AUX AMCA-H12/4R1A, AMCA-H09/4R1A, AMCA-H18/4R1A Service Manual

AUX DC Inverter Free Match 50HZ R410A

1

SERVICE MANUAL

(DC Inverter Free Match R410a)

AUX DC Inverter Free Match 50HZ R410A General description

2

Table of Contents

Part 1 General information ..................................................................................................3

Part 2 Indoor unit .................................................................................................................7

Part 3 Free Match outdoor unit ......................................................................................... 68

Part 4 Trouble shooting ..................................................................................................... 96

Part 5 Controller .............................................................................................................. 124

Part 6 Sensor resistance table ....................................................................................... 135

AUX DC Inverter Free Match 50HZ R410A General description

3

Part 1General information

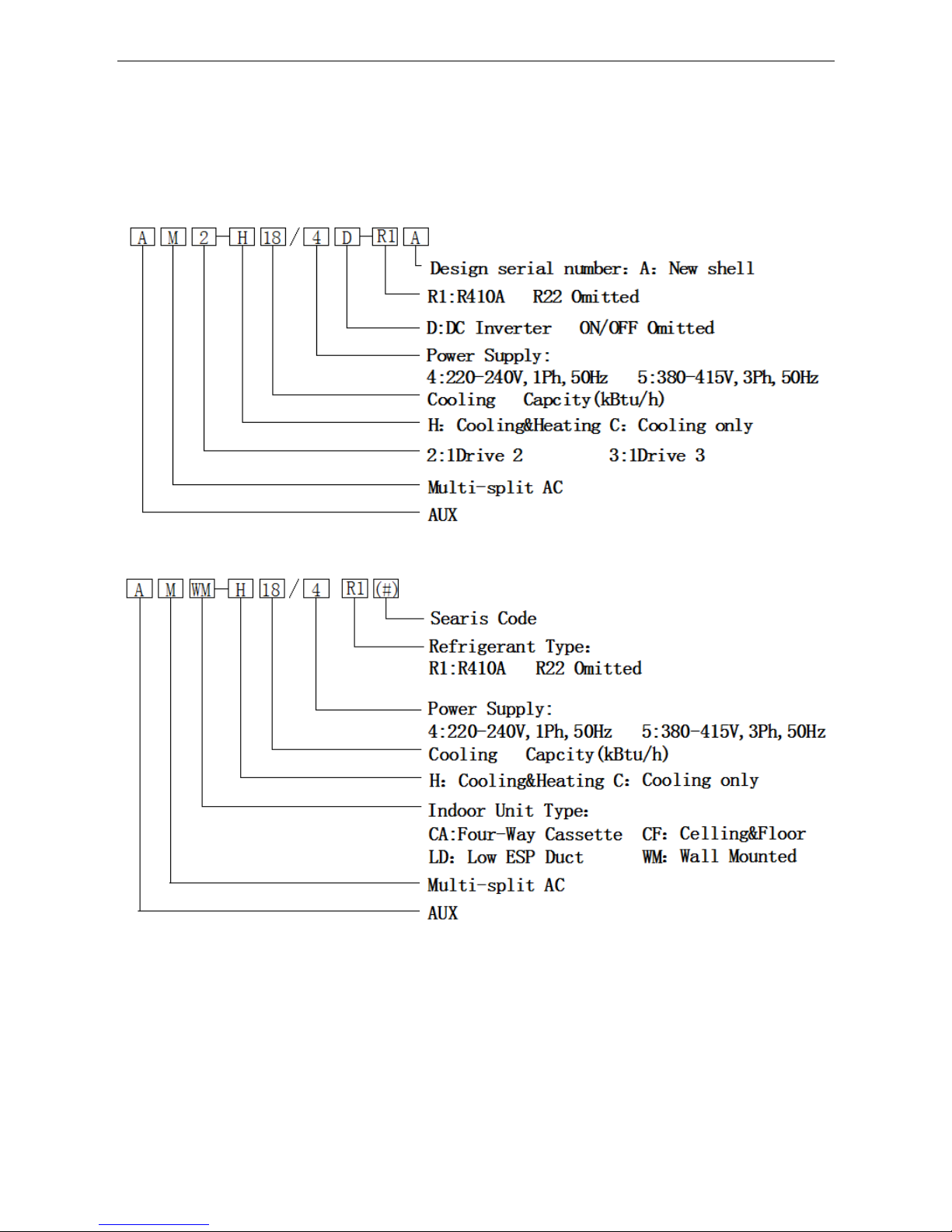

1. Nomenclature

Outdoor Unit

Indoor Unit

AUX DC Inverter Free Match 50HZ R410A General description

4

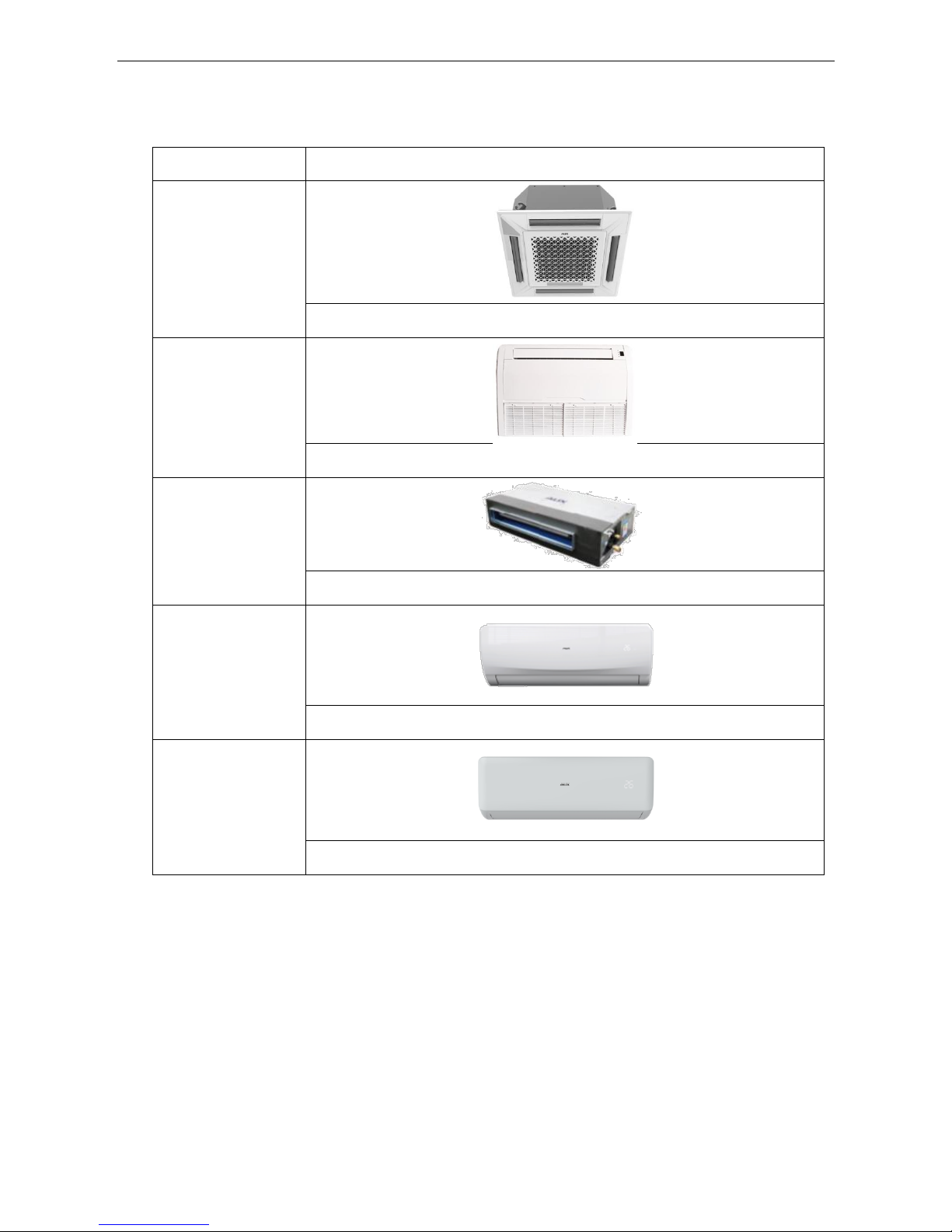

2. Unit Appearance

Series

Picture of the indoor unit

Four-way Cassette

(New)

9K~18K Btu/h

Ceiling &Floor

9K~18K Btu/h

Low ESP Duct

7K~18K Btu/h

Wall-mounted

(L Series)

7K~18K Btu/h

Wall-mounted

(F Series)

7K~18K Btu/h

AUX DC Inverter Free Match 50HZ R410A General description

5

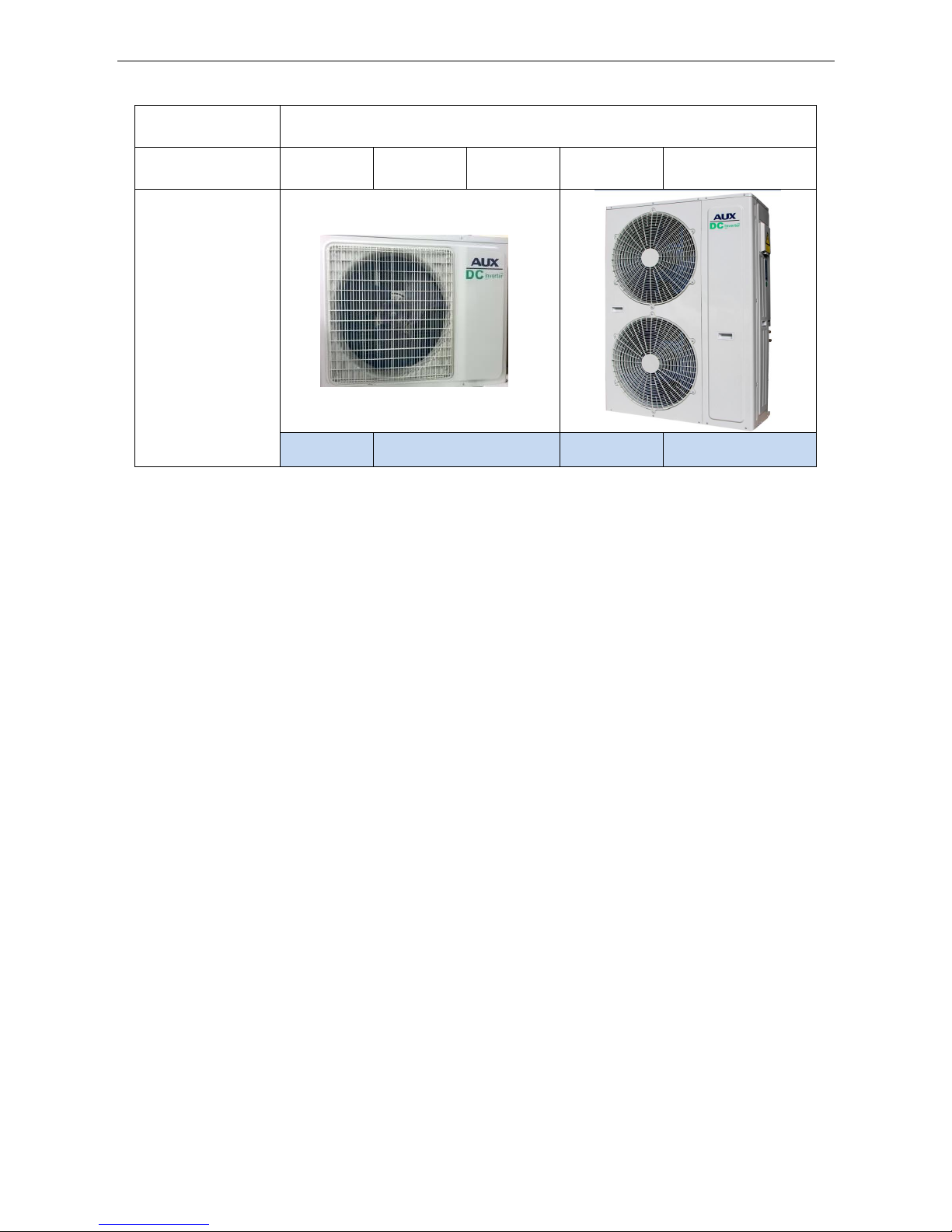

Series

Picture of the outdoor unit

Capacity(Btu)

18000

24000

27000

36000

42000

Outdoor Unit

(New)

