APDS-9300

Miniature Ambient Light Photo Sensor

with Digital (I2C) Output

Data Sheet

Description

The APDS-9300 is a low-voltage Digital Ambient Light

Photo Sensor that converts light intensity to digital signal

output capable of direct I2C interface. Each device consists

of one broadband photodiode (visible plus infrared) and

one infrared photodiode. Two integrating ADCs convert

the photodiode currents to a digital output that represents

the irradiance measured on each channel. This digital output can be input to a microprocessor where illuminance

(ambient light level) in lux is derived using an empirical

formula to approximate the human-eye response.

Application Support Information

The Application Engineering Group is available to assist

you with the application design associated with APDS9300 ambient light photo sensor module. You can contact

them through your local sales representatives for additional details.

Features

• Approximate the human-eye response

• Precise Illuminance measurement under diverse

lighting conditions

• Programmable Interrupt Function with User-Dened

Upper and Lower Threshold Settings

• 16-Bit Digital Output with I2C Fast-Mode at 400 kHz

• Programmable Analog Gain and Integration Time

• Miniature ChipLED Package

Height - 0.55mm

Length - 2.60mm

Width - 2.20mm

• 50/60-Hz Lighting Ripple Rejection

• Low 2.5-V Input Voltage and 1.8-V Digital Output

• Low Active Power (0.6 mW Typical) with Power Down

Mode

• RoHS Compliant

Applications

• Detection of ambient light to control display

backlighting

o Mobile devices – Cell phones, PDAs, PMP

o Computing devices – Notebooks, Tablet PC, Key

board

o Consumer devices – LCD Monitor, Flat-panel TVs,

Video Cameras, Digital Still Camera

• Automatic Residential and Commercial Lighting

Management

• Automotive instrumentation clusters.

• Electronic Signs and Signals

Ordering Information

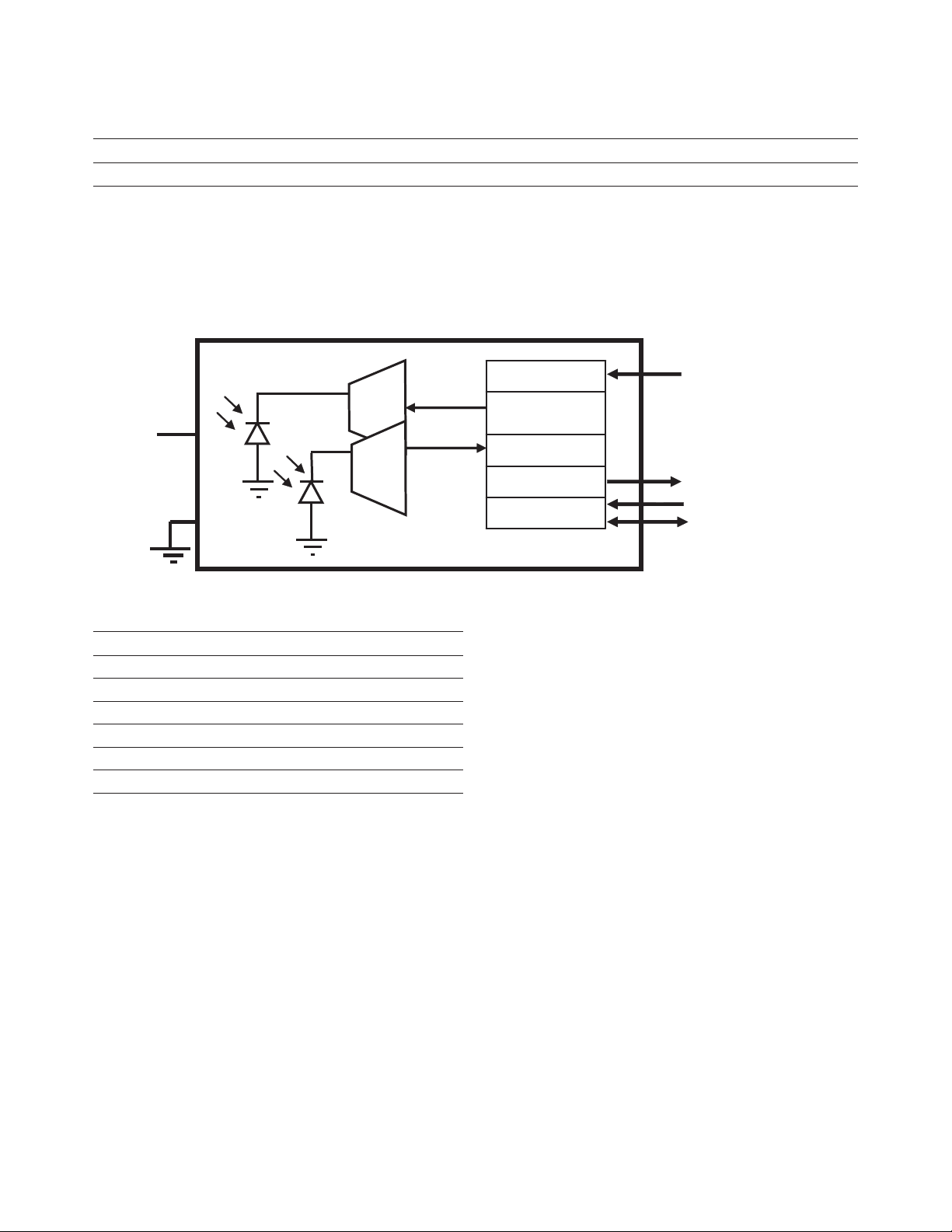

I2C

Interrupt

ADC Register

Command

Register

Address Select

Ch0 (Visible + IR)

