116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01, Autronica Fire And Security AS

Commissioning Handbook

AutroSafe Interactive Fire Detection System

Release 4

COPYRIGHT ©

This publication, or parts thereof, may

not be reproduced in any form, by any

method, for any purpose.

Autronica Fire and Security AS and its

subsidiaries assume no responsibility

for any errors that may appear in the

publication, or for damages arising

from the information in it. No

information in this publication should

be regarded as a warranty made by

Autronica Fire and Security AS. The

information in this publication may be

updated without notice.

Product names mentioned in this

publication may be trademarks. They

are used only for identification.

Commissioning Handbook, AutroSafe Interactive Fire Detection System, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01, Autronica Fire and Security

E-1676

This product contains static-sensitive devices . Av oi d an y electrosta tic disc har ge.

The WEEE Directive

When the marking belo w is shown on the

product and/or its liter ature, it means t hat

the product should n ot be disposed with

other household wastes at the en d of its

life cycle. During waste treatment,

disposal and collection, please separate

the product from other types of wastes

and recycle it responsi bly to promote the

sustainable reuse of material resources.

This product should not be mixed with

other commercial wastes for disposal.

Introduction

Table of Contents

1. Introduction ...................................................................... 5

1.1 About the Handbook .......................................................................... 5

1.2 The Reader ....................................................................................... 5

1.3 Reference Documentation................................................................. 6

2. Quick Reference Guide ................................................... 7

2.1 Initial Commissioning ........................................................................ 7

2.2 Upgrading System Software and Configuration ................................ 7

3. Verifying the Loops ......................................................... 8

3.1 AS-2000 Loop Diagnostic Tool ......................................................... 8

3.2 Verification Procedure ....................................................................... 8

4. Consistency Check of Configur ati on Da t a ..................... 9

4.1 Introduction ........................................................................................ 9

4.2 Parameters Used for the Consistency Check ................................... 9

4.3 Importing Loop Data from the AS-2000 Tool .................................... 10

4.4 Consistency Check Using the AS-2000 / Config Mismatch Tool ..... 10

4.5 Generating Configuration Files ......................................................... 10

5. Power Commissioning .................................................... 11

5.1 Addressing Power Boards on the AutroFieldBus .............................. 11

5.1.1 Switch Settings on Power Board BSF-400 ............................. 11

5.1.2 Location of Switches ............................................................... 11

5.1.3 AutroFieldBus Addresses ....................................................... 13

5.1.4 Power Board Configuration Switches ..................................... 14

5.2 Calibration Procedure - Power Unit BPS-410 ................................... 15

6. Addressing Panels .......................................................... 16

6.1 Definitions .......................................................................................... 16

6.1.1 Network ID .............................................................................. 16

6.1.2 Panel ID .................................................................................. 16

6.2 Location of Switches ......................................................................... 17

6.3 Assigning Network IDs ...................................................................... 18

6.4 Assigning Panel IDs .......................................................................... 19

7. Verifying the System Bef ore Startup .............................. 21

8. Startup Procedure ........................................................... 22

8.1 Applying Power to the System .......................................................... 22

8.2 IP Number Structure .......................................................................... 24

8.3 Assigning IP Adresses ...................................................................... 24

8.3.1 Automatic Addressing Mode ................................................... 25

8.3.2 Manual Addressing Mode ....................................................... 27

Introduction

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 4

8.3.3 Configuration Missing.............................................................. 28

8.4 Configuration File .............................................................................. 29

8.4.1 Name, Format and Extension ................................................. 29

8.4.2 Copying the Zip File to a USB Stick ........................................ 29

8.5 Uploading Configuration Files to the System .................................... 30

8.6 Configuration Mismatch ..................................................................... 33

8.7 Entering Required Access Levels ..................................................... 34

9. Verifying the System after an Upload ............................. 36

9.1 General System Verification Procedure ............................................ 36

9.2 Verifying Detection Loops During Normal Operation ........................ 37

10. Upgrading the System ..................................................... 38

10.1 Introduction ........................................................................................ 38

10.2 Upgrading During Normal Operation (SW/Config) ............................ 38

10.2.1 Introduction ............................................................................. 38

10.2.2 Upgrading Software During Normal Operation ....................... 39

10.2.3 Upgrading Configuration During Normal Operation ................ 39

10.3 Upgrading when Panels are Added/Removed .................................. 40

10.4 Upgrading if IP Addresses are to be Changed.................................. 40

10.5 Upgrading a Single Panel.................................................................. 40

10.6 Upgrading by Remote Access to a Web site..................................... 41

10.7 Upgrading Software Version 4.0.1 to 4.1.1 ....................................... 42

10.7.1 General ................................................................................... 42

10.7.2 Preparing a System in Normal Operation ............................... 42

10.7.3 Preparing a System in System Fault Condition ...................... 43

10.8 Upgrading Software Version 4.0.1 or 4.1.1 to 4.3.1 .......................... 44

10.8.1 Example 1: Upgrading all Panels from SW Version 4.0.1

or 4.1.1 to 4.3.1 ...................................................................... 44

10.8.2 Example 2: Adding a BS-420/BS-430 panel with SW

Version 4.1.1 to a System Running on SW Version 4.3.1 ......

44

10.8.3 Example 3: Adding a BC-420 Controller with SW Version

4.1.1 to a System Running on SW Version 4.3.1 ................... 44

10.8.4 Example 4: Adding a Panel with SW Version 4.3.1 to a

System Running on SW Version 4.1.1.................................... 45

11. Startup Procedure for a Dua l S afe ty System ................. 46

11.1 Introduction ........................................................................................ 46

11.2 Guidelines – Startup Proce dur e ........................................................ 47

12. Fault Messages duri ng Uploading .................................. 49

12.1 Introduction ........................................................................................ 49

12.2 Invalid File on USB Stick ................................................................... 49

12.3 Data Transmission Timeout .............................................................. 49

12.4 Corrupt File ........................................................................................ 49

12.5 Fail to Unpack Files ........................................................................... 50

Introduction

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 5

1. Introduction

E-1676

This product contains static-sensitive devices .

Always use an antistatic wrist strap / ground bracelet to avoid any

electrostatic discharge.

1.1 About the Handbook

This handbook is intended to provide all necessary information for the

commissioning of the AutroSafe Interactive Fire Detection System,

Release 4.

The handbook covers the commissioning of a standalone system (Fire

Alarm Control Panel), as well as the commissioning of a distributed

system with several system units, operating on Autronica’s local area

network; AutroNet, including:

Power Boards in Power Cabinet BP-405 and

Power Unit BPS-405/BPS-410 (AutroFieldBus addressing)

Fire Alarm Control Panel BS-420

Controller BC-420 / BC-440

Operating Panel BS-430

Repeater Panel BU-BV-420

1.2 The Reader

The handbook is intended to be used by Autronica Fire and Security

trained service and technical personnel who are responsible for the

installation of the AutroSafe Interactive Fire Detection System,

Release 4.