1 drive 2

1 drive 3

1 drive 4

1 drive 5

AUX DC Inverter Free Match 50HZ R410A General description

6

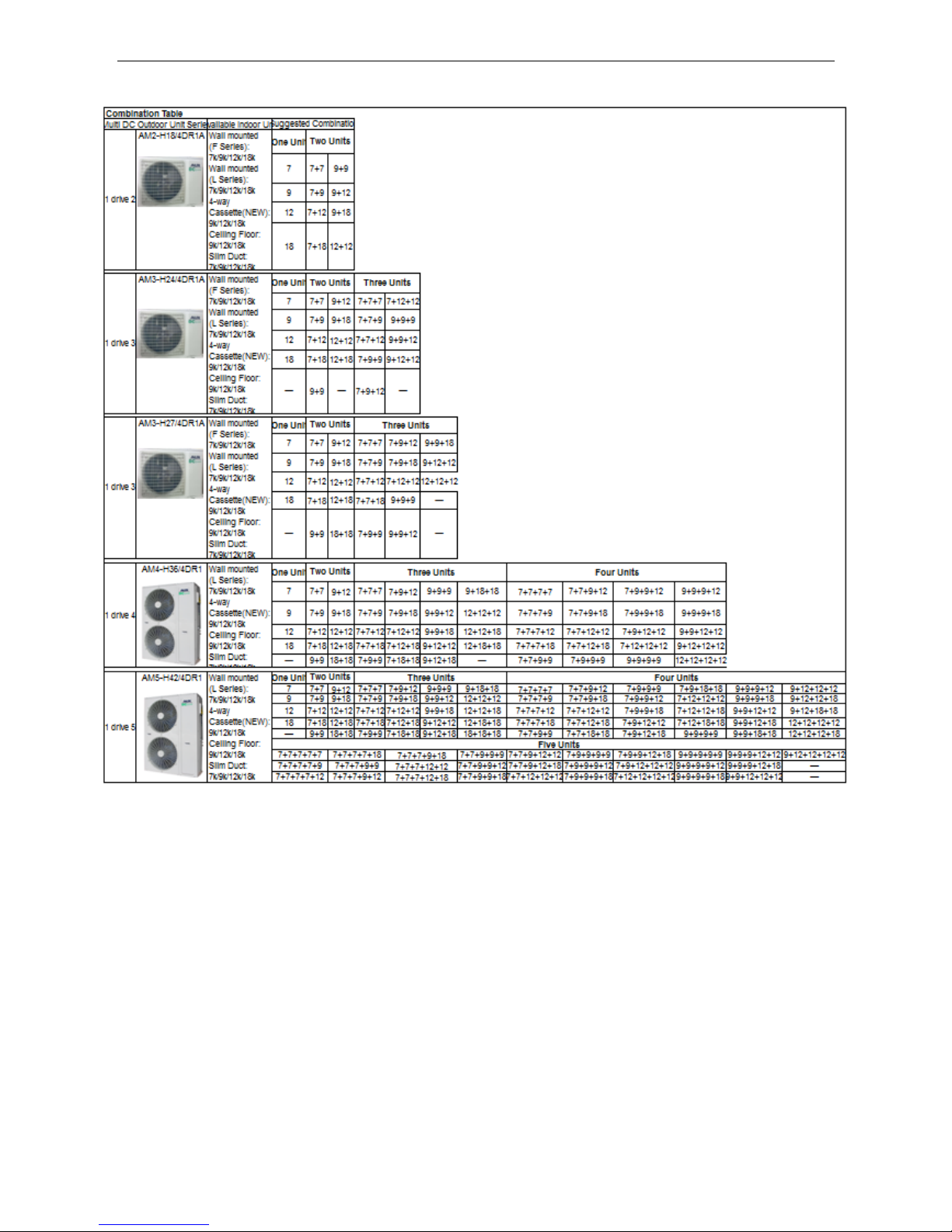

*Note:

① All of the above indoor unit can be freely matched and combined,but must be installed strictly

according to the above table.Orthe cooling capacity and stability would be decreased.

② The wall mounted indoor unit(F series) cannot be matched with the 36/42K outdoor unit.

AUX DC Inverter Free Match 50HZ R410A Indoor unit

7

Part 2 Indoor unit

Four-way cassette ...............................................................................................................5

Ceiling & floor type ............................................................................................................ 22

Low ESP Ducted Type ....................................................................................................... 35

Wall Mounted Type ............................................................................................................ 49

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

8

Four-way cassette

1. Function Introduction .....................................................................................................9

2. Specification .................................................................................................................. 10

3. Capacity Amendment .................................................................................................... 11

4. Dimension ...................................................................................................................... 14

5. Electrical Diagram ......................................................................................................... 14

6. Installation ..................................................................................................................... 15

7. Explode view .................................................................................................................. 20

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

9

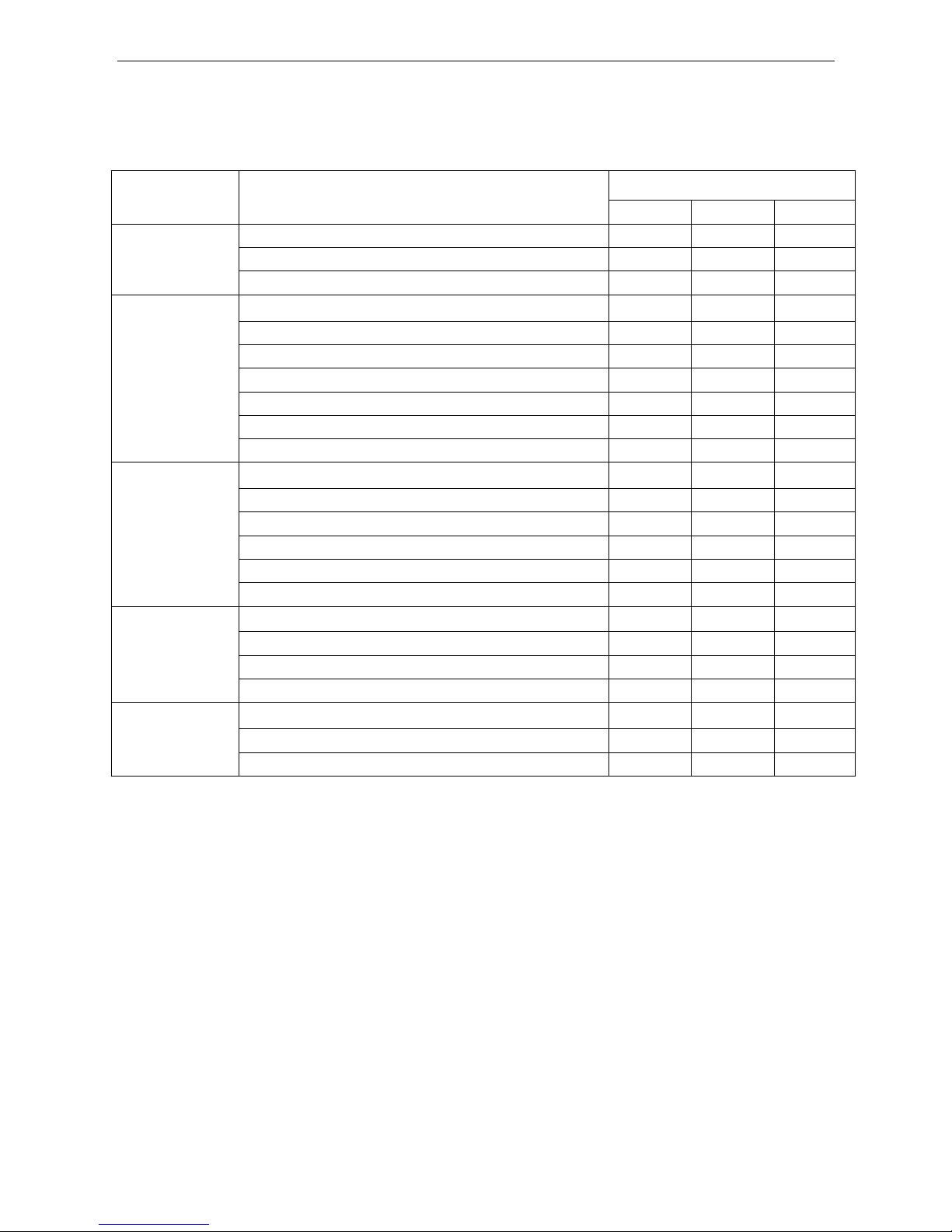

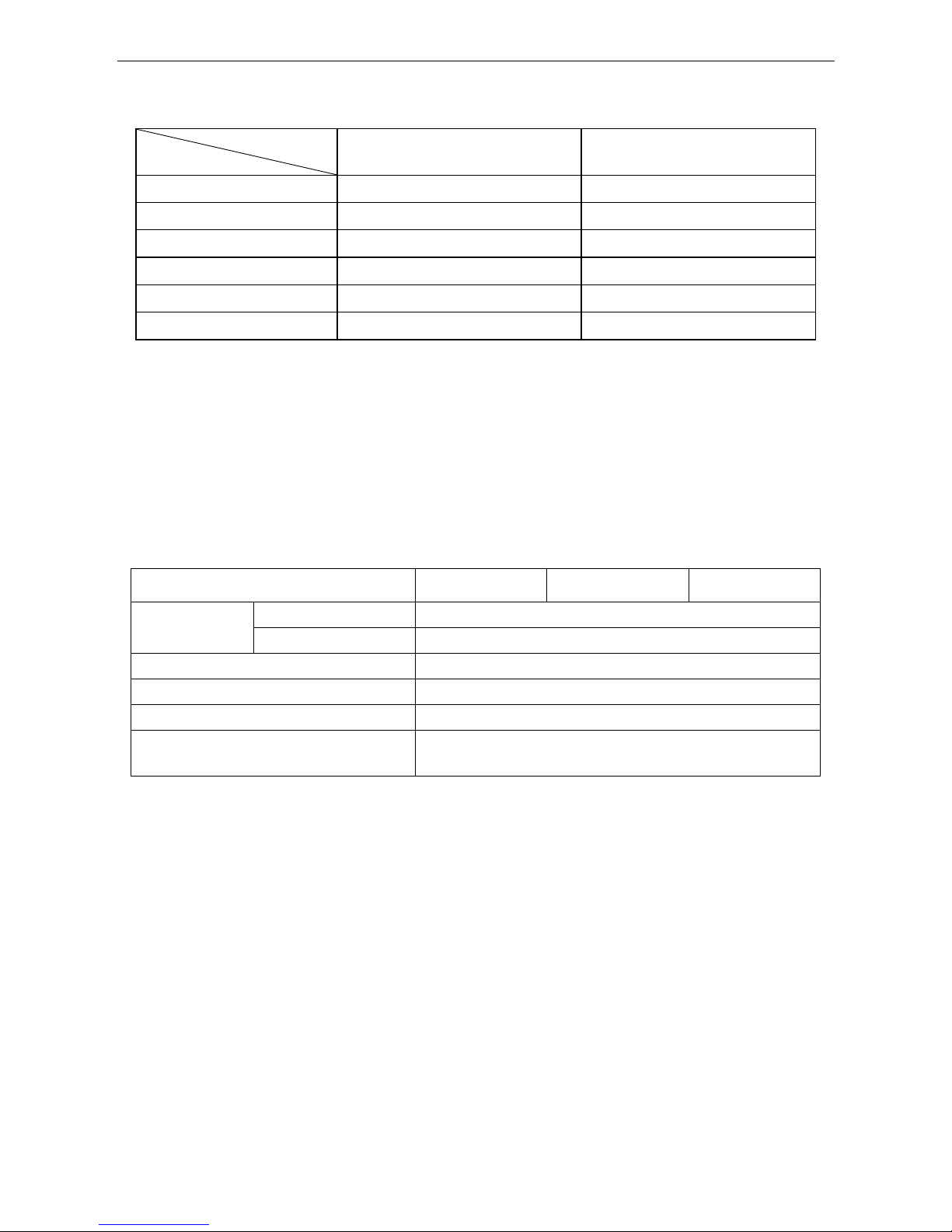

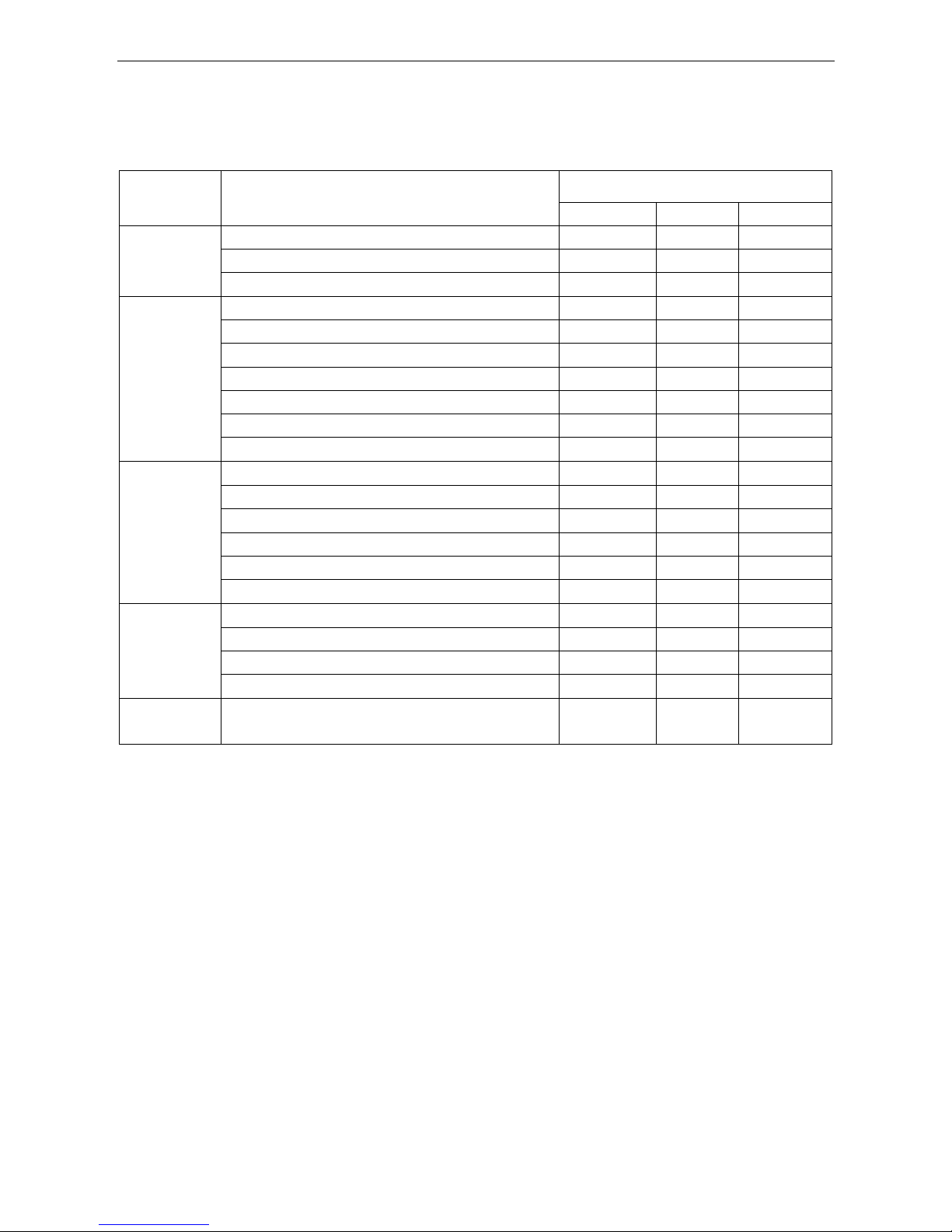

1. Function Introduction

Function

Name

AMCA-H*/4R1A

09

12

18

Protection

Function

Anti-freeze protection

○ ○ ○

Sensor failure alarm

○ ○ ○

Error code display function

○ ○ ○

Comfortable

Function

Cooling

○ ○ ○

Heating

○ ○ ○

3 fan speed

○ ○ ○

Auto-restart (optional)

