Page 1

Model Numbers:

GR-20

DGR-21A

GAS RANGE

INSTRUCTION MANUAL

CAUTION:

BEFORE USE, PLEASE READ AND FOLLOW ALL SAFETY RULES AND OPERATING

INSTRUCTIONS.

Avanti Products, A Division of The Mackie Co., Inc.

P.O. Box 520604 - Miami, Florida 33152

www.avantiproducts.com

Page 2

IMPORTANT SAFETY INSTRUCTIONS

Gas ranges have been thoroughly tested for safe and efficient operation. However, as with any

appliance, there are specific installation and safety precautions that must be followed to ensure safe

and satisfactory operation.

WARNING

To reduce the risk of fire, electrical shock, or injury when using your gas range, follow these

precautions:

• Read all instructions before using this appliance.

• Grounding instructions

This appliance must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of an electrical shock. This appliance is equipped with a three-prong cord

with a ground plug. Do not, under any circumstances, cut or remove the ground prong from

the power cord supplied with this appliance. This appliance must be plugged into an outlet

that is properly grounded. Do not use an adapter plug. Using an extension cord is not

recommended. Consult a qualified electrician for any questions as to whether your home or

business has the proper electrical grounding connections.

• Child Safety

An empty appliance can be a dangerous attraction to a child. Never allow children to play

with or crawl inside the appliance. Remove the door, door gasket, latches, or lids before

storing or abandoning the appliance.

• Never clean the appliance with flammable liquids. The fumes can create a fire hazard or

explosion.

• Do not store or use gasoline or other flammable products in the vicinity of this appliance. The

fumes can create a fire hazard or explosion.

A WARNING

Tip Over Hazard

Connect anti-tip bracket to the range back.

Reconnect anti-tip bracket if the range is moved.

Do not push down on the open oven door.

Follow the installation instructions.

Do not let children climb onto the oven door.

Failure to do so can result in death, burns, or other injury.

For more information see Anti-Tip Bracket Installation on Page 7.

A WARNING: If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

-Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

(3) Open windows.

CD Do not try to light any appliance.

(D Do not touch any electrical switch; do not use any phone in your building.

CD Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

(D If you cannot reach your gas supplier, call the fire department.

- A qiialifipri installnr Rprvir.p agr^nny nr thn gas siippljnr nnnc;i pnrfnrm in.«itallRtinn anr|

service.

Page 3

Table’of Contents

Important Safety Instructions,

Before Using Your Gas Range

Installation Requirements for Your Gas Range

Material Requirements

Space Requirements

Gas Requirements________________________

Electrical Requirements

Installation of Your Gas Range

Leveling of Range

Backguard

Anti-Tip Bracket,

Gas Connection

Electrical Connection

Mobile Home Installation

Operating Your Gas Range,

Operation of Surface Burners

To Light the Desired Surface Burner,

Operation of Oven Burner

Using Your Oven

Oven Light

CIock/Timer

Broiler Burner {DGR-21A Only)

Care and Maintenance ______

Removing Door for Cleaning

Cleaning Your Oven

Cleaning the Knobs and Control Panel

Cleaning the Utensil Supports, Cooktop, Backguard, and Surface Burners,

Converting Gas Type __________________________________________________

Pressure Regulator____________________________________________________

Burner Valves

Surface Burners.

Oven Burners

Broiling Burner {DGR-21A Only)

Troubleshooting Guide

Service For Your Gas range,

Your Avanti Products Warranty

Warranty Information and Registration Card

Help Us Help You

Parts and Features

Wiring Diagrams

_________

________________

__________________

________________________

_______

_________________________________________________________

_________________________

_

______________

___________________

_____________________

_____

_________

________________________________

__________

_ 2

_ 4

_ 4

_ 4

_ 5

_ 5

, 5

_ 6

_ 6

_ 6

_ 7

_ 7

_ 8

_ 8

_ 9

_ 9

10

10

11

11

11

12

12

12

13

13

13

13

13

14

14

15

15

16

18

19

20

21

22

23

Page 4

INSTALLATION INSTRUCTIONS

À WARNING

HAVE THIS RANGE INSTALLED BY A QUALIFIED INSTALLER.

Improper installation, adjustment, alteration, services, or

maintenance can cause injury or property damage. Consult a

qualified installer, service agency or the gas supplier.

Before Using Your Gas Range

• Remove the exterior and interior packing.

• . Check to be sure you have all of the parts listed below:

Oven Rack

Backguard with two screws

Orifice Packet

Anti tip bracket with two screws

Paper template for anti tip bracket

4 leveling legs

2 utensil supports

4 caps and 4 rings in the burner assembly

4 burner knobs

1 oven knob

Heat Deflector Panel (DGR-21A only)

Broiler Tray (DGR-21A only)

Clean the interior surface with lukewarm water using a soft doth. (See “Cleaning” on

Pg. 12)

Have the installer show you the location of the range’s gas shut-off valve and how to

shut it off if necessary.

Have your range installed and properly grounded by a qualified installer in

accordance with the Installation Instructions.

Do not attempt to repair or replace any part of your range unless it is specifically

recommended in this manual.

Be sure your range is correctly adjusted by a qualified service technician or installer

for the type of gas (natural or LP) that is being used.

