Page 1

HEDM-55xx/560x & HEDS-55xx/56xx

Quick Assembly Two and Three Channel Optical Encoders

Data Sheet

HEDM-55xx/560x HEDS-550x/554x, HEDS-560x/564x

Description

The HEDS-5500/5540, HEDS-5600/5640, HEDM-5500/5540

and HEDM-5600 are high performance, low cost, two

and three channel optical incremental encoders. These

encoders emphasize high reliability, high resolution, and

easy assembly.

Each encoder contains a lensed LED source, an integrated

circuit with detectors and output circuitry, and a codewheel

which rotates between the emitter and detector IC. The

outputs of the HEDS-5500/5600 and HEDM-5500/ 5600

are two square waves in quadrature. The HEDS-5540/5640

and HEDM-5540 also have a third channel index output in

addition to the two channel quadrature. This index output

is a 90 electrical degree, high true index pulse which is

generated once for each full rotation of the codewheel.

The HEDS series utilizes metal codewheels, while the

HEDM series utilizes a lm codewheel allowing for resolutions to 1024 CPR.

These encoders may be quickly and easily mounted to a

motor. For larger diameter motors, the HEDM-5600, and

HEDS-5600/5640 feature external mounting ears.

The quadrature signals and the index pulse are accessed

through ve 0.025 inch square pins located on 0.1 inch

centers.

Standard resolutions between 96 and 1024 counts per

revolution are presently available. Consult local Avago

sales representatives for other resolutions.

Features

• Two channel quadrature output with optional index

pulse

• Quick and easy assembly

• No signal adjustment required

• External mounting ears available

• Low cost

• Resolutions up to 1024 counts per revolution

• Small size –40°C to 100°C operating temperature

• TTL compatible

• Single 5 V supply

Applications

The HEDS-5500, 5540, 5600, 5640, and the HEDM-5500,

5540,5600 provide motion detection at a low cost, making

them ideal for high volume applications. Typical applications include printers, plotters, tape drives, positioning

tables, and automatic handlers.

Note: Avago Technologies encoders are not recommended for use in safety critical applications. Eg. ABS braking

systems, power steering, life support systems and critical

care medical equipment. Please contact sales representative if more clarication is needed.

ESD WARNING: NORMAL HANDLING PRECAUTIONS SHOULD BE TAKEN TO AVOID STATIC DISCHARGE.

Page 2

Package Dimensions

HEDS-5500/5540, HEDM-5500/5540

*Note: For the HEDS-5500 and HEDM-5500, Pin #2 is a No Connect. For the HEDS-5540 and HEDM-5540, Pin #2 is CH. I, the index output.

HEDS-5600/5640, HEDM-5600

*Note: For the HEDS-5600 and HEDM-5600, Pin #2 is a No Connect. For the HEDS-5640, Pin #2 is CH. I, the index output.

2

Page 3

Theory of Operation

The HEDS-5500, 5540, 5600, 5640, and HEDM-5500, 5540,

5600 translate the rotary motion of a shaft into either a

two- or a three-channel digital output.

