Page 1

www.avantiproducts.com

O

■o

■

3

O

iS

c5

00

MODEL

H2311W

H2312SS

■o

C

03

C)

O

C)

(/)

Model number:

Serial number:

08/05 Rev:1 ® Avanti

Page 2

www.avantiproducts.com

Page 3

j2

INSTALLATION

Specifications

FEATURES & CONTROLS

Controls Overview.

MAINTENANCE

Cleaning

Lights......................

TROUBLE SHOOTING

.................

..............

...2

...3

...4

...5

6

...7

...8

...9

...10

...11

...12

...12

...13

...14

...15-16

c

0)

c

o

o

o

0)

(0

Page 4

READ AND SAVE THESE INSTRUCTIONS

WARNING

8

TO REDUCE THE RISK OE EIRE OR ELECTRIC SHOCK, DO NOT US E THIS LAN WITH ANY SOLID-STATE

SPEED CONTROL DEVICE.

WARNING

TO RE DUCE THE RISK OE EIRE, ELECTRIC SH OCK, OR INJURY TO PERSONS, OBSERVE THE EOLLOWING:

a. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

b. Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent power from being

switched on accidentally.

When the service disconnecting means cannot be locked, securely fasten a prominent warnintj device, sucfi as tag, to thr; service; panel.

www.avantiproducts.com

'c5

(/>

t

0)

c

(0

o

D.

E

CAUTION

Eor General Ventilating Use Only. Do not Use to Exhaust Hazardous or Explosive Materials and Vapors.

Take care when using cleaning agents or detergents.Suitable for use in household cooking area.

WARNING

TO REDUCE THE RISKOE A RANGE TOP GREASE EIRE:

a. Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite. Heat oils slowly on low

or medium settings.

b. Always turn hood ON when cooking at high heat or when cooking flam being food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn

Beef Elambe)

c. Clean ventilatincj fans frequently. Grease; shoulcJ not be; allowecJto accumulate; on fan or filter

d. Use proper pan size. Always use cookware appropriate;for the size of the surface element.

e. Keep fan, filters and grease laden surfaces clean.

f. Use high setting on hood only when necessary.

g. Don’t leave hood unattended when cooking.

h. Always use cookware and utensils appropriate for the type of and amount of food

being prepared.

WARNING

TO REDUCE THE FilSKOE INJURY TO f^ERSONS IN THE EVENT OE A RA NG E TOP GREASE EIRE, OBSERVE THE EOLLOWING:

a. SMOTHE R ELAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the burner. BE CARE EUL TO PREVENT BUR NS.

If the flames do not go out immediately, EVACUATE AND CALL THE EIRE DEPARTMENT.

b. NEVER PICK UP A ELAMING PAN - You maybe burned.

c. DO NOT USE WATE R, including wet dishclothes or towels - a violentsteam explosion will result.

d. Use an extinguisherONLY if:

1. You know you have a class ABC extinguisher, and you already know howto operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire withyour back to an exit.

5. Based on "Kitchen Eire Safety Tips" published by NEPA.

WARNING .

TO REDUCETHE RISKOE EIRE, ELECTRIC SHOCK OR INJURY TO PERSONS, OBSERVE THE EOLLOWING:

a. Installation Work and Electrical Wiring Must be Done by Oualified Person (s) In Accordance with all Applicable Codes and Standards,

Including Eire-Rated Construction.

b. Sufficient air is needed for proper combustionand exhausting of gases throughthe flue (chimney) of fuel burningequipmen1:to prevent back

drafting, follow the heating equipmentmanufacturer's guideline and safety standards such as those published by the National Eire Protection

Association (NEPA), and the American Society for Heating, Refrigeration, and Air ConditionincjEngineers (AS HRAE) and the local code authorities

c. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

d. Ducted fans must always venttothe outdoors.

e. Ifthis unit is to be installed over a tub or shower, it must be marked as appropriate for the

application and be connected to a GFCL (Ground Fault Interrupter protected branch circuit).

g. NEVER place a switch where it can be reached from a tub or shower.

h. Make sure the power is off before installing, wiring or maintenancing.

WARNING

TO REDUCE THE RISKOE EIRE, USE ONLY METAL DUCTWORK.

CAUTION

To reduce risk of fire and to properijrexhaust air, be sure to duct air outside - Do not vent exhaust air into spaces within walls or ceilings or into

attics, crawl spaces or garages.

