AutoXray EZ-SCAN 6000, EX-SCAN 5000, EZ-SCAN 4000, EZ-SCAN 3000, EZ-READ 2000 User Manual

...

USERS MANUAL

WARNING: Read and understand all instructions in this manual.

Use appropriate personal safety equipment including hearing and eye

protection when using the scanner in or near the vehicle engine

compartment. Failure to comply can result in accidents involving fire,

electrical shock, or serious personal injury.

Electrical

• Do not allow anything to rest on the cable assembly. Do not allow

the cable assembly to be pinched. Keep the cable assembly away

from contact with heat, oil, sharp edges, or moving parts. Replace

damaged cables immediately. Damaged cables increase the risk of

electric shock.

• To reduce the risk of electrical shock do not disassemble the scanner.

There are no user repairable components inside the unit.

• Please dispose of used batteries properly. Do not incinerate batteries.

Consult your local waste authority for information regarding available

recycling and/or disposal options.

Use and Care

• Stay alert, pay attention to what you are doing, and use common

sense when operating the scanner. Several operational tests require

the engine in the vehicle to be running during testing. Keep all

children and visitors a safe distance from the work area.

• Keep the scanner dry, clean, and free from oil and grease. Use a

mild detergent on a clean cloth to wipe the outside of the scanner,

when necessary.

• Only use accessories that are recommended by AutoXray.

• Certain capture mode tests can be performed while driving the

vehicle. AutoXray recommends that the person operating the vehicle

does not use/view the scanner. Always use an assistant to operate

the scanner while driving the vehicle.

Service

Service must only be performed by AutoXray repair personnel. Service or

repair by unqualified personnel may result in risk of injury, damage to the

unit, and may void your warranty. Refer to the Product Warranty Policy

section of this manual.

SAFETY PRECAUTIONS AND WARNINGS

Page 2

Safety Precautions and Warnings................................................2

Table of Contents...........................................................................3

Introduction ....................................................................................5

Setup / Operating Instructions .....................................................8

SCAN - OBD-II, GM OBD-I, Chrysler OBD-I

SCAN...........................................................................................13

DATA - OBD-II, GM OBD-I, Chrysler OBD-I

View the Data...............................................................................16

Real Time Data Monitoring..........................................................18

View Freeze Frame Data.............................................................19

View Trouble Codes.....................................................................20

Clear the Codes...........................................................................22

Reset EMR Lamp-Chrysler (1989-95) ......................................... 23

Customizing Data Items...............................................................25

MON - OBD-II, GM OBD-I, Chrysler OBD-I

Capture Mode..............................................................................25

Oxygen Sensor Tests - OBD-II ....................................................29

Readiness Tests - OBD-II............................................................30

SCAN - Ford

SCAN the KOEO Codes - Ford...................................................33

SCAN the KOER Codes - Ford ...................................................35

SCAN the DCL Data - Ford .........................................................38

DATA - Ford

View the KOEO Codes - Ford......................................................39

View the Memory (Trouble) Codes - Ford ...................................40

View the KOER Codes - Ford ......................................................42

View the DCL Data - Ford ............................................................43

Clear Trouble Codes - Ford.........................................................45

MON - Ford

Activate the Wiggle Test - Ford....................................................46

DCL Data Capture - Ford .............................................................48

TABLE OF CONTENTS

Page 3

Troubleshooting

What to do When the Scanner Displays a Fault/Trouble Code ...51

What to do for a "Vehicle Is Not Responding" Message .............51

Screen Contrast Problems...........................................................52

How to Reset the Scanner ...........................................................52

Scanner Screen Menu Trees.......................................................53

Operational Data Items

OBD-II Generic Operational Data Items......................................57

Enhanced OBD-II Operational Data Items...................................59

OBD-II Oxygen Sensor Test Readings........................................61

GM Operational Data Items.........................................................63

Ford DCL Operational Data Items ...............................................76

Chrysler Operational Data Items .................................................79

Upgrade, Update, Specifications

Scanner Upgrade - Adding Capability (Phone or Internet)..........85

Registration Card.........................................................................86

Scanner Update - Loading New Software Version......................86

System Information......................................................................86

Set the Time Units for Capture Mode.........................................87

Technical Description of OBD-I and -II.......................................89

Product Warranty Policy .............................................................92

Additional Products / Accessories.............................................93

Index..............................................................................................95

Registration Card

Please complete the enclosed Registration Card and return it, or

call 480.804.1673. It is the only way AutoXray can notify you of

future updates / upgrades for your scanner.

Thank You for buying the EZ-SCAN Scanner from AutoXray, the

leading provider in cost effective automotive diagnostic scanners.

TABLE OF CONTENTS (CONT.)

Page 4

Figure 1. EZ-SCAN Scanner

• AutoXray designed this elegant EZ-SCAN tool with capabilities

that are the

best value on the market today. The compact

design has received proprietary patents and makes these

scanners so

simple and easy to use.

INTRODUCTION

Page 5

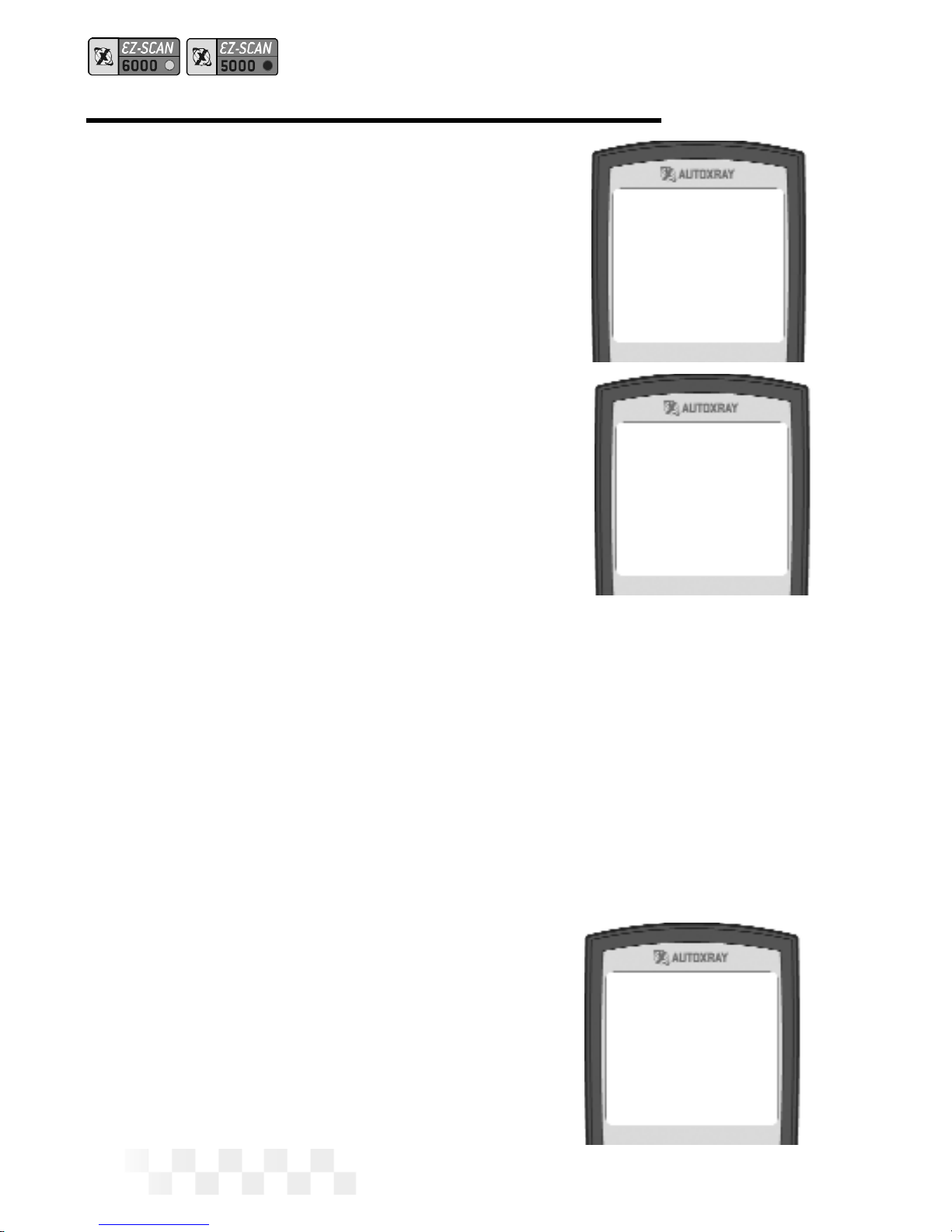

Display

Screen

MODE

Keys

ENTER

Key

POWER (ON/OFF)

Key

CONFIG

Key

UP / DOWN

BACK / NEXT

Arrow Keys

Battery

Compartment

RJ45

Connection Port

AMP Vehicle

Communications

Port

Your EZ-SCAN Scanner Will:

• Scan Collects All Values from Vehicles On-Board Computer

• Supports multiple trouble code requests, generic codes (mode 3),

pending codes (mode 7), enhanced codes (mode 13)

• On-screen definitions of OBD I trouble codes, OBD II generic and

OBD II manufacturer specific codes.

• Detects OBD-II Freeze Frame Information

• Displays Readiness Test Status

• Displays O2 Sensor Test

• Test Results (mode 6)

• Vehicle ID (mode 9)

• Live Data Stream Monitoring

• 29 Frame Capture Mode

• Reset Check Engine Lights

AutoXray has made sure your new scanner is computer safe.