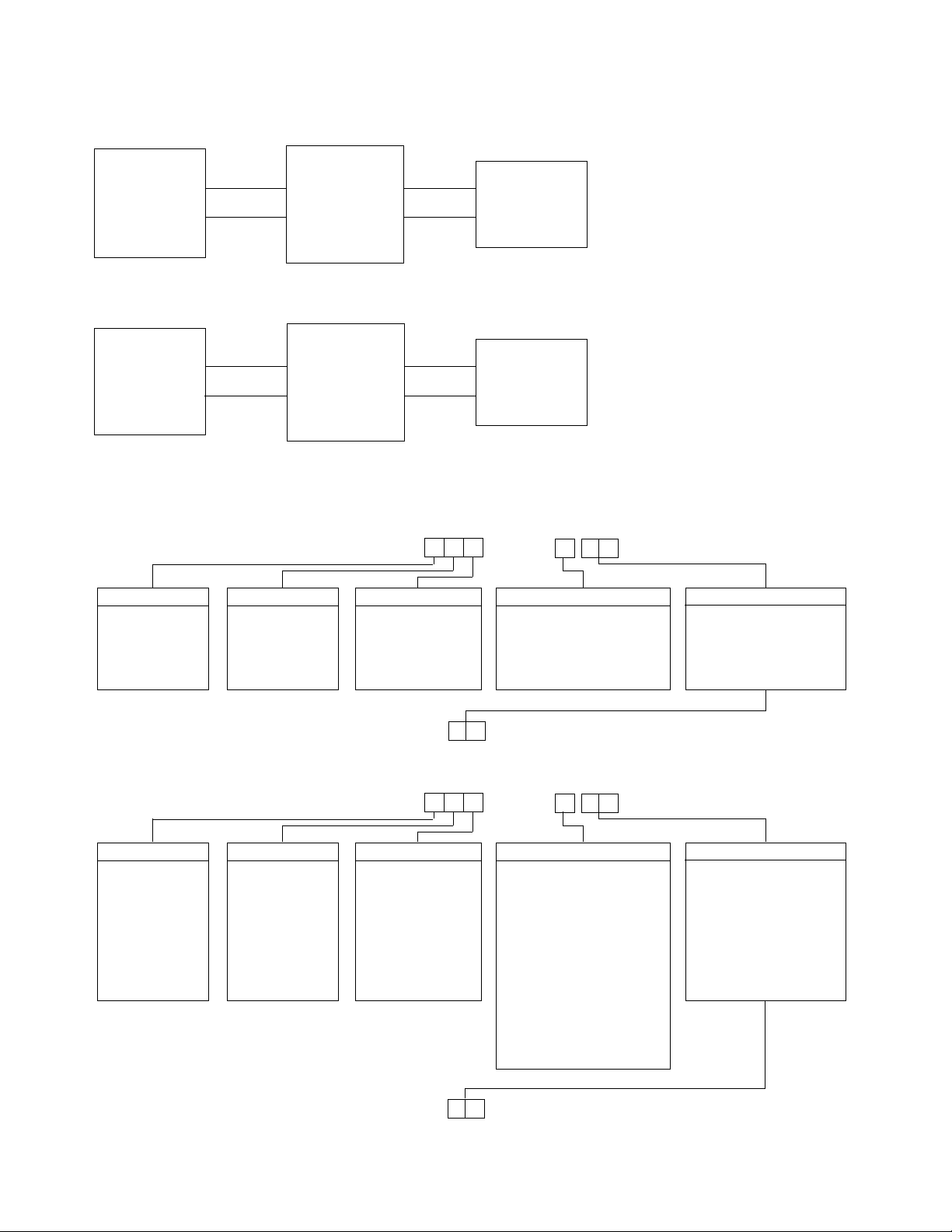

As seen in the block diagram, these encoders contain a

single Light Emitting Diode (LED) as its light source. The

light is collimated into a parallel beam by means of a

single polycarbonate lens located directly over the LED.

Opposite the emitter is the integrated detector circuit.

This IC consists of multiple sets of photodetectors and

the signal processing circuitry necessary to produce the

digital waveforms.

The codewheel rotates between the emitter and detector,

causing the light beam to be interrupted by the pattern

of spaces and bars on the codewheel. The photodiodes which detect these interruptions are arranged in a

pattern that corresponds to the radius and design of the

codewheel. These detectors are also spaced such that a

light period on one pair of detectors corresponds to a

dark period on the adjacent pair of detectors. The photodiode outputs are then fed through the signal processing

circuitry resulting in A, A, B and B (also I and I in the HEDS5540/5640 and HEDM-5540). Comparators receive these

signals and produce the nal outputs for channels A and

B. Due to this integrated phasing technique, the digital

output of channel A is in quadrature with that of channel

B (90 degrees out of phase).

In the HEDS-5540/5640 and HEDM-5540, the output of

the comparator for I and I is sent to the index processing

circuitry along with the outputs of channels A and B.

The nal output of channel I is an index pulse PO which

is generated once for each full rotation of the codewheel.

This output PO is a one state width (nominally 90 electrical degrees), high true index pulse which is coincident

with the low states of channels A and B.

Block Diagram

Denitions

Count (N): The number of bar and window pairs or counts

per revolution (CPR) of the codewheel.

One Cycle (C): 360 electrical degrees (°e), 1 bar and window

pair.

One Shaft Rotation: 360 mechanical degrees, N cycles.

Position Error (∆Θ): The normalized angular dierence

between the actual shaft position and the position

indicated by the encoder cycle count.

Cycle Error (∆C): An indication of cycle uniformity. The

dier¬ence between an observed shaft angle which

gives rise to one electrical cycle, and the nominal angular

increment of 1/N of a revolution.

