Autowel Finewel-180D, Finewel-160D, Finewel-200D, Finewel-350D, Finewel-500D User Manual

...

USER

MANUAL

I.G.B.T. INVERTER

I.G.B.T. INVERTER

I.G.B.T. INVERTERI.G.B.T. INVERTER

DC ARC(MMA) WELDER

DC ARC(MMA) WELDER

DC ARC(MMA) WELDERDC ARC(MMA) WELDER

Finewel-160D/180D/200D

Finewel-160D/180D/200D

Finewel-160D/180D/200DFinewel-160D/180D/200D

/250D/300D/350D

/250D/300D/350D

/250D/300D/350D/250D/300D/350D

/500D/600D/3.2AL

/500D/600D/3.2AL

/500D/600D/3.2AL/500D/600D/3.2AL

Table of Contents

◀ ▶

◀ ▶◀ ▶

1. Product Description

2. Configuration and Specification

3. Installation

4. Handling and Operation

Table of Contents◀ ▶

Table of ContentsTable of Contents

5. Safety Regulations

To increase product's life and welding efficiency,

please make sure to read this user manual before

using.

1. Product Description

1. Product Description

1. Product Description1. Product Description

Finewel- 160D/ 200D/ 250D/ 300D/ 350D/ 500D/ 3.2AL of Autowel are the

DC ARC welding machine. It is light weight and controls with IGBT

module type and prevents elec tric shock. It has very good radiant heat

structure, high duty cycle and digital meter to display the welding

current commended and operated.

The failure of operation of the DC ARC welding machine has never

broken out because it converts AC 85V~ 285V input power applying

SMPS circuit (free voltage) to supply power for the part of the board

circuit. Therefore, the DC ARC welding machine can be used even at a

bad time about power.

The trouble rate of the DC ARC welding machine is low. Because it' s

circuit is simple that all the welding signal of ARC control circuit are

consisted by microprocessor programing.

The trouble rate of the DC ARC welding machine during operation is

low by protecting the IGBT circuit because the speed sensing output

overload is swift by microprocessor programing.