Ch1 (IR)

SCL

SDA

ADDR SEL

VDD= 2.4 V

to 3.0 V

INT

ADC

ADC

GND

Part Number Packaging Type Package Quantity

APDS-9300-020 Tape and Reel 6-pins Chipled package 2500

Functional Block Diagram

I/O Pins Conguration Table

Pin Symbol Description

1 V

2 GND Ground

3 ADDR SEL Address Select

4 SCL Serial Clock

5 SDA Serial Data

6 INT Interrupt

DD

2

Voltage Supply

Absolute Maximum Ratings

Parameter Symbol Min Max Unit

Supply voltage V

Digital output voltage range V

Digital output current I

Storage temperature range T

ESD tolerance human body model - 2000 V

DD

O

O

stg

- 3.8 V

-0.5 3.8 V

-1 20 mA

-40 85 ºC

Recommended Operating Conditions

Parameter Symbol Min Typ Max Unit Conditions

Supply Voltage V

Operating Temperature T

SCL, SDA input low voltage V

SCL, SDA input high voltage V

DD

a

IL

IH

2.4 2.5 3.0 V

-30 - 85 ºC

-0.5 - 0.58 V

1.13 - 3.6 V 2.4 ≤ VDD ≤ 2.6

1.25 - 3.6 V 2.4 ≤ VDD ≤ 3.0

Electrical Characteristics

Parameter Symbol Min Typ Max Unit Conditions

Supply current I

INT, SDA output low voltage V

Leakage current I

DD

OL

LEAK

-

-

0

0

0.24

3.2

-

-

0.6

15

0.4

0.6

mA

μA

V

V

-5 - 5 μA

Active

Power down

3 mA sink current

6 mA sink current

3

Operating Characteristics, High Gain (16X), VDD = 2.5 V, Ta = 25 ºC, (unless otherwise noted) (see Notes 2, 3, 4, 5)

Parameter Symbol Channel Min Typ Max Unit Conditions

Oscillator frequency fosc 690 735 780 kHz

Dark ADC count value Ch0 0 4 counts Ee = 0, Tint = 402 ms

Ch1 0 4

Full scale ADC count value

(Note 6)

ADC count value Ch0 750 1000 1250 counts λp = 640 nm, Tint = 101 ms

ADC count value ratio: Ch1/

Ch0

Irradiance responsivity Re Ch0 27.5 counts/

Illuminance responsivity Rv Ch0 36 counts/

ADC count value ratio: Ch1/

Ch0

Illuminance responsivity,

low gain mode (Note 7)

(Sensor Lux) /(actual Lux),

high gain mode (Note 8)

Rv Ch0 2.3 counts/

Ch0 65535 counts Tint > 178 ms

Ch1 65535

Ch0 37177 Tint = 101 ms

Ch1 37177

Ch0 5047 Tint = 13.7 ms

Ch1 5047

Ch1 200 Ee = 36.3 µW/cm2

Ch0 700 1000 1300 λp = 940 nm, Tint = 101 ms

Ch1 820 Ee = 119 µW/cm2

0.15 0.2 0.25 λp = 640 nm, Tint = 101 ms

0.69 0.82 0.95 λp = 940 nm, Tint = 101 ms

λp = 640 nm, Tint = 101 ms

Ch1 5.5

Ch0 8.4 λp = 940 nm, Tint = 101 ms

Ch1 6.9

Ch1 4 Tint = 402 ms

Ch0 144 Incandescent light source:

Ch1 72 Tint = 402 ms

0.11 Fluorescent light source:

0.5 Incandescent light source:

Ch1 0.25 Tint = 402 ms

Ch0 9 Incandescent light source:

Ch1 4.5 Tint = 402 ms

0.65 1 1.35 Fluorescent light source:

0.60 1 1.40 Incandescent light source:

(µW/cm2)

Fluorescent light source:

lux

Tint = 402 ms

Tint = 402 ms

Fluorescent light source:

lux

Tint = 402 ms

Tint = 402 ms

4

Notes:

2. Optical measurements are made using small–angle incident radiation from light–emitting diode optical sources. Visible 640 nm LEDs and infrared

940 nm LEDs are used for nal product testing for compatibility with high–volume production.

3. The 640 nm irradiance Ee is supplied by an AlInGaP light–emitting diode with the following characteristics: peak wavelength lp = 640 nm and

spectral halfwidth Dl½ = 17 nm.

4. The 940 nm irradiance Ee is supplied by a GaAs light–emitting diode with the following characteristics: peak wavelength lp = 940 nm and spectral

halfwidth Dl½ = 40 nm.

5. Integration time Tint, is dependent on internal oscillator frequency (fosc) and on the integration eld value in the timing register as described in

the Register Set section. For nominal fosc = 735 kHz, nominal Tint = (number of clock cycles)/fosc.

Field value 00: Tint = (11 • 918)/fosc = 13.7 ms

Field value 01: Tint = (81 • 918)/fosc = 101 ms

Field value 10: Tint = (322 • 918)/fosc = 402 ms

Scaling between integration times vary proportionally as follows:

11/322 = 0.034 (eld value 00), 81/322 = 0.252 (eld value 01), and 322/322 = 1 (eld value 10).

6. Full scale ADC count value is limited by the fact that there is a maximum of one count per two oscillator frequency periods and also by a 2–count

oset.

Full scale ADC count value = ((number of clock cycles)/2 - 2)

Field value 00: Full scale ADC count value = ((11 • 918)/2 - 2) = 5047

Field value 01: Full scale ADC count value = ((81 • 918)/2 - 2) = 37177

Field value 10: Full scale ADC count value = 65535, which is limited by 16 bit register. This full scale ADC count value is reached for 131074

clock cycles, which occurs for Tint = 178 ms for nominal fosc = 735 kHz.

