Page 1

SAFETY NOTICE:

Cottage

Wood Stove

Owner's Manual

• Freestanding Stove

• Mobile-Home Approved

• Alcove Approved

If this appliance is not properly installed, a house

fir e ma y re s u l t. Fo r y o u r s a fe ty, fo l l o w th e

installation directions. Contact local building or

fire officials about restrictions and installation

inspection requirements in your area.

Copyright 2005, T.I.

$10.00 93508113

4050124

Tested to: U.L. 1482

Listed

Page 2

2 Introduction

Introduction

We welcome you as a new owner of an Avalon Cottage wood-burning stove. In purchasing an

Avalon Cottage you have joined the growing ranks of concerned individuals whose selection of an

energy system reflects both a concern for the environment and aesthetics. The Avalon Cottage is

one of the finest appliances the world over. This manual will explain the installation, operation, and

maintenance of this appliance. Please familiarize yourself with the Owner's Manual before operating

your appliance and save the manual for future reference. Included are helpful hints and suggestions

which will make the installation and operation of your new appliance an easier and more enjoyable

experience. We offer our continual support and guidance to help you achieve the maximum benefit

and enjoyment from your appliance.

Important Information

No other Avalon Cottage appliance has the same

serial number as yours. The serial number is stamped

onto the label on the back of the appliance.

This serial number will be needed in case you require

service of any type.

Model: Avalon Cottage

Serial Number:

Mail your Warranty Card Today,

and Save Your Bill of Sale.

To receive full warranty coverage, you will

need to show evidence of the date you

purchased your appliance. Do not mail

your Bill of Sale to us.

Purchase Date:

Purchased From:

We suggest that you attach your Bill of Sale

to this page so that you will have all the

information you need in one place should

the need for service or information occur.

Travis Industries 93508113 4050124

Page 3

Table of Contents 3

General Information

Introduction & Important Information ......................2

Safety Precautions.............................................4

Features & Specifications ....................................6

Stove Installation

Planning The Installation .....................................7

Preparation for Installation ...................................7

Stove Installation Considerations...........................7

Leg Installation..................................................8

Floor Protection Requirements..............................8

Stove Placement Requirements............................9

Clearances.......................................................9

Chimney Requirements.......................................10

Chimney Termination Requirements ......................11

Outside Air Requirements....................................11

Alcove Installation Requirements...........................12

Mobile Home Requirements.................................13

INSTALLATION DIAGRAMS

Standard Ceiling with a Factory Built Chimney.....14

Cathedral Ceiling with a Factory Built Chimney....14

Exterior Factory Built Chimney.........................15

Hearth Stove Positive Connection.....................15

Hearth Stove Direct Connection .......................16

Interior Masonry Chimney ...............................16

Maintaining Your Appliance

Daily Maintenance..............................................23

Remove Ash ................................................23

Clean The Glass ...........................................23

Monthly Maintenance..........................................24

Door and Glass Inspection ..............................24

Check For Creosote Buildup............................24

Yearly Maintenance............................................25

Touch Up Paint.............................................25

Blower Cleaning............................................25

Firebrick and Baffle Inspection .........................25

Door Parts........................................................26

Replacing the Glass.......................................26

Replacing the Door Gasket..............................26

Replacing the Door Handle..............................26

Firebox Parts ....................................................27

Floor & Side Firebrick Removal & Replacement...27

Baffle Removal and Replacement.....................28

Air Tube Removal and Replacement .................28

Warranty

Warranty..........................................................29

Listing Information

Listing Information..............................................30

Operating Your Appliance

Safety Notice ....................................................17

Before Your First Fire..........................................17

Opening the Door...............................................17

Starting a Fire ...................................................18

Adjusting the Burn Rate.......................................19

Ash Removal ....................................................19

Optional Blower Operation...................................20

Re-Loading the Stove .........................................20

Overnight Burn..................................................20

Normal Operating Sounds....................................20

Hints for Burning................................................21

Selecting Wood .................................................21

Dry Wood is Key ...........................................21

Testing Wood Moisture...................................21

Why Dry Wood is Key.....................................21

Wood Cutting and Storage ..............................21

Troubleshooting.................................................22

Optional Equipment

Outside Air Boot Installation .................................31

Rear Blower Installation.......................................32

Index

Index...............................................................36

Travis Industries 93508113 4020325

Page 4

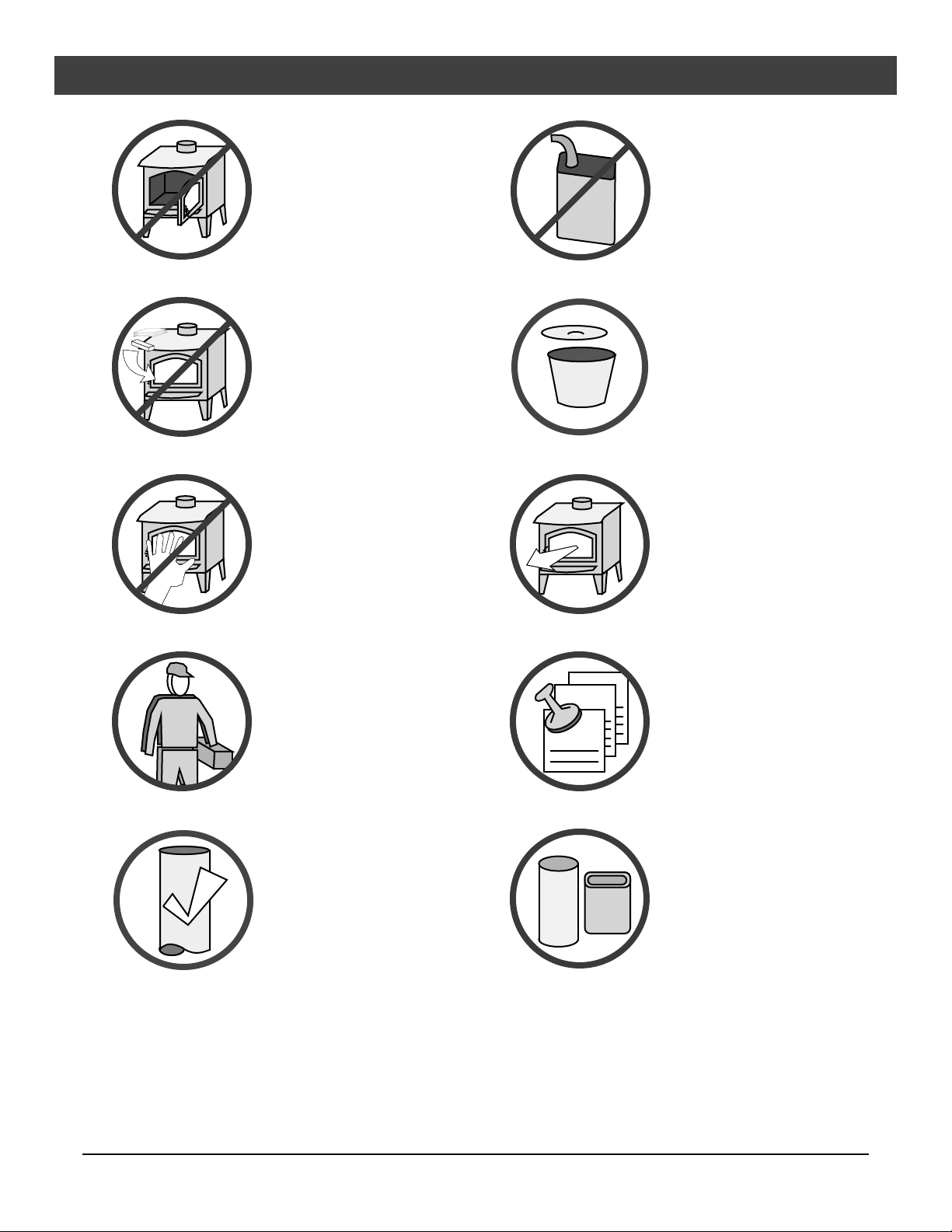

4 Safety Precautions

• The viewing door must be

closed and latched during

operation.

• Never block free airflow

through the air vents on this

appliance.

• This appliance is designed

and approved for the

burning of cord wood only.

Do not attempt to burn any

other type of fuel other than

cord wood in this appliance,

it will void all warranties and

safety listings.

• Do not touch the appliance

while it is hot and educate

all children of the danger of

a high-temperature

appliance. Young children

should be supervised when

they are in the same room

as the appliance.

ASHES

36"

Gas

• Gasoline or other flammable

liquids must never be used

to start the fire or "Freshen

Up" the fire. Do not store or

use gasoline or other

flammable liquids in the

vicinity of this appliance.

• Ashes must be disposed in

a metal container with a

tight lid and placed on a

non-combustible surface

well away from the home or

structure.

• Keep furniture, drapes,

curtains, wood, paper, and

other combustibles a

minimum of 36" away from

the appliance.

• This appliance must be

properly installed to prevent

the possibility of a house

fire. The instructions must

be strictly adhered to. Do

not use makeshift methods

or compromise in the

installation.

• Inspect the chimney

connector and chimney at

least twice monthly and

clean if necessary.

Creosote may build up and

cause a house fire.

• Do not connect this

appliance to any chimney

serving another appliance.

Type

HT

Ok

Clay

Liner

• Contact your local building

officials to obtain a permit

and information on any

installation restrictions or

inspection requirements in

your area. Notify your

insurance company of this

appliance as well.

• This appliance must be

connected to a listed high

temperature (HT) residential

type chimney or an

approved masonry chimney

with a standard clay tile, or

stainless steel liner.

Travis Industries 93508113 4020325

Page 5

Mobile

Home

Safety Precautions 5

• When installed in a mobile

home, this appliance must

be bolted to the floor, have

outside air, and not be

installed in the bedroom

(Per H.U.D. requirements).

Check with local building

officials.

• Do not place clothing or

other flammable items on or

near this appliance.

• Never try to repair or replace

any part of this appliance

unless instructions are given

in this manual. All other

work must be done by a

trained technician.

• Allow the appliance to cool

before carrying out any

maintenance or cleaning.

• Maintain the door and glass

seal and keep them in good

condition.

• Avoid placing wood against

the glass when loading. Do

not slam the door or strike

the glass.

• Do not make any changes

or modifications to an

existing masonry fireplace

or chimney to install this

appliance.

• Do not make any changes to

the appliance to increase

combustion air.

• Overfiring the appliance may

cause a house fire. If a unit

or chimney connector glows,

you are overfiring.

