APDS-9005

Miniature Surface-Mount Ambient Light Photo Sensor

Data Sheet

Description

The APDS-9005 is a low cost analog-output ambient

light photo sensor in miniature chipLED lead-free surface

mount package. It consists of a photo sensor, whose

spectral response is close to the CIE standard photopic

observer, as show in gure 2. The APDS-9005 is ideal for

applications in which the measurement of ambient light

is used to control display backlighting. Mobile appliances such as the mobile phones and PDAs that draw heavy

current from display backlighting will benet from incorporating these photo sensor products in their designs by

reducing power consumption signicantly.

Application Support Information

The Application Engineering Group is available to assist

you with the application design associated with APDS9005 ambient light photo sensor module. You can

contact them through your local sales representatives for

additional details.

Features

• Spectral responsivity close to that of human eye

• Miniature ChipLED Leadfree surface-mount package

Height – 0.55 mm

Width – 1.60 mm

Depth – 1.50 mm

• Low sensitivity variation across various light sources

• Recommended operating temperature : -40°C to 85°C

• Vcc supply 1.8 to 5.5V

• Lead-free package, RoHS compliance

• Output linearity across wide illumination range

Applications

• Detection of ambient light to control display

backlighting

Mobile devices – Mobile phones, PDAs

Computing devices – Notebooks, Webpads