Pulse Width (P): The number of electrical degrees that an

output is high during 1 cycle. This value is nominally 180°e

or 1/2 cycle.

Pulse Width Error ( ∆P): The deviation, in electrical degrees, of

the pulse width from its ideal value of 180°e.

State Width (S): The number of electrical degrees between a

transition in the output of channel A and the neighbouring transition in the output of channel B. There are 4 states

per cycle, each nominally 90°e.

State Width Error ( ∆S): The deviation, in electrical degrees, of

each state width from its ideal value of 90°e.

Phase (φ): The number of electrical degrees between the

center of the high state of channel A and the center of the

high state of channel B. This value is nominally 90°e for

quadrature output.

Phase Error (∆φ): The deviation of the phase from its ideal

value of 90°e.

Note: Circuitry for CH I is only for HEDS-5540, 5640 and HEDM 5540 Three Channel Encoder

3

Page 4

Absolute Maximum Ratings

Parameter HEDS-55XX/56XX HEDM-550X/560X HEDM-5540

Storage Temperature, TS -40°C to 100°C -40°C to +70°C -40°C to 100°C

Operating Temperature, TA -40°C to 100°C -40°C to +70°C -40°C to 100°C

Supply Voltage, VCC -0.5 V to 7 V -0.5 V to 7 V -0.5 V to 7 V

Output Voltage, VO -0.5 V to VCC -0.5 V to VCC -0.5 V to VCC

Output Current per Channel, I

Vibration 20 g, 5 to 1000 Hz 20 g, 5 to 1000 Hz 20 g, 5 to 1000 Hz

Shaft Axial Play ± 0.25 mm

Shaft Eccentricity Plus Radial Play 0.1 mm

Velocity 30,000 RPM 30,000 RPM 30,000 RPM

Acceleration 250,000 rad/sec2 250,000 rad/sec2 250,000 rad/sec2

-1.0 mA to 5 mA -1.0 mA to 5 mA -1.0 mA to 5 mA

OUT

(± 0.010 in.)

(0.004 in.) TIR

± 0.175 mm

(± 0.007 in.)

0.04 mm

(0.0015 in.) TIR

± 0.175 mm

(± 0.007 in.)

0.04 mm

(0.0015 in.) TIR

Direction of Rotation: When the codewheel rotates in the

counter¬clockwise direction (as viewed from the encoder

end of the motor), channel A will lead channel B. If the

codewheel rotates in the clockwise direction, channel B

will lead channel A.

Output Waveforms

Index Pulse Width (PO): The number of electrical degrees that

an index output is high during one full shaft rotation. This

value is nominally 90°e or 1/4 cycle.

4

Page 5

Recommended Operating Conditions

Parameter Sym. Min. Typ. Max. Units Notes

Temperature HEDS Series TA -40 100 °C

Temperature HEDM Series 5500/5600 TA -40 70 °C non-condensing

5540 T

A

-40 100 °C

Supply Voltage VCC 4.5 5.0 5.5 Volts Ripple < 100 mVp-p

Load Capacitance CL 100 pF 2.7 kΩ pull-up

Count Frequency f 100 kHz Velocity (rpm) x N/60

Shaft Perpendicularity

Plus Axial Play (HEDS Series)

Shaft Eccentricity Plus

Radial Play (HEDS Series)

Shaft Perpendicularity

Plus Axial Play (HEDM Series)

Shaft Eccentricity Plus

Radial Play(HEDM Series)

Note: The module performance is guaranteed to 100 kHz but can operate at higher frequencies. 2.7 kΩ pull-up resistors required for HEDS5540/5640 and HEDM-5540.

± 0.25

(±0.010)

0.04

(0.0015)

± 0.175

(±0.007)

0.04

(0.0015)

mm

(in.)

mm (in.)

TIR

mm

(in.)

mm (in.)

TIR

atmosphere

6.9 mm (0.27 in.)

from mounting surface

6.9 mm (0.27 in.)

from mounting surface

6.9 mm (0.27 in.)

from mounting surface

6.9 mm (0.27 in.)

from mounting surface

Encoding Characteristics

Part No. Description Sym. Min Typ.* Max. Units

HEDS-5500

HEDS-5600

(Two Channel)

HEDM-5500

HEDM-5600

(Two Channel)

HEDS-5540

HEDS-5640

(Three Channel)

HEDM-5540

(Three Channel)

Note: See Mechanical Characteristics for mounting tolerances. *Typical values specied at VCC = 5.0 V and 25°C.