• Do not use a grate or other

device to elevate the fire off

of the firebox floor. Burn the

fire directly on the bricks.

This

Manual

• Do not throw this manual

away. This manual has

important operating and

maintenance instructions

that you will need at a later

time. Always follow the

instructions in this manual.

• Travis Industries, Inc.

grants no warranty,

implied or stated, for

the installation or

maintenance of your

appliance, and

assumes no

responsibility of any

consequential

damage(s).

Travis Industries 93508113 4020325

Page 6

6 Features and Specifications

Installation Options:

• Freestanding

Features:

• EPA Phase II Approved

• 1.8 Cubic Foot Firebox Volume

• Freestanding in an Alcove

• Single Operating Control

• Freestanding in a Mobile Home

• Accepts Logs Up to 20" Long

• 5/16" and 3/16" Steel Plate Construction

• Heavy Duty Refractory Firebrick

• Optional High-Tech Blower

Heating Specifications:

Approximate Maximum Heating Capacity (in square feet)* 600 to 1,200

Maximum BTU's per Hour (Cord Wood Calculation) 71,000

Overall Efficiency (Oregon Method) 70.3 %

Maximum Burn Time Up to 9 Hours

* Heating capacity will vary depending on the home's floor plan, degree of insulation, and the outside

temperature. It is also affected by the quality and moisture level of the fuel.

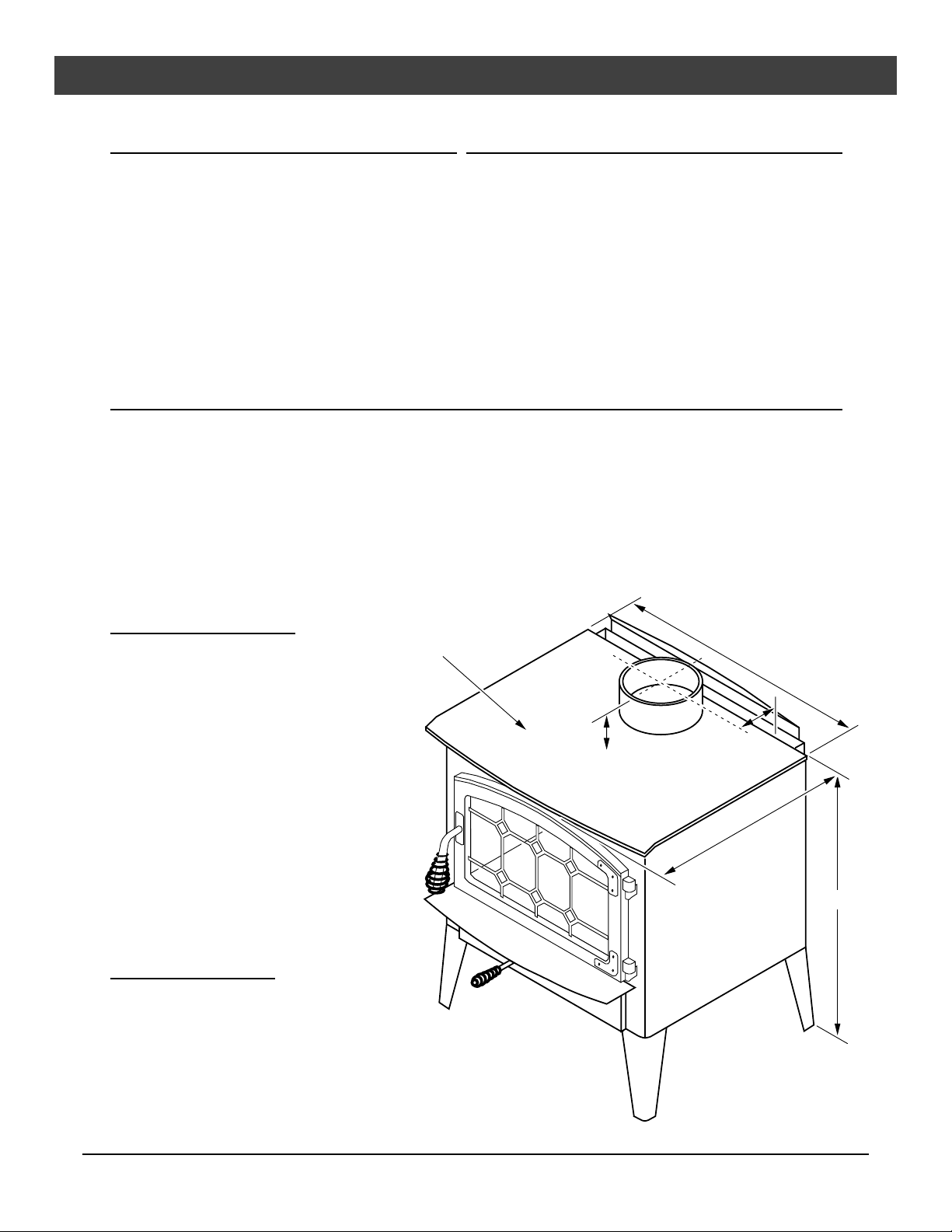

Dimensions:

Emissions:

2.9 Grams Per Hour (EPA

Phase II Approved) – Tests

conducted by Omni Test

Lab.

Measure clearances

from the stove top.

2-1/2”

25-1/8”

4-3/8”

19-1/8”

27-1/2”

Weight: 300 Lbs.

Travis Industries 93508113 4020325

Page 7

Installa tion (for qualified installers only) 7

SAFETY NOTICE:

If this ap plian c e is not properly ins talled , a house f ire may result. F or

your s a fety, follow th e insta lla tion direct ions . Co ntac t loca l building

or fire officials about restrictions and installation inspection

requirements in your area.

Planning The Installation

We suggest that you have an authorized Travis Industries dealer install your stove. If you install the

stove yourself, your authorized dealer should review your plans for installation.

Check with local building officials for any permits required for installation of this stove and notify your

insurance company before proceeding with installation.

Preparation for Installation

• Check for damage to the exterior of the stove (dents should be reported, scratches can be fixed by

applying touch up paint).

• Check the interior of the firebox (replace cracked firebrick and make sure baffle is in place).

The stove can be lightened by removing the firebricks and baffle. - see page 27.

Stove Installation Considerations

The table below details the six most common types of installations and the considerations for each

type. Alternative methods of installation are available if they comply with local building codes.

Installation Type Considerations

Standard Ceiling with a Factory Built Chimney

(Page 14)

Cathedral Ceiling with a Factory Built Chimney

(Page 14)

Exterior Factory Built Chimney

(Page 15)

Hearth Stove Positive Connection

(Page 15)

Hearth Stove Direct Connection

(Page 16)

Hearth Stove Horizontal Connection

(Page 16)

• Requires ceiling and roof penetration

• Provides best draft

• Cathedral style chimney support required

• Provides best draft

• Uses two elbows to route chimney outside

• Exterior chimney is hidden from the room

• Elbows reduce draft

• Optional exterior chase reduces cold air blockage

• Utilizes existing masonry or zero clearance (metal) chimney

• Provides good draft due to full reline

• Easier to clean than direct or horizontal hearth stove

• Utilizes existing masonry or zero clearance (metal) chimney

• Requires construction of a "block-off plate"

• Draft reduced due to elbows & chimney cross section

• Utilizes existing masonry chimney (not approved for zero

clearance (metal) fireplaces)

• Draft is good because of vertical section above stove

Travis Industries 93508113 4020325

Page 8

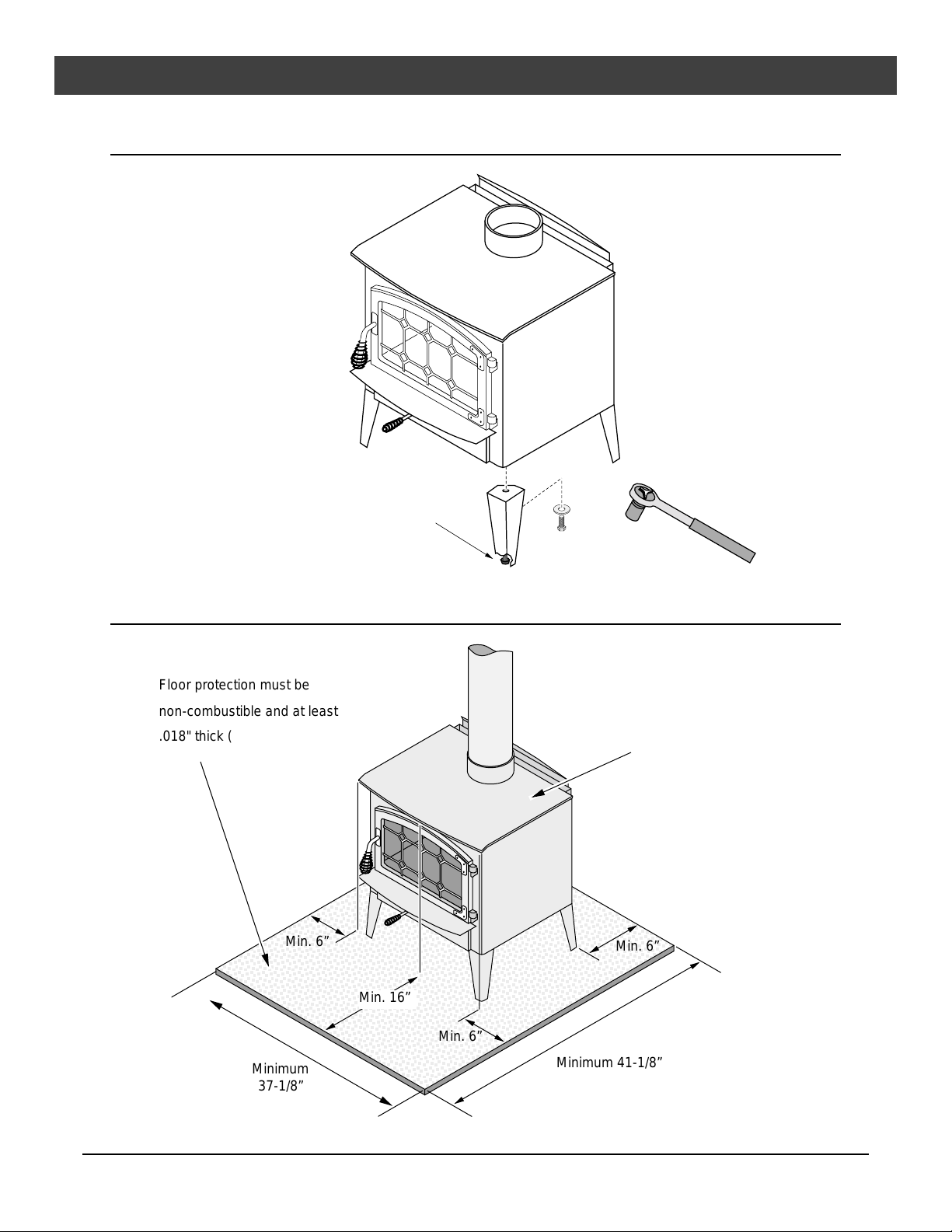

8 Installation (for qualified installers only)

Leg Installation

These rubber-tipped bolts are for leveling the

stove. Make sure they contact the floor. Do

not adjust with weight on the legs, the rubber

tips may tear.

