English

Operator's Manual

2017-

A423110 2017 1 EN 2017-

www.avanttecno.com

https://tractormanualz.com

Avant e5 2017 1

2

TABLE OF CONTENTS

INTRODUCTION ....................................................... 3

Foreword ................................................................................... 3

Make sure all relevant manuals are available ..................... 4

Intended use .............................................................................. 5

Avant warranty ......................................................................... 7

SAFETY FIRST ............................................................ 8

General safety instructions .................................................... 8

Operation on uneven surfaces, gradients, and near

excavations ................................................................................ 11

Personal safety and protective equipment......................... 12

Electric system and handling of the battery pack ............. 14

DESCRIPTION OF THE LOADER ............................ 17

Identification of the loader .................................................... 17

Main parts of the loader ......................................................... 18

Signs and decals ........................................................................ 19

Technical specifications .......................................................... 22

General specifications ............................................................. 23

Auxiliary hydraulics oil flow .................................................. 24

Tyres............................................................................................ 25

Wheel spacers .......................................................................... 25

Tipping load ............................................................................... 27

Tipping load - load chart ........................................................ 28

Rated operating capacity ........................................................ 29

CONTROLS AND OPTIONS OF THE LOADER .... 30

Dashboard .................................................................................. 31

Control of loader boom, auxiliary hydraulics and

other functions ......................................................................... 32

Parking brake switch ............................................................... 35

Multi-function display .............................................................. 35

Electric 12 V outlet .................................................................. 35

Seat - Seat belt and seat adjustments .................................. 36

Seat heater ................................................................................. 36

Lights ........................................................................................... 37

CAB L (optional extra) ........................................................... 38

Options ....................................................................................... 39

OPERATING INSTRUCTIONS ................................. 43

Starting the loader ................................................................... 44

Ignition key ................................................................................. 44

Battery disconnect switch ...................................................... 45

Stopping the loader (Safe stopping procedure) ................ 45

Drive control ............................................................................. 46

Material handling ....................................................................... 50

In case the machine tips over ................................................ 52

Transport instructions and tie down points ..................... 53

Lifting ........................................................................................... 54

Storage ........................................................................................ 55

WORKING WITH ATTACHMENTS ........................ 56

Requirements for attachments ............................................. 56

Coupling the attachments ...................................................... 57

Coupling the hydraulic hoses of the attachment ............. 60

Using the auxiliary hydraulics ................................................ 61

Releasing the residual pressure of hydraulic system ....... 62

BATTERY AND CHARGING ..................................... 63

Charging the battery ................................................................ 65

Charger plug type ..................................................................... 66

Battery maintenance - water refill ....................................... 68

Watering procedure ................................................................ 69

SERVICE AND MAINTENANCE ............................... 70

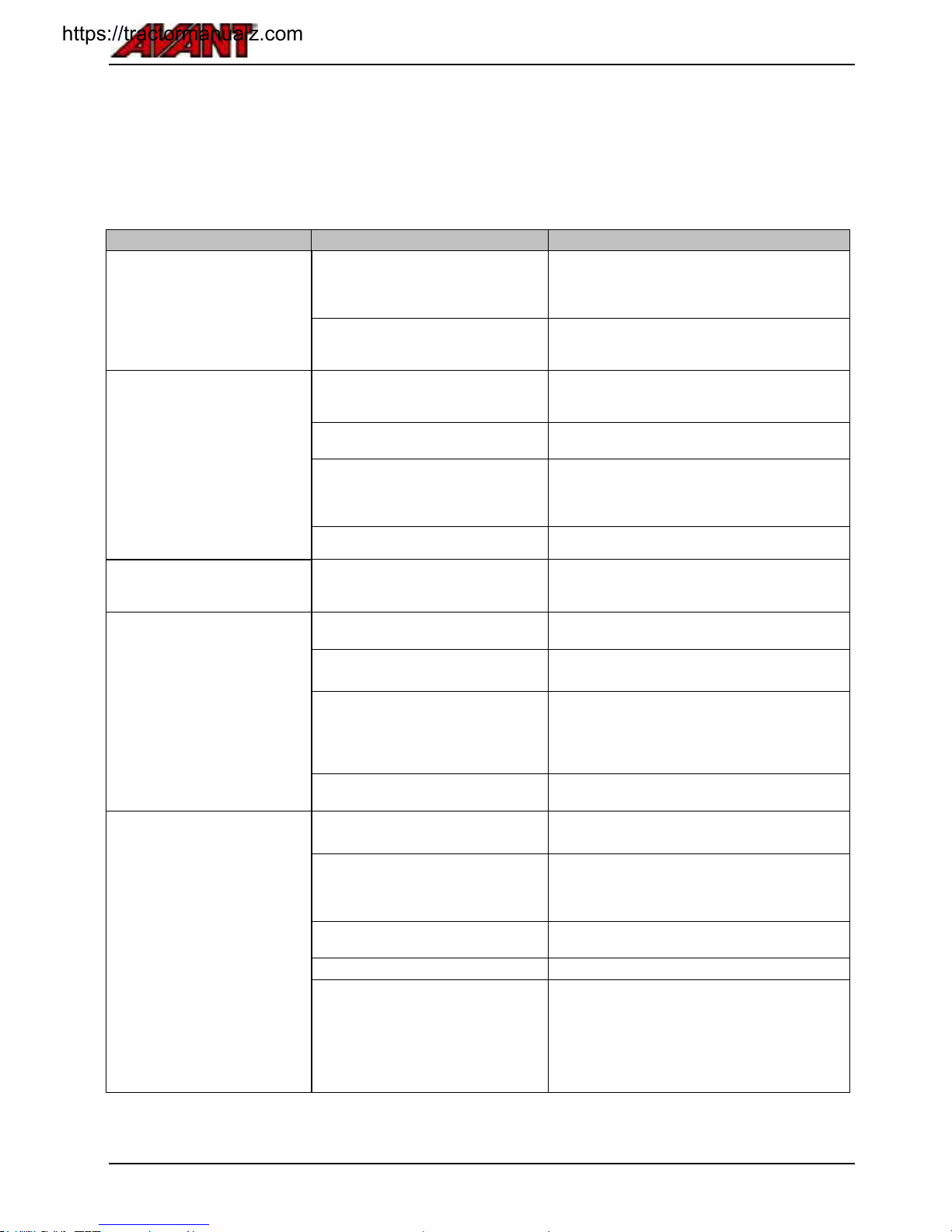

Access to electric motor compartment ............................. 71

Installing of service support and frame lock ...................... 72

Daily inspections ....................................................................... 73

Maintenance schedule ............................................................. 75

Loader maintenance ................................................................ 76

Battery maintenance ................................................................ 82

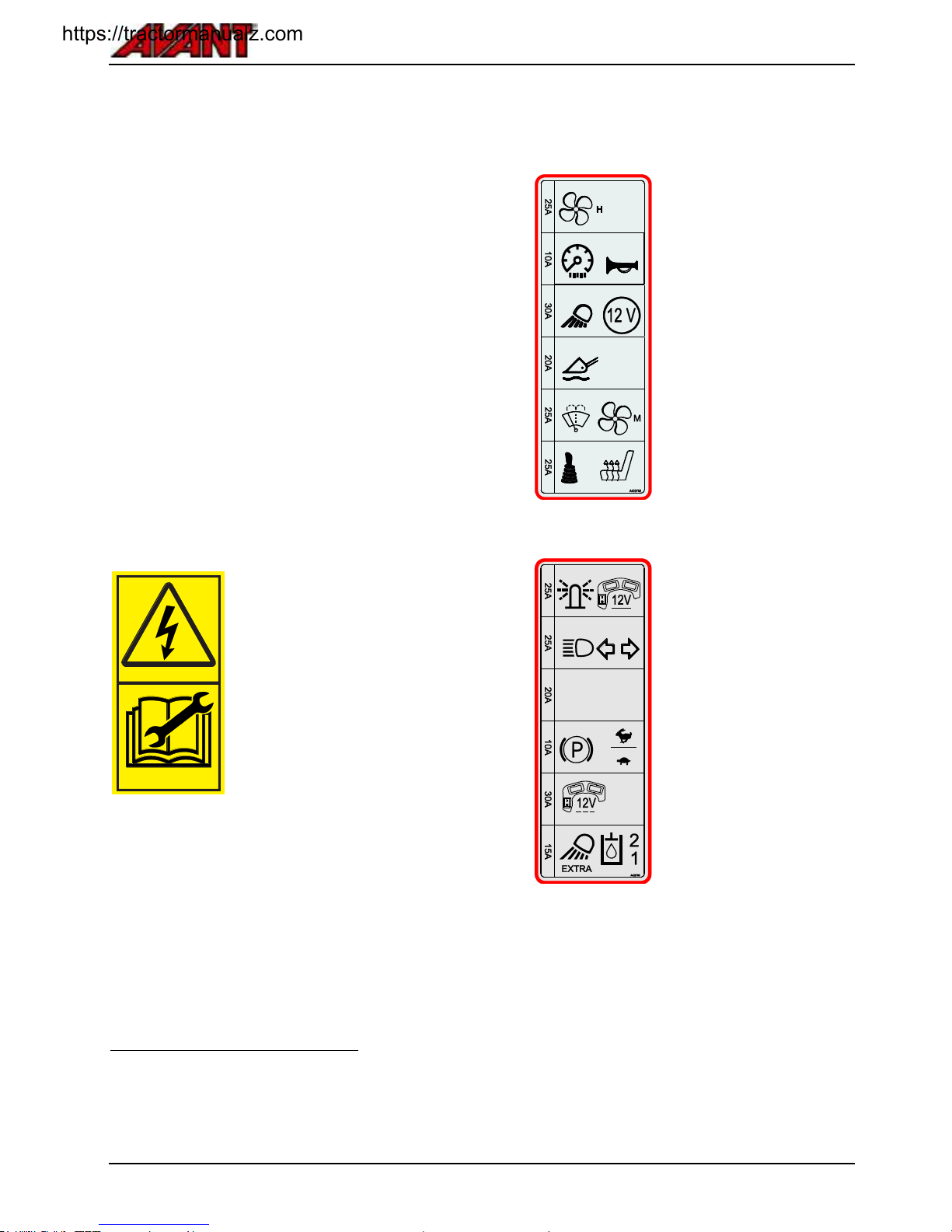

Electric system & fuses ........................................................... 85

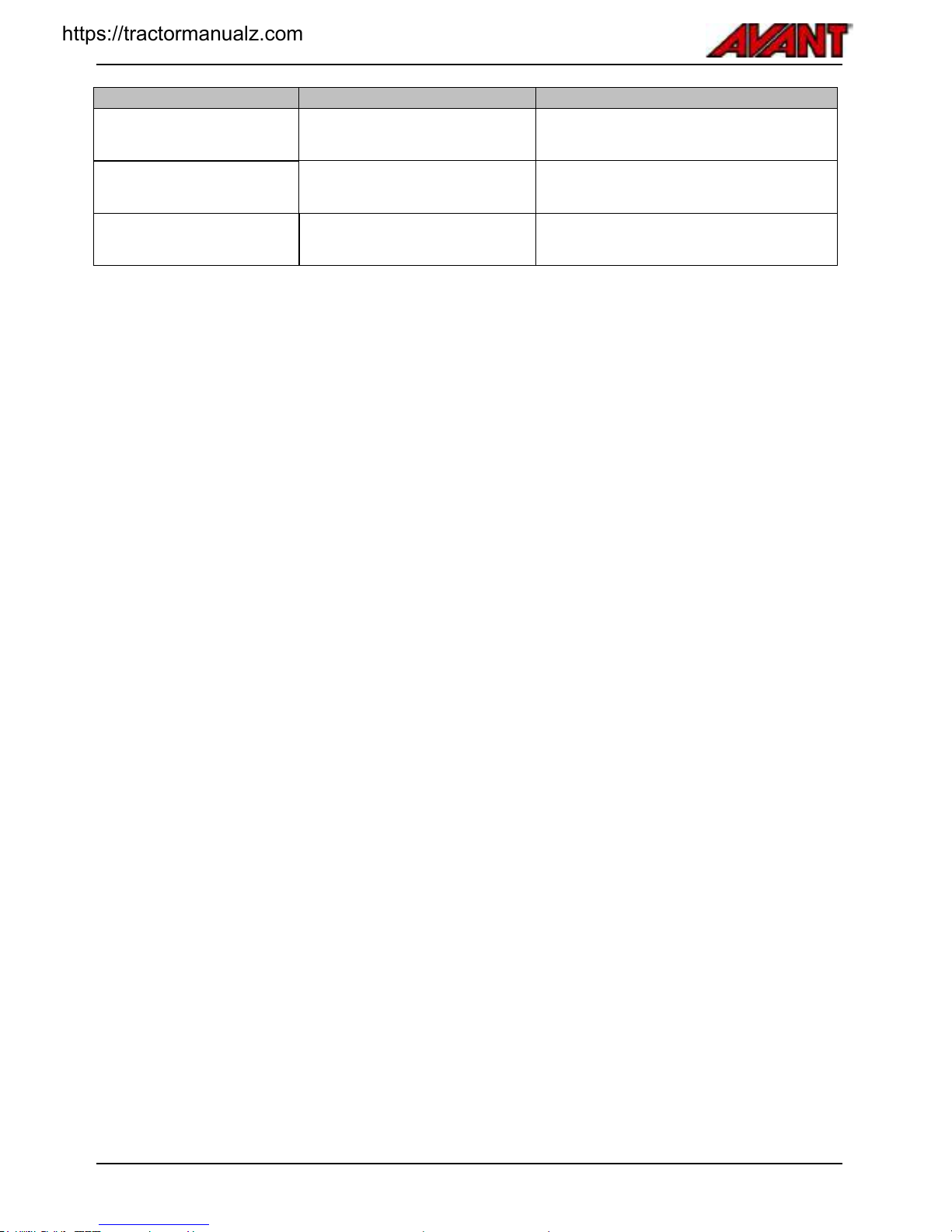

TROUBLESHOOT ...................................................... 87

SERVICES MADE ........................................................ 89

INDEX .......................................................................... 94

Original instructions

https://tractormanualz.com

Avant e5

3

Introduction

Foreword

AVANT TECNO OY wants to thank you for purchasing this fully electrically powered AVANT loader. It represents a

new level of quiet operation with no local emissions and low operating costs. The battery powered model line is

designed and built upon Avant’s long experience with compact loaders and is manufactured in Finland. We ask

you that you read and understand the contents of this manual completely before operating the loader. This

operator’s manual is intended to help you to:

operate this machine safely and efficiently

observe and prevent situations that may cause a risk or danger

keep the machine in good condition and its life span as long as possible

The following warning symbols are used throughout this manual to indicate factors that must be considered to

reduce the risk of personal injury or damage to property:

WARNING:

This safety symbol refers to important safety information in this manual.

It warns of an immediate hazard that could cause serious personal

injury.

Read the warning text accompanying the symbol carefully and ensure

that other operators are also familiar with the warnings, since personal

safety is at stake.

DANGER:

This signal word indicates a hazardous situation which, if not avoided, will cause death or

serious injury.

WARNING:

This signal word indicates a potentially hazardous situation which, if not avoided, could

cause serious injury or death.

CAUTION

This signal word is used when minor injury could result if the instructions are not followed

properly.

This signal word indicates information about the correct operation and maintenance

of the equipment.

Failure to observe the instructions accompanying the symbol can lead to equipment

breakdown or other property damage.

https://tractormanualz.com

Avant e5

4

.

Make sure all relevant manuals are available

DANGER

Wrong use of the equipment can cause death or severe injuries - Make sure to read

all relevant manuals and instructions thoroughly and keep them available for all

operators.

Using each attachment requires specific information about correct use, mounting

procedure, safety, and how to avoid hazardous situations. An attachment may introduce

risks that are not present when operating the loader with other kinds of attachments.

Always read the operator's manual of each attachment carefully.

Manuals of attachments

DANGER

Attachments can create significant risks that are not

covered by this Operator's manual of the loader.

Make sure you have all attachments manual available.

Wrong use of an attachment can cause serious injuries or

death.

Each attachment is accompanied by its own respective

Operator’s Manual. The manual will show important

information related to safety, and how to attach, use, and

maintain each attachment correctly.

Spare parts list

All spare parts of the loader are listed in a separate spare

parts list.

Contact your Avant service partner or dealer to order

parts. Have the serial number of the loader available when

ordering to ensure correct parts.

https://tractormanualz.com

Avant e5

5

.

Intended use

The Avant eSeries loaders are battery powered, hydraulically operated, articulated compact loaders. They are

designed and manufactured for both private and professional use. The loader can be equipped with a range of

attachments offered by Avant Tecno Oy, which enables you to do several different jobs with the same machine.

Because of this multi-purpose nature of the machine and the various attachments and tasks, read always not only

this Manual but also the Operator's Manual of the attachment, and follow all instructions. Every person who deals

with this machine must follow work safety regulations, all other generally accepted rules related to work health and

safety, and all road traffic regulations.

Remember that safety consists of several factors. The loader, by itself or equipped with an attachment, is very

powerful and can cause serious personal injuries or property damages if it is operated in a wrong or careless way.