○ ○ ○

Anti-cold wind

○ ○ ○

Blow exhaust heat

○ ○ ○

Timer

○ ○ ○

Opretating

display

Clock display

○ ○ ○

Operating mode display

○ ○ ○

Fan speed display

○ ○ ○

Defrosting display

○ ○ ○

Timing on/off display

○ ○ ○

Sleeping display

○ ○ ○

Operation

mode

Auto/Cool/Dry/Heat

○ ○ ○

Dehumidify operation

○ ○ ○

Auto defrosting

○ ○ ○

Ventilation function

○ ○ ○

Health

function

Removable air filter

○ ○ ○

Fresh air function preserved

○ ○ ○

Installation instruction plate is available

○ ○ ○

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

10

2. Specification

Model

Indoor

Unit

AMCA-H09/4R1A

AMCA-H12/4R1A

AMCA-H18/4R1A

Capacity

Cooling

Btu/h

9560(5120-12115)

12285(5800-12625)

17060(8530-19107)

kW

2.80(1.50-3.55)

3.60(1.70-3.70)

5.0(2.50-5.6)

Heating

Btu/h

10240(5460-13000)

13306(6930-15080)

19107(10340-24000)

kW

3.00(1.60-3.81)

3.9(2.03-4.42)

5.6(3.03-7.03)

Electric Data

Power Supply

V~,Hz,Ph

220~240,50,1

220~240,50,1

220~240,50,1

Cooling Power Input

W

70(17.5-109)

70(17.5-109)

70(17.5-109)

Heating Power Input

W

70(17.5-109)

70(17.5-109)

70(17.5-109)

Fan Motor

Model / XD30B

XD30B

XD30B

Output Power W 30

30

30

Capacitor

uF

2.0

2.0

2.0

Speed (Hi/Mi/Lo)

r/min

839/757/688

839/757/688

839/757/688

Indoor Coil

Number Of Row

/

2 2 2

Tube Pitchx Row Pitch

mm

20.5x 12.7

20.5x 12.7

20.5x 12.7

Fin Pitch

mm

1.5

1.5

1.5

Fin Material

/

Hydrophilic aluminum fin

Hydrophilic aluminum fin

Hydrophilic aluminum fin

Tube Outside Dia.&Material

mm

φ7, Inner grooved

φ7, Inner grooved

φ7, Inner grooved

Coil Length x Height x Width

mm

1352x205x 25.4

1352x205x 25.4

1352x205x 25.4

Heat Exchanging Area

m2

5.76

5.76

5.76

Performance

Air Flow Volume

m3/h

700/600/530

700/600/530

700/600/530

Sound Pressure Level

dB(A)

45/41/35

45/41/35

45/41/35

Dimension

Net Dim (W*D*H)

mm

570×570×260

570×570×260

570×570×260

Packing Dim (W*D*H)

mm

635x635x290

635x635x290

635x635x290

Net(Panel)

mm

650x650x55

650x650x55

650x650x55

Packing(Panel)

mm

710x710x80

710x710x80

710x710x80

Weight

Net(Body)

kg

18

18

18

Gross(Body)

kg

21

21

21

Net(Panel)

kg

3 3 3

Gross(Panel)

kg

5 5 5

Refrigerant Type

/

R410a

R410a

R410a

Pipe Dia

Liquid Side

mm(inch)

6.35(1/4)

6.35(1/4)

6.35(1/4)

Gas Side

mm(inch)

12.7(1/2)

12.7(1/2)

12.7(1/2)

Drainage

mm

20

20

20

Loading Qty

20/40/40H

unit

150/315/354

150/315/354

150/315/354

Note:

1. Cooling capacity test Condition:(27℃DB,19℃WB Indoor/35℃DB,24℃WB Outdoor);

Heating capacity test Condition:(20℃DB Indoor/7℃DB,6℃WB Outdoor);

connecting pipe length: 5M.

2. Datas may be changed withunit improvement. We keep the right to change the datas or specifications

withoutprior notice, please follow the datas listed on the nameplate.

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

11

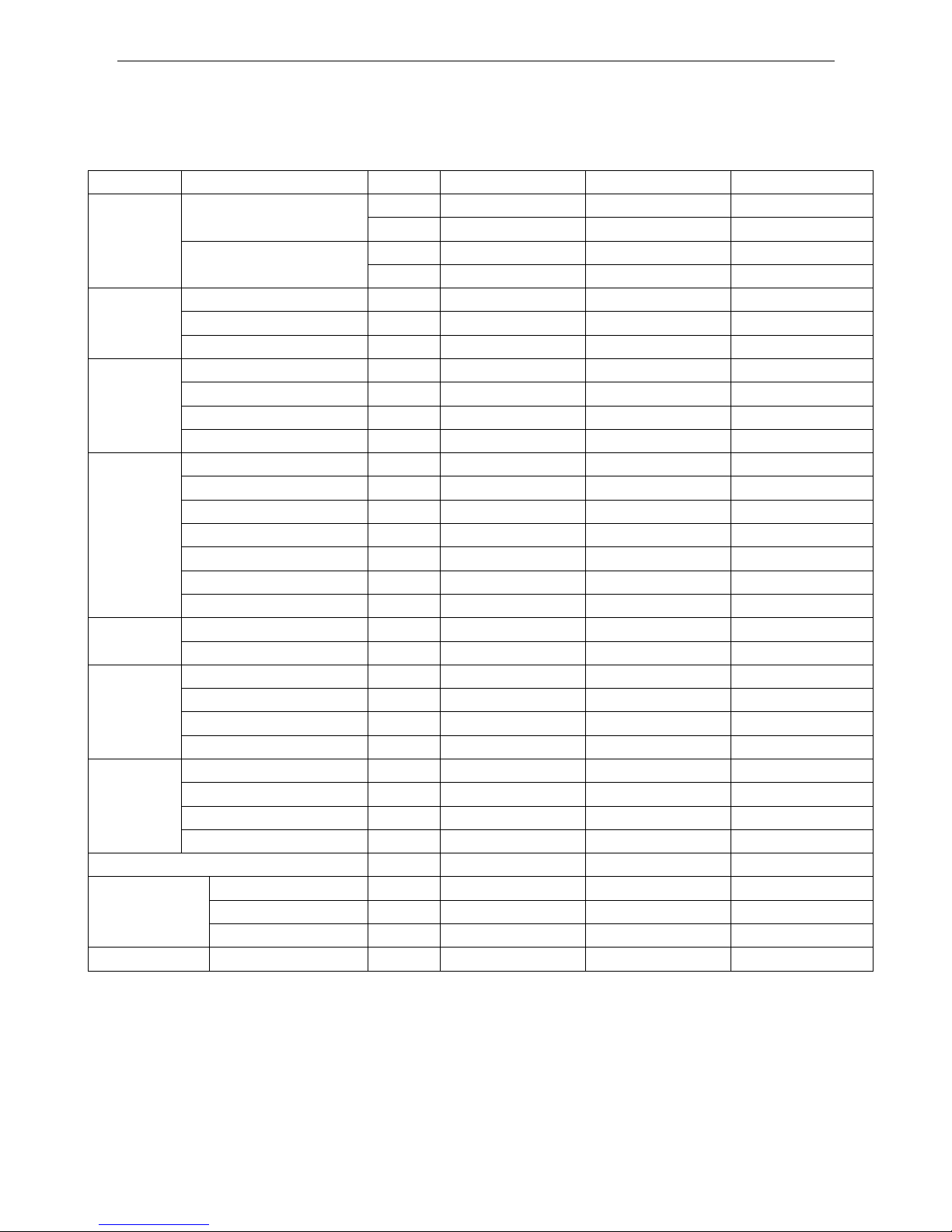

3. Capacity Amendment

3.1 Running range

Cooling capacity (Btu/h)

9000

12000

18000

Power supply

220-240V~/50Hz

Voltage

187~253V

Ambient

temperature

Cooling

-10~52℃

Heating

-15~24℃

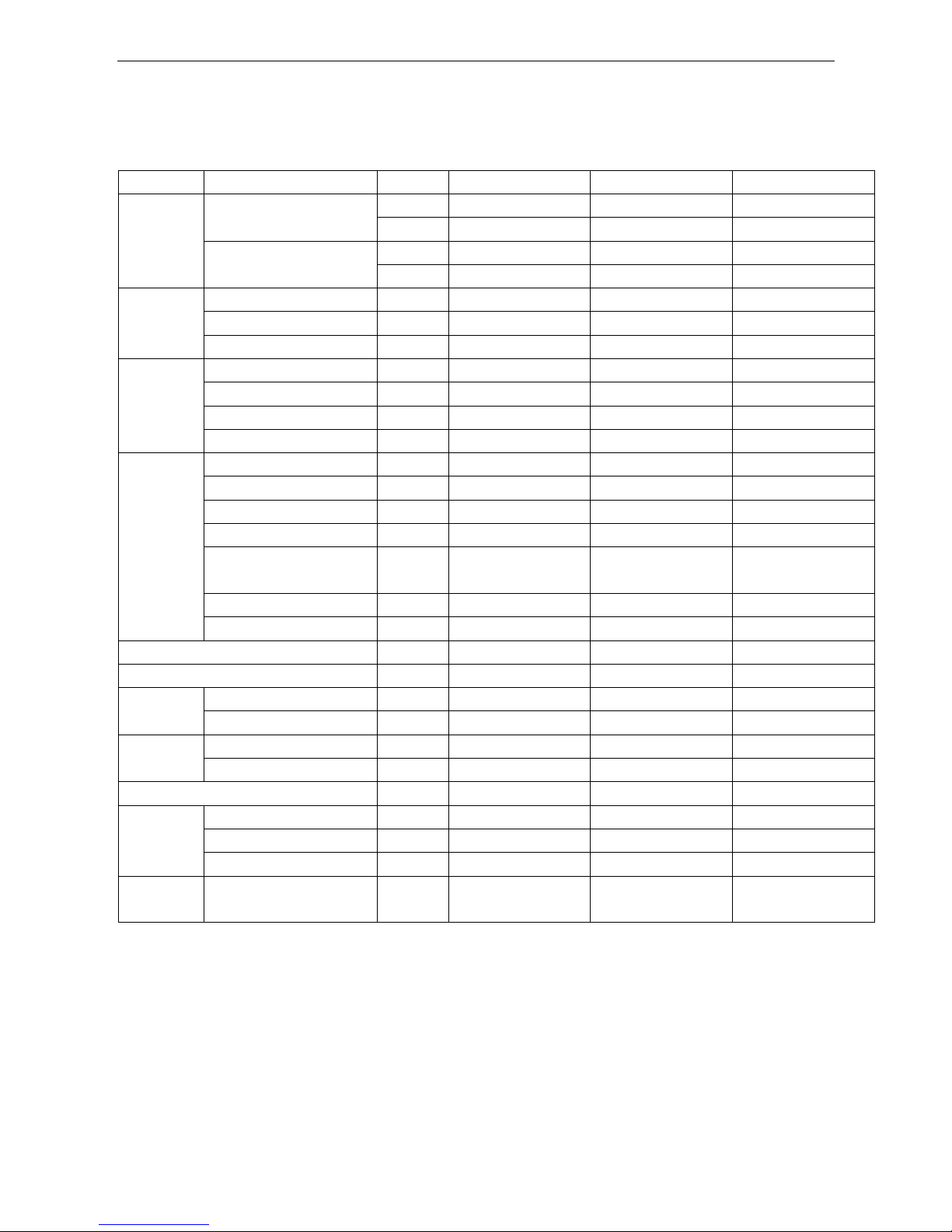

3.2Amendment coefficient of cooling capacity under different indoor/outdoor

temperature(K1)

Indoor

temperature(℃)

Outdoor temperature(DB)

DB

WB

25

30

35

40

45

50

22

15

0.97

0.92

0.87

0.96

0.77

0.75

24

17

1.03

0.98

0.94

0.89

0.84

0.80

27

19

1.10

1.05 1 0.95

0.90

0.86

29

21

1.16

1.11

1.06

1.02

0.96

0.91

32

23

1.22

1.17

1.13

1.08

1.02

0.98

Actual cooling capacity calculation:

Actual cooling capacity=amendment coefficient of cooling capacity × nominal cooling capacity

——nominal cooling capacity could be found from the performance parameters list

——amendment coefficient of cooling capacity could be found from table above.

