Page 1

Astoria 2003

Pellet Stove

• Horizontal Or Vertical Vent

• Freestanding Stove

• Mobile Home Approved

• Class A Chimney Retrofit

• Hearth Stove into Existing

Masonry Chimney , Masonry

Fireplace, or Z.C. Fireplace

-- Please read this entire manual

before installation and use of this

pellet fuel-burning room heater.

Failure to follow these instructions

could result in property damage

bodily injury or even death.

-- Contact local building or fire officials

about restrictions and installation

inspection requirements in your

area.

Installer: After installation give this manual to the home-

owner and explain operation of this stove.

$10.00 Copyright 2003, T.I. Part # 100-01154

4050504

Tested and Listed by

Omni-Test Laboratories, Inc.

Beaverton, Oregon

Report # 028–S–42-2

ASTME-1509 1995, ULCC 1482

10850 117th Place N.E. Kirkland, WA 98033

Page 2

Page 3

Introduction 1

Introduction

We welcome you as a new owner of an Astoria pellet heater. In purchasing an Astoria you have joined

the growing ranks of concerned individuals whose selection of an energy system reflects both a

concern for the environment and aesthetics. The Astoria is one of the finest home heaters the world

over. This manual will explain the installation, operation, and maintenance of this pellet-burning

heater. Please familiarize yourself with the Owner's Manual before operating your heater and save the

manual for future reference. Included are helpful hints and suggestions which will make the

installation and operation of your new heater an easier and more enjoyable experience. We offer our

continual support and guidance to help you achieve the maximum benefit and enjoyment from your

heater.

Important Information

No other Astoria heater has the same serial number as

yours. The serial number is on the hopper lid.

This serial number will be needed in case you require

service of any type.

Model: Astoria 2003

Serial Number:

Purchase Date:

Purchased From:

Mail your Warranty Card

Today, and Save Your Bill of

Sale.

To receive full warranty coverage,

you will need to show evidence of

the date you purchased your

heater. Do not mail your Bill of

Sale to us.

We suggest that you attach your

Bill of Sale to this page so that you

will have all the information you

need in one place should the need

for service or information occur.

Travis Industries 4050504 100-01154

Page 4

2 Safety Precautions

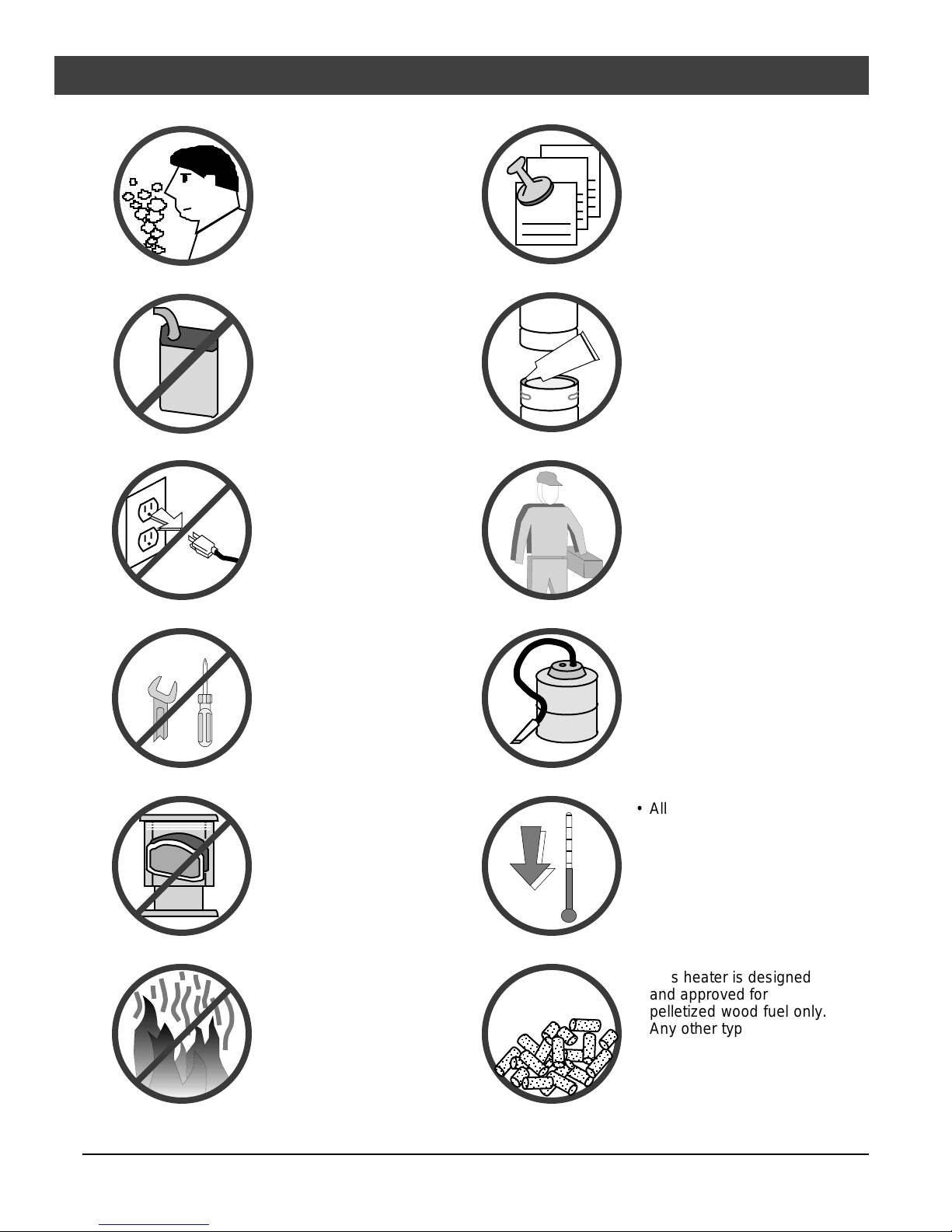

Gas

• Do not operate the

heater if you smell

smoke coming from

the heater. Turn the

MODE switch to

"OFF", monitor your

heater, and call your

dealer.

• Never use gasoline,

gasoline-type lantern fuel,

kerosene, charcoal lighter

fluid, or similar liquids to

start or 'freshen up' a fire in

this heater. Keep all such

liquids well away from the

heater while it is in use.

• Do not unplug the heater

if you suspect a

malfunction. Turn the

MODE SWITCH to "OFF"

and periodically inspect

the heater.

Ok

Sealant

• Contact your local building

officials to obtain a permit

and information on any

installation restrictions or

inspection requirements

in your area. Notify your

insurance company of this

heater as well.

• The exhaust system must

be completely airtight and

properly installed. The

pellet vent joints must be

sealed with RTV 500o F.

(260o C.) silicone sealant.

• This unit must be properly

installed to prevent the

possibility of a house fire.

The instructions must be

strictly adhered to. Do not

use makeshift methods or

compromise in the

installation.

• Never try to repair or

replace any part of the

heater unless instructions

are given in this manual.

All other work should be

done by a trained

technician.

• The viewing door and

ashpan must be closed

and latched during

operation.

• Never block free airflow

through the open vents of

the unit.

• Do not operate the heater

if the flame becomes dark

& sooty of if the firepot

overfills with pellets. Turn

the MODE SWITCH to

"OFF" and periodically

inspect the heater (see

"Running Your Heater").

• Your heater requires

periodic maintenance and

cleaning (see "Maintaining

Your Heater"). Failure to

maintain your heater may

lead to smoke spillage in

your home.

• Allow the heater to cool

before carrying out any

maintenance or cleaning.

Ashes must be disposed

in a metal container with a

tight lid and placed on a

non-combustible surface

well away from the home

or structure.

• This heater is designed

and approved for

pelletized wood fuel only.

Any other type of fuel

burned in this heater will

void the warranty and

safety listing.

Travis Industries 4050504 100-01154

Page 5

Safety Precautions 3

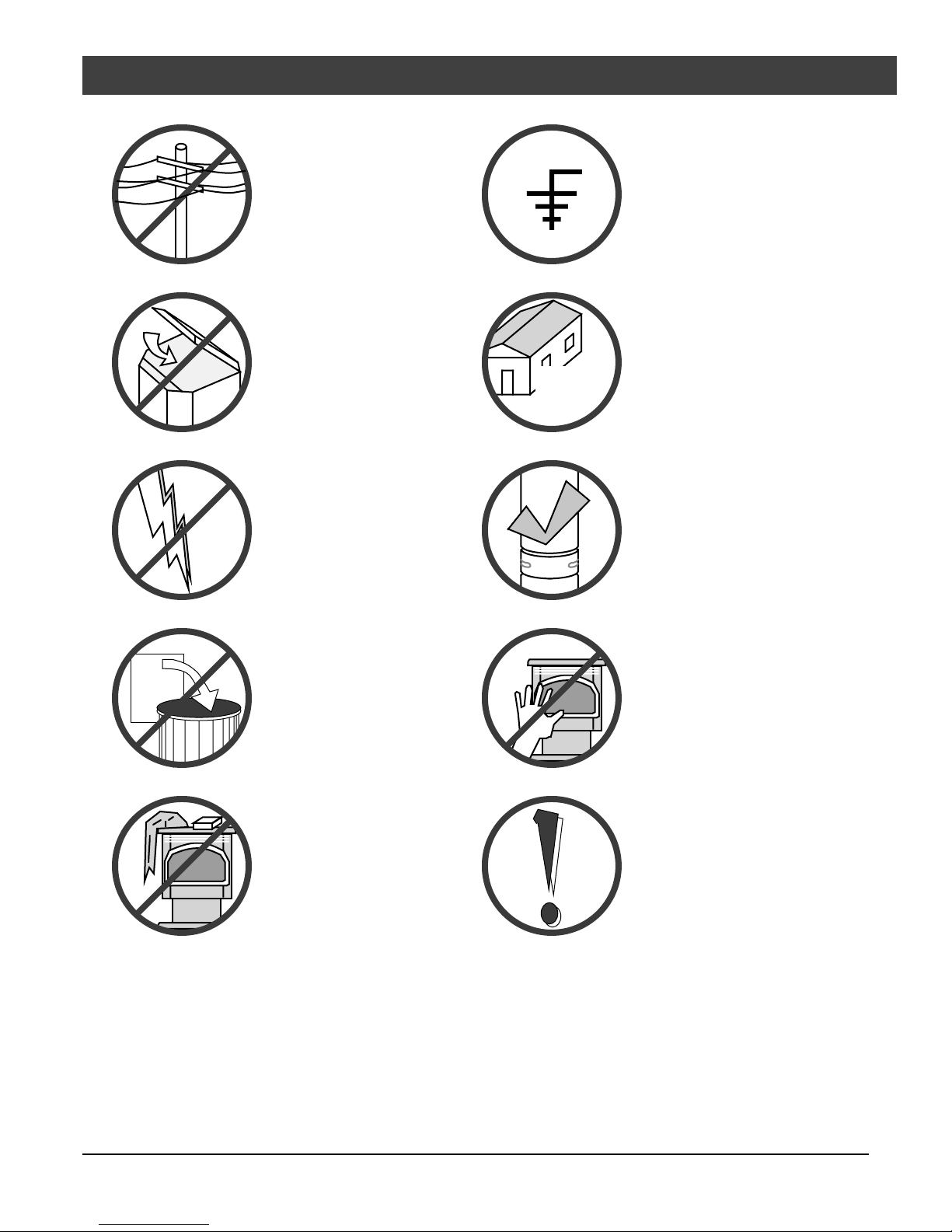

• The heater will not operate

during a power outage. If

a power outage does

occur, check the heater

for smoke spillage and

open a window if any

smoke spills into the room.

• Keep foreign objects out

?

of the hopper.

Mobile

Home

• Disconnect the power

cord before performing

any maintenance.

NOTE:

Turning the Mode Switch

to "OFF" does not

disconnect all power to

the heater.

• This heater must be

connected to a standard

115 V., 60 Hz grounded

electrical outlet. Do not

use an adapter plug or

sever the grounding plug.

Do not route the electrical

cord underneath, in front

of, or over the heater.

• When installed in a mobile

home, the heater must be

bolted to the floor, have

outside air, and NOT BE

INSTALLED IN THE

BEDROOM (Per H.U.D.

requirements). Check

with local building officials.

• The exhaust system

should be checked twice a

year minimum for any

build-up of soot or

creosote.

This

Manual

• Do not throw this manual

away. This manual has

important operating and

maintenance instructions

that you will need at a later

time. Always follow the

instructions in this manual.

• Do not place clothing or

other flammable items on

or near the heater.

Because this heater can

be controlled by a

thermostat there is a

possibility of the heater

turning on and igniting any

items placed on or near it.

• Do not touch the hot

surfaces of the heater.

Educate all children of the

danger of a hightemperature heater.

Young children should be

supervised when they are

in the same room as the

heater.

• Travis Industries, Inc.

grants no warranty,

implied or stated, for

the installation or

maintenance of your

heater, and assumes

no responsibility of

any consequential

damage(s).