Installation Requirements for Your Gas Range

> IVIaterial Requirements

• Gas line shutoff valve

• 1/2” NPT male pipe thread for connection to pressure regulator

• L.P. Gas resistant pipe-joint compound

----------

i—AGA ui CGA Uesiyii-cbiiLiried flexible melai uuimedui (4-5 feet) or rigid gas supply line as

needed

• Insulated pad or plywood if range is installed over carpeting

Page 5

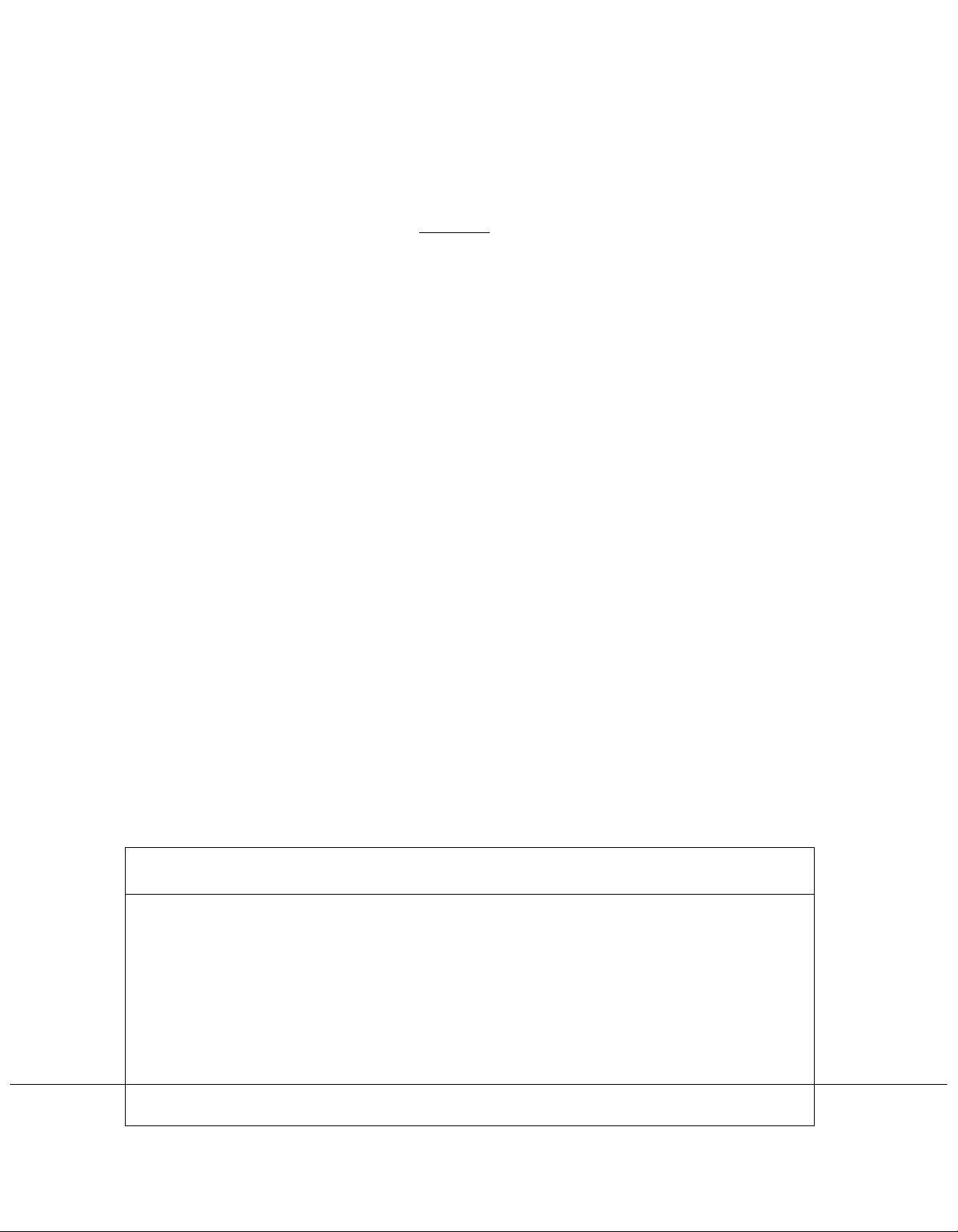

Space Requirements

Ç.9 bi ne [_dime n si on s/requ i re ments

13"max. upper'

cabinet dept

"В"орепПтд

18" min.

clearance upper

cabinet to

countertop

Conbet □ qiKilifled

Пост cmering irublter

b check that the Floor

covering can wilfuland

ol locut 90'F obovo room

temperature

tJie on insulated pad

or l/4‘ p^ood

under range, II installing

range over carpeting.

MODEL

36"

30"

20"

DIM. "A" DIM. "B" DIM. “C"

36"

30" . 30 3/16"

20" 20 1/4"

j^-^width

5" min' '

countertoff'’^

space to side

watt or other

combustible

material

36 3/16” 28 3/16”

"A"niln opening'"^

This shaded area recommended 24" min. when bottom

for installation of ripid qos pipe, metal cabinet is

Jexi^a flos pipe and aiectncoi pfotgeted by not less

22 3/16"

12 1/4"

ouriet ■(,'4" flame retardant

For minimum

clearance to top of

cooktop, see Note

к

¡Contour tino 1er

|bick sMool the

¡modo) 20" r»ngo

Do not pinch the power

supply cord between the

range and the wall

Do not seal the range

to the side cabinets

Oven side panels must

extend beyond cabinet

fronts by 1.'4" where 0”

(flush) of side

walils desired

millboard covered with not

less than N0.28 MSG sheet

steel, 0.015" stainless steel,

0.024" aluminum or 0,020"

copper.

30" min. clearance between

the top of the cooking

platform and the bottom of an

unprotected wood or metal

cabinet.

^ /-Х a

Gas Requirements

TYPICAL CONNECTIONS

FLEXIBLE CONNECTOR HOOK UP RIGID PIPE HOOK UP

PRESSURE

REGULATOR

^*n GAS FLOW

FLEX CONNECTOR-

ADAPTER

ADAPTER

Electrical Requirements

|Т|->к

‘fl

120VOLT, 60HZ, 15 AMP MINIMUM

!

i

i

GAS SHUT OFF VALVE

Page 6

INSTALLATION OF YOUR GAS RANGE

A WARNING

HAVE THIS RANGE INSTALLED BY A QUALIFIED INSTALLER.

Improper installation, adjustment, alteration, services, or

maintenance can cause injury or property damage. Consult a

qualified installer, service agency or the gas supplier.

