Page 1

By Avalon

Direct Vent Heater

• HORIZONTAL or VERTICAL VENT

• FREESTANDING STOVE or INSERT

• MOBILE HOME APPROVED

• CLASS A CHIMNEY RETROFIT

OMNI

ANSI Z21.44, Z21.11.4

CAN /CGA 1-2.19-M81, IR41, IR55, 2.17-M91

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer to this manual. For assistance or additional

information consult a qualified installer, service agency, or the gas supplier.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

- I nst al l at i on m us t be per for m ed by a qual i f ie d i ns ta l le r, s er vic e a gency or the ga s s uppl i er

IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Listed

AVANTI DV

Installer: After installation give this manual

to the homeowner and explain

operation of this heater.

- July, 1996 -

10850 117th Place N.E. Kirkland, WA 98033

Page 2

PAGE 2 SAFETY PRECAUTIONS

• IF YOU SMELL GAS:

* Do not light any appliance

* Extinguish any open flame

* Do not touch any electrical switch or plug or unplug anything

* Open windows and vacate building

* Call gas supplier from neighbor's house, if not reached, call fire

department

• This unit must be installed by a qualified installer to prevent the possibility of

an explosion. Your dealer will know the requirements in your area and can

inform you of those people considered qualified. The room heater should be

inspected before use and at least annually by a qualified service person. More

frequent cleaning may be required due to excessive lint from carpeting,

bedding material, etc.

• The instructions in this manual must be strictly adhered to. Do not use

makeshift methods or compromise in the installation. Improper installation

will void the warranty and safety listing.

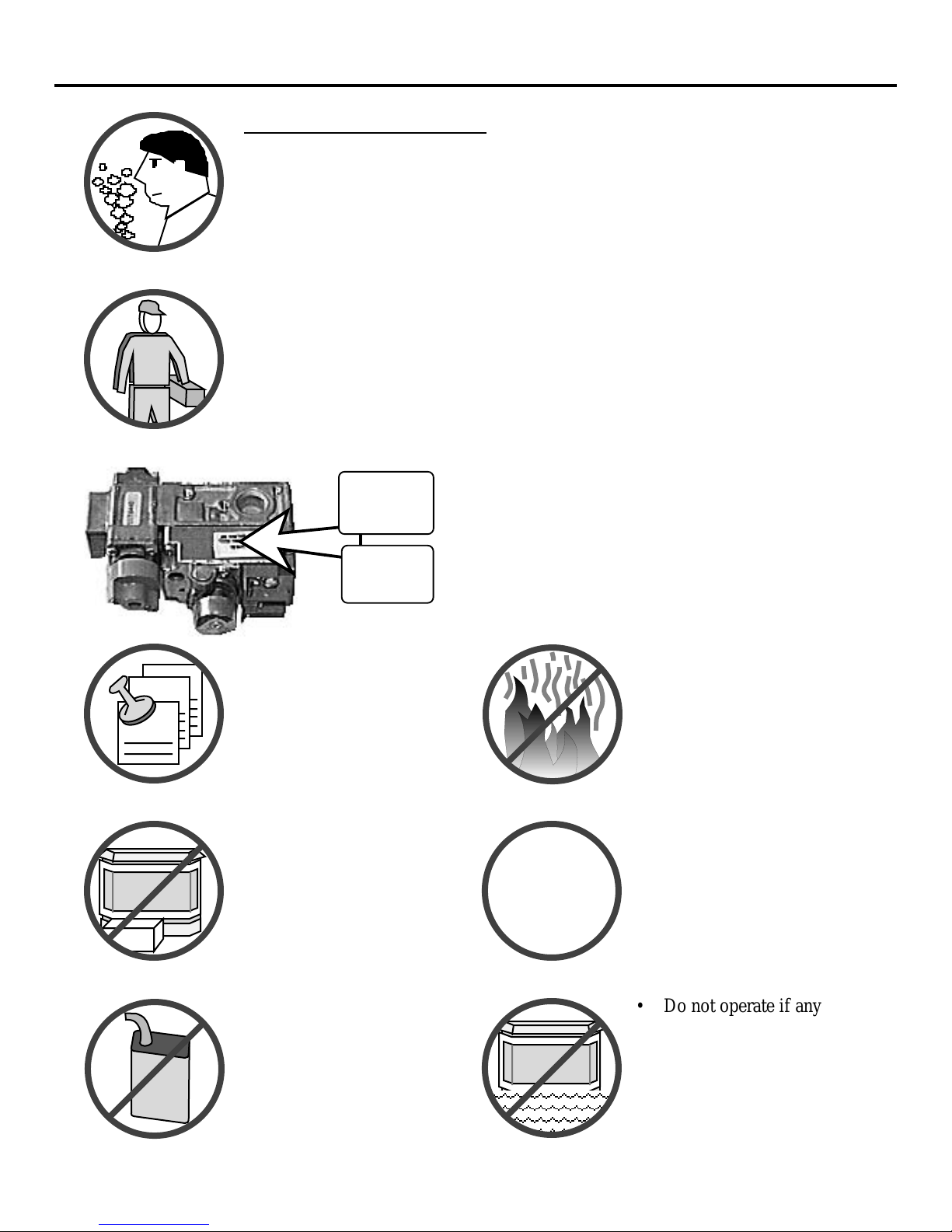

Ok

THIS CONTROL

HAS BEEN

CONVERTED FOR

NATURAL GAS

THIS CONTROL

HAS BEEN

CONVERTED TO

LP

• Contact your local

building officials to

obtain a permit and

information on any

installation restrictions or

inspection requirements

in your area. Notify your

insurance company of this

heater as well.

• It is imperative that

control compartments,

screens, or circulating air

passageways of the heater

be kept clean and free of

obstructions. These areas

provide the air necessary

for safe operation.

• This heater is either approved for natural gas

(NG) or propane (LP). Burning the incorrect

fuel will void the warranty and safety listing and

may cause an extreme safety hazard. Check the

label above the gas control valve to make sure it

matches the fuel being used. Direct questions

about the type of fuel used to your dealer.

• If the flame becomes

sooty, dark orange in

color, or extremely tall,

do not operate the heater.

Call your dealer and

arrange for proper

servicing.

• Do not operate the heater

if it is not operating

properly in any fashion or

if you are uncertain. Call

your dealer for a full

?

explanation of your heater

and what to expect.

• Do not store or use

gasoline or other

flammable liquids in the

vicinity of this heater.

Gas

• Keep all furniture or other

combustible items at least

36" away from the front

of the heater.

• Do not operate if any

portion of the heater was

submerged in water or if

any corrosion occurs.

Page 3

SAFETY PRECAUTIONS (CONTINUED) PAGE 3

• Do not place clothing or

other flammable items on

or near the heater.

Because this heater can be

controlled by a thermostat

there is a possibility of the

heater turning on and

igniting any items placed

on or near it.

• The viewing glass should

be opened for service

only (see the maintenance

section of this manual).

• Any safety screen or

guard removed for

servicing must be

replaced prior to

operating the heater.

• Operate the heater

according to the

instructions included in

this manual.

• If the main burners do not

start correctly turn the gas

off at the gas control

valve and call your dealer

for service.

• Light the heater using the

built-in piezo igniter. Do

not use matches or any

other external device to

light your heater.

• Never remove, replace,

modify or substitute any

part of the heater unless

instructions are given in

this manual. All other

work must be done by a

trained technician. Don't

modify or replace

orifices.

• Allow the heater to cool

before carrying out any

maintenance or cleaning.

• The pilot flame must

contact the thermopile

and thermocouple (see the

illustration to the left). If

it does not, turn the gas

control valve to "OFF"

and call your dealer.

• This unit is not for use

with solid fuel

• Do not place anything

inside the firebox (except

the included fiber logs).

• If the fiber logs become

damaged, replace with

Travis Industries log set.

• Do not touch the hot

surfaces of the heater.

Educate all children of the

danger of a hightemperature heater.

Young children should be

supervised when they are

in the same room as the

heater.

• Instruct everyone in the

house how to shut gas off

to the appliance and at the

gas main shutoff valve.

The gas main shutoff

valve is usually next to

the gas meter or propane

tank and requires a

wrench to shut off.

This

Manual

• Do not throw this manual

away. This manual has

important operating and

maintenance instructions

that you will need at a

later time. Always follow

the instructions in this

manual.

• Plug the heater into a

120V grounded electrical

outlet. Do not remove the

grounding plug.

• Don't route the electrical

cord in front of, over, or

under the heater

• Travis Industries, Inc.

grants no warranty,

implied or stated, for the

installation or

maintenance of your

heater, and assumes no

responsibility of any

consequential

damage(s).

Page 4

PAGE 4 TABLE OF CONTENTS

Introduction & Important Info. ................ 1

Safety Precautions .....................................2

Features & Specifications ........................5

Installation Options...................................5

Heating Specifications............................... 5

Dimensions............................................. 5

Fuel, Emissions, Electrical.......................... 5

Stove Installation

Installation Preparation.............................6

Items Required for Installation....................6

Packing Lists..........................................6

Order of Installation .................................6

Door Removal ........................................6

Pedestal Attachment................................6

Stove Shell Assembly...............................7

Gas Inlet Installation ................................9

Floor Protection Requirements...................10

Stove Placement Requirements .................10

Gas Line Installation ................................11

Vent Requirements..................................12

Approved Vent Configurations....................13

Restrictor Position .............................13

Elbows............................................13

How to Measure Vent Lengths .............13

Approved Vent Config's with No Elbows

or Two 45° Offsets (Vertical Term.) .......14

Approved Vent Config's with a

Horizontal Termination........................15

Approved Vent Config's with a Vertical

Termination and Two 90° Elbows..........16

Horizontal Vent Termination Requirements...17

Vertical Vent Termination Requirements ......17

Electrical Connection ...............................17

Insert Installation

Installation Preparation.............................18

Items Required for Installation....................18

Packing Lists..........................................18

Order of Installation .................................18

Installing the Power Cord..........................19

Insert Placement.....................................20

Floor Protection ......................................20

Gas Line Install.......................................21

Vent Requirements..................................22

Approved Vent Configurations....................23

Electrical Connection ...............................23

Surround Panel Installation........................24

Insert Shell Installation .............................25

Finalizing the Installation

1 Door Opening ......................................26

2 Log, Twig, and Ember Installation.............27

3 Glass Installation ..................................28

4 Purge and Leak Test the Gas Line ...........28

5 Pilot Flame Inspection............................28

6 Air Shutter Adjustment...........................29

7 Flame Inspection ..................................29

8 Explain Heater Operation to Owner ..........29

Operating Your Heater

Before You Begin....................................30

Location of Controls.................................30

Starting The Pilot Flame ...........................31

Starting the Stove for the First Time ............32

Turning the Stove On and Off ....................32

Adjusting the Flame Height........................32

Adjusting the Blower Speed.......................33

Normal Operating Sounds.........................33

Maintaining Your Stove

Maintaining Your Stove's Appearance..........34

Cleaning Your Stove................................34

Yearly Service Procedure..........................34

Troubleshooting

Troubleshooting Table..............................35

How this Stove Works ..............................36

Wiring Diagram.......................................37

Warranty ..................................................... 38

Listing Information .................................. 39

Optional Equipment

Propane (LP) Conversion Kit .....................40

Thermostat ............................................44

Remote Control Thermostat.......................45

Gold Trim Kit..........................................46

Addendum

Altitude Considerations.............................47

Class A Chimney Conversion Kit ................47

Interior Masonry Chimney Conversions........47

Index 48

Symbols Used in this Manual

The illustration below details what the symbols used along the left margin indicate.

Requirement

•1!?+

NoteWarningStep

Hint

Page 5

FEATURES AND SPECIFICATIONS PAGE 5

Installation Options:

• Residential or Mobile Home

• Freestanding Stove or Insert

• Bedroom Approved

• Alcove Approved

• Vertical or Horizontal Vent

Heating Specifications:

Approximate Heating Capacity (in square feet)* 600 - 1600 600 - 1600

High Burn Input Rate (In BTU's) 38,500 36,500

Low Burn Input Rate (In BTU's) 18,700 18,000

Efficiency** 81 % 81.5 %

AFUE (Annual Fuel Utilization Efficiency) 72.4 % 73 %

* Heating capacity will vary with the home's floor plan and insulation, natural gas or Propane BTU rating, and outside temperature.

