, significa que la gaveta de almacenaje está llena. La unidad parará de

hacer hielo hasta que se remueve hielo de la gaveta o se derriten lentamente los cubos.

Cuando el nivel de cubos se baje, la luz roja titilará por aproximadamente 3 minutos y el aparato

regresará al proceso de hacer hielo.

2. Ice Making(Verde)/(Haciendo Hielo):

Indicador que el aparato está en el proceso de hacer hielo.

Cuando este encendido el aparato está en proceso de hacer hielo.

3. Ice Harvest (Amarillo)/(Guardando Hielo):

Cuando esté encendido, significa que el aparato esté en el proces o de pasar los c ubos de hielo

del evaporador hacia la gaveta de almacenaje.

4. Mode (Modo): Prim ariamente usado para empezar el proc eso de hacer hielo o para servicio y

reparación. Oprime el botón para cambiar el proceso entre hacer hielo y guardar hielo.

5. Adjust (Ajuste): Primariamente usado para servicio. Oprime el botón por aproximadamente 3

segundos para cambiar el tamaño de los cubos.

Como cambiar el tamaño de los cubos:

1. Oprime el botón por aproximadamente 3 segundos. El aparato entrará en modo de ajuste. La luz

indicadora amarilla titilará continuo durante la selección del tamaño de los cubos.

2. Mientras que titila la luz amarilla oprime el botón marcado “Clean” ( - ) o “Mode” ( + ) para

seleccionar el tamaño deseado.

38

Page 39

Cubos de tamaño pequeño:

Gaveta llena

Hacer hielo

Guardar hielo

Oprime el botón marcado “Clean” ( - ) hasta que alumbre la luz verde para seleccionar cubos

pequeños.

Cubos de tamaño grande:

Oprime el botón marcado “Mode” ( + ) hasta que alumbre la luz roja para seleccionar cubos grandes.

Después de 10 segundos el aparato volverá al proceso de hacer hielo automáticamente.

NOTA:

• Si durante el proceso d e seleccionar el tam año de los cubos se alum bran las (3) tres luces a la

vez, esto indica que el tamaño mediano está seleccionado.

• Cuando el aparato es té en el proceso de autolimpieza, no perm ite ningún cambio a la selección

del tamaño de los cubos.

Como hacer hielo:

1. Abre la válvula, oprime el b otón m arcado O N/OF F para encend er la un idad y deje que el canalón

se llene de agua. El aparato empezará automáticamente. (El indicador ICE – Verde titilará)

2. Después de 3 minutos, el aparato empezará hacer hielo y escuchará el sonido de agua fluyendo.

3. Oprime el botón marcado MODE para em pezar el proceso de hacer hielo si no ha em pezado

automáticamente. (El indicador ICE – Verde titilará).

4. Cuando el hielo está formado completamente, los cubos caerán hacía la gaveta de almacenaje.

5. Cuando la gaveta de almacenaje esté llena, el aparato parará de hacer hielo automáticamente.

6. El aparato volverá hacer hielo cuando se remueve los cubos de la gaveta o se derriten

lentamente.

IMPORTANTE:

• Se recomienda botar los primeros cubos pr oducido después de instalación.

• Nunca cierre la válvula mientras que la unidad esté produciendo hielo.

• Nunca tocar el evaporador mientras que la unidad esté produciendo hielo

• Mantener la puerta cerrada para evitar que el hielo se derrita y asegurar función eficie nte del

aparato.

39

Page 40

CUIDADO Y MANET ENI MI EN T O

Desconecte la unidad de la tomacorriente y cierre la válvula antes de proceder con la

limpieza y mantenimiento de la unidad.

Posición correcta de

Como limpiar el aparato.

Si la máquina de hielo no se usa durante mucho tiempo, antes del próximo uso debe limpiarse a

fondo. Siga cuidadosamente las instrucciones proporcionadas para la limpieza o el uso de soluciones

desinfectantes. No deje ninguna solución dentro de la fábrica de hielo después de la limpieza.

Limpieza rutina asegurará eficiencia de función y v

Nota importante:

Nunca almacene artículos en la gaveta de almacenaje, el aparato no es un

congelador. Objetos como botellas de vino o cerveza no son sanitarios y las

etiquetas de las botellas pueden mojarse y caerse causando bloqueo en la

manguera de desagüe.

Limpieza de las partes exteriores

La puerta y el gabinete se pueden limpiar con una solución de un detergente suave y agua tibia (por

ejemplo 1 oz de jabón de lavar platos con 2 galones de agua tibia). No utilice químicos de limpieza

con solventes o abrasivos. Utilice una esponja suave y enjuague con agua lim pia.

Limpieza del parte interior

Se recomienda desinfectar y limpiar la gaveta de almacenaje frecuentemente. Limpie el canalón de

agua la primera vez que se usa y también después de tiempos largos sin uso.

1. D esc onec ta la unidad del tomacorriente.

2. R emueva el hielo y limpia el interior de la unidad c on una solución de 1 oz de clor o y 2 galones

de agua caliente.

3. R emueva la manguera de desagüe del interior de la unidad.

4. Enjuague con agua limpia.

5. D espués de drenar la unidad, inst ale la manguera de desagüe en s u

posición original (ver imagen).

6. Conecte la unidad al tomacorriente.

la manguera de

desagüe

40

Page 41

Como limpiar el condensador

Condenser

Surface

Un condensador sucio impide la circulación del aire y reduce la capacidad de hacer hielo, y causa

elevación de las temperaturas operativas que puede resultar en daños. Debe de limpiar el

condensador cada seis meses.

1. D esc onec te la unidad del tomacorriente.

2. Remueva la parrilla delantera.

3. Limpia el condensador con una aspiradora con broche

4. Instala la parrilla delantera

5. C onecta la unidad al tomacorriente, la unidad volverá a

funcionar automáticamente.

Fallo de alimentación

Usualmente la electric idad regresa en unas pocas hor as sin afectar la temperatura de su aparato,

siempre que la puerta no se abra muy frecuentemente. Si le va a faltar electricidad por un período de

tiempo más largo, usted debe tomar los pasos apropiados para proteger sus alimentos.

Tiempo de vacaciones

Vacaciones cortas: Deje la unidad en funcionamiento durante las vacaciones de menos de tres

semanas.

Vacaciones largas: Si e l aparato no va a utili zar durante varios m eses, retire todos los alim entos y