USER

MANUAL

I.G.B.T. INVERTER

DC TIG ARC WELDER

NICE - 350DT

NICE - 500DT

Autowel Co. Ltd.

Guarantee Certificate◀▶

* The warranty of products shall confirm to the specification set forth in

thearticle2"configurationandspecifications" for 14 months from the

date on Bill of Lading.

* The extent of seller's liability under this warranty shall be limited to the

repair or replacement as herein provided of any defective parts thereof.

* The warranty does not extend to following occasion:

- subjected to mis-use, neglect, accident or abuse

- improperly repaired, installed, transported, altered or modified

- used in violation of instructions furnished by user's manual

Model NICE -

Serial no.

manufacture

date

shipdate 년월일200

seller's name Autowel Co., Ltd.

company

client name

person

년월200

1. Warranty period is 14 months

from the date on Bill of Lading.

2. Except for the express limited

warranties set forth in this

guarantee certificate, Autowel has

no other liability.

Certified by Autowel CO., Ltd.

Warranty Card.

*Note:

1. The "Guarantee Certificate" shall practically be effected with seller's

signature after fill in blank of Warranty Card.

2. Users has to pay attention to the subjects set forth Article 3

"installation" when installing the main power units and accessories.

3. Autowel has no liability of accessories, which are consumable and not

to manufactured by Autowel

-1-

Table of contents◀▶

1. Product description

2. Composition and specification

3. Installation

4. Handling and operation

5. Safety regulations

6. Diagnosis and countermeasures

To increase product's life and welding efficiency, please

make sure to read this user manual before using.

-2-

1. Product description

NICE-350(500)DT of Autowel which is DC TIG welding machine can be

used as MMA as well. We maximized the efficiency through adopting

INVERTER method by PWM power control using I.G.B.T element. You

can select various welding functions so that this machine can be used

for specialists.

2. Composition and specification

1) Composition and standard parts

Name Type NICE-350DT NICE-500DT Q'ty

WELDING POWER DC 350A DC 500A 1

TORCH (SET)

Air cooling

350A 4M

Base metal CABLE 22SQ or more 38SQ or more 1

Chuck, body Ø2.4 Ø3.2 1

Tungsten Ø2.4 Ø3.2 1

Ceramic 6 8 1

Gas gauge ARGON ARGON 1

Hose 3M 3M 1

Air cooling

500A 4M

1

-3-

2) Rated specification

Item Type NICE-350DT NICE-500DT

AC 220V 1P, 3P

Input voltage

Input power

Frequency 50/60 ㎐

TIG

Output currency

ARC

Unloading voltage Approximately 70V Approximately 75V

(380V multiple use

OPTION)

