Page 1

Page 2

SAFETY PRECAUTIONS

VIEWING DOOR AND ASHPAN MUST BE CLOSED

•

AND LATCHED DURING OPERATION.

THIS UNIT MUST BE PROPERLY INSTALLED IN

•

ORDER TO PREVENT THE POSSIBILITY OF A HOUSE

FIRE. FOR YOUR SAFETY THE INSTALLATION

INSTRUCTIONS MUST BE STRICTLY ADHERED TO.

DO NOT USE MAKESHIFT METHODS OR COMPROMISE INSTALLATION.

CONTACT YOUR LOCAL BUILDING OFFICIALS TO

•

OBTAIN A PERMIT AND INFORMATION ON ANY INSTALLATION RESTRICTIONS OR INSPECTION REQUIREMENTS IN YOUR AREA. ALSO, NOTIFY

YOUR INSURANCE COMPANY THAT YOU ARE INSTALLING A PELLET BURNING APPLIANCE.

THIS UNIT'S EXHAUST SYSTEM WORKS WITH A

•

NEGATIVE COMBUSTION CHAMBER PRESSURE

AND A LOW POSITIVE CHIMNEY PRESSURE. IT IS

VERY IMPORTANT THAT THE EXHAUST SYSTEM

BE COMPLETELY AIRTIGHT AND PROPERLY INSTALLED. THE CHIMNEY JOINTS SHOULD BE

SEALED WITH RTV 500 DEGREES FAHRENHEIT

(500° F) (260° C) SILICONE SEALANT. IMPROPERLY

INSTALLED STOVES ARE THE MAJOR CAUSE OF

HOME FIRES.

THE AVALON 900 APPLIANCE IS DESIGNED AND

•

APPROVED FOR THE BURNING OF PELLETIZED

WOOD FUEL ONLY. THE BURNING OF ANY TYPE

OF FUEL OTHER THAN THAT LISTED WILL VOID

ALL WARRANTIES AND THE SAFETY LISTING OF

THE UNIT. DO NOT ATTEMPT TO BURN ANY

OTHER FUEL THAN SPECIFIED IN THIS MANUAL.

THE EXHAUST SYSTEM SHOULD BE CHECKED

•

TWICE A YEAR MINIMUM FOR ANY BUILD-UP OF

SOOT OR CREOSOTE.

GASOLINE OR OTHER FLAMMABLE LIQUIDS MUST

•

NEVER BE USED TO START THE FIRE OR

"FRESHEN UP" THE FIRE. DO NOT STORE OR

USE GASOLINE OR OTHER FLAMMABLE LIQUIDS

IN THE VICINITY OF THIS APPLIANCE.

ASHES MUST BE DISPOSED OF IN A METAL

•

CONTAINER WITH A TIGHT FITTING LID, AND

PLACED ON A NON-COMBUSTIBLE SURFACE

BEFORE FINAL DISPOSAL.

THIS UNIT MUST BE CONNECTED TO A GROUND-

•

ED, STANDARD 110 VOLT, 60 HZ ELECTRICAL

OUTLET. NEVER ROUTE THE POWER CORD

UNDER OR IN FRONT OF THE UNIT.

• NEVER BLOCK FREE AIRFLOW THROUGH THE

OPEN VENTS OF THE UNIT.

NEVER TRY TO REPAIR OR REPLACE ANY PART

•

OF THE APPLIANCE UNLESS INSTRUCTIONS ARE

GIVEN IN THIS MANUAL. ALL OTHER WORK

SHOULD BE DONE BY A TRAINED TECHNICIAN.

WAIT UNTIL THE APPLIANCE HAS COOLED BE-

•

FORE CARRYING OUT MAINTENANCE PROCEDURES.

TRAVIS INDUSTRIES, INC. GRANTS NO WAR-

•

RANTY, IMPLIED OR STATED, FOR THE INSTALLATION OR MAINTENANCE OF YOUR STOVE, AND

ASSUMES NO RESPONSIBILITY FOR ANY CONSEQUENTIAL DAMAGE(S).

DO NOT INSTALL IN A BEDROOM OF A MOBILE

•

HOME.

KEEP FOREIGN OBJECTS OUT OF THE HOPPER.

•

ALWAYS FOLLOW THE INSTRUCTIONS IN THE

•

OWNER'S MANUAL.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

•

REMOVE THE GROUNDING PRONG FROM THE

POWER CORD.

DO NOT USE AN ADAPTOR PLUG.

•

BEFORE REMOVING PANELS, DISCONNECT THE

•

POWER CORD FROM THE ELECTRICAL OUTLET.

NOTE: TURNING THE CONTROL SWITCH OFF

DOES NOT DISCONNECT THE POWER TO ALL

ELECTRICAL COMPONENTS.

WHEN INSTALLED IN A MOBILE HOME, THE UNIT

•

MUST BE GROUNDED TO THE STEEL CHASSIS OF

THE MOBILE HOME AND BOLTED TO THE FLOOR

IN COMPLIANCE WITH AND ACCORDING TO

H.U.D. REQUIREMENTS.

THE APPLIANCE WILL NOT OPERATE USING

•

NATURAL DRAFT OR WITHOUT A POWER

SOURCE FOR THE BLOWERS AND FUEL-FEEDING

SYSTEMS.

KEEP THIS MANUAL FOR LATER USE.

•

PAGE 2

Page 3

TABLE OF CONTENTS

Introduction and Important Information --------------------------------------------------------------------------------- 1

Safety Precautions ----------------------------------------------------------------------------------------------------------- 2

Features and Specifications - Stove & Insert-------------------------------------------------------------------------- 4

STOVE INSTALLATION:

Preparation for Installation ------------------------------------------------------------------------------------------------- 5

Freestanding Installation Specifications -------------------------------------------------------------------------------- 8

Horizontal Corner Installation --------------------------------------------------------------------------------------------- 9

Vertical Exterior Flue Installation ----------------------------------------------------------------------------------------- 11

Inside Vertical Installation with Roof Termination -------------------------------------------------------------------- 12

Hearth Stove Installation into existing Masonry Fireplace or Zero Clearance (Metal) Fireplace --------- 13

Vertical Installation into existing Factory-Built Chimney ------------------------------------------------------------ 14

Horizontal Installation ------------------------------------------------------------------------------------------------------- 15

Page

Freestanding Mobile Home Installation --------------------------------------------------------------------------------- 16

Freestanding Residential Alcove Installation -------------------------------------------------------------------------- 17

INSERT INSTALLATION:

Preparation For Installation ------------------------------------------------------------------------------------------------ 18

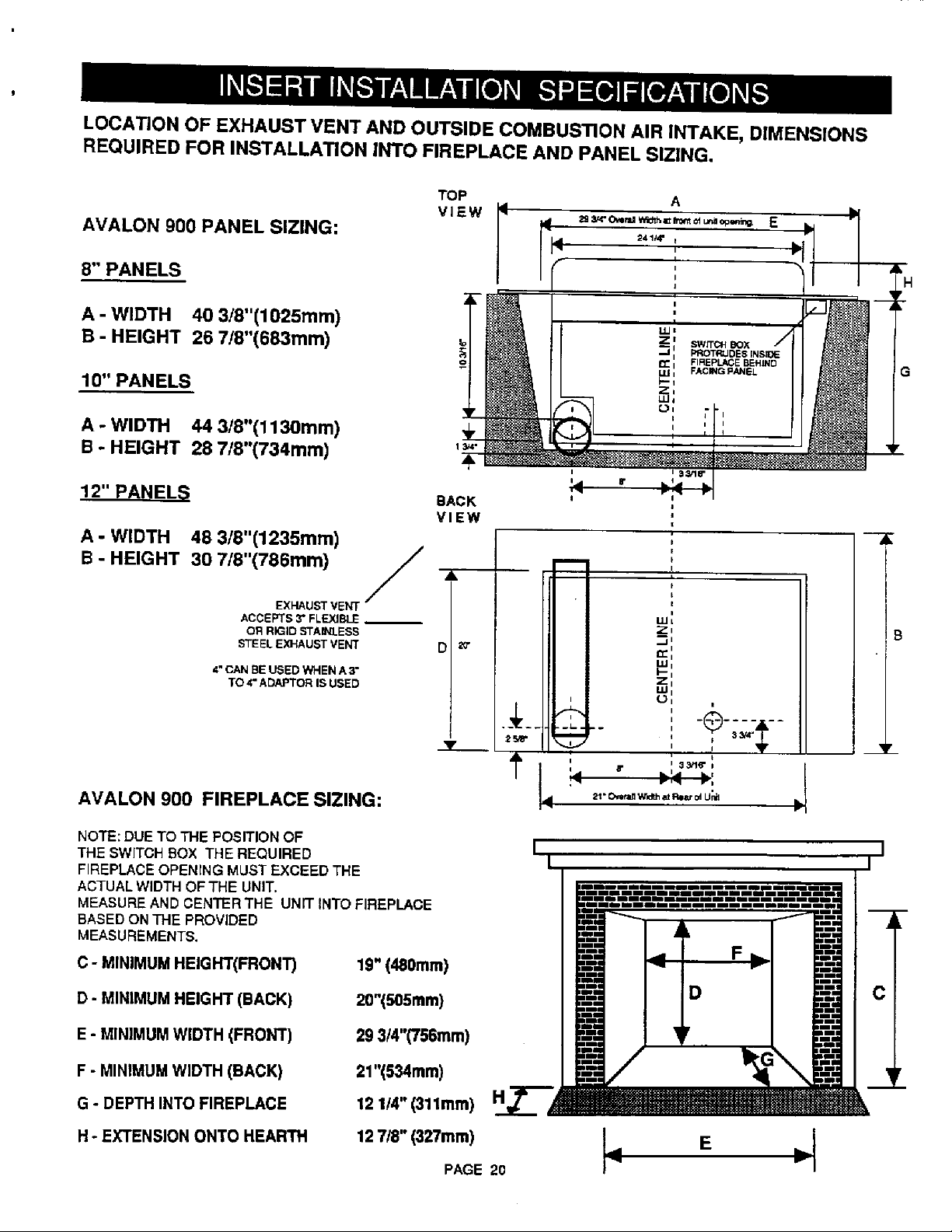

Insert Installation Specifications ----------------------------------------------------------------------------------------- 20

Insert Installation into Existing Masonry Fireplaces ----------------------------------------------------------------- 23

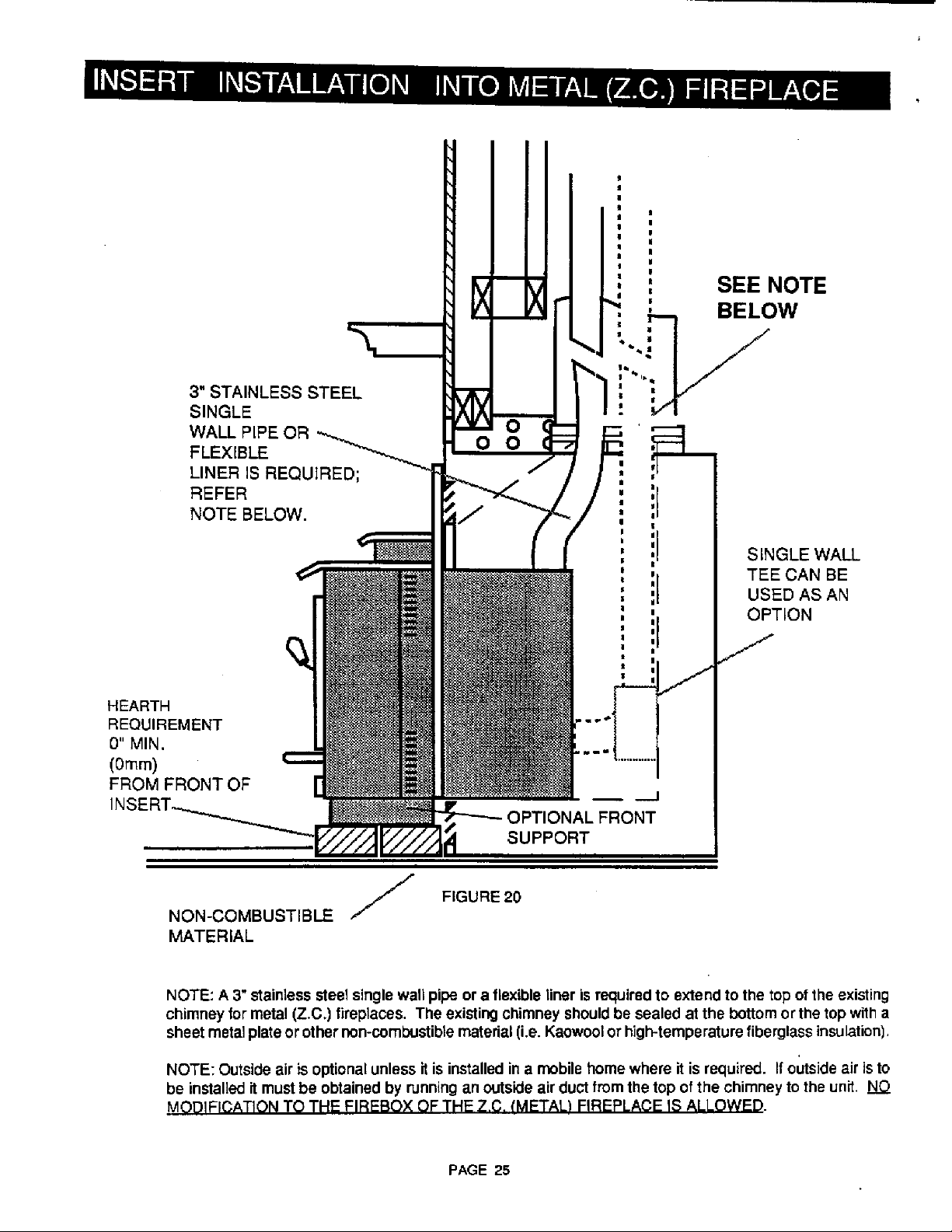

Insert Installation into Existing Zero Clearance (Metal) Fireplaces ---------------------------------------------- 25

Insert Installation - Zero Clearance (Built-In) Installation----------------------------------------------------------- 26

USE AND CARE: Pellet Stove and Pellet Insert

Location and Use of Controls --------------------------------------------------------------------------------------------- 28

Operating your Pellet Appliance ------------------------------------------------------------------------------------------ 29

Normal Operating Sounds ------------------------------------------------------------------------------------------------- 31

Care and Maintenance Schedule ---------------------------------------------------------------------------------------- 32

Care & Maintenance Instructions----------------------------------------------------------------------------------------- 33

Before Calling for Service -------------------------------------------------------------------------------------------------- 39

Replacement Parts List ----------------------------------------------------------------------------------------------------- 40

Limited Warranty ------------------------------------------------------------------------------------------------------------- 43

Product Listing Information ------------------------------------------------------------------------------------------------ 44