3.3 Amendment coefficient of heating capacity under different indoor/outdoor DB/WB

temperature K2

Outdoor temperature(℃)

Indoor temperature(DB)

DB

WB

15

20

25

-15

-16

0.64

0.59

0.55

-10

-12

0.71

0.66

0.62

-7

-8

0.76

0.72

0.67

-1

-2

0.79

0.74

0.70 2 1

0.81

0.76

0.72 7 6

1.04

1

0.96

10 9 1.10

1.06

1.01

15

12

1.16

1.12

1.07

Actualheatingcapacity calculation:

Actual heating capacity=amendment coefficient of heating capacity × nominal heating capacity

——nominal heating capacity could be found from the performance parameters list

——amendment coefficient of heating capacity could be found from table above.

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

12

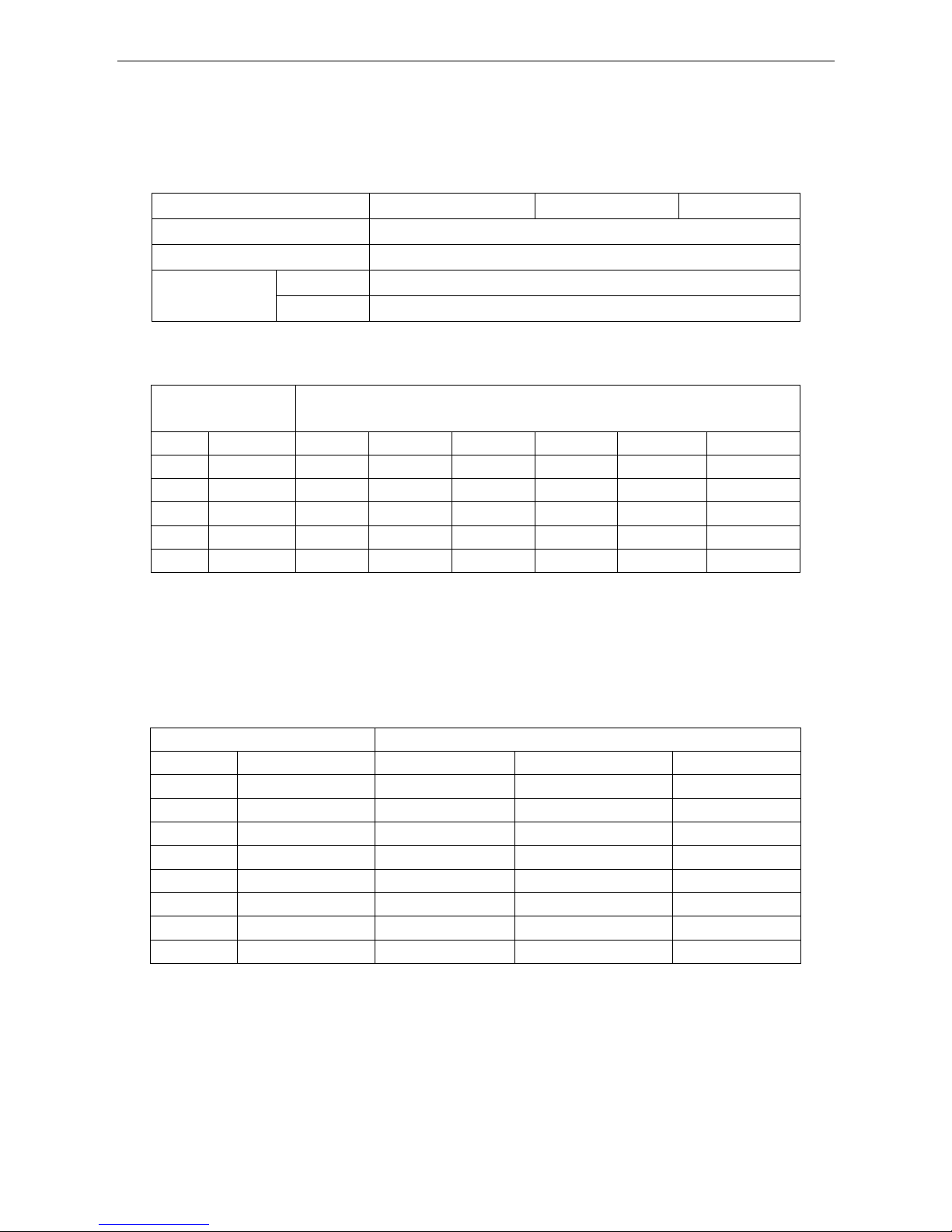

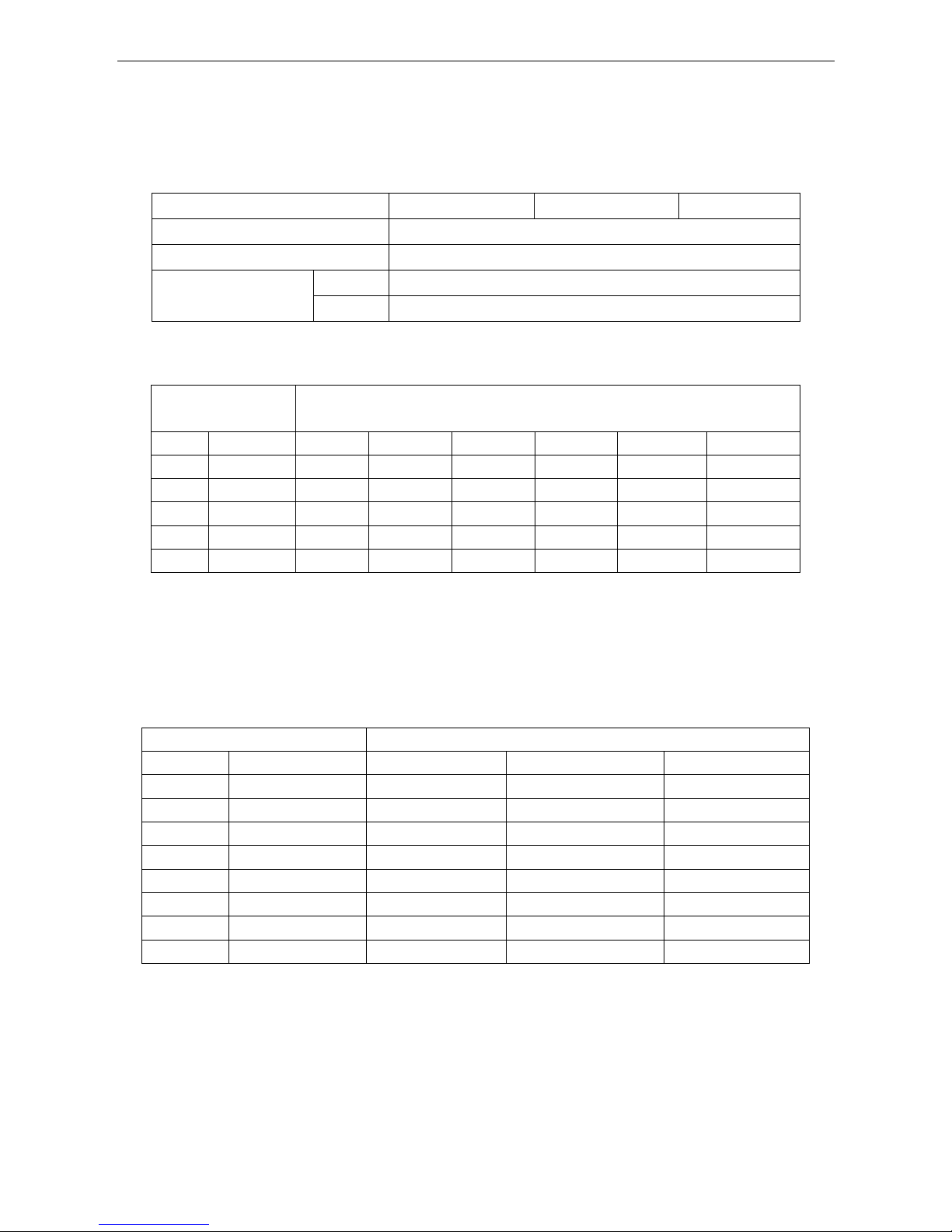

3.4 Amendment coefficients of heating and cooling capacity under different height

drop K3

Different Cooling Capacity modified coefficients at different height:

Note:

H = Height of Outdoor Unit - Height of Indoor Unit

Different Heating Capacity modified coefficients at different height:

Note:

H = Height of Outdoor Unit - Height of Indoor Unit

3.5 Correction capability

Cooling capacity = nominal cooling capacity xK1xK3

Heating capacity = nominal heating capacity xK2xK3

3.6 Equivalent Pipe length conversion

Equivalent pipe length means converting pipe elbow to straight pipe length after considerate the pressure

loss.

Height D

ifference H(m)

Cooling

Equivalent pipe length EL (m)

Height D

ifference H(m)

Equivalent pipe lengthEL(m)

Heat

ing

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

13

Bend and Oil Loop Conversion tablet

Type

Pipe Dia.(mm)

Bend

Oil Loop

6.35

0.10

0.7

9.52

0.18

1.3

12.70

0.20

1.5

15.88

0.25

2.0

19.05

0.35

2.4

22.02

0.40

3.0

Equivalent Pipe length L=Actual Pipe length L+ Bend Qty× Equivalent pipe bend length+ Oil Loop Qty ×

Equivalent Oil Loop length

Sample:

AMCA-H09/4R1AActual Pipe length is 25 meters, Gas pipe diameter is 9.52mm. If there’s 5 bends and 2

oil loops during the installation, then the equivalent pipe length should be:

L=25+0.18×5+1.3×2=28.5(m)

◇Specification of Connection Pipe for Indoor Unit and Outdoor Unit

Cooling Capacity(Btu/h)

9000

12000

18000

Connection Pipe

(mm)

Liquid Pipe

Φ6.35

Gas Pipe

Φ12.7

Max. Length(Each)

15

Max. Height (m)

10

Max. Bend Qty

5

Extra R410a per meter when the pipe length is

more than 5 meter (kg)

0.022

Caution:

1. The standard Pipe length is 5m, if the pipe length is less than this then no additional charging is

necessary. If the pipe length is more than this then you should charge more refrigerant into the system

according to the above Charging Data

2. The thickness of the pipe is 0.6-1.0, bearing pressure is 4.2MPa;

3. If the connection pipe is too long, the cooling capacity and stability would be decreased. And the more

bend quantity, the resistance in the piping system would be bigger, then the cooling and heating

capacity would be decreased even lead to compressor broken. We suggest you to use the shortest

connection pipe according to the pipe length parameter in this manual.If the height difference between

outdoor and indoor unit is more than 5m, an oil trap should be installed in the gas pipe for every 10

meters.