7. Low gain mode has 16x lower gain than high gain mode: (1/16 = 0.0625).

8. For sensor Lux calculation, please refer to the empirical formula in Application Note. It is based on measured Ch0 and Ch1 ADC count values for the

light source specied. Actual Lux is obtained with a commercial luxmeter. The range of the (sensor Lux) / (actual Lux) ratio is estimated based on

the variation of the 640 nm and 940 nm optical parameters. Devices are not 100% tested with uorescent or incandescent light sources.

CH1/CH0 Sensor Lux Formula

0 ≤ CH1/CH0 ≤ 0.52 Sensor Lux = (0.0315 x CH0) – (0.0593 x CH0 x ((CH1/CH0)

0.52 ≤ CH1/CH0 ≤ 0.65 Sensor Lux = (0.0229 x CH0) – (0.0291 x CH1)

0.65 ≤ CH1/CH0 ≤ 0.80 Sensor Lux = (0.0157 x CH0) – (0.0180 x CH1)

0.80 ≤ CH1/CH0 ≤ 1.30 Sensor Lux = (0.00338 x CH0) – (0.00260 x CH1)

CH1/CH0 ≥ 1.30 Sensor Lux = 0

1.4

))

AC Electrical Characteristics (VDD = 3 V, Ta = 25 ºC)

Parameter † Min. Typ. Max. Unit

t

(CONV)

f

(SCL)

t

(BUF)

t

(HDSTA)

t

(SUSTA)

t

(SUSTO)

t

(HDDAT)

t

(SUDAT)

t

(LOW)

t

(HIGH)

t

F

t

R

C

j

† Specied by design and characterization; not production tested.

Conversion time 12 100 400 ms

Clock frequency - - 400 kHz

Bus free time between start and stop condition 1.3 - - μs

Hold time after (repeated) start condition. After this

0.6 - - μs

period, the rst clock is generated.