Consumer devices – TVs, Video Cameras, Digital Still

Camera

• Automatic Residential and Commercial Lighting

Management

• Electronic Signs and Signals

1

Ordering Information

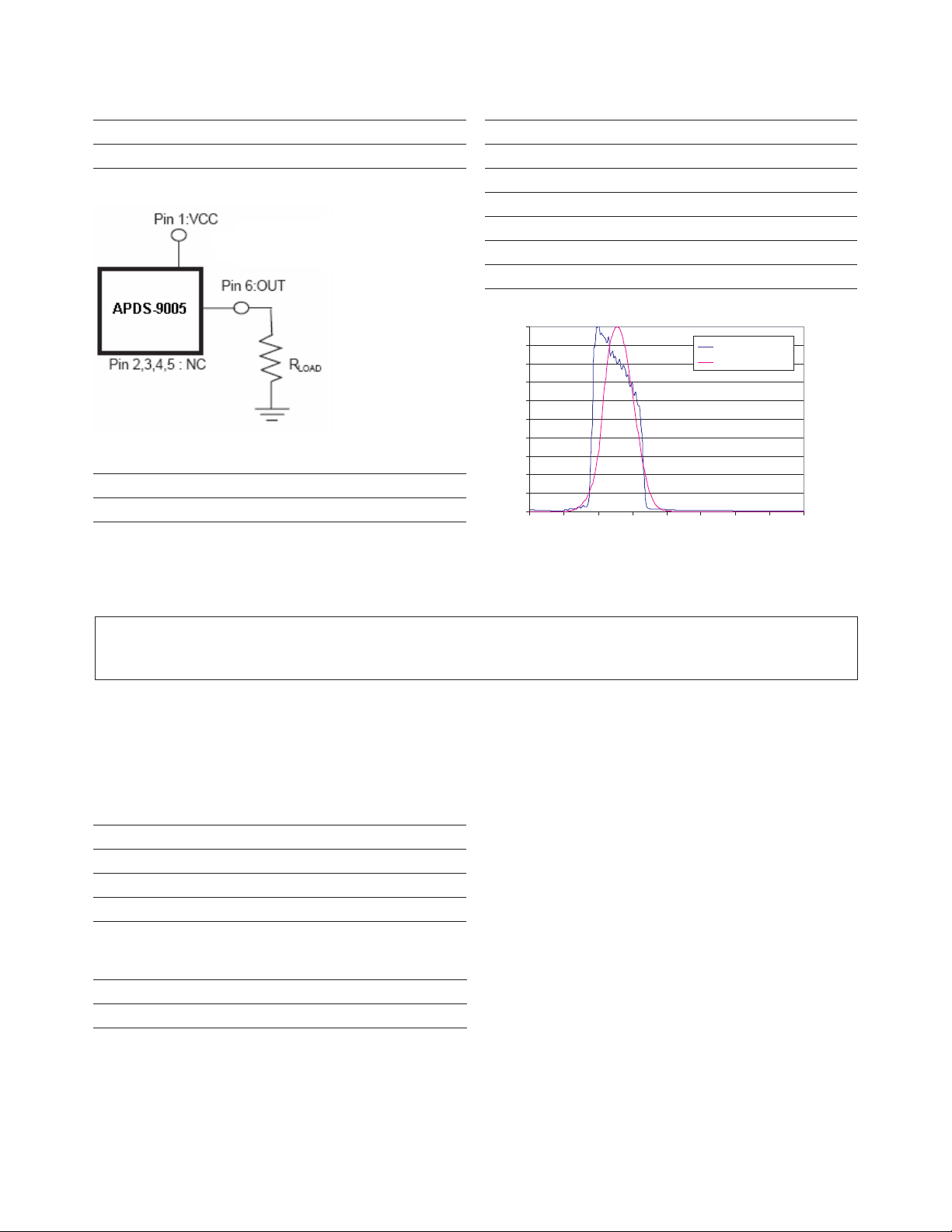

Normalized sensor spectral response

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

300 400 500 600 700 800 900 1000 1100

wavelength (nm)

Response (a.u.)

APDS-9005

Eye Response

I/O Pins Conguration Table

Part Number Packaging Type Package Quantity

APDS-9005-020 Tape and Reel 6-pins Chipled package 2500

Typical Application Circuit

Figure 1. Typical application circuit for APDS-9005

Component Recommended Application Circuit Component

RLOAD 1k ohm

Note :

Refer to Figure 11 for General Luminance Vs Typical Output Voltage for

dierent RLOAD values

Pin Symbol Description

1 VCC VCC

2 NC No Connect

3 NC No Connect

4 Nc No Connect

5 NC No Connect

6 Iout Out

Figure 2. Relative Spectral Response Vs Wavelength

CAUTIONS : It is advised that normal static precautions be taken in handling and assembly

of this component to prevent damage and/or degradation which may be induced by ESD

Absolute Maximum Ratings

For implementations where case to ambient thermal resistance is ≤ 50 °C /W

Parameter Symbol Min. Max. Units

Storage Temperature T

Operating temperature T

Supply Voltage V

S

A

CC

Recommended Operating Conditions

Parameter Symbol Min. Max. Units Conditions

Supply Voltage V

CC

1.8 5.5 V

2

-40 85 °C

-40 85 °C

0 6 V

Electrical & Optical Specications (Ta=25°C)