It

WILL NOT accidentally deploy airbags, change transmission

gears, affect ABS brake performance, or fire injectors and ignition

systems.

Additional Features:

OBD-II (for 1996 and newer Domestic, Asian and European

OBD-II compliant vehicles) -

Performs all other functions of

modes 1-7 of the OBD-II J1978 scan tool specification, including:

• Freeze Frame of data surrounding a trouble code event

• Access Oxygen Sensor Tests

• Display Monitoring Tests and Results

• Show Pending Trouble Codes

CHRYSLER OBD-I - (for 1983-1995 Chrysler SCI vehicles and

1991-1995 Jeep vehicles)

• Resets Engine Maintenance Reminder (EMR) Light

FORD OBD-I - (for 1983-1995 Ford EEC-IV vehicles)

INTRODUCTION (CONT.)

Page 6

• Performs Key-On Engine Off (KOEO)

• Key-On Engine Running (KOER) tests

• Continuous monitor (wiggle) test

GM OBD-I - (for 1982-1995 GM 12 pin ALDL vehicles)

Text Styles Used In This Manual

POWER text in this font is used to designate a

button/key on the front of the scanner

Config Unit text in this font is used to designate text that is

displayed on the scanner screen

WARNING: the word WARNING in this font is used to

identify an operation or activity that could cause

severe property damage or personal injury

CAUTION: the word CAUTION in this font is used to

identify an operation or activity that could cause

property damage or personal injury

NOTE: the word NOTE in this font is used to identify

information that will assist you while you are

using the scanner

Arrows will be displayed at the right side of the screen to indicate

text above and/or below the current screen. Use the arrow keys to

view the text.

NOTE: During the procedures in this manual, display all the available menu

options by using the

pand qarrow keys. Small arrows will be displayed

on the screen when there are more options available.

INTRODUCTION (CONT.)

Page 7

This section gives the information you need to set up and operate

your EZ-SCAN Scanner:

• Install New Batteries

• Configure the Scanner for Your Vehicle

• Set the Display Units (SAE/Metric)

• Connect the Scanner to Your Vehicle

Install New Batteries

The EZ-SCAN Scanner is powered by 4 AA batteries.

Before the scanner is used the first time, you need to

install batteries in the unit.

Make sure the batteries are put in according to the diagram on the

back of the battery compartment door. Refer to the illustration

below.

Figure 2. Battery Compartment

• If the screen becomes too dim to view, the batteries need to be

replaced. Replace all four batteries to avoid unit malfunction.

When it is time to change the batteries, the

Data Holder

Feature

will save all Data and configuration information if fresh

batteries are installed immediately after removing the old ones.

CAUTION: Leaving used or dead batteries in the scanner

beyond the battery date may result in damage to the unit.

SETUP / OPERATING INSTRUCTIONS

Page 8

• As long as good batteries are in the scanner, the vehicle engine

configuration and data will remain in the scanner’s memory,

even after the unit is powered off.

• Operational data, Trouble Codes, and all remaining scanned

information will remain in memory until the unit is reconfigured.

A

Power Miser Feature automatically powers the unit OFF

after 30 minutes of no activity.

Configure the Scanner for Your Vehicle

Before the scanner is used, it must be configured for your

specific vehicle. Don’t worry, it only takes a few steps.

1. Press POWER to turn the unit ON, then press CONFIG.

2. Make sure 1-Config Unit is displayed on the screen, then

press

ENTER.

3. Use the arrow keys until the correct vehicle

manufacturer name is highlighted, then press

ENTER to select it

(select

OBD-II Generic if your specific OBD-II

manufacturer is not listed).

4. Use the arrow keys to select the year of the vehicle, then press

ENTER.

NOTE: After the unit is configured, it will Initialize then display

the opening screen. Continue with

Section 3 to set the

display units.

5. For OBD-I vehicles, use the arrow keys to highlight the number

that matches the 8th Character from the VIN code on the vehicle. Press

ENTER to select the proper character.

6. Depending on the vehicle selected, you may be asked some

additional questions to complete the configuration process. Use

the arrow keys to highlight the correct answer, then press

ENTER to select it.

SETUP / OPERATING INSTRUCTIONS (CONT.)

Page 9

Set the Display Units (SAE/Metric)

The EZ-SCAN scanner can be set up to display in SAE

or Metric units. The

default setting is SAE. Go to

Section 4 if you do not need to change the display units.

1. To change the unit of measure, press CONFIG from the initial

screen.

2. Use the arrow keys until 2-System Config is

displayed, then press

ENTER.

3. Use the arrow keys to select 1-SAE/Metric, then press

ENTER.

4. Use the tand uarrow keys to select 1-SAE or 2-METRIC

then press ENTER to select the highlighted choice (or press the

CONFIG Key to Cancel and return to the initial screen).

Adjust the Display Contrast and Backlight

The contrast on your EZ-SCAN scanner can be adjusted for easier

Viewing under different lighting conditions. Note, if scanner is left

in direct sunlight the Display can turn completely black. Should this

happen, put the scanner in a cool dark place for approx. 10 to 15

minutes. The display should return to normal.

1. To adjust the contrast of the screen press CONFIG key.

2. Use the arrow keys until 2-System Config is displayed, then

press ENTER.

3. Use the arrow keys until 3-Contrast Adjust is displayed, then

press ENTER.

4. Use the

tand u arrow keys to adjust desired screen contrast

SETUP / OPERATING INSTRUCTIONS (CONT.)

Page 10

(Fine adjustment)

5. Use the

pand q arrow keys for course adjustment.

6. The MON key will turn the backlight off. The default position is

ON and can be left that way, however it will lessen the life of your

batteries.

7. Press the CONFIG or ENTER key to save settings and return

to the Opening screen.

NOTE: Not all Scanners support this feature.

Connect the Scanner to Your Vehicle

The EZ-SCAN Scanner communicates with the computer and sensors in your vehicle through a special connection cable. The scanner cable is plugged into a connector on the top of the scanner, and into a computer

interface connection in your vehicle.

Each vehicle manufacturer has its own specific computer

connection. Make sure that you have the proper EZ-SCAN scanner cable for your vehicle - each one has a unique shape/color. In

addition, the name of the vehicle manufacturer is molded into the

connector body. Refer to the scanner cable assembly connectors

and applications shown on the next page.

SETUP / OPERATING INSTRUCTIONS (CONT.)

Page 11

SETUP / OPERATING INSTRUCTIONS (CONT.)

Page 12

OBD-II Generic

Connector (Yellow)

This standardized cable is used to

scan 1996 and newer Domestic,

Asian, and European vehicles.

GM Connector

Works with OBD-I 1982-1995

vehicles with a 12 pin ALDL.

Ford Connector

Works with OBD-I 1983-1995

Ford vehicles with EEC-IV

computers.

OBD-II Manufacturer

Specific Connector (Blue)

For 1994-1995 GM OBD-I vehicles

with a 16 pin connector, as well

as for future OBD-II functions to be

released at a later date.

Chrysler Connector

Works with OBD-I 1983-1995

Chrysler vehicles with SCI

connectors

1. Locate the vehicle computer connection:

•

[OBD-II / GM OBD-I] On OBD-II and GM vehicles, the connector is usually located under the drivers side of the dashboard. On some vehicles, the connector is located behind

the kick panels, ashtray, or radio.

•

[Ford / Chrysler 83-95, OBD-I] The connector on Ford and

Chrysler vehicles is usually located in the engine

compartment, along the outside perimeter of the engine

compartment, or by the shock absorber towers.

NOTE: For additional connection location information, including

the “OBD Connector Locations Database,” please look at

the Customer Support page on the AutoXray web site

(www.autoxray.com).

2. Make sure that all the pins are straight and that the connecting

surfaces are free of oils, grease, and moisture.

CAUTION: Do not force the cable connector into the scanner or

into the vehicle computer connection.

3. Push the scanner cable and vehicle connectors together firmly.

•

[Ford] The EEC-IV Ford connector has a trapezoid shaped

connector and a small square connector next to it. Make

sure

both connectors are correctly plugged into the scanner

cable connector.

NOTE: Make sure the scanner cable and vehicle connectors are

always properly seated during all test procedures.

4. Insert the EZ-SCAN cable connector into the top of the scanner.

SCAN - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I

Page 13

CONGRATULATIONS! The EZ-SCAN scanner is now set

up, connected, and ready to test your vehicle.

• OBD-II, Chrysler, and GM OBD-I vehicles - Start on Page

13

• Ford vehicles - Start on Page 33

Before You Start

• Before scanning a vehicle, the EZ-SCAN scanner must be

correctly configured for

your vehicle. Refer to

“Setup / Operating

Instructions” on page 8 if

you need to configure

the scanner.

Scanning the Vehicle

1. Press POWER to display the

EZ-SCAN scanner opening

screen.

2. Turn the vehicle ignition key

to ON or start the engine.

3. Press SCAN.

• When the scanner is

ready to scan the vehicle,

ENTER to Scan

will be displayed on the

screen. Press

ENTER to

start scanning the vehicle computer/sensors.

(Pressing

SCAN again

will take the unit out of

SCAN - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I (CONT.)

Page 14

Initializing

Please wait

Enter to Scan

Scan to Exit

AutoXray 6000

OBD-II Generic

Scan mode and

display the opening

screen.)