Repeated start condition setup time 0.6 - - μs

Stop condition setup time 0.6 - - μs

Data hold time 0 - 0.9 μs

Data setup time 100 - - ns

SCL clock low period 1.3 - - μs

SCL clock high period 0.6 - - μs

Clock/data fall time - - 300 ns

Clock/data rise time - - 300 ns

Input pin capacitance - - 10 pF

5

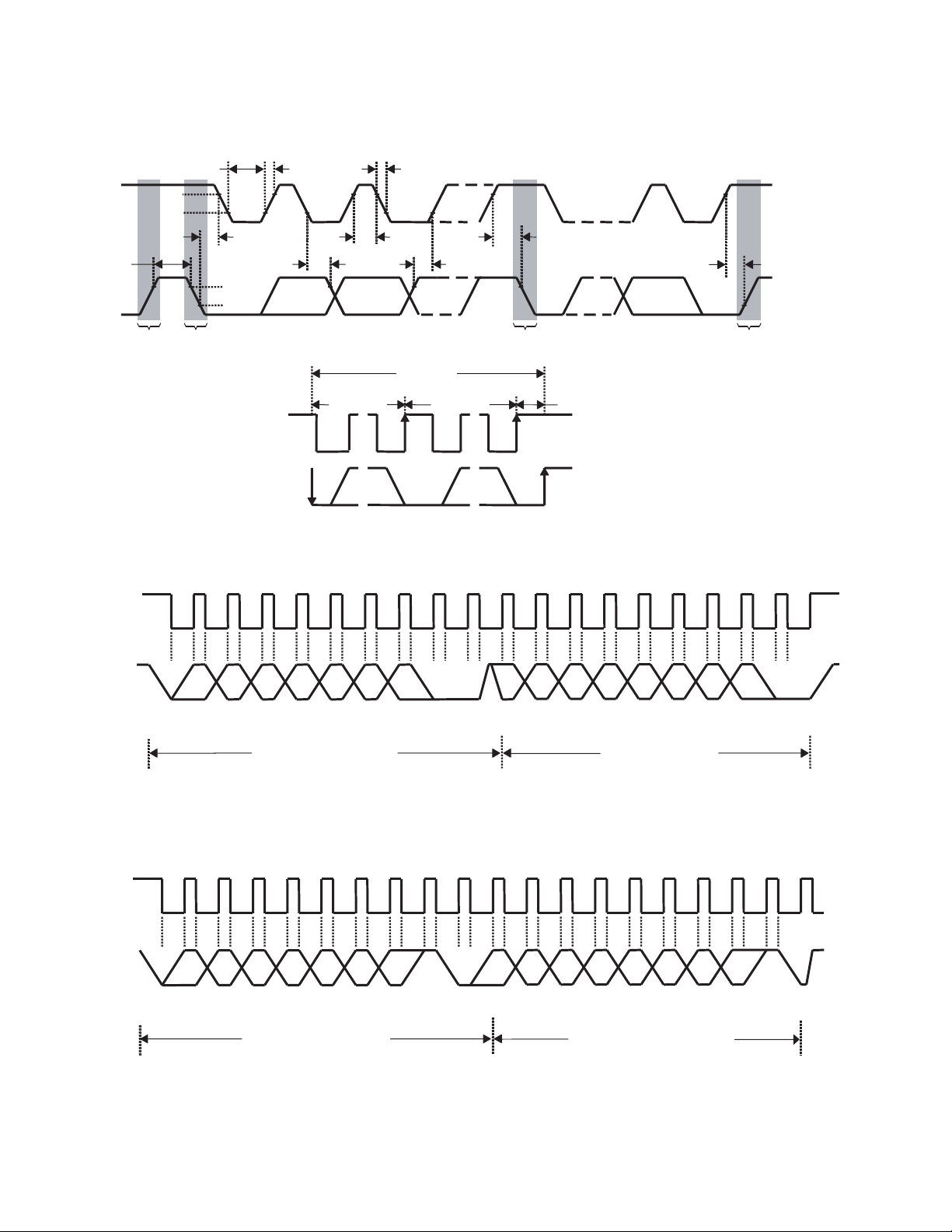

Parameter Measurement Information

A0A1A2A3A4A5A 6D1D2D3D4D5D6D7D0

R/W

Start by

Master

ACK by

APDS-9300

Stop by

Master

ACK by

APDS-9300

SDA

Frame 1 I2C Slave Address Byte

Frame 2 Command Byte

SCL

1 9 1 9

SDA

SCL

StopStart

SCL

ACK

t

(LOWMEXT)

t

(LOWMEXT)

t

(LOWSEXT)

SCL

ACK

t

(LOWMEXT)

SDA

SCL

Start

Condition

Stop

Condition

P

t

(SUSTO)

t

(SUDAT)

t

(HDDAT)

t

(BUF)

V

IH

V

IL

t

(R)

t

(LOW)

t

(HIGH)

t

(F)

t

(HDSTA)

V

IH

V

IL

P S

S

t

(SUSTA)

A0A1A2A3A4A5A6D1D2D3D4D5D6D7D 0

R/W

Start by

Master

ACK by

APDS-9300

Stop by

Master

NACK by

Master

SDA

Frame 1 I2C Slave Address Byte

Frame 2 Data Byte From APDS-9300

SCL

1 9 1

9

Figure 1. Timing Diagrams

Figure 2. Example Timing Diagram for I2C Send Byte Format

Figure 3. Example Timing Diagram for I2C Receive Byte Format

6

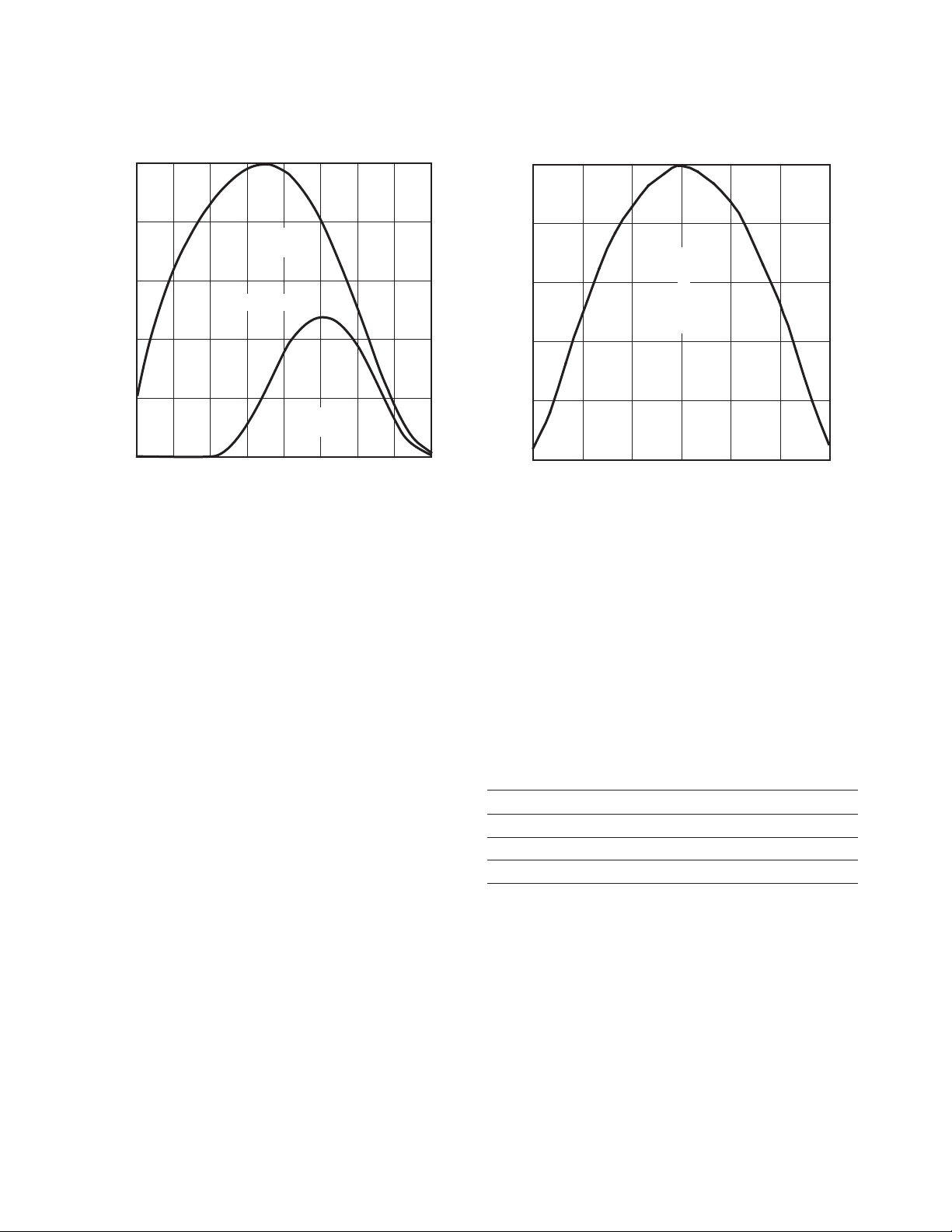

Typical Characteristics

SPECTRAL RESPONSIVITY

0

400

0.2

0.4

0.6

0.8

1

500 600 700 800 900 1000 1100

NORMALIZED RESPONSIVITY

300

CHANNEL 1

PHOTODIODE

CHANNEL 0

PHOTODIODE

- WAVELENGTH - nm

470 pF

ANGULAR DISPLACEMENT - °

NORMALIZED RESPONSIVITY

0

0.2

0.4

0.6

0.8

1.0

-90 -60 -30 0 30 60

90

OPTICAL AXIS

Figure 4. Normalized Responsivity vs. Spectral Responsivity Figure 5. Normalized Responsivity vs. Angular Displacement * CL Package