Introduction

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 6

1.3 Reference Documentation

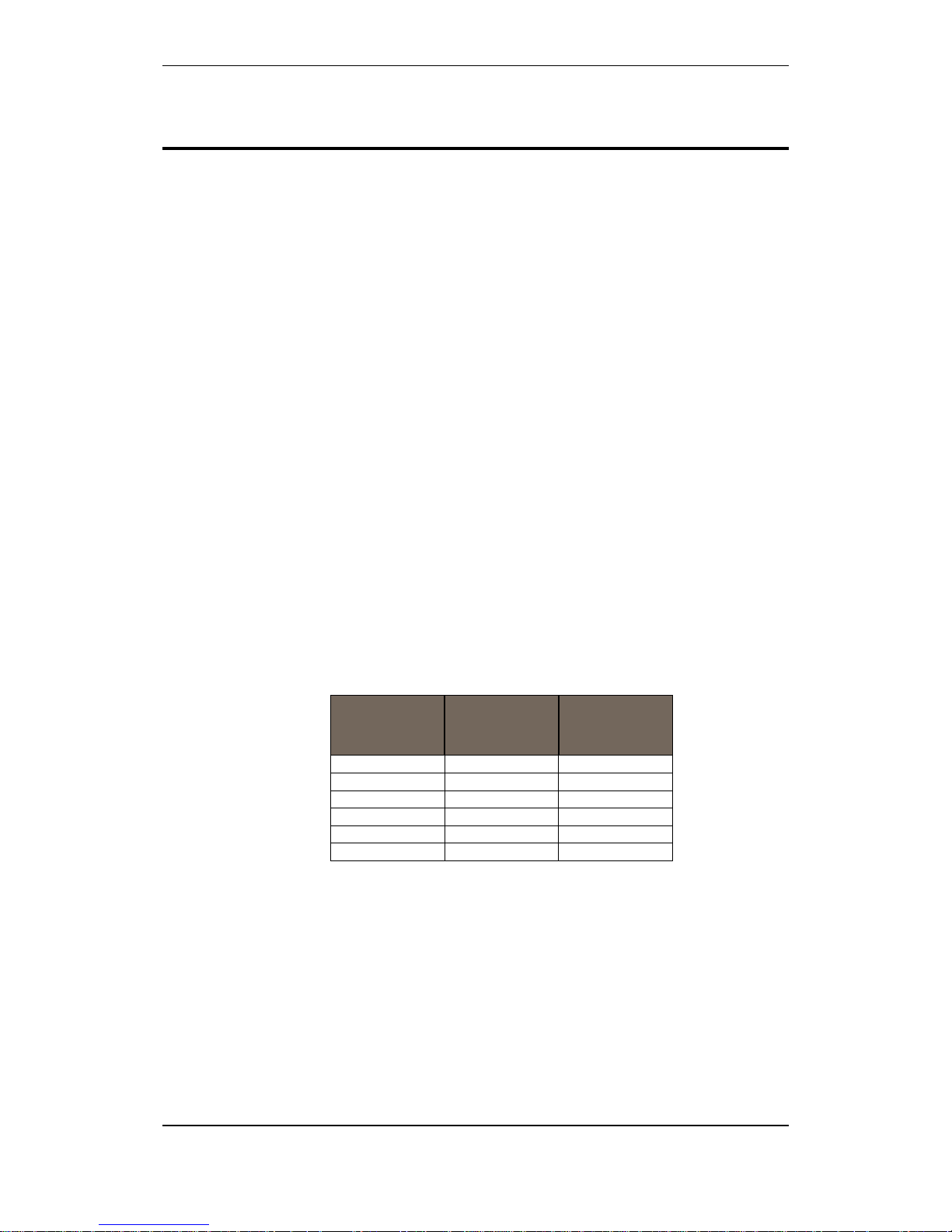

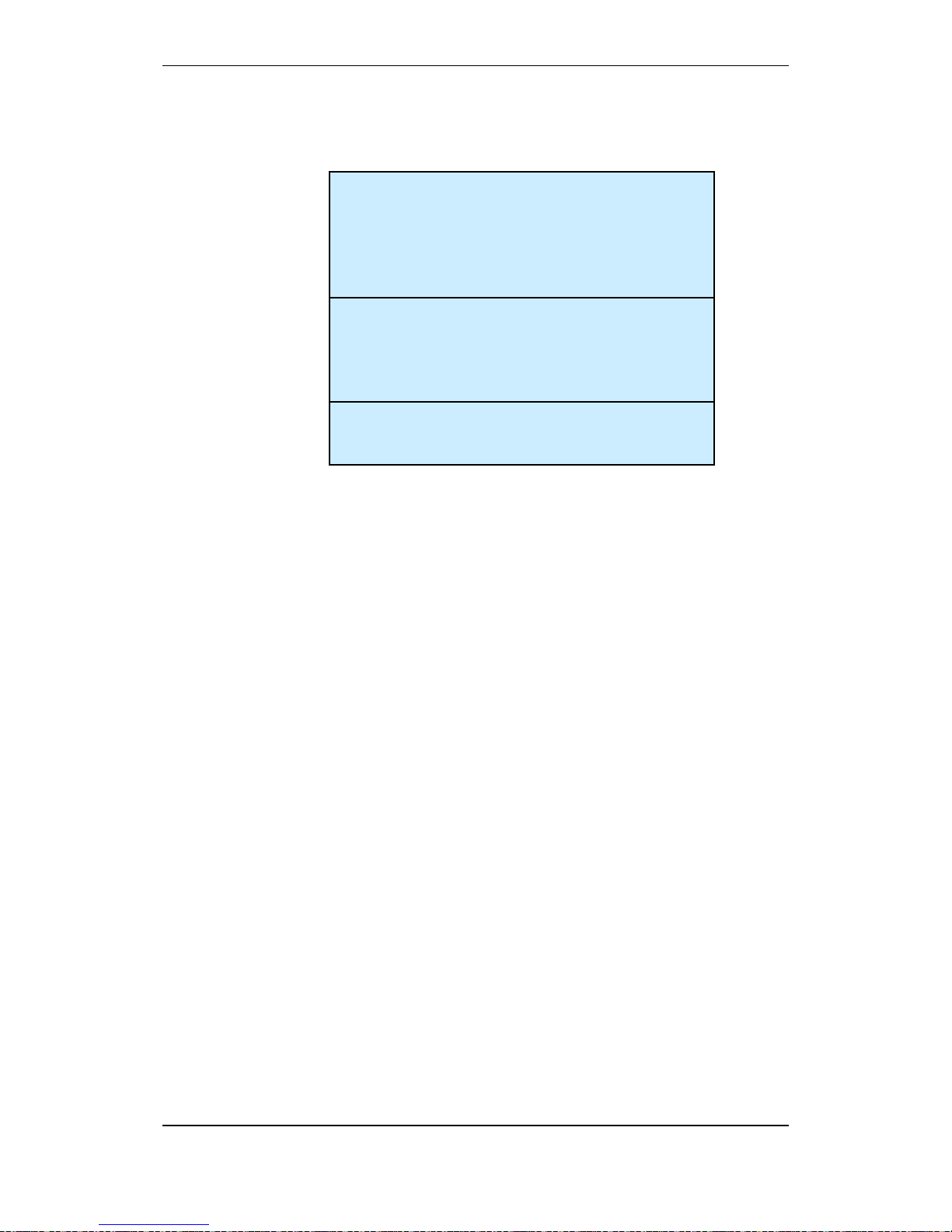

The table below shows an overview of the technical marketing

documentation for AutroSafe Interactive Fire Detection System,

Release 4.

Document Name

Part number

File name

System Description

116-P-ASAFE-SYSTEMD/EGB

asafesystemd_egb

Installation Handbook

116-P-ASAFE-INSTALL/DGB

asafeinstall_dgb

Commissioning Handbook

116-P-ASAFE-COMMISS/EGB

asafecommiss_egb

User Guide, Remote Access

116-P-ASAFE-REMOTEAC/EGB

asaferemoteac_egb

Connecting Loop Units

116-P-CONNECTLOOPUNIT/DGB

connectloopunit_dgb

Operator’s Handbook

116-P-ASAFE-OPERATE/FGB

asafeoperate_fgb

User Guide

116-P-ASAFE-USERGUI/LGB

asafeusergui_lgb

Wall Chart

116-P-ASAFE-WALLCHA/LGB

asafewallcha_lgb

Menu Structure

116-P-ASAFE-MENUSTR/MGB

asafemenustr_mgb

Datasheet; Fire Alarm Control Panel BS-420

116-P-BS420/CGB

bs420_cgb

Datasheet; Operator Panel BS-430

116-P-BS430/CGB

bs430_cgb

Datasheet; Repeater Panel BU-BV-420

116-P-BUBV420/CGB

bubv420_cgb

Datasheet; Fire Brigade Loop Panel BU-110

116-P-BU110/CGB

bu110_cgb

Datasheet; Information Loop Panel BV-110

116-P-BV110/CGB

bv110_cgb

Datasheet; Controller BC-420

116-P-BC420/CGB

bc420_cgb

Datasheet; Controller Unit Rack BC-440

116-P-BC440/CGB

bc440_cgb

Datasheet; Power Cabinet BP-405

116-P-BP405/CGB

bp405_cgb

Datasheet; Power Unit BPS-405

116-P-BPS405/CGB

bps405_cgb

Datasheet; Power Unit BPS-410

116-P-BPS410/CGB

bps410_cgb

Datasheet; AutroKeeper BN -180

116-P-BN180/CGB

bn180_cgb

Quick Reference Guide

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 7

2. Quick Reference Guide

This quick reference guide outlines all the necessary steps to

successfully commission the AutroSafe Interactive Fire Detection

System the very first time, assuming that the system software is

already uploaded to the system, and no configuration files have been

uploaded.

Configuration upgrade and system software upgrade are described in

a separate chapter (Chapter 10).

2.1 Initial Commissioning

Step Action Chapter

1

Verify the detection loops by means of the AS-2000 tool.

Chapter 3

2

Perform a consistency check of the configuration data

using the results from the AS-2000 verification and the data

that has been configured by means of the AutroSafe

Configuration Tool.

Chapter 4

3

Assign an AutroFieldBus address to each Power Board

BSF-400 (rotary switches) / AutroFieldBus unit.

Chapter 5

4

Assign a Network ID to each panel by means of rotary

switches (on BSA-400).

Chapter 6.3

5

Assign a Panel ID to each panel by means of switches (dipswitches and rotary switches on BSA-400).

Chapter 6.3

6

Verify the system before startup

Chapter 7

7

Apply power to the system

Chapter 8.1

8

Assign an IP Address to each panel

Chapter 8.3

9

Upload configuration data to all panels from one central

point (a panel).

Chapter 8.5

10

Verify the system after an upload

Chapter 9

2.2 Upgrading System Software and Configuration

For information regarding configuration upgrade and system software

upgrade, refer to Chapter 10.

Verifying the Loops

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 8

3. Verifying the Loops

3.1 AS-2000 Loop Diagnostic Tool

All loops should be verified with the AS-2000 Loop Diagnostic Tool

before startup. Although this is presumably already done at an earlier

stage (shortly after the installation), it is recommended that all loops

are verified once again in case minor changes have been done. By

doing this, you will eliminate possible pr ob lems which could occur

during the startup procedure and upgrading of configuration data.

The AS-2000 allows you to find all points connected to the selected

loop driver, and present them graphically.

AS-2000 can be connected directly to an AutroSafe

operating panel, or directly to a detection loop by means of an

external interface unit, WAS-2000.

3.2 Verification Procedure

Pressing the START button in the Topology window (AS-2000) tells

AS-2000 to find all points connected to the selected loop driver, and

present them graphically in a correct electrical sequence. Points will

be presented with unique symbols for each type of Loop Unit, and wi th

important information such as Production Number (PN), and the Loop

Sequence Index (LSI). In case of illegal topologies, like multiple

branch-offs and loop breaks, these will be presented with selfexplaining symbols.

Use the AS-2000 to;

register all loop units on each loop, including:

− the Loop Unit type

(detector type, manual call point, electronic sounder, I/O unit)

− Loop Sequence Indexes LSI

(order/location)

register all branch offs and loop break positions

locate any breaks on the loop wire (both positive and negative

wires)

measure the loops’ total resistance, current consumption and

voltage drop

earth fault

You will find detailed information on the installation and use of

AS-2000 in the User Guide, AS-2000 Loop Diagnostic Tool.

Consistency Check

of Configuration Data

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 9

4. Consistency Check

of Configuration Data

4.1 Introduction

4.2 Parameters Used for the Consistency Check

The table below provides a description of two of the parameters that

are used for the consistency check. These parameters are shown in

the Topology View in AS-2000, as well as in the topology view in the

AutroSafe Configuration Tool.

Parameter

Abbreviation

Description

Illustration

Loop Unit

The loop unit

can be a

detector, a

manual call

point, a loop

sounder or an

I/O unit.

(Examples)

Heat detector (BD-200/300/500)

Optical smoke detector (BH-200/300/500)

MultiSensor detector (BH-220/320/520)

Manual callpoint (BF-200/300/500)

Electronic addressable sounder

(BBR-200)

Input / Output unit (BN-300, BN-310, BN-320 etc.)

Loop

Sequence

Index

LSI

A loop specific

index telling the

exact Loop Unit

order on the

loop

(sequencially

numbered).

A branch-off is

described by a

decimal

followed by a

sequencial

index.

NOTE:

To ensure a problem-

free upload of configuration data, always

perform a consistency check, using the results from the

AS-2000 verification and the data that has been configured by

means of the AutroSafe Configuration Tool.

(Example)

Consistency Check

of Configuration Data

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 10

4.3 Importing Loop Data from the AS-2000 Tool

The AutroSafe Configuration Tool features an Import command

allowing you to import loop data directly from the AS-2000 Loo p

Diagnostic tool. In this way, it is possible to ensure that the point types

and sequence indexes in the configuration will be identical to the real

loop. Tag Names and optional Detection Zones (DZs) will be assigned

to the points during import.

For further information, refer to the Help System for AutroSafe

Configuration Tool and the User Guide for the AS-2000 Loop

Diagnostic Tool.

4.4 Consistency Check Using the

AS-2000 / Config Mismatch Tool

4.5 Generating Configuration Files

System configuration is done from a computer by the means of the

AutroSafe Configuration Tool. This tool allows you to generate

configuration files, which then can be uploaded to target after the

system has been verified.