•

[OBD-II] Before an

OBD-II vehicle is

scanned, the vehicle

computer and the EZSCAN scanner will

initialize, do a protocol

check, then do

Readiness Tests to

make sure the vehicle

emission control

system is working correctly. (VPW, PWM, ISO

9141, Keyword 2000,

and CAN (Controller

Area Network) protocols

are all supported.)

4. [OBD-II] The scanner will

indicate the MIL status

(Malfunction Indicator Lamp,

or Check Engine Light),

ON

or OFF.

If there are Trouble Codes

stored in the OBD-II system,

the scanner will display the

codes as they are read from

the vehicle computer. (These

codes can also be viewed

later. See “View Trouble

Codes-OBD-II, GM, Chrysler”

on page 20.)

Page 15

SAE VPW Protocol

Selected

!Scanning!

Please Wait

MIL Status

ON

Freeze Frame

Date Detected

SCAN - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I (CONT.)

5. After the scanner has read all

the data from the vehicle, the

Scan Successful mes-

sage will be

displayed on the screen.

If the scanner could not read

all the data from the computer or the vehicle sensors, an

error message will be displayed.

VIEW THE DATA - OBD-II, GM, CHRYSLER

Before You Start

• Your vehicle must be scanned before viewing the data. If

DATA is pressed, and the vehicle has not been scanned,

the scanner will display Press the Scan key to Scan New

Data. Refer to “Scanning the Vehicle” on page 13.

The EZ-SCAN scanner DOES NOT need to be connected to the

vehicle to view the scanned

data. The vehicle engine configuration and data will remain in

the scanner’s memory until a

vehicle is scanned again. This

allows you to review the data at

a later time, or to use EZ-PC to

load the data into a computer.

Page 16

! Scan !

*Successful*

Not All Scan

Data Available

AutoXray 6000

OBD-II Generic

SCAN - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I (CONT.)

Viewing the Data

1. If the EZ-SCAN scanner is not

ON, press

POWER to display

the opening screen.

2. Press DATA to display the

Data menu. Make sure

1-

Operational Data

is

highlighted, then press

ENTER.

3. Information from the computer/sensors in your vehicle

(Operational Data Items) will

be displayed on the scanner

screen.

A reference number is displayed to the right of each

sensor. (The total number of

sensors and sensor types will

vary with each type of vehicle.)

NOTE: The pand q arrow keys will step through the sensors

(1 at a time), and the

tand u arrow keys will page

through the sensors (10 at a time).

4. After viewing the scanned sensor information, press DATA to

exit Data mode and display the opening screen.

Page 17

1-Operational Data

2-Freeze Frame Data

3-Trouble Codes

4-Clear Codes

5-Customize Data

6-EZ-PC

Fuel System 1

Open Loop 01

Fuel System 2

Not Supported 02

Load Value

0.0% 03

Coolant Temp

VIEW THE DATA - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I (CONT.)

Operational Data Items

To see a description of each of the Operational Data Items for your

vehicle, refer to the appropriate section on the following pages:

• “OBD-II Generic Operational Data Items” on page 57

• “Enhanced OBD-II Operational Data Items” on page 59

• “OBD-II Oxygen Sensor Test Readings” on page 61

• “GM Operational Data Items” on page 63

• “Chrysler Operational Data Items” on page 79

Monitoring Real Time Data

1. Make sure the EZ-SCAN scanner

cable is correctly connected to the

scanner and to the vehicle, then

press

POWER.

2. Press DATA to display the Data

menu. Make sure

1-Operational

Data

is highlighted, then press

ENTER.

3. To toggle real-time monitoring ON

and OFF, press

MON.

4. An Initializing screen will be

displayed while the scanner establishes a connection to the

computer/sensor.

5. When the connection has been

made, the reference number to the

right of each sensor.

NOTE: If the communication link with

the vehicle is broken during

VIEW TROUBLE CODES - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I

Page 18

1-Operational Data

2-Freeze Frame Data

3-Trouble Codes

4-Clear Codes

5-Customize Data

6-EZ-PC

Initializing

Please Wait

REAL TIME DATA MONITORING

Monitor mode, the number

in the lower right corner

will stop flashing.

6. Use the tand uarrow keys to

step through the sensors (1 at a

time), and the

pand qarrow

keys to page through the sensors

(10 at a time) to view their realtime data.

7. When you are done viewing realtime data, press

MON. The number in the lower right corner will

stop flashing.

8. Press DATA to exit Data mode and dis-

play the opening screen.

Before You Start

• [OBD-II] Freeze Frame is only

available on certain OBD-II vehicles.

• Your vehicle must be scanned

before viewing Freeze Frame

data. If

DATA is pressed, and the

vehicle has not been scanned,

the scanner will display

Press

the Scan key to Scan

New Data

. Refer to “Scanning

the Vehicle” on page 13.

REAL TIME DATA MONITORING - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I

Page 19

Monitor Mode

Exiting

1-Operational Data

2-Freeze Frame Data

3-Trouble Codes

4-Clear Codes

5-Customize Data

6-EZ-PC

Fuel System 1

Open Loop 01

Fuel System 2

Not Supported 02

Load Value

0.0% 03

Coolant Temp

VIEW FREEZE FRAME

Viewing OBD-II Freeze Frame Data

1. If the EZ-SCAN scanner is not ON, press POWER to display the

opening screen.

2. Press DATA to display the Data menu. Press the arrow keys

until

2-Freeze Frame Data is highlighted, then press ENTER.

NOTE: If no Freeze Frame data is available, the scanner will dis-

play a

No Freeze Frame Data message, then dis-

play the Data Menu.

3. The Trouble Code which caused the Freeze Frame data to be

captured will be displayed on the screen.

• A down arrow on the screen

indicates more information. Use the

arrow keys to view the additional

text.

• Press

ENTER to view Freeze Frame

operation data.

VIEW TROUBLE CODES

Before You Start

• Your vehicle must be scanned before clearing trouble

codes. If

DATA is pressed, and the vehicle has not been

scanned, the scanner will display

Press the Scan

key to Scan New Data

. Refer to “Scanning the

Vehicle” on page 13.

Viewing Trouble Codes

1. If the scanner is not ON, press POWER to display the opening

screen.

2. Press DATA to display the Data menu. [GM, Chrysler] Use the

arrow keys until

2-Trouble Codes is highlighted, then press

ENTER.

Page 20

VIEW FREEZE FRAME - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I

P0760 Shift

Solenoid C

Malfunction

[OBD-II] Use the arrow keys until 3-

Trouble Codes

is high-

lighted, then press

ENTER.

3. [OBD-II] OBD-II vehicles read

both Pending Codes (codes

that have only been detected

once by the vehicle computer)

and Trouble Codes (codes that

have been detected multiple

times). Press

ENTER to select

either

1-Trouble Codes

or 2-Pending Codes

.

4. [GM] Some GM vehicles

show both history and current

trouble codes. Press

ENTER to

select either

1-History

Codes

or 2-Current

Codes

.

5. If no Trouble Codes are in the

vehicle’s computer,

No

Trouble Codes Found

will be displayed.

If a Trouble Code is detected,

the fault and its description will

be displayed on the scanner

screen. The fault code number

will be displayed in the upper

left corner of the screen.

• A down arrow on the

screen indicates more

information. Use the

p

Page 21

1-Trouble Codes

2-Pending Codes

No Trouble

Codes Found

VIEW TROUBLE CODES - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I

P0760 Shift

Solenoid C

Malfunction

1-Operational Data

2-Freeze Frame Data

3-Trouble Codes

4-Clear Codes

5-Customize Data

6-EZ-PC

and qarrow keys to view the additional text.

• Use the

tand uarrow keys to view any other Trouble

Codes.

CLEAR THE CODES

Before You Start

• Clearing Trouble Codes will remove any Trouble Codes

from the vehicle’s computer. You can use this feature to

make sure vehicle repairs were done correctly by doing a

new scan after clearing the codes.

•

[GM] The Clear Codes option is not available on all GM

vehicles.

• Your vehicle must be scanned before clearing trouble

codes. If

DATA is pressed, and the vehicle has not been

scanned, the scanner will display

Press the Scan

key to Scan New Data

. Refer to “Scanning the

Vehicle” on page 13.

Clearing Trouble Codes

1. Make sure the EZ-SCAN scanner cable is correctly connected to

the scanner and to the vehicle, the engine is OFF, and the vehicle ignition key is ON, then

press

POWER.

2. Press DATA to display the Data

menu.

[GM, Chrysler] Use the

arrow keys until

3-Clear

Codes

is highlighted, then

press

ENTER.

[OBD-II] Use the arrow keys

until

4-Clear Codes is

highlighted, then press

ENTER.

Page 22

AutoXray 6000

OBD-II Generic

VIEW TROUBLE CODES - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I

3. ENTER to Clear will be displayed on the screen. Press

ENTER

to clear all the codes in the vehicle’s computer. (Pressing

DATA

again will take the unit out of Data

mode and display the opening

screen.)

4. After the codes have been cleared,

Clear Successful will be

displayed. Press

DATA to display

the opening screen.

RESET EMR LAMP-CHRYSLER

(1989-95)

Before You Start

• [Chrysler] The Engine

Maintenance Repair (EMR)

lamp reset feature is only

available on Chrysler trucks,

vans, and 1991 and later

Jeeps.

