Flail mower 2016 2

Product number:

Flail Mower 1200

A36370

Flail Mower 1500

A36015

English

www.avanttecno.com

Operator's Manual for Attachment

Flail mower

Flail mower 2016 2

Flail mower 2016 2

CONTENTS

1. FOREWORD ........................................................................................................................................ 4

2. DESIGNED PURPOSE OF USE.......................................................................................................... 5

3. SAFETY INSTRUCTIONS FOR USING THE ATTACHMENT ...................................................... 6

4. TECHNICAL SPECIFICATIONS ....................................................................................................... 9

4.1 Safety labels and main components of the attachment .................................................................................... 9

5. ATTACHING THE ATTACHMENT ................................................................................................. 11

5.1 Connecting and disconnecting the hydraulic hoses ........................................................................................... 12

6. INSTRUCTIONS FOR USE ................................................................................................................ 14

6.1 Checks before use ..................................................................................................................................................... 15

6.2 Using the flail mower ................................................................................................................................................ 16

6.3 Operating position and floating .............................................................................................................................. 17

6.3.1 Transport position ............................................................................................................................................. 18

6.4 Adjusting cutting height ............................................................................................................................................ 18

6.5 Operating on inclined terrain .................................................................................................................................. 18

6.6 Preventing and clearing blockages.......................................................................................................................... 19

6.7 Blade options ............................................................................................................................................................... 20

7. MAINTENANCE AND SERVICE ....................................................................................................... 21

7.1 Checking hydraulic components ............................................................................................................................ 21

7.2 Cleaning the attachment ........................................................................................................................................... 22

7.3 Lubrication ................................................................................................................................................................... 22

7.4 Checking metal structures ....................................................................................................................................... 22

7.5 Blade maintenance ..................................................................................................................................................... 22

8. WARRANTY TERMS .......................................................................................................................... 23

4 (26)

WARNING:

This safety symbol refers to important safety information in this manual.

It warns of an immediate hazard that could cause serious personal

injury.

Read the warning text accompanying the symbol carefully and ensure

that other operators are also familiar with the warnings, since personal

safety is at stake.

This signal word indicates information about the correct operation and maintenance

of the equipment.

Failure to observe the instructions accompanying the symbol can lead to equipment

breakdown or other property damage.

1. Foreword

Avant Tecno Oy would like to thank you for your purchase of this attachment for your Avant loader. It has

been designed and manufactured on the basis of years of experience on product development and

manufacturing. By familiarising yourself with this manual and following the instructions, you ascertain your

safety and ensure the reliable operation and long service life of the equipment. Read the instructions carefully

before starting to use the equipment or performing maintenance.

The purpose of this manual is to help you to:

operate the equipment in a safe and efficient manner

observe and prevent any hazardous situations

keep the equipment intact and ensure a long service life

The following warning symbols are used throughout this manual to indicate factors that must be taken into

account to reduce the risk of personal injury or damage to property:

With these instructions, even an inexperienced user can use the attachment and loader safely. The manual

includes important instructions for experienced AVANT operators as well. Ensure that all persons using the

loader have received proper guidance and familiarised themselves with the manual of the loader, each

attachment that are used, and all safety instructions before using the equipment. Using the equipment for

other purposes or use in any other way than described in this manual is prohibited. Keep this manual at hand

throughout the service life of the equipment. If you sell or transfer the equipment, be sure to hand over this

manual to the new owner. If the manual is lost or damaged, you can request a new one from your Avant

dealer or from the manufacturer. Due to continuous product development some of the details shown in this

manual may differ from your equipment. This manual contains the original instructions in English.

In addition to the safety instructions included in this manual, you must observe all occupational safety

regulations, local laws, and other regulations concerning the use of the equipment. Particularly the regulations

concerning the use of the equipment on public road areas must be observed. We reserve the right to change

the contents of the manual without notification.

5 (26)

Avant

216

218

220

220

series 2

225

313S

320S

320S+

419

420

520

R20

525LPG

R28

528

630

R35

635

640

745

750

760i

A36730

(

A36015 - - - -

2. Designed purpose of use

This AVANT flail mower is an attachment suitable for use with AVANT multi purpose loaders. Flail mower is a

cylinder type cutter, and it is intended for cutting of long grass, scrub, bush and similar vegetation. The use of

the flail mower is possible at areas where there are tree branches of up to 20 mm thick.

The flail mowers are equipped with a floating system, which allows the mower to follow the ground surface so

that the loader boom floating is not necessary. Furthermore, the blades on the flail mower shaft move freely,

so in case they hit a solid obstacle, such as rocks, ground, tree stumps etc., the blades will give in rather than

break. This saves blade costs when operating at uneven on unfamiliar areas.

Flail mower is the optimal cutting device for places where a lot of cutting power is needed and a rougher cut

will do. The most common grounds for flail mowers are places with taller vegetation like meadows, road

banks, yard areas etc., which are not accessible with ordinary lawn mowers or where the power of a lawn

mower is not sufficient. The mower can be equipped with different types of blades, consult your dealer for

more information.

The attachment has been designed to require as little maintenance as possible. The operator can perform

regular maintenance tasks. All repair work can’t be performed by the operator, and demanding repair and

maintenance operations are to be left for professional maintenance. All maintenance work must be done using

proper safety equipment. Spare parts must be identical with original specifications, which can be ensured by

using only original spare parts. A separate spare parts catalogue may be available, consult your Avant dealer.

Familiarise yourself with the manual's instructions regarding service and maintenance. Please contact your

AVANT retailer if you have additional questions about the operation or maintenance of the equipment, or if

you require spare parts or maintenance services.

Table 1 - Flail mower - Compatibility with Avant loaders

When using with models marked with (), full performance may not be achieved. Additional counterweights

may also be required. For compatibility with a model not shown in table, contact your Avant dealer.