Never allow the compact size of the loader to distract from this fact and keep it in mind when you consider to allow

another user to operate it. Do not operate an attachment unless you have familiarised yourself with the use of it

and the eventual dangers and risks related to it. Take the keys with you when you leave the loader unattended to

prevent other, unfamiliar persons to operate the machine. The loader is not intended to lift or transport people or

be used as a work platform. Different jobs require different attachments, and it is not allowed to handle any

material or loads without any attachment fitted.

This loader has been designed to need as little maintenance as possible. The operator can perform the routine

maintenance operations. There are however more demanding service operations that can be done by professional

service personnel only. Wear appropriate protective equipment when you do any service or maintenance work.

Original spare parts must be used. Familiarise yourself with the service and maintenance instructions in this

Manual. Operating a loader that is in poor condition, or that has received unauthorised modifications, can be

hazardous to the operator and bystanders.

Contact your local AVANT dealer, if you are uncertain of anything concerning the operation and maintenance of

this loader, or for any questions, service, or spare parts.

In addition to the safety instructions included in this manual, you must observe all occupational safety regulations,

local laws, and other regulations concerning the use of the equipment. Particularly the regulations concerning the

use of the equipment on public road areas must be observed. Contact your Avant dealer for more information

about local requirements before you operate the loader on road areas.

This loader has been designed to require as little maintenance as possible. The operator can perform the routine

maintenance tasks. There are however more demanding service operations that must be done by professional

service personnel only. It is allowed to perform service operations only when wearing appropriate protective

equipment. Original spare parts must be used. Familiarise yourself with the service and maintenance instructions

in this Manual. Operating a loader that is in poor condition, or that has received unauthorised modifications, can be

hazardous to the operator and bystanders.

Battery operated e5

Ambient temperature will limit the energy that is available from the batteries. Battery performance may decrease

significantly at temperatures below 0ºC (32ºF) and batteries can be discharged more quickly. Charging of the

loader is not recommended at temperatures below 0ºC (32ºF). Discharged batteries may freeze in cold

environment and frozen batteries must never be charged. See instructions in this manual regarding operating

environment, charging, and safety of battery systems

The loader is designed to operate with the battery pack supplied with the loader and approved by the

manufacturer. The battery pack must be charged only with the charger provided with the loader, or other charging

system supplied by Avant for this loader model. Using any other batteries or chargers can cause fire or explosion

of batteries and risk of electric shock.

Maintenance tasks that you can do to this system without special training and qualification are limited to charging,

water fill, cleaning, replacement of fuse. Never connect any device directly to the battery.

https://tractormanualz.com

Avant e5

6

.

Operator qualification

Only operators who have studied this manual, and all relevant attachment manuals, are allowed to use this loader.

Regardless of your possible previous experience with lawn-mowers, loaders, ATVs, or other equipment, it is

important that you learn the driving principle of this loader. Practise how to operate the loader and its attachments

safely at an open area before you use the loader near other persons.

You must be in good physical and mental condition with the ability to stay alert and to observe the surrounding

area. Never use the equipment while under influence of medication which could impair your abilities to operate the

equipment safely. Do not operate the loader if you are under the influence of alcohol or any other intoxicant during

the work shift.

Depending on operating area, you may also be required to read, understand and comply with all applicable

Employer, Industry and Governmental rules, standards and regulations.

Electric qualification

You can replace the battery pack with a similar one supplied by the manufacturer. Other battery or electric related

maintenance that is not shown in this manual, is prohibited. Leave all electric parts from the battery connector

forward to authorised service professionals to avoid risk of electric shock, fire, and short-circuiting and explosion of

battery. High-voltage cables and connectors, inverter, and electric motors do not have components that can be

maintained by user.

Versions of this manual

Avant has a policy on continuous product development. Updated versions of the manual replace the previous

versions of this manual as long as the year on the cover page matches with the original manual. You can ask for

the latest manual from your dealer. Some of the features or technical details presented in this manual may change

without notice. The pictures in this manual may show optional equipment or features that are not currently

available in your market area. We reserve the right to change the contents of the manual without notification.

Keep this manual with the loader

Read this manual before use. Put this manual, as

well as manuals of attachments, into the storage

box behind driver's seat when you have read

those. Always keep this Operator's Manual with the

loader. If this Manual gets lost, ask for a new copy

from your Avant dealer. Also remember to give this

Manual to the new owner when the machine

changes ownership.

https://tractormanualz.com

Avant e5

7

.

Avant warranty

This warranty specifically applies to the Avant e5 loader only and not to any attachments used with this product.

The battery is covered by special warranty clauses listed below. Any repairs or modifications performed without the

prior authorisation of Avant Tecno Oy will cancel this warranty. During the first two years of operation or first 1000

hours (whichever is the soonest) Avant Tecno Oy warrants to replace any part or repair any defect which may

occur, subject to the terms detailed below:

1. The product has received regular maintenance in accordance with schedules given by the manufacturer.

2. Any damage caused by operation in a negligent manner or exceeding the approved specifications detailed in

this manual is excluded.

3. Avant Tecno Oy accepts no responsibility for interruption to working or any other consequential losses

resulting from any failure of the product.

4. Only Avant Tecno Oy approved replacement or original quality parts shall be used during routine

maintenance.

5. Any damage caused by the use of incorrect fuel, lubricants, cooling liquid, or cleaning solvents is excluded.

6. The Avant Warranty excludes any consumable parts (e.g. tyres, batteries, filters, belts etc.) except where it

can be clearly shown that these parts were defective on original supply.

7. Any damage caused resulting from the use of attachments not approved for use with this product is

excluded.

8. The battery must be used, recharged, and maintained as instructed in this manual. Damages caused by

neglected maintenance or repeated deep discharge cycles are not covered by the warranty. See warranty

period for battery below.

9. In the event a fault occurs which is attributable to manufacturing or assembly defect you should arrange to

return your AVANT to your authorised dealer for repair. Travel and freight costs are excluded.

Special warranty terms regarding the battery

During the first year of use, battery is under full warranty covering parts regarding the battery. After the first year

and until the end of second year (months 13 to 24) the battery is under partial warranty. During this 13 to 24 month

term warranty coverage is calculated by the age of the battery, and the cover declines by the operation age of the

battery. The responsibility of the customer regarding parts and material costs of the battery starts from month 13 of

the warranty period at 13/24 parts of the full cost of replaced parts, ending at full 24/24 at the end of the warranty

period.

.

..

https://tractormanualz.com

Avant e5

8

Safety First

DANGER

Incorrect or careless operation of the loader may cause a serious accident. Before you

operate the machine, familiarise yourself with the use of the machine and read and

understand this Operator's Manual, as well as all relevant safety instructions, local

regulations, and safe working practices.

Understand the limitations of speed, braking, steering and stability as well as loading

capacity of the machine before starting operation. Make sure that everyone who operates

or works with this equipment is familiar with these safety precautions.

If you have no previous experience of the machine, make sure to do all testing at a safe

and open place with no persons in the area of operation.

General safety instructions

1. Remember the correct working position. When

driving, be comfortably seated in the driver´s

seat, keep your feet in their proper place in the

footwell and at least one hand on the steering

wheel.

2. When seated, always keep the seat belt

fastened and keep hands and feet inside the

operator’s area.

3. Before leaving driver’s seat, always:

Lower the loader boom and place attachment

flat on ground

Relieve residual hydraulic pressure (see

page 62)

Engage the parking brake

Switch off the electric motors, remove the

ignition key

4. Start the operation slowly and carefully.

Practise driving of the machine at a safe and

open place before connecting any attachment,

and follow the instructions in this Manual and

also the operator's manual of the attachment.

5. Operate the control levers with careful and

deliberate movements. Avoid abrupt

movements when handling the load, in order to

prevent the load from falling and to keep the

machine stable.

6. Keep away from the danger zone of the lifted

boom and don’t let anyone go there.

7. Keep your hands, feet and clothing away from

all moving parts, hydraulic components, and

hot surfaces.

8. Make sure that there is enough open space

around the machine for safe driving.

9. Do not transport the load with the boom lifted.

Always carry bucket or attachment as low as

possible, and put the load down whenever you

leave the machine.

10. It is not allowed to transport persons with this

machine. Do not transport or lift persons in the

bucket or in any other attachment. Lifting of

persons is only allowed with the attachment

designed for this purpose: the Avant Leguan

50 access platform, following the instructions in

the Operator's Manual of Leguan 50

attachment.

11. Do not exceed the tipping load. Familiarise

yourself with and follow the load diagrams in

this Manual.

12. When turning with the machine, remember that

the driver´s seat extends beyond the turning

radius of the wheels (collision risk).

13. Do not operate the loader in an explosive

environment or in a place where dust or/and

gases can create a fire or explosion hazard.

14. Keep the areas around the battery, inverter,

electric motors, and cooling fan clean of

flammable materials.

15. Read the lifting, towing and transportation

instructions on page 54.

16. Remove the ignition key from the ignition

whenever leaving the machine unattended.

https://tractormanualz.com

Avant e5

9

17. Follow all inspection, service and maintenance

instructions. If you notice any faults or

damages on the machine, these must be

repaired before starting operation.

18. Before any maintenance or repair operation

always stop and switch off the loader, lower

the boom down and release pressure from

hydraulic system. Read safety instructions for

maintenance on page 70.

19. Do not let any person operate this loader who

has not read safety instructions and is not

familiar with the safe and correct use of this

loader.

20. Never operate the loader or attachments while

under the influence of alcohol, drugs,

medication that may impair judgement or

cause drowsiness, or if not otherwise medically

fit to operate the equipment.

.

..

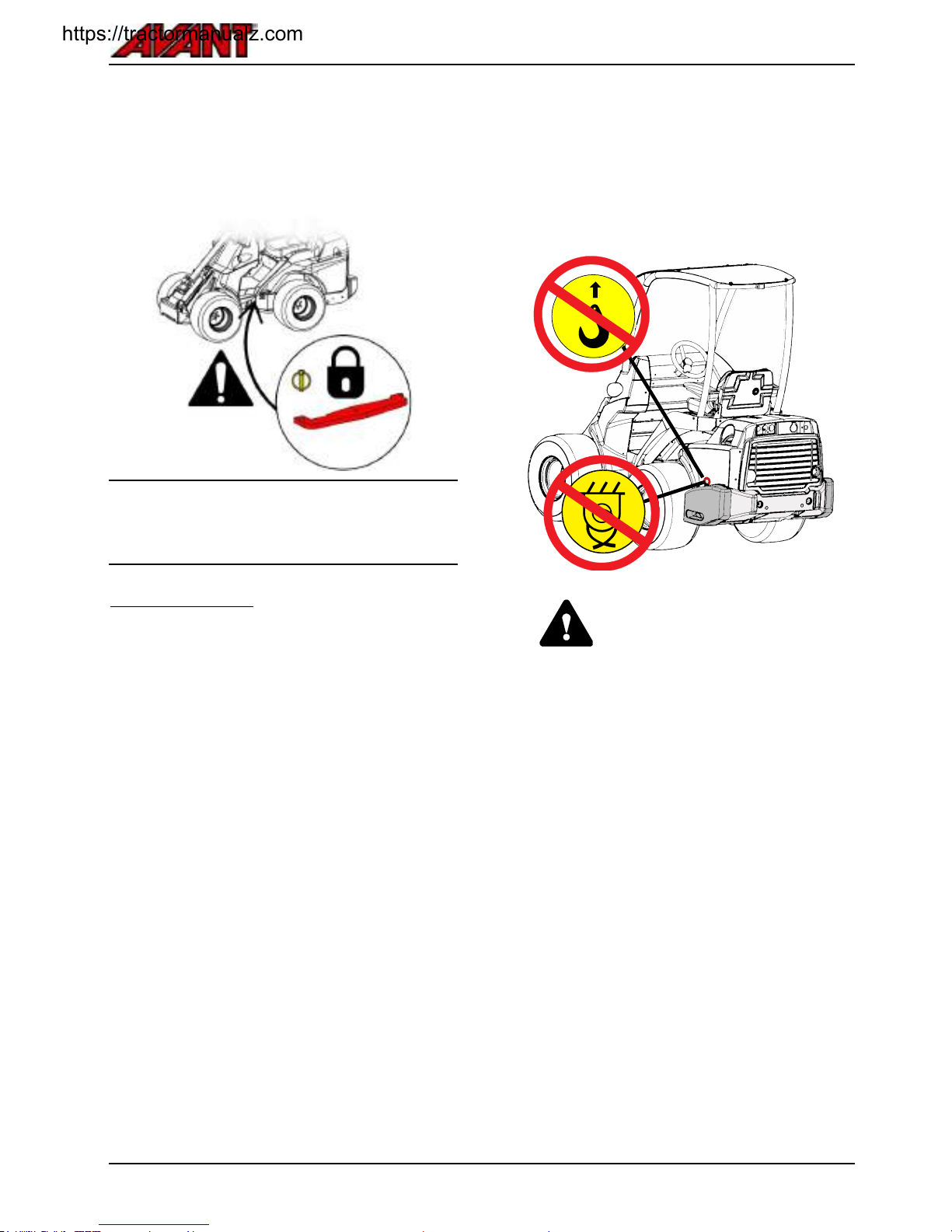

Safety devices are installed for your safety Never modify or bypass any safety function

DANGER

Safety functions are installed for

your safety. Never modify or block

any of the safety systems of the

loader. If you notice that a system

is not in good condition, stop the

use of the loader and make sure

the is serviced.

.

..

Sudden movements can tip the machine over Risk of overturning

WARNING

Movements, such as stopping,

turning, or lowering the boom

abruptly, can cause loss of

stability. Always drive slowly and

operate the controls of the loader

very carefully, especially when

handling heavy loads.

.

..

Articulated frame - Risk of overturning

WARNING

Turning articulated frame can lead

to overturning of the loader on

inclined terrain or when driving at

high speed. Never turn frame

towards the slope while operating

on inclined ground.

Always drive slowly when carrying

load or when turning with the

machine.

.

..

Overload - Risk of overturning

CAUTION

The high lift capacity of the loader

makes it possible to exceed the

stability of the loader when

handling loads. Read the

instructions regarding maximum lift

capacity and load handling in this

Operator's Manual. Following the

instructions reduces the risk of

tipping the machine over its front

axle, but the operator must be

aware of the limits of the machine

and follow safe working practises

to avoid overturning of the

machine.

.

..

https://tractormanualz.com

Avant e5

10

WARNING

Never take a heavy load on the

loader from high level – e.g. from

truck, shelf etc. – risk of tipping

over!

If the load is too heavy when lifting

load from a high level, the loader

could tip forward when reversing

with the loader.

Never reverse and drag with the

loader before you make sure that

the loader can handle the load that

is being lifted.

When loading, always keep the

loader frame as straight as

possible.

.

..

Falling of load or unexpected lowering of loader

boom - Risk of crushing

WARNING

Always remember that the boom

may lower unexpectedly due to

loss of stability, mechanical fault,

or if another person operates the

controls of the loader, leading to

crushing hazard. The attachment

or the loader are not intended to be

left to keep a load elevated for

longer periods. Lower the

attachment before leaving the

driver's seat. The stability of the

loader may change when leaving

the driver’s seat, leading to tipping

over of the machine.

.

..

Risk of falling objects

WARNING

Make sure load is securely on the

attachment. Never tilt the

attachment back when it is lifted

high. Operate only with machines

equipped with ROPS and FOPS

structures.

.

..

Falling of persons - Risk of crushing

WARNING

Never use the loader or its

attachments to lift persons or as

any kind of work platform even

temporarily. Never climb on the

loader or on the attachment.

Seating capacity: one person only.

.

..

Moving loader can crush - Engage parking brake

before working near the loader

WARNING

Follow safe stopping procedure to

prevent all movements of the

loader. Avoid leaving the loader

parked on hill. If necessary to park

on hill, use chocks or other

additional means to prevent the

loader from moving.

.

..

https://tractormanualz.com

Avant e5

11

Pinching points - Avoid pinching between loader

frame itself and between loader and walls - Keep

all body parts within the safety frame

CAUTION

Movements of the articulated

frame creates pinching hazards.

Keep your head, hands, and feet

inside the loader. Be especially

careful while you drive near walls

and trees. Keep your hands on

steering wheel and joystick.

.

..

Avoid pinching hazard for legs - Do not turn the

steering wheel while standing near the loader

CAUTION

Turning the articulated frame

creates a pinching hazard to a

person standing near the tyres of

the loader. Never grab the steering

wheel while entering or leaving the

driver's seat to avoid turning of the

frame. Stop the loader if other

persons get close to the machine.

Check that tyres that are larger

than standard tyres leave enough

space between the tyres for safe

use.

Operation on uneven surfaces,

gradients, and near excavations

Extra caution is needed when using the equipment

on inclined terrains and slopes. Drive slowly

especially on inclined, uneven, or slippery surfaces,

and avoid sudden changes in speed or direction.

Operate the controls of the loader with careful and

smooth movements. Watch out for ditches, holes on

the ground, and other obstacles, as hitting an

obstacle may cause the loader to tip over.