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

14

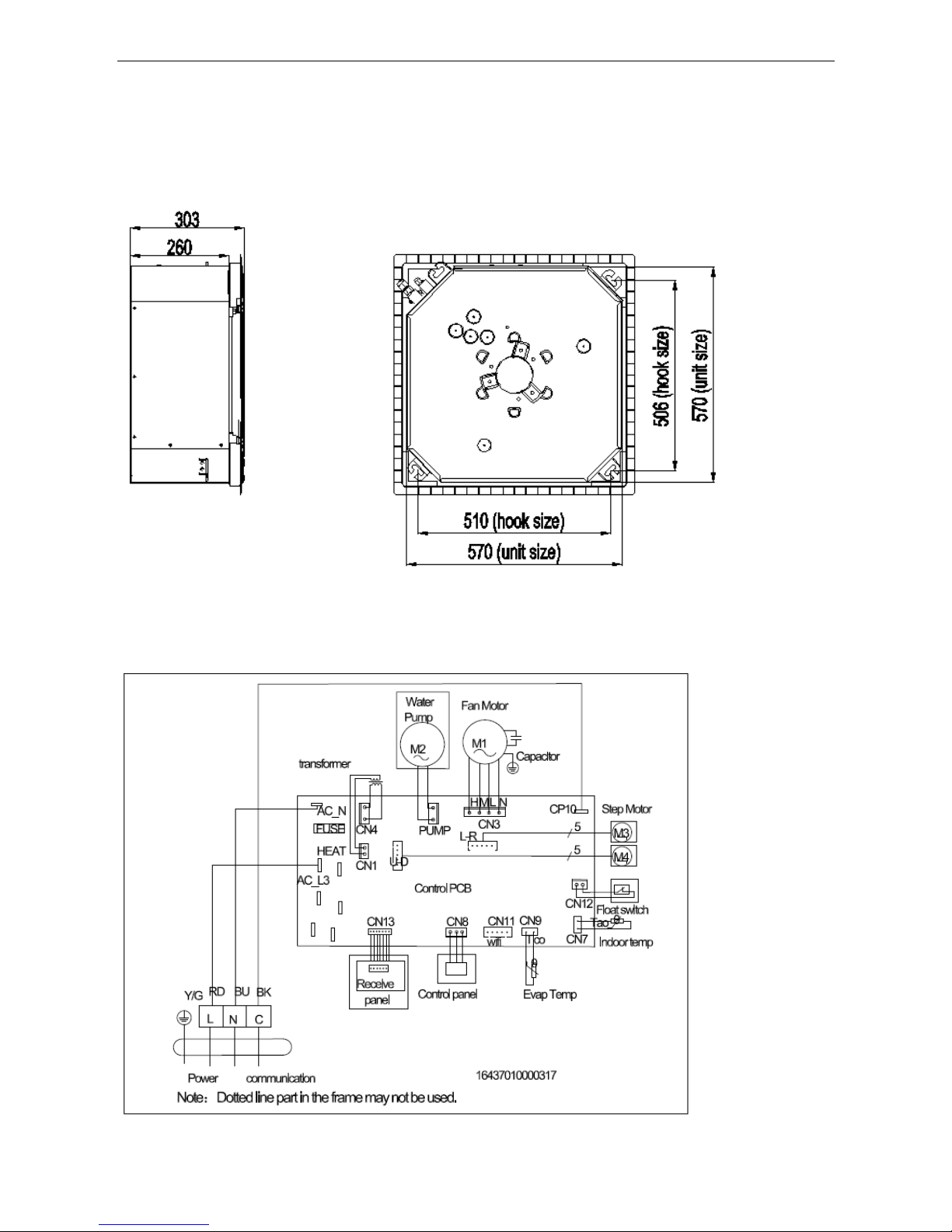

4. Dimension

AMCA-H09/4R1A, AMCA-H12/4R1A, AMCA-H18/4R1A

5. Electrical Diagram

AMCA-H09/4R1A, AMCA-H12/4R1A, AMCA-H18/4R1A

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

15

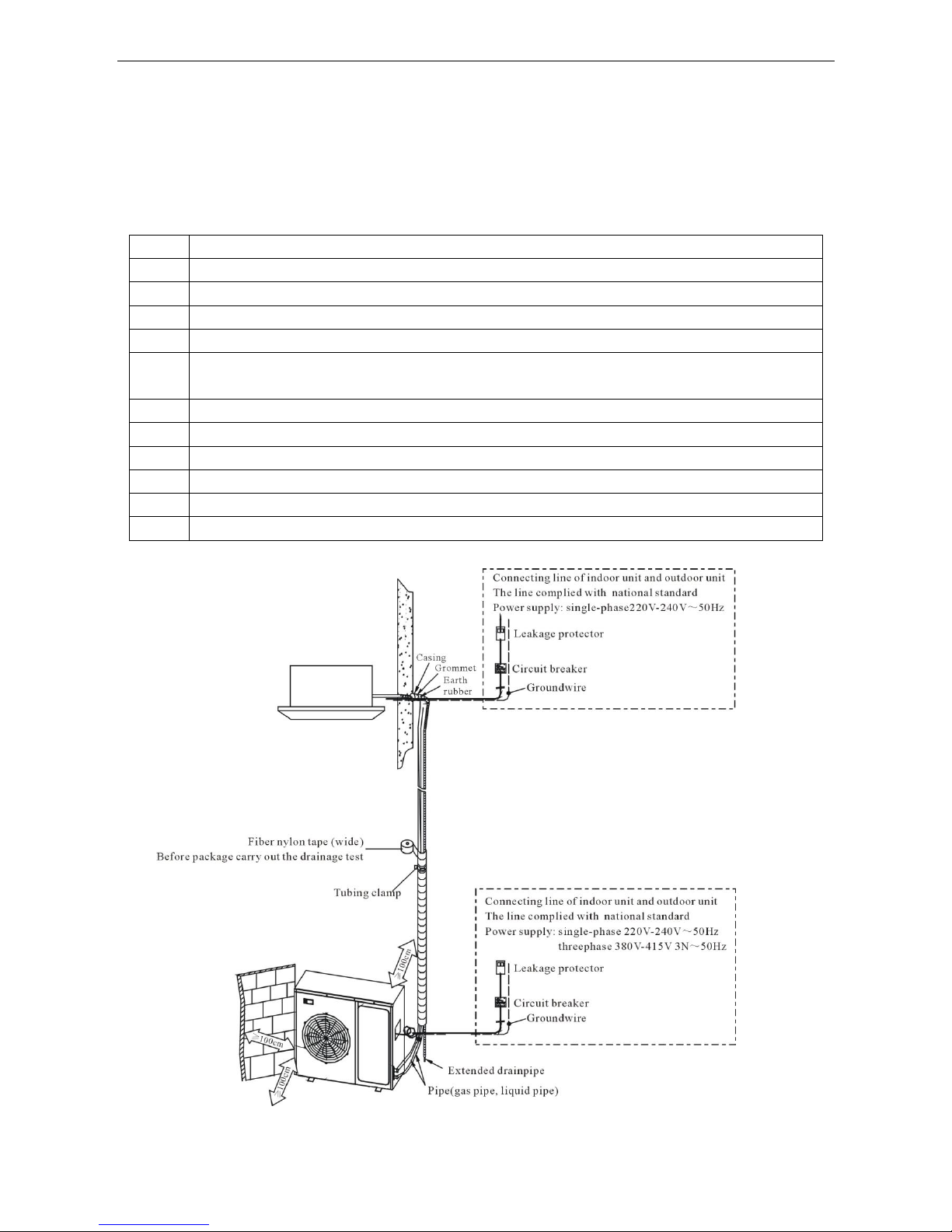

6. Installation

6.1 Preparation before installation

6.1.1Please buy following spare parts from your local market before installation

1

Hung bolts M12, 4 pcs

2

Drainage pipe PVC

3

Copper pipe

4

Adhesive belt (big size) 5 pcs, (small size) 5 pcs

5

Heat insulation material used to connect copper pipe (PE foam material, its thickness is more than 8mm)

6

Power cable, electrical wire between indoor and outdoor unit(Must be in accordance with the wire diameter

in the wiring diagram)

7

Acetylene cylinders, oxygen cylinders (when longer pipe used it should be welded)

8

One set pipe cut machine. (cut copper pipe)

9

Refrigerant cans, electronic balance (when longer pipe used additional gas should be charged)

10

Pressure gauges, pipe clamp, welding torch, 2B silver electrode

11

Wrench 2 pcs, one of them is with adjustable torque wrench(42N.m,65N.m,100N.mm)

12

Nitrogen cylinder (in order to prevent oxidation when welding, using Nitrogen to replace the air)

6.2 Installation drawing

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

16

6.3 Installation precaution

◇ Hanging location should be able to support the unit’s weight, there should be no increasement in

noiseand vibration. If the hanging location needs reinforcement, it should be reinforced before

installation;

◇ Choose the space above the ceiling that can put the indoor unit inside;

◇ The location should be easy for drainage;

◇ The unit should not be installed in the heat source, steam or oil mist source (such as machine room,

kitchen, laundry room, mechanical workshop, etc.)

◇ Choose the location at least 1 meter away from TV and radio, in order to avoid interference to them

◇ There should be certain distance between indoor unit and obstaclesfor maintenance;

◇ In case of leakage of refrigerant, units should immediately stop running, and contact with maintenance

personnel in time. There must be no fire at the site, because the refrigerant will turn to harmful gas

when get to the fire.

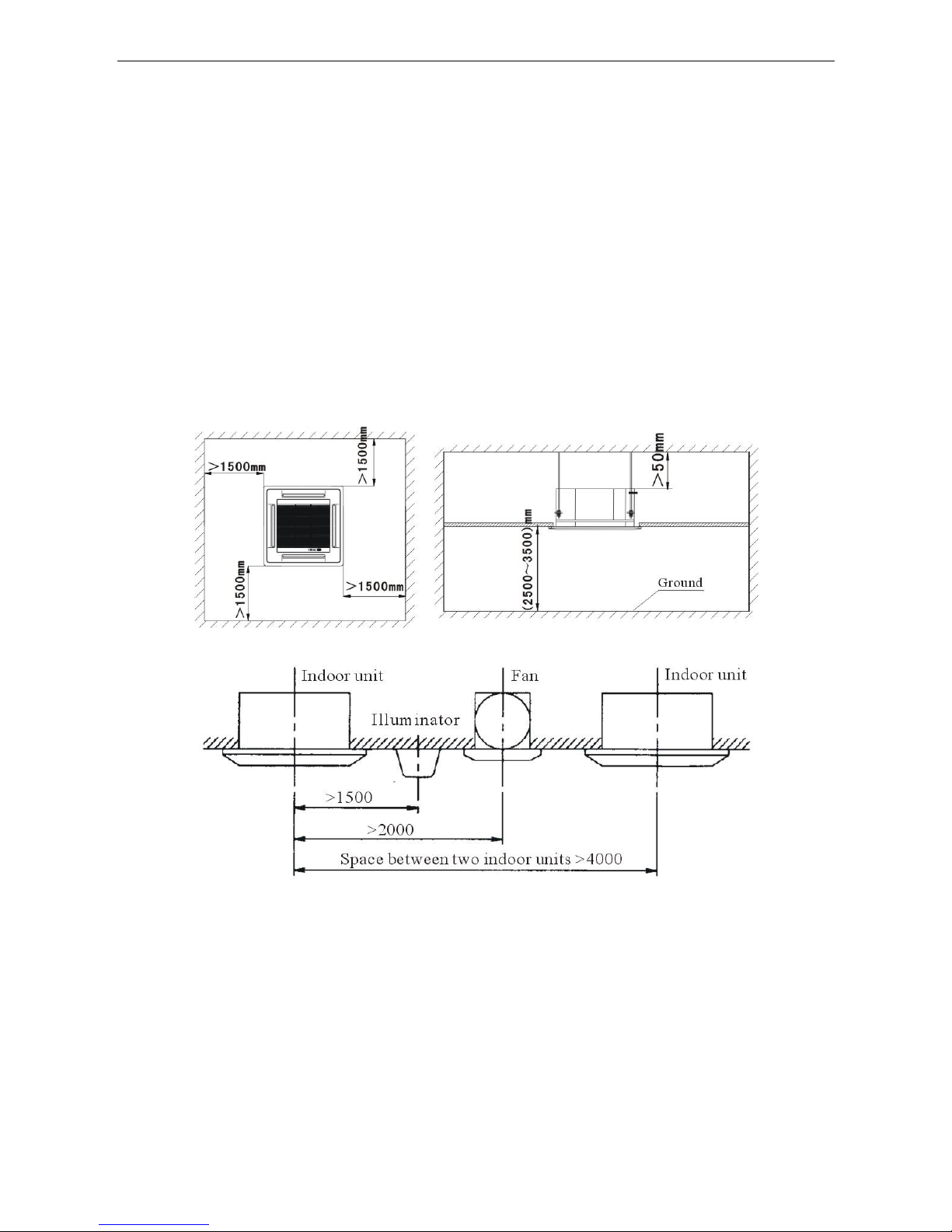

6.4 The distance between indoor unit and obstacle

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

17

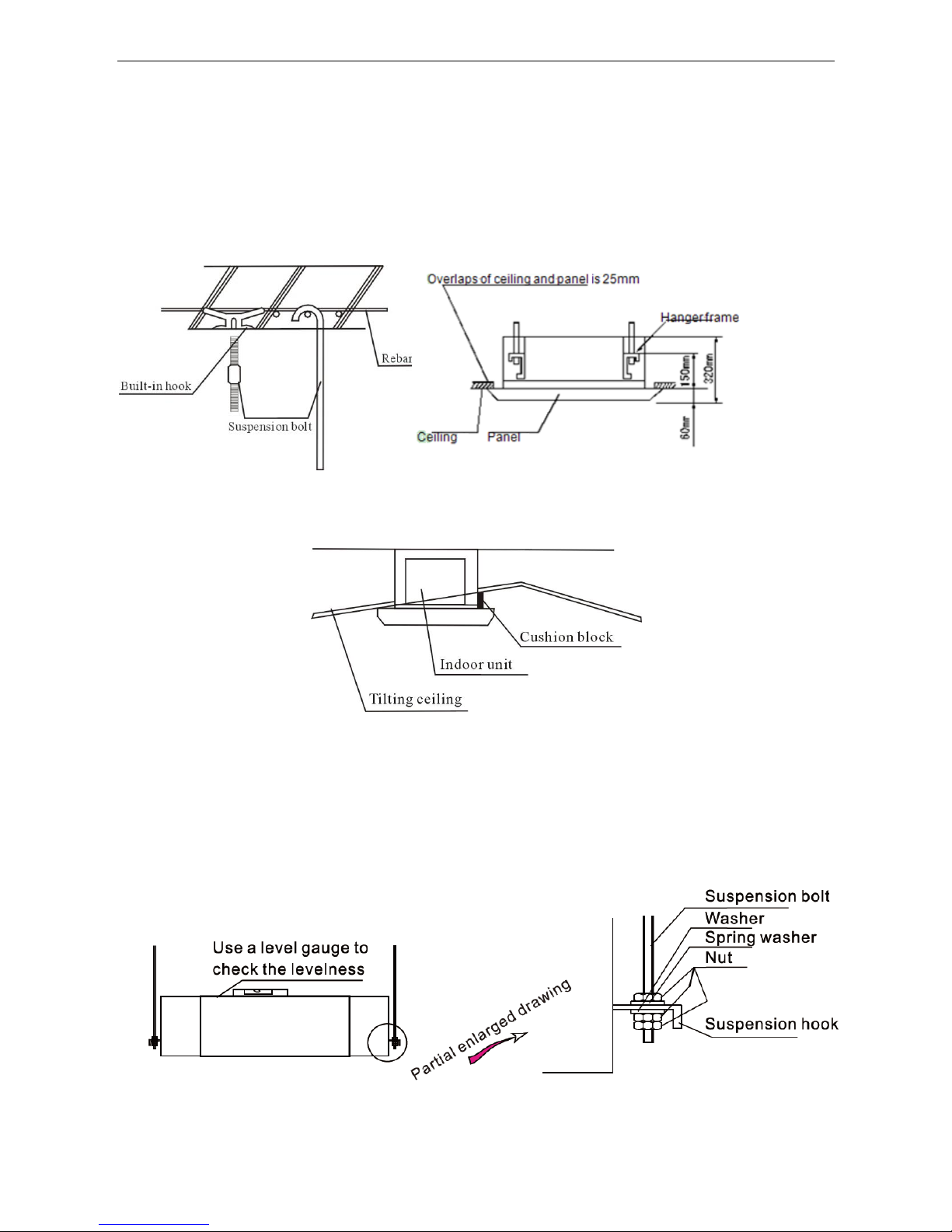

6.5 Indoor unit suspension

◇ Select the suspension foundation:

The suspension foundation is a structure of either wooden frame or reinforced concrete. It must be

firm and reliable to bear at least 4 times weight of itself and capable of bearing vibration for long

periods.

