Page 1

EVBD-ACSL-7210 PROFIBUS / SPI Evaluation Board

5

ACSL-7210 Dual-Channel (Bidirectional) 25 MBd

CMOS Buered Input Digital Optocoupler

User Guide

Product Description

Avago’s ACSL-7210 optocoupler utilizes the latest CMOS

IC technology to achieve outstanding speed and low

power performance of minimum 25 MBd data rate.

Available in SO-8 package, the basic building blocks of

each channel in ACSL-7210 are a CMOS LED driver IC, a

high speed LED and a CMOS detector IC. A CMOS logic

input signal controls the LED driver IC, which supplies current to the LED. The detector IC incorporates an integrated

photodiode, a high speed trans-impedance amplier, and

a voltage comparator with an output driver.

Functional Diagram

8

VDD

1

1

2

VO

A

VI

3

B

4

GND

1

Shield

ACSL-7210

TRUTH TABLE (POSITIVE LOGIC)

Input side

VDD state

Power

Supplied

No Power Power

Output side

VDD state V

Power

Supplied

Supplied

VDD

2

7

VI

A

VO

6

B

GND

2

I

HIGH OFF HIGH

LOW ON LOW

X OFF HIGH

LED V

O

Features

• Dual-Channel (Opposite direction orientation)

• 3.3 V and 5 V CMOS Compatibility

• High Speed: DC to 25 MBd

• CMOS output and buer input

• Operating temperature: –40°C to +105°C

• Safety and Regulatory Approvals:

- UL 1577 – 3750 Vrms for 1 minute

- IEC/EN/DIN EN 60747-5-5

About the Evaluation Board

The ACSL-7210 PROFIBUS / SPI evaluation board is congurable for either PROFIBUS (RS-485) or SPI communication. The board will accept both 3.3V and 5V power supplies.

When congured for PROFIBUS communication, the

ACSL-7210 bi-directional optocoupler provides isolation

for both the transmitting and receiving channels. Isolation

for the Tx Enable signal is provided by the ACPL-M61L, ultra low power 10MBd CMOS digital optocoupler. A standard RS-485 transceiver (max. data rate of 20Mbps) is included on the board.

For SPI interface, the ACSL-7210 is used for serial data in/

out isolation. Isolation for the clock signal is provided by

ACPL-077L, low power 25MBd CMOS digital optocoupler.