Overturning of machine can lead to death or

serious injury

WARNING

The stability and the load handling

capacity of the loader are

significantly reduced on inclined

terrains and maximum lifting

capacity can be achieved only on

firm, level ground. On horizontally

tilted terrain the load must be kept

close to the ground and must

never be lifted high.

.

..

Handle heavy loads only on even surfaces.

Drive very slowly on uneven terrains. Load,

unload, and turn the machine on flat level ground

only. Lifting a load or turning on uneven surfaces

can lead to loss of stability.

Do not drive on too steep a gradient - watch out

for ditches, manholes and steep gradients, which

may cause the loader to tip over.

Never drive along an excavation. Note that the

excavation or trench may suddenly cave in.

Exercise extreme caution when driving near

ditches or embankments, and avoid driving along

a ditch or trench, as the machine could suddenly

tip over if an edge caves in. Avoid driving along

trenches and keep at least a distance equal to

width of a trench.

Do not park the machine on a surface with a

gradient. Should this be necessary, engage the

parking brake and preferably turn the machine

sideways and put down the load. If needed, use

chocks behind the wheels.

https://tractormanualz.com

Avant e5

12

Personal safety and protective

equipment

Wear safe clothing and personal protective

equipment.

Protect yourself against work hazards like noise,

ejecting debris or dust for example.

Follow regulations regarding protective

equipment. Wear eye protection and hard hat or

other protective equipment as needed.

Read Operator's Manual of the attachment for

more information about protective equipment

needed in the work.

The noise level at the driver's

seat may exceed 85 dB(A).

Wear hearing protection while

working with the loader.

Wear protective gloves.

Wear safety boots whenever

working with the loader.

Wear safety glasses when

handling hydraulic components.

Always fasten seat belt while

operating the machine.

When working at construction

sites, a safety helmet is

recommended and may be

mandatory in addition to the

falling objects protective

structure (FOPS) on the loader.

Depending on work and working

area, also a respirator mask may

be required. Find out about other

necessary safety equipment at

your specific work site.

CAUTION

Silica dust warning. Prolonged

exposure to crystalline silica can

cause a lung disease called

silicosis. Occupational health and

safety officials recommend limiting

exposure to dust that is present at

most earth-moving and many other

work sites. Avoid spreading of dust

where possible, keep loader cabin

clean from dust, use respiration

mask when necessary.

Safety frame (ROPS) and safety

canopy (FOPS)

The loader is equipped with a Rolling Over Protective

Structure (ROPS) and a Falling Object Protective

structure (FOPS). These safety structures are

important parts of operator safety, and they must be

fitted on the machine.

Safety frame (ROPS) protects the operator in case

the machine tips over. Fasten seat belt while

operating a machine with a ROPS. All cab versions

are ROPS & FOPS tested and certified.

Crushing hazard - Always keep safety structures

installed

WARNING

Never take off the safety

structures, modify them, or attempt

to repair. If damaged, contact

service.

Always fasten the seat belt in order

to stay inside the protected area of

the safety frame.

Modifications

Any modification to this machine must be approved

beforehand by an authorised Avant representative. If

you modify the loader or attachment, it can become

dangerous and cause serious injuries or even death.

Unauthorised modifications can increase the risk of

accidents and damage or shorten the service life of

the machine. Modifications to electric systems can

make the no longer compliant with regulations

concerning electromagnetic emissions. Use only

original spare parts to make sure that the product is

kept in safe operating condition.

https://tractormanualz.com

Avant e5

13

Working near powerlines

Digging may expose buried electric cables, and

some attachments may make it possible to reach

overhead powerlines with the loader, creating hazard

of electric shock and electrocution.

Plan work ahead and take necessary safety

precautions.

Stay away from electric cables - Electrocution

hazard

DANGER

Electric shock hazard - Contact

with or working too close to electric

wires can result in lethal electric

shock. Keep the loader and any

attachment at a sufficient distance

from all electric cables, see table

below.

Table 1 - Safety distance from powerlines

Voltage level

Safety distance

0 - 1000 V

2 m

1 - 45 kV

3 m

110 kV

4 m

220 kV -

5 m

Unknown voltage

5 m

If electric cables are exposed during digging, or in

case of inadvertent contact or proximity with live

electric source:

Do not leave the loader until the electricity has

been disconnected by qualified technicians,

usually local electric company.

If absolutely necessary, jump out from the

loader, keeping feet next to each other, until at a

safe distance.

Warn others not to approach the loader until safe

to do so.

Fire prevention

Clean the loader to avoid build-up of flammable

debris, such as dust, leaves, hay, straw, etc.

There are many parts on the electric system that

operate at high temperatures in normal use. To

avoid fire, and to ensure that the cooling of

electric systems is ensured, keep the electric

parts clean. Overheating of electric parts can

shorten their service life.

Static electricity can produce sparks when

removing plastic covers.

Do not smoke while you work near the battery, or

do any maintenance work of the hydraulic

system.

Add hydraulic oil only at a well ventilated place.

Oil leaks can ignite on hot components. Repair

any damaged or leaking components before

using machine.

Know where fire extinguishing equipment is located

near your working site. At some areas a fire

extinguisher may be mandatory. Keep a

multi-purpose, approved type fire extinguisher

available near the place where you store the loader.

https://tractormanualz.com

Avant e5

14

.

Electric system and handling of the battery pack

WARNING

The loader is fitted with a high-energy battery pack that can output hazardous, lethal

levels of current and voltage. Misuse or using of damaged battery system creates a

risk of battery explosion, fire, hazardous electric shock, and acid spill from battery.

Follow the instructions regarding charge, use, and maintenance of the battery and the

electric systems in this manual.

Battery systems on e5

The energy from the battery pack is used in two

parallel systems:

48-volt supply from battery is converted by an

inverter to a high-voltage and high-current

electric power to drive the electric motors

A 48 v to 12 v converter supplies electricity to the

control systems of the loader, hydraulic valves,

dashboard, electric socket etc.

Never modify the 48-volt system or connect any

device directly to it. This system can output high

current that can kill or cause electric shock and

burns, if handled carelessly and safety systems are

bypassed. See maintenance instructions on page

75.

DANGER

Short-circuit can cause the

battery to explode or burn Disconnect battery before

maintenance.

Isolate the battery from the electric

systems of the loader by

separating its quick connector

before working on the electric

systems of the loader, see page

82. Check that all insulator sleeves

and caps are in good condition and

that battery terminals are not

exposed. Never lay metal objects

on the battery.

Handle battery with care

Battery contains corrosive sulphuric acid which

causes serious burns upon skin contact. Avoid

contact with skin or clothes. If electrolyte gets on

your skin or clothes, flush with a lot of water. In

case of contact with eyes, flush with a lot of

water for at least 15 minutes and see a doctor

immediately.

If a fuse is blown repeatedly, find out the cause.

Always use fuses with correct rating.

Disconnect the battery by separating the main

connector. Never disconnect individual battery

cells.

CAUTION

Risk of exposure to battery acid

- Handle battery with care and

read maintenance instructions.

Using a damaged battery, extreme

heat, improper charging procedure,

or other type of wrong use can

cause the battery cells to rupture

and leak or spray acid electrolyte.

Always follow use and

maintenance instructions. Never

use damaged battery.

CAUTION

Lead warning - Wear protective

gloves. Battery and its terminals

contain lead, a harmful substance

which should not be handled more

than what is necessary. Wear

protective gloves when handling

battery. Wash hands with soap and

water after handling the battery.

https://tractormanualz.com

Avant e5

15

WARNING

Risk of electric shock and

contact with acid - Never

disassemble the battery pack.

Battery pack does not include

other serviceable parts than those

described on page 75. Never

remove individual battery cells

from the battery pack. Keep all

insulators in place.

First aid measures

WARNING

Risk of serious burns - Avoid

contact with battery acid.

Battery contains sulphuric acid

as electrolyte. This acid is highly

corrosive and can cause serious

skin burns, in case of contact

with skin. If acid gets to eyes,

there is a serious risk of severe

eye injury. Follow correct

handling instructions of battery to

avoid exposure to acid. Always

use only battery that is in good

condition.

In case you are exposed to battery electrolyte

(sulphuric acid):

After contact to skin:

Rinse immediately with plenty of water. Remove

and wash wetted clothing.

After contact with eyes:

Rinse immediately with plenty of running water

for several minutes and seek medical advice

immediately.

If you inhale acid mist:

Inhale fresh air and seek medical advice:

After swallowing:

Drink a lot of water immediately. Swallow

activated carbon and seek medical advice

immediately.

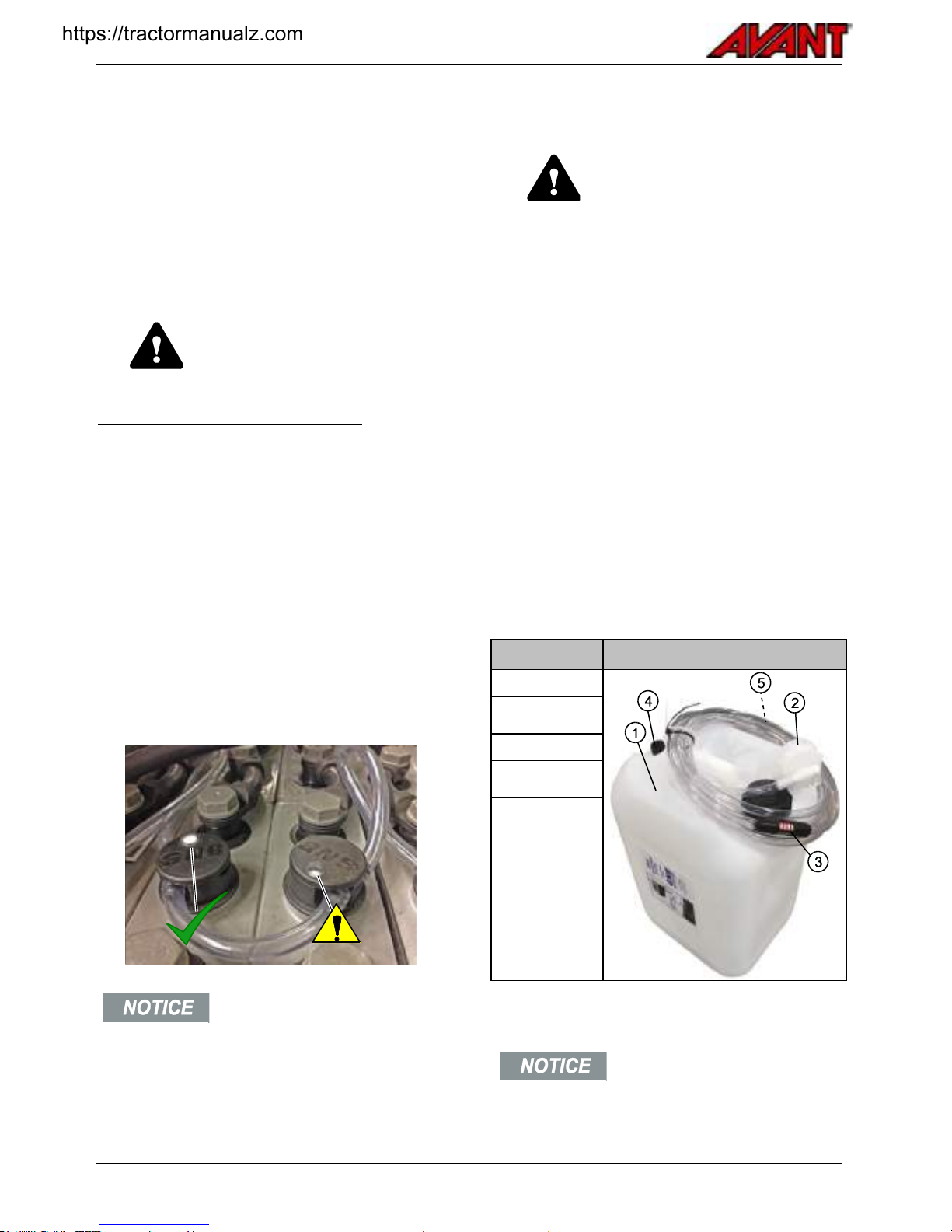

Follow correct charging procedure

Ensure ventilation and remove the rear cover

before recharge

Recharge the loader only at a well-ventilated place.

Never recharge in a small garage or shed, where

there is no fan-operated ventilation to ventilate gases

to outdoor air.

To allow the battery gas to ventilate properly, remove

the rear top cover and leave open when recharging

the battery. Leaving the rear cover removed will also

allow the battery to cool better during recharge.

Use only the integrated charger of the loader to

charge the battery

Use only the original, integrated charger to charge

the battery. This ensures that the charge voltage and

current are optimised in different phases of the

charge cycle. Other charger types, especially those

with higher output current, can overheat the battery.

Overheating can cause the electrolyte to boil and

battery can deteriorate or its useful life will be

shortened as a result.

During charge, some of the water in the battery is

broken into hydrogen and oxygen gases. This gas

mixture is highly flammable and can become

explosive, if enough gas is accumulated. The area

where the loader is charged must be ventilated so

that the amount of these released gases will not

become explosive.

Make sure that the ventilation is sufficient when

charging the battery. Preferably charge the

loader outdoors.

Keep arcs, sparks, flames, lighted tobacco and

other sources of heat away from battery.

Charge the battery only with the built-in charger

of the loader. If you connect any other charger to

the battery, the battery can get too hot, too high

current can cause electrolyte to spill from the

battery, and the battery can be damaged.

Check the battery for external damages,

leakages, and deformations. Never charge the

battery or operate the loader if you see that the

battery is damaged.

https://tractormanualz.com

Avant e5

16

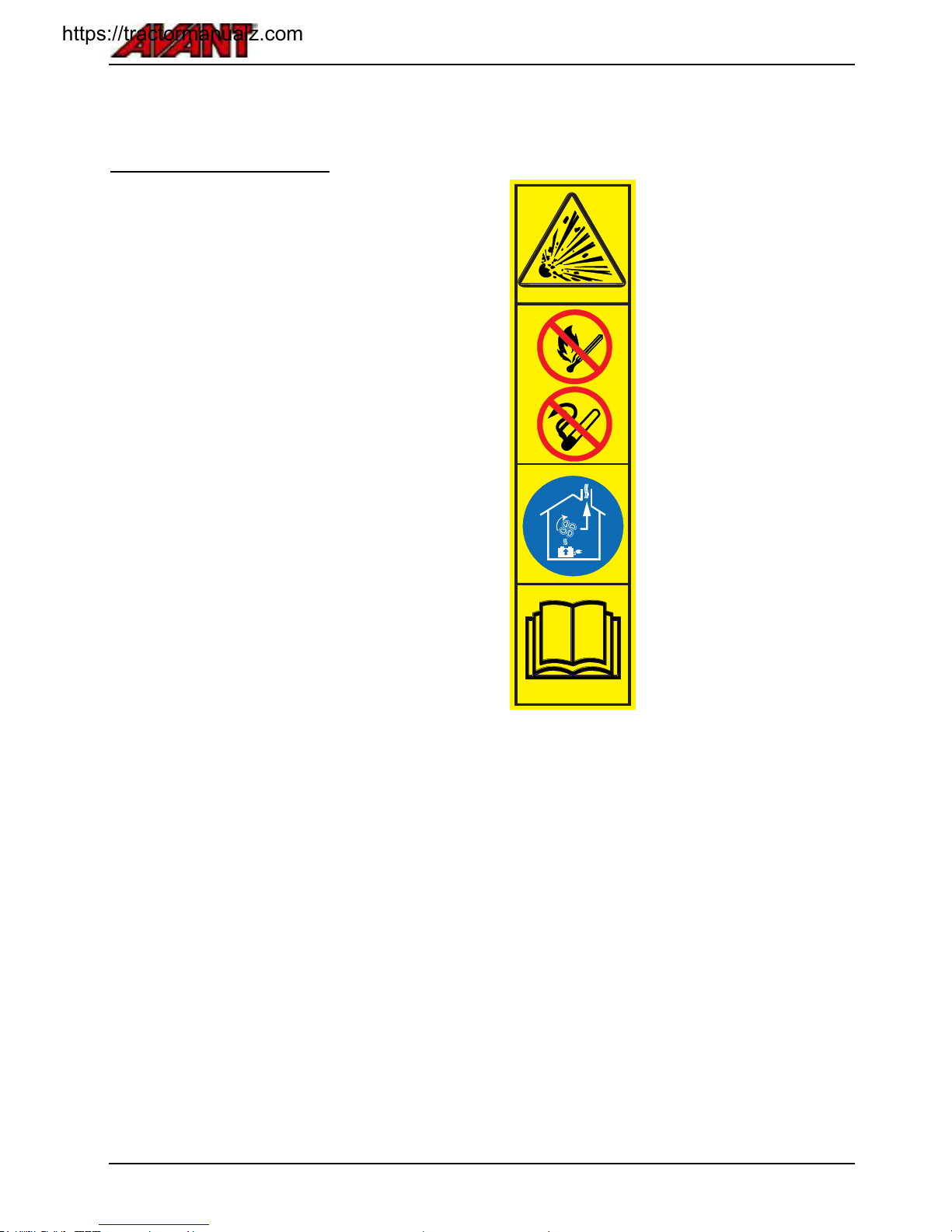

WARNING

Battery produces explosive

gas during recharge - Make

sure to charge only on well

ventilated area.

