HDSP Series

14.2 mm (0.56 inch)

Seven Segment Displays

Data Sheet

HDSP-K40x, HDSP-550x, HDSP-552x, HDSP-560x,

HDSP-562x, HDSP-570x, HDSP-572x, HDSP-H15x,

HDSP-H40x Series

Description

The 14.2 mm (0.56 inch) LED seven segment displays are

designed for viewing distances up to 7 metres (23 feet).

These devices use an industry standard size package and

pinout. Both the numeric and ±1 overow devices feature a

right hand decimal point. All devices are available as either

common anode or common cathode.

These displays are ideal for most applications. Pin for pin

IFAVG DATA SHEET = 10 mA

h

= 1.3

Peak

IV DATA SHEET = 2800 mcd

Therefore

IvAVG = (10 mA/10 mA)

(1.3)(2800 mcd)

= 3640 mcd

Devices

Features

• Industry Standard Size

• Industry Standard Pinout

15.24 mm (0.6 in.) DIP Leads on 2.54 mm (0.1 in.) Centers

• Choice of Colors

AlGaAs Red, High Eciency Red, Yellow, Green, Orange

• Excellent Appearance

Evenly Lighted Segments

Mitered Corners on Segments

Gray Package Gives Optimum Contrast

±50° Viewing Angle

• Design Flexibility

Common Anode or Common Cathode

Single and Dual Digits

Right Hand Decimal Point

±1. Overow Character

• Categorized for Luminous Intensity

Yellow and Green Categorized for Color

Use of Like Categories Yields a Uniform Display

• High Light Output

• High Peak Current

• Excellent for Long Digit String Multiplexing

• Intensity and Color Selection Option

See Intensity and Color Selected Displays Data Sheet

• Sunlight Viewable AlGaAs

Orange AlGaAs Red HER Yellow Green Package

HDSP- HDSP-

H401 H151 5501 5701 5601 Common Anode Right Hand Decimal A

H403 H153 5503 5703 5603 Common Cathode Right Hand Decimal B

H157 5507 5707 5607 Common Anode ±1. Overow C

H158 5508 5708 5608 Common Cathode ±1. Overow D

K401 5521 5721 5621 Two Digit Common Anode Right Hand Decimal E

K403 5523 5723 5623 Two Digit Common Cathode Right Hand Decimal F

Note:

1. These displays are recommended for high ambient light operation. Please refer to the HDSP-H10X/K12X AlGaAs and HDSP-555X HER data sheet

for low current operation.

[1]

HDSP-

[1]

HDSP- HDSP- Description Drawing

Contrast Enhancement

The objective of contrast enhancement is to provide good

display readability in the end use ambient light. The concept

is to employ both luminance and chrominance contrast

techniques to enhance the readability. This is accomplished

by having the OFF dots blend into the display background

and the ON dots stand out vividly against this same background. Therefore, these display devices are assembled

with a gray package and matching encapsulating epoxy

in the dots.

Contrast enhancement may be achieved by using one of

the following suggested lters:

Standard Red and AlGaAs Red (HDSP-5300/H150)

Panelgraphic RUBY RED 60

SGL-Homalite H100-1605 RED

3M Louvered Filter R6610 RED or N0210 GRAY

HER (HDSP-5500)

Panelgraphic SCARLET RED 60

SGL-Homalite H100-1670 RED or H100-1250 GRAY

3M Louvered Filter R6610 RED or N0210 GRAY

Yellow (HDSP-5700)

Panelgraphic YELLOW 27 or GRAY 10

SGL-Homalite H100-1720 AMBER or H100-1250 GRAY

3M Louvered Filter A5910 AMBER or N0210 GRAY

Mechanical

Specially developed plastics are used to optimize the

displays optical performance. These plastics restrict the

solvents that may be used for cleaning. Only mixtures of

Freon (F113) and alcohol should be used for vapor cleaning processes. Total immersion time in the vapors is two

minutes. Some suggested mixtures are Freon TE, Arklone

A or K, or Genesolv DI-15 or DE-15. A 60°C (140°F) water

cleaning process may also be used. This process includes

a neutralizer rinse (3% ammonia solution or equivalent),

a surfactant rinse (1% detergent solution or equivalent),

a water rinse, and a thorough air dry. Room temperature

cleaning may be done with Freon T-E35 or T-P35, Ethanol,

Isopropanol, or water with a mild detergent.