Resetting the EMR Lamp

1. Make sure the EZ-SCAN scanner cable is correctly connected to

the scanner and to the vehicle, the vehicle engine is OFF, the

vehicle ignition key is ON, then press

POWER.

2. Press DATA to display the Data menu. Use the arrow keys until

4-EMR Reset is highlighted, then press ENTER.

CLEAR THE CODES - ALL OBD-II, GM OBD-I, CHRYSLER OBD-I

Page 23

1-Operational Data

2-Freeze Frame Data

3-Trouble Codes

4-Clear Codes

5-Customize Data

6-EZ-PC

Press the ENTER key

to Clear Codes

Press the Data key

to Exit

Clear

*Successful*

3. ENTER to Clear will be

displayed on the screen.

Press

ENTER to reset the

EMR lamp. (Pressing

DATA

again will take the unit out of

Data mode and display the

opening screen.)

4. After the EMR lamp has been

reset,

Function

Successful

will be

displayed. Press

DATA to dis-

play the opening screen.

Page 24

AutoXray 6000

CHRY ‘95 VIN=C

1-Op Data

2-Trouble Codes

3-Clear Codes

4-EMR Reset

5-EZ-PC

Press the ENTER key

to Clear Codes

Press the Data key

to Exit

!Function!

*Successful*

RESET EMR LAMP-CHRYSLER (1989-95) (CONT.)

1. Make sure you have completed a vehicle scan. Then press

POWER.

2. Press DATA to display the Data menu. Use the arrow keys until

5-Customize Data is highlighted, then press ENTER.

3. From the menu, you have several options, for selecting and des-

electing operational data items. The simplest option is to use the

down arrow key. A menu screen will display DESELECT ALL?

Press ENTER on YES. All data items are now deselected. Use

the left or right arrow keys to scroll through the data items and

press the ENTER key for each data item you would like to select,

for viewing data, in the OPERATIONAL DATA or CAPTURE DATA

modes.

NOTE: The maximum number of data items that can be viewed in

Capture Mode is 20.

Before You Start

• Use Capture Mode to help diagnose intermittent problems

that occur while driving the vehicle by capturing data before,

during, and after a problem occurs.

NOTE: [GM] On carbureted vehicles and a few fuel injected

vehicles, the on-board computer is placed into Service

Mode, a mode which fixes the timing and the idle speed.

If the idle speed on your fuel injected vehicle is affected

during scanning, AutoXray recommends that you do not

drive your vehicle while it is scanned.

•

[OBD-II] The Capture Mode will capture up to a maximum

of 20 data items. Use Customize Data function to select

which data items to be captured and displayed. See page

CUSTOMIZING DATA ITEMS - OBD-II

Page 25

CAPTURE MODE - OBD-II, GM, CHRYSLER

25 “Customizing Data Items - OBD-II”.

•

[ALL] Your vehicle must be scanned before using Capture

Mode. If

ENTER is pressed to select 1-Capture Mode,

and the vehicle has not been scanned, the scanner will display

Press the Scan key to Scan New Data.

Refer to “Scanning the Vehicle” on page 13.

CAUTION: AutoXray recommends that the person operating the

vehicle does not use/view the scanner. Always use an assistant to

operate the scanner while driving the vehicle.

Capturing the Problem

1. Make sure the EZ-SCAN

scanner cable is out of the

driver’s way, and is correctly

connected to the scanner and

to the vehicle, then press

POWER.

2. Press MON to display

Monitor menu.

[OBD-II] Make

sure

1-Capture Mode is

highlighted, then press

ENTER.

[All] Make sure 1-Start

Capture

is highlighted, then

press

ENTER.

3. The screen will display

Capture Mode and then up to

seven ‘>’ symbols. Each ‘>’

symbol represents a user

defined length of time.

NOTE: When CaptureMode is start-

Page 26

1-Capture Mode

2-O2 Sensor Tests

3-Readiness Tests

4-Test Results

5-Veh. Information

1-Start Capture

2-View Data

[Capture Mode]

>>>>>>

CAPTURE MODE - OBD-II, GM, CHRYSLER (CONT.)

ed, the scanner will begin displaying

‘>’ symbols. Each symbol represents

two frames of data. The default setting for each frame is one second.

Refer to “Set the Time Units for

Capture Mode” on page 87 to

change the setting.

4. Press ENTER when an intermit-

tent problem occurs. The scanner

will capture the data at the trigger

point, then will display a ‘

T’ followed by seven ‘<’ symbols. After

the “T” is displayed wait for the capture to complete. The display

will then return to an opening menu (refer to Viewing the

Capture Data)

N

OTE: You can press ENTER at any time, even if all seven ‘>’ sym-

bols are not displayed. The scanner always keeps the most

recent data while waiting for ENTER (trigger point) to be

pressed. After the “T” is displayed, wait for capture to complete. Pressing MON at any time will abort the capture.

Viewing the Capture Mode Data

Capture Mode data can be viewed on the scanner, or you can use

EZ-PC to download the data to your personal computer to save it

and display it graphically. Data stored on your computer can be

used to keep a history of data for the

vehicle.

1. Press POWER to display the EZ-

SCAN scanner opening screen.

2. Press MON to display Monitor

Page 27

Capture Mode

>>>>>>>T>>>>>>>

1-Capture Mode

2-O2 Sensor Tests

3-Readiness Tests

4-Test Results

5-Veh. Information

CAPTURE MODE - OBD-II, GM, CHRYSLER (CONT.)

menu. [OBD-II] Make sure

1-Capture Mode is

highlighted, then press

ENTER.

[All] Use the arrow keys

until

2-View Data is

highlighted, then press

ENTER.

3. Data from each sensor will

be displayed on the

screen. Use the arrow

keys to view data changes

as you move up and down

the capture time line. The

(-) indicates time intervals

before the trigger point,

and (+) indicates time

intervals after the trigger

point.

• Use the

tand u

arrow keys to view

other sensors.

4. Press MON to exit Capture Mode and display the opening

screen.

Page 28

1-Start Capture

2-View Data

Fuel System 1

Open Loop 01

Fuel System 2

Not Supported 02

Load Value

0.0% 03

Coolant Temp

CAPTURE MODE - OBD-II, GM, CHRYSLER (CONT.)

Before You Start

• [OBD-II] Oxygen Sensor Tests are OBD-II specific tests

of each of the oxygen sensors on a vehicle. Although there

are up to eight possible sensors the scanner can test, certain vehicles may not support all eight tests, and most vehicles use only two or four. Oxygen Sensor Test values are

divided in two types, a constant reading and a calculated

reading. Constant readings are provided by the vehicle computer,

calculated readings are determined from the sensor data.

• Your vehicle must be scanned

before viewing Oxygen Sensor

Test data. If

MON is

pressed, and the vehicle

has not been scanned,

the scanner will display

Press the Scan

key to Scan New

Data

. Refer to

“Scanning the Vehicle”

on page 13.

• Refer to “OBD-II Oxygen

Sensor Test Readings”

on page 54 to see a

description of each

Oxygen Sensor Test

data item.

Viewing Oxygen Sensor

Test Data

1. Press POWER to display the EZ-SCAN

scanner opening screen.

Page 29

1-Capture Mode

2-O2 Sensor Tests

3-Readiness Tests

4-Test Results

5-Veh. Information

Select O2 Sensor

1-O2 Sensor 1

2-O2 Sensor 2

Low Volt Switch

Time 0.400V

OXYGEN SENSOR TESTS - OBD-II

2. Press MON to display Monitor menu. Use the arrow keys until

2-Oxygen Tests is highlighted, then press ENTER.

3. Use the arrow keys to select an O2 Sensor number, then press

ENTER.

4. Use the tand uarrow keys to select which Oxygen Sensor

Test to view.

5. Press MON to exit the Oxygen Sensor Tests and display the

opening screen.

Before You Start

• [OBD-II] Your scanner must be connected, and the key in

the ON position, before viewing OBD-II Readiness Test

data. If

MON is pressed, and the vehicle has not been

scanned, the scanner will display

Press the Scan

key to Scan New Data

. Refer to “Scanning the

Vehicle” on page 13.

1. Press POWER to display the EZ-

SCAN scanner opening screen.

2. Press MON to display Monitor

menu. Use the arrow keys until

3-Readiness Test is high-

lighted, then press

ENTER.

3. The name of the Readiness Test

will be displayed, followed by its

status. Status is either Completed,

Not Completed, or Not Supported.

• A down arrow on the screen

indicates other test results.

Use the arrow keys to view

these other test results.

Page 30

1-Capture Mode

2-O2 Sensor Tests

3-Readiness Tests

4-Test Results

5-Veh. Information

MIL Status

ON

OXYGEN SENSOR TESTS (CONT.)

READINESS TEST - OBD-II

The following Readiness Tests are supported by the scanner:

CONTINUOUS NON-CONTINUOUS

Misfire Monitoring Catalyst Monitoring

Fuel System Monitoring Heated Catalyst Monitoring

Comprehensive Evaporative System Monitoring

Component Monitoring Secondary Air System Monitoring

A/C System Refrigerant Monitoring

O2 Sensor Monitoring

O2 Sensor Heater Monitoring

EGR System Monitoring

4. Press MON to exit the Readiness Test and display the opening

screen.

Test Results - OBD-II

• [OBD-II] Your scanner must be

connected, and the key in the

ON position, before viewing

OBD-II Readiness Test data. If

MON is pressed, and the vehicle has not been scanned, the

scanner will display

Press

the Scan key to Scan

New Data

. Refer to “Scanning

the Vehicle” on page 13.