Page 5

1 - Hood

2-Light bulbs, 40W R16

2 - Metallic Mesh Filters

1 - 3 1/4” X 10” rectangular starting collar with damper

1 - Air Recirculation Kit (pre-installed)

1 - Charcoal Filter

1 - Air Diverter Plate (must install for use in ducted mode)

1 - Charcoal Filter Holder

1 - Air Recirculation Louver Plate

1 - Air recirculation Cover Plate (for use in ducted mode)

1 - Hardware packet containing:

3 - Wire connector caps 18g

4 - Wood Screws 2”

4 - Wood Screws 1 1/2”

4 - Wood Screws 1 ”

4 - Washers

N0 DUCTING IS INCLUDED

(0

0)

IS

s

o

%

* Note:

but are readily available at most hardware stores.

Use 50LB EZ anchors if mounting hood onto drywall. These are not provided,

Page 6

(/>

0)

0)

c

o

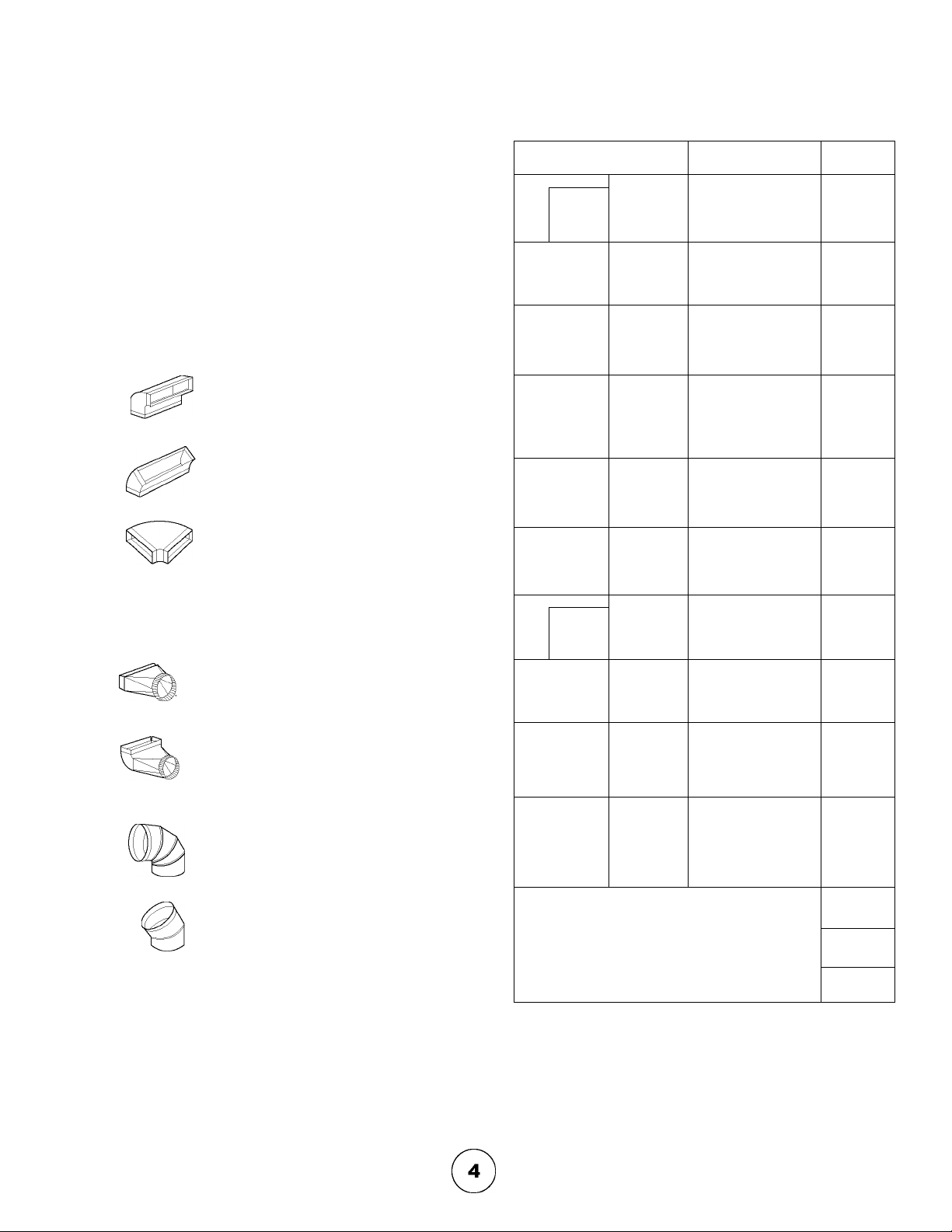

Duct Attachments Not Included

Duct pieces

3 1/4" X 10"

Rect.,

straight

7" Round,

straight

Equivalent number

length X used =

1 Ft. X (

1 Ft. X (

Total

Ft.