6 (26)

Misuse, careless use, or using an attachment that is in poor condition, may cause

risk of serious injuries. Familiarise yourself with the controls of the loader, correct

coupling procedure, and the correct way to operate the attachment at a safe area.

Study especially how to stop the equipment in a safe manner. Read all safety

precautions carefully.

When attaching an attachment to the loader, ensure that the locking pins of the

loader's quick attach plate are in the lower position and that they have locked

the attachment to the loader. Never lift or move an unlocked attachment.

The Flail mower is designed to be used by one operator at a time. Do not let others

near the danger area of the equipment when it is in use.

Always transport the attachment as low as possible to keep the centre of gravity low,

and keep the telescopic boom retracted during driving.

Impact hazard - thrown objects. Do not let bystanders stand near the machine. Stop

the attachment if others get closer 5 metres from the attachment.

Severing and crushing hazard - sharp and strong blades rotate at high speed. Use

the mower only while lowered against the ground. Stop if others are present at

working area. Use only if all covers in place.

Never leave the driver’s seat when the flail mower is running or if the auxiliary

hydraulics control lever is locked on. The blades of the flail mower move for a short

period after the hydraulic supply has been shut off. Wait until the blades have

stopped completely before going near the machine

Be sure not to tilt the flail mower too far up, since this can make it swing over onto the

loader boom as the floating mechanism allows the flail mower to move. Keep the flail

mower at a low height.

Hazard of entanglement - Rotating parts. Stop the equipment following the safe

stopping procedure and lower the attachment firmly on the ground before leaving the

driver’s seat, or when other persons are present at the working area.

Keep hands and feet away from moving components. Wearing loose clothes, such as

loose shoelaces, or long scarves, should be avoided when working with the

attachment.

Stop the attachment by following the safe stopping procedure before going near the

attachment or the loader boom.

Always transport the attachment as low and close to the machine as possible to keep

the centre of gravity low. On slippery surfaces drive slowly and deliberately. Operate

the controls of the loader slowly and calmly especially on inclined terrain.

3. Safety instructions for using the attachment

Please bear in mind that safety is the result of several factors. The loader-attachment combination is highly

powerful and improper or careless use or maintenance may cause serious personal injury or property

damage. Due to this, all operators must carefully familiarise themselves about correct use and the operator's

manuals of both the loader and the attachment before starting operation. Do not use the attachment if you

have not completely familiarised yourself with its operation and the related hazards.

Read all safety instructions carefully before handling the attachment

7 (26)

Do not leave the driver’s seat when the loader boom is lifted. Going under a raised

attachment or loader boom is dangerous. Always remember that the boom may lower

due to loss of stability, mechanical fault, or if another person operates the controls of

the loader.

Use the attachment only for its intended use and only with original tools and spare

parts.

Shut down the loader and place the attachment to a safe position as shown in Safe

stopping procedure before any cleaning, maintenance, or adjustments.

Pay attention to the surroundings and any other persons and machines moving in the

vicinity. Pay attention to the contours of the terrain and other hazards, such as

branches and trees that can reach to the driver's area, loose rocks, and slippery

surfaces.

Make sure to use only an attachment that is in good condition. Do not modify the

attachment in any way that could affect its safety.

Use the attachment only for its intended purpose. Other use may create unnecessary

safety risks, and the equipment may get damaged.

Make sure that the loader is equipped with necessary safety components, and that

they are in working condition. Seat belt must be used. If there are specific hazards

related to the operating area, use appropriate safety equipment.

Also read the safety instructions and correct use of the loader from the operator's

manual of the loader.

Never allow anyone to get under the raised load or the loader boom. Keep in mind that the

loader boom can be lowered or tilted even if the engine has been shut down (crushing

hazard). The loader is not intended to be left to keep a load elevated for longer periods.

Always lower the attachment to a safe position before leaving the driver's seat.

.

8 (26)

Remember to wear proper protective clothing:

The noise level at the driver's seat may exceed 85 dB(A). Wear hearing

protection while working with the loader.

Wear protective gloves.

Wear safety boots whenever working with the loader.

At some areas or surfaces the brush may throw debris. Wear safety glasses.

Wear safety glasses when handling hydraulic components.

.

..

Always stop the attachment following safe stopping procedure before leaving the

driver's seat. Safe stopping procedure prevents all unintentional movements of the

attachment. Note that the loader boom can move down even if the engine of the

loader is turned off. Safe stopping procedure:

Lower the boom and the attachment on the ground.

Shut down the loader engine and lock the parking brake.

Release residual pressure from the hydraulic system; move all hydraulic control

levers to their extreme positions a couple of times.

Prevent starting of the machine, remove ignition key.

Beware of entanglement and crushing hazards especially when cleaning or removing

blockages. Always stop the attachment by turning the auxiliary hydraulics control lever to

its neutral position before leaving the driver’s seat, shut down the loader engine and

release the residual pressure of the hydraulic system to prevent rotating parts from

moving when clearing a blockage.

Wrong, improper, or careless use of the attachment causes serious risk of severe injuries

or death. Familiarise yourself with the controls of the loader in a safe area. Pay particular

attention to the safe stopping of the attachment and the loader; follow the safe stopping

procedure shown in this manual before leaving the driver's seat.

.