1. Press POWER to display the EZ-

SCAN scanner opening screen.

2. Press MON to display Monitor menu.

Use the arrow keys until

4- Test Results is highlighted,

then press

ENTER.

3. The Test Result will be displayed, fol-

Page 31

READINESS TESTS - OBD-II (CONT.)

AutoXray 6000

OBD-II Generic

1-Capture Mode

2-O2 Sensor Tests

3-Readiness Tests

4-Test Results

5-Veh. Information

lowed by its status.

• Each reading will give the

Test Number, the Component

Number, Pass or Fail status,

whether it is a "Hi" value or

"Low" value test, the value

reported by the on-board

computer, and the limit for

that value.

• A down arrow on the screen

indicates other test results. Use the

arrow keys to view these other test results.

NOTE: OBD-II equipped vehicles, are required to report the

results of diagnostic tests for all non-continuously

monitored emissions related components, for instance the

catalytic converter or the EGR valve. These tests vary

among manufacturers and the numbers are assigned

arbitrarily by them and should be listed in the service

manual for the vehicle.

4. Press MON to exit the Readiness Test and display the opening

screen.

Page 32

TEST RESULTS - OBD-II (CONT.)

Test ID $01 Pass

Component ID $11

Pass Low

0400 >=0200

description not

specified

Before You Start

• Before scanning a vehicle, the EZ-SCAN scanner must be

correctly configured for your vehicle. Refer to “Setup /

Operating Instructions” on page 8 if you need to configure

the scanner.

Key ON, Engine OFF (KOEO) Scan

The KOEO scan causes the vehicle EEC-IV computer to actuate

the sensors and test the different computer controlled functions of

the vehicle. The KOEO test will detect faults at the time of testing

(hard faults) and intermittent faults stored as Memory Codes.

1. Run the engine until it is at

normal

operating temperature.

2. Make sure ALL electrical loads

(air conditioning, radio, blower

fan, etc.) are OFF.

3. Connect the EZ-SCAN scanner

cable to the scanner and to the

vehicle EEC-IV computer connector, then press

POWER to

display the EZ-SCAN scanner

opening screen.

4. Make sure the vehicle ignition

key has been OFF for at least

ten seconds after warm up.

Turn the ignition key to the

KOEO position, then press

SCAN.

• Vehicles that support

DCL will

display a Scan menu.

Make sure

1-KOEO/KOER Scan is

SCAN THE KOEO CODES - FORD

Page 33

AutoXray 6000

FORD ‘90 VIN=N

1-KOEO/KOER Scan

2-DCL Data Scan

Enter to Scan

Scan to Exit

highlighted, then press

ENTER.

5. When the scanner is ready to

scan the vehicle,

ENTER to

Scan

will be

displayed on the screen. Press

ENTER to start scanning the

vehicle computer/sensors.

(Pressing

SCAN again will take

the unit out of Scan mode and

display the opening screen.)

6. Scanning Data will be displayed while the KOEO codes

and memory codes are

retrieved from the vehicle computer. A normal scan can take

up to three minutes.

• Vehicles equipped with

4.9 liter engines with a

manual transmissionPush the clutch in during

the entire test.

• Vehicles equipped with 7.3 liter diesel engines - Press the

accelerator to the floor for the entire test.

7. After the scanner has read all the data from the vehicle, the

Scan Successful message will be displayed on the screen,

followed by the opening screen.

Page 34

*Scanning Data*

Please Wait

! Scan !

*Successful*

AutoXray 6000

FORD ‘90 VIN=N

SCAN THE KOEO CODES - FORD (CONT.)

Before You Start

• Before scanning a vehicle, the EZ-SCAN scanner must be

correctly configured for your vehicle. Refer to “Setup /

Operating Instructions” on page 8 if you need to configure

the scanner.

• Make sure to read these instructions completely before the

KOER test is started. Several user interactions may be

required during the scan. If these steps are not completed

correctly, the engine computer will store a Trouble Code as

if the system was not functioning properly. If one of these

trouble codes are stored,

repeat the scan with the necessary steps to eliminate the

problem. For example, the

error

RPM too low dur-

ing KOER test

can be

corrected by pressing the gas

pedal to the floor during the

Dynamic Response section of

the scan.

Key ON, Engine Running

(KOER) Scan

The KOER scan causes the vehicle

EEC-IV computer to test the different

sensors and computer controlled

functions while the

vehicle engine is running.

1. Run the engine until it is at normal

operating temperature.

2. Make sure ALL electrical loads

(blower fan, air conditioning, radio,

etc.) are OFF.

SCAN THE KOER CODES - FORD (CONT.)

Page 35

AutoXray 6000

FORD ‘90 VIN=N

1-KOEO/KOER Scan

2-DCL Data Scan

3. Connect the EZ-SCAN scanner cable to the scanner and

to the vehicle EEC-IV computer connector, then press

POWER to display the EZSCAN scanner opening

screen.

4. Make sure the vehicle ignition

key has been OFF for at least

ten seconds after warm up.

Turn the ignition key to start

the engine, then press

SCAN.

• Vehicles that support

DCL will display a Scan

menu. Make sure

1-

KOEO/KOER Scan

is

highlighted, th en pres s

ENTER.

5. When the scanner is ready to

scan the vehicle,

ENTER to

Scan

will be displayed on the

screen. Press

ENTER to start

scanning the vehicle computer/sensors. (Pressing

SCAN

again will abort Scan mode

and display the opening

screen.)

6. Scanning Data will be

displayed while the vehicle

computer is scanned. A normal scan can take up to five

minutes.

Page 36

Enter to Scan

Scan to Exit

*Scanning Data*

Cylinders = 8

*Scanning Data*

Dynamic Response

SCAN THE KOER CODES - FORD (CONT.)

• Vehicles equipped with a

Power Steering Pressure

Switch - Turn the steering

wheel 1/2 turn and release,

when prompted.

• Vehicles equipped with a Brake

ON/OFF Switch - Press and

release the brake, when

prompted.

7. If the vehicle is equipped with an

automatic transmission, place the

car into Drive and then back into

Park, when prompted.

8. If Dynamic Response is dis-

played, briefly accelerate the engine

to wide open throttle, and release.

(Snap throttle)

9. After the scanner has completed

the KOER scan, the

Scan

Successful

message will be displayed on the screen, fol-

lowed by the opening screen.

• If these steps are not completed correctly, the engine computer will store a Trouble Code as if the system was not functioning properly. If one of these trouble codes are stored, repeat

the scan with the necessary steps to eliminate the problem.

For example, the error

RPM too low during KOER

test

can be

corrected by pressing the gas pedal to the floor during the

Dynamic Response section of the scan.

Page 37

! Scan !

*Successful*

AutoXray 6000

FORD ‘90 VIN=N

SCAN THE KOEO CODES - FORD (CONT.)

Before You Start

• Before scanning a vehicle,

the EZ-SCAN scanner

must be correctly configured for your vehicle.

Refer to “Setup /

Operating Instructions” on

page 8 if you need to configure the scanner.

Data Communications Link

(DCL) Scan

This scan displays live operational data from vehicles that support DCL. Certain vehicles from

1989 to 1995 support the DCL

scan.

1. Connect the EZ-SCAN scanner cable to the scanner and to

the vehicle EEC-IV computer

connector, then press

POWER

to display the EZ-SCAN scanner opening screen.

2. Turn the vehicle ignition key to

ON or start the engine.

3. Vehicles that support DCL will

display a Scan menu. Use the

arrow keys until

2-DCL Data

Scan

is highlighted, then

press

ENTER.

4. When the scanner is ready to

scan the vehicle,

ENTER to

Page 38

AutoXray 6000

FORD ‘90 VIN=N

1-KOEO/KOER Scan

2-DCL Data Scan

Enter to Scan

Scan to Exit

*Scanning Data*

Please Wait

SCAN THE DCL DATA - FORD

Scan will be displayed on the

screen. Press

ENTER to start

scanning the vehicle

computer/sensors. (Pressing

SCAN again will abort Scan

mode and display the opening

screen.)

5. Initializing will be displayed when entering the DCL

scan. A normal scan can take

up to one minute or longer.

6. After the scanner has read all the data from the vehicle, the

Scan Successful message will be displayed on the screen,

followed by the opening screen.

Operational Data Items

To see a description of each of the Operational Data Items for your

vehicle, refer to “Ford DCL Operational Data Items” on page 57.

Before You Start

• Your vehicle must be scanned before viewing the KOEO

codes. If

DATA is pressed, and the vehicle has not been

scanned, the scanner will display

Press the Scan

key to Scan New Data

. Refer to “Key ON, Engine

OFF (KOEO) Scan” on page 33.

The EZ-SCAN scanner DOES NOT need to be connected to the

vehicle to view the scanned data. The vehicle engine configuration

and data will remain in the scanner’s memory until a vehicle is

scanned again. This allows you to review the data at a later time,

or to use EZ-PC to load the data into a computer.

Page 39

! Scan !

*Successful*

SCAN THE DCL DATA - FORD (CONT.)

VIEW THE KOEO CODES - FORD

1. Press POWER to display the EZ-

SCAN scanner opening screen.

2. Press DATA to display the Data

menu. Make sure

1-KOEO Codes

is highlighted, then press ENTER.