◇ Fixing of suspension foundation:

◇ Fix the suspension bolts either as shown in the picture or by a steel or wooden bracket.

◇ If this unit is installed on a sloping ceiling, a cushion block should be installed between the ceiling and

the air outlet panel, in order to ensure that the unit is installed on a level surface.

This is as shown in the drawing as follows:

◇ Adjust the relative position of the suspension hook on the suspension bolt so that the unit can be in

level position in all directions. Check with a level gauge after installation to ensure that the indoor unit

is horizontal, otherwise it will cause water leakage, air leakage etc.

◇ Tighten the bolt and ensure that four hooks are in close contact with the nuts and washers,to fix the

indoor unitunder the ceiling.

◇ After the unit is installed ensure it is secure and does not shake or sway.

◇ Ensure that the centre of the indoor unit is in alignment with the centre of the opening in the ceiling.

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

18

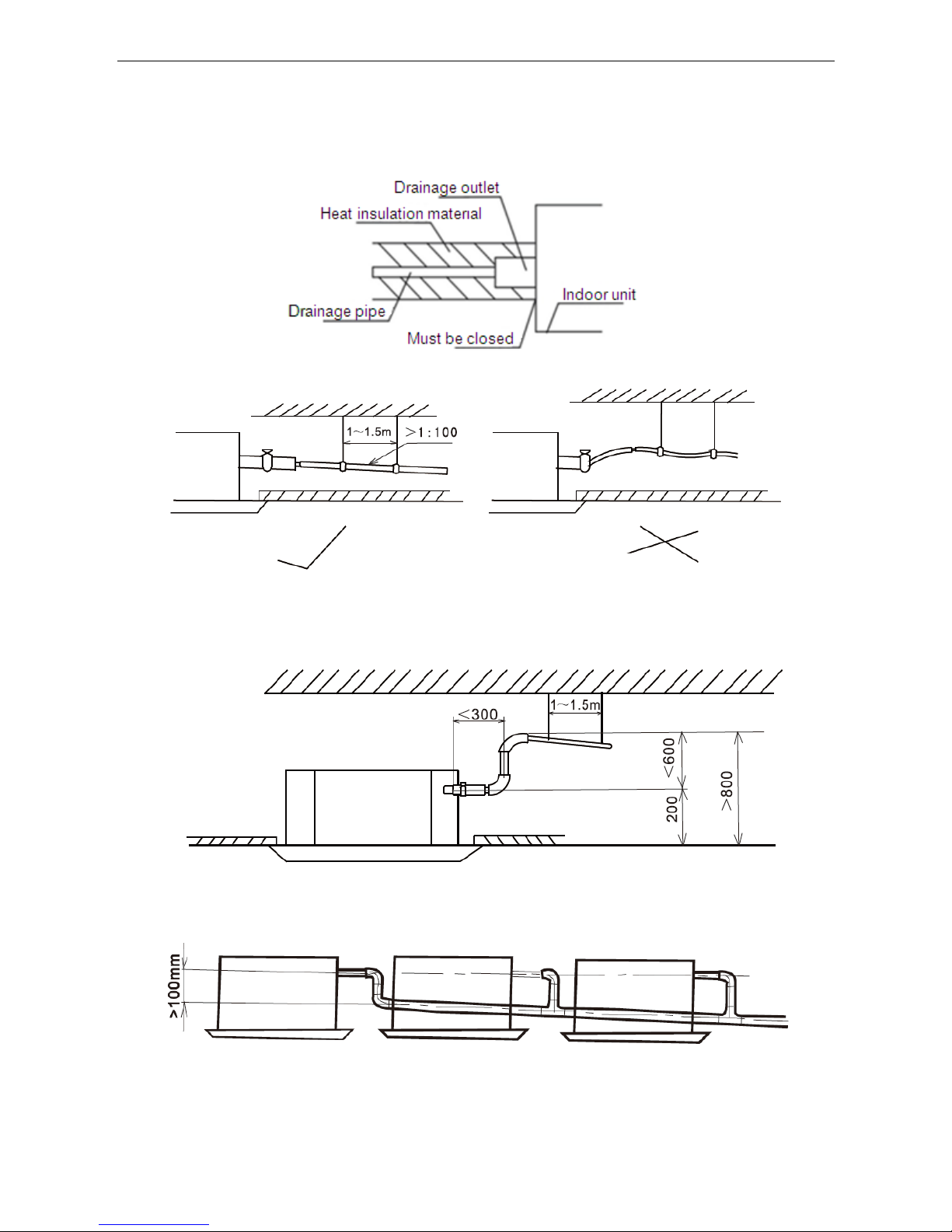

6.6 Drainage pipe installation

The drainage pipe should be properly insulated to prevent the generation of condensation.Heat insulation

material: the thickness of rubber insulation pipe should be more than 8mm

◇ Drainage pipe must have a downward gradient (1 / 50 1 / 100) to avoid water backflow or leakage etc.

◇ The unit has a drain pump which will lift up to 1200mm. However after the pump stops the water left in

the pipe will drain back and may overflow the drain tray causing water leakage. For this reason please

install the drain pipe as shown

◇ When draining multiple units into a common drain line, this common drain should be installed about

100mm below each units drain outlet, as shown in the drawing.

◇ When finish installation please carry out the drainage test to ensure that the water flow through the

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

19

pipeline fluently, and carefully observe the junction to ensure that there is no water leakage. If the unit

is installed in the newly built house, strongly recommend that this test taken before the ceiling

installation. Even it is the heating only unit, this test is unavoidable.

6.7 Panel installation

As to the MB13 panel please refer to the following picture, the panel has four hooks which attach to

corresponding hangers on the unit and the panel should be positioned using these first. The panel is then

fixed into position by four bolts which are accessed through the four corner panels on the grille.

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

20

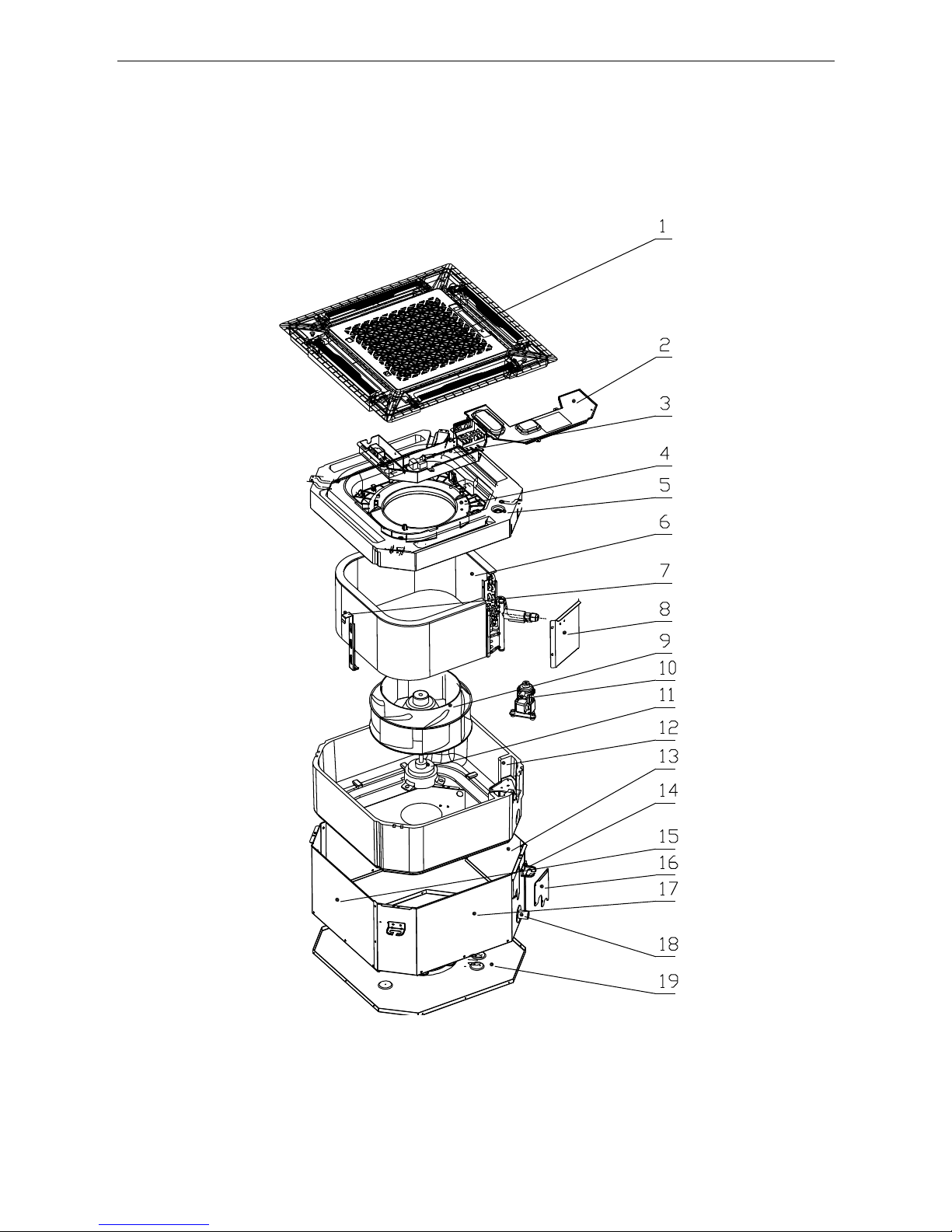

7. Explode view

AMCA-H09/4R1A, AMCA-H12/4R1A, AMCA-H18/4R1A

AUX DC Inverter Free Match 50HZ R410A Four-way cassette

21

No.

BOM Code

Part Name

Qty

Remark

1

16108022000016

Panel MB13 new 1

1.1

16420010000015

Return-air grille assembly

1 1.2

16420012000012

Air filter net 1

1.3

16420007000023

guide wind vane 4

1.4

16430001000133

Step motor

4

24BYJ48-2

1.5

16422015000007

Display board

1

SX-DISP-01

1.6

16420014000035

Panel frame assembly

1 2

16321005000025

Cover for electric components

1 3

16330001000016

Electric assembly

1 3.1

11330010000089

capacitance

1

2.5μF/450V a.c

3.2

11222542000029

PCB board

1

QRD-SN3F(18-60)K(485)-SYE1(SY)

3.3

16422005000017

Transformer

1

TDB-14-B4B(PTC)

3.4

16427001000064

Terminal board

1

600V 2.5mm2

3.5

16430007000007

Sensor 1

1

20K3950 XH2

3.6

16430007000003

Sensor 2

1

15K3950 XH2

4

16320005000040

Water pan 1

5

16432016000037

Rubber plug 1

6

16324005000082

Evap assembly 1

6.1

16325005000086

Evap part 1

6.2

16325005000087

Evap outlet tube assembly

1 6.3

16421024000110

Evap inlet tube assembly

1 7

16421007000143

Evap Pothook 2

8

16444001000037

Evaporator connect board

1 9

16330005000017

Wind wheel

1

Ф283×166

10

16421026000368

Drain pump

1

PLD-700

10.1

16430001000638

Bodder switch 1

10.2

16421040000053

Drain pump support

1 11

16430001000638

Fan motor

1

XD30B

12

16421040000042

Water pan holder

1

13

16421010000073

Air Blower EPS 4

14

16421014000089

Pothook 4

15

16421010000072

Boarding A 1

15.1

16432019000008

Boarding B 1

16

16321001000071

Valve board 1

17

16108022000016

Boarding B 1

18

16420010000015

Plastic drainage pipe

1 19

16420012000012

Chassis 1

AUX DC Inverter Free Match 50HZ R410A Ceiling & Floor Type

22

Ceiling & floor type

1. Function Introduction ......................................................... Error! Bookmark not defined.

2. Specfication ................................................................................................................... 24

3. Capacity amendment .................................................................................................... 25

4. Dimension ...................................................................................................................... 28

5. Electrical Diagram ......................................................................................................... 29

6. Installation ..................................................................................................................... 30

7. Explode view .................................................................................................................. 33