Travis Industries 4050504 100-01154

Page 6

4 Table of Contents

Introduction

Introduction ......................................................1

Important Information .........................................1

Safety Precautions

Safety Precautions............................................2

Specifications

Heating Specifications ........................................5

Dimensions.......................................................5

Electrical Specifications......................................5

Fuel.................................................................5

EPA Compliance................................................5

Installation

Before you Begin ...............................................6

Installation Options ............................................6

Planning the Installation ......................................6

Stove Placement ...............................................6

Floor Protection Requirements..............................6

Clearances - Straight Installation ..........................7

Clearances - Corner Installation............................7

Venting the Pellet Stove......................................8

Maximum Venting Distance .............................8

Pellet Vent Type............................................9

Installing the Pellet Vent .................................9

Pellet Vent Termination...................................9

Mobile Home Requirements..................................10

Outside Air .......................................................10

Alcove Installation Requirements ..........................11

Restrictor Adjustment .........................................11

Installation Example: Direct "Through the Wall" ........12

Installation Example: Interior Vertical.....................13

Installation Example: Type A Chimney Retrofit.........14

Installation Example: Masonry Fireplace.................15

Installation Example: Zero-Clearance (Metal) Firepl...16

Installation Example: Interior Masonry Chimney.......17

Operation

Safety Notice ....................................................18

Location of Controls ...........................................18

Starting the Heater for the First Time......................18

Curing the Paint ............................................18

Priming the Auger..........................................18

Loading Pellets..................................................19

The Two Modes of Operation ................................19

Operation (continued)

Manual Mode.....................................................20

Auto Mode........................................................21

Restrictor Adjustment .........................................22

Adjusting the Fan Speed......................................22

Start-Up Sequence.............................................23

"AUGER ON" Light..............................................23

"FAULT" Light....................................................23

Power Outages..................................................23

Maintenance

Daily Maintenance (whenever using the stove).........24

Inspect the Burn ...........................................24

Make Sure Pellets are not Piling Up...................24

Check Firepot for Clinkers...............................24

Cleaning the Firepot.......................................25

Bi-Weekly Maintenance (or every 10 bags pellets)....26

Clean the Heat Exchange Tubes.......................26

Vacuum Hopper ............................................26

Clean the Gold Door.......................................26

Opening the Door ..........................................27

Sweep Ash Into Ashpan..................................28

Check Ashpan, Dispose if Necessary................29

Clean the Glass ............................................29

Yearly Maintenance (or every two tons)..................30

Clean the Exhaust Duct..................................30

Clean the Exhaust Blower ...............................31

Clean the Vent..............................................31

Check for Air Leaks - Door, Glass and Ashpan ....32

Normal Operating Sounds

Normal Operating Sounds....................................33

Safety Label

Safety Label .....................................................34

Warranty

Warranty..........................................................35

Optional Equipment

Thermostat.......................................................36

Pellet Log.........................................................37

Index

Index...............................................................38

Travis Industries 4050504 100-01154

Page 7

Specifications 5

Heating Specifications:

Approximate Maximum Heating Capacity (in square feet)*.................................800 to 2,250 Sq. Feet

Burn Rate (Pounds per Hour)**.......................................................................1.7 to 5.5

Maximum Burn Time on Low Burn**................................................................67.5 Hours

Hopper Capacity............................................................................................115 Pounds

* Heating capacity will vary depending on the home's floor plan, degree of insulation, and the outside

temperature. It is also affected by the fuel size, quality, and moisture level.

** Small pellets will increase or decrease the stated burn rates and burn times. Differences of plus or minus 20%

depending on fuel quality may occur.

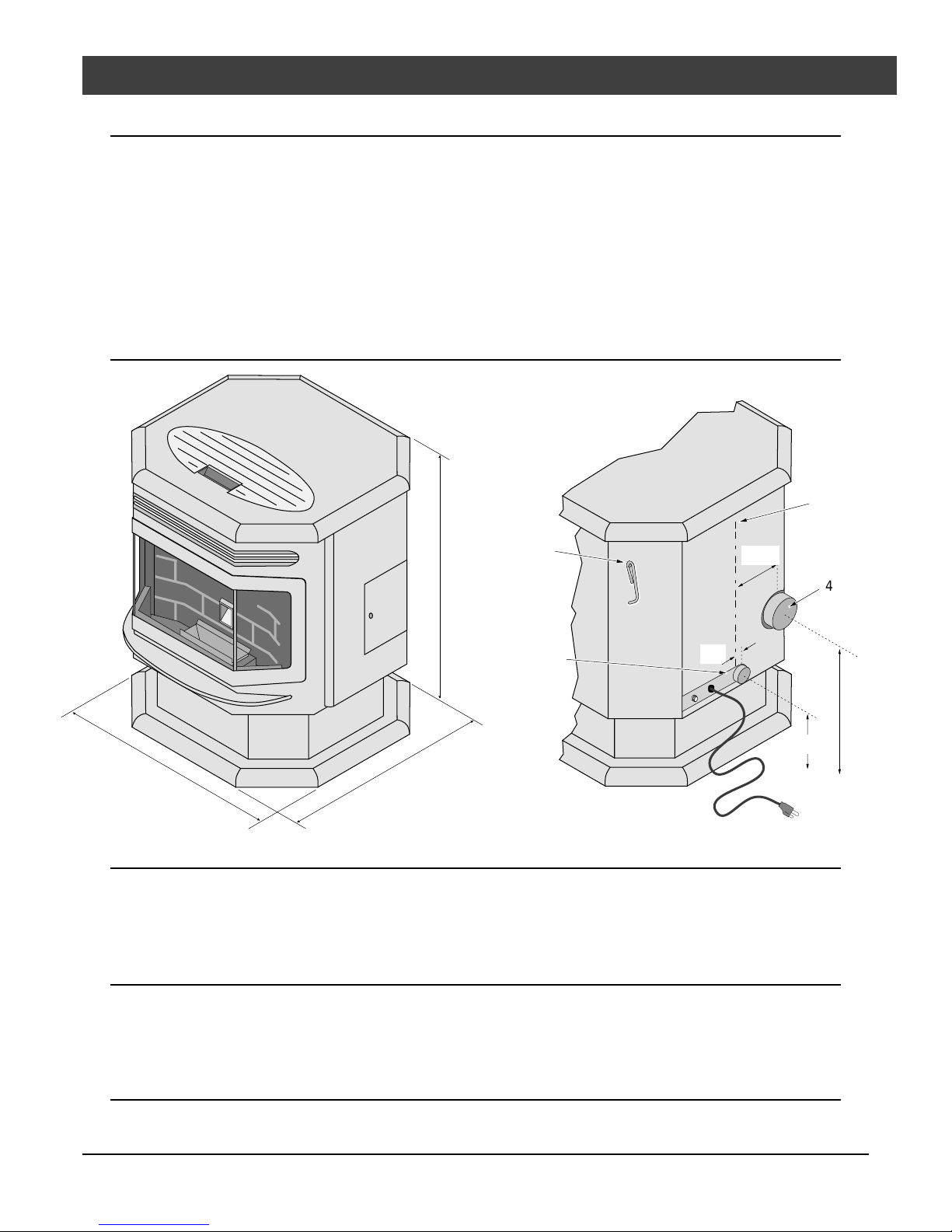

Dimensions:

33-3/8"

28"

This tab is for

the scraper

rod tool.

Air Inlet

(1-3/4"

Outside

Diameter)

26-1/2"

Weight: 250 Lbs.

7-1/4"

1/2"

10-1/2”

Electrical Specifications:

Electrical Rating.......................................................................................115 Volts, 3.6 Amps, 60 Hz

Watts During Start-Up Sequence..............................................................400 (approximately)

Watts During Operation............................................................................180 (approximately)

Center

Line

4"

Diameter

Exhaust

17-5/8"

Fuel:

The unit is designed for wood pellets that comply with the standards set by the Association of Pellet

Fuel Industry (density of at least 40 lbs. per cubic foot, 1/4" to 5/16" diameter, length no greater than

1–1/2", 8200 BTU's/lb., moisture under 8% by weight, ash under 1% by weight, and salt under 300

parts per million). If the fuel does not comply to this standard, the unit may not operate as designed.

EPA Compliance:

This heater has been tested exempt from EPA Phase II Requirements by OMNI Test Labs.

Travis Industries 4050504 100-01154

Page 8

6 Installation

Before You Begin

READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE THIS HEATER.

FAILURE TO FOLLOW THE INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE,

BODILY INJURY, OR EVEN DEATH.

Check with local building officials for any permits required for installation of this pellet heater and notify

your insurance company before proceeding with installation.

Packing List

• Thermostat & Wire • Scraper Rod Tool • Brush • Fuses (2)

Installation Options:

• Residential or Mobile Home (see the section "Mobile Home Requirements")

• Alcove Compatible (see the section "Alcove Installation")

• Horizontal or Vertical Vent

• Outside Air Compatible

• Vent with L-Vent, L-Vent Fireplace Liner, or Type A Chimney (with adapter)

Planning The Installation

HINT: Have an authorized Travis Industries dealer install this heater. If you install the heater

yourself, have your dealer review your installation plans.

HINT: Sketch out a detailed plan of the installation including dimensions. Then verify the

dimensions with the requirements listed in this manual.

HINT: When determining the location of the stove, locate the wall studs (for horizontal

penetrations) and ceiling trusses (for vertical penetrations). You may wish to adjust the

stove position slightly to ensure the vent does not intersect with a framing member.

HINT: Place the heater outside and load 10 pounds of pellets inside the hopper. Plug the

heater in and let it run on HIGH until the pellets run out. This will cure the paint and burn

off any oil on the steel, eliminating any smell inside the home.

Stove Placement

• Stove must be placed so that no combustibles are within, or can swing within (e.g. drapes,

doors), 36" of the front of the heater.

? If the stove is placed in a location where the ceiling height is less than 7', it must follow the

requirements in the section "Alcove Installation Requirements".

HINT: REDUCING CLEARANCES - Clearances may be reduced by methods specified in NFPA

211, listed wall shields, pipe shields, or other means approved by local building or fire

officials.

• Heater and floor protection must be installed on a level, secure floor.

Floor Protection Requirements

• The heater must be installed on a non-combustible floor protector extending the full width

and depth of the heater and extending 6" in front (Minimum 28" wide by 32-1/2" deep)

(minimum .018" thick - 26 gauge) .

• Must extend under and 2" to each side and rear of a "Tee" (if used).

Travis Industries 4050504 100-01154

Page 9

Installation 7

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

AAAAA

AAAAA

AAAAA

AAAAA

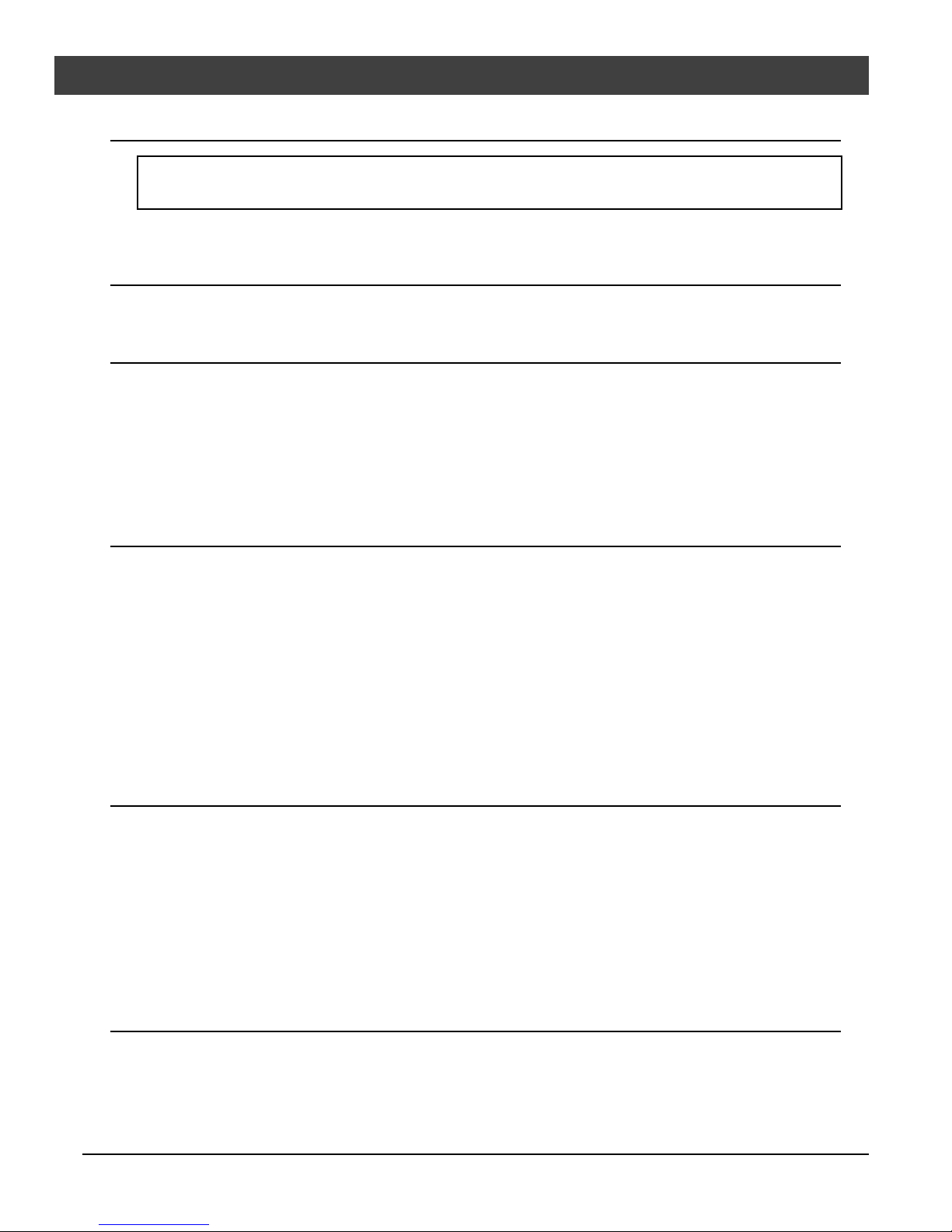

Clearances - Straight Installation

Through the Wall Installations

3” Minimum

AAAAAA

AAAAAA

9” Minimum

AAAAAA

AAAAAA

AAAAAA

AAAAAA

6” Minimum

AAAAAA

Clearances - Corner Installation

Through the

Wall Vents

Floor Protection

3”

Minimum

Interior Vertical Vents

AAAAAAA

AAAAAAA

“Tee”

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

6” Minimum

AAAAAAA

Interior Vertical

Vents

2”

Minimum

9” Minimum

3” Minimum

45°

6” Minimum

upward-turning elbow or "Tee". It will vary in depth depending on the brand of pellet vent

used (it is approximately 5"). Before placing the heater, connect the elbow or "Tee" and

measure off the 3" clearance.