9/16" Socket

Wrench

Attach each leg to

the stove by

inserting a bolt and

washer through the

hole in the leg and

into the threaded

hole on the stove.

Floor Protection Requirements

Floor protection must be

non-combustible and at least

.018" thick (26 gauge).

Min. 6”

Min. 16”

Min. 6”

Minimum

37-1/8”

Measure minimum floor

protection from the stove

top.

Min. 6”

Minimum 41-1/8”

Travis Industries 93508113 4020325

Page 9

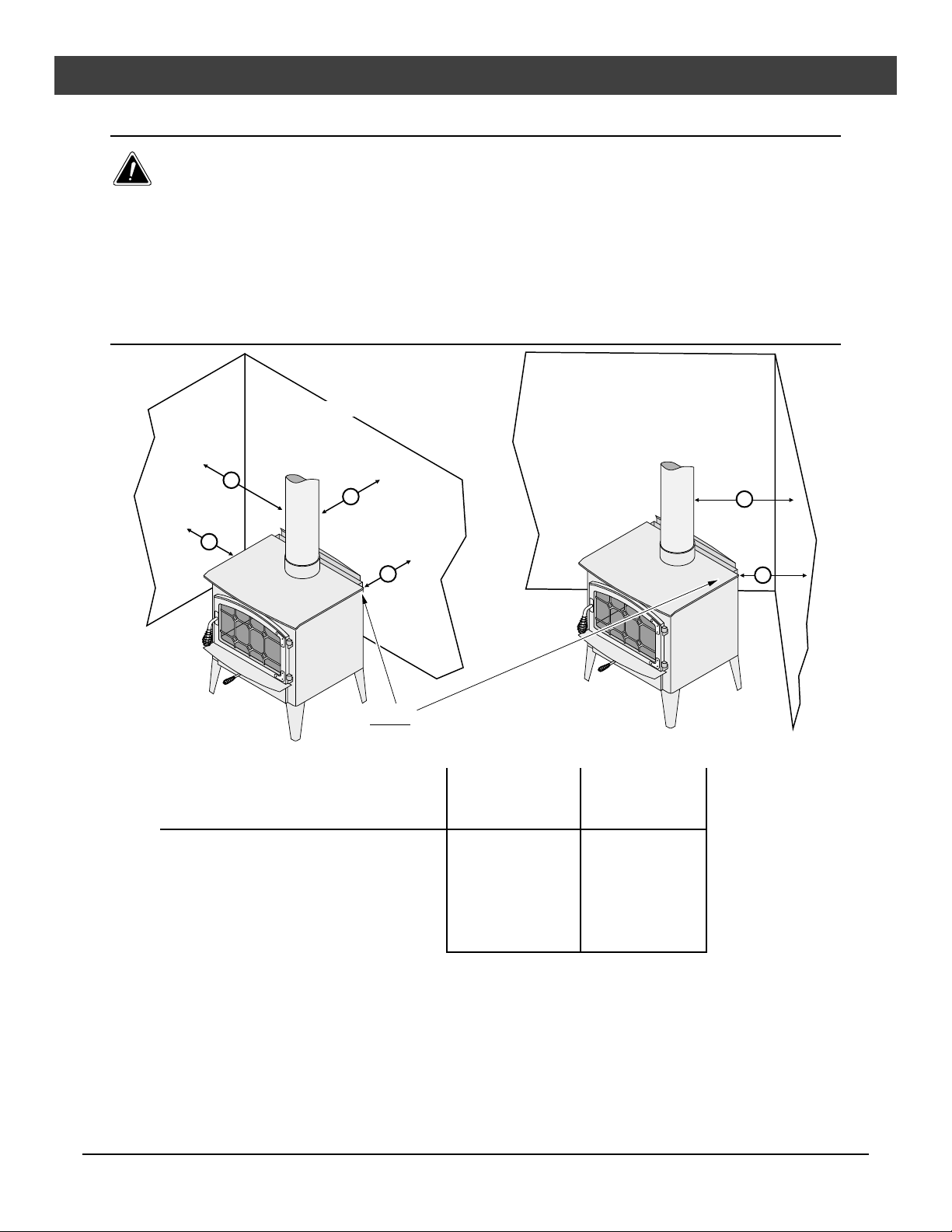

Installa tion (for qualified installers only) 9

Stove Placement Requirements

Clearances may be reduced by methods specified in NFPA 211, listed wall shields, pipe shields, or

other means approved by local building or fire officials.

• Stove must be placed so that no combustibles are within, or can swing within (e.g. drapes, doors),

36" of the front of the stove

• If the stove is placed in a location where the ceiling height is less than 7', it must follow the

requirements in the section "Alcove Installation Requirements"

• Must maintain the clearances to combustibles listed below (drywall, furniture, etc.):

Clearances

Corner Installations

Straight Installations

d

a

Minimum Clearance

(See the illustration

e

b

NOTE:

Measure stove clearances to the stove top.

Singlewall

Connector

f

c

Reduced

Clearance*

above)

A Sidewall to stove 18" 18"

B Backwall to stove 18" 11-1/2"

C Cornerwall to stove 10" 10"

D Connector to sidewall 27-3/4" 27-1/4"

E Connector to backwall 19-1/2" 12-1/2"

F Connector to cornerwall 19" 18-1/2"

*Reduced clearance installations require one of the chimneys and connectors listed below:

• DURAVENT model DVL with DURATEC chimney

• DURAVENT model DVL with DURA-PLUS chimney

• AMERI-TEC model DCC with model HS chimney

• SECURITY model DL with SECURITY model ASHT or S2100 chimney

• METAL-FAB model DW with TG chimney

NOTE: Standard residential installations with reduced clearance connector may use the clearance

determined by the manufacturer of the connector for the connector to wall clearance or the

clearance listed in this manual. Offsets must be used to maintain the stove to wall clearance.

NOTE: Reduced clearance connectors may not connect to the flue collar – order an appliance

adapter for the connector being used.

• GSW Double Wall Chimney Connector with Super Chimney Twenty-One

• SELKIRK METALBESTOS model DS connector with model SSII chimney

• I.C.C. Excel (2100-2 Can.) (103-HT USA) chimney with HP connector

• Standard Masonry Chimney with any one of the above listed connectors

Travis Industries 93508113 4020325

Page 10

10 Installation (for qualified installers only)

Chimney Requirements

• Chimney connector must be a minimum 24 MSG black or 26 MSG blued steel

• Use 6" diameter type HT chimney from one manufacturer (do not mix brands). Chimney must be

used from the first floor or wall penetration to the chimney cap.

• Chimney connector and chimney must be fastened to the stove and each adjoining section

• Follow the chimney manufacturer's clearances and requirements

• Use the chimney manufacturer's fire stops, attic guards, roof supports, and flashings when

passing through a ceiling or thimble when passing through a combustible wall

• No more than 180o of elbows (two 90o elbows, or two 45o & one 90o elbow, etc.)

NOTE: Additional elbows may be allowed if draft is sufficient. Whenever elbows are used the draft is

adversely affected. Additional chimney height may be required to boost draft.

Chimney Cap

(See the section

"Chimney Termination

Requirements" for

more details)

Roof Penetration Equipment

Factory Built

Chimney

Sections

}

(Roof Radiation Shield,

Flashing, Storm Collar)

Minimum System 15'

Maximum System 33'

Floor Penetration

Equipment (Attic

Radiation Shield with

Chimney Support)

Reduceced

Clearance

Chimney

Connector

Sections

Floor

Protection

Drafting

Performanc

e

• Standard residential installations may use single-wall connector (Mobile-Homes may not )

• Standard residential installations with reduced clearance connector may use the clearance

determined by the manufacturer of the connector for the connector to wall clearance or the clearance

listed in this manual. Offsets must be used to maintain the stove to wall clearance. Mobile homes

must use the clearances listed in this manual under "Additional Requirements for Mobile Home

Installations".

This appliance relies upon natural draft to operate. External forces, such as wind, barometric

pressure, topography, or factors of the home (negative pressure from exhaust fans, chimneys,

air infiltration, etc.), may adversely affect draft. Travis Industries can not be responsible for

external forces leading to less than optimal performance.

}

}

Minimum Air Space to

Combustibles (See

Chimney Manufacturer's

Instructions - usually 2")

Standard residential installations with

reduced clearance connector may use the

clearance determined by the manufacturer

of the connector for the connector to wall

clearance or the clearance listed in this

manual.

Mobile home installations must use the

the reduced clearance connector

clearances listed in this manual under

“Additional Requirements for Mobile Home

Installations”.