Make sure that

ventilation is sufficient

when charging the

battery.

Never charge the

loader in a small

garage or shed where

there is no ventilation.

Keep arcs, sparks,

flames, and lighted

tobacco away from

battery.

Never charge damaged

or frozen battery.

See detailed

instructions about

charge process starting

from page 63.

WARNING

Risk of battery explosion - Never

charge frozen battery.

Discharged battery can freeze. A

frozen battery can explode during

charging. Never charge a frozen

battery, allow the loader to warm at

a warm place first, if loader has

been left in freezing temperatures

with low battery. Prevent freezing

by keeping the battery charged

especially when there are chances

of freezing temperatures.

To ensure fire safety during recharge

Follow correct recharge instructions. Battery

produces explosive gases during recharge and

therefore ventilation must be ensured. Sparks,

lighted tobacco products, and other sources of

ignition must be kept away from loader during

recharge.

Plug the loader only to a grounded mains plug.

It is recommended to use a mains outlet with a

residual current switch device to protect from

electric shock in case insulation of cables is

damaged. Those devices must be tested

periodically.

Use extension cables only if necessary. Use as

short cables as possible. Choose only high

quality cables with large conductor cross-section.

Poor quality cables can heat up and even burn.

Avoid cable loops to prevent heating of the

cable. Unwind any long cable that is coiled,

otherwise the cable can overheat and burn.

During charge, the electric power that runs

through the cable is about 2300 watts.

Make sure the fuses of the mains plug are

adequate for the loader.

Avoid creating static electricity while loader is

charging. Do not wipe or otherwise clean the

loader during charge.

Make sure all charger and battery cables are

insulated and correctly connected.

https://tractormanualz.com

Avant e5

17

Description of the loader

.

..

Identification of the loader

Write down the identification information of your loader in the following fields, it facilitates ordering of spare parts

etc.

1.

Loader model

2.

Loader serial no.

Serial number of the loader is printed on the type plate, which also indicates the loader model.

Dealer:

Contact information

Loader identification

Loader identification plate is located on the right

side of the steering wheel.

https://tractormanualz.com

Avant e5

18

.

Main parts of the loader

Following picture shows the main parts of the loader:

1. Front frame

On the front frame are mounted: driver’s seat,

operating controls, parking brake, hydraulic control

valves, hydraulic oil tank, auxiliary hydraulics outlet,

front wheels, hydraulic motors and the loader boom

with attachment coupling plate.

2. Back frame

On the back frame are mounted: battery pack,

electric motors, integrated charger and its socket,

hydraulic pumps, rear wheels, hydraulic motors, and

counterweights.

3. Articulation joint

Articulation joint connects the front and back frame.

The loader is steered hydraulically by the steering

cylinder which is mounted between the front and

back frames. Hydraulic hoses and electric wires are

conducted through the articulation joint.

4. Loader boom

Loader boom is mounted on the front frame and is

controlled with control lever from the driver's seat.

The attachment coupling plate is mounted at the end

of the boom. The boom is telescopic, extending 600

mm hydraulically. The boom can be fitted with a

hydraulic self-levelling system

5. Attachment coupling plate

Attachments are mounted on the attachment

coupling plate. The locking pins on the plate can be

operated manually (standard) or hydraulically

(option).

6. Auxiliary hydraulics outlet

The hydraulic hoses of hydraulically operated

attachments are mounted on this outlet. The outlet is

equipped with the multi connector quick coupling

system and is double acting: it has two pressure

lines and one tank line, see page 61. If the loader is

equipped with the optional Attachment control switch

pack, its electric socket is integrated in the multi

connector.

In addition, as an option, it is also possible to install a

double-acting auxiliary hydraulics outlet in the front.

The quick coupling of this extra outlet will be located

under the multi connector.

7. ROPS safety frame

ROPS frame (Roll-over protective structure)

complies with the standard ISO 3471:1994 with

Amendment 1:1997 and Technical Corrigendum

1:2000 for a maximum machine configuration mass

of 2720 kg.

8. FOPS canopy

FOPS canopy (Falling objects protective structure)

mounts on the ROPS. It meets the ISO 3449:2005

(1365 J) criteria.

.

..

https://tractormanualz.com

Avant e5

19

.

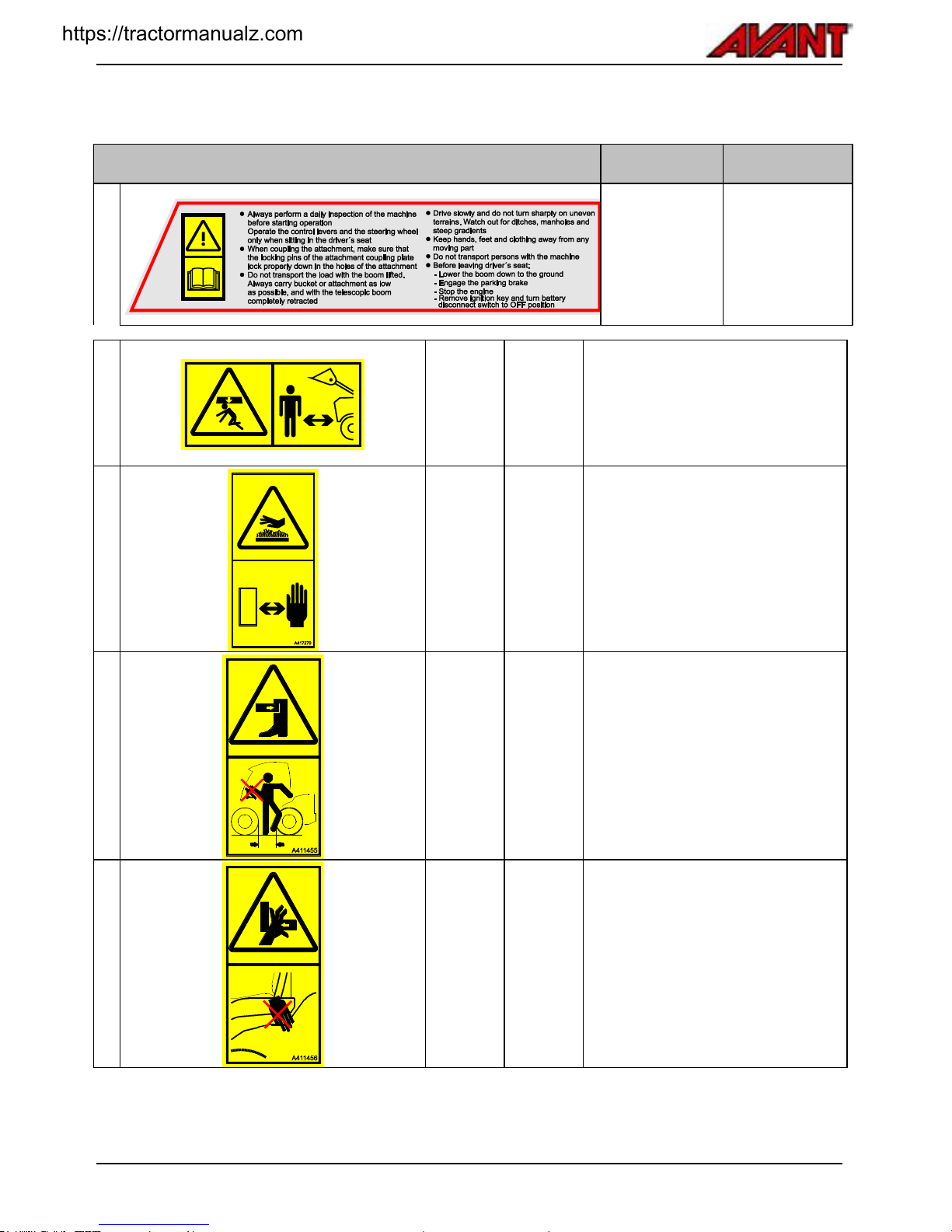

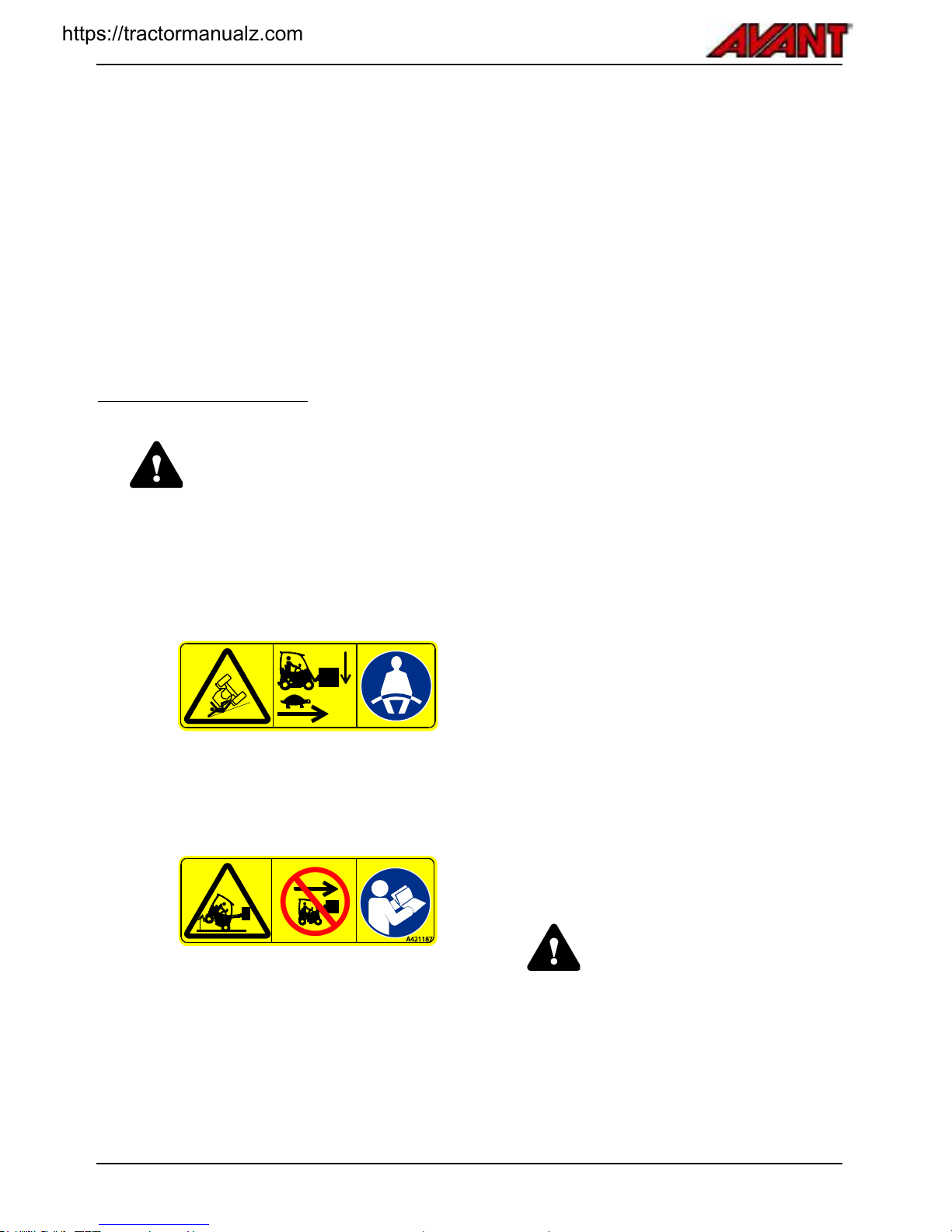

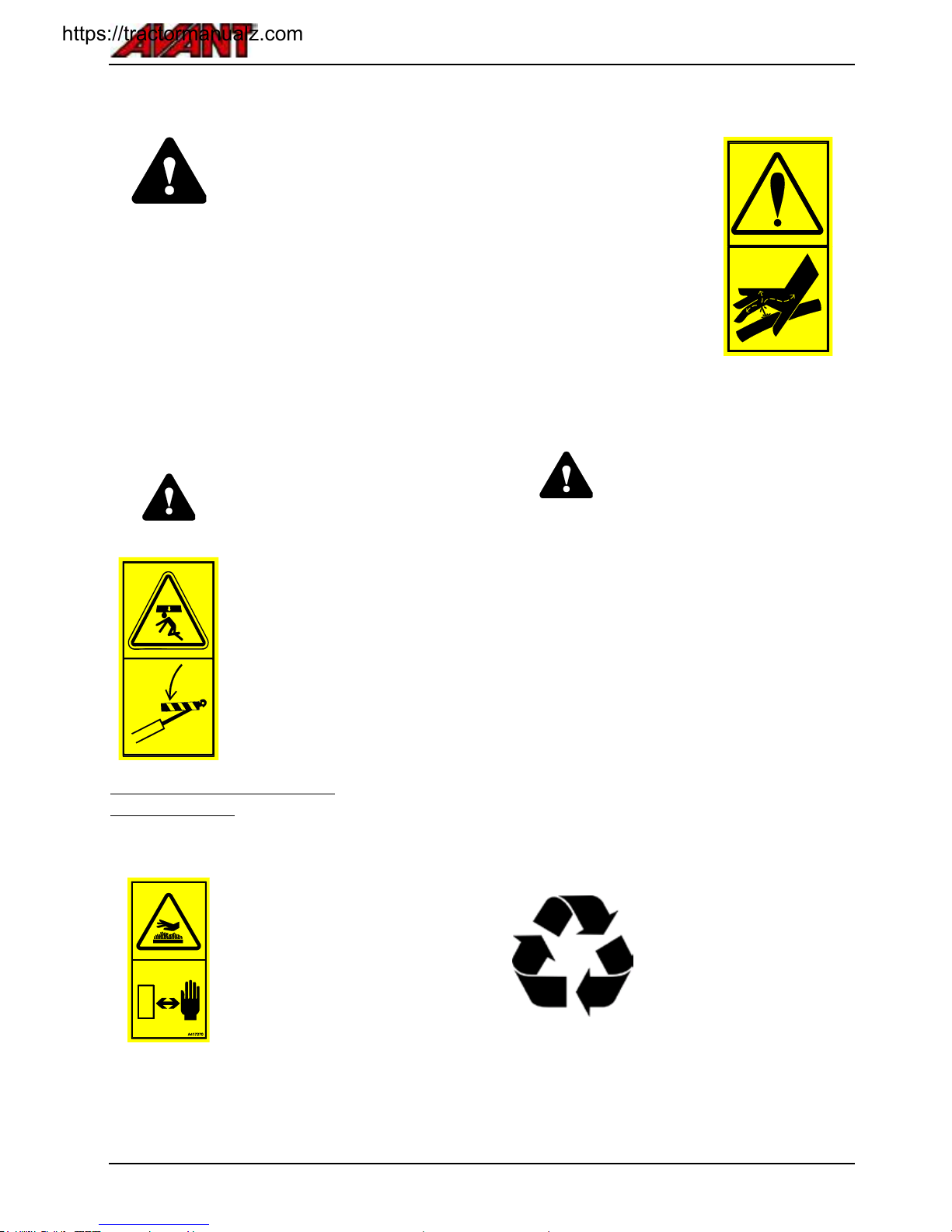

Signs and decals

Shown in the figure below and listed on the following page are the labels and markings, which must be visible on

the equipment. Replace any warning label which has become unclear, or has detached completely. New labels are

available via your retailer or contact information provided on the cover.

Before applying a new decal, clean the surface from dirt, dust, grease, or other material. Peel small portion of the

decal backing paper and apply exposed adhesive to cleaned surface, aligning the decal properly. Peel rest of

backing paper and press with hands to smooth out the decal.

The warning labels contain important safety information and they help to identify and

remember the hazards related to the equipment.

Make sure that the following signs and decals are clean, undamaged and readable. If any

of these decals is missing or is unreadable it should be replaced without delay. Ask for

new decals from your local Avant dealer.

https://tractormanualz.com

Avant e5

20

.