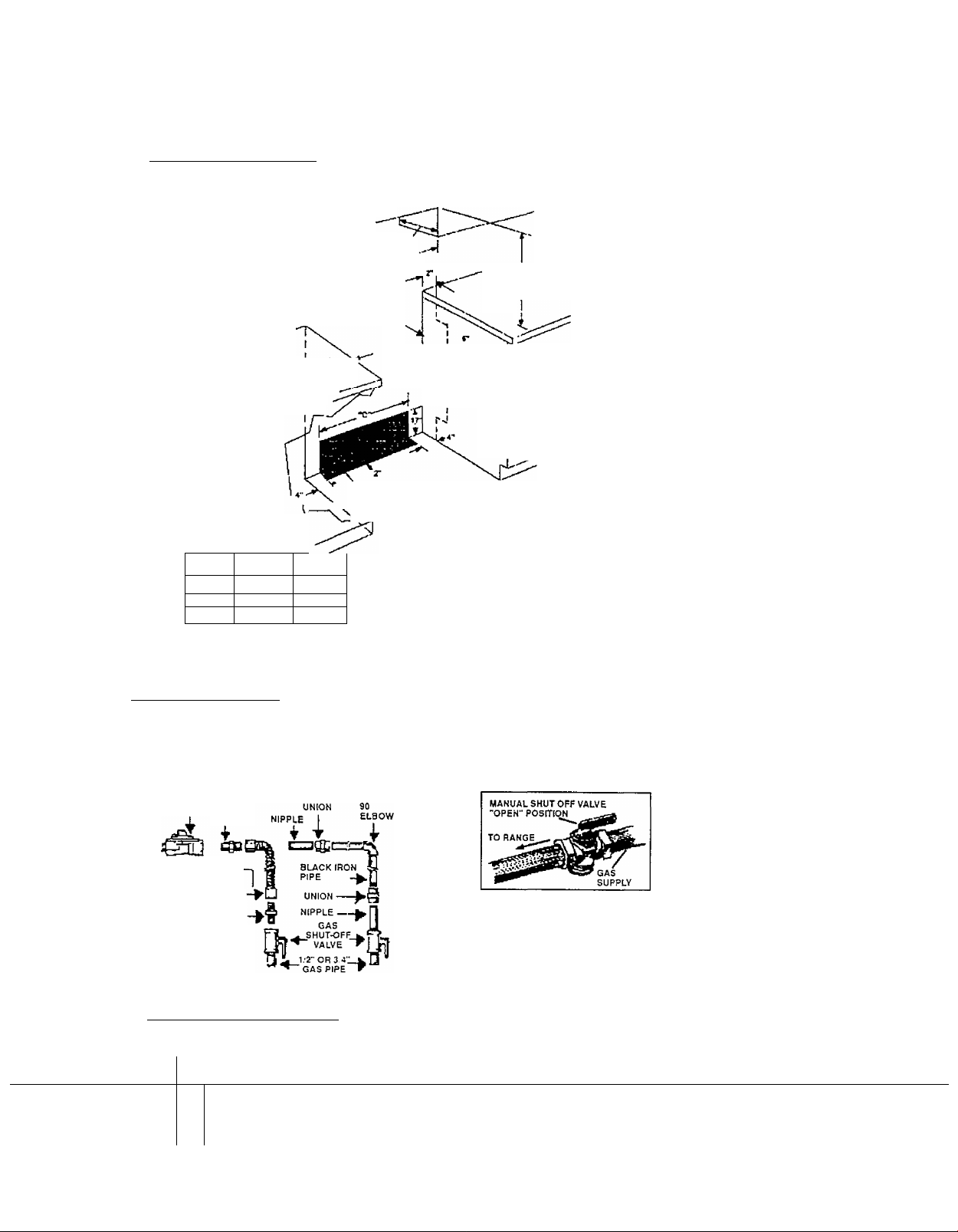

^ Leveling of Range

The range must be level to obtain proper cooking results. The screwed leveling legs located on

the corner brackets at the bottom of range should be adjusted by turning them clockwise to

make the range higher or counter-clockwise to lower the range until the range is level

(See Figure 1). Use a level on the cookware supports to check the leveling of the range.

HIGHER LOWER

Fig. 1

Fig. 2

Backguard Installation

• Place the backguard on top of the cooktop at the rear of the range (Figure 2)

• Line up the holes on the backguard with the holes on cooktop.

• Fasten the backguard to cooktop by using the screws, washers and nuts supplied with

the range.