3. If no faults are detected during the

KOEO test, the vehicle’s computer

will store

code 11 or code 111

System Pass

. If a fault is detected, the fault and its description will be

displayed on the scanner screen.

The fault code number will be displayed in the upper left corner of the

screen.

• A down arrow on the screen

indicates more information. Use

the arrow keys to view the additional text.

• Use the

tand uarrow keys to

view any other faults.

4. Press DATA to exit Data mode and display the opening screen.

VIEW THE MEMORY (TROUBLE) CODES - FORD

Before You Start

• Your vehicle must be scanned before viewing the data. If

DATA is pressed, and the vehicle has not been scanned,

the scanner will display

Press the Scan key to

Scan New Data

. Refer to “Key ON, Engine OFF

(KOEO) Scan” on page 33.

• Memory Codes are intermittent faults that are detected by

Page 40

111 System Pass

VIEW THE KOEO CODES - FORD (CONT.)

1-KOEO Codes

2-Memory Codes

3-KOER Codes

4-Clear Codes

5-DCL Data

6-EZ-PC

the vehicles computer during

normal operation, and are

stored in memory.

1. Press POWER to display the EZ-

SCAN scanner opening screen.

2. Press DATA to display the Data

menu. Use the arrow keys until

2-

Memory Codes

is highlighted,

then press

ENTER.

3. If no Memory Codes are in the

vehicle’s computer,

code 11 or

code

111 System Pass will

be displa y e d . If a Memory Code is

detected, the fault and its description will be displayed on the scanner screen. The fault code number

will be displayed in the upper left corner of the screen.

• A down arrow on the screen indicates more information. Use

the arrow keys to view the additional text.

• Use the

tand uarrow keys to view any other faults.

4. Press DATA to exit Data mode and display the opening screen.

Page 41

123 Throttle

Position sensor is

out of range

VIEW THE MEMORY (TROUBLE) CODES - FORD (CONT.)

1-KOEO Codes

2-Memory Codes

3-KOER Codes

4-Clear Codes

5-DCL Data

6-EZ-PC

Before You Start

• Your vehicle must be scanned

before viewing the KOER data. If

DATA is pressed, and the vehicle

has not been scanned, the scanner will display Press the

Scan

key to Scan New Data

.

Refer to “Key ON, Engine

Running (KOER) Scan” on page

33.

1. Press POWER to display the EZ-

SCAN scanner opening screen.

2. Press DATA to display the Data menu.

Use the arrow keys until

3-KOER

Codes

is highlighted, then press

ENTER.

3. If no KOER faults are in the vehicle’s

computer,

code 11 or code 111

System Pass

will be displayed.

If a fault is detected, the fault and its

description will be displayed on the

scanner screen. The fault code number will be displayed in the upper left

corner of the screen.

• A down arrow on the screen indicates more information. Use the

arrow keys to view the additional

text.

• Use the

tand uarrow keys to

view any other faults.

4. Press DATA to exit Data mode and

display the opening screen.

Page 42

111 System Pass

123 Throttle

Position sensor is

out of range

VIEW THE KOER CODES - FORD

1-KOEO Codes

2-Memory Codes

3-KOER Codes

4-Clear Codes

5-DCL Data

6-EZ-PC

Before You Start

• Your vehicle must be

scanned before viewing the

data. If

DATA is pressed, and

the vehicle has not been

scanned, the scanner will display

Press the Scan

key to Scan New

Data

. Refer to “Data

Communications Link (DCL)

Scan” on page 33.

The EZ-SCAN scanner DOES NOT

need to be connected to the vehicle

to view the scanned data. The vehicle engine configuration and data will

remain in the scanner’s memory until

a vehicle is scanned again. This

allows you to review the data at a

later time, or to use EZ-PC to load

the data into a computer.

Viewing the DCL Data

1. If the EZ-SCAN scanner is not ON,

press

POWER to display the open-

ing screen.

2. Press DATA to display the Data

menu. Use the arrow keys until

5-DCL Data is highlighted, then

press

ENTER.

3. Information from the DCL computer/sensors in your vehicle

(Operational Data Items) will be dis-

VIEW THE DCL DATA - FORD

Page 43

1-KOEO Codes

2-Memory Codes

3-KOER Codes

4-Clear Codes

5-DCL Data

6-EZ-PC

Engine Speed

643 RPM 01

Spark Advance

10.0

o02

Throttle Posn

3.8 VOLTS 03

1-KOEO Codes

2-Memory Codes

3-KOER Codes

4-Clear Codes

5-DCL Data

6-EZ-PC

played on the scanner screen. A reference number is displayed in the

lower right corner of the screen. (The

total number of sensors and sensor

types will vary with each type of

vehicle.)

NOTE: The tand uarrow keys will

step through the sensors

(1 at a time), and the

pand q

arrow keys will page through the

sensors (10 at a time).

4. After viewing the scanned DCL data,

press

DATA to exit Data mode and

display the opening screen.

Monitoring Real Time Data

1. Make sure the EZ-SCAN scanner

cable is correctly connected to the

scanner and to the vehicle, then

press

POWER.

2. Press DATA to display the Data menu.

Use the arrow keys until

5-DCL

Data

is highlighted, then press

ENTER.

3. To toggle real-time monitoring ON

and OFF, press

MON.

4. An Initializing screen will be

displayed while the scanner establishes a

connection to the computer/sensor.

5. When the connection has been made, the

reference number in the lower right corner

will begin to flash.

VIEW THE DCL DATA - FORD (CONT.)

Page 44

Initializing

Please wait...

Engine Speed

643 RPM 01

Spark Advance

10.0

o02

Throttle Posn

3.8 VOLTS 03

Engine Speed

643 RPM 01

Spark Advance

10.0

o02

Throttle Posn

3.8 VOLTS

03

Engine Speed

643 RPM 01

Spark Advance

10.0

o02

Throttle Posn

3.8 VOLTS 03

NOTE: If the communication link with the vehicle is broken during

Monitor mode, the number in the lower right corner will

stop flashing.

6. Use the tand uarrow keys to step through the sensors (1 at a

time), and the

pand qarrow keys to page through the sensors

(10 at a time) to view their real-time data.

7. When you are done viewing real-time data, press MON. The

number in the lower right corner will stop flashing.

8. Press DATA to exit Data mode and display the opening screen.

Before You Start

• Clearing Trouble Codes will remove any Trouble Codes

from the vehicle’s computer. You can use this feature to

make sure vehicle repairs were done correctly by doing a

new scan after clearing the codes.

• Your vehicle must be scanned before clearing trouble

codes. If

DATA is pressed, and the vehicle has not been

scanned, the scanner will display

Press the Scan

key to Scan New Data

. Refer to “Key ON, Engine

OFF (KOEO) Scan” on page 33, “Key ON, Engine Running

(KOER) Scan” on page 35, or “Data Communications Link

(DCL) Scan” on page 38.

Clearing Trouble Codes

1. Make sure the EZ-SCAN scanner cable is correctly connected to

the scanner and to the vehicle. Turn the vehicle ignition key OFF

for at least 10 seconds, turn the key ON, then press

POWER.

2. Press DATA to display the Data menu. Use the arrow keys until

4-Clear Codes is highlighted, then press ENTER.

3. ENTER to Clear will be displayed on the screen. Press

Page 45

CLEAR TROUBLE CODES - FORD

VIEW THE DCL DATA - FORD (CONT.)

ENTER to clear all the codes in the vehicle’s computer. (Pressing

DATA again will abort Data mode and display the opening

screen.)

4. After the codes have been cleared, Function Successful

will be displayed. Press DATA to display the opening screen.

Before You Start

• The wiggle test, or continuous monitor test,

allows you to test sensor systems for intermittent faults. Activating the

wiggle test, then tapping, wiggling, or moving suspect wires or

sensors may reveal an

intermittent short or

open in the circuit.

CAUTION: Do not drive the

vehicle while doing this test.

1. Make sure the EZ-SCAN

scanner cable is correctly

connected to the scanner

and to the vehicle. Turn the

vehicle ignition key OFF for

at least 10 seconds.

• For a KOEO Wiggle

Test, turn the key ON,

then press

POWER.

• For a KOER Wiggle Test, start

ACTIVATE THE WIGGLE TEST - FORD

Page 46

1-Wiggle Test

2-DCL Capture

ENTER to Test

MON to Exit

AutoXray 6000

FORD ‘90 VIN=N

CLEAR TROUBLE CODES - FORD (CONT.)

the engine, then press

POWER.

2. Press MON to display Monitor

menu. Make sure

1-Wiggle

Test

is highlighted, then

press

ENTER.

3. ENTER to Test will be

displayed on the screen.

Press

ENTER to start the wig-

gle test. (Pressing

MON again

will take the unit out of

Monitor mode and display the

opening screen.)

4. Tap, wiggle, or move wires

and sensors to detect a fault.

5. FAULT will be displayed if a

fault is detected during the

test.

NO FAULT will be displayed if

there are no faults detected

during the test.

6. Press MON to exit the Wiggle

Test and display the opening

screen.

NOTE: If a fault was detected, run a

KOEO test, then check the

Memory Codes to see the error.

ACTIVATE THE WIGGLE TEST - FORD (CONT.)

Page 47

Wiggle Test Mode

FAULT

NO FAULT

AutoXray 6000

FORD ‘90 VIN=N

NOTE: Only applies to cars equipped with DCL.