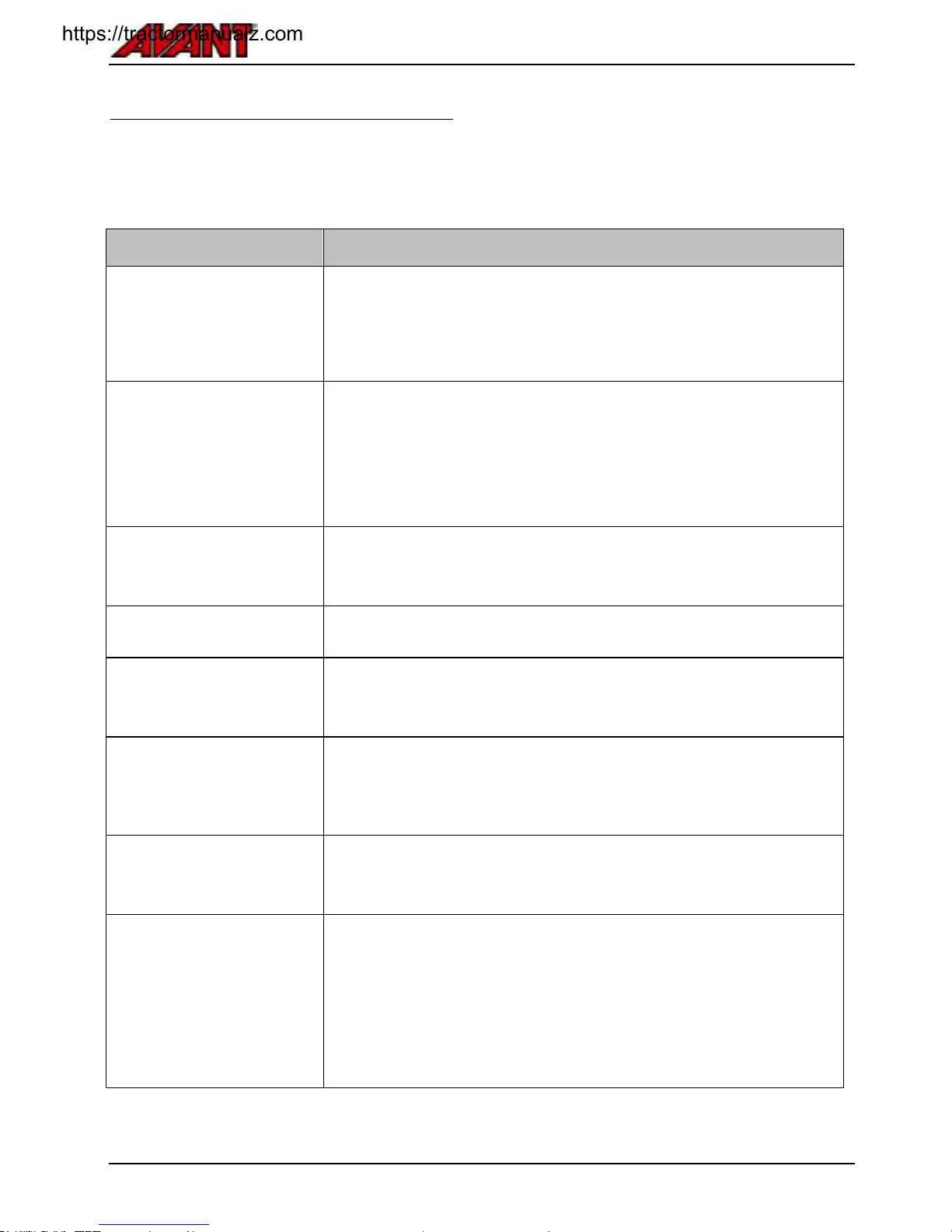

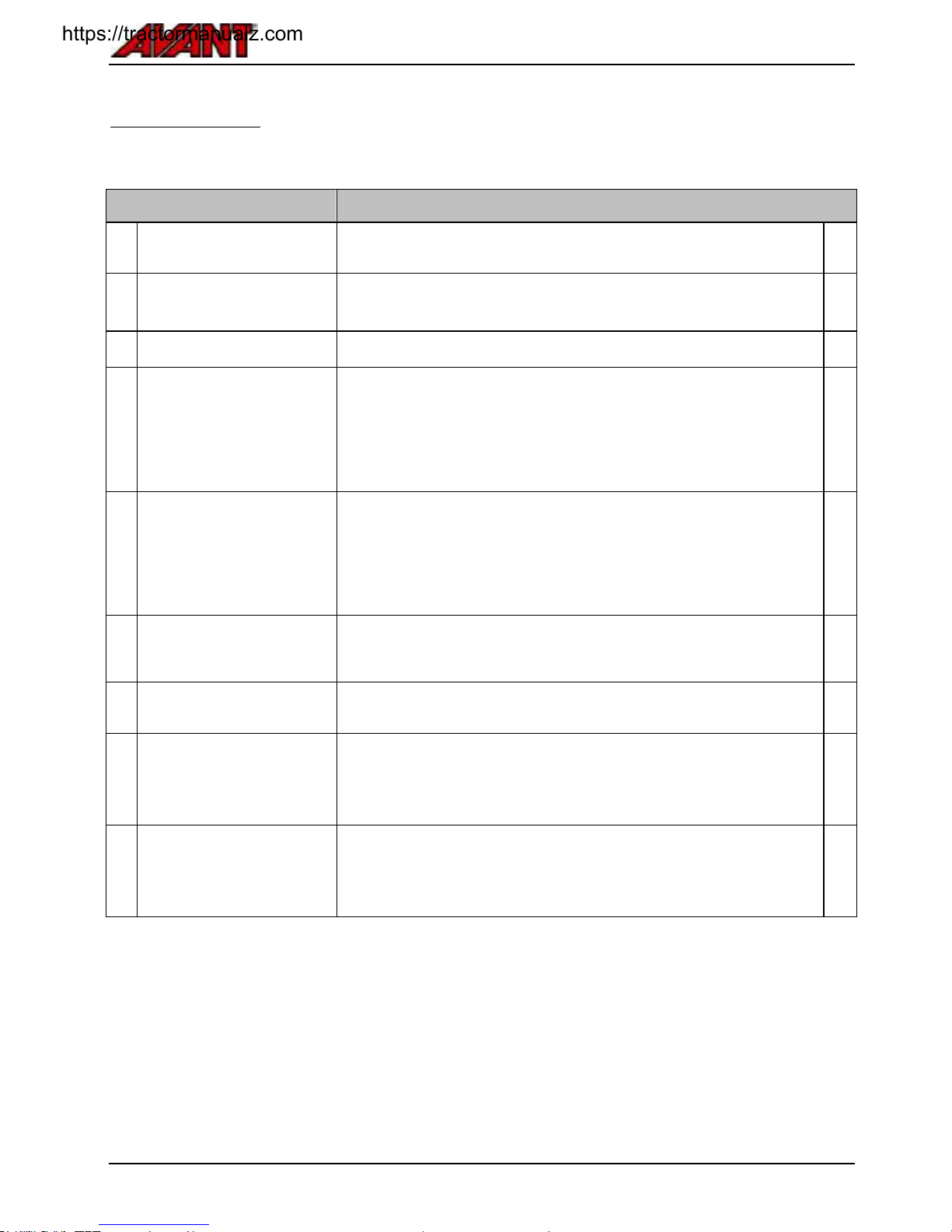

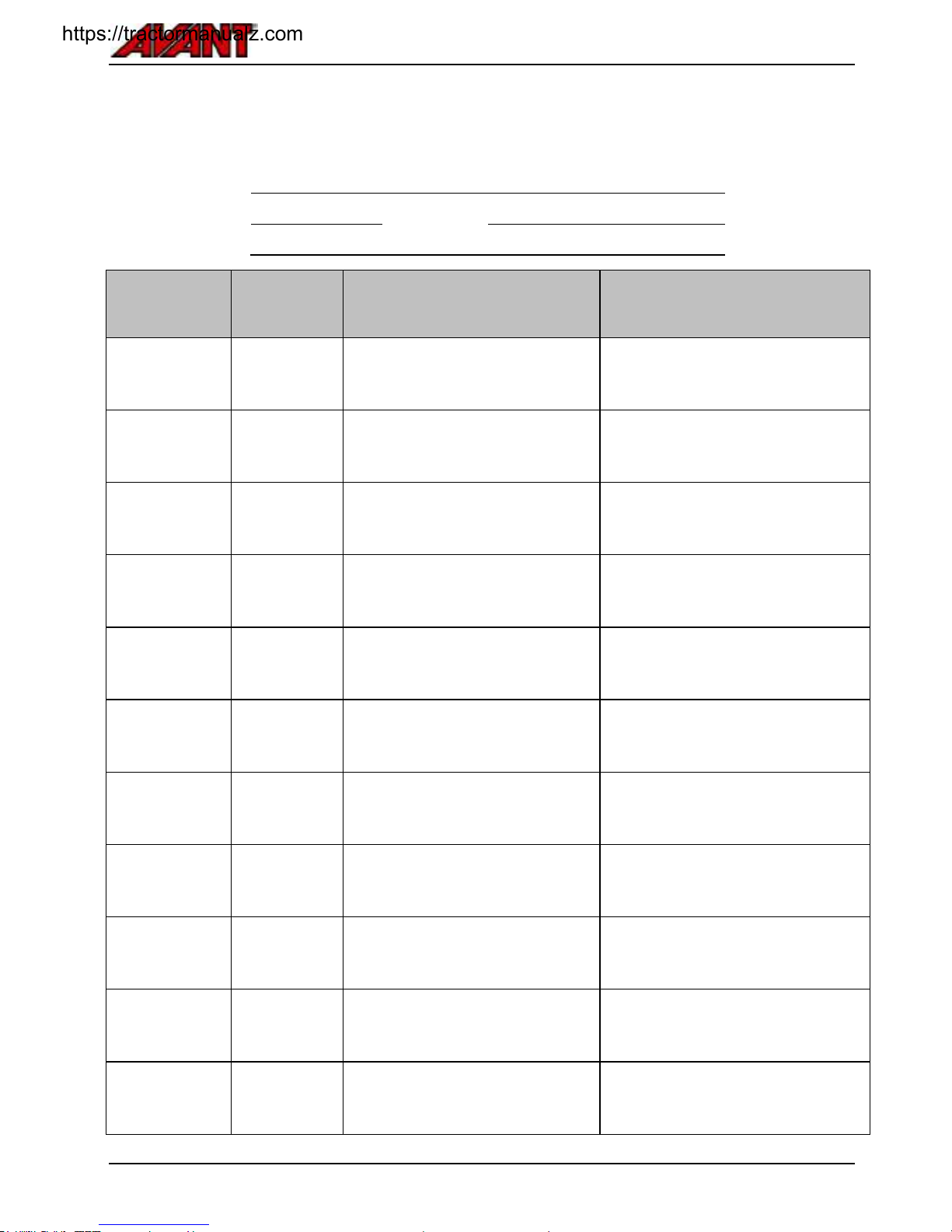

Table 2 - List of safety labels and markings on the machine

Label

Location

Product code

1

Below steering

wheel

A414690

2

Boom, on

both sides

A417273

(2 pcs)

DANGER

Lowering of loader boom can crush,

causing death or serious injury.

Keep out from the danger zone of the

machine.

3

Near

electric

motors

A417270

WARNING

Risk of burns - Extremely hot surfaces.

Keep clear.

Allow loader to cool completely before

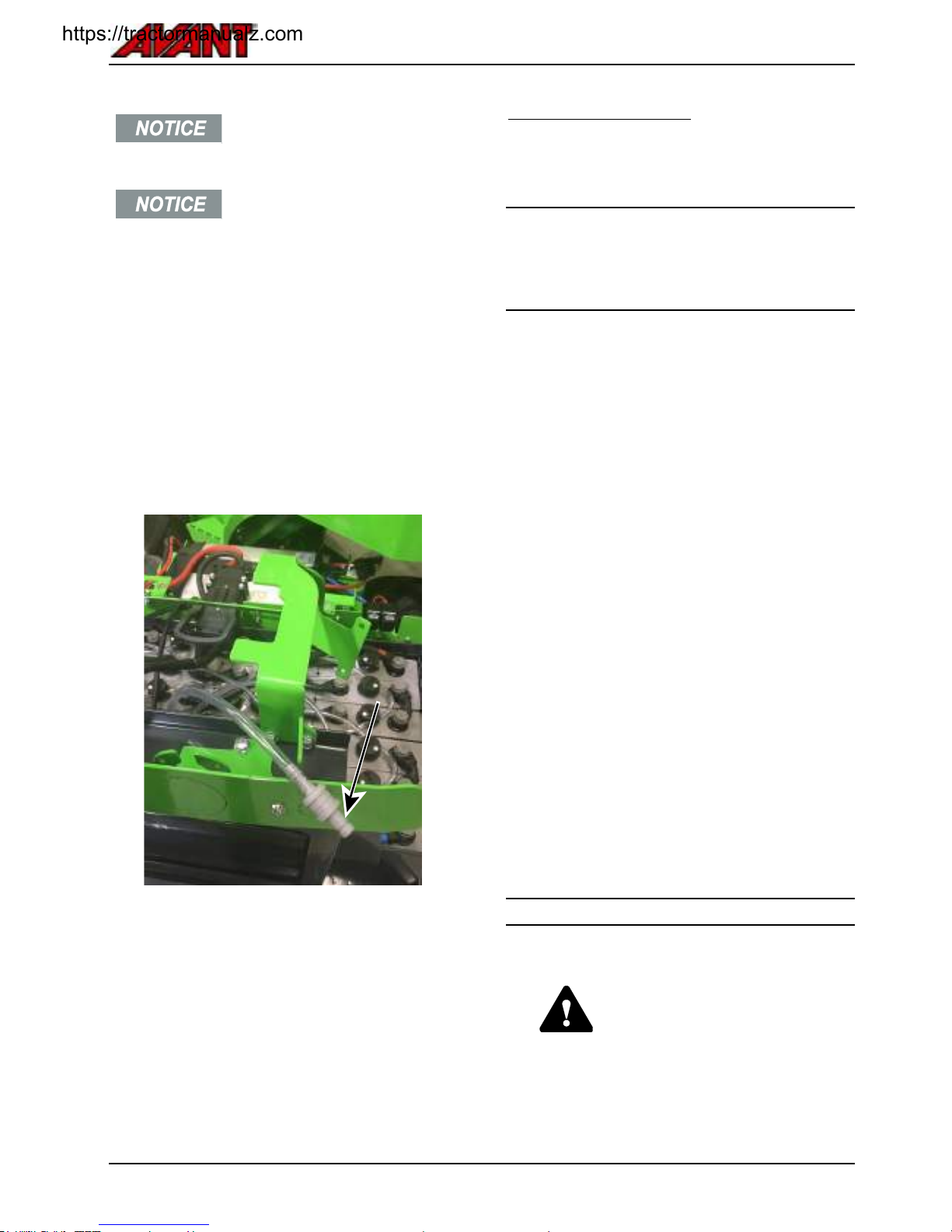

maintenance.

4

At loader

entry point

A411455

WARNING

Risk of crushing - Small gap between

tyres of articulated loader. Do not grip

the steering wheel from outside the

machine or when getting into the

driver’s seat to prevent moving of the

wheels.

5

At loader

entry point

A411456

WARNING

Risk of crushing - Keep hands and feet

within the driver's area.

https://tractormanualz.com

Avant e5

21

Table 2 Continued - List of safety labels and markings on the machine

Label

Location

Product

code

Message

6

Next to

steering

wheel

A420354

CAUTION

Using the parking brake while machine

is moving may cause locking of wheels

and sudden stop.

Always engage the parking brake after

stopping the machine first. The parking

brake should be used to stop the

machine only in emergency. Repeated

use while driving will damage the

brakes.

Table 3 - Information labels

Label

Location

Product

code

Message

7

ROPS

frame

A420726

ROPS/FOPS Approval

8

Right

panel near

driver's

seat

A43600

Sound pressure level 88 dB(A) at

driver's seat

9

Right

panel near

driver's

seat

A411047

Sound power level 101 dB(A)

2000/14/EC

10

Front

panel

below

driver's

seat

A415780

Correct type of hydraulic oil

https://tractormanualz.com

Avant e5

22

.