The AutroSafe Configuration Tool allows you to do a

consistency check of configuration data by means of a menu

called AS-2000 / Config Mismatch Tool (in the Tool menu).

This feature allows you to easily compare the actual

configuration data downloaded from a detection loop and

imported to the AutroSafe Configuration Tool (using

the AS-2000) with the configuratio n d ata you have entered in

the AutroSafe Configuration Tool.

Power Commissioning

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 11

5. Power Commissioning

5.1 Addressing Power Boards on the AutroFieldBus

5.1.1 Switch Settings on Power Board BSF-400

The board is configured by means of two switches:

Rotary switches X10 and X11 - AutroFieldBus address switch.

Each Power Board is given a unique address.

Dipswitch S5/S6 – configuration (refer to dipswitch table, chapter

5.1.4)

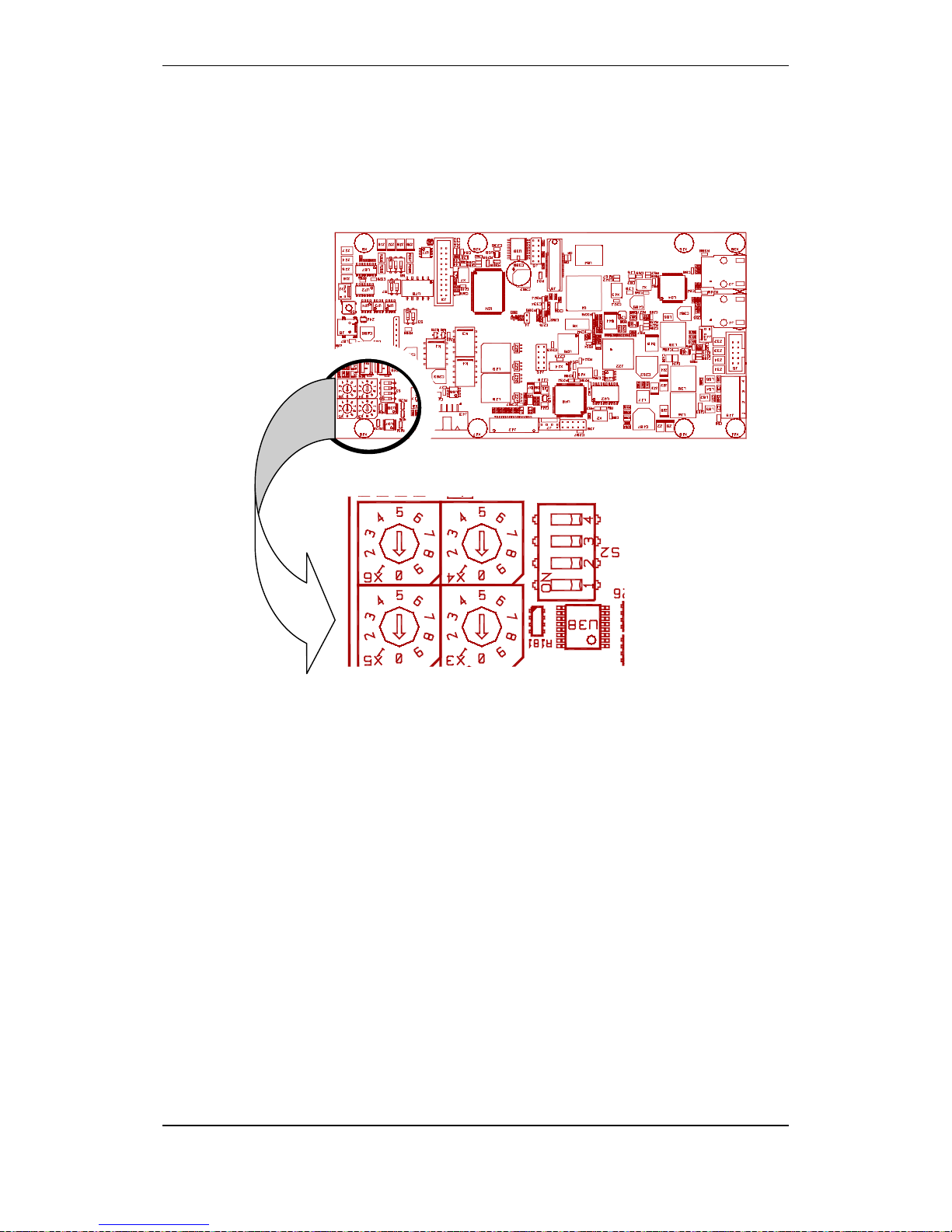

5.1.2 Location of Switches

The location of the dipswitch S5 and S6, plus the rotary switches X10

and X11 are shown on the drawing.

Power Commissioning

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 12

1

2

3

AFB A

AFB A"

AFB CT A

4

5

6

AFB Earth Fault Sense

AFB B

AFB B"

7

8

AFB CT B

AFB Earth Fault Sense

J2

1

6

1

2

3

A

A

R

4

5

6

F

F

F

F1

F2

J19

S1 Reset

High Low

8

7

6

5

4

3

2

1

J24

J23

J22

0V

C2

J21

F2AL

F3 B1

F2AL

F4 B2

F2AL

F5 C1

F2AL

F6 C2

A

1

2

3

Earth Fa

Battery

AFB pre

4

5

6

Battery

61

S6

ON

OFF

15

5

4

3

2

1

Therm.+

Therm.PSF

-V

Vcon

+

-

BATT

J20

J17

F7 Battery

F8 Charger

1

Charger +24V

J18

+

0V

+

C1

0V

+

B2

0V

+

B1

0V

+

A2

0V

+

A1

X11

X10

BP-410/01

BP-405/01

T10T5T10

T5

F7 F8

AH AH

AH AH

S5

AFB Earth Fault Off

AFB Earth Fault On

1

OFF

ON

2

OFF

ON

Dipswitch S6

AutroFieldBus

Address Switch

X10, X11

Dipswitch S5

S1 Reset button

Power Commissioning

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 13

5.1.3 AutroFieldBus Addresses

Each AutroFieldBus unit/Power Board BSF-400 on an AutroFieldBus

must be assigned a unique address by means of an rotary switch (see

previous page).

The drawing below shows the AutroFieldBus connections on the main

terminal block, list L1 mounted on a DIN rail inside the cabinet

(BS-420/BC-420). The first AutroFieldBus unit is connected to the

terminals L1.9 / L1.11 (AFB A). The last unit is connected to L1.3 /

L1.5 (AFB B).

CT (CenterTap) of transformer shall not be connected (terminal 3 and

11). Shield is connected to earth at one end only.

L1.3

L1.5

L1.7

L1.15

L1.9

L1.11

L1.13

Last AFB unit

First AFB unit

SA 400 with shielded AF cable

A maximum of 31 AutroFieldBus units can be connected to one

AutroFieldBus, giving the number range 01 to 31. The physical

addresses are set by means of the rotary switches on the board.

The illustration below shows an example of the system topology

window. 4 AutroFieldBus units are added to the AutroFieldBus

interface.

The sequence of the units in the topology window determines the

switch settings on each unit, i.e. the first unit (the uppermost unit in

the topology window) is to be given switch address 01, the next is to

be given switch address 02, and so on.

Note that the physical sequence of AutroFieldBus units on the

AutroFieldBus must not necessarily corres p ond to the s equence

shown in the topology window, however this is recommended.

Addressing AutroFieldBus units on the AutroFieldBus

Fire Alarm Control

Panel BS-420

BSA-400

BSF-400

BSD-321

BSF-400

AutroFieldBus

Switch

Address 01

BSF-400

Switch

Address 02

Switch

Address 03

Switch

Address 04

Always address 00

The first AutroFieldBus unit

Example: System topology window in

the AutroSafe Configuration Tool

Switch address 01

Switch address 02

Switch address 03

Switch address 04

Main terminal block, list L1

inside the BS-420/BC-420

AFB

AFB

Power Commissioning

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 14

5.1.4 Power Board Configuration Switches

The settings of the dipswitches are read during startup. If the switches

are changed for any reason, the changes will not take affect until the

Power Board is restarted (pressing the reset button S1 on the Power

Board).

Dipswitch table – S5

S5.1

S5.2

Function

OFF

OFF

AutroFieldBus earth fault OFF

ON

ON

AutroFieldBus earth fault ON

Dipswitch table – S6

Switch

Name

Comment

S6-1 Earth Fault

ON: Earth fault monitoring

activated

OFF: Earth fault monitoring

deactivated

S6-2 NA

Must always be set to OFF

(default).