Cleaning agents from the ketone family (acetone, methyl

ethyl ketone, etc.) and from the chlorinated hydrocarbon

family (methylene chloride, trichloroethylene, carbon

tetrachloride, etc.) are not recommended for cleaning

LED parts. All of these various solvents attack or dissolve

the encapsulating epoxies used to form the package of

plastic LED parts.

Green (HDSP-5600)

Panelgraphic GREEN 48

SGL-Homalite H100-1440 GREEN or H100-1250 GRAY

3M Louvered Filter YG6610 RED or N0210 GRAY

For further information on contrast enhancement please

see Application Note 1015.

2

These displays are ideal for most applications. Pin for pin

equivalent displays are also available in a low current design.

The low current displays are ideal for portable applications.

For additional information see the Low Current Seven Segment Displays data sheet.

Part Numbering System

5 08 2 - X XX X - X X X X X

H DS P - X X X X- X X X X X

Mechanical Options

[1]

00: No Mechanical Option

Color Bin Options

[1,2]

0: No Color Bin Limitation

Maximum Intensity Bin

[1,2]

0: No Maximum Intensity Bin Limitation

Minimum Intensity Bin

[1,2]

0: No Minimum Intensity Bin Limitation

Device Conguration/Color

[1]

1: Common Anode

3: Common Cathode

Device Specic Conguration

[1]

Refer to Respective Datasheet

Package

[1]

H: 14.2 mm (0.56 inch) Single Digit Seven Segment Display

Notes:

1. For codes not listed in the gure above, please refer to the respective datasheet or contact your nearest Avago representative for details.

2. Bin options refer to shippable bins for a part number. Color and Intensity Bins are typically restricted to 1 bin per

tube (exceptions may apply). Please refer to respective datasheet for specic bin limit information.