A

WARNING

- ALL RANGES

CAN TIP

• INJURY TO PERSONS

COULD RESULT

• INSTALL ANTi'TIP

DEVICES PACKED

WITH RANGE

• SEE INSTALLATION

INSTRUCTIONS

Page 7

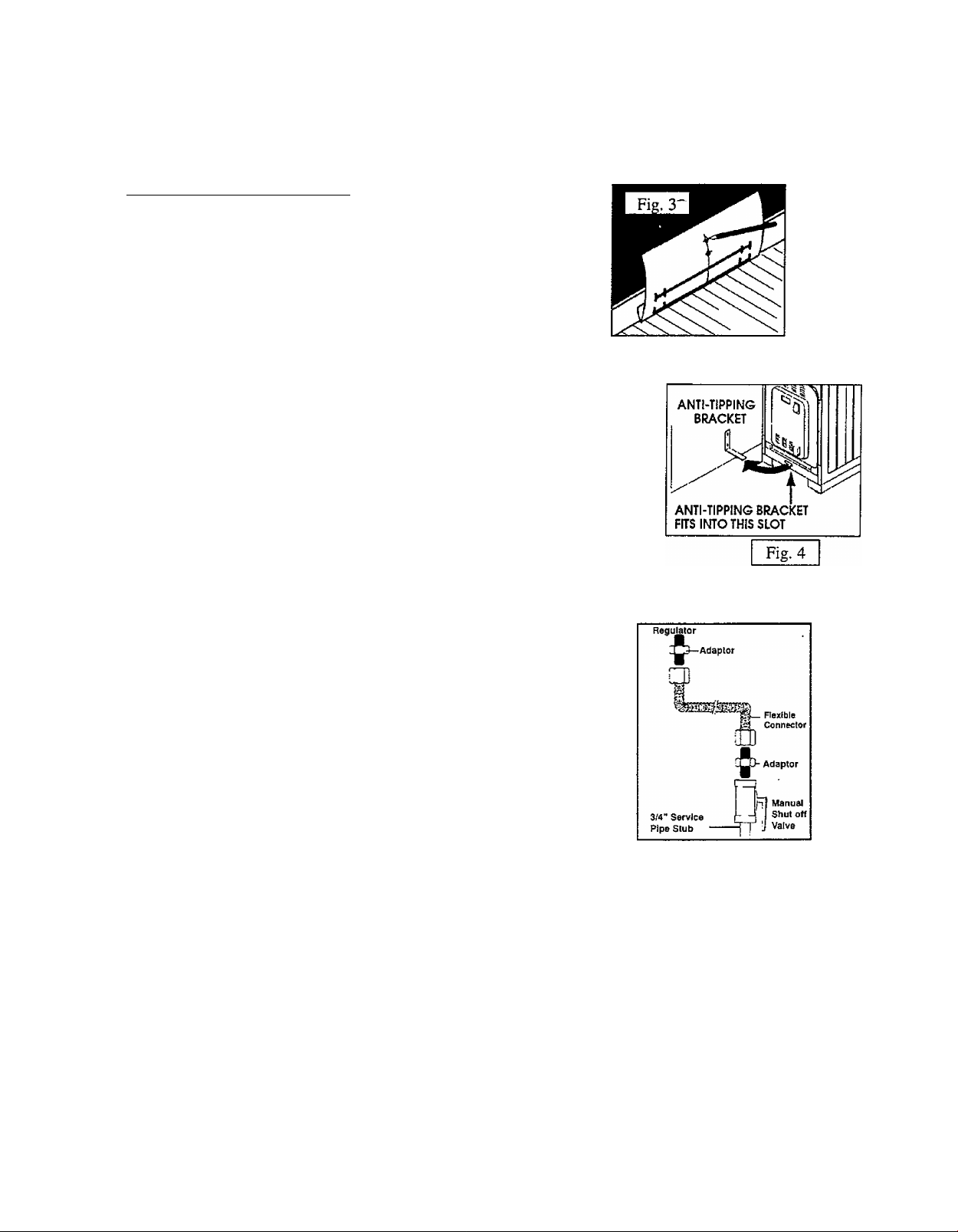

Anti-Tip Bracket Installation

To reduce the risk of tipping the appliance by abnormal usage

or improper door loading, the appliance must be secured by

properly installing the anti-tip device packed

\with the appliance.

The paper template supplied with the range should be used to

indicate the locations of screws that fix the anti-tip bracket to

adjacent wall.

Fold the paper template along the lower thick black line and

hold it against the floor and wall in the position you intend the range to be

fitted. (See Figure 3). The thick black lines are the same width as the

range.

Mark the centers of the two fixing holes with a pencil on the wall.

If you are fixing to a timber skirting board, make two pilot holes with a

center-punch before screwing the bracket to the wall. If you are fixing to

a plastered/brick/stone wall, use a masonry drill bit and the anchors

supplied.

Finally, screw the anti-tip bracket into the wall and insert the tip of the

bracket to the slot located on the lower rear part of the range

(See Figure 4).

Gas Connection

Gas connection must be made in accordance with local codes

or in absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1-Latest Edition.

Connect gas supply to regulator using a flexible connector, as

shown in Figure 5. Pressure regulator supplied with this range

has a 1/2-inch NPT female connection.

A manual shutoff, not supplied with this range, must be installed

in an accessible location outside of the range.

Use joint compound that is resistant to action of natural or

propane gas on all male pipe threads.

Use supplied pressure regulator only.

Do not over tighten gas fitting when attaching to pressure

regulator. Overtightening may crack regulator.

Appliance and individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test

pressures In excess of 1/2 psi (3.5 kPa).

Appliance must be isolated from gas supply piping system by loosening manual shutoff

valve during any pressure testing of the gas supply piping system at test pressures

equal to or less then 1/2 psi (3.5 kPa).

Gas supply pressure for checking regulator setting must be at least 1-inch water column

above manifold pressure shown on nameplate.

After final gas connection is made, turn on manual gas valve and test all connections in

gas supply piping and range for gas leaks.

Fie. 5

Page 8

In order to avoid property damage or serious personal injury, never use a lighted match.

If a leak is present, tighten joint or unscrew, apply more joint compound, tighten again

and retest connection for leak.

Electrical Connection

• Electrical connection must be made in accordance with local codes or in absence of

local codes, with the National Electrical Code, ANSMNFPA No.70-Latest Edition.

• Connect the 2-prong supply cord to a 120-voIt, 60 Hz, 2-prong wall receptacle.

• Electrical connection must not interfere with gas connection. (See“lnstallation

Requirements" Page 6)

Warning

Improper use of the grounded plug can result in a risk of electrical shock. If the power

cord is damaged have it replaced by an authorized Avanti Products service center.

> Mobile Home Installation

The installation of this range must conform with the Manufactured Home construction and

Safety Standard, Title 24 CFR, Part 3280 {formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24, HUD (Part 280)} or. when such standard is not applicable, the

Standard for Manufactured Home Installations, ANSI A 225.1 and Manufactured Home

Installations, Sites, and Communities ANSI/NFPA 501 A, or with local codes.

When this range is installed in a mobile home, it must be secured to the floor during transit. Any

method of securing the range is adequate as long as it conforms to the standards listed above.

Copies of the standards may be obtained from:

*National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

*American Gas Association

1515 Wilson Blvd.

Arlington, VA 22209

Page 9

OPERATING YOUR GAS RANGE

Before operating the unit, read this section thoroughly. The first time

the burners are operated, a small amount of smoke may be

generated due to burning of grease on the burners, especially on

oven and broiler burners. This is not dangerous. For that reason, it is

advisable to operate the burners without any cooking purpose for 10

minutes. This range is equipped with an electric ignition system to

ignite the burners. Therefore, it must be supplied with electricity.

If any electric power failure occurs, using a match can ignite the burners.

A constant supply of air is needed for combustion. Therefore, allow sufficient

ventilation into the room where the range is placed.

Manual Lighting of the oven burner during power outage

You should place a lighted match next to the entrance of the burner hole.

Depress the oven burner knob and turn counterclockwise.

Keep the control knob depressed for 10 seconds after lighting.