Safe stopping of the attachment, before going near the attachment:

9 (26)

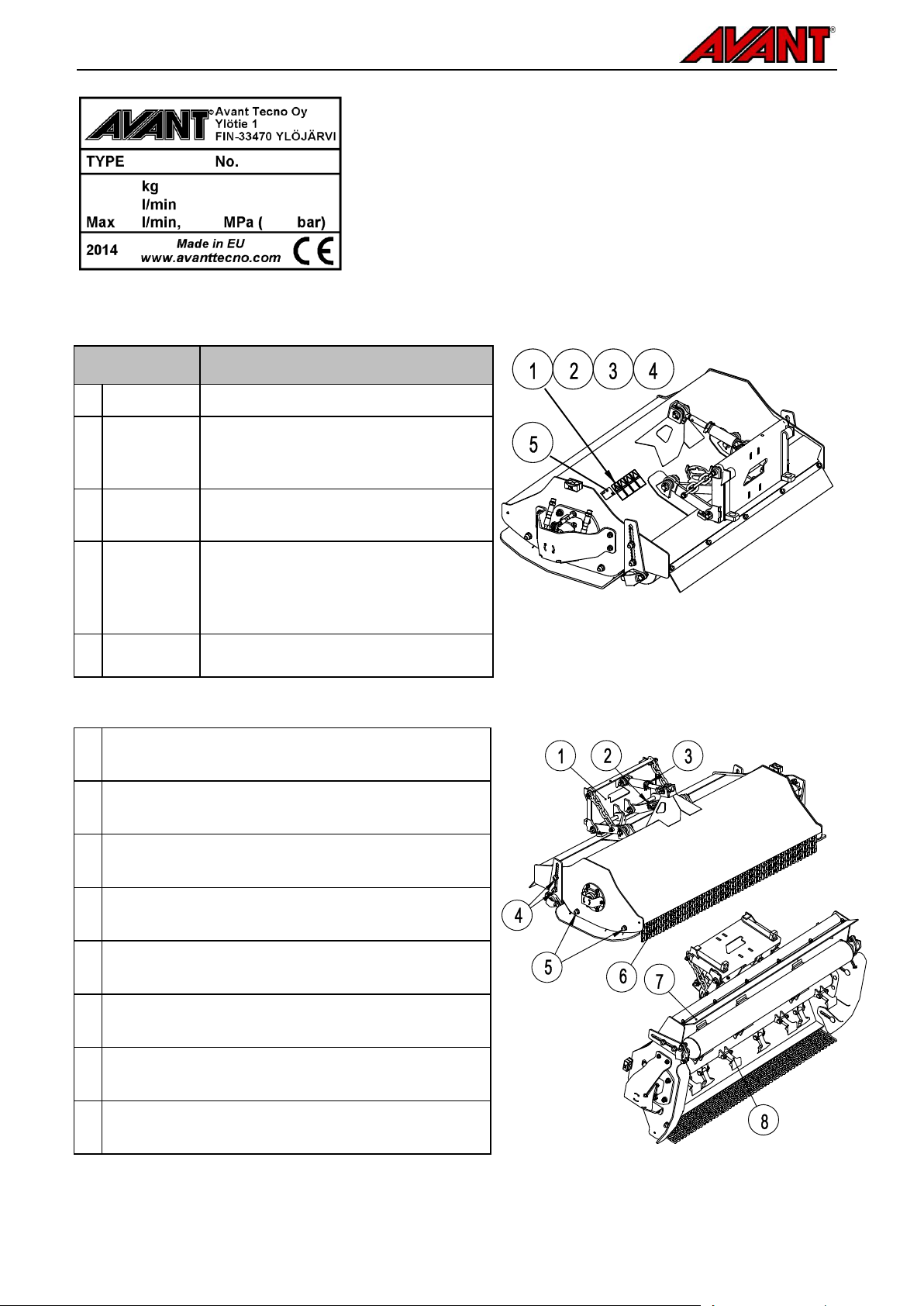

Product number

A36730

A36015

Cutting width:

1200 mm

1500 mm

Total width:

1580 mm

1880 mm

Cutting height:

25 - 100 mm

Standard flails type/pcs:

Hammer flails

16 cps

Hammer flails

20 pcs

Optional flail types:

Y-flails A419931

L-flails A420305

Weight:

240 kg

270 kg

Recommended oil flow:

30 l/min

60 l/min

Maximum input of hydraulic energy:

34 l/min

20,0 MPa (200 bar)

68 l/min

20,0 MPa (200 bar)

Compatible AVANT loaders:

See Table 1

The warning labels contain important safety information and they help to identify and

remember the hazards related to the equipment. Replace damaged or missing

warning labels with new ones.

A46771

A46772

A46799

A46802

4. Technical specifications

Table 2 - Flail mower - Technical specifications

4.1 Safety labels and main components of the attachment

Listed below are the labels and markings, which must be visible on the equipment. Replace the warning

labels, if they have become unclear or if they have detached completely. New labels are available via your

retailer or contact information provided on the cover.

10 (26)

Attachment identification plate A420283 / A420282

Decal

Warning message

1

A46771

Read instructions before use.

2

A46772

Crushing hazard - Do not go under a

raised attachment; stay away from raised

equipment.

3

A46799

Beware of thrown objects; keep a safe

distance from the equipment. (2 m).

4

A46802

Beware of sharp blades – never reach to

the rotating components and do not use

the equipment without all covers in

place.

5

A420283 /

A420282

Attachment identification plate

1

Frame with quick coupling brackets

2

Multiconnector holder

3

Top link and top link locking

4

Roller and roller height adjustment bolts

5

Skid adjustment bolts

6

Front guard, chains

7

Rear guard, rubber plate

8

Flail shaft with 16 or 20 flails / flail pairs

Table 3 - Decal locations and warning messages

Table 4 - Main components of the Flail mower

11 (26)

Make sure that an unlocked attachment will not move or fall over. Do not stay in the

area between the attachment and the loader. Mount the attachment only on level

surface.

Never move or lift an attachment that has not been locked.