PAGE 3

Page 4

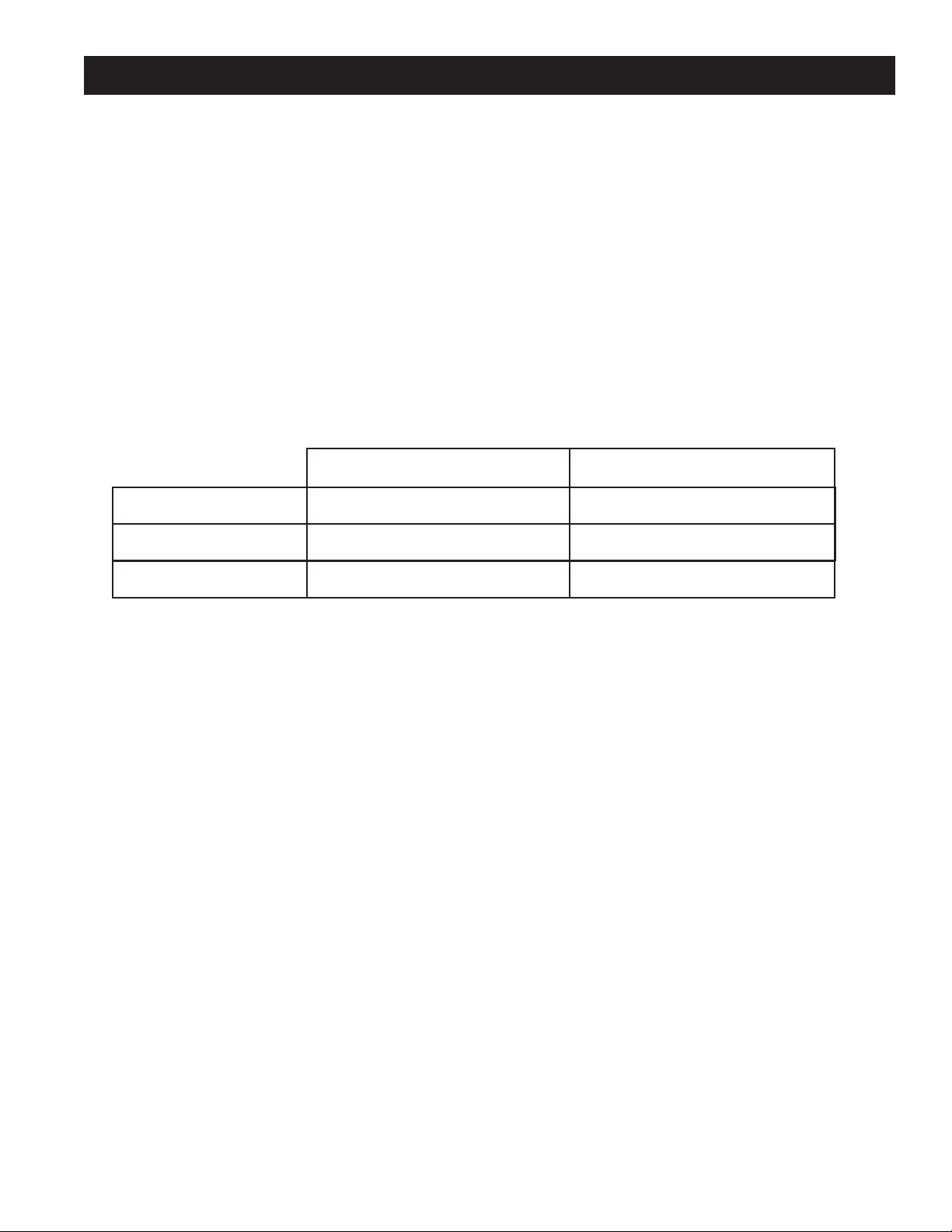

FEA TURES AND SPECIFICA TIONS

* FREESTANDING

CONVENIENT

LONG BURN TIME

* ALCOVE

VERSATILE

CLOSE CLEARANCES

* MOBILE HOME

DURABLE

* MASONRY FIREPLACE INSERT

* FACTORY-BUILT (Z.C.)

FIREPLACE INSERT

Stove

Heating Capacity SQ/FT ........................ 800 to 2000 Maximum ..................800 to 2000 Maximum

Burn Rate lbs/hr .................................... 1.2 to 4.7 ..................1.2 to 4.7

Emissions Grams/per hour..................... .8 (EPA Exempt) .................. .8 (EPA Exempt)

Maximum Burning Time (Hours) ............ Up to 50 ..................Up to 40

Flue Opening Diameter ..........................3.0" (76 mm) ..................3.0" (76mm)

Height from floor to top of stove on:

Pedestal.............................. 31 3/4" (806 mm) Depth Into Fireplace............ 12 1/4 " (311mm)

Legs, Brass......................... 27 7/8" (708 mm) Extension on to Hearth ....... 12 7/8" (326mm)

Legs, Cast .......................... 27 7/8" (708 mm) Width into Fireplace *.......... See Page 20

Legs, Black .........................26 3/8" (670 mm) Overall Height (Add 1" for flue)....19 " (483mm)

Overall Width..........................................24" (610 mm) .................. 24 1/4" (616 mm)

Overall Depth (Add 2 1/4" for flue) ........25 1/4" (641 mm) .................. 25 3/16 " (640 mm)

Hopper Capacity (lbs) ............................ 60 (27 KG) (Estimated) ..................50 (23 KG) (Estimated)

Unit Weight (lbs).....................................260 (118 KG) ..................240 (109 KG)

Electrical Rating ..................................... 115 Volts, 3 Amps, 60 HZ ..................115 Volts, 3 Amps, 60 HZ

Watts ............................................ 180 (Approx.) ..................180 (Approx.)

POWERFUL EFFICIENT FANS

SUPERIOR AUGER SYSTEM

HUGE HOPPER

STAINLESS STEEL FIREPOT

QUIET OPERATION

Insert

* See Page 20 for exact fireplace sizing

FUEL: The unit is designed to operate using 1/4 inch diameter pellets that comply with A.P.F.I.• standards. If the fuel

does not comply to this standard, the unit may not operate as designed. If the pellets are larger that 1/4 inch diameter

the unit may need adjustments; consult with your dealer.

NOTE: • Store pellets in a clean dry place.

• Emissions information and efficiency information based on tests conducted by E.E.M.C. Laboratory.

BTU. output will vary depending on pellet size, moisture content, burn rate and pellet type. Heating

capacity is subject to variations due to pellet type, relative moisture content, floor plan, degree of home

insulation, and temperature zone.

• A.F.P.I. - Association of Pellet Fuel Industries.

• Heating Capacity is based on maximum burn rate.

• Maximum burn time is based on low burn rate.

PAGE 4

Page 5

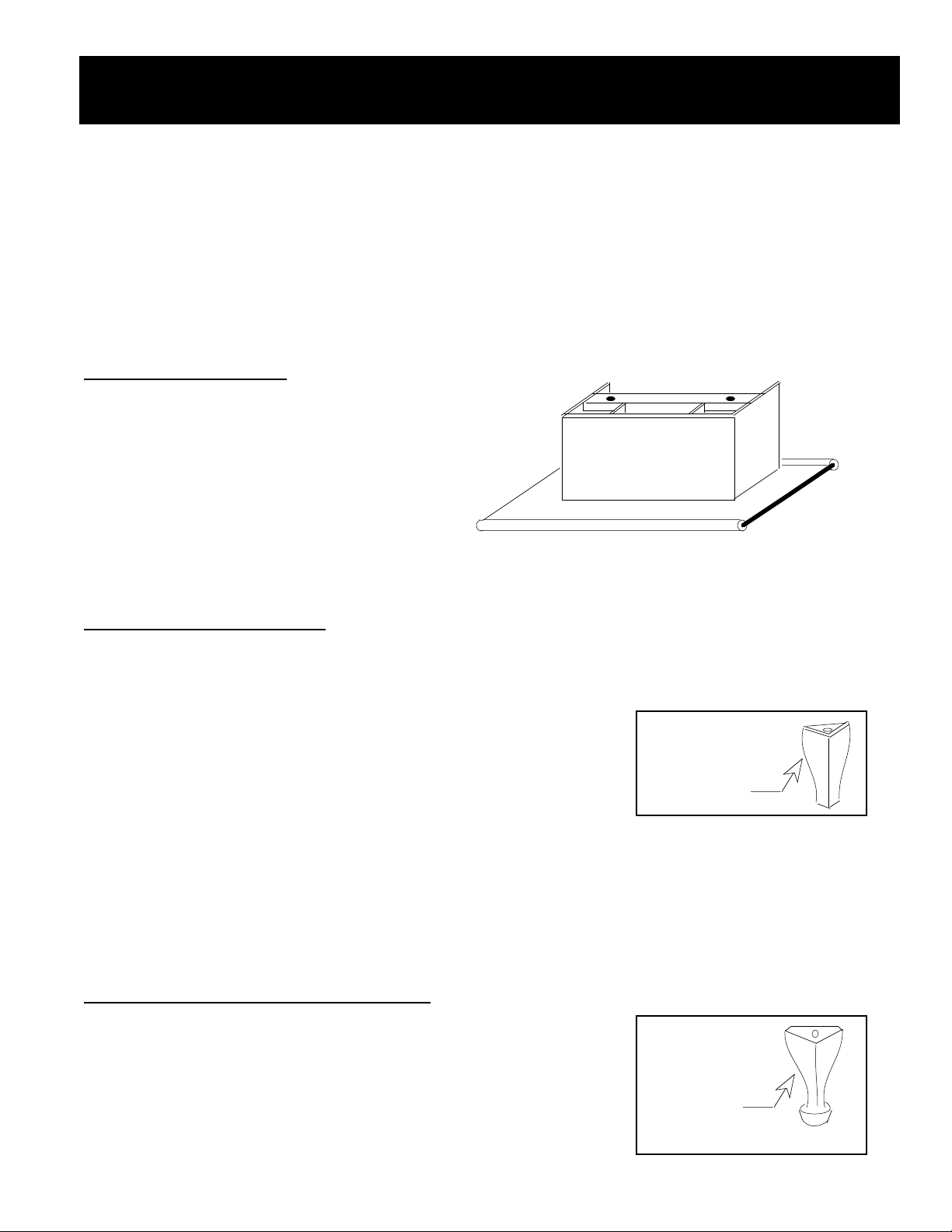

PREPARATION FOR INSTALLATION — PELLET STOVE

READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW APPLIANCE. FAILURE TO

FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR EVEN DEATH.

PREPARATION:

1. Remove all tape and packaging.

2. Remove the wood shipping frame from around and under the appliance.

3. Check that no parts have become loose and the appliance has not been damaged during shipping.

4. Remove the hardware pack from the appliance.

5. READ THE OWNER'S MANUAL BEFORE PROCEEDING.

* Appliance should be located such that no doors, drapes, furniture or other combustibles can be placed close or

swing closer than the minimum stated clearances.

* The appliance must be installed in a level, secure position.

* Required Floor Protection:

Minimum size 26 1/8"W x 31 1/2"D (664mmW x 800 mmD)

of non-combustible material with a minimum thickness

of 26 gauge (.018", .5mm) floor protection must extend

Chimney Lengths

Vertical

Horizontal

Combined Horizontal &

Vertical

NOTE #1: On chimneys with vertical heights that exceed 15' and/or horizontal runs that exceed 4', a 4" diameter

pellet vent is recommended.

NOTE #2: When this unit is installed above 4000' in altitude, 4" diameter pellet vent should be used.

* Do not obtain combustion air from attic, garage, unventilated crawl space or any other enclosed space. Do not

locate combustion air inlet at an elevation higher than exhaust termination.

* Outside air (combustion air intake) is recommended, but not required, for all residential installations, but is

required for mobile home installations. If an outside air intake (combustion air intake) is used, it must be

connected to a 1-3/4", or larger, metal or aluminium duct with a rodent screen fixed to the termination.

Do not use P.V.C .duct.

NOTE: TRAVIS INDUSTRIES, INC., recommends that an outside air (combustion air) intake be used in all

installations. If one is not used, there is a possibility of combustion gases (smoke) being released into your home,

if there is a power outage while the unit is in operation.

Maximum

33' (10.06 m)

10' (3.05 m)

4' Horizontal 30' Vertical

10' Horizontal 25' Vertical

Front - 6" (152 mm)

Sides - 0" ( 0 mm)

Back - 0" ( 0 mm)

Minimum

Subject to installation. See Fig. 9

Subject to installation. See Fig. 4&9

Any Lesser Combination is

Acceptable.

* The AVALON 900 pellet stove exhaust vent accepts 3" diameter pellet vent pipe. Some of the brands

available for use with the AVALON 900 are:

1. Duravent Model PL-Vent

Simpson Dura-Vent

P.O. Box 1510

Vacaville, CA 95688

(707) 446-1786 or

1-800-227-8846

NOTE: 4" diameter may be substituted when a 3" to 4" adapter is used.

See manufacturer’s installation instructions for precautions required for passing vent through a combustible wall

or ceiling. Do not connect this appliance to a vent serving another appliance.

All sections of pellet vent must be fastened to each other with sheet metal screws and silicone sealed with type

500 degree Fahrenheit (260°C) RTV (high heat) silicone sealer, to ensure that the joints are airtight.

2. James A. Ryder MFG Model PL-Vent

Ryder Mfg., Inc.

241 Arvin Avenue

Stoney Creek, Ontario Canada

(416) 662-1701

PAGE 5

3. MetalFab Model Pellet Vent

P.O. Box 1138

Wichita, KS 67201

(316) 943-2351

Page 6

PREPARATION FOR INSTALLATION Ð

PELLET STOVE (cont.)

Your Pellet Stove appliance comes completely assembled. Options are available for the different types of

installations. The options are listed below and are boxed separately from the appliance. They require assembly.

1. Pedestal.

2. Leg Kit, Black.

3. Leg Kit, Brass.

4. Leg Kit, Cast Black

5. Vertical Pipe Adapter

When lifting the appliance, you may choose to remove the interior components to make it lighter. Refer to the

care & maintenance instructions in this manual for the proper sequence of removal and replacement of internal

components.

1. Pedestal Assembly:

Open the box marked Pedestal and remove the

pedestal and the two attachment bolts and washers

(3/8" diameter - 16 X 3/4" hex. head bolt).

Lift the stove onto the pedestal. Line up the

threaded bolt holes in the bottom of the stove with

the two holes in the mounting angle of the pedestal

(some models use clips that attach to the side of

the pedestal -- the same directions apply).

Using a 9/16" open-end or socket wrench, fasten the pedestal to the stove with the supplied bolts and washers.

NOTE: Keep the two front leg bolts in place when installing on a pedestal -- otherwise air will enter through these

holes.

2. Leg Kit, Black Assembly:

Open the box marked Leg Kit, Black and remove the four 6-1/2" high black steel legs, complete with rubbertipped leveling bolts (on certain models they are not rubber tipped Ð the same directions apply), the four

attachment bolts (3/8" diameter - 16 X 3/4" hex. head bolt) and the washers.

Raise the stove on some pieces of lumber to a height of about 7". Make sure

to level the stove at this point using shims under the pieces of lumber. Line up

the hole in the top of the leg with the threaded bolt hole in each corner of the

stove bottom. Using a 9/16" open end or socket wrench, fasten the leg to the

stove with the supplied attachment bolts and washers, making sure the legs are

flush with the corners of the stove.

To level the stove, first make sure the leveling bolts with the rubber ends (some models come with steel bolts -the same directions apply) are screwed into position and backed off just enough to penetrate below the steel

portion of the leg. Unscrew each leveling bolts just enough so each leveling bolt is an equal distance from the

floor. You may wish to use a piece of wood or other spacer to measure this distance. As long as the lumber

holding the stove in place is properly leveled, the stove will be level when the leveling bolts are adjusted properly

and the lumber is removed. Next, lower the stove onto the ground and check for a level position. If slight

adjustments need to be made, make sure to first raise the stove before turning the leveling bolts. The rubber tips

of the leveling bolts will tear if they are adjusted while weight is applied to them.

3. & 4. Leg Kit, Brass or Cast Black Assembly:

Open the box marked Leg Kit, Brass (or Cast) and remove the four 7-7/8"

high legs, complete with rubber-tipped leveling bolts(on certain models they are

not rubber tipped Ð the same directions apply), the four attachment bolts (3/8"

diameter - 16 X 3/4" hex. head bolt) and the washers.

Use the same directions listed above for the Leg Kit, Black assembly. The one

difference is that the Brass (or Cast) legs are taller, and the stove should be

lifted approximately 8 1/2" above the floor before attachment.

PAGE 6

Attach Bolt (with

washer) to Stove

From Below

Attach Bolt (with

washer) to Stove

From Below

Page 7

PREPARATION FOR INSTALLATION Ð

PELLET STOVE (cont.)

5. Vertical Pipe Adapter:

The vertical pipe adapter is an optional item used to center the pellet vent on the pellet stove. It allows for a more

compact installation then using offsets on the pellet vent. To install the vertical pipe adapter, follow the directions

below.

1. Take the vertical pipe adapter, along with the 5 screws, out of the box and inspect for any damage.

2. When determining the final position of the stove, take into consideration the location of the vertical pipe

adapter once it is installed. It is best to install the vertical pipe adapter before determining the location of

the stove, making the final alignment with the pellet vent more accurate.

3. The vertical pipe adapter allows for the use of 3" pellet vent or 6" singlewall or doublewall stovepipe. Use

the appropriate collar for the vent type used.

4. Insert the vertical pipe adapter onto the pellet stove and align it so the length of the adapter is vertical. On

the the vertical pipe adapter where it connects to the exhaust pipe there are three holes. One is on the

outward side, one is on the top, and one is located on the bottom. Make a mark on the exhaust tube

where these holes line up. Make sure the pipe adapter is all the way against the exhaust pipe and

properly aligned when making these marks. Take the vertical pipe adapter off and drill a 9/64" hole where

the three marks where placed on the exhaust pipe.