** Efficiency rating is a product of thermal efficiency rating determined under continuous operation independent of installed system.

To measure the net BTU's, multiply the BTU input by the efficiency percentage.

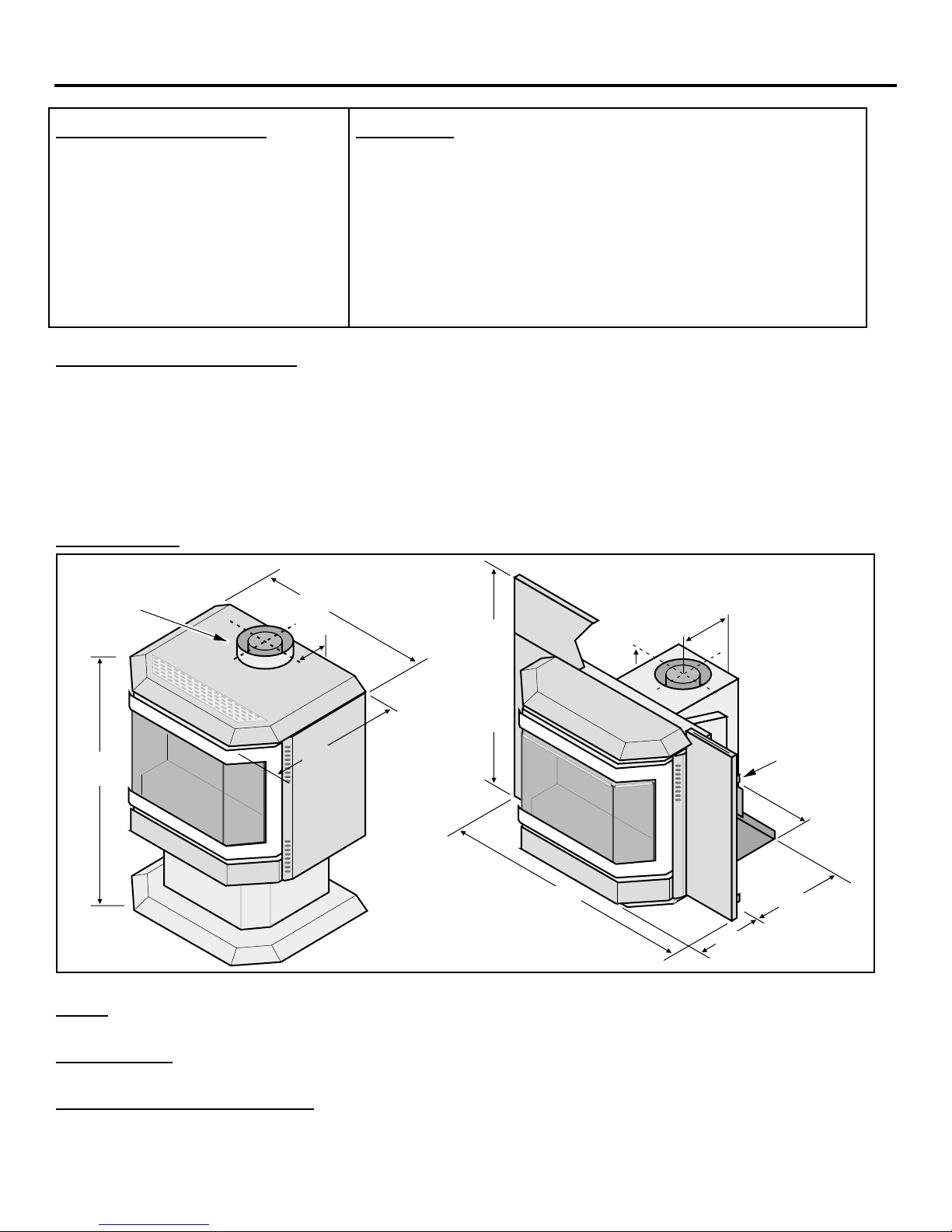

Dimensions

The starter section is 2-5/8"

(67 mm) above the top panel

(includes flue collar

extension).

24-1/2" (622 mm)

4-5/8"

(117 mm)

Features:

• Works During Power Outages (standing pilot)

• High Efficiency

• Optional Thermostat or Remote Control

• Realistic "Wood Fire" Look

• Convenient Operating Controls

• Variable-Rate Heat Output

• Quiet Blower for Effective Heat Distribution

• Low Maintenance

Natural Gas LP (Propane)

4-5/8"

(117 mm)

28-7/8"*

(733 mm)

8x10

Panels

31-7/8"*

(810 mm)

10x13

Panels

19-1/2"

(495 mm)

31-1/8"

(791 mm)

20"

(508 mm)

40-3/8"* 8x10 Panels

(1026 mm)

44-3/8"* 10x13 Panels

(1127 mm)

* Includes trim & standoffs

8-3/4"*

(222 mm)

Standoff

21-3/4"

(552 mm)

11-1/4"*

(286 mm)

Fuel: The stove is designed either for natural gas or for propane. Check

the sticker on the top of the gas control valve.

Emissions: This unit has passed the ANSI emission standards for vented room

heaters as tested by OMNI Environmental Services, Inc.

Electrical Specifications: 120 Volts, 1.3 Amps, 60 Hz (150 watts on high)

Page 6

PAGE 6 STOVE INSTALLATION - For Qualified Installers Only!

Installation Preparation

! Failure to follow all of the requirements may result in property damage, bodily injury, or even

death.

! This appliance must be installed in accordance with all local codes, if any; if not, follow ANSI

Z223.1 and NFPA 54(88).

! In Manufactured or Mobile Homes must confirm with: In USA, Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280; In Canada, CSA Z240.4 and Gas-Equipped

Recreational Vehicles and Mobile Housing. This appliance may be installed in Manufactured

Housing only after the home is site located.

! This appliance is designed for natural gas or propane (LP). Check the sticker on top of the gas

control valve.

! All exhaust gases must be vented outside the structure of the living-area. Combustion air is drawn

from outside the living-area structure.

! Notify your insurance company before hooking up this appliance.

! The requirements below are divided into sections - all requirements must be met simultaneously.

ms Required for Installation

• Avanti Stove Shell • Gas Hookup Equipment

ms Packed with the Avanti DV

• Avanti DV (with gold door)

• Log Set (2 Logs, 2 Twigs, Embers)

• Two Gas Inlet Pipes (the longer one is for stoves)

• Owner's Manual

• Simpson Duravent with Silicone (see page 12 for part #'s)

• Avanti Pedestal (Part # 99200115)

• Propane Conversion Kit

• Strain Relief (for power cord)

• Strain Relief Bracket (for inserts only - may be discaded)

ms Packed with the Stove Shell

• Top, Left, Right, and Rear Stove Panels

• Control Cover

• Black Grill

• Eight 10-32 Hex Nuts with Attached Lock Washers

• Two 10-24 Pan Head Screws

ms Packed with the Pedestal

• Pedestal

• Two 3/8 x 3/4" Bolts

der of Installation

1 If the heater is to use propane, install the propane

conversion kit (see pages 40 - 45)

2 Attach the pedestal

3 Attach the stove shell to the heater

destal Attachment

9/16" Wrench

Use a 9/16" wrench to

attach the two pedestal

bolts to the bottom of the

heater.

• Twelve 10-24 Self-Tapping Screws

• Nine U-Nuts

• Two 6" strips of self-adhesive gasket

• Gas Line Plate

• Left & Right Forward Mounting Brackets

• Two Washers

• Two Lag Bolts

4 Install the gas inlet (17-1/4" length of 3/8" pipe)

5 Position the heater, use floor protection if needed

6 Connect the gas line. Connect the gas vent.

7 Follow the instructions under "Finalizing the

Installation" on pages 26 through 29.

Lift from here

NOTE: Keep the heater

level to prevent the door

from shifting loose.

The lag bolts and washers

may be inserted through

these holes to anchor the

pedestal to the floor.

Page 7

STOVE INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 7

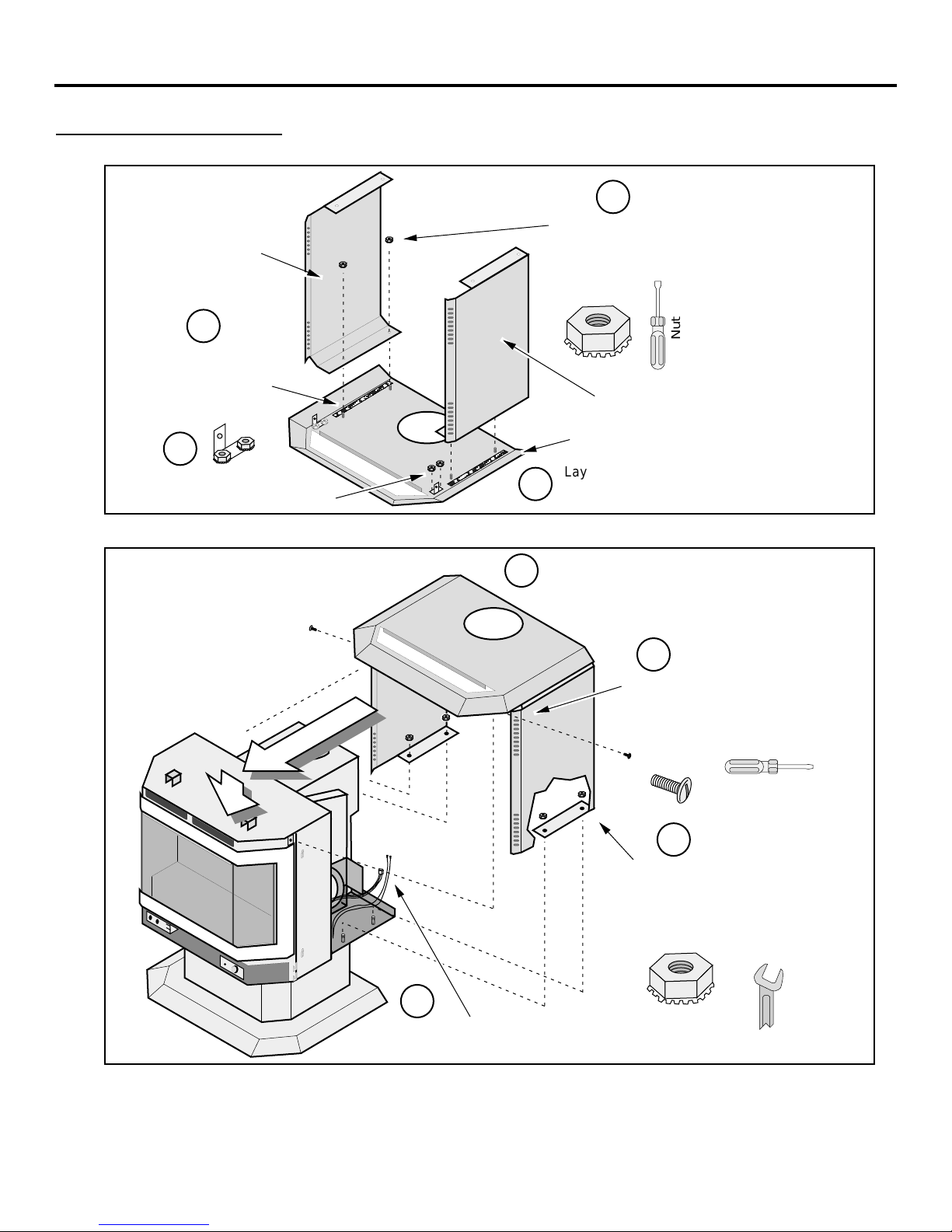

Stove Shell Assembly

1 Follow the directions below to install the side panels to the top panel.

Attach the side panels to the top panel with

Right side panel

the four 10-32 hex nuts (the smaller of the

two sizes) until the gasket compresses.

b

Apply the two 6" long

gaskets along the

outside of the studs

d

3/8" Nutdriver

Left side panel

Do not over-tighten

the nuts – this may

cause damage to

the enamel finsih.

c

Attach each Forward Mounting

Bracket with two 10-32 nuts.