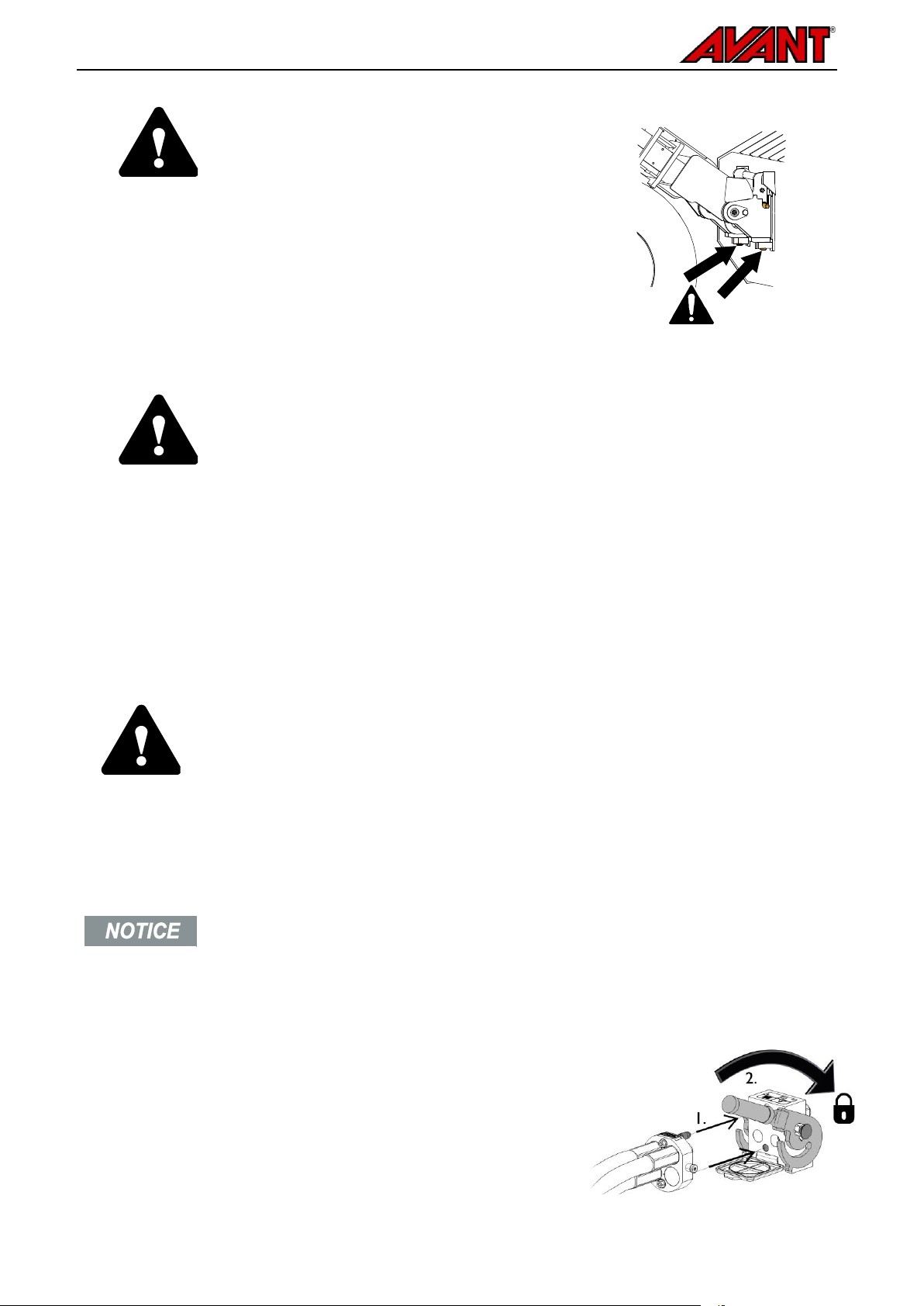

Avant quick coupling system:

Step 1:

Lift the quick attach plate locking pins up and turn them backwards into the slot

so that they are locked in the upper position.

If your loader is equipped with a hydraulic attachment locking system, see

additional instructions about the use of the locking system from the relevant

manuals.

Ensure that the hydraulic hoses (and the electric harness, if applicable) are not

in the way during installation.

Step 2:

Turn the quick attach plate hydraulically to an obliquely forward position.

Drive the loader onto the attachment. If your loader is equipped with a

telescopic boom, you can utilise this.

Align the upper pins of the loader’s quick coupling plate so that they are under

the corresponding brackets of the attachment.

Step 3:

Lift the boom slightly – pull the boom control lever backward to raise the

attachment off the ground.

Turn the boom control lever left to turn the bottom section of the quick attach

plate onto the attachment.

Lock the locking pins manually or lock the hydraulic locking.

Always check the locking of pins.

5. Attaching the attachment

Attaching the attachment to the loader is quick and easy, but it must be done carefully. The attachment is

mounted to the loader boom by using the quick attach plate on the loader boom and the counterpart on the

attachment.

If the attachment is not locked to the loader, it may detach from the loader and cause a hazardous situation.

The loader must not be driven and the boom must never be lifted when the attachment has not been locked.

To prevent hazardous situations, always follow the coupling procedure shown below. Also remember the

safety instructions shown in this manual. The attachment is mounted to the loader as follows:

12 (26)

An attachment that has not been completely

locked to the loader may fall on the boom or

towards the operator, or fall under the loader

during driving, causing loss of control of the

loader. Never move or lift an attachment that

has not been locked. Before moving or lifting

the attachment, make sure that the locking

pins are in the lower position and come

through the fasteners on the attachment on

both sides.

Excessive tilting or lifting of an unlocked attachment increases the risk of tipping the

attachment over. Do not use the automatic locking of the locking pins when the

attachment is lifted more than one meter from the ground. If the locking pins do not

return to the normal position when tilting, do not tilt or raise the attachment any

more. Lower the attachment on the ground and secure the locking manually.

Never connect or disconnect quick couplings or other hydraulic components while the

control lever of the auxiliary hydraulics control lever is locked on or if the system is

pressurized. Connecting or disconnecting the hydraulic couplings while the system is

pressurized may lead to unintended movements of the attachment, or ejection of

high-pressure fluid, which can cause serious injuries or burns. Follow safe stopping

procedure before disconnecting hydraulics.