Note: If interior vertical pellet vent is used, the clearance to the backwall is determined by the

Travis Industries 4050504 100-01154

45° Elbow

3” Minimum

Floor Protection

6” Minimum

3”

Minimum

3” Minimum

2”

Minimum

“Tee”

3”

Minimum

Page 10

8 Installation

Venting the Pellet Stove

• PELLET VENT MUST MAINTAIN A MINIMUM 3" CLEARANCE TO ANY

COMBUSTIBLE (INSTALL VENT AT CLEARANCES SPECIFIED BY THE

VENT MANUFACTURER).

• DO NOT CONNECT THE PELLET VENT TO A VENT SERVING ANY

OTHER APPLIANCE OR STOVE.

• DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM

OF THIS UNIT.

• USE AN APPROVED WALL THIMBLE WHEN PASSING THE VENT

THROUGH WALLS AND A CEILING SUPPORT/FIRE STOP SPACER

WHEN PASSING THE VENT THROUGH CEILINGS (MAKE SURE TO

MAINTAIN 3" CLEARANCE TO ANY COMBUSTIBLES.

• No more than one tee and 180° of elbows (one tee with two 90° elbows, one tee with one

90° and two 45° elbows, etc.).

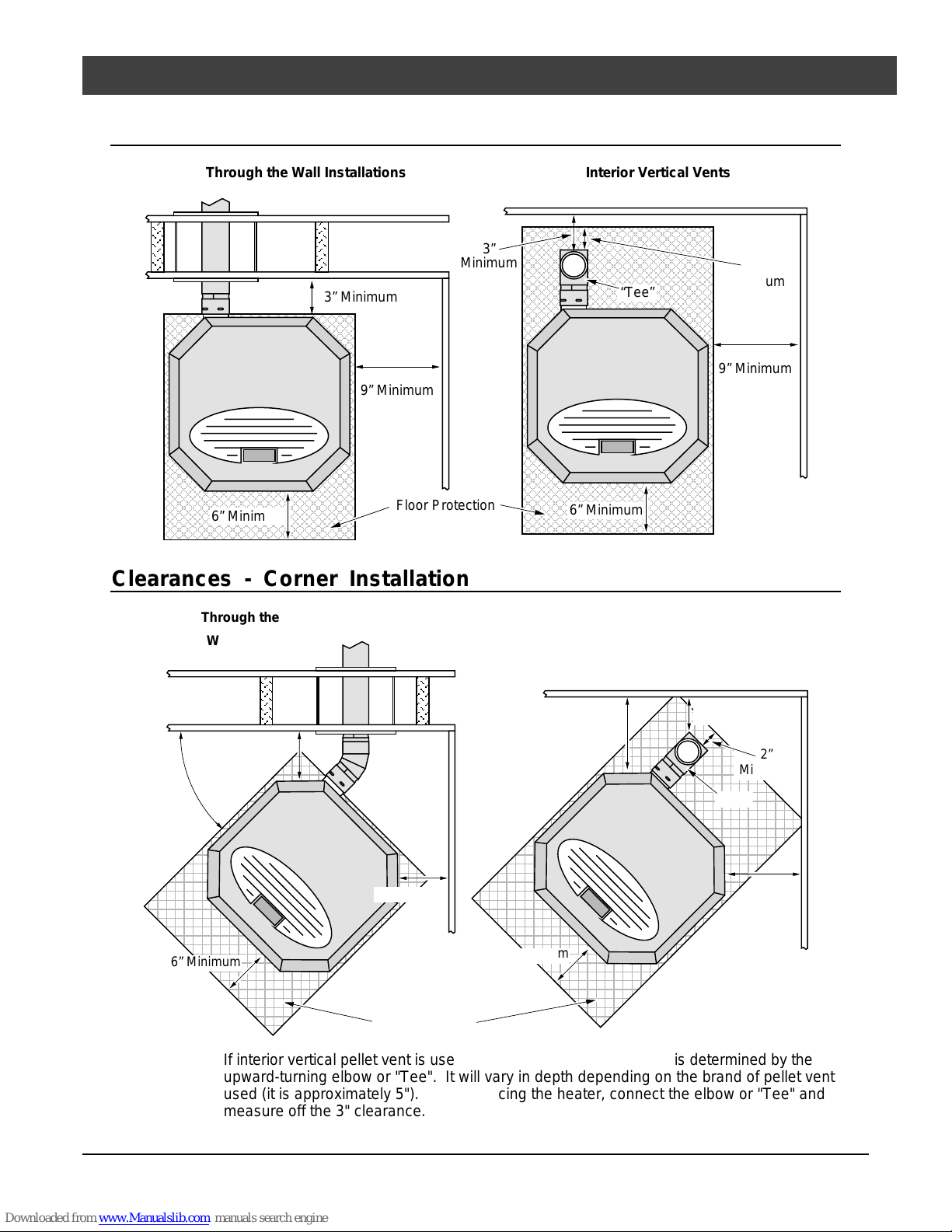

33 Feet

(max.)

Maximum Venting

Distance:

• Vent must have a support

bracket every 5' of pellet vent

when exterior of structure

The vent height and run

must not exceed the

distance shown in the

shaded region shown to the

right.

Venting into this shaded

area may require restrictor

adjustments. See the

section “Restrictor

Adjustment” for details.

NOTE: To achieve optimum

performance, we

recommend keeping the

vent as short as possible

(horizontal run especially).

30 Feet

25 Feet

20 Feet

15 Feet

10 Feet

5 Feet

Travis Industries 4050504 100-01154

0 Feet

5 Feet

10 Feet

(max.)

0 Feet

Page 11

Installation 9

Pellet Vent Type

• Must be 4" diameter Type "L"(except for masonry fireplace installations) - or - connect the

vent to a factory built type "A" chimney. All vent joints (including adapters, elbows, etc…)

must be sealed with 500° F. RTV silicone.

Installing the Pellet Vent

Seal each vent section (including

adapters, elbows, etc...) by

500° F. RTV

Silicone

• Horizontal sections must have a 1/4" rise every 12" of travel.

• Pellet vent connections must be sealed airtight with 500° F. RTV silicone and screwed

together with at least three sheet metal screws.

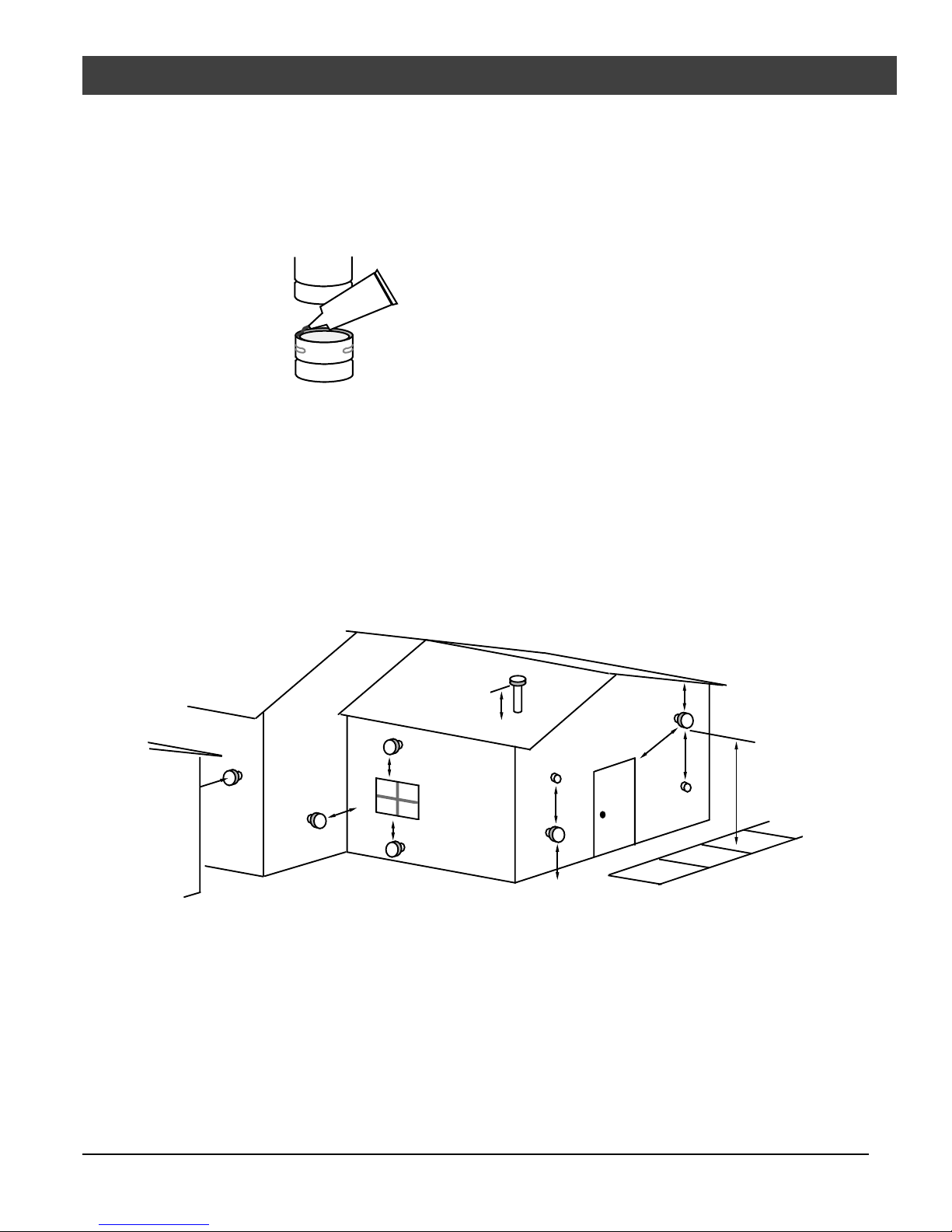

Pellet Vent Termination (See the illustration below)

• Must have an approved cap (to prevent water from entering) or a 45° downturn.

• If the termination is located on a windy side of the house, an approved house shield is

recommended to prevent soot from building up on the side of the house.

• Must not be located where it will become plugged by snow or other material.

• Horizontal terminations must protrude 12" from the wall, verticall terminations require 24".

injecting a liberal amount of 500°

F. RTV silicone into the gap

between sections.

X

A

B

C

NOTE: Measure clearances to the nearest edge of the exhaust hood.

A Minimum 4' clearance below or beside any door or window that opens

B Minimum 1' clearance above any door or window that opens

C Minimum 2' clearance from any adjacent building

D Minimum 7' clearance above any grade when adjacent to public walkways

NOTE: Vent may not terminate in covered walkway or breezeway.