3

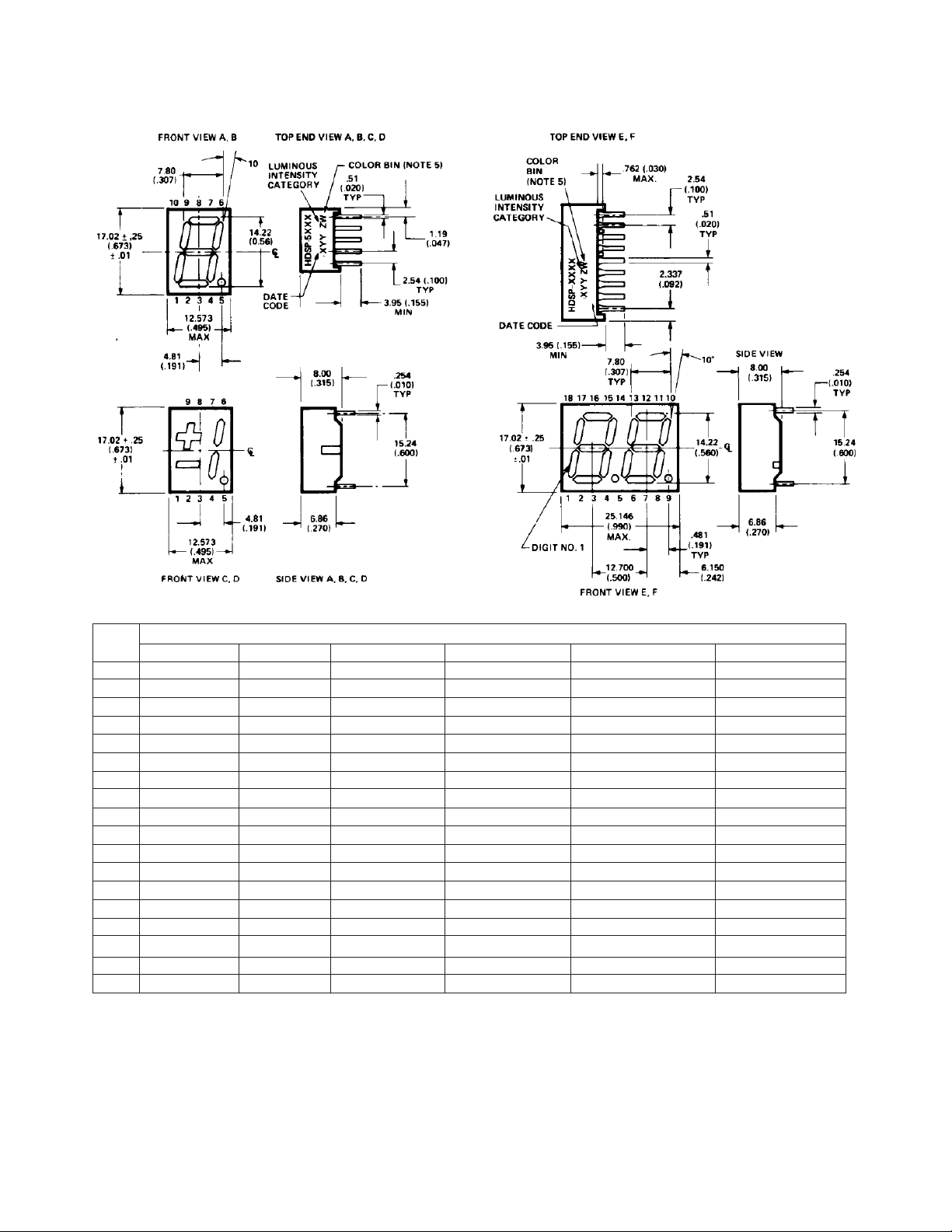

Package Dimensions

FUNCTION

PIN A B C D E F

1 CATHODE e ANODE e CATHODE c ANODE c E CATHODE NO. 1 E ANODE NO. 1

2 CATHODE d ANODE d ANODE c, d CATHODE c, d D CATHODE NO. 1 D ANODE NO. 1

3 ANODE

[3]

CATHODE

[4]

CATHODE b ANODE b C CATHODE NO. 1 C ANODE NO. 1

4 CATHODE c ANODE c ANODE a, b, DP CATHODE a, b, DP DP CATHODE NO. 1 DP ANODE NO. 1

5 CATHODE DP ANODE DP CATHOPDE DP ANODE DE E CATHODE NO. 2 E ANODE NO. 2

6 CATHODE b ANODE b CATHODE a ANODE a D CATHODE NO. 2 D ANODE NO. 2

7 CATHODE a ANODE a ANODE a, b, DP CATHODE a, b, DP G CATHODE NO. 2 G ANODE NO. 2

8 ANODE

[3]

CATHODE

[4]

ANODE c, d CATHODE c, d C CATHODE NO. 2 C ANODE NO. 2

9 CATHODE f ANODE f C ATHODE d ANODE d DP CATHODE NO. 2 DP ANODE NO. 2

10 CATHODE g ANODE g NO PIN NO PIN B CATHODE NO. 2 B ANODE NO. 2

11 A CATHODE NO. 2 A ANODE NO. 2

12 F CATHODE NO. 2 F ANODE NO. 2

13 DIGIT NO. 2 ANODE DIGIT NO. 2 CATHODE

14 DIGIT NO. 1 ANODE DIGIT NO. 1 CATHODE

15 B CATHODE NO. 1 B ANODE NO. 1

16 A CATHODE NO. 1 A ANODE NO. 1

17 G CATHODE NO. 1 G ANODE NO. 1

18 F CATHODE NO. 1 F ANODE NO. 1

NOTES:

1. ALL DIMENSIONS IN MILLIMETRES (INCHES).

2. ALL UNTOLERANCED DIMENSIONS ARE FOR REFERENCE ONLY.

3. REDUNDANT ANODES.

4. REDUNDANT CATHODES.

5. FOR HDSP-5600/-5700 SERIES PRODUCT ONLY.

4

Internal Circuit Diagram

Absolute Maximum Ratings

HER/Orange

HDSP-5500

AlGaAs Red HDSP-H40x Yellow Green

HDSP-H150 HDSP-K40x HDSP-5700 HDSP-5600

Description Series Series Series Series Units

Average Power per Segment or DP 96 105 80 105 mW

Peak Forward Current per 160

[1]

90

Segment or DP

DC Forward Current per Segment or DP 40

Operating Temperature Range -20 to +100

[2]

30

[9]

-40 to +100 °C

Storage Temperature Range -55 to +100 °C

Reverse Voltage per Segment or DP 3.0 V

Wavesoldering Temperature for 3 Seconds 250 °C

(1.60 mm [0.063 in.] below body)

Notes:

1. See Figure 2 to establish pulsed conditions.

2. Derate above 46°C at 0.54 mA/°C.

3. See Figure 7 to establish pulsed conditions.

4. Derate above 53°C at 0.45 mA/°C.

5. See Figure 8 to establish pulsed conditions.

6. Derate above 81°C at 0.52 mA/°C.

7. See Figure 9 to establish pulsed conditions.

8. Derate above 39°C at 0.37 mA/°C.

9. For operation below -20°C, contact your local Avago

components sales oce or an authorized distributor.

[3]

60

[4]

20

[5]

90

[6]

30

[7]

mA

18]

mA

5

Electrical/Optical Characteristics at TA = 25°C

AlGaAs Red

Device

Series

HDSP- Parameter Symbol Min. Typ. Max. Units Test Conditions

Luminous Intensity/Segment

(Digit Average)

1.8 IF = 20 mA

Forward Voltage/Segment or DP VF V

2.0 3.0 IF = 100 mA

H15X

Peak Wavelength l

Dominant Wavelength

Reverse Voltage/Segment or DP

Temperature Coecient of ∆VF/°C -2 mV/°C

VF/Segment or DP

Thermal Resistance LED Junction- Rq

to-Pin Seg

[1,2,5]

IV 9.1 16.0 mcd IF = 20 mA

645 nm

PEAK

[3]

ld 637 nm

[4]

VR 3.0 15 V IR = 100 µA

400 °C/W/

J-Pin

High Eciency Red

Device

Series

HDSP- Parameter Symbol Min. Typ. Max. Units Test Conditions

900 2800 IF = 10 mA

Luminous Intensity/Segment

1 of 6 df

(Digit Average) 3700 IF = 60 mA Peak:

Forward Voltage/Segment or DP VF 2.1 2.5 V IF = 20 mA

55XX

Peak Wavelength l

Dominant Wavelength

Reverse Voltage/Segment or DP

Temperature Coecient of ∆VF/°C -2 mV/°C

VF/Segment or DP

Thermal Resistance LED Junction- Rq

to-Pin Seg

[1,2,6]

IV µcd

635 nm

PEAK

[3]

ld 626 nm

[4]

VR 3.0 30 V IR = 100 µA

345 °C/W/

J-Pin

6

Yellow

Device

Series

HDSP- Parameter Symbol Min. Typ. Max. Units Test Conditions

600 1800 IF = 10 mA

Luminous Intensity/Segment

1 of 6 df

(Digit Average) 2750 IF = 60 mA Peak:

Forward Voltage/Segment or DP VF 2.1 2.5 V IF = 20 mA

57XX

Peak Wavelength l

Dominant Wavelength

Reverse Voltage/Segment or DP

Temperature Coecient of ∆VF/°C -2 mV/°C

VF/Segment or DP

Thermal Resistance LED Junction- Rq

to-Pin Seg

[1,2]

IV µcd

583 nm

PEAK

[3,7]

ld 581.5 586 592.5 nm

[4]

VR 3.0 40 V IR = 100 µA

345 °C/W/

J-Pin

Orange

Device

Series

HDSP- Parameter Symbol Min. Typ. Max. Units Test Conditions

Luminous Intensity/Segment IV 2.37 mcd IF = 10 mA

(Segment Average)