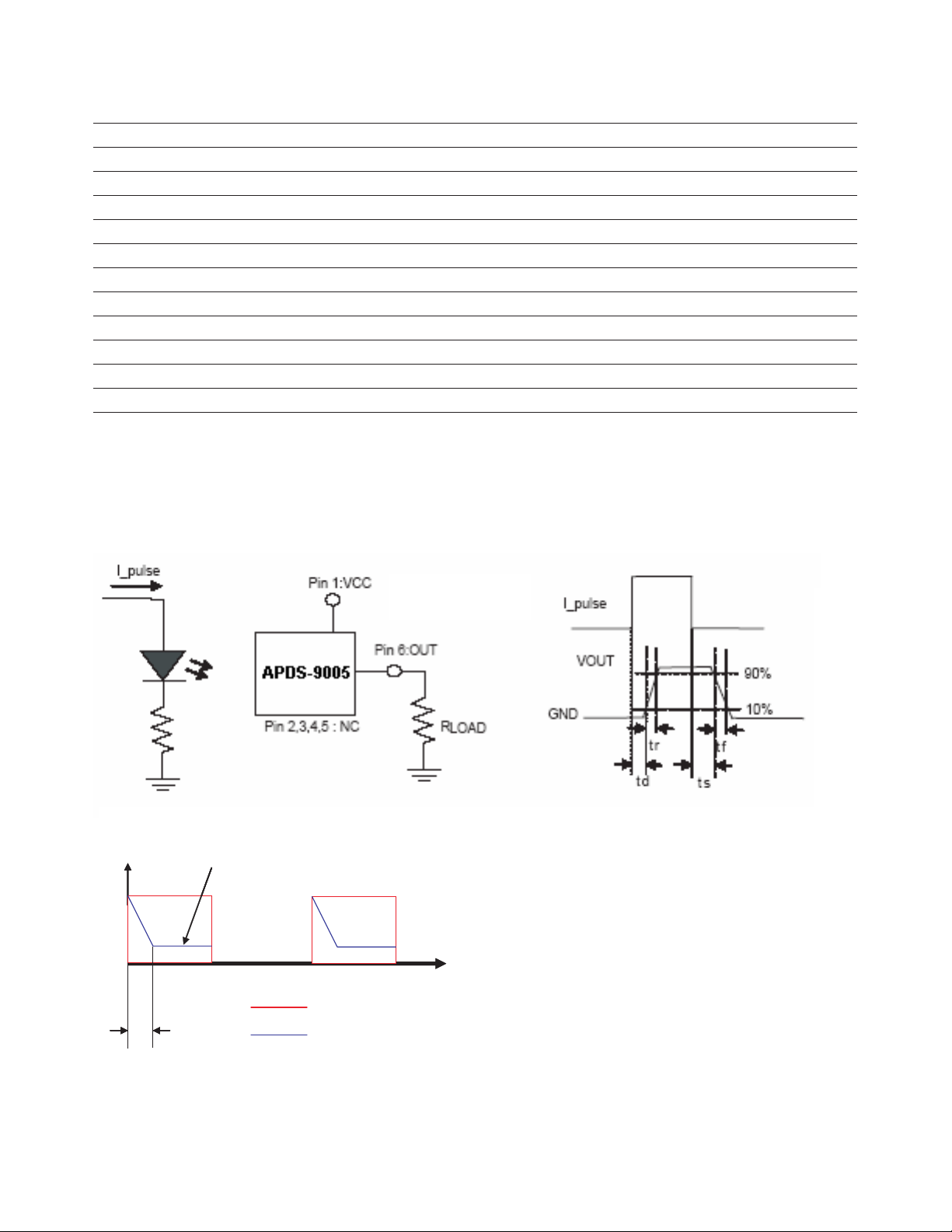

sensor-output attains ~95% of

its voltage magnitudecorresponds to the set light level

Tset

VCC Pulse from PG

Sensor Output at Load

Parameter Symbol Min. Typ. Max. Units Conditions

Photo Current (I) I

Photo Current (II) I

Dark Current I

Light Current Ratio I

Rise Time T

Fall Time T

Peak sensitivity wavelength

Settling Time pulsed at Vcc T

Propagation delay T

Storage delay T

_PH1

_PH2

_DARK

_PH3

r

f

l

set

d

s

/ I

_PH2

28 40 52 uA Vcc =1.8V, Lux = 100 (2)

- 44 - uA Vcc =1.8V, Lux = 100 (1)

- 300 - nA Vcc = 3V, Lux = 0

- 1.1 - -

- 5 - ms Rl = 1Kohm, Lux = 100

- 5 - ms R1 = 1Kohm, Lux=100

- 500 - nm

- 10 - ms Vcc pulsed = 0V to 3V; Rload = 2.4K ohms; Lux = 100

- 5 - ms Rl = 1Kohm, Lux = 100

- 5 - ms R1 = 1Kohm, Lux=100

Saturation voltage Vsat 1.0 - - V R1 = 150Kohm, Lux = 100

Note :

1) Illuminance by incandescent lamp

2) White LED is used as light source

Light Measurement Circuit and Waveforms

(2)

3

AVG REL-IOUT Vs TEMP at 320LUX/1.8V

0

0.2

0.4

0.6

0.8

1.0

1.2

-40 -20 0 20 40 60 80 100

TEMPERATURE [˚C]

REL I-OUT

ANGULAR RESPONSE

0

0.2

0.4

0.6

0.8

1

1.2

-100 -50 0 50 100

ANGLE in DEGREE[˚]

REL I-OUT

AVG RISE TIME Vs LOAD RESISTANCE at VCC=1.8V

000.0E+0

2.0E-3

4.0E-3

6.0E-3

8.0E-3

10.0E-3

12.0E-3

14.0E-3

16.0E-3

18.0E-3

0 2000 4000 6000 8000 10000 12000

LOAD RESISTANCE [Ohms]