2 Follow the instructions below to install the side and top panels.

b

Lay the top panel on a non-

a

scratching surface upside down.

Slide the top and side panels into place,

making sure they go underneath the wires

and gas line.

Top panel

c

Attach the forward brackets of

the top panel to the heater with

the two black screws.

Standard

Screwdriver

d

Attach the side panels to the heater

with four 1/4-20 hex nuts (reach in

from the rear of the heater with a

7/16" wrench to tighten).

a

Route the on/off switch and blower

wires to the right rear of the heater.

7/16" Wrench

Page 8

PAGE 8 STOVE INSTALLATION (CONT.) - For Qualified Installers Only!

A

A

A

A

A

A

A

3 Slide the nine U-Nuts into place (see the illustration below).

4 Install the on/off switch (see the illustration below).

? If installing a thermostat or remote control, do so now (see pages 46 & 47).

5 Disconnect the power cord, insert it through the rear panel, and re-attach it to the molex connector

leading from the heater (see the illustration below).

6 Attach the rear panel to the heater (see the illustration below).

Slide the nine U-Nuts onto the holes

on the top and side panels (with the

flat portion out).

U-Nut

Back of Heater

Jumper Wire

(leave in place)

Disconnect the on/off switch from the red and brown wires

leading from the heater. Insert the switch into the hole in

the upper left of the rear panel until it locks in place. Reattach the red and brown wires (orientation does not

matter).

Rear Panel

Molex

Connection

Disconnect the power cord, insert it through the rear panel, and

re-attach it to the molex connector leading from the heater.

5/16" Nutdriver

Attach the rear panel to the

heater with the twelve 10-24

self-tapping screws. Use a

5/16" nutdriver to tighten.

Page 9

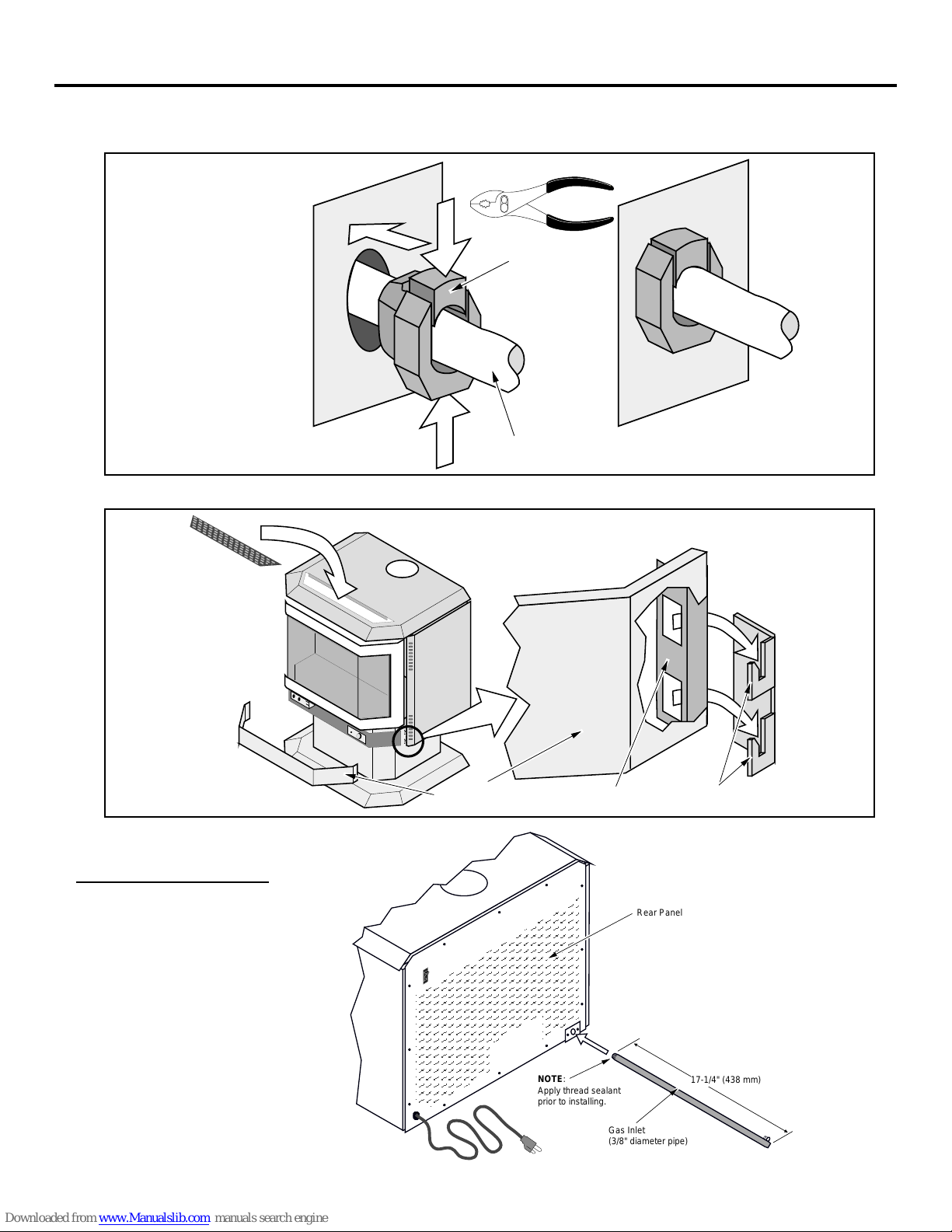

STOVE INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 9

6 Pull gently on the power cord to take out any extra slack. Attach the strain relief (it is shipped

attached to the power cord - see the illustration below).

TO INSTALL THE

STRAIN RELIEF

Compress the strain

relief from the top and

bottom and insert it

into the hole until it

locks in place.

7 Attach the control cover by sliding it over the attachment hooks. Place the black grill in place.

Strain Relief

Power Cord

Grill

s Inlet Installation

• Apply thread sealant to

one end of the gas inlet

and insert it through the

rear panel and into the

90° elbow on the gas

control valve. Tighten

with a pipe wrench.

! Leak check all gas line

connections.

The control cover hangs on two sets of hooks on both sides. Align

the control cover and slide the bracket onto the hooks and then

move downwards.

Control Cover

Bracket on

Control Cover

NOTE:

Apply thread sealant

prior to installing.

Hooks on Side of Heater

Rear Panel

17-1/4" (438 mm)

Gas Inlet

(3/8" diameter pipe)

Page 10

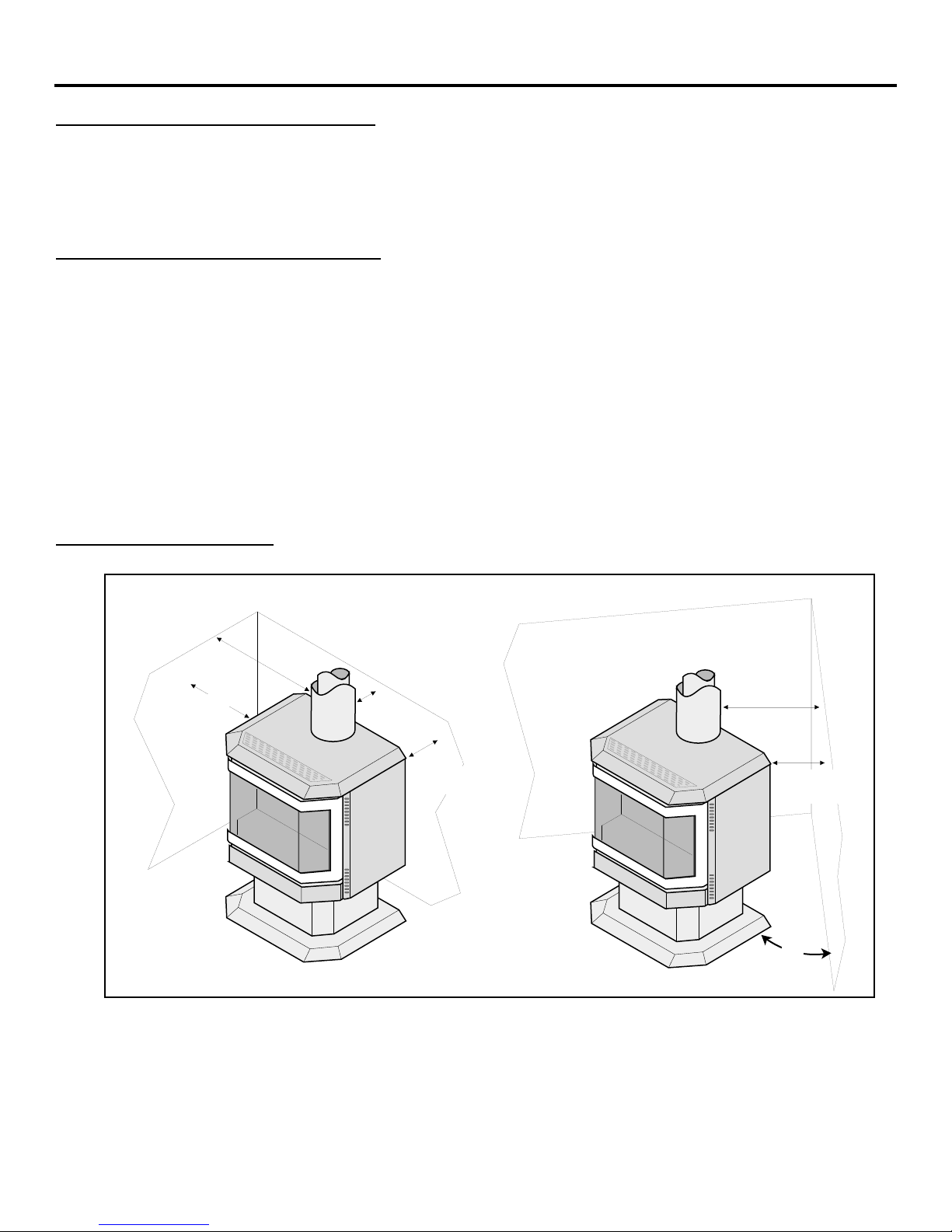

PAGE 10 STOVE INSTALLATION (CONT.) - For Qualified Installers Only!

Floor Protection Requirements

• When the stove is installed directly on carpeting, vinyl or other combustible material other than

wood flooring, the stove must be installed on a metal or wood protection panel extending the full

width and depth of the pedestal (Minimum 24-1/2" (622 mm) wide by 20" (508 mm) deep).

Stove Placement Requirements

• Heater must be installed on a level surface capable of supporting the heater and vent

• Due to the high temperature of the heater, it should be located out of traffic and away from furniture

and draperies. Heater must be placed so no combustibles are within, or can swing within 36" (910

mm) of the front of the heater (e.g. drapes, doors)

? When placed in a location where the floor to ceiling height is under 7 feet (2130 mm), the

installation is considered an alcove and must meet the following requirements:

• The alcove floor to ceiling height must be at least 58" (1470 mm) tall

• The alcove must not be more than 48" (1220 mm) deep before the ceiling returns to 7' (2130 mm)

• The alcove must be at least 44-1/2" (1130 mm) wide

• The stove must not be placed so the vents below or above the door, along the sides of stove, or along

the back of the heater can become blocked.

Minimum Clearances

Straight Installations Corner Installations

10" Min.

(254 mm)

When installed with

this clearance, the

vent is 4-1/4" (108

mm) from the back

wall, 19" (483 mm)

from the side wall.

3" Min.

(76 mm)

When installed with

this clearance, the

vent is 12-3/4" j(324

mm) from the wall.

4" Min.

(102 mm)

45°

Page 11

STOVE INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 11

Gas Line Install

! The gas line must be installed in accordance with all local codes, if any; if not, follow ANSI Z223.1

and the requirements listed below.

! The heater and gas control valve must be disconnected from the gas supply piping during any

pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPA). For pressures under

1/2 psig (3.45 kPA), isolate the gas supply piping by closing the manual shutoff valve.

• Leak test all gas line joints and the gas control valve prior to and after starting the heater.

uel

• This heater is designed for natural

gas but can be converted to propane.

Check the sticker on the top of the

gas control valve to make sure the

correct fuel is used.