E Minimum 2' clearance above any grass, plants, or other combustible materials

F Minimum 3' clearance from any forced air intake of any other appliance

G Minimum 2' clearance below eaves or overhangs

H Minimum 1' clearance horizontally from combustible wall

X Must be a minimum of 2' above the roof

H

A

F

E

G

F

D

Travis Industries 4050504 100-01154

Page 12

10 Installation

AA

AA

AA

AA

AA

AAAAAAAA

AAAAAAAA

AAAAAAAA

AAAAAAAA

AAAAAAAA

AAAAAAAA

AAAAAAAA

AAAAAAAA

AAAAAAAA

AAAAAAAA

AAAAAAAA

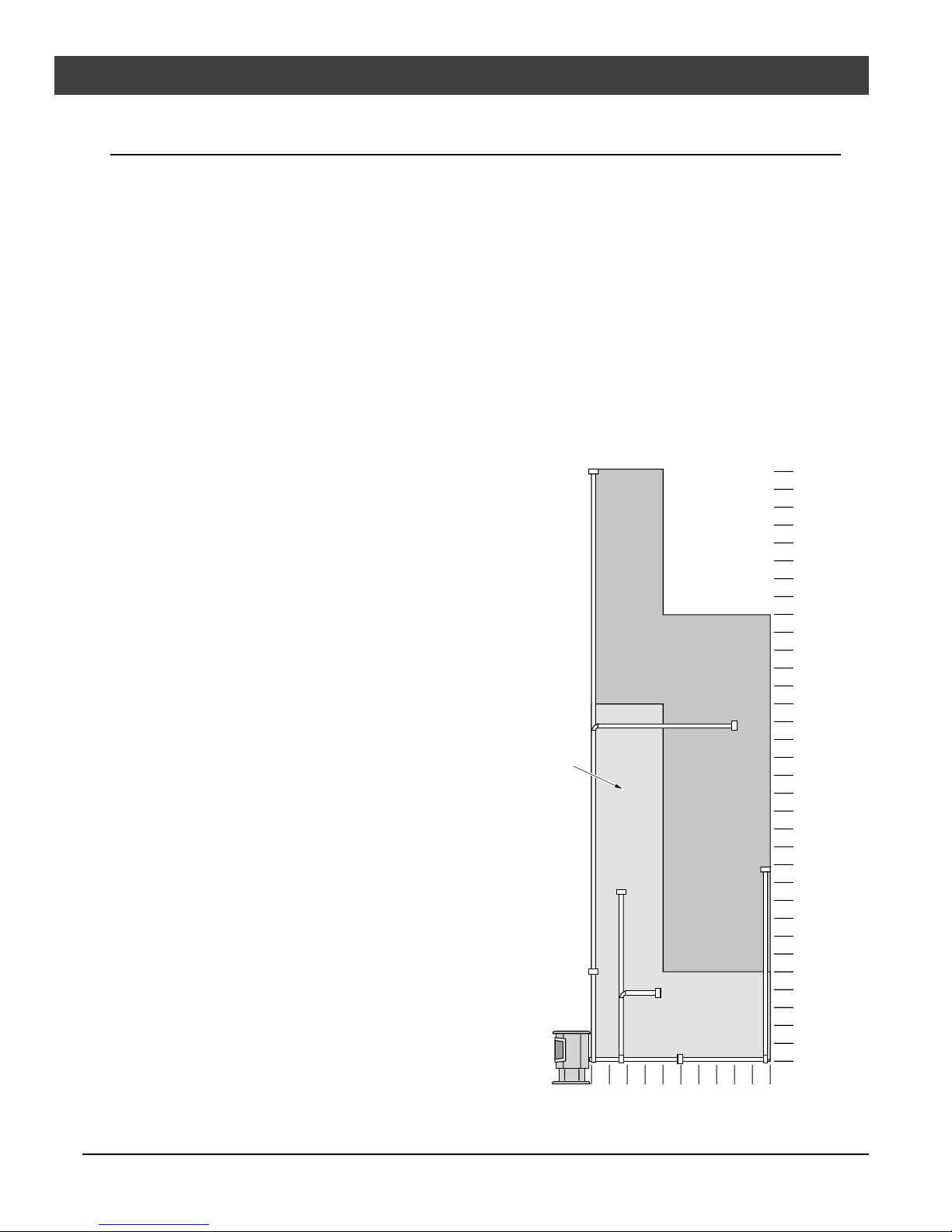

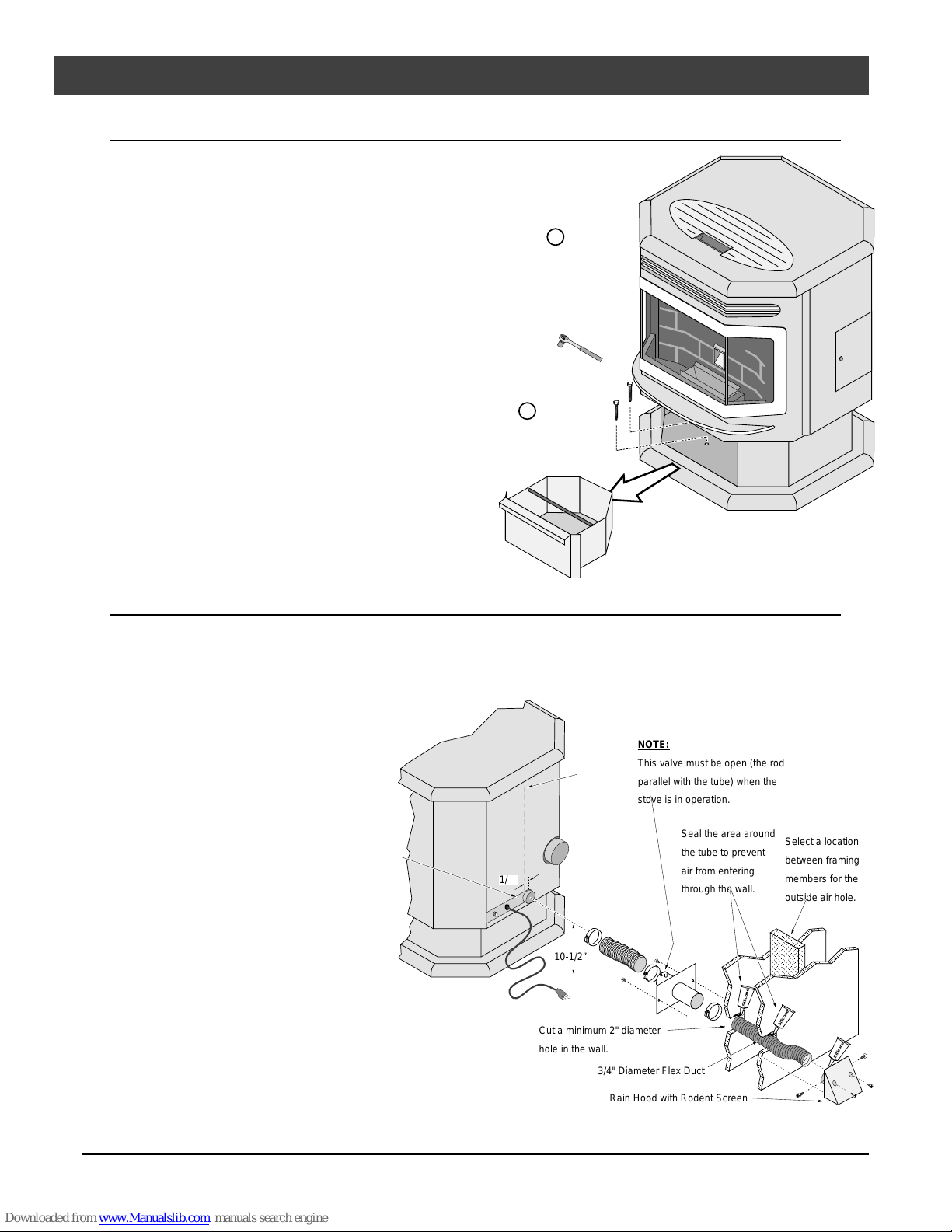

Mobile Home Requirements

• Outside air is required (used for

combustion) - see the directions

below.

• The heater must be bolted to the

floor (Some states do not require

this; check with your local building

department). See the illustration

to the right.

• The heater must be grounded to

the steel chassis of the mobile

home (Some states do not require

this; check with your local building

department).

WARNING: DO NOT INSTALL IN

SLEEPING ROOM.

CAUTION: THE STRUCTURAL

INTEGRITY OF THE

MANUFACTURED HOME

FLOOR, WALL, AND

CEILING/ROOF MUST BE

MAINTAINED.

Use the lag bolts (used

to secure the stove to

the pallet) to screw the

pedestal to the floor.

a

Remove the ash pan

(see page 29).

b

7/16”

Socket

Outside Air (used for combustion)

• Must not be drawn from an enclosed space (garage, unventilated crawl space).

HINT: Travis Industries strongly suggests outside air for all residential installations, especially for

those that are energy efficient, air-tight homes.

• Must not be over 15'

long.

• Must be made with 1 3/4"

diameter or larger metal

or aluminum duct with a

metal screen attached to

the end to keep out

rodents (P.V.C. or other

combustible materials

may not be used). We

recommend the Travis

Industries Outside Air Kit

(part # 99200136).

• Must not terminate above

or within 1' of the

chimney termination.

• Must have a rain cap or

down-turned elbow to

prevent water from

entering.

• Must be located so that it

will not become plugged

by snow or other material.

Travis Industries 4050504 100-01154

Air Inlet

(1-3/4"

Outside

Diameter)

1/2"

10-1/2”

Cut a minimum 2" diameter

hole in the wall.

NOTE:

Center

Line

1-3/4" Diameter Flex Duct

This valve must be open (the rod

parallel with the tube) when the

stove is in operation.

Seal the area around

the tube to prevent

air from entering

through the wall.

Rain Hood with Rodent Screen

Select a location

between framing

members for the

outside air hole.

Silicone

Silicone

Silicone

Page 13

Installation 11

Alcove Installation Requirements

When the pellet stove is placed in a location where the ceiling height is less than 7' tall, it is considered

an alcove installation. Because of the reduced height, the requirements listed below must be met.

• Minimum height is 60"

• Minimum width is 46"

Baffle Installation

Install the baffles included with the stove (see page 29 for details).

Restrictor Adjustment

The exhaust restrictor “fine tunes” your appliance, ensuring it pulls the correct amount of air through

the firebox. Altitude, vent configuration, and other factors make restrictor adjustment necessary for

every installation.

NOTE : the optimal restrictor position will vary over time as soot builds up inside the exhaust system –

make sure the homeowner knows how to visually inspect the flame and adjust the restrictor.

Not Enough Air:

If clinkers develop or the

flame appears lazy and

slow to blow the ash out of

the firepot, pull the

restrictor outward until the

flame becomes active and

the firepot holes remain

clean. NOTE: If the

restrictor is fully out (“5”),

yet the firepot does not

remain clean, the stove

needs to be cleaned and

checked for air leaks (see

“Maintenance” section of

this manual).

• Maximum depth is 48"

• Minimum clearance of 9" on each side and 3" on back

Too Much Air:

If the flames are too active

(small, flickering flames) or

if burning pellets are

expelled from the firepot,

move the restrictor rod

inwards until the flame

slows down and no

burning pellets are

expelled. Another

symptom of too much air is

the heater “blowing the fire

out” – a condition in which

the pellets burn faster than

they are fed (this is most

common on low).

Travis Industries 4050504 100-01154

Page 14

12 Installation

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Installation Example: Direct "Through-the-wall" Installation

Horizontal Rain Cap

12” Minimum

Wall Thimble (note

3” clearance

between vent and

combustibles)

Type "L"

Vent

3” Minimum

AAAAAA

AAAAAA

AAAAAA

AAAAAA

AAAAAA

AAAAAA

AAAAAA

6” Minimum

Outside Air

House Shield - prevents discoloration to outside of

home - HIGHLY RECOMMENDED

Seal each vent

section (including

adapters, elbows,

etc...) by injecting a

liberal amount of

500° F. RTV

silicone into the gap

between sections.

9” Minimum

Floor Protection

500° F. RTV

Silicone

12”

Minimum

Travis Industries 4050504 100-01154

3” Minimum

17-5/8”

10-1/2”

Floor Protection

Page 15

Installation 13

A

A

A

A

A

A

A

A

A

A

A

Installation Example: Interior Vertical Installation

Minimum

Type "L" Vent

Floor Protection

Vertical Cap

Storm Collar

Roof Flashing

3”

AAAAA

“Tee”

AAAAA

AAAAA

AAAAA

AAAAA

AAAAA

AAAAA

AAAAA

6” Minimum

AAAAA

24” Minimum

2”

Minimum

Outside

Air

(optional)

9” Minimum

Vent must

maintain 3”

clearance to

combustibles.

3” Min.

2” Min.

AA

AA

Insulation

must maintain

3” clearance.

Ceiling Support / Fire Stop Spacer

“L” Vent

Outside air may be drawn from

a ventilated crawl space.

500° F. RTV

Silicone

Floor Protection

Seal each vent

section (including

adapters, elbows,

etc...) by injecting a

liberal amount of

500° F. RTV

silicone into the gap

between sections.