5. Apply a high-temperature silicone sealant (type 500 degree RTV) around the outside perimeter of the

exhaust pipe near the end and slide the vertical pipe adapter into place. Attach the vertical pipe adapter

to the exhaust pipe by sliding it into place and screwing in the three sheet-metal screws through the

vertical pipe adapter and into the holes that were drilled in step 4. Inspect the connection between the

exhaust pipe and vertical pipe adater for an airtight seal. Apply more high-temperature silicone sealant if

necessary.

6. The vertical pipe adapter has a sheet metal bracket used to secure the vertical pipe adapter to the stove.

It attaches to the back of the stove in two locations. Drill the 9/64" holes in the back of the stove. Drill

only enough to penetrate the first layer of metal. Screw in the remaining two sheet-metal screws with a

phillips-head screwdriver.

7. The vertical pipe adapter can now be attached to the vent. Make sure to seal the connection between the

vertical pipe adapter and vent with a high-temperature silicone sealant (type 500 degree RTV).

Drill Three Holes for the

Screws that hold the

Vertical Pipe Adapter

to the Exhaust Pipe

Collar for 3"

Pellet vent

Collar for 6"

Stovepipe

Sheet Metal Bracket Used

to Secure the Vertical Pipe

Adapter to the Stove

Remove this Plate to Clean the Vertical Pipe Adapter

Use the Three Holes on the Verttical Pipe Adapter to mark the

Three Holes that will be drilled into the Exhaust Pipe (Make sure

the Vertical Pipe Adapter is Vertical and fully inserted)

PAGE 7

Page 8

FREESTANDING INSTALLATION - SPECIFICATIONS

24 1/4" [616 mm]

3 3/16"

83 mm

Accepts 3" DIA

Pellet Vent

1 3/4" O.D.

(44mm)

"A"

23 " Min. [603]

“A”

PEDESTAL 13 3/4" (348mm) 14 7/8" (387mm)

LEGS, BRASS 9 3/4" (248mm) 10 7/8" (276mm)

LEGS, CAST 9 3/4" (248mm) 10 7/8" (276mm)

LEGS, BLACK 8 3/8" (213mm) 9 1/2" (241mm)

FIGURE 1

“B”

"B"

PAGE 8

Page 9

FREESTANDING INSTALLATION SPECIFICATIONS (cont.)

FLOOR PROTECTION: (Fig. 2 & 3)

G. Front 6" (152 mm) NOTE: Front floor protection is measured from the door opening.

H. Sides 0" (0mm)

H. Back 0" (0mm)

NOTE: Floor protector should extend to areas below and 2" (50 mm) to each side of a "tee" when used (See Fig. 6).

CLEARANCE TO COMBUSTIBLES:

INTERIOR VERTICAL FLUE INSTALLATION

Figures 2 & 3

A Sidewall to unit 9" - (229 mm)

B Backwall to unit 11" - (279 mm)

C Corner wall to unit 2" - ( 51 mm)

D Flue vent/chimney 3" - ( 76 mm)

NOTE: Dimension "C" , corner to unit, and "B", backwall to unit, will vary depending on the type and brand of

pellet vent or interior connector used. Always maintain the "D" dimension, pellet vent/interior connector

clearance, when installing this unit. Check your pellet vent/interior connector instructions for information on its

size and clearance required to comustibles. NOTE: Singlewall interior connectors require a minimum 3"

clearance to combustibles.

HORIZONTAL THROUGH THE WALL INSTALLATION OR VERTICAL

EXTERIOR INSTALLATION

Figures 2 & 3

A Sidewall to unit 9" - (229 mm)

B Backwall to unit 3" - ( 76 mm)

C Corner Wall to unit 2" - ( 51 mm)

D Flue vent/chimney 3" - ( 76 mm)

VERTICAL

PIPE

ADAPTER

3" Pellet Vent 6" Stovepipe

9" - (229 mm) 9" - (229 mm)

7" - (178 mm) 9" - (229 mm)

2" - ( 51 mm) 2" - ( 51 mm)

3" - ( 76 mm) 3" - ( 76 mm)

SIDEWALL

BACKWALL

B

A

D

G

H

H (0")

FIGURES 2 & 3

PAGE 9

CORNER WALL

CORNER WALL

C

H

H (0")

C

G

Page 10

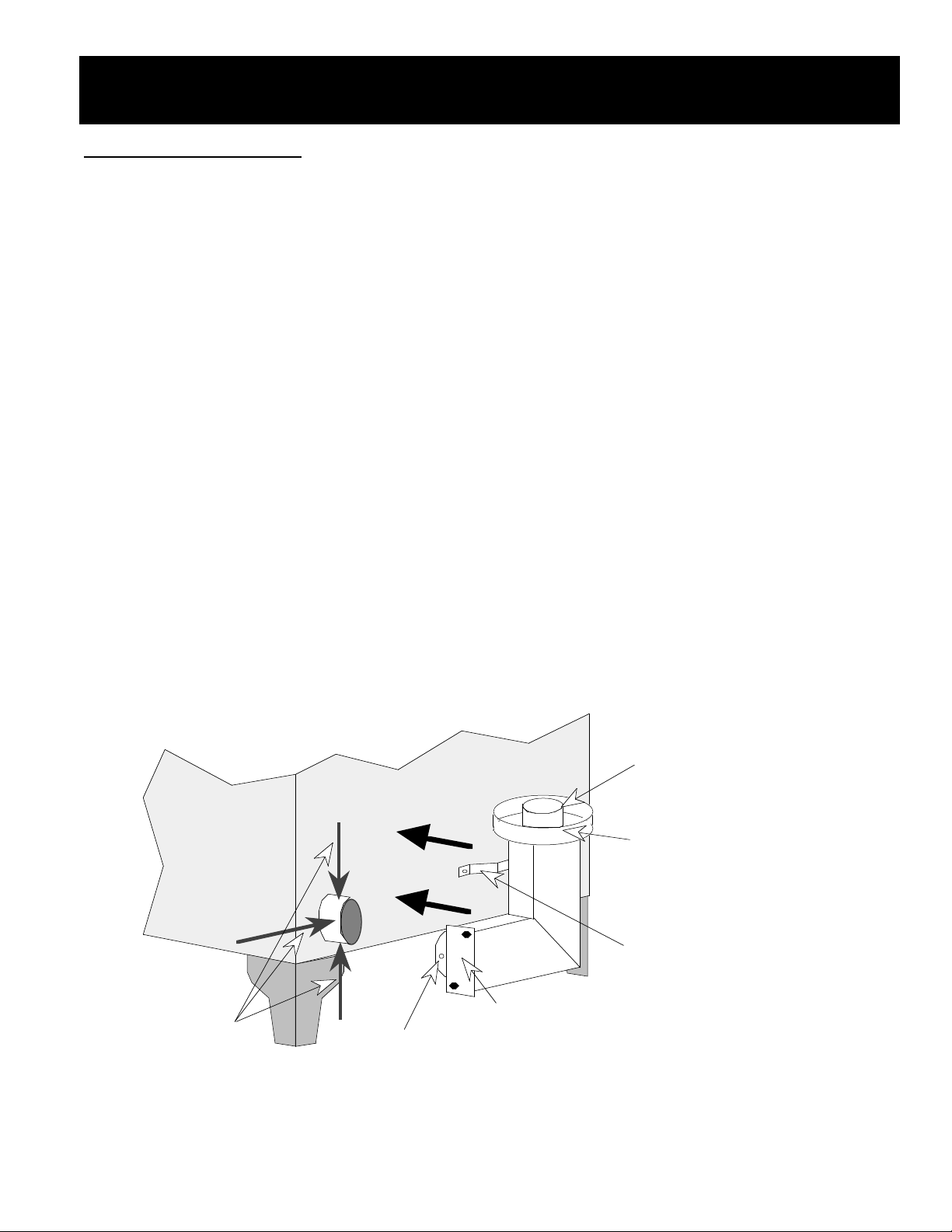

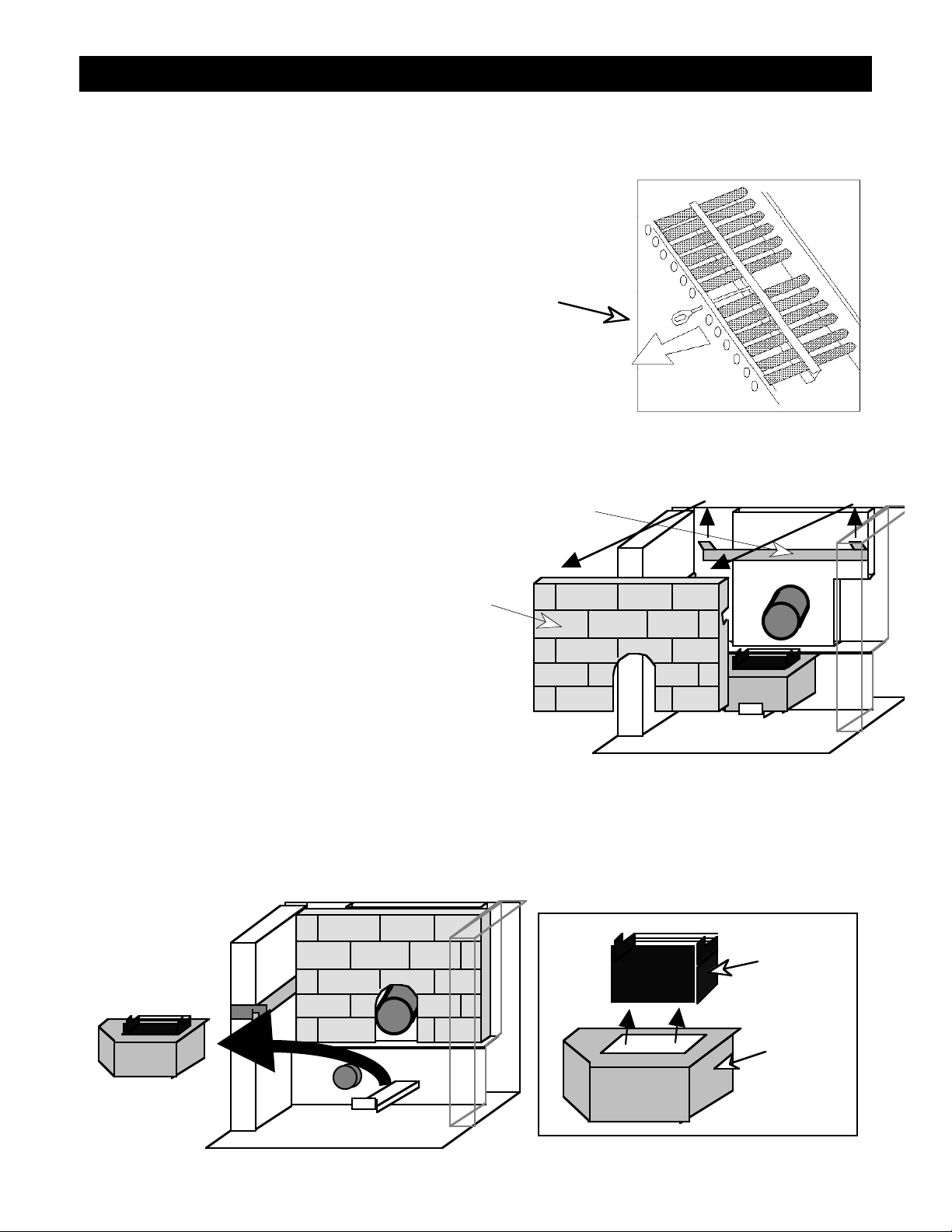

HORIZONTAL CORNER INSTALLATION

OPTIONAL AIR INTAKE

PELLET VENT

CHIMNEY CAP

FIGURE 4

The exhaust vent termination on either vertical or horizontal installations shall be located as follows:

• A minimum of 4 feet (1219 mm) below or beside and a minimum of 1 foot (305 mm) above any door

or window that opens, or any opening into a building.

• A minimum of 2 feet (610 mm) from any adjacent building.

• A minimum of 7 feet (2134 mm) above grade, when located adjacent to public walkways.

• A minimum of 2 feet (610 mm) above grass, plants or other combustible surfaces.

PAGE 10

Page 11

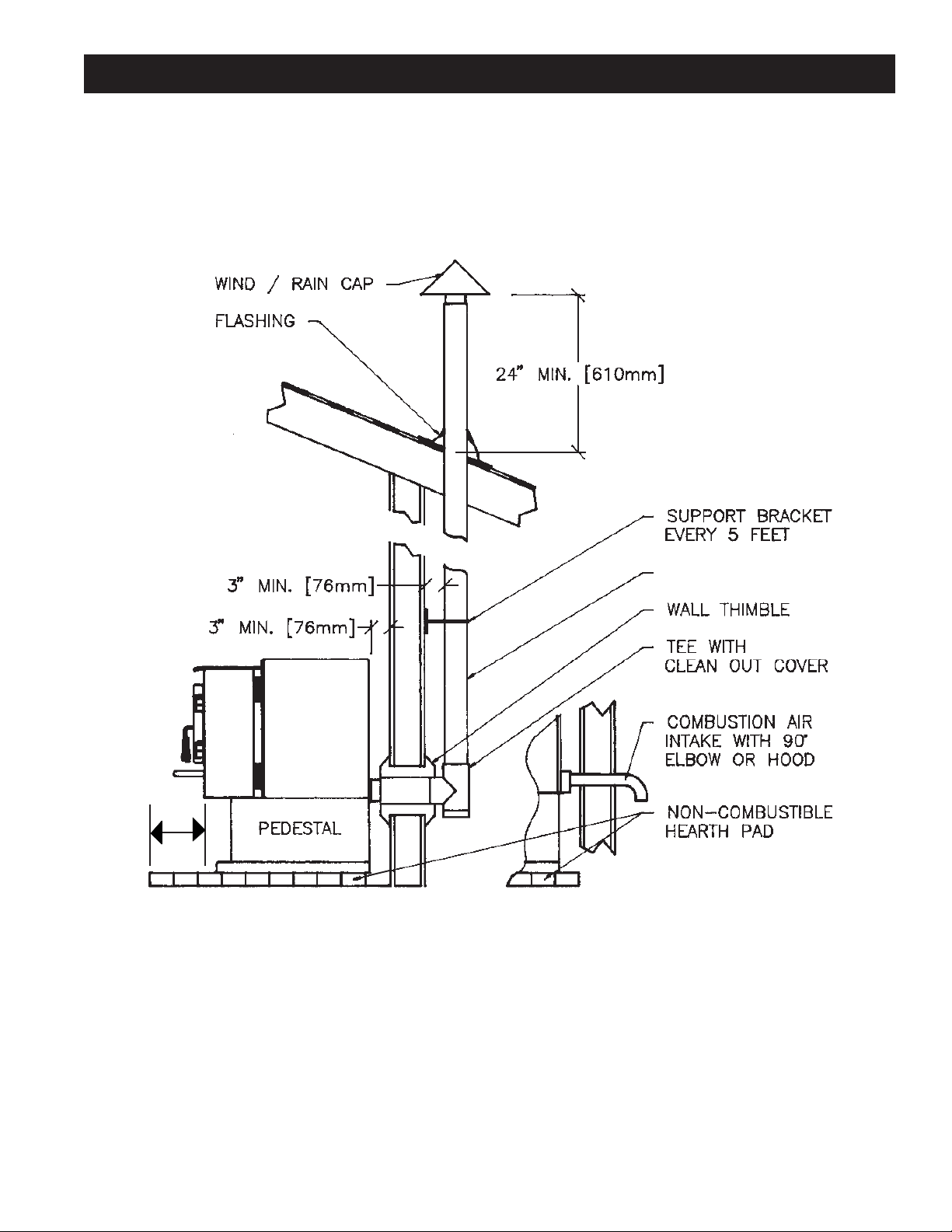

VERTICAL EXTERIOR FLUE SYSTEM

NOTE: FOR STANDARD OR CORNER INSTALLATION, STANDARD INSTALLATION SHOWN.

PELLET VENT

OPTIONAL

6" MIN.

(152mm)

▲

▲

FIGURE 5

The exhaust vent termination on either vertical or horizontal installations shall be located as follows:

• A minimum of 4 feet (1219 mm) below or beside and a minimum of 1 foot (305 mm) above any door

or window that opens, or any opening into a building.