AUX DC Inverter Free Match 50HZ R410A Ceiling & Floor Type

23

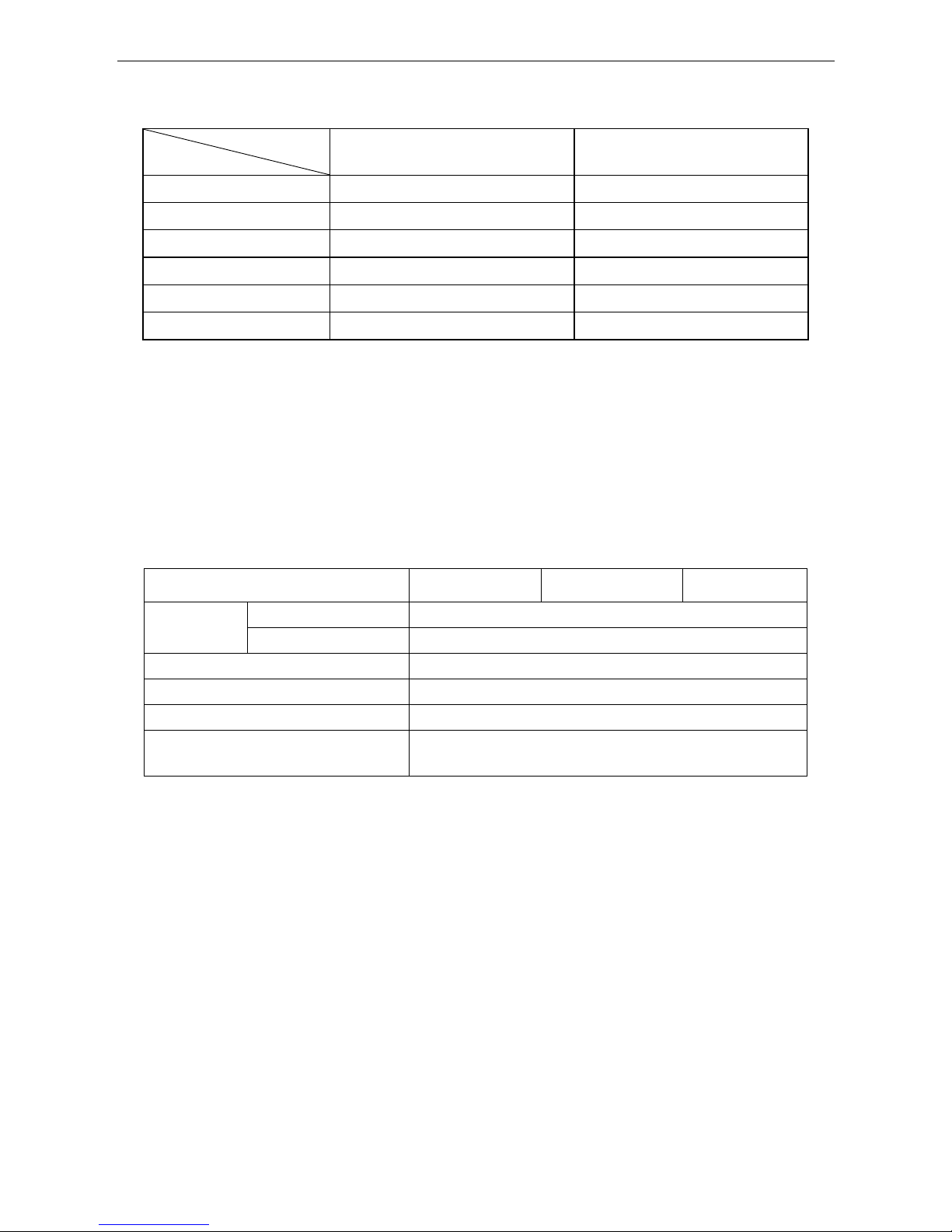

1. Function Introduction

Function

Name

AMCF-H*/4R1

09

12

18

Protection

Function

Anti-freeze protection

○ ○ ○

Sensor failure alarm

○ ○ ○

Error code display function

○ ○ ○

Comfortable

Function

Cooling

○ ○ ○

Heating

○ ○ ○

3 fan speed

○ ○ ○

Auto-restart (optional)

○ ○ ○

Anti-cold wind

○ ○ ○

Blow exhaust heat

○ ○ ○

Timer

○ ○ ○

Opretating

display

clock display

○ ○ ○

operating mode display

○ ○ ○

fan speed display

○ ○ ○

defrosting display

○ ○ ○

timing on/off display

○ ○ ○

sleeping display

○ ○ ○

Operation

mode

Auto operation

○ ○ ○

Dehumidify operation

○ ○ ○

Auto defrosting

○ ○ ○

Ventilation function

○ ○ ○

Health

function

Removable air filter

○ ○ ○

AUX DC Inverter Free Match 50HZ R410A Ceiling & Floor Type

24

2. Specfication

Model

Indoor

Unit

AMCF-H09/4R1

AMCF-H12/4R1

AMCF-H18/4R1

Capacity

Cooling

Btu/h

9560(5120-12115)

12285(5800-12625)

18080(8530-19107)

kW

2.80(1.50-3.55)

3.60(1.70-3.70)

5.3(2.50-5.6)

Heating

Btu/h

10240(5460-13000)

13306(6930-15080)

19790(10340-24000)

kW

3.00(1.60-3.81)

3.9(2.03-4.42)

5.8(3.03-7.03)

Electric

Data

Power Supply

V~,Hz,Ph

220~240,50,1

220~240,50,1

220~240,50,1

Cooling Power Input

W

80(20-125)

80(20-125)

80(20-125)

Heating Power Input

W

80(20-125)

80(20-125)

80(20-125)

Fan Motor

Model / YSK-25W-4

YSK-25W-4

YSK-40W-4

Output Power W 25

25

40

Capacitor

uF

1.5

1.5

2.5

Speed (Hi/Mi/Lo)

r/min

1030/866/735

1030/866/735

1250/1100/900

Indoor Coil

Number Of Row

/

2 2 3

Tube Pitchx Row Pitch

mm

20.5x 12.7

20.5x 12.7

20.5x 12.7

Fin Pitch

mm

1.6

1.6

1.6

Fin Material

/

Hydrophilic aluminum

Hydrophilic aluminum

Hydrophilic aluminum

Tube Outside Dia.&

Material

mm

φ7, Inner grooved

φ7, Inner grooved

φ7, Inner grooved

Coil L x H x W

mm

599x246x 25.4

599x246x 25.4

599x246x 38.1

Heat Exchanging Area

m2

4.21

4.21

6.32

Air Flow volume

m3/h

620/504/441

620/504/441

850/680/595

Sound Pressure Level

dB(A)

39/36/30

39/36/30

43/39/36

Dimension

Net Dim(W*D*H)

mm

929×660×205

929×660×205

929×660×205

Packing Dim(W*D*H)

mm

1010×720×290

995×710×280

995×710×280

Weight

Net

kg

24

24

25

Gross

kg

27

27

28

Refrigerant Type

/

R410a

R410a

R410a

Pipe Dia

Liquid Side

mm(inch)

6.35(1/4)

6.35(1/4)

6.35(1/4)

Gas Side

mm(inch)

12.7(1/2)

12.7(1/2)

12.7(1/2)

Drainage

mm

20

20

20

Loading

Qty

20/40/40H

unit

136/280/315

136/280/315

136/280/315

Note:

1.Cooling capacity test Condition:(27℃DB,19℃WB Indoor/35℃DB,24℃WB Outdoor);

Heating capacity test Condition:(20℃DB Indoor/7℃DB,6℃WB Outdoor);

connecting pipe length: 5M.

2.Datas may be changed with unit improvement. We keep the right to change the datas or specifications

withoutprior notice, please follow the datas listed on the nameplate.

AUX DC Inverter Free Match 50HZ R410A Ceiling & Floor Type

25

3. Capacity amendment

3.1 Running range

Cooling capacity (Btu/h)

9000

12000

18000

Power supply

220-240V~/50Hz

Voltage

187~253V

Ambient temperature

Cooling

-10~52℃

Heating

-15~24℃

3.2 Amendment coefficient of cooling capacity under different indoor/outdoor

temperature(K1)

Indoor

temperature(℃)

Outdoor temperature(DB)

DB

WB

25

30

35

40

45

50

22

15

0.97

0.92

0.87

0.96

0.77

0.75

24

17

1.03

0.98

0.94

0.89

0.84

0.80

27

19

1.10

1.05 1 0.95

0.90

0.86

29

21

1.16

1.11

1.06

1.02

0.96

0.91

32

23

1.22

1.17

1.13

1.08

1.02

0.98

Actual cooling capacity calculation:

Actual cooling capacity=amendment coefficient of cooling capacity × nominal cooling capacity

——nominal cooling capacity could be found from the performance parameters list

——amendment coefficient of cooling capacity could be found from table above.

3.3 Amendment coefficient of heating capacity under different indoor/outdoor

temperature K2

Outdoor temperature(℃)

Indoor temperature(DB)

DB

WB

15

20

25

-15

-16

0.64

0.59

0.55

-10

-12

0.71

0.66

0.62

-7

-8

0.76

0.72

0.67

-1

-2

0.79

0.74

0.70 2 1

0.81

0.76

0.72 7 6

1.04 1 0.96

10 9 1.10

1.06

1.01

15

12

1.16

1.12

1.07

Actualheatingcapacity calculation:

Actual heating capacity=amendment coefficient of heating capacity × nominal heating capacity

——nominal heating capacity could be found from the performance parameters list

——amendment coefficient of heating capacity could be found from table above.

AUX DC Inverter Free Match 50HZ R410A Ceiling & Floor Type

26

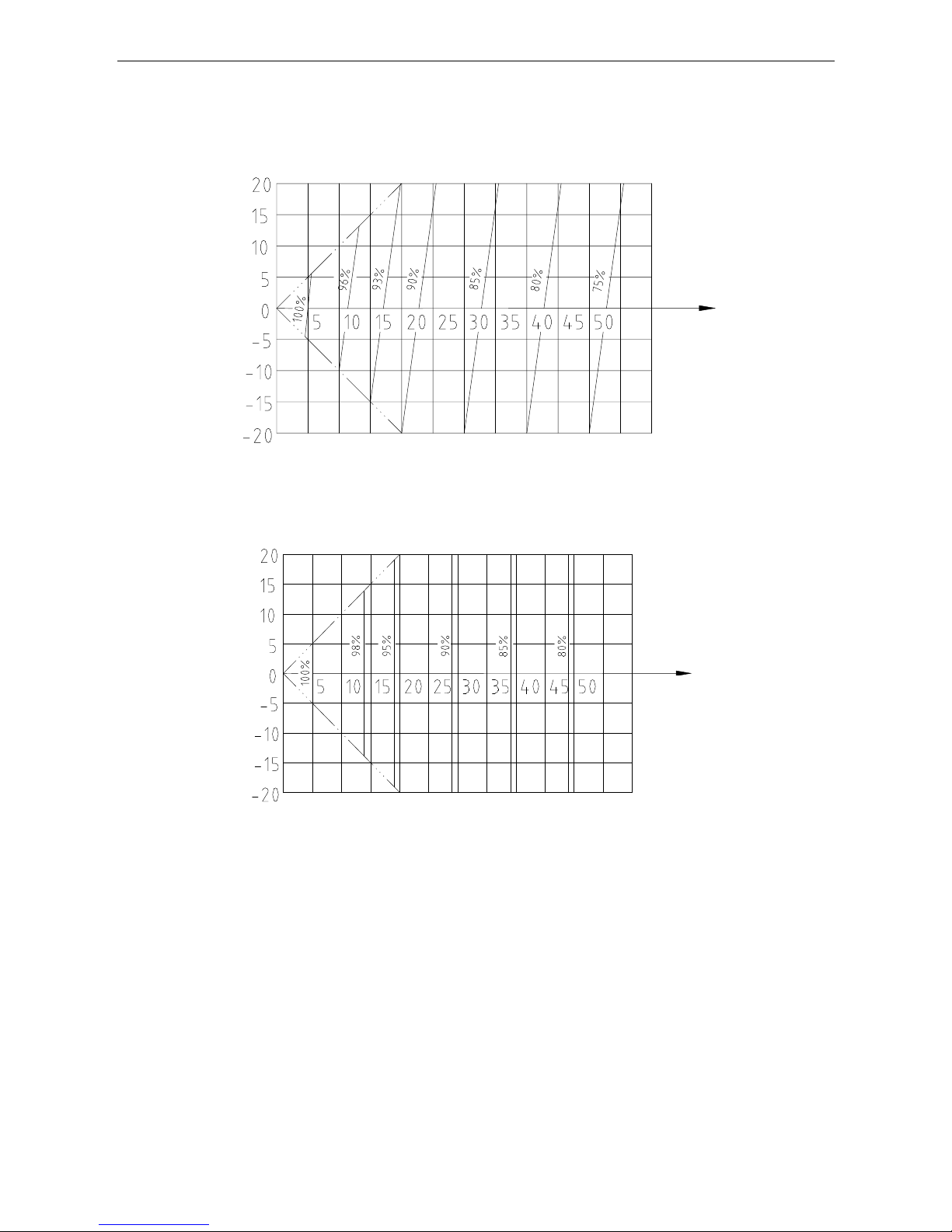

3.4 Amendment coefficients of heating and cooling capacity under different height

dropK3

Different Cooling Capacity modified coefficients at different height:

Note:

H = Height of Outdoor Unit - Height of Indoor Unit

Different Heating Capacity modified coefficients at different height:

Note:

H = Height of Outdoor Unit - Height of Indoor Unit

3.5 Correction capability

Cooling capacity = nominal cooling capacity xK1xK3

Heating capacity = nominal heating capacity xK2xK3

3.6 Equivalent Pipe length conversion

Equivalent pipe length means converting pipe elbow to straight pipe length after considerate the

pressure loss.