Principles of Operation

Analog–to–Digital Converter

The APDS-9300 contains two integrating analog–to–digital converters (ADC) that integrate the currents from the

channel 0 and channel 1 photodiodes. Integration of both

channels occurs simultaneously, and upon completion of

the conversion cycle the conversion result is transferred to

the channel 0 and channel 1 data registers, respectively.

The transfers are double buered to ensure that invalid

data is not read during the transfer. After the transfer, the

device automatically begins the next integration cycle.

Digital Interface

Interface and control of the APDS-9300 is accomplished

through a two–wire serial interface to a set of registers

that provide access to device control functions and output data. The serial interface is compatible to I2C bus Fast–

Mode. The APDS-9300 oers three slave addresses that

are selectable via an external pin (ADDR SEL). The slave

address options are shown in Table 1.

Table 1. Slave Address Selection

ADDR SEL Terminal Level Slave Address

GND 0101001

Float 0111001

V

DD

NOTE:

The Slave Addresses are 7 bits and please note the I2C protocols. A read/

write bit should be appended to the slave address by the master device

to properly communicate with the APDS-9300 device.

1001001

7

I2C Protocols

Wr

71 81 1 1 1

Data ByteSlave AddressS A PA

X X

A Acknowledge (this bit position may be 0 for an ACK or 1 for a NACK)

P Stop Condition

Rd Read (bit value of 1)

S Start Condition

Sr Repeated Start Condition

Wr Write (bit value of 0)

X Shown under a field indicates that that field is required to have a value of X

... Continuation of protocol

Master –to–Slave

Slave –to–Master

P

Wr

81 81 1 1 17

Slave AddressS A

A

Command Code Data Byte A

1

P

Wr

1

71 81 1 1 81 17 1 1

Data Byte

Slave AddressS A

A

Command Code Slave Address

A

ASr Rd

P

Wr

1

81 81 1 1 8 17 1

Data Byte High

Slave Address

SAA

Command Code

Data Byte Low

A

A

Wr

71 81 1 1 17 1 1

Slave Address

SAA

Command Code

Slave Address

ASrRd

8 1

Data Byte Low

A

…

P

1

8 1

Data Byte High

A

1

Each Send and Write protocol is, essentially, a series of

bytes. A byte sent to the APDS-9300 with the most signicant bit (MSB) equal to 1 will be interpreted as a COMMAND byte. The lower four bits of the COMMAND byte

form the register select address (see Table 2), which is

used to select the destination for the subsequent byte(s)

received. The APDS-9300 responds to any Receive Byte requests with the contents of the register specied by the

stored register select address.

The APDS-9300 implements the following protocols of

the Philips Semiconductor I2C specication:

• I2C Write Protocol

• I2C Read Protocol

For a complete description of I2C protocols, please review

the I2C Specication athttp://www.semiconductors.philips.com

Figure 6. I2C Packet Protocol Element Key

Figure 7. I2C Write Protocols

Figure 8. I2C Read (Combined Format) Protocols

Figure 9. I2C Write Word Protocols

Figure 10. I2C Read Word Protocols

8

Register Set

The APDS-9300 is controlled and monitored by sixteen registers (three are reserved) and a command register accessed

through the serial interface. These registers provide for a variety of control functions and can be read to determine results of the ADC conversions. The register set is summarized in Table 2.

Table 2. Register Address

Address Register Name Register Function

-- COMMAND Species register address

0h CONTROL Control of basic functions

1h TIMING Integration time/gain control

2h THRESHLOWLOW Low byte of low interrupt threshold

3h THRESHLOWHIGH High byte of low interrupt threshold

4h THRESHHIGHLOW Low byte of high interrupt threshold

5h THRESHHIGHHIGH High byte of high interrupt threshold

6h INTERRUPT Interrupt control

7h -- Reserved

8h CRC Factory test — not a user register

9h -- Reserved

Ah ID Part number/ Rev ID

Bh -- Reserved

Ch DATA0LOW Low byte of ADC channel 0

Dh DATA0HIGH High byte of ADC channel 0

Eh DATA1LOW Low byte of ADC channel 1

Fh DATA1HIGH High byte of ADC channel 1

The mechanics of accessing a specic register depends on the specic I2C protocol used. Refer to the section on I2C

protocols. In general, the COMMAND register is written rst to specify the specic control/status register for following

read/write operations.

9

Command Register

ADDRESSCLEARCMD WORD Resv

67 5 4 23 1 0

00 0 0 00 0 0Reset Value:

COMMAND

POWERResvResv ResvResv Resv Resv

67 5 4 23 1 0

00 0 0 00 0 0Reset Value:

CONTROL

0h

The command register species the address of the target register for subsequent read and write operations. The Send

Byte protocol is used to congure the COMMAND register. The command register contains eight bits as described in

Table 3. The command register defaults to 00h at power on.

Table 3. Command Register

Field BIT Description

CMD 7 Select command register. Must write as 1.

CLEAR 6 Interrupt clear. Clears any pending interrupt.

This bit is a write–one–to–clear bit. It is self clearing.