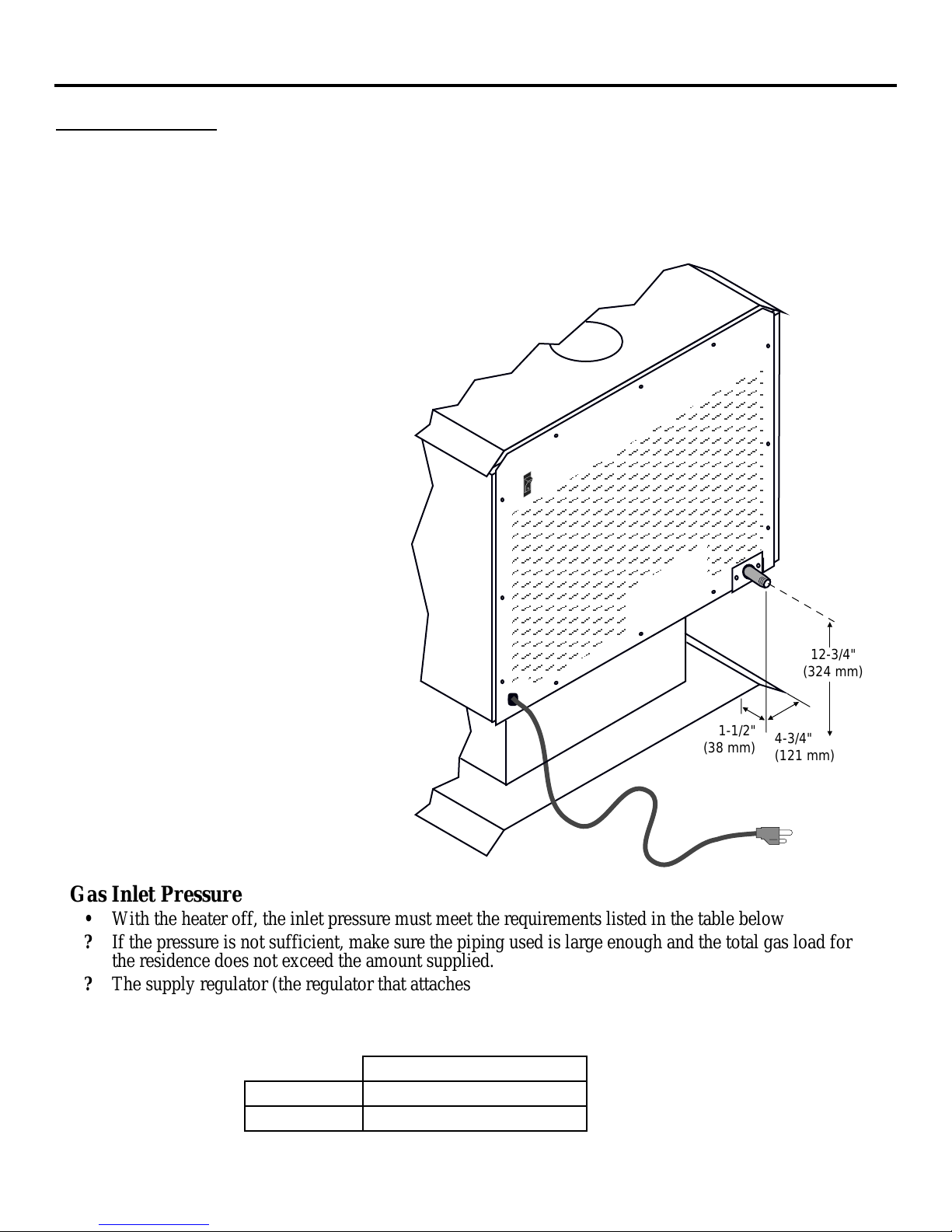

as Line Connection

• The gas inlet accepts a 3/8" F.P.T.

Fitting

• The location of the gas inlet is

shown to the right

• A manual shutoff valve is required

for installation (it must be located

within 3' (910 mm) of the heater)

12-3/4"

(324 mm)

1-1/2"

(38 mm)

4-3/4"

(121 mm)

Gas Inlet Pressure

• With the heater off, the inlet pressure must meet the requirements listed in the table below

? If the pressure is not sufficient, make sure the piping used is large enough and the total gas load for

the residence does not exceed the amount supplied.

? The supply regulator (the regulator that attaches directly to the residence inlet or to the propane tank)

should supply gas at the suggested input pressure listed below. Contact the local gas supplier if the

regulator is at an improper pressure.

Standard Input Pressure

Natural Gas 7" W.C. (1.74 kPA)

Propane 11" W.C. (2.73 kPA)

Page 12

PAGE 12 STOVE INSTALLATION (CONT.) - For Qualified Installers Only!

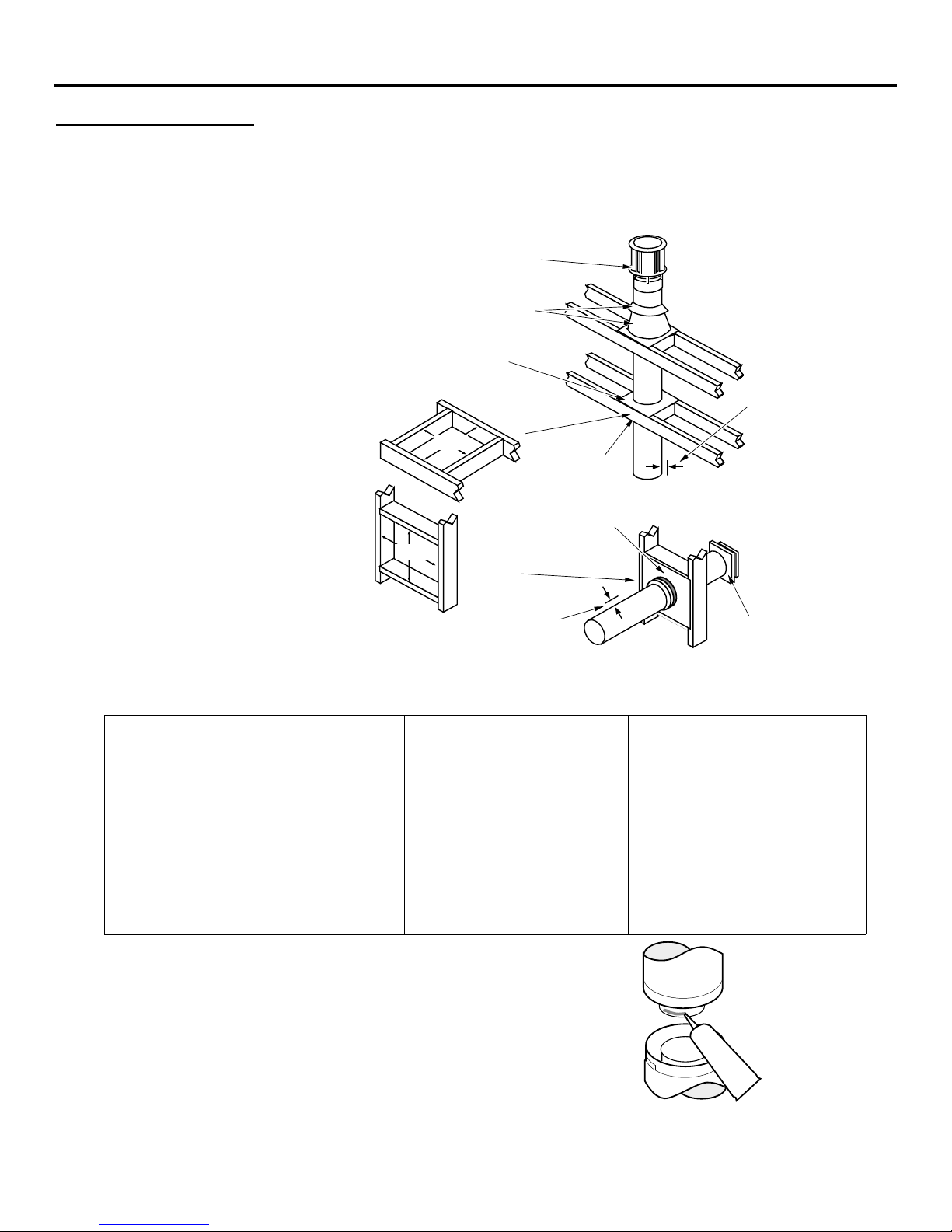

Vent Requirements

! Always maintain the required 1" clearance (air space) to combustible materials to prevent a fire

hazard. Do not fill air spaces with insulation.

! The gas appliance and vent system must be vented directly to the outside of the building, and never

be attached to a chimney serving a separate solid fuel or gas-burning appliance. Each direct vent gas

appliance must use it's own separate vent system.

8-5/8"

(220 mm)

Vertical Termination

(Duravent Part # 991)

Minimum framing

for fire stop

8-5/8"

(220 mm)

Minimum

Framing for

wall thimble

Use a support box

on exposed vent

Use a wall thimble

whenever passing

through a wall

(Duravent Part #942)

Vertical Vent

Requirements

Maintain a minimum 1"

(25 mm) clearance from

vent to any combustible

(vent is 6 5/8" (170 mm)

diameter)

Horizontal Vent

Requirements

! If the stove is installed at an

altitude over 3,000 feet

(1,000 M) the flame quality

will need to be carefully

evaluated. See Addendum

#1, "Altitude

Considerations", on page 38.

• When the vent passes through

a wall, a wall thimble is

required. When the vent

passes through a ceiling, a

support box or firestop is

required. When the vent

passes through the roof, a

roof flashing and storm collar

are required. Follow the

instructions provided with the

Use a roof flashing and storm collar

whenever passing through the roof

(Duravent Part #953 & #943 or #943S)

Use a firestop spacer whenever

passing through a ceiling

(Duravent Part #963)

vent (from Duravent®) for

installing these items.

Maintain a minimum 1" (25 mm)

clearance from vent to any combustible

(vent is 6 5/8" (170 mm) diameter)

Horizontal Termination

(Duravent Part #984)

• Use Model GS Direct Vent manufactured by Simpson Dura-Vent only (or the Chimney Conversion

Kit - see Addendum #2). Follow the installation instructions included with the vent. For the nearest

Simpson Dura-Vent supplier, call (800) 835-4429. Part numbers and descriptions are listed below.

Straight Lengths

908B 6" Pipe Length, Black (interior)

907B 9" Pipe Length, Black (interior)

906 12" Pipe Length, Galvanized

906B 12" Pipe Length, Black (interior)

904 24" Pipe Length, Galvanized

904B 24" Pipe Length, Black (interior)

903 36" Pipe Length, Galvanized

903B 36" Pipe Length, Black (interior)

902 48" Pipe Length, Galvanized

902B 48" Pipe Length, Black (interior)

911B 11" to 14 5/8" Pipe, Adjustable, Black (interior)

• Apply high-temperature silicone to the male section of inner

pipe (on the upper section of vent) so the silicone seals the

inner pipe from the outer pipe when the sections are

assembled. Slide the sections together and turn 1/4 turn until

the sections lock in place. Install three metal screws through

each joint to lock the outer section in place (see the

Vent Terminations

981 Snorkel Termination (36" rise)

(for basement or raised

termination installations)

982 Snorkel Termination (14" rise)

(for basement or raised

termination installations)

984 Horizontal Square Termination

950 Vinyl Siding Standoff

991 Vertical Termination

Elbows

990 90• Elbow

990B 90• Elbow, Black (interior)

945 45° Elbow

945B 45° Elbow, Black (interior)

Penetration, Support Parts

942 Wall Thimble

941 Cathedral Ceiling Support Box

943 Flashing, 0/12 to 6/12 Roof Pitch

943S Flashing, 7/12 to 12/12 Roof Pitch

953 Storm Collar

963 Ceiling Firestop

988 Wall Strap

Apply a 1/8" (3 mm)

bead of hightemperature silicone

to the inner pipe.

The silicone must

seal the inner pipe

Silicone

from the outer pipe.

instructions included with the vent for further details).

• Horizontal sections require a 1/4" rise every 12" of travel

+ Exterior Vent Diameter = 6-5/8", Inner Vent Diameter = 4"

• Horizontal sections require non-combustible support every three feet (e.g.: plumbing tape)

• Seal the inner vent to the appliance.