3 phase 10.5 KVA

Single phase 6.3 KVA

3 phase 5 350A~

Single phase 5 250A~

3 phase5 220A~

Single phase 5 200A~

AC 220V/380V

multiple use

1P, 3P

3phase 18KVA

Single phase9.2 KVA

3 phase5 500A~

Single phase 5 380A~

3 phase5 350A~

Single phase 5 300A~

Loading voltage 22V 24V

Efficient 60 %

Size (WXDXH) 270X440X400 330X570X560

Weight 25KG 35KG

-4-

3. Installation

* Installation description

NFB ARGON

REGULATOR GAS

EARTH

TORCH

BASE METAL

-5-

4. Handling and operation

4-1. Front panel structure and name

-6-

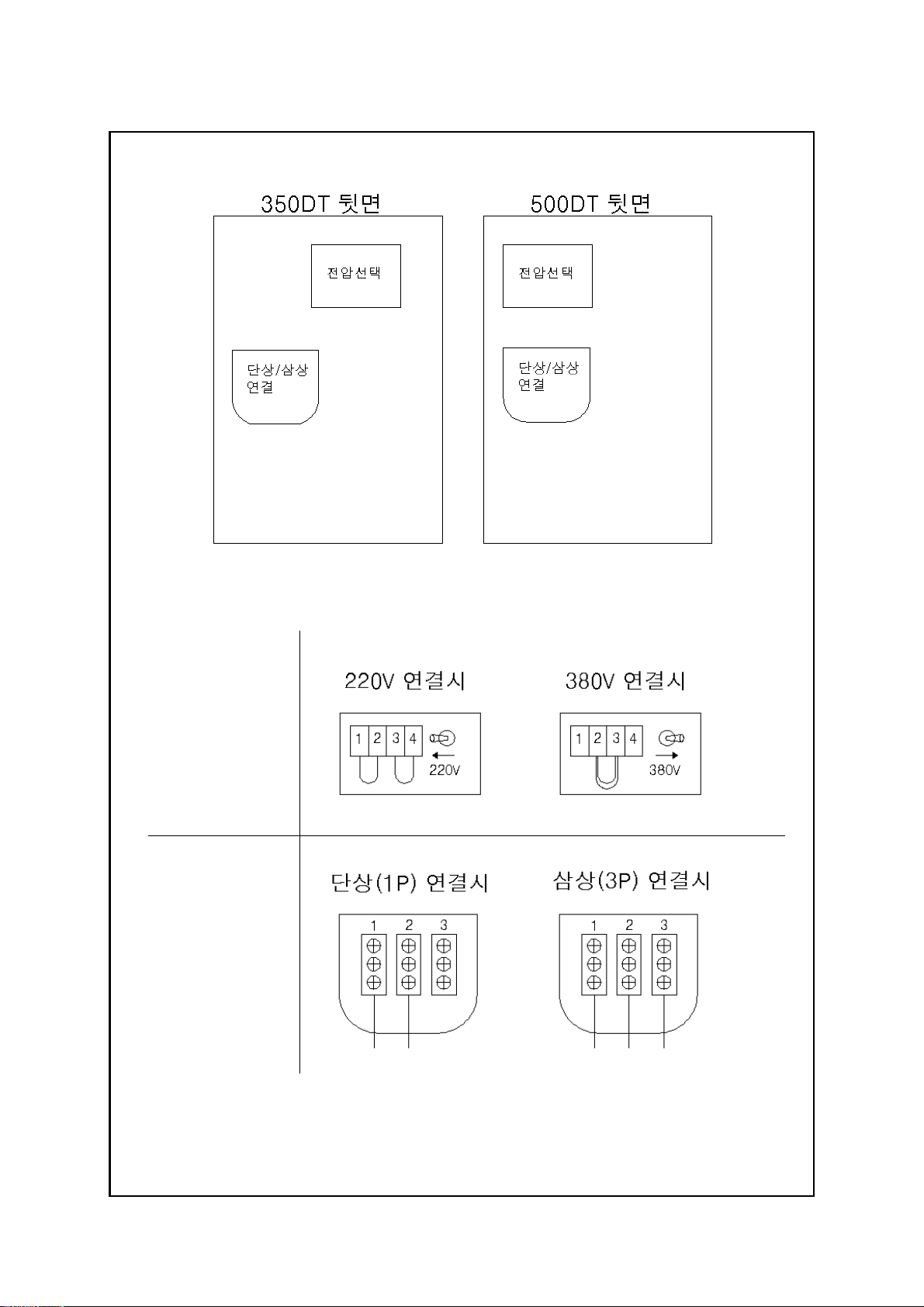

Power

selection

Single

phase/

3phase

connection

Rear wiring diagram

-7-

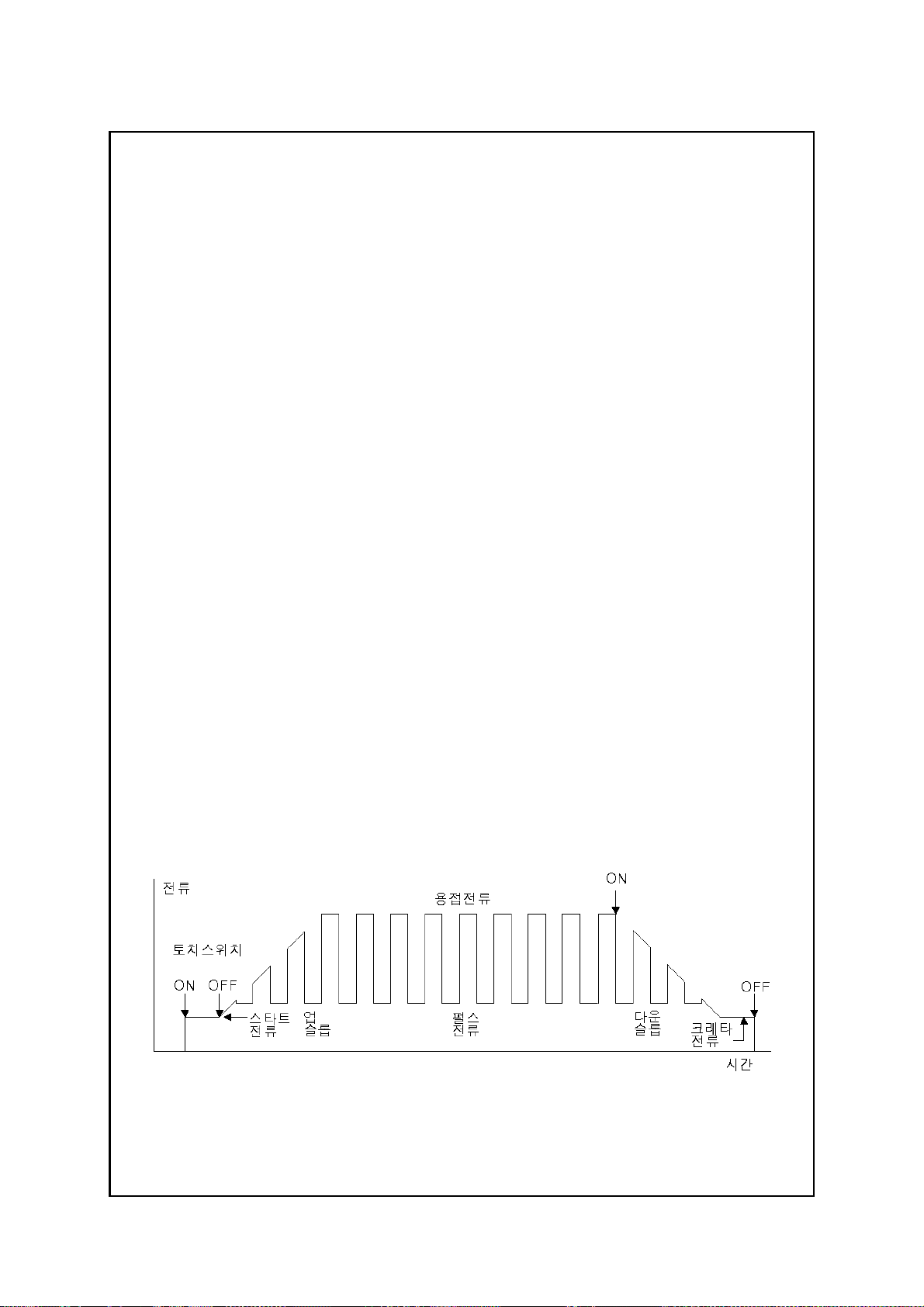

4-2. Functions and operations

1)CURRENTMeter:Itisoutputcurrentinwelding.

2) WARNING lamp:

Power error- It will be turned on (off) when imput voltage goes①

down by more than 20% from standard voltage.

Overload- It will be turned on (off) when welding current goes up②

rapidly.

Temperature error- It will be turned on (off) when inner③

temperature of the machine is higher than 85 and it is able to use℃

the machine when this lamp is turned off after certain period of time.

3) FUSE: It is for protecting PCB and FAN. (350DT : 3A, 500DT : 5A)

4) Power lamp: It indicates power is supplied to welding machine.

5) Power switch: It turns ON/OFF the welding machine and it will shut

off the power in overloading.

6) WELDING SELECTION switch

No crater (OFF) - It operates only when torch switch is ON.①

With crater (SINGLE) - Crater current is generated when②

pressing torch switch and welding will be done with this crater current.