• A minimum of 2 feet (610 mm) from any adjacent building.

• A minimum of 7 feet (2134 mm) above grade, when located adjacent to public walkways.

• A minimum of 2 feet (610 mm) above grass, plants or other combustible surfaces.

PAGE 11

Page 12

INSIDE VERTICAL INSTALLATION

WITH ROOF TERMINATION

NOTE: FOR STANDARD OR CORNER INSTALLATION, STANDARD INSTALLATION SHOWN.

PELLET VENT

3" MIN. (76MM)

OPTIONAL

6" MIN.

(152mm)

The exhaust vent termination on either vertical or horizontal installations shall be located as follows:

▲

▲

FIGURE 6

NON-COMBUSTIBLE

MATERIAL TO

EXTEND UNDER TEE

• A minimum of 4 feet (1219 mm) below or beside and a minimum of 1 foot (305 mm) above any door

or window that opens, or any opening into a building.

• A minimum of 2 feet (610 mm) from any adjacent building.

• A minimum of 7 feet (2134 mm) above grade, when located adjacent to public walkways.

• A minimum of 2 feet (610 mm) above grass, plants or other combustible surfaces.

PAGE 12

Page 13

HEARTH STOVE INSTALLATION INTO EXISTING

MASONRY & ZERO CLEARANCE (METAL) FIREPLACE

SEAL COVER PLATE TO

CHIMNEY WITH SILICONE

SEALER.

POSITIVE CONNECTION

(COMPLETE RELINE)

3" STAINLESS STEEL SINGLE

☛

WALL PIPE OR FLEXIBLE

LINER CAN BE USED.

(SEE NOTE BELOW).

SINGLE WALL TEE CAN BE

USED AS AN OPTION.

BLOCK-OFF PLATE OR

☛

NON-COMBUSTIBLE

MATERIAL MAY BE USED

AT THE FIREPLACE

DAMPER LOCATION. THIS

SEAL MUST BE AIRTIGHT.

(SEE BELOW)

▼

TERMINATION OF

12"

DIRECT CONNECTION.

▼

OPTIONAL

6" MIN.

(152mm)

NOTE: Masonry fireplace installations require a direct connection or positive (complete reline) connection to the

chimney flue. With a direct connection a block-off plate made of metal or other non-combustible material

(i.e. Kaowool or high temperature fiberglass insulation) must be used at the damper location and sealed

airtight. The singlewall pipe or flexible liner must extend past the block-off plate or insulation by one (1) foot

(305 mm) or to the first flue tile if the chimney has a tile lining.

With a positive connection, the block-off plate at the damper location is optional, but a sealed cover plate

is required at the top of the chimney. A positive connection (complete reline) is recommended for ease of

cleaning. Zero clearance (metal) fireplace installations require a complete reline to top of chimney.

▲

▲

FIGURE 7

PAGE 13

Page 14

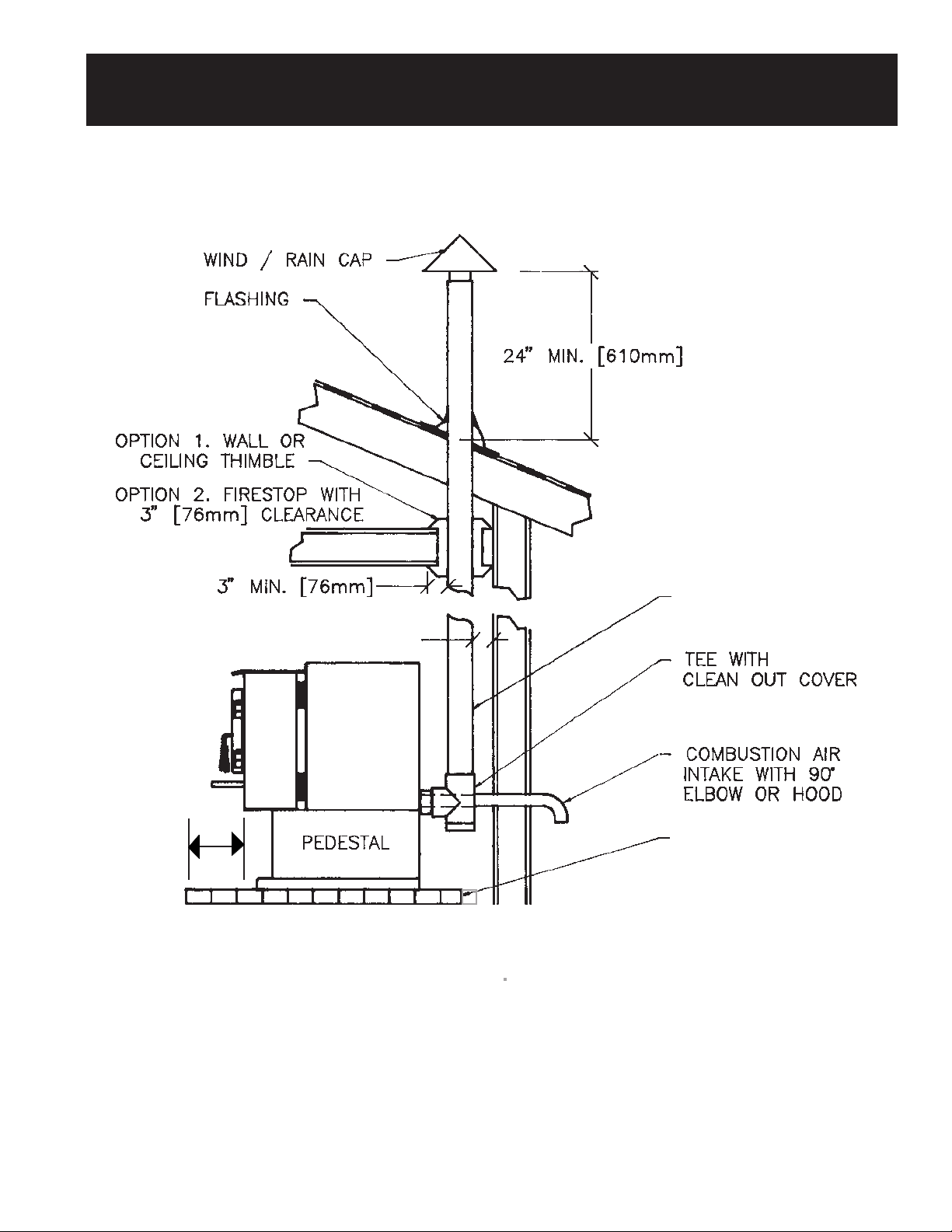

VERTICAL INSTALLATION INTO EXISTING

FACTORY BUILT CHIMNEY

NOTE: FOR STANDARD OR CORNER INSTALLATION, STANDARD INSTALLATION SHOWN.

Flashing

24" Min. (610mm)

OPTION 1. Wall Or

Ceiling Thimble

OPTION 2. Firestop With

3" (76mm) Clearance

Keep Clearance Specified

By Factory Built Chimney

Manufacturer

6" Min.

(152mm)

3" Min. (76mm)

Pellet Vent To Factory

Built Adaptor Required

Pellet Vent

Tee With

Clean Out Cover

Optional

Combustion Air

Intake With 90˚

Elbow Or Hood

Non-Combustible

Material To Extend

Under The Tee

FIGURE 8

The exhaust vent termination on either vertical or horizontal installations shall be located as follows:

• A minimum of 4 feet (1219 mm) below or beside and a minimum of 1 foot (305 mm) above any door

or window that opens, or any opening into a building.

• A minimum of 2 feet (610 mm) from any adjacent building.

• A minimum of 7 feet (2134 mm) above grade, when located adjacent to public walkways.

• A minimum of 2 feet (610 mm) above grass, plants or other combustible surfaces.

PAGE 14

Page 15

HORIZONTAL INSTALLATION

24"

▼

24" (610mm)

▼

REFER NOTE

▼

▼

12" MIN

CHIMNEY CAP

305mm

6" MIN.

(152mm)

▲

▲

OPTIONAL

MATERIAL

FIGURE 9

NOTE: A 6 ft. (1829mm) vertical rise is recommended to maintain a better draft. However, a shorter rise may

be used. Vertical installation as in Figure 5 is preferred. If a shorter rise is used and the termination is under

an eave or overhang, the termination must be at least 24" (610mm) from the combustible material, and the

chimney must be vented at least 12" (305mm) from the dwelling.

The exhaust vent termination on either vertical or horizontal installations shall be located as follows:

• A minimum of 4 feet (1219 mm) below or beside and a minimum of 1 foot (305 mm) above any door

or window that opens, or any opening into a building.

• A minimum of 2 feet (610 mm) from any adjacent building.

• A minimum of 7 feet (2134 mm) above grade, when located adjacent to public walkways.

• A minimum of 2 feet (610 mm) above grass, plants or other combustible surfaces.

PAGE 15

Page 16

Page 17

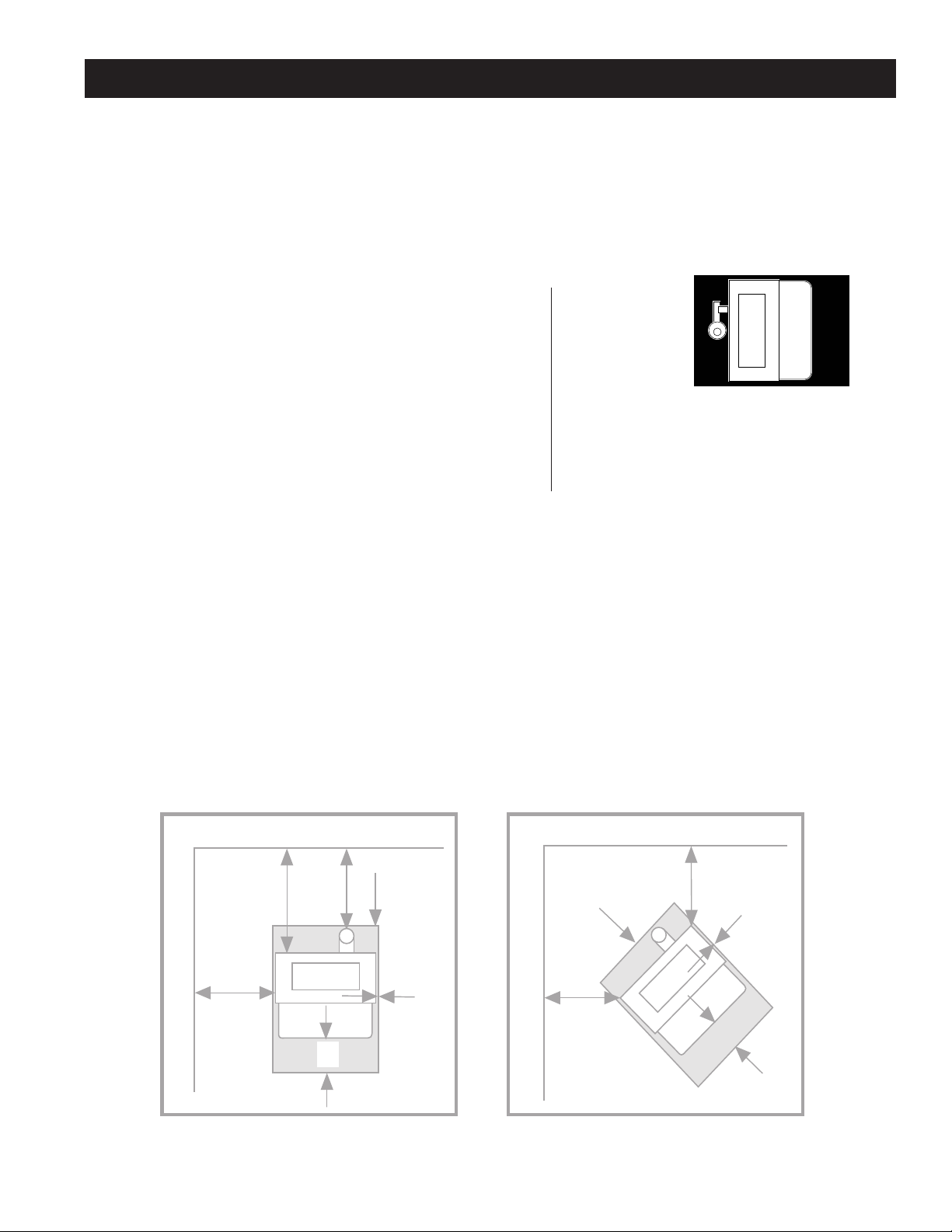

RESIDENTIAL ALCOVE INSTALLATION

9" MIN.

(229mm)

9" MIN.

(229mm)

42 1/4" (1074mm)

44 1/8"

FIGURE 11

MINIMUM ALCOVE HEIGHT 60" - (1524mm)

MAXIMUM ALCOVE DEPTH 48" - (1219mm)

PAGE 17

1121

Page 18

PREPARATION FOR INSTALLATION — PELLET INSERT

READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW APPLIANCE. FAILURE TO

FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR EVEN DEATH.

PREPARATION:

1. Remove all tape and packaging.

2. Remove the wood shipping frame from around and under the appliance.

3. Check that no parts have become loose and the appliance has not been damaged during shipping.

4. Remove the hardware pack from the appliance.

5. READ THE OWNER'S MANUAL BEFORE PROCEEDING.

* Appliance should be located such that no doors, drapes, furniture or other combustibles can be placed close or

swing closer than the minimum stated clearances.

* The appliance must be installed in a level, secure position.

* Required Floor Protection: (Fig. 10)

NOTE: Minimum hearth extension 24" W (610 mm) x 16" D (406 mm) from fireplace opening.

Chimney Lengths

Vertical

Horizontal

Combined Horizontal &

Vertical

NOTE #1: On chimneys with vertical heights that exceed 15' and/or horizontal runs that exceed 4', a 4" diameter

pellet vent is recommended.

NOTE #2: When this unit is installed above 4000' in altitude, 4" diameter pellet vent should be used.

* Do not obtain combustion air from attic, garage, unventilated crawl space or any other enclosed space. Do not

locate combustion air inlet at an elevation higher than exhaust termination.

* Outside air (combustion air intake) is recommended, but not required, for all residential installations, but is

required for mobile home installations. If an outside air intake (combustion air intake) is used, it must be

connected to a 1-3/4", or larger, metal or aluminum duct with a rodent screen fixed to the termination.

Do not use P.V.C .duct.

NOTE: TRAVIS INDUSTRIES, INC., recommends that an outside air (combustion air) intake be used in all

installations. If one is not used, there is a possibility of combustion gases (smoke) being released into your home,

if there is a power outage while the unit is in operation.

* The AVALON 900 pellet insert exhaust vent accepts 3" diameter pellet vent pipe. Some of the brands

available for use with the AVALON 900 are:

Maximum

33' (10.06 m)

10' (3.05 m)

4' Horizontal 30' Vertical

10' Horizontal 25' Vertical

Minimum

Subject to installation. See Fig. 9

Subject to installation. See Fig. 4&9

Any Lesser Combination is

Acceptable.

1. Duravent Model PL-Vent

Simpson Dura-Vent

P.O. Box 1510

Vacaville, CA 95688

(707) 446-1786 or

1-800-227-8846

NOTE: 4" diameter may be substituted when a 3" to 4" adapter is used.

See manufacturer’s installation instructions for precautions required for passing vent through a combustible wall

or ceiling. Do not connect this appliance to a vent serving another appliance.

All sections of pellet vent must be fastened to each other with sheet metal screws and silicone sealed with type

500 degree Fahrenheit (260°C) RTV (high heat) silicone sealer, to ensure that the joints are airtight.

2. James A. Ryder MFG Model PL-Vent

Ryder Mfg., Inc.

241 Arvin Avenue

Stoney Creek, Ontario Canada

(416) 662-1701

PAGE 18

3. MetalFab Model Pellet Vent

P.O. Box 1138

Wichita, KS 67201

(316) 943-2351

Page 19

PREPARATION FOR INSTALLATION —

NOTE

TABS

UNLATCH

SECOND

REMOVE

GASKET

PELLET INSERT (cont.)

NOTE: The fireplace cavity must be thoroughly cleaned prior to installation. It should be cleaned with a wire brush or

scraper and then painted with a latex paint to eliminate the possibility of odors from the fireplace being circulated into

the house by the room air fan of the pellet insert.