Pulse Width Error

Logic State Width Error

Phase Error

Position Error

Cycle Error

Pulse Width Error

Logic State Width Error

Phase Error

Position Error

Cycle Error

Pulse Width Error

Logic State Width Error

Phase Error

Position Error

Cycle Error

Index Pulse Width

CH.I rise after

-40°C to +100°C t

CH.A or CH. B fall

CH.I fall after

-40°C to +100°C t

CH.A or CH. B rise

Pulse Width Error

Logic State Width Error

Phase Error

Position Error

Cycle Error

Index Pulse Width

CH.I rise after

-40°C to +100°C t

CH.A or CH. B fall

CH.I fall after

-40°C to +100°C t

CH.A or CH. B rise

∆P

∆S

∆Φ

∆Θ

∆C

∆P

∆S

∆Φ

∆Θ

∆C

∆P

∆S

∆Φ

∆Θ

∆C

Po 55

1

2

-300 100 250 ns

70 150 1000 ns

∆P

∆S

∆Φ

∆Θ

∆C

Po 50

1

2

200 1000 1500 ns

0 300 1500 ns

7

5

2

10

3

10

10

2

10

3

5

5

2

10

3

90

10

10

2

10

6

90

45

45

20

40

5.5

45

45

15

40

7.5

45

35

15

40

5.5

125

45

45

15

40

12

130

°e

°e

°e

min. of arc

°e

°e

°e

°e

min. of arc

°e

°e

°e

°e

min. of arc

°e

°e

°e

°e

°e

min. of arc

°e

°e

5

Page 6

Electrical Characteristics

Electrical Characteristic over Recommended Operating Range

Part No. Parameter Sym. Min Typ.* Max. Units Notes

HEDS-5500

HEDS-5600

HEDS-5540

HEDS-5640

HEDM-5500

HEDM-5600

HEDM-5500

HEDM-5600

HEDM-5540 Supply Current

* Typical values specied at VCC = 5.0V and 25ºC

Supply Current

High Level Output Voltage

Low Level Output Voltage

Rise Time

Fall Time

Supply Current

High Level Output Voltage

Low Level Output Voltage

Rise Time

Fall Time

Supply Current

High Level Output Voltage

Low Level Output Voltage

Rise Time

Fall Time

High Level Output Voltage

Low Level Output Voltage

Rise Time

Fall Time

I

CC

V

2.4

OH

V

OL

t

r

t

f

30

I

CC

2.4

V

OH

V

OL

t

r

t

f

I

30

CC

V

2.4

OH

V

OL

t

r

t

f

I

30

CC

V

2.4

OH

V

OL

t

r

t

f

17 40

0.4

200

50

57 85

0.4

180

40

57 85

0.4

180

40

57 85

0.4

200

80

mA

V

V

ns

ns

mA

V

V

ns

ns

mA

V

V

ns

ns

mA

V

V

ns

ns

IOH = -40�A max�A maxA max

IOL= 3.2mA

CL= 25 pF

RL = 11 kΩ pull-up

IOH = -200�A max�A maxA max

IOL= 3.86mA

CL= 25 pF

RL = 2.7 kΩ pull-up

IOH = -40�A max�A maxA max

IOL= 3.86mA

CL= 25 pF

RL = 3.2 kΩ pull-up

IOH = -200�A max�A maxA max

IOL= 3.86mA

CL= 25 pF

RL = 2.7 kΩ pull-up

6

Page 7

Mechanical Characteristics

Parameter Symbol Dimension Tolerance

Codewheel Fits These Standard

Shaft Diameters

Moment of Inertia J 0.6 (8.0 x 10-6) g-cm2 (oz-in-s2)

Required Shaft Length[2] 14.0 (0.55) ± 0.5

Bolt Circle[3] 2 screw mounting 19.05

3 screw mounting 20.90

external mounting ears 46.0

Mounting Screw Size[4] 2 screw mounting M 2.5 or (2-56) mm (in.)

3 screw mounting M 1.6 or (0-80) mm (in.)

external mounting ears M 2.5 or (2-56) mm (in.)

Encoder Base Plate Thickness 0.33 (0.130) mm (in.)

Hub Set Screw (2-56) (in.)