Stove Clearance

(as outlined in this manual)

Travis Industries 93508113 4020325

Page 11

Installa tion (for qualified installers only) 11

M

d

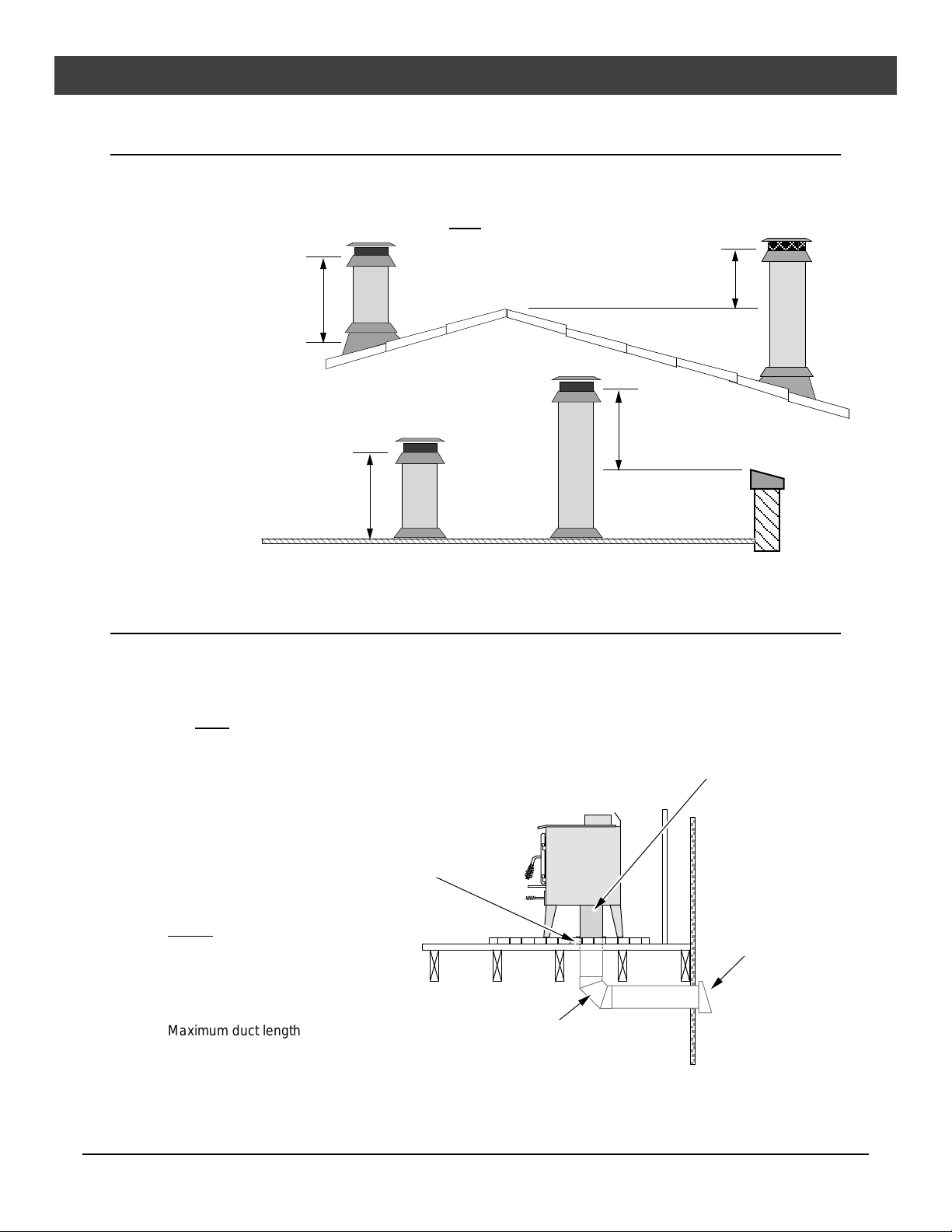

Chimney Termination Requirements

• Must have an approved cap (to prevent water from entering)

• Must not be located where it will become plugged by snow or other material

• Must terminate at least 3' above the roof and at least 2' above any portion of the roof within 10'

Slanted Roofs

Chimney must

extend 3'

above the roof

Flat Roofs

Chimney must

extend 3'

above the roof

Chimney must extend 2'

above any portion of the roof

within 10' of the chimney

Chimney must extend 2'

above any portion of the roof

within 10' of the chimney

Outside Air Requirements

• Required for mobile homes & in certain localities (check with building officials)

• Must not be drawn from an enclosed space (garage, unventilated crawl space)

• Requires the optional outside air boot (see page 31).

HINT:

When using outside air, find a location where the chimney and

outside air hole do not interfere with structural members of the home.

Outside

Air Boot

A hole must be cut through the floor protection and

floor and the rodent screen nailed in place here (see

the optional equipment instructions for exact sizes)

NOTE:

Air may be drawn from a ventilated

crawl space or through an air duct.

aximum duct length is 15’ with a cross section of 16 square inches (e.g. 8” by 2”

uct). If under 5’ long, the cross section may be a minimum 12 square inches.

Outside air entrance

must be placed so it

does not become

blocked by snow.

Travis Industries 93508113 4020325

Page 12

12 Installation (for qualified installers only)

Alcove Installation Requirements

Whenever the stove is placed in a location where the ceiling height is less than 7' tall, it is considered

an alcove installation. Because of the reduced height, the special installation requirements listed

below must be met.

• Chimney connector and chimney must be one of the following types:

• DURAVENT model DVL with DURATEC chimney

• DURAVENT model DVL with DURA-PLUS chimney

• AMERI-TEC model DCC with model HS chimney

• SECURITY model DL with SECURITY model ASHT or S2100 chimney

• METAL-FAB model DW with TG chimney

• GSW Double Wall Chimney Connector with Super Chimney Twenty-One

• SELKIRK METALBESTOS model DS connector with model SSII chimney

• I.C.C. Excel (2100-2 Can.) (103-HT USA) chimney with HP connector

• Standard Masonry Chimney with any one of the above listed connectors

Minimum Clearance

(See the illustration above)

Combustibl

e Alcove

Non-

Combustible

Alcove

A Sidewall to stove 18" 8"

B Backwall to stove 11-1/2" 3"

D Connector to sidewall 27-1/4" 17-1/4"

E Connector to backwall 12-1/2" 4-1/2"

G Maximum Depth of Alcove 48" 48"

H Minimum Width of Alcove 61-1/8" 41-1/8"

J Minimum Height of Alcove 84" 6" Above Stove Top

• Alcoves are classified as combustible or non-combustible. Non-combustible alcoves must have

walls and a ceiling that are 3 1/2" thick of a non-combustible material (brick, stone, or concrete).

This non-combustible material must be spaced and ventilated at least 1" off of all combustible

materials (walls, ceiling, etc.) to allow air to move around the non-combustible walls and ceiling.

All other alcoves are considered combustible. The clearances below must be met:

Non-combustible alcove

construction (on walls

and ceiling) - see the

explanation above.

Ventilated

air space

1" Min.

3 1/2" thick noncombustible

material

j

d

e

a

b

Combustible

materials

Non-combustible

reinforcer

h

g

Travis Industries 93508113 4020325

Page 13

Installa tion (for qualified installers only) 13

Mobile Home Requirements

• Outside air must be installed - see "Outside Air Requirements" on page 11

• Chimney connector and chimney must be one of the following types:

• DURAVENT model DVL with DURATEC chimney

• DURAVENT model DVL with DURA-PLUS chimney

• AMERI-TEC model DCC with model HS chimney

• SECURITY model DL with SECURITY model ASHT or S2100 chimney

• METAL-FAB model DW with TG chimney

NOTE: Reduced clearance connectors may not connect to the flue collar – order an appliance

adapter for the connector being used.

• Stove placement must maintain the following clearances to combustibles (drywall, furniture, etc.)

Minimum Clearance

(See the illustration

below)

A Sidewall to stove 18"

B Backwall to stove 11-1/2"

C Cornerwall to stove 10"

D Connector to sidewall 27-1/4"

E Connector to backwall 12-1/2"

F Connector to cornerwall 18-1/2"

Straight Installations

• GSW Double Wall Chimney Connector with Super Chimney Twenty-One

• SELKIRK METALBESTOS model DS connector with model SSII chimney

• I.C.C. Excel (2100-2 Can.) (103-HT USA) chimney with HP connector

• Standard Masonry Chimney with any one of the above listed connectors

Reduced Clearance

Connector

Corner Installations

d

a

e

b

NOTE:

Measure stove clearances to the stove top.

• If using offsets, use the connector

clearance listed to the right, not the

connector manufacturer's

clearance.

• The appliance must be secured to the floor

(not required in all areas - consult your

building official). Secure the outside air

boot to the floor and stove to insure the

stove does not dislocate.

• The appliance must be grounded to the

chassis of the mobile (not required in all

areas - consult your building official).

• The appliance must not be located in the

bedroom of a mobile home (not required in

all areas - consult your building official).

f

c

12” Min.

Connector Clearance

(as outlined above)

Stove Clearance

(as outlined above)

Travis Industries 93508113 4020325

Page 14

14 Installation (for qualified installers only)

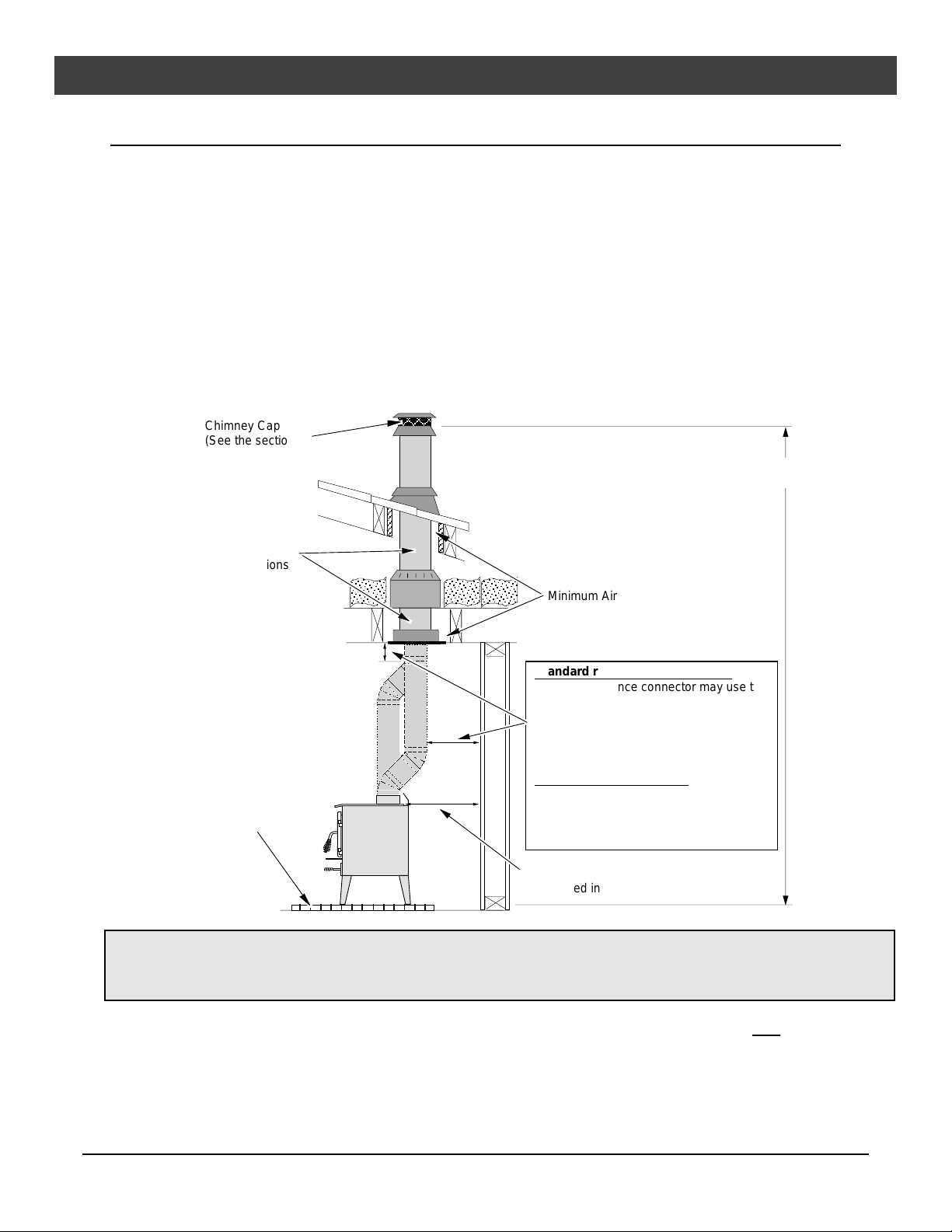

Standard

Ceiling

with a

Factory

Built

Chimney

Chimney Cap

(See the section "Chimney

Termination Requirements"

for more details)

Chimney Sections

Insulation

Follow the chimney

manufacturer's instructions

and clearances for floor

penetrations. A ceiling

support is required, an attic

insulation shield is required

where insulation is present.