Page 13

STOVE INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 13

Approved Vent Configurations

estrictor Position

• A vent restrictor is built

into the appliance to

adjust the flow rate of

exhaust gases. This

ensures proper flames

for the wide variety of

vent configurations. The

restrictor consists of a

butterfly valve below the

starter section of pipe

and an adjustment plate

with index holes used to

hold the valve in a fixed

position. Depending

upon the vent

configuration, you may

be required to adjust the

restrictor position. The

charts for approved vent

configurations describe

which position the vent

restrictor must be in.

To Adjust the Restrictor:

1

Determine the correct

restrictor position (see the

charts under "Approved

Vent Configurations" - the

stock position is #1).

2

Remove the screw with a

1/4" nutdriver (or

screwdriver).

3

Rotate the adjustment plate

clockwise until the correct

index hole is below the pivot

point.

4

Insert the screw into the

correct index hole and

tighten.

The eleven holes on the

restrictor plate

correspond to the eleven

restrictor positions.

NOTE:

Position #1 is the

fully open position

Adjustment

Plate

1/4" Nutdriver

Screw

1

2

Pivot Point

11

10

8

7

6

5

4

3

9

Rotate the

adjustment

plate to change

the restrictor

position.

Index Holes

This restrictor is

in Position #5.

lbows

• 2 Elbow

maximum

(two 45° or

two 90°, not

one 45° and

one 90°)

easuring Vent

engths

Elbows add 3" (75 mm) to the

length of the vent system.

Side

View

9-5/8"

(245 mm)

3" (75 mm)

1-1/2" (37 mm)

Vent sections overlap each

other by 1-1/2" (37 mm)

Vent Length

(3', 4', etc.)

(910, 1210 mm)

1-1/2"

(37 mm)

Vent Height is

calculated to the

top of the vent on

horizontal

terminations and

to the top of the

termination on

vertical

terminations.

Vent

Height

Vent Horizontal Run

(measure from the closest

edge of the starter section to

the end of the termination)

12-3/8" (310 mm) tall

with 1-1/2" (37 mm)

of overlap

8-3/4" (220 mm) wide

with 1-1/2" (37 mm)

to 3-3/8" (85 mm) of

overlap

The starter section is 7/8"

(22 mm) below the top (if

using the flue collar

extension, if is 2-5/8" (67

mm) above the top panel)

Page 14

PAGE 14 STOVE INSTALLATION (CONT.) - For Qualified Installers Only!

m

m

)

)

)

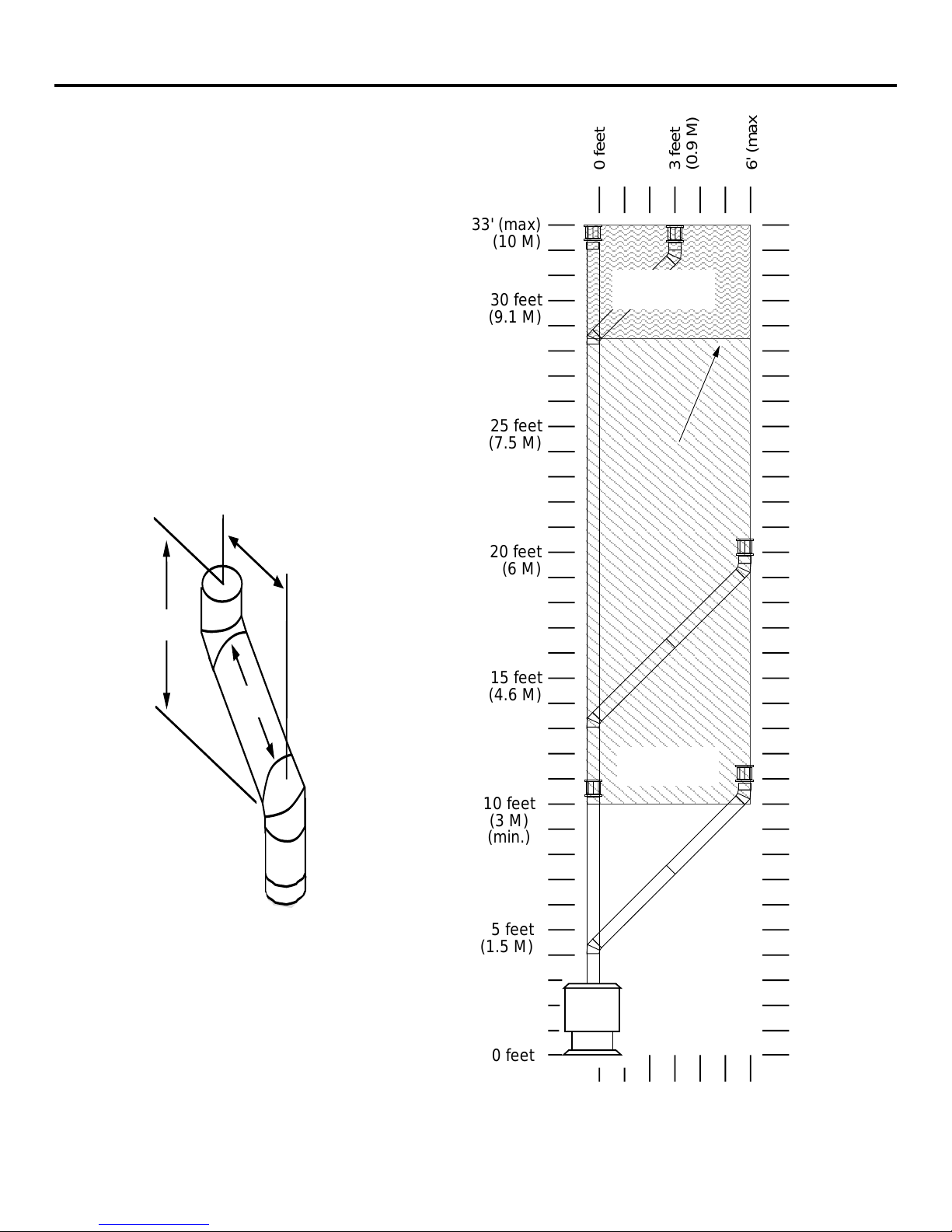

pproved Venting Configurations for

ertical Terminations with (or without)

wo 45° Elbows

0 feet

3 feet

(0.9 M)

6' (max)

(1.8 M)

• 10' (3 M) Minimum System Height

(with or without offsets)

• 33' (10 M) Maximum System Height

• 6' (1.8 M) Maximum Offset

• The termination must fall within the shaded

area shown in the chart. Use the indicated

restrictor position.

• If using offsets, use the table below to

calculate the vertical rise and horizontal

offset

Horizontal

Offset

Vertical

Rise

33' (max)

(10 M)

30 feet

(9.1 M)

25 feet

(7.5 M)

20 feet

(6 M)

Restrictor

Position # 7

NOTE:

Restrictor positions

are based upon lab

tests. The ideal

restrictor position

may vary slightly,

especially when the

termination is near

a demarkation line.

33' (max)

(10 M)

30 feet

(9.1 M)

25 feet

(7.5 M)

20 feet

(6 M)

Offset

Length

Offset Length Hor. Offset Vert. Rise

None 5" (125 mm) 1' (300 mm)

1' Section 1' (300 mm) 1' 7" (480 m

2' Section 1' 9" (530 mm) 2' 4" (710 m

3' Section 2' 5" (740 mm) 3' (915 mm)

4' Section 3' 2" (965 mm) 3' 8" (1.12 M

4' + 1' Section 3' 9" (1.14 M) 4' 4" (1.32 M

4' + 2' Section 4' 6" (1.37 M) 5' (1.52 M)

4' + 3' Section 5' 2" (1.57 M) 5' 9" (1.75 M

15 feet

(4.6 M)

10 feet

(3 M)

(min.)

5 feet

(1.5 M)

0 feet

Restrictor

Position # 5

The maximum

offset lengths is

two 4' sections.

Do not place an

offset directly off the

top of the heater.

0 feet

3 feet

(0.9 M)

15 feet

(4.6 M)

10 feet

(3 M)

(min.)

5 feet

(1.5 M)

0 feet

(1.8 M)

6' (max)

Page 15

STOVE INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 15

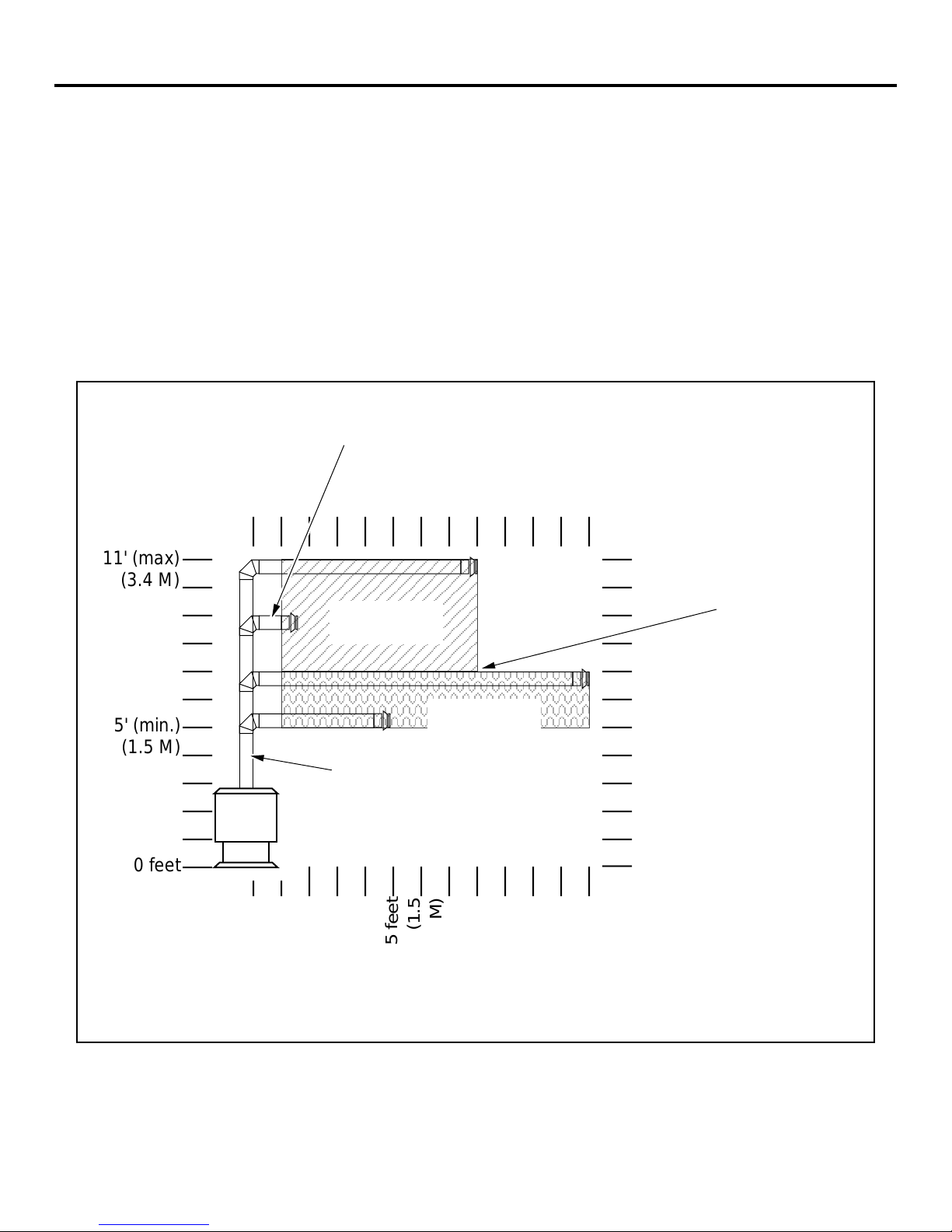

Approved Venting Configurations with a Horizontal Termination

• A Minimum of 2' (.5 M) rise is required directly off of the stove

• A minimum of 1' (.3 M) run is required

• If using a Snorkel Termination (14"[.4 M] or 36" [.9 M]) add the snorkel height to the vertical

height.