Forward Voltage/Segment or DP VF 2.1 2.5 V IF = 20 mA

Peak Wavelength l

H40x Dominant Wavelength

K40x Reverse Voltage/Segment or DP

Temperature Coecient of ∆VF/°C -2 mV/°C

VF/Segment or DP

Thermal Resistance LED Junction- Rq

to-Pin Seg

[1,2]

600 nm

PEAK

[3]

ld 603 nm IF = 10 mA

[4]

VR 3.0 30 V IR = 100 µA

345 °C/W/

J-Pin

7

High Performance Green

Device

Series

HDSP- Parameter Symbol Min. Typ. Max. Units Test Conditions

900 2500 IF = 10 mA

Luminous Intensity/Segment

1 of 6 df

(Digit Average)` 3100 IF = 60 mA Peak:

Forward Voltage/Segment or DP VF 2.1 2.5 V IF = 10 mA

56XX

Peak Wavelength l

Dominant Wavelength

Reverse Voltage/Segment or DP

Temperature Coecient of ∆VF/°C -2 mV/°C

VF/Segment or DP

Thermal Resistance LED Junction- Rq

to-Pin Seg

Notes:

1. Device case temperature is 25°C prior to the intensity measurement.

2. The digits are categorized for luminous intensity. The intensity category is designated by a letter on the side of the package.

3. The dominant wavelength, ld, is derived from the CIE chromaticity diagram and is that single wavelength which denes the color of the device.

4. Typical specication for reference only. Do not exceed absolute maximum ratings.

5. For low current operation, the AlGaAs HDSP-H10X series displays are recommended. They are tested at 1 mA dc/segment and are pin for pin

compatible with the HDSP-H15X series.

6. For low current operation, the HER HDSP-555X series displays are recommended. They are tested at 2 mA dc/segment and are pin for pin com-

patible with the HDSP-550X series.

7. The Yellow (HDSP-5700) and Green (HDSP-5600) displays are categorized for dominant wavelength. The category is designated by a number

adjacent to the luminous intensity category letter.

[1,2]

IV µcd

566 nm

PEAK

[3,7]

ld 571 577 nm

[4]

VR 3.0 50 V IR = 100 µA

345 °C/W/

J-Pin

AlGaAs Red

Figure 1. Maximum Tolerable Peak Current vs. Pulse Duration – Red.

8

Figure 2. Maximum Tolerable Peak Current vs. Pulse Duration

– AlGaAs Red.

Figure 3. Maximum Allowable DC Current vs. Ambient Temperature. Figure 4. Forward Current vs. Forward Voltage.

I

DC

MAX. – MAXIMUM DC CURRENT PER SEGMENT – mA

20

0

TA – AMBIENT TEMPERATURE – C

30 90 120

50

30

7050

AlGaAs RED

10

20

5

15

25

35

40 60 80 100 110

40

45

Rθ

J-A

= 770 C/W

I

F

– FORWARD CURRENT PER SEGMENT – mA

0

0

VF – FORWARD VOLTAGE – V

160

100

60

2.0 4.0

80

20

1.0 3.0

40

AlGaAs RED

0.5 1.5 2.5 3.5

120

140

RELATIVE LUMINOUS INTENSITY

(NORMALIZED TO 1 AT 20 mA)

0

0

IF – FORWARD CURRENT PER SEGMENT – mA

2.00

1.50

1.25

0.75

0.25

20 40

1.75

1.00

0.50

10 305 15 25 35

AlGaAs RED

η

PEAK

– NORMALIZED RELATIVE EFFICIENCY

0.5

0.6

I

PEAK

– PEAK FORWARD CURRENT

PER SEGMENT – mA

50.0 150.0

1.4

0.8

5.0

1.0

1.2

AlGaAs RED

Figure 5. Relative Luminous Intensity vs. DC Forward Current. Figure 6. Relative Eciency (Luminous Intensity per Unit Current) vs.

Peak Current.

HER, Yellow, Green, Orange

Figure 7. Maximum Tolerable Peak Current vs. Pulse Duration – HER,

Orange.