Notes:

1. These are tolerances required of the user.

2. The HEDS-55X5 and 56X5, HEDM-5505, 5605 provide an 8.9 mm (0.35 inch) diameter hole through the housing for longer motor shafts. See

Ordering Information.

3. The HEDS-5540 and 5640 must be aligned using the aligning pins as specied in Figure 3, or using the alignment tool as shown in “Encoder

Mounting and Assembly”. See also “Mounting Considerations.”

4. The recommended mounting screw torque for 2 screw and external ear mounting is 1.0 kg-cm (0.88 in-lbs). The recommended mounting screw

torque for 3 screw mounting is 0.50 kg-cm (0.43 in-lbs).

2 3 4

5 6 8

5/32 1/8

3/16 1/4

(0.750)

(0.823)

(1.811)

+0.000

-0.015

+0.0000

-0.0007

(± 0.02)

± 0.13

(± 0.005)

± 0.13

(± 0.005)

± 0.13

(± 0.005)

[1]

Units

mm

in

mm (in.)

mm (in.)

mm (in.)

mm (in.)

Electrical Interface

To insure reliable encodingperformance, the HEDS5540/5640 and HEDM-5540 three channel encoders

require 2.7 kΩ (± 10%) pull-up resistors on output pins 2, 3,

and 5 (Channels I, A, and B) as shown in Figure 1. These pullup resistors should be located as close to the encoder as

possible (within 4 feet). Each of the three encoder outputs

Figure 1. Pull-up Resistors on HEDS-5X40 and HEDM-5540 Encoder Outputs.

can drive a single TTL load in this conguration. The HEDS5500, 5600, and HEDM-5500, 5600 two channel encoders

do not normally require pull-up resistors. However, 3.2

kΩ pull-up resistors on output pins 3 and 5 (Channels A

and B) are recommended to improve rise times, especially

when operating above 100 kHz frequencies.

7

Page 8

Mounting Considerations

The HEDS-5540 and 5640 three channel encoders and the

HEDM Series high resolution encoders must be aligned

using the aligning pins as specied in Figure 3, or using

the HEDS-8910 Alignment Tool as shown in Encoder

Mounting and Assembly.

The use of aligning pins or alignment tool is recommended but not required to mount the HEDS-5500 and 5600.

If these two channel encoders are attached to a motor

with the screw sizes and mounting tolerances specied

in the mechanical characteristics section without any

additional mounting bosses, the encoder output errors

will be within the maximums specied in the encoding

characteristics section. The HEDS-5500 and 5540 can be

mounted to a motor using either the two screw or three

screw mounting option as shown in Figure 2. The optional

aligning pins shown in Figure 3 can be used with either

mounting option. The HEDS-5600, 5640, and HEDM-5600

have external mounting ears which may be used for

mounting to larger motor base plates. Figure 4 shows the

necessary mounting holes with optional aligning pins and

motor boss.

Figure 2. Mounting Holes.

Figure 4. Mounting with External Ears.

Figure 3. Optional Mounting Aids.