S6-3 AutroFieldBus

ON: AutroFieldBus connected

OFF: AutroFieldBus not

connected

S6-4

NA

-

S6-5

Battery

ON: Battery connected

OFF: Battery not connected

S6-6

Power Unit Type

ON: BPS-405

OFF: BPS-410

Power Commissioning

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 15

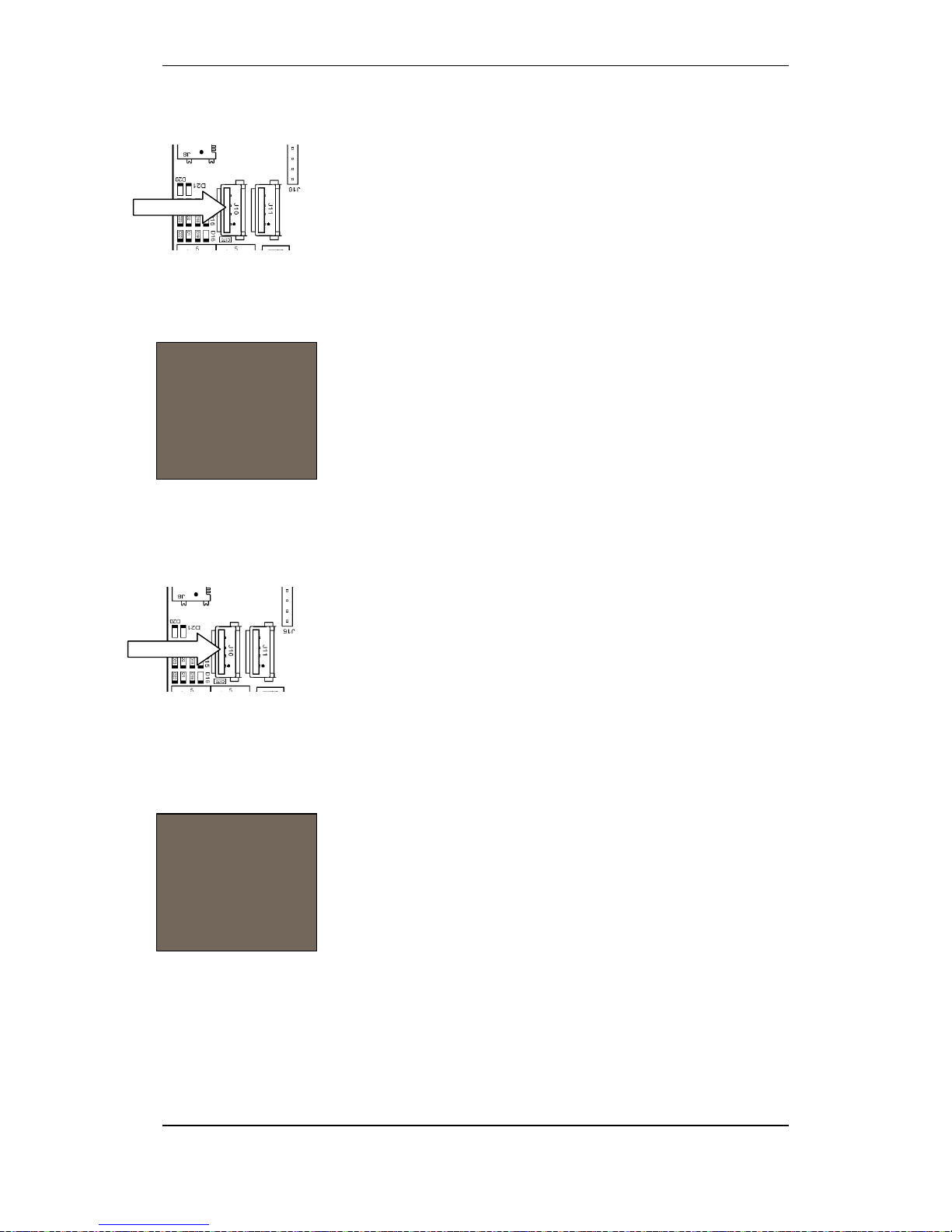

5.2 Calibration Procedure - Power Unit BPS-410

When using Power Unit BPS-410 (including a 24V/10A power supply),

a calibration procedure must be performed. This is necessary in order

to obtain a correct temperature compensated charging voltage to the

batteries. The procedure is as follows:

Before applying power to the system, the power supply’s

temperature sensor (thermistor delivered with the power unit) must

be temporarily replaced with a fixed 2,2k resistor (terminal point 2

and 6 from the left, marked with a stippled line from terminal point

2 to the thermistor symbol at point 6).

Apply power to the system by connecting the mains cable to the

mains socket or by switching the power ON from an external main

fuse box.

Measure the voltage on the BSF-400’s battery terminals (BATT +/-)

while adjusting the voltage with a small screw driver to 27,4V on

the power supply (OUT ADJ).

Disconnect mains power from the power supply and remove

charger fuse F8.

Remove the resistor and reinsert the thermistor.

Insert the charger fuse F8 and re-connect mains power to the

power supply.

15

5

4

3

2

1

Therm.+

Therm.PSF

-V

Vcon

+

-

BATT

J20

J17

arger

1

+24V

BP-405/01 T5 T5

AH AH

AH AH

0V

C2

15

5

4

3

2

1

Therm.+

Therm.PSF

-V

Vcon

+

-

BATT

J20

J17

F7 Battery

F8 Charger

1

Charger +24V

BP-410/01

BP-405/01

T10T5T10

T5

F7 F8

AH AH

AH AH

Measure

Adjust

Charger fuse F8

Addressing Panels

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 16

6. Addressing Panels

6.1 Definitions

6.1.1 Network ID

A panel’s Network ID indicates which system and unique configuration

a panel belongs to. All panels communicating on the same AutroNet

network must have the same Network ID, usually set to 01 (switch

setting; rotary switches X5 and X3).

The Network ID also determines the specific number series of the IP

Addresses (which are set during commissioning by operating the

AutroSafe menu).

6.1.2 Panel ID

Each panel in the system must be assigned a unique Panel ID (switch

setting; rotary switches X6 and X4, plus the settings of dip-switch S2).

For each different panel type (i.e. BS-420 or BU-420) the addressing

on the rotary switches always starts on 0-1.

The Configuration Tool generates a catalogue structure with the

following number series of Panel IDs for the different panel types.

(Note that the physical adressing on the rotary switches does not

follow the numbering series generated by the Configuration Tool).

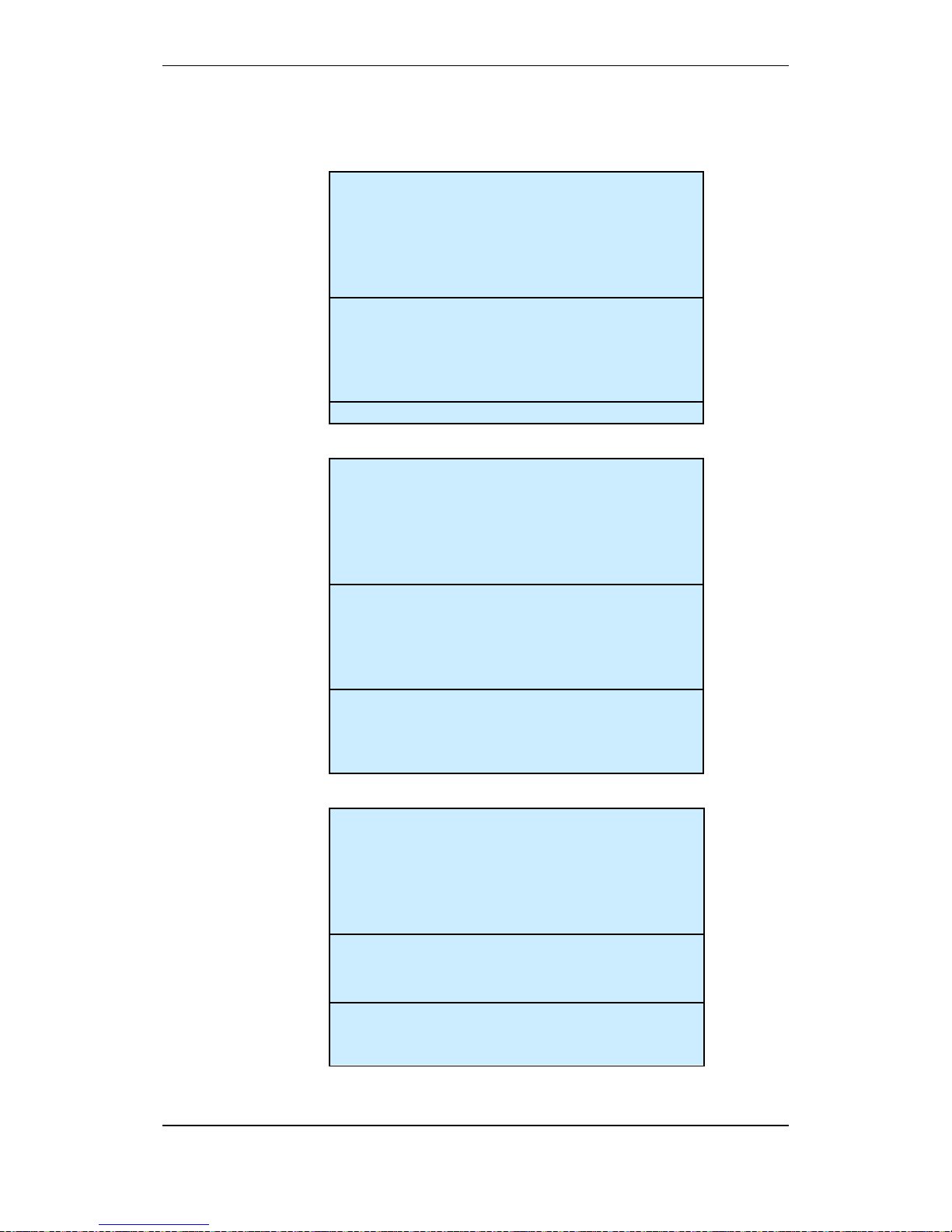

Panel Panel IDs

Number Series

Panel IDs

Hexadecimal

values

BS-420

1-31

01-1F

BC-420

33-63

21–3F

BC-440

33-63

21–3F

BS-430

65-95

41-5F

BU-420

97-159

61-9F

BV-420

161-223

A1-DF

Addressing Panels

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 17

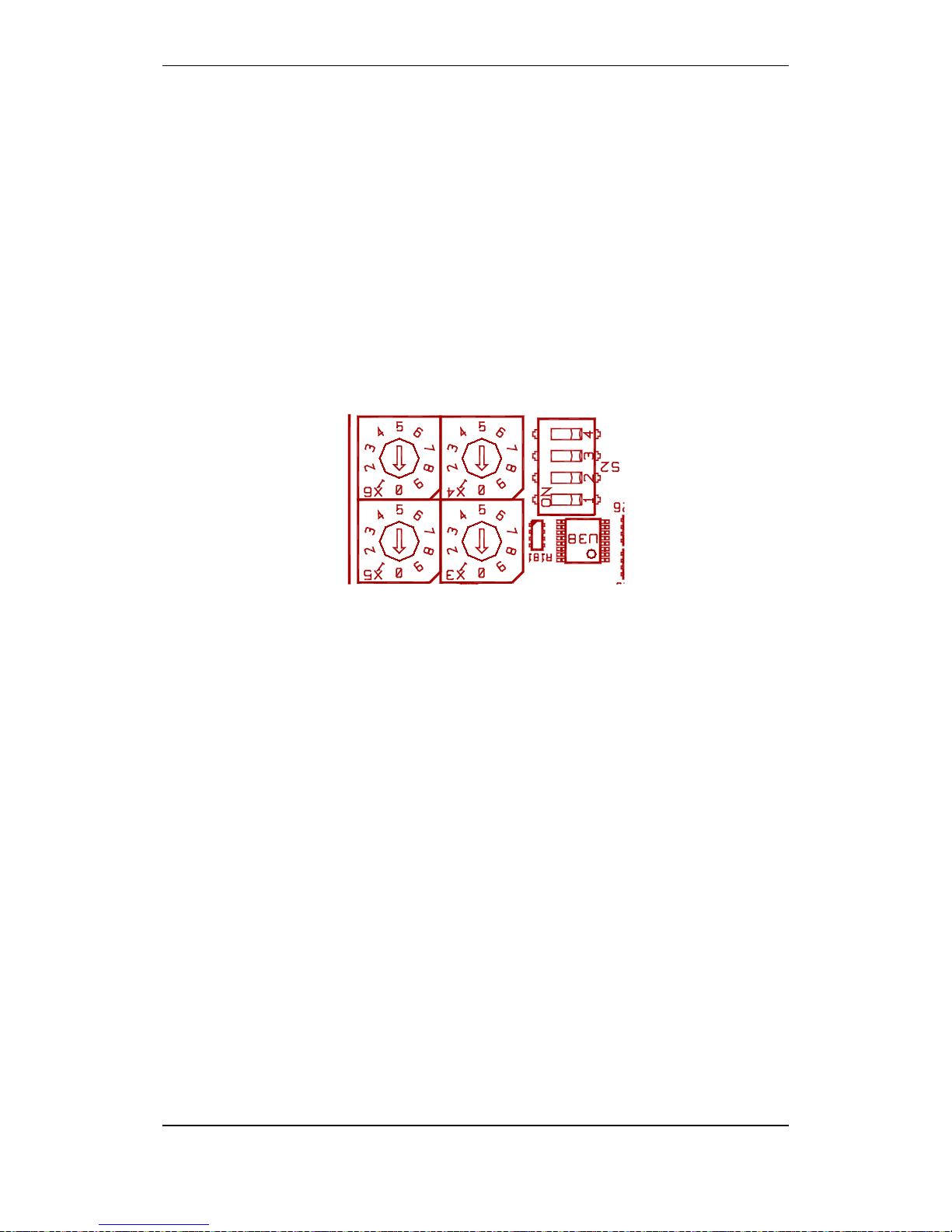

6.2 Location of Switches

The switches are located on the lower left hand side of the BSA-400

circuit board, easily access ible throu gh the hol e in the metal cover.