Travis Industries 4050504 100-01154

Page 16

14 Installation

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

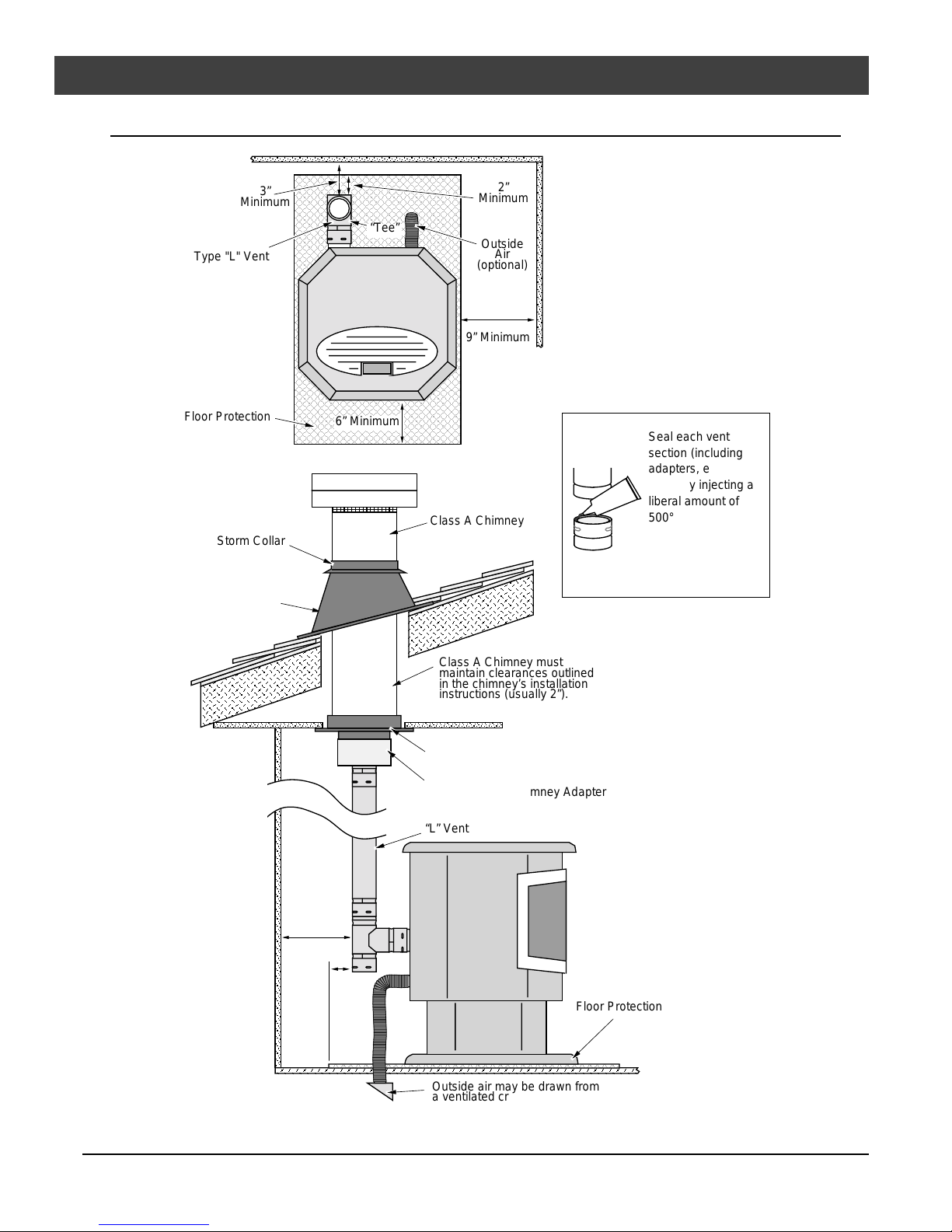

Installation Example: Class A Chimney Retrofit

3”

Minimum

Type "L" Vent

Floor Protection

Storm Collar

Roof Flashing

AAAAAAA

AAAAAAA

“Tee”

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

AAAAAAA

6” Minimum

AAAAAAA

AAAA

Class A Chimney

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

Class A Chimney must

maintain clearances outlined

in the chimney’s installation

instructions (usually 2”).

2”

Minimum

Outside

Air

(optional)

9” Minimum

500° F. RTV

Silicone

Seal each vent

section (including

adapters, elbows,

etc...) by injecting a

liberal amount of

500° F. RTV

silicone into the gap

between sections.

3” Min.

2” Min.

Travis Industries 4050504 100-01154

Class A Chimney Ceiling Support

“L” Vent to Class A Chimney Adapter

“L” Vent

Floor Protection

Outside air may be drawn from

a ventilated crawl space.

Page 17

Installation 15

AA

A

A

A

A

A

A

A

A

AAAA

A

A

AA

AA

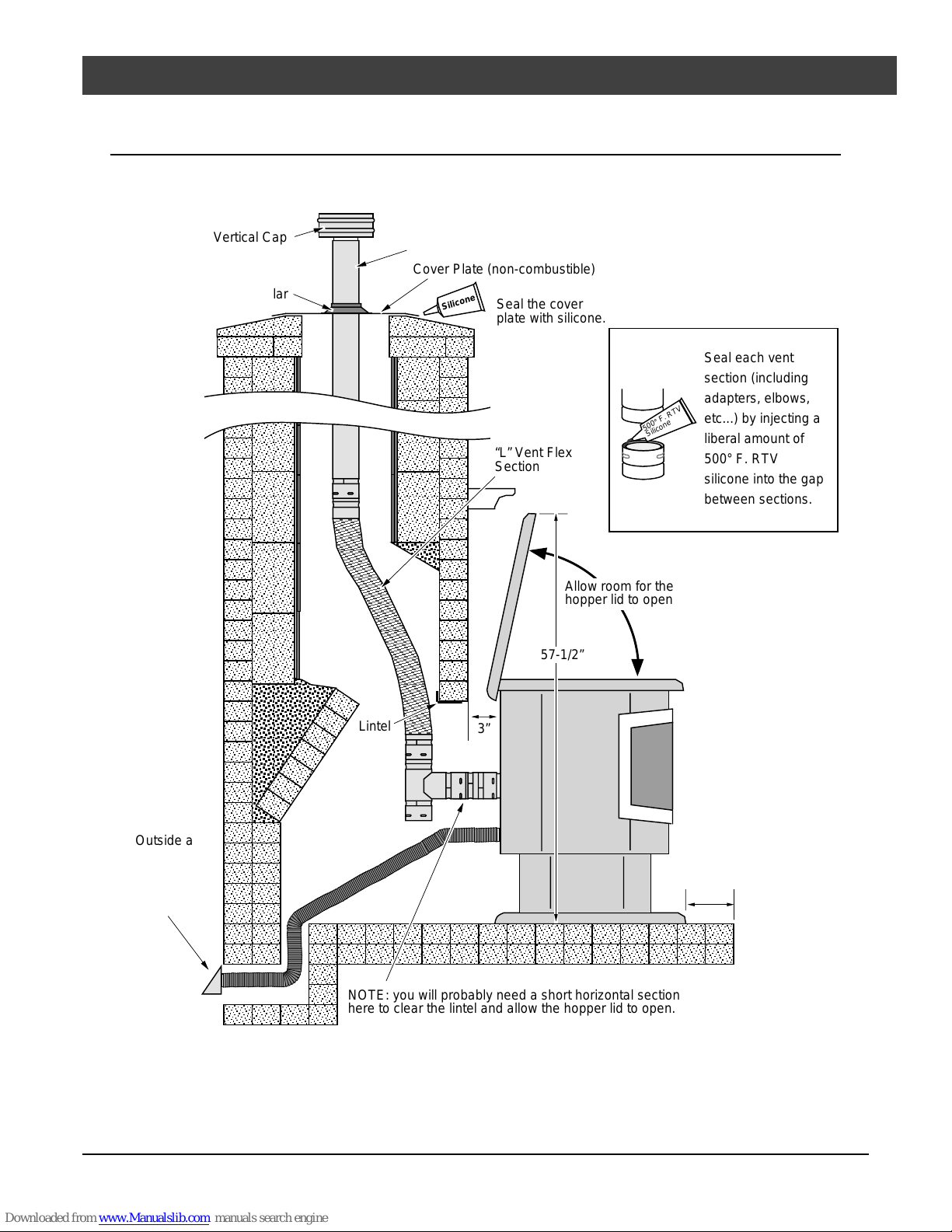

Installation Example: Masonry Fireplace Hearth Stove

AA

AA

Vertical Cap

Storm Collar

“L” Vent

Cover Plate (non-combustible)

Silicone

Seal the cover

plate with silicone.

A

AA

A

A

AA

“L” Vent Flex

Section

A

Allow room for the

hopper lid to open

57-1/2”

500° F. RTV

Silicone

Seal each vent

section (including

adapters, elbows,

etc...) by injecting a

liberal amount of

500° F. RTV

silicone into the gap

between sections.

Outside air

may be

drawn from

the ash

cleanout.

Travis Industries 4050504 100-01154

Lintel

NOTE: you will probably need a short horizontal section

here to clear the lintel and allow the hopper lid to open.

3”

6” Min.

Page 18

16 Installation

AA

AAAAA

AAAAA

AAAAA

AAAAA

A

A

A

A

Installation Example: Zero-Clearance (Metal) Fireplace Hearth Stove

Vertical Cap

Storm Collar

“L” Vent

AA

AA

“L” Vent Flex

Section

Cover Plate (non-combustible)

Silicone

Seal the cover

plate with silicone.

AA

AA

Allow room for the

hopper lid to open

500° F. RTV

Silicone

Seal each vent

section (including

adapters, elbows,

etc...) by injecting a

liberal amount of

500° F. RTV

silicone into the gap

between sections.

57-1/2”

3”

6” Min.

NOTE: you will probably need a short horizontal section

here to clear the lintel and allow the hopper lid to open.

Travis Industries 4050504 100-01154

Page 19

Installation 17

A

A

A

A

A

Installation Example: Interior Masonry Chimney

AA

“L” Vent Flex

Section

Vertical Cap

Storm Collar

“L” Vent

Cover Plate (non-combustible)

Seal the cover

Silicone

plate with silicone.

A

A

“L” Vent

Sections

500° F. RTV

Silicone

Seal each vent

section (including

adapters, elbows,

etc...) by injecting a

liberal amount of

500° F. RTV

silicone into the gap

between sections.

Clean-Out Access

AAAAAAA

AAAAAAA

Minimum

3”

Allow room for the

hopper lid to open

57-1/2”

6” Min.

Travis Industries 4050504 100-01154

Page 20

18 Operation

Safety Notice

Read this entire manual (especially the "Safety Precautions" on pages 2 and 3)

before using this stove. Failure to follow the instructions may result in property

damage, bodily injury, or even death.

! Do not unplug the stove to turn it off. This stove relies upon electricity to push the flue

gases out the pellet vent – unplugging it may lead to smoke entering your room.

! Failure to maintain your heater will lead to a restricted combustion air system, leading to

poor performance and in some cases, smoke spillage into the room. See the

"Maintenance" section for details.

Location of Controls

To Open the Control Panel:

Use the knob to open up this panel,

revealing the control panel.

Restrictor

The restrictor

adjusts the amount

of air flowing to the

flame.

Firepot

Starting the Heater for the First Time

Curing the Paint

This stove uses a heat-activated paint that will

emit some fumes while starting the first fire.

Open doors and windows to the room to vent

these fumes. You may also notice oil burning

off of the interior of the stove. This ruststopping agent will soon dissipate.

2 to 4 hours

Control Panel

50 60 70 80 90

Robertshaw

50 60 70 80 90

Thermostat or Remote

(required for Auto

Operation)

°F

°F

SET TEMP

TIMER

MIN

ROOM TEMP

OFF

Time

Time

o

t

u

A

Set

Cancel

Priming the Auger

Because of its electronic control panel, this stove does not require priming. If you run out of pellets

you may notice it will take approximately 5 minutes longer for the stove to start.

Travis Industries 4050504 100-01154

Page 21

Operation 19

Loading Pellets

Lift the hopper lid to its vertical position. Pour pellets into the hopper until full. NOTE: The hopper

holds approximately 115 pounds of pellets.