For your safety, examine the fireplace and chimney prior to installation of the pellet insert to determine that they are

free from cracks, loose mortar, creosote deposits, blockages, or other signs of deterioration. If evidence of

deterioration is noted, the pellet insert should not be installed until after repairs have been made. Any opening

between the masonry of the fireplace and the facing masonry must be permanently sealed.

Your pellet insert is listed for installation into masonry fireplaces, and is approved to be installed with or without

positive or direct chimney connection.

Your pellet insert is also approved for installation into metal or zero-clearance (Z.C.) fireplaces. Metal or Z.C.

installation requires a full reline with a 3" stainless steel single-wall pipe or a flexible liner.

Your Avalon 900 Pellet Insert appliance comes completely assembled, with the exception of the switch box, panels

and panel trim. Options available for the different types of installations are:

1. Adjustable Front Insert Support.

2. Panels - 8", 10", or 12"

3. Ceramic Log

The above items come boxed separately and require assembly.

VENT CONFIGURATION:

The 900 Pellet Insert is equipped with a dual vent configuration. It can be vented vertically or horizontally. Before

installing, you must determine which configuration will best suit your installation.

The unit comes set up for a vertical installation (Fig. 12-A). To change it to a horizontal venting configuration,

remove the 1/4" hex head bolt and clamp holding the vertical vent to the base of the unit, next release the spring clip

on the side of the lower vent duct , (Fig. 12-B) and remove the vent assembly then release the spring clip holding the

round portion of the vent to the rectangular portion (Fig. 12-C). To complete the change over, clip the round portion

into the lower vent duct bracket (Figs. 12 D & E).

NOTE: Make sure that the gaskets are not damaged and are in the proper position before latching the spring clip.

FIG. 12-A

UNLATCH FIRST

FIG. 12-D

FIG. 12-B

NOTE

TABS

LEAVE GASKETING

IN PLACE

TAKE OFF

VERTICAL FLUE

ATTACHMENT

FIG. 12-E

FIG. 12-C

MAKE SURE

GASKETING

IS IN PLACE

NOTE

TABS

NOTE

TABS

PAGE 19

RELATCH

Page 20

Page 21

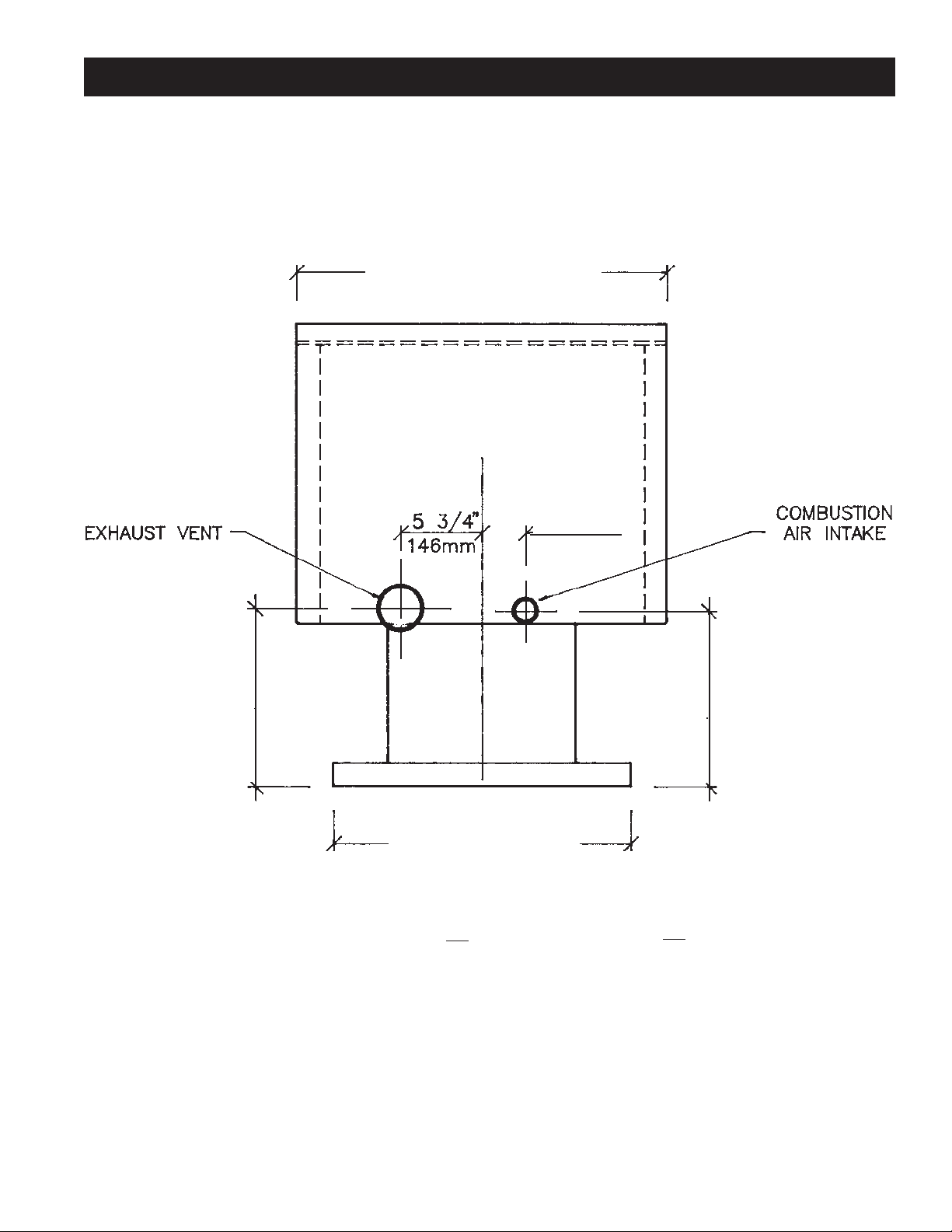

INSERT INSTALLATION SPECIFICATIONS (Cont.)

FLOOR PROTECTION: (Fig.10 )

E. Front 0" (0mm)

F. Sides 0" (0mm)

NOTE: Although a non-combustible hearth extension is not required to extend past the front and sides of

the insert, the insert must be installed on a non-combustible hearth that extends to the front and side

edges of the insert.

CLEARANCE TO COMBUSTIBLES: (Fig. 10)

A. Adjacent Sidewall 9" (229mm)

B. Side Facing 8" (203mm)

C. Top Facing 12" (305mm)

D. Mantle 13" (330mm)

NOTE: For clearances, use this clearance diagram (fig. 10 ) or the clearance diagram on the

safety label attached to the back of the appliance.

MANTLE

D

GH

SIDEWALL

DIRECT CONNECTION:

1. Make sure the fireplace and chimney are thoroughly cleaned, inspected and repaired where necessary to

make it safe. Paint with a latex paint as explained on Pg. 19.

A

I

F

0"

Figure 10

E

C

0"

B

J

2. Wire open or remove the firebox damper.

3. Measure the area of the firebox below the damper opening and above the lintel. Transfer these

measurements to a piece of galvanized sheet metal (min. 24 gauge) and add 2" to each side. Mark the

position of several holes on each side, to suit your specific installation, and drill 1/4" diameter holes. Next

bend the 2" extended side to a 45° angle. The 2" lip with the 1/4" diameter holes will allow you to screw

the plate to the firebox walls.

PAGE 21

Page 22

INSERT INSTALLATION SPECIFICATIONS - (cont.)

DIRECT CONNECTION: (Continued)

4. A hole must be cut in the plate to allow the chimney connector to pass through from the appliance into the

chimney. Mark the hole position on the plate so that the center of the hole is in line with the center line of the

appliance flue. A flexible stainless steel connector works best if an offset is required.

5. Position the plate in the firebox where the measurements were taken. Secure the plate with screws through

the holes in the lip, and seal around the outside edges of the plate with fiberglass insulation, furnace cement,

or both.

6. Insert the chimney connector (flexible or rigid single-wall stainless steel, 3" diameter and at least 24" long) up

through the hole in the plate and damper opening into the chimney. Seal where vent passes through blockoff plate. This should be done on completion of connection.

NOTE: Masonry fireplace installations require a direct connection or positive (complete reline) connection to

the chimney flue. With a direct connection a block-off plate made of metal or other non-combustible material

(i.e. Kaowool or high temperature fiberglass insulation) must be used at the damper location and sealed

airtight. The singlewall pipe or flexible liner must extend past the block-off plate or insulation by one (1) foot

(305 mm) or to the first flue tile if the chimney has a tile lining.

With a positive connection, the block-off plate at the damper location is optional, but a sealed cover plate is

required at the top of the chimney. A positive connection (complete reline) is recommended for ease of

cleaning.

PANEL INSTALLATION:

7. Lay a protective covering such as a towel or blanket on the floor to protect the floor and the panel finish. Remove,

from the box marked Panels, one top panel and two side panels. Make sure that the panels are large enough to

cover the fireplace opening. NOTE: Route the power cord out of the fireplace so it exits through the lower outside

front corner of the fireplace opening. DO NOT ROUTE THE POWER CORD UNDER THE UNIT.

8. Align the side panels with the sides of the unit. The panels are notched and simply clip onto the sides of the unit.

9. Unwrap the Switch Box (shipped inside the firebox of the appliance) and clip it into the panel. The Power Switch

should be at the top and the Blower Control at the bottom. This must be done prior to the installation of the top

panel.

10. Position the top panel over the unit. Align the clips and slide the top panel over the side panel flanges and the top

of the unit. Press down firmly to make a secure fit.

11. Place the trim face down on the floor, as it would appear on the unit. Place the corner brackets in the appropriate

slots, insert the set screws and tighten firmly.

12. Slide the completed trim assembly over the panels.

You may wish to use two-sided tape at the ends of the

trim to hold it firmly against the bottom of the side

panels.

13. Push the assembled insert, panels and trim into the

fireplace until the spacers make contact with the face of

the fireplace. Be careful not to scratch the hearth.

NOTE: Maintain at least a 3/8" air gap around the

outside edge of the panels. This allows air to flow

around the unit. If this gap is not maintained, the unit

could overheat.

14. Make sure that the insert is square in the fireplace

opening.

PAGE 22

Switch Box

Attaches to

Side Panel Here

Page 23

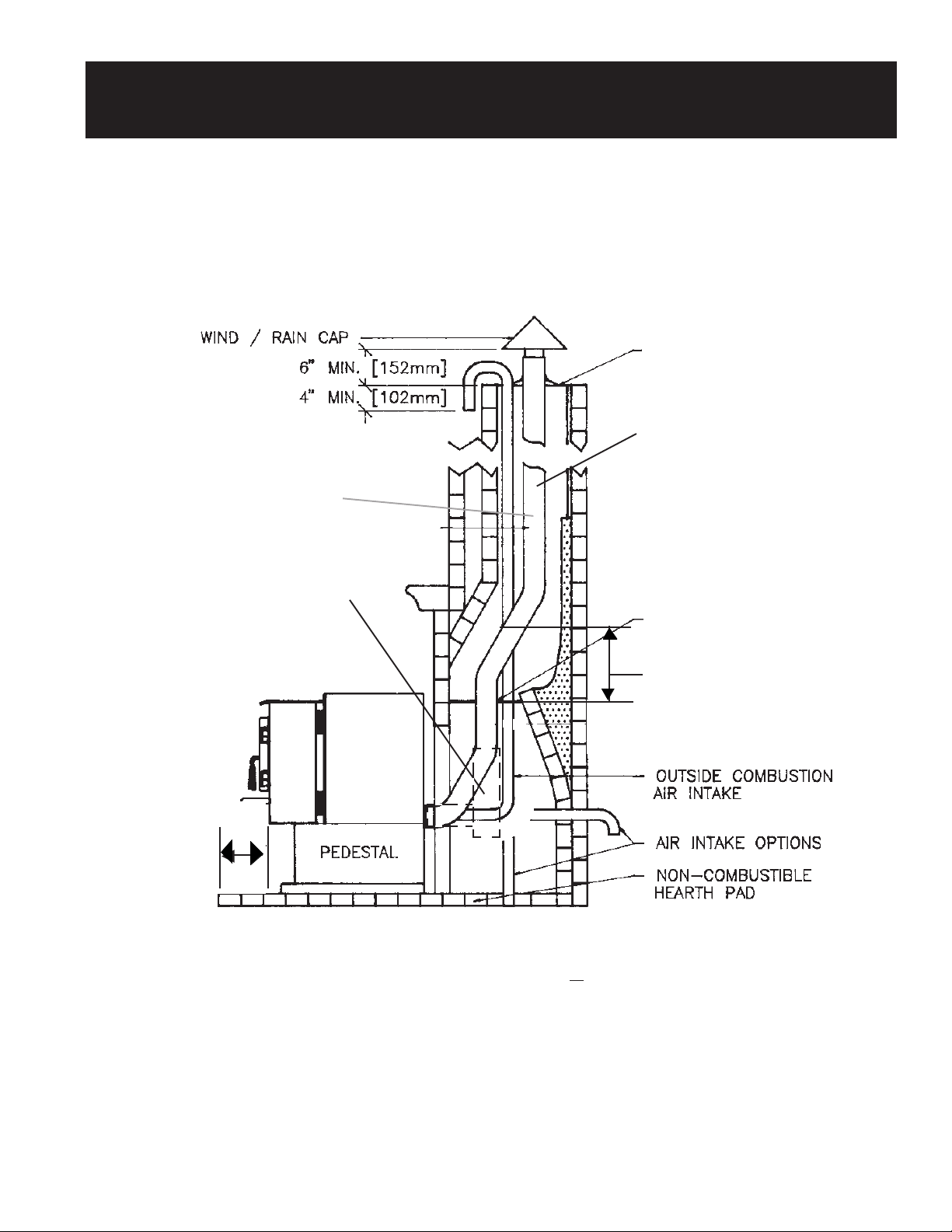

INSERT INSTALLATION INTO EXISTING

MASONRY FIREPLACE

WIND / RAIN CAP

6" MIN. (152mm)

4" MIN. (102mm)

3" STAINLESS STEEL

☛

SINGLE

WALL PIPE OR

FLEXIBLE

LINER IS REQUIRED;

REFER

NOTE BELOW.

▼

▼

▼

▼

OUTSIDE COMBUSTION

AIR INTAKE

POSITIVE CONNECTION

(FULL RELINE)

SEE NOTE

BELOW

12" DIRECT CONNECTION

TERMINATION

SINGLE WALL TEE

CAN BE USED AS AN

OPTION

HEARTH

REQUIREMENT

0" MIN.

(0mm)

FROM

FRONT

OF INSERT

NON-COMBUSTIBLE

MATERIAL

NOTE: Masonry fireplace installations require a direct connection or positive (complete reline) connection to the chimney

flue. With a direct connection a block-off plate made of metal or other non-combustible material (i.e. Kaowool or

high temperature fiberglass insulation) must be used at the damper location and sealed airtight. The singlewall

pipe or flexible liner must extend past the block-off plate or insulation by one (1) foot (305 mm) or to the first flue

tile if the chimney has a tile lining.

FIGURE 24

AIR INTAKE OPTIONS

OPTIONAL

OUTSIDE

AIR INTAKE

With a positive connection, the block-off plate at the damper location is optional, but a sealed cover plate is

required at the top of the chimney. A positive connection (complete reline) is recommended for ease of cleaning.

PAGE 23

Page 24

INSERT INSTALLATION INTO EXISTING

3" STAINLESS STEEL

SINGLE

WALL PIPE OR

FLEXIBLE

LINER IS REQUIRED;

REFER

NOTE BELOW.

MASONRY FIREPLACE (cont.)

SEE NOTE

BELOW

12" DIRECT CONNECTION

TERMINATION

SINGLE WALL TEE

CAN BE USED AS AN

OPTION

HEARTH

REQUIREMENT

0" MIN.

(0mm)

FROM

FRONT

OF UNIT

NON-COMBUSTIBLE

MATERIAL

NOTE: Masonry fireplace installations require a direct connection or positive (complete reline) connection to the chimney

flue. With a direct connection a block-off plate made of metal or other non-combustible material (i.e. Kaowool or

high temperature fiberglass insulation) must be used at the damper location and sealed airtight. The singlewall

pipe or flexible liner must extend past the block-off plate or insulation by one (1) foot (305 mm) or to the first flue

tile if the chimney has a tile lining.

With a positive connection, the block-off plate at the damper location is optional, but a sealed cover plate is

required at the top of the chimney. A positive connection (complete reline) is recommended for ease of cleaning.