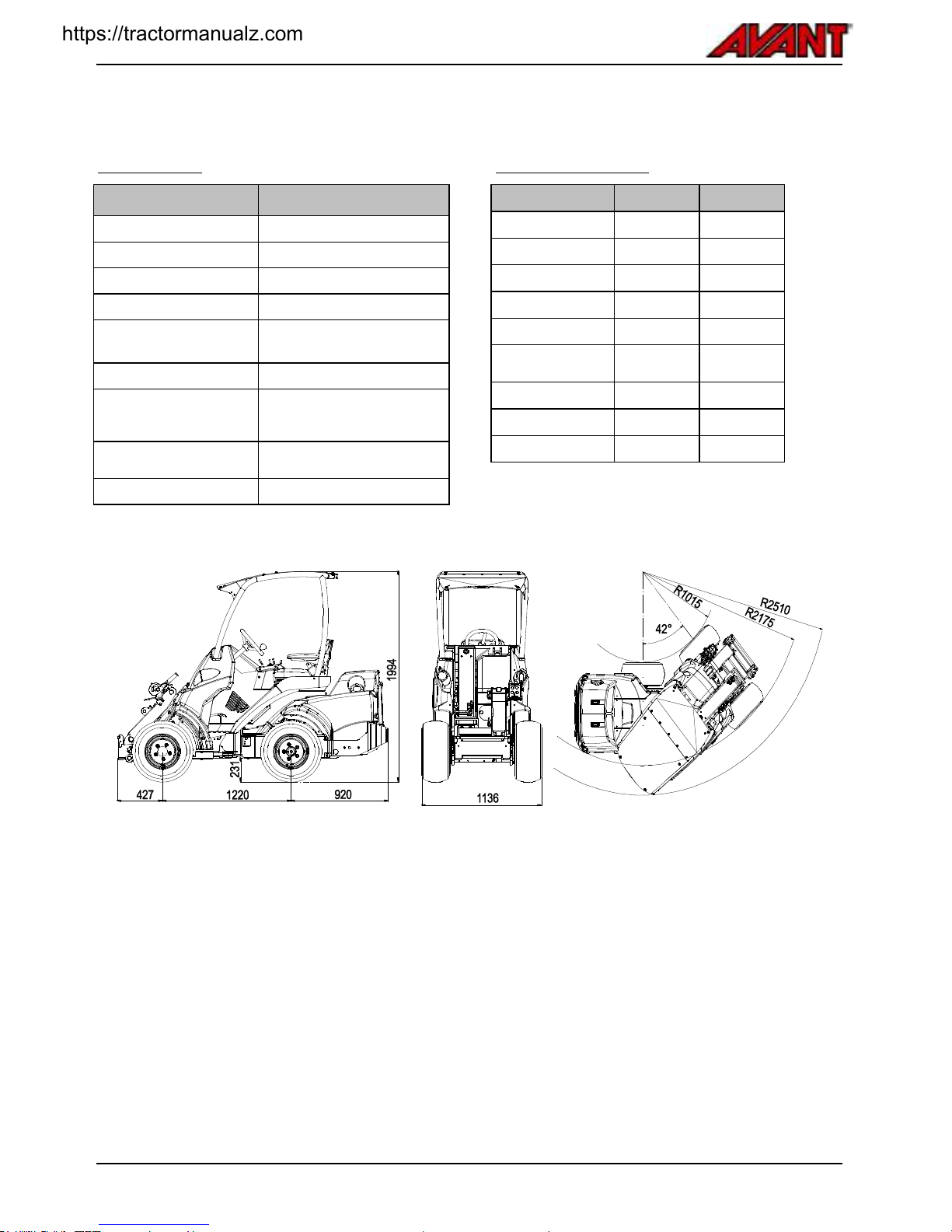

Technical specifications

Dimensions

General dimensions

Length

2550 mm

Width

1130 mm (with standard tyres)

Height

1985 mm (with standard tyres)

Mass (empty)

1600 kg

Tyres

Standard:

23 x 10.50-12" TR / GR

Lifting height

2820 mm

Max reach

1100 mm (distance from

standard front wheels to quick

coupling plate)

Turning radius,

inside/outside

995 mm / 2050 mm

Ground clearance

200 mm

Height and width

Tyre

Width

Height

23 x 8.50-12" TR

1080 mm

1980 mm

23 x 10.50-12" TR

1130 mm

1985 mm

26 x 12.00-12" TR

1290 mm

2013 mm

320/60-12" HD TR

1290 mm

2013 mm

27 x 8.50-15" TR

1030 mm

2026 mm

26.5 x 14.00-12"

TR

1420 mm

2020 mm

23 x 8.50-12" GR

1080 mm

1980 mm

23 x 10.50-12" GR

1130 mm

1895 mm

26 x 12.00-12" GR

1290 mm

2013 mm

.

..

.

..

https://tractormanualz.com

Avant e5

23

.

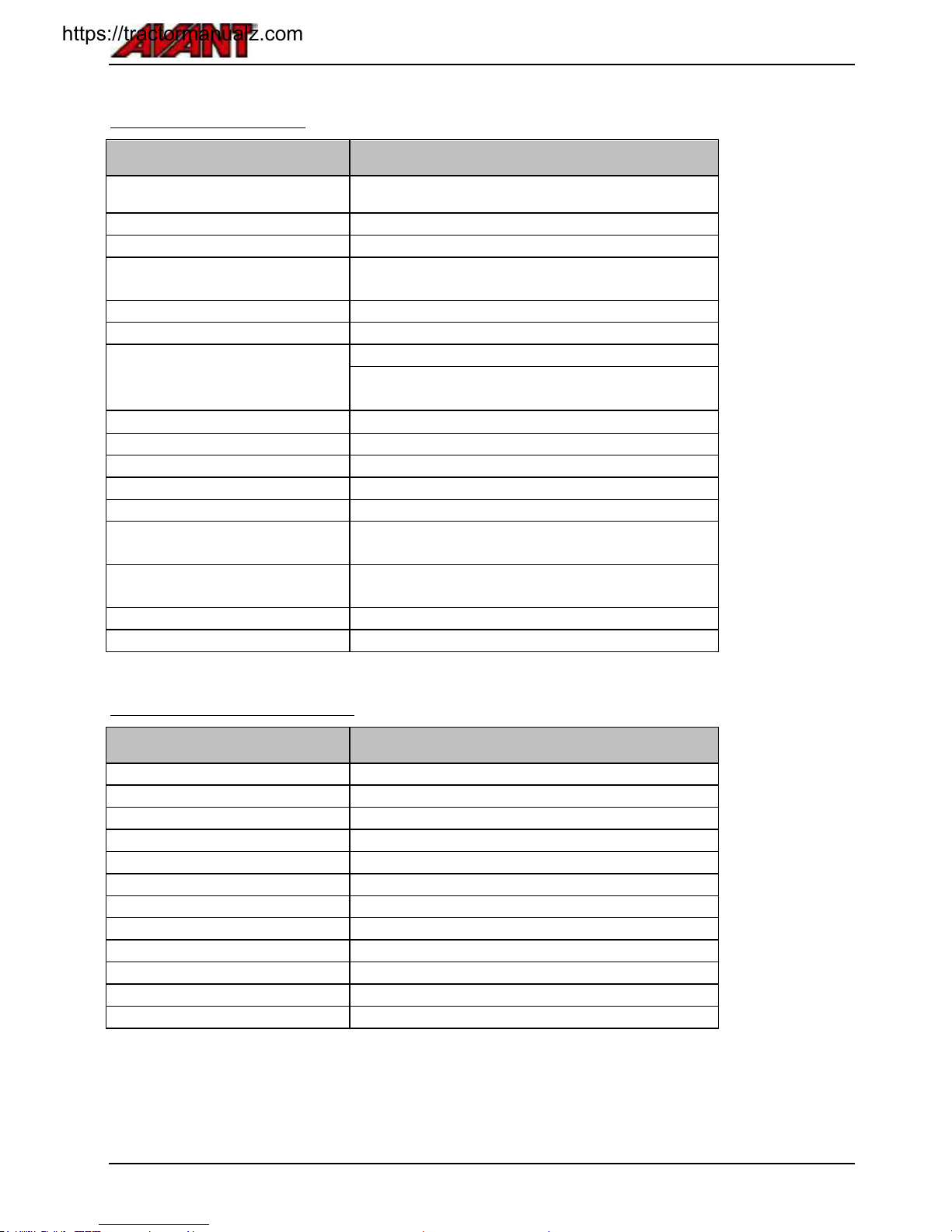

General specifications

e5

Category

Earth-moving machinery / Loader /

Compact loader EN ISO 6165

Product code

A21714

Drive system

Hydrostatic 4WD

Tipping load ISO 14397-1

(see also page 27)

970 kg

Rated operating capacity

480 kg

Pulling force

Static min 640 daN

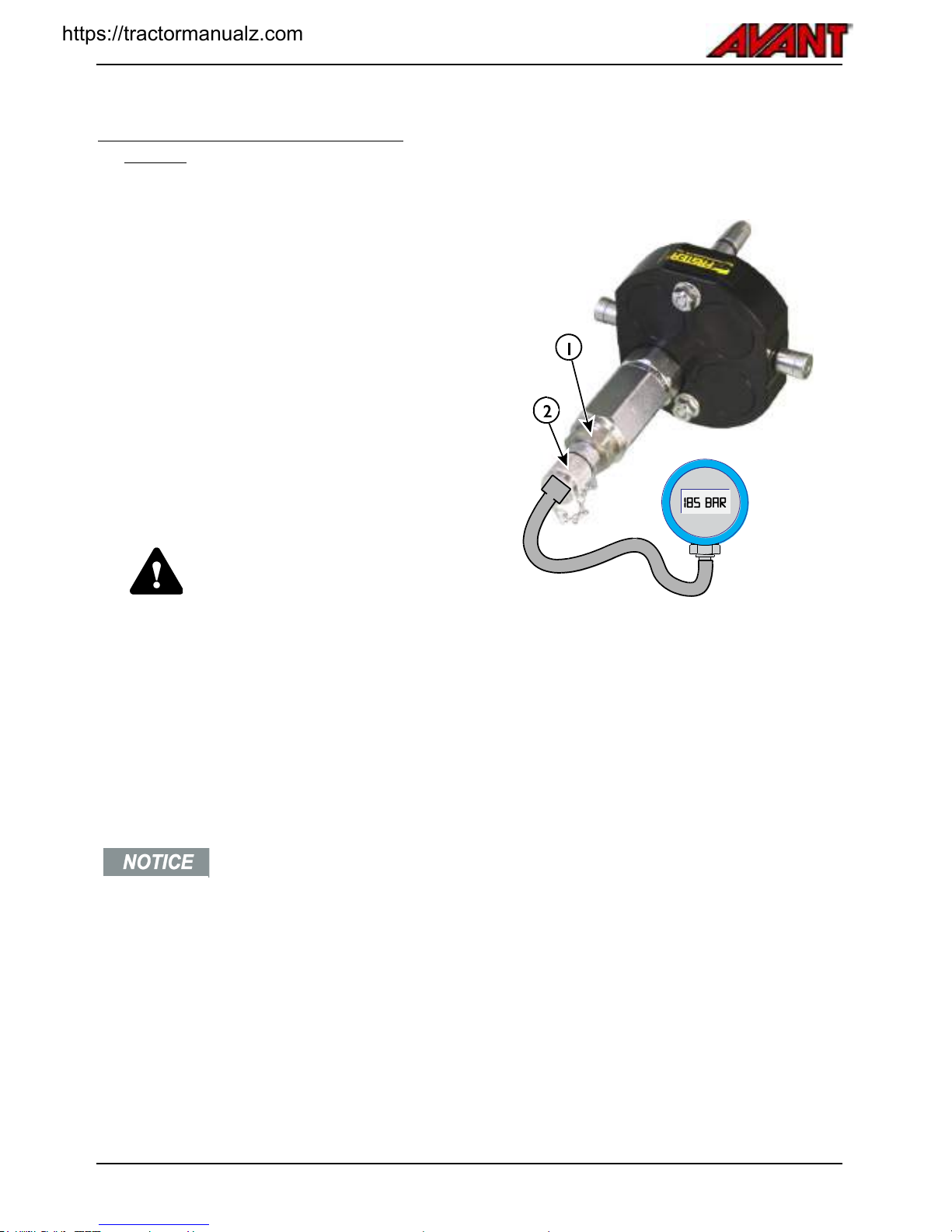

Auxiliary hydraulics

*See also page 24

Max 18,5 MPa (185 bar)

Max flow

Front: 30 l/min

Hydraulic pumps

2

Auxiliary hydraulics

Standard: Faster multiconnector system on front

Attachment coupling

Avant quick coupling attachment plate

Hydraulic oil capacity

<HydroilC_e5>

Hydraulic oil type

ISO VG 46, mineral oil only

Sound pressure level

2000/14/EC Lp, ISO 6396

88 dB(A) dB(A)

Sound power level

2000/14/EC Lp, ISO 6395

101 dB(A) dB(A)

Hand-arm vibration, total

< 2,5 m/s2

Whole-body vibration, max.

< 0,5 m/s2

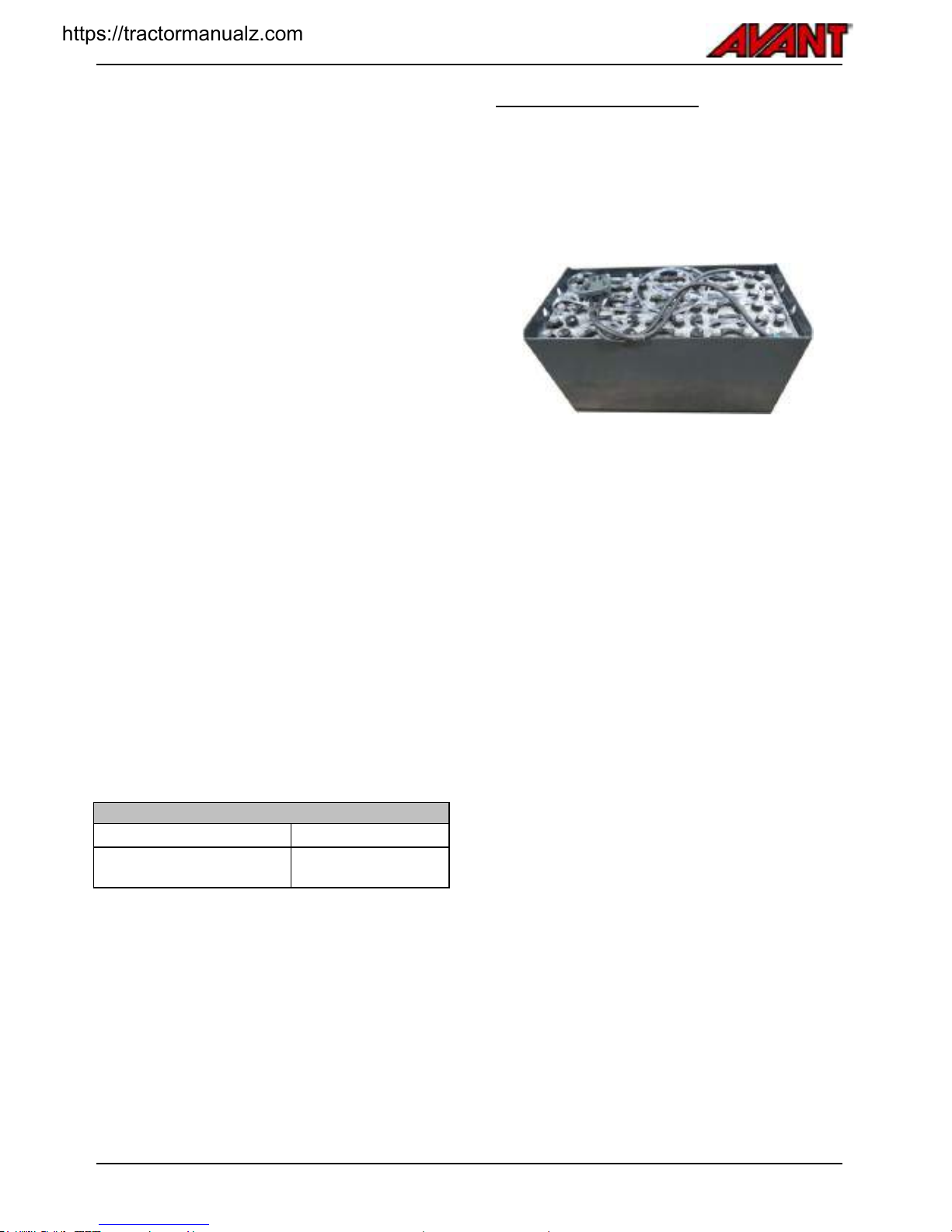

Electric system and battery

e5

Battery type

Lead acid battery pack

Battery product code

66390

Stored energy

11,5 kWh

Capacity

240 Ah

Voltage (nominal)

48 V

Electric motors

2

Battery cycle life

1500 cycles (estimate). See page 64

Control system and accessories

12 V / 22 A DC-DC converter

Charging system

Integrated charger

Mains current plug for charger

Schuko, grounded

Charger voltage and current

See page 66

Charging current

Controlled by charger, max 40 A ,48 v / 10 A, 230 v

https://tractormanualz.com

Avant e5

24

.

Auxiliary hydraulics oil flow

The graph below shows auxiliary hydraulics output

flow at different rpm levels of the electric motor. The

rpm of electric motor of the auxiliary hydraulics pump

is controlled with the hand throttle lever.

Some attachment may work optimally at certain flow

level, use the graph to estimate correct rpm setting.

The hand throttle lever controls

only the auxiliary hydraulic pumps.

The position of the hand throttle

lever does not affect the speed or

pushing power of the drive system.

Keep the rpm setting as low as

possible to smoothly operate the

attachment to conserve energy.

Pull the throttle lever back when

not operating an attachment.

Maximum auxiliary hydraulics oil

flow cannot be used with all

attachments. Check correct rpm

level for each attachment with the

help of this graph and the

Operator's Manual of each

individual attachment. Attachment

may get damaged, run too fast, or

it may be difficult to control

precisely when oil flow is too high.

.

Drive speed and pulling force

Tyre

Drive speed

Pulling

force

e5

TR

23 x 8.50-12" TR

9 km/h

100 %

23 x 10.50-12" TR

9 km/h

100 %

26 x 12.00-12" TR

9 km/h

85 %

320/60-12" HD TR

10 km/h

80 %

27 x 8.50-15" TR

10 km/h

80 %

26.5 x 14.00-12" TR

11 km/h

75%

e5

GR

23 x 8.50-12" GR

9 km/h

95 %

23 x 10.50-12" GR

9 km/h

100 %

26 x 12.00-12" GR

9 km/h

85 %

* The maximum speed of the loader is the highest

speed that can be achieved in optimal conditions.