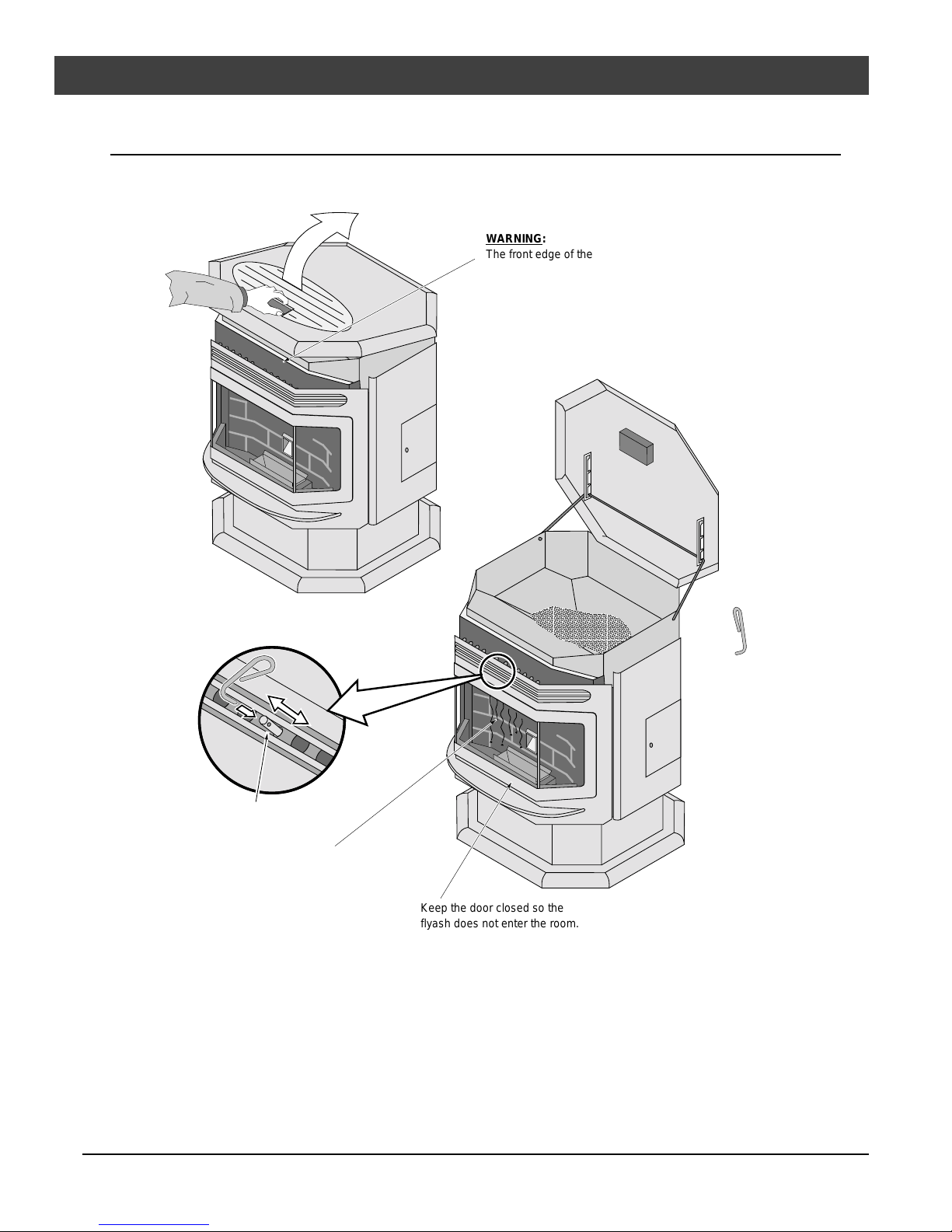

To Close the Hopper Lid:

lift the lid, pull this tab forward,

then lower the lid down.

To Open the Hopper Lid:

lift the hopper lid from this handle.

P

Make sure pellets

are not left on this

heat shield.

Warning:

The front edge of the

hopper lid becomes very

hot, do not touch the area

below the handle.

The Two Modes of Operation:

Manual

Manual mode requires the user to turn

the heater on and off manually.

Auto (requires a thermostat)

Auto mode allows you to use a

thermostat to control room

temperature. The stove automatically

turns on when the temperature drops

below the thermostat setting. Once the

stove reaches operating temperature,

the stove then runs at the heat output

setting selected.

Switching Modes While in

Operation

Whenever the stove is switched from

one mode to another while in

operation, the stove will enter the "startup" sequence for a minimum of 20

minutes.

e

These notches allow

you to open the hopper

lid to the level you wish.

e

l

l

t

s

H

E

HIGH

A

T

O

MED

U

T

P

U

LOW

T

AUTO

MANUAL

AUGER

ON

These

indicator

lights are

used to

determine

which mode

you are in.

HEAT OUTPUT

E

D

W

O

W

O

L

L

M

E

M

FAN

H

I

AUTO

G

H

OFF

MANUAL

D

H

I

G

H

MANUAL

START

FAULT

Use the

mode switch

to determine

the mode.

Travis Industries 4050504 100-01154

Page 22

20 Operation

Manual Mode

Manual mode requires the user to turn the

heater on and off manually.

To Start

Press the "Manual Start" button. That's it. The

stove automatically goes to a medium burn rate

and high fan while the igniter starts the fire

burning within 10 minutes. If the stove does

not start in 30 minutes, the stove turns off.

Once up to temperature, the stove will burn at

the burn rate selected on the "Heat Output"

dial.

To Shut Down

Move the mode switch to "OFF". The exhaust

blower will still run until the heater cools down.

HEAT OUTPUT

E

D

M

W

O

L

E

D

M

W

O

L

FAN

HEAT OUTPUT

E

D

M

E

M

FAN

H

I

G

H

MANUAL

D

H

I

G

H

W

O

L

W

O

L

H

I

AUTO

G

H

MANUAL

H

I

G

H

AUTO

OFF

OFF

MANUAL

START

FAULT

MANUAL

START

To Adjust the Heat

Adjust the "Heat Output" dial to meet the

heating requirements you desire.

H

E

HIGH

A

T

O

U

T

P

U

T

MANUAL

MED

LOW

HEAT OUTPUT

D

E

M

W

O

L

W

O

L

H

I

G

H

D

E

M

H

I

G

H

FAN

FAULT

AUTO

AUGER

ON

AUTO

OFF

MANUAL

MANUAL

START

FAULT

These lights

indicate the

heat output

setting.

Travis Industries 4050504 100-01154

Page 23

Operation 21

Auto Mode

Auto mode allows you to use a thermostat to control room temperature. The stove automatically turns

on when the temperature drops below the thermostat setting. Once the stove reaches operating

temperature, the stove then runs at the heat output setting selected.

To Adjust Room Temperature (or

Start the Stove)

Move the thermostat to the heat setting

desired. If the room is cooler than the setting,

the stove will go through the start-up

sequence for approximately 10 minutes. Once

up to temperature, the stove will then run at

the heat output setting selected on the control

panel. If the room is too hot, move the

thermostat to a lesser setting.

50 60 70 80 90

50 60 70 80 90

Robertshaw

To Adjust the Heat

Adjust the "Heat Output" dial to meet the

heating requirements you desire.

NOTE:

If you find that the stove turns on and off

repeatedly, you may wish to turn the heat

output to a lesser setting. The lower setting

will provide a more consistent heat output over

time, eliminating the need for the thermostat to

repeatedly turn the stove off.

NOTE:

If the thermostat calls for heat while the stove is

still cooling down, the stove will go through the

start-up sequence.

To Shut Down

Move the mode switch to "OFF". The exhaust

blower will still run until the heater cools down.

H

E

HIGH

A

T

O

U

T

P

U

T

MED

LOW

MANUAL

AUGER

HEAT OUTPUT

D

E

M

W

O

L

W

O

L

H

I

G

H

MANUAL

D

E

M

H

I

G

H

FAN

HEAT OUTPUT

E

D

M

W

O

L

E

D

M

AUTO

ON

AUTO

OFF

H

I

AUTO

G

H

MANUAL

MANUAL

START

FAULT

OFF

These lights

indicate the

heat output

setting.

Travis Industries 4050504 100-01154

W

O

L

FAN

H

I

G

H

MANUAL

START

FAULT

Page 24

22 Operation

Restrictor Adjustment

The exhaust restrictor “fine tunes” your appliance, adjusting the amount of air flowing to the flame.

NOTE : the optimal restrictor position will vary over time as soot builds up inside the exhaust system.

Not Enough Air:

If clinkers develop or the flame

appears lazy and slow to blow the

ash out of the firepot, pull the

restrictor outward until the flame

becomes active and the firepot

holes remain clean. NOTE: If the

restrictor is fully out (“5”), yet the

firepot does not remain clean,

the stove needs to be cleaned

and checked for air leaks (see

“Maintenance” section of this

manual).

Too Much Air:

If the flames are too active (small,

flickering flames) or if burning

pellets are expelled from the

firepot, move the restrictor rod

inwards until the flame slows

down and no burning pellets are

expelled. Another symptom of

too much air is the heater

“blowing the fire out” – a

condition in which the pellets

burn faster than they are fed (this

is most common on low).

Adjusting the Fan Speed

Use the FAN dial to adjust the

convection blower speed.

HEAT OUTPUT

E

D

M

E

M

FAN

H

AUTO

I

G

H

OFF

MANUAL

D

H

I

G

H

MANUAL

START

FAULT

W

O

L

W

O

L

Travis Industries 4050504 100-01154

Page 25

Operation 23

Start-Up Sequence

This stove utilizes a start-up sequence whenever the mode switch is changed or the heater is started

when cold. This is to ensure proper operation through all possible settings and operational states (hot

or cold, pellets burning or not burning, etc.). This sequence over-rides all user settings (except the

"OFF" position) to set the auger feed rate to medium, the exhaust blower to high, and the igniter on.

"AUGER ON" Light

This light comes on when the auger is turning. This allows the operator to determine when the auger

is turning.

"FAULT" Light

This light comes on when an error occurs:

• The stove runs out of pellets

• During initial start-up (for a split second) or for improper electrical frequency

• A start-up sequence that does not result in the heater coming up to temperature

HEAT OUTPUT

D

E

M

E

M

FAN

H

I

AUTO

G

H

OFF

MANUAL

D

H

I

G

H

MANUAL

START

FAULT

W

O

L

W

O

L

To reset the fault light, turn the mode switch to off and re-start the stove.

Power Outages

If a sustained power outage occurs while in "Manual", the stove will go to a "cool down" mode to

vacate smoke once power returns. If the power outage was short, the heater will go to the start-up

sequence. If in "Auto", the stove will re-start (if the room is cool).

! Because this stove relies upon a blower to evacuate the smoke, some smoke may enter

the home during a power outage. To keep to a minimum, leave the door closed.

Travis Industries 4050504 100-01154

Page 26

24 Maintenance

A

A

Daily Maintenance (whenever using the stove)

Inspect the Burn

When burning on high, the

flames should be bright orange

with embers jumping from the

firepot.

NOTE : the optimal restrictor

position will vary over time as soot

builds up inside the exhaust

system. See "Restrictor

Adjustment" for details.

Make Sure Pellets are

Not Piling Up

If the pellets pile up over the burn

pot, turn the mode switch to

"OFF".

The most likely causes are:

• Restrictor needs adjustment

(see “Restrictor Adjustment”

in the installation section of

this manual)

• The door, glass, or ashpan is

open or has an air leak

• The firepot requires cleaning

• The exhaust system requires

cleaning

Travis Industries 4050504 100-01154

Page 27

Maintenance 25

A

A

Daily Maintenance (whenever using the stove) - Continued

Check Firepot for

Clinkers

If the flames seem to be

coming only from the sides,

or are orange/black, turn

the heater off and check for

clinkers.

The most likely causes are:

• Restrictor needs

adjustment (see

“Restrictor

Adjustment” in the

installation section of

this manual)

• Poor pellet quality

• The door or glass has

an air leak

• The exhaust system

requires cleaning

Cleaning the Firepot

WARNING:

Make sure the heater

has fully cooled

(approximately 25

minutes) before

opening the door and

conducting service.

To clean the firepot, open

the door (see page 26) and

knock away any debris on

the firepot with a

screwdriver. If severely

clogged, remove the

firepot to gain better

access.

Travis Industries 4050504 100-01154

Page 28

26 Maintenance

Bi-Weekly Maintenance (or every 10 bags of pellets)

Clean the Heat Exchange Tubes

Open the hopper lid.

WARNING:

The front edge of the

hopper lid becomes very

hot, do not touch the area

below the handle.

Store the scraper

rod tool by hanging

it on the hanger on

the back of the

stove.

Heat Exchanger

Cleaning Rod

With the door closed, insert the included

tool into the hole on the heat exchanger

cleaning rod. Move the heat exchange

cleaner up and down several times.

Keep the door closed so the

flyash does not enter the room.

Vacuum Hopper

Run the stove until the pellets run out. Open the hopper and vacuum out the entire hopper. The

dust and any other debris near the bottom should be removed to prevent excessive build-up.

Cleaning the Optional Gold Surfaces (Door and optional Grill)

Fingerprints or other marks left on gold surfaces may become etched in place if they are not wiped

clean prior to turning the stove on. Clean the gold with denatured alcohol and a soft cloth (make sure

the heater is cool). Other cleaners may leave a film that may become etched into the gold.

Travis Industries 4050504 100-01154

Page 29

Maintenance 27

AAAAAAA

AAAAAAA

AAAAAAA

Bi-Weekly Maintenance (or every 10 bags of pellets) - Continued

Opening The Door

Phillips

Screwdriver

Door Frame

Bracket (attached to side of

heater)

Pawl

Lock Nut

When securing the door, make sure the

pawl fits over the bracket before tightening.

NOTE: Do not overtighten the pawl.

This can permanently damage the

latch and prematurely wear out the

door gasket.

With the pawl free of the bracket,

the door may be swung open.