Ft.

Duct pieces

c

www.avantiproducts.com

6" Round

wall cap

with damper

6" Round,

roof cap

Equivalent number

length X used =

30 Ft. x( ) =

30 Ft. x( ) =

Total

Ft.

Ft.

o

1

Ü

Q

3

Ü

(0

0

o

7" Round,

straight

3 1/4" X 10"

Rect. 90 "

eibow

3 1/4" X 10"

Rect. 45 "

eibow

3 1/4" X 10"

Rect. 90 "

fiat eibow

1 Ft.

15 Ft.

9 Ft.

24 Ft.

3

3 1/4" X 10"

I

c

c

Rect.

waii cap

with damper

3 1/4" X 10"

Rect. to

6" round

transition

3 1/4" X 10"

Rect. to

6" round

transition

90° eibow

6" Round,

90° eibow

30 Ft.

5 Ft.

15 Ft.

15 Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

c

«a.

6" round to

3 1/4" X 10"

rect.

transition

6" round to

3 1/4" X 10"

rect.

transition

90° elbow

7" Round,

90° elbow

7" Round,

45° elbow

7" Round

wall cap

with damper

7" Round,

roof cap

7" round to

3 1/4" X 10"

rect.

transition

7" round to

3 1/4" X 10"

rect.

transition

90° elbow

1 Ft. X ( ) =

16 Ft. x( ) =

15 Ft. x( ) =

9 Ft. x( ) =

30 Ft. x( ) =

30 Ft. x( ) =

8 Ft. x( ) =

15 Ft. x( ) =

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

6" Round,

45° eibow

9 Ft.

Subtotal column 1 =

Maximum Duct Length: For satisfactory air movement,

the totai duct iength of a 3 1/4"x 10" rectangular, 6" or 7"

diameter round duct shouid not exceed 100 equivalent feet.

Ft.

Ft.

Subtotal column 2 =

Subtotal column 1 =

Total ductwork =

Ft.

Ft.

Ft.

Page 7

Minimum mount height between range top to hood bot

tom shouid be no iess than 24".

Maximum mount height shouid be no higher than 32".

0)

o

c

DUCTING

A minimum 3-1/4 x 10"rectanguiar duct

must be used to maintain maximum air

fiow efficiency.

it is important to instaii the hood at the proper mounting

height. Hoods mounted too iow couid resuit in heat

damage and fire hazard; whiie hoods mounted too high

wiii be hard to reach and wiii iose its performance and

efficiency.

if avaiiabie, aiso refer to range manufacturer's height

ciearance requirements and recommended hood

mounting height above range. Aiways check your iocai

codes for any differences.

Cut Out Size

24" 23 3/4"

Minimum Duct Size:

Rectangular- 3-1/4 x 10" minimum

(rear or top)

Net Width

s

(5

_g>

O

o3

U)

'o

U)

c

c

3

o

c

o

Aiways use rigid type metai ducts oniy.

Fiexibie ducts couid restrict air fiow by up

to 50%.

Use caicuiation worksheet to compute totai

duct work.

ALWAYS, when possibie, reduce the number

or transitions and turns, if a reducer is used,

instaii a iong reducer instead of a pancake

reducer. Reduce duct size as far away from

opening as possibie.

if turns or transitions are required:

instaii as far away from opening and as far

apart, between 2, as possibie.

DAMAGE-SHIPMENT/INSTALLATION:

• Piease fuiiy inspect unit for damage

before instaiiation.

if unit is damaged in shipment, return

the unitto the store in which it was

bought for repair or repiacement.

if the unit is damage by the customer,

repair or repiacement is the

responsibiiity of the customer.

if the unit is damage by the instaiier (if

other than the customer), repair or

repiacement must be made by

arrangemnt between customerand

instaiier.

%

c

Page 8

www.avantiproducts.com

Q

D)

C

0

3

1

c

o

c

WARNING FIRE HAZARD

NEVER exhaust air or terminate duct work into spaces between waiis, crawi spaces, ceiiing.attics or garages.

Aii exhaust must be ducted to the outside, uniess using the recircuiating option.

Use singie waii rigid Metai ductwork oniy.