2. Configuration and Specification

2. Configuration and Specification

2. Configuration and Specification2. Configuration and Specification

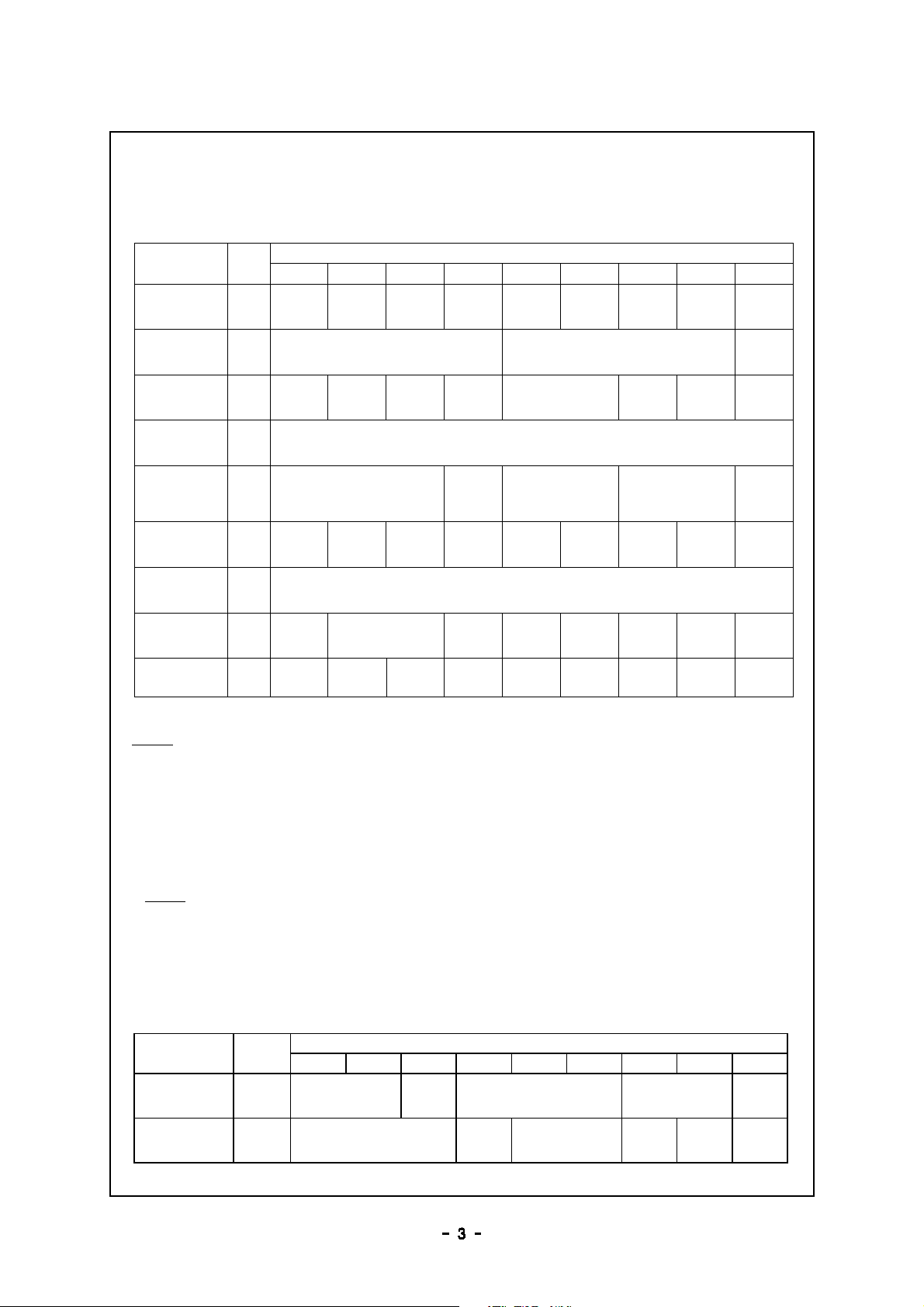

2- 1. Standard Specification

2- 1. Standard Specification

2- 1. Standard Specification2- 1. Standard Specification

Model

Model

Description

Description Unit

DescriptionDescription

Rated Input

Rated Input

Rated InputRated Input

power

power

powerpower

Rated Input

Rated Input

Rated InputRated Input

Volt.

Volt.

Volt.Volt.

Rated

Rated

RatedRated

Output Cur.

Output Cur.

Output Cur.Output Cur.

Input

Input

InputInput

Frequency

Frequency

FrequencyFrequency

Max.

Max.

Max.Max.

Open- circuit

Open- circuit

Open- circuitOpen- circuit

Voltage

Voltage

VoltageVoltage

Load

Load

LoadLoad

Voltage

Voltage

VoltageVoltage

Duty Cycle

Duty Cycle

Duty CycleDuty Cycle

(* )

(* )

(* )(* )

Dimension

Dimension

DimensionDimension

(WxDxH)

(WxDxH)

(WxDxH)(WxDxH)

Unit

UnitUnit

KVA 5 6 7 10 11 12 18 21 6

V 220V, 1P (380)220/ 415/ 440V, 3P

A 150 180 200 250 300 400 500 150

Hz 50/ 60

V 75 80 82 85 120

V 26 27 28 30 34 32 36 38 30

% 60

mm

160D

160D 180D

160D160D

140x41

0x200

180D 200D

180D180D

170x460x240

200D 250D

200D200D

250D 300D

250D250D

225x46

5x330

ModelModel

300D 350D

300D300D

270x44

0x400

350D 500D

350D350D

225x46

5x330

500D 600D

500D500D

370x73

0x600

600D 3.2AL

600D600D

405x83

0x635

3.2AL

3.2AL3.2AL

220V,

1P

170x46

0x240

Net Weight

Net Weight Kg 7 9 10 17 28 18 50 60 11

Net WeightNet Weight

Note: 1. Specification can be changed without notice

2. The function of “ electrical shock prevention” is included.

2- 2. Optional Accessories

2- 2. Optional Accessories

2- 2. Optional Accessories2- 2. Optional Accessories

Arc Holder, Earth clamp, Welding cable 5M, Earth cable 3M

Note: 1. When ordering a set menu, above 4 optional accessories are

supplied.

2. Standard scope is only power unit without above accessor

- ies.