WORD 5 I2C Write/Read Word Protocol.

1 indicates that this I2C transaction is using either the I2C Write Word or Read Word protocol.

Resv 4 Reserved. Write as 0.

ADDRESS 3:0 Register Address.

This eld selects the specic control or status register for following write and read commands according to Table 2.

Control Register (0h)

The CONTROL register contains two bits and is primarily used to power the APDS-9300 device up and down as shown

in Table 4.

Table 4. Control Register

Field BIT Description

Resv 7:2 Reserved. Write as 0.

POWER 1:0 Power up/power down. By writing a 03h to this register, the device is powered up.

By writing a 00h to this register, the device is powered down.

NOTE: If a value of 03h is written, the value returned during a read cycle will be 03h. This feature can be used to verify that the device is communicating

properly.

10

Timing Register (1h)

INTEGMANUALResvResv GAIN ResvResv

67 5 4 23 1 0

00 0 0 00 1 0Reset Value:

TIMING

1h

The TIMING register controls both the integration time and the gain of the ADC channels. A common set of control bits

is provided that controls both ADC channels. The TIMING register defaults to 02h at power on.

Table 5. Timing Register

Field BIT Description

Resv 7-5 Reserved. Write as 0.

GAIN 4 Switches gain between low gain and high gain modes.

Writing a 0 selects low gain (1x);

Writing a 1 selects high gain (16x).

MANUAL 3 Manual timing control.

Writing a 1 begins an integration cycle.

Writing a 0 stops an integration cycle.

NOTE: This eld only has meaning when INTEG = 11.

It is ignored at all other times.

Resv 2 Reserved. Write as 0.

INTEG 1:0 Integrate time. This eld selects the integration time for each conversion.

Integration time is dependent on the INTEG FIELD VALUE and the internal clock frequency. Nominal integration times

and respective scaling between integration times scale proportionally as shown in Table 6. See Note 5 and Note 6 on

page 4 for detailed information regarding how the scale values were obtained.

Table 6. Integration Time

Integ Field Value Scale Nominal Integration Time

00 0.034 13.7 ms

01 0.252 101 ms

10 1 402 ms

11 -- N/A

The manual timing control feature is used to manually start and stop the integration time period. If a particular integration time period is required that is not listed in Table 6, then this feature can be used. For example, the manual timing

control can be used to synchronize the APDS-9300 device with an external light source (e.g. LED). A start command to

begin integration can be initiated by writing a 1 to this bit eld. Correspondingly, the integration can be stopped by

simply writing a 0 to the same bit eld.

11

Interrupt Threshold Register (2h - 5h)

PERSISTResvResv INTR

67 5 4 23 1 0

00 0 0 00 0 0Reset Value:

INTERRUPT

6h

The interrupt threshold registers store the values to be used as the high and low trigger points for the comparison function for interrupt generation. If the value generated by channel 0 crosses below or is equal to the low threshold specied,

an interrupt is asserted on the interrupt pin. If the value generated by channel 0 crosses above the high threshold specied, an interrupt is asserted on the interrupt pin. Registers THRESHLOWLOW and THRESHLOWHIGH provide the low byte

and high byte, respectively, of the lower interrupt threshold. Registers THRESHHIGHLOW and THRESHHIGHHIGH provide

the low and high bytes, respectively, of the upper interrupt threshold. The high and low bytes from each set of registers

are combined to form a 16–bit threshold value. The interrupt threshold registers default to 00h on power up.

Table 7. Interrupt Threshold Register

Register Address Bits Description

THRESHLOWLOW 2h 7:0 ADC channel 0 lower byte of the low threshold

THRESHLOWHIGH 3h 7:0 ADC channel 0 upper byte of the low threshold

THRESHHIGHLOW 4h 7:0 ADC channel 0 lower byte of the high threshold

THRESHHIGHHIGH 5h 7:0 ADC channel 0 upper byte of the high threshold

NOTE: Since two 8–bit values are combined for a single 16–bit value for each of the high and low interrupt thresholds, the Send Byte protocol

should not be used to write to these registers. Any values transferred by the Send Byte protocol with the MSB set would be interpreted as the

COMMAND eld and stored as an address for subsequent read/write operations and not as the interrupt threshold information as desired. The Write

Word protocol should be used to write byte–paired registers. For example, the THRESHLOWLOW and THRESHLOWHIGH registers (as well as the

THRESHHIGHLOW and THRESHHIGHHIGH registers) can be written together to set the 16–bit ADC value in a single transaction.

Interrupt Control Register (6h)

The INTERRUPT register controls the extensive interrupt capabilities of the APDS-9300. The APDS-9300 permits traditional level–style interrupts. The interrupt persist bit eld (PERSIST) provides control over when interrupts occur. A value

of 0 causes an interrupt to occur after every integration cycle regardless of the threshold settings. A value of 1 results

in an interrupt after one integration time period outside the threshold window. A value of N (where N is 2 through15)

results in an interrupt only if the value remains outside the threshold window for N consecutive integration cycles. For

example, if N is equal to 10 and the integration time is 402 ms, then the total time is approximately 4 seconds.

When a level Interrupt is selected, an interrupt is generated whenever the last conversion results in a value outside of

the programmed threshold window. The interrupt is active–low and remains asserted until cleared by writing the COMMAND register with the CLEAR bit set.

NOTE: Interrupts are based on the value of Channel 0 only.

Table 8. Interrupt Control Register

Field Bits Description

Resv 7:6 Reserved. Write as 0.

INTR 5:4 INTR Control Select. This eld determines mode of interrupt logic according to Table 9,

below.

PERSIST 3:0 Interrupt persistence. Controls rate of interrupts to the host processor as shown in Table 10,

below.