RISE TIME [Seconds]

Avg REL I-Out Vs VCC

0.5

0.6

0.7

0.8

0.9

1

1.1

1.2

1.3

1.4

1.5

0 1 2 3 4 5 6

VCC

REL I-OUT

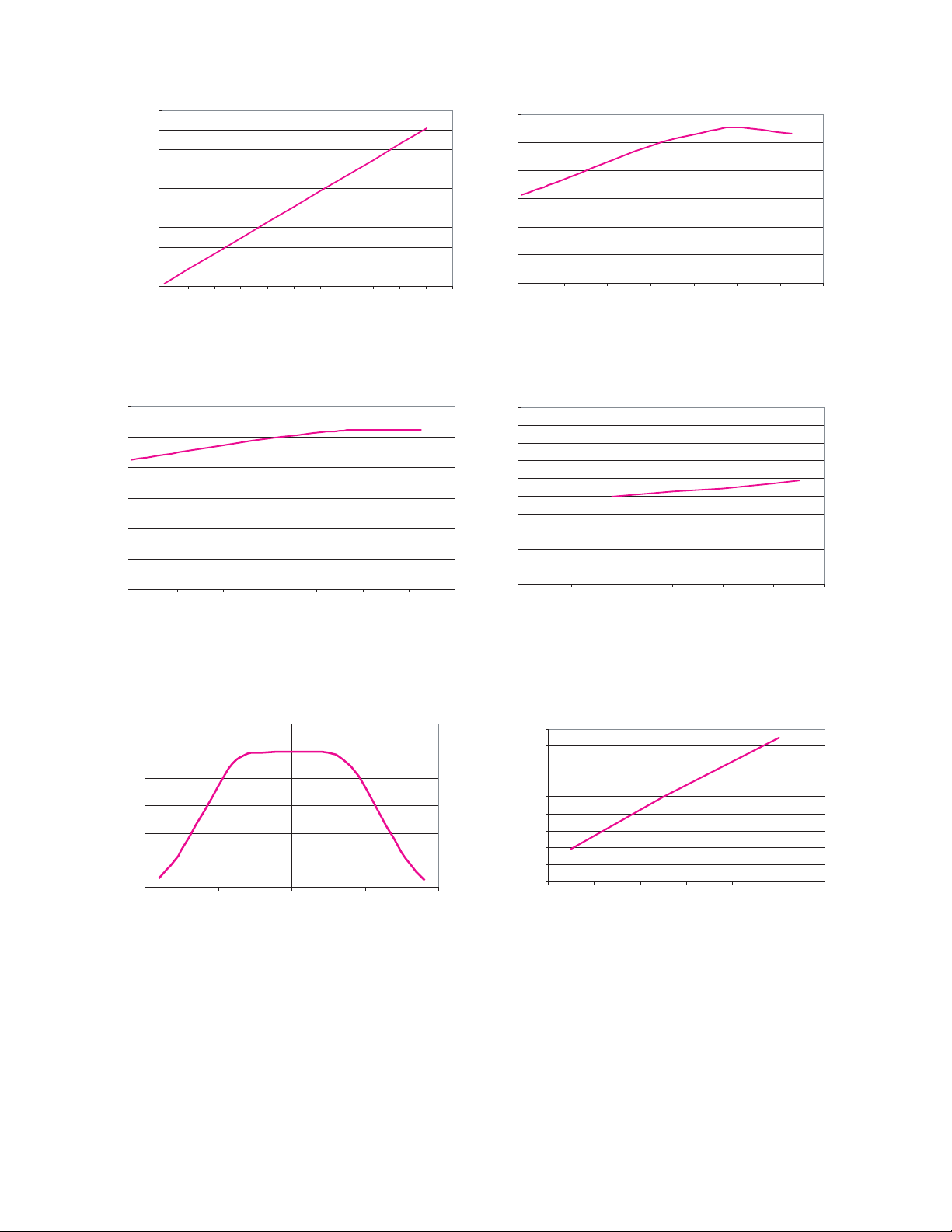

Figure 3. Average Iout Vs Lux (Vcc = 1.8V, T=25°C, White LED source) Figure 4. Average relative Iout Vs Temp (Vcc = 1.8V, T=25°C, 100 Lux)