• The termination must fall withinin the shaded area shown in the chart. Use the indicated restrictor

position.

NOTE:

A minimum 1' (.3 M)

horizontal run is required.

11' (max)

(3.4 M)

5' (min.)

(1.5 M)

0 feet

0 feet

0 feet

5 feet

(1.5

M)

Restrictor

Position # 5

Restrictor

Position # 1

NOTE:

A minimum 2' (.5 M) rise is

required directly off of the stove.

M)

(1.5

5 feet

12'(max)

(3.7 M)

11' (max)

(3.4 M)

5' (min.)

(1.5 M)

0 feet

12'(max)

(3.7 M)

NOTE:

Restrictor positions

are based upon lab

tests. The ideal

restrictor position may

vary slightly,

especially when the

termination is near a

demarkation line.

NOTE:

Horizontal sections require a 1/4" (6 mm) rise every 12" (300 mm) of travel.

Page 16

PAGE 16 STOVE INSTALLATION (CONT.) - For Qualified Installers Only!

Approved Venting Configurations for Vertical Terminations with Two 90° Elbows

• The termination must fall within the shaded area shown in the chart. Use the indicated restrictor position.

35' (max)

(10.7 M)

30 feet

(9.1 M)

25 feet

(7.5 M)

20 feet

(6 M)

15 feet

(4.6 M)

0 feet

Restrictor

Position # 7

5 feet

(1.5 M)

10 feet

Restrictor

Position #6

Restrictor

Position # 5

Restrictor

Position # 4

(3 M)

16'(max)

(4.9 M)

35' (max)

(10.7 M)

30 feet

(9.1 M)

25 feet

(7.5 M)

20 feet

(6 M)

15 feet

(4.6 M)

NOTE:

The vent

must

terminate

within one

of the

shaded

regions.

11 feet (min.)

10 feet

(3 M)

8 feet (min.)

(2.4 M)

5 feet

(1.5 M)

0 feet

0 feet

NOTE:

Restrictor positions are

based upon lab tests.

The ideal restrictor

position may vary

NOTE:

A min. 8' (2.4 M) of vertical

vent must be used.

NOTE:

Horizontal sections require a 1/4" (6 mm)

rise every 12" (300 mm) of travel.

5 feet

(1.5 M)

slightly, especially when

the termination is near a

demarkation line.

(3 M)

10 feet

10 feet

(3 M)

8 feet (min.)

(2.4 M)

5 feet

(1.5 M)

0 feet

(4.9 M)

16'(max)

Page 17

STOVE INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 17

Horizontal Vent Termination Requirements (see the illustration below)

A Minimum 9" (225 mm) clearance from any door or window

B Minimum 12" (300 mm) above any grade, veranda, porch, deck or balcony

C Minimum 12" (300 mm) from outside corner walls

D Minimum 12" (300 mm) from inside corner walls

E Minimum 11" (275 mm) clearance below unventilated soffits or roof surfaces

Minimum 18" (450 mm) clearance below ventilated soffits

Minimum 6" (150 mm) clearance from roof eaves

NOTE: Vinyl surfaces require 24" (600 mm)

F Minimum 18" (450 mm) clearance below a veranda, porch, deck or balcony (must have two open sides)

G Minimum 48" (1220 mm) clearance from any adjacent building

H Minimum 84" (2130 mm) clearance above any grade when adjacent to public walkways or driveways

NOTE: may not be used over a walkway or driveway shared by an adjacent building

I Minimum 48" (1220 mm) clearance from any mechanical air supply inlet, 72" (1820 mm) for Canada

J Minimum 36" (910 mm) clearance above and 48" (1220 mm) below and to the sides of non-mechanical air supply inlet

K Minimum 36" (910 mm) from the area above the meter/regulator (vent outlet)

L Minimum 36" (910 mm) from the meter/regulator (vent outlet)

Roof

Surface

11” Min.

6” Min.

Roof

Eaves

E

E

K

G

NOTE: Measure clearances to the nearest edge of the exhaust hood.

F

D

A

I

C

L

B

A

J

• Use the vinyl siding standoff (#950) when installing on an exterior with vinyl siding.

• Vent termination must not be located where it will become plugged by snow or other material

• These clearances meet UMC-1994 and the CNA/CGA-B149 code standards

Vertical Vent Termination Requirements (see the illustration below)

Use the vertical

termination (Part #991)

Use the

chart to the

right to

determine

the required

vent

termination

height.

Roof

Pitch

Height

Roof Pitch

Flat to 6/12

6/12 to 8/12

8/12 to 9/12

9/12 to 10/12

10/12 to 11/12

11/12 to 12/12

12/12 to 14/12

14/12 to 16/12

16/12 to 18/12

18/12 to 20/12

20/12 or greater

Minimum Height*

1' (.3 M)*

1.5' (.45 M)*

2' (.6 M)

2.5' (.75 M)

3.25' (1 M)

4' (1.2 M)

5' (1.5 M

6' (1.8 M)

7' (2.15 M)

7.5' (2.25 M)

8' (2.45 M)

* In Canada the

vent termination

must be a

minimum 2' (.6 M)

tall and 2' (.6 M)

above any portion

of the roof within

10' (3 M) of the

vent.

H

Electrical Connection

• Plug the power cord into a grounded 120 Volt outlet (do not remove the grounding plug).

Page 18

PAGE 18 INSERT INSTALLATION - For Qualified Installers Only!

Installation Preparation

! Failure to follow all of the requirements may result in property damage, bodily injury, or even death.

! This appliance must be installed in accordance with all local codes, if any; if not, follow ANSI

Z223.1 and NFPA 54(88).

! In Manufactured or Mobile Homes must confirm with: In USA, Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280; In Canada, CSA Z240.4 and Gas-Equipped

Recreational Vehicles and Mobile Housing. This appliance may be installed in Manufactured

Housing only after the home is site located.

! This appliance is designed for natural gas or propane (LP). Check the sticker on top of the gas

control valve.

! All exhaust gases must be vented outside the structure of the living-area. Combustion air is drawn

from outside the living-area structure.

! Notify your insurance company before hooking up this appliance.

! The requirements below are divided into sections - all requirements must be met simultaneously.

Items Required for Installation

• Avanti Insert Shell and Surround Panels

• Direct Vent Insert Adapter (see page 22)

• Gas Hookup Equipment

Items Packed with the Avanti DV

• Avanti DV (with gold door)

• Log Set (2 Logs, 2 Twigs, Embers)

• Two Gas Inlet Pipes (the shorter one is for inserts)

• Owner's Manual

• Propane Conversion Kit

• Flue Collar Extension (not used for insert installations)

• Strain Relief (for power cord)

• Strain Relief Bracket

Items Packed with the Insert Panel Kit

• Top, Left, and Right Surround Panels

• Two Leveling Bolts

Items Packed with the Insert Shell Kit

• Upper Top

• Control Cover

Order of Installation

1 If the heater is to use propane, install the propane

conversion kit (see pages 40 - 45)

2 Install the gas inlet (8-3/4" (222 mm) length of 3/8" pipe)

3 Install the power cord

4 Position the heater (see "Heater Placement")

5 Connect the gas line. Connect the gas vent.

Installing the Gas

Inlet

• Locate the 8-3/4" (222

mm) gas inlet pipe

included with the

heater (the longer one

may be discarded).

Apply thread sealant to

one end and insert it

through the rear of the

insert into the 90°

elbow on the gas

control valve (see the

illustration below).

Tighten with a pipe

wrench.

Back of

Heater

NOTE:

Apply thread sealant

prior to installing.

8-3/4" (222 mm)

Gas Inlet

(3/8" diameter pipe)

• Trim Kit (3 pieces trim, 2 "L" brackets, set screws, double-

back tape)

• Hardware Pack (2 Upper Top Brackets, 4 6-32 Nuts, 2 10-24

Phillips Screws)

6 Install the logs and test the heater (see the instructions

under "Finalizing the Installation")

7 Install the insert panel kit.

8 Install the insert shell kit.

9 Follow the instructions under "Finalizing the

Installation" on pages 26 through 29.

NOTE:

With the insert in

place, the gas line

center is located

4-1/4" (108 mm)

back from the

fireplace opening,

1-5/8" (41 mm)

above the hearth,

and 7-1/2" (191

mm) from the

center of the

insert.

Insert the gas inlet through

here and into the elbow directly

off the gas control valve.

Page 19

INSERT INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 19

Installing the Power Cord

1 The power cord may be located on either side. Place the strain relief bracket (included in the owner's

pack) over the two studs and tighten with two 1/4-20 hex nuts (see illustration below).

Back of

Heater

Molex

Connection

7/16" Nutdriver

Attach the strain relief bracket

with two 1/4-20 hex nuts.

Disconnect the power cord, insert it through the rear panel, and

re-attach it to the molex connector leading from the heater.

2 Pull gently on the power cord to take out any extra slack. Attach the strain relief (it is shipped

attached to the power cord - see the illustration below).

TO INSTALL THE

STRAIN RELIEF

Compress the

strain relief from

the top and

bottom and

insert it into the

hole until it locks

in place.

Strain

Relief

Power Cord

Page 20

PAGE 20 INSERT INSTALLATION (CONT.) - For Qualified Installers Only!

Insert Placement

Min. 27-3/4" (705 mm) WIde - includes

6" (150 mm) for gas line installation

Min. 21-1/2"

(550 mm) Tall includes 2" (50

mm) for vent

installation

The gas line faces to the rear

and its center is 4-1/4" (108 mm)

back from the fireplace opening,

1-5/8" (41 mm) above the

hearth, and 7-1/2" (191 mm)

from the center of the insert.

Run the power cord to

either side of the insert

along the facing.

The insert must be in place with

the gas line and vent attached

prior to installing the panels.

The Insert Must be

Placed 11-1/4" (286 mm)

into the Fireplace.

NOTE:

When using the 45° vent, an

additional 4" (100 mm) is

required behind the rear

edge of the baseplate for

vent hook-up.

Use the leveling bolts for

fireplaces with recessed

floors (included with the

surround panels).

Run the brown and red

wire (for the on/off switch)

to the right side along the

facing.

• Insert must be placed so no combustibles are within, or can swing within 36" (910 mm) of the front

of the heater (e.g. drapes, doors)

• The insert may be placed inside a masonry fireplace or listed zero-clearance (metal) fireplace

• The insert must be installed in a level, undamaged fireplace (damage must be repaired prior to

installation).

• The insert must maintain 10" (254 mm) clearance to sidewalls (measure from the upper top)

• Non-combustible facing (e.g. brick, tile) must extend 8" (203 mm) minimum from the side and 12"

(305 mm) to the top of the insert (measure from the upper top)

• Combustible mantles must be a minimum 17-1/2" (445 mm) above the top of the insert (measure

from the upper top)

Floor Protection

• The heater must be installed on a non-combustible hearth and may not extend over combustible

flooring

Page 21

INSERT INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 21

Gas Line Install

! The gas line must be installed in accordance with all local codes, if any; if not, follow ANSI Z223.1

and the requirements listed below.

! The heater and gas control valve must be disconnected from the gas supply piping during any

pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPA). For pressures under

1/2 psig (3.45 kPA), isolate the gas supply piping by closing the manual shutoff valve.

• Leak test all gas line joints and the gas control valve prior to and after starting the heater.

Gas Line Connection

• The gas inlet accepts a 3/8" F.P.T. Fitting

• The location of the gas inlet is shown below

• A manual shutoff valve is required on the gas line within 3' (910 mm) of the heater

Back of

Heater

NOTE:

With the insert in place, the gas line

center is located 4-1/4" (108 mm)

back from the fireplace opening,

1-5/8" (41 mm) above the hearth,

and 7-1/2" (191 mm) from the center

of the insert.

Fuel

• This heater is designed for natural gas but can be converted to propane. Check the sticker on the top

of the gas control valve to make sure the correct fuel is used.

Gas Inlet Pressure

• With the heater off, the inlet pressure must meet the requirements listed in the table below

? If the pressure is not sufficient, make sure the piping used is large enough and the total gas load for

the residence does not exceed the amount supplied.

? The supply regulator (the regulator that attaches directly to the residence inlet or to the propane tank)

should supply gas at the suggested input pressure listed below. Contact the local gas supplier if the

regulator is at an improper pressure.