FIGURE 25

PAGE 24

AIR INTAKE OPTIONS

OPTIONAL OUTSIDE

COMBUSTION AIR INTAKE

OUTSIDE COMBUSTION

AIR INTAKE

OPTIONAL

OUTSIDE

AIR INTAKE

Page 25

Page 26

INSERT INSTALLATION - ZERO CLEARANCE (BUILT-IN)

The minimum combustible framing dimensions using 3" diameter type "L" listed pellet vent is listed below:

A = Height of 27"

A

B = Depth of 16"

C = Width of 32 1/2"

B

C

This type of installation requires the use of the floor shield kit. The floor shield is boxed separately and can be installed

by following the directions below:

1. Take the floor shield out of the box and make sure the insulation is still placed on the floor shield. The box contains

the floor shield, the bottom panel extension, 8 self-tapping screws, and 2 front leveling bolts.

2. Prop up the front of the insert approximately one foot so that it rests on its rear edge. Remove the front leveling

bolts already attached to the insert and discard. Remove the rear leveling bolts (if attached). Attach the floor shield

to the bottom of the insert by screwing in the eight screws with a phillip-head screwdriver. Attach the two front

leveling bolts included with the floor shield to the floor shield. Then re-attach the two rear leveling bolts through

the floor shield and into the insert.

3. Return the stove to the upright position.

4. The insert can then be placed in the zero clearance cavity and leveled. To level, first measure the step-down

before placing the insert into the cavity. Adjust the front and rear leveling bolts to accomodate any difference. Final

leveling can be done by lifting the insert and turning the leveling bolts to accomodate the level installation. The

magnetized bottom panel extension comes with the floor shield and can be attached by placing it against the insert

panels.

INSERT

Insulation

Front Leveling

Bolts (2)

Holes for back Leveling Bolts

PAGE 26

Page 27

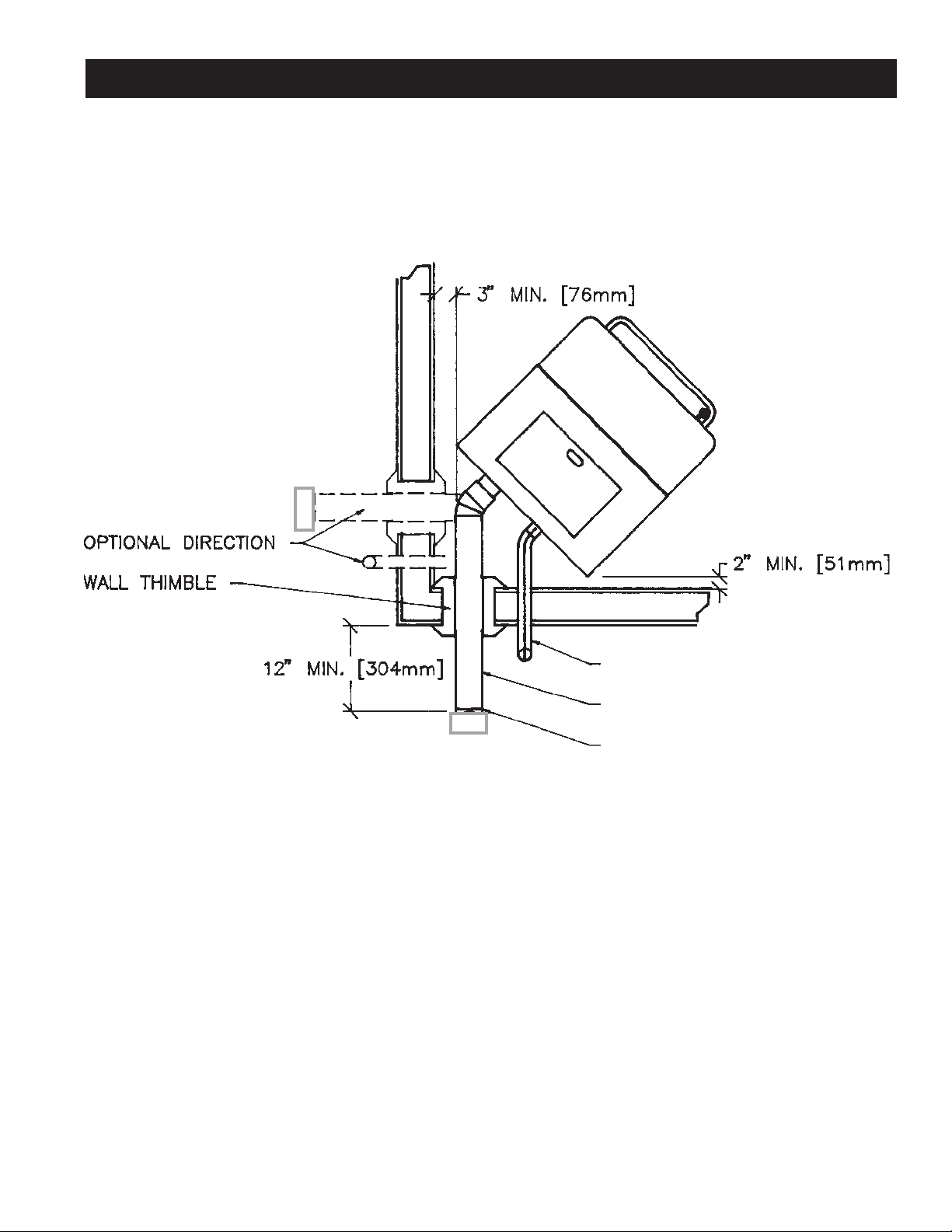

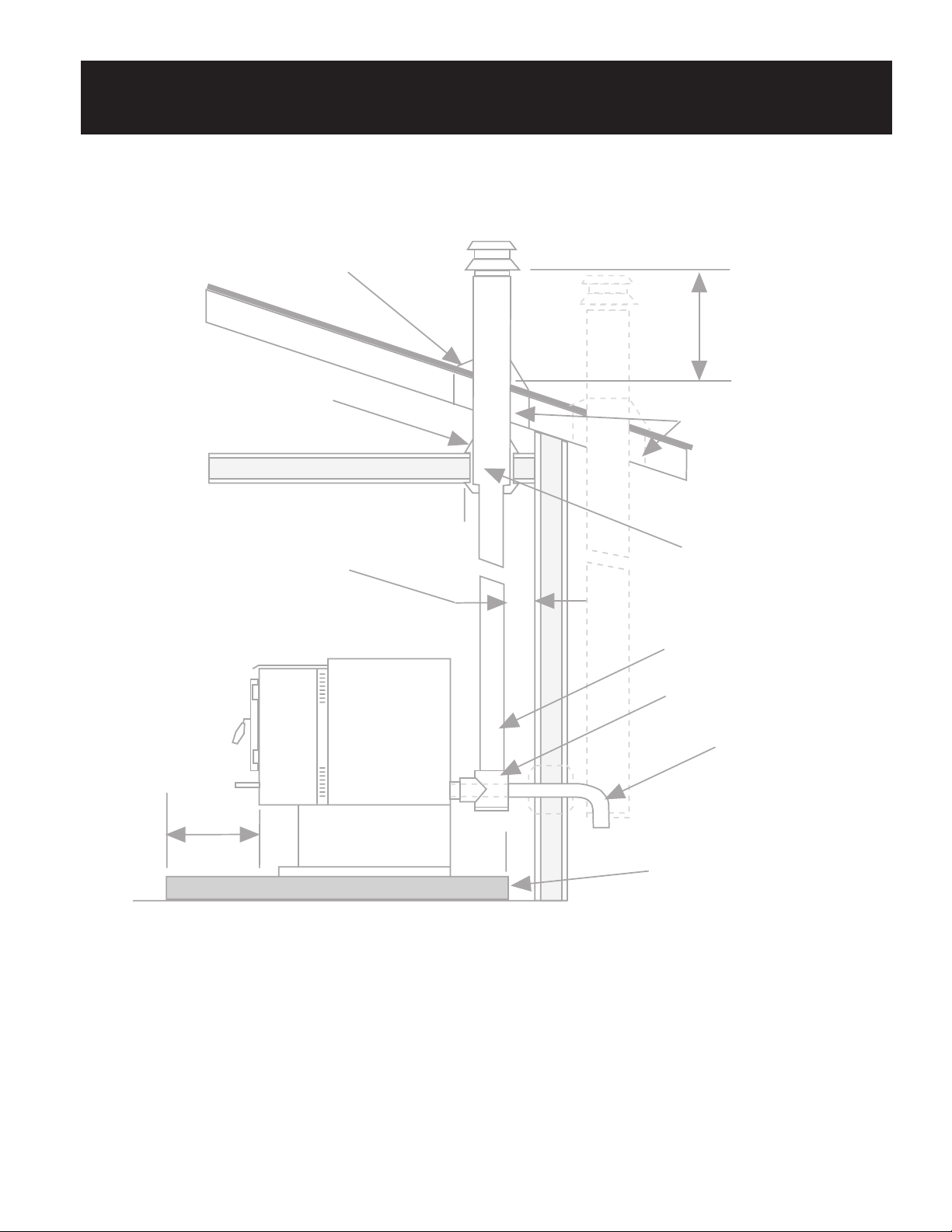

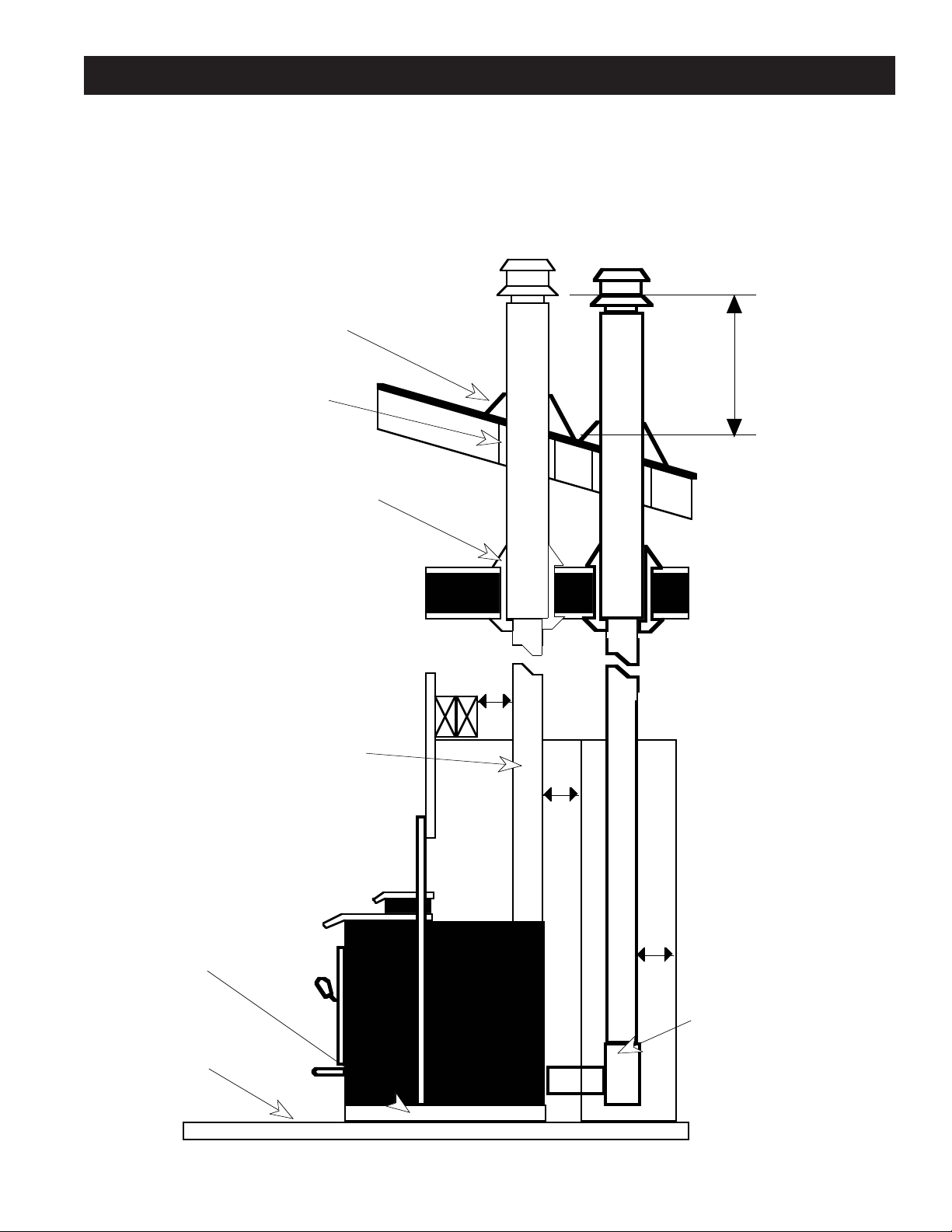

INSERT INSTALLATION - ZERO CLEARANCE (BUILT-IN)

(CONTINUED)

The pellet vent must maintain a 3" clearance from any combustible. Make sure to follow the clearance specified by the

manufacturer for the factory built chimney when making the opening in the roof. Whenever a ceiling or floor is penetrated

an approved thimble or firestop with 3" clearance must be used. See the illustration below for other specifications that must

be met.

Flashing

24" Min.

Keep Clearance Specified

By Factory Built Chimney

Manufacturer

OPTION 1.

Wall or Ceiling

Thimble

OPTION 2.

Firestop With 3"

(76mm) Clearance

Floor Shield

HEARTH

RQUIREMENT

0" FROM

FRONT OF

INSERT

Pellet Vent

3" Min.

3"

Min.

3"

Min.

Optional Flue Direction

(Requires an increase

in the minimum framing

dimension) - Must Have

Non-Combustible

Material Under the Tee.

PAGE 27

Page 28

Page 29

OPERATING YOUR PELLET APPLIANCE

STEP 1. RECOMMENDED FUEL TYPES & SIZES:

The unit is designed to operate using 1/4" diameter pellets that comply with A.P.F.I. * standards. If the fuel does

not comply to this standard, the unit may not operate as designed. If the pellets are larger than 1/4" diameter,

the unit may need adjustments. Consult with your dealer. NOTE: Store pellets in a clean, dry place. Check

frequently for foreign objects that may get mixed in with the pellets.

* A.P.F.I. = Association of Pellet Fuel Industries.

STEP 2. PRIMING THE AUGER:

Priming the auger is only required when the unit is new or when the hopper has completely run out of pellets.

A. Load the hopper with pellets.

B. Set the burn rate control knob to "HIGH".

C. Switch the power switch to "ON".

D. Press the start switch and release when indicating light comes on.

This will start the auger and begin the priming process. Once pellets are feeding into the firepot (about ten

minutes), turn the power switch "OFF." You are now ready to start a fire.

STEP 3. STARTING YOUR APPLIANCE:

A. Open the door and place a wax-impregnated wood fire starter or add gelled firestarter on a few

pellets in the center of the firepot and light. When the fire starter is burning, close the door.

B. Push the black "AIR CONTROL KNOB" in to the closed position. (Located on the lower left side of

the unit). Press the power switch "ON." Adjust the burn rate control to the "OFF"

position and press the start switch. The amber indicator light will come on.

C. Once the pellets are burning and you have established a fire, set the burn rate to the "HIGH"

position. Then pull the black "AIR CONTROL KNOB" out to the open position.

D. Before turning the unit to a lower burn setting, it is necessary to run the unit on "HIGH"

for at least 15-20 minutes after a fire has been established. This allows the unit to reach proper operating

temperature. Failure to do this could result in an inadequate operating temperature and the unit will turn

itself off. If this happens, you will have to repeat the entire start-up procedure.

E. The convection blower will be OFF for approximately 15 minutes after start-up of the appliance.

This is to allow the appliance to reach operating temperature before the convection fan comes on.

The fan will also continue to run after the stove has been shut off until the unit has cooled down.

NOTE: The first couple of times the unit is operated it will emit an odor and smoke for the first few hours of

operation while the paint and oils on the metal cure.

STEP 4. RUNNING YOUR APPLIANCE:

A. Burn rate control and air control settings for normal operation when the burn rate setting is set on:

"HIGH", Air Control knob is pulled completely out for fully "Open" position.

"MEDIUM RANGE", Air Control knob is between fully "Closed" and "Open."

"LOW BURN", Air Control knob is pushed completely in for fully "Closed" position.

NOTE: The Air Control knob settings for your unit could vary due to type and quality of fuel used.