9

Figure 8. Maximum Tolerable Peak Current vs. Pulse Duration

– Yellow.

Figure 9. Maximum Tolerable Peak Current vs.

I

F

– FORWARD CURRENT PER SEGMENT – mA

1

0

VF – FORWARD VOLTAGE – V

90

70

60

30

10

3 5

80

50

20

2 4

40

HER SERIES,

ORANGE

SERIES

GREEN SERIES

YELLOW SERIES

RELATIVE LUMINOUS INTENSITY

(NORMALIZED AT 10 mA)

0

0

IF – DC FORWARD CURRENT – mA

4.0

3.0

2.5

1.5

0.5

20 40

3.5

2.0

1.0

10 305 15 25 35

HER, YELLOW,

GREEN, ORANGE

h

V

– RELATIVE EFFICIENCY

(NORMALIZED TO 1 AT 10 mA PER SEGMENT)

0

0.6

I

PEAK

– PEAK FORWARD CURRENT

9020 70 80 100

1.6

1.4

1.3

1.1

0.9

0.8

6050403010

HER SERIES,

ORANGE SERIES

GREEN SERIES

0.7

1.0

1.2

1.5

YELLOW SERIES

Pulse Duration – Green.

Figure 10. Maximum Allowable DC Current vs. Ambient

Temperature.

Figure 11. Forward Current vs. Forward

Voltage.

Electrical/Optical

For more information on electrical/optical characteristics,

please see Application Note 1005.

Contrast Enhancement

For information on contrast enhancement please see Application Note 1015.

Figure 12. Relative Luminous Intensity vs. DC

Forward Current.

Soldering/Cleaning

Cleaning agents from the ketone family (acetone, methyl

ethyl ketone, etc.) and from the chlorinated hydrocarbon

family (methylene chloride, trichloro–ethylene, carbon

tetrachloride, etc.) are not recommended for cleaning LED

parts. All of these various solvents attack or dissolve the

encapsulating epoxies used to form the package of plastic

LED parts.

For information on soldering LEDs please refer to Application Note 1027.

Figure 13. Relative Eciency (Luminous

Intensity per Unit Current) vs. Peak Current.

Intensity Bin Limits (mcd)

AlGaAs Red

HDSP-H15x

IV Bin Category Min. Max.

K 9.20 16.90

L 13.80 25.30

M 20.70 38.00

N 31.10 56.90

O 46.60 85.40

HER

HDSP-550x/552x

IV Bin Category Min. Max.

E 0.91 1.67

F 1.37 2.51

G 2.05 3.76

H 3.08 5.64

I 4.62 8.64

J 6.93 12.70

K 10.39 19.04

Yellow

HDSP-570x/572x

IV Bin Category Min. Max.

D 0.61 1.11

E 0.91 1.67

F 1.37 2.51

G 2.05 3.76

H 3.08 5.64

I 4.62 8.64

J 6.93 12.70

K 10.39 19.04

Orange

HDSP-H40x/K40x

IV Bin Category Min. Max.

B 0.77 1.17

C 0.95 1.45

D 1.19 1.82

E 1.49 2.27

F 1.85 2.89

G 2.32 3.54

H 2.90 4.43

Color Categories

Dominant Wavelength (nm)

Color Bin Min. Max.

Yellow 1 581.50 585.00

3 584.00 587.50

2 586.50 590.00

4 589.00 592.50

Green 2 573.00 577.00

3 570.00 574.00

4 567.00 571.00

5 564.00 568.00

Note:

All categories are established for classication of products. Products

may not be available in all categories. Please contact your Avago representatives for further clarication/information.

Green

HDSP-560x/562x

IV Bin Category Min. Max.

E 0.91 1.67

F 1.37 2.51

G 2.05 3.76

H 3.08 5.64

I 4.61 8.46

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies Limited in the United States and other countries.

Data subject to change. Copyright © 2008 Avago Technologies Limited. All rights reserved. Obsoletes 5988-4273EN

AV02-1107EN - March 17, 2008

11

Loading...

Loading...