Average I-Out Vs LUX at VCC=1.8V

000.0E+0

50.0E-6

100.0E-6

150.0E-6

200.0E-6

250.0E-6

300.0E-6

350.0E-6

400.0E-6

450.0E-6

0 100 200 300 400 500 600 700 800 900 1000 1100

LUX

Output Current [A]

AVG REL-IOUT Vs TEMP at 100LUX/1.8V

0

0.2

0.4

0.6

0.8

1

1.2

-40 -20 0 20 40 60 80 100

TEMPERATURE [˚C]

REL I-OUT

Figure 5. Relative Output Current Vs Temp (Vcc = 1.8V, 100 Lux) Figure 6. Relative Output Current Vs Vcc (Ta = 25°C, 100Lux)

Figure 7. Relative Iout Vs Angle (Vcc = 1.8V, Ta = 25°C) Figure 8. Average Rise Time Vs Load Resistance at Vcc = 1.8V

4

Average Vout vs Lux (Vcc = 1.8V, T = 25C, White LED Source)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0 100 200 300 400 500 600 700 800 900 1000

Lux

Average Vout (V)

RL = 1kohm

RL = 1.8kohm

RL = 2.2kohm

RL = 2.7kohm

RL = 3.3kohm

RL = 4.3kohm

RL = 5kohm

RL = 7.5kohm

RL = 12kohm

Figure 9. Average Fall Time Vs Load Resistance at Vcc = 1.8V Figure 10. Dark current Vs temperature

AVG FALL TIME Vs LOAD RESISTANCE at VCC=1.8V

0.00E+00

2.00E-03

4.00E-03

6.00E-03

8.00E-03

1.00E-02

1.20E-02

1.40E-02

1.60E-02

1.80E-02

0 2000 4000 6000 8000 10000 12000

LOAD RESISTANCE [Ohms]

FALL TIME [Seconds]

Average IDark Vs TEMP at VCC=1.8V

000.0E+0

100.0E-9

200.0E-9

300.0E-9

400.0E-9

500.0E-9

600.0E-9

700.0E-9

800.0E-9

900.0E-9

1.0E-6

-40 -20 0 20 40 60 80 100

TEMPERATURE [˚C]

DarkCUrrent[A]

Figure 11. General Luminance vs Typical Output Voltage

(Vcc = 1.8V, T = 25°C, Light Source = White LED)

5

APDS-9005 Package Outline

Top View

Bottom View

6

APDS-9005 Tape and Reel Dimension

7

Moisture Proof Packaging

Units in A Sealed

Mositure-Proof

Package

Package Is

Opened (Unsealed)

Environment

less than 30 deg C, and

less than 60% RH ?

Package Is

Opened less

than 168 hours ?

Perform Recommended

Baking Conditions

No Baking

Is Necessary

No

Yes

No

Yes

All APDS-9005 options are shipped in moisture proof

package. Once opened, moisture absorption begins. This

part is compliant to JEDEC Level 3.

Baking Conditions:

If the parts are not stored in dry conditions, they must be

baked before reow to prevent damage to the parts.

Package Temperature Time

In Reel 60°C 48 hours

In Bulk 100°C 4 hours

Baking should only be done once.

Recommended Storage Conditions:

Storage Temperature 10 °C to 30 °C

Relative Humidity below 60% RH

Time from unsealing to soldering:

After removal from the bag, the parts should be soldered

within 7 days and if stored at the recommended storage

conditions. If times longer than 7 days are needed, the

parts must be stored in a dry box.