Therefore, it is suggested that you establish the settings that best suit your particular fuel needs.

This is done by adjusting the air control knob "OPEN" or "CLOSED" to allow more or less

combustion air. Flame should be yellow in color and brisk with a gentle agitation of pellets in the burn pot.

PAGE 29

Page 30

OPERATING YOUR PELLET APPLIANCE (cont.)

STEP 5. TURNING THE UNIT OFF:

A. Turn the power switch to the "OFF" position. The unit will automatically turn the convection and

combustion fans off when the temperatures have reached the shut down range.

AUTOMATIC SAFETY FEATURES:

1. POWER OUTAGES

During a power outage the unit will shut itself down safely. It will not restart unless there is a

sufficient firepot temperature to sustain combustion.

2. OVERHEATING

This unit is equipped with an overheat sensor. If the unit becomes overheated, it will shut itself

down safely. The appliance will not restart until it has cooled to a safe level. It may be necessary

to restart the unit if this occurs. If this happens frequently, turn the unit off and consult with your

dealer to determine the problem.

3. BLOCKED FLUE OR DOWN DRAFT PROTECTION

This unit is equipped with a draft flow switch. If a draft restriction or back draft occurs, the unit

will automatically shut itself off. If the restriction or back draft is momentary, it will automatically

resume operation. If not, you will need to locate the restriction and correct it before restarting

your unit.

PAGE 30

Page 31

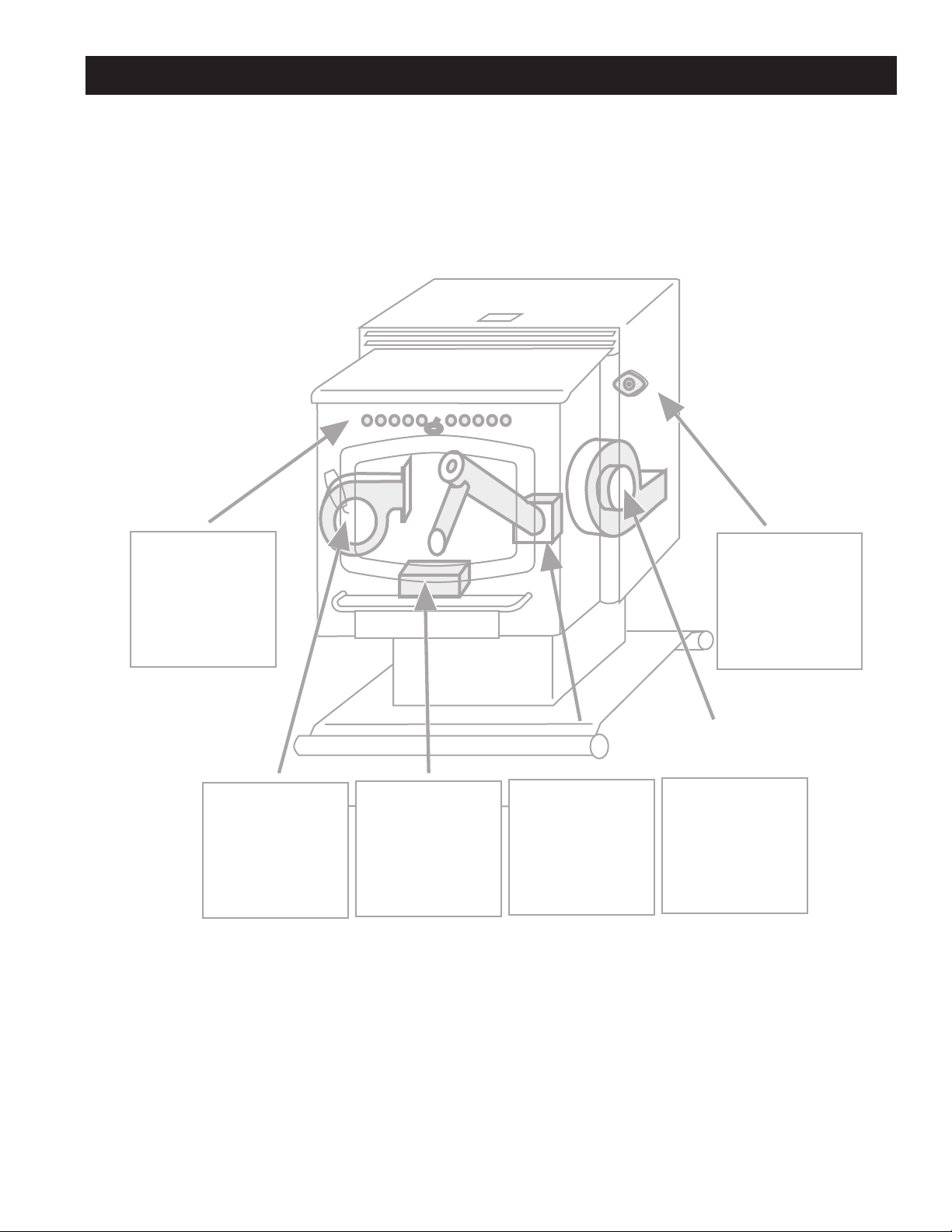

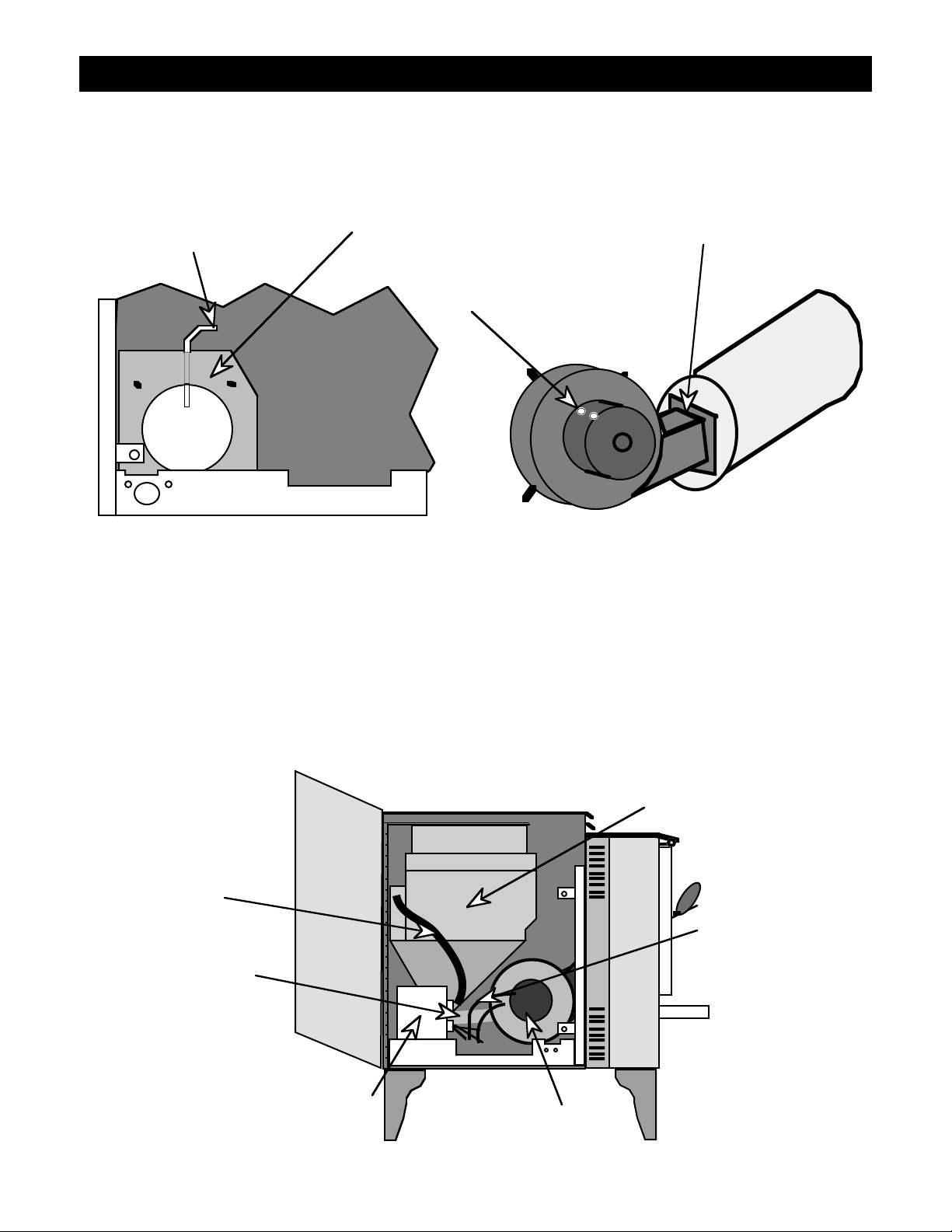

NORMAL OPERATING SOUNDS

Heat Exchange

Tubes

You will hear air

being forced through

the heat exchange

tubes by the

convection fan.

Convection Fan

The modern high

efficiency fan may

have a hum or

pulsating sound,

particularly on the high

setting. This sound

may change as the

speed is varied.

Firepot

As pellets are fed to

the firepot, a light

clicking sound may

be heard.

FIGURE 29

Auger Motor

When the auger

feeds pellets you

may hear the

intermittent buzz of

this motor running.

Thermostatic

Thermostatic

Control

Control Switch

This part can

produce a clicking

sound as it

automatically turns

the convection fan

"ON" or "OFF".

Exhaust Fan

The flow of exhaust

gasses through this

air-cooled induction

motor creates a

steady low-pitched

hum.

PAGE 31

Page 32

CARE AND MAINTENANCE

SEE THE CARE & MAINTENANCE INSTRUCTIONS FOR DETAILS ON THESE PROCEDURES.

Weekly Maintenance:

There are several areas and parts of the unit that must be inspected and cleaned at least once a week during

operation. However, depending on fuel quality and burning habits, this maintenance may have to be performed more

frequently. These are:

A. Heat exchanger tubes.

B. Ceramic log set. (Optional)

C. Brick refractory.

D. Firepot and holder.

E. Ashpan.

F. Glass and door maintenance.

1000 Pounds (1/2 ton) of Fuel Used Maintenance:

There are several areas and parts of the unit that should be inspected and cleaned after every 1000 pounds (1/2 ton)

of fuel used. These are:

Repeat items A through F.

G. Exhaust ducts.

H. Hopper and auger tube area.

6000 Pounds (3 tons) of Fuel Used Maintenance:

The 6000 pounds (3 tons) of fuel used maintenance requires disassembly of the unit and its components. We

recommend this procedure be carried out by a trained service person or your dealer. The following areas should be

inspected, cleaned and serviced after every 6000 pounds (3 tons) of fuel used.

Repeat Items A through H.

I. Exhaust fan (including exhaust duct system).

J. Convection fan.

K. Chimney system.

PAGE 32

Page 33

CARE & MAINTENANCE INSTRUCTIONS

PRIOR TO CARRYING OUT MAINTENANCE, ENSURE THE APPLIANCE IS UNPLUGGED

AND HAS COOLED DOWN SUFFICIENTLY TO HANDLE THE PARTS WITH SAFETY.

A. HEAT EXHANGER TUBES

To clean the heat exhange tubes, push the built-in

cleaner located above the door back and forth a

couple of times.

Make sure to keep the door closed while doing this to

eliminate any flyash from coming out.

After performing this procedure, you may wish to

brush any loose flyash into the ash pan.

B. CERAMIC LOG SET (OPTIONAL)

Remove the ceramic log and log holder from the firebox and brush off any flyash that may have accumulated using a stiff

brush.

Built in

Cleaner

Handle

C. FIREBRICK

Firebrick Refractory Holder

REFRACTORY

Remove the firebrick refractory by grasping it

on either side, lifting it up approximately 1/4 to

1/2", tilting it towards the front of the stove and

lifting it through the doorway out of the unit.

Brush away any flyash that may have

accumulated on the firebrick. Then vacuum or

dump the flyash into a suitable disposal

container.

Firebrick

Refractory

D. FIREPOT AND HOLDER

Remove the firepot holder by pulling it towards the front of the unit while lifting up. Once the firepot holder is removed, the

firepot can be removed by pulling it straight up and out of the holder.

Brush away any flyash that may have attached to the bottom of the firepot or firepot holder. Then vacuum or dump the

flyash into a suitable disposal container.

PAGE 33

Firepot

Firepot Holder

Page 34

CARE & MAINTENANCE INSTRUCTIONS (Cont.)

E. ASHPAN

Remove the ash pan by twisting the knob left or right and pulling the ashpan straight away from the unit.

Brush away any flyash that may have accumulated on the bottom of the pan with a brush. Then vacuum or dump the flyash into a

suitable disposal container.

FRONT VIEW WITH ASHLIP REMOVED

Ash Pan (Turn Knob to

Remove)

F. GLASS MAINTENANCE

Should soot or creosote deposits accumulate on the glass during operation, clean when the stove is cold with a non-abrasive glass

cleaner.

Inspect the gaskets on the door, glass and ashpan. If they show signs of deterioration, replace them. See your dealer for the proper

type and size of gaskets.

If the glass should break, wait until the stove and glass is cool before removing. Do not leave the fire unattended during this cool down

period as sparks could escape through the broken glass. Do not operate appliance with broken glass.

To replace the glass, simply remove the door and unscrew the glass clips. Replace the broken glass with Travis Industries Inc.

replacement glass only (available at your dealer). The replacement glass is high temperature, high shock ceramic glass 5 mm thick.

Under normal operating conditions the glass will not break.

G. EXHAUST DUCTS

To inspect and clean the exhaust ducts, it is

first necessary to remove the ashpan,

firepot assembly, and firebrick refractory.

Remove the Firebrick Refractory holder by

unscrewing the two phillips head screws

that hold it in place.

Remove Firebrick

Refractory holder

by unscrewing

the two phillips

head screws

Metal

Brackets that

hold the Side

Combustion

Air Duct in

place.

PAGE 34

Page 35

CARE & MAINTENANCE INSTRUCTIONS (Cont.)

G. EXHAUST DUCTS

(Cont.)

The next step is to remove the left or right

side exhaust duct:

Step 1 - Lift 1/4"

Step 1 ¥ Lift the side exhaust duct up 1/4"

Step 2 ¥ Pull it towards the front of the

unit

Step 3 ¥ Tilt the bottom towards the

opposite side of the unit

Step 4 ¥Pull it through the door opening

Repeat these steps for removing the

opposite side exhaust duct.

Remove the lower exhaust duct to

complete the removal of internal firebox

components.

Remove the two rear exhaust clean-outs

by prying them loose with a screwdriver

(only on certain models). They are held

in place with expaninging metal clips that

are attached to the clean-outs.

Bend a piece of piano wire or other

similar wire into an "L" shape. Use this to

insert into the space behind the rear

exhaust clean-outs and remove any

blocking flyash. There should be very

little (if any).

Step 2 -Pull

Towards Front

Step 3 - Tilt

Bottom Towards

Opposite Side

Step 4 - Pull Out Through Door Opening

Rear Exhaust

Clean-Outs

Then brush away any flyash that may have accumulated on the floor of the firebox or on the exhaust ducts with a brush.

Then vacuum or dump the flyash into a suitable disposal container.

H. HOPPER AND

AUGER TUBE

AREA

Vacuum the inside of the

hopper area and remove any

foreign objects that may have

wedged between the auger

flight and auger tube.

Fro nt

PAGE 35

Auger

Tube

Hopper

Auger Flight

Page 36

CARE & MAINTENANCE INSTRUCTIONS (Cont.)

I. EXHAUST FAN

Open the left side panel by taking a standard screwdriver and turning the three screws located on the left side one-half turn

counter-clockwise. These screws are actually cogs that hold the panel in place, and only need to be turned slightly to

release. Then swing the panel back on the hinge located on the very back of the left side.

To re-attach, use a screwdriver to turn the screws one-half turn while pressing them against their sockets. See the

illustration below.

To Remove, Twist and Pull

Hinge

Fasteners (Turn

one-half revolution

with standard

screwdriver)

Next, disconnect the pellet vent/interior connector that connects to the back of the stove. With the left panel opened, use a

3/8" nut driver to remove the three mounting nuts that hold the exhaust fan in place. Two of the nuts are located on the top

of the exhaust fan while one is on the lower left and can only be accessed through a hole in the sheet metal. See the

illustration below for reference. Disconnect the two power leads going to the exhaust fan. Remove the insulation

surrounding the exhaust fan. Tilt the exhaust fan outwards and slide towards the opening to remove. With the exhaust fan

removed, check the gasketing that insulates the connection between the exhaust fan and the exhaust housing. If the

gasket has deteriorated, replace. Follow directions in reverse order to re-attach the exhaust fan. NOTE: The two electrical

leads coming from the exhaust fan are black. They are connected to a green wire and a brown wire. It does not matter

which color goes to which black exhaust fan lead.