Travis Industries 4050504 100-01154

Page 30

28 Maintenance

Bi-Weekly Maintenance (or every 10 bags of pellets) - Continued

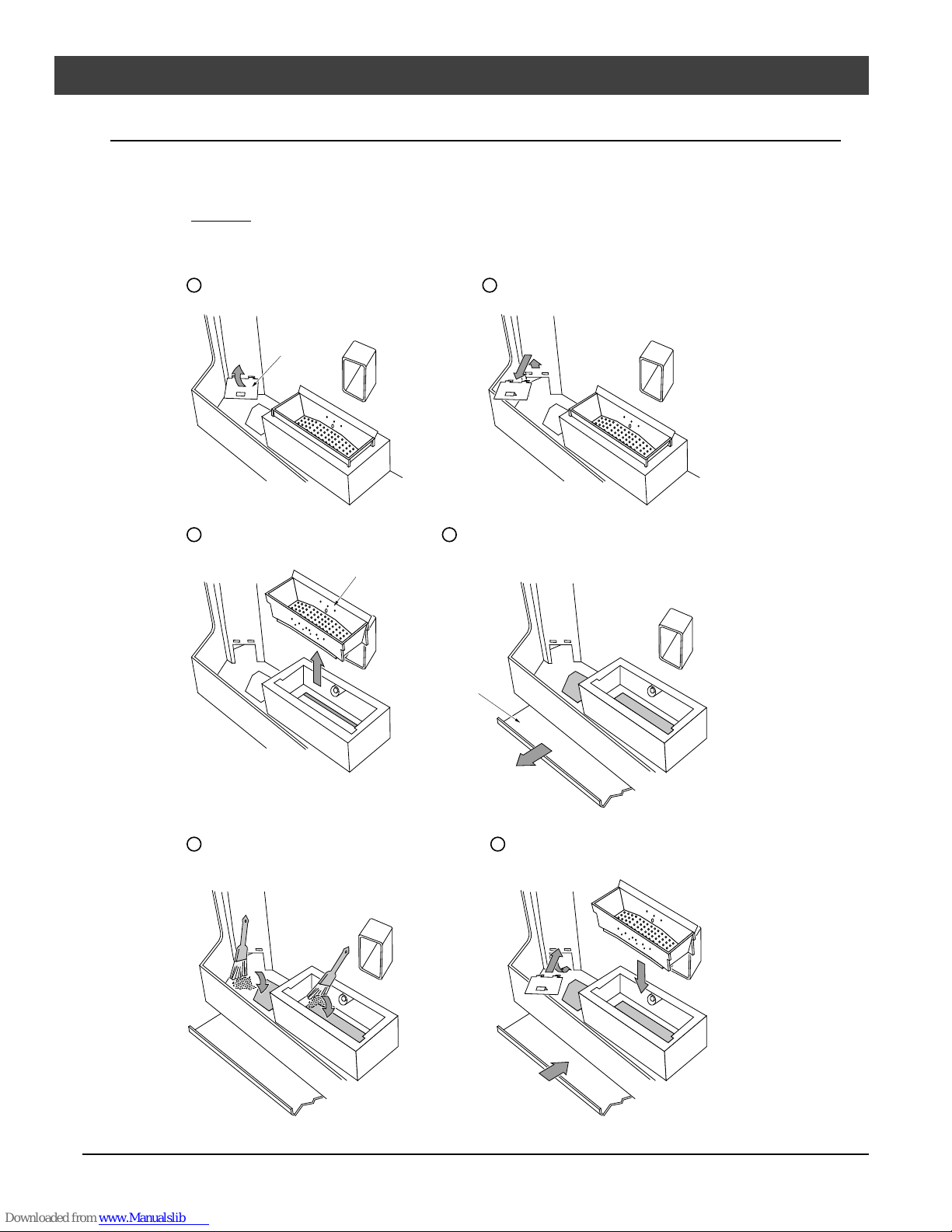

Sweep Ash Into Ashpan

HINT: The more often you clean out the flyash, the more efficient your heater will burn.

WARNING:

The firebox becomes very hot during operation. Let the stove cool completely before conducting service.

a

Swing the side ash trap door up.

Ash Trap

Door

c

Lift the firepot out of its holder.

Firepot

Lift it up and away from the firebox.

b

Repeat for the opposite side.

Slide the ash pan trap door forward to expose the ash

d

dumps (the door can be removed and cleaned if necessary)

Ash Pan

Trap Door

Brush all flyash into the ash dumps, including

e

the flyash inside the firepot holder.

Travis Industries 4050504 100-01154

Replace the ash trap doors and firepot.

f

Slide the ash pan trap door forward.

Page 31

Bi-Weekly Maintenance (or every 10 bags of pellets) - Continued

Check Ashpan, Dispose if necessary

NOTE: The left baffle is larger than the right baffle.

Cleaning the Baffles

Use both hands to lift each baffle

up and forward. Then tilt the baffle

downwards to remove any flyash

that may have accumulated on top

of the baffle. NOTE: you do not

need to remove the baffle from the

firebox.

Maintenance 29

BAFFLE INSTALLATION

The firebox baffles install on ledges at the top of

the firebox. The two tabs (at the outside back

corners) insert into notches at the right and left

rear corners of the firebox walls.

Air Tubes

The baffles install on

ledges above the

firebrick.

The ash pan has a built in

handle to ease

transportation of the ashes.

NOTE:

When replacing the ash pan make

sure it is pushed all the way in.

Disposal of Ashes – Ashes should be placed in a metal container with a tight fitting lid. The closed

container of ashes should be placed on a noncombustible floor or on the ground, well

away from all combustible materials, pending final disposal. If the ashes are disposed of

by burial in soil or otherwise locally dispersed, they should be retained in the closed

container until all cinders have been thoroughly cooled.

Clean the Glass

Open the door and clean the glass with a non-abrasive glass cleaner and rag. This will increase the

amount of light and heat given off by the heater.

Firebrick

Travis Industries 4050504 100-01154

Page 32

30 Maintenance

Yearly Maintenance (or every two tons)

WARNING: Disconnect the power cord prior to conducting service.

The following section details extensive maintenance procedures. We strongly suggest these items

be carried out by a trained service technician, possibly by a service agreement set up with your dealer.

Soot and Flyash: Formation and Need for Removal – The products of combustion will

contain small particles of flyash. The flyash will collect in the exhaust venting system and restrict the

flow of the flue gases. Incomplete combustion, such as occurs during startup, shutdown, or incorrect

operation of the room heater will lead to some soot formation which will collect in the exhaust venting

system. The exhaust venting system should be inspected at least once every year to determine if

cleaning is necessary.

Clean the Vertical Exhaust Duct (the stove must be cool and unplugged)

Clean the refractory and

the entire area behind it

Remove both

refractory clips.

(both sides).

Clean the Exhaust Duct

(the stove must be cool and

unplugged)

Remove these doors to

remove fallen flyash and

soot (see “Bi-Weekly

Open the hopper lid and remove the two

a

screws holding the side doors in place.

Phillips

Screwdriver

Swing the side panels open.

b

c

Remove the

cover plates over

the exhaust duct

(both sides)

Cover Plate

d

Use a vacuum or bottle

brush to remove all

flyash from the exhaust

duct (if the gasket is

damaged, replace).

7/16" Nutdriver

Travis Industries 4050504 100-01154

Page 33

Maintenance 31

Yearly Maintenance (or every two tons) - Continued

Clean the Exhaust Blower (make sure the stove is cool and unplugged)

a

Open the hopper lid

and remove the

screw holding the

left door in place.

Remove the knob

on the restrictor

rod. Swing the left

side panel open.

Phillips

Screwdriver

Remove the six screws holding the

b

exhaust blower motor in place.

11/32" Socket

Pull the motor out (be careful not

c

to damage the wiring or blades replace gasket if it is damaged).

Blower

Blades

Exhaust

Motor

Exhaust Box

Blower

Housing

Clean the blower blades, blower housing,

d

Restrictor Knob

and exhaust box. You may wish to use a

Clean the Vent (make sure the stove and vent is cool)

Make sure the cap is free of debris

(especially if it has a screen that could

become blocked).

Check the vent sections for creosote

accumulation (indicating a poorly burning

stove). Accumulation over 1/4” must be

removed.

Flyash will deposit along

sections that are horizontal.

Warning: Whenever any portion of the pellet vent is disconnected, the joints must be sealed with

RTV 500° F. silicone sealant.

On vertically vented systems, the dirtiest

portion is often the point where the vent turns

upwards (i.e. the "Tee"). Fortunately, the "Tee"

has a built-in clean out cover. Remove the

cover and vacuum out. While open, use a

flashlight to look up the pellet vent to check for

build-up.

Travis Industries 4050504 100-01154

Page 34

32 Maintenance

A

A

A

AAA

AAA

AAA

AAA

AAA

Yearly Maintenance (or every two tons) - Continued

Check for Air Leaks Around the Door, Glass, and Ashpan

! Air leaks into the firebox will decrease the stove's performance greatly, leading to excessive

sooting, inefficient burning, and perhaps a malfunction.

• Test the door seal by shutting the door on a dollar bill in various locations. If the bill can be easily

slid out, air may be leaking around the door seal – inspect the door gasket and door catch

carefully.

• Inspect the door gasket to make sure it is fully attached. Use stove gasket cement to re-attach if

necessary. If the door gasket is worn or flattened, replace.

• Check the door to make sure it latches correctly. Slight adjustments can be made to the door

catch if necessary (do not over-tighten this catch, an over-tightened catch will damage the door).

The latch should engage with a slight amount of resistance, yet not be difficult to engage.

• If the glass is cracked, replace. The glass is held in place by glass clips that are underneath the

airwash brackets. See the illustration below for details.

• Remove the ashpan and inspect the gasket around the perimeter of the ashpan. Re-attach, or

replace the gasket if necessary.

Door Trim

Door

Gasket

Attachment

Nuts

5/16"

Nutdriver

Airwash

Spacer

Glass Clip

Airwash Bracket

Door

Frame

Door

Gasket

Glass (with

channel gasket)

Replacement Parts

Blower, Combustion 93005535 Igniter 99300149

Blower, Convection 98900755A Knob, Air Control Cover 91001606

Outside Air Kit 99200136

Travis Industries 4050504 100-01154

Glass Clips

Airwash Spacers

Airwash Brackets

Page 35

Normal Operating Sounds 33

Exhaust Blower

The flow of exhaust gases

may create a low-pitched

hum. This sound will

change as the FEED RATE

is altered.

Heat Exchanger Tubes

You may hear the heated

air being forced through

these tubes by the

convection fan.

Auger Motor

When feeding pellets, you

may hear the intermittent

buzz of this motor running.

Covection Fan

The modern high efficiency

fan may produce a low

hum, particularly on

"HIGH". This sound will

change as the FAN dial is

turned.

Firepot

As pellets are fed into the

firepot, a light clicking

sound may be heard.

Travis Industries 4050504 100-01154

Page 36

34 Safety Label

BACKWALL

LEFT SIDEWALL

FLOOR PROTECTOR

A

C

HH

B

G

E

ADJACENT WALL

ADJACENT WALL

D

D

RIGHT SIDEWALL

E

WARNING - DO NOT REMOVE OR COVER THIS LABEL

Listed Pelletized

Solid Fuel Burning Appliance

Also for Use in Mobile Homes

Report No. 028-S-42-2

Tested to: ASTM E, 1509-95, Room Heater Pellet Burning Type (UM) 84 HUD

Electrical Rating: 115V, 60Hz, 3 Amp; Start 3 Amps, Run 1.5 Amps

Maximum Input Rating: 5.5 lbs (2.5kg)/hr

This pellet fired appliance has been tested and listed for use in manufactured (mobile) homes in accordance

with OAR 814-23-900 through 814-23-909.

WARNING - FOR MANUFACTURED HOMES: Do not install appliance in a sleeping room. Must utilize outside

combustion air inlet (part #99200136) or equivalent. Structural integrity of the manufactured home floor,

ceiling, and walls must be maintained.

Install only in accordance with the manufacturer’s installation and operating instructions. Contact local

building or fire officials about restrictions and installation inspection in your area.

Use only listed 4 in./100 mm diameter listed type “L” or “PL” venting system. See manufacturer ’s installation

instructions and local codes for precautions required for passing chimney through a combustible wall or

ceiling. Do not connect this appliance to a vent serving another appliance. Inspect and clean exhaust venting

system frequently in accordance with manufacturer’s instructions.

May be installed in a sleeping room with use of outside combustion air inlet (Part #99200136) or equivalent.

Minimum Clearance to Combustible Materials (Measured to Stove Top)

Interior Vertical Horizontal Through

Flue Installation the Wall Installation

Left Sidewall A 9” 9”

Right Sidewall B 9” 9”

Backwall C ** 3”

Corner D 3” 3”

Flue Vent E 3” 3”

Model: Astoria PS

Serial No:

Maximum alcove depth 48 in/1220 mm, minimum ceiling height 60 in/1525 mm, minimum alcove width

46 in/1165 mm.

Combustible floor must be protected by a non-combustible material, extending to the front (G) 6 in/150 mm

and to the sides (H) 0 in/0 mm.

EXCEPTIONS: Non-combustible floor protection must extend beneath a vent tee when installed.

** This dimension will vary depending on brand of listed type “L” vent. See manual for details.

For use with 1/4 in/6 mm to 5/16 in/7 mm diameter pelletized wood fuels only.

Replace glass only with 5 mm ceramic glass available from your dealer.

DANGER: Risk of electrical shock. Disconnect power supply before servicing. Route power cord away from

unit. Do not route power cord beneath heater.

Operate only with viewing door and ash removal tray tightly closed. Do not obstruct combustion air openings.

The space beneath heater must not be obstructed. Keep all furnishings away from heater.

Mfg. by TRAVIS INDUSTRIES, INC.

10850 117th Pl N.E.

Kirkland, WA98033

U.S. ENVIRONMENTALPROTECTION AGENCY

This model is exempt from EPA certification under 40 CFR 60.531 by definition

[Wood Heater (A) “Air-to-fuel Ratio”].

Date of Manufacture

2001 2002 2003 Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

DO NOT REMOVE THIS LABEL MADE IN U.S.A.