Limit of cable size

Limit of cable size

Limit of cable sizeLimit of cable size

Model

Model

Description

Description Unit

DescriptionDescription

Input

Input

InputInput

Cable

Cable

CableCable

Holder

Holder

HolderHolder

Cable

Cable

CableCable

Unit

UnitUnit

SQ 4 6 10 16 4

SQ 16 25 35 50 70 16

160D

160D 180D

160D160D

180D 200D

180D180D

200D 250D

200D200D

250D 300D

250D250D

ModelModel

300D 350D

300D300D

350D 500D

350D350D

500D 600D

500D500D

600D 3.2AL

600D600D

3.2AL

3.2AL3.2AL

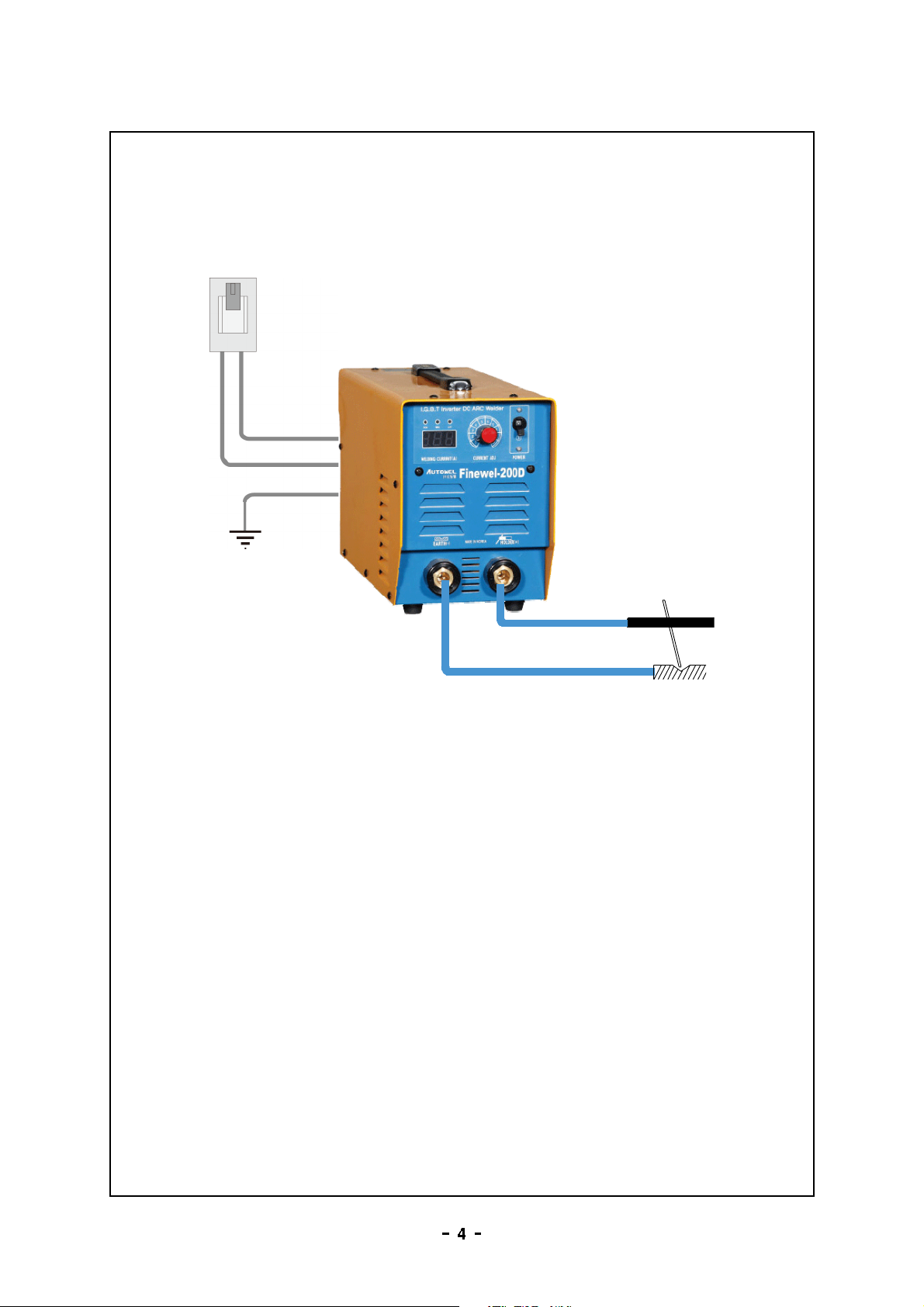

3. Installation

3. Installation

3. Installation3. Installation

3- 1. Installation Configuration

3- 1. Installation Configuration

3- 1. Installation Configuration3- 1. Installation Configuration

- Input electrical connection: refer to specification (2- 1), and

should be checked before switch ON. And the Ground line

should be connected.