Keep all fittings as clean as possible; use the protective caps on both the attachment and

the loader. Dirt, ice, etc. may make using the fittings significantly more difficult. Never

leave the hoses hanging on the ground; place the couplings onto the holder on the

attachment.

Connecting the multi connector system:

1. Align the pins of the attachment connector with corresponding

holes of the loader connector. The multi connector will not

connect if the attachment connector is upside down.

2. Connect and lock the multi connector by turning the lever towards

the loader.

5.1 Connecting and disconnecting the hydraulic hoses

On the 200 series 2 and 400-700 series loaders the hydraulic hoses are connected using the multi connector

system. If you have an Avant 300-700 series loader with the conventional quick couplers and wish to change

to the multi connector system, contact your Avant dealer or service point for instructions or installation

services.

13 (26)

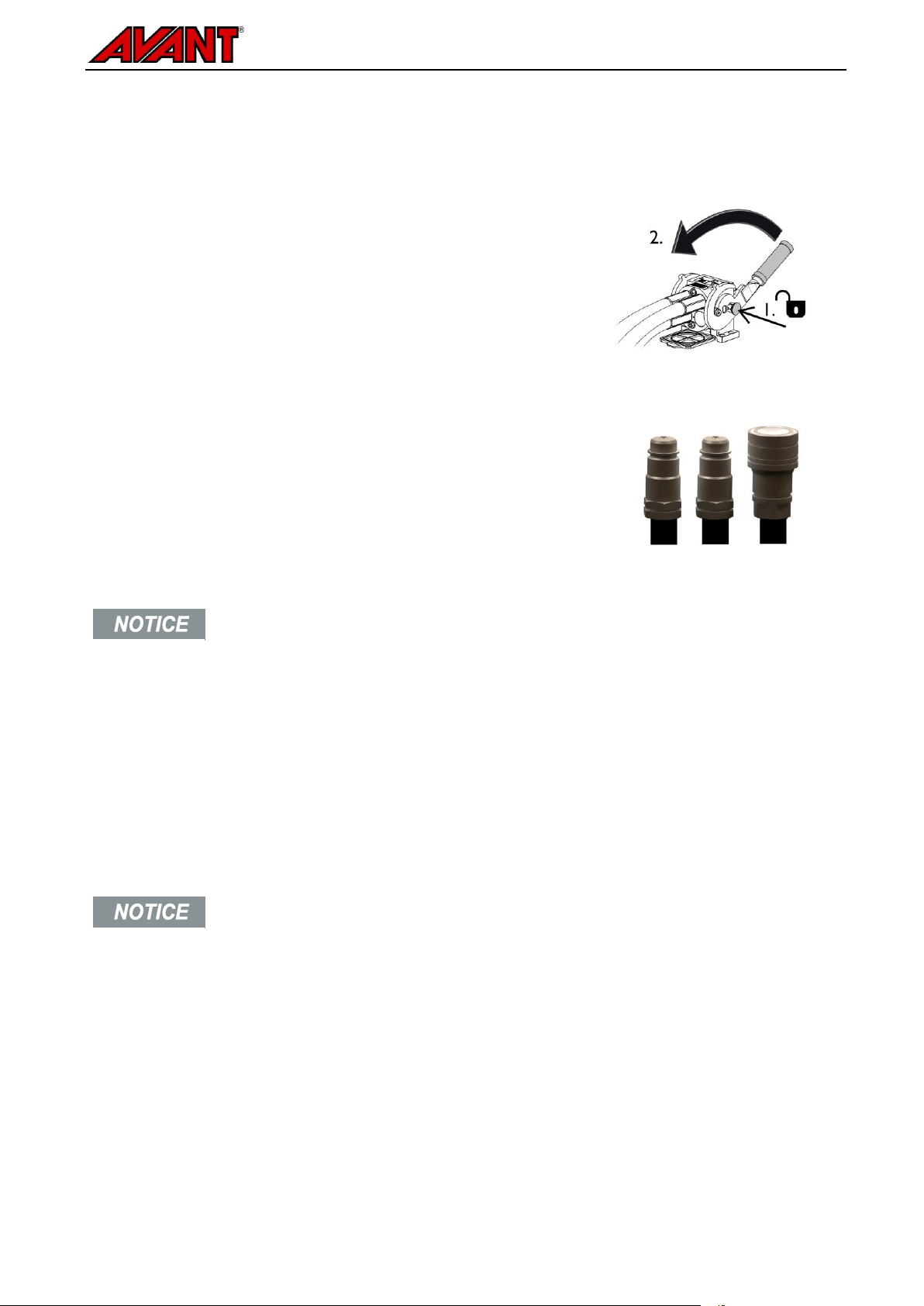

To disconnect the multi connector system:

Before disconnecting put the attachment down on a solid and even

surface.

1. Switch off the auxiliary hydraulics of the loader.

2. While pushing unlock button, turn the lever to disconnect the

connector.

3. After ending operation put the multi connector on its holder on the

attachment.

Conventional quick couplings

(alternative couplings for some loader models):

Before connecting or disconnecting the standard quick couplings, the

residual pressure must be released as shown below. The conventional

quick couplings will not connect, if there is pressure in the hydraulic

system.

Make sure that all three quick coupling fittings are properly connected, otherwise the

hydraulic motor of the attachment may get damaged.

When uncoupling the attachment, always disconnect the hydraulic couplings before

unlocking the quick attach plate, to prevent hose damage and any oil spills. Reinstall the

protective caps on the fittings to prevent impurities from entering the hydraulic system.

The lever should move easily all the way to its locking position. If the lever does not slide smoothly, check the

alignment and position of the connector and clean the connectors. Also shut down the loader and release the

residual hydraulic pressure.