The BSA-400 circuit board

X3

X5

X6

X4

S2

Addressing Panels

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 18

6.3 Assigning Network IDs

The settings of the rotary switches X5 and X3 determine the panel’s

Network ID, i.e. which system and unique configuration the panel

belongs to.

All panels communicating on the same AutroNet network must have

the same Network ID, usually set to 01.

X5 is set to 0

X3 is set to 1

If there is a second network, this network can be set to 02, a third can

be set to 03, etc.

Switch X5 corresponds to the most significant digit in the address.

X3

X5

Addressing Panels

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 19

6.4 Assigning Panel IDs

Each panel in the system must be assigned a unique Panel ID (switch

setting; rotary switches X6 and X4, plus the settings of dip-switch S2).

For each different panel type (i.e. BS-420 or BU-420) the addressing

on the rotary switches always starts on 0-1.

Note that a standalone Fire Alarm Control Panel BS-420 always has

Panel ID=00.

Switch X6 corresponds to the most significant digit in the address.

Note that the correct switch settings for the panel type in question is

preset at the factory (dipswitch S2) - except for the BU-BV-420 panel,

as this panel can be defined both as a Information Panel and Fire

Brigade Panel.

The following table deals with the Panel IDs when several panels

communicate on the AutroNet (local area network).

Panel

Panel ID

Panel ID

Hex.

values Rotary

switch X6

Rotary

switch X4

Panel Type

Dip-switch S2

0=OFF, 1=ON

Switch 1 2 3 4

BS-420

1-31

01-1F

0-3

0-9

0 0 0 0

BC-420

33-63

21–3F

0-3

0-9

1 0 0 0

BC-440

33-63

21–3F

0-3

0-9

1 0 0 1

BS-430

65-95

41-5F

0-3

0-9

0 1 0 0

BU-420

97-159

61-9F

0-6

0-9

1 1 0 0

BV-420

161-223

A1-DF

0-6

0-9

1 0 1 0

X6

X4

S2

Addressing Panels

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 20

Example:

A network configuration consists of two BS-420 panels, one BS-430

panel and one BU-BV-420 panel (a BU-BV-420 panel defined as a

Fire Brigade Panel).

In this example, the following addressing applies:

Panel

Panel ID

Rotary

switch X6

Rotary

switch X4

Panel Type

Dip-switch S2

0=OFF, 1=ON

Switch 1 2 3 4

BS-420

1 0 1

0 0 0 0

BS-420

2 0 2

0 0 0 0

BS-430

65 0 1

0 1 0 0

BU-BV-420

97 0 1

1 1 0 0

Verifying the System Before Startup

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 21

7. Verifying the System Before

Startup

Before verifying the system, all parts in all system units must be

installed and properly connected, and all panels and AutroFieldBus

units must be addressed correctly.

Installation, cabling and connections

Verify all internal cabling in all system units (all panels)

Verify that all IO modules in the Fire Alarm Control Panel and

Controller are installed in the cabinet

Verify all external connections in the Fire Alarm Control Panel and

Controller (to detector loops, other input / output connections)

Verify all network connections

Addressing

Verify that all AutroFieldBus units (Power Boards BSF-400) are

addressed correctly

Verify that all panels are assigned correct Panel IDs

Verfiy that all panels are assigned Network IDs

Check power for correct mains voltage

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 22

8. Startup Procedure

When the AutroFieldBus units (Power Boards BSF-400, BSD-321 and

all panels) have been addressed, and the configuration files have

been generated by means of the AutroSafe Configuration Tool, power

is to be applied to the system.

The commissioning can take place from any Fire Alarm Control Panel

BS-420 or Operator Panel BS-430 in the system (freely selected

panel).

During uploading of configuration files (or system software), the

system may report possible faults. If such fault messages occur, the

panel in question should be rebooted (Service

Menu/Upgrade/Reboot). For detailed information on possible errors,

refer to chapter 12, Fault Messages during Uploading.

8.1 Applying Power to the System

Always connect the cables to the batteries first, then power up the

system by connecting the mains cable to a mains socket (230V/115V

AC) or by switching the power ON from an external main fuse box.

When power is applied to the system the very first time, an

initialization of the system will automatically take place.

Apply power to the system.

The display will show the following information (example):

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2

BS-420 01.01: 4.3.1 Commiss. Star

BU-420 01.01: 4.3.1 Commiss. ??

Detecting network structure…

5. Update panel list

The system will automatically detect the network structure that is

used, either Star Topology or Ring Topology. If both topologies are

detected, the message: “Conflicting Network Structure” will appear,

and it will not be possible to proceed.

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 23

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2 of 2

BS-420 01.01: 4.3.1 Commiss. Star

BU-420 01.01: 4.3.1 Commiss. Star

IP not set, select addressing mode:

1. Automatic 2. Manual

(Note that, to prepare the system for later reconfigurations or software

upgrades, a hardware reset must be performed. Refer to Upgrading

the System, chapter 10.)

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 24

8.2 IP Number Structure

Example:

172.16.101.21

172.17.101.117

172.16.101.21

8.3 Assigning IP Adresses

When the initialization is completed, the display will show the

following:

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2 of 2

BS-420 01.01: 4.3.1 Commiss. Star

BU-420 01.01: 4.3.1 Commiss. Star

IP not set, select addressing mode:

1. Automatic 2. Manual

If Automatic Mode is selected, default IP Adresses will be assigned to

each panel. The number series which is used depends on the switch

settings for the panel’s Network ID.

Note:

Use automatic addressing mode if you are not absolutely sure how to

set IP addresses.

Panel ID (+20), unique ID assigned to each panel.

Network ID (+100), identifies the unique network the

panel belongs to.

Subnet ID, common number for all panels. 172.16.x.x

for primary and 172.16.x.x for secondary network.

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 25

8.3.1 Automatic Addressing Mode

Selecting Automatic Addres s ing Mode wi ll ass ign default IP

Addresses to all panels.

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2 of 2

BS-420 01.01: 4.3.1 Commiss. Star

BU-420 01.01: 4.3.1 Commiss. Star

IP not set, select addressing mode:

1. Automatic 2. Manual

Press 1 to select Automatic Addressing.

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

NETWORK ADDRESS: 172.16/172.17

BS-420 01.01: 101.21

BU-420 01.01: 101.117

Do you want to save or set manually?

1. Save 2. Set Address Manually

When the automatic addressing is completed, you can either save the

automatic addressing (proceed to next step), or set addresses

manually (refer to chapter 8.3.2, Manual Addressing Mode).

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 26

To save the addressing, press 1.

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2 of 2

BS-420 01.01: 4.3.1 Commiss. Star

BU-420 01.01: 4.3.1 Commiss. Star

Config missing

Verify config on switch settings

3. Upgrade software 4. Upgrade config

6. Reboot panels

When the IP addressing is completed, proceed to chapter 8.5,

Uploading Configuration Files.

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 27

8.3.2 Manual Addressing Mode

If you have to take into consideration IP Addresses that are already

assigned to other existing components on the network, IP Addresses

can be set manually. In this way, you can freely select IP Addresses

within the given ranges of 3 different number series, each

representing a specific class (Class A, B or C).

Note that the standard IP version 4 addressing is applied. This means

that once a specific class is selected (A, B or C), only numbers within

the range of this class can be selected.

Class A: number series 1-127

Class B: number series 128-191

Class C: number series 192-223

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

IP ADDRESS: 172.16/172.17

BS-420 01.01: 101.21

BU-420 01.01: 101.117

Please set the SUB A network address:

<10 . . . >

<11 . . . >

Set the network addresses

If necessary, press 1 to change host address

Press 2 to save the manual addressing

When the manual IP addressing is completed, proceed to chapter 8.5,

Uploading Configuration Files.

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 28

8.3.3 Configuration Missing

If no configuration has been uploaded to the system previously, the

message “Config Missing” will be shown.

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2

BS-420 01.01: 4.3.1 Commiss. Star

BU-420 01.01: 4.3.1 Commiss. Star

Config missing

1. Import config from USB stick

2. Reboot all panels

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 29

8.4 Configuration File

8.4.1 Name, Format and Extension

The AutroSafe Configuration Tool generates the following compressed

file:

AC_Vnn_mm_filename.tar.bz2

AC

AutroSafeConfiguration

Vnn

Main interface model number

mm

Sub interface model number

filename

The AutroSafe configuration file name, valid characters are

[0-9a-zA-Z] and underscore '_'. If the filename contains non-valid

characters the file name will be replaced with the name

"Configuration".

The zip file cannot contain more than 127 characters, if so the

filename will be truncated.

8.4.2 Copying the Zip File to a USB Stick

Make sure to copy and paste the files in the root directory of the USB

stick. Also make sure to remove all other files from the memory stick.

When the configuration zip file is generated by means of the

AutroSafe Configuration Tool, copy the file to a USB memory stick

(root catalogue).

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 30

8.5 Uploading Configuration Files to the System

When the IP addressing is completed, configuration files can be

uploaded to the system from one central point (any BS-420/BS-430

panel in the system).

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2

BS-420 01.01: 4.3.1 Commiss. Star

BU-420 01.01: 4.3.1 Commiss. Star

Config missing

Verify config on switch settings

3. Upgrade software 4. Upgrade config

6. Reboot panels

Press 4 (Upgrade config).