Check that the burner is lit (Figure 7),

> Operation of Surface Burners

There are 3 different types of surface burners with

different size and heat output on the cook top.

* A rapid burner (Front Right)

* Two semi-rapid burners (Back)

* A simmer burner (Front Left)

A WARNING-i

DO NOT ATTEMPT TO OPERATE ANY

SURFACE BURNER WITHOUT INSTALLING

IT. OTHERWISE, THERE IS A RISK OF

EXPLOSION.

First, they must be installed correctly, as seen in Figure 6.

The ring and its cap must be in its place. The burners should be level with the surface of

• The cookware supports must be in place on the cooktop.

These plastic rings are already in place and are used to

prevent rocking as shown in Figure 8.'Extra rings are

supplied for your convenience. Use stable cookware with a

flat bottom and always place the utensil on the cookware

supports before lighting the burner.

• The surface burners are controlled by knobs located on

control panel at front side of the appliance, as seen in

Figure 9.

____________________________________

1

Fiii. 8

Page 10

There is a symbol over the knob on control panel in order to identify which knob

controls which burner. Also, there is a symbol indicator on the knobs, to aid in

setting the burner to the desired temperature.

To Light a Desired Surface Burner

• Push the control knob in.

• After the burner ignites, turn the knob counterclockwise without releasing it to adjust the

flame size. Then release the knob.

• For maximum heat output, align the large flame symbol on the knob with the vertical line

on the control panel. In order to decrease the heat output, turn the knob in the direction of

the small flame symbol. For minimum heat output, align the small flame symbol on the

knob with the vertical line on the control panel.

• The amount of food being cooked, the amount of liquid, or the size of the pan should

determine the heat settings. Always position the utensil on the burner grate before

lighting the burner. For your safety, the flame should not extend beyond the sides of the

pan.

• To turn the burner off, turn the knob clockwise until it reaches the (•) symbol.

The oven is controlled by a knob located at left side of control

panel. (See Figures 9&10)

This knob has two functions.

■ To control oven burner. (GR-20 and DGR-21A)

■ To control broiling burner. (DGR-21A ONLY)

When the knob is turned in a counterclockwise direction, it controls the oven. When the

knob is turned in the clockwise direction, the broiler is engaged. Those burners do not

run simultaneously.

The oven burner is controlled by a thermostat and has a flame failure device. The

numbers on the knob indicate the temperature in the center of oven cavity in degrees of

Fahrenheit.

lO

Page 11

Using Your Oven

• Open oven door to confirm nothing is stored in oven cavity and set racks to proper height.

• Push the oven knob in and turn it counterclockwise to the desired temperature.

• Observe that the oven burner is lit. Wait for ten seconds for the heating of flame failure

device, then release the knob. Never pull up or out the bottom panel of the oven for

observation or operation of oven. Always, make use of slots on the bottom panel of oven

for observation.

• It is usually necessary to preheat the oven. Close the oven door and wait for 10-20

minutes depending on desired temperature, then place food in the oven.

• When selected temperature is reached, the burner will maintain it.

• Do not forget that because the heat rises, the top of the oven will always be hotter than

the bottom.

• After cooking time elapses, remove food and turn oven knob to OFF position, until you

hear a second dick.

> Oven Light f DGR-21A only)

The switch located at the extreme left of the control panel turns the oven light on and off (See

Figure 9). When the button is depressed, the light will be on.

> Clock/Timer fPGR-21A only)

The clock/timer serves two functions: as a clock and as a

cooking timer. It does not control the oven or the cooktop.

You set the timer to remind you of a desired time, at which

a buzzer will sound.

To set the clock (See Figure 11):

• Depress the button located below the TIME display

and turn it to the right until the correct time Is

displayed on the clock.

• Release the button.

To set the cooking time:

• Turn the button located at the left of the TIME display

(do not depress it) until the desired start time of cooking is displayed on the clock.

• Keep in mind that the timer function does not control the oven functions or actual cooking

time. It will alert you when the desired time has passed with a bell.

11

Page 12

Operation of Broiler Burner

The knob controlling the oven burner is also used for operating the

broiler burner. (See Figure 9) When the knob is turned in clockwise

direction, it controls the broiler.

When the knob is'turned in the counter-clockwise direction, the oven

is engaged.

Those burners do not run simultaneously. The broiling burner has

one position. It is full on. The burner can not be set to other heat

outputs.

To operate the broiler burner:

• Open oven door to confirm nothing is stored in oven cavity.

• Place the heat deflector panel, as shown in figure 12.

A WARNINGS

If the heat deflector is not in place, the control panel will

overheat. This could damage the control knobs, and

creates risk of burn injury.

Place food on a cold ungreased broiling pan and set rack to

proper height.

Close the oven door, until it touches the heat deflector panel.

Push the oven knob forward. Ignition starts.

Turn it in the clockwise direction to BROIL position without releasing the knob.

Observe that the broiler burner is lit. Wait ten seconds for the heating of flame

failure device, then release the knob.

Broiling does not require preheating.

All food should be turned at least once.

When the food is cooked enough, remove the food and turn the knob to ‘OFF’ position.

CARE AND MAINTENANCE

The appliance should be cleaned regularly for long-term operation.

Make sure that all parts of the range are cool before cleaning.

> Removing the Oven Door for Cleaning

Open the door fully.

There is a small ring on each hinge. Pull the ring over the claw-like

hook, which is part of the hinge mechanism. Do not forget to do this

on both hinges before the next step. (See Figure 13)

Raise the door slightly and puli it straight outwards away from

the oven. The door will come completely off.

When replacing the door, locate it back into the hinge holes. Pull it

down fully and slip the rings off the claw-like hooks.

Close the door and make sure that it sits in place fully. If not, repeat steps all

above steps.

12

Page 13

> Cleaning your Oven

The oven door glass (DGR-21A) should be cleaned regularly with a non-abrasive liquid cleaner. Rinse

with a damp cloth and then a dry one. The enameled and metal parts of the oven should be cleaned with

hot water and suitable liquid enamel cleaner.

Do not use harsh abrasive cleaners on the enameled panels.