8

Recommended Reow Prole

50

100 150 200 250 300

t-TIME

(SECONDS)

25

80

120

150

180

200

230

255

0

T - TEMPERATURE (˚C)

R1

R2

R3

R4

R5

217

MAX 260˚C

60 sec to 90 sec

Above 217˚C

P1

HEAT

UP

P2

SOLDER PASTE DRY

P3

SOLDER

REFLOW

P4

COOL DOWN

Process Zone Symbol DT

Heat Up P1, R1 25°C to 150°C 3°C/s

Solder Paste Dry P2, R2 150°C to 200°C 100s to 180s

Solder Reow P3, R3 200°C to 255°C 3°C/s

Cool Down P4, R5 200°C to 25°C -6°C/s

Time maintained above 217°C > 217°C 60s to 90s

Peak Temperature 260°C

Time within 5°C of actual Peak Temperature > 255°C 20s to 40s

Time 25°C to Peak Temperature 25°C to 260°C 8mins

Maximum DT/Dtime

or Duration

P3, R4 255°C to 200°C -6°C/s

The reow prole is a straight-line representation of a nominal temperature prole for a convective reow solder

process. The temperature prole is divided into four process zones, each with dierent DT/Dtime temperature change

rates or duration. The DT/Dtime rates or duration are detailed in the above table. The temperatures are measured at

the component to printed circuit board connections.

Process zone P1, the PC board and APDS-9005 pins are heated to a temperature of 150°C to activate the ux in the

solder paste. The temperature ramp up rate, R1, is limited to 3°C per second to allow for even heating of both the PC

board and APDS-9005 pins.

Process zone P2 should be of sucient time duration (100 to 180 seconds) to dry the solder paste. The temperature is

raised to a level just below the liquidus point of the solder, usually 200°C (392°F).

Process zone P3 is the solder reow zone. In zone P3, the temperature is quickly raised above the liquidus point of

solder to 255°C (491°F) for optimum results. The dwell time above the liquidus point of solder should be between 20

and 40 seconds. It usually takes about 20 seconds to assure proper coalescing of the solder balls into liquid solder and

the formation of good solder connections. Beyond a dwell time of 40 seconds, the intermetallic growth within the

solder connections becomes excessive, resulting in the formation of weak and unreliable connections. The temperature is then rapidly reduced to a point below the solidus temperature of the solder, usually 200°C (392°F), to allow the

solder within the connections to freeze solid.

Process zone P4 is the cool down after solder freeze. The cool down rate, R5, from the liquidus point of the solder to

25°C (77°F) should not exceed 6°C per second maximum. This limitation is necessary to allow the PC board and APDS9005 pins to change dimensions evenly, putting minimal stresses on the APDS-9005.

It is recommended to perform reow soldering no more than twice.

9

Appendix A: SMT Assembly Application Note

0.4

0.4

0.2

0.9

0.3

C

L

0.45

0.4

Metal Stencil For

Solder Paste

Printing

Stencil

Aperture

Solder

Mask

Land

Pattern

PCBA

Mounting

Center

Unit: mm

0.2 MIN.

2.7

2.6

1.7

0.11

1.6

Unit: mm

Aperture

Opening

1.0 Solder Pad, Mask and Metal Stencil Aperture

Figure A1. Stencil and PCBA

1.1 Recommended Land Pattern

1.2 Recommended Metal Solder Stencil Aperture

It is recommended that a 0.11 mm (0.004 inches) thick

stencil be used for solder paste printing. Aperture

opening for shield pad is 0.4mm x 0.4mm and 0.2mm x

0.4mm (as per land pattern). This is to ensure adequate

printed solder paste volume and no shorting.

Figure A3. Solder Stencil Aperture

1.3 Adjacent Land Keepout and Solder Mask Areas

Adjacent land keep-out is the maximum space occupied

by the unit relative to the land pattern. There should be

no other SMD components within this area.

The minimum solder resist strip width required to avoid

solder bridging adjacent pads is 0.2 mm.

Note: Wet/Liquid Photo-Imageable solder resist/mask is recommended.

Figure A2. Recommended Land Pattern

10

Figure A4 Adjacent Land Keepout and Solder Mask Areas

Appendix B: Optical Window Design for APDS-9005

Z

L

T

D1

WD

Top View

D2 D1

APDS-9005

Light Receving Area

2.0 Optical Window Dimensions

To ensure that the performance of the APDS-9005 will not

be aected by improper window design, there are some

constraints on the dimensions and design of the window.

There is a constraint on the minimum size of the window,

which is placed in front of the photo light sensor, so that

it will not aect the angular response of the APDS-9005.

This minimum dimension that is recommended will

ensure at least a ±35° light reception cone.