To connect and disconnect the standard couplings, move the collar at the end of the female fitting. The hoses

should be connected so that the fitting equipped with a coloured cap is connected to the corresponding fitting

of the loader. Note that the protective caps on the loader and the attachment can be fastened to each other

during operation to reduce the accumulation of dirt. When disconnecting the standard quick couplings a small

amount of oil may drip from the couplings. Wear protective gloves and have some cloth at hand to keep the

equipment clean.

Disconnecting hydraulic hoses:

Before disconnecting the fittings, lower the attachment to safe position on solid and level surface. Turn the

control lever of the auxiliary hydraulics to its neutral position.

Releasing residual hydraulic pressure:

In case residual pressure is left in the hydraulic system of the attachment, it is often possible to disconnect the

hydraulic couplings, but it may be difficult to connect them the next time. If the fittings will not connect, the

residual pressure must be released by turning the auxiliary hydraulics control lever of the loader, when the

engine is turned off. To make sure that there will not be residual pressure in the hydraulic system of the

attachment, shut down the loader engine and move the auxiliary hydraulics control lever of the loader back

and forth before disconnecting the couplings.

14 (26)

Always keep a safety distance of at least two metres to

other persons. Note that the attachment may throw

stones, gravel, or other objects found in the area at high

speed. Keep bystanders away.

Avoid overturning of the machine. Do not extend the

telescopic boom, when the load approaches the lifting

capacity of the loader, or when the loader boom is in

horizontal position. If the load indicator of the loader (if

fitted) signals, lower the load calmly and retract the

telescopic boom. Avoid sudden changes in speed or

direction whenever the load is lifted. Use additional

counterweights as needed.

Keep a safe distance from the attachment when it is

irunning and stay back if other person operates the

controls of the loader. Be careful not to reach into a

running attachment by any means. Beware of the

rotating parts which create entanglement hazard. Shut

down the loader engine if reaching into the attachment

is necessary

6. Instructions for use

Check the attachment and the operating environment once more before starting to work, and that all obstacles

have been removed from the operating area. Quick inspection of the equipment and the operating area before

use are parts of ensuring safety and the best performance of the equipment.

15 (26)

.

..

Check that all blades are connected securely and that none of the blades is missing.

Loose, damaged, or missing blades can cause ejection of parts from the mower. Only

use locking nuts for fastening if the blades.

Pay attention that a heavy load or long distance between the loader and the centre of

gravity of the load will affect the balance and handling of the loader. The use of additional

counterweights is recommended especially when operating smaller loader models. For

200-series loader the wheel weights are recommended. With heavy loads, the telescopic

boom must be kept retracted while moving with the loader.

Never allow anyone to get under the raised load or the loader boom. Keep in mind that the

loader boom can be lowered or tilted even if the engine has been shut down (crushing

hazard). The loader is not intended to be left to keep a load elevated for longer periods.

Always lower the attachment to a safe position before leaving the driver's seat.

.

6.1 Checks before use

Check that all obstacles, including any possibly hidden ones, have been removed from the working

area before operation.

Check daily that the blades are intact and can rotate freely. Never use if blades are missing or broken.

Check that there is no string or other foreign material around the flail shaft.

Ensure that bystanders are at a safe distance when operating the equipment. Do not let anyone to

enter danger area of the boom or to stay directly in front of the loader. Also make sure that it is safe to

reverse with the loader. Never assume that bystanders will remain where you last saw them;

especially children are often attracted to the moving equipment.

Check the general condition of the attachment and the loader, and check for possible hydraulic oil

leaks. The attachment must not be used, if there is a fault in the hydraulic system of the loader or the

attachment. Refer to Chapter 7 for maintenance instructions.

Operate the attachment and the controls of the loader only when seated on the driver’s seat. Ensure

that the loader and the attachment are used in a safe manner and as intended. Do not allow children

to operate the equipment.

Never operate the loader or attachments while under the influence of alcohol, drugs, medication that

may impair judgement or cause drowsiness, or if not otherwise medically fit to operate the equipment.

Remember correct working methods and avoid leaving the driver’s seat unnecessarily.

16 (26)

Move the auxiliary hydraulics control

lever of the loader towards its locking

position (or use electric buttons on

joystick, if equipped) to operate the

mower.

Stop by releasing the lever to neutral

position.

The mower is intended to be operated

only to forward driving direction.

The mower will only rotate to intended

running direction. Reverse direction of

the auxiliary hydraulics control has no

effect.

Operate the attachment keeping the hydraulic flow within recommended range. Never

exceed maximum allowed input of hydraulic energy.

Operating the attachment at too high speed may cause material be thrown from the

attachment, or damage that could lead to personal injury. See recommended input flow in

this manual.

Never leave the equipment running unattended. Start the attachment only when it is

ready to be used. Do not go near the equipment when another person operates the

controls of the loader.

.

6.2 Using the flail mower

Before starting the mower:

Set and adjust the mower to correct operating position. See following chapters about floating system and

adjustments.

Starting the mower:

Recommended operating speed and maximum allowed oil flow:

17 (26)

Normal operating position:

Keep top link unlocked

Lower attachment on the ground

Keep the quick coupling plate to near vertical

position

Adjust the boom height so that the mower can

move freely up and down

Lifted position:

When operating the flail mower on tall vegetation or

thick scrub, it may be useful to tilt the front of the

mower up.

To lock the top link:

To lock the front end of the mower up, use the pin

to lock the top link to fully retracted position.

The locking pin is stored on the frame of the

attachment (1).

6.3 Operating position and floating

.

18 (26)

When driving with the loader, keep the flail mower

lifted off the ground and tilted back slightly, as shown

in adjacent figure.

Keep the top link unlocked or locked to extended

position (see page 17 for top link locking).

The cutting height of the flail mower can

be adjusted by changing the settings of

the roller and the skids, highlighted in the

adjacent figure.