> Cleaning of Knobs and Control Panel

• Pull forward on the knobs to remove them.

• Wash in a water solution with a mild detergent mix. Do not use an abrasive cleaner or abrasive

action. Abrasive action will scratch away the knob markings.

• The control panel should be cleaned by using a damp cloth with mild detergent. Never rinse with

an abrasive cleaner or use abrasive action.

> Cleaning of Utensil Supports, Cooktop, Backquard and Surface Burners

• utensil supports are made of enamel coated steel.

• They can be cleaned at the sink with detergent or soap-filled scouring pads. They can also be put

in a dishwasher.

• The cook top and backguard are also made of enameled-coated steel. They should be cleaned

with hot water and suitable liquid enamel cleaner.

• The aluminum burner rings may be damaged if soaked or put into a dishwasher. They should be

washed with a fine soapy wire wool.

• The burner caps are made of enameled sheet. They can be cleaned in the same manner as

utensil supports. It is very important that the burner be dry before replacing it in the range. A wet

burner will not allow the gas ignite properly.

Converting Gas Type

This range arrives from factory, adjusted for use with Natural Gas. The setting is indicated on

the nameplate. It is important that the range is converted, if the factory adjusted gas type is not

desired.

To avoid electric shock that can cause personal injury or death, disconnect the appliance from

the electric outlet before servicing.

> Conversion of Pressure Regulator

The gas pressure regulator must be set for the type of gas being

used. The inlet pressure of the gas supply shall be in accordance

with the nominal inlet pressure of the regulator used on the range

or 1/2 psi (3.5 kPa) pressure maximum. On the factory setting for

Natural Gas operation, the pressure regulator will regulate the

pressure to 6 inches water column pressure. When set for LP-

Propane gas operation, it will regulate the pressure to 10 inches

water column pressure.

To change the pressure regulator setting:

• Unplug the main supply cord of the range.

' • Unscrew the cap on the pressure regulator.

_________________________

• Lift out cap and turn it over. If set for LP-Propane gas operation, the cap

must show "LP". If set for Natural Gas operation, the cap must show none.

13

Page 14

Conversion of Burner Valves

• Unplug the main supply cord of the range.

• Remove burner control knobs from range by pulling them out.

• Remove the screws on the front surface of control panel.

• Remove two screws located on the bottom surface of control

panel.

• Pull out the control panel.

• Using a small screwdriver, loosen or tighten the screws located

on each valve. If set for LP-Propane gas operation, the screws

must be tightened fully. In the factory setting for Natural Gas

operation, the screws must be loosened by turning them

counterclockwise 3/4 turn.

• Replace the control panel and screws.

• Replace the control knobs. (See Figure 15)

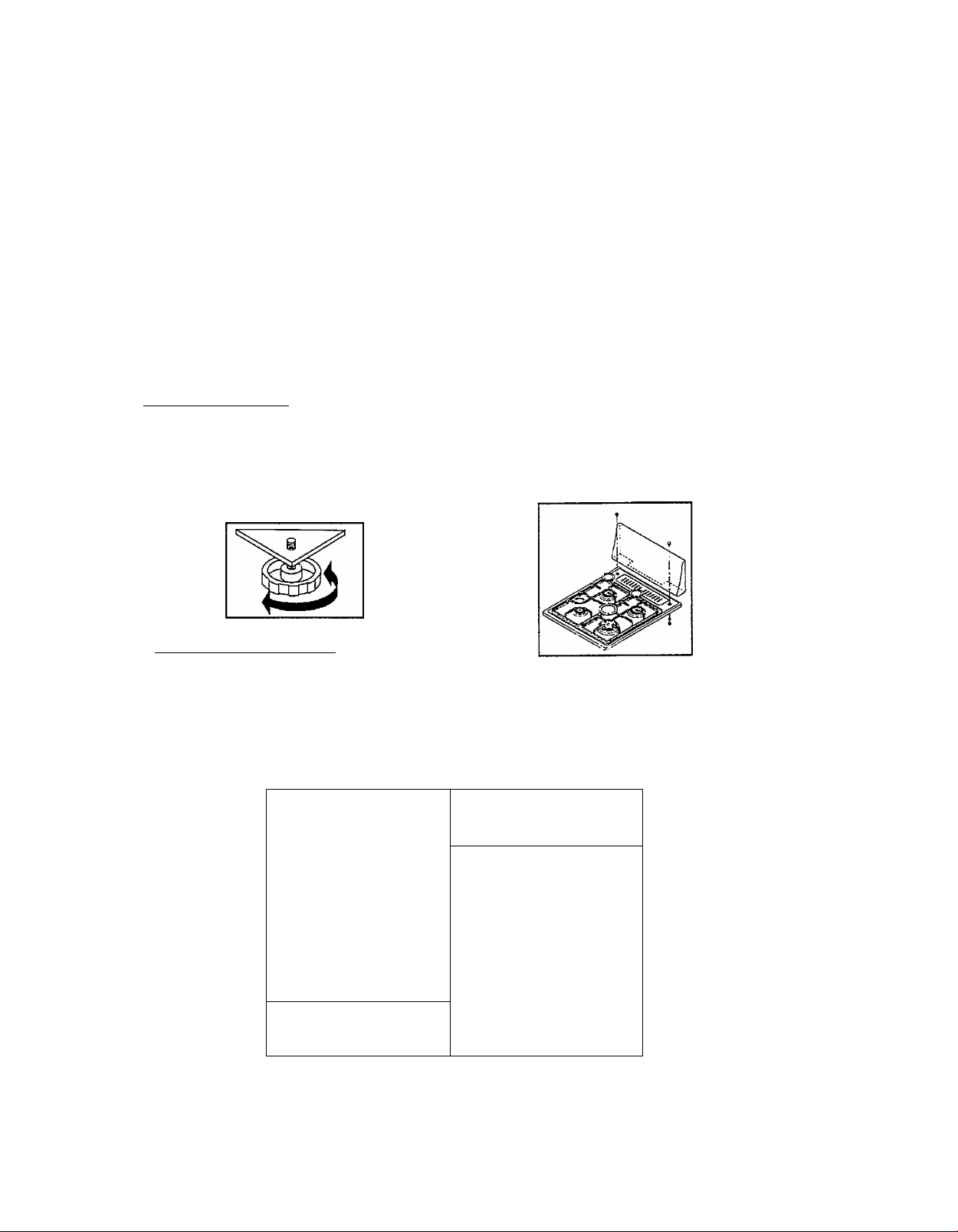

Conversion of Surface Burners

• Unplug the main supply cord of the range.