Height D

ifference H(m)

Cooling

Equivalent pipe length EL (m)

Height D

ifference H(m)

Equivalent pipe lengthEL(m)

Heat

ing

AUX DC Inverter Free Match 50HZ R410A Ceiling & Floor Type

27

Bend and Oil Loop Conversion tablet

Type

Pipe Dia.(mm)

Bend

Oil Loop

6.35

0.10

0.7

9.52

0.18

1.3

12.70

0.20

1.5

15.88

0.25

2.0

19.05

0.35

2.4

22.02

0.40

3.0

Equivalent Pipe length L=Actual Pipe length L+ Bend Qty× Equivalent pipe bend length+ Oil Loop

Qty × Equivalent Oil Loop length

Sample:

AMCF-H09/4R1Actual Pipe length is 25 meters, Gas pipe diameter is 9.52mm. If there’s 5 bends and

2 oil loops during the installation, then the equivalent pipe length should be:

L=25+0.18×5+1.3×2=28.5(m)

◇Specification of Connection Pipe for Indoor Unit and Outdoor Unit

Cooling Capacity(Btu/h)

9000

12000

18000

Connection

Pipe (mm)

Liquid Pipe

Φ6.35

Gas Pipe

Φ12.7

Max. Length(Each)

15

Max. Height (m)

10

Max. Bend Qty

5

Extra R410a per meter when the pipe

length is more than 5 meter (kg)

0.022

Caution:

1. The standard Pipe length is 5m, if the pipe length is less than this then no additional charging is

necessary. If the pipe length is more than this then you should charge more refrigerant into the system

according to the above Charging Data

2. The thickness of the pipe is 0.6-1.0, bearing pressure is 4.2MPa;

3. If the connection pipe is too long, the cooling capacity and stability would be decreased. And the

more bend quantity, the resistance in the piping system would be bigger, then the cooling and heating

capacity would be decreased even lead to compressor broken. We suggest you to use the shortest

connection pipe according to the pipe length parameter in this manual.If the height difference between

outdoor and indoor unit is more than 5m, an oil trap should be installed in the gas pipe for every 10

meters.

AUX DC Inverter Free Match 50HZ R410A Ceiling & Floor Type

28

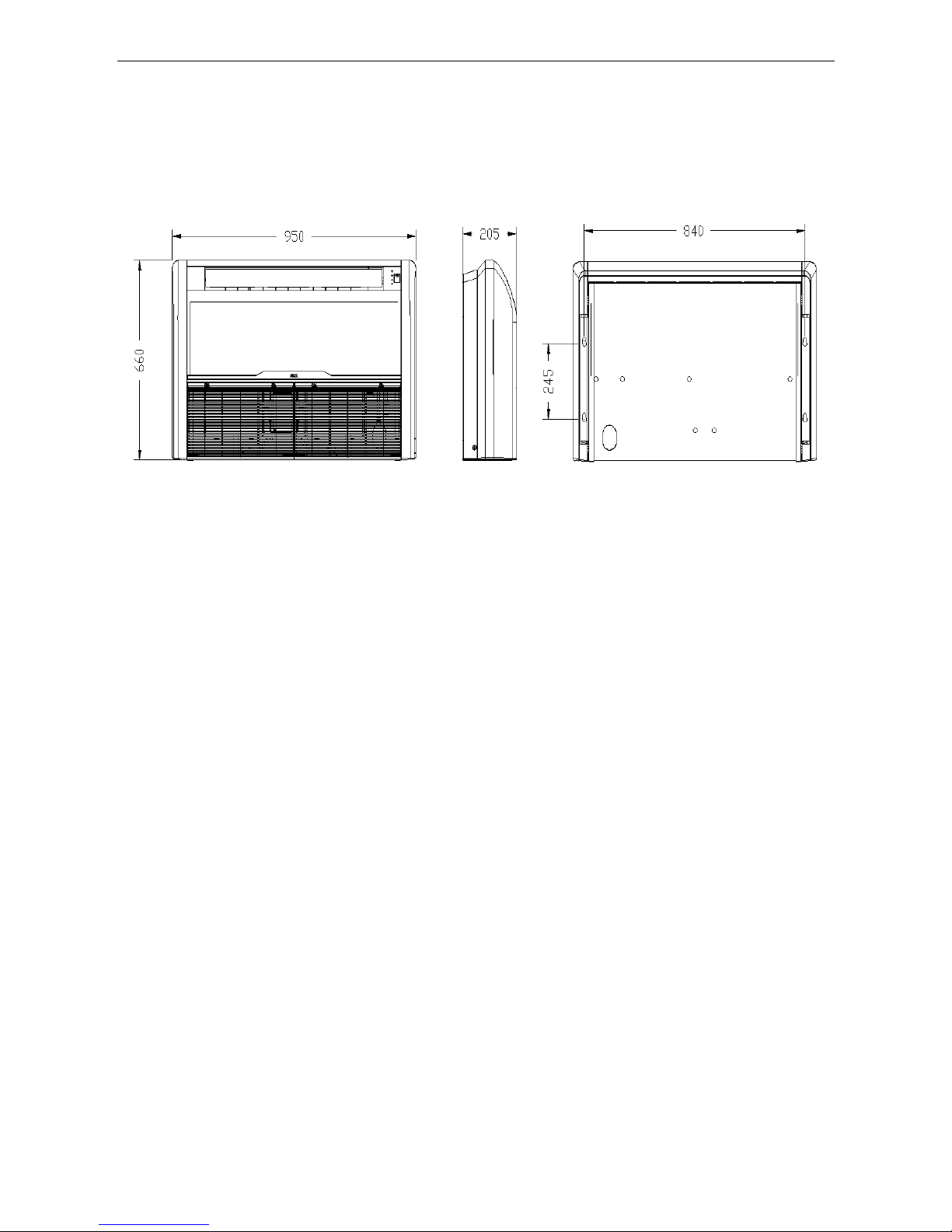

4. Dimension

AMCF-H09/4R1, AMCF-H12/4R1, AMCF-H18/4R1

AUX DC Inverter Free Match 50HZ R410A Ceiling & Floor Type

29

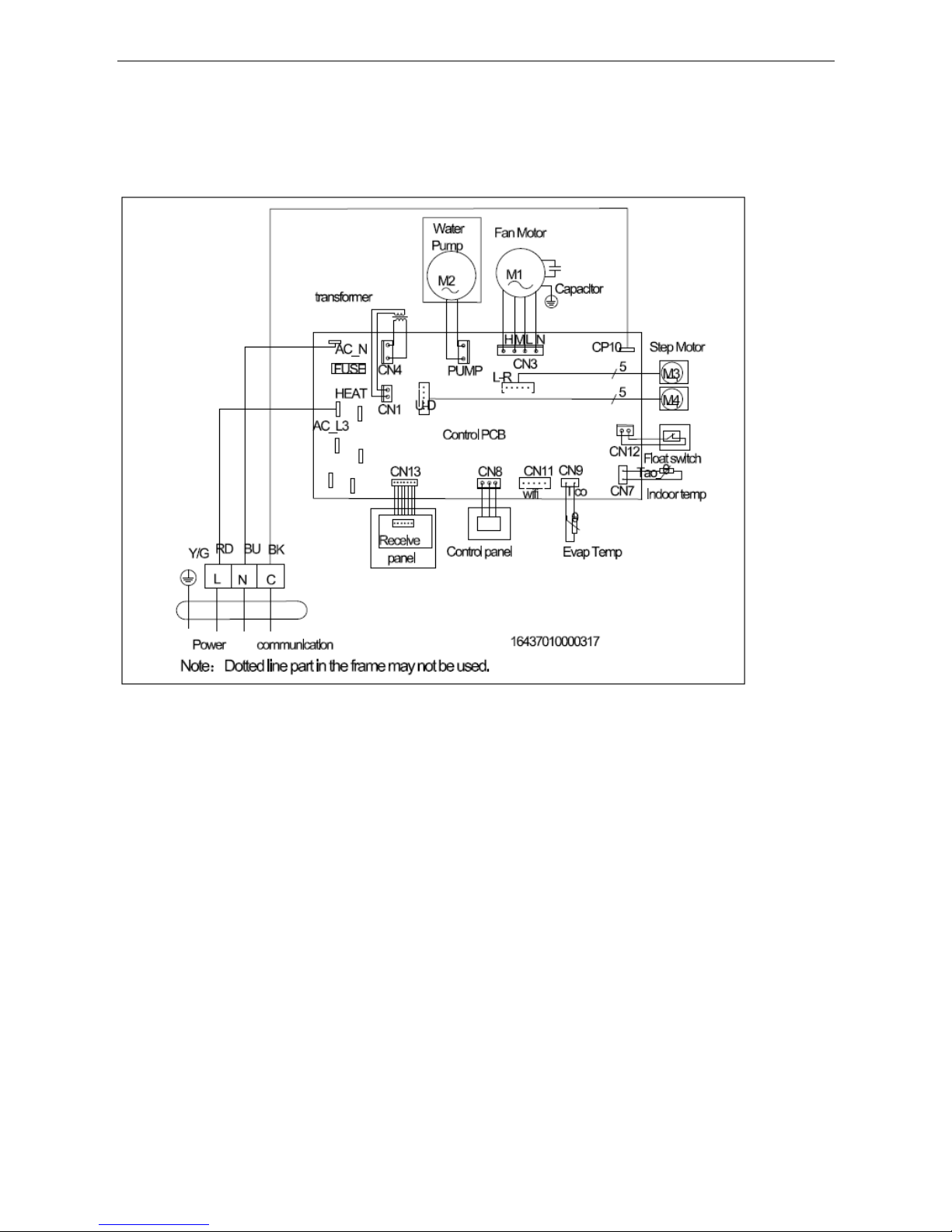

5. Electrical Diagram

AMCF-H09/4R1, AMCF-H12/4R1, AMCF-H18/4R1

AUX DC Inverter Free Match 50HZ R410A Ceiling & Floor Type

30

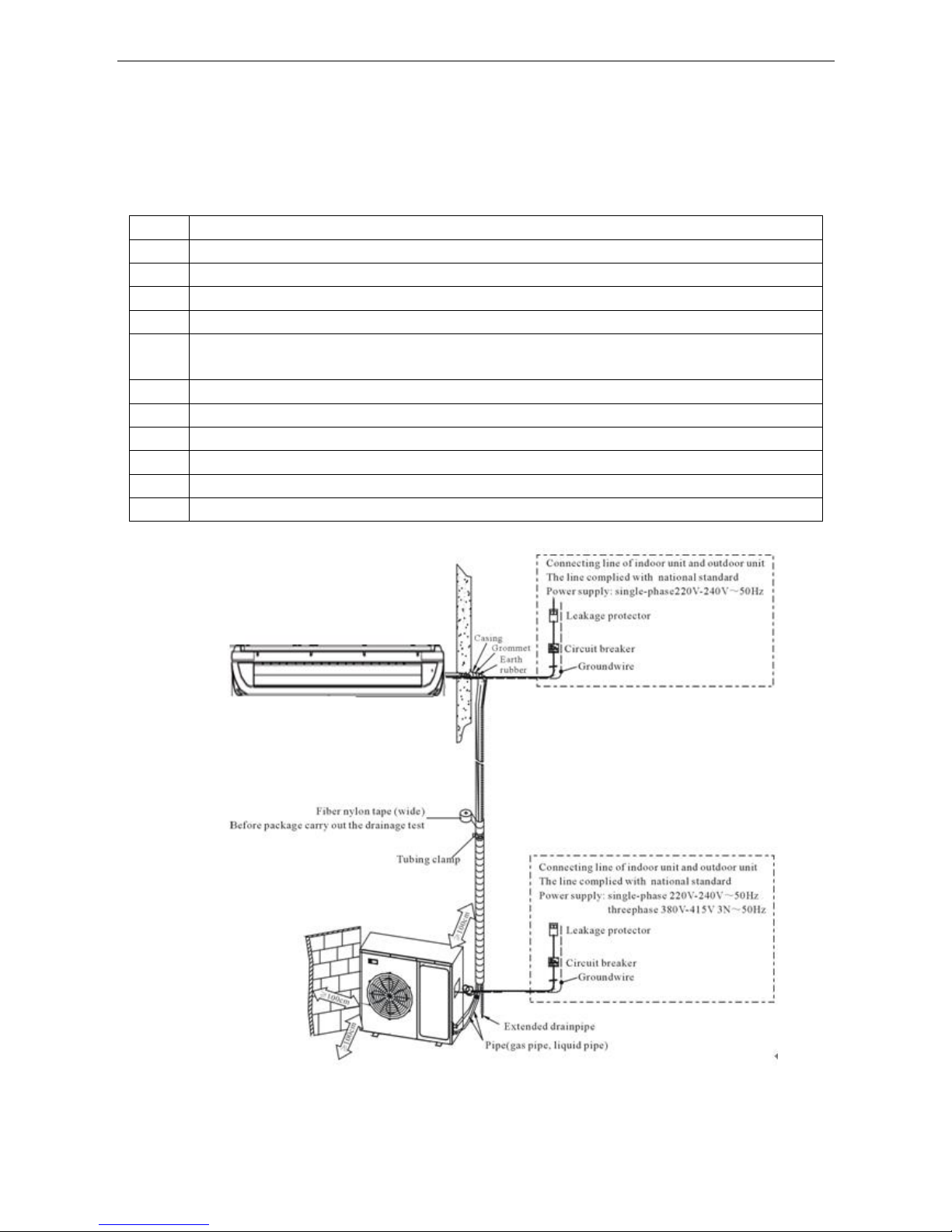

6. Installation

6.1 Preparation and equipments before installation

6.1.1Please buy following spare parts from your local market before installation

1

Hung bolts M12, 4 pcs

2

Drainage pipe PVC

3

Copper pipe

4

Adhesive belt (big size) 5 pcs, (small size) 5 pcs

5

Heat insulation material used to connect copper pipe (PE foam material, its thickness is more than 8mm)

6

Power cable, electrical wire between indoor and outdoor unit(Must be in accordance with the wire diameter

in the wiring diagram)

7

Acetylene cylinders, oxygen cylinders (when longer pipe used it should be welded)

8

One set pipe cut machine. (cut copper pipe)

9

Refrigerant cans, electronic balance (when longer pipe used additional gas should be charged)

10

Pressure gauges, pipe clamp, welding torch, 2B silver electrode

11

Wrench 2 pcs, one of them is with adjustable torque wrench(42N.m,65N.m,100N.mm)

12

Nitrogen cylinder (in order to prevent oxidation when welding, using Nitrogen to replace the air)

6.2 Installation drawing

Loading...

Loading...