Chimney Connector Sections

Floor Protection

(See the section "Floor

Protection Requirements"

for more details)

}

}

Follow the chimney

manufacturer's instructions

and clearances for roof

penetrations. A storm collar

and flashing are required

(some require a radiation

shield).

Minimum Air Space to

Combustibles (See

Chimney Manufacturer's

Instructions - usually 2")

Minimum 15'

Maximum 33'

Stove Clearances

(See the section "Stove

Placement Requirements"

for more details)

Cathedral

Ceiling

with a

Factory

Built

Chimney

Chimney Cap

(See the section "Chimney

Termination Requirements"

for more details)

Chimney Sections

Minimum Air Space to

Combustibles (See Chimney

Manufacturer's Instructions usually 2")

Chimney

Connector

Sections

Floor Protection

(See the section "Floor

Protection Requirements"

for more details)

}

Follow the chimney

manufacturer's instructions

and clearances for roof

penetrations. A storm

collar, flashing, and

cathedral-style chimney

support are required

(some require a radiation

shield).

Minimum 15'

Maximum 33'

Stove Clearances

(See the section "Stove

Placement Requirements"

for more details)

Travis Industries 93508113 4020325

Page 15

Installa tion (for qualified installers only) 15

C

(

T

f

M

C

C

I

Exterior

Factory

Built

Chimney

NOTE:

Exterior chimneys

are subject to

greater moisture

and creosote

accumulation due

to the lower

temperatures. An

insulated chase

will reduce these

accumulations

(the proper

clearances to the

chimney must be

maintained).

himney Cap

See the section "Chimney

ermination Requirements"

or more details)

Chimney Sections

inimum Air Space to

ombustibles (See

himney Manufacturer's

nstructions - usually 2")

Min. 18"

clearance to

ceiling

Chimney Connector

Sections

Floor Protection

(See "Floor

Protection

Requirements"

for details)

Wall Bands

and

Supports

}

Minimum 15'

Maximum 33'

}

Stove Clearances

(See the section "Stove

Placement Requirements"

for more details)

Follow the chimney

manufacturer's

instructions and

clearances for roof

penetrations. A storm

collar and flashing are

required (some

require a radiation

shield).

Insulated Tee

(with cleanout )

Follow the chimney

manufacturer's

instructions and

clearances for wall

penetrations. A

wall radiation shield

(thimble) is

required.

Optional

insulated

chase

Hearth

Stove

Positive

Connectio

n

NOTE:

Most factory-built

chimney

manufacturers

make stainless

steel chimney

liners, either

flexible or rigid.

This provides a

wide variety of

installation

options. Make

sure to follow the

manufacturer's

instructions for

installation and

support.

NOTE: The entire fireplace and

chimney must be clean, undamaged,

and meet all local building codes

(UBC, etc.). Damage must be

repaired prior to installation. The

chimney must be 15' to 33' tall.

Combustible

Mantle

Min. 18"

Floor Protection

(See the section

"Floor Protection

Requirements"

for more details)

Cap and flashing

prevents water from

entering

The liner must be

stainless steel connector

or flexible vent. Follow

the liner manufacturer's

instructions for installation

and support.

Airtight Insulated

Clean-Out

Remove damper

or wire it open

See the section

"Stove Placement

Requirements" for

minimum clearances

required.

Travis Industries 93508113 4020325

Page 16

16 Installation (for qualified installers only)

NOTE: The chimney must have a clay

Hearth

Stove

Direct

Connectio

n

NOTE:

Direct

connections

require installation

of an airtight, noncombustible

block-off plate or

damper adapter.

tile liner. If it does not, the installation

must use a positive connection (full

reline). The entire fireplace and

chimney must be clean, undamaged,

and meet all local building codes (UBC,

etc.). Damage must be repaired prior

to installation. The chimney must be

15' to 33' tall.

Combustible

Mantle

Min. 18"

Clay

Liner

Stainless steel

chimney connector

must Extend 1' past

the block-off plate or

to the flue liner

Airtight

Insulated

Clean-Out

Remove damper

or wire it open

Block-off plate or

damper adapter

Interior or

Exterior

Masonry

Chimney

NOTE:

This type of

installation

requires a UBC

approved

masonry

connector or a

factory built (U.L.

Listed) wall

thimble.

Floor Protection

(See the section "Floor

Protection Requirements"

for more details)

NOTE: The chimney must have a

clay tile liner. If it does not, the

installation must use a positive

connection (full reline). The

entire fireplace and chimney must

be clean, undamaged, and meet

all local building codes (UBC,

etc.). Damage must be repaired

prior to installation. The chimney

must be 15' to 33' tall.

See the section "Stove

Placement Requirements" for

minimum clearances required.

Chimney connector sections

See the section

"Stove Placement

Requirements" for

minimum clearances

required.

Clay Liner

Min. 18"

clearance

to ceiling

This type of

installation requires

a UBC approved

masonry connector

or a factory built

(U.L. Listed) wall

thimble.

See the section

"Floor Protection

Requirements"

Make sure the

clean-out seals in

place.

Travis Industries 93508113 4020325

Page 17

Operating Your Appliance 17

Safety Notice:

If this appliance is not properly installed, a house fire may result. For your safety, follow the installation

directions. Contact local building or fire officials about restrictions and installation inspection

requirements in your area.

Read and follow all of the warnings on pages 4 and 5 of this manual.

Before Your First Fire

Verify the Installation

Before starting the stove, verify that the stove is properly installed and all of the requirements in this

manual have been followed.

Keep all flammable materials 36" away from the front of the stove (drapes, furniture, clothing, etc.).

Curing the Paint

This heater uses a heat-activated paint that

will emit some fumes while starting the first

fire. Open doors and windows to the room to

vent these fumes. This typically lasts two to

four hours. You may also notice oil burning off

of the interior of the heater. This rust-stopping

agent will soon dissipate.

2 to 4 hours

Over-Firing the Stove

This stove was designed to operate at a high temperature. But due to differences in vent

configuration, fuel, and draft, this appliance can be operated at an excessive temperature. If the

stove top or other area starts to glow red, you are over-firing the stove. Shut the air control down to

low and allow the stove to cool before proceeding.

Opening the Door

Rotate

the door

Swing

handle.

the door

open.

The door becomes hot during use. Use a glove to open the door if the handle is hot.

To prevent smoke from entering the room, open the door a small amount and let air enter the firebox.

This stabilizes the air flow before opening the door completely.

Travis Industries 93508113 4020325

Page 18

18 Operating Your Appliance

Starting a Fire

Since the dawn of time man has debated the best way to start a fire. Some use the boy-scout "teepee", some prefer the "tic-tac-toe" stack. Either way, review the hints and warnings below to ensure

proper fire starting.

• Make sure the air control is pushed in. If additional air is needed, open the doors 1/4" during the first

five minutes of start-up.

Never use gasoline, gasoline-type lantern fuel, kerosene, charcoal lighter fluid, or similar liquids to start

or "freshen up" a fire in this stove. Keep all such liquids well away from the stove while it is in use.

If using a firestarter, use only products specifically designed for stoves - follow the manufacturer's

instructions carefully.

If the smoke does not pass up the chimney, ball up one sheet of newspaper, place it in the center of the

grate and light it. This should start the chimney drafting (this eliminates "cold air blockage").

Use plenty of kindling to ensure the stove reaches a proper temperature. Once the kindling is burning

rapidly, place a few larger pieces of wood onto the fire.

Travis Industries 93508113 4020325

Page 19

Operating Your Appliance 19

Adjusting the Burn Rate

Use the air control slider to control the burn rate of the stove. See the illustration below for details.

Use the air control to

change the burn rate.

Low Burn

(air control closed)

High Burn

(air control open)

Approximate Air Control

Settings:

The air control becomes hot during operation - use gloves or a tool to prevent burns.

Overnight Burn.............. Fully closed to 1/64" open

Medium Burn.................. 1/64" open to 1/32" open

Medium High Burn........ 1/32" open to 1/16" open

High Burn........................ 1/16" to fully open

The air control may take several minutes to influence the burn rate. When making adjustments, you may

wish to let the stove burn for 10 minutes to gauge performance.

Ash Removal

Ashes should be placed in a metal container with a tight fitting lid. The closed container of ashes

should be placed on a noncombustible floor or on the ground, away from all combustible

ASHES

Travis Industries 93508113 4020325

materials, pending final disposal. Ashes should be retained in the closed container until all

cinders have thoroughly cooled.

Page 20

20 Operating Your Appliance

Optional Blower Operation

The blower will turn on once the stove is up to temperature. This is typically 15 to 30 minutes after

starting the fire. Follow the directions below to alter the blower speed.

OFF

Turn the dial all the way counterclockwise until it clicks off.

OFF

HI

LO

BLOWER

CONTROL

The high position is all the way counterclockwise,

HIGH

without clicking off.

OFF

HI

LO

BLOWER

CONTROL

LOW

Turn the dial all the

way clockwise.

OFF

HI

LO

BLOWER

CONTROL

The blower may be used to affect heat output (i.e.: to reduce heat output, turn the blower down).

Re-Loading the Stove

Follow the directions below to minimize smoke spillage while re-loading the stove.