12

Table 9. Interrupt Control Select

REVNOPARTNO

67 5 4 23 1 0

-- - - -- - -Reset Value:

ID

Ah

Intr Field Value Read Value

00 Interrupt output disabled

01 Level Interrupt

Table 10. Interrupt Persistence Select

Persist Field Value Interrupt Persist Function

0000 Every ADC cycle generates interrupt

0001 Any value outside of threshold range

0010 2 integration time periods out of range

0011 3 integration time periods out of range

0100 4 integration time periods out of range

0101 5 integration time periods out of range

0110 6 integration time periods out of range

0111 7 integration time periods out of range

1000 8 integration time periods out of range

1001 9 integration time periods out of range

1010 10 integration time periods out of range

1011 11 integration time periods out of range

1100 12 integration time periods out of range

1101 13 integration time periods out of range

1110 14 integration time periods out of range

1111 15 integration time periods out of range

ID Register (Ah)

The ID register provides the value for both the part number and silicon revision number for that part number. It is a

read–only register, whose value never changes.

Table 11. ID Register

Field Bits Description

PARTNO 7:4 Part Number Identication

REVNO 3:0 Revision number identication

13

ADC Channel Data Registers (Ch - Fh)

The ADC channel data are expressed as 16–bit values spread across two registers. The ADC channel 0 data registers,

DATA0LOW and DATA0HIGH provide the lower and upper bytes, respectively, of the ADC value of channel 0. Registers

DATA1LOW and DATA1HIGH provide the lower and upper bytes, respectively, of the ADC value of channel 1. All channel

data registers are read–only and default to 00h on power up.

Table 12. ADC Channel Data Registers

Register Address Bits Description

DATA0LOW Ch 7:0 ADC channel 0 lower byte

DATA0HIGH Dh 7:0 ADC channel 0 upper byte

DATA1LOW Eh 7:0 ADC channel 1 lower byte

DATA1HIGH Fh 7:0 ADC channel 1 upper byte

The upper byte data registers can only be read following a read to the corresponding lower byte register. When the

lower byte register is read, the upper eight bits are strobed into a shadow register, which is read by a subsequent read

to the upper byte. The upper register will read the correct value even if additional ADC integration cycles end between

the reading of the lower and upper registers.

NOTE: The Read Word protocol can be used to read byte–paired registers. For example, the DATA0LOW and DATA0HIGH registers

(as well as the DATA1LOW and DATA1HIGH registers) may be read together to obtain the 16–bit ADC value in a single transaction

14

APDS-9300 PACKAGE OUTLINE

Pin 1 : V

Pin 2 : GND

Pin 3 : ADDR SEL

Pin 4 : SCL

Pin 5 : SDA

Pin 6 : INT

UNIT: mm

Tolerance: +/- 0.2mm

Notes:

1. All dimensions are in millimeters. Dimension tolerance is ±0.2 mm unless otherwise stated

PCB Pad Layout

The suggested PCB layout is given below:

DD

Notes:

1. All linear dimensions are in millimeters

15

Tape and Reel Dimensions - APDS-9300

16

Moisture Proof Packaging Chart

UNITS IN A SEALED

MOISTURE-PROOF PACKAGE

ENVIRONMENT

LESS THAN 30 °C

AND LESS THAN

60% RH

PACKAGE IS OPENED

(UNSEALED)

PACKAGE IS

OPENED LESS

THAN 168 HOURS

NO BAKING IS

NECESSARY

PERFORM RECOMMENDED

BAKING CONDITIONS

YES

YES

NO

NO

All APDS-9300 options are shipped in moisture proof package. Once opened, moisture absorption begins.

This part is compliant to JEDEC Level 3.

BAKING CONDITIONS CHART

Recommended Storage Conditions

Storage Temperature 10°C to 30°C

Relative Humidity Below 60% RH

Time from Unsealing to Soldering

After removal from the bag, the parts should be soldered

within seven days if stored at the recommended storage

conditions. When MBB (Moisture Barrier Bag) is opened

and the parts are exposed to the recommended storage

conditions more than seven days the parts must be baked

before reow to prevent damage to the parts.

Baking conditions

If the parts are not stored per the recommended storage

conditions they must be baked before reow to prevent

damage to the parts.

Package Temp. Time

In Reels 60°C 48 hours

In Bulk 100°C 4 hours

Note: Baking should only be done once.

17

Recommended Reow Prole

50

100 150 200 250 300

t-TIME

(SECONDS)

25

80

120

150

180

200

230

255

0

T - TEMPERATURE (°C)

R1

R2

R3

R4

R5

217

MAX 260°C

60 sec to 90 sec

Above 217°C

P1

HEAT

UP

P2

SOLDER PASTE DRY

P3

SOLDER

REFLOW

P4

COOL DOWN

Process Zone Symbol DT

Heat Up P1, R1 25°C to 150°C 3°C/s

Solder Paste Dry P2, R2 150°C to 200°C 100s to 180s

Solder Reow P3, R3 200°C to 260°C 3°C/s

Cool Down P4, R5 200°C to 25°C -6°C/s

Time maintained above liquidus point , 217°C > 217°C 60s to 90s

Peak Temperature 260°C -

Time within 5°C of actual Peak Temperature - 20s to 40s

Time 25°C to Peak Temperature 25°C to 260°C 8mins

Maximum DT/Dtime

or Duration

P3, R4 260°C to 200°C -6°C/s

The reow prole is a straight-line representation of a

nominal temperature prole for a convective reow solder process. The temperature prole is divided into four

process zones, each with dierent DT/Dtime temperature

change rates or duration. The DT/Dtime rates or duration

are detailed in the above table. The temperatures are

measured at the component to printed circuit board connections.