8

Page 9

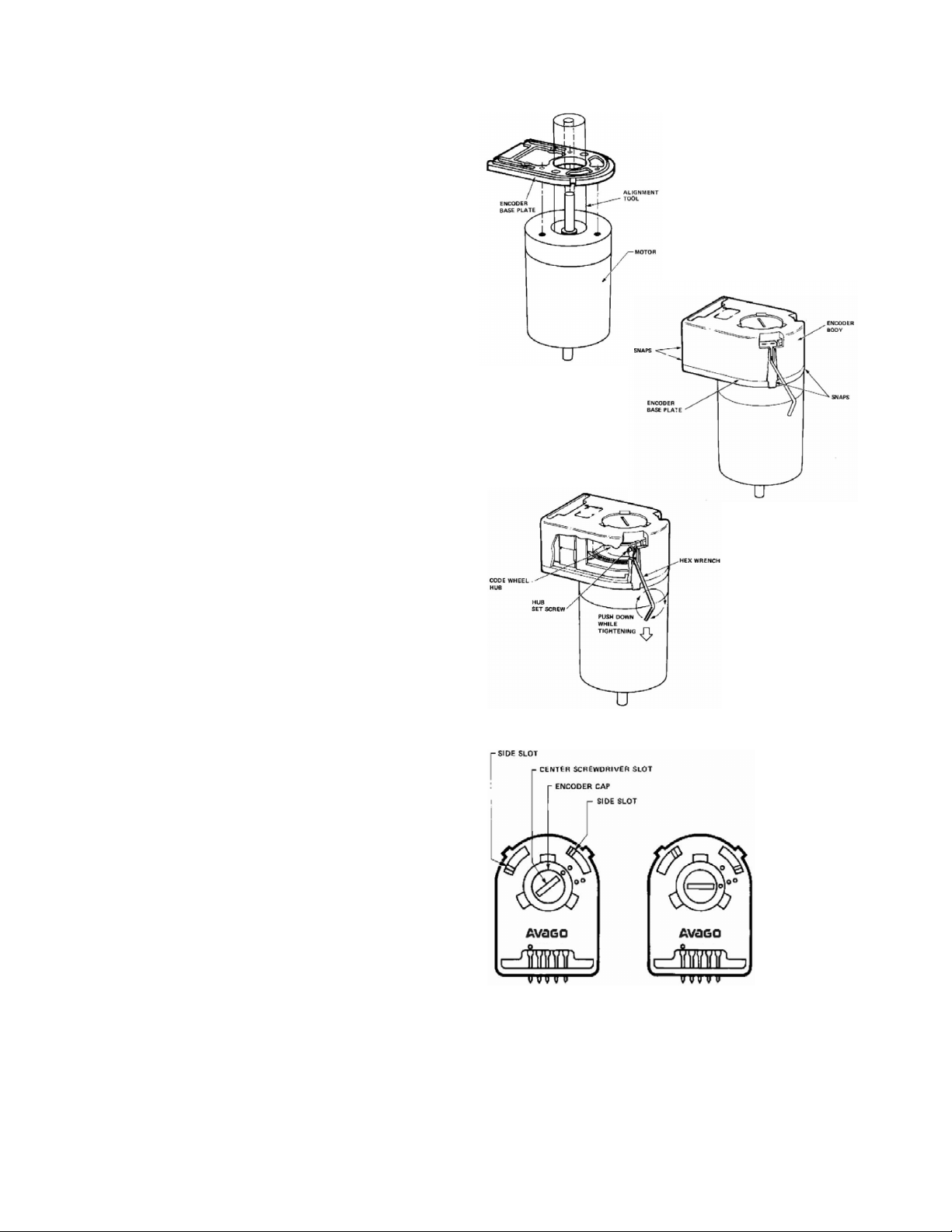

Encoder Mounting and Assembly

1a. For HEDS-5500 and 5600: Mount encoder base plate

onto motor. Tighten screws. Go on to step 2.

1b. For HEDS-5540, 5640 and HEDM-5500, 5600, 5540 :

Slip alignment tool onto motor shaft. With alignment

tool in place, mount encoder baseplate onto motor

as shown above. Tighten screws. Remove alignment

tool.

1c. It is recommended that adhesive* is applied to the

screw-baseplate interface to prevent screw loosening

due to eect of high temperature on plastic

2. Snap encoder body onto base plate locking all 4

snaps.

3a. Push the hex wrench into the body of the encoder to

ensure that it is properly seated into the code wheel

hub set screws. Then apply a downward force on the

end of the hex wrench. This sets the code wheel gap

by levering the code wheel hub to its upper position.

3b. While continuing to apply a downward force, rotate

the hex wrench in the clockwise direction until the

hub set screw is tight against the motor shaft (The

recommended torque to tighten the setscrew is 1518 ozf.inch). The hub set screw attaches the code

wheel to the motor’s shaft.

3c. Remove the hex wrench by pulling it straight out of

the encoder body.

4. Use the center screwdriver slot, or either of the two

side slots, to rotate the encoder cap dot clockwise

from the one dot position to the two dot position. Do

not rotate the encoder cap counterclockwise beyond

the one dot position.

The encoder is ready for use!

9

Page 10

Connectors

42.50

1.673

31.40

1.236

14.00

.551

16.50

.650

7.20

.283

1. Dimensions are in

2. All tolerances are within ±0.5

millimeters

Inches

Manufacturer Part Number

AMP 103686-4

640442-5

Avago (designed to mechanically lock into the

HEDS-5XXX, HEDM-5X0X Series)

Molex 2695 series with 2759 series term.