1 Push the air control all the way in (high burn).

2 Open the door slightly. Let the airflow inside the firebox to stabilize before opening the doors fully.

3 Load wood onto the fire.

Overnight Burn

This stove is large enough to accommodate burn times up to eight hours. Follow the steps below to

achieve an overnight burn.

1 Move the air control to high burn and let the stove become hot (burn for approximately 15 minutes).

2 Load as much wood as possible. Use large pieces if possible.

3 Let the stove burn on high for 15 minutes to keep the stove hot, then turn the air control to low.

4 In the morning the stove should still be hot, with embers in the coal bed. Stir the coals and load small

pieces of wood to re-ignite the fire, if desired.

Differences if chimney height and draft may lower overall burn times.

Normal Operating Sounds

Creaks and Clicks:

The 3/16" and 5/16" steel may creak or click

when the stove heats up and cools down - this

is normal.

Blower Sounds:

The blower will make a slight "humm" as it

pushes air through the stove.

Travis Industries 93508113 4020325

Page 21

Operating Your Appliance 21

W

W

Hints for Burning

• Get the appliance hot before adjusting to low burn

• Use smaller pieces of wood during start-up and high burns to increase temperature

• Use larger pieces of wood for overnight or sustained burns

• Stack the wood tightly together to establish a longer burn

• Leave a bed of ashes (1/2" deep) to allow for longer burns

• Be considerate of neighbors & the environment: burn dry wood only

• Burn small, intense fires instead of large, slow burning fires when possible

• Learn your appliance's operating characteristics to obtain optimum performance

Selecting Wood

Dry Wood is Key

et

ood

Dry

Wood

Dry wood burns hot, emits

less smoke and creates

less creosote.

Leads

To

Testing Wood

Moisture

Split wood stored in a dry

area will be fully dry within

a year. This insures dry

wood. If purchasing wood

for immediate use, test the

wood with a moisture

meter. Some experienced

wood burners can measure

wood moisture by knocking

pieces together and

listening for a clear "knock"

and not a "thud".

Less

Heat

Leads

To

More Smoke

and Creostoe

More

Heat

Less Smoke

and Creostoe

Why Dry Wood is Key

Wet wood, when burned, must release water stored within the wood. This cools the fire, creates

creosote, and hampers a complete burn. Ask any experienced wood burner and he or she will agree:

dry wood is crucial to good performance.

Leads

To

Leads

To

Wood Cutting and Storage

Cut wood to length and

chop into quarters.

Store the wood off the ground in a

covered area. Allow for airflow

around the wood to dry the wood.

Air Flow

Air Flow

Air Flow

Travis Industries 93508113 4020325

Page 22

22 Operating Your Appliance

Troubleshooting

Problem Possible Cause

Smoke Enters Room

During Start-Up

Kindling Does Not Start Fire Smolders

Smoke Enters Room

While Re-Loading

Stove Does Not Burn Hot

Enough

• Cold Air Blockage - burn a piece of newspaper to

establish a draft.

• Close the doors - if the flame is not getting enough air,

first make sure the air control is open (all the way in).

If additional air is needed, a small crack in the door is

all that is needed.

• Cold Air Blockage - burn a piece of newspaper to

establish a draft.

• Not enough starter paper - use additional newspaper if

necessary.

• Not enough air - first make sure the air control is open

(all the way in). If additional air is needed, a small

crack in the door is all that is needed.

• Let the air stabilize before fully opening the door. Push

the air control in before opening the door. Then open

the door approximately 1 inch. Let air go into the

firebox for a few seconds. Once the smoke appears to

be flowing up the chimney consistently, open the door.

• Insufficient Draft - Chimney height and outside

conditions can negatively affect draft. In these cases a

small amount of smoke may enter the home. Adding

more pipe or a draft-inducing cap may help.

• Wood is Wet - see the section "Selecting Wood" on

page 21 for details on wood.

• Insufficient Draft - Chimney height and outside

conditions can negatively affect draft. In these cases

the fire may burn slowly. Adding more pipe or a draftinducing cap may help.

• Air Control is Not Wide Open - Make sure the air

control is all the way in. Slide the control back and

forth to insure the control is not stuck.

Blower Does Not Run

Stove Does Not Burn

Long Enough

• Stove is Not Up to Temperature - This is normal. The

blower will come on when the stove is hot - usually 15

to 30 minutes.

• Electricity is Cut to the Blower - Check the household

breaker or fuse to make sure it is operable.

• This appliance burns for up to 8 hours. Depending

upon wood, draft, and other factors, the burn time may

be shorter. Make sure the doors are sealing and not

allowing air into the firebox - See the section "Door and

Glass Inspection" on page 24 for details.

• Check the ash bed for coals. Often, coals are still

glowing under a slight bed of flyash. By raking these

into a pile you can re-start your stove quickly.

Travis Industries 93508113 4020325

Page 23

Maintaining Your Appliance 23

Failure to properly maintain and inspect your appliance may reduce the performance and life of the

appliance, void your warranty, and create a fire hazard.

Daily Maintenance (while stove is in use)

Remove Ash (if necessary)

Ash removal is not required once it builds up. 1/2" to 1" of ash may be desirable because it slows the

burn rate. Generally, remove ash once it has built up over 1". Follow the directions below to remove

ash.

1 Let the stove cool completely (at least two hours after the last coal has extinguished).

2 Place a cloth or cardboard protector over the hearth to catch ash and protect against

scratching.

3 Open the doors and scoop the ash into a metal container with a tight fitting lid. The

closed container of ashes should be placed on a noncombustible floor or on the ground,

away from all combustible materials, pending final disposal.

Improperly disposed ashes lead to fires. Hot ashes placed in cardboard boxes, dumped in back yards,

or stored in garages, are recipes for disaster.

Wood-burning stoves are inherently dirty. During cleaning have a vacuum ready to catch spilled ash

(make sure ash is entirely extinguished).

ASHES

There are vacuum cleaners specifically made to remove ash (even if the ash is warm). Contact your

dealer for details.

Clean the Glass (if necessary)

This appliance has an airwash to keep the glass clean. However, burning un-seasoned wood or

burning on lower burn rates leads to dirtier glass (especially on the sides). Clean the glass by

following the directions below.

Allow the stove to fully cool. Apply glass

cleaner or soapy water to the inside of

the glass. Wipe with newspaper or a

paper towel.

For Stubborn Creosote:

Dip newspaper or a paper towel in cool

ashes and wipe it on the glass. The ash

acts as a light abrasive.

The glass will develop a very slight haze over time. This is normal and will not affect viewing of the fire.

Travis Industries 93508113 4020325

Page 24

24 Maintaining Your Appliance

Monthly Maintenance (while appliance is in use)

Make sure the appliance has fully cooled prior to conducting service.

Door and Glass Inspection

The door must form an air-tight seal to the firebox for the stove to work correctly. Inspect the door

gasket to make sure it forms an air-tight seal to the firebox.

The door can be lifted off the hinges. Open the door and lift straight up to remove the door.

High-Temperature

anti-sieze may be

used on the door

hinges to eliminate

squeaks.

Use wood stove gasket

cement to re-adhere

loose gasket.

If the glass is damaged, replace

it - see “Replacement Parts” for

details.

Severely frayed or thread-bare

gasket should be replaced.

The door latch should pull the door against the face of the stove (but not so tight as to not allow full

handle rotation). If the latch requires adjustment, follow the directions below.

Door Frame (with gasket)

Cam

9/16" Wrench

Door Cam Adjustment:

To tighten the door cam, remove the door handle and discard one of the washers

betwen the door frame and cam. To loosen the door cam, add a washer between

the door frame and cam.

Nut

Washers

Door Handle

Check for Creosote Buildup

Creosote buildup should be checked monthly during the heating season. Either look down the chimney

from the top or remove a chimney connector section. Any more than 1/4" of buildup requires chimney

cleaning. Creosote develops quickest when burning at a low temperature or when burning unseasoned wood. When wood is burned slowly, it produces tar and other vapors which combine with

moisture to form creosote. Creosote vapors condense in the relatively cool chimney flue and creosote

residue accumulates on the flue lining. When ignited, this creosote makes an extremely hot fire.

If you are not certain of creosote inspection, contact your dealer or local chimney sweep for a full

inspection. Excess creosote buildup may cause a chimney fire, that may result in property damage,

injury, or death.

Travis Industries 93508113 4020325

Page 25

Maintaining Your Appliance 25

Yearly Maintenance

Make sure the appliance has fully cooled prior to conducting service.

Touch Up Paint

Included with the owner's pack of this appliance is a can of Stove-Brite®

paint. To touch up nicks or dulled paint, apply the paint while the

appliance is cool. Sand rusted or damaged areas before preparation (use

120 grit sandpaper). Clean and dry the area to prepare the surface. Wait

at least one hour before starting the appliance. The touched up area will

appear darker than the surrounding paint until it cures from heat. Curing

will give off some fumes while curing – open windows to ventilate.

Blower Cleaning (if applicable)

The optional blower should be vacuumed every year to remove any buildup of dust, lint, etc.

Touch-Up

Paint

BOTTOM OF

STOVE

Use a vacuum cleaner to remove any

buildup on the screens of the blower.

Firebrick and Baffle Inspection

Use the illustration on page 27 as a reference for checking the following items. Make sure the

appliance is cool before proceeding.

Baffle Firebricks - check the bricks along the ceiling of the firebox to make sure they are intact and

have no gaps between them. Slide the bricks to eliminate any gaps.

Baffle Supports - make sure the front and back baffle supports in are place and not degraded. Slight

scaling or rusting of the metal is normal.

Secondary Air Tubes - Check the three air tubes and collars to make sure they are intact and not

severely deteriorated. Slight scaling or rusting of the metal is normal. Make sure the push pins hold

the air tubes in place.

Floor and Wall Firebricks - replace any severely damaged firebrick along the side or floor of the

firebox.

Travis Industries 93508113 4020325

Page 26

26 Maintaining Your Appliance

Door Parts

Door Cross

Section

Glass

Gasket

Door

Frame

5/16" Nutdriver

Glass

Glass

Retainer

Door

Gasket

14

15

9/16" Wrench

ID

Description Qty Part # ID # Description Qt

#

1 Door Frame 1 93008500 9 Door Gasket 1 99900402

2 Washers 4 (see #3) 10 Glass Channel Gasket 1 99900404

3 Door Handle Asbly 1 99900422 11 Door Decor - Handle 1

4 Door Cam 1 99900416 12 Door Decor - Upper 1 93008501

5 3/8" Jam Nut 1 (see #3) 13 Door Décor - Lower 1 93008502

6 Glass 1 99400321 14 Door Shell Screws 12

7 Spring Handle 1 99300603 15 Door Gasket Cement 99900409

8 Glass Retainer 1 93008504

Part #

y

Replacing the Glass

The perimeter of the glass is enclosed with channel gasket to prevent damage. The glass retainer

holds the glass against the door frame and is secured with 12 screws. Remove the screws and

door retainer to access the glass. When installing, do not over-tighten the screws.