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2

BS-420 01.01: 4.3.1 Commiss. Star

BU-420 01.01: 4.3.1 Commiss. Star

Insert USB stick in USB port

Insert the USB memory stick into one of the USB host ports on the

BSA-400 Controller Board.

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 31

The following will appear on the display:

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2

Transfering to panels (1 of 2)

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2

Unpacking to panel (1 of 2)

Please wait, upgrade in progress

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2

Upgrading config…

Finished

3. Upgrade software 4. Upgrade config

6. Reboot panels

Remove the USB stick when the uploading is completed, then

press 6 to reboot the system.

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 32

Selection 3. “Upgrade Software” is shown only if the software is not

already upgraded.

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2

Rebooting the system

Please wait, upgrade in progress

When the system is rebooted, the system will enter normal operation

mode.

To run initialization, press 1 or wait (countdown).

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 33

8.6 Configuration Mismatch

If the system has an existing configuration, and the new configuration

you have uploaded does not match the installation in question, the

message “Config Mismatch” will appear.

If the software to be used is not supported by the config model, the

message “Config Mod el Mismatch” will appear (see screenshot

below).

The “Config Faulty” message will appear if the configuration files for

some reason are corrupt.

The “Config Market Mismatch” message will appear if the panel does

not match the market that has been selected in the configuration.

Autrosafe software version 4.5.0

Config model 4.5

Market version: Land

Switch address 01-001

Searching for panels, found 2

BS-420 01.01: 4.3.1 Commiss. Star

BU-420 01.01: 4.3.1 Commiss. Star

Config model mismatch

Verify Config

3. Upgrade software 4. Upgrade config

6. Reboot panels

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 34

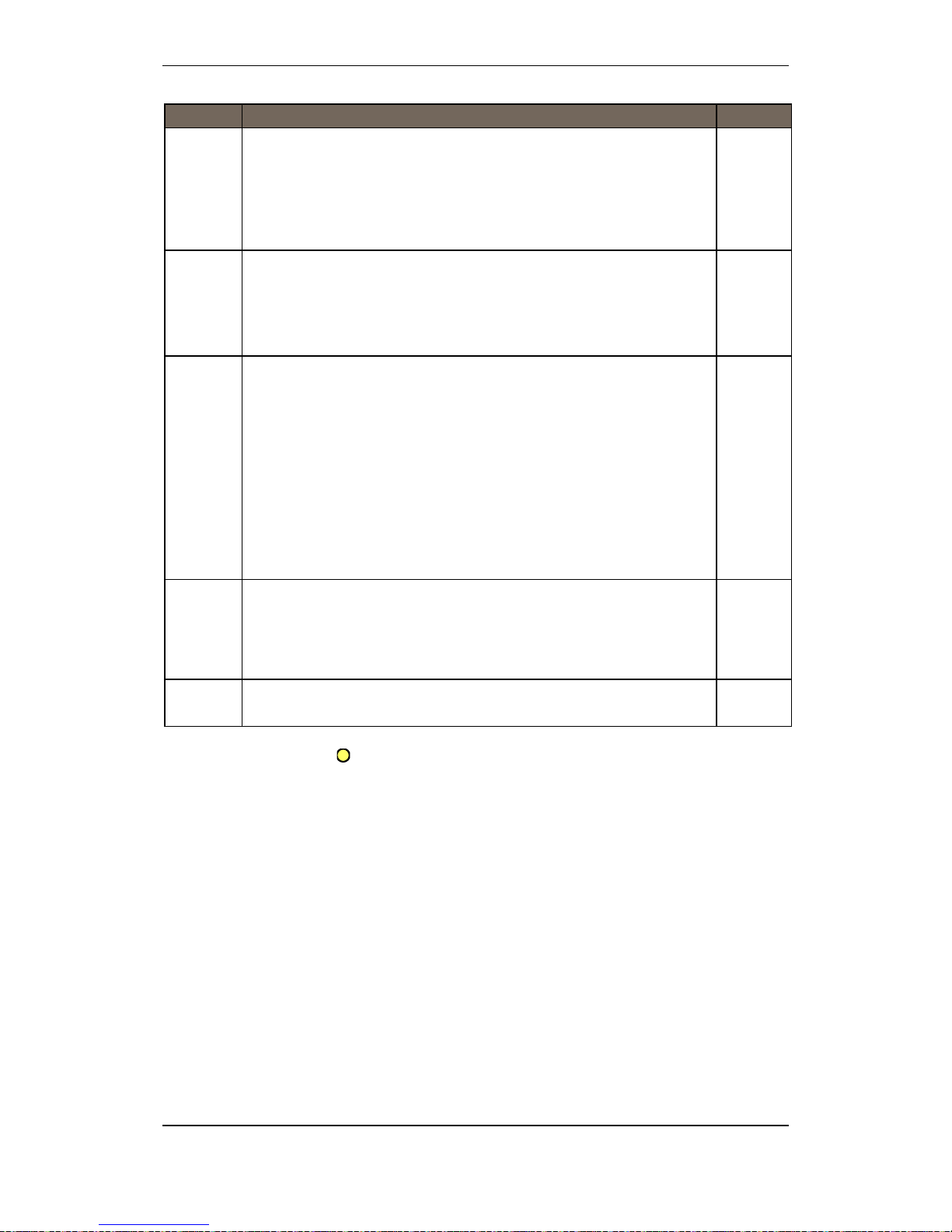

8.7 Entering Required Access Levels

All user interface controls are classified as belonging to one of the

different access levels described below:

Access Level

Access Remedy

Description

1 No key or password

required.

Accessible by members of the general public. A ll mand atory

indications are visible at access level 1 without prior manual

intervention.

2 Access by key.

Accessible by persons having a specified responsibility for

safety.

3 Password restricted. Accessible by persons trained and authorized to do

reconfiguration of site specific data and maint en anc e

according to the manufacturer’s published instruction.

To be able to verify the system after an upgrade, Access Level 2 must

be entered. Access Level 2 is accessed by the key (turn the key

counter-clockwise).

Access level 3 is entered as described in the procedure below.

Step

Actions to be taken

Display Indication

1

To enter the Main Menu from normal Operation

Mode, press

2

To select SYSTEM, press 4.

19:23

MAIN MENU

1 SHOW STATUS

2 DISABLE

3 ENABLE

4 SYSTEM

5 SERVICE

6 OUTPUT CONTROL

19:23

MAIN MENU

1 SHOW STATUS

2 DISABLE

3 ENABLE

4 SYSTEM

5 SERVICE

6 OUTPUT CONTROL

SYSTEM

1 DATE AND TIME

2 INFORMATION

3 ACCESS LEVEL 3

4 PRINTER

5 CHANGE LANGUAGE

6 INITIALIZE

7 DAY/NIGHT TIMERS

19:23

SYSTEM

1 DATE AND TIME

2 INFORMATION

3 ACCESS LEVEL 3

4 PRINTER

5 CHANGE LANGUAGE

6 INITIALIZE

7 DAY/NIGHT TIMERS

19:23

Startup Procedure

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 35

Step

Actions to be taken

Display Indication

3

To select ACCESS LEVEL 3, press 3.

4

To enter ACCESS LEVEL 3, press 1.

5

Enter the password, then press

twice.

SYSTEM

ACCESS LEVEL 3

1 ENTER ACCESS LEVEL 3

2 LEAVE ACCESS LEVEL 3

3 SET PASSWORD

19:23

SYSTEM

ACCESS LEVEL 3

1 ENTER ACCESS LEVEL 3

2 LEAVE ACCESS LEVEL 3

3 SET PASSWORD

19:23

SYSTEM

ACCESS LEVEL 3/ENTER ACCESS LEVEL 3

Enter password:

19:23

SYSTEM

ACCESS LEVEL 3/ENTER ACCESS LEVEL 3

Enter password:

19:23

SYSTEM

ACCESS LEVEL 3/ENTER ACCESS LEVEL 3

Enter password: ****

Successfully Completed

19:23

SYSTEM

ACCESS LEVEL 3/ENTER ACCESS LEVEL 3

Enter password: ****

Successfully Completed

19:23

Verifying the System after

an Upload

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 36

9. Verifying the System after

an Upload

9.1 General System Verification Procedure

To ensure that the system works properly during normal operation

after an upload, the whole system (control panel, detectors, control

functions) should be verified after an upload.

Step

Description

√

1

To test the panel indicator lights and internal buzzer, press and hold the Reset button for at

least 5 seconds. All indicators are lit and the buzzer is turned on. The test will automatically

stop. The lamp test can be performed in access level 1 (no use of key).

2

Test all operating keys by pressing each key (refer also to Operator’s Handbook):

All buttons will give a short "Beep" when pressed except Mute button, Menu button and

Reset System button (plus the ones that are not supported, see below).

Note that the left/right arrow buttons and the two buttons in the lowermost right hand corner

(indicated with a white line) are not yet supported:

‘

3

Perform a visual and functional inspection of manual call-points and automatic detectors.

4

Disable any alarm transference to the Fire Alarm Routing Equipment -FARE output.

5

Activate the alarm system. Test all sounders by activating an alarm from a corresponding

manual call-point.

6

Test all control functions.

7

Activate alarms from at least one detector/manu al call-point in each zone and a check that

Mute Panel button

Silence Alarms button

Reset System button

Menu button

Close Window button

Alphanumeric keyboard

Manoeuvre buttons

Verifying the System after

an Upload

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 37

Step

Description

√

all respective outputs are activated.

8

Test the action of any auxiliary operating functions (disabling, cancelling and resetting

buttons).

9

Check the alarm transference outputs by connecting from outgoing outputs (potential free

relay and 24V output) activated by alarm in a zone.

10

Check the fault warning function from detector zones by removing a detector in each zone.

Activate a fault (remove battery fuse) and observe:

- the Fault indicator starts to blink

- a fault warning is displayed

- the internal buzzer is turned ON

- the Fault Warning Routing Equipment (FWRE) output i s activated (if any)

11

Verify all conditions, i.e.:

- Fire Alarm condition

- Fire Warning condition

- Fault Warning condition

- Disablement condition

- Test condition

12

On completion of checks, ensure that only the green "Power" indicator is ON when the

panel is in its idle state (normal operation).

13

Enable alarm transference to the Fire Alarm Routing Equipment -FARE output.

9.2 Verifying Detection Loops During Normal Operation

It may be necessary to verify the detection loops (checking the loop

topology, the types of loop units, the location of loop units, the Loop

Sequence Indexes, etc.) during normal operation using the AS-2000

Loop Diagnostic Tool.

Before applying the tool, prepare the system for the verification as

follows:

Enter the Service Menu (5), select Upgrade (5), then Reboot

System (6).

The system will now enter system fault condition.

Remove fuse A1 and A2 from the Power Board BSF-400.

Connect and apply the tool, and do the necessary verifications.