Fasten aii connections with sheet metai screws and tape aii joints w/ certified Siiver Tape or DuctTape.

Some Ducting Options:

cabinet

air recircuiation

A

/p:

3 1/4" X 10" rear discharge

w/side waii gravity damper

■Tn

Page 9

Installation - Specifications

Page 10

Q

"O

www.avantiproducts.com

D)

C

o

3

c

(0

15

o

o

_g>

LU

(0

c

o

0

3

D?

c

1

c

o

1. Remove filters.

3. If using a cable lock (not provided) pry

open the desired electrical knockout, either

on the top or the back. Feed the wires

through the 3/4” cable lock. Note: Some

local codes require the use of a cable lock

check your local codes for this information.

'2.. Remove two phillips head screws and

cover from junction box to gain access

to eiectricai wiring.

4. If using hood in air recirculation mode,

skip steps 4 and 5.

Pry open the desired 3 1/4x 10”

ducting knockout, either on the top or the

back.

Cable lock example

lo

c

5. Attach the 3 1/4” X 10 starting collar

with damper to the duct opening you

exposed.

8

Page 11

If using hood in air recircuiation mode, skip these steps

0)

"O

o

"O

0)

0

3

Q

1

1. Pull up and twist the two spring loaded

clips around the carbon filter holder.

3. Insert air diverter plate and screw

into place.

2. Remove the carbon filter and carbon

filter holder.

4. Remove the air recirculation louver plate

on top of the hood.

c

o

c

5. Finally, attach the cover plate to the

top of the hood.

Page 12

www.avantiproducts.com

"O

ELECTRICAL-WARNING

o

o

0)

D)

c

c

3

o

c

All Electrical work must by performed by qualified

electrician or person with similar technical know how

and background.

For personal safety, remove house fuse or open circuit

breaker before beginning Installation.

Do not use extension cord or adapter plug with

this appliance.

Follow National electrical codes or prevailing local

codes and ordinances.

Electrical Supply:

This appliance requires a 120V 60Hz electrical supply.,

and connected to an Individual, properly grounded branch

circuit, protected by a 15 or 20 ampere circuit breaker or

time delay fuse. Wiring must be 2 wire w/ ground. Please

refer to Electrical Diagram labeled on product. You must

be a qualified technician ora service personnel to Install

this unit.

1. Temporarely position the hood in the

desired mounting location. Measure and

mark the mounting holes, duct and electri

cal access locations with a pencil. Remove

hood and drill/cut out the requirred open

ings for duct and electrical access.

o

c

2. Attach house electrical wiring to

hood wiring. Make sure the power source

is turned off before working with any

electrical wiring.

4. Attach duct work. Use aluminum duct

tape to make joints secure and air tight.

NOTE: This step is not necessary if hood is

in air recirculation mode.

3. Hang hood from mounting screws

provided. Slide hood toward wall until

mounting screws are engaged in narrow

end of keyholes. Tighten mounting screws

securely. CAUTION: Do not push on safety

grill when installing, this may result in

damage to the motor.

5. If not already done, install light bulbs by

screwing in clockwise.

10

Page 13

Blower On/Off/Speed Selection ^ Lights On/Off/Dim

o>

t

0)

>

O

o

^ Blower On/Off/Speed Selection

This switch turns the blower on and off and controls the speed selection.

0 is off, I is low speed, II is medium speed and III is high speed.

^ Lights On/Off/Dim

0 is off, I is bright, II is dim.

c

o

0

1

o

c

o

o

o8

tf>

0)

(0

0)

11

Page 14

www.avantiproducts.com

j5

"O

(0

3

U)

U)

c

o

a.

0)

c

(0

U)

c

Aluminum Mesh Filters:

Clean frequently using hot water and a mild, non abrasive detergent. Filters are dishwasher safe.

Carbon Filters:

Clean carbon filters holder frequently with a damp cloth and mild detergent. DO NOT Immerse carbon filter In water

or put In dishwasher. The carbon filters should be replaced every 4to6 months under normal use.

Hood Surface:

Remove filters. Use a damp cloth and a mild detergent to wipe all residue-laden surfaces. Use care when cleaning fan

blades, It must not become bent or misaligned. DO NOT ALLOW WATER TO ENTER MOTOR. Make sure surfaces

are completely dry before re-lnstalling filters and using hood.

Replacing Light Buibs:

CAUTION: Light bulbs become extremely hot when turned on. DO NOT touch bulbs until switched off and cooled.

Touching hot bulbs may cause serious burns.