Loosen the nuts with a single 24 mm

tool

Do not fully remove the nut -

loosen only enough to move the

bolt so that the height can be

adjusted.

Ensure the stability of the flail mower

during adjustments; use blocks of

wood for example. The mower

should be kept attached to loader for

performing the adjustments.

Set all fasteners to the same level.

.

6.3.1 Transport position

6.4 Adjusting cutting height

6.5 Operating on inclined terrain

Extra caution is needed when using the equipment on inclined terrains and slopes. Drive slowly especially on

inclined, uneven, or slippery surfaces, and avoid sudden changes in speed or direction. Operate the controls

of the loader with careful and smooth movements. Watch out for ditches, holes on the ground, and other

obstacles, as hitting an obstacle may cause the loader to tip over.

Maximum lifting capacity can not be achieved on inclined terrain. On horizontally tilted terrain the load must

not be lifted high. The loader frame articulation should be kept straight when lifting heavy loads; turning the

load during lifting operation will affect the stability of the loader and may lead to overturning of the machine.

19 (26)

Warning - cutting hazard. Clearing a blockage can start the flail unexpectedly immediately

after clearing the blockage, if the auxiliary hydraulics of the loader is left on.

Always stop the loader by following the safe stopping procedure before going near the

mower. Never reach to the cutting deck if the mower or its blades can move.

To prevent accidents, turn the auxiliary hydraulics control lever of the loader to its neutral

position, shut down the loader engine and release the residual pressure always before

going near the attachment.

To make sure that the attachment will not rotate, disconnect the multiconnector (or

hydraulic quick couplings) before going near it.

.

6.6 Preventing and clearing blockages

Keeping the rotating speed sufficiently high and drive speed low on demanding conditions are essential to

avoid blockages. Keep the equipment clean, so that material will not stick on it.

Wet, thick and log grass can get coiled around the flail shaft if drive speed is too high. When mowing high or

wet hay more than one run may be needed for even results. Also, adjusting the cutting height to higher

setting, or operating at lifted operating position, will help avoiding blockages.

If blockage occurs, it needs to be cleared manually using suitable tools. Follow safe stopping procedure

before going near the mower.

20 (26)

Number of blades

Flail mower

1200/1500

Hammer type

blade

(standard)

64243

Good all-round

performance

Good for shrub and

brushwoods

16 / 20 pcs

Pair of Y-flails

A419931

Powerful grass or hay

cutting

16 / 20 pairs

Pair of L-flails

A420305

Good cut finish for short

grass areas

16 / 20 pairs

.

6.7 Blade options

As standard, the flail mower is equipped with hammer type blades, which give good all-round performance. In

some operating areas or conditions different blade types can be used. Contact your Avant dealer for new

blades.

Blades

Note: Always fit the spacers shown in figures above when using Y- or L-flails.

When replacing blades, also the fastening bolt and the locking nut should be replaced ( M14*80 bolt with

nyloc nut).

Use only locking nuts for fastening of the blades

Check if replacement of the spacers of the Y- and L-flail is necessary

21 (26)

Make sure the attachment is properly supported during all maintenance work. Never go

under a lifted attachment. The loader boom may lower unexpectedly during maintenance

causing serious injuries even when the loader engine is not running. All maintenance and

service must be performed when the attachment has been lowered down to a safe

position.

Never handle hydraulic components when the

hydraulic system is pressurised, since a fitting

may break or become loose and the released

oil may cause serious injuries. Do not use the

equipment, if you have discovered a fault in

the hydraulic system.

Regularly clean the loader oil cooler core; refer to the operator's manual of the loader for

more instructions. Overheating oil decreases the power and affects the service life of the

hydraulic components of both the attachment and the loader.

7. Maintenance and Service

The attachment has been designed to be as maintenance free as possible. Continuous maintenance includes

regular cleaning and lubrication, and monitoring the condition of the attachment. Because of the crushing

hazard caused by lowering machine parts, all maintenance work must be done when moving parts have been

lowered down completely and the attachment is lowered flat against the ground.

7.1 Checking hydraulic components

Check the condition of the hydraulic hoses and components when the engine has been turned off and the

pressure has been relieved. Do not use the equipment, if you have discovered a leak in the hydraulic system

of the attachment or the loader. Leaking hydraulic fluid may penetrate skin and cause serious injuries. Seek

medical attention immediately in case hydraulic fluid penetrates the skin. Wash any part of body that has been

in contact with hydraulic oil carefully with water and soap. Hydraulic fluid is also harmful to the environment

and any leak to the environment must be prevented. Repair all leaks immediately after detecting them; a small

leak can quickly grow into a big one. Operate the attachment only with type of hydraulic oil that is accepted for

use in Avant loaders.

Check hoses visually for cracks or abrasions. If there are signs of leaks, to check a component, hold up a

piece of cardboard in the area where a leak is suspected. Do not use hands to search for leaks. Monitor the

wearing of the hoses and stop the use, if the surface layer of any hose has worn off. Check the routing of the

hoses; adjust the hose clamps to avoid abrasion to the hoses. The hoses have limited service life. Depending

on operating conditions all hoses must be inspected thoroughly no later than after 3 to 5 years of use, and if

required, they must be replaced with new ones.

Finding any fault means that the hydraulic hose or component must be replaced and the equipment must not

be used until it is repaired. Spare parts are available from your nearest AVANT retailer or authorised service

point. Leave the repair work to professional service technicians, if you don’t have adequate knowledge and

experience about hydraulic assemblies and how to perform the repairing safely.

22 (26)

There are lubricating points at the roller bearings.

Suitable lubrication interval depends heavily on

operating conditions but lubricant must be added

at least after every 10 hours of use. Adequate

lubrication must be ensured, and if the bearings

are dirty, lubricant must be added; added

lubricant will push out dirt.