Replacing the Door Gasket

The door gasket inserts into the outer groove of the door frame. Stove gasket cement holds it in

place. Before installing, remove any residual cement. Lay the gasket in place (start at the upper

left corner) and cut off any excess gasket (do not stretch the gasket. The cement fully cures with

heat from the stove. You may need to open and close the door repeatedly to get the gasket to

seat fully.

Replacing the Door Handle

The door handle consists of several components. See the illustration above for a component list

and installation order. For details on adjusting the door handle see page 25.

Travis Industries 93508113 4020325

Page 27

Maintaining Your Appliance 27

Firebox Parts

1

6

6

7

6

6

5

4

2

3

8

8

9

10

12

ID#Description Qty Part # ID # Description Qt yPart #

1 Baffle Support Rear 1 98900309 7 Firebrick, 4.25" x 9" 1 251-00012

2 Baffle Support Front 1 98900308 8 Firebrick, 4.5" x 7.375" 4 251-00013

3 Air Tubes (all 3) with

Collars and Pins

4 Baffle Center Plate 1 98900310 10 Firebrick, 4.5" x 5.875" 2 251-00016

5 Air Tube Push Pins 6 98900353 11 Firebrick, 3.5" x 9" 2 251-00015

6 Firebrick, Full 4.5" x 9" 10 175-00001 12 Firebrick, 1.5" x 8" 1 251-00017

1 98900211 9 Firebrick, 1.375" x 7.375" 2 251-00014

6

6

6

11

Floor and Side Firebrick Removal & Replacement

Do not pry firebrick - they chip and crack easily. Remove the floor firebricks first. The

side firebrick are removed later because they are pinned in place by the floor firebrick. Clean the

firebox prior to replacing the firebrick.

Travis Industries 93508113 4060407

Page 28

28 Maintaining Your Appliance

Baffle Removal & Replacement

a

Front Baffle Support

Baffle

Center

Plate

c

Side Air Channel

Baffle

Firebrick

Air Tubes

The baffle center plate rests on the side

air channels. Its back edge (the larger

flange) rests against the center air tube.

Remove it by sliding it forward and out.

Rear

Baffle

Support

Air Tube Removal & Replacement

The front and middle air tubes are identical. The rear air tube has air holes that are farther apart.

Remove the front baffle support

by lifting it up and forward.

The rear baffle support rests behind the

rear air tube on the side air channels. It

d

is removed by sliding forward and out.

Slide each baffle firebrick

b

forward and rotate it down to

remove.

Air Tube

Air Tube Collar

Push Pin

Remove the left pin on the air tube collar

a

(it may be a roll pin or push pin).

Roll Pin

Slide the air tube to the left, swing it

b

down and remove from the firebox.

Travis Industries 93508113 4020325

Page 29

Limited 7 Year Warranty 29

To register your TRAVIS INDUSTRIES, INC. 7 Year Warranty, complete the enclosed warranty card and mail it within ten (10) days of the

appliance purchase date to: TRAVIS INDUSTRIES, INC., 4800 Harbour Pointe Blvd. SW, Mukilteo, WA 98275. TRAVIS INDUSTRIES, INC.

warrants this gas appliance (appliance is defined as the equipment manufactured by Travis Industries, Inc.) to be defect-free in material and

workmanship to the original purchaser from the date of purchase as follows:

Check with your dealer in advance for any costs to you when arranging a warranty call.

Mileage or service charges are not covered by this warranty. This charge can vary from store to store.

Years 1 & 2 - COVERAGE: PARTS & LABOR

Firebox Assembly:

Firebox, Baffle Supports, Air Tubes, Air Channels, Convection Chamber

Door Assembly:

Solid Brass or Cast Door, Latch Assembly, Glass Retainers

Plated Finish

Plated Door, Legs, etc… See "Conditions & Exclusions" # 9 below.

Air Control Assembly

Slider Plate, Pressure Plate

Exclusions: Paint, Gasketing

Years 3 Through 5 - COVERAGE: PARTS & LABOR

Firebox Assembly:

Firebox, Baffle Supports, Air Tubes, Air Channels, Convection Chamber

Air Control Assembly

Slider Plate, Pressure Plate

Exclusions: Paint, Gasketing, Plated Finish, Accessories (Legs, Pedestal, Panels, Blower), Glass, Firebrick, Re-Installation Allowance

Years 6 & 7 - COVERAGE: PARTS ONLY

Firebox Assembly:

Firebox, Baffle Supports, Air Tubes, Air Channels, Convection Chamber

Exclusions: Paint, Gasketing, Plated Finish, Accessories (Legs, Pedestal, Panels, Blower), Glass, Firebrick, Re-Installation Allowance, One-

Way Freight Allowance, Labor

CONDITIONS & EXCLUSIONS

1. This new appliance must be installed by a qualified installer. It must be installed, operated, and maintained at all times in accordance with the instructions in the Owner’s Manual. Any

alteration, willful abuse, accident, neglect, or misuse of the product shall nullify this warranty.

2. This warranty is nontransferable, and is made to the ORIGINAL purchaser, provided that the purchase was made through an authorized Travis dealer.

3. Discoloration and some minor expansion, contraction, or movement of certain parts and resulting noise, is normal and not a defect and, therefore, not covered under warranty. Over-firing

(operation where the steel may glow red) of this appliance can cause serious damage and will nullify this warranty.

4. The warranty, as outlined within this document, does not apply to the chimney components or other Non-Travis accessories used in conjunction with the installation of this product. If in

doubt as to the extent of this warranty, contact your authorized Travis retailer before installation.

5. Travis Industries will not be responsible for inadequate performance caused by environmental conditions such as nearby trees, buildings, roof tops, wind, hills or mountains or negative

pressure or other influences from mechanical systems such as furnaces, fans, clothes dryers, etc.

6. This Warranty is void if:

a. The unit has been operated in atmospheres contaminated by chlorine, fluorine or other damaging chemicals.

b. The unit is subject to submersion in water or prolonged periods of dampness or condensation.

c. Any damage to the unit, combustion chamber, heat exchanger or other components due to water, or weather damage which is the result of, but not limited to, improper chimney/venting

installation.

7. Exclusions to this 7 Year Warranty include: injury, loss of use, damage, failure to function due to accident, negligence, misuse, improper installation, alteration or adjustment of the

manufacturer's settings of components, lack of proper and regular maintenance, damage incurred while the appliance is in transit, alteration, or act of God.

8. This 7 Year warranty excludes damage caused by normal wear and tear, such as paint discoloration or chipping, worn or torn gasketing, chipped or cracked firebrick, etc. Also excluded is

damage to the unit caused by abuse, improper installation, modification of the unit, or the use of fuel other than that for which the unit is configured (use cord wood only).

9. Damage to brass or plated surfaces caused by fingerprints, scratches, melted items, or other external sources left on the surfaces from the use of abrasive cleaners is not covered in this

warranty. Damage to the surfaces from over-firing (operation where the steel may glow red) is not covered in this warranty.

10. TRAVIS INDUSTRIES, INC. is free of liability for any damages caused by the appliance, as well as inconvenience expenses and materials. Incidental or consequential damages are not

covered by this warranty. In some states, the exclusion of incidental or consequential damage may not apply.

11. This warranty does not cover any loss or damage incurred by the use or removal of any component or apparatus to or from the Travis appliance without the express written permission of

TRAVIS INDUSTRIES, INC. and bearing a TRAVIS INDUSTRIES, INC. label of approval.

12. Any statement or representation of Travis products and their performance contained in Travis advertising, packaging literature, or printed material is not part of this 7 year warranty.

13. This warranty is automatically voided if the appliance’s serial number has been removed or altered in any way. If the appliance is used for commercial purposes, it is excluded from this

warranty.

14. No dealer, distributor, or similar person has the authority to represent or warrant Travis products beyond the terms contained within this warranty. TRAVIS INDUSTRIES, INC. assumes no

liability for such warranties or representations.

15. Travis Industries will not cover the cost of the removal or re-installation of hearths, facing, mantels, venting or other components.

16. If for any reason any section of this warranty is declared invalid, the balance of the warranty remains in effect and all other clauses shall remain in effect.

17. This 7 year warranty is the only warranty supplied by Travis Industries, Inc., the manufacturer of the appliance. All other warranties, whether express or implied, are hereby expressly

disclaimed and purchaser’s recourse is expressly limited to the warranties set forth herein.

IF WARRANTY SERVICE IS NEEDED:

1. If you discover a problem that you believe is covered by this warranty, you MUST REPORT it to your Travis dealer WITHIN 30 DAYS, giving them proof of purchase, the purchase date, and

the model name and serial number.

2. Travis Industries has the option of either repairing or replacing the defective component.

3. If your dealer is unable to repair your appliance’s defect, he may process a warranty claim through TRAVIS INDUSTRIES, INC., including the name of the dealership where you

purchased the appliance, a copy of your receipt showing the date of the appliance’s purchase, and the serial number on your appliance. At that time, you may be asked to ship

your appliance, freight charges prepaid, to TRAVIS INDUSTRIES, INC. TRAVIS INDUSTRIES, INC., at its option, will repair or replace, free of charge, your appliance if it is

found to be defective in material or workmanship within the time frame stated within this 7 year warranty. TRAVIS INDUSTRIES, INC. will return your appliance, freight charges

(years 1 to 5) prepaid by TRAVIS INDUSTRIES, INC., to your regional distributor, or dealership.

4. Check with your dealer in advance for any costs to you when arranging a warranty call. Mileage or service charges are not covered by this warranty. This charge can vary from store to store.

Ceramic Glass

Glass (breakage from thermal shock)

Firebrick

Breakage from thermal shock

Accessories

Legs, Pedestal, Panels, Blower

Door Assembly:

Solid Brass or Cast Door, Latch Assembly,

Glass Retainers

Door Assembly:

Solid Brass or Cast Door, Latch Assembly, Glass Retainers

Re-Installation Allowance

In cases where heater must be removed from home for

repairs, a partial cost of re-installation is covered (preauthorization required)

One-Way Freight Allowance

One-way freight allowance on pre-authorized repair done

at factory is covered.