Natural Gas 7" W.C. (1.74 kPA)

Propane 11" W.C. (2.73 kPA)

Standard Input Pressure

Page 22

PAGE 22 INSERT INSTALLATION (CONT.) - For Qualified Installers Only!

Vent Requirements

! The gas appliance and vent system must be vented directly to the outside of the building, and never

be attached to a chimney serving a separate solid fuel or gas-burning appliance. Each direct vent gas

appliance must use it's own separate vent system.

! Make sure the exhaust pipe (the inner pipe) on the heater connects to the exhaust portion of the cap

(the inner pipe). The illustrations below show how the flex liners should be attached.

! If the heater is

installed at an

altitude over 3,000

(1,000 M) feet the

flame quality will

need to be carefully

evaluated. See

Addendum #1,

"Altitude

Considerations", on

page 49.

? When using flexible

gas vent, do not

crimp or rupture the

liner when bending it

into chimney offsets

• When installed, the

vent must meet all of

the vent

manufacturer's

requirements

+ There are two

options for vent

installation:

Flex Re-Line

(Full Re-Line or Exhaust

Only Re-Line):

• Appliance Connector

(Part # 923TCL)

• 3" (75 mm) Listed

B-vent liner

• Termination Kit

(part # 923GK).

• Vertical Termination

(part # 991)

• Block-Off Plate

Co-Axial & Flex:

• Appliance Connector

(Part # 923TCL)

• 3" (75 mm) Listed

B-vent liner

• Block-Off Plate

• Termination Kit

(part # 923GK).

• Dura-Vent Co-Axial Vent and

Cap (see pg 8 for part #'s).

3" (75 mm)

B-vent liner

Zero Clearance

(Metal) Fireplace

(may be used

with a masonry

fireplace as well)

Zero Clearance

(Metal) Fireplace

Listed

Co-Axial Vent Re-Line

3" (75 mm)

B-vent liner

Listed

Dura-Vent Termination Kit

Exhaust Only

You may terminate the inlet

above the a block-off plate

that is sealed air-tight to the

walls of the fireplace and to

the vents. Combustion air is

then drawn down the

chimney. Any cracks or

damage inside the chimney

must be repaired.

Optional Block-Off Plate

(non-combustible)

Dura-Vent Appliance

Connector (Part # 923TCL)

High-Temp.

Silicone

Z.C. (Metal) firebox

Direct Vent Cap

(part # 991)

(part # 923GK)

Re-Lines

Optional cover plate

Dura-Vent Termination Kit

High-Temp.

Connector (Part # 923TCL)

Silicone

Seal the adapter box to the heater

with high-temperature silicone

(seal the outside only)

Z.C. (Metal)

firebox

Direct Vent Cap

(part # 991)

to keep rain out.

Direct Vent

Sections

(part # 923GK)

Block-Off Plate

(non-combustible)

Dura-Vent Appliance

Masonry

Fireplace

High-Temp.

Silicone

Apply high-temperature

silicone to the 3" (75

mm) outlets on both

adapter boxes. Install

the flex duct and secure

with 2 screws.

High-Temp.

Silicone

Seal the adapter to the

heater with hightemperature silicone

(seal the outside only)

Apply a 1/8" (3 mm)

bead of high-

High-Temp.

Silicone

Apply high-temperature

silicone to the 3" (75 mm)

flex duct at both ends.

Install the flex duct and

secure with 2 screws.

temperature silicone

to the inner pipe.

The silicone must

seal the inner pipe

from the outer pipe.

High-Temp.

Silicone

Page 23

INSERT INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 23

Approved Vent Configurations

Restrictor Position

• A vent restrictor is

built into the

appliance to adjust

the flow rate of

exhaust gases. This

ensures proper

flames for the wide

variety of vent

configurations. The

restrictor consists of

a butterfly valve

below the starter

section of pipe and

an adjustment plate

with index holes

used to hold the

valve in a fixed

position. Depending

upon the vent

configuration, you

may be required to

adjust the restrictor

position. Use the

illustrations below to

determine the correct

restrictor position

To Adjust the Restrictor:

1

Determine the correct

restrictor position (see the

charts under "Approved

Vent Configurations" - the

stock position is #1).

2

Remove the screw with a

1/4" nutdriver (or

screwdriver).

3

Rotate the adjustment plate

clockwise until the correct

index hole is below the pivot

point.

4

Insert the screw into the

correct index hole and

tighten.

The eleven holes on the

restrictor plate

correspond to the eleven

restrictor positions.

NOTE:

Position #1 is the

fully open position

Adjustment

Plate

1/4" Nutdriver

Screw

1

2

Pivot Point

11

10

8

7

6

5

4

3

9

Rotate the

adjustment

plate to change

the restrictor

position.

Index Holes

This restrictor is

in Position #5.

Full Flex Re-Line Co-Axial Vent Re-Line

Max. Ht. 30' (9.1 M)

Min. Ht. 10' (3 M)

10' (3 M) - 24' (7.3 M)

Use restrictor position 7

24' (7.3 M) - 30' (9.1 M)

Use restrictor position 5

Max. Ht. 30' (9.1 M)

Min. Ht. 10' (3 M)

10' (3 M) - 16' (4.9 M)

Use restrictor position 5

16' (4.9 M) - 30' (9.1 M)

Use restrictor position 7

1' offset

(max.)

Electrical Connection

• Plug the power cord into a grounded 120 Volt outlet (do not remove the grounding plug).

1' (.3 M)

maximum

offset

Page 24

PAGE 24 INSERT INSTALLATION (CONT.) - For Qualified Installers Only!

)

)

Surround Panel Installation

+ The surround panels come in the variety of sizes and colors listed below

COLOR PANEL SIZE WIDTH HEIGHT PART #

Black (Paint) 8" x 10" 40-3/8" (1026 mm) 28-7/8" (733 mm) 99300410

Black (Paint) 10" x 13" 44-3/8" (1127 mm) 31-7/8" (810 mm) 99300420

Almond (Enamel

Almond (Enamel

Green (Enamel) 8" x 10" 40-3/8" (1026 mm) 28-7/8" (733 mm) 99300412

Green (Enamel) 10" x 13" 44-3/8" (1127 mm) 31-7/8" (810 mm) 99300422

1 The insert must be in place with the gas line and vent attached prior to installing the panels. The rear

edge of the insert must be 11-1/4" (286 mm) behind the facing of the fireplace for the panels to fit

correctly.

2 Run the power cord to either side of the insert along the facing.

3 Locate the two red wires leading to the on/off switch (they can be found on the right side of the

insert near the rear). Disconnect the on/off switch from the wires and run the wires to the right side

of the insert. Keep the green jumper wire attached to the on/off switch.

4 Follow the instructions below for installing the panels and trim.

Install each side panel by lining up the two tabs on the side of the insert with the two slots on the side

a

of the panel. Slide each panel over the tabs and downwards to lock in place.

8" x 10" 40-3/8" (1026 mm) 28-7/8" (733 mm) 99300411

10" x 13" 44-3/8" (1127 mm) 31-7/8" (810 mm) 99300421

Install the top panel so the two tabs on the bottom insert into

b

the slots on top of the side panels. The sides may need to be

pulled forward - do not flex panels, the enamel may chip.

Top Trim

"L" Bracket

Top

Panel

Construct the panel trim. Insert

one leg of each "L" bracket into

the top and side trim piece.

Align the trim to form a precise

corner, then tighten the two set

screws with a small standard

Side

Panel

screwdriver. Slide the trim over

the panels. Attach a piece of

included double-back tape to the

bottom of each side trim to keep

it from flaring at the bottom.

Hole for

On/Off

Switch

Top Trim

Slot

Side

Panel

Tab

Tighten the set screws

from the back side with a

small standard screwdriver

c

"L" Bracket

Right Side

Trim

Double-Back Tape

Right Side Trim

Page 25

INSERT INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 25

Surround Panel Installation (continued)

5 Thread the red wires for the on/off switch

through the hole in the upper right of the

panels and trim (thread the wires from the

inside).

? If installing a thermostat or remote control,

install it at this point (see the owner's

manual or the instructions included with

the kit).

6 Attach the two red wires to the top posts of

the on/off switch. Press the switch into the

hole in the panel and trim until it locks in

place.

Insert Shell Installation

+ The insert shell comes in the

following colors

COLOR PART #

Black (Paint) 99200310

Almond (Enamel) 99200311

Green (Enamel) 99200312

Upper

Right of

Trim

Keep the jumper wire in

place while installing.

Disconnect the on/off switch from the

red and brown wires leading from the

heater. Insert the switch into the hole

in the upper right of the panel trim

until it locks in place. Re-attach the

red and brown wires (orientation does

not matter).

1 Place the upper top upside down

against a non-scratching surface.

Attach the two upper top

mounting brackets to the upper

top with the four included nuts

(use a 3/8" nutdriver).

Upper Top

Mounting Brackets

Upper Top

WARNING: Do not

over-tighten the nuts,

this may cause the

enamel to chip or crack.

5/16" Nutdriver

2 Place the upper top on the insert so the flange on the back of the upper top goes over the flange on the

top panel. Push the upper top towards the rear until it forms an even gap with the top panel. Attach

the upper top to the insert with the two screws (use a phillips screwdriver). Install the control cover.

Place the upper top

over this flange.

Insert the two screws the the upper

top mounting brackets and into the

two brackets on the insert.

Phillips

Screwdriver

Hooks on

Side of

Heater

Control Cover

Bracket on Control Cover

Page 26

PAGE 26 FINALIZING THE INSTALLATION - For Qualified Installers Only!

! Turn the gas control valve to "OFF" prior to conducting any service.

1 Follow the directions below to open the door.

Lift the control cover off the heater

Hooks on Side

of Heater

Remove the two screws holding

the door in place.

Control Cover

Swing the door open.

7/16" Nutdriver

Page 27

FINALIZING THE INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 27

2 Install the logs, twigs, and embers.

Burner Pan

The front log rests on

these platforms.

Twig

Installation

These clips keep the rear log

from tilting backwards.

The rear log has a

flat portion that

rests on this ledge.

Log Installation

The front edge of

the front log rests

on this ledge.

The rear log contacts

the air deflectors.

The rear log

protrudes over the

burner pan on both

Rear Log (largest)

Front Log

Slide the front log all the way

back against the air deflector.

sides.

Align the holes

in the left twig

over the pegs

on the front and

back logs.

Ember

Installation

Align the holes

in the right twig

over the pegs

on the left twig

and back log.

Place the embers on this ledge at the

front of the firebox . Do not place the

embers over the burner holes.

! We recommend you purge the gas line at this time (with the glass removed). This allows gas to be

detected once it enters the firebox, ensuring gas does not build up.

Page 28

PAGE 28 FINALIZING THE INSTALLATION (CONT.) - For Qualified Installers Only!

3 Close the door. Make sure the door is centered and the attachment screws are tightened to form a

seal around the door opening.

4 Turn on gas to the heater. Leak test all gas joints prior to starting the appliance. Start the pilot. Start

the main burner. Leak test all gas joints again.

5 Check the pilot flame to make sure it looks like the illustration below. Adjust the pilot flame if

necessary.

The pilot flame should impinge the top 3/8” (10 mm)

of the thermopile. If it does not, you may need to

turn the pilot up.

Thermopile

3/8” (10 mm)

Thermocouple

Pilot Hood

To adjust the pilot flame, remove the cover screw (and

gasket) and turn the needle valve. Clockwise lowers

the flame while counter-clockwise raises it.

ON

OFF

T

P

O

I

L

PILOT ADJ

Cover Screw Gasket

The cover screw and

gasket must be

replaced to prevent gas

from leaking

Needle Valve

Micro (1/16”)

Standard

Screwdriver

Cover Screw

Standard

Screwdriver

Page 29

FINALIZING THE INSTALLATION (CONT.) - For Qualified Installers Only! PAGE 29

6 Let the heater burn for fifteen minutes. Adjust the air shutter, if necessary, to achieve the correct

looking flame (see the illustration below).

• The air shutter adjusts the amount of air that mixes with the gas before it exits the burner holes.

It is used to fine-tune the flame for differences in altitude and vent configuration.