Hood comes with (2) 40W medium base. Incandescent appliance bulbs.

Remove bulb by unscrewing counter-clockwise. Use a suction cup or rubber/latex glove to grip the bulb If removing bulb

Is difficult.

_0)

o

c

(0

0)

o

c

(0

c

0)

c

CO

12

Page 15

I. Upon completion of installation

nothing works.

Check if unit has been plugged in, make sure that all power has been

turned back on and all electrical wiring are properly connected.

D)

C

2. Light is on but blower is not

turning at all or seems to be

scraping on something.

3. When blower is on,

something seems to be loose

and spinning around inside.

4. Vibration when blower is on Unit might not have been secured properly on cabinet. Or cabinet

5. Blower noise Our blowers are designed to perform up to 280 cfm. A properly

6. Light is not working Light bulb might need to be replaced. On some instances, the fragile

7. Blower seems \A/eak Check duct size used, duct size should be at least 3 1/4" x lO".

Blower blade unit might have been mounted too low and scraping

the bottom or jammed. Loosen hex screw on blade unit and adjust to

proper height.

There might have been foreign particles left within the discharge

opening or rocks, leaves, branches, etc. that might have fell in from

old duct work. Disconnect duct work to inspect and remove any

foreign particles.

might need to be further secured into studs on wall.

functioning motor itself should be relatively quiet. Nevertheless, due

to vacuum created by the suction, noise level up to 4 sones will be

generated when blower unit is turned on at its maximum speed.

Employing low speeds will suffice moderate cooking such as steam

ing, broiling etc.

bulb could have been damaged during the shipping process.

Replace light bulb.

Range hood WILL NOT function properly with the insufficient

duct size.

Check if duct is clogged or if dumper unit is not opening properly. A

tight mesh on a side wall cap unit might also cause restriction to the

air flow.

Use a damper type sidewall cap.

Reduce the number of elbows and length of duct work or increase

duct size.

Check if all joints are properly connected, sealed and taped.

o

o

(/>

o

3

o

8. Cooking fumes and smoke

dissipates before it reaches

the blower.

Check if unit is installed at the recommended height. The range hood

should also be able to cover the entire cooking area from left to right

and most areas from rear to front.

Open doors and windows might also distract air flow before it reach

es the blower.

Make sure blowers are on high speed for heavy cooking.

13

Page 16

www.avantiproducts.com

C

SH

(5

TO OBTAIN SERVICE UNDER WARRANTY:

or any Service Related Questions, please call:

1-800-220-5570

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

TO OBTAIN SERVICE UNDER WARRANTY: You must present proof of original purchase date.

Please keep a copy of your dated proof of purchase (sales slip) in order to obtain service under warranty.

One Year Service Repair Warranty:

For one year from date of original purchase, we will provide free of charge, service labor to repair any failed parts or

components due to manufacturing defects.

Two Year:; Part:; Warranty:

Fortwoyears from date of original purchase, we will provide free of charge, nonconsumable replacement parts or

components that failed due to manufacturing defects. Consumable parts not covered by this warranty include: Light Bulbs,

Metal and Carbon Filters.

Who is Covered:

This warranty is extended to the original purchaser for products purchased for ordinary home use in the 48 mainland states,

Hawaii and Washington D.C. In Canada and Alaska, this warranty Is Limited. There might be costs associated with

shipping the products to our designated service locations or you might need to pay service technician's travel costs, to have

the appliance repaired In-home.

This Warranty will be Voided when:

Product damaged through negligence, misuse, abuse, accident. Improper installation and failure to follow installation instruc

tions. When product is used commercially or other than its intended purpose. Damaged because of improper connection with

equipment of other manufacturers. Repaired or modified by anyone other than Avanti's Authorized Agents.

What is Not Covered:

Consumable parts such as light bulbs, filters, and fuses. Services outside of service area and the labor cost incurred in

connection with the removal, shipping and reinstallation cost, nor does it cover any other contingent expenses. The natural

wear of finish, and wear due to improper maintenance, use of corrosive and abrasive cleaning products, pads, and oven

cleaner products. Chips, dents or cracks due to abuse, misuse, freight damage, or improper installation. Service trips to your

home to teach you how to use the product. Damage of product caused by accident, fire, floods or act of God.

This warranty is valid in the United States and Canada. It is non-transferable and applies only to the original purchaser and does not extend to

subsequent owners of this product. Any applicable implied warranties, including the warranty of merchantability, are limited in duration to a period

of express warranty as provided herein beginning with the date of original purchase at retail and, no warranties, whether express or implied, shall

apply to this product thereafter.