Exhaust

Housing

To Fasten, Push and Twist

Exhaust Fan

(Lined with

Insulation)

Power Leads to

Exhaust Fan

Mounting Nuts

Once the exhaust fan is removed, place it so the side that holds the gasket is up. Check the impeller blades for any damage

and replace if necessary. Use a vacuum cleaner or brush to clear away any flyash that may have accumulated. Lubricate

the exhaust fan bearings located on both sides of the fan motor with two drops of light machine oil.

PAGE 36

Exhaust Fan

Page 37

CARE & MAINTENANCE INSTRUCTIONS (Cont.)

I. EXHAUST FAN (Cont.)

At this time you should also clean away any flyash that is on or in the exhaust housing and check to make sure the flow

switch nipple is not clogged or dirty. See the illustration below for reference.

Flow Switch Nipple (Make sure it

is not clogged - Check both ends)

Prior to replacing the fan assembly, check that the silicone seal at the fan and exhaust tube. If fractured, use Type RTV 500

degree silicone sealant to reseal the joint.

Exhaust Housing (clean any flyash) Check Silicone Seal

Oil Bearings Through These

Two Holes (2 drops each)

J. CONVECTION FAN

Open the right side panel by taking a standard screwdriver and turning the three screws located on the right side one-half

turn counter-clockwise.

These screws are actually cogs that hold the panel in place, and only need to be turned slightly to release. Then swing the

panel back on the hinge located on the very back of the left side.

To re-attach, use a screwdriver to turn the screws one-half turn while pressing them against their sockets. See the

illustration in the exhaust fan section for reference.

Hopper

Electrical Leads

From Control Box

to Switch Box

Convection Fan

Electrical Leads

Combustion Air Duct

Control Box

Convection Fan

PAGE 37

Page 38

CARE & MAINTENANCE INSTRUCTIONS (Cont.)

J. CONVECTION FAN (Cont.)

With the right side panel open, disconnect the two black

power leads coming from the motor. These two wires

must be connected to the convection fan during assembly,

but their orientation does not matter.

Take a 7/16" socket or wrench and remove the single bolt

located at the top of the convection fan.

The convection fan can now be pulled out of the unit for

cleaning and servicing. With the convection fan removed,

check the gasketing that insulates the connection between

the convection fan and the appliance. If the gasket has

deteriorated, replace. Follow directions in reverse order to

re-attach the convection fan.

Once the convection fan is removed, place it so the impeller blades are facing up. Check the impeller blades for any

damage and replace if necessary. Use a vacuum cleaner or brush to clean away any flyash that may have accumulated.

Lubricate the convection fan bearings by dropping two drops of light machine oil into the two holes located on the outward

side. Over-oiling can damage your fan.

K. CHIMNEY SYSTEM

Check the chimney system for soot and creosote build-up, and have it cleaned by a certified chimney sweep if necessary.

Wind/Rain Cap

Factory-Built Chimney Sections

Tee with Clean Out Cover

Attachment to

Pellet-Burning Appliance

PAGE 38

Page 39

BEFORE CALLING FOR SERVICE

SAVE TIME AND MONEY - CHECK THIS LIST BEFORE YOU CALL FOR SERVICE.

To eliminate unnecessary service calls, first read all the instructions in this manual carefully. The following checklist

provides possible solutions to common occurrences that are not the result of defective workmanship or materials in

this appliance. Always make sure unit is plugged in and that the circuit breaker has not tripped.

If you do have a problem that you cannot fix yourself, call the dealer where you purchased your appliance. When

calling, have this manual handy with the model, serial number and purchase date of your appliance.

Problem

Firepot overfills on start-up.

Start-up fire extinguishes

itself.

Possible Cause

Starting appliance on

"HIGH BURN" range.

Combustion air inlet blocked.

Door ajar.

Ashpan open or ajar.

Firepot not in correct position.

Lack of ignition.

Don't Call for Service

Until You Check

Burn rate control is set to the "OFF"

position.

Inlet tube is not blocked outside house.

Door is latched securely.

Ashpan is latched and sealed.

Firepot is in correct position.

Ensure firestarter is ignited.

Lazy orange flame,

smoking exhaust or firepot

overfills with pellets.

Restriction in combustion intake tube.

Door or ashpan open or ajar.

Firepot plugged.

PAGE 39

Combustion tube intake is not blocked.

Door and ashpan are latched.

Firepot is clean.

Page 40

BEFORE CALLING FOR SERVICE (Cont.)

Problem

Lazy orange flame,

smoking exhaust or firepot

overfills with pellets. (cont.)

Fire smolders.

Possible Cause

Incorrect air control setting.

Exhaust duct restricted.

Fuel.

Power outage.

Restricted exhaust.

Firepot overfilled.

Pellets are wet.

Don't Call for Service

Until You Check

Air control is set to suit burn rates.

(Open control until fire brightens up).

Flyash buildup behind exhaust ducts is

removed.

Fuel is not poor quality or wet.

Unit has power.

Exhaust is not restricted.

Refer to previous check items.

Pellets in hopper are dry and all

stored pellets are dry.

Pellets not feeding.

Auger not primed.

Hopper empty.

Start switch not pressed.

Power switch not "ON".

Appliance not plugged into power

outlet or no power available at

outlet.

Auger flight jammed by foreign

object.

PAGE 40

Auger is primed.

Hopper has pellets.

Start switch is pressed and amber

indicating light is on.

Power switch is "ON".

Appliance is plugged into outlet.

Circuit breaker or fuse has not

tripped.

Remove pellets from hopper and

check for foreign objects jammed in

auger flights.

Page 41

BEFORE CALLING FOR SERVICE (Cont.)

Problem

Smoke smell in house

and unit has gone off.

Unit has shut off and

hopper is full of pellets.

Possible Cause

Intermittent power failure has shut

unit off.

Automatic safety feature has shut

unit off.

Unit was unplugged while under full

operation.

Automatic safety feature has shut

unit off.

Auger flights jammed with foreign

object.

Don't Call for Service

Until You Check

Power is on.

Refer to "Operating Your Pellet

Stove", page 30, "Automatic Safety

Features" or wait 1/2 hour and relight. If unit won't light consult your

dealer.

Re-plug unit in and restart if

necessary.

Refer to "Operating Your Pellet

Stove", page 30, "Automatic Safety

Features" or wait 1/2 hour and relight. If unit won't light consult your

dealer.

Remove pellets from hopper and

check for foreign objects.

Fire goes out on low

burn

Air control setting is too high, blowing

flame out.

NOTE: Pellets dropping into burn pot

will cause the flame to be knocked

down but the flame should come

back; this is normal.

Firepot may not be in proper

position.

PAGE 41

Check air control.

Make adjustment to match

feed amount; low feed for low

air, high feed for high air.

To adjust it properly, look in

the burn pot; there should be

a slight movement of pellets.

Firepot is in correct position.

Page 42

REPLACEMENT PARTS LIST

All parts listed may be ordered from your AVALON 900 dealer. When ordering replacement parts, always give the

following information:

1. Part Number

2. Part Description

3. Serial Number

4. Date of Purchase

PART NUMBER PARTS DESCRIPTION

90-0191 Auger Motor

91-0291 Auger Assembly

90-0391 Exhaust Fan

90-0491 Convection Fan

92-0591* Control Panel with Switches -- FREESTANDING 92-0591, INSERT 92-0592

91-0691 Power Control Box

91-0791 Draft Flow Switch

90-0991 120° Degrees F N.O. Snap Disc

90-1091 Power Cord

90-1191 Draft Flow Switch Tube

92-1292 Firepot

90-1391 Ashpan & Door Gasket Set

A91-1491 Door Glass

92-1591 Ceramic Log

91-1691 Brick Refractory

91-1791 200˚ F. N. C., Snap Disc

PAGE 42

Page 43

LIMITED WARRANTY

TRAVIS INDUSTRIES, INC. warrants the AVALON 900-PS or PI pellet appliance to be defect-free in material and workmanship for five (5)

years from the date of purchase, with the exception of the electrical components, fans, gaskets, refractory, auger assembly, firepot and moving

parts. This does not include service call cost or any other additional charges. Check with your dealer for all costs if arranging a warranty call. The

exceptions listed are warranted for one (1) year from the date of purchase to be defect-free in material and workmanship.

Exclusions to this limited warranty include: Injury malfunction to the product, loss, damage, defect, failure to function due to accident, negligence,

misuse, improper installation, alteration or adjustment of the manufacturers settings of components, lack of proper and regular maintenance,

damage incurred while the unit is in transit, alteration, or act of God.

This limited warranty excludes damage caused by normal wear and tear, such as paint discoloration or chipping, worn or torn gasketing, eroded or

cracked refractory, etc. Also excluded is damage to the unit caused by abuse, improper installation, the use of fuel or fuel loads other than

specified by the manufacturer or use not set forth in the Owner’s Manual. An overfired condition will cause warped metal parts and discolored or

burned-off paint.

TRAVIS INDUSTRIES, INC. is free of liability for any damages caused by the unit, as well as inconvenience expenses, material and labor charges

incurred by the removal or reinstallation of any AVALON 900-PS or PI unit. Incidental or consequential damages are not covered by this

warranty. In some states, the exclusion of incidental or consequential damage may not apply.

This warranty does not cover any loss or damage incurred by the use or removal of any component or apparatus to or from the AVALON 900-

PS or PI unit without the express written permission of TRAVIS INDUSTRIES, INC. and bearing a TRAVIS INDUSTRIES, INC. label of

approval.

Any statement or representation of AVALON 900-PS or PI products and their performance contained in AVALON 900-PS or PI

advertising, packaging literature, or printed material is not part of this limited warranty.

This warranty is automatically voided if the unit’s serial number has been removed or altered in any way.

Only the original purchaser of an AVALON 900-PS or PI appliance is covered by this warranty. If the unit is used for commercial purposes,

it is excluded from this warranty.

No dealer, distributor, or similar person has the authority to represent or warrant AVALON 900-PS or PI products beyond the terms

contained within this warranty. TRAVIS INDUSTRIES, INC. assumes no liability for such warranties or representations.

THIS LIMITED WARRANTY IS THE ONLY WARRANTY SUPPLIED BY TRAVIS INDUSTRIES, INC., THE MANUFACTURER OF THE UNITS.

ALL OTHER WARRANTIES, WHETHER EXPRESS OR IMPLIED, ARE HEREBY EXPRESSLY DISCLAIMED AND PURCHASER’S RECOURSE

IS EXPRESSLY LIMITED TO THE WARRANTIES SET FORTH HEREIN.

This warranty is limited to the time frame set forth above. In some states, time limitations on warranties do not apply.

HOW TO USE YOUR AVALON 900-PS or PI FIVE-YEAR WARRANTY: If you find your unit to be defective in workmanship or material

within a 5-year period from the date of purchase contact your local authorized AVALON 900-PS or PI dealer. If your dealer is unable to

repair your unit’s defect, he may process a warranty claim through TRAVIS INDUSTRIES, INC., including the name of the dealership where you

purchased the unit, a copy of your receipt showing the date of the unit’s purchase, and the serial number on your unit. At that time, you will be

asked to ship your unit, freight charges prepaid, to TRAVIS INDUSTRIES, INC. TRAVIS INDUSTRIES, INC., at its option, will repair or replace,

free of charge, your AVALON 900-PS or PI unit if it is found to be defective in material or workmanship within the time frame stated within

this limited warranty. TRAVIS INDUSTRIES, INC. will ship your unit, freight charges prepaid by TRAVIS INDUSTRIES, INC., to your regional

distributor, or dealership.

To register your TRAVIS INDUSTRIES, INC. Five-Year Warranty, complete the enclosed warranty card and mail it within ten (10) days of the unit

purchase date to: TRAVIS INDUSTRIES, INC., 10850 117th Place N.E., Kirkland, Washington 98033.

OTHER RIGHTS:

This warranty provides you with certain legal rights. You may have additional rights, which vary from state to state, in regards to this warranty.

UNIT SERIAL NUMBER____________________________________

DATE OF PURCHASE_______________________________________

DEALER NAME AND ADDRESS : ______________________________________________________

______________________________________________________

______________________________________________________

Travis Industries, Inc. reserves the right to change, without notice, product features or specifications described.

Complete and

save for your

records

10850 117TH PLACE N.E. KIRKLAND, WA 98033

PAGE 43

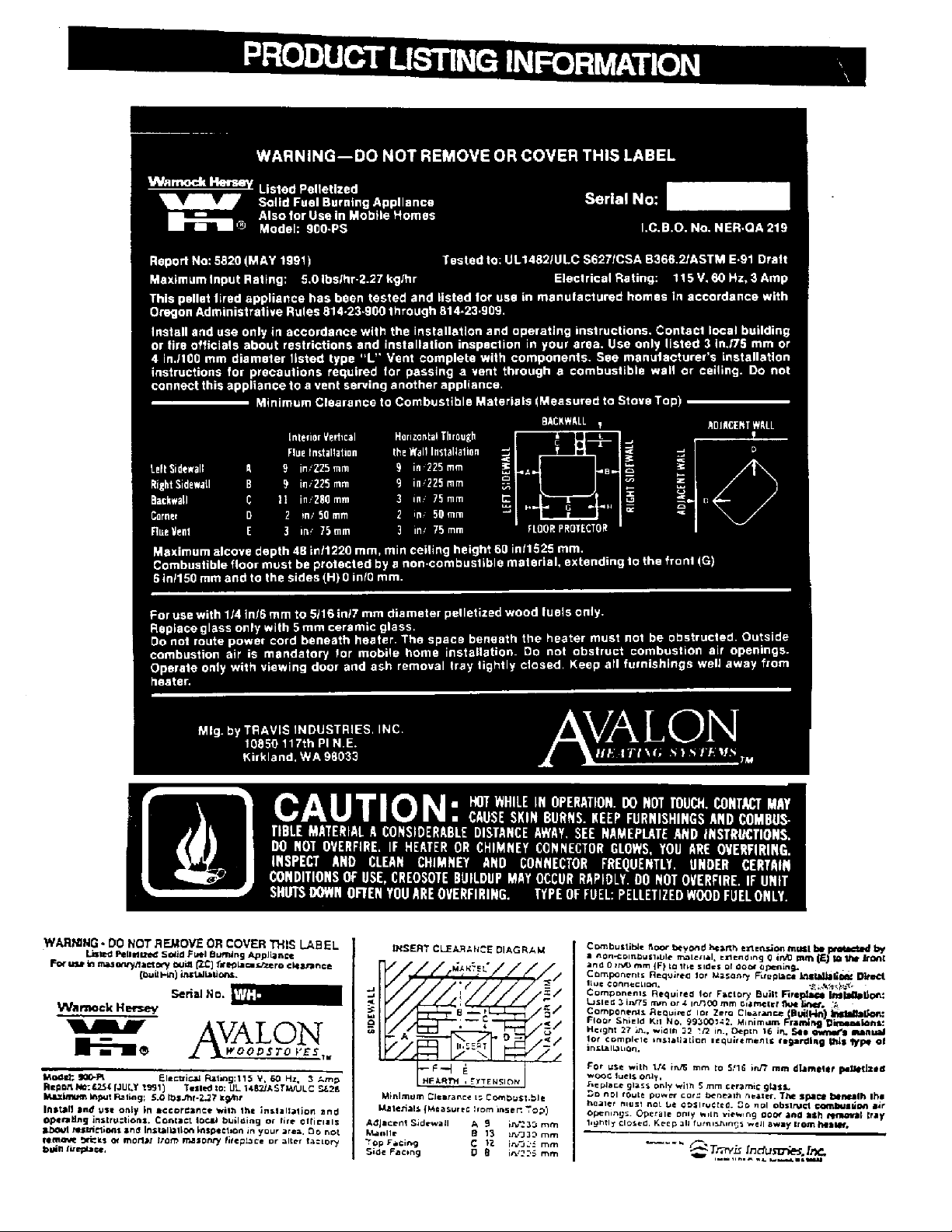

Page 44

Loading...

Loading...