Locate the air shutter adjustment

lever behind the gas control valve.

Move it up or down until the flame

looks correct. Pushing up gives the

flame more air (making it bluer).

Pulling it down cuts air down,

making it more orange.

NOTE: If the air control is all the

way up, yet the flames remain

sooty, shut off gas to the fireplace

and contact a qualified gas service

technician.

ON

PILOT ADJ

Gas Control Valve

P

I

L

OFF

O

T

VENT

HI

LO

NOTE: The logs must be installed correctly to

monitor the flame while adjusting the air shutter.

Correct

Flames should be blue at the

base, yellow-orange on the top.

If the flames are too tall or sooty on

the ends, push up on the lever.

Not Enough Air Too Much Air

If the flames are all blue and

short, pull down the lever.

! If the air shutter is in its fully open position, yet the flames remain sooty, shut off gas to the

heater and contact your Travis Industries Dealer for a remedy.

! If the vent configuration is installed incorrectly the vent may cause the flames inside the fireplace

to lift or "ghost" – a dangerous situation. Inspect the flames after installation to insure proper

performance. If the vent configuration is correct, yet the flames are lifting or ghosting, shut off

gas to the fireplace and contact the dealer for information on remedying the problem.

Burner Ports

(consists of slots

Burner Pan

The flames should burn right off

the top of the burner ports (if they

are too blue, adjust the air control).

If the flames are lifting, yet the

vent configuration is correct,

contact your dealer.

and holes)

If the flames are ghosting, yet the

vent configuration is correct,

contact your dealer.

7 Turn the flame adjust knob to its highest position - the flames should be approximately 12". Check

the flame on low position. The flames should burn off of each burner hole. If the heater does not

work correctly, contact your dealer for a remedy.

8 Give this manual to the home owner and fully explain the operation of this heater.

Page 30

PAGE 30 OPERATING YOUR HEATER

Before You Begin

! Read this entire manual before you use your new stove (especially the section "Safety

Precautions" on pages 2 & 3). Failure to follow the instructions may result in property

damage, bodily injury, or even death.

Location of Controls - See explanation below

ON/OFF

Switch

The on/off switch is located on the

rear panel on stoves, on the top

right surround panel on inserts.

TO ACCESS THE

CONTROLS:

O

N

O

F

F

Grasp the control cover with both

hands and lift it up and off the hooks

that hold it in place. Place it on a

non-scratching surface.

Gas

Control

Valve

ON

T

O

I

L

PILOT ADJ

Gas Control

Knob

OFF

P

VENT

HI

LO

Flame Adjust

Knob

The Pilot Flame can be

found below the back log

on the left side.

PILOT

IGNITER

Pilot Igniter

OFF

LO

Blower Knob

HI

BLOWER

On/Off Switch This control is used to turn the main burner on and off.

Gas Control Knob This knob is used to control gas to the stove and for starting the pilot. There

are three positions, ON, OFF, & PILOT. The pointer directly below the knob

indicates the position this knob is in.

Flame Adjust Knob This knob controls the flame height from low ("LO") to high ("HI"). The

pointer to the upper left of the knob points to the position this knob is in.

Pilot Igniter The pilot igniter is used only to start the pilot. When pressed, it sends an

electrical charge to the pilot assembly. This creates a blue spark directly next

to the pilot, igniting the pilot flame.

Blower Knob This knob controls the speed of the internal convection blower that pushes the

heated air into the room.

? If using a remote control or thermostat, the On/Off Switch must be left "ON". Turning the On/Off

Switch "OFF" will keep the stove off always.

Page 31

OPERATING YOUR HEATER (CONTINUED) PAGE 31

Starting The Pilot Flame

The pilot flame is required to ignite the main burners (it also plays a safety role). It should be

left on once lit. It will stay lit unless the gas control valve is turned to "OFF". However, the

pilot will go out if the gas is shut off or if the stove malfunctions. If the pilot turns off

frequently, call your dealer for information. To start the pilot follow the directions below:

NOTE: IF YOU'RE TRYING TO RE-LIGHT THE PILOT BECAUSE SERVICE WAS

PERFORMED ON THE UNIT (I.E. GAS LINE REMOVED THEN RE-INSTALLED OR

BECAUSE TANK RAN OUT OF GAS), FOLLOW THE INSTRUCTIONS FOR REMOVING

THE GLASS AND LOGS ON PAGES 26 THROUGH 28 THEN BLEED THE GAS LINE.

A Push the gas control knob in

slightly and turn it to the

"OFF" position. The knob

will not turn from "ON" to

"OFF" unless the knob is

depressed slightly.

B Wait five minutes to let any

gas that may have

accumulated inside the

firebox escape. If you smell

gas, follow the directions on

the cover "IF YOU SMELL

GAS".

C Turn the gas control knob to

the "PILOT" position and

press the knob in, this will

allow gas to flow to the pilot

light. Press the red button

on the pilot igniter

repeatedly until you see the

pilot light. KEEP THE GAS

CONTROL KNOB

DEPRESSED FOR 30

SECONDS ONCE IT IS

LIT. NOTE: IF THE

PILOT DOES NOT

LIGHT AFTER 15

SECONDS, RELEASE

THE KNOB AND CALL

YOUR DEALER FOR

SERVICE.

D Release the gas control

knob. If the pilot goes out,

repeat step C. If the pilot

refuses to stay lit, call your

dealer for service.

E Turn the gas control knob

counter-clockwise to "ON".

The pilot is now lit and the

stove can be turned on and

off.

AB

C

D

T

O

L

I

T

T

OFF

P

PILOT ADJ

ON

O

I

L

PILOT ADJ

ON

O

I

L

PILOT ADJ

ON

ON

Do not press knob in for more than

OFF

P

OFF

P

5 minutes

15 seconds if pilot does not light.

Call Your Dealer For Service

PILOT

IGNITER

30 seconds

E

?

OFF

T

P

O

I

L

ON

P

I

OFF

L

O

T

PILOT ADJ

PILOT ADJ

Page 32

PAGE 32 OPERATING YOUR HEATER (CONTINUED)

j

j

Starting the Stove for the First Time

+ Fumes and smoke from the paint curing and oil burning off the steel may occur the first time you

start your stove. This is normal. We recommend you open windows to vent the room.

+ Condensation may appear on the glass each time you start the stove - this is normal.

+ Blue Flames will occur on the stove when it first comes on. After fifteen minutes the flames will

turn a more realistic yellow and orange color.

? Certain installations use a remote "wall switch" to turn the stove on and off. If this is the case, leave

the ON/OFF switch "ON".

Turning the Stove On and Off

After the pilot has been started...

For systems with thermostats,

use this switch to control the

temperature (right is hotter, left

cooler). Some systems

require the on/off switch to be

on.

O

N

O

Use this switch to

turn the main burner

on and off manually.

F

F

See the instructions

included with the

remote for changing

the battery.

See the instructions included

with the remote for details on

operation.

! Do not place any combustible items on top of or directly in front of the stove, even temporarily. The

optional thermostat may start the stove causing a combustible item to ignite.

? If the stove turns on and off frequently while using the thermostat, you may want to adjust the flame

height down until it produces just enough heat needed.

Adjusting the Flame Height

+ Your stove has an adjustable flame to tailor the look and heat output to your specific needs. It is

adjusted by turning the middle dial on the gas control valve.

Flame Height

ustment Knob

Ad

VENT

T

O

PILOT ADJ

ON

OFF

P

L

I

Turn clockwise to ad

Index Mark

VENT

HI

HI

LO

ust the flame higher, counter-clockwise to lower.

LO

Page 33

OPERATING YOUR HEATER (CONTINUED) PAGE 33

Adjusting the Blower Speed

+ The blower helps transfer the heat from the stove into the room. It will not turn on until the stove is

up to temperature (approximately 10 minutes after starting). See the illustration below for

instructions on adjusting the blower speed.

PILOT

IGNITER

LO

Normal Operating Sounds

Pilot Flame

The pilot flame,

which remains on,

makes a very slight

"whisper" sound.

OFF

HI

Blower Knob

Turn the knob all the way counter-clockwise to turn

the blower off. One click clockwise turns the

blower to high speed. Turning the knob clockwise

from the high position decreases the speed of the

BLOWER

blower.

Blower

This heater uses a blower to push

heated air into the room. You will hear

the sound of air movement that

increases as the speed is increased.

The appliance will

creak with change of

temperature.

Gas Control Valve

As the gas control

valve is turned on

and off you will hear

a dull clicking

sound. This is the

valve opening up

and shutting down.

Blower Snap Disk

This part can

produce a clicking

sound as it turns the

blower on and off.

Page 34

PAGE 34 MAINTAINING YOUR HEATER

Maintaining Your Stove's Appearance

! The enameled surfaces may chip if struck. Damaged surfaces may be repaired using the enamel touch-up paint available

from Travis Industries.

! Fingerprints or other marks left on the gold surface may become etched in place if they are not wiped clean prior to

turning the stove on. Clean the surfaces with denatured alcohol and a soft cloth.

Cleaning Your Stove

• Use denatured alcohol and a soft cloth to clean the gold surfaces (make sure the appliance is cool). Other cleaners may

leave a film that may become etched into the gold.

• Enameled surfaces may be cleaned with a soft rag, soap and water.

Yearly Service Procedure

! Failure to inspect and maintain the heater may lead to improper combustion and a potentially dangerous situation. We

recommend the following procedures be done by a qualified technician.

1 Check the pilot flame. It should engulf approximately 3/8" of the top of the thermocouple (see illustration below). If it

does not, contact your dealer for service.

2 Shut off gas to the heater by turning the gas control knob to "OFF" (see step A under "Starting the Pilot" on page 31).

Let the heater cool for 15 minutes. Open the door (see step 1 on page 26).

3 Remove the logs, twigs and embers (see page 27 - NOTE: the logs are fragile). If any log is cracked or deteriorated,

replace it when re-installing. Check the logs for sooting. A small amount of soot along the bottom of the logs is normal.

If excessive sooting is found, the heater will require adjustment. Contact your dealer.

4 Clean the burner pan (especially in the burner holes and slots) and inspect the following:

• Check for burner pan holes that are cracked, severely warped, or corroded.

• Make sure the burner pan assembly fits flat against the floor of the firebox.

• Check the firebox and area around the pilot to make sure there is no warping or damage.

If any problem is found, discontinue use and contact your dealer for service.

Before Disassembly: Check the pilot flame. It should

impinge the top 3/8” of the thermopile and engulf the

thermocouple.

Thermopile

Pilot Hood

Check the walls and

ceiling of the firebox

for deterioration.

Burner Pan

Make sure the

burner pan seals

against the floor

of the firebox.

3/8”

5 Replace the log set. Inspect the glass and door gasket. If it is deteriorated, replace. It may be re-attached using high-

temperature gasket cement. If the glass is damaged, replace it. Close the door. Make sure the gasket forms a seal and

the side pieces of glass butt up against the center piece. If needed, re-align or replace the gasket to insure an air-tight

seal. Replace the door.

6 Inspect the area behind the control cover. Check the gas control valve and all of the gas lines. If any damage is found,

discontinue use and contact your dealer for service.

7 Start the pilot and turn on the main burner. The flames should be orange/yellow and not touch the top of the firebox. If

the pilot or main burners do not burn correctly, contact your dealer for service. Monitor the blower operation.

8 Remove any debris or vegetation near the vent termination. Contact your dealer if any sooting or deterioration is found

near the vent termination.

Thermocouple

Check the burner

holes and slots.

Page 35

TROUBLESHOOTING PAGE 35

Problem: Possible Cause: Don't Call for Service

Until You:

Pilot Will Not Flame A gas shut off valve is turned off

The gas control knob isn't turned to "PILOT"

The valve control knob isn't pushed in

The igniter wasn't pressed repeatedly

Main Burners Will Not

Start

Remote Control Does

Not Work

The pilot flame has gone out

The gas control valve is turned to "PILOT" or "OFF"

The ON/OFF switch is turned to "OFF"

The remote control is not working correctly

The thermostat is disconnected or set too high

The pilot light has gone out

The gas control valve is turned to "PILOT" or "OFF"

The ON/OFF switch is turned to "OFF"