One-Way Freight Allowance

One-way freight allowance on pre-authorized repair

done at factory is covered.

Air Control Assembly

Slider Plate, Pressure Plate

Travis Industries 93508113 4050124

Page 30

30 Listing Information

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT

INSTALLATION AND RESTRICTIONS IN YOUR AREA.

LISTED SOLID FUEL BURNING APPLIANCE SUITABLE FOR USE IN

RESIDENTIAL, ALCOVE AND MOBILE HOME INSTALLATIONS.

PREVENT HOUSE FIRES - Install and use only in accordance with the manufacturer’s installation and operating instructions. Contact

your local building or fire officials about restrictions and installation inspection in your area. Refer to local building codes and

manufacturer’s instructions for precautions required for passing a chimney through a combustible wall or ceiling. Do not run a

chimney connector through a combustible wall or ceiling. Do not connect this unit to a chimney flue serving another appliance.

Clearances may be reduced by methods specified in NFPA 211, listed wall shields, pipe shields, or other means approved by local

building or fire officials. For use with solid wood fuel only (cord wood). Operate with feed door closed - open to feed fire only. Do not

use a grate to elevate fire - build fire directly on hearth.

DANGER: Risk of electrical shock. Disconnect power supply before servicing. Route power cord away from unit. Do not route power

cord over or under appliance.

DO NOT OVERFIRE - If heater or chimney connector glows, you are overfiring.

Inspect and clean chimney frequently - under certain conditions of use, creosote buildup may occur rapidly.

DO NOT REMOVE THIS LABEL

• DURAVENT model DVL with DURATEC chimney

• DURAVENT model DVL with DURA-PLUS chimney

• AMERI-TEC model DCC with model HS chimney

• SECURITY model DL with SECURITY model ASHT or S2100 chimney

• GSW model Super Chimney Twenty-One connected directly to appliance

• SELKIRK METALBESTOS model DS connector with model SSII chimney

• ICC EXCEL (2100-2 Can.) (103-HT USA) chimney with HP connector

MODEL:

COTTAGE

TESTED TO UL 1482, ULC-S627, CSA B366.2

Room Heater, Solid Fuel Type - Also For Use In Mobile Homes

SERIAL

NUMBER

FREESTANDING INSTALLATION

CLEARANCE

REQUIREMENTS:

A. SIDEWALL TO UNIT

B. BACKWALL TO UNIT

C. CORNERWALL TO UNIT

D. SIDEWALL TO CONNECTOR

E. BACKWALL TO CONNECTOR

F. CORNERWALL TO CONNECTOR

STANDARD RESIDENTIAL

INSTALLATION (SINGLEWALL

CONNECTOR)

18.0”

18.0”

10.0”

27.75”

19.5”

19.0”

MOBILE HOME AND ALCOVE

INSTALLATIONS

(DOUBLE WALL CONNECTOR)

18.0”

11.5”

10.0”

27.25”

12.5”

18.5”

STOVE

NON-COMBUSTIBLE

FLOOR PROTECTOR

6"

MIN.

6" MIN.

16" MIN.

45˚

STOVE

ADJACENT WALL

ADJACENT WALL

F

C

STOVE

BACKWALL

SIDEWALL

EDB

A

MINIMUM CLEARANCES TO COMBUSTIBLES:

Report No. 028-S-33-2

STANDARD RESIDENTIAL FREESTANDING INSTALLATIONS REQUIRE: 6” diameter, minimum 24 MSG black or 25 MSG blued steel

connector, with listed (type HT) factory-built chimney, suitable for use with solid fuels or masonry chimney. Do not install in a

sleeping room of a mobile home.

ALCOVE INSTALLATIONS REQUIRE: One of the Listed doublewall connectors listed below. Maximum alcove depth 48”, minimum

alcove height 84”, minimum alcove width 61-1/8”.

MOBILE HOME INSTALLATIONS REQUIRE: One of the Listed doublewall connectors listed below. Mobile home installations also

require outside air - use the Avalon optional outside air boot.

OPTIONAL EQUIPMENT: Rear Blower

Electrical rating: 115V, 60 Hz., 1.8 Amps

Replace glass only with AVALON supplied

ceramic glass (5mm).

U.S. ENVIRONMENTAL PROTECTION AGENCY

Certified to comply with July 1990 particulate emission standards.

DOUBLEWALL CONNECTORS

2000 2001 2002 Jan. Feb. Mar. Apr. May June July Aug. Sep. Oct. Nov. Dec.

DATE OF MANUFACTURE

0378

Manufactured By:

10850 117th Pl. N.E. Kirkland, WA 98033

Travis Industries 93508113 4020325

Page 31

Optional Equipment 31

Outside Air Boot Installation (Part number 99200134)

The outside air boot routes outside air to the stove for combustion. Refer to the section "Outside Air

Requirements" on page 11 for installation concerns. The directions below detail installation.

1 Install the cover plate following the directions below.

2 Refer to the illustration below to

determine the location and size of the

hole penetrating the floor and. Cut the

hole prior to locating the stove.

3 Attach gasket to the bottom edge of the

lower air boot section (near the screen).

Attach gasket on top of the flanges on

the upper air boot section. Slide the two

sections together with both seams facing

the rear (do not attach the two sections

at this time).

4 With the legs installed, follow the

directions below for attaching the upper

section of the air boot (with gasket) to the

stove.

5 Slide the lower section down until it

contacts the hearth. Attach the two

sections together following the directions

below.

a

Detach the air intake

cover and cover plate

to expose the air

channel underneath

the firebox.

Phillips

Screwdriver

b

Install the 8” wide cover

plate included with the

outside air boot. It has a

clip to secure it to the

plate under the air contro

Replace the cover to

finalize installation.

Attach the included

gasket to all four top

edges of the air boot.

NOTE:

When in place, the front of

the air boot is 8” in back of

the front edge of the stove

top.

Attach gasket to the bottom

edge of the air boot.

Bottom of Stove

8-7/8”

Floor (and hearth)

5-1/8”

Attach the air boot with

the two screws included

with the kit.

1/4" Nutdriver

Use the included screws to attach

the two telescoping portions of air

boot together. The included drill bit

should be used to drill the hole.

Make sure the air boot is expanded

to the correct size before drilling.

9/64” Drill Bit

5/16" Nutdriver

The hole in the floor (and hearth)

must be a minimum 16 square

inches. It should be 1/2” smaller

than the footprint of the air boot in

each dimension to allow for the

gasket to seal.

Travis Industries 93508113 4020325

Page 32

32 Optional Equipment

Rear Blower Installation (Part number 97000138)

The rear blower improves heat transfer by pushing heated air through the convection channel.

Operating instructions are described in the section "Blower Operation" on page 20.

1 The stove should be in place with the legs installed prior to installing the rear blower.

2 Follow the directions below to install the thermodisk.

a

Detach the air intake

cover and cover plate

to expose the air

channel underneath

the firebox. Replace

after installing the

thermodisk.

Phillips

Screwdriver

3 Install the wire clip following the directions below.

Slide the wire clip

over the edge of the

strip of metal between

the two knock-outs.

Wire Clip

Snap Disk

Wires

Twist the wires together and feed them through the

b

channel, out the hole at the back left of the stove

(see the illustration below).

c

Wedge the snap disk directly in front of the

stiffener on the left side, away from air flow.

NOTE:

Bend the legs on the

Snap Disk

Assembly

Feed the two snap disk wires into

the eye of the wire clip. Remove

all slack from the wire, making

sure not to dislodge the snap disk.

Pinch the eye of the wire clip to

secure the wires.

WARNING:

To prevent electrical shock, the

wires must be secured so they do

not contact the firebox above the

convection channel.

snap disk assembly to

insure a snug fit.

Travis Industries 93508113 4020325

Page 33

Optional Equipment 33

4 Attach the blower following the directions below.

b

Attach the quick-connects

leading from the snap disk to the

a

quick-connects from the blower

(orientation does not matter).

Plug the power cord into a 110 V. outlet after installing the

c

blower.

The blower attaches to the stove with the three

included screws. Use a 3/8” socket driver or wrench.

3/8" Nutdriver

NOTE:

Prior to attaching the blower,

tuck all excess wire into the

area inside the blower.

Travis Industries 93508113 4020325

Page 34

34 Optional Equipment

Travis Industries 93508113 4020325

Page 35

Optional Equipment 35

Travis Industries 93508113 4020325

Page 36

36 Index

Air Control....................................................19

Air Tube Part Number ....................................27

Air Tube Removal & Replacement ....................28

Alcove.........................................................12

Ash Disposal................................................23

Baffle Parts..................................................27

Baffle Removal and Replacement.....................28

Blower Cleaning............................................25

Blower Does Not Run (Troubleshooting) ............22

Blower Installation .........................................32

Blower Operation (optional).............................20

Burn Rate....................................................19

Cathedral Ceiling...........................................14

Ceiling Penetration ........................................14

Chimney Cleaning.........................................24

Chimney Inspection (Creosote) ........................24

Chimney Requirements ..................................10

Chimney Termination Requirements..................11

Cleaning the Ash...........................................19

Cleaning the Glass ........................................23

Clearances ..................................................9

Close Clearance Connectors ...........................9

Connector Requirements ................................10

Creosote Check............................................24

Daily Maintenance.........................................23

Dimensions..................................................6

Door and Glass Inspection ..............................24

Door Assembly .............................................26

Door Gasket Replacement ..............................26

Door Handle Replacement ..............................26

Door Opening...............................................17

Door Parts ...................................................26

Draft Performance.........................................10

Elbows (Chimney) .........................................10

Emissions....................................................6

EPA Approval...............................................6

Exterior Chimney...........................................15

Features......................................................6

Fire Starting .................................................18

Firebox Assembly..........................................27

Firebox Parts................................................27

Firebrick and Baffle Inspection .........................25

Firebrick Removal & Replacement....................27

Floor Protection Requirements.........................8

Glass Cleaning .............................................23

Glass Replacement .......................................26

Hearth (Floor Protection).................................8

Hearth Stove................................................15

Heating Specifications....................................6

Hints for Burns..............................................21

Installation (planning).....................................7

Installation Options........................................6

Installation ...................................................7

Leg Installation .............................................8

Listing Label.................................................30

Maintenance ................................................23

Masonry Fireplace.........................................15

Mobile Home Requirements ............................13

Monthly Maintenance.....................................24

Noise (Normal Operating Sounds) ....................20

Non-Combustible Alcove.................................12

Opening the Door..........................................17

Operation ....................................................17