In process zone P1, the PC board and component pins are

heated to a temperature of 150°C to activate the ux in

the solder paste. The temperature ramp up rate, R1, is limited to 3°C per second to allow for even heating of both

the PC board and component pins.

Process zone P2 should be of sucient time duration (100

to 180 seconds) to dry the solder paste. The temperature

is raised to a level just below the liquidus point of the solder.

18

Process zone P3 is the solder reow zone. In zone P3, the

temperature is quickly raised above the liquidus point of

solder to 260°C (500°F) for optimum results. The dwell time

above the liquidus point of solder should be between 60

and 90 seconds. This is to assure proper coalescing of the

solder paste into liquid solder and the formation of good

solder connections. Beyond the recommended dwell time

the intermetallic growth within the solder connections

becomes excessive, resulting in the formation of weak

and unreliable connections. The temperature is then rapidly reduced to a point below the solidus temperature of

the solder to allow the solder within the connections to

freeze solid.

Process zone P4 is the cool down after solder freeze. The

cool down rate, R5, from the liquidus point of the solder to

25°C (77°F) should not exceed 6°C per second maximum.

This limitation is necessary to allow the PC board and

component pins to change dimensions evenly, putting

minimal stresses on the component.

It is recommended to perform reow soldering no more

than twice.

Appendix A: Window Design Guide

Z

L

T

D1

Top View

APDS-9300

Photo Light Sensor

WD

D2 D1

D2

A1: Optical Window Dimensions

To ensure that the performance of the APDS-9300 will not

be aected by improper window design, there are some

criteria requested on the dimensions and design of the

window. There is a constraint on the minimum size of the

window, which is placed in front of the photo light sensor,

so that it will not aect the angular response of the APDS-

9300. This minimum dimension that is recommended will

ensure at least a ±35° light reception cone.

If a smaller window is required, a light pipe or light guide

can be used. A light pipe or light guide is a cylindrical

piece of transparent plastic, which makes use of total internal reection to focus the light.

The thickness of the window should be kept as minimum

as possible because there is a loss of power in every optical

window of about 8% due to reection (4% on each side)

and an additional loss of energy in the plastic material.

Figure A1 illustrates the two types of window that we

have recommended which could either be a at window

or a at window with light pipe.

Table A1 and Figure A2 show the recommended dimensions of the window. These dimension values are based

on a window thickness of 1.0mm with a refractive index

1.585.

The window should be placed directly on top of the light

sensitive area of APDS-9300 (see Figure A3) to achieve

better performance. If a at window with a light pipe is

used, dimension D2 should be 1.55mm to optimize the

performance of APDS-9300.

Figure A1. Recommended Window Design

WD: Working Distance between window front panel & APDS-9300

D1: Window Diameter

T: Thickness

L: Length of Light Pipe

D2: Light Pipe Diameter

Z: Distance between window rear panel and APDS-9300

All dimensions are in mm

Figure A2. Recommended Window Dimensions

19

Table A1. Recommended dimension for optical window

WD

(T+L+Z)

Flat Window

(L=0.0 mm, T=1.0 mm)

Z D1 D1 L

Flat window with Light Pipe

(D2=1.55mm, Z =0.5mm, T=1.0mm)

1.5 0.5 2.25 - -

2.0 1.0 3.25 - -

2.5 1.5 4.25 - -

3.0 2.0 5.00 2.5 1.5

6.0 5.0 8.50 2.5 4.5

Figure A3. APDS-9300 Light Sensitive Area

Notes:

1. All dimensions are in millimeters

2. All package dimension tolerance in ± 0.2mm unless otherwise specied

A2: Optical Window Material

The material of the window is recommended to be polycarbonate. The surface nish of the plastic should be

smooth, without any texture.

The recommended plastic material for use as a window is

available from Bayer AG and Bayer Antwerp N. V. (Europe),

Bayer Corp.(USA) and Bayer Polymers Co., Ltd. (Thailand),

as shown in Table A2.

20

Table A2. Recommended Plastic Materials

Visible light

Material number

Makrolon LQ2647 87% 1.587

Makrolon LQ3147 87% 1.587

Makrolon LQ3187 85% 1.587

transmission Refractive index

Appendix B: Application circuit

APDS-9300

Pin 1: V

DD

Pin 5

Pin 4

V

IO

Pin 6

Pin 2: GND

0.1uF

Pin 3

** ADDR_SEL

INT

SDA

SCL

Pin 1

Pin 2

MCU

** Note:

ADDR_SEL Float : Slave address is 0111001

R1

R2

R3

Figure B1. Application circuit for APDS-9300

The power supply lines must be decoupled with a 0.1 uF

capacitor placed as close to the device package as possible, as shown in Figure B1. The bypass capacitor should

have low eective series resistance (ESR) and low eective series inductance (ESI), such as the common ceramic

types, which provide a low impedance path to ground at

high frequencies to handle transient currents caused by

internal logic switching.

Pull-up resistors, R1 and R2, maintain the SDA and SCL

lines at a high level when the bus is free and ensure the

signals are pulled up from a low to a high level within the

required rise time. For a complete description of I2C maximum and minimum R1 and R2 values, please review the

I2C Specication at http://www.semiconductors.philips.

com.

A pull-up resistor, R3, is also required for the interrupt

(INT), which functions as a wired-AND signal in a similar

fashion to the SCL and SDA lines. A typical impedance

value between 10 kΩ and 100 kΩ can be used.

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies Limited in the United States and other countries.

Data subject to change. Copyright © 2008 Avago Technologies Limited. All rights reserved.

AV02-1077EN - March 11, 2008

Loading...

Loading...