Alternative 1:

Disconnect a detection loop. Use the AS-2000 Was-box to verify

the loop. Perform a verification for each loop in turn.

Alternative 2:

Disconnect the ribbon cable to BSL-310. Connect the AS-2000.

Run an initialization.

When the verificat ion is co mpleted, disconnect the tool/PC, re-

connect the cables, then re-place the fuses.

Reboot the system again.

1

2

3

AFB A

AFB A"

AFB CT A

4

5

6

AFB Earth Fault Sens

AFB B

AFB B"

7

8

AFB CT B

AFB Earth Fault Sens

J2

J19

S

High Low

J24

J18

+

B

0V

+

A2

0V

+

A1

X11 X10

S5

AFB Earth Fault Off

AFB Earth Fault On

1

OFF

ON

2

OFF

ON

Power Board BSF-400

Fuse A1

and A2

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 38

10. Upgrading the System

10.1 Introduction

After the very first startup of a system, a running system can be

upgraded at any time using the service menu commands (shown in

the next chapter). The upgrading can be performed from any Fire

Alarm Control Panel BS-420 or Operator Panel BS-430 in the system

(a freely selected panel).

Note that once you have selected a “master” panel for upgrading, the

system will temporarily block all other panels during the upgrade

procedure, preventing the system from being upgraded from other

panels.

This chapter deals with upgrading by means of a USB memory stick.

Upgrading can also be performed by using a computer remotely

connected to a web site (refer to separate handbook).

10.2 Upgrading During Normal Operation (SW/Config)

10.2.1 Introduction

The Service Menu includes submenus which allows you to upgrade

both the system software and the configuration (or either of them)

during normal operation (see following chapters).

Note that if both the software and the configuration are to be

upgraded, the system software and configuration have to be

supported by the same config model. As a general rule, if both the

software and the configuration are to be upgraded, always upgrade

the software version first, then the configuration.

To use the Service Commands, access level 3 is required (refer to

Operator’s Handbook).

Upgrade

Upgrade SW

Upgrade Config

Export Config

Export Log

View Upgrade Status

Reboot System

After an upgrade, a reboot must always be executed for changes

to take effect (software and/or configuration ugrade).

Note that it is possible to upgrade both software and the

configuration in turn bef ore r eboot in g, i.e. it is not nece s s ar y to

reboot after each single upgrade.

NOTE:

When upgrading the

system by means of a

USB memory stick, do

not remove the USB stick

from the USB port until

you are sure that the

upgrade procedure is

completed.

Enter the menu “View

Upgrade Status” to follow

the progress and verify

that the procedure is

completed.

Upgrading the System

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 39

10.2.2 Upgrading Software During Normal Operation

Note that before executing this command, insert the USB memory

stick with the correct and valid file into one of the USB ports on the

BSA-400 Controller Board.

After the stick is inserted, wait at least 5 seconds before executing

the command.

From the panel front, press 5 to enter the Service Menu (Access

Level 3).

To select Upgrade, press 5.

To Upgrade SW press 1.

To view the upgrade status, the View Upgrade Status command

can be used.

If you do not intend to upgrade the configuration at this point, the

panel has to be rebooted for changes to take effect.

If you also intend to upgrade the configuration, do not reboot at this

point, but go to Upgrade Config (see next chapter).

When the upgrade is completed, press 6 to run the Reboot System

command.

10.2.3 Upgrading Configuration During Normal Operation

Note that before executing this command, insert the USB memory

stick with the correct and valid file into one of the USB ports on the

BSA-400 Controller Board.

After the stick is inserted, wait at least 5 seconds before executing

the command.

From the panel front, press 5 to enter the Service Menu (Access

Level 3).

To select Upgrade, press 5.

To Upgrade Config press 2.

To view the upgrade status, the View Upgrade Status command

can be used.

If you do not intend to upgrade the software at this point (if not

already done), the panel has to be rebooted for changes to take

effect.

If you also intend to upgrade the software (supported by the sam e

config model), do not reboot at this point, but go to Upgrade

Software (see previous chapter).

When the upgrade is completed, press 6 to run the Reboot System

command,.

NOTE:

Do not remove the

USB stick from the

USB port until you

are sure that the

upgrade procedure

is completed.

NOTE:

Do not remove the

USB stick from the

USB port until you

are sure that the

upgrade procedure

is completed.

Upgrading the System

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 40

10.3 Upgrading when Panels are Added/Remo ved

If panels are added or removed, or it is necessary to change IP

addresses, a reboot must be executed. The continuing procedure is

similar to the startup procedure, chapter 8.

Go to chapter 8 and follow the procedure.

10.4 Upgrading if IP Addresses are to be Changed

If it is necessary to change IP addresses, a reboot must be executed.

The continuing procedur e i s desc r ibed in the startup procedure,

chapter 8.

Go to chapter 8 and follow the procedure.

10.5 Upgrading a Single Panel

If a single panel in a network system for some reason has a wrong

software and/or configuration version, the process of upgrading the

entire system could be both unnecessarily time-consuming, or even

impossible if the software versions are incompatible. To simplify the

version correction in such a case, the system features an upgrade

procedure of a single panel. Before the upgrade procedure is carried

out, the file name of the software and/or configuration file has to be

changed.

Locate the software/configuration file(s) in question on your

computer.

Change the name of the software file:

Add the text _Recovery to the name of the software file as follows:

Example:

The file name AS_V4_3_0_0_C4_34.tar.bz2 is changed to

AS_V4_3_0_0_C4_34_Recovery.tar.bz2

Change the name of the configuration file:

Remove the text representing the “file name” (in this example,

Tiller) and replace it with the text Recovery:

Example;

AC_4_34_Tiller.tar.bz2 is changed to AC_4_34_Recovery.tar.bz2

Copy the file(s) onto your USB memory stick.

Insert the USB memory stick into one of the USB ports on the

BSA-400 Controller Board, then reboot the panel.

The panel will automatically be upgraded.

If the panel has a display, the process similar to the startup

procedure will be shown (chapter 8).

If the panel does not ha ve a display, the process will be indicated

by means of the yellow LED indicator D2 on the BSA-400 board as

follows (see illustration, chapter 10.7.3):

- Slow blink: upgrade in progress

-

Fast blink: upgrade failed

-

Steady yellow light: Upgrade completed, remove stick

to reboot the panel

NOTE:

Do not remove the

USB stick from the

USB port until you

are sure that the

upgrade procedure

is completed.

Upgrading the System

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 41

10.6 Upgrading b y Remo te Access to a Web site

Upgrading can be performed by means of a computer with remote

access to a web site providing several service functions.

From the Service menu, press 6 to select Remote Access.

For further information, refer to separate handbook.

Upgrading the System

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 42

10.7 Upgrading Software Version 4.0.1 to 4.1.1

10.7.1 General

This chapter deals with the upgrade from software version 4.0.1 to

4.1.1.

Before reconfiguring the system or upgrading the system software, a

hardware reset must be executed. All panels belonging to the same

system will be reset and upgrading can then take place.

If the system is in normal operation, go to chapter 10.7.2.

If the system is in system fault condition, go to chapter 10.7.3.

10.7.2 Preparing a System in Normal Operation

Push the reset button S5 less than 1 second to shut down the

panel in a controlled manner.

Wait until the blue LED indicator D22 (see illustration on next page)

goes off.

The panel has now entered system fault condition.

Go to chapter 10.7.3.

IMPORTANT:

Follow the upgrade procedure as described in detail below.

During the upgrade to software version 4.1.1, the system will

enter system fault condition.

Do NOT disconnect the mains power or press the front panel’s

Reset System button.

Press the front panel’s Mute button to silence the buzzer.

Note that a panel that has been upgraded to software version

4.1.1 cannot be downgraded to software version 4.0.1.

Upgrading the System

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 43

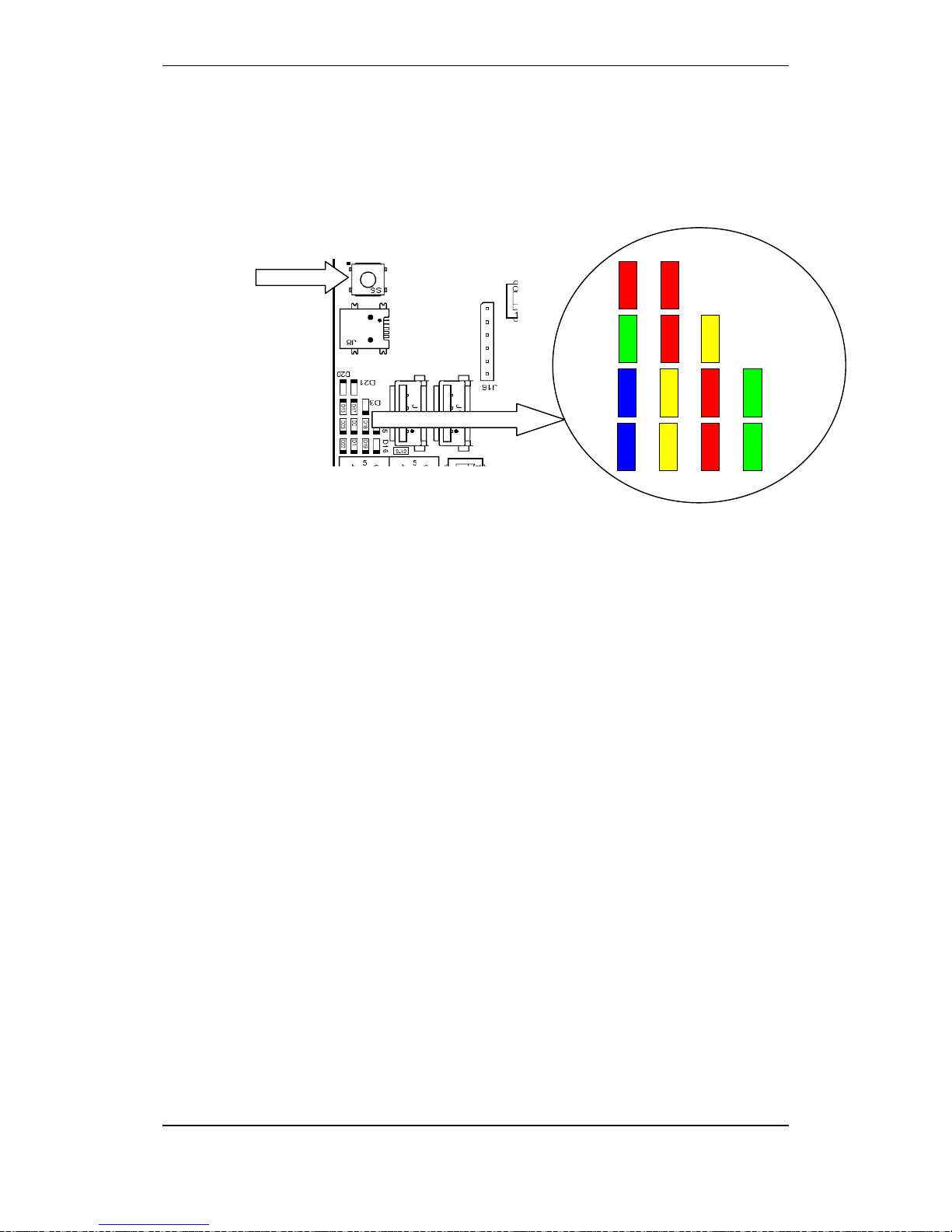

10.7.3 Preparing a System in System Fault Condition

To perform a hard reset, push and hold down the reset button S5

until the red LED indicator D20 and D21 are lit for a short moment

and you hear a click from the relay.