If a smaller window is required, a light pipe or light guide

can be used. A light pipe or light guide is a cylindrical

piece of transparent plastic, which makes use of total

internal reection to focus the light.

The thickness of the window should be kept as minimum

as possible because there is a loss of power in every

optical window of about 8% due to reection (4% on

each side) and an additional loss of energy in the plastic

material.

Figure B1 and B2 illustrate the two types of window

that we have recommended which could either be a at

window or a at window with light pipe.

Table 1 and Figure B3 below show the recommended

dimensions of the window. These dimension values are

based on a window thickness of 1.0mm with a refractive

index 1.585.

Figure B3. Recommended Window Dimensions

WD: Working Distance between window front panel

& APDS-9005

D1: Window Diameter

T: Thickness

L: Length of Light Pipe

D2: Light Pipe Diameter

Z: Distance between window rear panel and

APDS-9005

Table 1. Recommended minimum dimension for optical window

Figure B1. Window Size Determination for Flat Window

Figure B2. Window Design of Flat Window with Light Guide

WD

(T+L+Z)

Flat Window

(L=0.0)

Z D1 D1/D2 T/L/Z

Flat window

with Light Pipe

1.5 0.5 2.05 - -

2.0 1.0 2.75 - -

2.5 1.5 3.45 - -

3.0 2.0 4.15 2.0/1.2 1.0/1.5/0.5

All dimensions are in mm

The window should be placed directly on top of the light

receiving area (active area) of the photo sensor to achieve

better performance and if a at window with a light pipe

is used, dimension D2 should be 1.2mm to optimize the

performance of APDS-9005.

The recommended minimum window dimension is based

on the assumption that the center of the window and the

center of the light receiving of the photo sensor are the

same. It is recommended that the tolerance for assembly

be considered as well. The recommended minimum

window size which will take into account of the assembly

tolerance is dened as:

D1 (min + assembly tolerance) = D1min + 2*(assembly

tolerance) (Dimensions are in mm)

D2 (min + assembly tolerance) = D2min + 2*(assembly

tolerance) (Dimensions are in mm)

11

APDS-9005

A/D

micro-

controller

1

2,3,4,5

6

Vcc

NC

Vout

R L

Light

C

Source

2.1 Optical Window Material

The material of the window is recommended to be polycarbonate. The surface nish of the plastic should be

smooth, without any texture.

The recommended plastic material for use as a window is

available from Bayer AG and Bayer Antwerp N. V. (Europe),

Bayer Corp.(USA) and Bayer Polymers Co., Ltd. (Thailand),

as shown in Table 2.

Table 2. Recommended Plastic Materials

Visible

Material number

Makrolon LQ2647 87% 1.587

Makrolon LQ3147 87% 1.587

Makrolon LQ3187 85% 1.587

light transmission Refractive index

Appendix C : General Application Guide for APDS-9005

The APDS-9005 is a low cost analog-output ambient light

photo sensor whose spectral response closely emulates

the human eyes. APDS-9005 consists of a photo sensor

that is able to produce a high gain photo current to a

sucient level that can be converted to voltage with a

standard value of external resistor. APDS-9005 can easily

be integrated into systems that use ADC input which is

available for sampling of the external source, as shown in

gure C1 below.

The amount of converted voltage, Vout, is mainly

dependant proportionally on the photo current which

generated by the brightness of the light shone on the

photo sensor and the load resistor used, RL. Increasing

the brightness of the light or/and the load resistor will

increase the output voltage.

Brightness is measured as “LUX” unit, which describes how

intense a light source that our eyes perceive. LUX meter

is the equipment for “LUX” measurement. Light sources

with the same LUX level appear at the same brightness to

the human eyes.

Selection of the load resistor RL will determine the

amount of current-to-voltage conversion in the circuit.

Light source e.g. uorescent light consists of ac noise

frequency of about 100Hz. A capacitor of 10uF, which

act as a low-pass lter, is recommended to add in parallel

with the load resistor to reduce the ripples.

Figure C1. Conguration of APDS-9005

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies Limited in the United States and other countries.

Data subject to change. Copyright © 2007 Avago Technologies Limited. All rights reserved. Obsoletes AV01-0598EN

AV02-0080EN - January 16, 2007

Loading...

Loading...