Before You Start

• Use Capture Mode to help diagnose intermittent problems

that occur while driving the vehicle by capturing data before,

during, and after a problem occurs.

CAUTION: AutoXray recommends that the person operating the

vehicle does not use/view the scanner. Always use an assistant to

operate the scanner while driving the vehicle.

Capturing the Problem

1. Make sure the EZ-SCAN scanner cable is out of the driver’s

way, and is correctly connected to the scanner and to the vehicle, then press

POWER.

2. Press MON to display Monitor

menu. Use the arrow keys until

2-DCL Capture is highlighted,

then press

ENTER.

3. Make sure 1-Start Capture

is highlighted, then press ENTER.

4. The screen will display Capture

Mode

and then up to seven ‘>’

symbols. Each ‘>’ symbol represents a user defined length of

time.

NOTE: When Capture Mode is

started, the scanner will

begin displaying ‘>’ sym-

bols. Each symbol repre-

sents two frames of data.

The default setting for each

DCL DATA CAPTURE - FORD

Page 48

1-Wiggle Test

2-DCL Capture

1-Start Capture

2-View Data

frame is one second. Refer to “Set

the Time Units for Capture Mode”

on page 78 to change the setting.

5. When the scanner is put in

Capture Mode it is ready to capture real-time data (for those

problems that only seem to

occur while driving). Press

ENTER when the intermittent

problem occurs. The scanner will

capture the data at the trigger

point, then will display a ‘

T’

followed by seven ‘<’ symbols as

vehicle data after the trigger is

captured and stored.

NOTE: You can press ENTER at

any time, even if all seven

‘>’ symbols are not displayed. The scanner always

keeps the most recent data while waiting for

ENTER (trigger

point) to be pressed. After the “T” is displalyed, wait for the

capture to complete. Pressing

MON at any time to abort the

capture.

Viewing the Capture Mode Data

Capture Mode data can be viewed on the scanner, or you can use

EZ-PC to download the data to your personal computer to save it

and display it graphically. Data stored on your computer can be

used to keep a history of data for the vehicle.

1. Press POWER to display the EZ-SCAN scanner opening screen.

Page 49

[Capture Mode]

>>>>>

Capture Mode

>>>>>>>T<<<<<<<

DCL DATA CAPTURE - FORD (CONT.)

2. Press MON to display Monitor menu. Use the arrow keys until

2-DCL Capture is highlighted,

then press

ENTER.

3. Use the arrow keys until 2-View

Data

is highlighted, then press

ENTER.

4. Data from each sensor will be displayed on the screen. Use the

arrow keys to view data changes

as you move up and down the

capture time line. The (-) indicates

time intervals before the

trigger point, and (+) indicates

time intervals after the trigger

point.

• Use the

tand uarrow keys

to view other sensors.

5. Press MON to exit Capture Mode

and display the opening screen.

Page 50

1-Wiggle Test

2-DCL Capture

1-Start Capture

2-View Data

Engine Speed

643 RPM 01

Spark Advance

10.0

o02

Throttle Posn

3.8 VOLTS 03

DCL DATA CAPTURE - FORD (CONT.)

This section contains the following Troubleshooting subjects:

• What to do When the Scanner Displays a Fault/Trouble Code

• What to do for a "Vehicle Is Not Responding" Message

• Screen Contrast Problems

• How to Reset the Scanner

• Scanner Screen Menu Trees

What to do When the Scanner Displays a

Fault/Trouble Code

NOTE: AutoXray recommends obtaining a service manual or

repair manual to assist in automotive diagnostics.

Manuals are available at your local parts store, book

store, or library.

1. Check the connection to the sensor.

2. Look for obvious damage to any wires or vacuum hoses.

3. Locate a service or repair manual to look up the troubleshooting

tree for that fault code.

4. Follow the tree to determine the cause of the code.*

NOTE: Remember, the sensor itself is not always the cause of

the trouble code.

What to do for a "Vehicle Is Not Responding" Message

1. Make sure the vehicle ignition key is in the full ON position (not

ACC) and is making contact.

2. Make sure the diagnostic connector is clean.

3. Make sure the cable connectors are pushed in firmly.

4. Make sure the pins in the connectors are not bent and are

making contact.

5. Make sure the year and VIN are correctly entered.

6. Try wiggling the connector during the attempted scan.

Page 51

TROUBLESHOOTING

"Vehicle Is Not Responding" Message (continued)

Check the following “Manufacturer Specific” items:

•

[Ford] Make sure to connect both the multi-wire and the

single-wire connectors to the AutoXray cable.

•

[Ford] At the beginning of a KOEO test, listen for solenoids

clicking under the hood.

•

[Ford] Make sure the vehicle is fully warmed up before

attempting the KOER test and give enough time to bring up

"Scan Successful".

•

[GM] Answer any exception questions correctly.

•

[GM] On carbureted models, make sure the Check Engine

Light is rapidly flashing during the attempted scan.

Screen Contrast Problems

Some users have experienced problems concerning screen

contrast with newer batteries like the Duracell Ultra. These

batteries produce a higher than normal voltage and can affect

the scanner screen contrast, making the screen difficult to read.

We apologize for the inconvenience. If you encounter this

problem, run your scanner for approximately 2 hours to run off

the high voltage causing the problem. (It will be necessary to

press a key occasionally to override the EZ-SCAN scanner

power miser function.)

NOTE: After these batteries reach their rated voltage (1.5V) the

battery life should still be approximately 500 hours.

How to Reset the Scanner

1. Power Scanner on.

2. Open the battery compartment and remove one battery.

3. Hold down POWER for 5 seconds.

4. Put the battery back in, and power on.

Page 52

TROUBLESHOOTING (CONT.)

NOTE: These steps will re-set the scanner. If your problem

persists please contact AutoXray technical support.

Scanner Screen Menu Trees

POWER

>AutoXray EZ-SCAN opening screen

CONFIG

>1-Config Unit

GM

Year

Ford

Year

Chrysler

Year

OBD-II Generic

GEO OBD-II

Honda OBD-II

Hyundai OBD-II

Isuzu OBD-II

Kia OBD-II

Mazda OBD-II

Mitsubishi OBD-II

Nissan OBD-II

Subaru OBD-II

Scanner Screen Menu Trees (Cont.)

Suzuki OBD-II

Toyota OBD-II

>2-System Config

1-SAE/Metric

2-Capture Time

3-Contrast Adjust

>3-User Upgrade

Serial Number

Select Upgrade

Seed

>4-Download

Page 53

TROUBLESHOOTING (CONT.)

Connect to EZ-PC software Enter to begin

>5-System Info

Software Version: V X.XX K X.XX

Serial Number: 9999999

ID#1=XXXXXXXX

ID#2=XXXXXXXX

Systems Avaliable

SCAN - OBD-II, GM, Chrysler

>ENTER to Scan, SCAN to Exit

SCAN - Ford

>1-KOEO/KOER Scan

>2-DCL Data Scan

MON - OBD-II

>1-Capture Mode

1-Start Capture

2-View Data

>2-Oxygen Tests

1-O2 Select 1

2-O2 Select 2 (supports up to 8 sensors)

>3-Readiness Tests

>4-Test Results

>5-Veh. Information

MON - GM, Chrysler

>1-Start Capture

>2-View Data

Scanner Screen Menu Trees (Cont.)

MON - Ford

>1-Wiggle Test

>2-DCL Capture

1-Start Capture

2-View Data

DATA-OBD-II

Page 54

TROUBLESHOOTING (CONT.)

>1-Operation Data

>2-Freeze Frame Data

>3-Trouble Codes

1-Trouble Codes

2-Pending Codes

>4-Clear Data

>5-Customize Data

>6-EZ-PC

DATA-GM OBD-I

>1-Op Data

>2-Trouble Codes

>3-Clear Codes

>4-EZ-PC

DATA - Ford OBD-I

>1-KOEO Codes

>2-Memory Codes

>3-KOER Codes

>4-Clear Codes

>5-DCL Data

>6-EZ-PC

DATA - Chrysler OBD-I

>1-Op Data

>2-Trouble Codes

>3-Clear Codes

>4-EMR Reset (Not all vehicles)

>5-EZ-PC

Page 55

TROUBLESHOOTING (CONT.)

• See “OBD-II Generic Operational Data Items” on page 57.

• See “Enhanced OBD-II Operational Data Items” on page 59.

• See “OBD-II Oxygen Sensor Test Readings” on page 61.

• See “GM Operational Data Items” on page 63.

• See “Ford DCL Operational Data Items” on page 76.

• See “Chrysler Operational Data Items” on page 79.

Page 56

OPERATIONAL DATA ITEMS

Mass Air Flow (Grams/Sec) Range: 0 to 105 gr/sec

High Perf. Vehicles: 0 to 255 gr/sec

Mass air flow sensor input is used by the ECM to calculate fuel delivery.

As the air flow increases, the fuel delivery must also increase. Displayed

in grams per second.

Calculated Load Value Range: 0% to 100%

An indication of the current airflow divided by peak airflow, where peak

airflow is corrected for altitude, if available. This value is not engine

specific. It gives the service technician an indication of the percent of

engine capacity being used (with a full load as 100%).

Commanded Secondary Air Status

Commanded Secondary Air provided to the exhaust system.

Engine Coolant Temperature Range: -40 C to 215 C

The temperature of the vehicle coolant is used to determine when to

transition into closed loop and to calculate spark advance during cold

starts. The PCM converts the voltage from the sensor to a temperature.