The system will now detect all running panels, and prompt you to

reboot the entire system (all running panels).

Verify that all panels in the system are detected.

Press 2 to select Reboot running panels.

When all panels are rebooted, four selections will appear.

Press 3 (“Upgrade Software”).

Insert the USB memory stick with the valid file into one of the USB

host ports on the BSA-400 Controller Board.

The display will indicate when the uploading is completed.

Remove the USB stick.

The system will automatically reboot.

After a short while, the panel will indicate system fault condition.

Do NOT disconnect the mains power or press the front panel’s

Reset System button.

Press the front panel’s Mute button to silence the buzzer.

When the system is rebooted, the system will be upgraded (the new

system software version) and the system will enter normal operation

mode.

Proceed with the upgrading procedure.

Reset button S5

LEDs

LEDs

Controller Board

BSA-400

D20

D21

D13

D17

D23

D2

D22

D1

D19

D16

D18

D15

D3

Upgrading the System

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 44

10.8 Upgrading Software Version 4.0.1 or 4.1.1 to 4.3.1

This chapter shows examples of how to upgrade from software

version 4.0.1 or 4.1.1 to 4.3.1.

10.8.1 Example 1: Upgrading all Panels from SW Version 4.0.1 or

4.1.1 to 4.3.1

All panels have software version 4.0.1 or 4.1.1 ins ta lle d.

Upgrade all panels simultaneously by using a USB stick including

program version 4.3.1 (or later when available).

10.8.2 Example 2: Adding a BS-420/BS-430 panel with

SW Version 4.1.1 to a System Running on SW Version 4.3.1

A system is running on software version 4.3.1. A new BS-420/BS-430

panel with software version 4.1.1 installed is going to be added.

Start the new panel without connecting it to the AutroNet.

Install version 4.3.1 by using an USB stick .

Connect the new panel to the system AutroNet.

Restart the system and upgrade the new system configuration data

by using an USB stick.

10.8.3 Example 3: Adding a BC-420 Controller with SW Version 4.1.1 to

a System Running on SW Version 4.3.1

A system is running with software version 4.3.1. A new BC-420

Controller with software version 4.1.1 installed is going to be added.

Disconnect a BS-420 panel from the system AutroNet.

Restart and downgrade the BS-420 panel to run version 4.1.1 by

using a USB stick.

Temporarily, connect the downgraded panel and the new BC-420

Controller together by using an AutroNet connection.

Start the two system units and upgrade them to run version 4.3.1

by using an USB stick.

Connect the two system units to the original system AutroNet.

Restart the system and upgrade the new system configuration data

by using an USB stick.

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 45

10.8.4 Example 4: Adding a Panel with SW Version 4.3.1 to a

System Running on SW Version 4.1.1

A system is running on software version 4.1.1. A new panel with

software version 4.3.1 installed is going to be added.

Start the system without connecting the new panel to the AutroNet.

Upgrade the system to run version 4.3.1 by using a USB stick.

Connect the new panel to the system AutroNet.

Restart the system and upgrade the new system configuration data

by using an USB stick.

Startup Procedure for a Dual Safety System

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 46

11. Startup Procedure for a Dual

Safety System

11.1 Introduction

This chapter describes the initial startup procedure of a system

consisting of a Primary System and a Secondary System (AutroSafe

Dual Safety concept).

In principle, the startup procedure is identical to the startup procedure

of a normal system, however, the startup procedure must be carried

out for each system in turn (both the Primary System and the

Secondary System).

The startup of the Primary System can take place from any selected

Fire Alarm Control Panel BS-420 or Operator Panel BS-430 belonging

to the Primary System. Likewise, the startup of a Secondary System

can take place from any panel belonging to the Secondary System.

There are two AutroKeepers BN-180 for each detection loop in a Dual

Safety System. One must be assigned to the Primary System and the

other to the Secondary System (dipswitch settings). Furthermore, the

type of protocol for the AutroFieldBus Protocol Converter BSD-321 (if

used) must be set to Al_Com+ (rotary switch setting).

In the following guidelines, a startup of the Secondary System is

carried out first, then the Primary System. When the startup of both

systems is completed, the Primary System will be in Active Mode (it

controls the detecton loops), and the Secondary System will be in

Standby Mode (ready to take over control of the detection loops).

Startup Procedure for a Dual Safety System

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 47

11.2 Guidelines – Startup Procedure

The following guidelines apply:

Step Action Chapter

1

Perform the following actions for both the Primary and the

Secondary System:

Verify the detection loops by means of the AS-2000 tool.

Perform a consistency check of the configuration data using the

results from the AS-2000 verification and the data that has been

configured by means of the AutroSafe Configuration Tool.

Assign an AutroFieldBus address to each AutroFieldBus unit.

Assign a Panel ID to each panel by means of switches (dip-switches

and rotary switches on BSA-400).

Assign a Network ID to each panel by means of rotary switches (on

BSA-400).

Verify the system before startup (chapter 7).

3, 4, 5,

6 and 7.

2

Define the type of protocol and assign an Au troFieldBus address

on the AutroFieldBus Protocol Converte r BSD-321

The BSD-321’s default protocol by delivery is Al_Com+. If needed, the

procedure for selecting the protocol type is described below.

Set the actual AutroFieldBus address in the range of 1-31 according

to the specific configuration.

The type of protocol is defined by on-board rotary switches.

To select protocol type:

Apply power to the converter.

Set the switches to 70 (Al_Com+), then press the reset button.

The indicators will start flashing.

When the indicators stop flashing after a short while.

Set the actual AutroFieldBus address, then press reset.

3

Set switches for Primary or Secondary on the AutroKeepers

(BN-180)

Set dipswitch 1 in postion OFF for the BN-180 that belongs to the

Primary System

Set dipswitch 1 in postion ON for the BN-180 that belongs to the

Secondary System

Apply power to BN-180 (24V DV external power).

Startup Procedure for a Dual Safety System

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 48

Step Action Chapter

4

Apply power to the panel belonging to the S eco n d ary System,

then:

Select Automatic addressing mode to assign an IP Address to each

panel.

Upload configuration data to all panels from the panel in question.

Start system, perform an initialization.

8.1, 8.3,

8.5

5

Apply power to the panel belonging to the P rimary System, then:

Select Automatic addressing mode to assign an IP Address to each

panel.

Upload configuration data to all panels from the panel in question.

Start system, perform an initialization.

8.1, 8.3,

8.5

6

Verify the Dual Safety functionality:

The Primary System is now in Active Mode. The Secondary System is

in Standby Mode (the indicator Dual Safety Stdby on this panel has a

steady yellow light).

Perform a manual transfer of control from the Primary System to the

Secondary System.

From the Primary System, enter the Service Menu, and select Dual

Safety, then Transfer to Secondary

As soon as the loop control is transferred to the Secondary System,

the indicator Dual Safety Stdby will be lit on the Prim ary S ystem’s

panel and will go off on the Secondary System’s panel.

7

Transfer the control back to the Primary System

From the Primary System, enter the Service Menu, and select Dual

Safety, then Transfer to Primary

As soon as the loop control is transferred to the Primary System, the

indicator Dual Safety Stdby will be lit on the Secondary System’s panel.

8

Verify the entire system after an upload.

9

Dual Safety Stdby

Applicable to systems using the Dual Safety concept; a system with

redundant loop control consisting of a Primary and Secondary System.

Steady yellow light:

The panel is in Standby Mode, i.e. this panel does not control the

detection loops. The panel(s) in the other system controls the detection

loops and is in Active Mode.

Blinking light: the panel does not control all detection loops/loop units,

and/or loop control is being transferred. Actions must be taken.

Fault Messages during Uploading

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 49

12. Fault Messages during

Uploading

12.1 Introduction

During uploading, the system may report possible faults. If such fault

messages occur, the panel in question should be rebooted by means

of the reset button S5 on the Controller Board BSA-400 inside the

panel.

To perform a hard reset, push and hold down the reset button S5

(approximately 6 to10 seconds) until the red LED indicators D20

and D21 are lit for a short moment and you hear a click from the

relay.

12.2 Invalid File on USB Stick

Invalid file is found on the USB stick

Example:

Software: "Software Upgrade, File with syntax

AS_V*_*_*_*_C*_*.tar.bz2 not found in root folder"

Config: "Config Upgrade, File with syntax AC_V4_5_*.tar.bz2 not

found in root folder"

12.3 Data Transmission Timeout

The transmission of data to a panel takes too long (timer) due to a

possible network failure:

"Transfer to panel <NN> timed out"

12.4 Corrupt File

File found, but it is corrupt (crc).

Example:

"Corrupt file AS_V4_0_0_1_C4_5.tar.bz2"

Fault Messages during Uploading

Commissioning Handbook, AutroSafe Interactive Fire Detection System, Release 4, 116-P-ASAFE-COMMISS/EGB Rev.F, 2014-04-01,

Autronica Fire and Security AS

Page 50

12.5 Fail to Unpack Files

If the unpacking of files on a panel is not successful, one of the

following error messages may occur:

"Failed to unpack, file system error on panel <NN>"

"Failed to unpack, panel error on panel <NN>"

Autronica is a leading innovator, manufacturer and supplier of fire safety equipment. Our

products ensure safety in applications on land and sea worldwide. The company is owned by

United Technologies Corporation (UTC) and employs more than 380 people with great skill and

experience in the developing, manufacturing and marketing of fire safety equipment.

Autronica Fire and Security AS is an international company based in Trondheim, a dynamic city

known as the technological hotspot of Norway.

Protecting life, environment and property

Autronica Fire and Security AS

Haakon VIIS gt. 4, NO-7041 Trondheim, Norway | Tel: +47 90 90 55 00 | Fax: +47 73 58 25 01

E-mail: info@autronicafire.no | www.autronicafire.com

Loading...