HEDS-8902 (2 ch.) with 4-wire leads

HEDS-8903 (3 ch.) with 5-wire leads

Figure 5. HEDS-8902 nd 8903 connectors

Protective Silicon Cover

Protective Silicon Rubber cover gives an extra protection

for HEDS-5xx0 and HEDM-5xx0 family when operating in

dusty environment.

The protective silicon cover is installed to HEDS-5xx0

or HEDM-5xx0 prior to the connector to the encoder is

installed.

Part Number

Material

Used With

Temperature Range

HEDS-8907-001

Silicon Rubber- Semi transparent-ESD

protective material

HEDS-5xx0 and HEDM-5xx0

-40ºC to 100ºC

10

Page 11

Shaft Diameter

01 - 2 mm 06 - 1/4 in.

02 - 3 mm 11 - 4 mm

03 - 1/8 in. 14 - 5 mm

04 - 5/32 in. 12 - 6 mm

05 - 3/16 in. 13 - 8 mm

Mounting Type

5 - Standard

6 - External

Mounting Ears

Resolution (Cycles/Rev)

B - 1000 CPR

J - 1024 CPR

Through Hole

0 - None

5 - 8.9 mm (0.35 in.)

Outputs

0 - 2 Channel

HEDS-8910 0 Alignment Tool

HEDM-5 0 Option

HEDS-5 Option

Shaft Diameter

01 - 2 mm 06 - 1/4 in.

02 - 3 mm 11 - 4 mm

03 - 1/8 in. 14 - 5 mm

04 - 5/32 in. 12 - 6 mm

05 - 3/16 in. 13 - 8 mm

Mounting Type

5 - Standard

6 - External

Mounting Ears

Through Hole

0 - None

5 - 8.9 mm (0.35 in.)

Outputs

0 - 2 Channel

4 - 3 Channel

4 - 3 Channel

HEDS-8910 0 Alignment Tool

Resolution (Cycles/Rev)

(HEDS-550X, 560X 2 Channel)

S - 50 CPR F - 256 CPR

K - 96 CP G - 360 CPR

C - 100 CPR H - 400 CPR

D - 192 CPR A - 500 CPR

E - 200 CPR I - 512 CPR

(HEDS-554X, 564X 3 Channel)

S - 50 CPR

K - 96 CPR

C - 100 CPR

E - 200 CPR

F - 256 CPR

G - 360 CPR

H - 400 CPR

A - 500 CPR

I - 512 CPR

Typical Interfaces

HOST

PROCESSOR

HEDS–55XX

OR

HEDS-56XX

OR

HEDM-5X0X

HCTL-20xx

QUADRATURE

DECODER/

COUNTER

CH. A

CH. B

HOST

PROCESSOR

CH. B

CH. A

HEDS–55XX

OR

HEDS-56XX

OR

HEDM-5X0X

HCTL-1100

MOTION

CONTROL IC

Ordering Information

Encoders with Film Codewheels

(Included with each order of HEDM-550X/560X two channel encoders and HEDM-554X three Channel encoders)

(Included with each order of HEDS-554X/564X three channel encoders)

11

Page 12

01 02 03 04 05 06 11 12 13 14

HEDM-5500 B * * * * * * *

J * * * * *

HEDM-5505 B *

J * * *

HEDM-5540 B * * * * * *

HEDM-5545 B *

HEDM-5600 B * *

J *

HEDM-5605 B *

J *

HEDS-5500 A * * * * * * * * * *

C * * * * * * * * * *

E * * * * * * *

F * * * * * * * *

G * * * * *

H * * * *

I * * * * * * * * * *

K * * * *

S *

HEDS-5505 A * * * *

C * * * *

E * * *

F * * *

G * *

H * *

I * * *

K *

HEDS-5540 A * * * * * * * * * *

C * * * * * * *

E * * *

F * * *

G *

H * *

I * * * * * * *

01 02 03 04 05 06 11 12 13 14

HEDS-5545 A * *

C *

H * *

I *

HEDS-5600 A * * * *

C * * *

E *

G * *

H * *

I * *

HEDS-5605 A * *

C *

E *

F *

G *

H * *

I *

HEDS-5640 A * * *

E *

F *

H *

HEDS-5645 A * * *

C *

E *

G *

H * * *

I *

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies Limited in the United States and other countries.

Data subject to change. Copyright © 2007 Avago Technologies Limited. All rights reserved.

AV02-1046EN - February 29, 2008

Loading...

Loading...