Have your product proof of purchase with date ready for warranty issues.

Or write to:

Customer Service

Avanti Products

10880 NW ;50 Street

Miami, FL 331712

Page 17

(Jl

o

<

o

iD

o

U1

7J

(D

<

!=C!

IND

CO

, ro

ro o>

Exploded View Diagram - H2311W/ H2312SS

Page 18

CO

CM

(0

0

n

E

t:

(C

Q.

www.avantiproducts.com

H2311W

Spare Parts List

Ref# Part#

1

3

4

5

6 HXP001211-27 Motor Holder 1

7

8

10

11

12

13 XP018133-2

14

15 XP018133-4 Carbon Filter Grille 1

16

17

18

19

20 XP01868-14 Slide Switch Gasket-B (Fan) 1

21

26

28 XP02802-4 Capacitor 4.5uf/300v 1

29

30 XP02901-2 Light socket, left 1

40 XP13804-1 Light Bulb, R14,120V 40W 2

41

42

43

44

45 XP14438-7

46 XP14444 Light cover 2

52

53

54

61 XP22302 Carbon Filter 1

63

64

65

66

M033

HXP001211-13

HXP001211-16 Left side panel

HXP001211-19 Right side panel

XP00613

XP00613-1

XP018111 Residue Secure Switch

XP018133

XP018133-1

XP018133-3 Residue Pan

XP01868

XP01868-03

XP01868-06

XP01868-09

XP021174-2

XP02746-3 Electrical wires

XP02901-1

XP14438-1

XP14438-2

XP14438-3

XP14438-4

XP164190-05A

XP164190-29 Top Cover Plate

XP164190-33

XP26501 Fan Blade

XP26601

XP26603 Fan Blade cover panel

XP26701-1 Metal Filter

Description

per Hood

Motor 1

Support Panel 1

Slide switch, motor 1

Slide switch, light 1

Air diverter panel 1

Air diverter panel cover 1

Blowerwheel cover

Slide Switch Gasket-W (Light) 1

Slide Switch Stem - W (Fan) 1

Slide Switch Stem - W (Light) 1

Switch Spacer 1

Decal

Light socket, right 1

Junction Box Cover 1

Control Cover

Light Housing 2

Blowerwheel

Air Recirculation cover plate (W)

Hood Body

Light Panel (W) 1

Rectangular Starting Collar 1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

Page 19

www.avantiproducts.com

H2312SS

Spare Parts List

Ref# Part#

1

3

4

5

6 XP001211-27 Motor Holder 1

7

8

10

11

12

13 XP018133-2 Blower wheel cover 1

14

15 XP018133-4 Carbon Filter Grille 1

16

17

18 XP01868-07 Slide Switch Stem - B (Light) 1

19

20 XP01868-12 Slide Switch Gasket-B (Fan) 1

21

26

28 XP02802-4 Capacitor 4.5uf/300v 1

29

30 XP02901-2 Light socket, left 1

40 XP13804-1

41

42

43

44

45

46 XP14444 Light cover 2

52

53

54

61 XP22302 Carbon Filter 1

63

64

65

66

M033

XP001211-13

XP001211-16 Left side panel

XP001211-19 Right side panel

XP00613

XP00613-1

XP018111 Residue Secure Switch

XP018133

XP018133-1

XP018133-3 Residue Pan

XP01868-01

XP01868-04 Slide Switch Stem - B (Fan) 1

XP01868-10

XP021174

XP02746-3 Electrical wires

XP02901-1

XP14438-1

XP14438-2

XP14438-5

XP14438-4 Blower wheel 1

XP14438-6

XP001211-02

XP001211-28 Top Cover Plate

XP001211-32

XP26501 Fan Blade

XP26601

XP26603 Fan Blade cover panel

XP26701-1 Metal Filter

Description

per Hood

Motor 1

Support Panel 1

Slide switch, motor 1

Slide switch, light 1

Air diverter panel 1

Air diverter panel cover 1

Slide Switch Gasket-B (Light) 1

Switch Spacer 1

Decal

Light socket, right 1

LightBulb, R14,120V40W

Junction Box Cover 1

Control Cover

Light Housing 2

Air Recirculation cover plate (B) 1

Hood Body

Light Panel (S)

Rectangular Starting Collar 1

CO

CO

CM

CO

CM

1

1

(0

0

n

E

2

t:

1

1

1

2

1

1

1

1

1

1

2

(C

CL

Loading...

Loading...