• Remove the rings of surface burners.

• Pull up the burner rings with their caps and unscrew the orifices

using a 7mm-spanner socket.

• Use orifices located on the information card in a plastic bag at

lower rear side of the range. In order to choose the required orifice

for particular burner and gas type; see the mark located on orifices

and look at the information card.

• Screw each orifice to proper matching burner.

• Place the burner rings to their original locations. Be careful that the

burner rings are level with the surface of the main top.

• Keep the remaining orifices in their plastic bag for future use. (See Figure 16 and

Table 1)

BURNERS

RAPID

SEMl-RAPlD

SIMMER

OVEN

BROILER*

Table 1 - Marks on orifices

1 LP GAS NATURAL GAS

i

0.92

i 0.65 0.97

! 0.50

i 0.90

! 0.90 1.32

1.40

0.75

1.32

•MODEL DGR-21A ONLY

14

Page 15

Conversion of Oven Burner

• Unplug the main supply cord of the range.

• Open oven door.

• Remove the bottom panel of oven pushing it backwards, then lifting

the front edge up and out as shown in Figure 17.

• Loosen the screw which holds the burner in place, and remove the

burner completely (See Figure 18)

• Loosen and remove the orifice at the bottom rear of oven using a

7mm-spanner socket. Replace the orifice supplied with the range.

For the mark of orifice, see Table 1.

• Loosen the retaining screw on the burner ring, if setting for LPPropane gas operation, slide the ring towards the burner to open the

burner hole completely. In the factory setting for Natural Gas

operation, the ring must be located in a place that maintains a gap of

4 mm. (See Figure 19)

• Replace the burner in the oven and replace the screw. Replace the

bottom panel of oven.

• Keep the remaining orifice in its plastic bag for future use.

r^^l]

^

_____

Fig. 17

■1

Conversion of Broiling Burner (Model DGR-21A)

• Unplug the main supply cord of the range.

• Remove the screw and washer holding the burner in place (See

Figure 20).

• Pull out the burner until it releases.

• Remove the orifice using a 7mm-spanner socket. Replace the orifice

supplied with the range. For the mark of orifice, see Table 1.

• Replace the burner and the guard in the oven. Replace the washer

and tighten the screw. Be sure that the burner sits completely in

place while doing this.

• Keep the remaining orifice in its plastic bag for future use.

Fig. 19

Page 16

PROBLEMS WITH YOUR APPLIANCE?

You can solve many common appliance problems easily, saving you the cost of a possible service call.

Try the suggestions below to see if you can solve the problem before calling the servicer.

TROUBLESHOOTING GUIDE

FIND YOUR PROBLEM HERE

POSSIBLE CAUSE

HOW TO FIX IT

Surface burners do not light

Flame burns halfway round.

Surface control has not been

completely turned to the LITE

position.

Burner ports are clogged.

Burners not positioned

properly.

Range not set for appropriate

gas input

Range power cord is

disconnected from the outlet.

Burner ports are clogged.

Moisture is present after

cleaning.

Range is not set for appropriate

gas input

- Push in and turn control to the

LITE position until burner ignites,

then turn control to desired flame

setting.

- Use a small gauge wire or needle

to open parts.

- Verify that the burners are

positioned properly on the orifice

hoods and the burners are sitting

flat on the burner support with tabs

engaged in slots.

- See range conversion section of

this manual.

- Be sure power cord is plugged

into grounded outlet.

Use a small gauge wire or

needle to open ports.

Lightly fan the flame and allow

burner to operate until flame is

full, or dry burners thoroughly

following instructions in range

"Cleaning” section.

See range conversion section

of this manual.

Flame is orange.

Oven light does not work.

Dust particles in main line.

Range is not set for

appropriate gas input

Burned out or loose bulb.

16

- Allow burner to operate for a

few minutes until flame turns blue.

- See range conversion section of

this manual.

- Tighten or replace oven light

bulb. (DGR-21Aonly)

Page 17

Oven or broiler does not heat.

Range is not set for

appropriate gas input.

Temperature control not set

properly.

Flame safety device does not

allow the gas flow

Range cord is disconnected

from outlet

-See range conversion section of

this manual.

-Make sure temperature control is

set at desired temperature.

-Push forward the control knob fully

for ten seconds. If the burner lights

on and does not maintain it, the

thermocouples must be cleaned.

-Be sure the power cord is plugged

into a grounded outlet.

Oven temperature is inaccurate.

Oven capillary bulb not

positioned properly.

- Temperature control not set

properly.

Improper use of foil.

Vent blocked.

Range not set for appropriate

gas input

Smoke or odor on initial oven

-This is normal.

operation.

Range is not level.

- Poor installation.

- Weak or unstable floor.

Kitchen cabinet misalignment

may make range appear to be

unlevel.

Oven smokes excessively. Meat too close to broiler

burner.

Meat not prepared properly.

-Verify that capillary bulb is

snapped in clips straight and not

touching sides or coated with oven

cleaner or food.

-Make sure the temperature control

knob is set at the desired

temperature.

-Keep foil clear of holes in oven

bottom and off of oven racks.

-Keep vent at front of backguard

clear.

-See range conversion section in

this manual.

Place oven rack in center of

oven. Place a level on the

rack. Adjust leveling legs.

Be sure floor is level and can

adequately support range.

Contact carpenter to correct

sagging or sloping floor.

Be sure cabinets are square

and have sufficient room for

range clearance. Contact

cabinetmaker to correct

problem.

Reposition the broiler pan to

provide more clearance

between the meat and the

broiler burner. (See "Operation

of Broiler")

Remove excess fat from meat.