Clean the end of the nipple before greasing and

add only a small amount of grease at a time. All

lubrication nipples are standard R1/8" nipples.

Replace any damaged nipples.

The fastening bolts and nuts should be replaced with new ones when replacing blades.

.

7.2 Cleaning the attachment

Clean the attachment regularly to prevent accumulation of dirt which is more difficult to remove. A pressure

washer and mild detergent can be used for cleaning. Do not use strong solvents, and do not spray directly at

the hydraulic components, or at the labels on the attachment.

7.3 Lubrication

7.4 Checking metal structures

Also the metal structures of the attachment must be inspected regularly. Check visually for damages and

inspect the quick attach brackets and their surrounding area carefully. The attachment must not be used if it is

deformed, cracked, or torn.

Welding repairs are only allowed to be carried out by professional welders. When welding, only methods and

additives suited for steel used in bucket must be used. For more information about repairs contact your

nearest service point.

7.5 Blade maintenance

The condition of the cutting blades should be checked at least after every few uses The blades wear down in

normal use and can get damaged if hitting a rock or other obstacle.

If the cutting results have weakened from the original, the cutting blades have probably become blunt or some

of the blades have been damaged. Uneven cutting results, increased power requirement and increased

vibration level are signs of blunt or damaged blades.

To protect the blades and other components when hitting rocks or other obstacles, the blades are fitted to the

axle in a way that allows them to move. Check that all of the blades move freely and are not stuck. The Y- and

L-type blades are sharpened from the both sides and they can be installed the other way round. When

reinstalling the blades, make sure, that you fix them in the same manner as they were originally. Do not over

tighten the blade screws.

23 (26)

Check that all blades are connected securely and that none of the blades is missing.

Loose, damaged, or missing blades can cause ejection of parts from the mower. Only

use locking nuts for fastening if the blades.

If the blades have large notches or cracks or have worn down excessively, they must be

replaced. Always use good protective gloves when handling the blades.

Check that the flail mower is balanced to avoid damage to the bearings. Repair the

mower, if you notice any abnormal vibration or noise. Contact service for assistance.

.

..

8. Warranty terms

Avant Tecno Oy grants a warranty of one year (12 months) from the date of purchase for the attachment it

manufactures.

The warranty covers repair costs as follows:

Work costs are covered, if the repair is not performed at the factory.

The factory replaces any defective components or consumables.

The factory may reimburse the price of components purchased by the customer in special cases that have

been agreed in advance.

The warranty does not cover:

Normal maintenance work or parts and consumables required for it.

Damages caused by unusual operating conditions or ways of use, negligence, structural changes made

without the consent of Avant Tecno Oy, use of non-original parts or lack of maintenance.

Consequences of a defect, such as interruption of work or other possible additional damages.

Travel and/or freight costs caused by the repair.

Flail mower 2016 2

EY-vaatimustenmukaisuusvakuutus

EG-försäkran om överensstämmelse

EU samsvarserklæring

EF-overensstemmelseserklæring

EC Declaration of Conformity

EG-Konformitätserklärung

Déclaration de conformité CE

Valmistaja / Tillverkare / Produsent / Producent / Manufacturer / Hersteller

Fabricant:

AVANT TECNO OY

Osoite / Adress / Adresse / Address / Adresse:

Ylötie 1

33470 YLÖJÄRVI, FINLAND

Avant

Hydraulitoiminen niittomurskain; Avant-kuormaajan työlaite

Hydraulisk slaghackaggregat; arbetsredskap för Avant lastare

Hydraulisk beitepusser; redskap for Avant minilastere

Hydraulisk slagleklipper; redskab til Avant Minilæssere

Hydraulic flail mower; attachment for Avant loaders

Hydraulische Schlegelmulcher; Anbaugerät für Avant Radlader

Debroussailleuse à commande hydraulique destinée à être utilisée avec les chargeuses Avant

A36532

Vakuutamme täten, että alla mainitut tuotteet täyttävät konedirektiivin turvallisuus- ja terveysvaatimukset (direktiivi

2006/42/EY muutoksineen). Seuraavia yhdenmukaistettuja standardeja on sovellettu /

Vi försäkrar härmed att nedan beskrivna produkter överensstämmer med hälso- och säkerhetskrav i EG-maskindirektiv

(EG-direktiv 2006/42/EG som ändrat). Följande harmoniserade standarder har tillämpats /

Vi erklærer herved at produktet som er oppgitt under er i samsvar med forskriftene i Maskindirektivet (direktiv 2006/42/EC

med endringer). Følgende harmoniserte standarder har blitt anvendt /

Vi erklærer herved, at nedenstående produkter er i overensstemmelse med bestemmelserne i maskindirektivet (direktiv

2006/42/EF indeholdende ændringer). Følgende harmoniserede standarder er anvendt /

We hereby declare that the products listed below are in conformity with the provisions of the Machinery Directive (directive

2006/42/EC as amended). The following harmonized standards have been applied /

Wir erklären hiermit, dass die nachstehend aufgeführte Maschine konform ist mit den Bestimmungen der

EG-Maschinenrichtlinie (EG-Richtlinie 2006/42/EG mit Änderungen). Die folgende harmonisierte Normen wurden

angewandt:

Nous déclarons par la présente que les produits mentionnés ci-dessous sont conformes aux exigences en matière de

sécurité et de santé de la directive relative aux machines (directive 2006/42/CE, avec ses modifications) Les normes

harmonisées suivantes ont été appliquées

SFS-EN ISO 12100, SFS-EN ISO 4413

Mallit / Modeller / Modeller / Modeller / Models / Modellen:

21.4.2016 Ylöjärvi, Finland

Risto Käkelä,

Toimitusjohtaja / Verkställande direktör / Administrerende direktør /

Managing Director / Geschäftsführer / Directeur général

Loading...

Loading...