Load distribution, tyre pressures, ground surface,

and many other conditions influence the maximum

speed.

** The pulling force depends on the size of the tyres.

In the table pulling force with each tyre model is

listed as comparison with the standard tyres (100 %).

https://tractormanualz.com

Avant e5

25

.

Tyres

The loader can be equipped with different type of tyres for different operating conditions. Grass pattern (GR) tyres

will damage the ground surface less than tractor (TR) tyres, but provide less traction.

Tyre

Tread

pattern

Code

Fill

pressure

Fits with fenders

Fits with snow chains

Front

Rear

SD

HD

27 x 8.50-15"

TR

65414

4,2 bar - -

65723

-

23 x 8.50-12"

TR

65995

3,4 bar x x

64746

64455

23 x 8.50-12"

GR

65994

4,6 bar x x

64746

64455

23 x 10.50-12"

TR

65997

2,5 bar x x

-

64745

23 x 10.50-12"

GR

65996

3,0 bar x x

-

64745

26 x 12.00-12"

TR

65739

3,4 bar x x

-

64973

26 x 12.00-12"

GR

65212

3,4 bar x x

-

64973

320/60-12" HD

TR

65224

4,0 bar x x

-

65603

26.5 x 14.00-12"

TR

65787

1,8 bar - -

-

-

* When using the 26,5x14.00-12" tyres (code 65787), use of 40 mm wheel spacers is mandatory to fit these tyres.

See more information below.

For the best stability and controllability, always use

the largest tyres possible. Tyres that are narrower

than the standard tyres are intended for special

purposes only with width restriction on the machine.

Use only tyres and rims that meet the original

specifications and dimensions to avoid potential

issues with load capacity, tyre size, or bearing load

on drive motors. Special tyres, such as studded

wheels may also be available. Consult your dealer

for further information.

Use widest tyres possible

WARNING

Risk of tipping over - Make sure

tyres are not damaged. Loss of

tyre pressure can cause loader to

tip over. Make sure there are no

visible damages on tyres. Keep

tyre pressure within

recommendations.

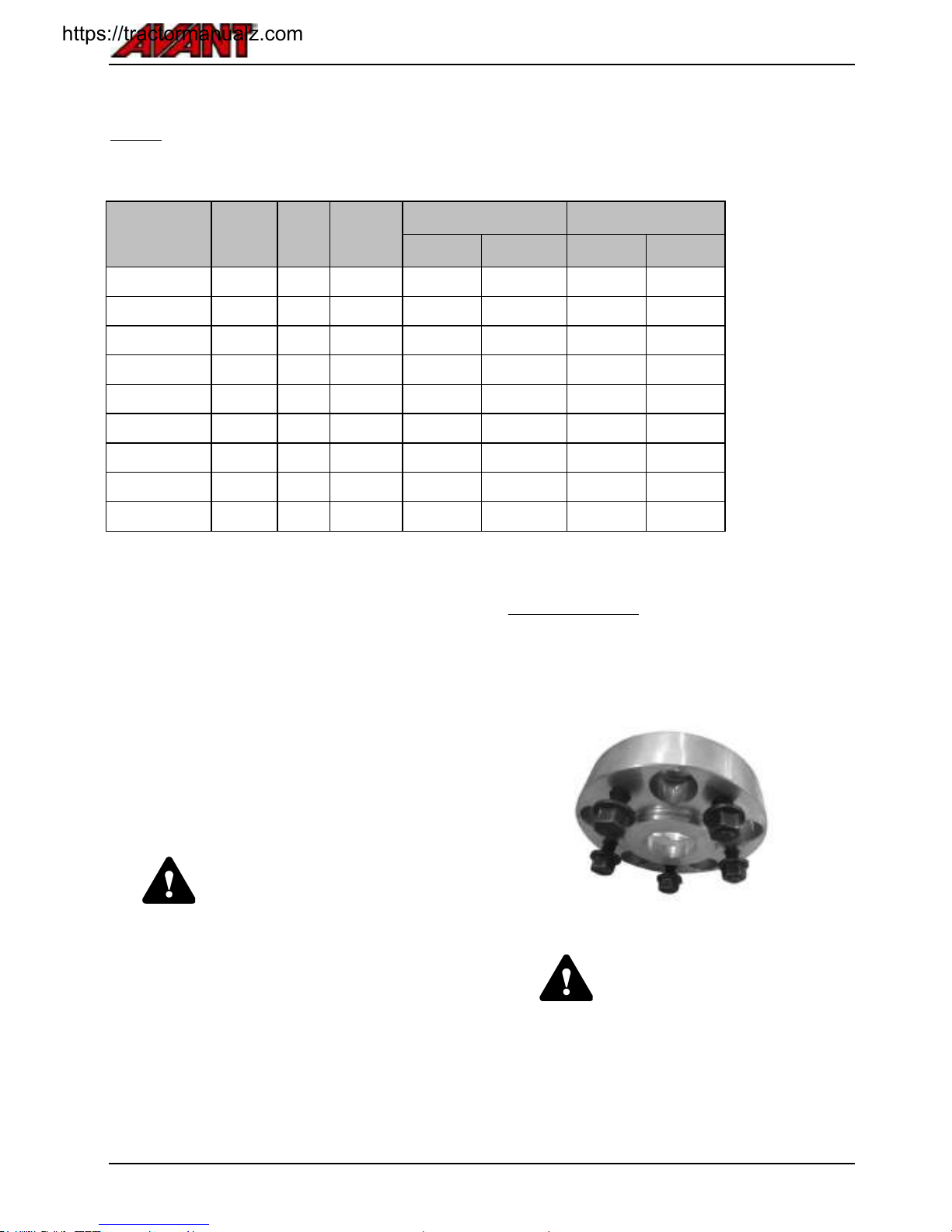

Wheel spacers

The wheels can be fitted with spacers that increase

the width of the loader for better stability. The

spacers A417486 are 40 mm thick. They must be

installed in order to fit the wide 26.5x14.00-12" tyres.

WARNING

Wheel spacers improve the lateral

stability of the loader. Do not

remove the wheel spacers unless

operating the loader on flat areas,

where the total width of the loader

must be reduced to as narrow as

possible.

https://tractormanualz.com

Avant e5

26

Use only spacers recommended by

the manufacturer. Too thick spacers

may damage the hydraulic motors.

Contact your Avant dealer for more

information.

Snow chains

Snow chains available at time of print of this manual

are listed in tyre table above. When using snow

chains, the fenders must be removed when using

larger tyre models.

There are two types of snow chains. See the table on

page 25 for a list of chains that are available for

the tyre size of your loader.

SD HD

Check that snow chains fit without hitting any part of

the loader. Check also that the snow tyres will fit

when the loader is turned to maximum articulation.

.

Ballasted tyres

Some tyres can be filled with special type of heavy

foam that creates additional counterweight. The filled

tyres are also useful in area where frequent tyre

puncture with normal tyres would be expected.

When driving with a loader that has ballasted tyres,

the acceleration and stopping distances may be

increased.

Ballasted tyres do not have air pressure inside them

and do not require air pressure checks.

CAUTION

Ballasted tyres are heavy - Handle

ballasted tyres with care. Filling of

tyres should be left to professional

tyre service.

When the loader is equipped with ballasted tyres, the

following symbol must be applied to a visible location

on the loader frame near tyres. If you replace the

tyres and install normal tyres, make sure to also

remove this label.

https://tractormanualz.com

Avant e5

27

.

Tipping load

Tipping load is the load at which the rear tyres lose

contact with the ground and the loader starts to tip

forward. A tipping load chart is shown on the next

page. The tipping load depends on many factors,

and the chart shows the influence of the position of

the loader boom.

The lifting capacity and the stability of the loader are

at the best, when:

the loader frame is kept straight

the centre of gravity of the load is as close to the

loader as possible

counterweights are fitted to the loader

swinging of the load is prevented and all controls

are used in a calm and careful manner

There are many influencing factors that affect the

stability of the loader in practise. Use the load chart

and ROC table to estimate the load handling

capacity of the loader. Observe the instructions and

information given in this manual.

See also page 50 for more information about safe

handling of heavy loads and page 51 for a list of

typical factors that influence the stability of the

loader.

.

WARNING

Risk of tipping over - Follow

safety instructions. The lifting

capacity of the loader is limited by

the possibility of tipping around the

front axle.

The operator must pay attention to

safe operating conditions

whenever handling loads.

.

..

WARNING

All counterweights affect

stability - Also the driver. Always

keep in mind: If the driver leaves

the machine, tipping and max.

loads are reduced respectively.

The indicated tipping loads and the ROC table are valid, when:

The ground is firm and level

Loader is stationary or driven max 2 km/h, with smooth and slow control movements

Driver 75 kg is seated on the driver’s seat

Load is distributed evenly on pallet forks, with the load centre of gravity at 400 mm from the vertical part of

pallet fork arms. The weight of the fork attachment is taken into account in the indicated load values

https://tractormanualz.com

Avant e5

28

.

Tipping load - load chart

With the load diagram below, you can estimate the

load handling capability of the loader.

The tipping load depends according to the distance

between the centre of gravity of the load and the

front axle of the loader.

The diagram represents the forward stability only. It

does not refer to maximum available lift force.

.

..

.

WARNING

Avoid overloading the loader Know the load and lifting

capacity of the loader.Heavy load

can cause tipping over when

moving the load. The diagram is

valid only on firm and level ground,

with the conditions listed above.

When the boom is moved to

another position, the load can

exceed tipping load and loader can

tip over.

Load chart e5

How to read the load chart

a Tipping load with the loader frame

in straight position.

b Tipping load with the loader frame

in maximum articulation.

ROC (Rated operating capacity),

defined as 60 % of tipping load for

pallet forks.

Example: If the centre of gravity of the

load is 970 mm in front of the front axle

(400 mm from the pallet forks at ground

level)

Tipping load is about 1230 kg with a

driver weighing 75 kg, and with the

articulated frame turned to max

articulation.

When lifting to horizontal position,

the tipping load is reduced to about

830 kg.

This means that a pallet with a total

weight of 1200 kg can be lifted just

off the ground.

.

..

https://tractormanualz.com

Avant e5

29

.

Rated operating capacity

To easily determine how much load the loader can

handle safely, a table of the tipping load and a

calculated Rated Operating Capacity (ROC) is

shown in the adjacent label. The label is also visible

from the driver's seat.

Rated operating capacity depends on type of use of

the loader:

In bucket and general application the rated

operating capacity is 50% of tipping load

In pallet fork application the rated operating

capacity is 60% of tipping load

The information shown in the table is the worst case

minimum load, with the conditions listed on page

27. Actual lifting capacity could be significantly

higher, or it may be lower, depending on terrain

conditions, available lifting force, and load

distribution. Adding or removing counterweights will

affect the indicated ROC.

Rated operating capacity label

Different loader configurations, rows in the label:

1. Loader frame in straight position, additional

180 kg counterweights fitted

2. Loader frame in straight position, standard

counterweight fitted

3. Loader frame in fully articulated position,

standard counterweight fitted

Different positions of the loader boom, columns

in the label:

1. Maximum tipping load, stability when lifting

load just off the ground with pallet forks

2. Boom lifted to horizontal position

3. Boom lifted to horizontal position, telescopic

boom fully extended (least stable position)

4. Rated operating capacity in pallet fork

application, telescopic boom retracted

5. Rated operating capacity in pallet fork

application, telescopic boom fully extended

https://tractormanualz.com

Avant e5

30

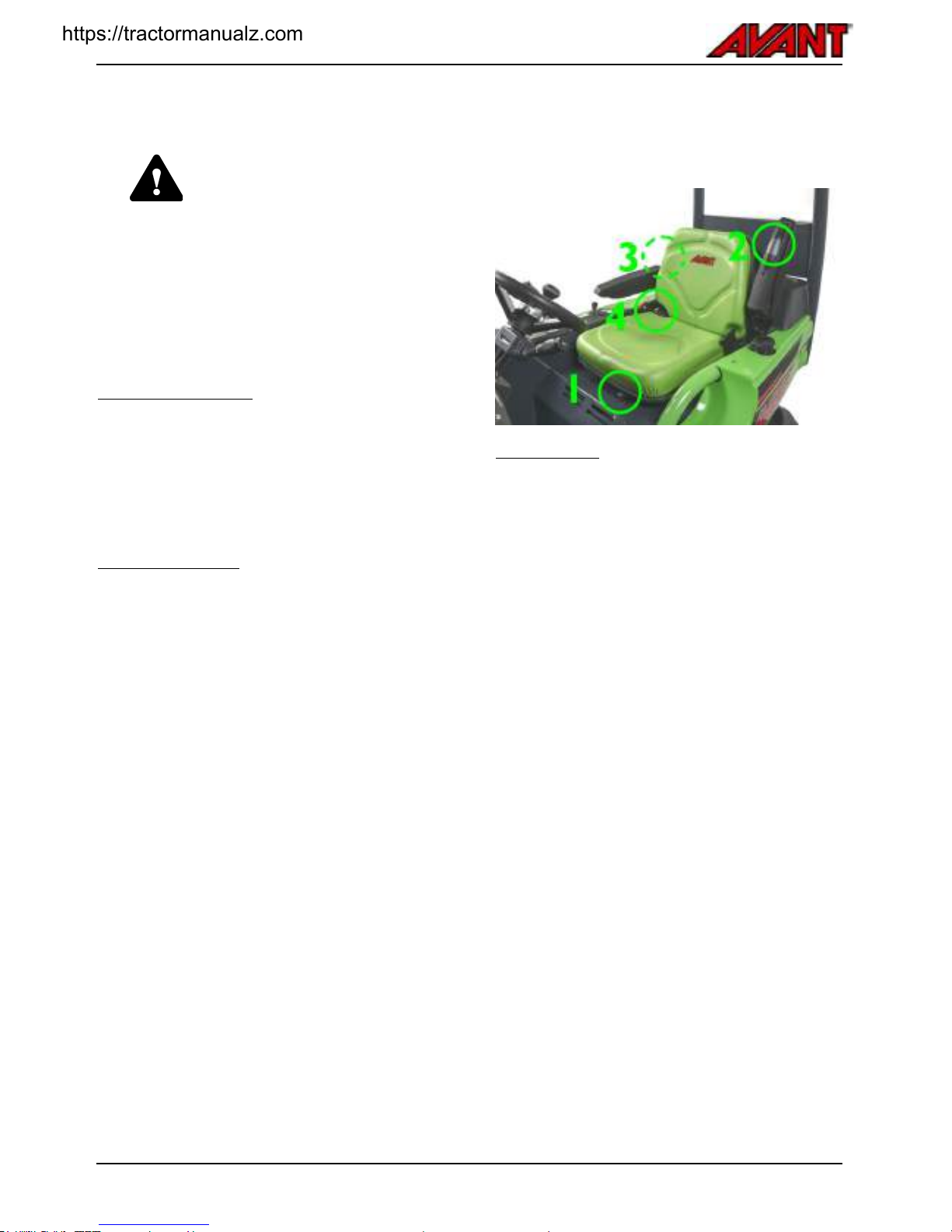

Controls and options of the Loader

Following picture shows the location of operating controls. The location and function of controls may be slightly

different in different models, see following pages.

Reference

Page

1.

Dashboard

Ignition switch

31

2.

Multi-function Display

35

3.

Charger status lights

31

4.

Signal horn switch

Control switches (see below)

5.

Control lever of boom and bucket

32

6

Auxiliary hydraulics control lever

32

7.

Boom telescope control

33

8.

Hand throttle lever

34

9.

12 V outlet (max 15 A)

35

Controls in footwell

A

Drive pedal, right: drive forward

(see below)

B

Drive pedal, left: drive backward

(see below)

.

..

Switches on the panel

NOTE: Some of the

switches presented

here are for optional

equipment and might

not be installed on

the loader.

The position of the

switch may be

different than shown

in here.

Auxiliary

hydraulics outlet

selection switch

Optional

equipment

See page 41

Extra work lights

on the ROPS

frame, 2 front, 1

rear

Optional

equipment

Drive mode /

speed range

selection switch.

See page 47

Warning beacon

Optional

equipment

See page see

page 37

Operation mode

selection switch

See page 46

Hydraulic locking

pins, attachment

coupling

Optional

equipment

See page 58

Parking brake

See page 35

Windscreen

wiper and

washer (CAB L

option)

see page 38

Emergency

blinker

Optional

equipment

https://tractormanualz.com

Avant e5

31

.

Dashboard

Dashboard e5

On the dashboard there is the ignition key, and

additional switches and indicator lamps.

The multi-function display shows information about

battery charge level, hours of use, and diagnostics

related trouble codes. The display is backlit

whenever the ignition key is switched on. The hour

metre runs whenever the electric motors are running.

Indicator lights

Symbol

Colour

Remarks

1

Not in use in this loader model

2

Red

Hydraulic oil cooler fan fuse

Hydraulic oil cooler malfunction.