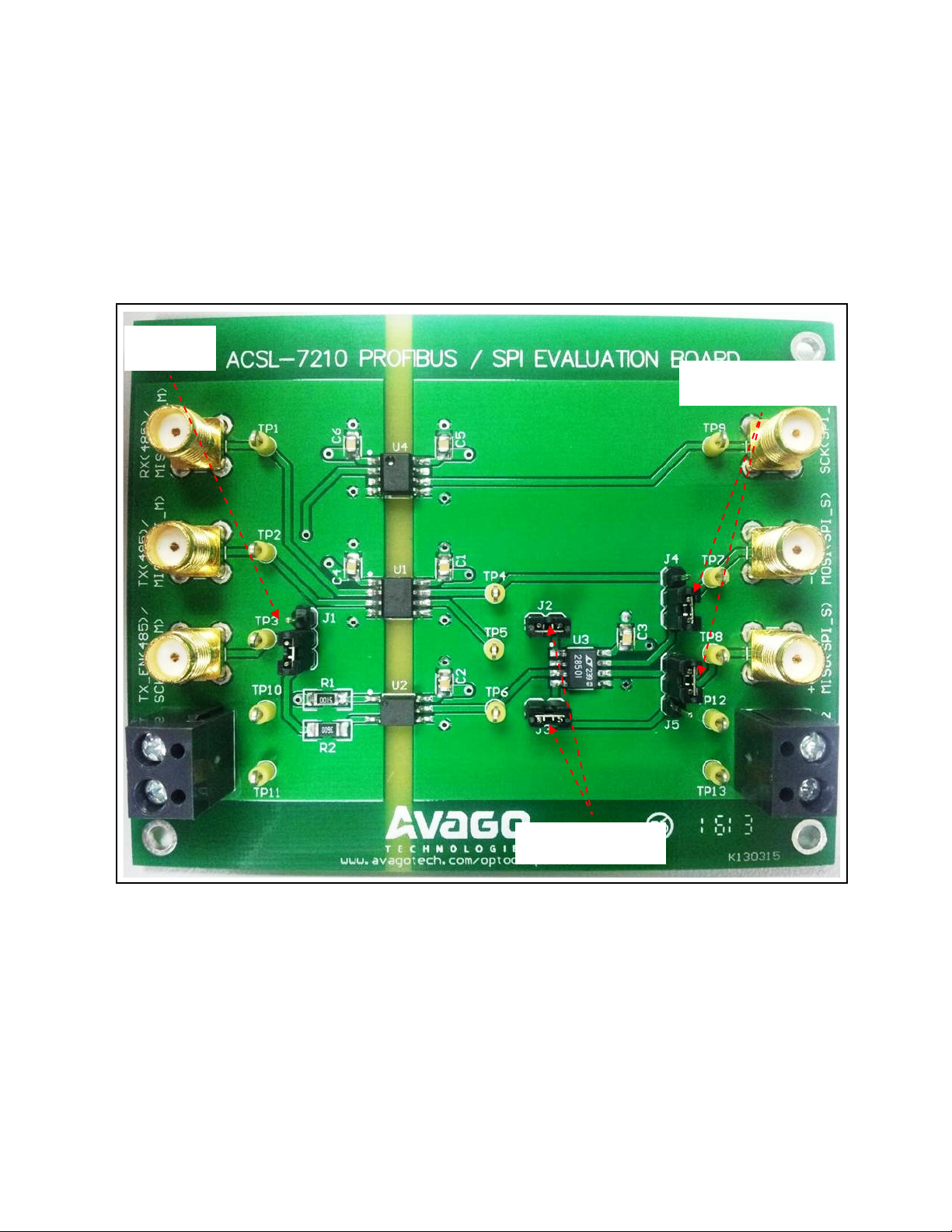

Figures 1 and 2 shows the jumper settings for PROFIBUS

and SPI operation. Figure 3 shows the schematic diagram

of the evaluation board.

Page 2

Board Connection and Operation

PROFIBUS Operation (Refer to Figure 1)

1. Short i) lower 2 pins of J1, ii) lower 2 pins of J4, and iii) upper 2 pins of J5.

2. The jumpers on J2 and J3 should be connected.

3. Connect a 3.3/5V power supply to VDD1 and GND1.

4. Connect a 3.3/5V power supply to VDD2 and GND2.

5. Connect the RS-485 dierential lines to SMA connectors +(485) and –(485).

6. Connect SMA connectors TX_EN(485), TX(485) and Rx(485) to microcontroller.

Short lower

2 pins of J1

Short lower 2 pins of J4,

and upper 2 pins of J5

Figure 1. Conguration for PROFIBUS (RS-485) Operation

2

Jumpers on J2 and J3

should be connected.

Page 3

SPI Operation (Refer to Figure 2)

1. Short i) upper 2 pins of J1, ii) upper 2 pins of J4, and iii) lower 2 pins of J5.

2. J2 and J3 should be left open.

3. Connect a 3.3/5V power supply to VDD1 and GND1.

4. Connect a 3.3/5V power supply to VDD2 and GND2.

5. The master device should be connected to SCK(SPI_M), MOSI(SPI_M), and MISO(SPI_M).

6. The slave device should be connected to SCK(SPI_S), MOSI(SPI_S), and MISO(SPI_S).

Short upper

2 pins of J1

Short upper 2 pins of J4,

and lower 2 pins of J5

Figure 2. Conguration for SPI Operation

3

J2 and J3 should

be left open

Page 4

C6

100n

VDD1

U4

1

2

3

4

ACPL-077L

VDD1

VI

NC

GND1

VDD2

GND2

VDD2

C5

100n

8

7

NC

6

VO

5

TP9

SCK(SPI_S)

VDD1

C4

U1

100n

1

VDD1

2

VOA

3

VIB

GND14GND2

ACSL-7210

VDD1

U2

R1

1

AN

510

R2

3

CA

360

ACPL-M61L

TP10 TP12

VDD1

TP11 TP13

RX(485)/MISO(SPI_M)

TX(485)/MOSI(SPI_M)

TX_EN(485)/SCK(SPI_M)

VDD1

GND1

TP1

TP2

TP3

J1

3

2 1

1

2

Figure 3. Schematic Diagram for ACSL-7210 Evaluation Board

VDD2

VOB

VDD

GND

VIA

VDD2

C1

100n

C2

100n

TP5

TP6

TP4

1

2

J2

1 2

J3

1

VDD2

GND2

21

J4

-(485)/MOSI(SPI_S)

3

TP7

21

J5

VDD2

U3

1

RO

RE_

DE

DI

VCC

B

A

GND

2

3

4

2

RS485 Trans

C3

100n

8

7

6

5

+(485)/MISO(SPI_S)

3

TP8

8

7

6

5

VDD2

6

5

VO

4

VDD2

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2013 Avago Technologies. All rights reserved.

AV02-4309EN - September 30, 2013

Loading...

Loading...