Engine RPM

Engine Speed reading displayed in revolutions per minute.

Fuel Pressure (Gage) Range: 0 to 765 kPaG

Fuel pressure of the fuel delivery system.

Fuel System Status

Information describing the operation of the fuel control.

Open loop - Operating condition during engine warm up/idle in which the

fuel mixture isn’t being corrected to compensate for a rich/lean condition.

Closed Loop - Operating condition in which the fuel mixture is being

corrected for a rich/lean condition.

OL Drive - Vehicle in Open Loop due to driving conditions (power

enrichment, deceleration).

OL Fault - Vehicle in Open Loop due to a detected system fault.

CL O2 Fault - Vehicle in Closed Loop, but a fault with at least one oxygen

sensor - may be using simple oxygen sensor for fuel control.

Ignition Timing Advance Range: -64 to 63.5

The relationship between ignition timing and top dead center, displayed in

crankshaft degrees.

Page 57

OBD-II GENERIC OPERATIONAL DATA ITEMS

Intake Air Temperature Range: -40 C to 215 C

Temperature of the air drawn through a cleaner and distributed to each

cylinder for use in combustion.

Intake Manifold Pressure Range: 10 to 105 kPa, or 0 to 5 Volts

The manifold absolute pressure displayed in kilopascals or volts. A low

reading will indicate that the pressure is low (vacuum is high) and a high

reading will indicate that the pressure is high (vacuum is low).

Long Term Fuel Trim (Bank 1 / Bank 2)

Long Term adjustments to the Bank 1 fuel calibration schedule which

compensate for vehicle differences and gradual changes that occur over

time. Range: -100.00% to 99.92% (-100% indicating a maximum lean

condition, 99.92% indicating a maximum rich condition, and 0% indicating

no adjustment).

OBD-II Require

Requirement level for the On Board Diagnostics designed for the vehicle.

OBD-II (CARB) - Vehicle designed with OBD requirements for California

Air Resource Board OBD-II.

OBD (Fed EPA) - Vehicle designed with OBD requirements for Federal

EPA OBD.

OBD and OBD-II - Vehicle designed with OBD requirements for OBD and

OBD-II.

OBD-I - Vehicle designed with OBD requirements for OBD-I.

Not Intended - Vehicle not intended to meet any OBD requirements.

Oxygen Sensor

The detection of Oxygen (O2) content in the exhaust gases. The sensor

readings are used by the ECM to help calculate the air-fuel mixture to

maintain proper vehicle performance.

Short Term Fuel Trim (Bank 1/2)

Dynamic or instantaneous adjustments to the Bank 1 base fuel schedule.

Range: -100.00% to 99.92% (-100% indicating a maximum lean

condition, 99.92% indicating a maximum rich condition, and 0% indicating

no adjustment).

Vehicle Speed (MPH)

Sensor reading displayed in miles per hour.

Page 58

OBD-II GENERIC OPERATIONAL DATA ITEMS (CONT.)

ENHANCED OBD-II OPERATIONAL DATA ITEMS

Activating Enhanced OBD-II

AutoXray features select makes of Enhanced OBD-II upgrades that

will give you up to 50% or more operational data items. To activate

the Enhanced OBD-II upgrades, your scanner will need to be operating software version 1.42 or higher. You can always update your

software version using PC-Link (part # 41000), then call AutoXray

Customer Service to activate the Enhanced OBD-II upgrades.

There is a charge to activate teh Enhanced OBD-II upgrades.

When you call 1.800.595.9729, a representative will step you

through the upgrade process.

Each vehicle will vary on what specific parameters are available.

The list below is a sample of the type of additional data items that

are available for Enhanced OBD-II. Please check the AutoXray

website for the latest upgrade information at www.autoxray.com

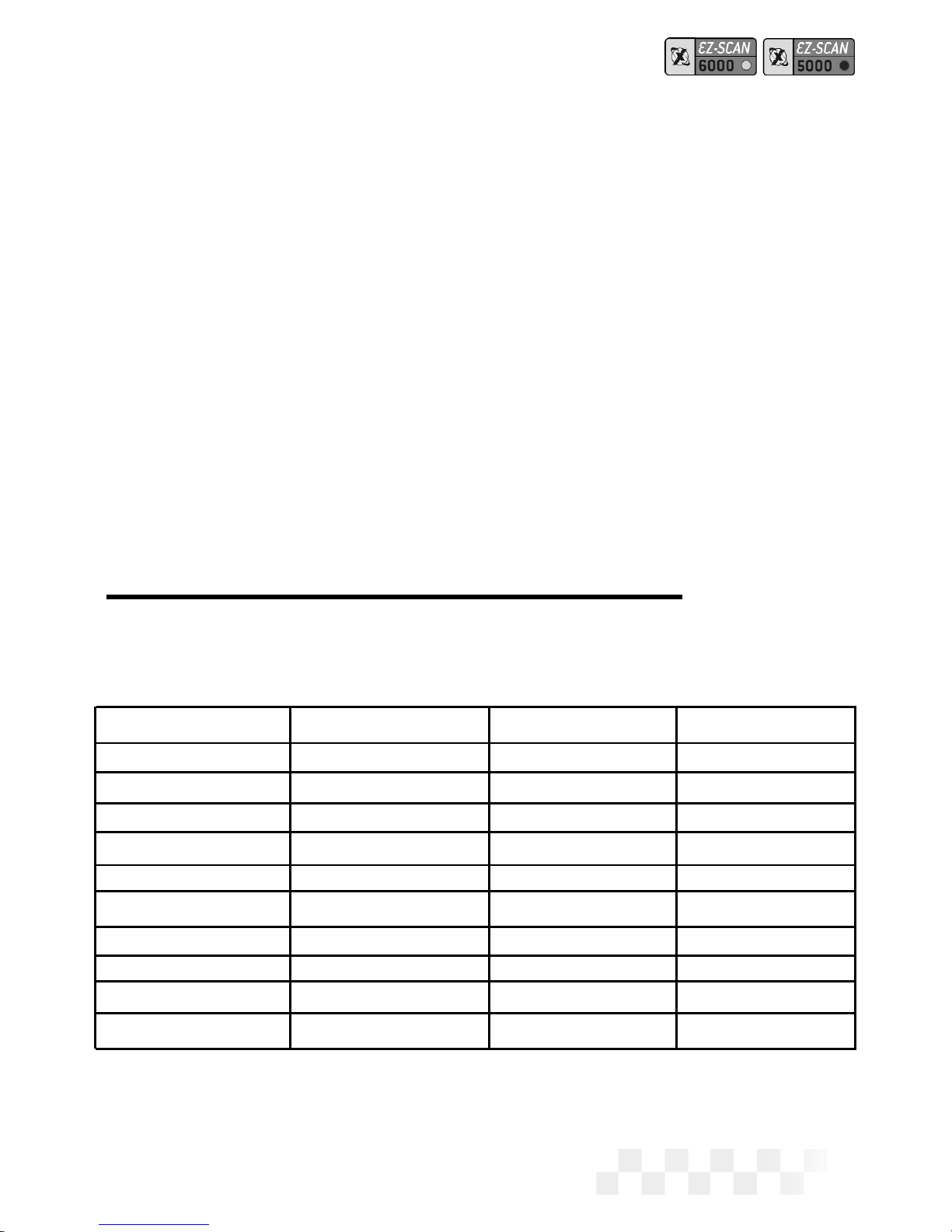

Additional Parameters and Values

Parameters Values Parameters Values

A/C Requested / Not Req. Block Learn Idle Numeric

A/C Clutch Engaged / Not Eng. Brake Depressed Yes / No

A/C Pressure Sensor High / Low Calc Air Flow g/s lbs/min

Actual EGR Duty Percentage Calculated Load Percentage

Air Fuel Ratio Numeric Cam Position Err Percentage

Baro Pressure kPa/Hg/PSI Cam Resync Cnt Count

Battery Voltage Volts Cam Retard Degrees

Block Learn Accel Numeric Canister Purge Requested/Not Req.

Block Learn Cruise Numeric Canister Purge Solen Percentage

Block Learn Decel Numeric Catalyst Freq Bank1 Hz

Page 59

Parameters Values Parameters Values

Catalyst Freq Bank2 Hz High Adapt Knock Retard Degrees

Catalytic Convtr Temp C or F High Speed Fan On / Off

Coast Clutch Solenoid On / Off IAC Duty Cycle Percentage

Cool. Gauge Cmd Numeric IAC Position Steps

Coolant Sensor Volts IAC with A/C Steps

Coolant Temp C or F IAC without A/C Steps

Cruise Set Speed Kph/Mph Injector Pulse Bank1 mS

Cruise Switch Volts Injector Pulse Bank2 mS

Current Gear Numeric Intake Air Sensor Volts

Desired EGR Posn Percentage Intake Air Temp C or F

Desired IAC Posn Steps Knock Count Count

Desired Idle RPM Knock Retard Degrees

EGR DECEL Trip Numeric Knock Sensor Volts

EGR Duty Cycle Percentage Lean to Rich Avg Time mS

EGR Position Volts Lean to Rich Counts Count

EGR Posn Error Percentage Line Press. Ctrl kPa/Hg/PSI

EGR Sensor Volts Long Term Cell Numeric

EGR Valve Posn Percentage Long Term Trim Bank1 Percentage

Engine Load Percentage Long Term Trim Bank2 Percentage