- Earth(- ) clamp with base metal, and Holder(+) with welding

electrode

- low humidity and low dust

- Flat and strong floor

- More than 30cm far from dry wall

- Operating temperature: - 10 ~ 40°C

- No rainy and direc t sunshine

- Altitude should be below 1000m

3- 2. Input Electricity

3- 2. Input Electricity

3- 2. Input Electricity3- 2. Input Electricity

- When using engine generator, the power should be 2 times of

rated input power.

- NFB should be c onnected with welding mac hine as one by one.

- Input power should be grounded as above picture.

4. Handling and Operation

4. Handling and Operation

4. Handling and Operation4. Handling and Operation

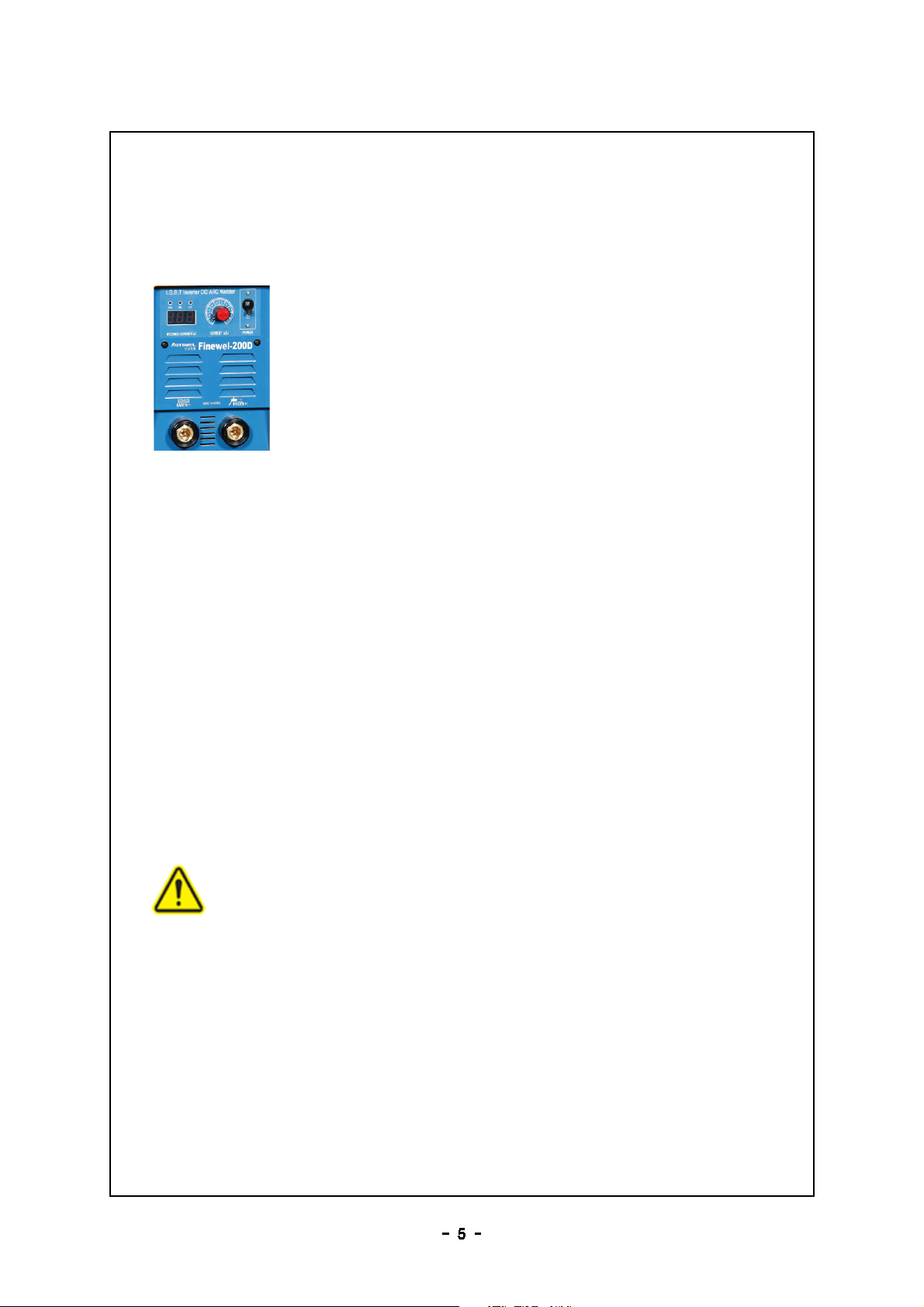

4- 1. Name Plate of Front Panel

4- 1. Name Plate of Front Panel

4- 1. Name Plate of Front Panel4- 1. Name Plate of Front Panel

② ④ ①

② ④ ① 1) Power Switch : On and off

② ④ ①② ④ ①

③③③③ 2) 3 signal Lamp : Power, welding and over temp

3) Welding Current : 3 digit meter

4) Welding Current adjustment volume lever

5) Earth(- ) for Base Metal

⑤ ⑥

⑤ ⑥ 6) Holder(+) for Welding Electrode

⑤ ⑥⑤ ⑥

4- 2. Function of Operation Panel

4- 2. Function of Operation Panel

4- 2. Function of Operation Panel4- 2. Function of Operation Panel

- Electrical Power Switch

- 3 dif f. Signal Lamp: 1stlamp indication power on/ off,

2ndlamp welding, 3rdlamp warning

- Digital Indicator: Display Welding Current

- Set of welding current by volume lever

- Earth(- ) terminal c onnect with base metal

- Holder(+) terminal connect with welding electrode

5. Safety Regulations

5. Safety Regulations

5. Safety Regulations5. Safety Regulations

- At clean and well arranged working floor

- Not use at the plac e where is rain, high humid and water

puddle.

- Do not use in near by inflammable liquid and gas

- With right clothes and safe glass with mask

- During the period of non- use and maintenance, input power

switch should be off

- Input electric power should be earthed

- Right cable should be used, and of course no damaged one.

- Terminal should be fastened