See page 85

3

Blue

High beam headlights on

Road traffic light kit only

4

Green

Turn signal indicator

Road traffic light kit only

5

Green

Seat heater on

6

Yellow

Boom floating on

(optional equipment)

Boom floating See page 39

7

Green

Work lights on

Work light switch at lower part

of dashboard

8

Not in use in this loader model

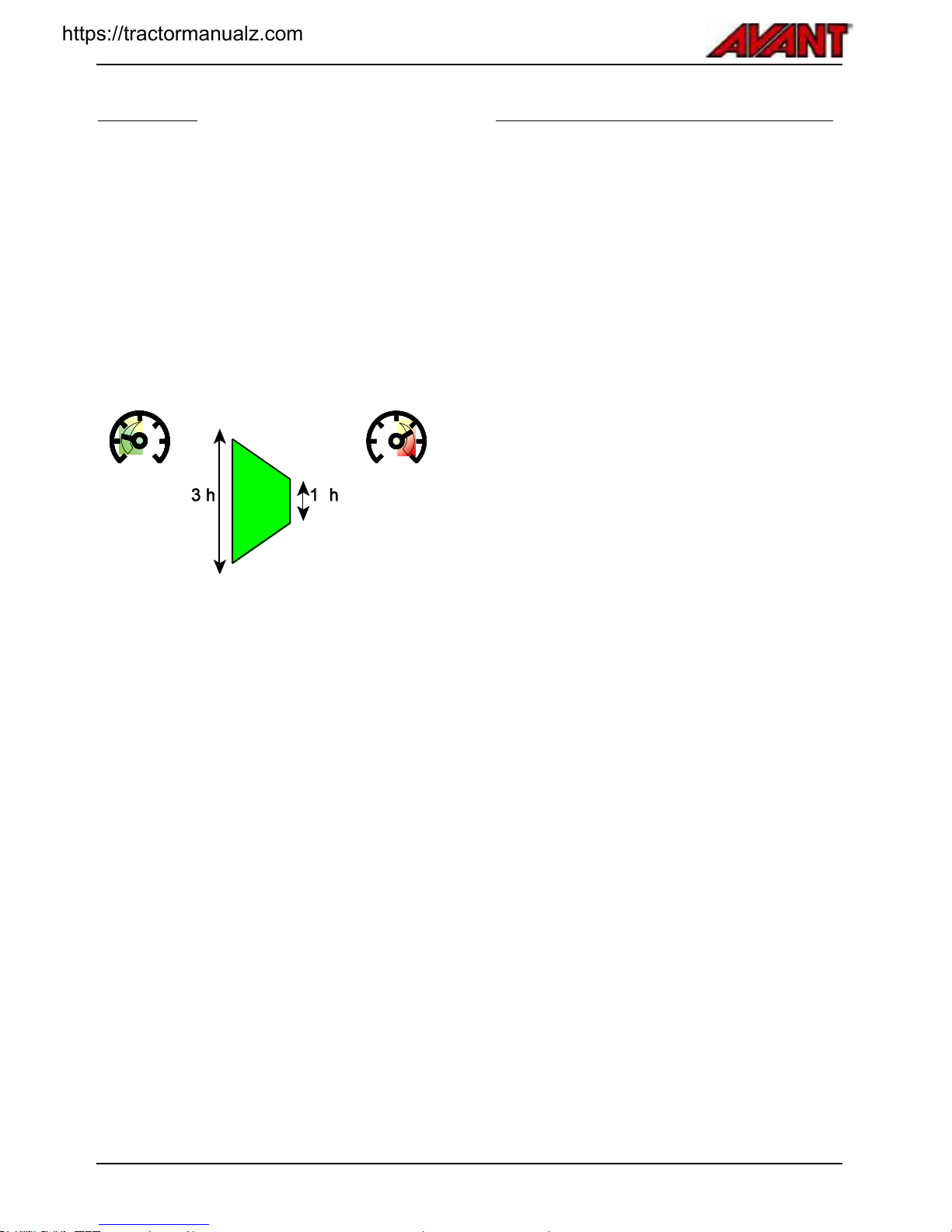

Charging indicator lights

Symbol

Colour

Remarks

9

Green

Battery fully charged

10

Yellow

Charge in progress

Full charge will take about 4

hours. Battery charge process

See page 63.

11

Red

Battery not charging

Charging system has detected

a fault and has prevented

charging to protect the battery

from damage, see

troubleshoot on page 87.

.

..

.

..

Switches on the dashboard

LOCK

Switch not in

use with this

loader model

Standard work

lights

Boom floating

Seat heater

https://tractormanualz.com

Avant e5

32

.

Control of loader boom, auxiliary hydraulics and other functions

Most of the functions of the loader are controlled with the controls at the right side of the operator: Boom and

bucket movements, auxiliary hydraulics (attachments), auxiliary hydraulics pump speed etc., depending on loader

model. Following paragraphs show the different functions.

1. Control lever of boom and bucket

The loader boom and bucket are controlled with the multi-function lever sideways (tilt) and back & forward (boom

up & down).

Pull backward to lift the

boom

Push forward to lower the

boom

Push left to raise the tip of

the bucket (filling)

Push right to lower the tip of

the bucket (emptying)

2. Control lever of auxiliary hydraulics (hydraulically operated attachments)

Hydraulically operated attachments are connected to the loader using the multi connector system, for more

information see page 61.

Operation directions depend on the attachment used.

When using an attachment for the first time, carefully

move the lever to test and check the operating direction

of the attachment.

For continuous operation of rotating attachments, turn to

direction 1 and turn to locking position.

If operating the buttons of the electric joystick, this lever will

not move. Either the lever or the buttons can be used to

control the attachment as needed.

When you operate attachments that require continuous flow,

such as attachments with hydraulic motors, it is important to

have the control lever in fully engaged position. If the control

valve is not fully open, restricting the flow of hydraulic oil,

hydraulic system may overheat quickly.

If necessary, adjust the locking plate so that the lever is

locked to fully open position.

https://tractormanualz.com

Avant e5

33

3. Telescopic boom control lever

The telescopic boom makes many tasks easier, also

those that do not involve lifting. You can, for

example, push material further with a bucket, reach

into difficult areas, and improve visibility to the work

area with some attachments.

The telescopic boom can be

extended by 600 mm. It increases

the maximum lifting height by 485

mm.

Turn the control lever of the

telescopic boom to the right to

extend the boom, and turn to the

left to retract it.

WARNING

Risk of tipping over - Extended

boom can cause the loader to tip

over. Use telescopic boom with

caution. The stability of the loader

depends on the distance of the

load from the front of the loader.

When you extend the boom, you

increase the effect of the weight

and reduce safe handling capacity.

See pages 27 and 50 for

further instructions about tipping

load and safe material handling.

.

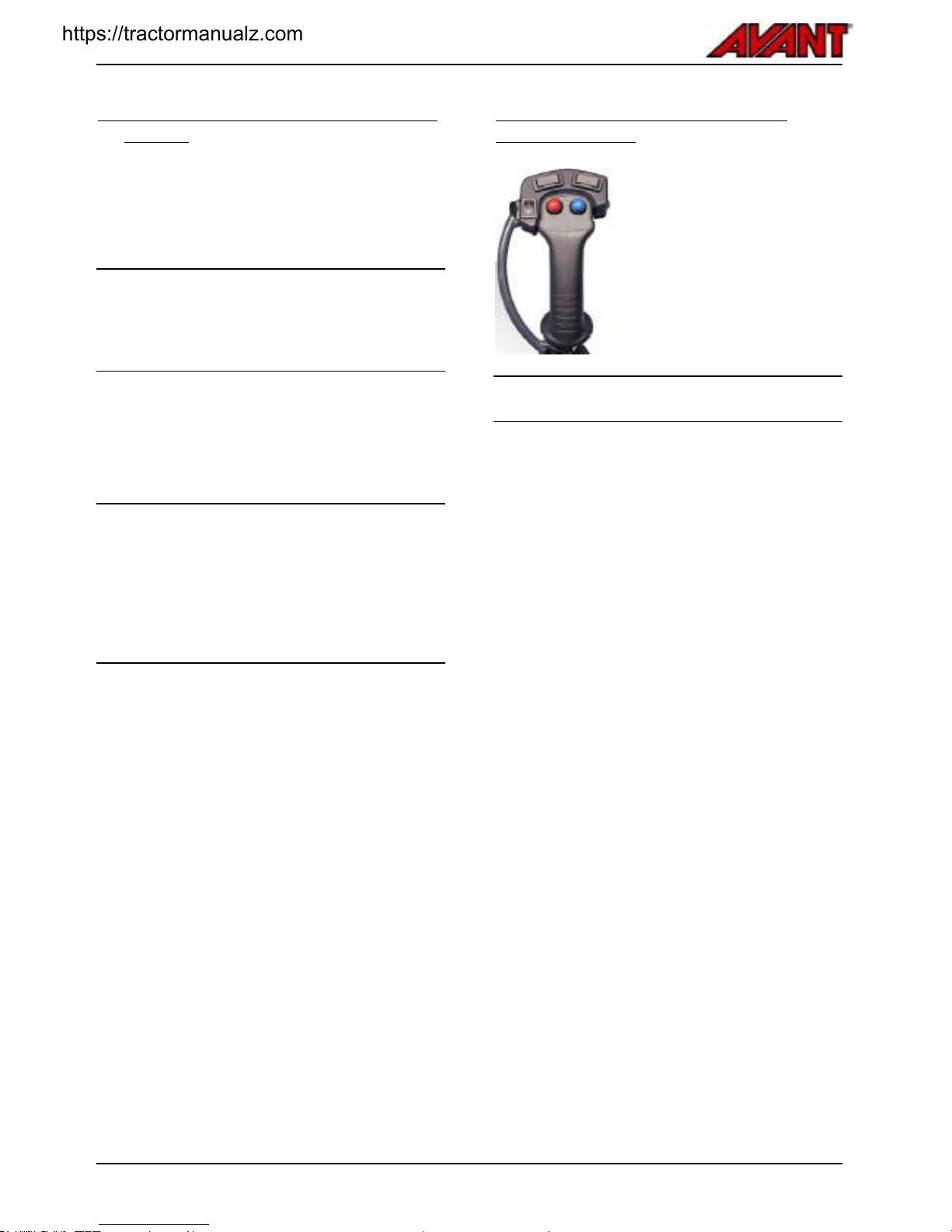

4. Joystick - 6 function (optional

extra)

If the loader is equipped with the optional 6 function

joystick, the auxiliary hydraulics can be controlled

with electric buttons on the joystick:

Push and hold either button to

operate hydraulic feature of the

attachment. While holding a

button, the manual control lever

also moves to corresponding

direction.

The operation of the buttons

depends on the attachment,

see Operator's Manual of the

attachment.

Release buttons to stop.

Make sure the manual control

lever is not locked when

operating electric joystick.

CAUTION

Avoid abrupt movements of an

attachment - Use electric

buttons with caution. When you

use certain attachments with the

electric joystick buttons, the

attachments can move abruptly.

This can cause falling of material

from the attachment, loss of

stability, or damage to attachment.

https://tractormanualz.com

Avant e5

34

.

5. Hand throttle lever for pump RPM

control

The electric motors run when the ignition key is

switched to ON position, and when the operator is

seated on driver's seat, or other operating mode is

selected. See more information about the operator

presence control on page 46.

The hand throttle lever controls the output and

rotation speed of the auxiliary hydraulics pump. The

drive system is controlled with drive pedals and the

hand throttle lever will influence only the auxiliary

hydraulics pump, not the drive system.

Push the lever forward to increase rpm of

hydraulic pumps and increase auxiliary

hydraulics oil flow

Pull backward to reduce rpm of hydraulic pumps

and to decrease auxiliary hydraulics oil flow

The auxiliary hydraulics pump will also provide

pressure for the release of the parking brake, and to

flush the drive circuit. This is why the auxiliary

hydraulics pump will operate whenever the loader is

ready to be driven. However, to conserve battery

energy, adjust the speed of the pump to a minimum

setting whenever not actively using a hydraulic

attachment.

As the hand throttle lever controls the output of

hydraulic flow, this will also influence the speed of a

hydraulically driven attachment. In general, the more

throttle, the faster the attachment operates. Make

sure not to exceed max. allowed oil flow of the

attachment, see Auxiliary hydraulics oil flow on

page 24.

.

Attachment control switch pack

(optional extra)

If your loader is equipped with

the optional attachment control

switch pack, the electric

functions of an attachment can

be controlled with the extra

buttons fitted on the joystick.

Check the operator's manual of the attachment to

see how to control each attachment.

When the loader is equipped with the Attachment

control switch pack, the Multi connector ( see page

61) includes also an electric socket, so that the

hydraulic hoses and the electric cable of an

attachment with electric function(s) can be coupled

simultaneously with the multi connector system.

https://tractormanualz.com

Avant e5

35

.

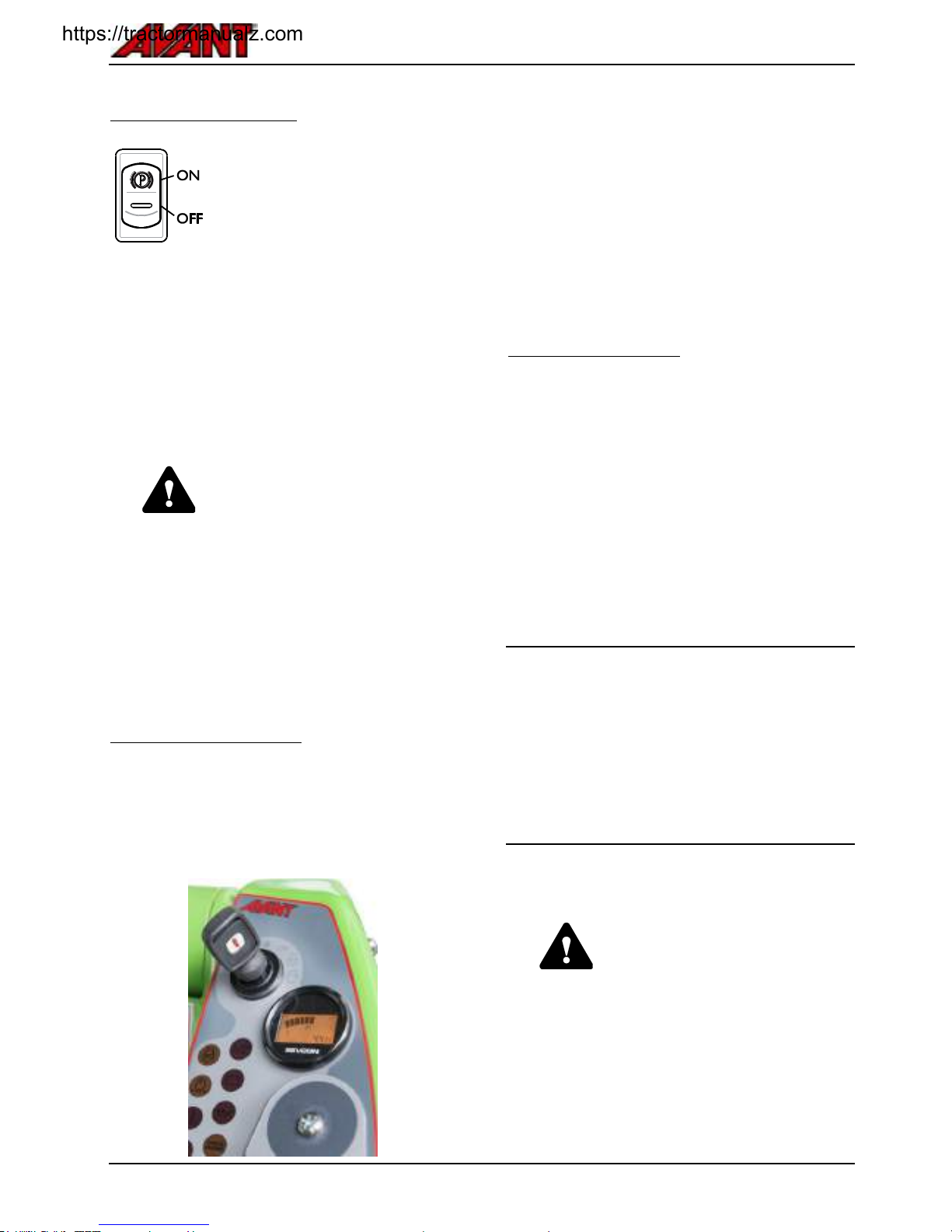

Parking brake switch

Switch on the parking brake

whenever leaving the driver's

seat.

The loader is equipped with a

brake system that locks the rear

wheels. The parking brake is

activated when loader is switched

off or when hydraulic pressure is

otherwise lost due to a failure.

Parking brake can be released

only when the loader is running

and the auxiliary hydraulics pump

creates enough pressure for the

brakes to release.

CAUTION

Using the parking brake while

machine is moving may cause

locking of wheels and sudden stop.

Always engage the parking brake

after stopping the machine first.

The parking brake should be used

to stop the machine only in

emergency. Repeated use while

driving will damage the brakes.

Multi-function display

The multi-function display shows the following