0406

Travis Industries 4050504 100-01154

Page 37

Warranty 35

To register your TRAVIS INDUSTRIES, INC. 7 Year Warranty, complete the enclosed warranty card and mail it within ten (10) days of the appliance

purchase date to: TRAVIS INDUSTRIES, INC., 10850 117th Place N.E., Kirkland, Washington 98033. TRAVIS INDUSTRIES, INC. warrants this

appliance (appliance is defined as the equipment manufactured by Travis Industries, Inc.) to be defect-free in material and workmanship to the original

purchaser from the date of purchase as follows:

Years 1 & 2 - COVERAGE: PARTS & LABOR

Firebox Assembly:

Firepot, Firepot Holder, Ash Cleanout Doors, Ashbox or Ash

Dump, Cast Fireback, Heat Exchanger Tubes, Exhaust

Manifold, Exhaust Box

Door Assembly:

Door Frame, Latch Assembly, Glass Retainers

Auger Assembly

Auger Flight, Auger Tube, Auger Bushings

Exclusions: Paint, Gasketing

Years 3 Through 5 - COVERAGE: PARTS & LABOR

Firebox Assembly:

Firepot, Firepot Holder, Ash Cleanout Doors, Ashbox or Ash

Dump, Cast Fireback, Heat Exchanger Tubes, Exhaust

Manifold, Exhaust Box

Exclusions: Paint, Gasketing, Ceramic Glass, Igniter System, Electrical System, Accessories (panels, legs, pedestal, gold trim, ceramic log, gold

door), Re-Installation Allowance

Years 6 & 7 - COVERAGE: PARTS ONLY

Firebox Assembly:

Firepot, Firepot Holder, Ash Cleanout Doors, Ashbox or Ash Dump, Cast

Fireback, Heat Exchanger Tubes, Exhaust Manifold, Exhaust Box

Exclusions: Paint, Gasketing, Ceramic Glass, Igniter System, Electrical System, Accessories (panels, legs, pedestal, gold trim, ceramic log, gold

door), Auger Assembly, Re-Installation Allowance, One-Way Freight Allowance, Labor

CONDITIONS & EXCLUSIONS

1. This new appliance must be installed by a qualified installer. It must be installed, operated, and maintained at all times in accordance with the instructions in

the Owner’s Manual. Any alteration, willful abuse, accident, neglect, or misuse of the product shall nullify this warranty.

2. This warranty is nontransferable, and is made to the ORIGINAL purchaser, provided that the purchase was made through an authorized Travis dealer.

3. Discoloration and some minor expansion, contraction, or movement of certain parts and resulting noise, is normal and not a defect and, therefore, not covered

under warranty.

4. The warranty, as outlined within this document, does not apply to the chimney components or other Non-Travis accessories used in conjunction with the

installation of this product. If in doubt as to the extent of this warranty, contact your authorized Travis retailer before installation.

5. Travis Industries will not be responsible for inadequate performance caused by environmental conditions such as nearby trees, buildings, roof tops, wind, hills

or mountains or negative pressure or other influences from mechanical systems such as furnaces, fans, clothes dryers, etc.

6. This Warranty is void if:

a. The unit has been operated in atmospheres contaminated by chlorine, fluorine or other damaging chemicals.

b. The unit is subject to submersion in water or prolonged periods of dampness or condensation.

c. Any damage to the unit, combustion chamber, heat exchanger or other components due to water, or weather damage which is the result of, but not limited

7. Exclusions to this 7 Year Warranty include: injury, loss of use, damage, failure to function due to accident, negligence, misuse, improper installation,

8. This 7 Year warranty excludes damage caused by normal wear and tear, such as paint discoloration or chipping, worn or torn gasketing, chipped or cracked

9. Damage to gold or nickel surfaces caused by fingerprints, scratches, melted items, or other external sources left on the gold or nickel from the use of cleaners

10. TRAVIS INDUSTRIES, INC. is free of liability for any damages caused by the appliance, as well as inconvenience expenses and materials. Incidental or

11. This warranty does not cover any loss or damage incurred by the use or removal of any component or apparatus to or from the Travis appliance without the

12. Any statement or representation of Travis products and their performance contained in Travis advertising, packaging literature, or printed material is not part of

13. This warranty is automatically voided if the appliance’s serial number has been removed or altered in any way. If the appliance is used for commercial

14. No dealer, distributor, or similar person has the authority to represent or warrant Travis products beyond the terms contained within this warranty. TRAVIS

15. Travis Industries will not cover the cost of the removal or re-installation of hearths, facing, mantels, venting or other components.

16. If for any reason any section of this warranty is declared invalid, the balance of the warranty remains in effect and all other clauses shall remain in effect.

17. This 7 year warranty is the only warranty supplied by Travis Industries, Inc., the manufacturer of the appliance. All other warranties, whether express or

to, improper chimney/venting installation.

alteration or adjustment of the manufacturer's settings of components, lack of proper and regular maintenance, damage incurred while the appliance is in

transit, alteration, or act of God.

firebrick, etc. Also excluded is damage to the unit caused by abuse, improper installation, modification of the unit, or the use of fuel other than that for which

the unit is configured.

other than denatured alcohol is not covered in this warranty.

consequential damages are not covered by this warranty. In some states, the exclusion of incidental or consequential damage may not apply.

express written permission of TRAVIS INDUSTRIES, INC. and bearing a TRAVIS INDUSTRIES, INC. label of approval.

this 7 year warranty.

purposes, it is excluded from this warranty.

INDUSTRIES, INC. assumes no liability for such warranties or representations.

implied, are hereby expressly disclaimed and purchaser’s recourse is expressly limited to the warranties set forth herein.

IF WARRANTY SERVICE IS NEEDED:

1. If you discover a problem that you believe is covered by this warranty, you MUST REPORT it to your Travis dealer WITHIN 30 DAYS, giving them proof of

purchase, the purchase date, and the model name and serial number.

2. Travis Industries has the option of either repairing or replacing the defective component.

3. If your dealer is unable to repair your appliance’s defect, he may process a warranty claim through TRAVIS INDUSTRIES, INC., including the name of the

dealership where you purchased the appliance, a copy of your receipt showing the date of the appliance’s purchase, and the serial number on your appliance.

At that time, you may be asked to ship your appliance, freight charges prepaid, to TRAVIS INDUSTRIES, INC. TRAVIS INDUSTRIES, INC., at its option, will

repair or replace, free of charge, your appliance if it is found to be defective in material or workmanship within the time frame stated within this 7 year warranty.

TRAVIS INDUSTRIES, INC. will return your appliance, freight charges (years 1 to 5) prepaid by TRAVIS INDUSTRIES, INC., to your regional distributor, or

dealership.

4. Check with your dealer in advance for any costs to you when arranging a warranty call. Dealers may require you to pay a service or trip charges for any

warranty work. This charge can vary from store to store.

Ceramic Glass

Glass (breakage from thermal shock)

Igniter System

Igniter, Igniter Leads

Electrical System

Auger Motor, Convection Blower, Exhaust Blower, Circuit

Board, Snap Disks, Wiring Harness, Vacuum Switch

Door Assembly:

Door Frame, Latch Assembly, Glass Retainers

Auger Assembly

Auger Flight, Auger Tube, Auger Bushings

Door Assembly:

Door Frame, Latch Assembly, Glass Retainers

Accessories

Panels, Legs, Pedestal, Gold Trim, Ceramic Log with Log Shelf,

Gold Door (See # 9 below)

Re-Installation Allowance

In cases where heater must be removed from home for repairs, a

partial cost of re-installation is covered (pre-authorization required)

One-Way Freight Allowance

One-way freight allowance on pre-authorized repair done at factory

is covered.

One-Way Freight Allowance

One-way freight allowance on pre-authorized repair done at

factory is covered.

Travis Industries 4050504 100-01154

Page 38

36 Optional Equipment

Thermostat (Part # 99300650)

! Do not connect 120 VAC to the thermostat circuit

of this heater (do not use a household thermostat

used for a wall-board or other electrical heater).

1 Attach the thermostat wire to the circuit board.

Route the thermostat wire through the hole in the

rear panel (make sure to leave enough slack to

allow the control panel to open).

2 Determine a location for the thermostat that is

within range of the 50' length of thermostat wire. It

should be centralized in the room and away from

the heater. The wire may be routed externally on

the wall or behind the wall (preferred).

3 Follow the directions below to attach the

thermostat and thermostat wires.

Pull the cover off the thermostat

50 60 70 80 90

Attach the quickconnects to the

thermostat posts

on the circuit

board (orientation

does not mater).

Robertshaw

50 60 70 80 90

Run the thermostat wires

through the wall (cut off excess

wire, leaving 6” of slack).

Expose 1/2” of wire and

attach to these two posts.

Standard

Screwdriver

Attach the thermostat to

the wall through these

two holes.

Travis Industries 4050504 100-01154

Page 39

Optional Equipment 37

Remote Thermostat

• Follow the instructions included with the remote thermostat for installation.

Using the Remote Thermostat

The remote thermostat has a 1 to 2 minute lag time between the time the thermostat is turned up and

the heater turns on. Included with the remote thermostat is a set of instructions that details the

operating characteristics of this optional component.

Pellet Log (part # 98900126)

1 Assemble the log shelf following the directions below.

Left Log Shelf Leg

Right Log Shelf Leg

Nuts

Log Shelf Cross Brace

3/8" Nutdriver

3 Remove the firepot from the pellet stove. Center the log shelf assembly (with extender attached)

over the burnpot holder. Replace the burnpot. Place the log on the log shelf extender.

Center the log on the log shelf and

b

push it back so it rests against

these two tabs.

NOTE:

On inserts, the ash box must be

installed before placing the log shelf

assembly.

Place the log shelf assembly so the

a

back edge contacts the cast firebrick

in the rear of the firebox. Note how

the taper on the assembly matches

the taper on the cast firebrick.

Travis Industries 4050504 100-01154

Page 40

38 Index

Adjusting the Fan Speed......................................22

Air Leaks..........................................................32

Alcove Installation Requirements ..........................11

Ashpan (Opening and Disposing Ashes).................29

AUGER ON Light................................................22

Auto Mode........................................................21

Bi-Weekly Maintenance (or every 10 bags pellets)....26

Blower (Exhaust Blower Cleaning) .........................31

Blower Speed Adjustment....................................22

Cap (Pellet Vent Termination) ...............................9

Check for Air Leaks - Door, Glass and Ashpan.........32

Chimney Retrofit (wood stove)..............................14

Clean the Exhaust Blower....................................31

Clean the Exhaust Duct.......................................30

Clean the Glass.................................................29

Clean the Heat Exchange Tubes ...........................26

Clean the Vent...................................................31

Cleaning Ashpan (Opening and Disposing Ashes).....29

Cleaning the Firebox (Sweep Ash Into Ashpan) ........28

Cleaning the Firepot...........................................25

Cleaning the Hopper (Vacuum Hopper) ...................26

Clearances - Corner Installation............................7

Clearances - Straight Installation ..........................7

Clinkers (Check Firepot for Clinkers)......................25

Controls...........................................................18

Curing the Paint.................................................18

Daily Maintenance (whenever using the stove).........24

Dimensions.......................................................5

Direct "Through the Wall" Installation......................12

Door (cleaning the gold).......................................26

Door (Opening)..................................................27

Door Gasket (inspection, removal) ........................32

Electrical Specifications......................................5

Emissions (EPA Compliance) ...............................5

EPA Compliance................................................5

Exhaust Blower (Cleaning)...................................31

Exhaust Duct (Cleaning)......................................30

Fan (Adjusting the Fan Speed)..............................22

FAULT Light......................................................23

Firebox (Cleaning)..............................................28

Fireplace Installation ..........................................15

Firepot Cleaning.................................................25

Firepot Inspection (Inspect the Burn) .....................24

Flames (Inspect the Burn)....................................24

Floor Protection Requirements..............................6

Fuel.................................................................5

Gasket (door, glass - inspection & removal) ............32

Glass (Cleaning)................................................29

Glass Removal.................................................. 32

Gold (cleaning).................................................. 26

Hearth (Floor Protection Requirements).................. 6

Hearth Fireplace................................................ 15

Heat Exchange Tubes (cleaning) .......................... 26

Heating Specifications........................................ 5

Hopper Cleaning (Vacuum Hopper)........................ 26

Important Information .........................................1

Installation Options............................................ 6

Installation Warnings (Before you Begin)................ 6

Interior Vertical Vent Installation........................... 13

Introduction...................................................... 1

Listing Label..................................................... 34

Loading Pellets ................................................. 19

Manual Mode ....................................................25

Masonry Fireplace ............................................. 15

Mobile Home Requirements.................................. 10

Modes of Operation............................................ 19

Noise (Normal Operating Sounds) ......................... 33

Normal Operating Sounds.................................... 33

Opening the Door............................................... 27

Outside Air....................................................... 10

Parts List ......................................................... 32

Pellet Vent Termination....................................... 9

Pellets (Fuel) .................................................... 5

Pellets (loading) ................................................ 19

Pellets Piling Up ................................................ 24

Placing the Stove .............................................. 6

Planning the Installation...................................... 6

Power Outages ................................................. 23