- Trouble shooting and pre- maintenance periodically.

- When finishing the operation, immediately input power terminal

should be separated.

- Should be operated at indoor and clean place.

- To avoid gas poisoning and breathing difficulty, dirty air should

be ventilated and changed to fresh air.

- Pay attention of heated base metal after welding, and is to be

a cause of fire

- Should be far from the inflammable materials.

- Do not use welder in near by inflammable materials

- As soon as finishing welding, heated base metal should be far

from inflammable materials.

- Should install a fire extinguisher in near welding place.

- Do not see the flash arc, and should use saf e glass, mask.

- To avoid poison fumes occurred by welding, should use safe

mask and ventilation system.

- Should pay attention a damage of cable from heavy moving

cart.

- Otherwise cable should be protected by safety c over.

- All connection and screws like terminals and adapters should

be fastened.

- Welding adapter and earth adapter should be insulated.

- Do not pull the cables strongly. It is a cause of damage of

cable and short circuit.

- Do not use very long cable, because it is a cause of voltage

drop.

Autowel Co., Ltd.

Autowel Co., Ltd.

Autowel Co., Ltd.Autowel Co., Ltd.

Tel : +82- 32- 818- 8925 / +82- 32- 819- 8925

Tel : +82- 32- 818- 8925 / +82- 32- 819- 8925

Tel : +82- 32- 818- 8925 / +82- 32- 819- 8925Tel : +82- 32- 818- 8925 / +82- 32- 819- 8925

Fax : +82- 32- 819- 8926

Fax : +82- 32- 819- 8926

Fax : +82- 32- 819- 8926Fax : +82- 32- 819- 8926

Website : http:/ / www.autowel.co.kr

Website : http:/ / www.autowel.co.kr

Website : http:/ / www.autowel.co.krWebsite : http:/ / www.autowel.co.kr

E- mail : nice@autowel.co.kr

E- mail : nice@autowel.co.kr

E- mail : nice@autowel.co.krE- mail : nice@autowel.co.kr

Address : 363- 4, Gojan- dong, Namdong- gu, Incheon,

Address : 363- 4, Gojan- dong, Namdong- gu, Incheon,

Address : 363- 4, Gojan- dong, Namdong- gu, Incheon,Address : 363- 4, Gojan- dong, Namdong- gu, Incheon,

Korea

Korea

KoreaKorea

Loading...

Loading...