Nuisance sparking while oven is in

operation

Oven burner cycles high and low

Improperly grounded or

reversed polarity electrical

outlet

This is normal

17

Have outlet corrected by a

qualified electrician

Page 18

SERVICE FOR YOUR GAS RANGE

We are proud of our customer service organization and the network of professional service

technicians that provide service on your Avanti appliances. With the purchase of your Avanti

appliance, you can have the confidence that if you ever need additional information or

assistance, the Avanti Products Customer Service team will be here for you. Just call us tollfree.

AVANTI PRODUCTS CUSTOMER SERVICES

Product Information

800-323-5029

Part Orders

800-220-5570

In-Home Repair Service

800-220-5570

Whatever your questions are about our

products, help is available.

You may order parts and accessories that

will be delivered directly to your home.

You may order these items by personal

check, money order, Master Card, or Visa.

An Avanti Products authorized service

center will provide expert repair service,

scheduled at a time that is convenient for

you. Our trained Servicers know your

appliance inside and out.

18

Page 19

WARRANTY - GAS RANGE

LENGTH OF WARRANTY

FULL ONE-YEAR WARRANTY FROM

DATE OF PURCHASE ON ALL PARTS

EXCEPT GLASS PARTS

FULL 30-DAY WARRANTY FROM DATE

OF PURCHASE ON GLASS PARTS AND

FINISH OF PORCELAIN ENAMEL,

PAINTED OR BRIGHT METAL FINISHED

PARTS

WE WILL NOT PAY FOR

A. Service calls to:

1. Correct the installation of your range.

2. Instruct you how to use your range.

3. Replace house fuses or correct house wiring.

4. Replace owner-accessible light'bulbs.

B. Pickup and delivery. Your range is designed to be repaired in the home.

C. Damage to your range caused by accident, misuse, fire, flood, acts of God, or use of products not

mentioned in this manual.

D. Repairs to parts or systems caused as a result of unauthorized modifications made to the

appliance.

E. Repairs when your range is used in other than normal, single-family household use.

"we will PAY FOR

REPLACEMENT PARTS AND REPAIR

LABOR TO CORRECT DEFECTS IN

MATERIALS OR WORKMANSHIP.

SERVICE MUST BE PROVIDED BY AN

AUTHORIZED SERVICE COMPANY.

REPLACEMENT PARTS AND REPAIR

UBOR TO CORRECT DEFECTS IN

MATERIAL OR WORKMANSHIP. SERVICE

MUST BE PROVIDED BY AN AUTHORIZED

SERVICE COMPANY.

AVANTI PRODUCTS SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

this exclusion or limitation may not apply to you. This warranty gives you specific legal rights,

and you may also have other rights that vary from state to state.

This warranty is not valid outside the United States.

19

Page 20

Warranty Information

Thank you for purchasing this fine Avanti product. Please fill out this card and return it within

100 days of purchase and receive these

important benefits:

> Confirm your warranty:

Your prompt product registration confirms your right to the protection available under the

terms and conditions of your Avanti warranty.

> Protect your product:

We will keep the mode! number and date of purchase of your new Avanti product on file

to help you refer to this information in the event of an insurance claim such as fire or

theft.

> Promote better products:

We value your input. Your responses will help us develop products designed to best

meet your future needs.

“(detach here)-

Avanti Registration Card

Name Model #

Address

City

State

Zip

Date Purchased

Occupation

Area Code Phone Number

Did You Purchase An Additional Warranty:

□Extended GNone

Reason For Choosing This Avanti Product:

Please indicate the most important factors

that influenced your decision to purchase

this product.

□Price

□Product Features

□Avanti Reputation

□Product Quality

□Salesperson Recommendation

□Friend/Relative Recommendation

□Warranty

□Other

Serial #

/

Store/Dealer Name

As Your Primary Residence. Do You:

□Own GRent

Your Age:

□ under 18 118-25 □26-30

□ 31-35 136-50 Gover 50

Marital Status:

□Married “Single

Is This Product Used In The:

□Home OBusiness

How Did You Learn About This Product:

□Advertising

□ In Store Demo

□Other

_______

□Product Features

□ Personal Demo

Comments

20

Page 21

HELP US HELP YOU...

Read this guide carefully.

It is intended to help you operate and

maintain your new gas range properly.

Keep it handy to answer your questions.

If you don't understand something or you

need more help, please call:

Avanti Customer Service

800-220-5570

Keep proof of original purchase date (such

as your sales slip or cancelled check) with

this guide to establish the warranty period.

Write down the model and serial

numbers.

You’lLJpd them on a plate located on the left

wall inside the gas range.

Please write these numbers here:

Date of Purchase

Model Number

Serial Number

Use these numbers in any correspondence

or service calls concerning your gas range.

If you received a damaged gas range,

immediately contact the dealer (or builder)

that sold you the gas range.

IF YOU NEED SERVICE

We're proud of our service and want you to

be pleased. If for some reason you are not

happy with the service you receive, here are

some steps to follow for further help.

FIRST, contact the people who serviced

your appliance. Explain why you are not

pleased. In most cases, this will solve the

problem.

Save time and money. Before you call for

service, check the Problem Solver Guide. It

lists causes of minor operating problems

that you can correct yourself.

NEXT, if you are still not pleased, write all

the details, including your telephone

number, to:

Customer Service

Avanti Products

10880 NW 30 Street

Miami, FL 33172

21

Page 22

Parts and Features

DGR-21A

Parts and Feature

FOUR SEALED BURNERS

THREE TYPES :

A RAPID BURNER

TWO SEHI-RAPID

BURNERS

A SIMMER BURNER

DUAL PORCELAIN

ENAMEL COOK TOP

FULL CONTROL

PANEL FOR EASE OF

OPERATION

OVEN TEMPERATURE

CONTROL DIAL

GR-20

Parts and Feature

-jBACKGUARPl

SURFACE BURNER

MARKER TO

INDICATE INDIVIDUAL

BURNER SETTING

AUTOMATIC

ELECTRONIC IGNITION

DUAL PORCELAIN

ENAMEL OVEN DOOR

22

Page 23

Wiring Diagrams

MODEL DGR-21A

MODEL GR-20

23

Loading...

Loading...