If pressing this switch again, crater current will be generated and

welding will be stopped when releasing this switch.

Crater REPEAT - Above condition will be maintained. If keeping③②

the torch away from base metal it will be OFF.

-8-

Arc SPOT - SPOT welding is possible. Welding is done during④

torch switch is ON and it will be OFF when it reaches arc spot time

set.

Manual welding (MMA) - It is used in general arc welding and⑤

the holder is connected to (+) electrode and earth to (-) electrode.

7) PULSE CYCLE: It can adjust the frequency between 10 500 .~㎐

8) PULSE WIDTH: It can adjust pulse width (500DT).

9)WELDINGCURRENT:Itisusedtoadjusttheweldingcurrent.

10) PULSE SELECTION: High - 10 500 adjustment①~㎐

(PULSE SELECTION) Low - 0.5 25 adjustment②~㎐

None - No pulse used.③

11) TIG SPOT TIME / DOWN SLOPE: Spot time can be adjusted

when welding selection switch is in Arc Spot position. If selecting With

Crater or Crater Repeat, you can adjust the time the welding current

changes into crater current.

12) AFTER FLOW: It adjusts gas generating time after completion of

the welding.

13) TORCH S/W: This is a CONNECTOR of the torch switch.

14) GAS OUTLET: This is gas discharging outlet.

15) Torch terminal (-): This is connected with torch and it is used as

ground in manual welding.

16) Ground terminal (+): Connected with base metal and used as holder

in manual welding.

-9-

17) TIG welding condition set up

Metal thickness

(mm)

Electrode

Ø

Welding

current

Gas quantity

/minℓ

Electrode

Ø

(A)

0.1-0.5

5-40

1.0-1.6

1.60.6-1.0 20-60

4

1.0-2.0

40-100

1.6-2.4

2.0-3.0 60-120 2.6

3.0-5.0

2.4-3.2

100-160

5

3.2

5.0-7.0 160-240 4.0

7.0-9.0

220-300

2.4-3.2

65.09.0-12 250-500

이상12 3.2-6.4 350-500

5. Safety regulations

1) Power facility: Have one switch for each welder and use 5.5SQ of

service wire for 350DT and 8.0SQ or higher for 500DT.

2) Welding terminal: Please keep your hands, PC or electric products

away from welder during operation as there is high voltage generated

at torch side of the terminal.

3)Gad:PleaseuseonlyArgongasasprovided.

4) Ground: Comply with Class 3 ground.

5) Circumstance: Avoid the places with moisture, dust and high

temperature around and install it at the place of good ventilation.

Ventilation is particularly closely related with the efficiency.

6) Movement: Make sure to check input power and connecting condition

of input/output line when using after moving the welder.

7) Body safety: Be careful for burning as torch is high temperature and

wear safety mask and cloth as arc ray may damage eye and skin.

Install a ventilating facility and take rest regularly as welding gas is

harmful for body.

-10-

6. Diagnosis and countermeasures

Order Status Cause Countermeasures

Main NFB defect

1Noreaction

FAN is running

but welder

2

doesn't

operate

Gasisnot

3

discharged

Gas is

Check service line

Check power supplied

Torch switch defect Replace switch

Warning lamp flickers

Warning lamp is ON

continuously

There is no gas or it is

not connected

Solenoid valve defect Exchange

Control PCB error Request A/S

Turn off the power

Check and replace

High temperature

(Use after certain

period of time)

Resistance wire

break due to

overcurrent

(Request A/S )

Check

Remove foreign

substances from

4

5

discharged

continuously

Start is not

smooth

Solenoid valve defect Exchange

Control PCB error Request A/S

Shortage of gas

Overage of gas

High frequency is not

generated

Circuit break of base

metal

Torch defect

the valve

Adjust gas

pressure

Request A/S

Exchange

Autowel Co., Ltd

TEL : 032) 819-8925 / 818-8925 FAX : 032) 819-8926

http://www.autowel.co.kr e-mail : autowel@autowel.co.kr

Address: 363-4 Kojan-dong, Namdong-ku Incheon City

Korea

-12-

Loading...

Loading...